Knitting fabric for clothing and processing method thereof

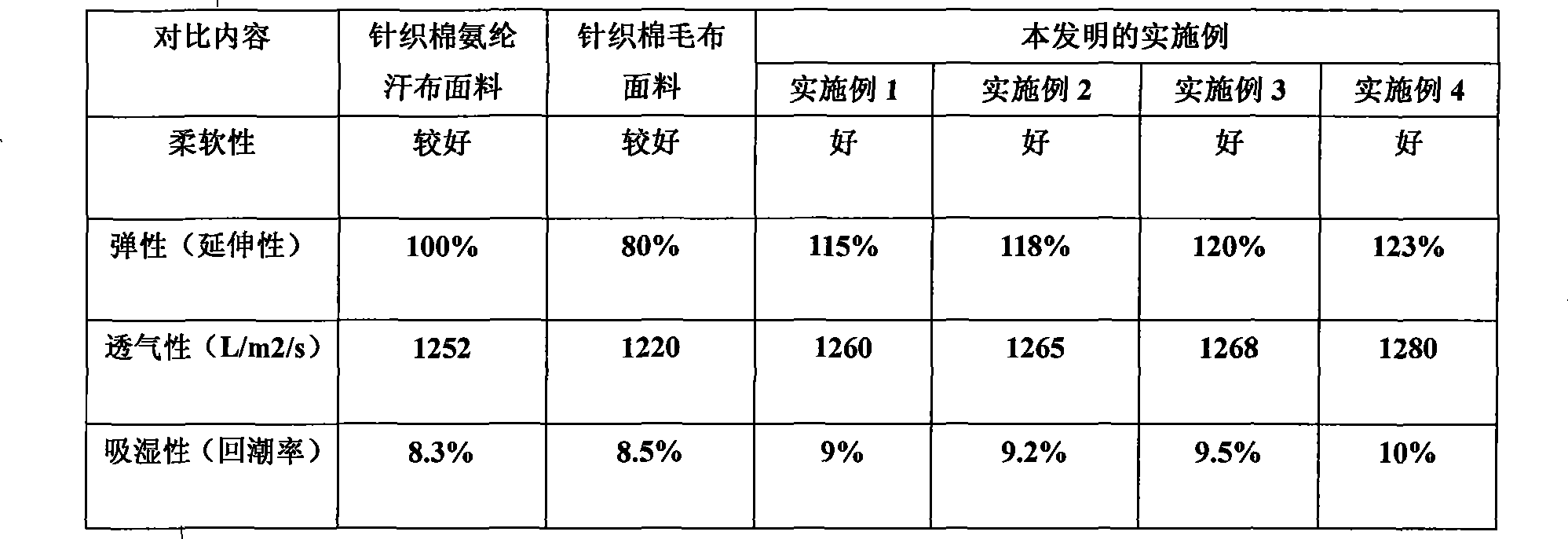

A technology of knitted fabrics and processing methods, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of consumers being discouraged, lack of fluffy feeling, lack of shape retention effect, etc., and achieve excellent elasticity, uneven feeling, hygroscopicity And the effect of good fluffy feeling and good shape retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A) Weaving, choose polyester spandex core-spun yarn (also known as polyester core-spun spandex yarn) as the bottom structure, wherein the specification of polyester fiber is 75D / 36F, the specification of spandex fiber is 70D, and 24S cotton yarn is selected as the surface structure, wherein: The content of polyester fiber in the whole fabric is 2.4%, the content of spandex fiber in the whole fabric is 0.6%, and the content of cotton fiber in the whole fabric is 97%. , 30 o'clock single-sided circular knitting machine or a 24-needle, 30-hour single-sided large circular knitting machine produced in Hong Kong, China, to obtain white gray cloth;

[0024] B) pre-treatment, put the white gray cloth obtained in step A) into a dyeing machine for processing, such as a high-temperature overflow dyeing machine widely used in the printing and dyeing industry, and then add it to the water (usually tap water) in the dyeing machine Adding preferred but not limited to the brand KDM-A23...

Embodiment 2

[0029] A) Weaving, choose polyester spandex core-spun yarn (also known as polyester core-spun spandex yarn) as the bottom structure, wherein the specification of polyester fiber is 75D / 36F, the specification of spandex fiber is 70D, and 26S cotton yarn is selected as the surface structure, wherein: The content of polyester fiber in the whole fabric is 3.2%, the content of spandex fiber in the whole fabric is 0.8%, and the content of cotton fiber in the whole fabric is 96%. , 30 o'clock single-sided circular knitting machine or a 24-needle, 30-hour single-sided large circular knitting machine produced in Hong Kong, China, to obtain white gray cloth;

[0030] B) pre-treatment, put the white gray cloth obtained in step A) into a dyeing machine for processing, such as a high-temperature overflow dyeing machine widely used in the printing and dyeing industry, and then add it to the water (usually tap water) in the dyeing machine Add the environment-friendly phosphorus-free refining...

Embodiment 3

[0035] A) Weaving, choose polyester spandex core-spun yarn (also known as polyester core-spun spandex yarn) as the bottom structure, wherein the specification of polyester fiber is 75D / 36F, the specification of spandex fiber is 70D, and 28S cotton yarn is selected as the surface structure, wherein: The content of polyester fiber in the whole fabric is 4%, the content of spandex fiber in the whole fabric is 1%, and the content of cotton fiber in the whole fabric is 95%, and then put it into a single-sided machine such as 24 needles produced in Taiwan , 30 o'clock single-sided circular knitting machine or a 24-needle, 30-hour single-sided large circular knitting machine produced in Hong Kong, China, to obtain white gray cloth;

[0036] B) pre-treatment, put the white gray cloth obtained in step A) into a dyeing machine for processing, such as a high-temperature overflow dyeing machine widely used in the printing and dyeing industry, and then add it to the water (usually tap water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com