Automatic sheet-fetching system of ultra-thin glass

An ultra-thin glass and glass technology, applied in thin material handling, pile separation, packaging item types, etc., can solve problems such as blockade, film removal, and incomplete development of stacking equipment, so as to improve yield and packaging quality. , to avoid the effect of surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

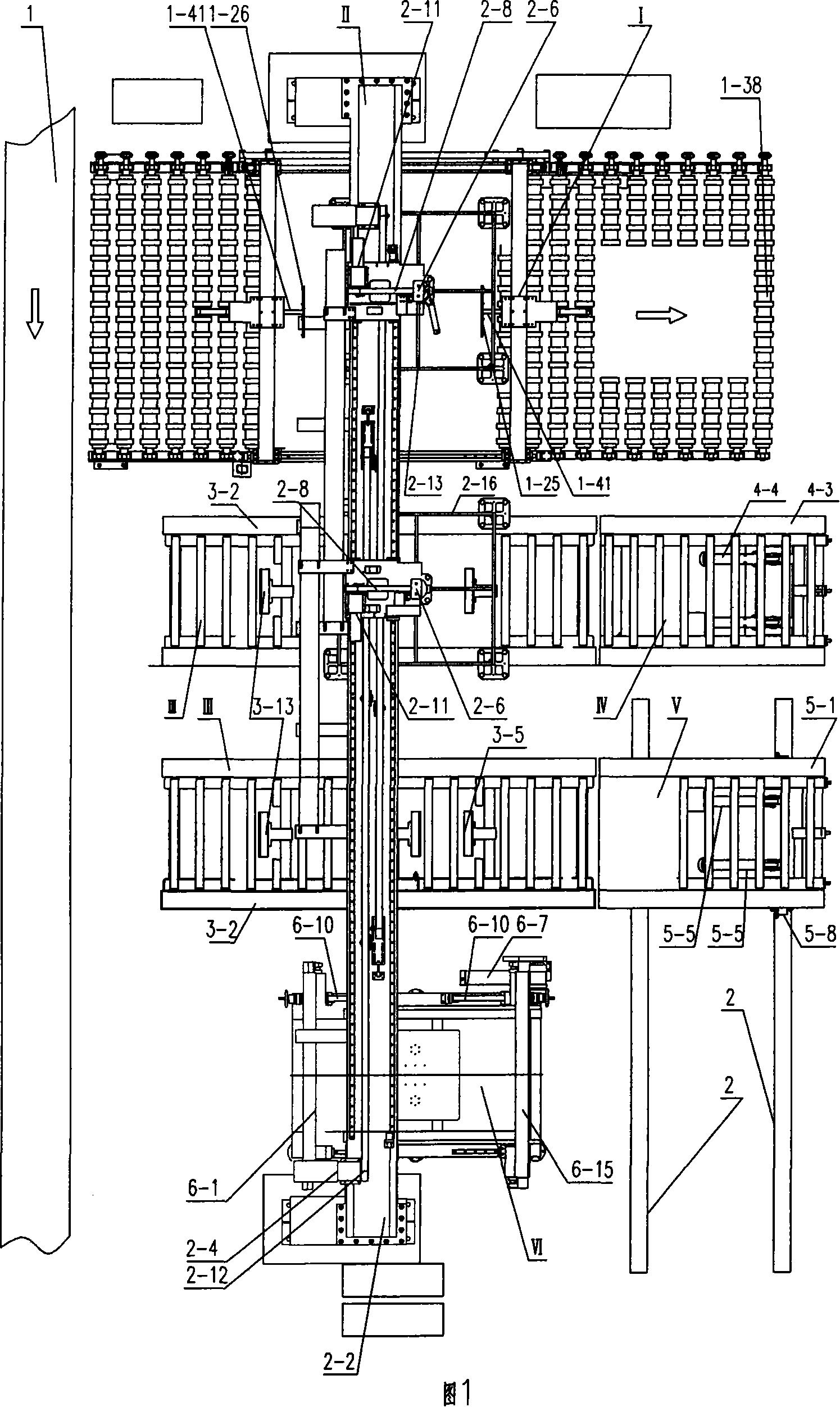

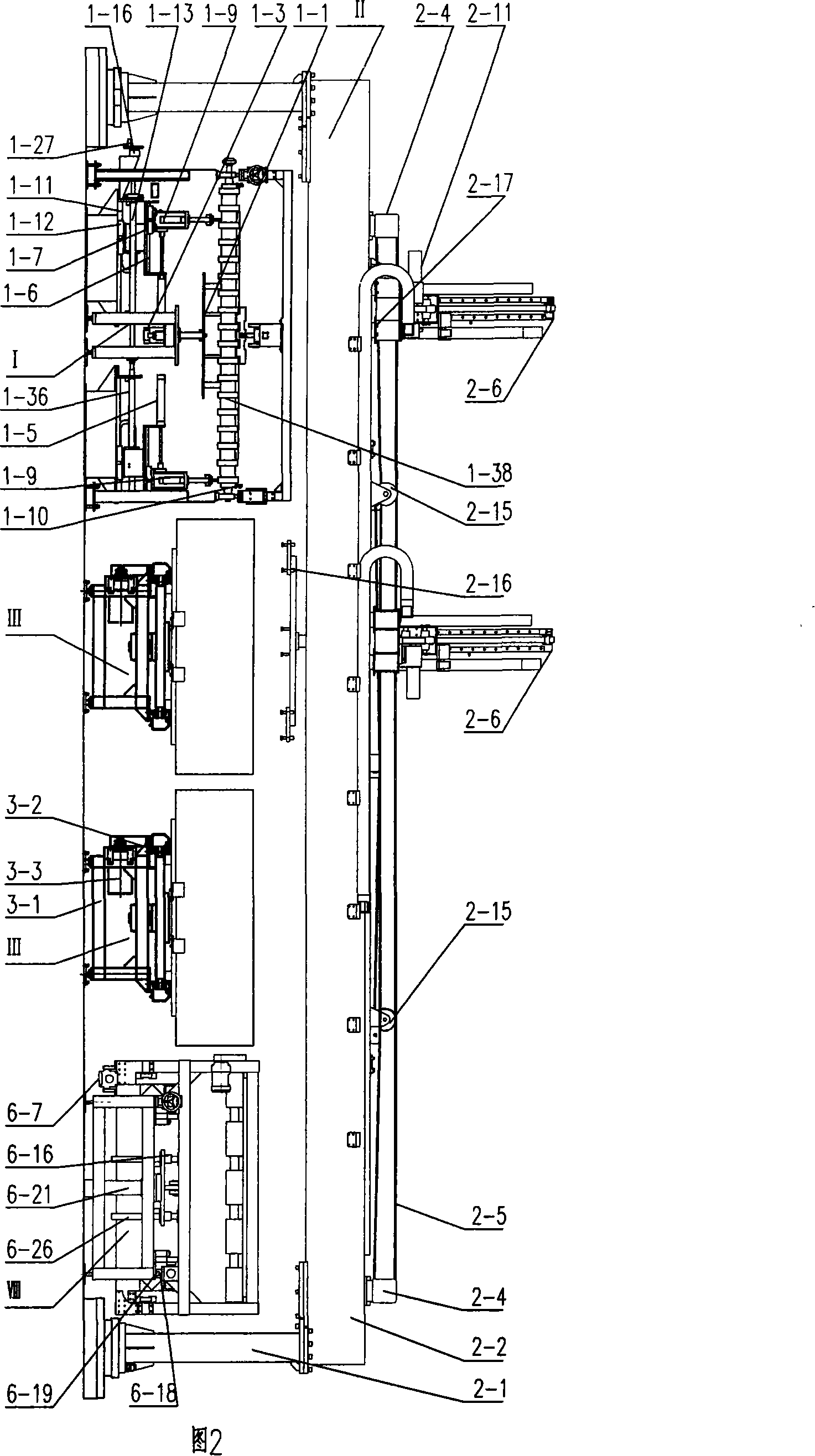

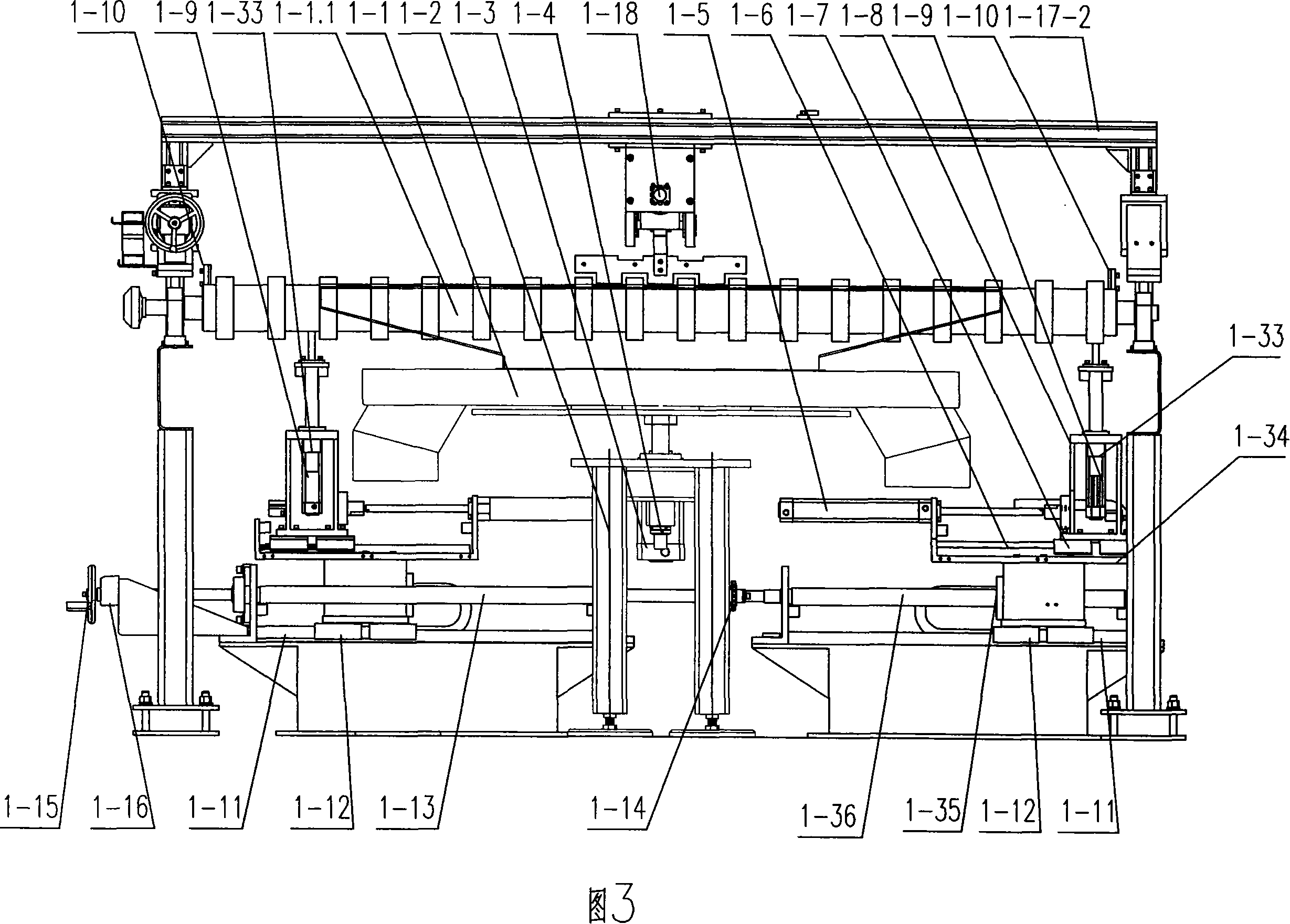

[0043] In conjunction with the accompanying drawings, specific embodiments of the present invention are described.

[0044] As shown in Figures 1 and 2: the present invention includes a glass conveying branch line, a glass centering and positioning unit I, a clean handling robot II, a packing case conveying and positioning unit III, a packing case fixed turning unit IV, a packing case moving turning unit V and interlayers The paper supply unit VI, the glass main conveying line 1 and the glass conveying branch line 1-38 are vertically arranged, and the glass centering and positioning unit I is arranged above and below the glass conveying branch line 1-38. Install two packing case conveying and positioning units III in parallel with the glass conveying branch line 1-38, wherein the end of the packing case conveying and positioning unit III installed close to the glass conveying branch line 1-38 is installed with packing case fixed turning unit IV. The packaging box moving and tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com