Silica fume pellet binder formula

A technology of micro-silica powder and formula, which is applied in the field of binder formula design, can solve the problems such as micro-silica fume is difficult to recycle, and achieve the effect of reducing silica consumption, cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

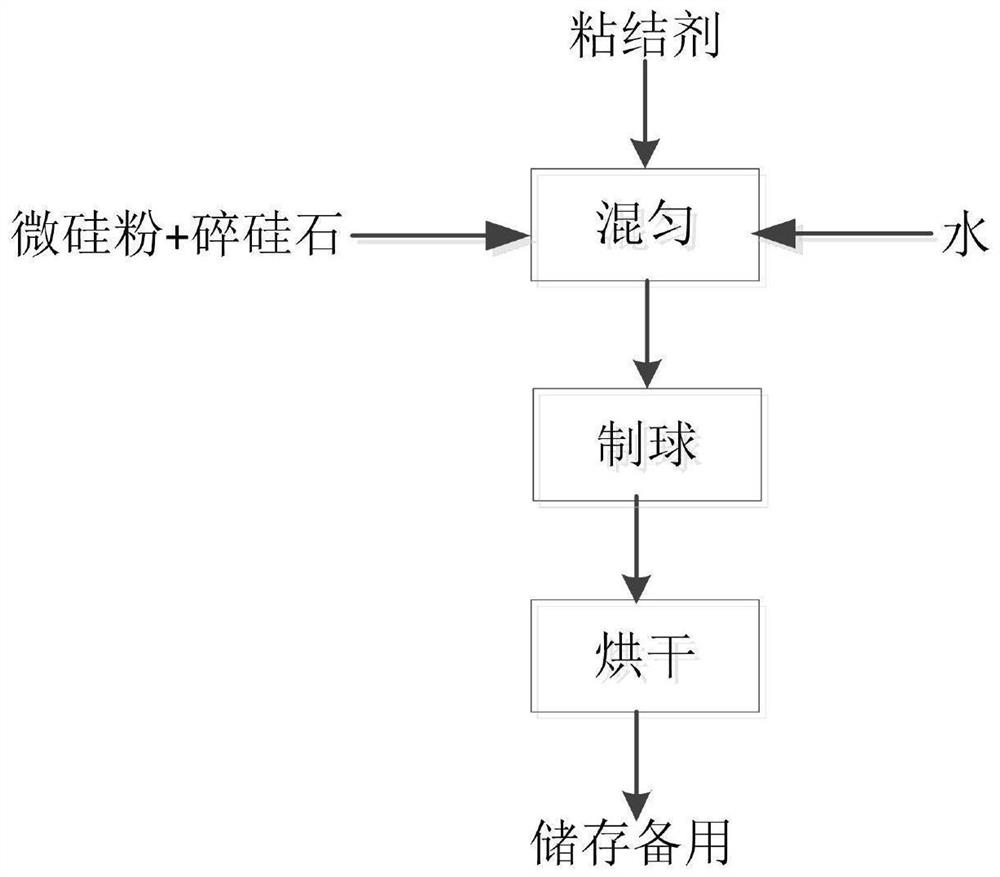

Image

Examples

Embodiment 1

[0029] Add organic binders such as starch, lignin, polyacrylamide, and silane coupling agent in a certain proportion, add inorganic binders such as sodium silicate and sodium hydroxide in a certain proportion, mix well, and prepare a high-temperature binder. The component content is: 15% of starch, 10% of lignin, 8% of polyacrylamide, 3% of silane coupling agent, 50% of sodium silicate and 14% of sodium hydroxide.

[0030] Add the main raw materials micro-silica fume, crushed silica, binder and water in a certain proportion, mix evenly, press and form in the briquetting equipment, dry at 150°C to control the moisture content to be less than 1%, store it for later use, control the mixing ratio of raw materials: the amount of water added 6%, binder 3%, fine silica 15%, micro silica fume 76%. Control ball pressure conditions: roller speed 6r / min, pressure 50MPa, mixing time 10min.

Embodiment 2

[0032] Add organic binders such as starch, lignin, polyacrylamide, and silane coupling agent in a certain proportion, add inorganic binders such as sodium silicate and sodium hydroxide in a certain proportion, mix well, and prepare a high-temperature binder. The component content is: 15% of starch, 12% of lignin, 8% of polyacrylamide, 4% of silane coupling agent, 45% of sodium silicate and 16% of sodium hydroxide.

[0033] Add the main raw materials micro-silica fume, crushed silica, binder, and water in a certain proportion, mix evenly, press and shape in the ball pressing equipment, dry at 180°C to control the moisture content to less than 1%, and store it for later use. Control the mixing ratio of raw materials: the amount of water added 8%, binder 5%, fine silica 12%, micro silica fume 75%. Control ball pressure conditions: roller speed 6r / min, pressure 70MPa, mixing time 6min.

Embodiment 3

[0035] Add organic binders such as starch, lignin, polyacrylamide, and silane coupling agent in a certain proportion, add inorganic binders such as sodium silicate and sodium hydroxide in a certain proportion, mix well, and prepare a high-temperature binder. The component content is: 18% of starch, 15% of lignin, 8% of polyacrylamide, 4% of silane coupling agent, 40% of sodium silicate and 15% of sodium hydroxide.

[0036] Add the main raw materials micro-silica fume, crushed silica, binder and water in a certain proportion, mix evenly, press and form in the briquetting equipment, dry at 150°C to control the moisture content to be less than 1%, store it for later use, control the mixing ratio of raw materials: the amount of water added 6%, binder 3%, fine silica 15%, micro silica fume 76%. Control ball pressure conditions: roller speed 6r / min, pressure 50MPa, mixing time 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com