Patents

Literature

1276results about "Liquid/gas/vapor removal by squeezing rollers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

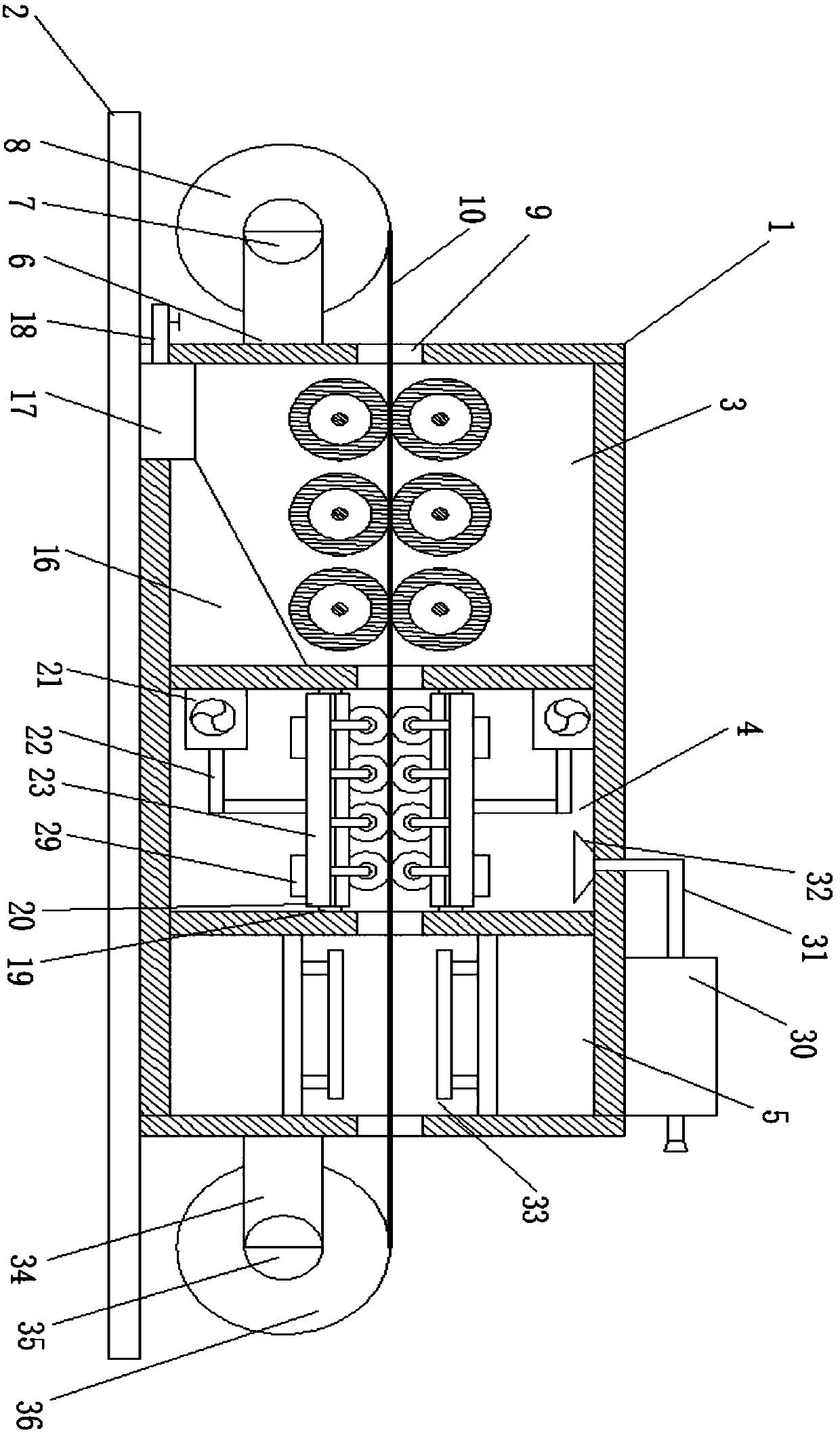

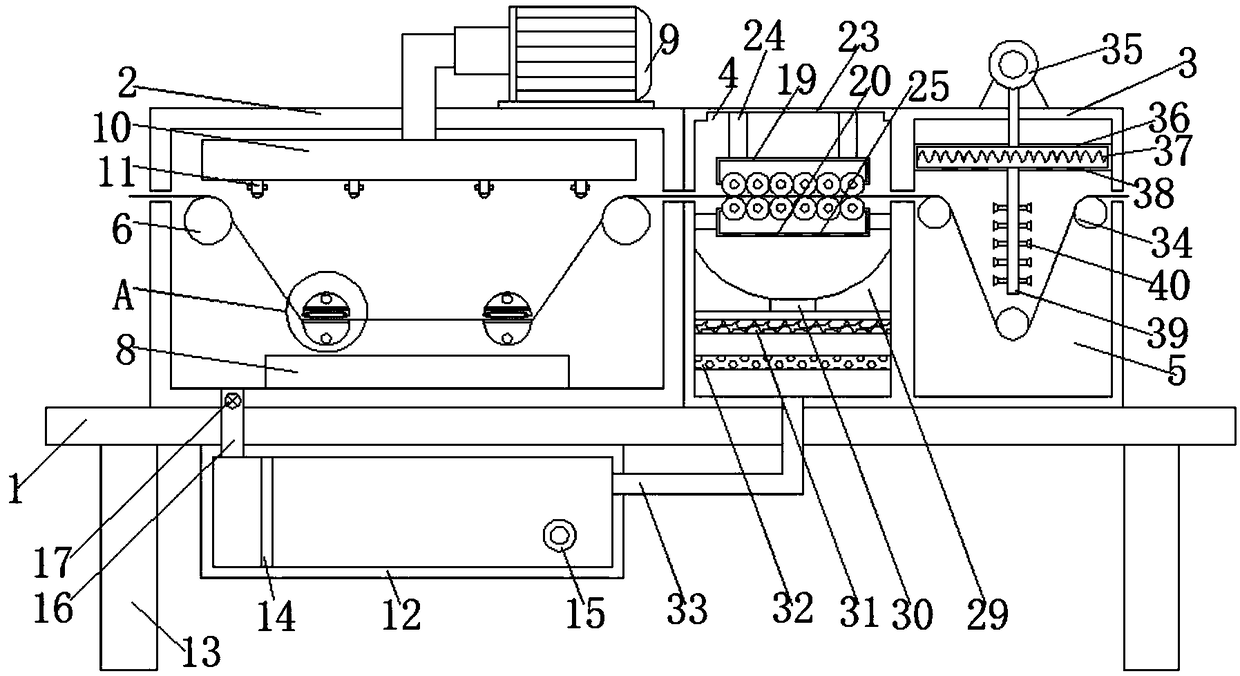

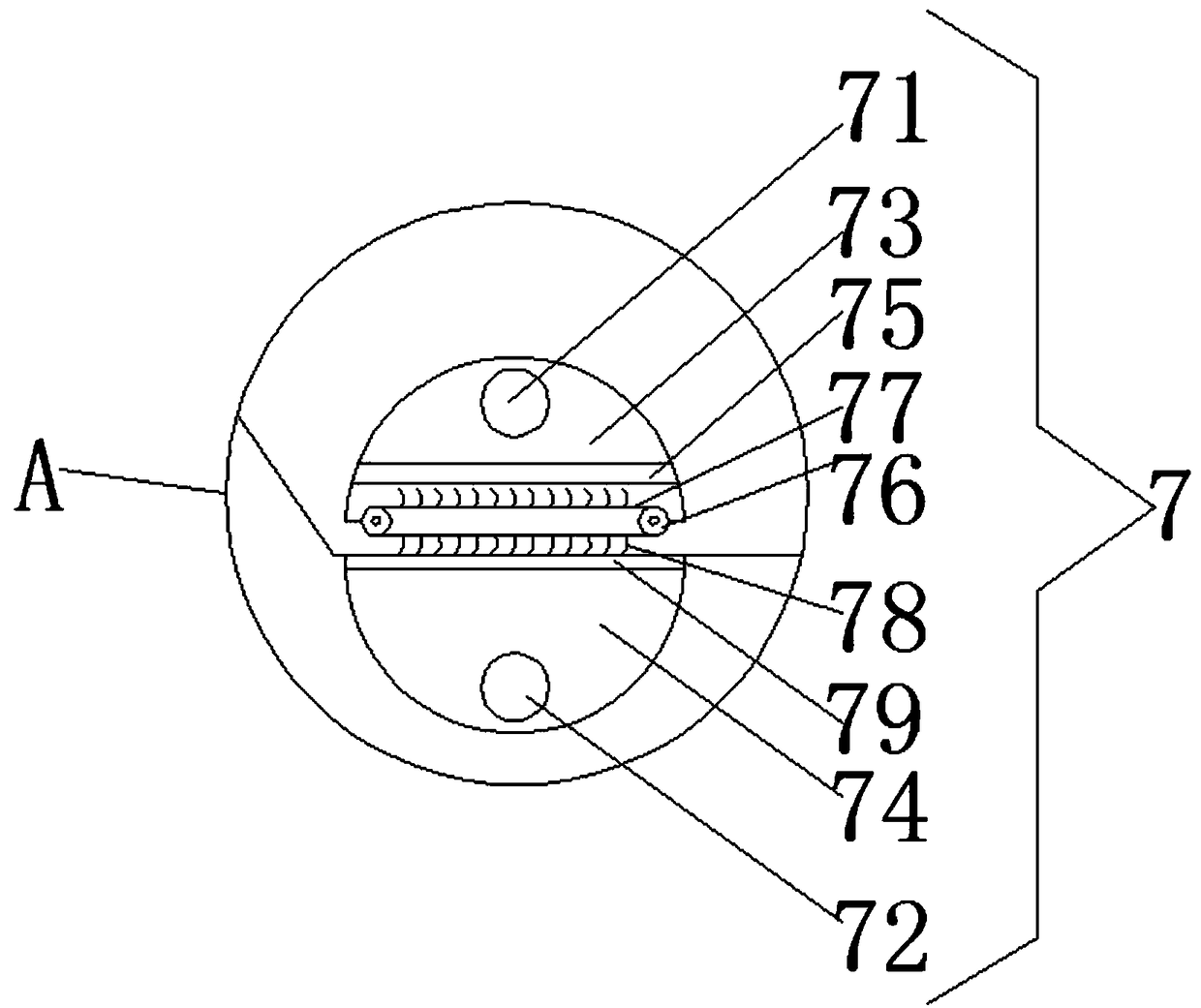

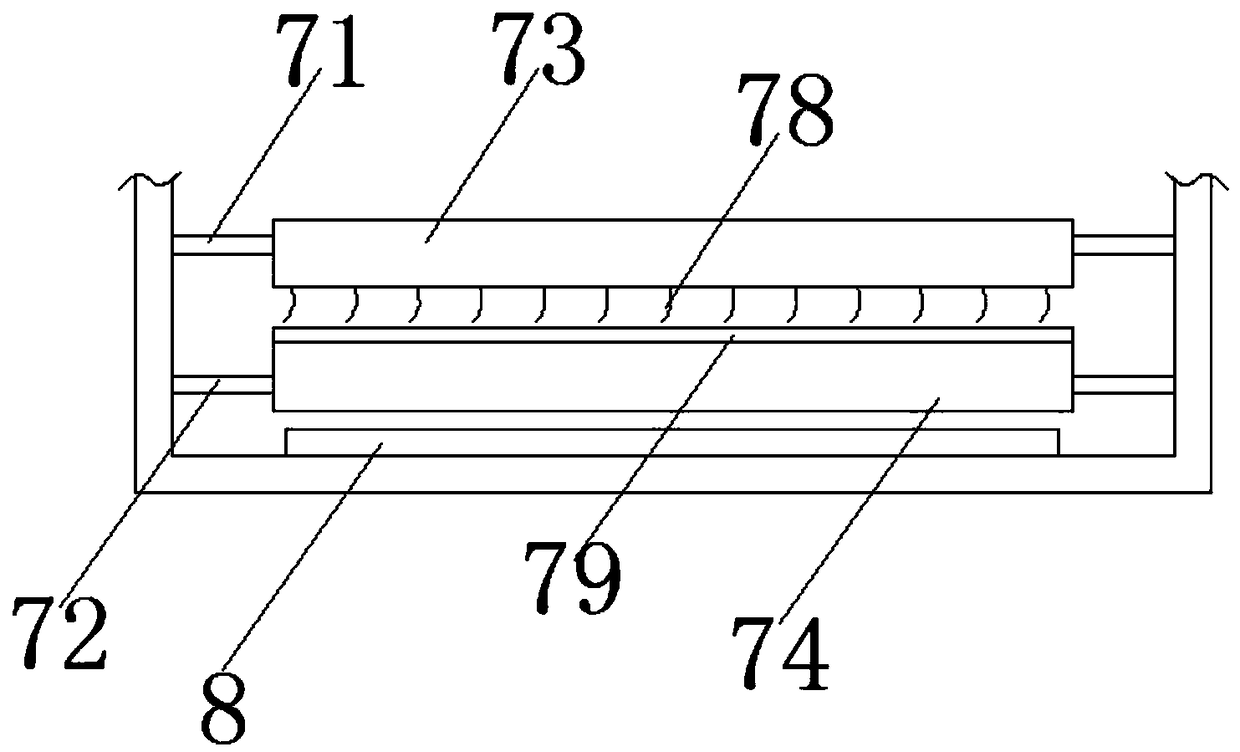

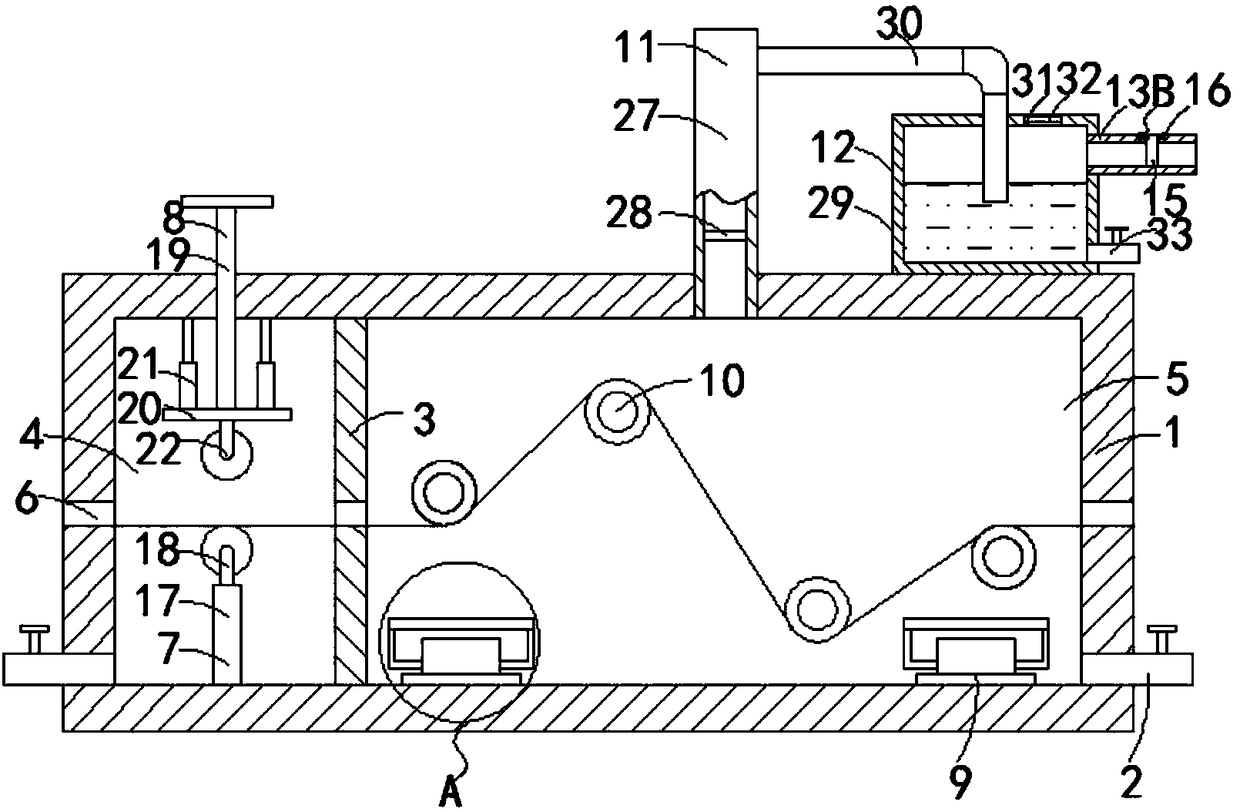

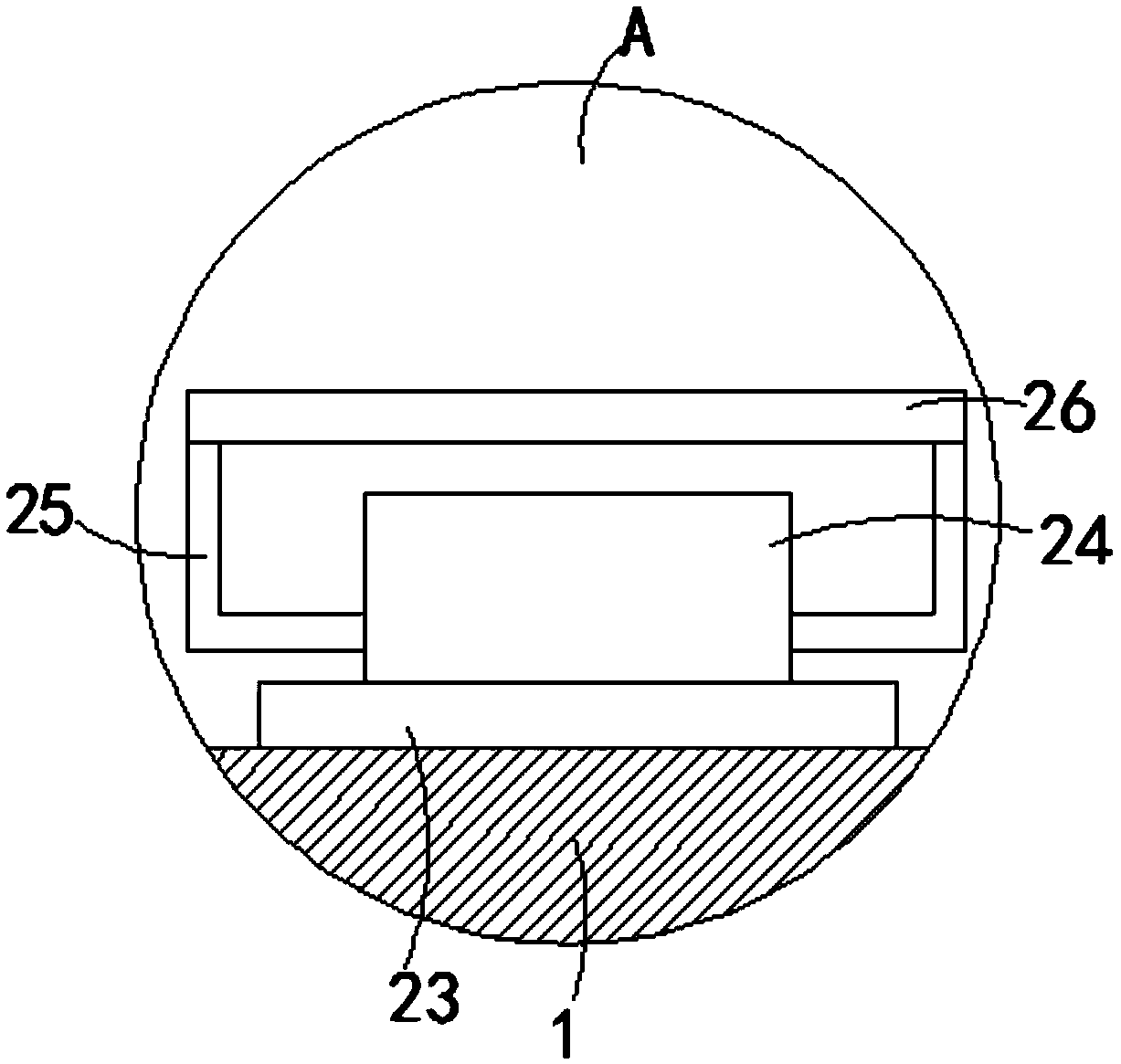

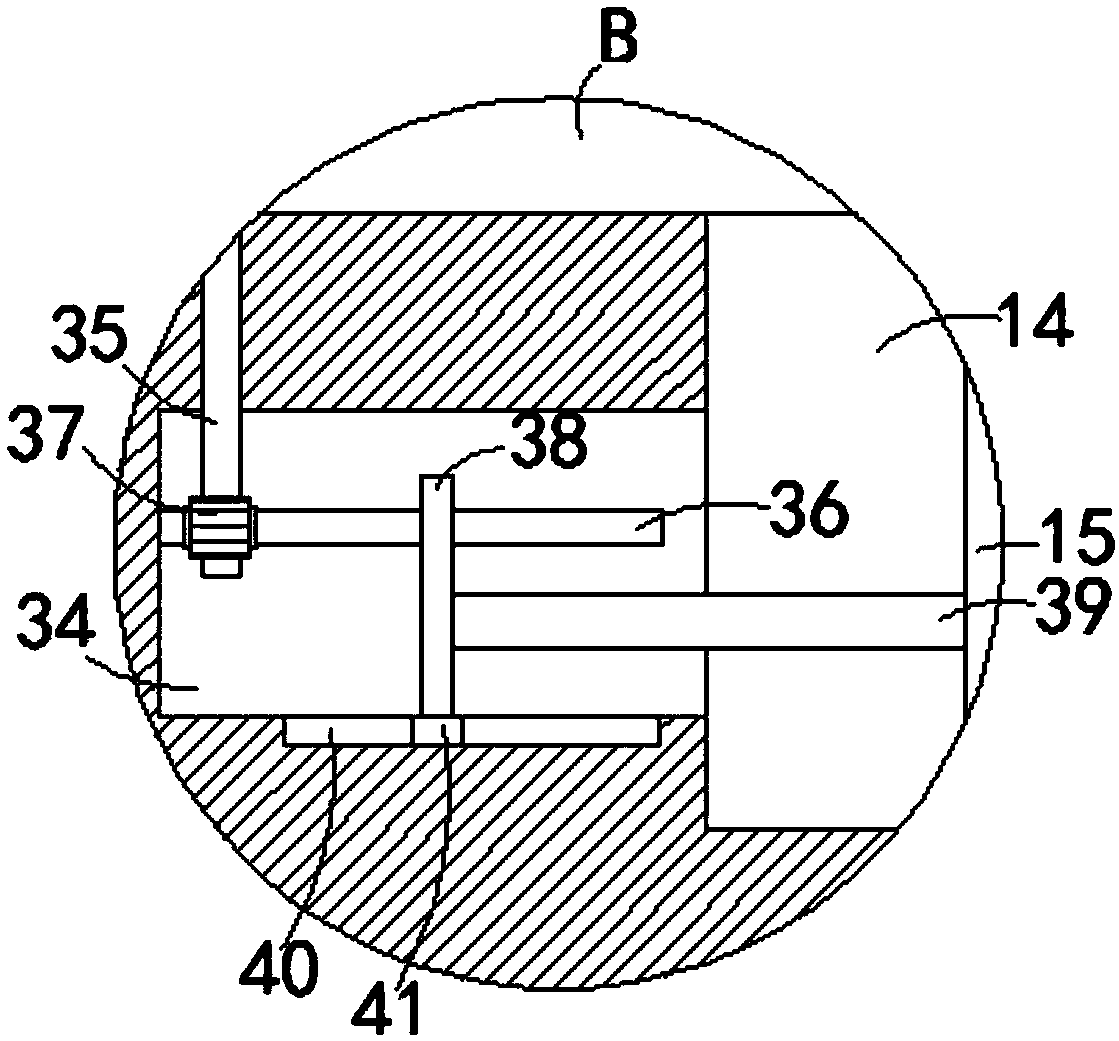

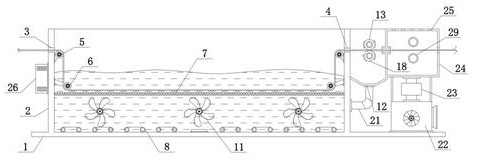

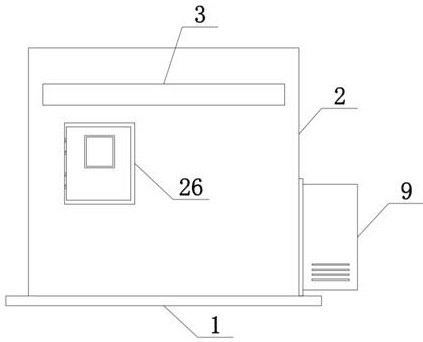

Cloth cleaning, drying and finishing integrated machine

InactiveCN107090680AImprove processing efficiencyEasy to cleanLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater filterPulp and paper industry

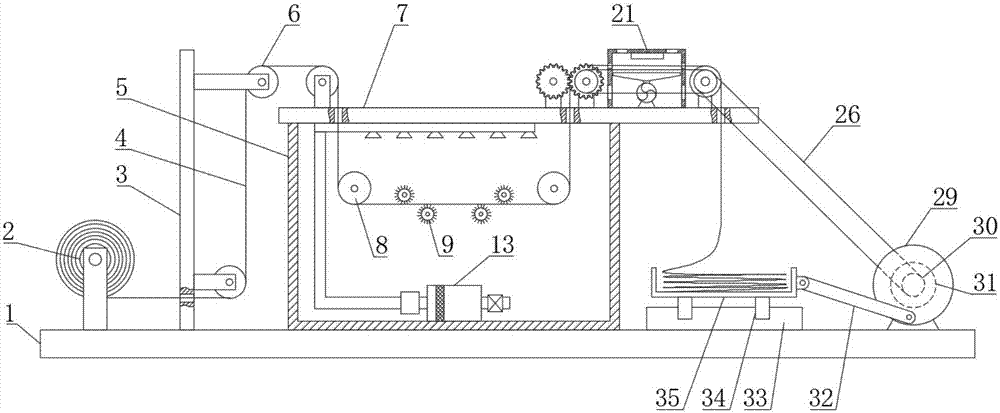

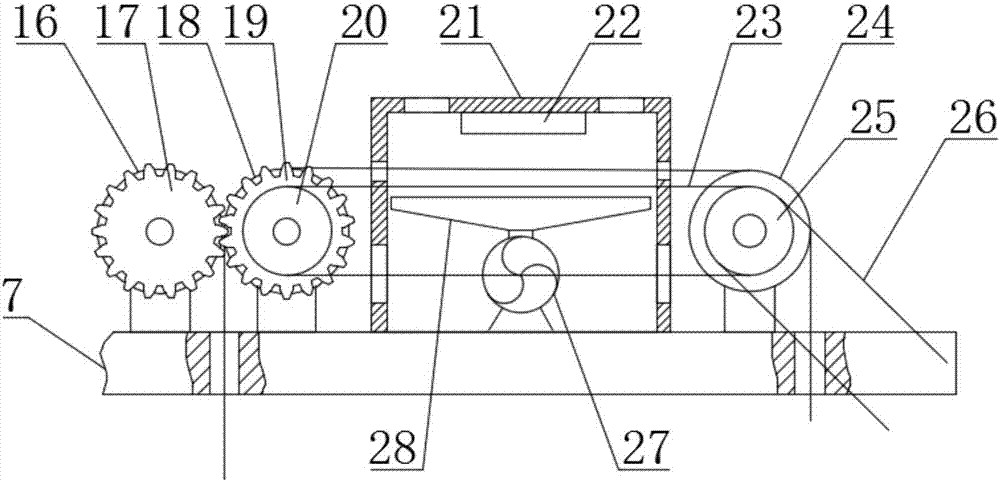

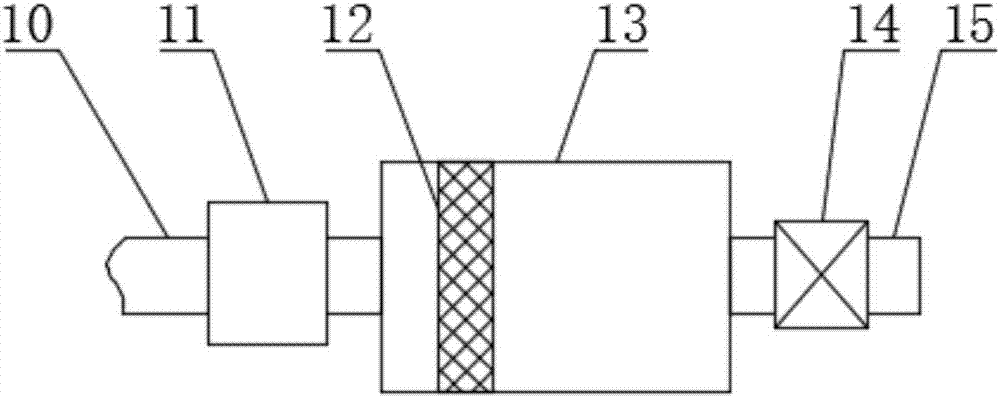

The invention discloses an integrated machine for cleaning, drying and finishing cloth, which comprises a base, a cleaning box is arranged on the base, two second guide rollers are rotatably connected to the front and rear side walls of the cleaning box, and a brush roller; the bottom of the cleaning box is provided with a filter box; the top of the cleaning box is provided with a top plate, and the right side of the top plate is provided with a drying box; A first gear is fixedly connected to the front end of a squeeze roller, and a second gear is fixedly connected to the front end of the second squeeze roller; a slide rail is also arranged on the base, and a fabric receiving basket is slidably connected to the slide rail through a slider , the right end of the fabric receiving basket is hinged with a connecting rod, and the other end of the connecting rod is rotationally connected with the front end of the motor. The invention integrates cloth cleaning, drying and sorting into one, which greatly improves the cloth processing efficiency; the washed water is filtered by a filter screen and then reused, which saves water resources.

Owner:王兴民

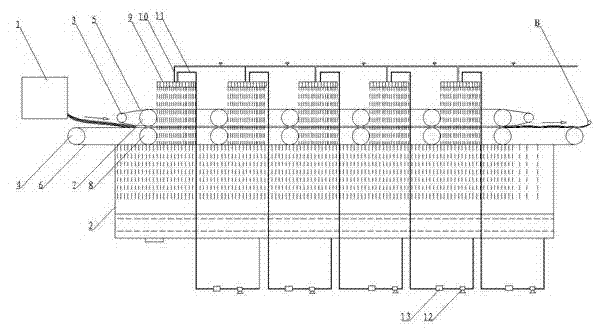

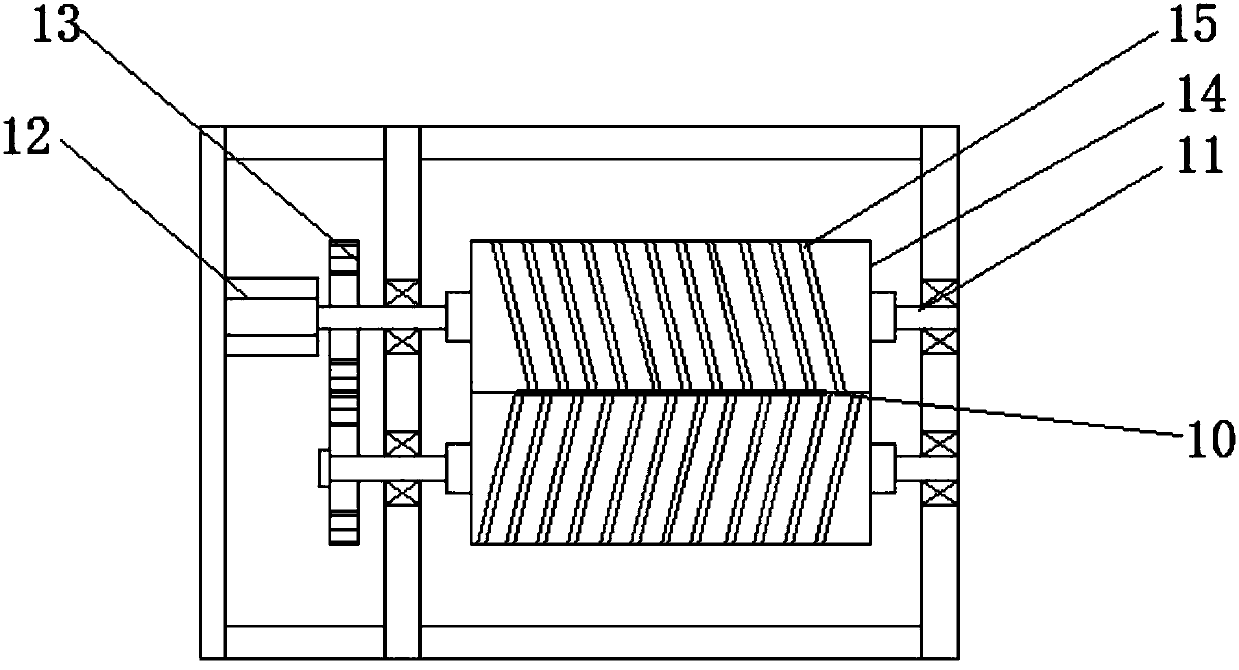

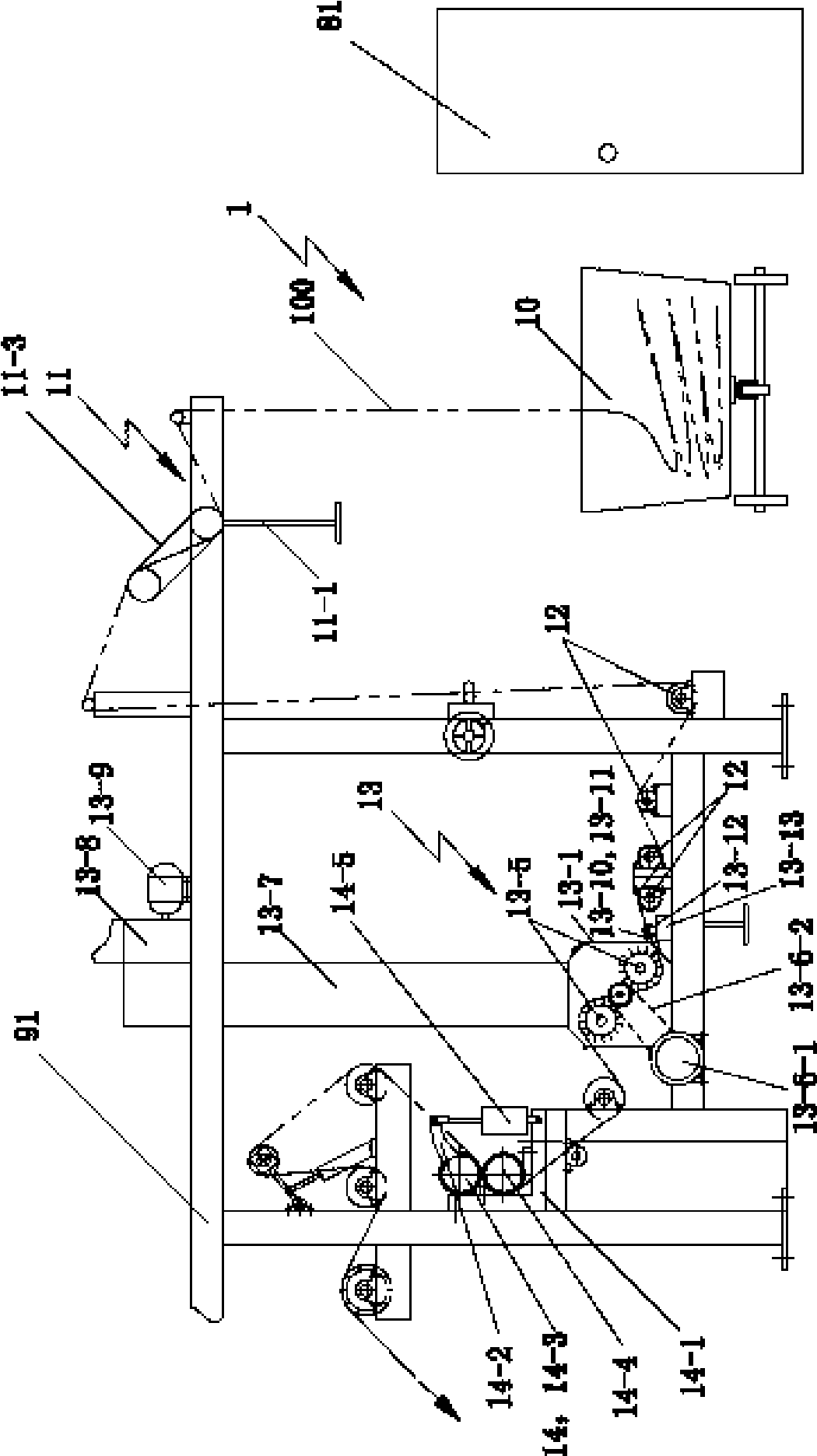

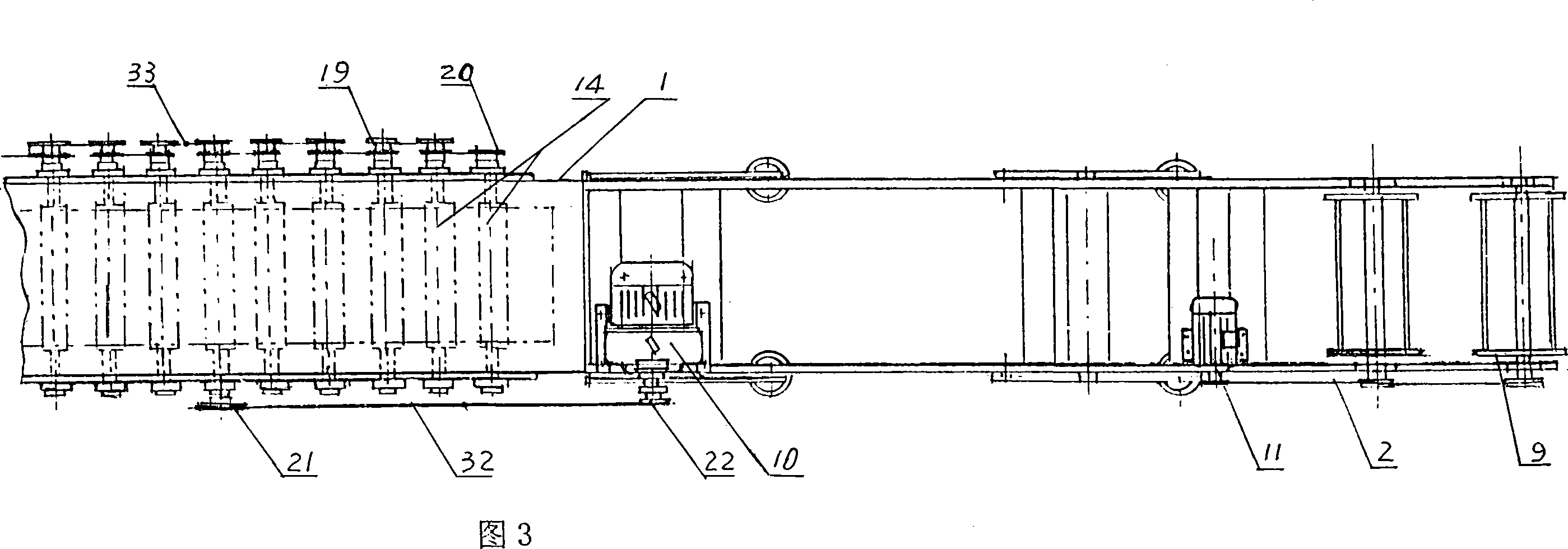

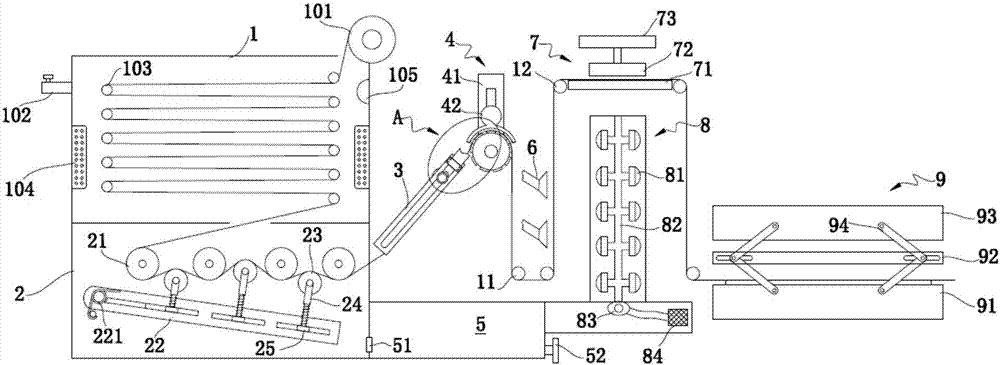

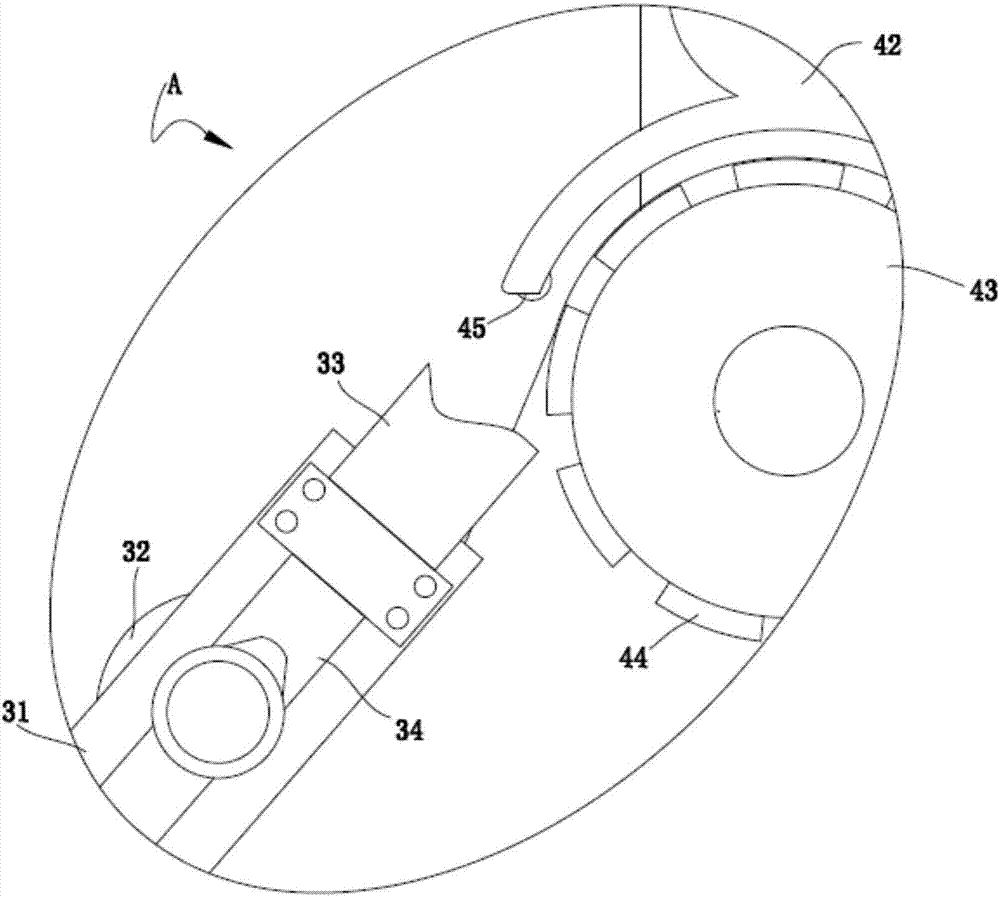

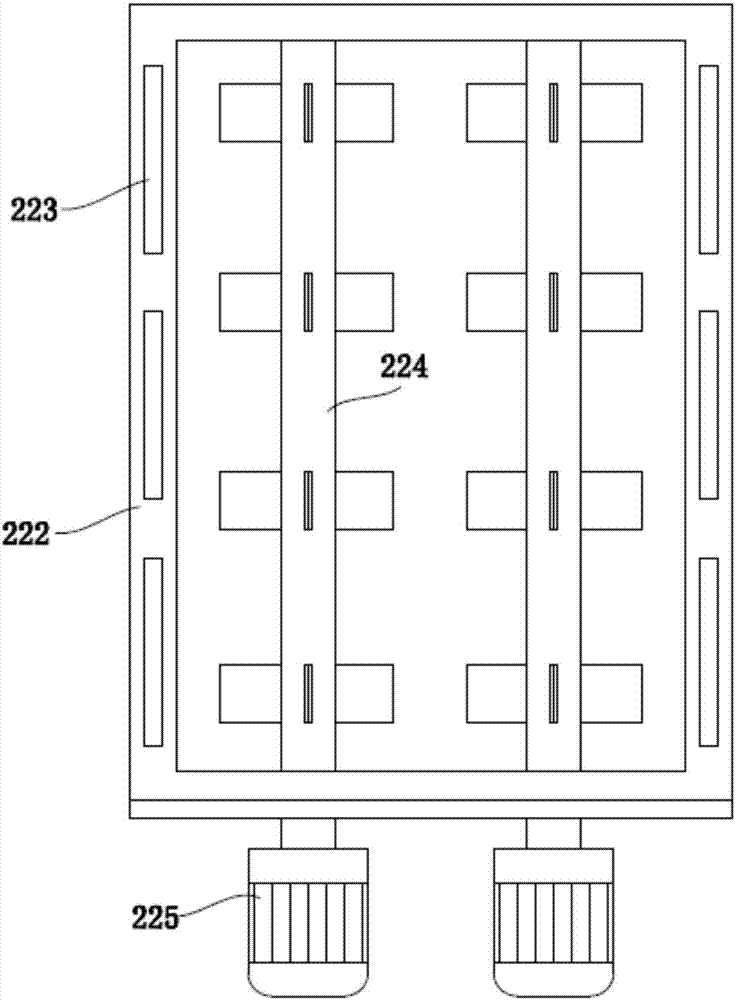

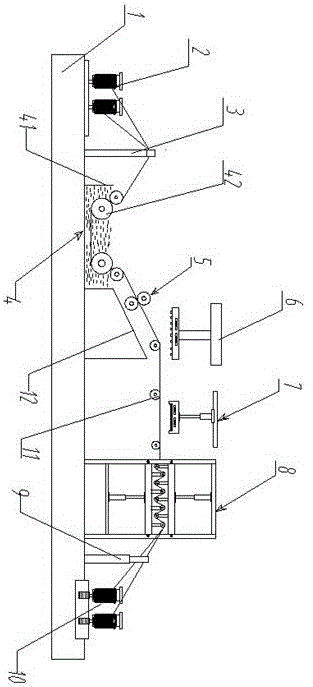

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

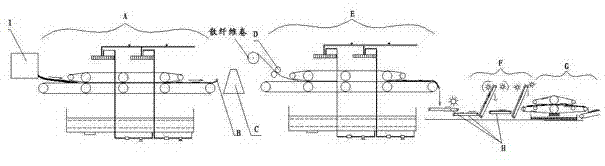

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

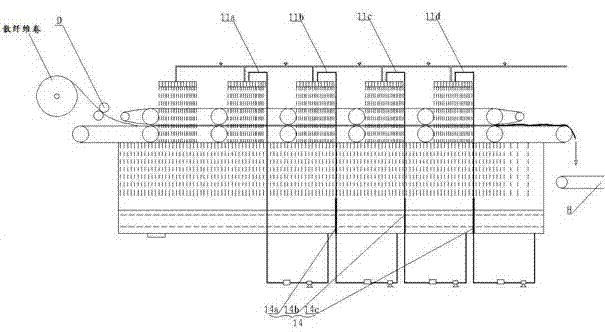

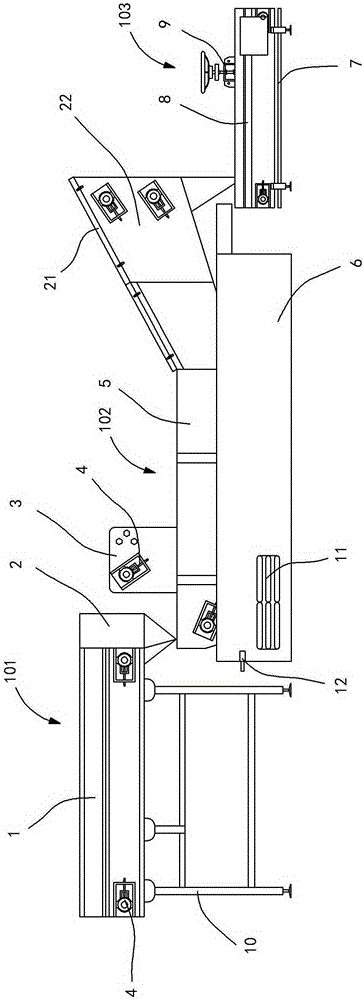

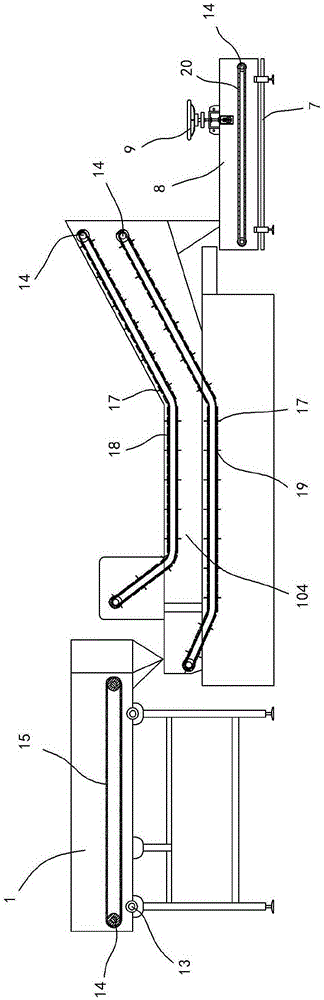

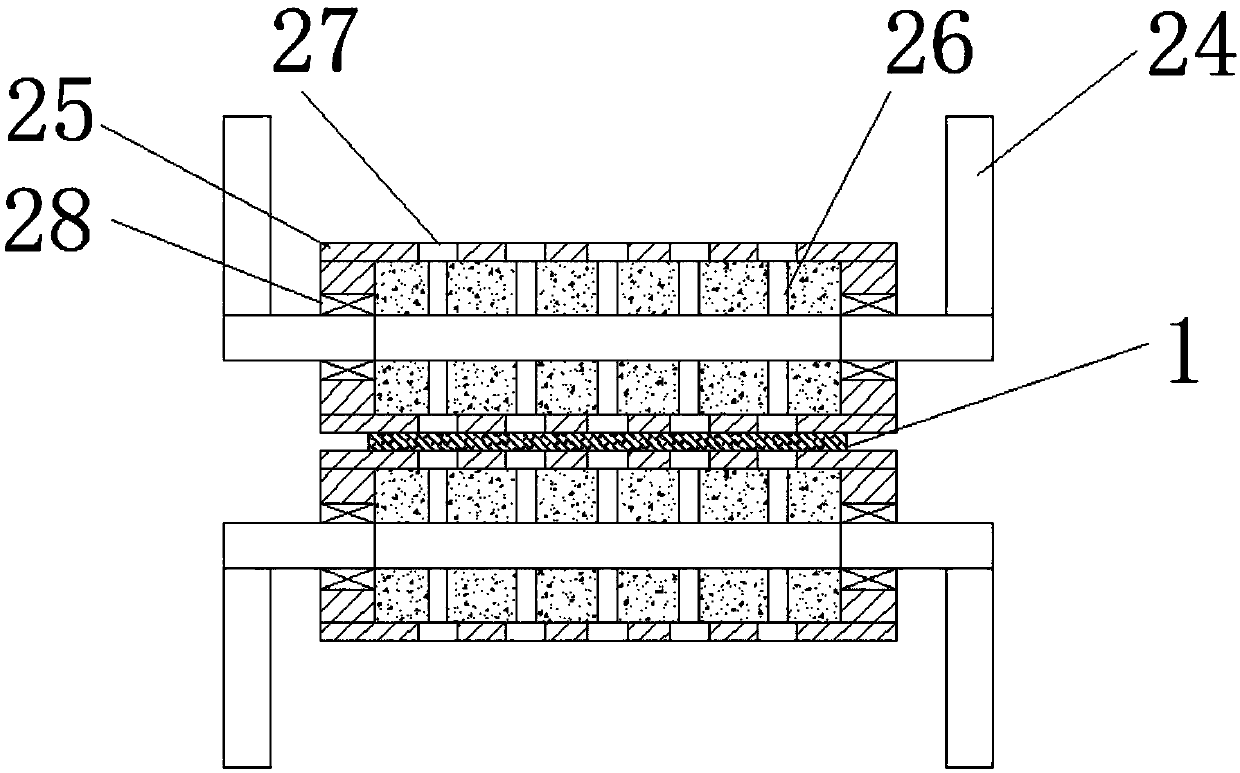

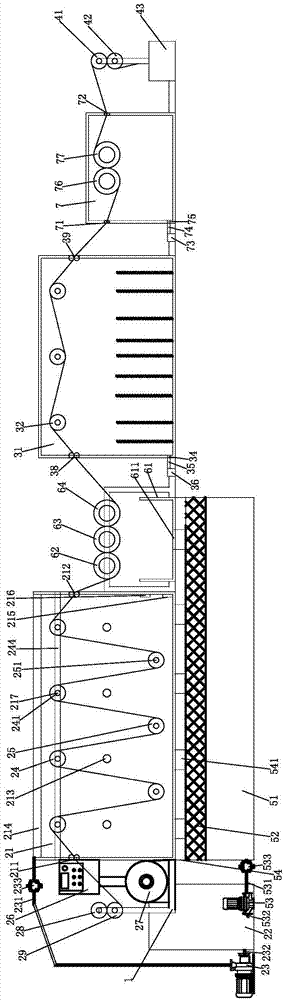

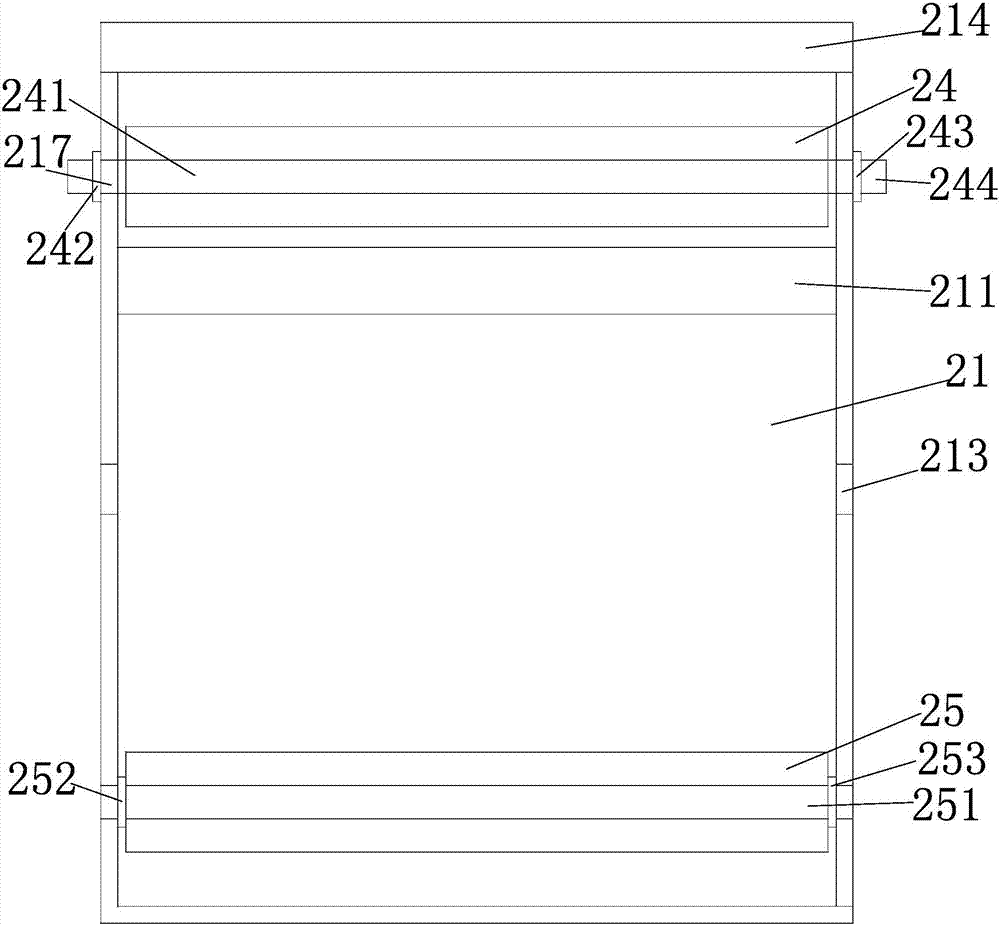

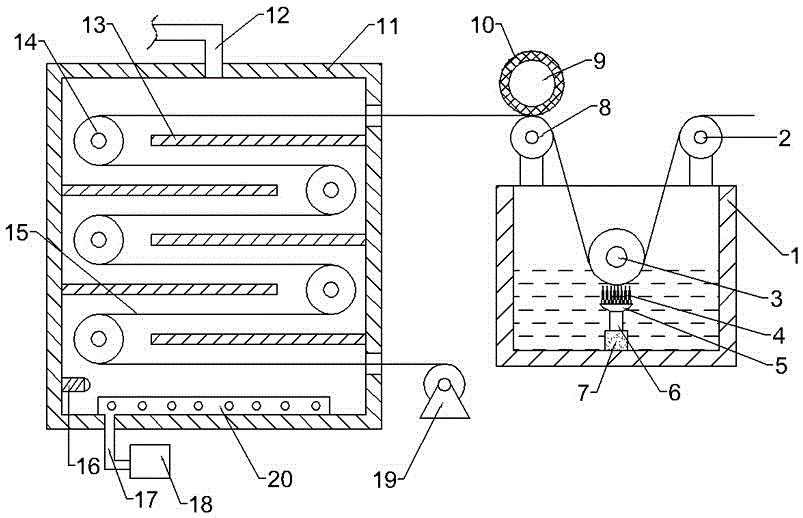

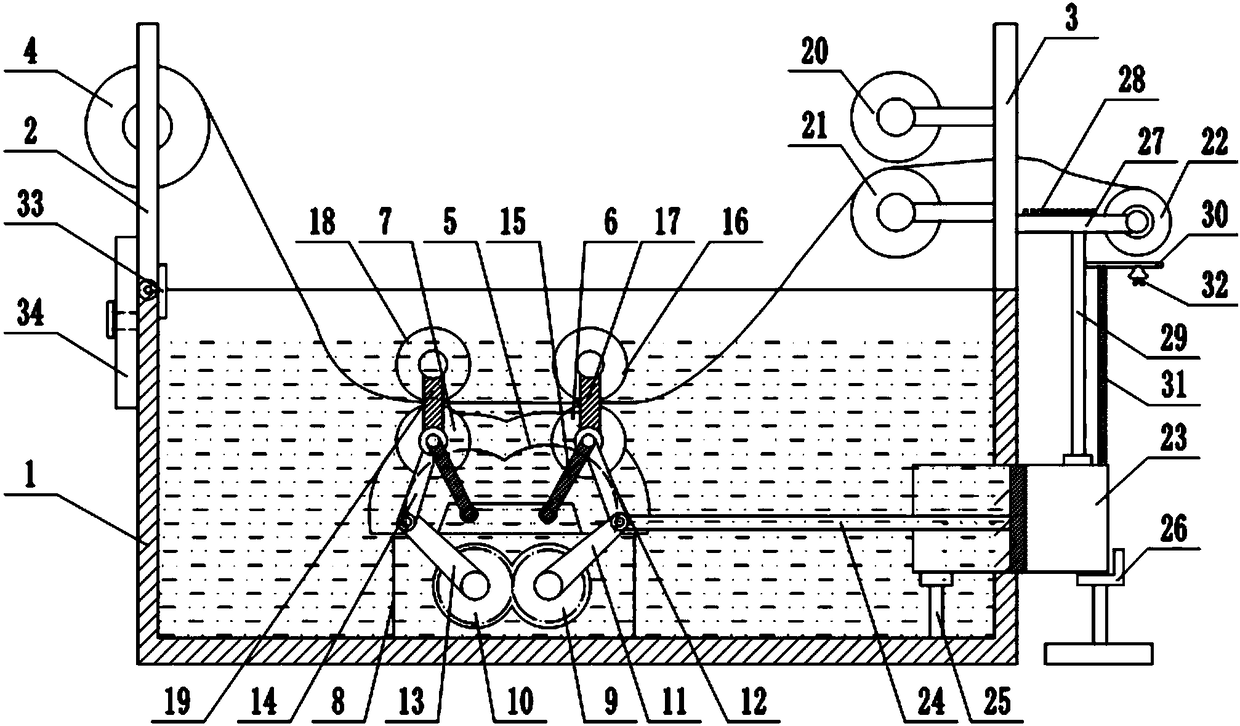

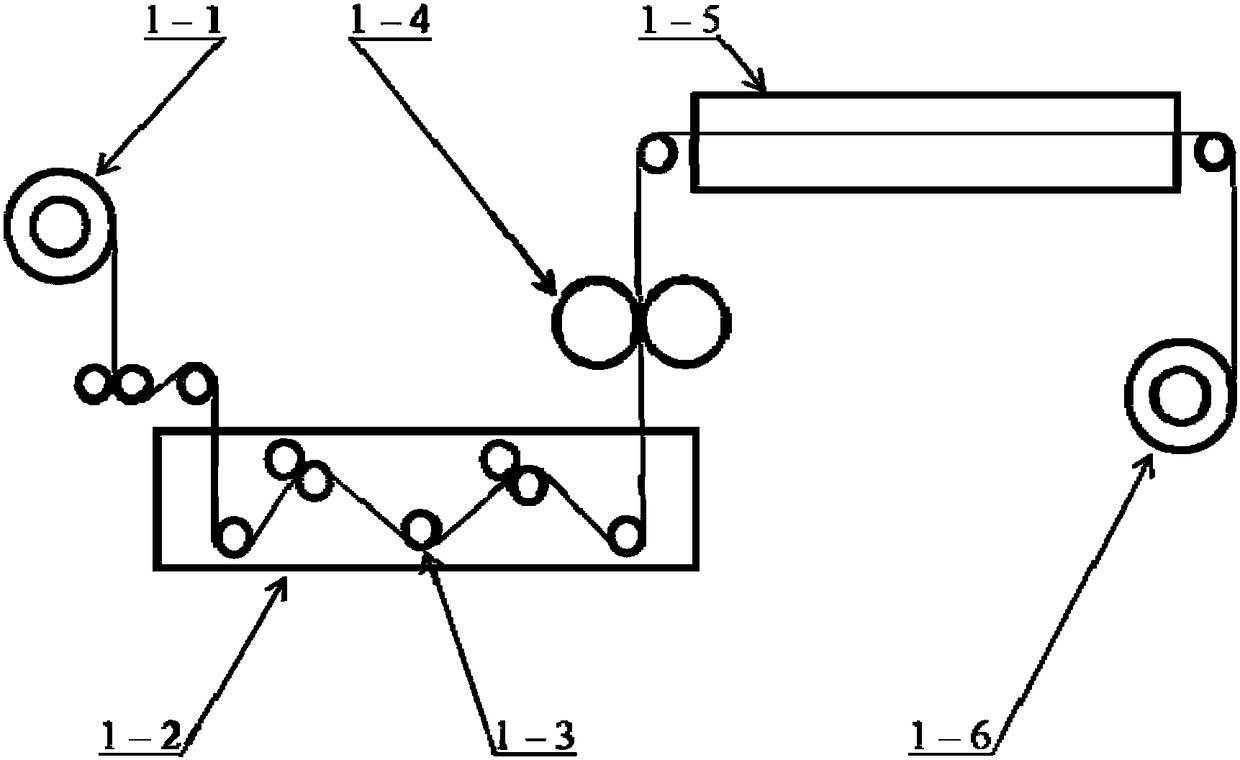

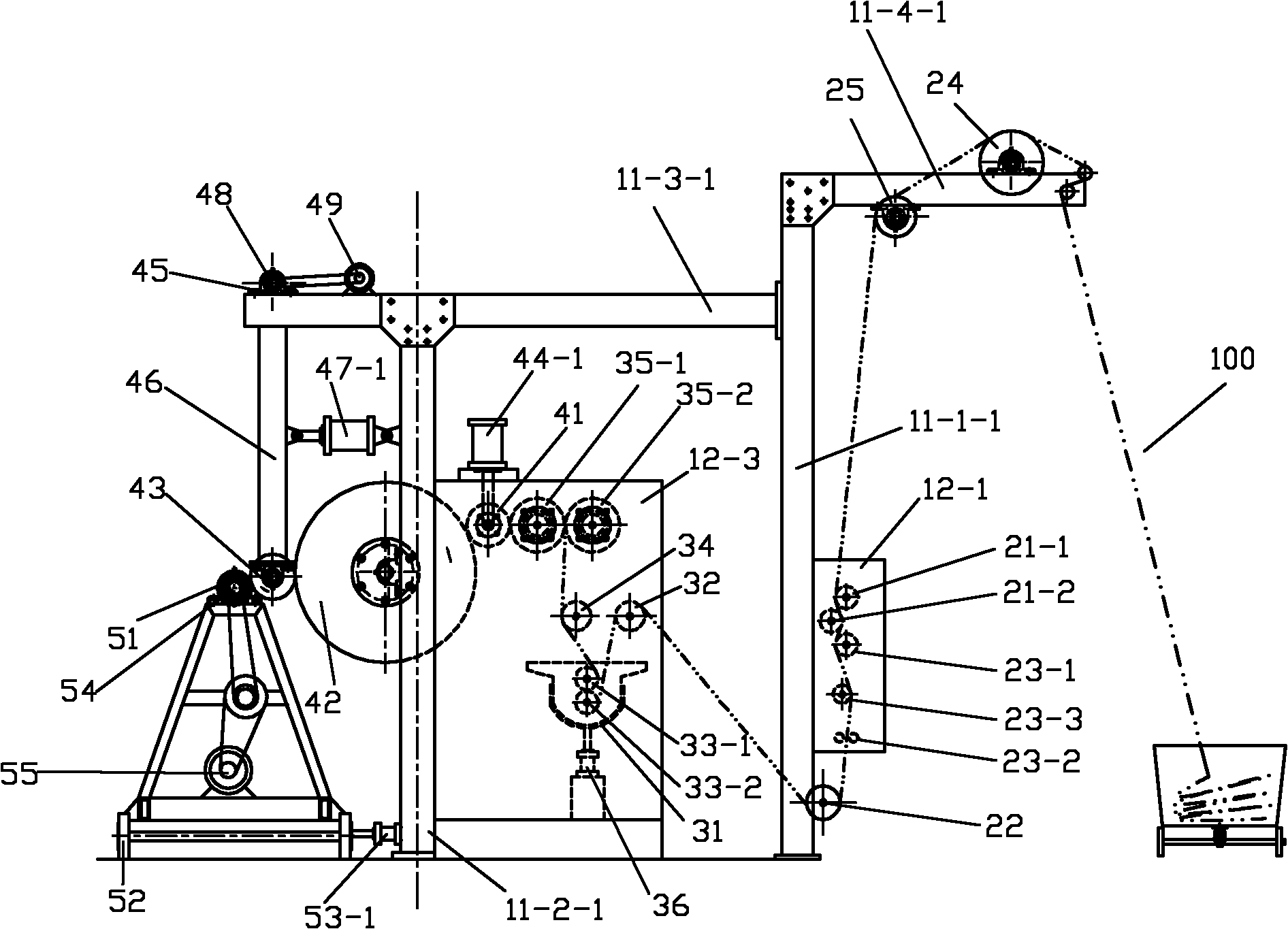

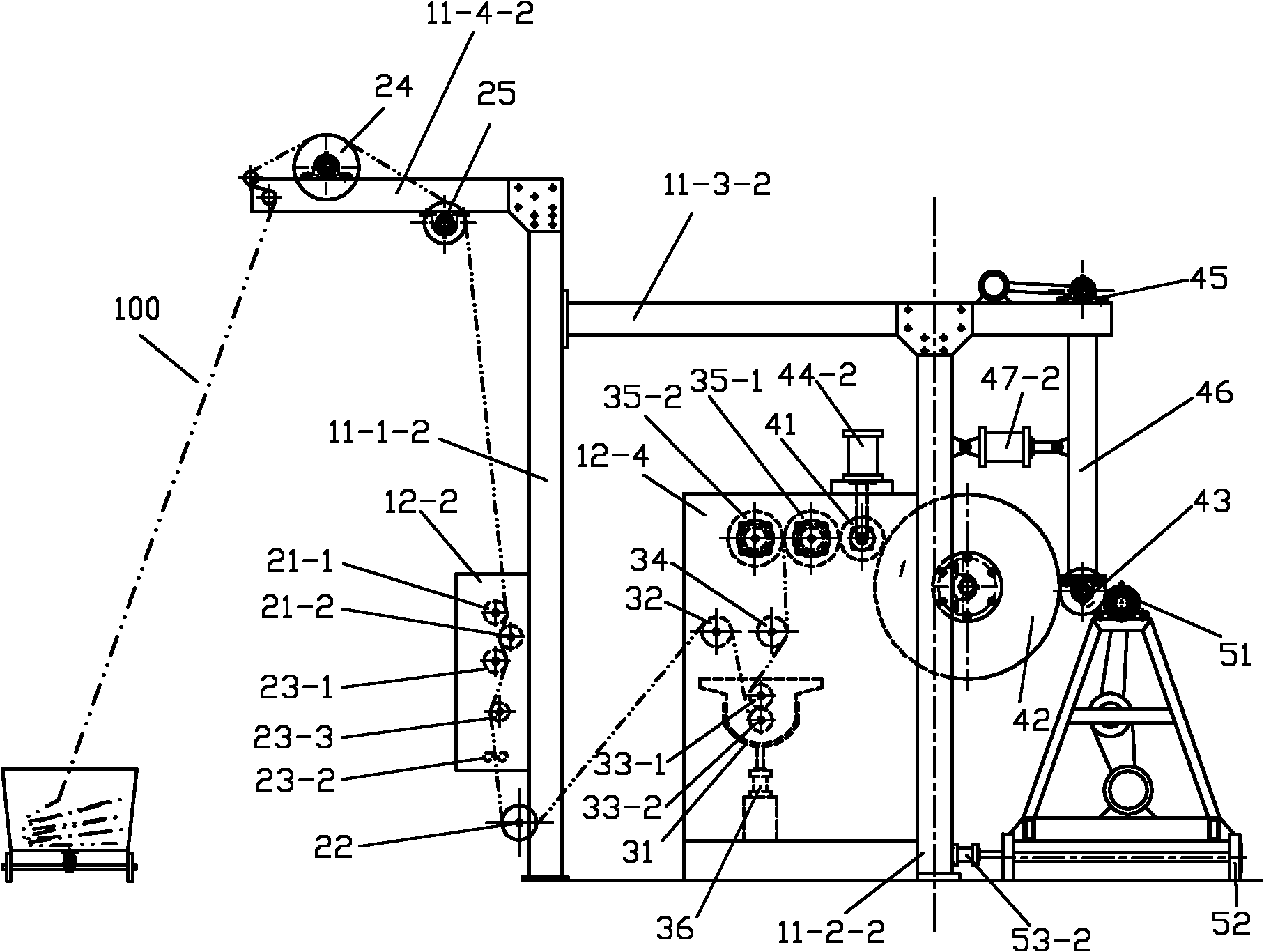

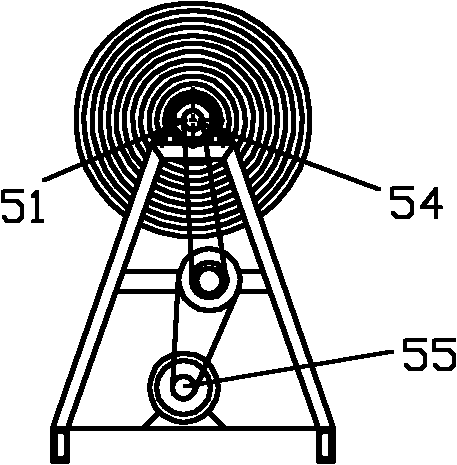

Fiber after-treatment equipment

ActiveCN105113160AIncrease productivityImprove qualityLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberAfter treatment

The invention discloses fiber after-treatment equipment which comprises a fiber input mechanism (101), a fiber soaking mechanism (102) and a fiber output mechanism (103). An outlet of the fiber input mechanism (101) is formed in an inlet of the fiber soaking mechanism (102). An outlet of the fiber soaking mechanism (102) is formed in an inlet of the fiber output mechanism (103). The fiber after-treatment equipment improves the production efficiency, greatly improves the quality of products, and reduces the product reject ratio in the production process.

Owner:JIANGSU XILUN NANO BIOTECH CO LTD

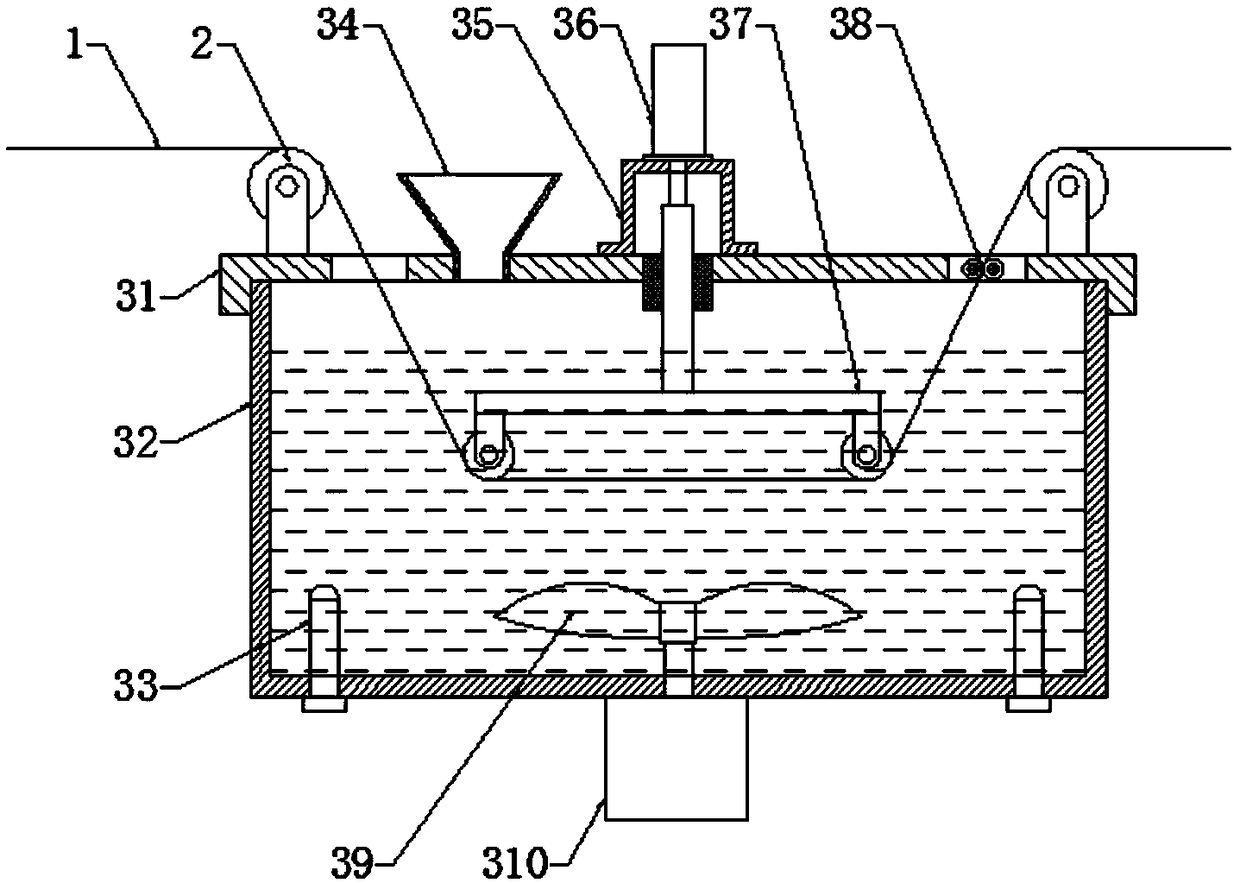

Washing and drying integrated machine for high-end fabric

InactiveCN107090682AWashing to achieveNo wasteSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersTextile technologyWater storage tank

The invention provides a washing and drying integrated machine for high-end fabric, belongs to the technical field of textile and solves the technical problem that the washing and drying effect of an existing washing and drying integrated machine for high-end fabric is not high. The washing and drying integrated machine for the high-end fabric comprises a rack, wherein a washing device for washing the fabric, a drying device for drying the washed fabric, a fabric collecting device for collecting the dried fabric and a wastewater recycling device for recycling wastewater produced during fabric washing are arranged on the rack, the washing device, the drying device and the fabric collecting device are sequentially arranged along the rack, the washing device comprises a washing tank, a water storage tank and a water pump I, multiple upper drums and multiple lower drums are horizontally arranged in the washing tank, multiple overflow ports are formed in the middle of the washing tank, the upper drums are located above the overflow ports, the lower drums are located below the overflow ports, and a nozzle is arranged at the top of the washing tank. The washing and drying effect of the machine is good, and the water resource is saved.

Owner:HAINING MEILI KNITTING CO LTD

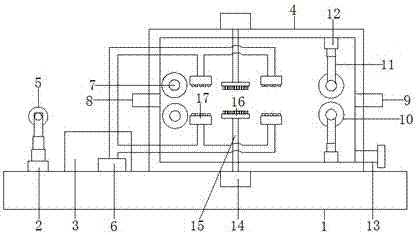

Drying device of long medical gauze

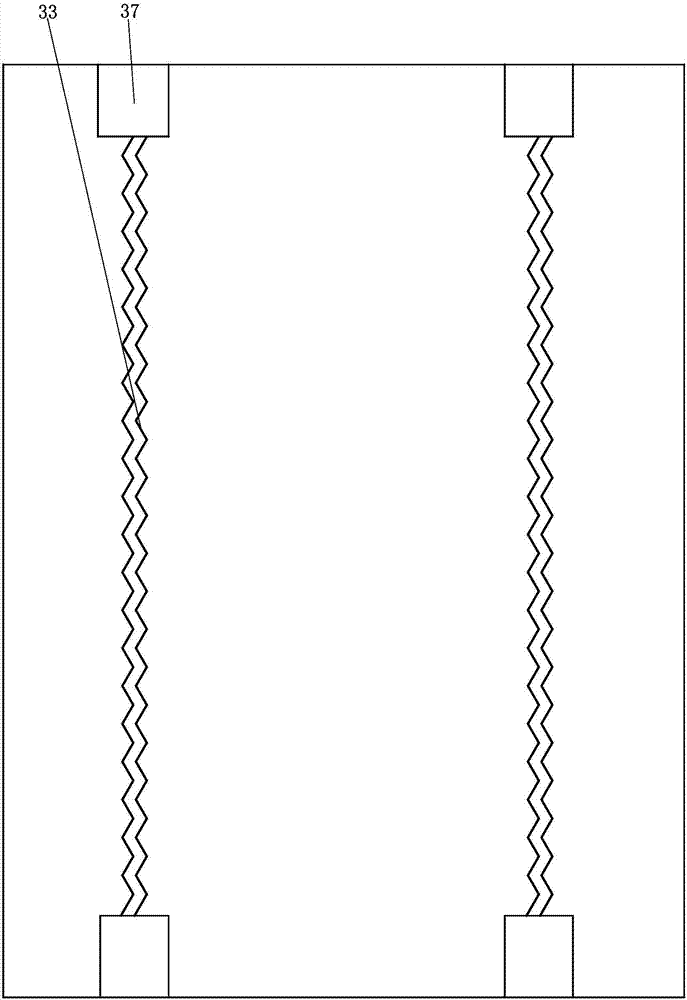

InactiveCN107620185AEasy to moveImprove the extrusion effectLiquid/gas/vapor removal by squeezing rollersIroning machinesGear driveFixed frame

The invention discloses a drying device of long medical gauze. The drying device of the long medical gauze comprises a device case and a base. A first fixing frame and a second fixing frame are installed at the front and back sides of the device case respectively. A delivery rotation shaft and a collection rotation shaft are arranged on the first fixing frame and the second fixing frame respectively in a running-through mode. A delivery wheel disc and a collection wheel disc are mounted on the delivery rotation shaft and the collection rotation shaft respectively. The device case is divided into a dehydration room, a drying room and a disinfection room. Material through holes are formed in all the middles of the front and back walls of the dehydration room, the drying room and the disinfection room. The dehydration room, the drying room and the disinfection room are communicated by the material through holes. The gauze is wound around the delivery wheel disc. The gauze runs through thedehydration room, the drying room and the disinfection room through the material through holes, and the tail end of the gauze is wound around the collection wheel disc. According to the drying deviceof the long medical gauze, a gear drives a squeeze roller to rotate to squeeze the gauze to play the role of fully dehydration; an iron cylinder and the surface of the gauze are in contact, and therefore the role of high-temperature disinfection is further played.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

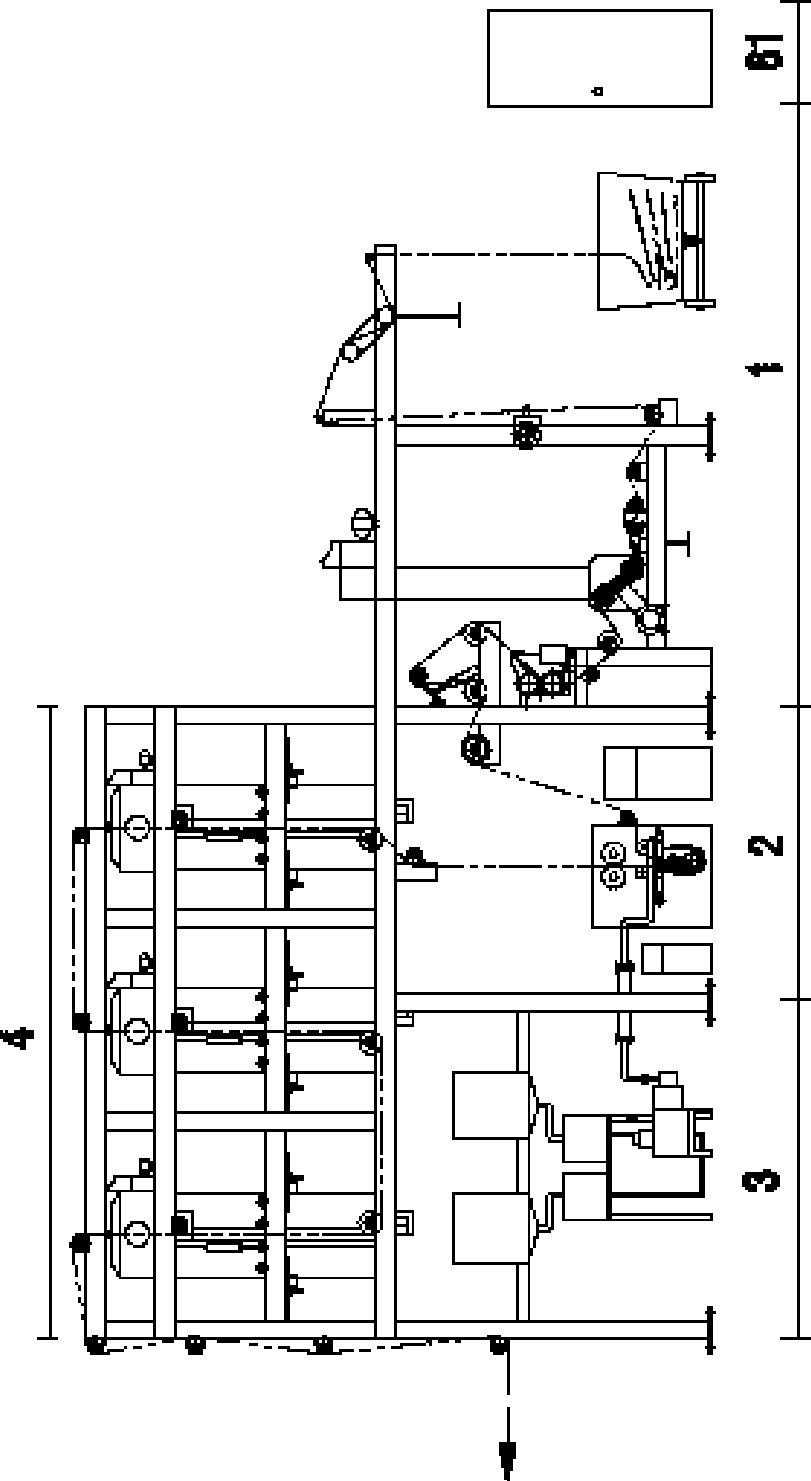

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

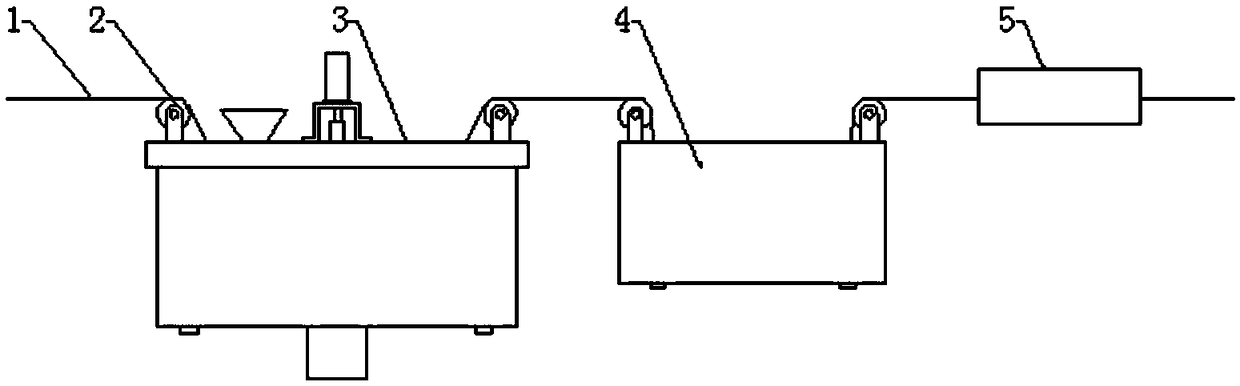

High-grade fabric washing and drying integrated machine with waste water recovery device

InactiveCN107326580ASave waterWashing to achieveMechanical cleaningPressure cleaningTextile technologyWater resources

The invention provides a high-grade fabric washing and drying integrated machine with a waste water recovery device and belongs to the technical field of textiles. The problem that an existing high-grade fabric washing and drying integrated machine cannot fully utilize waste water is solved. The high-grade fabric washing and drying integrated machine with the waste water recovery device comprises a rack, wherein a washing device for washing fabrics, an extrude-drying device for extruding washed fabrics dry, a waste water recovery device for recovering waste water produced during fabric washing, a drying device for drying the washed fabrics and a fabric collecting device for collecting dried fabrics are arranged on the rack, the washing device, the extrude-drying device, the drying device and the fabric collecting device are sequentially arranged along the rack, the waste water recovery device is located below the washing device and the extrude-drying device. The high-grade fabric washing and drying integrated machine achieves the advantages of recycling waste water and improving the utilization rate of water resources.

Owner:HAINING MEILI KNITTING CO LTD

Cleaning drying device used for gauze production

ActiveCN108930110AImprove product qualityAvoid secondary adsorptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryImpurity

The invention provides a cleaning drying device used for gauze production, and relates to the technical field of gauze production and manufacturing equipment. The cleaning drying device used for gauzeproduction comprises a base. The top of the base is fixedly provided with a cleaning box and a drying box. The drying box is divided into a dehydration chamber and a drying chamber. The cleaning boxis internally provided with a first cloth guide roller and a cleaning device. The cleaning device comprises an upper supporting rod and a lower supporting rod. Using the leaning drying device used forgauze production, through cooperation of an upper supporting rod, a lower supporting rod, an upper cleaning roll, a lower cleaning roll, a scraper blade, a rotating disk, and a banister brush, gauzedrives a driving belt to drive on the rotating disk, and the banister brush on the driving belt cleans the surface of the gauze. Under operation of the driving belt, the banister brush drives impurities into the upper cleaning roll, and the impurities on the banister brush are removed through the scraper blade. Impurities pass through the scraper blade and enter into the upper cleaning roll, and the impurities on the surface of the gauze are removed in cleaning, so that product quality of the gauze is improved.

Owner:陈剑璋

Method for manufacturing high-strength viscose-based active carbon fiber fabrics

ActiveCN101864635AHigh mechanical strengthWell-developed microporous structureLiquid/gas/vapor removal by squeezing rollersWoven fabricsCarbonizationHigh intensity

The invention discloses a method for manufacturing high-strength viscose-based active carbon fiber fabrics. In the method, viscose fiber fabrics woven by using long viscose fibers as a precursor are used as raw materials; according to the composition and structural characteristics of the viscose fiber fabrics, a phosphorus-free chemical reagent is used as a fire retardant and graphitizer which can improve the mechanical strength of the active carbon fiber fabric is added, and thus the high-strength viscose-based active carbon fiber fabrics with a developed microporous structure are manufactured by continuous low-and high-temperature carbonization, activation, drawing and other processes. In the invention, the production process, which is simple and easy to control, allows for continuous production and can be optimized according to actual application requirements, is adopted to manufacture the high-strength viscose-based active carbon fiber fabric products of different specifications. The method can be widely used for manufacturing products including protective products, such as fireproof, antitoxin and antichemical products, decorative products and the like.

Owner:DALIAN UNIV OF TECH +1

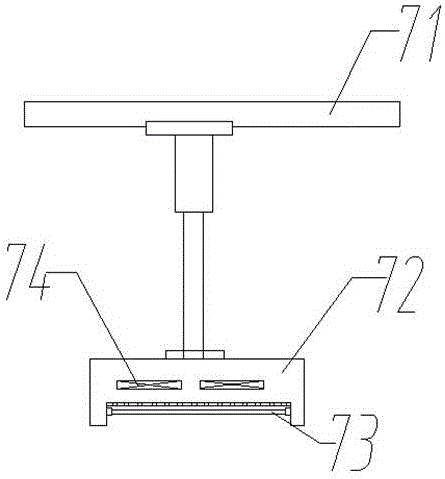

Environment-friendly cloth drying device

ActiveCN108253763AImprove drying efficiencyPromote environmental protectionLiquid/gas/vapor removal by squeezing rollersDrying machines with progressive movementsPulp and paper industryHole making

The invention belongs to the technical field of textile equipment, and particularly relates to an environment-friendly cloth drying device. The device comprises a drying box, a plurality of first liquid discharge pipes are connected to the side walls of the left end and the right end of the drying box, a separation plate is vertically arranged on the drying box, the upper end and the lower end ofthe separation plate are fixedly connected with the top surface and the bottom of the drying box correspondingly, the separation plate divides the drying box into a dehydrating chamber and a drying chamber in a separating mode, the inner walls of the left end and the right end of the dehydrating chamber and the inner walls of the left end and the right end of the drying chamber are provided with cloth through openings, the bottom of the dehydrating chamber is provided with a lower extruding device, the top surface of the dehydrating chamber is provided with an upper extruding device, the upperextruding device is located right above the lower extruding device, a plurality of drying devices are arranged at the bottom of the drying chamber, a plurality of guide rollers are rotationally connected to the inner wall of the rear end of the drying chamber, and a first through hole making the inside and the outside communicate is formed in the top surface of the drying chamber. The device hasthe advantages that the drying efficiency of the cloth can be effectively improved, harmful gas generated by drying the cloth can be absorbed, and the environmental protection property of cloth dryingis effectively improved.

Owner:常熟三和兴针纺织品有限公司

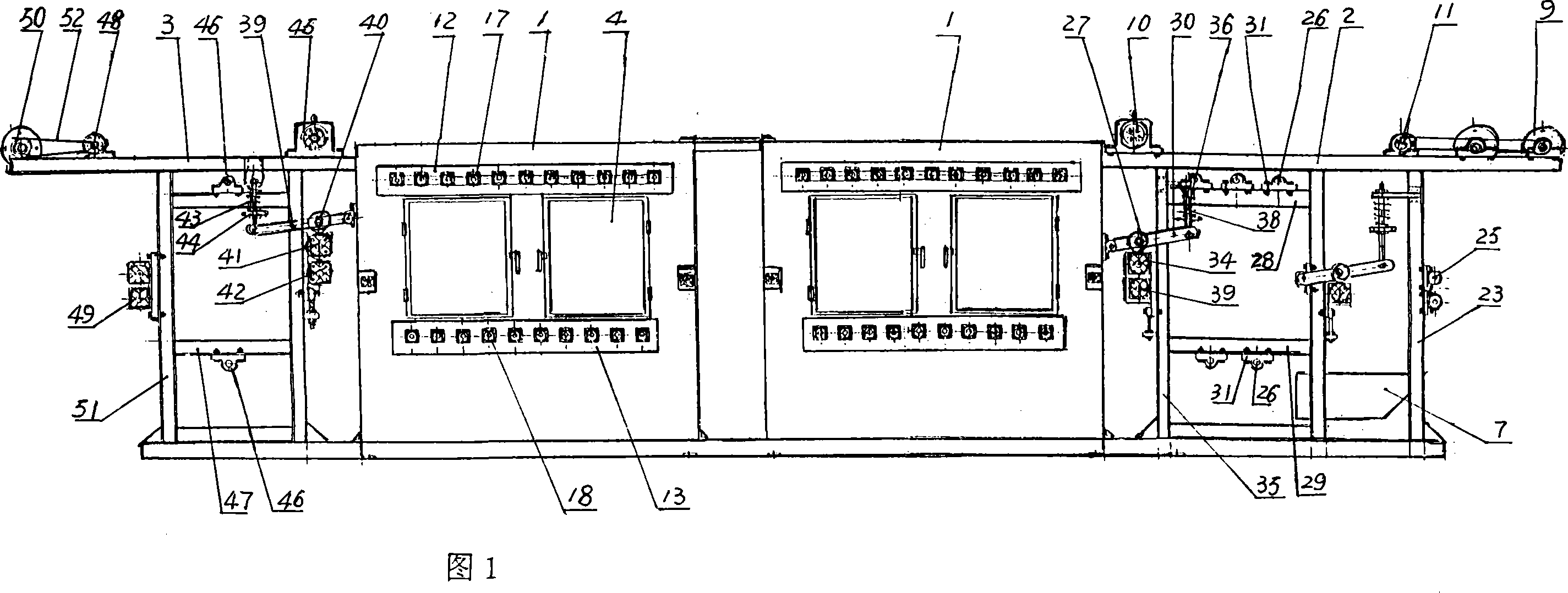

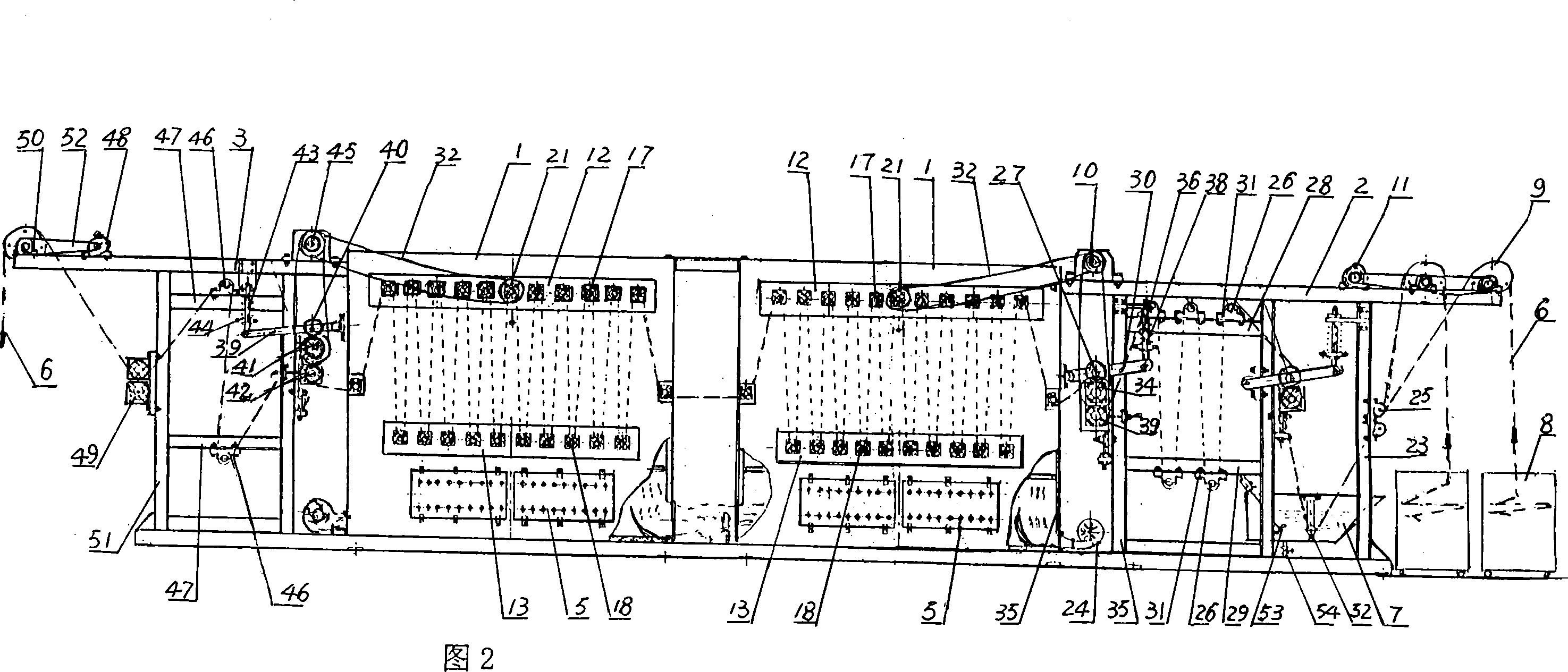

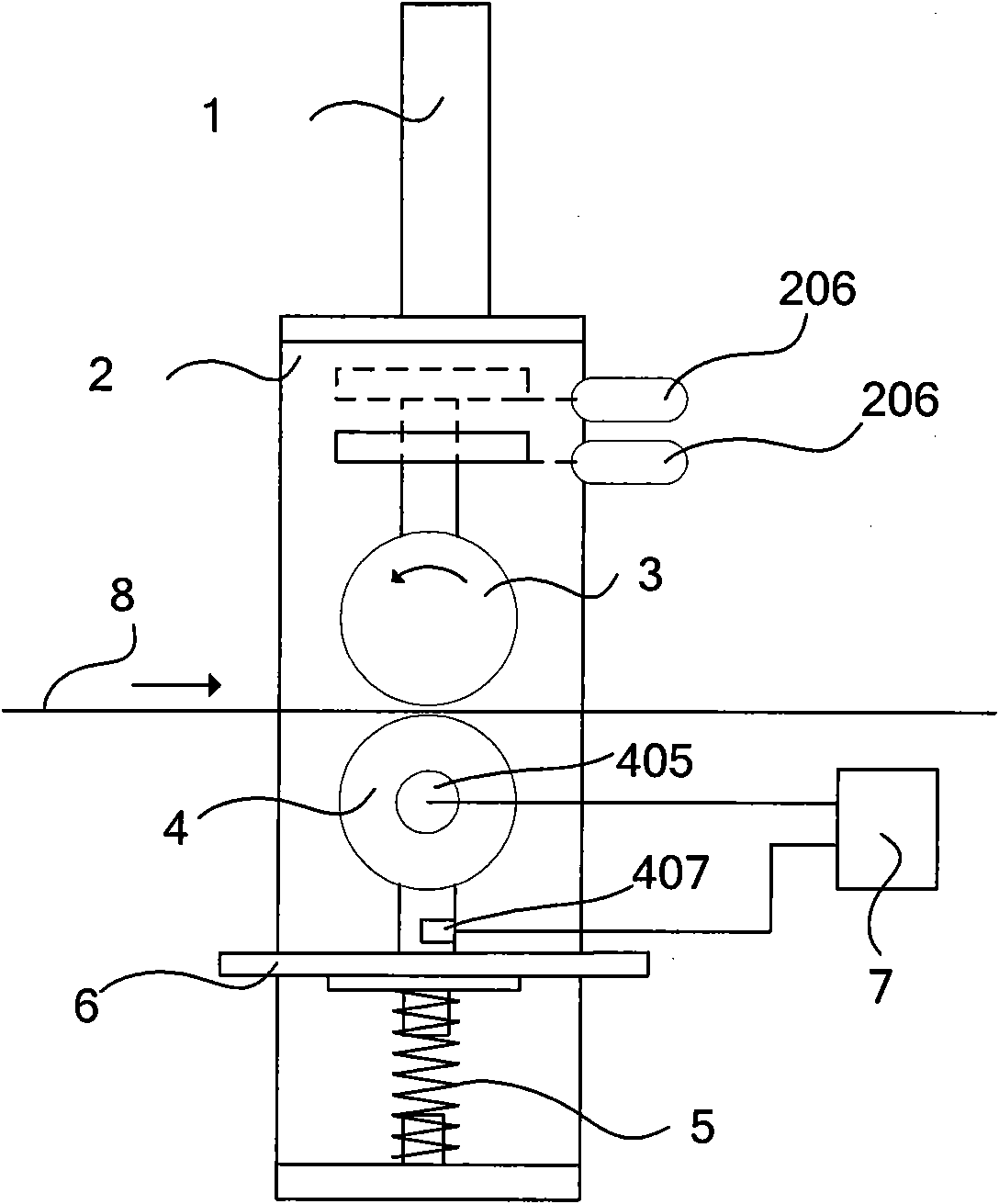

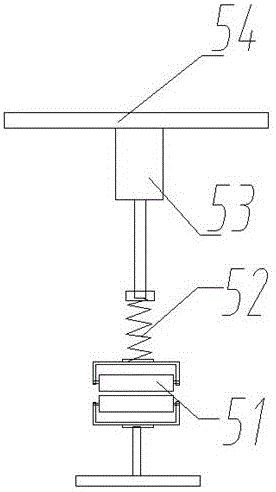

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

Integrated cleaning and drying apparatus for nonwoven fabric production

InactiveCN106087304AEasy to cleanImprove cleanlinessLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersBristlePulp and paper industry

An integrated washing and drying apparatus for nonwoven fabric production comprises a washing device and a drying device, the washing device comprises a washing box, a feed roller is disposed on the upper right of the washing box, a first guide roller is provided in the washing box, a second guide roller is provided on the upper left of the washing box, nonwoven fabric runs sequentially through the feed roller, the first guide roller and the second guide roller, a motor is provided below the first guide roller and is fixedly connected with the inner bottom of the washing box, a rotary shaft is connected to the upper side of the motor and is provided with a washing brush, and the washing brush is provided with bristles; a squeezing roller is provided above the second guide roller, and a squeezing layer is provided outside the squeezing roller. The integrated washing and drying apparatus for nonwoven fabric production has the advantages that the bristles on the washing brush can effectively wash nonwoven fabric to ensure cleanness of the nonwoven fabric; the squeezing layer squeezes the nonwoven fabric so that most water in the nonwoven fabric is squeezed out to facilitate a subsequent drying step.

Owner:泉州中投文化发展有限公司

Cool induction processing method of nylon knitting face fabric

InactiveCN101408000ANo side effectsReduce the temperatureFibre treatmentLiquid/gas/vapor removal by squeezing rollersBiological agentEngineering

The invention relates to a cool feeling processing method of nylon knitting fabrics, which utilizes a setting machine and adopts a dry cloth padding method to carry out cool feeling processing. A cool feeling solution is prepared by taking xylitol substances with heat-absorbing function as the main material, and a plurality of auxiliary agents. The method adopts the xylitol substances as a cool feeling agent, and the xylitol is a biological agent and does not have toxic and side effect to the human body. The nylon knitting fabrics processed by adopting the method can lower the temperature of the human body.

Owner:SHANGHAI JIALE

Spunlace nonwoven fabric and manufacture method

InactiveCN105220357AHas anti-inflammatory propertiesGood hygroscopicityLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionEngineeringMoisture absorption

The invention discloses spunlace nonwoven fabric and a manufacture method. Aloe is adopted by raw material and the spunlace nonwoven fabric is manufactured by a spunlacing method. The manufacture method comprises following steps of: (1) extraction of raw material; (2) opening and mixing; (3) combing; (4) cross lapping; (5) drafting; (6) pre-wetting; (7) afterfinish; (8) drying; (9) winding into finished products. The spunlace nonwoven fabric and the manufacture method have following beneficial effects: the spunlace nonwoven fabric adopts aloe as raw material and manufactured by the manufacture method and has the anti-inflammatory function of the human skin and is also characterized by being high in moisture absorption and strength, low in fuzzing performance, good in breathability, soft in handfeel and fine in drapability.

Owner:徐波

Polyester yarn dyeing device and method

InactiveCN109281097ARealize flow dyeingRealize streamlined dyeing processLiquid/gas/vapor open-width material treatmentSucessive textile treatmentsPolyesterYarn

The invention discloses a polyester yarn dyeing device and method. The polyester yarn dyeing device comprises polyester yarn, a dyeing mechanism, a washing mechanism and a drying mechanism; the washing mechanism and the drying mechanism are arranged on one side of the dyeing mechanism in sequence, the polyester yarn penetrates through the dyeing mechanism, the washing mechanism and the drying mechanism in sequence, and yarn guide wheels are arranged at the left and right ends of the upper surface of the dyeing mechanism and the left and right ends of the upper surface of the washing mechanismrespectively. According to the polyester yarn dyeing device and method, the polyester yarn is subjected to flow dyeing through the yarn guide wheels and dyeing guide wheels of the dyeing mechanism, surface dye of the polyester yarn is washed through the washing mechanism, finally, the polyester yarn is dried through the drying mechanism, and thus flow dyeing processing of the polyester yarn is achieved; no repeated dyeing operation is needed, and time and labor are saved; meanwhile, extruding rollers extrude out redundant dye carried by the polyester yarn, redundant dye is prevented from beingcarried out, and thus resource waste is greatly reduced.

Owner:福建省天和纺织实业有限公司

Cloth dyeing equipment

PendingCN108517634AAvoid the problem of uneven dyeingSpeed up dippingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingEngineering

The invention relates to cloth processing field and discloses cloth dyeing equipment. The cloth dyeing equipment comprises a dyeing tank, wherein a first support rod is rotationally connected to one side of the dyeing tank, a second support rod is fixedly connected to the other side of the dyeing tank, a feeding roll is rotationally connected to the first support rod, and a first transfer roll anda second transfer roll are movably connected to the inner wall of the dyeing tank; a driving gear and a driven gear are rotationally connected to the inner wall of the dyeing tank, the driven gear ismeshed with the driving gear, a driving rod is fixedly connected to the driving gear, a first connecting rod is rotationally connected to a free end of the driving rod, and a free end of the first connecting rod is rotationally connected to the first transfer roll; a driven rod is fixedly connected to the driven gear, a second connecting rod is rotationally connected to a free end of the driven rod, and a free end of the second connecting rod is rotationally connected to the second transfer roll; and a discharging roll is rotationally connected to one side of the second support rod, an air cylinder is fixedly connected to the side wall of the dyeing tank, and a piston rod of the air cylinder is rotationally connected to the driving rod. According to the cloth dyeing equipment, the problemthat the stacked cloth cannot be uniformly dyed by virtue of an existing dyeing machine during the dip dyeing is solved.

Owner:重庆曹浩思瑗电子商务有限公司

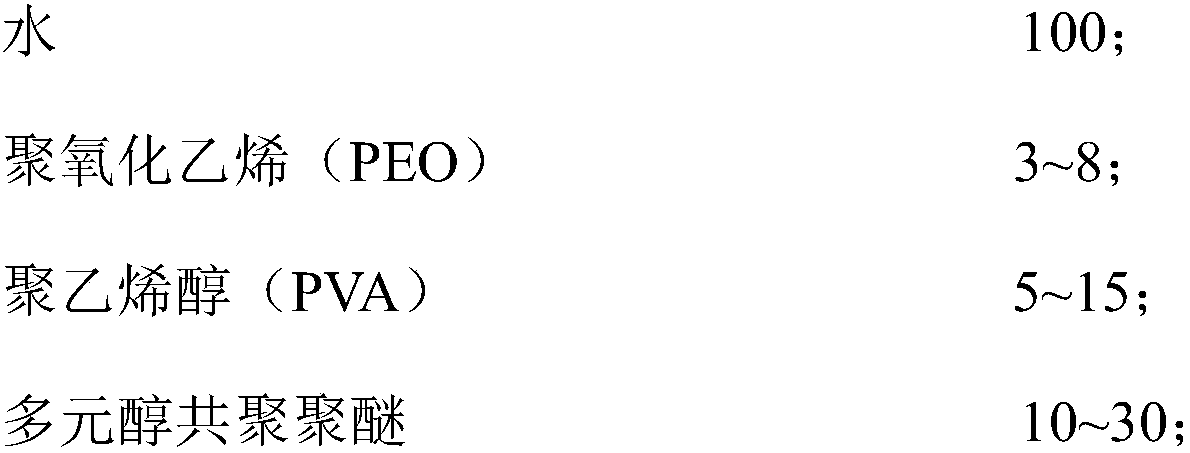

Padding finishing method for polyvinyl alcohol nonwoven fabric

ActiveCN108221386AImprove performanceImprove processing efficiencyLiquid/gas/vapor removal by squeezing rollersGrip property fibresProcess efficiencyNonwoven fabric

The invention discloses a padding finishing method for polyvinyl alcohol nonwoven fabric. The method comprises steps as follows: the polyvinyl alcohol nonwoven fabric is unreeled and guided into an impregnating tank, the nonwoven fabric is sufficiently impregnated by an impregnation liquid in the impregnating tank and then is rolled to be dry, dried through a drying channel and wound, and the polyvinyl alcohol nonwoven fabric subjected to padding finishing is obtained. With adoption of the padding finishing method, the polyvinyl alcohol nonwoven fabric without heat sealing performance originally is endowed with heat sealing performance of secondary processing, and realization of processes such as automatic mechanical edge sealing, opening sealing, continuous bag making and the like is facilitated, so that processing efficiency of a product is substantially improved, and cost is reduced; meanwhile, fiber nodes in the polyvinyl alcohol nonwoven fabric are firmer, and therefore, mechanical properties of the polyvinyl alcohol nonwoven fabric are further improved; besides, elongation at break of polyvinyl alcohol is increased, and accordingly, the polyvinyl alcohol nonwoven fabric becomes softer and more comfortable.

Owner:GUANGZHOU LITE NEW MATERIAL TECH CO LT

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177AAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

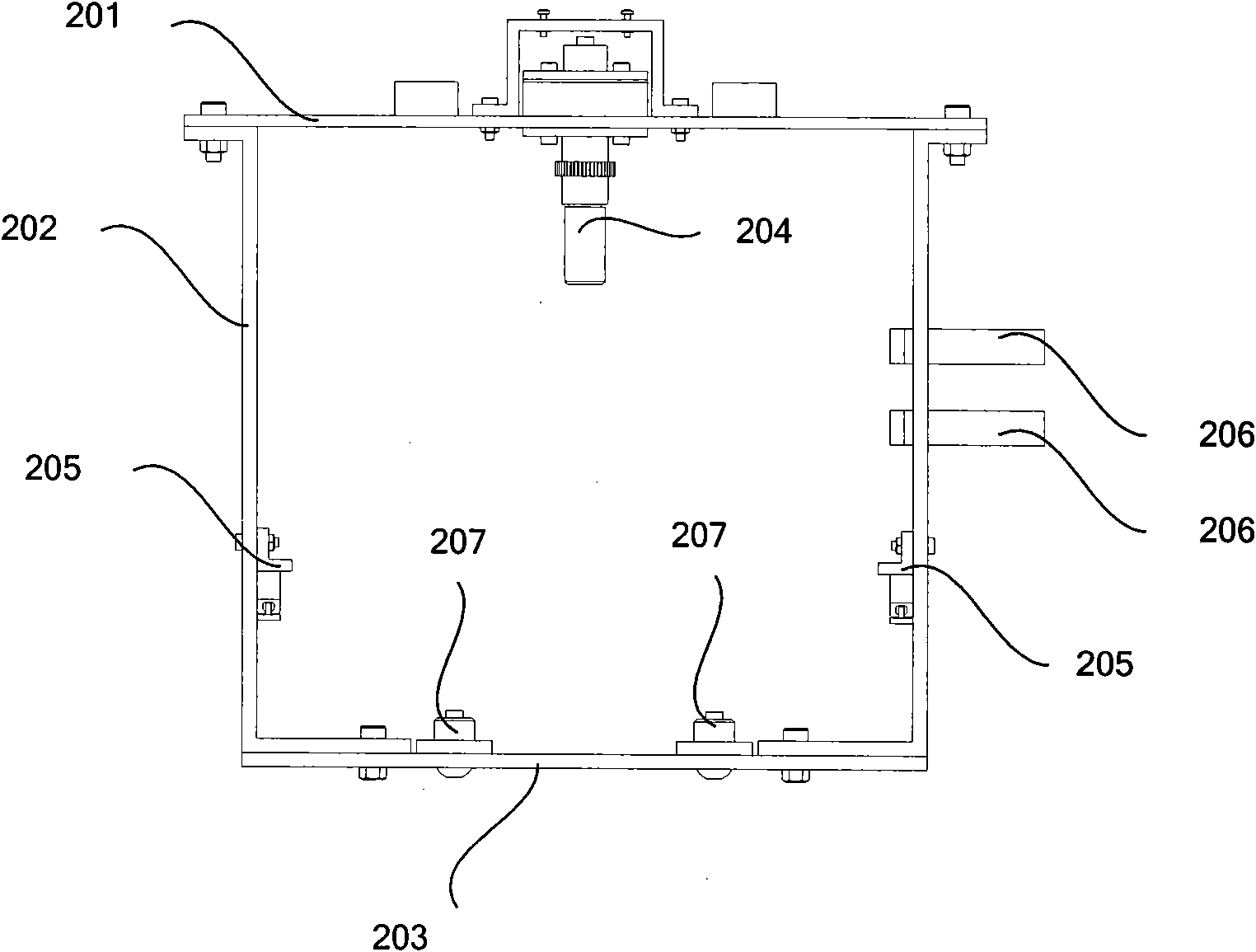

Cold pad-batch dyeing device for open-width knitted fabrics

InactiveCN101818422APrevent deviationAdjustable distanceTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersEngineeringControl circuit

The invention discloses a cold pad-batch dyeing device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a dyeing padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are arranged on the frame one after another; the cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the dyeing padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and eventually, the open-width knitted fabrics are flatly rolled onto a cloth roller in the form of big batch which can be rotatably piled up like woven fabrics, and the dyeing is completed during the rotatable pile-up, which not only reduces various consumptions and saves cost remarkably, but also improves the quality of the knitted fabrics.

Owner:蔡宗义

Textile cloth cleaning device for textile cloth production

InactiveCN107287783AAdjustable tensionAvoid pollutionLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention discloses a textile cloth cleaning device for textile cloth production in the technical field of textile cloth production equipment. A tension adjustment roller is installed on the top of the device, and the other end of the rotating shaft runs through the outer wall of the cleaning box to install a brush. The left and right sides of the cleaning box are respectively equipped with a cloth inlet and a cloth outlet, which can clean the two sides of the textile cloth. Washing, and in the process of washing, the motor drives the brush to rotate to wash the textile cloth, which improves the cleaning efficiency. Two sets of electric telescopic rods are used to drive two sets of extrusion rollers, which can squeeze out the washed textile cloth The remaining water stains on the surface can prevent water stains from polluting the workshop. The tension adjustment roller can be driven up and down by the hydraulic lifting device, which can realize the adjustment of the tension of the textile fabric and improve the cleaning efficiency.

Owner:湖州南浔贵丰纺织有限公司

Printing and dyeing equipment

ActiveCN107974786AUniform dyeingAutomatically adjust the tensionLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryTextile dyeing

The invention provides printing and dyeing equipment. The printing and dyeing equipment comprises a dyeing box, a dewatering and drying mechanism and a printing machine which are arranged from left toright sequentially. The dewatering and drying mechanism comprises a dewatering mechanism, a water absorbing mechanism, an ironing mechanism and a drying machine which are arranged from left to rightsequentially. The dewatering mechanism comprises a guide rail frame. A water pressing roller is mounted in a groove of the guide rail frame movably through a wheel. An air cylinder is arranged on theright side of the guide rail frame. A piston rod of the air cylinder is connected with the water pressing roller. The water absorbing mechanism comprises a water pressing plate and a water absorbing roller. The printing and dyeing equipment has the advantages that centrifugal dewatering is not needed after textile dyeing through the dewatering and drying mechanism, so that flattening degree of textiles is guaranteed, and flattening on a scutcher is not needed; the dyeing equipment, the dewatering and drying equipment and the printing equipment are combined, so that equipment replacement time during working is reduced, dyeing and printing can be completed on one equipment, and working efficiency is improved.

Owner:TONGXIANG LONGXIANG PRINTING & DYEING CO LTD

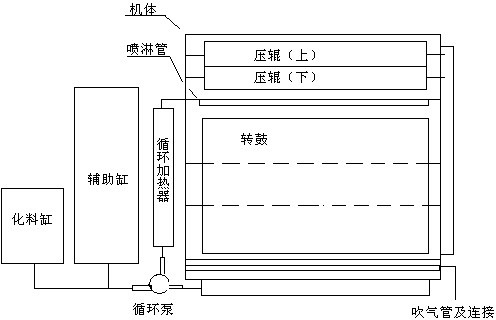

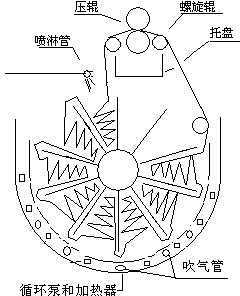

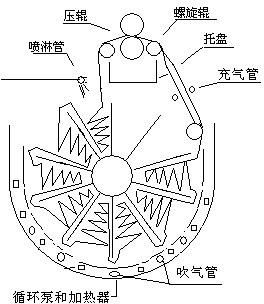

Textile dyeing machine

InactiveCN102587056AReduce dosageImprove washing efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile dyeingMechanical engineering

The invention discloses a textile dyeing machine which comprises a cylindrical dye vat, the cylindrical dye vat is internally provided with a rotary drum coaxial with the dye vat, blades are uniformly distributed on the rotary drum, and a group of press rolls arranged above one another is arranged above the cylindrical dye vat. The textile dyeing machine is also provided with a dye solution circulating pipe, one end of the dye solution circulating pipe is communicated with the bottom of the dye vat, the other end of the dye solution circulating pipe is communicated with a sprayer above the dye vat, and a heater and a circulating pump are arranged on the dye solution circulating pipe. The raffinate containing rate after each time of liquid discharge is reduced by the press rolls, so as to improve the washing efficiency, and greatly reduce the use amount of water, electricity and steam. A loose processing manner is adopted for the textile dyeing machine so as to adapt to all textiles and non-woven fabrics; and in operation, no mechanical friction exists between the fabric and the equipment, the fabric is free from rapid impact of the dye solution, and the fabric surface is lint-free.

Owner:SHANDONG COMPANION GROUP

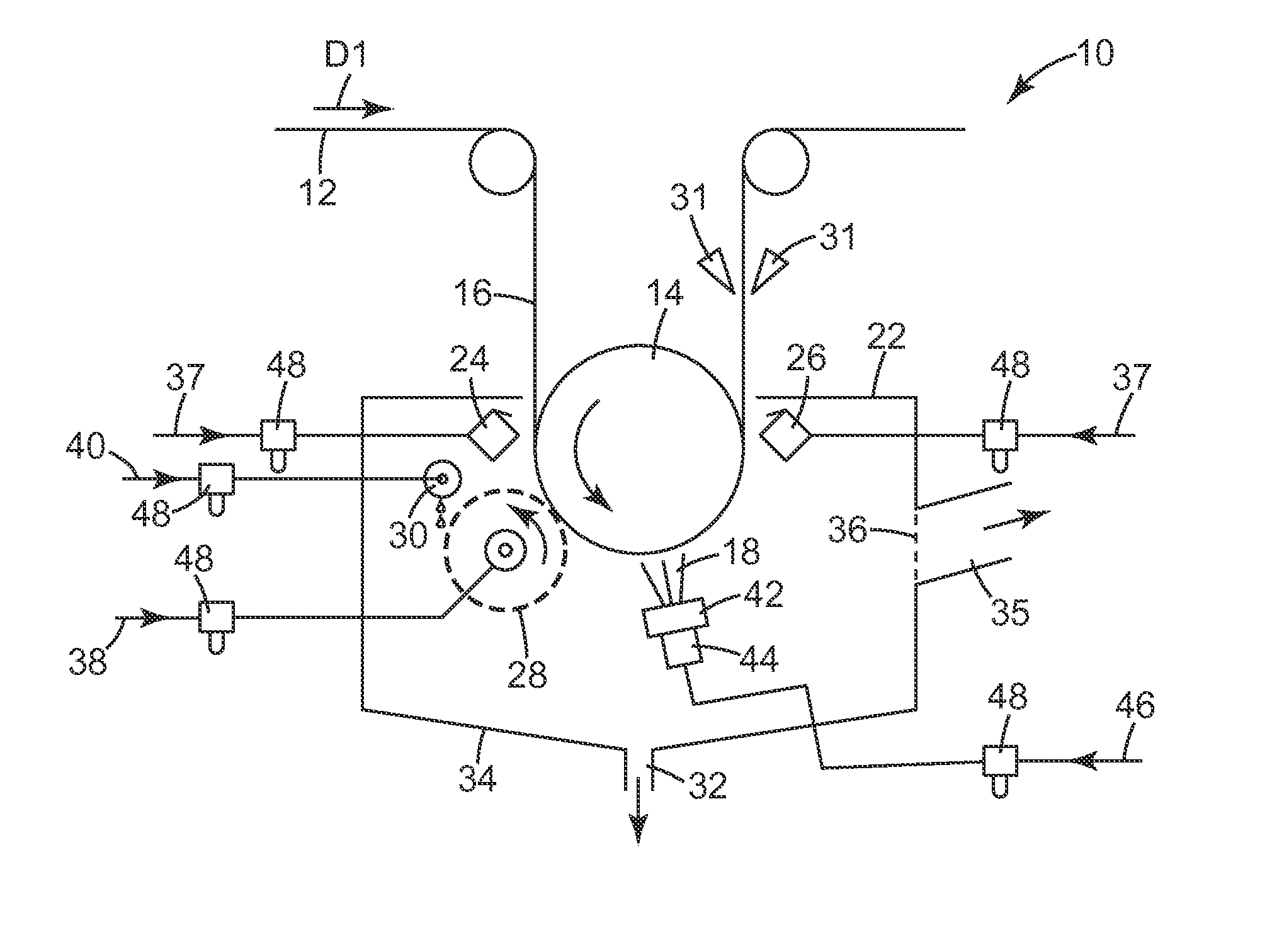

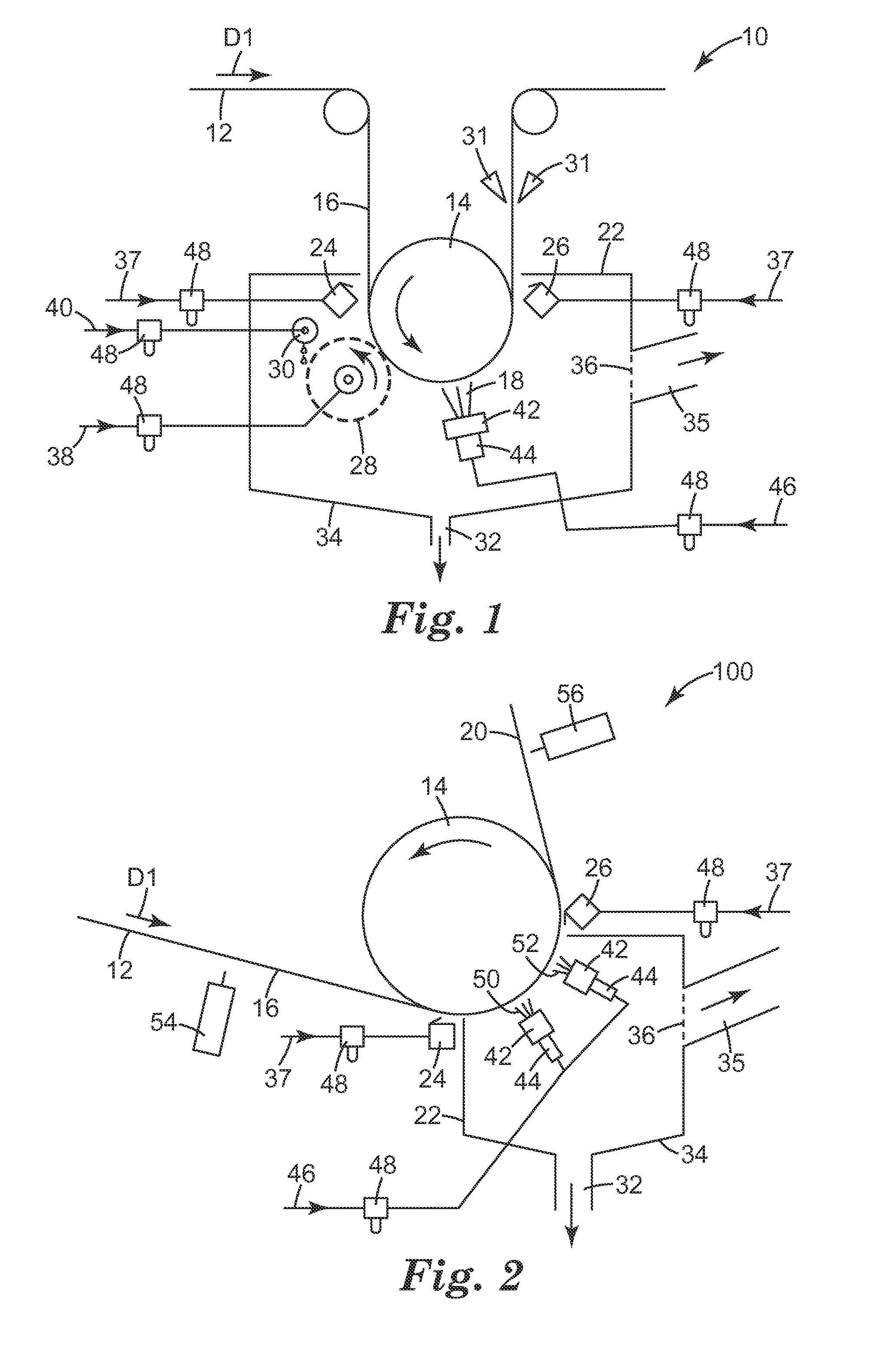

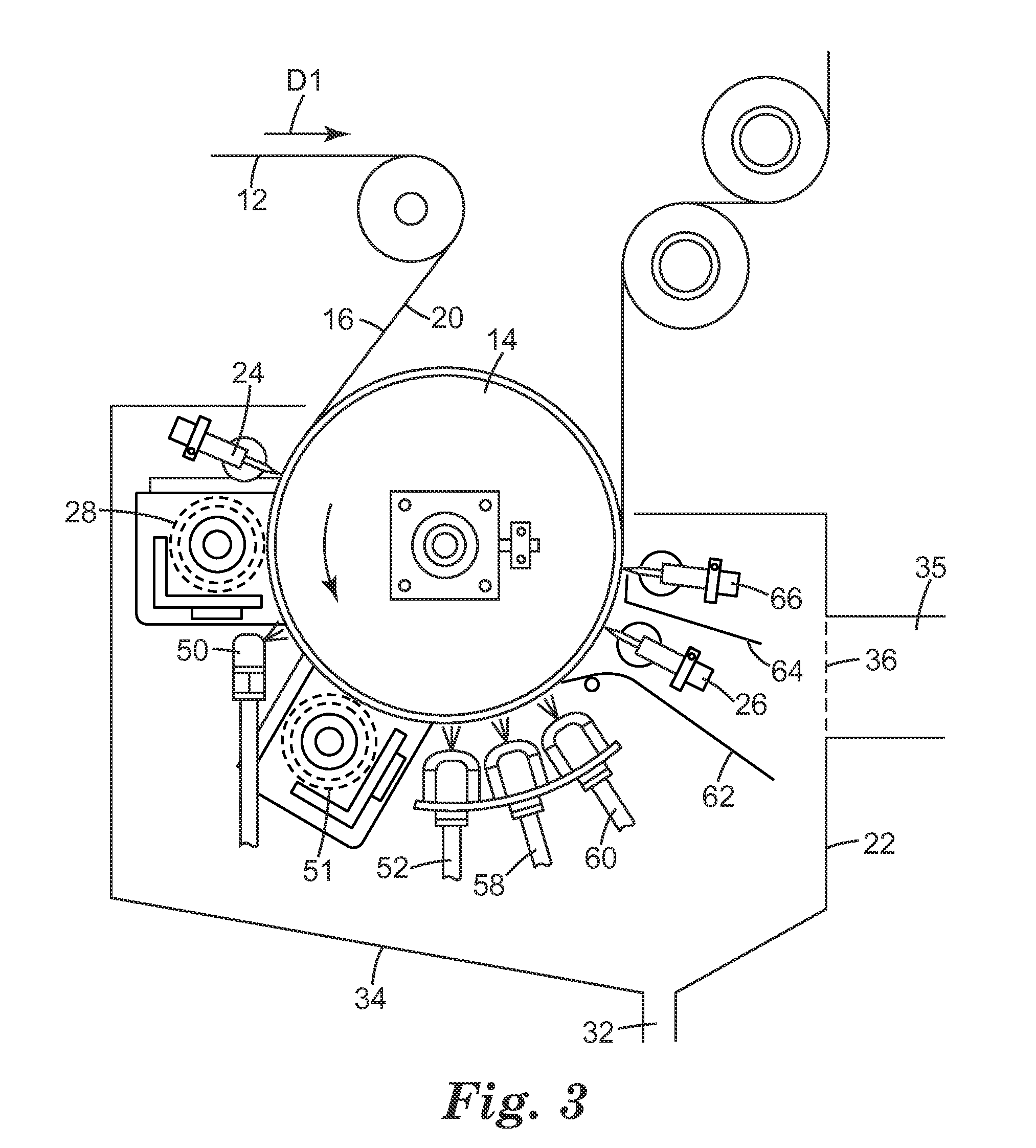

Apparatus and Method for Cleaning Flexible Webs

ActiveUS20110220147A1Photosensitive materialsSemiconductor/solid-state device manufacturingEngineeringCleaning methods

A method of web cleaning, particularly relatively soft polymeric webs, without using dipping baths or ultrasonic energy. The method includes conveying the web against a backup roller and spraying the web with a high pressure liquid while the web is supported by the backup roller. Thereafter, residual fluid from the high pressure stream is stripped from the web by a gas curtain while the web is supported by the backup roller. In many convenient embodiments, the web is contacted with a cleaning roller while the web is in contact with the backup roller.

Owner:3M INNOVATIVE PROPERTIES CO

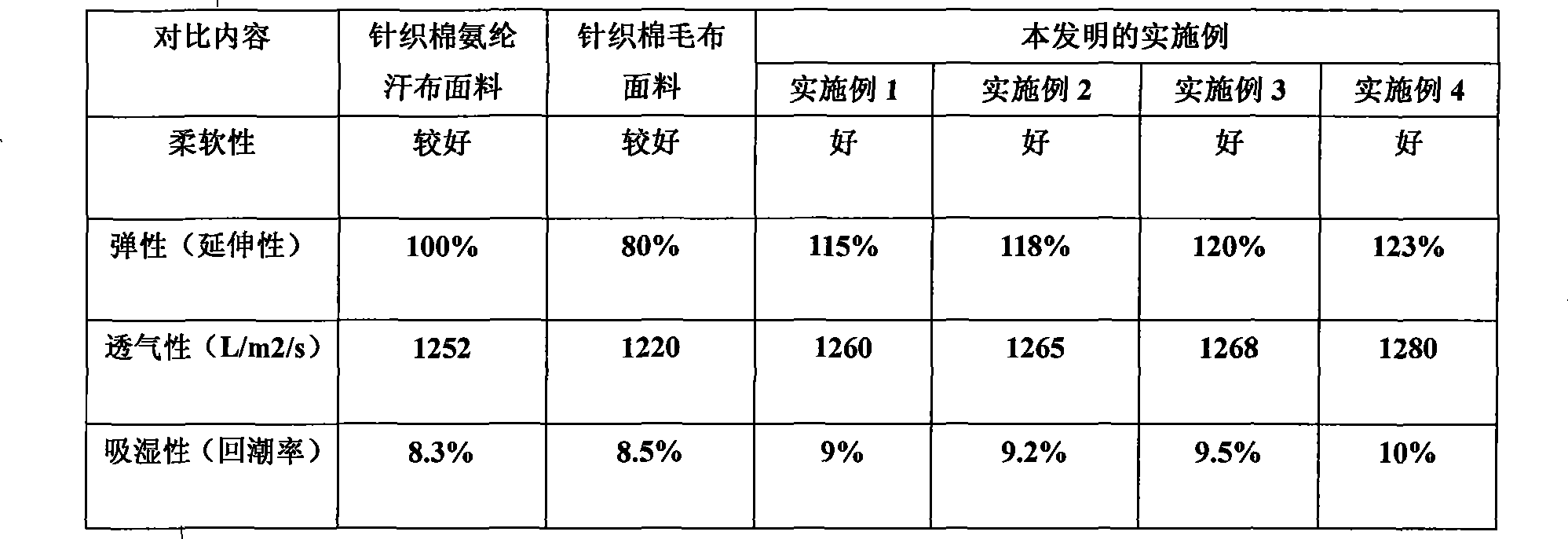

Knitting fabric for clothing and processing method thereof

InactiveCN101445993AReasonable proportion by weightImprove economyWeft knittingWarp knittingYarnAfter treatment

The invention relates to a knitting fabric for clothing and a processing method thereof. The knitting fabric comprises a covering weave and a ground weave, wherein, the raw material of the covering weave is cotton yarn, the raw material of the ground weave is terylene and spandex core-spun yarn, the content of the cotton yarn accounts for 94-97 percent, the content of the terylen fiber accounts for 2-5.7 percent, and the content of the spandex fiber accounts for 0.3-1 percent. The invention has the advantages that the knitting fabric for clothing has ideal softness, elasticity, air permeability and hygroscopicity, good fluffy effect, small water shrinkage and good shape-preserving effect; the method that the loop drying working procedure is arranged after the heat setting working procedure in the after treatment step is recommended, so that the fabric has soft hand-feel, ideal air permeability, excellent elasticity and concave-convex feel.

Owner:JIANGSU JINCHENZHEN TEXTILE

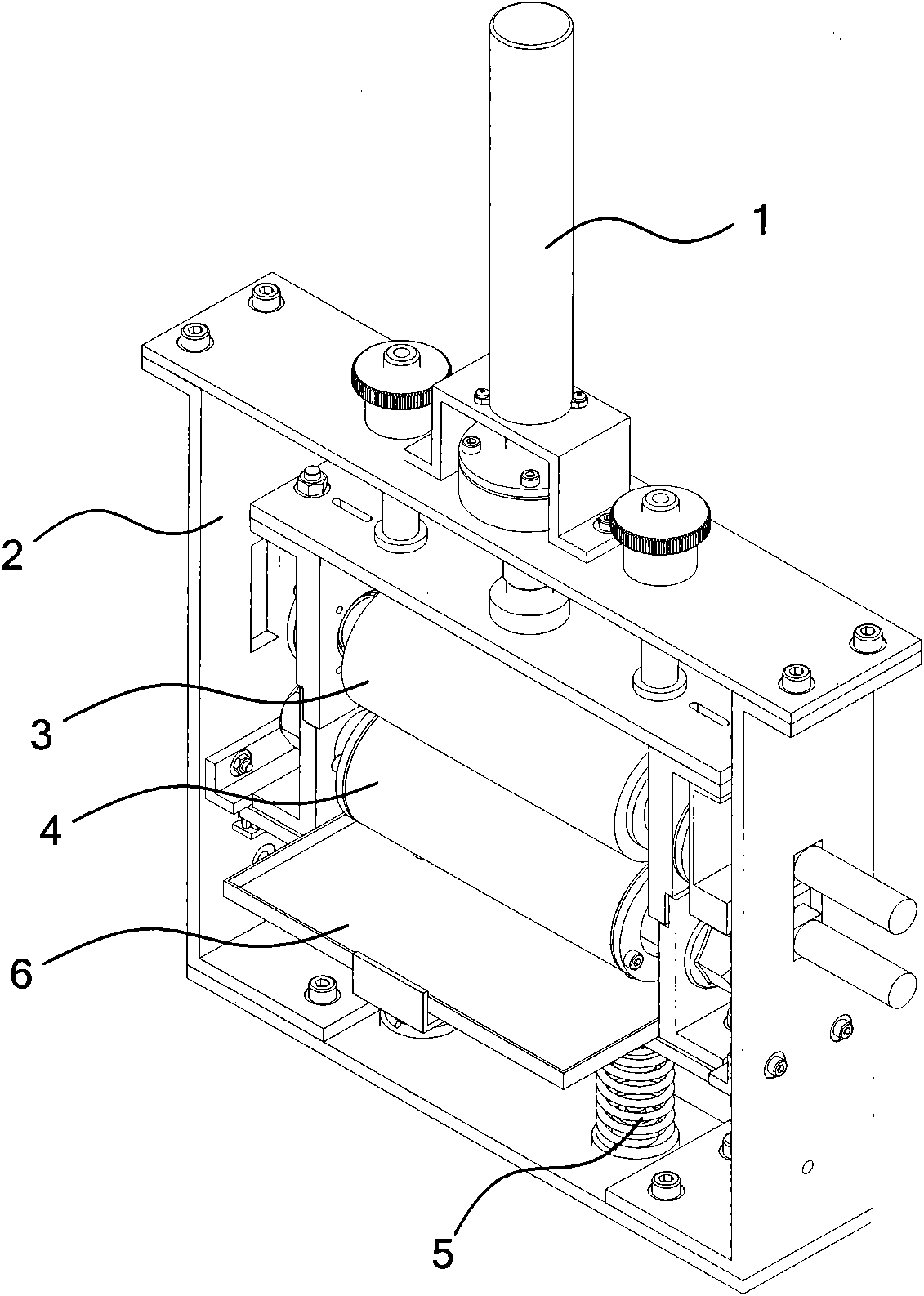

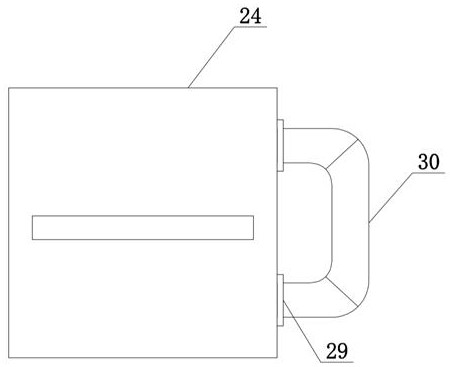

Glue extrusion device for fiber gluing equipment of winding machine

InactiveCN101775724AGuaranteed liquidityFully maceratedLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberTemperature control

The invention discloses a glue extrusion device for fiber gluing equipment of a winding machine, comprising a servo motor, a box body, an upper glue extrusion roller, a lower glue extrusion roller, a damping spring, a glue receiving box and a temperature control system, wherein the servo motor is installed on the box body, two ends of the upper glue extrusion roller and the lower glue extrusion roller are respectively fixed at two sides of the box body and can move freely, the damping spring is fixed between the lower glue extrusion roller and the bottom of the box body, the glue receiving box is arranged below the lower glue extrusion roller, a heating rod and a temperature sensor are arranged in the lower glue extrusion roller, the temperature control system forms a temperature control circuit with the heating rod and the temperature sensor, fiber passes through the place between the upper glue extrusion roller and the lower glue extrusion roller to be subjected to the extrusion of two rollers, and redundant glue solution on the fiber is extruded out and then flows onto the glue receiving box along the two rollers. The device can continuously adjust and control the gluing amount on fiber to control the temperature of the fiber and keep the flowability of the glue solution, the roller type extrusion ensure the glue solution to be more completely macerated on the fiber, the device has stronger adaptability to the fiber, and the fiber is not easy to fracture.

Owner:BEIHANG UNIV

Overflow dyeing device, and liquid utilization method using same

PendingCN107151885ASave waterTrue colorLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsEngineeringSewage

The invention relates to an overflow dyeing device. The overflow dyeing device comprises a dye vat and a liquid remaining device; the liquid remaining device is arranged at the top of the dye vat; the liquid remaining device comprises a liquid guide groove; a first side plate and a second side plate which are mutually parallel are symmetrically arranged on the two sides of the top end of the liquid guide groove; a lower roller positioned in the liquid guide groove is arranged between the first side plate and the second side plate; an upper roller parallel with the lower roller is arranged above the lower roller; a guide block is arranged at each of the two ends of the upper roller; a guide rail corresponding to the guide block is arranged on the inner wall of each of the first side plate and the second side plate; and driving devices positioned at the tops of the first side plate and the second side plate are arranged at the tops of the guide blocks. The invention provides a liquid utilization method using the device. By the method, environmental protection pressure is reduced, sewage treatment is reduced, meanwhile, secondary utilization of dye and aids is realized, the aims of reducing pollution and saving cost are fulfilled, and the competitiveness of products is improved.

Owner:红柳纺织科技沭阳有限公司

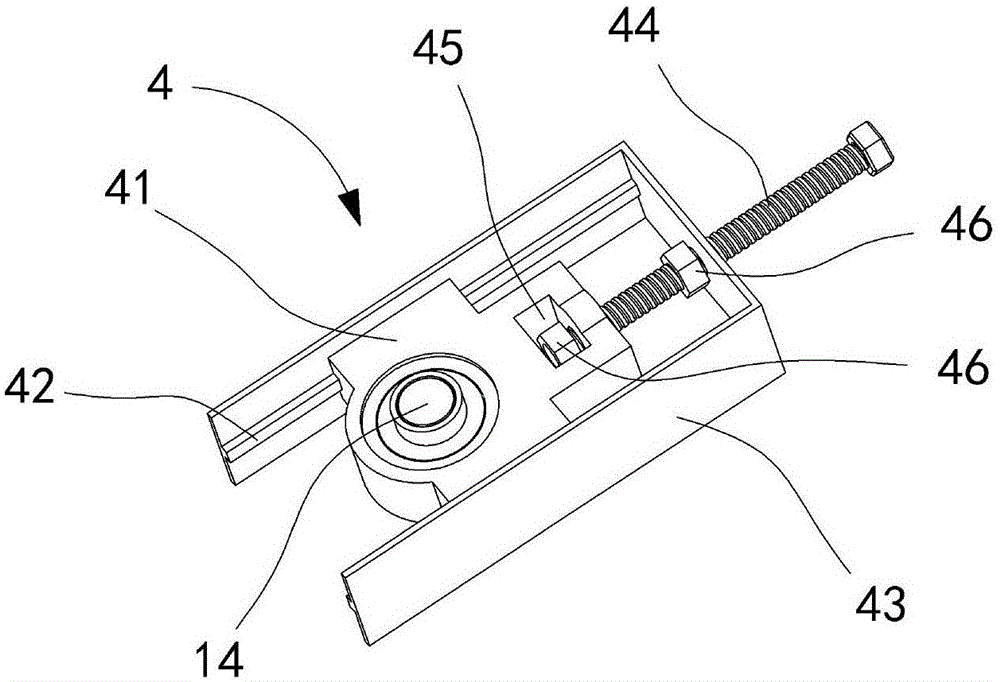

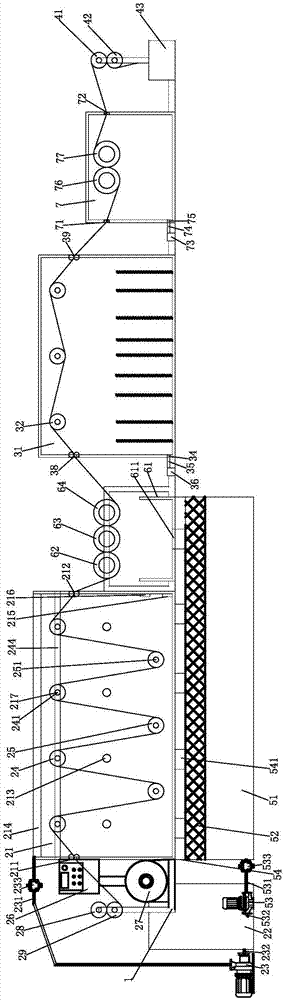

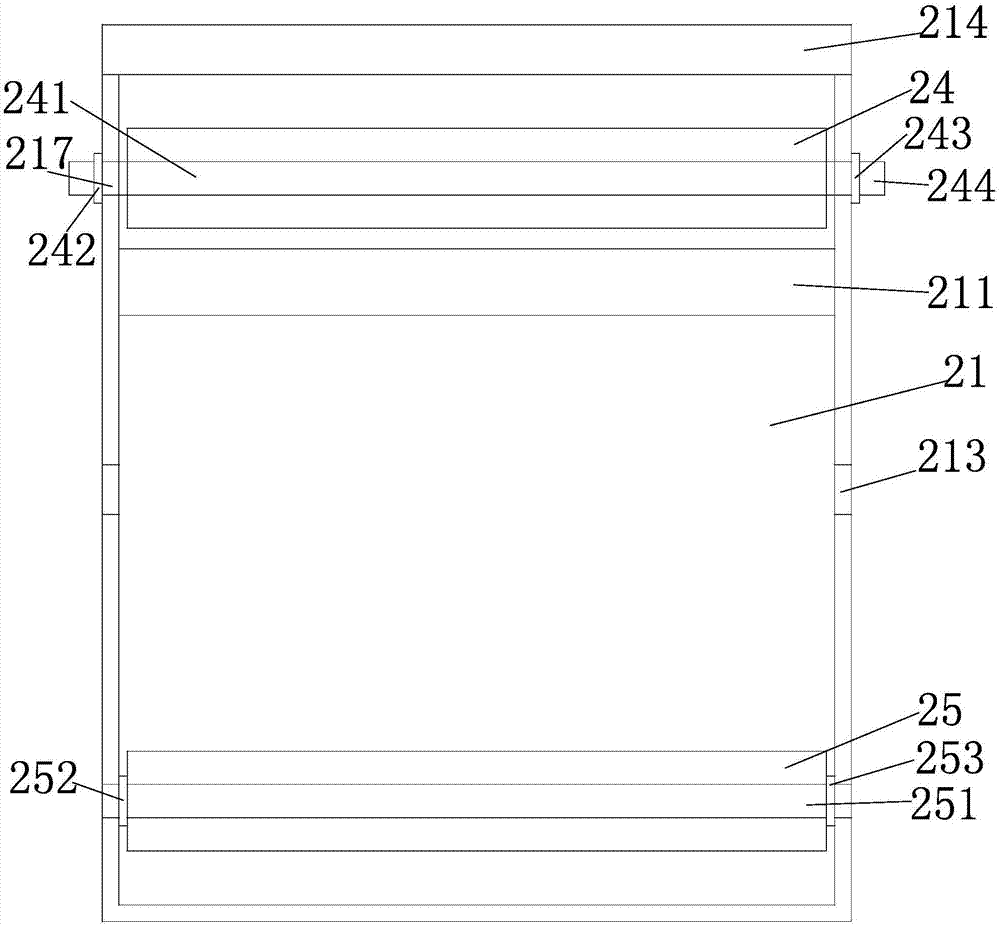

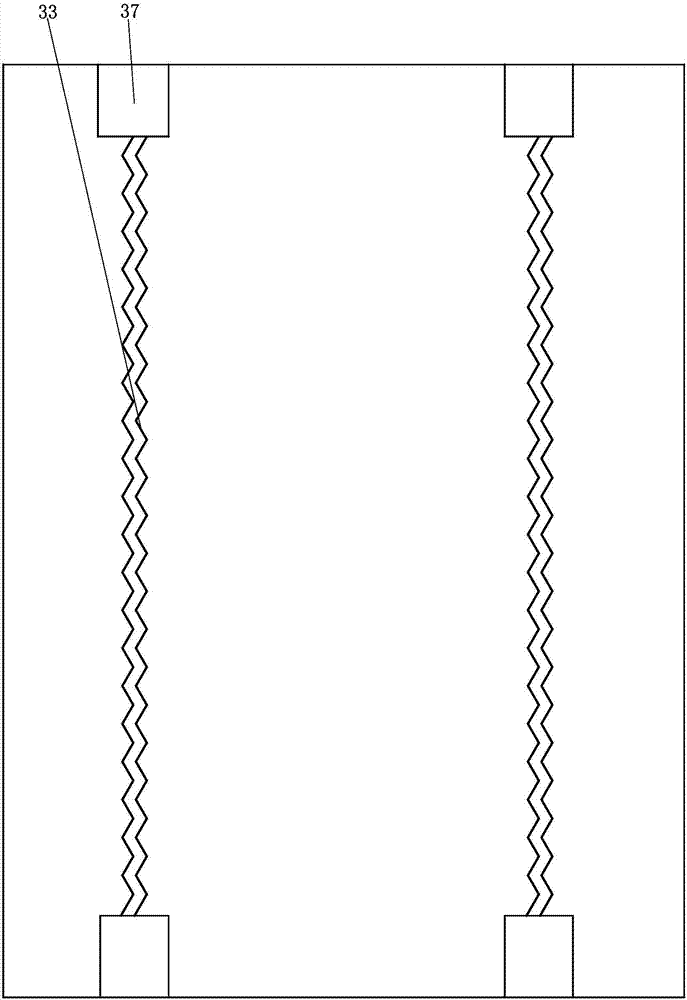

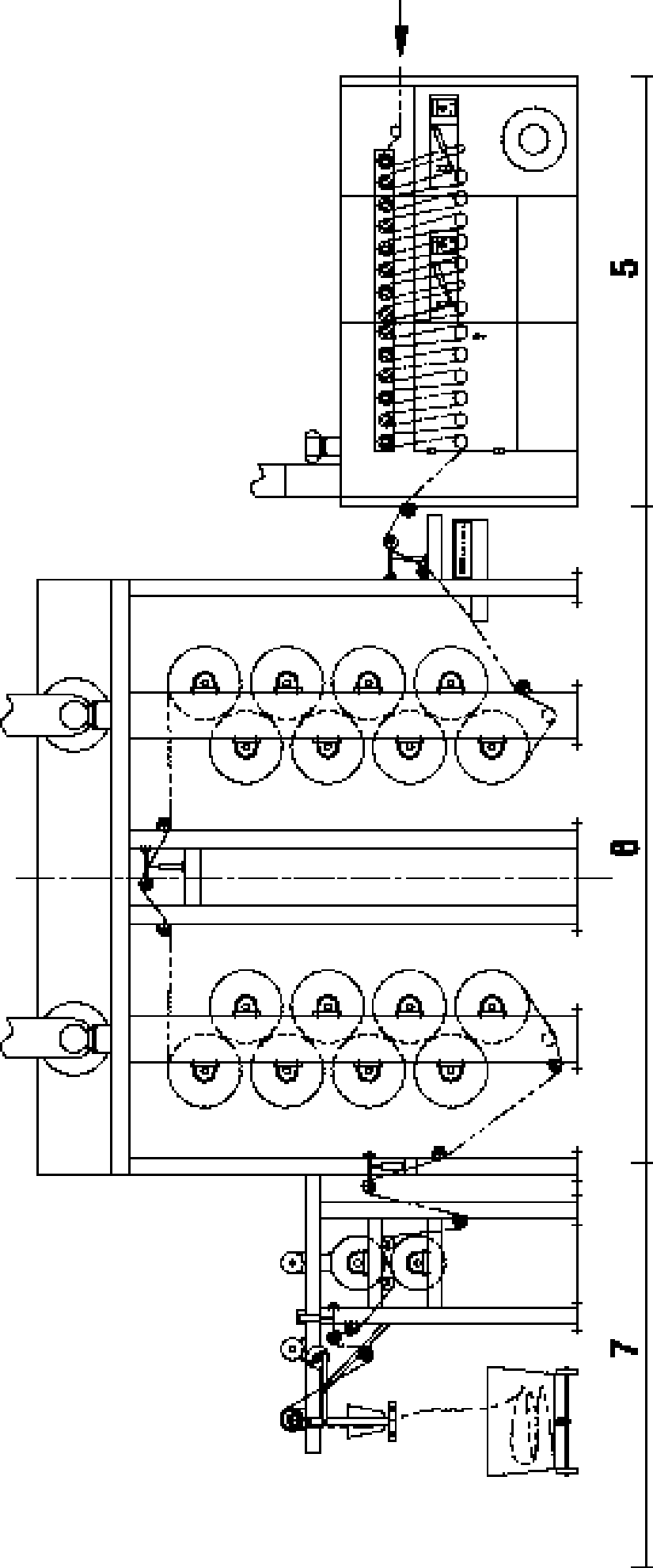

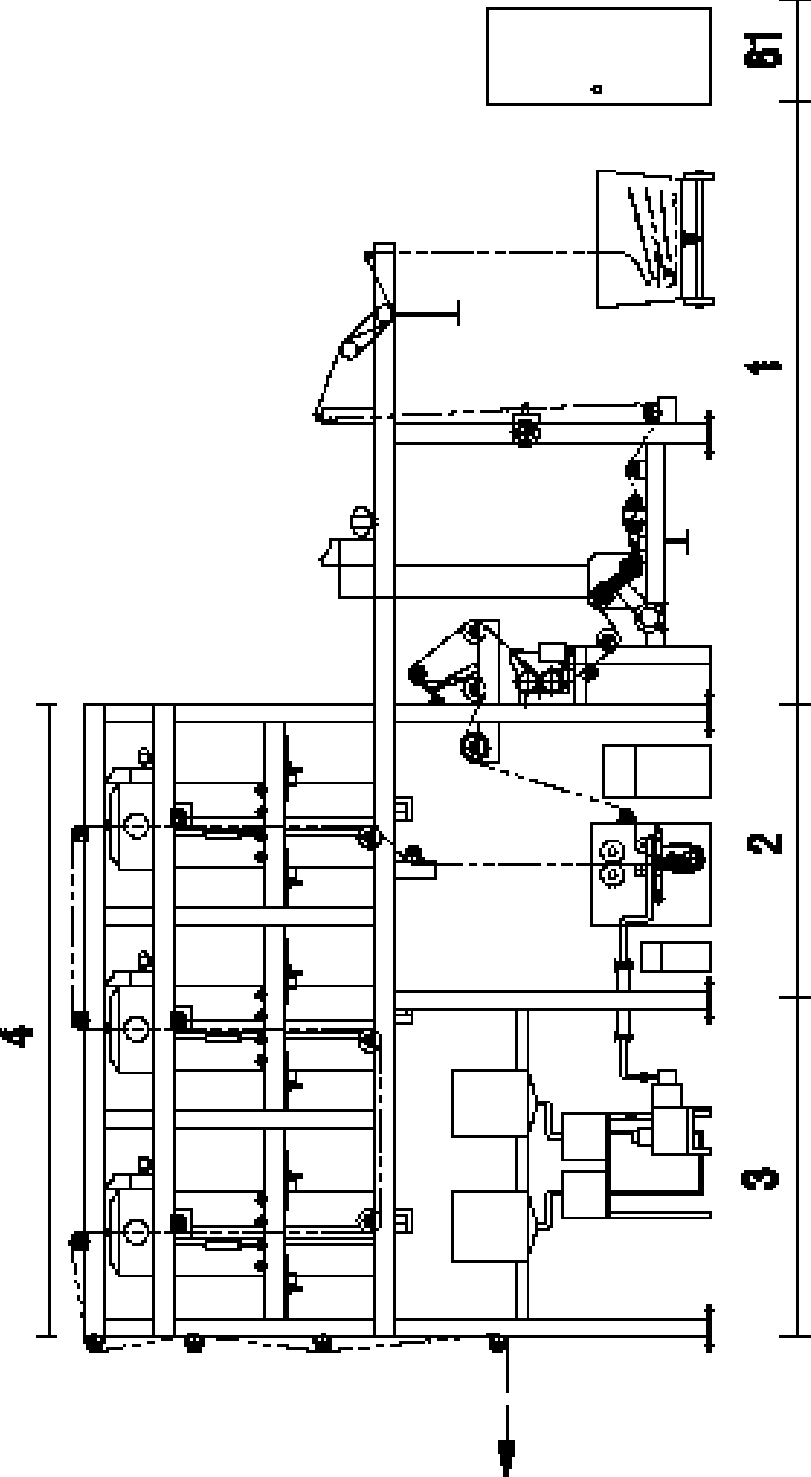

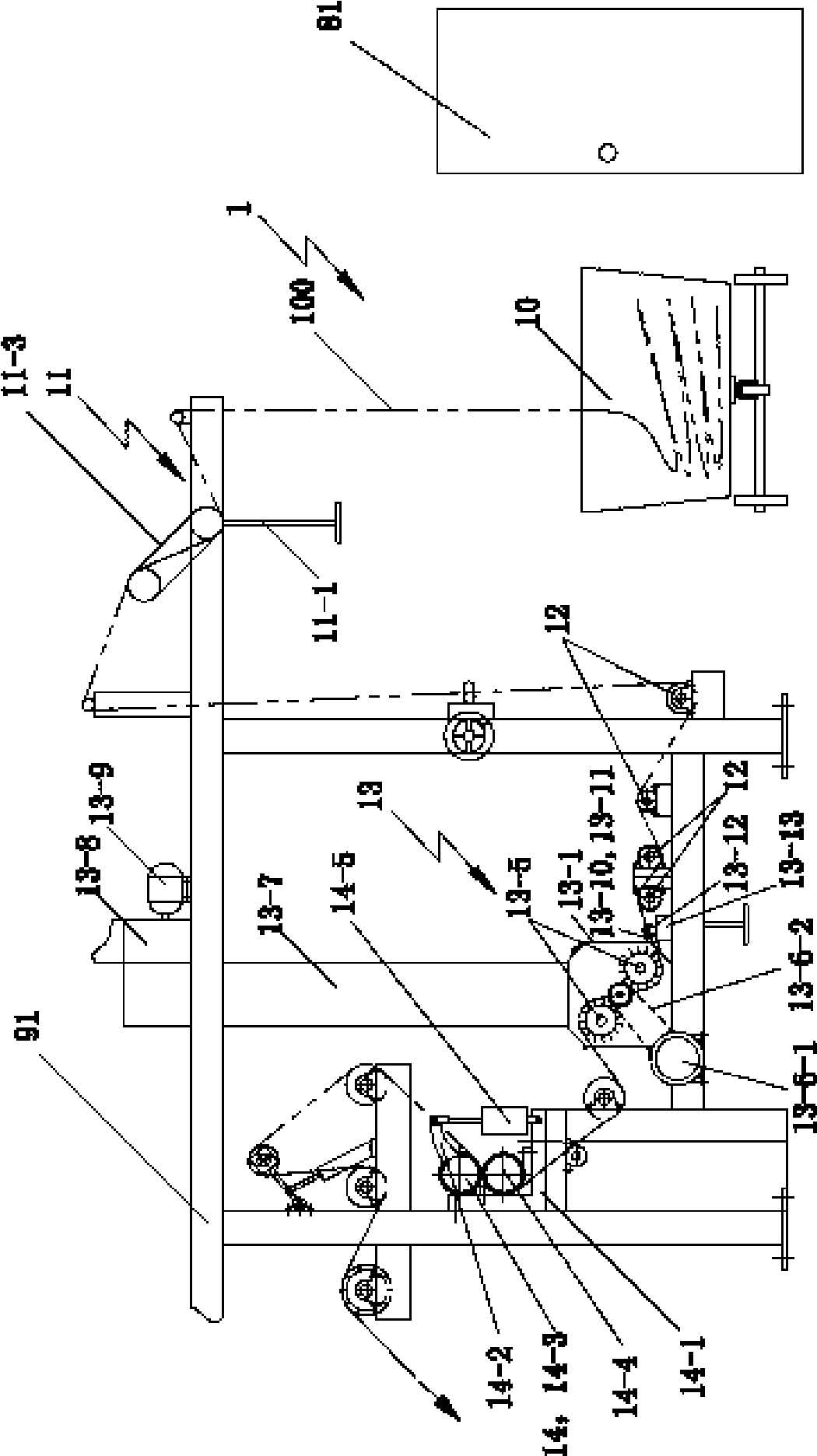

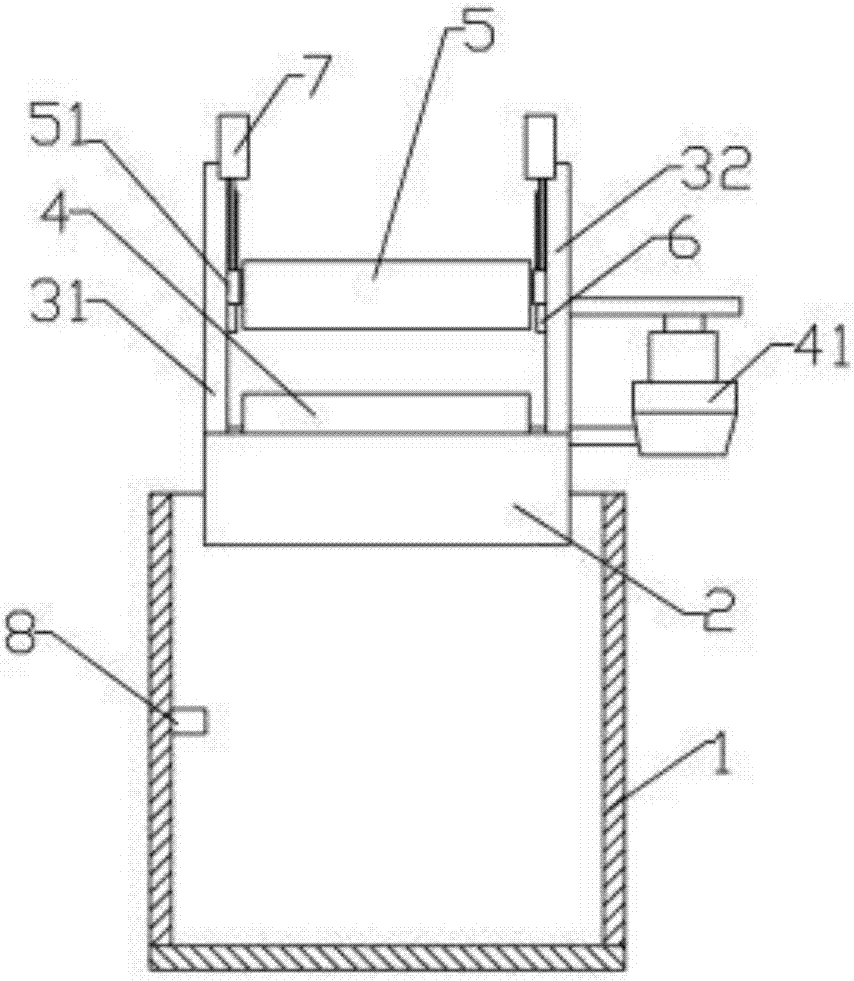

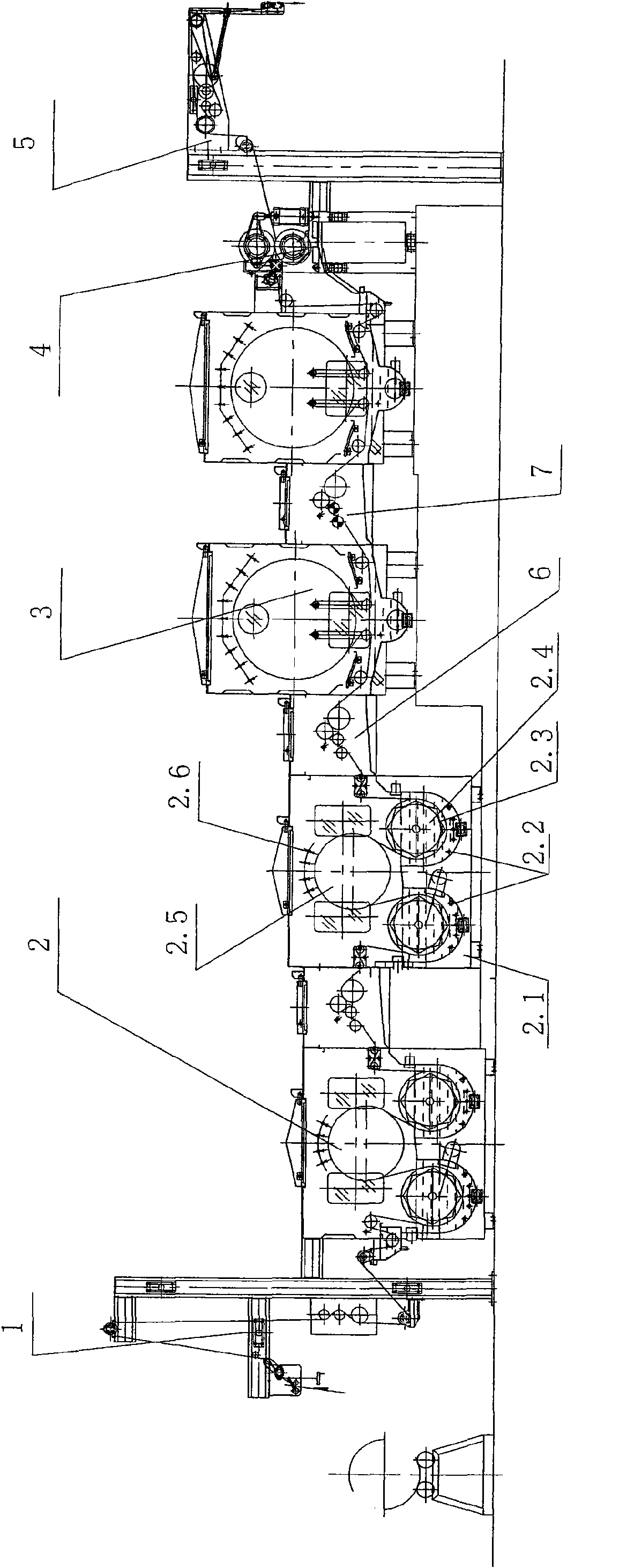

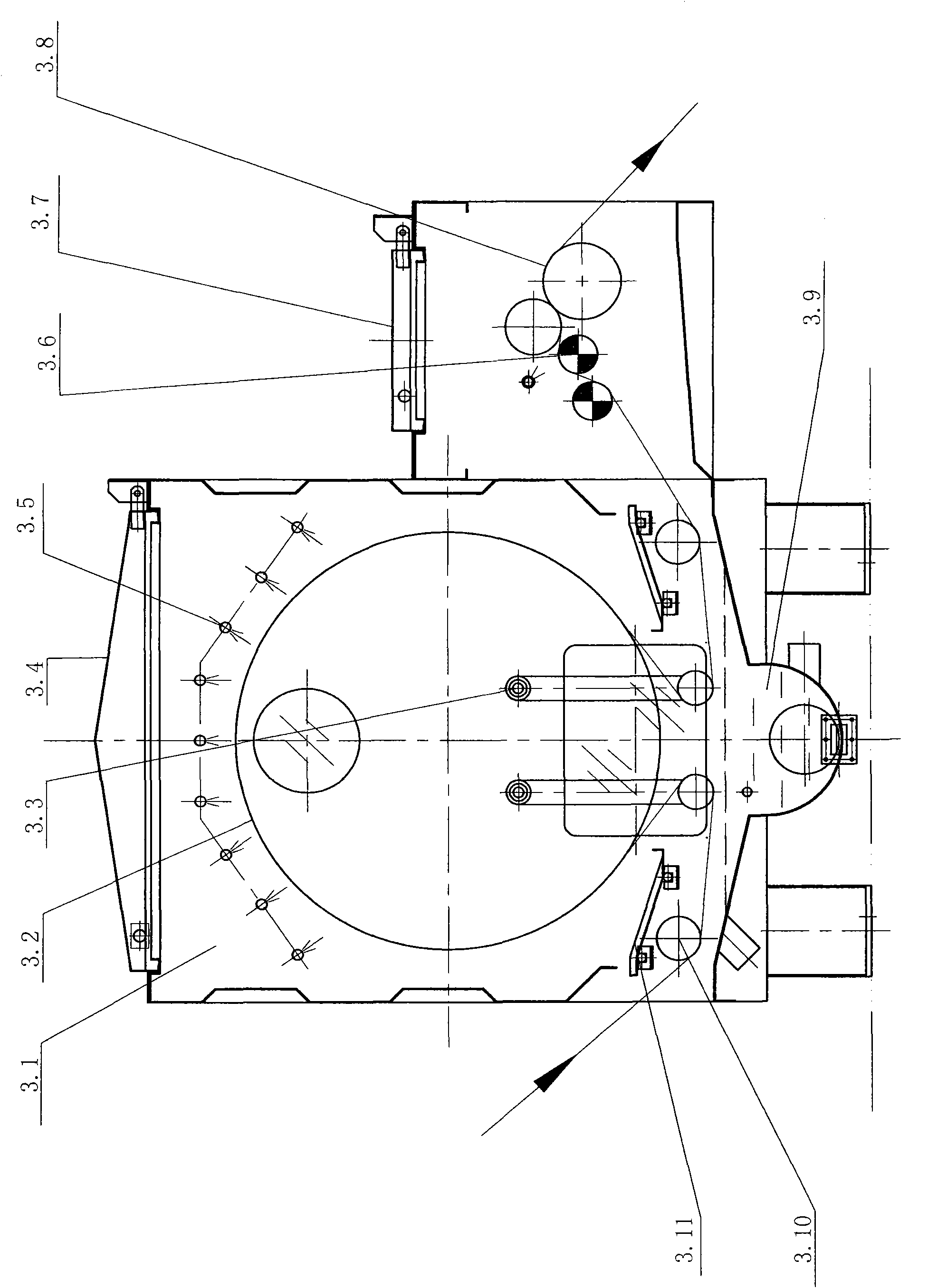

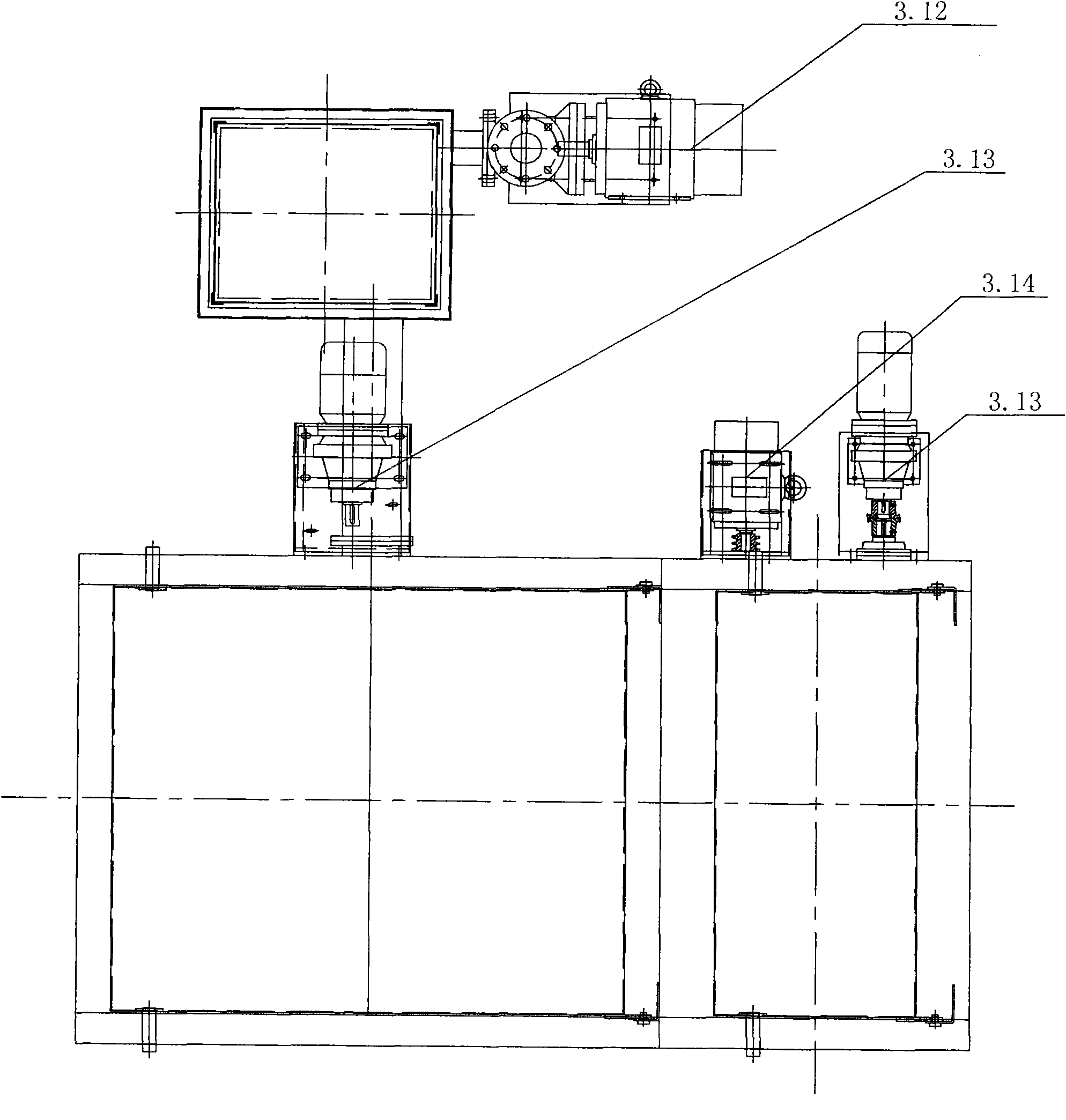

Combination machine for open width oil removal, moist heat relaxation and pre-shrinking water rinse

InactiveCN101575784AReduce tensionRealize low tension cloth transportationSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberWater rinsing

The invention relates to a combination machine for open width oil removal, moist heat relaxation and pre-shrinking water rinse, which is applicable to the open width oil removal, pre-shrinking and refining water rinse processes of knitting, urethane elastic fiber, terylene, chinlon and combined fiber fabrics. The combination machine comprises an open width cloth feeding bracket (1), a double-oscillation water rinse tank (2), single rotating drum rinsing machines (3), a two-roll heavy padder (4) and an open width doffing cloth bracket (5) in turn from the front to back, wherein the number of the single rotating drum rinsing machines (3) is at least two groups, and an internal two-roll padder II (7) is arranged between adjacent two groups of single rotating drum rinsing machines (3). The combination machine is characterized in that: each group of single rotating drum rinsing machine (3) comprises a tank body II (3.1), a sink II (3.9), two guide rails (3.10), two water baffles (3.11), a netlike rotating drum II (3.2), a suspended tensioning rack (3.3) and a spraying pipe II (3.5); and the front of a rolling point of a roller (3.8) of the internal two-roll padder II is provided with positive and negative strippers (3.6). The combination machine can realize low-tension cloth delivery, and efficient cloth spread and edge toggle. Therefore, the combination machine can be applied to the fabrics with large elasticity.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

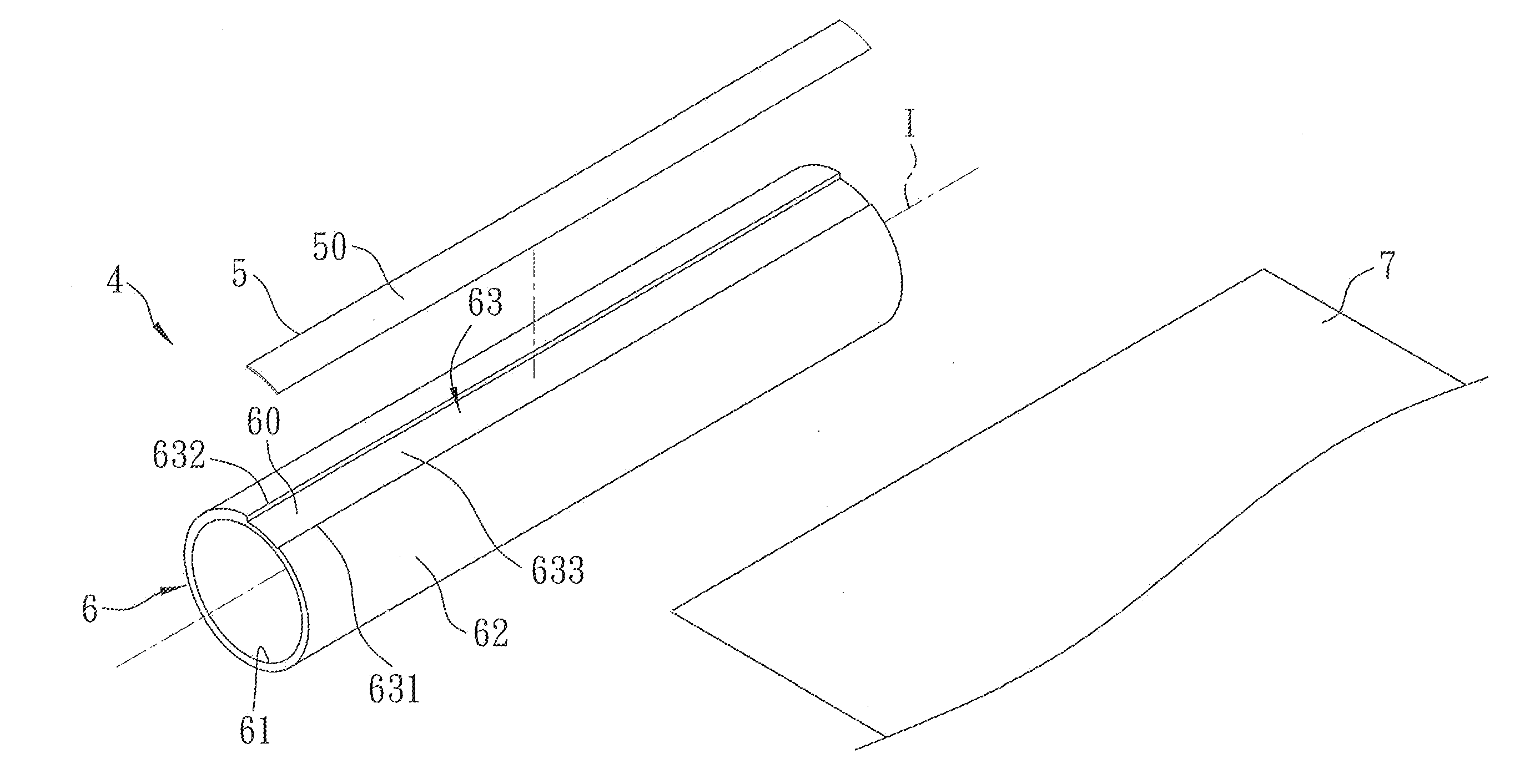

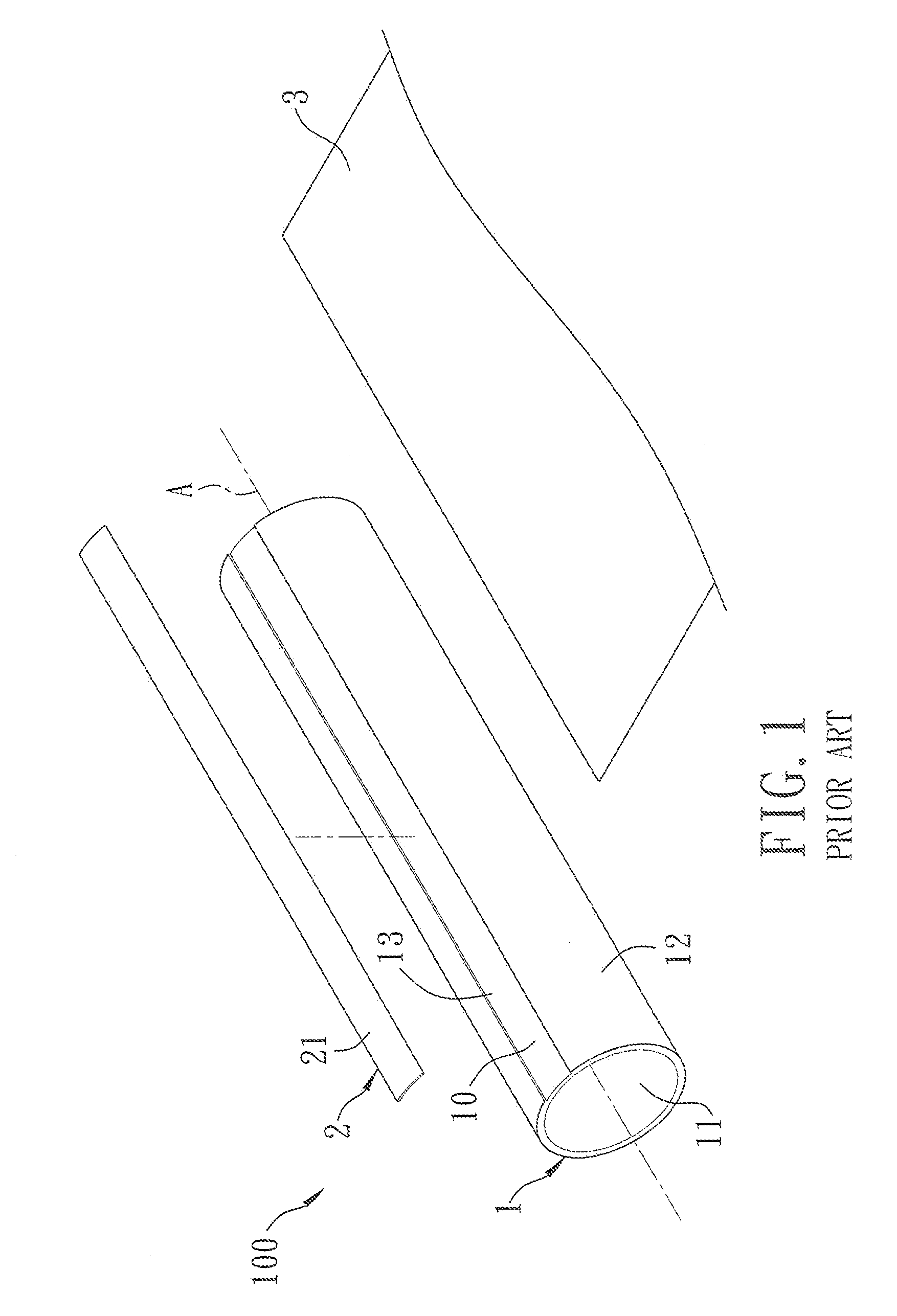

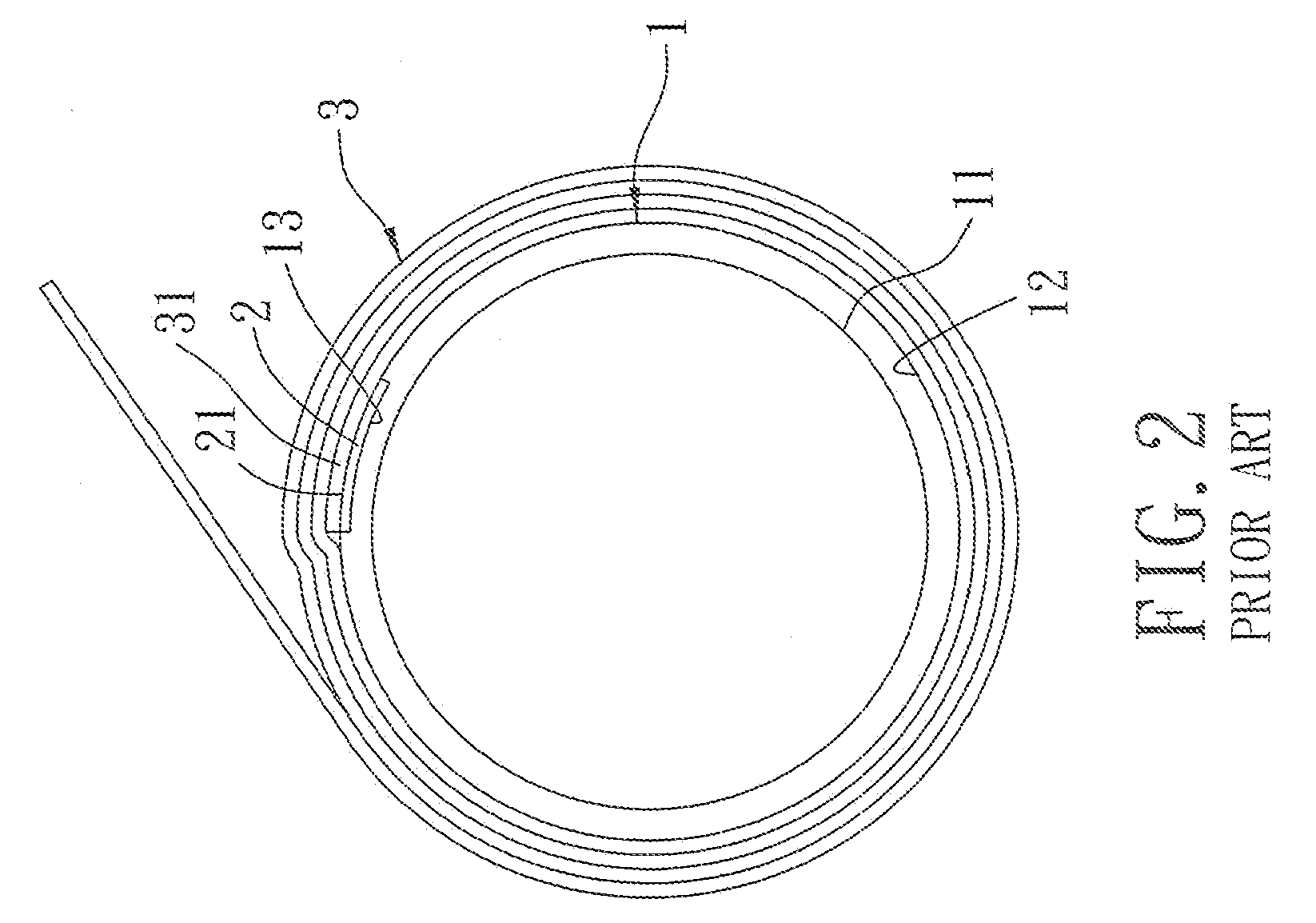

Spool assembly

A spool assembly for winding of a sheet-like material thereon includes a tubular hub body and a securing member. The tubular hub body is formed with a groove, and has a radial cross-section that has grooved and non-grooved segments. The non-groove segment extends from the grooved segment, and has opposite first and second ends, and a radial thickness that increases gradually from the first end to the second end thereof. The securing member is mounted in the groove in the tubular hub body for securing a securing end of the flexible sheet-like material to the tubular hub body.

Owner:WU HANS

Cloth soaking and coloring automatic equipment and operation method thereof

PendingCN111826853AUniform colorImprove production efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFuel tankElectric machinery

The invention discloses cloth soaking and coloring automation equipment and an operation method thereof, and belongs to cloth soaking and coloring automation equipment. The cloth soaking and coloringautomation equipment comprises a base, wherein the upper end of the base is fixedly connected with a dye box; and a feeding hole and a discharging hole are formed in the two sides of the upper end ofa fuel tank respectively. During cloth dyeing, driving motors in the motor box are started and drive a stirring paddle to rotate, and the stirring paddle stirs liquid in the dye box, so that the liquid in the dye box is always kept uniform; the uniform coloring of the cloth during dyeing can be ensured; and the situation of secondary processing of unqualified products is avoided. Moreover, an airbellow works to suck and blow external air flow into a heating box, the heating box heats and conveys the blown air into the drying box, and the hot air flow can dry the cloth in an accelerated manner, so that the cloth making efficiency can be improved, and the cloth can be dried more quickly.

Owner:常胜男

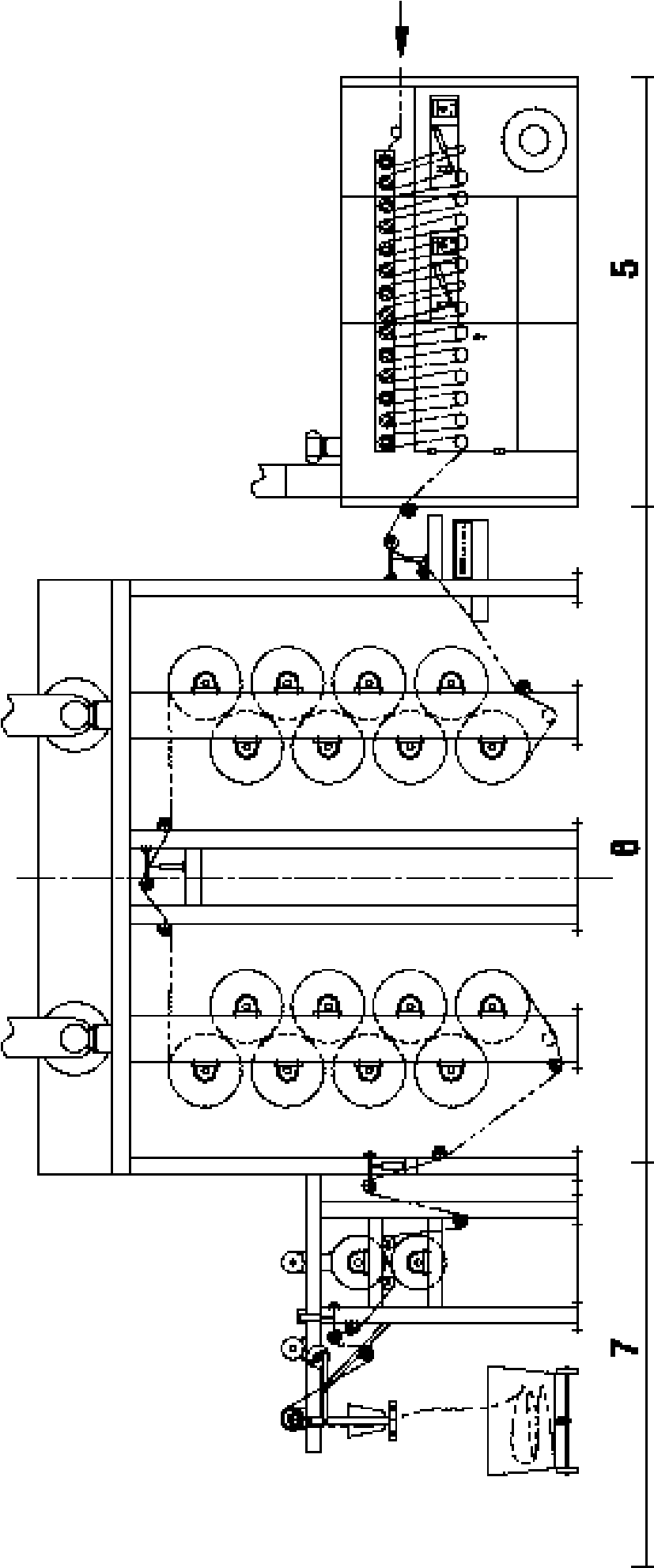

Yarn printing and dyeing automatic cleaning mechanism

InactiveCN106801304AHigh degree of automationImprove work efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersYarnAgricultural engineering

The invention discloses a yarn printing and dyeing automatic cleaning mechanism. The yarn printing and dyeing automatic cleaning mechanism comprises a frame, a yarn unreeling device, a first yarn separating rack, a yarn rinsing device, a water squeezing mechanism, a water blowing mechanism, a thermal drying mechanism, a yarn storage mechanism, a second yarn separating rack, a reeling device and a plurality of groups of transmission rollers, wherein the yarn unreeling device, the first yarn separating rack, the yarn rinsing device, the water squeezing mechanism, the water blowing mechanism, the thermal drying mechanism, the yarn storage mechanism, the second yarn separating rack and the reeling device are arranged on the frame; the transmission rollers are arranged between the unreeling device and the reeling device. The yarn printing and dyeing automatic cleaning mechanism can automatically achieve the steps of automatic yarn unreeling, cleaning, drying, reeling and the like, thereby being high in automation degree and working efficiency, and by means of the yarn storage mechanism, can temporarily store cleaned yarn reels to achieve continuous production, to avoid downtime and further to improve the production efficiency.

Owner:张丹丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com