Patents

Literature

138results about How to "Avoid surface scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

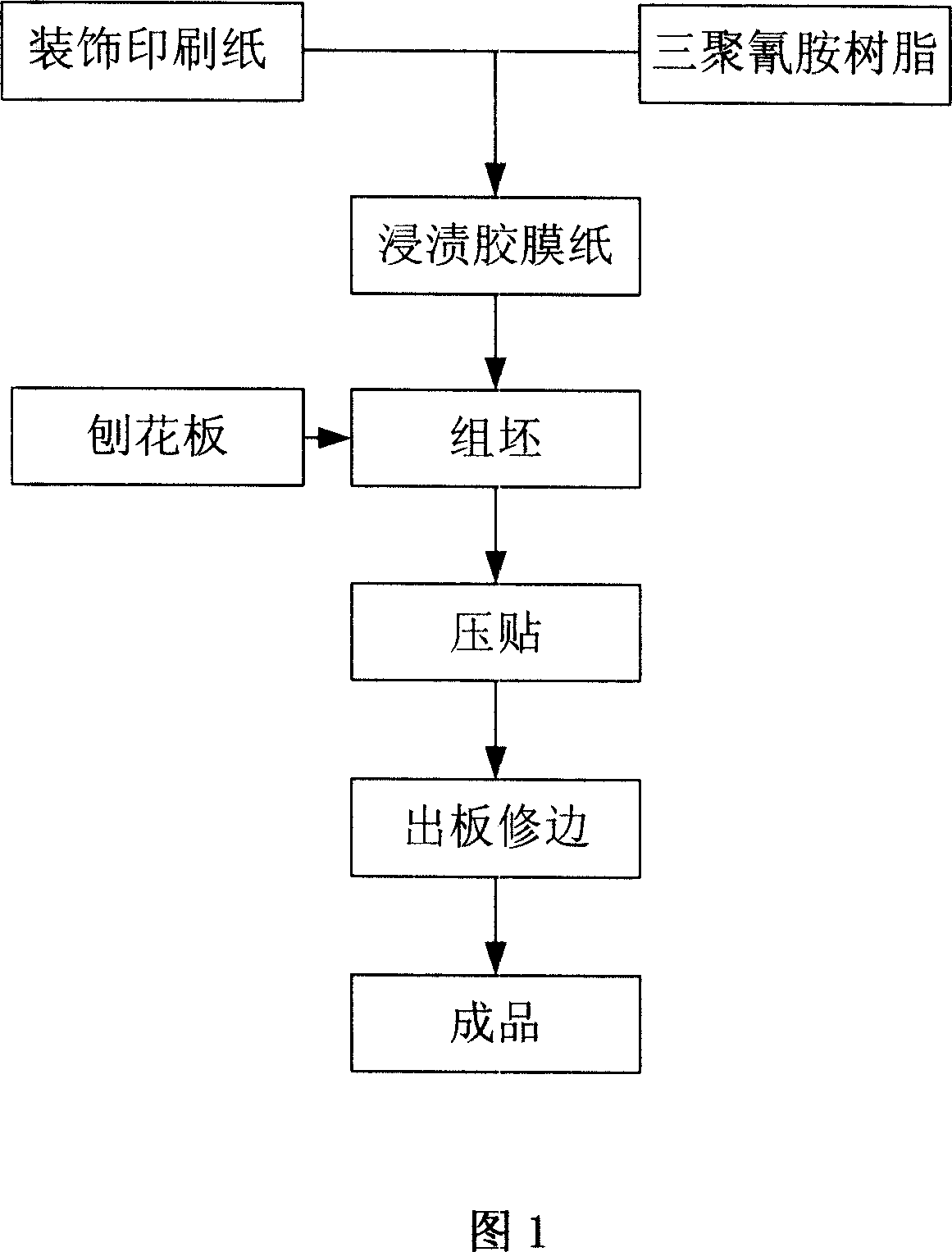

Bright mirror surface and facing artificial plate and manufacturing technique thereof

InactiveCN101011828AIncrease usageOvercoming the deficiency of low brightnessNon-macromolecular organic additionPaper/cardboardDiethylene glycolPulp and paper industry

A melamine impregnated bond paper and chipboard compressed bright surface wood based board is composed of 60-70 portions of water, 100 portions of melamine, 90-130 portions of formaldehyde, diethylene glycol monoethylether 10-15 portions, aminocaprolactam 3.5-5.5 portions and caustic soda 0.3-0.6 portions. Firstly, it wipes off the powder on the surface of the chipboard, aligning them with melamine impregnated bond paper covering the chipboard, increasing the temperature, sending the chipboard and the paper into the compressing machine, ensuring the aligning of the center line of the chipboard and that of the compressing machine, closing the compressing machine, sending out the board, trimming, and getting the bright artificial board. It is bright, with good luster saturation, fine wearing resistance, heat, burning, crack, light and corrosion features.

Owner:吴根水

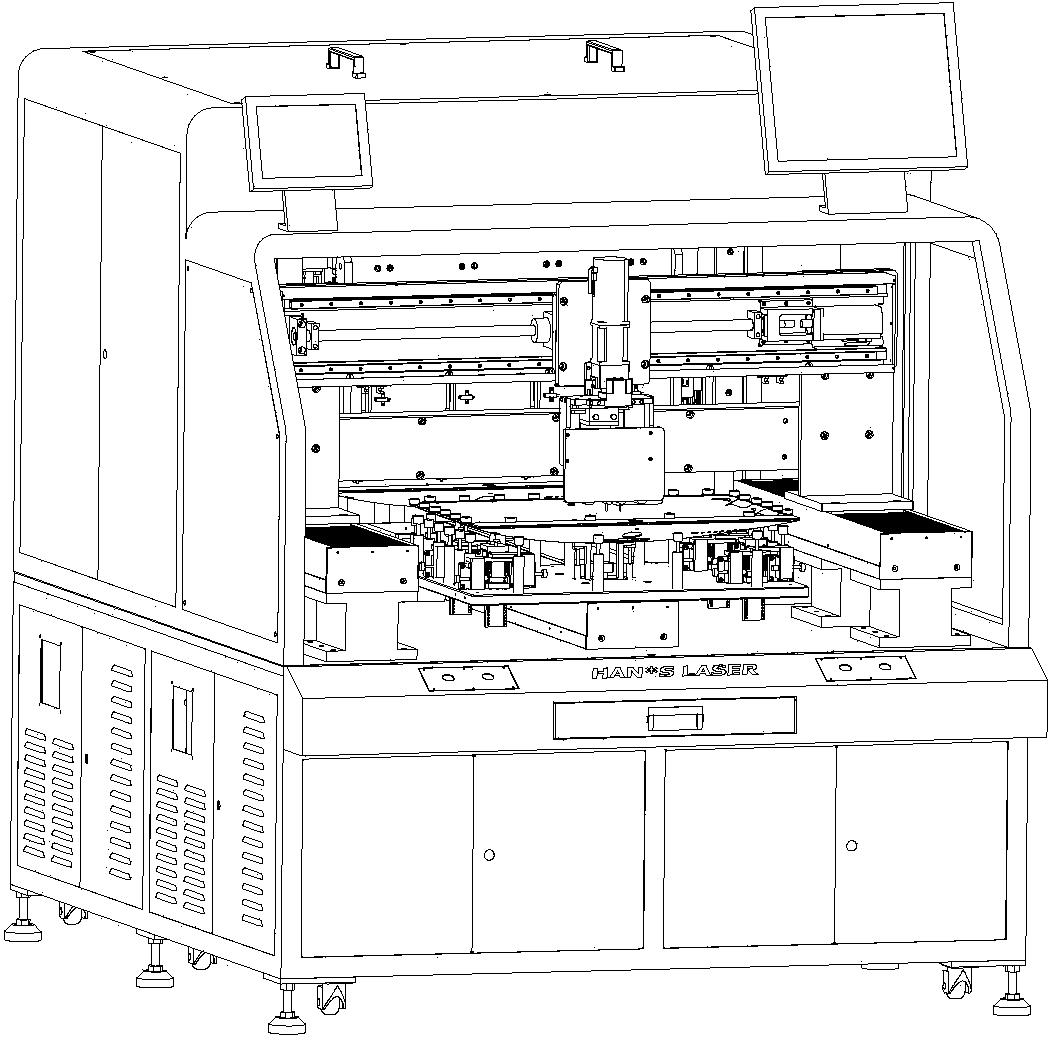

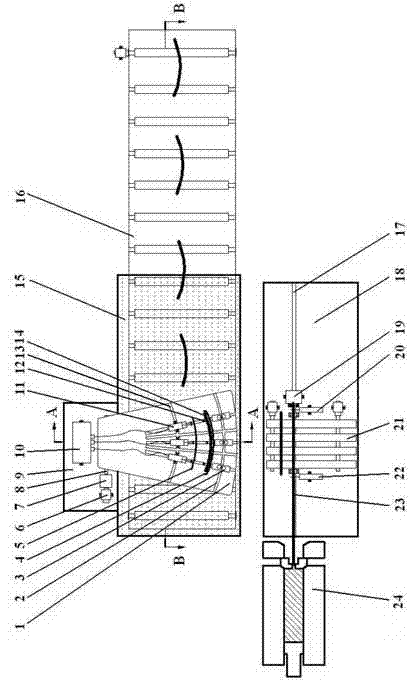

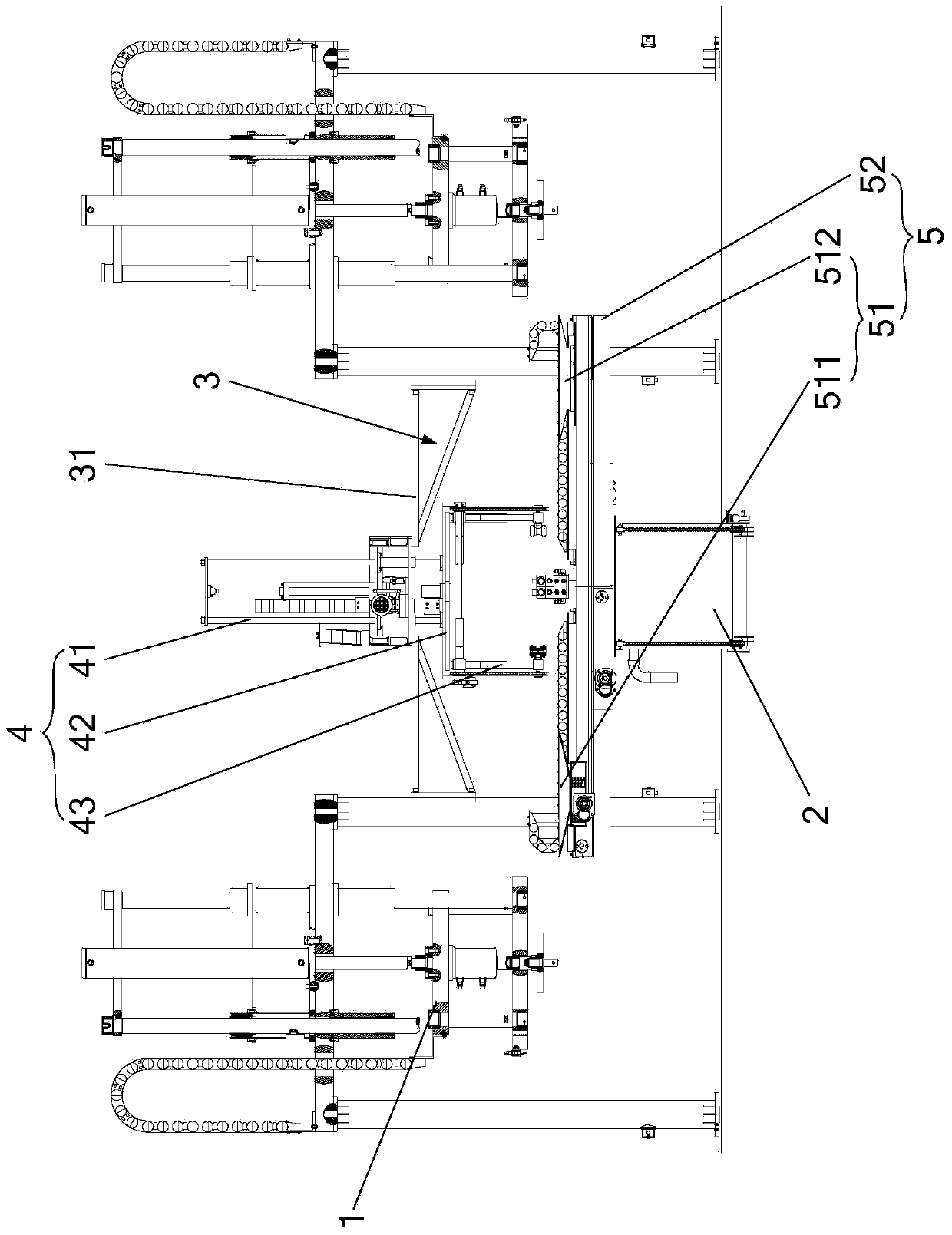

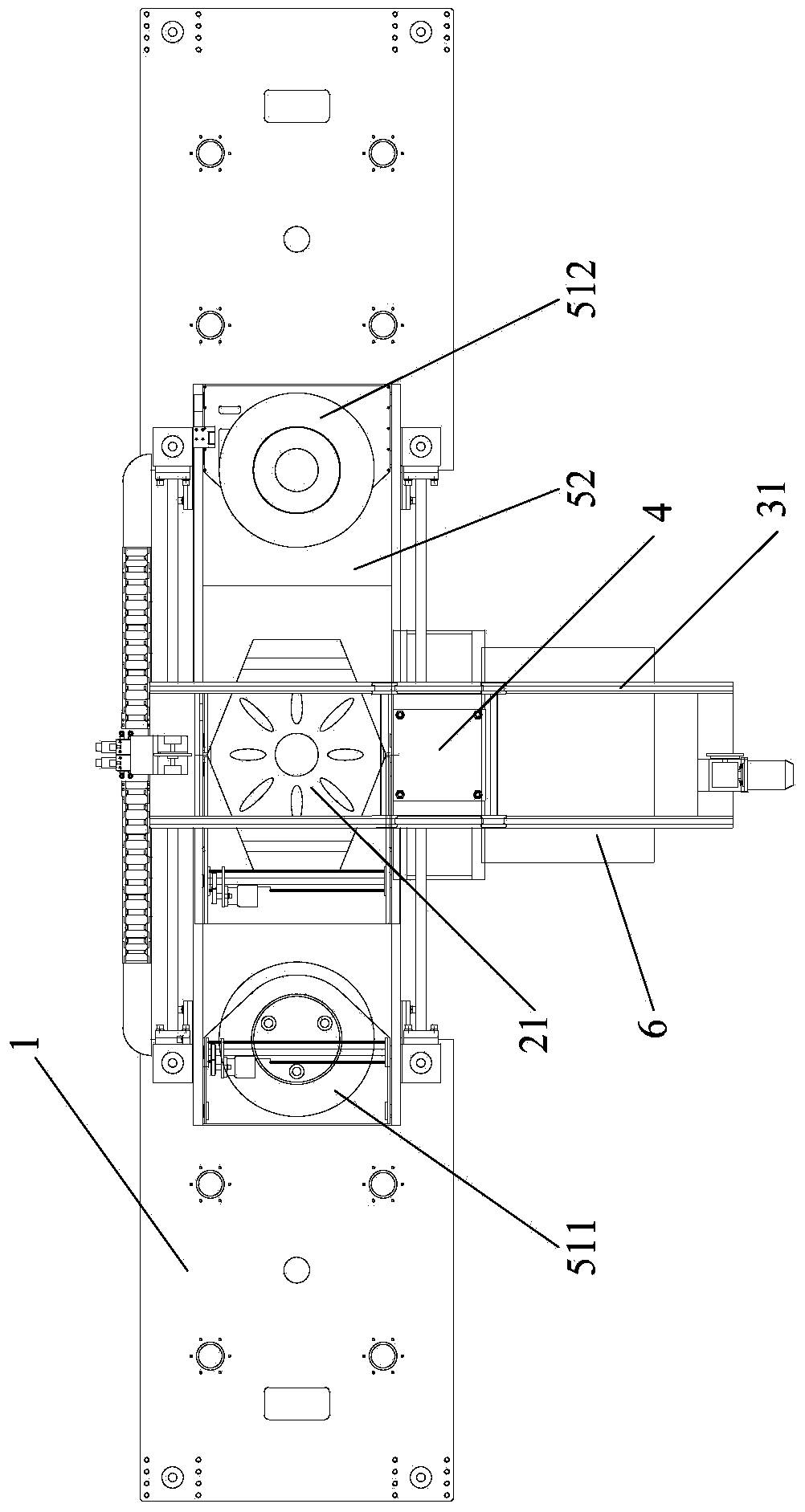

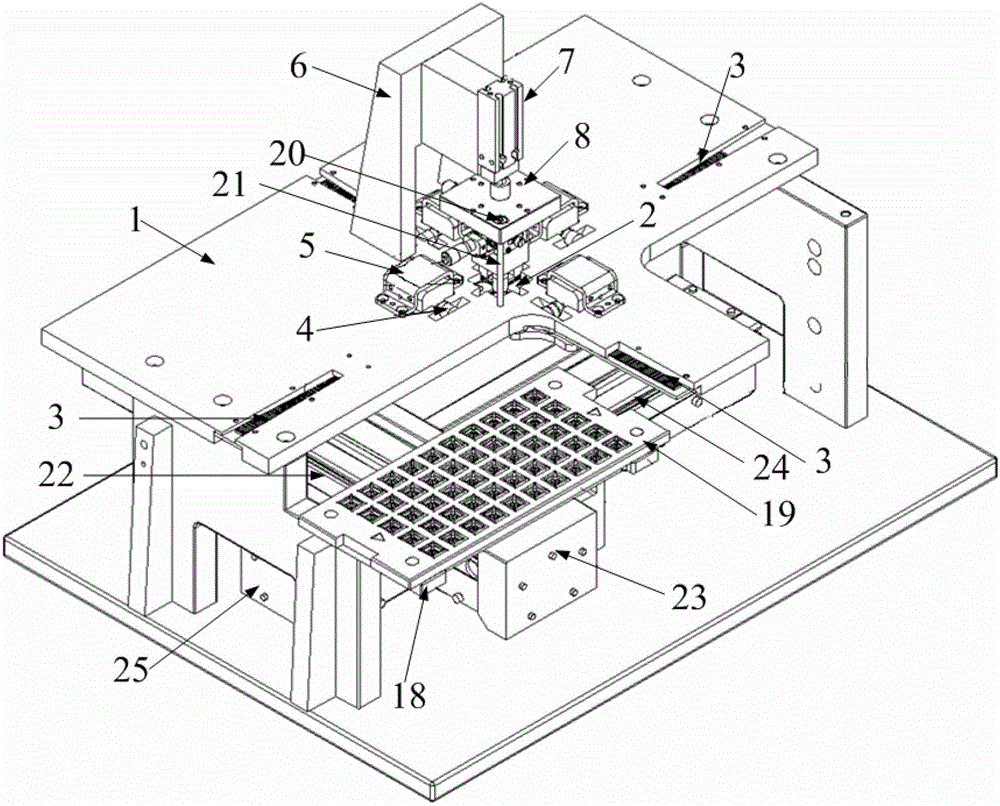

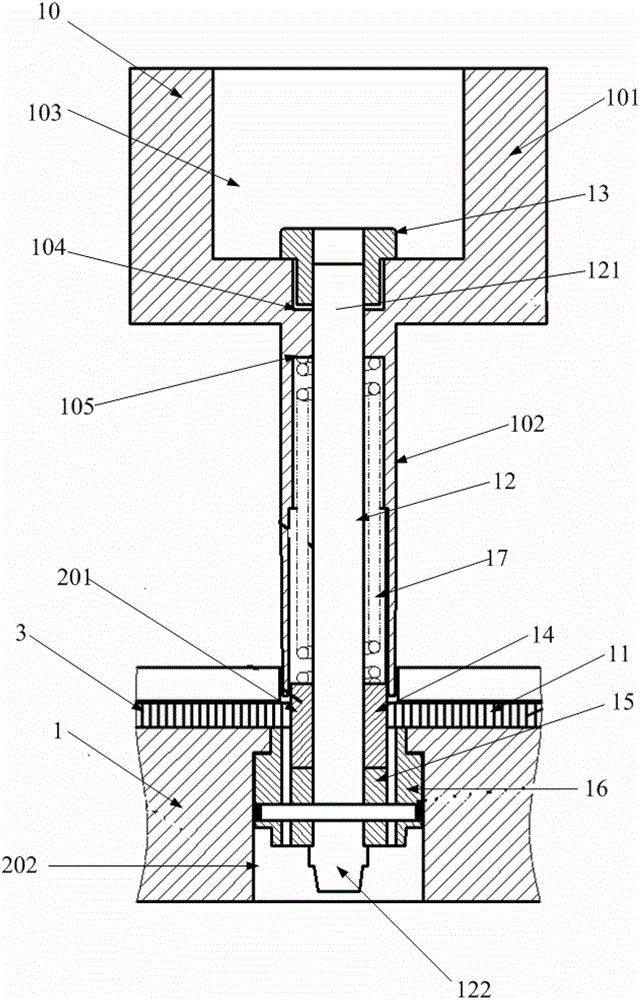

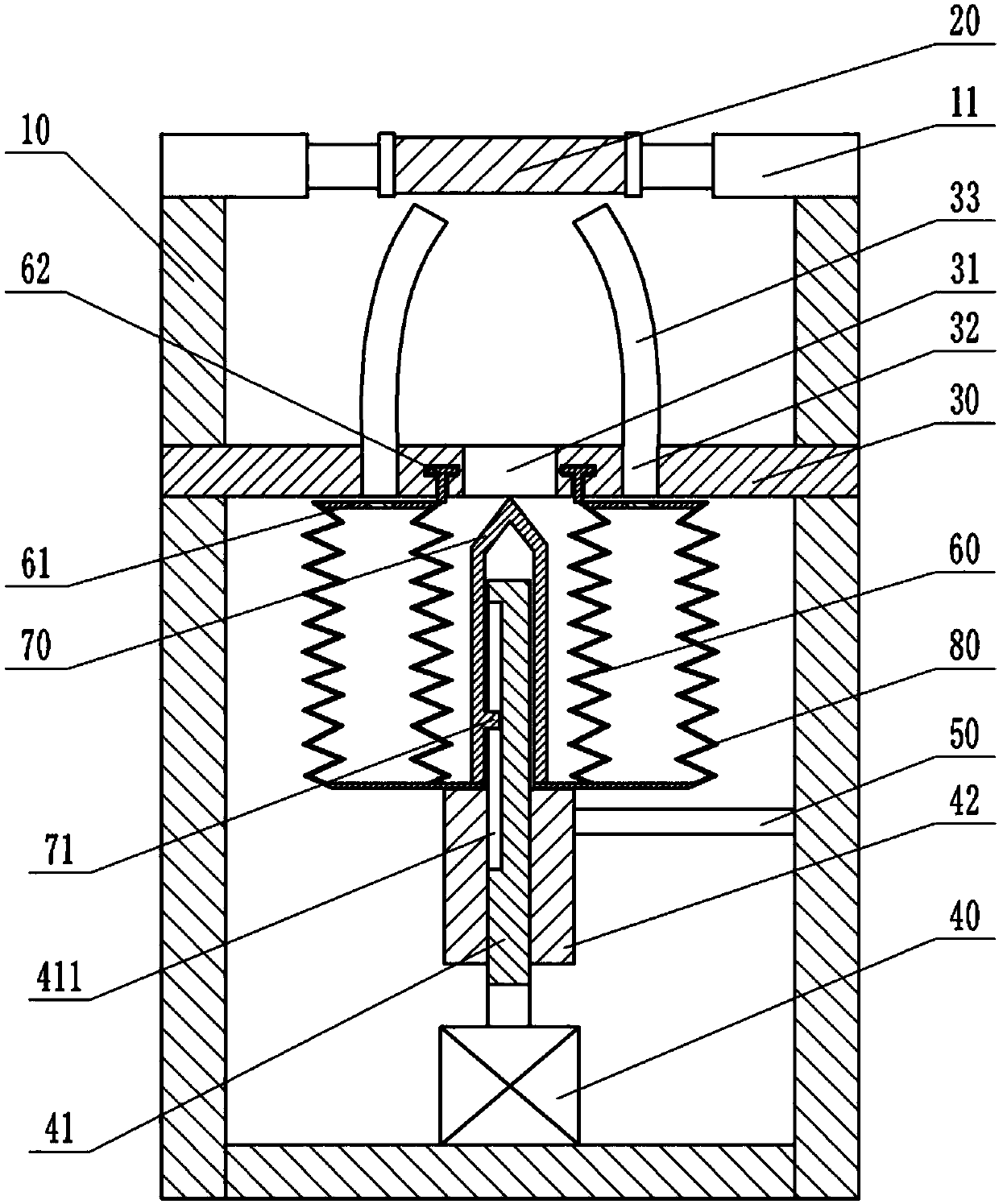

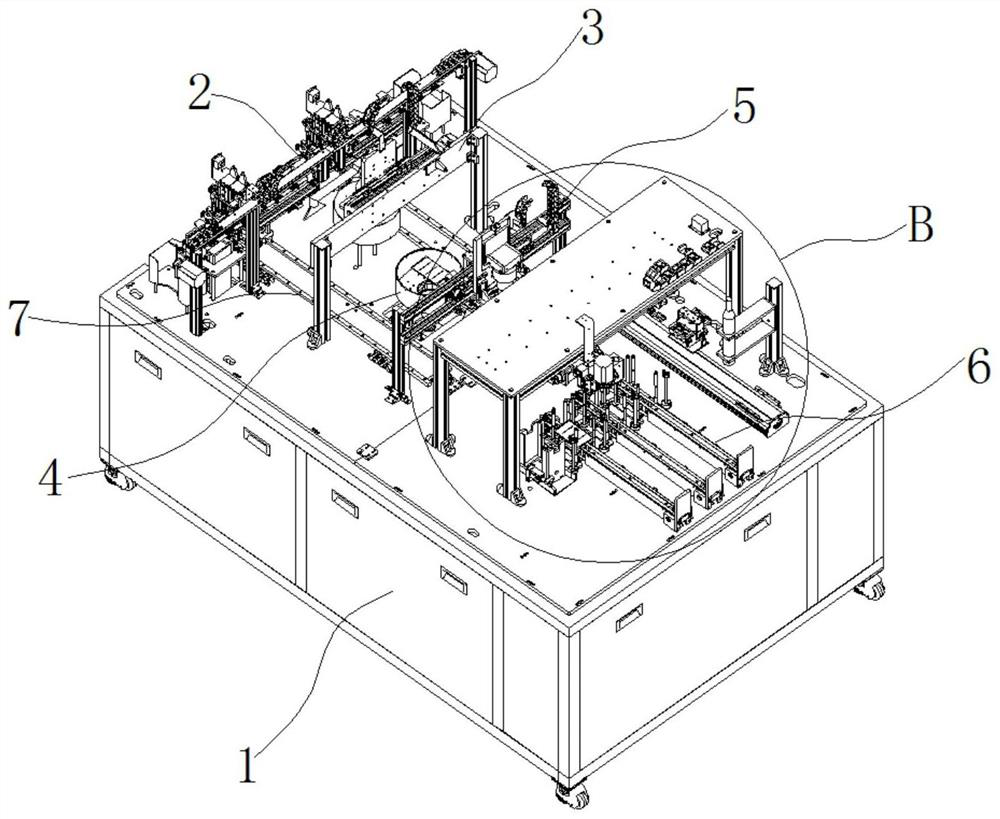

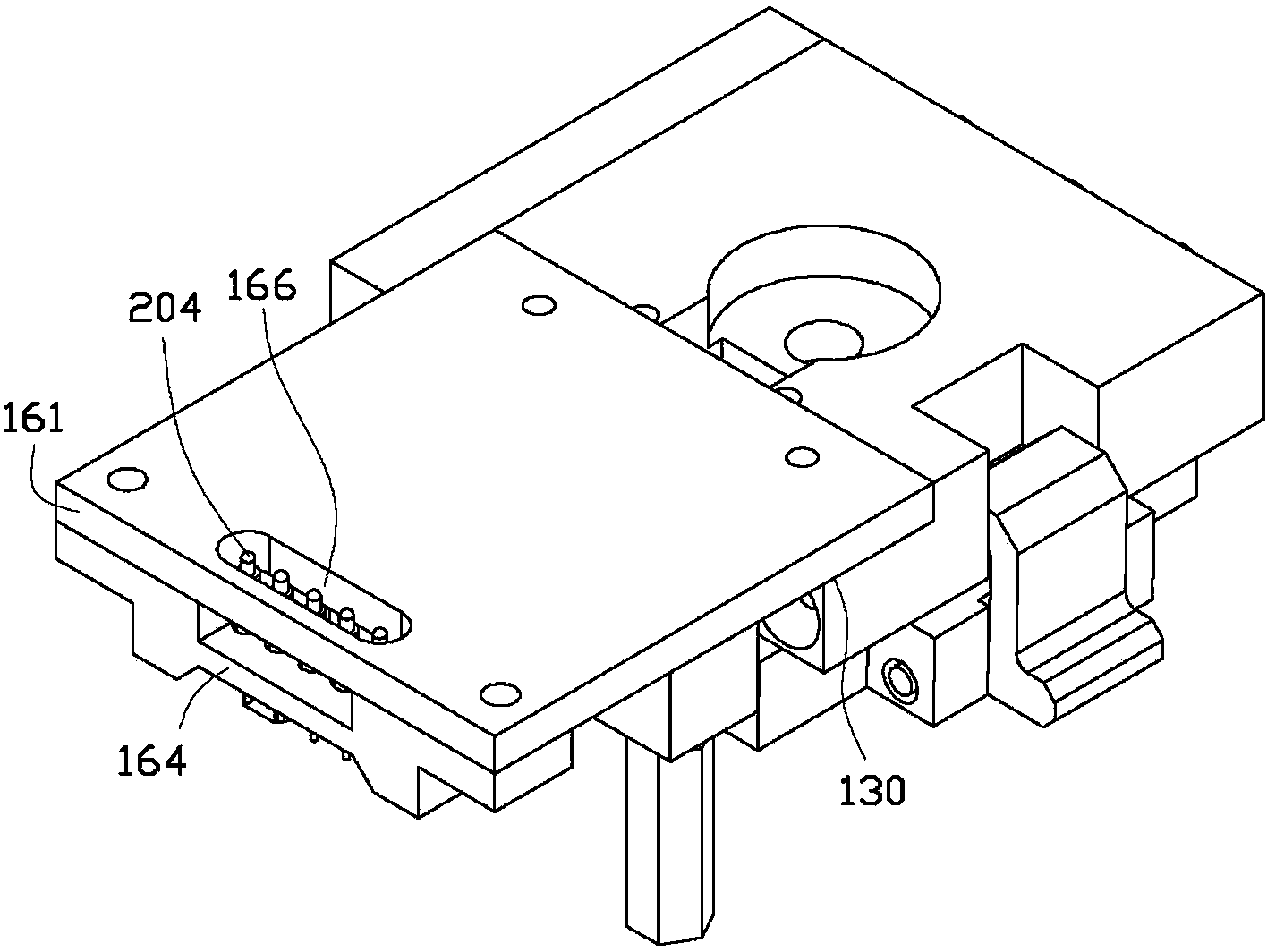

Planeness detection and correction all-in-one machine and detection and correction method

ActiveCN103453858AIncrease productivityImprove detection accuracyUsing optical meansPortal frameCorrection method

The invention relates to a planeness detection and correction all-in-one machine which comprises a machine cabinet assembly, a fixture assembly for clamping a workpiece to be detected and corrected and a control assembly for controlling the detection and correction. The all-in-one machine further comprises a detection assembly and a correction assembly, wherein the detection assembly comprises a portal frame assembly achieving moving on an X axis, a Y axis and a Z axis and a laser displacement sensor, and the correction assembly comprises a correction mechanism and a contact type digital sensor. The detection assembly and the correction assembly are connected with the control assembly to carry out information interaction to achieve the detection and the correction of the planeness. The planeness detection and correction all-in-one machine can detect whether products are qualified or not, can also carry out correction on sub-quality products, and the effects of improving production efficiency, detection precision and the product percent of pass and reducing cost are achieved.

Owner:深圳市大族半导体装备科技有限公司

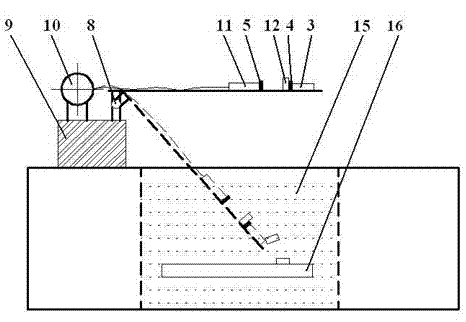

Aluminium alloy bumper bar section bar bending forming method and device for automobile

ActiveCN102729048AAdjustable bend radiusReduce generationOther manufacturing equipments/toolsEngineeringWaste material

The invention relates to an aluminium alloy bumper bar section bar bending forming method and device for an automobile, and belongs to the field of metal ductility processing technology and equipment. The device is characterized in that the outlet of a horizontal extruder is provided with a straightening cutting device, a hydraulic drive bending device and a quenching device, an aluminium alloy blank forms a required section bar through hot extrusion, then the section bar is dragged to the required length, the section bar is straightened and cut so as to be transferred to the hydraulic bending device; after the section bar is bent, the bent section bar is quenched under a tepefaction state, less processes are utilized to realize the bending forming and quench treatment of the extruded section material; the different bending radiuses are realized through adjusting the number and position of hydraulic rods and locating pieces, the extrusion section bar is straightened and cut at the outlet of the extruder so as to be directly bent and quenched; the section bar is bent under the tepefaction state, the section transformation and surface scratch are prevented from appearing in cold bending, and the bending radiuses of the section bar is adjusted; and the volume production is realized, the production rate is improved, the generation of spent materials is reduced, and the cost is reduced.

Owner:CHINA AUTOMOTIVE ENG RES INST +1

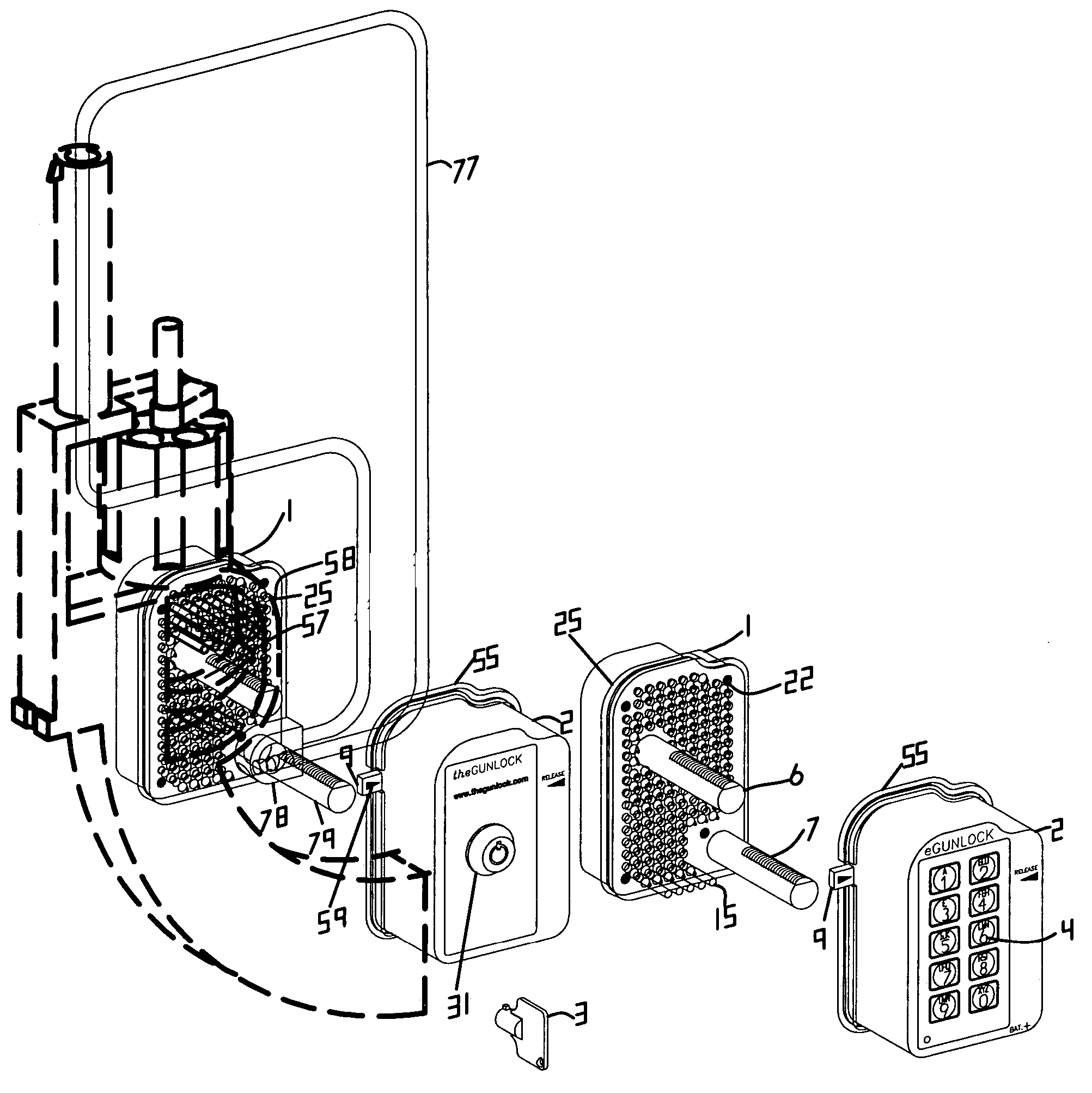

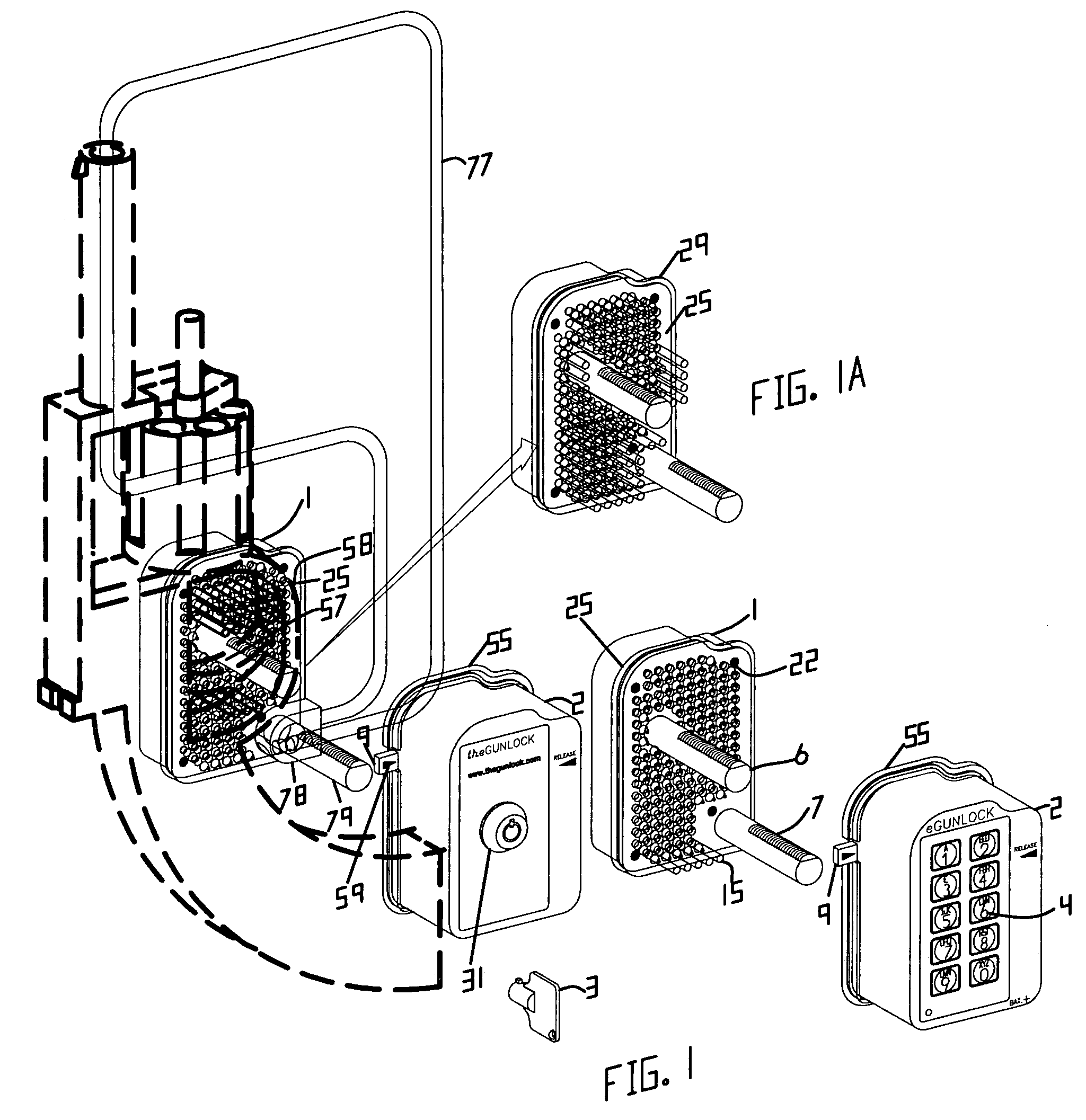

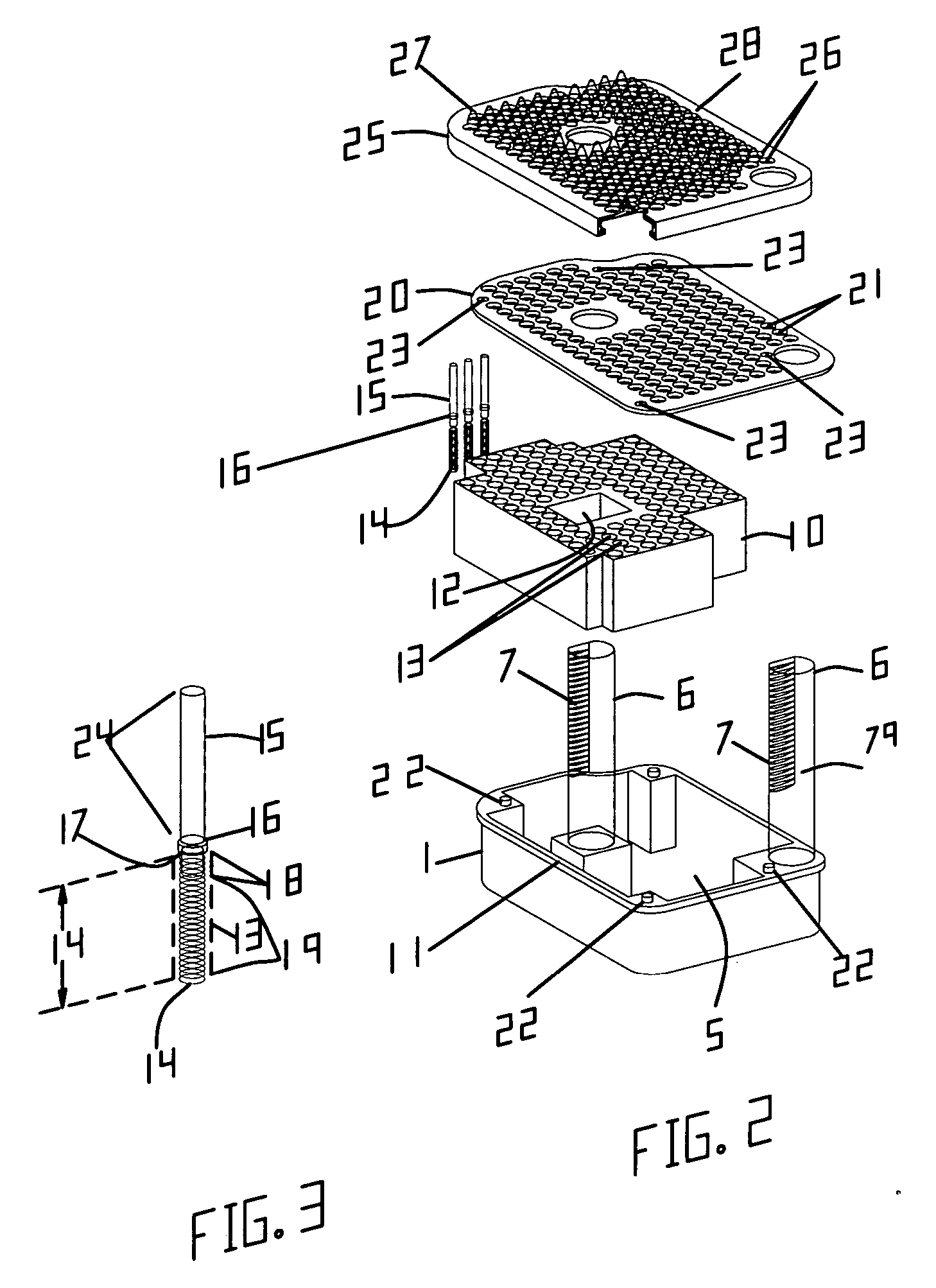

Gun lock

InactiveUS20060112605A1Avoid surface scratchesAvoid accidental movementSafety arrangementLocking mechanismEngineering

This invention relates to a gun lock, a device for locking a gun or parts thereof by securely situating the gun or parts thereof such as the trigger and the trigger guard between a gun lock base and a locking base. The gun lock base house a plurality of spring loaded pins for totally surrounding the gun or parts of the gun such as the trigger and / or the trigger guard when placed on top of the pins. The gun lock base pairs with a locking base housing a locking mechanism. The plurality of spring loaded pins covering the surface of a gun lock base immobilize the gun, trigger or trigger guard. The device can also be used to lock other objects in place aside from a gun or parts of the gun.

Owner:SOPKO RILEY M

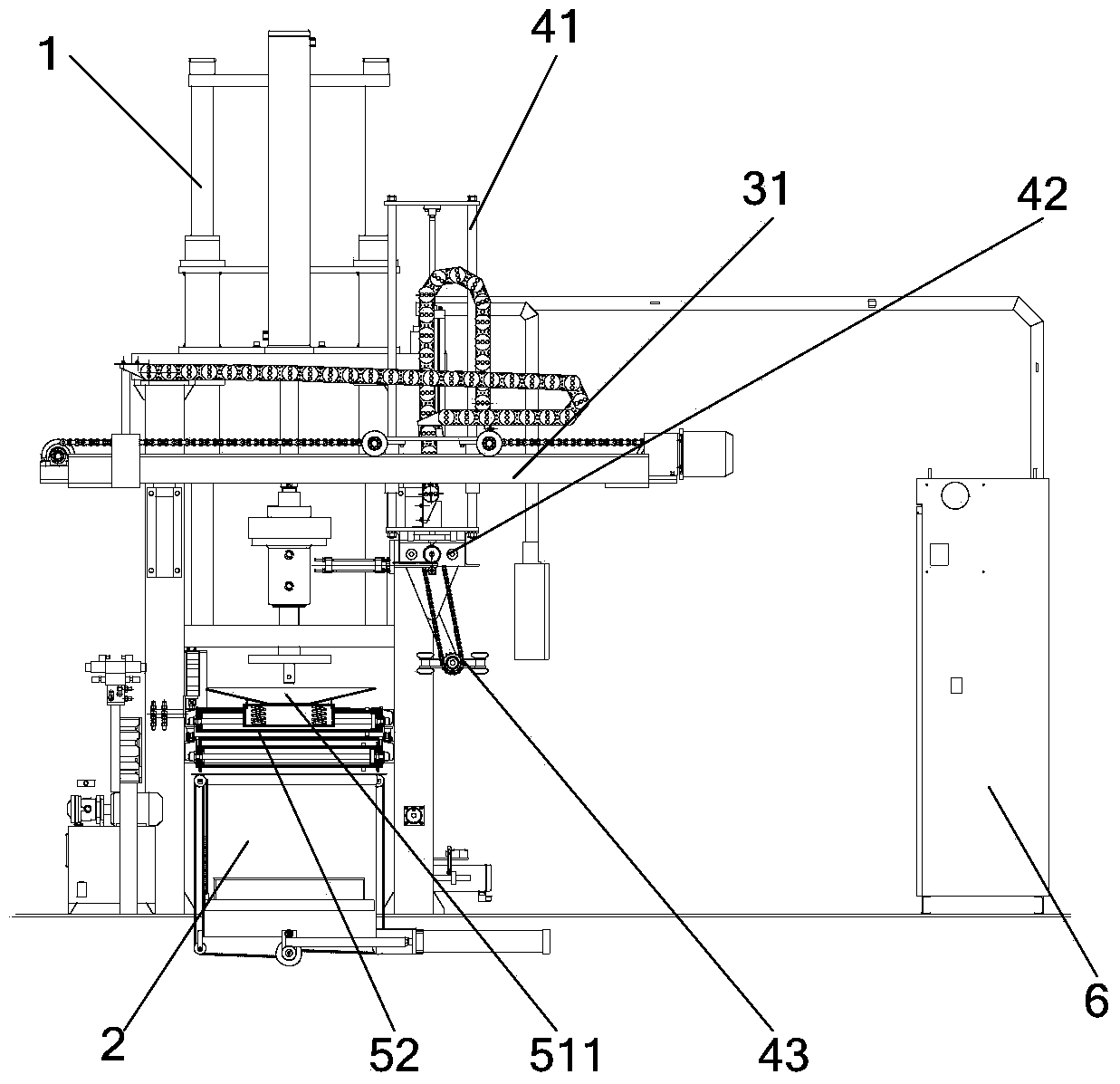

Wheel hub automatic water soaking device

ActiveCN103736981AIncrease productivityThe process of soaking in water and cooling is simple and convenientEngineeringManipulator

The invention provides a wheel hub automatic water soaking device. The wheel hub automatic water soaking device comprises a water soaking tank, a gantry frame, a mechanical arm and a material collecting mechanism; a water soaking platform which is arranged inside the water soaking tank can move vertically; the gantry frame is arranged above the water soaking tank; the mechanism arm which is installed on the gantry frame in a movable mode is arranged above the water soaking tank; the material collecting mechanism which is arranged between two wheel hub casting machines is located between the mechanical arm and the water soaking tank; the material collecting mechanism can convey die released castings of the wheel hub casting machines to above the water soaking tank; the mechanical arm grabs and places the castings on the water soaking platform after the castings are turned over; the water soaking platform moves downward to perform water soaking and cooling on the castings; the water soaking platform moves upward after the castings are cooled; the mechanical arm grabs and turns over the castings to drain water and then conveys the castings to a follow-up work bench after rotation. The wheel hub automatic water soaking device has the advantages of being simple in structure, saving time and force due to the fact that the castings are conveyed through the material collecting mechanism and the mechanical arm, effectively solving potential risks and improving the production efficiency of wheel hubs.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

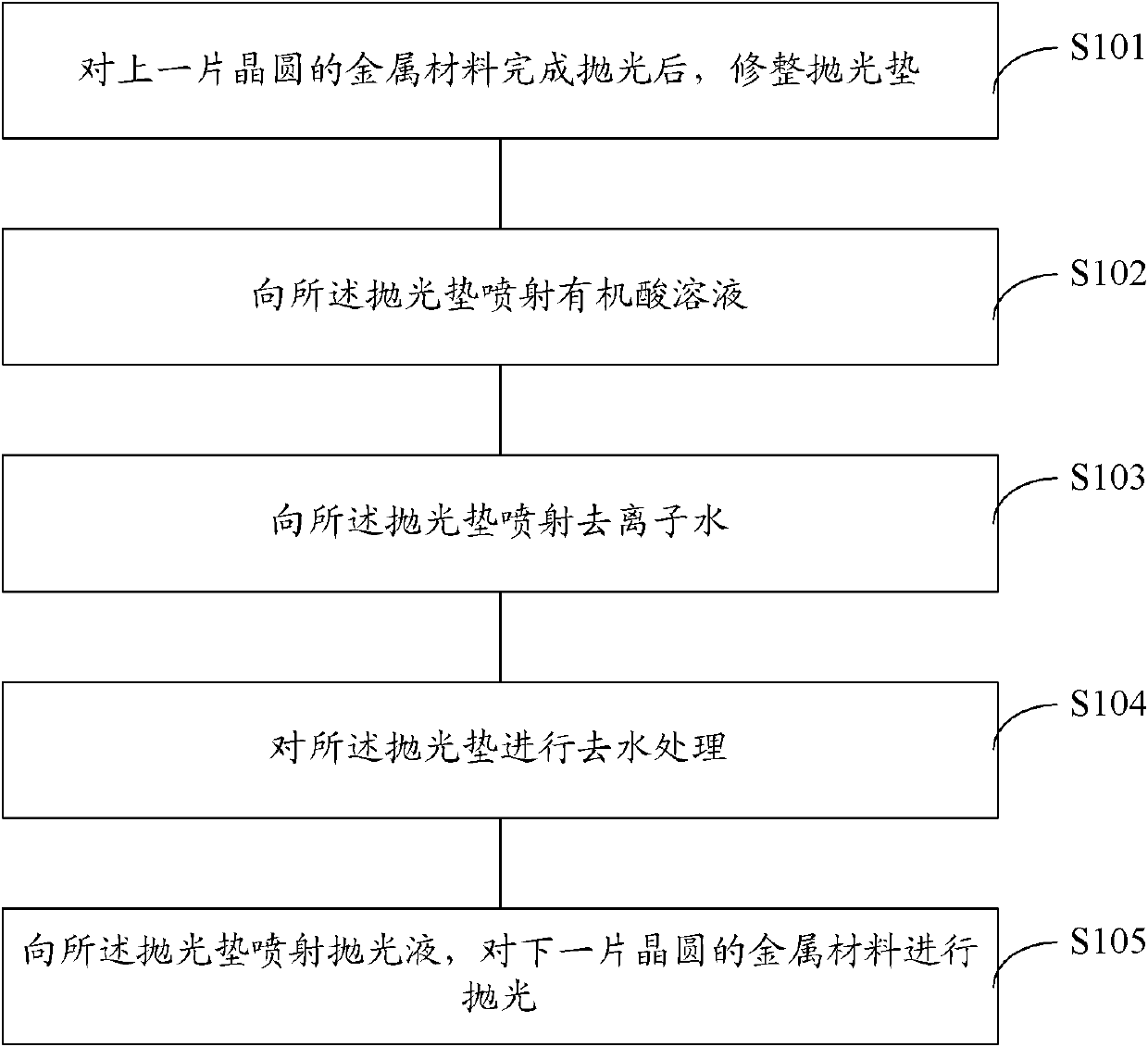

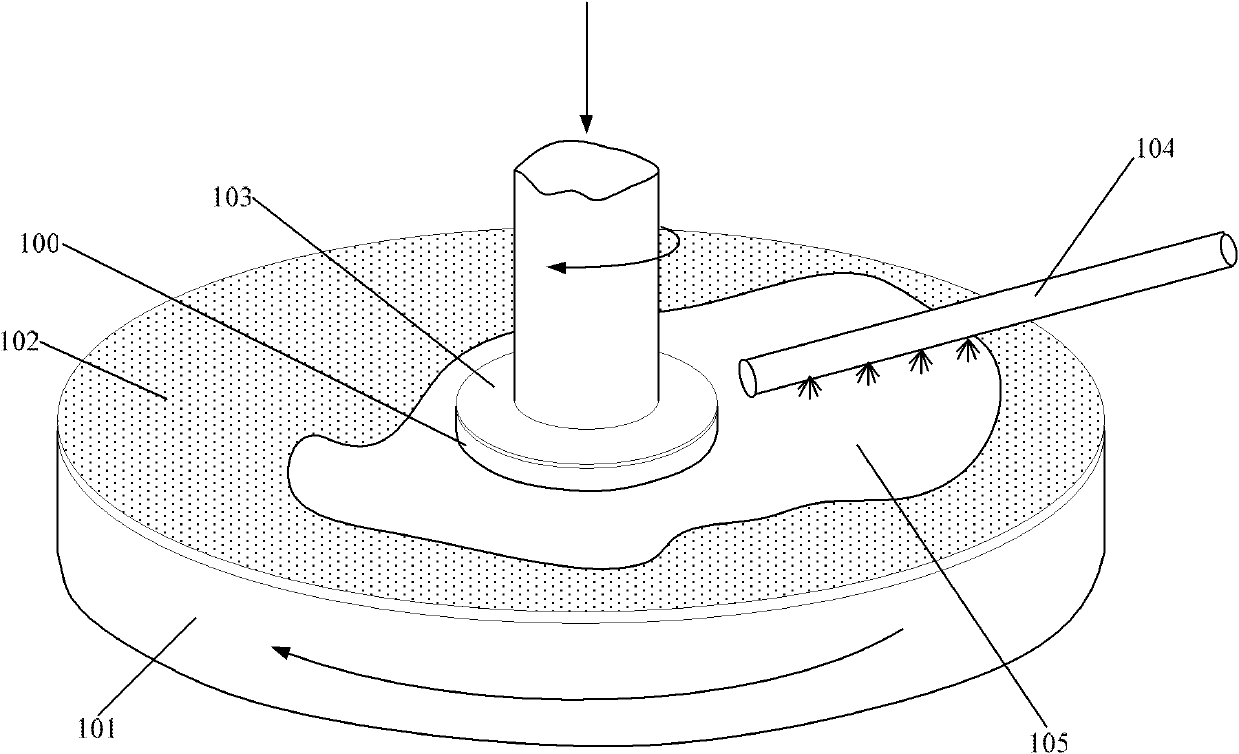

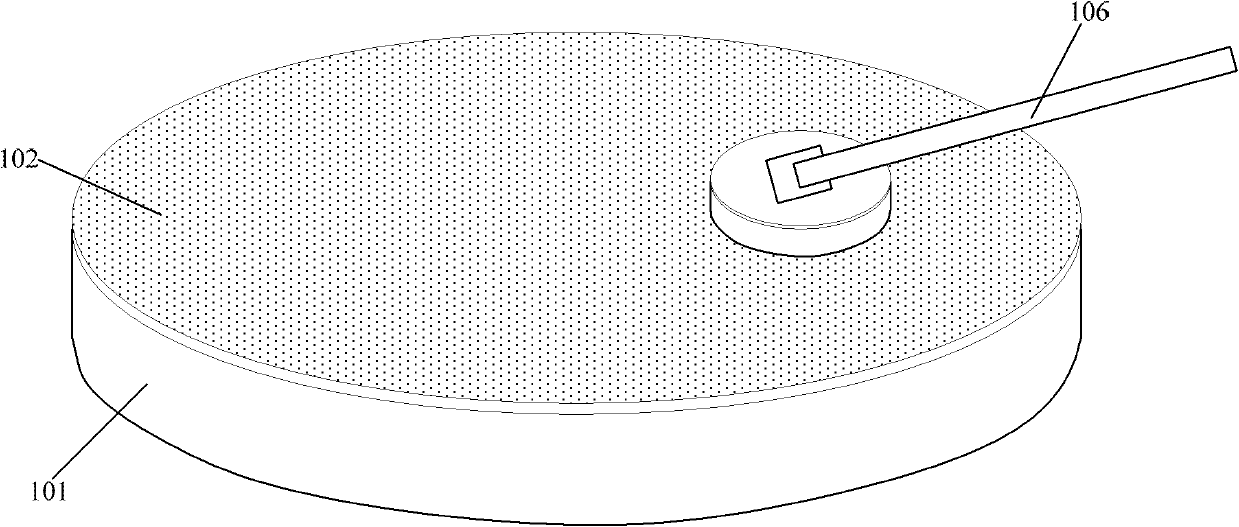

Polishing method

ActiveCN102554748AAvoid surface scratchesEfficient removalPolishing machinesAbrasive surface conditioning devicesMetallic materials

The invention discloses a polishing method. The polishing method comprises the following steps of: polishing a metal material of the last wafer, finishing a polishing pad, spraying an organic acid solution to the polishing pad, and spraying de-ionized water to the polishing pad; and carrying out water removal treatment on the polishing pad, spraying a polishing solution on the polishing pad, and polishing the metal material of the next wafer. The polishing method provided by the invention can be used for preventing the surface of the metal material of the wafer from being scratched, and improving the yield.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

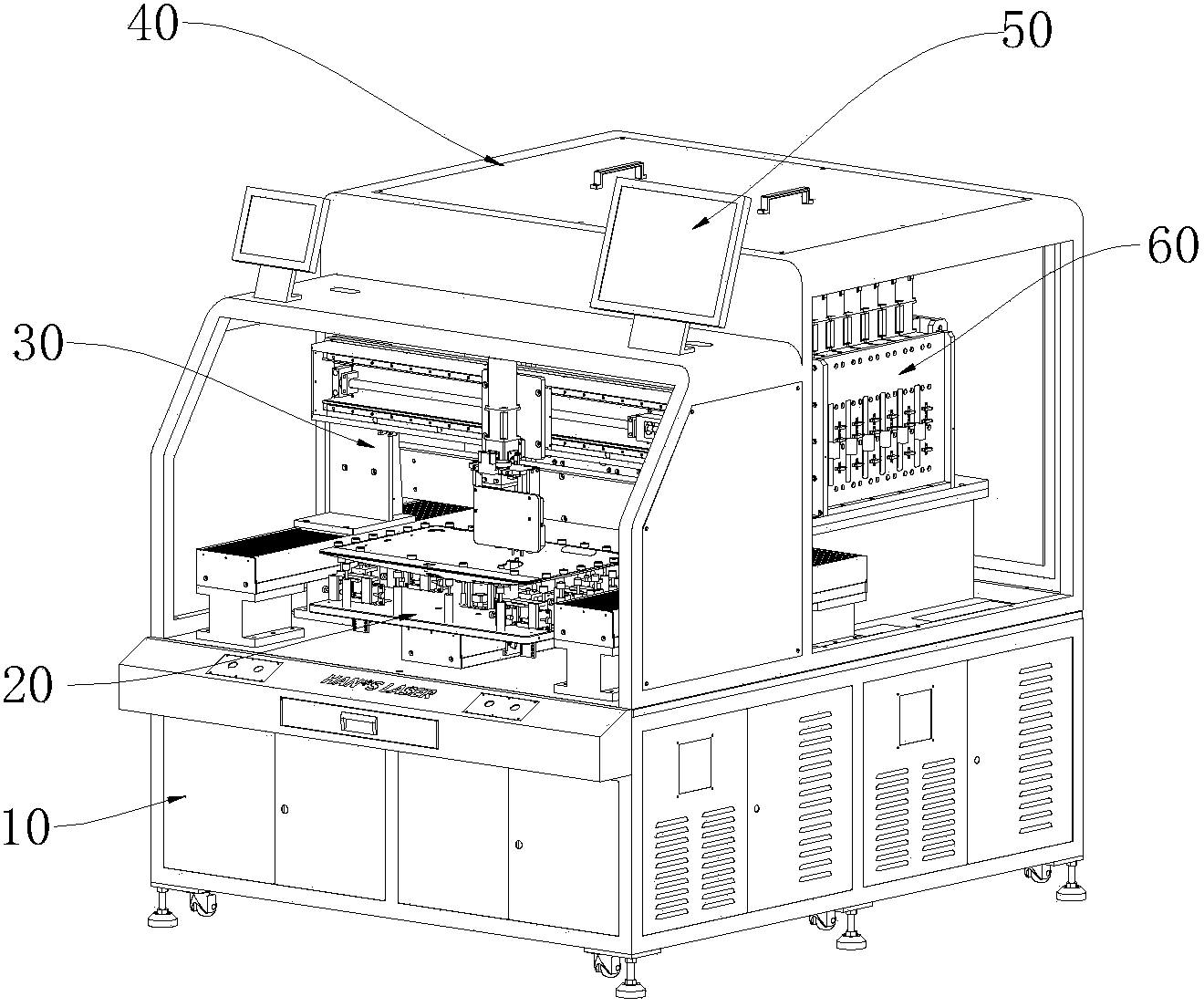

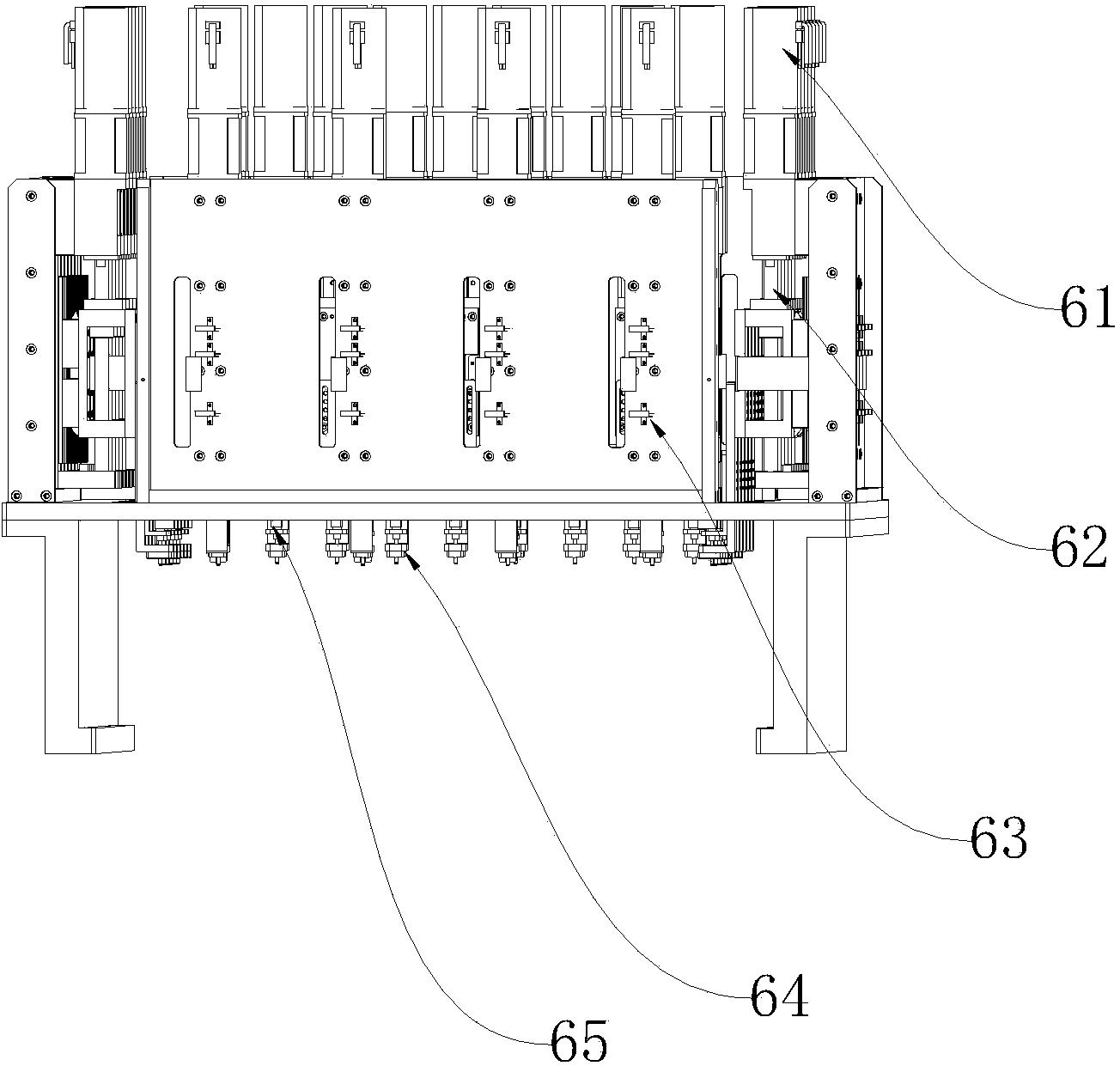

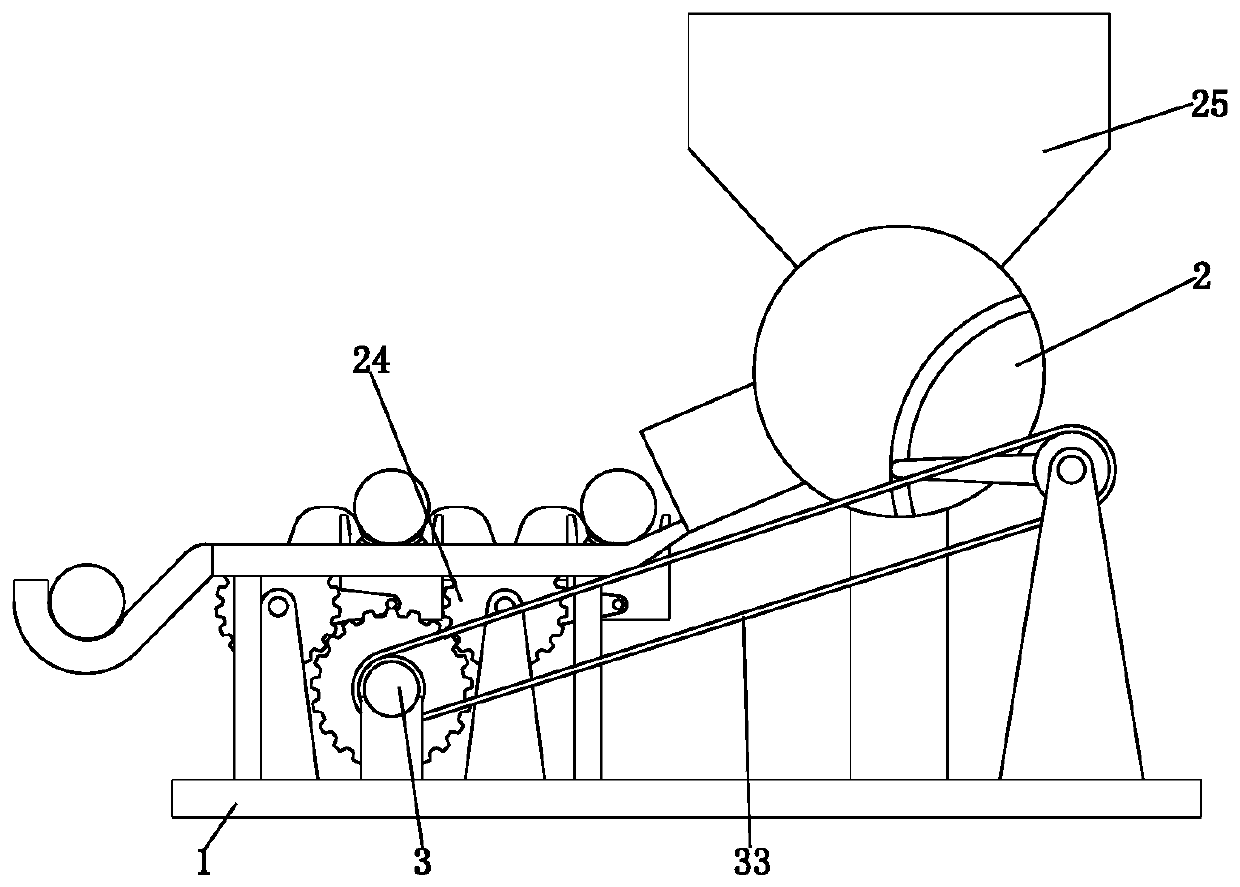

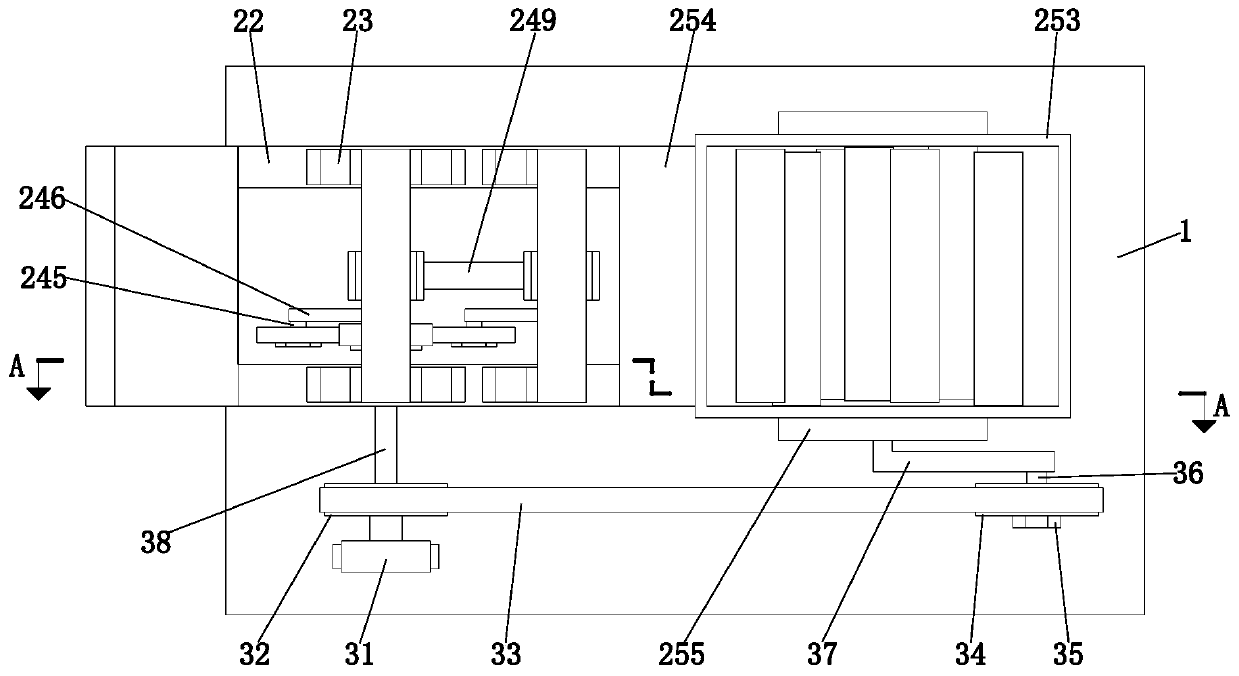

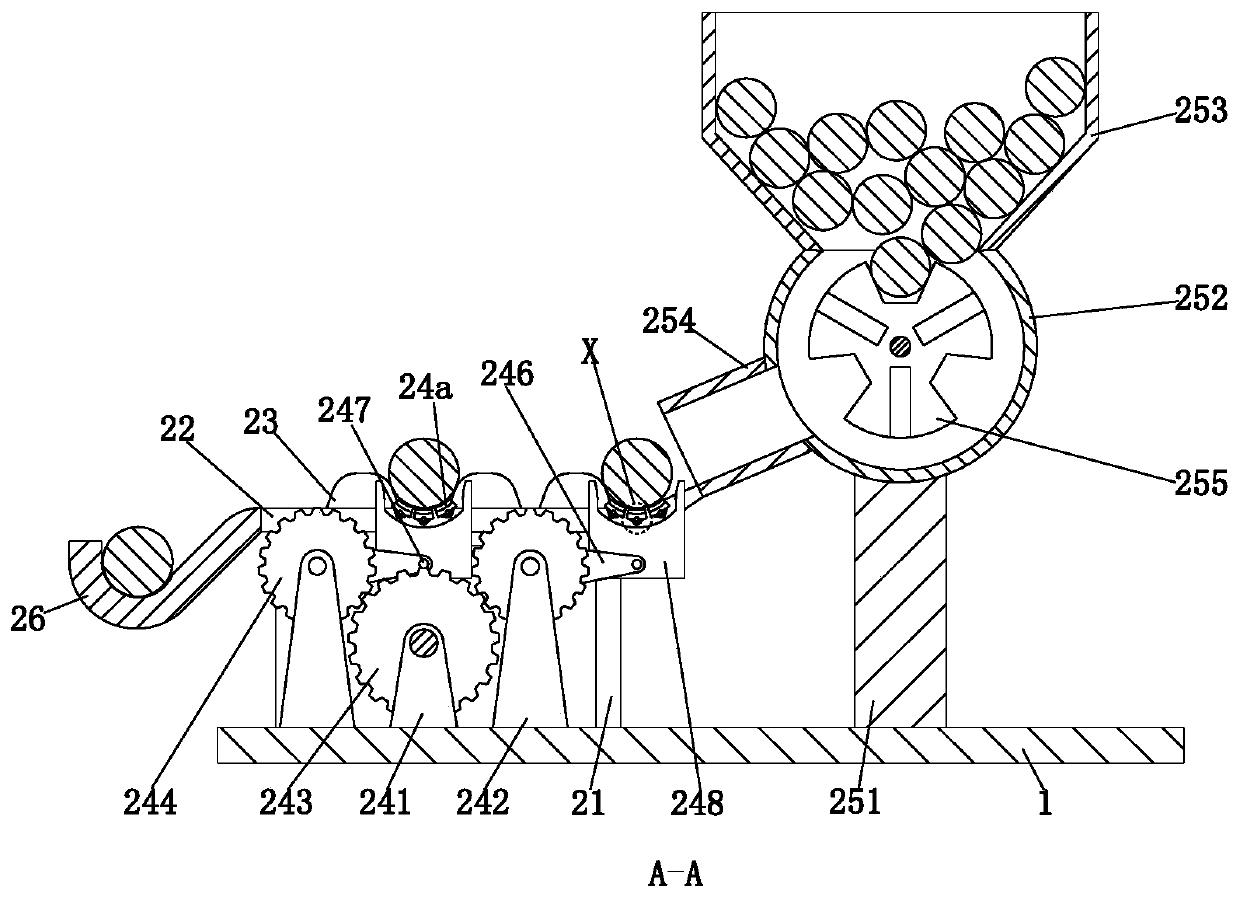

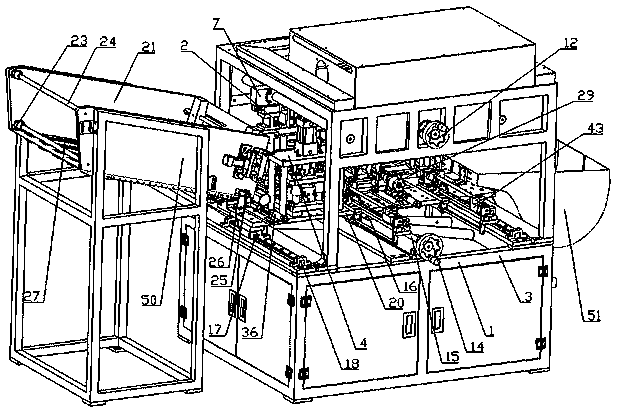

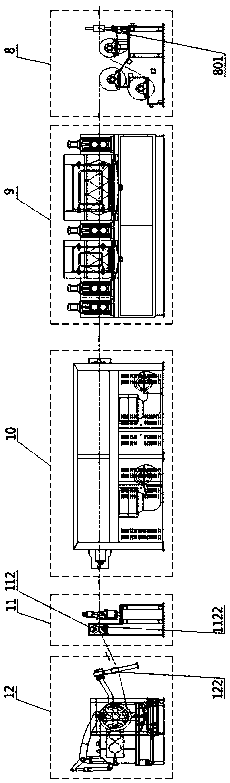

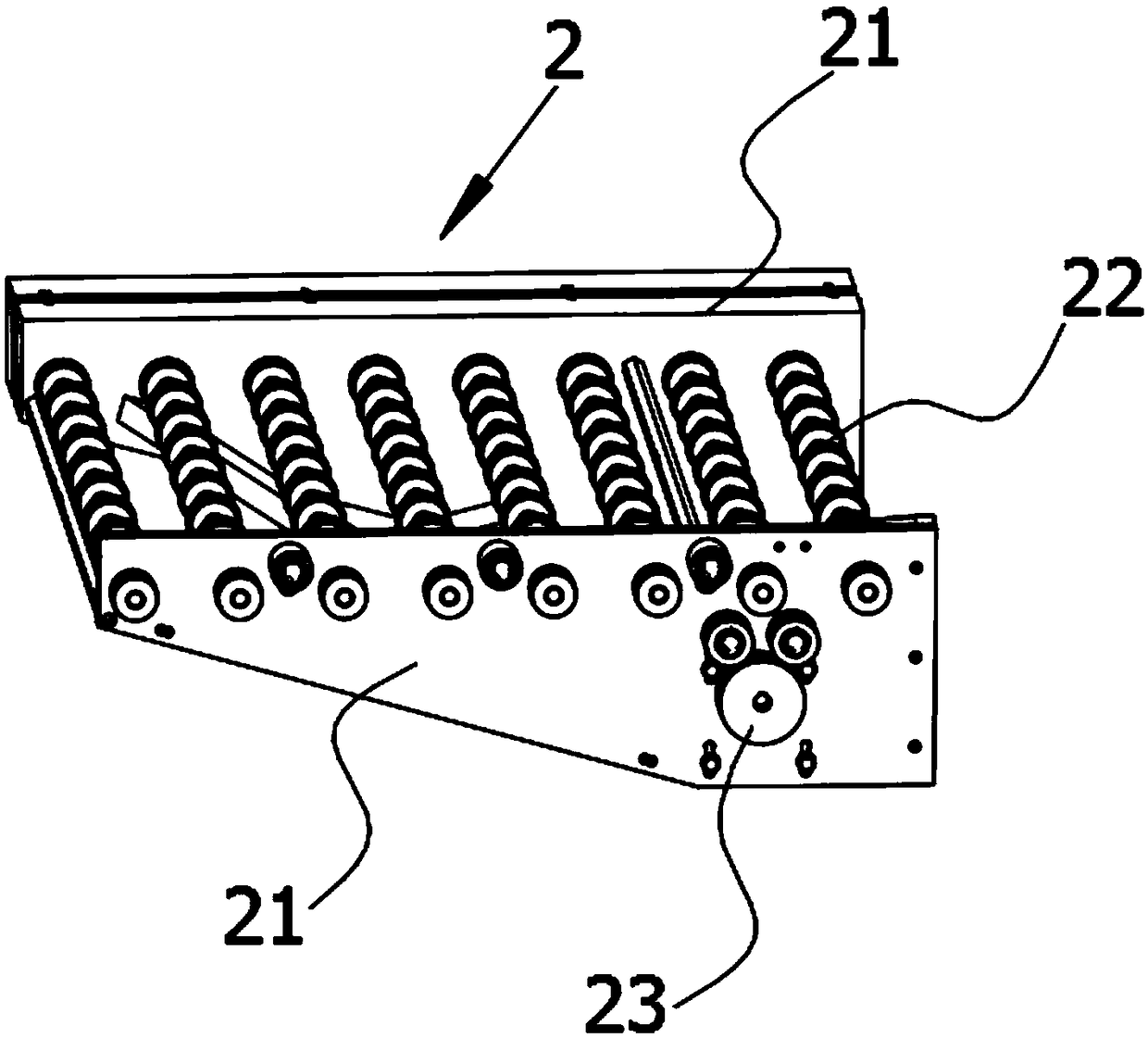

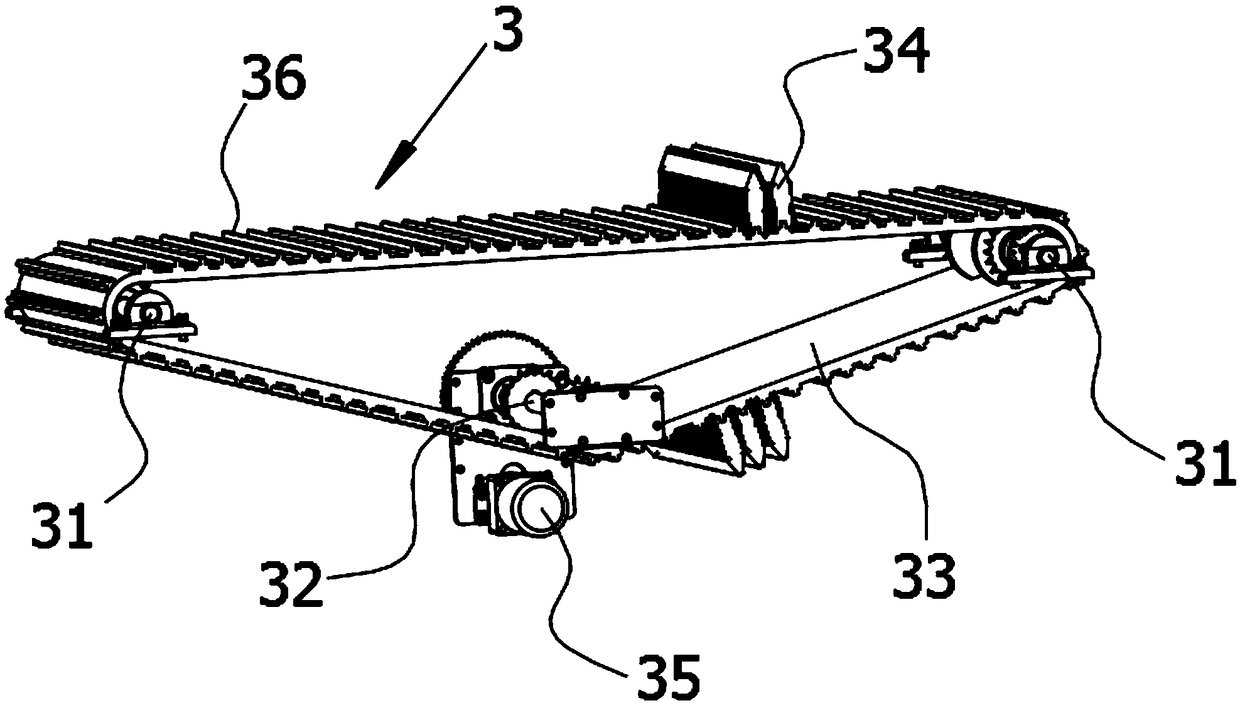

Voice Coil Motor (VCM) magnetic sheet assembly device

ActiveCN102946169AAvoid surface scratchesAvoid breakingManufacturing dynamo-electric machinesControl systemEngineering

The invention discloses a Voice Coil Motor (VCM) magnetic sheet assembly device. The device comprises a bench, a feed system, a feeding system, a carrying system and a control system, wherein a feeding hole is arranged on the bench, the feed system which is used for feeding a magnetic sheet to the feeding hole is arranged at the position of the inside of the bench, which corresponds to the magnetic sheet installation position, the feeding system which is used for automatically assembling the magnetic sheet fed by the feed system to motors to be assembled is arranged at the position of the upper portion of the bench, which corresponds to the feeding hole, the carrying system which is used for fixing the motors to be assembled is arranged at the position of the lower portion of the bench, which corresponds to the feeding device, and the control system is used for controlling the working of the feed system, the feeding system and the carrying system. The feeding system which moves vertically is matched with a magnetic sheet feed system, magnets sheets which are required to be assembled are assembled to the carrying system for fixing the motors to be assembled one time, the carrying system is set to move along an X axis and a Y axis, a plurality of motor fixing groove for fixing motors to be assembled are fixedly arranged on a fixture carrier, a plurality of motors can be assembled continuously, and the production efficiency and the pass percentage are improved.

Owner:辽宁中蓝光电科技有限公司

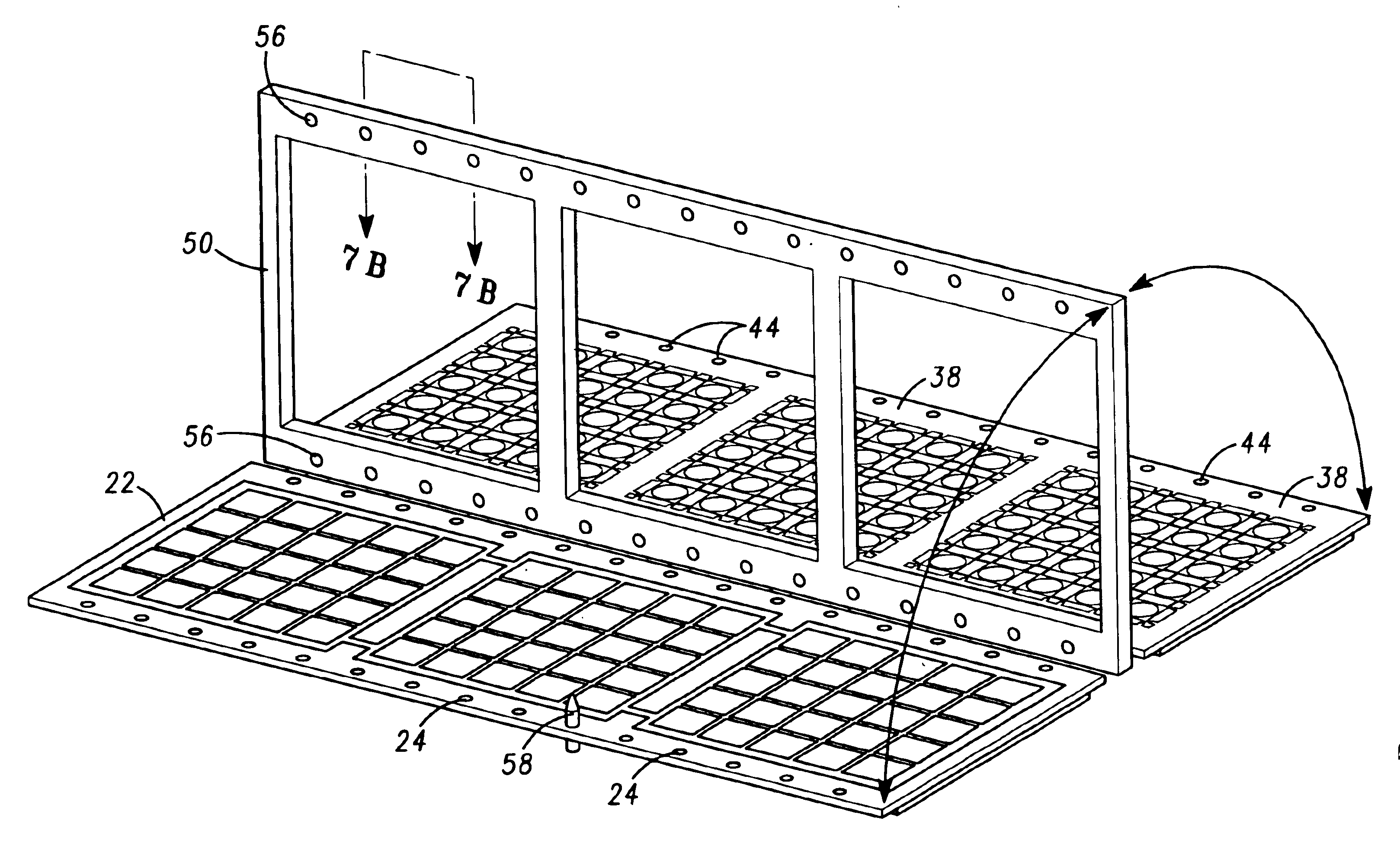

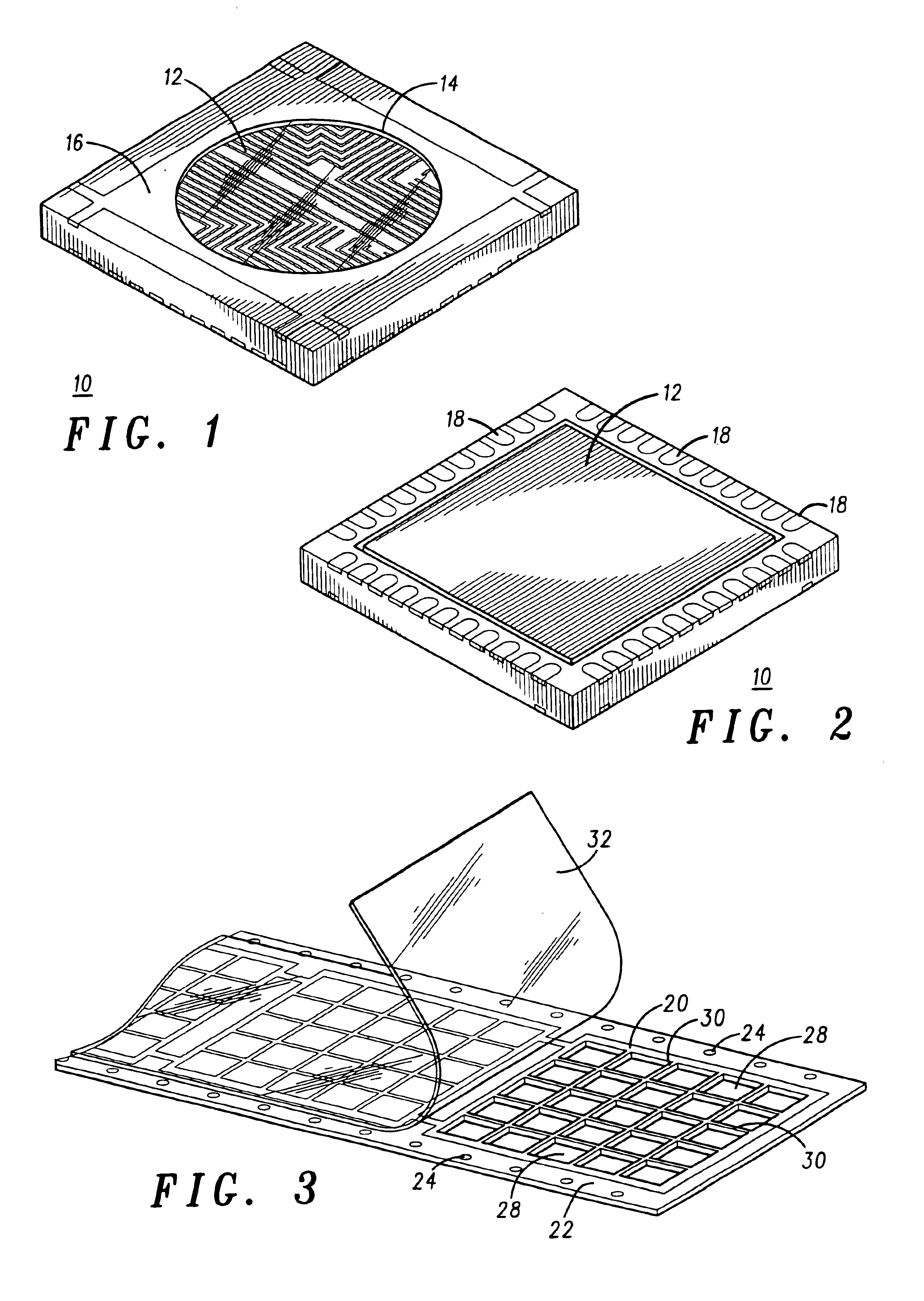

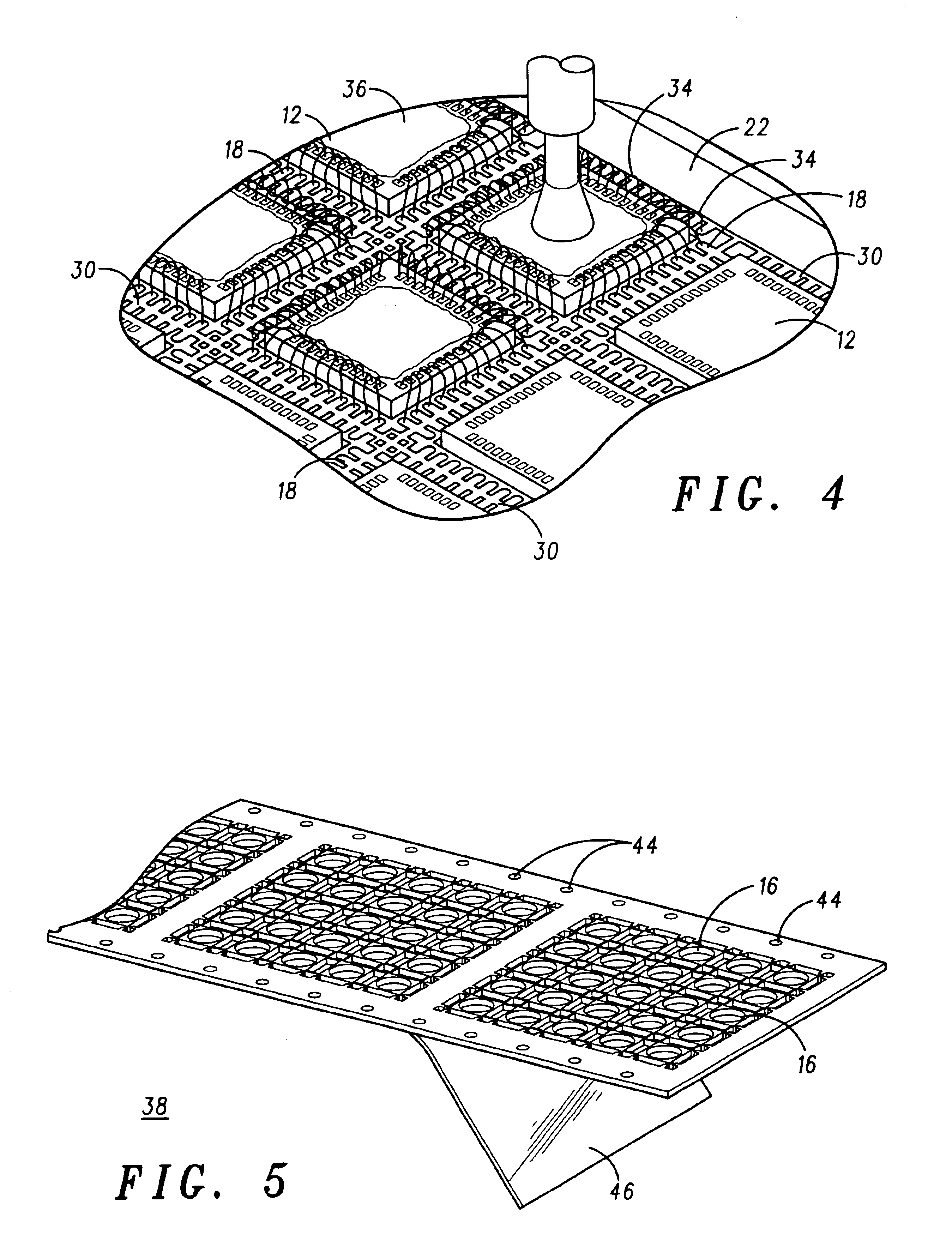

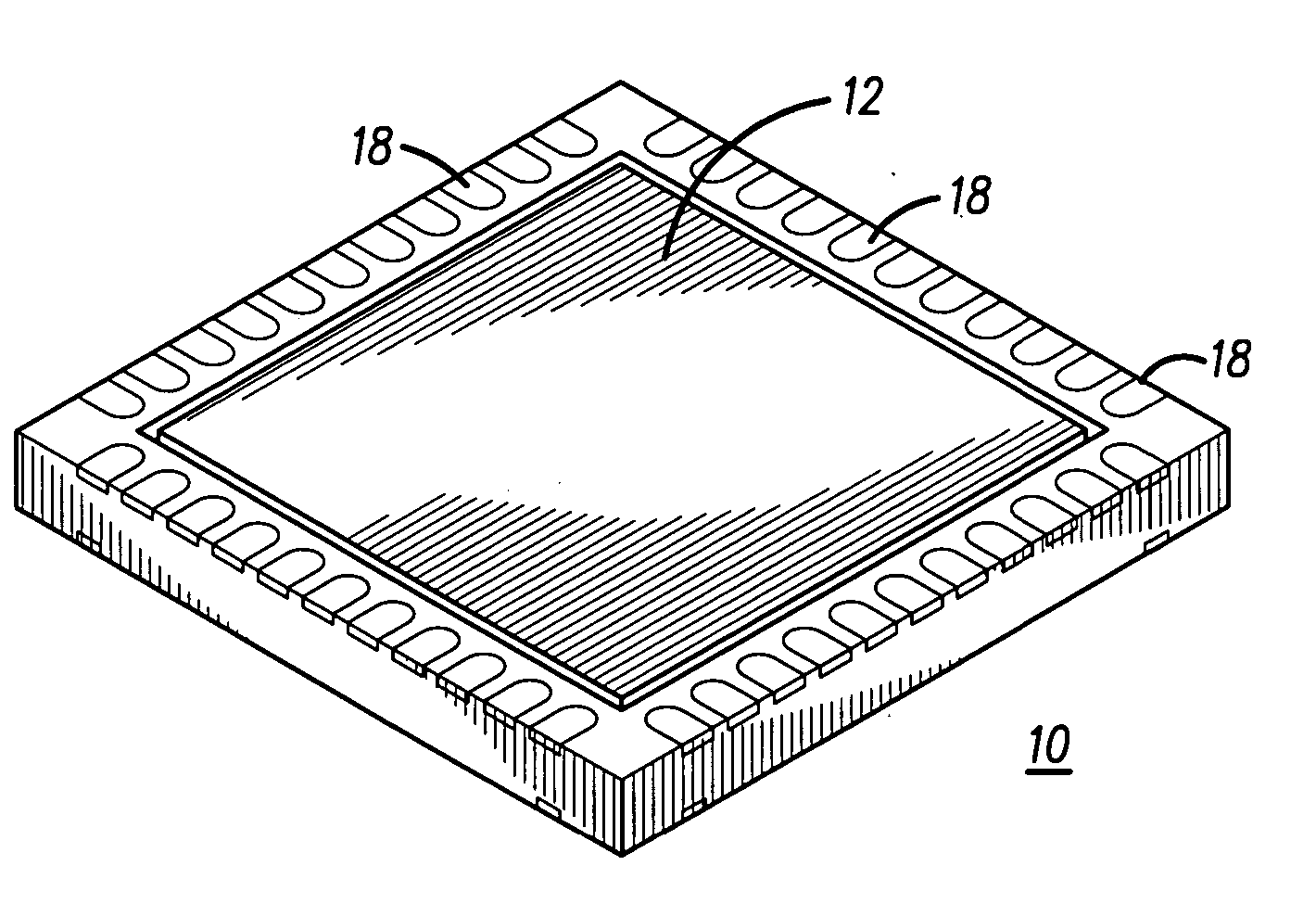

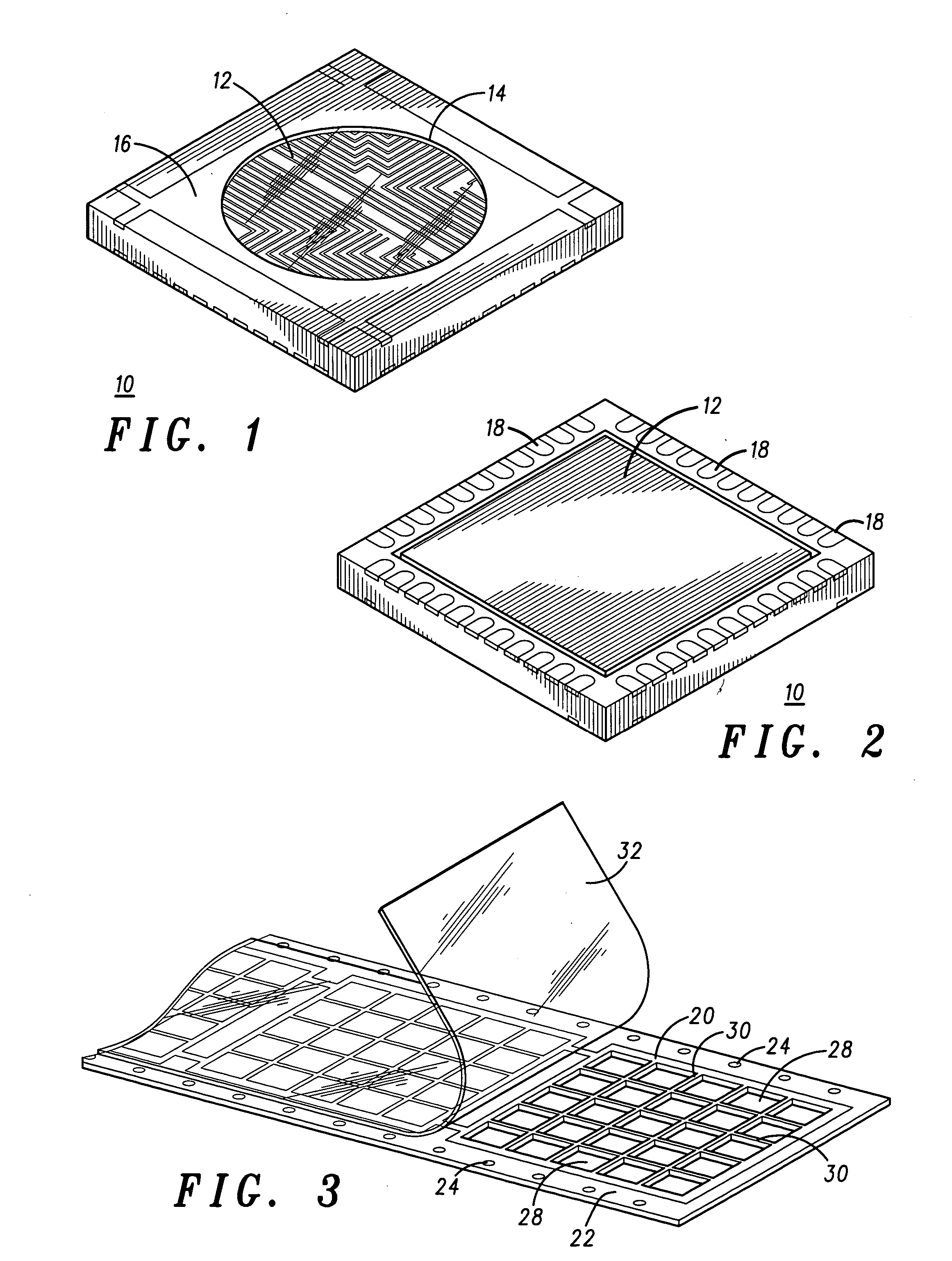

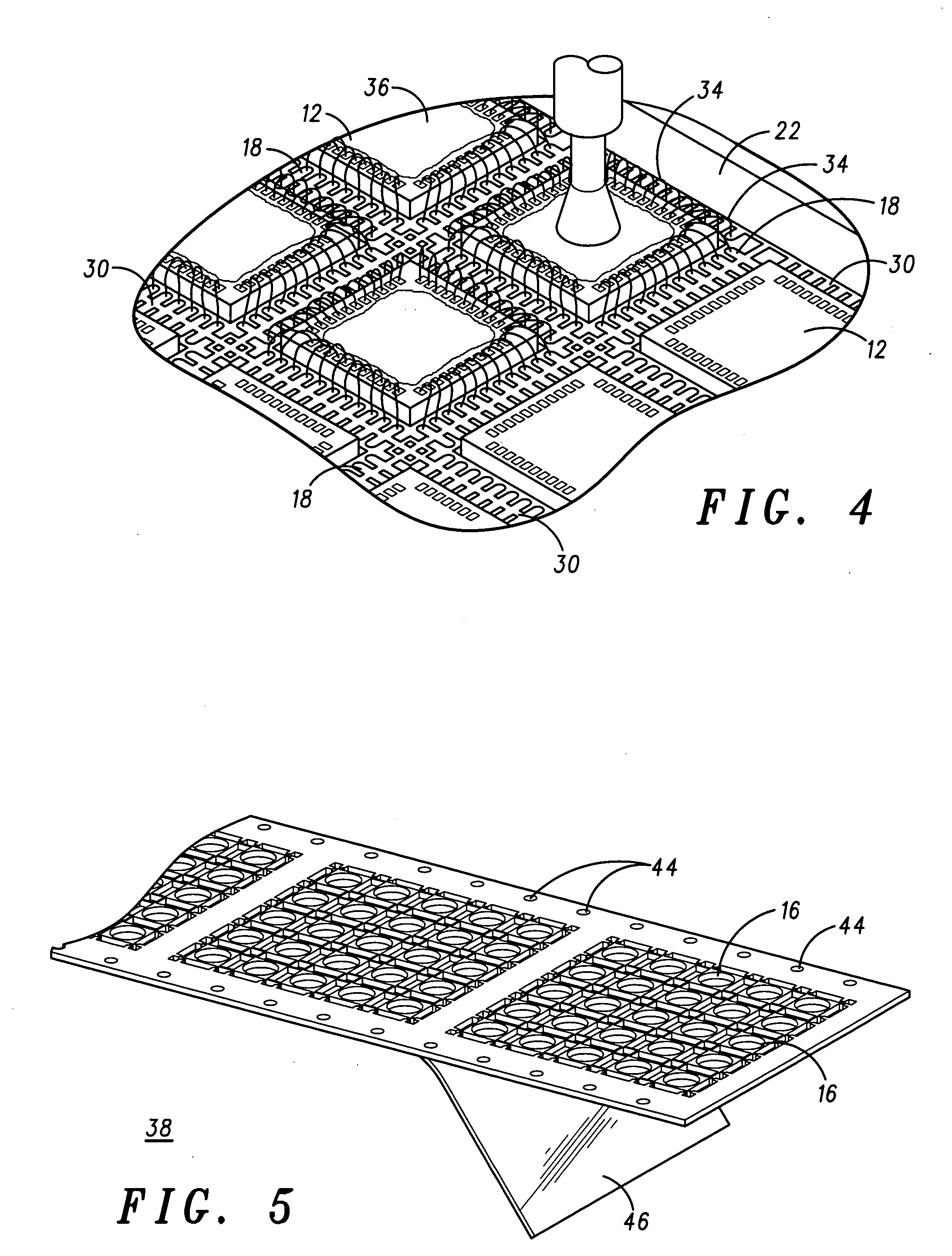

Method of packaging an optical sensor

InactiveUS6905910B1Avoids potential surface scratchingLow costSemiconductor/solid-state device detailsSolid-state devicesMultiple sensorLead frame

An image sensor device includes a first, QFN type leadframe to which a sensor IC is electrically connected. A second leadframe is provided for holding a lens. A third leadframe is positioned between the first and second leadframes to appropriately space the IC from the lens. Multiple sensor devices are assembled at the same time by the use of leadframe panels.

Owner:INTELLECTUAL VENTURES II

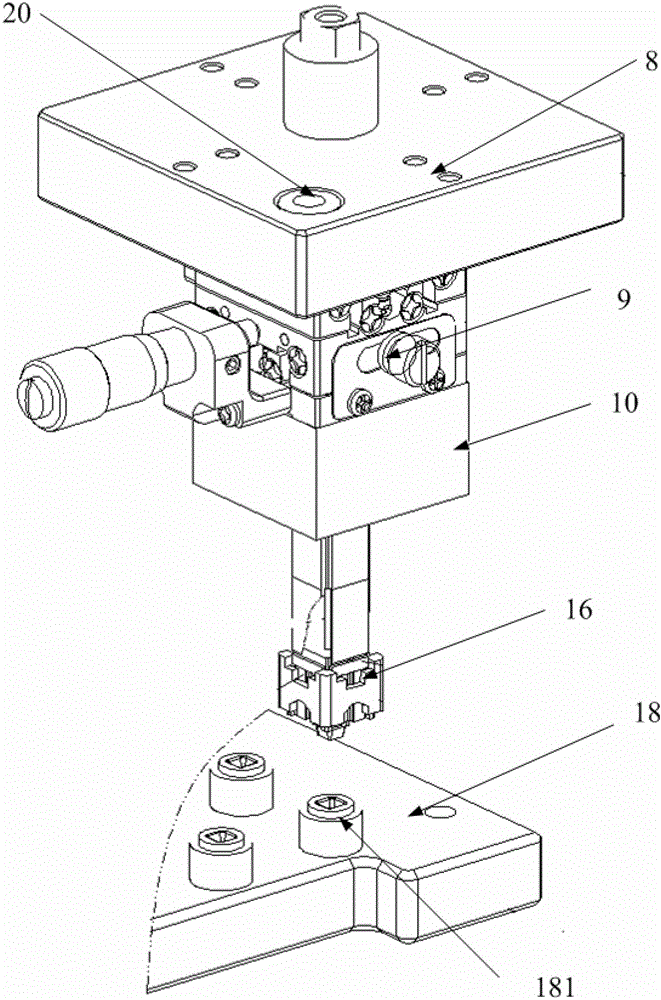

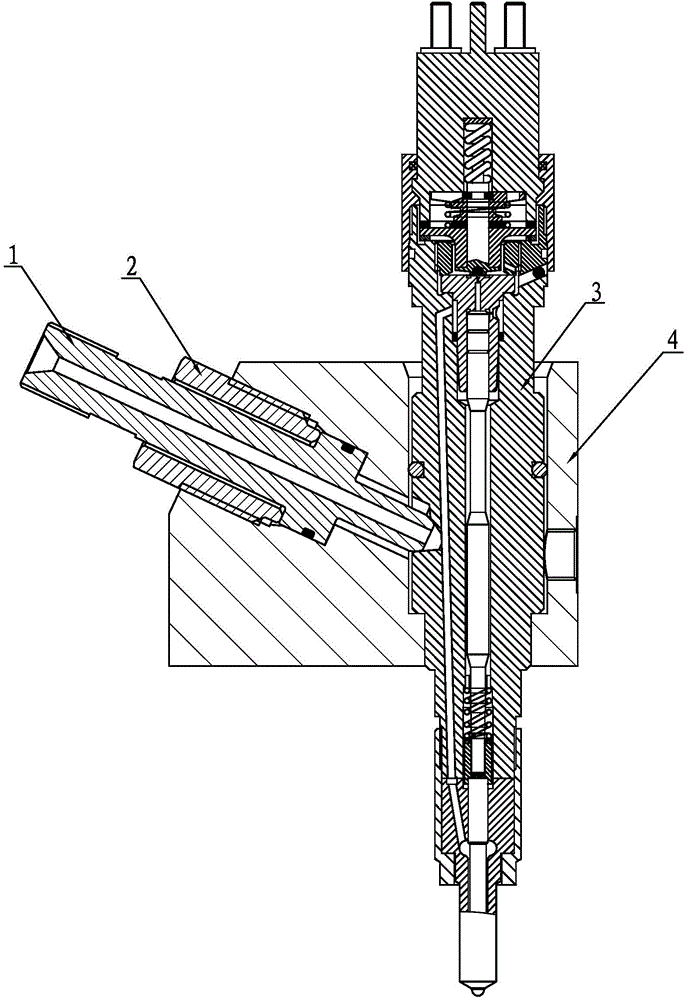

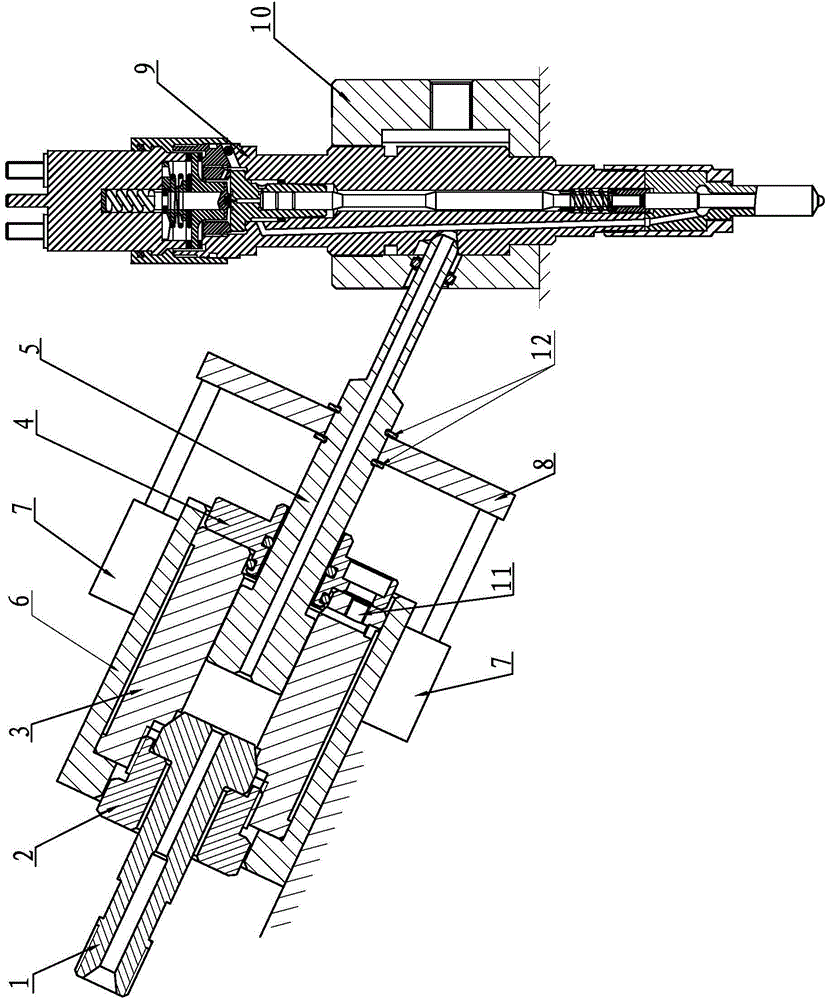

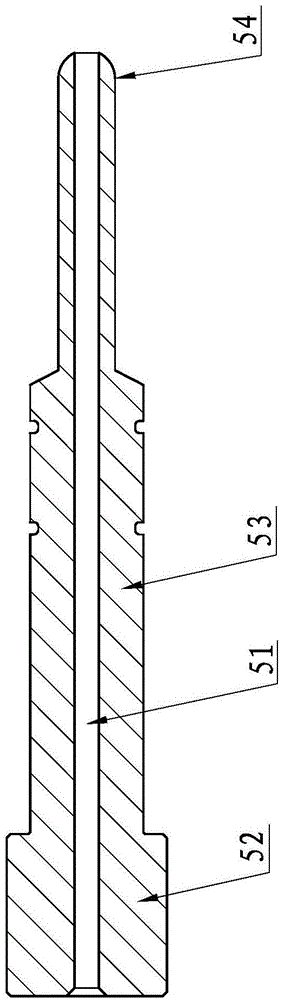

Synchronous oil supply and hold-down device for detecting high-pressure common-rail oil sprayer online and application method thereof

ActiveCN104454275AImprove high pressure sealing performanceIncrease authenticity and reliabilityEngine testingFuel injection apparatusPistonFuel oil

The invention provides a synchronous oil supply and hold-down device for detecting a high-pressure common-rail oil sprayer online. The synchronous oil supply and hold-down device comprises a high-pressure oil supply and sealing butt joint component and a preliminary butt joint and disengagement mechanism, wherein the high-pressure oil supply and sealing butt joint component is composed of a high-pressure oil injection connector, a fastening nut sleeve, a piston sleeve, a pressure relief end cover and an oil injection piston, and the preliminary butt joint and disengagement mechanism is composed of a fixed socket sleeve, an air cylinder and a connecting plate. The common-rail oil sprayer is perpendicularly mounted on an oil sprayer mounting sleeve in a sleeved mode. The axis of an oil inlet taper hole of the common-rail oil sprayer and the axis of the oil injection piston are collinear. Since the synchronous oil supply and hold-down device is used for detecting the common-rail oil sprayer online, the detection time is shortened from existing three minutes per piece to 55 seconds per piece, the auxiliary time is shortened from existing 135 seconds to 10 seconds, and benefits are remarkable. In the force application process, the oil injection piston will not rotate in the axial direction, the surface of the oil injection piston will not be scratched, and the oil injection piston can also be prevented from getting stuck. In the operating process, high-pressure oil leaks through a gap between the oil injection piston and the piston sleeve, and the leaked fuel oil can be collected by the pressure relief end cover and led back to an oil tank, so the utilization rate of the fuel oil and the cleanliness of a working table are guaranteed.

Owner:常州博瑞油泵油嘴有限公司

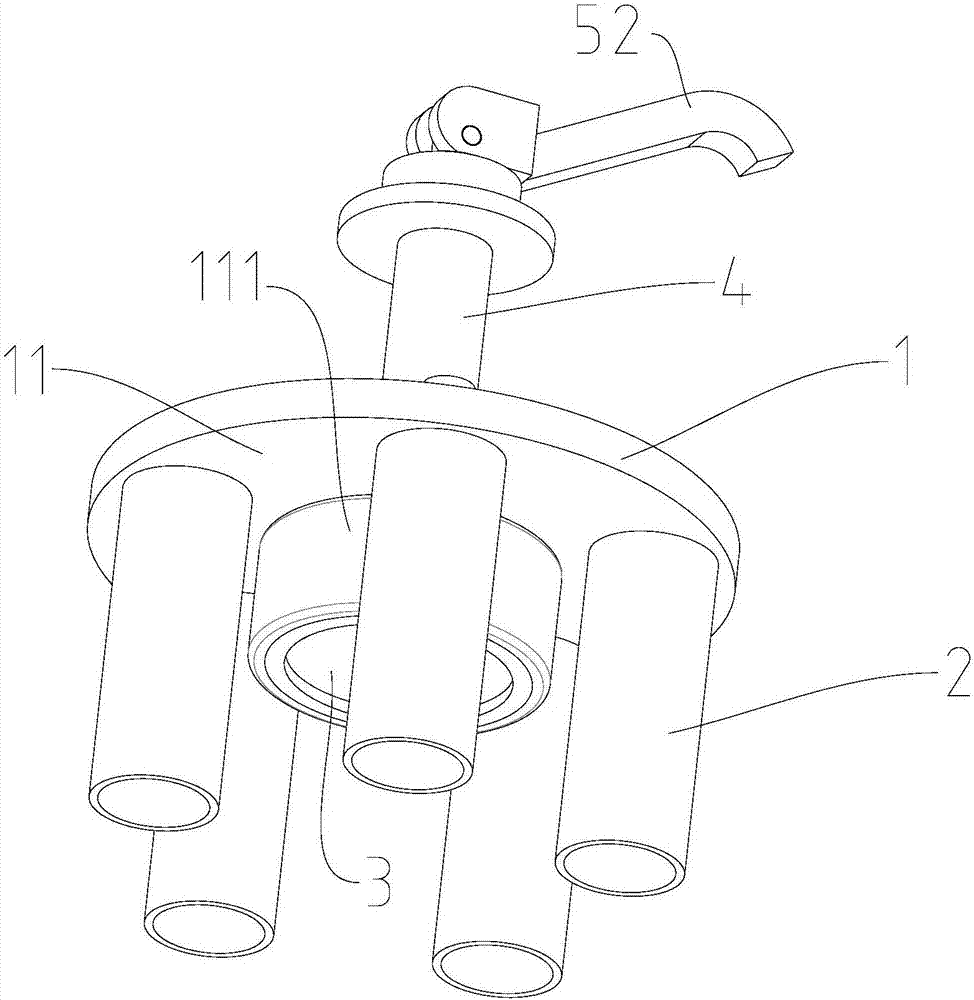

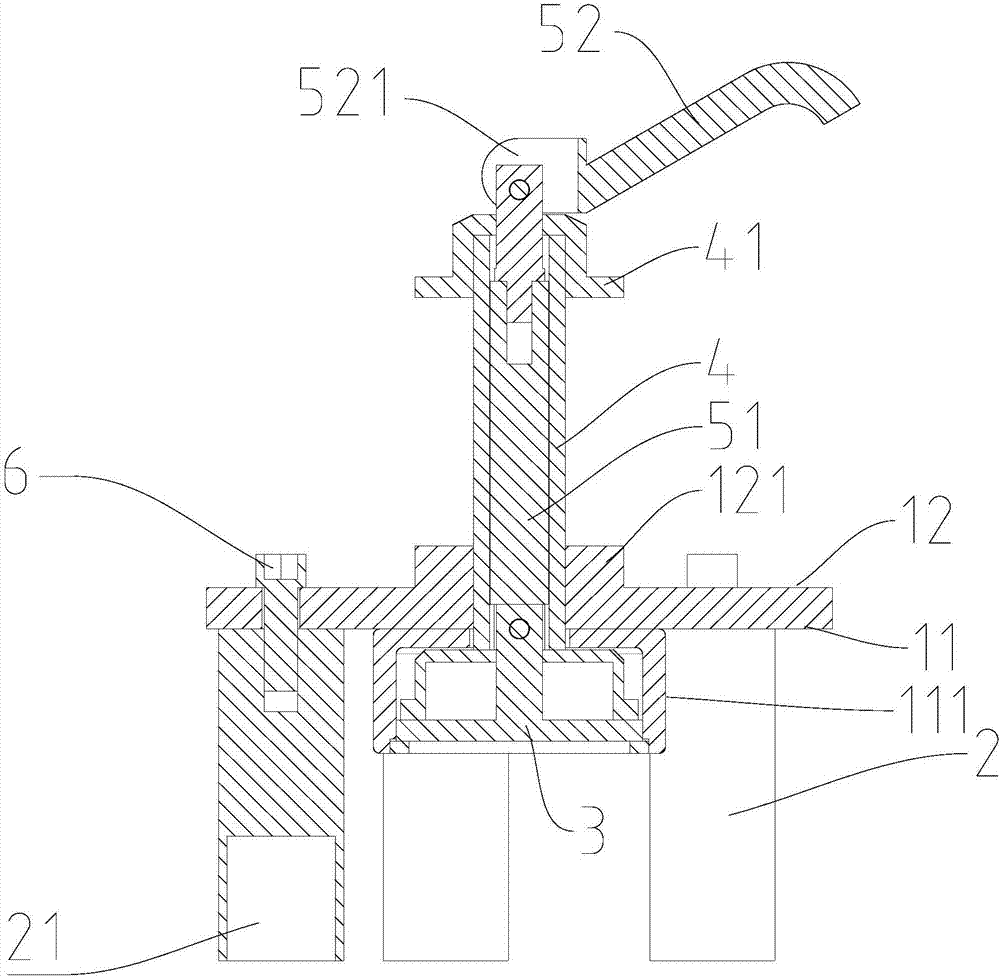

Tool for disassembling hub decorative cover

PendingCN106864170AQuick releaseAvoid surface scratchesWheel assembling toolsSuction forceStructural engineering

Owner:BEIJING HYUNDAI

High-haze colored ultra-thin high-frequency cover film and preparation method thereof

ActiveCN108966519AGood weather resistanceHas matte propertiesCircuit optical detailsLayered product treatmentAdhesiveHardness

Owner:KUSN APLUS TEC CORP

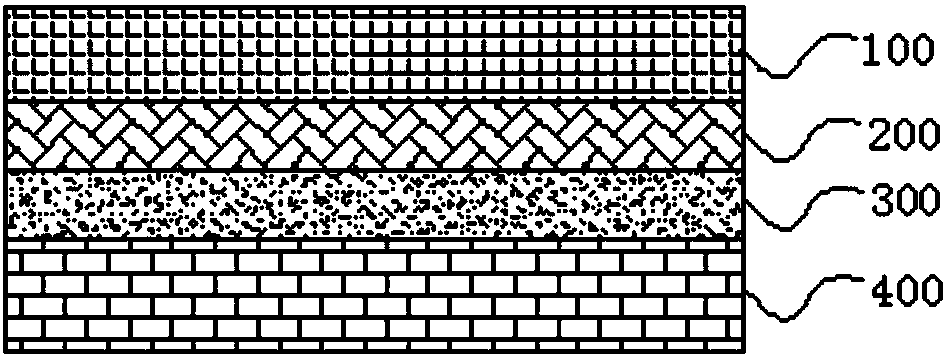

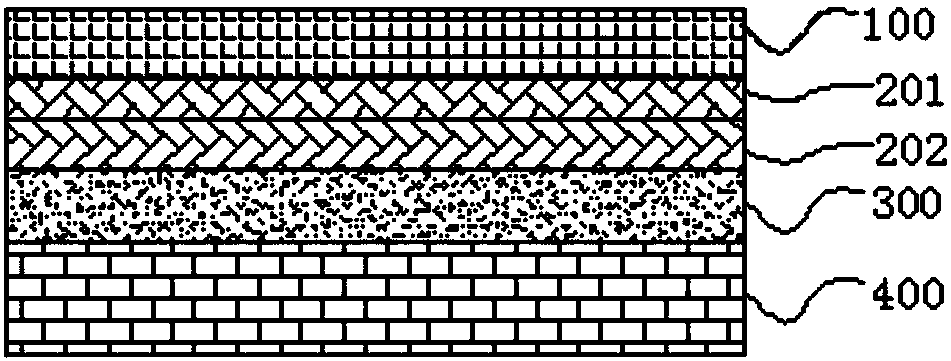

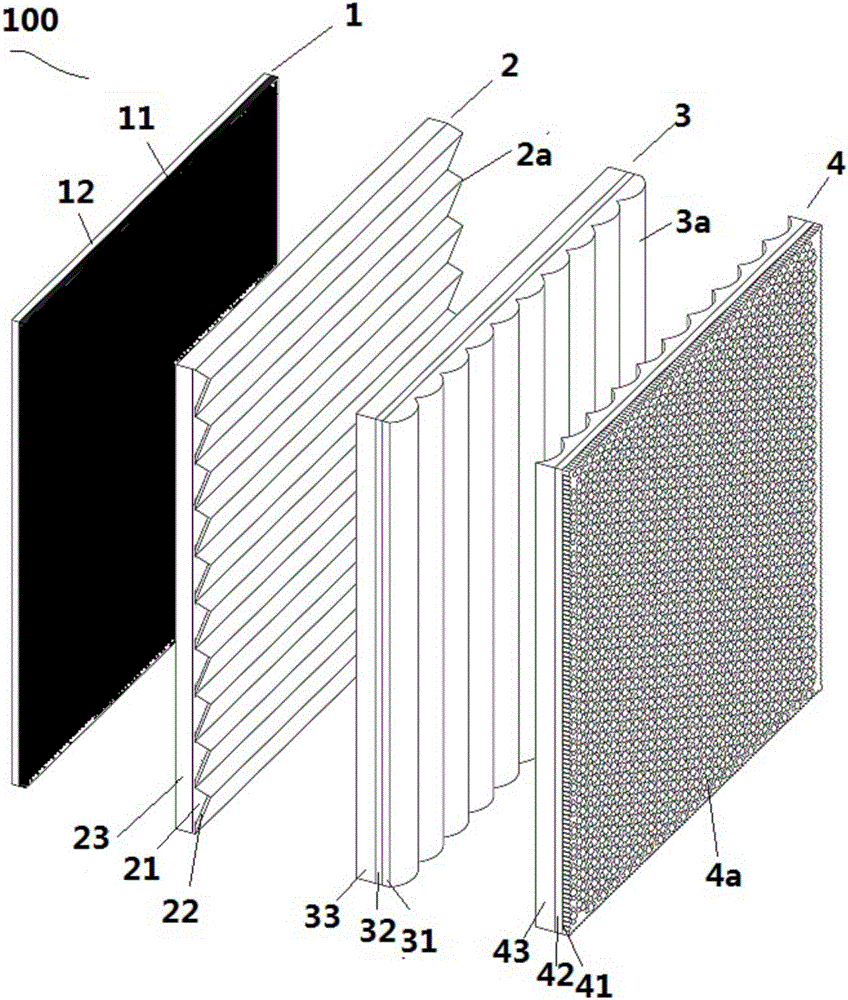

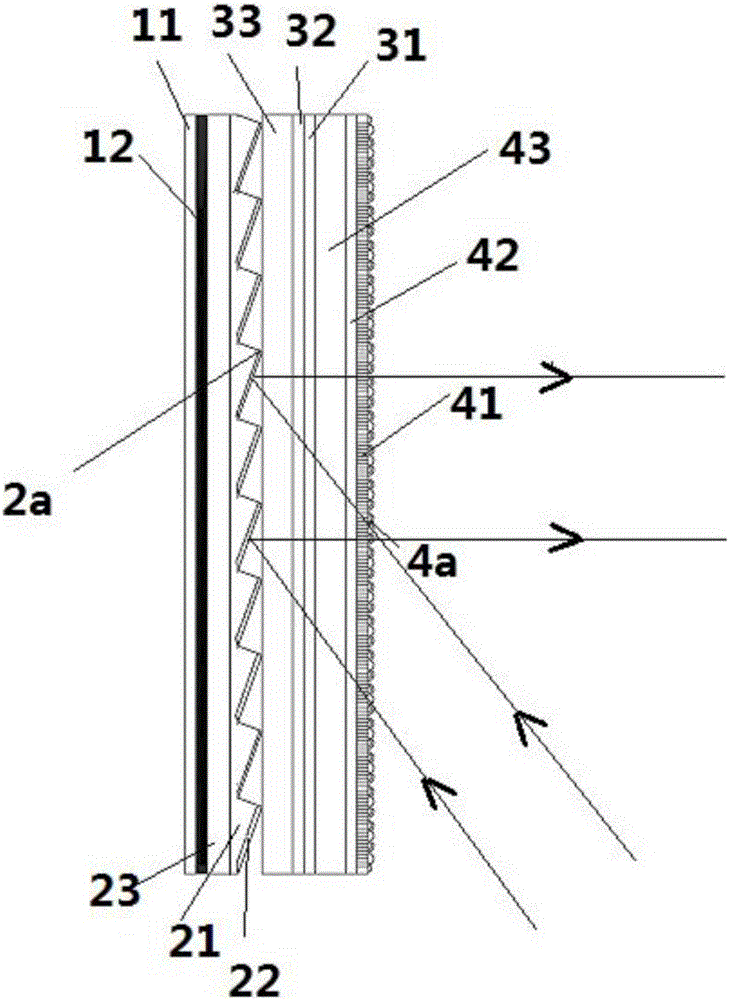

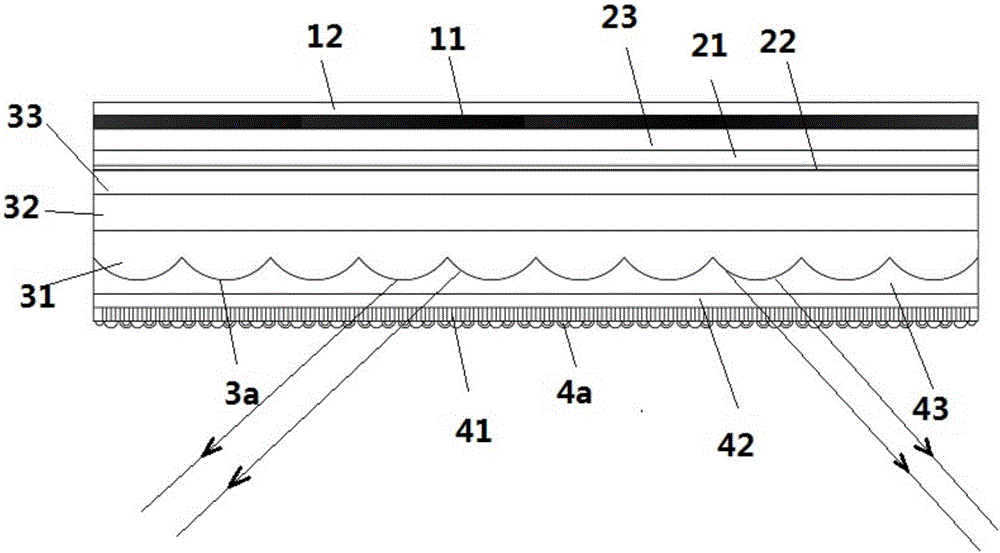

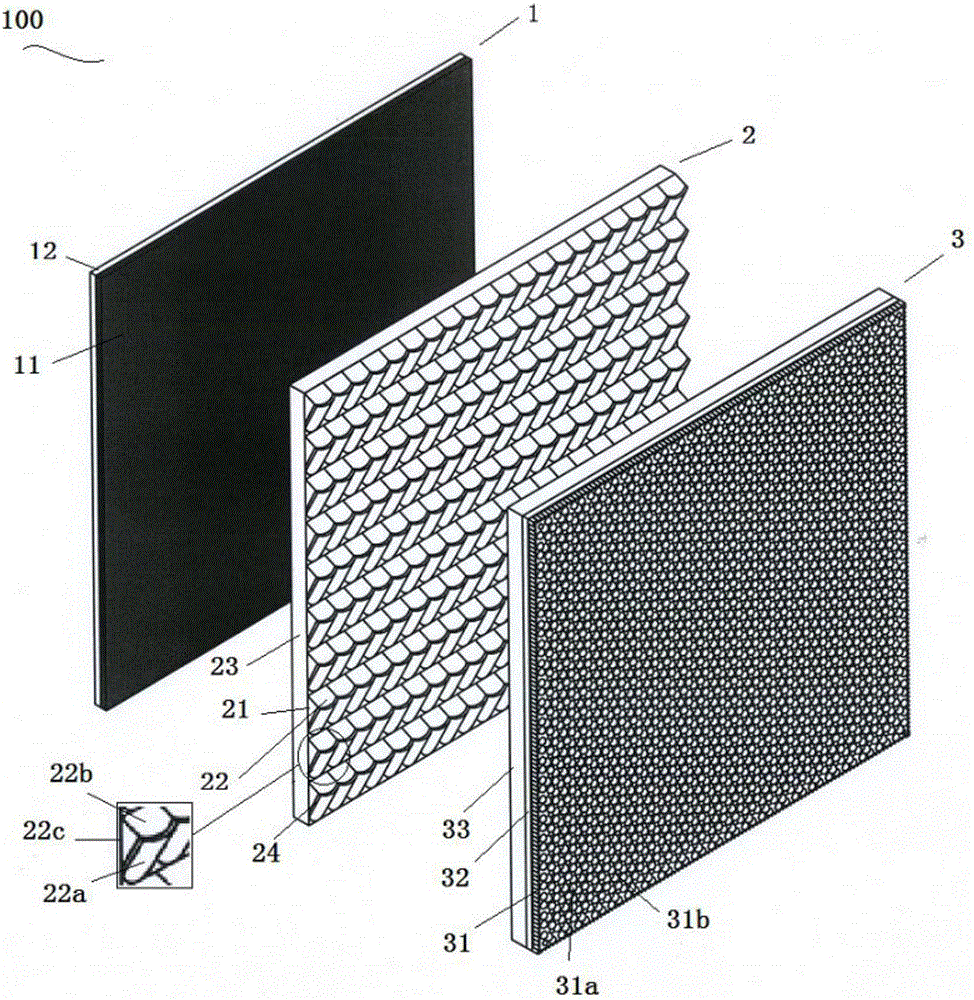

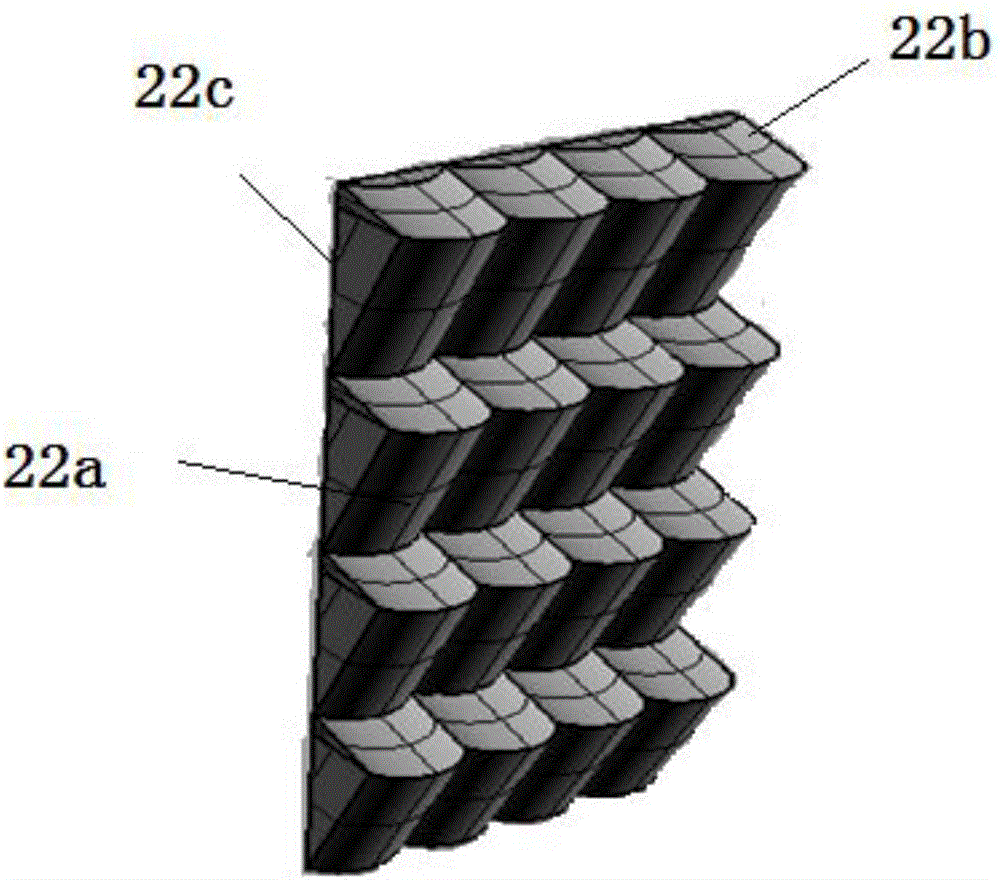

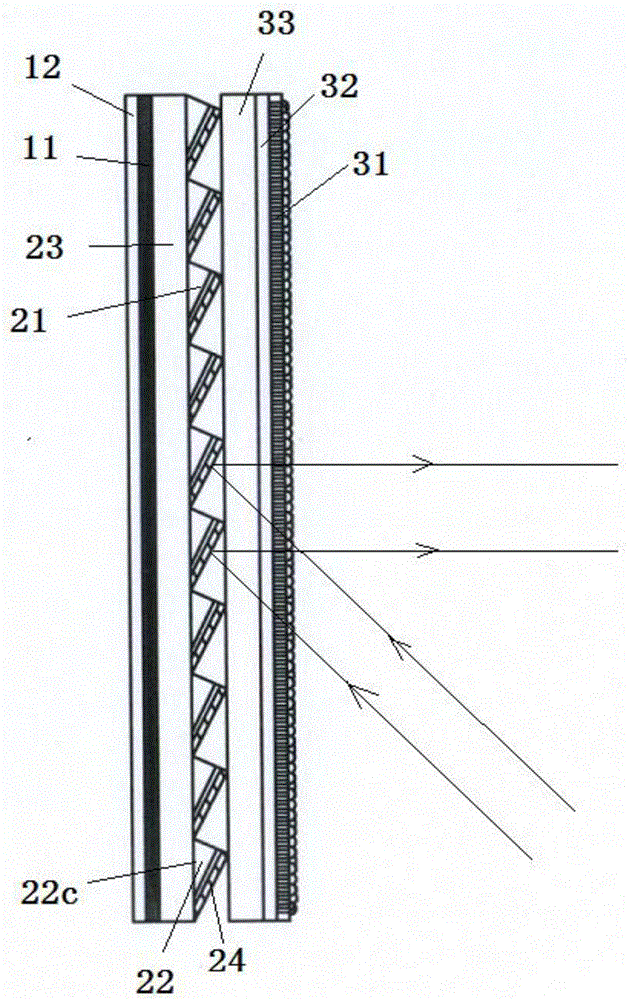

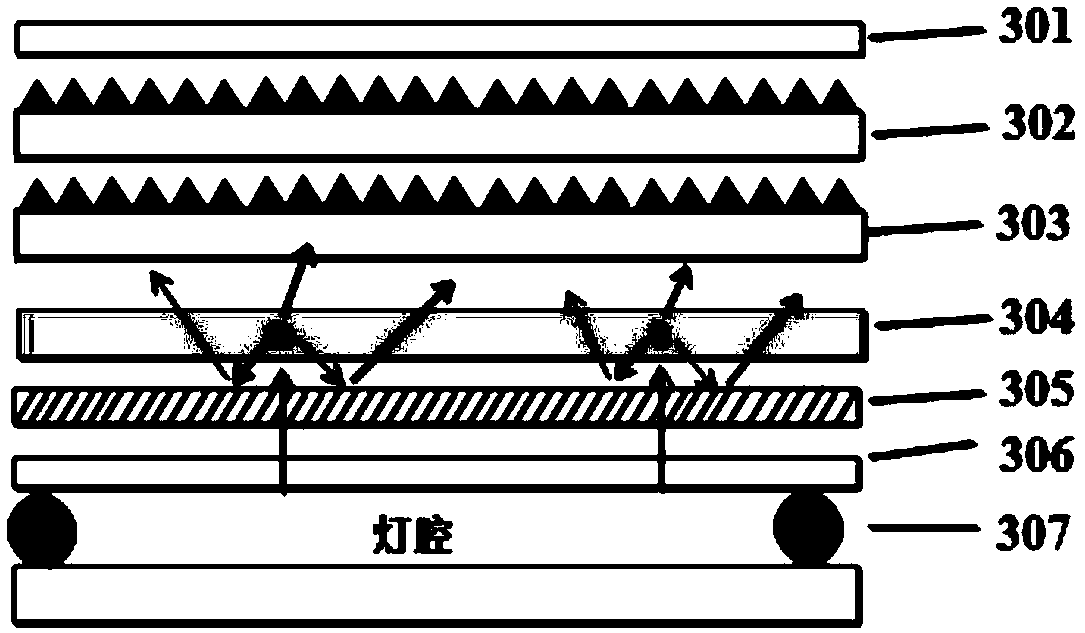

Ultra-short-focus projection curtain

The invention relates to an ultra-short-focus projection curtain. The ultra-short-focus projection curtain mainly comprises a bottom layer, a first intermediate layer, a second intermediate layer and a surface layer which are successively pasted from back to front. The bottom layer comprises a black glue layer. The first intermediate layer comprises a prism layer and a reflection layer. A plurality of strip-shaped tooth prisms with triangular cross sections are successively connected and arranged in parallel to form the front surface of the prism layer, and the strip-shaped tooth prisms extend along the horizontal direction. The reflection layer is a film and is tightly adhered to the prism surface of the strip-shaped tooth prisms. The second intermediate layer comprises a lens layer. A plurality of cylindrical convex lenses are connected in parallel to form the front surface of the lens layer. The surface layer includes a first diffusion layer whose rough surface is formed by a plurality of micro-particle-shaped projections, and the surface layer is doped with black dying ink. The ultra-short-focus projection curtain disclosed by the invention has the advantages that ultra-short distance projection is realized, the high gain is maintained, and a wide visual angle is also realized; in addition, the surface of the curtain is light resistant, anti-glare and scraping resistant, the black-white contrast is high, washing and cleaning are convenient, and the application value is extremely high.

Owner:简铭镇 +1

Galvanized steel pipe manufacturing and machining intermittent feeder

ActiveCN110577073AImprove stabilityAutomatically adjust the angleConveyorsConveyor partsEngineeringSteel tube

The invention provides a galvanized steel pipe manufacturing and machining intermittent feeder. A bottom plate, a feeding device and a driving device are included. The galvanized steel pipe manufacturing and machining intermittent feeder is characterized in that the feeding device is arranged at the middle portion of the upper end of the bottom plate, the driving device is arranged right in frontof the feeding device, and the driving device is arranged on the bottom plate. The galvanized steel pipe manufacturing and machining intermittent feeder can solve the problems that continuous feedingis mostly adopted in an existing galvanized steel pipe feeder feeding manner, galvanized steel pipe collisions and stacking are likely to happen in the feeding process, and consequently the surfaces of galvanized steel pipes are scratched; and in the existing galvanized steel pipe feeder feeding process, under influences from the galvanized steel pipe structure, clamping is not firm, swinging anddeflecting happen, transportation is not stable, consequently, the galvanized steel pipes disengage from a workbench, and later machining work of the galvanized steel pipes is influenced.

Owner:广州富力通管道设备有限公司

Drilling equipment used for machine parts

InactiveCN108031902AImprove processing efficiencySimple structureFeeding apparatusPositioning apparatusElectric machineryGeotechnical engineering

The invention belongs to the technical field of machining, and particularly discloses drilling equipment used for machine parts. The drilling equipment comprises a rack, a drilling unit and a clampingunit, the clamping unit is fixed to the rack and is located above the drilling unit, the drilling unit comprises a rigid corrugated pipe with the closed lower end, a threaded rod and a motor drivingthe threaded rod to rotate, the rigid corrugated pipe is rotationally connected to the rack, a spiral bit is fixed into the rigid corrugated pipe, and the axis of the spiral bit is coincident with theaxis of the rigid corrugated pipe in position; a strip-shaped groove is formed in the side wall of the threaded rod, the upper side of the threaded rod is connected into the spiral bit in a sliding manner, the axis of the threaded rod is coincident with the axis of the spiral bit, and a protrusion connected into the strip-shaped groove in a sliding manner is arranged in the spiral bit; and a pushing sleeve is in threaded connection to the threaded rod, a sliding groove is formed in the pushing sleeve, and a limiting rod with one end clamped into the sliding groove is fixed to the rack. By means of the drilling equipment, the problem that when placed on a working table, the machine parts are prone to being scrapped to be damaged by metal chippings is solved.

Owner:宁波德深机械设备有限公司

Packaging substrate, semiconductor package and fabrication methods thereof

ActiveCN104009006AAvoid surface scratchesAvoid chippingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A packaging substrate is disclosed, which includes: an encapsulant having opposite first and second surfaces; a plurality of conductive elements embedded in the encapsulant, wherein each of the conductive elements has a first conductive pad exposed from the first surface of the encapsulant and a second conductive pad exposed from the second surface of the encapsulant; and a protection layer formed on the second surface of the encapsulant and the second conductive pads so as to protect the second surface of the encapsulant from being scratched.

Owner:SILICONWARE PRECISION IND CO LTD

Surface finishing technology of paper packing box

ActiveCN104210262AReduce the amount requiredAvoid pollutionInksOther printing apparatusScreen printingSurface finish

The invention relates to the field of package printing, in particular to a surface finishing technology of a paper packing box. The surface finishing technology of the paper packing box, which is provided by the invention, adopts a silk-screen printing manner or a gravure printing manner to coat lisson printing ink on the surface of paper of the packing box so as to carry out surface finishing. The surface finishing technology of the paper packing box, which is provided by the invention, adopts the finishing technology to carry out finishing on the surface of a package printed matter, so that the surface of the packing box printed by a paper material generates a lisson effect and is like as scattering a layer of paillette, and a twinkling gloss effect appears under irradiation of rays, thus the packaging of the product is more exquisite, the surface abrasion caused by production and transportation processes is avoided, and box gluing forming is not influenced. The surface finishing technology has the advantages of environmental friendliness and no pollution, and can adapt to high-speed printing production on a large scale.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

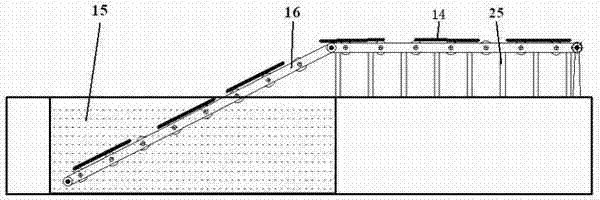

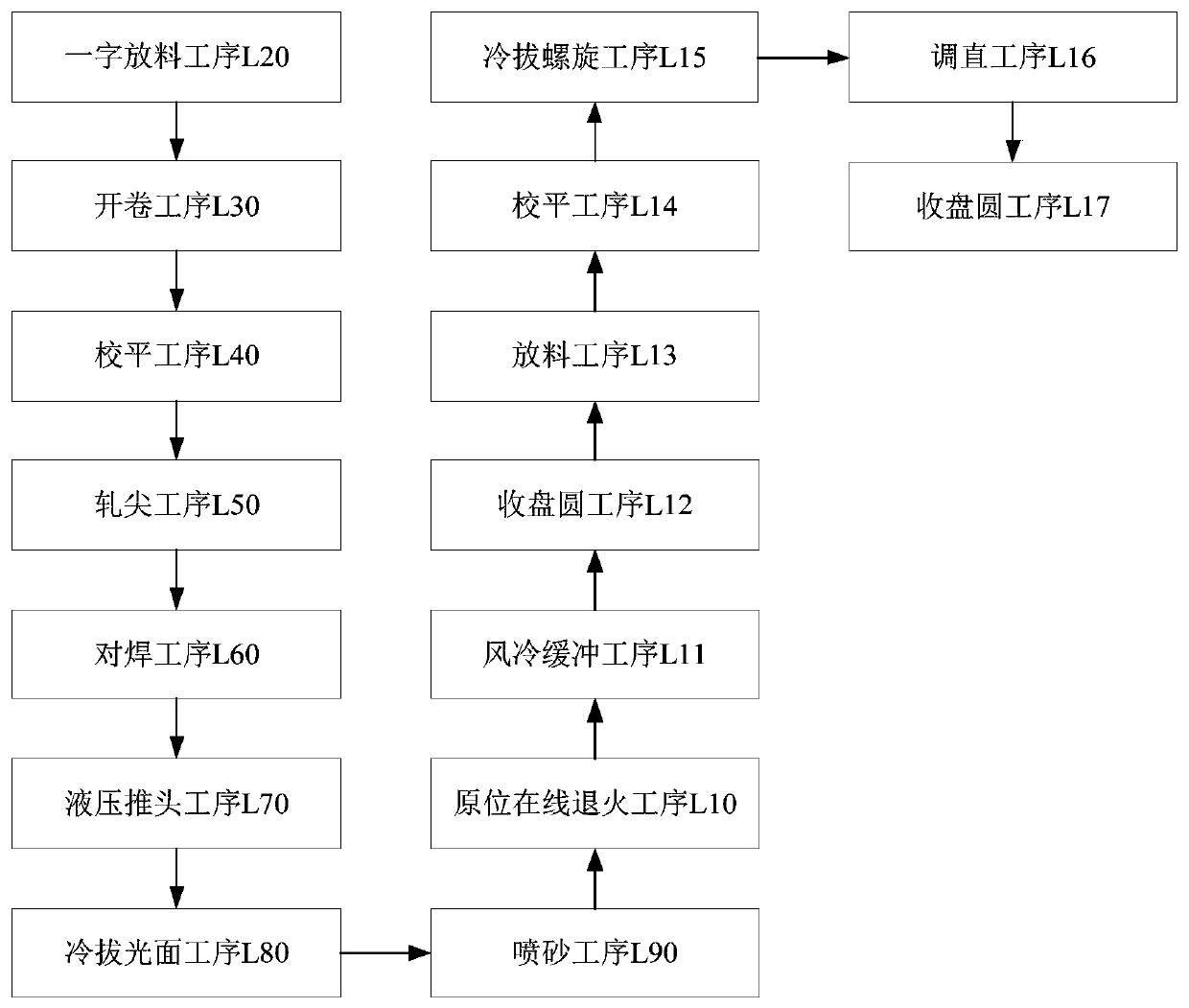

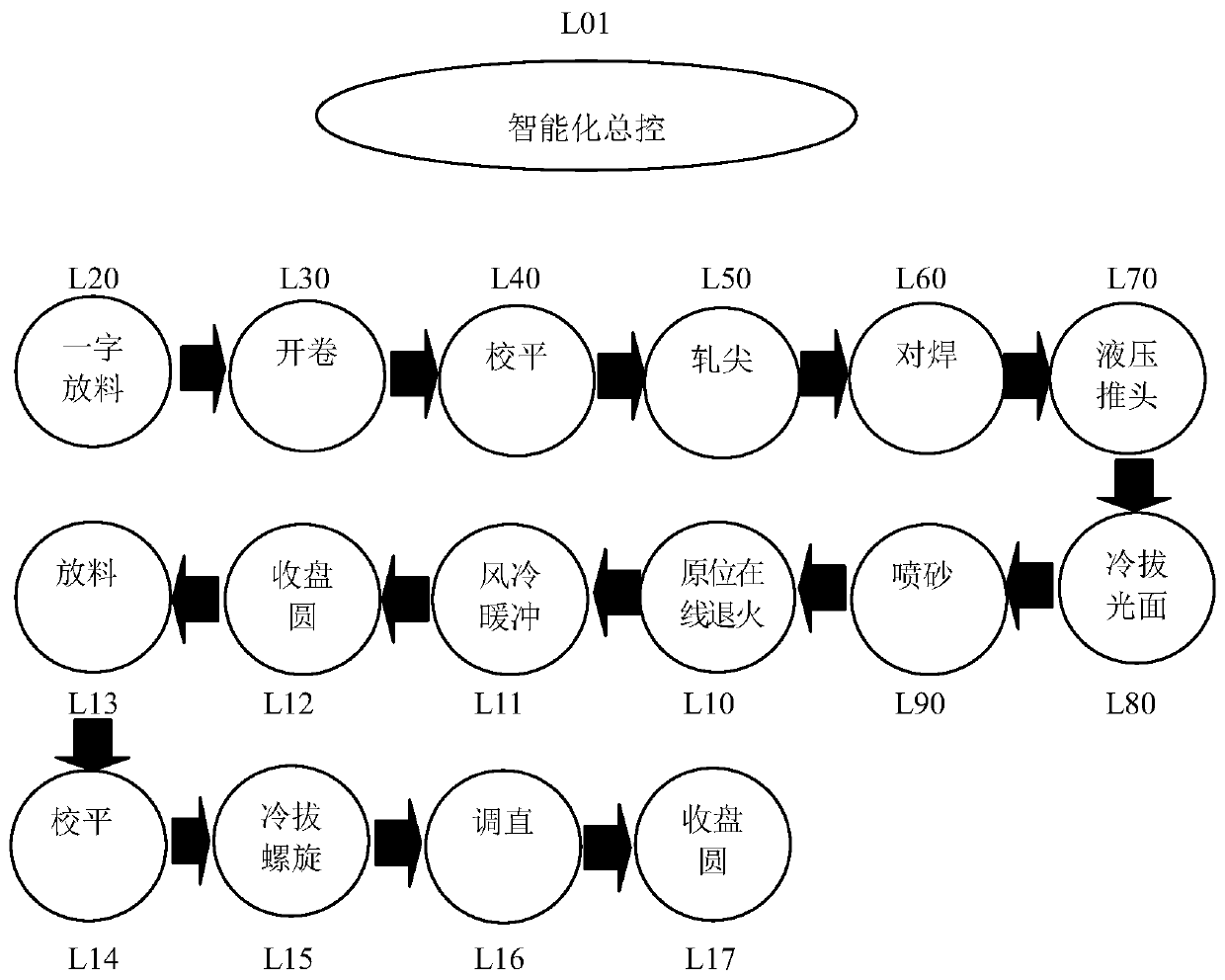

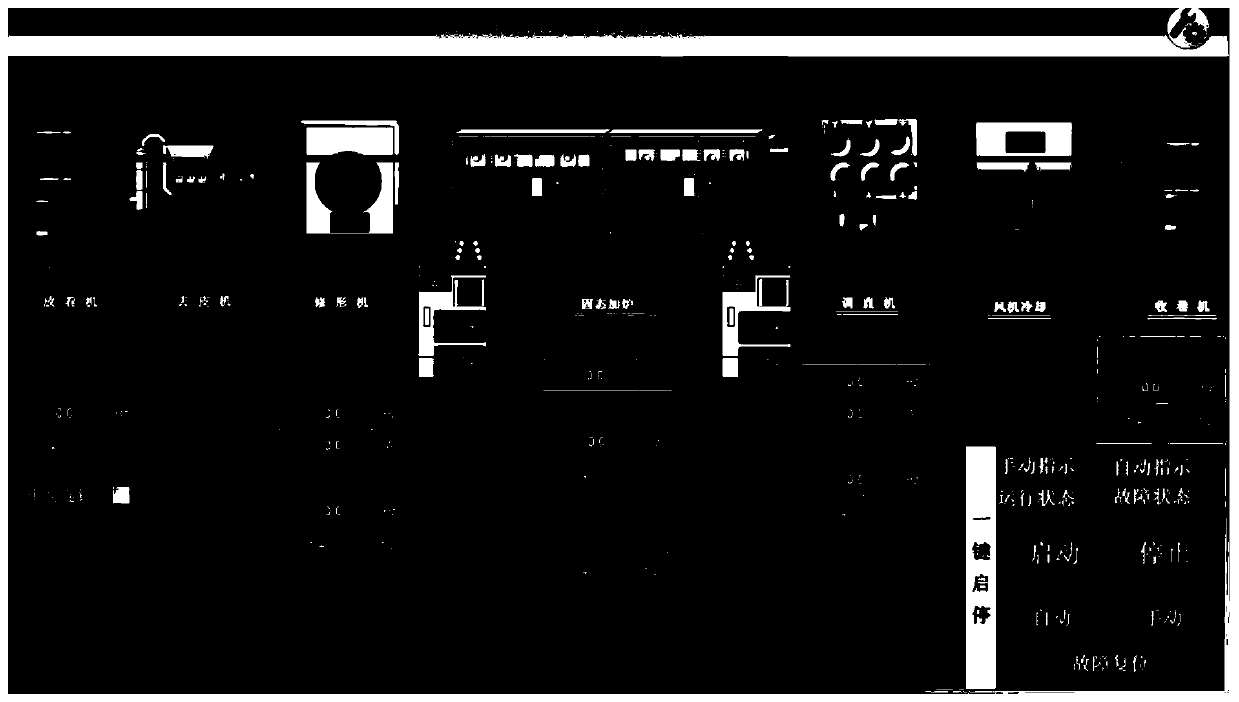

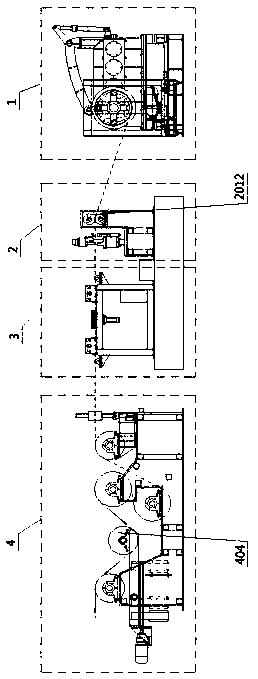

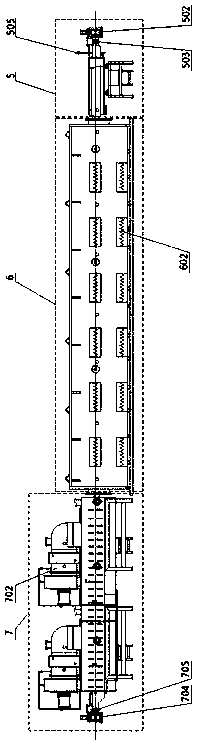

Machining process of NPR steel bar wire rod

ActiveCN110523801AAvoid surface scratchesAvoid bending etc.Wire articlesMetal rolling arrangementsWire rodButt welding

The invention discloses a machining process of an NPR steel bar wire rod. An NPR steel bar is in a cold machining state, the diameter of the NPR steel bar is smaller than 14 mm, the yield strength ofthe NPR steel bar is 800 MPa to 950 MPa, the tensile strength is 900 MPa to 1100 MPa, and the maximum force elongation rate is larger than or equal to 20%. The machining process comprises the following steps of a linear emptying process L20; an uncoiling process L30; a leveling process L40; a pointing process L50; a butt welding process L60; a hydraulic head pushing process L70; a cold drawing smooth surface process L80; a sand blasting process L90; an in-situ online annealing process L10; an air cooling buffer process L11; a coiling process L12; an emptying process L13; a leveling process L14; a cold drawing spiral process L15; a straightening process L16; and a coiling process L17. According to the machining process of the NPR steel bar wire rod, the whole-process intellectualization canbe achieved, the machining requirement of the NPR steel bar wire rod is met, and the full-automatic intellectualized production requirement of the NPR steel bars, the NPR cold-rolled spiral steel bars and the NPR prestressed steel bars is met.

Owner:何满潮 +1

Light diffusion plate and preparation method thereof

The invention discloses a light diffusion plate and a preparation method thereof. The light diffusion plate comprises, by mass, 95-100 parts of optical PP (polypropylene), 3-10 parts of optical PS (polystyrene), 2-5 parts of optical PMMA (polymethylmethacrylate), 2-5 parts of optical PC (polycarbonate), 10-25 parts of a light diffuser, 0.2-0.9 part of a nucleating agent, and 5-10 parts of a wear-resistant ceramic material, wherein the light diffuser is made with organosilicon microspheres, titanium dioxide and silicone oil in a mass ratio of (0.5-1):(0.05-0.9):(10-20). The light diffusion plate prepared herein helps relieve surface unevenness and low transparency due to non-uniform mixing in the traditional production process; the wear-resistant ceramic material helps improve the surface hardness of the light diffusion plate; the suitable light diffuser provides the light diffusion plate with high transparency, high fog level and certain mechanical properties.

Owner:江苏恒隆通新材料科技有限公司

Optical glass cleaning agent

InactiveCN105039036AImprove protectionImprove permeabilitySurface-active non-soap compounds and soap mixture detergentsCleansing AgentsOptical glass

The invention discloses an optical glass cleaning agent. The cleaning agent comprises the following components in percentage by weight: 1 to 6% of osmotic agent, 3 to 7% of dispersant, 5 to 15% of chelating agent, 10 to 20% of organic alkali, 10 to 20% of water, 1 to 3% of surfactant, 2 to 6% of sodium silicate, and 4 to 10% of ammonium sulfate. The provided optical glass cleaning agent has strong permeability, will not scratch the glass surface, has a good cleaning effect, and improves the work efficiency. The formula is simple, and the cleaning agent is convenient to produce, will not corrode the glass during the washing process, and well protects the environment.

Owner:SUZHOU YONGCHUANGDA ELECTRONICS

Novel full-automatic punching device with pipe visual inspection function

PendingCN109676013AGuaranteed correctnessAvoid overvoltagePerforating toolsMetal-working feeding devicesPunchingVisual inspection

The invention discloses a novel full-automatic punching device with a pipe visual inspection function. The novel full-automatic punching device comprises a machine body, a feeding funnel, an upper rack, a lower rack and a discharging funnel. The feeding funnel, the upper rack, the lower rack and the discharging funnel are all arranged on the machine body. A feeding station, a punching station, a turnover station and a discharging station are arranged on the lower rack. Shaking plates, a pipe adjusting assembly and a jacking assembly are arranged on the feeding funnel, and the shaking plates are arranged at the bottom of the feeding funnel at intervals. A pipe visual inspection assembly is arranged at the feeding station. A punching mold further comprises a pipe pushing in-mold assembly, apipe waste clearing assembly and an oil supply lubricating device. The novel full-automatic punching device is suitable for carrying out punching on pipes of different types; automatic feeding and discharging are achieved; the machining efficiency is high; the problem of pipe collision is effectively solved; surface scratching and damage are avoided; the machining quality is high; demounting is convenient; problems happening to equipment in the production process can be found in time; maintenance is carried out rapidly; and the maintenance cost is reduced.

Owner:广州英固特智能装备有限公司

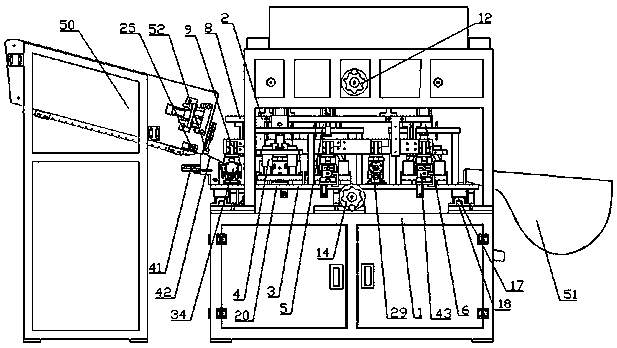

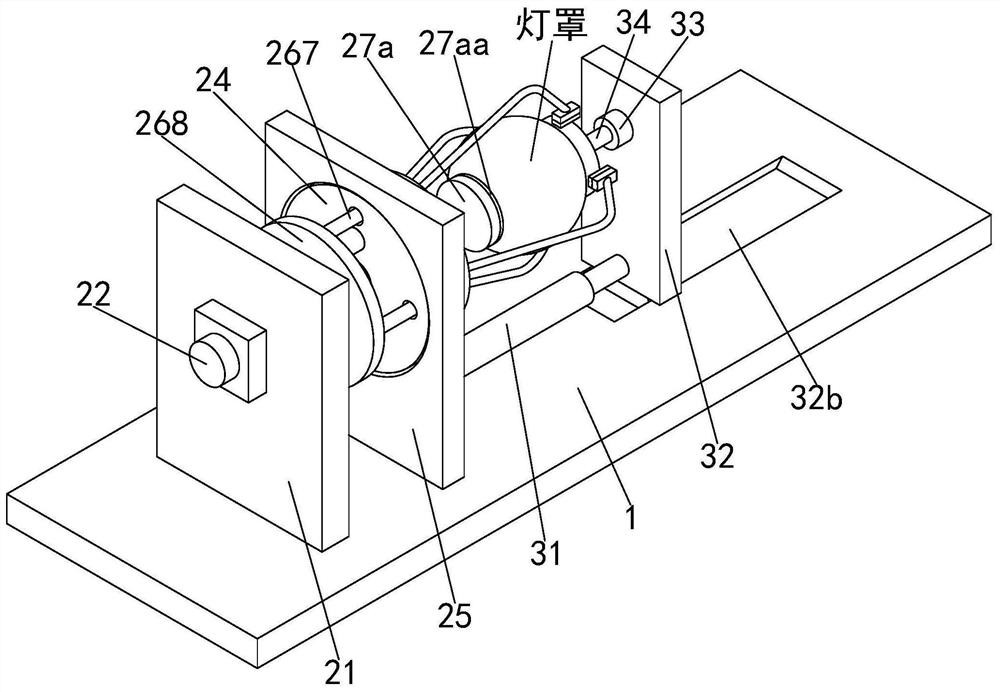

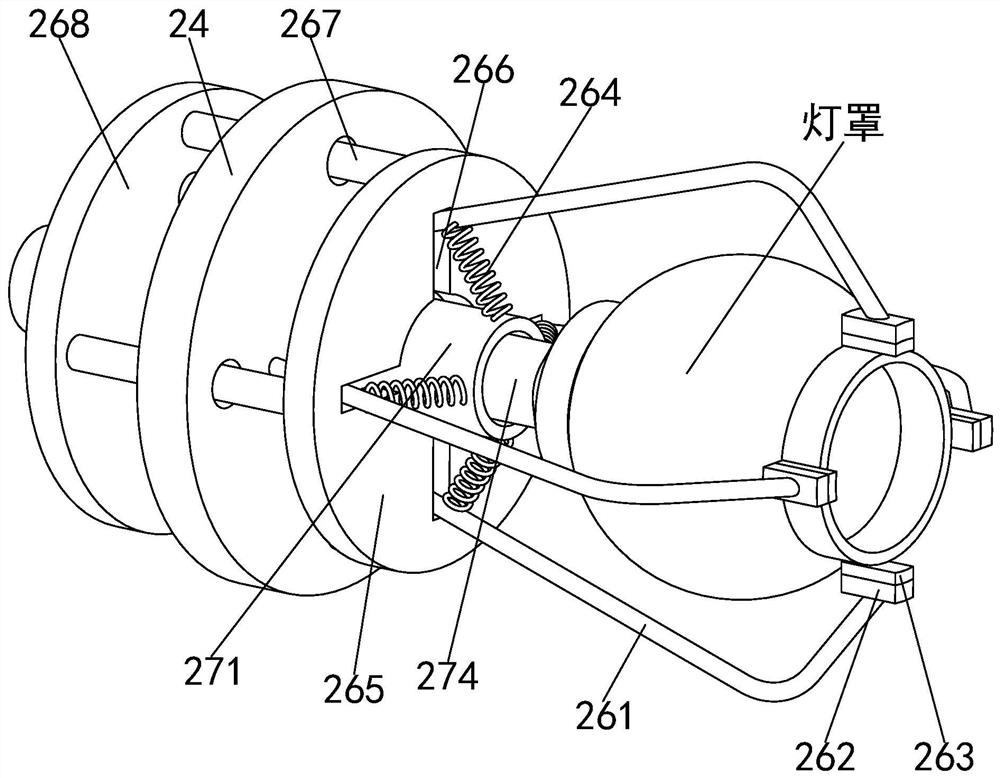

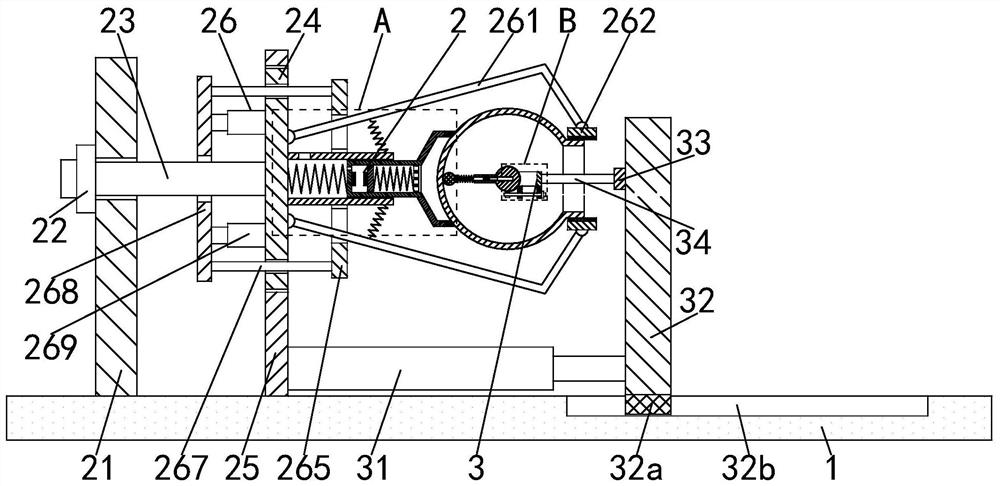

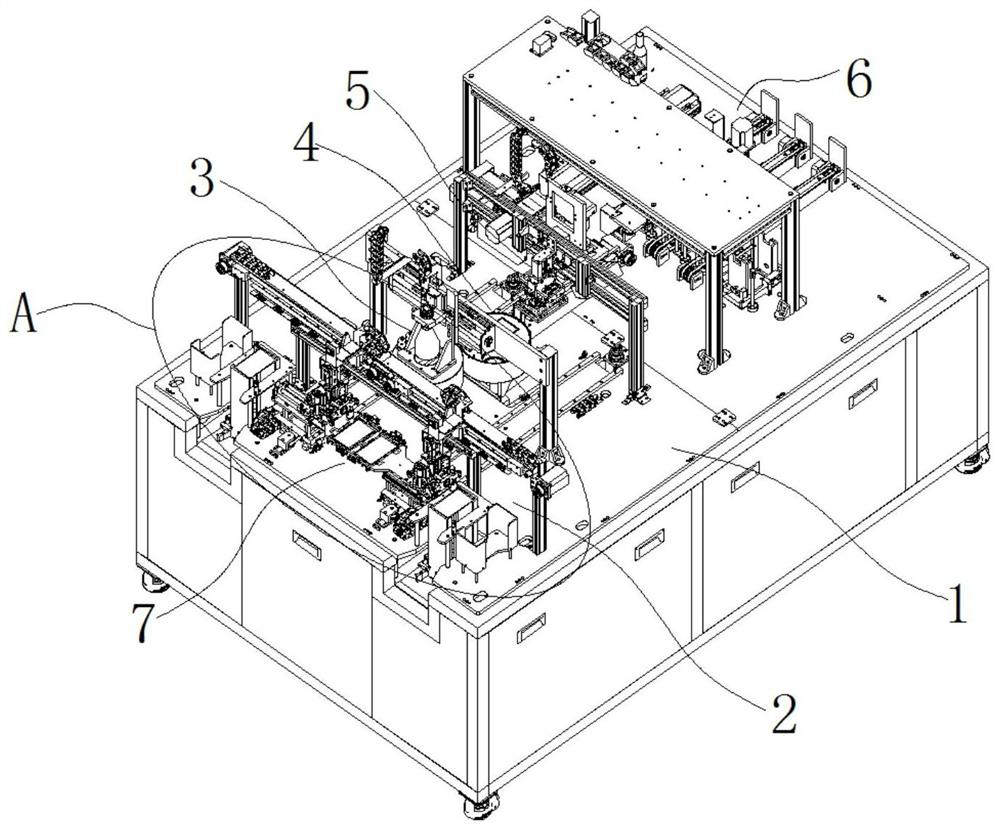

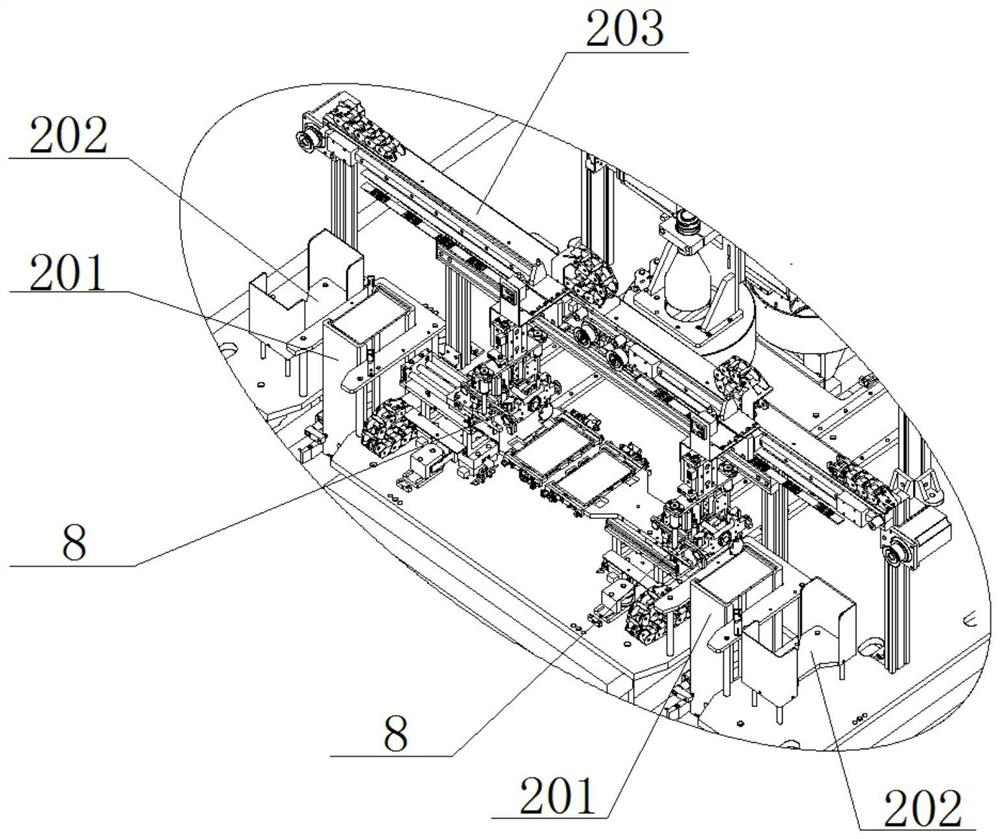

Fine machining equipment for manufacturing lampshade of solar street lamp and machining method

InactiveCN113714873APolished evenlyNot practicalGrinding carriagesRevolution surface grinding machinesPolishingSolar street light

The invention provides fine machining equipment for manufacturing a lampshade of a solar street lamp and a machining method. The fine machining equipment comprises a workbench, a clamping device and a grinding device, and the clamping device and the grinding device are sequentially arranged on the upper end face of the workbench from left to right. The fine machining equipment can solve the following problems existing in the manufacturing and finish machining process of the lampshade of the solar street lamp, specifically, a, in the machining and polishing process of the inner wall of a traditional lampshade of the solar street lamp, due to the fact that the overall structure of the lampshade is light, an existing clamping device is prone to causing clamping deformation of the lampshade and scratching of the outer surface during clamping, and therefore, the lampshade needs to be subjected to secondary maintenance processing; b, when the inner wall of the existing lampshade of the solar street lamp is polished, a polishing head generally needs to be moved into the lampshade, so that the polishing head is difficult to observe manually during polishing, and all-dimensional uniform polishing of the inner wall of the lampshade cannot be guaranteed; and c, most existing polishing equipment cannot polish lampshades of different sizes, and the practicability of the equipment is not high.

Owner:江苏二五七特显科技集团有限公司

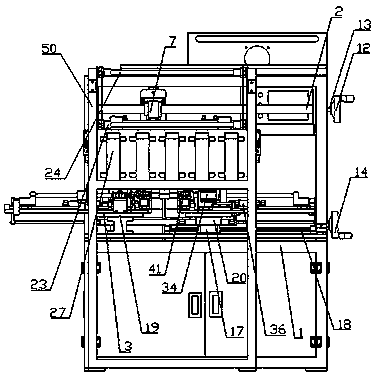

Testing method of LED frame products

PendingCN112147150AReduce labor intensityKeep the relative position unchangedOptically investigating flaws/contaminationUsing optical meansProduct testingProcess engineering

The invention discloses a testing method of LED frame products. The testing method adopts an LED frame product testing system for testing, and comprises the following steps that two material frame bins filled with materials are respectively placed in two material frame lifting mechanisms for feeding, and separation paper is laid between adjacent material frame products; grabbing mechanisms grab and convey the material frame products in the material frame lifting mechanisms correspondingly below the grabbing mechanisms into conveying devices to be conveyed and suck and convey the separation paper into a separation paper storage mechanism of a feeding device, and the two grabbing mechanisms work alternately in sequence; the two conveying devices alternately work in sequence to convey the material frame products, and in the conveying process of the material frame products, the material frame products sequentially pass through a first optical detection device, a second optical detection device and a third optical detection device to be subjected to multiple times of optical detection; and a material receiving device is used for classifying, stacking and collecting the material frame products subjected to optical detection. The testing method of LED frame products has the advantages of being high in automation degree, accurate in test result, and capable of reducing the labor intensity of workers, improving the working efficiency and improving the product yield.

Owner:江阴新基电子设备有限公司

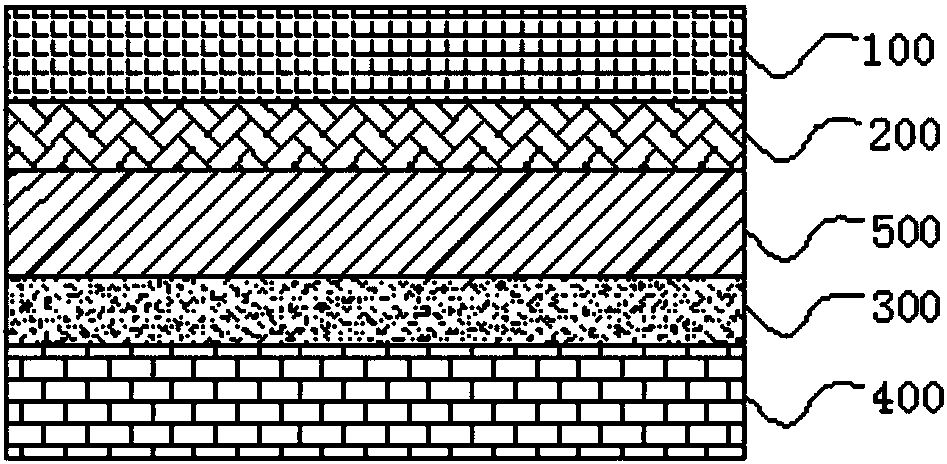

Ultra-short focus anti-light projection curtain

The invention relates to an ultra-short focus anti-light projection curtain and a projection system of applying the projection curtain. The projection curtain comprises a bottom and a prism layer pasted from the back forwards, the bottom layer comprises a black rubber layer, the back surface of the prism layer is a plane fitted on the front surface of the bottom layer, the front surface of the prism layer is formed by in sequence connected multiple lines of prisms in parallel arrangement along the vertical direction, each line of prisms are formed by multiple triangular convex lens in sequence connected along the level direction, each triangular convex lens comprises two inclined planes respectively facing forward upside and forward downside and a bottom surface facing the rear end, wherein the inclined plane facing the front downside is a convex plane protruding forward in the horizontal direction, and the convex plane is provided with a projection reflection layer. The projection curtain and the projection system can better avoid the interference of external ambient light while achieving the ultra-short focus projection, and can obtain a larger angle of view range while maintaining a high projection gain, and have a better visual effect compared with the traditional projection screen.

Owner:简铭镇 +1

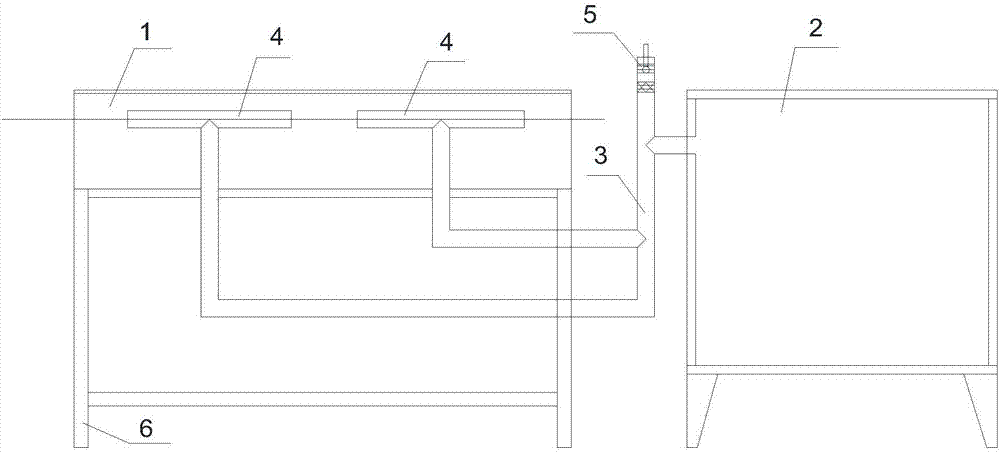

Online solid solution heat treatment process for high-performance copper alloy strip

ActiveCN110541132AAvoid surface scratchesPrevent oxidationFurnace typesHeat treatment furnacesInternal stressGas protection

The invention discloses an online solid solution heat treatment process for a high-performance copper alloy strip. The online solid solution heat treatment process for the high-performance copper alloy strip is based on an online solid solution heat treatment device for the copper alloy strip. The copper alloy strip is unrolled from a coiled material and is heated, and then the heat preservation,the air cooling, the strip profile correction and other technological operations are performed, so that the continuous online solid solution treatment of the copper alloy strip is realized. The onlinesolid solution heat treatment process has the following five advantages: one. the feed-in speed of the copper alloy strip is synchronized with the rotating speeds of a synchronous roller sealing doorand a rewinding synchronous tensioning wheel to prevent the surface of the copper alloy strip from being scratched; two. the reducing gas protection is adopted to prevent oxidation of the surface ofthe strip; three. the strip is heated by stage, the temperature rises gradually and is uniform, the surface of the strip is free during cooling treatment, and therefore, the residual internal stress is small; four. the profile of the copper alloy strip is corrected by adopting a furnace front S-roller device, multiple sets of middle pinch rolls and a furnace rear S-roller device, so that the stripprofile of the finished product is flat; and five. the process has the characteristics of uniform cooling and fast speed, and the finished copper alloy strip has extremely high mechanical propertiesand consistency.

Owner:珠海大华新材料有限公司

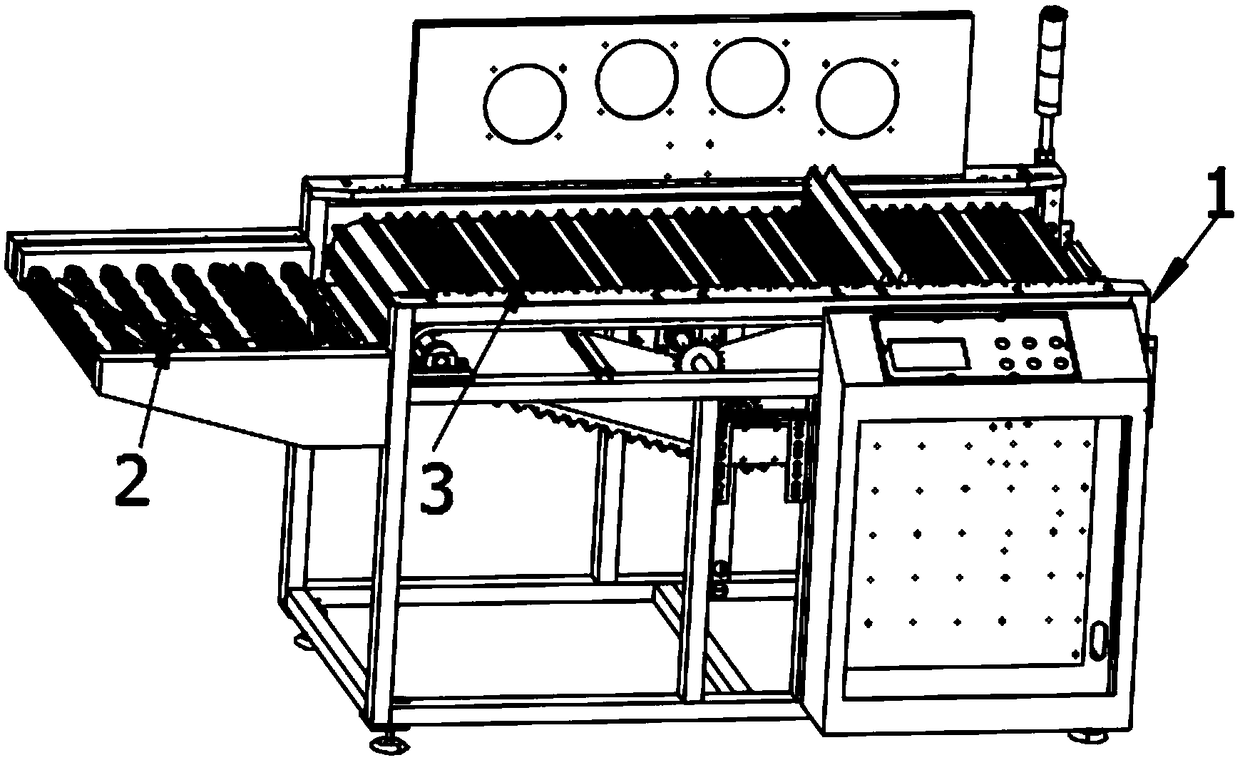

Universal type plate placing machine

InactiveCN109051525AWill not cause scratchesIncrease frictionConveyorsConveyor partsMechanical engineeringEngineering

The invention discloses a universal type plate placing machine. The universal type plate placing machine comprises a machine frame, a drive mechanism and a conveying turnover mechanism, wherein the drive mechanism and the conveying turnover mechanism are fixed on the machine frame. The conveying turnover mechanism comprises two driven rollers and a drive roller which are fixed on the machine frame, a conveying belt which are connected with the driven roller and the drive roller, and a turnover clamping plate which are detachably connected with the conveying belt. The drive roller is located between the two driven rollers, and a first motor is connected to one end of the drive roller. A plurality of clamping blocks are arranged on the peripheral surface of the conveying belt, and the lengthdirection of the clamping blocks is parallel to the width direction of the conveying belt. Clamping grooves connected with the clamping blocks in a clamping mode are formed in the lower end of the turnover clamping plate, anti-skid structures are arranged on the left and right side walls of the turnover clamping plate separately, and the anti-skid structures are formed by connecting a plurality of anti-skid protruded strips in sequence. The universal type plate placing machine can realize efficient and stable conveying of PCB with different thickness and perform 180 degrees turnover, and canfurther avoid the scratch of PCB surface.

Owner:大江南电子科技(昆山)有限公司

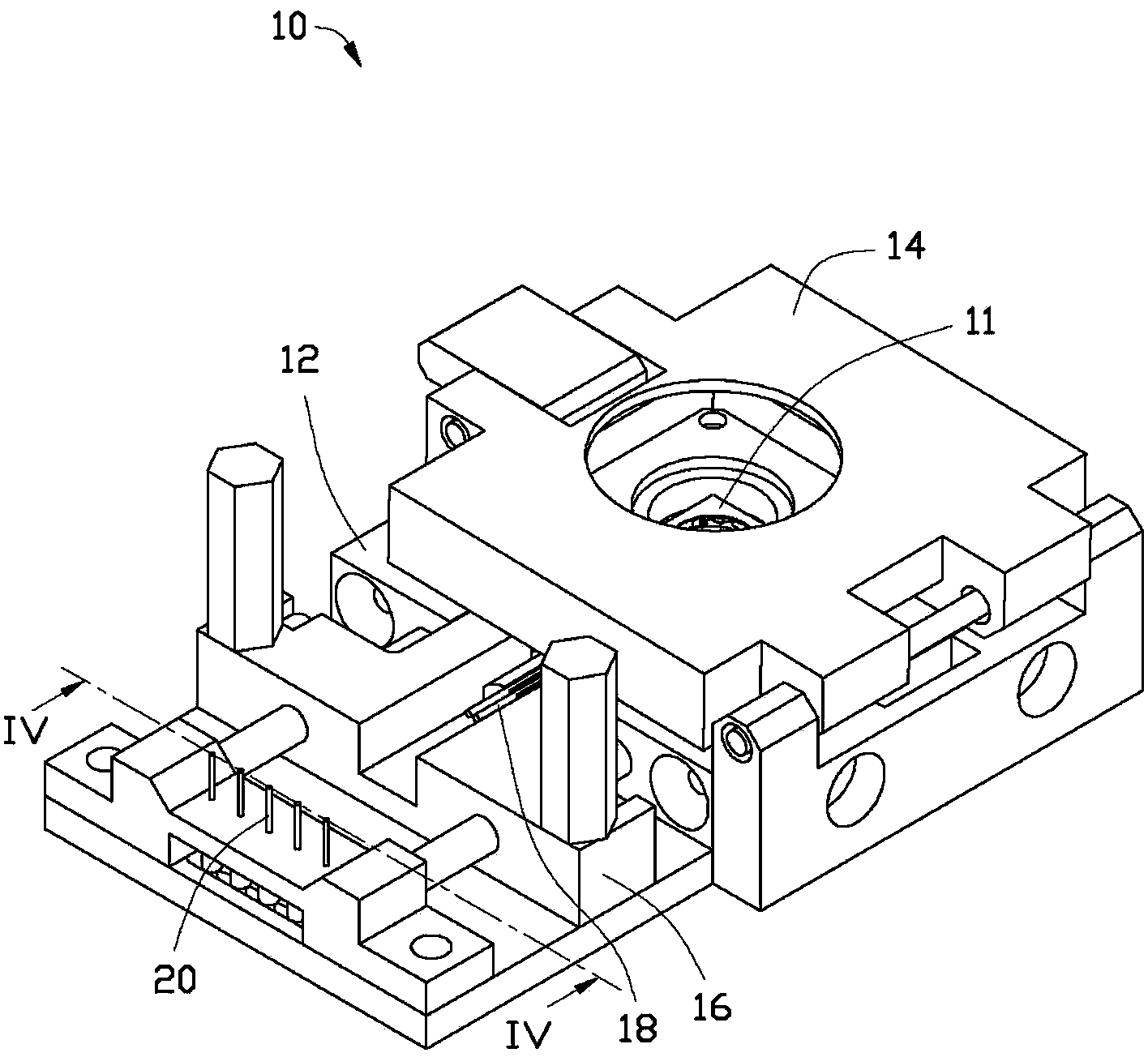

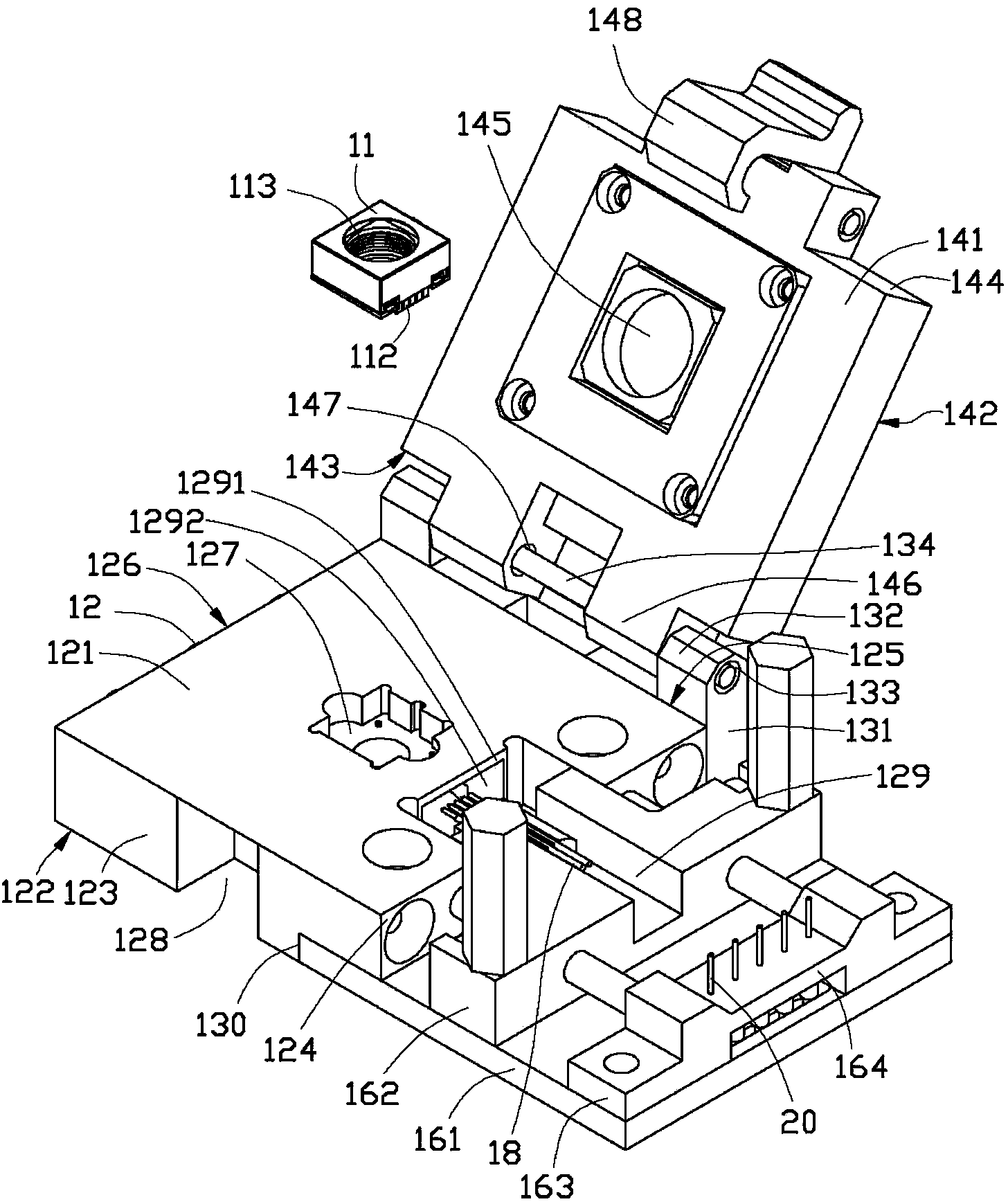

Measuring tool and measuring apparatus for electronic device

InactiveCN104049114AAvoid damageAvoid surface scratchesElectrical testingMeasurement instrument housingFistElectricity

The invention relates to a measuring tool and measuring apparatus for an electronic device having a plurality of electrical connecting terminals. The measuring tool comprises a device fixed seat, a probe fixed seat, a plurality of first probes and a plurality of second probes; the device fixed seat includes a device accommodation groove for accommodating a to-be-measured electronic device; the probe fixed seat is fixed at one side of the device fixed seat; and the plurality of first probes are fixed at the probe fixed seat and one end of each first probe is electrically connected with one electrical connecting terminal. The plurality of second probes fixed at the probe fixed seat include first electrical connection pin portions and second electrical connection pin portions, wherein the first electrical connection pin portions and the second electrical connection pin portions are opposite to each other; the plurality of first electrical connection pin portions are respectively and electrically connected to the plurality of fist pins; and the second electrical connecting pin portions are electrically connected to an electrically measuring device. In addition, the invention also relates to a measuring device using the tool.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

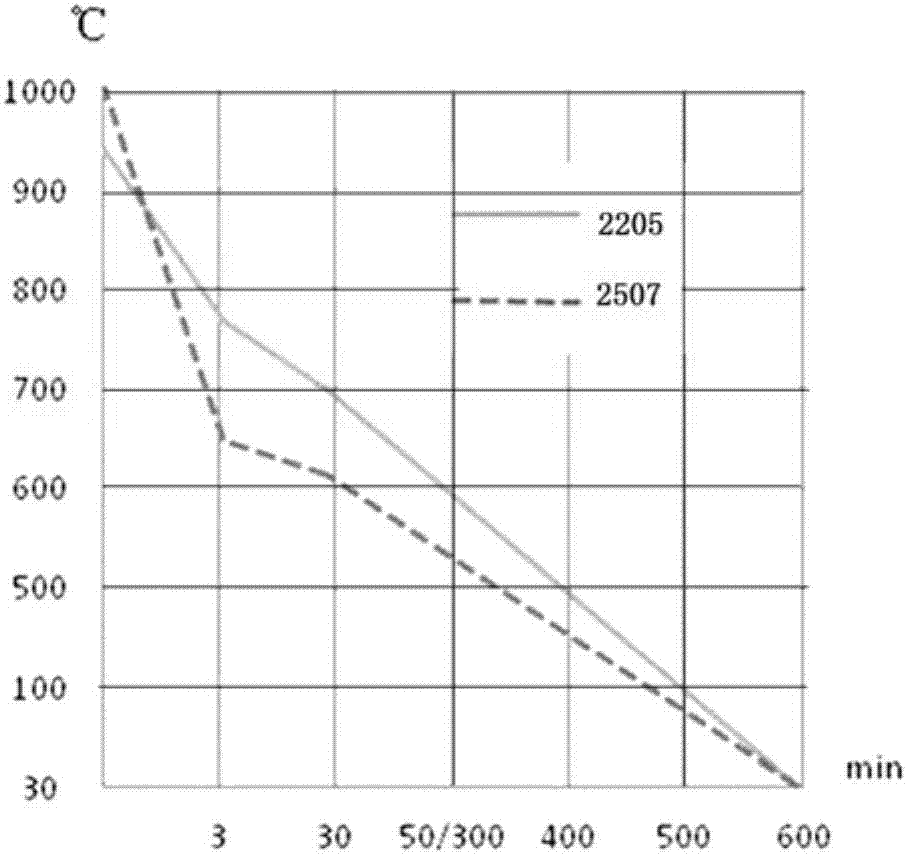

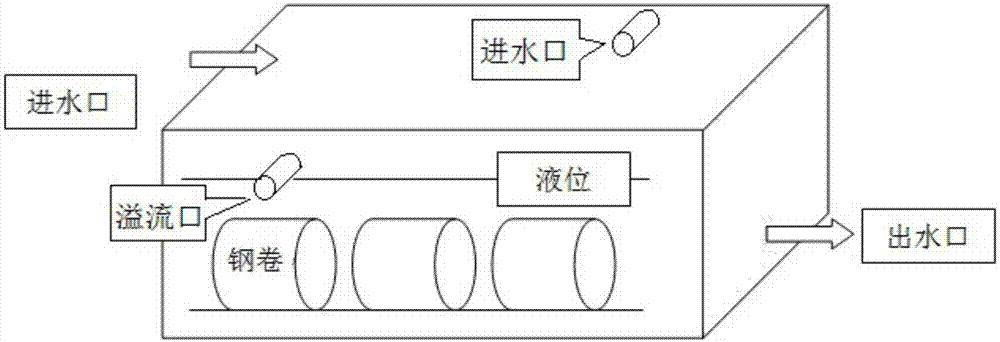

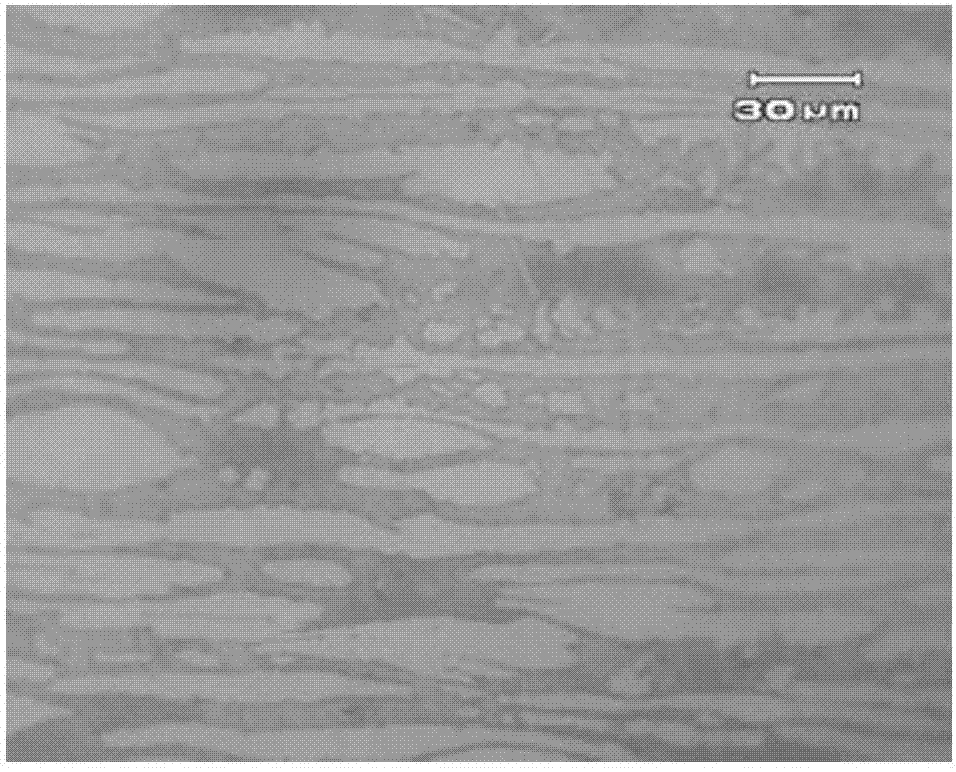

Coiling method for stainless steel dual-phase steel

InactiveCN107470373AControl end temperatureNo σ phase precipitationTemperature control deviceFurnace temperatureLaminar cooling

The invention provides a coiling method for stainless steel dual-phase steel. The coiling method comprises the following steps: placing a roughly-rolled dual-phase steel plate blank in a coiling furnace of a fine rolling machine and carrying out fine rolling calendering to obtain dual-phase steel strip steel subjected to the fine rolling calendering; sequentially carrying out laminar cooling, coiling and water-cooling pool cooling on the dual-phase steel strip steel subjected to the fine rolling calendering; and cooling the dual-phase steel strip steel to achieve room temperature and then obtaining a dual-phase steel product, wherein the furnace temperature of the coiling furnace of the fine rolling machine is 1000-1050 DEG C, and the coiling temperature is 450-750 DEG C. The dual-phase steel plate blank comprises 2205 steel grade or 2507 steel grade, wherein the coiling temperature of the 2205 steel grade is 600-750 DEG C; and the coiling temperature of the 2507 steel grade is 450-700 DEG C.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

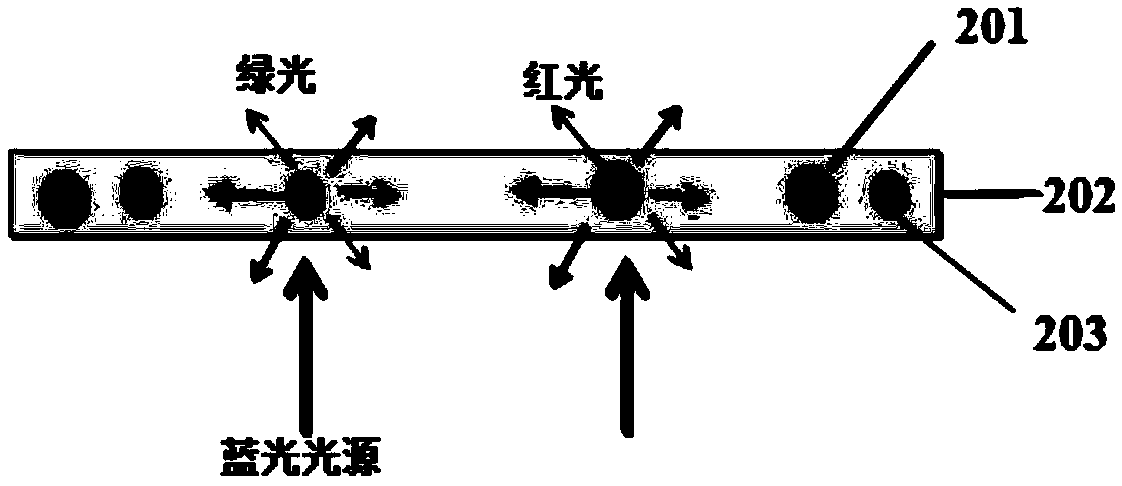

Functional film capable of transmitting blue light and reflecting red and green light and preparation method thereof

The invention relates to an optical film, in particular to a functional film capable of transmitting blue light and reflecting red and green light and a preparation method thereof in the field of quantum dot display. The functional film capable of transmitting the blue light and reflecting the red and green light and the preparation method thereof are used for increasing the utilization rate of the red and green light obtained by exciting red and green quantum dots in a quantum dot film by a blue light source. The functional film capable of transmitting the blue light and reflecting the red and green light sequentially comprises a scratch-resistant layer, a base material layer, an undercoat layer and a functional layer. The functional layer is composed of cholesteric liquid crystal molecules, a chiral agent, a photoinitiator and a polymerization inhibitor. By controlling the screw pitch of cholesteric liquid crystals formed in the functional layer, the functional film can selectively transmit the blue light within the wave range from 380 nm to 500 nm and reflect the red and green light within the wave range from 500 nm to 800 nm at the same time, and the good effects of selectivelytransmitting the blue light and reflecting the red and green light are achieved. The functional film not only can selectively transmit the blue light and reflect the red and green light but also hasexcellent optical properties such as high scratch resistance and high light transmittance.

Owner:NINGBO EXCITON TECH

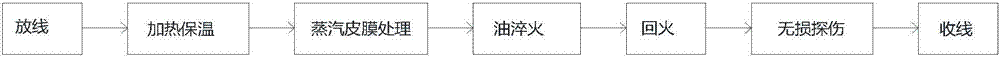

Production process for oil-tempered spring steel wire

InactiveCN106893815AIncrease productivityAvoid surface scratchesFurnace typesHeat treatment furnacesQuenchingSpring steel

The invention discloses a production process for an oil-tempered spring steel wire. The production process includes the steps of (1) paying off, (2) heating and heat preservation, (3) steam skin membrane treatment, (4) oil quenching, (5) tempering, (6) nondestructive inspection and (7) taking up. By the adoption of the production process, lubricity of the steel wire in the winding process is improved, the internal steel wire can be effectively protected, the spring production efficiency is improved, and the steel wire quality is improved.

Owner:启东市海纳特钢有限公司

Method of packaging an optical sensor

InactiveUS20050146001A1Low costImprove optical qualitySemiconductor/solid-state device detailsSolid-state devicesMultiple sensorEngineering

An image sensor device includes a first, QFN type leadframe to which a sensor IC is electrically connected. A second leadframe is provided for holding a lens. A third leadframe is positioned between the first and second leadframes to appropriately space the IC from the lens. Multiple sensor devices are assembled at the same time by the use of leadframe panels.

Owner:INTELLECTUAL VENTURES II

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com