Gun lock

a technology of gun lock and latch plate, which is applied in the direction of weapons, weapon components, safety arrangements, etc., can solve the problems of not providing an array of spring loaded pins, unauthorized use of guns, and time-consuming, so as to prevent surface scratching, prevent undesired movement of latch plate, and prevent surface scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

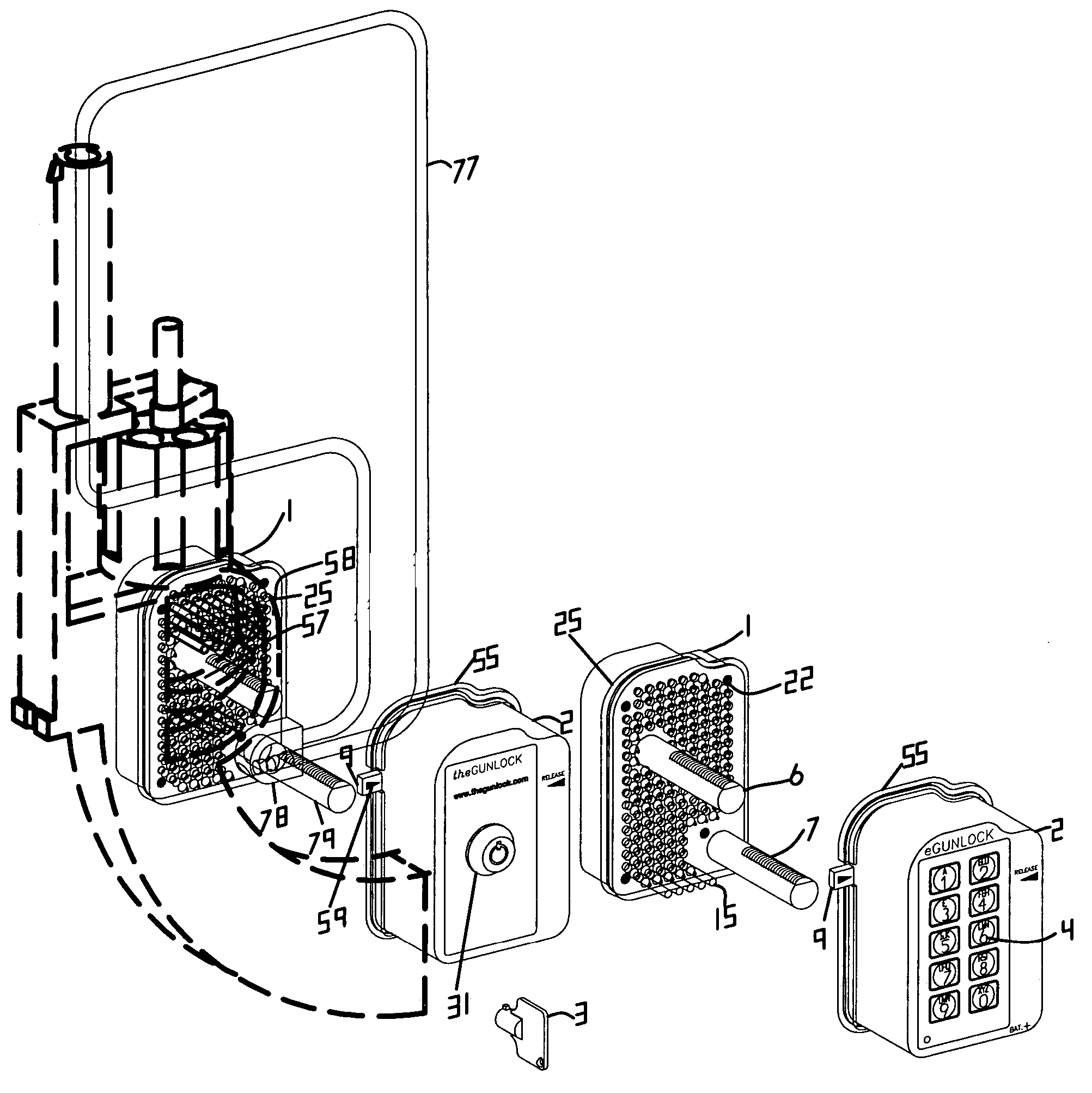

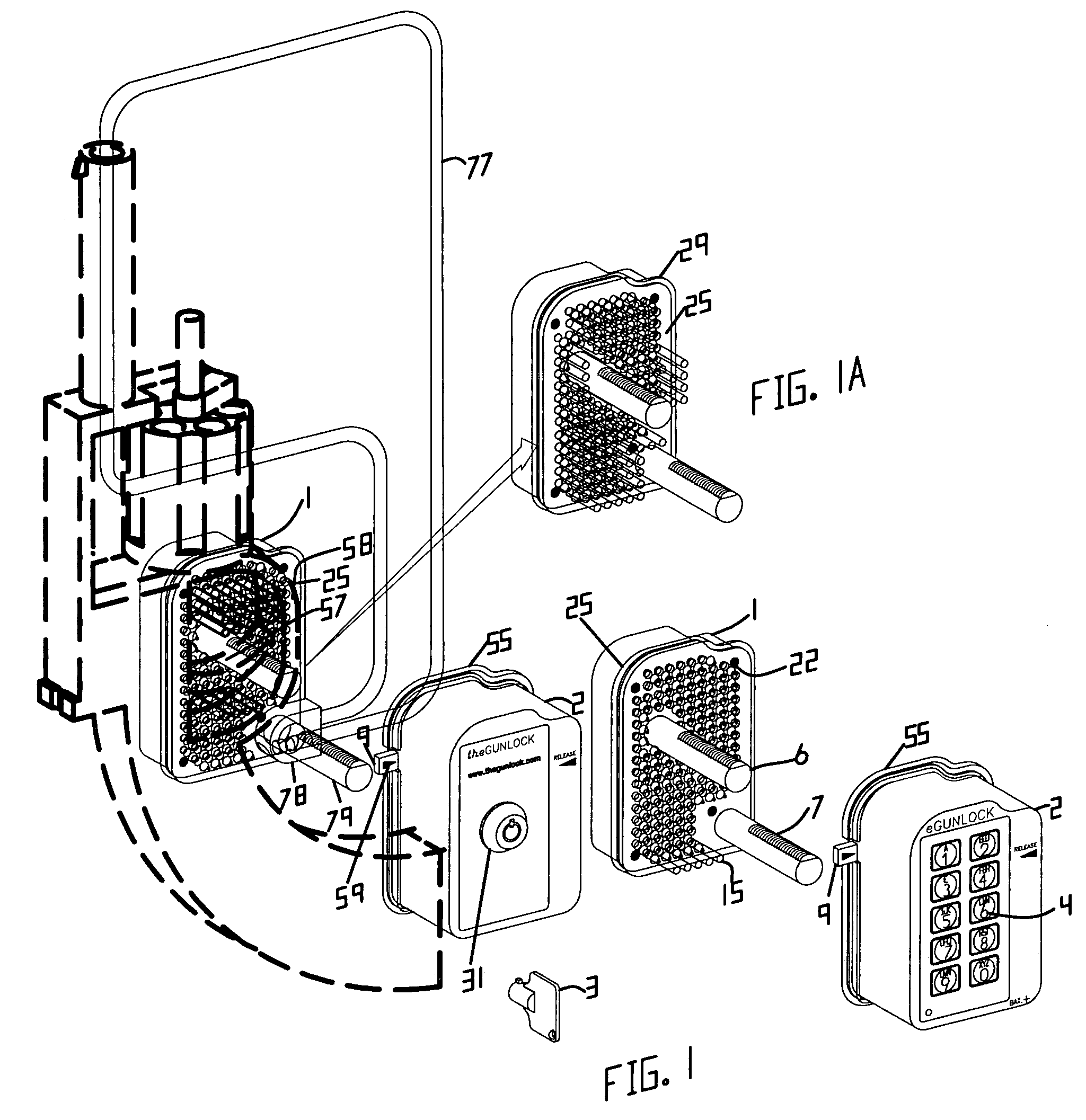

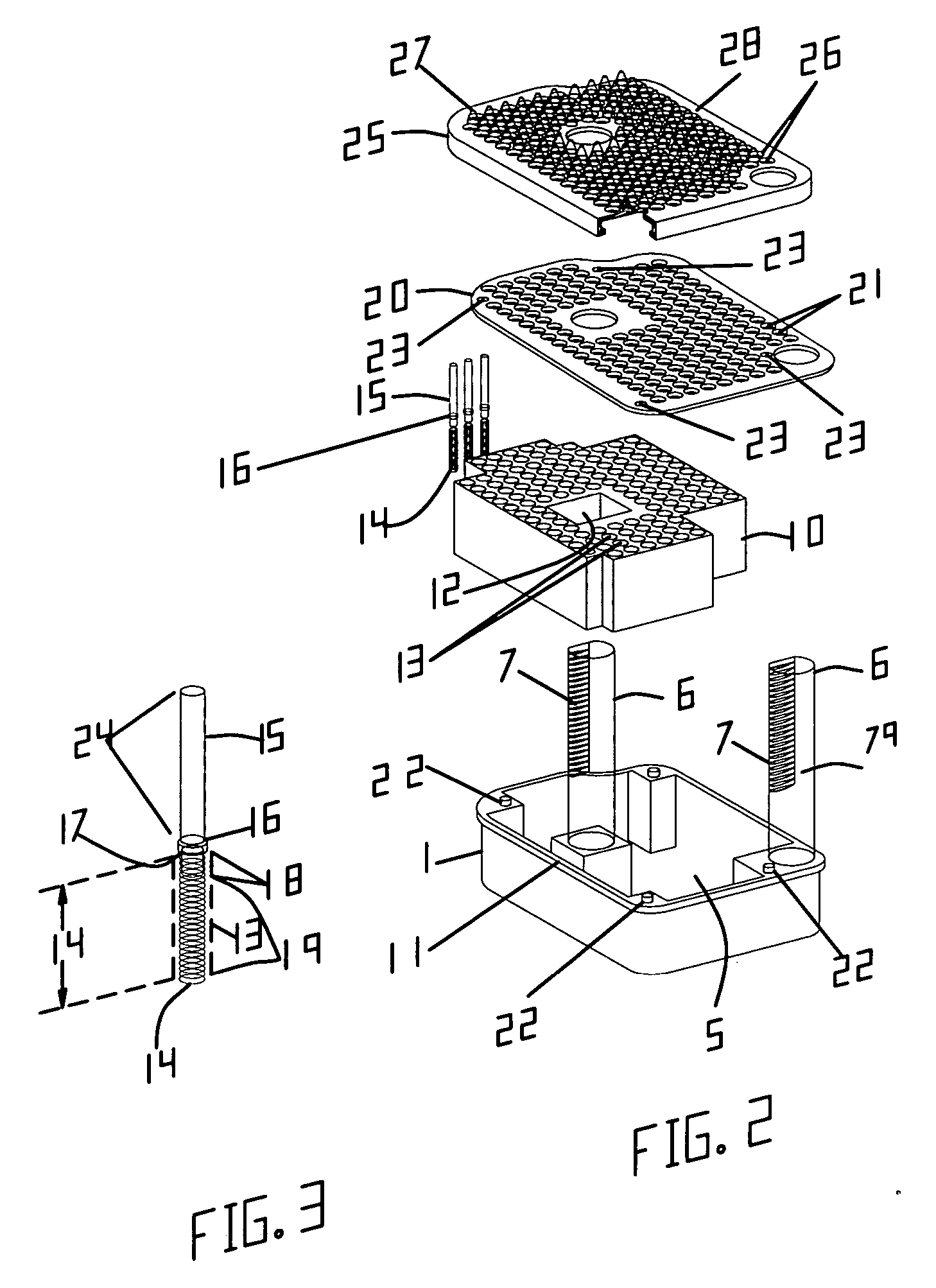

[0030] The detailed description represented-herein is not intended to represent the only way or the only embodiment in which the claimed invention may be practiced. The description herein is provided merely as an example or examples or illustrations of the claimed invention and should not be construed as the only way or as preferred or advantageous over other embodiments or means of practicing the invention. Any means of surrounding an object, herein a trigger and a trigger guard as examples, with a plurality of pins that automatically recess proportionately according to the pressure exerted by the object, usually its weight, is within the scope of this invention. In the example of the claimed gun lock herein, the restraining function of the plurality of pins automatically surrounding the trigger and / or the trigger guard on the gun lock base is coupled with a locking mechanism utilizing a latching plate with at least one engagement tooth for engaging with a corresponding locking tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com