Patents

Literature

195results about How to "The process is simple and mature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

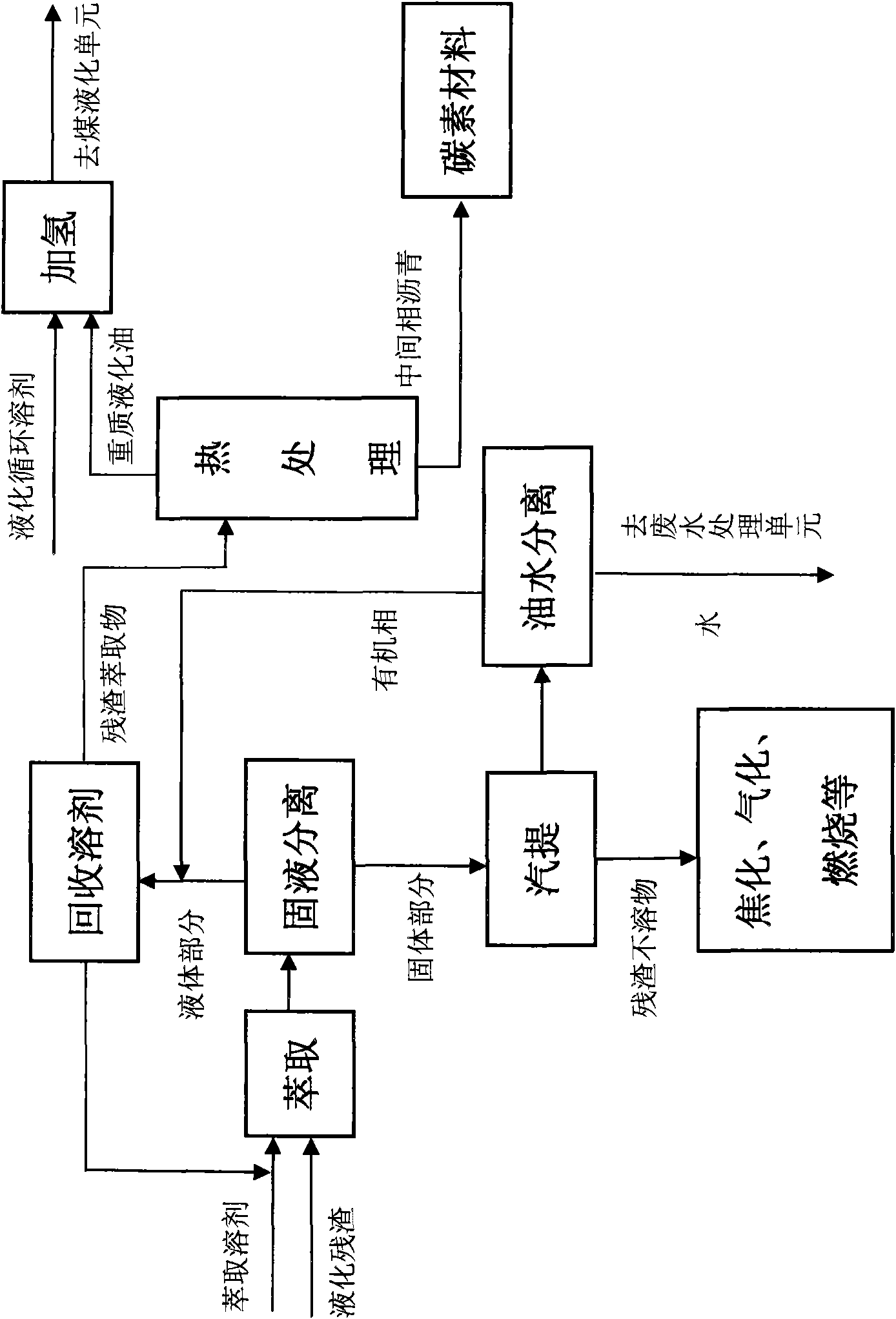

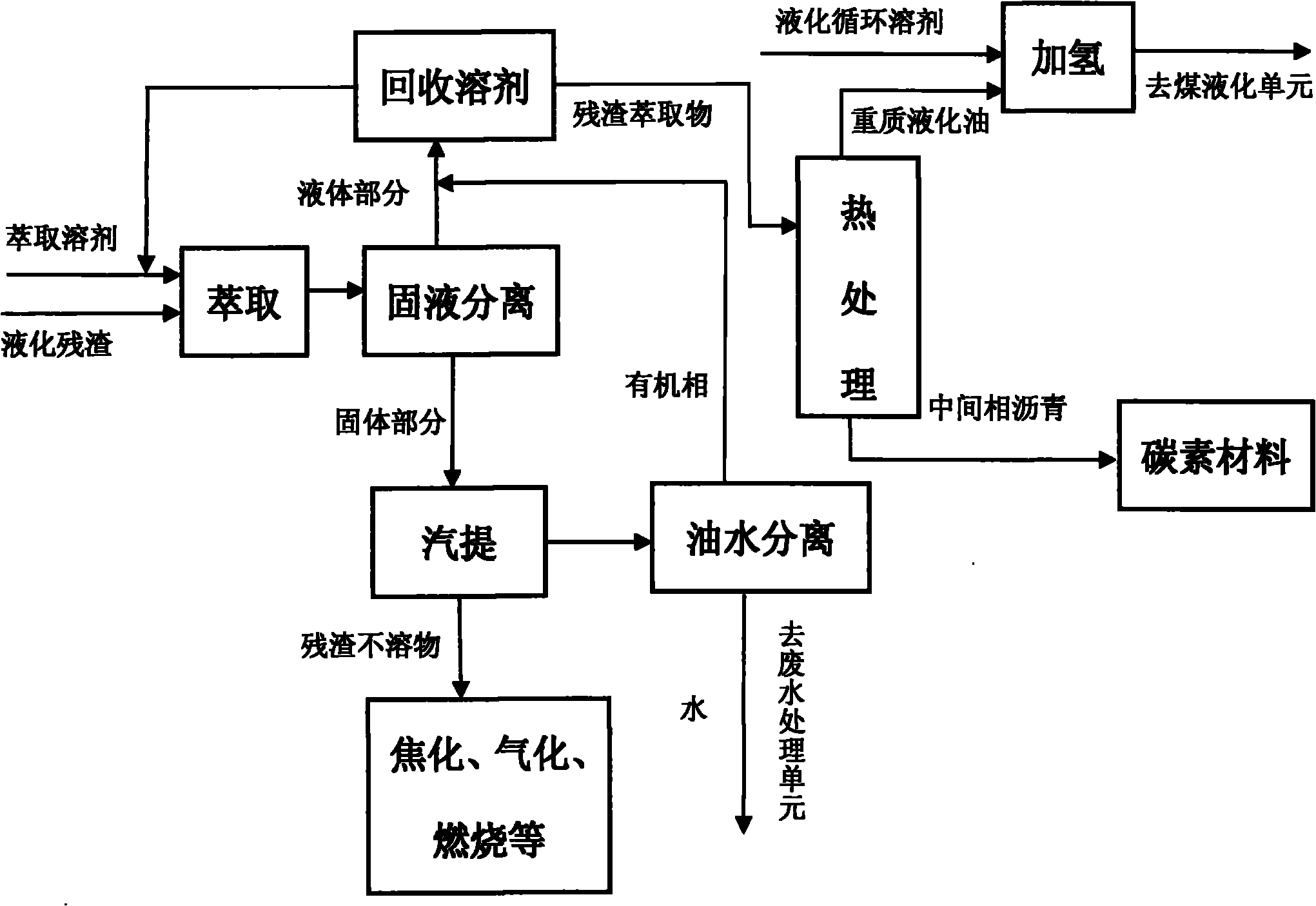

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

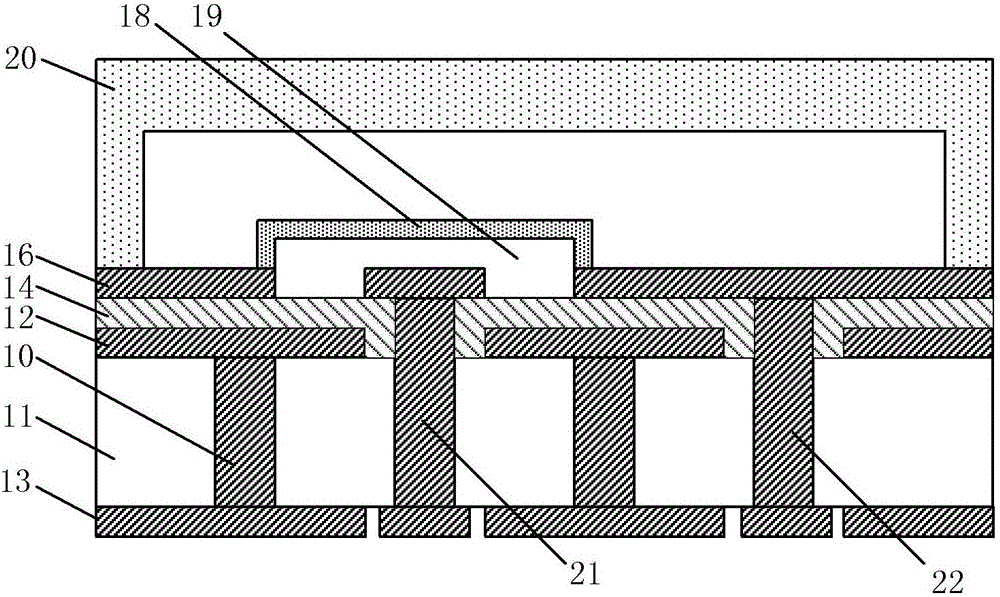

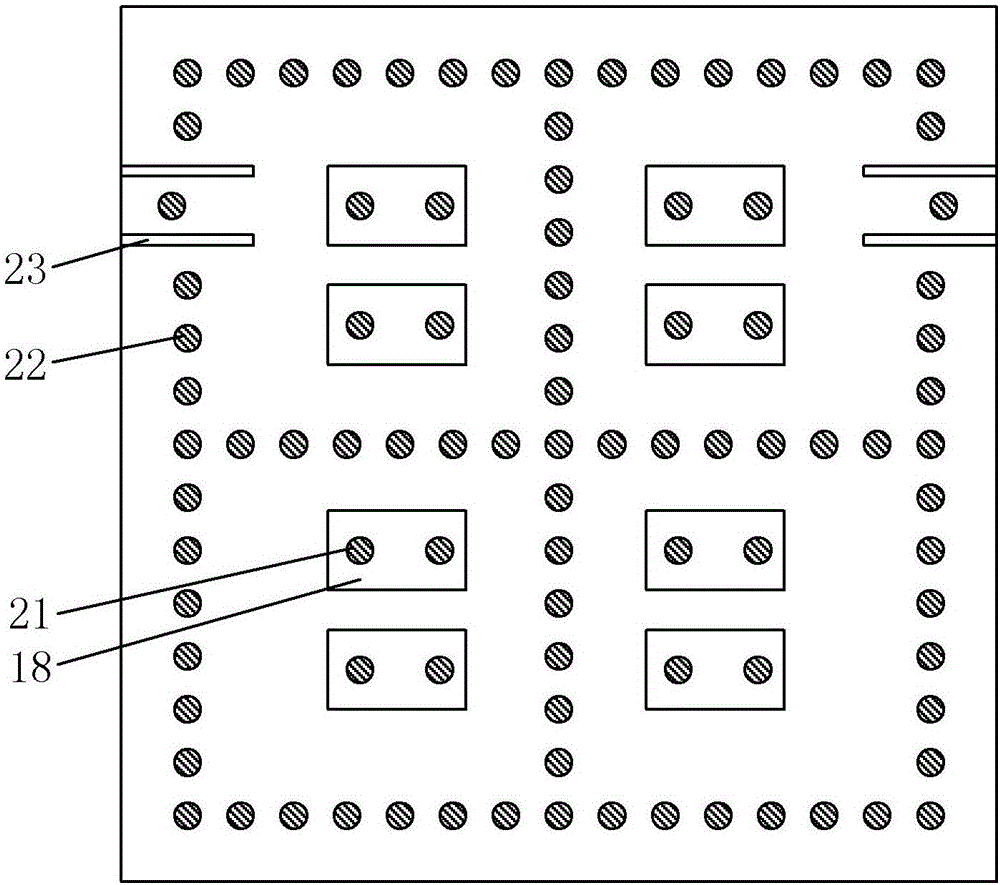

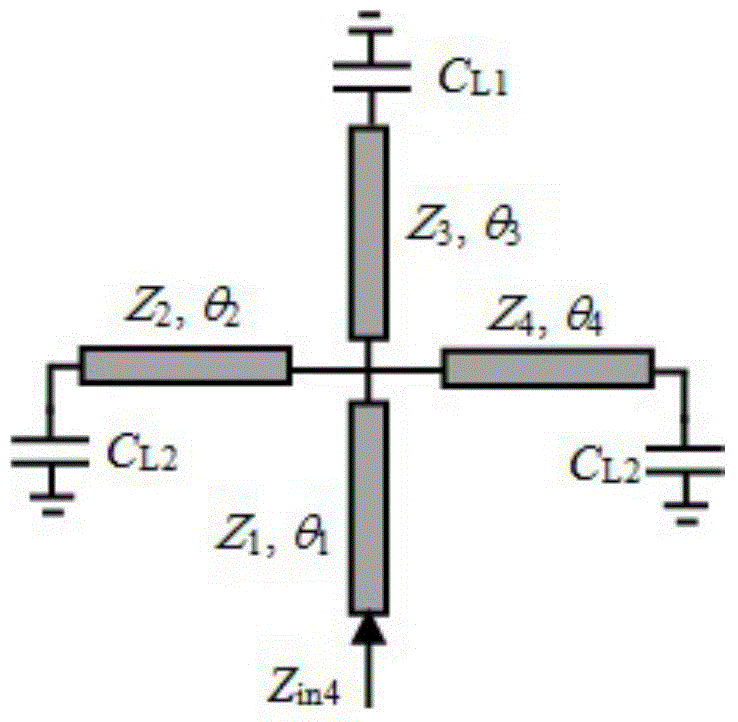

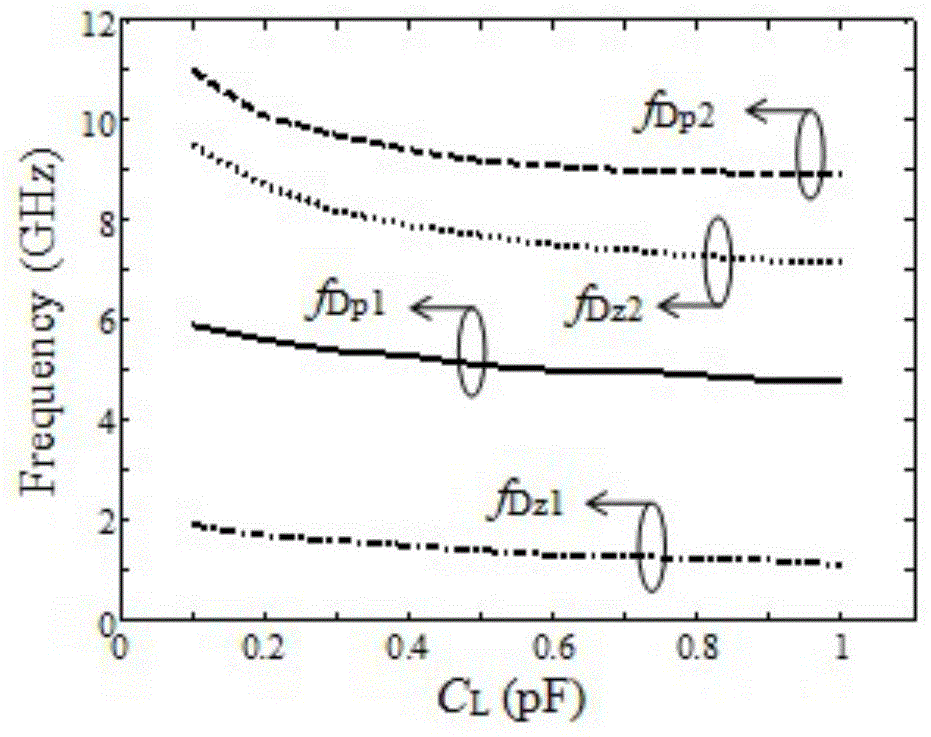

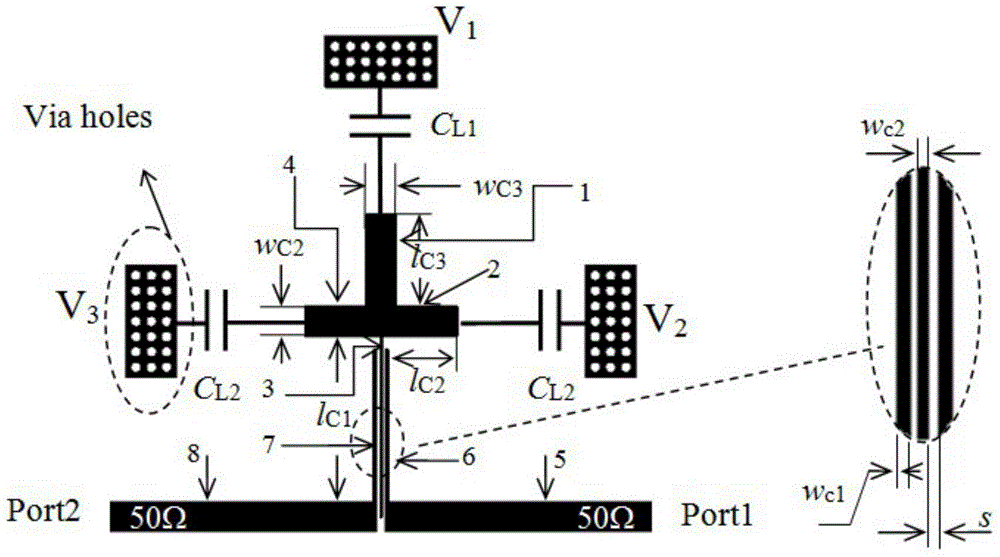

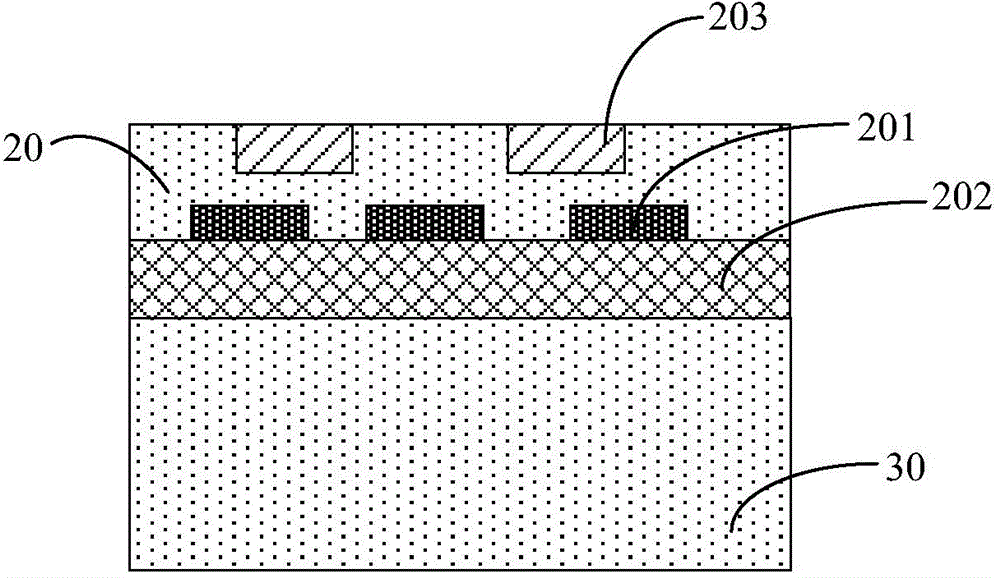

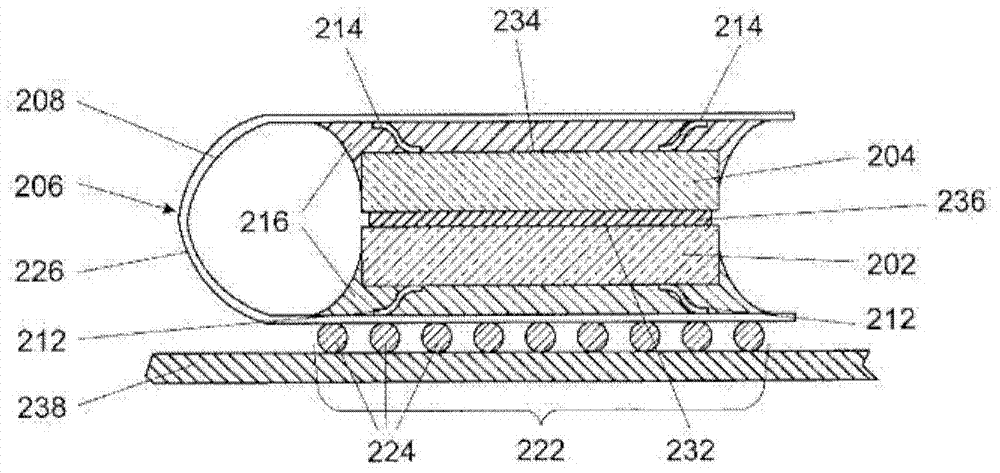

Central frequency adjustable substrate integrated waveguide filter and manufacturing method thereof

ActiveCN106252800ALow costThe process is simple and matureWaveguide type devicesResonant cavityElectrical and Electronics engineering

The invention provides a central frequency adjustable substrate integrated waveguide filter and a manufacturing method thereof. According to an electric adjustment method of the waveguide resonant frequency, tuning conductive poles loaded in a filter resonant cavity, The resonant frequency of the resonant cavity is disturbed, a switch composed of a conductive film bridge is formed on the top metal layer to gate the tuning conductive poles, and the central frequency of the substrate integrated waveguide filter is adjusted. The application range and adjustability of the filter are improved greatly.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

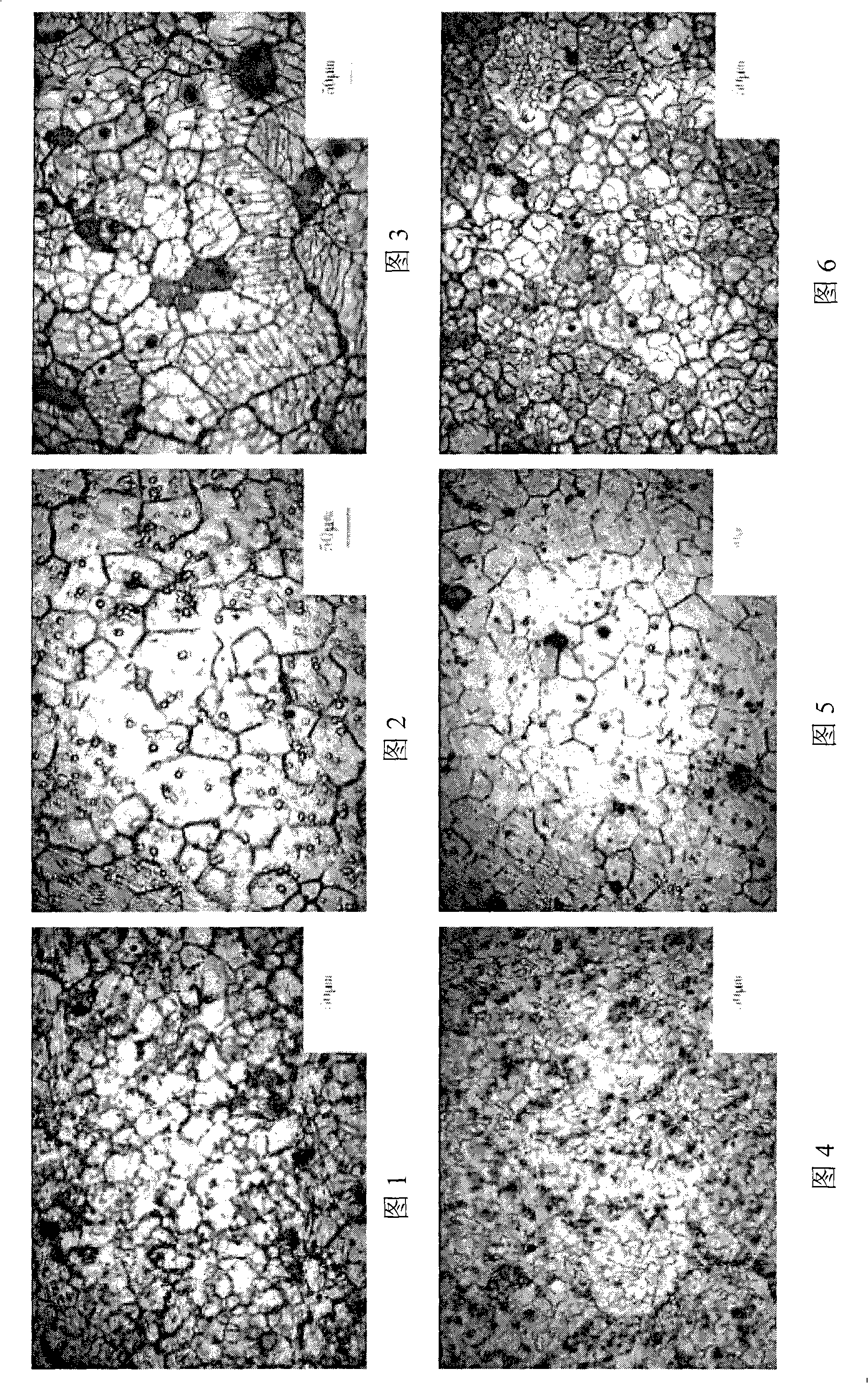

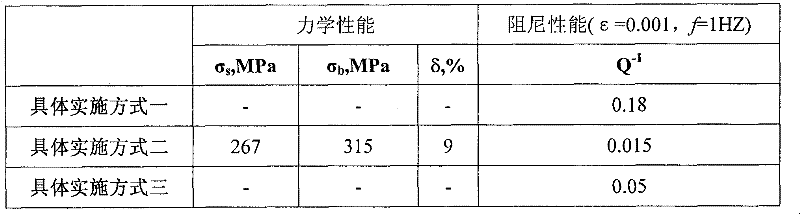

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864ASolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

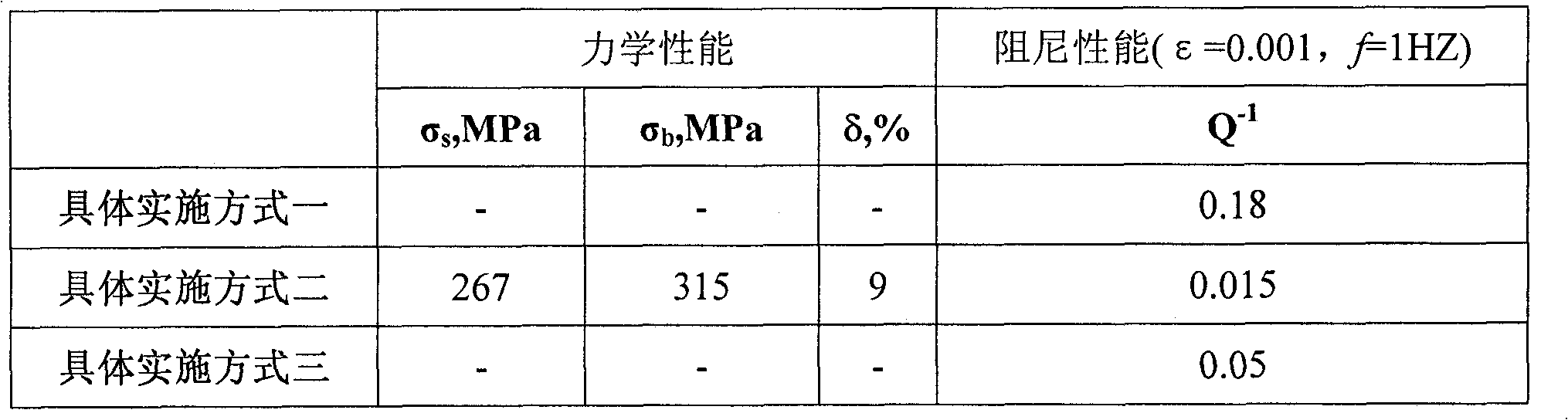

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are added in the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operation and lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

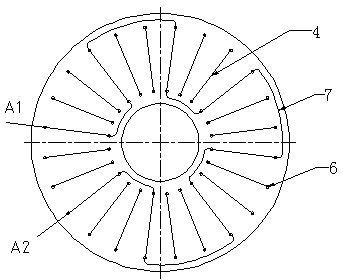

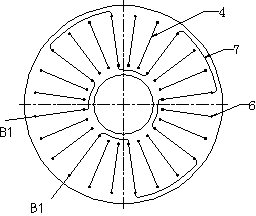

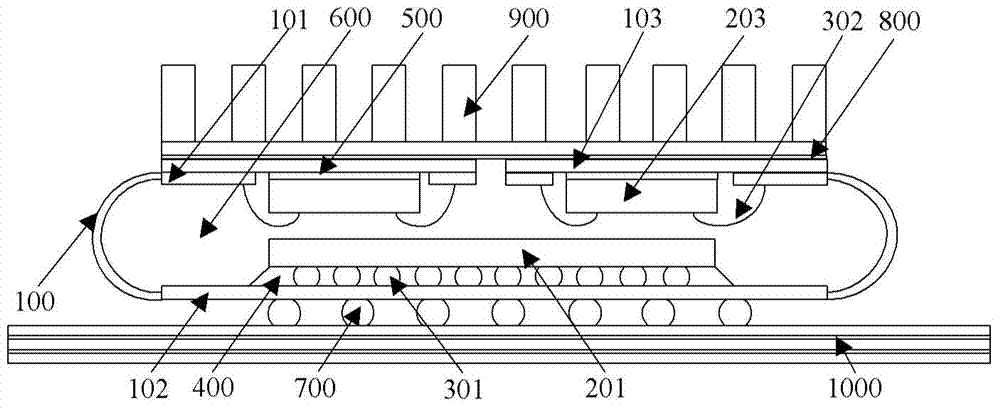

Printed circuit board disk type motor without iron core

InactiveCN103001426AReduce weightOptimize volumeWindings conductor shape/form/constructionEngineeringPrinted circuit board

The invention discloses a printed circuit board disk type motor without an iron core. The printed circuit board disk type motor without the iron core comprises a motor shaft and two rotor disks, a stator disk is arranged between the two rotor disks, permanent magnets are simultaneously installed on the two rotor disks, air gaps are formed between magnetic steel surfaces of the two rotor disks and two end faces of the stator disk respectively, the stator disk is formed by superposing at least two layers of printed circuit axial boards, a plurality of radialized straight guide wires are uniformly spread on the circumferential surface of each layer of printed circuit board, two ends of a part of straight guide wires are sequentially in a series connection through arc-shaped guide wires spread on the printed circuit boards, and thereby a phase of winding in a multi-phase motor is formed. By means of the structure, the printed circuit board disk type motor without the iron core has the advantages of being light, small in size, good in power density and control performance, low in manufacturing costs, convenient to process and suitable for batch production.

Owner:HUBEI HAISHAN TECH CO LTD +1

Ultrahigh-glowing filament temperature and flame-retardant reinforced PBT (polybutylece terephthalate) composite material and preparation method thereof

The invention relates to a macromolecular material and a preparation method thereof, in particular to a PBT (polybutylece terephthalate) composite material and a preparation method thereof. The PBT composite material comprises the following components in percentage by weight: 20-25 percent of polybutylene terephthalate, 6-20 percent of bromine containing flame retardant, 5-15 percent of phosphorus and nitrogen containing flame retardant, 5-15 percent of inorganic flame retardant, 20-40 percent of glass fiber, 2-8 percent of toughening agent, 0.2-0.4 percent of antioxidant and 0.3-2 percent of lubricating dispersant. The preparation method comprises the following steps of weighing the components in the percentage by weight; putting plastic and adjuvant into a high-speed mixing machine, mixing the plastic and the adjuvant for 2-5 minutes and discharging a mixture; controlling a double-screw extruder to extrude and granulate the mixture; and adding glass fiber in the extruding process to obtain the PBT composite material. The flame-retardant property and the strength of the PBT composite material are obviously improved; using requirements of more occasions can be met; the PBT composite material has high application value and good market prospect; and the used raw materials are the conventional products in the field of engineering plastics and are low in cost.

Owner:中山市纳普工程塑料有限公司

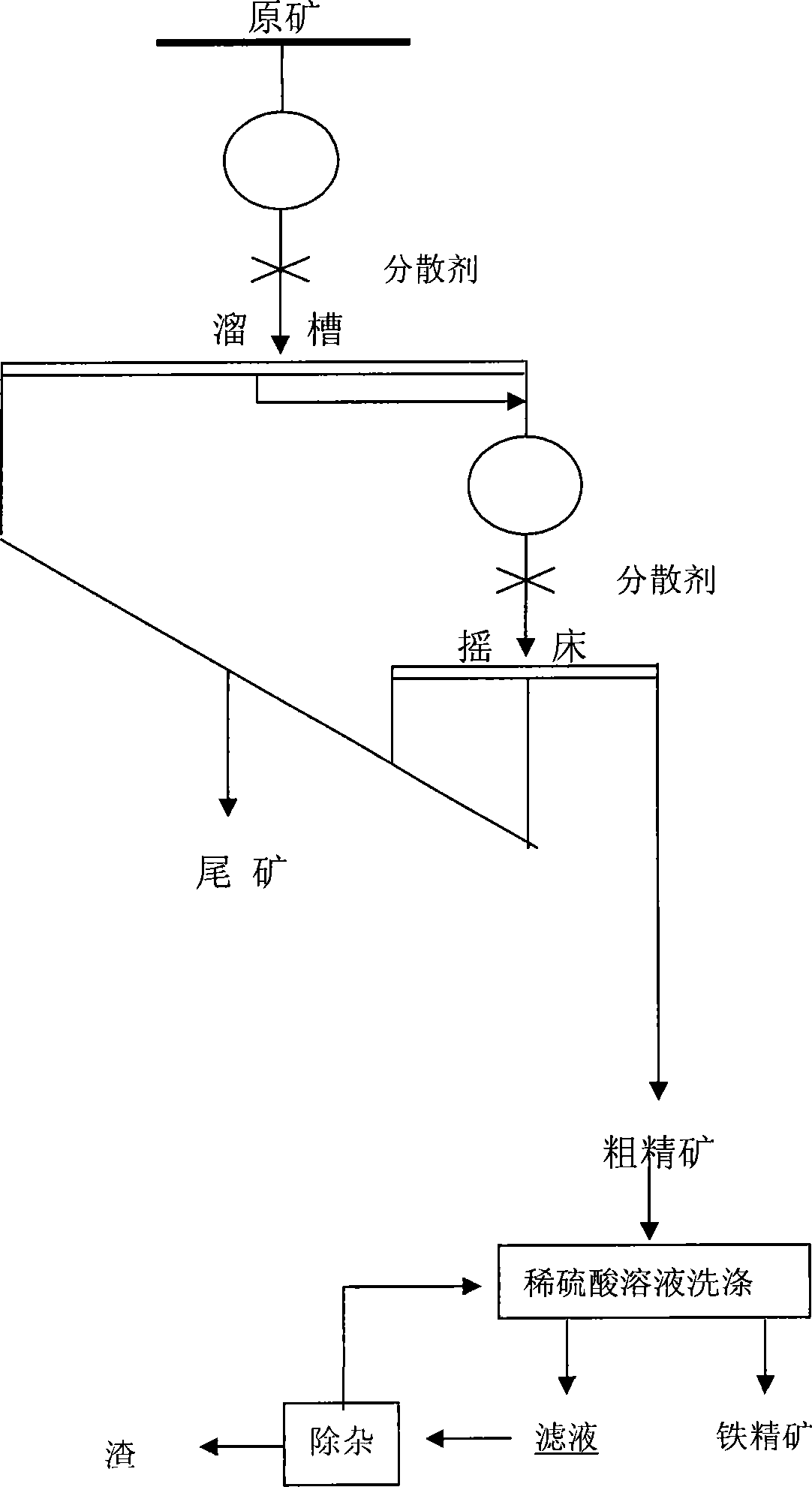

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

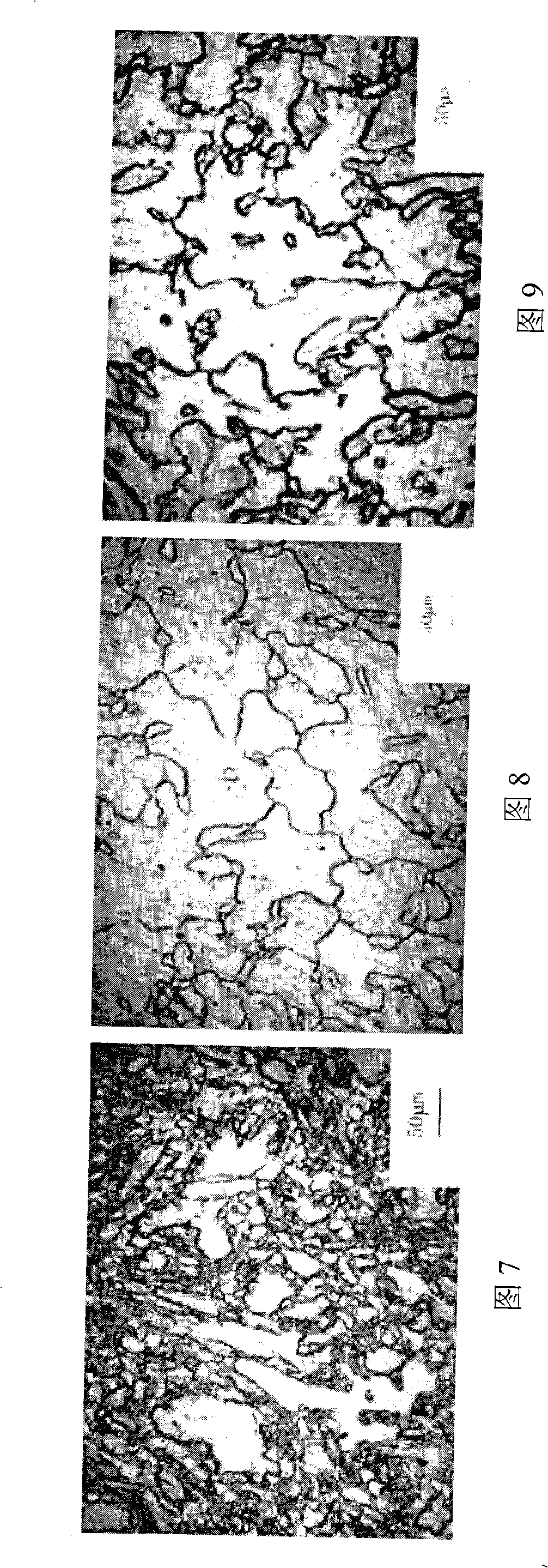

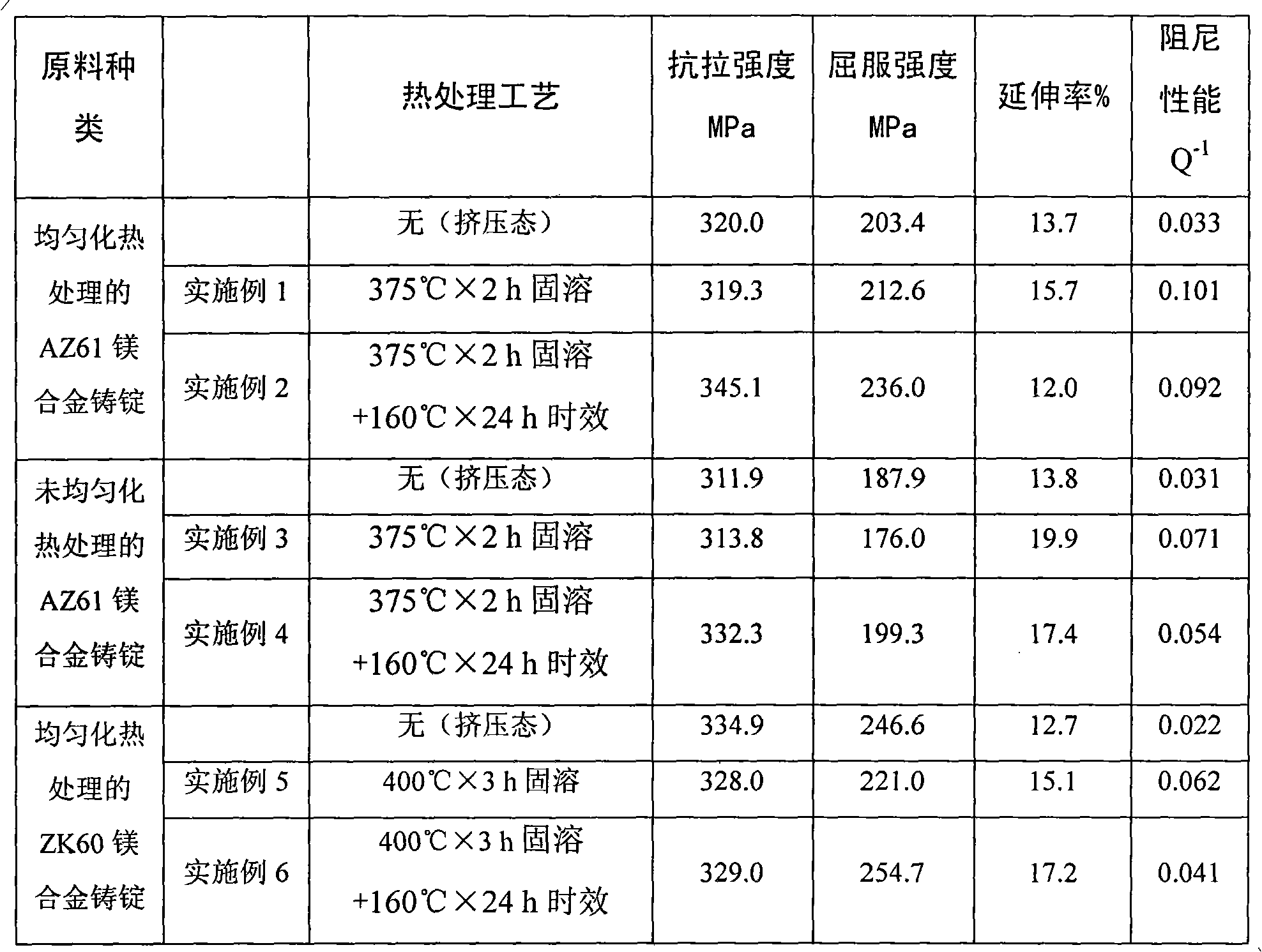

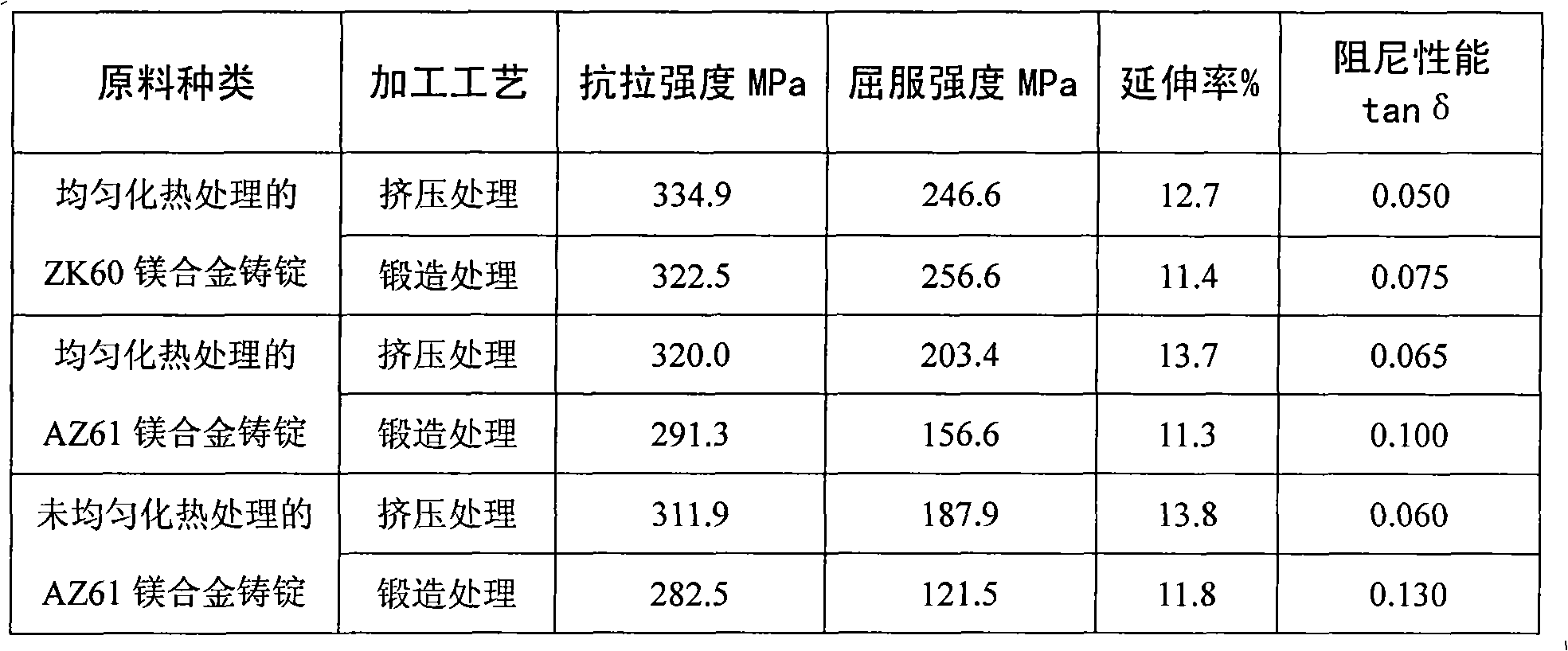

Heat treatment process improving high strength wrought magnesium alloy damping performance

The invention provides a heat treatment process for improving the damping properties of high-strength deformed magnesium alloy. A magnesium alloy ingot which is extruded for plastic deformation is subjected to solid solution at a temperature between 350 and 400 DEG C, has heat preserved for 2 to 4 hours, and is water-quenched to a room temperature; and the deformed magnesium alloy processed via the technical proposal is heated to be between 140 and 160 DEG C for aging, has heat preserved for 20 to 30 hours, and is air-cooled to the room temperature. The heat treatment process exponentially improves the damping properties of the high-strength deformed magnesium alloy at the same time when ensuring good mechanical properties, thereby successfully solving the contradiction between the strength and damping properties of the magnesium alloy. The deformed magnesium alloy processed via the heat treatment process is wide in application range, and can meet the actual demand for high-strength high-damping lightweight materials in the high-speed train, automobile, aerospace, national defense military and other fields. Moreover, the heat treatment process is simple in equipment, low in cost and easy to operate.

Owner:CHONGQING UNIV

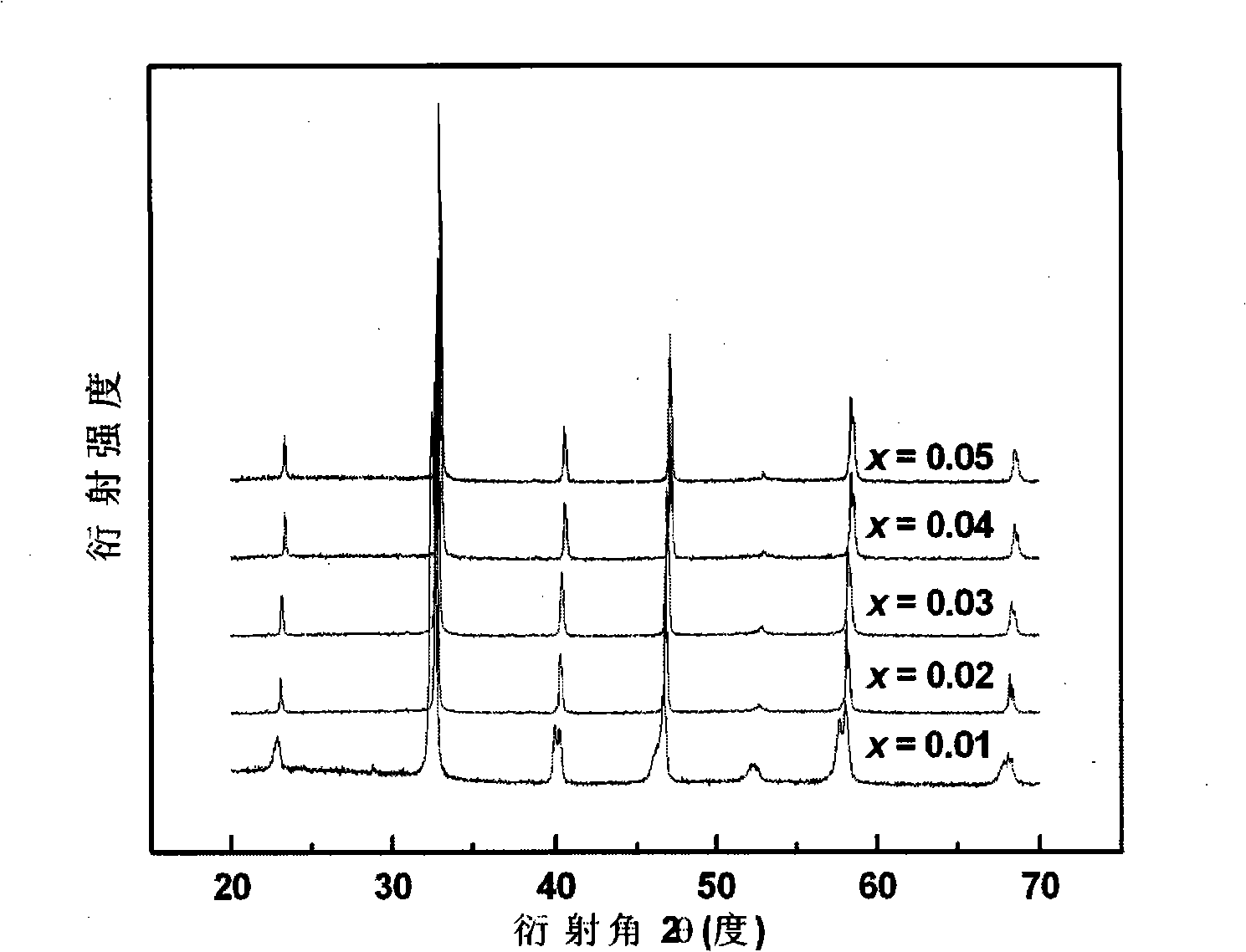

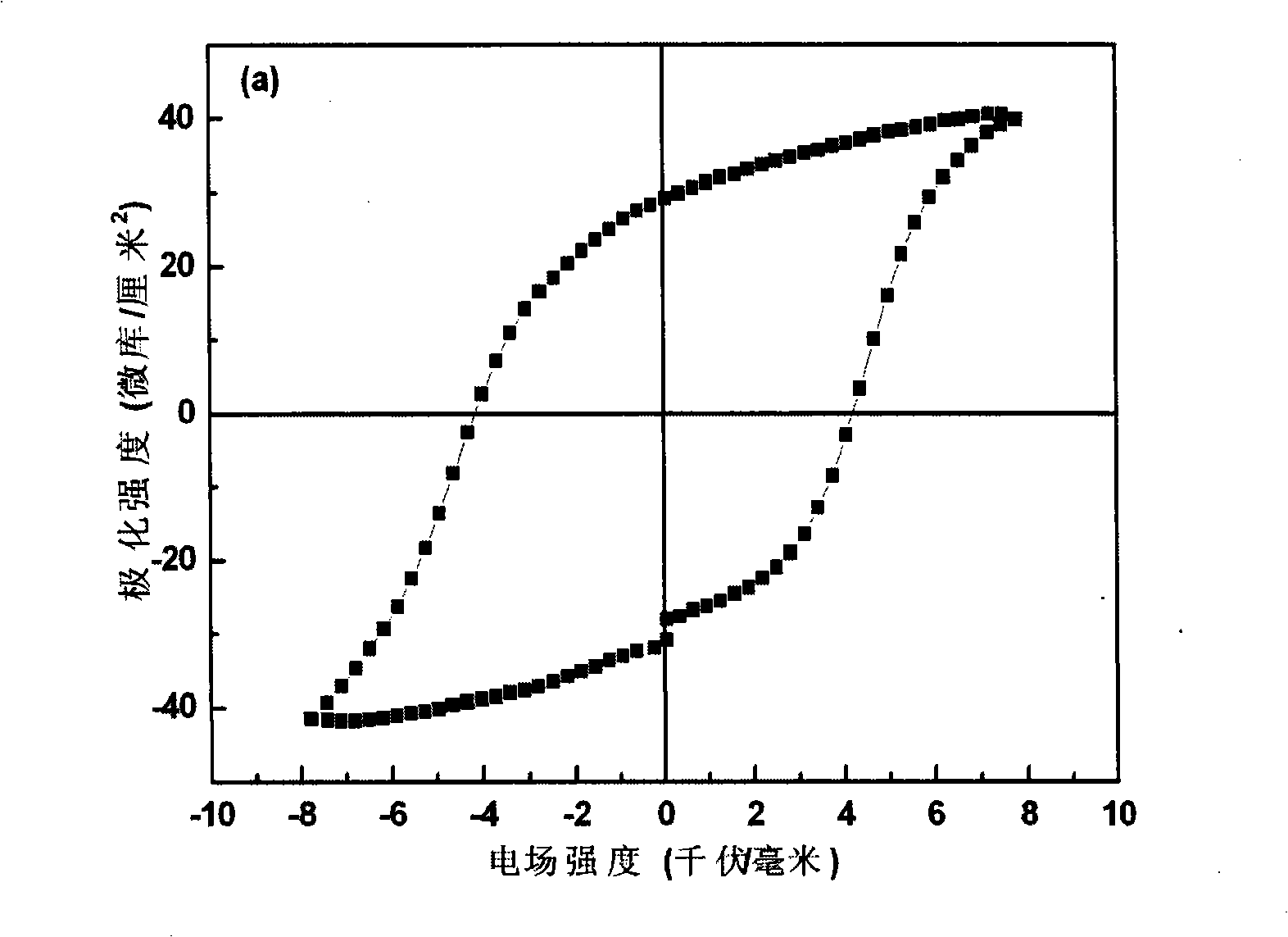

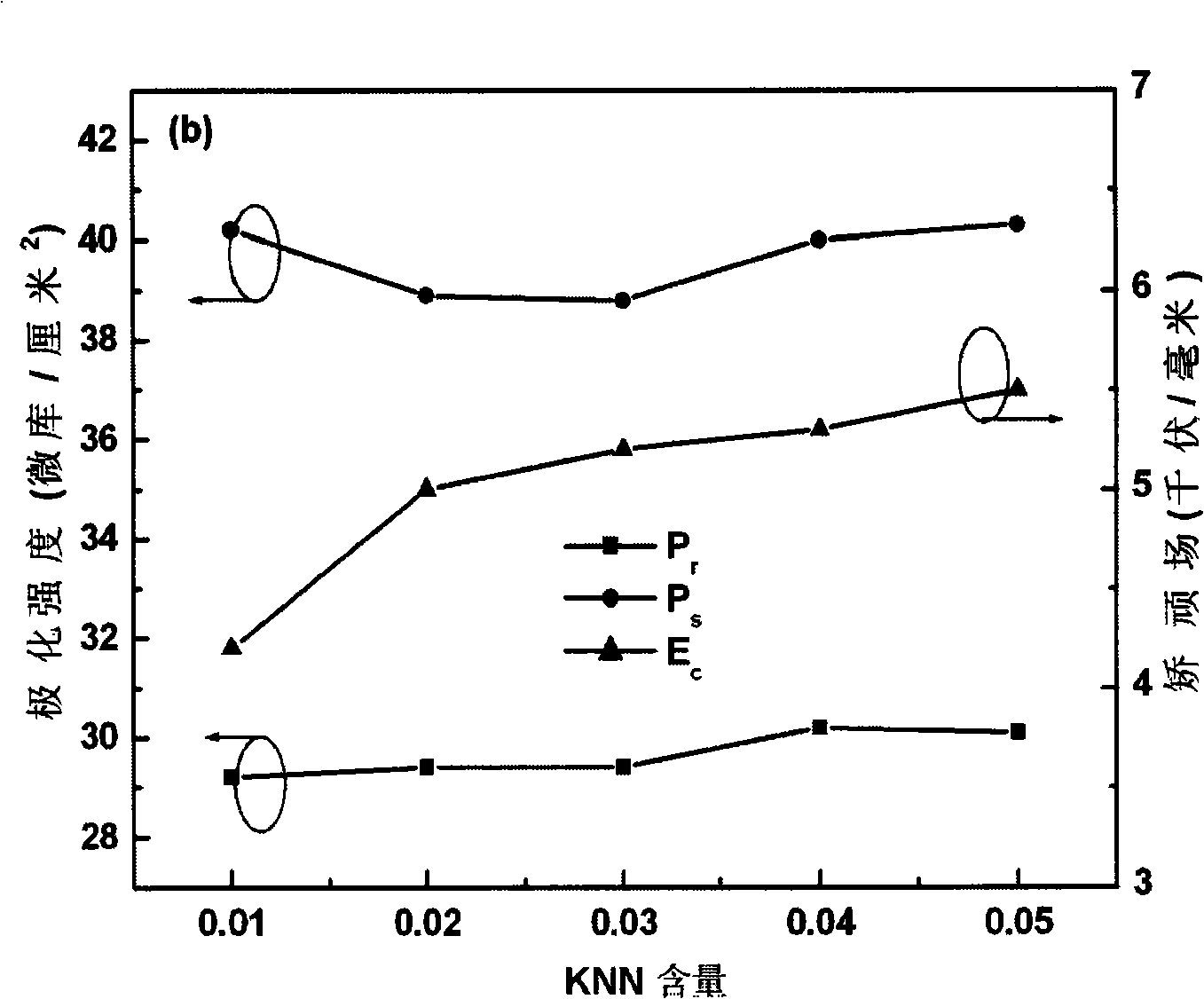

Leadless piezoelectric ceramics and method for preparing the same

InactiveCN101323522ARaise the depolarization temperatureLow costPiezoelectric/electrostrictive/magnetostrictive devicesPhase boundarySolid state reaction method

The invention discloses a leadless piezoelectric ceramics and a corresponding preparation method. The chemical formula of the leadless piezoelectric ceramics is as follows: 0.94Bi0.5Na0.5TiO3-(0.06-x)BaTiO3-xK0.5Na0.5NbO3, wherein, x is larger than 0 and less than 0.06. The leadless piezoelectric ceramics is manufactured through a solid state reaction method, and the structure of the ceramics is similar to a tripartite-orthogonal morphotropic phase boundary and has better ferroelectric and piezoelectric capability, and a residual polarization is about 30 Mu C / cm<2> and a saturation polarization is about 40 Mu C / cm<2> without depending on the contents, and the coercive field alters from 4.2 to 5.5kV / mm and increases as the increase of parameter x; and a piezoelectric coefficient d33 and an electro-mechanical coupling factor Kp decrease as the increase of parameter x, d33 alters from 86 to 118pC / N and kp alters from 0.26 to 0.29. A depolarization temperature (T<d>) increases from 108 to 146 DEG C as the increase of KNN.

Owner:NANJING UNIV

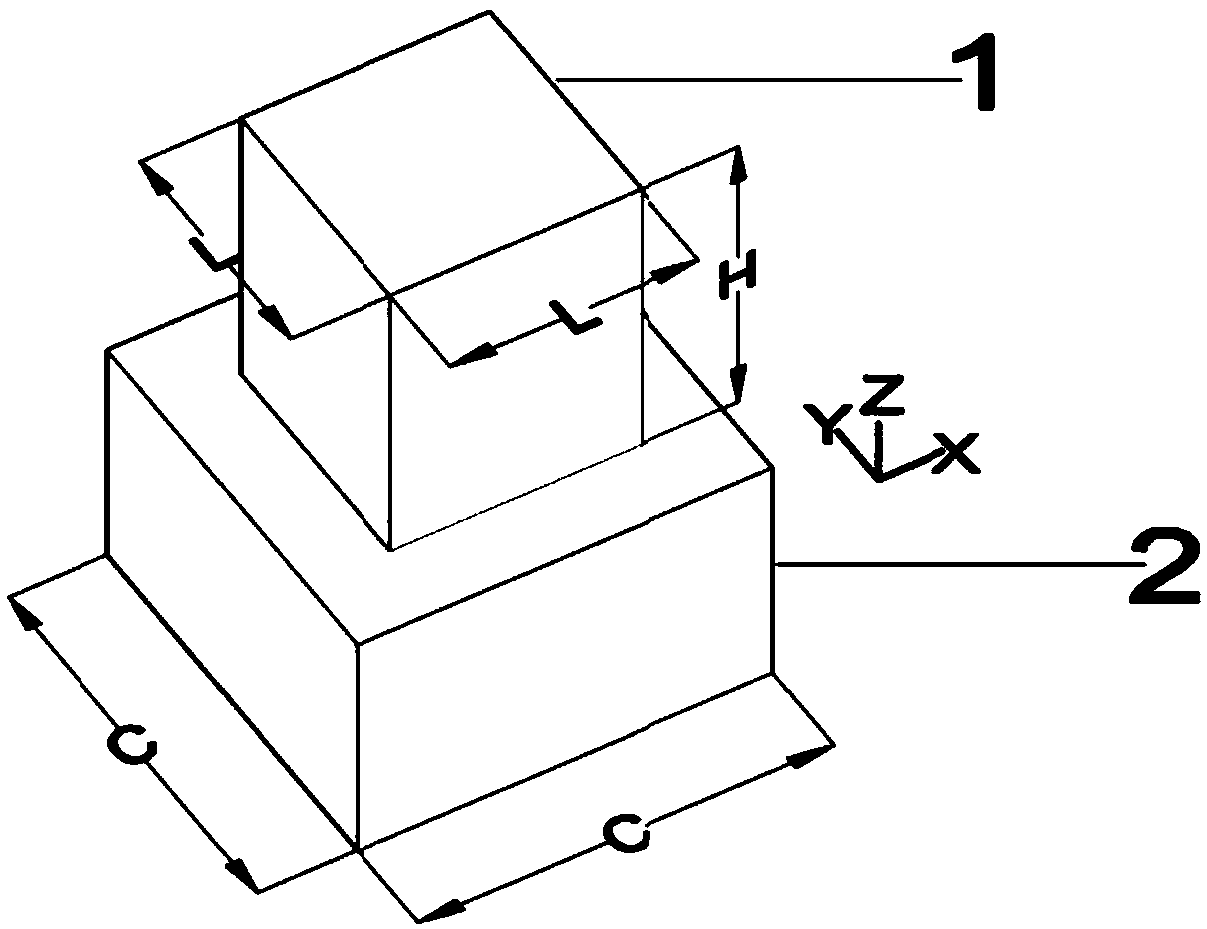

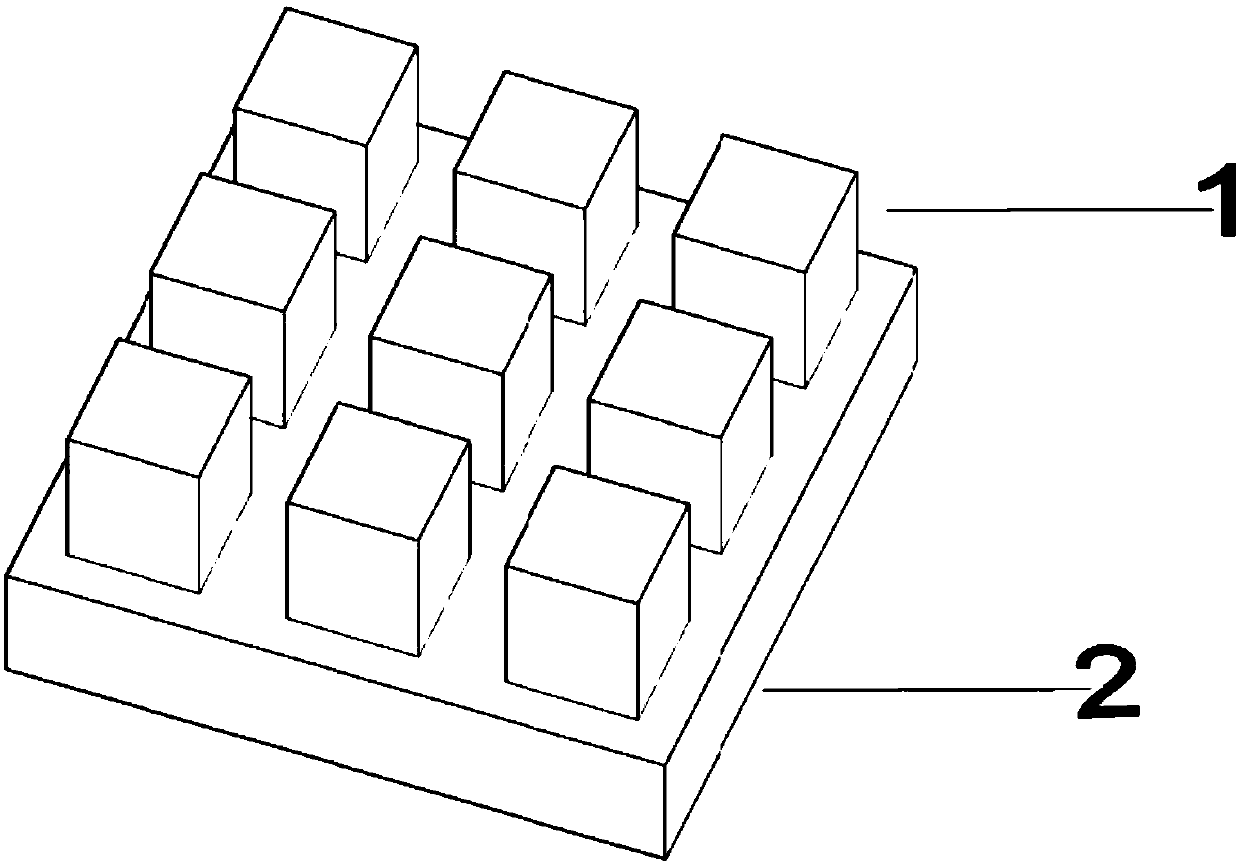

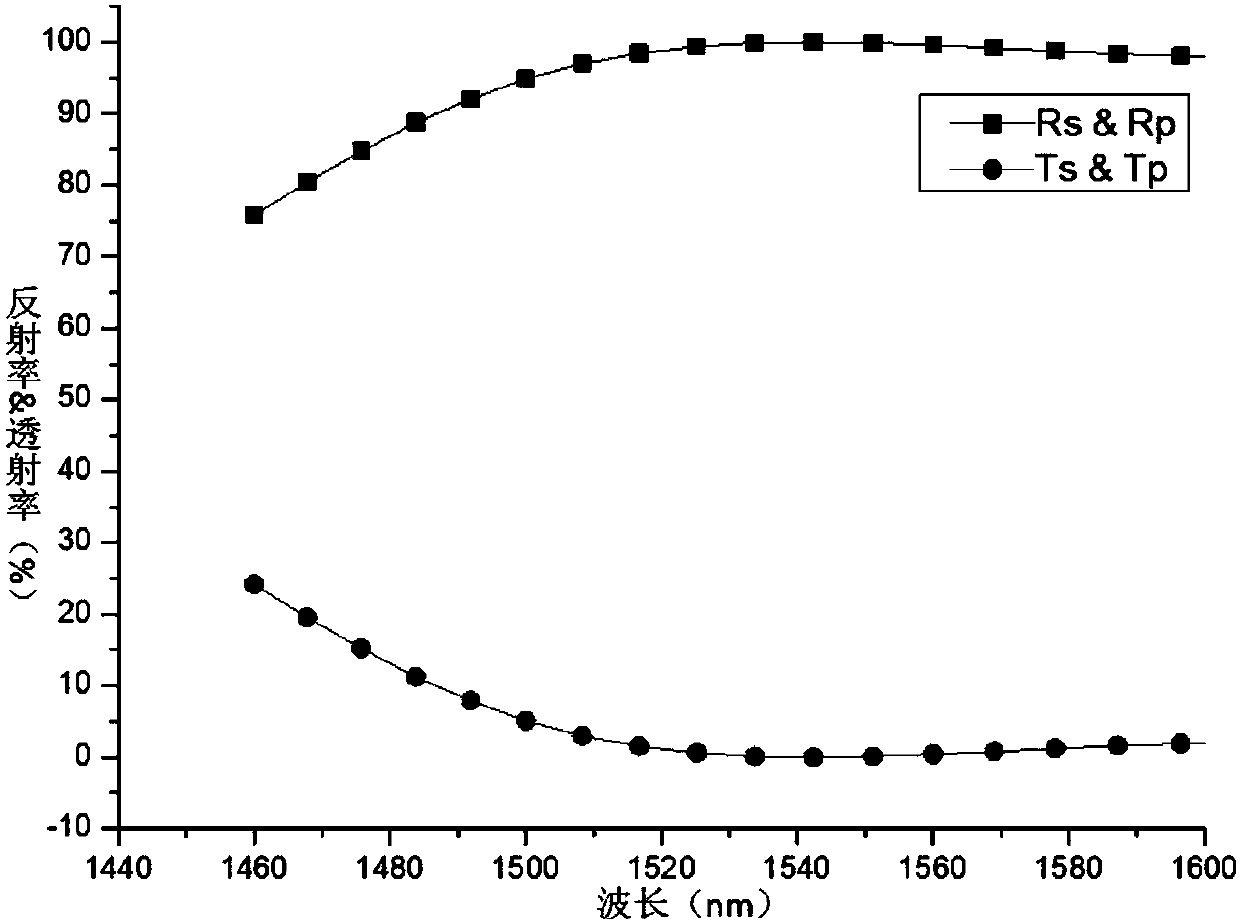

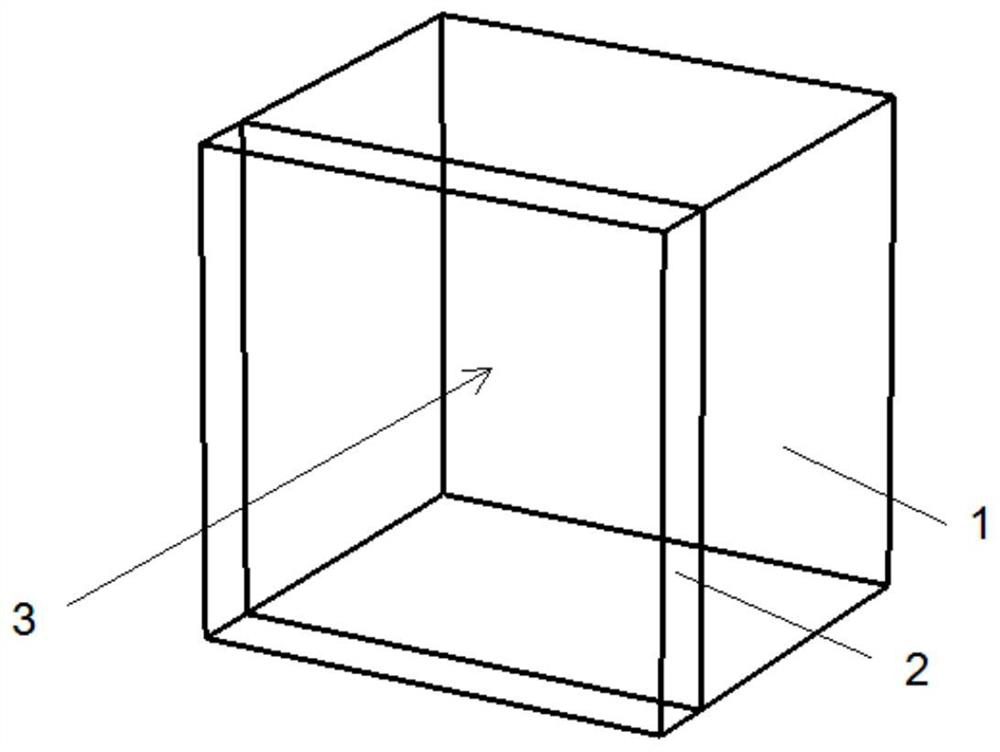

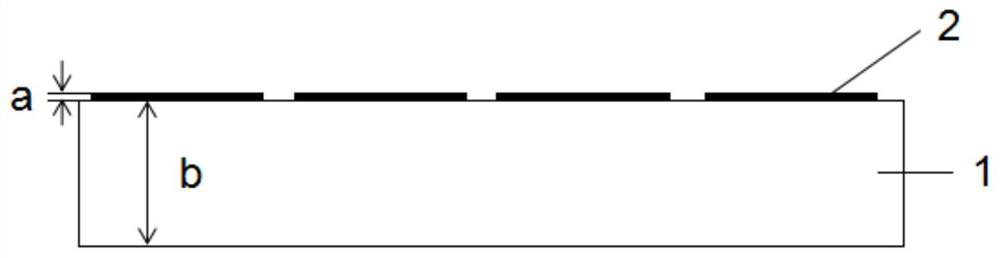

Dielectric nano-brick array structure and application thereof as high-reflection film and high-permeability film

The invention discloses a dielectric nano-brick array structure and the application thereof as a high-reflection film and a high-permeability film. The dielectric nano-brick array structure comprisesa substrate and a dielectric nano-brick array on the substrate. The dielectric nano-brick array is formed by periodically arranging dielectric nano-bricks and the dielectric nano-bricks are in a regular quadrangular prism shape. The bottom surfaces of the dielectric nano-bricks are square, wherein the length, the width and the height of the dielectric nano-bricks are sized in sub-wavelength scale.When the dielectric nano-brick array structure is used as a high-reflectivity film, the structural parameters of the dielectric nano-brick array structure are optimized. In this way, the Mie resonance can be generated when the s-wave and the p-wave are incident at a working wavelength. When the dielectric nano-brick array structure is used as a high-permeability film, the structural parameters ofthe dielectric nanometer brick array structure are optimized. In this way, the equivalent refractive index of a mixed layer is between the refractive index of a medium around the mixed layer and therefractive index of the substrate. According to the technical scheme of the invention, the high-reflection film and the high-permeability film, based on the dielectric nano-brick array structure, arehigh in working efficiency in the whole communication wave band.

Owner:WUHAN UNIV

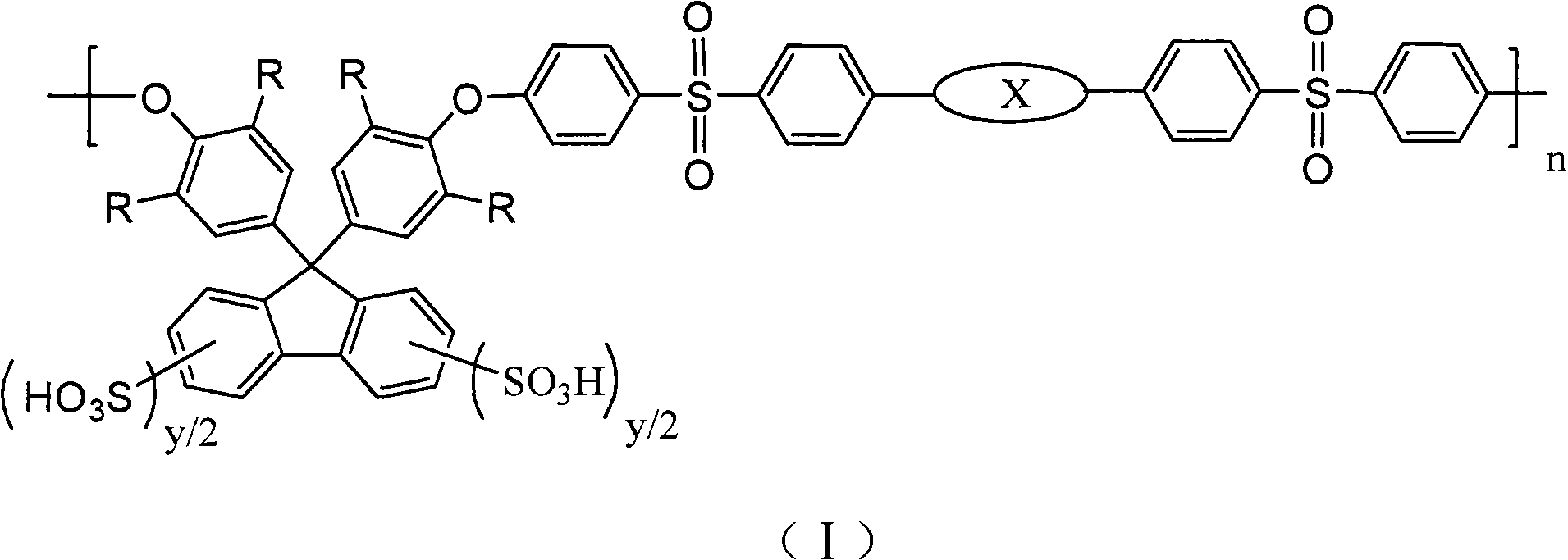

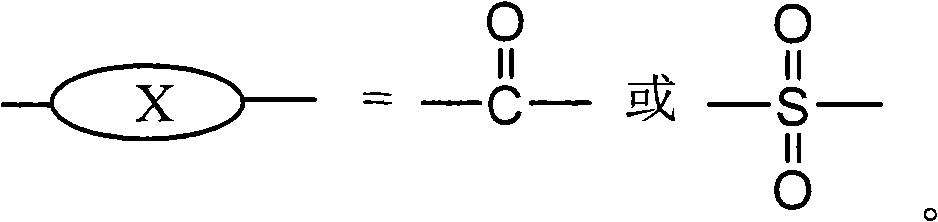

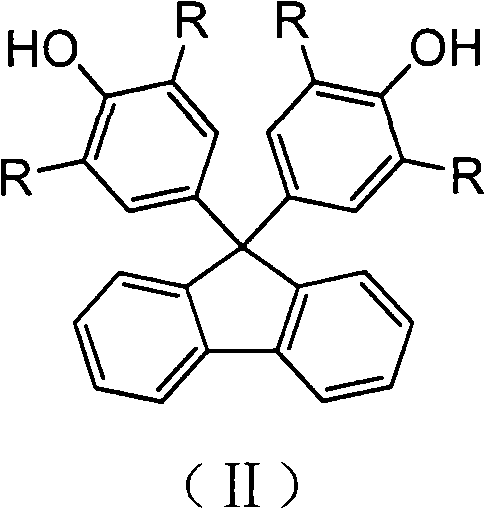

Sulfonated fluorene-containing polyether sulphone for proton exchange membrane of all-vanadium flow battery and preparation method and application thereof

InactiveCN101628979ASimple processThe process is simple and matureCell component detailsCoatingsPolymer scienceSolvent

The invention discloses sulfonated fluorene-containing polyether sulphone for a proton exchange membrane of an all-vanadium flow battery and a preparation method and an application thereof. The preparation method of the invention adopts fluorene-containing bisphenol with different structures and different dihalide monomers to perform copolymerization in non-proton polar solvent under the action of potassium carbonate catalyst, then uses chlorosulfonic acid to sulfonate the obtained polymer and finally adjusts the dosage of chlorosulfonic acid to prepare a kind of sulfonated fluorene-containing polyether sulphones with different degrees of sulfonation. The polymer can be directly casted to prepare single component film, mixed with other polymers to prepare composite film, mixed with inorganic matter to prepare doped film or combined with other ion exchange films to prepare multi-layer film. The films are characterized by low vanadium ion permeability, low water absorption, high proton conductivity, good stability, low cost and the like, thus being applicable to being used as proton exchange films of the all-vanadium flow battery.

Owner:SUN YAT SEN UNIV

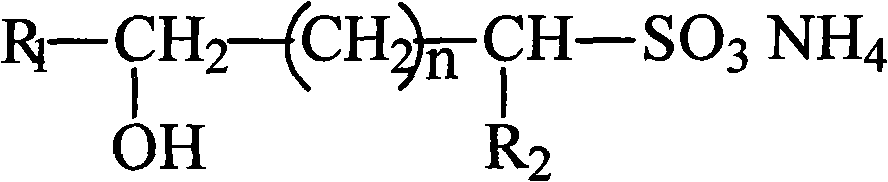

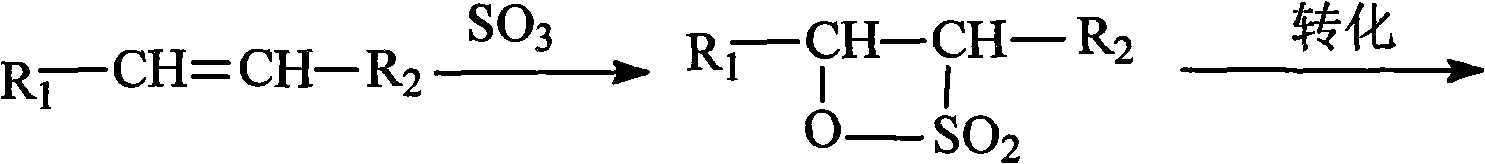

Nanometer silicon dioxide modified sulphonate oil-displacing agent and preparation method thereof

InactiveCN101570686AHigh interface activityImprove salt resistanceDrilling compositionSulfonateCapillary Resistance

The invention provides a nanometer silicon dioxide modified sulfonate oil-displacing agent and a preparation method thereof, which belong to synthesis of a chemical oil-displacing agent in tertiary recovery by a simple and convenient and easily industrialized method. The method comprises the following steps that: firstly, naphthene base crude oil is sulfonated and neutralized at a temperature of between 10 and 80 DEG C to obtain sulfonate; secondly, the sulfonate is subjected to graft modification by nano-grade silicon dioxide; and finally, the nanometer modified sulfonate oil-displacing agent is obtained. The nanometer silicon dioxide modified sulfonate oil-displacing agent comprises 60 to 90 portions of naphthene base sulfonate and 10 to 40 portions of nanometer silicon dioxide by mass portion. The oil-displacing agent can be used for an oil-displacing experiment; when mass fraction of dosage of the oil-displacing agent is 0.3, the oil-displacing agent can reduce the tensile force of oil-water boundary to 5*10mN.m to effectively reduce adhesive force of residual oil, so that the residual oil is easy to deform and separate; meanwhile, the capillary resistance is reduced, so that the residual oil drop is easy to aggregate to form an oil wall and the oil recovery efficiency is improved. The oil-displacing agent has low price, simple synthesis process and convenient popularization and application.

Owner:SINOPEC PETROLEUM ENG DESIGN

High-intensity high-damping deforming magnesium alloy with rear earth yttrium

The invention discloses a high-intensity high-damping deforming magnesium alloy with rear earth yttrium, which is characterized by comprising the following components by weight percent: 2.9-3.1 percent of Al, 0.9-1.1 percent of Zn, 0.5-2 percent of Y, 0.29-0.31 percent of Mn and the rest of Mg and unavoidable impurities. The high-intensity high-damping deforming magnesium alloy with rear earth yttrium can greatly increase the mechanical property and the damping performance of the high-intensity AZ series deforming magnesium alloy, successfully solve the conflict of the mechanical property andthe damping performance of the magnesium alloy and satisfy the actual requirements for a high-intensity high-damping light-weight material in the fields of very high-speed trains, automobiles, aerospace, national defense war industry, and the like, moreover, the magnesium alloy material has lower cost, and a technical device is the normal universal device with strong portability and easy operation.

Owner:CHONGQING UNIV

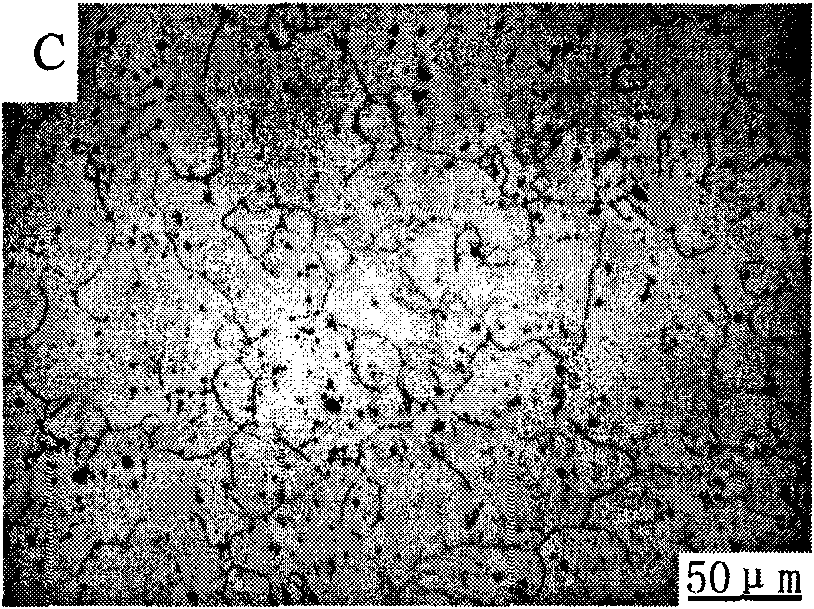

Plastic working technique for increasing damping performance of high-strength wrought magnesium alloys

InactiveCN101332560AHigh dampingImprove mechanical propertiesMetal-working apparatusIngotUltimate tensile strength

Owner:CHONGQING UNIV

Preparation method of lacquer tree seed wax oil

InactiveCN103849470AEasy to separateNot easy to stickFatty substance recovery/refiningAgricultural engineeringLacquer tree

The invention discloses a preparation method of lacquer tree seed wax oil. The preparation method comprises the following steps: cooling lacquer tree seeds, rubbing the seeds, screening, crushing, pneumatically conveying and selecting, cooking, solvent extracting, filtering, separating and finally obtaining the lacquer tree seed wax oil. The preparation method of the lacquer tree seed wax oil can enable preparation, extraction and separation of the lacquer tree seed wax oil to be continuous, improves production efficiency, material utilization rate and wax quality, and improves wax market competitiveness. By applying the method, the husk-core separating efficiency of the lacquer tree seeds reaches over 95%, and the lacquer tree seed core perfectness ratio reaches over 90%; and moreover, compared with the existing separating method, the whole set of process flow is reliable in operation and strong in economical efficiency, so that processing cost for per tonnage of seeds is lowered by over 15%.

Owner:云南省轻工业科学研究院有限公司 +1

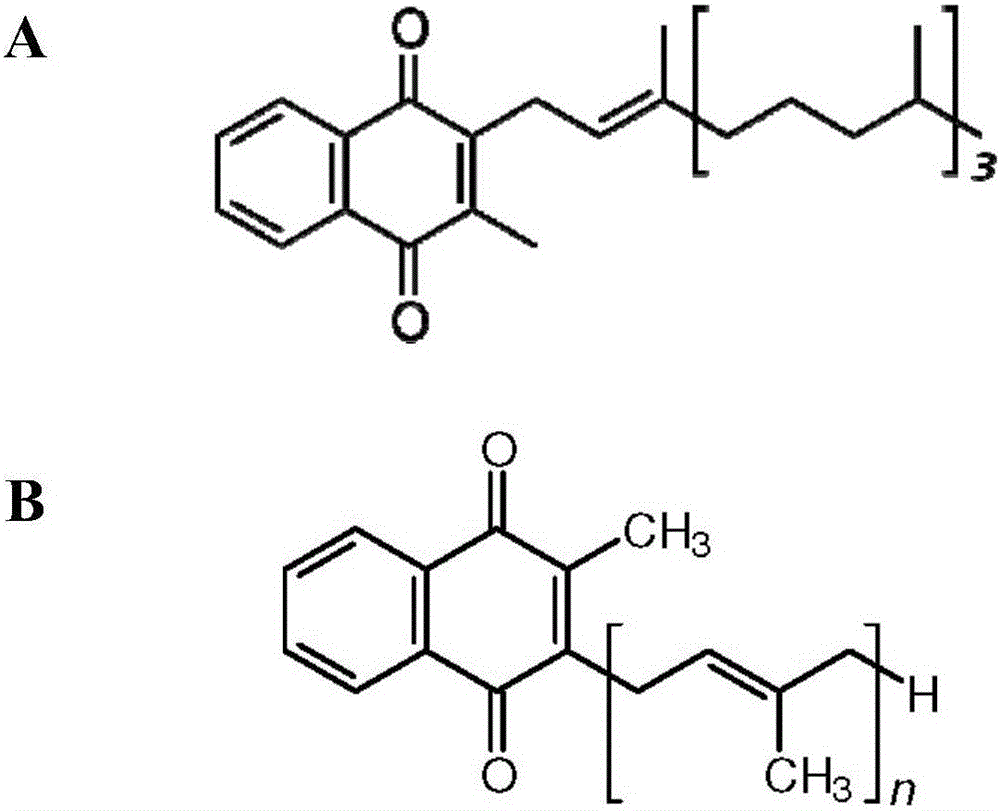

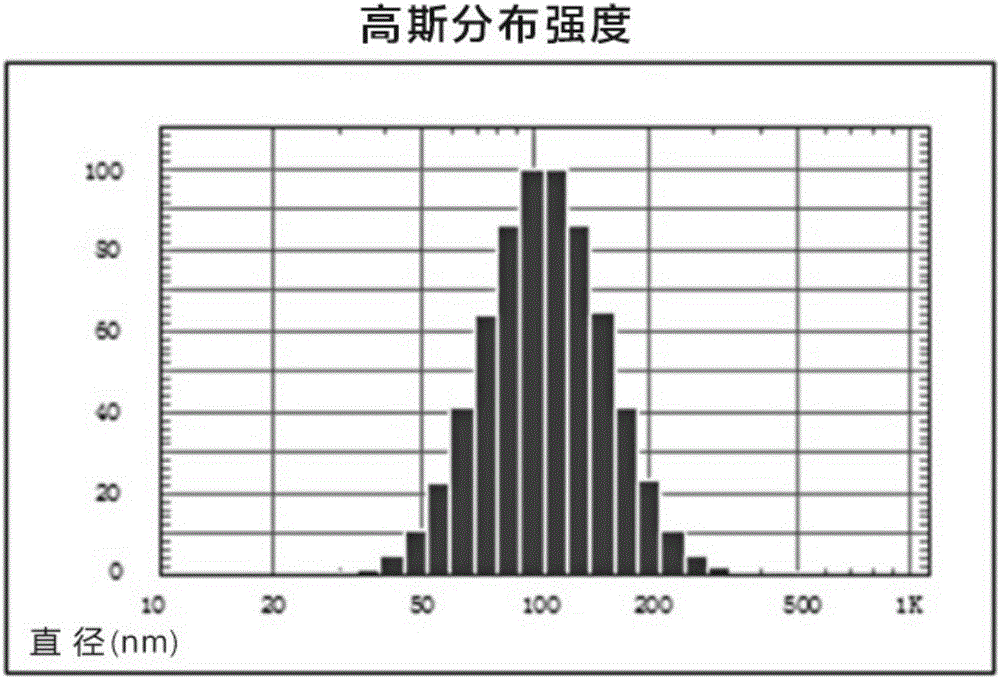

Stable vitamin K2 submicron emulsion and preparing method

InactiveCN106074377AImprove stabilityFreeze-thaw toleranceOrganic active ingredientsSkeletal disorderFreeze thawingEmulsion

Vitamin K2 submicron emulsion is prepared from, by weight, 0.0005-1% of vitamin K2, 1.0-10% of oil, 0.1-1.2% of phospholipid, 0.5-2.3% of emulgator, 0.5-3.0% of antifreezing agent and water according to the total weight of the vitamin K2 submicron, wherein emulgators except phospholipid can serve as the emulgator in the emulsion. The vitamin K2 submicron emulsion is good in sterilization stability and freeze-thaw stability, and the expected shelf life can reach two years or more.

Owner:SUNGEN BIOSCIENCE CO LTD

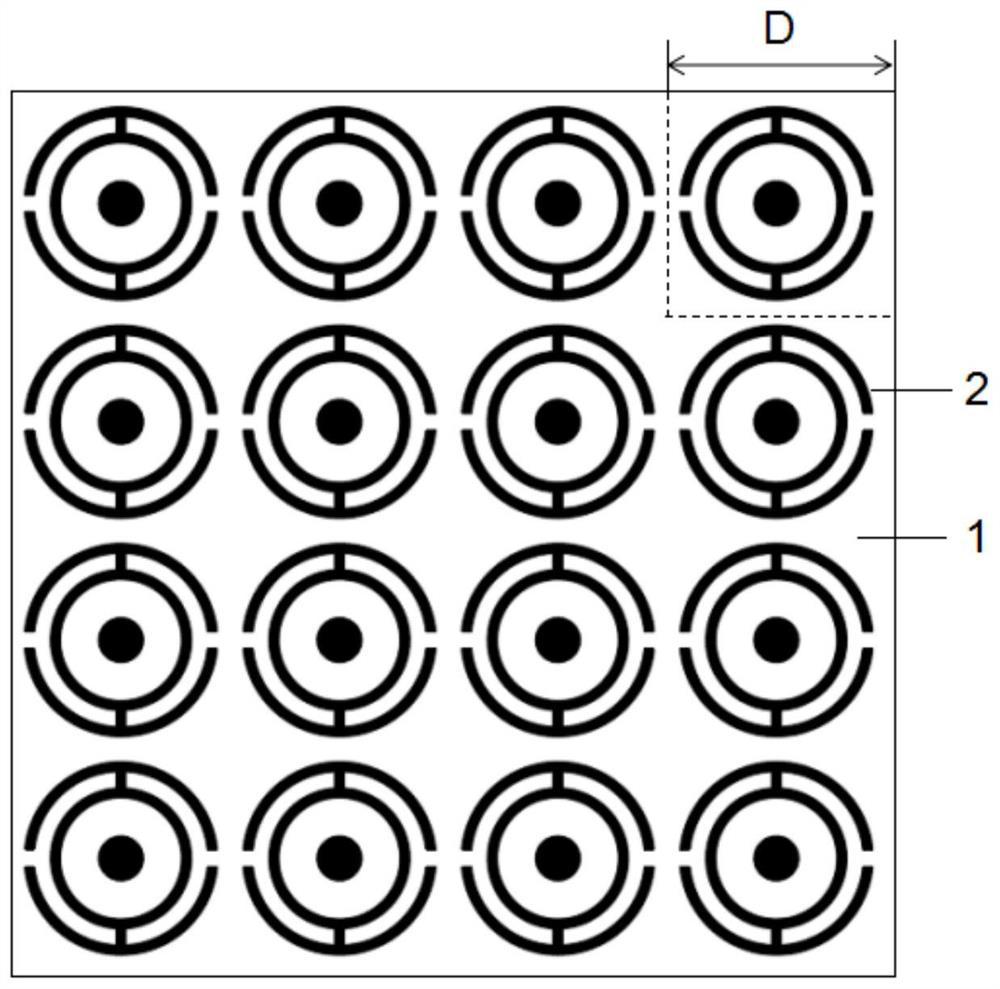

Terahertz dual-band elimination filter

The invention discloses a terahertz dual-band elimination filter. The terahertz dual-frequency band elimination filter comprises N * N identical square units which are periodically arranged on a planeperpendicular to a wave incident direction, and no interval exists between the units; each unit comprises a metal resonance layer and a substrate; and each metal resonance layer comprises a first semi-metal ring, a second semi-metal ring, a metal ring, a first metal strip, a second metal strip and a metal circle; the metal circle is arranged in the center of the metal ring, the first metal stripand the second metal strip are respectively arranged right above and right below the metal ring, the first semi-metal ring and the second semi-metal ring are respectively arranged right above and right below the first metal strip and the second metal strip, and the first semi-metal ring and the second semi-metal ring form a circular ring with two gaps. The dual-stop-band characteristic of the filter in the terahertz wave band is achieved, and the filter has the advantages of being low in loss, simple in structure and low in material and process cost.

Owner:HEFEI UNIV OF TECH

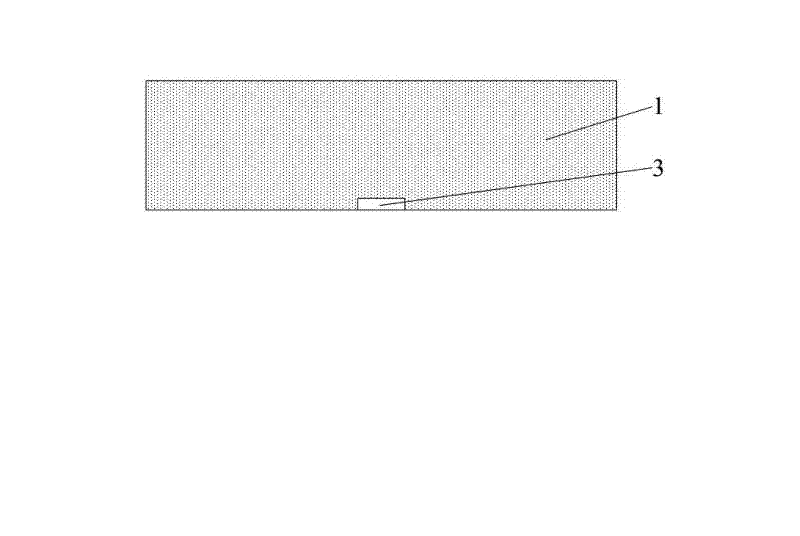

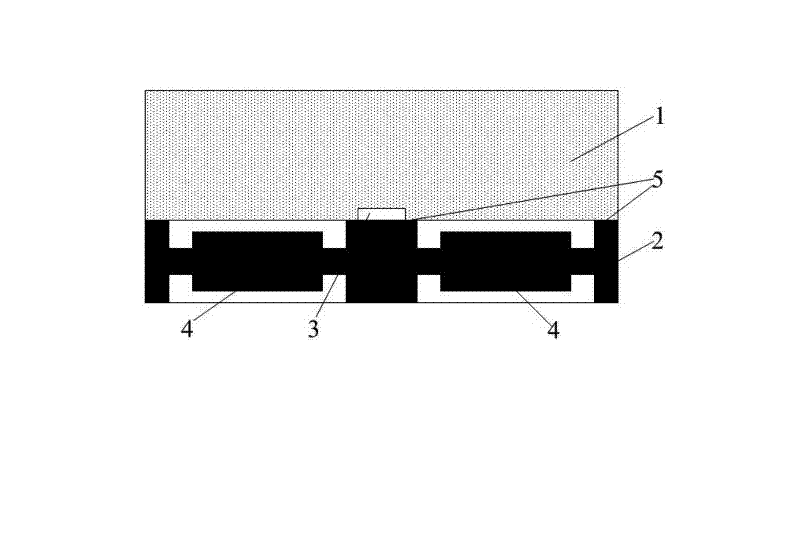

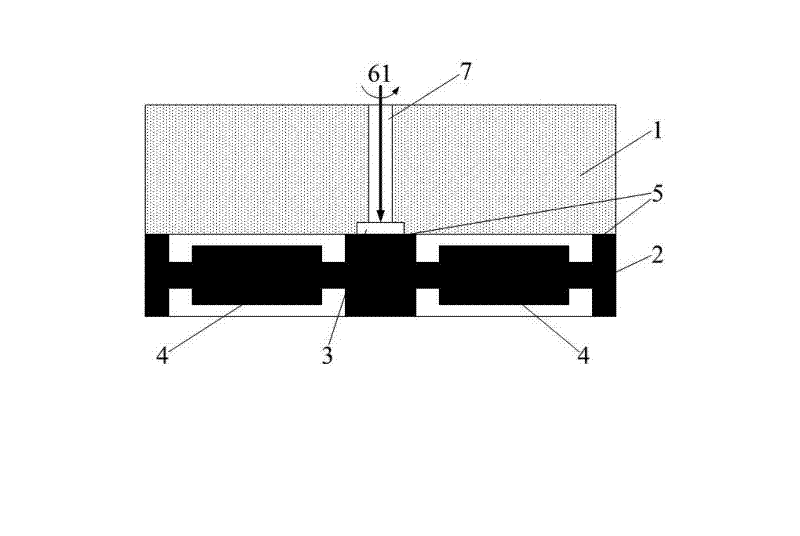

Bonded wafer with thermal stress relief structure and laser scribing process

ActiveCN102285624ALow costAvoid crackingDecorative surface effectsSolid-state devicesCrystallographyWafer

The invention discloses a bonded wafer with a thermal stress release structure. The bonded wafer comprises a glass wafer and a silicon wafer which are jointed with each other; a thermal stress release structure for laser scribing is arranged at the position close to a bonding contact surface of the bonded wafer; the thermal stress release structure is correspondingly arranged along a drafted laser scribing track; the stress release structure of the bonded wafer provided by the invention can prevent an original bonding region close to the scribing track from cracking, improve the laser scribing yield of the bonded wafer and reduce the scribing cost. The invention further discloses a laser scribing process; the laser scribing process comprises a thermal stress release structure process step, bonding wafer and laser scribing processing steps and the like; the laser scribing process can effectively release the thermal stress in the process of laser scribing so as to inhibit a thermal crack on a bonding contact surface, the mechanical property of the bonding contact surface is greatly improved, which is beneficial to the improvement of the MEMS (micro-electromechanical system) chip property; meanwhile, the process is simple and mature and can guarantee lower cost and higher yield.

Owner:NAT UNIV OF DEFENSE TECH

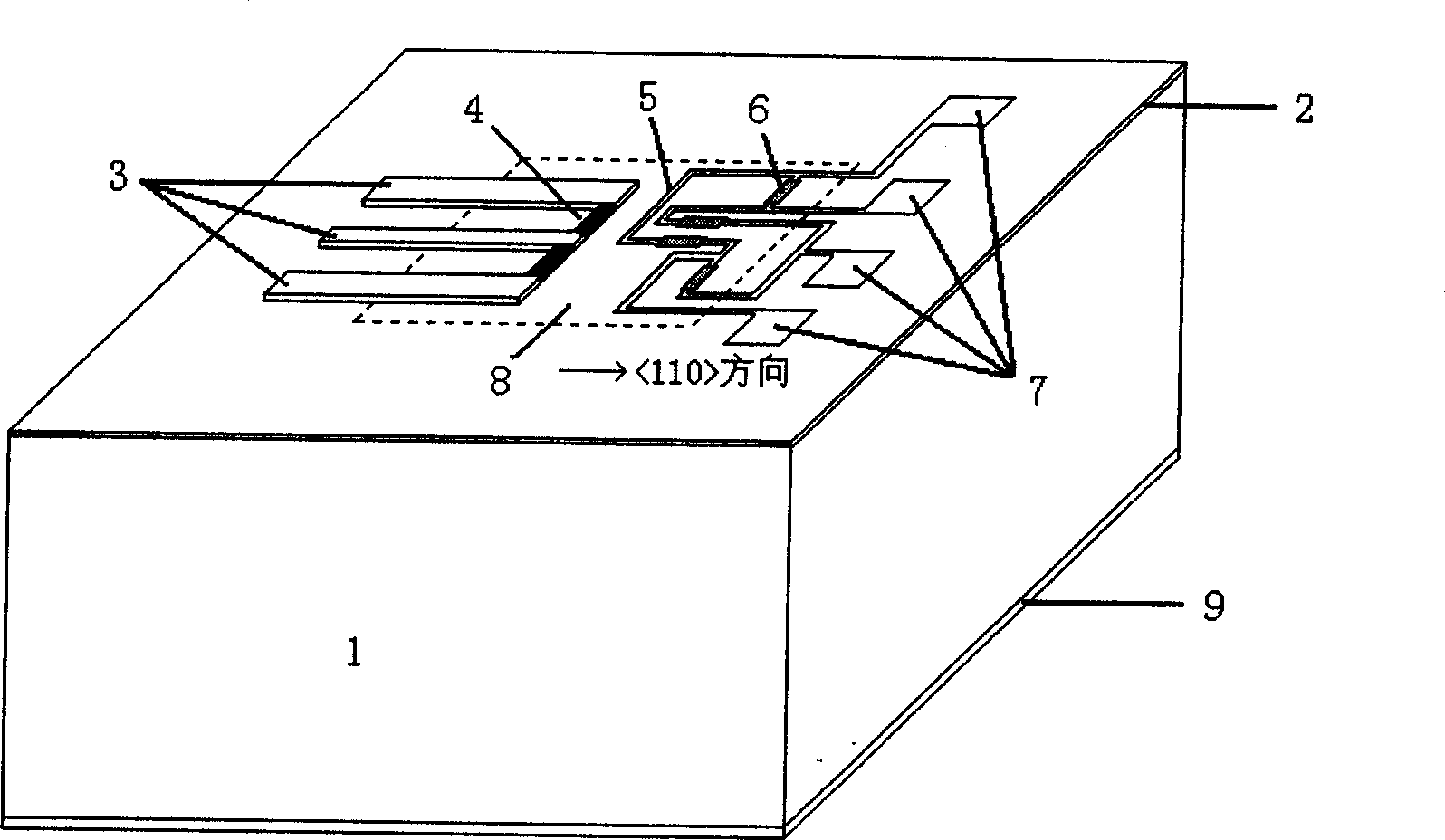

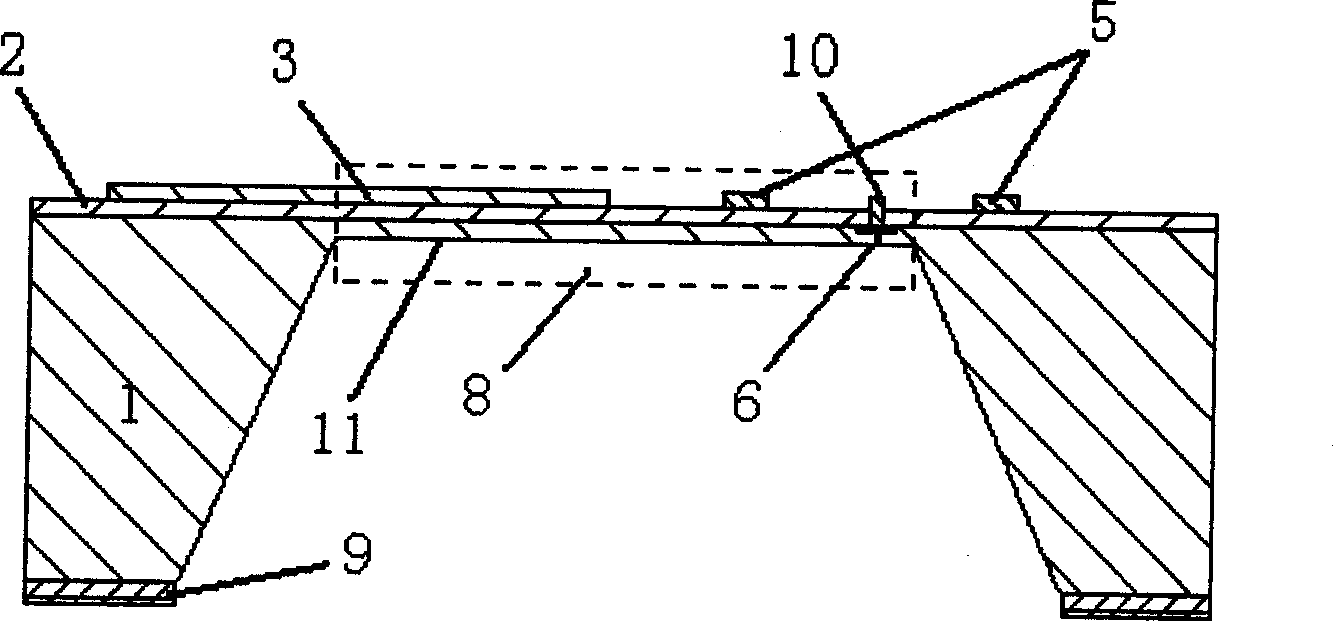

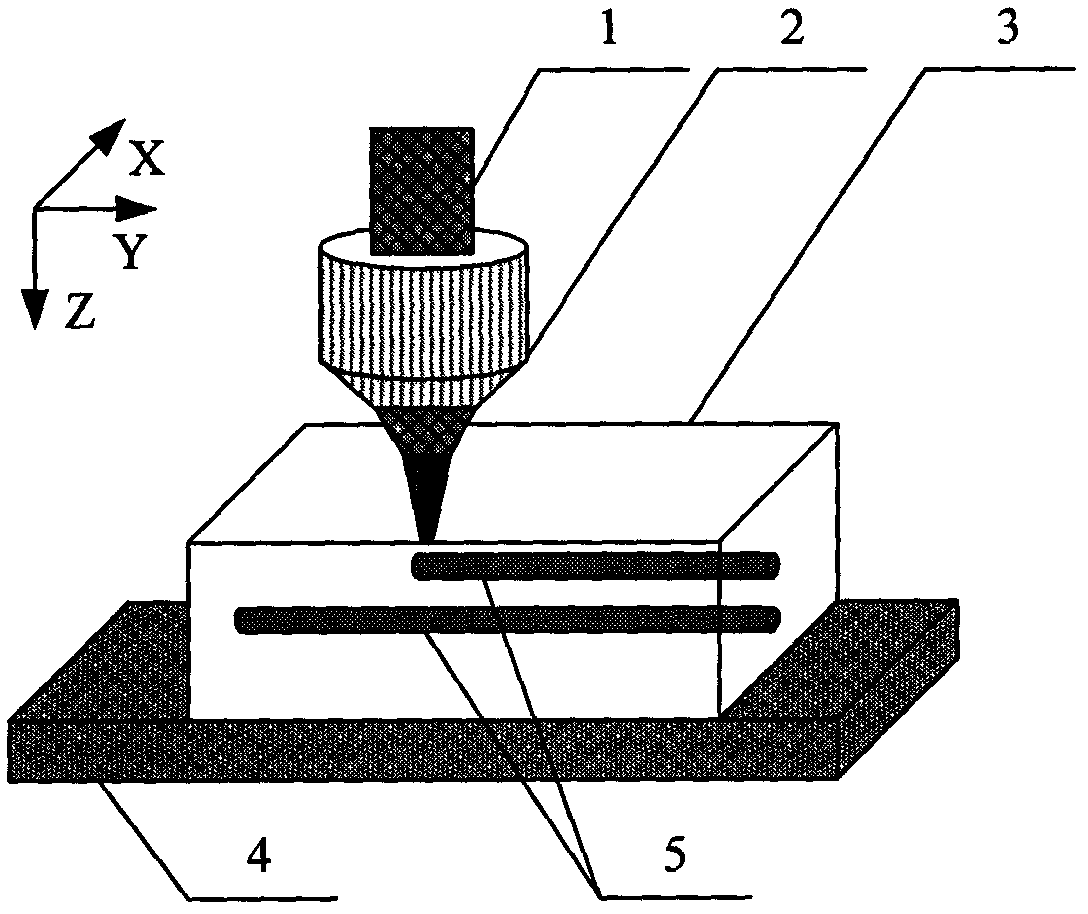

Piezoresistance type microwave power sensor and microwave power sensing method thereof

InactiveCN1885047AImprove linearityWide frequency rangeElectrical testingElectromagentic field characteristicsElectrical resistance and conductanceMicrowave power

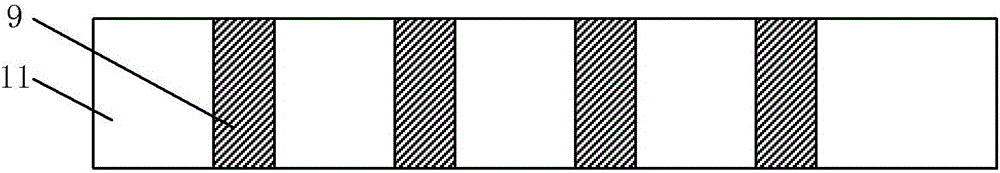

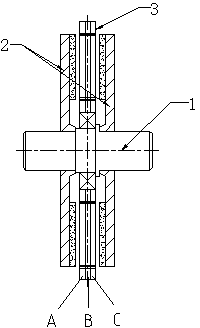

The invention relates to a piezoresistance microwave power sensor which uses terminal resistance to absorb the microwave power to heat to generate film stress, and uses piezoresistance to test the input microwave power, wherein said sensor uses Si substrate (1) as substrate; the Si3N4 / SiO2 layer (9) is arranged on the bottom of substrate; the Si substrate is arranged with SiO2 insulated layer (2); said SiO2 insulated layer (2) and the silicon film (11) etched on Si substrate form dual-layer film (8) structure arranged with common-surface waveguide (3). The terminal of common waveguide is arranged with matched resistance (4).

Owner:SOUTHEAST UNIV

Recombinant trapped wave frequency band ultra wide band-pass filter based on cross resonator

The invention discloses a recombinant trapped wave frequency band ultra wide band-pass filter based on a cross resonator. The recombinant trapped wave frequency band ultra wide band-pass filter comprises a cross resonator, and parallel coupling feeder line structures, wherein three stub lines of the cross resonator are connected with capacitors to the ground. Micro band line design with distribution parameters is adopted. The recombinant trapped wave frequency band ultra wide band-pass filter has the advantages of light weight, small size, high reliability, excellent property, good temperature stability, large-scale production, low cost and the like, and is particularly applicable to ultra wide band communication systems, digital radar, single soldier satellite movement, military and civil multimode and multi-channel communication system terminals in different working environments, and corresponding systems with harsh requirements on weight, property and reliability.

Owner:NANJING UNIV OF SCI & TECH

Transparent lacquer protective film and application thereof

ActiveCN109837028AHigh light transmittanceImprove self-healing performancePolyurea/polyurethane coatingsPressure sensitive film/foil adhesivesPressure sensitiveTransmittance

The invention relates to the field of functional films, in particular to a transparent lacquer protective film and application thereof. In order to solve the problem that the current lacquer protective film has poor impact resistance and large water contact angle, the invention provides a transparent lacquer protective film and application thereof. The transparent lacquer protective film providedby the invention comprises a self-healing layer, a substrate layer and a pressure-sensitive adhesive layer. The raw materials of the self-healing layer are composed of the following materials (by weight): 55-80 parts of polyol resin, 3-18 parts of a crosslinking agent, 5-32 parts of inorganic nanoparticles, 0.2-3 parts of a catalyst, and 0.5-3 parts of an ultraviolet light absorber. The prepared lacquer protective film not only has high light transmittance and self-repairing property, but also has excellent performances such as high impact performance and low water contact angle. The lacquer protective film provided by the invention has simple preparation process, is easy to operate, and is convenient for industrial production.

Owner:NINGBO EXCITON TECH

Protein extracting and separating method from defatted cotton dregs

InactiveCN1448065AImprove qualityReduce lossesProtein composition from vegetable seedsAnimal feeding stuffFodderImpurity

The process of extracting and separating protein from defatted cotton seed residue includes the following steps: alkali dissolving defatted cotton seed residue; first separation to obtain solid phaseand supernatant liquid; drying solid phase to obtain feed protein; and acid precipitation, second separation, neutralization, homogenization, sterilization and spray drying of the supernatant liquid to obtain protein. It has the advantages of reasonable apparatus layout, high quality of protein product, high protein extracting rate and no need of eliminating gossypol.

Owner:XINJIANG WESTERN ANIMAL HUSBANDRY

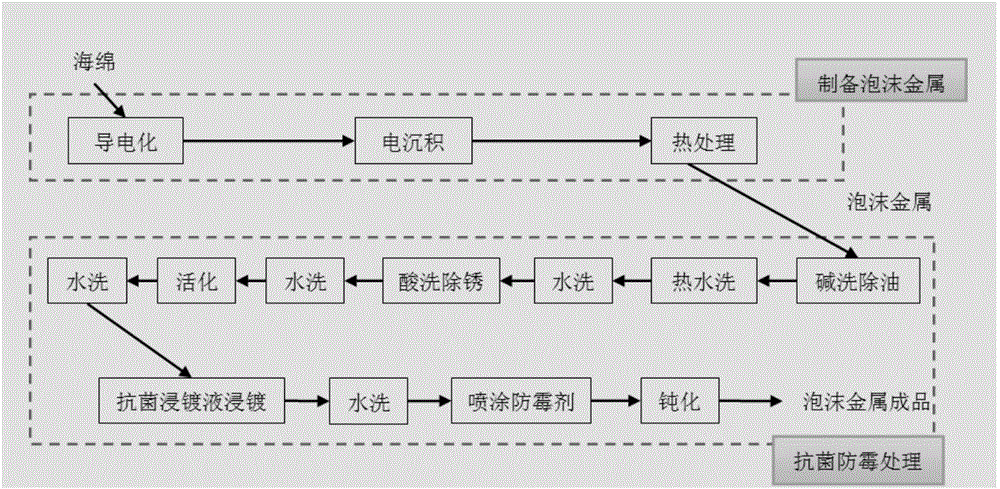

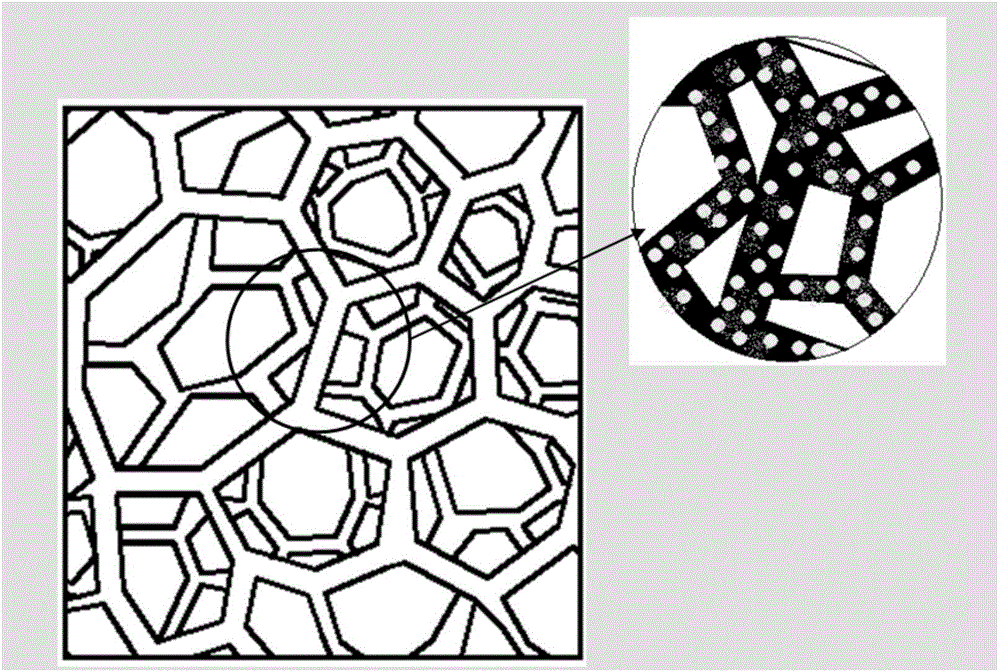

Lampblack filtering material comprising porous foam metal and preparation method of lampblack filtering material

InactiveCN104888537ALarge specific surface areaReduce wind resistanceFiltration separationAir filtrationFilter material

The invention relates to a lampblack filtering material comprising porous foam metal and a preparation method of the lampblack filtering material. The lampblack filtering material comprises the porous foam metal of an open-type porous network structure, wherein the porosity of the porous foam metal ranges from 90% to 99%, and the pore size ranges from 20PPI to 200PPI. The pore surface of the porous foam metal comprises one or two of antibacterial plating solution and mildew preventive. The porous-foam-metal lampblack filtering material used for lampblack air filtration, especially the porous-foam-metal lampblack filtering material with bacteria inhibition and mildew prevention performance, is particularly applicable to filtration of indoor lampblack air.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

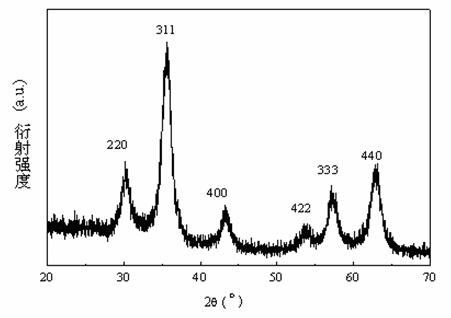

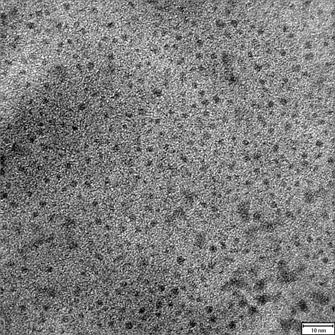

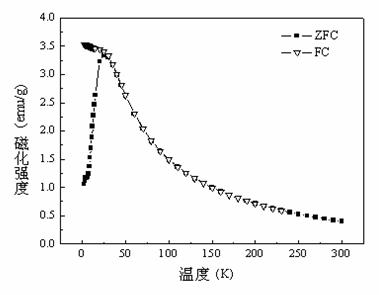

Method for preparing nano quantum dot level Fe3O4 superparamagnetic particles

InactiveCN102153149AShort reaction cycleEasy to operateFerroso-ferric oxidesNanotechnologyAlcoholEther

The invention discloses a method for preparing nano quantum dot level Fe3O4 superparamagnetic particles, which comprises the following steps of: adding ferric metal salt into alcohol ether to prepare a solution with the ferric ion concentration of 0.01-0.5 mol / L; and heating the solution to react by using a two-stage heating method, firstly heating to 100 DEG C to uniformly mix the solution, secondly heating to 230-270 DEG C, and reacting until the solution becomes brown to obtain Fe3O4 superparamagnetic particles. In the invention, alcohol ether is simultaneously used as a stabilizing agent, a reducing agent and a protecting agent, a common vessel and a regular synthesis device are used, and the regulation on the pH value is not required. The reaction is carried out at normal temperature and pressure, has a short period, is convenient to operate, and can be controlled through temperature, and the process is simple and mature. The particle size of obtained Fe3O4 nano quantum dots is less than 5 nm, the shape can reach 100%, and the yield is high.

Owner:UNIV OF JINAN

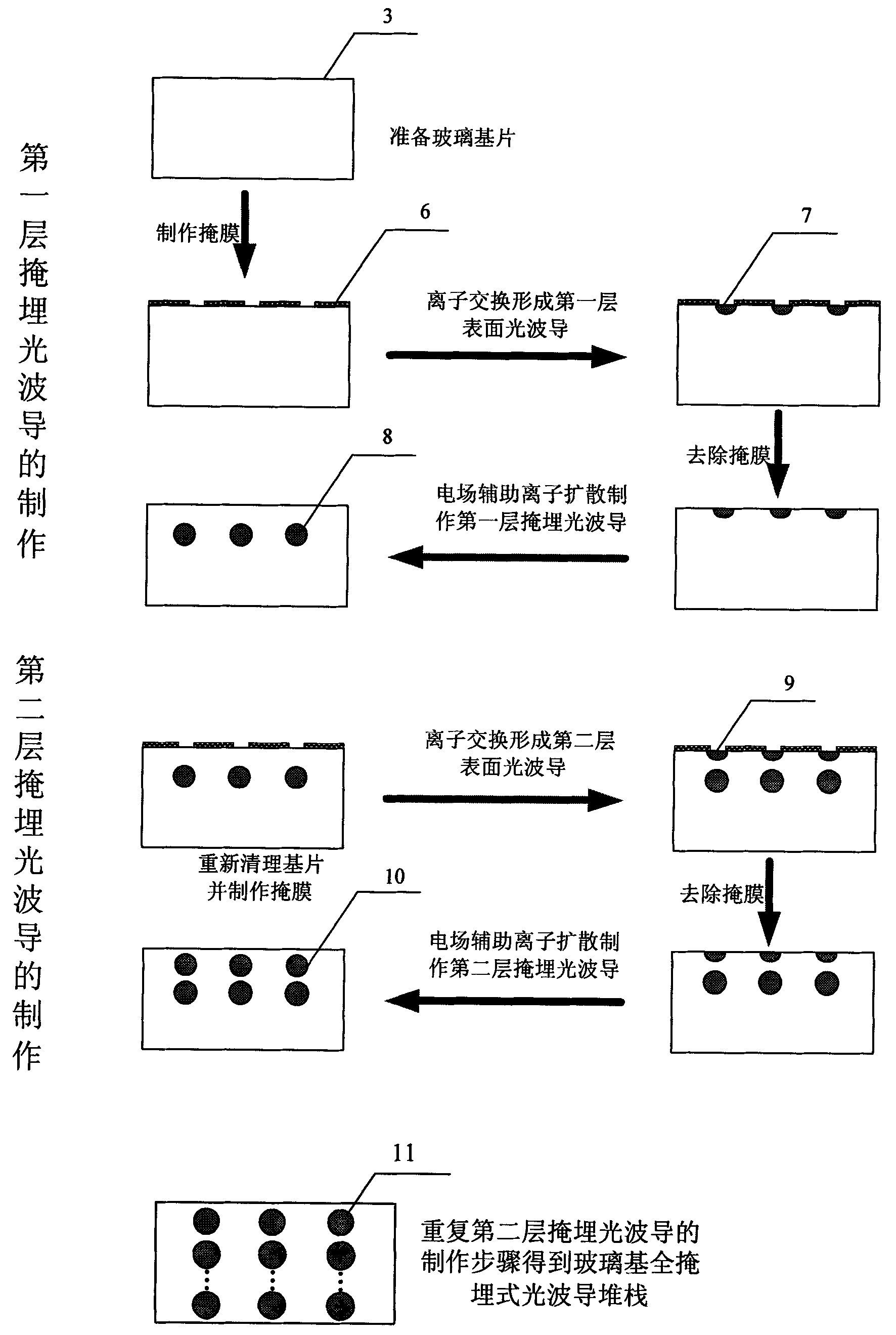

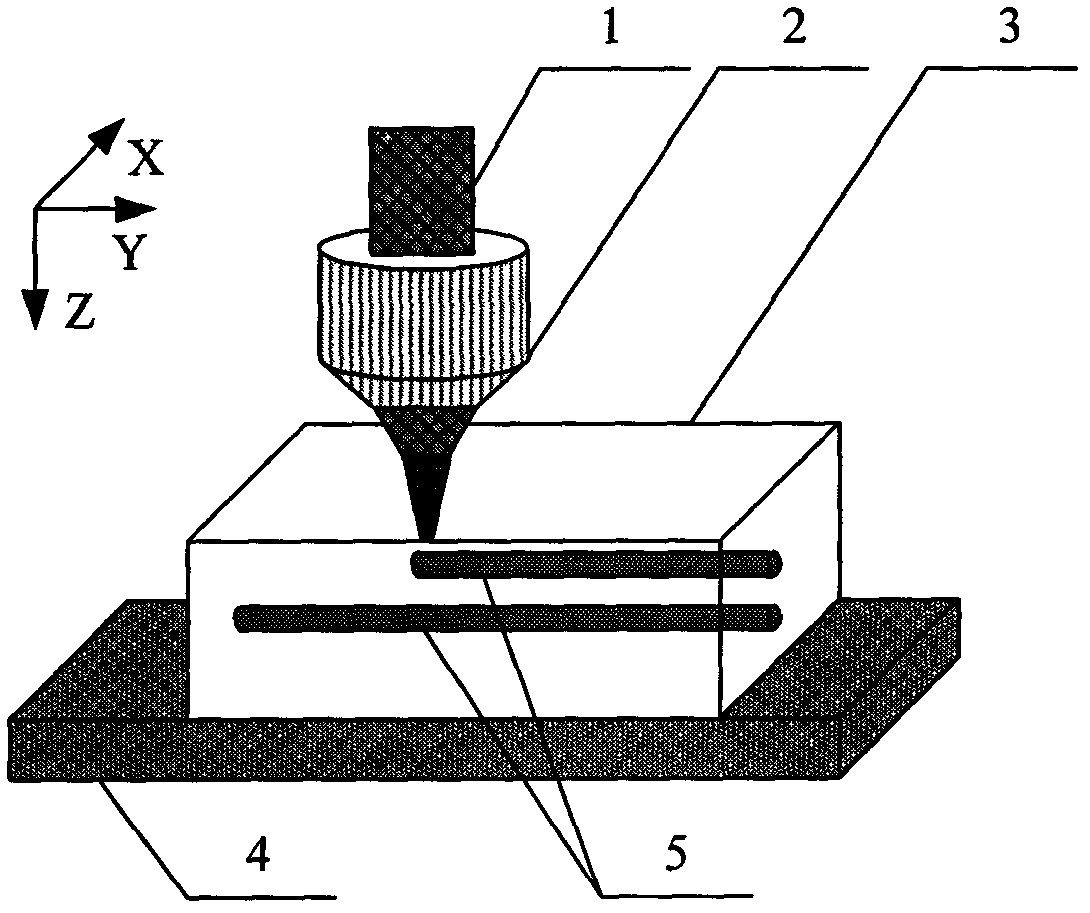

Method for manufacturing glass substrate all buried strip-type optical waveguide stack

InactiveCN102193146AEasy to integrateThe process is simple and matureOptical waveguide light guideIon exchangeWaveguide

The invention discloses a method for manufacturing glass substrate all buried strip-type optical waveguide stack. The glass substrate all buried strip-type optical waveguide stack is formed by manufacturing a plurality of layers of buried optical waveguides on a glass substrate in sequence through an ion exchange and electric field assisted ion diffusion technology. The strip-type optical waveguide stack which is manufactured by the method has the characteristics of simple and mature process, simple integration and low loss; and the shape of a core part of the obtained optical waveguide is symmetrical.

Owner:ZHEJIANG UNIV

Preparation method of electronic-grade polycrystalline silicon

The invention provides a preparation method of electronic-grade polycrystalline silicon. The preparation method includes the steps: purifying a trichlorosilane liquid and / or chlorosilane liquid to obtain trichlorosilane, wherein the chlorosilane liquid includes trichlorosilane; and carrying out a reducing reaction with hydrogen and trichlorosilane to obtain electronic-grade polycrystalline silicon. The purification step includes the steps: carrying out primary rectification process of the trichlorosilane liquid and / or chlorosilane liquid, to obtain a crude product of trichlorosilane; carryingout a complexing reaction of the crude product of trichlorosilane with a complexing agent to convert impurities in the crude product of trichlorosilane into complexes, to obtain intermediate products,wherein the impurities include one or more of the group composed of B, P, Fe and Al; and carrying out secondary rectification process of the intermediate products, to remove the complexes, and thus obtaining trichlorosilane. The high-purity trichlorosilane raw material undergoes reduction reaction with hydrogen to obtain the electronic-grade polycrystalline silicon. The preparation method has theadvantages of mature and simple technological process, low energy consumption, stable product quality and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

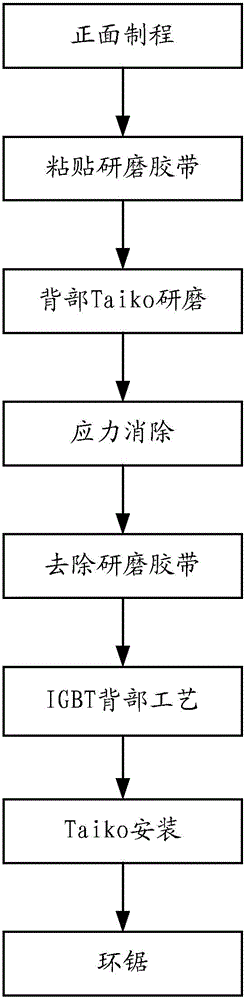

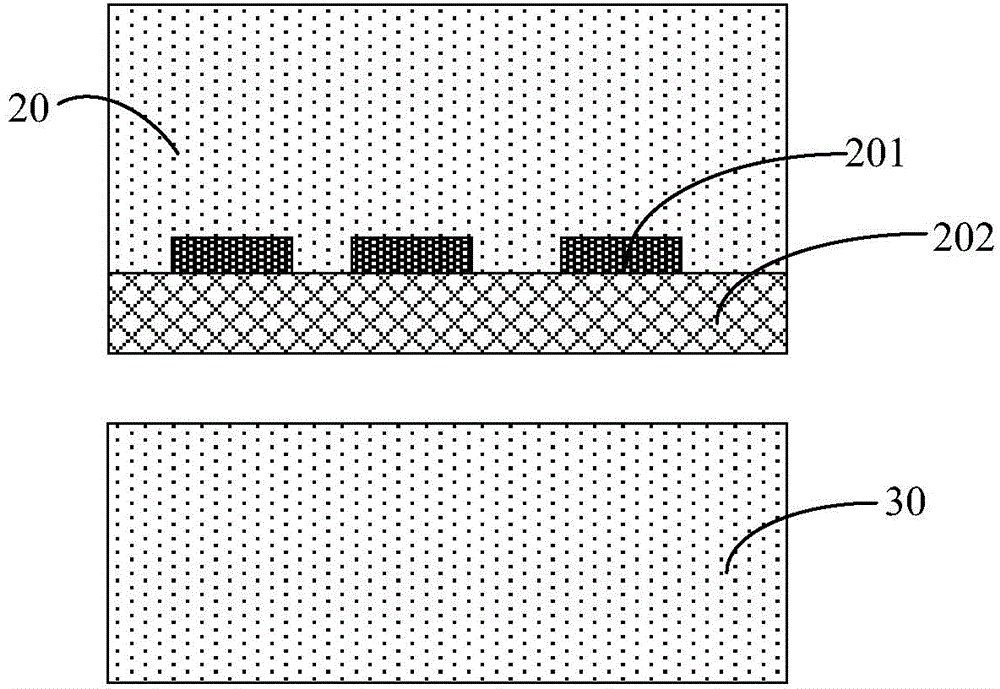

Semiconductor device and manufacturing method thereof, and electronic apparatus

ActiveCN105374862ALow costImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesBond interfaceInterface layer

The invention provides a semiconductor device and a manufacturing method thereof, and an electronic apparatus. The manufacturing method comprises the following steps of providing a device wafer and forming a first bonding interface layer on a right side of the device wafer; providing a support wafer and forming a second bonding interface layer on a surface of the support wafer, wherein the support wafer executes hydrogen ion implantation; forming a hydrogen ion implantation layer in an area, wherein a predetermined depth is arranged between the area and the second bonding interface layer; carrying out a bonding technology and making the first bonding interface layer of the device wafer be connected to the second bonding interface layer of the support wafer; carrying out thinning on a back side of the device wafer; executing annealing processing and realizing hydrogen embrittlement fragmentation de-bonding so as to peel most of the support wafer; and removing the residual support wafer. According to the manufacturing method in the invention, other bonding mediums are not needed; cost is low and efficiency is high; the process is mature and simple; by using a de-bonding method, uniformity is good; other tools are not needed; the process is simple and the operability is high.

Owner:SEMICON MFG INT (SHANGHAI) CORP

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864BSolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are addedin the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operationand lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049BSolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesVanadium oxidesSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

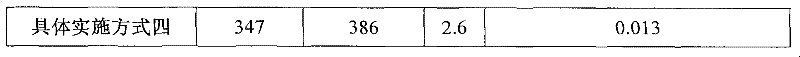

Water-based fireproof coating suitable for railway vehicle chassis and preparation method thereof

InactiveCN110591509AHigh expansion factorStable structureFireproof paintsEpoxy resin coatingsWater basedMelamine phosphate

The invention relates to a water-based fireproof coating suitable for railway vehicle chassis and a preparation method thereof, and belongs to the field of water-based fireproof coating. The water-based fireproof coating disclosed by the invention is prepared from the following substances in parts by mass: 20-30 parts of a film-forming substance, 40-60 parts of an intumescent flame-retardant system, 5-8 parts of titanium dioxide, 2-4 parts of nano magnesium aluminum hydroxide, 1-2 parts of organic bentonite, 1-3 parts of expandable graphite, 9-17 parts of deionized water, 0.8-1.3 parts of a film-forming aid, 0.2-0.5 part of a dispersing agent and 0.2-0.5 part of a defoaming agent; the intumescent flame-retardant system is prepared from melamine phosphate, dipentaerythritol and melamine, and the mass part ratio of the melamine phosphate to the dipentaerythritol to the melamine is 1.8-2.3: 0.8-1.2: 0.8-1.2. The water-based fireproof coating can met structure fire-resistant requirement of the chassis of the railway vehicles; no volatilization of harmful substances such as organic solvents is caused in the construction and drying processes; the occupational health and safety of constructors are guaranteed; equipment can be flexibly selected for use according to different scenes; investment of special equipment is reduced; and production cost is reduced.

Owner:河北萨迪科轨道交通科技有限公司

Method for manufacturing three-dimensional package heat dissipation structure of rigid-flexible joint board

ActiveCN103594433AImprove cooling effectEfficient releaseSemiconductor/solid-state device detailsSolid-state devicesEngineeringSolder paste

The invention discloses a method for manufacturing a three-dimensional package heat dissipation structure of a rigid-flexible joint board. The method comprises the steps that a flexible substrate is manufactured; a bottom substrate and two rigid substrates are pressed on the flexible substrate; cavities are formed in the two rigid substrates in a dug mode respectively; two copper substrates fixedly adhere to the back surfaces of the two rigid substrates respectively; a bottom chip is welded to the bottom substrate, two top chips are welded to or adhere to the two copper substrates which are exposed because the cavities are formed in the rigid substrates in the dug mode, and the two top chips are bonded to the rigid substrates; the flexible substrate is bent, the two rigid substrates on two sides of the flexible substrate are arranged above the bottom chip of the bottom substrate, and filling of plastic package material is conducted to achieve fixing and forming; solder paste is welded to a bonding pad on the back surface of the bottom substrate in a brushed mode, a BGA ball is implanted in a steel net, backflow is conducted, and a package body is formed; the back surface of the bottom substrate is fixed on a PCB, and radiators are arranged on the two copper substrates. By means of the method, the number of heat dissipation routes of the package body is increased, and heat can be dissipated more effectively.

Owner:NAT CENT FOR ADVANCED PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com