Air pipe, drying device using same and drying technology thereof

A technology of air duct and air outlet duct, which is applied in the field of drying device and its drying process, which can solve the problems of high liquid content on the surface, rapid drying of cloth, etc., and achieve low production cost, easy operation, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

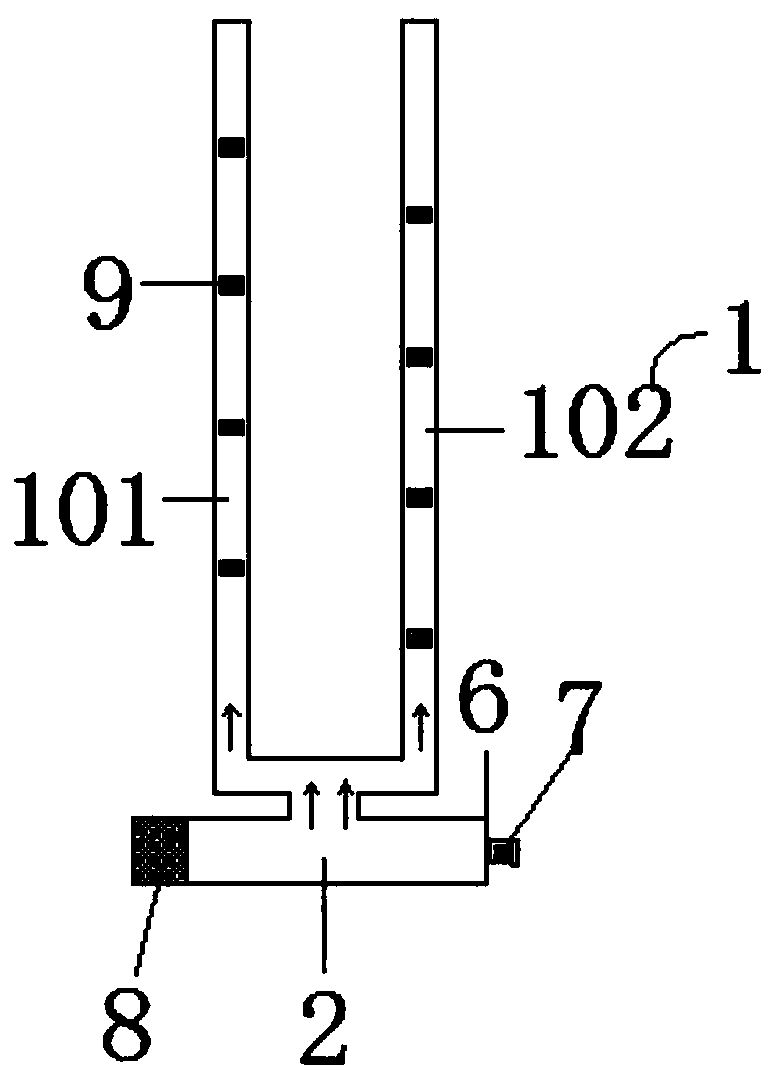

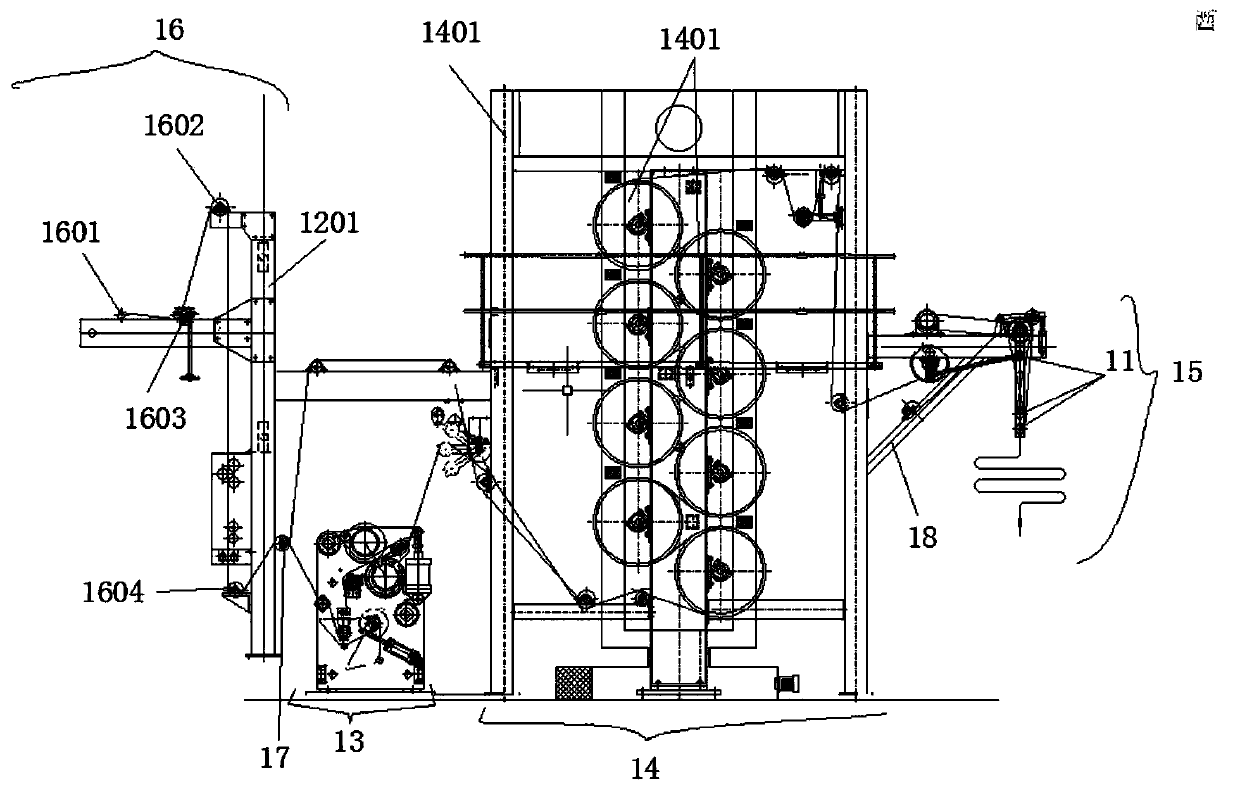

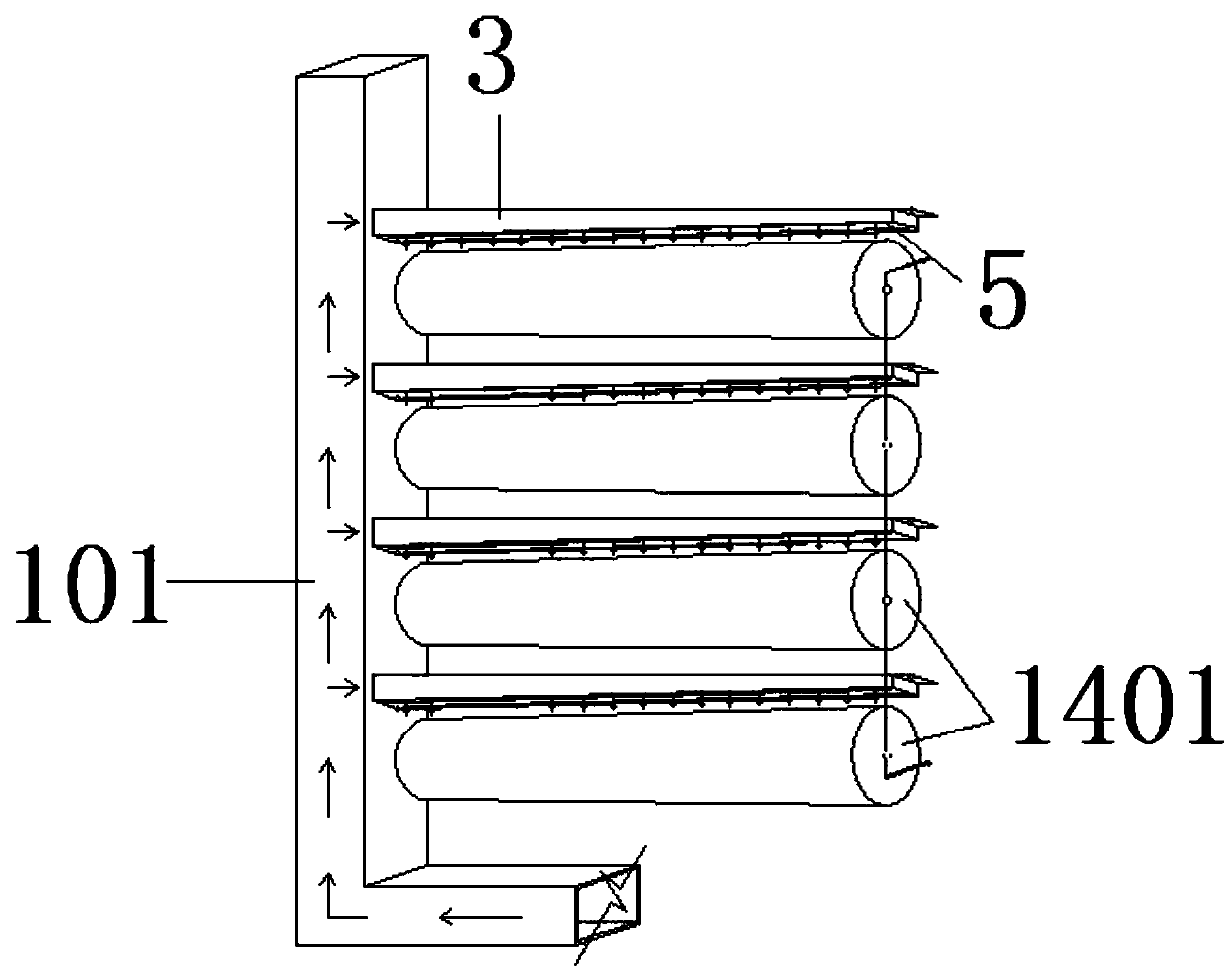

[0027] Embodiment 1: see figure 1 Now, an air duct 1 provided by the present invention will be described. The air duct 1 includes a first pipe body 101 and a second pipe body 102 that communicate with each other and are not collinear. The first pipe body 101 and the second pipe body 101 A pressure box 2 is provided at the connection of the pipe body 102, and a first air outlet pipe 3 and a second air outlet pipe 4 are respectively arranged on the first pipe body 101 and the second pipe body 102, and the first air outlet pipe 3 and the second air outlet pipe 4 are arranged respectively. One end of the pipe 3 close to the first pipe body 101 communicates with the first pipe body 101, and the other end is a closed end, and one end of the second air outlet pipe 4 close to the second pipe body 102 is connected to the first pipe body 101. The second pipe body 102 is connected, and the other end is a closed end. An air outlet 5 is set on the pipe wall of the first air outlet pipe 3 a...

Embodiment 2

[0028] Example 2: see figure 1 , as an improvement of the present invention, the inner diameters of the first pipe body 101 and the second pipe body 102 are the same. Setting the inner diameters of the first pipe body and the second pipe body to be the same can facilitate the installation with the pressure box, and at the same time, the difference in the flow rate of the air blown to the fabric is small, achieving the effect of uniform blowing.

Embodiment 3

[0029] Embodiment 3: see figure 1 , as an improvement of the present invention, the air outlet 5 is detachably connected to the air nozzle 9 . There is a detachable connection between the air outlet and the air nozzle. After a period of use, dust and stains will accumulate on the air nozzle. The detachable connection is beneficial to the cleaning of the air nozzle, and it is easy to install and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com