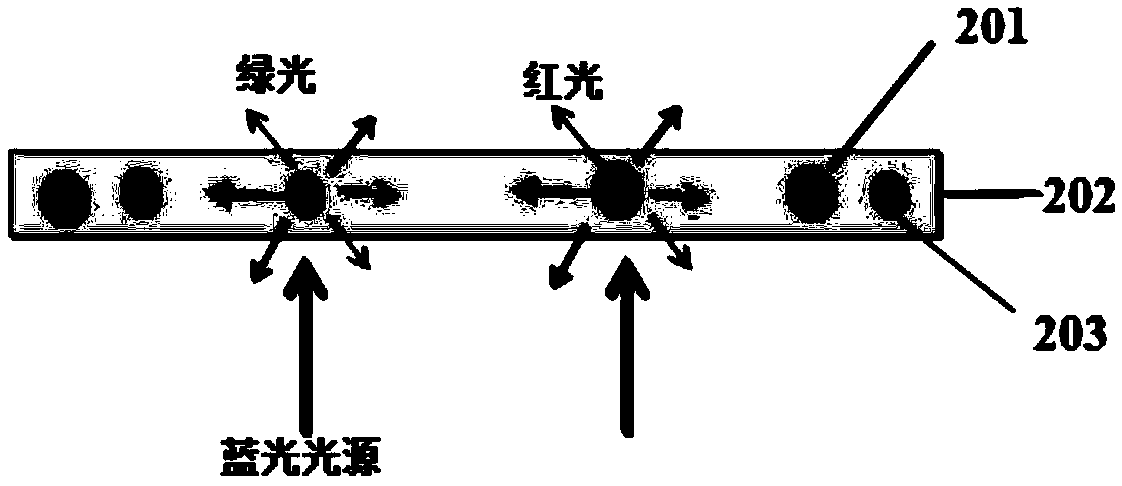

Functional film capable of transmitting blue light and reflecting red and green light and preparation method thereof

A technology of red and green light and blue light, applied in optics, nonlinear optics, instruments, etc., can solve the problems of red and green light waste, energy waste, reception, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

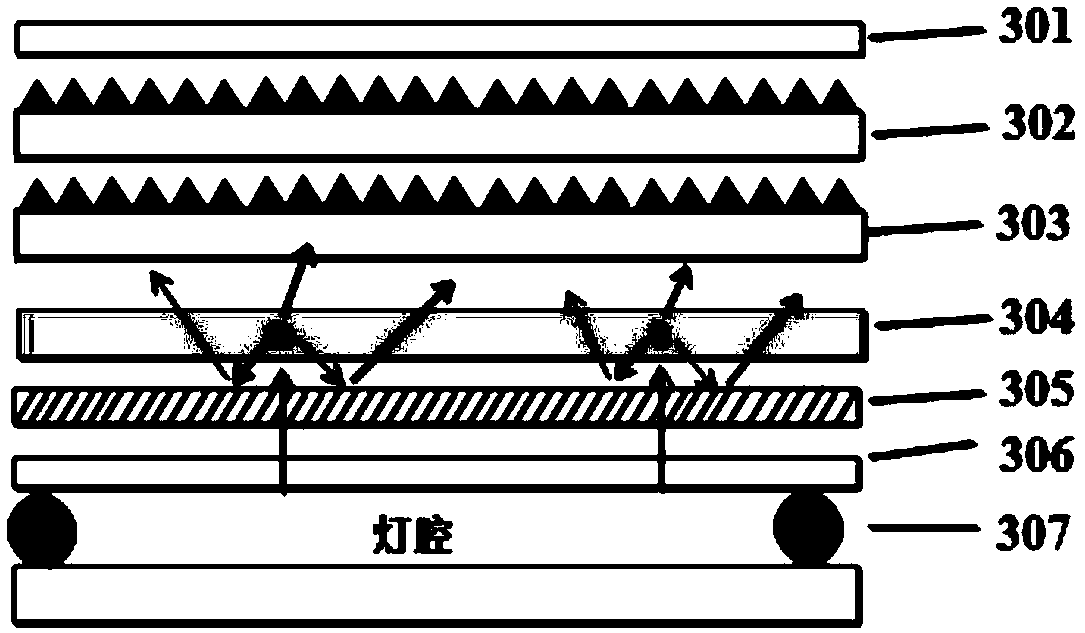

[0088] The preparation method of the functional film that transmits blue light and reflects red and green light provided by the present invention comprises the following steps:

[0089] (1) Coating a scratch-resistant layer coating solution on one side of the substrate layer, and obtaining a scratch-resistant layer after ultraviolet curing;

[0090] (2) coating the primer coating solution on the other side of the substrate layer, after heating and curing, the primer coat is obtained;

[0091] (3) Carry out directional friction to the surface of the primer layer with a flannelette stick, so that the surface of the primer layer is rubbed to produce groove orientation;

[0092] (4) Coating the functional layer coating liquid on the surface of the undercoat layer after rubbing, heating in an oven to make the surface of the coating dry, and then curing the functional layer through ultraviolet light; that is, a functional film that transmits blue light and reflects red and green light...

Embodiment 1

[0108] The invention provides a functional film that transmits blue light and reflects red and green light. The protective film sequentially includes a scratch-resistant layer, a base material, a primer layer and a functional layer.

[0109] The preparation method of the described functional film that transmits blue light and reflects red and green light comprises the following steps:

[0110] (1) Coating a scratch-resistant layer coating solution on one side of the substrate layer, and obtaining a scratch-resistant layer after ultraviolet curing;

[0111] (2) coating the primer coating solution on the other side of the substrate layer, after heating and curing, the primer coat is obtained;

[0112] (3) Carry out directional friction to the surface of the primer layer with a flannelette stick, so that the surface of the primer layer is rubbed to produce groove orientation;

[0113] (4) Coating the functional layer coating liquid on the surface of the undercoat layer after rub...

Embodiment 2

[0119] For the functional film that transmits blue light and reflects red and green light as described in Example 1, the base material layer is made of PMMA with a thickness of 1 μm; the thickness of the scratch-resistant coating is 1 μm; the material of the primer layer is polyurethane, and the thickness of the coating is 1 μm. 1 μm; the coating thickness of the functional layer is 2 μm.

[0120] Wherein, the described functional layer coating solution consists of the following components:

[0121] The structural formula of the cholesteric liquid crystal molecule is b, where n=0, and the parts by weight are 85 parts by weight; the structural formula of the chiral agent is f, where q=3, and the parts by weight are 5 parts by weight; the photoinitiator is 2, 4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), parts by weight are 10 parts by weight; polymerization inhibitor is methyl hydroquinone, parts by weight are 0.1 parts by weight; organic solvent is cyclohexane Ketone, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com