Patents

Literature

38results about How to "Reduce water storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molten-slag-resistant spray paint for lade and application method thereof

The invention provides molten-slag-resistant spray paint for a ladle. The molten-slag-resistant spray paint comprises the following components in percentage by weight: 70-80 percent of aggregate, 16-25 percent of a bonding agent, 1-10 percent of a molten-slag-resistant functional additive and 0.01-1 percent of an additional additive, wherein the bonding agent is a composite bonding agent, and comprises silica powder, silicate cement, sodium silicate powder and bentonite. A method for applying the spray paint comprises the following steps: firstly, preparing a mixture in the weight ratio; secondly, adding water in an amount of 5-8 percent based on the weight of the mixture under strong stirring; and lastly, spraying the mixture onto a molten slag resisting position on the ladle through a spray gun. Compared with the prior art, the molten-slag-resistant spray paint provided by the invention has the advantages of high strength, high molten slag resistance, molten slag erosion resistance, oxidation resistance and high thermal shock resistance. Moreover, a waste sliding plate reclaimed material is taken as a main component for the aggregate of the molten-slag-resistant spray paint, so that the production cost of the molten-slag-resistant spray paint is lowered greatly, and high comprehensive benefit is achieved.

Owner:北京利尔高温材料股份有限公司

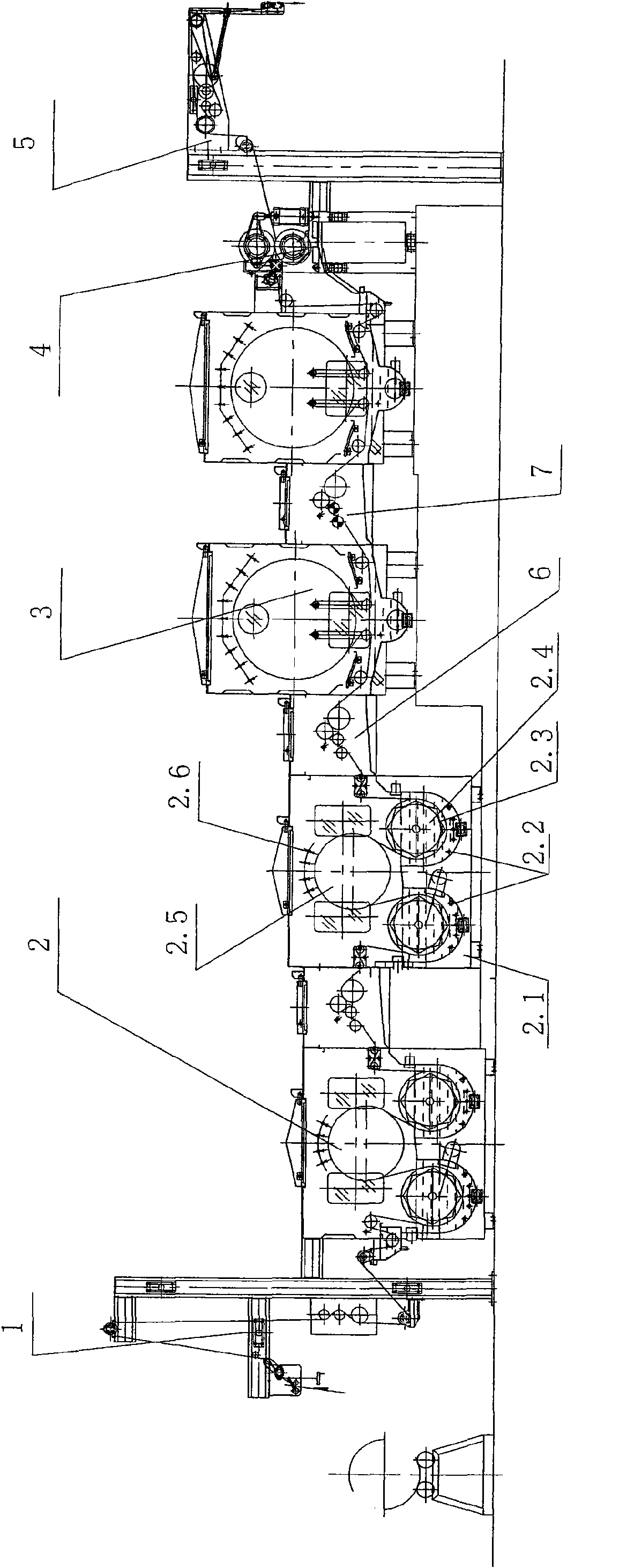

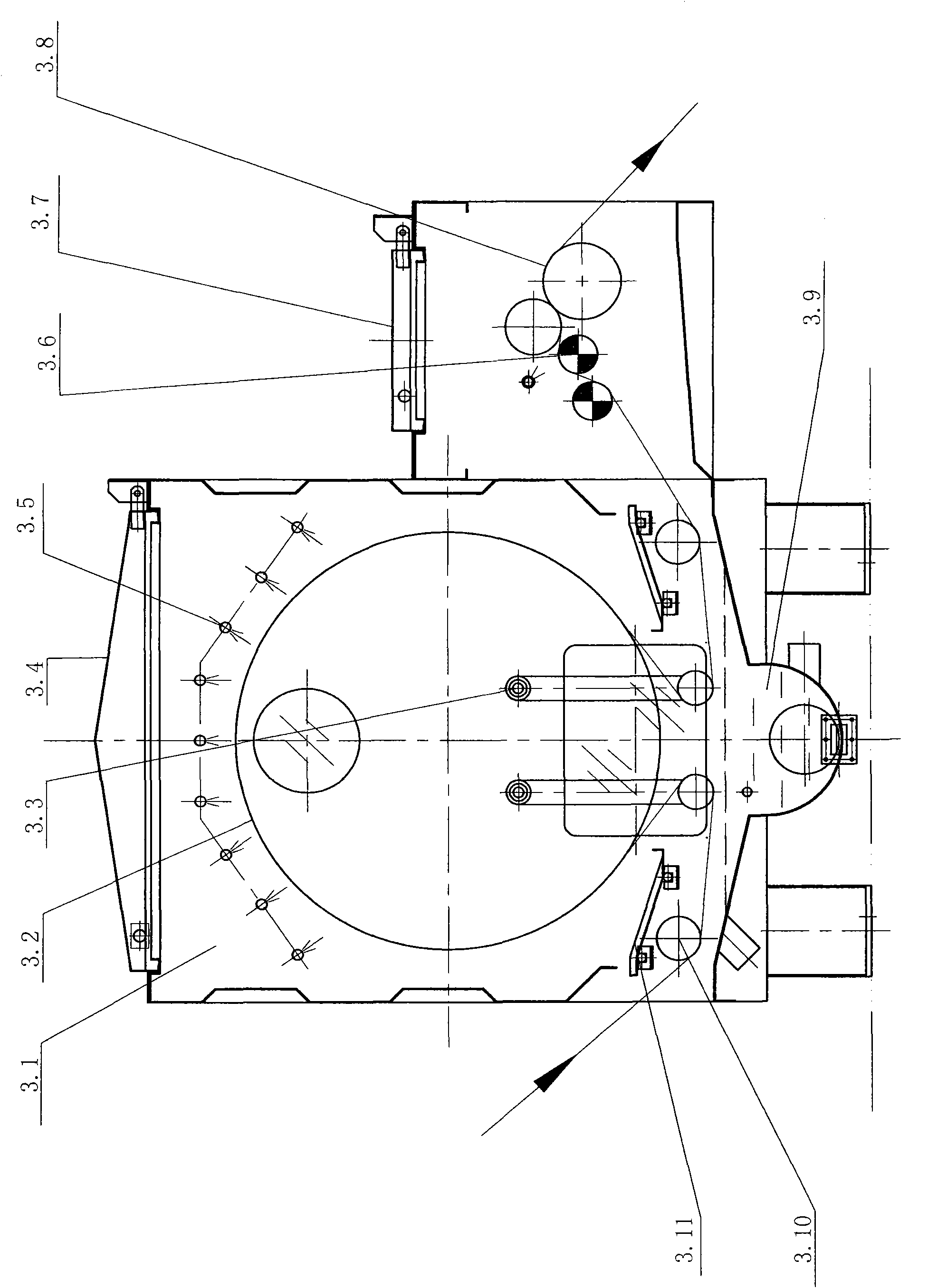

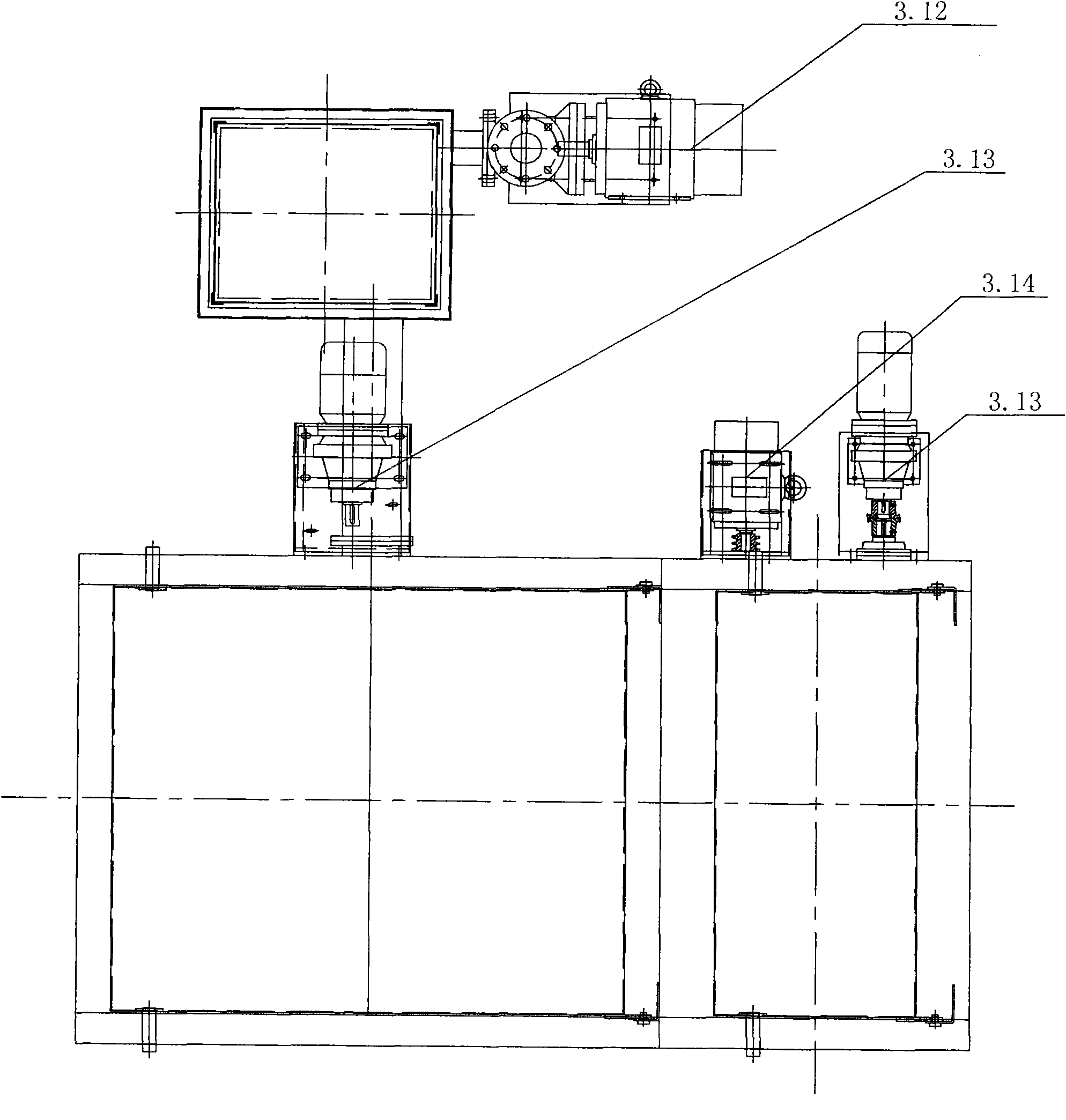

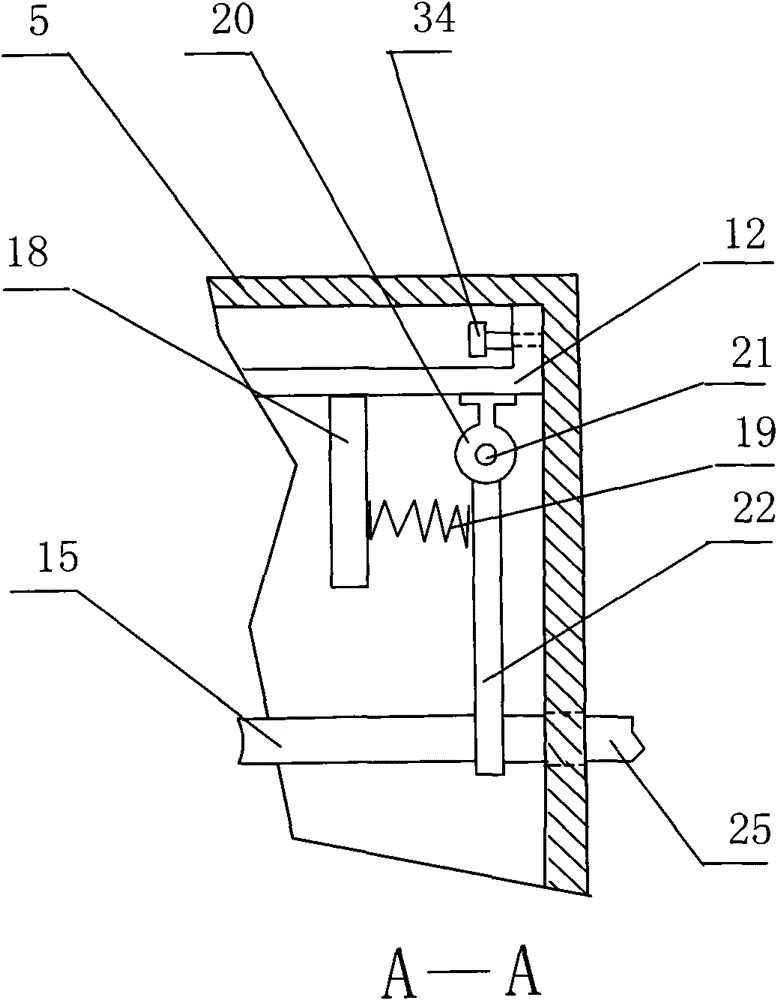

Combination machine for open width oil removal, moist heat relaxation and pre-shrinking water rinse

InactiveCN101575784AReduce tensionRealize low tension cloth transportationSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberWater rinsing

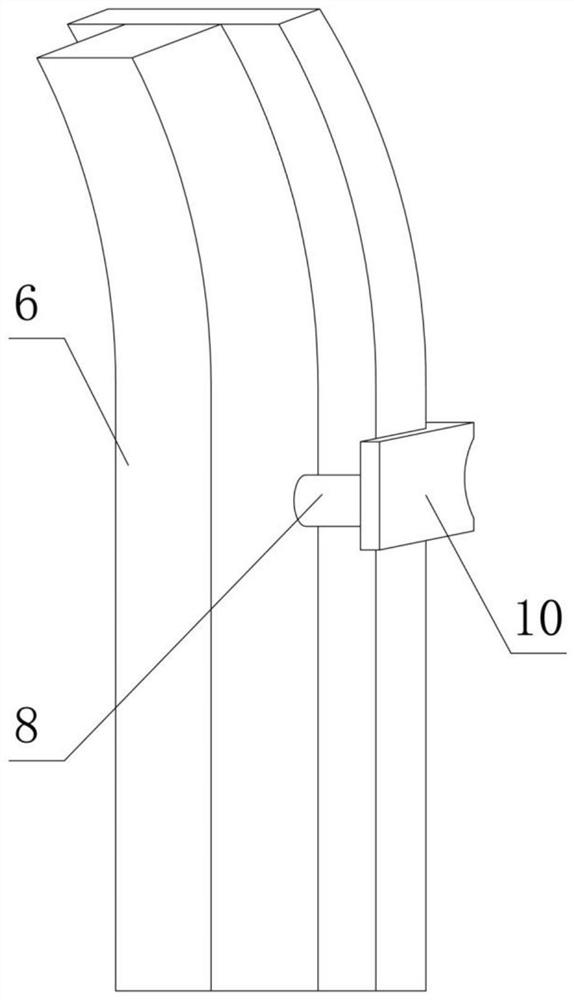

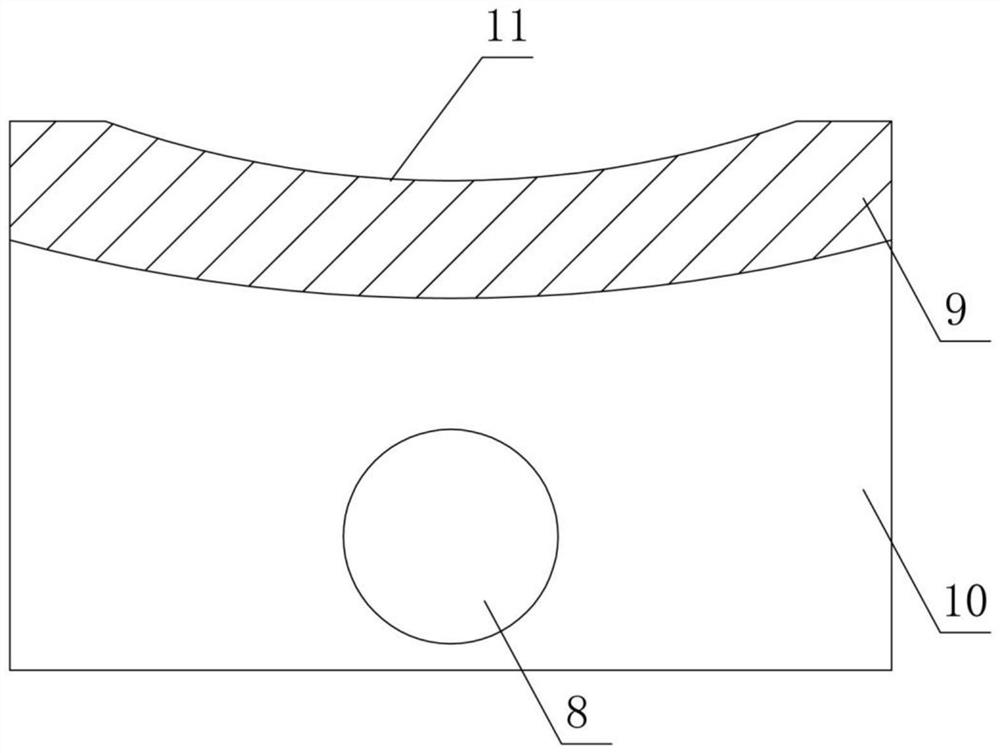

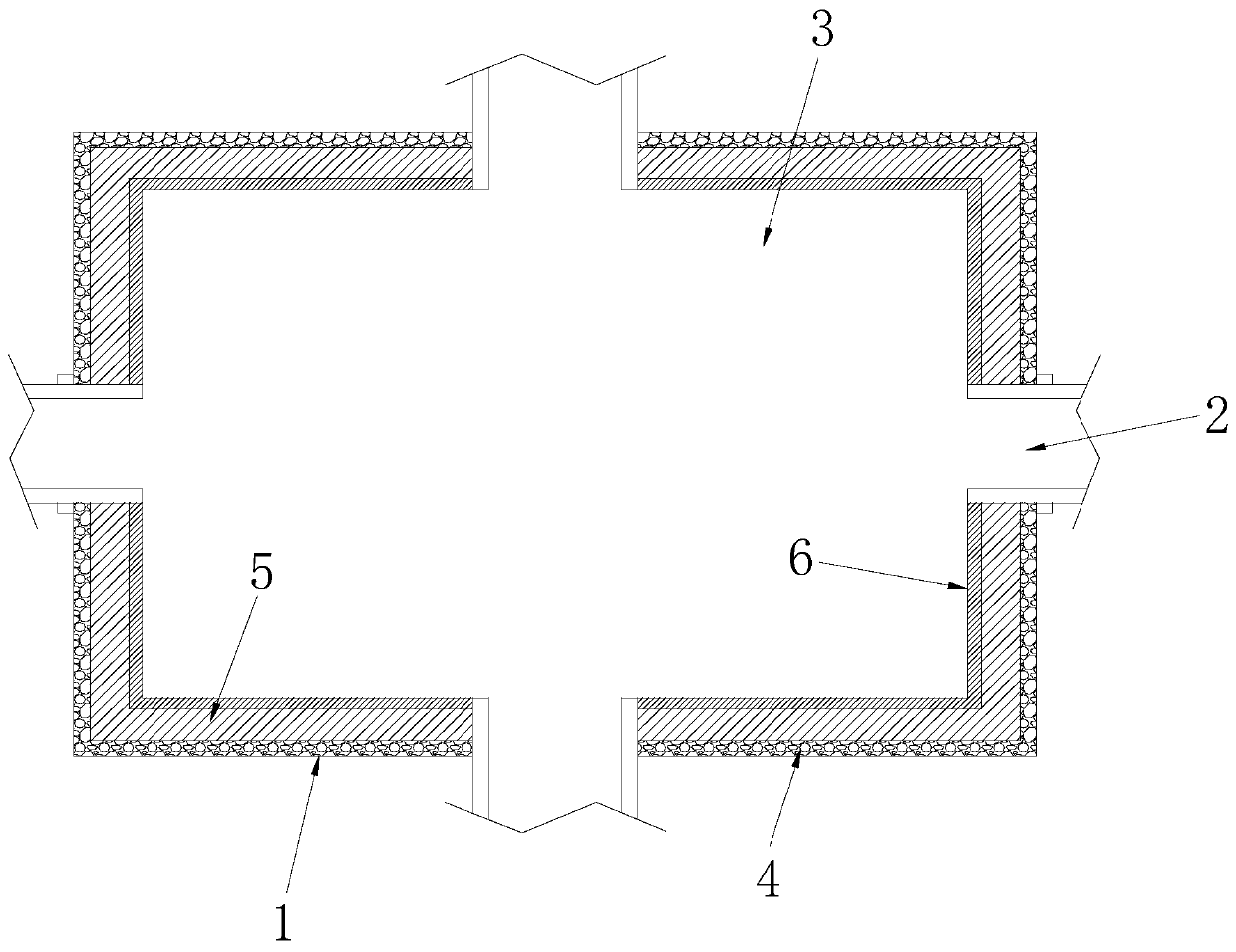

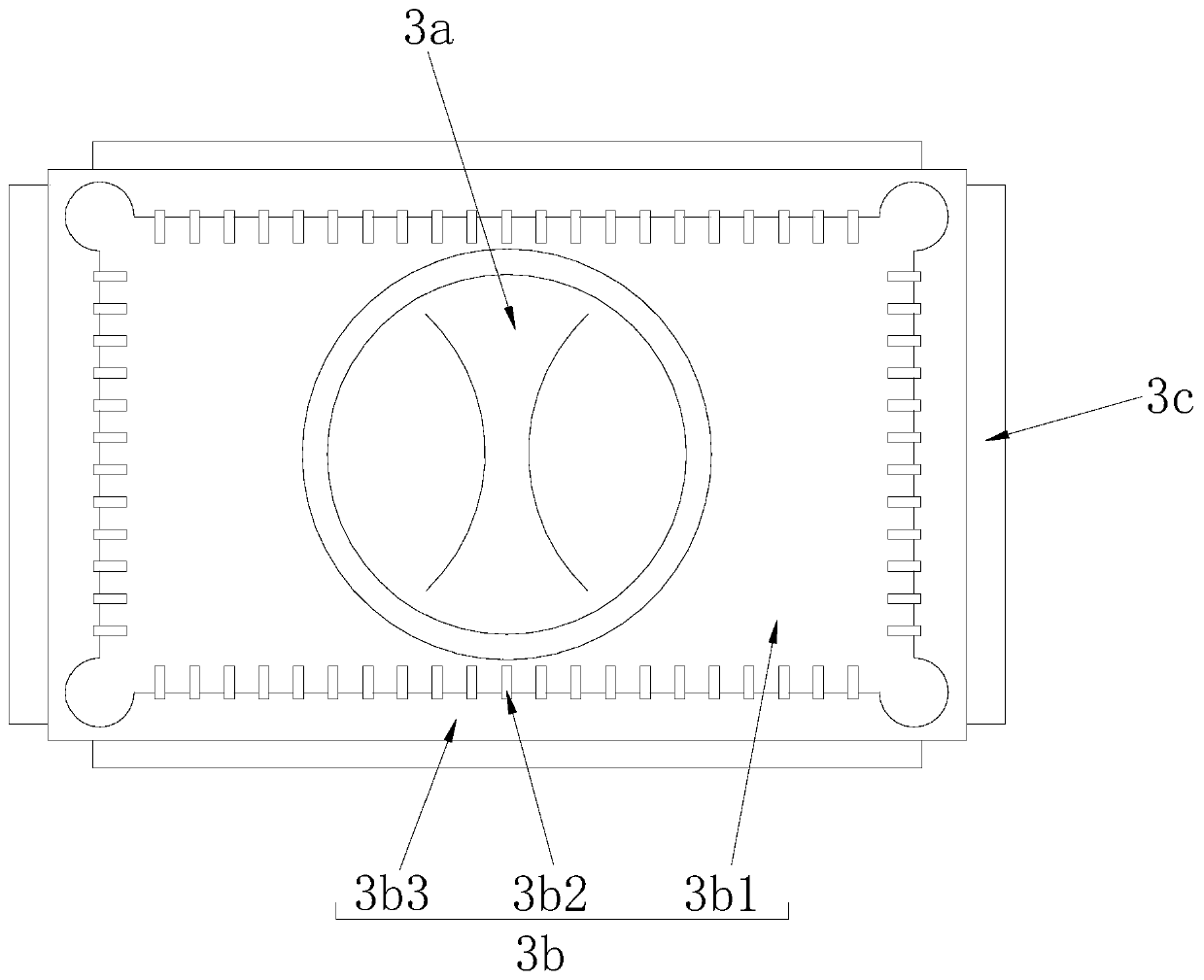

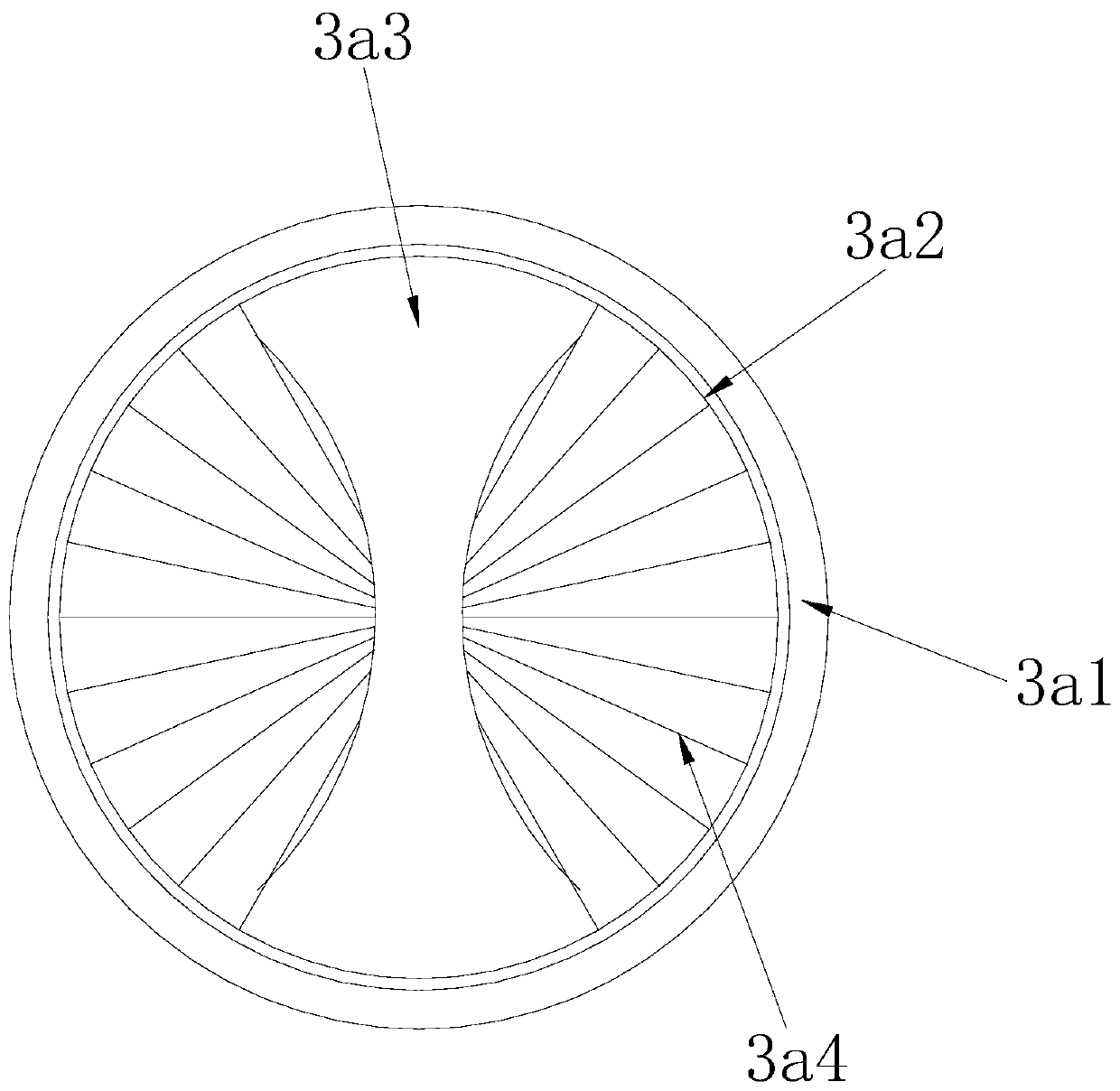

The invention relates to a combination machine for open width oil removal, moist heat relaxation and pre-shrinking water rinse, which is applicable to the open width oil removal, pre-shrinking and refining water rinse processes of knitting, urethane elastic fiber, terylene, chinlon and combined fiber fabrics. The combination machine comprises an open width cloth feeding bracket (1), a double-oscillation water rinse tank (2), single rotating drum rinsing machines (3), a two-roll heavy padder (4) and an open width doffing cloth bracket (5) in turn from the front to back, wherein the number of the single rotating drum rinsing machines (3) is at least two groups, and an internal two-roll padder II (7) is arranged between adjacent two groups of single rotating drum rinsing machines (3). The combination machine is characterized in that: each group of single rotating drum rinsing machine (3) comprises a tank body II (3.1), a sink II (3.9), two guide rails (3.10), two water baffles (3.11), a netlike rotating drum II (3.2), a suspended tensioning rack (3.3) and a spraying pipe II (3.5); and the front of a rolling point of a roller (3.8) of the internal two-roll padder II is provided with positive and negative strippers (3.6). The combination machine can realize low-tension cloth delivery, and efficient cloth spread and edge toggle. Therefore, the combination machine can be applied to the fabrics with large elasticity.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

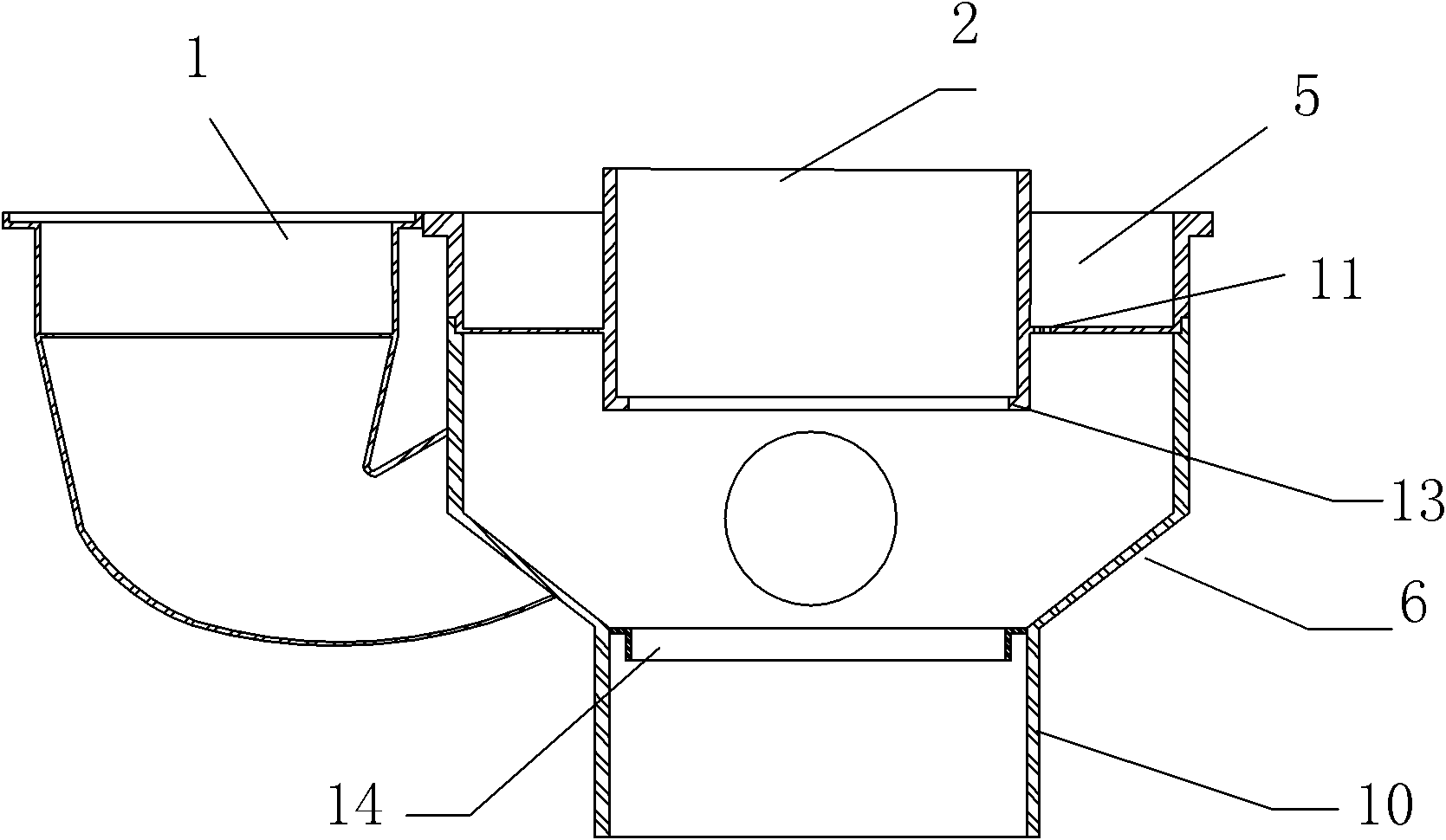

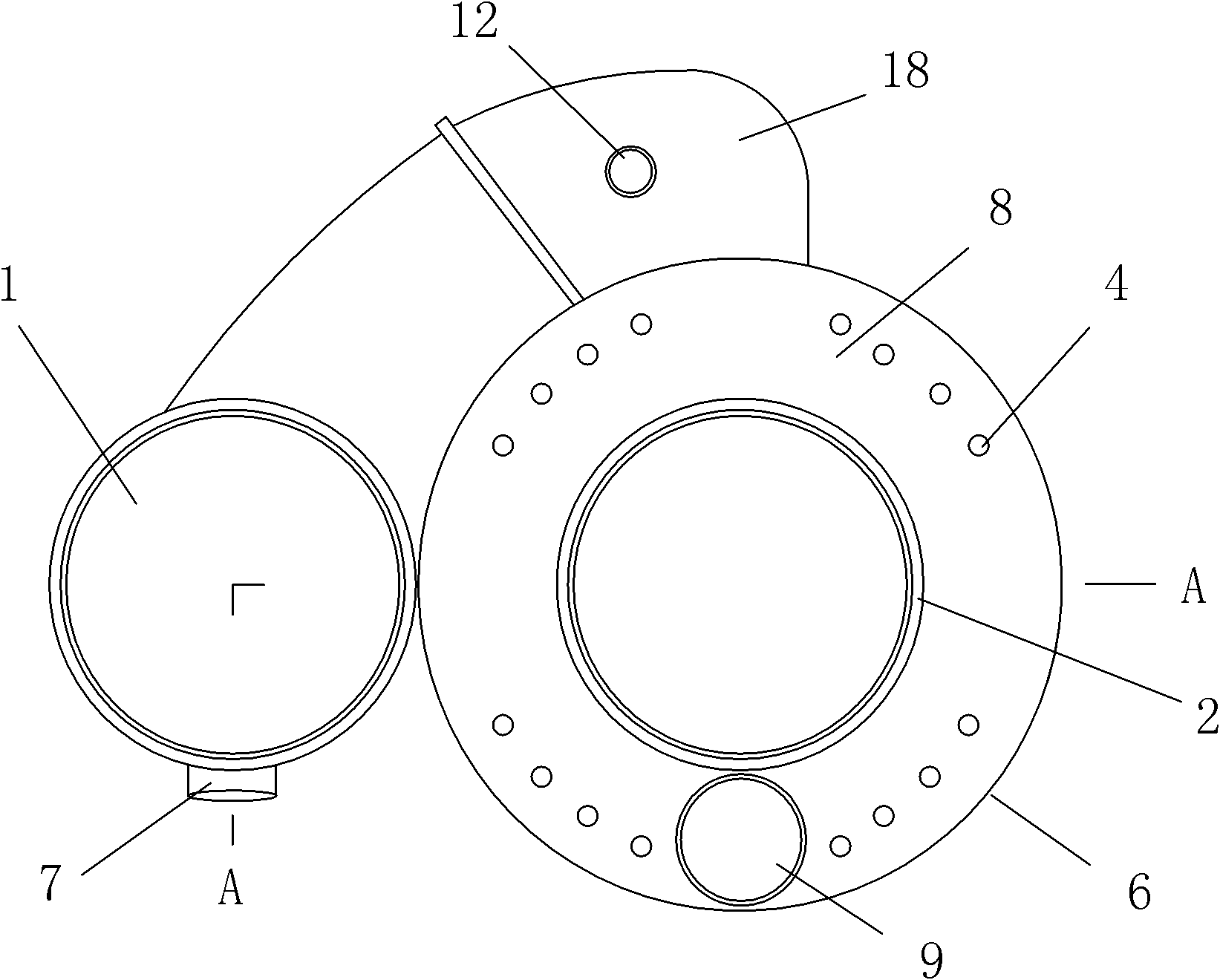

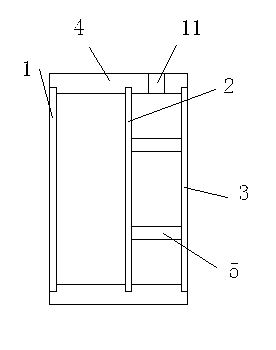

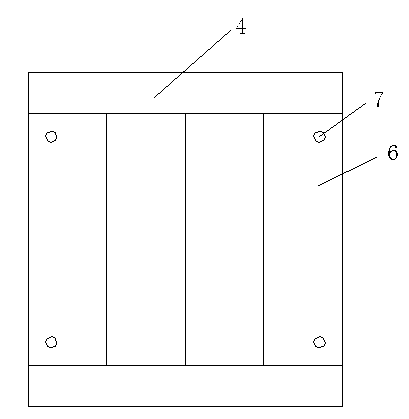

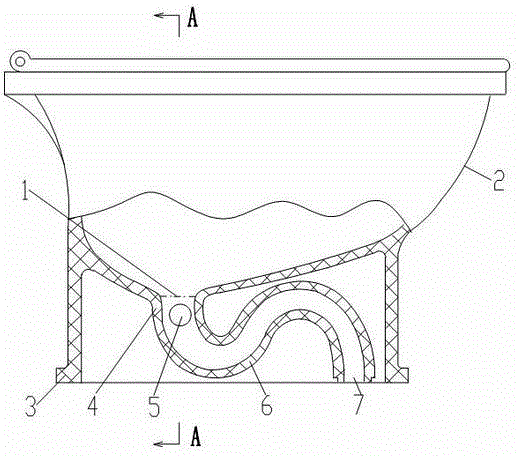

Combined drainage device

The invention discloses a combined drainage device, which comprises a water leakage device (6), wherein the water leakage device (6) is provided with main building siamese and a water collection tank (5); and a drain trap (1) is connected to the water leakage device (6) and is communicated with the main building siamese to form a whole. The combined drainage device is a drainage system, which can integrate the drain traps of a plurality of sanitary fixtures and floor drains in kitchens and toilets into a main water seal device and randomly realize serial connection and parallel connection, and is convenient to arrange and scientific, rational and humanized; positions of the sanitary fixtures, the floor drains and bath facilities in decoration can be randomly determined by users, and are not limited by the positions of the siameses; and the combined drainage device has the characteristics of simple structure, convenient and fast mounting, capability of saving the construction cost of developers, benefits to the state and citizens, low manufacture cost, vast market prospect, and high economic value and application value.

Owner:张超

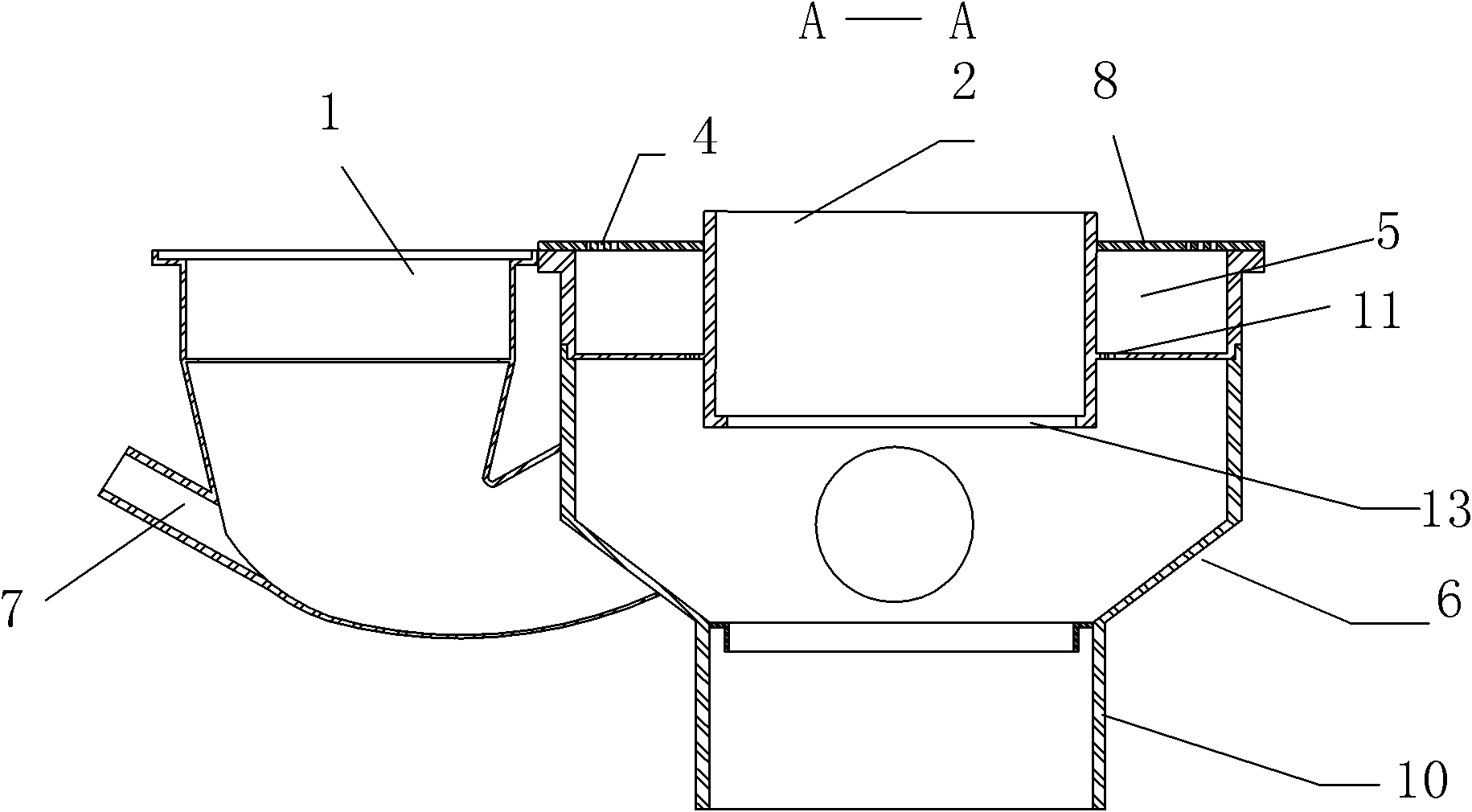

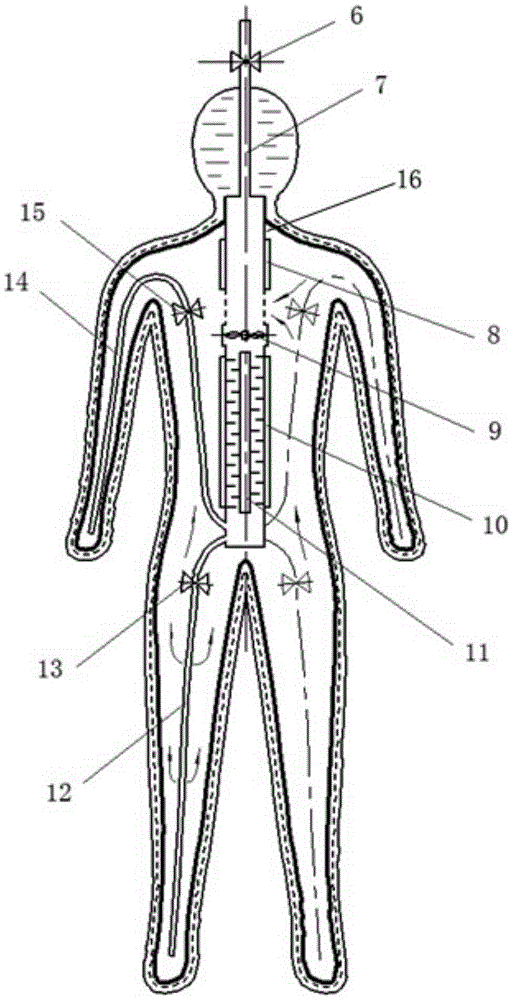

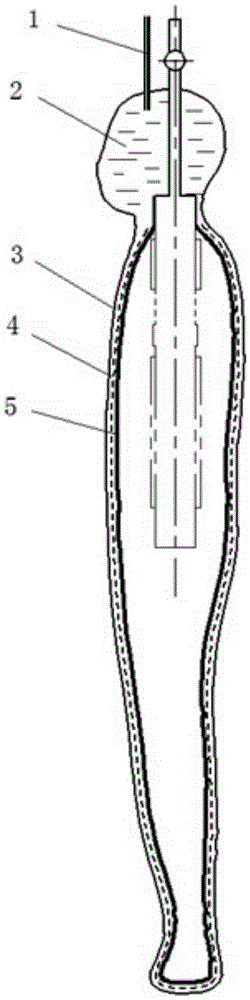

Air-filled sweating thermal manikin

InactiveCN105241914AImprove liquidityBalance resistanceMaterial thermal analysisSurface layerThermal manikin

The invention relates to an air-filled sweating thermal manikin. A surface layer of the manikin is a micro-pore membrane composite fabric sweating skin. A water filling pipe is arranged in a head part. An air-filled rubber liner is arranged inside the surface layer of the manikin and is matched with the micro-pore membrane composite fabric sweating skin with a certain gap formed. In the gap, a water-retention network fabric is arranged. An air heating system and an air recycling system are disposed in the rubber liner so that uniform distribution of temperature in the whole body of the manikin is formed. The air-filled sweating thermal manikin is light in weight, is stable in size, and can ensure uniform sweating in all zones in the whole body.

Owner:DONGHUA UNIV

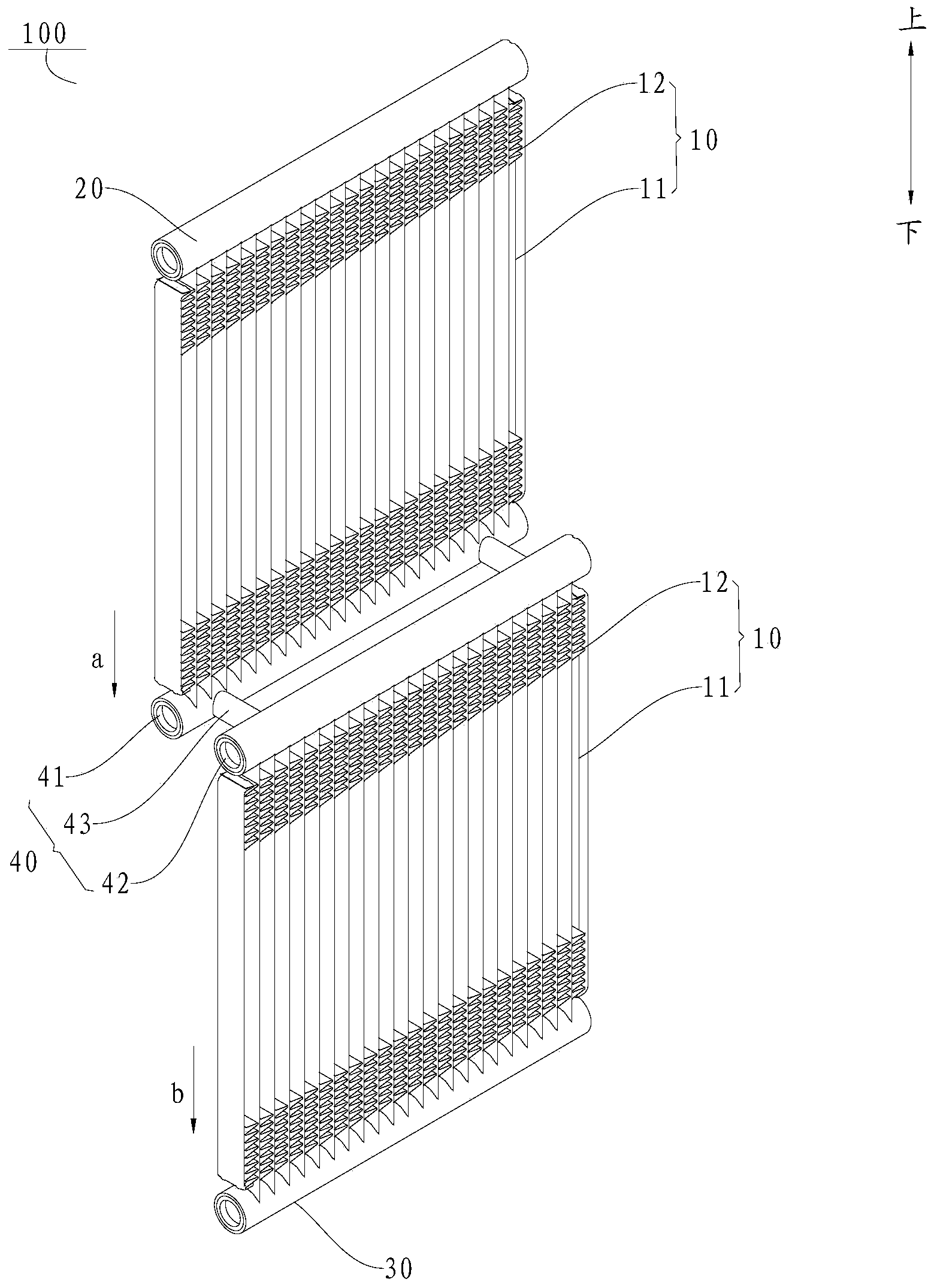

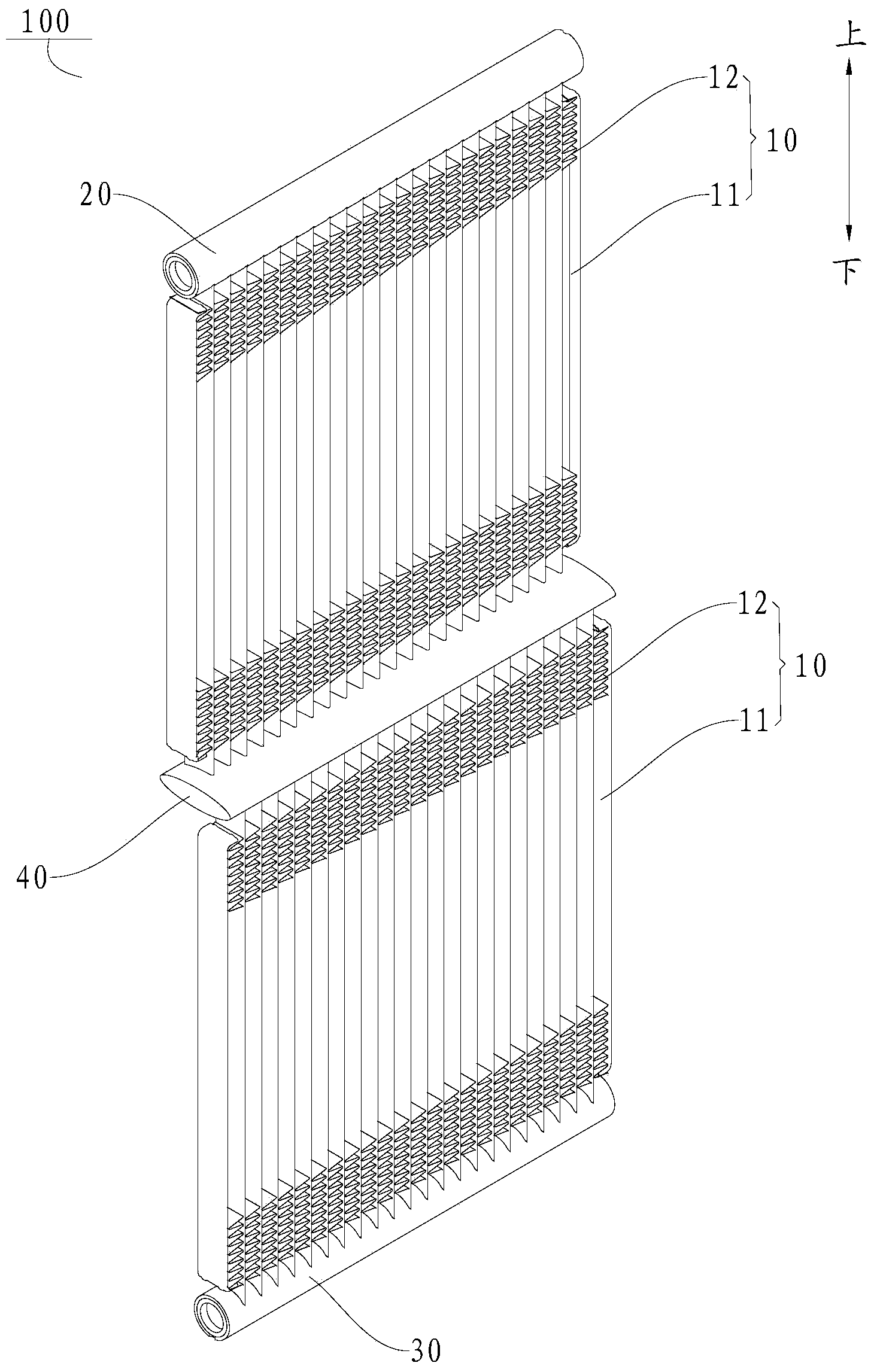

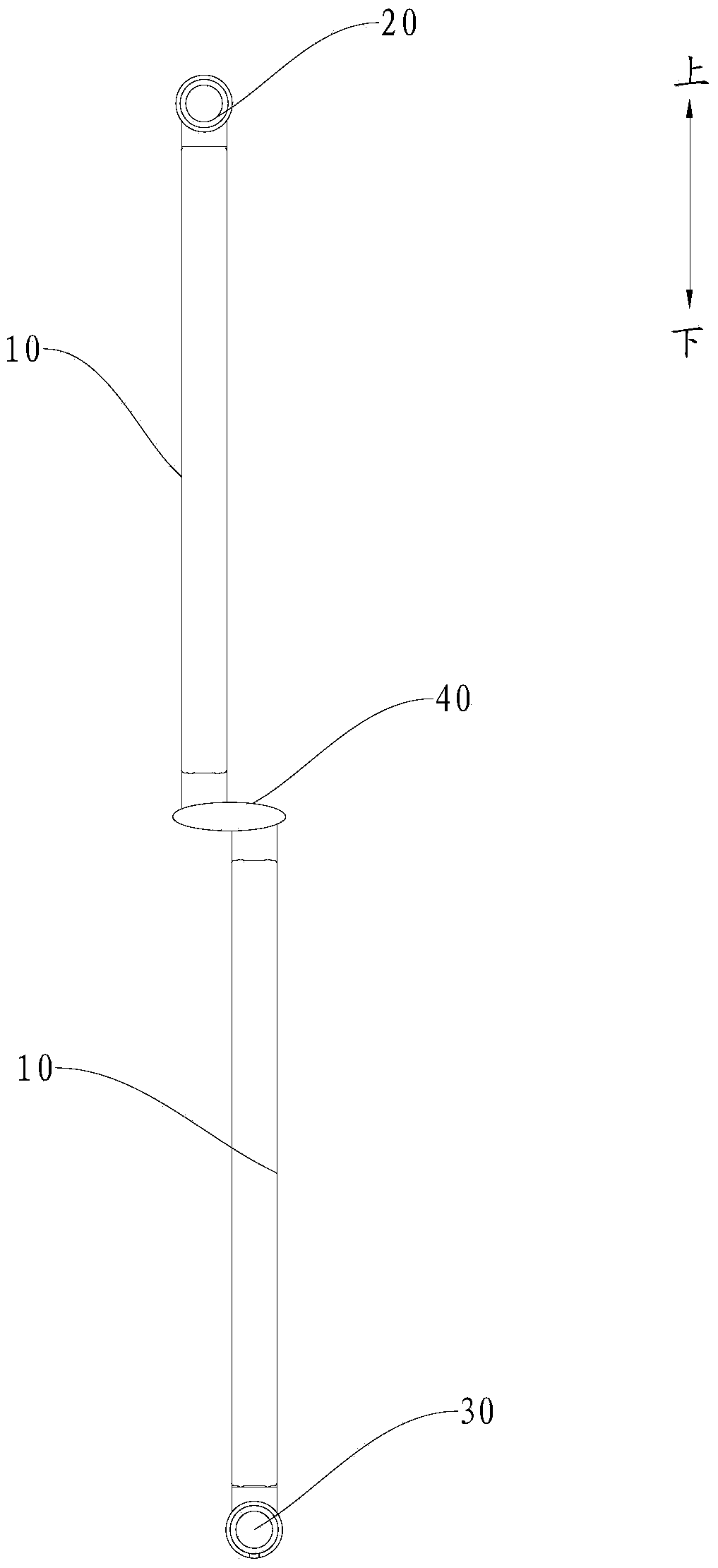

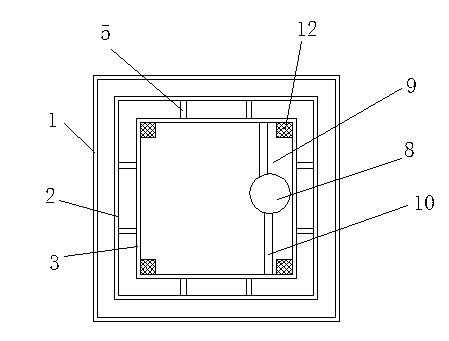

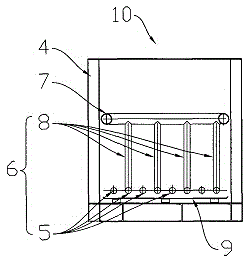

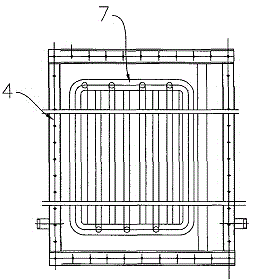

Heat exchanger

ActiveCN104296424AImprove drainage efficiencyReduce frosting speedEvaporators/condensersHigh humidityEngineering

The invention discloses a heat exchanger. The heat exchanger comprises a plurality of heat exchange cores arranged in the vertical direction, a first collecting main, a second collecting main and a communicating piece. A heat exchange pipe of the upper heat exchange core of every two adjacent heat exchange cores is communicated with a heat exchange pipe of the lower heat exchange core through the communicating piece. Every two adjacent heat exchange cores are located in the different planes. Due to the fact that every two adjacent heat exchange cores are located in the different planes, condensate water generated by every two adjacent heat exchange cores flows in the different planes, multiple different drainage paths are provided for drainage of condensate water, the drainage amount borne by each drainage path is greatly reduced, the drainage efficiency of the heat exchanger is improved, the frosting speed of the heat exchanger is effectively reduced under the outdoor low-temperature and high-humidity working condition, the frosting amount is reduced, the refrigeration and heat exchange capacity and the heat exchange performance of the heat exchanger are improved, and energy consumption is reduced.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

Quick-dry phase change waterproof heat insulation coating and preparation method thereof

InactiveCN103113792AImprove insulation effectReduced heat retentionRadiation-absorbing paintsFiberWater requirement

The invention relates to a quick-dry phase change waterproof heat insulation coating and a preparation method thereof. The quick-dry phase change waterproof heat insulation coating is prepared from the following materials by weight percent: 10-50% of styrene acrylate copolymer emulsion, 1-45% of acrylic emulsion, 1-15% of hollow glass microbead composite material, 0.5-10% of perlite composite material, 0.5-8% of kieselguhr composite material, 1-9% of glass fiber, 1-10% of wollastonite fiber, 0.5-5% of titanium dioxide, 5-20% of talcum powder, 0.1-3% of dispersing agent, 0.1-1.0% of antifoaming agent, 0.1-0.5% of antiseptic agent, 0.1-2% of thickening agent and 15-25% of water. The heat insulation property of the coating is superior to that of a traditional heat insulation coating, the complementary function is realized by jointly adding the three composite materials, the workability, plasticity and water requirement of the coating can be adjusted so as to meet the application performance requirement under different temperatures and different occasions, and the production cost can be lowered.

Owner:北京立高科技股份有限公司

Novel heat preservation board room

InactiveCN102704708AImprove heating efficiencyWith characteristicsLighting and heating apparatusWallsBrickEngineering

The invention provides a technical scheme of a novel heat preservation board room. According to the scheme, the novel heat preservation board room comprises a steel structural framework and is characterized in that a wall is fixed on the steel structural framework, and the wall is a heat preservation wall; and the heat preservation wall is fixed on the steel structural framework through connecting holes. According to the scheme, the heat preservation wall is used for replacing the conventional brick wall, and an outer heat preservation material and inner water are connected to a boiler through a water outlet pipe and a water inlet pipe, so that circular heating is realized, heat loss caused by poor heat preservation effect of the wall can be effectively avoided, and energy consumption and cost required for heating are reduced.

Owner:王麦田

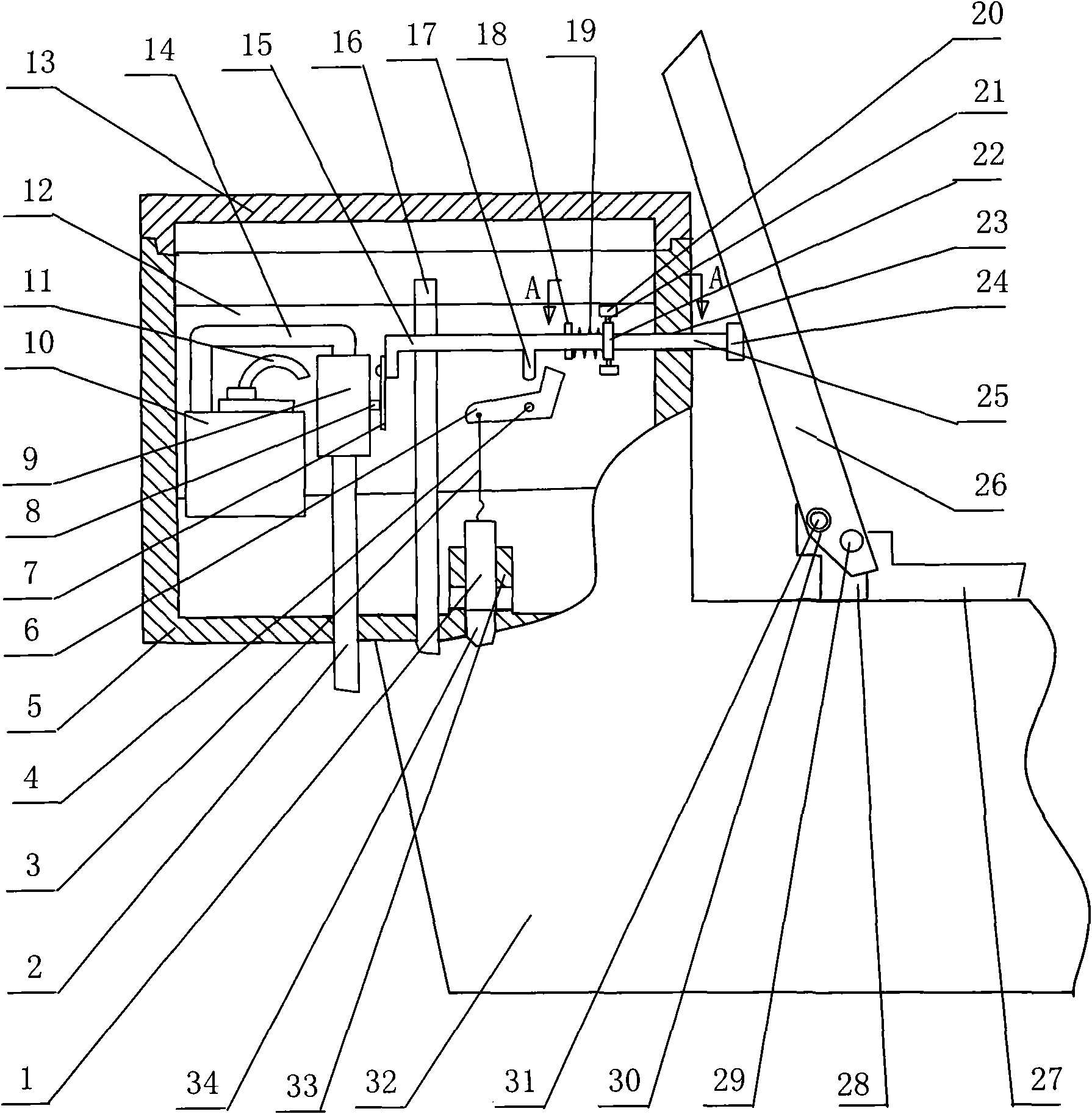

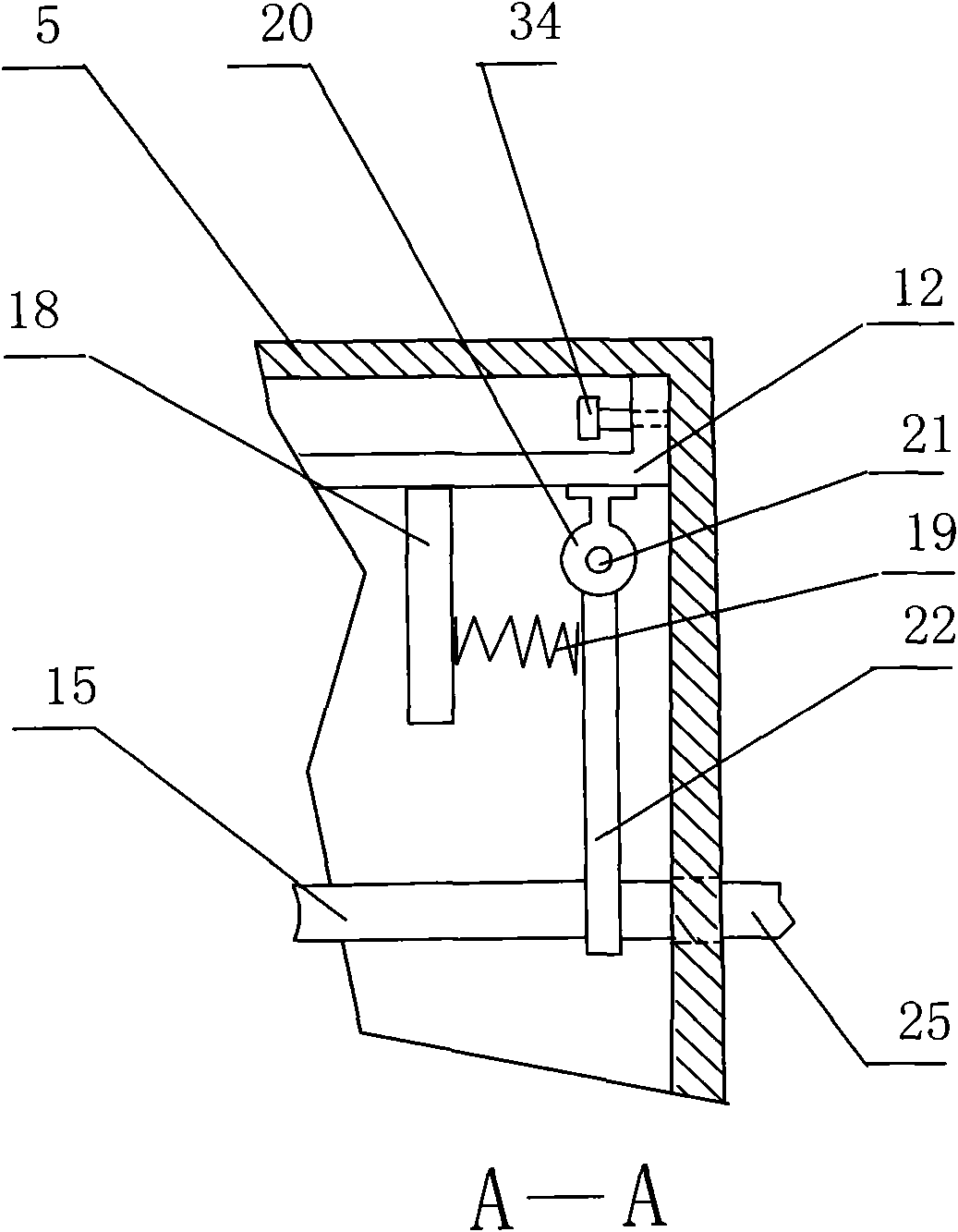

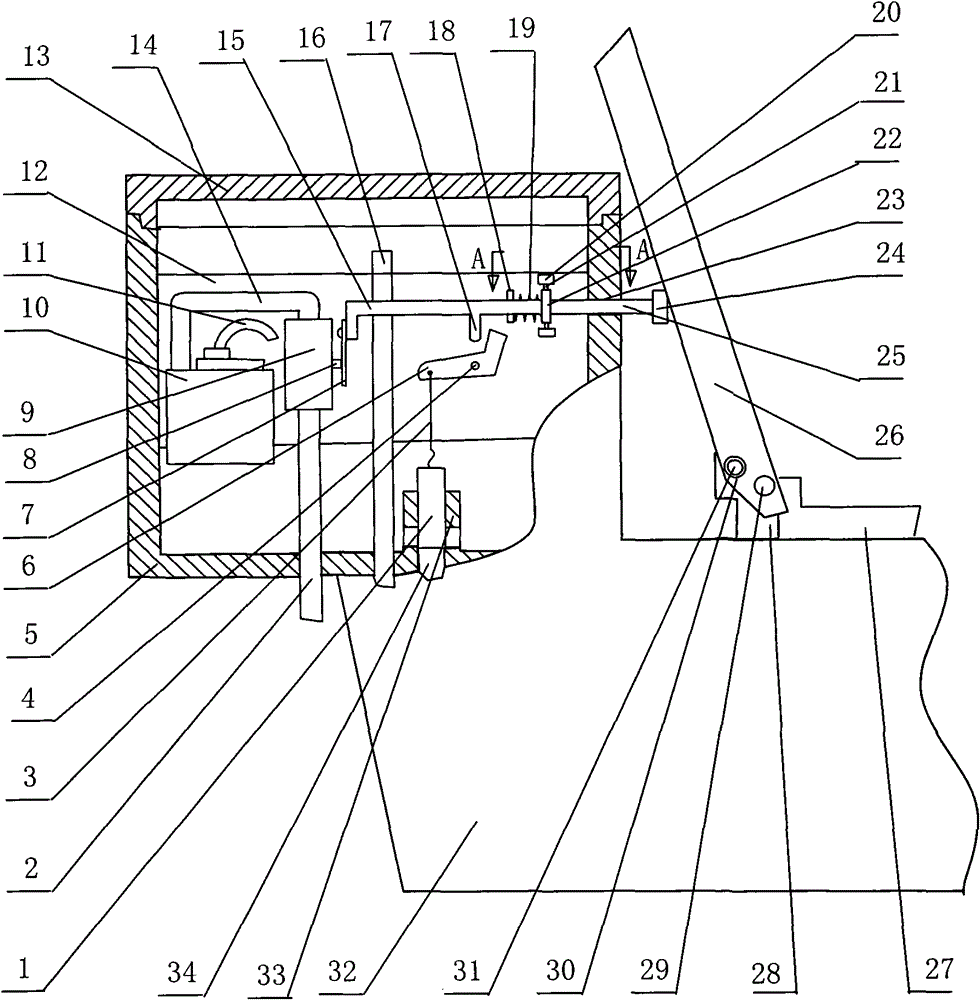

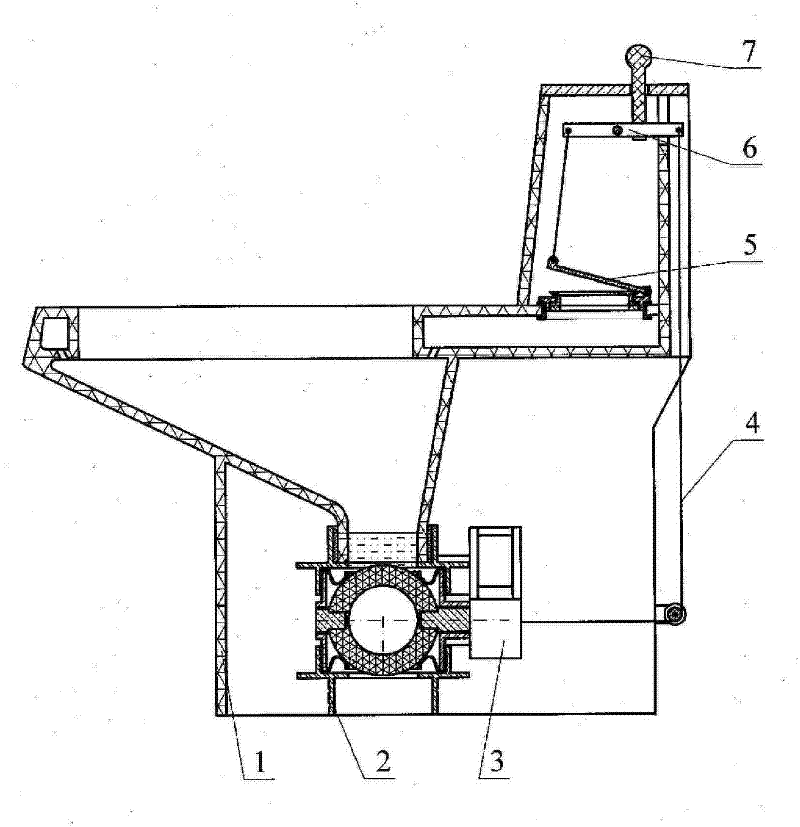

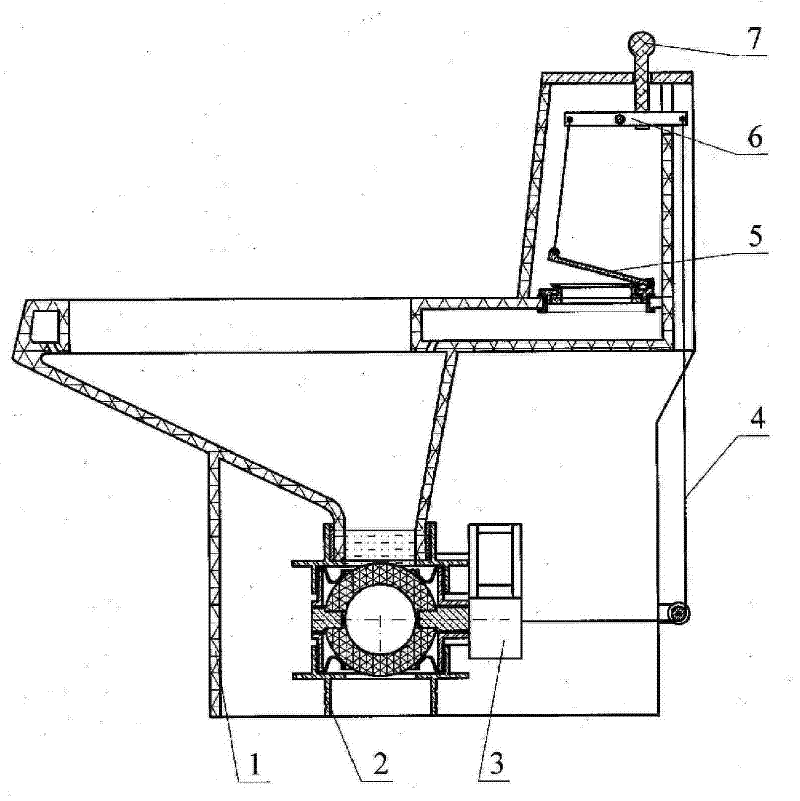

Method capable of reducing water leakage of water closet

The invention discloses a method capable of reducing water leakage of a water closet. A micro water inlet valve for allowing water to enter a buoyancy valve and a rotating shaft sleeve are arranged in a water tank; a rotating shaft is arranged in the rotating shaft sleeve; a rotating rod acted by spring force is fixedly connected on the rotating shaft; a working rod capable of pushing the contact of the micro water inlet valve and a flashing valve line lifter is fixed on one side of the rotating rod, and a push rod is fixed on the other side of the rotating rod; an interactive force is generated between the push rod and a water closet cover leaning against the side of the tank, and the interactive force can overcome the spring force of the push rod and drives the working rod so that the micro water inlet valve is opened and the flushing valve is in a closed state after the pull line of the flushing valve is loosened; and when the water closet cover is covered, the spring force of the rotating rod recovers stretching, the push rod lifts the pull line connected with a flushing valve post on the flashing valve line lifter, the flushing valve finishes flushing, the push rod is separated from the contact of the micro water inlet valve, the micro water inlet valve stops water feed, and the water tank cannot be fed with water before the cover is lifted again. Because the water feeding time is extremely short, the water leakage is only in the toilet using time of water flow.

Owner:扬中市检验检测中心

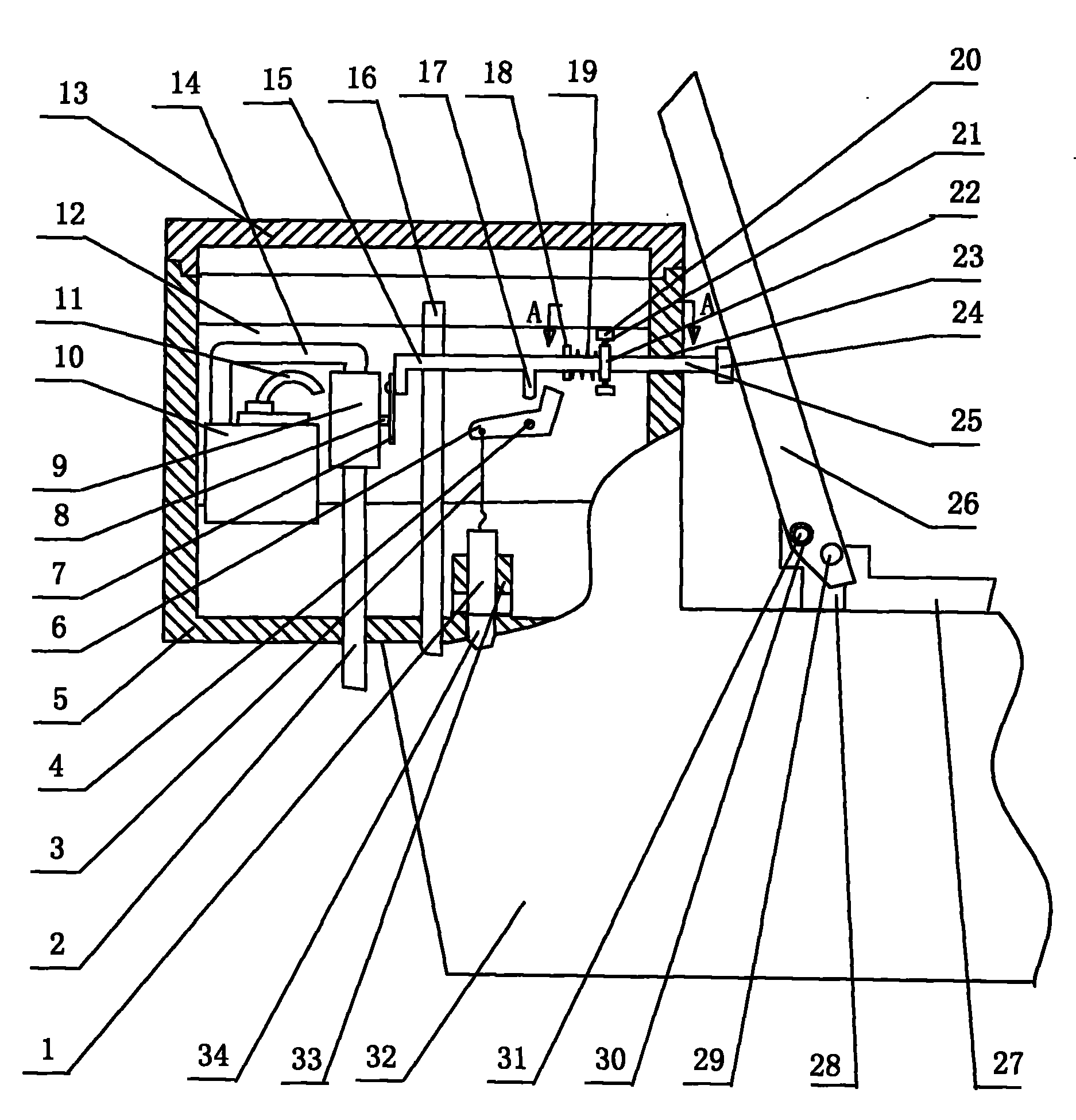

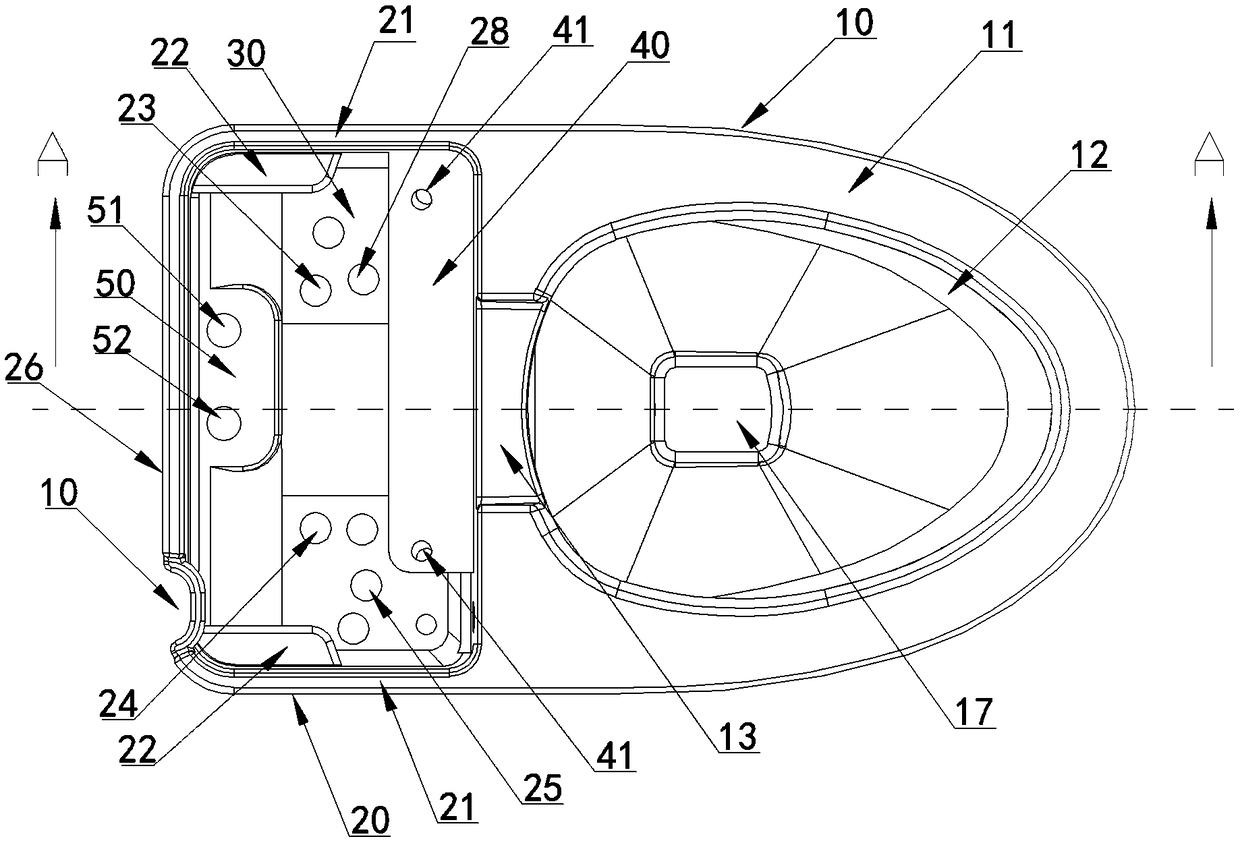

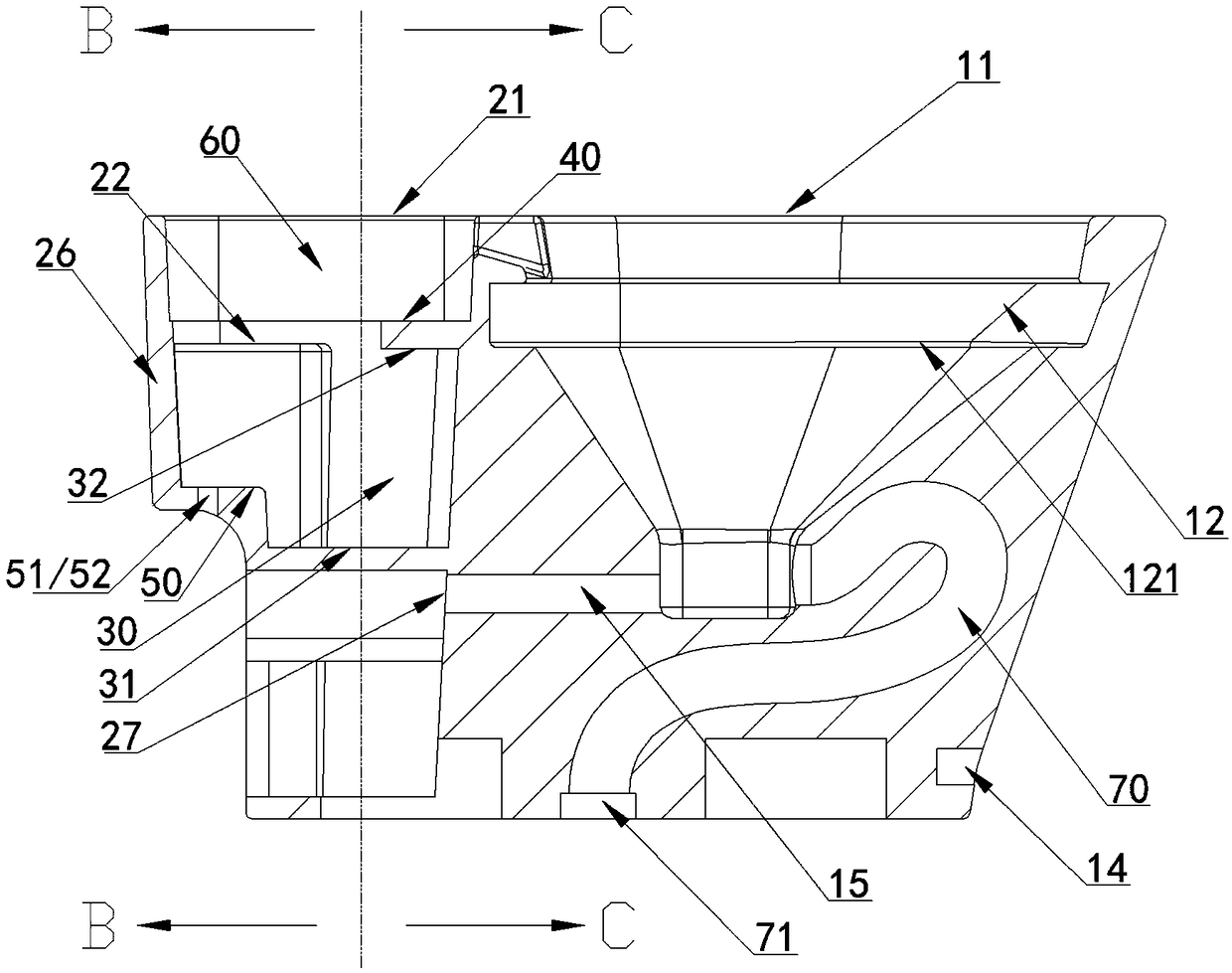

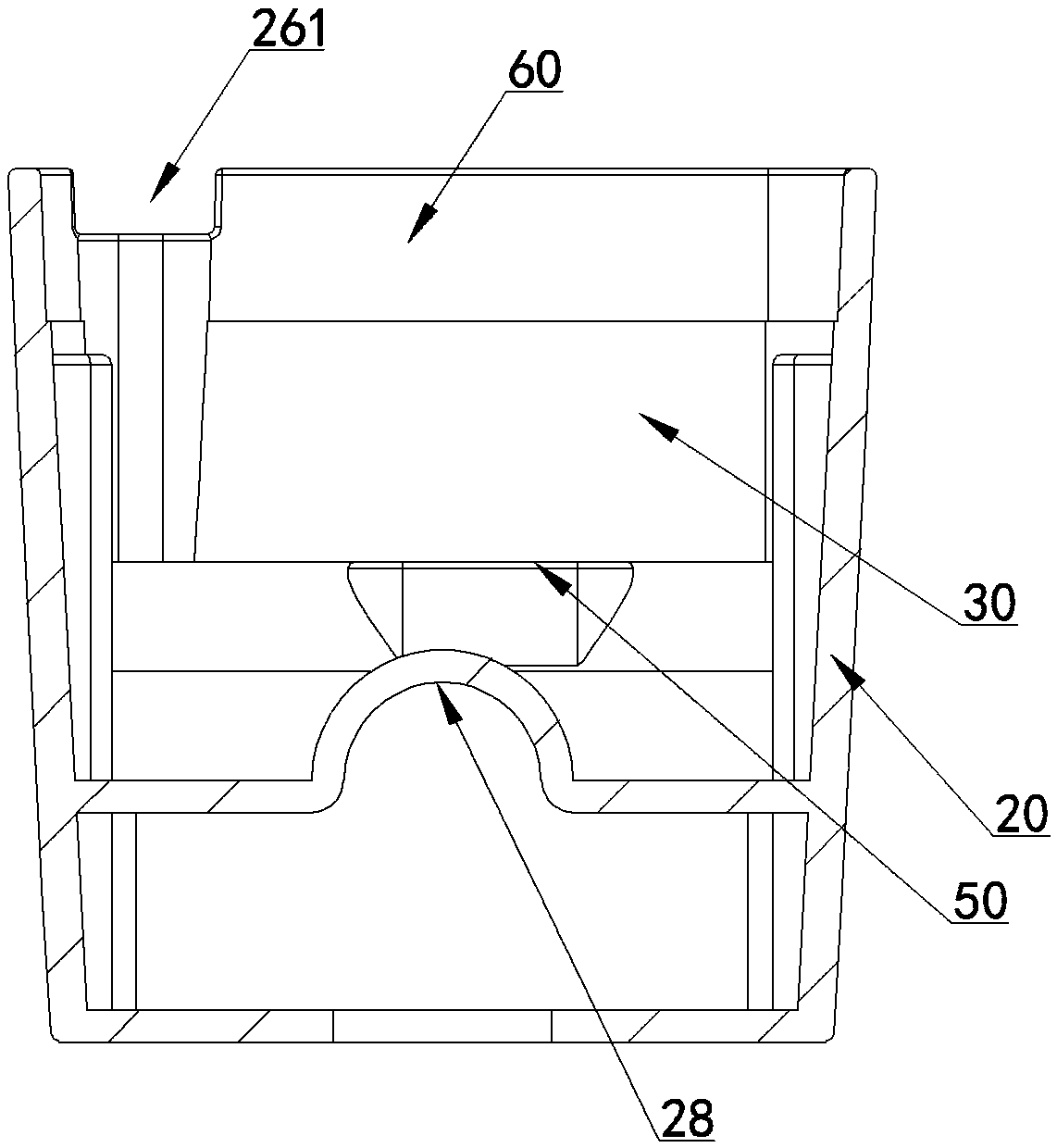

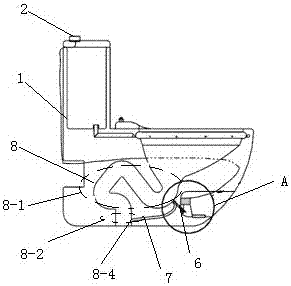

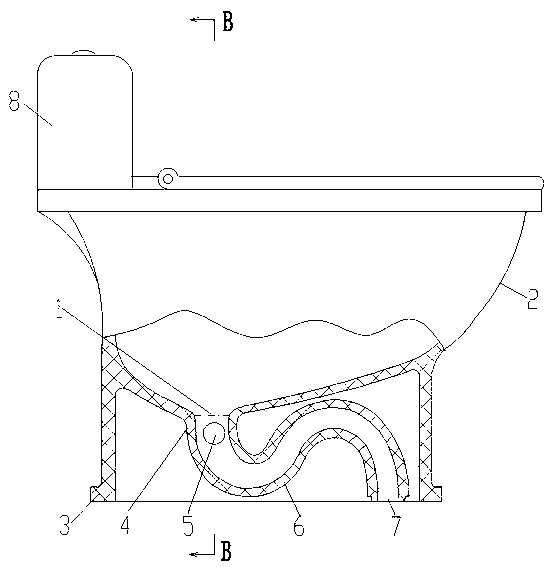

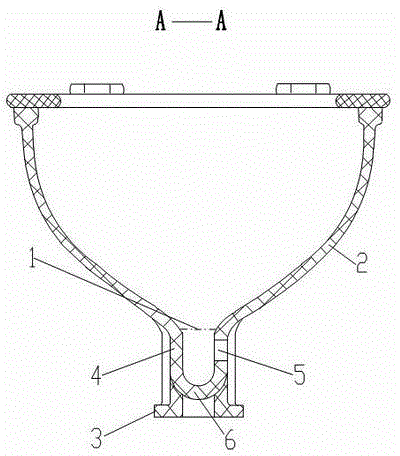

Intelligent closestool ceramic main body structure with sunken water tank

PendingCN109487873AReasonable layoutImprove the sense of layoutUrinalsWater closetsWater storageMetallurgy

The invention discloses an intelligent closestool ceramic main body structure with a sunken water tank. The structure comprises a ceramic main body. The rear end surface of the ceramic main body is lower than or is flush with the upper end surface of the ceramic front end for mounting and supporting a seat. A water storage flushing water tank is arranged below the top surface of the rear end of the ceramic main body, and the water storage flushing water tank is of a built-in sunken flushing water tank structure at the rear end of the ceramic main body. The ceramic main body is more reasonablein layout and convenient to use, avoids use inconvenience and embarrassment caused by insufficient water pressure, and saves the total water usage per flushing. People can better utilize the limited height space above the water storage flushing water tank fully and conveniently, the grade of the overall layout of a bathroom can be improved, and the consumer demand is improved in the product market.

Owner:温岭琅优电子科技有限公司

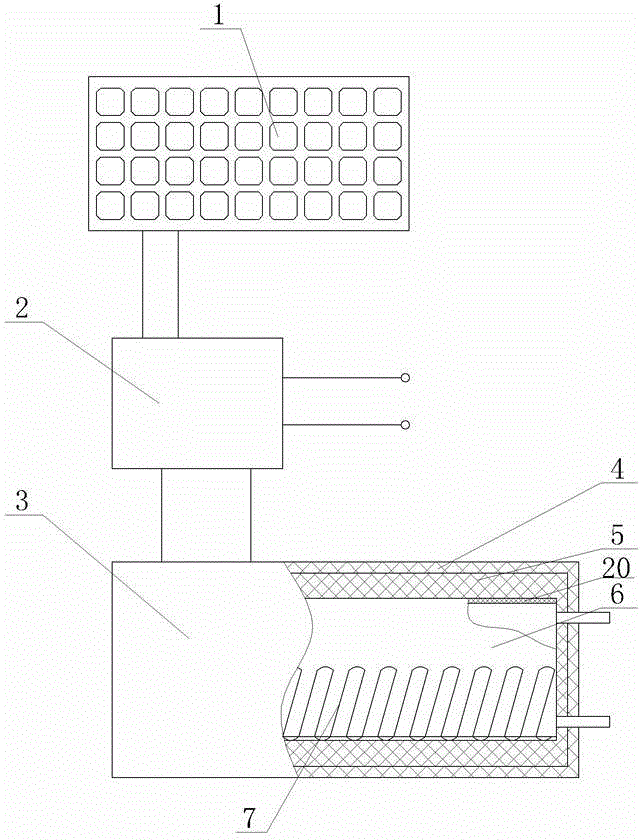

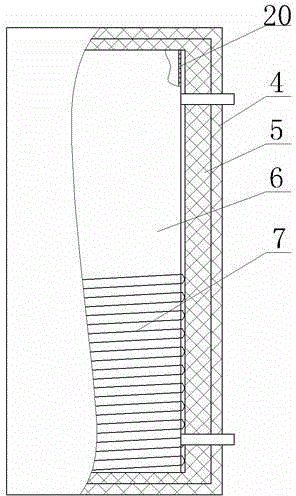

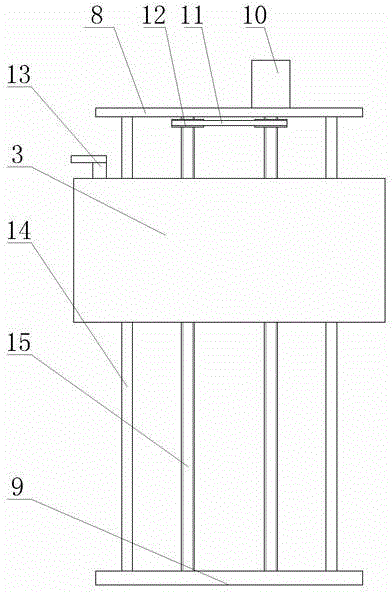

Photovoltaic solar direct-supply carbon fiber water heater

InactiveCN105318527AReduce water storageProtection from Lightning Strike SituationsWater heatersFiberCarbon fibers

Disclosed is a photovoltaic solar direct-supply carbon fiber water heater. The photovoltaic solar direct-supply carbon fiber water heater is characterized in that the water heater comprises a solar cell panel, an electric conversion device and a water heater body; the electric conversion device is composed of an alternating-current transformer and a voltage converter, the solar cell panel is connected with the electric conversion device through an output line, and the electric conversion device is connected with the water heater body through a wire; the water heater body comprises an outer shell, an inner container is arranged in the outer shell, and carbon fiber heating wires are wound on the lower half portion of the periphery of the inner container and are connected with the electric conversion device. According to the photovoltaic solar direct-supply carbon fiber water heater, the solar cell panel is in a wall-hanging type and is directly mounted on the apricus side of a building, and due to the fact that the solar cell panel is located at a low position, effective lightning protection can be achieved; heated water flows out of the water heater body directly, the flowing-out water is hot water and can be used directly, the waste phenomenon of discharging cold water is avoided, and water can be effectively saved; no pipeline exists outside, and the phenomenon of water leakage can be avoided.

Owner:林忠

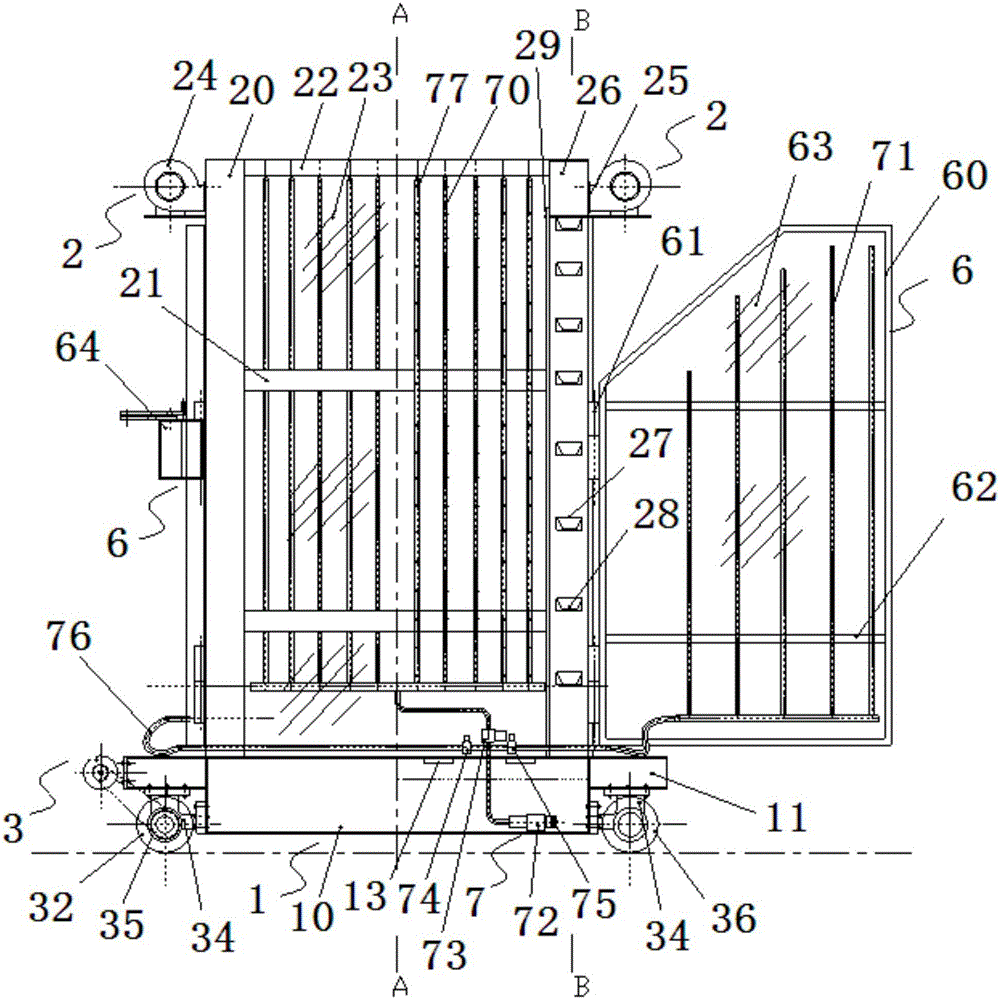

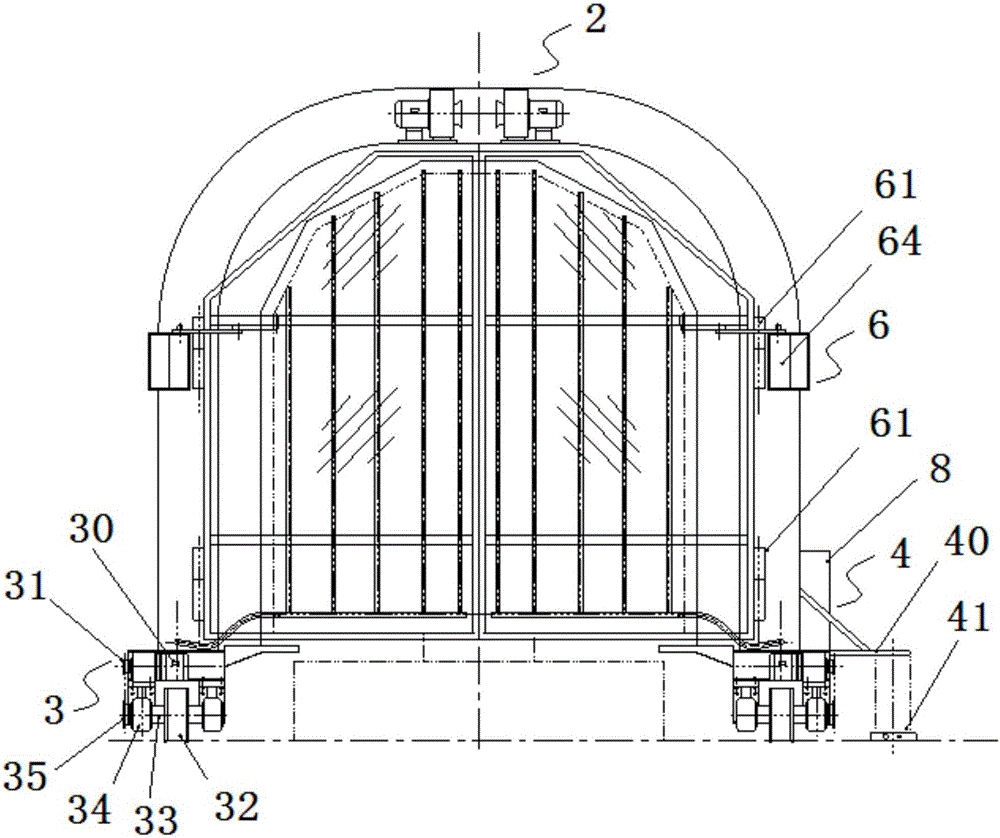

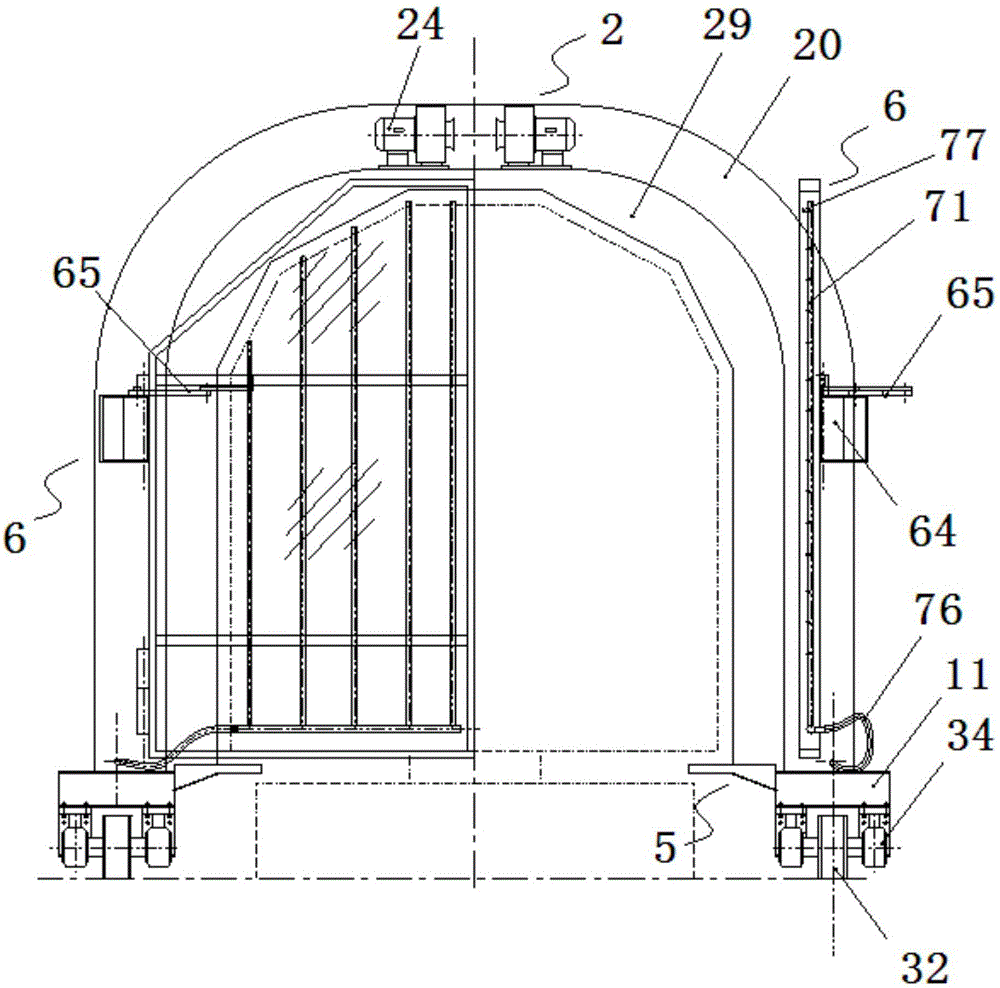

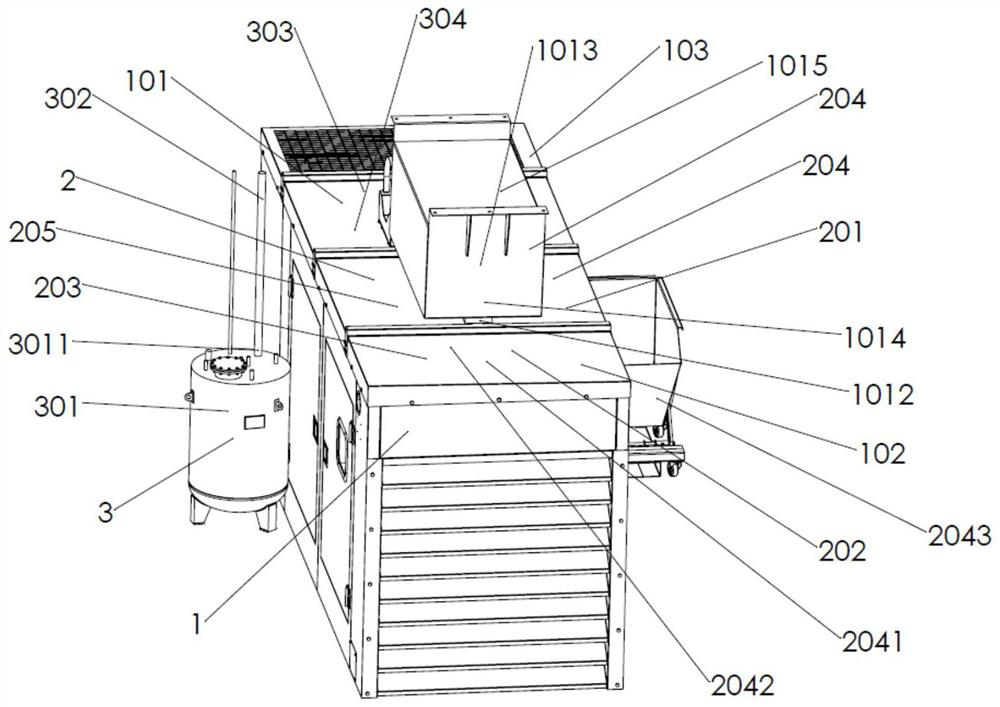

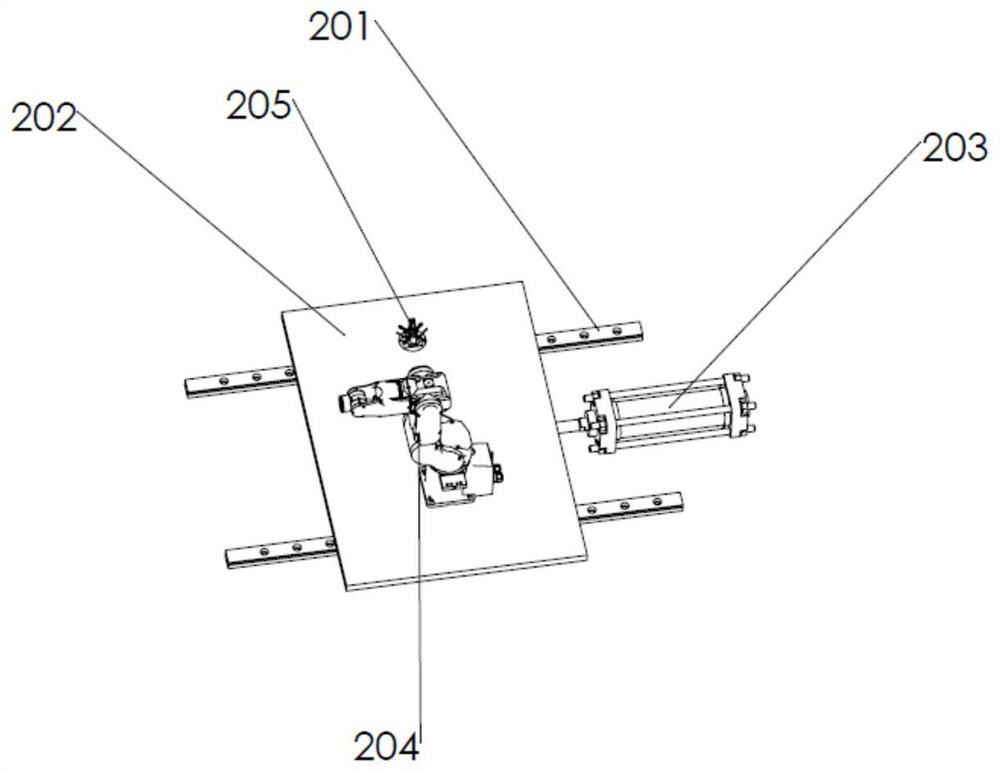

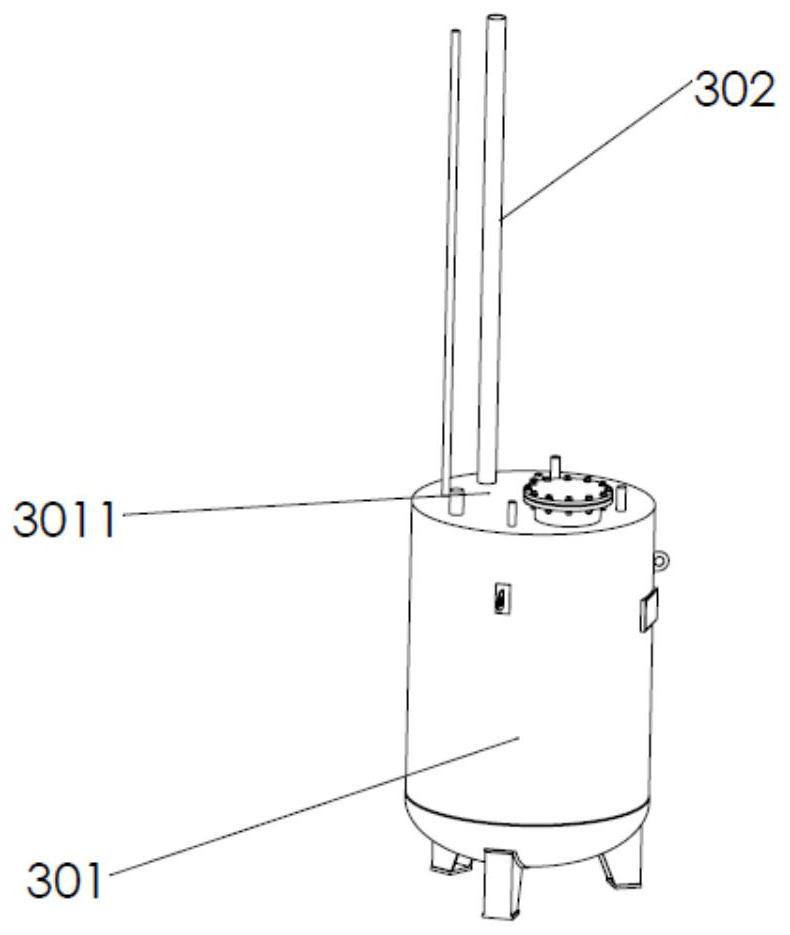

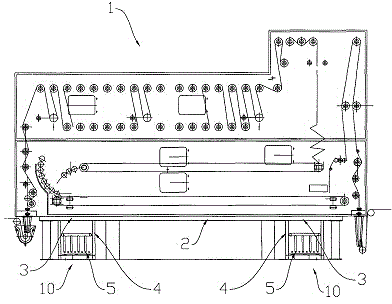

Railway freight car mobile leakage test apparatus

ActiveCN105157926ALow costEasy to installRailway vehicle testingFluid-tightness measurement using fluid/vacuumThermal sprayingWater source

The invention relates to a railway freight car mobile leakage test apparatus, which comprises a two-box-shaped bottom beam that is set symmetrical; the upper part of each box-shaped bottom beam is respectively connected with one end of a tunnel-shaped framework body and an air blow-dry system fixedly; the lower part of the two-box-shaped bottom beam is connected with a wheel and a traction mechanism fixedly; one side of one-box-shaped bottom beam is provided with a tow chain system for power supply and water supply outside; the inner side of the two-box-shaped bottom beam is provided with a set of water reclamation pallet respectively; a set of double door mechanism is respectively set on the two ends of the tunnel-shaped framework body and the air blow-dry system fixedly; a set of water spray exhaust system is respectively set on the two ends of the tunnel-shaped framework body and the air blow-dry system; and an electric appliance control system is used to control the parts above work. According to the invention, water can be recycled to reuse; hydrops can be blown dry quickly; occupation of work space in the workshop is small; and the apparatus can be widely used in railway freight car body leakage (water spraying, watering) tests.

Owner:CRRC QIQIHAR ROLLING CO LTD

A kind of anti-adhesive slag spray coating for iron cladding and its application method

The invention provides an anti-stick slag spray coating for iron clad, which comprises the following components by weight: 70-80% of aggregate, 16-25% of binder, 1-10% of anti-stick slag functional additive, and external additives 0.01-1%, the binder is a composite binder, including microsilica, Portland cement, water glass powder and bentonite. When using, firstly prepare the mixture according to the above weight ratio, secondly add water with a weight ratio of 5 to 8% of the mixture under strong stirring, and finally spray it onto the iron-clad anti-sticking slag position through a spray gun. Compared with the prior art, the anti-stick slag spray coating for iron ladle proposed by the present invention has high strength, good anti-slag effect, strong slag erosion resistance and oxidation resistance, and good thermal shock resistance. The use of waste skateboard recycled material as the main component of the aggregate of the anti-stick slag spray coating greatly reduces the production cost of the anti-stick slag spray coating, and the comprehensive benefit is high.

Owner:北京利尔高温材料股份有限公司

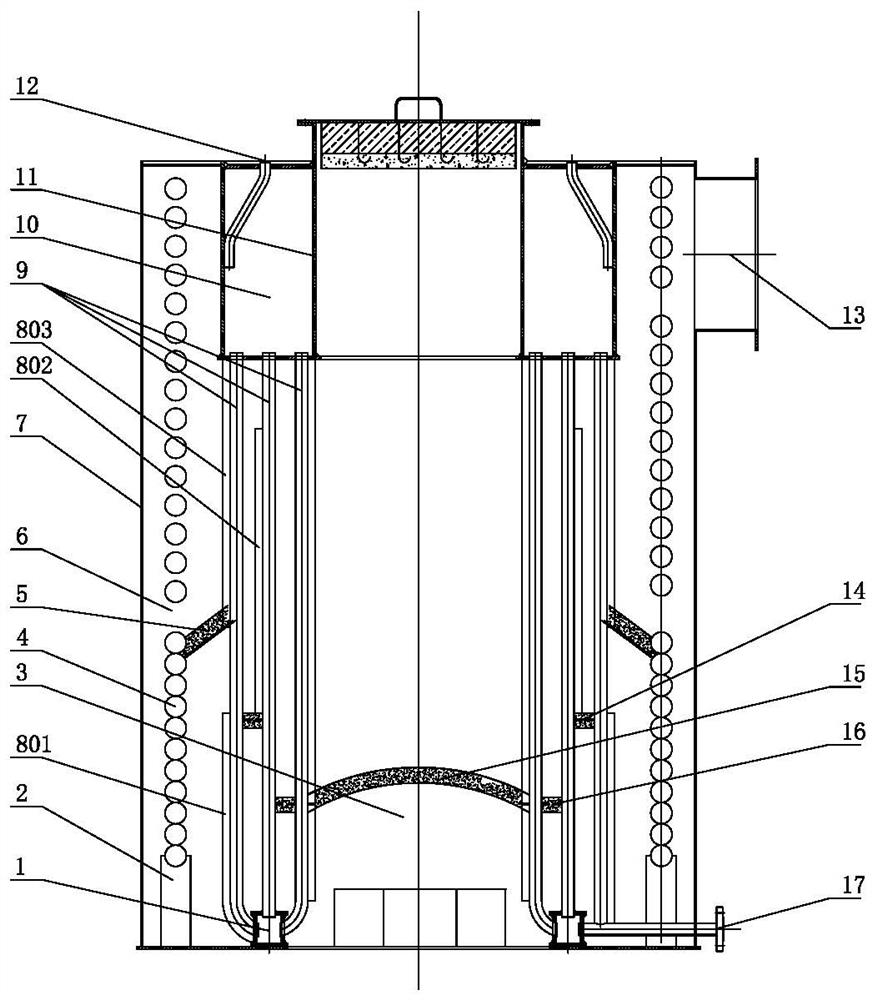

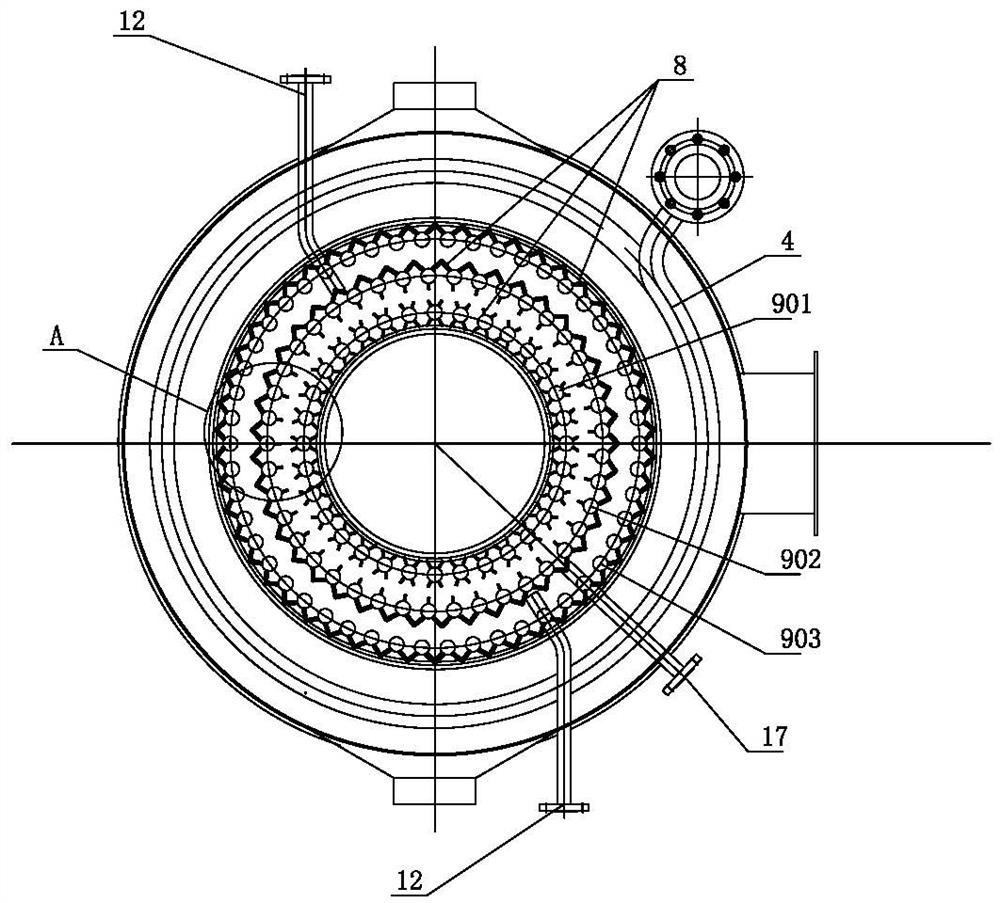

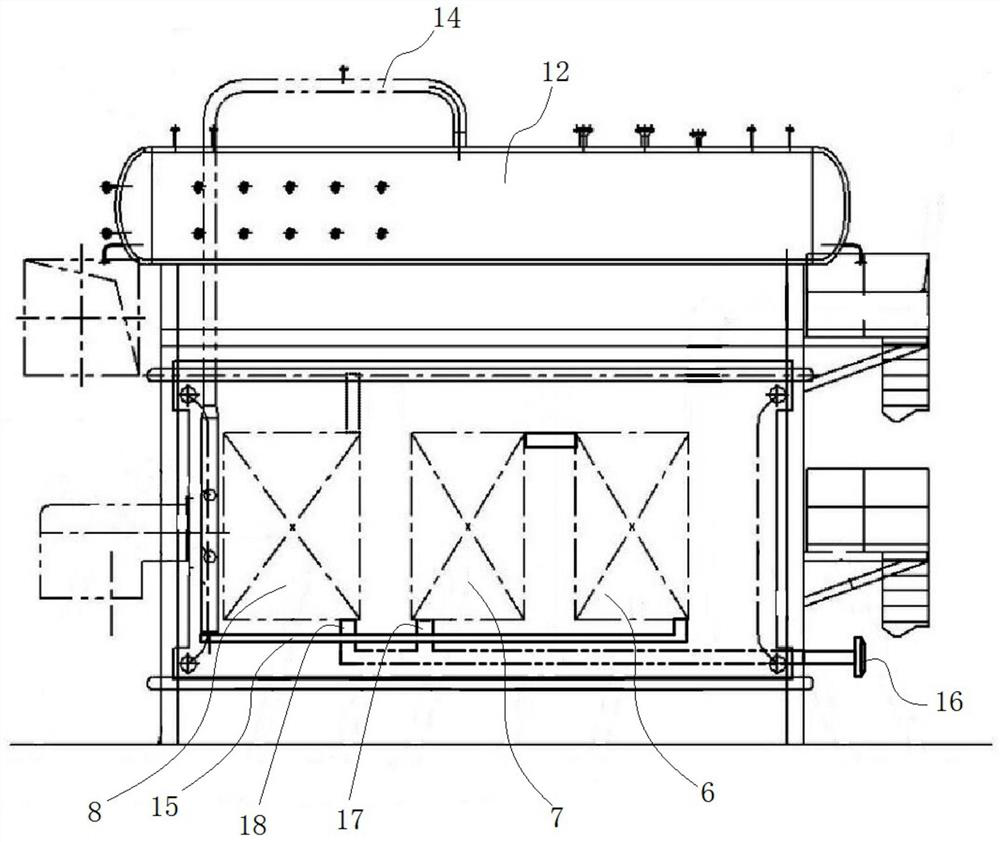

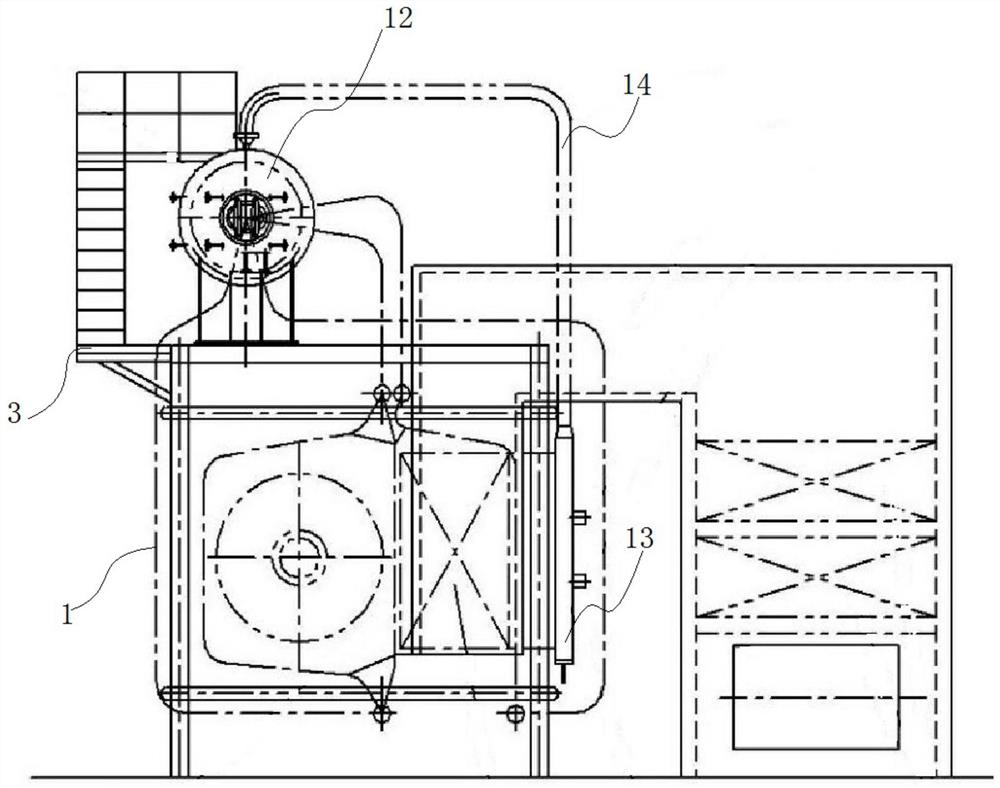

Flame pressing type water tube boiler

PendingCN113606566AReasonable designSufficient heat exchangeSteam generation using pressureWater-tube boilersWater storageFuel oil

The invention discloses a flame pressing type water tube boiler in the field of steam generation devices, which comprises a vertically arranged boiler body, tubes are vertically arranged in the boiler body, the tubes are arranged in a concentric annular array, three layers of tubes are arranged from inside to outside, a flame pressing plate is arranged in a circular cavity formed by the tubes on the inner layer, and a hearth is arranged below the flame pressing plate; a spiral coil pipe is also arranged on the periphery of the tube array in the boiler body; and smoke baffles are arranged between the tubes on the adjacent layers and between the tubes on the outer layer and the spiral coil pipe respectively, flow separation components are arranged between the tubes on the same layer and on the inner sides or the outer sides of the tubes on the same layer, a vertically reciprocating baffling channel is formed between the flow separation components and the smoke baffles in the space in the hearth, and the outermost side of the baffling channel is connected to a smoke outlet. The flame pressing type water tube boiler is small in water storage amount and large in steam production amount. The flame pressing type water tube boiler can be made into fire coal, fuel oil, natural gas or biomass energy boilers and can be applied to various places needing steam.

Owner:扬州大唐热能机械制造有限公司

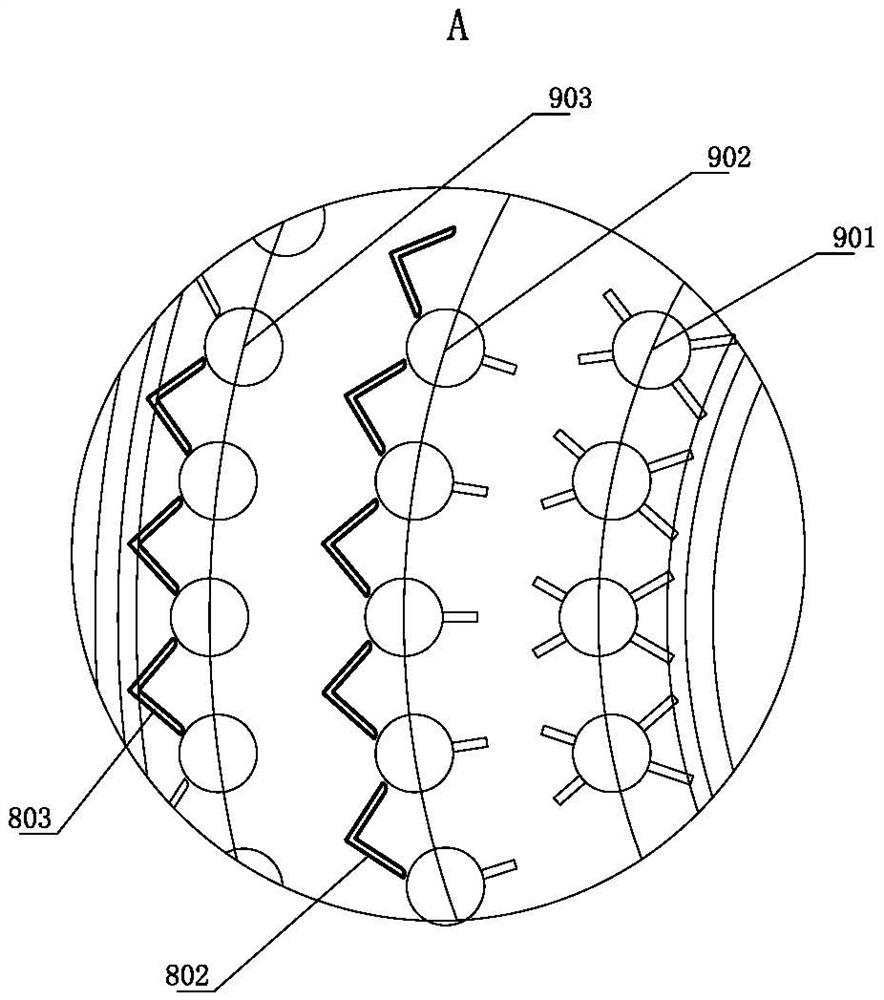

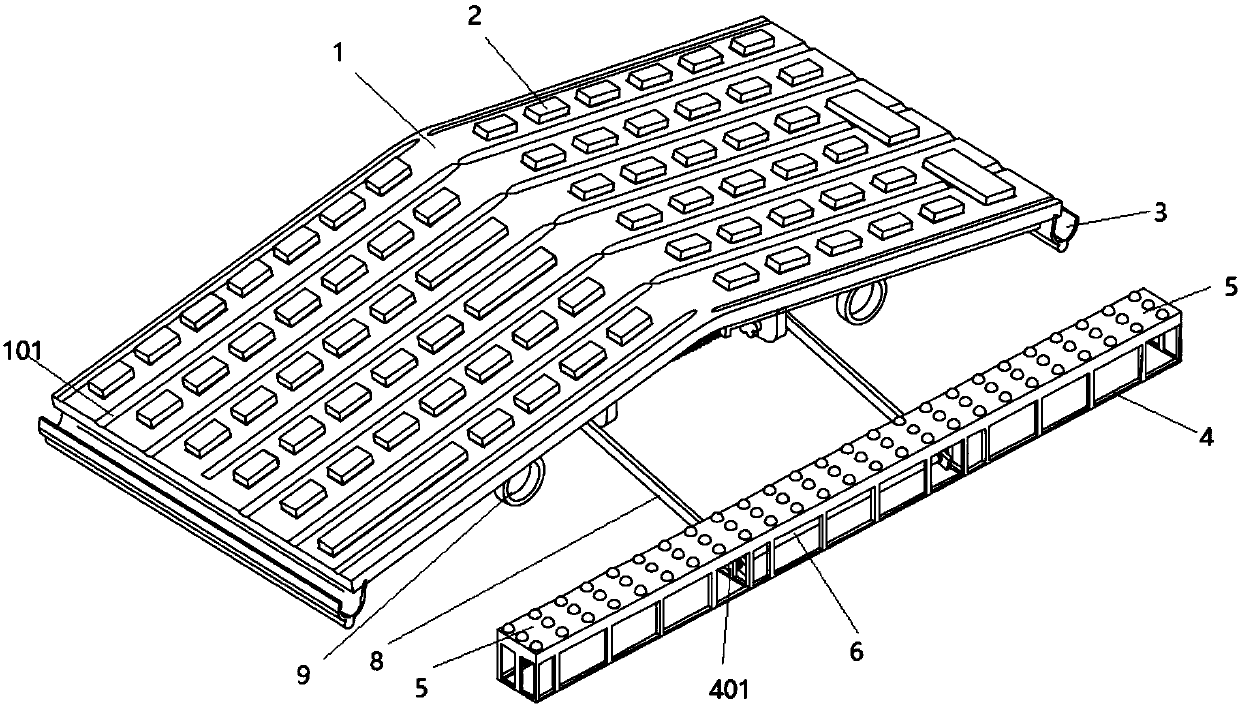

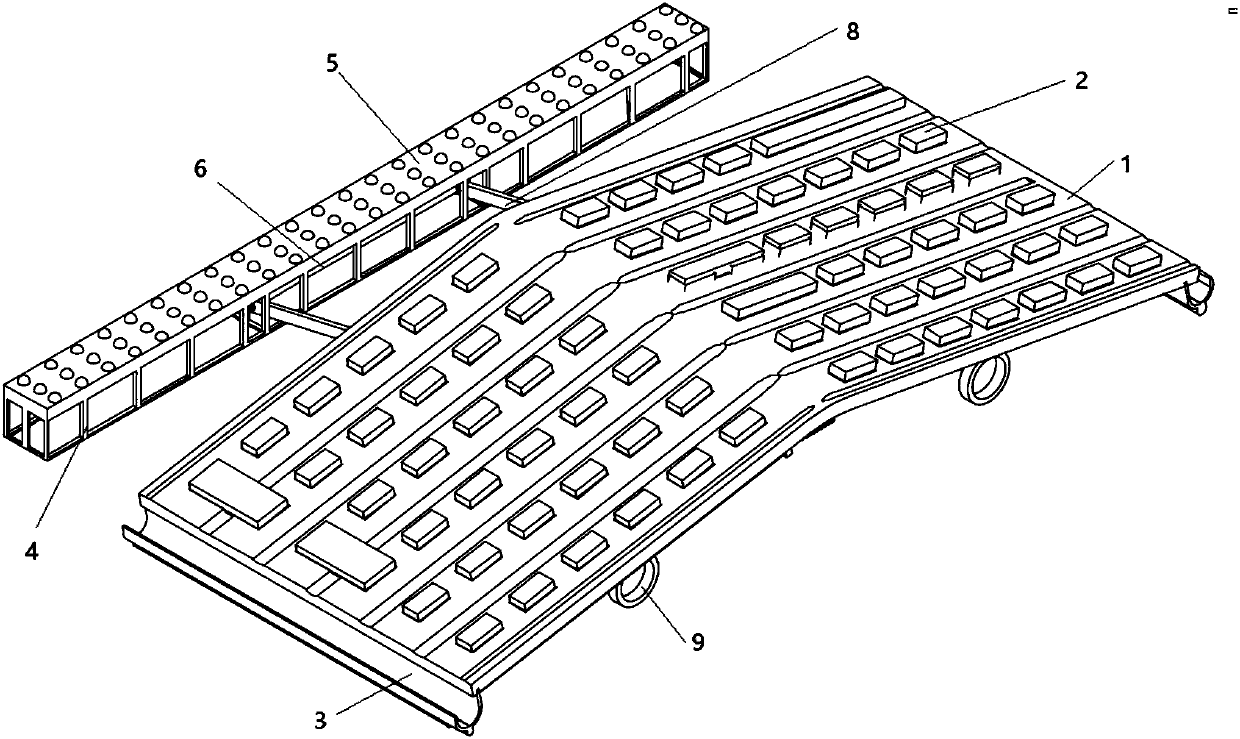

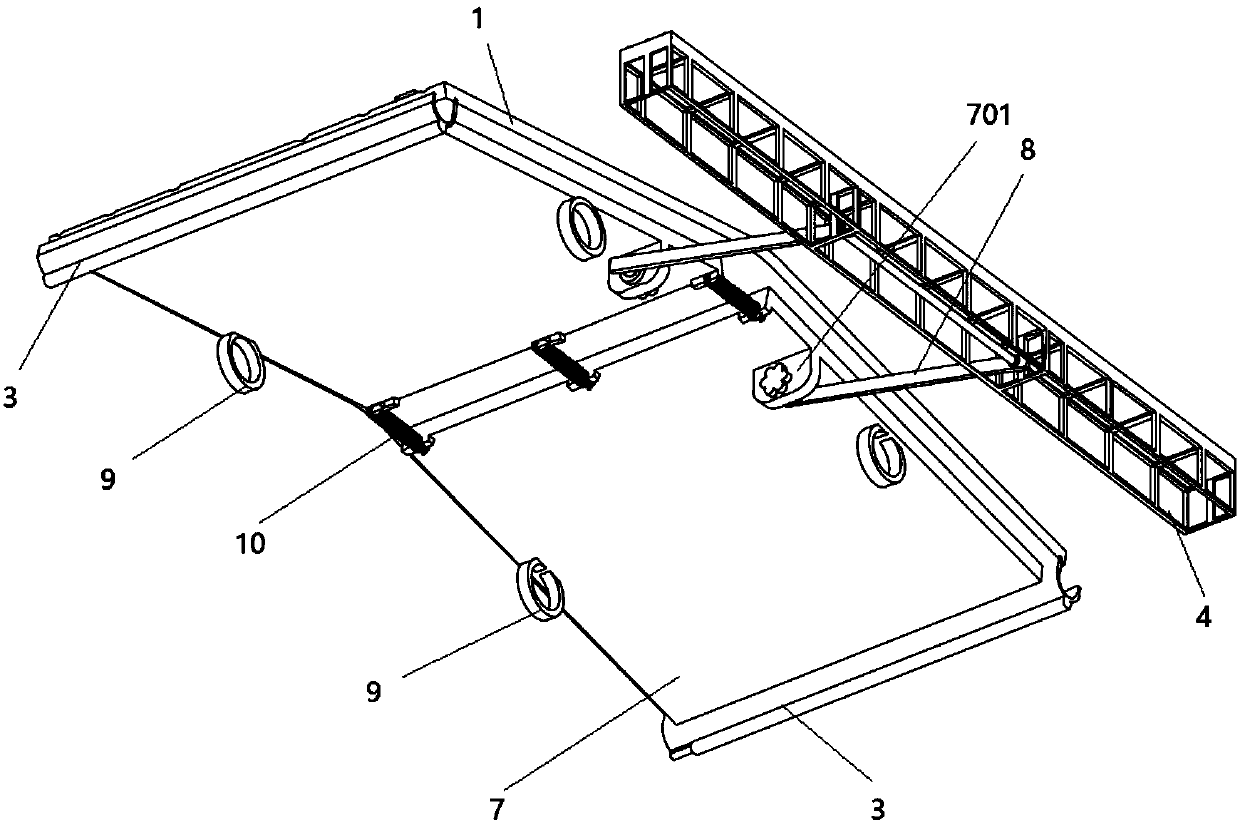

Arched water-proof computer keyboard for computer

InactiveCN107728801AIncreased flexibility of useReduce water storageInput/output for user-computer interactionAdhesiveEaves

The invention provides a waterproof computer keyboard with a computer arch structure, which includes a circuit board compartment, a positioning ear plate, a connecting inclined plate, a locking bolt, a buffer ring and a tension spring, and the bottom plates of the two circuit board compartments are also symmetrical There are two positioning lugs for hoisting, the two positioning lugs are set close to the right outer eaves of the two circuit board warehouses, and a through jack is opened on the two positioning lugs; the connecting slant plates are symmetrical There are two places, and the inner side of the rear end of the two connecting slant plates is supported to be provided with a limit fixing seat, and a threaded hole is opened in the center of the two limit fixing seats; the top of the supporting plate frame A layer of cotton-containing cushion is pasted on the pallet, and a number of hemispherical sponge balls are uniformly arrayed on the sponge cushion. The arrangement of the water guide grooves of the present invention, the seven water guide grooves can guide the water sprinkled on the top plate of the keyboard frame to the inside of the left and right drain pipes for centralized discharge, and reduce the water storage on the keyboard surface to the greatest extent.

Owner:叶生祥

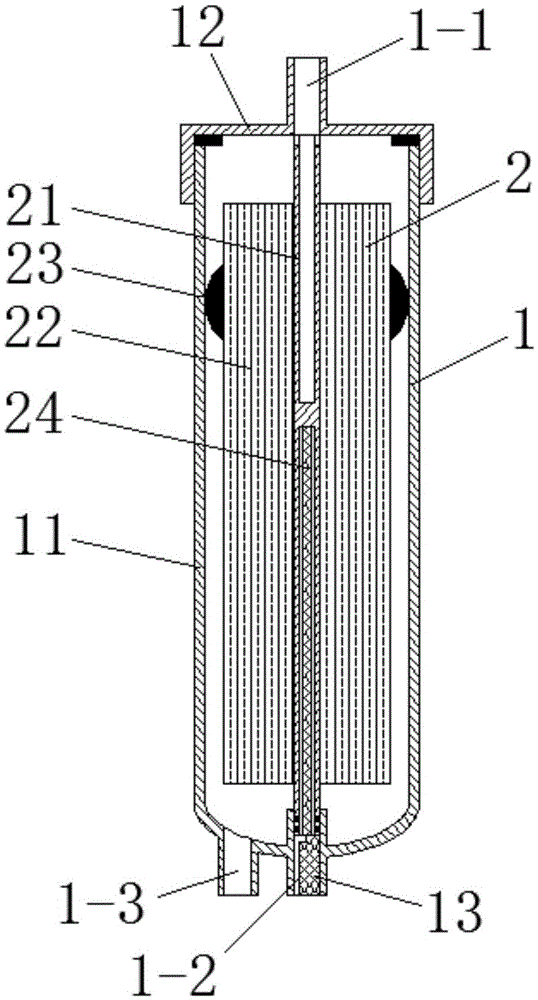

Anti-splashing device for discharging closestool

PendingCN106906880AEasy to operateComfortable and hygienic use environmentFlushing devicesIndustrial engineeringPush-button

The invention discloses an anti-splashing device for a discharging closestool. The anti-splashing device comprises a closestool hood shell. A dirt discharging pipe is disposed in the closestool hood shell; an anti-splashing assembly is further disposed in the closestool hood shell; the anti-splashing assembly has a button, a controller, a steering engine, a gear, a shift rod and a water discharging pipe; the button is mounted on the upper end of the closestool hood shell and connected with an input end of the controller via a lead; the steering engine is connected with an output end of the controller and an output shaft of the steering engine is connected with the gear; the gear is engaged with one end of the shift rod; the other end of the shift rod extends into the water discharging pipe and separates the water discharging pipe and the dirt discharging pipe; the water discharging pipe is mounted on the dirt discharging pipe and communicates the upper part and the lower part of the dirt discharging pipe. The anti-splashing device for the discharging closestool can be simply operated; an anti-splashing function can be achieved with water seal and odor prevention; and comfortable and hygiene use environment is provided for users.

Owner:HENAN INST OF ENG

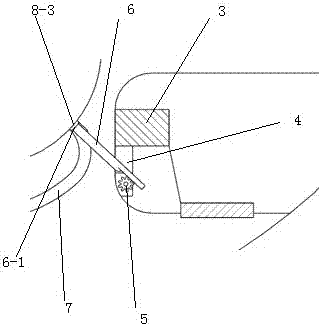

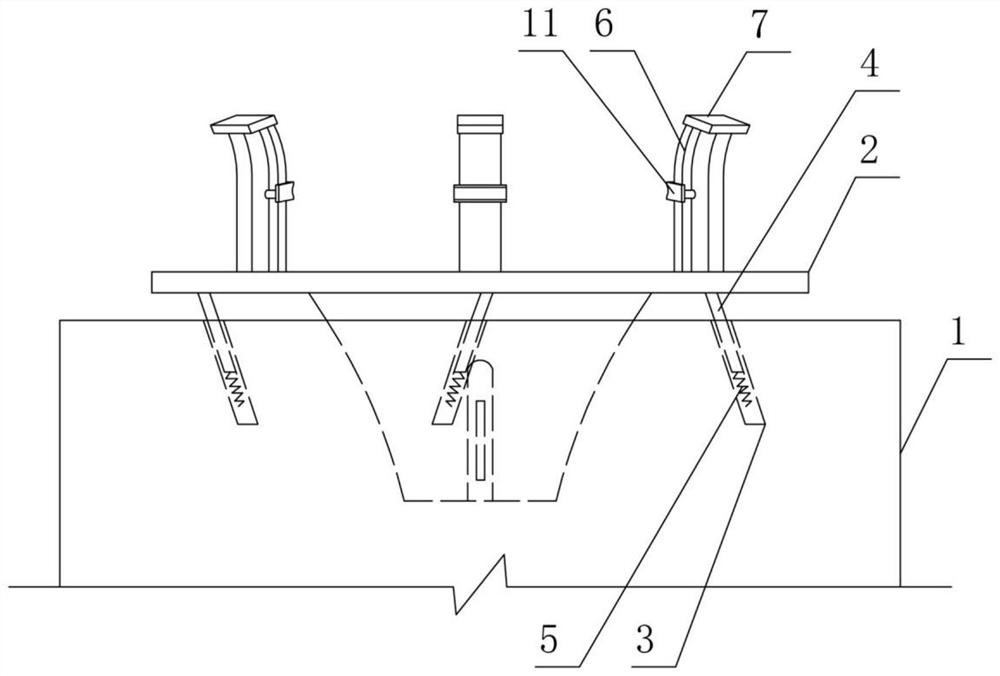

Sponge city rain collection and irrigation system

InactiveCN109797805AReduce water storageReduce pipe cloggingRoot feedersGeneral water supply conservationPower controlStormwater

The invention applies to the technical field of sponge city irrigation and provides a sponge city rain collection and irrigation system, comprising a collection module, a filter module, an anti-evaporating module, a water storage module, a desilting module, a water delivery module, a water quantity control module, an irrigation module, a power control module, an external power module, and a solarmodule. The collection module collects rain and is connected with the filter module; the water quantity control module is connected with the irrigation module; the irrigation module irrigates plants;the external power module is connected with the power control module so as to supply a power source to the water delivery module via the power control module; the solar module is connected with the power control module to supply a power source to the water delivery module through the power control module; the power control module activates the external power module to supply water when the solar module has low power level.

Owner:南京林业大学工程规划设计院有限公司

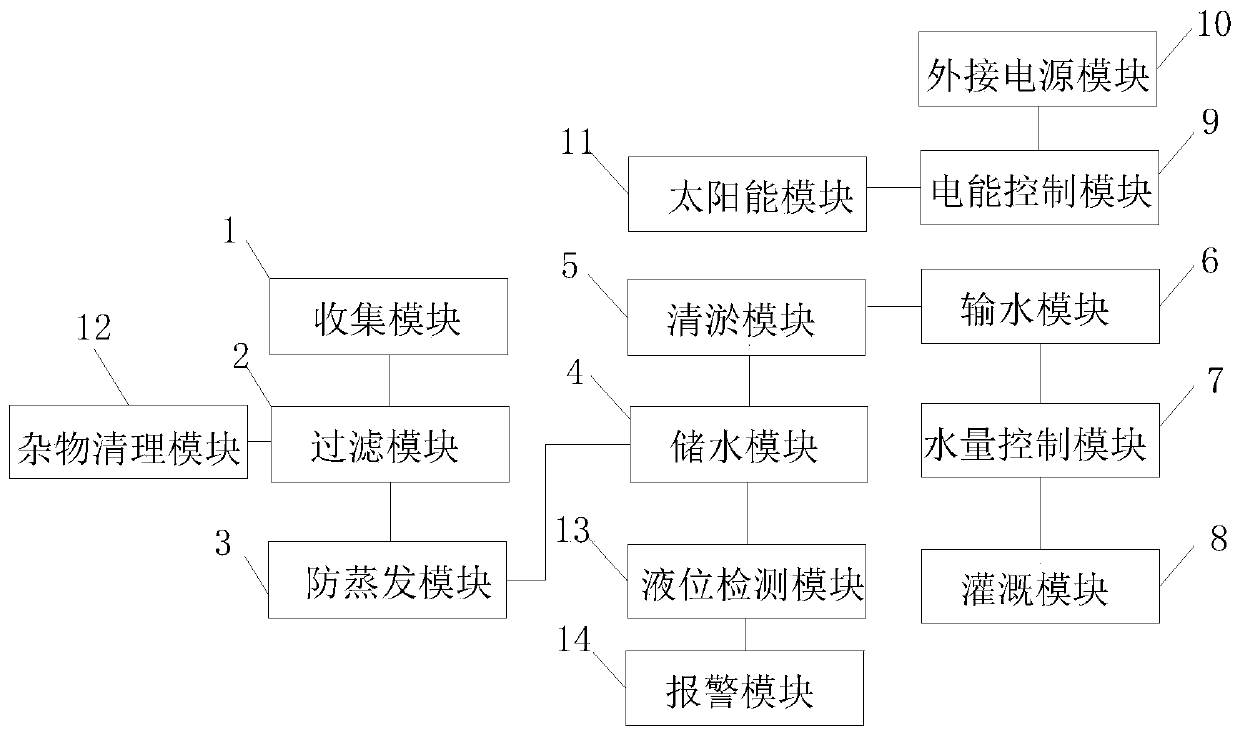

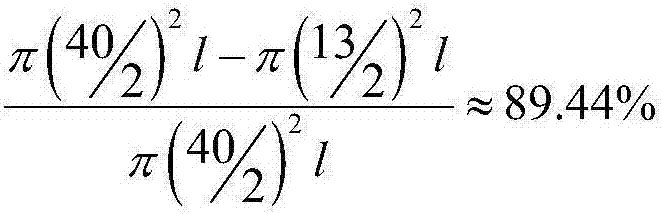

Spiral wound membrane component and membrane processor adopting spiral wound membrane component

InactiveCN105536546ASmall volumeReduce water storageSemi-permeable membranesMembranesMembrane configurationEngineering

The invention discloses a spiral wound membrane component and a membrane processor adopting the spiral wound membrane component. The spiral wound membrane component comprises a core tube, a membrane group and a sealing ring; a water producing flow channel is formed in the core tube; a first filling block which cannot block the water producing flow channel is arranged in the water producing flow channel, or the diameter of the cross section of the water producing flow channel is not greater than 5 mm; the membrane group is wound on the core tube; the sealing ring is arranged on the outside of the membrane group in a sleeving manner. According to the spiral wound membrane component disclosed by the invention, the first filling block is arranged in the water producing flow channel, or the diameter of the cross section of the water producing flow channel is not greater than 5 mm. Compared with the prior art, the volume of the water producing flow channel can be reduced remarkably, so that the water storage amount of the water producing flow channel can be effectively reduced; when a water purifier performs re-purification, the re-purification time can be reduced remarkably; the time required for a re-purification process before the water purifier is started to make water can be reduced remarkably.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

Intelligent tobacco seedling raising shed based on Internet of Things and use method

InactiveCN113519316AReduce morbidityImprove survival rateClimate change adaptationGreenhouse cultivationAgricultural scienceNicotiana tabacum

The invention discloses an intelligent tobacco seedling raising shed based on the Internet of Things. The intelligent tobacco seedling raising shed comprises a shed body, a shearing mechanism and a pesticide supply mechanism, wherein a top plate is arranged at one end of the top of the shed body, the other end of the top of the shed body is connected to the shearing mechanism, a plurality of shielding nets are arranged on the top plate, the density of the shielding nets is controlled through a driving motor, the shearing mechanism comprises a guide rail sliding block, the guide rail sliding block is connected to the two sides of a fixing block, one end of the fixing block is connected to an air cylinder, a mechanical arm and a spray head system are arranged at the other end of the fixing block, the pesticide supply mechanism comprises a pesticide supply box, a plurality of pipelines are arranged on the pesticide supply box, and the pipelines are all connected to the spray head system. According to the intelligent tobacco seedling raising shed based on the Internet of Things and the use method, in the growth stage of tobacco seedlings, frequent manual operation including fertilization, pesticide spraying, water storage, leaf cutting and the like in the seedling raising period can be reduced, the probability that seedbed virus infection is caused by human activities is reduced, a main propagating source is cut off, the key approach of tobacco morbidity is reduced, and therefore the survival rate in the tobacco seedling raising period is effectively increased.

Owner:广西壮族自治区烟草公司百色市公司

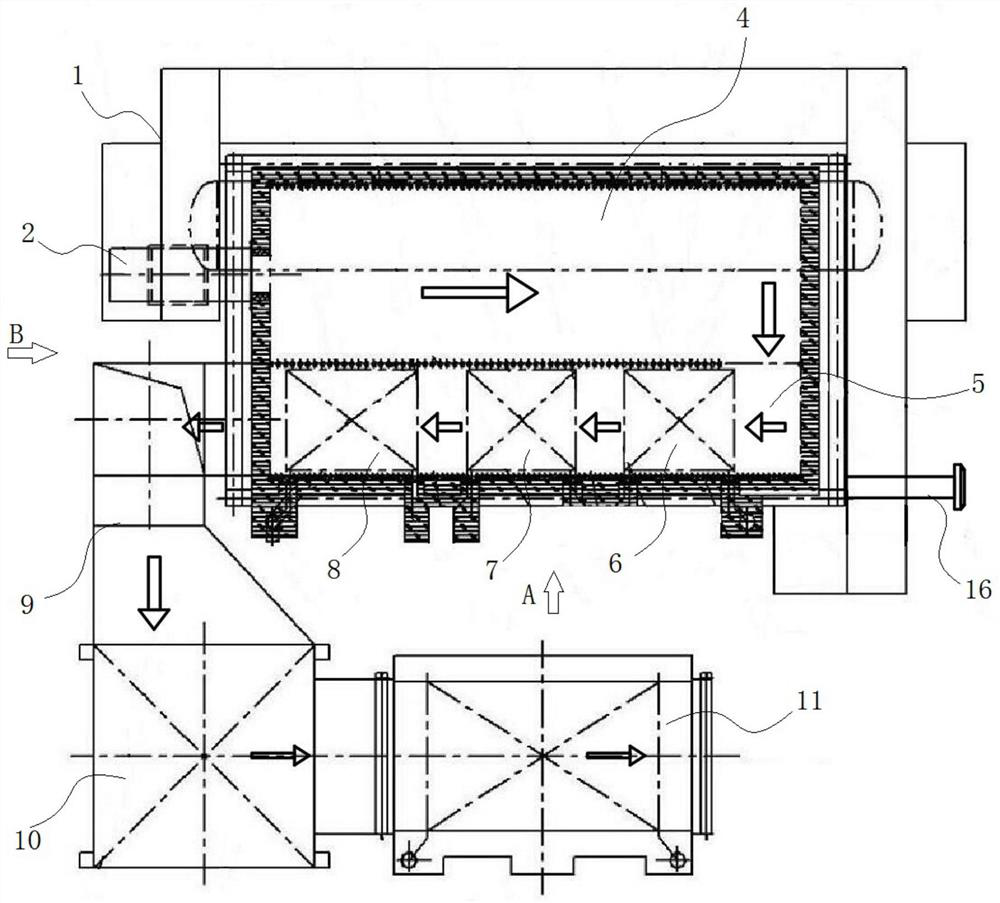

Rapid saturated steam generating device for steaming box

InactiveCN104654264AEvenly distributedUniform temperatureSteam generation heating methodsHeating timeEngineering

The invention relates to a rapid saturated steam generating device for a steaming box. The rapid saturated steam generating device for the steaming box is characterized in that at least one channel is formed in the box bottom of the steaming box; tank bodies which are lower than the box bottom of the steaming box is correspondingly connected with the channel; steam sleeves with steam outlet holes are arranged at the lower parts of the tank bodies; the steam sleeves are connected to the outside of the tank bodies through steam inlet pipes. According to the rapid saturated steam generating device for the steaming box, the channel is formed in the box bottom of the steaming box; the rapid saturated steam generating device, which is lower than the box bottom of the steaming box and mainly comprises the tank bodies and the steam sleeves which are provided with the steam outlet holes and arranged at the lower part of the tank bodies is connected correspondingly to the channel; the water storage amount is reduced, so that the temperature in the steaming box rises quickly; the heating time is short; the saturated steam generating time is also short; due to the arrangement of the steam sleeves, the steam sleeves are positioned in water during use, so that no matter how much steam enters, the uniform steam exit can be guaranteed, and the saturated steam distribution and the temperature distribution in the overall steaming box are uniform; the uniform infiltration and ageing of a fabric are promoted.

Owner:浙江宏涛印染机械有限公司

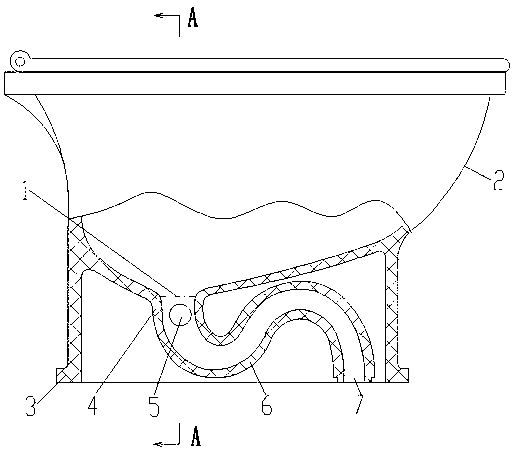

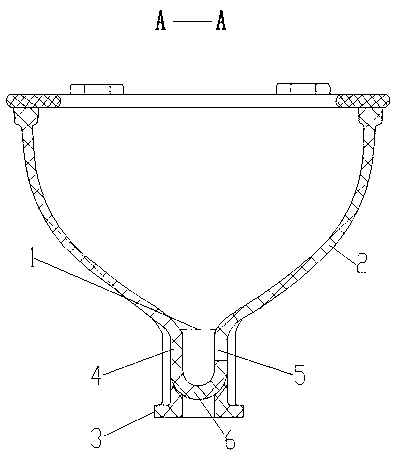

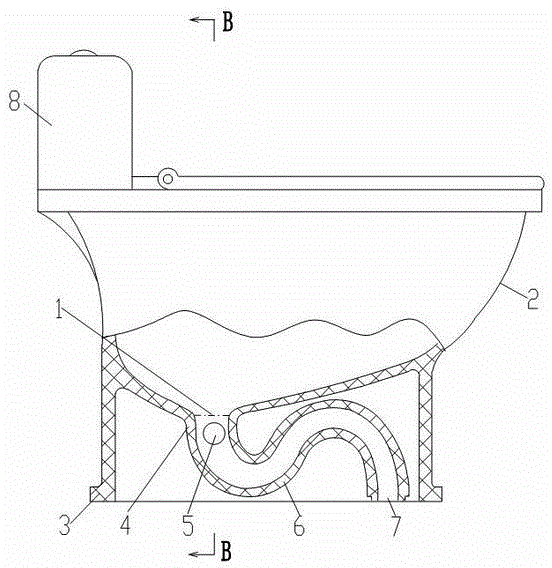

Water-saving toilet bowl

InactiveCN103276788AEasy to collect and reuseLower the altitudeWater closetsDomestic plumbingWater savingWater channel

The invention discloses a water-saving toilet bowl which comprises a basin and a discharge pipeline, wherein the bottom of the basin is communicated with the discharge pipeline. The water-saving toilet bowl is characterized in that a water inlet hole is formed in the wall of the discharge pipeline between the upper end face of an inlet of the discharge pipeline and the lower portion 200mm away from the inlet of the discharge pipeline. Another water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 160mm away from the inlet of the discharge pipeline, a third water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 120mm away from the inlet of the discharge pipeline, a flushing tank is arranged in the rear of the top end of the basin, an annular water channel is formed inside a convex edge at the top end of the basin, a discharge hole facing the inner wall of the basin is formed at the bottom of the annular water channel, and a water outlet of the flushing tank is communicated with the annular water channel. Waste water can transversely impact the discharge pipeline of the toilet bowl to flush the toilet bowl at the lowest position, the waste water is conveniently collected and recycled, energy is not consumed, and the toilet bowl is flushed by the flushing tank of the toilet bowl when no waste water is available.

Owner:李武

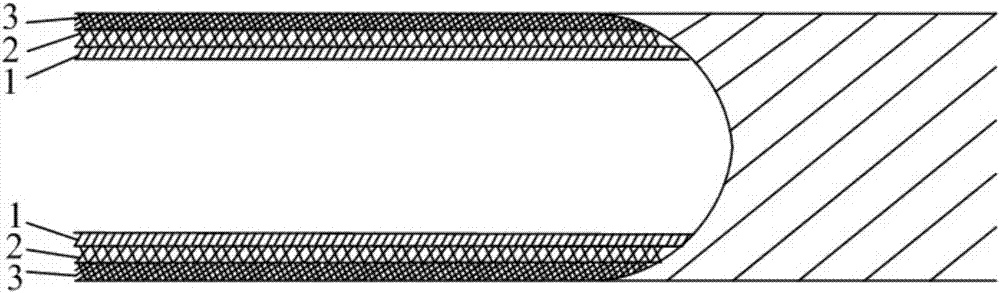

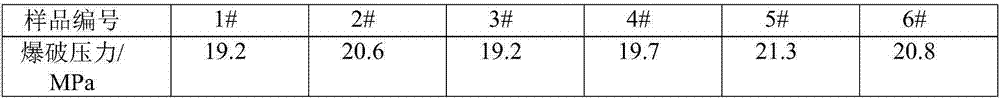

Abrasion-resistant, high-temperature, and high-pressure resistant flexible water pipes for long-distance extinguishing of mountain fires on transmission lines

ActiveCN106402519BStrong pressure capacityMeet delivery pressure requirementsFlexible pipesPolyesterWear resistant

The invention relates to a wear-resistant, high-temperature, and high-pressure resistant flexible water pipe for long-distance extinguishing of mountain fires in power transmission lines. The water pipe includes three layers from inside to outside, the innermost layer is a polyurethane-PVC composite material layer, and the middle layer is a synthetic fiber layer. The outermost layer is a polyester cotton layer, the middle layer and the outermost layer are braided by thin ropes, and the innermost layer and the middle layer are bonded together; the polyurethane-PVC composite material layer consists of 15 to 20 parts by mass It is prepared by compounding thermoplastic polyurethane, 62-72 parts of PVC, 8-12 parts of DOP, 1-5 parts of heat stabilizer and 1-2 parts of copper salt. The water pipe of the present invention has strong pressure bearing capacity and meets the transmission pressure requirements required for fire extinguishing of mountain fires and high mountains in power transmission lines; the inner tank is made of polyurethane-PVC composite material to prevent corrosion of high-efficiency fire extinguishing fluid, and improve the mechanical properties and service life of the water pipe. The outer layer of polyester cotton has good high temperature resistance and flame retardancy, which prevents the water pipe from being burned in a high temperature fire.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

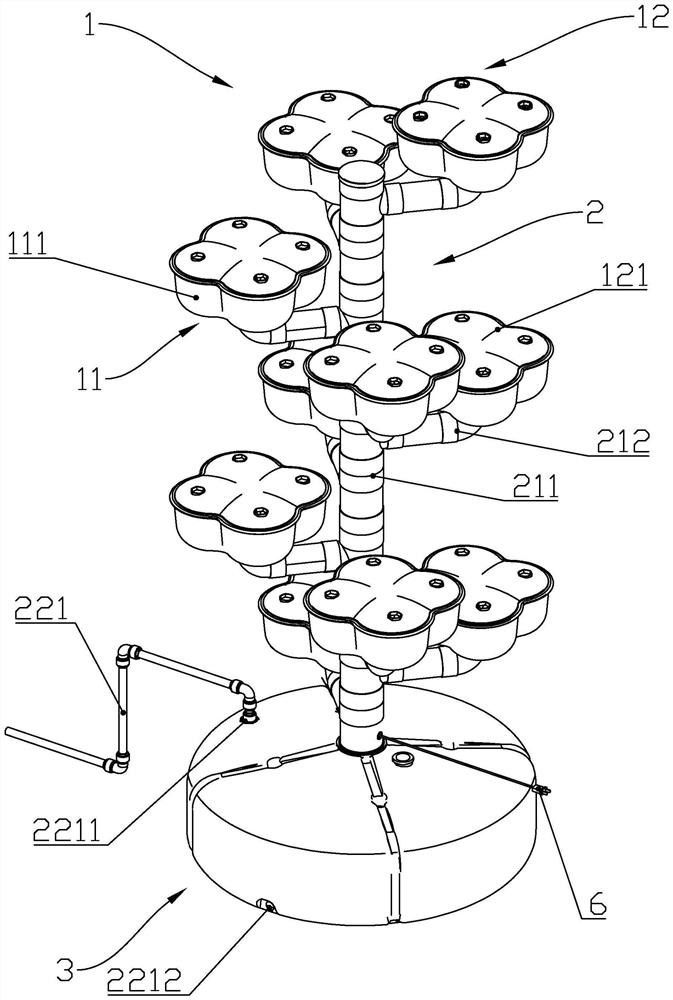

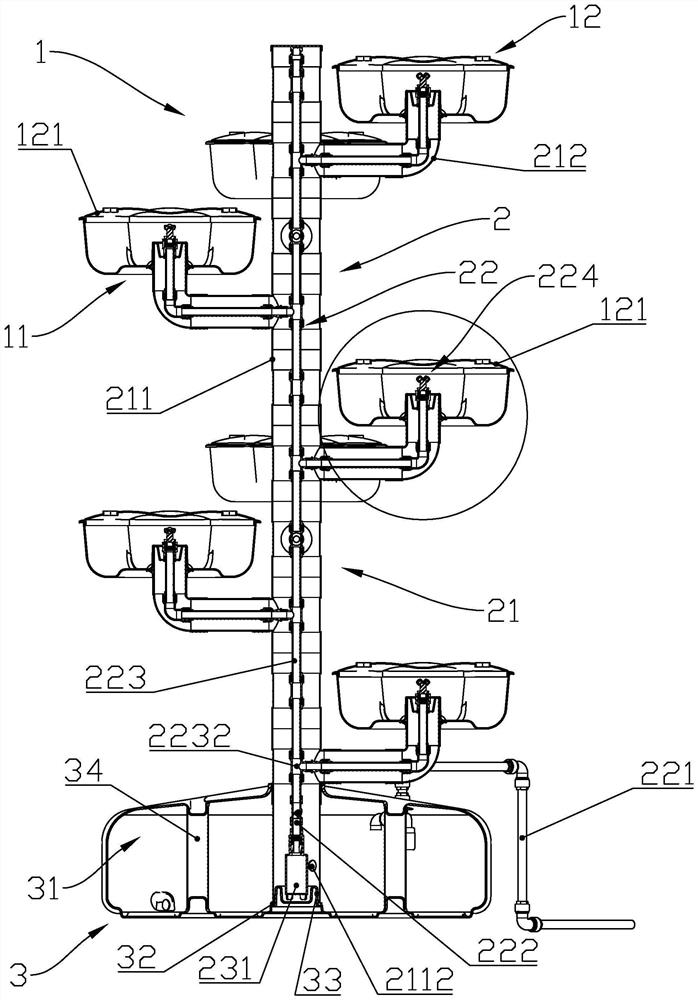

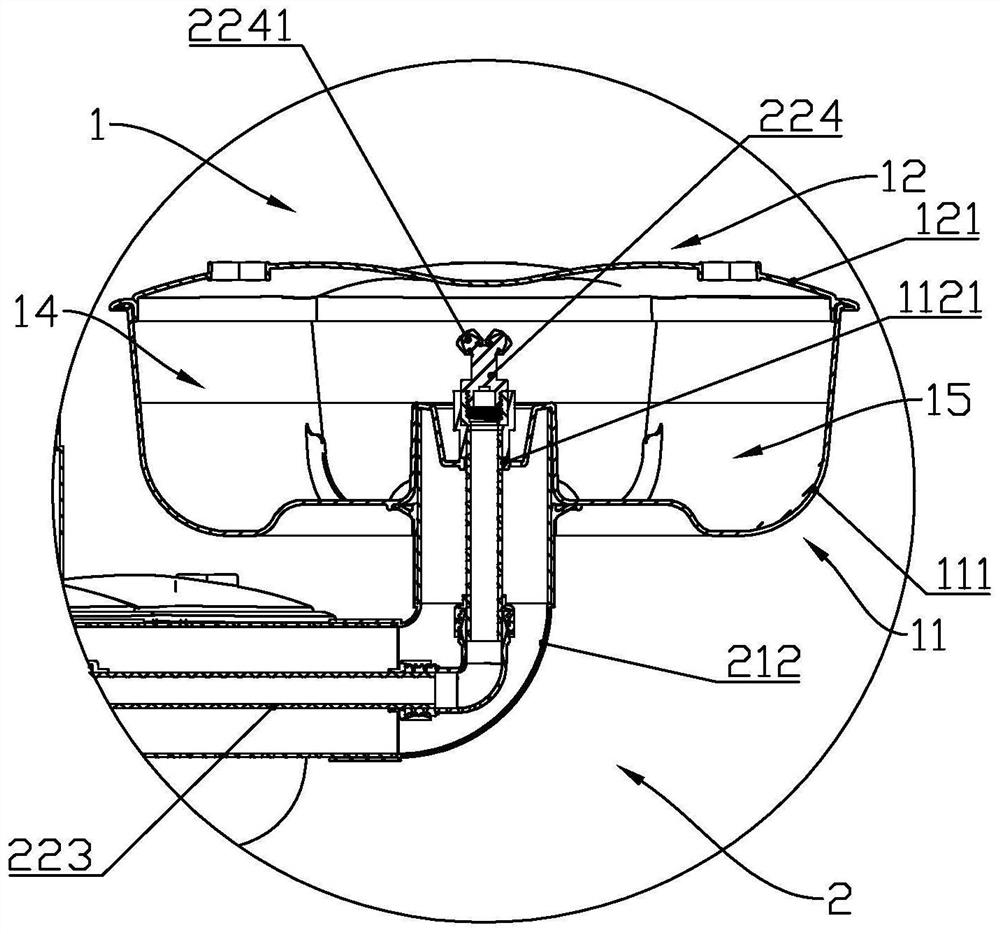

Three-dimensional planting device

PendingCN114402989APrecise water controlSave spaceAgriculture gas emission reductionCultivating equipmentsWater storageAgricultural science

The invention discloses a three-dimensional planting device, and relates to the technical field of planting devices. Comprising a mounting seat used for supporting a planting device; the inner side of the mounting seat is at least provided with a water storage chamber for storing water; the planting mechanisms are used for planting plants; the base is at least provided with a first planting component for placing plants; the pipeline mechanism is used for supporting the planting mechanism and realizing a circulating water path; wherein the pipeline mechanism is at least provided with a supporting component, the supporting component is at least provided with a vertically-arranged main pipeline, one end of the supporting component is connected with the mounting base, the other end of the main pipeline vertically extends upwards, and the two sides of the main pipeline are connected with the multiple planting mechanisms respectively; the sprinkling irrigation component is located in the water storage chamber, the main pipeline and the planting mechanism and used for driving water flow to enter the planting mechanism through the water storage chamber and the main pipeline in sequence; the spray irrigation component and the main pipeline are further provided with a backflow channel which is used for guiding water flow to flow back to the water storage cavity from the planting mechanism.

Owner:浙江贸美农业科技有限公司

Method capable of reducing water leakage of water closet

The invention discloses a method capable of reducing water leakage of a water closet. A micro water inlet valve for allowing water to enter a buoyancy valve and a rotating shaft sleeve are arranged in a water tank; a rotating shaft is arranged in the rotating shaft sleeve; a rotating rod acted by spring force is fixedly connected on the rotating shaft; a working rod capable of pushing the contactof the micro water inlet valve and a flashing valve line lifter is fixed on one side of the rotating rod, and a push rod is fixed on the other side of the rotating rod; an interactive force is generated between the push rod and a water closet cover leaning against the side of the tank, and the interactive force can overcome the spring force of the push rod and drives the working rod so that the micro water inlet valve is opened and the flushing valve is in a closed state after the pull line of the flushing valve is loosened; and when the water closet cover is covered, the spring force of the rotating rod recovers stretching, the push rod lifts the pull line connected with a flushing valve post on the flashing valve line lifter, the flushing valve finishes flushing, the push rod is separated from the contact of the micro water inlet valve, the micro water inlet valve stops water feed, and the water tank cannot be fed with water before the cover is lifted again. Because the water feeding time is extremely short, the water leakage is only in the toilet using time of water flow.

Owner:扬中市检验检测中心

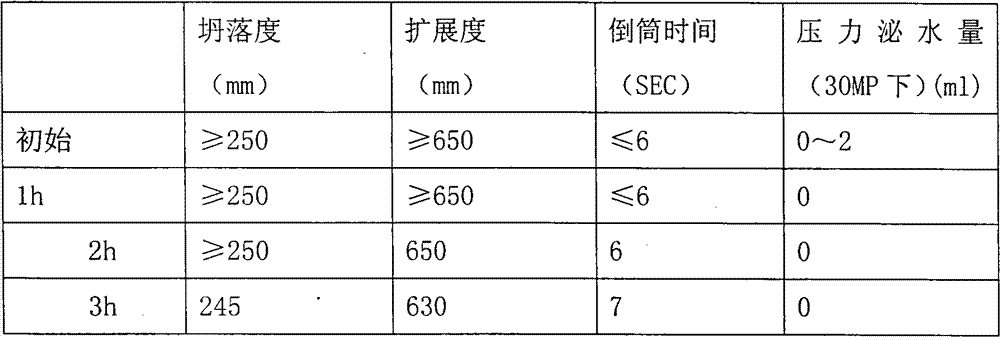

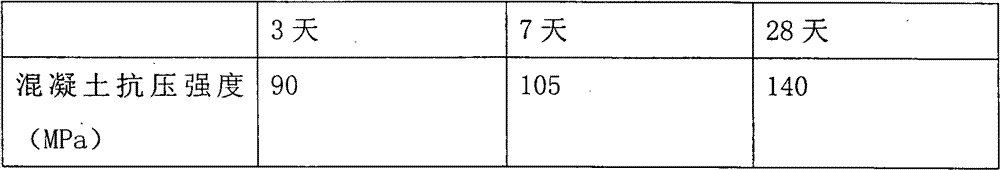

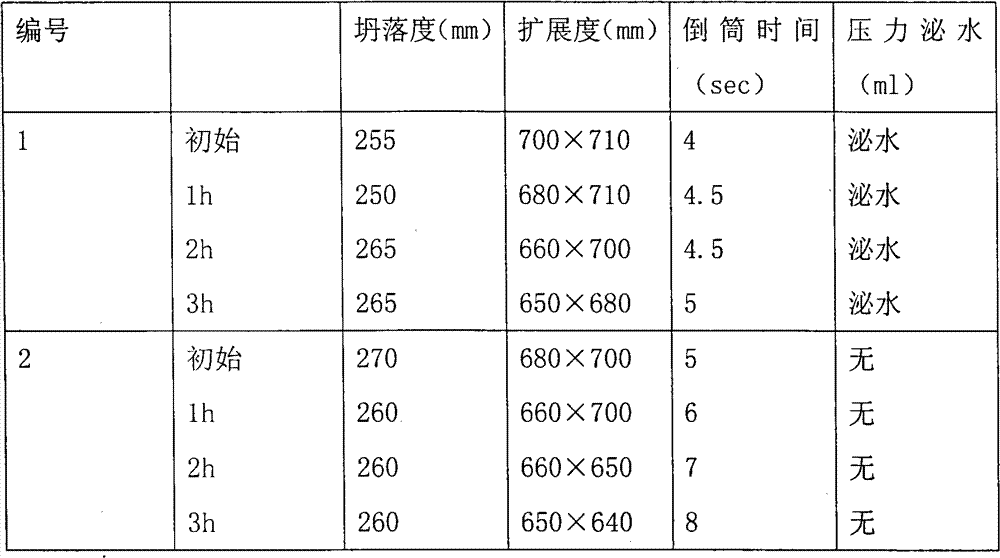

Manufacturing method for high pumping concrete

The invention relates to a manufacturing method for high pumping concrete, and belongs to the technical field of engineering construction materials. The manufacturing method comprises the following steps of: weighing silicate cement, ultrafine powder, river sand or washed sea sand, gravel, water and a water reducer according to a proportion, pouring the weighed silicate cement and ultrafine powder into a stirrer, and stirring; adding the weighed river sand or washed sea sand, and stirring; pouring the weighed water and water reducer, and stirring; and pouring the weighed gravel, and stirring to obtain the concrete. The concrete manufactured by the method can retain plasticity for a long time, so that slump, expansion and rewinding time are basically invariable for 3 to 4 hours, and bleeding is prevented; therefore, the requirements of an ultrahigh pumping technology are met.

Owner:冯乃谦 +2

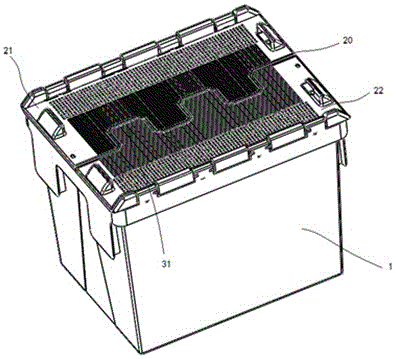

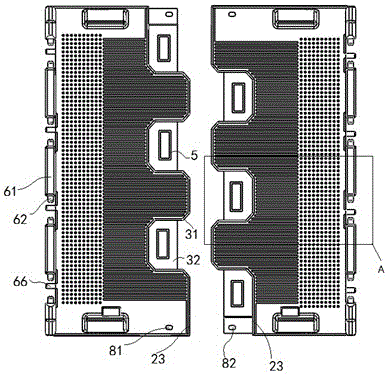

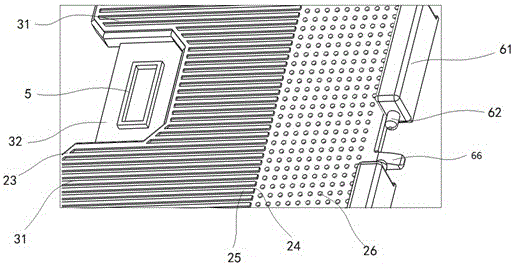

A waterproof turnover box

ActiveCN104291005BIncreased load-bearing capacityEasy to stackLidsNon-removalbe lids/coversEngineeringCrate

Owner:青岛冠宇工业设备有限公司

Gas-fired boiler and using method thereof

PendingCN113883491AImprove energy efficiencyReduce usageSteam superheatersCasings/liningsCombustion chamberCombustor

The invention discloses a gas-fired boiler and a using method thereof, and relates to the technical field of boilers. The boiler comprises a boiler body, a burner and a steel frame stand column. A combustor is installed on the boiler body, and a combustion chamber and a superheated area flue are arranged in the boiler body. Membrane type water cooling walls are arranged on the inner wall of the front side and the inner wall of the rear side of the boiler body respectively. A membrane type water cooling wall extending transversely is further arranged in the boiler body, and the membrane type water cooling wall divides the inner space of the boiler body into the combustion chamber located on the rear side and the superheated area flue located on the front side. The combustor is located at the inlet side end of the combustion chamber. A first superheater, a second superheater and a third superheater are sequentially arranged in the superheated area flue in the smoke flowing direction. Dead steam collected by a storage tank and used by a steam turbine and other ship equipment becomes superheated steam through two-stage superheating treatment of the first superheater and the second superheater, a gaseous water circulation is formed, the energy efficiency of the ship boiler is improved, the use amount of fresh water is reduced, and the water storage amount of a ship is reduced.

Owner:中船九江锅炉有限公司

Water-saving toilet bowl

InactiveCN103276788BEasy to collect and reuseLower the altitudeWater closetsDomestic plumbingWater savingWater channel

The invention discloses a water-saving toilet bowl which comprises a basin and a discharge pipeline, wherein the bottom of the basin is communicated with the discharge pipeline. The water-saving toilet bowl is characterized in that a water inlet hole is formed in the wall of the discharge pipeline between the upper end face of an inlet of the discharge pipeline and the lower portion 200mm away from the inlet of the discharge pipeline. Another water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 160mm away from the inlet of the discharge pipeline, a third water inlet hole is formed in the wall of the discharge pipeline between the upper end face of the inlet of the discharge pipeline and the lower portion 120mm away from the inlet of the discharge pipeline, a flushing tank is arranged in the rear of the top end of the basin, an annular water channel is formed inside a convex edge at the top end of the basin, a discharge hole facing the inner wall of the basin is formed at the bottom of the annular water channel, and a water outlet of the flushing tank is communicated with the annular water channel. Waste water can transversely impact the discharge pipeline of the toilet bowl to flush the toilet bowl at the lowest position, the waste water is conveniently collected and recycled, energy is not consumed, and the toilet bowl is flushed by the flushing tank of the toilet bowl when no waste water is available.

Owner:李武

Pre-water injecting closestool

InactiveCN101413285BGuaranteed blowdown functionEasy to useFlushing devicesWater savingEnvironmental engineering

The invention relate to a pedestal pan with a function of advance water injection, which consists of a pedestal pan body, a water tank, a sealed pollution discharging device, and an advance water injection device. The advance water injection device injects certain mount of water into the pedestal pan before defecation so as to realize the aim of more water for the defecation and less water for urination, and achieve the aims of water saving and convenient use.

Owner:戴长虹

A water dispenser with guiding function

ActiveCN108652446BSimple structureAvoid the problem of tilting the force directionBeverage vesselsWater leakageMachine

The invention discloses a water dispenser having a guiding function. The water dispenser includes a machine body and a smart base disposed in a columnar accommodating chamber of the machine body. Damping mechanisms are disposed at the corresponding positions of the upper end face of the machine body and the lower end face of the smart base. The upper end face of the smart base is provided with a guiding mechanism for guiding a water bucket for placement. The structure of the machine body and the smart base is improved, and the problem of water leakage in the bucket replacement process is solved fundamentally.

Owner:王芊蔚

Municipal underground water pollution treatment system

InactiveCN111249961AEffective agitationAvoid depositionSludge treatmentShaking/oscillating/vibrating mixersSludgeGroundwater contamination

The invention discloses a municipal underground water pollution treatment system. The municipal underground water pollution treatment system structurally comprises a foundation pit, a pipeline, a mudpressing device, a built wall, a waterproof layer and putty. The beneficial effects are as follows, a flow stirring structure and a flow guide structure are matched with each other; sludge contained in the sewage is removed; an effective stirring effect is achieved when the slurry is deposited in a foundation pit; the downward drainage effect is achieved on the sludge; therefore, a large amount ofsludge is prevented from being deposited at the bottom in the foundation pit; an oscillation assembly arranged in the pressing mechanism is used in cooperation, further extrusion drying treatment iscarried out on the sludge obtained after flow guiding, then maximum storage treatment is carried out on the sludge, and the dried sludge is used for reinforcing the foundation of the underground watertreatment system.

Owner:刘新用

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com