Patents

Literature

99 results about "Polyphenylsulfone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

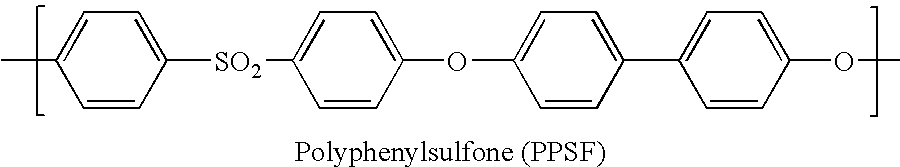

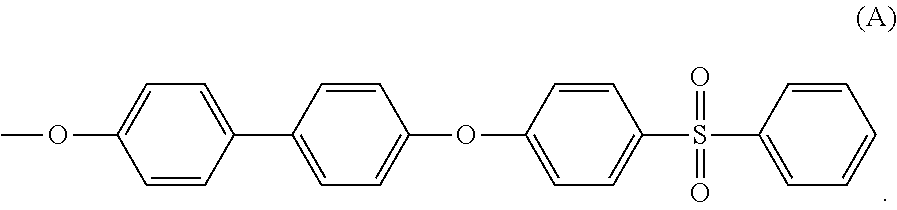

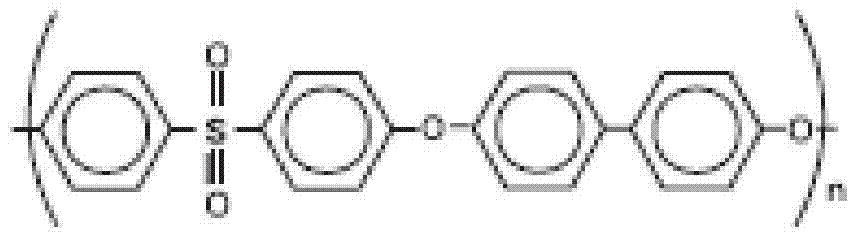

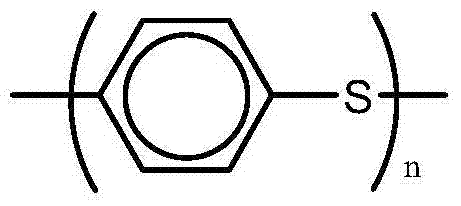

Polyphenylsulfone (PPSF or PPSU) is a type of high performance polymer usually consisting of aromatic rings linked by sulfone (SO2) groups.

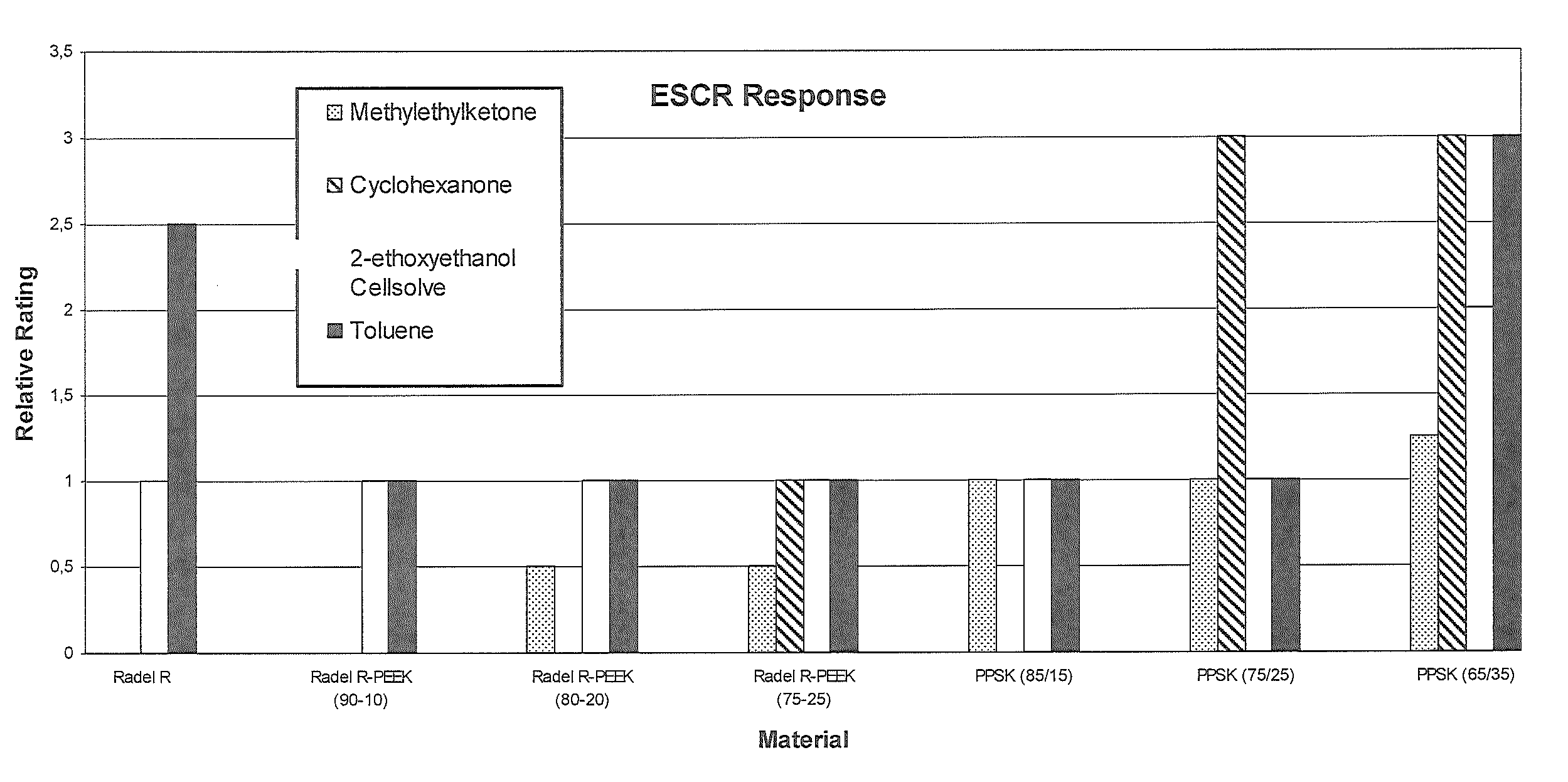

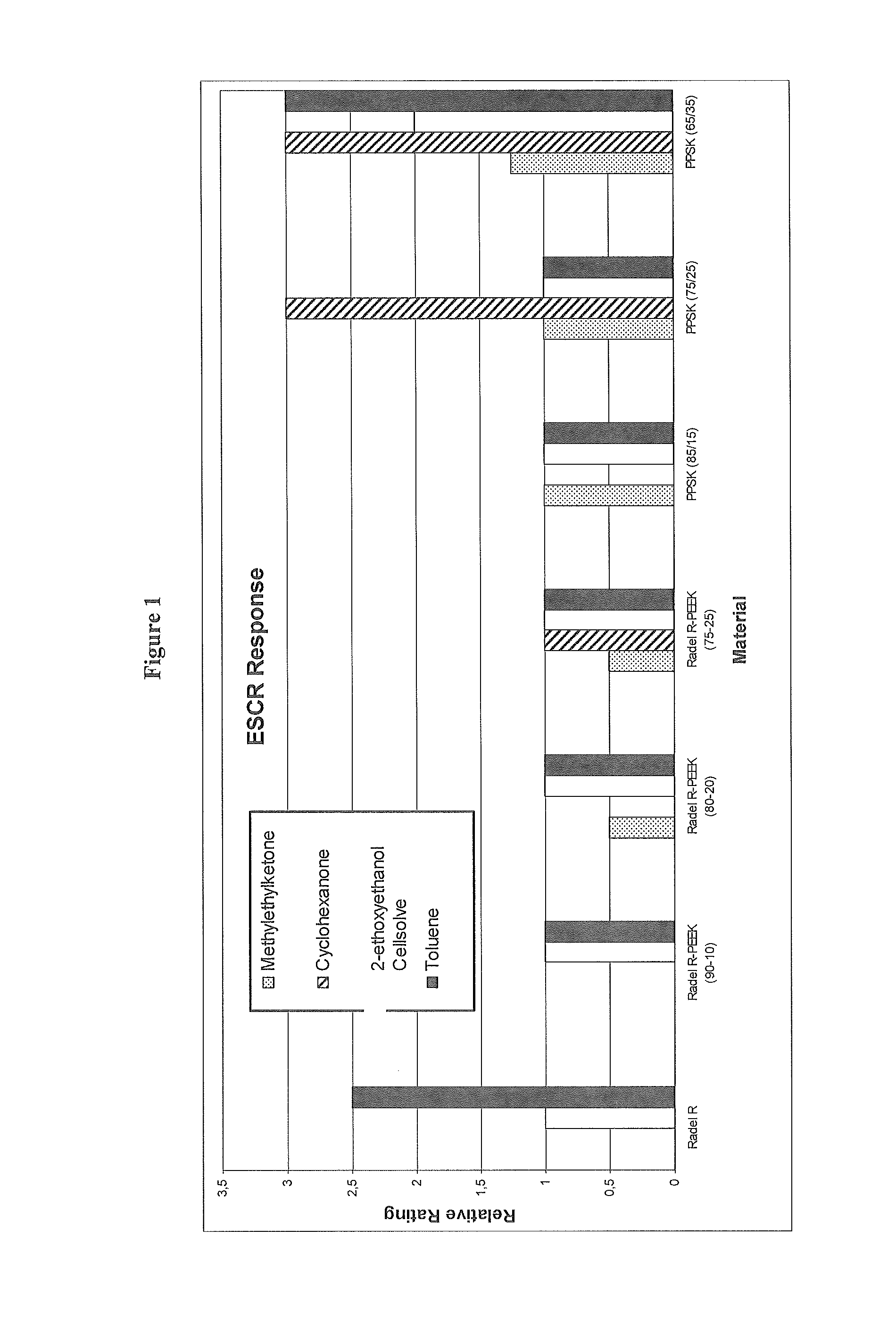

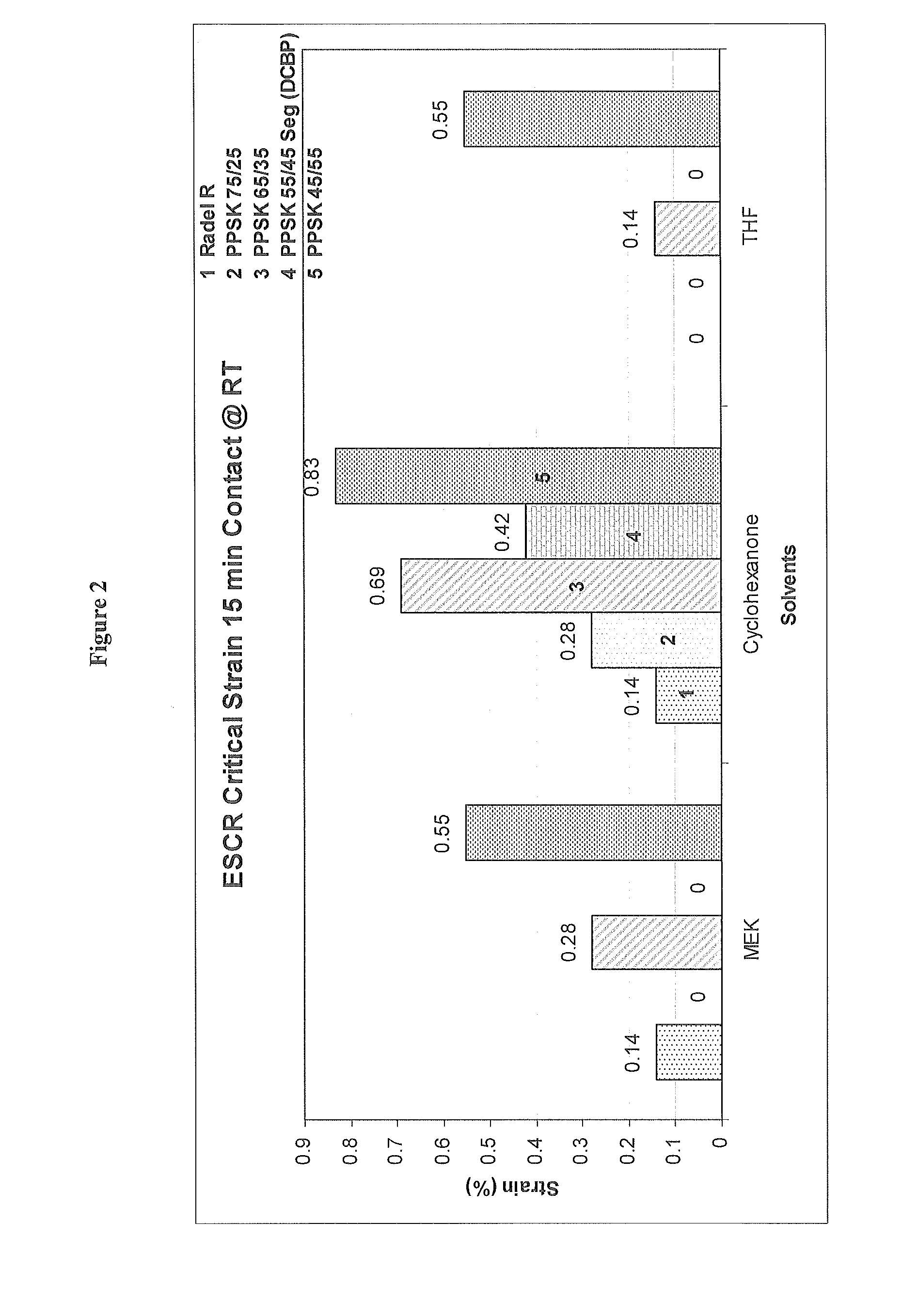

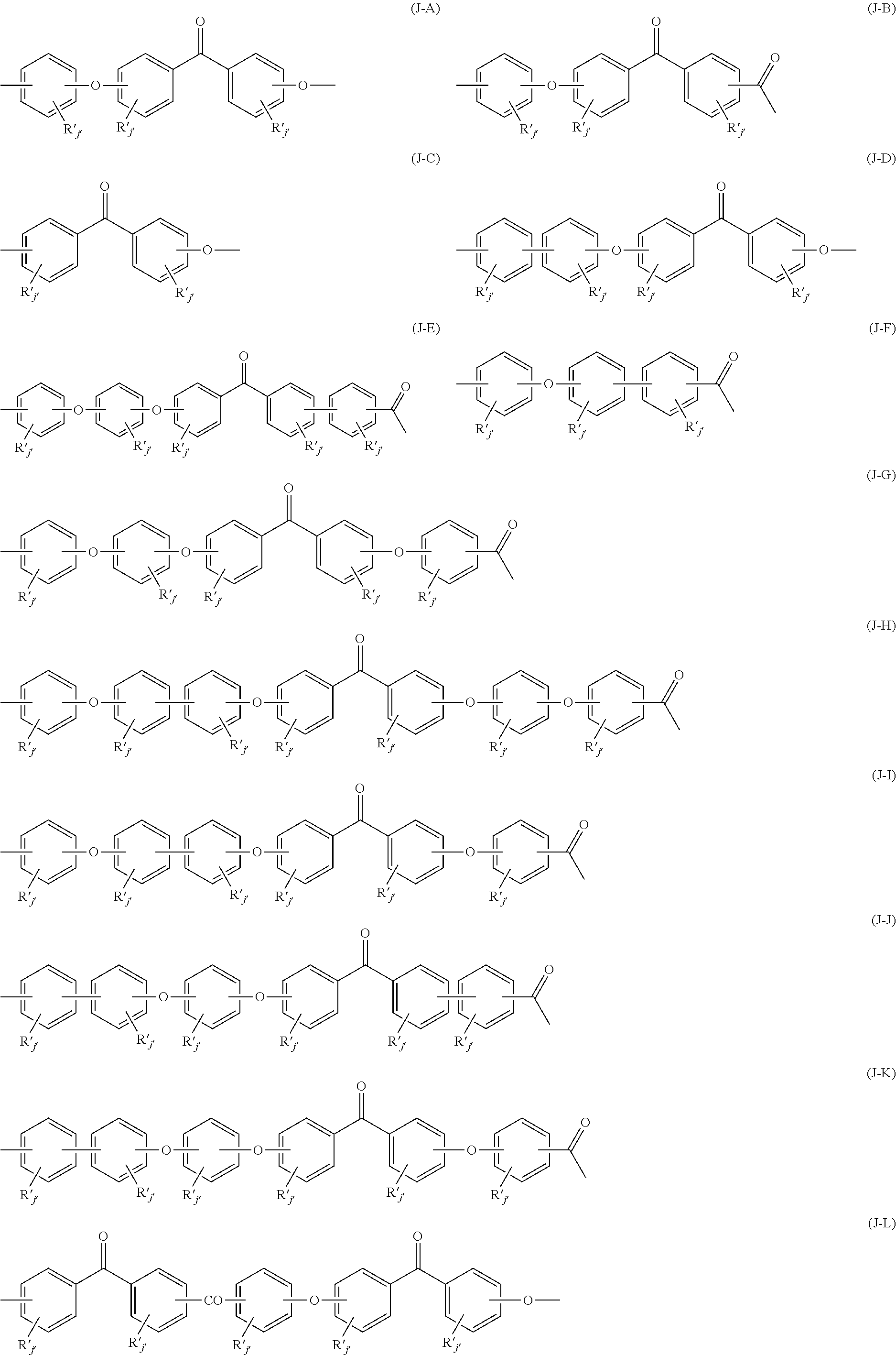

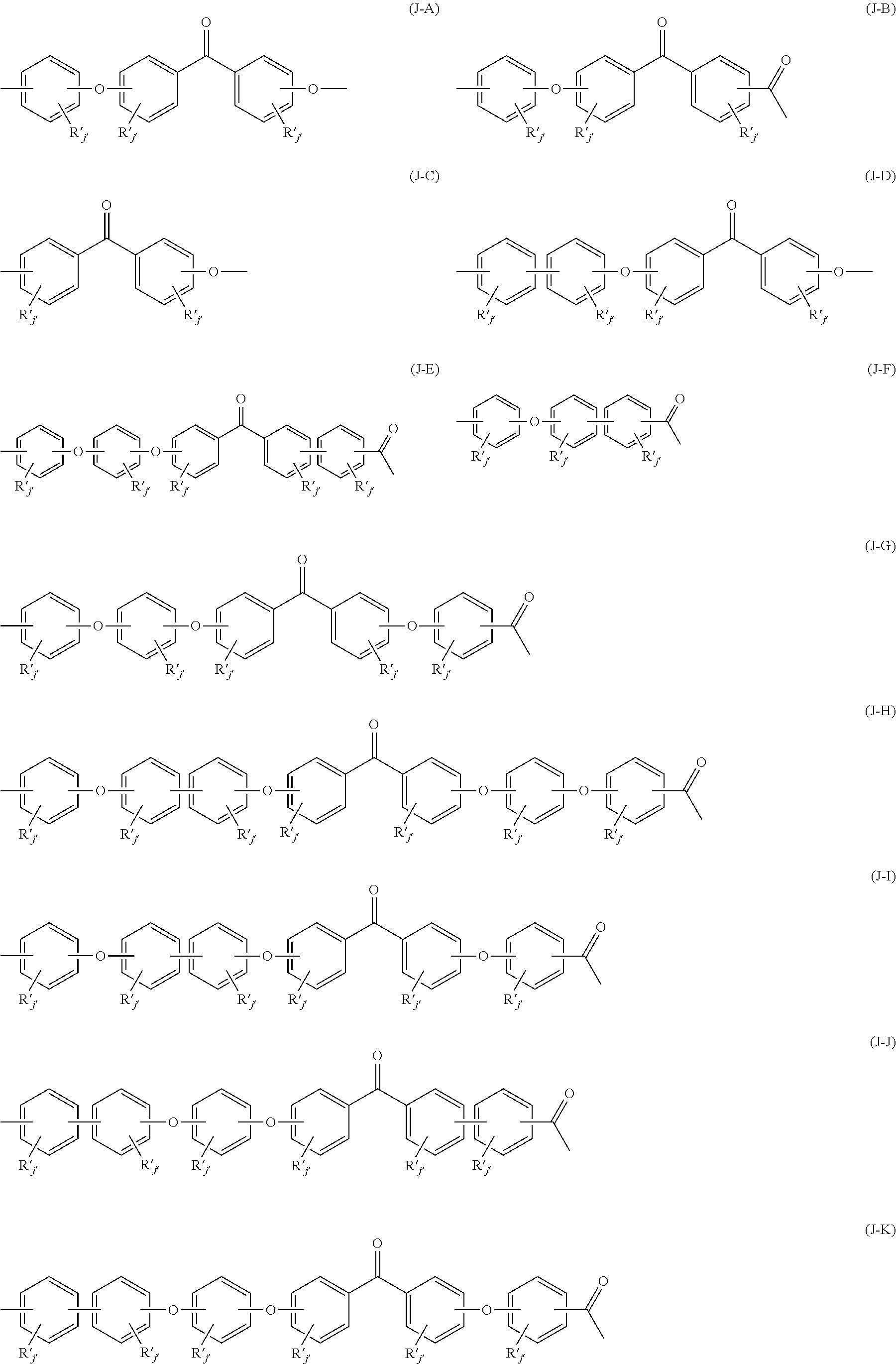

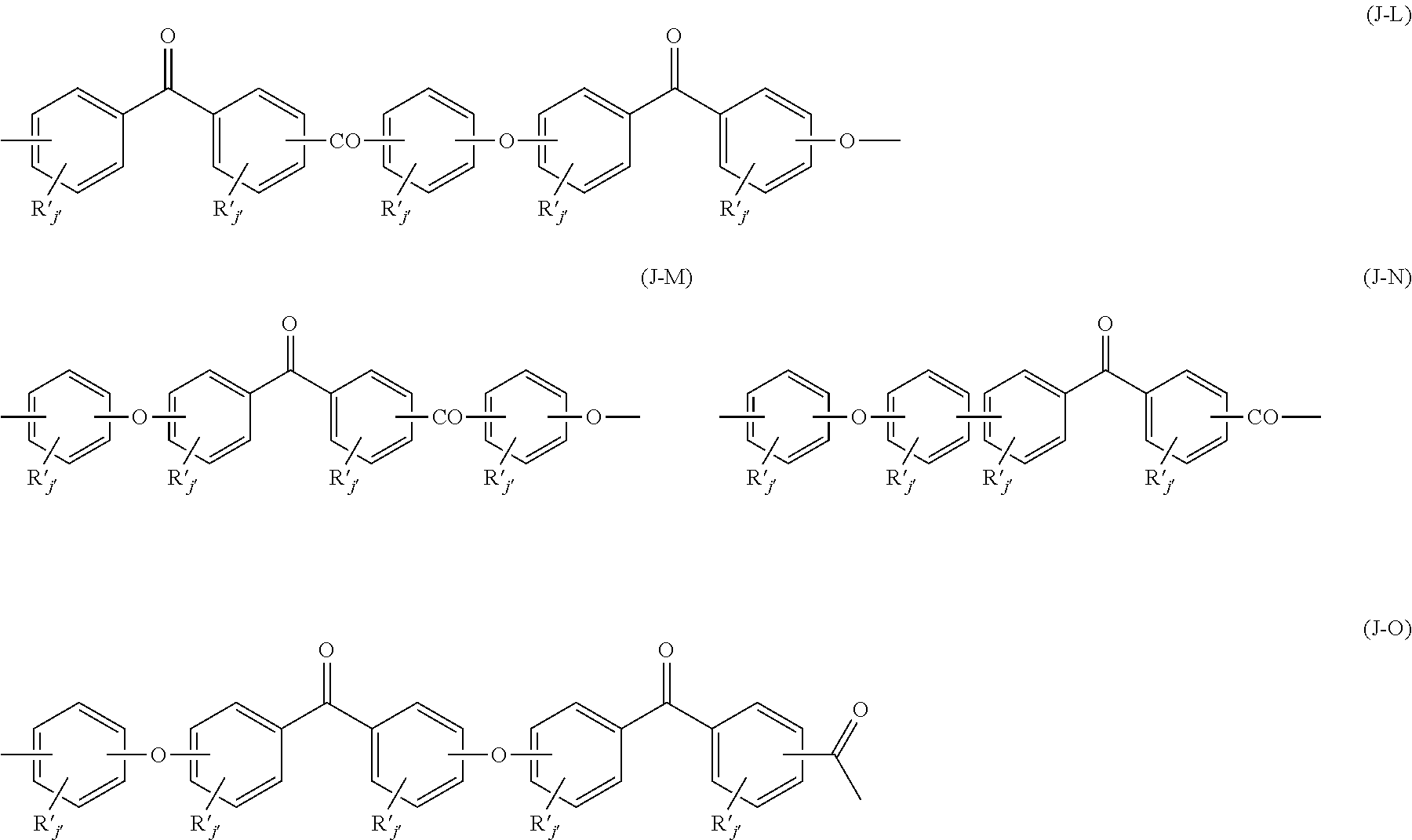

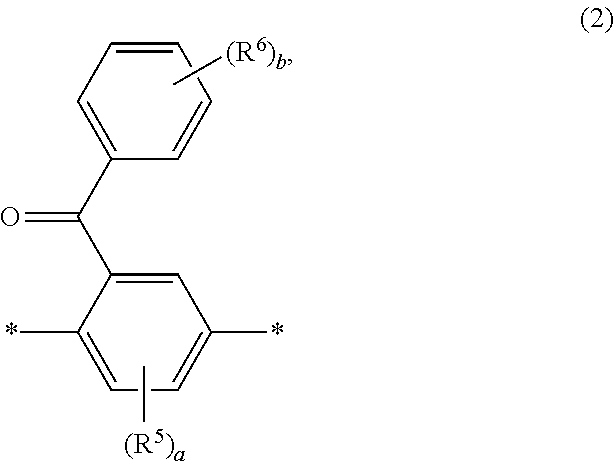

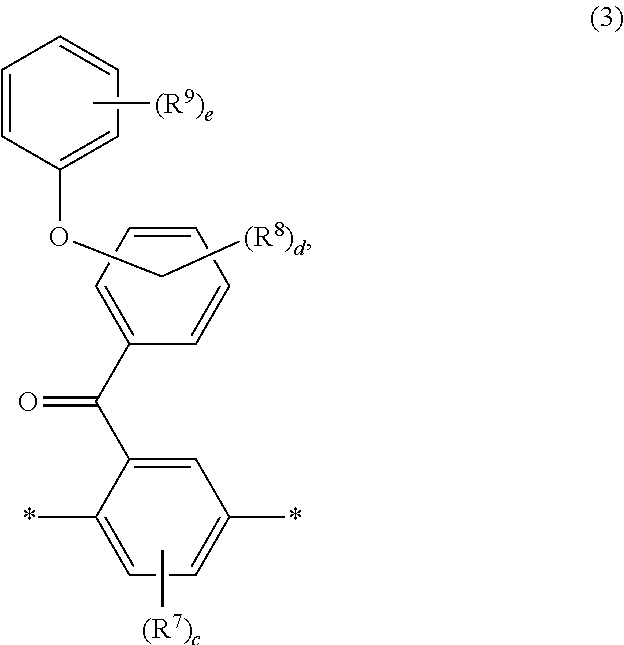

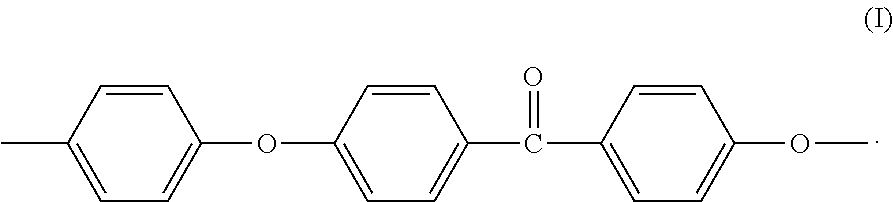

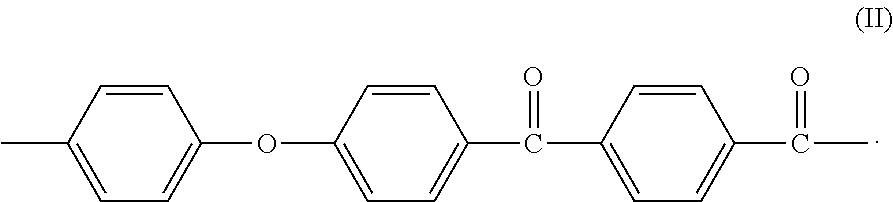

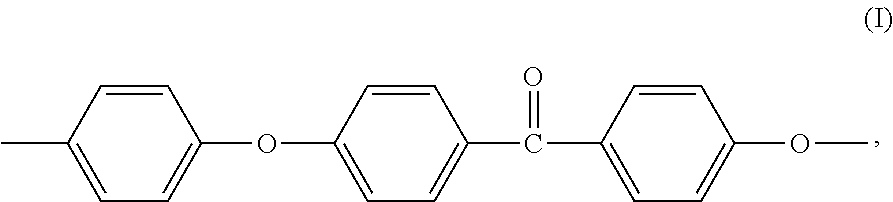

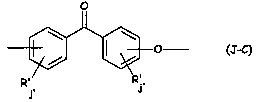

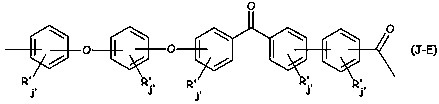

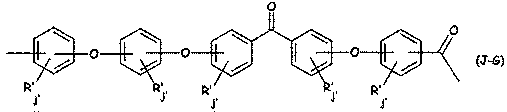

Polyphenyl sulfone ketone copolymers

InactiveUS20100310804A1Improve the immunityLow creepLayered productsThin material handlingPolymer scienceKetone

A polymer comprising sulfone groups, ketone groups and optionally substituted polyarylene groups, wherein the number of moles of sulfone groups over the number of moles of ketone groups ratio is greater than 1. A process for making such polymer, a composition comprising such polymer, and articles made therefrom.

Owner:SOLVAY ADVANCED POLYMERS LLC

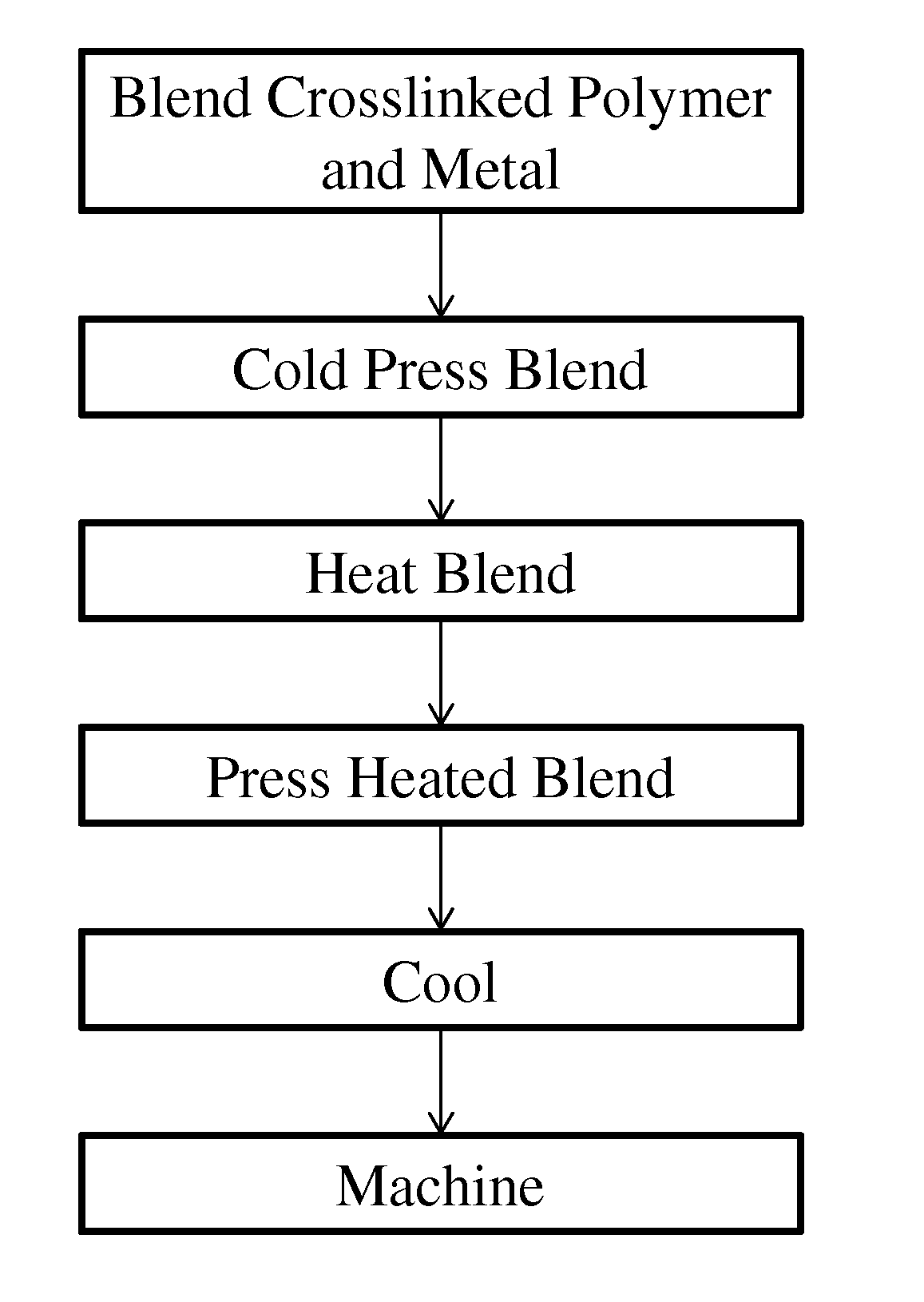

Mixed metal polymer composite

InactiveUS20140018489A1Conductive materialNon-conductive material with dispersed conductive materialPolymer scienceSelf reinforced

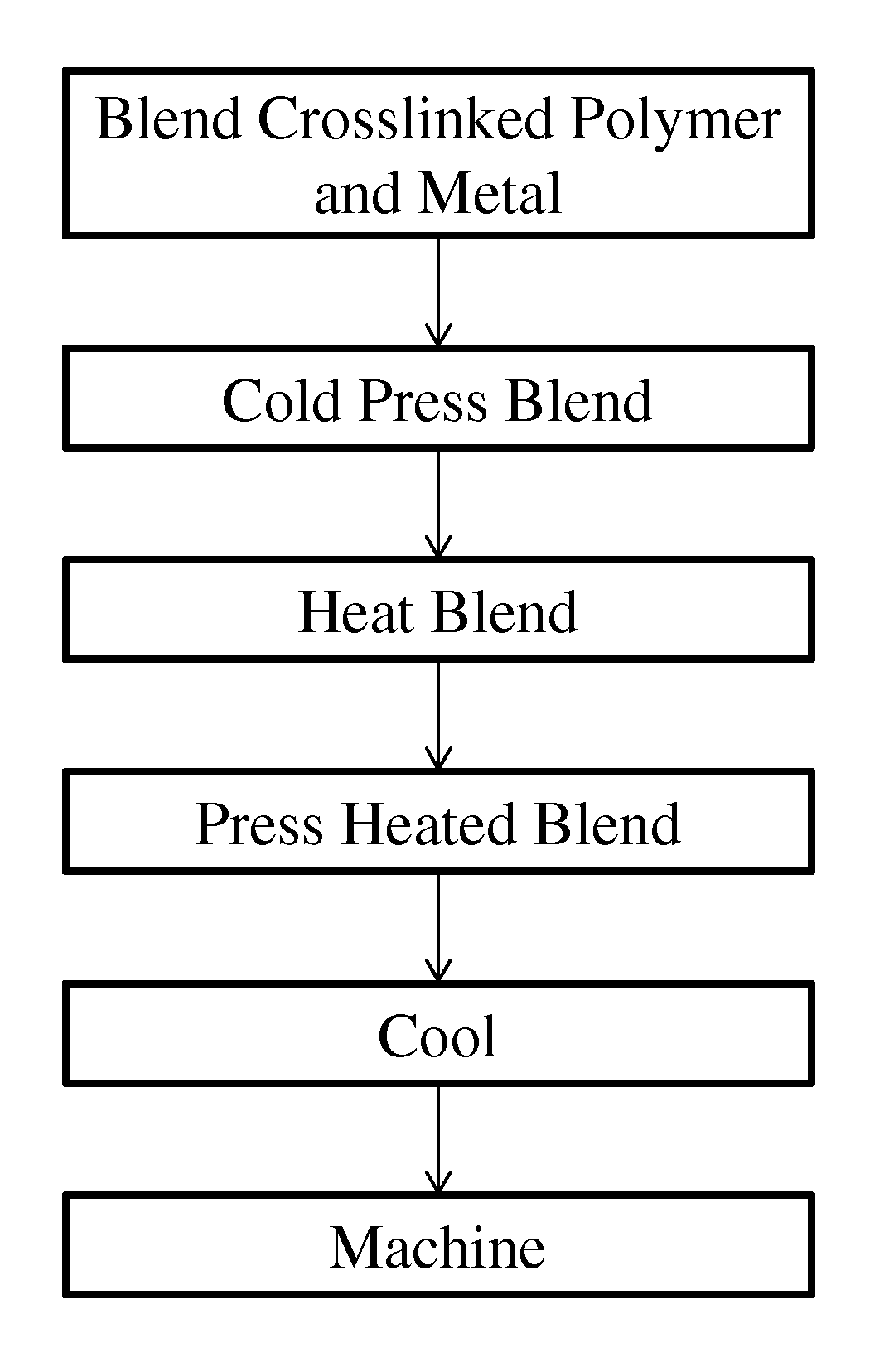

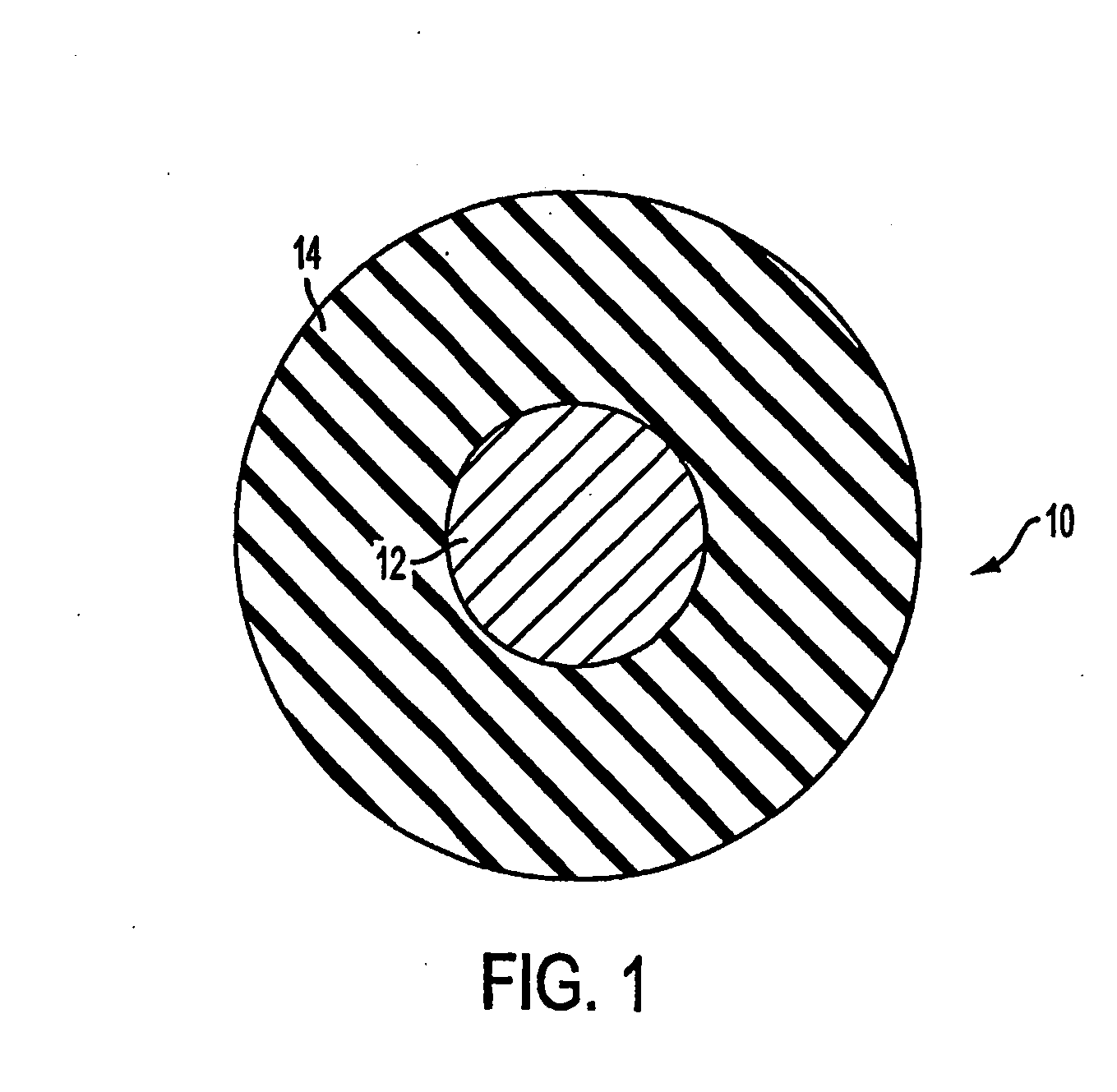

A metal-polymer composite includes a crosslinked polymer; and a metal which is removably disposed among the crosslinked polymer. A method of making the metal-polymer composite includes combining a crosslinked polymer and a metal; blending the crosslinked polymer and the metal to form a blend; cold pressing the blend; heating the blend to a forging temperature; and applying pressure to the blend at the forging temperature to form the metal-polymer composite. A downhole article includes a crosslinked polymer including a crosslinked product of a polymer including polyphenylene sulfide, polyphenylsulfone, self-reinforced polyphenylene, polysulfone, polyethersulfone, polyarylsulfone, derivatives thereof, or a combination comprising at least one of the foregoing; and a metal disposed among the crosslinked polymer and removable by contact with a downhole fluid.

Owner:BAKER HUGHES INC

High temperature resistant polysulfone insulation for pipe

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of about 200° C. or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant polysulfone having sulfone, ether and isopropylidene bridging groups, and / or a polyphenylsulfone or a polyethersulfone.

Owner:SHAWCOR LTD

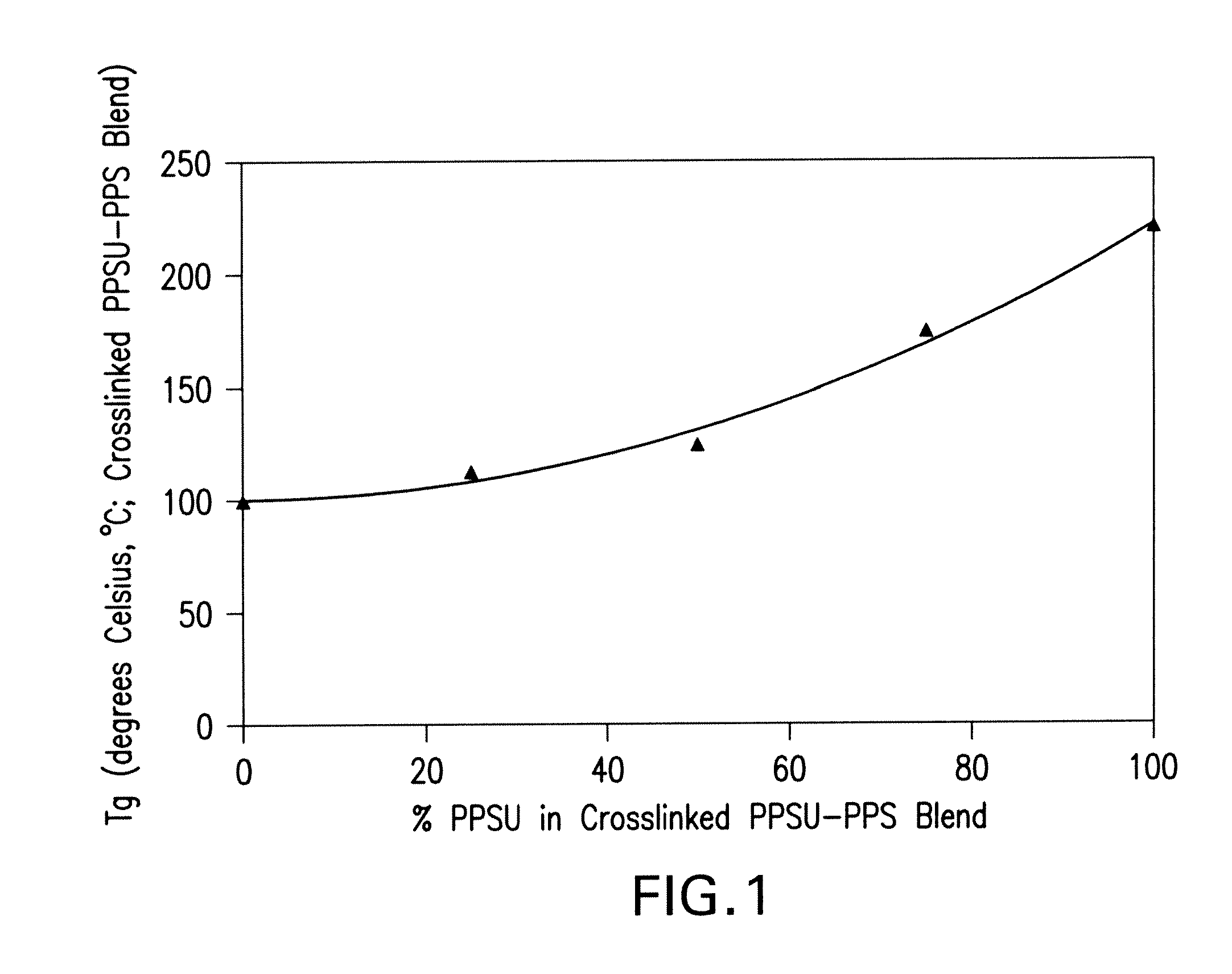

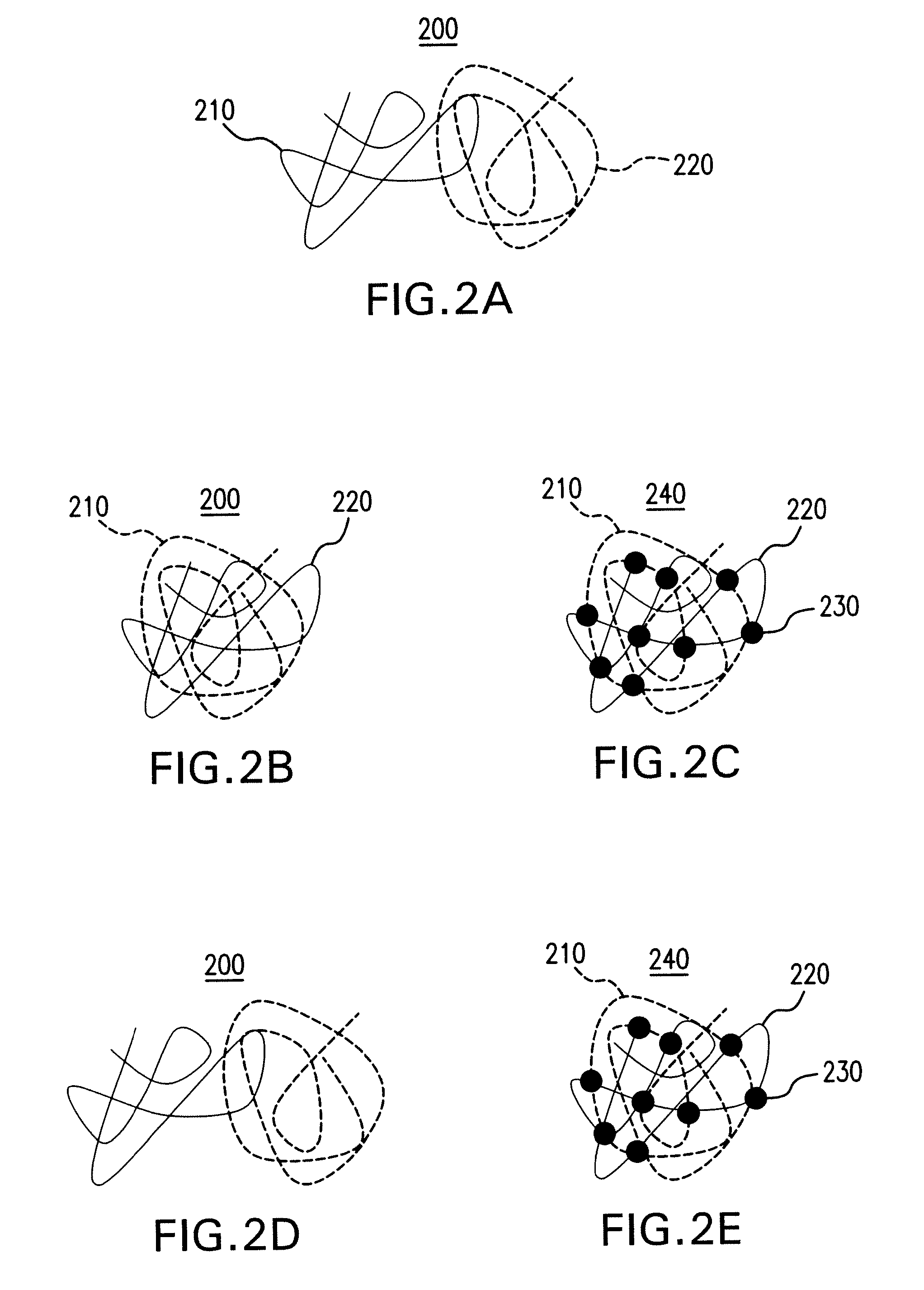

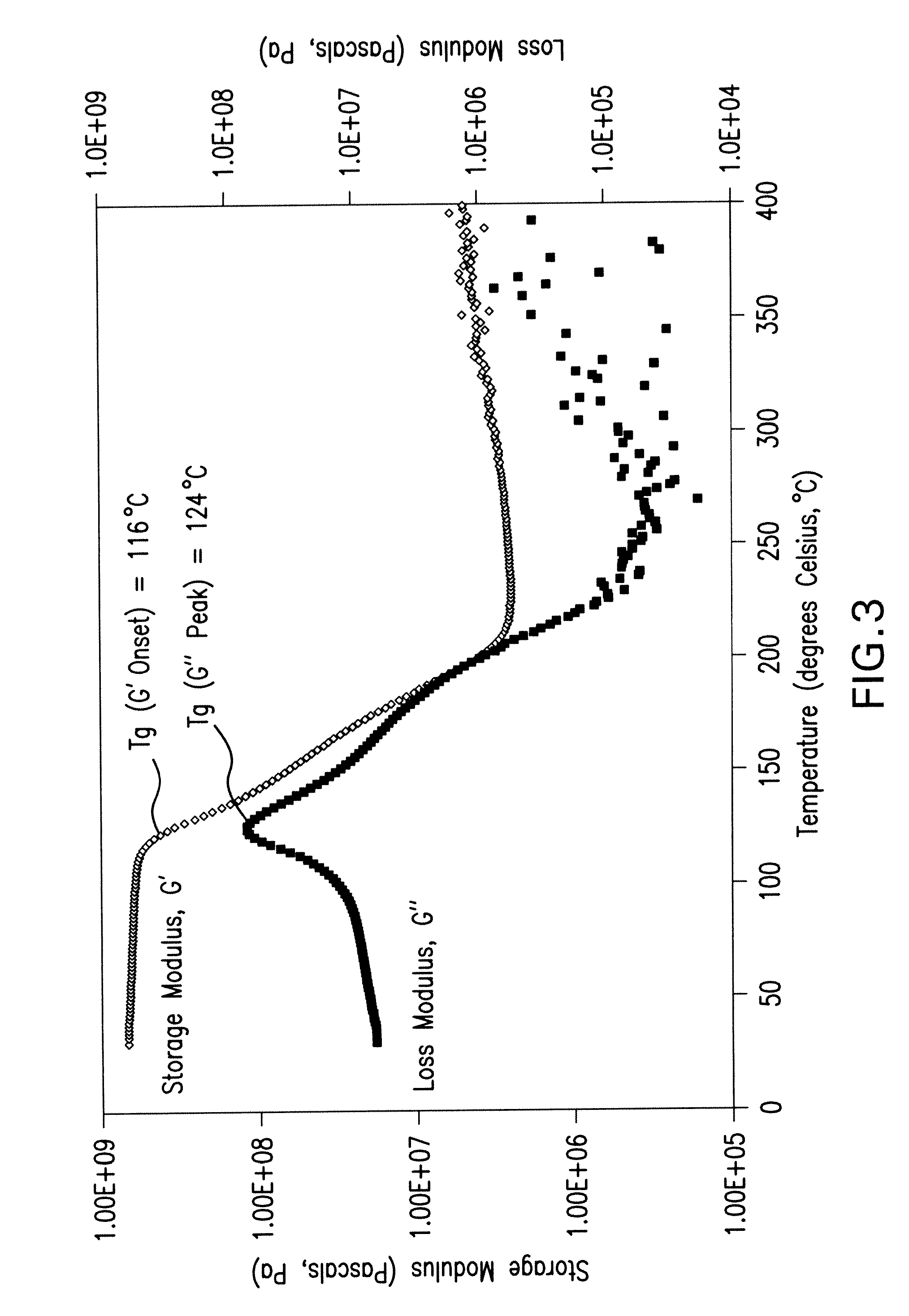

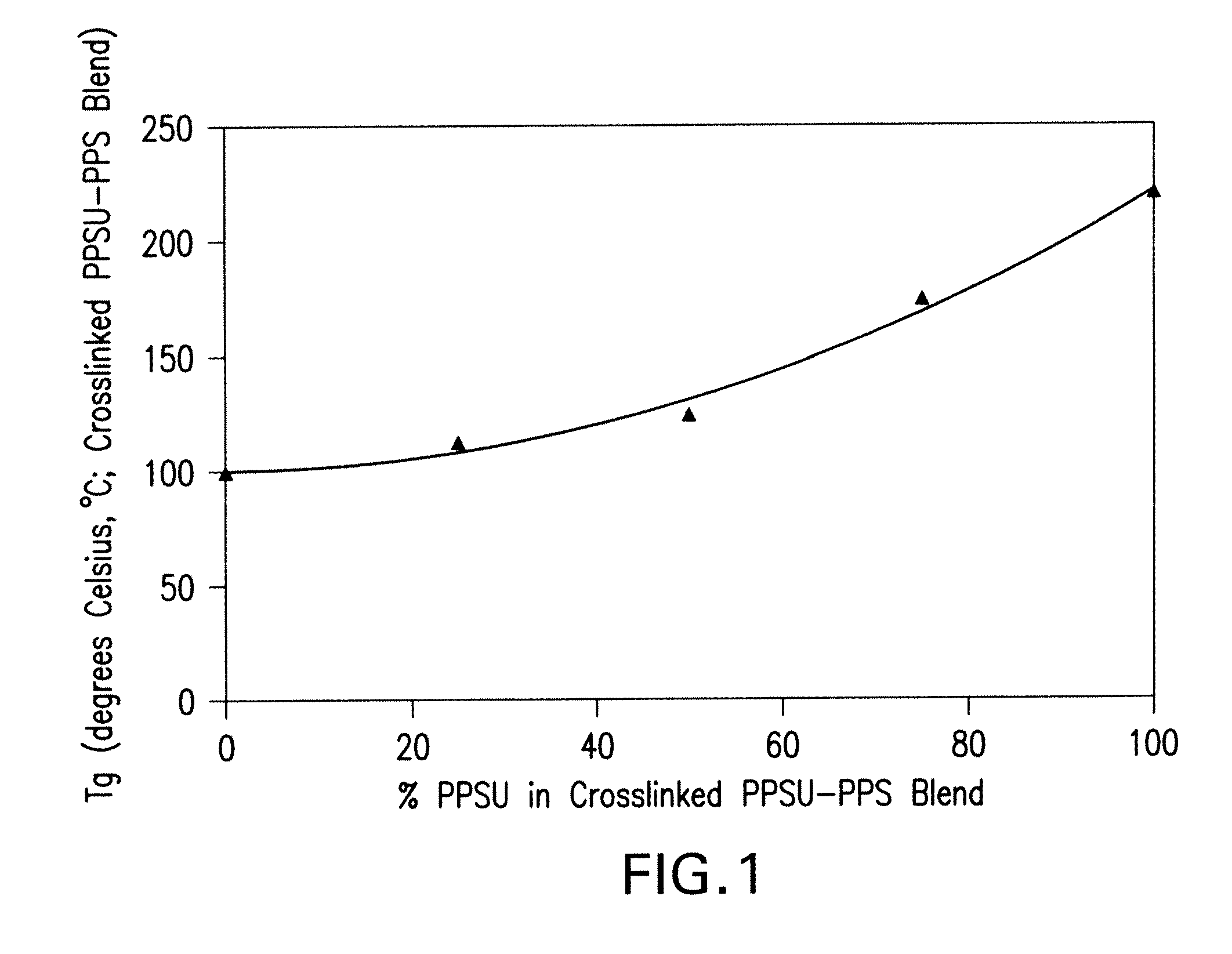

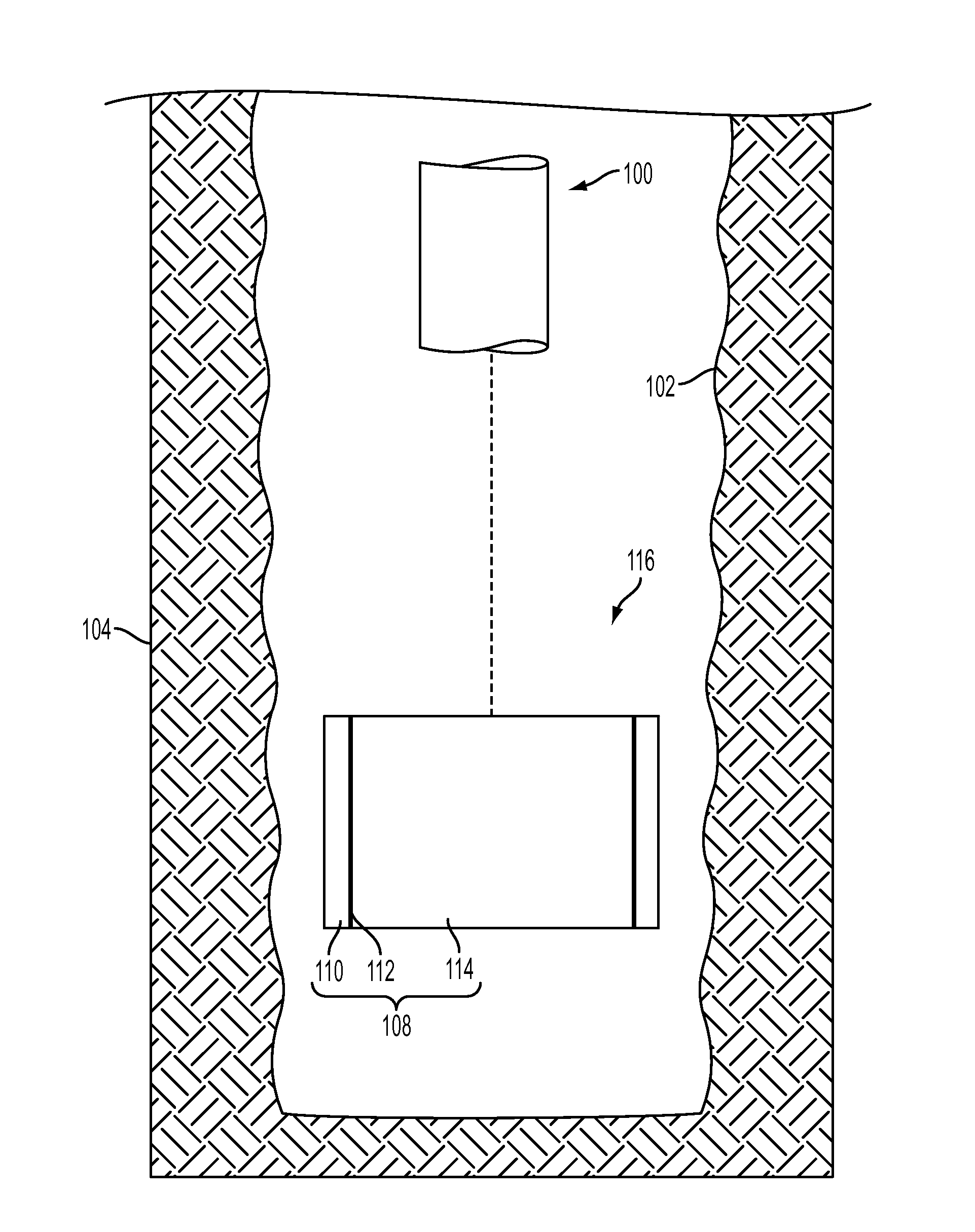

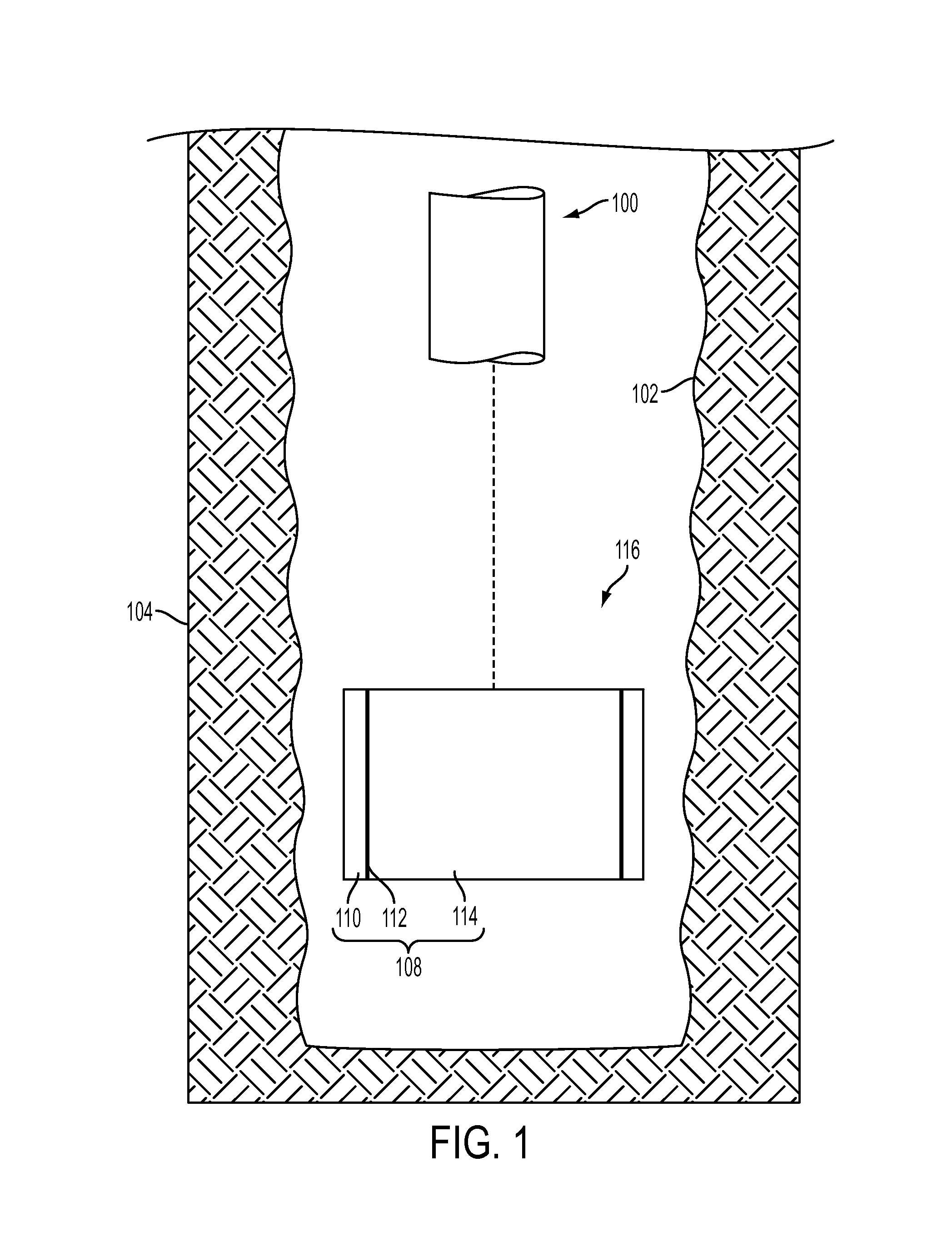

Crosslinked blends of polyphenylene sulfide and polyphenylsulfone for downhole applications, methods of manufacture, and uses thereof

A composition includes a crosslinked product of a polyphenylene sulfide and a polyphenylsulfone. A method for the manufacture of the crosslinked product of a polyphenylene sulfide and a polyphenylsulfone includes heating the polyphenylene sulfide and the polyphenylsulfone in presence of a crosslinking agent at a temperature and for a time effective to form the crosslinked product of polyphenylene sulfide and polyphenylsulfone.

Owner:BAKER HUGHES INC

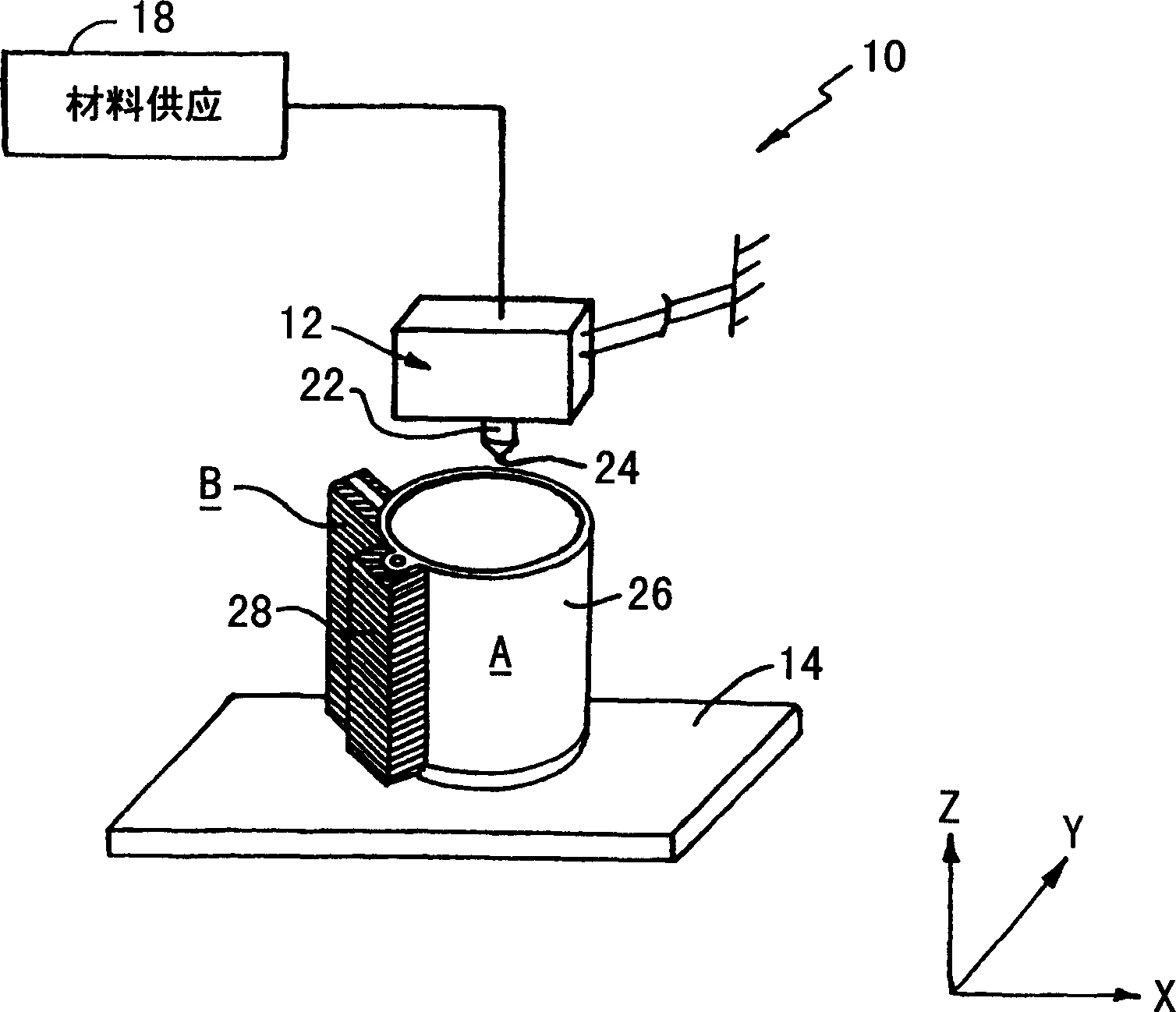

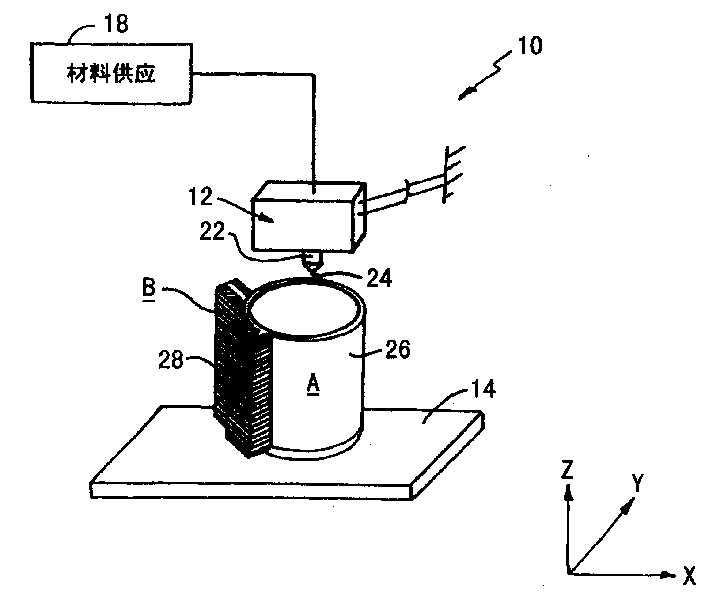

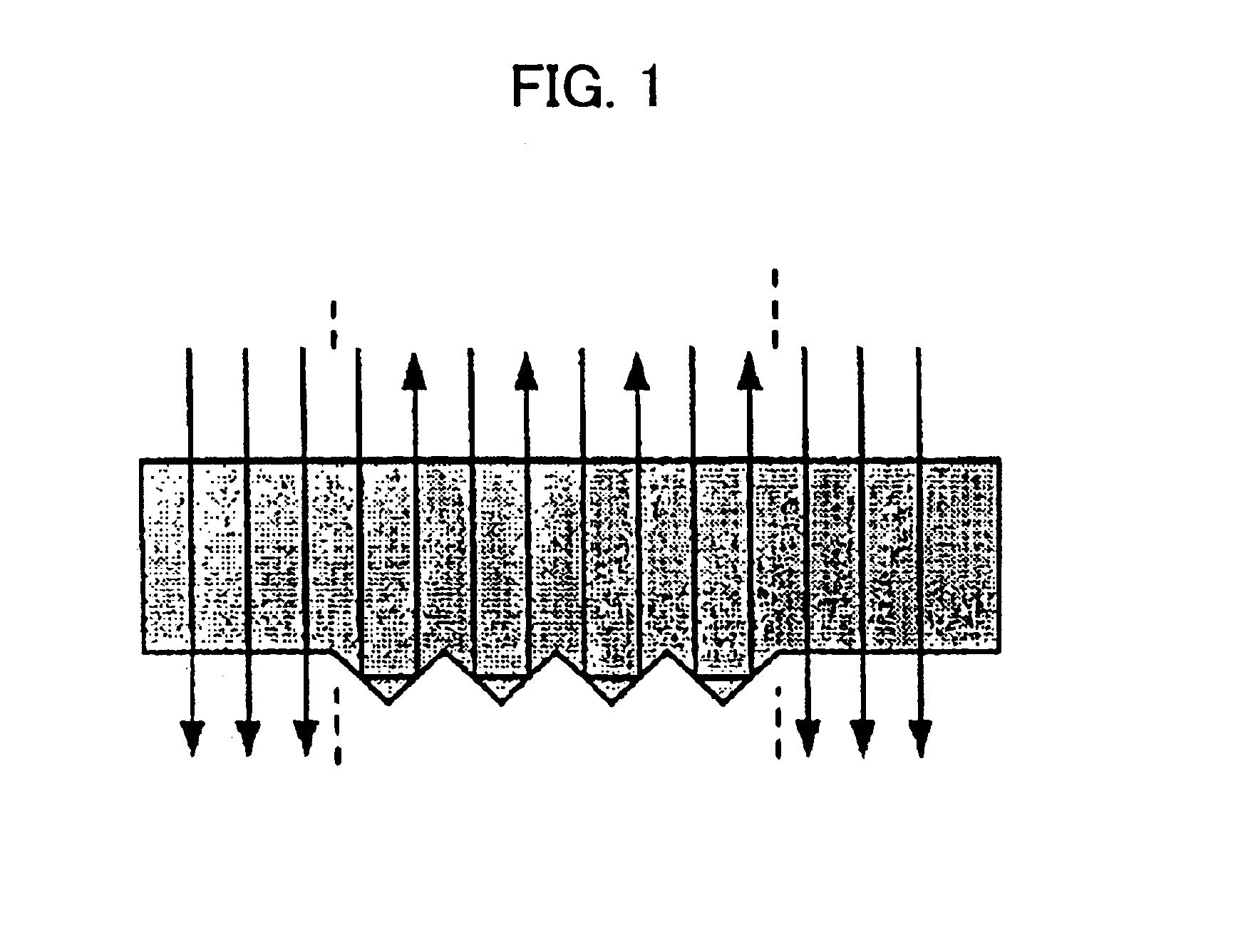

Material and method for three-dimensional modeling

Disclosed is a high-performance thermoplastic material used to build a three-dimensional model and its support by using fusion deposition modeling technology. The molding material used to build the model (26) consists of a thermoplastic resin with a heat deflection temperature higher than 120°C. Amorphous thermoplastic resins that can be self-laminated and weakly bonded to modeling materials have a heat deflection temperature similar to that of modeling materials, and a tensile strength between 34-83MPa (5000psi-12000psi), which is used to build support structures ( 28) Support material. In a preferred embodiment, the thermoplastic resin constituting the support material is selected from a mixture of polyphenylene ether and polyolefin, a mixture of polyphenylsulfone and amorphous polyamide, a mixture of polyphenylsulfone and polysulfone, and amorphous polyamide. group.

Owner:STRATASYS LTD

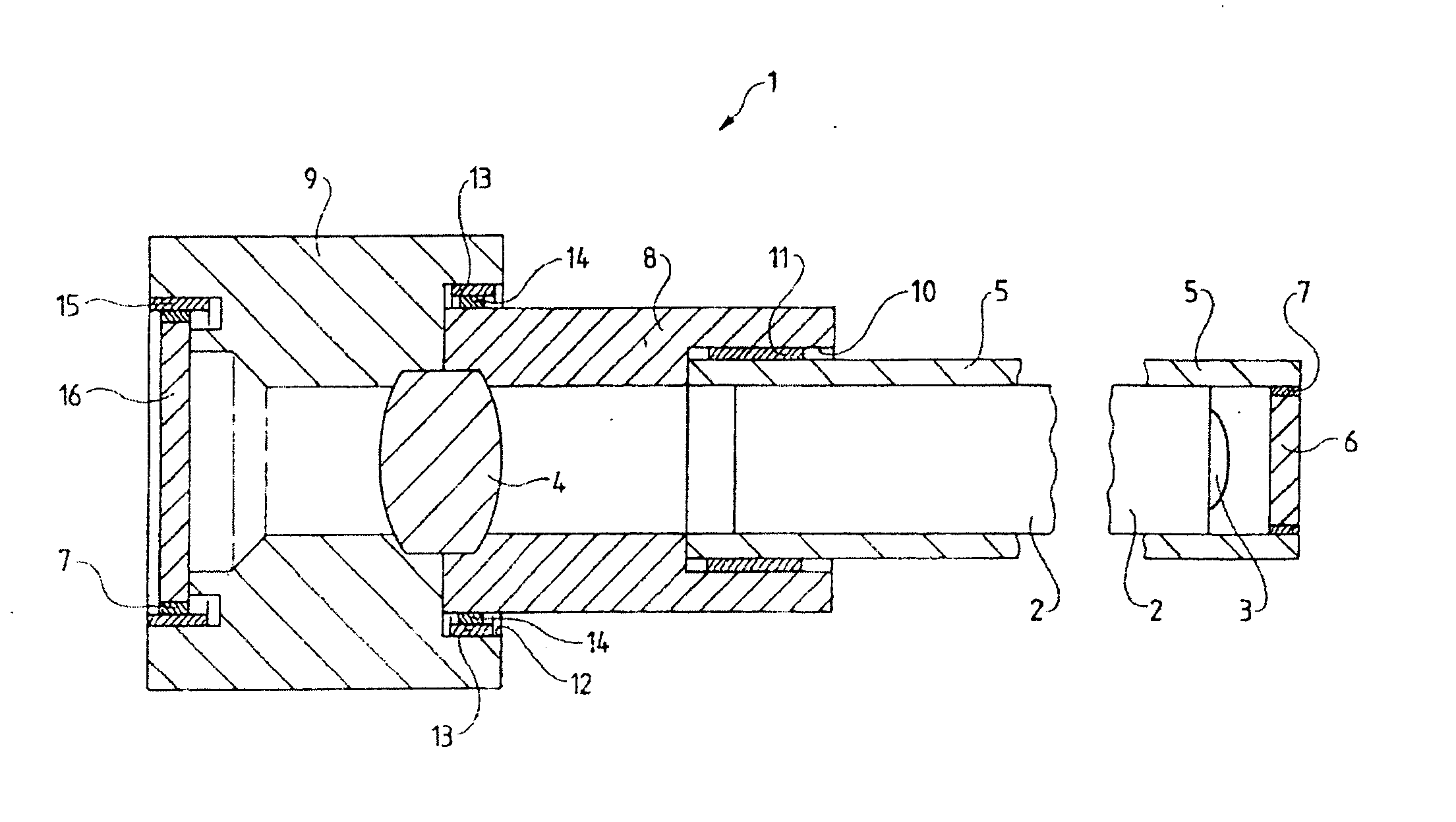

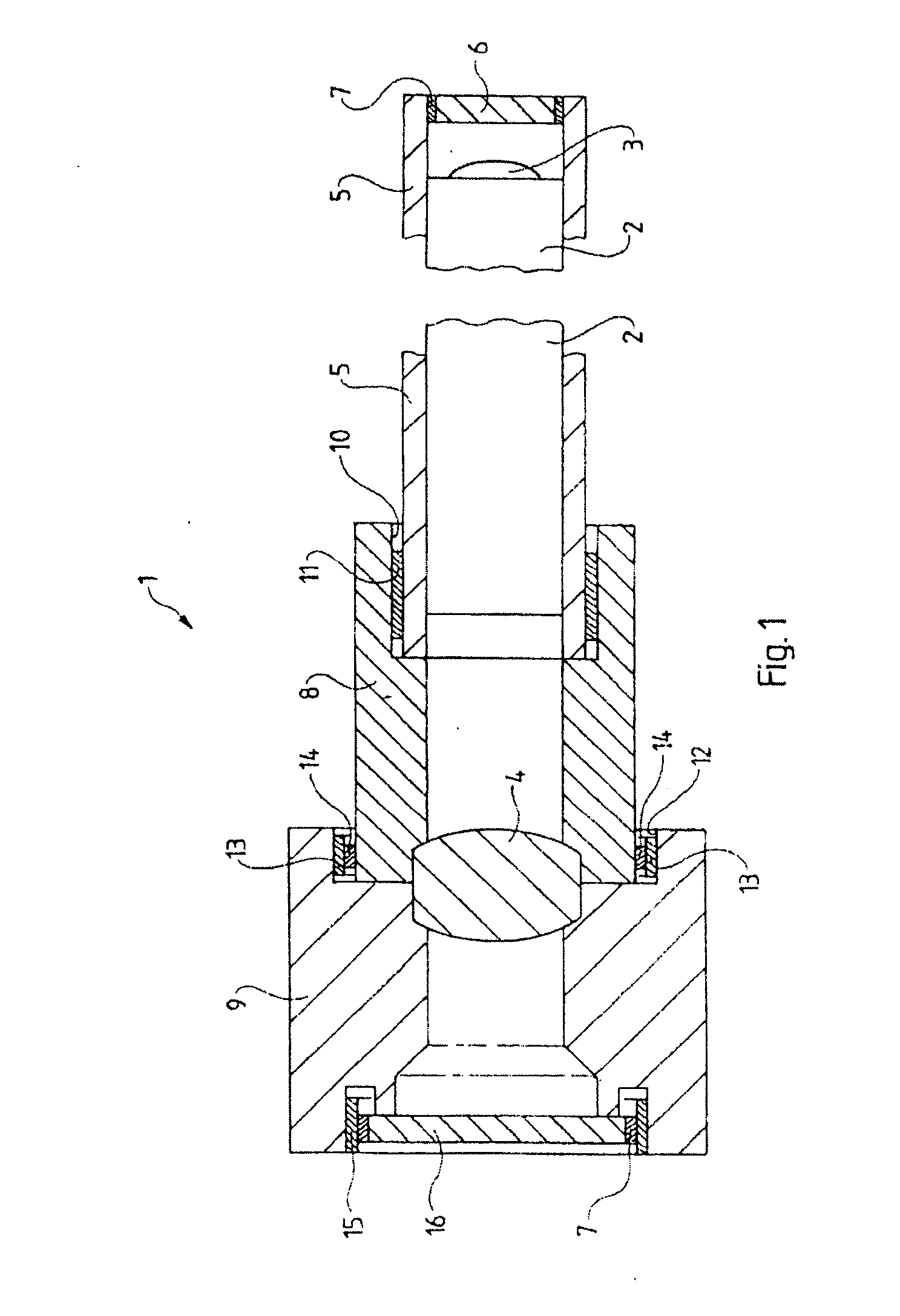

Rigid endoscope optics with a compound housing

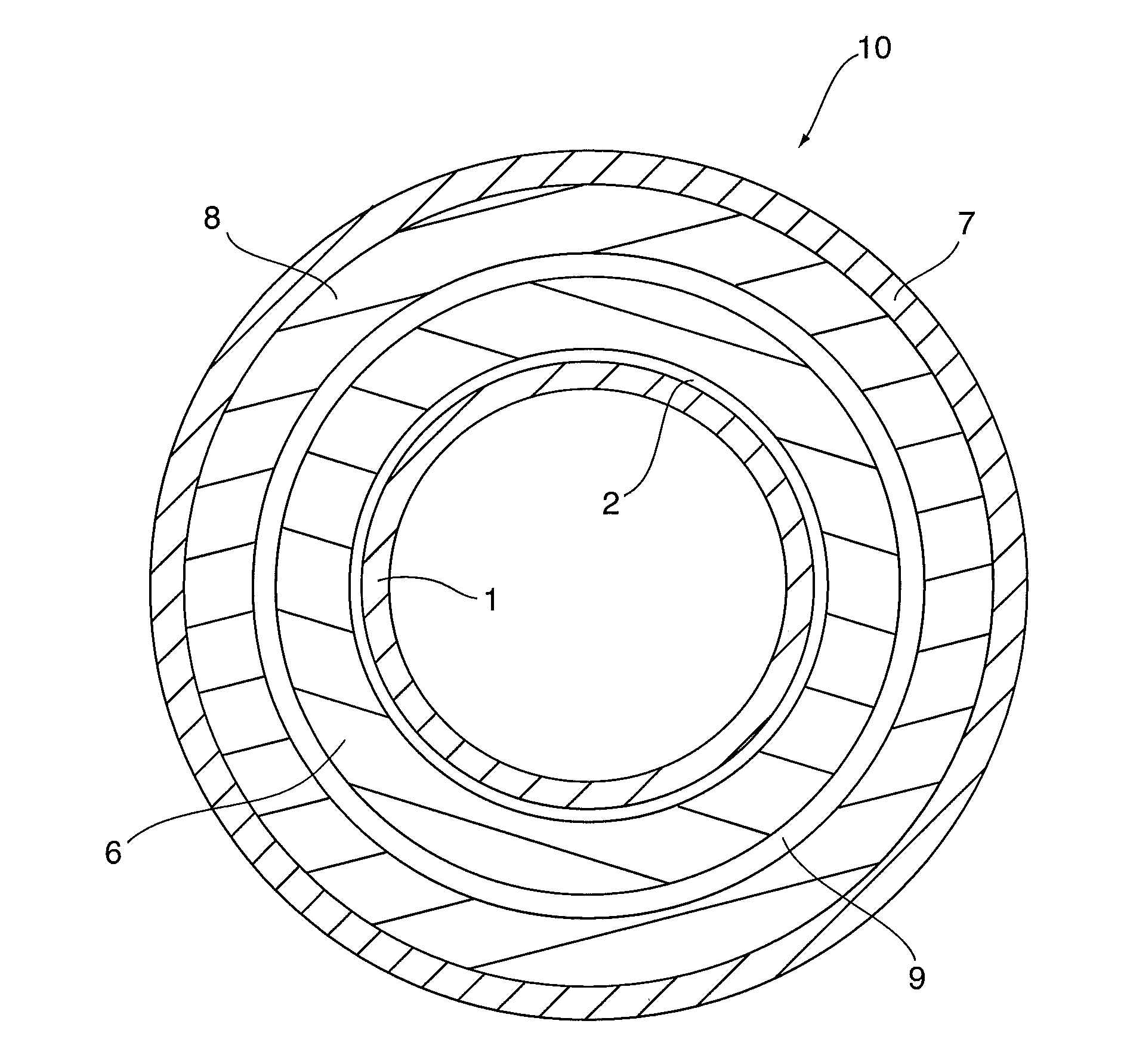

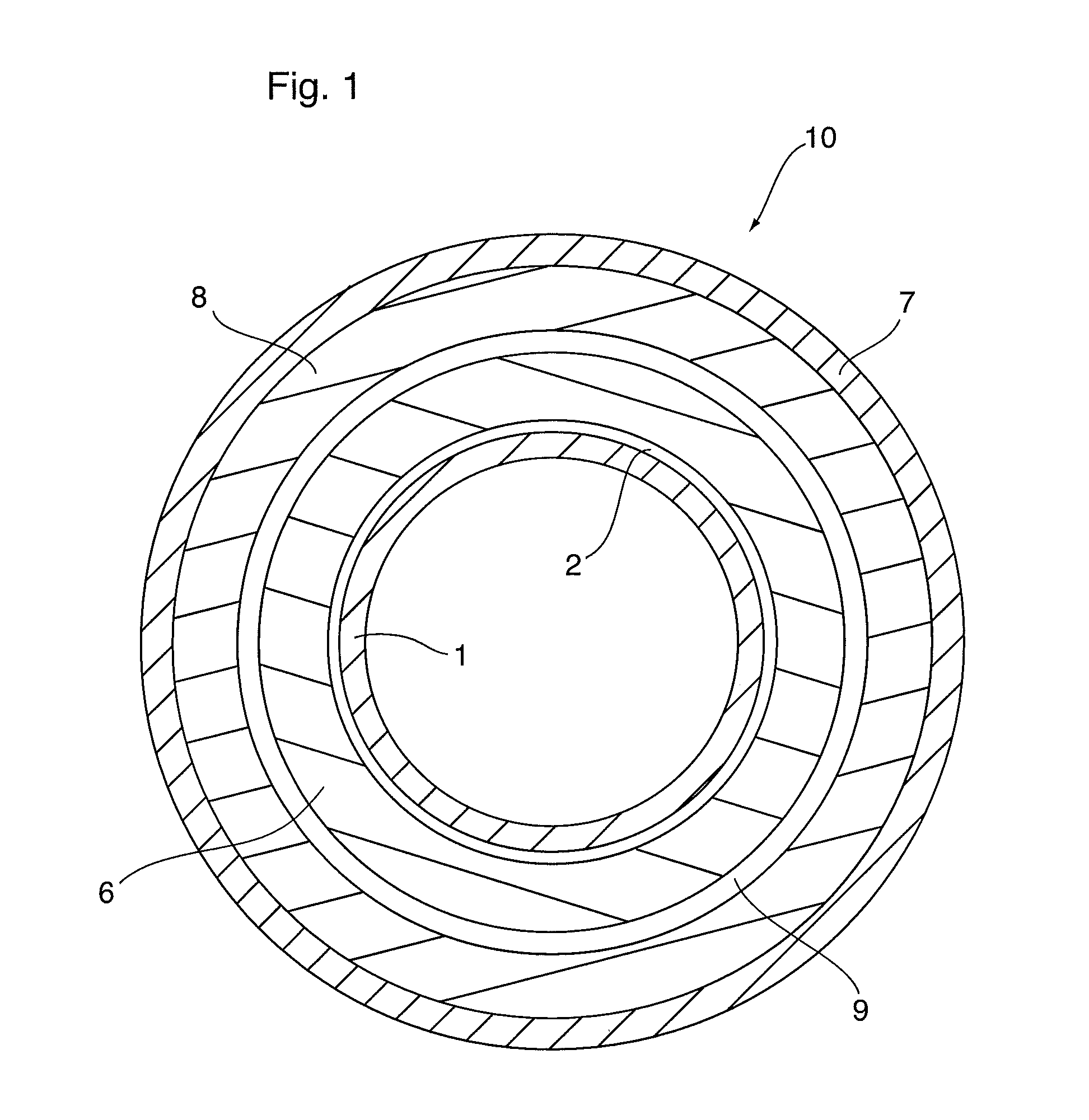

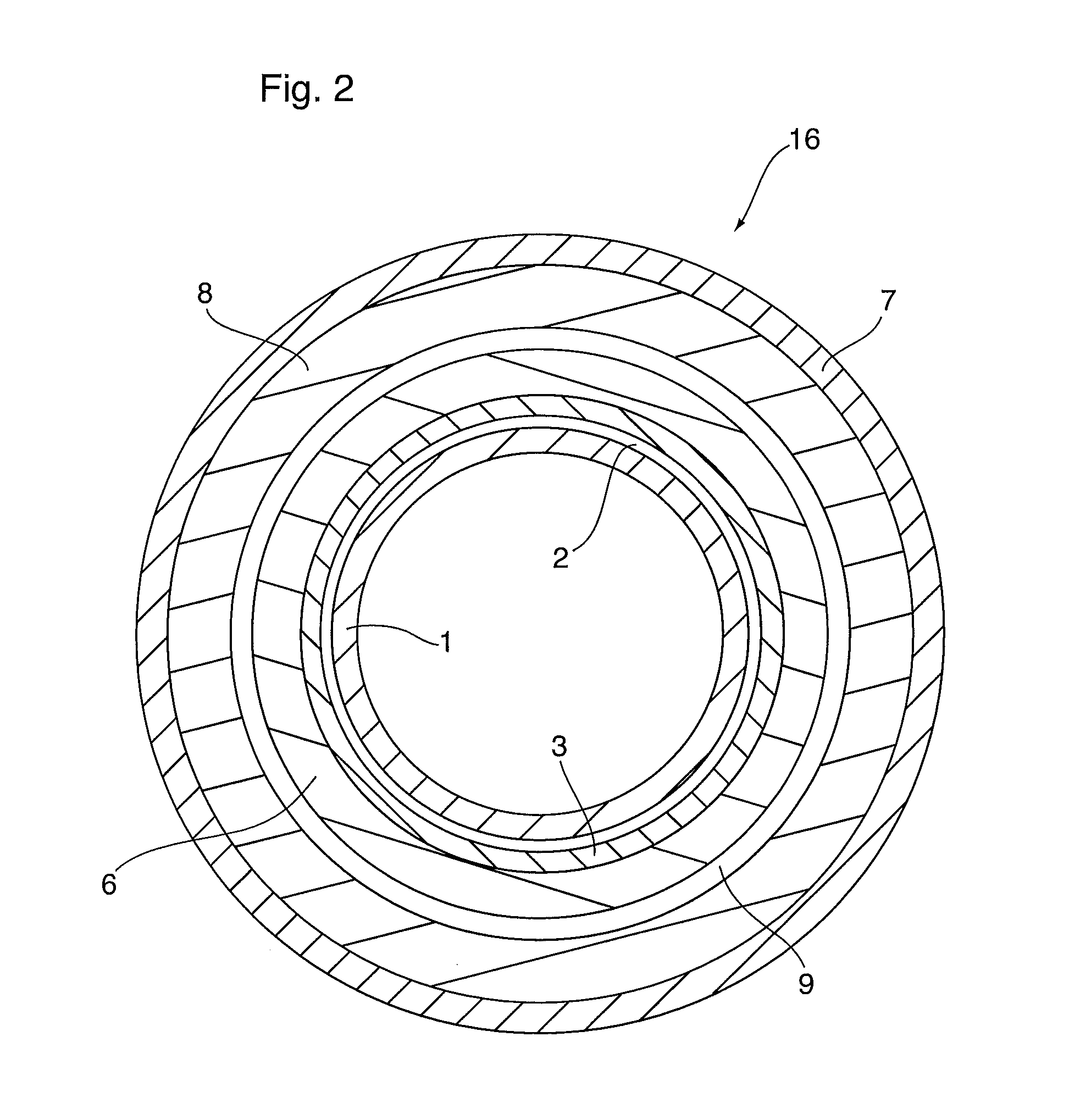

A rigid endoscope optics (1) including a housing consisting of several housing parts (5, 8, 9, 6, 16) which hermetically encloses optic elements (3, 2, 4) and which is fitted with a hermetic connection (13, 14; 7, 15) between two housing parts (9,8; 9, 16) is characterized in that one (9) of the connected housing parts is made of PPS (polyphenylenesulfide) plastic or of PPSU (polyphenylsulfone) plastic, and the other (8, 16) connected housing part is made of PPS, PPSU or glass, the housing parts (8, 9, 16) being fitted with a metal coating (7, 13, 14, 15) at the connection site (13, 14; 7, 15) and are soldered to one another.

Owner:OLYMPUS WINTER & IBE

Crosslinked blends of polyphenylene sulfide and polyphenylsulfone for downhole applications, methods of manufacture, and uses thereof

A composition includes a crosslinked product of a polyphenylene sulfide and a polyphenylsulfone. A method for the manufacture of the crosslinked product of a polyphenylene sulfide and a polyphenylsulfone includes heating the polyphenylene sulfide and the polyphenylsulfone in presence of a crosslinking agent at a temperature and for a time effective to form the crosslinked product of polyphenylene sulfide and polyphenylsulfone.

Owner:BAKER HUGHES INC

Preparing method for polyethylene sulfone resin

The invention belongs to the technical field of high polymer materials and particularly relates to a preparing method for polyethylene sulfone resin. The preparing method for polyethylene sulfone resin comprises the steps that a polymerization reaction is carried out, and precipitation treatment and purification treatment are carried out on a reaction product, wherein the method of dripping a precipitation solution is adopted in precipitation treatment, the precipitation solution is a mixture prepared from deionized water and polyethylene sulfone at 1:1 by the mass ratio, the precipitation solution accounts for 8-12% of the total mass of added polyethylene sulfone, the dripping time ranges from 40 min to 60 min, stirring continues to be carried out for 30-60 min after the precipitation solution is added, and completely precipitated white polyethylene sulfone paste can be obtained; polyethylene sulfone resin is obtained by carrying out purification treatment on the white paste. According to the method, the problem that the technological process is inconsecutive due to the fact that products need to be smashed in the existing production process of polyethylene sulfone resin is solved, and meanwhile the problem that the purity of high polymer products is not high due to the fact that inorganic salt particles wrapped by product particles cannot be thoroughly removed by washing in the traditional technology is also solved.

Owner:湖南国圆新材料科技有限公司

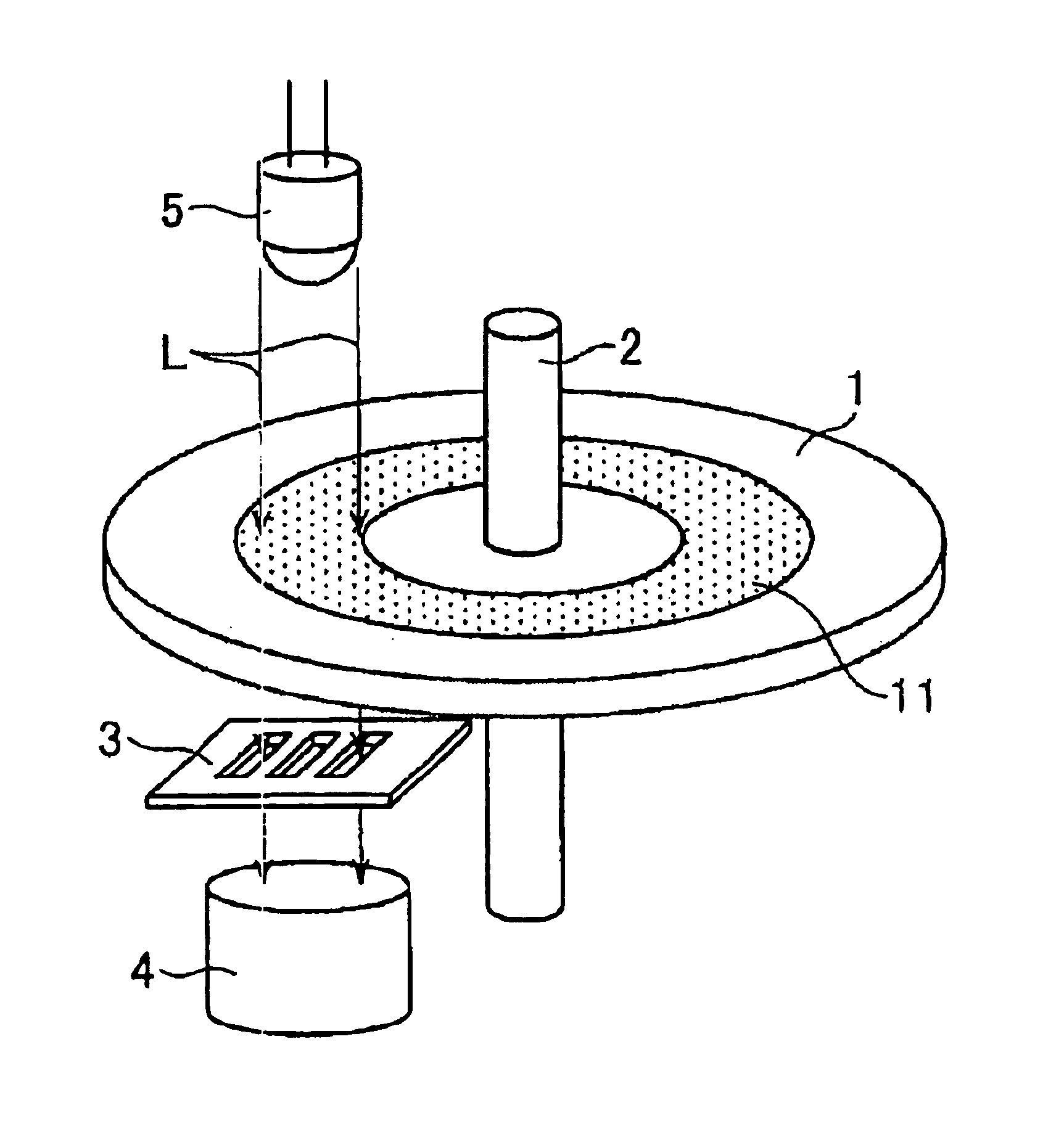

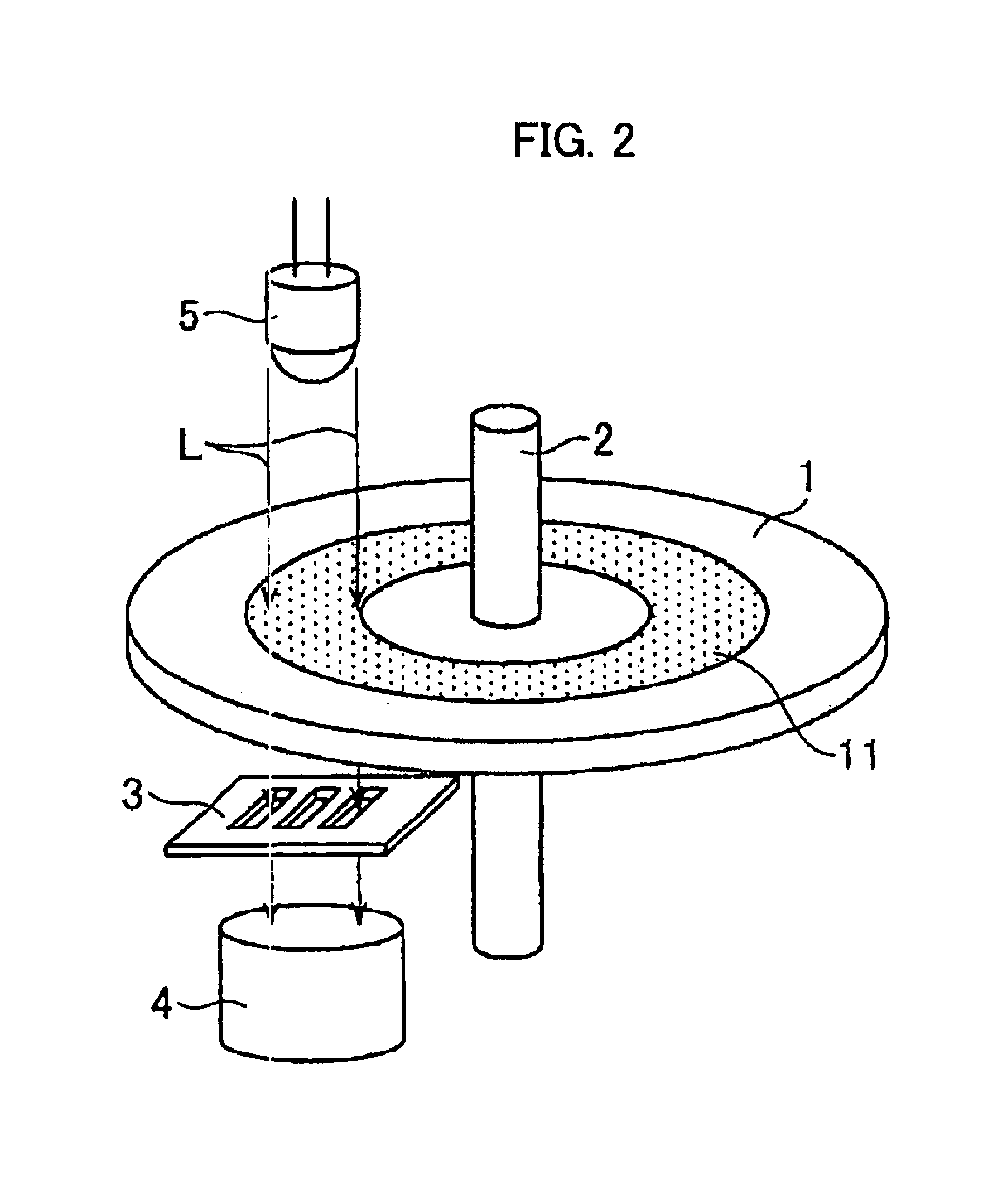

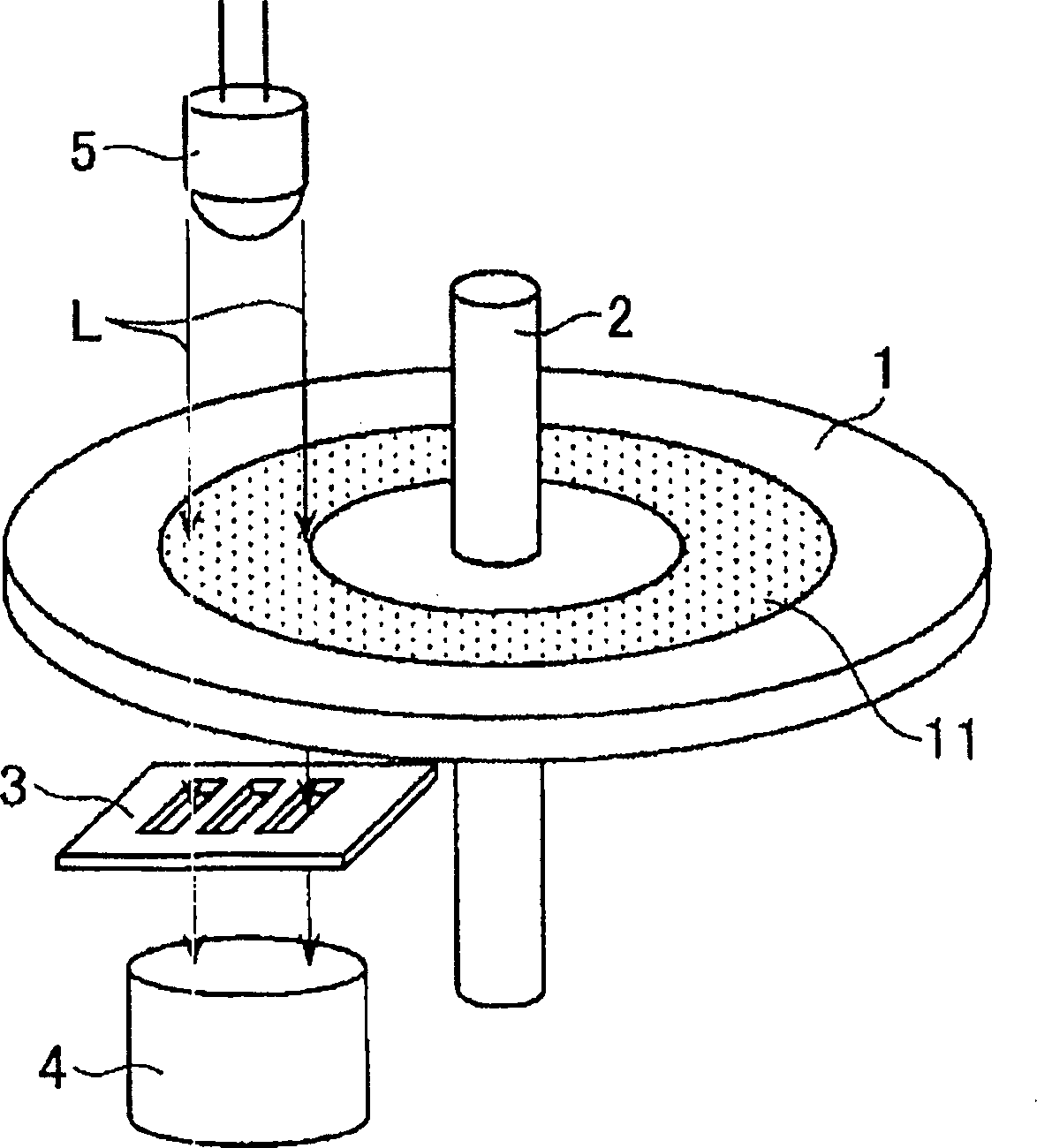

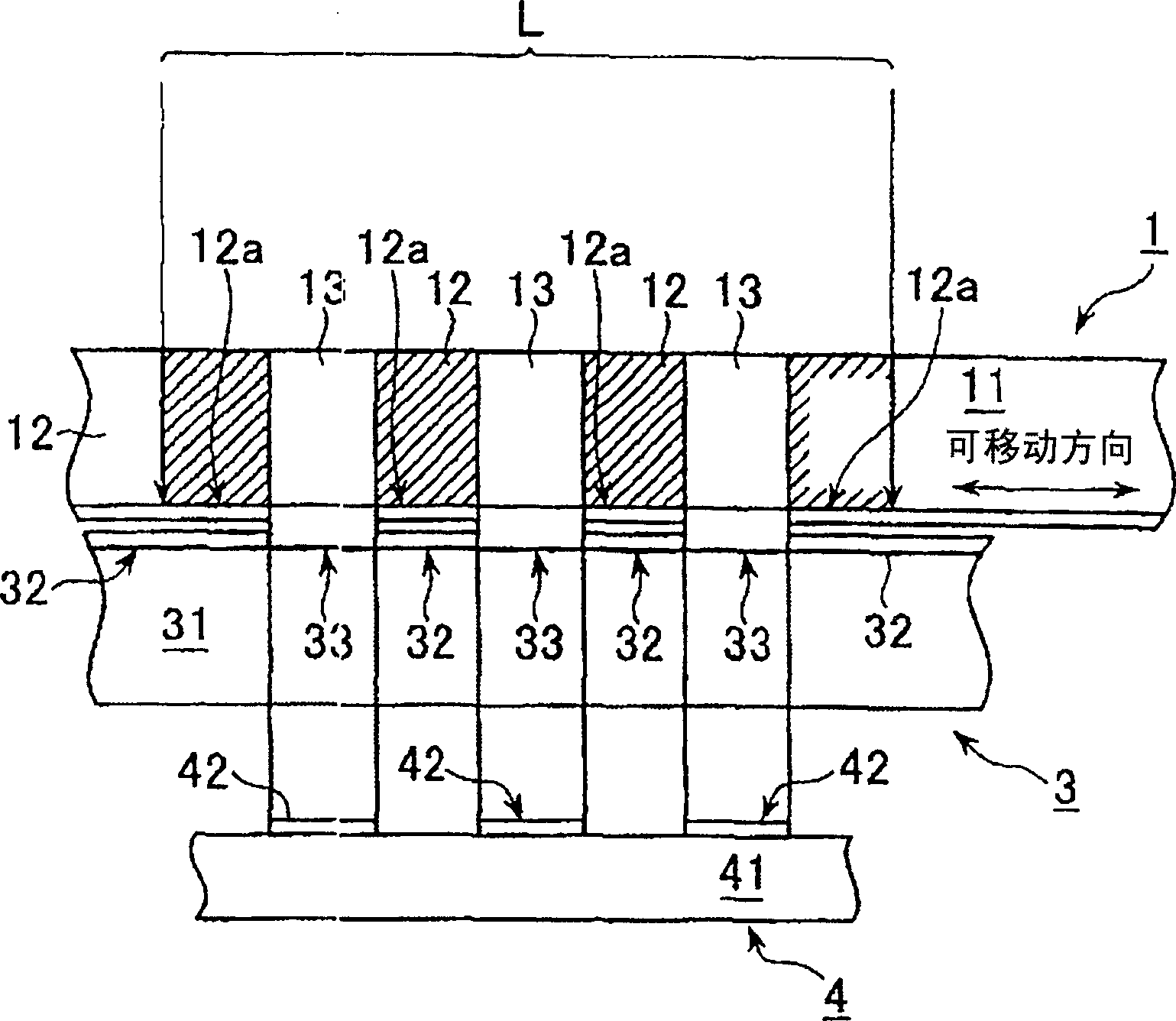

Optical encoder

ActiveUS6927388B2High spectral transmittanceIncrease resistanceElectric signal transmission systemsMaterial analysis by optical meansEnvironmental resistancePolyetherimide

An optical encoder whose environmental resistance is improved by increasing the variety of options of materials for a resin-made code plate thereof. Used as material for at least a code pattern of the code plate of the optical encoder is one which meets the condition that the material has spectral transmittance of 70% or more with respect to detection light and that of 50% or less with respect to partial light (for example blue light) of visible wavelengths in translucent sections. If infrared light having wavelengths between 800 nm and 1000 nm is used as detection light, it is preferable to apply polyetherimide, polyethersulfone or polyphenylsulfone as a colored resin material. These materials are excellent in heat resistance, oil resistance, etc., compared to transparent and colorless materials (PMMA, PC, glass, etc.) which have been conventionally used, and hardly cause melting, deformation, white turbidity, etc., in a harsh environment.

Owner:FANUC LTD

Methods of forming structures for downhole applications, and related downhole structures and assemblies

InactiveUS20160101600A1Improve propertiesImprove efficiencyLamination ancillary operationsSynthetic resin layered productsSelf reinforcedEngineering

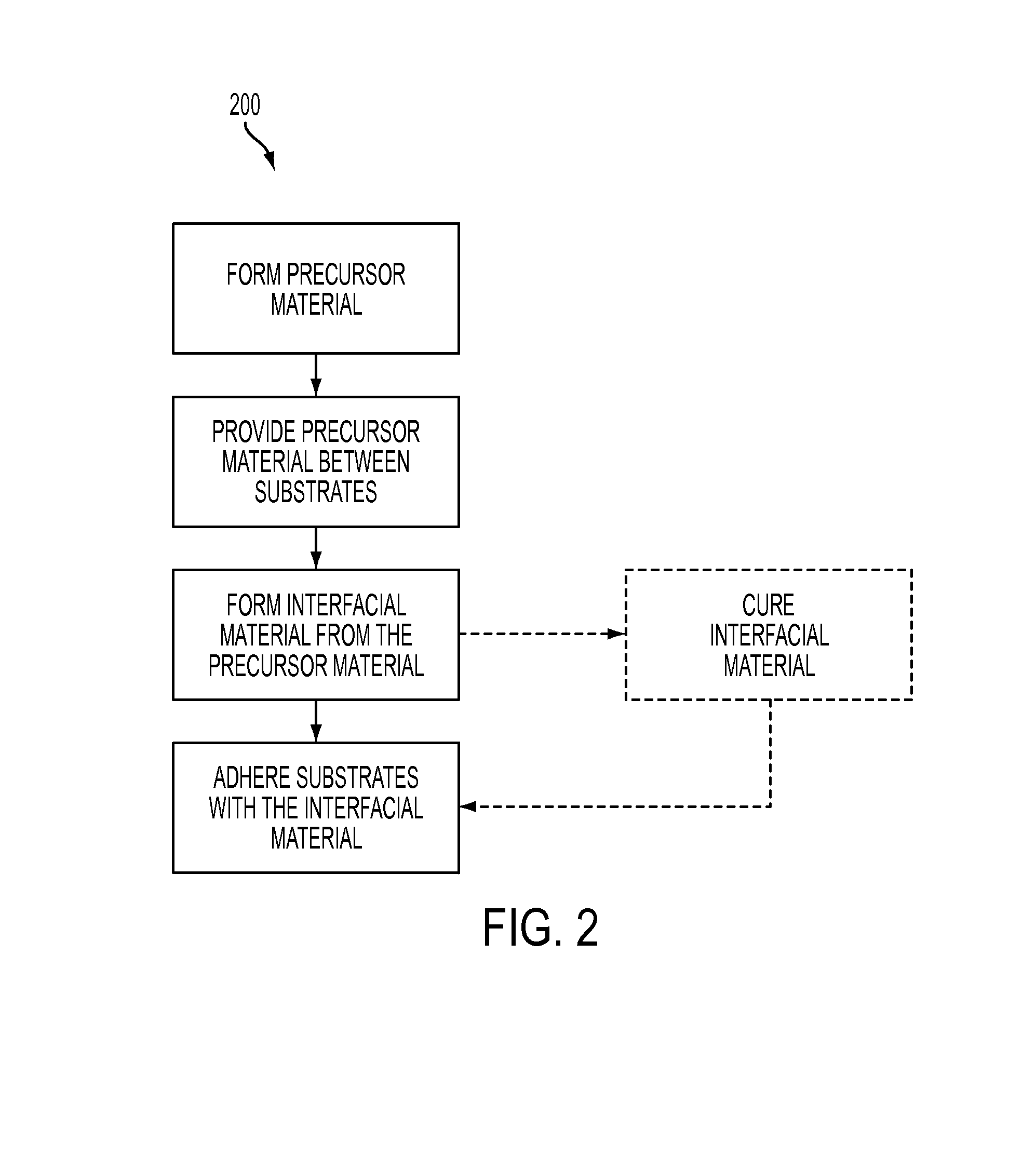

A method of forming a structure for a downhole application comprises forming an interfacial material comprising at least one of self-reinforced polyphenylene, polyphenylene sulfide, polysulfone, and polyphenylsulfone between opposing surfaces of a first substrate and a second substrate. A downhole structure and a downhole assembly are also described.

Owner:BAKER HUGHES INC

Magnet wire insulation comprising a high-temperature sulfone polymer blend

InactiveUS20060057380A1Robust electrical insulationReduce the amount requiredPlastic/resin/waxes insulatorsInsulated cablesArylEther

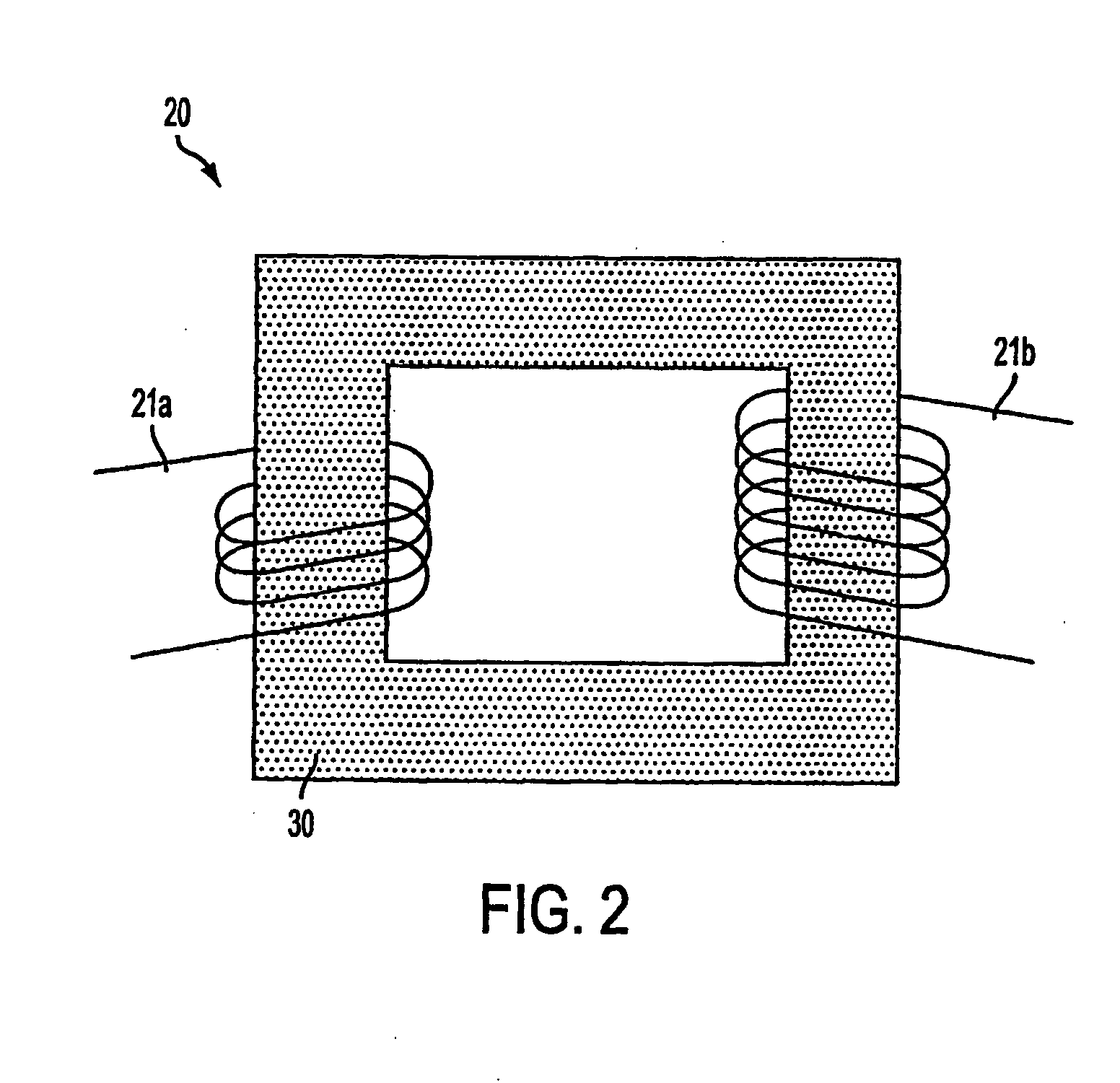

A magnet wire containing a melt processable, thermoplastic resin blend insulative coating developed for use in high temperature electrical insulation systems. The invention relates to a high temperature electrical insulation containing a sulfone polymer blend for particular use with magnet wire. The sulfone polymer blend contains two poly(aryl ether sulfones), such as polyphenylsulfone and polysulfone.

Owner:SOLVAY ADVANCED POLYMERS LLC

High Performance Sulfone Polymer Composition

ActiveUS20140322462A1High elongation at breakHigh impact strengthLayered productsSpecial tyresGlass fiberPolymer science

The present invention relates to a polymer composition (C) comprising at least one polyaryletherketone (PAEK), at least one polyphenylsulfone (PPSU), at least one polysulfone (PSU) and glass fibers having an elastic modulus of at least 76 GPa as measured according to ASTM D2343. Polymer composition (C) is very well suited for the manufacture of articles useful in areas as various as plumbing and electronics.

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

Optical coder

ActiveCN1540431AOptical analogue/digital convertersConverting sensor output opticallyEnvironmental resistancePolyetherimide

An optical encoder whose environmental resistance is improved by increasing the variety of options of materials for a resin-made code plate thereof. Used as material for at least a code pattern of the code plate of the optical encoder is one which meets the condition that the material has spectral transmittance of 70% or more with respect to detection light and that of 50% or less with respect to partial light (for example blue light) of visible wavelengths in translucent sections. If infrared light having wavelengths between 800 nm and 1000 nm is used as detection light, it is preferable to apply polyetherimide, polyethersulfone or polyphenylsulfone as a colored resin material. These materials are excellent in heat resistance, oil resistance, etc., compared to transparent and colorless materials (PMMA, PC, glass, etc.) which have been conventionally used, and hardly cause melting, deformation, white turbidity, etc., in a harsh environment.

Owner:FANUC LTD

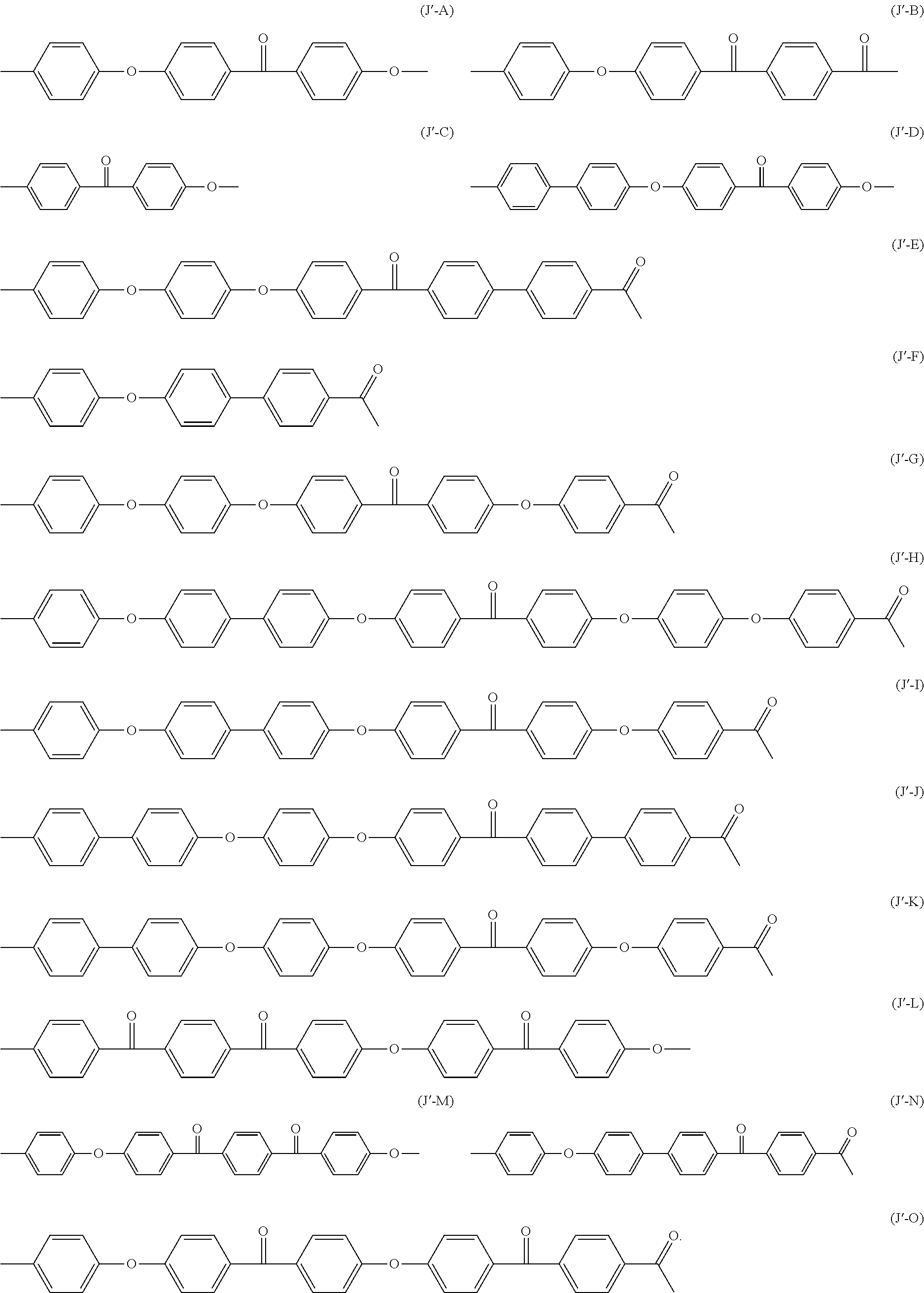

PAEK/PAES compositions

A composition [composition (C)] comprising from 1 to 90% by weight (wt. %) of at least one poly(aryl ether ketone) [(PAEK) polymer, herein after], from to 25 wt. % of at least one polyphenylsulfone polymer [(PPSU) polymer, herein after], from 1 to 90% wt. % of at least one poly(aryl ether sulfone) polymer [(P1) polymer, herein after], selected from a group consisting of at least one high temperature poly(aryl ether sulfone) polymer [(PAESHT) polymer, herein after] and at least one polyethersulfone polymer [(PESU) polymer, herein after]; from 0 to 50% wt. % of at least one reinforcing filler, and wherein all % are based on the total weight of the composition (C).

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

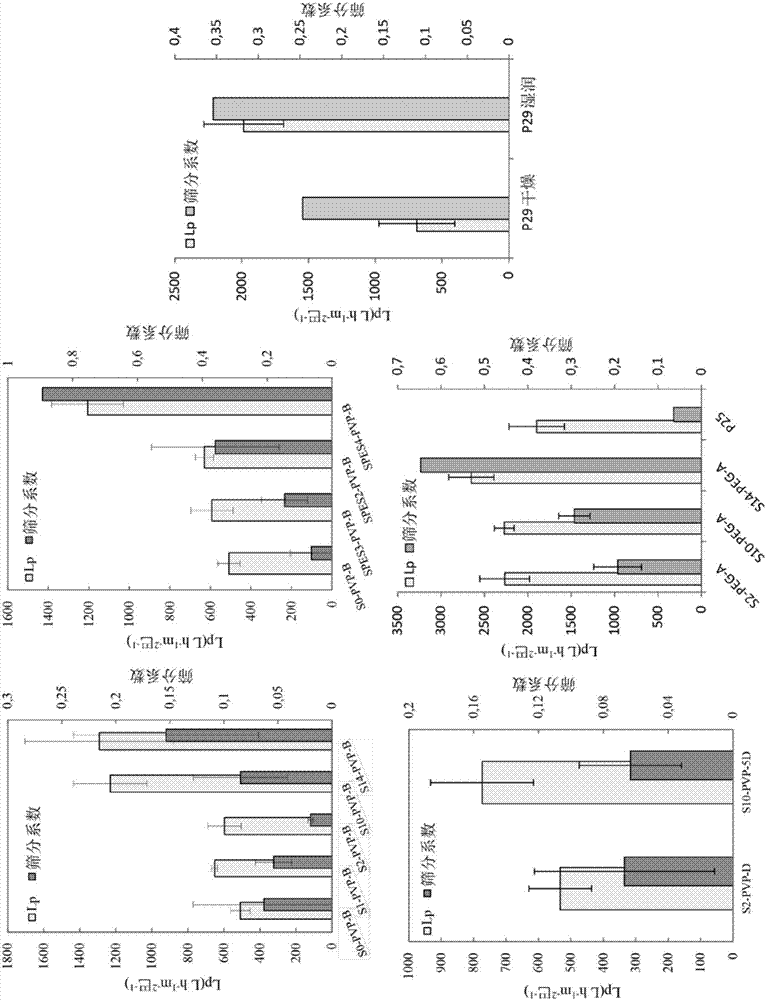

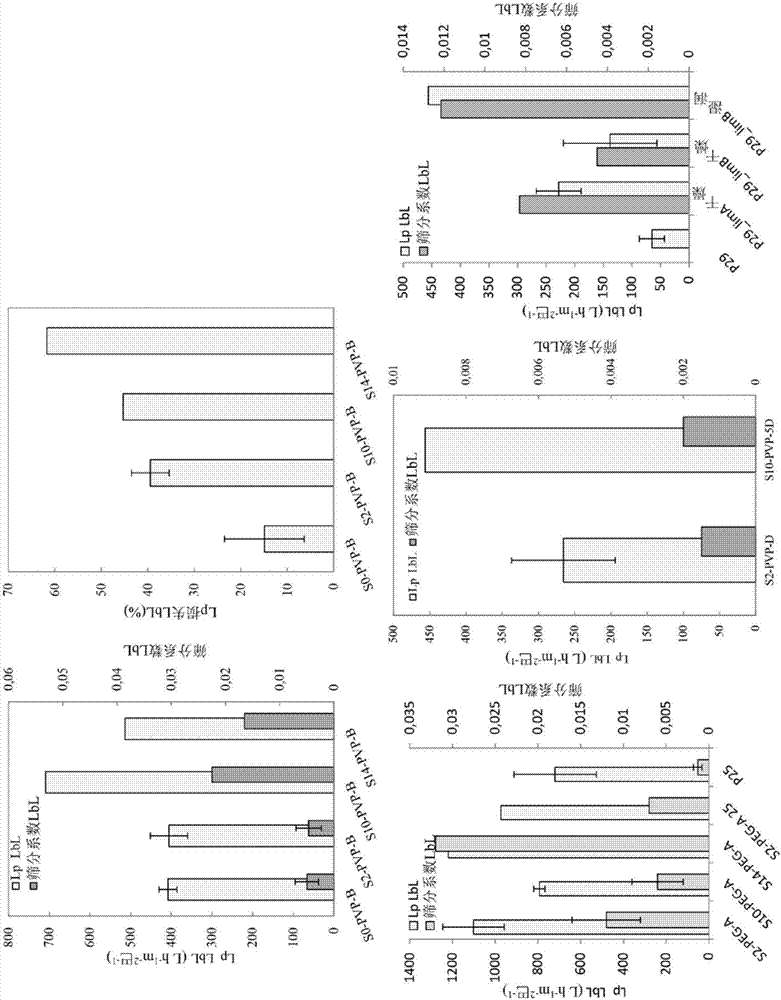

Dialysis membrane and method for its production

A membrane for the purification of blood, or a dialysis membrane, in hollow-fiber membrane or flat membrane geometry, made of a composite assembled from at least a base membrane based on at least one polysulfone or a polyphenylsulfone with at least one pore-forming hydrophilic additive and at least one functional layer arranged on the base membrane, whereby the functional layer is formed from at least one polymeric polycationic bonding agent and at least one polymeric polyanion, whereby the base membrane is made of a material which is selected from: a polysulfone [PSU], a sulfonated polysulfone [SPSU], a polyethersulfone [PES], a sulfonated polyethersulfone [SPES], a polyphenylsulfone [PPSU], a sulfonated polyphenylsulfone [SPPSU]; and mixtures of these. The membranes according to the present invention exhibit high water permeability and low BSA sieving coefficients.

Owner:B BRAUN AVITUM

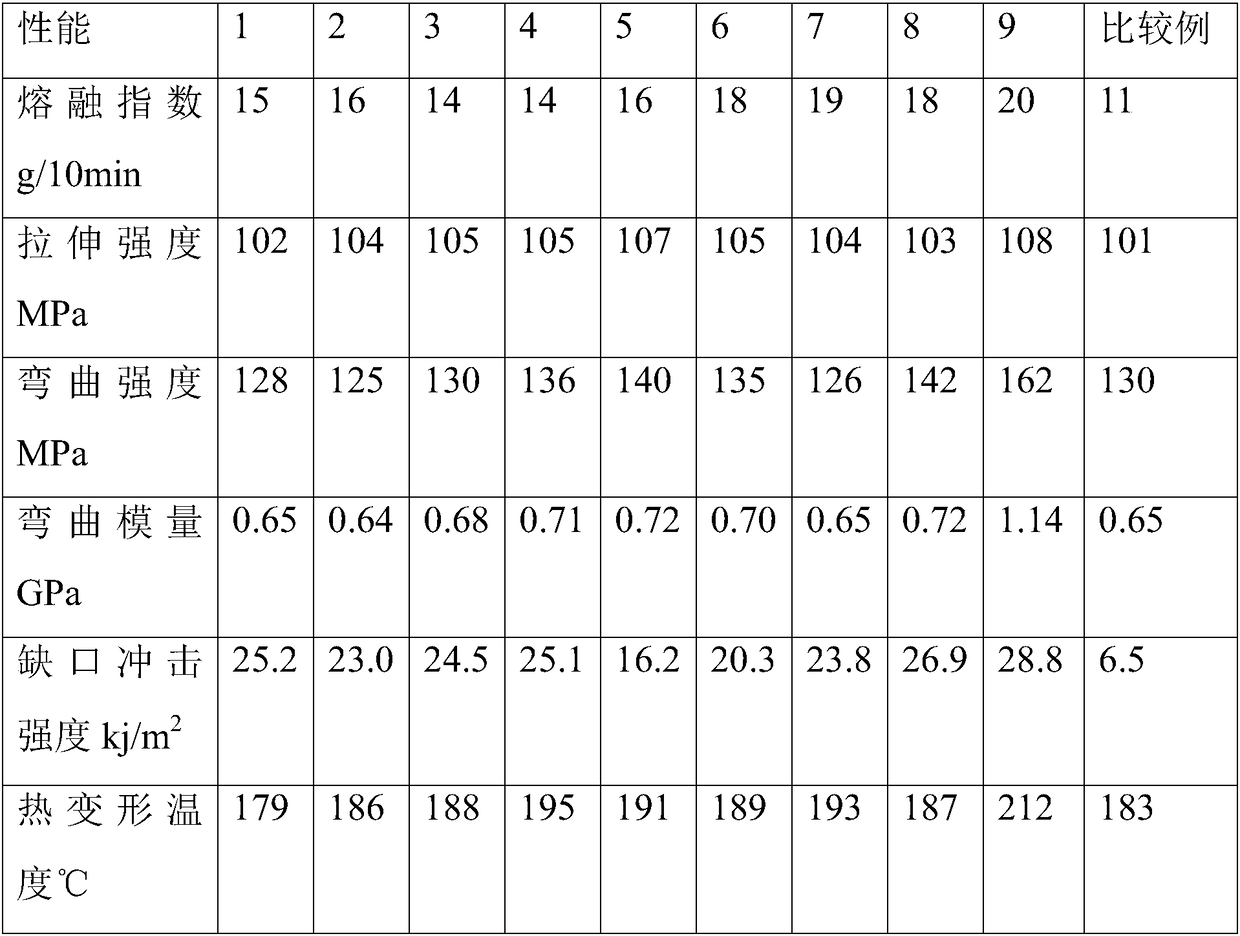

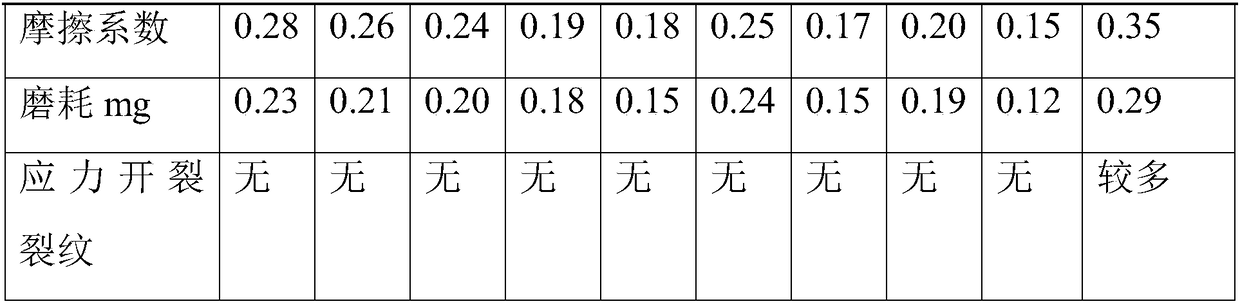

Modified polysulfone composite material as well as preparation method and application thereof

The invention relates to a high-modulus and high-strength stress cracking and wear-resistant polysulfone composite material which is prepared by blending and compounding first resin, second resin, third resin, fibers and a certain amount of wear-resistant agent, a flow modifier and an antioxidant; the first resin is polysulfone (PSU) and has a dosage of 50-80 percent by weight; the second resin has a toughening effect; the third resin has a stress cracking-resistant effect; the second resin and the third resin are any two or three of polyphenylsulfone, a polyester polymer and polyamide resin;the sum of the dosages of the second resin and the third resin is 5-20 percent by weight; the fibers have an enhancing effect and have a dosage of 10-30 percent by weight; and the balance is the wear-resistant agent, the flow modifier and the antioxidant. The high-modulus and high-strength stress cracking and wear-resistant polysulfone composite material provided by the invention has excellent performance and can be widely applied to hot water system pump bodies, impellers, valve bodies, engine oil seals, oil pumps and valves, transmission bearing retainers, sliding bearings and other fields.

Owner:长沙五犇新材料科技有限公司

Method for preparing a high temperature polymer coating

A method for coating a substrate includes impacting a substrate with a plurality of particles such that the particles adhere to the substrate, bonding the particles to the substrate to form an overlayer, and crosslinking the particles in the overlayer to coat the substrate with a crosslinked polymer coating. The particles comprise a polyphenyl polymer. An article includes a substrate and a crosslinked polymer coating bonded to the substrate. The crosslinked polymer coating is a product of crosslinking polyphenylene sulfide, polyphenylsulfone, self-reinforced polyphenylene, or a combination thereof on a surface of the substrate.

Owner:BAKER HUGHES INC

Object made by additive manufacturing and method to produce said object

PendingUS20200070404A1Small volumeReduce porosity3D object support structuresManufacturing data aquisition/processingPolymer sciencePolyetherimide

A three-dimensional object created by Fused Deposition Modeling (FDM) of a modeling material from polyaryletherketones (PAEK), polyphenylsulfides, polyamide-imide, polyethersulfon, polyetherimide, polysulfon, polyphenylsulfon, polycarbonates (PC), polyacrylonitrile butadiene styrene) (ABS), polymethylmethacrylate (PMMA), polyethyleneterephtalate (PET), polystryrene (PS), acrylonitrilstyrene acrylate, polypropylene (PP), polylactic acid (PLA), polyvinylalcohol (PVA), polyethylene (PE), polyoxymethylene, polyurethane (PU), copolymers of polyvinylalcohol and butenediolvinylalcohol and mixtures thereof, optionally filled with inorganic or organic fillers, wherein the object has a porosity of less than 5 vol %, as determined according to the porosity test procedure ‘Porosity test’. The objects are leak tight and show improved mechanical properties. FDM printing of PEEK generating parts having high isotropy.

Owner:BOND HIGH PERFORMANCE 3D TECH BV

Polymer composition

Polymer composition (C) comprisinga poly(aryl ether ketone) (P1) chosen from polyetheretherketones, polyetherketoneketones and polyetheretherketone-polyetherketoneketone copolymers,a polyphenylsulfone (P2), anda reinforcing fiber (F),with the exception ofa polymer composition consisting of90 wt %, based on the total weight of the polymer composition, of a polymer blend consisting of 85 parts by weight of a polyphenylsulfone and 15 parts by weight of a polyetheretherketone, and10 wt %, based on the total weight of the polymer composition, of glass fiber.

Owner:SOLVAY ADVANCED POLYMERS LLC

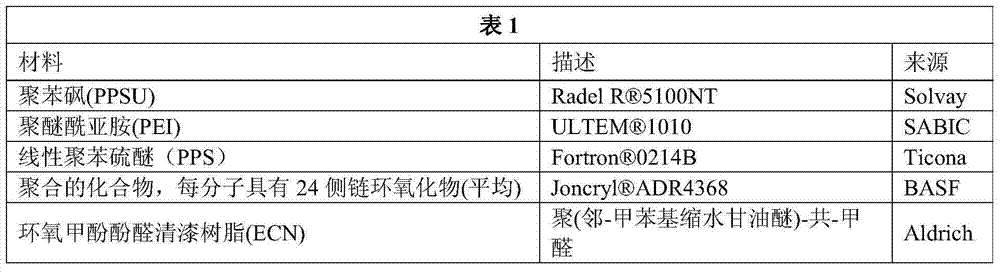

Blends of polyphenylene sulfones and polyphenylene sulfide

Blends of a polyphenylene sulfone (PPSU); a polyphenylene sulfide (PPS); and, a polyetherimide and epoxy. The polyetherimide and epoxy are present in an amount effective to act as a compatibilizer for the polyphenylene sulfone (PPSU) and polyphenylene sulfide (PPS). Methods of compatibilizing a blend of polyphenylene sulfone (PPSU) and polyphenylene sulfide (PPS). The method can include melt mixing a polyphenylene sulfone (PPSU) and a polyetherimide; and melt mixing a polyphenylene sulfide (PPS) and an epoxy.

Owner:SABIC GLOBAL TECH BV

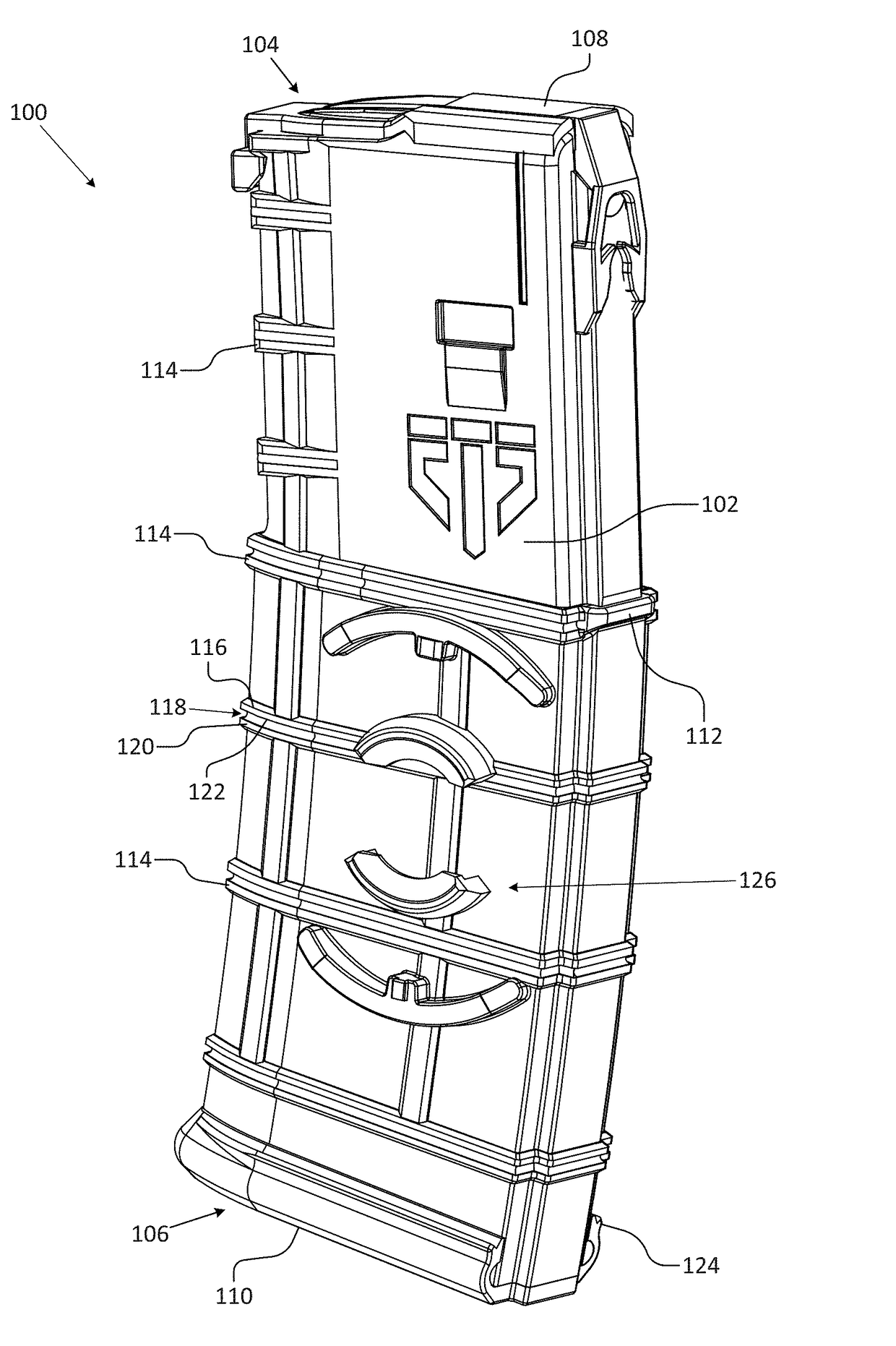

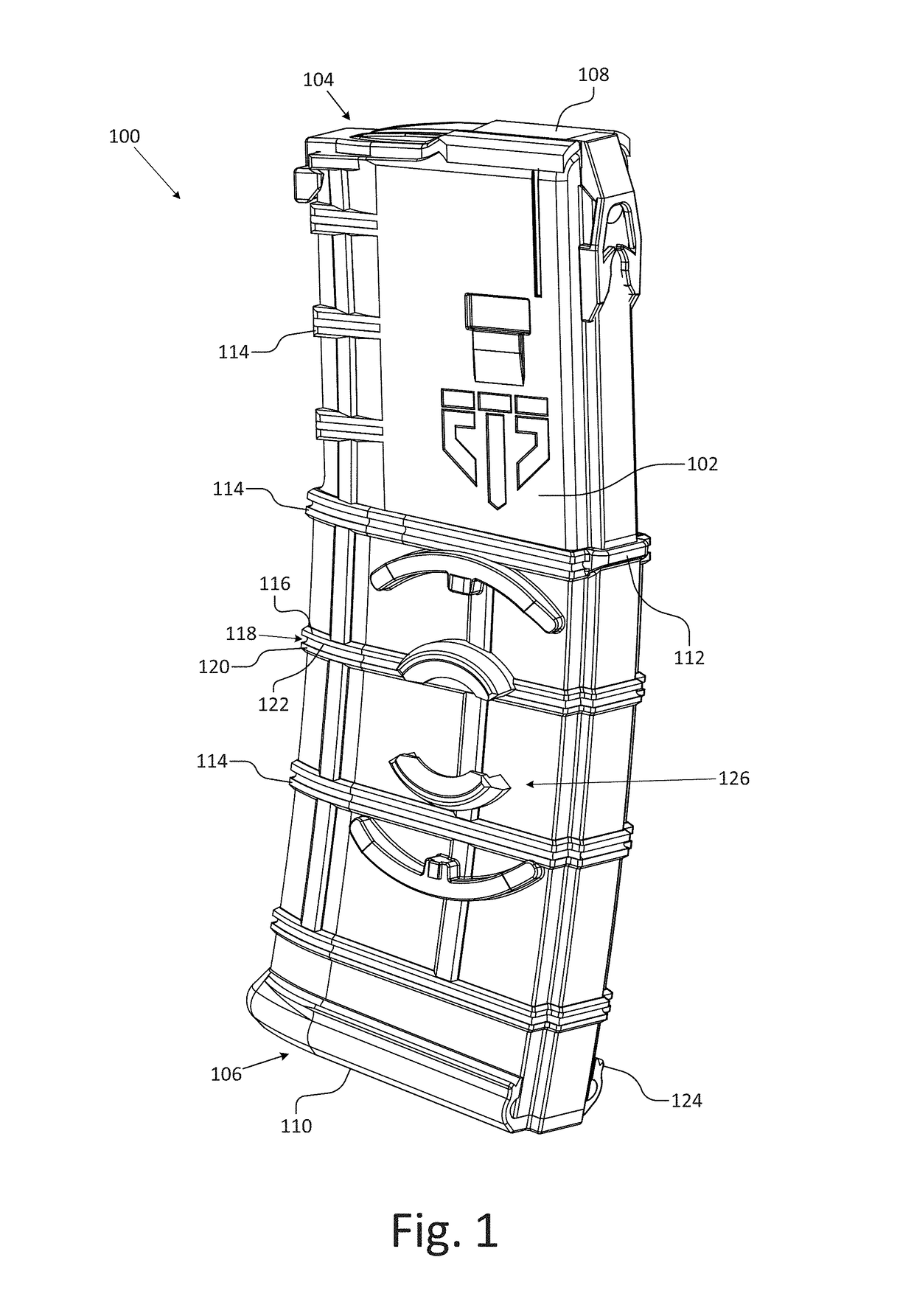

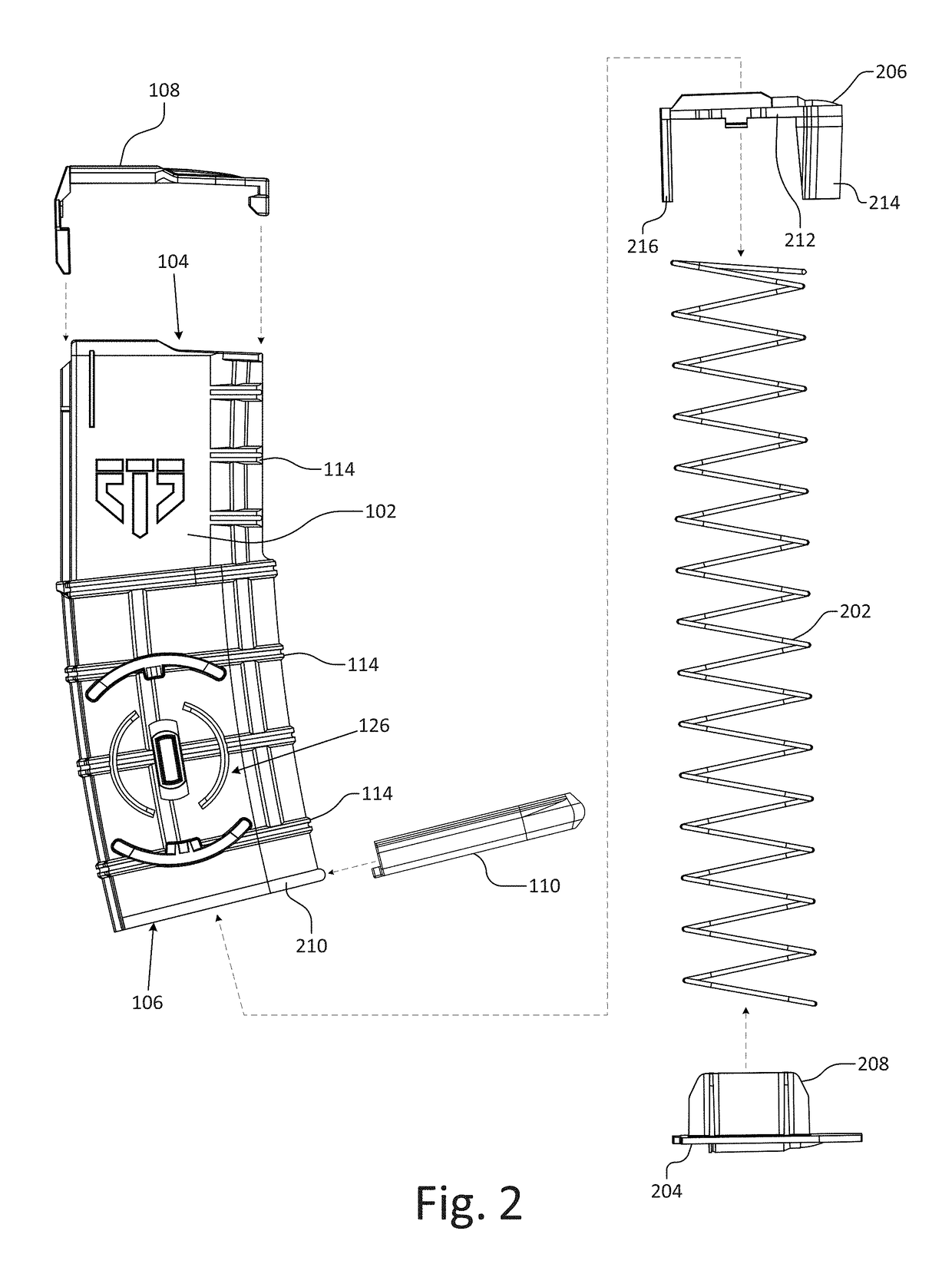

Ammunition magazine

Aspects of a magazine for use with a repeating firearm are described. One unique aspect is that the magazine is fabricated completely from a translucent polymer, particularly a polyphenylsulfone (PPSU) and, preferably, an unreinforced PPSU that is highly resistant to mechanical, chemical, and thermal failures commonly affecting magazines. Another aspect of the magazine is the inclusion of a coupling system fully integrated into the housing that allows magazines to be securely joined together without the use of tools or additional components. A further aspect of the magazine is the easy release button design allowing the magazine to be disassembled by large or gloved fingers without need for a tool to depress the release button.

Owner:ELITE TACTICAL SYST GRP LLC

High-performance polymer composition for mobile electronic devices

The present invention relates to mobile electronic devices comprising at least one structural part made of a polymer composition (C) comprising at least one polyaryletherketone (PAEK), at least one aromatic sulfone polymer (SP) such as polyphenylsulfone (PPSU), polyethersulfone (PESU), polysulfone (PSU) or mixture thereof, and at least one reinforcing filler.

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

Fabric with good antibacterial property for curtains

InactiveCN108437589AHigh strengthImprove high temperature resistanceSynthetic resin layered productsMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

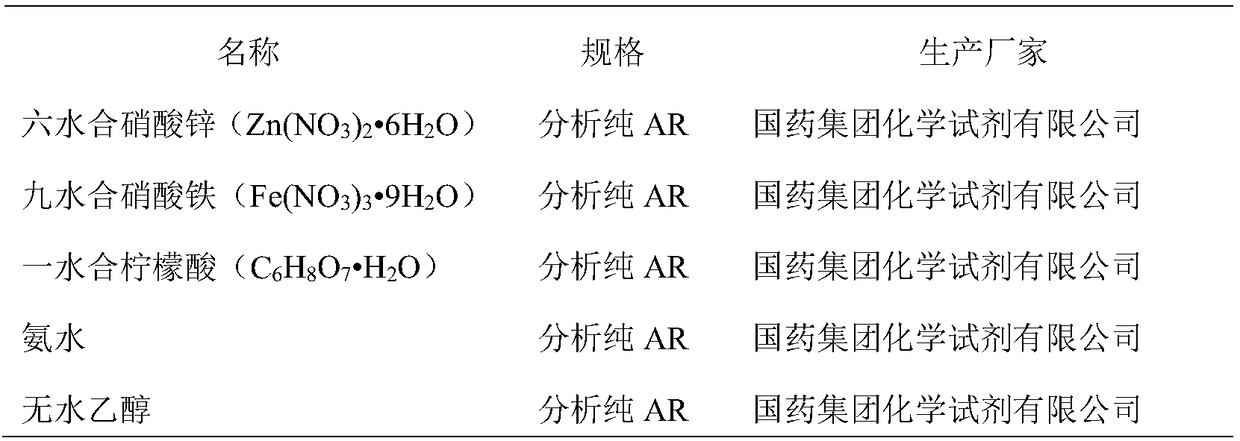

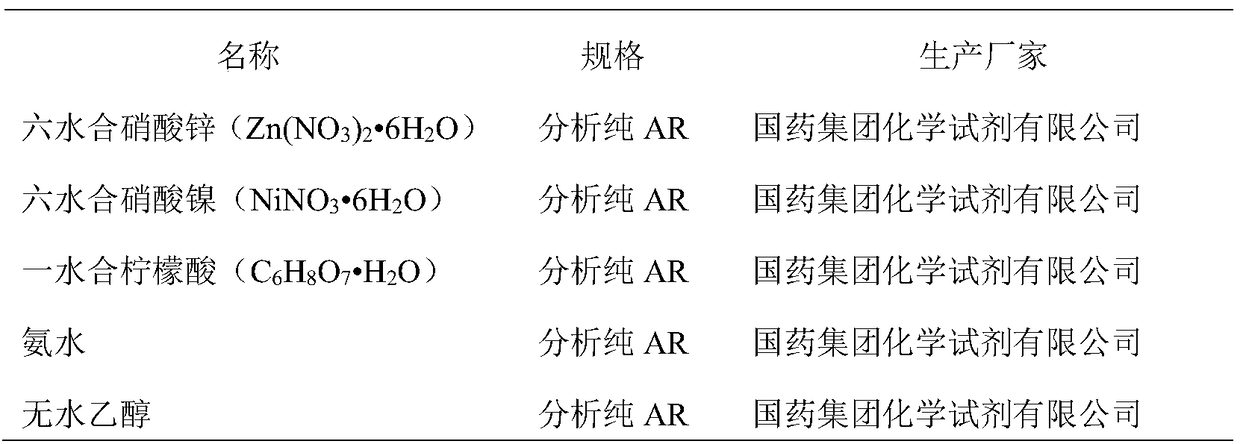

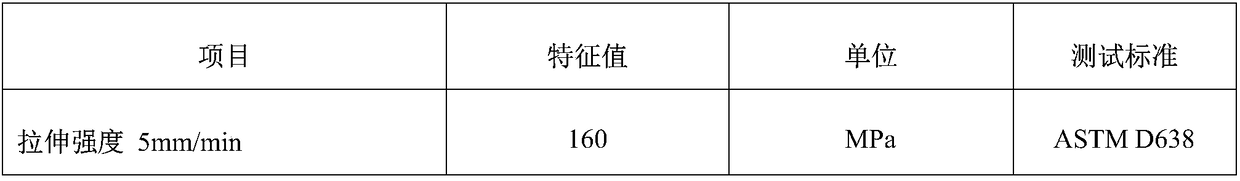

The invention relates to a fabric with a good antibacterial property for curtains. The fabric comprises a first shell fabric layer, a second shell fabric layer, a third fabric layer and a fourth fabric layer which are arranged from top to bottom; the first shell fabric layer is woven by blending polyester fibers and polyphenylsulfone amide fibers; the second fabric layer is woven by blending polyimide fibers and vinylon fibers; the third fabric layer is woven by blending polyaniline conductive polyester fibers and polypropylene fibers; and the fourth fabric layer is woven by blending apocynumvenetum fibers and banana stem fibers. The polyester fibers in the first fabric layer are antibacterial polyester fibers, and the forming process of the antibacterial polyester fibers is as follows: first preparing an antibacterial agent I and an antibacterial agent II, carrying out mixing for forming an antibacterial agent mixture, then blending pure polyethylene terephthalate (PET) sections withthe antibacterial agent mixture for preparing antibacterial modified PET sections, and then obtaining the antibacterial polyester fibers through a melt spinning mode, wherein the antibacterial polyester fibers comprise the following components in percentage by weight: 0.5-0.7 wt% of the antibacterial agent I, 0.9-1.1 wt% of the antibacterial agent II, and the balance of polyester fibers.

Owner:梧州井儿铺贸易有限公司

Composite material for plastic bearing as well as preparation method and application thereof

The invention discloses a composite material for a plastic bearing as well as a preparation method and application thereof. The composite material is prepared from polyphenylene sulfide, carbon fibers, polyether sulfone, polyphenylsulfone, polytetrafluoroethylene, modified nano silicon carbide, an antioxidant and a copolymer, wherein monomers of the copolymer must comprise styrene and maleic anhydride and further selectively comprise methacrylate and / or glycidyl methacrylate, and the modified nano silicon carbide is prepared by carrying out reaction on phenyl trimethoxysilane and nano siliconcarbide. The preparation method comprises the following steps that 1) the phenyl trimethoxysilane and the nano silicon carbide are mixed for reaction so as to prepare the modified nano silicon carbide; and 2) the polyphenylene sulfide, the polyether sulfone and the polyphenylsulfone are dried and then are mixed with the prepared modified nano silicon carbide and the rest raw materials, and fusingand extruding are carried out so as to obtain the composite material and the plastic bearing prepared from the composite material. According to the composite material for the plastic bearing as well as the preparation method and application thereof, the prepared plastic bearing is suitable for complex working conditions and has the advantages of being high-temperature-resistant, wear-resistant, self-lubricating, flame-retardant and relatively low in cost compared with PEEK and PAI materials.

Owner:江苏新孚达复合材料有限公司

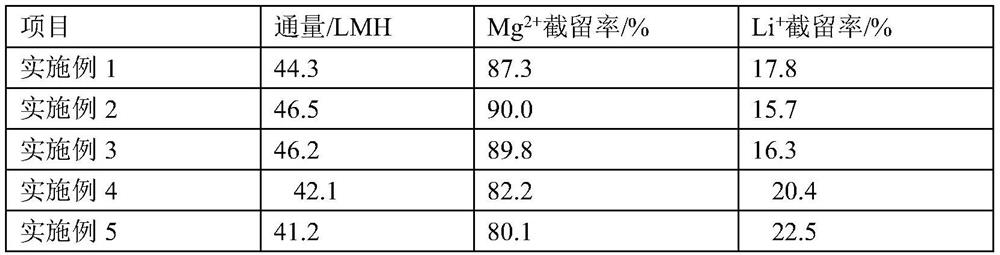

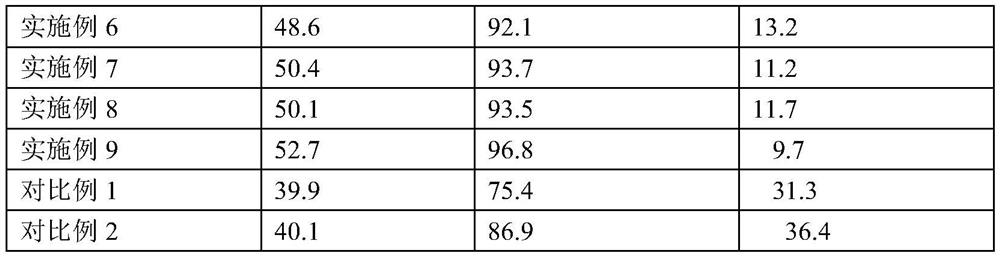

Nanofiltration membrane for extracting lithium from salt lake and preparation method of nanofiltration membrane

ActiveCN114377566AImprove hydrophilicityReduce adsorptionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChlorosulfuric acidPolyamide

The invention relates to the technical field of nanofiltration membranes, and particularly discloses a nanofiltration membrane for extracting lithium from a salt lake and a preparation method of the nanofiltration membrane. The nanofiltration membrane comprises a bottom membrane and a polyamide layer formed on the bottom membrane, the bottom membrane is modified polyphenyl sulfone, the modified polyphenyl sulfone is prepared by modifying polyphenyl sulfone with chlorosulfonic acid, and nano-zinc oxide is contained in the polyamide layer and on the surface of the polyamide layer; the preparation method comprises the following steps: adding polyamine into water, uniformly mixing, adding nano zinc oxide, and uniformly mixing to obtain a water-phase solution; uniformly mixing polyacyl chloride and an organic solution to obtain an oil phase solution; and immersing the base membrane into the water phase solution for 2-8 minutes, taking out the base membrane, removing excess water on the surface, immersing the base membrane into the oil phase solution for 0.5-2 minutes, taking out the base membrane, removing excess oil on the surface, and carrying out heat treatment to obtain the nanofiltration membrane. The nanofiltration membrane for extracting lithium from the salt lake has the advantage of improving the separation effect on lithium ions through the synergistic effect of the raw materials.

Owner:GUANGDONG TAIQUAN ENVIRONMENTAL PROTECTION TECH CO LTD

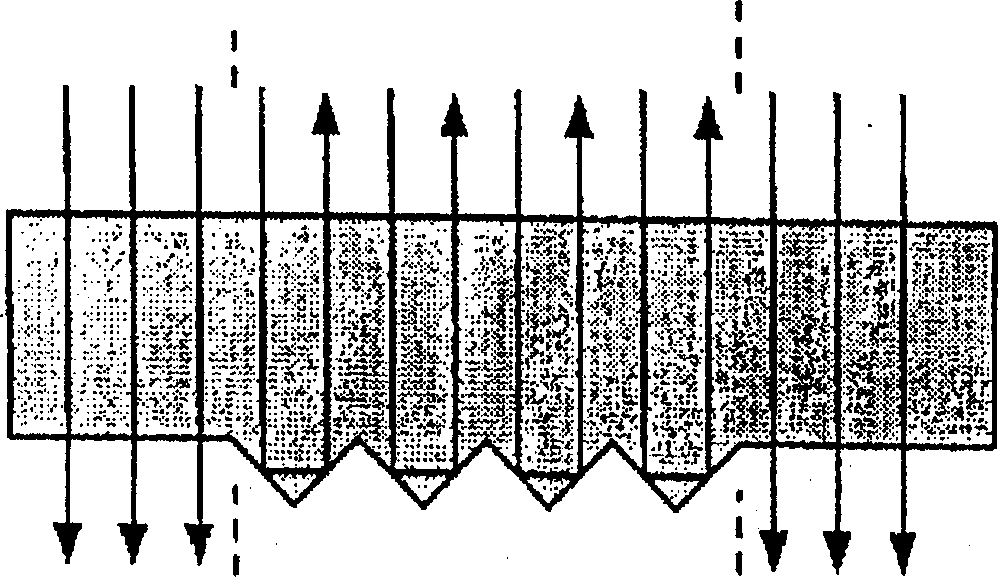

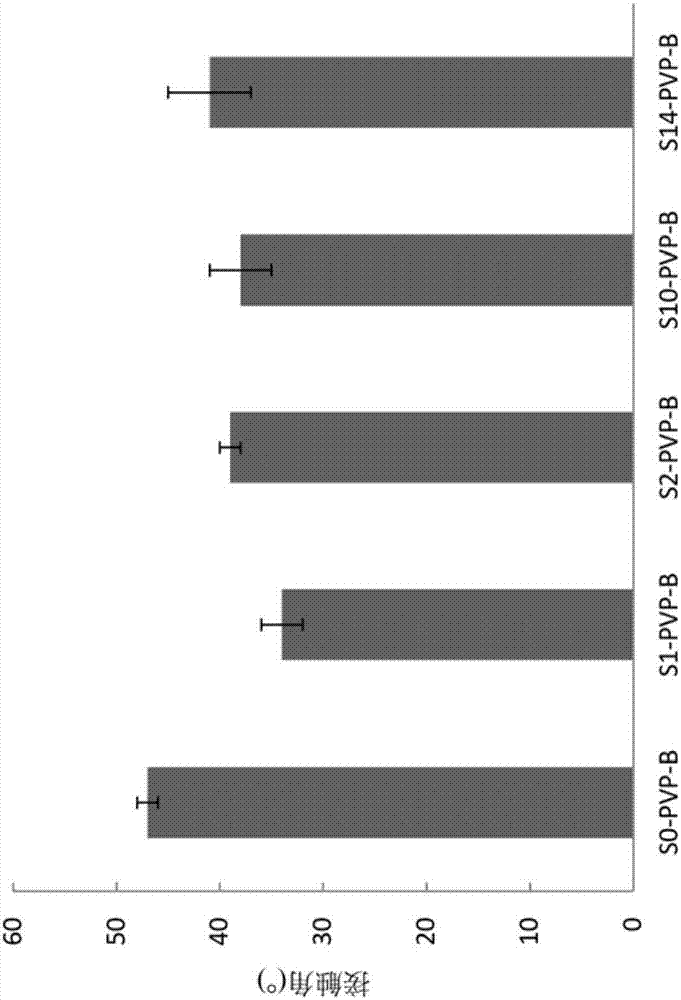

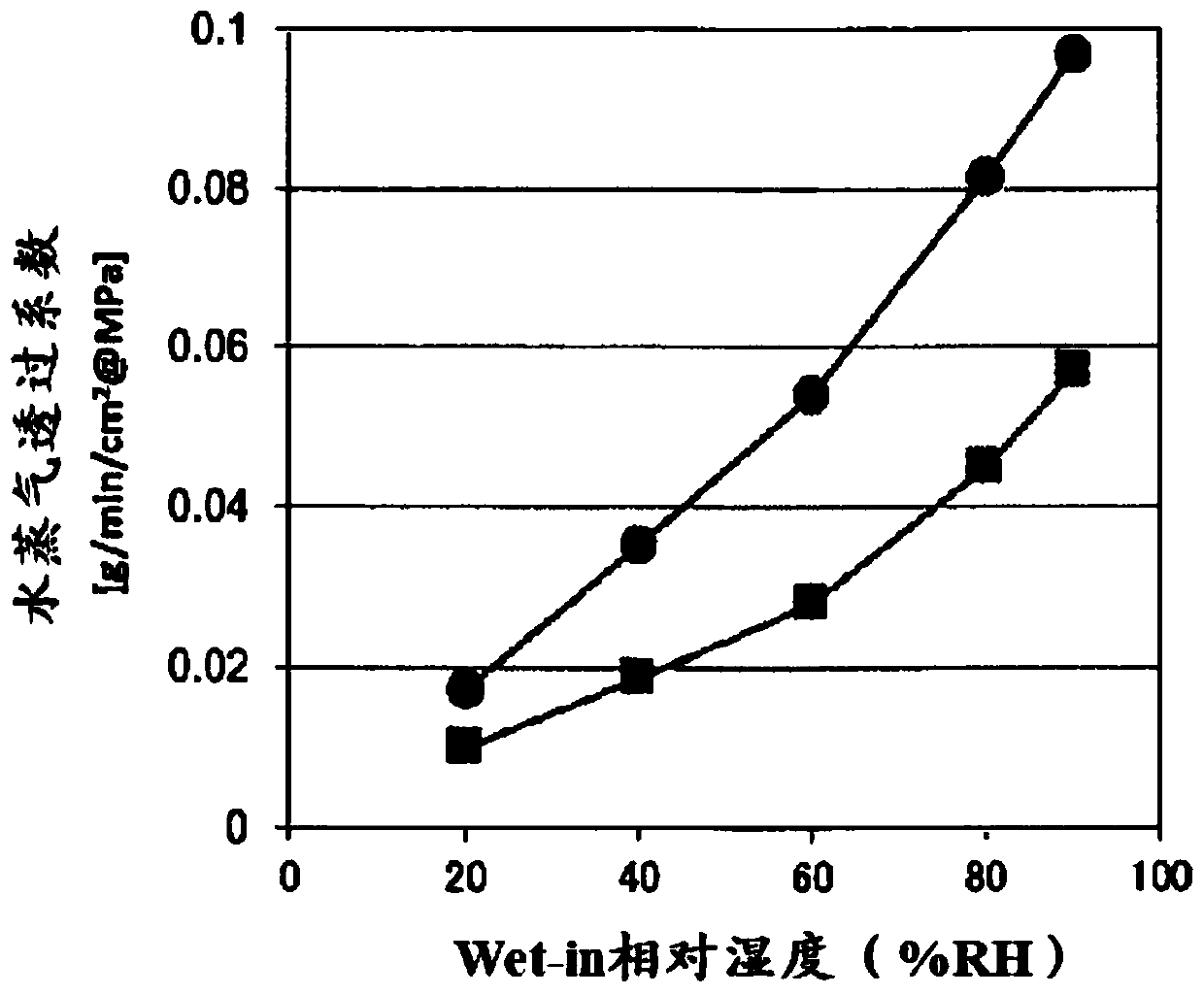

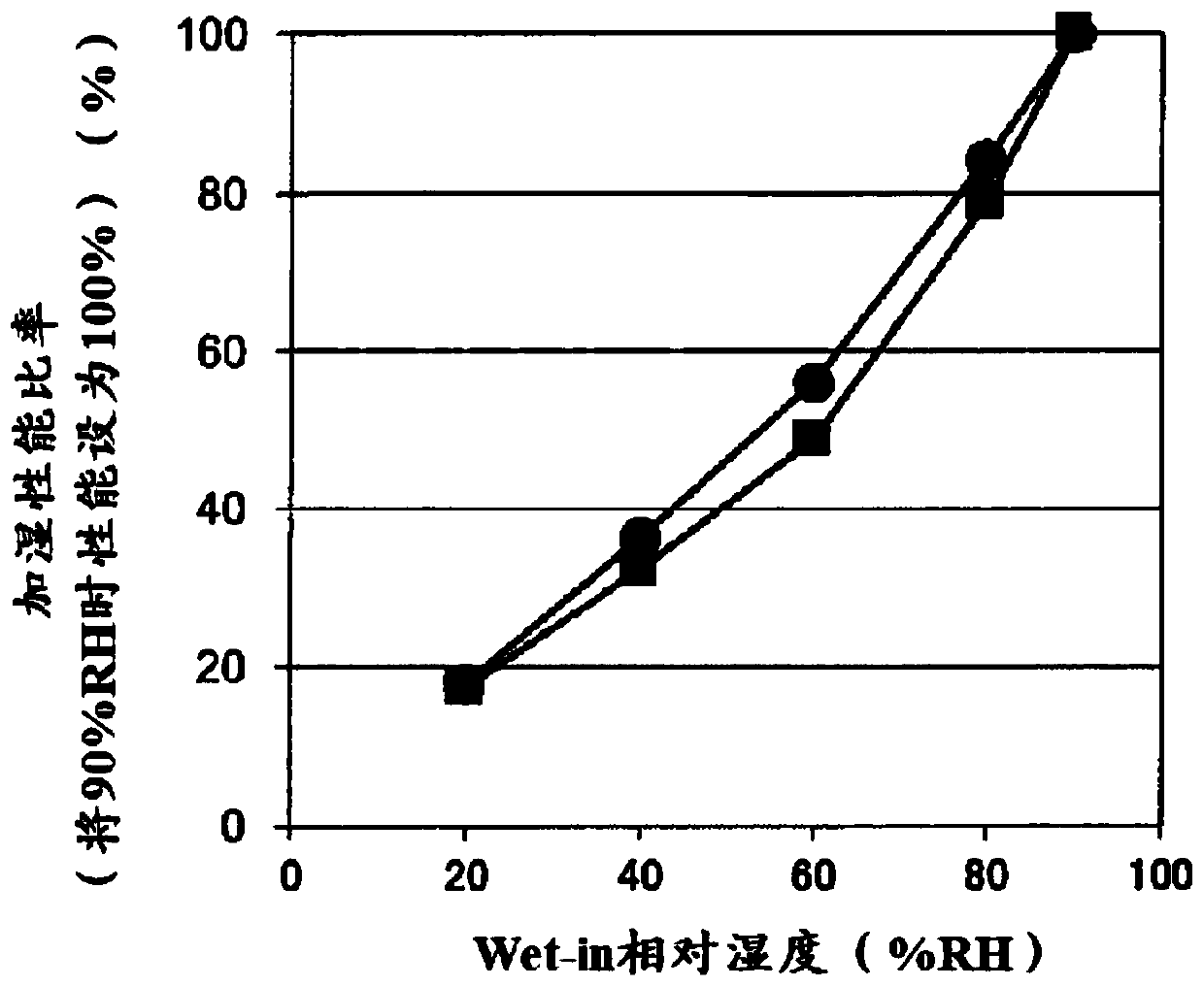

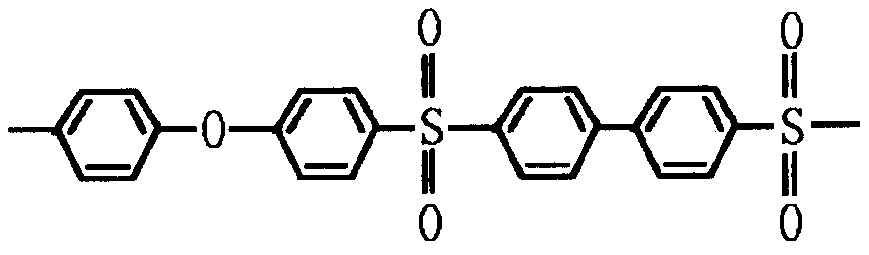

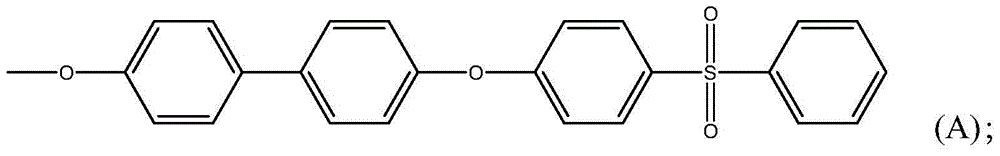

Manufacturing method for polyphenyl sulfone hollow-fiber membrane for use in humidification film

ActiveCN111278543AInhibition of segregationReduced humidification performanceSemi-permeable membranesMembranesPolymer scienceFuel cells

A hollow-fiber membrane produced by this manufacturing method has high water permeability, and, when used as a humidification film, provides a linear relation between supplied humidity and humidification level, and thus can effectively serve such uses as a humidification film for a fuel cell. This polyphenyl sulfone hollow-fiber membrane manufacturing method is not only capable of providing a humidification film in which segregation and crosslinking of hydrophilic macromolecules associated with the operation of the humidification film is suppressed, and in which deterioration in humidificationperformance due to the operation thereof is suppressed, but also capable of producing a polyphenyl sulfone hollow-fiber membrane which is for use in a humidification film, which exhibits high water permeability, and which, when used as a crosslinked humidification film, provides a linear relation between supply humidity and humidification level.

Owner:NOK CORP

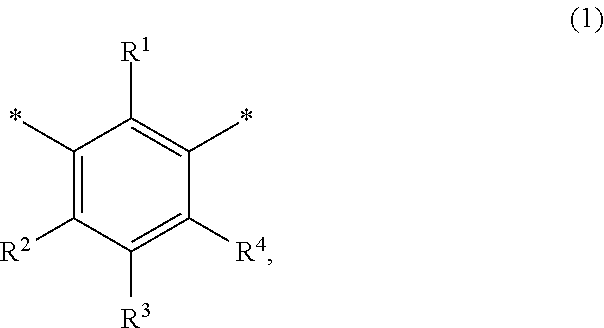

Polyarylene foam materials

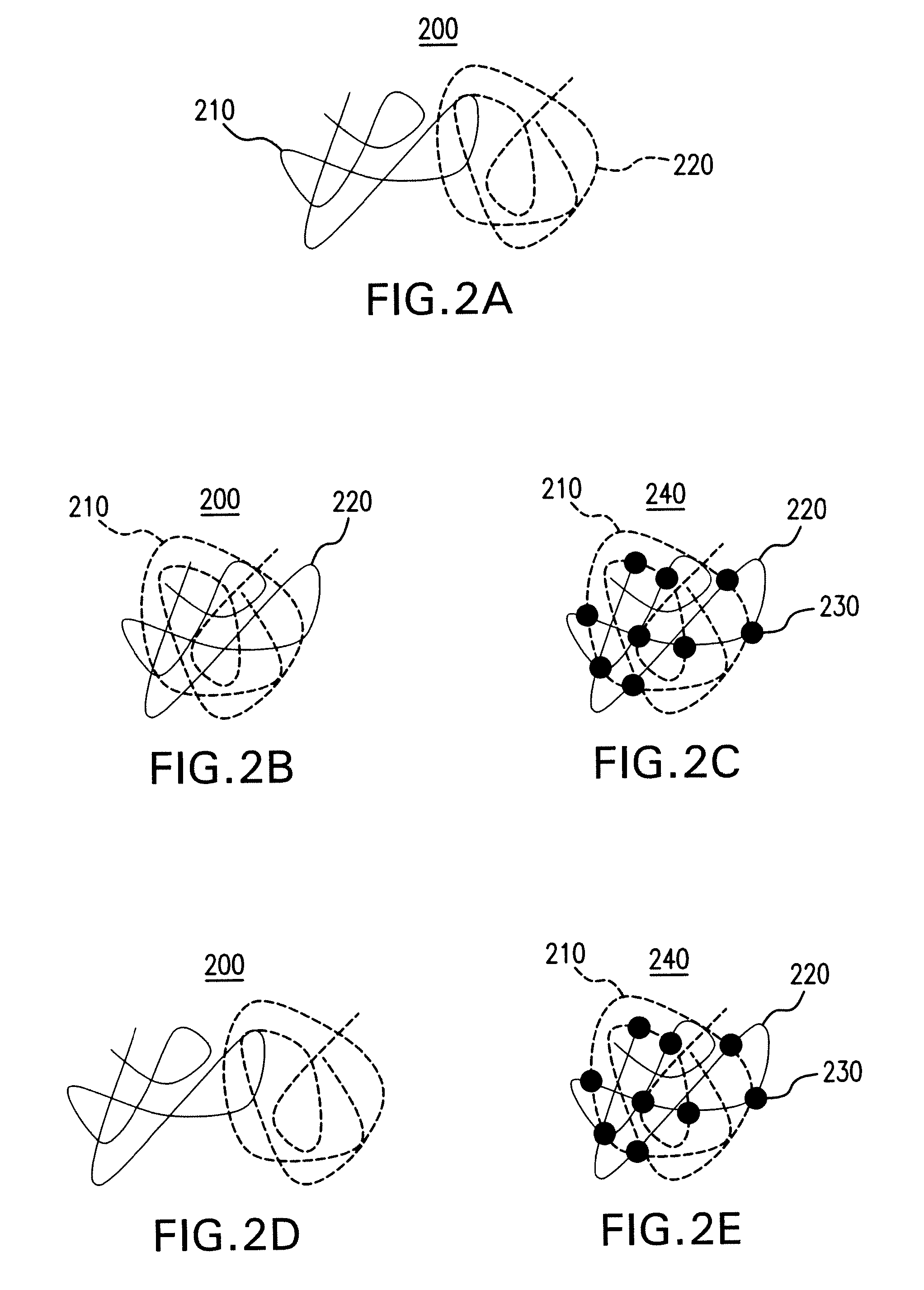

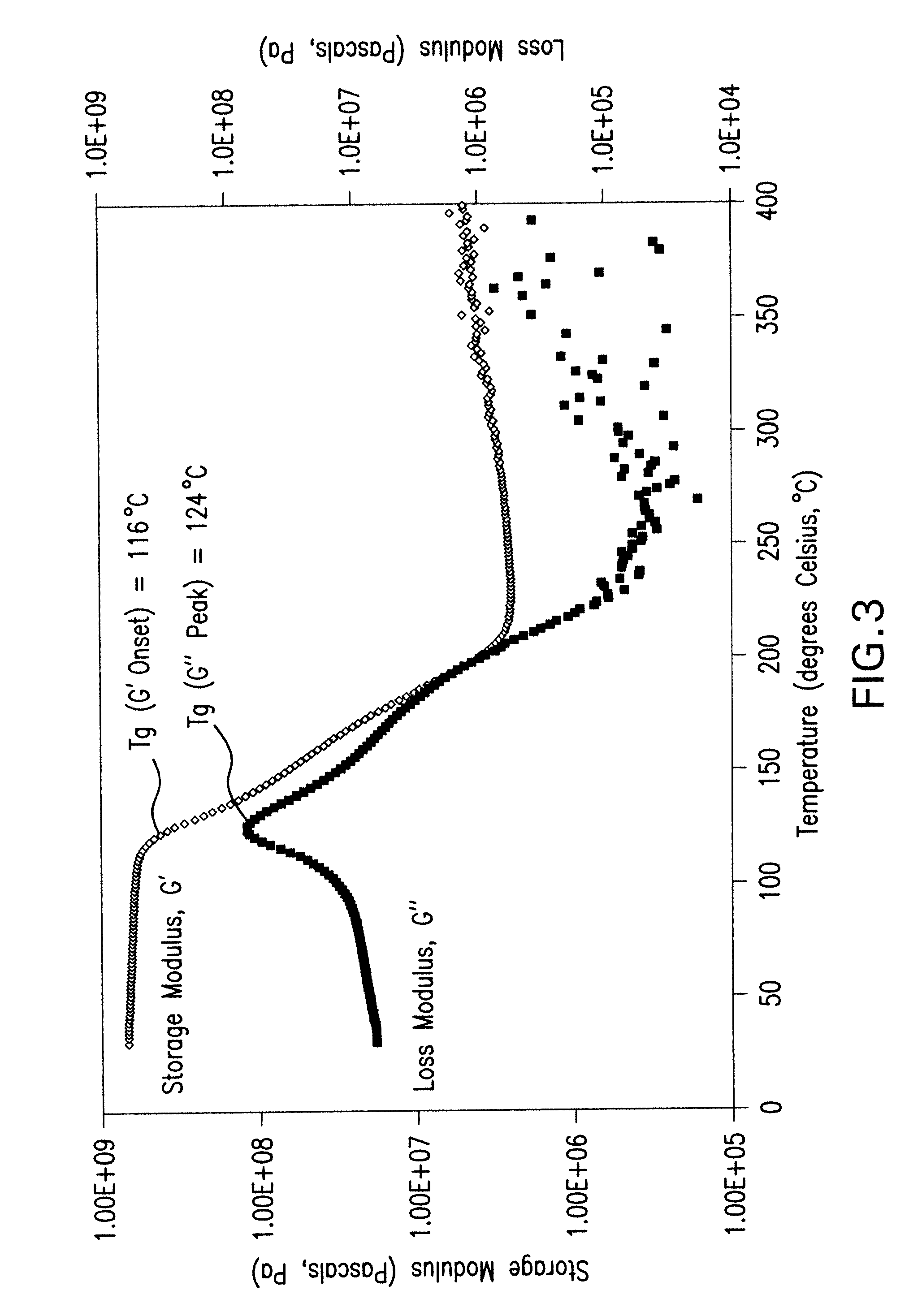

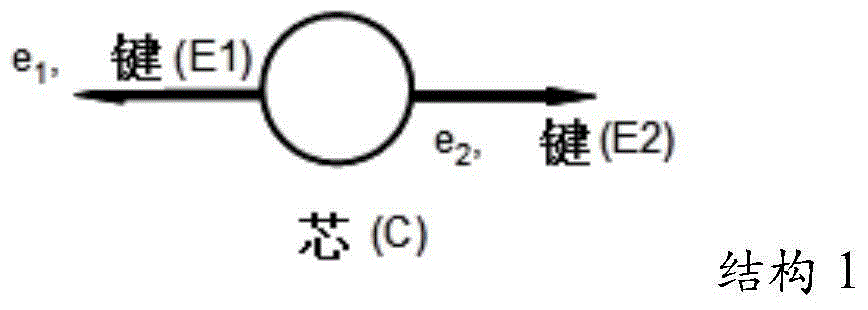

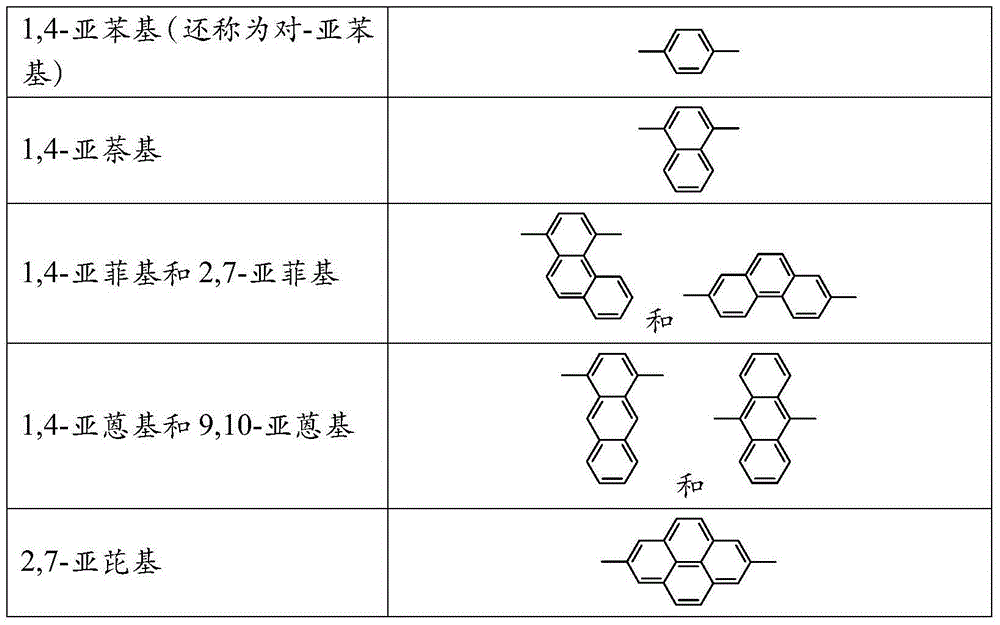

A foam material having one glass transition temperature (Tg) and made from an immiscible composition having at least two glass transition temperatures (Tg) by an extrusion process wherein said composition (C) comprises at least one polyarylene (P1) polymer, wherein more than 50 % by moles (moles %) of the recurring units of said (P1) polymer are recurring units (R1) consisting of an arylene group, wherein said arylene group is a hydrocarbon divalent group consisting of one core composed of one benzene ring or of a plurality of benzene rings fused together by sharing two or more neighboring ring carbon atoms, said benzene ring being optionally substituted, wherein each of said arylene group is bound to two other arylene groups of neighboring recurring units (R1) through a first C-C bond (E1) and a second C-C bond (E2), wherein at least 20 moles % of recurring units (R1) are kink- forming arylene units (R1-b), the remainder being rigid rod- forming arylene units (R1-a) different from aryleneR1_b units, wherein in said aryleneR1_a units the bond (E1) and the bond (E2) are co-linear and anti- parallel towards each other, said (P1) polymer being present in composition (C) in an amount of below 75 % by weight (wt. %) and above 10 wt. % based on the total wt. % of (P1) polymer and (PPSU) polymer, and (ii) at least one polyphenylsulfone polymer, said (PPSU) polymer being present in composition (C) in an amount of below 90 wt. % and above 25 wt. % of based on the total wt. % of polyarylene (P4) polymer and (PPSU) polymer.

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

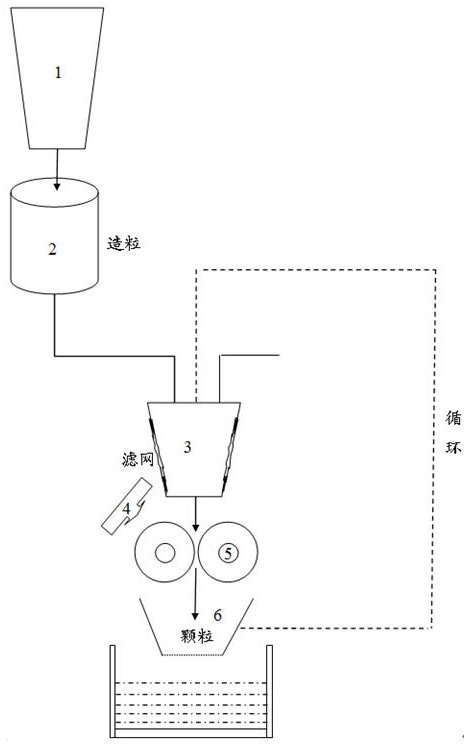

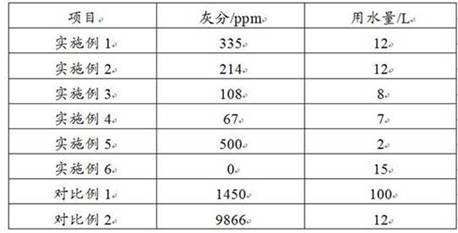

Polymer purification process and purification system

ActiveCN113980288AReduce dosageImprove washing efficiencyStationary filtering element filtersPoly ether ether ketoneEngineering

The invention belongs to the technical field of polymer impurity removal, and provides a polymer purification process and a purification system. The purification process comprises the following steps: firstly, adding a polymerization solution containing salt impurities into an eluate, to obtain polymer particles; extruding the polymer particles obtained in the step one under the condition of spraying the eluate, and removing the salt impurities in the polymer to obtain a cleaned polymer; dissolving the salt impurities in the eluate; and finally, removing the eluate from the cleaned polymer obtained in the step two to obtain the purified polymer. The liquid content of extruded polymer particles is low, cross contamination between the eluate and washing solutions is reduced, and the treatment cost, solvent loss and waste water and waste liquid discharge of various washing solutions are greatly reduced. The process can be applied to the production process of polysulfone, polyphenylsulfone, polyethersulfone and copolymers thereof, the production process of polyphenylene sulfide and copolymers thereof, and the production process of polyether-ether-ketone, polyarylene ether nitrile and copolymers thereof.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

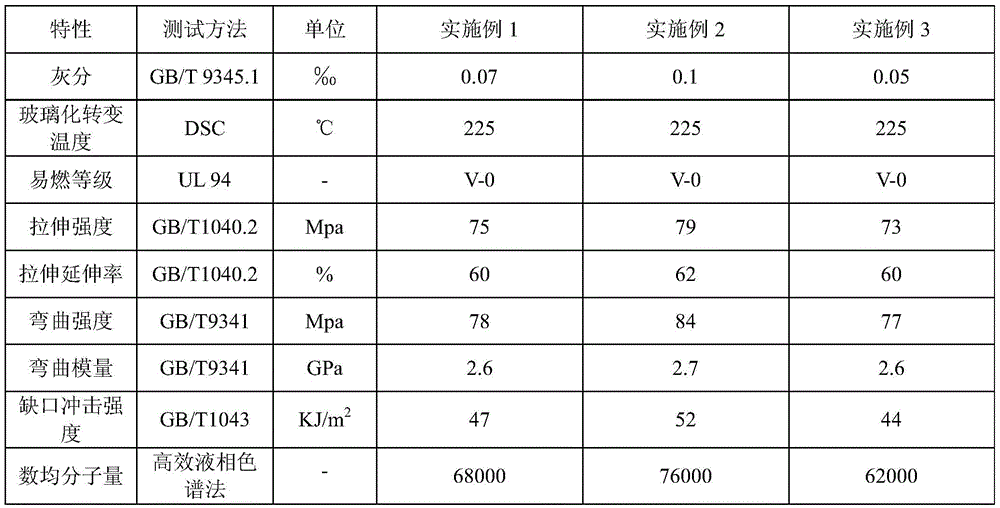

Preparation method of polyphenylsulfone resin

The invention provides a preparation method of polyphenylsulfone resin and belongs to the technical field of synthesis of organic macromolecular materials. Polymerization reaction is conducted withoutadopting a dehydrating agent scheme is not adopted, so that the reaction rate is increased, protective gas is recycled, loss is reduced and the production cost is further reduced; furthermore, the protective gas is blown off in the dehydration process, superfluous water in a reaction system is removed, the protective gas nearly does not take away a catalyst in the protective gas blowoff process,and the active molecules of the catalyst are not reduced and still maintain efficient catalytic performance, so that the reaction rate is increased, the use amount of the catalyst can be reduced and the production cost is further reduced.

Owner:重庆晟淦新材料科技有限公司

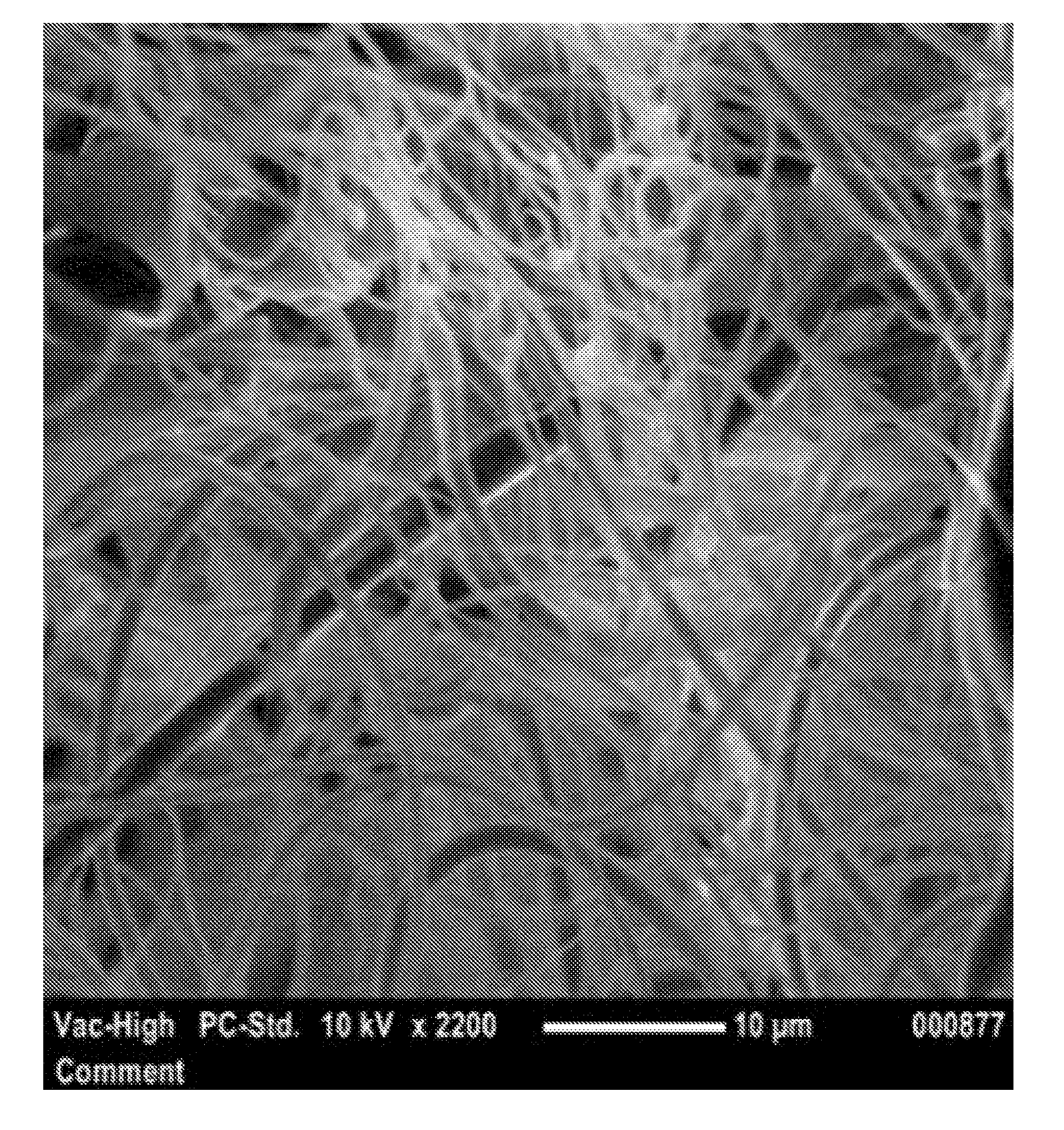

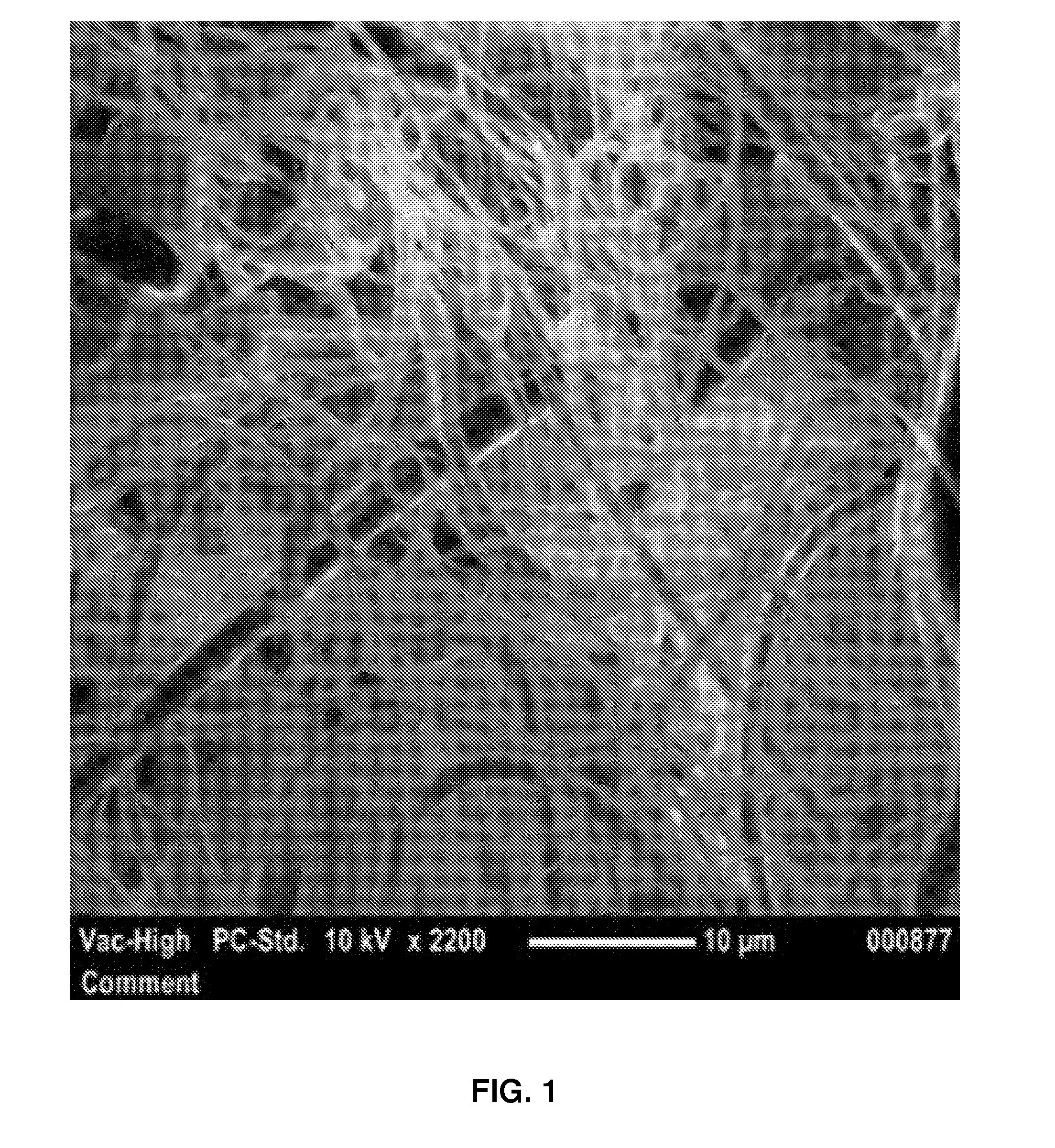

Shear spun sub-micrometer fibers

A process including shearing a first dispersion medium and a second dispersion medium under conditions that precipitate a plurality of polymeric fibers; and collecting the plurality of polymeric fibers at a rate of at least 300 grams / hour. The first dispersion medium is a solution including at least one polymeric component. The at least one polymeric component includes a poly-etherimide component selected from the group consisting of polyetherimide homopolymers, polyetherimide co-polymers, poly etherether ketones homopolymers, polyetherether ketones copolymers, polyphenylene sulfones homopolymers, polyphenylene sulfones copolymers, and combinations thereof. Products produced by the process can be non-woven paper, medical implants, ultra-fine filters, membranes, hospital gowns, electrical insulation paper, honeycomb structures and personal hygiene products, dialyzers, blood, oxygenator filters, intravenous (IV) filters, diagnostic test filters, and blood / apheresis filters.

Owner:SHPP GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com