Patents

Literature

847 results about "Polyether sulphone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

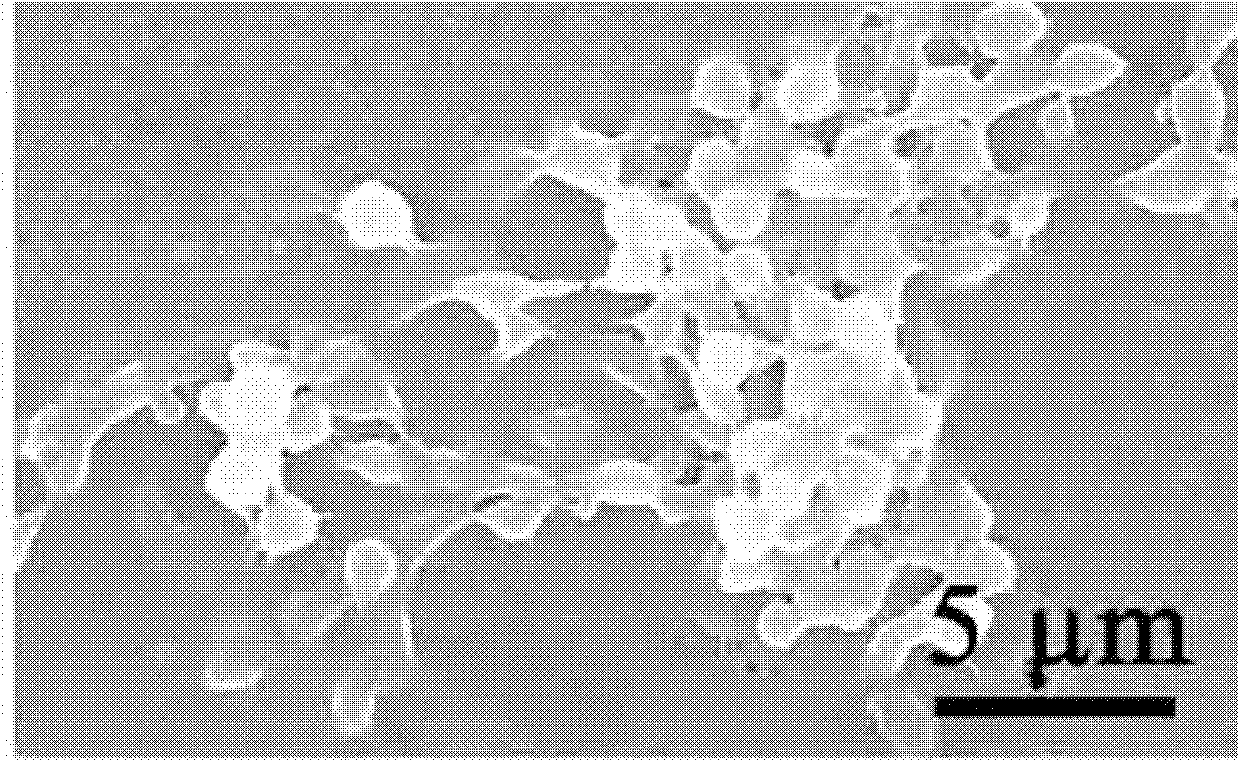

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

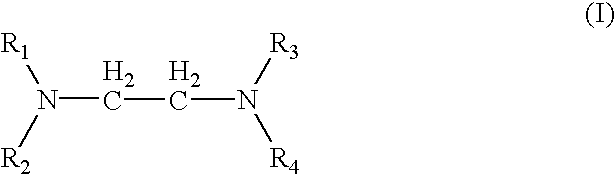

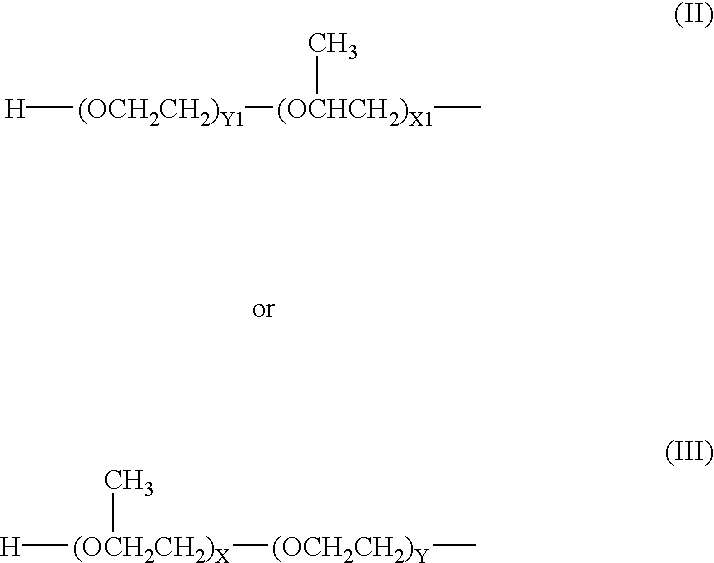

Membrane which comprises a blend of a polysulphone or a polyether sulphone and polyethylene oxide/polypropylene oxide substituted ethylene diamine

A membrane which can be used in membrane filtration processes and which has a reduced tendency to fouling is a polysulphone or a plyether sulphone and a polyethylene oxide / polypropylene oxide substituted diamine and can be made by a phase inversion process in the presence of pore modifying agents such as an alcohol, glycerol or glycol to give a membrane which has a pore size of 0.1.mu. to 1 micron and is hydrophilic.

Owner:HYDRANAUTICS

Method for preparing composite nanofiltration membrane

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

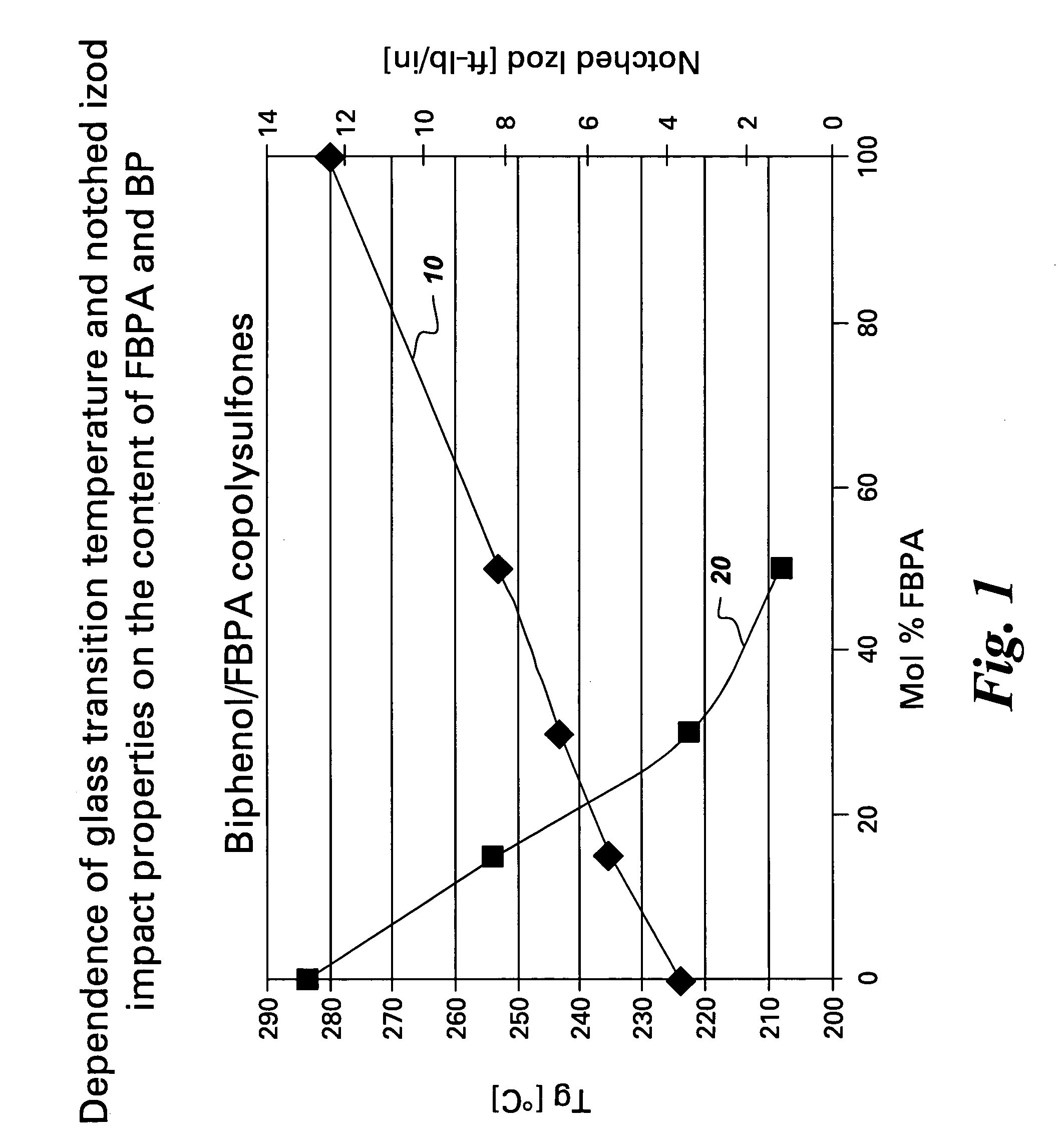

Polyethersulfone compositions with high heat and good impact resistance

A polyethersulfone composition is disclosed which comprises structural units derived from a monomer mixture comprising fluorenylidene bisphenol-A and at least 50 mole percent of 4,4′-biphenol based on total moles of diphenolic monomers, wherein the polyethersulfone has a minimum glass transition temperature of 235° C. and a notched Izod impact value of 1 ft-lb / in. as measured by ASTM D256.

Owner:GENERAL ELECTRIC CO

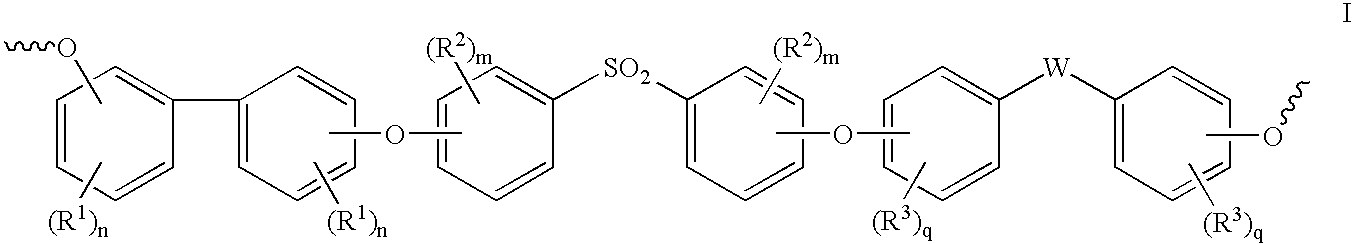

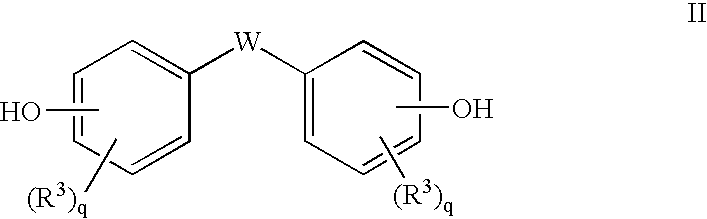

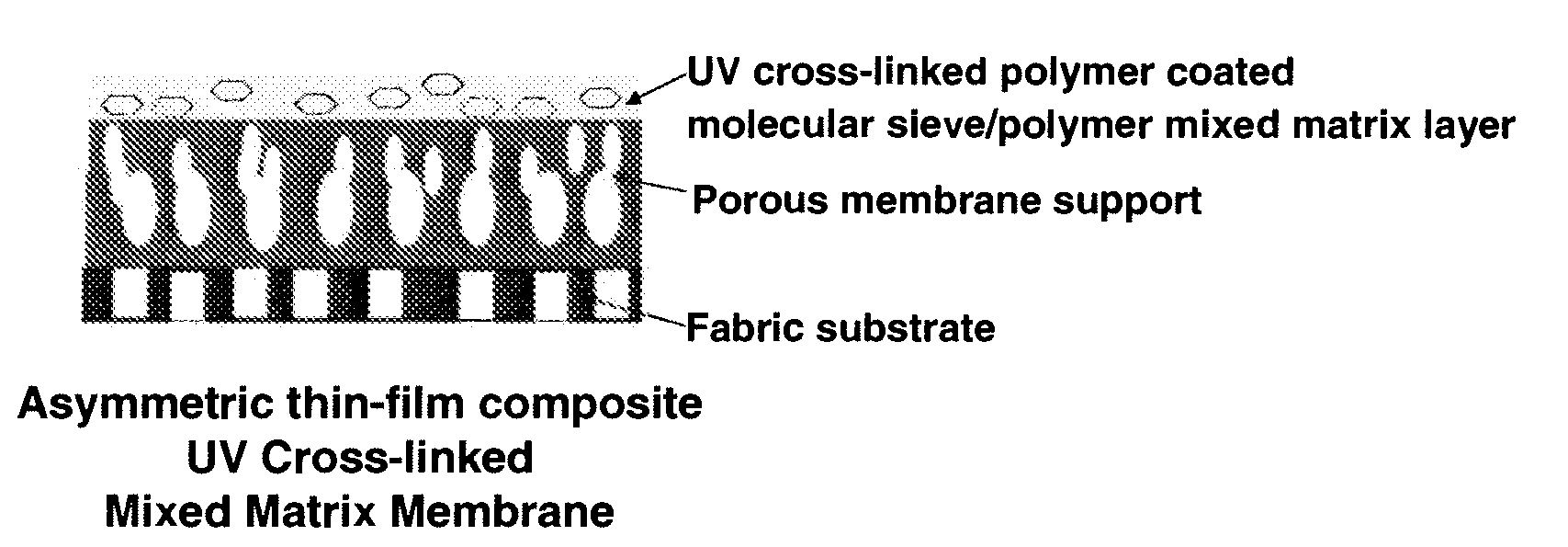

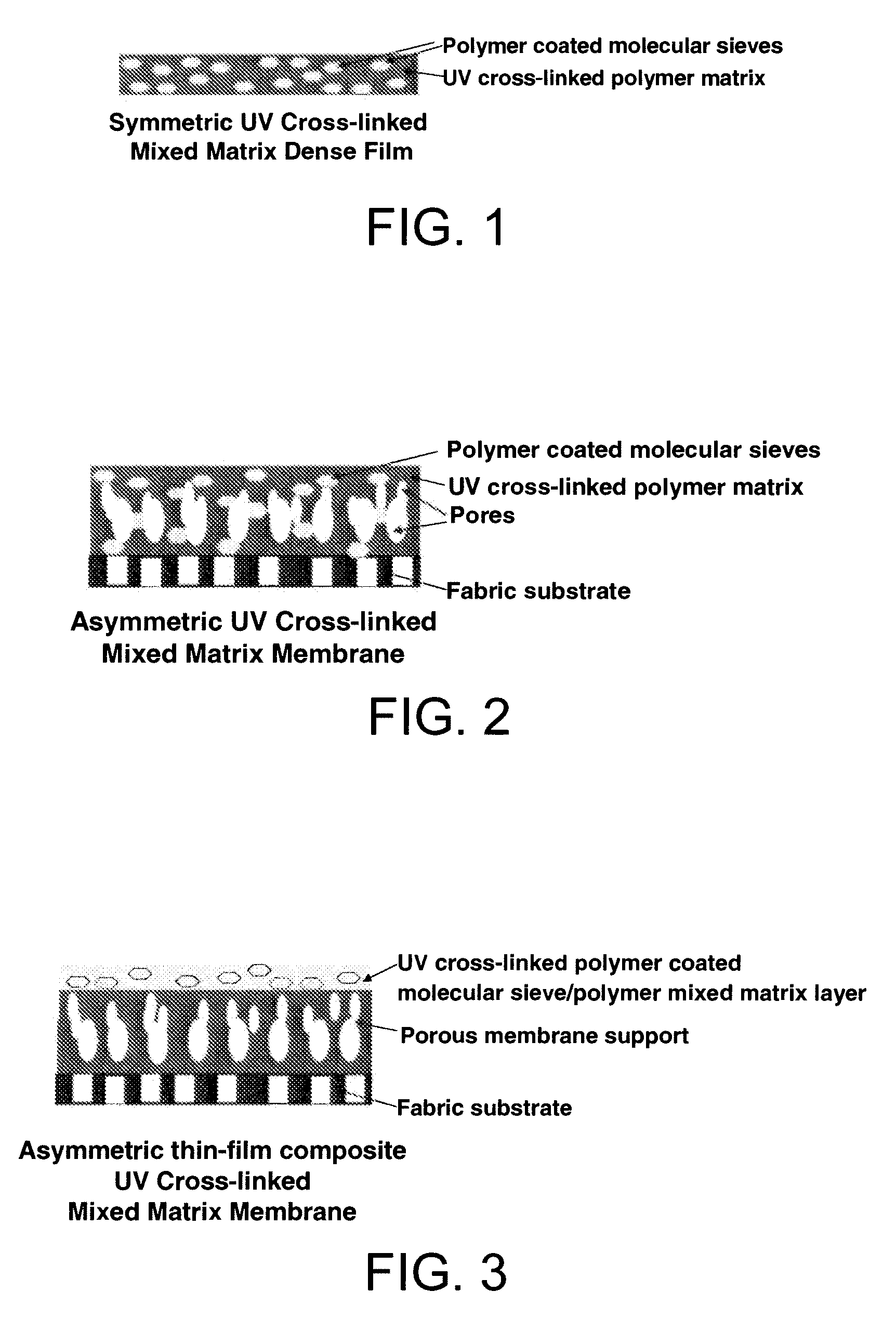

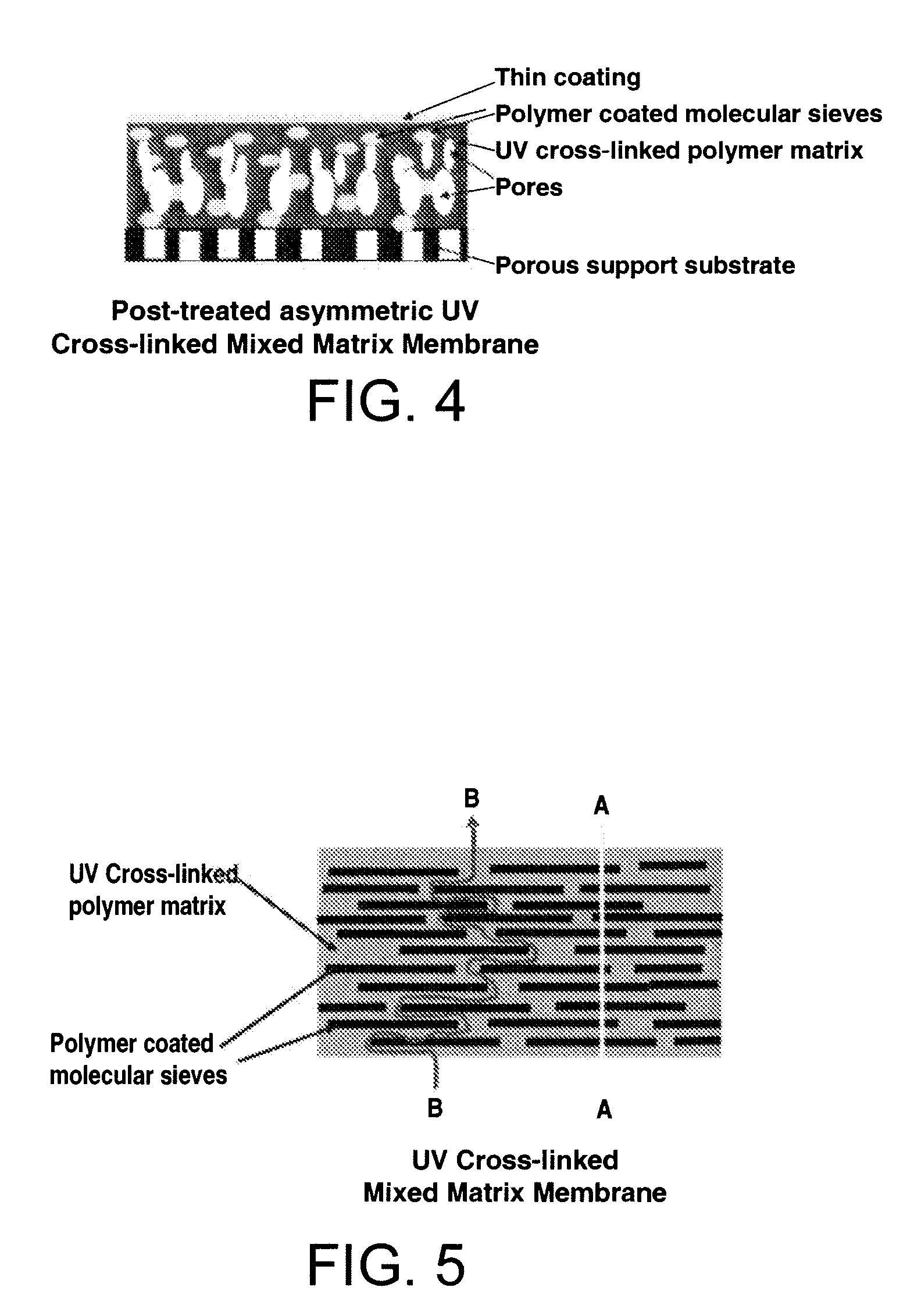

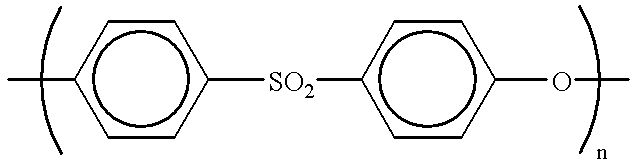

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

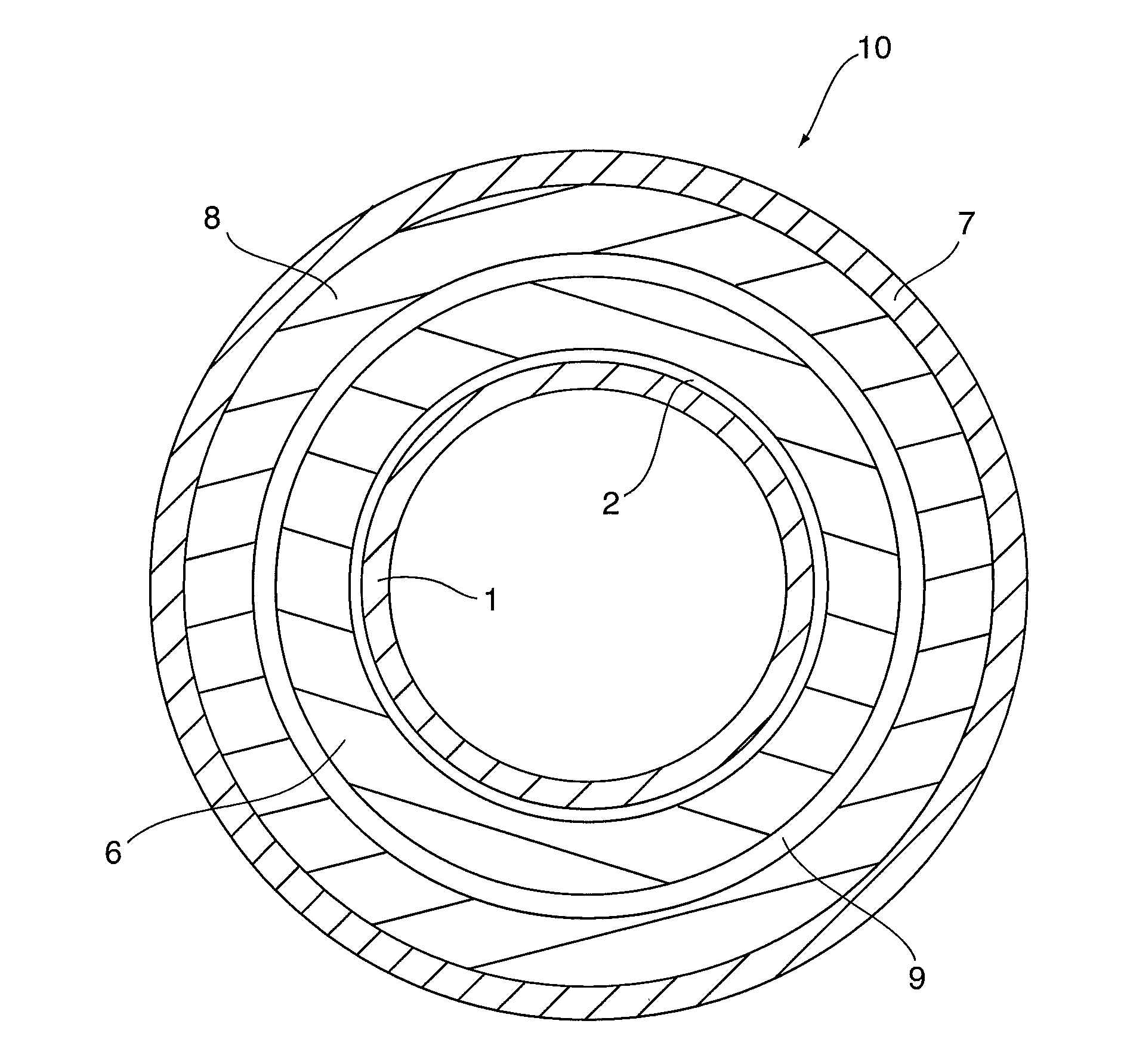

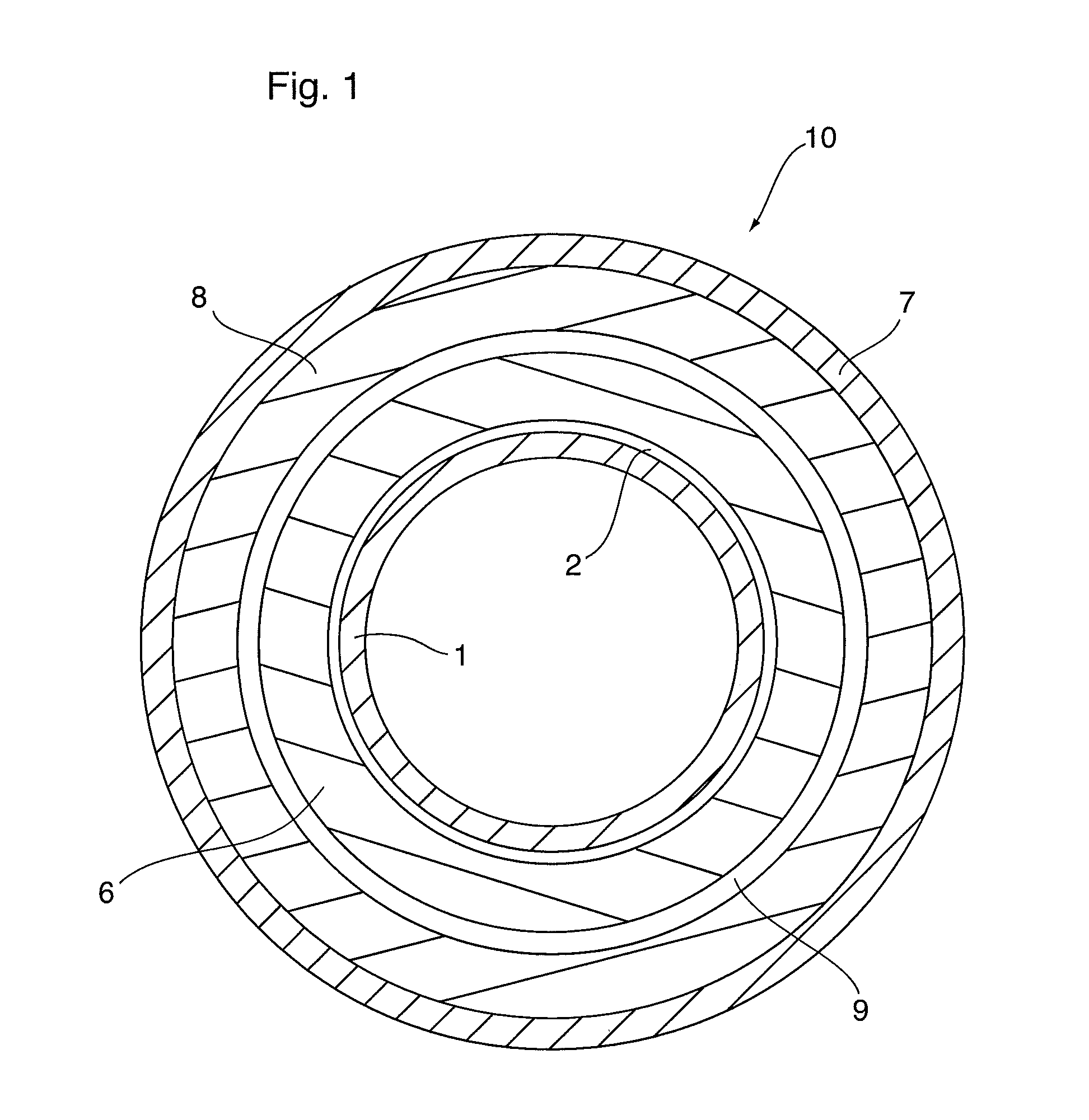

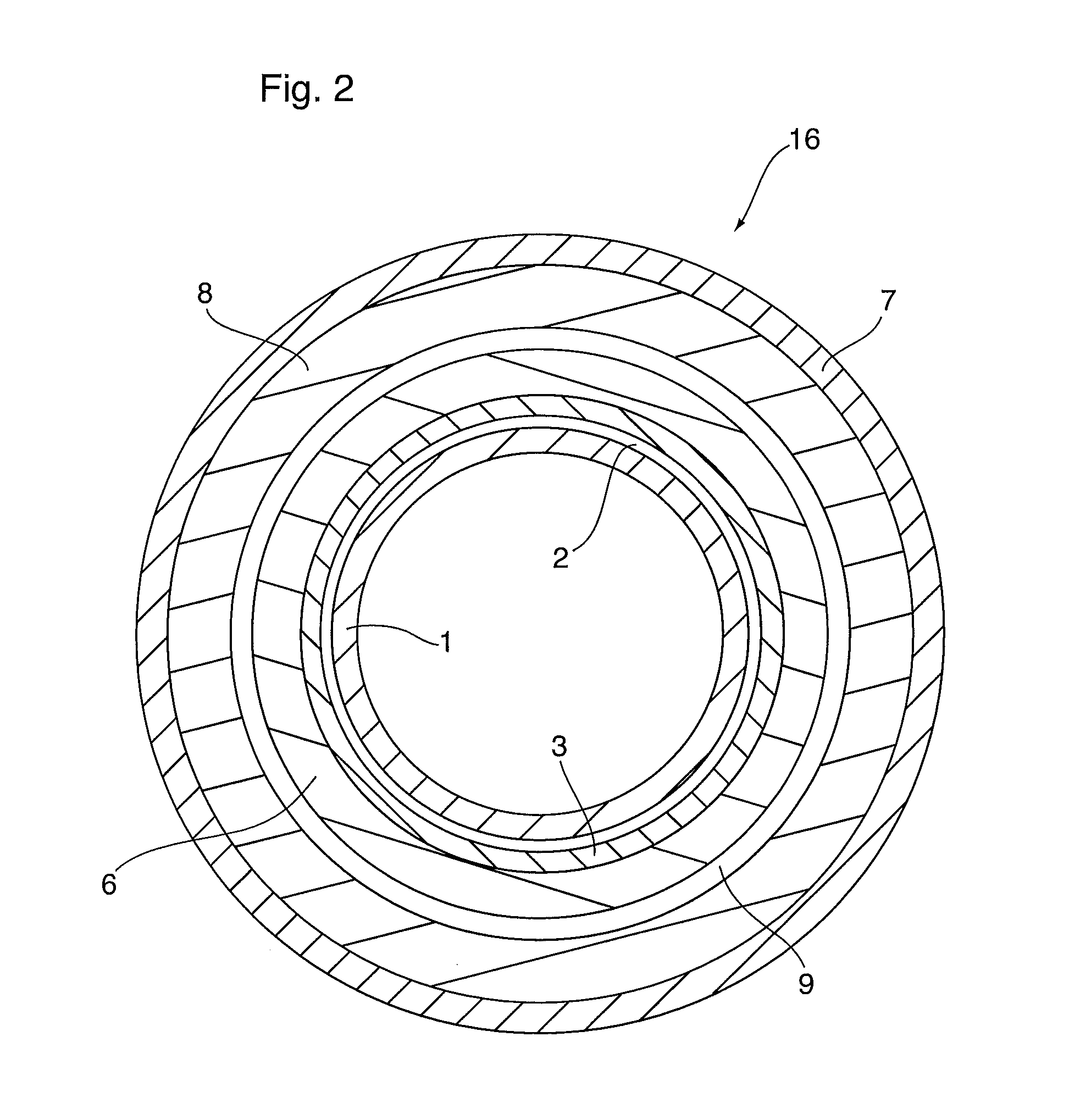

Multilayer insulated wire and transformers made by using the same

InactiveUS6329055B1Good effectLowered in electric propertyPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolymer sciencePolyetherimide

There is disclosed a multilayer insulated wire which comprises a conductor and solderable extrusion-insulating layers made up of two or more layers for covering the conductor, wherein at least one insulating layer is formed by a mixture comprising 100 parts by weight of a resin (A), of at least one selected from the group consisting of polyetherimide resins and polyethersulfone resins, 10 parts by weight or more of a resin (B), of at least one selected from the group consisting of polycarbonate resins, polyarylate resins, polyester resins, and polyamide resin, and 15 to 200 parts by weight of an inorganic filler (C). There is also disclosed a transformer which utilizes the multilayer insulted wire. The multilayer insulated wire is excellent in heat resistance, solderability, high-frequency characteristic, and coilability, and it is favorably suitable for industrial production. Further, the transformer utilizing the multilayer insulated wire is excellent in electrical properties and high in reliability, since when used at high frequencies, electric properties are not lowered and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

Polyelectrolyte compositions

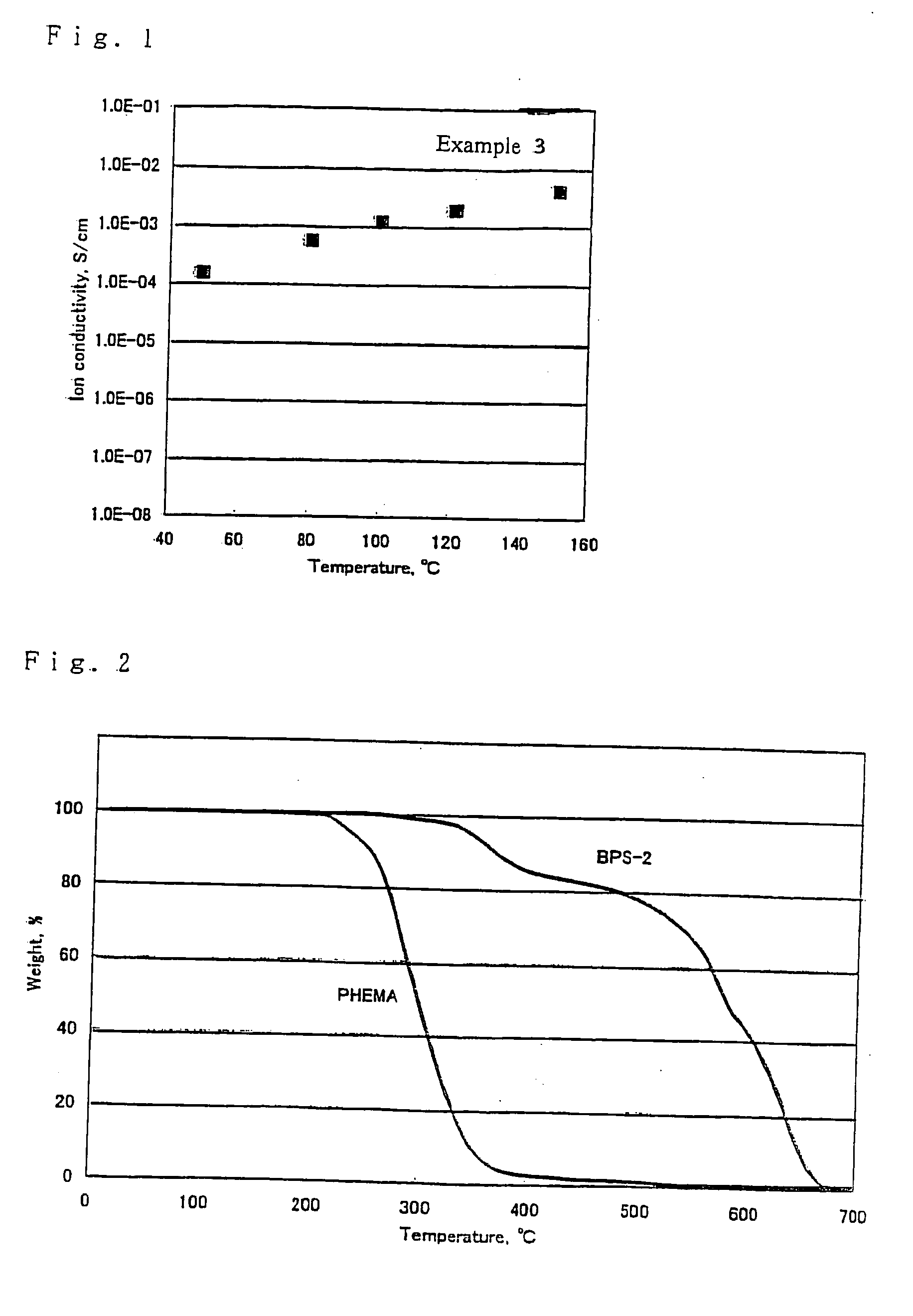

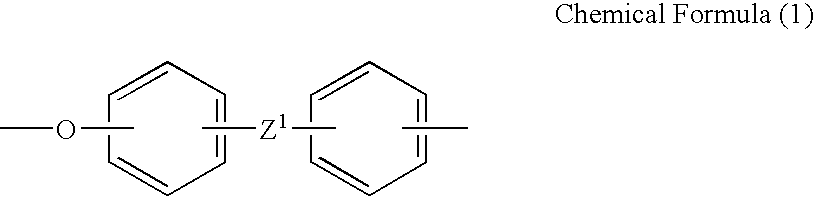

InactiveUS20050069780A1Improve ionic conductivityInexpensive and durableElectrolyte holding meansConductive materialPolyelectrolytePolymer science

An inexpensive and durable polyelectrolyte composition includes both an aromatic polymer containing carbonyl linkages and / or sulfonyl linkages in the backbone chain and bearing cation-exchange groups and a fused salt exhibits a high ionic conductivity even in the absence of water or a solvent. The aromatic polymer is preferably an aromatic polyether sulfone comprising specific structural units and bearing cation-exchange groups, an aromatic polyether ketone comprising specific structural units and bearing cation-exchange groups, an aromatic polyether sulfone block copolymer consisting of at least one hydrophilic segment bearing cation-exchange groups and at least one hydrophobic segment free from cation-exchange groups, and / or an aromatic polyether ketone block copolymer consisting of at least one hydrophilic segment bearing cation-exchange groups and at least one hydrophobic segment free from cation-exchange groups. The use of such a block copolymer as the aromatic polymer gives polyelectrolyte compositions which are excellent in maintenance of structure even at high temperature.

Owner:UBE IND LTD

Method for purifying polyether ketone/polyether sulfone polymers

The invention discloses a method for purifying polyether ketone / polyether sulfone polymers, which comprises: grinding polymers containing impurities, sieving, and filling in a container together with deionized water, treating in ultrasound at 20 to 95 DEG C for 20 to 60 minutes, filtering the material mixed liquid treated in ultrasound in a centrifuge to remove water, drying at 130 DEG C and under vacuum till constant weight, and thus obtaining the purified polymers, wherein in the ultrasonic treatment process, acid solution can be added to improve a purifying effect. The purified product contains less sodium, potassium, aluminum, calcium, iron, phosphorus, sulfur and the like. The method can quickly and efficiently purify polyether ketone / polyether sulfone polymers, adopt simple equipment, lower polymer purification temperature and pressure, greatly save energy, reduce production cost, easily apply to large-scale production line and meet requirements of industrial large-scale production. The polyether ketone / polyether sulfone polymers purified by the invention can be used for processing parts of electronic and electrical parts and manufacturing medical appliances.

Owner:KINGFA SCI & TECH CO LTD +1

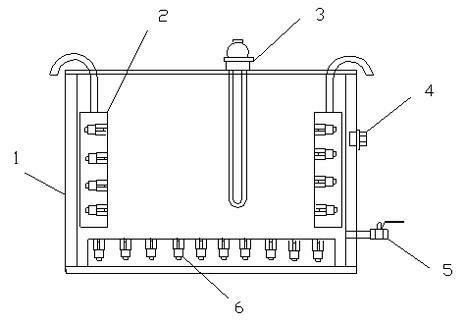

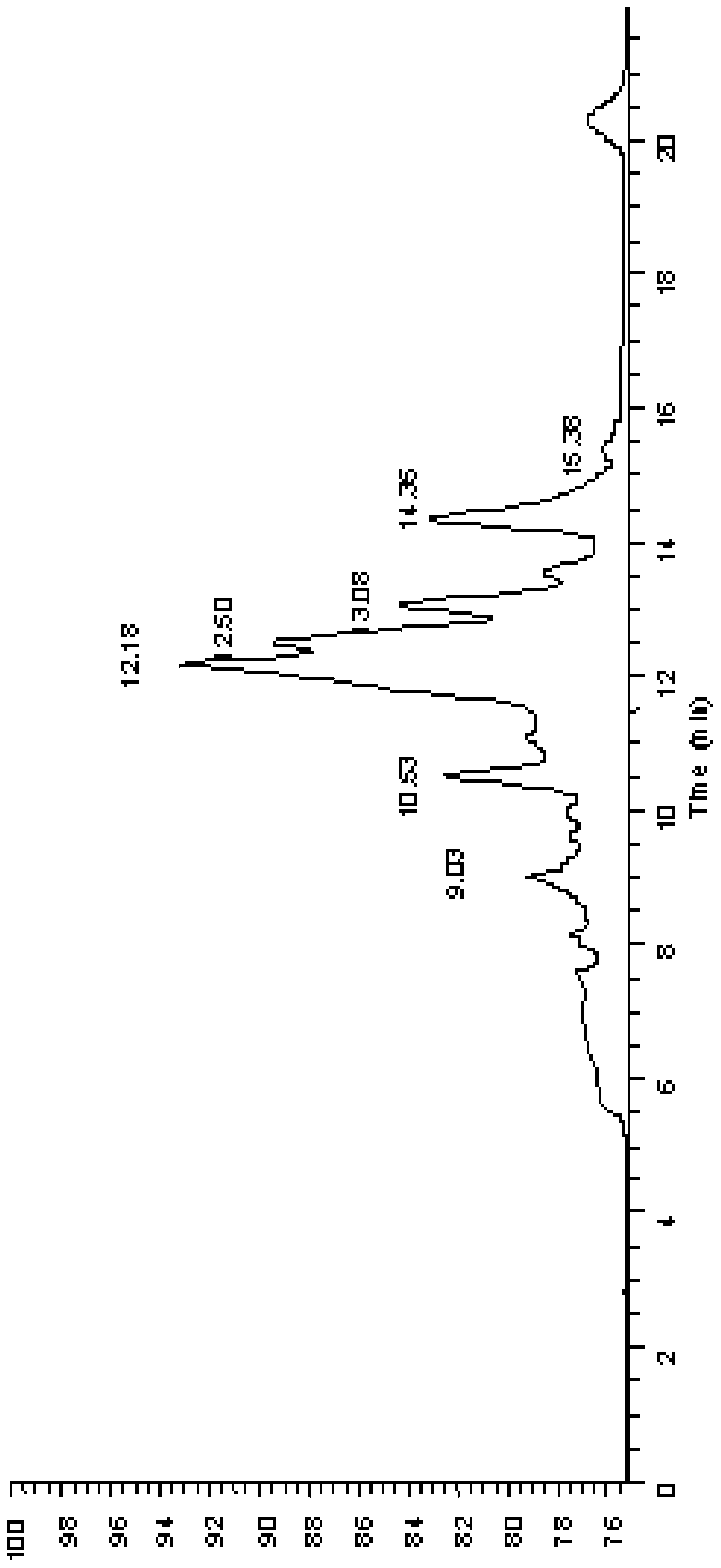

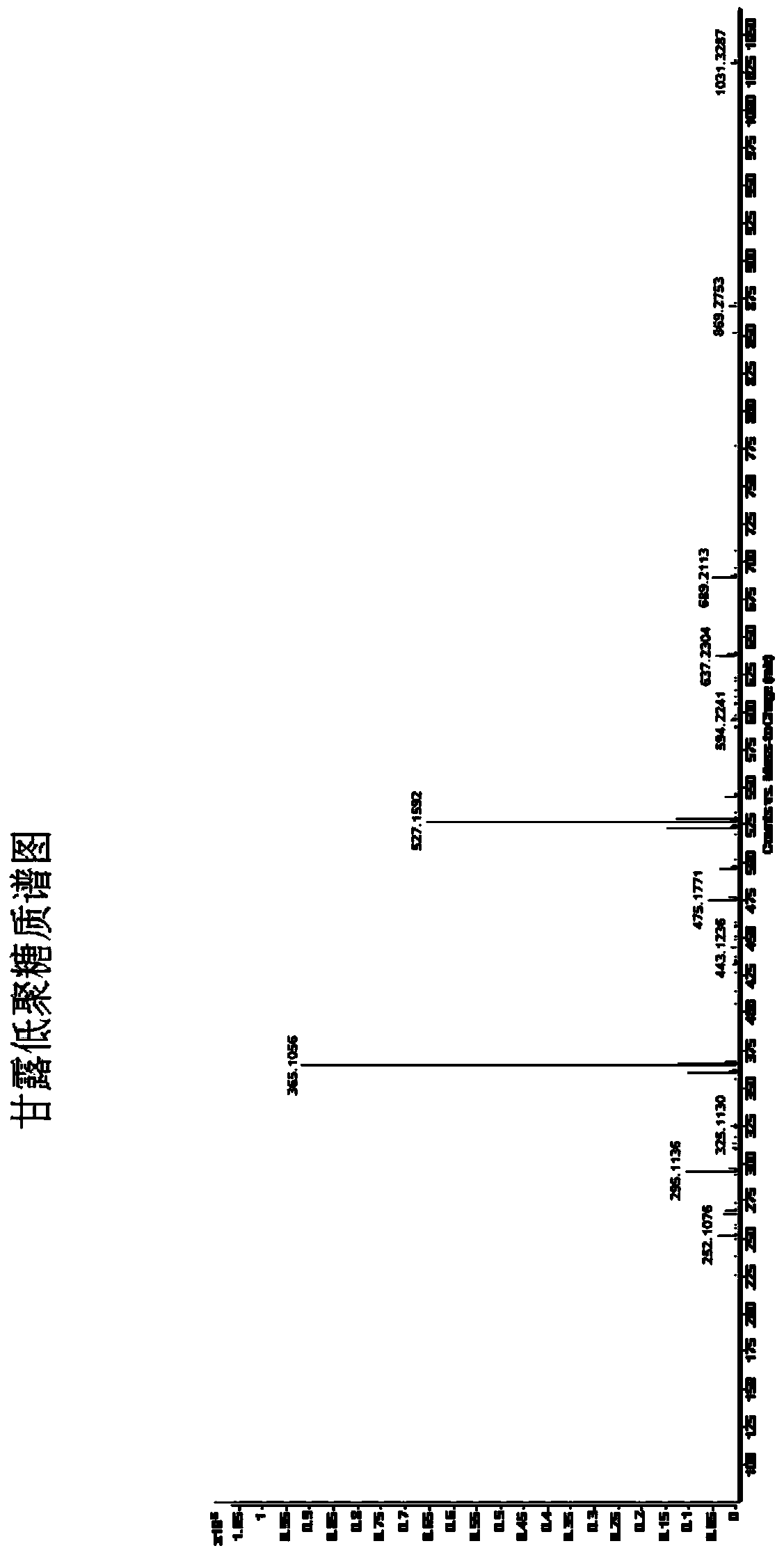

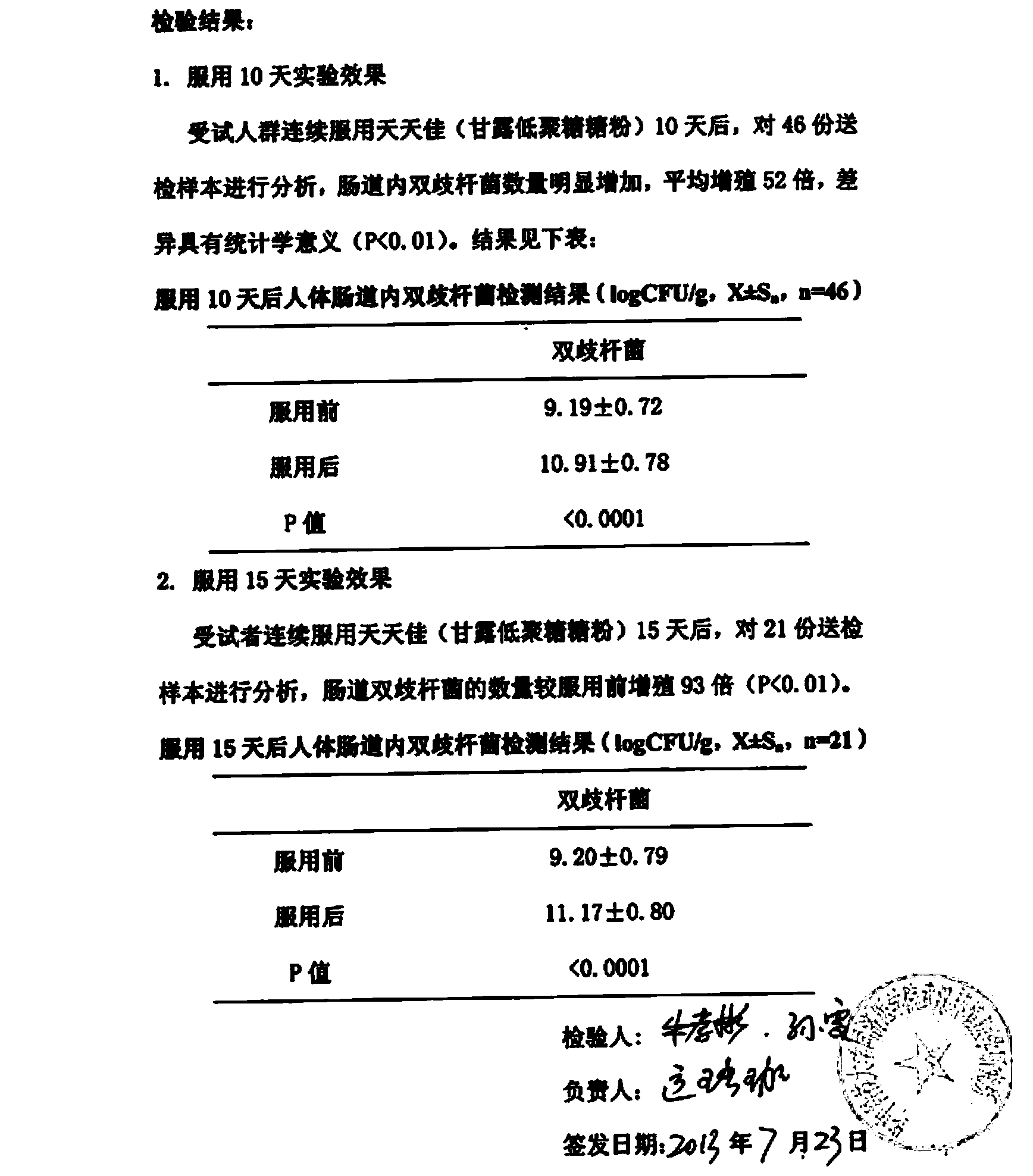

Preparation method of high-purity mannan oligosaccharide

ActiveCN103468766AHigh purityHigh light transmittanceSugar derivativesOligosaccharidesUltrafiltrationHydrolysate

The invention discloses a preparation method of high-purity mannan oligosaccharide. The preparation method comprises the steps of 1, producing a mannan oligosaccharide mixture through enzymolysis conversion; 2, carrying out centrifugal separation: separating enzymatic hydrolysate through a centrifugal machine; 3, carrying out ceramic membrane filtration: filtering centrifugate through a ceramic membrane group as precision separation to remove protein, starch and polysaccharide substances; 4, carrying out ion exchange refining: desalting, decoloring and deodorizing filtrate through a mannan oligosaccharide ceramic membrane; 5, carrying out 2000 molecular weight ultrafiltration: ultrafiltering ion exchange refining liquid through a polyether sulfone-polyamide composite membrane with interception as Dalton to obtain a polymerization degree; 6, carrying out nanofiltration: filtering sugar liquid through a ceramic membrane, ion exchange refining and an ultrafiltration membrane; and 7, carrying out spray drying: preheating a nano-filtered concentrated solution, and drying in a spray drying tower. The dried product contains more than 95% of mannan oligosaccharide, and has an obvious function of multiplying bifidobacterium; meanwhile, the product, as a most promising substitute, can reduce harmful bacteria.

Owner:ENSHI TINJOY BIO TECH

Method for preparing asymmetric nanofiltration membrane by blending polyether sulfone and sulfonated polysulfone high polymers

InactiveCN101979132AChlorine resistantHigh temperature resistantSemi-permeable membranesPolymer scienceFluid phase

The invention discloses a method for preparing an asymmetric nanofiltration membrane by blending polyether sulfone and sulfonated polysulfone high polymers. A blending nanofiltration membrane with an asymmetric structure is prepared in one step by the nanofiltration membrane through a phase transformation method. The method comprises the following steps of: preparing casting membrane liquid, namely mixing the polyether sulfone, the sulfonated polysulfone high polymers, an additive and a solvent to prepare the casting membrane liquid; and forming a membrane by the phase transformation method, wherein the membrane comprises a flat membrane and a hollow fibrous membrane. The interception rate of the nanofiltration membrane to 0.5 to 1.5 g / L sodium chloride and 0.5 to 1.5 g / L sodium sulfate under the operating pressure of between 0.1 and 0.8 MPa is between 20 and 95 percent, the interception rate of the nanofiltration membrane to polyethylene glycol with the relative molecular mass of between 600 and 2,000 is between 40 and 99.9 percent, and the pure water flux of the membrane is between 10 and 250 L / (m2hbar). The asymmetric nanofiltration membrane of the invention has the advantages of high strength and toughness, high compactness resistance, chlorine resistance and high-temperature resistance, and can be applied to aspects of water treatment, wastewater treatment, material separation and the like.

Owner:天津森诺过滤技术有限公司

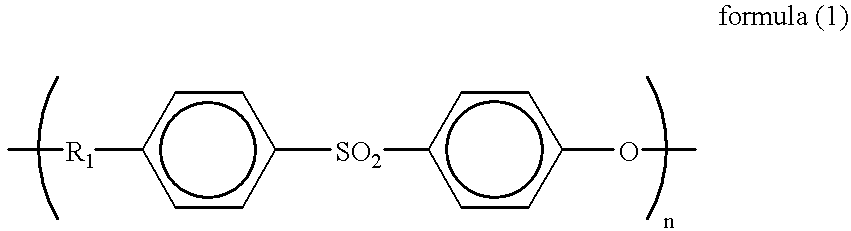

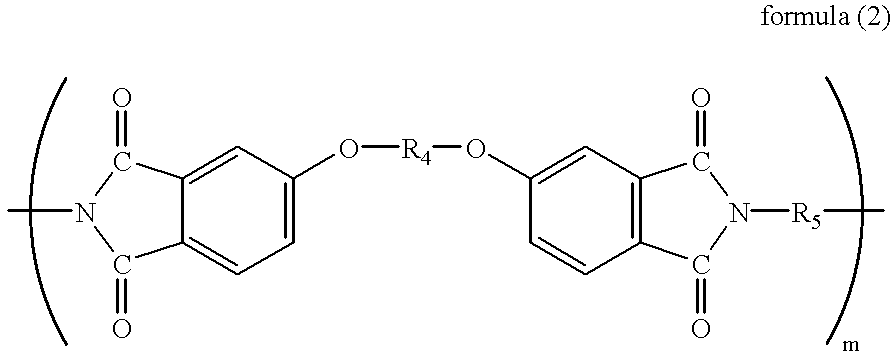

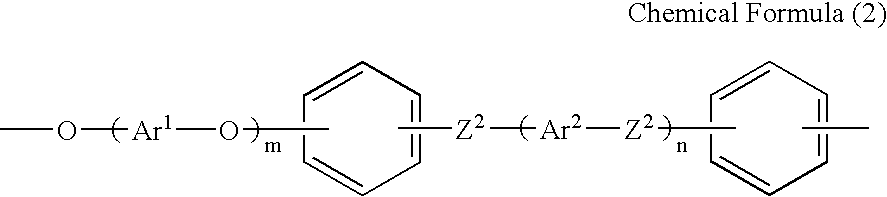

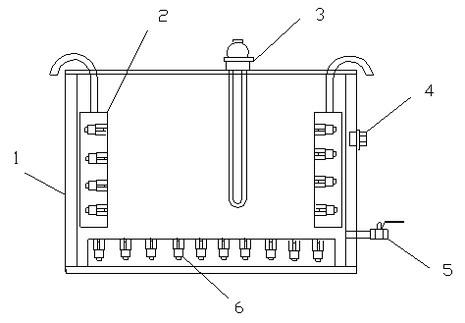

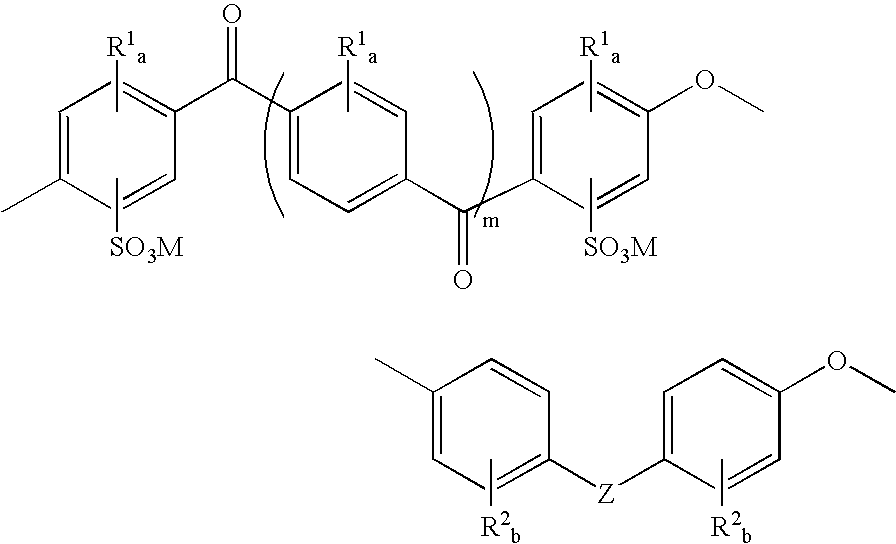

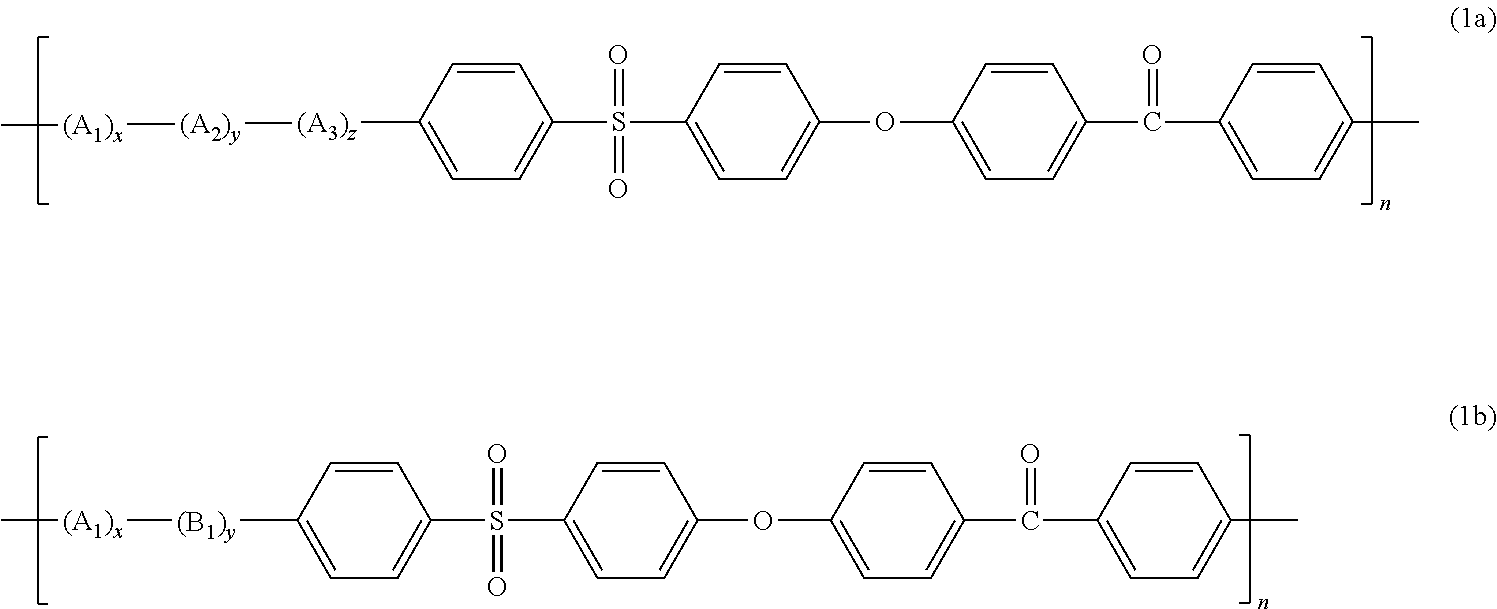

Mixed-sulfonation block copolymers

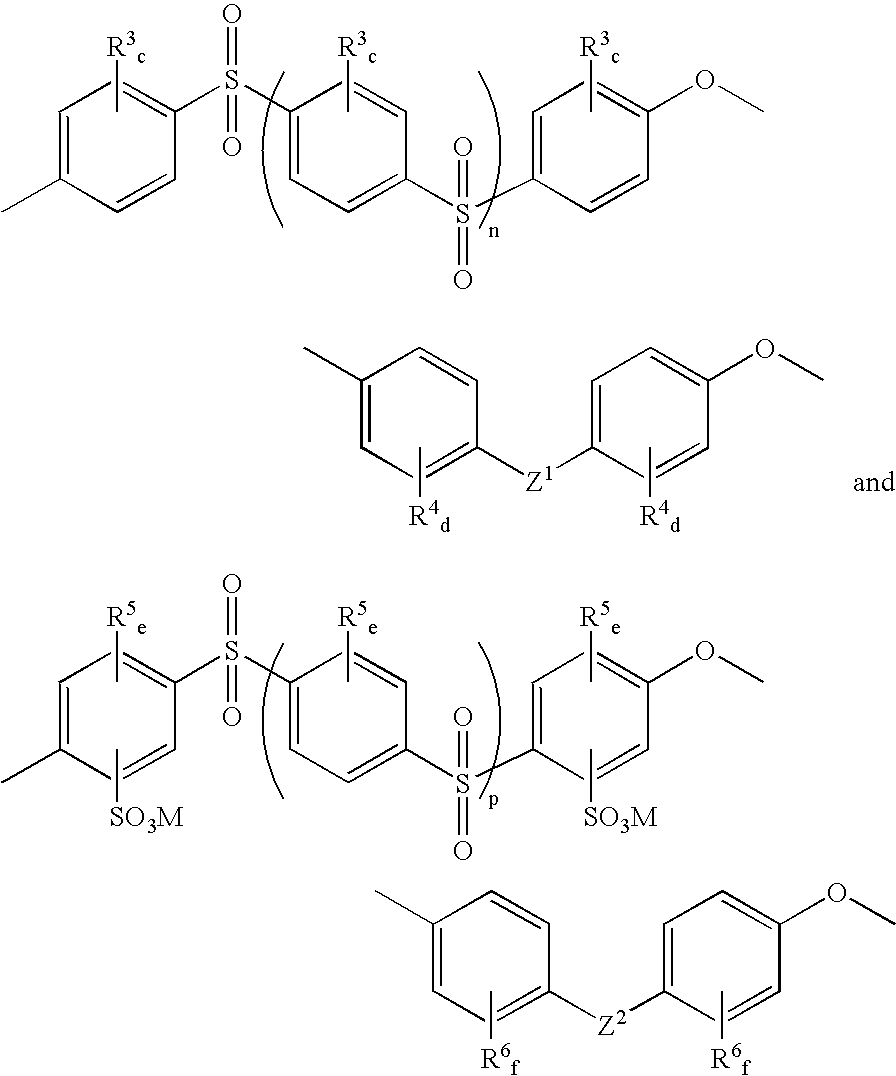

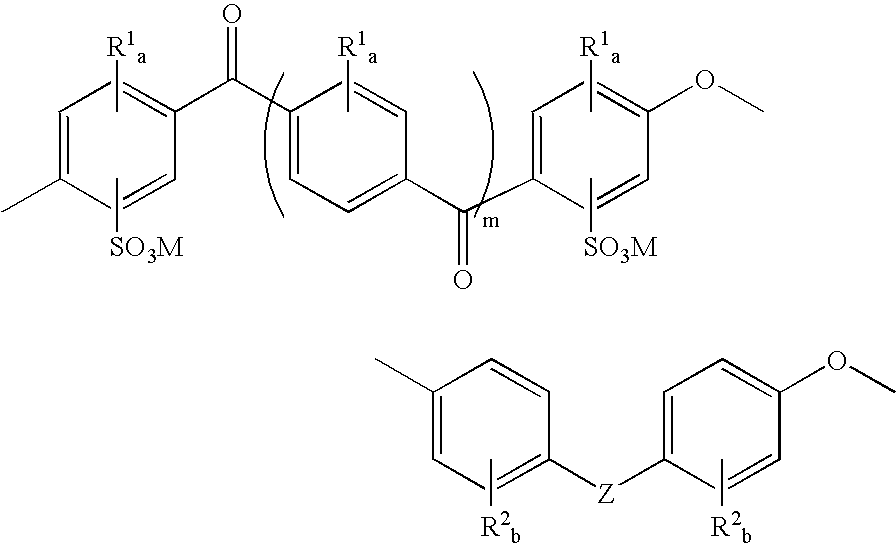

Sulfonated block copolymers that may be used as membranes for fuel cells include sulfonated polyaryletherketone blocks and lightly sulfonated polyethersulfone blocks. The sulfonated polyaryletherketone blocks include structural units of formula and the lightly sulfonated polyethersulfone blocks include structural units of formula wherein R1, R2, R3, R4, R5 and R6 are independently C1-C10 alkyl, C3-C12 cycloalkyl, C6-C14 aryl, allyl, alkenyl, alkoxy, halo, or cyano; Z, Z1 and Z2 are independently a direct bond or O, S, (CH2)r, (CF2)r, C(CH3)2, C(CF3)2, or a combination thereof; M is H, a metal cation, a non-metallic inorganic cation, an organic cation or a mixture thereof; a and e are independently 0 or an integer from 1 to 3; b, c, d, and f are independently 0 or an integer from 1 to 4; m, n and p are independently 0 or 1; and r is an integer from 1 to 5.

Owner:GENERAL ELECTRIC CO

High temperature resistant polysulfone insulation for pipe

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of about 200° C. or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant polysulfone having sulfone, ether and isopropylidene bridging groups, and / or a polyphenylsulfone or a polyethersulfone.

Owner:SHAWCOR LTD

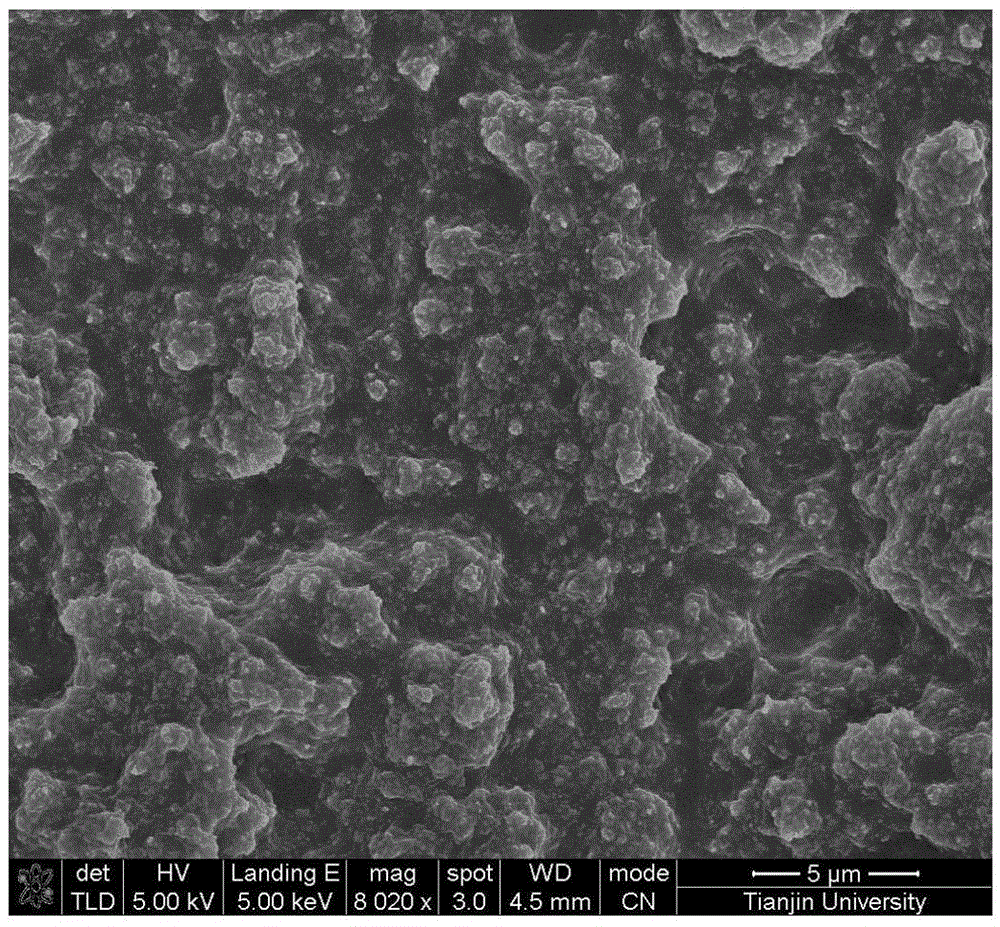

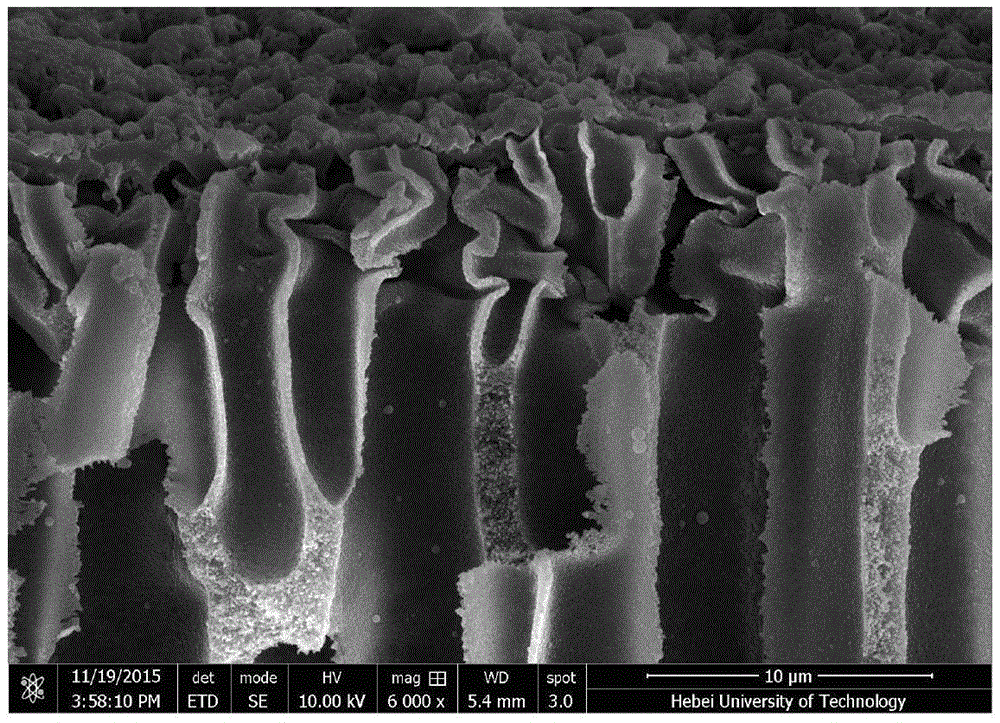

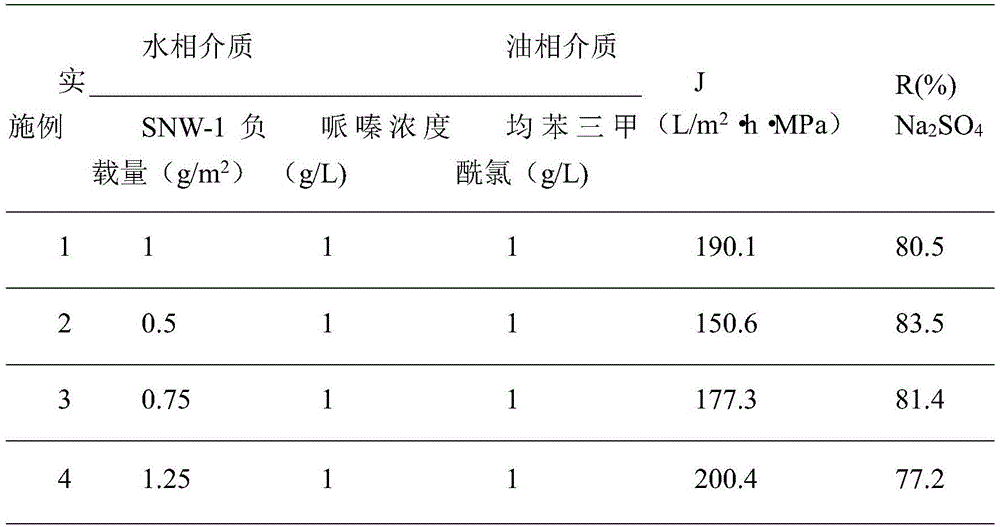

Polyamide/COFs hybridized nanofiltration composite membrane and preparation method thereof

ActiveCN105642133AImprove interface compatibilityHigh retention rateSemi-permeable membranesPolymer sciencePolyamide

The invention provides a polyamide / COFs hybridized nanofiltration composite membrane. The composite membrane comprises a composite layer and a loaded porous frame material. The composite layer is a layer of polyamide compound formed by conducting polymerization reaction on piperazine and trimesoyl chloride, and the thickness is 100-500 nm. The porous frame material is SNW-1 obtained when melamine and terephthalaldehyde react, and is a compound layer with the loading amount of 0.5-3 g / m<2>. A covalent organic framework is effectively hybridized in a separation layer of the composite membrane, and more water channels are provided for the nanofiltration membrane. By means of the method, various types of COFs can be introduced onto a polyether sulfone base membrane, the water flux can reach 200 L / m<2>.h.MPa and increased by 2 times, the sodium sulfate retention rate of the nanofiltration membrane is still kept at 80% or above, and the high water flux and the high retention rate are achieved.

Owner:HEBEI UNIV OF TECH

Method for preparing hydrophilic porous membrane

InactiveCN101862604AStable structureUniform pore sizeSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention provides a method for preparing a hydrophilic porous membrane. The method comprises the following steps of: preparing a polymer membrane by using a known blending modification method, wherein a membrane forming polymer is one of polyvinylidene fluoride, polysulfone, polyether sulphone, polrvinyl chloride, polyamide or polyacrylonitrile; a modification additive is one of or a mixture of more of polyvinylpyrrolidone, polyvinylpyrrolidone copolymer, polyethylene glycol, polypropylene glycol, polyvinyl alcohol, polyacrylic acid or polyelectrolyte; and then performing chemical crosslinking or radiation crosslinking treatment on the prepared polymer membrane to obtain the porous membrane with stable hydrophilicity. The prepared porous membrane has more uniform bore diameters, and the membrane flux is higher than that of the unprocessed membrane by 2 to 10 times.

Owner:XIAMEN LEEBAM MEMBRANE TECH

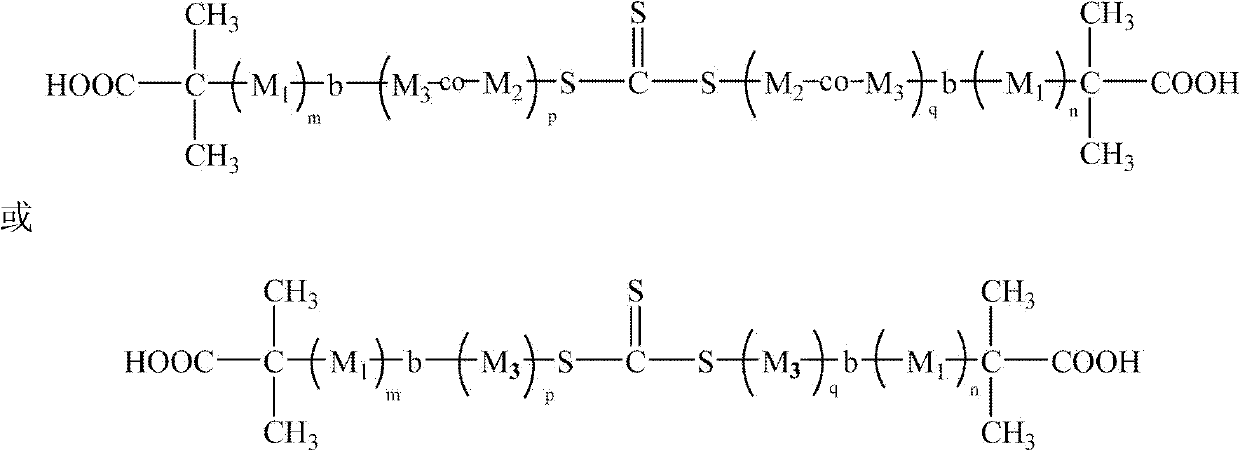

Amphiphilic triblock copolymer, preparation method thereof, and polyethersulfone hollow fiber membrane blend-modified by using amphiphilic triblock copolymer

InactiveCN102432782AGood blood compatibilityGood physical and chemical stabilitySemi-permeable membranesHollow filament manufactureDecompositionAcrylonitrile

The invention discloses an amphiphilic triblock copolymer with a structural general formula represented as the following. In the formula, when M1 is vinylpyrrolidone and M2 is acrylic acid, M3 is styrene or acrylonitrile or methyl methacrylate; or when M1 is vinylpyrrolidone and M2 is a chemical bond, M3 is styrene or acrylonitrile. m, n, p, q, are all lager than 1. A number-average molecular weight of the copolymer is 30000 to 100000, a glass-transition temperature of the copolymer is 90-180 DEG C, and a decomposition temperature of the copolymer is 180-430 DEG C. The invention also discloses a preparation method of the copolymer, and a polyethersulfone hollow fiber membrane blend-modified by using the amphiphilic triblock copolymer. The amphiphilic triblock copolymer provided by the invention is insoluble in water. When the amphiphilic triblock copolymer is blended with polyethersulfone and is prepared into a polyethersulfone hollow fiber membrane, the amphiphilic triblock copolymeris hard to precipitate. Therefore, the polyethersulfone hollow fiber membrane is provided with permanent hydrophilicity, protein pollution resistance and excellent blood compatibility. The polyethersulfone hollow fiber membrane can be used in the field of blood purification. The preparation method provided by the invention is simple, and is easy to operate. With the method, industrialization is easy to realize.

Owner:SICHUAN UNIV

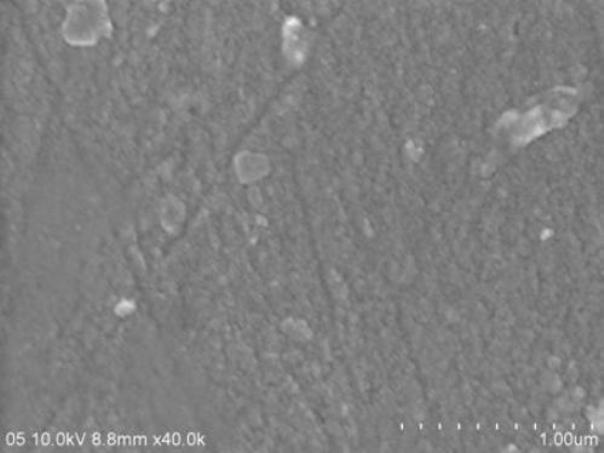

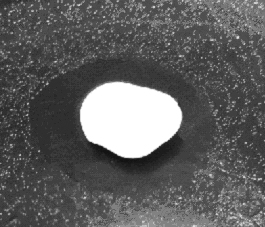

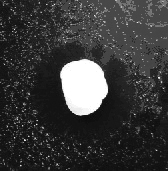

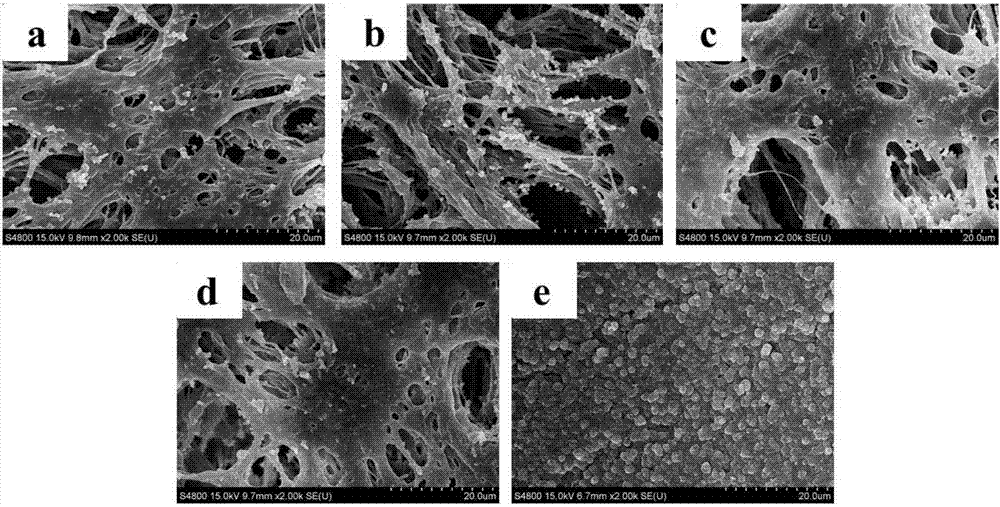

Metal ion-carried nerchinskite nano tube/polyether sulfone hybridized antibacterial membrane and preparation method thereof

ActiveCN102049204AIncreased pure water fluxGood antibacterial effectSemi-permeable membranesAnti bacterialSulfone

The invention discloses a preparation method of a metal ion-carried nerchinskite nano tube / polyether sulfone hybridized antibacterial membrane, and belongs to the technical field of membranes. The invention is characterized in that: the antibacterial property and the contamination resistance of the membrane are improved by using the antibacterial property of a metal ion-carried nerchinskite nano tube and the hydrophilic property of the nerchinskite nano tube under the condition that the water flux and the interception rate of the polyether sulfone ultra-filtration membrane are not reduced. Meanwhile, the preparation method and preparation equipment are simple. The membrane serving as a novel ultra-filtration membrane is expected to be applied in wastewater treatment more widely.

Owner:ZHENGZHOU UNIV

Cross-linked sulfonated polysulfone/polyether sulfone-sulfonated polysulfone composite membrane and manufacturing method thereof

InactiveCN104524993AImprove hydrophilicityImprove performanceSemi-permeable membranesCross-linkFiltration

The invention relates to a cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane and a manufacturing method of the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane. Polyhydroxyl or multi-amino or hyperbranched substances are selected, a polyether sulfone / sulfonated polysulfone blended ultra-filtration base membrane is coated with a cross-linked sulfonated polysulfone solution to manufacture the composite membrane, a composite membrane separation layer of which the thickness is 1 micrometer-10 micrometers is formed on the surface of the base membrane, the water contact angle of the surface of the composite membrane separation layer ranges from 40 degrees to 90 degrees, and the composite membrane separation layer has good osmosis and separation properties. The manufacturing method includes the steps that sulfonated polysulfone of different concentrations and sulfonation degrees, m-phenylenediamine, polyethylene glycol, dopamine, H30 and other cross-linking agents are dissolved in solvent to manufacture the coating solution, with the polyether sulfone / sulfonated polysulfone blended ultra-filtration being the base membrane, the composite membrane separation layer is manufactured under vacuum conditions, and finally the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane which is hydrophilic is obtained. The manufactured composite membrane has the good osmosis and separation properties, and can be used for nanofiltration and forward osmosis processes and membrane separation processes including seawater desalting, waste water treatment, domestic water treatment and bio-separation.

Owner:张一琛

Hybrid battery binder

Disclosed is a composition comprising an ethylene copolymer and a polyetherimide, polyamideimide, polycarbonate, polyetheretherketone, polysulfone or polyethersulfone wherein the ethylene copolymer comprises or is produced from repeat units derived from ethylene and a comonomer selected from the group consisting of an α,β-unsaturated monocarboxylic acid or its derivative, an α,β-unsaturated dicarboxylic acid or its derivative, an epoxide-containing monomer, a vinyl ester, or combinations of two or more thereof; and the composition can further comprise a curing agent to crosslink the ethylene copolymer. The composition is useful as a binder for a lithium ion battery.

Owner:PERFORMANCE MATERIALS NA INC

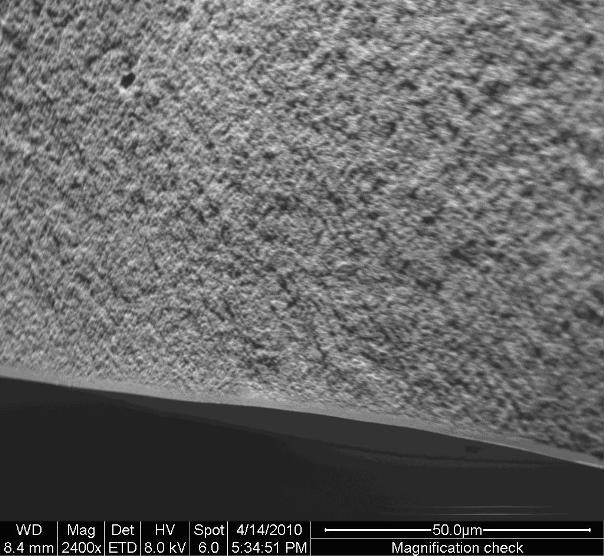

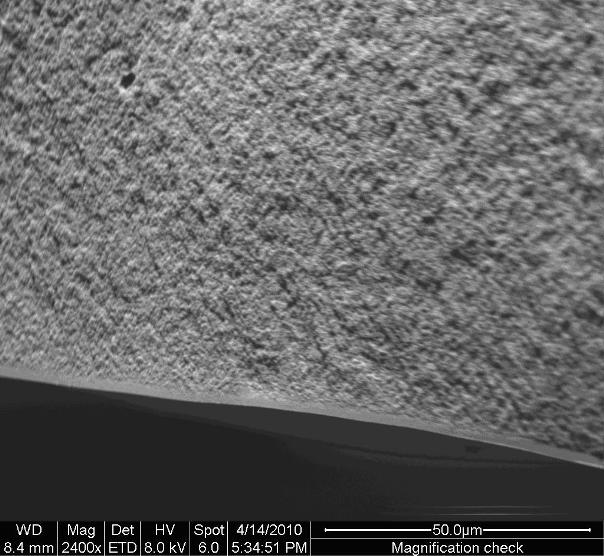

Hollow fibrous membranes of modified poly(ether sulfone) and their production

ActiveCN1680010ALarge ultrafiltration rateGood biocompatibilitySemi-permeable membranesFiberWater baths

A hollow modified polyethersulfone fibre membrane is prepared through proportionally mixing polyethersulfone, hydrophilic high-molecular material, pore-forming agent and solvent, stirring at 75-95 deg.C for 2-24 hr, dissolving the bioactive macro-molecular material in water, slowly adding it to said solution of polyethersulfone, stirring, fitlering, defoaming, curing, dry-wet spinning, shaping in water bath at 20-42 deg.C, drafting, winding and post-treating.

Owner:成都欧赛医疗器械有限公司

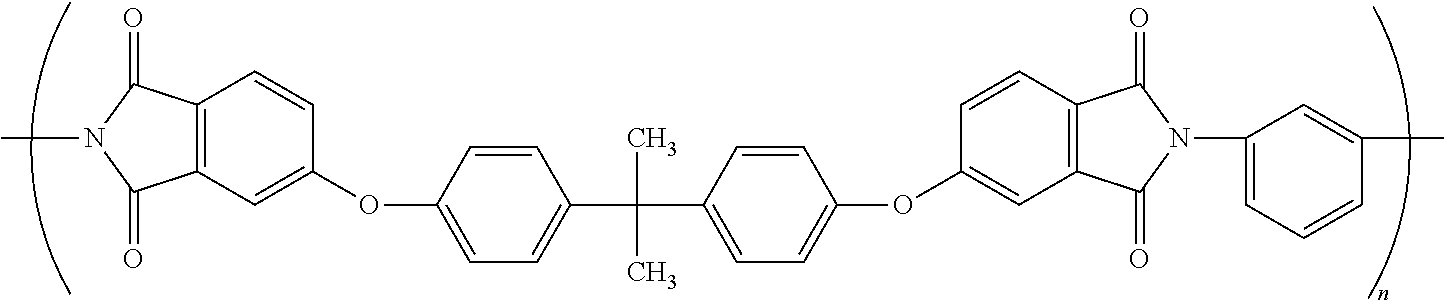

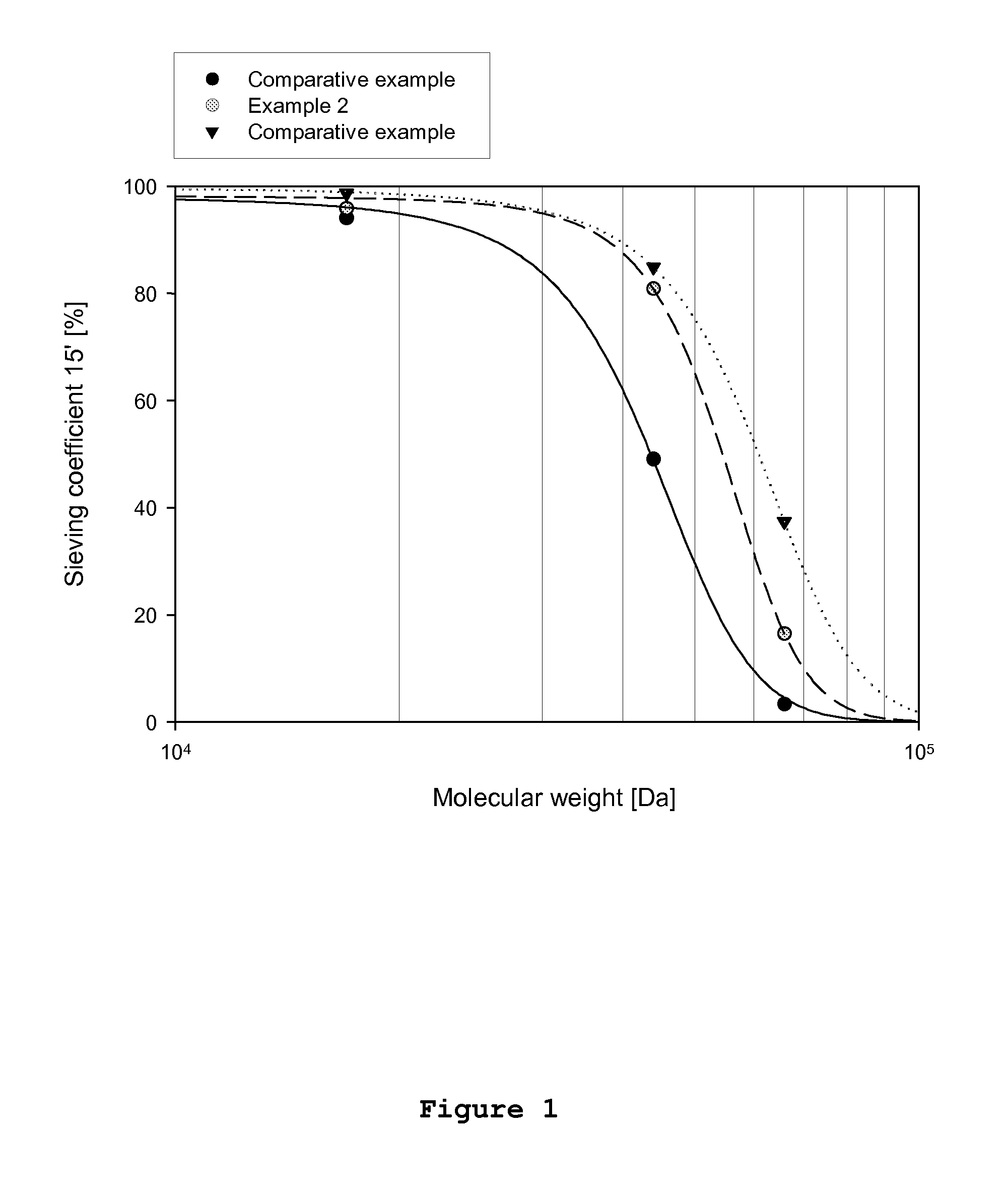

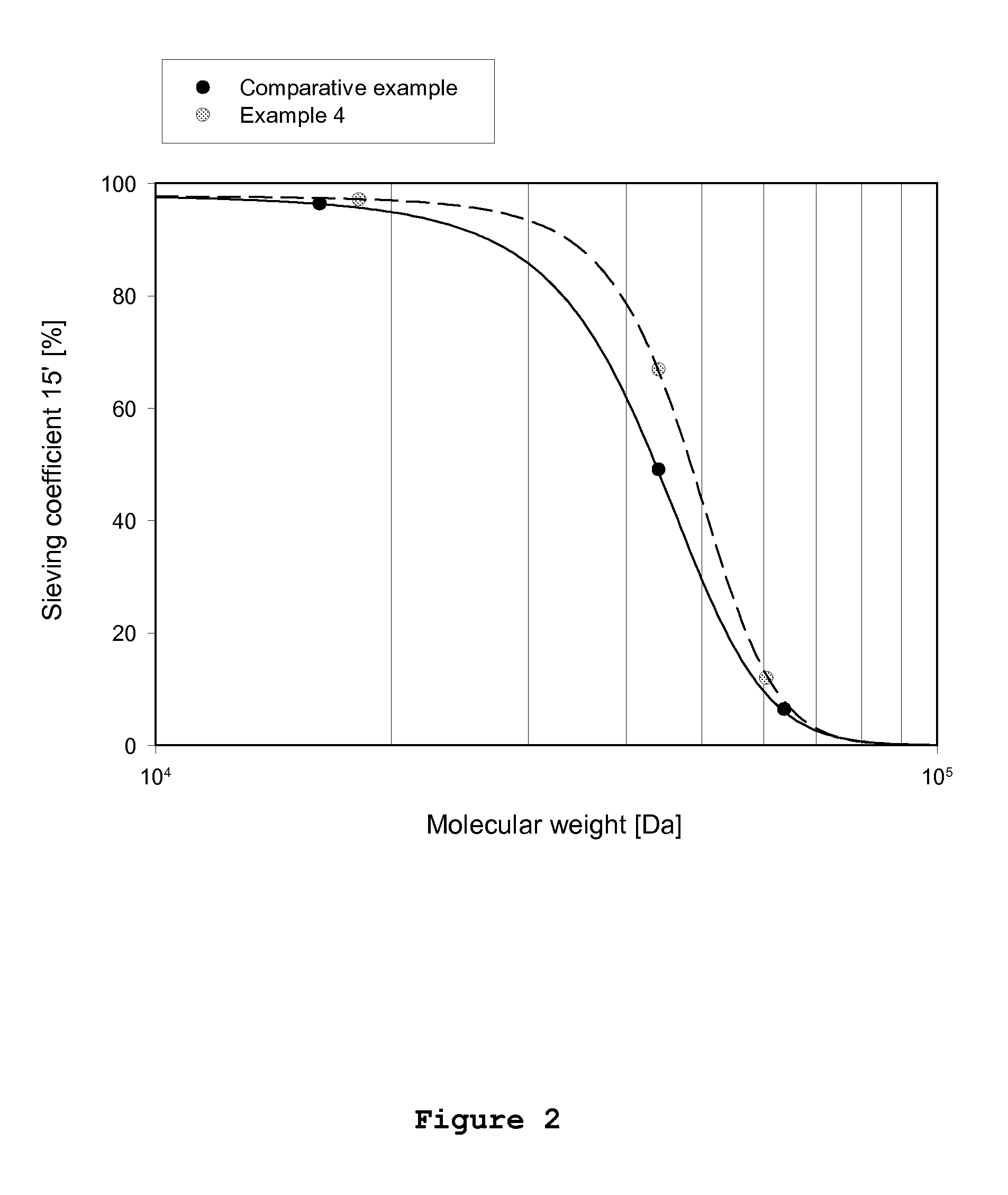

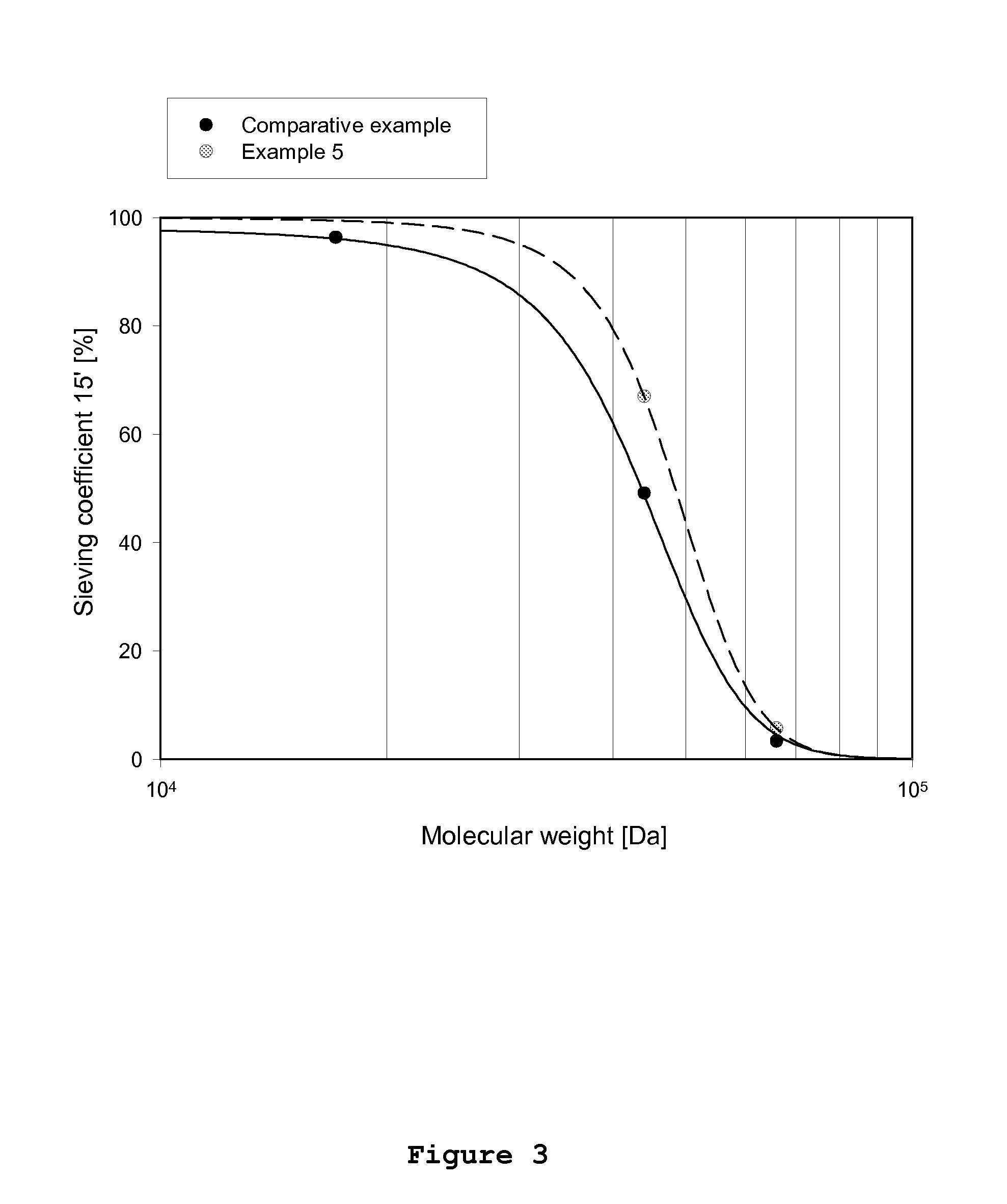

Membranes having improved performance

ActiveUS20120074063A1Improve performanceInflammatory mediatorSolvent extractionDialysisPhosphoryl cholineProtein solution

Permselective asymmetric membranes suitable e.g. for hemodialysis, hemodiafiltration and hemofiltration of blood, and having improved sieving characteristics providing enhanced removal of middle molecular weight substances, e.g. inflammatory mediators having a molecular weight between 20 and 40 kDa. The membranes comprise polyethersulfone and polyvinylpyrrolidone and are coated with hyaluronic acid or copolymers of 2-methacryloyloxyethyl phosphoryl choline and other vinyl polymerizable monomers. Processes for the preparation of these membranes, devices comprising these membranes, and the use of these membranes in hemodialysis, hemodiafiltration and hemofiltration of blood, as well as in bioprocessing, plasma fractionation and the preparation of protein solutions.

Owner:GAMBRO LUNDIA AB

Multilayer composite ultrafiltration membrane and preparation method thereof

ActiveCN105032202AImprove antifouling performanceEnhanced water fluxUltrafiltrationSynthetic resin layered productsCellulosePolymer science

The invention discloses a multilayer composite ultrafiltration membrane and a preparation method thereof. The multilayer composite ultrafiltration membrane is characterized by being provided with five layers of structures, wherein each of the inner and outer surfaces of the ultrafiltration membrane is a PET or PP non-woven fabric base body, each of the inner and outer subsurfaces of the ultrafiltration membrane is a polymer nanofiber membrane layer, and the middle layer of the ultrafiltration membrane is a cellulose nanofiber membrane layer. A polymer in the polymer nanofiber membrane layer is selected from one of polyether sulfone, polysulfone, polyacrylonitrile and polyvinylidene fluoride film forming polymers, and then is processed to prepare a spinning solution, and electrostatic spinning dope forms the polymer nanofiber membrane layers on PET or PP non-woven fabrics serving as the base bodies for electrostatic spinning collection. The cellulose nanofiber membrane layers are prepared by selecting one of bamboo, wood, cotton and linen, dissociating fiber slurry and processing. The multilayer composite ultrafiltration membrane prepared by the method has good hydrophily, higher pollutant resistance and water flux, and better interception characteristic, and is more economical in use and longer in service life.

Owner:上海展恒环保科技有限公司

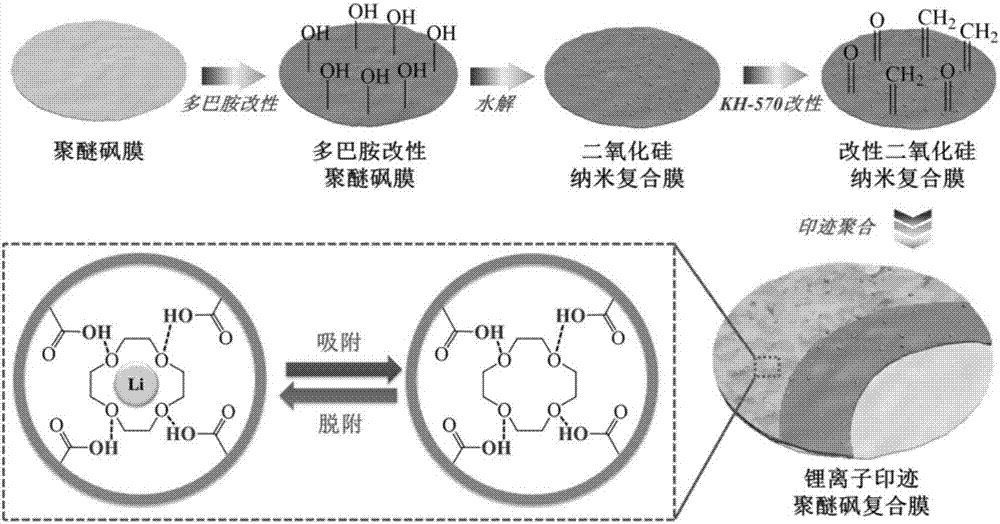

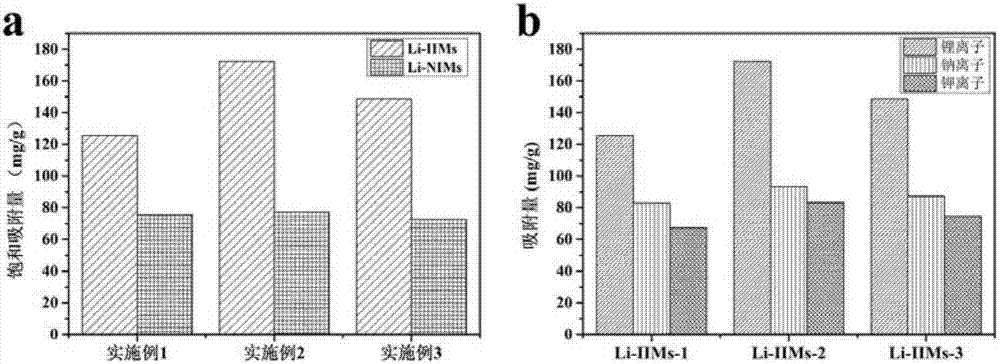

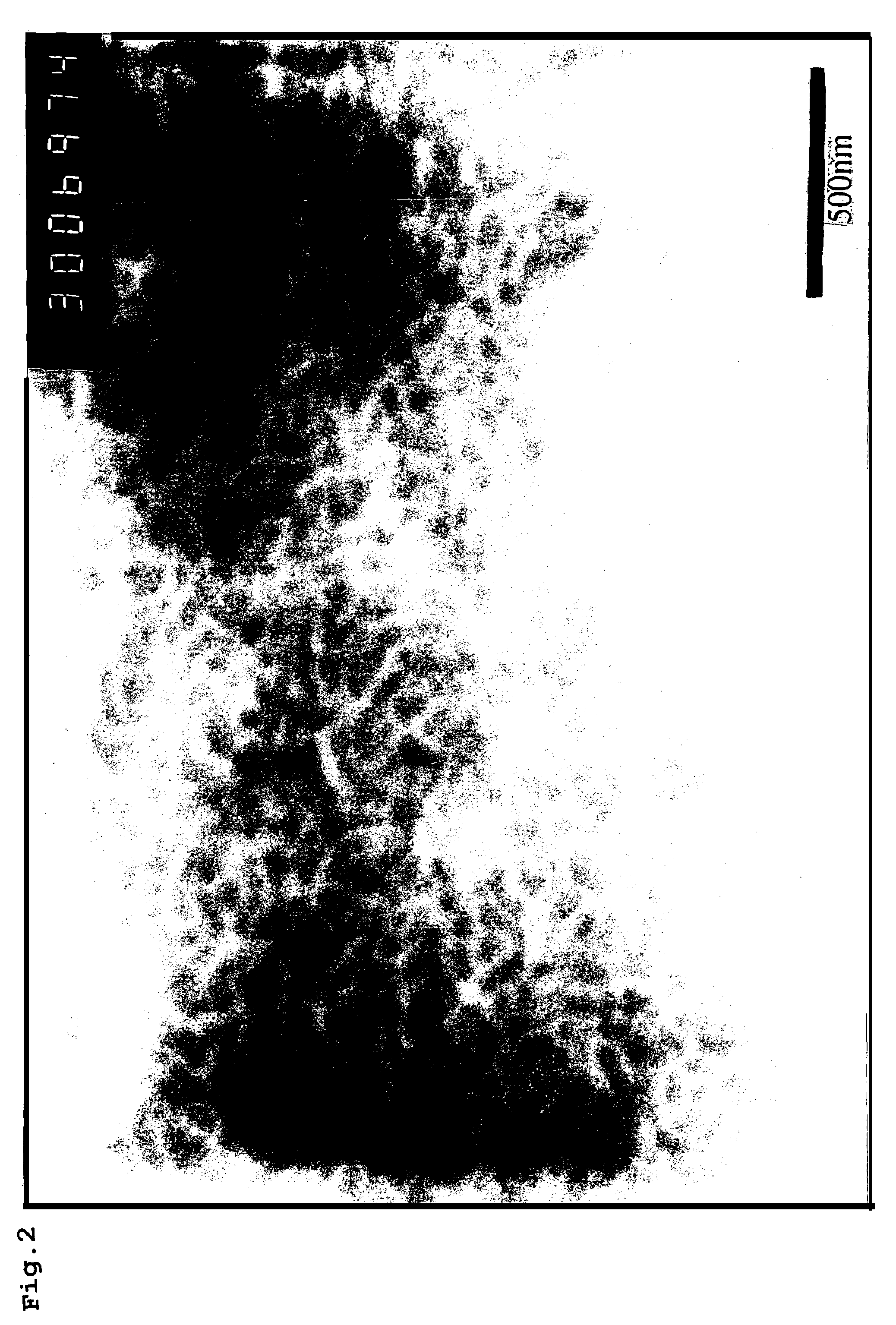

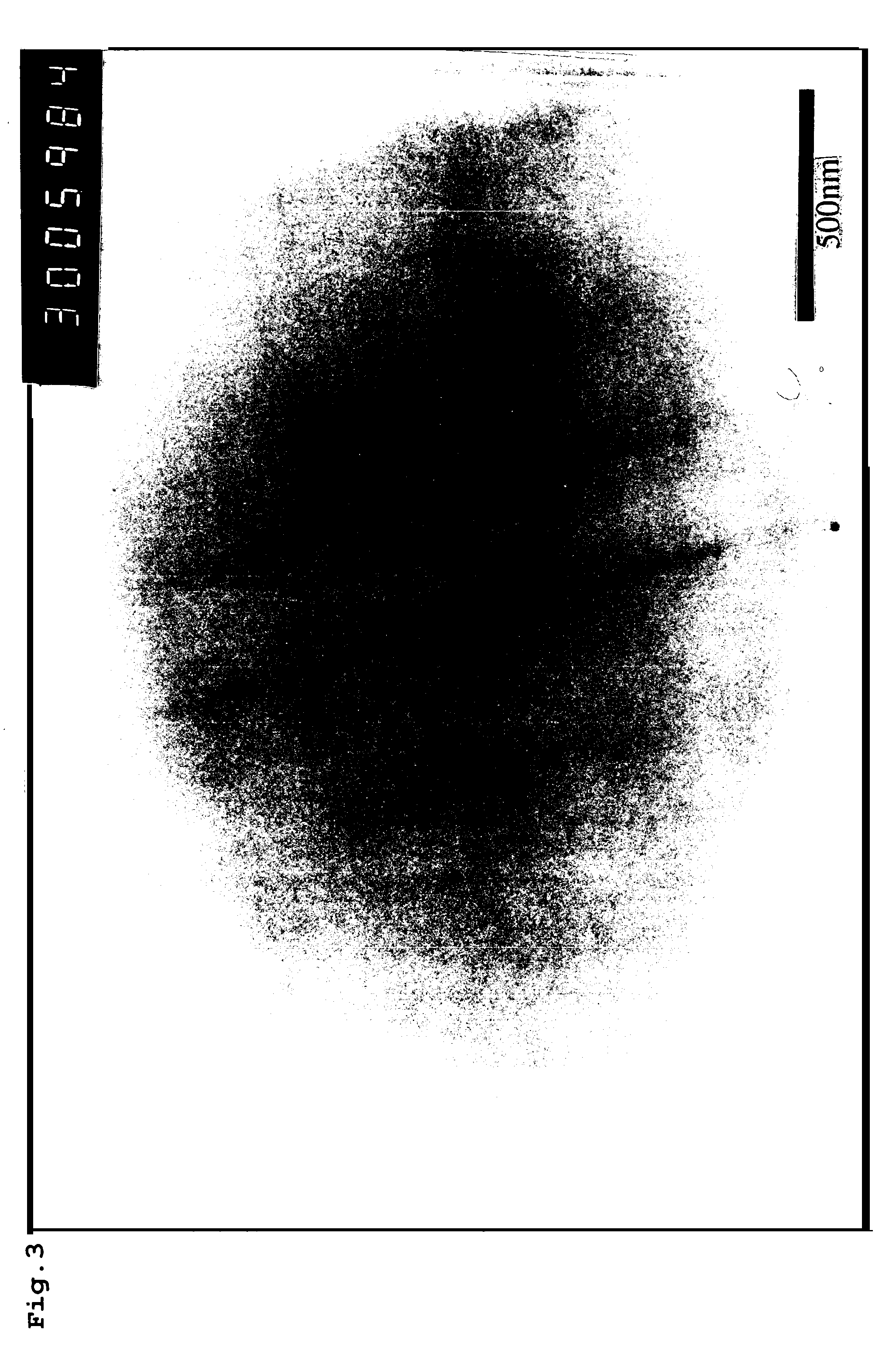

Preparation method and application of lithium-ion-imprinted polyethersulfone composite membrane

ActiveCN106902654AAchieving identifiabilityAchieve adsorptionSemi-permeable membranesOther chemical processesCross-linkFunctional monomer

The invention provides a preparation method and application of a lithium-ion-imprinted polyethersulfone composite membrane, belonging to the technical field of preparation of functional materials. The lithium-ion-imprinted polyethersulfone composite membrane is prepared with a polyethersulfone membrane as a substrate membrane material, lithium ions as a template, 12-crown-4-ether as a binding site, methacrylic acid as a functional monomer, ethylene glycol dimethacrylate as a cross-linking agent and azodiisobutyronitrile as an initiator by using a combination of dopamine surface modification technology, silica nanometer compounding technology and imprinted polymerization technology. Static adsorption experiments are conducted to research the adsorption equilibrium, kinetic performance and selective recognition performance of the prepared lithium-ion-imprinted polyethersulfone composite membrane; and selective permeation experiments are carried out to research the permeation action of the prepared lithium-ion-imprinted polyethersulfone composite membrane on target ions (lithium ions) and non-target ions (sodium ions and potassium ions). The lithium-ion-imprinted polyethersulfone composite membrane prepared in the invention has high specific lithium ion adsorption capability and lithium ion recognition and separation capability.

Owner:JILIN NORMAL UNIV

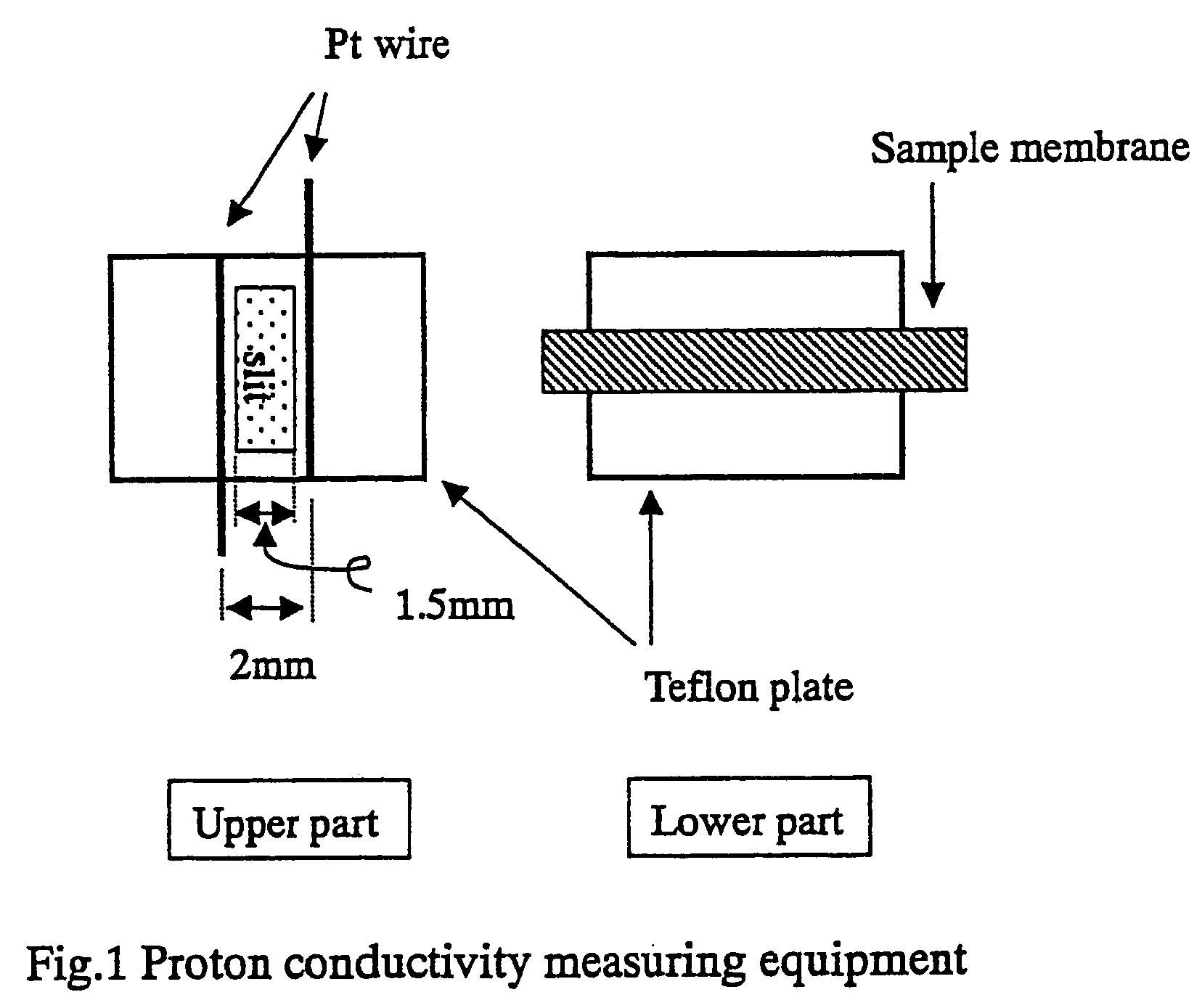

Polymer electrolyte for solid polymer type fuel cell and fuel cell

InactiveUS7258941B2Less susceptibleIon-exchanger regenerationConductive materialPolyelectrolytePolymer electrolytes

A polyelectrolyte for a solid polymeric fuel cell comprising an aromatic polyether sulfone block copolymer comprising a hydrophilic segment containing sulfonic acid groups and a hydrophobic segment having no sulfonic acid group at a hydrophilic segment weight fraction W2 to hydrophobic segment weight fraction W1 ratio falling within a range of 0.6<W2 / W1<2.0. The polyelectrolyte for a solid polymeric fuel cell is inexpensive and durable, and its proton conductivity is less influenced by humidity and temperature.

Owner:UBE IND LTD

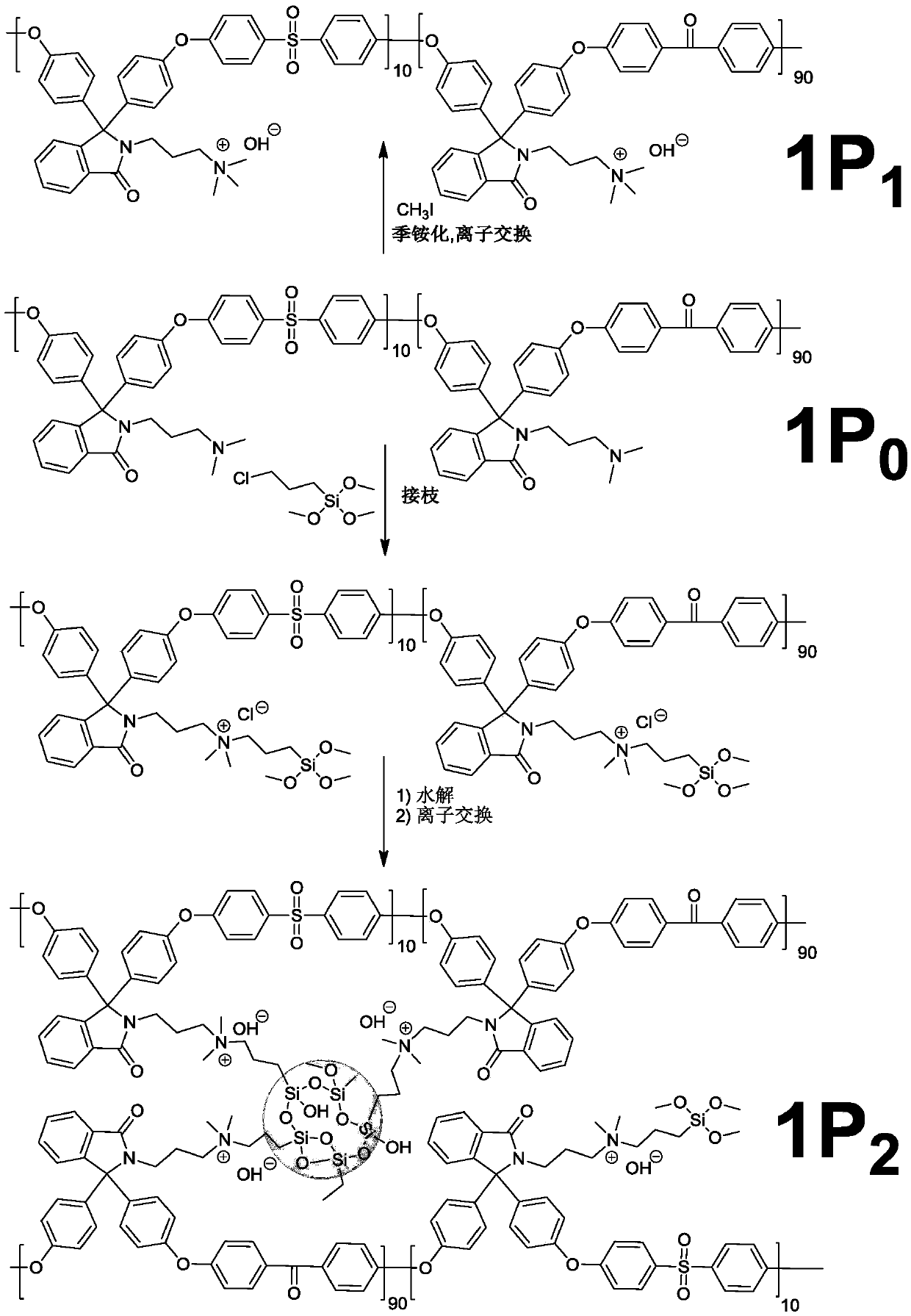

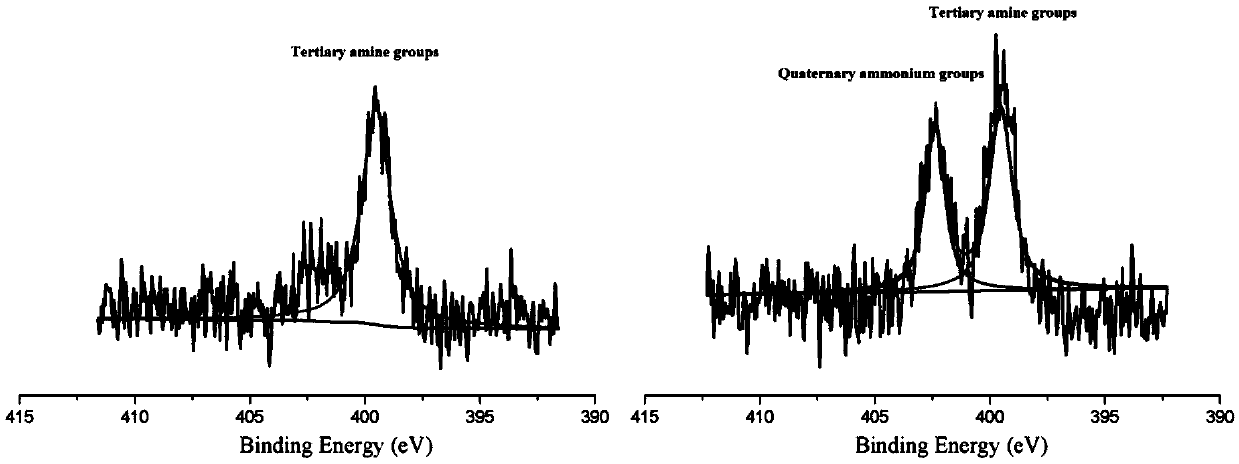

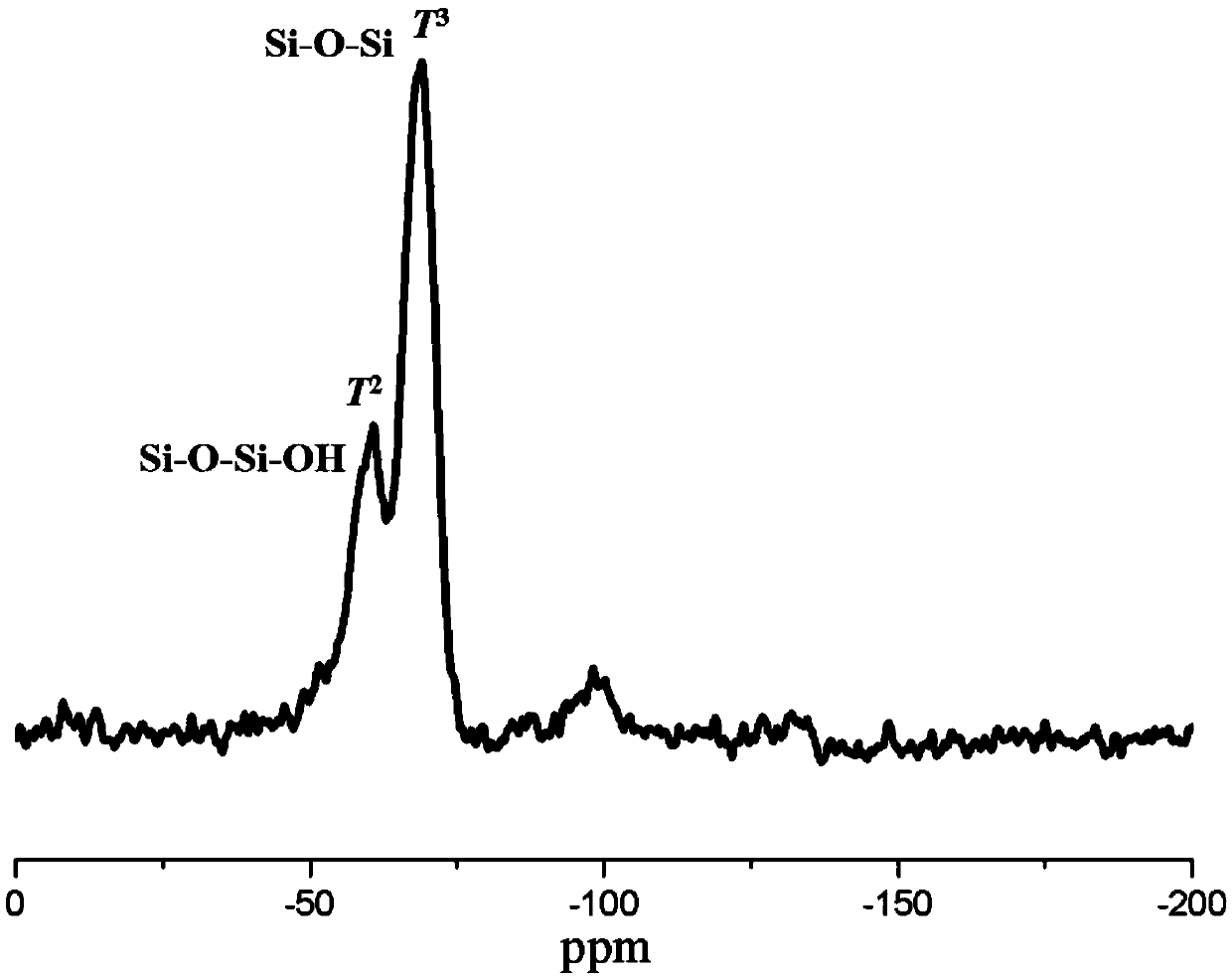

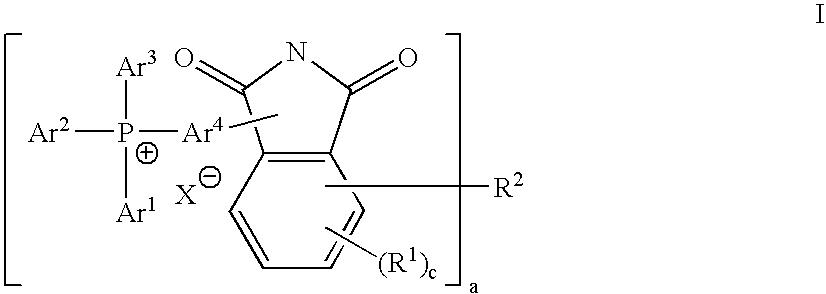

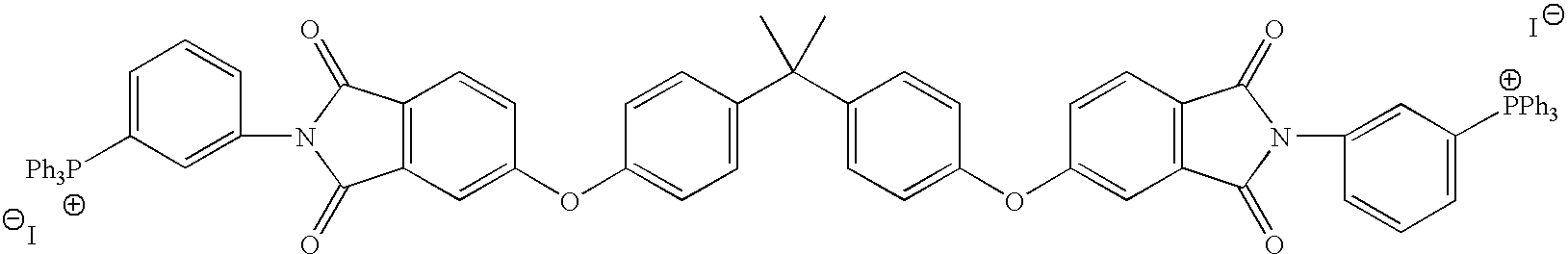

Polymer containing quaternary ammonium group, anion exchange membrane and preparation method thereof

The invention provides a polymer containing a quaternary ammonium group. The polymer is obtained through a reaction of a quaternization reagent and a polymer with a side chain containing a tertiary amine group. The polymer with the side chain containing the tertiary amine group is one or more of polyether sulphone with a side chain containing a tertiary amine group and polyaryletherketone with a side chain containing a tertiary amine group and PPESK with a side chain containing a tertiary amine group. The quaternization reagent is one or more of iodomethane, (3-chloropropyl) trimethoxy silane and a (3-chloropropyl) trimethoxy silane system. According to the polymer, the polyether sulphone with the side chain containing the tertiary amine group and the polyaryletherketone with the side chain containing the tertiary amine group and the PPESK with the side chain containing the tertiary amine group are adopted as raw materials, grafting is performed on the appropriate condition to generate the quaternary ammonium group, a siloxane group and the quaternary ammonium group exist in a novel anion exchange membrane material structure in a covalent bond binding mode, the alkali stability and the size stability of the membrane material are improved, and meanwhile the tenacity and mechanical performance of the membrane material can be improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

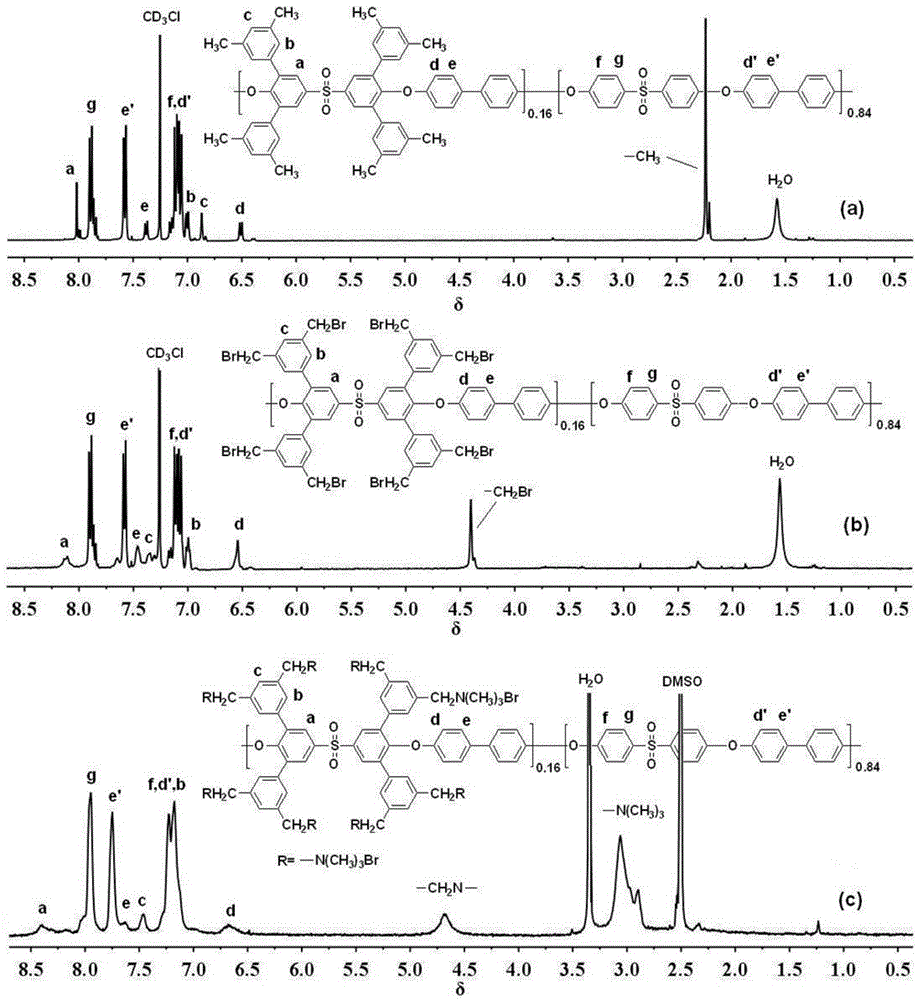

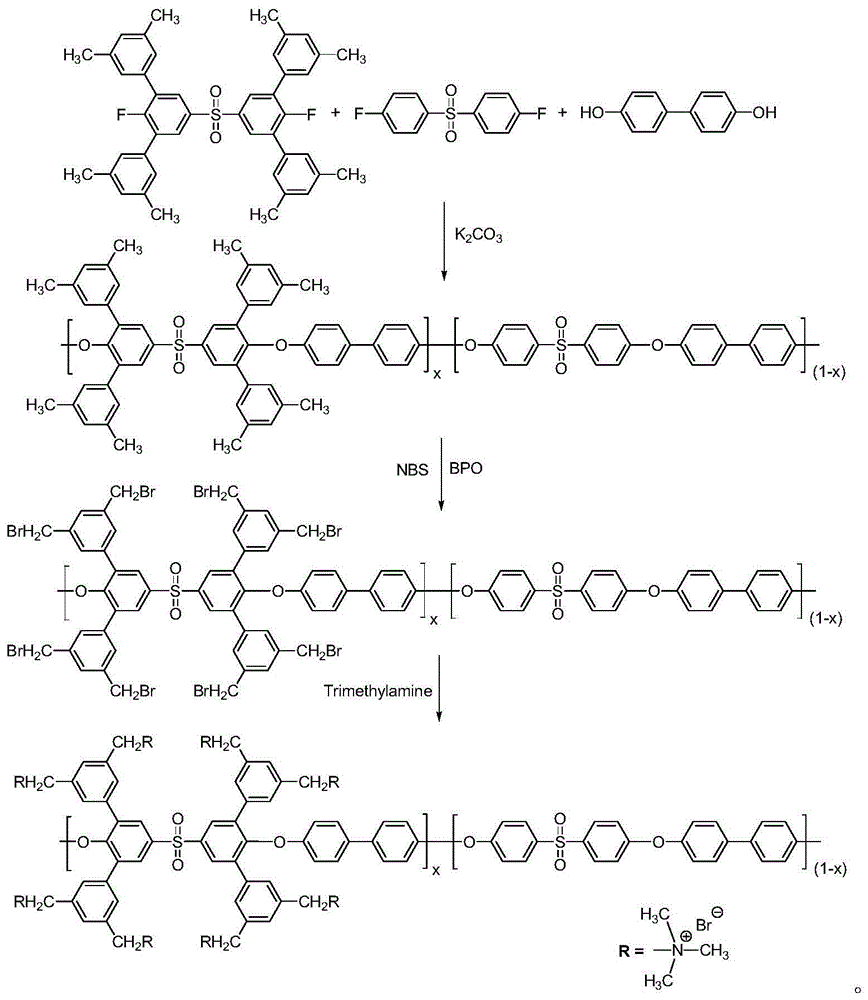

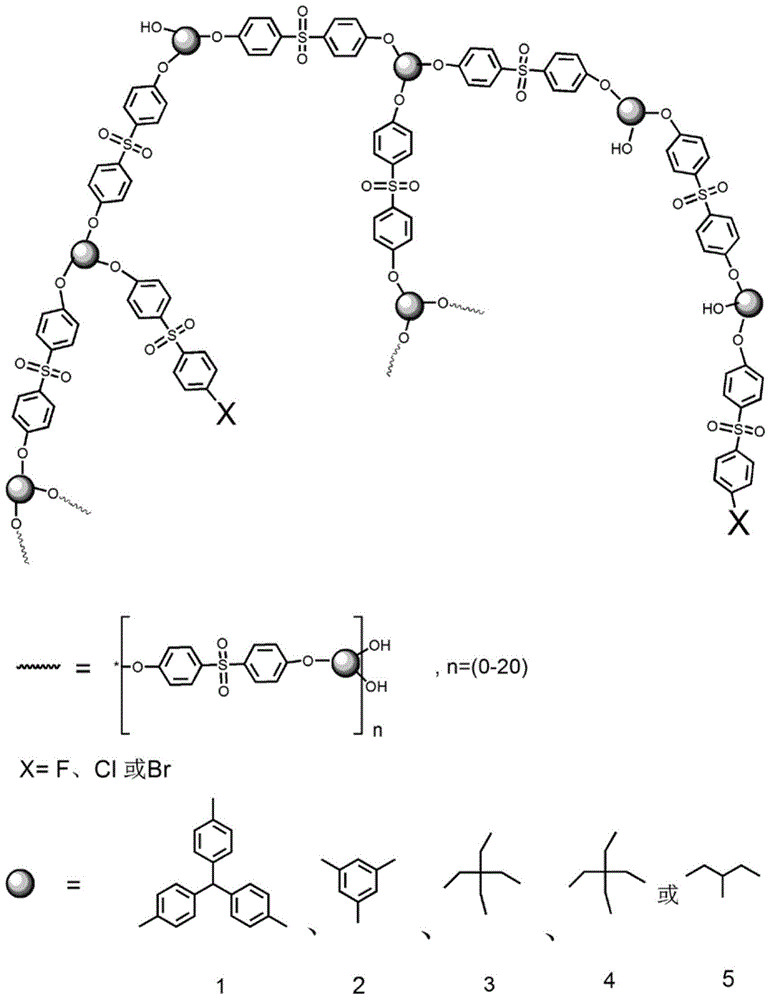

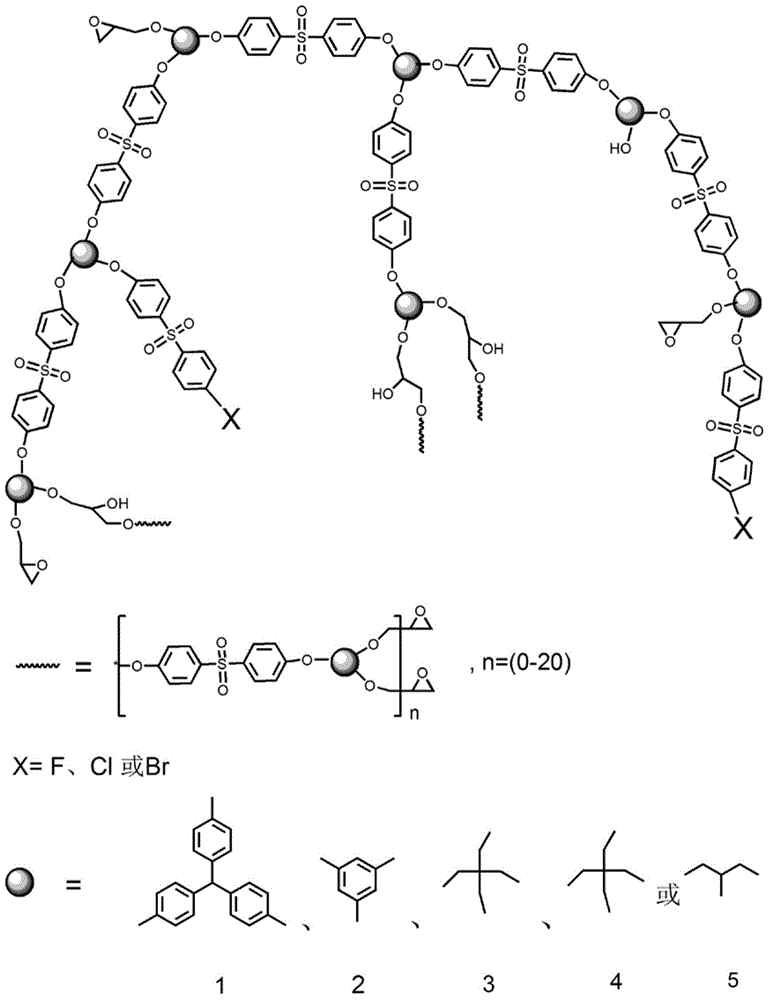

Polyether sulphone containing plurality of quaternary ammonium salt phenyl side group structures and preparation method for polyether sulphone

The invention provides polyether sulphone containing a plurality of quaternary ammonium salt phenyl side group structures. The preparation method for polyether sulphone comprises the following steps: firstly, producing copolycondensation of an active difluorosulphone monomer containing the polymethyl structure, 4,4'-difluorodiphenyl sulfone and biphenol to prepare polyether sulphone containing a polymethyl structure; secondly, converting prepared polyether sulphone containing the polymethyl structure into a polymer containing a bromomethyl structure by utilizing a bromination reaction; finally, by utilizing a nucleophilic substitution reaction, reacting the polymer containing the bromomethyl structure with trimethylamine to obtain polyether sulphone containing the plurality of quaternary ammonium salt phenyl side group structures. Polyether sulphone has good film-forming property; a prepared polymer thin film has good alkali resistance, relatively high ionic conductivity and excellent size stability, and can serve as an anion exchange membrane material for alkaline fuel cells.

Owner:CHANGZHOU UNIV

Preparation method and using method of carbon fiber compounded polyether sulfone resin sizing agent

The invention provides a preparation method and a using method of a carbon fiber compounded polyether sulfone resin sizing agent. A new carbon fiber sizing agent component for polyether sulfone resin is prepared for solving the problem that an epoxy sizing agent is not suitable for the carbon fiber compounded polyether sulfone material, and can effectively improve the interface bonding property of carbon fibers and polyether sulfone and improve the high temperature resistance of a composite material. A preparation method comprises the steps of processing polyether sulfone resin with a sulfonating agent to obtain a main component (sulfonic polyether sulfone) of the sizing agent; preparing a sizing solution and dipping the carbon fiber to obtain the sizing carbon fiber. The method can improve the interface bonding property of the carbon fiber compounded polyether sulfone resin and can fully achieve high specific strength of the carbon fiber and high temperature resistance of the polyether sulfone.

Owner:BEIJING UNIV OF CHEM TECH

Compositions and methods for polymer composites

This invention relates to organic salt compositions useful in the preparation of organoclay compositions, polymer-organoclay composite compositions, and methods for the preparation of polymer nanocomposites. In one embodiment, the present invention provides a method of making a polymer-organoclay composite composition, said method comprising melt mixing a quaternary organoclay composition comprising alternating inorganic silicate layers and organic layers, said organic layers comprising a quaternary organic cation with a polymeric resin comprising at least one polymer selected from the group consisting of polyamides, polyesters, polyarylene sulfides, polyarylene ethers, polyether sulfones, polyether ketones, polyether ether ketones, polyphenylenes, and polycarbonates, said polymeric resin being substantially free of polyetherimides; said melt mixing being carried out at a temperature in a range between about 300° C. and about 450° C. to provide a polymer-organoclay composite composition, said polymer-organoclay composite composition being characterized by a percent exfoliation of at least 10 percent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

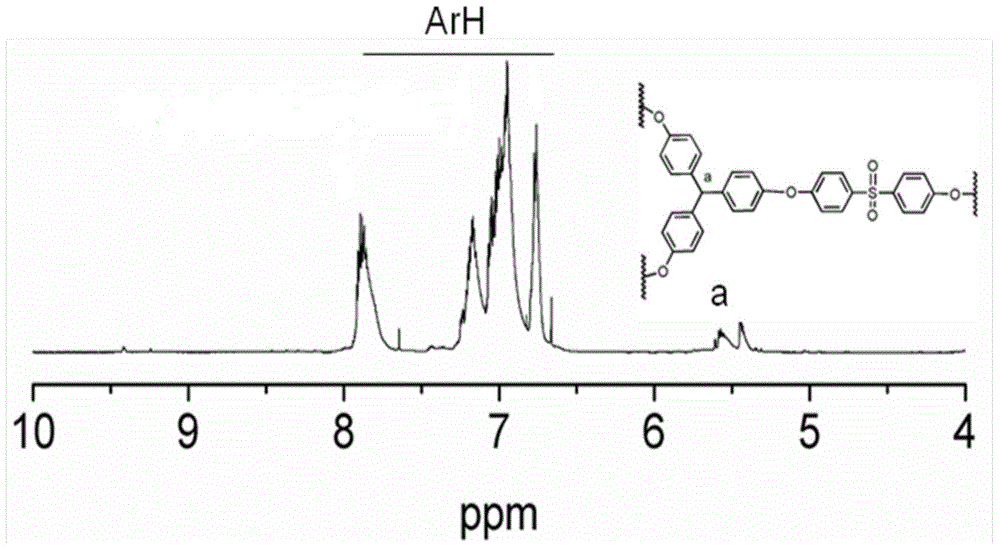

Preparation method of polyethersulfone type hyper branched epoxy resin and application in toughening of linear epoxy resin

The invention relates to a preparation method of polyethersulfone type hyper branched epoxy resin and application in toughening of linear epoxy resin. A polyethersulfone type hyper branched polymer is prepared by one-step method, the hyper branched polymer is prepared from disulfone, triol and trihydric phenol as raw materials by reaction between different end groups, and the polyethersulfone type hyper branched epoxy resin is prepared by end group epoxidation. A linear epoxy resin toughened modified material involved in the invention is prepared by using bisphenol A type linear epoxy resin as a base material, the polyethersulfone type hyper branched epoxy resin as a super toughening agent and adding a curing agent. The dosage of the polyethersulfone type hyper branched epoxy resin is 3%-30% of the epoxy resin weight. The impact strength of the epoxy modified material is increased by 89.9% compared with that of a pure bisphenol A type epoxy material, the elongation at break is increased by 73.9%, the tensile strength is increased by 19.6%, and the glass transition temperature is increased by 13.7%.

Owner:BEIJING UNIV OF CHEM TECH

Waterborne Anticorrosion Coating Composition and Process for Providing a Corrosion-Resistant Coating on a Metal Surface

InactiveUS20150267061A1Improve anti-corrosion performanceImprove the lubrication effectWashersSynthetic resin layered productsPolyamideCorrosion resistant

A waterborne coating composition, a process for providing a corrosion-resistant coating on a corrodible metal surface, an anticorrosion film formed by the composition, as well as an anticorrosive article, are disclosed. The coating composition comprises 10-35% by weight of one or more fluoropolymer; 30-65% by weight of one or more phenoxy resin; one or more crosslinking agent; a liquid carrier medium; and 0-40% by weight of an auxiliary binder consisting of one or more of polyethersulfone, polyphenylene sulfide, polyamide, polyimide, polyamideimide, polyether ether ketone, polyetherimide, polyurethane, alkyd resin, polyester, or acrylic polymers.

Owner:THE CHEMOURS CO FC LLC

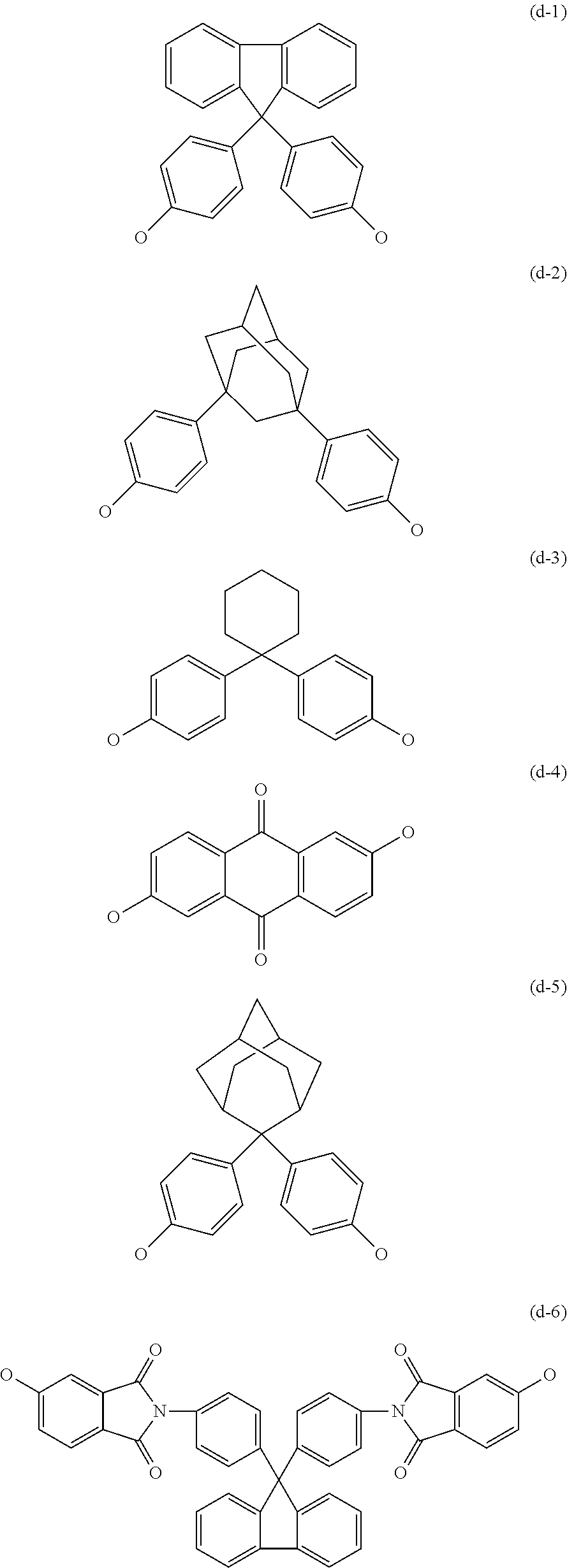

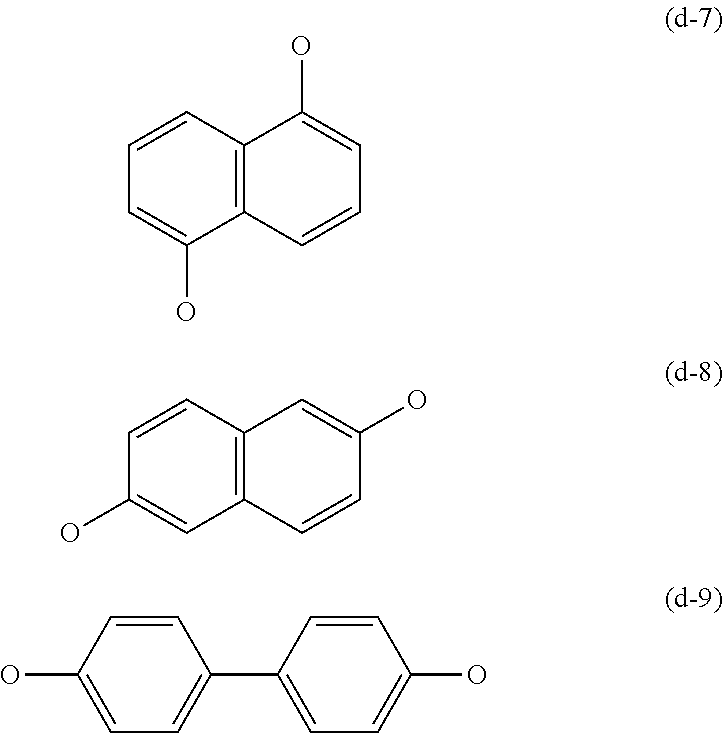

Transparent Polyarylene Ether Polymer With High Heat Resistance And Method For Preparing The Same

InactiveUS20120130041A1High glass transition temperatureGood film formingPolymer scienceHeat resistance

The present disclosure relates to a transparent polyarylene ether polymer with high heat resistance and a method for preparing the same. More particularly, the present disclosure relates to a polyarylene ether polymer and a method for preparing the same, wherein the polyarylene ether polymer has a repeating structure in which cardo-type aromatic diols having a large molecular volume, polyether sulfones which are amorphous polymers having a high glass transition temperature and superior film formability, and polyether ketones which are crystalline polymers having superior heat resistance and mechanical properties are sequentially arranged. The polyarylene ether polymer is both transparent and heat resistant and, thus, can be used, for example, for a flexible plastic substrate.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com