Patents

Literature

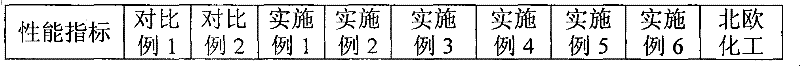

144results about How to "Improve nucleation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

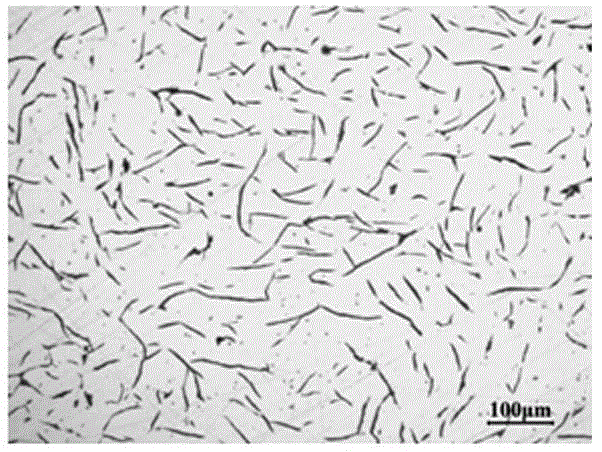

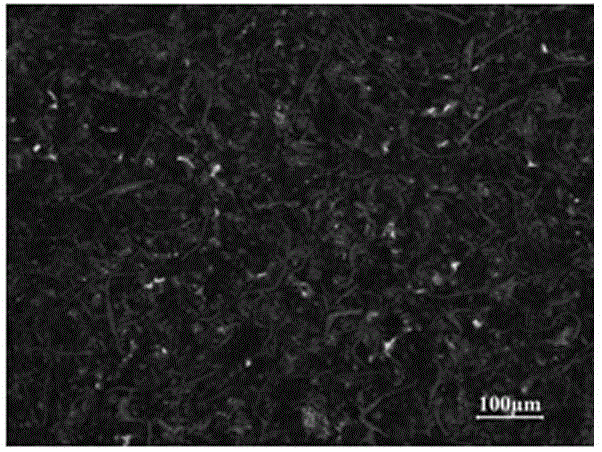

High-nickel type lithium Ni-Co manganate precursor with specific morphology and preparation method thereof

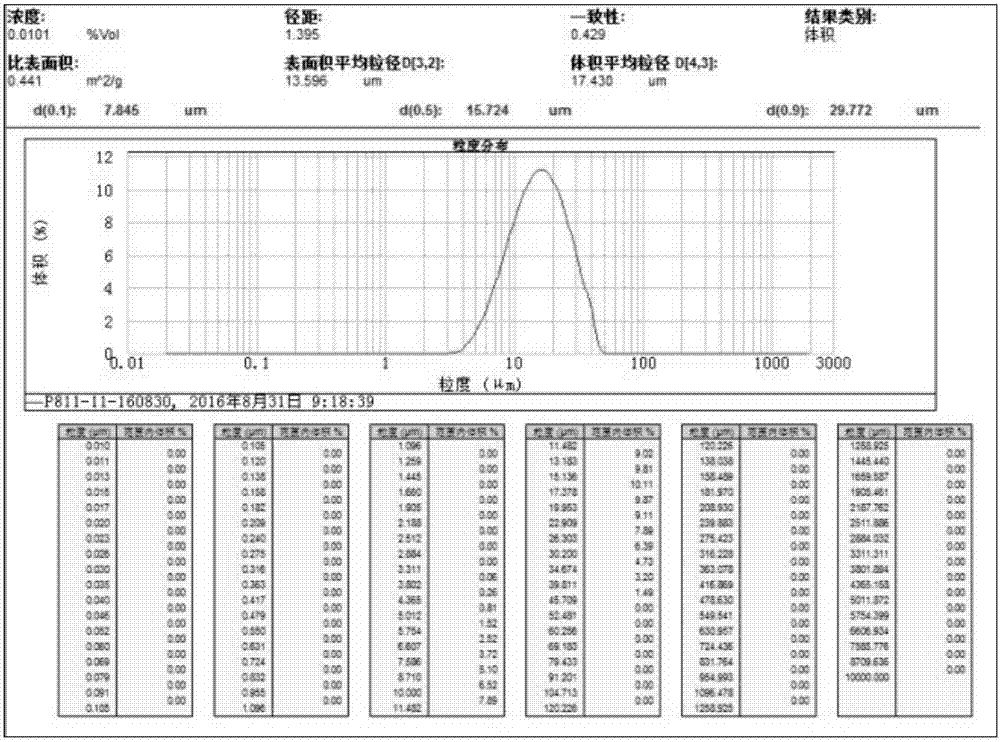

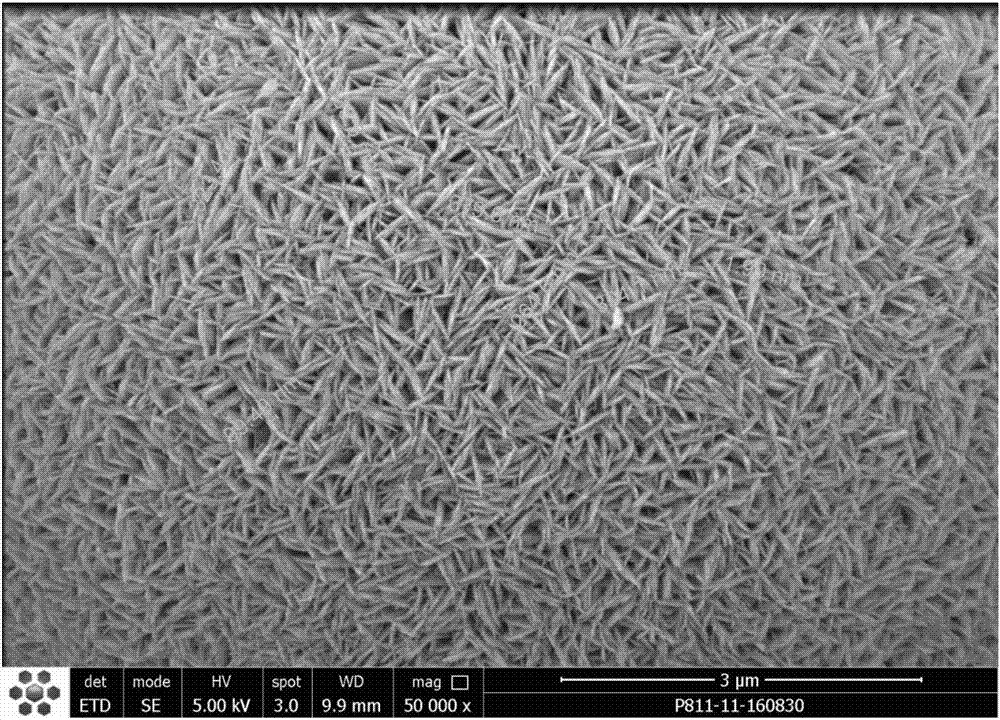

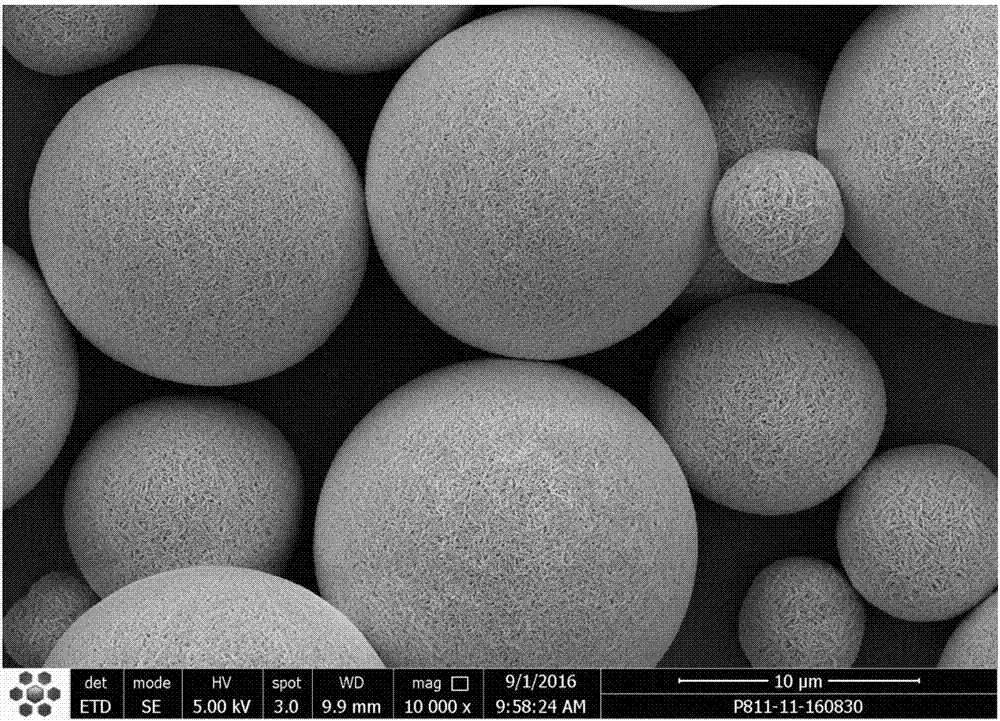

The invention discloses a high-nickel type lithium Ni-Co manganate precursor with specific morphology. The mean grain size of the primary particle of the precursor is 200-500nm; the granularity D10 of the secondary particle aggregate is not less than 6 microns; D50=11-15 microns, D90 is not more than 30 microns, the degree of sphericity of each of the secondary large particle and the secondary small particle is perfect, and the primary particle is filamentous. The preparation of the precursor comprises the following steps: firstly preparing a soluble mixed salt solution; adding ammonia water as the reaction kettle base solution, and regulating the pH of the base solution; inflating the nitrogen into the reaction kettle and starting the stirring; combining the configured soluble mixed water solution, the alkali and the ammonia water to add in the reaction kettle to perform the stirring reaction, reacting for some time, circularly pumping the early unqualified material into the reaction pump, performing ageing, filter-pressing and washing on the overflow material, drying, screening and then saving. The product disclosed by the invention is good in consistency and has specific morphology; the process efficiency is higher, and the product stability is better.

Owner:SHANSHAN ENERGY (NINGXIA) CO LTD

Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

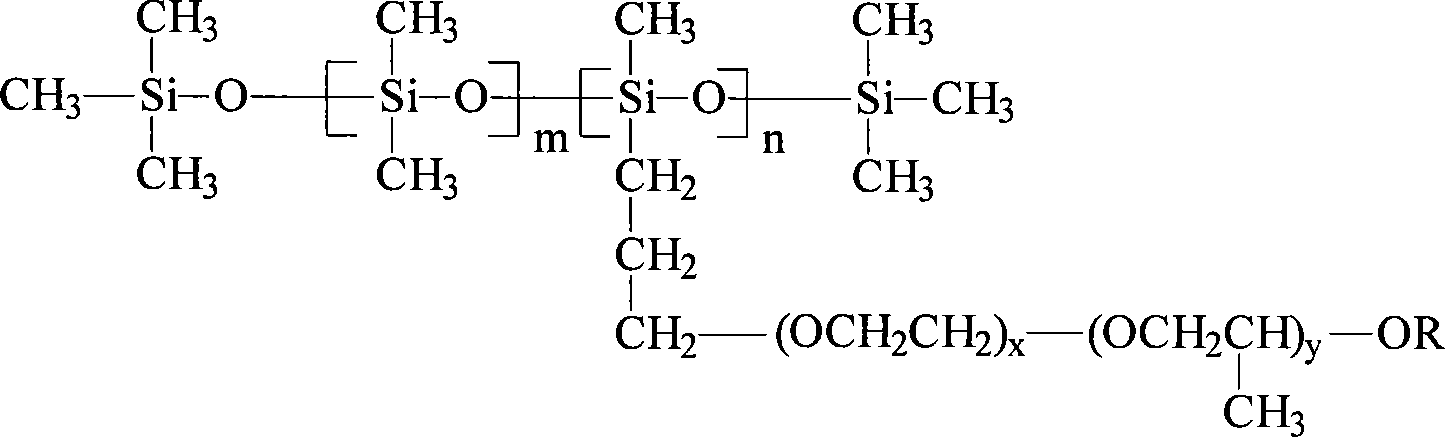

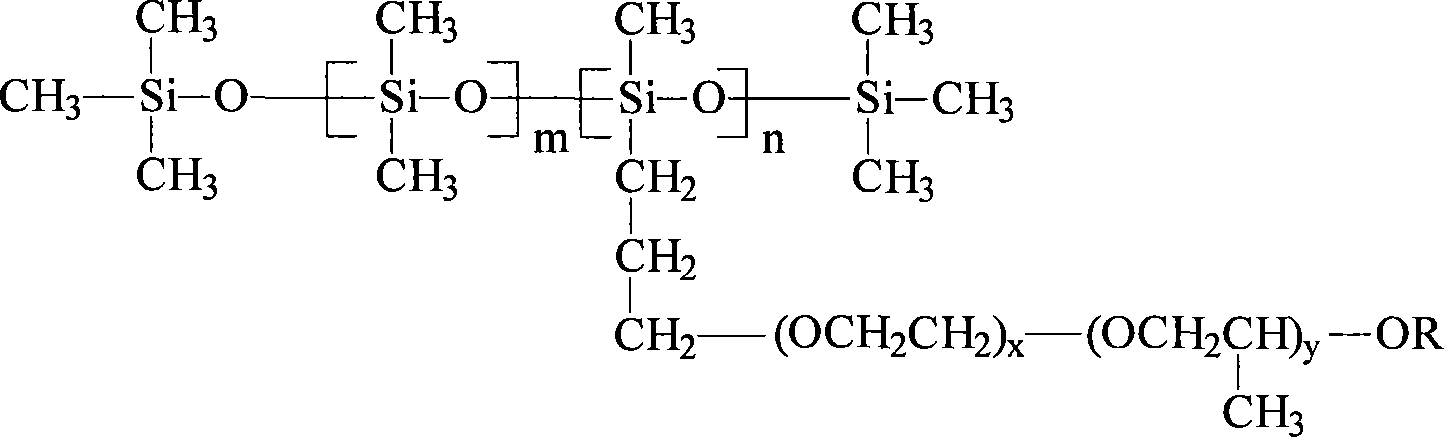

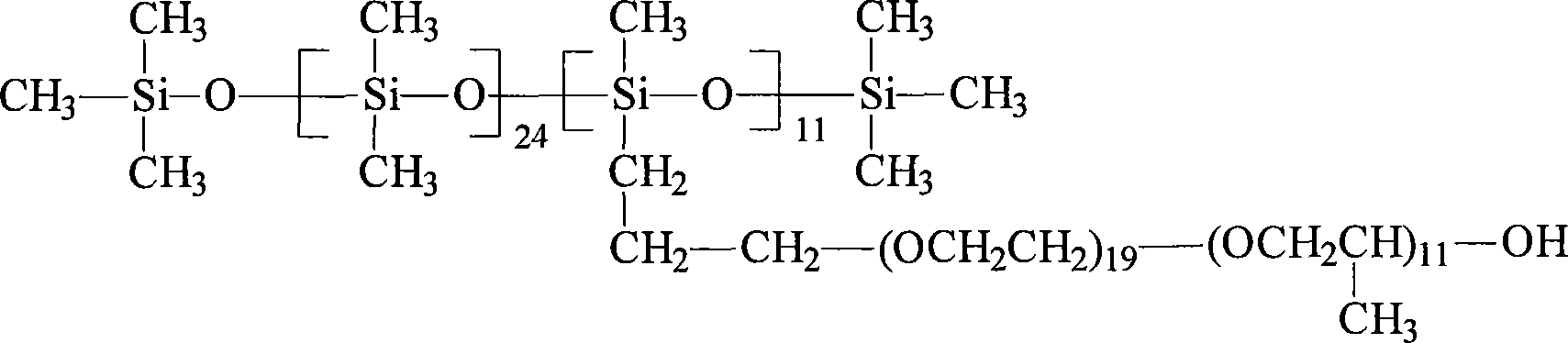

The invention discloses a low-density and low thermal-conduction-index polyurethane foam stabilizer and a preparation method thereof. The stabilizer can be widely used in polyurethane blowing technique, and enable the thermal conduction index of the pentane-blowing polyurethane foam to be lowered down to 0.0195-0.0200W / m.K, and has excellent functions of heat protection and heat preservation. The low-density and low thermal-conduction-index polyurethane foam stabilizer of the invention is provided with the structures: wherein, the figure of m is 10-80, the figure of n is 1-10, the figure of x is 10-70, the figure of y is 0-30, and m plus n is 11-90, x plus y is 10-100; R can be paraffin, radical aromatic, acyloxy or hydrogen atom that contains 1-4 carbon atoms.

Owner:JIANGSU MAYSTA CHEM

PPR (polypropylene randon coplymer) pipe material with excellent low-temperature toughness and preparation method thereof

The invention relates to a PPR (polypropylene randon coplymer) pipe material with excellent low-temperature toughness. The PPR pipe material is prepared from the following raw materials in parts by mass: 100 parts of polypropylene randon coplymer, 0.1 to 5 parts of coupling agent, 1 to 20 parts of toughening agent, 1 to 20 parts of crystal whisker loaded beta nucleating agent, 0.1 to 3 parts of antioxygen, and 0.1 to 5 parts of color master batch. The PPR pipe material provided by the invention has excellent low-temperature toughness, and has better rigidity, strength and pressure resistance at the same time; according to the PPR pipe material with the excellent low-temperature toughness provided by the invention, the reliability in transporting and applying the pipe material in a low-temperature environment is improved.

Owner:GUANGDONG LIANSU TECH INDAL

High-efficiency flocculant

InactiveCN103253752AExtensive sources of raw materialsReduce manufacturing costWater/sewage treatment by flocculation/precipitationChemistryPerlite

The invention discloses a high-efficiency flocculant which is composed of the following components in parts by weight: 15-25 parts of polyaluminum silicate sulfate-aluminum potassium sulfate mixture, 5-10 parts of ferric citrate, 3-5 parts of potassium ferrate, 2-5 parts of polyferric chloride phosphate, 5-10 parts of polyferric phosphate, 5-10 parts of polyaluminum chloride, 10-15 parts of soluble coating and 3-5 parts of flocculant activating component. The flocculant activating component is selected from one or combination of expanded perlite micropowder and fly ash micropowder, wherein the weight ratio of the expanded perlite micropowder to the fly ash micropowder is 3:2-5:3. The flocculant disclosed by the invention has the advantages of wide raw material sources, low production cost, low material input, favorable flocculation activating effect and low flocculation processing cost.

Owner:CHUZHOU YOULIN TECH DEV

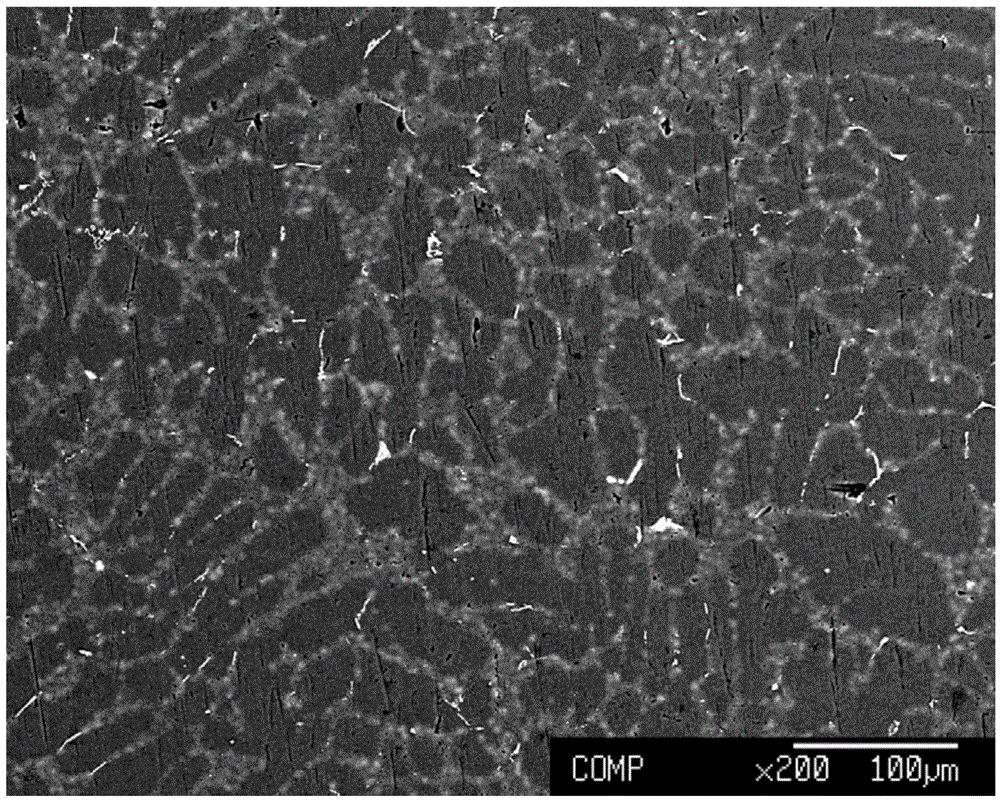

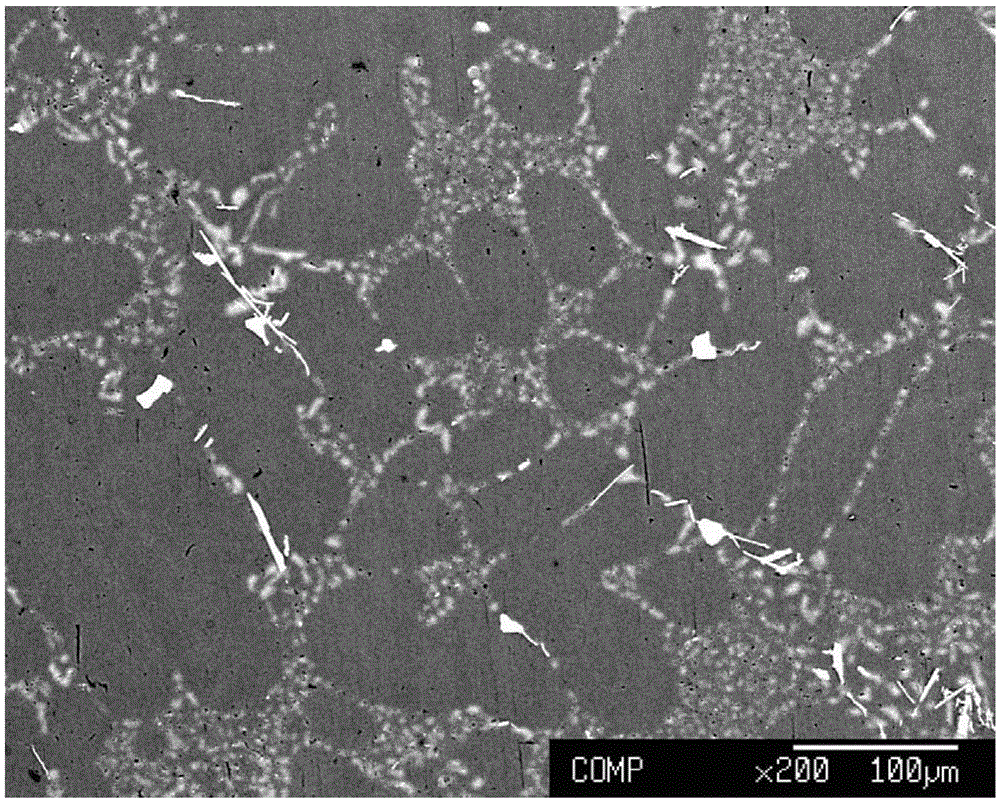

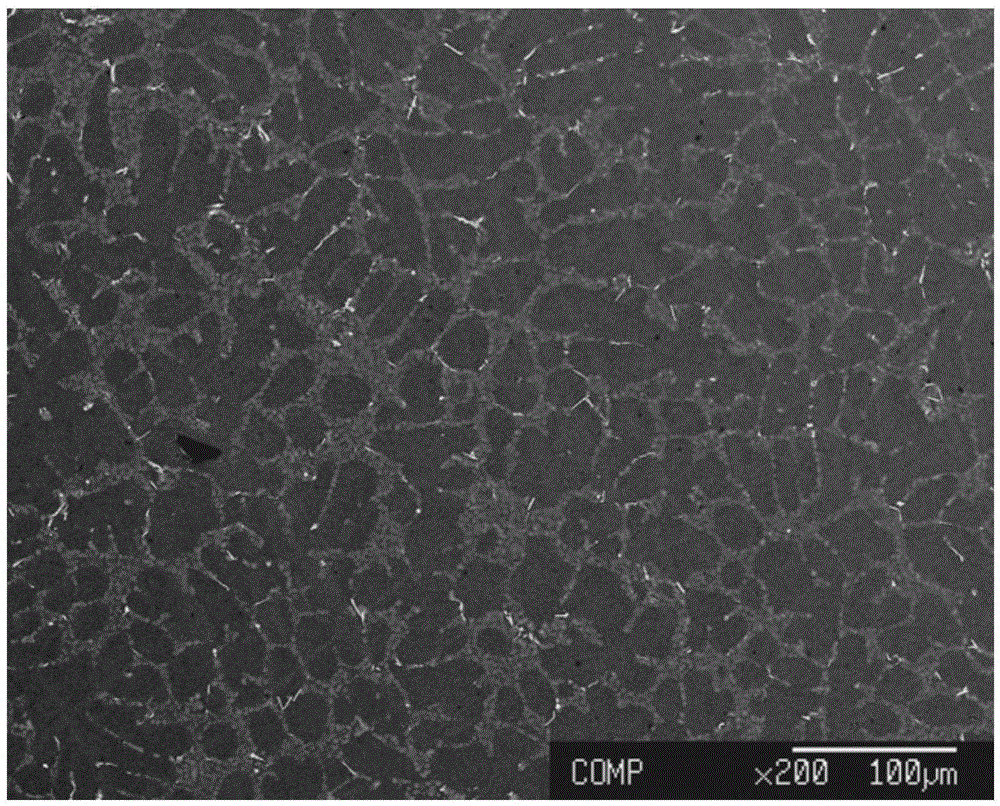

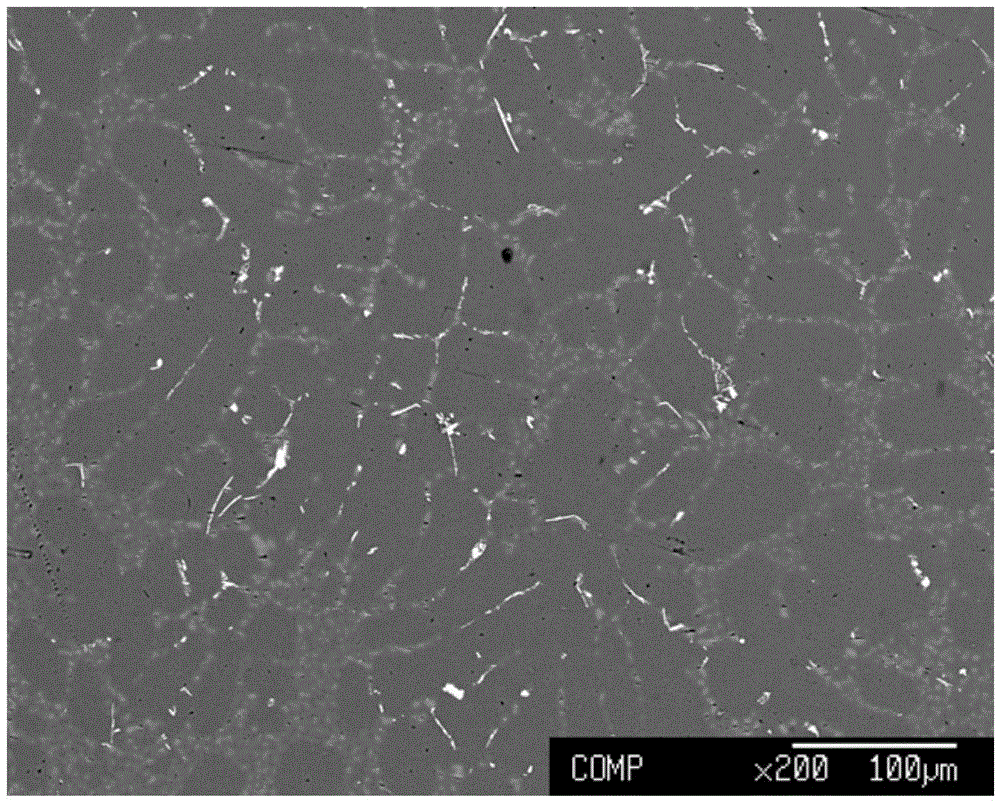

High-strength, high-elasticity modulus and low-stress gray cast iron and manufacturing method thereof

ActiveCN104894466AReduce harmful trace elementsImprove nucleation abilityProcess efficiency improvementPearliteIron phosphide

The invention discloses high-strength, high-elasticity modulus and low-stress gray cast iron and a manufacturing method thereof; and under the conditions of improving the carbon equivalent and the silicon-carbon ratio, the gray cast iron with excellent comprehensive performances is obtained through optimizing the raw material ratio by combining with the alloying, the smelting improvement, the inoculation and the aging treatment process. The gray cast iron comprises the components of 3.15-3.25% of C, 1.80-2.00% of Si, 3.75-3.90% of CE, 0.70-1.00% of Mn, P not more than 0.07%, 0.06-0.10% of S, 0.50-0.70% of Cu, and 0.20-0.30% of Cr; and the gray cast iron has the structure and the performance as follows: the pearlite content is not lower than 95%; the length of A type graphite is 4-5 grade; the content of cementite and iron phosphide eutectic is lower than 0.5%; the tensile strength is not higher than 300 MPa; the elasticity modulus is not higher than 120 GPa; the hardness HB is 190-220; and the internal stress is not lower than 20 MPa. The gray cast iron solves the technical difficulty that a gray iron casting for a machine tool is difficult to synchronously achieve high strength, high elasticity modulus and low stress, and effectively reduces the deformation and the rupture of the casting caused by the release of residual stress along with the time.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

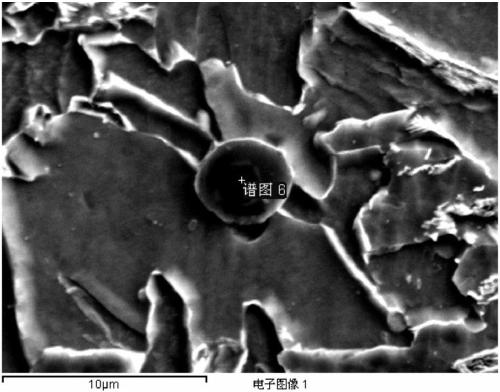

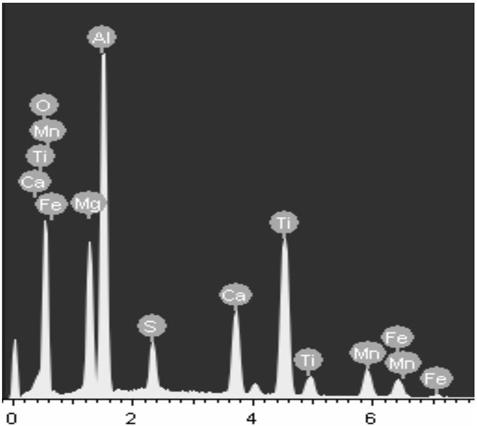

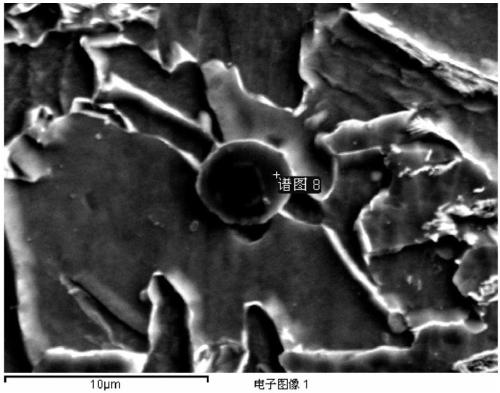

Thick steel plate suitable for large heat input welding in EH420 grade marine engineering and preparation method thereof

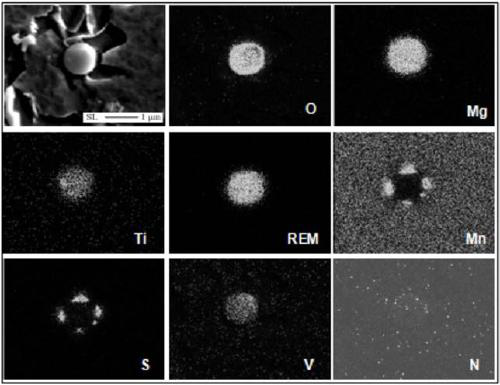

ActiveCN109321847AImprove nucleation abilityGood for fine dispersionMetal rolling arrangementsManganeseAlloy

The invention belongs to the technical field of low-alloy high-strength steel, and particularly relates to a thick steel plate suitable for large heat input welding in EH420 grade marine engineering and a preparation method of the thick steel plate. The steel plate comprises the following chemical components of, by mass percentage, 0.05-0.12% of C, 0.1-0.3% of Si, 1.0-1.7% of Mn, 0.001-0.01% of P,0.001-0.005% of S, 0.01-0.04% of Nb, 0.005-0.025% of Ti, 0.2-0.5% of Cu, 0.2-0.5% of Ni, 0.001-0.006% of N, 0.001-0.005% of O, 0.005-0.025% of Al, 0.0005-0.005% of Mg, 0.0005-0.005% of Ca and the balance of Fe. Al-Mg-Ti-Ca-Mn-O-S composite inclusions account for more than 10% of inclusions with the sizes of 0.5-5 [mu]m in the steel plate and have special compositions. The steel plate is preparedaccording to the steps of adding silicon and manganese when steel is discharged from a converter, and feeding calcium wires, titanium wires, magnesium wires and aluminum wires during LF and RH refining; and adopting two-stage controlled rolling and controlled cooling. Particles of the inclusions in the steel plate are favorable for fine dispersion and distribution, have a better capability of promoting acicular ferrite nucleation, and can obviously improve low-temperature toughness of large heat input welding.

Owner:NORTHEASTERN UNIV +1

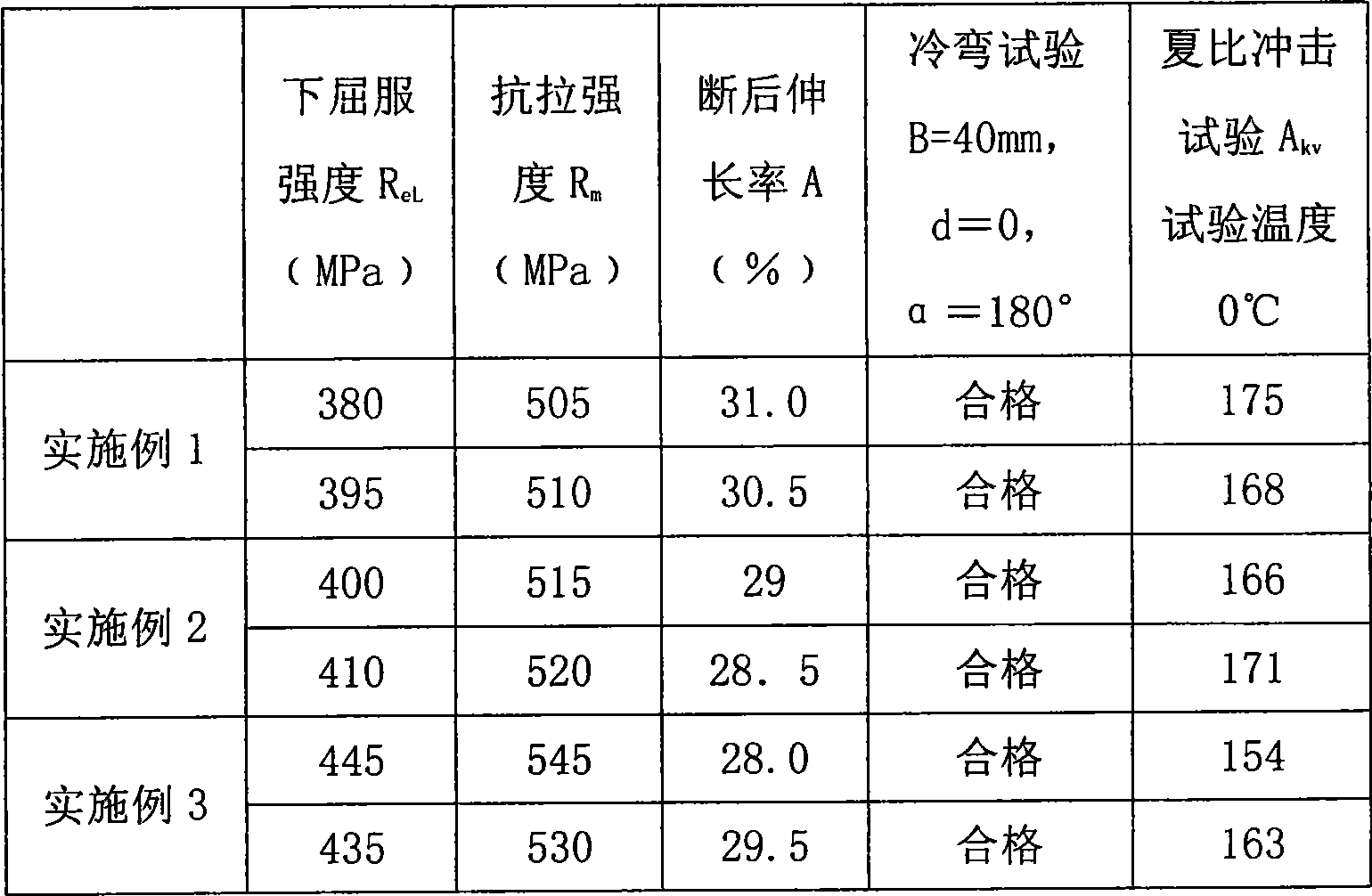

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

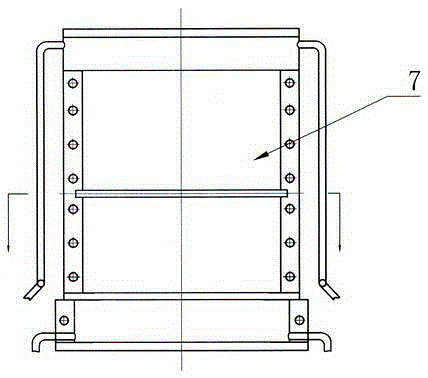

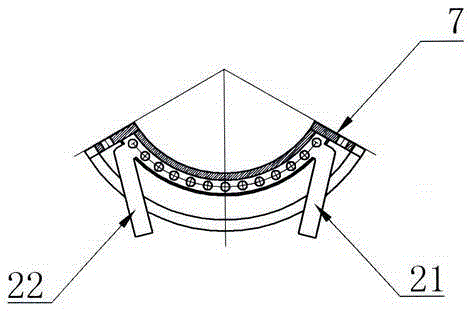

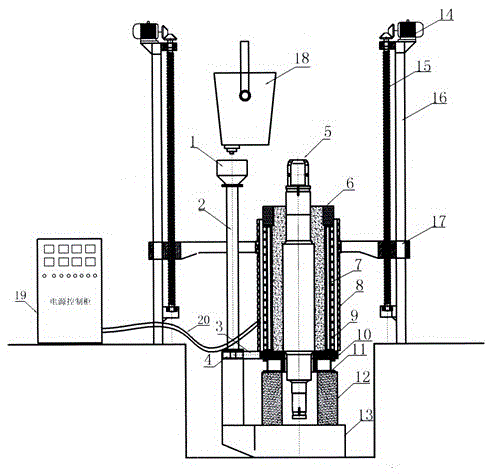

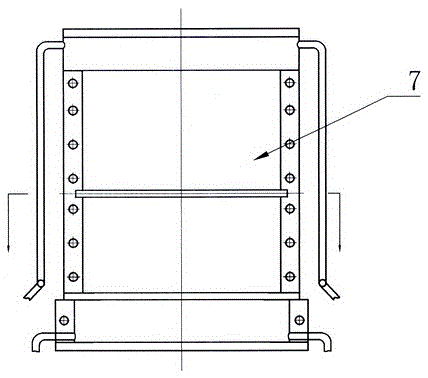

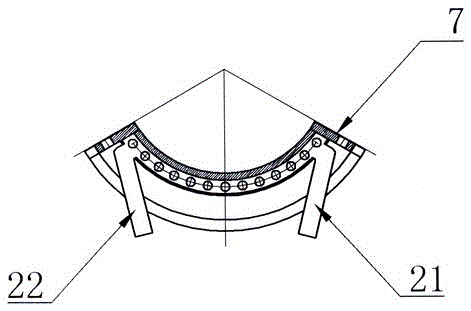

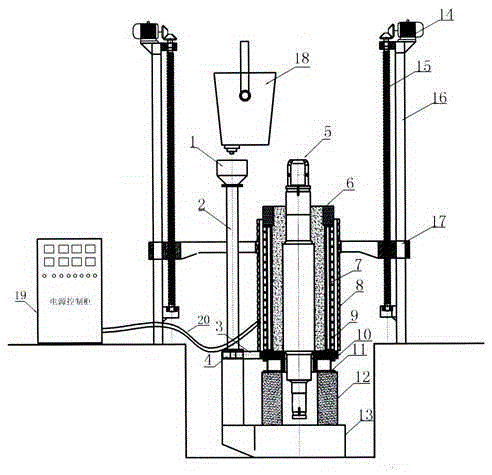

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

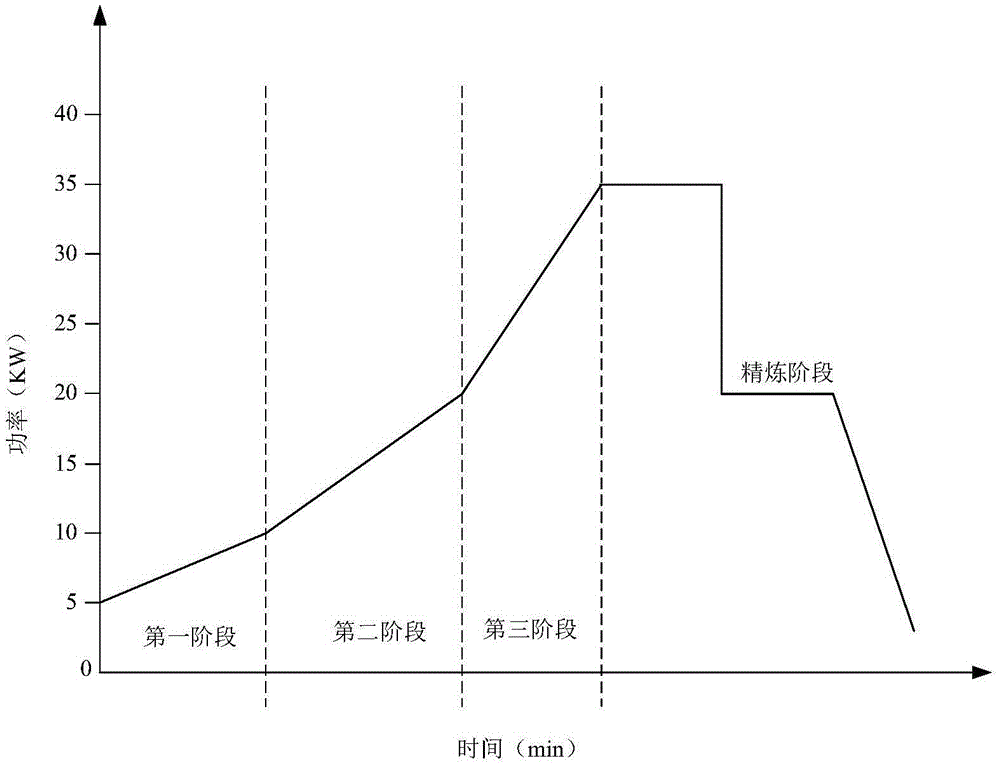

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

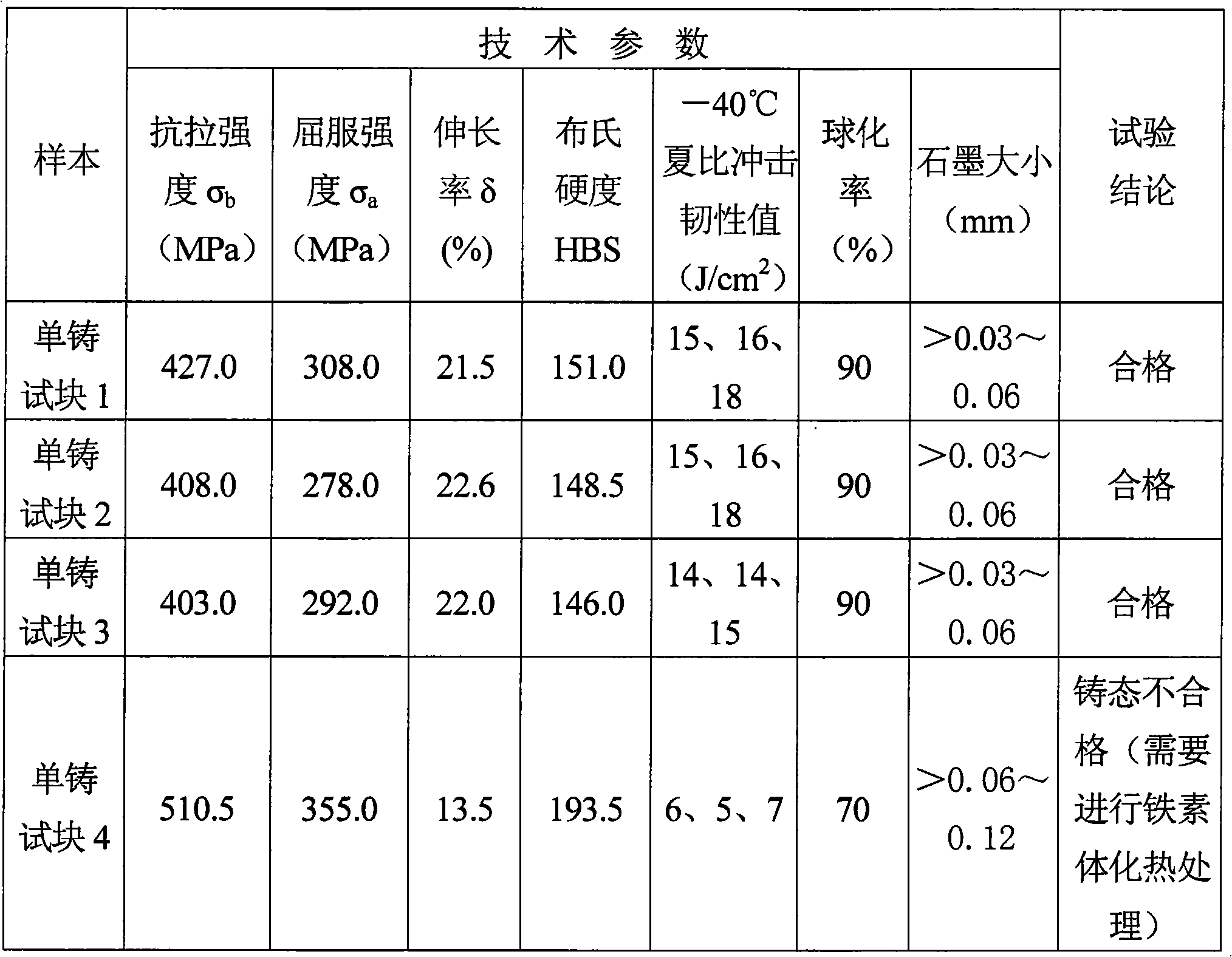

Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

The invention discloses low-temperature-resistance high-toughness as-cast ductile iron, which comprises the following chemical ingredients in percentage by weight: 3.4 to 3.6 percent of C, 2.0 to 2.3 percent of Si, at most 0.2 percent of Mn, at most 0.02 percent of P, at most 0.01 percent of S, 0.035 to 0.05 percent of Mg residue, 0.015 to 0.025 percent of sigma Re residue, 0.05 to 0.1 percent of Sr, 0.15 to 0.25 percent of Ni, 0.10 to 0.15 percent of Ti and the balance Fe. The invention also discloses a production method and application of the low-temperature-resistance high-toughness as-cast ductile iron to the preparation of wind-power generator accessories, automobile accessories, boat accessories and petrochemical engineering. The low-temperature-resistance high-toughness as-cast ductile iron produced by the method provided by the invention can reach each technical index of QT400-18L of GB / T1348-2009 in the cast state, the graphitizing annealing heat treatment is avoided, the energy consumption is reduced, and meanwhile, the low-temperature-resistance high-toughness as-cast ductile iron has the outstanding advantages of stable quality and the like, and the operation is simple and convenient.

Owner:四川海工科技有限公司

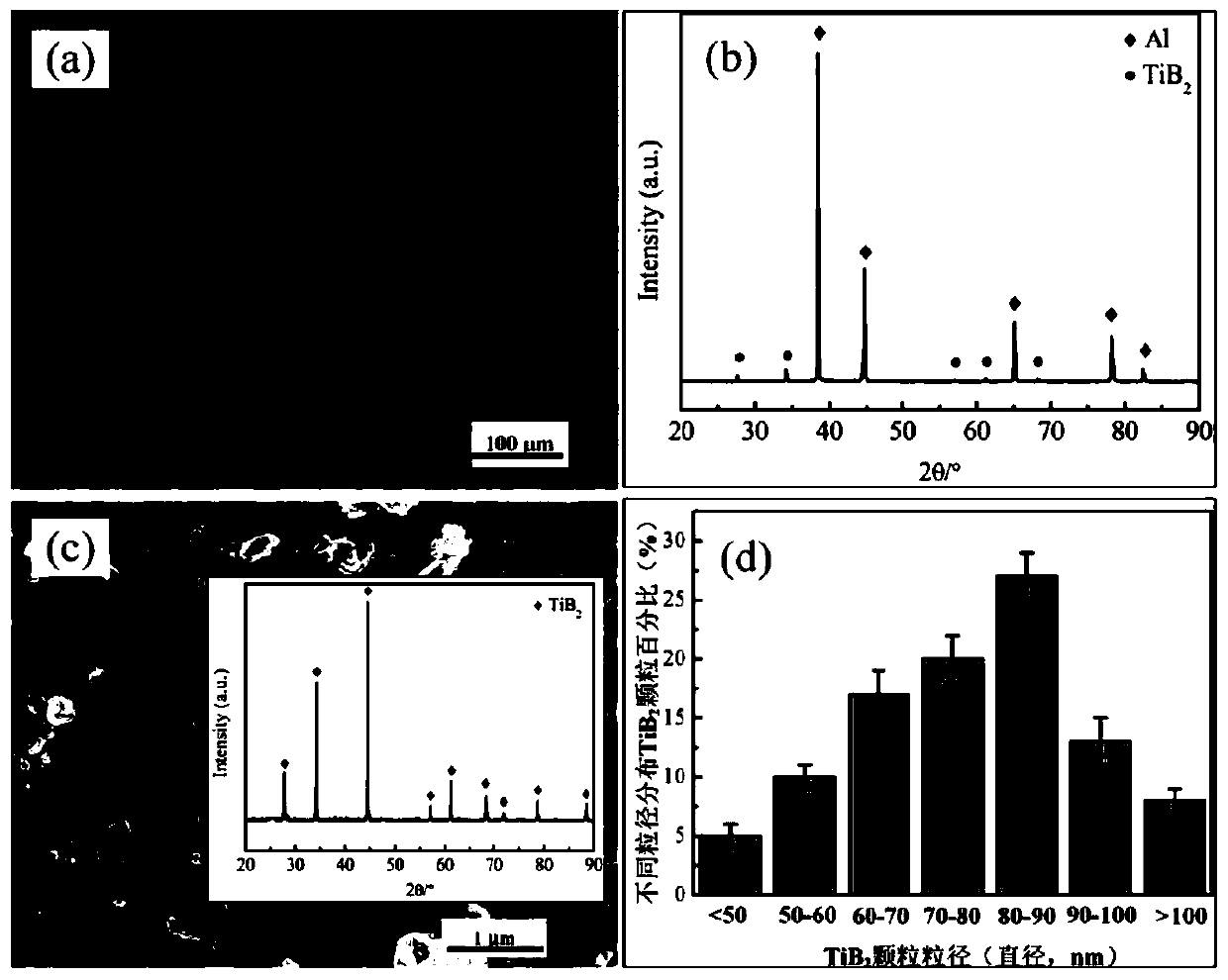

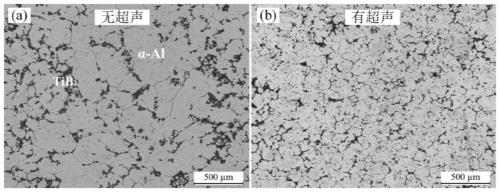

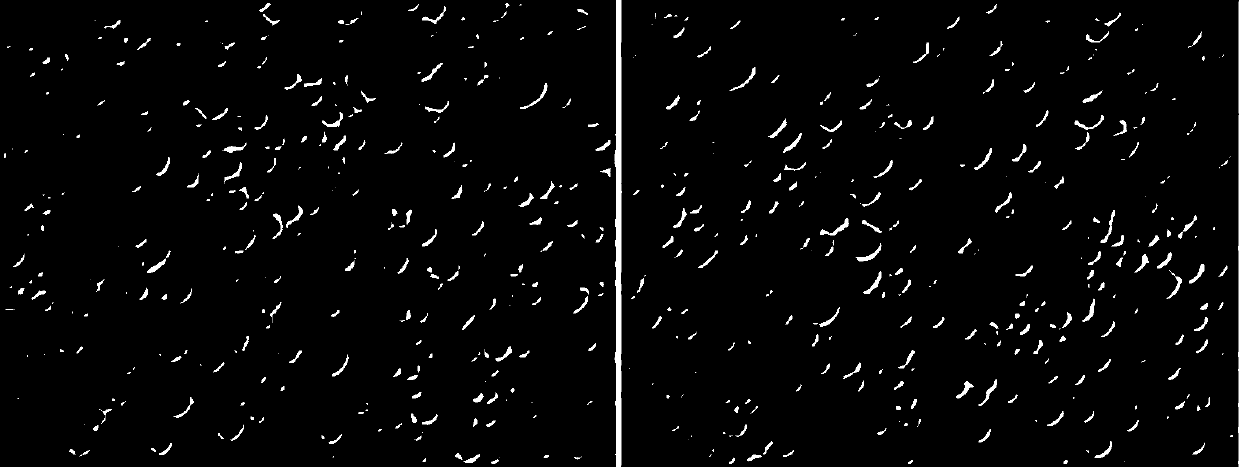

High-dispersive-distribution nano-titanium diboride particle reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material and a preparation method thereof. Firstly, a uniform-structure Al-TiB2 intermediate alloy is prepared through an ultrasound assisted mixed salt reaction (K2TiF6 / KBF4-Al), wherein the average particle diameter of in-situ endogenous TiB2 particles is smaller than 100nm; the Al-TiB2 intermediate alloy and Al are used as raw materials, or Al-TiB2 intermediate alloy, Al and alloy elements are used as raw materials, the nano-TiB2 particles are introduced into an aluminum (alloy) matrix through an intermediate alloy dilution method, ultrasound agitation treatment is used as assistance, then pouring into a mold is performed, and ultrasound is applied during solidification (introduction through a bottom introduction method); and thus the high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material is obtained.

Owner:咸阳瞪羚谷新材料科技有限公司

Combined flocculant

InactiveCN103241817AReduce manufacturing costReduce the amount of feedWater/sewage treatment by flocculation/precipitationMetasilicatePotassium ferrate

The invention discloses a combined flocculant composed of the following components in parts by weight: 5-10 parts of polymeric aluminum calcium chloride, 10-20 parts of aluminum trichloride, 10-20 parts of ferric citrate, 5-8 parts of polysulfide ferric chloride, 6-9 parts of polymeric ferric metasilicate, 2-3 parts of potassium ferrate, 5-10 parts of polyaluminum chloride, 10-15 parts of soluble coatings and 3-5 parts of flocculant activating components, wherein the flocculant activating components are selected from one or a combination of two from porous perlite micro powder and coal ash micro powder, and the particle size of the porous perlite micro powder is 200-300. The combined flocculant is good in humidity resistance, favorable in quality stability, long in quality guarantee period, high in adaptability for the natural environment and convenient to use.

Owner:CHUZHOU YOULIN TECH DEV

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

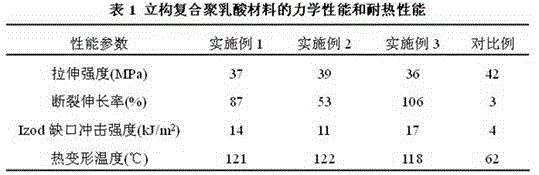

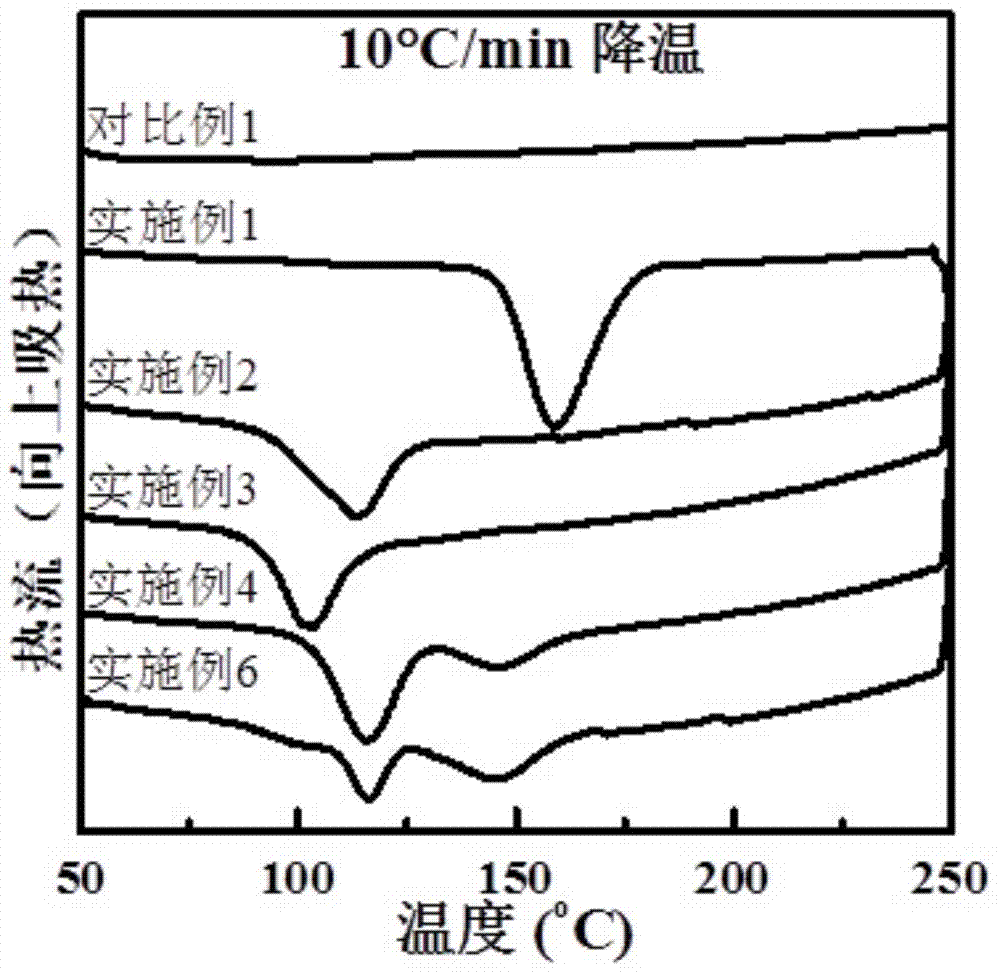

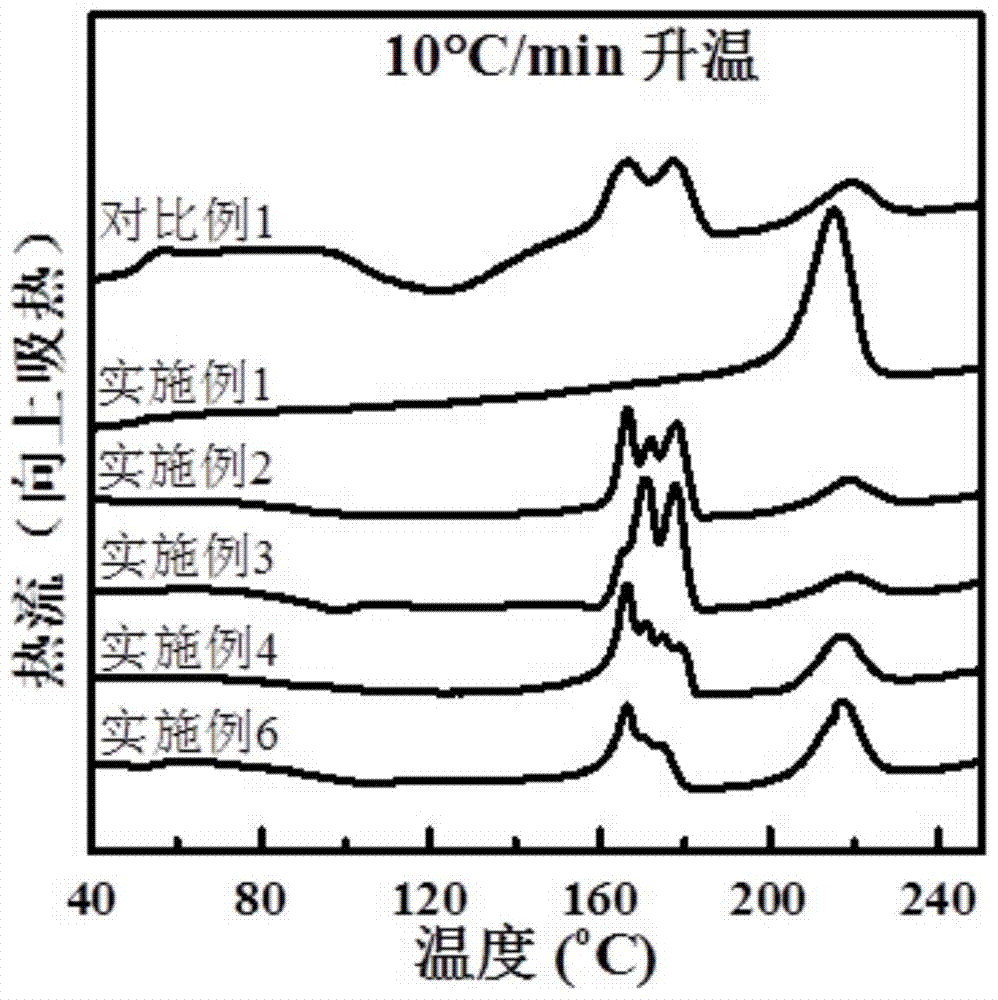

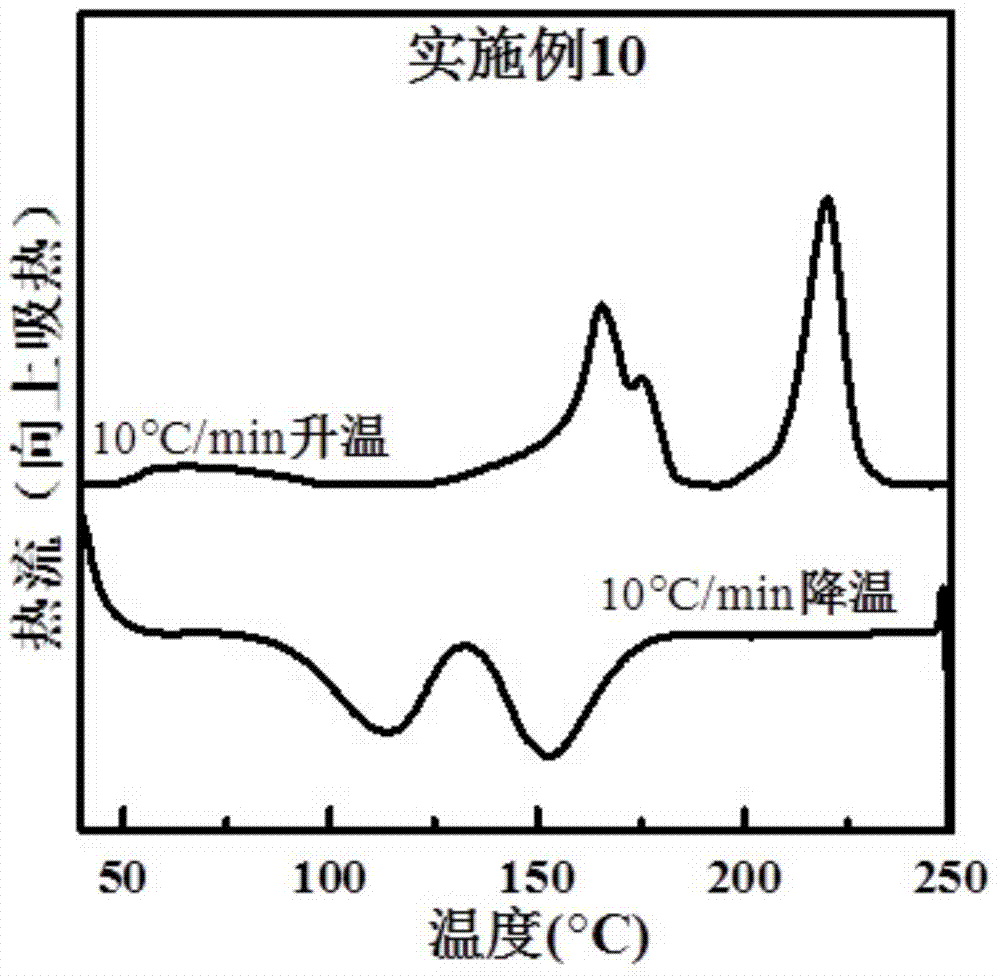

Composite polylactic acid material for 3D printing and preparation method thereof

ActiveCN106046726AImprove crystallization speedImprove heat resistanceAdditive manufacturing apparatusPolymer scienceUracil

The invention relates to a composite polylactic acid material for 3D printing. The high-toughness high-heat-resistance steric composite polylactic acid material suitable for 3D printing is prepared by melt blending of , by weight, 58-85% of PLLA and PDLA mixture, 0.2-2% of uracil derivative nucleating agent, 5-10% of polyethylene glycol and 10-30% of hydroxyalkanoate copolymer. The material can effectively increase crystallization speed and improve heat resistance of the polylactic acid steric composite, meets the requirement of 3D printing forming, remarkably improves impact strength of steric composite polylactic acid, remarkably increases breaking elongation and effectively solves the problem that 3D printing polylactic acid products are hard and fragile.

Owner:山西阳宸中北科技有限公司

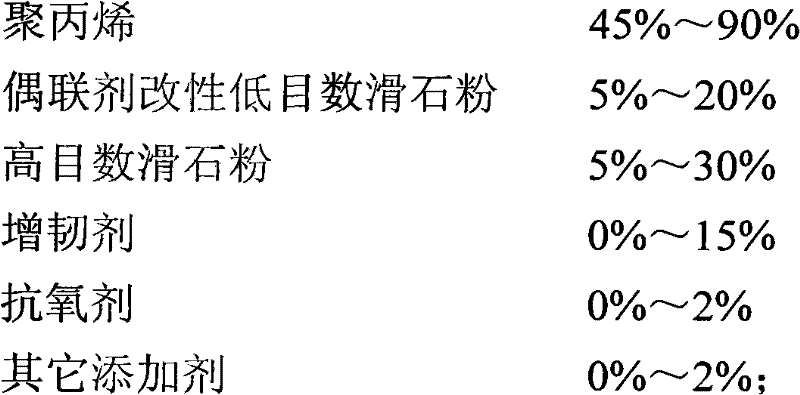

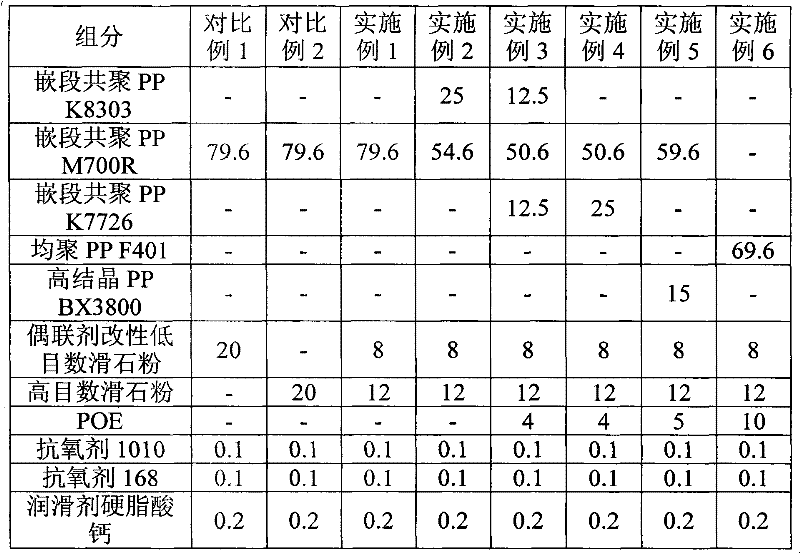

Rigidity-toughness balanced polypropylene

The invention discloses rigidity-toughness balanced polypropylene. The rigidity-toughness balanced polypropylene comprises: by weight, 45 to 90% of polypropylene, 5 to 20% of coupling agent-modified low-mesh talcum powder, 5 to 30% of high-mesh talcum powder, 0 to 15% of a flexibilizer, 0 to 2% of one or more antioxygens and 0 to 2% of one or more other additives. A preparation method of the coupling agent-modified low-mesh talcum powder comprises diluting a coupling agent by an appropriate amount of absolute ethanol and mixing the diluted coupling agent and low-mesh talcum powder well to obtain the desired product. Particle sizes of the low-mesh talcum powder are in a range of 400 to 1500 meshes and particle sizes of the high-mesh talcum powder are in a range of 2000 to 10000 meshes. Because of balance between rigidity and toughness, the rigidity-toughness balanced polypropylene can be utilized widely for interior and exterior decorations of middle / high-grade automobiles with a natural color or other colors. The invention also discloses a preparation method of the rigidity-toughness balanced polypropylene. The preparation method does not adopt special equipment.

Owner:中广核俊尔(上海)新材料有限公司 +1

Cast aluminum-zinc-magnesium-copper-tantalum alloy and manufacturing method thereof

Cast aluminum-zinc-magnesium-copper-tantalum alloy is formed by following ingredients, by weight percentage, of 0.02-0.51% of Ta, 1.5-3% of Mg, 1.5-2.5% of Cu, 6-10% of Zn, 0.0004-0.0102% of cerium-enriched mischmetal and the balance of Al. The invention also provides a manufacturing method for the cast aluminum-zinc-magnesium-copper-tantalum alloy. According to the cast aluminum-zinc-magnesium-copper-tantalum alloy, tantalum element is dissolved in aluminum grain in an atom manner along with magnesium element and copper element in a solid manner to generate a solid solution strengthening function. Furthermore, TaAl3-xZnx particles are formed and dispersed in an aluminum base body to generate a dispersion strengthening function. The particles have strong nucleation ability on aluminum grain, the aluminum grain is refined, and a refined crystalline strengthening effect is generated. The refined crystalline strengthening effect can enable zinc, magnesium, copper and compound to be distributed more evenly, microcosmic ingredient segregation is reduced, and the alloy strength is further improved.

Owner:UNIV OF JINAN

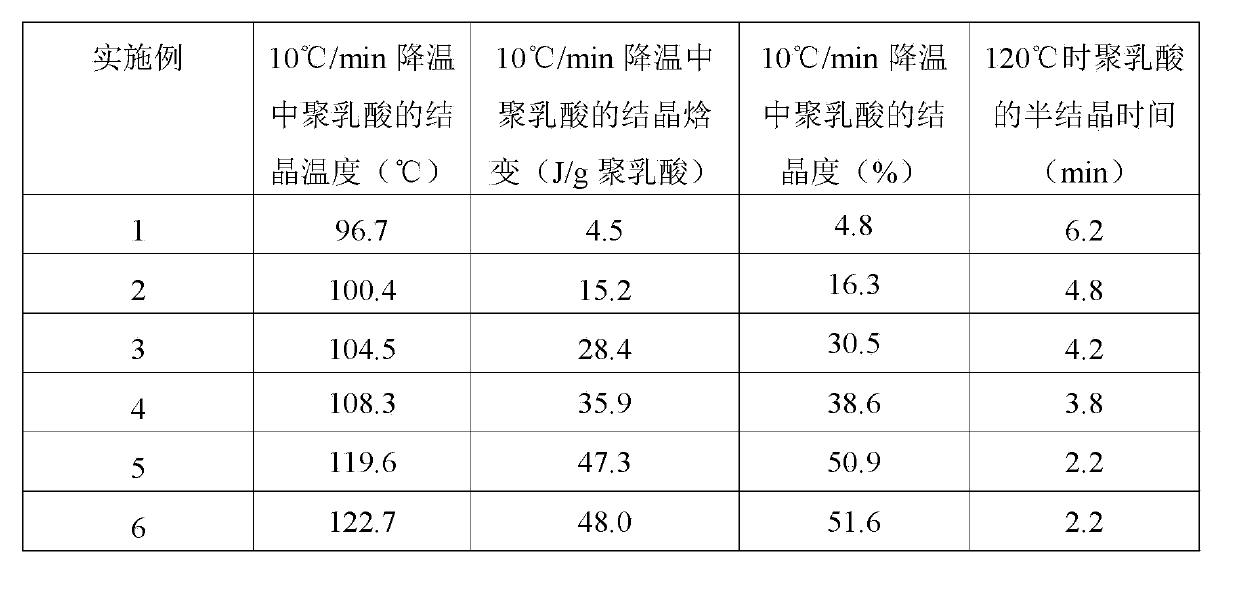

Method for accelerating crystallization of polylactic acid resin

ActiveCN103396659AImprove crystallization propertiesIncreased crystallinity and crystallization speedPolyvinylidene fluoridePolylactic acid

The invention relates to the technical field of polylactic acid modification and aims to provide a method for accelerating crystallization of polylactic acid resin. The method comprises the specific steps of: adding a semi-crystalline polylactic acid resin and a polymer-type crystallization promoter into a mixing apparatus; then mixing well in the mixing apparatus; and extruding for granulation, so as to obtain a rapid crystallization modification polylactic acid resin. The method employs organic high-molecular polymer-type crystallization promoter to improve crystallization performance of the polylactic acid, and the promoter has good compatibility with polylactic acid, improves nucleation effect, accelerates crystallization of polylactic acid, and improves processability and thermal behavior of the polylactic acid. Furthermore, a commercialized semi-crystalline polymer polyvinylidene fluoride having similar melting point as polylactic acid is used as the crystallization promoter for polylactic acid, and a melt blending method can be employed. The method provided by the invention has simple process, low cost and can realize large-scale industrialized production.

Owner:ZHEJIANG UNIV

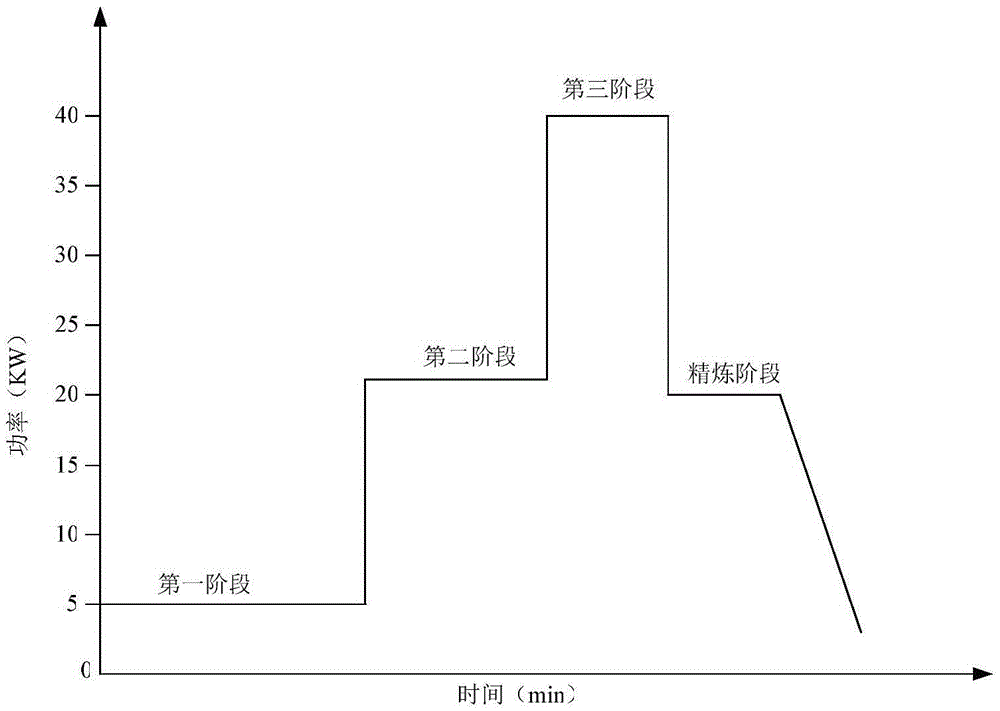

High-strength nickel-containing gray pig iron and casting method thereof

ActiveCN107267855AIncrease the amount of inoculationImprove nucleation abilityProcess efficiency improvementFerrosiliconScrap

The invention discloses high-strength nickel-containing gray pig iron. The high-strength nickel-containing gray pig iron comprises the following elements, by mass, including 2.9%-3.4% of C, 1.3%-1.7% of Si, 0.05%-0.1% of S, 0.6%-1.0% of Mn, 0.4%-0.9% of Cu, 0.15%-0.4% of Cr, 0.1%-0.3% of Ni, less than 0.07% of P and the balance Fe and negligible impurities and elements. Mainly, steel scrap, recirculated iron, silicon carbide, a carburant, ferromanganese, copper, silicon iron and nickel are smelted into molten iron, ladle inoculation and ladle-to-ladle inoculation are sequentially carried out, and the high-strength nickel-containing gray pig iron is obtained through casting molding. The invention further discloses a casting method of the gray pig iron. The gray pig iron provided through the method is high in strength, a prepared engine wall is thin, and the requirement for the engine performance at present is met.

Owner:GUANGXI YUCHAI MASCH CO LTD

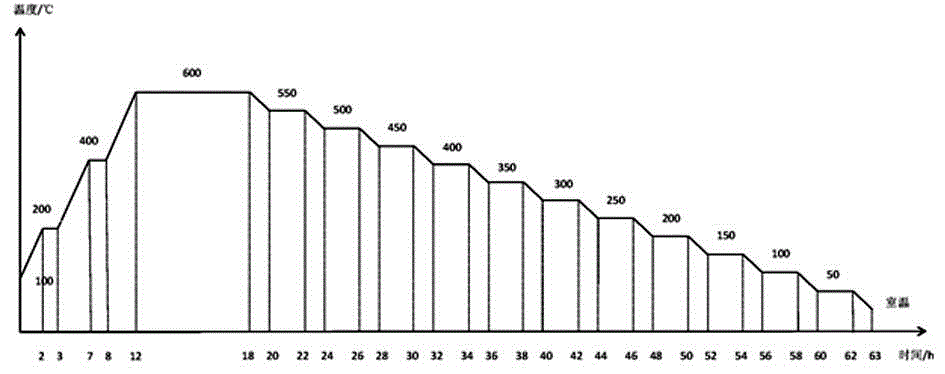

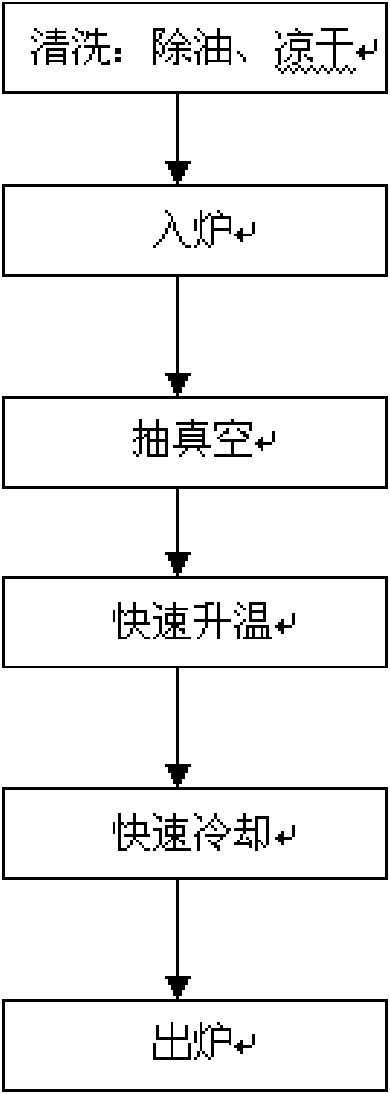

Vacuum annealing method for tantalum tube

InactiveCN101603164AGood organization and performanceFine and uniform grainFurnace typesHeat treatment furnacesAir dryingEnergy consumption

The invention relates to a rapid vacuum annealing method for a tantalum tube, which comprises the steps of: washing and air-drying the tantalum tube; placing the washed tantalum tube into a heat-resistant casing, and axially sending the washed tantalum tube and the heat-resistant casing to a vacuum induction annealing furnace together; adopting a three-stage vacuum system to work, and ensuring that the three-stage vacuum system pumps until the vacuum degree is 10Pa; ensuring that the inside of the vacuum induction annealing furnace is in a high vacuum state; and annealing the tantalum tube in the vacuum induction annealing furnace, namely finishing the temperature increase by heating and quick cooling in the furnace. The annealing by the method has the advantages of quick temperature increase of the tantalum tube, good product structure and performance of the tantalum tube, good mass conformance of the tantalum tube, low energy consumption, low operation cost, low investment on annealing equipment, and simple disassembly and maintenance. The method does not perform heat preservation for a long time and has low power consumption. The admissible stress of the tantalum tube is improved by 60 percent or so compared with the prior vacuum annealing furnace after the annealing is performed by the method; and under the same service strength, the method can save about 40 percent of tantalum materials and has remarkable economic benefit.

Owner:长沙南方钽铌有限责任公司

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Composite modification method for hypereutectic aluminum-silicon alloy

ActiveCN103361524AHighlight substantive featuresSignificant progressSilicon alloyMechanical property

The invention relates to a composite modification method for a hypereutectic aluminum-silicon alloy. According to the composite modification method, P and Ca are adopted for performing composite modification on the hypereutectic aluminum-silicon alloy, and a modification process comprises the following steps of: overheating a hypereutectic aluminum-silicon alloy melt to 760-850 DEG C, rapidly pressing a P modification agent into the melt, standing, performing heat preservation for 10-240min, degassing, refining, adjusting the temperature of the melt to 740-800 DEG C, adding a Ca modification agent into the melt, standing, performing heat preservation for 5-120min, and then molding by casting, wherein the casting temperature is controlled at 70-170 DEG C above a liquid phase line and the cooling speed is 10-1000 DEG C / s. According to the method, primary silicon in the hypereutectic aluminum-silicon alloy with the silicon content of 14-23% is refined to below 30mu m, the distribution is uniform, eutectic silicon is fibrous or dotted, and the mechanical properties are significantly improved.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

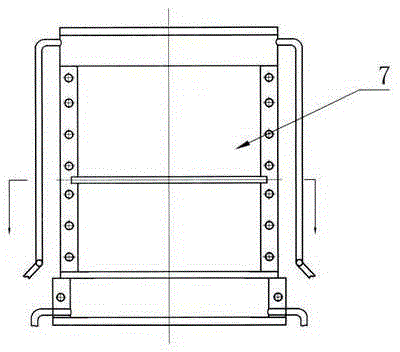

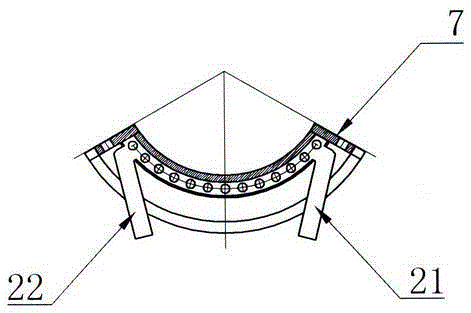

Manufacturing technique and equipment for high-performance composite roller shaft

The invention discloses a manufacturing technique and equipment for a high-performance composite roller shaft. The manufacturing technique comprises the steps that a mandril installed in a combined water-cooling crystallizer is integrally heated to 840-1100 DEG C through an induction heater; molten liquid of a working layer of the roller shaft is poured into the mandril, and then the mandril is continued to be heated for 10-50 minutes; a lifting device is stared so as to lift the heater at a certain speed for 5-15 minutes, and the heater is stopped in the position of a heat-insulating ring; and heating is continued for 10-50 minutes, feeding is conducted on a dead head, and after heating is stopped, cooling is conducted for 30 minutes to 24 hours through water. When the composite roller shaft is manufactured through the manufacturing technique, the number of controllable technological parameters is small, the interface of a composite layer is easy to control, the technique is simple, the efficiency is high, the power consumption is low, the cost is low, the composite layer is free of composition segregation, and the service life of the roller shaft is long; the defect of a centrifugation method that structure segregation is prone to occurring is overcome, and the problems of a CPC method and an ESR method that the production technique is complex, and the cost is high are solved.

Owner:丹阳恒庆复合材料科技有限公司

Low-cooling-rate-sensitivity high-nucleation-capability AlNbBRE refiner for cast aluminum alloy and preparation method of refiner

The invention discloses a low-cooling-rate-sensitivity high-nucleation-capability AlNbBRE grain refiner for cast aluminum alloy and a method for preparing the refiner by adopting induction smelting; the ingredients of the refiner are Al-xNb-yB-zRE, wherein x is larger than 0.01wt% and smaller than or equal to 6wt%, y is larger than 0.01wt% and smaller than or equal to 3wt%, z is larger than 0.01wt% and smaller than or equal to 1wt%, and the balance is Al; RE is one of or a mixture of two of La, Ce, Nd, Er, Gd, Y, Yb and Sc. The method is simple in preparation process and capable of accurately controlling the ingredients of the refiner. The refiner is excellent in refining effect when being used for performing grain refinement on cast aluminum-silicon alloy and is relatively low in cooling rate sensitivity on the refining effect of the positions, complicated in shape and different in thickness, of a cast piece, namely of the positions different in cooling rate; the mechanical properties of the refined alloy are remarkably improved; the performance differences of the positions which are different in cooling rate are remarkably reduced.

Owner:BEIHANG UNIV

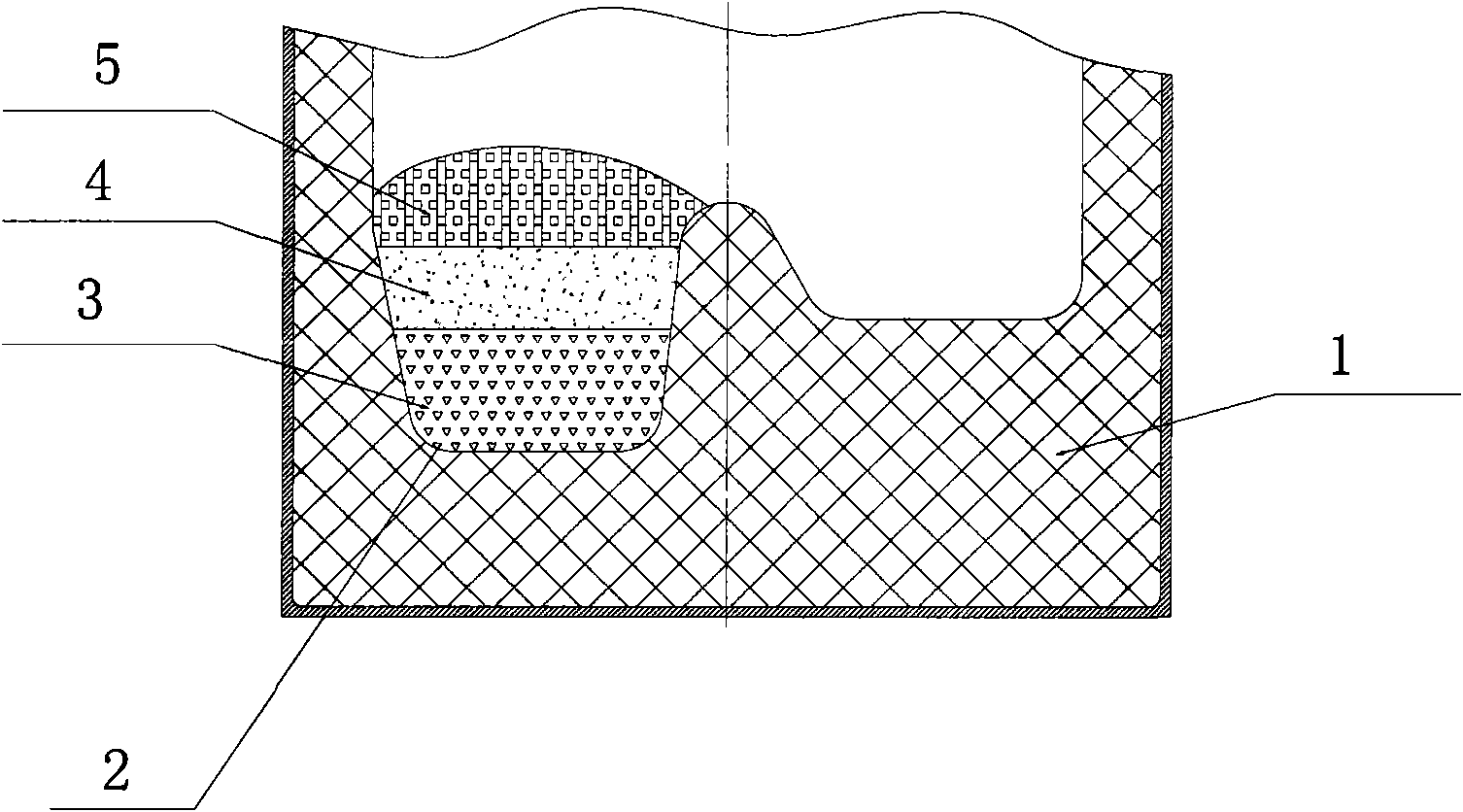

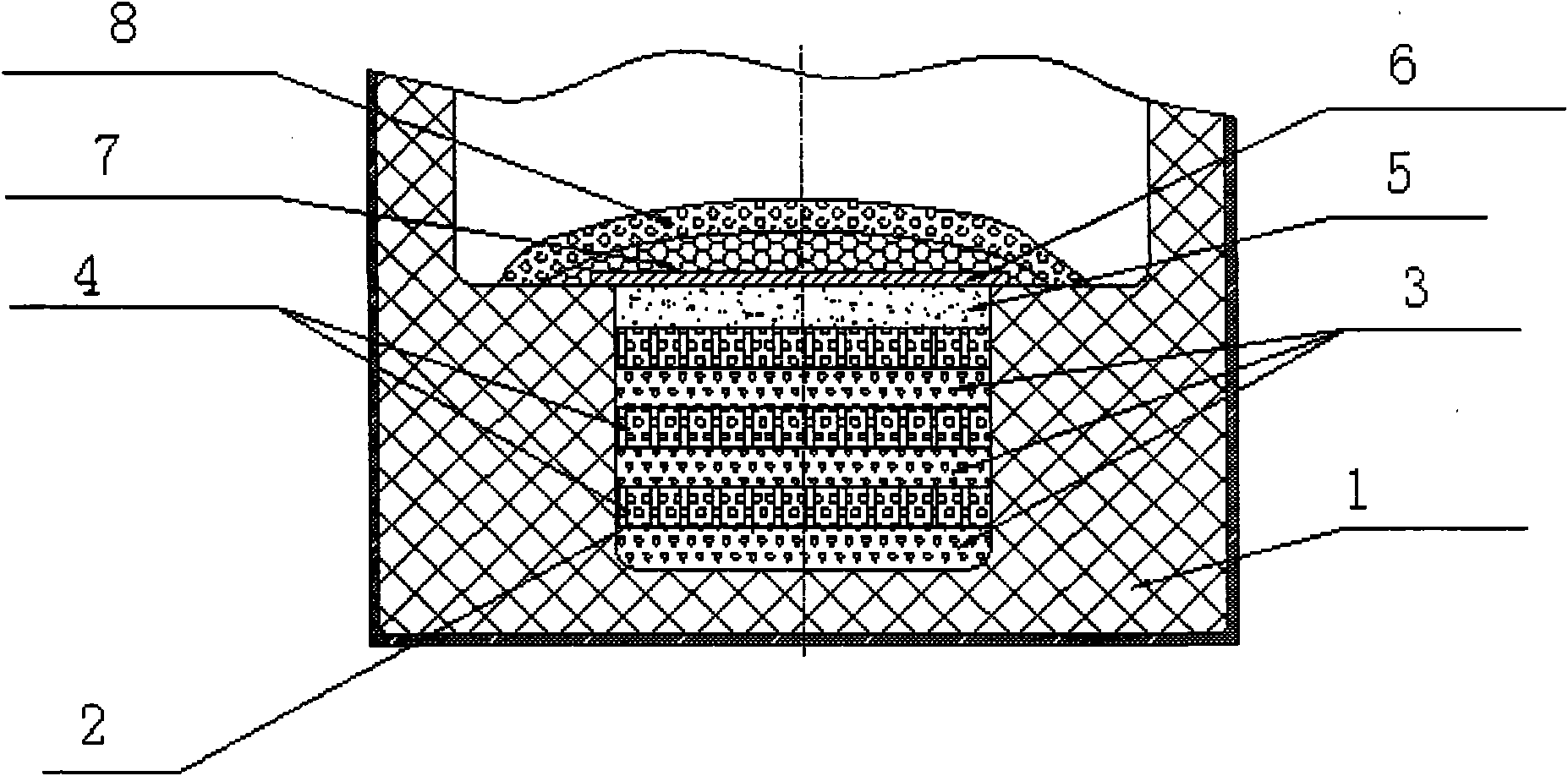

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Organic/inorganic compound type flocculant

InactiveCN103241818AWide variety of sourcesReduce manufacturing costWater/sewage treatment by flocculation/precipitationCelluloseInorganic compound

The invention discloses an organic / inorganic compound type flocculant which consists of the following components in parts by weight: 10-20 parts of aluminum potassium sulfate, 10-15 parts of ferric citrate, 3-5 parts of ferrate, 5-10 parts of polyaluminum chloride, 10-15 parts of mixture of polyacrylamide, gelatin and soluble cellulose, 3-5 parts of flocculant activation component, 5-10 parts of dicyanodiamine, 5-10 parts of formaldehyde and 15-25 parts of polycalcium aluminum chloride sulfate. The flocculant disclosed by the invention has the advantages of wide source of raw materials, low production cost, small investment, good flocculation excitation effect and low flocculation treatment cost, remarkably reduces the water content of waste residues, and greatly improves the removal rate of suspended solids.

Owner:CHUZHOU YOULIN TECH DEV

Preparation method of high-molecular polylactic acid (PLA) three-dimensional composite material capable of being crystallized rapidly

The invention relates to the technical field of modification of biological high-molecular materials, and aims to provide a preparation method of a high-molecular PLA three-dimensional composite material capable of being crystallized rapidly. The high-molecular PLA three-dimensional composite material capable of being crystallized rapidly can be prepared by solution or melt blending of a PLA matrix and an organic metal phosphonate nucleating agent. According to the invention, three-dimensional composite crystallization of a high-molecular PLLA / PDLA (Poly L Lactic Acid / Poly-D-Lactic Acid) blend is promoted by adopting organic metal phosphonate; the homogeneous crystallization is inhibited; the three-dimensional composite crystallization speed and the crystallization degree of the blend are greatly increased; the three-dimensional composite crystallization degree can be above 40%; the processibility, the heat-resistant property and the mechanical property of the PLLA / PDLA blend are increased effectively; simultaneously, the solvent resistance and the degradation resistance of PLA are also improved.

Owner:ZHEJIANG UNIV

Low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and preparation method of low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy

The invention discloses a low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and a preparation method of the low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy. The low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier is prepared from Al-xNb-yTi-zB-kRE, wherein 0.01<x<=6wt%, 0.01<y<=6wt%, 0.01<z<=1wt%, 0.01<k<=1wt%, and the balance is Al; and RE is one of La, Ce, Nd, Er, Gd, Y, Yb and Sc or a mixture of two or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. A preparation technology is simple, and the compositions can be precisely controlled. The composite refining modifier is used for processing aluminum alloy, and the refining effect and the modifying effect are excellent; for all parts of castings complex in shape and different in thickness, namely, all parts with different cooling rates, the cooling rate sensitivity of the refining effect is low; and the mechanical performance of the obtained alloy is remarkably improved, and the performance difference between the parts with different cooling rates is remarkably reduced.

Owner:北京航大新材科技有限公司

Steel sheet applicable to ultrahigh heat input welding and manufacturing method thereof

PendingCN109321817AInhibit grain coarseningImprove nucleation abilityChemical compositionHeat-affected zone

The invention belongs to the technical field of low-alloy and high-strength steels, and particularly relates to a steel sheet applicable to ultrahigh heat input welding and a manufacturing method. Thesteel sheet comprises the chemical components of C, Si, Mn, Nb, V, Ti, P, S, Cu, Ni, Cr, Mo, B, N, O, Al, Mg, one of Zr and REM, and the balance Fe, wherein the types of inclusions with different sizes in the steel sheet are controlled, and thus the obvious refining of a structure in a welding heat influencing area is realized; the adding technology of Ti, Zr, REM, Mg, V and N in the smelting process is controlled; special inclusion distribution in the steel is realized; and meanwhile, the high toughness of the steel sheet is improved through a controllable rolling and cooling technology. Thesteel sheet is applicable to 500-1500kj / cm ultrahigh heat input welding and meets the demands of the fields such as the field of buildings on steels for ultrahigh heat input welding.

Owner:NORTHEASTERN UNIV

Water treatment flocculating agent

InactiveCN103232101AWide variety of sourcesReduce manufacturing costWater/sewage treatment by flocculation/precipitationPolyamineCoal

The invention discloses a water treatment flocculating agent. The water treatment flocculating agent consists of the following components: 15 to 30 weight parts of aluminum-containing compound, 15 to 20 weight parts of ferric citrate, 5 to 8 weight parts of polymeric ferric sulfate, 3 to 5 weight parts of sodium ferrate, 5 to 10 weight parts of polymeric aluminum chloride. 10 to 15 weight parts of non-ionic polyacrylamide, 5 to 10 weight parts of polyamine compounds and 3 to 5 weight parts of the mixer of porous perlite micro-powder and coal ash micro-powder. According to the water treatment flocculating agent, the molecular weight of the flocculating agent is increased by introducing the polyamine compounds, so that the water treatment flocculating agent is high in viscosity and high in stability, facilitates industrial production,and has the characteristics of quick sedimentation, good decoloring effect and the like.

Owner:CHUZHOU YOULIN TECH DEV

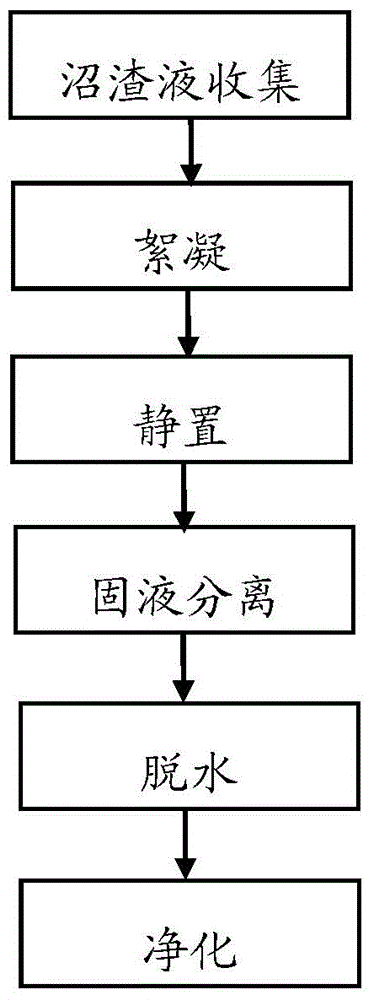

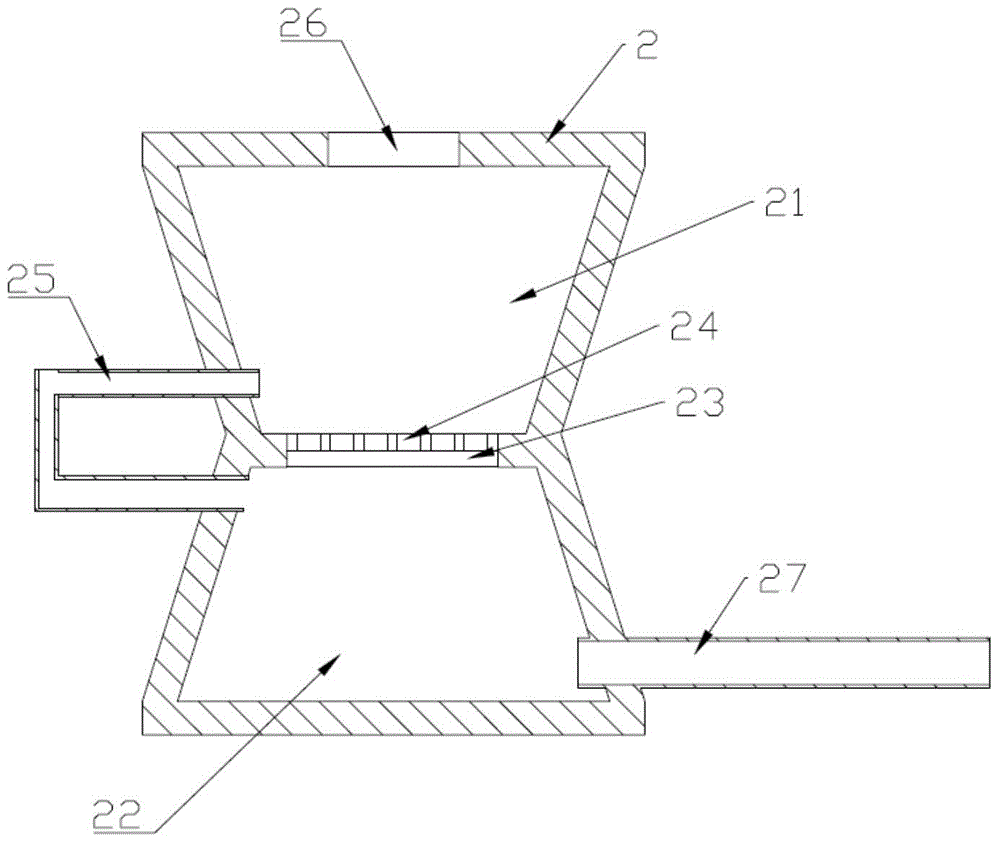

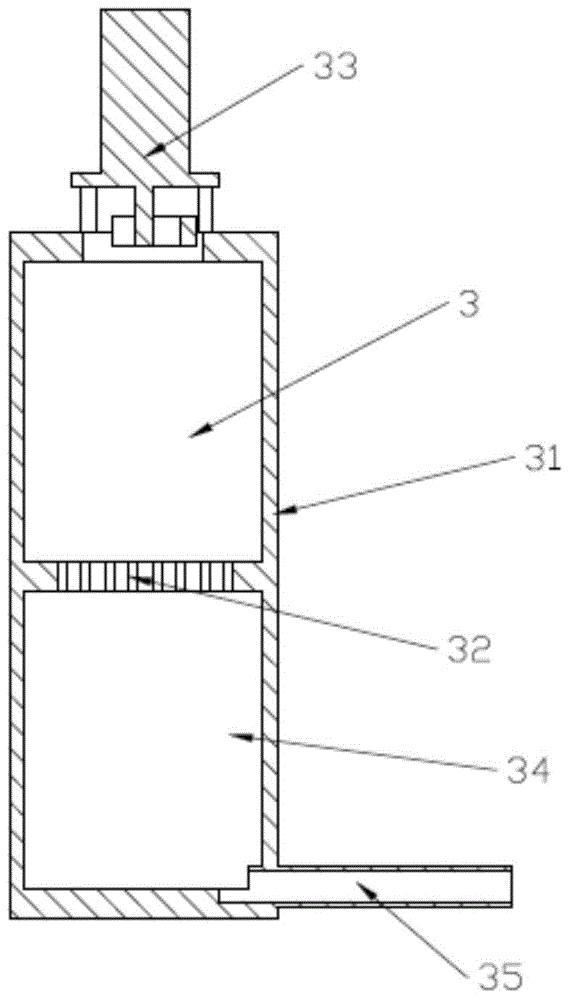

Biogas residue liquid processing method

InactiveCN104030482AImprove use valueImprove processing efficiencyMultistage water/sewage treatmentFlocculationPollution

The invention discloses a biogas residue liquid processing method suitable for large biogas digesters. The method comprises the steps of biogas residue liquid collection, flocculation standing, solid-liquid separation, dehydration and purification. The dehydration rate is improved through flocculation, standing solid-liquid separation, pre-dehydration and dehydration steps, so the utilization values of the biogas residue liquid are improved, and the treatment efficiency of the biogas residue liquid is improved; and additionally, biogas residues and a biogas liquid are not leaked in the whole treatment process, and are recovered respectively, so the utilization rates of the biogas residues and the biogas liquid are improved, and secondary pollution risks are reduced.

Owner:HUIZHOU TIANJIAN NEW ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com