Austenitic stainless steel

An austenitic stainless steel, an unavoidable technology, applied in the field of austenitic stainless steel, which can solve the problems of non-guaranteed non-magnetic properties, insufficient strength, poor pitting corrosion resistance, etc., achieve good neutron irradiation resistance, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

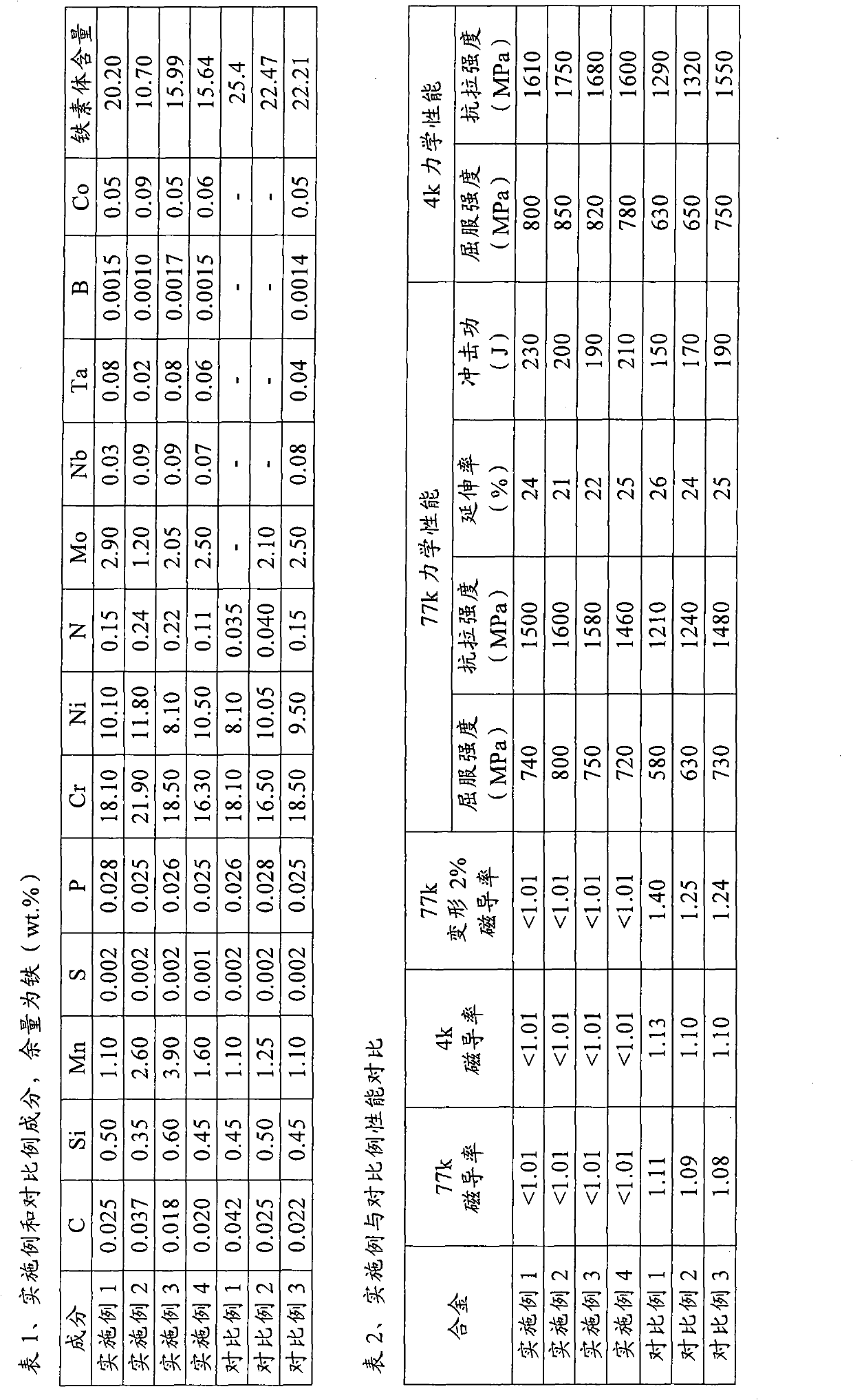

[0045]The composition of austenitic stainless steel is shown in Table 1. It was smelted by electric furnace + AOD, cast into continuous casting slabs, hot rolled into 30mm thick plates, annealed and pickled at 1080°C to obtain austenitic stainless steel plates. The plate has high low-temperature strength, toughness, non-magnetic properties, and good resistance to neutron radiation, see Table 2 for details. The magnetic properties of austenitic stainless steel are mainly measured by measuring its magnetic permeability. When the magnetic permeability is lower than 1.01, it means that the material has non-magnetic properties, and when the magnetic permeability is higher than this value, it means that the material has certain magnetic properties. The magnetic properties cannot meet the requirements of non-magnetic properties. The non-magnetic property of the material after deformation at 77k temperature is measured by measuring its magnetic property after performing 2% pre-denatur...

Embodiment 2

[0047] The composition of austenitic stainless steel is shown in Table 1. It was smelted by electric furnace + AOD, cast into continuous casting slabs, hot rolled into 8mm coils, and annealed and pickled at 1080°C to obtain hot rolled austenitic stainless steel coils. The plate has high low-temperature strength, toughness, non-magnetic properties, and good resistance to neutron radiation, see Table 2 for details.

Embodiment 3

[0049] The composition of austenitic stainless steel is shown in Table 1. It was smelted by electric furnace + AOD, cast into continuous casting slabs, hot-rolled and cold-rolled into 1mm coils, and annealed and pickled at 1080°C to obtain cold-rolled austenitic stainless steel coils. The plate has high low-temperature strength, toughness, non-magnetic properties, and good resistance to neutron radiation, see Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com