Heavy type free shuttling trolley with tracks

A small car, free technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem of the mother car occupying the main track, unable to face the complex logistics situation, etc., to achieve large deadweight tonnage, economical and reliable, reliable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

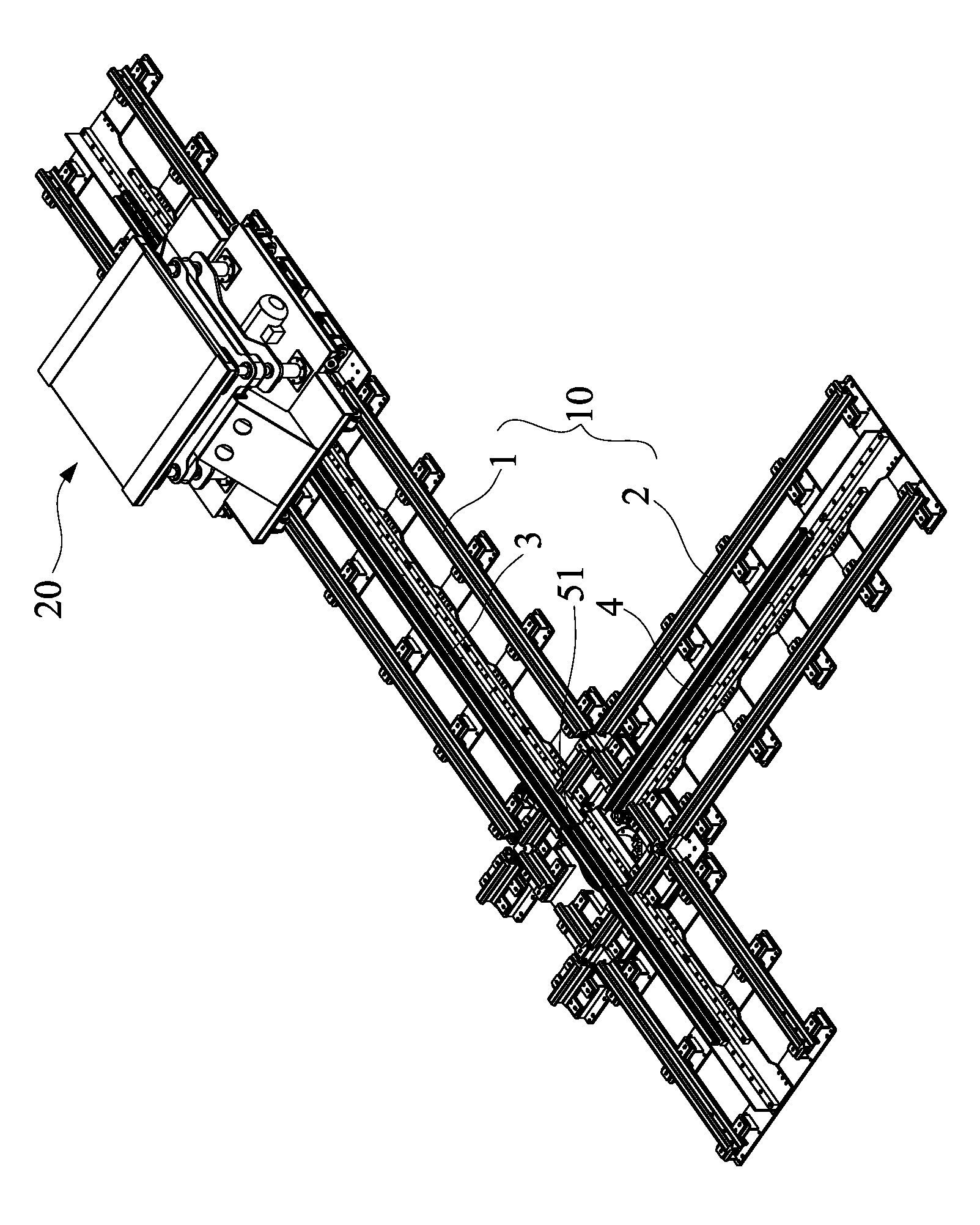

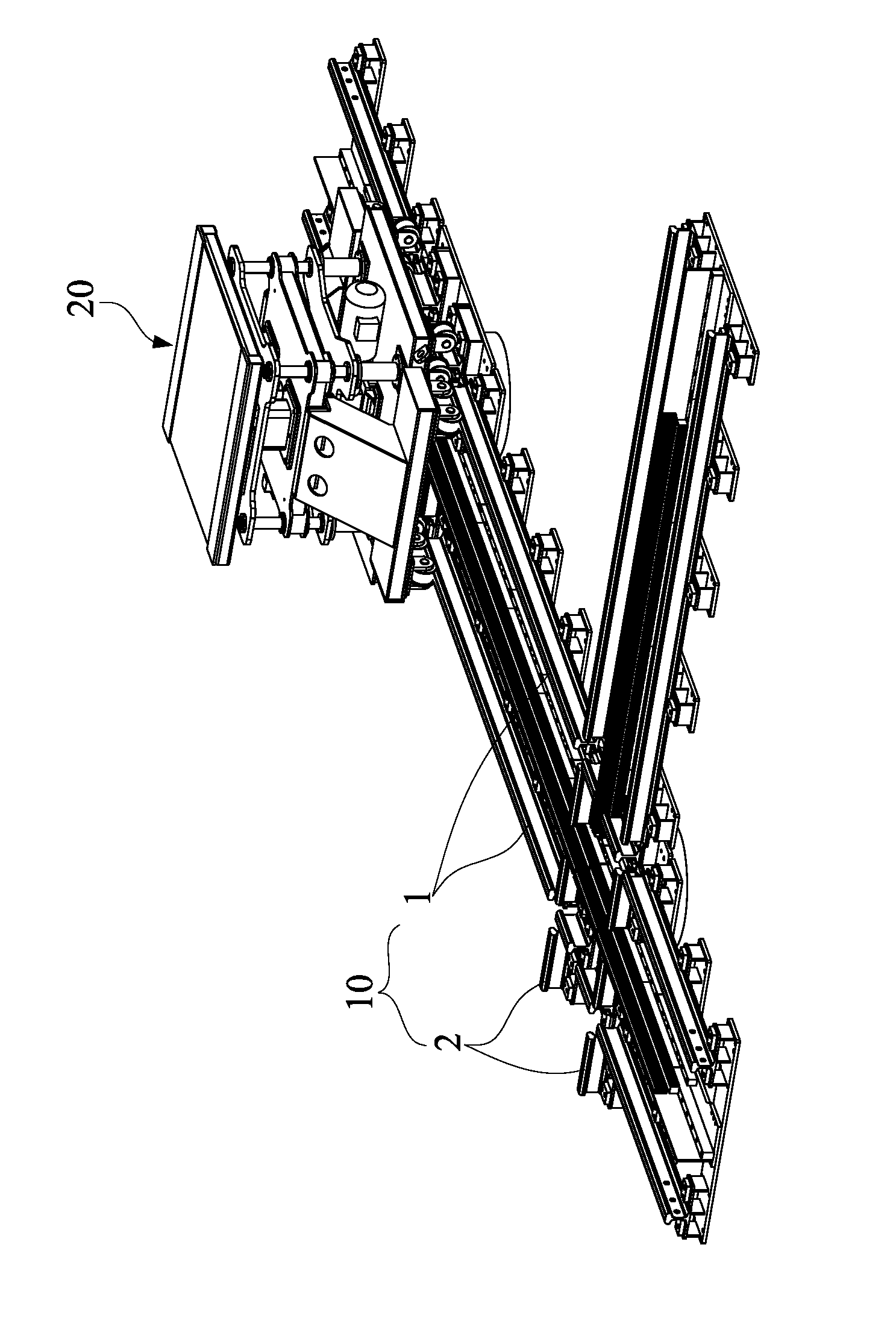

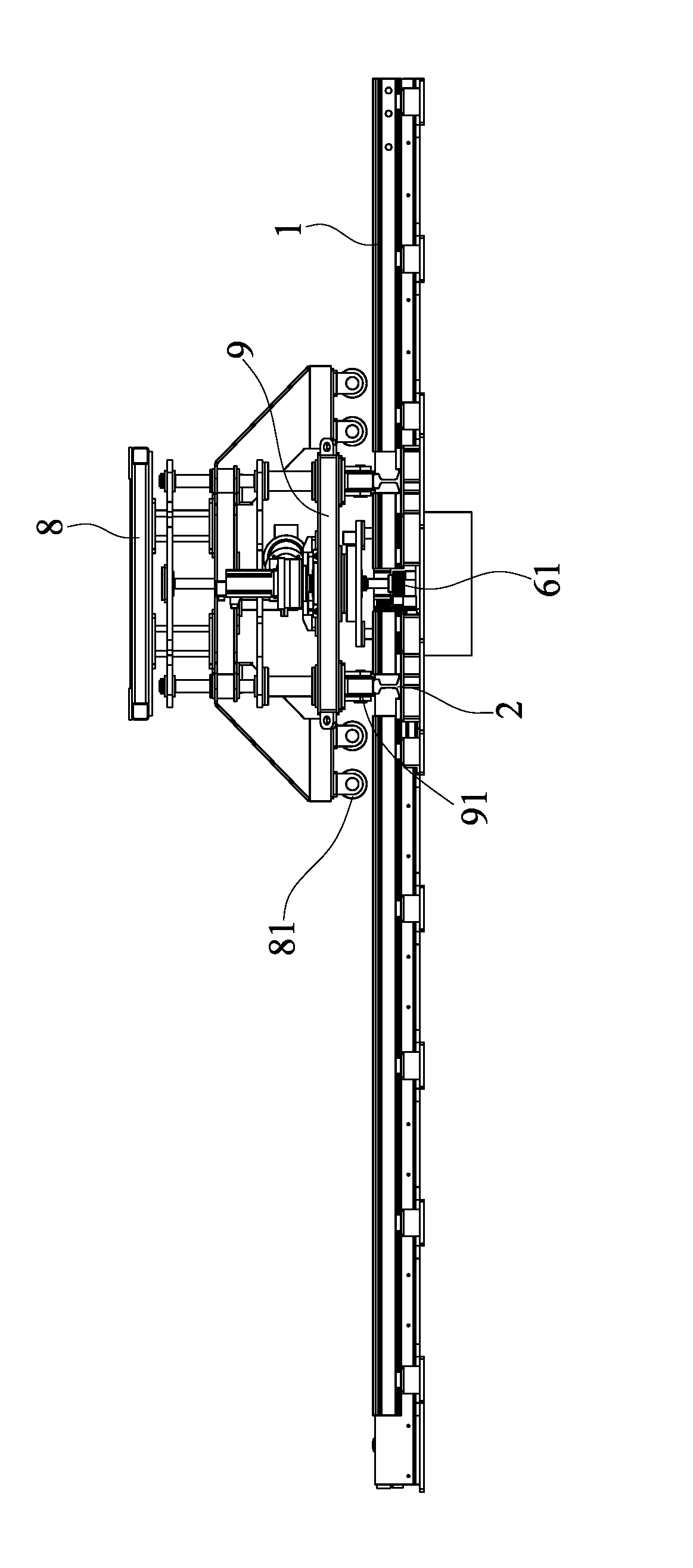

[0039] As shown in Fig. 1 and Fig. 2, what the present invention discloses is a kind of heavy-duty rail free shuttle trolley, two parts of track 10 and trolley 20, comprise main rail 1, branch rail 2, main line rack 3, branch line rack 4, Movable rack 51, walking drive mechanism 6, reversing lifting mechanism 7, transfer drive mechanism 5, main line vehicle frame 8, branch line vehicle frame 9, main line traveling wheel 81, branch line traveling wheel 91 and driving gear 61.

[0040] The track 10 includes two parts, the main rail 1 and the branch rail 2. The main rail 1 and the branch rail 2 are vertically intersected. One main rail 1 can be connected to multiple branch rails 2; 1 and the track seat of the branch rail 2, a movable rack 51 and a transfer drive mechanism 5 are installed on the track seat at the intersection node of the main rail 1 and the branch rail 2, and the movable rack 51 can be driven by the transfer drive mechanism 5 to rotate to the same position as The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com