Polymer purification process and purification system

A purification process and polymer technology, which is applied in the field of purification process and purification system of polymer particles, can solve the problems of little progress and inconspicuous effect, and achieve stable results, good impurity removal effect and clean washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

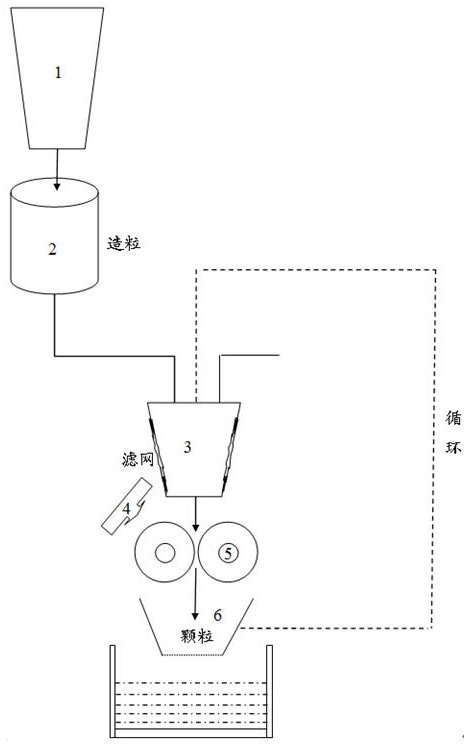

Method used

Image

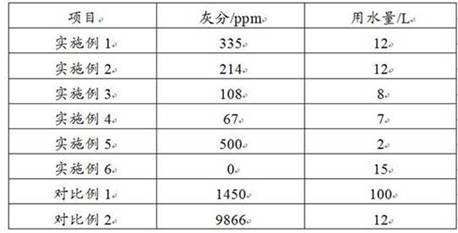

Examples

Embodiment 1

[0111] The polymerization solution tank is equipped with 10L of polysulfone polymer solution with a mass concentration of 25% N, N-dimethylacetamide as the solvent, which is added dropwise at a constant speed through the connecting pipe to the eluate tank with 10L deionized water as the eluate , to obtain polysulfone polymer particles (by controlling the dropping speed and the stirring speed in the eluate tank, the particle size is controlled between 0.3 and 10 mm). Then the precipitated polysulfone particles are introduced into the extrusion rollers, the extrusion roller speed is set at 100rpm, and the extrusion distance of each group of extrusion rollers is 0.6mm, the polysulfone particles are extruded by three groups of extrusion rollers successively, and the extruded At the same time, a spraying device is used to spray the eluate to the extruded polysulfone granules, extrude to remove salt impurities in the granules, and obtain washed polysulfone granules.

[0112] The was...

Embodiment 2

[0114] The polymerization solution tank is equipped with 10L of polysulfone polymer solution with a mass concentration of 25% N, N-dimethylacetamide as the solvent, which is added dropwise at a constant speed through the connecting pipe to the eluate tank with 10L deionized water as the eluate , to obtain polysulfone polymer particles (by controlling the dropping speed and the stirring speed in the eluate tank, the particle size is controlled between 0.3 and 10 mm). Then the precipitated polysulfone particles are introduced into the extrusion rollers, the extrusion roller speed is set at 100rpm, and the extrusion distance of each group of extrusion rollers is 0.6mm, the polysulfone particles are extruded by six groups of extrusion rollers in turn, and the extruded At the same time, the extruded polysulfone particles are sprayed with a spray device to remove the salt impurities in the particles. After the polysulfone particles extruded once are mixed with the eluate, the extrus...

Embodiment 3

[0117] The polymerization solution tank is equipped with 10L of polyphenylene sulfide polymer solution with a mass concentration of 25% N,N-dimethylacetamide as the solvent, which is added dropwise to 6L of deionized water and methanol mixture ( Water: methanol = 1:1) in the eluate tank to obtain polyphenylene sulfide polymer particles (by controlling the dropping speed and stirring speed in the eluate tank, the particle size is controlled between 0.3 and 10mm) . Then the precipitated polyphenylene sulfide particles are introduced into the squeeze rollers, the speed of the squeeze rollers is set at 100rpm, the extrusion distance of each set of squeeze rollers is 0.6mm, and the polyphenylene sulfide particles are squeezed through 6 sets of squeeze rollers in turn , While extruding, use a spray device to spray the precipitated liquid on the extruded polysulfone particles, and extrude to remove the salt impurities in the particles. After the polyphenylene sulfide particles extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com