Patents

Literature

2669 results about "Branch line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

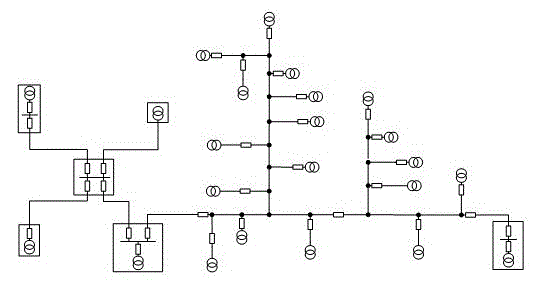

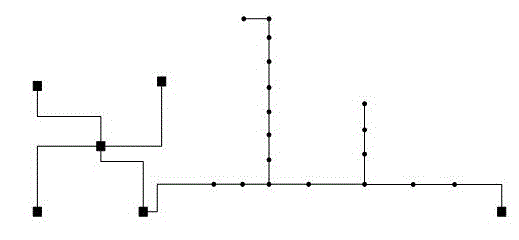

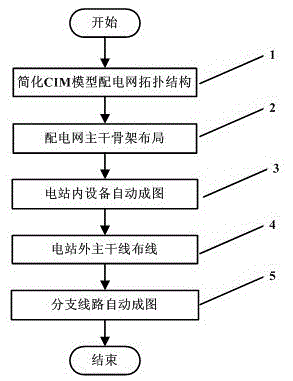

Automatic generation method used for single line diagram of distribution network and based on topological hierarchy

ActiveCN103150425ARealize automatic generationRealize a reasonable layoutSpecial data processing applicationsMassive gravityPower station

The invention discloses an automatic generation method used for a single line diagram of a distribution network and based on topological hierarchy. The method comprises the following steps: deleting related equipment in a topological structure of the distribution network, and simplifying the topological structure of the distribution network; acquiring key nodes of the topological structure of the distribution network, and generating a main framework of the topological structure of the distribution network; arranging the positions of the key nodes based on a gravitation-repulsion model, and obtaining a skeletal structure based on the gravitation-repulsion; describing the topological structure of the distribution network through an outgoing line-trunk line-T-shaped key node-branch line model of a power station; finishing the arrangement and the automatic mapping of the equipment in the power station on the basis of the topological structure of the equipment in the power station; and performing routing mapping without overlap or intersection on decibels of the trunk line and the branch line respectively. The automatic generation method achieves automatic generation of the single line diagram of the distribution network above a certain scale, and simultaneously, the generated single line diagram is clearer and more attractive through the routing algorithm without overlap or intersection.

Owner:SHANGHAI JIAO TONG UNIV

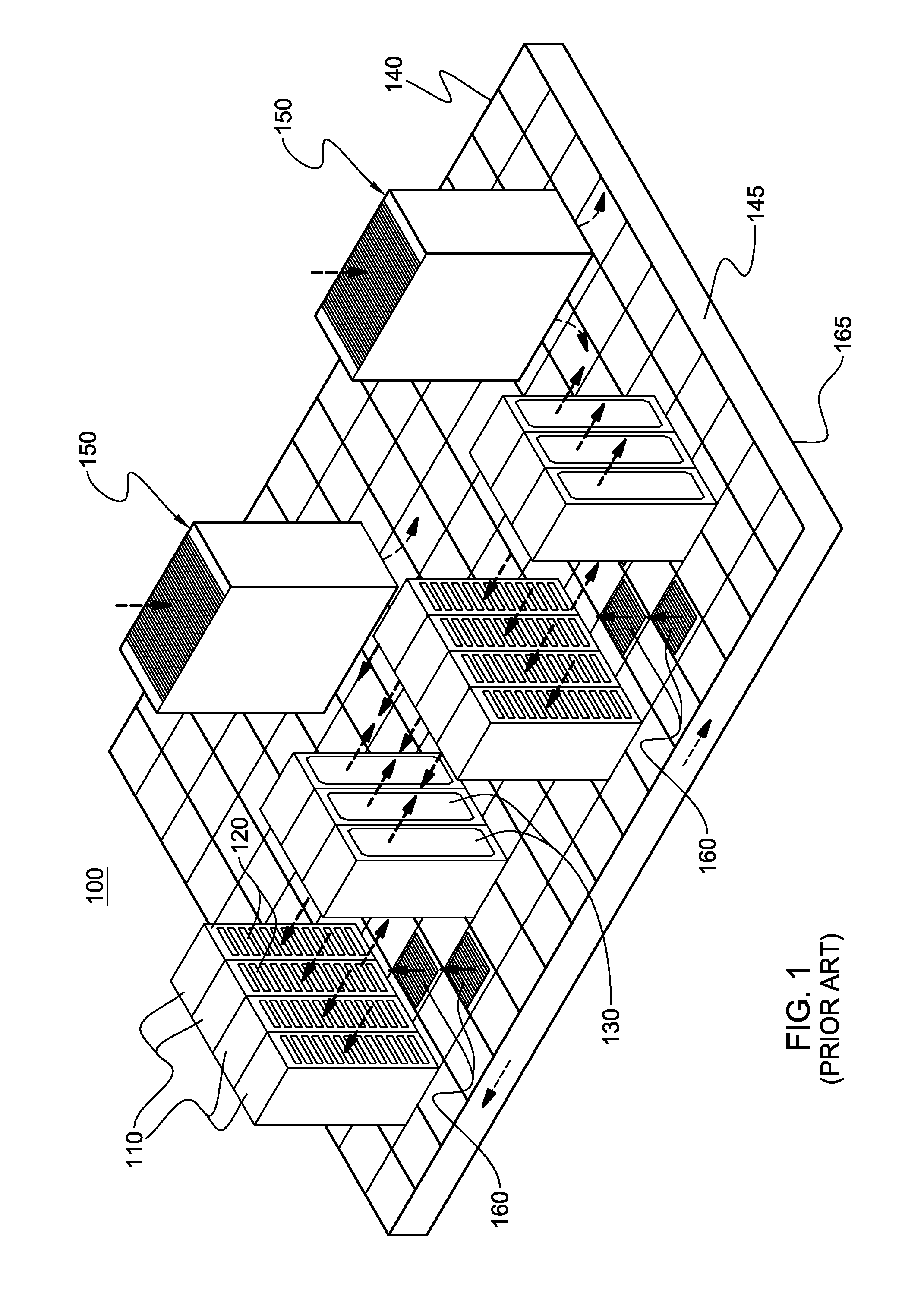

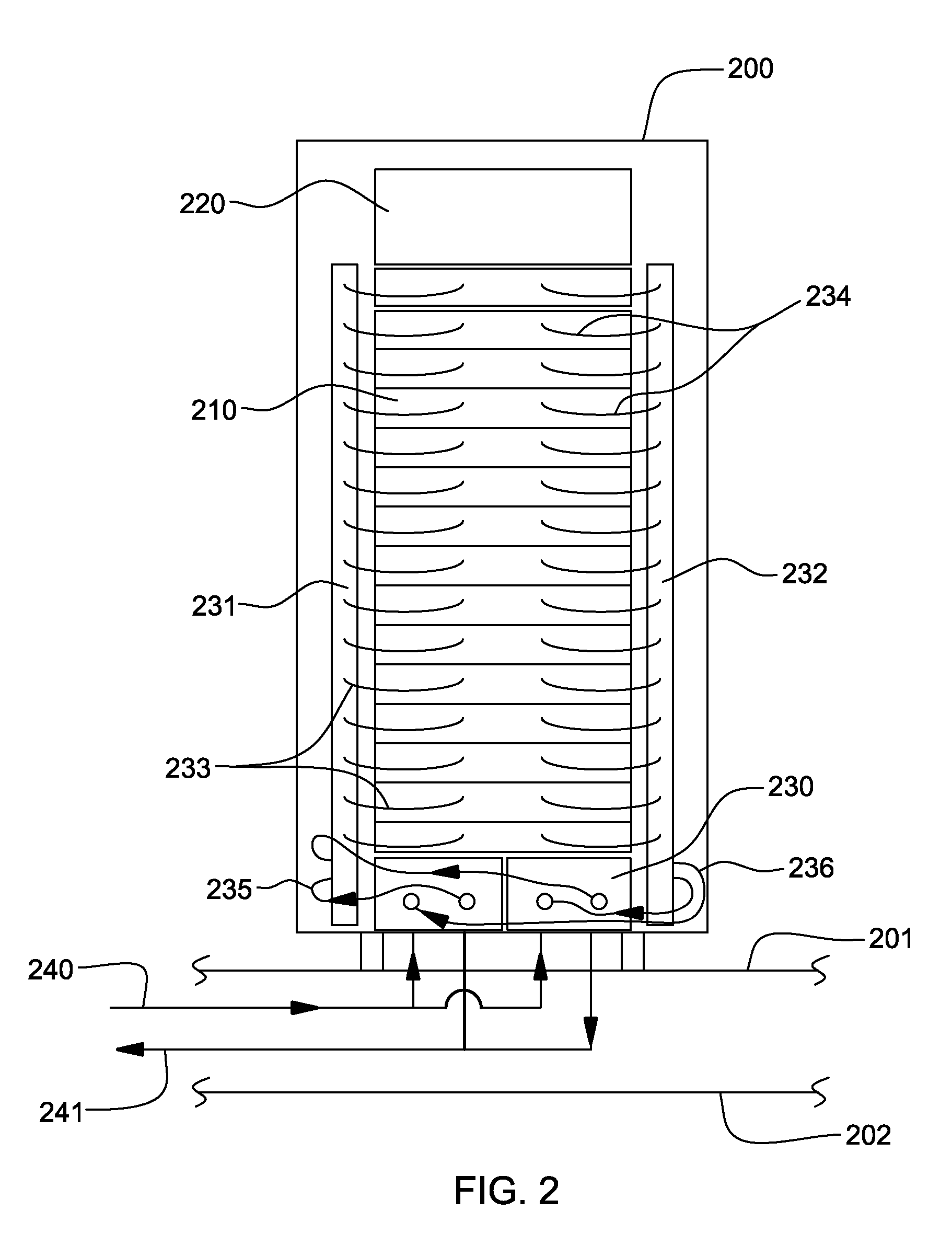

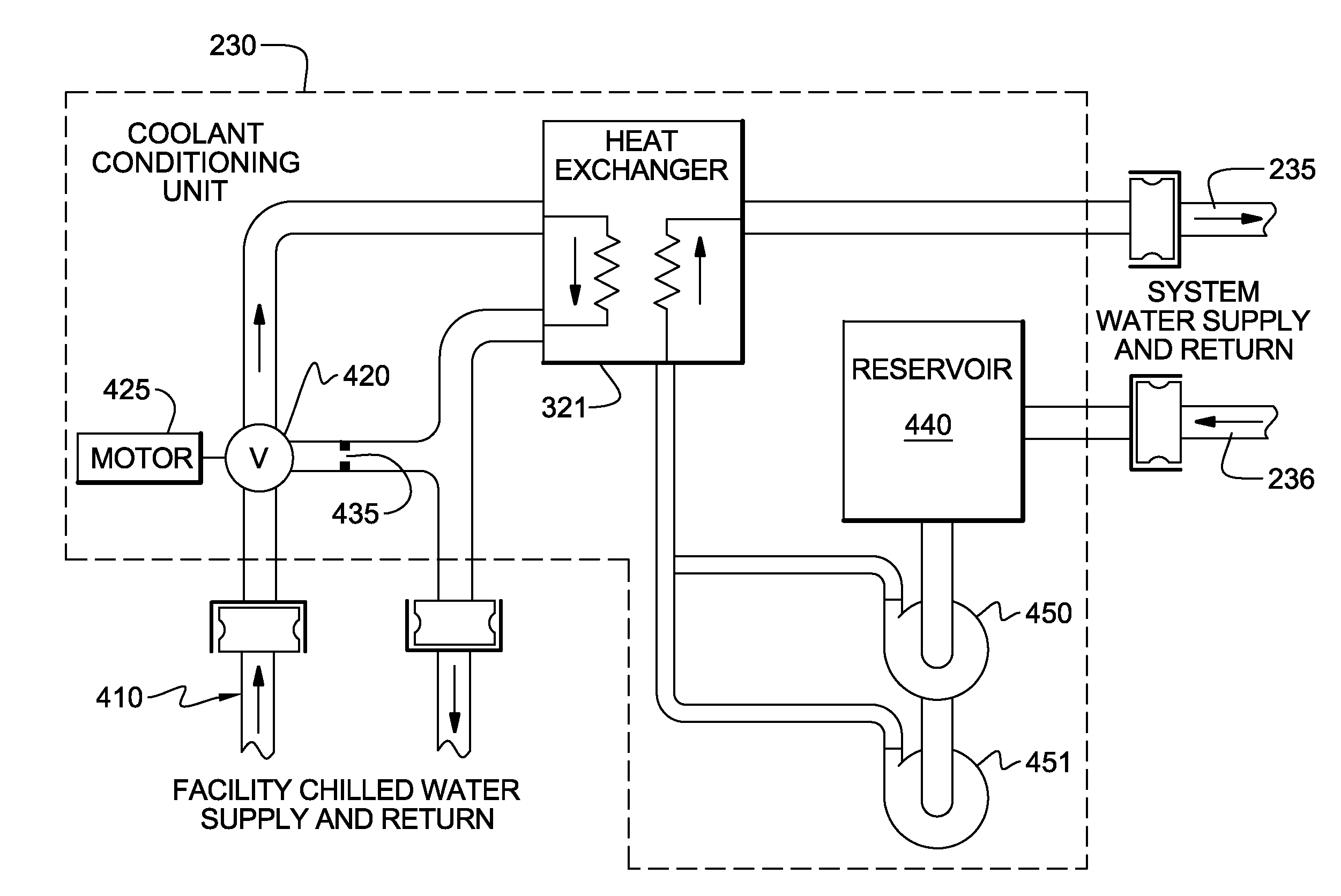

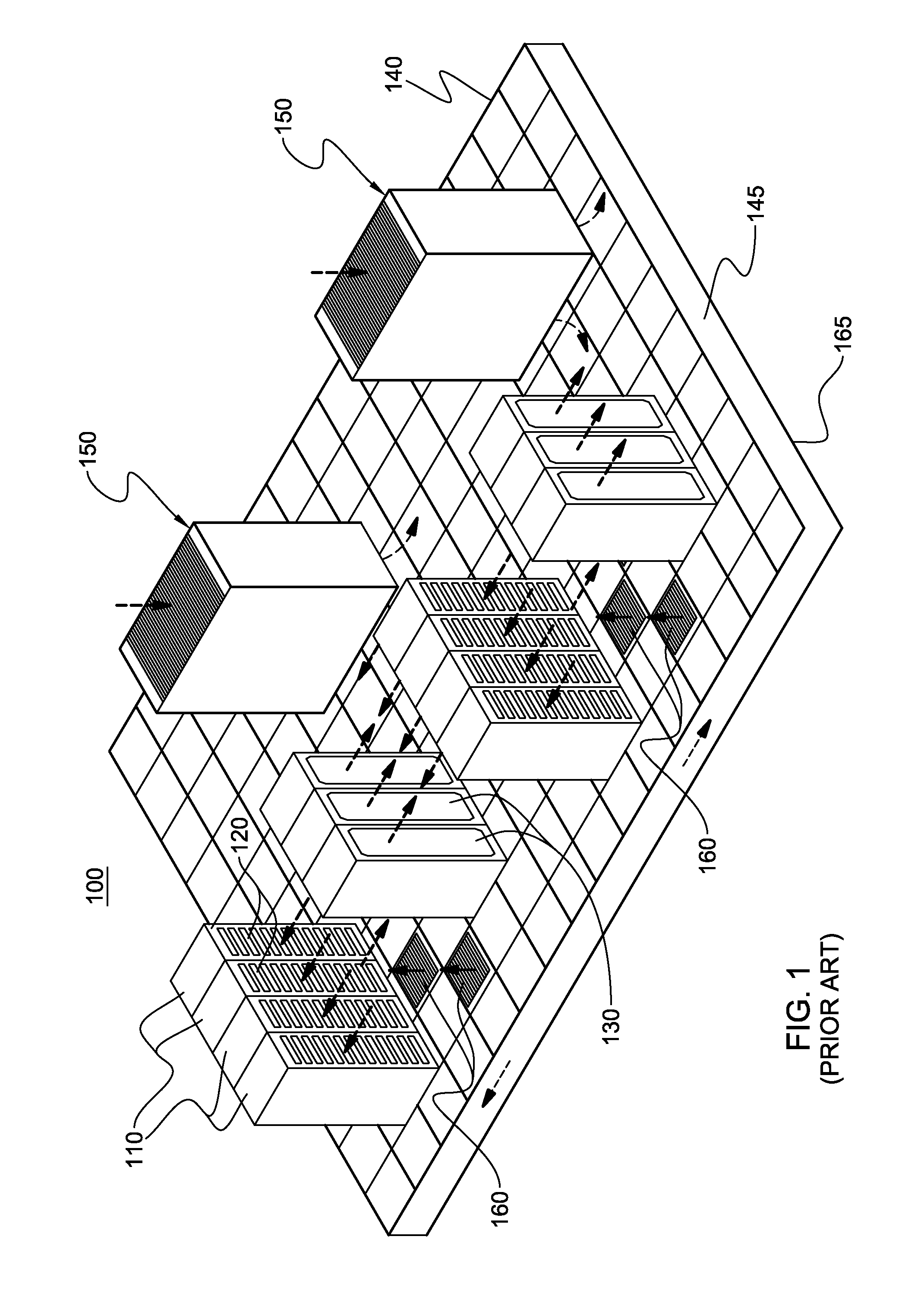

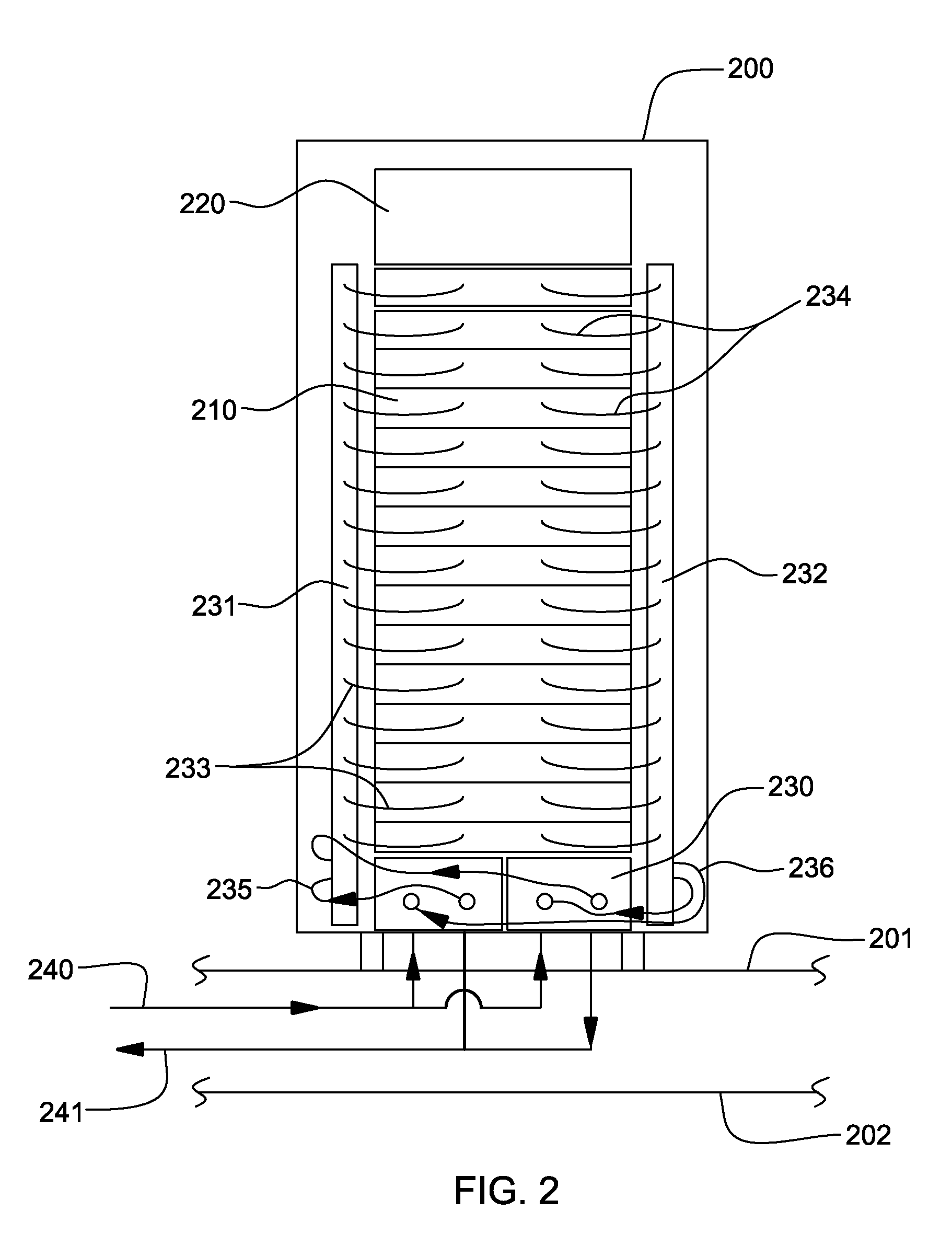

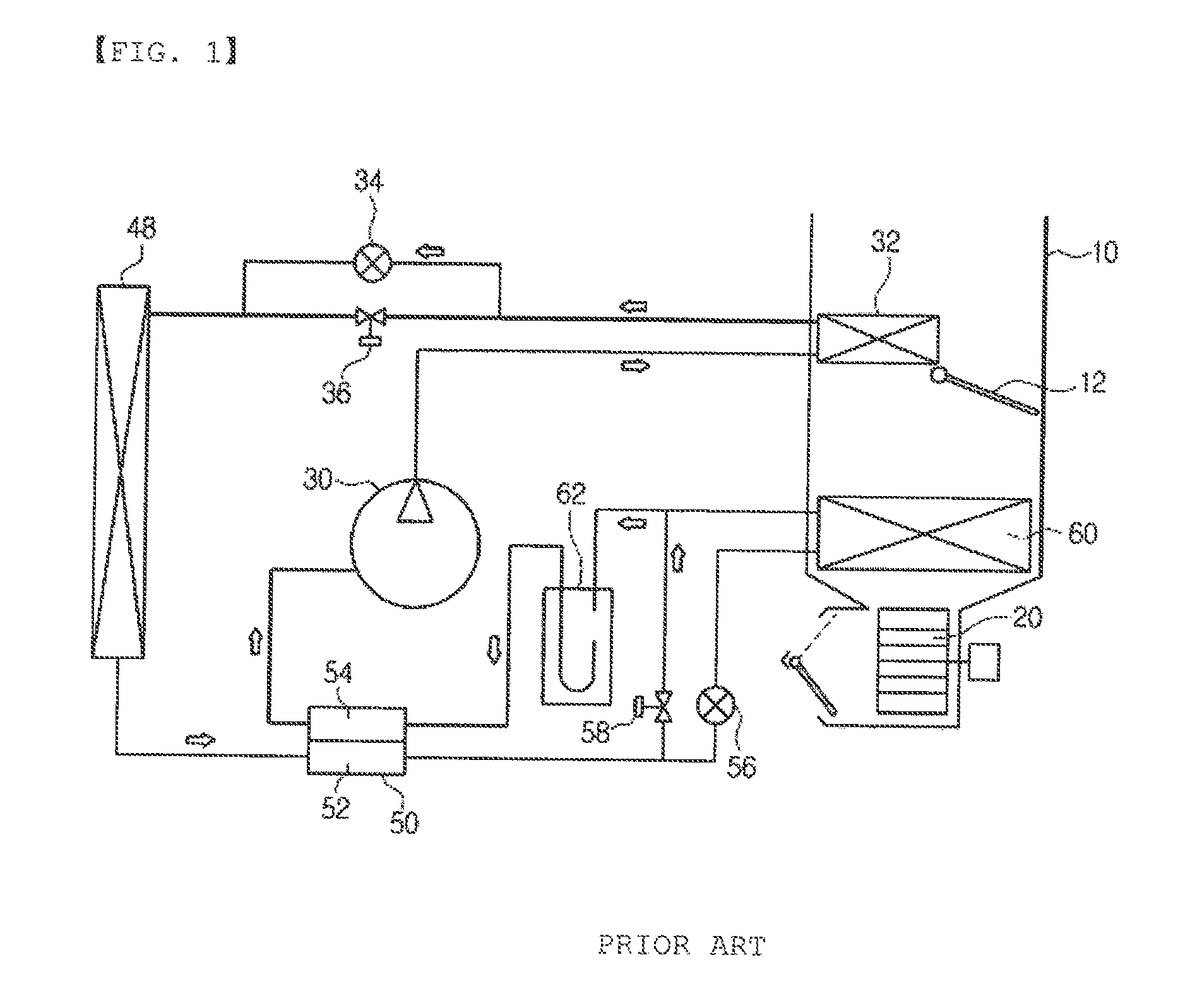

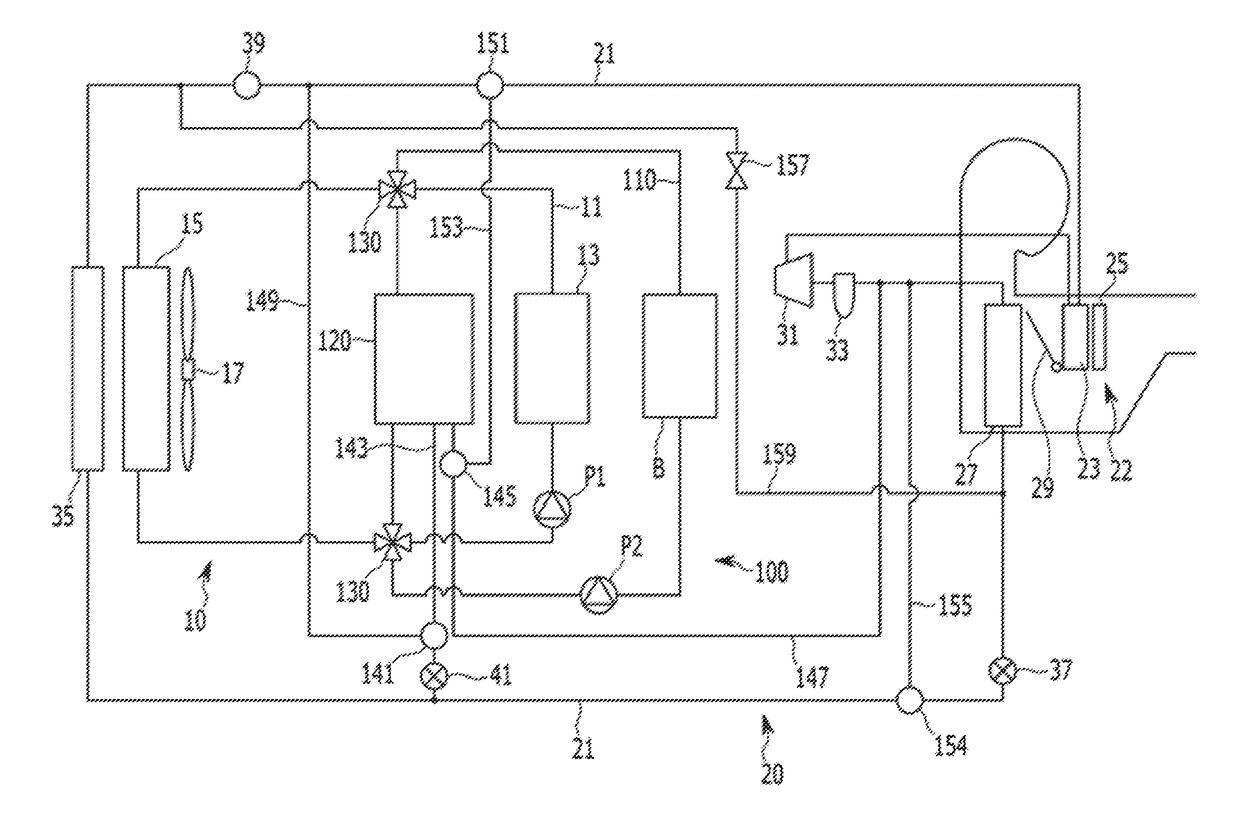

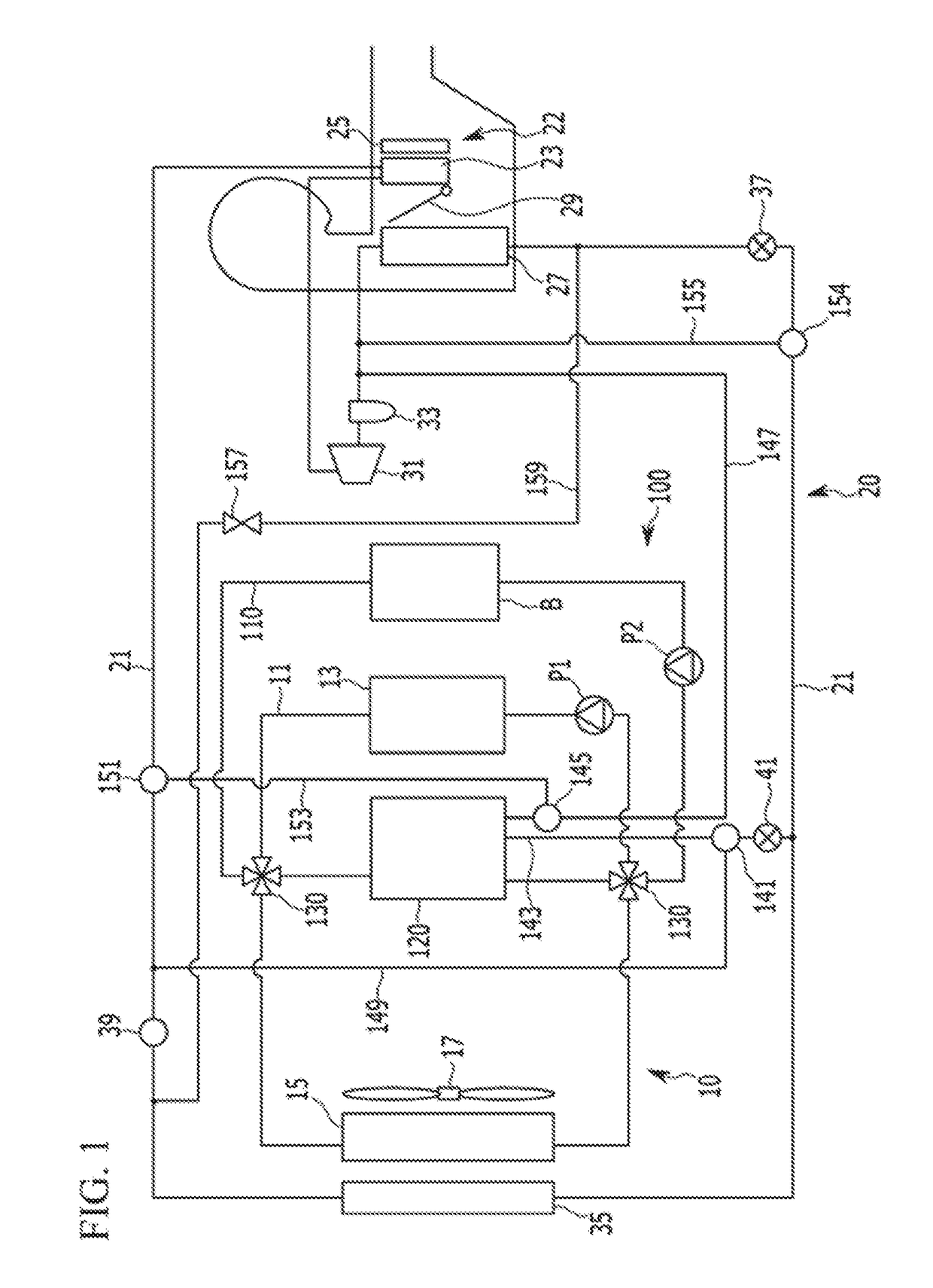

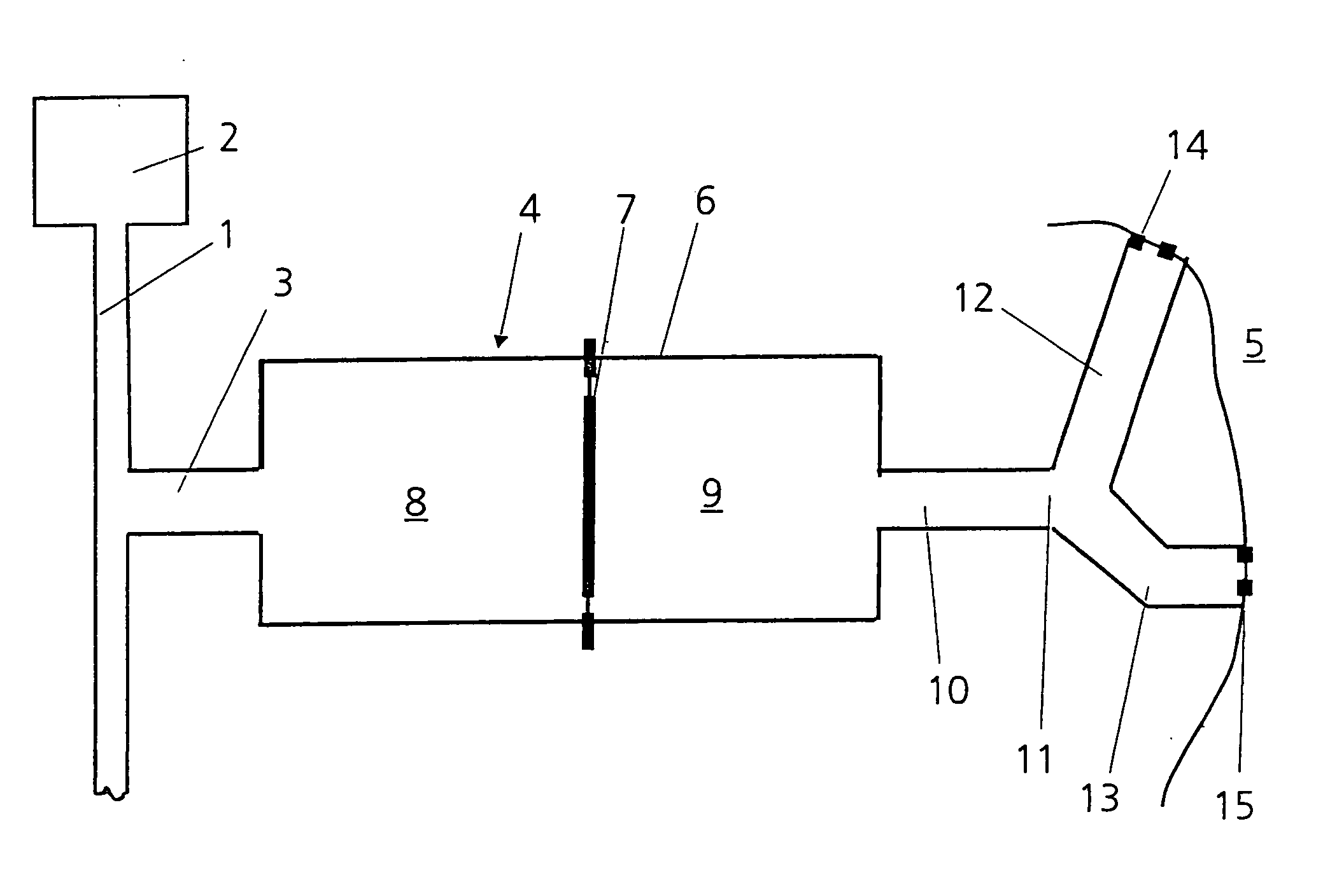

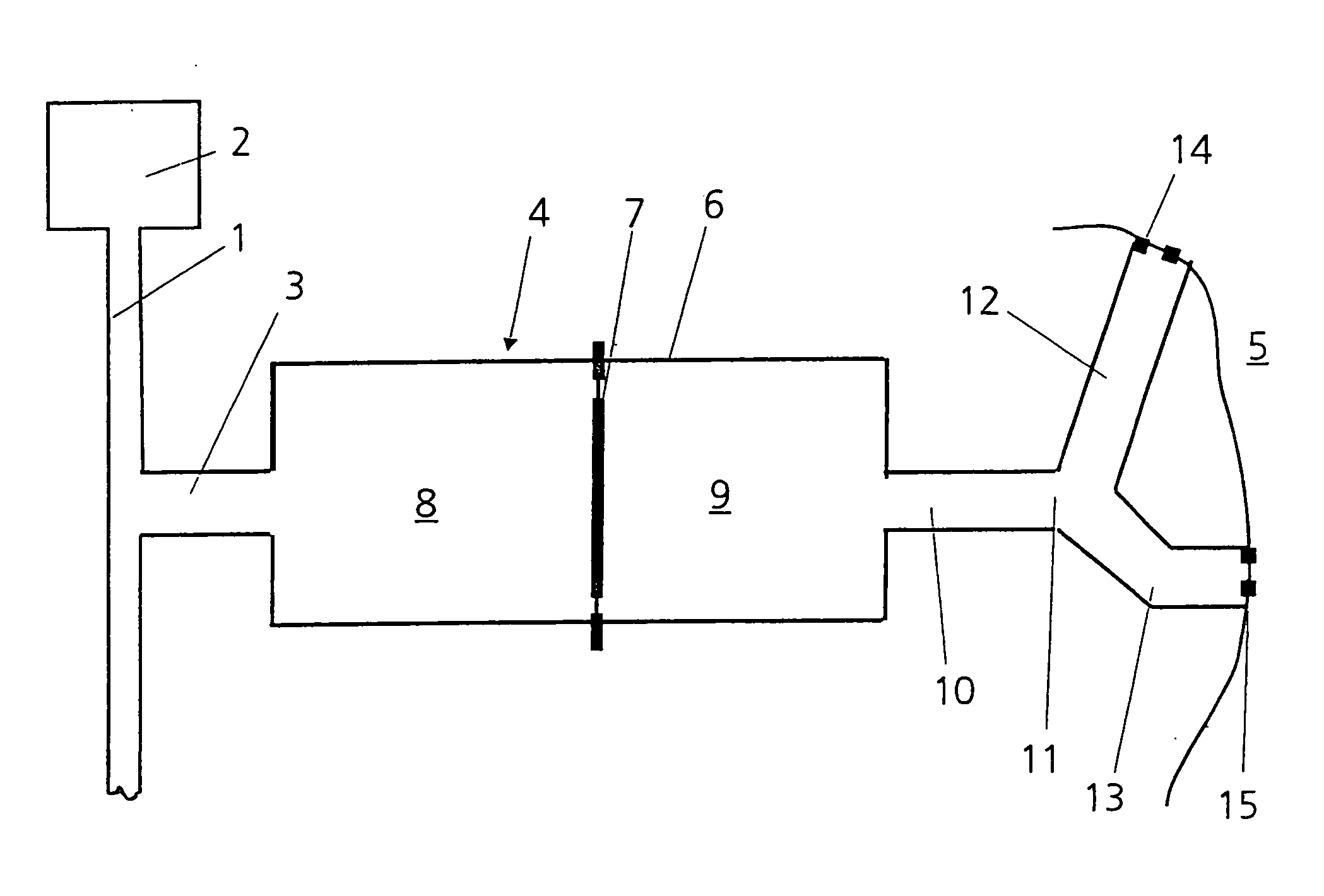

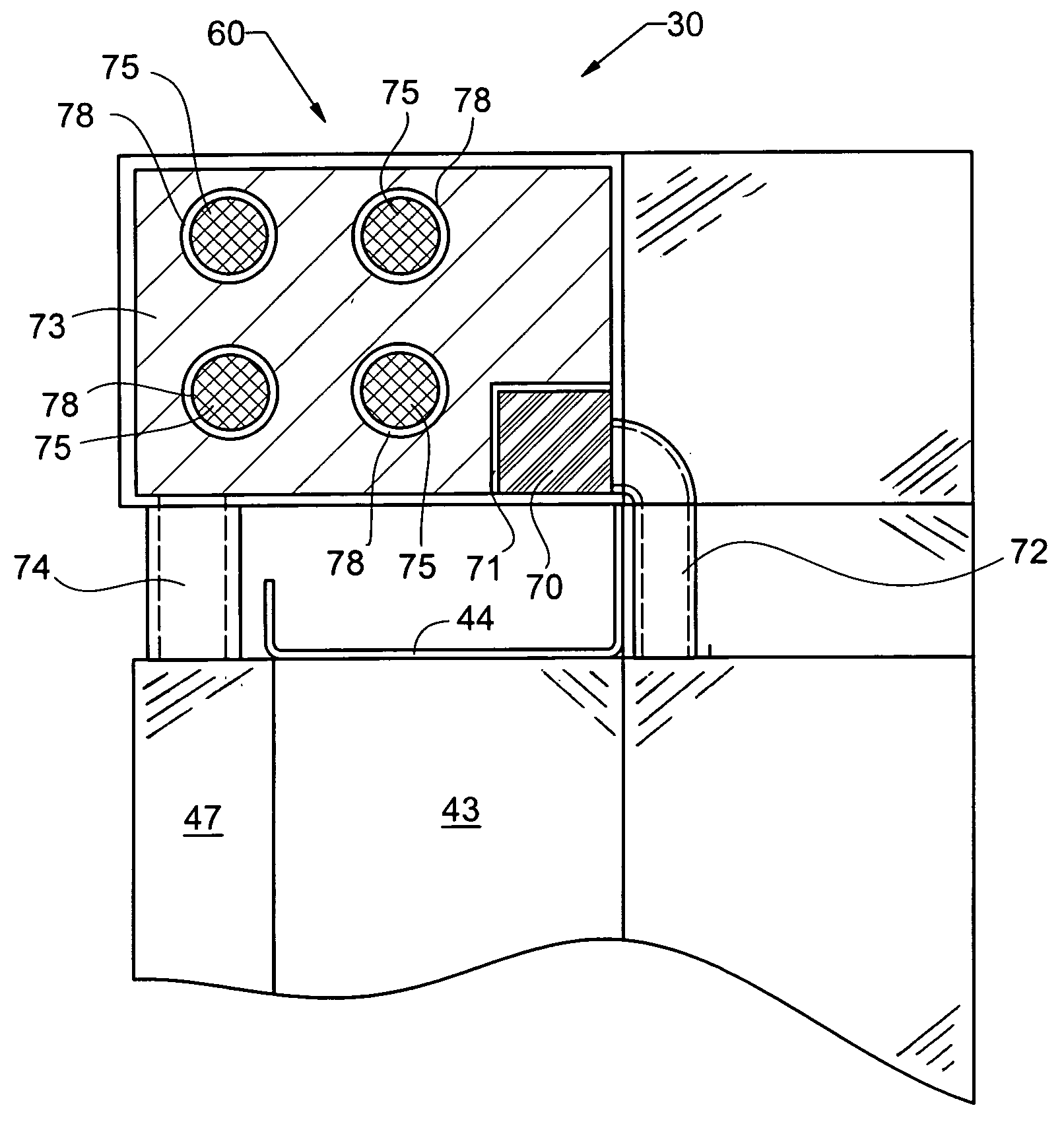

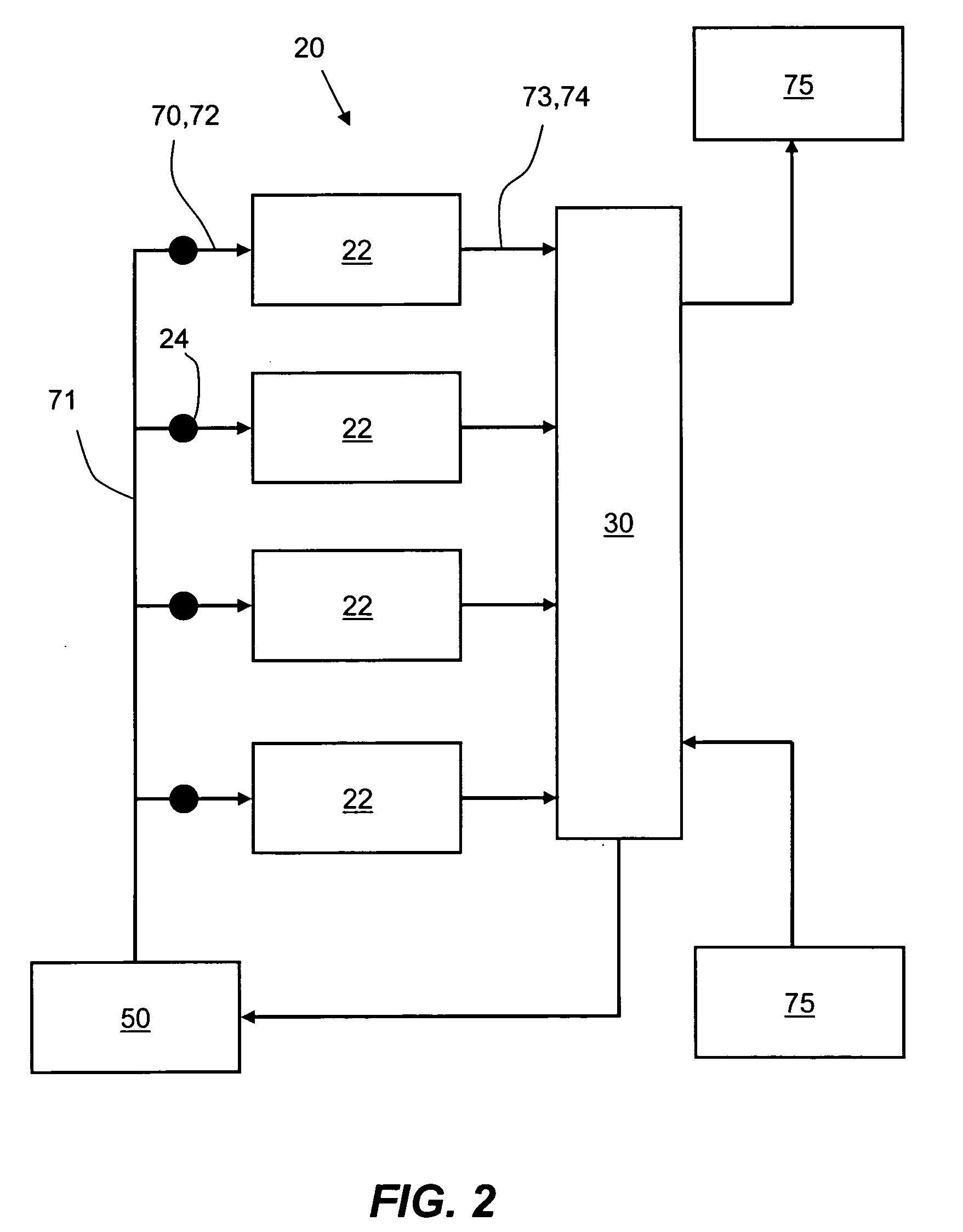

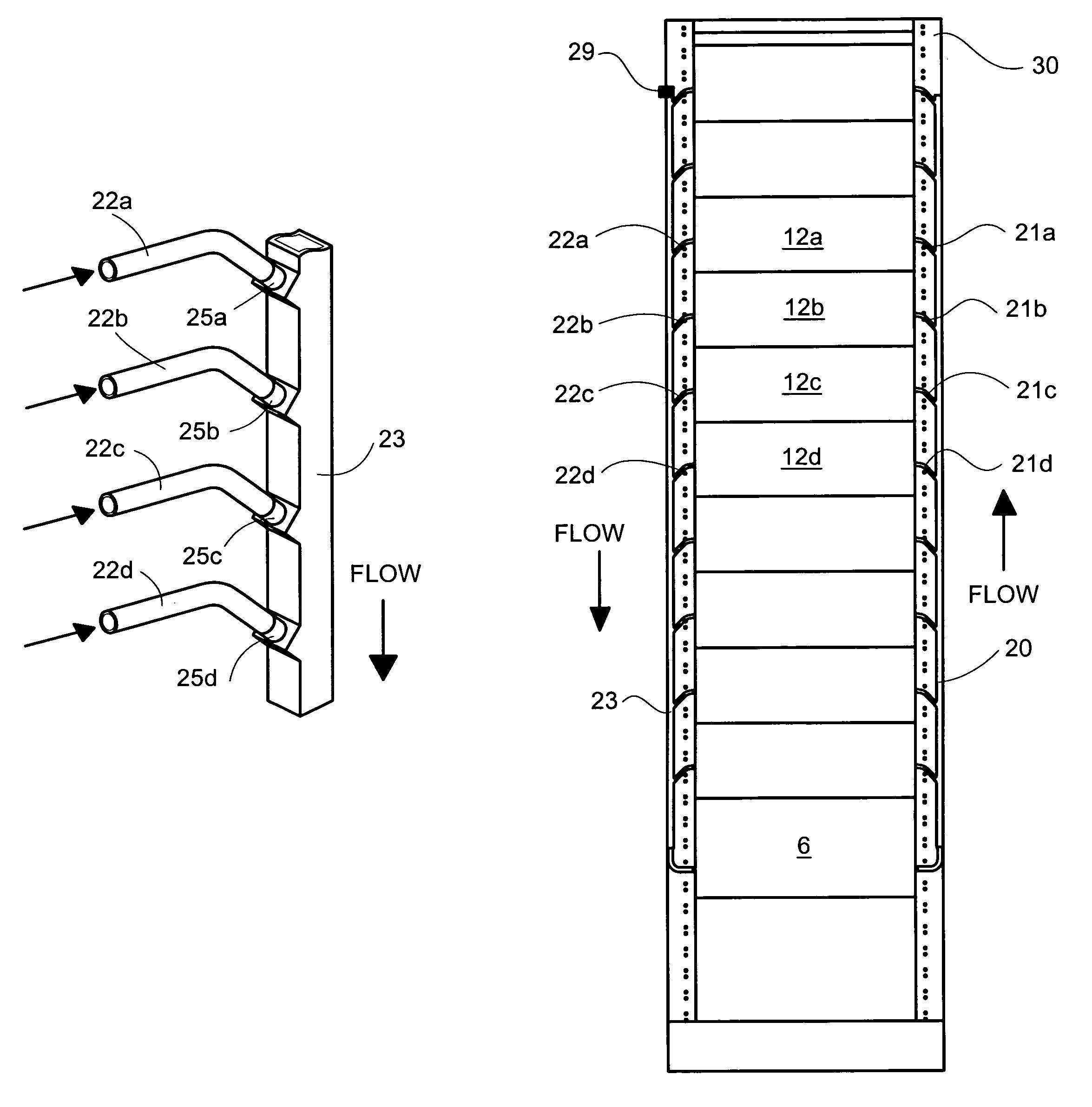

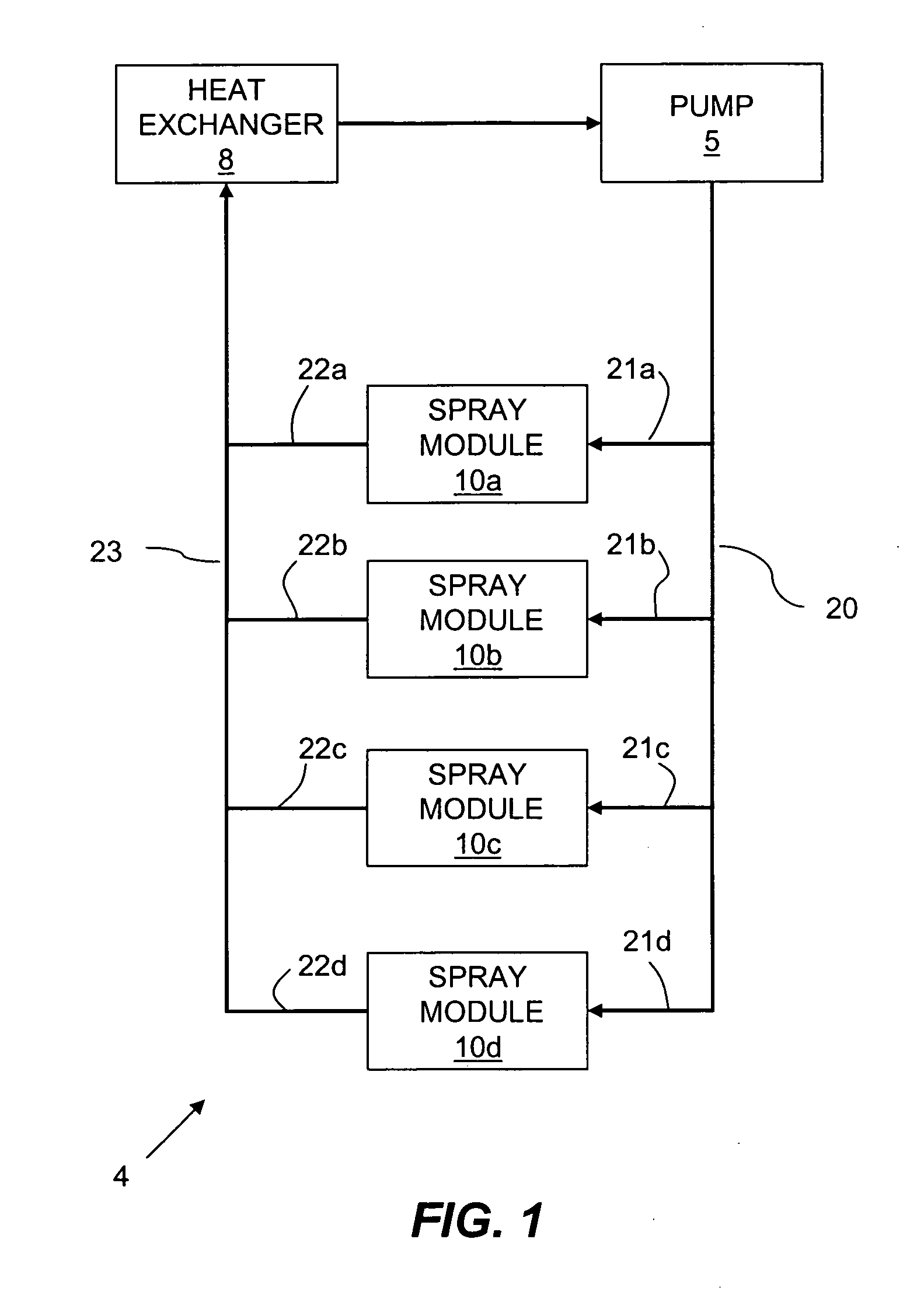

System and method for facilitating parallel cooling of liquid-cooled electronics racks

InactiveUS8208258B2Easy to passImprove cooling effectSpace heating and ventilation safety systemsDomestic cooling apparatusNuclear engineeringCooling fluid

A cooling system and method are provided for facilitating cooling of multiple liquid-cooled electronics racks. The cooling system includes a main system coolant supply loop with a plurality of system coolant supply branch lines for facilitating supply of cooled system coolant to the electronics racks, and a main system coolant return loop with a plurality of system coolant return branch lines for facilitating return of exhausted system coolant from the electronics racks. When operational, cooled system coolant circulates through the coolant supply loop and exhausted system coolant circulates through the coolant return loop. A plurality of modular cooling units are coupled to the coolant supply loop and coolant return loop. Each modular cooling unit includes a heat exchanger to facilitate cooling of a portion of the exhausted coolant circulating through the main system coolant return loop for return as cooled system coolant to the main system coolant supply loop.

Owner:LENOVO GLOBAL TECH INT LTD

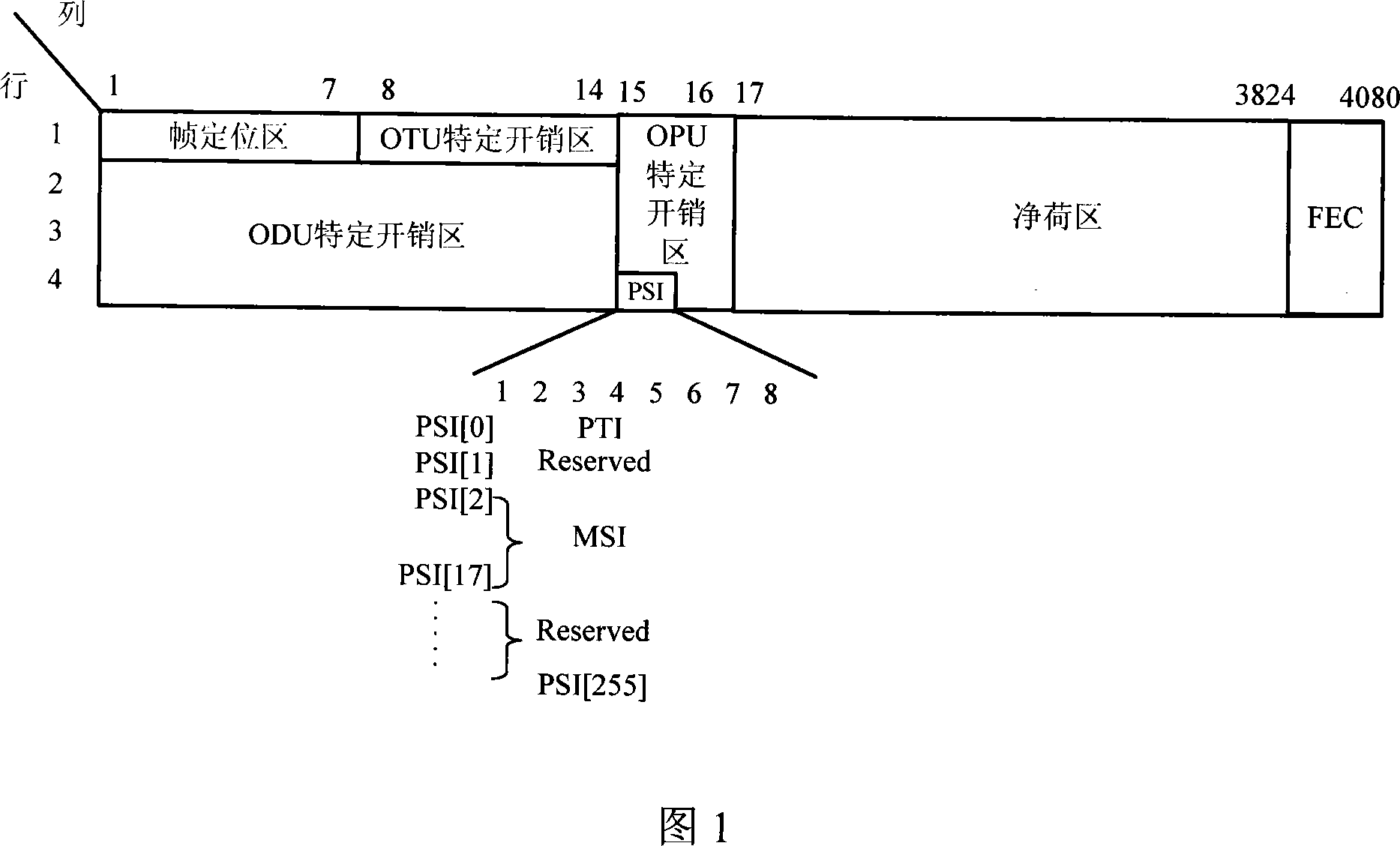

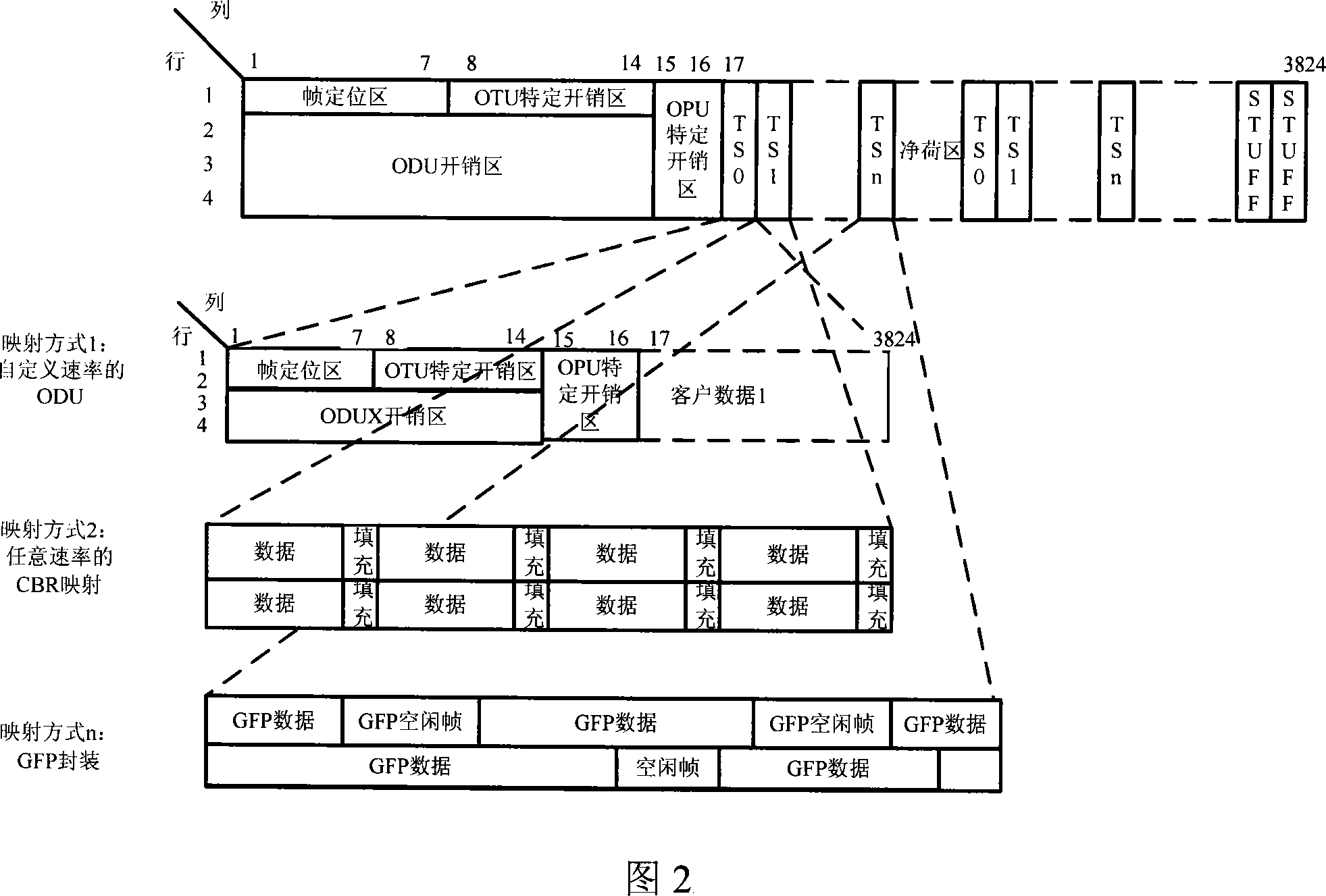

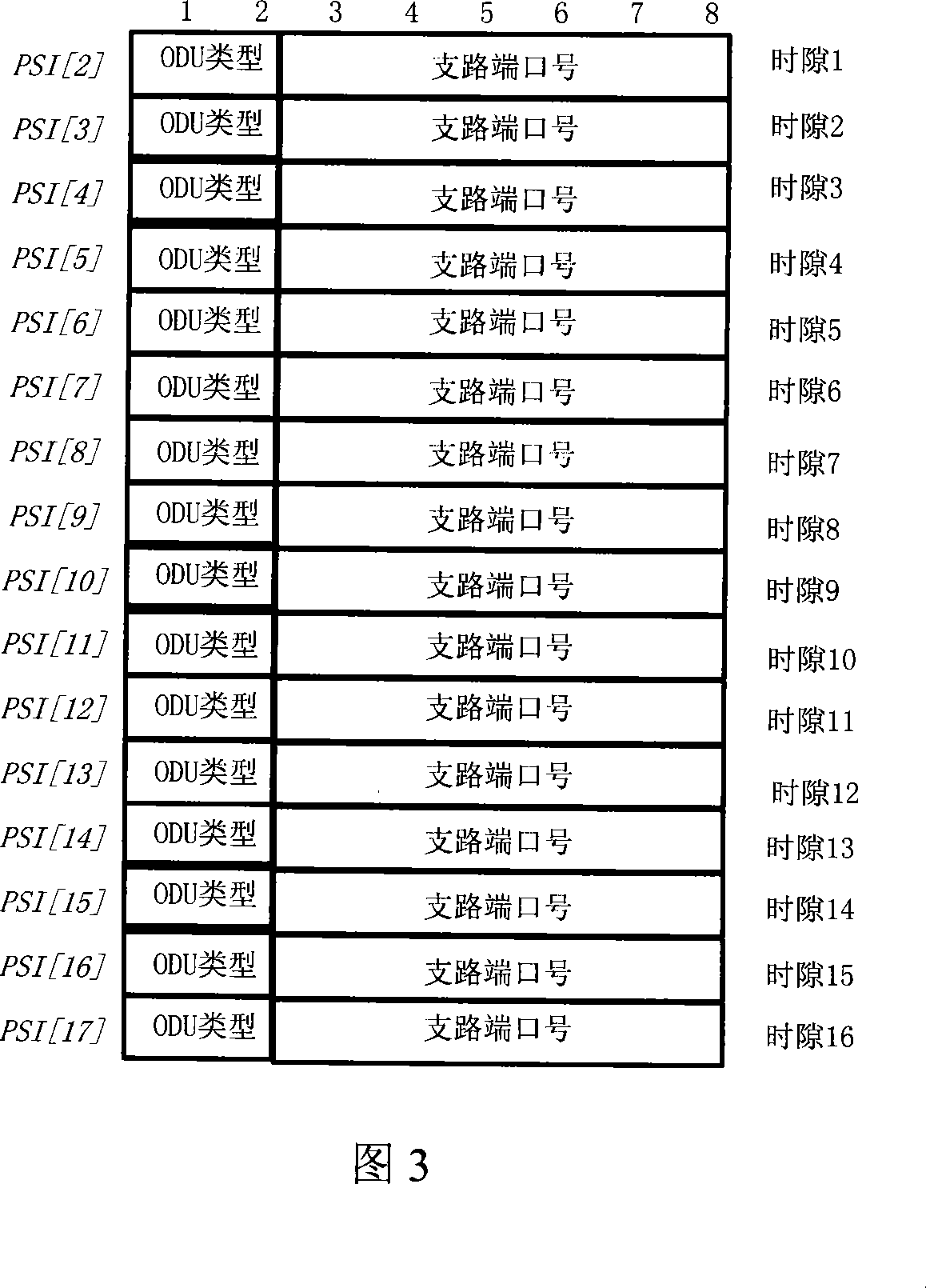

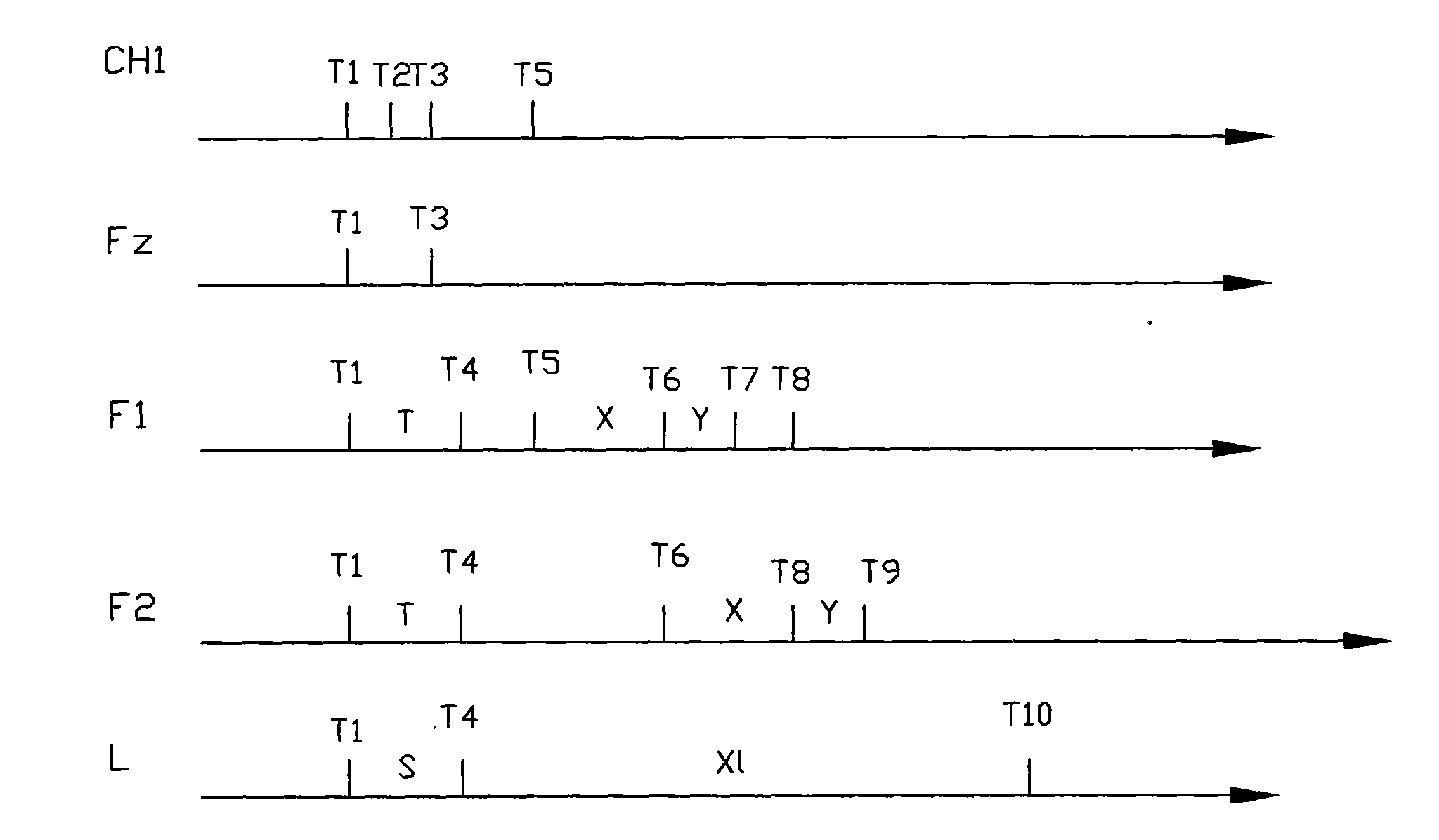

Method for time slot partition and overhead processing of optical payload unit in light transmission network

ActiveCN101155016AImprove effectivenessIncrease flexibilityError preventionTime-division multiplexMultiple frameComputer compatibility

The present invention relates to a method for dividing the time slot and treating the spending of optical payload unit in the optical transport network, which comprises the steps of: A. confirming the time slot number of the optical payload unit in the payload area according to the character of the business signal, doing time slot division to the payload area and confirming the mapping mode of corresponding business of each time slot; B. expending the value of the payload structure identifying byte in the spending of the optical payload unit according to the dividing condition of the time slot, saving the mapping structure, time slot number, and the branch line port number and mapping mode corresponding to each time slot in the payload structure identifying byte; C. representing the undefined first to sixth bit assignment value as the multi-frame and distributing the spending loop spend by the optical payload unit in the spending of the optical payload unit. The invention increases the availability of band width and the flexibility of the mapping mode by redefining the spending byte in the original specification, increasing the relevant portion divided by the time slot with a low cost, and the invention has a better compatibility.

Owner:NANJING ZHONGXING XIN SOFTWARE CO LTD

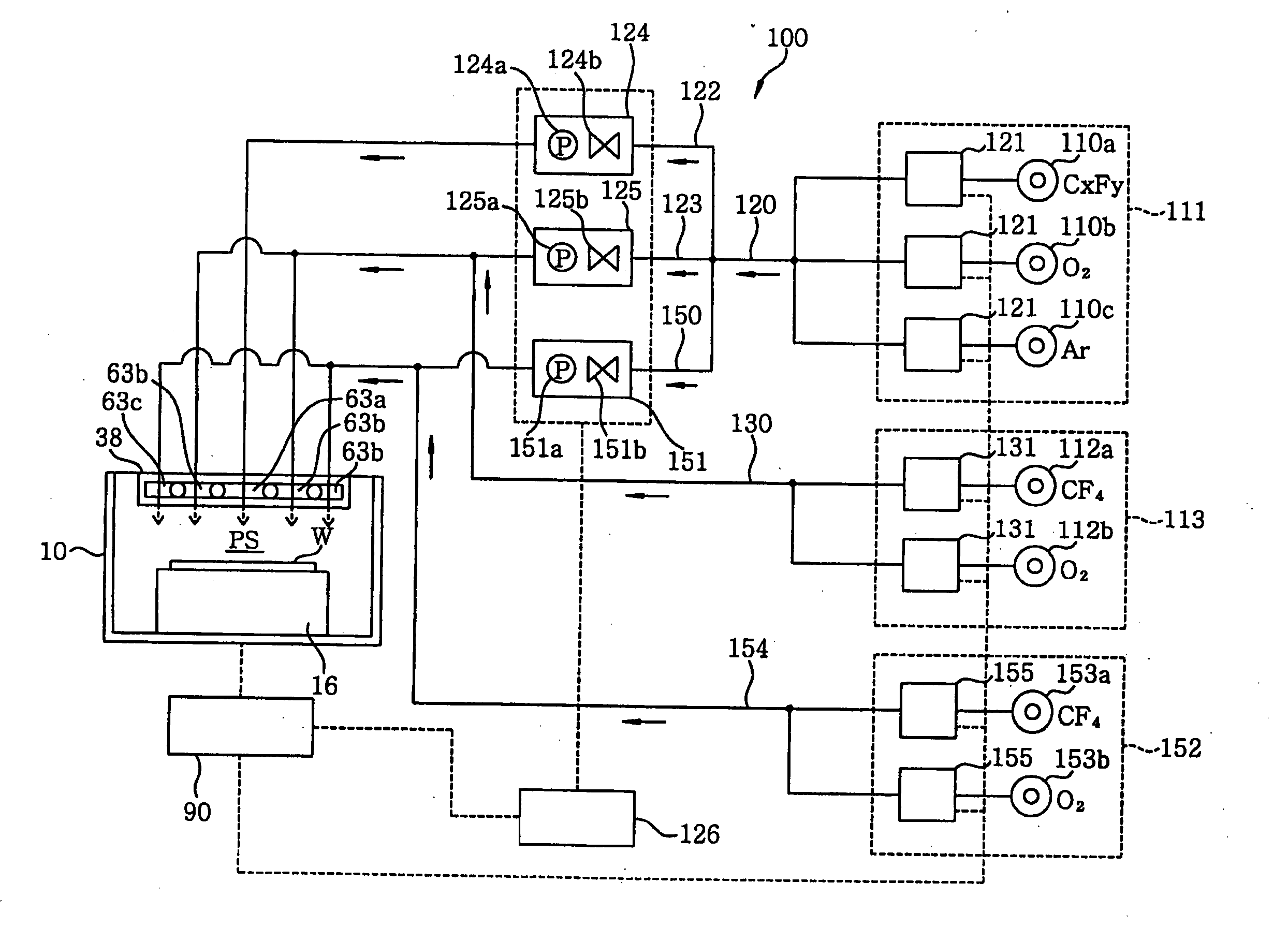

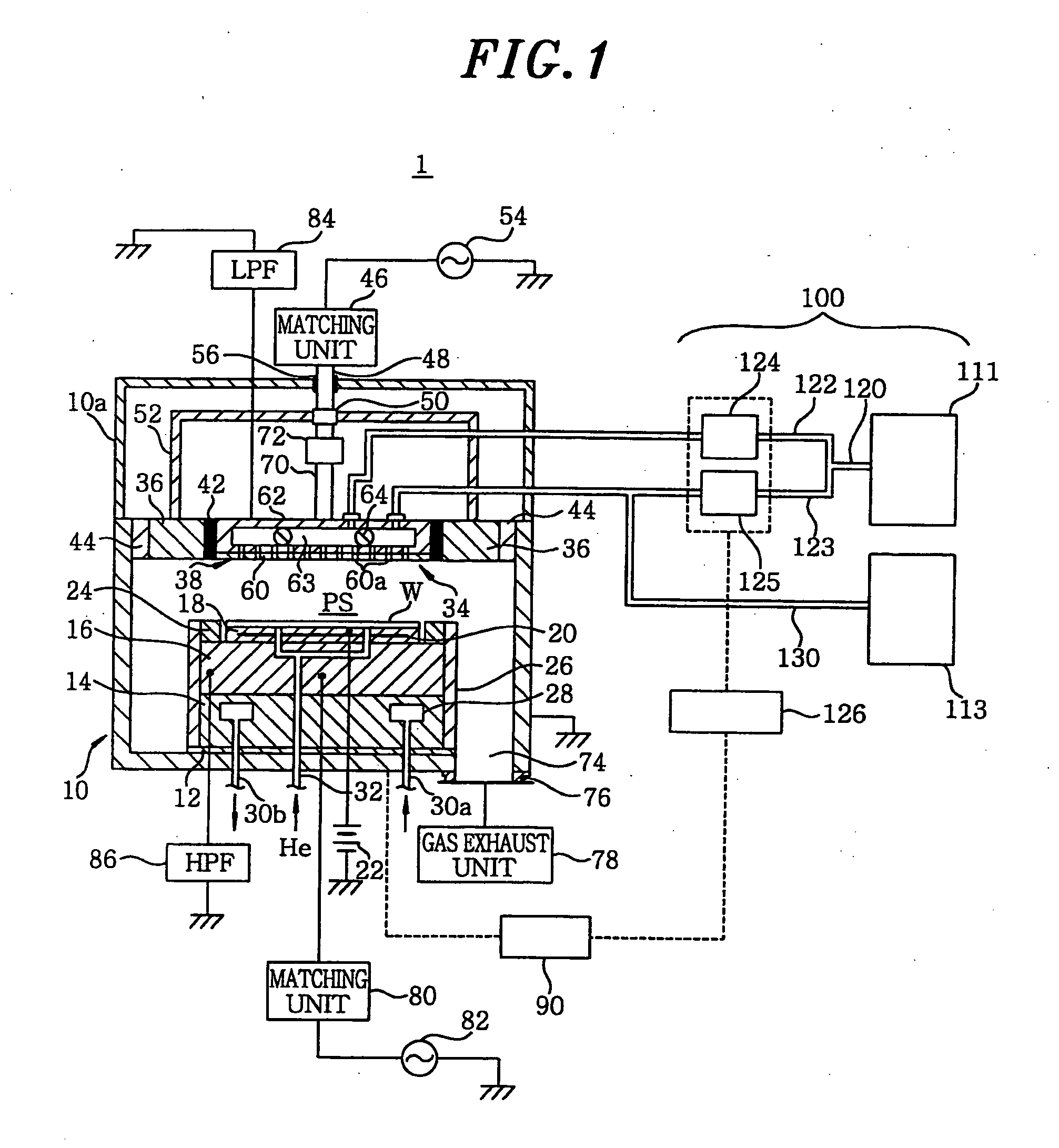

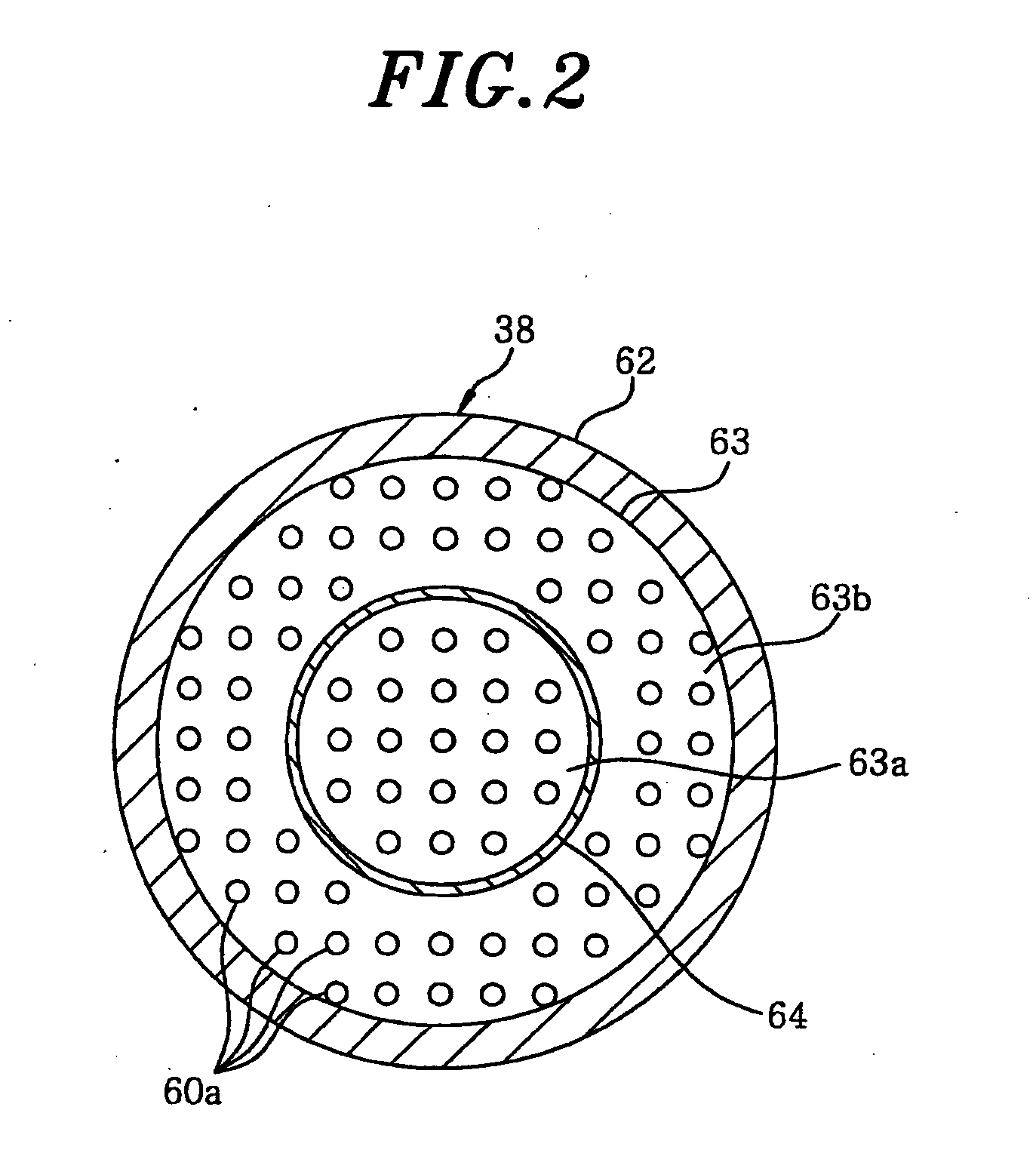

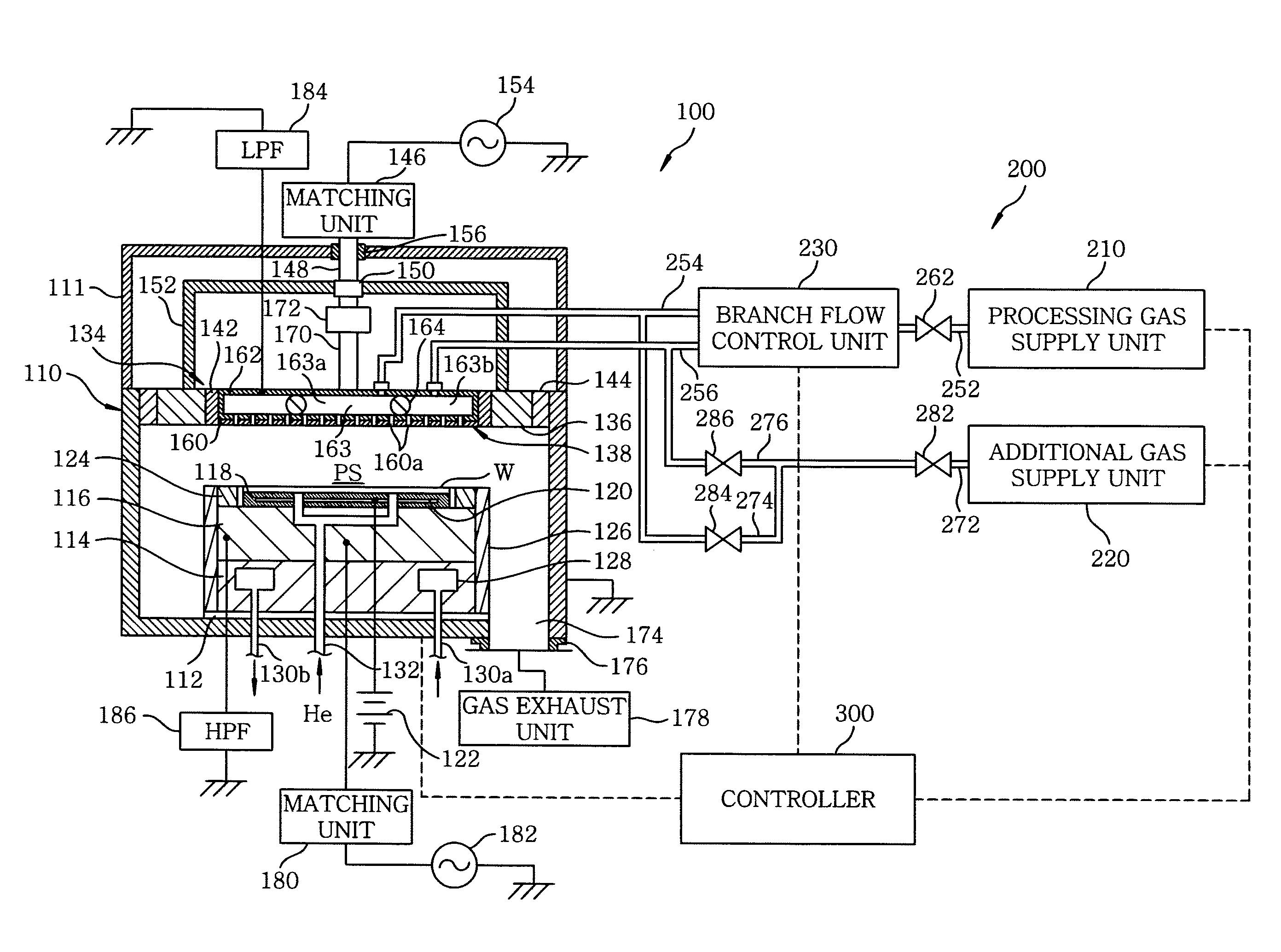

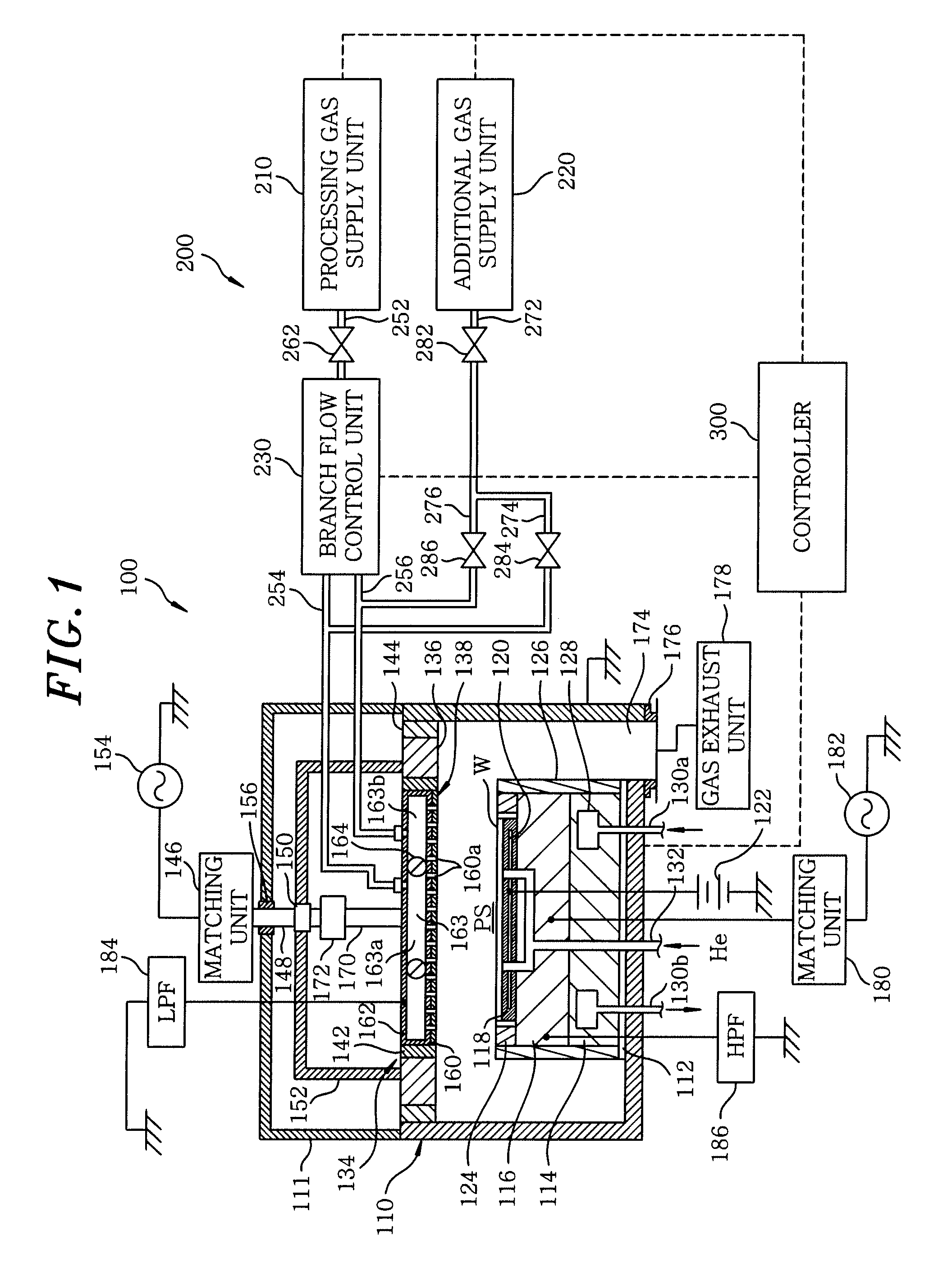

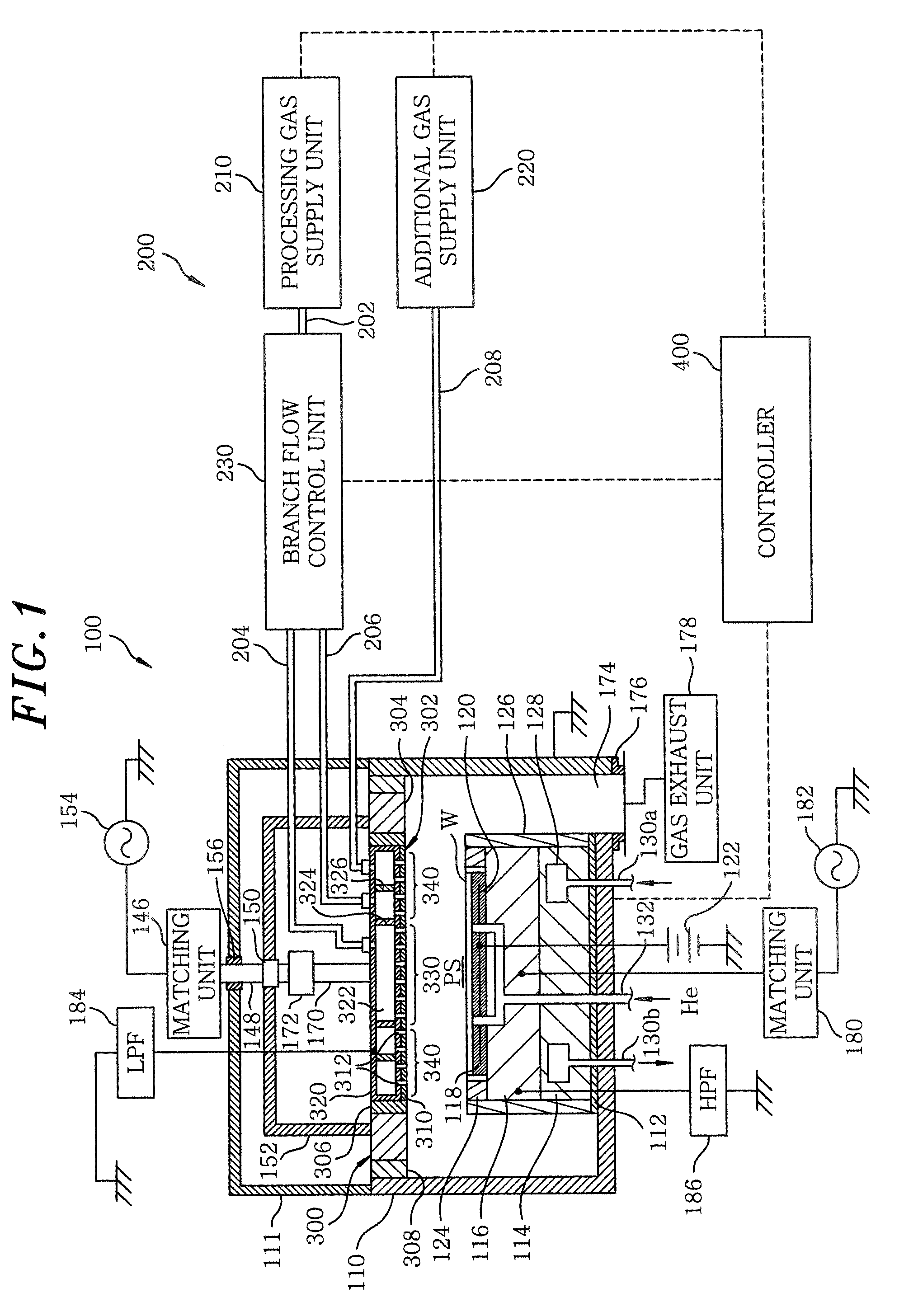

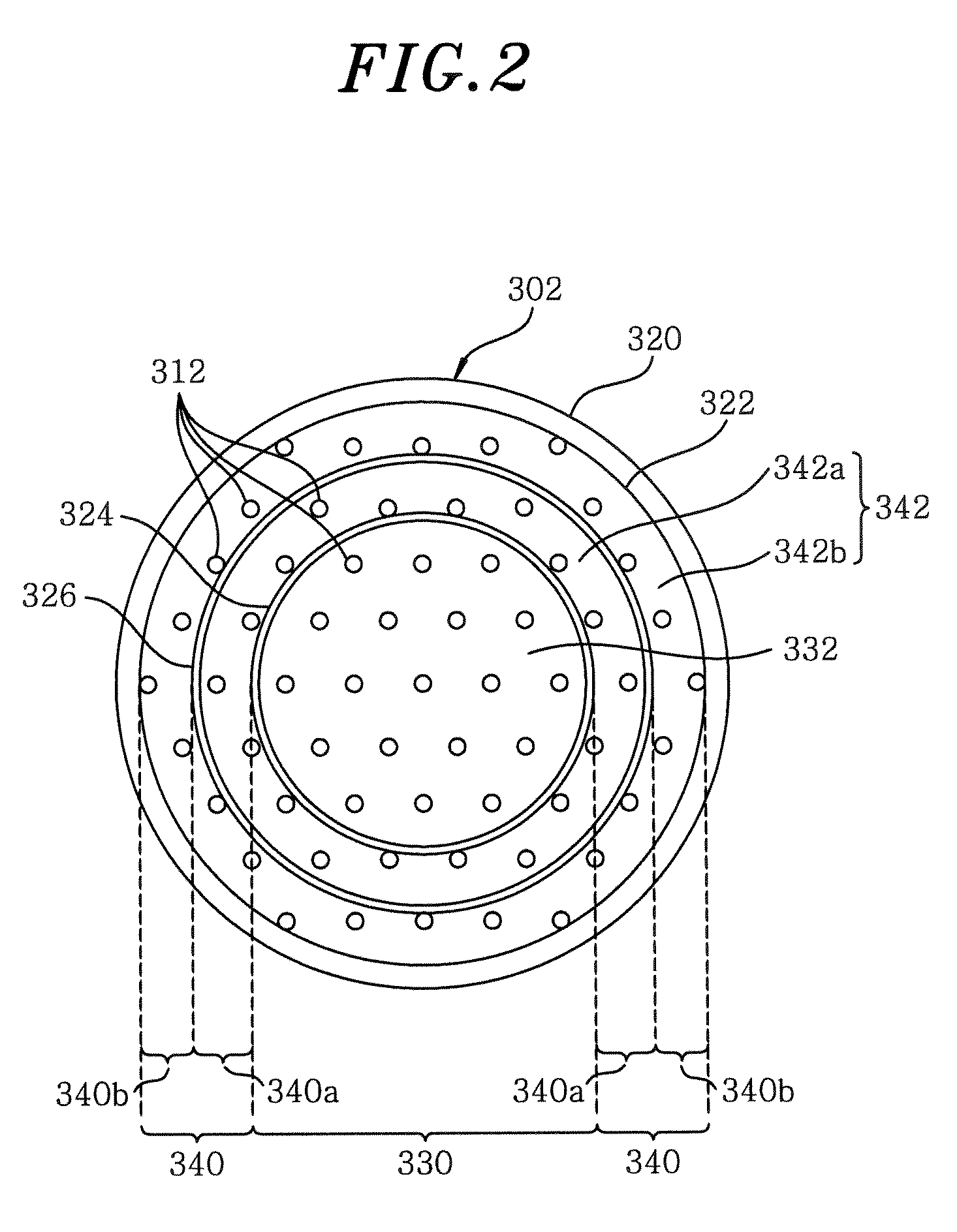

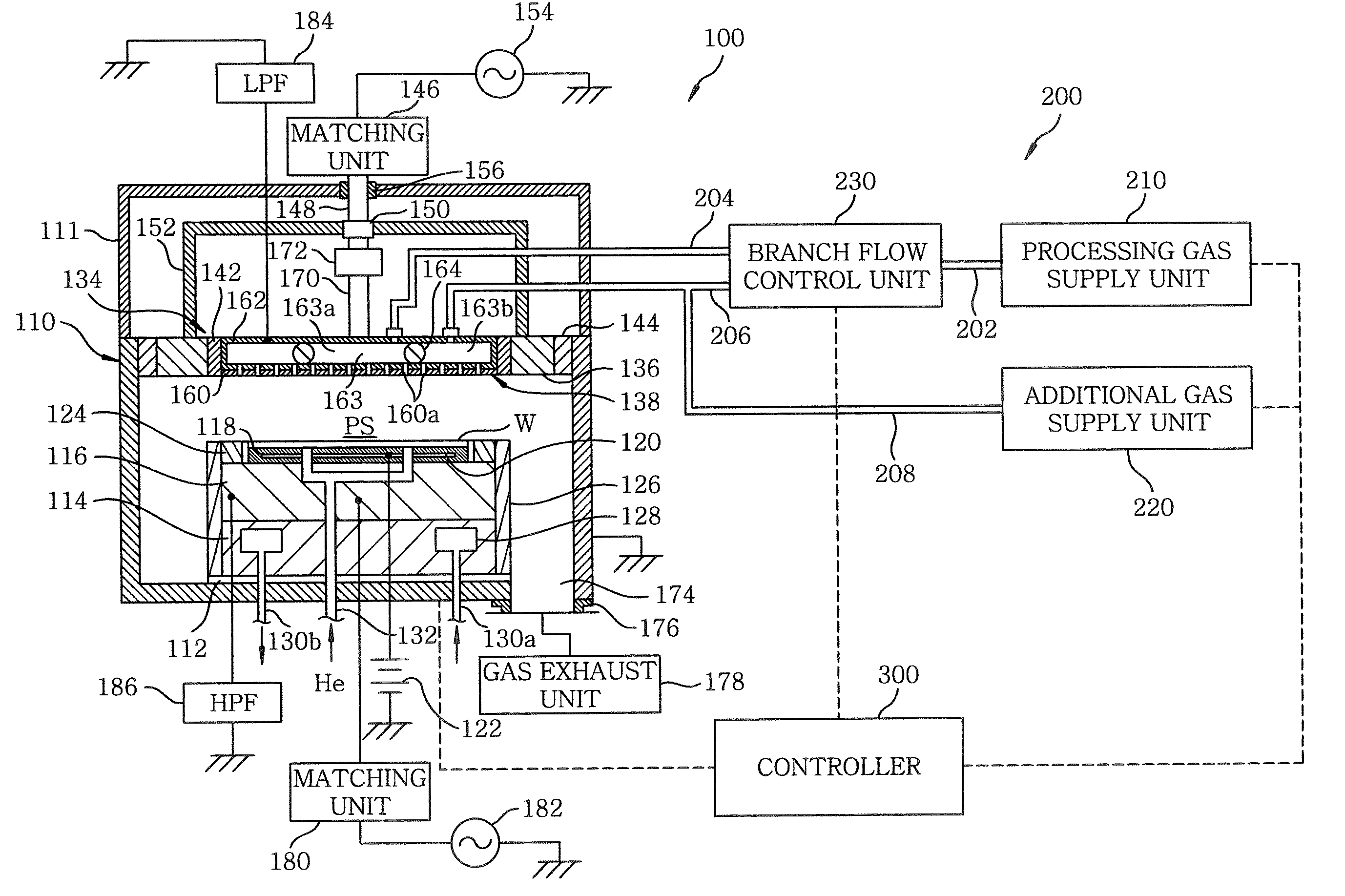

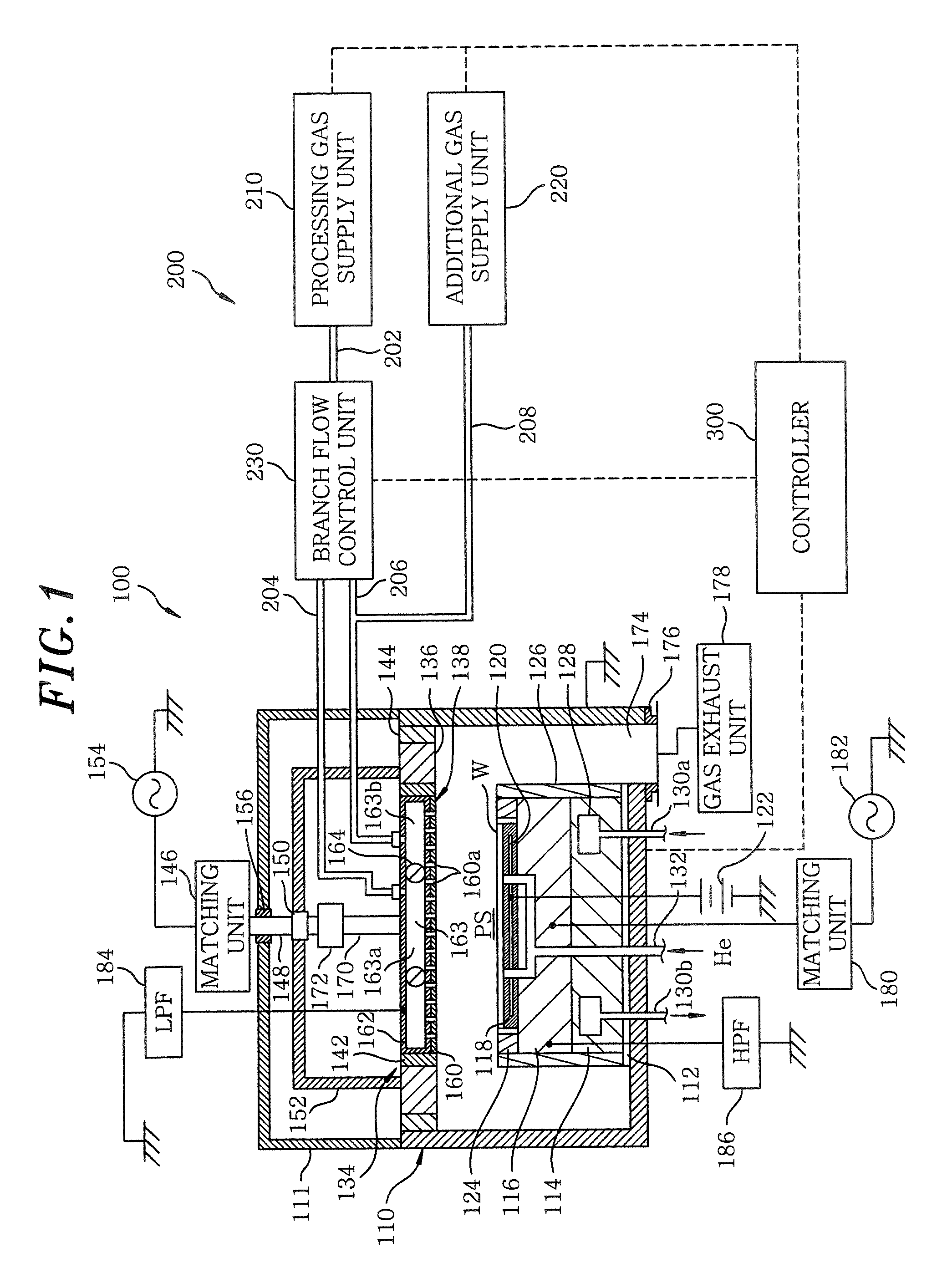

Gas supply unit, substrate processing apparatus, and supply gas setting method

InactiveUS20060124169A1Low costReduce spacingElectric discharge tubesSemiconductor/solid-state device manufacturingLine tubingProcess engineering

A gas supply unit, for supplying a gas into a processing chamber in which a substrate is processed, includes a plurality of gas supply sources, a mixing line for mixing a plurality of gases supplied from the gas supply sources to make a gaseous mixture, a multiplicity of branch lines for branching the gaseous mixture to be supplied to a multiplicity of places in the processing chamber, and an additional gas supply unit for supplying a specified additional gas to a gaseous mixture flowing in at least one branch line. The gas supply unit also includes pressure gauges and valves for adjusting gas flow rates in the branch lines, respectively, and a pressure ratio controller for controlling that gaseous mixtures branched into the branch lines to have a specified pressure ratio by adjusting opening degrees of the valves based on measurement results obtained by using the pressure gauges.

Owner:TOKYO ELECTRON LTD

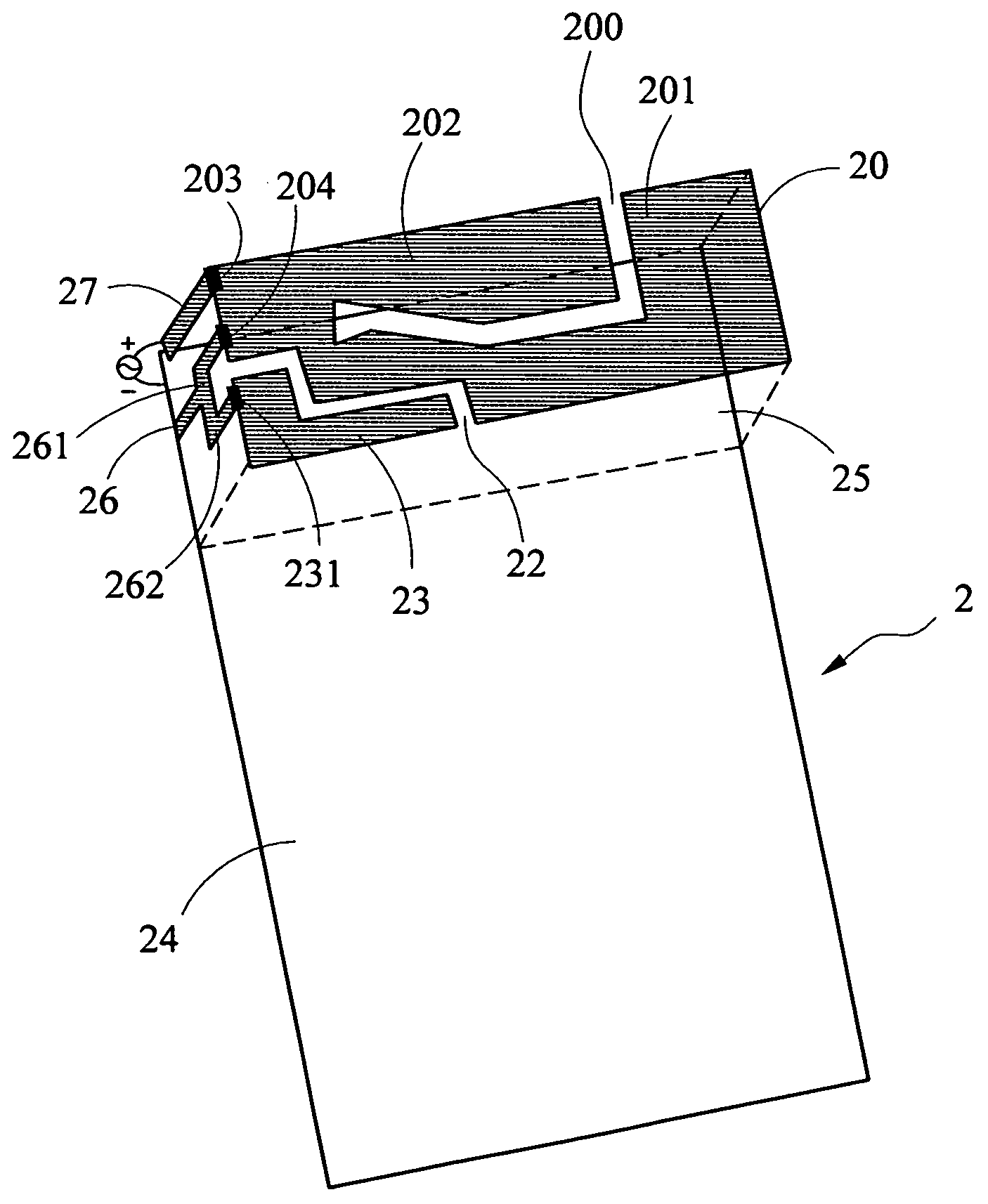

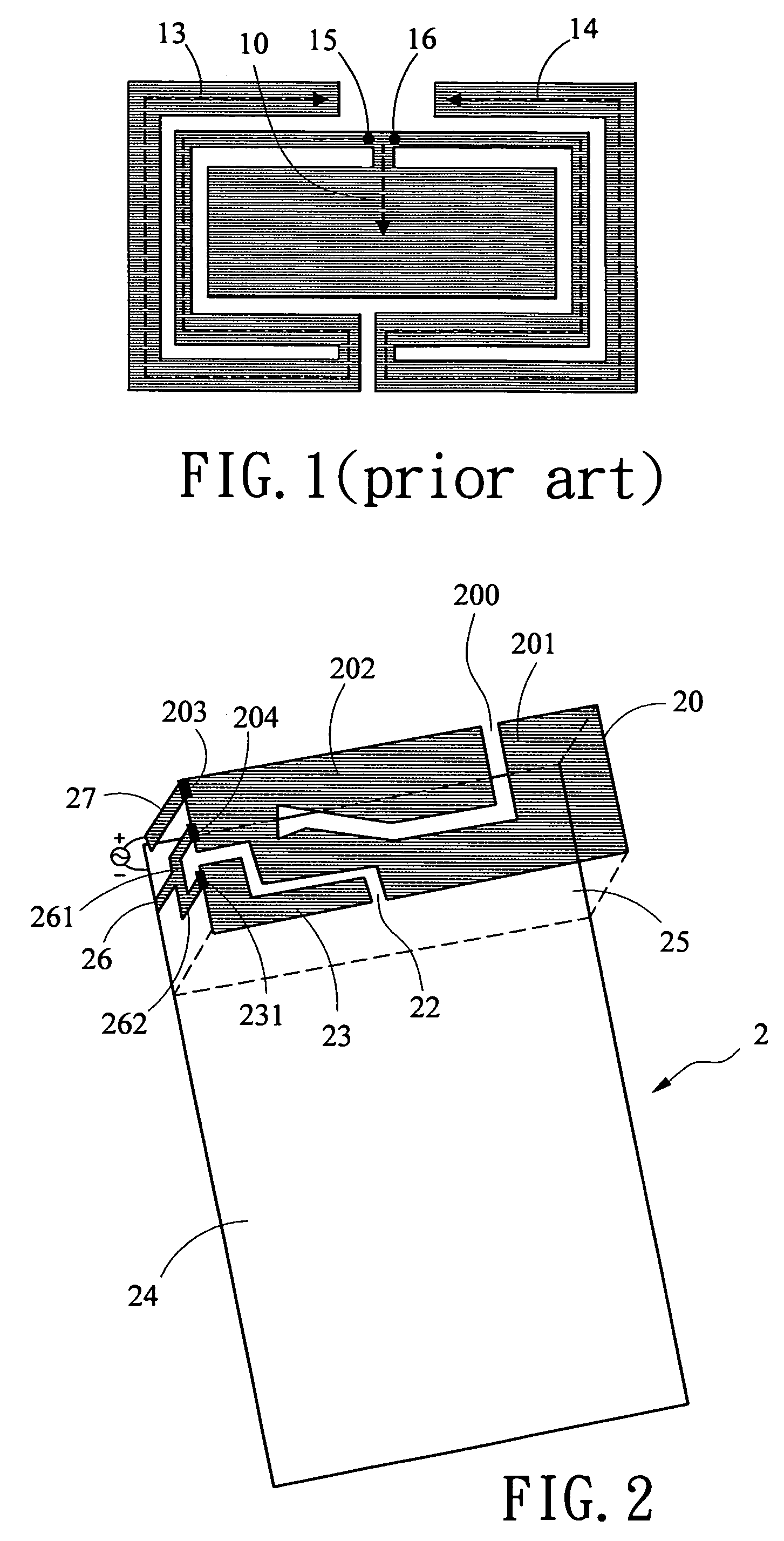

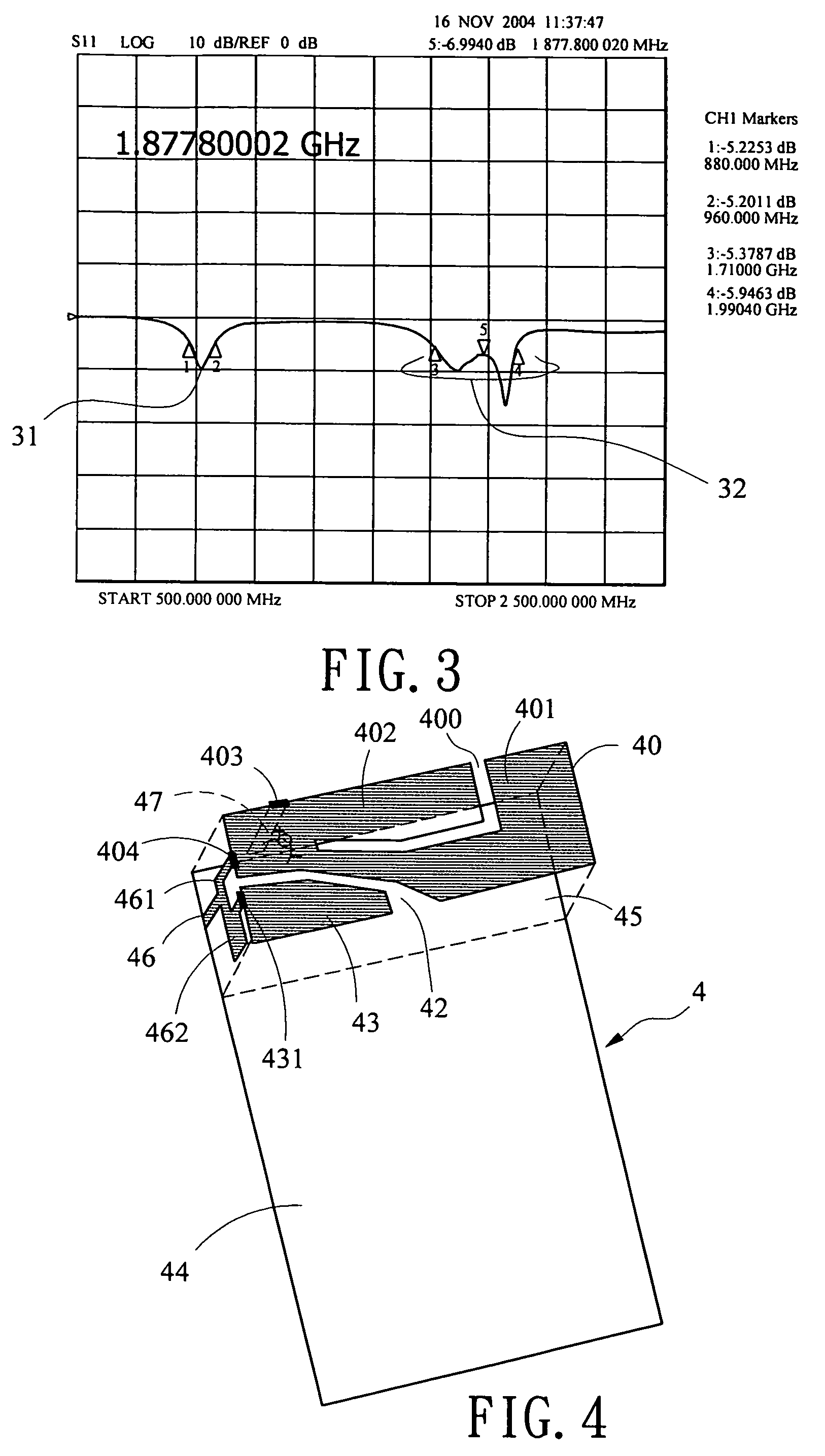

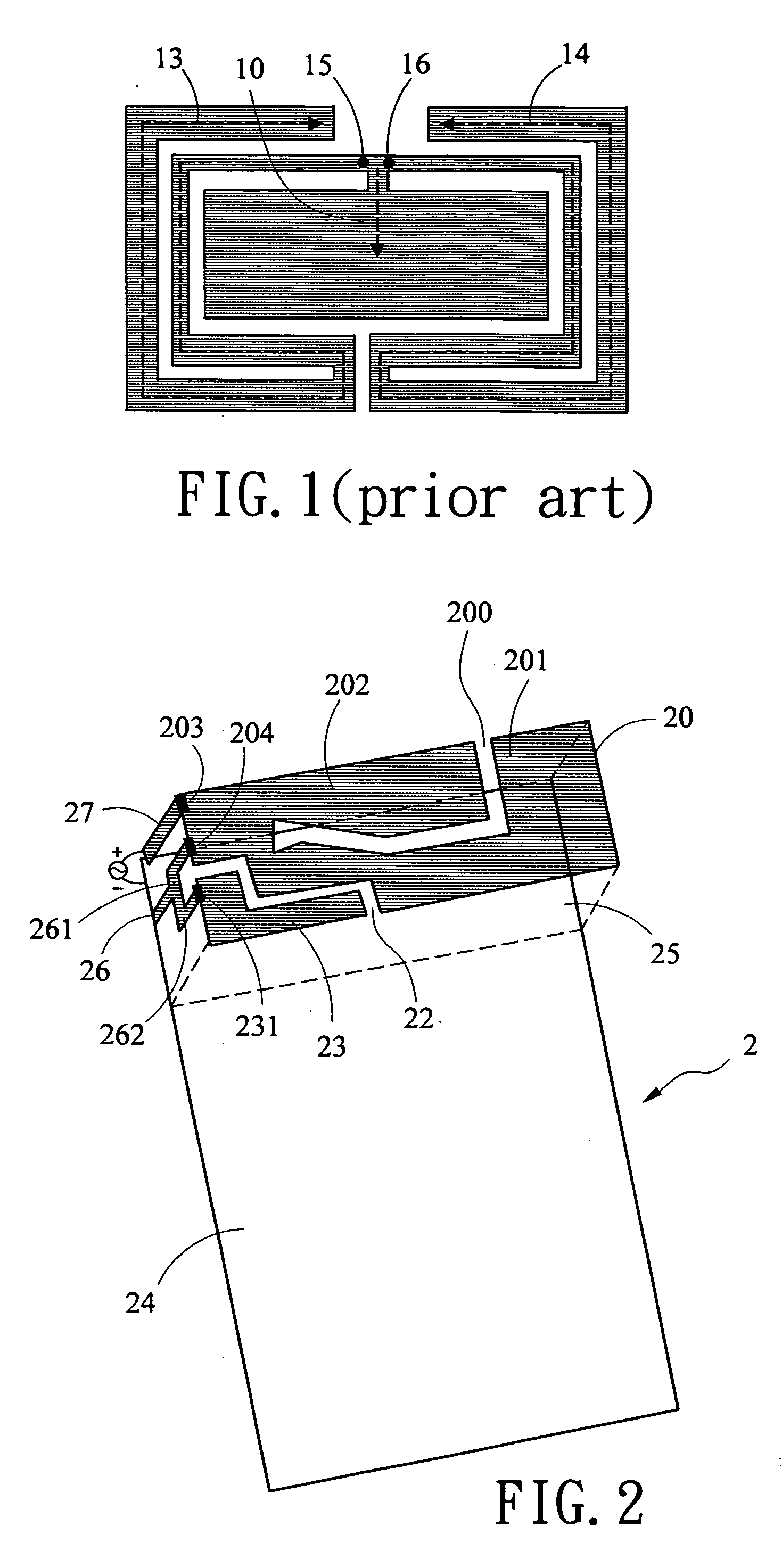

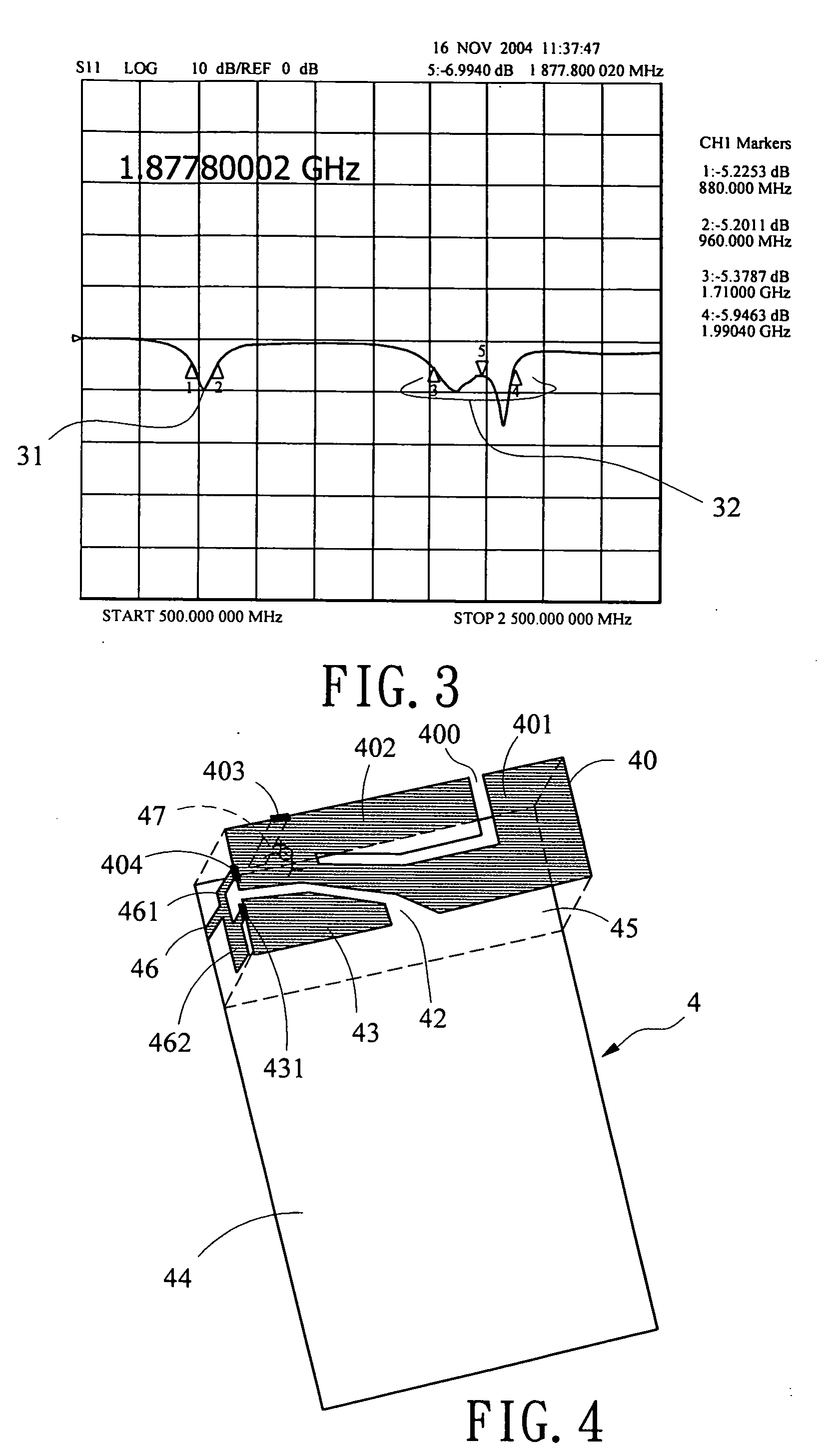

Dual-band inverted-F antenna with a branch line shorting strip

Provided is dual-band inverted-F antenna for GSM, DCS, and PCS bands comprising a primary radiating member including integral first and second metallic strips, a feeding point, and a first shorting point wherein a long current path is created in the first strip such that the antenna can operate in a first low frequency operating mode, and a shorting current path is created in the second strip such that the antenna can operate in a second high frequency operating mode; a secondary radiating member comprising a second shorting point; a branch line shorting strip having one grounded end and a bifurcation including a first branch connected to the first shorting point and a second branch connected to the second shorting point; and a feeding member interconnected the feeding point and a signal source. Operating frequencies of the antenna are 90 MHz and 300 MHz respectively when it operates in 3.5:1 VSWR impedance bandwidth.

Owner:ADVANCED CONNECTEK INC

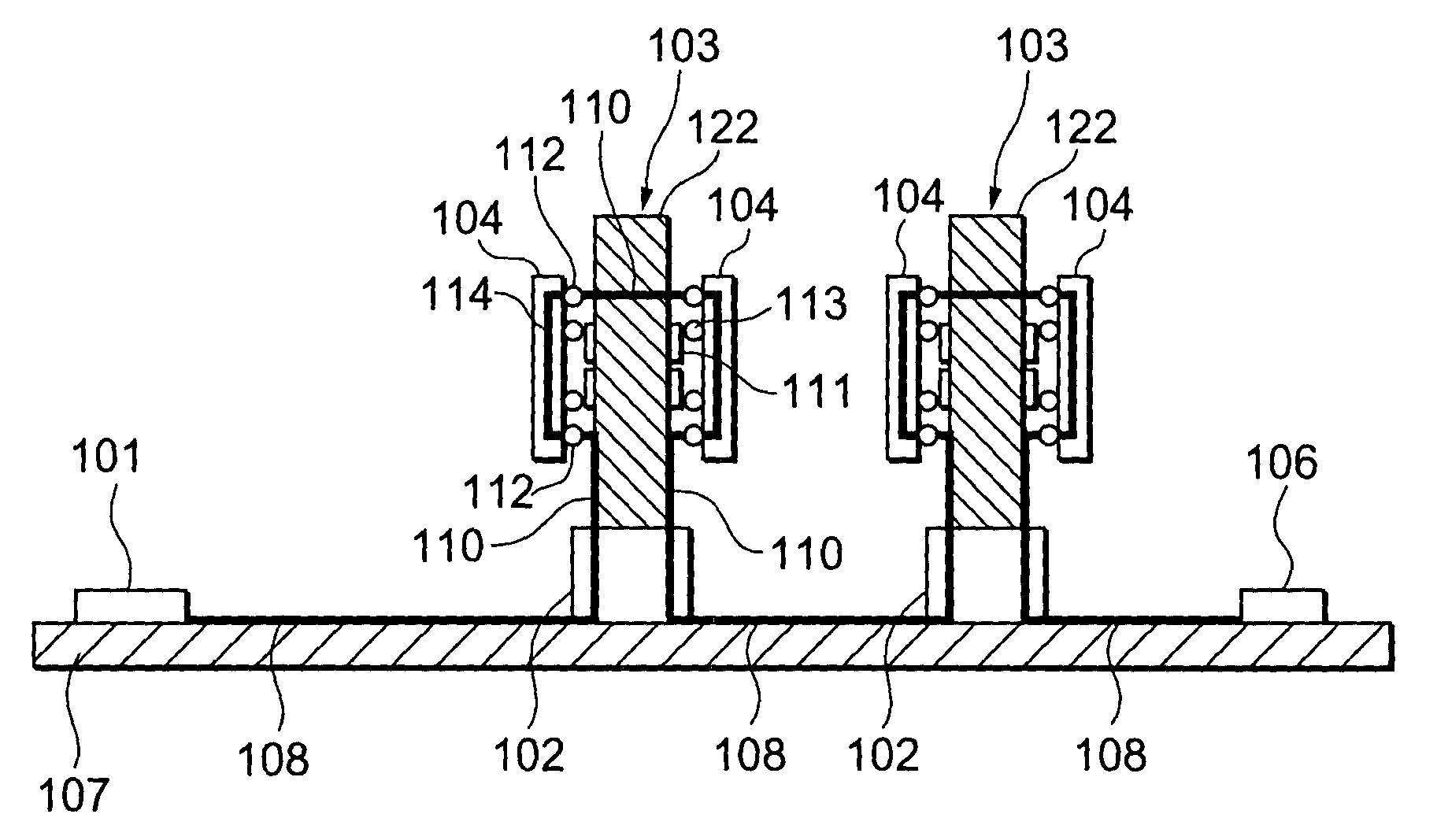

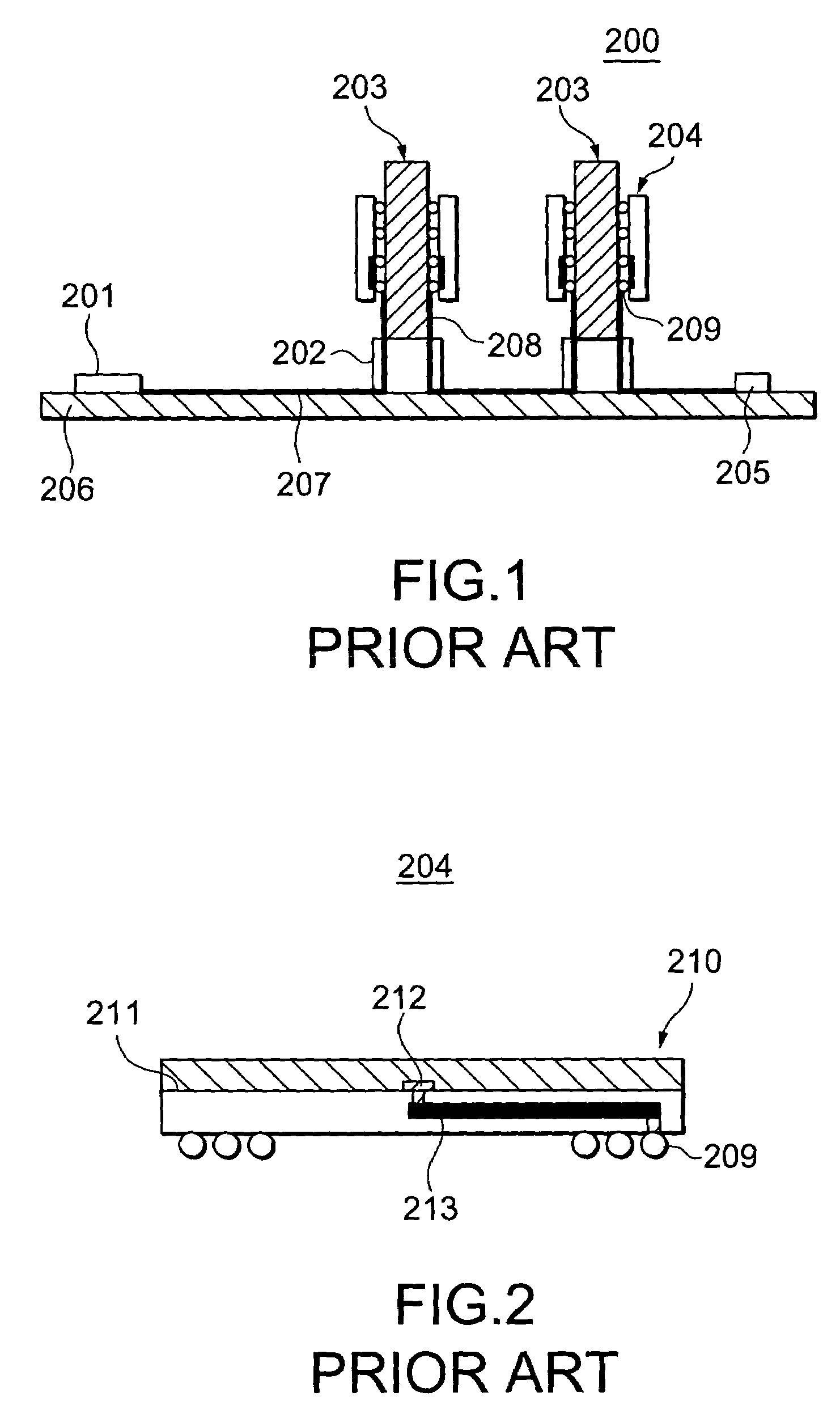

Semiconductor unit having two device terminals for every one input/output signal

InactiveUS7633147B2Shorten the lengthShorten the line lengthFinal product manufactureSemiconductor/solid-state device detailsMemory chipEngineering

A semiconductor unit constituting a memory device has a memory chip, a package substrate having three wiring layers. Power-supply surfaces (VDD surface) and (GND surface) are wired on the package substrate while an intra-package DQ bus is wired on an intermediate layer between both of the power-supply surfaces. The memory device has two DQ pins every one intra-package DQ bus. The intra-package DQ bus is connected to a signal terminal pad of the memory chip through a via hole. In view of the two DW pins, a via hole for connecting the intra-package DQ bus with the signal terminal pad constitutes a branch wire.

Owner:KOMORO MURATA MFG +1

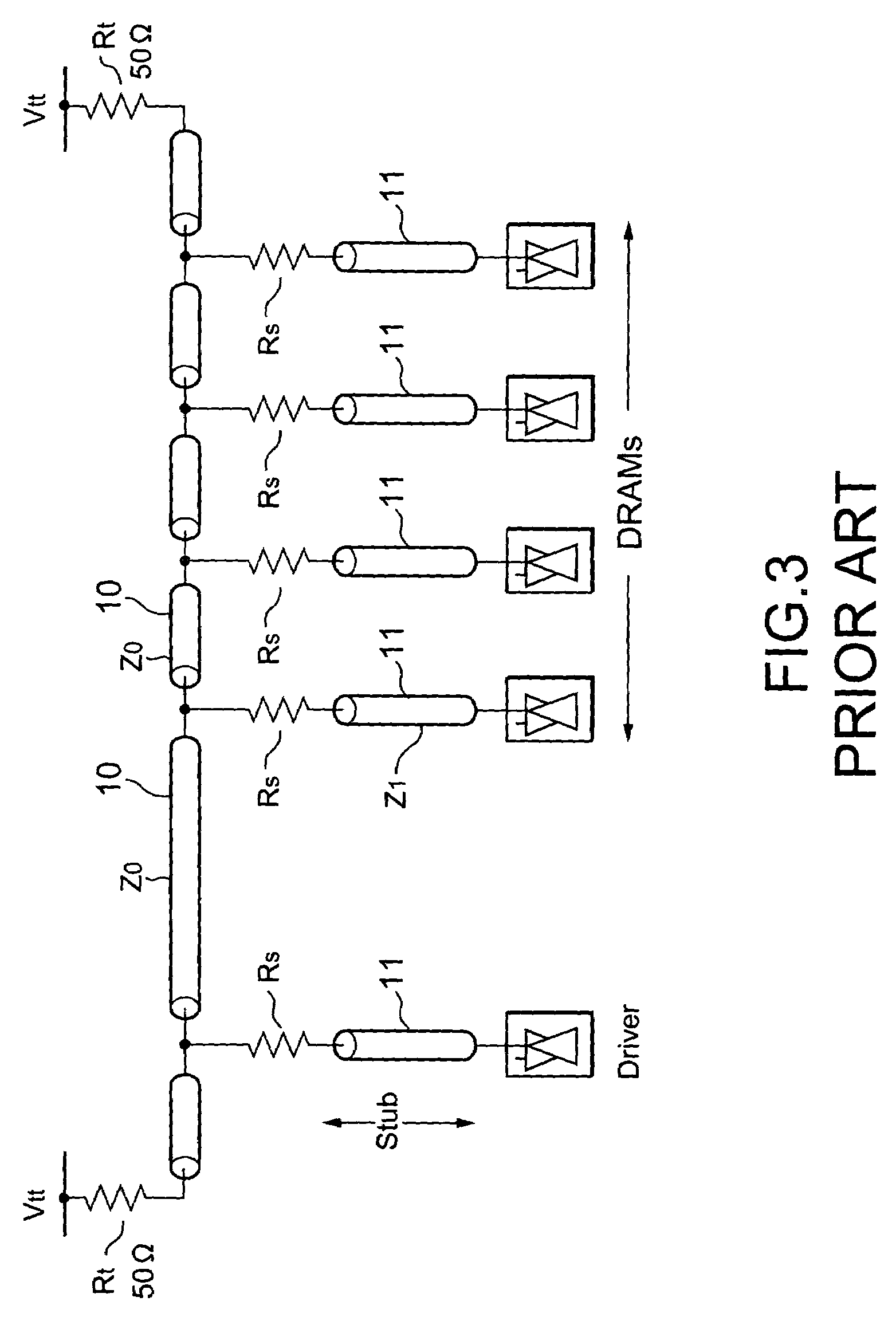

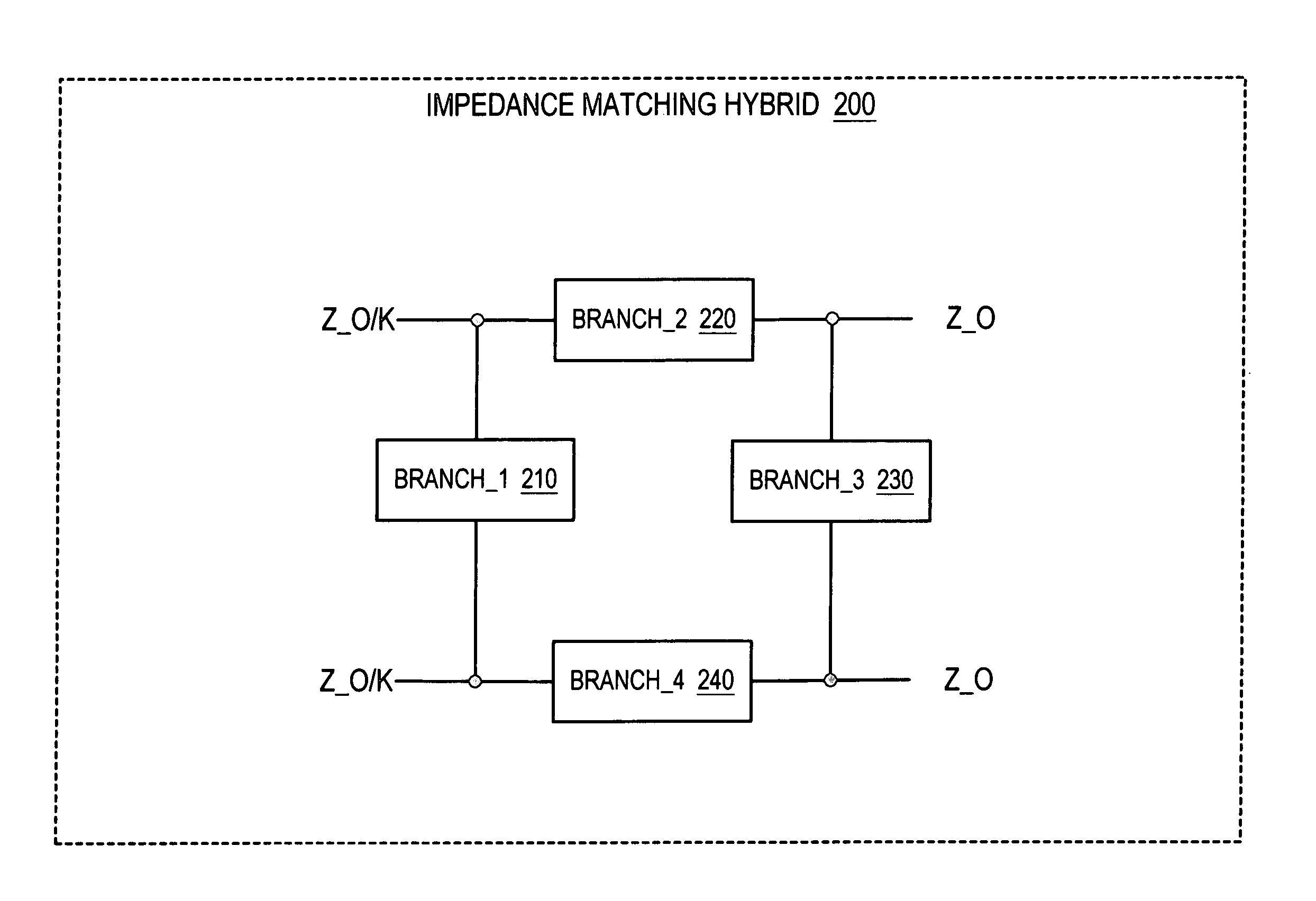

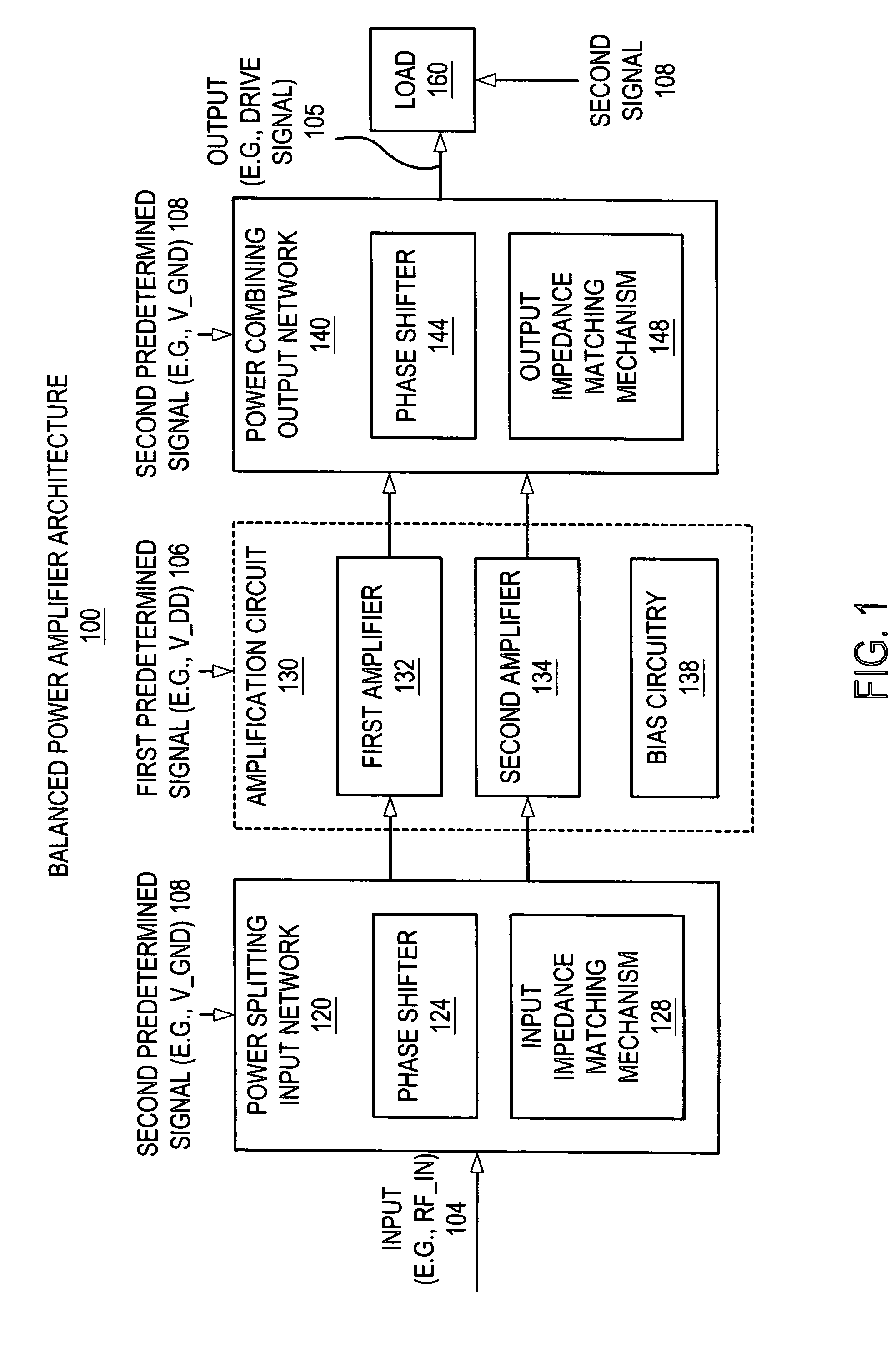

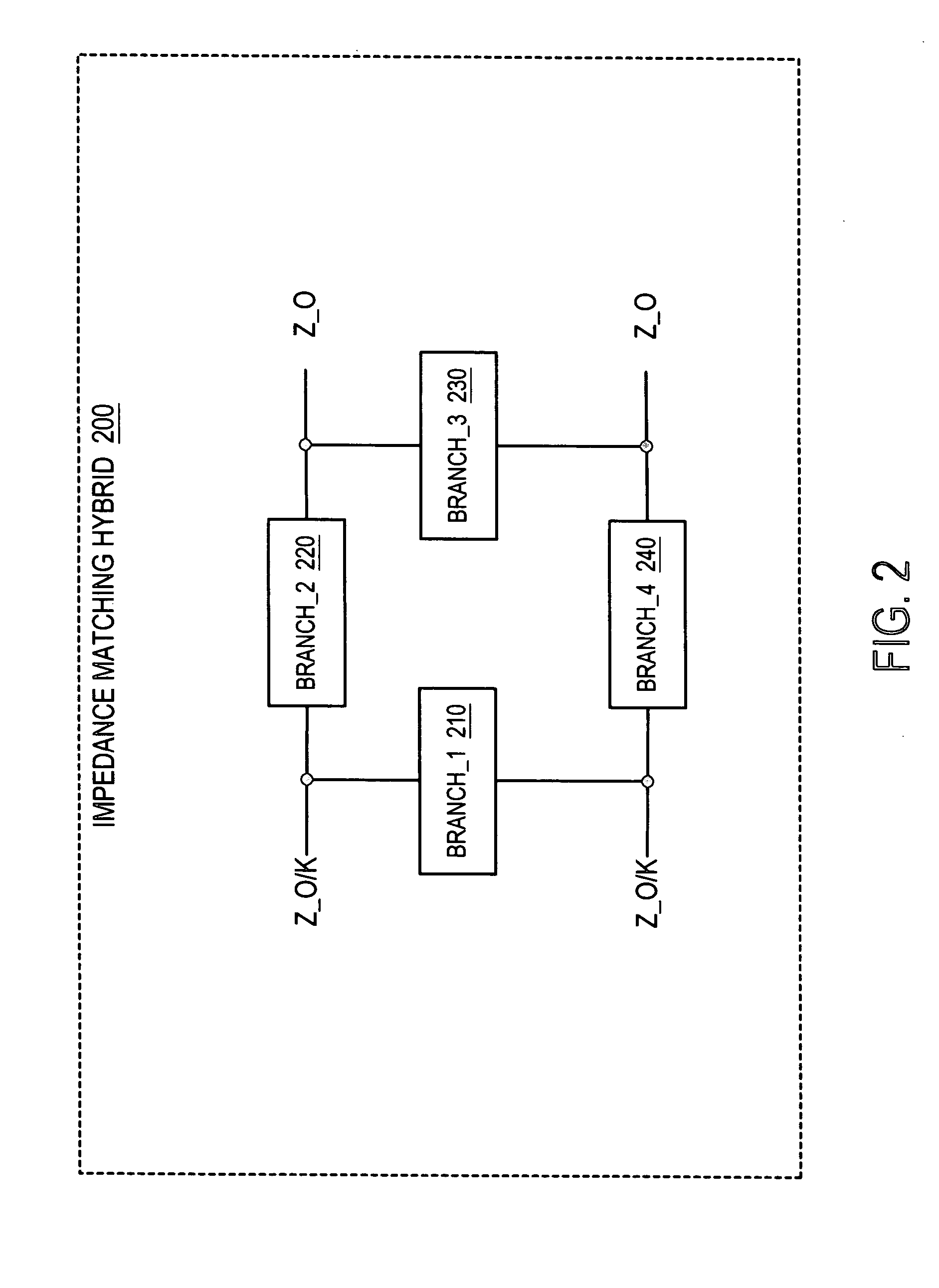

Power amplifier utilizing quadrature hybrid for power dividing, combining and impedance matching

InactiveUS20060290444A1Reduce the amount requiredAmplifier modifications to reduce non-linear distortionMultiple-port networksAudio power amplifierPhase shifted

A balanced power amplifier that includes two or more power amplifiers with equal but phase-shifted signal paths. Balanced power amplifiers need to achieve phase delay and also need to perform power combining. A power amplifier includes at least one quadrature hybrid (also referred to as a branch-line coupler). The quadrature hybrid is utilized for multiple functions, such as power dividing, power combining, impedance matching or a combination thereof. This implementation with the quadrature hybrid reduces the amount of area needed to implement the balanced power amplifier.

Owner:AVAGO TECH INT SALES PTE LTD

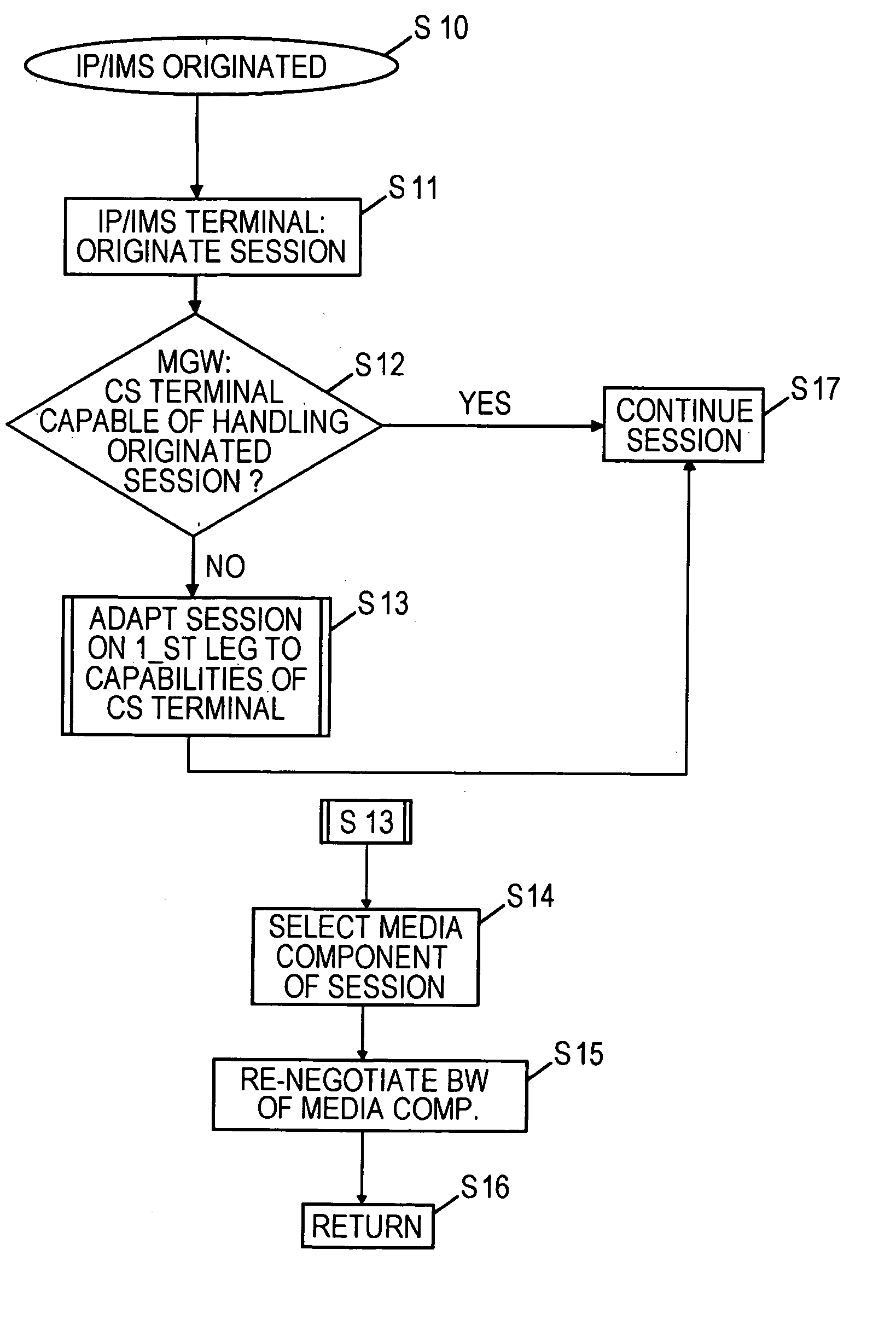

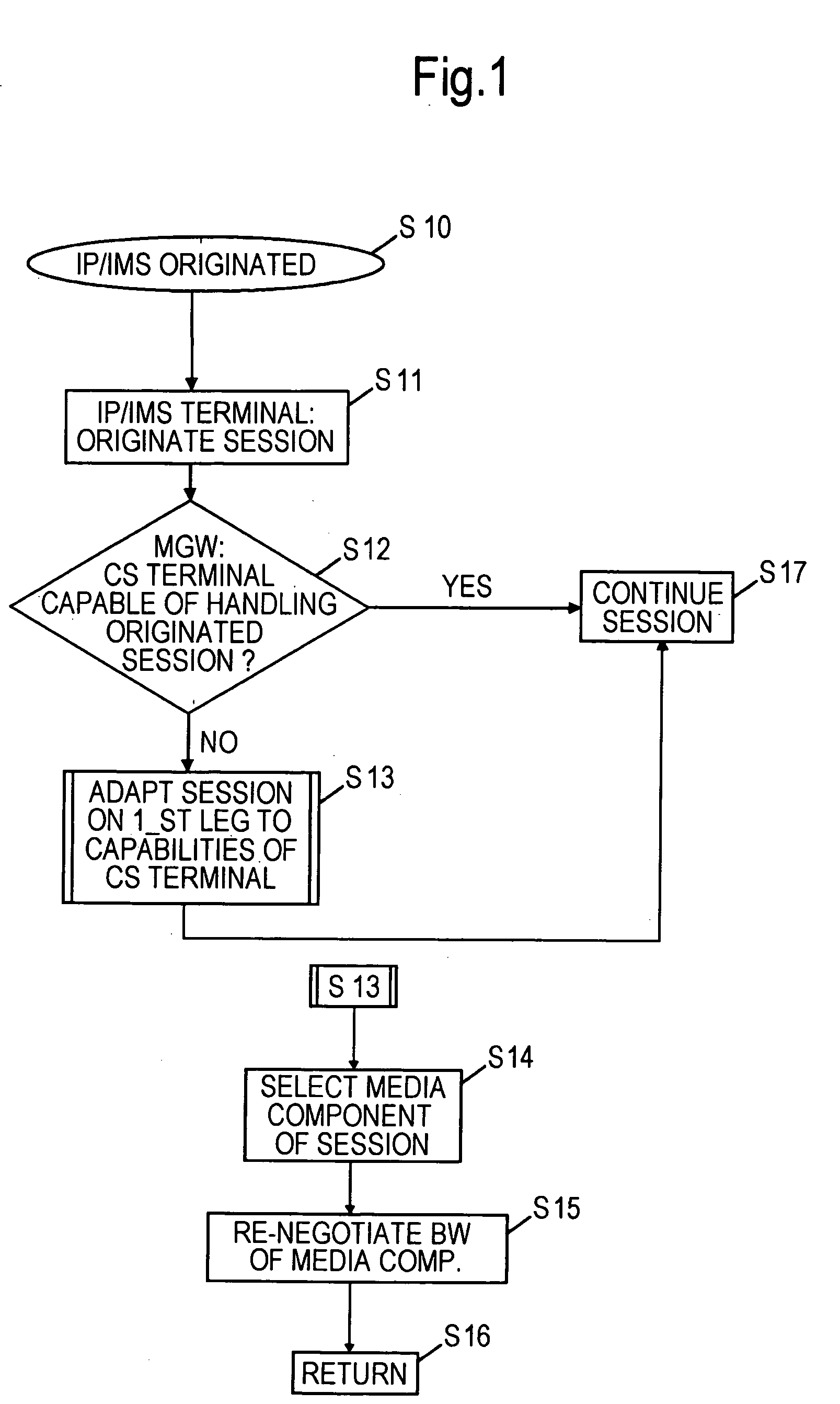

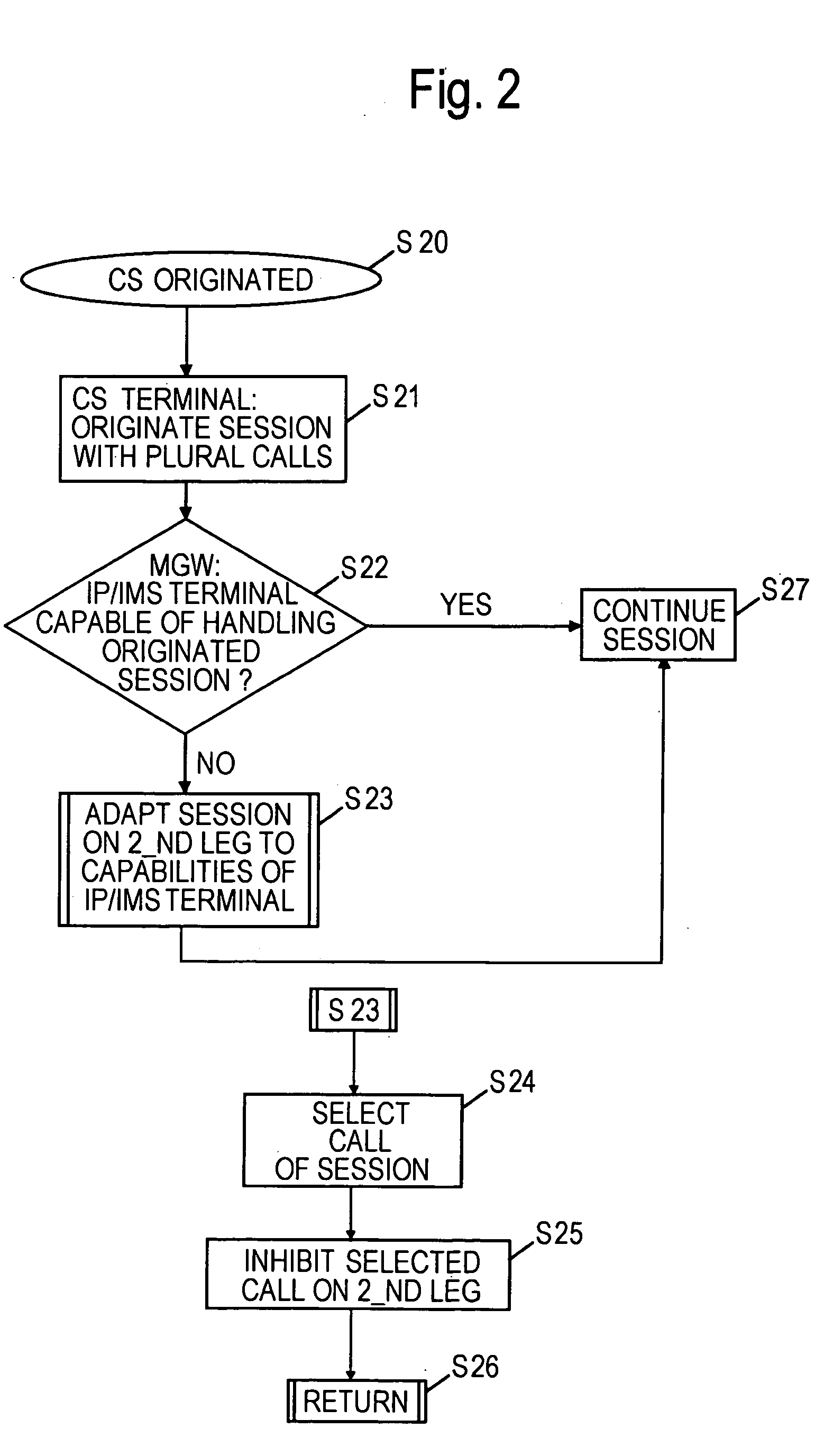

Interworking between domains of a communication network operated based on different switching principles

ActiveUS20050141484A1Interconnection arrangementsData switching by path configurationTelecommunicationsData rate

Multimedia calls addressed an increased data rate are disclosed. The multimedia calls use the multicall supplementary service in circuit switched mobile networks and a multilink operation to separate calls for each portion of the total session. The calling entity establishes several calls to the same party. The sending entity splits the data into the separate simultaneous channels / calls. The receiving entity combines the data received from the separate simultaneous calls (multicall, multilink). IP-based multimedia uses one session for each media component. The IP / CS interworking is arranged, if the CS leg uses a multicall / multilink operation.

Owner:NOKIA TECHNOLOGLES OY

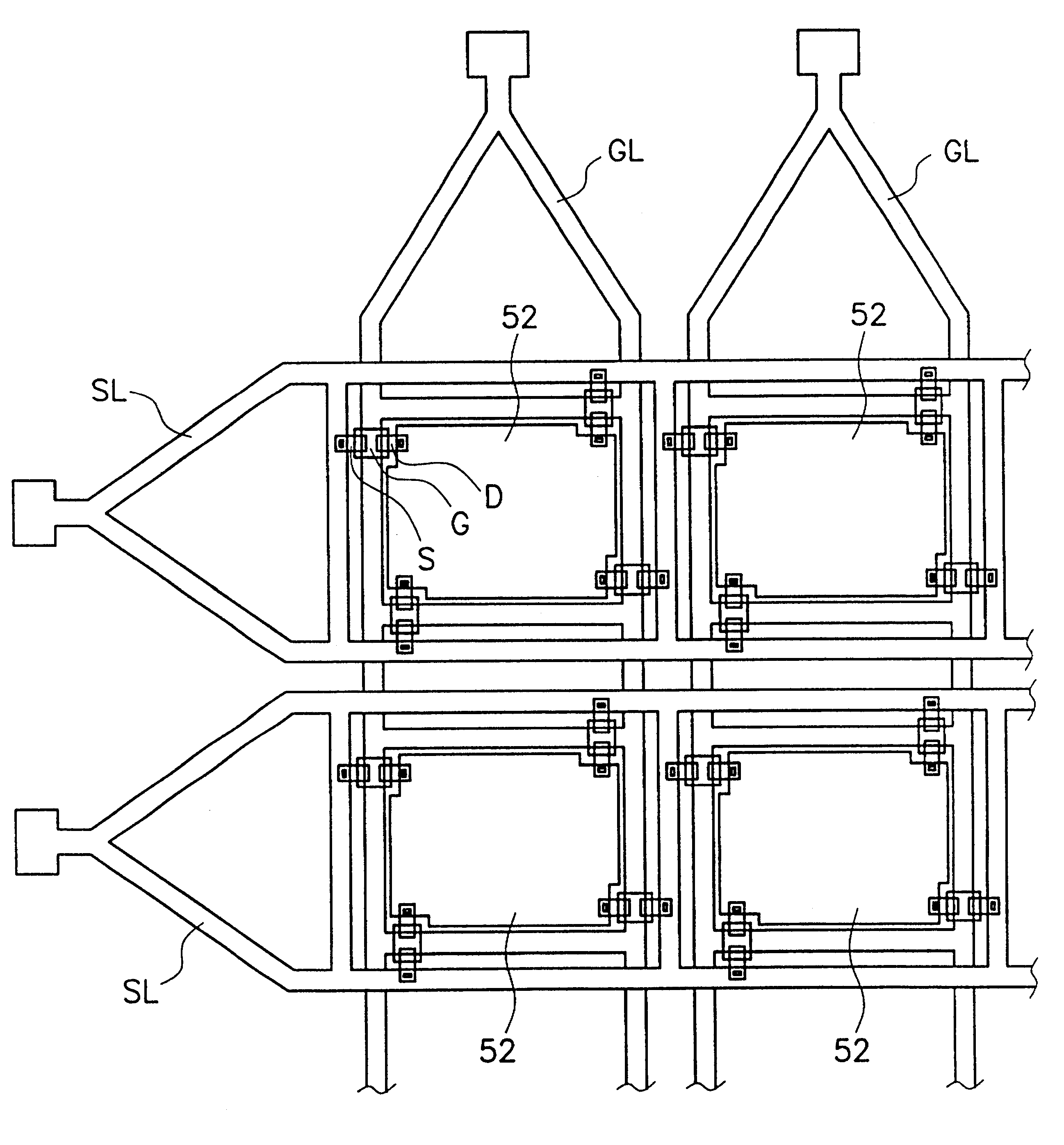

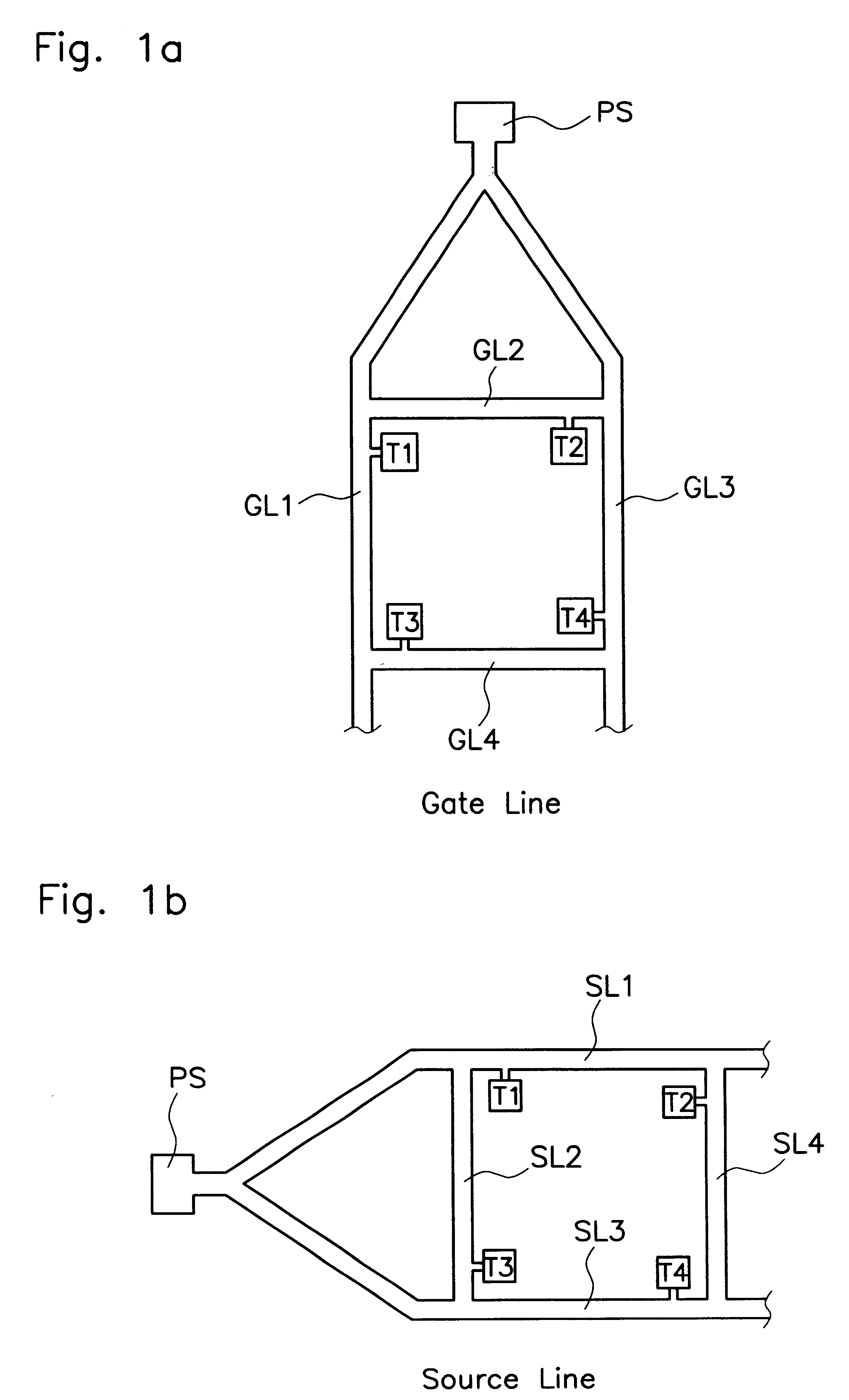

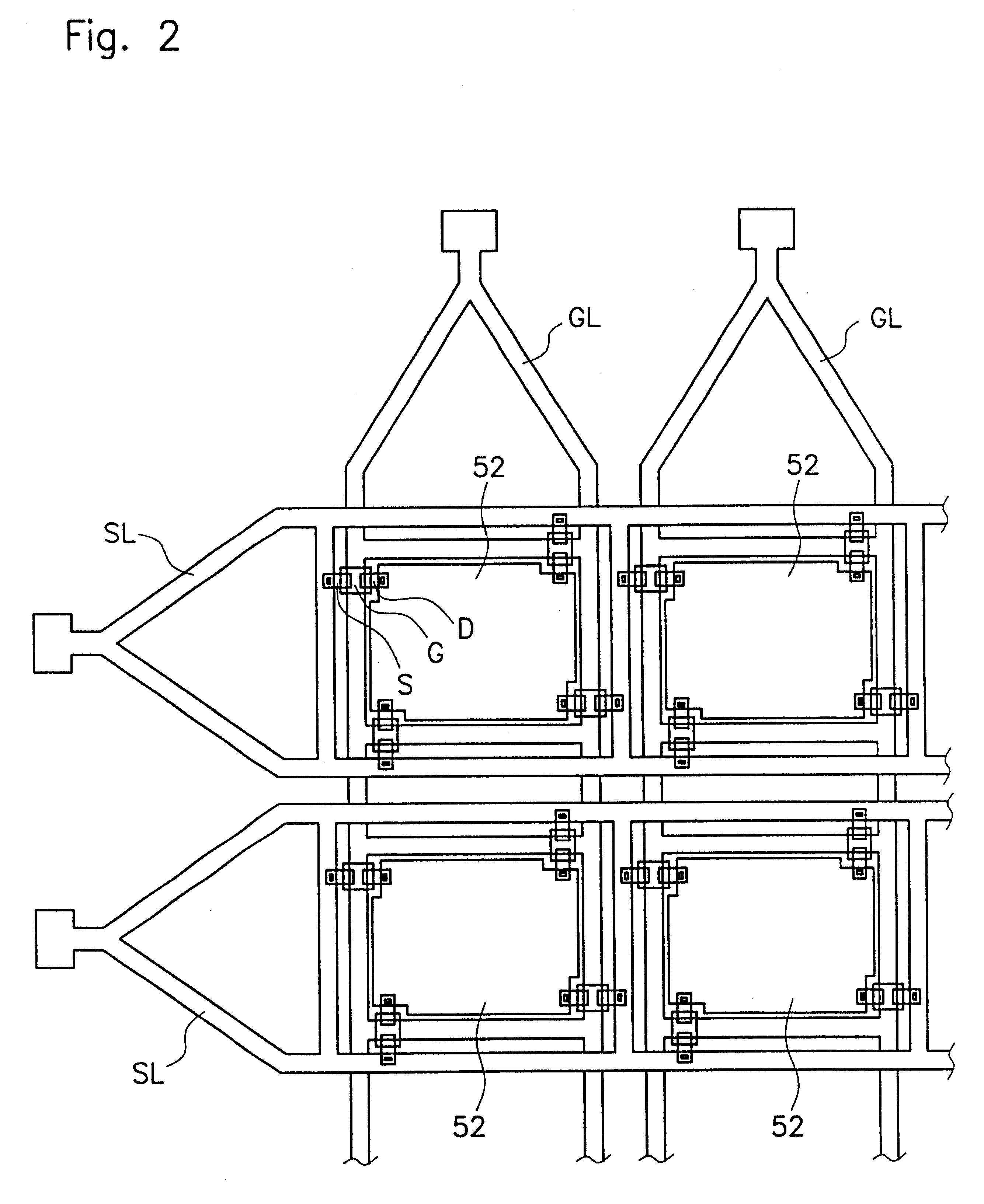

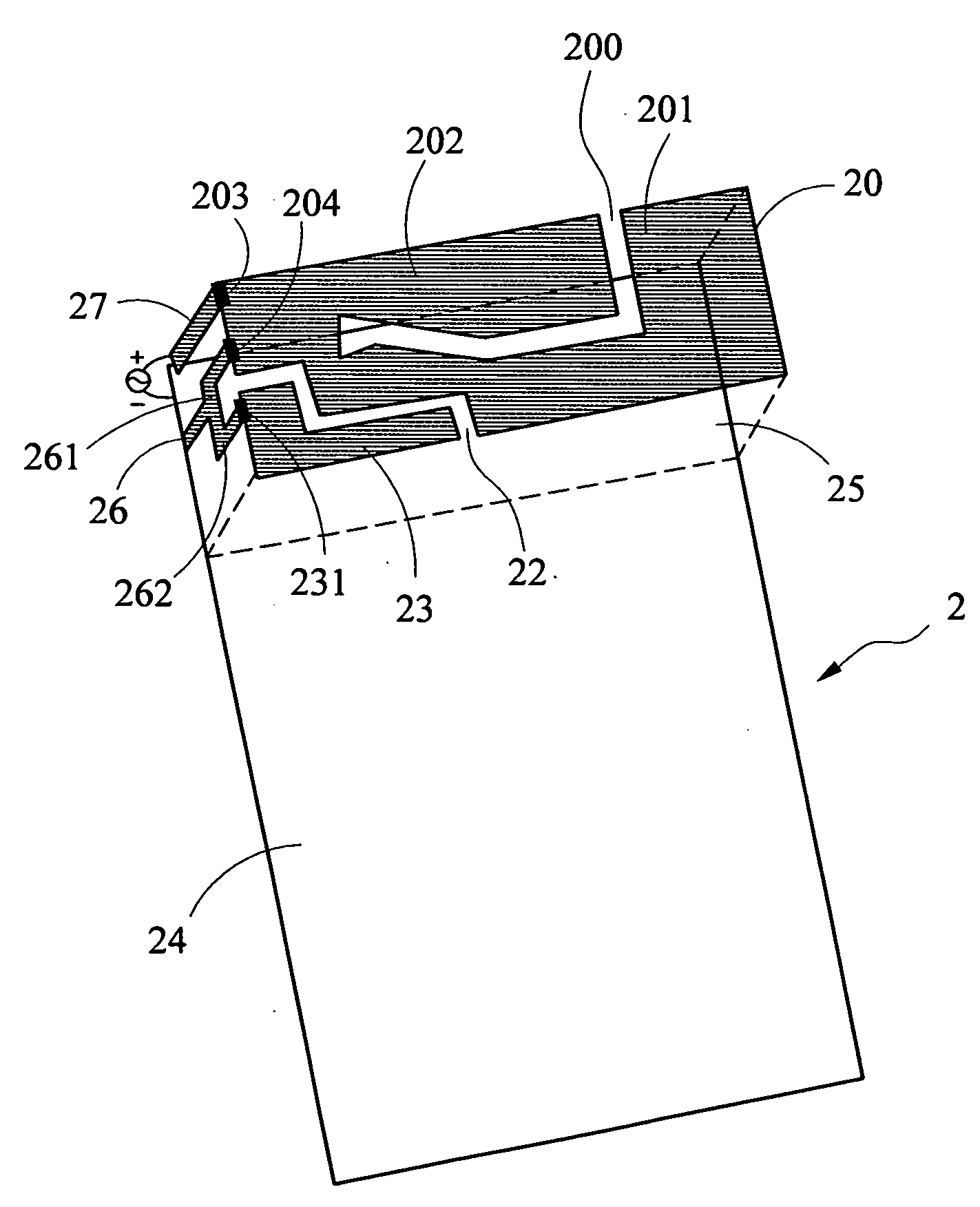

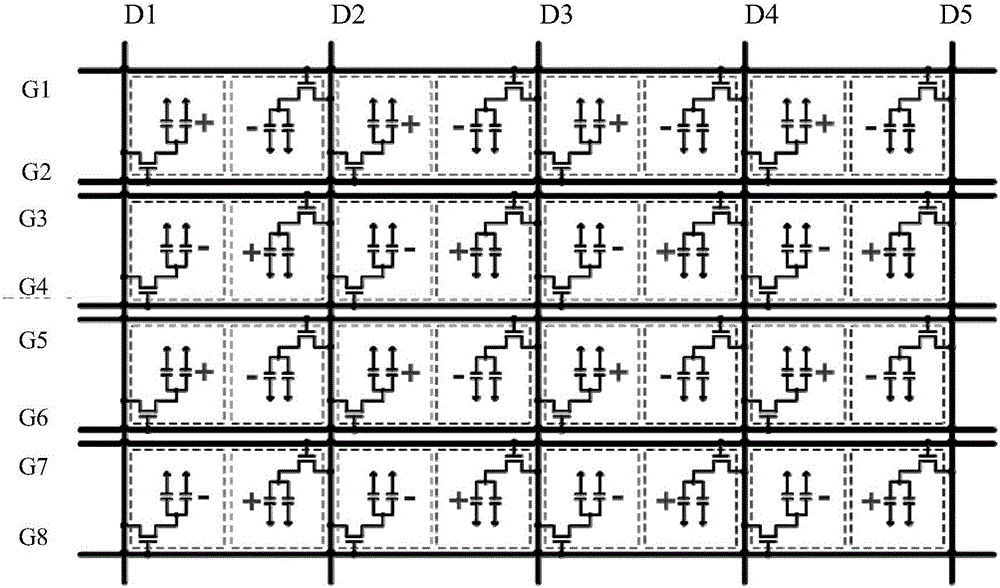

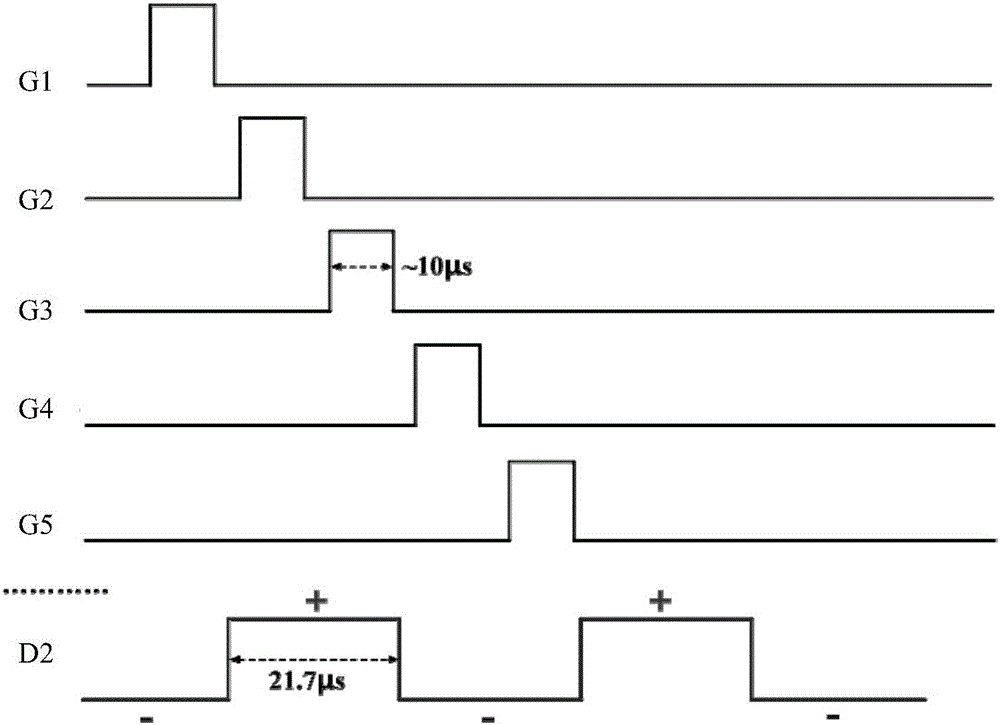

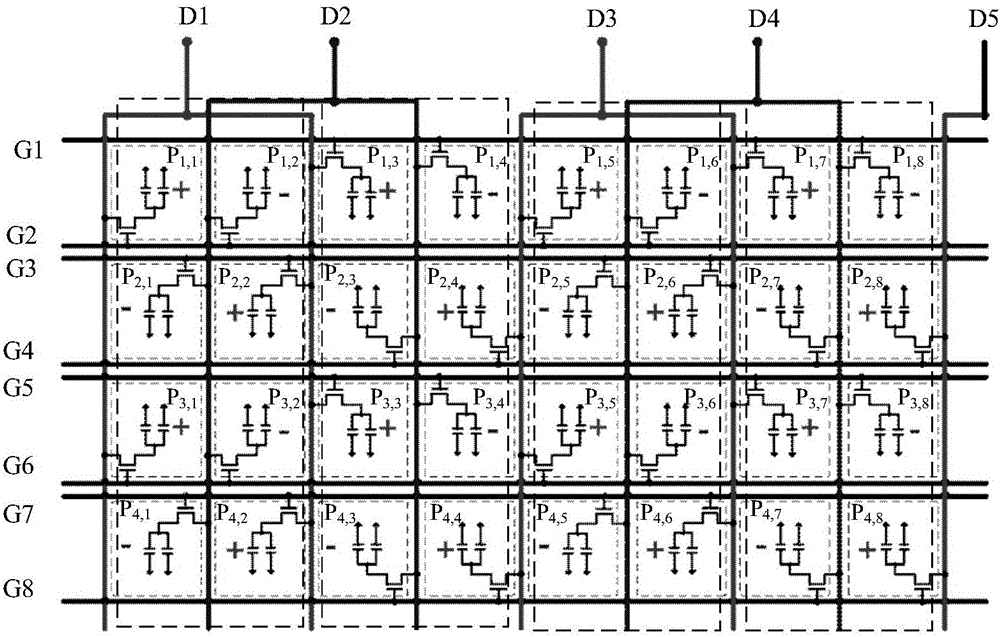

Thin film transistor liquid crystal display including at least three transistors associated with an unit pixel

A thin film transistor liquid crystal display according to the present invention provides against cut-off of lines for supplying a predetermined "ON'- or "OFF'-signal to thin film transistors and improves "ON'-current characteristic of the thin film transistors arranged in parallel. The thin film transistor liquid crystal display comprises primary lines and secondary lines to supply scanning signals and data signals respectively wherein each of said primary and secondary lines are branched and a thin film transistor is electrically coupled to each of the branched lines such that at least two transistors are turned on and off simultaneously when one of primary lines and one of secondary lines are applied with scanning signals and data signals respectively. Particularly, the primary and secondary lines are patterned in a trapezoid shape to define a lattice having two vertical sides and two horizontal sides for a unit pixel electrode.

Owner:SAMSUNG DISPLAY CO LTD

Dual-band inverted-f antenna with a branch line shorting strip

InactiveUS20060145924A1Increase working frequencySimultaneous aerial operationsAntenna supports/mountingsGSMOperating frequency

Provided is dual-band inverted-F antenna for GSM, DCS, and PCS bands comprising a primary radiating member including integral first and second metallic strips, a feeding point, and a first shorting point wherein a long current path is created in the first strip such that the antenna can operate in a first low frequency operating mode, and a shorting current path is created in the second strip such that the antenna can operate in a second high frequency operating mode; a secondary radiating member comprising a second shorting point; a branch line shorting strip having one grounded end and a bifurcation including a first branch connected to the first shorting point and a second branch connected to the second shorting point; and a feeding member interconnected the feeding point and a signal source. Operating frequencies of the antenna are 90 MHz and 300 MHz respectively when it operates in 3.5:1 VSWR impedance bandwidth.

Owner:ADVANCED CONNECTEK INC

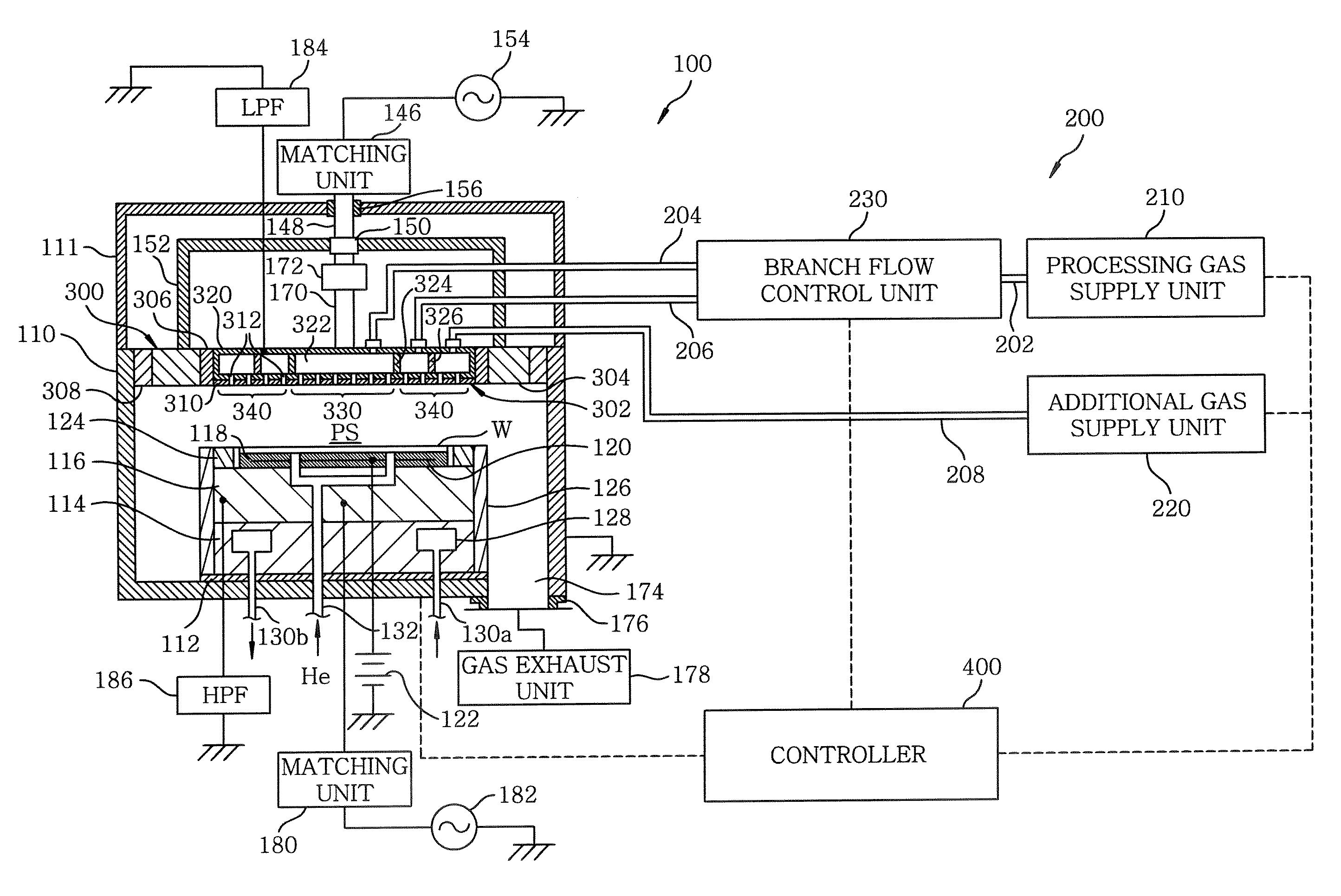

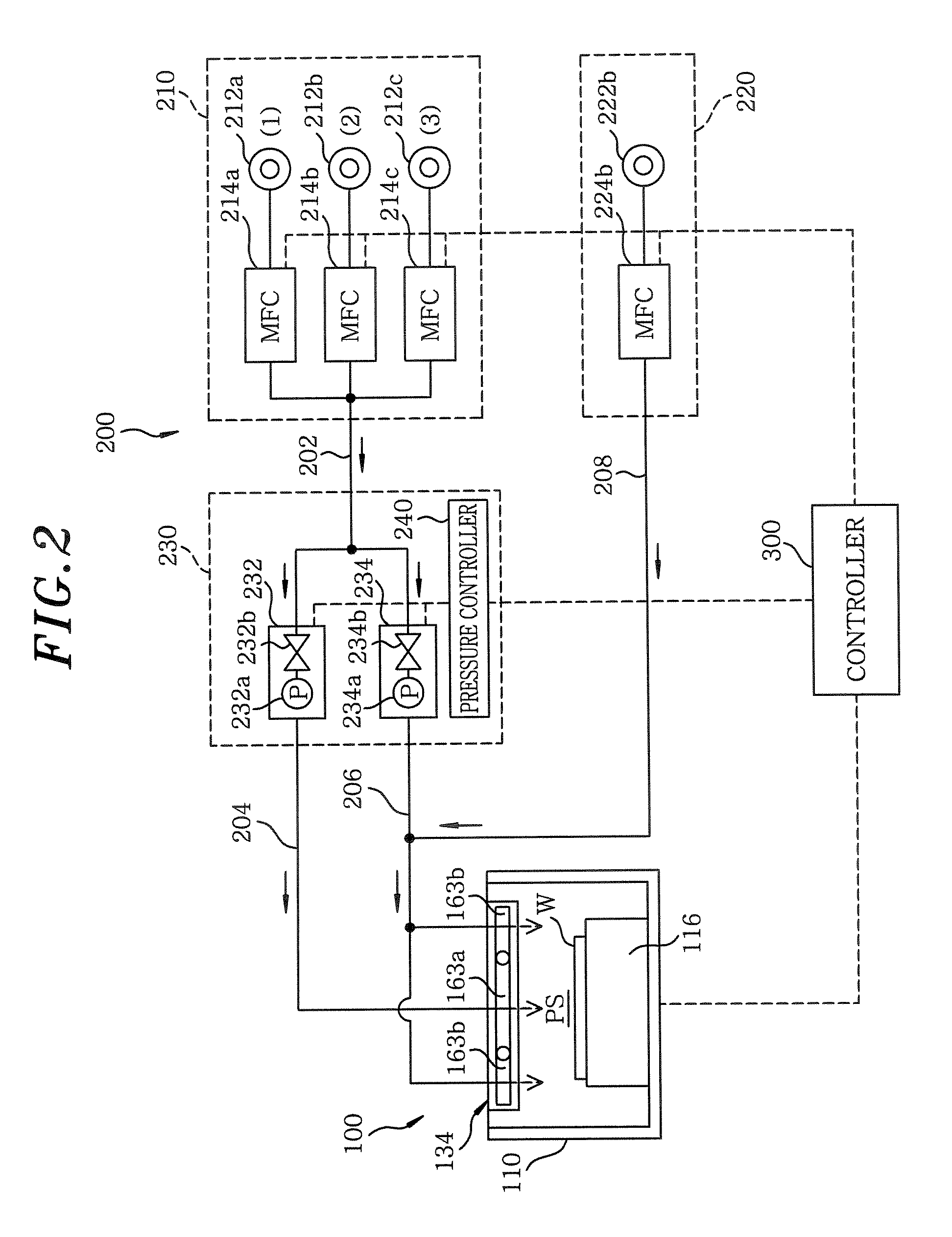

Gas supply system, substrate processing apparatus and gas supply method

InactiveUS20070175391A1Desired in-surface uniformityEasy to operate and controlLiquid surface applicatorsSemiconductor/solid-state device manufacturingInternal pressureProcess engineering

A gas supply system for supplying a gas into a processing chamber for processing a substrate to be processed includes: a processing gas supply unit; a processing gas supply line; a first and a second processing gas branch line; a branch flow control unit; an additional gas supply unit; an additional gas supply line; a first and a second additional gas branch line; a flow path switching unit; and a control unit. Before processing the substrate to be processed, the control unit performs a pressure ratio control on the branch flow control unit while the processing gas supply unit supplies the processing gas. After the inner pressures of the first and the second processing gas branch line become stable, the control unit switches the pressure ratio control to a fixed pressure control, and then the additional gas supply unit supplies the additional gas.

Owner:TOKYO ELECTRON LTD

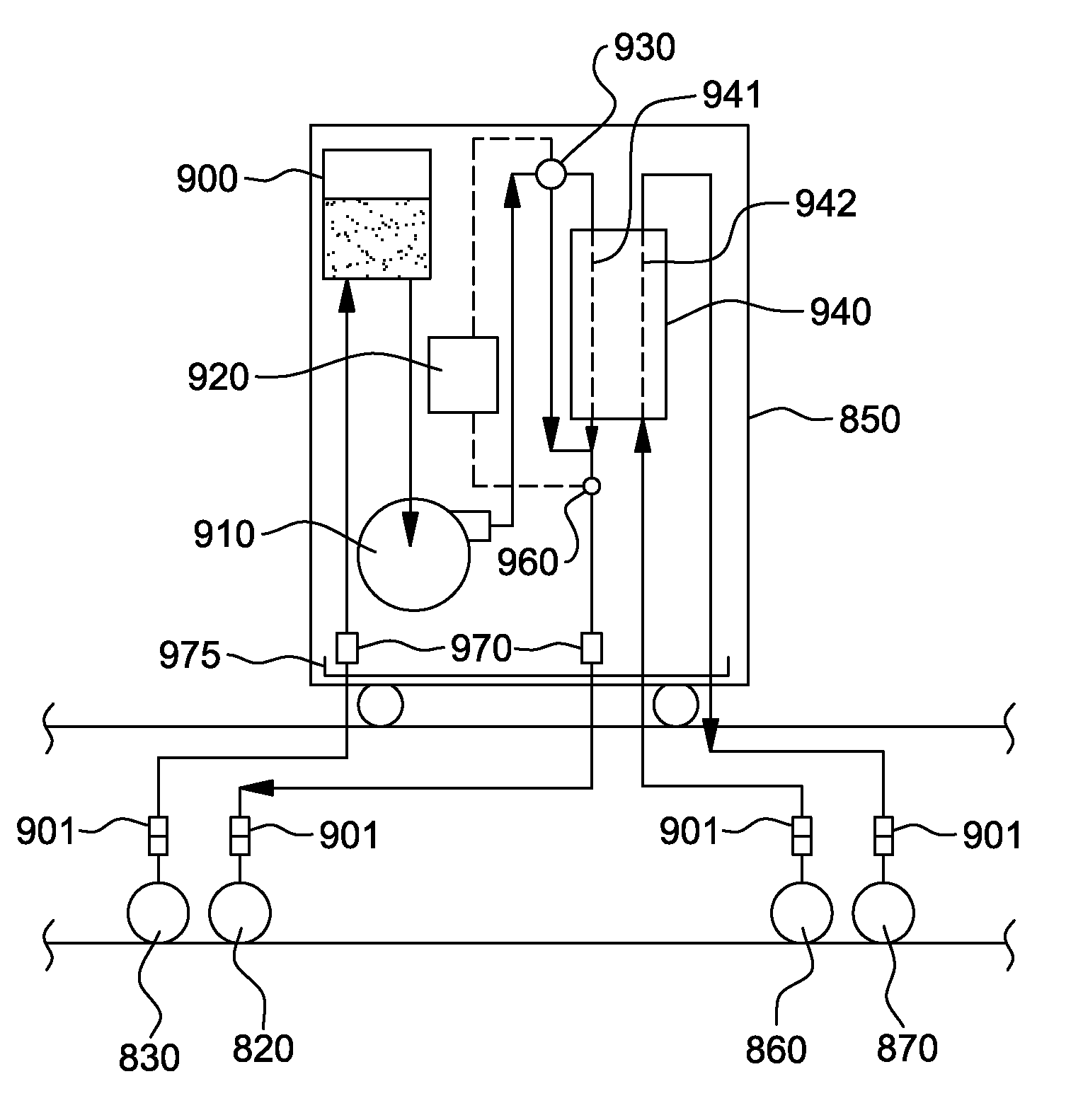

System and method for facilitating parallel cooling of liquid-cooled electronics racks

InactiveUS20110056674A1Easy to passImprove cooling effectSpace heating and ventilation safety systemsDomestic cooling apparatusNuclear engineeringCooling fluid

A cooling system and method are provided for facilitating cooling of multiple liquid-cooled electronics racks. The cooling system includes a main system coolant supply loop with a plurality of system coolant supply branch lines for facilitating supply of cooled system coolant to the electronics racks, and a main system coolant return loop with a plurality of system coolant return branch lines for facilitating return of exhausted system coolant from the electronics racks. When operational, cooled system coolant circulates through the coolant supply loop and exhausted system coolant circulates through the coolant return loop. A plurality of modular cooling units are coupled to the coolant supply loop and coolant return loop. Each modular cooling unit includes a heat exchanger to facilitate cooling of a portion of the exhausted coolant circulating through the main system coolant return loop for return as cooled system coolant to the main system coolant supply loop.

Owner:LENOVO GLOBAL TECH INT LTD

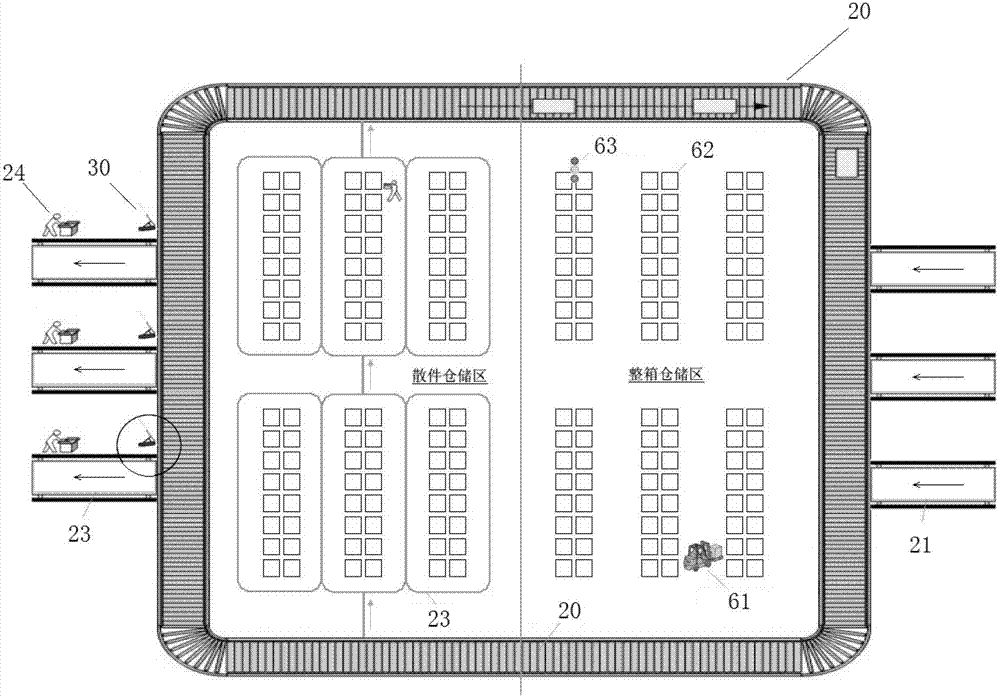

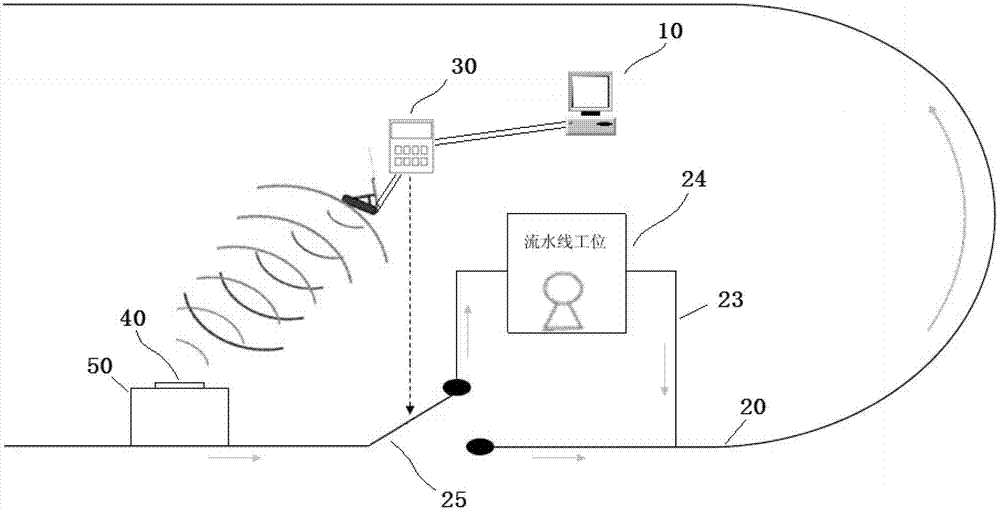

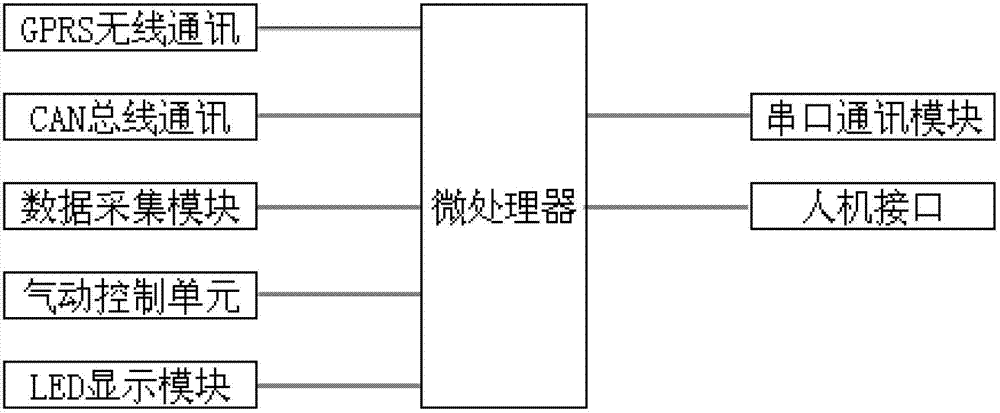

Automatic sorting and distributing system and method of production line

ActiveCN102968709AImprove equalization performanceReduce handlingLogisticsProduction lineControl valves

The invention discloses an automatic sorting and distributing system and method of a production line. The system comprises a flow line, a plurality of intelligent terminals and a management server, wherein the flow line comprises a main conveyor line and one or more conveyor branch lines; intersections of the flow line are provided with control valves as required; the intelligent terminals comprise RFID (radio frequency identification) units and valve control units; the RFID units are used for identifying RFID tags arranged on objects / package boxes to acquire information of the objects / package boxes and transmitting identification results to the management server; and the management server is used for transmitting control commands to the valve control units of the corresponding intelligent terminals according to the information of the objects / package boxes and the configured flow line step arrangement, and the valve control units control states of the control valves so as to control the conveyance directions of the objects / package boxes. According to the automatic sorting and distributing system of the production line and the method of the system, disclosed by the invention, purposes of improving the production efficiency, accelerating the export period and reducing the production cost are realized so that the competiveness of the industry is basically improved.

Owner:SHANGHAI YILI INFORMATION TECH CO LTD

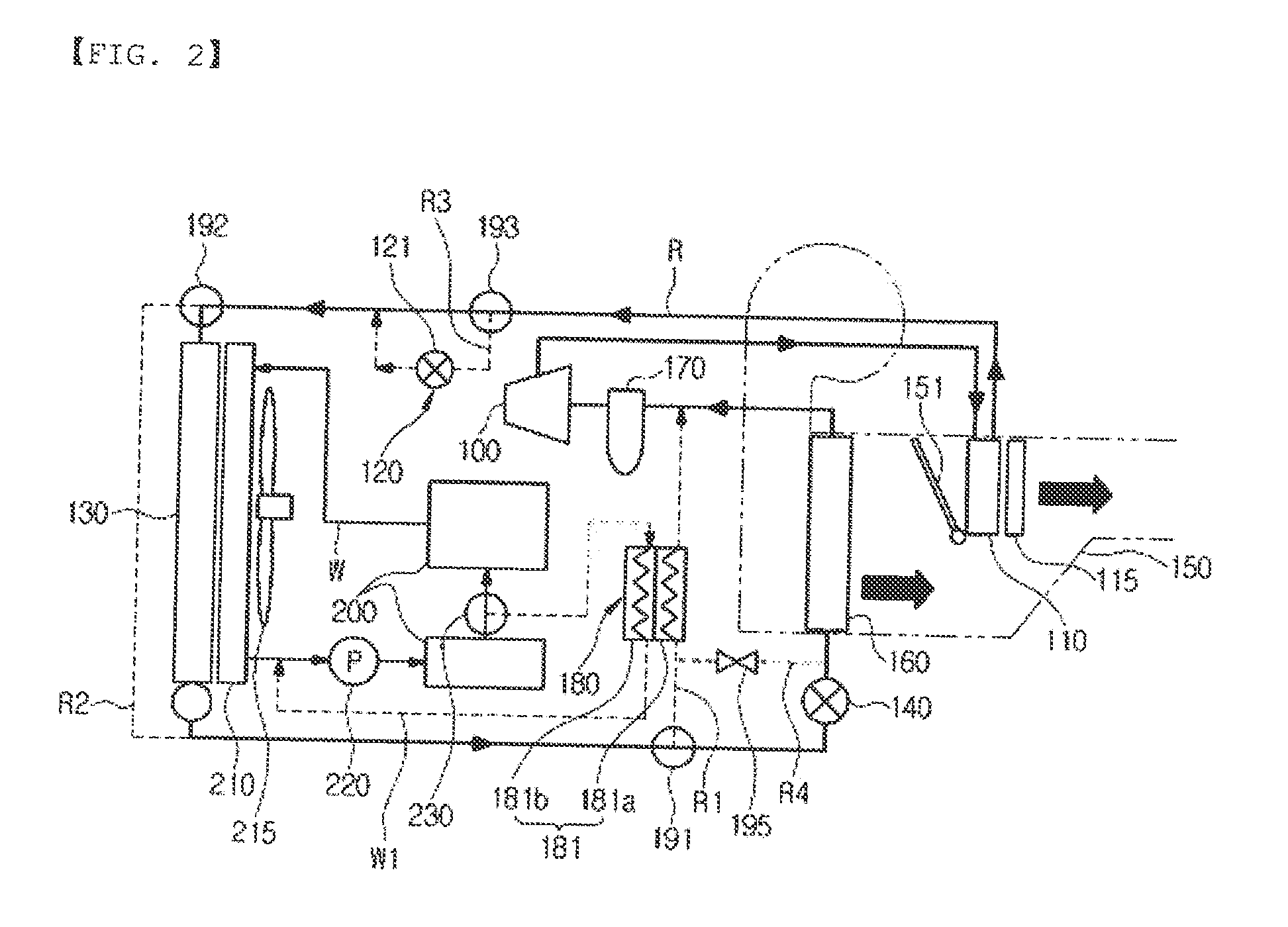

Heat pump system for vehicle

ActiveUS20120227431A1Minimize impactImprove heating performanceHeat pumpsCorrosion preventionElectricityEngineering

A heat pump system including a water-cooled type heat exchanger, which is a heat supply means, mounted on a first bypass line bypassing a second indoor heat exchanger to collect waste heat of vehicle electric devices to thereby enhance a heating efficiency of the heat pump system. The heat pump system for a vehicle includes: a branch line for connecting a refrigerant circulation line of the second indoor heat exchanger and the first bypass line with each other; a second bypass line, which bypasses an outdoor heat exchanger; and a control part that controls a flow of the indoor air to be introduced into an air-conditioning case, whereby the heat pump system can minimize influences of the outdoor air of low temperature even when the outdoor temperature is below zero, enhance the operation and the heating performance of the heat pump system by collecting waste heat of the vehicle electric devices and heat sources of the indoor air, and increase the mileage of the vehicle by minimizing operation of an electric heater.

Owner:HANON SYST

Feeder automation processing method and device of distribution network

InactiveCN101662144AMeet various needsMeet needsEmergency protective circuit arrangementsPower stationNetwork on

The invention relates to a feeder automation processing method and a device of a distribution network, wherein a first-time reclosing of a power station outlet recloser is used for eliminating transient line fault, if the first-time reclosing fails, the line fault of the time is permanent fault, section switches on all main networks on the line are separated, and then normal power supply of non-fault sections is recovered by being matched with time to isolate the fault sections according to the voltage and change condition thereof; if the permanent fault on a short branch line occurs, the section switch at the forficate part of the short branch line is separated and locked after two times of overcurrent pulse is counted and two sides of the switch lose power, thus realizing automatic isolation of the fault sections. In addition, the scheme also fully considers the processing during sing-phase earth fault. The invention leads fault processing to be simple, convenient and reliable, and can recover the normal power supply of all lines with transient fault or non-fault lines during permanent fault in a short time to the maximal extent.

Owner:胡诚

Gas supply system, substrate processing apparatus and gas supply method

InactiveUS20070181181A1Simple line configurationEasy to operate and controlElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringProduct gas

A gas supply system includes a first and a second branch line branched from a processing gas supply line to be respectively connected with a first and a second gas introduction section for introducing a gas from different portions in a processing chamber and a branch flow control unit for controlling branch flows of the processing gas distributed from the processing gas supply line to the first and the second branch line based on pressures in the first and the second processing gas branch line. The gas supply system further includes an additional gas supply unit for supplying an additional gas and an additional gas supply line for allowing the additional gas to flow therein. The first or second gas introduction section is divided into a processing gas introduction section connected with the branch lines and an additional gas introduction section connected with the additional gas supply line.

Owner:TOKYO ELECTRON LTD

Gas supply system, substrate processing apparatus and gas supply method

ActiveUS20070181255A1Desired in-surface uniformitySimple line configurationLiquid surface applicatorsElectric discharge tubesProcess engineeringGas supply

A gas supply system for supplying a gas into a processing chamber for processing a substrate to be processed includes: a processing gas supply unit; a processing gas supply line; a first and a second branch line; a branch flow control unit; an additional gas supply unit; an additional gas supply line; and a control unit. The control unit performs, before processing the substrate to be processed, a processing gas supply control and an additional gas supply control by using the processing gas supply unit and the additional gas supply unit, respectively, wherein the additional gas supply control includes a control that supplies the additional gas at an initial flow rate greater than a set flow rate and then at the set flow rate after a lapse of a period of time.

Owner:TOKYO ELECTRON LTD

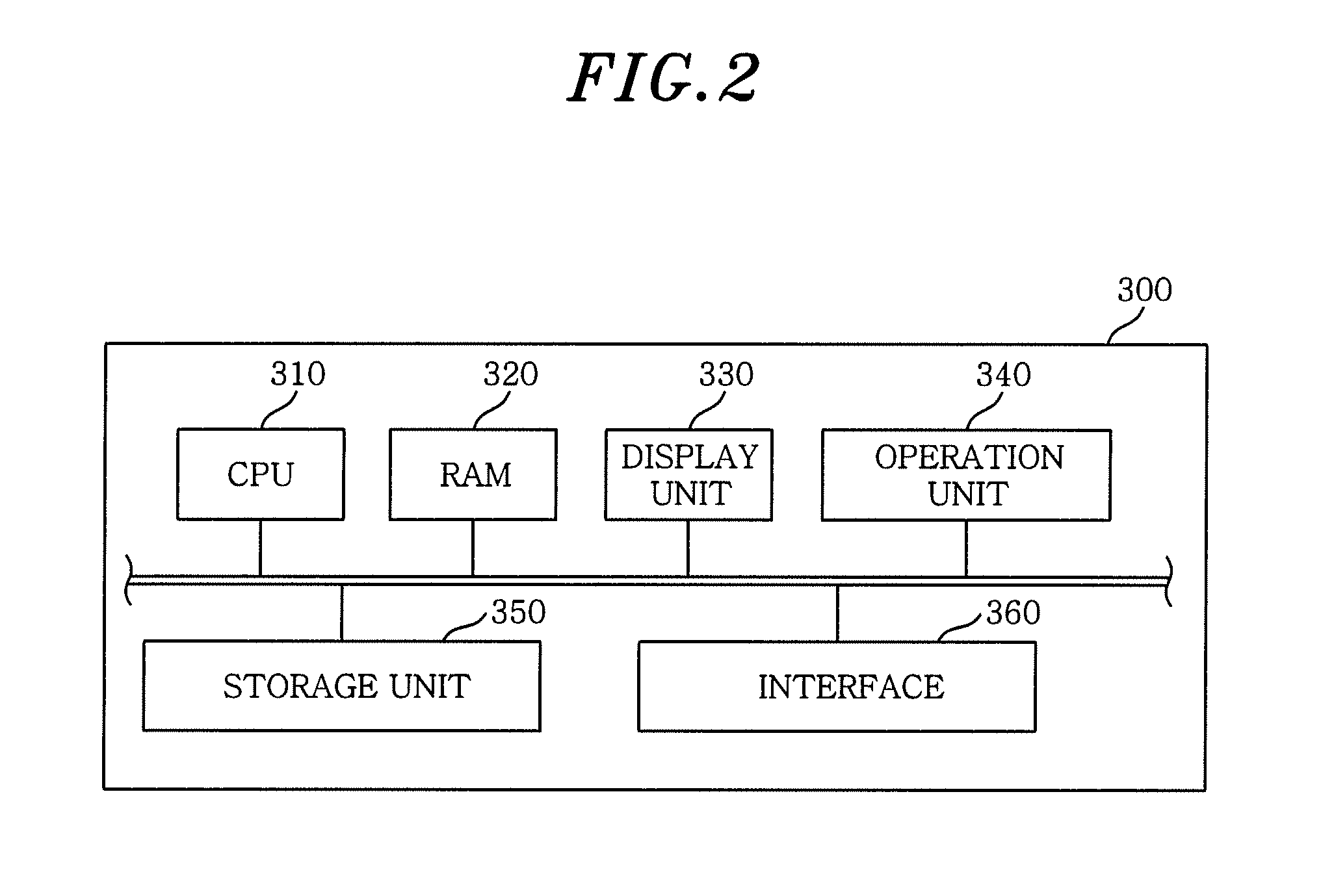

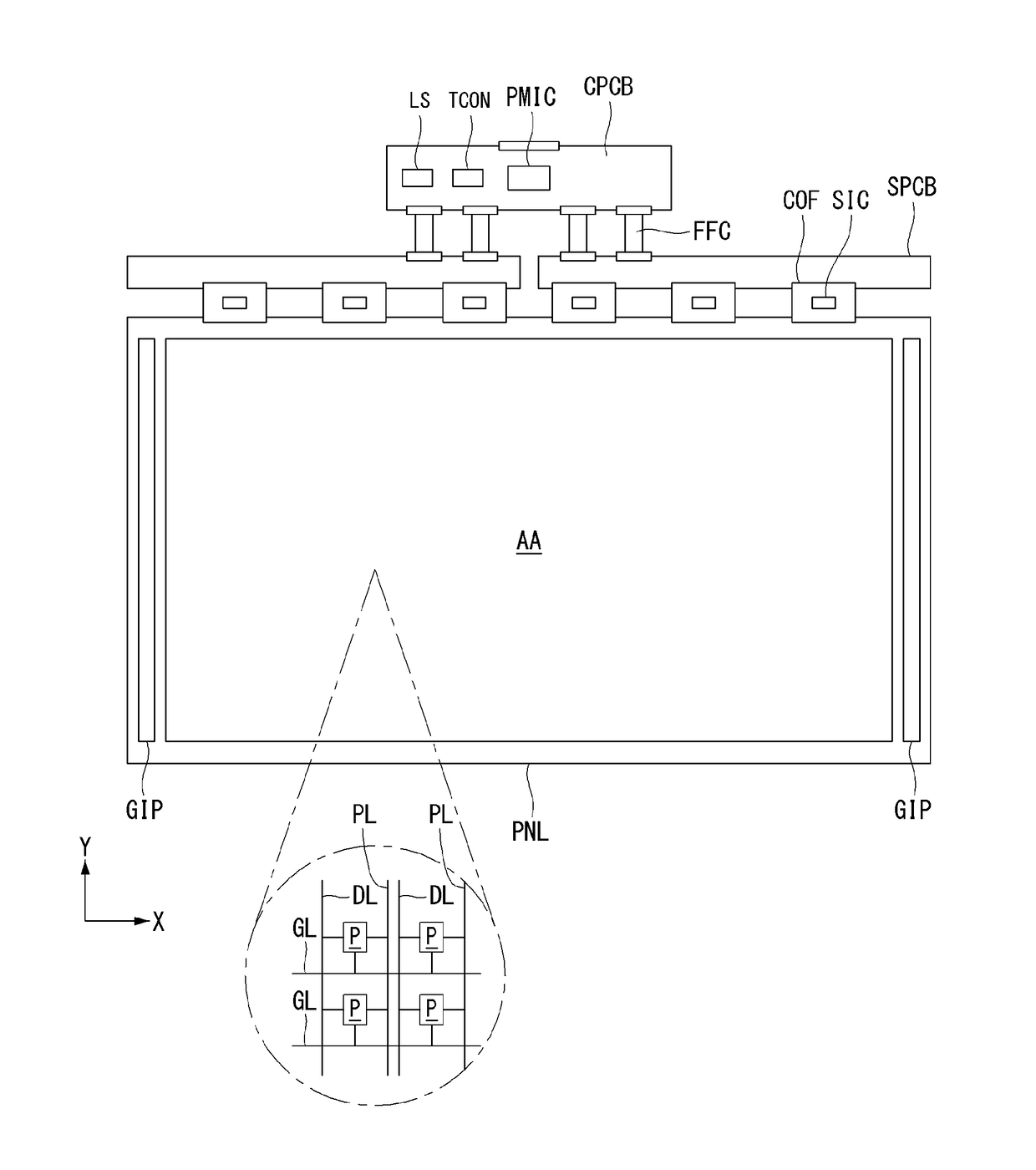

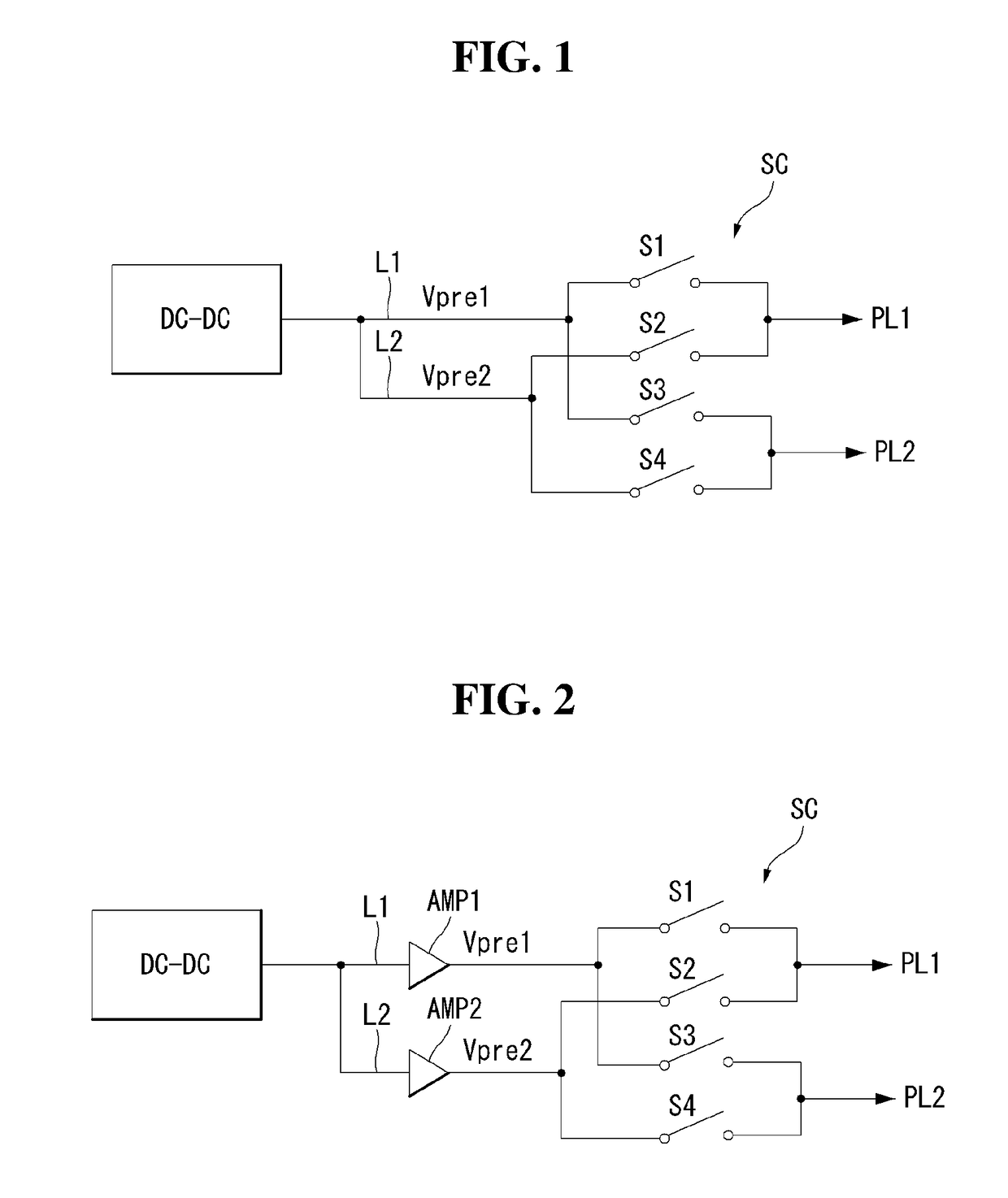

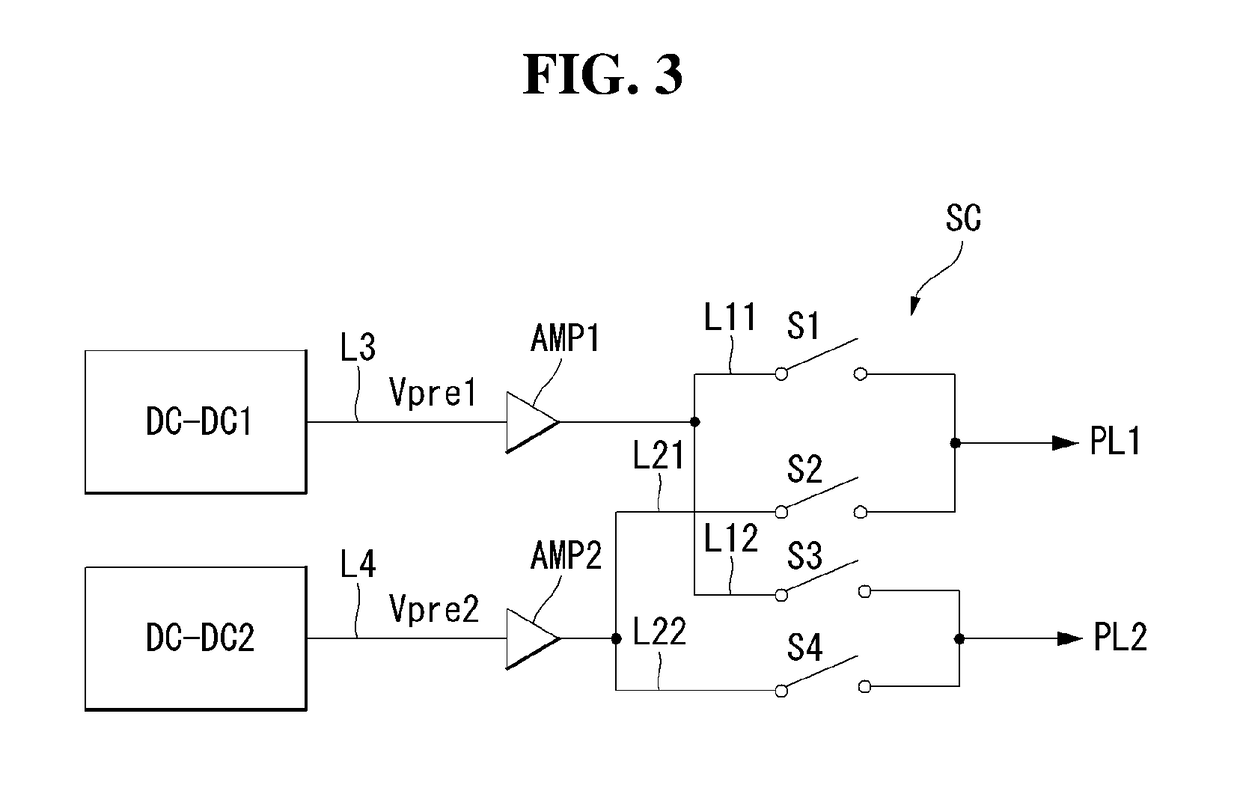

Display device

A display device is disclosed. The display device includes a display panel including data lines, panel lines, scan lines, and pixels, a power circuit configured to output a reference voltage for initializing subpixels of the pixels, a plurality of branch lines configured to divide a path of the reference voltage into a plurality of paths, and a switch circuit configured to switch a path between the branch lines and the panel lines in response to a switch control signal. The switch circuit changes the path between the branch lines and the panel lines at intervals of predetermined time.

Owner:LG DISPLAY CO LTD

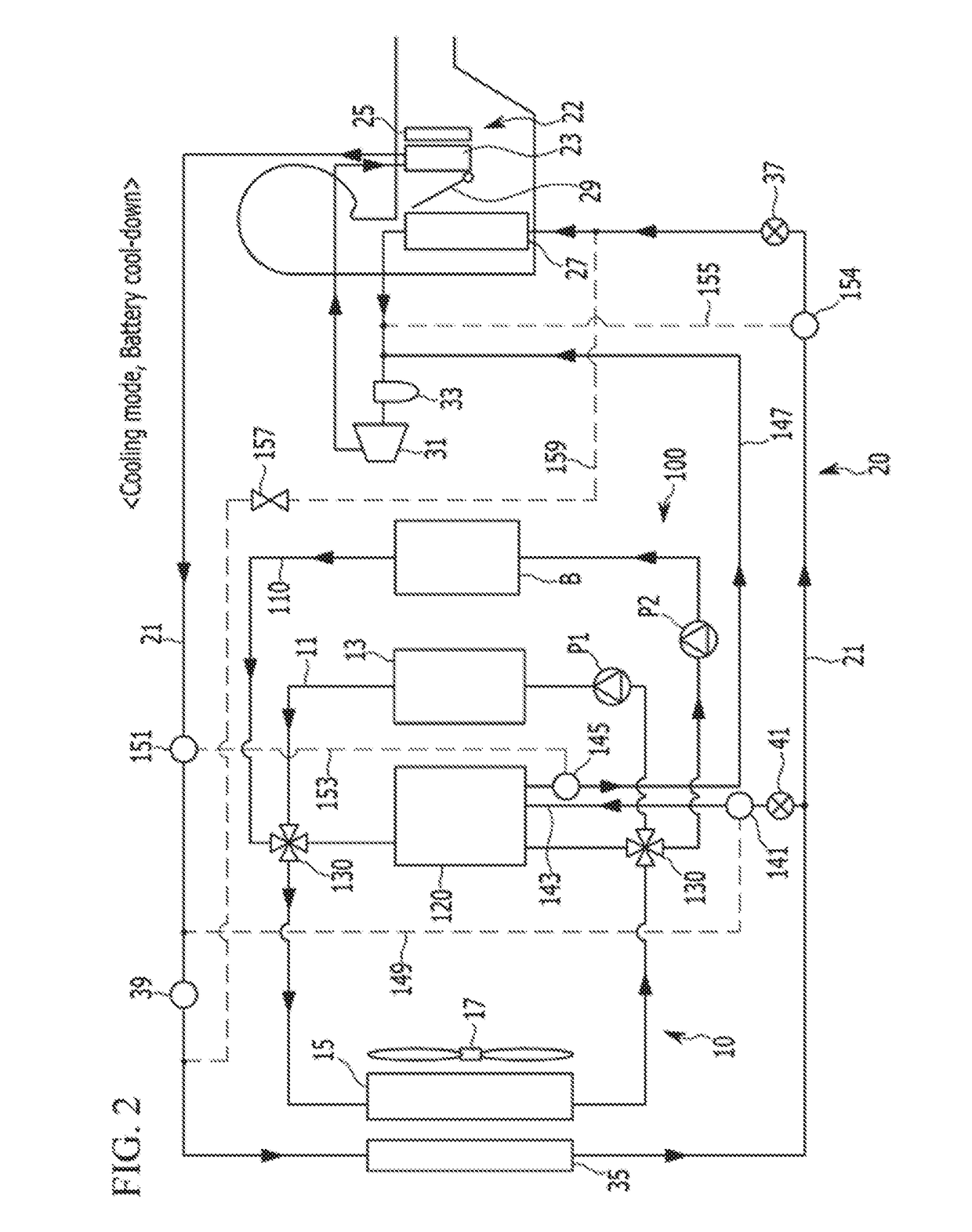

Battery cooling system for a vehicle

ActiveUS20170106725A1Simple processEffectively warmedAir-treating devicesSecondary cellsLine tubingElectrical battery

A battery cooling system for a vehicle, to warm up or cool down a battery installed in the vehicle by selectively using a refrigerant and a coolant according to a mode of the vehicle may include a heat exchanger, connected with a refrigerant line of a heat pump system through first and second connection lines, connected with a cooling line of a cooling system for an electric device through a battery cooling line, and configured to selectively eat-exchange between the coolant and refrigerant introduced into the heat exchanger, two first valves disposed in the battery cooling line with the heat exchanger disposed therebetween, and selectively connecting the cooling line and the battery cooling line, a first branch line connected with the refrigerant line through a second valve, and a second branch line selectively connecting the refrigerant line and the second connection line through a third valve and a fourth valve.

Owner:HYUNDAI MOTOR CO LTD +1

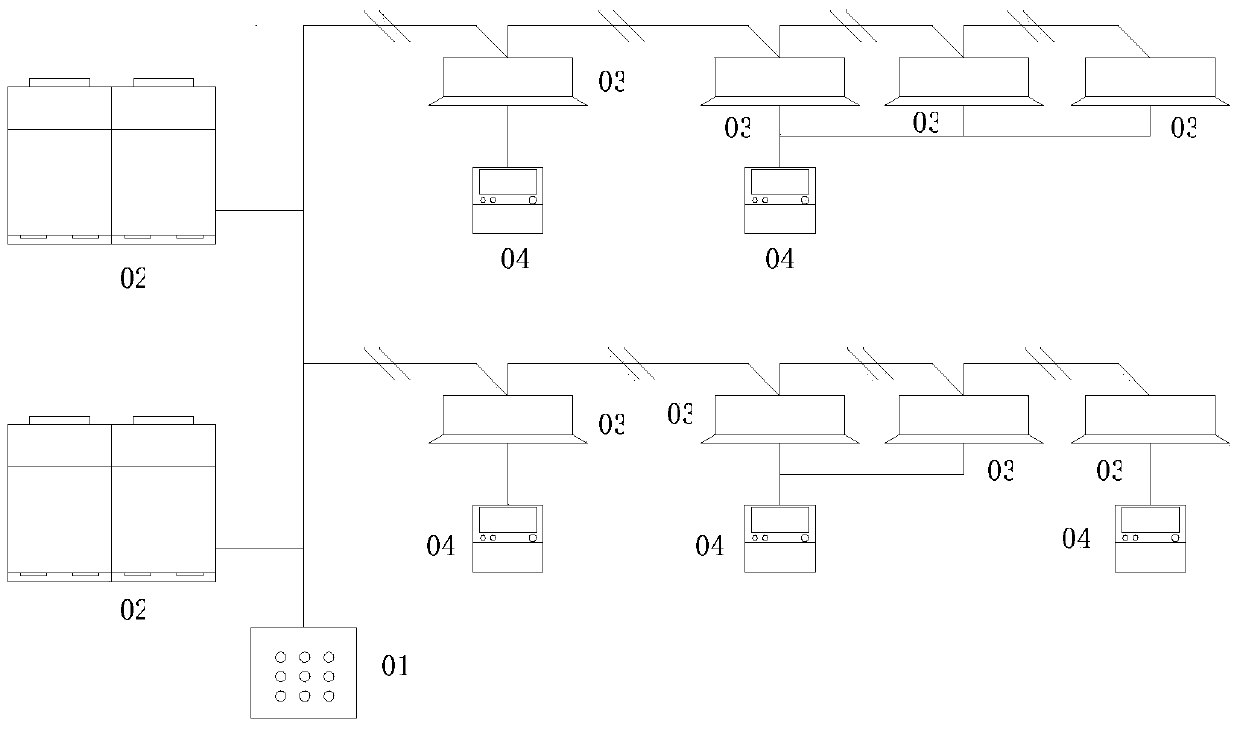

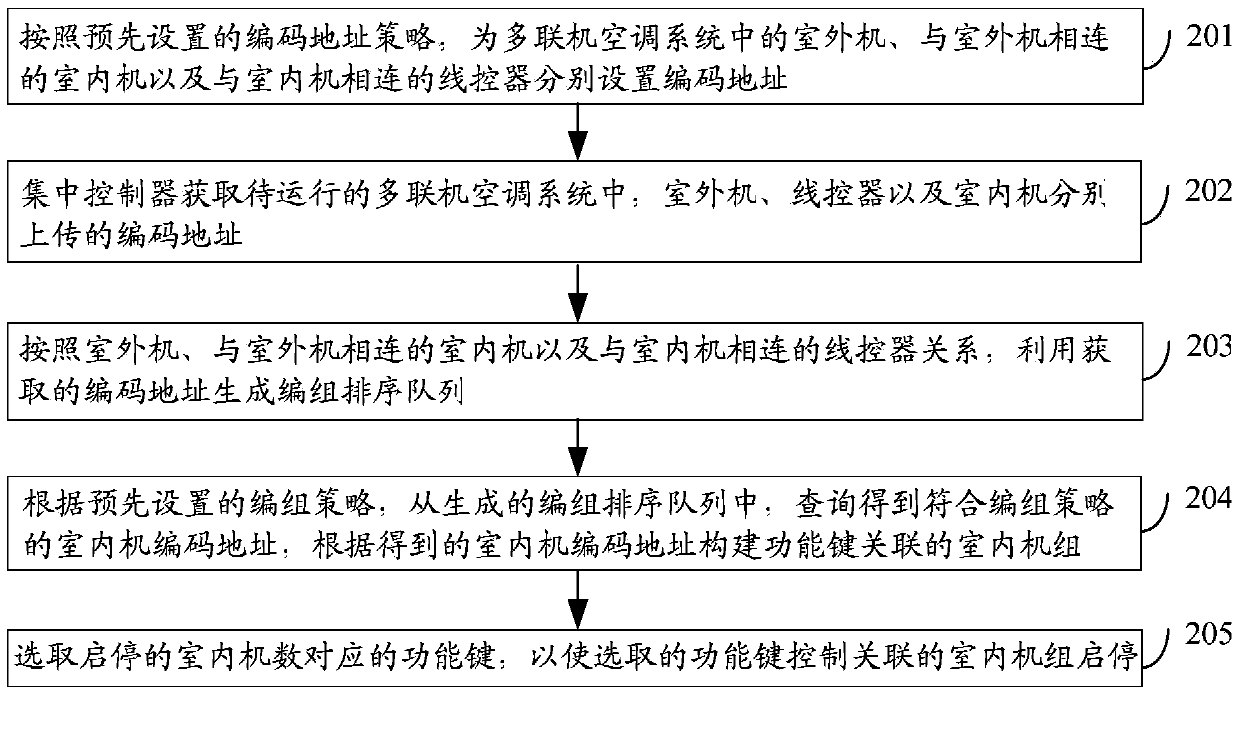

Air conditioner centralized control method based on indoor unit marshalling and multi-online-air-conditioner system

ActiveCN103615789AReduce settingsEasy to operateSpace heating and ventilation safety systemsLighting and heating apparatusReal-time computingBranch line

The invention discloses an air conditioner centralized control method based on indoor unit marshalling and a multi-online-air-conditioner system. The method includes the steps that a centralized controller acquires pre-configured coded addresses of outdoor units, pre-configured coded addresses of line controllers and pre-configured coded addresses of indoor units; the acquired coded addresses of the outdoor units are ranked according to the situation that the coded address of each outdoor unit corresponds to a ranking branch line, the acquired coded addresses of the indoor units which are connected with the outdoor units are ranked and then inserted into corresponding ranking branch lines according to the situation that the coded address of each indoor unit corresponds to a column of one ranking branch line, in each ranking branch line, the line controller coded addresses corresponding to the line controllers which are connected with the indoor units are identified, and then a marshalling ranking queue is generated; the indoor units corresponding to the indoor unit coded addresses, meeting a preset address marshalling policy, in the marshalling ranking queue serve as an indoor unit set, and then one or more indoor unit sets are acquired; corresponding function keys are selected for the indoor unit sets. By the application of the air conditioner centralized control method and the multi-online-air-conditioner system, procedures of indoor unit centralized control operation can be simplified, and air conditioner centralized control cost can be lowered.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Device for establishing noise in a motor vehicle

InactiveUS20050133300A1Combustion-air/fuel-air treatmentSilencing apparatusInterior spaceNoise generation

In a device for establishing noise in a motor vehicle with a housing, which is divided by at least one sound transmission device into at least two spaces, of which one space is in connection via an inlet line with a gas-carrying part of an internal combustion engine of the vehicle and the other space is acoustically coupled, by means of an outlet line, to an interior space of the vehicle and / or to the space surrounding the vehicle. The outlet line has at least one branch area, from which at least two branch lines extend to different locations in the interior space of the vehicle and / or the space surrounding the vehicle.

Owner:HOFMANN MARCUS +1

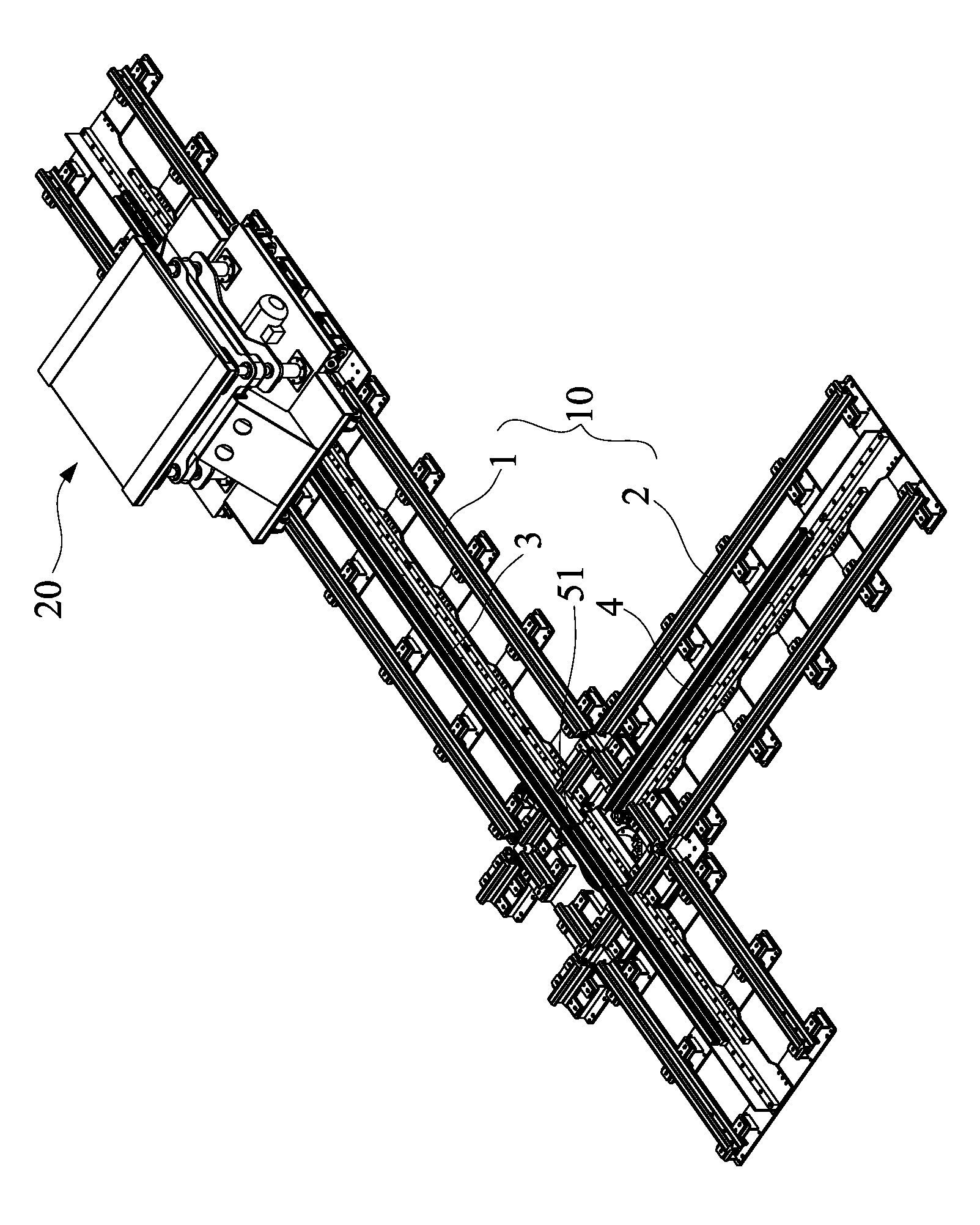

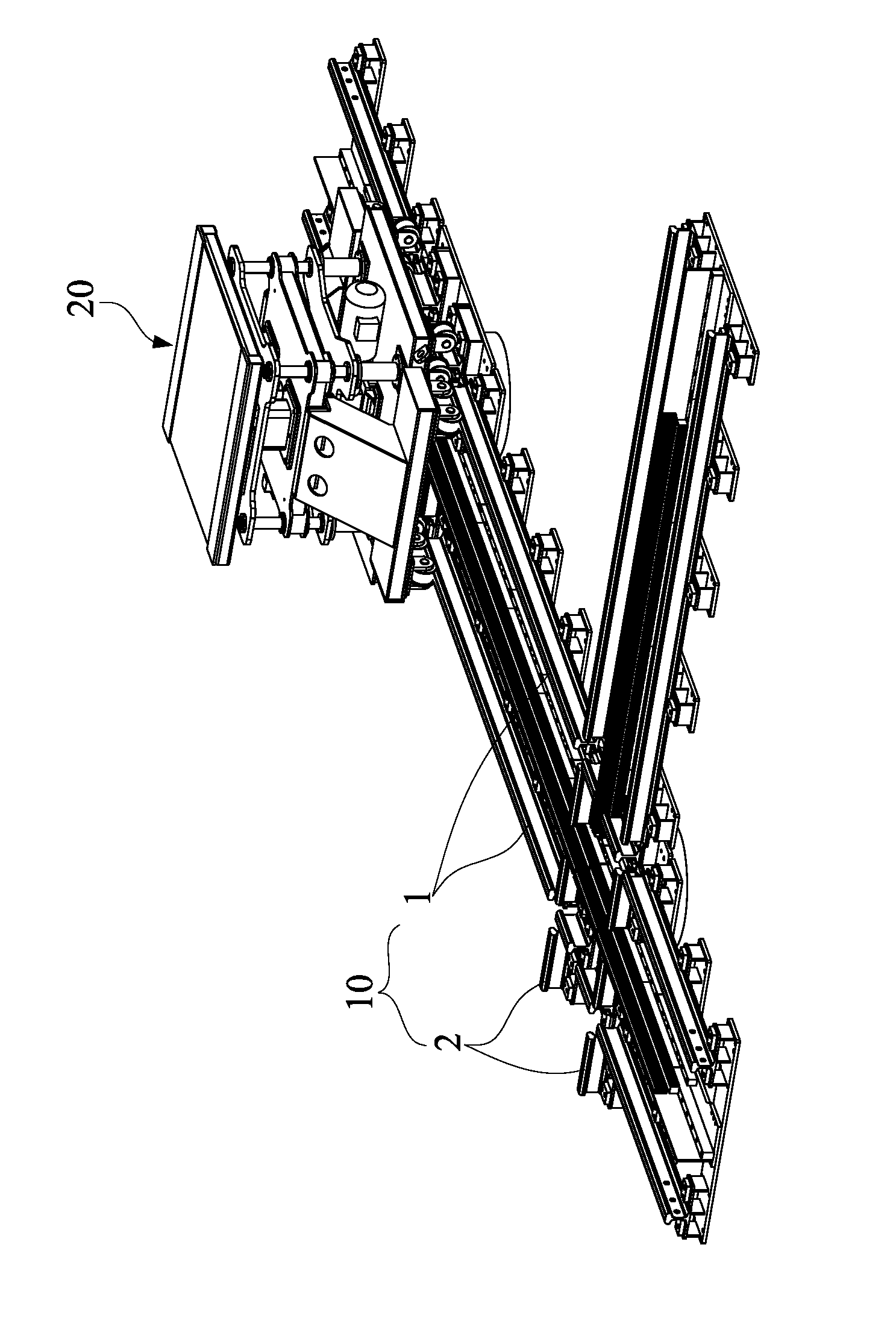

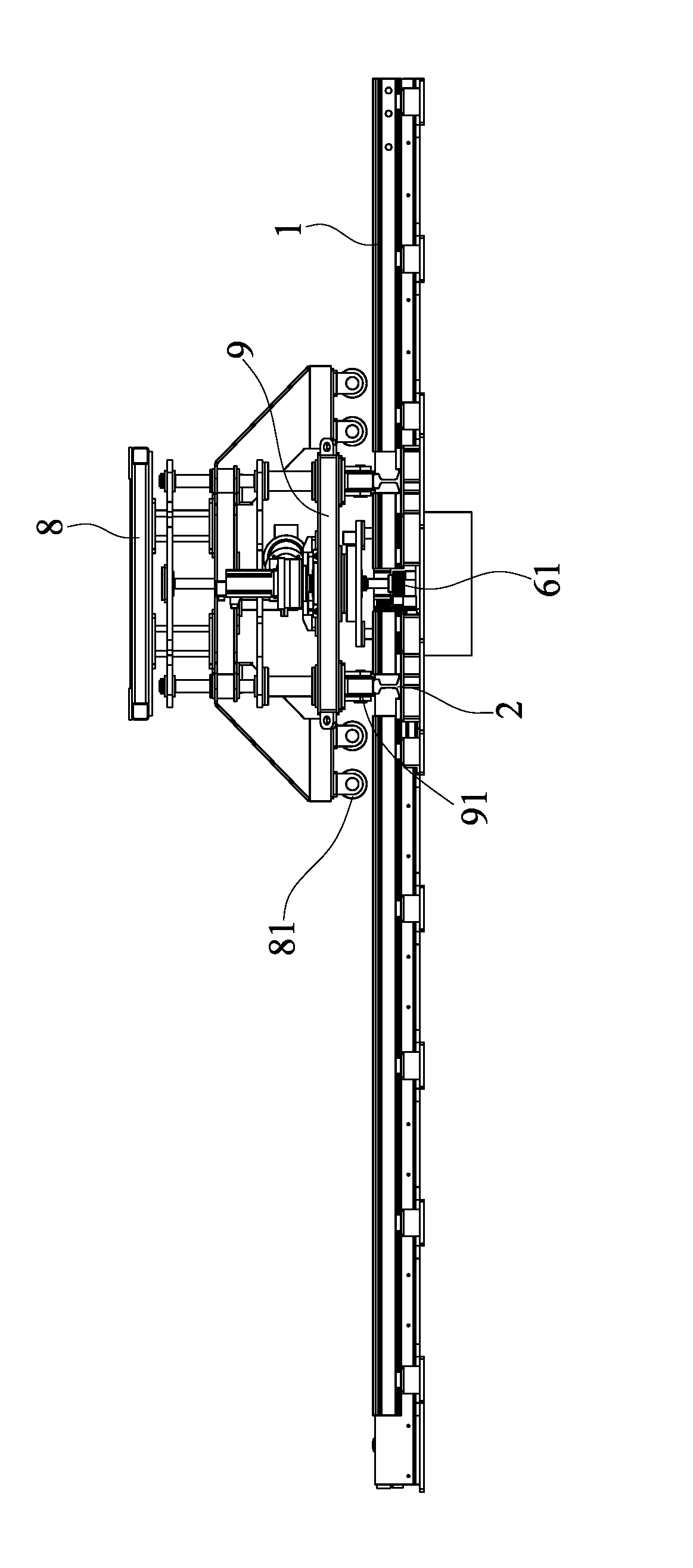

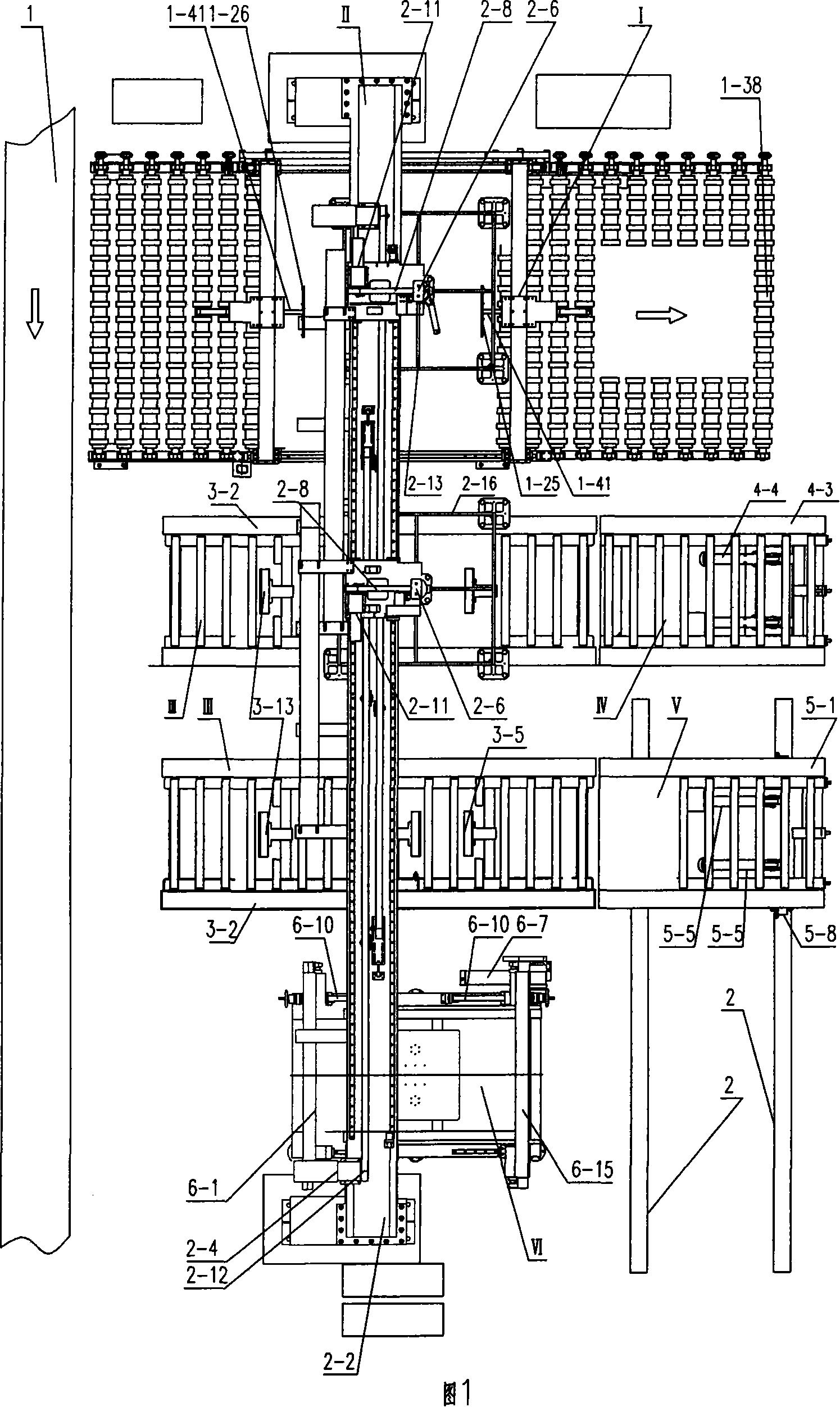

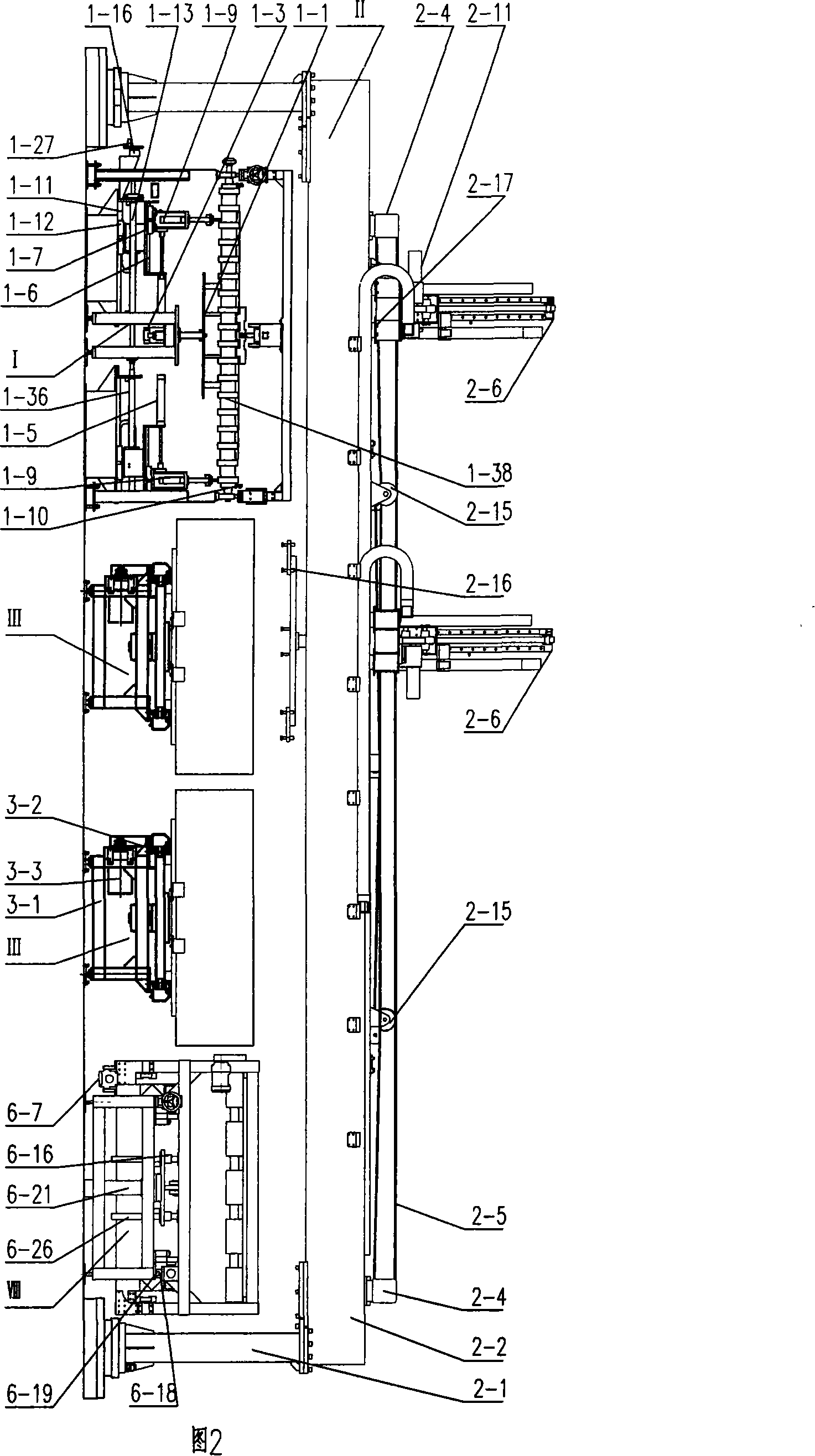

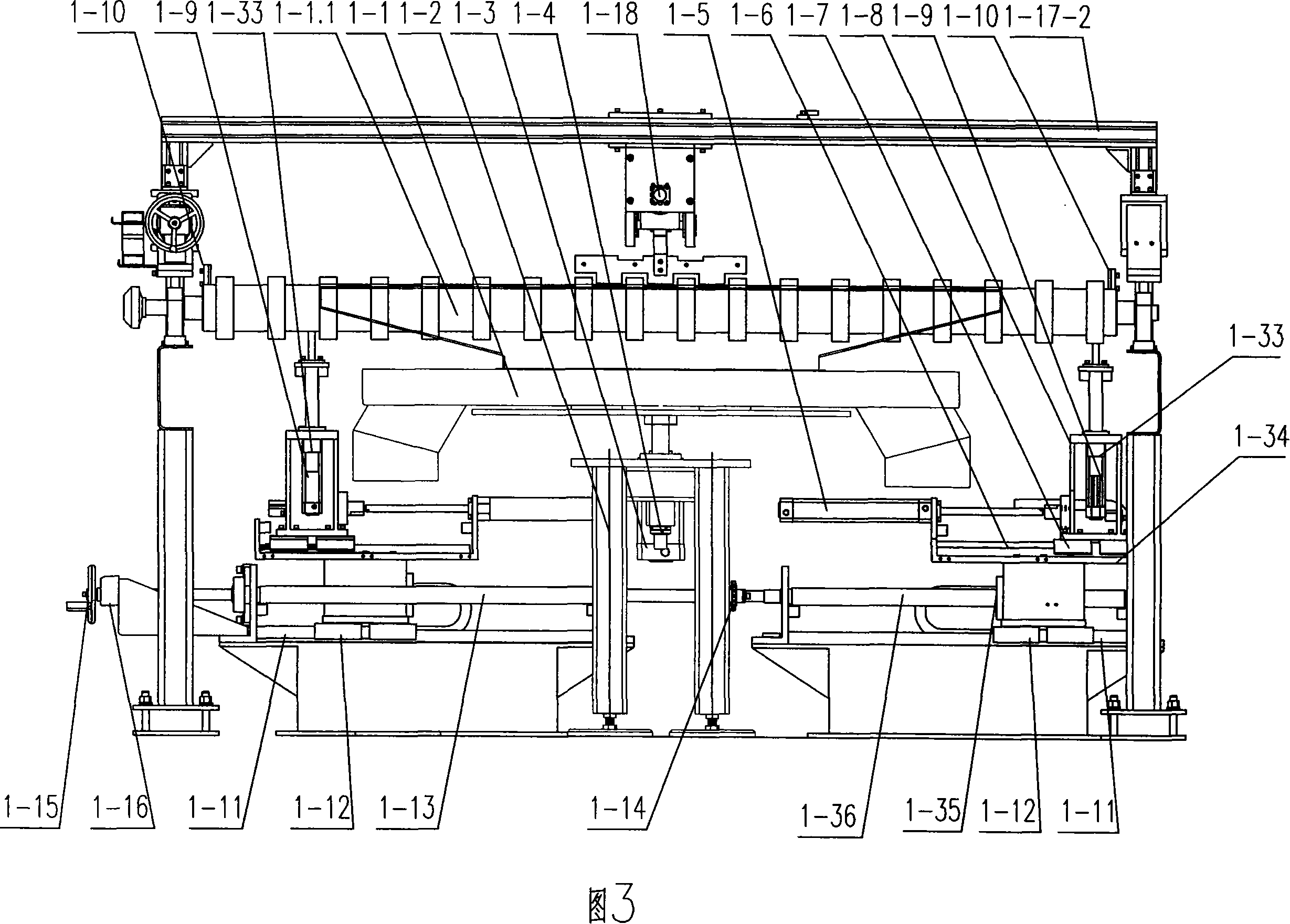

Heavy type free shuttling trolley with tracks

ActiveCN102849423ARealize clamping and conveyingImprove adaptabilityMechanical conveyorsVehicle frameButt joint

The invention discloses a heavy type free shuttling trolley with tracks. The heavy type free shuttling trolley comprises a main track, a branch track, a main line rack, a branch line rack, a movable rack, a traveling driving mechanism, a reversing lifting mechanism, a switch-over driving mechanism, a main line trolley support, a branch line trolley support, a main line traveling wheel, a branch line traveling wheel and a driving gear. The main track and the branch track are perpendicular with each other in crossing mode, the main line rack and the branch line rack are arranged on track bases of the main track and the branch track respectively, a movable track and the switch-over driving mechanism are arranged at a crossing node position of the main track and the branch track, and the movable rack is driven by the switch-over driving mechanism and is in butt joint with the main line rack or the branch line rack. The main line trolley support and the branch line trolley support are stacked together to form the trolley, a main line traveling wheel and a branch line traveling wheel are arranged on the lower portion respectively, and the reversing lifting mechanism is arranged between the main line trolley support and the branch line trolley support and used for conducting relative lifting so that the main line traveling wheel is matched with the main track or the branch line traveling wheel is matched with the branch track. The traveling driving mechanism is arranged on the trolley so that the driving gear is matched with the main line rack, the branch line rack or the movable rack. The heavy type free shuttling trolley is suitable for material conveying, economical, reliable and high in efficiency.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

Automatic sheet-fetching system of ultra-thin glass

ActiveCN101139015ATimely crawlSolve the key technical problems of offlineRegistering devicesCharge manipulationEngineeringThin glass

The present invention discloses a ultra-thin glass automatic slicing system and comprises a glass transmission branch, a clean transportation robot and a packing box fixed turnover unit as well as a glass centering positioning unit, a packing box transmission positioning unit, a packing box moving turnover unit and a septum paper supplying unit. A glass transmission main line is vertical to the glass transmission branch and the glass centering positioning unit is arranged above and below the glass transmission branch; two packing box transmission positioning units are arranged in parallel with the glass transmission branch, wherein, the terminal of the packing box transmission positioning unit arranged close to the glass transmission branch is provided with the packing box fixed turnover unit; the terminal of the packing box transmission positioning unit far away from the glass transmission branch is provided with the packing box moving turnover unit; the septum paper supplying unit is arranged in parallel to the packing box transmission positioning unit; the present invention can meet the quality standard of glass in electronic industry and packing requirement of ultra-thin glass storage and transmission at the same time, and improve yield and packing quality of ultra-thin float glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Array substrate, liquid crystal display panel and liquid crystal display device

ActiveCN105096899AConvenient charging caseReduce power consumptionStatic indicating devicesSolid-state devicesLiquid-crystal displayData signal

The invention discloses an array substrate, a liquid crystal display panel and a liquid crystal display device. The array substrate comprises multiple scanning lines; and multiple data lines which are matched with the scanning lines to form multiple areas. Each area is internally provided with a pixel. The data lines are formed by the branch lines of multiple data signal lines. Two branch lines are formed by one data signal line so as to drive two pixels of the same line on the array substrate. Odd number of pixels are arranged between the two pixels, and one line of the two adjacent lines of pixels are coupled with the data lines of the left side and the other line of pixels are coupled with the data lines of the right side so as to realize pixel point inversion in inversion of the data line columns. Power consumption of the display panel can be reduced, the pixel charging condition can be improved and display quality of the panel can be enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

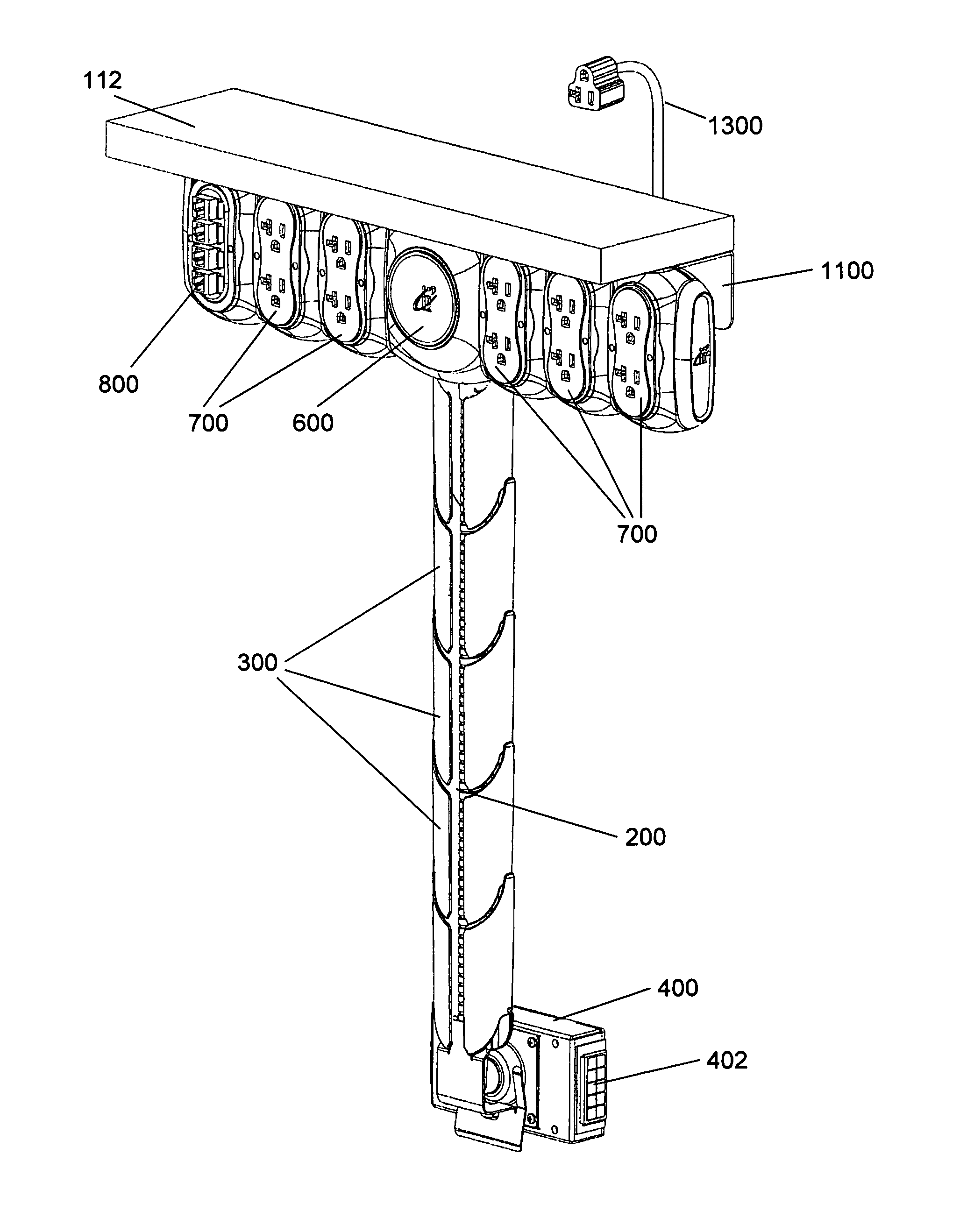

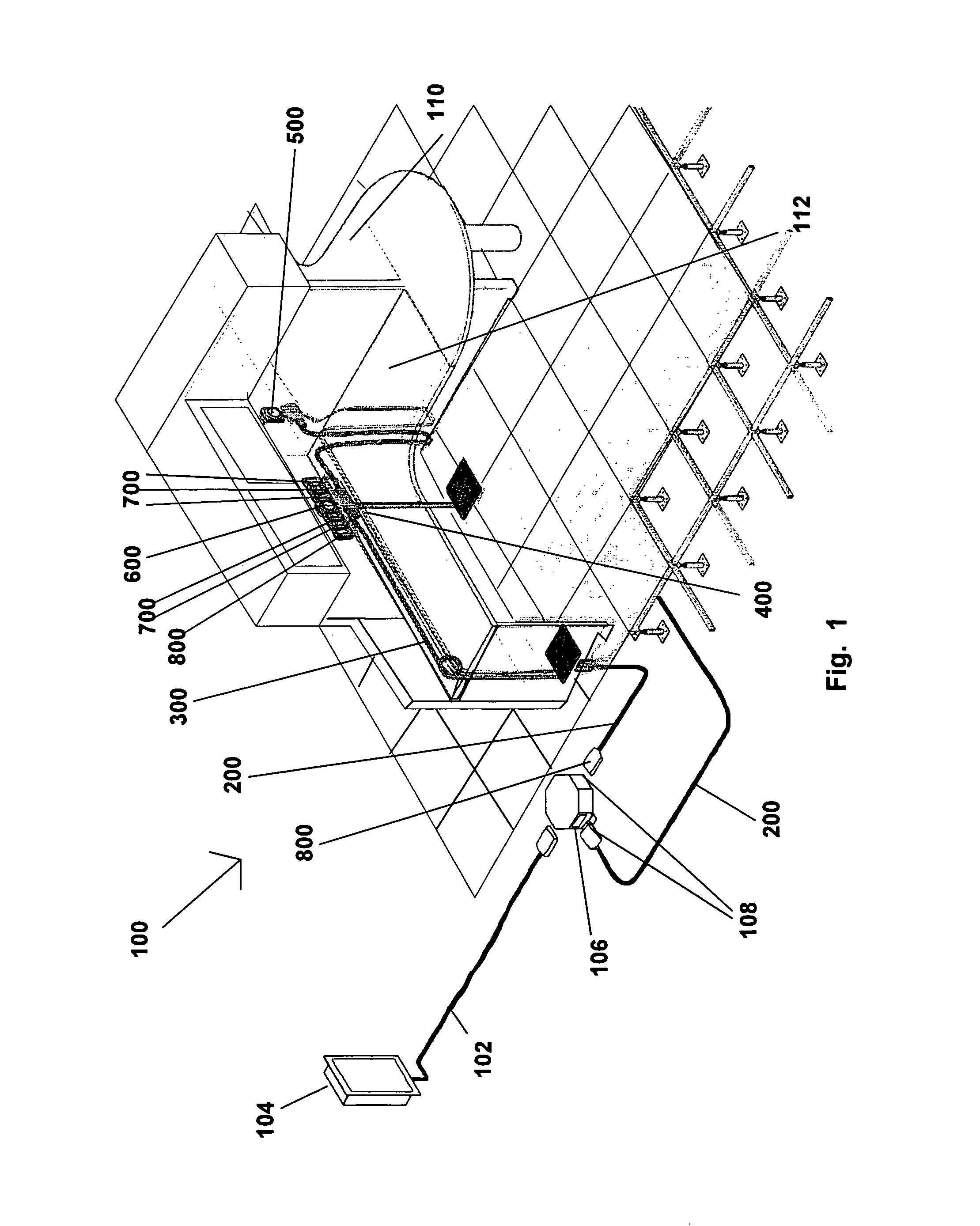

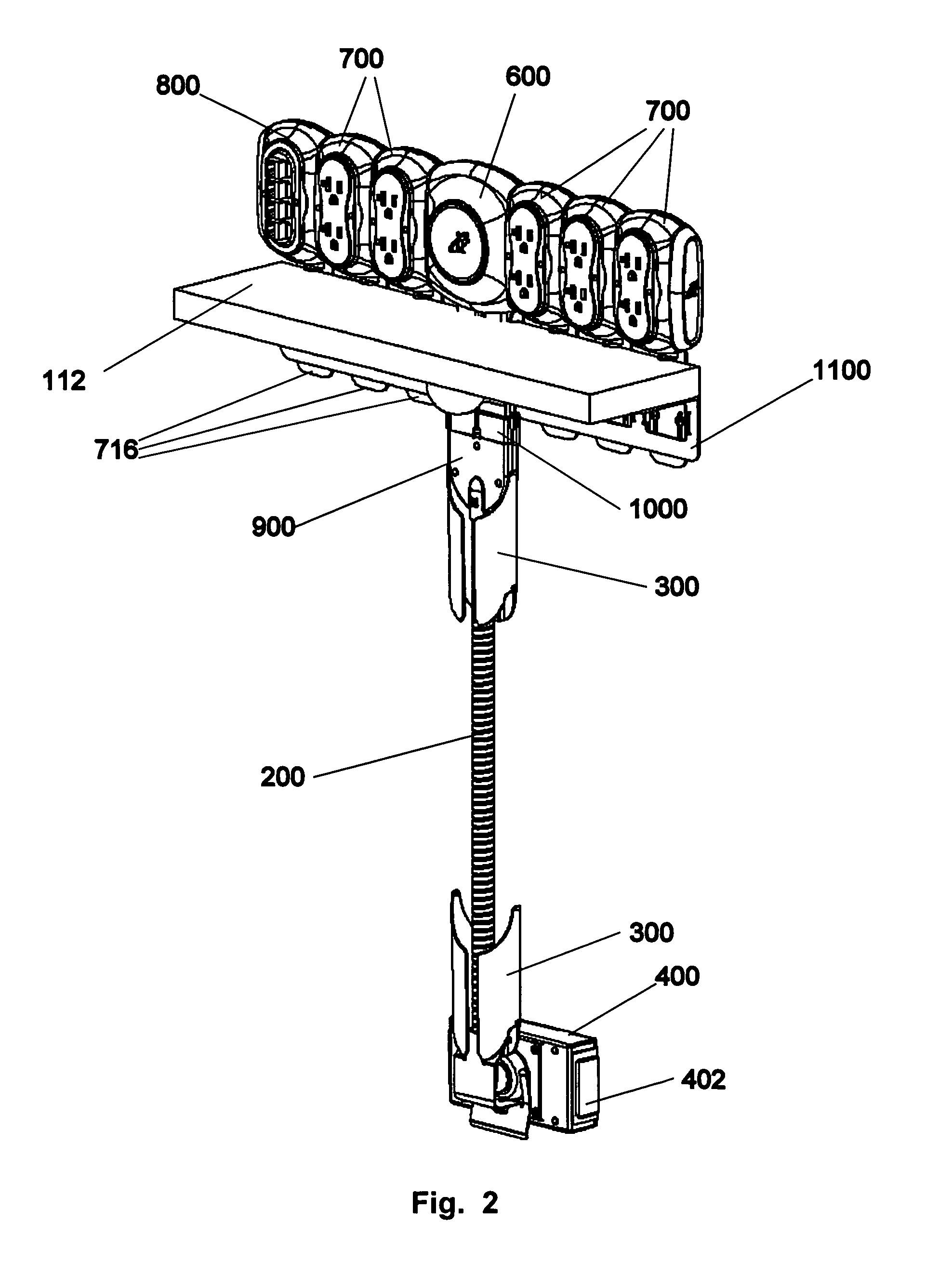

Modular utility system

ActiveUS7893567B1Bus-bar/wiring layoutsElectric signal transmission systemsElectrical conductorLow voltage

A modular office wiring system comprising a power distribution module, at least one data hub, at least one ten-conductor high-voltage cable, a cable carrier, connectors, at least one power core, at least one high-voltage power module, and at least one low-voltage data module. The system may additionally include one or more splitters that provide branch power lines, with additional power cores positioned on the branch lines and additional high-voltage power modules and low-voltage data modules connected to the additional power cores. In addition, a method is provided for installing and uninstalling the modules to each other.

Owner:COMM INTEGRATORS

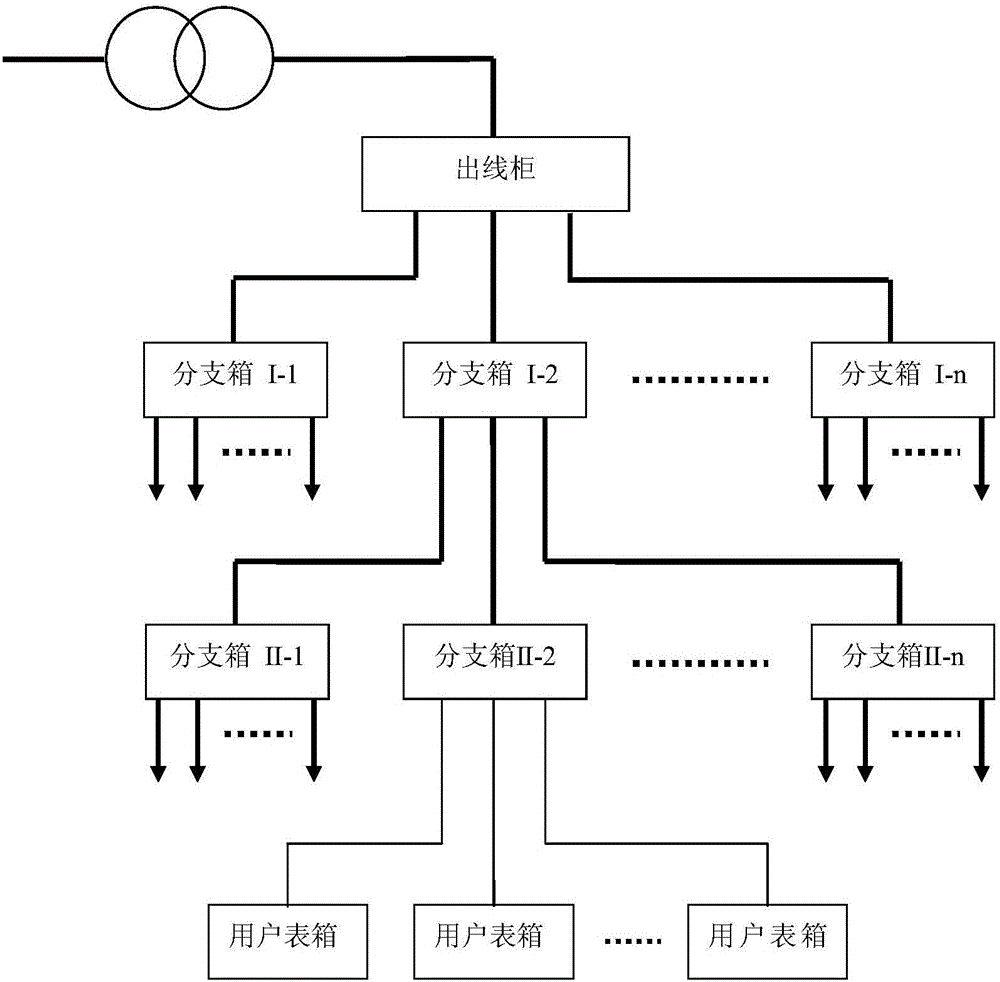

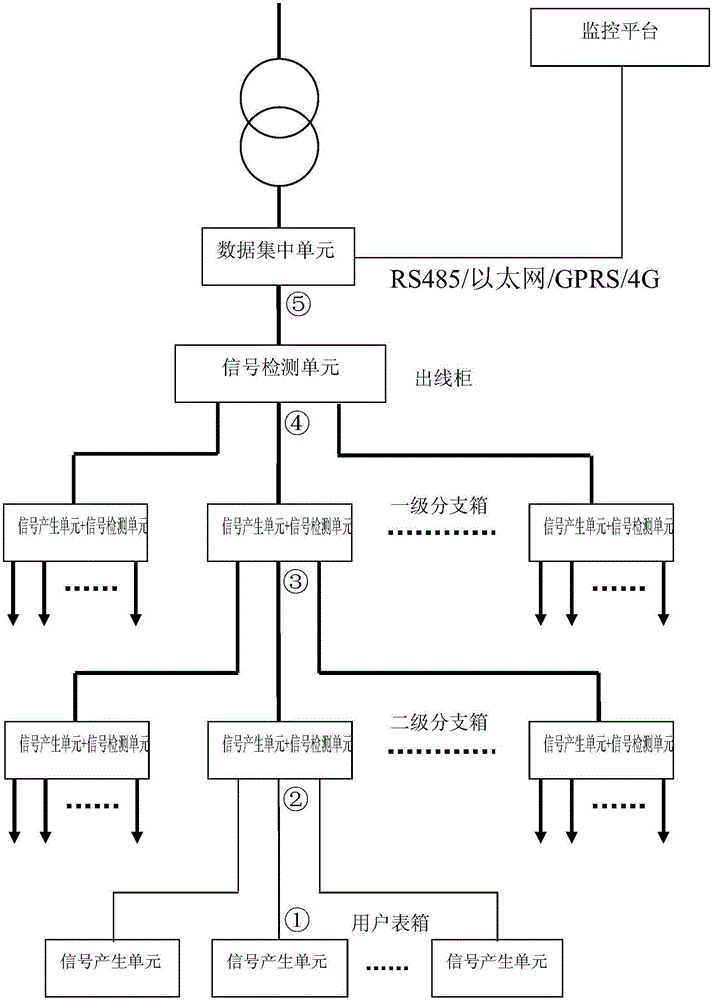

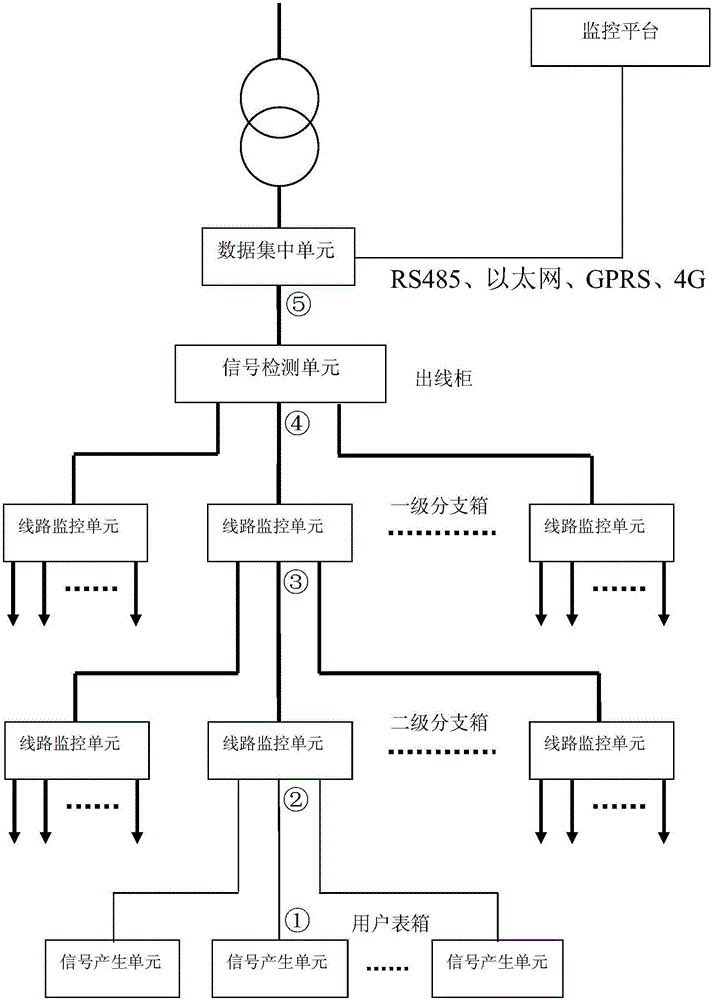

Low-voltage transformer area physical topology online generating and real-time monitoring method and system

ActiveCN106026408ATimely detection of topology changesGuaranteed uptimeCircuit arrangementsSustainable buildingsElectricityDistribution transformer

The invention relates to the technical field of low-voltage distribution network line detection, in particular to a low-voltage transformer area physical topology online generating and real-time monitoring method. The method includes the steps that signal generating units, signal detecting units and a data transmitting unit are reasonably deployed on a transformer area line, and the data transmitting unit communicates with an electricity power monitoring platform; after a topology online generating instruction is sent, all branch line physical topologies are generated one by one and are combined into an integral low-voltage transformer area physical topology to be stored; the generated physical topology is compared with that stored before, and if the generated physical topology is different from that stored before, the change position is marked. The invention further provides a low-voltage transformer area physical topology online generating and real-time monitoring system. The signal generating units are arranged on equipment at the tail end and the middle of the transformer area line, the signal detecting units are arranged on equipment in the middle and the head end of the transformer area line, and the data transmitting unit is arranged at the low-voltage side of a distribution transformer. The transformer area line physical topology can be generated on line and monitored in real time, topology changes of the line are found in time, and reliable operation of an electric system is ensured.

Owner:SHANDONG SENTER ELECTRONICS

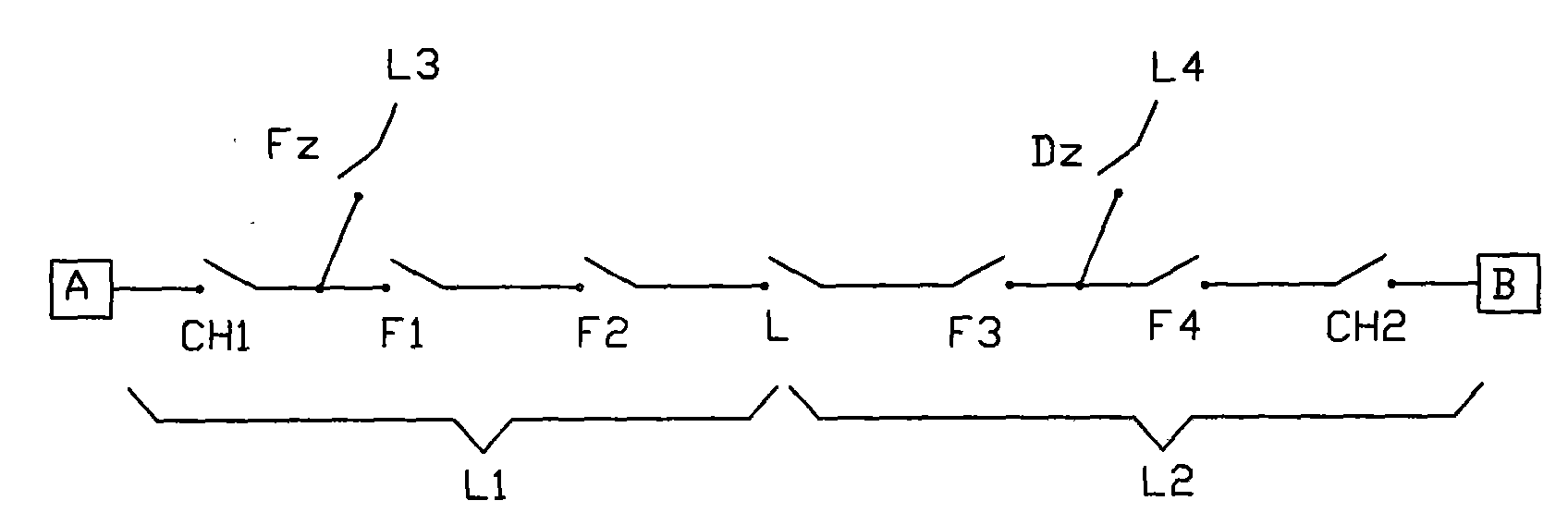

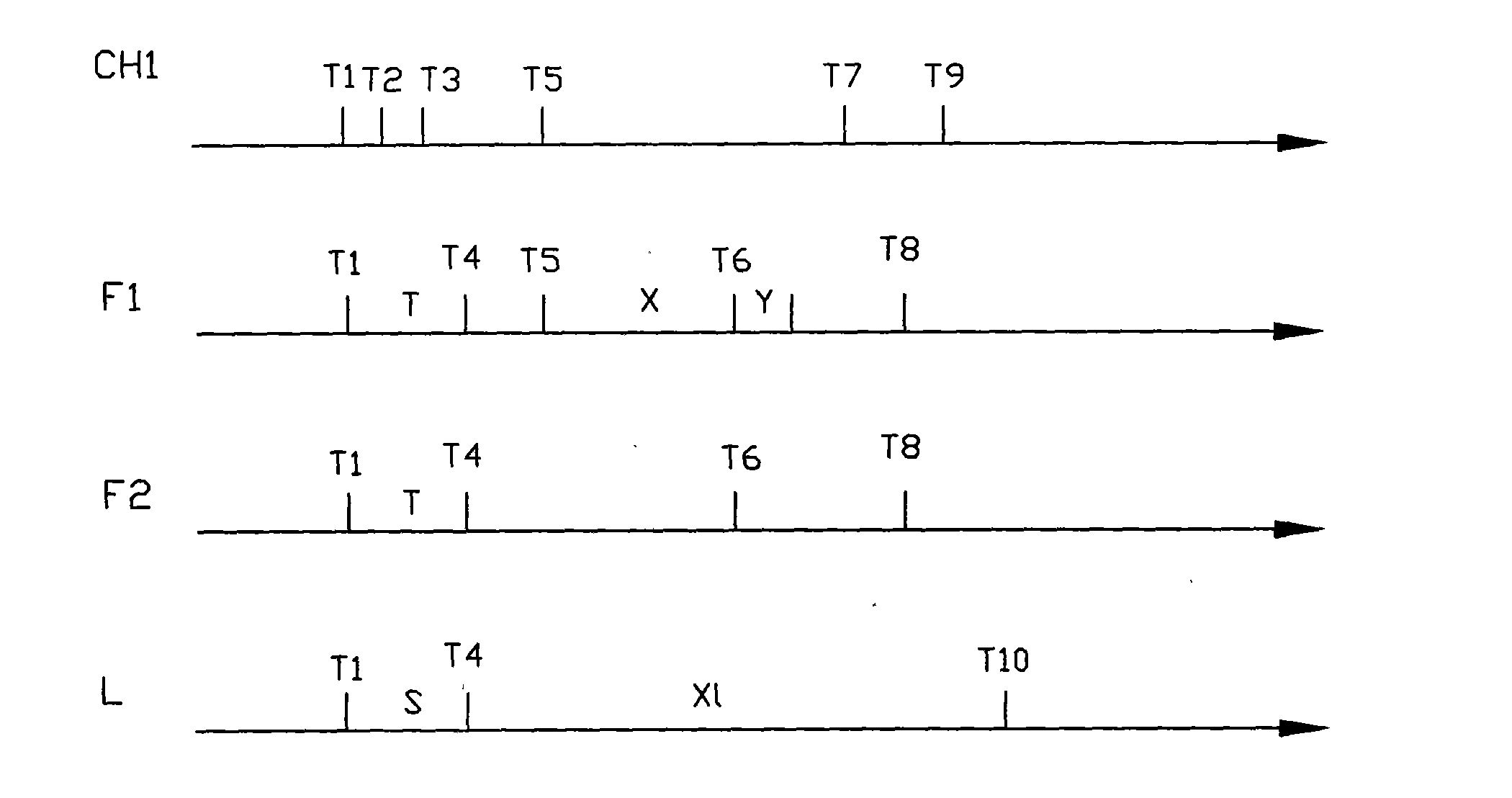

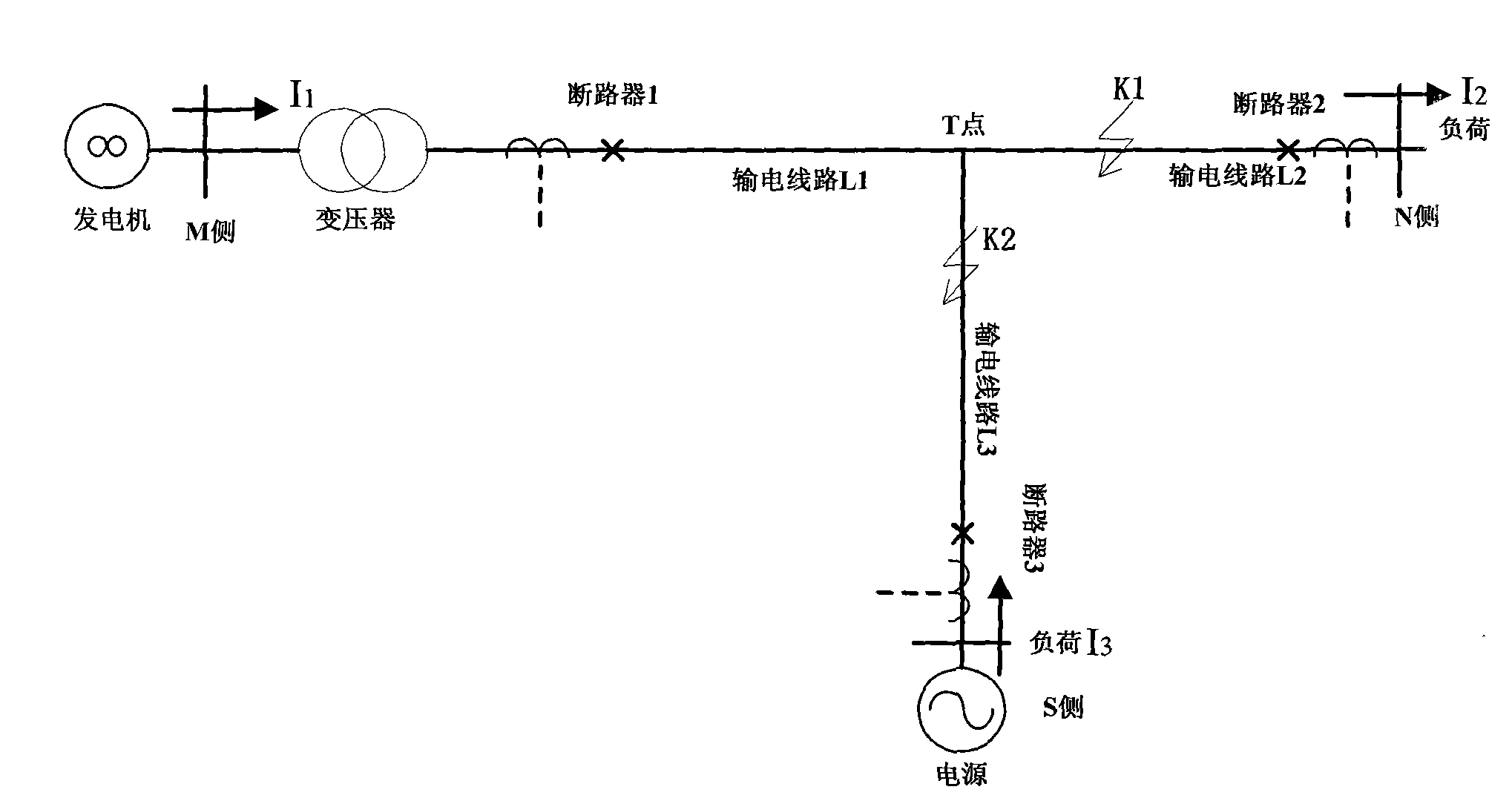

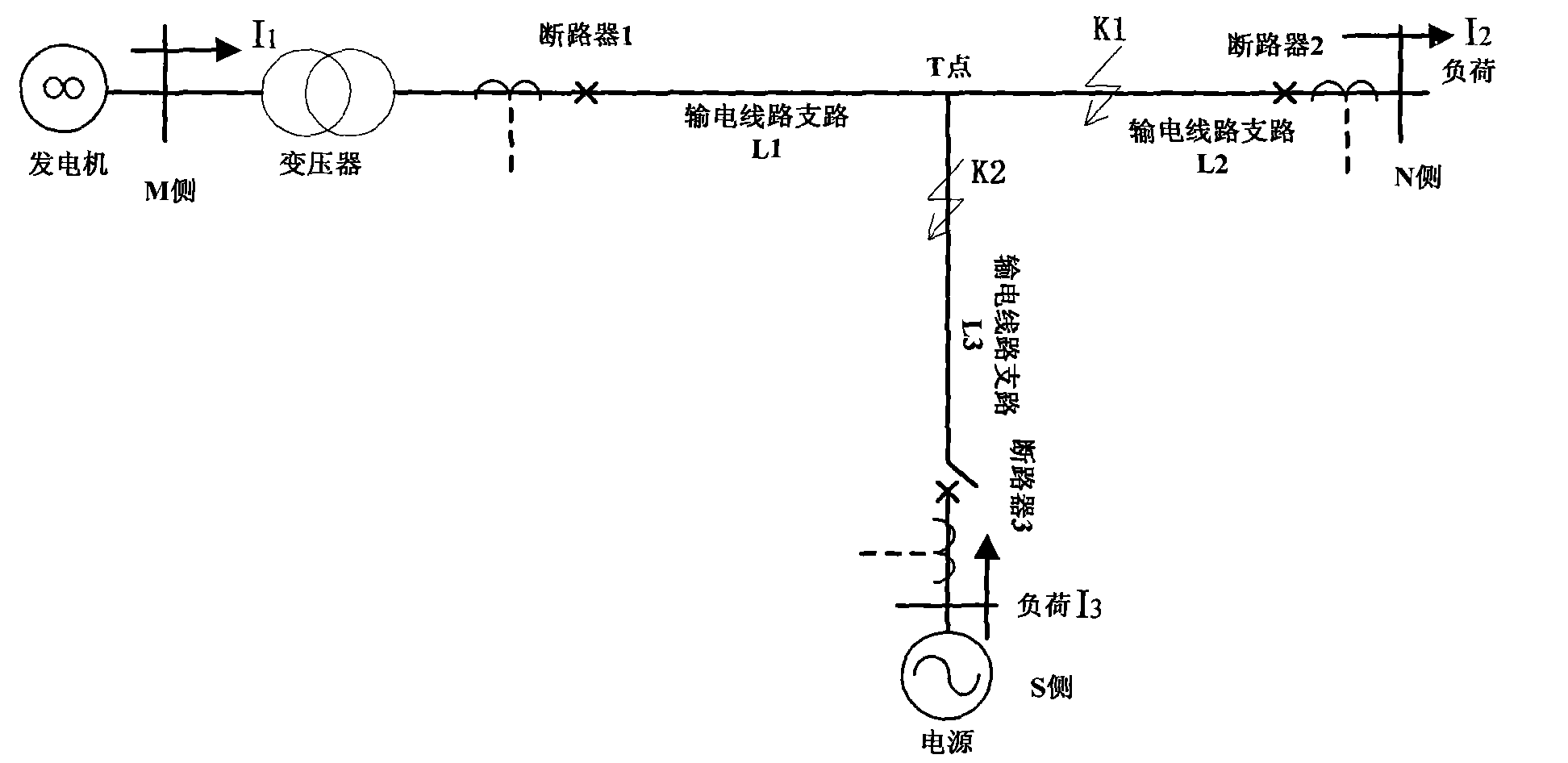

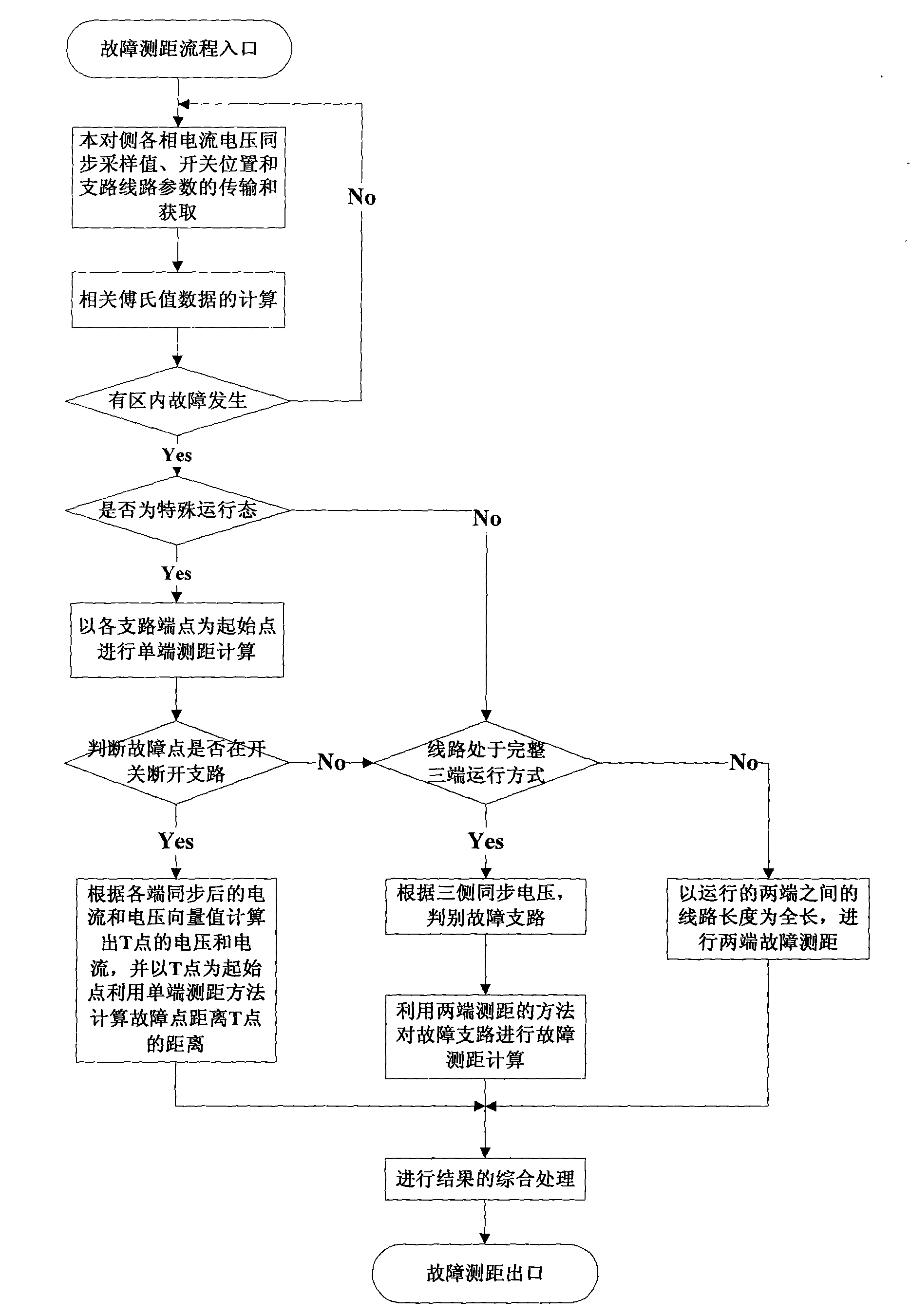

Fault localization method suitable for three-terminal T connection electric transmission line

ActiveCN101666847AMeet fault location requirementsAccurate fault locationFault locationInformation technology support systemCable fault locationReliability engineering

The invention discloses a fault localization method suitable for a three-terminal T connection electric transmission line, comprising the following steps: firstly, judging the running state of the three-terminal electric transmission line: if the line is in a three-terminal running mode, firstly identifying a fault branch line, and calculating the fault distance according to the electric quantityof both ends of a T connection point and the endpoint of the fault branch line; if the line is in a two-terminal running mode or one side branch line is in a three-terminal running mode in a hot standby state, firstly determining if a fault point is at a switch cut-off branch line or not, if so, adopting a single-terminal localization method to calculate the distance from the T connection point tothe fault point, thereby obtaining the fault distance from the endpoint of the branch line to the fault point; but if the fault point is not at the switch cut-off branch line, respectively carrying out fault localization calculation under the two-terminal running mode or the three-terminal running mode. The invention provides a fault localization method before / after converting the running mode ofthe three-terminal electric transmission line and a fault localization method when the line is in the two-terminal running mode or one side branch line is in the three-terminal running mode under thehot standby condition.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

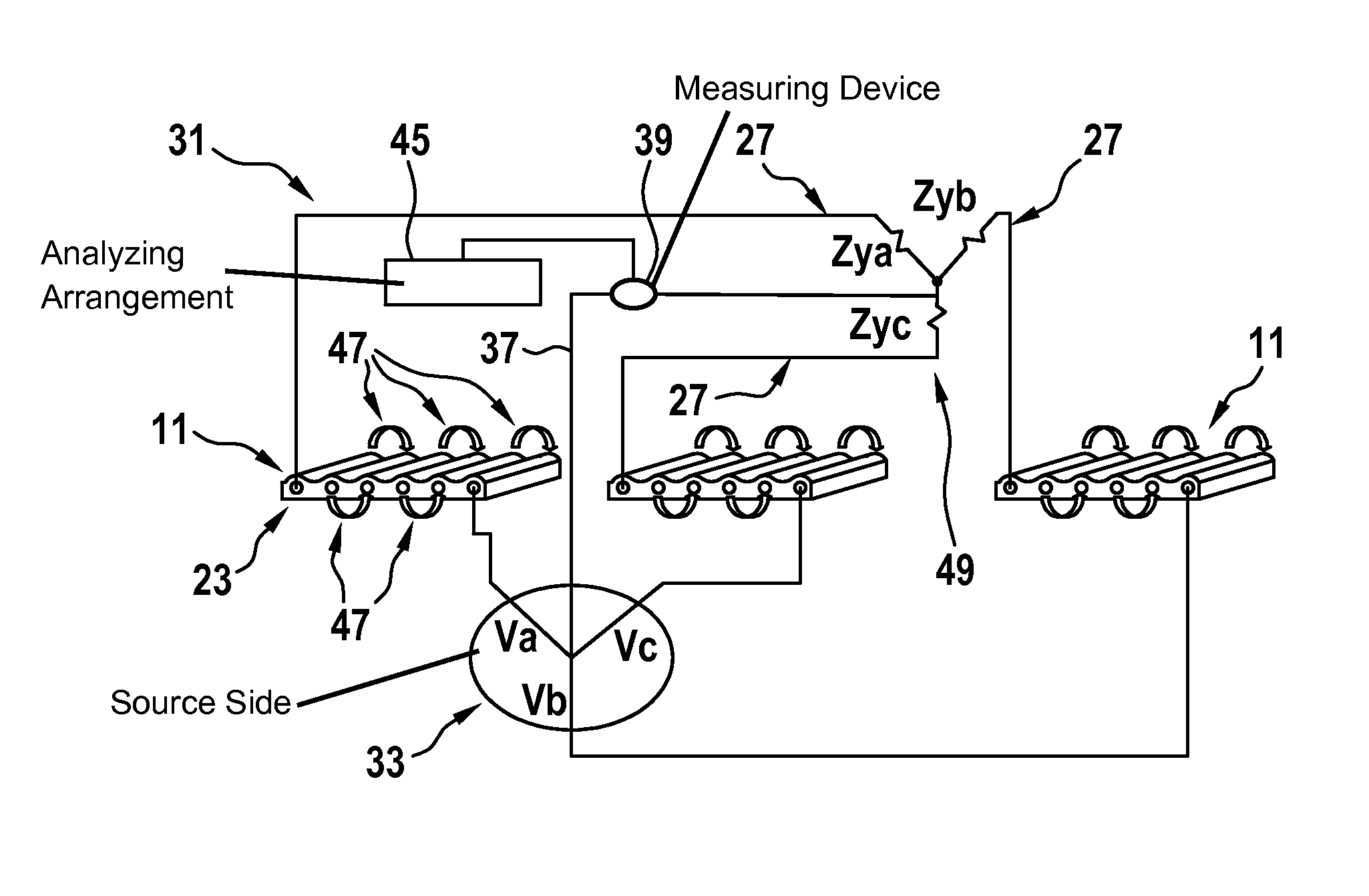

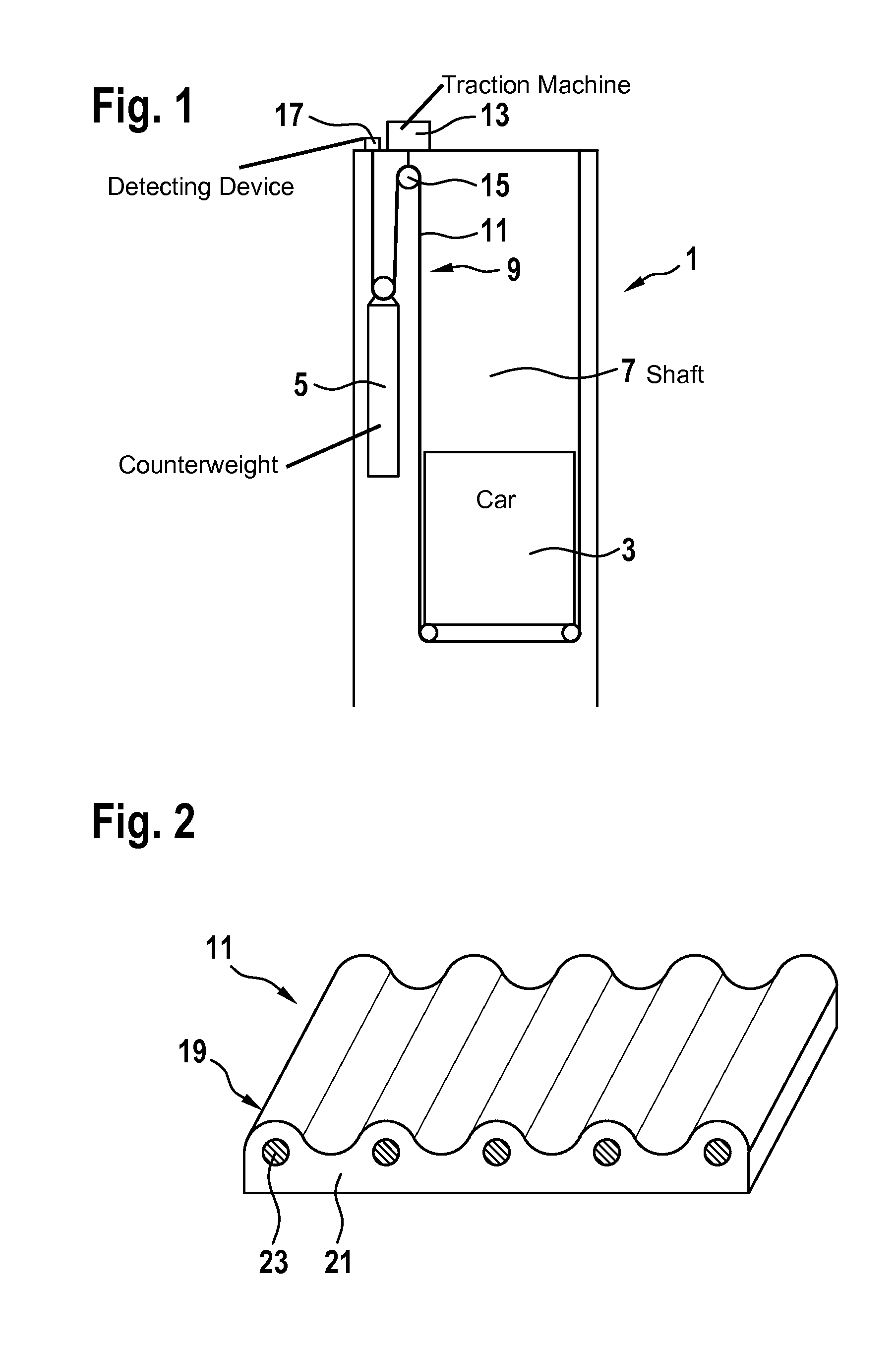

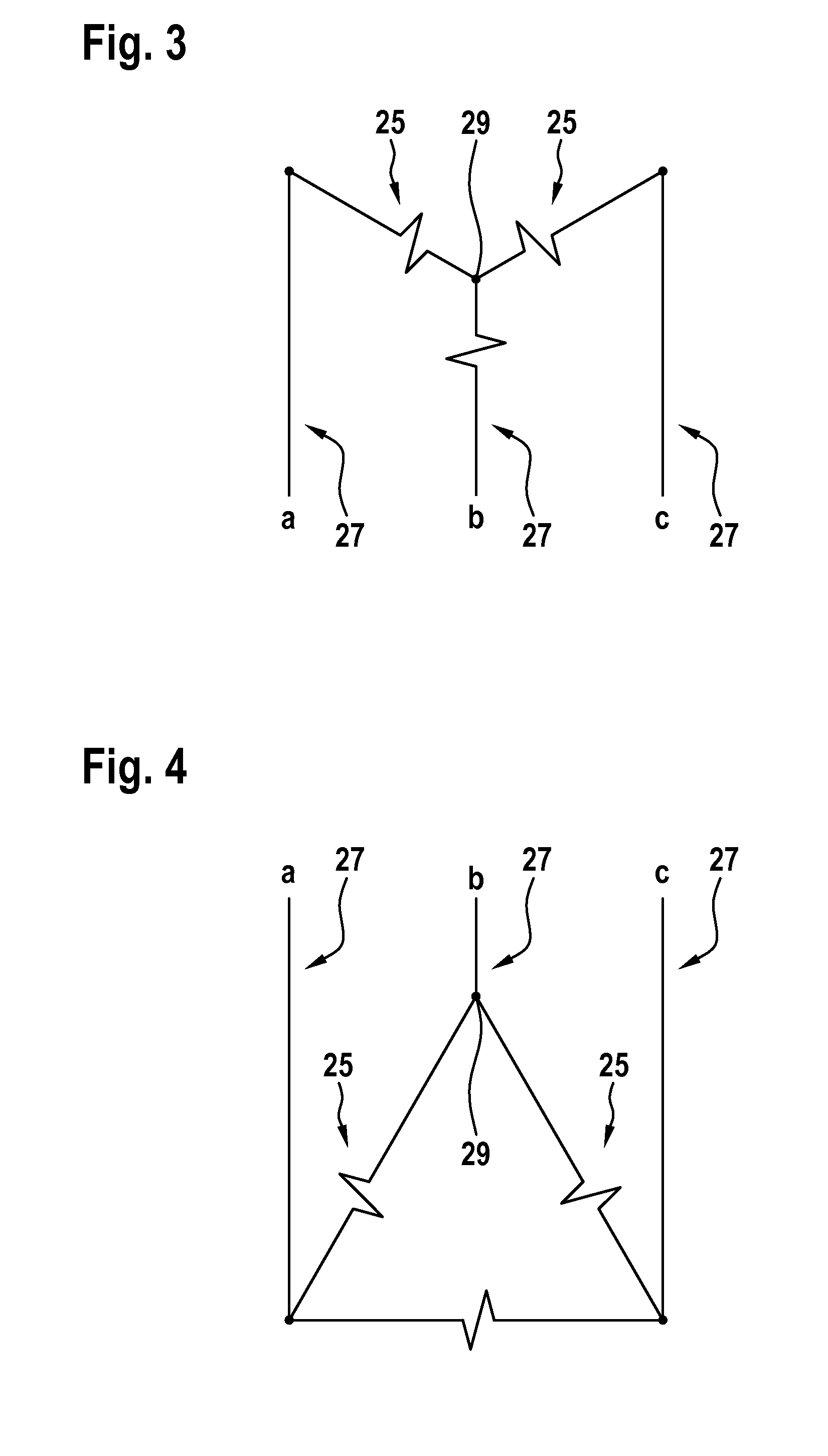

Method and device for detecting a deterioration state of a load bearing capacity in a suspension member arrangement for an elevator

ActiveUS20170029249A1Easy to measureEqually distributedFault location by conductor typesTesting electric installations on transportElectricityPeak current

A deterioration state of load bearing capacity in an elevator suspension member having a plurality of electrically conductive cords is detected by: providing a multi-phase alternating current circuitry including electrically conductive legs; applying at least one phase of a multi-phase alternating current to at least one of the cords electrically connected to one of the legs; applying at least another phase of the current to at least another cord and at least one resistor electrically connected to at least another leg; measuring an electric indicator current being at least one of a net sum of all phases of the current and an electric bypass current through a neutral wire being connected in parallel to the circuitry, wherein a peak current in each phase is shifted by a phase angle with respect to a peak current in another phase; and determining the deterioration state based on the measured indicator electric current.

Owner:INVENTIO AG

Heat exchanging fluid return manifold for a liquid cooling system

InactiveUS20080066889A1Safety devices for heat exchange apparatusSemiconductor/solid-state device detailsNuclear engineeringLiquid cooling system

The present invention is a two-phase liquid cooling system that cools a plurality of electronic components connected in parallel. A pump delivers a cooling fluid, as a liquid, to a supply manifold wherein it splits into distinct branch lines. Preferably, the branch lines feed coolant to individual spray modules. The liquid coolant removes heat from the components to be cooled through evaporation. The resulting liquid and vapor mixture exits the spray modules via return branches. Each individual return branch feeds into a return manifold wherein the manifold is sized sufficiently for the separation of liquid and vapor under the influences of gravity. In addition, a heat exchanger is located within the return manifold and provides for the condensation of vapor. The heat exchanger may also provide liquid subcooling.

Owner:ISOTHERMAL SYST RES

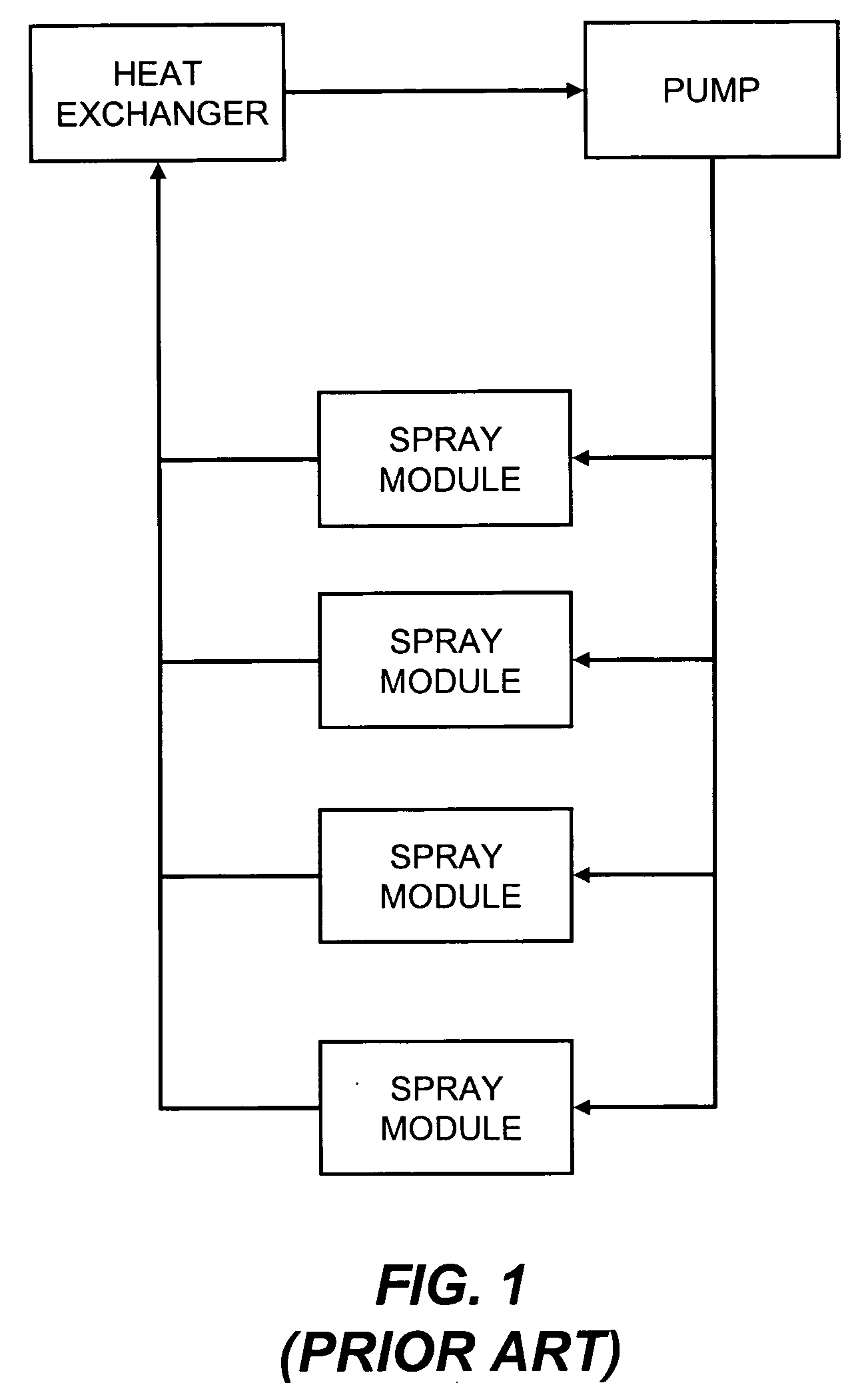

Low momentum loss fluid manifold system

InactiveUS6958911B2Reduce momentumLoss of momentumDomestic cooling apparatusPower cablesAcute angleComputer module

The present invention is a two-phase liquid cooling system that cools a plurality of electronic components connected in parallel. A pump delivers a cooling fluid, as a liquid, to a supply manifold wherein it splits into distinct branch lines. Preferably, the branch lines feed coolant to individual spray modules. The liquid coolant removes heat from the components to be cooled. The resulting liquid and vapor mixture exit the spray modules via a plurality of return branches. Each individual return branch feeds into a return manifold at an acute angle. The angular transitions between the return branches and the return manifold provides low manifold losses and a more efficient system.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com