Combination machine for open width oil removal, moist heat relaxation and pre-shrinking water rinse

A combined machine and washing machine technology, applied in textiles and papermaking, textile processing machine accessories, liquid/gas/vapor removal with squeeze rollers, etc., can solve the problems of slow exchange, curling, unenvironmental protection, etc. Fast and efficient distribution and exchange of fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

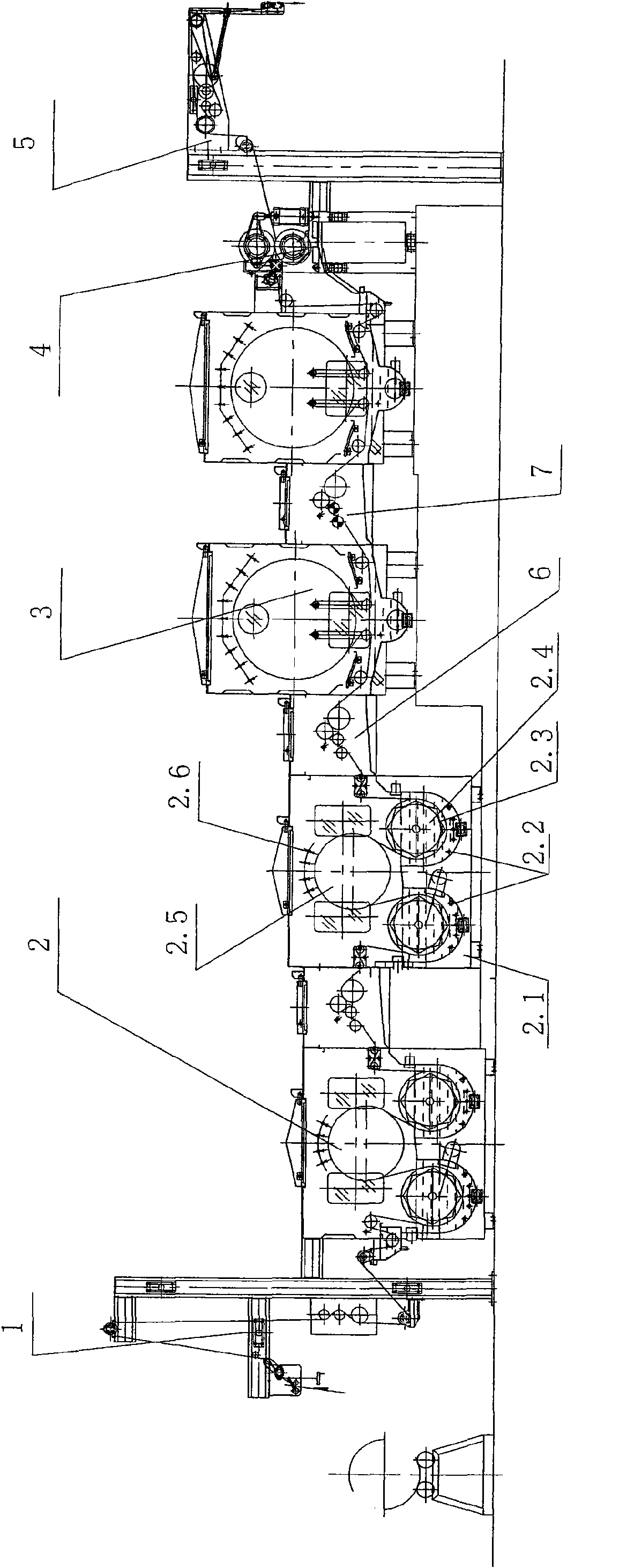

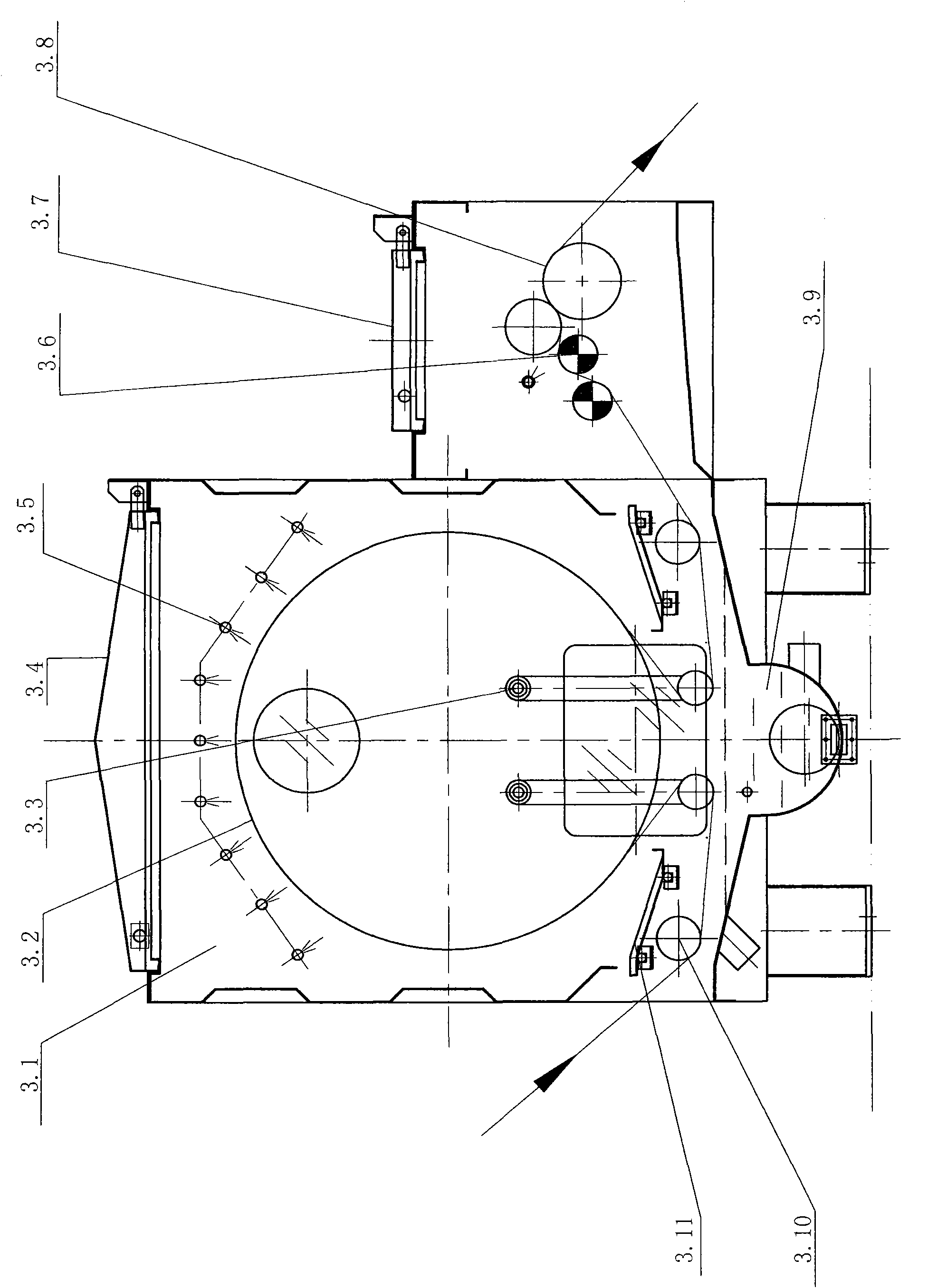

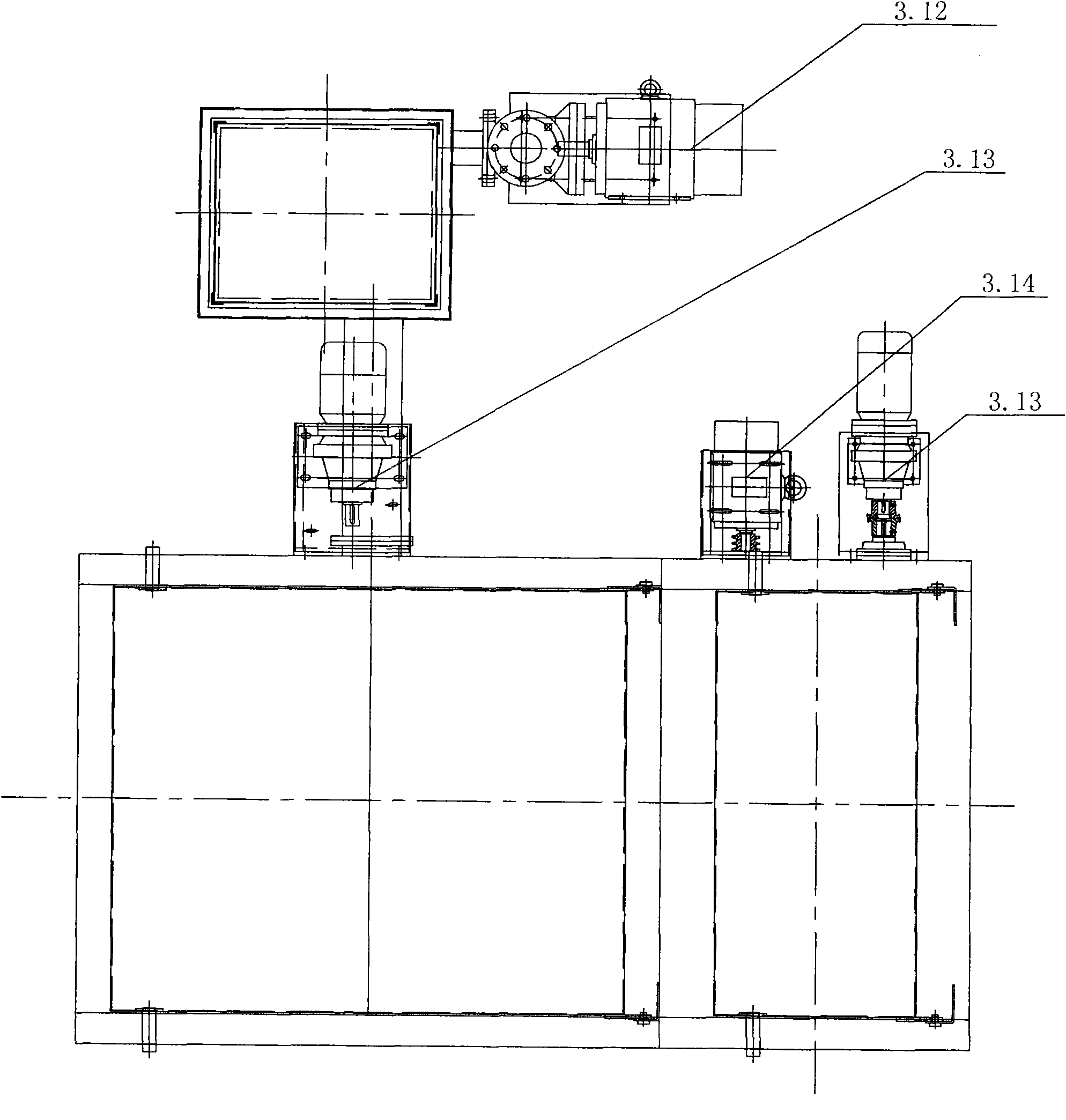

[0022] see figure 1 , the combined open-width degreasing, damp-heat relaxation and pre-shrinking washing machine of the present invention consists of the open-width cloth feeding frame (with centering device) 1, double-oscillating washing boxes (four groups) 2, and single-drum washing from front to back. Machine (two groups) 3, two-roller heavy rolling car (8T) 4 and flat width swing cloth drop frame 5 are composed.

[0023] The open-width cloth feeding frame 1 is made of steel plate folding, and is provided with a stretching frame, a cloth guide roller, and an edge suction device.

[0024] There are four groups of the double-oscillating washing boxes 2, and the four sets of double-oscillating washing boxes 2 are arranged in parallel from front to back, and a built-in two-roll rolling car 16 is arranged between two adjacent groups of double-oscillating washing boxes 2, and each group of double-oscillating washing boxes 2 The box 2 includes a box body I 2.1, and the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com