Patents

Literature

51results about How to "Meet manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying ultra-pure hydrofluoric acid

ActiveCN101125639AIt is not easy to solve this difficult problemHigh purityFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention relates to a purifying method of ultrahigh pure hydrofluoric acid, comprising the technological steps as follows: filling industrial anhydrous hydrogen fluoride liquid into a rectifying still, and adding potassium permanganate with 0.16 to 1 percent weight, stirring, then stopping; after that, adding hydrogen peroxide with 0.16 to 1 percent weight, stirring, then stopping; heating up to 60 to 80 DEG C, the hydrogen fluoride liquid is gasified and generated into purified hydrogen fluoride gas; subsequently, filling the purified hydrogen fluoride gas which goes out of the rectifying still into a cooler for cooling and filtering; injecting deionized water into an absorption tower whose bottom is provided with a gas distribution plate tube, after that, filling the hydrogen fluoride gas which goes out of the cooler into the gas distribution plate tube at the bottom of the tower; after sprayed out of the gas distribution holes on the tube wall of the gas distribution plate tube, the hydrogen fluoride gas is absorbed by the deionized water and produced into semi finished product of hydrofluoric acid; finally, filling the semi finished product of hydrofluoric acid which goes out of the absorption tower into a filter in 0.05Mum, after that, obtaining the finished product of ultrahigh pure hydrofluoric acid. The product prepared by the method of the invention has high fineness and output, according to the requirements of the environmental protection.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

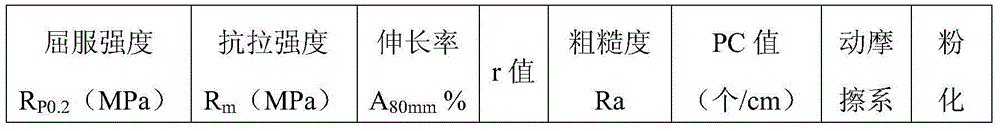

Self-lubrication alloying galvanized steel plate for automobiles and preparation method of self-lubrication alloying hot galvanized steel plate

The invention discloses a self-lubrication alloying hot galvanized steel plate for automobiles and a preparation method of the self-lubrication alloying galvanized steel plate. The self-lubrication alloying galvanized steel plate is prepared from the following chemical components in percentage by mass: 0.0007-0.002% of C, less than or equal to 0.01% of Si, 0.08-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.009% of S, 0.02-0.04% of Als, 0.06-0.09% of Ti, less than or equal to 0.004% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: pre-treating molten iron, smelting in a converter, refining, performing continuous casting, performing hot continuous rolling, pickling, performing cold continuous rolling, annealing, performing hot galvanizing, alloying, rolling a self-lubrication coating by using a roller, drying, and finishing. By controlling the roller system polishing precision and the surface roughness of a roll coating machine, the roller coating process parameters, the temperature of a drying furnace, the machine set speed and the finishing process parameter, the self-lubrication property is achieved. The preparation method is low in production cost and simple in production process, when a self-lubrication alloyed plate prepared by using the preparation method is compared with an ordinary alloyed plate, the lubrication is remarkably improved, the stamping property is also remarkably improved, and the manufacturing of complex components can be completely met.

Owner:WUHAN IRON & STEEL (GROUP) CORP

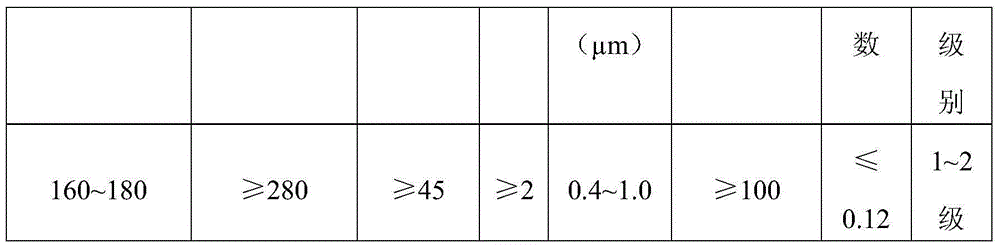

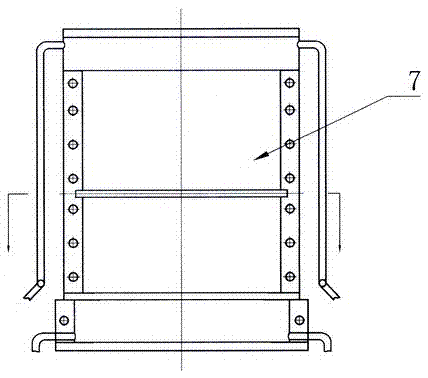

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

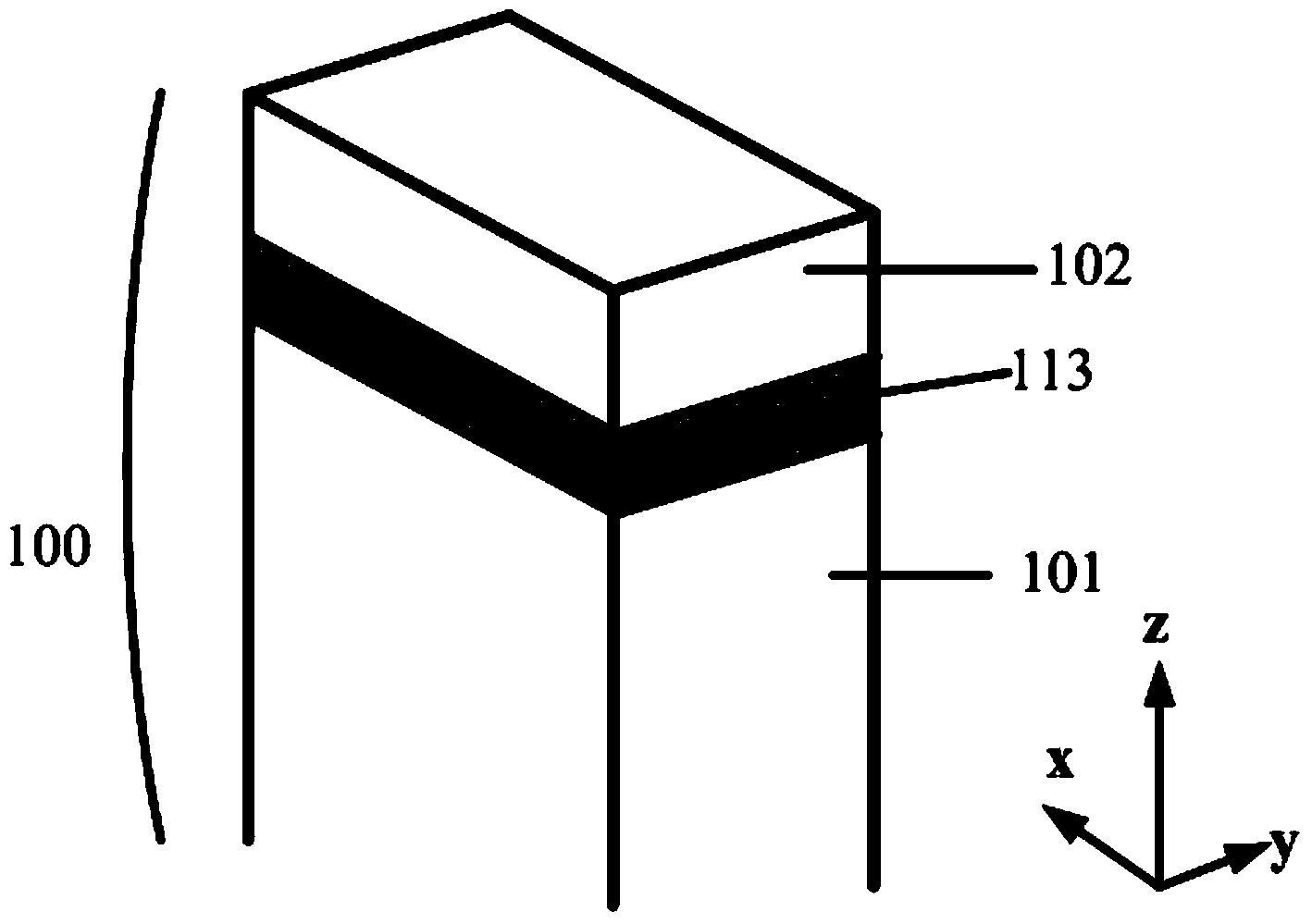

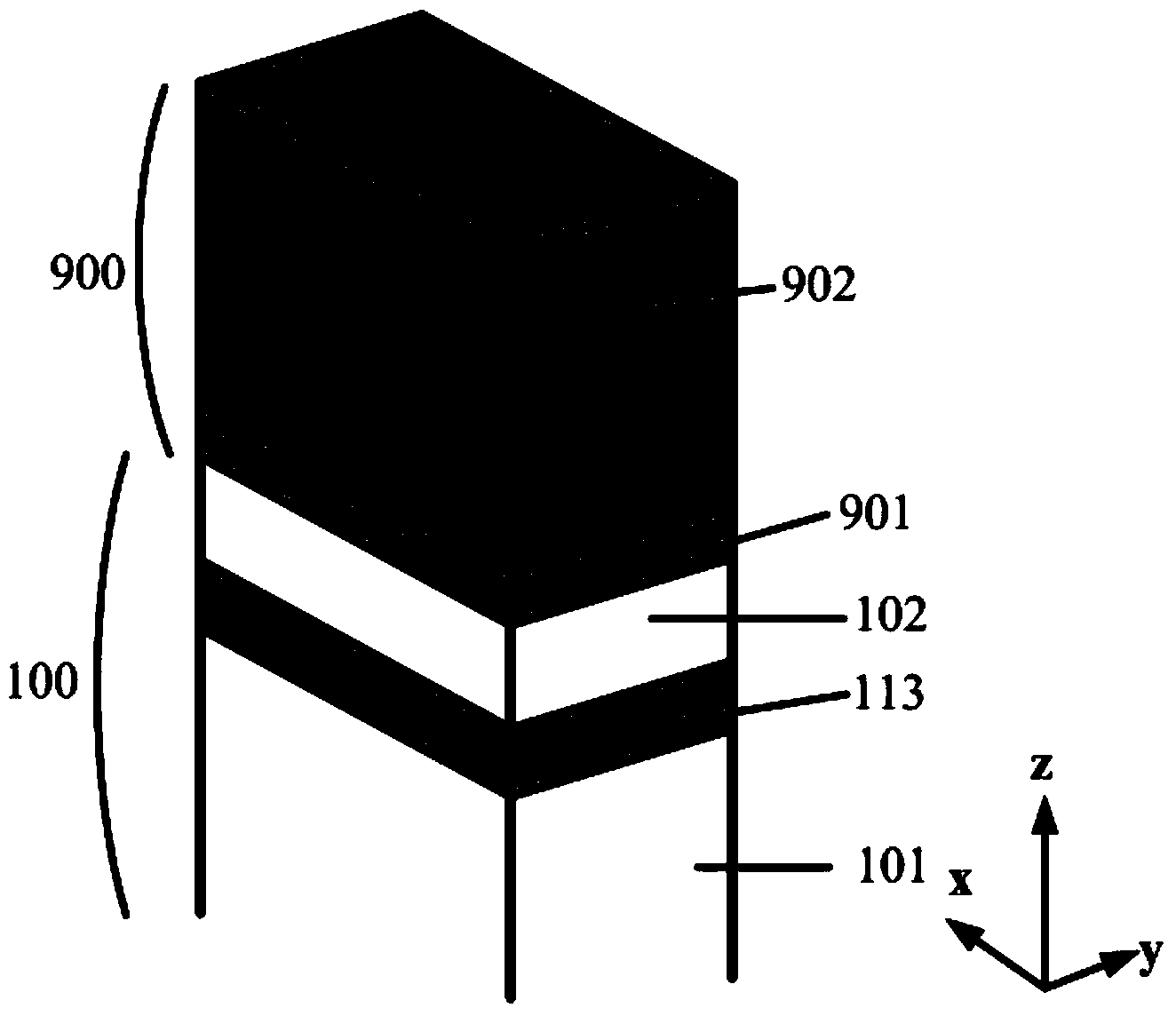

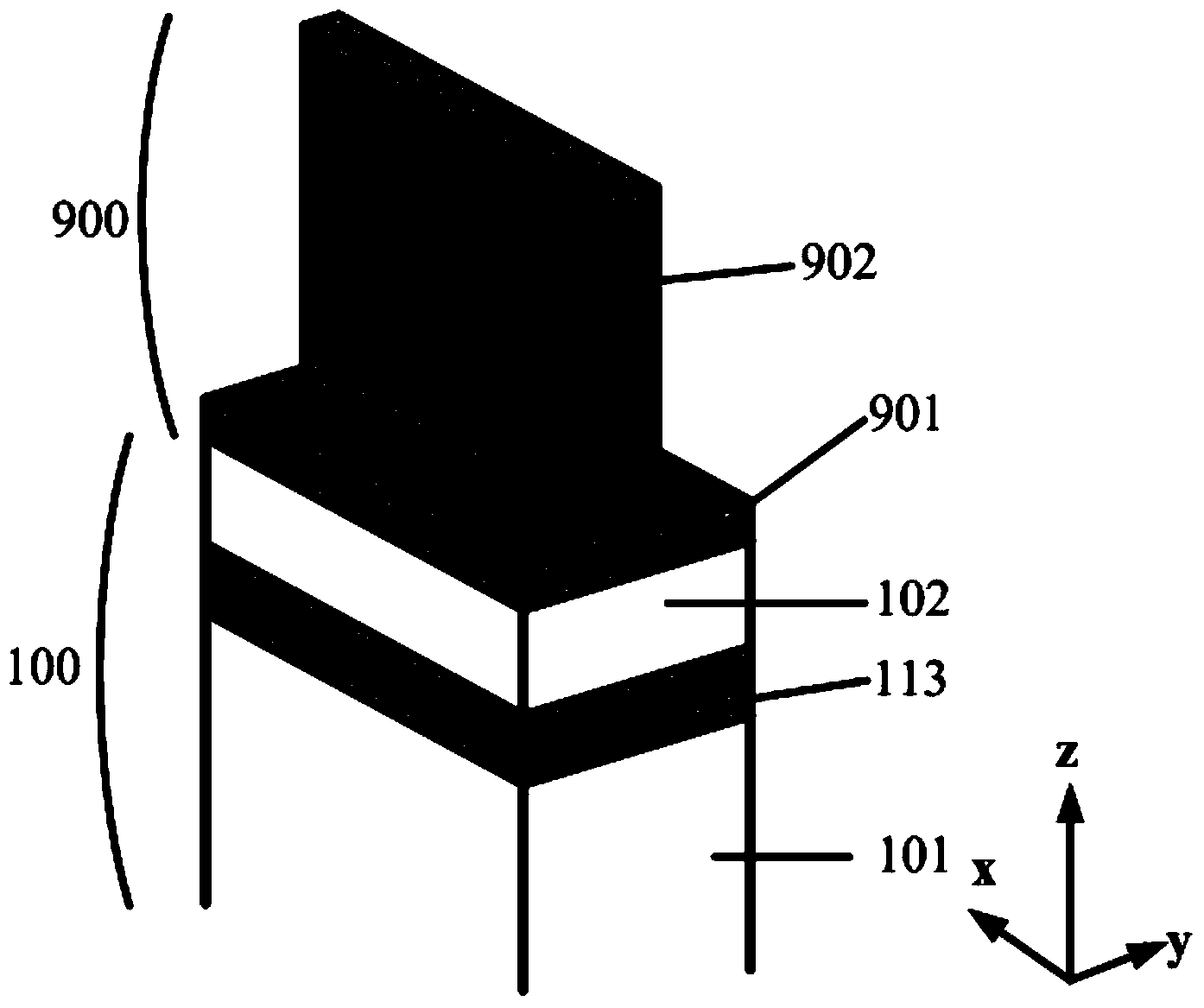

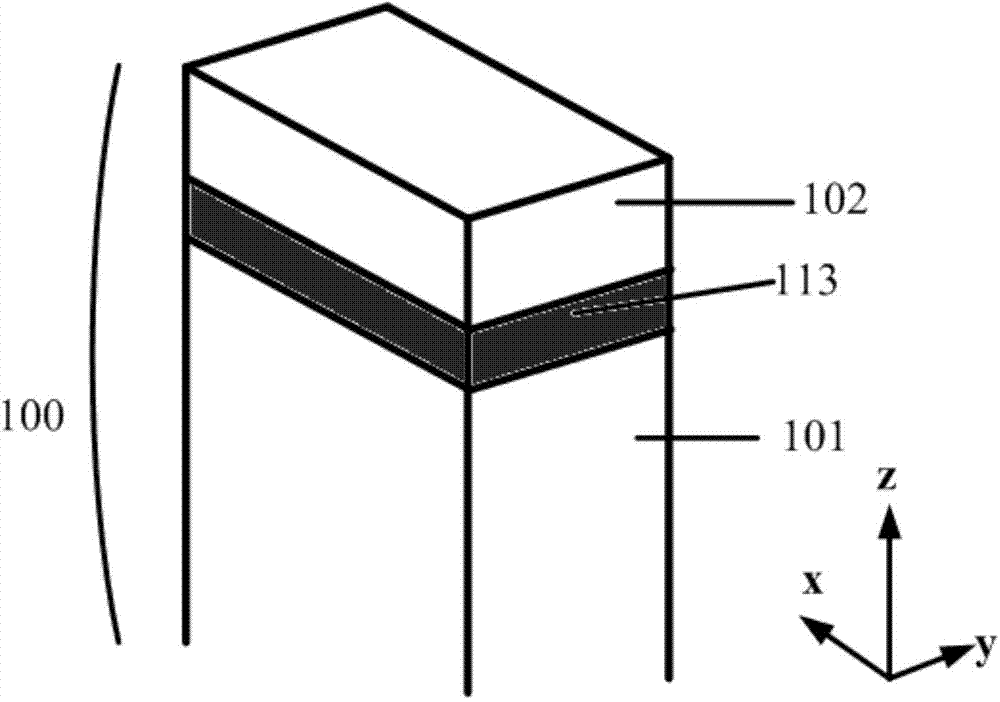

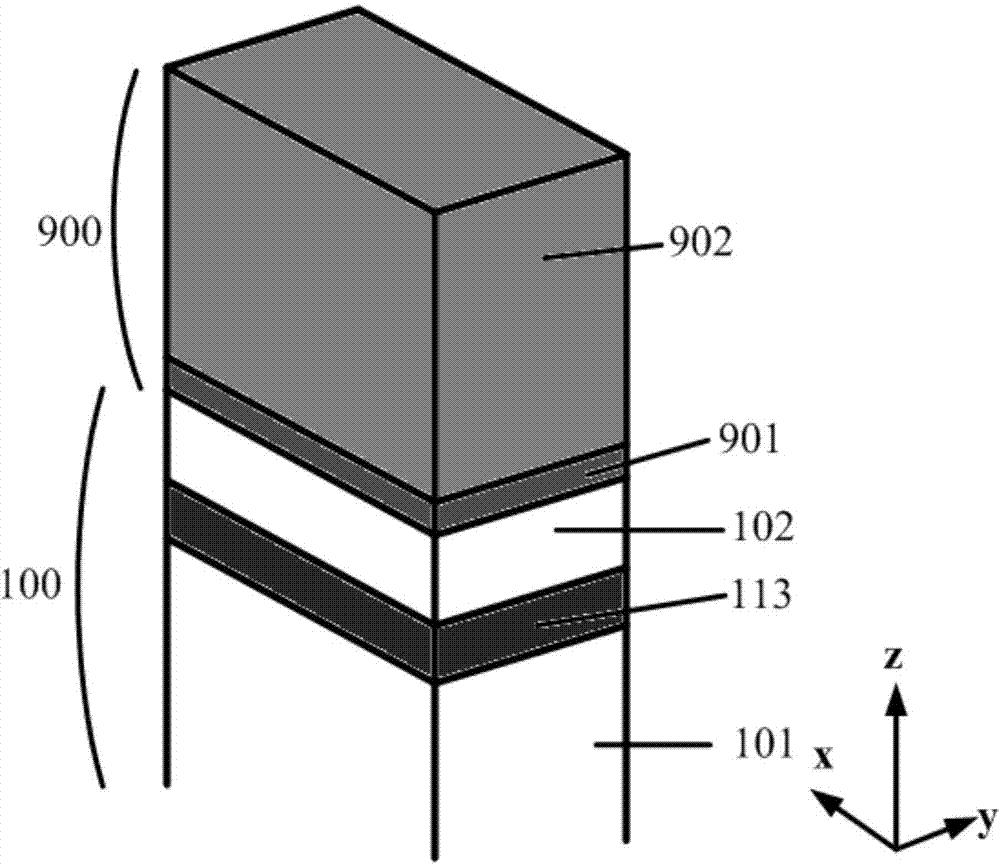

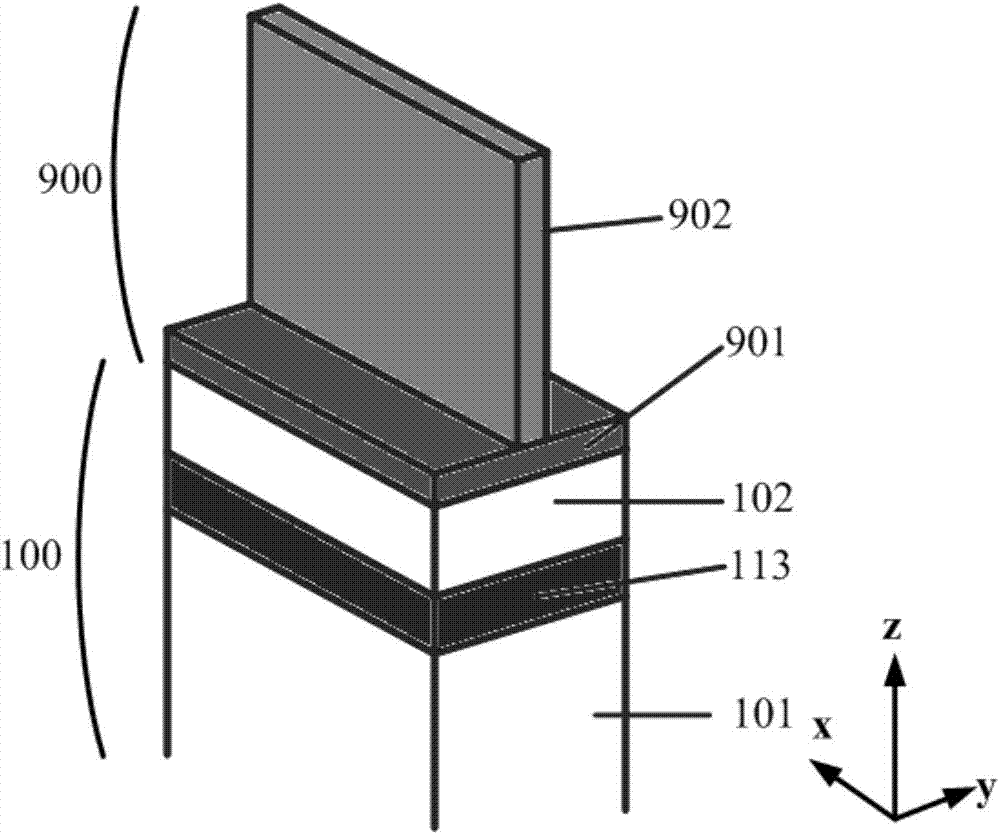

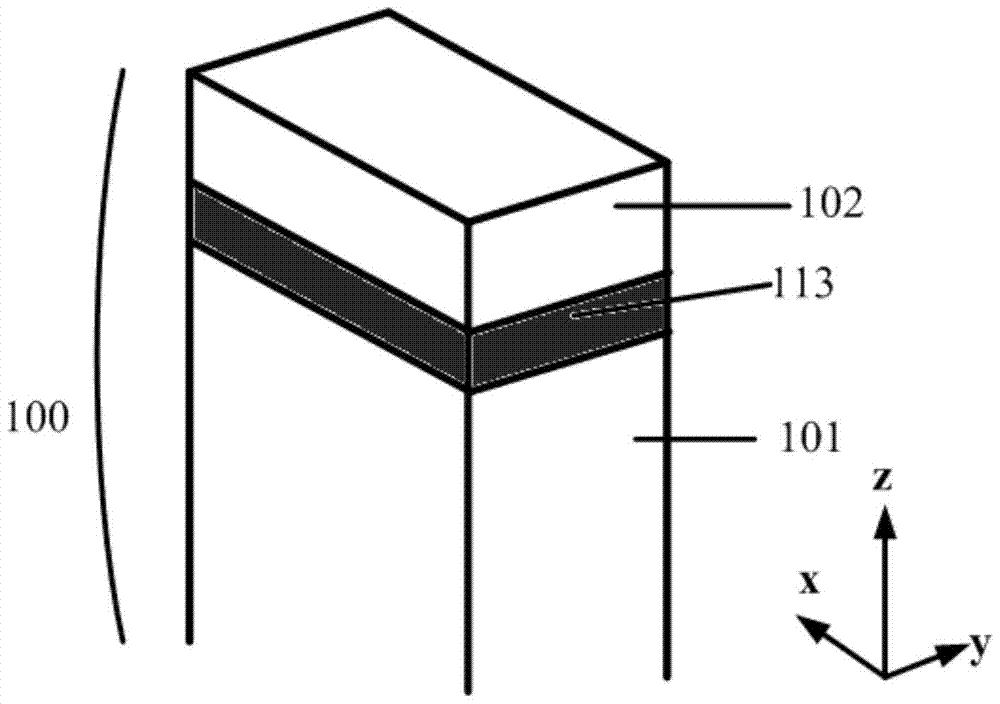

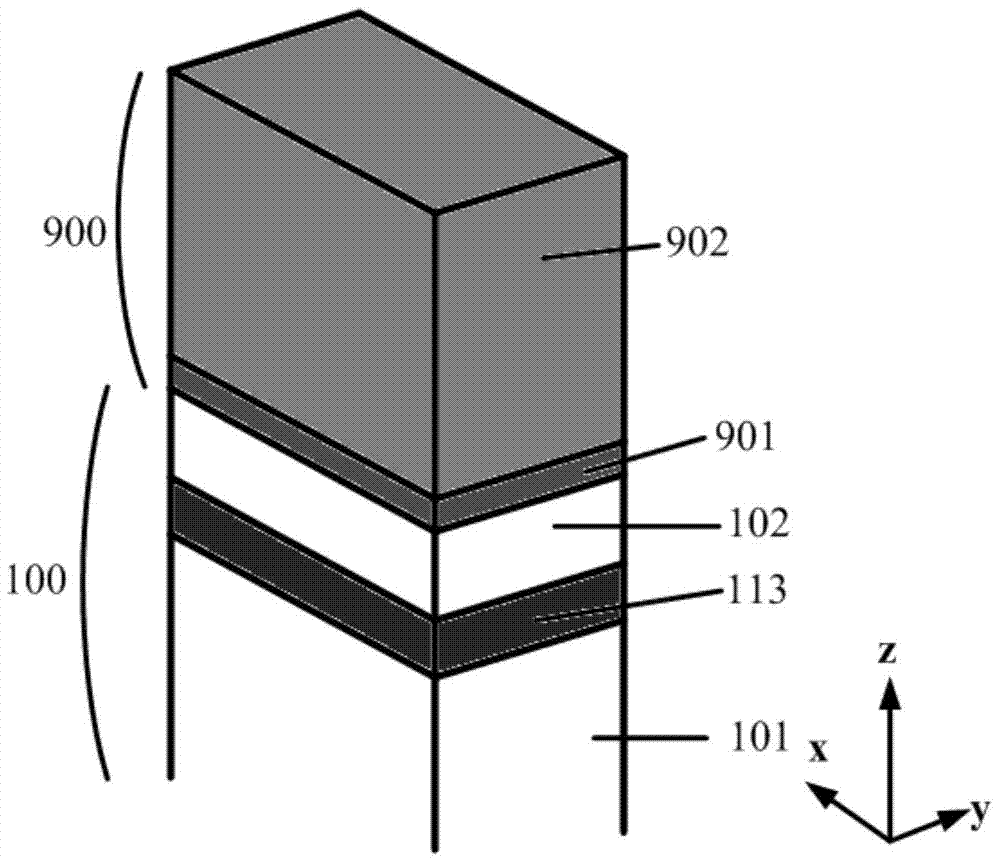

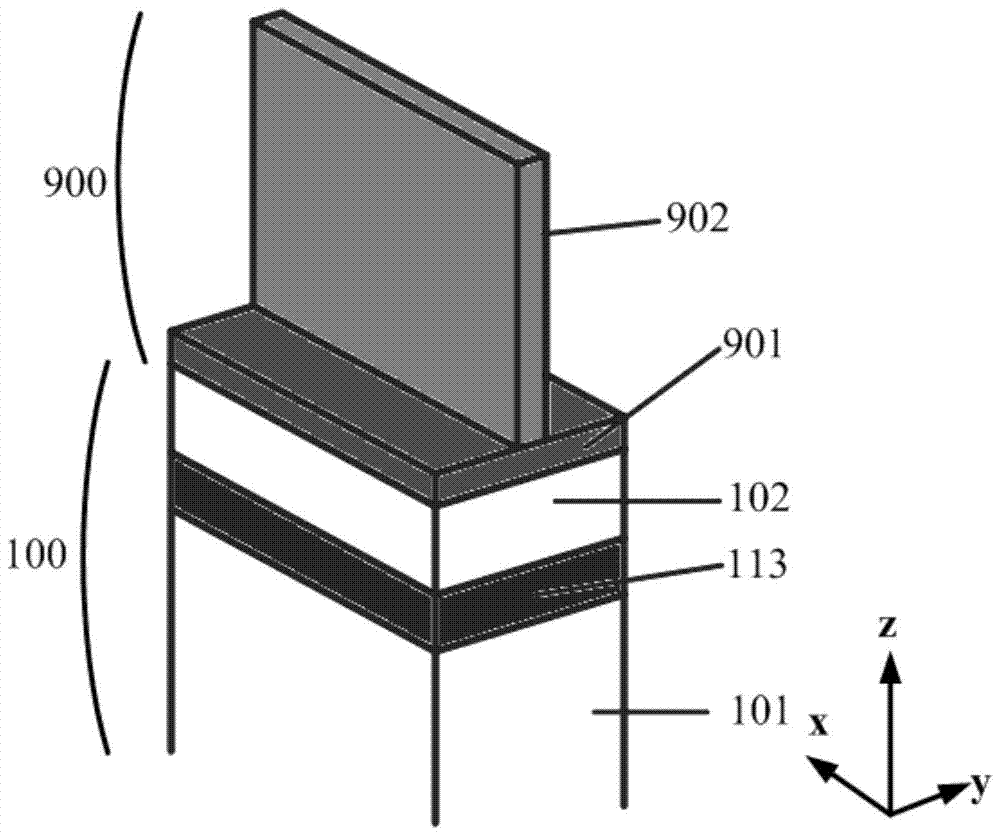

Fin type semiconductor structure and forming method thereof

ActiveCN103915504AReduce leakage currentImprove controlSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a fin type semiconductor structure which is capable of effectively controlling leakage currents between a source region and a drain region and improving gate control capacity. The fin type semiconductor structure comprises a fin type substrate, the source region, the drain region, a gate structure, shallow ridge isolation parts and an isolation region, wherein the fin type substrate is provided with a lower substrate and a fin part, the source region and the drain region are formed on the fin part, the gate structure is formed between the source region and the drain region and stretches across the fin part, the shallow ridge isolation parts are formed on the two sides of the fin part and are located below the gate structure, and the isolation region is formed in the fin part. The isolation region can be basically located below the source region and / or basically located below the drain region, and / or basically located below the gate structure. The invention further provides a method for forming the fin type semiconductor structure.

Owner:唐棕

High temperature-resistant heat-bonding enamelled wire paint and preparation method thereof

InactiveCN101818023AImprove heat resistanceImprove application adaptabilityPolyamide coatingsInsulating bodiesWire rodFurnace temperature

The invention discloses high temperature-resistant heat-bonding enamelled wire paint and a preparation method thereof. The high temperature-resistant heat-bonding enamelled wire paint consists of patient base resin such as modified co-polymerized nylon and phenolic resin, mixing dissolvent and assistant. The high temperature-resistant heat-bonding enamelled wire paint meets the requirement of heat-resistant condition more than 180 DEG C, the appearance of the finished product is brown thick liquid, the weight solid part is 18-28%, and the rotating viscosity is 800-2000mPa.s at 25 DEG C. The patient is used for the outer layer of a high temperature-resistant coil wire material, and can be solidified with polyesterimide base paint at the same furnace temperature.

Owner:广东省石油化工研究院

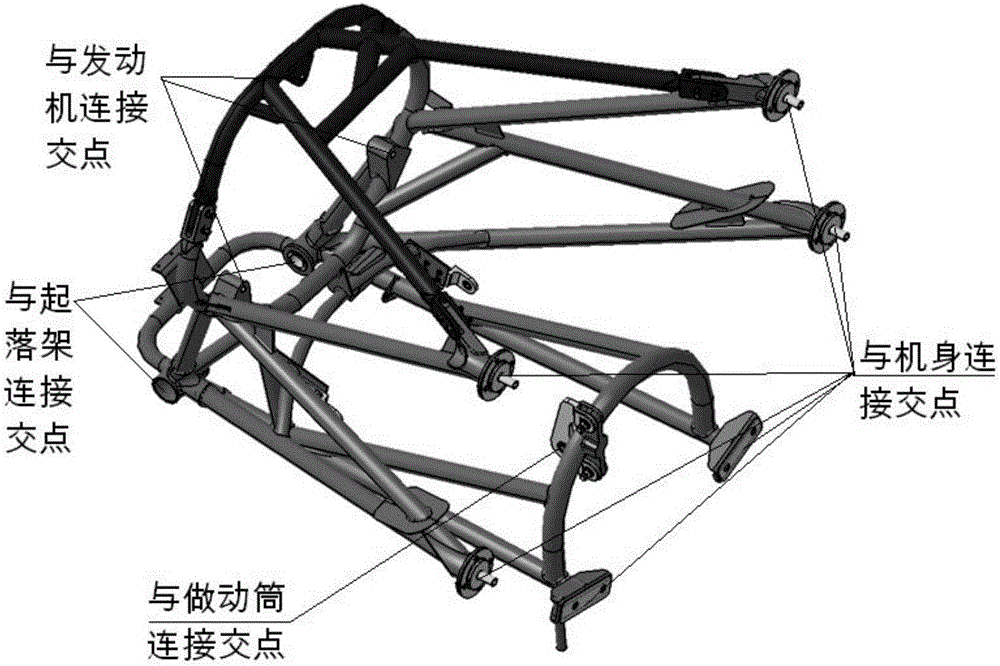

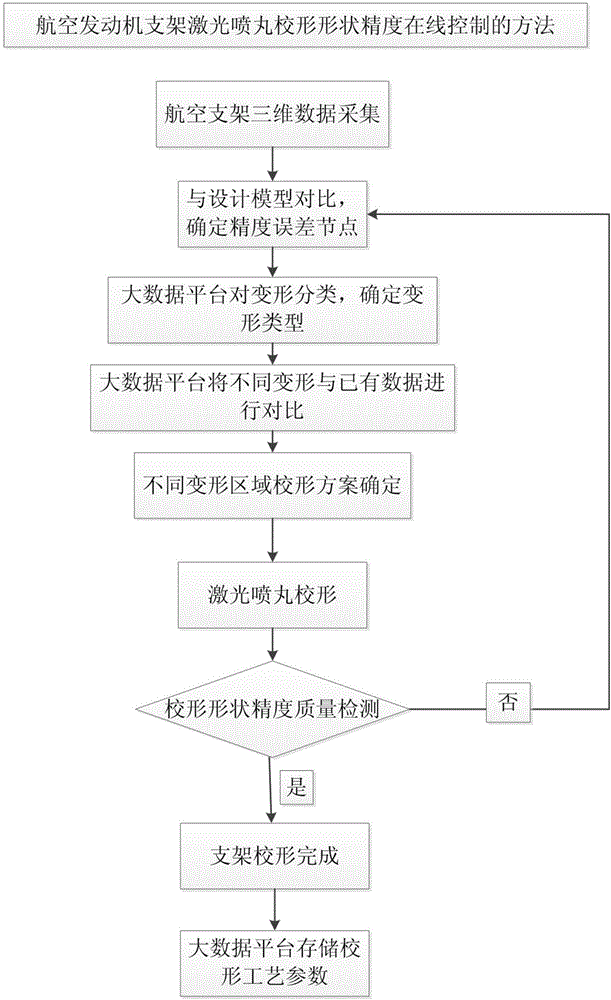

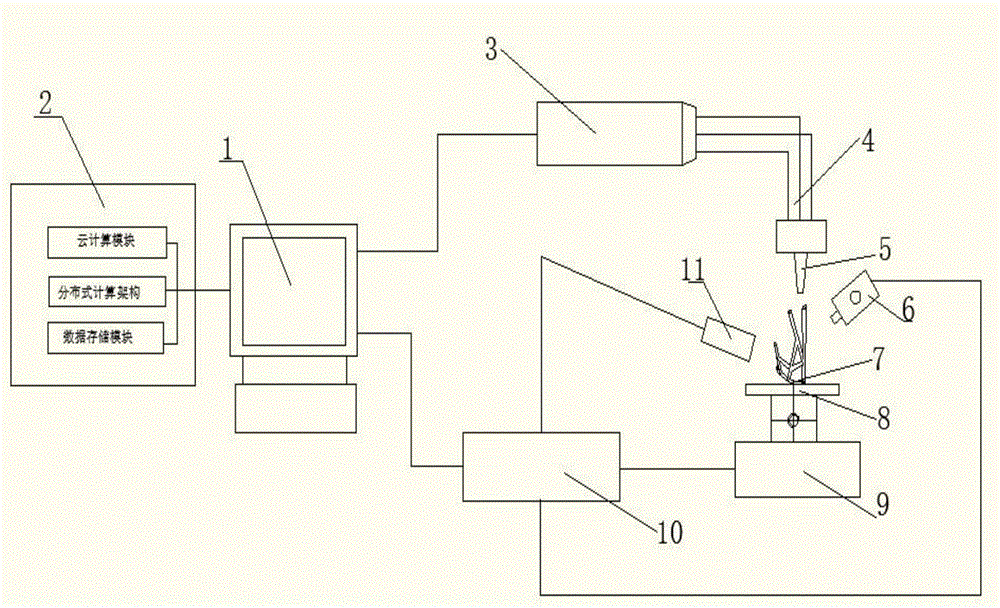

Method and device for controlling laser peening correcting shape precision of aero-engine bracket on line

ActiveCN106312299ASolve the problem of residual deformation in the welding manufacturing processResolve Residual DistortionLaser beam welding apparatusAviationData platform

The invention discloses a method for controlling laser peening correcting shape precision of an aero-engine bracket on line. The method comprises the following steps of (1) detecting the outline of a welding bracket, and measuring deformation amount and residual stress near a welding region and nodes through a three-dimensional shape measuring system; (2) inputting measured data into a large data platform, wherein welding nodes with different structures are divided in comparison with an existing designed structural scheme, and deformation types of the welding nodes are respectively analyzed; (3) according to different divided types, calculating shape precision errors of bracket tube units of deformation node regions, determining needed correcting amount, planning sequence for correcting the deformed regions and determining the optimal correcting scheme; (4) correcting the deformation nodes of the aero-engine bracket according to the optimal correcting scheme, carrying out shape detecting on the corrected modes through a three-dimensional shape measuring instrument, and inputting data into the large data platform; and (5) evaluating the correcting effect through the large data platform, determining whether secondary correcting is needed or not, repeating steps (1) to (3) if needed, and approaching step by step until the designed needed shape precision is reached.

Owner:GUANGDONG UNIV OF TECH

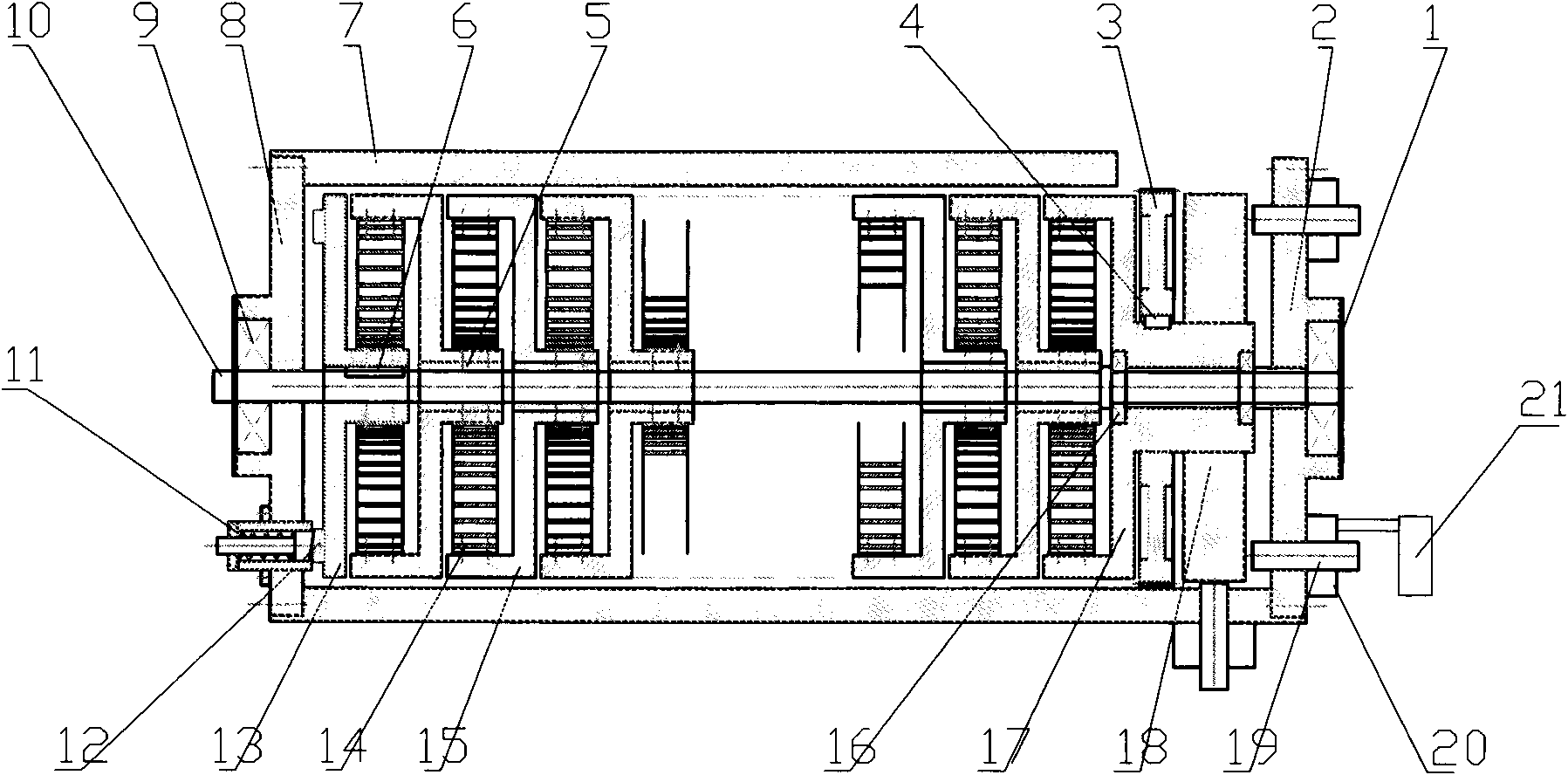

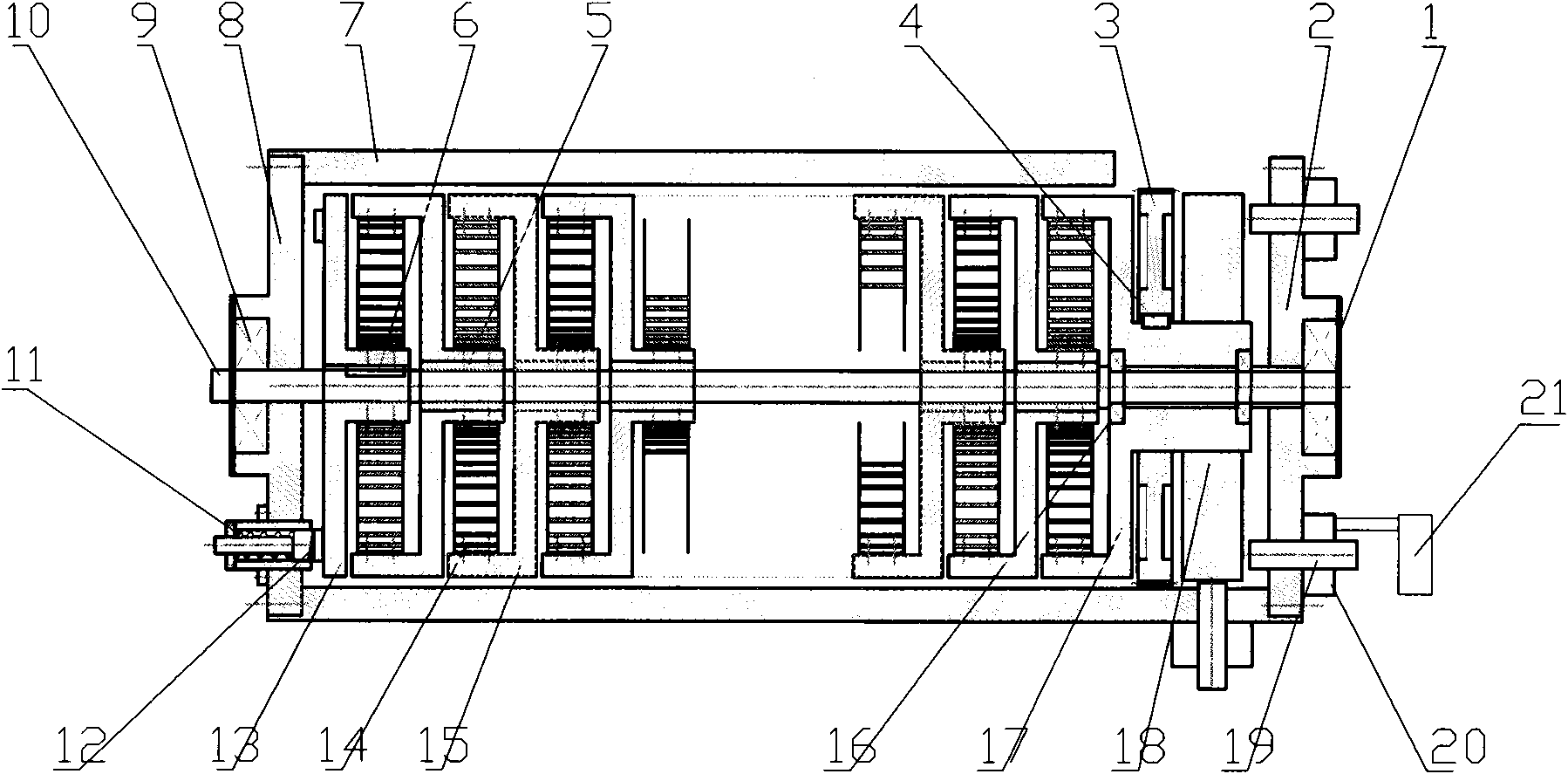

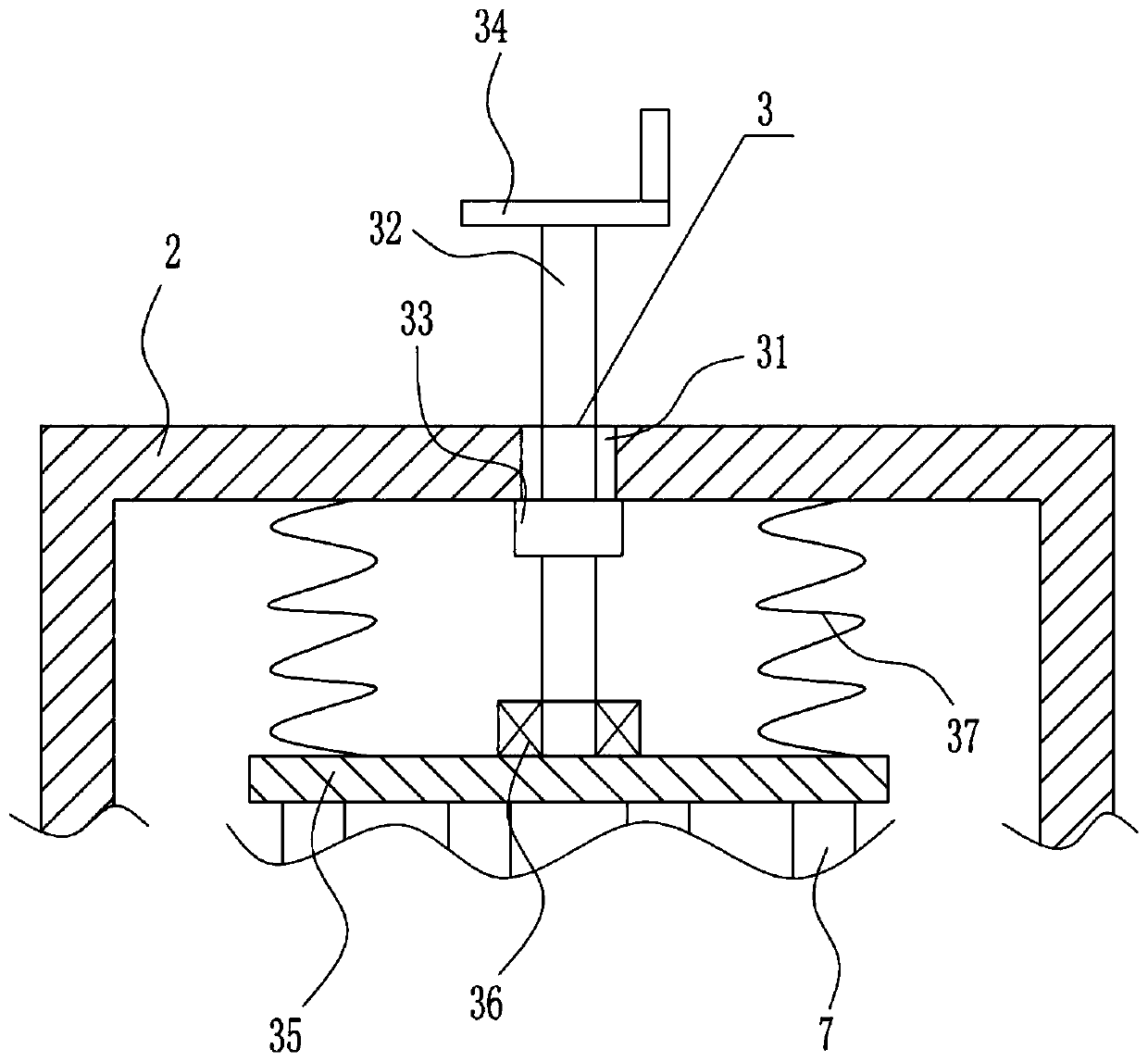

Environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device

InactiveCN101936269ANo pollution in the processNo pollutionSpring motorMachines/enginesDrive wheelEngineering

The invention relates to an environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device. The environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device comprises a box body, an input part, an energy-storing part and an output part, wherein the input part consists of an input shaft and an input driving wheel; the energy-storing part is formed by connecting n clockwork energy-storing units in series; and the output part comprises an output gear and an energy-releasing speed governor. Compared with the priorart, the environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device has the advantages that: a plurality of clockworks are used for storing energy so the energy-storing capacity is large and the defect of deficient energy-storing capacity by a single clockwork is overcome; an energy-releasing speed governor is adopted, so the energy can be released according to the rotating speed required by the load and the requirements of various working conditions can be met; the environmentally-friendly and high-efficiency multi-clockwork energy-storing and energy-releasing device is simple in structure, easy in manufacturing and low in cost and has a wide application range; and the device does not have any pollution to environments and is a clean energy-storing device.

Owner:李颖超

Biodegradable composite material prepared by excessive processing materials of high-starch crops and preparation method thereof

The invention discloses a biodegradable composite material prepared by excessive processing materials of high-starch crops and a preparation method thereof. The preparation method for the composite material comprises the following steps: subjecting PLA (polylactic acid), PBS (polybutylene succinate), the excessive materials of the crops, and a cross-linking agent to vacuum drying respectively, and enabling the temperature to be lower than 65 DEG C; sufficiently mixing the dried raw materials in an agitating pan, feeding the uniformly mixed material to a double-screw extruder; and mixing and extruding the material through screws in the double-screw extruder to obtain a granulous product which is the biodegradable composite material prepared by the excessive processing materials of the high-starch crops. The toughness of the biodegradable composite material is better than that of PLA, the tensile strength is slightly poorer than that of PLA but does not affect the utilization, and the material can be subjected to secondary forming processing by a frequently-used plastic processing manner such as injection molding, performing and the like.

Owner:常州龙骏天纯环保科技有限公司

Method for purifying high-yield superclean high-purity hydrofluoric acid

InactiveCN102009957AHigh purityIncrease productionFluorine/hydrogen-fluoridePotassium permanganateHydrogen fluoride

The invention relates to a method for purifying high-yield superclean high-purity hydrofluoric acid, which comprises the following process steps of: introducing industrial anhydrous hydrogen fluoride into an oxidation treater A, adding potassium permanganate solution for oxidation, introducing the liquid in the oxidation treater A into an oxidation treater B through a filter A, oxidizing by using hydrogen dioxide solution, introducing the liquid into the oxidation treater B into a rectifying tower through a filter B, and gasifying hydrogen fluoride liquid to generate purified hydrogen fluoride gas; introducing the hydrogen fluoride gas out of the rectifying tower into a cooler for cooling and filtering; injecting deionized water into an absorption tower, arranging a distribution coil at the bottom of the absorption tower, introducing the hydrogen fluoride gas out of the cooler into the distribution coil at the bottom of the absorption tower, injecting from distribution holes on the upper and lower walls of the distribution coil, and absorbing by using the deionized water to prepare a hydrofluoric acid semi-finished product; and introducing the hydrofluoric acid semi-finished product out of the absorption tower into a 0.05 mu m filter to obtain the superclean high-purity hydrofluoric acid finished product. The product prepared by the method has high purity and yield, and meets environmental protection requirement.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

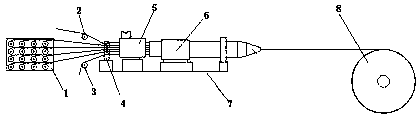

Method for manufacturing metal filament products

ActiveCN105945226AImprove yieldReduce manufacturing costAdditive manufacturing apparatusFoundry mouldsMetal filamentDissolution

The invention provides a method for manufacturing metal filament products. The method includes the step of manufacturing a filament product model; placing the filament product model into gypsum slurry and enabling the gypsum to be hardened; removing the filament product model through dissolution or fusion or gasification, forming a cavity in the gypsum, and obtaining a gypsum model; injecting metal in a fluid state into the gypsum model; and removing the gypsum after the metal is hardened, thereby obtaining the filament products. By means of the method, metal filament products with small thicknesses and large sizes can be manufactured, and metal filament products of complex structures such as large-curvature curved surfaces, surfaces with a large height difference and inner corners can also be manufactured.

Owner:上海渊泉集币收藏品有限公司

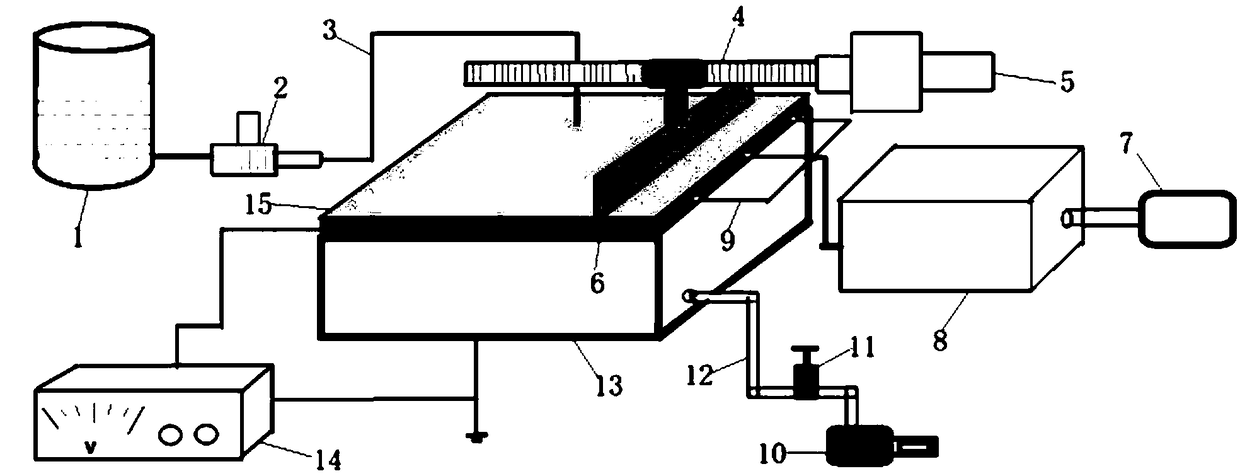

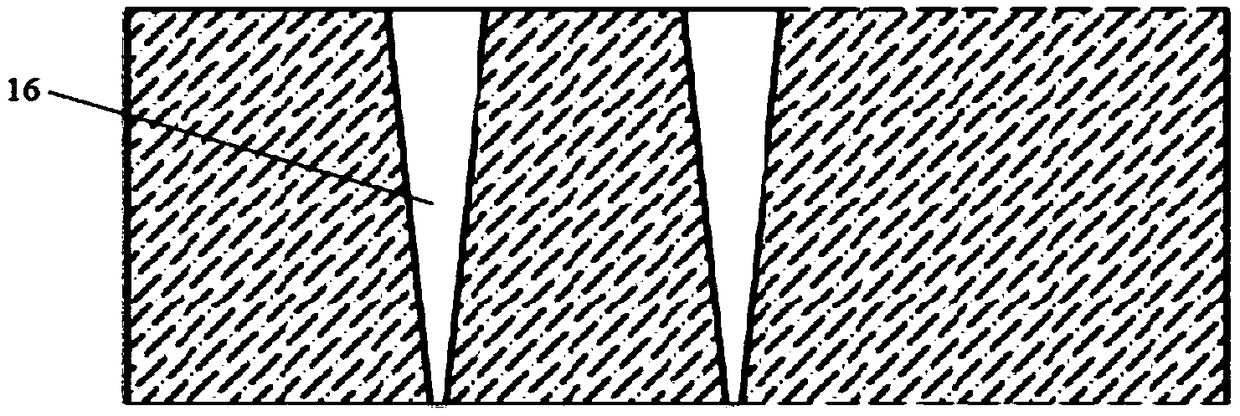

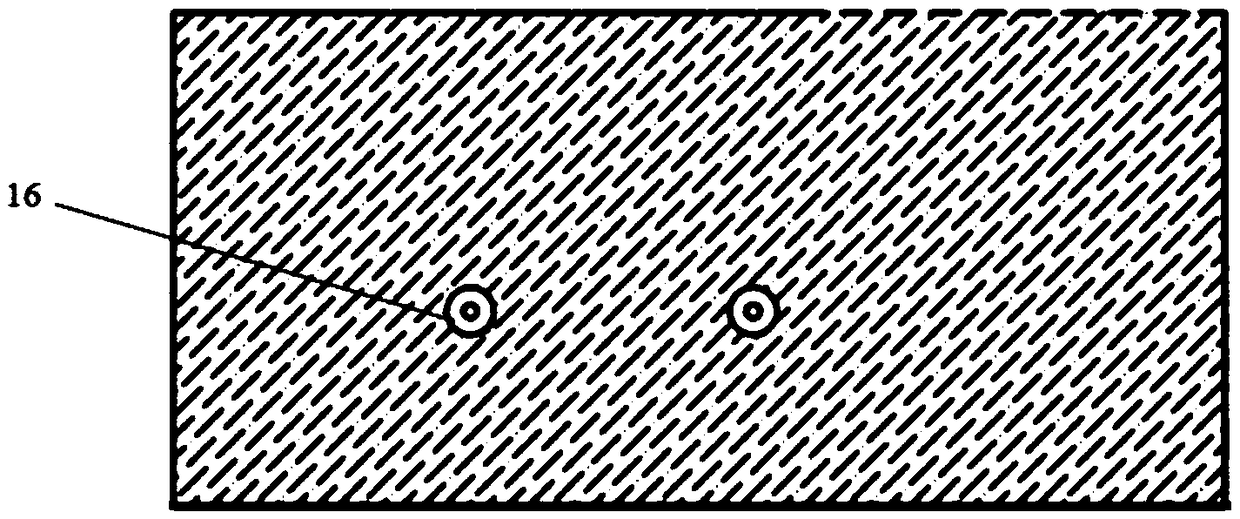

Polymer microneedle preparation system and method

The invention relates to a polymer microneedle preparation system and method. The system comprises a raw material solution storage tank, a metering and conveying pump, a flow-casting and film-scrapingdevice, a microneedle mold, an open metal box, a high-voltage electrostatic generator, a negative pressure regulating device and a hot air device; the raw material solution storage tank, the meteringand conveying pump and the microneedle mold are sequentially connected through pipelines; the flow-casting and film-scraping device comprises a scraper, a threaded push rod and a motor which are sequentially connected, and the scraper is located above the microneedle mold; the microneedle mold and the open metal box are connected through an insulating material and define a cavity; a positive electrode and a negative electrode of the high-voltage electrostatic generator are electrically connected with the microneedle mold and the open metal box respectively, the negative pressure regulating device is connected with the open metal box through a pipeline, and a hot air pipeline of the hot air device is located above the microneedle mold. The polymer microneedle preparation system is simplein equipment, convenient to operate, low in energy consumption and cost and capable of achieving large-scale production.

Owner:广州蔻原生物科技有限责任公司

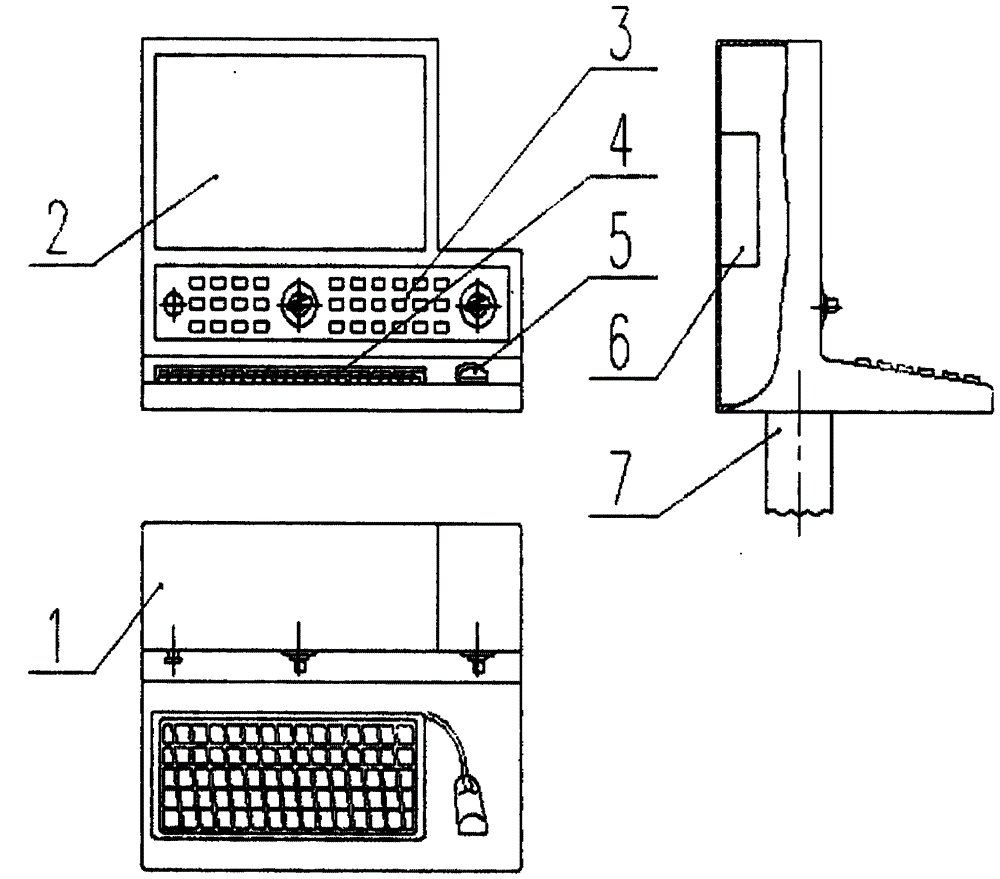

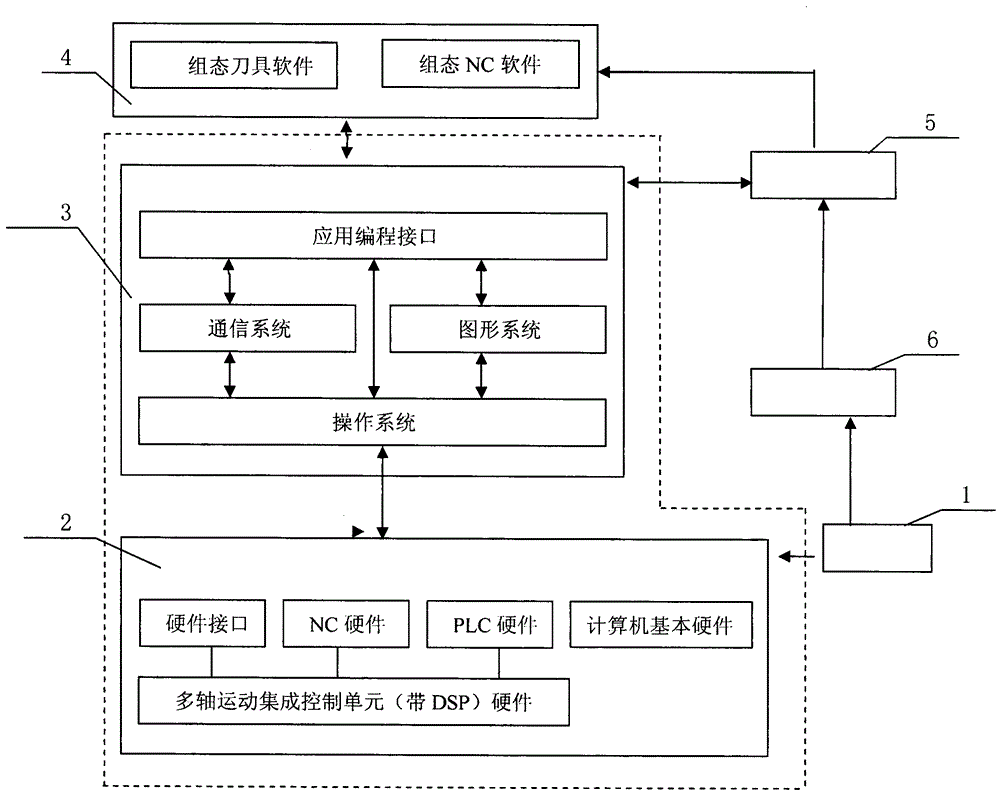

Configuration computer numerical control system for five-axis linkage tool grinder

InactiveCN105182910AAvoid designAvoid developmentNumerical controlSoftware engineeringIntegrated operations

The invention discloses a configuration computer numerical control system for a five-axis linkage tool grinder, and the dedicated system is constructed through the configuration computer numerical control technology, and is of an open type. The system employs a windows operating system which enables configuration application software to be installed and operated directly. The basic system is of a five-axis linkage type, wherein the maximum number of axes can be 32, the number of axes can be selected freely, and the axes can be controlled in a linkage manner. After a machine tool is configured, the five-axis linkage tool grinder or a multi-axis linkage tool grinder can be formed. The manufacturing and grinding of a precise and complex tool are achieved through employing the technology of tool grinding and the technology of automatic programming. According to the invention, the structure of the basic system consists of a configuration system platform (a configuration hardware platform and a configuration software platform), the configuration application software, an application software library, and a configuration system. The structure of a basic device consists of a clipper extension integrated control unit, a PC, an integrated operation panel, and a cabinet with an operation platform. The clipper extension integrated control unit is disposed in the cabinet, and the PC and the integrated operation panel are disposed on a panel of the cabinet. A keyboard and a mouse are disposed on the operation platform of the cabinet, and a cabinet connection part is connected with a machine tool.

Owner:西安高商智能科技有限责任公司 +2

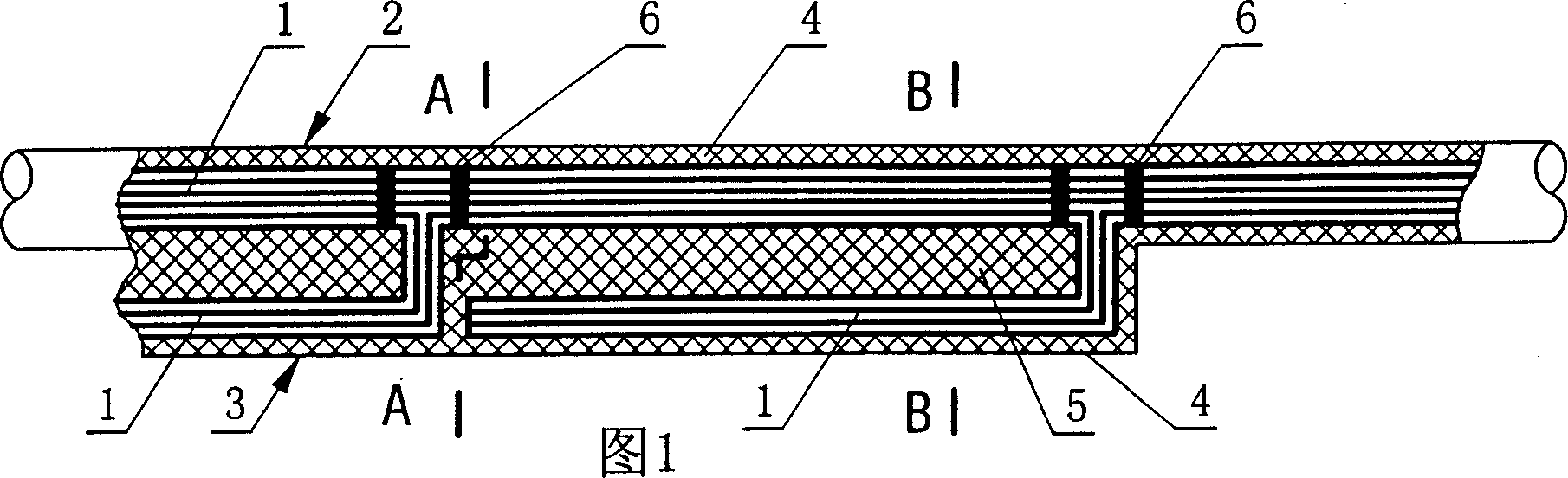

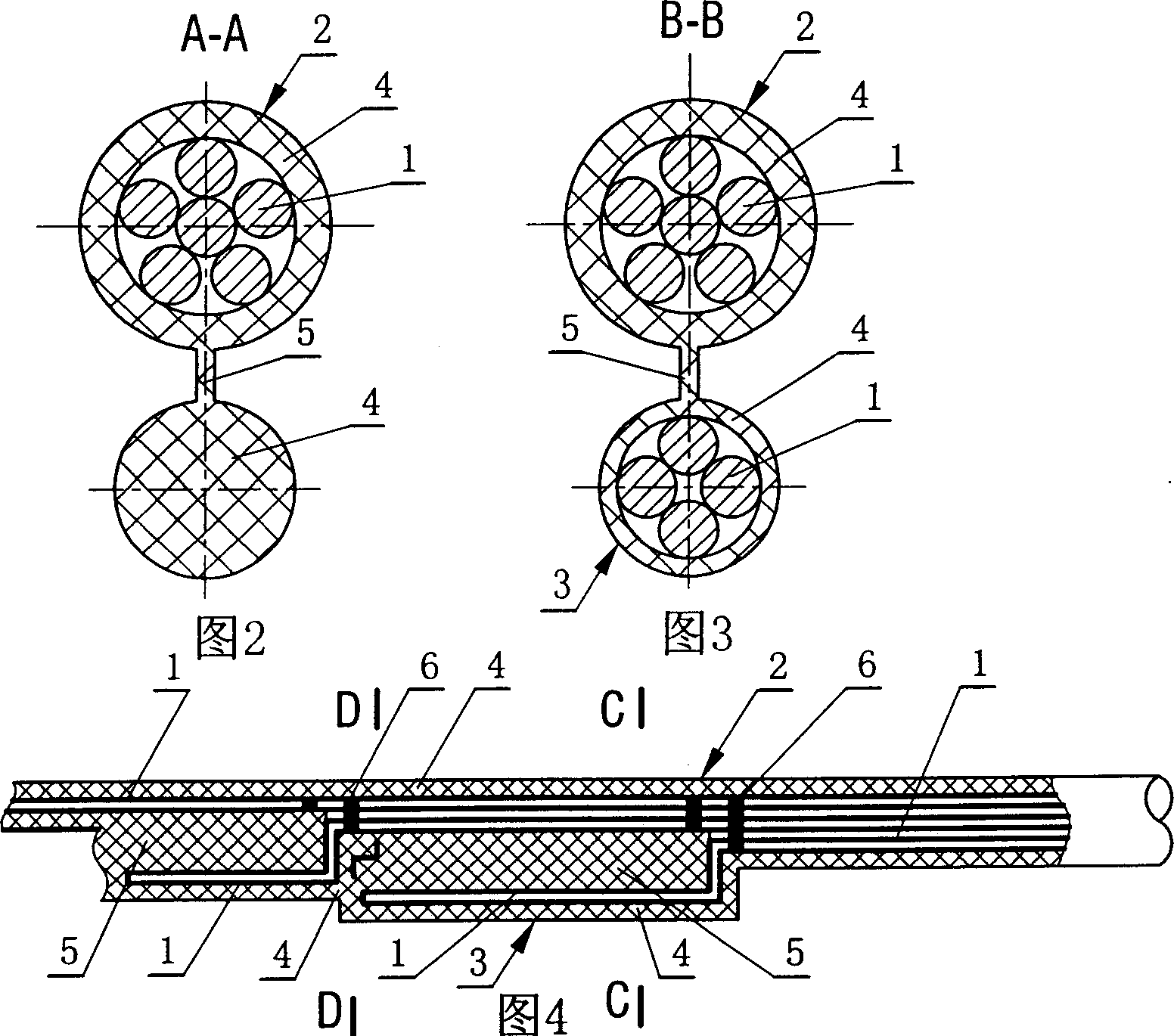

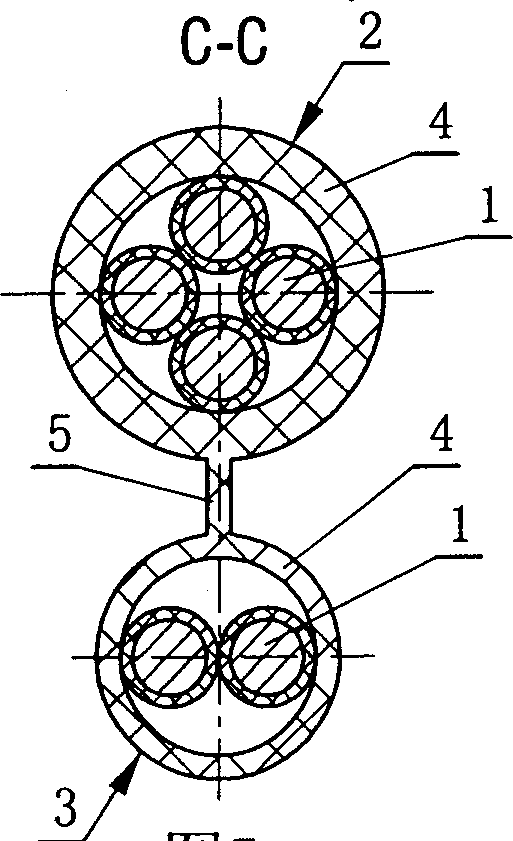

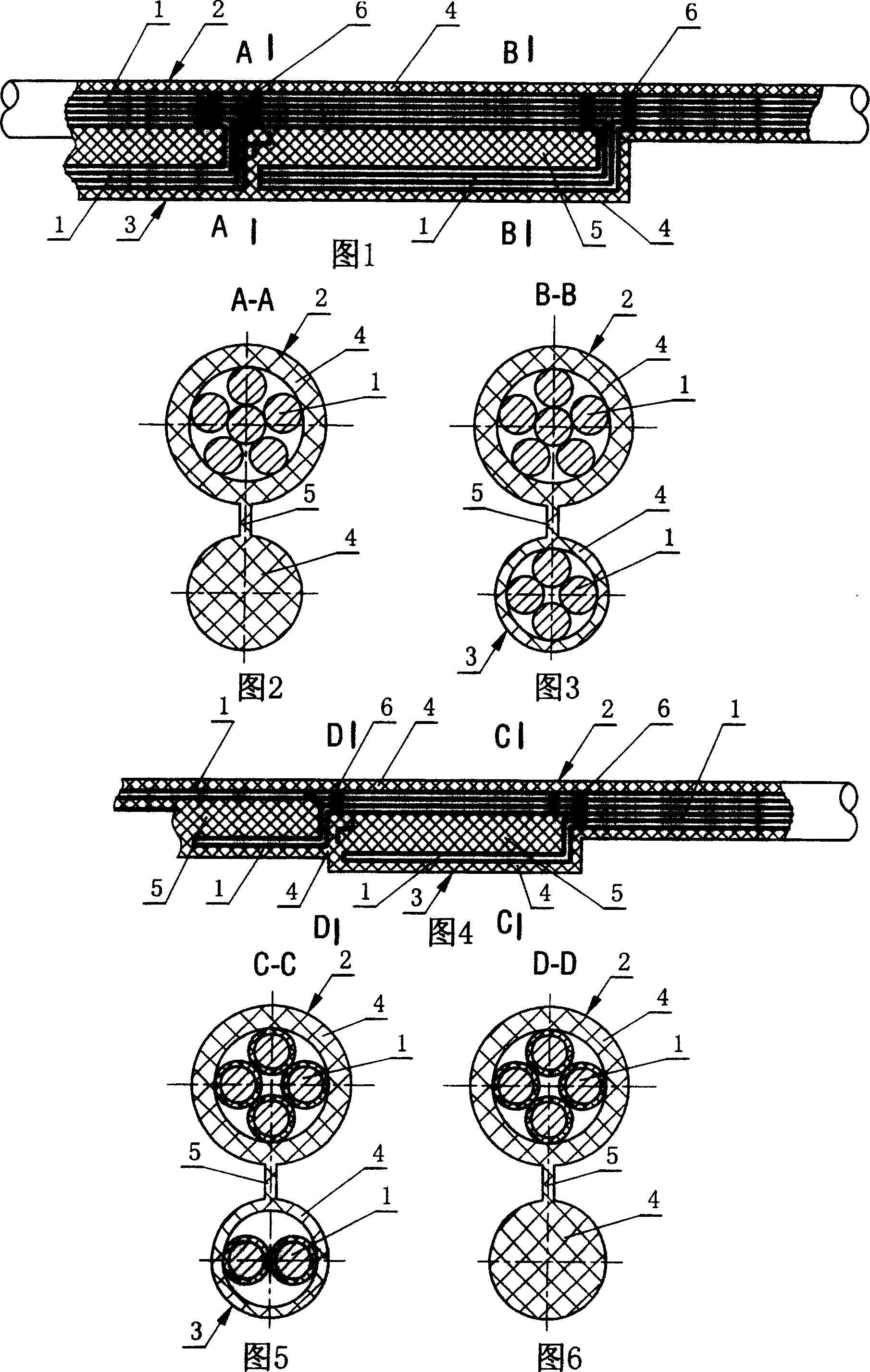

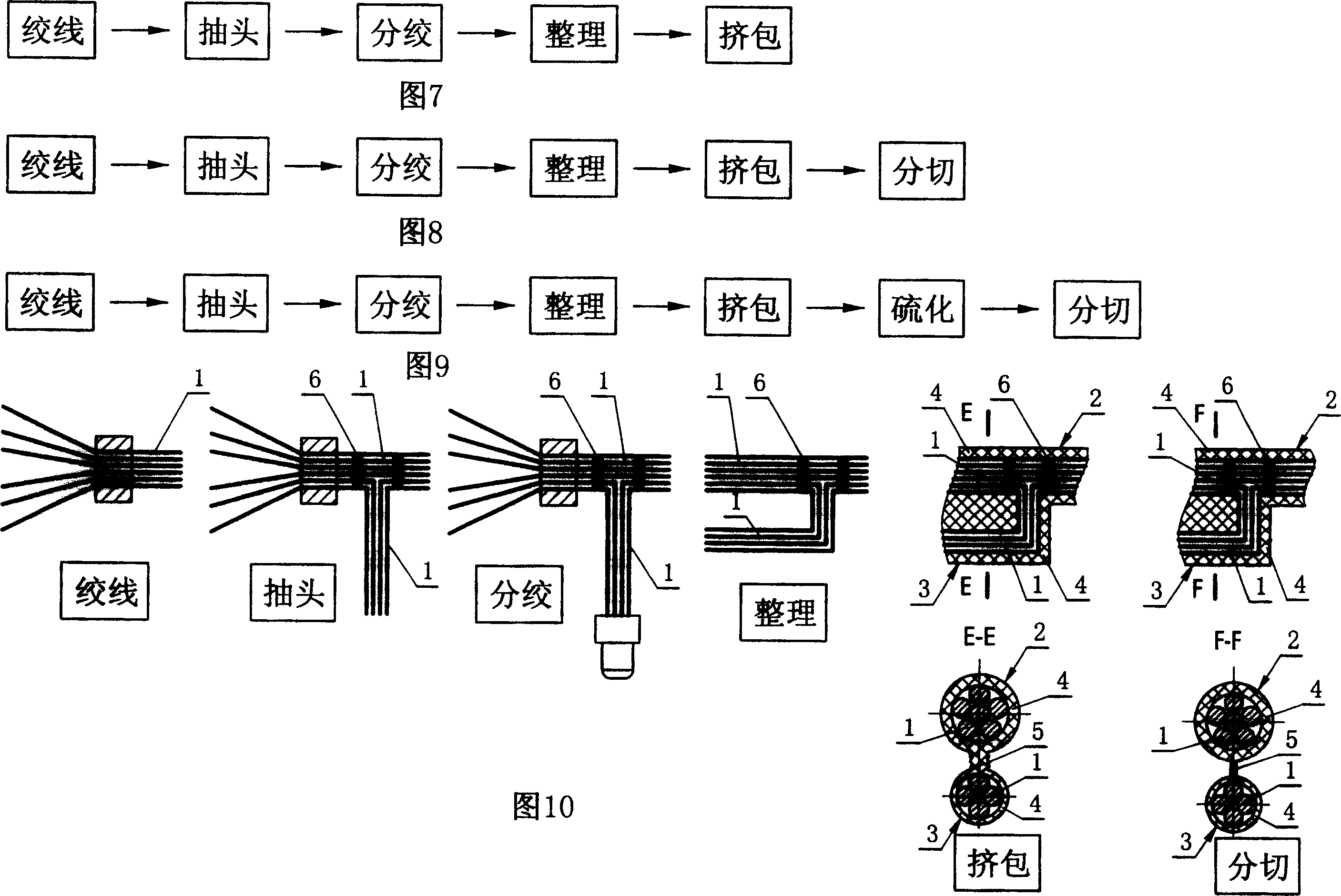

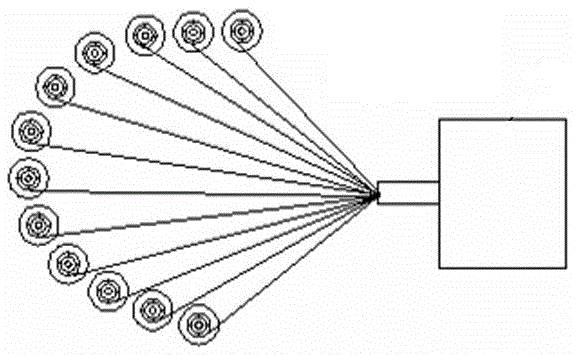

Branched wires and cables and their manufacture

ActiveCN1713309AReduce the cross-sectional areaReduce the number of core wiresInsulated cablesInsulated conductorsElectrical conductorInsulation layer

The invention consists of main cable composed of metal conductor or cored metal conductor, branch cable composed of metal conductor or cored metal conductor, and insulating layer or sheath layer covering the main cable and branch cable. The branch cable is composed of metal conductor and cored metal conductor which is drawn out from several points on main cable. The main cable is connected with branch cable by bonding layer through insulation layer and sheath layer. There is no contact point in main cable and branch cable. The manufacturing method includes following steps: twisting line; tapping; leasing cord; collating; extruding wire.

Owner:GUANGDONG NANYANG CABLE CO LTD

Method for purifying ultra-pure hydrofluoric acid

ActiveCN100546903CIt is not easy to solve this difficult problemHigh purityFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention relates to a method for purifying ultra-high-purity hydrofluoric acid, which comprises the following process steps: passing industrial anhydrous hydrogen fluoride liquid into a rectification kettle, adding 0.16-1% by weight of potassium permanganate, stirring, and standing still; then adding 0.16-1% by weight of potassium permanganate % by weight of hydrogen peroxide, stirring, standing still; heating up to 60-80°C, hydrogen fluoride liquid gasification to generate purified hydrogen fluoride gas; the purified hydrogen fluoride gas from the rectification tank is passed into the cooler for cooling and filtering; injected into the absorption tower For deionized water, a gas distribution coil is installed at the bottom of the absorption tower, and the hydrogen fluoride gas from the cooler is passed into the gas distribution coil at the bottom of the absorption tower, and then it is sprayed out from the gas distribution hole on the wall of the gas distribution coil and then absorbed by deionized water The semi-finished product of hydrofluoric acid is made; the semi-finished product of hydrofluoric acid from the absorption tower is passed through a 0.05 μm filter to obtain the finished product of ultra-high-purity hydrofluoric acid. The product prepared by the method of the invention has high purity and high yield, and meets environmental protection requirements.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Fin-shaped semiconductor structure and forming method thereof

ActiveCN103928521AReduce leakage currentImprove controlSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a fin-shaped semiconductor structure capable of effectively controlling leakage current between a source region and a drain region and improving grid control ability. The fin-shaped semiconductor structure comprises a fin-shaped substrate, the source region, the drain region, a grid structure, shallow channel isolating devices and an isolation region, wherein the fin-shaped substrate is provided with a lower substrate body and a fin part, the source region and the drain region are formed on the fin part, the grid structure is formed between the source region and the drain region and crosses the fin part, the shallow channel isolating devices are formed on the two sides of the fin part and located below the grid structure, and the isolation region is formed in the fin part and is arranged below the grid structure. The upper surface of each shallow channel isolation device is lower than the upper surface of the isolation region, and a side wall and an interlevel dielectric layer are located on the two sides of the grid structure respectively. The invention further provides a forming method of the fin-shaped semiconductor structure.

Owner:唐棕

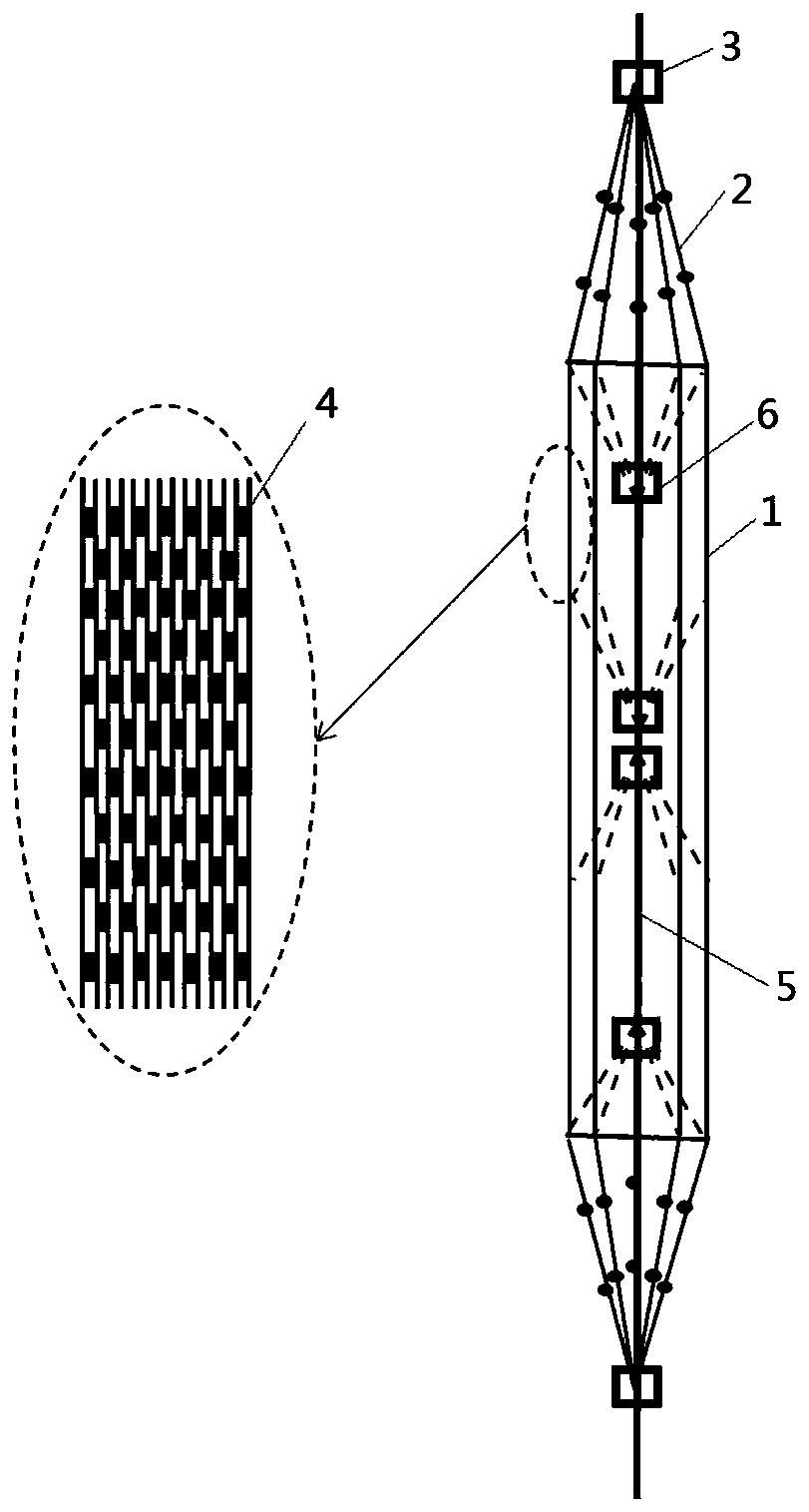

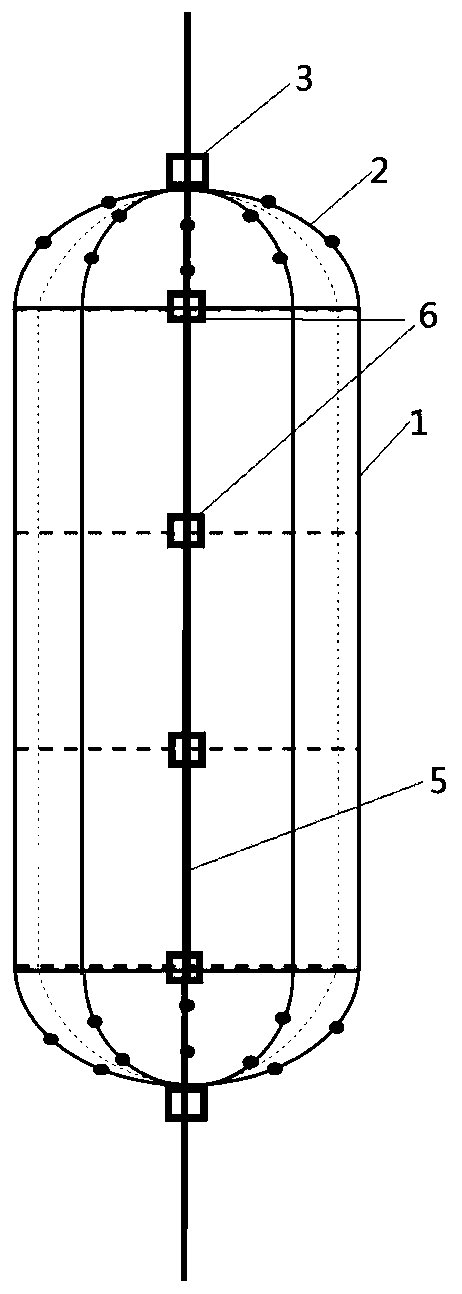

Large-size no-lining composite material storage tank mold and using method and application

The invention discloses a large-size no-lining composite material storage tank mold and a using method and application, and belongs to the technical field of aerospace material molds. According to themold and the method and application, a high-temperature-resistant stable-size metal material is adopted as a main force bearing framework, a telescopic corrugated plate interlayer structure is adopted as a shape keeping surface, a modular tool is designed, and the mold convenient to disassemble is prepared through reasonable assembly, so that the weight of the mold is effectively reduced, the size precision of a composite material product subjected to high-temperature curing is improved, manufacturing of a large-size lining-free composite material storage tank can be achieved; and in addition, the mold and the design method can also be popularized to manufacturing of other large no-lining container components.

Owner:DALIAN UNIV OF TECH

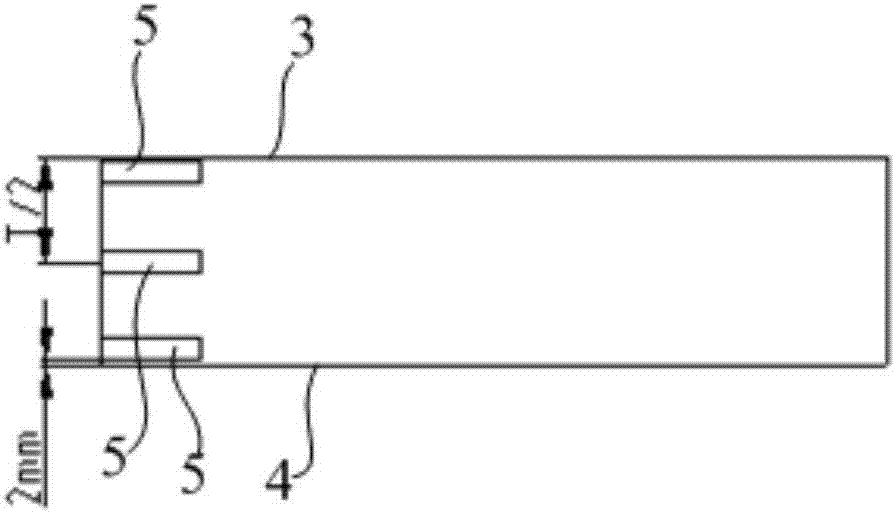

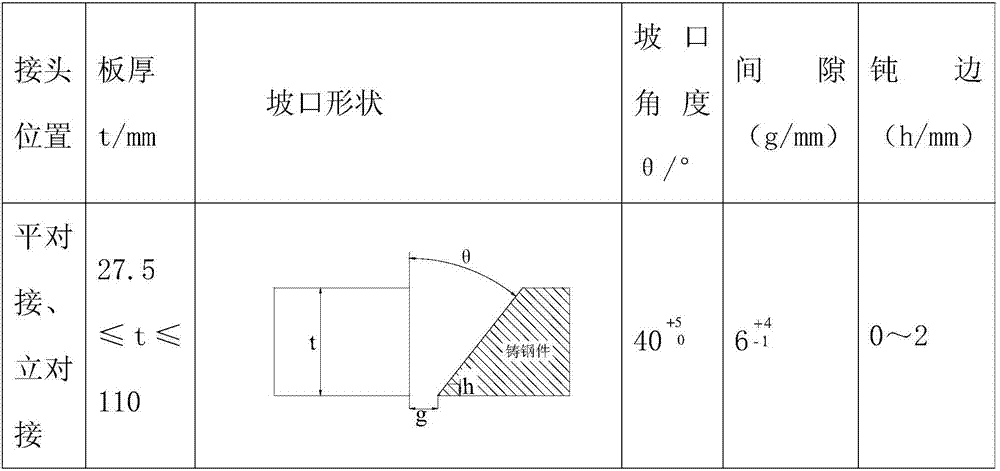

Welding method for low-temperature steel casting and marine plate

InactiveCN106964912AQuality improvementImprove low temperature impact performanceWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneThermal treatment

The invention discloses a welding method for a low-temperature steel casting and a marine plate. The welding method comprises the steps that S10, materials are prepared, namely the low-temperature steel casting and the marine plate are provided; the low-temperature steel casting is firstly chamfered and then is subjected to thermal treatment; the marine plate is not chamfered; S20, preheating is performed before welding, and the welded plates are preheated to 100 DEG C; S30, welding is performed; and multi-layer weld beads are arranged; each layer starts from the marine plate and ends at the low-temperature steel casting until the whole weld beads are finished. The low-temperature steel casting is chamfered before thermal treatment, and through thermal treatment, stress at chamfers is eradicated, so that welding quality is improved; the low-temperature steel casting and the marine plate are preheated before welding, and thermal preservation is performed during welding, so that welding joint defects are decreased after welding through the special arrangement of the weld beads; low-temperature impact performance of the welding joints and heat-affected areas is effectively improved; welding quality is ensured; and the welding joints can withstand low-temperature impact test at 60 DEG C after welding.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

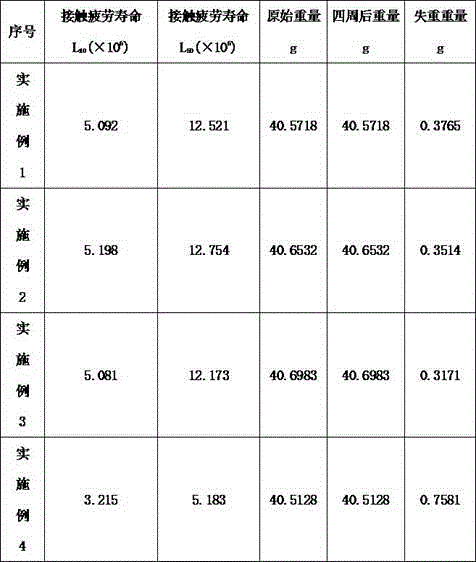

Precision casting bearing steel

InactiveCN106119729AGood corrosion resistance, wear resistance and temperature resistanceCorrosion-resistant, wear-resistant and temperature-resistantUltimate tensile strengthWear resistance

The invention discloses precision casting bearing steel, which is prepared from the following components in percent by weight: 0.95-1.02% of C, 0.15-0.25% of Si, 0.55-0.75% of Mn, 0.03-0.05% of S, 14-17% of Cr, 0.01-0.02% of P, 0.020-0.035% of Al, 0.30-0.40% of N, 0.8-1.0% of Mo, and the balance of Fe and inevitable impurities. The performances such as corrosion resistance and wear resistance of the bearing steel in the prior art cannot meet the use requirements, but in the present invention, C, N, Cr and Mo are reasonably proportioned, such that the material has very good corrosion resistance, wear resistance and temperature resistance, as well as mechanical property and fatigue strength.

Owner:娄土岭

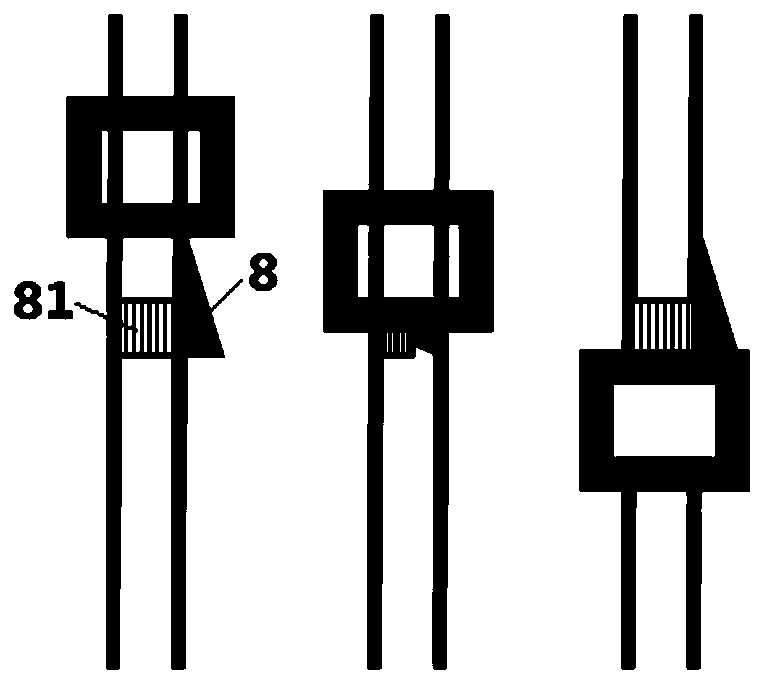

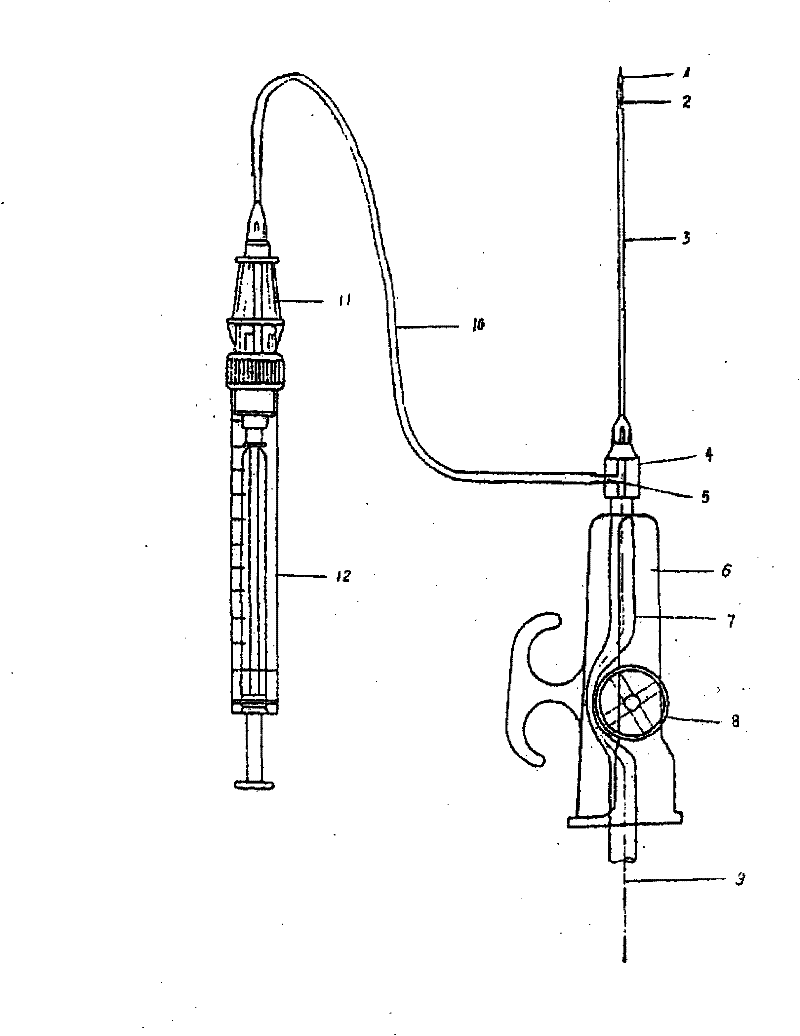

Implanted emergency cardiac care pace-making device

The invention discloses an implanted emergency cardiac care pace-making device, which consists of a needle head, a needle tube, a handle, a hose, an enclosing piece, an electrode lead, a catheter, a connector and an injector. Negative and positive electrodes are arranged on an endocardium and a cardiac muscle for performing emergency pace-making on patients suffering from cardiac arrest, heart block and life-endangering arrhythmia and saving lives. The implanted emergency cardiac care pace-making device is suitable for sickrooms, operating rooms, rescue rooms, ambulances and first-aid stations of medical institutions of all levels, public places, households and the like, and has the advantages of simple structure, safety, reliability, convenience for using, good effect, disposability, and the like.

Owner:XIAN KEWEI MEDICAL TECH

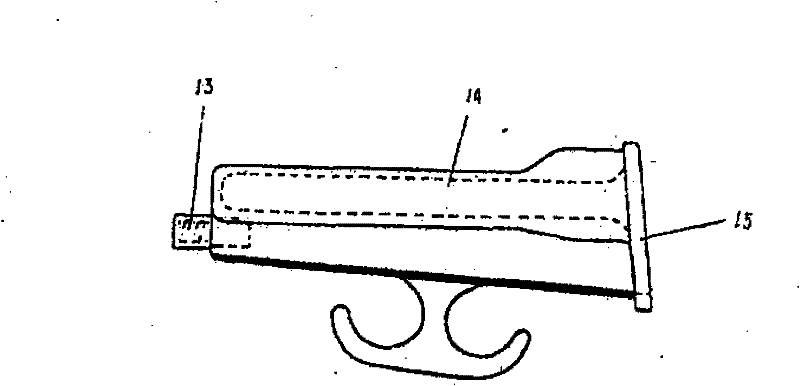

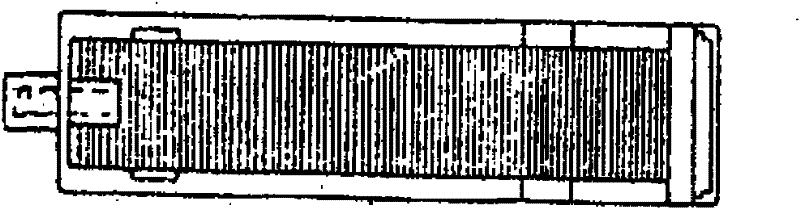

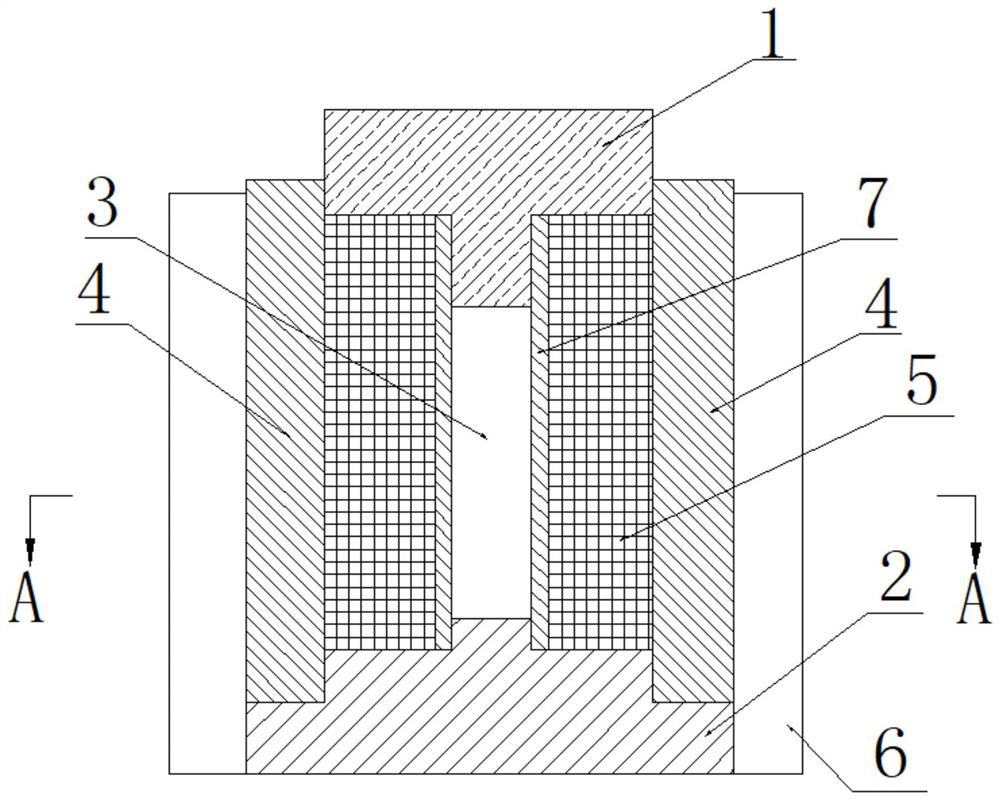

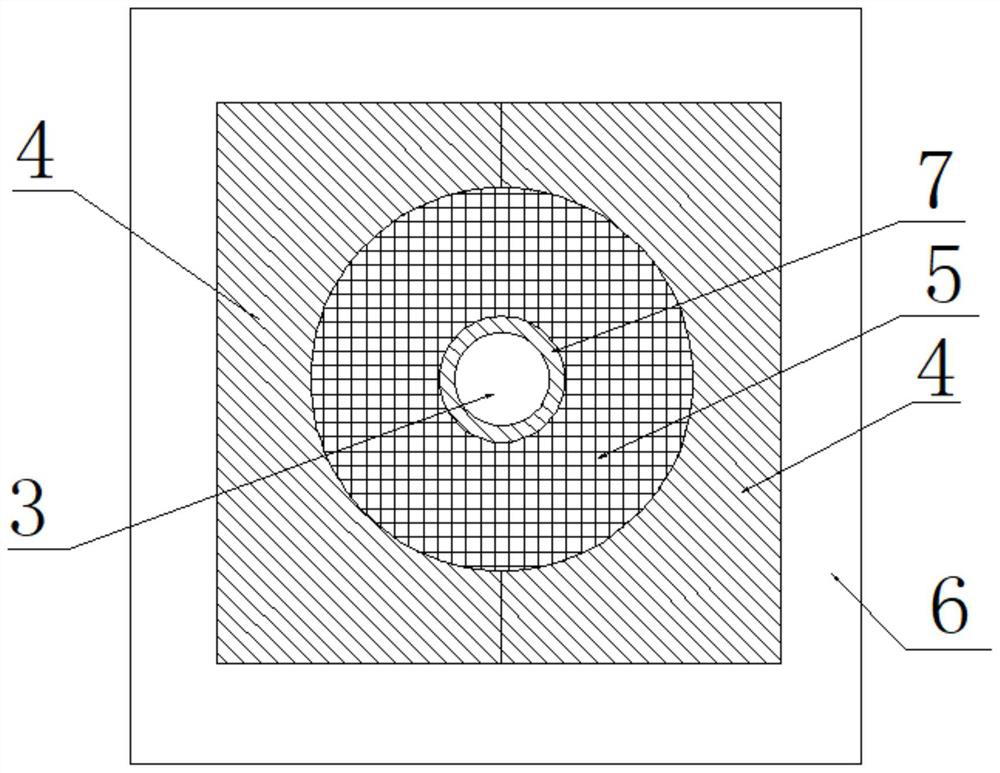

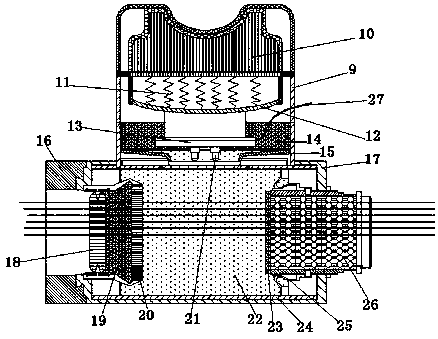

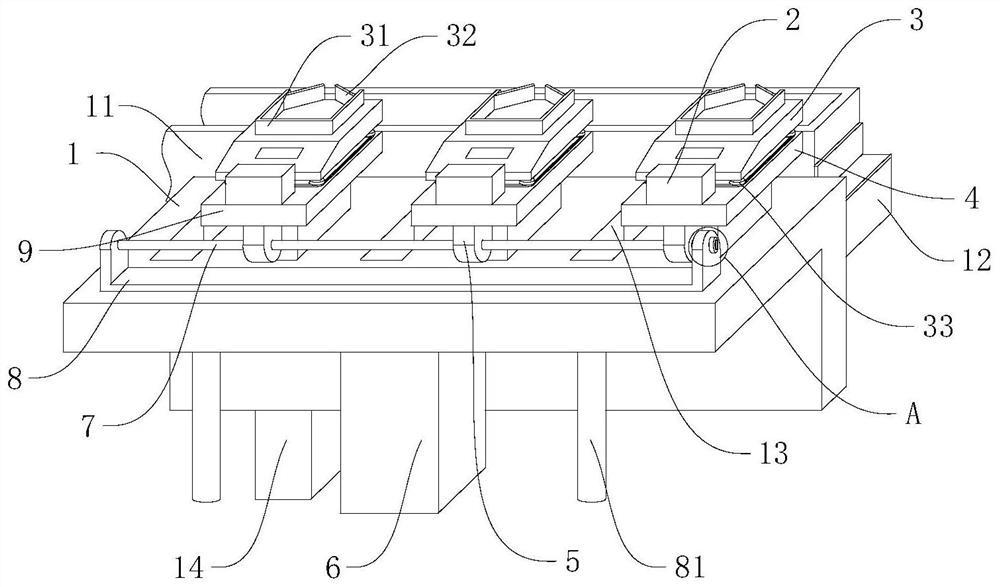

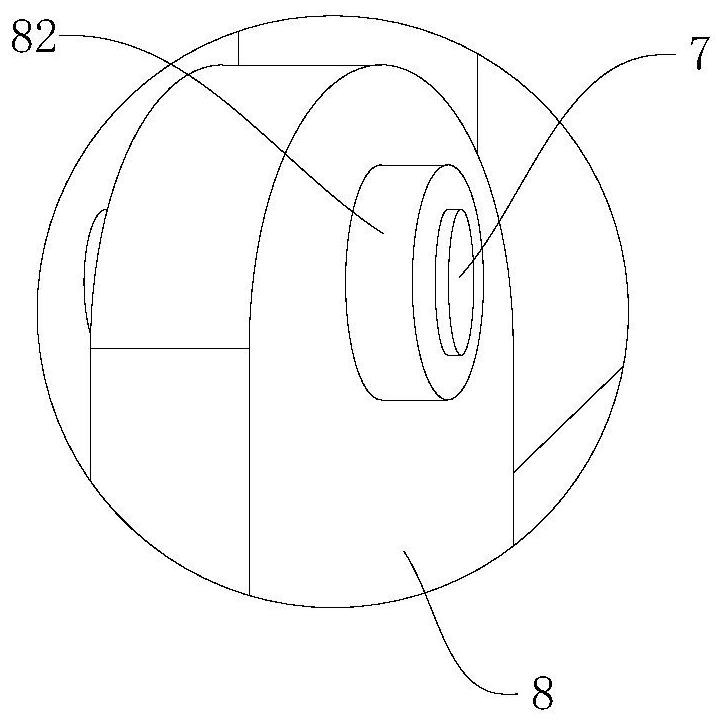

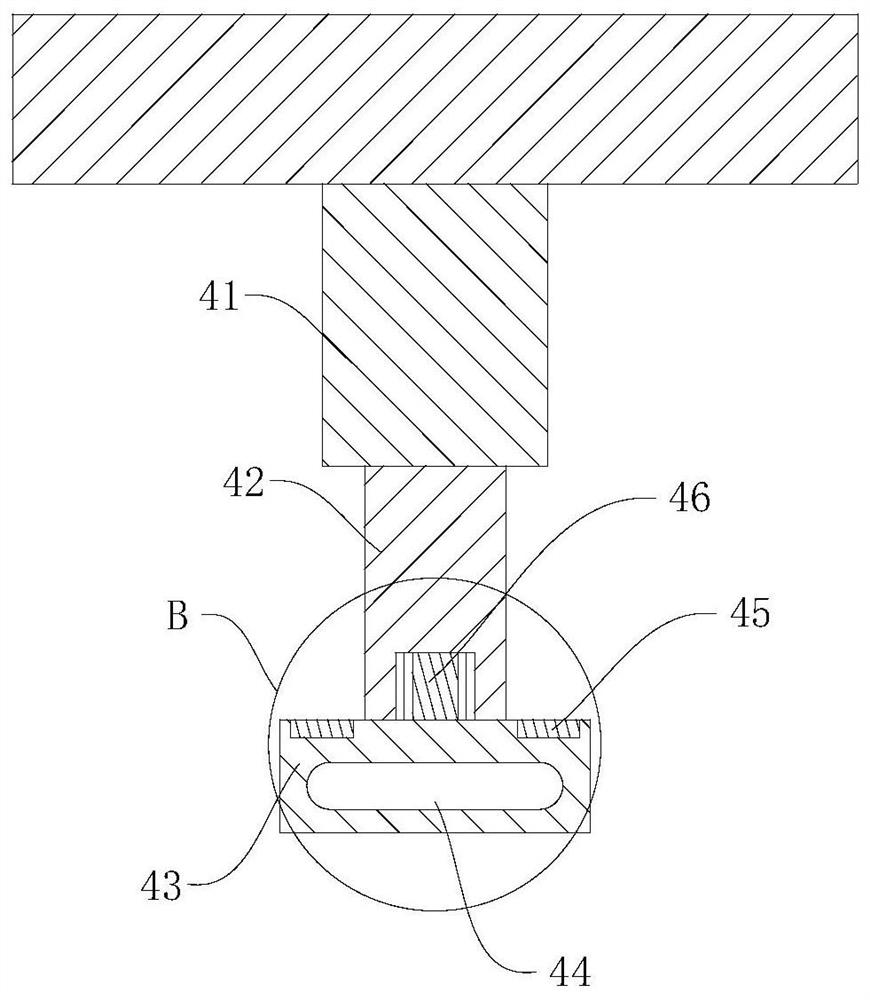

A pet feed compression molding device

ActiveCN107874304BMeet manufacturingQuality improvementFeeding-stuffCompression moldingCompression device

Owner:邢台诺德宠物用品有限公司

Branched wires and cables and their manufacture

ActiveCN1332401CEasy to manufactureMeet manufacturingInsulated cablesCable/conductor manufactureElectrical conductorInsulation layer

The invention consists of main cable composed of metal conductor or cored metal conductor, branch cable composed of metal conductor or cored metal conductor, and insulating layer or sheath layer covering the main cable and branch cable. The branch cable is composed of metal conductor and cored metal conductor which is drawn out from several points on main cable. The main cable is connected with branch cable by bonding layer through insulation layer and sheath layer. There is no contact point in main cable and branch cable. The manufacturing method includes following steps: twisting line; tapping; leasing cord; collating; extruding wire.

Owner:GUANGDONG NANYANG CABLE CO LTD

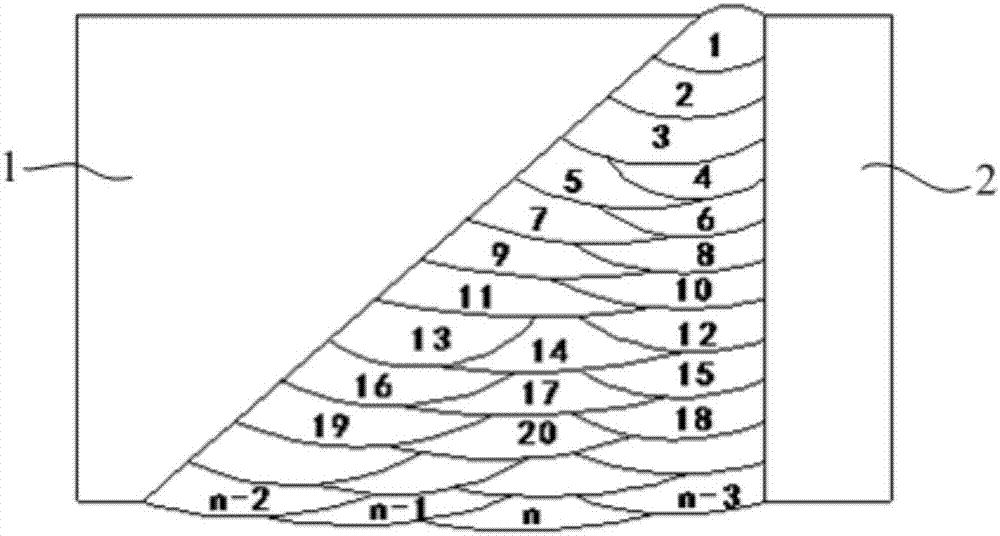

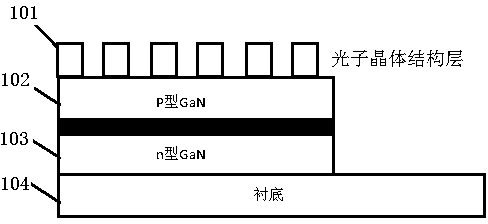

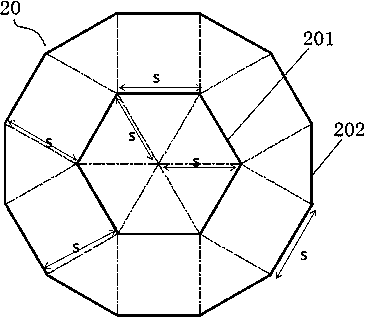

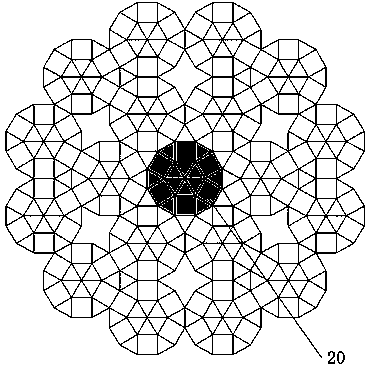

Unit figure of LED photonic crystal structure and use method thereof

ActiveCN105511218AOptimizing the photolithography processHigh resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistPhotonic crystal structure

The invention discloses a lithography splicing method of a photonic crystal process layer. The method is characterized by including: step 1. defining a photonic crystal structure figure characteristic, which refers to a figure structure with a spacing to the figure center of s, a regular hexagon inner ring and a regular dodecagon outer ring, wherein the s is two times larger than that of projection mask aligner minimum resolution R; step 2. forming a photonic crystal structure according to the photonic crystal structure figure characteristic; step 3. extracting a hexagon structure from the photonic crystal structure to serve as the unit figure; and step 4. taking a mask image containing the unit figure as the exposure field exposure field of view. The invention also discloses a mask containing the unit figure of the photonic crystal structure, a making method of the photonic crystal process layer, and a making method of the mask containing the unit figure of the photonic crystal structure.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

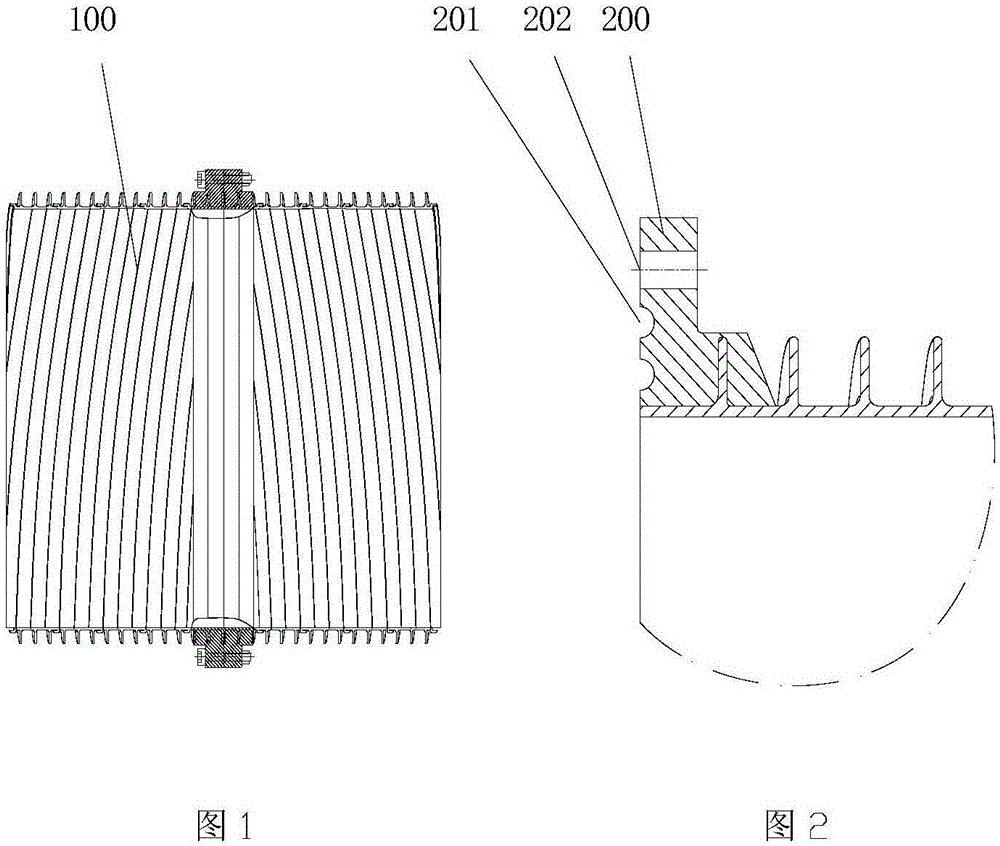

Preparation method of MoNiB metal ceramic thread element

PendingCN112893843AHas tensile strengthWith bending strengthTurbinesOther manufacturing equipments/toolsRound barMetal mold

The invention discloses a preparation method of a MoNiB metal ceramic thread element. The preparation method comprises the following steps that Mo-Ni-B metal mixed powder is prepared; a steel tubular core rod is machined; a metal mold is prepared; the steel tubular core rod is placed in the mold, and the space among a outer mold, a core mold and a lower mold is filled with the Mo-Ni-B metal mixed powder; the metal mold filled with the powder is placed into a pressure chamber of press equipment, static pressure molding is performed, and demolding is performed to form a composite molding body with the steel core hollow round rod inside and the Mo-Ni-B metal mixed powder on the outer layer; the composite forming body is machined into a thread element blank; the blank is subjected to vacuum sintering, and a finished blank is obtained; and the finished blank is subjected to finish machining, and the steel-based MoNiB composite metal ceramic product thread element finished product is obtained. The MoNiB metal ceramic thread element has ultrahigh corrosion resistance and wear resistance at the same time.

Owner:CHINA UNIV OF MINING & TECH +1

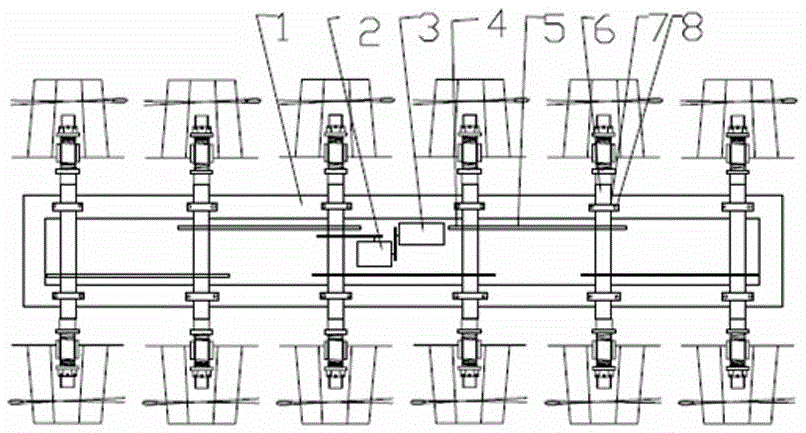

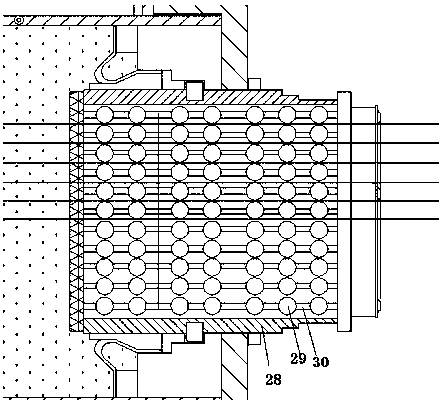

Multi-reel take-up machine

The invention discloses a multi-reel take-up machine. The multi-reel take-up machine comprises a plurality of take-up reels each mounted on a rack through a transmission shaft. Each of the multiple transmission shafts is mounted on the rack through a corresponding bearing and a corresponding bearing pedestal in parallel relative to an extruder, and the two ends of each transmission shaft are each provided with the corresponding take-up reel for wire blank wrapping through a shaft sleeve. A motor is further mounted on the rack and directly or indirectly connected with the transmission shafts through a chain wheel transmission mechanism. The number of the take-up reels is 8 to 16, every two take-up reels are fixedly mounted at the two ends of the corresponding transmission shaft, and each take-up reel is provided with a scissor plug capable of blocking a wire blank in the take-up process. The parts, on the two sides of the corresponding shaft sleeve, of each transmission shaft are each sleeved with a spring pressed to the corresponding shaft sleeve. The outer ends of the springs on the inner sides are pressed on baffles arranged on the transmission shafts in a sleeving manner, the outer ends of the springs on the outer sides are also pressed on the baffles arranged on the transmission shafts in a sleeving manner, and the outer sides of the baffles are fixed at least through nuts. The multi-reel take-up machine has the beneficial effects of being simple and reasonable in structure and convenient to use, fully meeting tin-based alloy wire manufacturing and the like.

Owner:浙江亚通冶金科技有限公司

A new type of optical cable manufacturing equipment

ActiveCN108828742BSo as not to damageImprove the preparation effectFibre mechanical structuresBiochemical engineeringOptical fiber cable

The invention discloses a novel optical cable manufacturing device which can ensure the coating uniformity and stability of factice in the manufacturing process of an optical cable. A method of usingthe oil immersion pad is used for coating so as to achieve a good coating effect. A vibration component is disposed to not only improve the oil supply performance of an oil supply head, but also provide vibration for the oil immersion pad so that the factice on the oil immersion pad is stably immersed in the oil. An oil-scraping component scrapes the oil by a holding frame and an oil-scraping ballso as to achieve good oil-scraping uniformity and high efficiency, guides an optical cable, does not damage the optical cable, and improves the manufacturing effect of the optical cable. Further, thecable-laying frame of the novel optical cable manufacturing device is provided with a plurality of reels in order to lay cables of different colors and basically realize the manufacture of various types of optical cables.

Owner:NANTONG MEIMING CHINLON

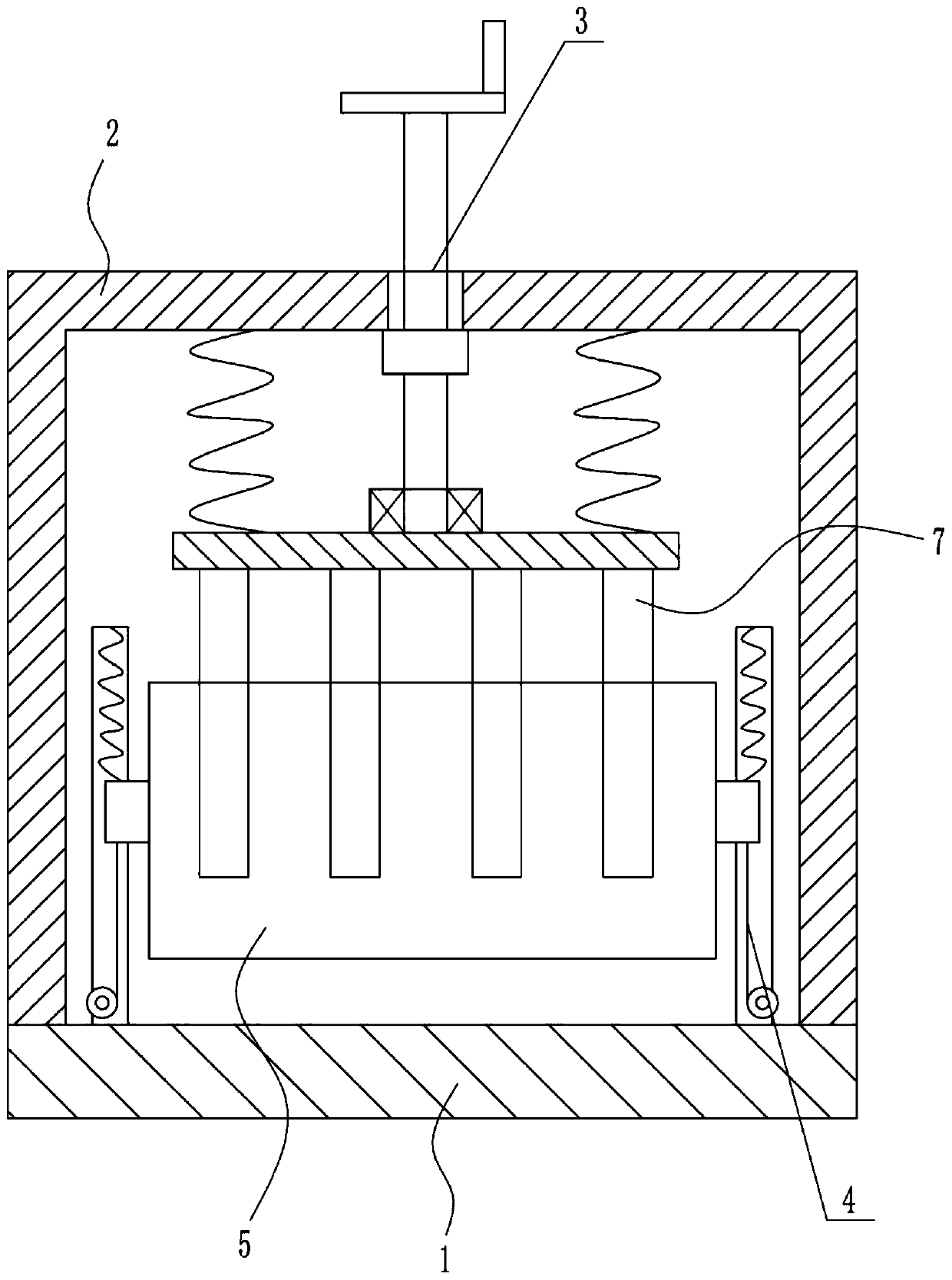

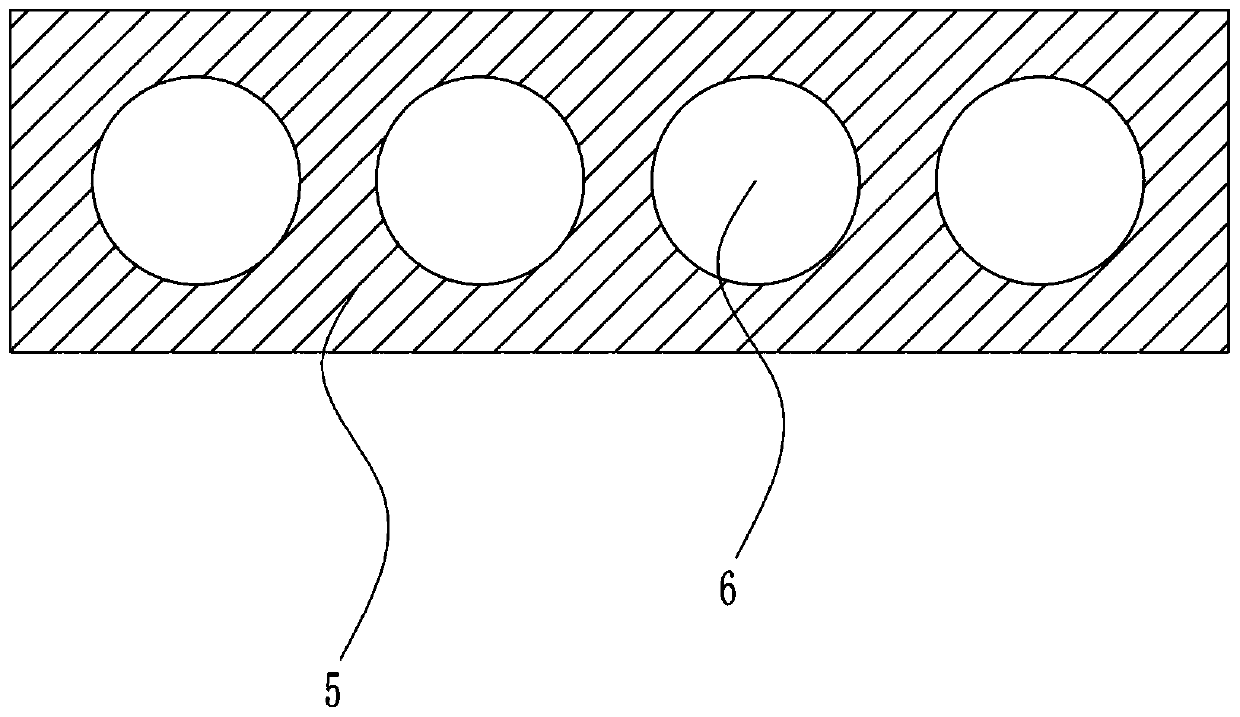

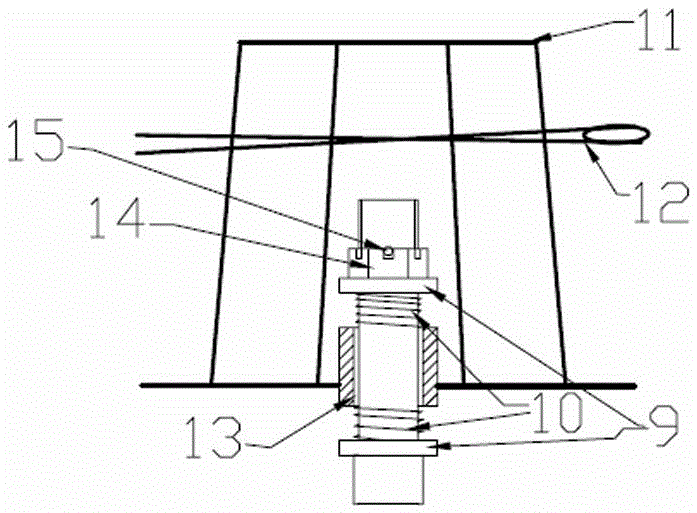

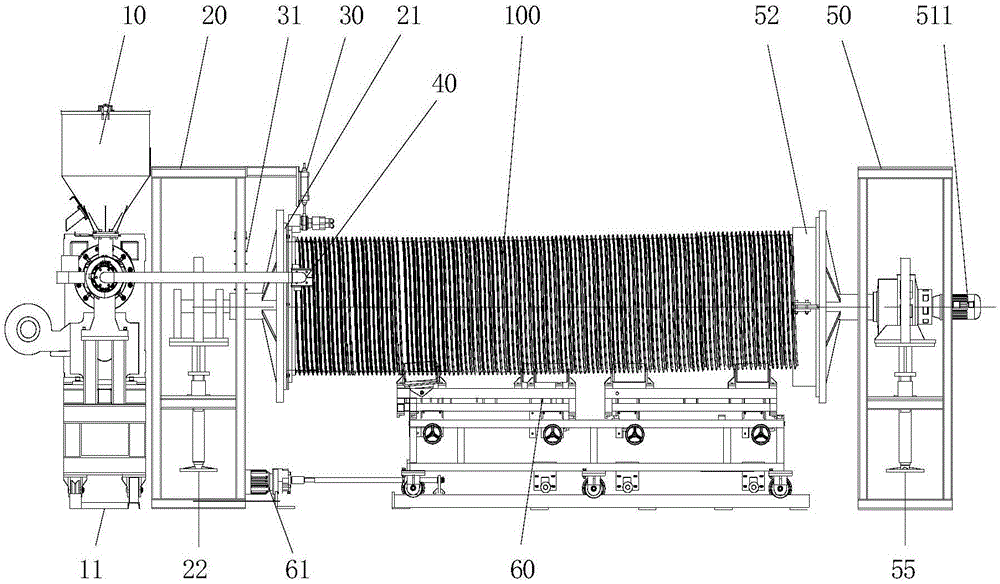

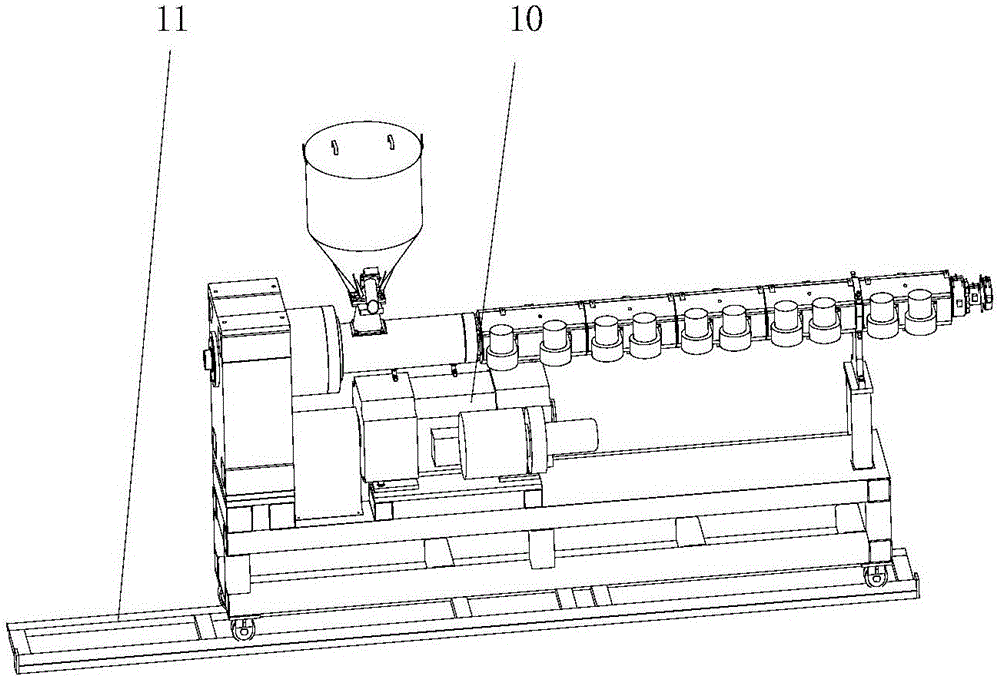

A manufacturing system for large-diameter steel-plastic winding pipe flanges

ActiveCN104494158BAchieve preparationMeet manufacturingManufacturing cost reductionInjection moulding

The invention discloses a system for manufacturing a large-caliber steel-plastic winding pipe flange. The system comprises plastifying extrusion equipment, a rotary power mechanism, a positioning mechanism, a compression roller mechanism, a cooling device output pipe and a bracket, wherein the plastifying extrusion equipment extrudes melt sheets by an extruder by virtue of a mold; the rotary power mechanism is opposite to the positioning mechanism and can be respectively connected with two ends of a steel-plastic winding pipe of a to-be-manufactured flange in a matched mode; the bracket is positioned between the rotary power mechanism and the positioning mechanism; the positioning mechanism is positioned at the extrusion end of the plastifying extrusion equipment; and the mold of the plastifying extrusion equipment is positioned nearby a pipeline supporting and positioning flange of the positioning mechanism and is positioned at a melt sheet position coated with the manufactured winding pipe flange. According to the extruded melt sheets and a coating and rolling process, the large-caliber steel-plastic winding pipe flange is manufactured, and the defect that the large-caliber steel-plastic winding pipe flange cannot be manufactured by adopting a traditional injection molding method is overcome; and moreover, a lift adjusting device is adopted by the rotary power mechanism and the positioning mechanism, the manufacturing requirements of the steel-plastic winding pipe flanges of different specifications are met, and the manufacturing cost is reduced.

Owner:华瀚管道系统科技有限公司

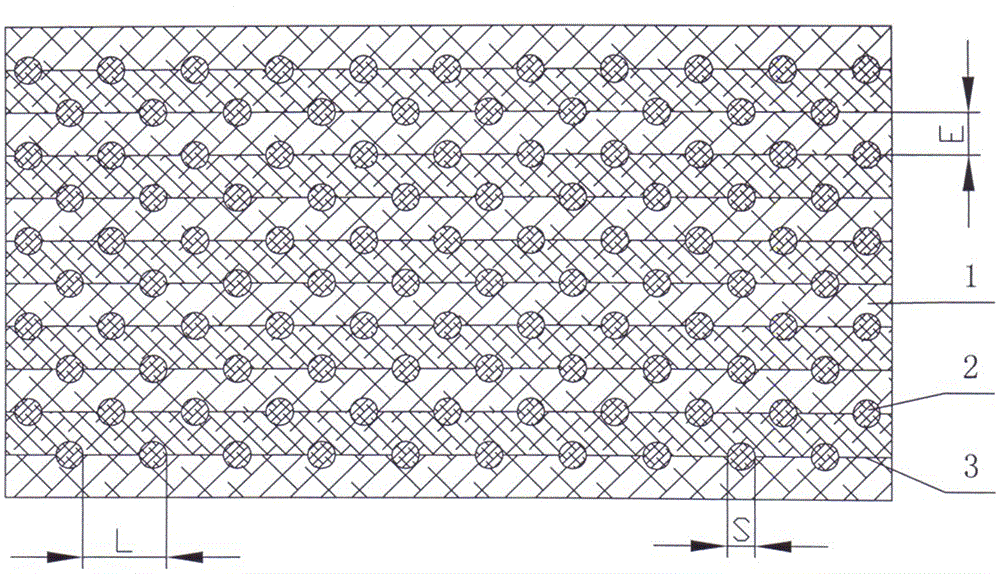

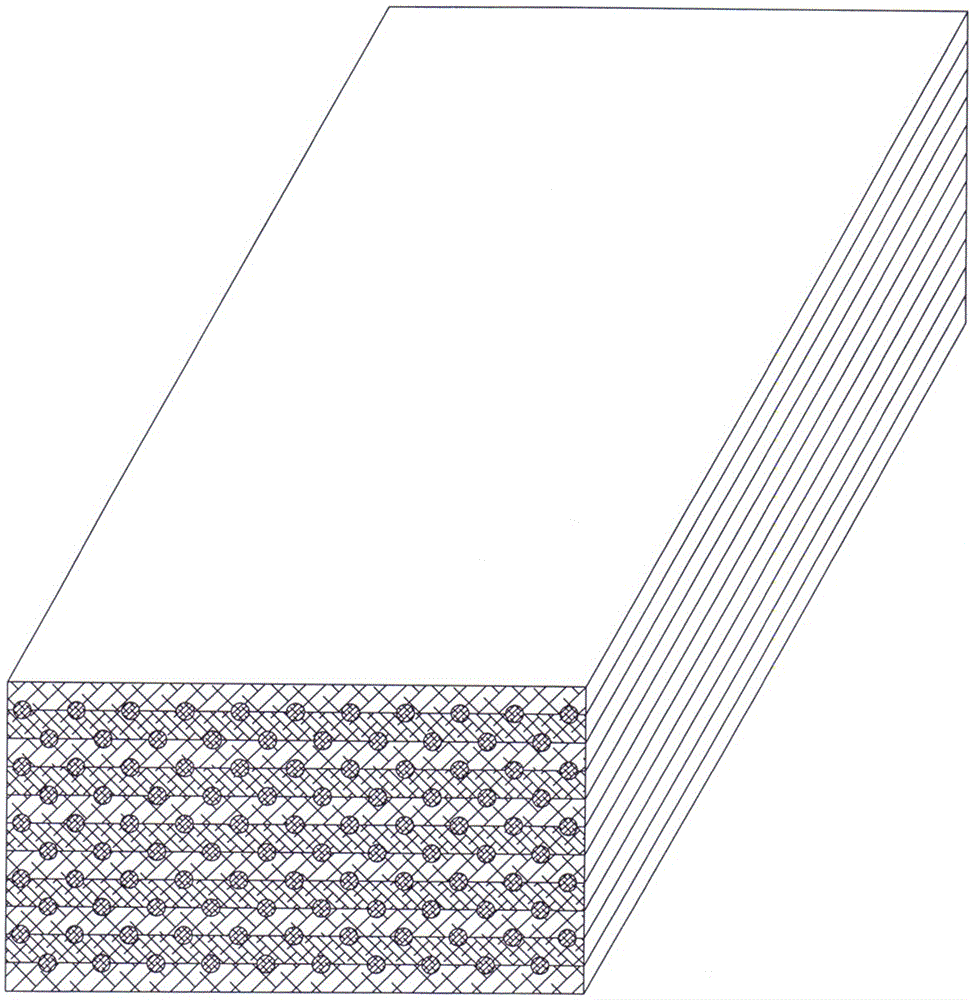

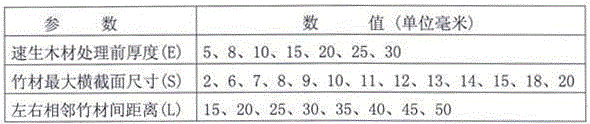

Bamboo-wood composite modified material

InactiveCN105058518AWide variety of sourcesImprove use valueWood veneer joiningWood layered productsAdhesiveMaterial consumption

The invention discloses a bamboo-wood composite modified material, and aims at providing the bamboo-wood composite modified material which is simple in structure, convenient to manufacture and capable of greatly improving the mechanical property of modified wood. The bamboo-wood composite modified material comprises multiple layers of sheet fast-growing wood, and is characterized in that long-strip-shaped bamboo wood placed in rows at intervals is arranged between the multiple layers of sheet fast-growing wood; the fiber direction of the bamboo wood is consistent with the length direction of the bamboo wood; adhesives are sprayed between the fast-growing wood and the bamboo wood; and by means of conventional high-temperature and high-pressure modification treatment, the bamboo wood can be embedded in the modified wood, and the modified wood and the bamboo wood are combined into a whole. The effect achieved after the two types of materials are combined is the same as the effect achieved after reinforcing steel bars are added in concrete. In the use process, the massive bamboo-wood composite modified material can be partitioned and cut through a saw like ordinary wood according to use requirements, and the requirement for manufacturing various components is met. The material has the beneficial effects of being simple in manufacturing process, high in production efficiency, low in material consumption and production cost, good in environmental protection property, good in use performance, high in material utilization rate and capable of meeting the requirement for manufacturing various wood structure components.

Owner:JIASHAN HUIJIALE DECORATION MATERIALS CO LTD

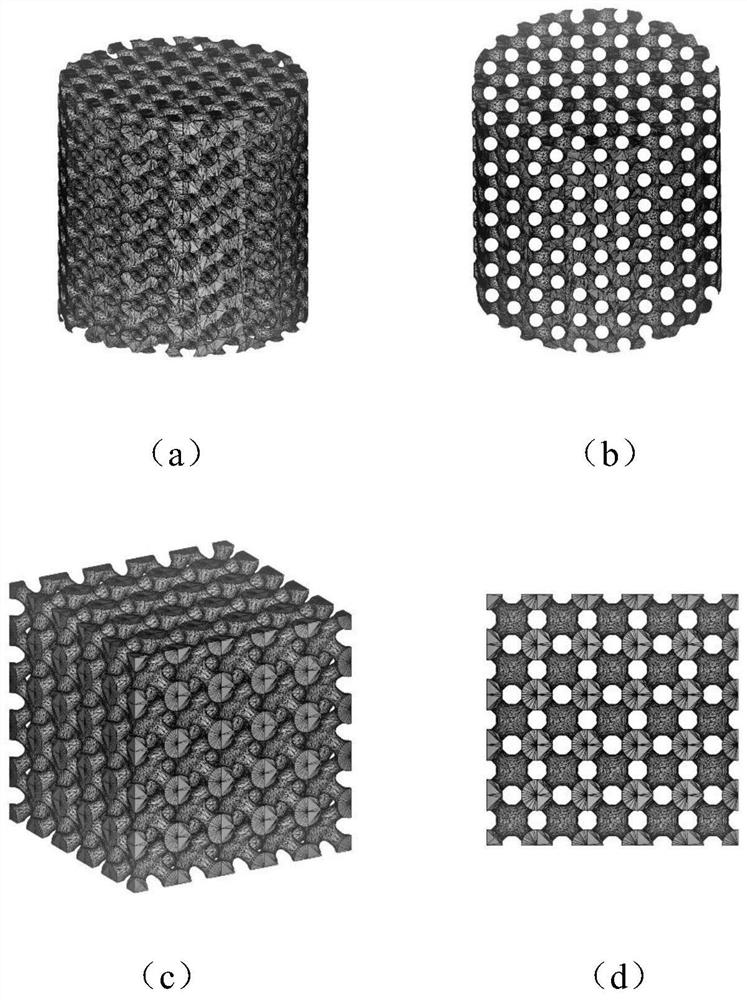

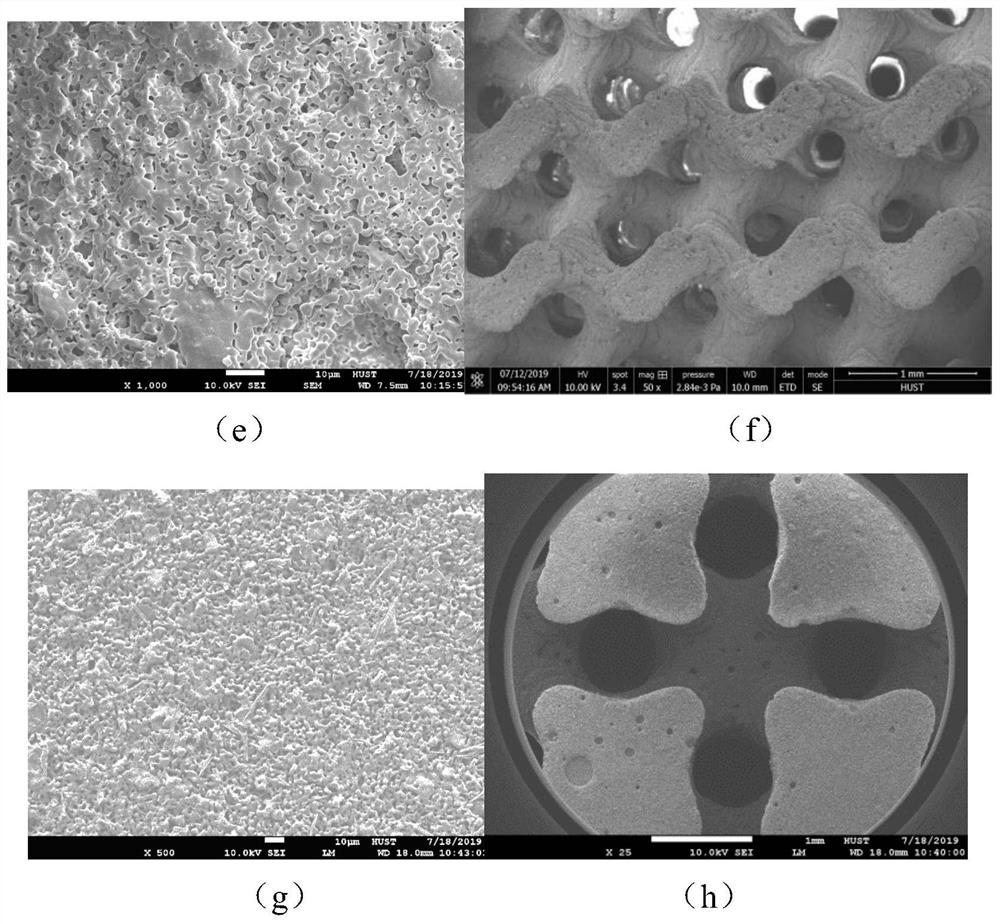

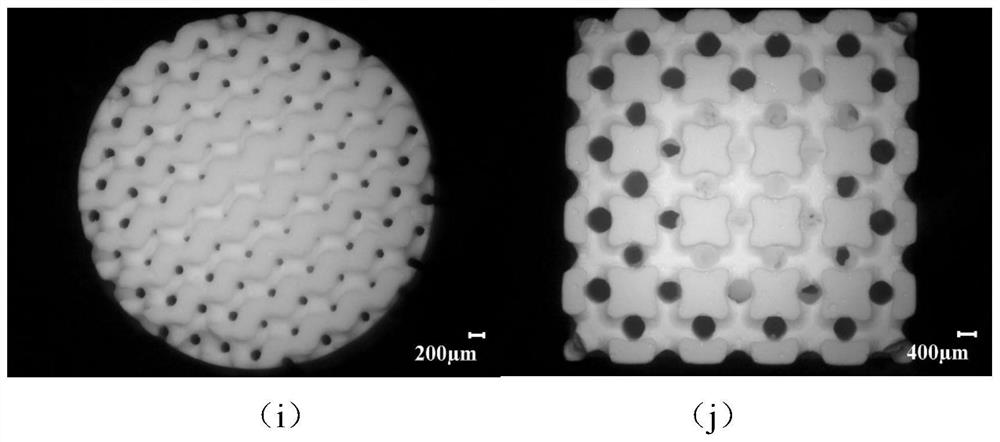

Biocomposite ceramic scaffold with controllable degradation performance and strength and preparation method thereof

ActiveCN110668807BEven by forceImprove stabilityAdditive manufacturing apparatusMicron scaleComposite ceramic

The invention belongs to the field of biomedical materials and additive manufacturing, and relates to a biocomposite ceramic support with controllable degradation performance and strength and a preparation method thereof. The method includes: S1. taking hydroxyapatite powder, β-calcium phosphate powder and Micron-sized biological glass powder with a total mass of m; after mixing different kinds of photocurable resin monomers and / or their prepolymers in a predetermined ratio, adding a plasticizer and a dispersant for ultrasonic mixing, and then adding a photoinitiator and a photoresist Coagulant, release agent and lubricant, fully mixed to obtain a solvent; S2. Add the three powders to the solvent for stirring and vacuum ball milling to obtain a printing slurry; S3. Use the printing slurry for DLP 3D printing and / or optical printing Solidify to obtain a bioceramic green body; S4. Degrease and sinter the bioceramic green body to obtain a finished biocomposite ceramic stent. The invention can obtain composite bioceramics with excellent mechanical properties and degradation properties, and can be applied to bone tissue engineering technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Fin-type semiconductor structure and forming method thereof

ActiveCN103915504BReduce leakage currentImprove controlSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a fin type semiconductor structure which is capable of effectively controlling leakage currents between a source region and a drain region and improving gate control capacity. The fin type semiconductor structure comprises a fin type substrate, the source region, the drain region, a gate structure, shallow ridge isolation parts and an isolation region, wherein the fin type substrate is provided with a lower substrate and a fin part, the source region and the drain region are formed on the fin part, the gate structure is formed between the source region and the drain region and stretches across the fin part, the shallow ridge isolation parts are formed on the two sides of the fin part and are located below the gate structure, and the isolation region is formed in the fin part. The isolation region can be basically located below the source region and / or basically located below the drain region, and / or basically located below the gate structure. The invention further provides a method for forming the fin type semiconductor structure.

Owner:唐棕

Weighing device for cleaning material manufacturing

ActiveCN112747811AImprove work efficiencyQuick disassemblySpecial purpose weighing apparatusStructural engineeringCylinder block

The invention provides a weighing device for cleaning material manufacturing, which comprises an L-shaped metal plate. A U-shaped frame is attached to the upper end of the front side of the transverse part of the L-shaped metal plate, a bolt rod is installed in the upper side of the U-shaped frame, and the annular end of the bolt rod is rotatably connected with a plurality of connecting plates. The lower end of the front side of the transverse part of the L-shaped metal plate is fixedly connected with a cylinder body of a first electric push rod, the movable end of the first electric push rod is fixedly connected with the middle position of the lower end of the U-shaped frame, a plurality of supporting mechanisms are arranged at the upper end of the transverse part of the L-shaped metal plate at equal intervals, a mounting plate is arranged at the upper ends of the supporting mechanisms in an attached mode, and an electronic weighing device is fixedly connected to the upper end of themounting plate. Compared with the prior art, the device has the following beneficial effects that through the first electric push rod, the U-shaped frame, the bolt rod and the multiple connecting plates, the multiple electronic weighing devices incline synchronously, synchronous weighing and feeding of all raw materials are achieved, and the working efficiency is improved.

Owner:绍兴市上虞区武汉理工大学高等研究院

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com