Branched wires and cables and their manufacture

A wire and cable branching technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of insulation performance degradation, complicated manufacturing process, leakage, etc., and achieve the effects of saving metal materials, reducing engineering investment, and narrowing wiring channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

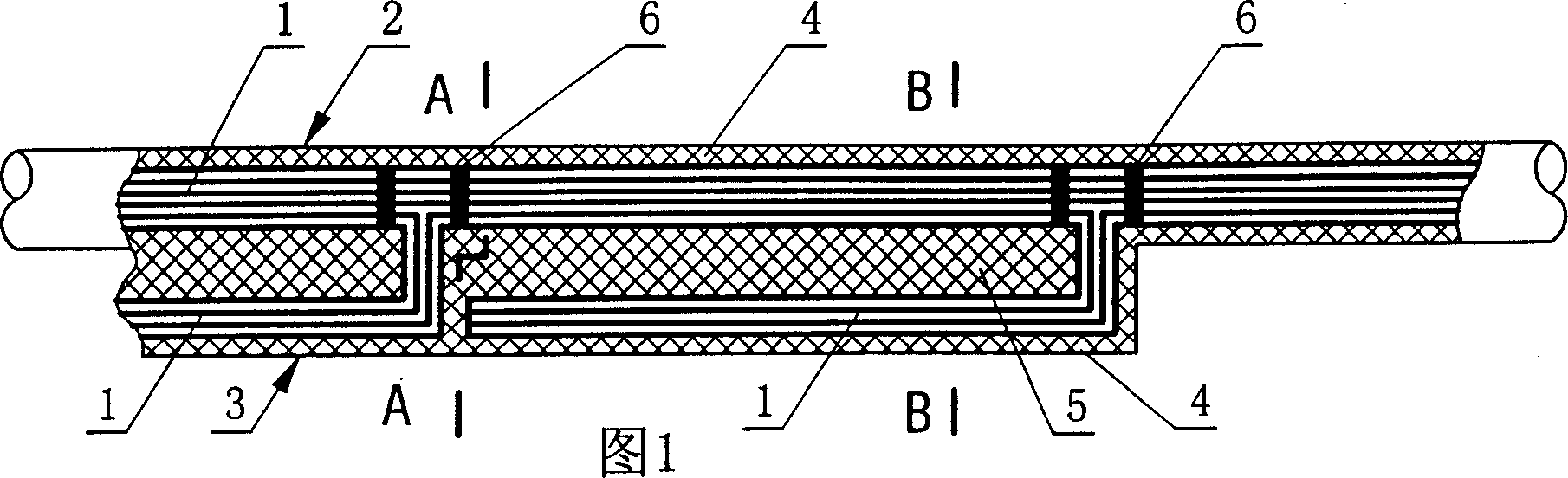

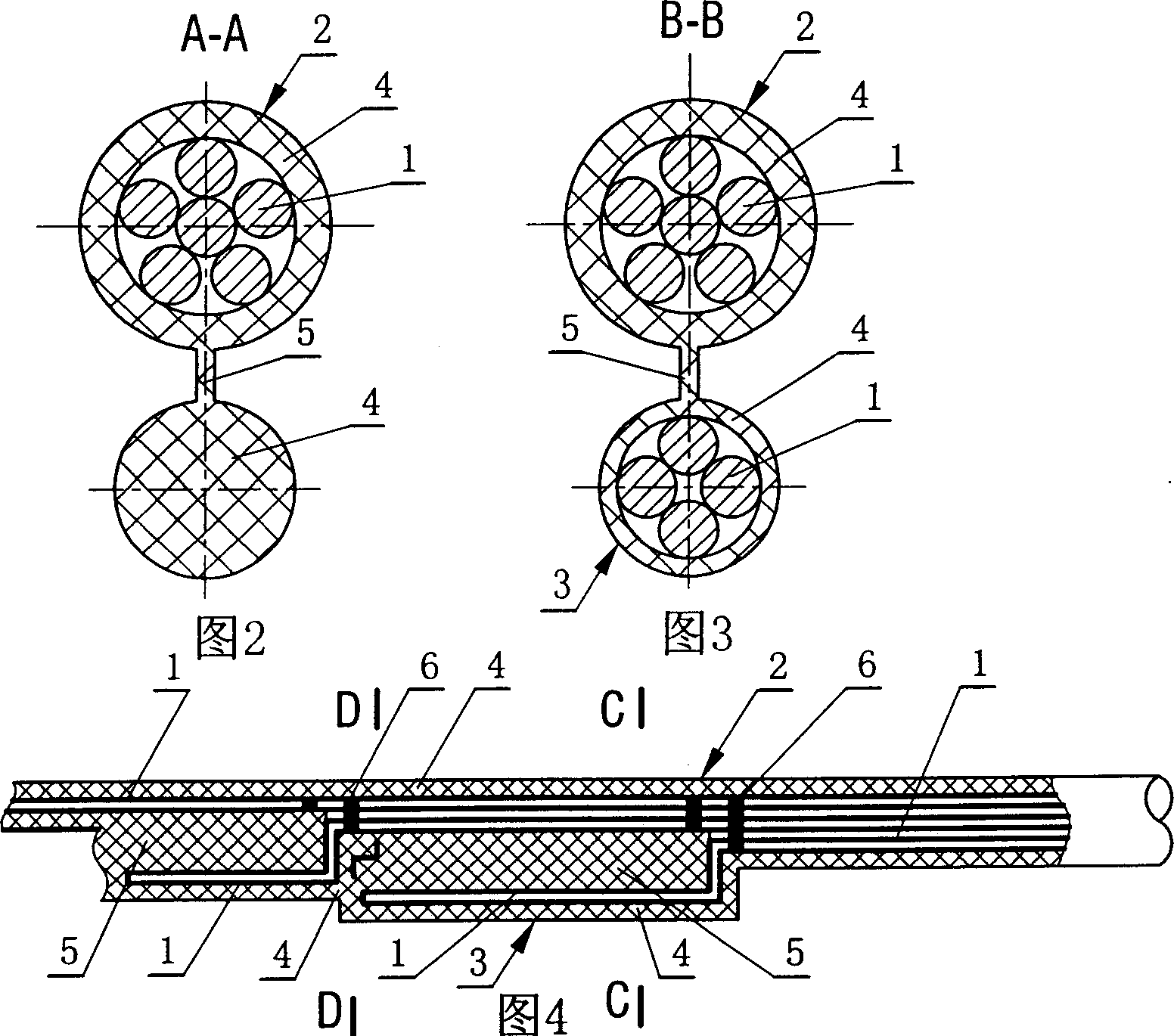

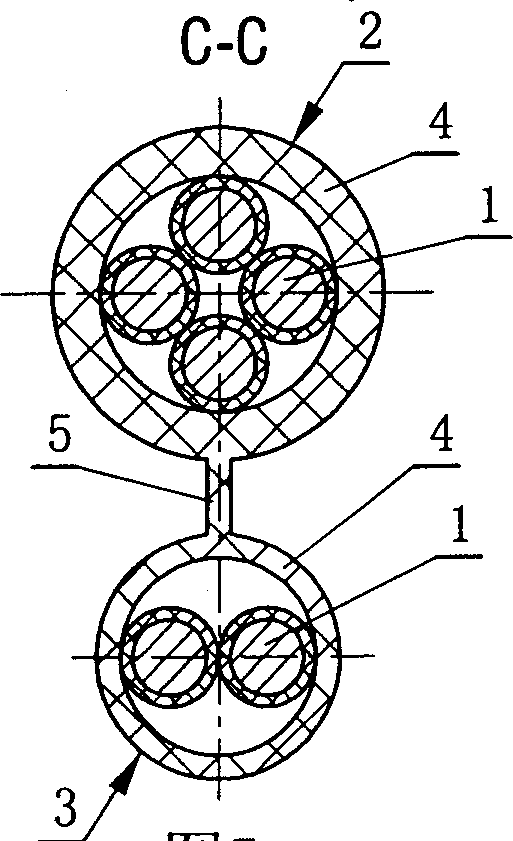

[0041] One of the specific embodiments is shown in Figures 1, 2 and 3. A branched electric wire, consisting of a main line 2 composed of a metal conductor 1, a branch line 3 composed of a metal conductor 1, and an insulating layer 4 wrapped on the main line 2 and the branch line 3; in the main line 2 A plurality of metal conductors 1 are extracted at any distance to form a branch line 3, and the main line 2 and the branch line 3 are connected parallel to each other by a connecting layer 5 through an insulating layer 4. On the trunk line 2 where the metal conductor 1 is extracted, a fixing piece 6 for fastening the trunk line 2 is provided; the material of the fixing piece 6 is the same as that of the metal conductor 1 . The distance between the main line 2 and the branch line 3 parallel to each other = the thickness of the insulating layer 4 of the main line 2 + the thickness of the insulating layer 4 of the branch line 3 + a coefficient of 1 ~ 3mm; both the main line 2 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com