Patents

Literature

31results about How to "Low liquid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

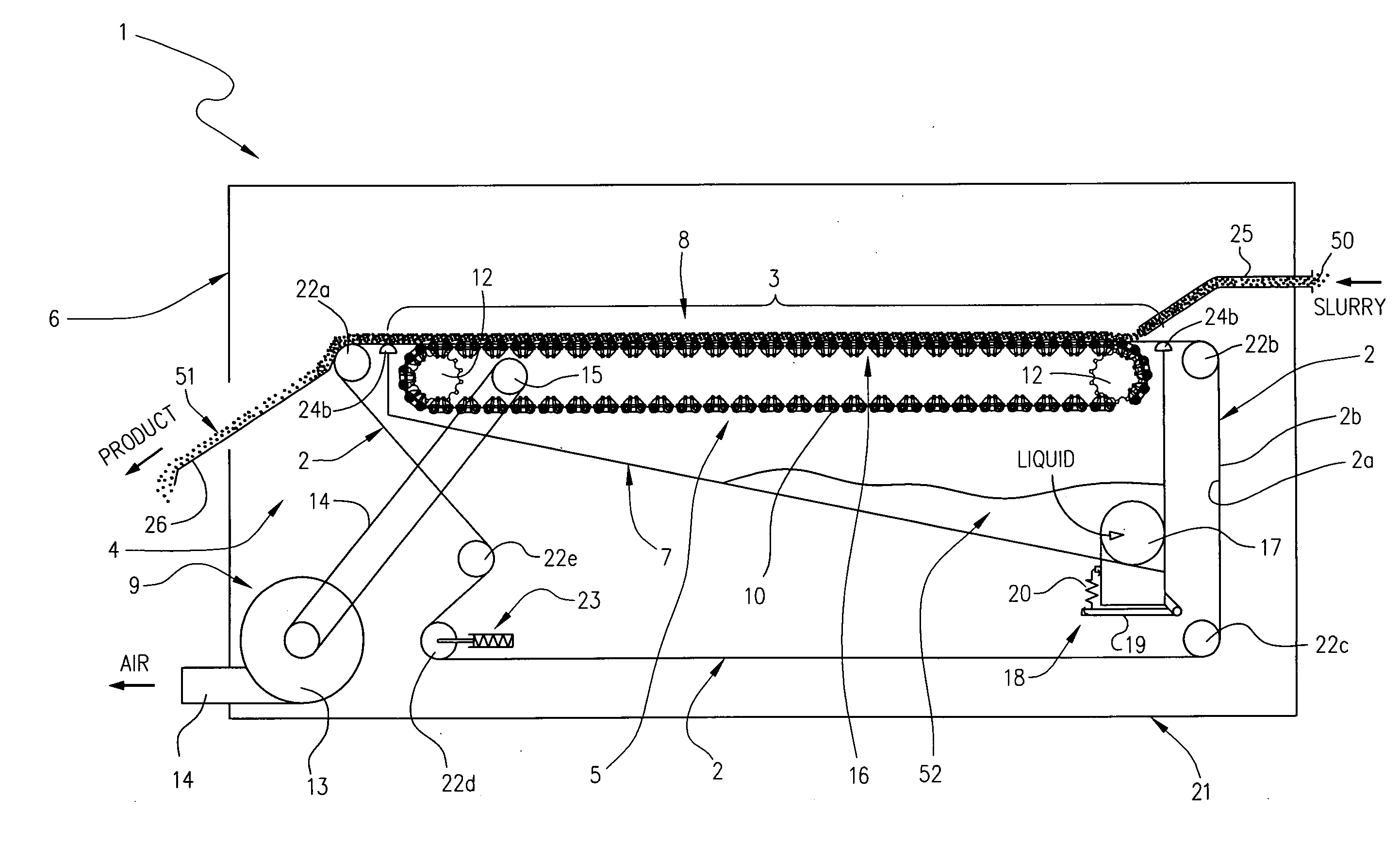

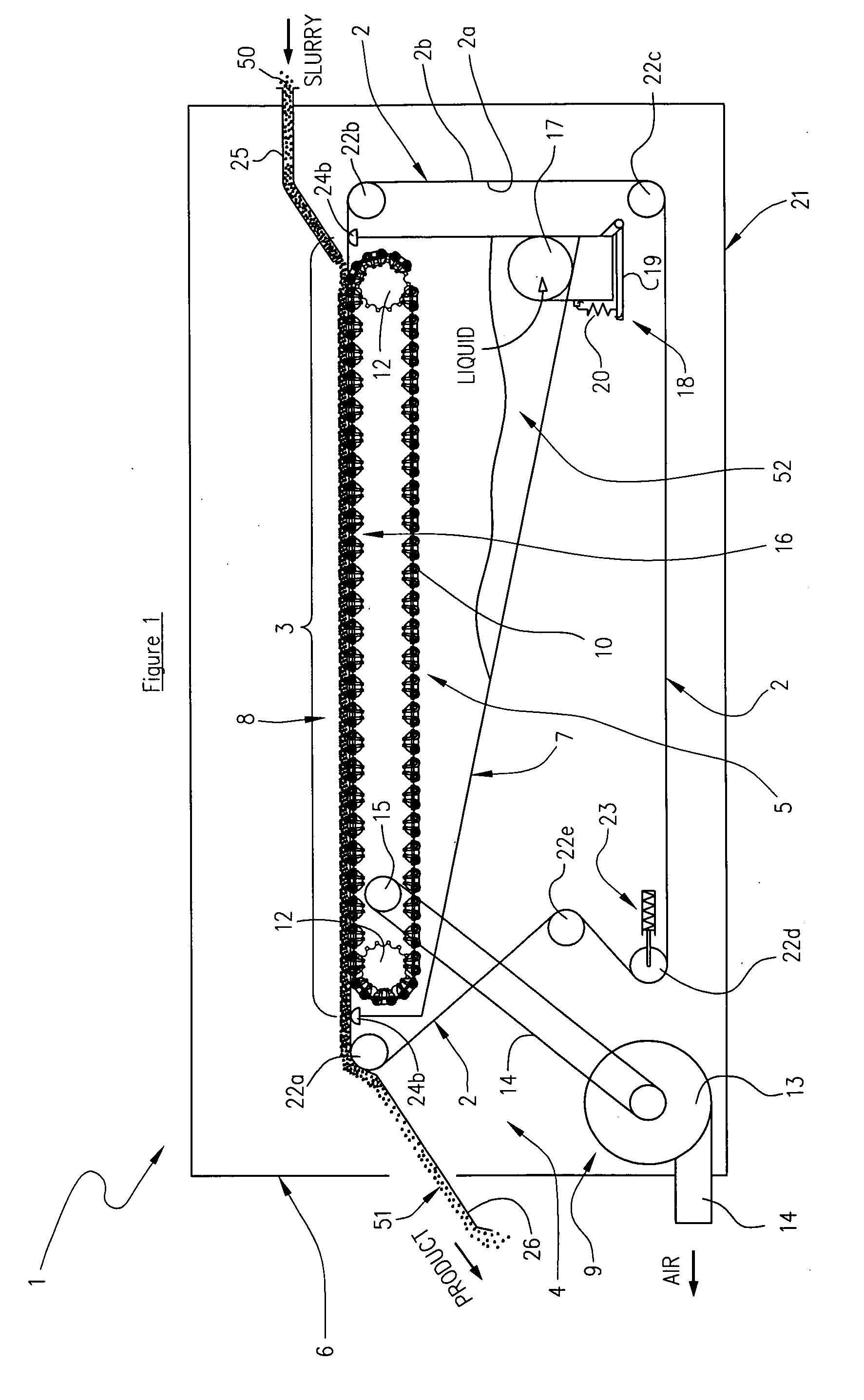

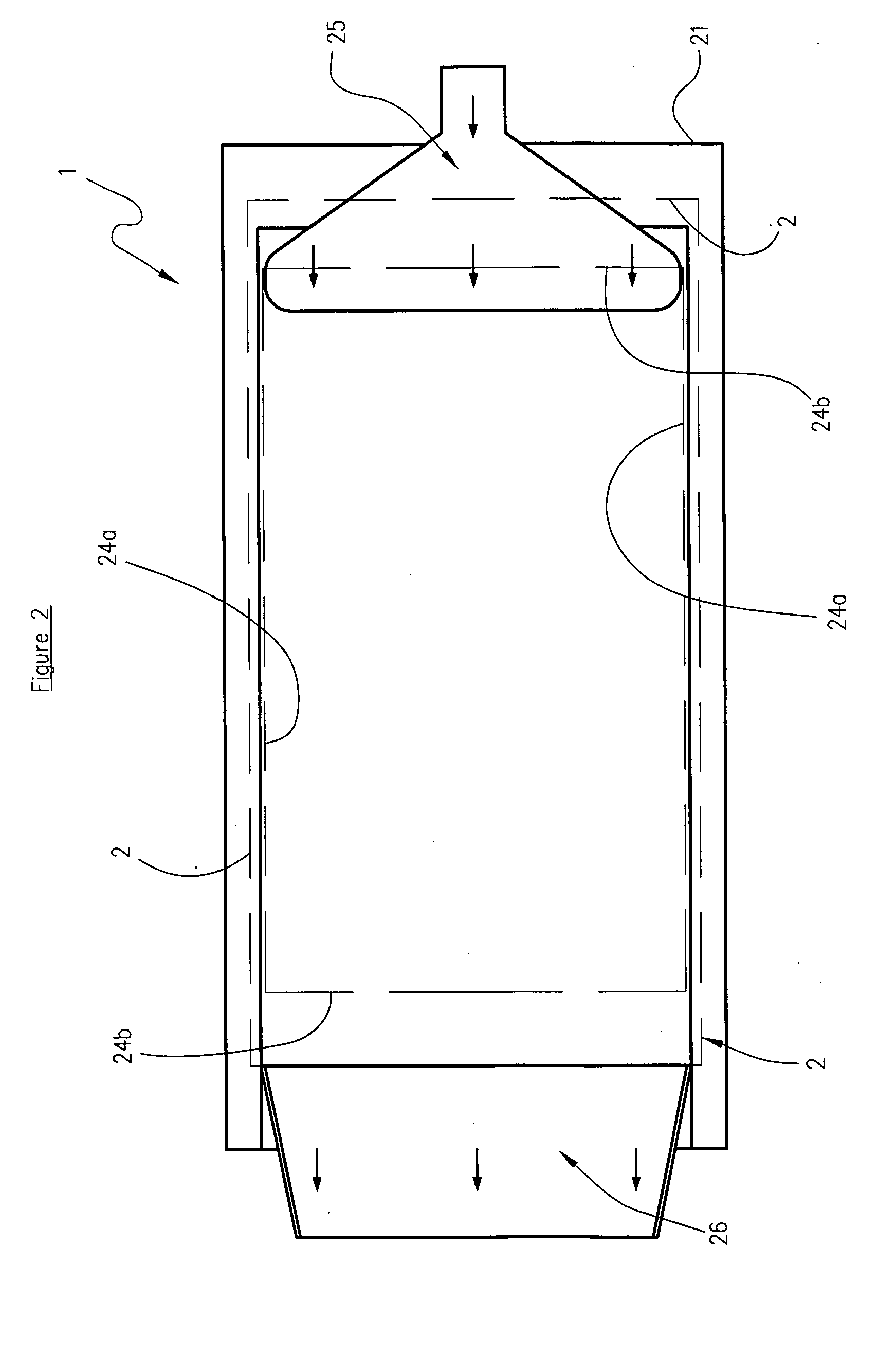

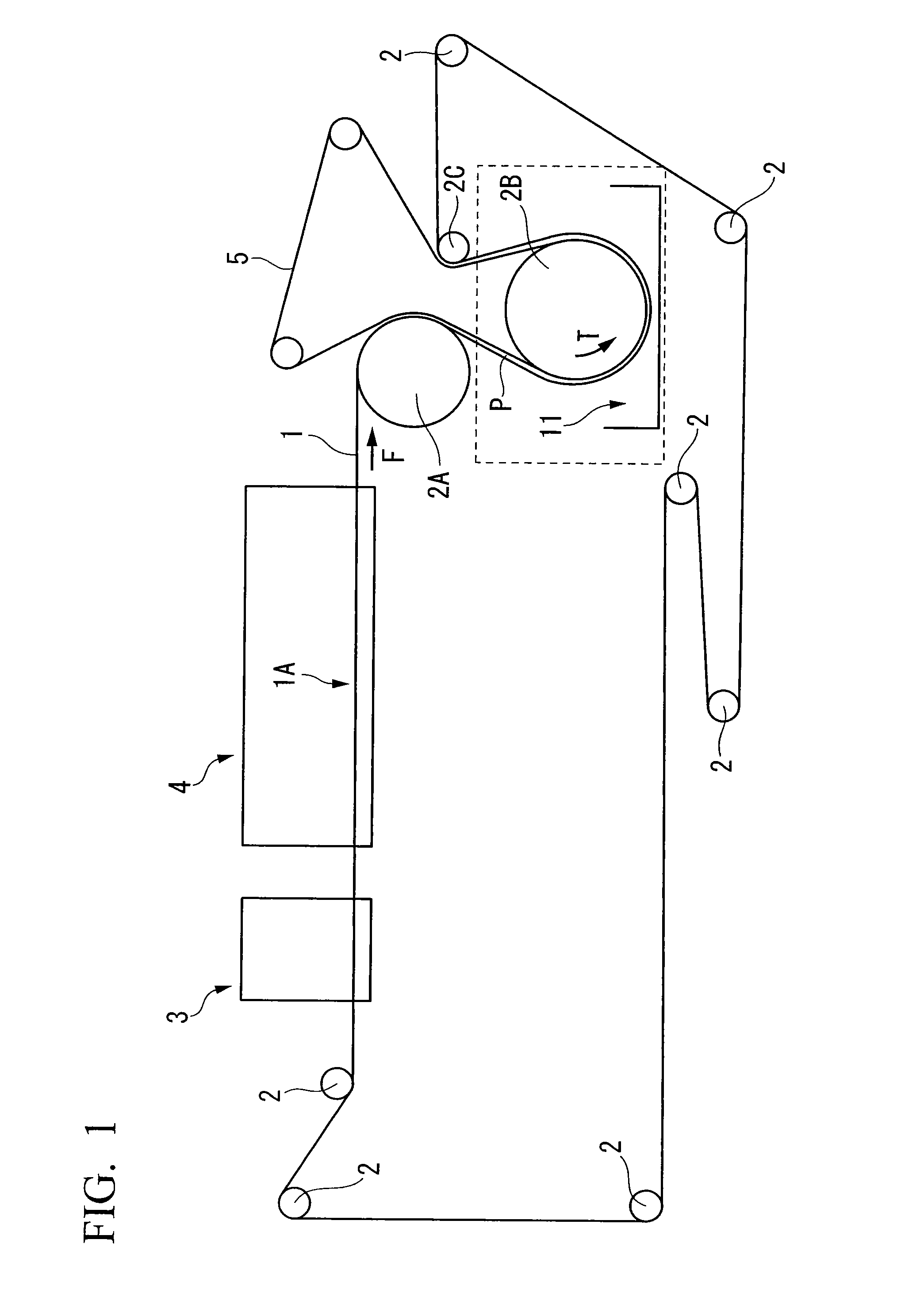

Liquid removal apparatus

ActiveUS20110089122A1Prevent lodgingHigh solid contentWater/sewage treatmentSedimentation separationSupporting systemDifferential pressure

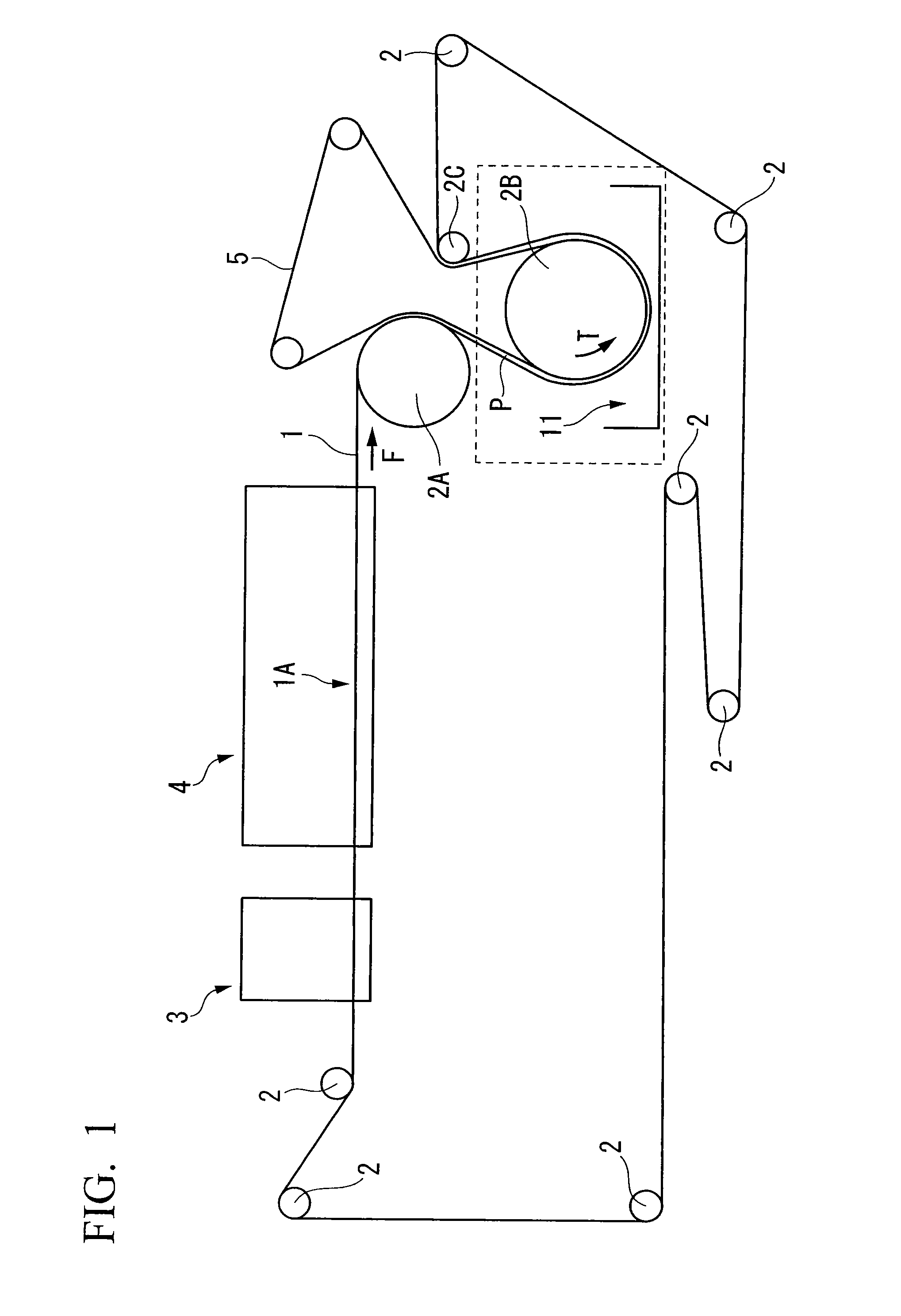

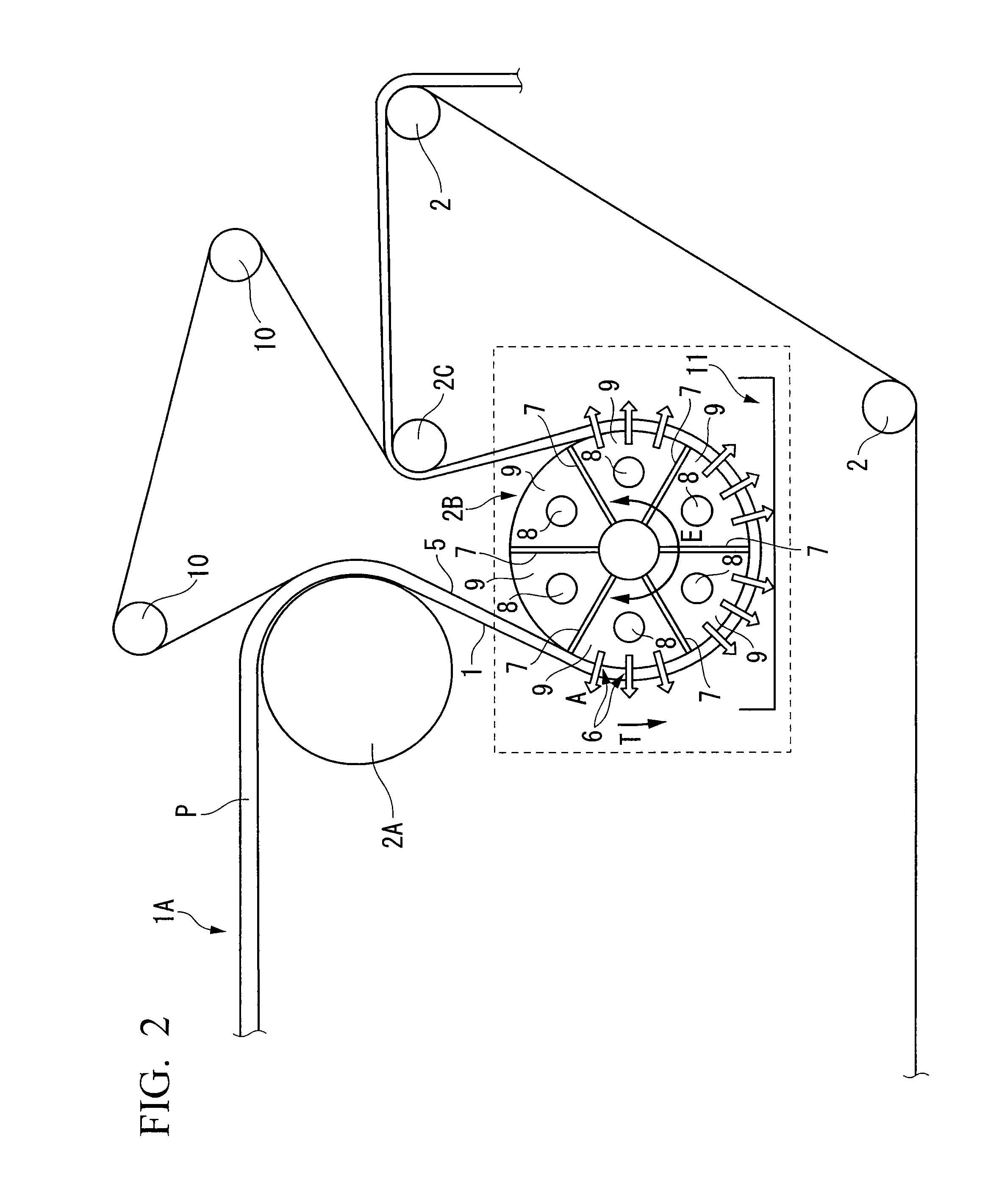

A liquid removal apparatus adapted to separate liquid from a composite slurry of liquid and solids. The apparatus includes a movable, permeable membrane having opposing first and second sides. A ‘loaded belt portion’ of the second side is configured to receive the slurry. A permeable membrane support system is configured to provide movable support for the loaded belt portion and includes a transport deck located in contact with the first side of the permeable membrane below the loaded belt portion. The liquid removal apparatus has a housing with a low-pressure chamber in sealing contact with the first side of the permeable membrane. A pressure conditioning system applies a differential pressure via the housing to generate a lower pressure on the first filter belt side than on the second side. The transport deck is located within the low pressure chamber.

Owner:CT CIVIL LTD

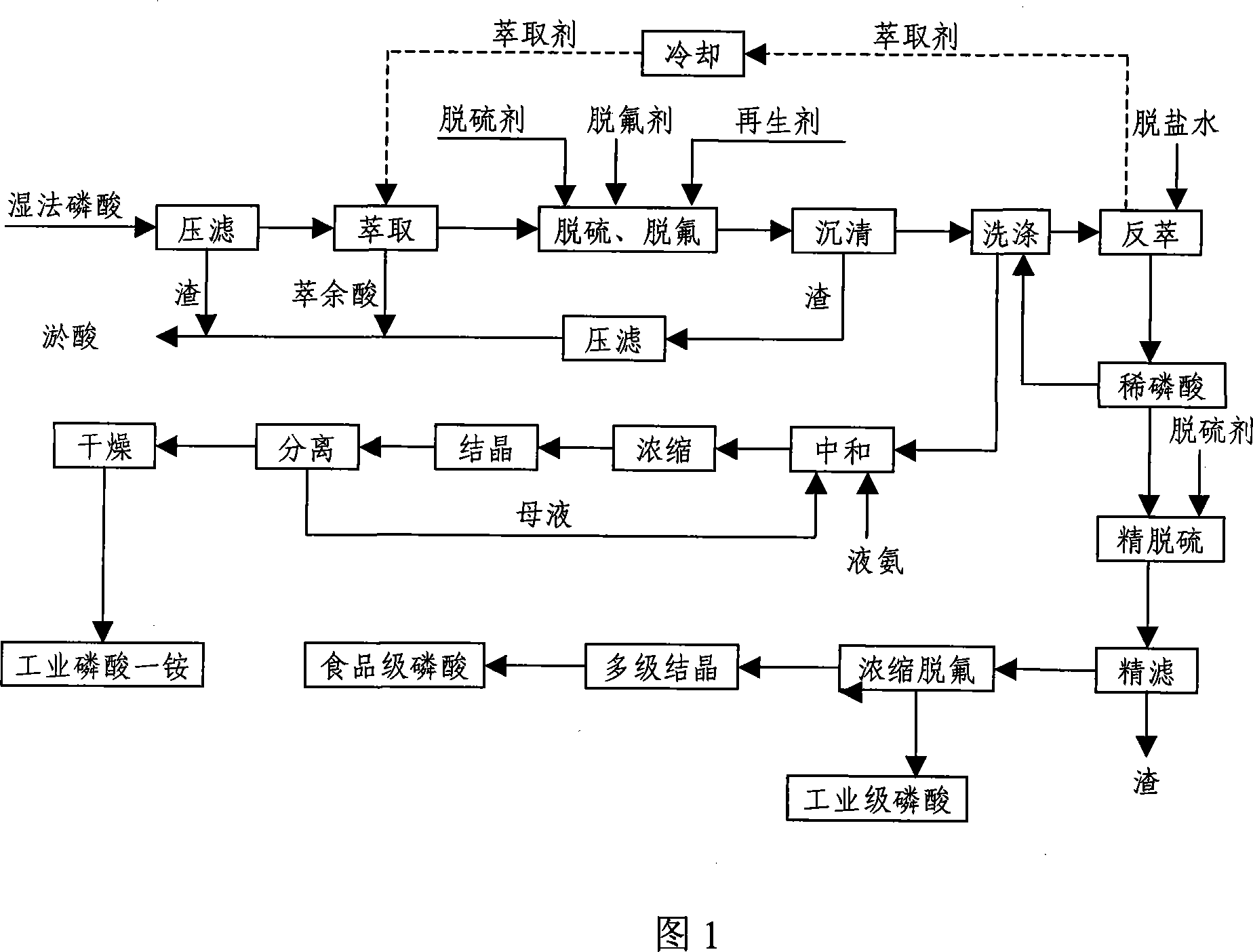

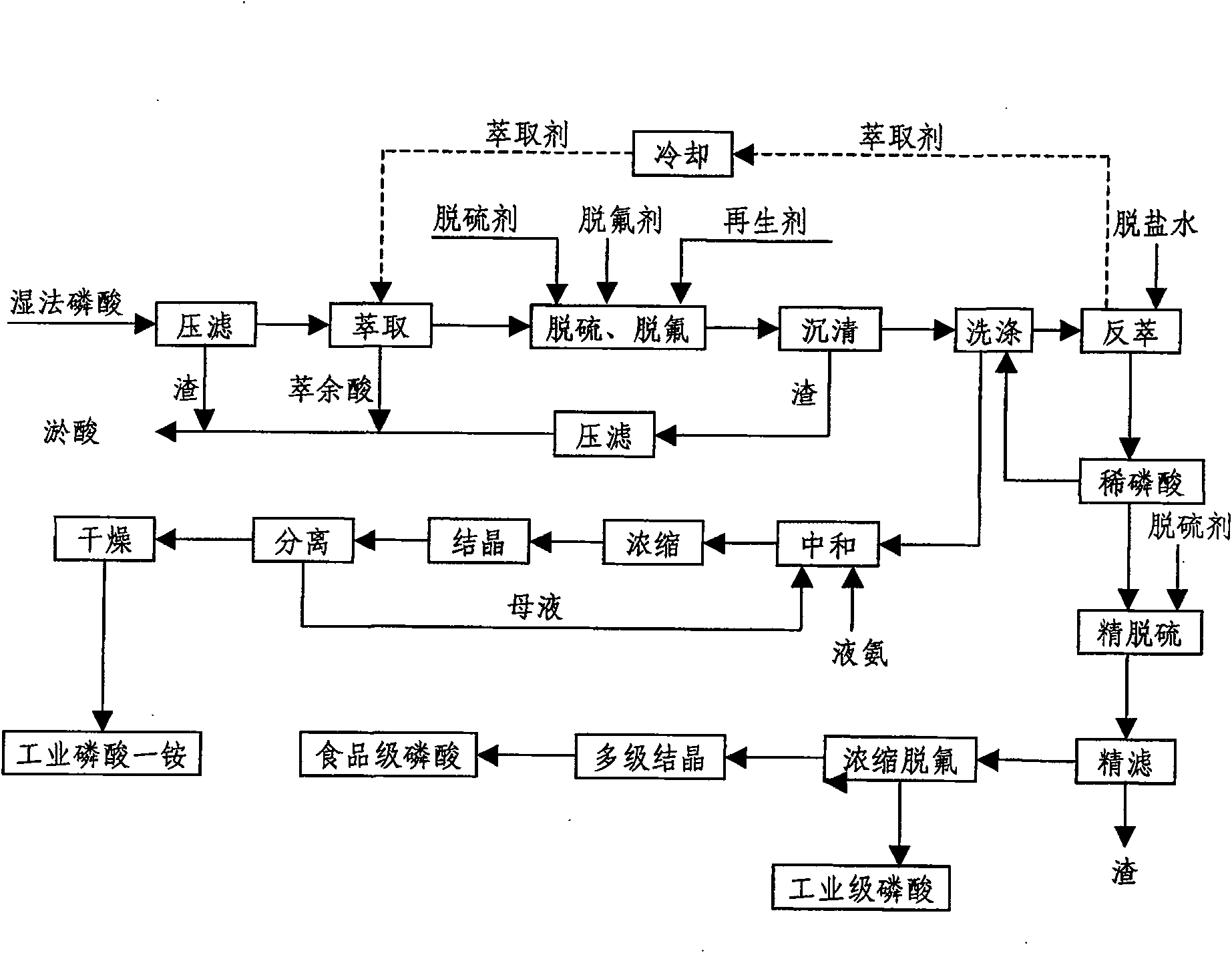

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

Apparatus and method for processing of animal manure wastewater

InactiveUS20060138054A1Low liquid contentLow contentLiquid separation auxillary apparatusSludge treatmentScrew pressSewage

Owner:MERI ENTSORGUNGSTECHN FUR DIE PAPIERIND

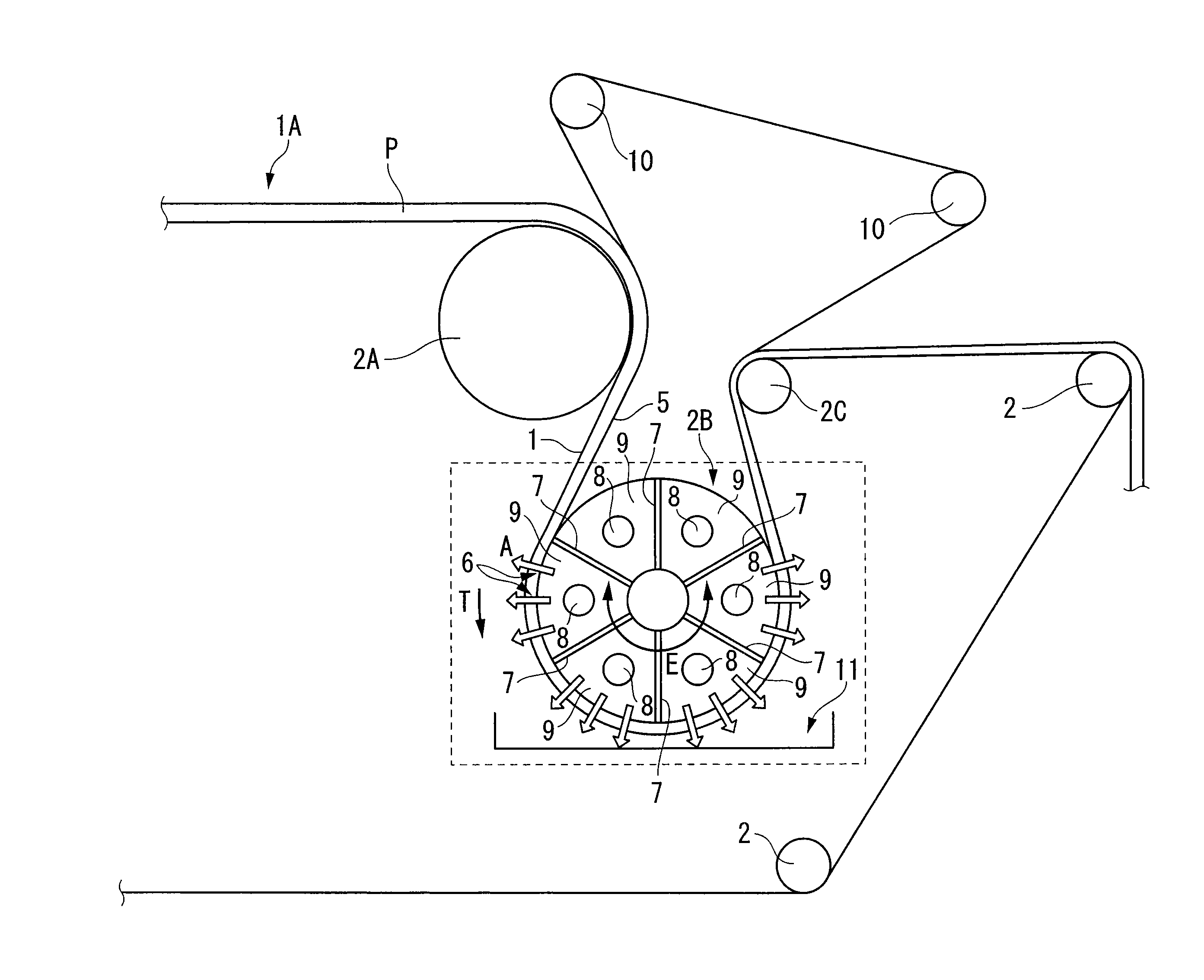

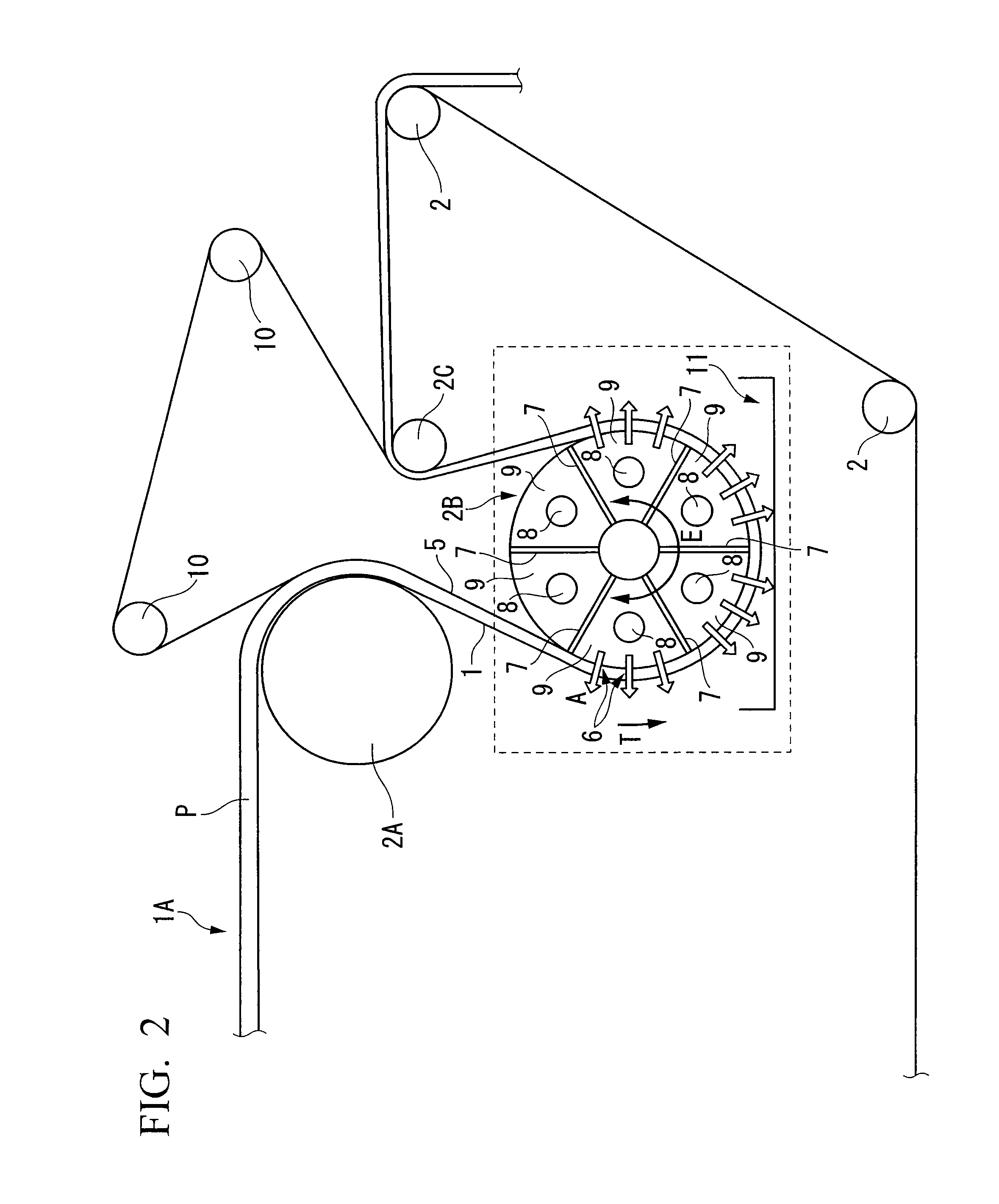

Solid-Liquid Separating Device, Filtering Apparatus, and Solid-Liquid Separating Method

ActiveUS20110036769A1Effective squeezeComponents is relatively effectiveFiltration circuitsPressesEngineeringMaterial supply

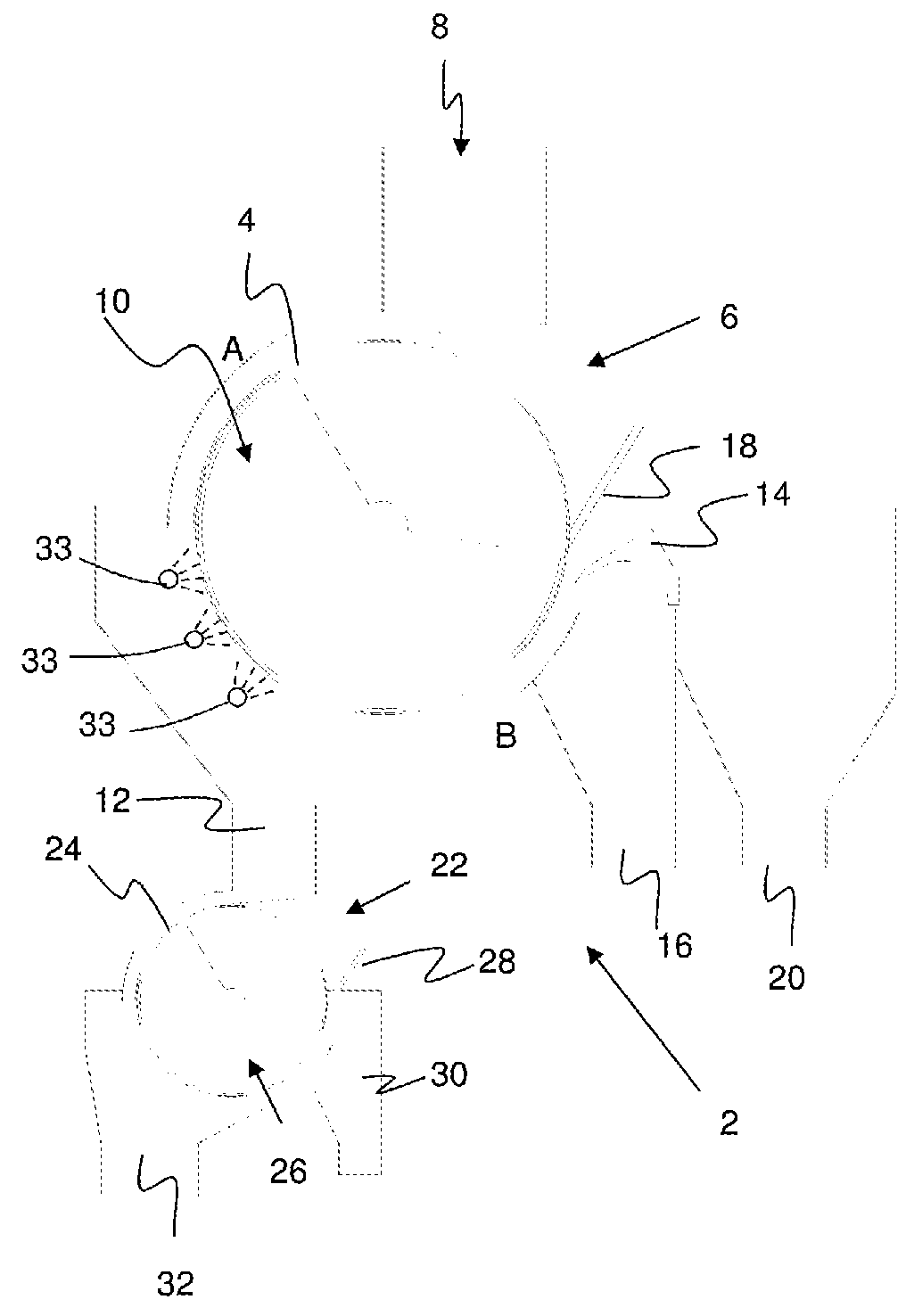

A solid-liquid separating apparatus is provided with: a separating roll which has a substantially cylindrical shape with a plurality of through holes, which penetrate between an inner surface and an outer surface in radial direction thereof, and is rotatable in circumferential direction thereof; and a pair of separating filter cloths which is endless belts capable of traveling in a rotation direction of the separating roll and are wound around the outer circumference of the separating roll so as to overlap each other, wherein a material supplied between the pair of filter cloths is squeezed by being rolled together with the pair of filter cloths therebetween on the outer circumference of the separating roll, and the material is dehydrated by ventilating via each through hole.

Owner:TSUKISHIMA KIKAI CO LTD

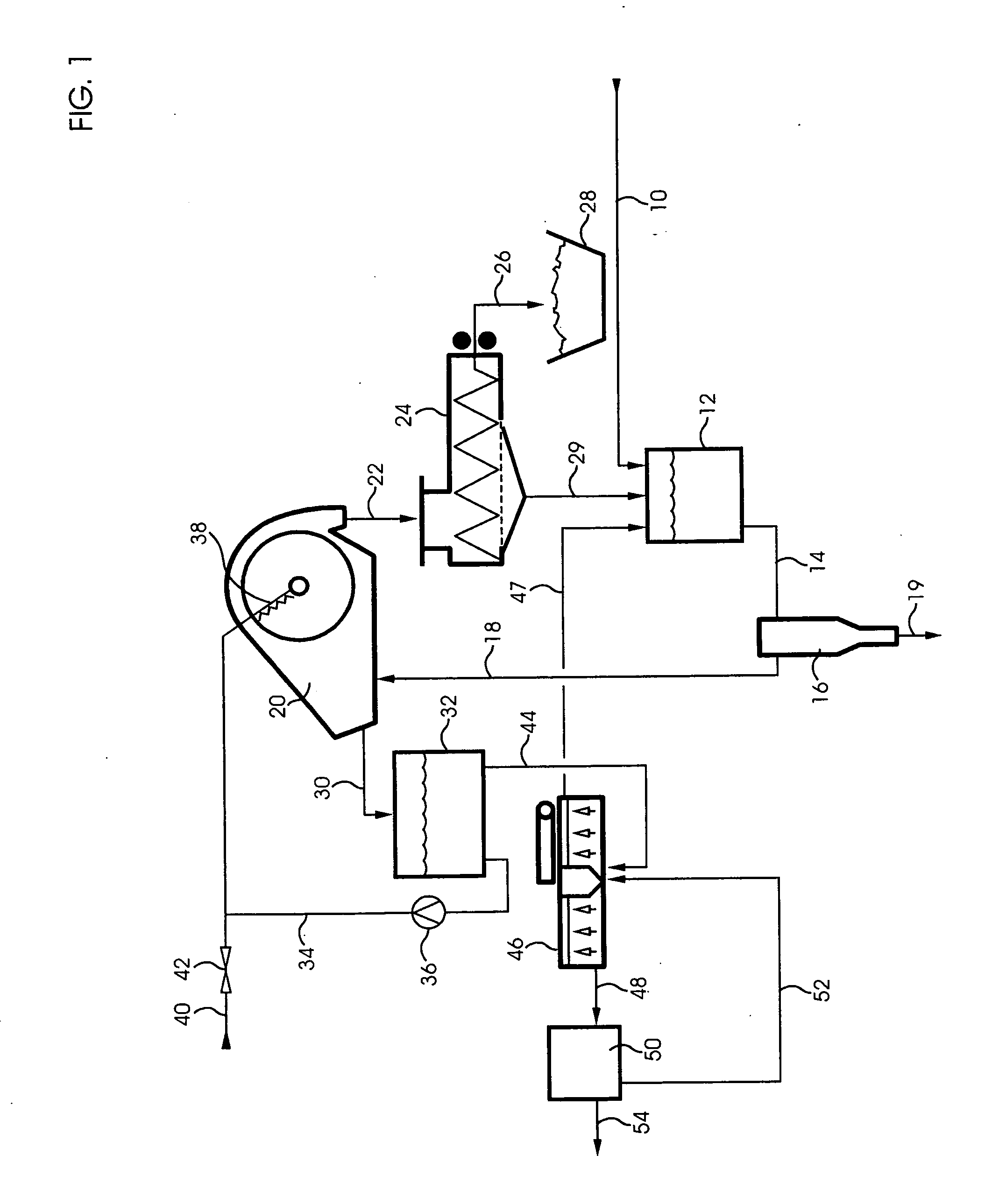

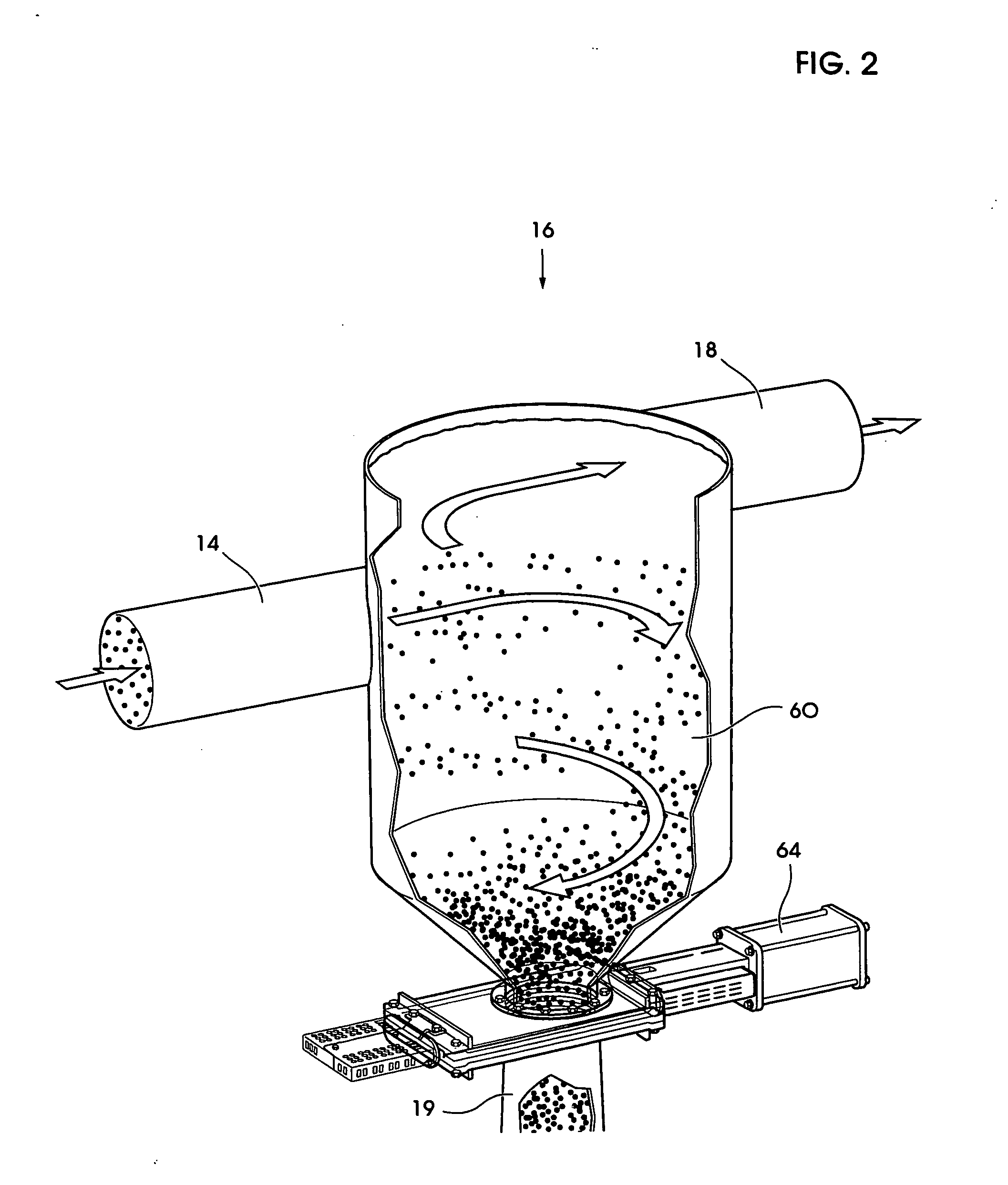

A method and apparatus for separating magnetic material from a slurry

ActiveUS20160030947A1Efficiently reprocessedNot to wasteWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSlurryMechanical engineering

A method and apparatus for separating magnetic material from a slurry is disclosed, the method including the steps of providing a first moving surface, depositing the slurry onto the first moving surface, attracting at least a portion of the magnetic material of the slurry onto the first moving surface by first magnetic means, arranging the first moving surface such that liquid from the slurry is removed due to the portion of the magnetic material being attracted to the moving surface by the first magnetic means to form a magnetic material cake, separating an inner portion of the magnetic material cake from an outer portion of the magnetic material cake, with respect to the first moving surface, such that the inner portion has a lower liquid content than the outer portion.

Owner:STEINERT AUSTRALIA

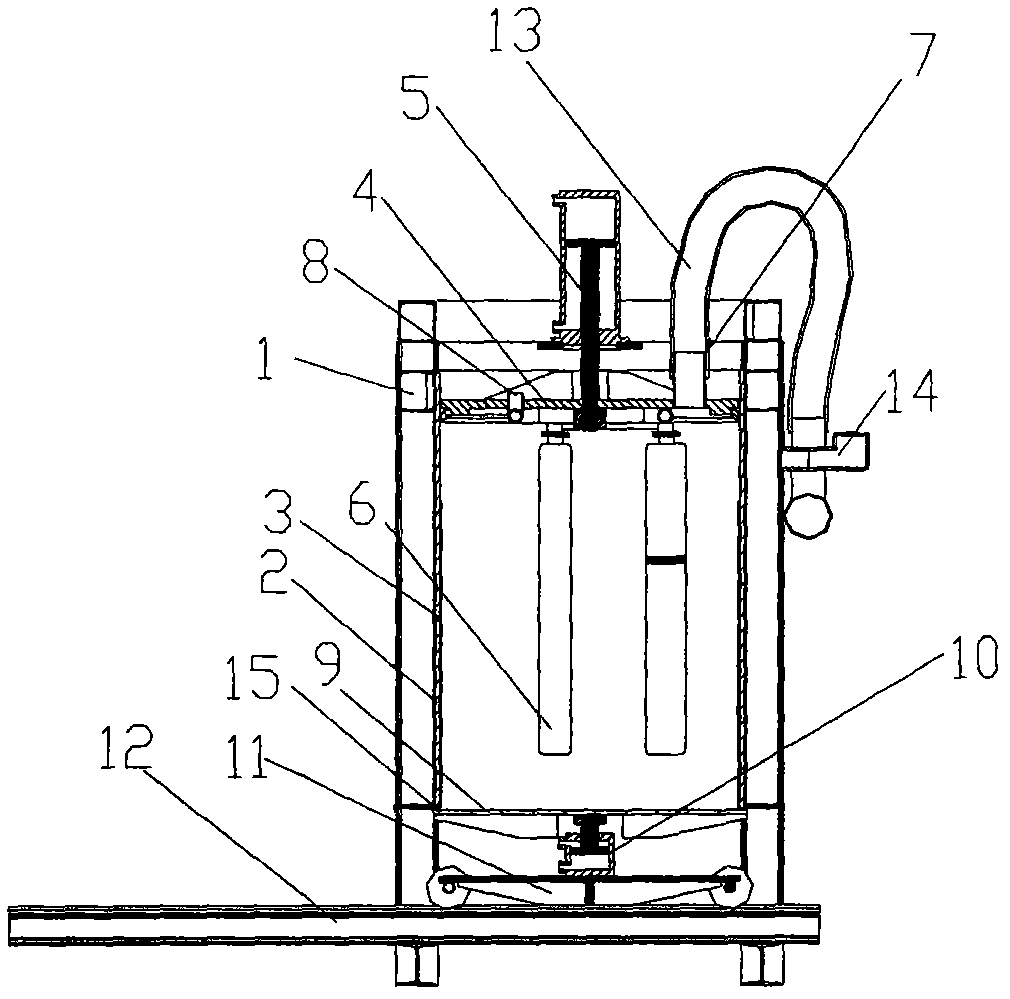

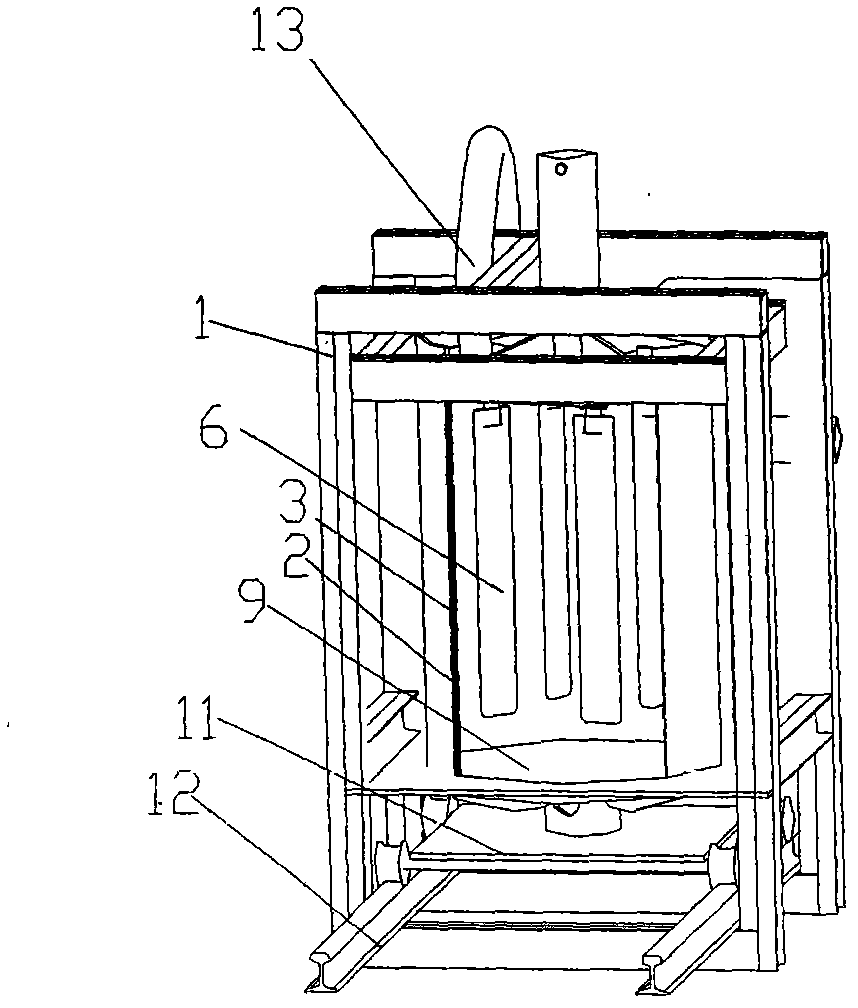

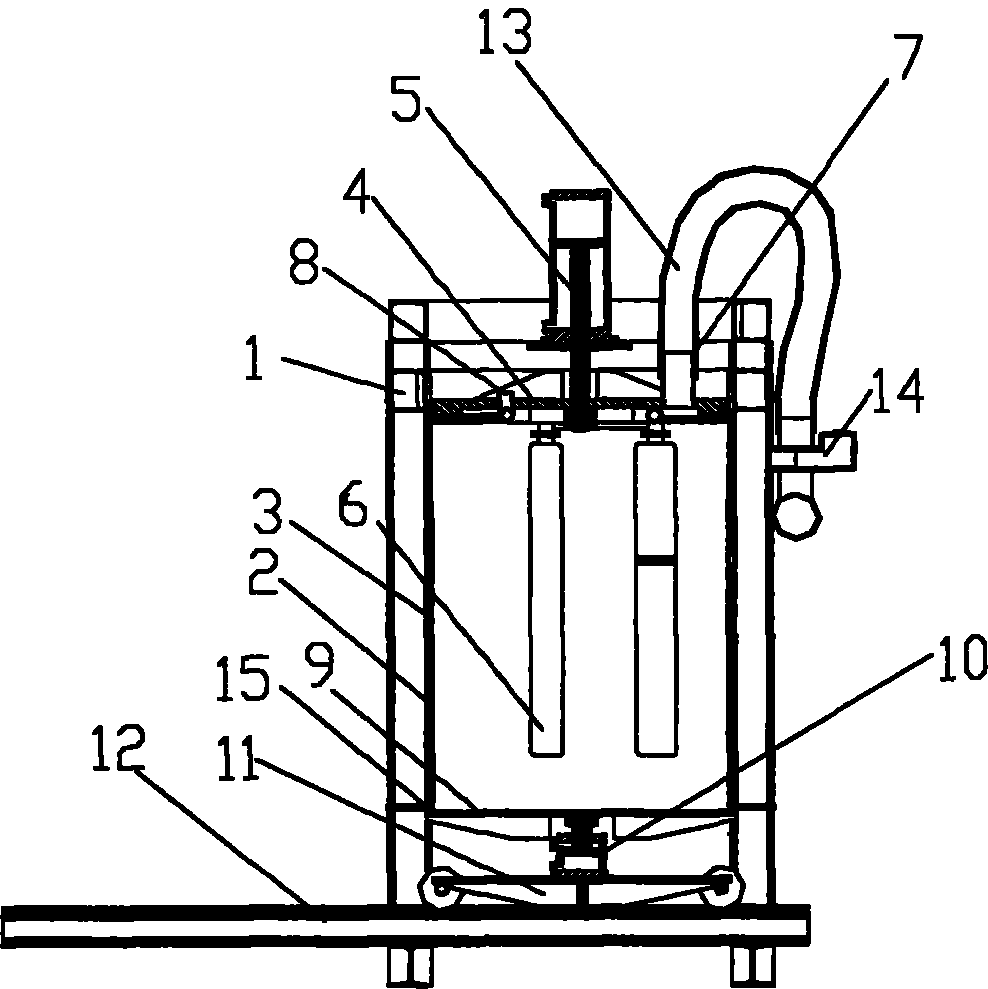

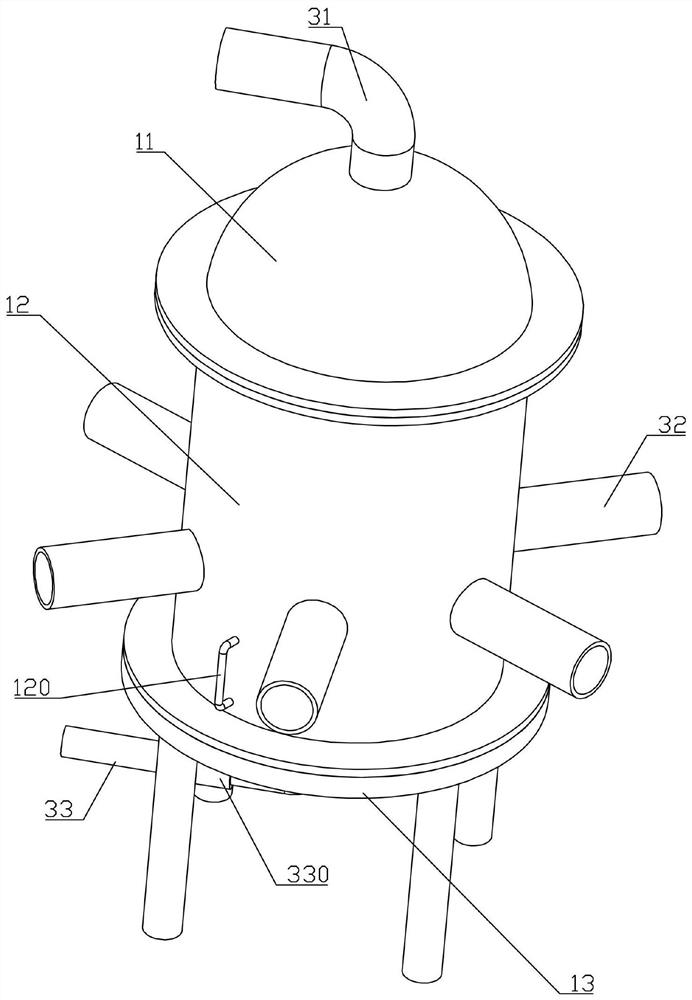

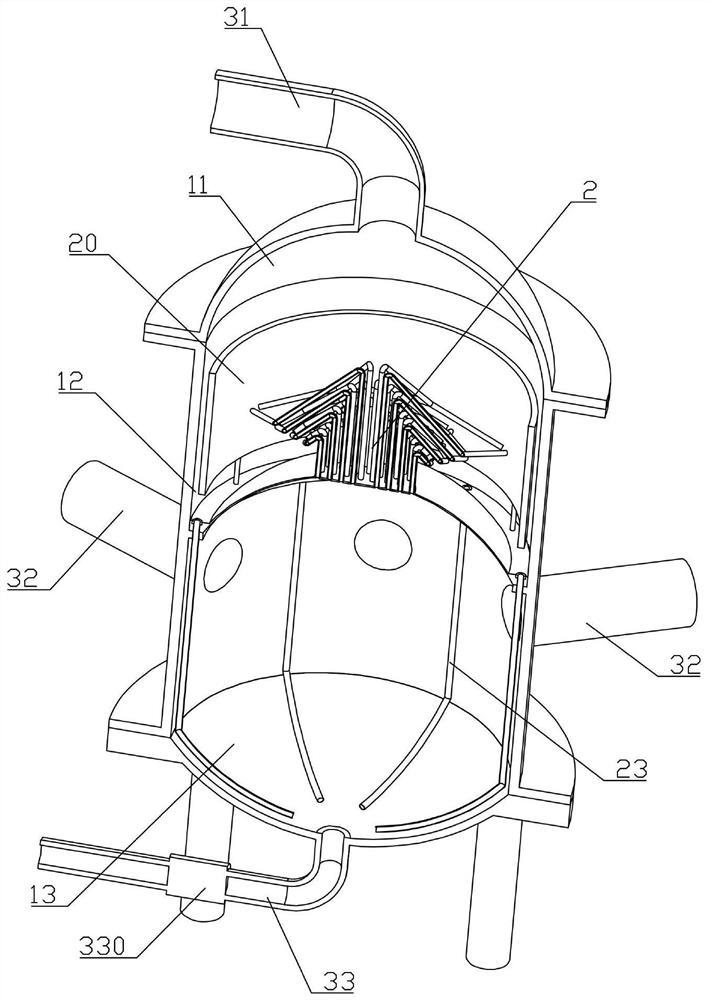

Solid and liquid separation device for sewage

InactiveCN102652889AImprove efficiencyEliminate auxiliary workStationary filtering element filtersEngineeringSewage

The invention relates to a solid and liquid separation device for sewage. The solid and liquid separation device comprises a stander, a filter barrel supported by the stander, an upper filter barrel cover which can move in the filter barrel up and down, a lower filter barrel cover, a moving device of the lower filter barrel cover and a filtrate inlet connected to the filter barrel. The solid and liquid separation device has a simple structure, high working efficiency, a good solid and liquid separation effect and high automation degree.

Owner:唐志

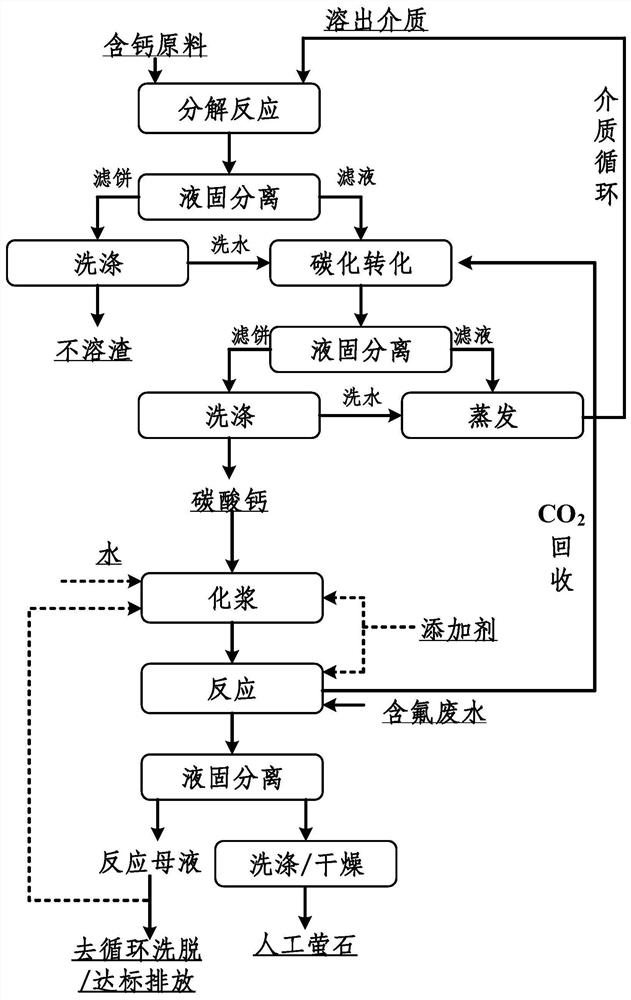

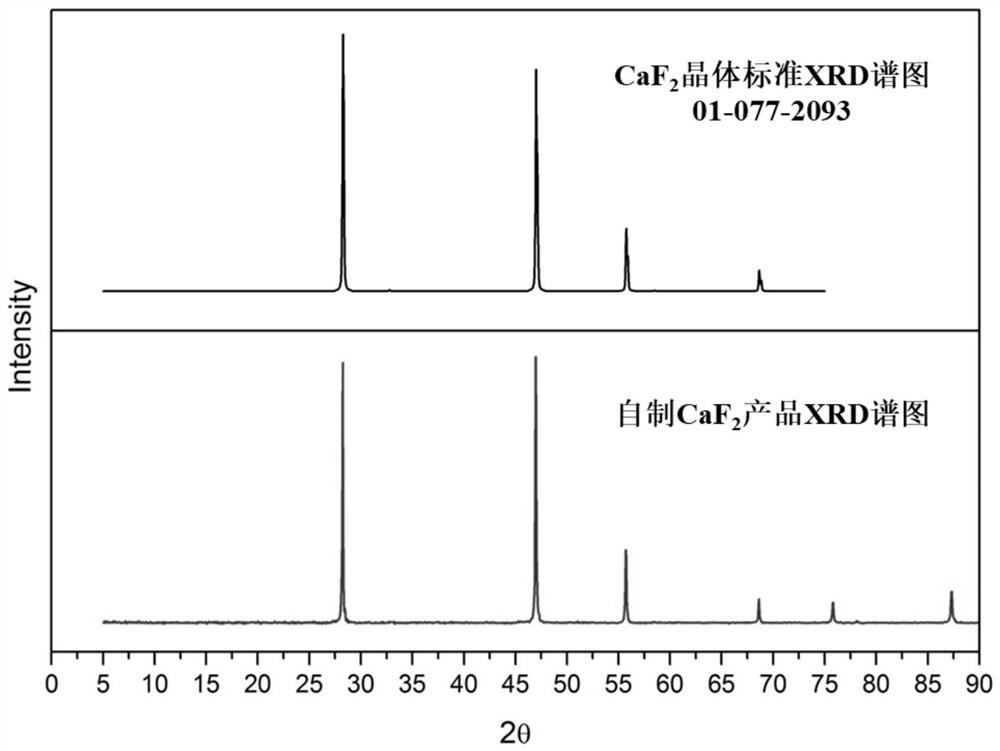

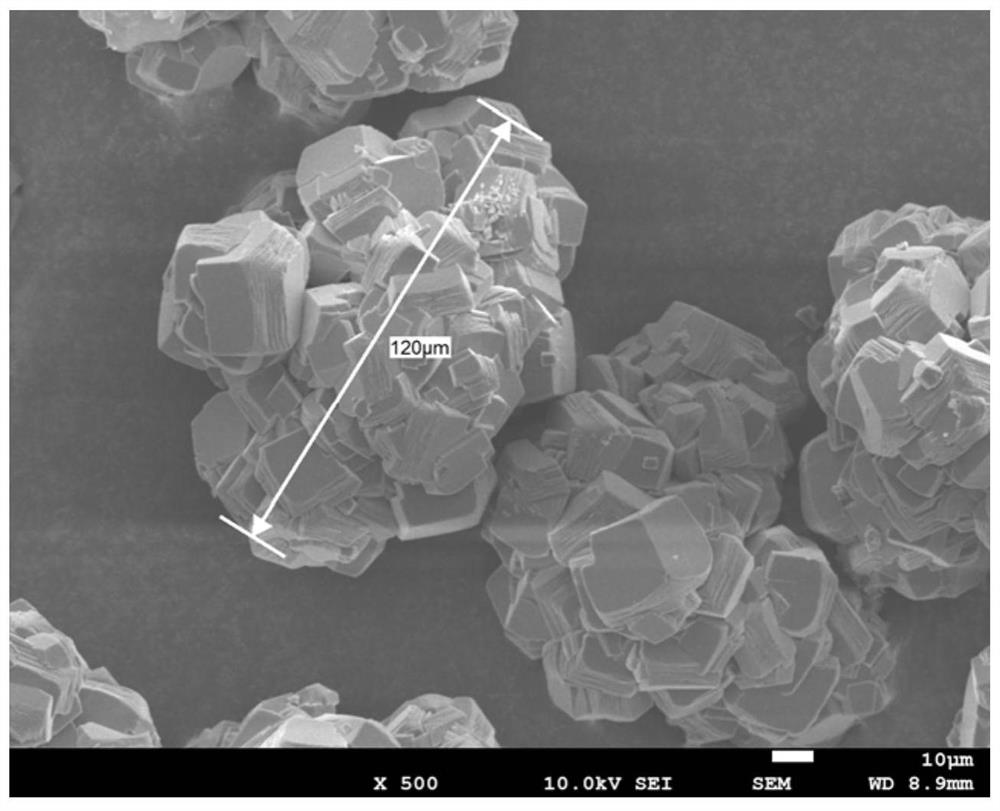

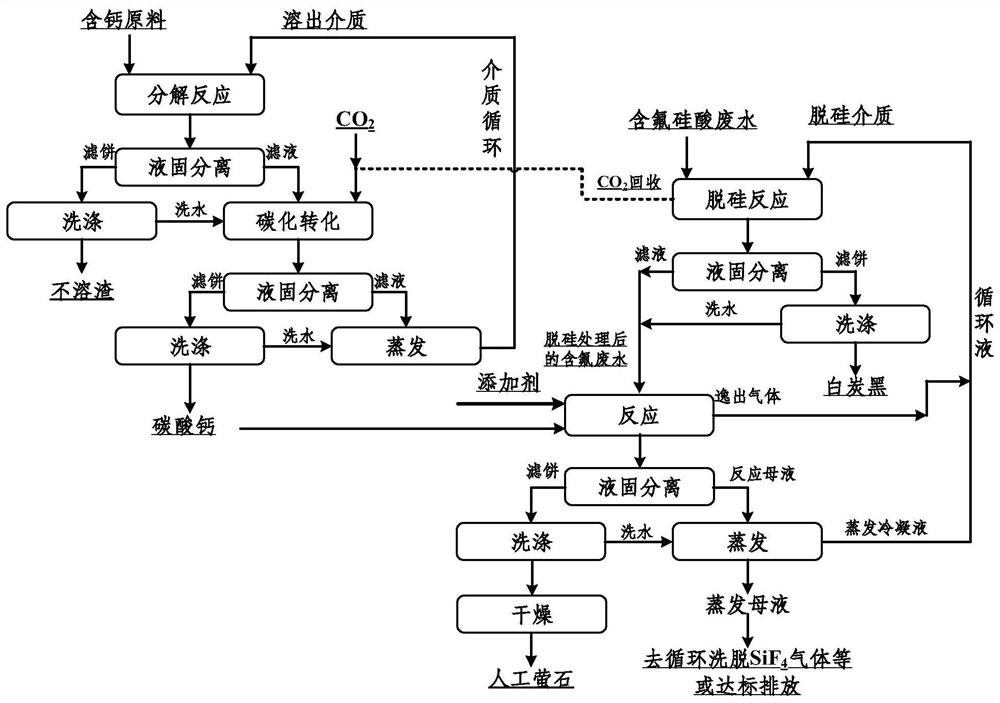

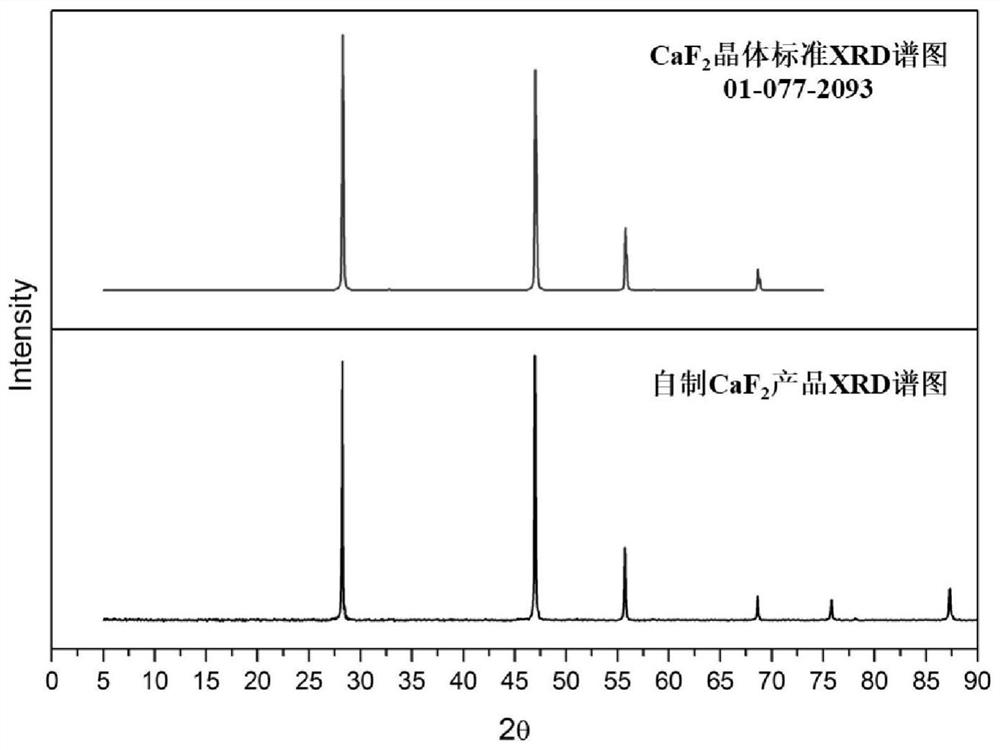

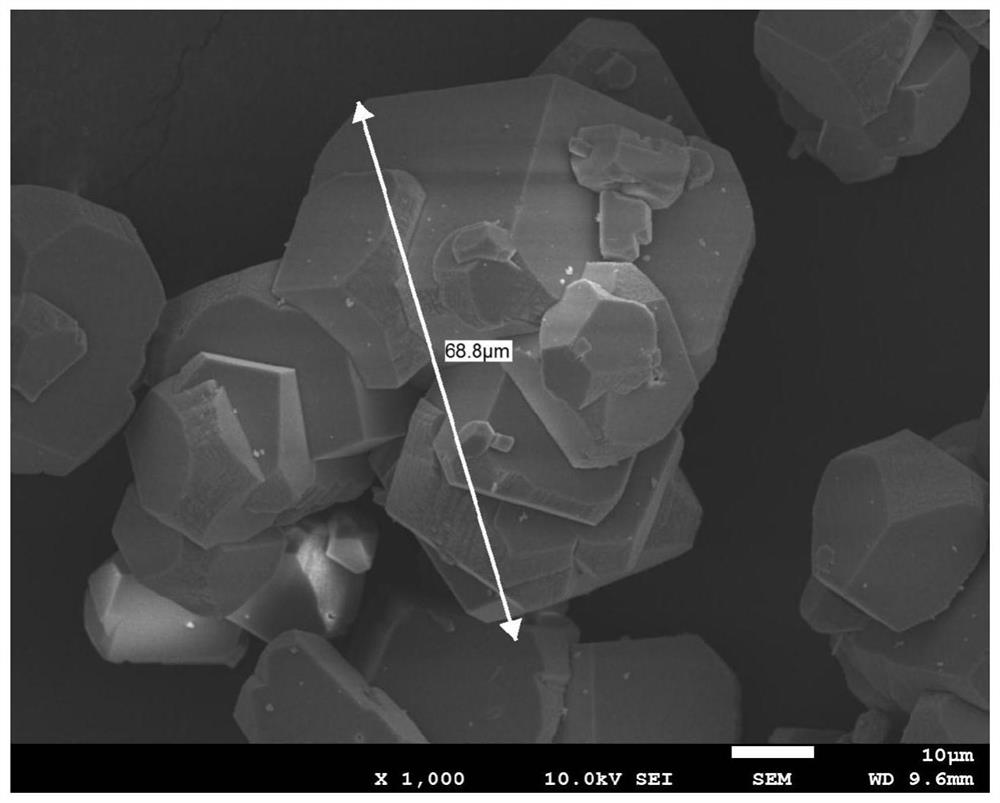

Method for preparing calcium fluoride from fluorine-containing wastewater

ActiveCN113120938AHigh recovery rateZero emissionCalcium/strontium/barium fluoridesSludgeResource recovery

The invention relates to a method for preparing calcium fluoride from fluorine-containing wastewater. The preparation method comprises the following steps: carrying out decomposition reaction on a calcium-containing raw material and a dissolution medium, carrying out carbonization conversion reaction on a calcium-containing solution obtained by the decomposition reaction and carbon dioxide, and mixing and reacting a calcium carbonate solid obtained by the carbonization conversion reaction with the fluorine-containing wastewater and an additive to obtain a calcium fluoride solid. According to the preparation method, a high-quality artificial fluorite product with controllable morphology, controllable granularity and controllable purity can be prepared, and the fluorine resource recovery rate can be increased to 90% or above; and in addition, the preparation method realizes efficient circulation of the medium and carbon dioxide, avoids the generation of fluorine-containing sludge, and has the advantages of mild process conditions, no special requirements on equipment materials and types, strong industrial operability and wide application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

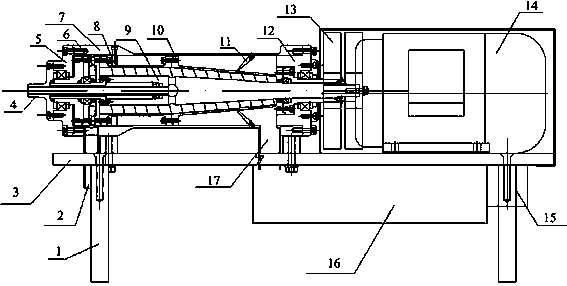

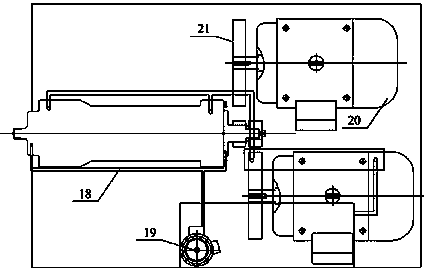

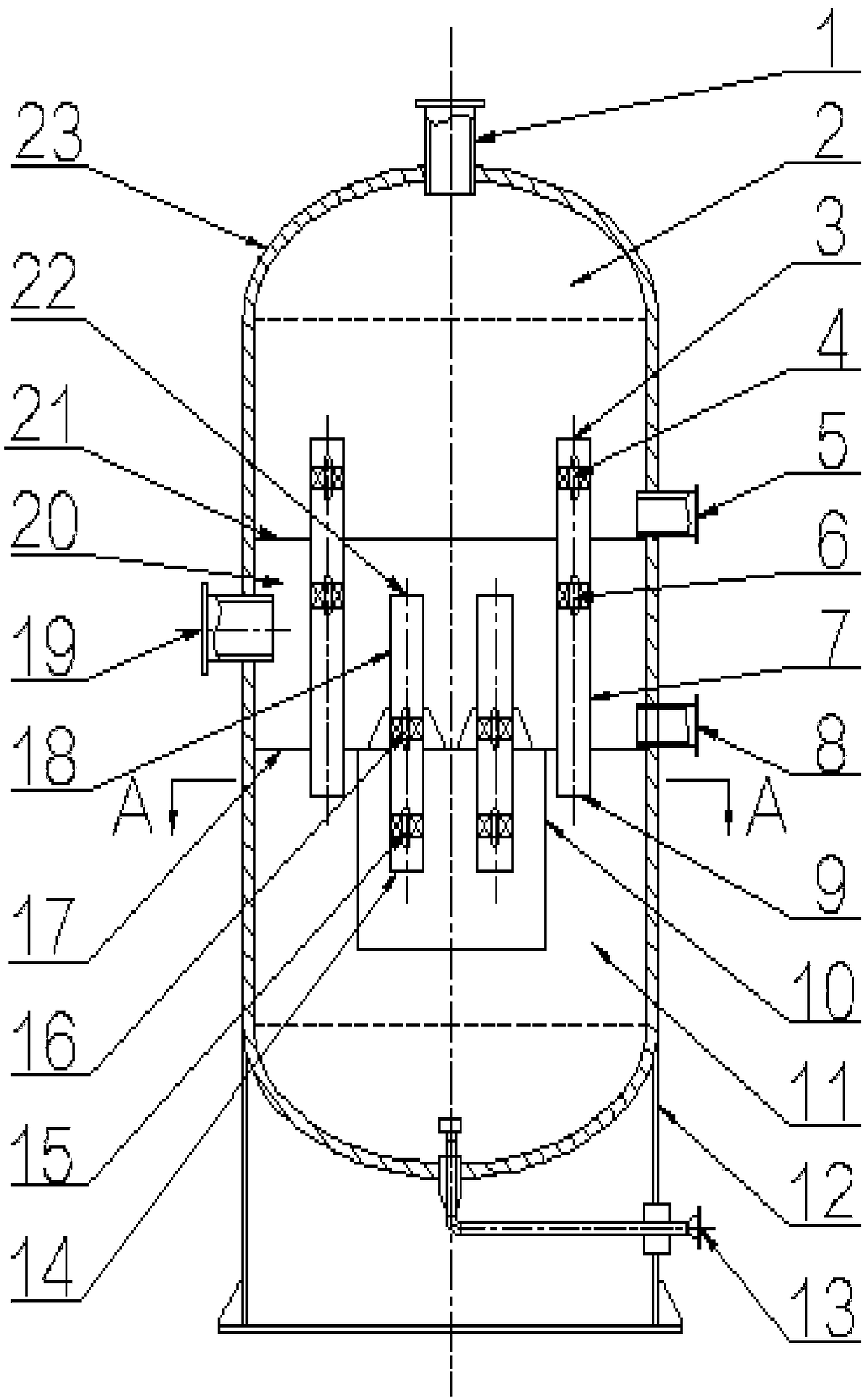

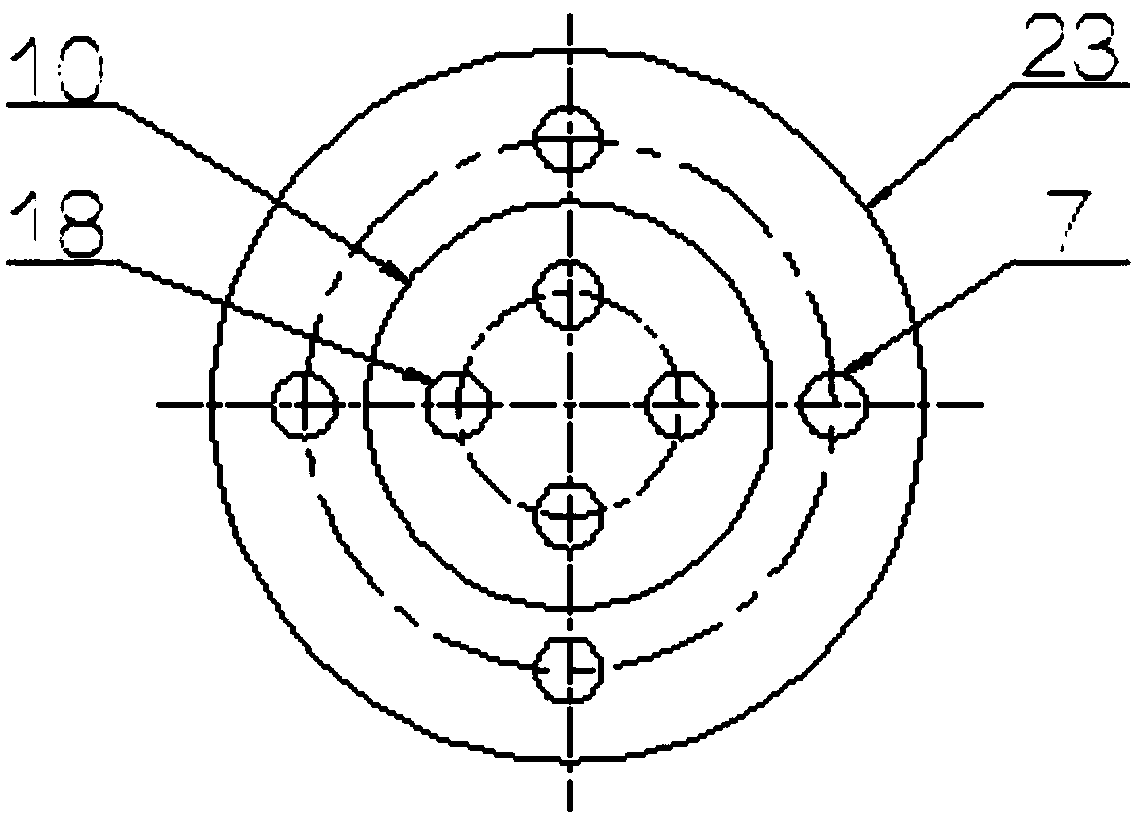

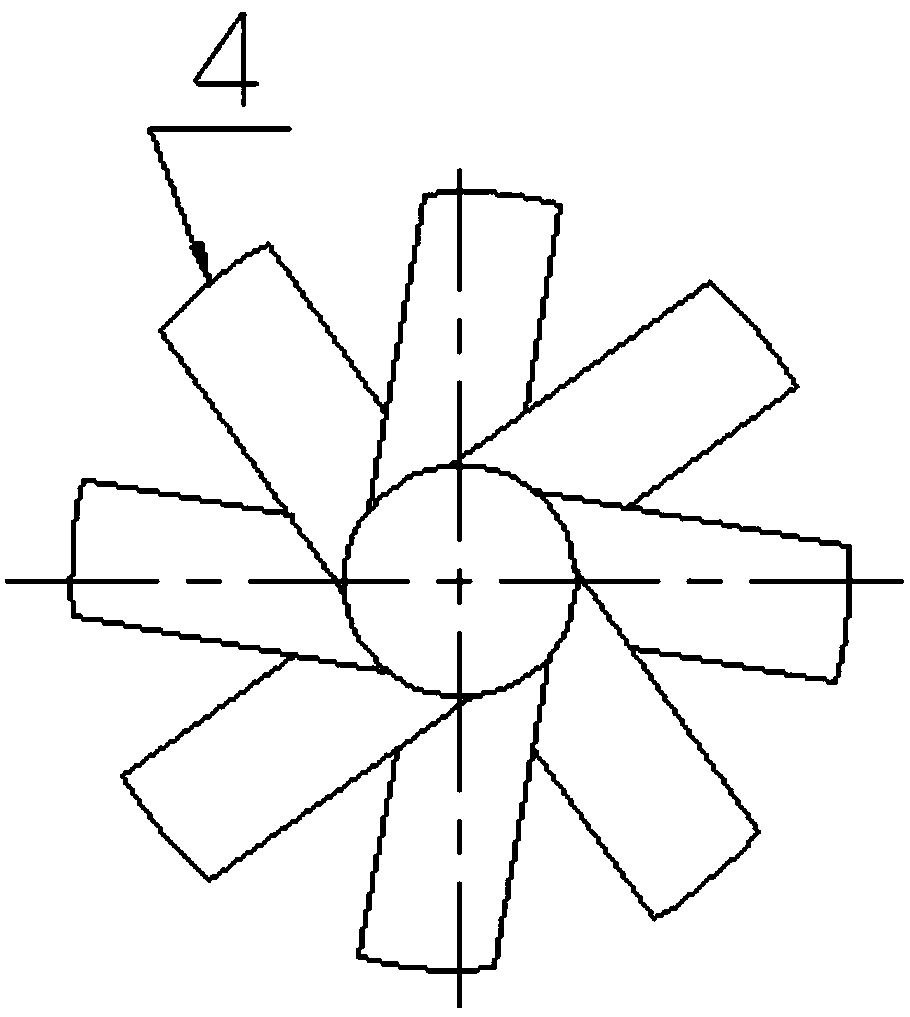

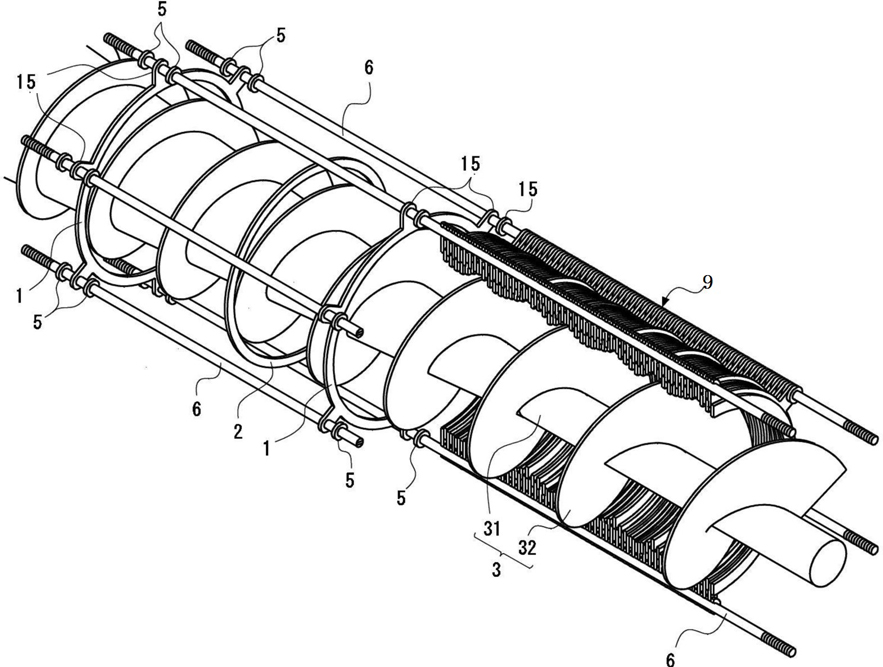

Small super-speed horizontal helical centrifugal machine

InactiveCN103406212ALow liquid contentEasy to handleRotary centrifugesAgricultural engineeringFully automatic

The invention relates to a small super-speed horizontal helical centrifugal machine, and belongs to the technical field of solid-liquid separation equipment. According to the horizontal helical centrifugal machine, a platform is arranged on supporting feet and provided with an outer shell barrel, the two ends of the outer shell barrel are provided with positioning steps, the positioning steps are provided with a front bearing block and a rear bearing block respectively, a feeding pipe is arranged in a bearing end cap on the front bearing block, the side face of the feeding pipe is provide with a liquid level adjustment plate and a liquid stopping ring, the rear bearing block is provided with a rotary drum, a helical body is arranged in the rotary drum, a position, close to the rear bearing block, of the rotary drum is provided with a fixed blocking ring, the side, close to the rear bearing block, of the fixed blocking ring is provided with a discharging outlet, the outside of the rear bearing block is provided with a first motor and a second motor, the first motor is provided with a first synchronous wheel connected with the helical body, and the second motor is provided with a second synchronous wheel connected with the rotary drum. The separation factor of the horizontal helical centrifugal machine can reach 4500, the rotation speed can reach 10000r / min, a solid-liquid mixture with a solid containing rate of 10%-90% can be separated, the liquid rate of solids is small after processing, and the horizontal helical centrifugal machine is suitable for fine production and fully-automatic dehydration processing at small amount.

Owner:黄韧浩

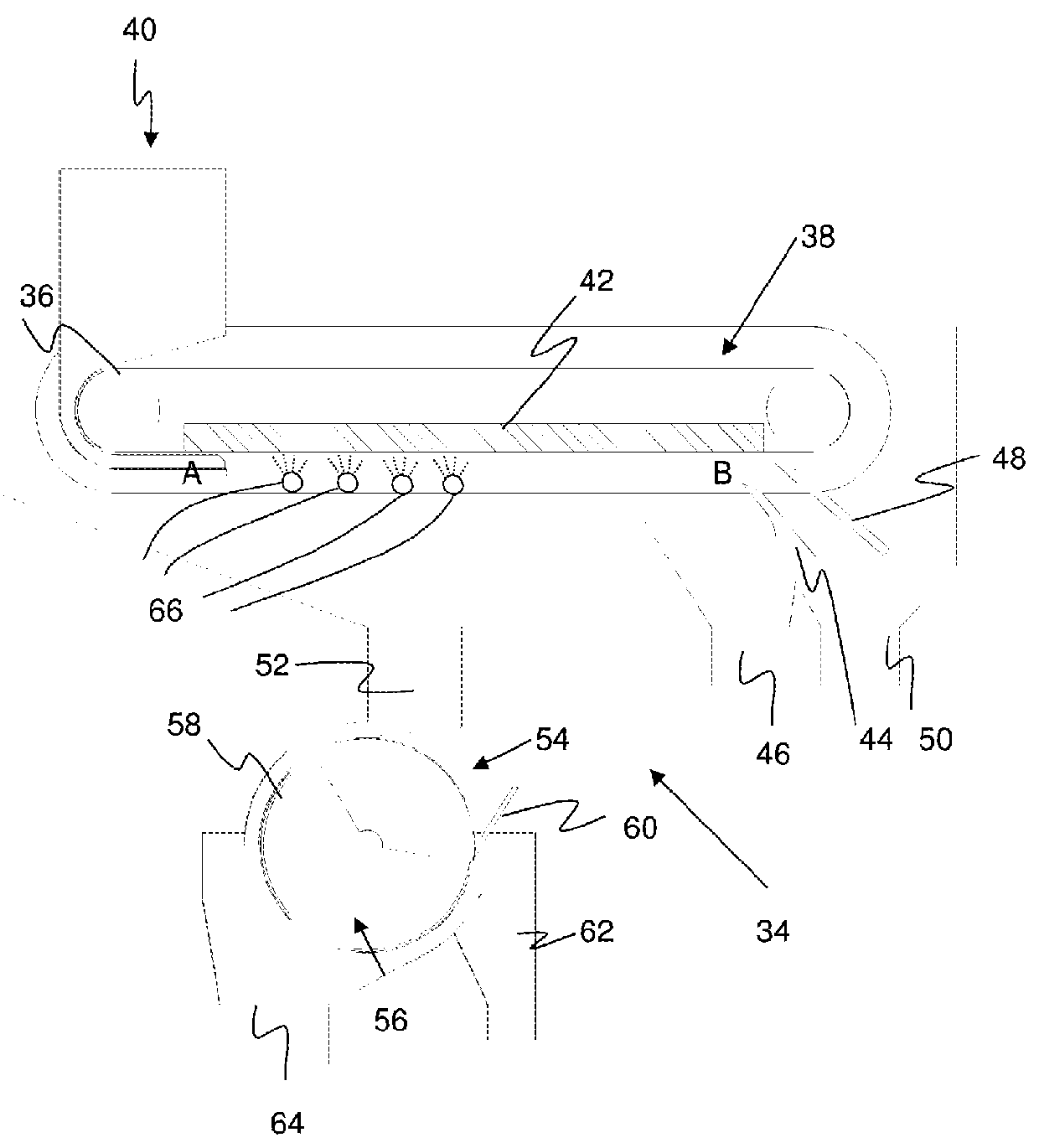

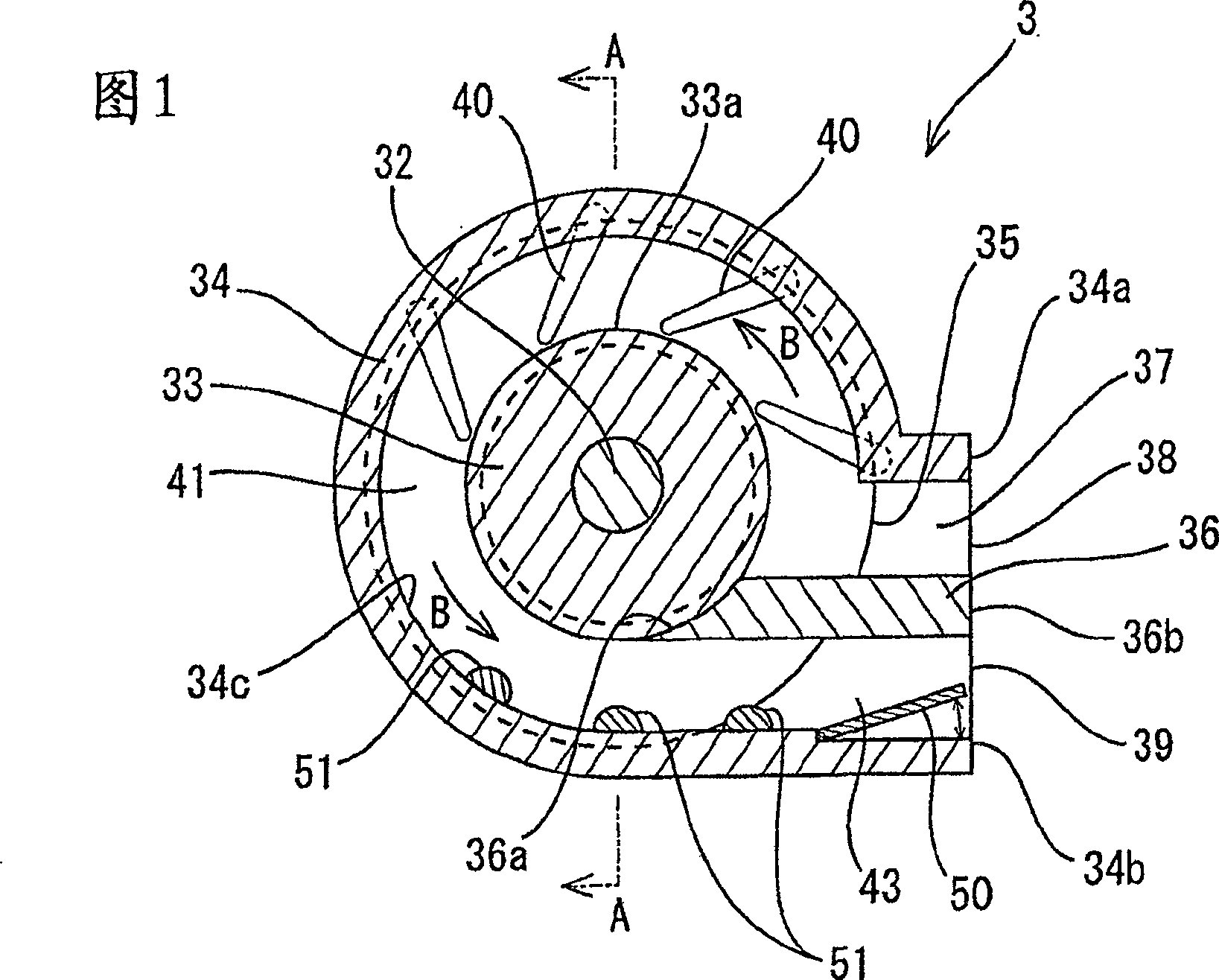

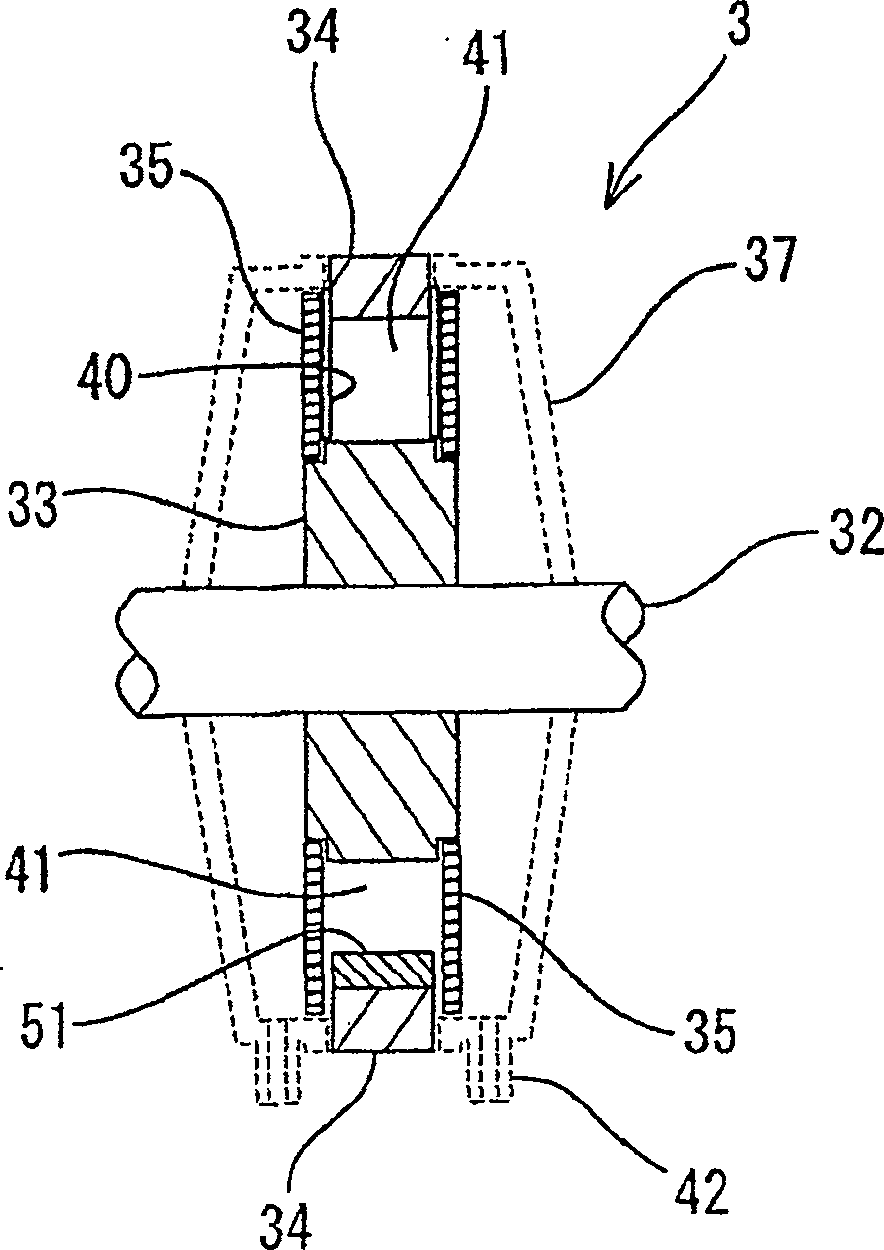

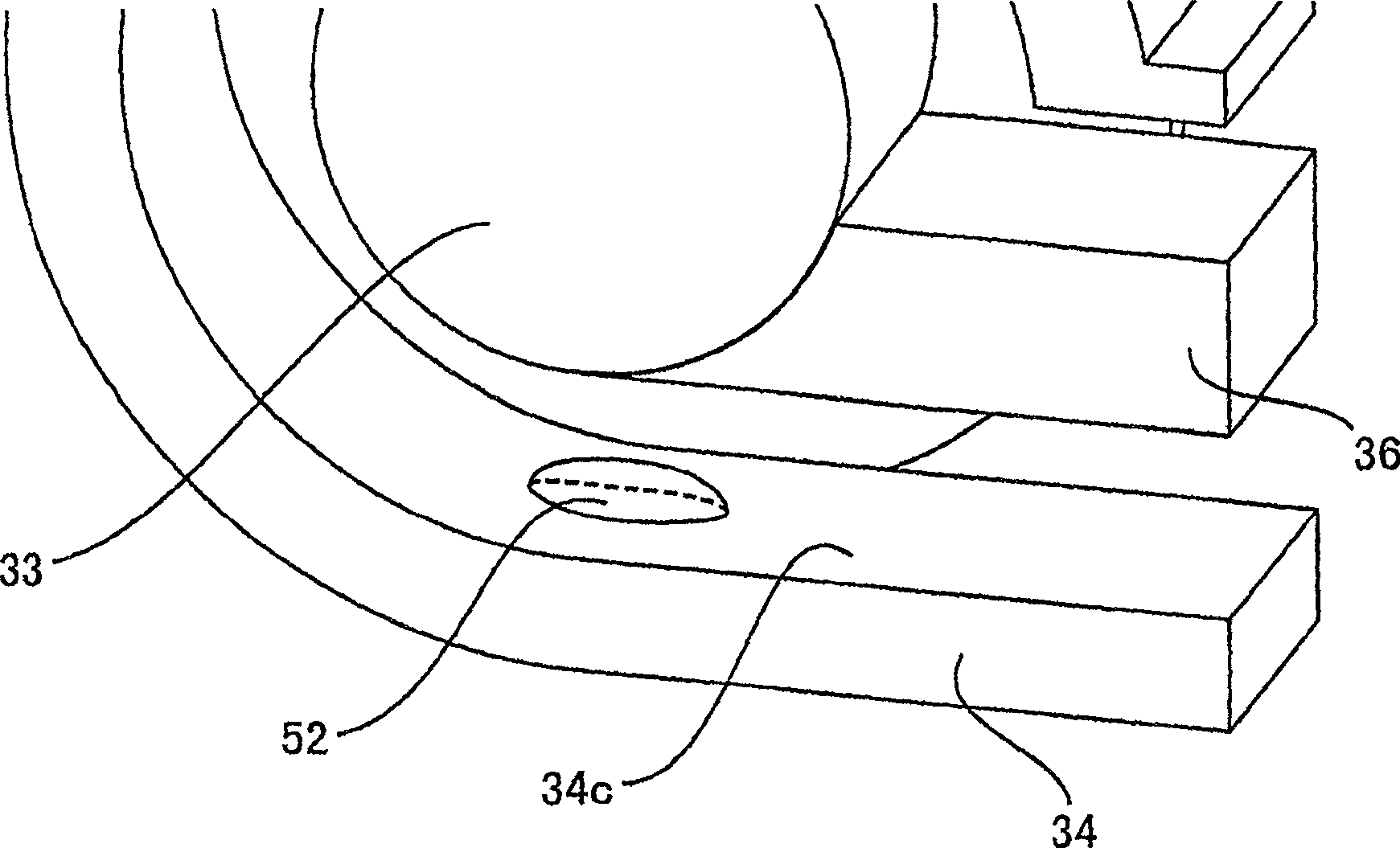

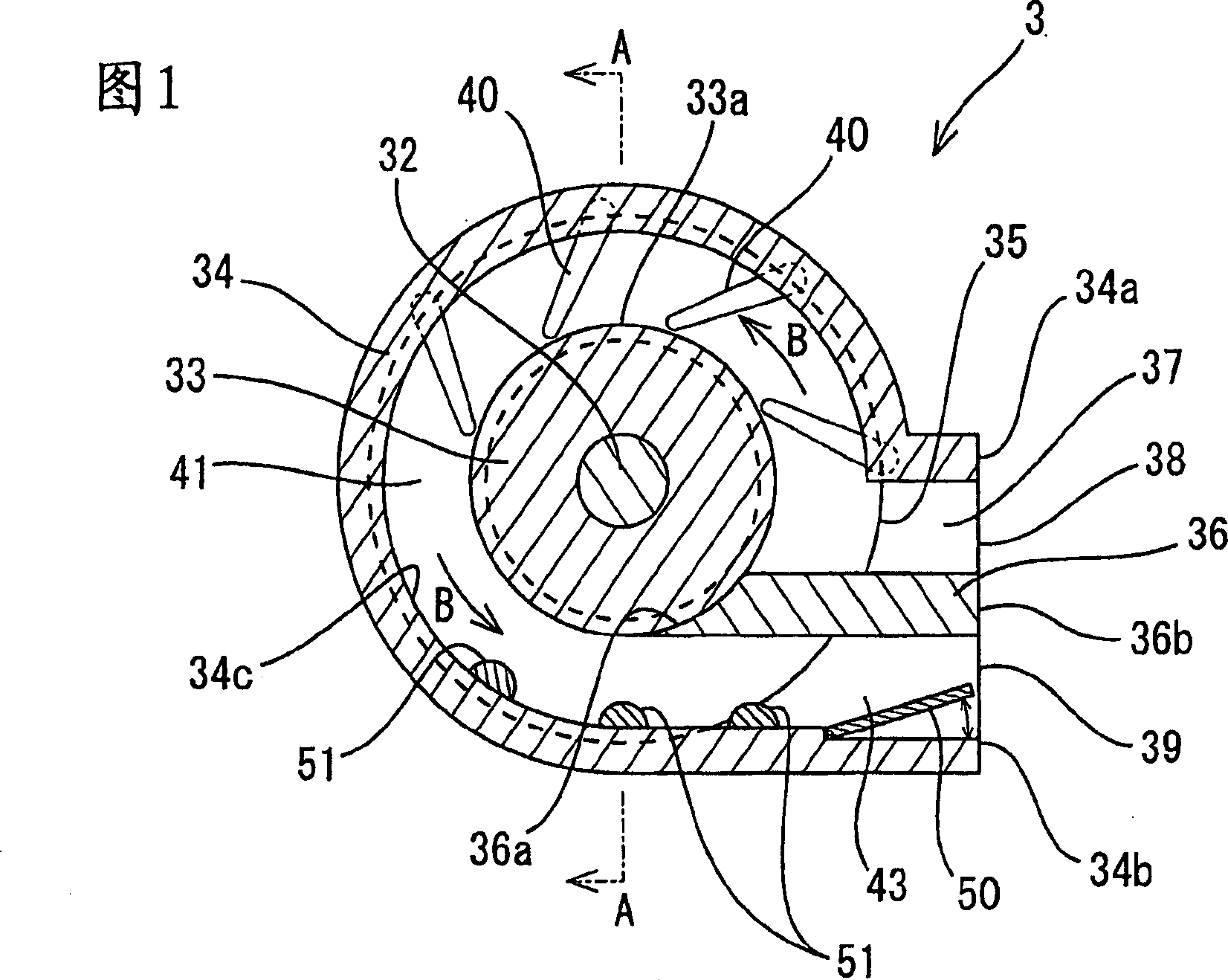

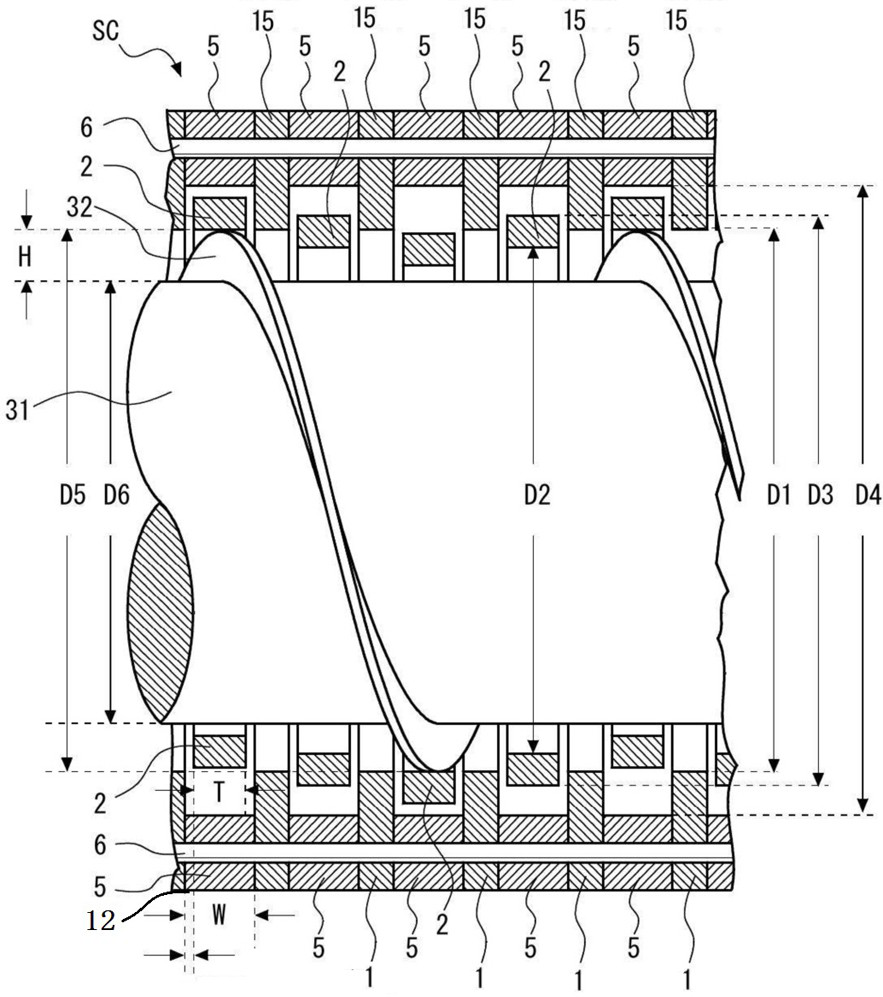

High dehydration type rotary pressurization dehydrator

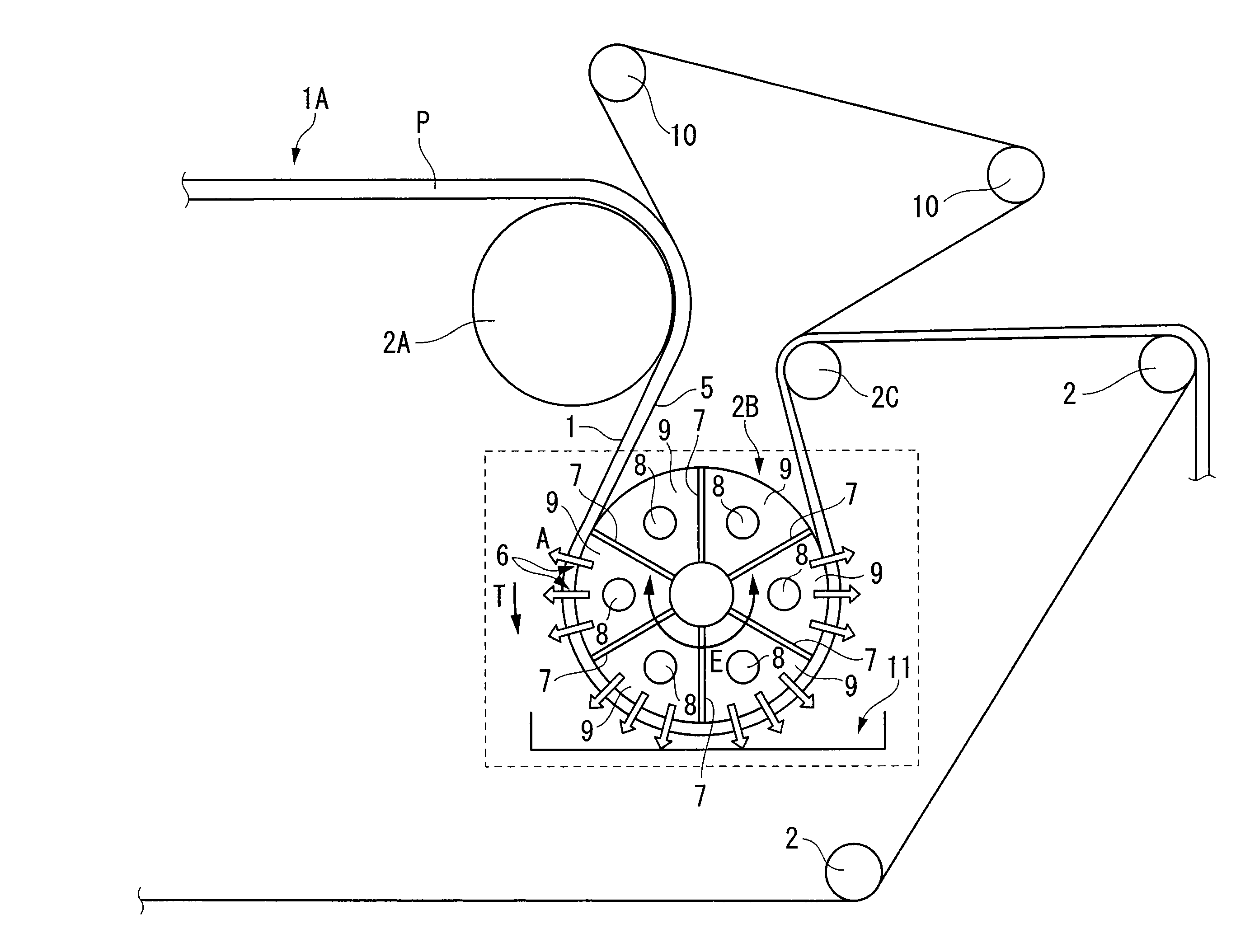

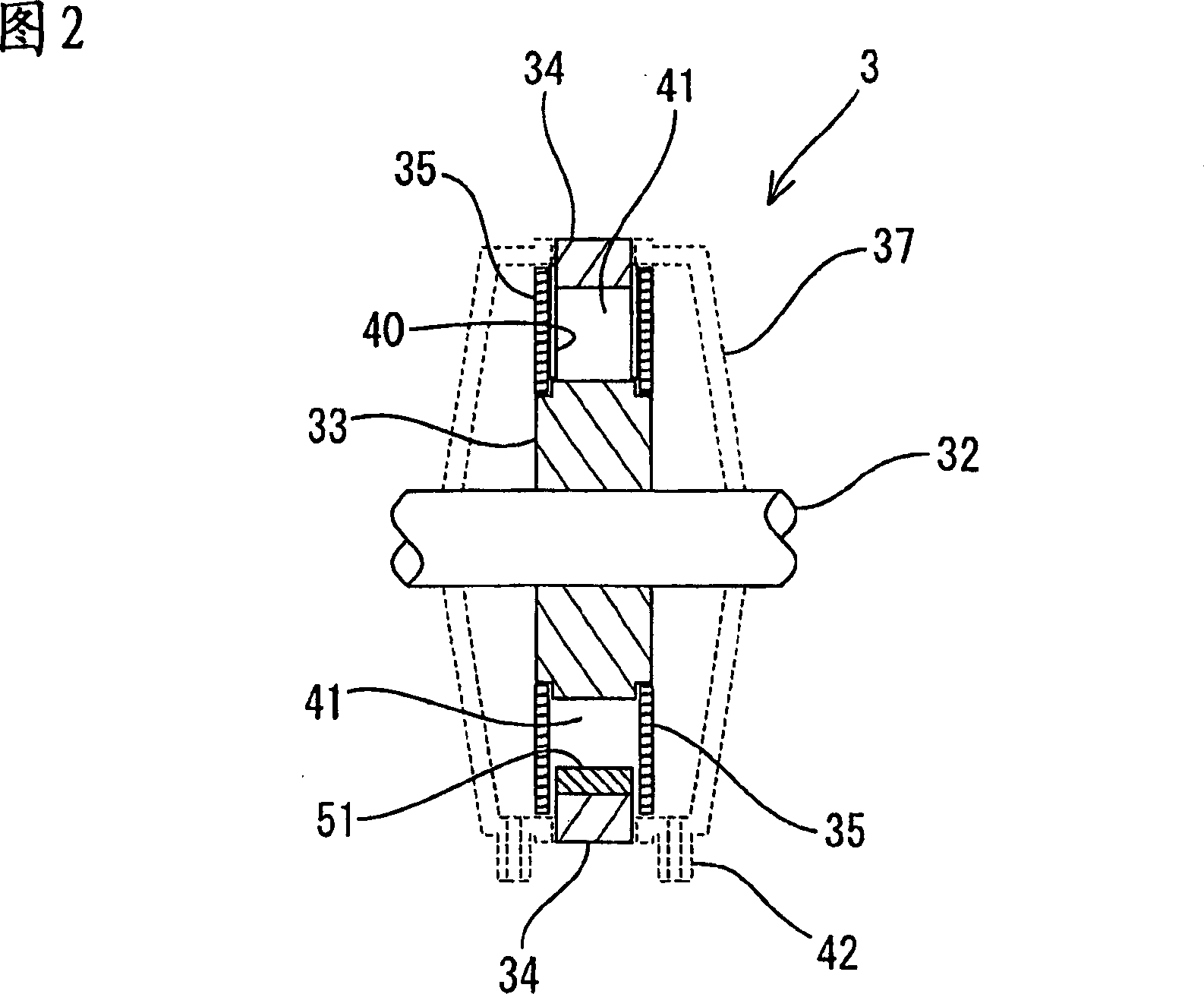

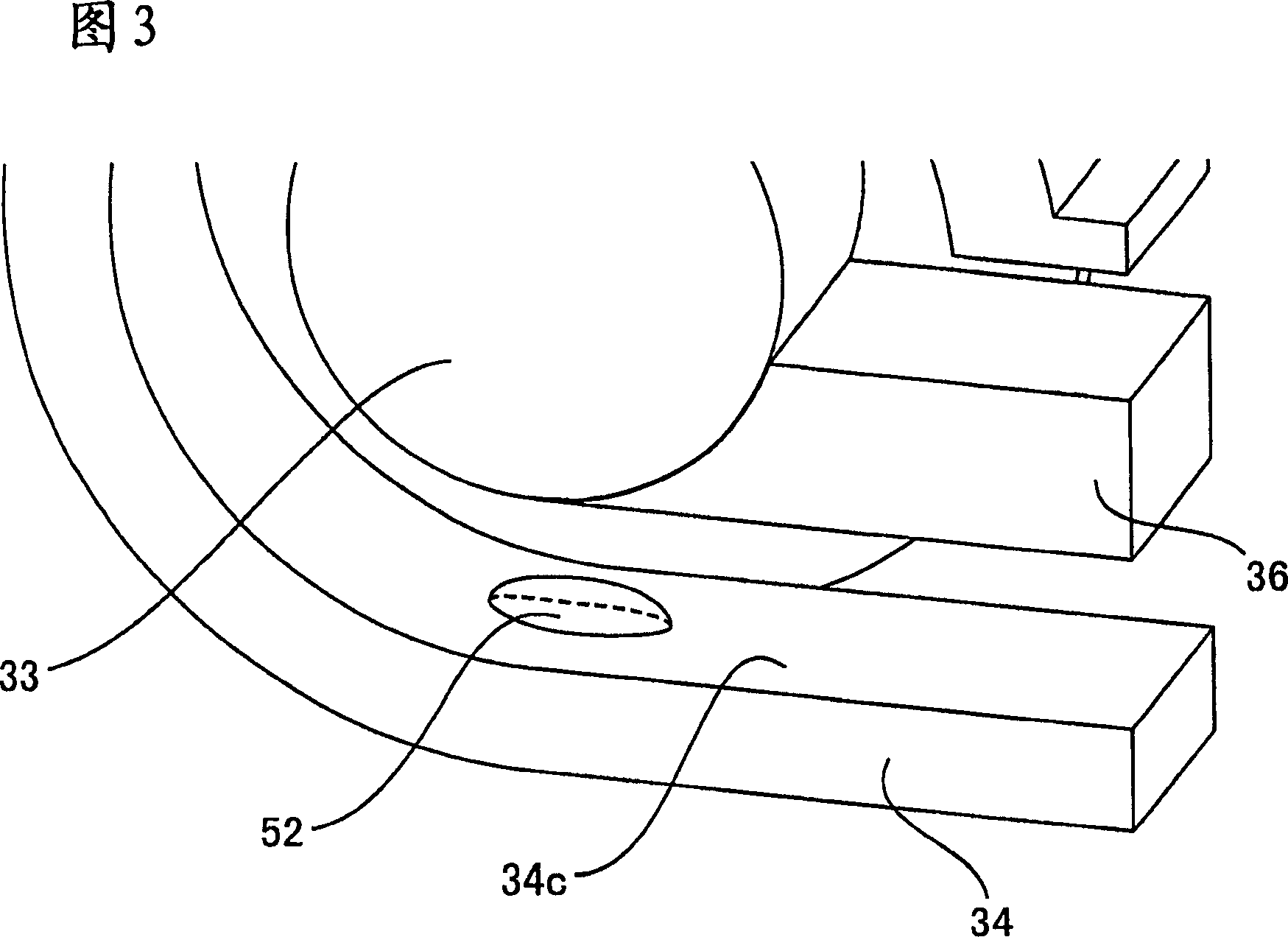

A rotation pressurization dehydrator adapted to locally increase the compressive force on moving dehydrated cake so as to efficiently reduce the liquid content of its region for which dehydration has not been sufficient by a conventional rotation pressurization dehydrator, whereby in discharged, dehydrated cake, the difference in liquid content among regions is made small. In a rotation pressurization dehydrator (3) which, as a raw material advances in an annular filter chamber (41) formed around a rotary shaft (32), gradually applies a pressure to the material to change the liquid material into cake, thereby dehydrating the material, projections (51) are disposed on the inner peripheral surface (34c) of an outer ring spacer (34) so as to further reduce the liquid content of the dehydrated cake.

Owner:TOMOE ENGINEERING CO LTD

High dehydration type rotation pressurization dehydrator

A rotation pressurization dehydrator adapted to locally increase the compressive force on moving dehydrated cake so as to efficiently reduce the liquid content of its region for which dehydration has not been sufficient by a conventional rotation pressurization dehydrator, whereby in discharged, dehydrated cake, the difference in liquid content among regions is made small. In a rotation pressurization dehydrator (3) which, as a raw material advances in an annular filter chamber (41) formed around a rotary shaft (32), gradually applies a pressure to the material to change the liquid material into cake, thereby dehydrating the material, projections (51) are disposed on the inner peripheral surface (34c) of an outer ring spacer (34) so as to further reduce the liquid content of the dehydrated cake.

Owner:TOMOE ENGINEERING CO LTD

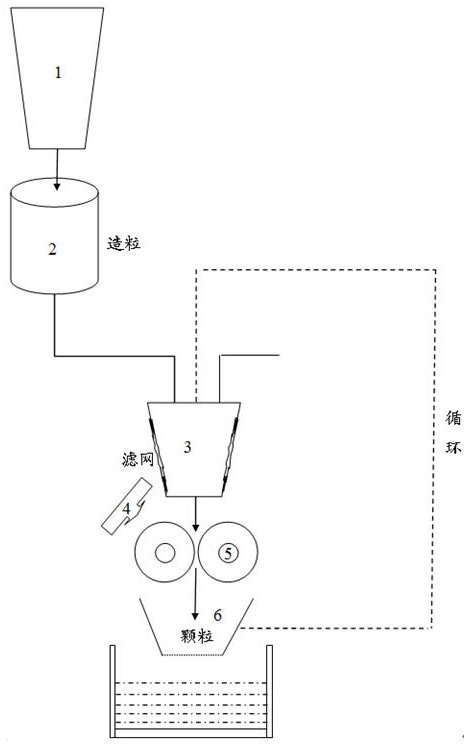

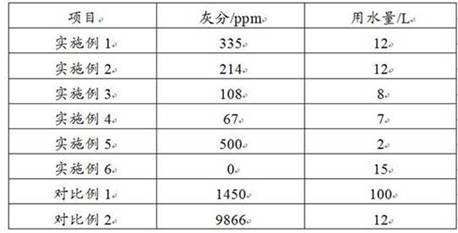

Polymer purification process and purification system

ActiveCN113980288AReduce dosageImprove washing efficiencyStationary filtering element filtersPoly ether ether ketoneEngineering

The invention belongs to the technical field of polymer impurity removal, and provides a polymer purification process and a purification system. The purification process comprises the following steps: firstly, adding a polymerization solution containing salt impurities into an eluate, to obtain polymer particles; extruding the polymer particles obtained in the step one under the condition of spraying the eluate, and removing the salt impurities in the polymer to obtain a cleaned polymer; dissolving the salt impurities in the eluate; and finally, removing the eluate from the cleaned polymer obtained in the step two to obtain the purified polymer. The liquid content of extruded polymer particles is low, cross contamination between the eluate and washing solutions is reduced, and the treatment cost, solvent loss and waste water and waste liquid discharge of various washing solutions are greatly reduced. The process can be applied to the production process of polysulfone, polyphenylsulfone, polyethersulfone and copolymers thereof, the production process of polyphenylene sulfide and copolymers thereof, and the production process of polyether-ether-ketone, polyarylene ether nitrile and copolymers thereof.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

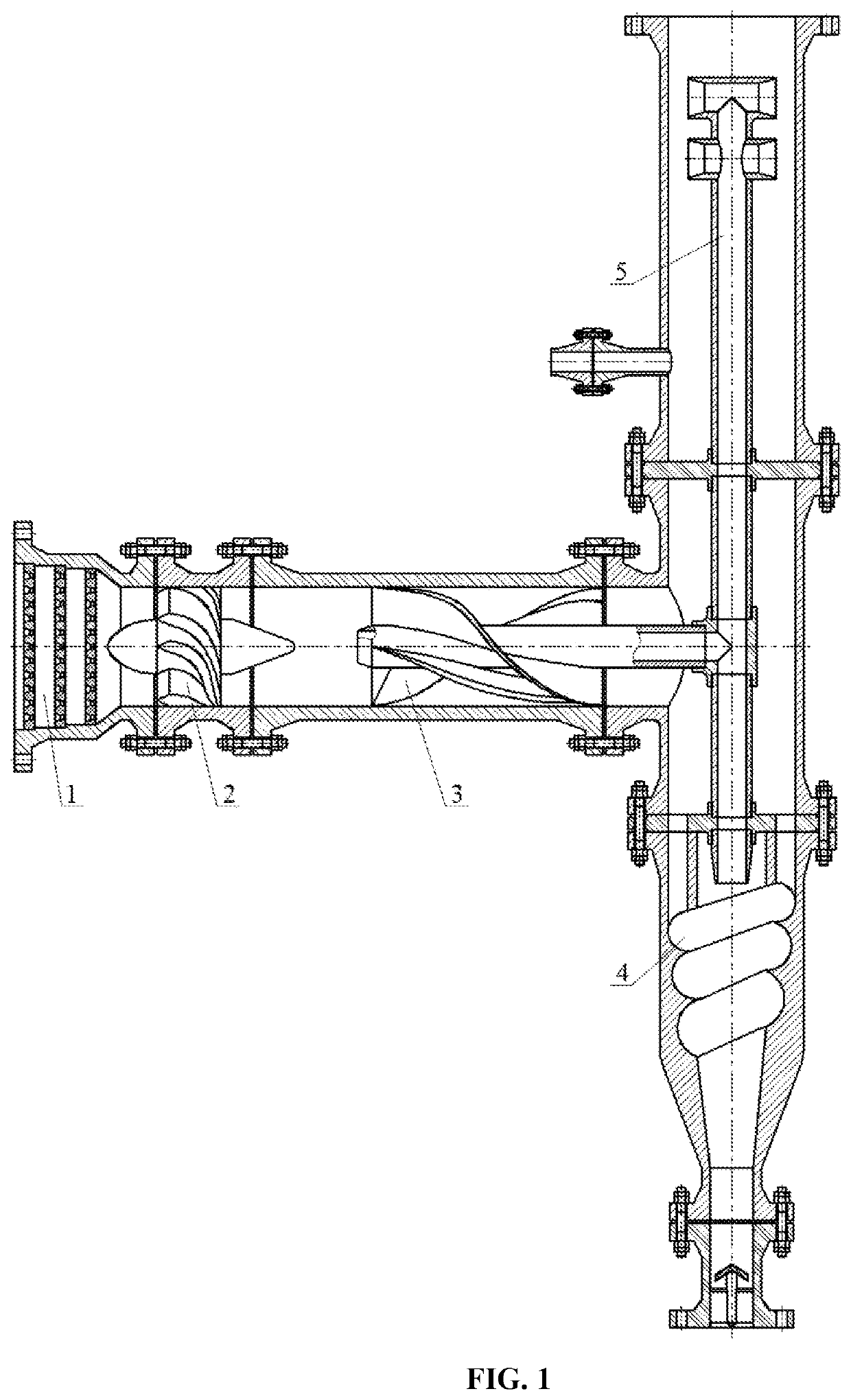

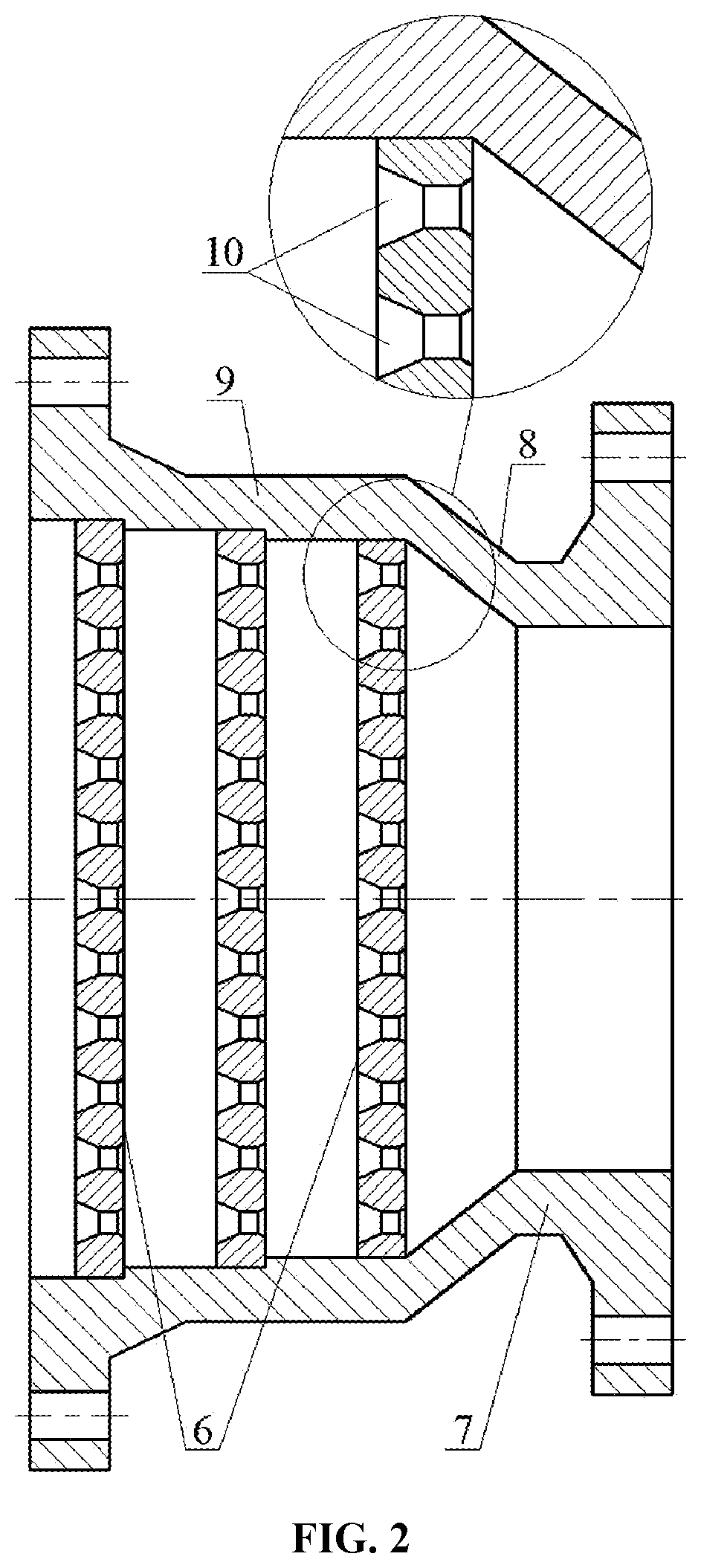

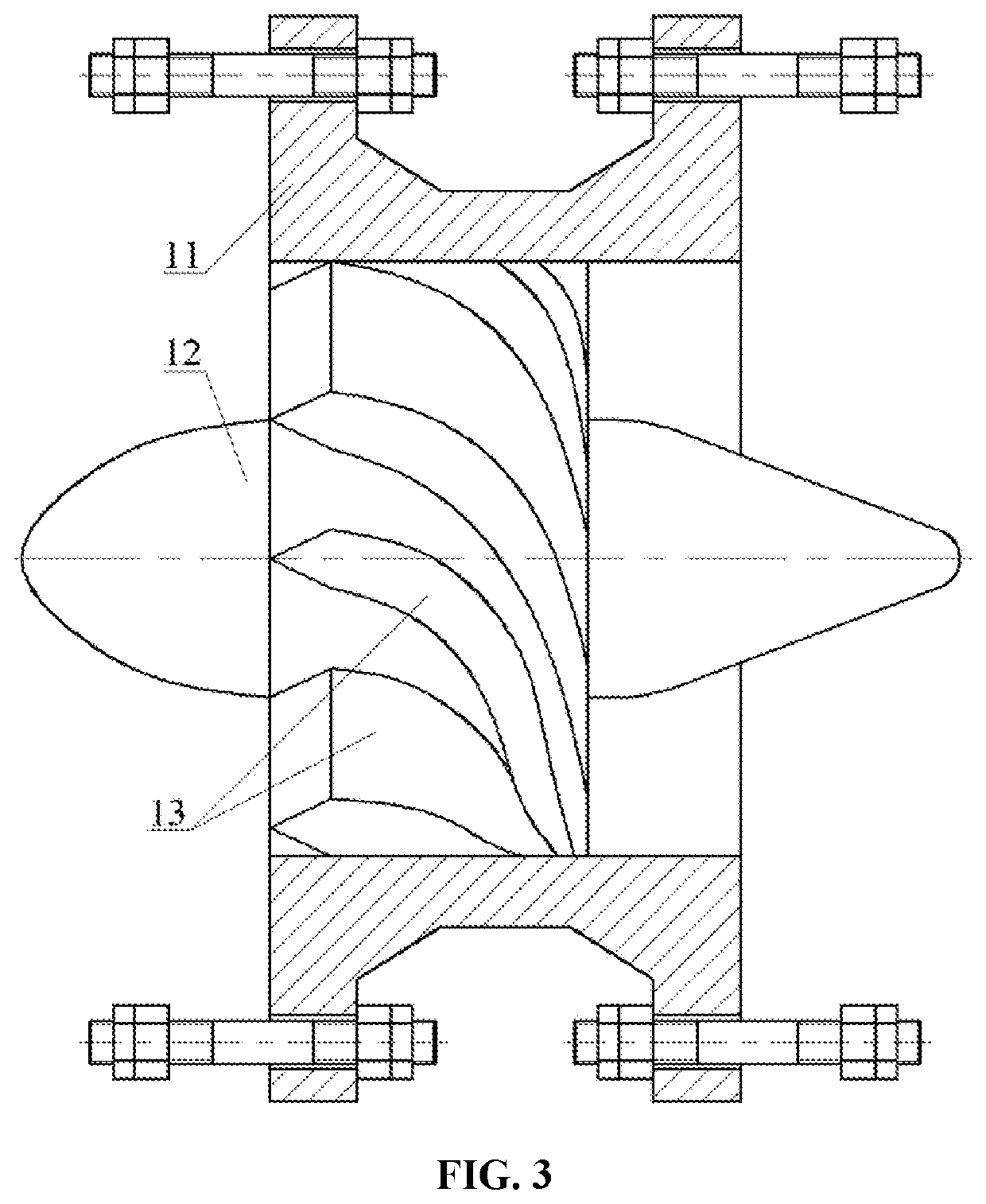

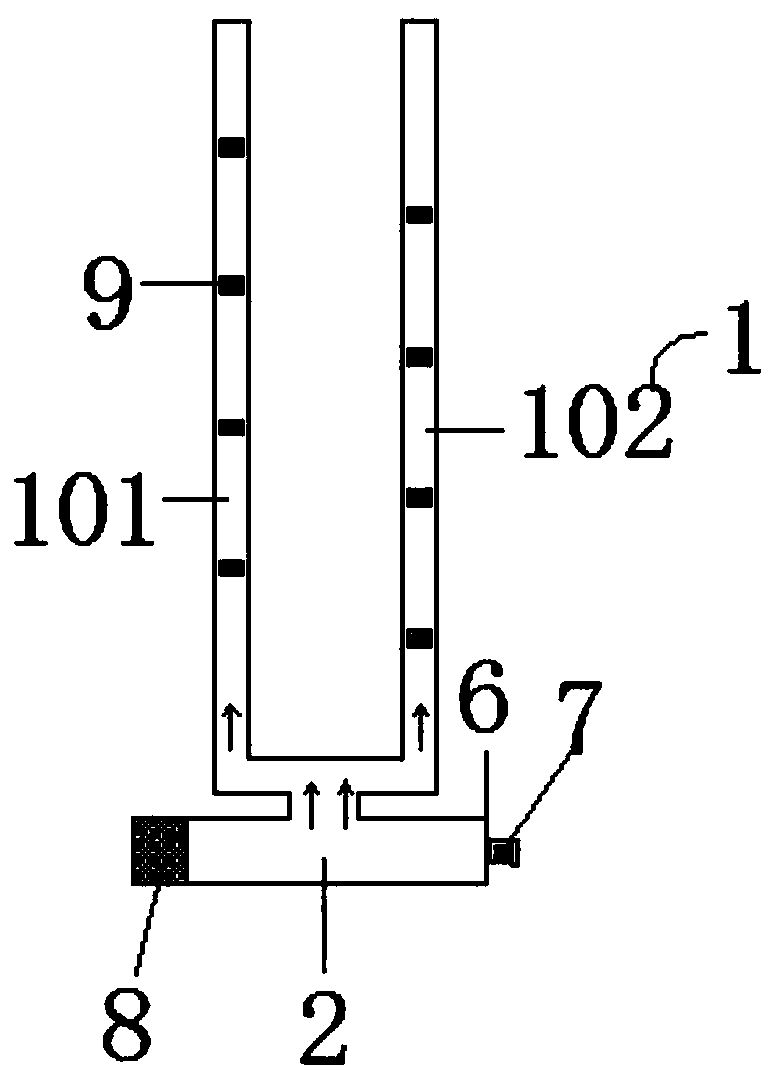

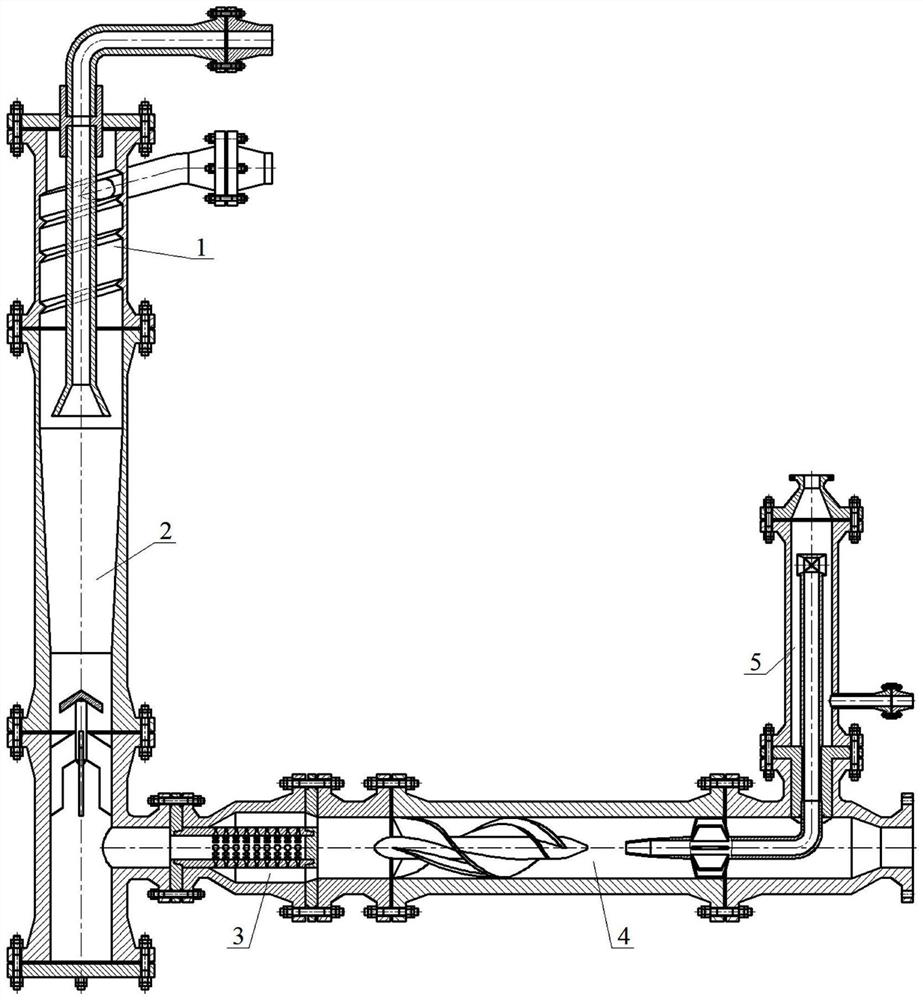

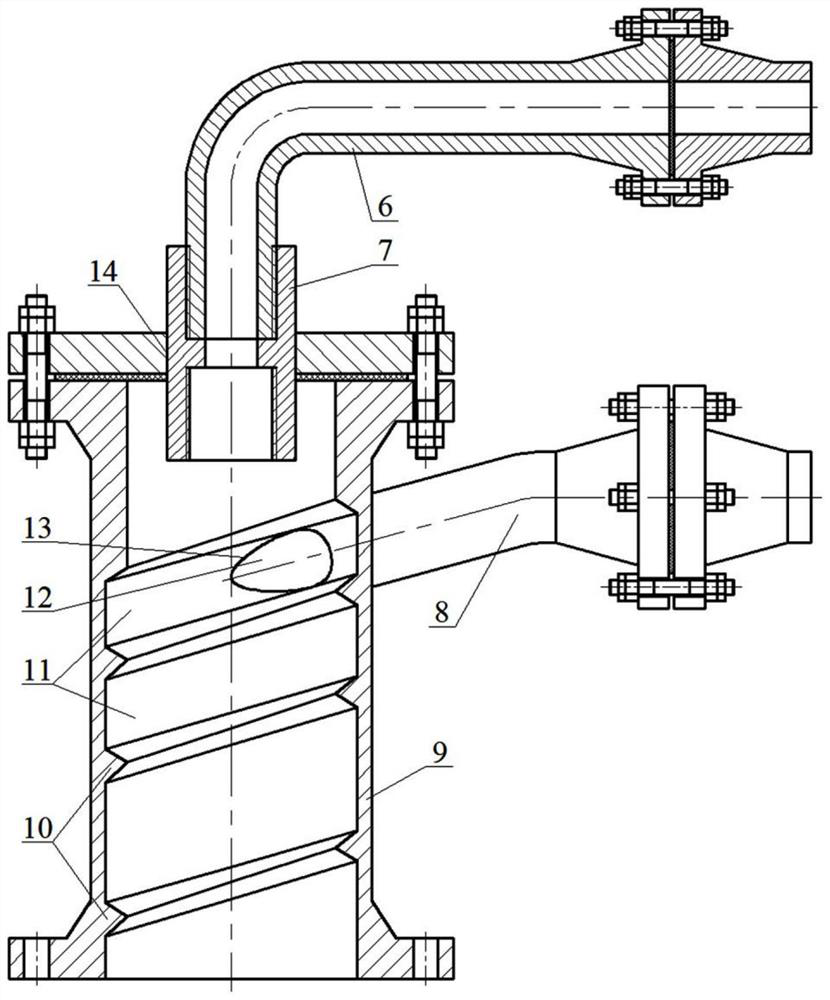

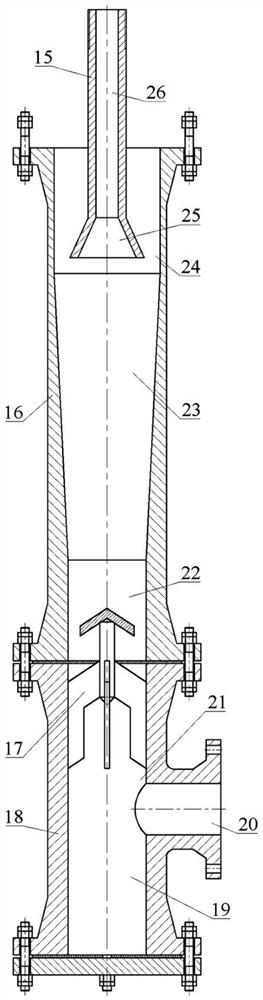

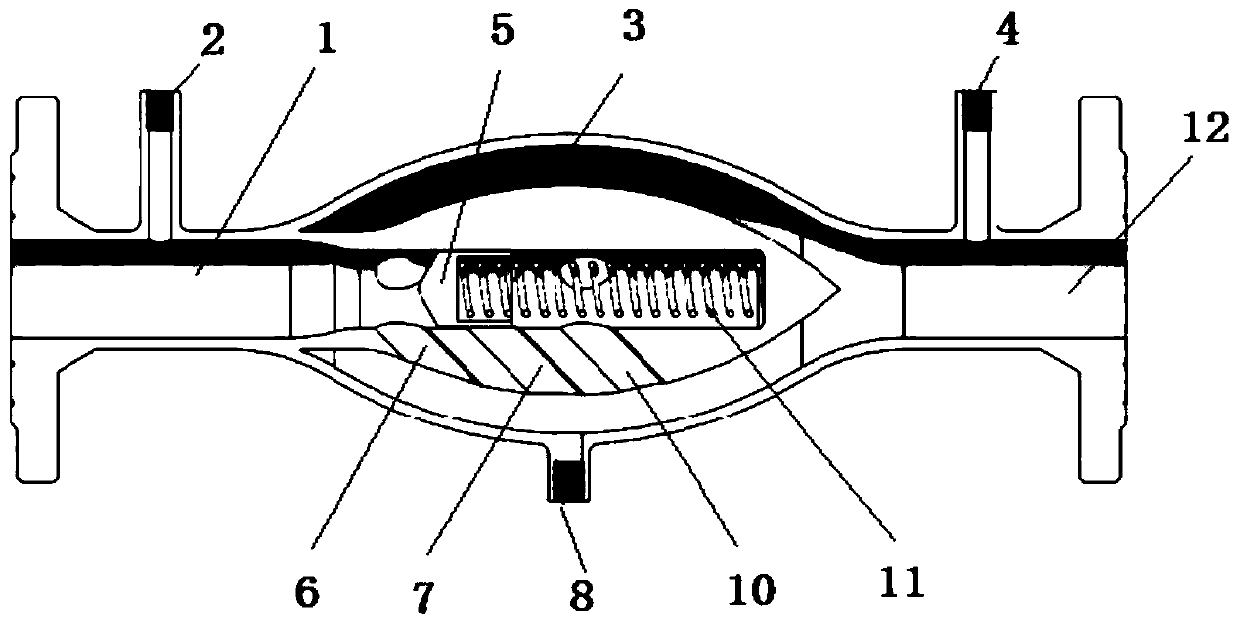

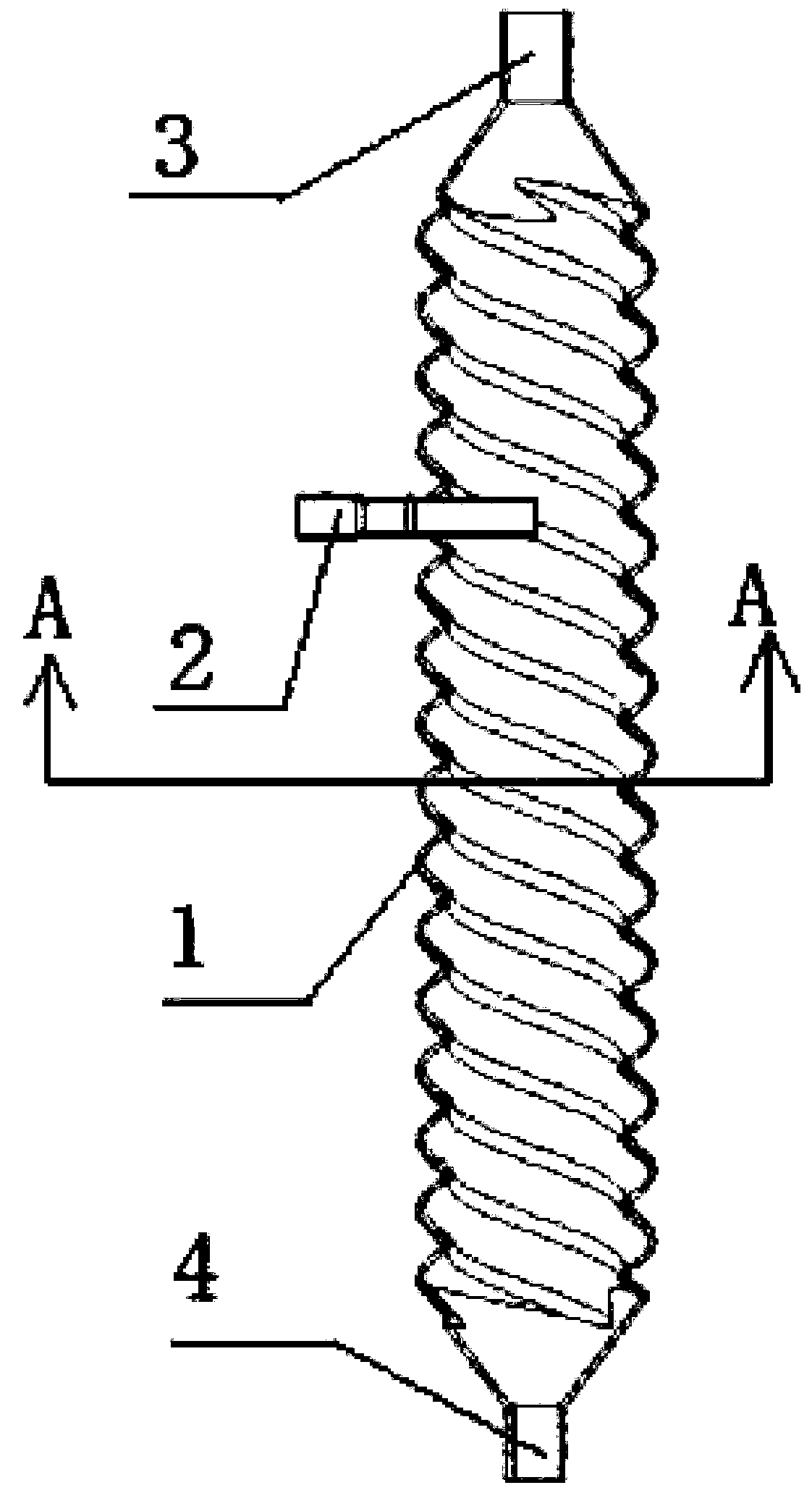

Three-stage tubular t-shaped degassing device with microbubble axial flow and spiral flow fields

PendingUS20220219100A1Low liquid contentEfficient solutionFluid removalLiquid degasification arrangementsDegasserMicrobubbles

A three-stage tubular T-shaped degassing device with microbubble axial flow and spiral flow fields is provided, which is applied to quick degassing of a gas-liquid two-phase flow. The three-stage tubular T-shaped degassing device adopts a quick degassing technology combining a microbubble uniform mixed rotational axial flow field and a spiral runner conical spiral flow field with layered jet collision reversing depth degassing. A microbubble uniform mixer is configured to adjust gas-liquid two-phase flow containing big bubbles into microbubble uniform mixed axial flow. A microbubble cyclone is configured to adjust the microbubble uniform mixed axial flow into multiple strands of rotational axial flows containing microbubbles. A rotational axial flow degasser implements the horizontal type microbubble uniform mixed multiple strands rotational axial flow degassing operation to remove most microbubbles to form axial flow gas and axial flow liquid.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Air pipe, drying device using same and drying technology thereof

PendingCN109797510ASimple structureOperating routineLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsProduct gasEngineering

The invention discloses an air pipe. The air pipe comprises a first pipe body and a second pipe body which are mutually communicated and not positioned in a same thread. A communicating place of the first pipe body and the second pipe body is provided with a pressure feeding box. The interior of the pressure feeding box is provided with a cavity, and the cavity comprises an air inlet. The air inlet is provided with a pressurizing fan. A box body of the pressure feeding box is provided with a high-temperature heat source. Through the pressure feeding box installed at the communicating place ofthe first pipe body and the second pipe body and the high-temperature heat source on the box body, heat and cold wind is exchanged, wherein there are multiple sources of the high-temperature heat source, for example steam heating, conduction oil heating, and natural gas direct-fired heating, there are multiple modes, operation is conventional and easy, a generated high-temperature gas is used as the high-temperature heat source, a pressure is increased by operation of the matched pressurizing fan so as to form a high-temperature high-pressure wind source, and the high-temperature gas is directly conveyed to the air outlet through pipes of a first air outlet pipe and a second air outlet pipe on the first pipe body and the second pipe body, finally the high-temperature gas is sprayed from atool bore of an air nozzle under a high pressure.

Owner:江苏康尼纺织品有限公司

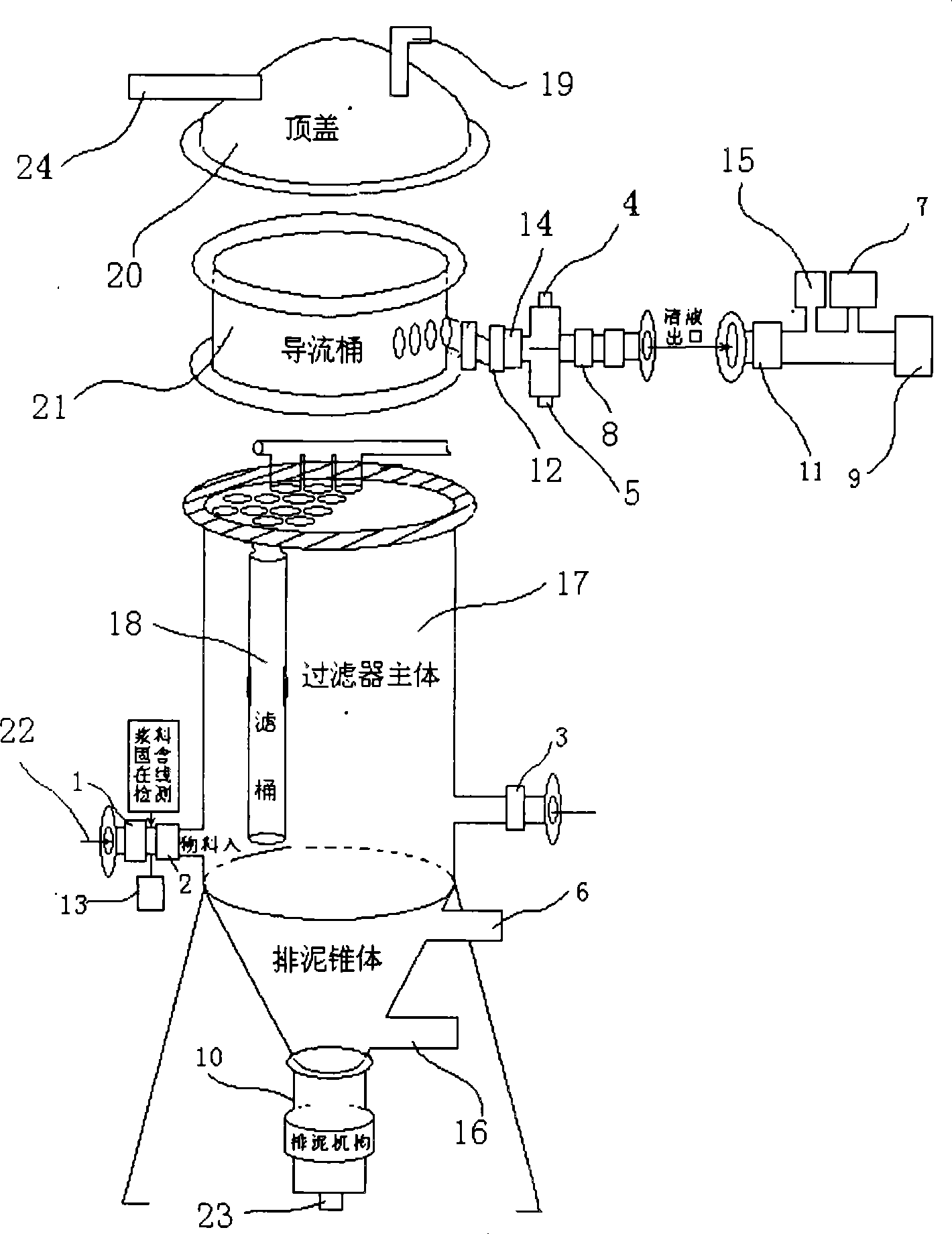

Aluminium oxide full-automatic on-line spoil removing solid-liquid separation method

InactiveCN101381089ASolution to short lifeShort lifeAluminium oxides/hydroxidesProcess engineeringSlurry

The invention relates to a method for solid-liquid separation and dreg removal in the process of producing alumina, in particular to a full automatic on-line method for solid-liquid separation and dreg removal in alumina production. The method at least comprises a filtering process A, a filter mass discharging process B and a filter mass removing process C which are carried out repeatedly. A novel sintering net made of a filtering material is utilized to form a novel full automatic continuous type filter. A diluted serous fluid is pumped in from a feed port of the filter; and a material obtained from a discharge port of the filter is a fine solution meeting the requirement of aluminum hydroxide. The filter can realize continuous production by a single filter. The production process is wholly subjected to on-line monitoring; and a computer is used for providing the diluted serous fluid, the flow of the fine solution, the temperature, the solid content, the content of suspended matters and other main technical parameters for the whole production process of the alumina in real time. If equipment is subjected to proper parameter adjustment, the equipment can be conveniently used for the production process of molybdenum industry.

Owner:贾剑平

Compact l-shaped column-cone combined tubular three-stage axial flow degasser

ActiveCN112302614BEfficient separationLow liquid contentCombination devicesDispersed particle filtrationImpellerCyclone

The invention provides a compact L-shaped column-cone combined tube type three-stage axial flow degassing device, which is applied to the efficient separation of gas-containing fluids. The three-stage axial flow degassing device adopts the high-efficiency degassing technology of the vertical high-speed swirl field combined with the vertical pipe, horizontal pipe and T-shaped pipe, the horizontal fast axial flow field and the vertical reversing scrubbing field. The cyclone adjusts the oblique incident gas-containing fluid and forms a vertical high-speed cyclone flow. The first-stage degasser implements the first-stage segmented vertical high-speed cyclone degassing operation, removes most of the gas phase of the gas-containing fluid and forms The first-stage gas and the first-stage fluid, the microporous homomixer breaks the large particle size bubbles of the first-stage fluid to form a gas-liquid uniform flow, and the second-stage degasser implements the second-stage horizontal impeller to create a fast axial flow degassing operation , remove most of the gas phase in the gas-liquid homogeneous flow and form secondary gas and secondary fluid, and the third-stage degasser implements the third-stage vertical reversing deep degassing operation to remove a small amount of remaining liquid phase of the secondary gas And form tertiary gas and tertiary fluid.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

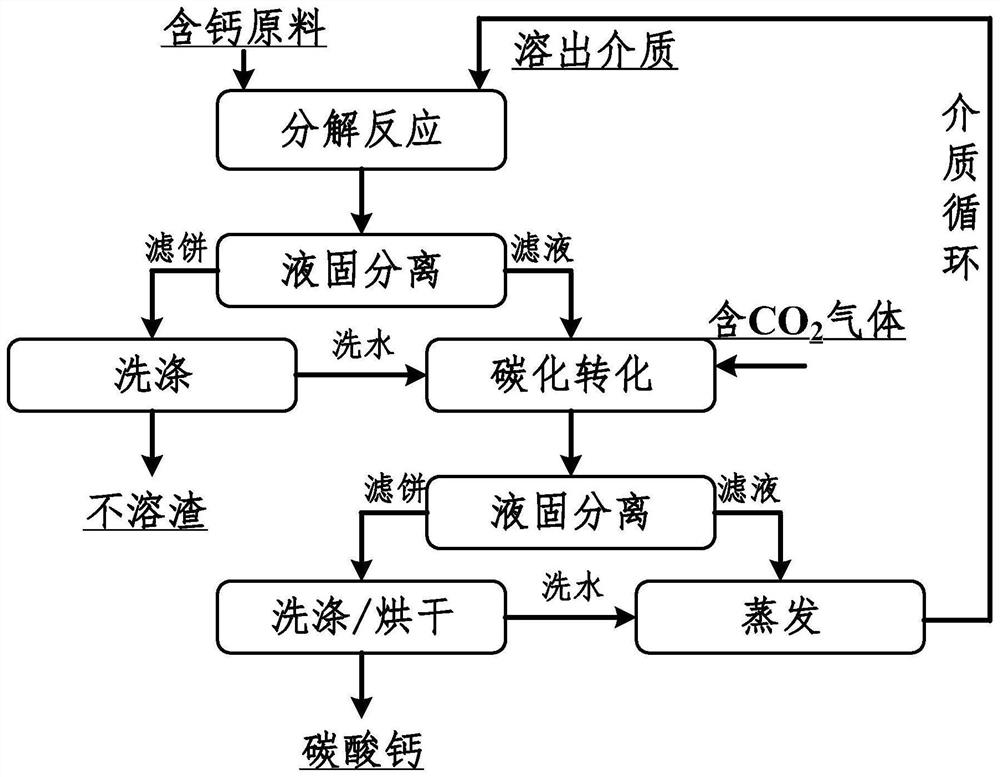

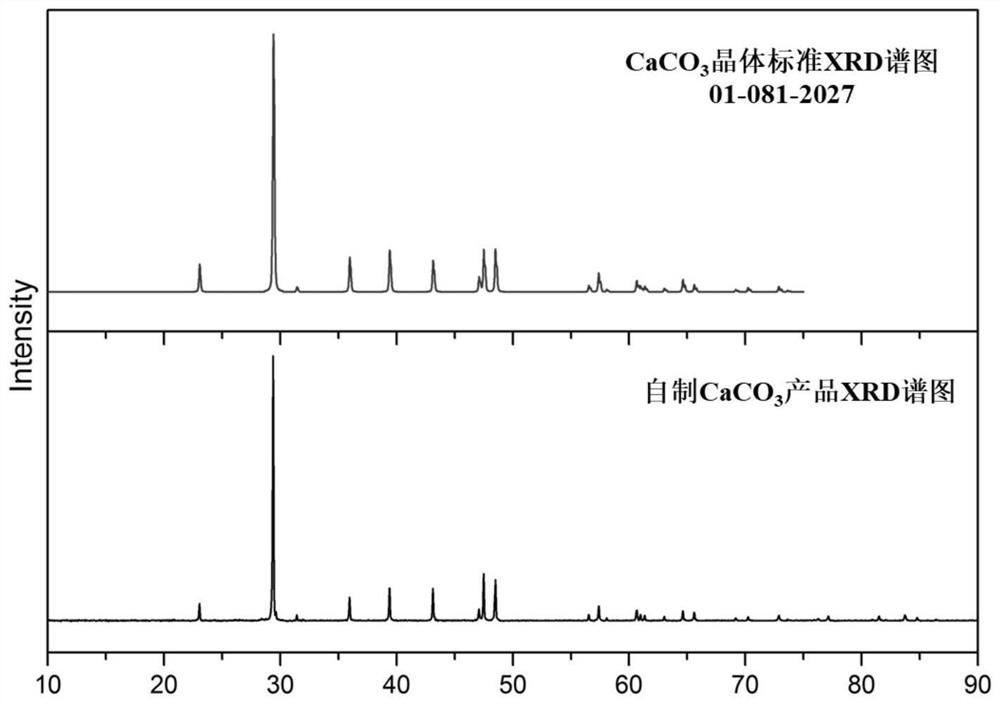

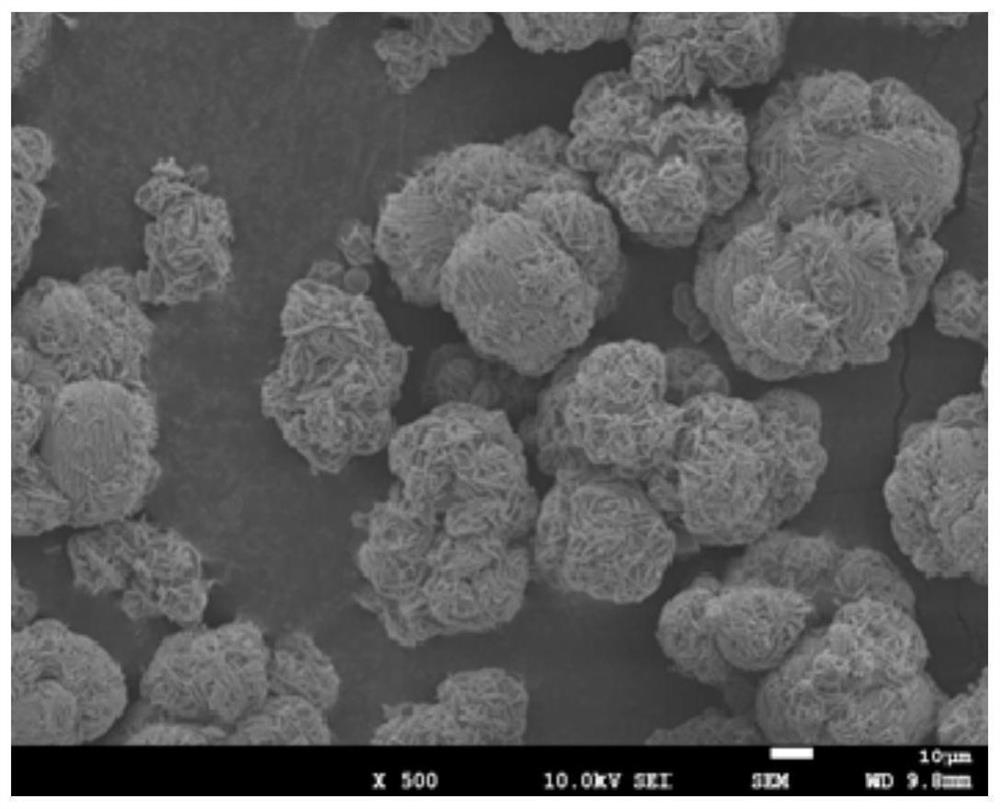

Calcium carbonate and preparation method thereof

ActiveCN113120935AShape is easy to controlGranularity controllableCalcium/strontium/barium carbonatesPhysical chemistryCarbonization

The invention relates to calcium carbonate and a preparation method thereof, and the preparation method comprises the following steps: (1) mixing a calcium-containing raw material with a dissolution medium, carrying out a decomposition reaction, and carrying out liquid-solid separation on the calcium-containing material liquid after the reaction to obtain a calcium-containing solution and insoluble slag; and (2) contacting the calcium-containing solution obtained in the step (1) with a gas containing carbon dioxide, carrying out a carbonization reaction, and carrying out liquid-solid separation on a carbonized material liquid obtained after the reaction to obtain calcium carbonate and a carbonized mother solution. The preparation method not only can realize controllable morphology, controllable granularity and controllable purity of artificially synthesized calcium carbonate, but also can realize efficient circulation of a medium. The purity of the calcium carbonate obtained by the preparation method is higher than 99%, the morphology is regular, and the granularity is uniform and adjustable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Efficient low-resistance separator for high-liquid-content gas-liquid two-phase flow

InactiveCN109045848AIncrease throughputImprove spinning abilityDispersed particle separationCycloneEngineering

The invention provides an efficient low-resistance separator for high-liquid-content gas-liquid two-phase flow, and belongs to the field of separators. The efficient low-resistance separator for the high-liquid-content air-liquid two-phase flow comprises a gas-liquid two-phase inlet, a gravity sedimentation chamber, a first-stage cyclone tube, a liquid collecting chamber, a liquid collecting chamber draining port, a second-stage cyclone tube, a gas exhausting port, an air exhausting chamber and the like, and is used for gas-liquid separation on high-liquid-content gas. According to the separator, an operation mode that the cyclone tubes at the same stage are connected in parallel and the cyclone tubes at different stages are connected in series is performed in one separator, namely, a plurality of cyclone tubes are connected in parallel to form a stage, and cyclone tubes at two stages are synchronously arranged, so that the separation efficiency is effectively improved while the processing capacity of the device is improved; in addition, the separator can be adapted to the working condition of high-liquid-content gas-liquid two-phase flow; two stages of guide blades connected in series are arranged in each cyclone tube at each stage, so that the separation capacity of the cyclone tubes at each stage can be improved; and meanwhile, the cyclone production synergistic effect between the two-stage guide blades connected in series can be realized, so that the resistance is low, and the requirements on pressure in a following process can be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

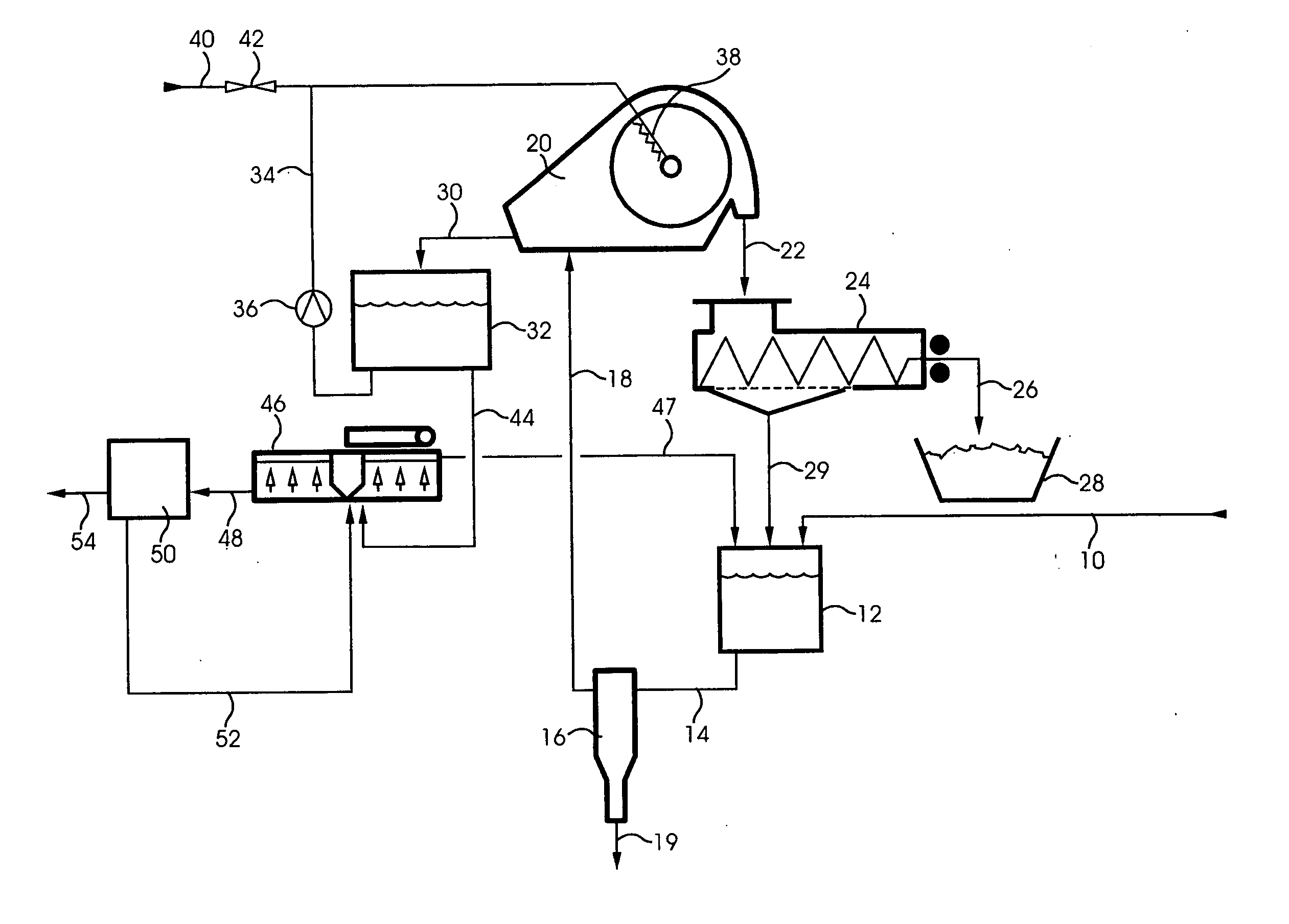

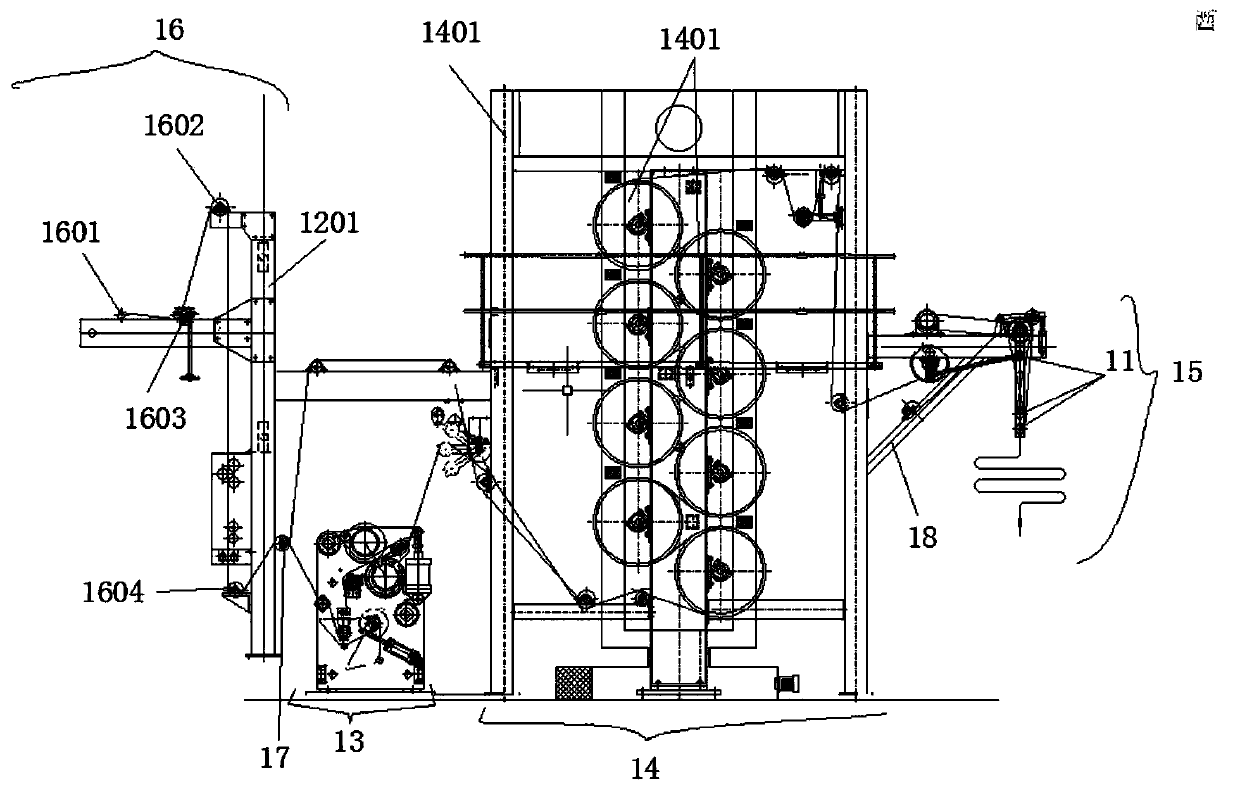

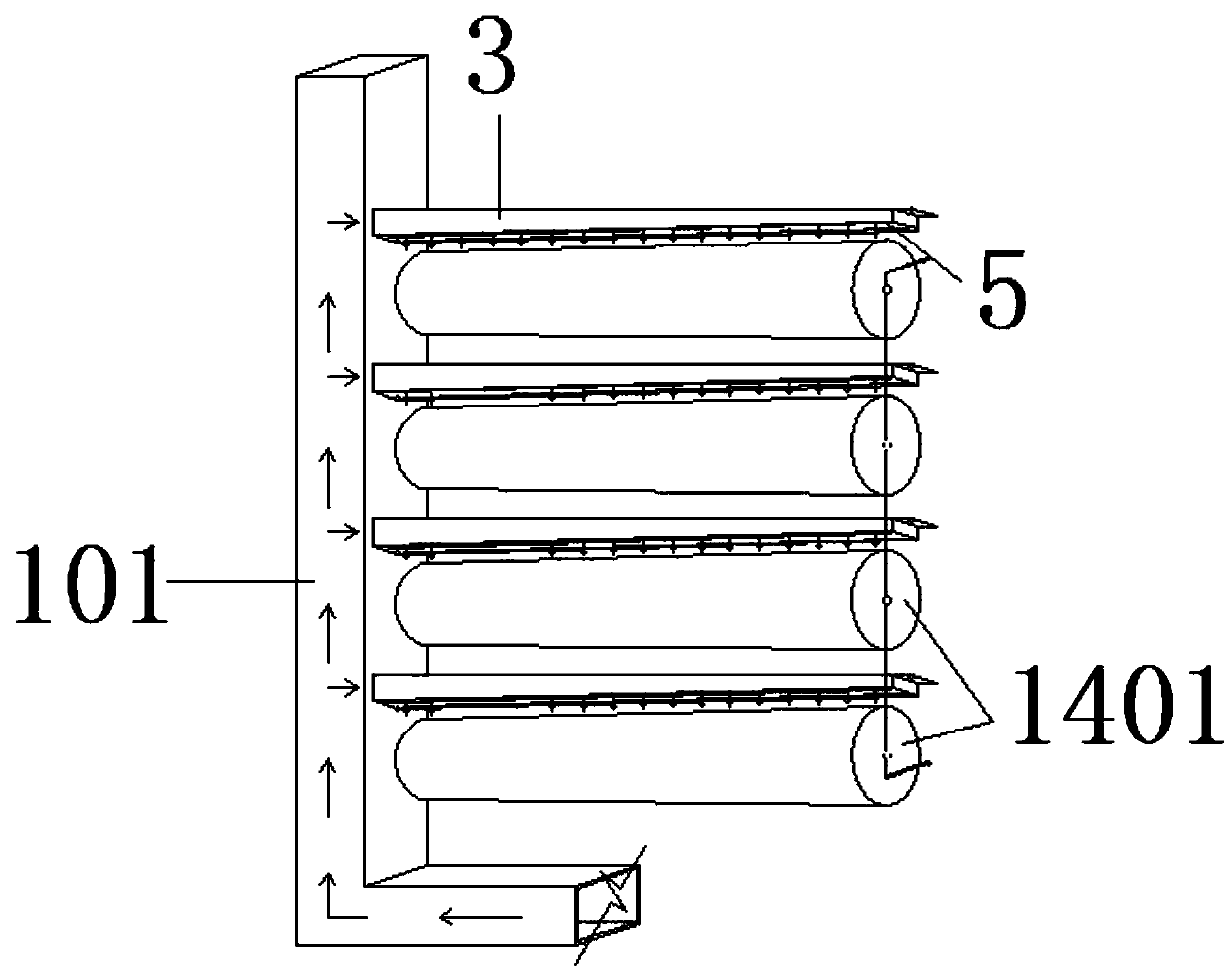

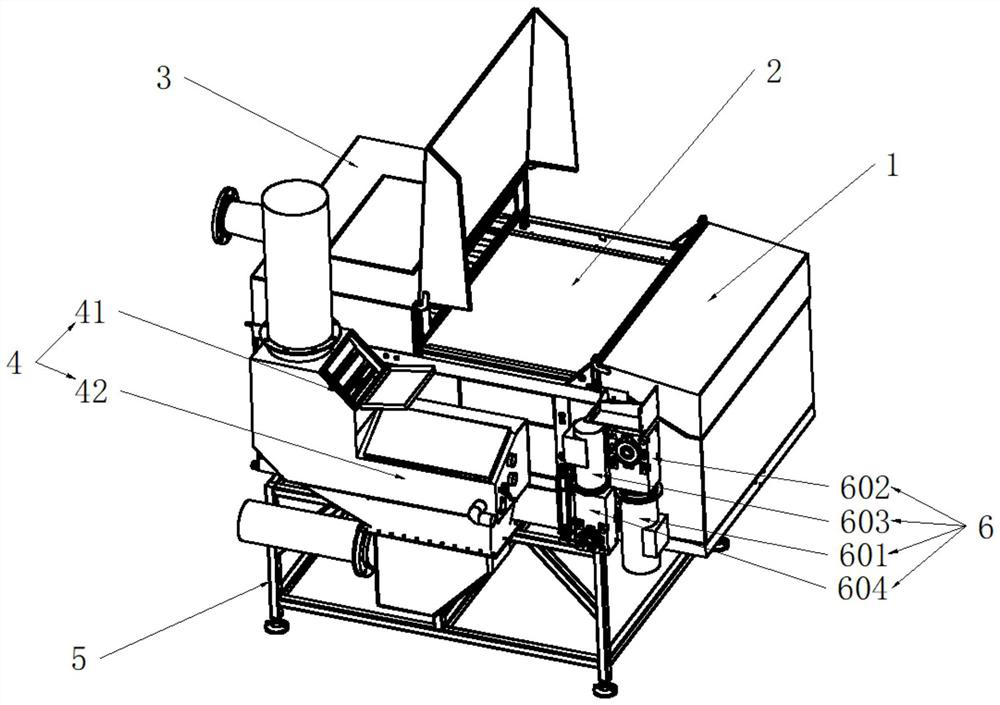

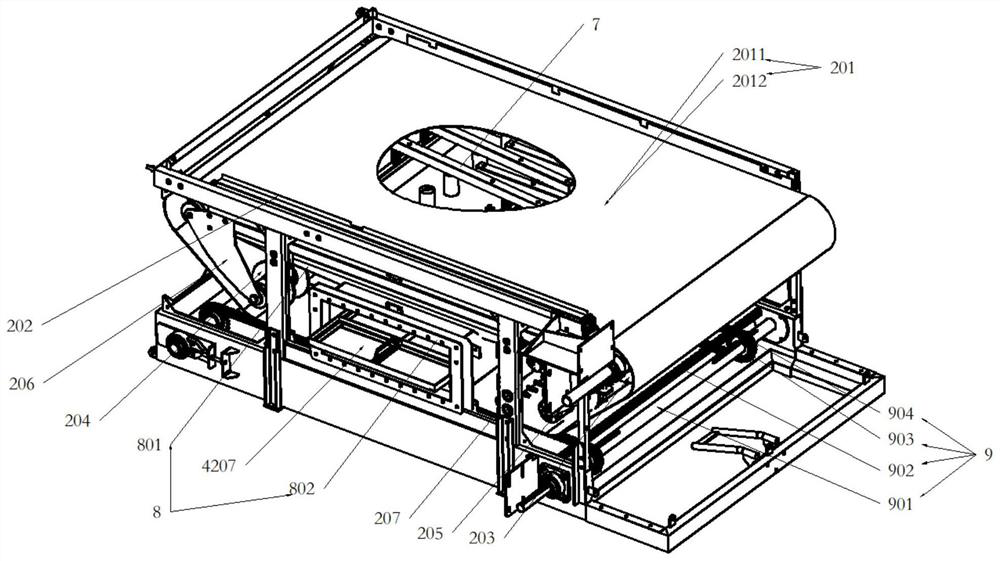

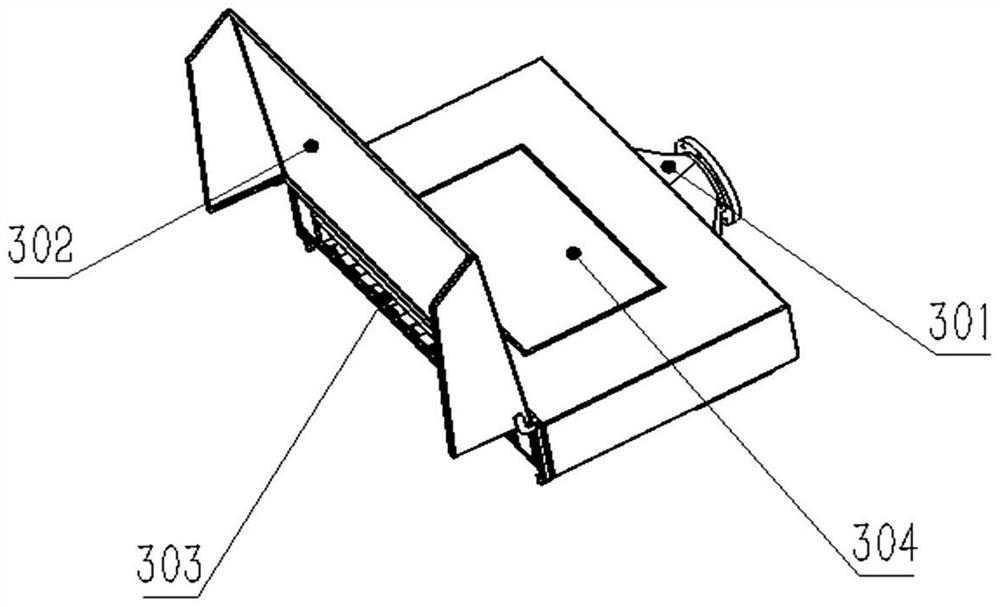

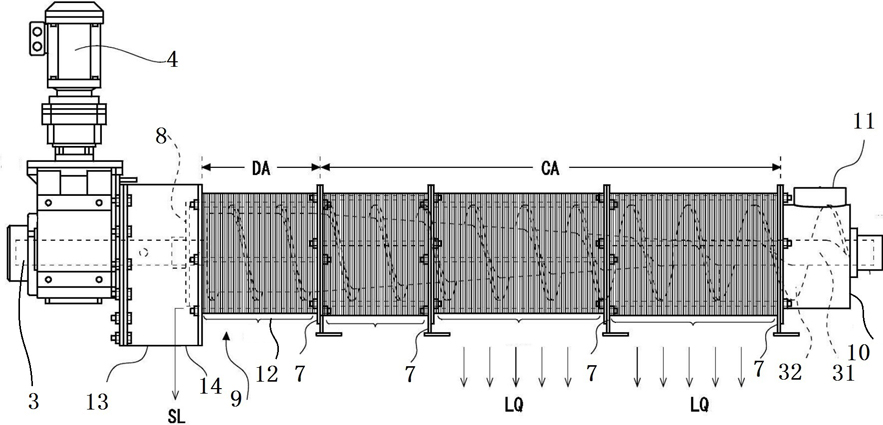

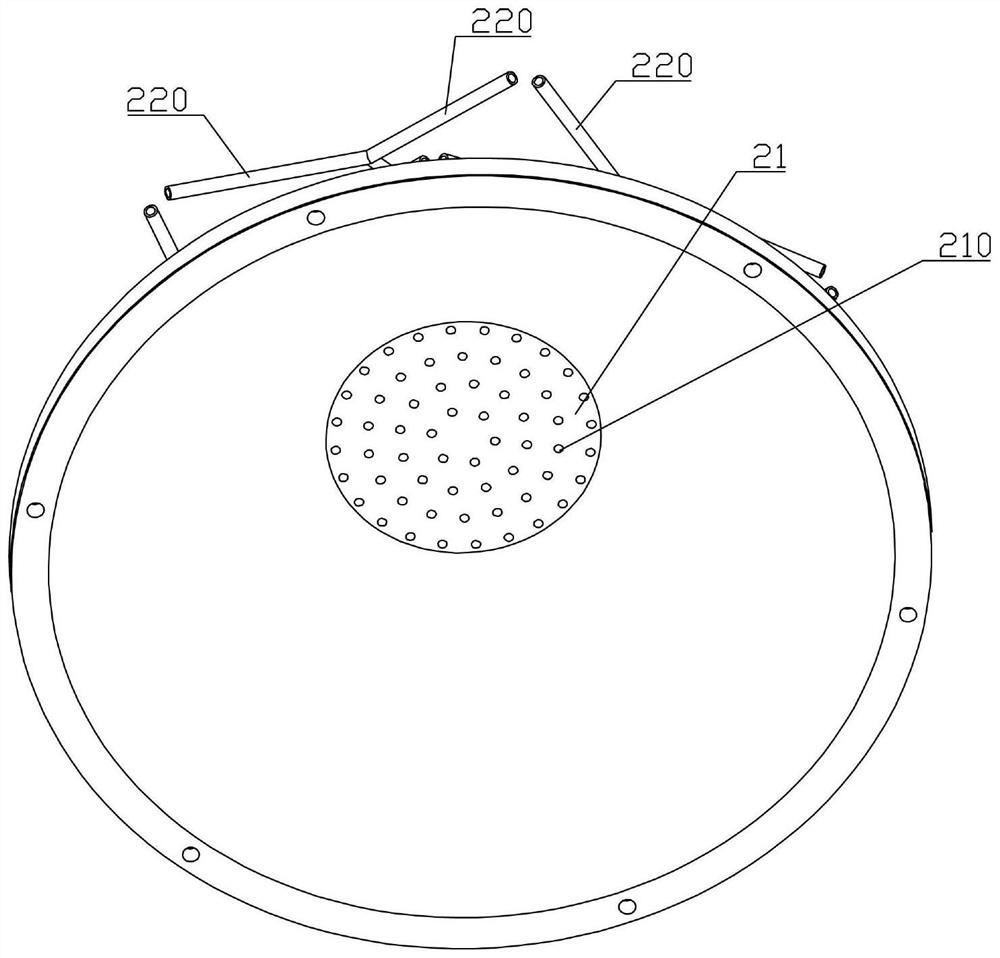

Novel negative pressure slurry treatment system

PendingCN112759217AImprove processing efficiencyImprove separation efficiencyCombination devicesSludge treatmentEngineeringSlurry

The invention provides a novel negative pressure slurry treatment system which comprises a rack, a belt type screen transmission device, a head box, a side box, a supporting frame, a micro-vibration device, a negative pressure diversion trench, a screen cleaning device and a driving device. The belt type screen transmission device comprises a screen, a rubber filtering support belt, a side leakage prevention apron board, a driving roller, a guide roller, a front roller support plate, a rear roller support plate and a tensioner; the head box comprises a feeding hole, an upper sealing cover, a shunting buffer tray and an observation window; the side box comprises a secondary filtering device and a gas filtering device; the micro-vibration device comprises a vibration rod, a damping spring, a pneumatic vibration exciter and a fixing rod; the negative pressure diversion trench comprises a negative pressure trench body and a liquid outlet; the driving device comprises a screen driving motor, a screen speed reducer, a mud scraping plate driving motor and a mud scraping plate speed reducer; rapid separation of slurry and rock debris particles is achieved through the micro-vibration device, the filtering device and the negative pressure system, the slurry treatment efficiency is improved, the cost is reduced, and environmental pollution is reduced.

Owner:孙腾飞 +1

A kind of method of producing magnesium ammonium phosphate slow-release fertilizer

ActiveCN103936489BSimple production processLow dry softening pointFertilizer mixturesControl releasePhosphoric acid

The invention provides a method for producing magnesium ammonium phosphate controlled-release fertilizer by utilizing an ammoniated slurry filtration filter cake produced in a process of producing industrial-grade monoammonium phosphate by adopting wet process phosphoric acid. The filter cake reacts with light calcined magnesia powder to generate the magnesium ammonium phosphate controlled-release fertilizer with magnesium ammonium phosphate as a main active ingredient. The method for producing the magnesium ammonium phosphate controlled release fertilizer product is simple, the magnesium ammonium phosphate controlled release fertilizer can be easily dried, and fertilizer efficiency is high.

Owner:昆明隆祥化工有限公司

Solid-liquid separating device, filtering apparatus, and solid-liquid separating method

ActiveUS8663482B2Effective squeezeEfficient separationWater/sewage treatmentFiltration circuitsEngineeringMaterial supply

A solid-liquid separating apparatus is provided with: a separating roll which has a substantially cylindrical shape with a plurality of through holes, which penetrate between an inner surface and an outer surface in radial direction thereof, and is rotatable in circumferential direction thereof; and a pair of separating filter cloths which is endless belts capable of traveling in a rotation direction of the separating roll and are wound around the outer circumference of the separating roll so as to overlap each other, wherein a material supplied between the pair of filter cloths is squeezed by being rolled together with the pair of filter cloths therebetween on the outer circumference of the separating roll, and the material is dehydrated by ventilating via each through hole.

Owner:TSUKISHIMA KIKAI CO LTD

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method for preparing industrial-grade phosphoric acid, food-grade phosphoric acid and industrial monoammonium phosphate with wet-process phosphoric acid. Using wet-process phosphoric acid as raw material, the wet-process phosphoric acid is subjected to a series of chemical precipitation + organic solvent extraction + concentration + recrystallization, etc. Composite purification technology prepares industrial-grade phosphoric acid and food-grade phosphoric acid respectively; at the same time, the present invention uses partially purified dilute phosphoric acid to prepare industrial monoammonium phosphate. The co-production of industrial-grade phosphoric acid, food-grade phosphoric acid and industrial monoammonium phosphate in the present invention enables rational graded utilization of wet-process phosphoric acid, increases the added value of phosphorus, and further develops downstream industrial-grade and food-grade phosphates.

Owner:中化重庆涪陵化工有限公司

Method and apparatus for separating magnetic material from a slurry

A method and apparatus for separating magnetic material from a slurry is disclosed, the method including the steps of providing a first moving surface, depositing the slurry onto the first moving surface, attracting at least a portion of the magnetic material of the slurry onto the first moving surface by first magnetic means, arranging the first moving surface such that liquid from the slurry is removed due to the portion of the magnetic material being attracted to the moving surface by the first magnetic means to form a magnetic material cake, separating an inner portion of the magnetic material cake from an outer portion of the magnetic material cake, with respect to the first moving surface, such that the inner portion has a lower liquid content than the outer portion.

Owner:STEINERT AUSTRALIA

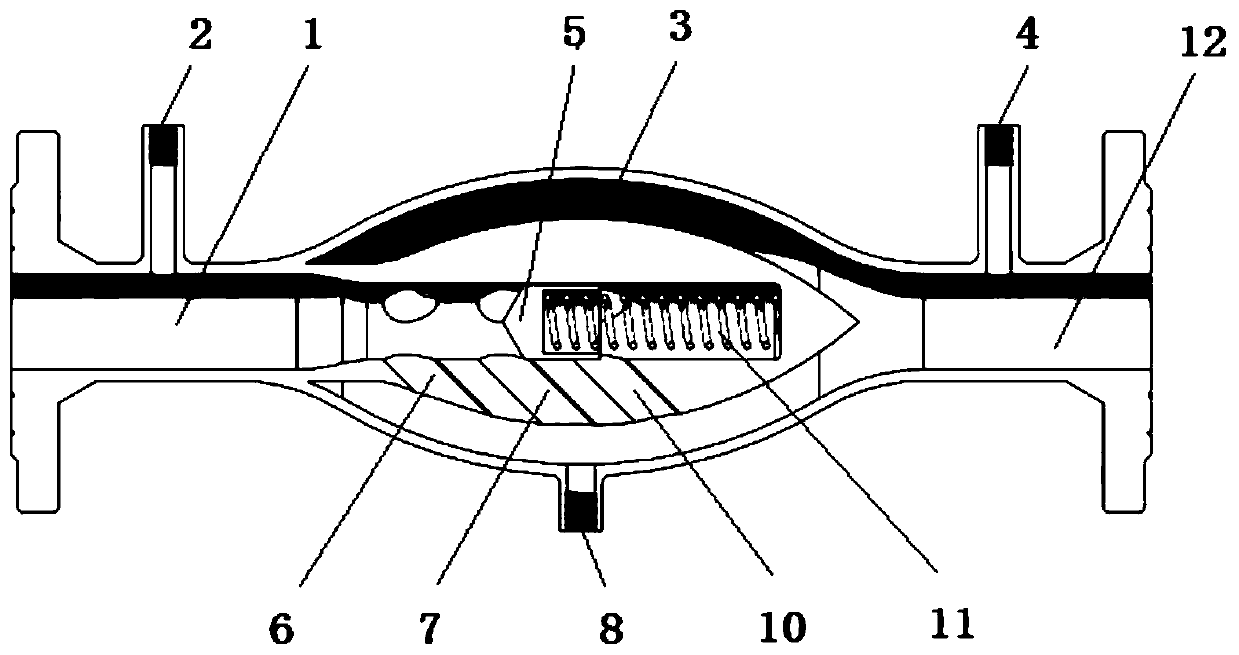

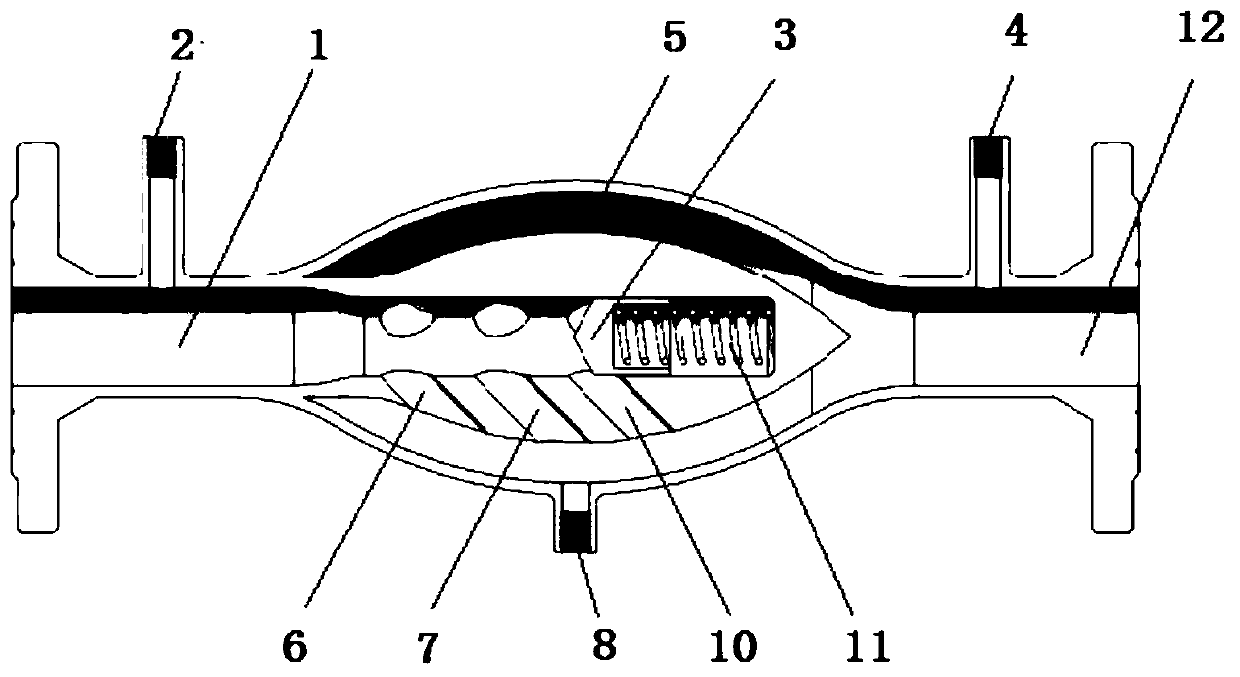

Differential pressure type compressor gas lift wellhead pressure reduction device and pressure reduction method applying same

PendingCN111502613ALow liquid contentIncrease the pressure ratingSurveyFluid removalSpool valveGas lift

The invention discloses a differential pressure type compressor gas lift wellhead pressure reduction device and a pressure reduction method applying the same, and belongs to the technical field of drainage gas recovery matching devices. A pressure reduction device channel of a pressure reduction device separation chamber of the wellhead pressure reduction device communicates with a gas inlet pipe,and a gas-liquid separation channel communicates with a gas outlet pipe; each flow guide unit is used for enabling the pressure reduction channel to communicate with the gas-liquid separation channeland used for carrying out step-by-step pressure reduction along the direction from the gas inlet pipe to the gas outlet pipe; each flow guide units at least comprises two flow guide channels, a slidevalve structure is arranged in the pressure reduction channel and used for pressure relief of the flow guide channels of each flow guide unit; a liquid discharge channel provided with a liquid discharge valve is arranged at the bottom of the gas-liquid separation channel and is used for discharging separated liquid; and the air inlet pipe and the air outlet pipe each are provided with a pressuredetection piece. The invention further discloses the compressor gas lift wellhead pressure reduction method applying the pressure reduction device. The wellhead pressure reduction device guarantees the continuous working duration of a compressor, the liquid drainage efficiency is improved, and the continuity of compressor gas lift measures is guaranteed.

Owner:西安朗益软件科技有限公司

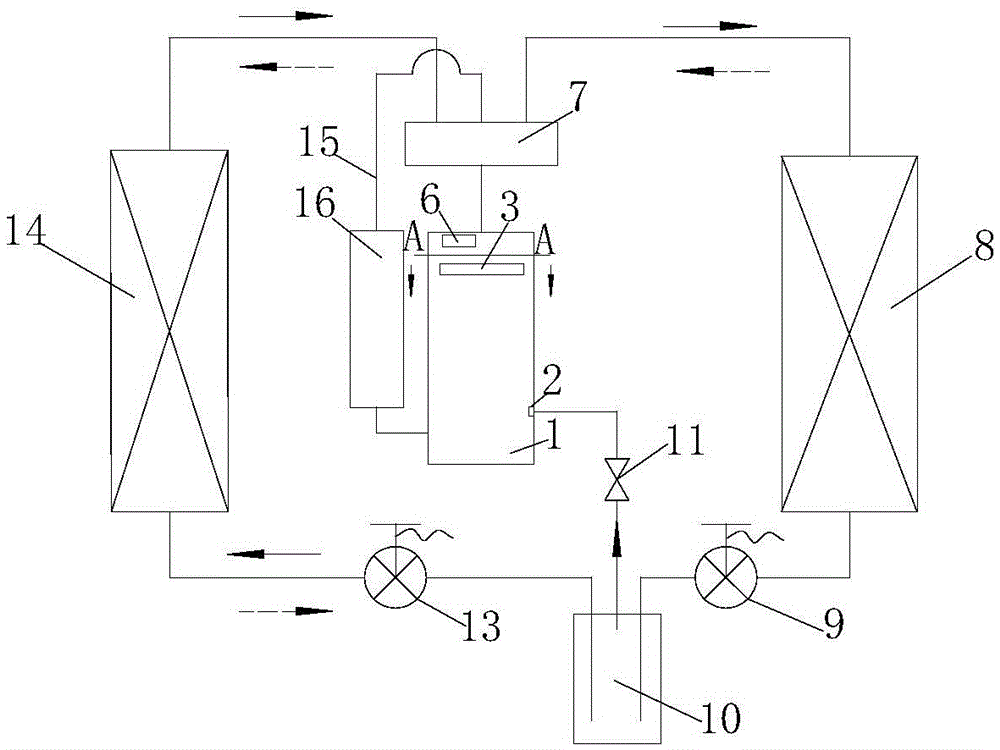

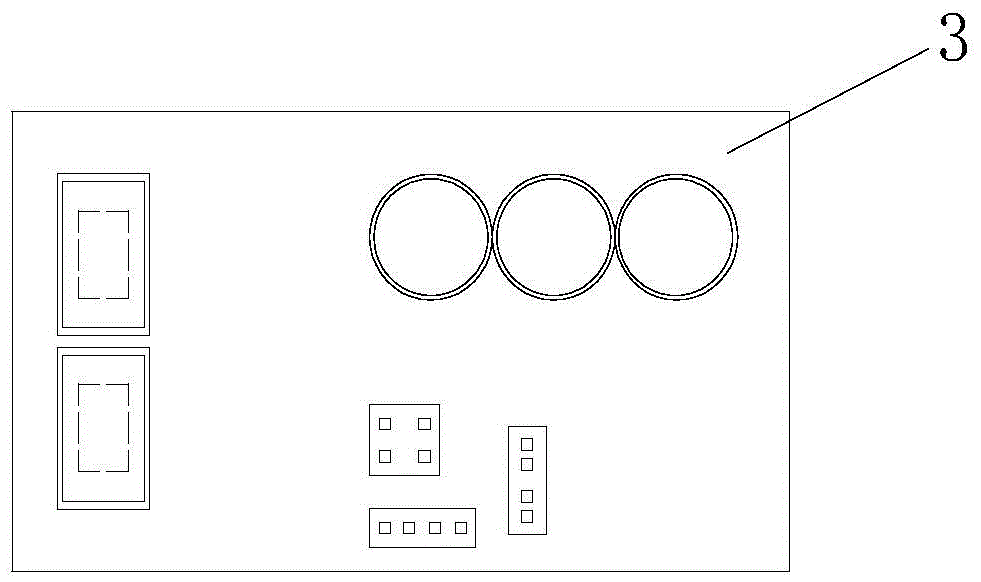

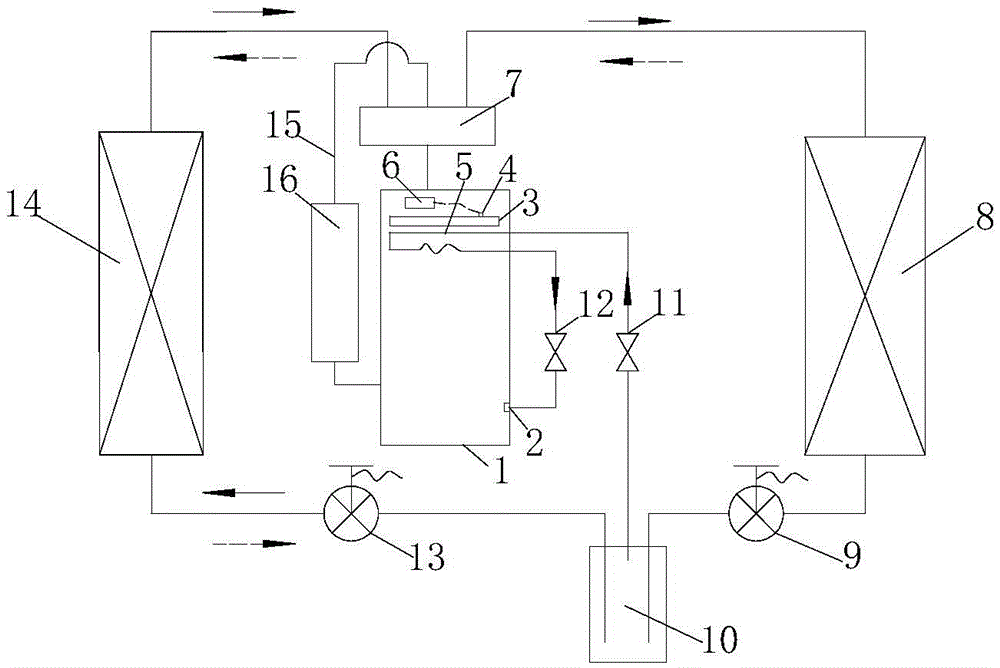

A Novel Air Supplementary Enthalpy Increase System and Its Control Method

ActiveCN104154692BImprove heat transfer efficiencyReduce the temperatureRefrigeration safety arrangementCooling/ventilation/heating modificationsFrequency changerEngineering

The invention discloses a novel air supply and enthalpy increasing system and a control method thereof. A frequency converter module of the system is arranged between an air supply electromagnetic valve and a compressor air supply opening, the frequency converter module is provided with a frequency converter module temperature detection device, and a frequency converter module heat exchange device is arranged at the bottom of the frequency converter module. Flash evaporation refrigerating fluid in a flash-tank enters the frequency converter module heat exchange device through the air supply electromagnetic valve, the frequency converter module heat exchange device exchanges heat with the frequency converter module, and accordingly the temperature of the frequency converter module is lowered. The frequency converter module temperature detection device is connected with a master controller. The master controller is connected with the air supply electromagnetic valve, a first electronic expansion valve arranged between the flash-tank and an indoor heat exchanger, and a second electronic expansion valve arranged between the flash-tank and an outdoor heat exchanger. The invention further provides the control method of the system. The problems that according to an existing air supply and enthalpy increasing technology, under a hostile working condition, namely an ultralow temperature or superhigh temperature working condition, the temperature of the frequency converter module is excessively high, so that the stability of the frequency converter module and even the entire air supply and enthalpy increasing system gets worse, and the service life is shortened can be solved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

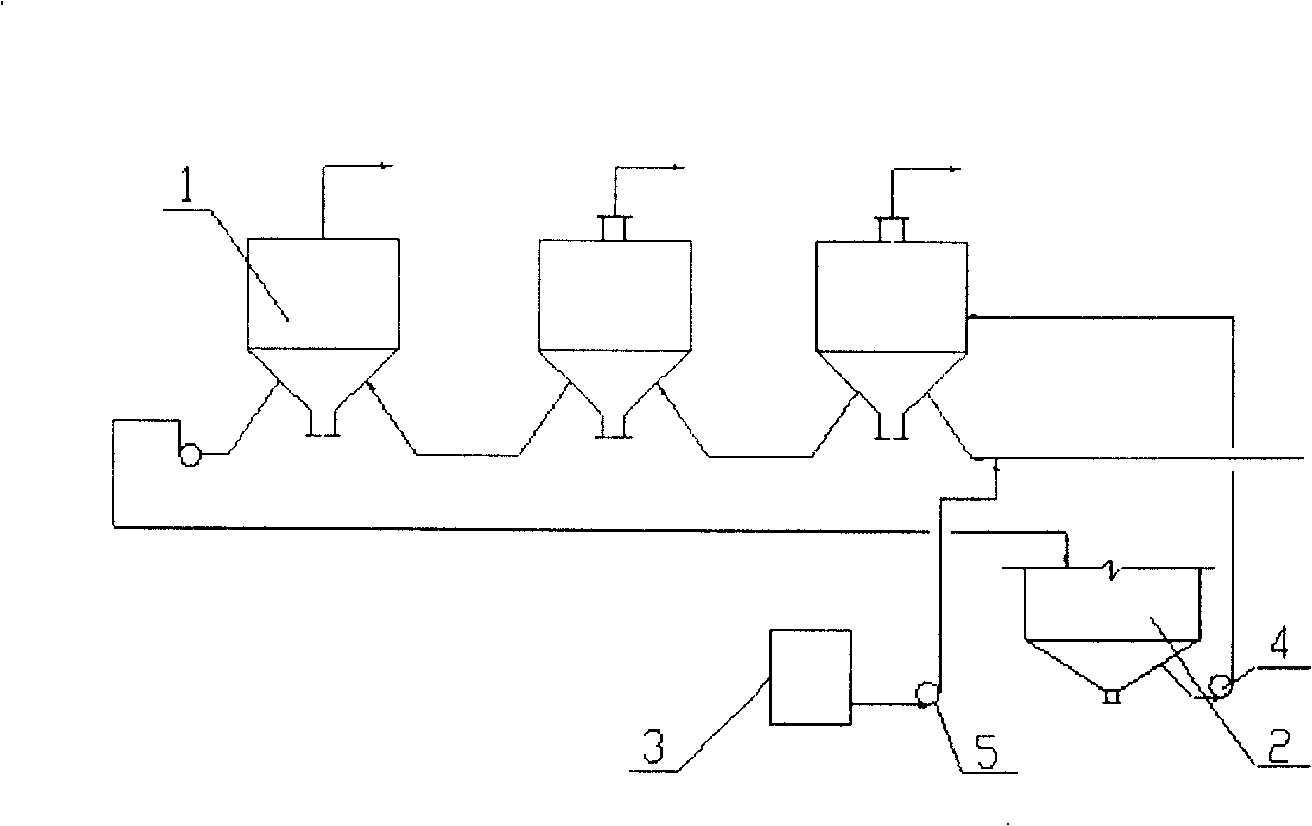

Carbonate-removing method in alumina production

InactiveCN100450931CAccelerated settlementImprove filtering effectAluminates/aluminium-oxide/aluminium-hydroxide purificationHigh concentrationSodium carbonate anhydrous

This invention discloses a method for removing carbonates during the aluminum oxide production and the apparatus thereof, which comprises: salt-removal equipment(forced-circulation evaporator or flash evaporation tank), salt settling tank, high concentration caustic alkali tank, salt seed crystal pump, lye pump and corresponding pipes. During the forced-circulation and flash evaporation salt-removing process, add appropriate amount of carbonate seed crystal and high concentration caustic alkali, so as to improve the salt-removing efficiency and obtain mostly anhydrous sodium carbonate with good settling and filtering properties in the removed salt.

Owner:GUIYANG AL-MG DESIGN & RES INST

Solid-liquid separation device

The invention discloses a solid-liquid separation device, and relates to the technical field of solid-liquid separation. The solid-liquid separation device comprises fixed rings, floating rings, screw conveyors, a driving device and a filter cartridge; the filter cartridge comprises a plurality of fixed rings arranged at intervals in the axis direction and the floating rings arranged in gaps among the fixed rings; the screw conveyors are sleeved with the fixed rings and the floating rings; lead screw bearings and spiral blades arranged on the peripheries of the lead screw bearings are arranged in the screw conveyors; each lead screw bearing is provided with a conical part extending from the base end to the other end, a cylindrical part formed at the other end of the conical part and a miniature cylindrical part formed by extending from the base end of the conical part to one end; the conical parts arranged in the fixed rings and the floating rings form a concentration region; the cylindrical parts arranged in the fixed rings and the floating rings form a dehydration region; and in a barrel-shaped body formed by the fixed rings and the floating rings, by configuring the screws conveyor with the conical parts and the cylindrical parts, the liquid rate in solid can be reduced, and the solid removal rate can be improved.

Owner:江苏康泰环保装备有限公司

Petroleum associated gas oil removal device

ActiveCN112177587AAvoid secondary collisionIncrease liquid contentCombination devicesGaseous fuelsEngineeringPetroleum oil

The invention belongs to the technical field of oil-gas separation equipment, and particularly relates to a petroleum associated gas oil removal device. The device comprises a shell, a constant-temperature anti-freezing structure and an air cooling tube bundle structure, wherein the shell comprises a top cover, a body and a bottom cover; the air cooling tube bundle structure comprises a partitionplate and a plurality of air cooling tube bundles evenly and fixedly arranged on the partition plate, and the constant-temperature anti-freezing structure wraps the air cooling tube bundles; the partition plate divides the interior of the shell into an upper cavity and a lower cavity, and the air cooling tube bundle structure is fixedly arranged on the inner wall of the body through the partitionplate; a plurality of circulating holes are further formed in the edge of the partition plate, the free ends of the air cooling tube bundles are bent downwards, a plurality of through holes are formedin the middle part of the partition plate, and the air cooling tube bundles are fixedly arranged in the through holes; and a gas phase outlet pipe is arranged on the top cover, gas phase inlet pipesare arranged at the positions, below the partition plate, of the side wall of the body, and a liquid discharging pipe is arranged at the lower end of the bottom cover. The petroleum associated gas oilremoval device aims to solve the problem of low gas-liquid separation efficiency caused by structural defects of an existing oil removal device.

Owner:杭州勃扬能源设备有限公司

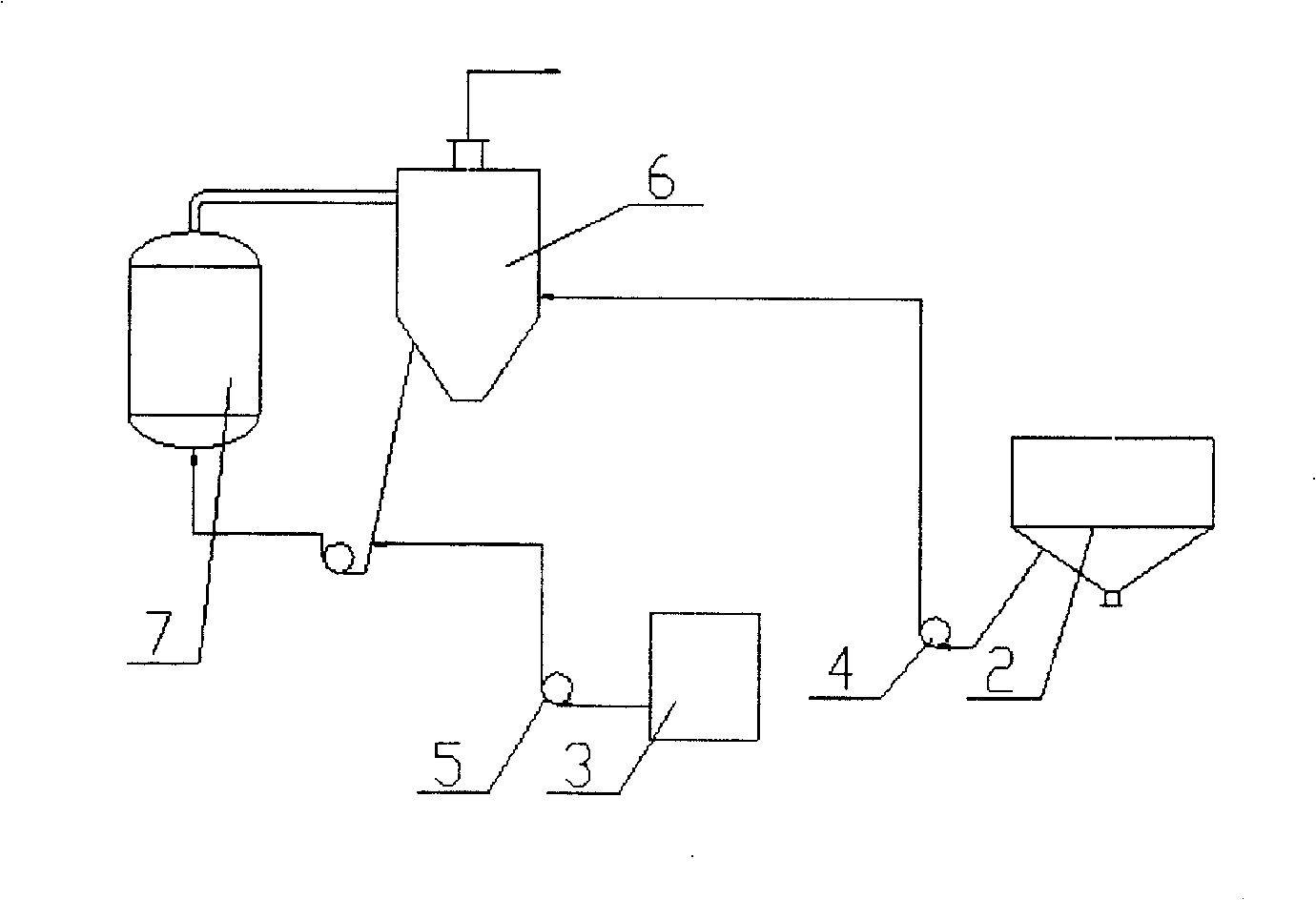

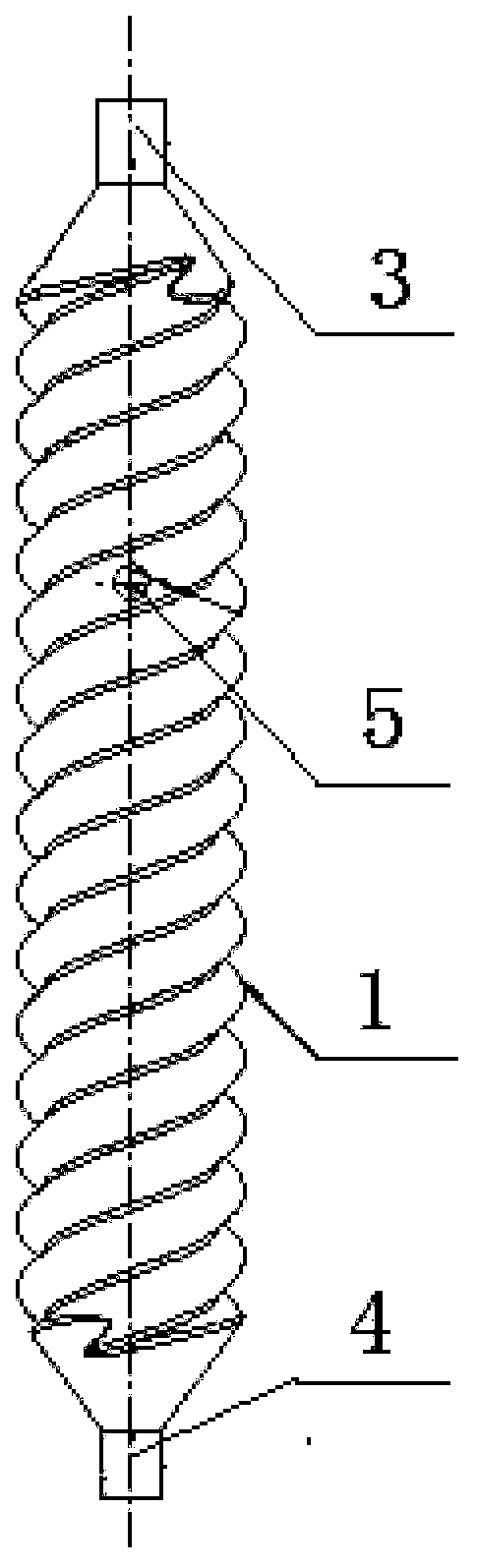

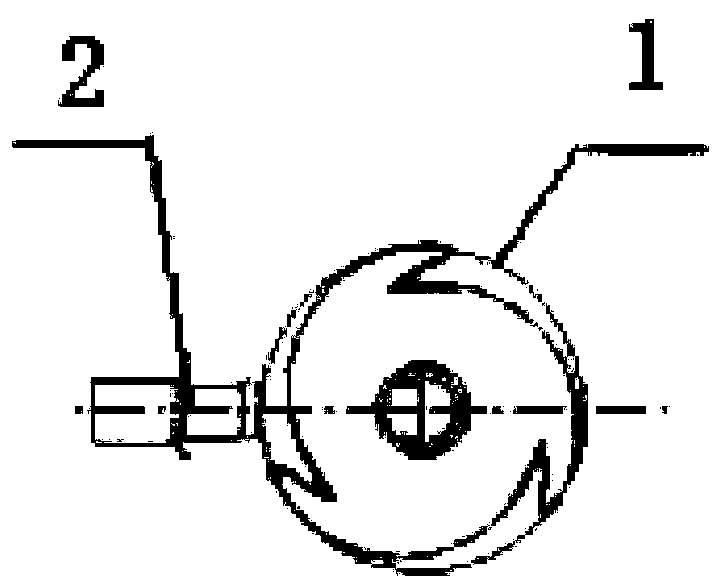

Three-dimensional spiral double-effect vertical flash evaporator and heat pump system with same

The invention is applicable to the technical field of chemical equipment manufacturing, and provides a three-dimensional spiral double-effect vertical flash evaporator and a heat pump system with thesame. The flash evaporator comprises a shell, a gas outlet and a liquid outlet are formed in the two ends of the shell, the shell is connected with a gas-liquid two-phase inlet through a mounting hole, and the shell is of a three-dimensional spiral structure. The invention further provides the heat pump system with the flash evaporator. According to the flash evaporator and the system, the gas-liquid separation efficiency is high, the low liquid content of supplemented gas can be ensured along with the change of working conditions, the compression work of a compressor is saved, the efficiencyof the heat pump system is greatly improved, and the safety and the stability of the compressor are improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Comprehensive utilization method of fluosilicic acid-containing wastewater

ActiveCN113120937AHigh purityMeet purity requirementsCalcium/strontium/barium fluoridesCarbonizationPhysical chemistry

The invention relates to a comprehensive utilization method of fluosilicic acid-containing wastewater, which comprises the following steps: carrying out decomposition reaction on a calcium-containing raw material and a dissolution medium, carrying out carbonization conversion reaction on a calcium-containing solution obtained by the decomposition reaction and carbon dioxide, mixing a calcium carbonate solid obtained by the carbonization conversion reaction with silicon-removal fluorine-containing wastewater and an additive, and reacting to obtain calcium fluoride solids, wherein the fluosilicic acid-containing wastewater is mixed with a silicon-removal reaction medium, a silicon-removal reaction is carried out, and silicon-removal fluorine-containing wastewater and white carbon black are obtained through liquid-solid separation. According to the comprehensive utilization method, the calcium fluoride solid with controllable morphology, controllable granularity and controllable purity can be prepared, the purity of the calcium fluoride solid can be higher than 99.9%, white carbon black byproducts can be obtained, the comprehensive recovery rate of fluorine resources is increased to 90% or above, the technological conditions are mild, no special requirements for equipment materials and types exist, industrial operability is high, and the application range is wide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

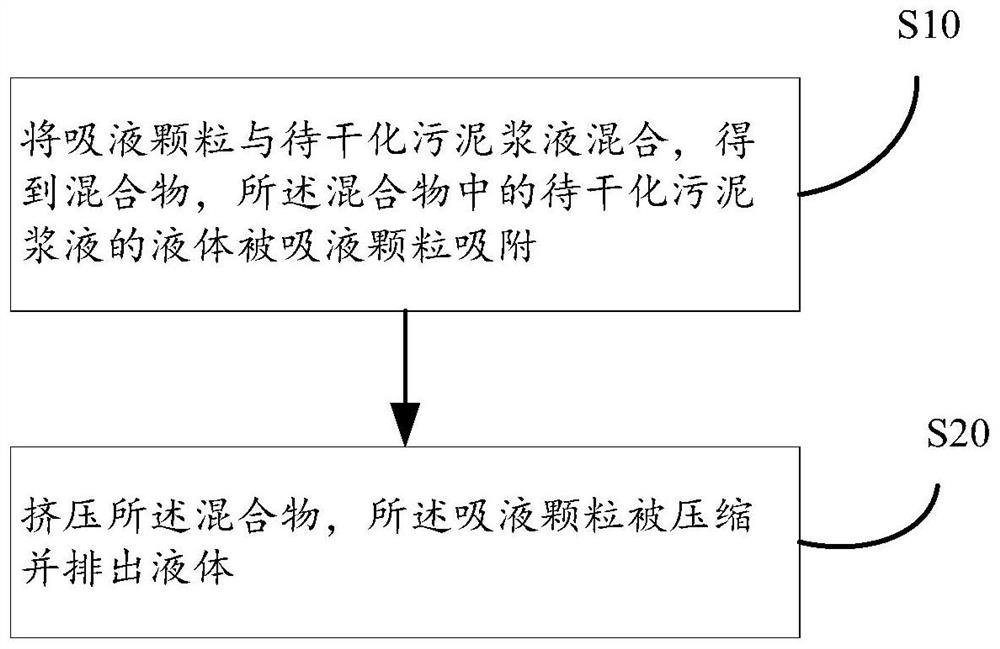

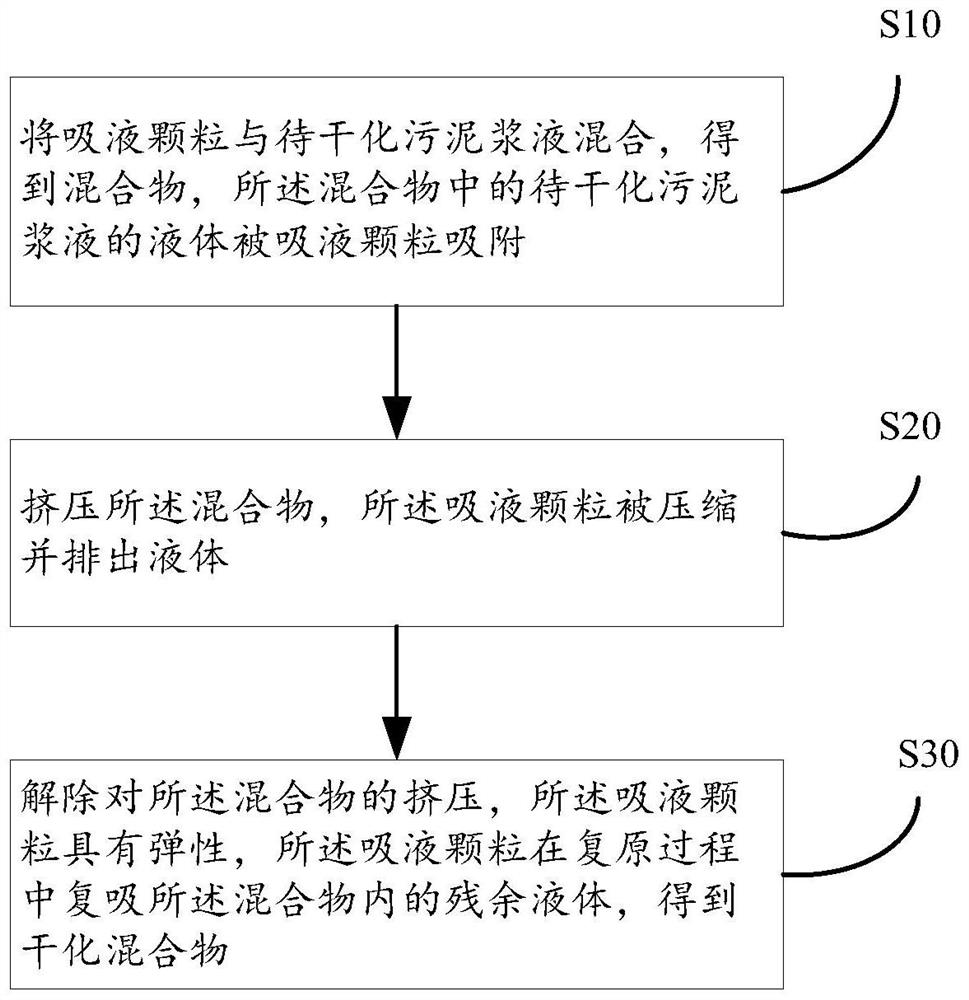

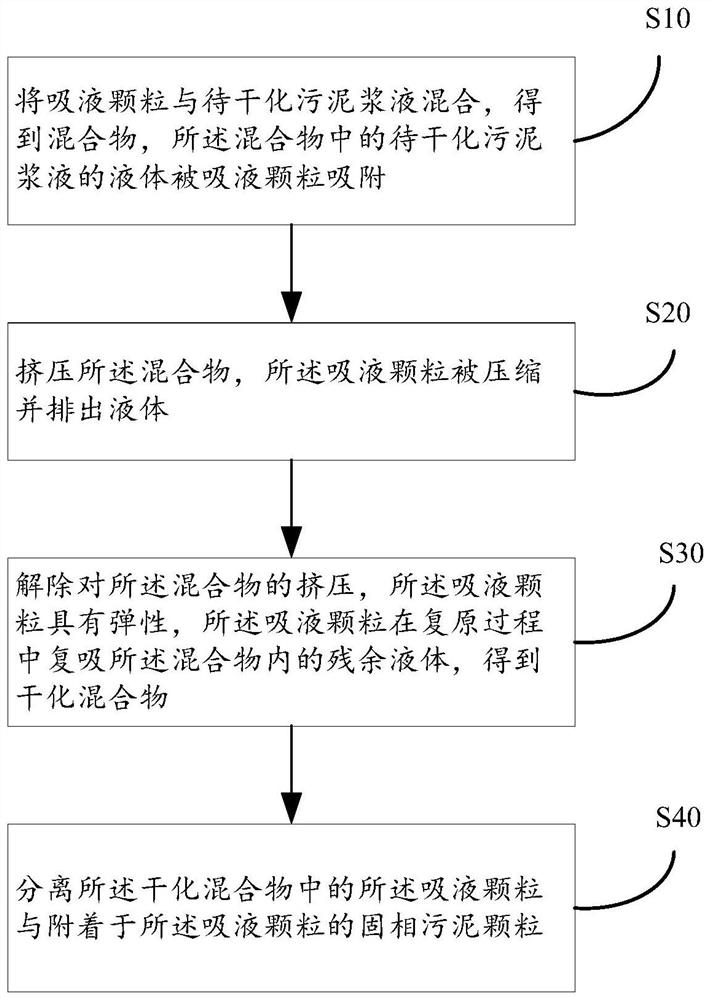

Sludge drying method and equipment

PendingCN112340955ALow liquid contentHas adsorption propertiesSludge treatment by de-watering/drying/thickeningSludgeSlurry

The invention provides a sludge drying method and equipment. The method comprises the following steps: mixing liquid absorption particles with to-be-dried sludge slurry to obtain a mixture, and adsorbing liquid of the to-be-dried sludge slurry in the mixture by the liquid absorption particles; pressing the mixture, so that the liquid absorption particles are compressed and the liquid is discharged. According to the method, the liquid content of the dried sludge is reduced.

Owner:ZHAOYUAN HUICHAO NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com