Coiling method for stainless steel dual-phase steel

A technology of dual-phase steel and stainless steel, applied in the direction of temperature control, etc., can solve the problem of not being raised, and achieve the effect of preventing brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

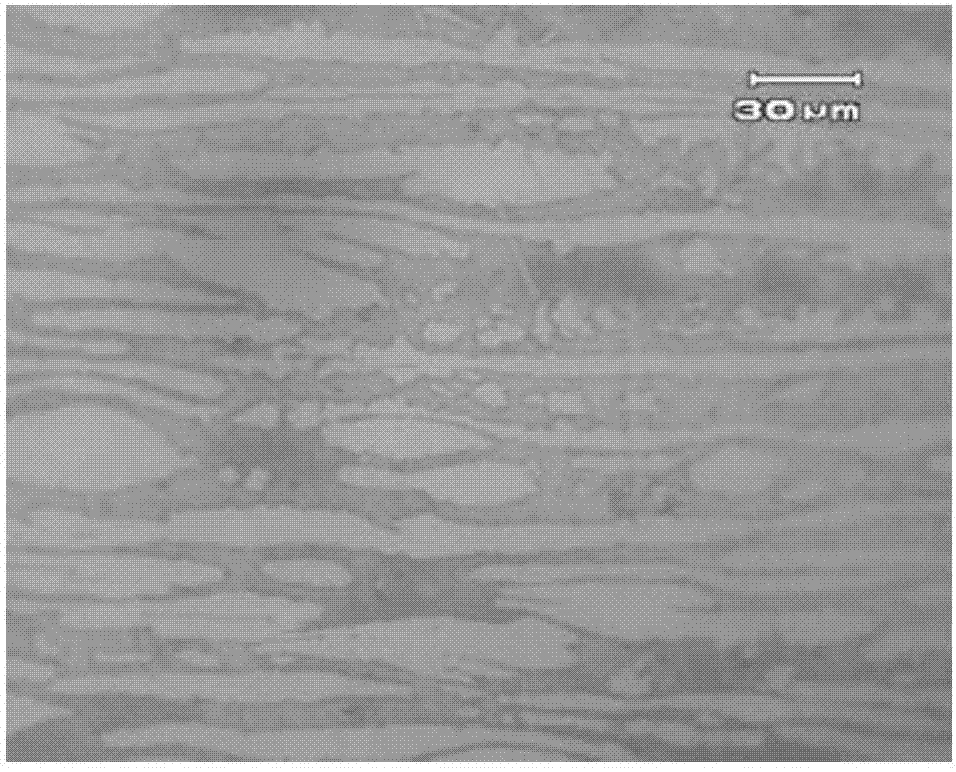

[0042] The present embodiment provides a kind of coiling method of 2205 steel types, and it comprises the following steps:

[0043] Set the furnace temperature of the coil furnace of the finishing mill to 1000-1050°C, and control the final rolling temperature of 2205 steel to >1000°C;

[0044] Place the rough-rolled 2205 strip in the coil furnace of the finishing mill for finish rolling to obtain 3.0mm-10mm thick finish-rolled 2205 strip;

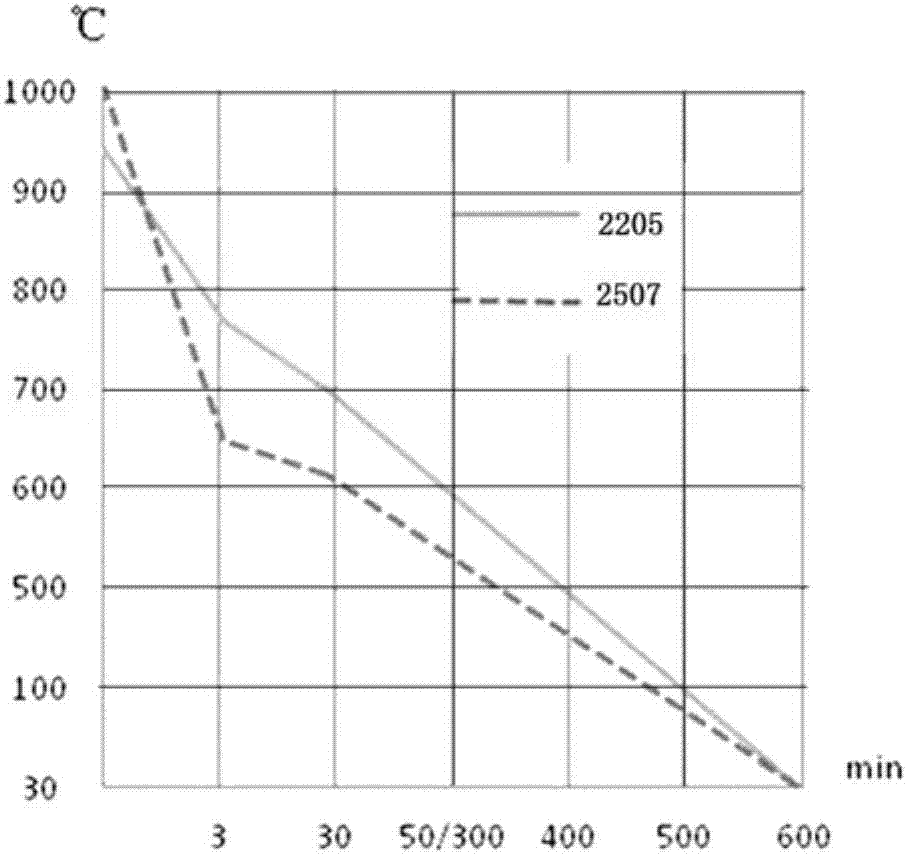

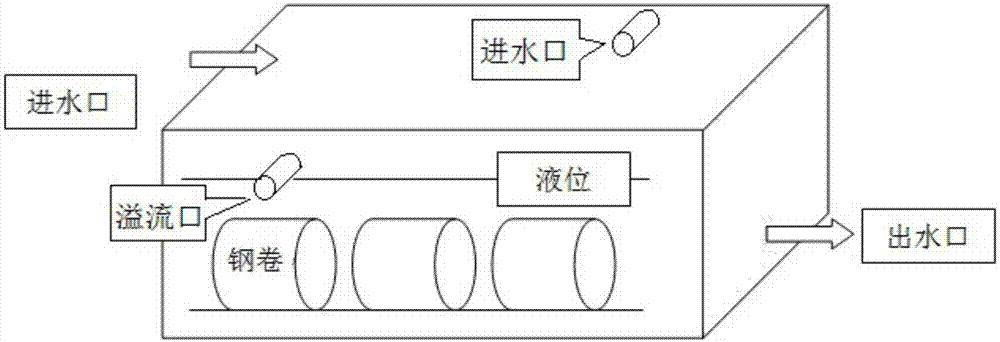

[0045] Laminar cooling is carried out on the 2205 steel strip after the above finish rolling, and the cooling water flow rate is preset according to the final rolling temperature, thickness and forward speed of the 2205 steel type, and the surface temperature of the 2205 steel strip is detected in real time by the temperature detection device , feed back the detected real-time temperature to the cooling water flow control device, adjust the dynamic switch of the laminar cooling water nozzle (header) to control the cooling water flow, make t...

Embodiment 2

[0051] Present embodiment provides a kind of coiling method of 2507 steel grades, and it comprises the following steps:

[0052] Set the furnace temperature of the coil furnace of the finishing mill to 1010-1050°C, and control the final rolling temperature of 2507 steel to >1020°C;

[0053] Place the 2507 steel strip after the rough rolling in the coil furnace of the finishing mill and carry out the finishing rolling to obtain the 2507 steel strip after the finishing rolling with a thickness of 5.0m-8.0mm;

[0054] Laminar cooling is carried out on the 2507 steel strip after the above finish rolling, and the cooling water flow rate is preset according to the final rolling temperature, thickness and forward speed of the 2507 steel type, and the surface temperature of the 2507 steel strip is detected in real time by the temperature detection device , feed back the detected real-time temperature to the cooling water flow control device, adjust the dynamic switch of the laminar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com