Method for preparing ADI nodular cast iron capable of resisting impact of low temperature of 40 DEG C below zero

A nodular cast iron, low-temperature impact technology, applied in the direction of improving process efficiency, etc., can solve the problem of low impact energy, achieve the effect of increasing the pressure in the bag, increasing the nucleation ability of graphite, and good absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

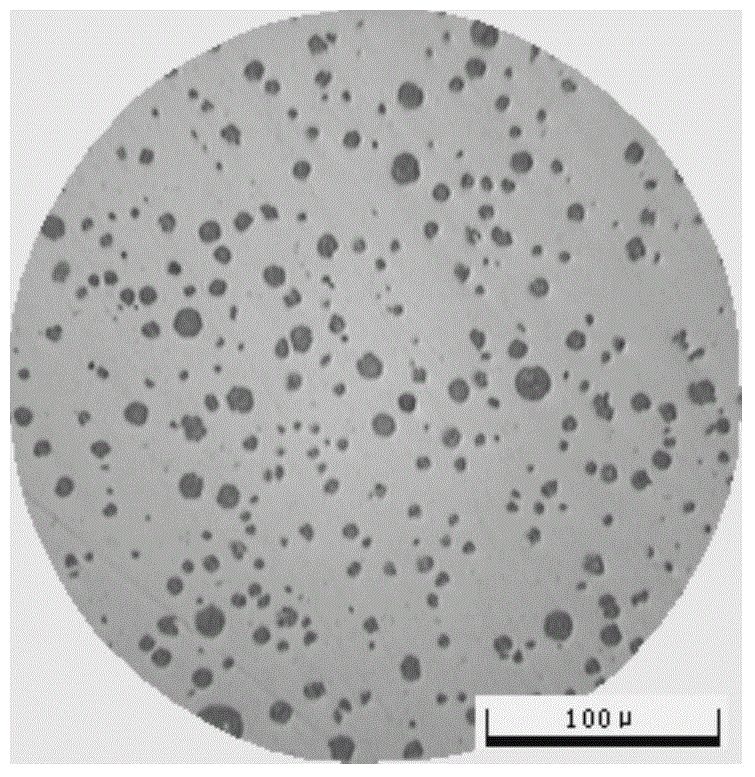

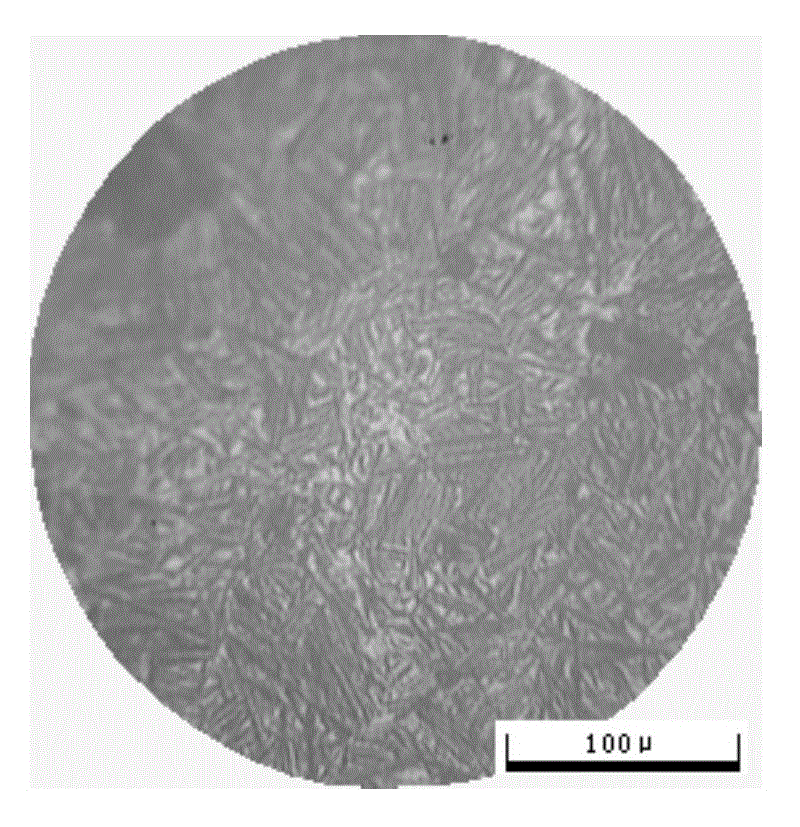

[0022] Embodiment 1: The preparation method of the ADI ductile iron resistant to -40°C low temperature impact of the present embodiment is carried out according to the following steps:

[0023] 1. Mix 70 parts of ductile pig iron Q10, 10 parts of low manganese scrap and 20 parts of return material according to the parts by mass, then heat up to 1510℃~1530℃ to melt, then add ductile iron Q10, low manganese scrap and return material with a total mass of 0.4 %~0.5% nickel plate is smelted, and after smelting, ductile pig iron Q10, low manganese scrap steel and red copper plate with a total mass of 1.1%~1.3% of the returned charge are added to smelt to obtain molten iron;

[0024] 2. Put the spheroidizing agent on the bottom side of the spheroidizing bag, and cover the 75% ferrosilicon inoculant on the spheroidizing agent. The inoculant is covered with a layer of low manganese scrap steel of the same quality as the inoculant, and the bag is covered. Cover, and then adopt the punch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com