Patents

Literature

130 results about "Spiral wound membrane" patented technology

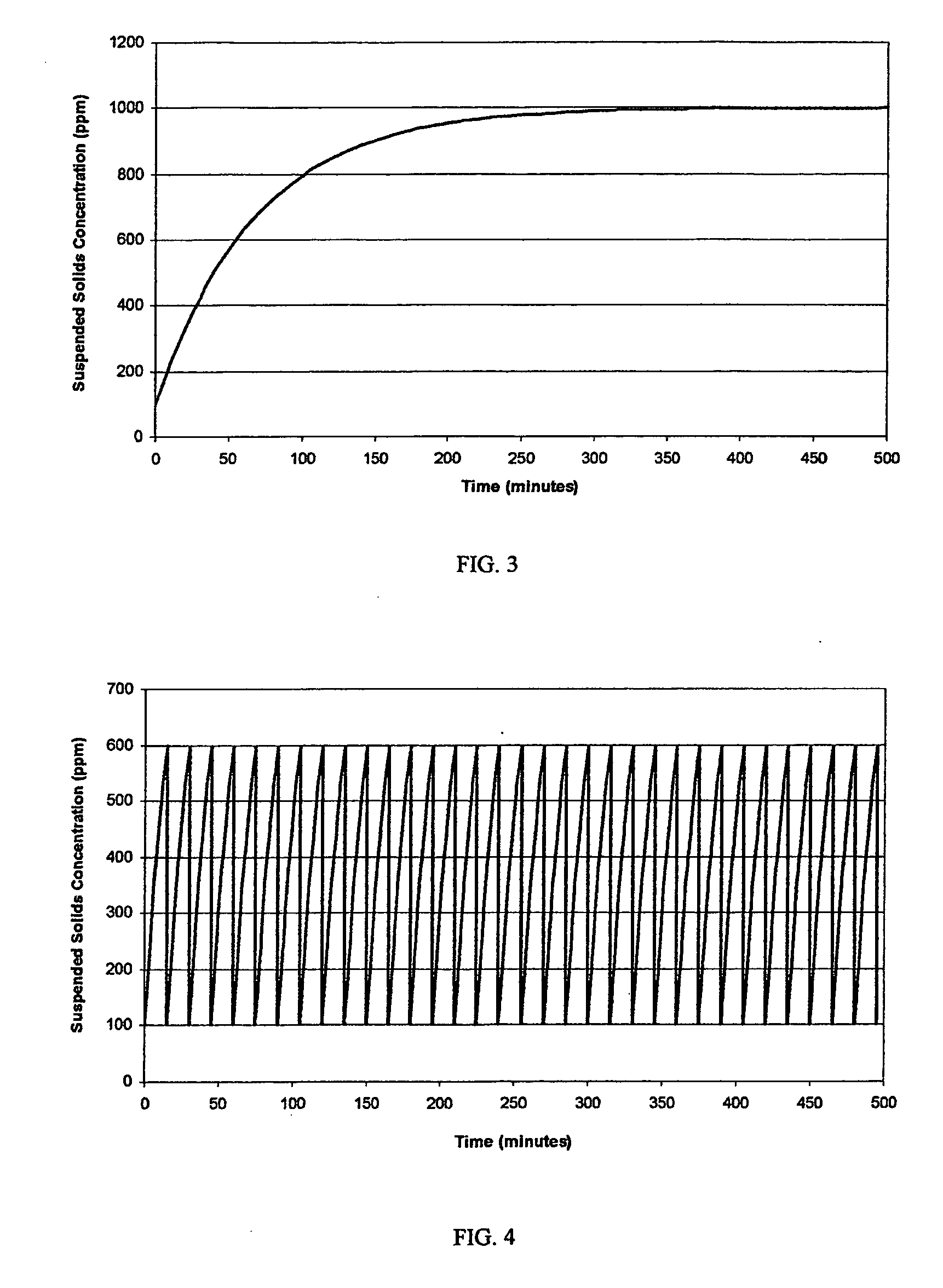

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

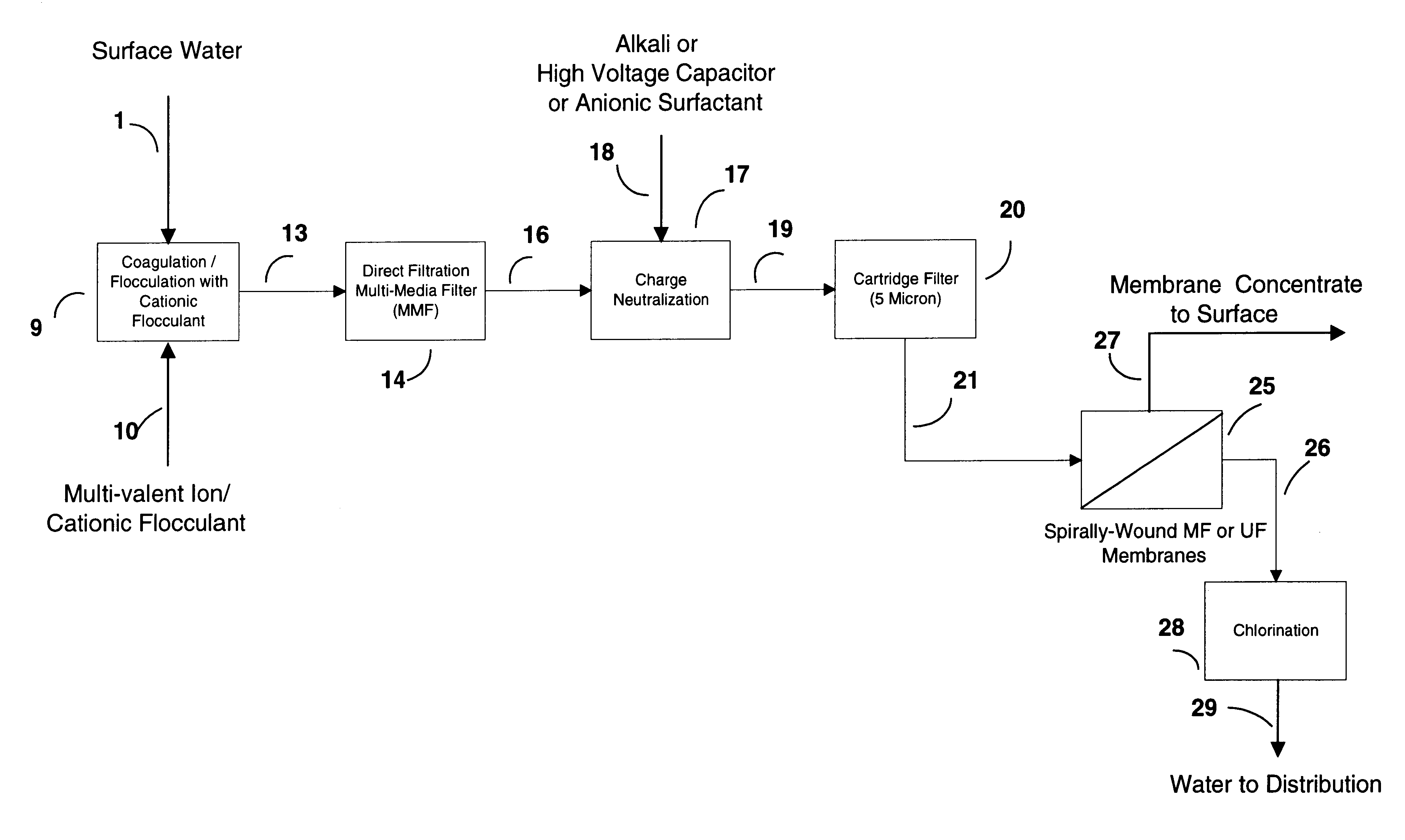

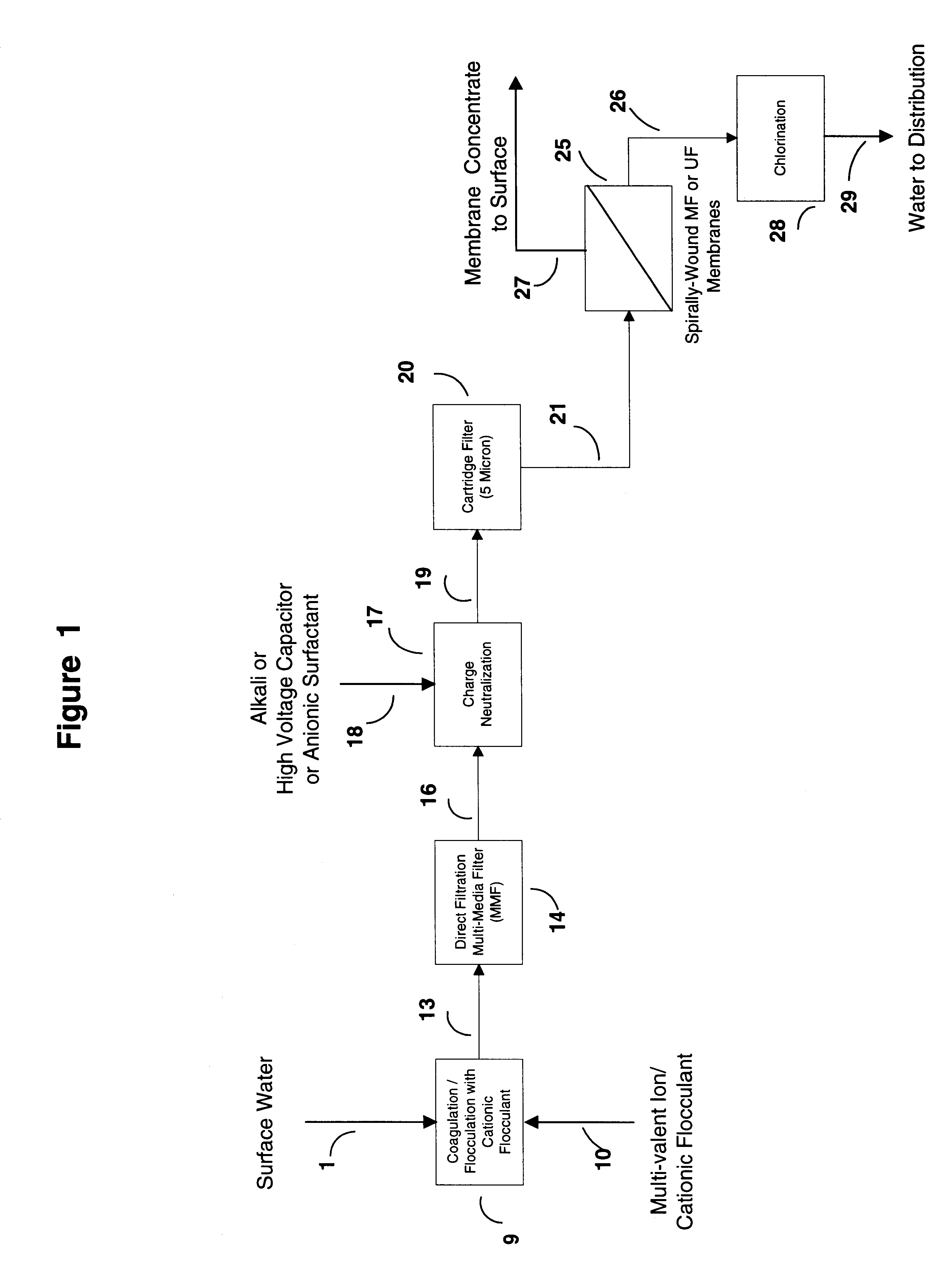

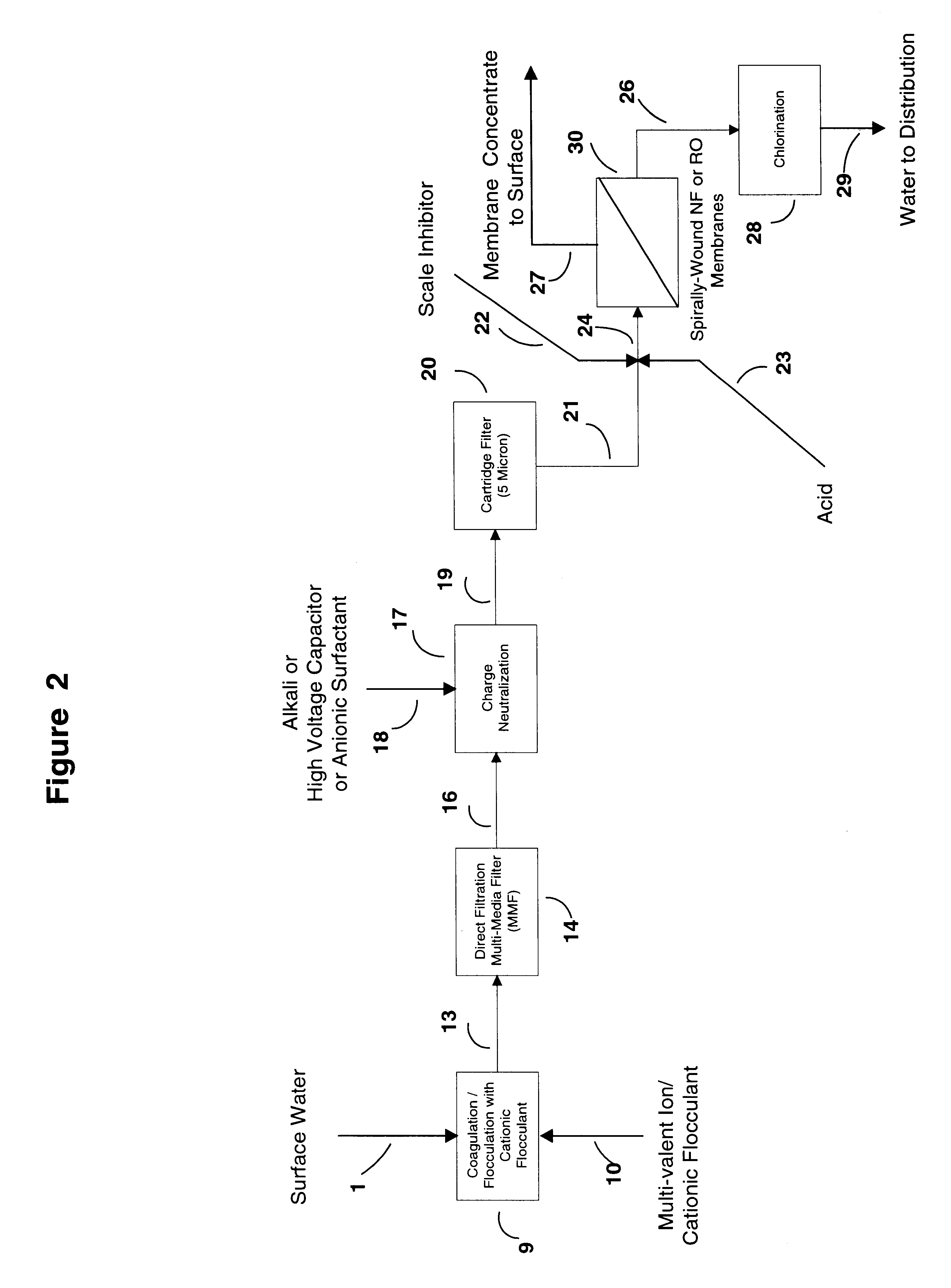

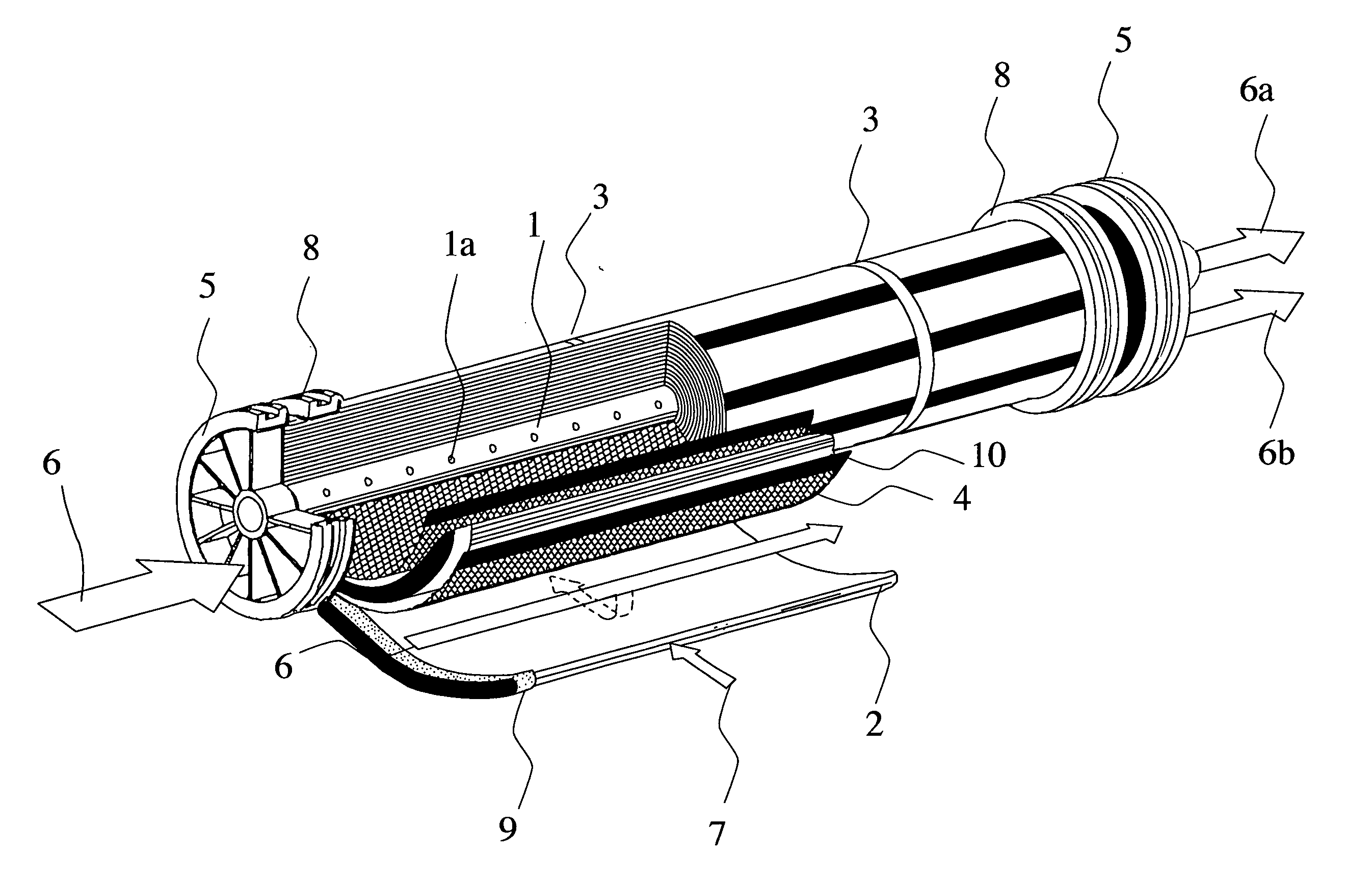

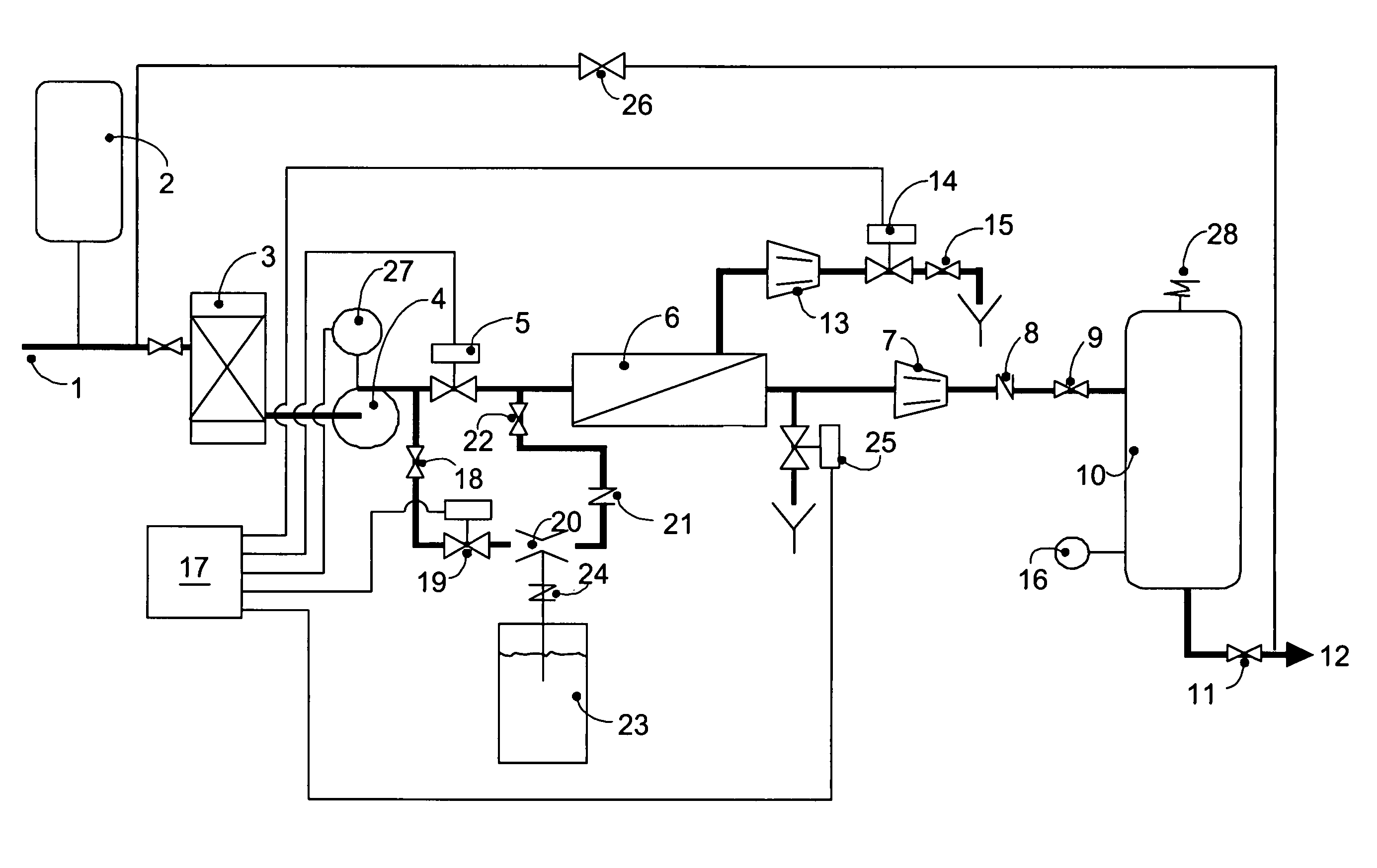

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

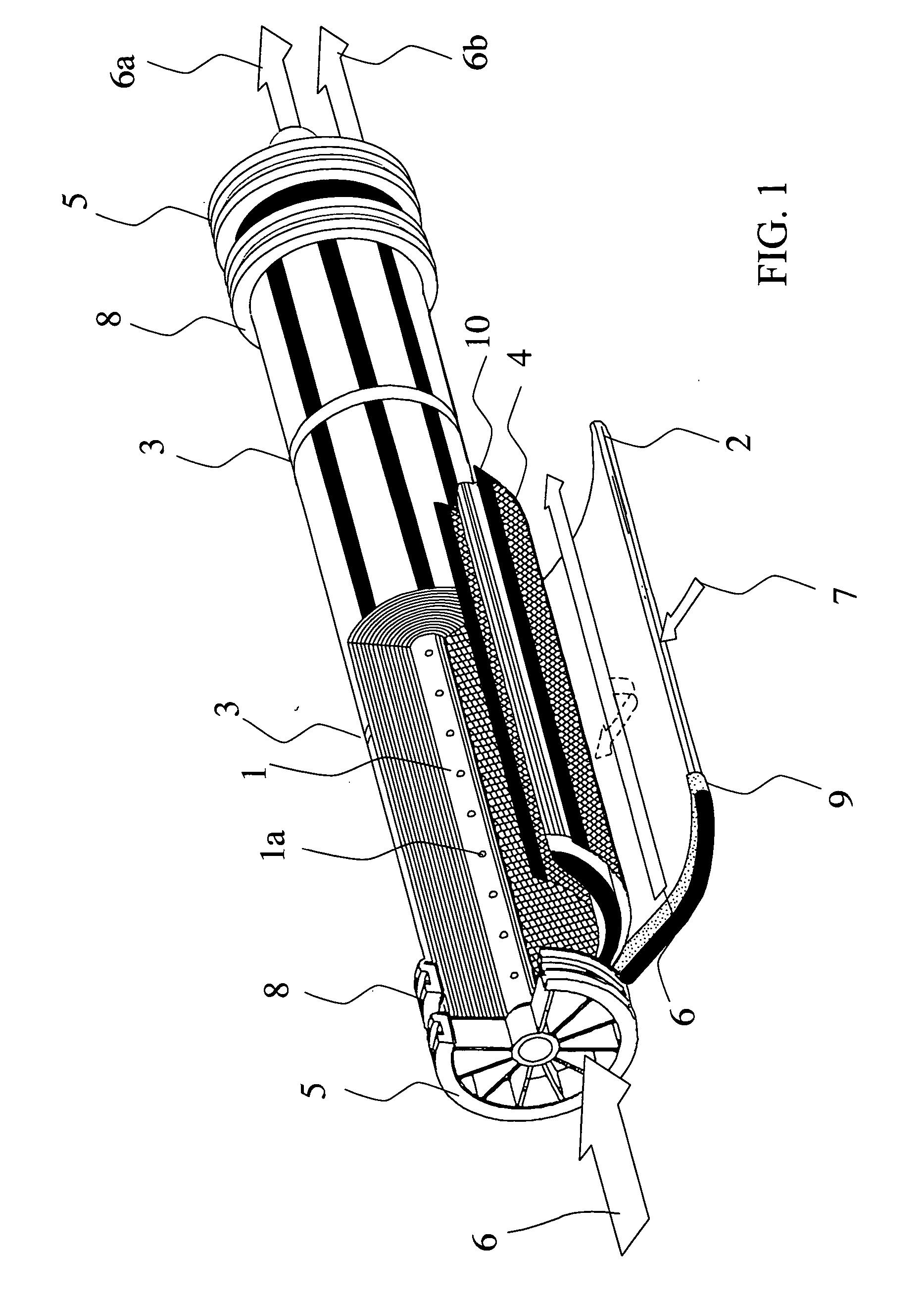

Spiral-wound liquid membrane module for separation of fluids and gases

InactiveUS20060131235A1Lower energy requirementsEfficient separationMembranesSolid sorbent liquid separationChemical physicsSpiral wound

The present invention is a filtering and chemical separation device that performs the operations of solvent extraction and pervaporation in a single piece of equipment, configured as a spiral-wound membrane module, and provides for the replenishment of the solvent in the supported liquid membrane while the module continues in operation. It provides a solution to the problem of separating miscible compounds efficiently and with low energy requirements.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

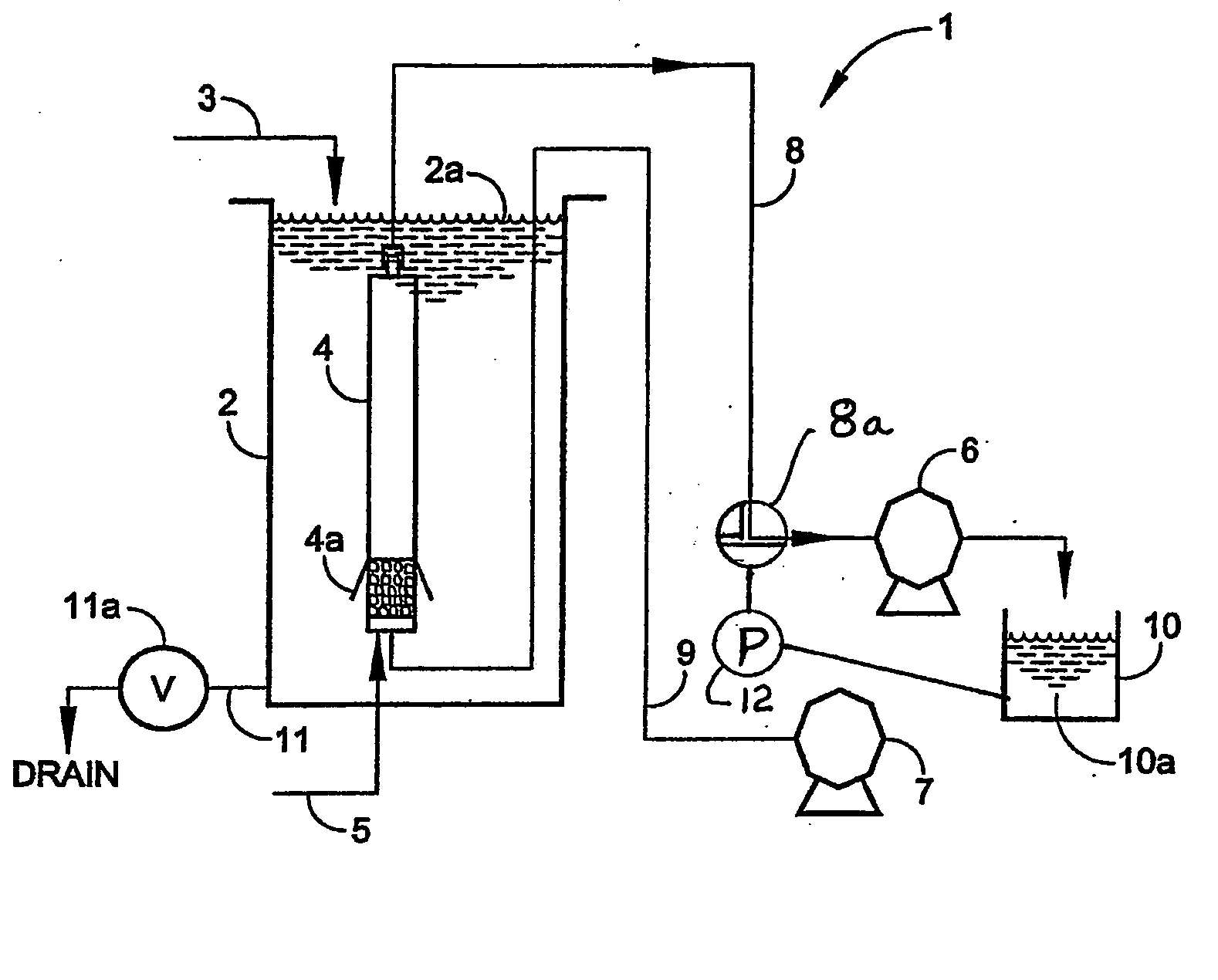

Low pressure filtration

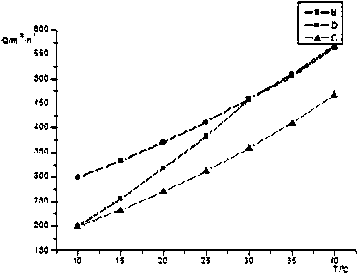

ActiveUS20070131614A1Produced economicallyReduce energy consumptionMembranesUltrafiltrationFiltrationStreamflow

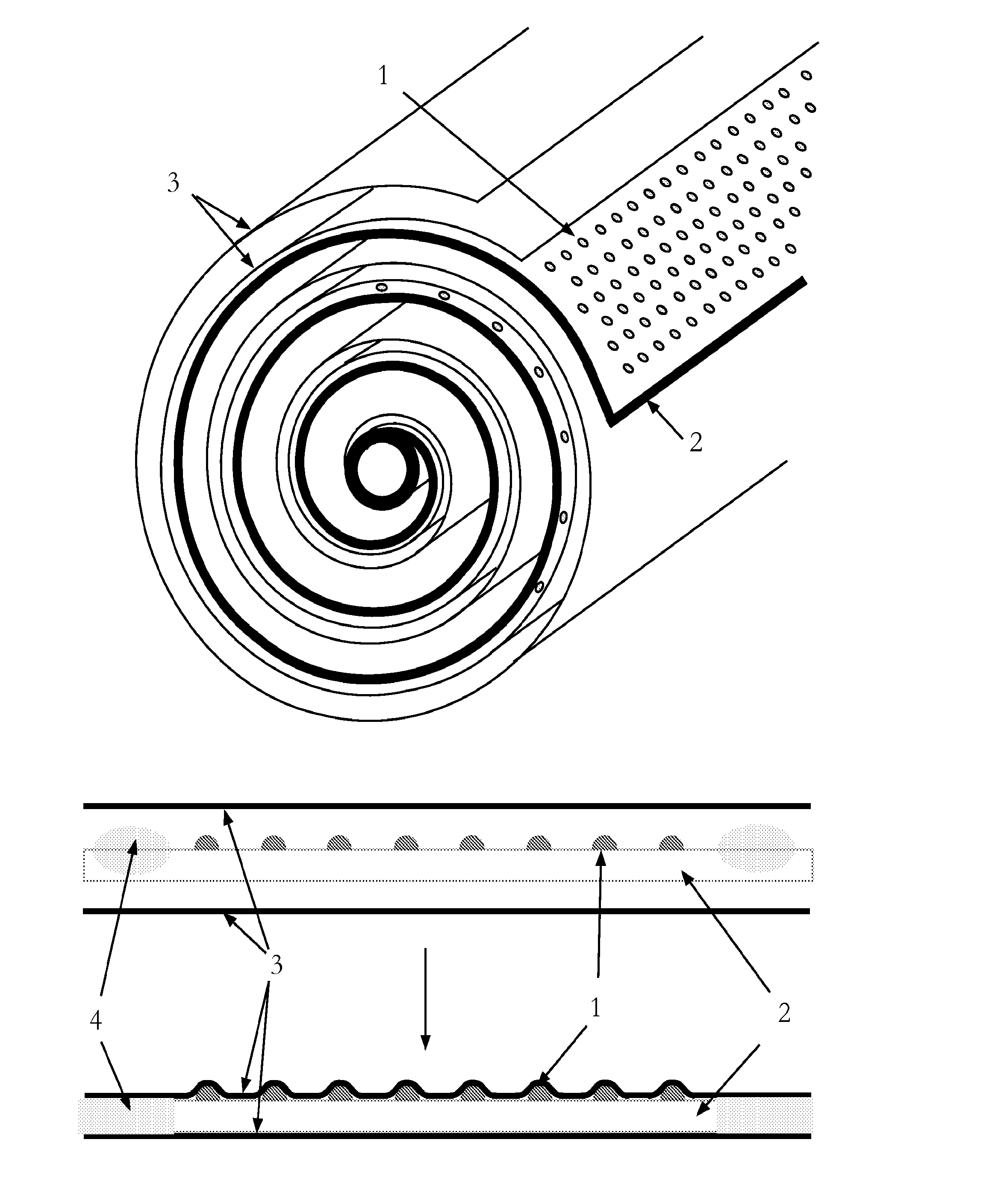

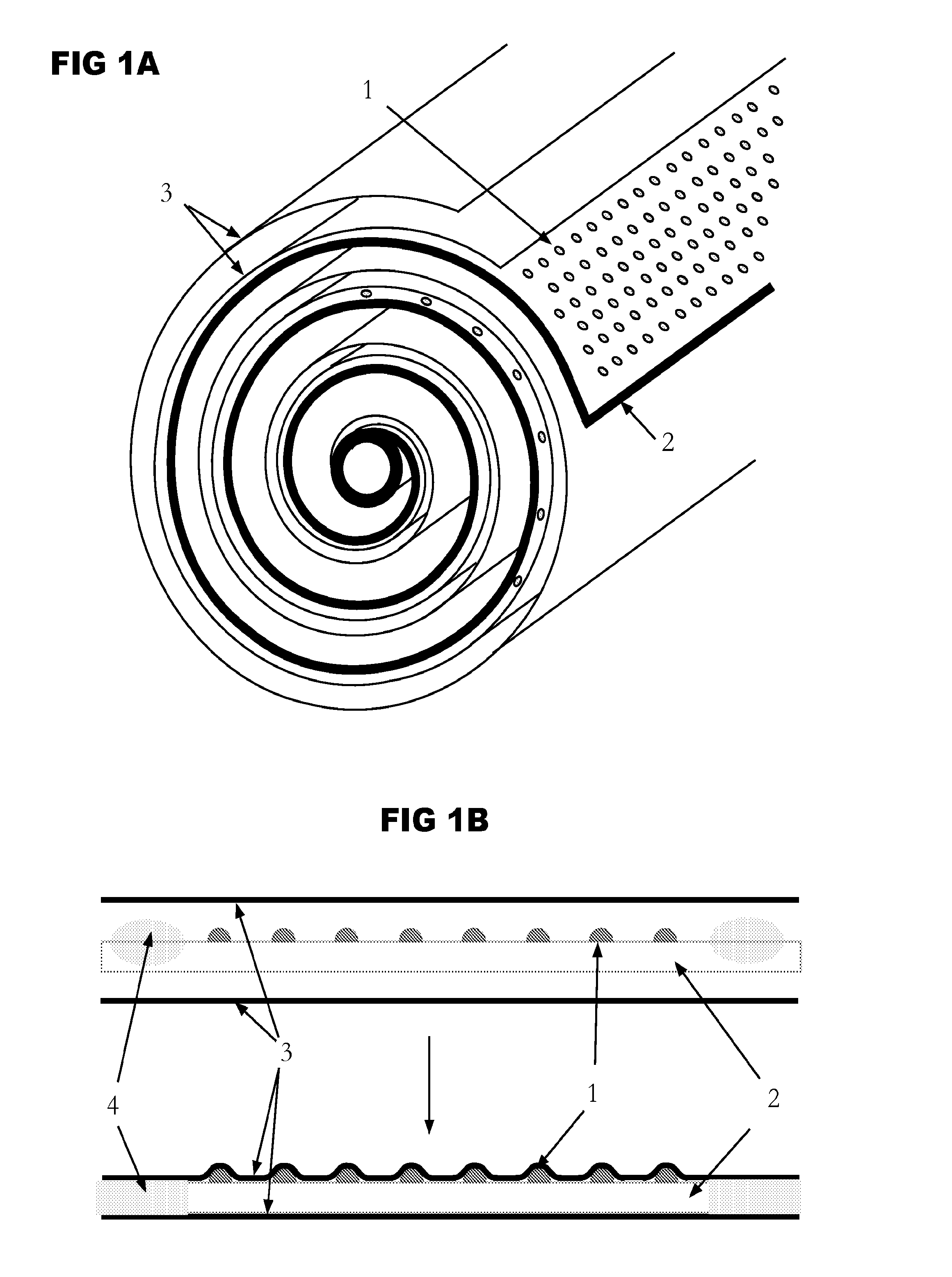

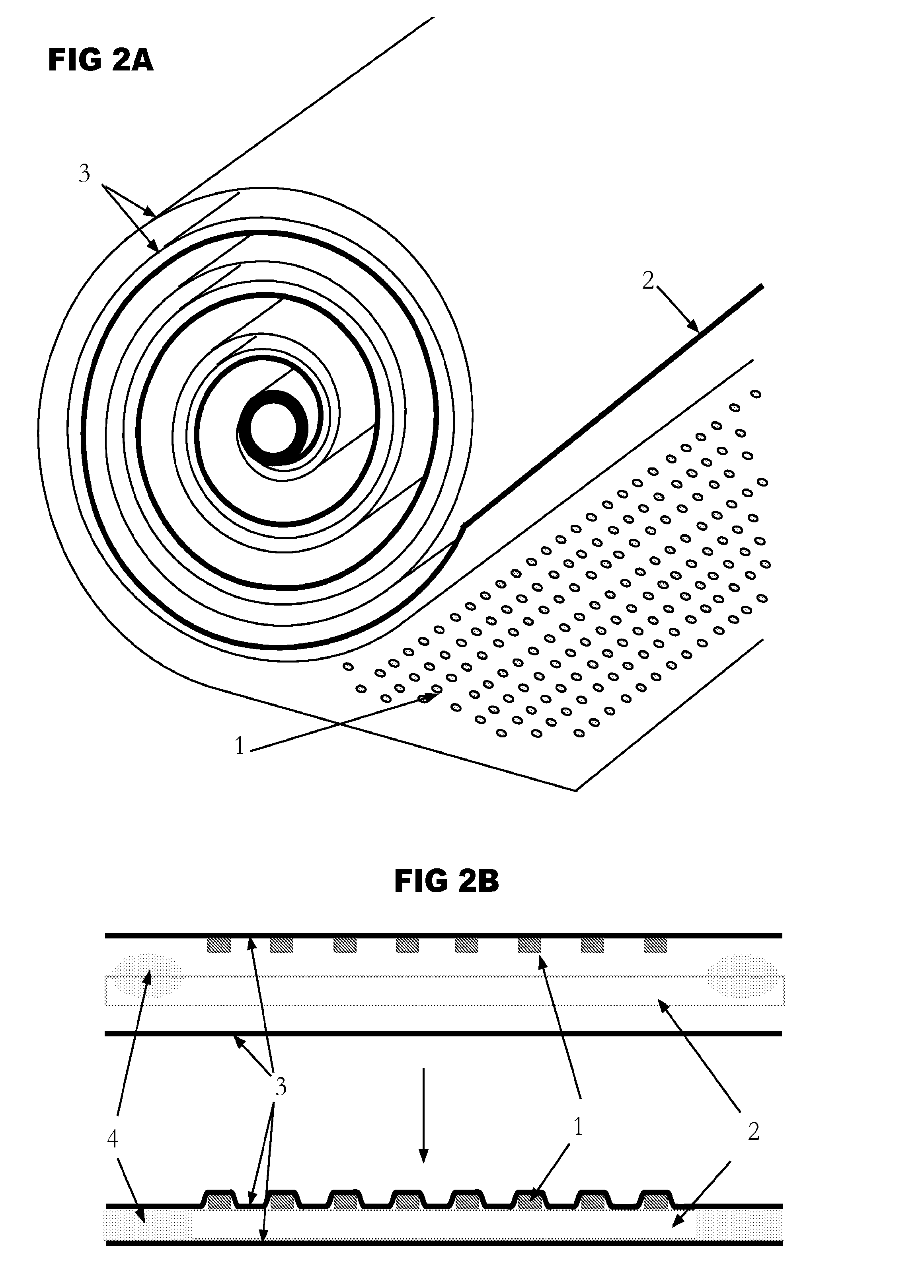

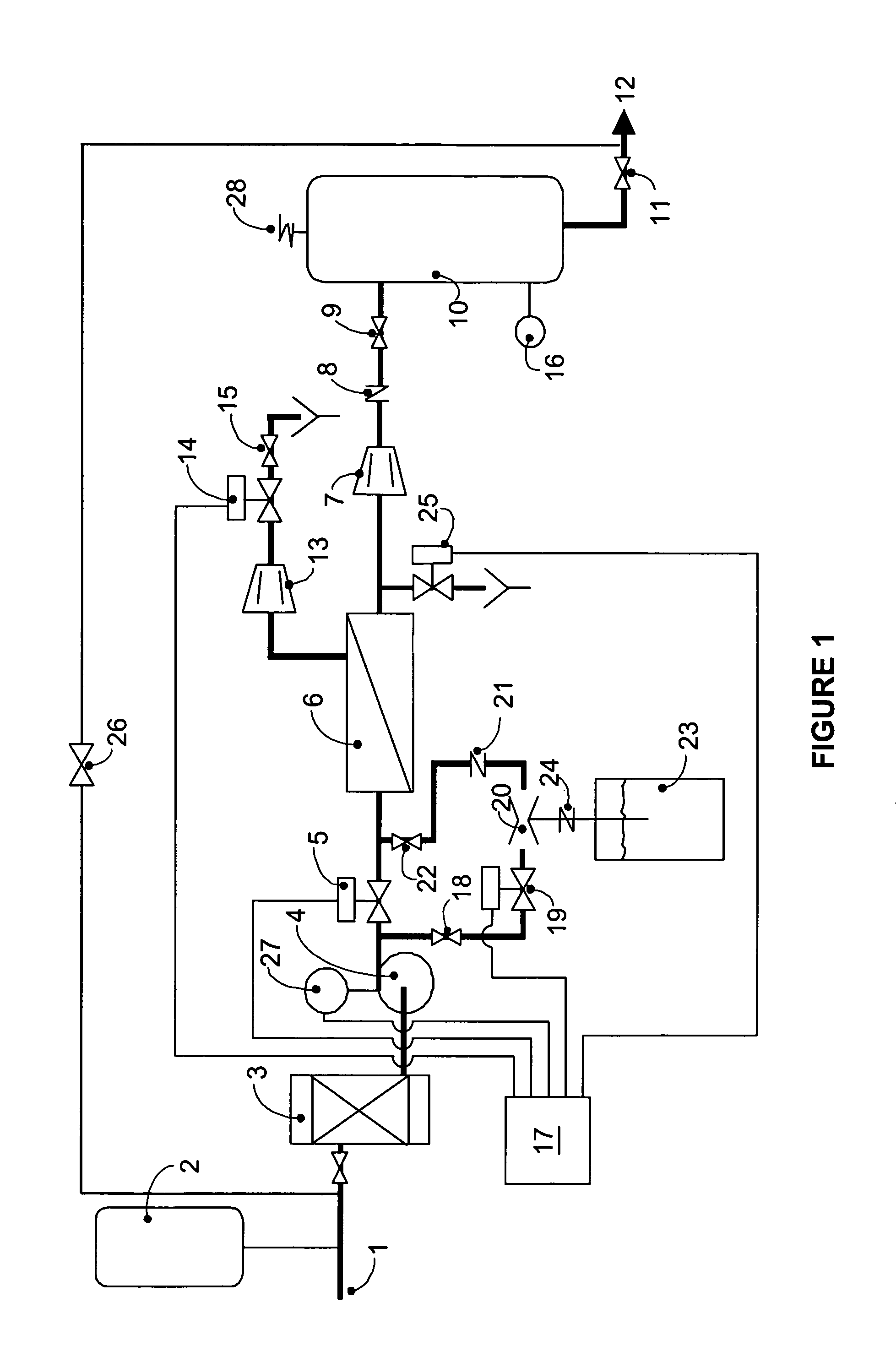

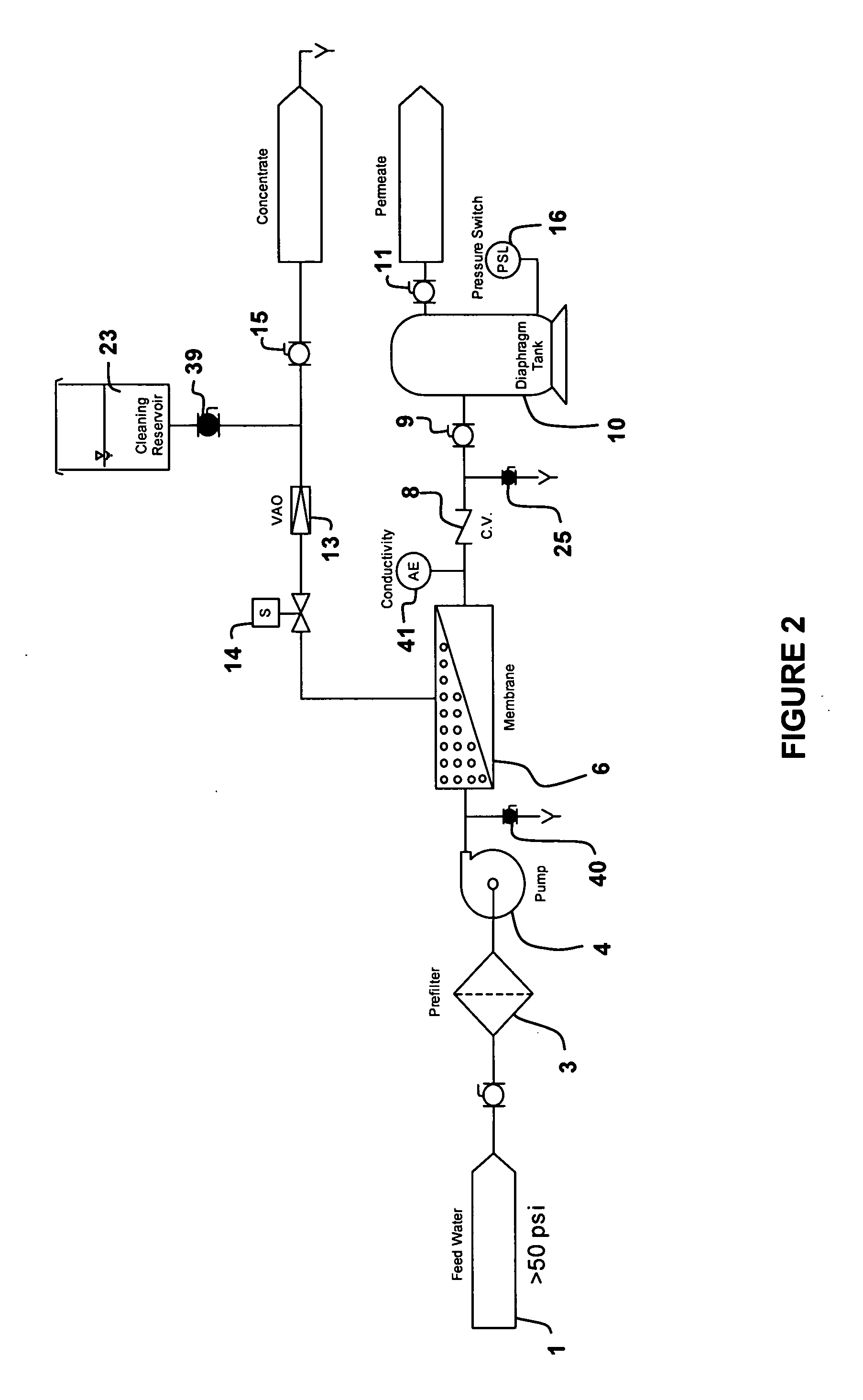

High flow, low-pressure ultrafiltration or microfiltration spiral wound membrane cartridges are used in filtration of liquid feedstocks having high suspended solids. Applications may utilize either vacuum or pumping for transmembrane drive pressure (TMP), and gas may optionally be bubbled up through the cartridges with certain feedstocks. Water permeate flux rates as high as 90 gallons per square foot per day (gfd) can be obtained at TMPs below 5 pounds per square inch. By locating each spiral wound cartridge in its own casing and supplying liquid feedstock to an open lower end of the casing, as opposed to submerging such cartridges in a tank filled with feedstock, overall low pressure performance is greatly improved. High permeate flow can be maintained for long periods of time between shutdowns for intensive cleaning. TMP is gradually increased to maintain a substantially constant rate of permeate discharge until a target is reached, indicative of solids accumulation on the membrane surface to an undesirable extent; then backflushing is effected for a short time. Discarding the hold-up volume of feedstock in the cartridge, the backflushing fluid and dislodged solids, allows production to be promptly resumed with fresh feedstock at performance at near original levels.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

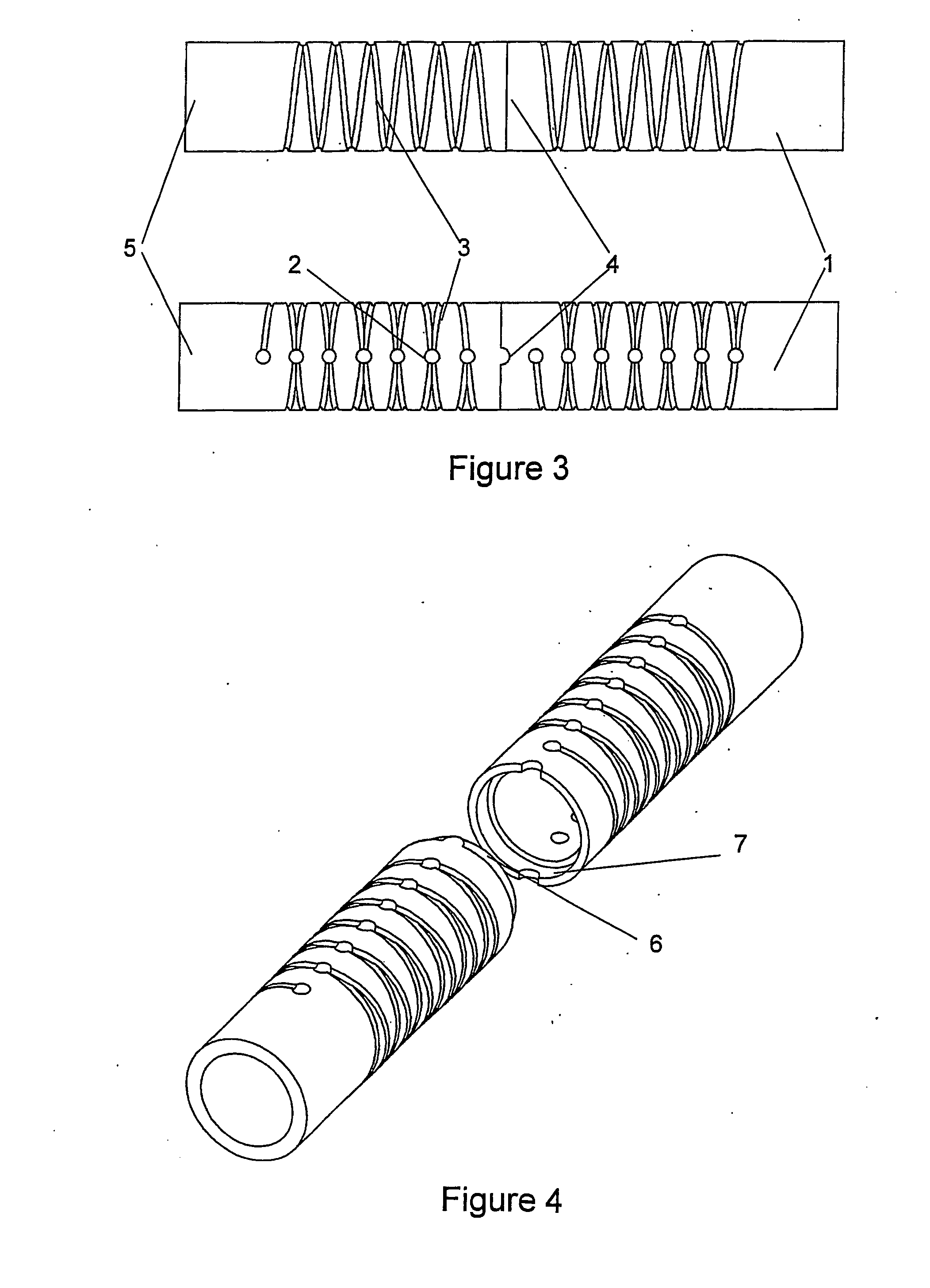

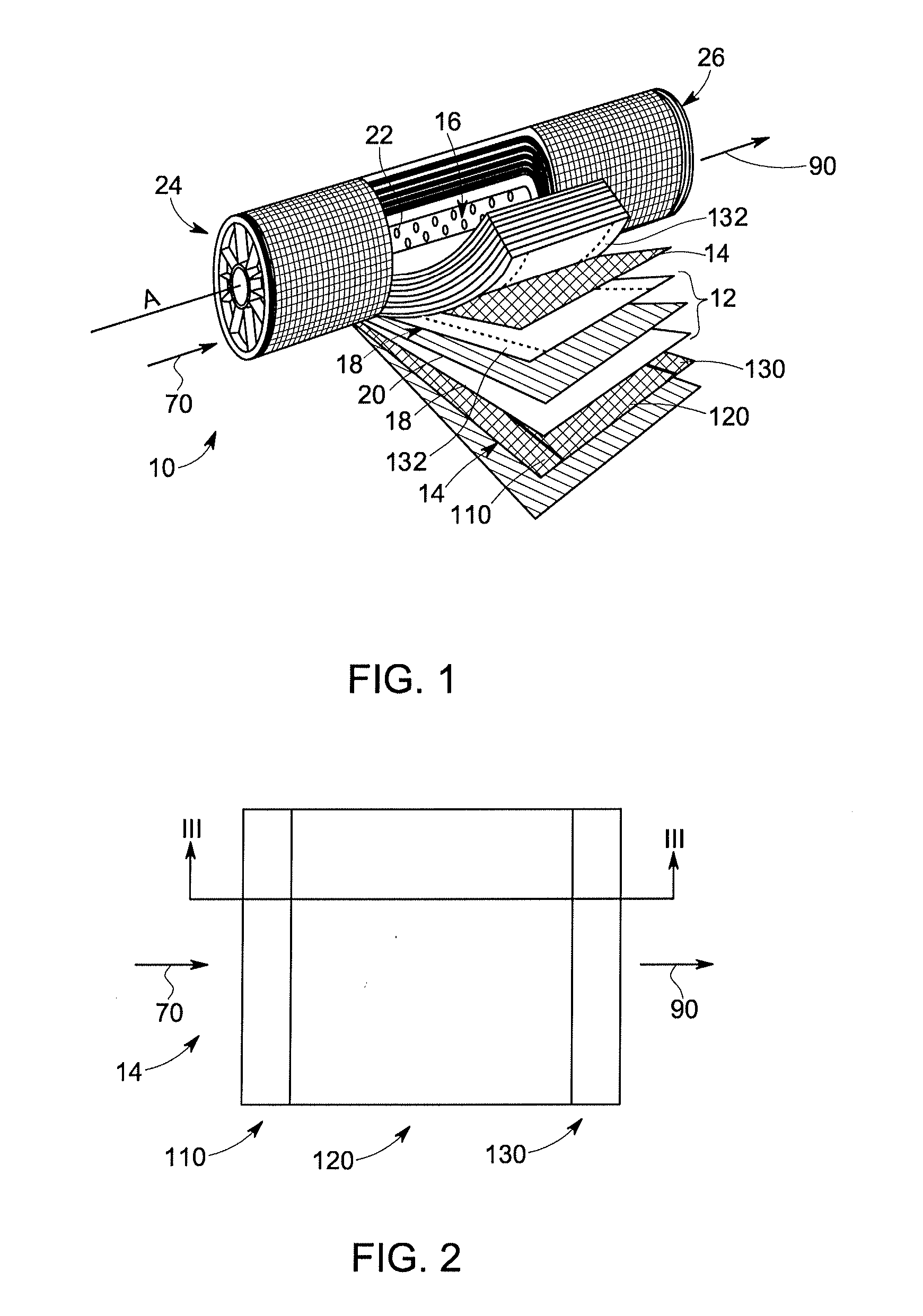

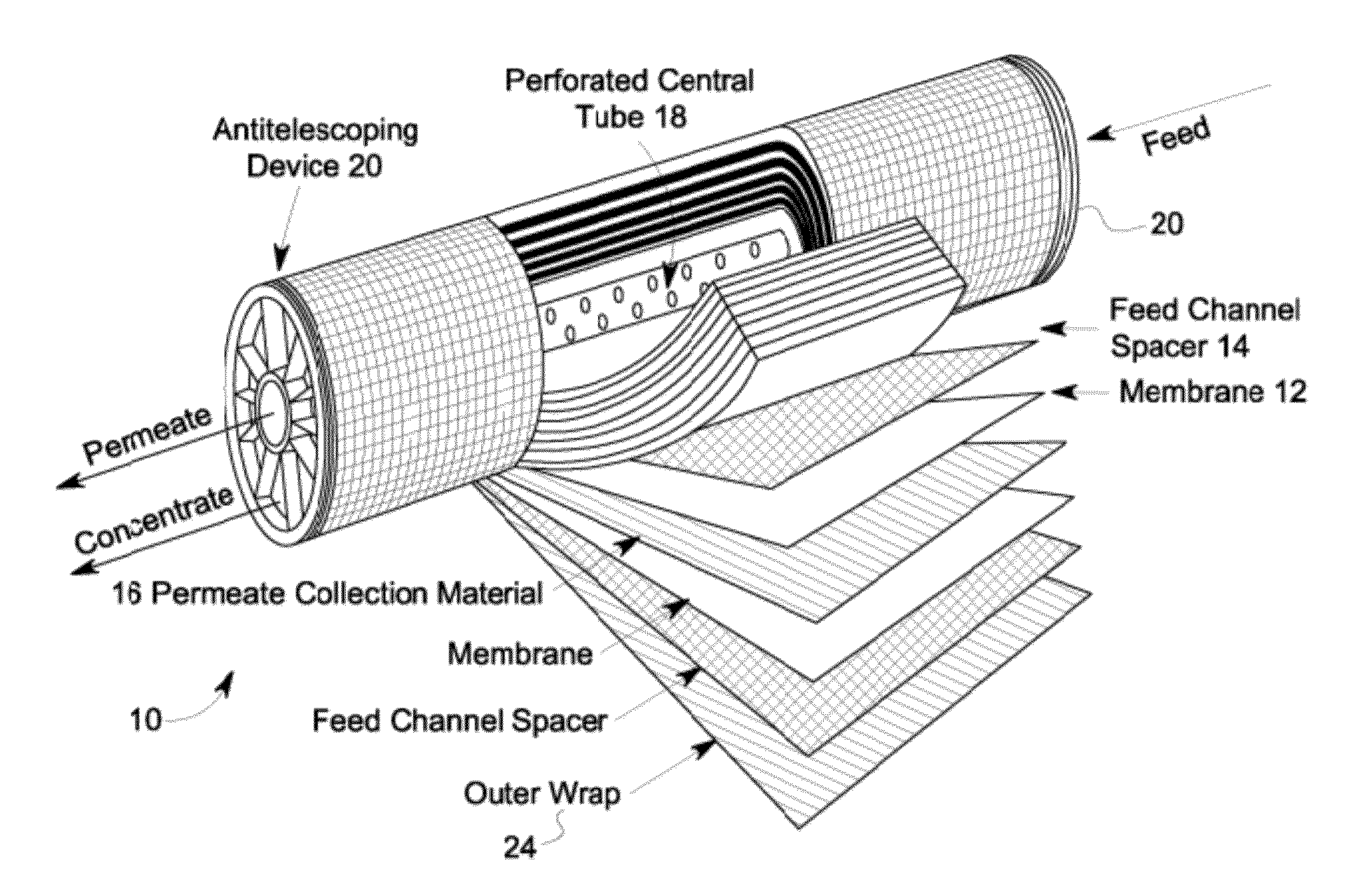

Improved Spiral Wound Element Construction

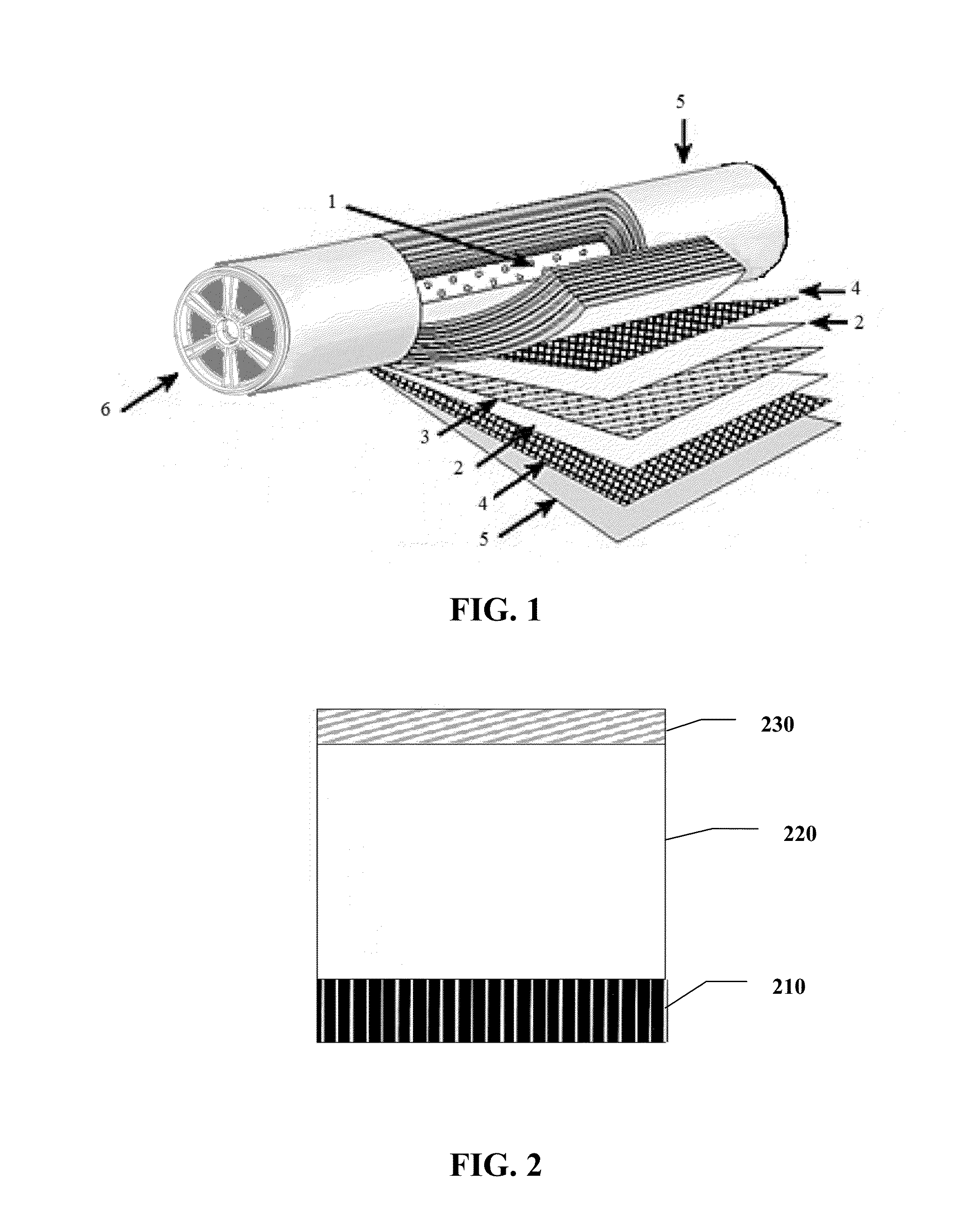

InactiveUS20160008763A1Paper/cardboard wound articlesLoose filtering material filtersFiltrationMembrane surface

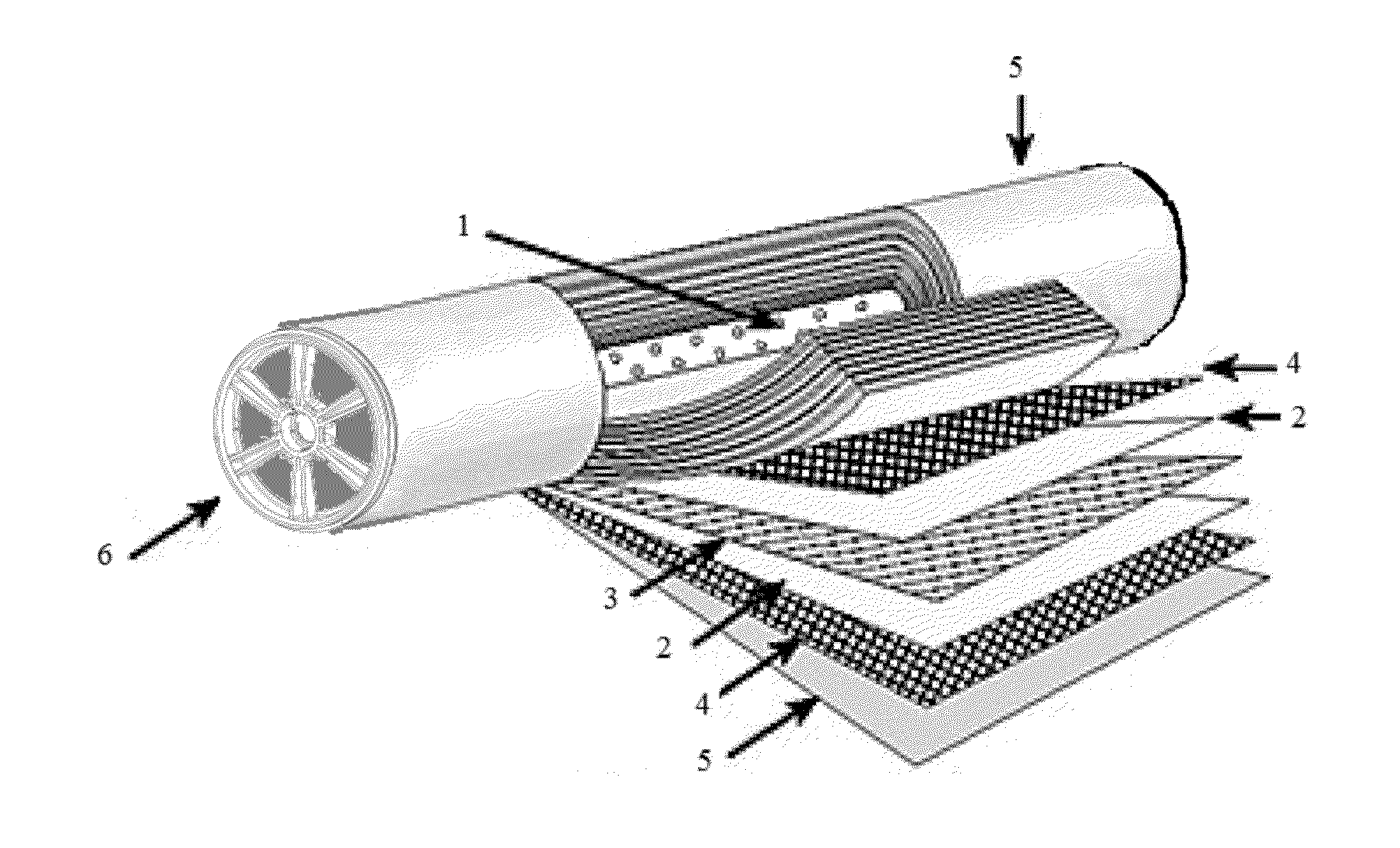

Embodiments of the present invention provide replacement of conventional separate feed spacer mesh with features placed, deposited or integrated on or into either the porous permeate carrier, the inactive side of the membrane sheet, or select portions of the membrane surface. Spiral-wound membrane filtration elements well known in the art consist of a laminated structure comprised of a membrane sheet sealed to or around a porous permeate carrier which creates a path for removal of the fluid passing through the membrane to a central tube, while this laminated structure is wrapped spirally around the central tube and spaced from itself with a porous feed spacer to allow axial flow of the fluid through the element.

Owner:AQUA MEMBRANES

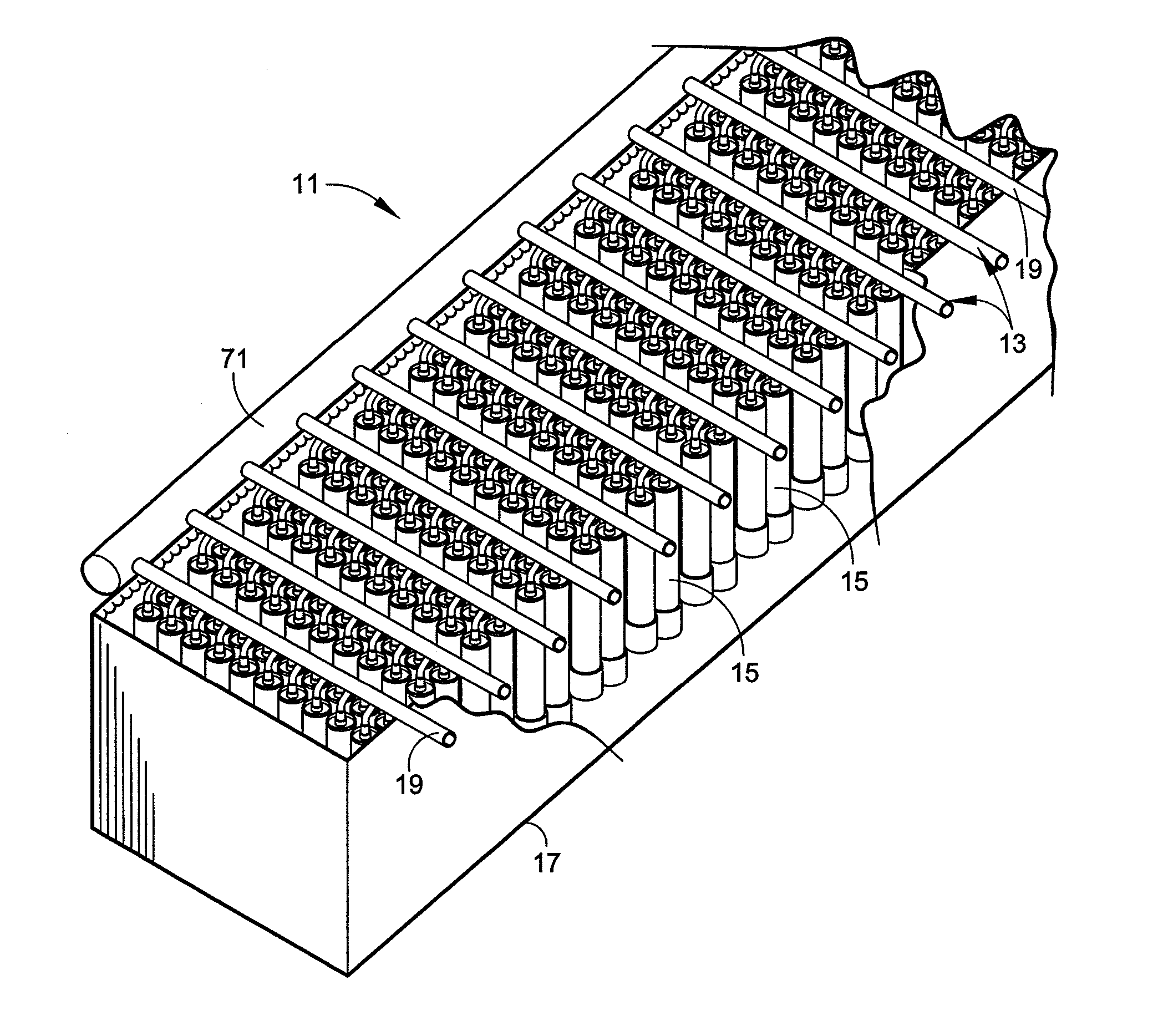

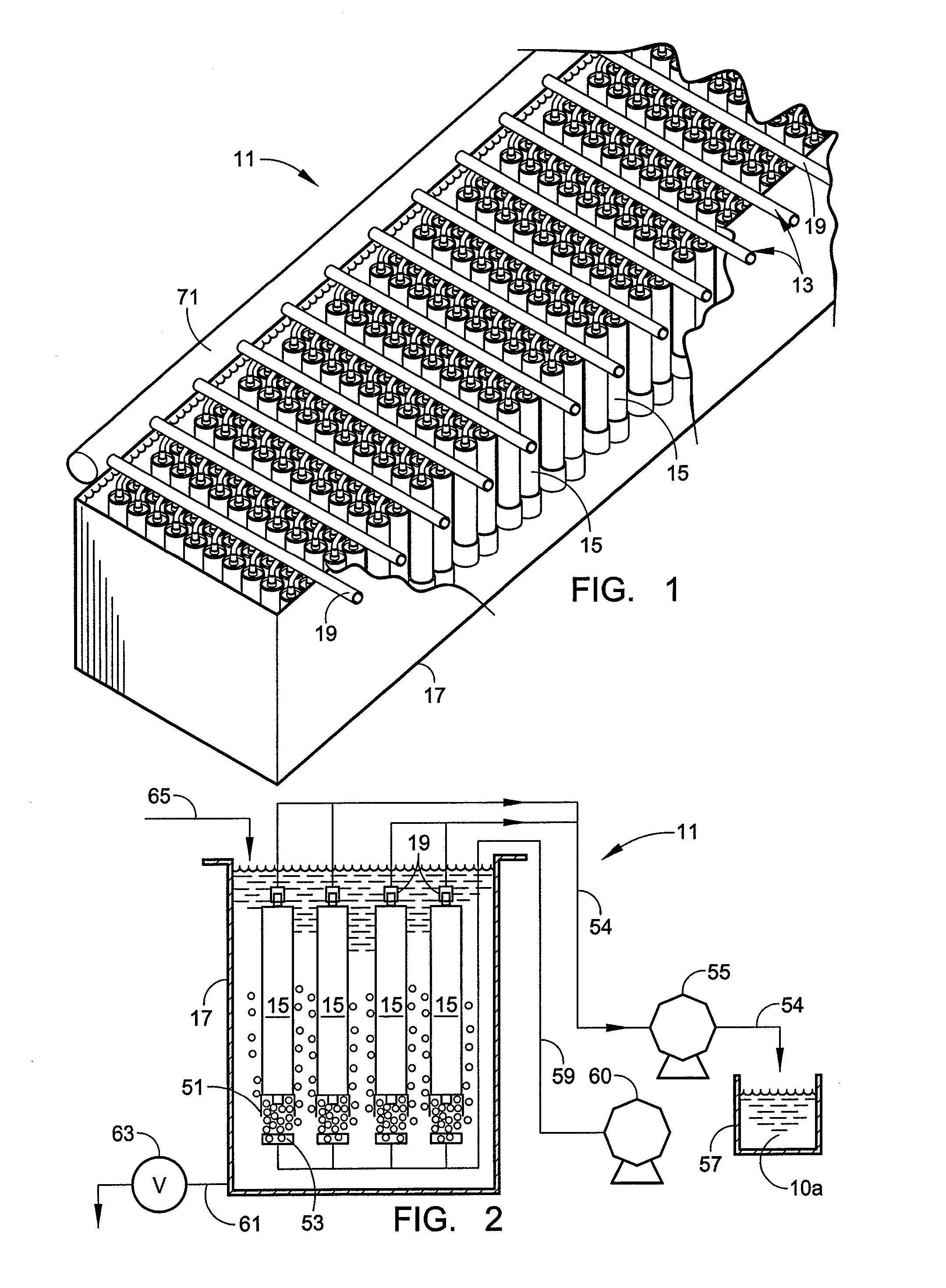

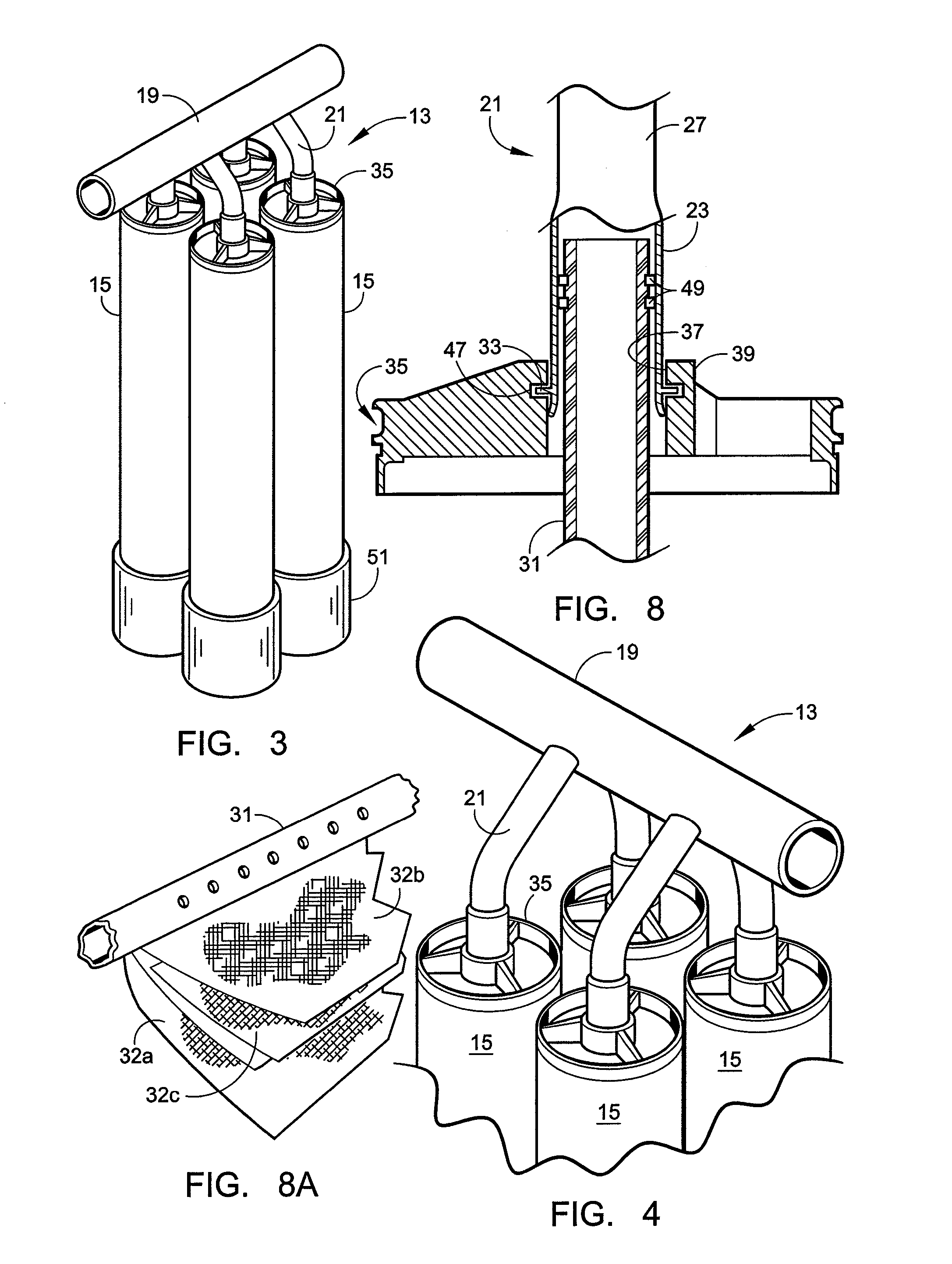

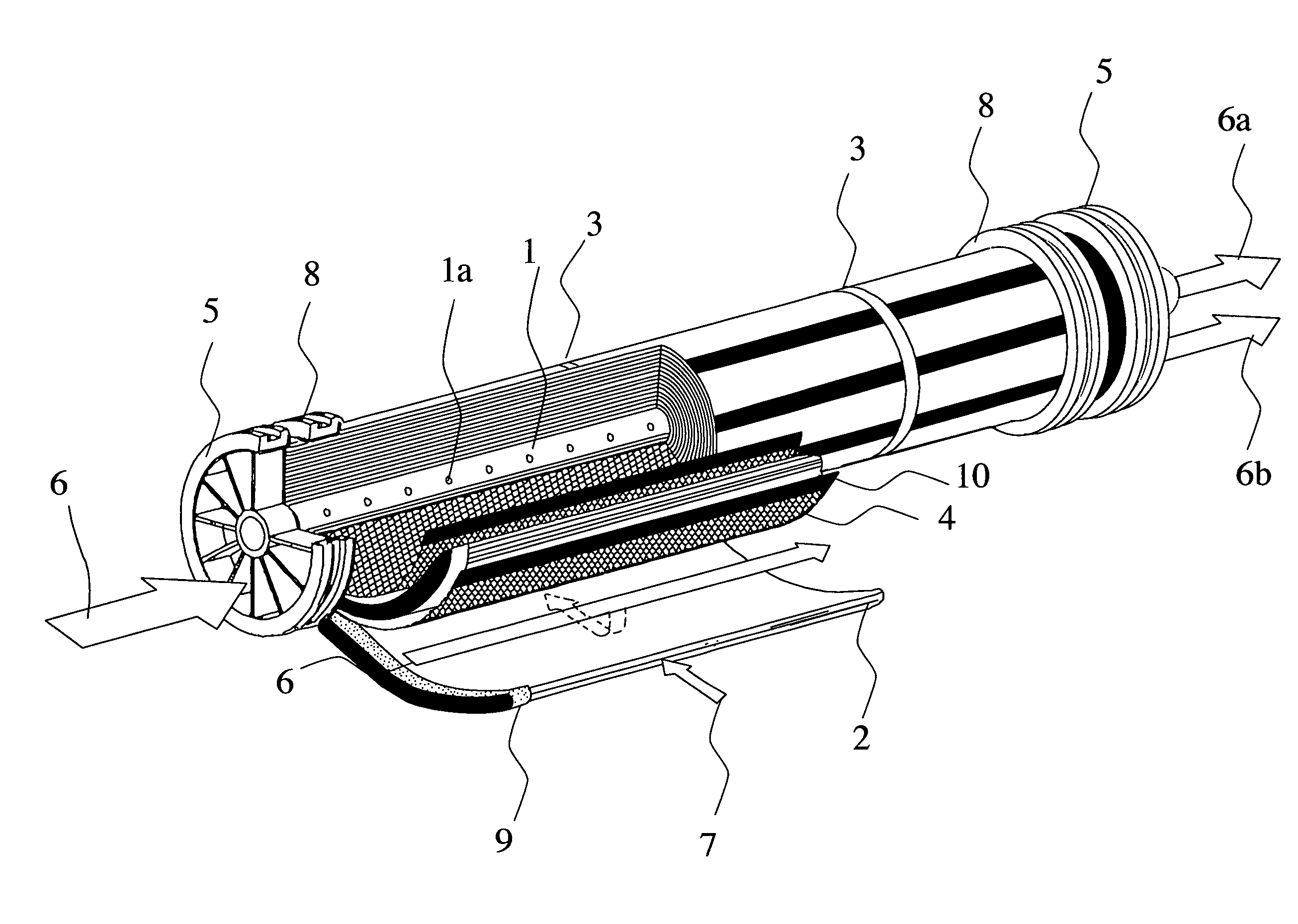

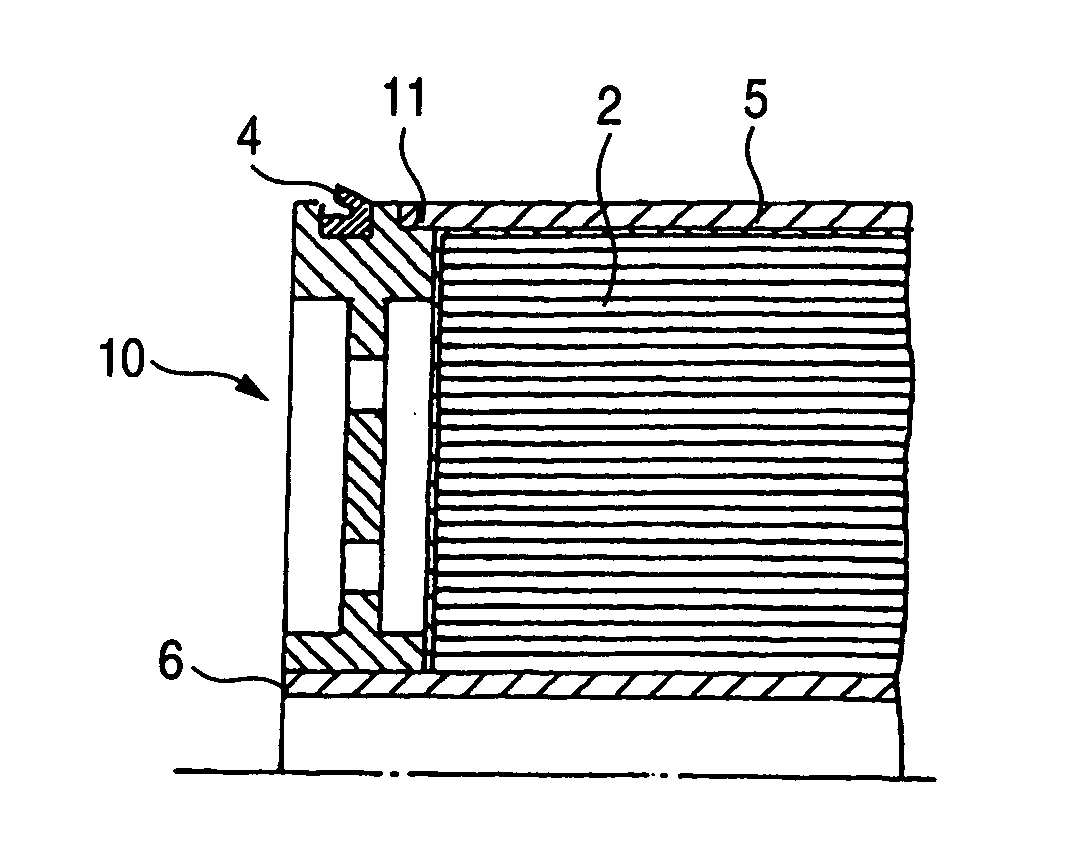

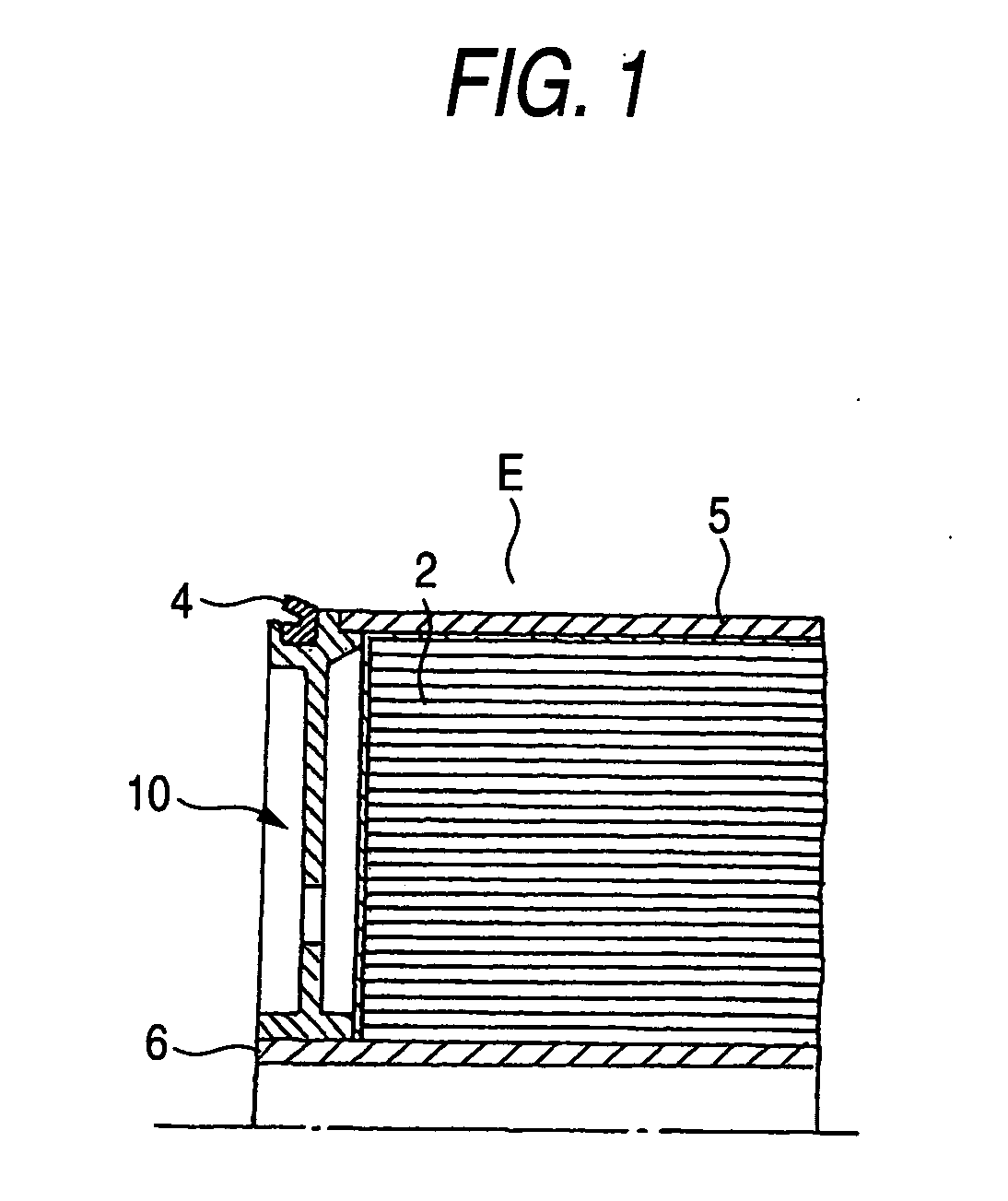

Network for supporting spiral wound membrane cartridges for submerged operation

Methods and apparatus are provided for positioning a plurality of cylindrical spirally wound membrane filtration elements in a body of aqueous feedstock employing manifold conduits that support vertically aligned filtration elements via short lengths of pipe. Efficient and effective connections are made between the ends of such support pipes and the adjacent end of each filtration element by bayonet-type fittings, which allow straightforward, detachable interconnection by axially moving the cylindrical element into place and then rotating the element a quarter turn. Support in this manner provides full access to the open lower ends of the element through which, during operation, streams of rising gas bubbles are caused to pass, fed from underlying bubblers or the like. The manifold conduits may be located either above or below the preferably vertically oriented filtration elements.

Owner:TRISEP CORP

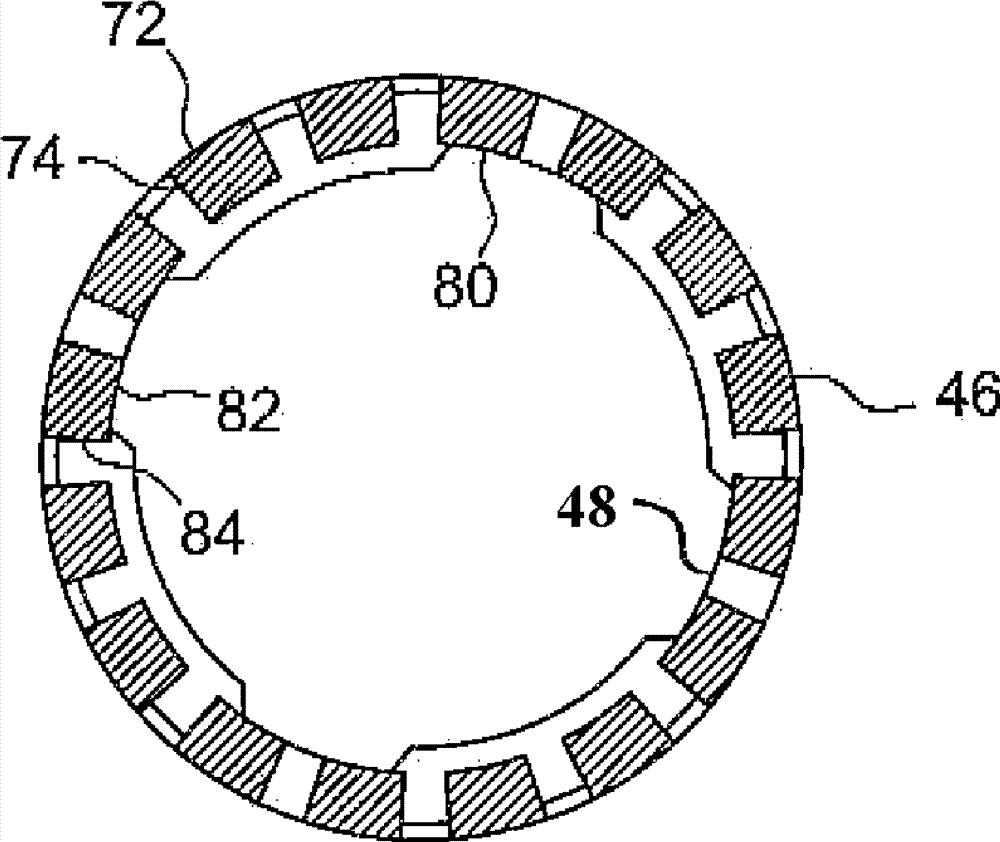

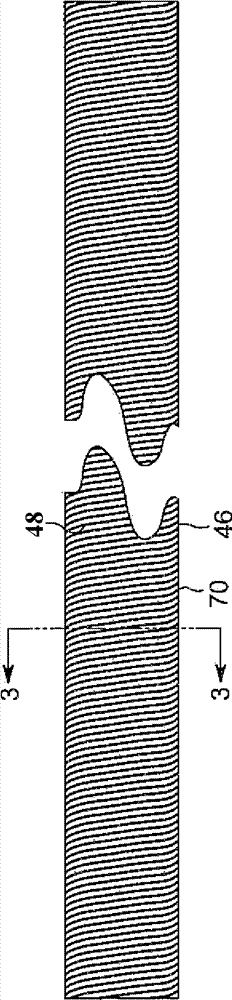

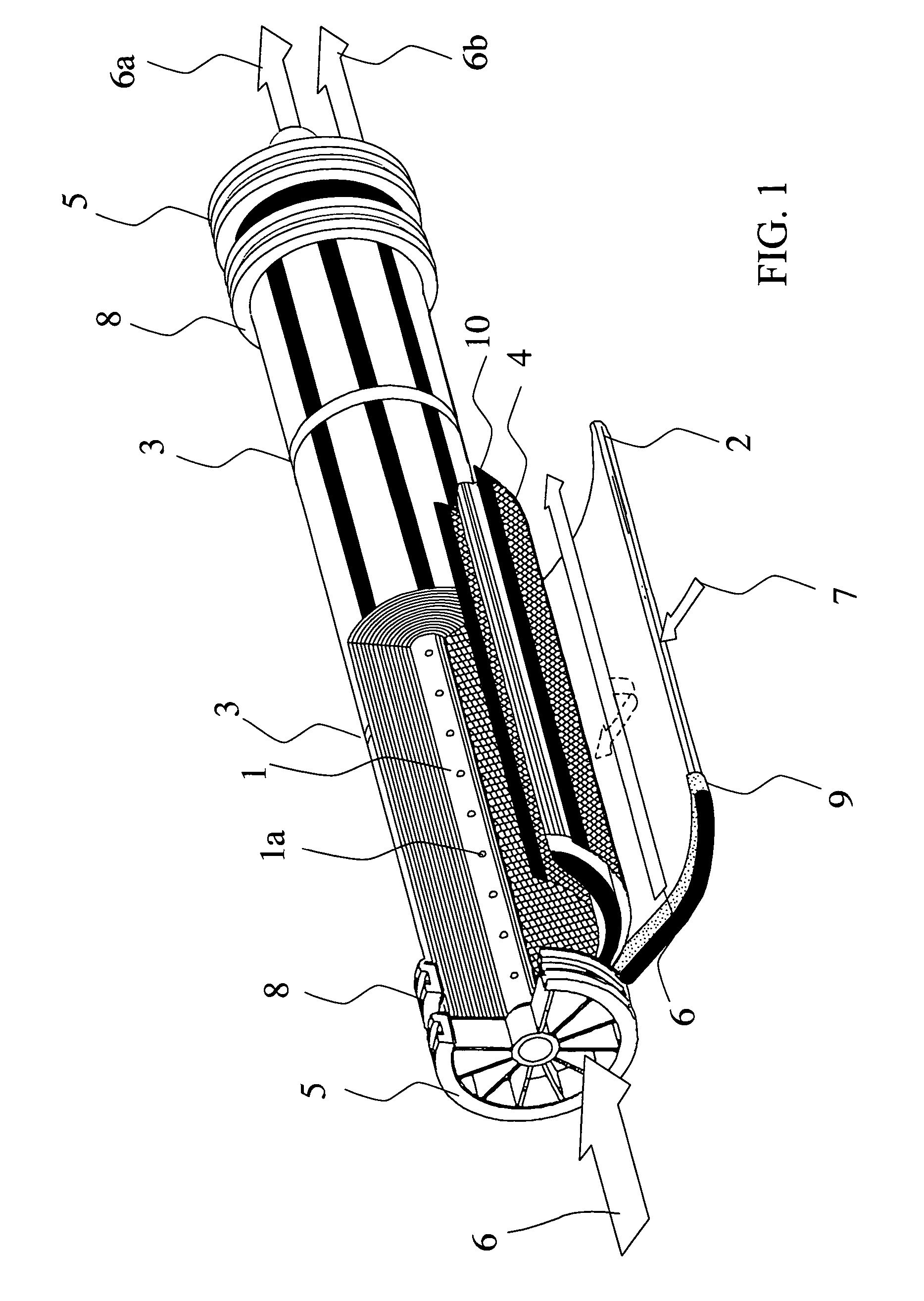

Spiral wound membrane element product water tube with external flow grooves

The disclosed product water tube (70) is for use with a spiral wound filter element having a filter membrane. The product water tube has a tube wall with a plurality of apertures (48) formed therein to allow permeate from the filter membrane to pass through the tube wall and into a center portion of the tube. The tube wall has an outer surface having a pattern of ridges (72) and channels (74) that conduct the permeate across the outer surface of the tube to the apertures.

Owner:BL TECH INC

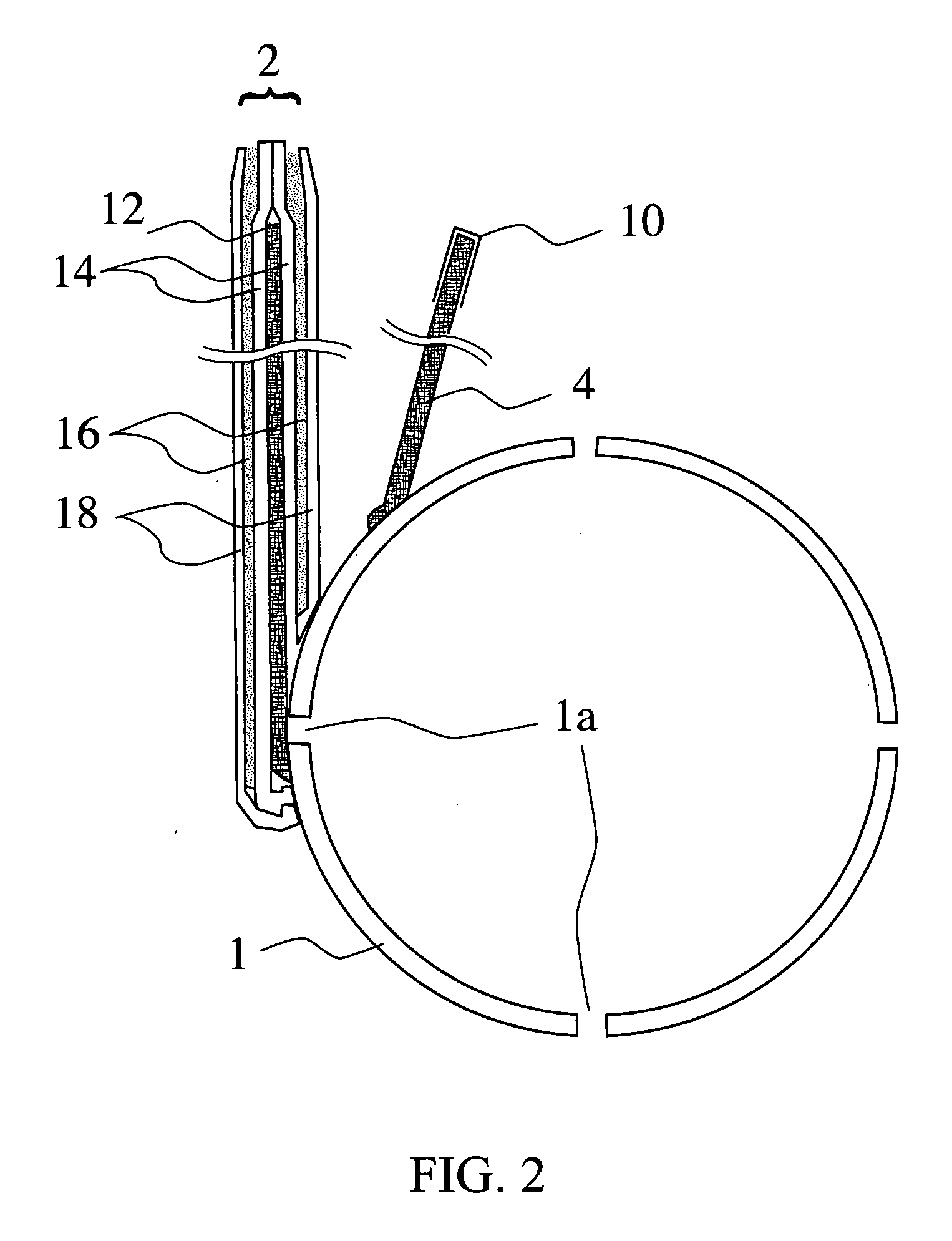

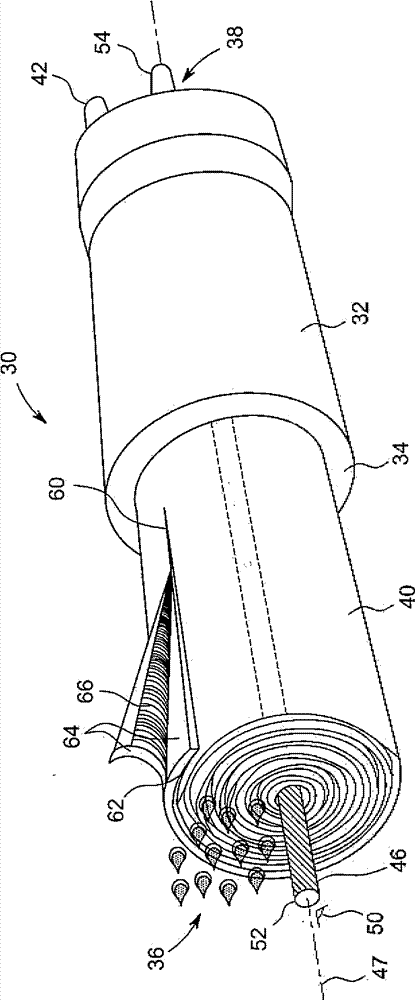

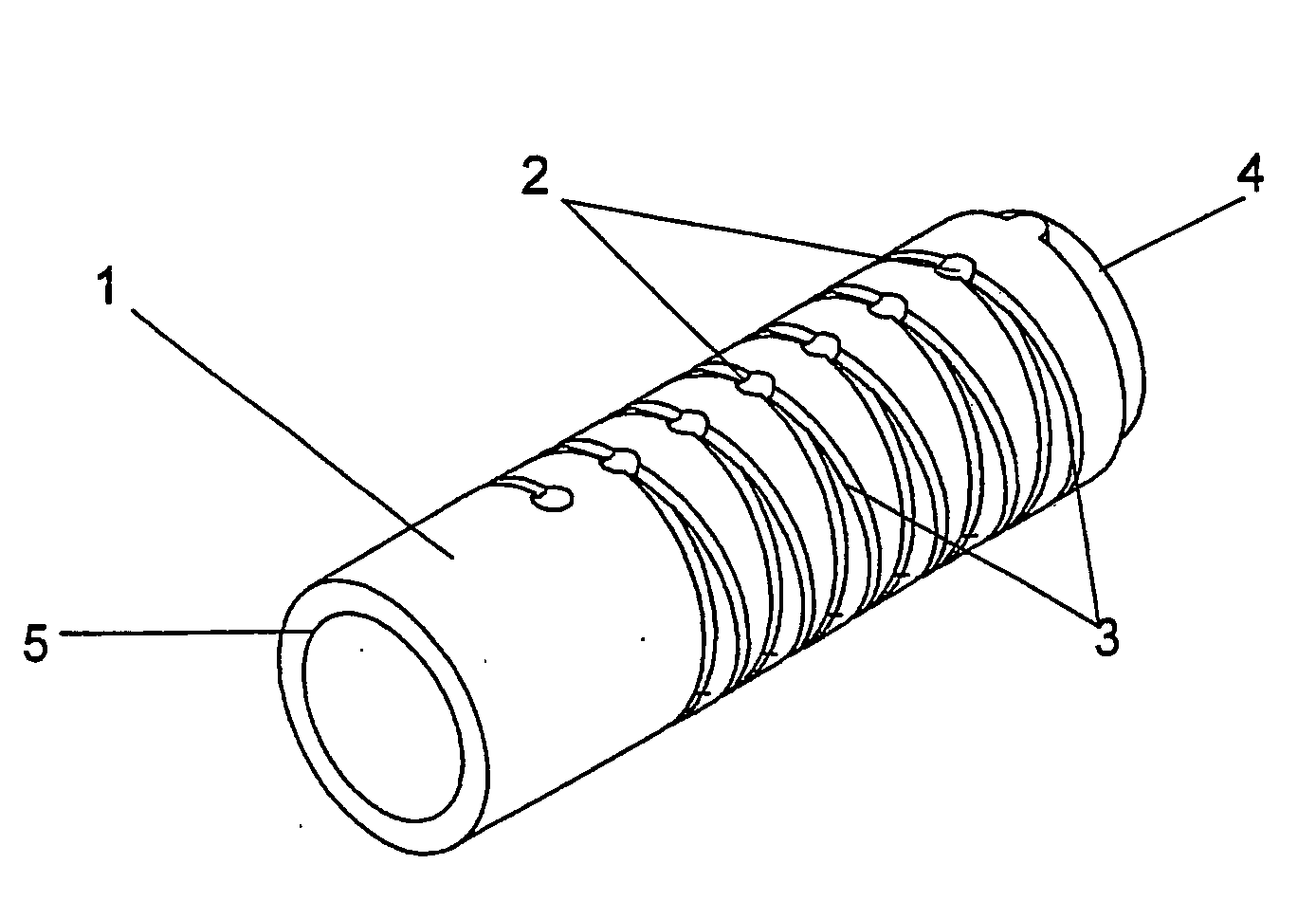

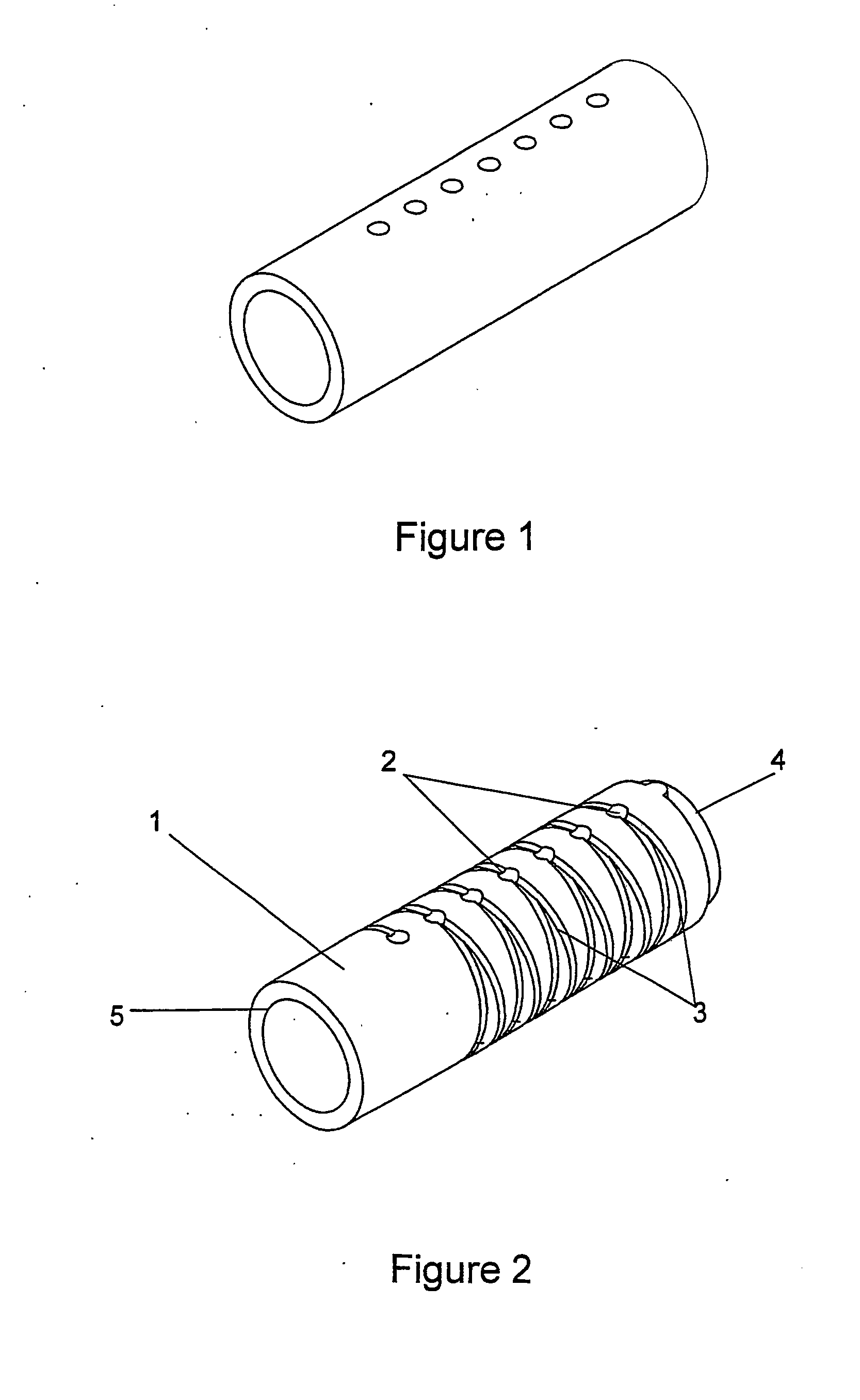

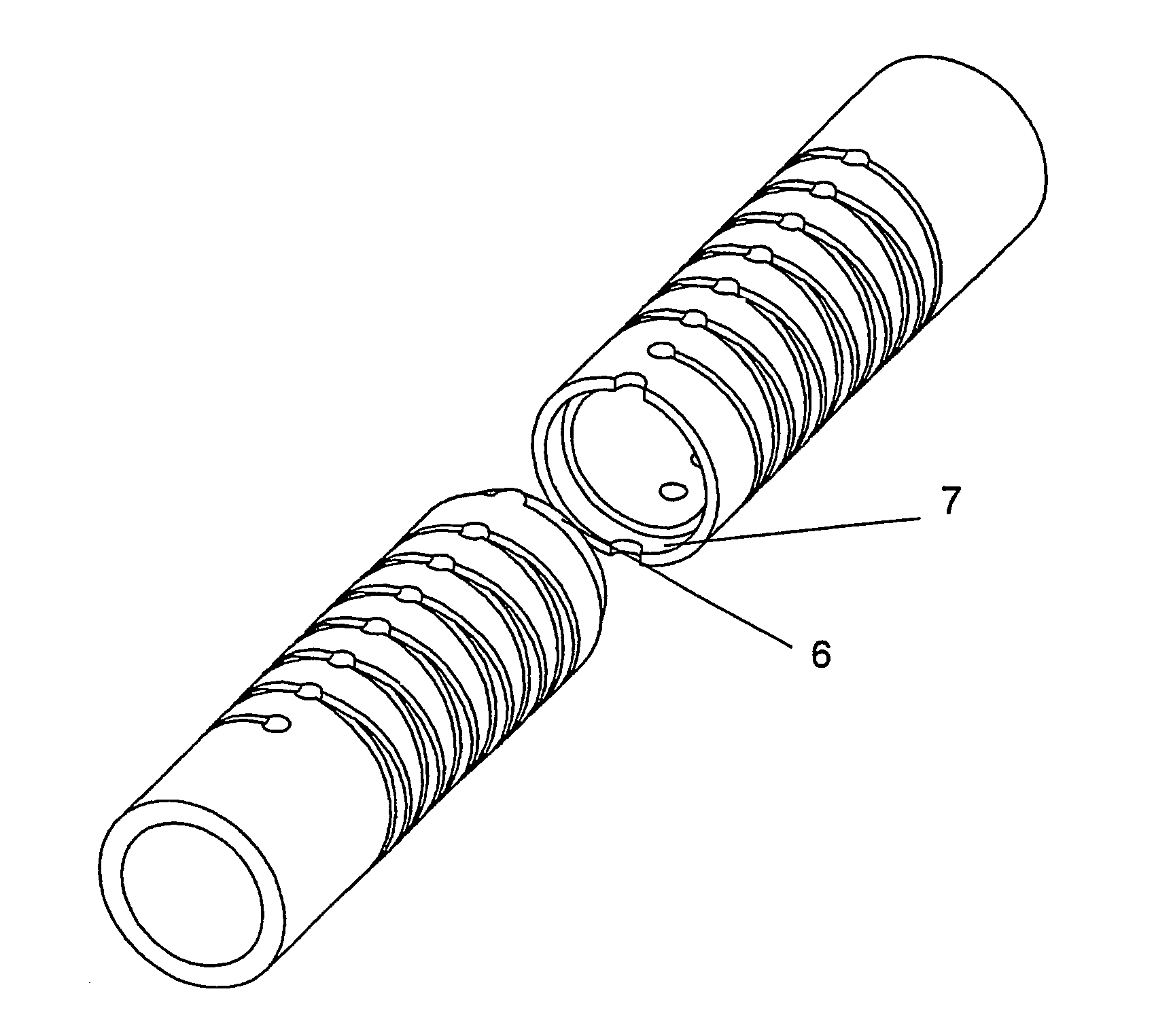

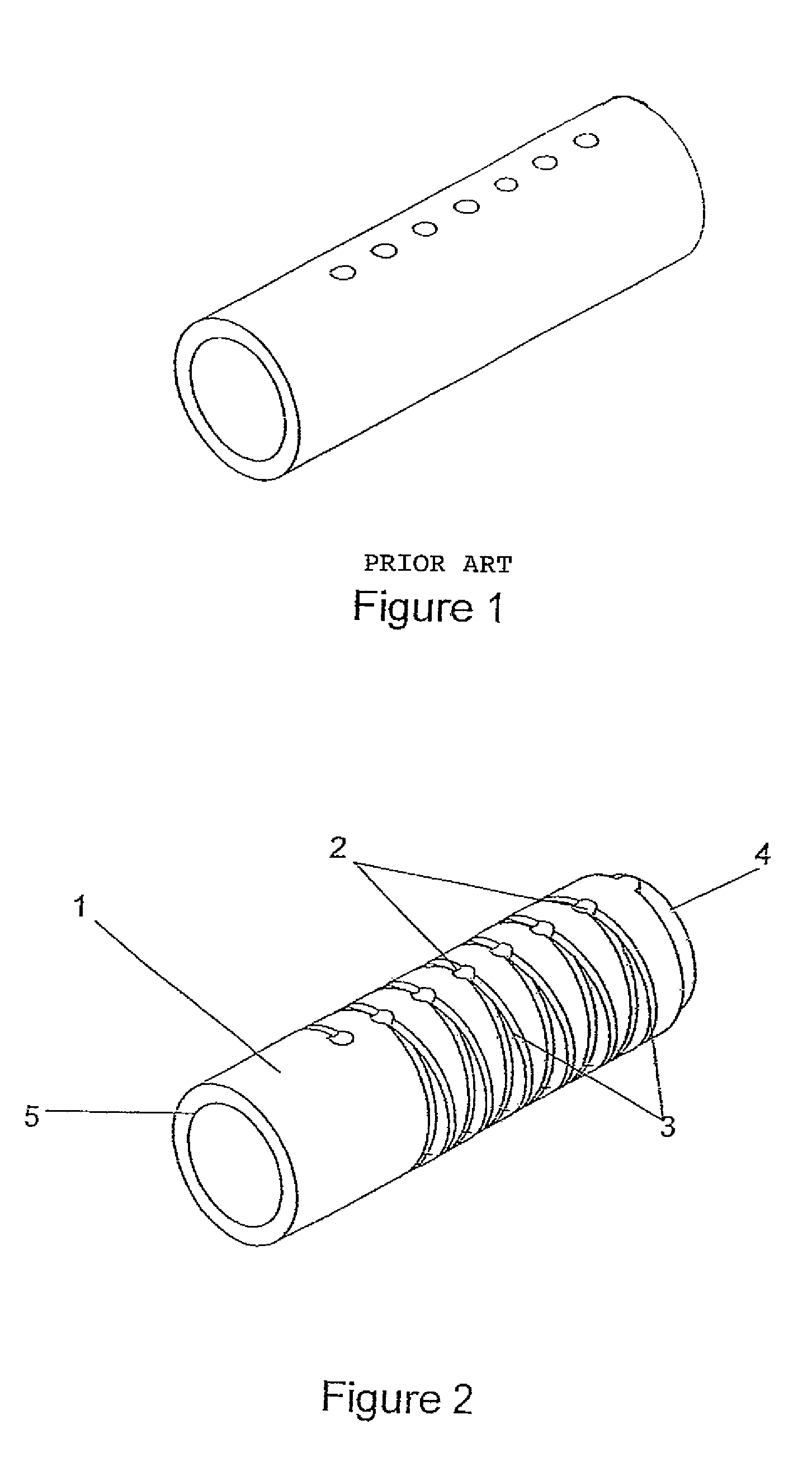

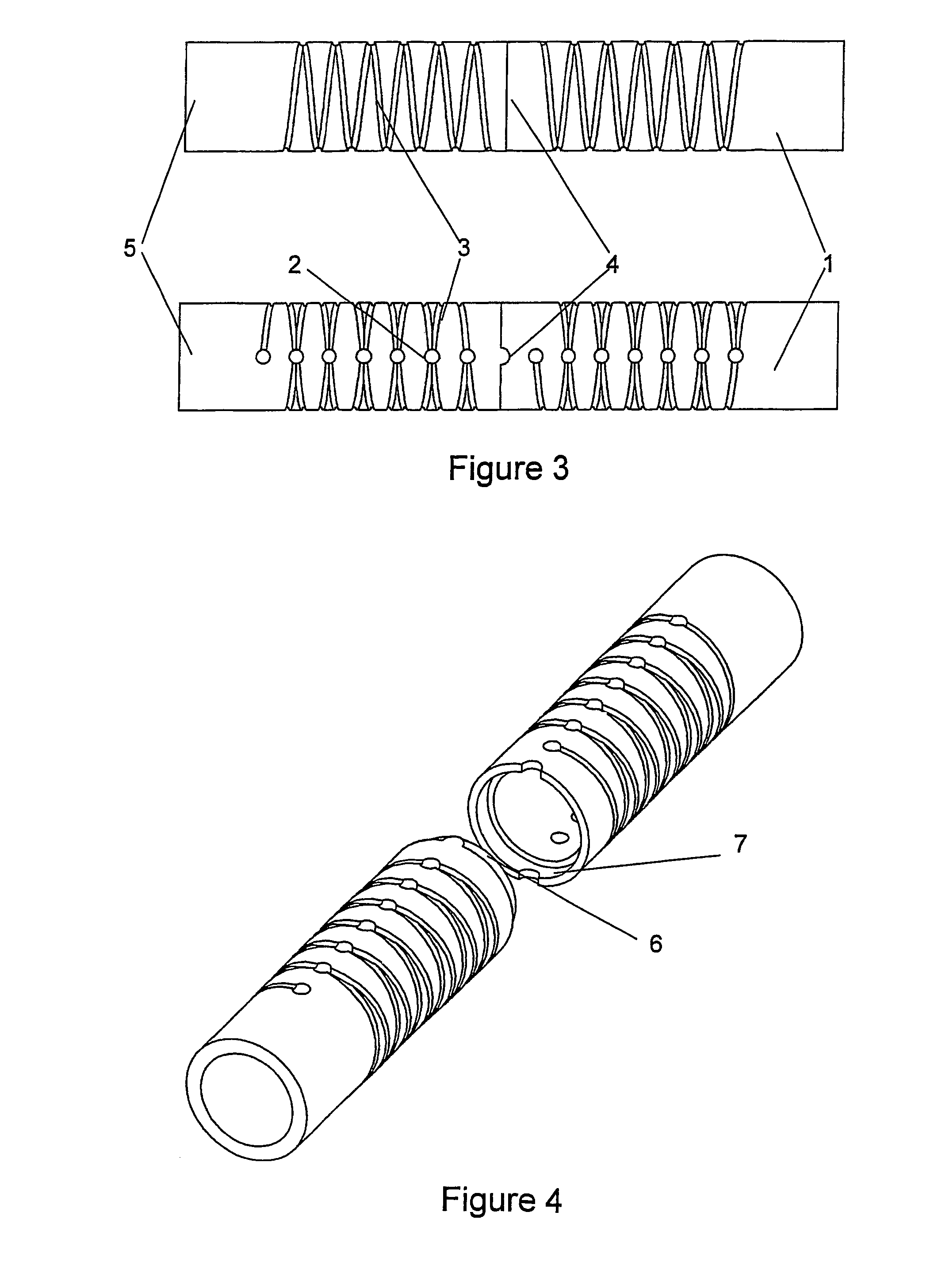

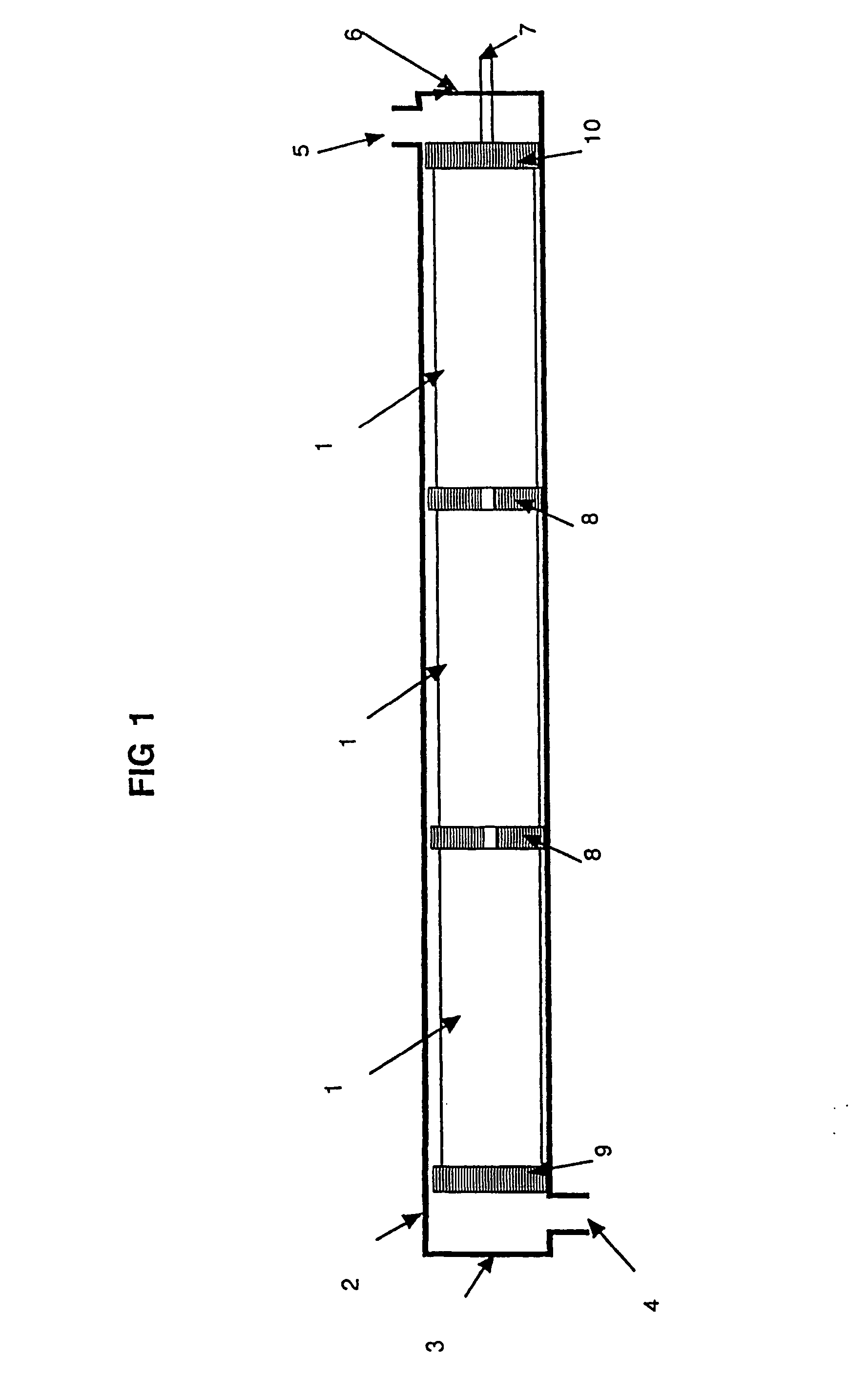

Permeate tube

ActiveUS20090294361A1Envelopes/bags making machineryGeneral water supply conservationViscosityBiomedical engineering

A permeate tube for spiral wound membrane comprising at least one tubular unit, which unit has spaced along its length a plurality of permeate transfer means, and one or more external grooves forming flow channels connecting the permeate transfer means. The present invention relates further to a process for treating a material having a viscosity less than 50 cP by the use of a spiral wound membrane comprising a permeate tube having at least one tubular unit, which unit has spaced along its length a plurality of permeate transfer means, and one or more external grooves forming flow channels connecting the permeate transfer means, around the permeate tube are one or more permeate transfer leaves, one or more membrane leaves and one or more space leaves wound. The present invention relates also to a process of operating a spiral wound membrane. The present invention relates further to uses of the spiral wound membrane.

Owner:ALFA LAVAL CORP AB

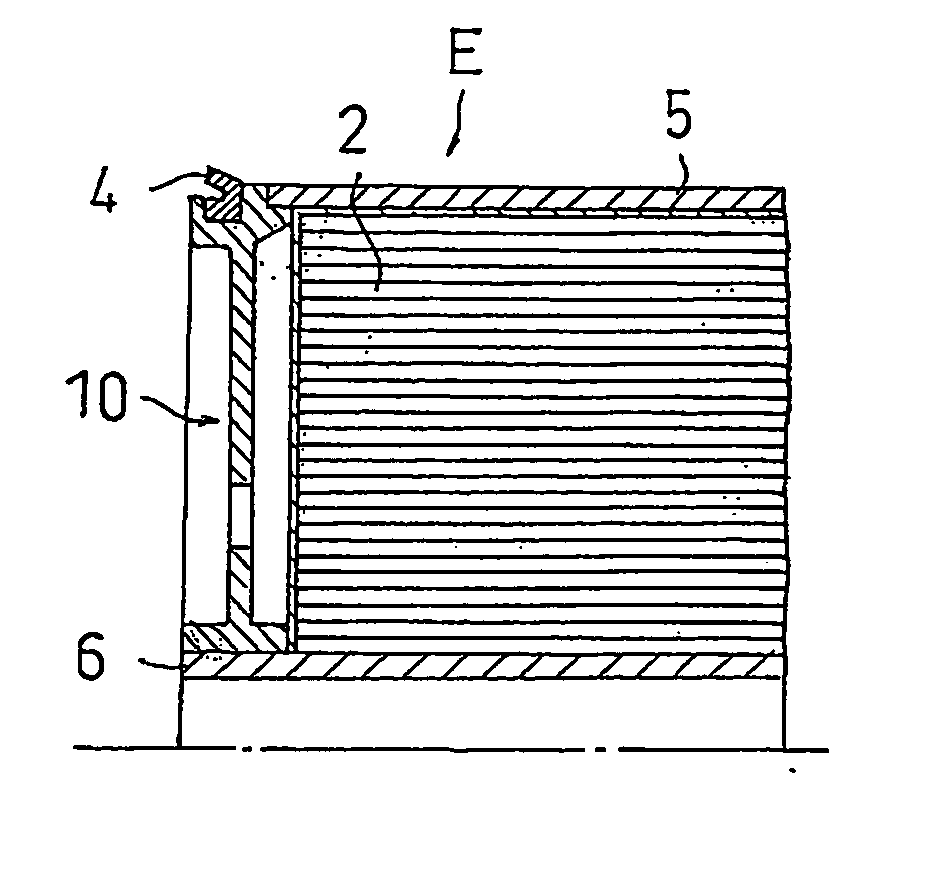

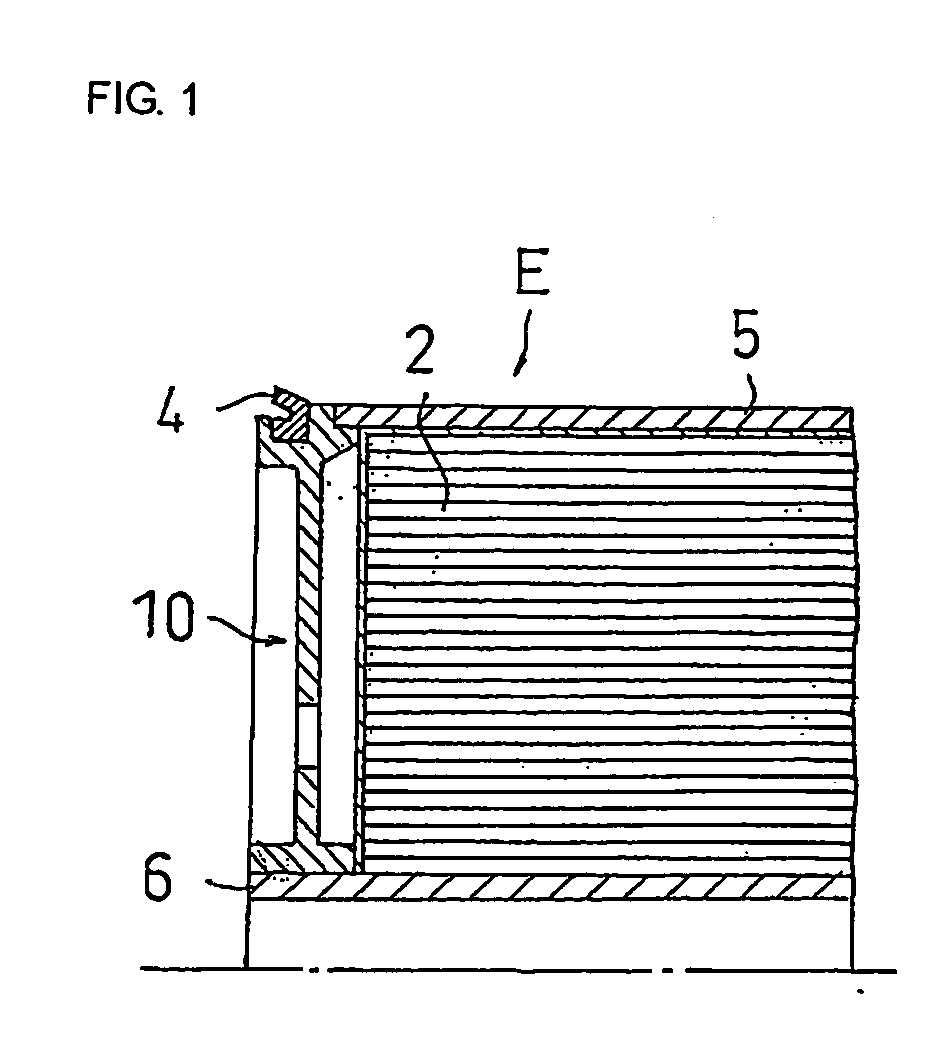

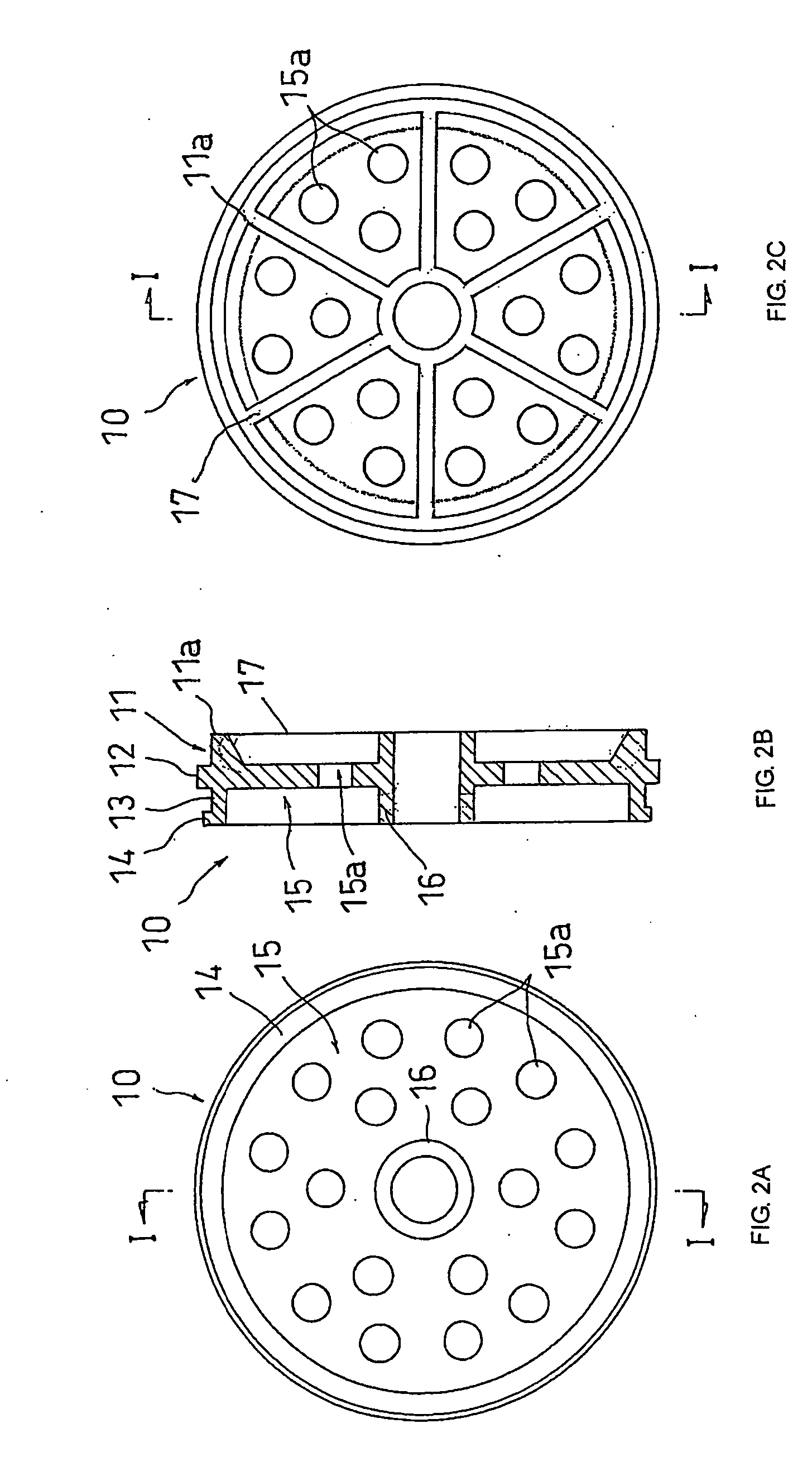

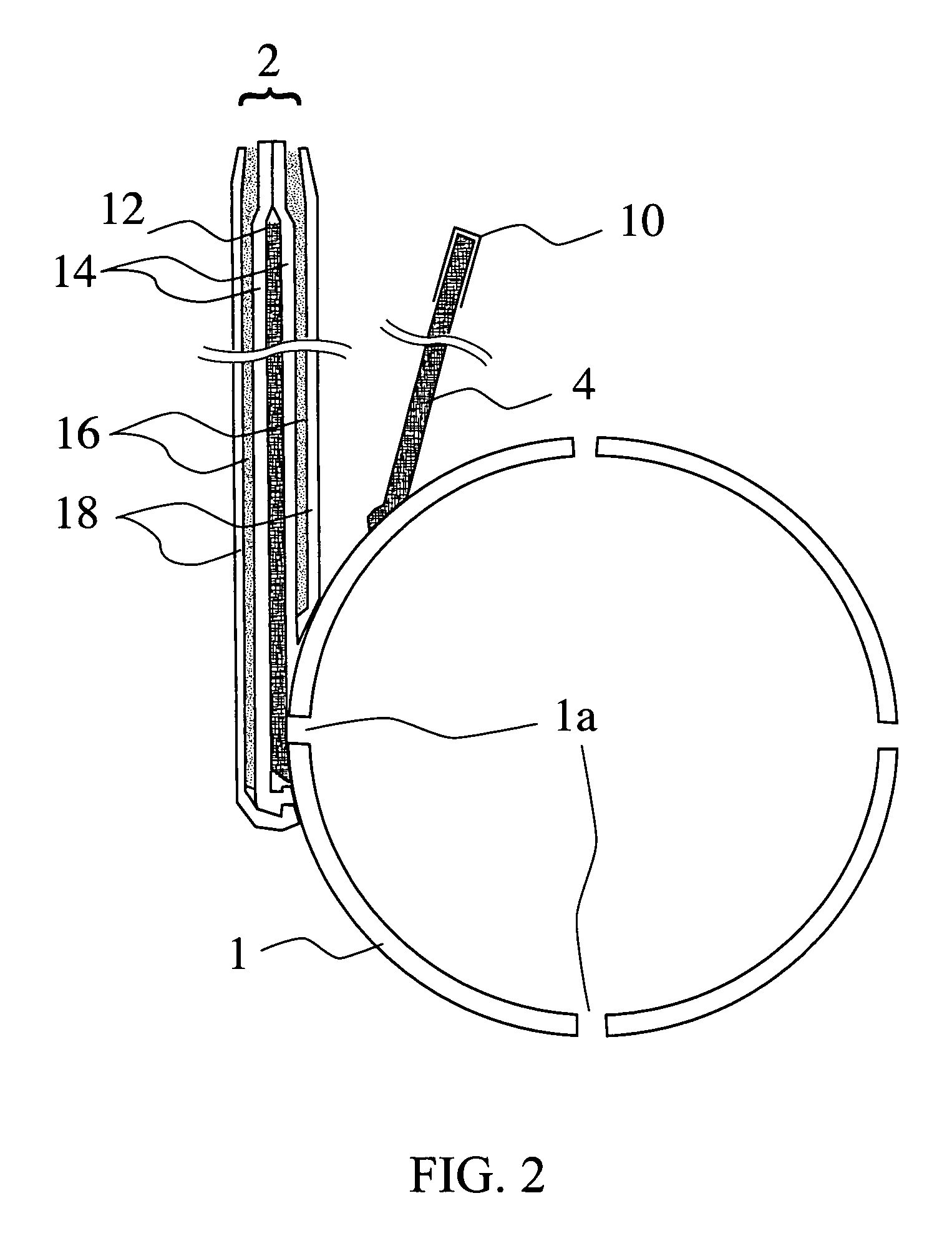

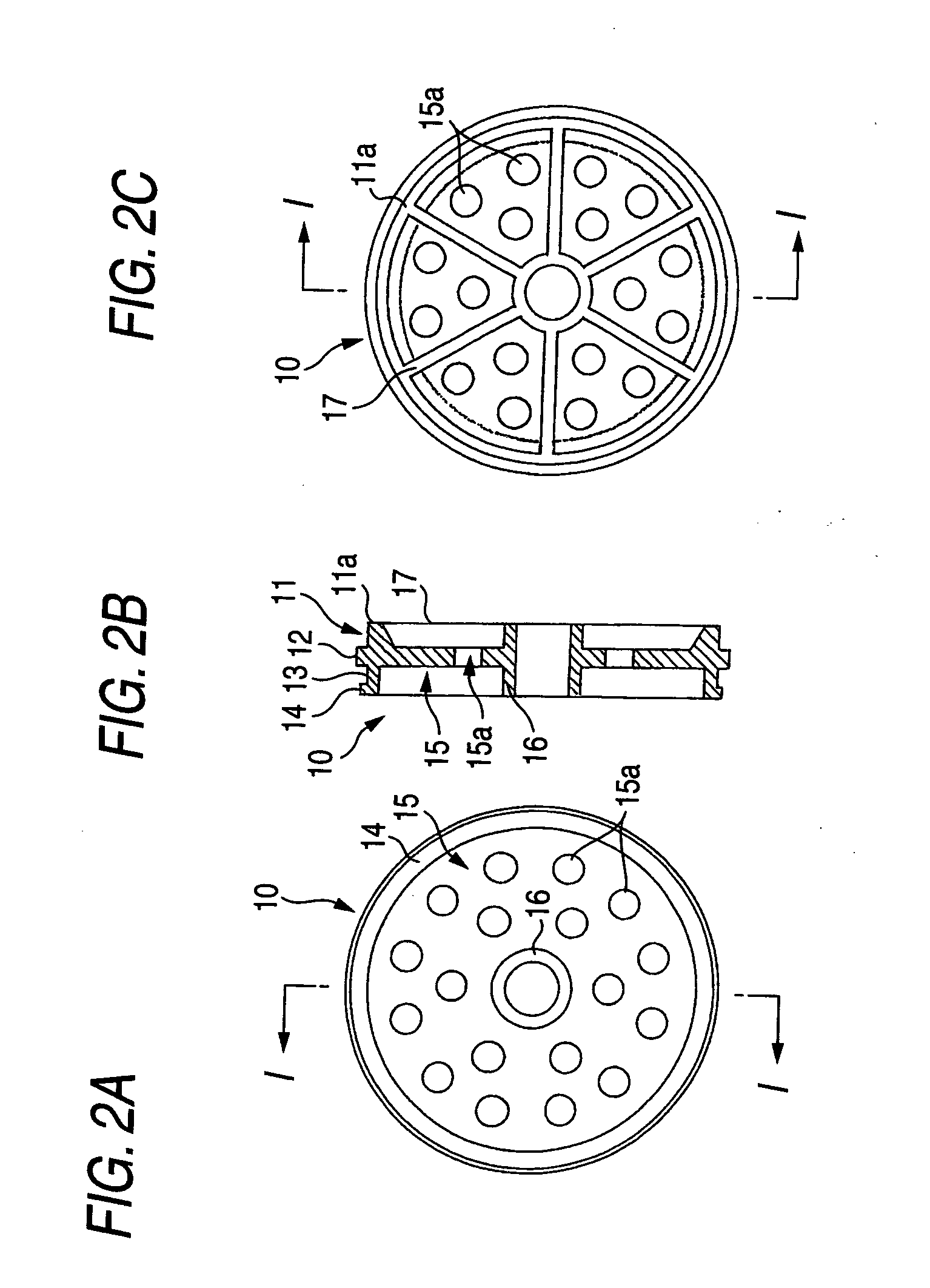

Seal ring holder for membrane element and membrane element

ActiveUS20050057002A1Increase the areaLarge caliberSemi-permeable membranesEngine sealsEngineeringMechanical engineering

A seal ring holder for membrane elements which is capable of attaining an increase in the area of membranes packed per element; and a membrane element using the seal ring holder, are provided. The seal ring holder for membrane elements which is disposed at an end part of a spiral wound membrane element to hold a ring seal ring on the outer periphery thereof while allowing a raw liquid to flow into a membrane end part of the membrane element, includes: a first ring part which has a side wall facing an upstream-side membrane end part of the membrane element and is inserted into an end part of a sheathing member of the membrane element; a projecting ring part which has been formed upstream from the first ring part and has side walls respectively on both sides, an edge face of the sheathing member and the downstream-side edge face of the seal ring being fixable respectively to the side walls; a second ring part which is formed upstream from the projecting ring part and to the outer periphery of which the seal ring is to be fitted; and a third ring part which is formed upstream from the second ring part and to which the upstream-side end face of the seal ring is fixable.

Owner:NITTO DENKO CORP

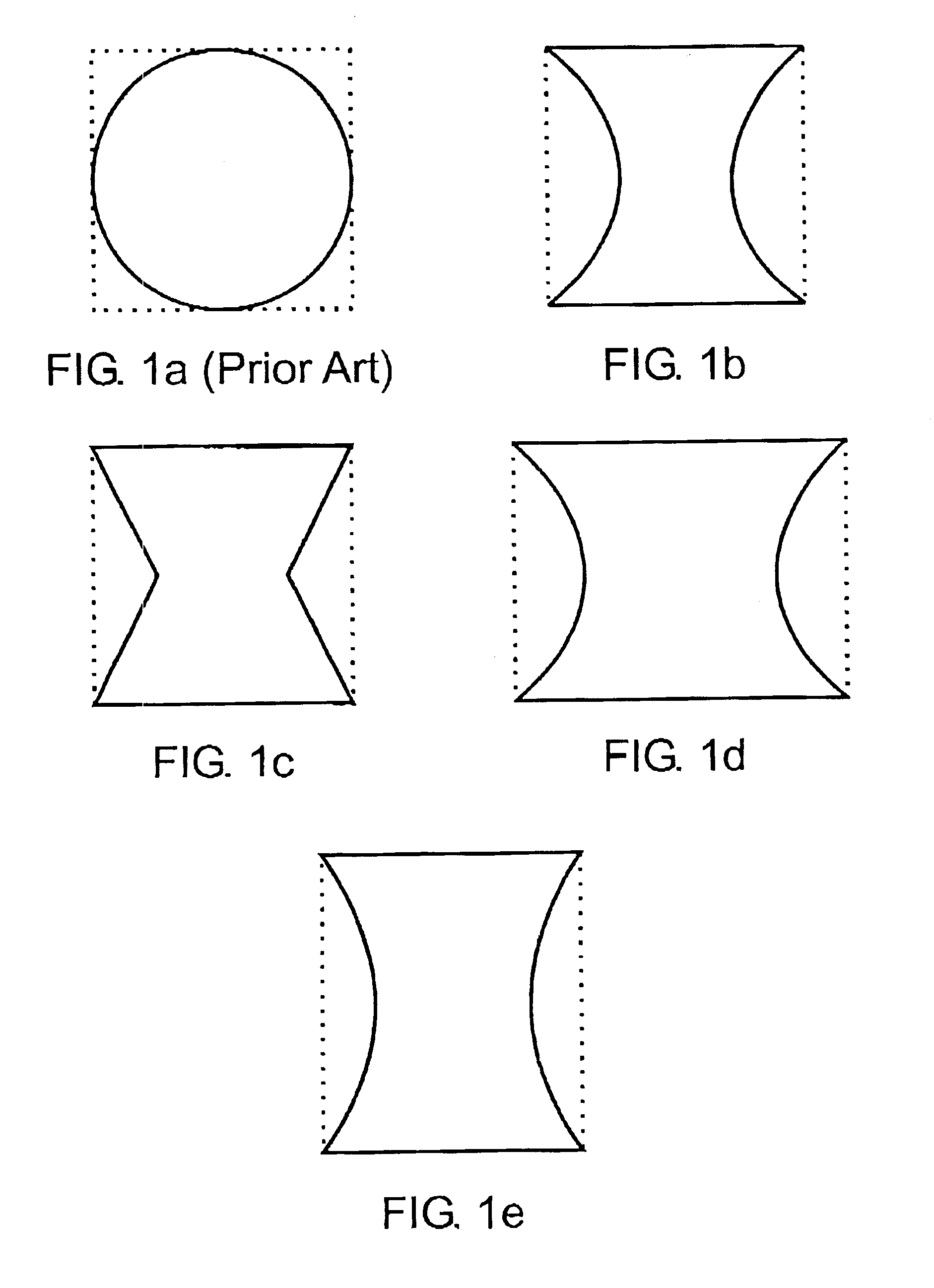

Feed spacers for spiral wound membrane element

InactiveUS20130146531A1Reduce the overall heightIncreasing active membrane area of elementMembranesSemi-permeable membranesMembrane surfaceEngineering

A feed channel spacer for a spiral wound membrane element has inlet and outlet edges that are thinner than the rest of the spacer material. The edges may be made thinner, for example, by passing the edges of a sheet of feed spacer material through a pair of hot rollers or by compressing the edges of the sheet in a heated press. The thinned edges of the feed spacer material are located in the element between glue lines applied to the permeate spacers of the element. The thin edges allow a greater membrane surface area to be provided in a given element diameter. A feed channel spacer may also have an area with obstructions to create micro-mixing effects. These obstructions may be provided on a feed spacer sheet of constant thickness, or one with thin edges.

Owner:GENERAL ELECTRIC CO

Spiral-wound liquid membrane module for separation of fluids and gases

InactiveUS7341663B2Lower energy requirementsEfficient separationMembranesSolid sorbent liquid separationChemical physicsSpiral wound

Owner:US SEC AGRI

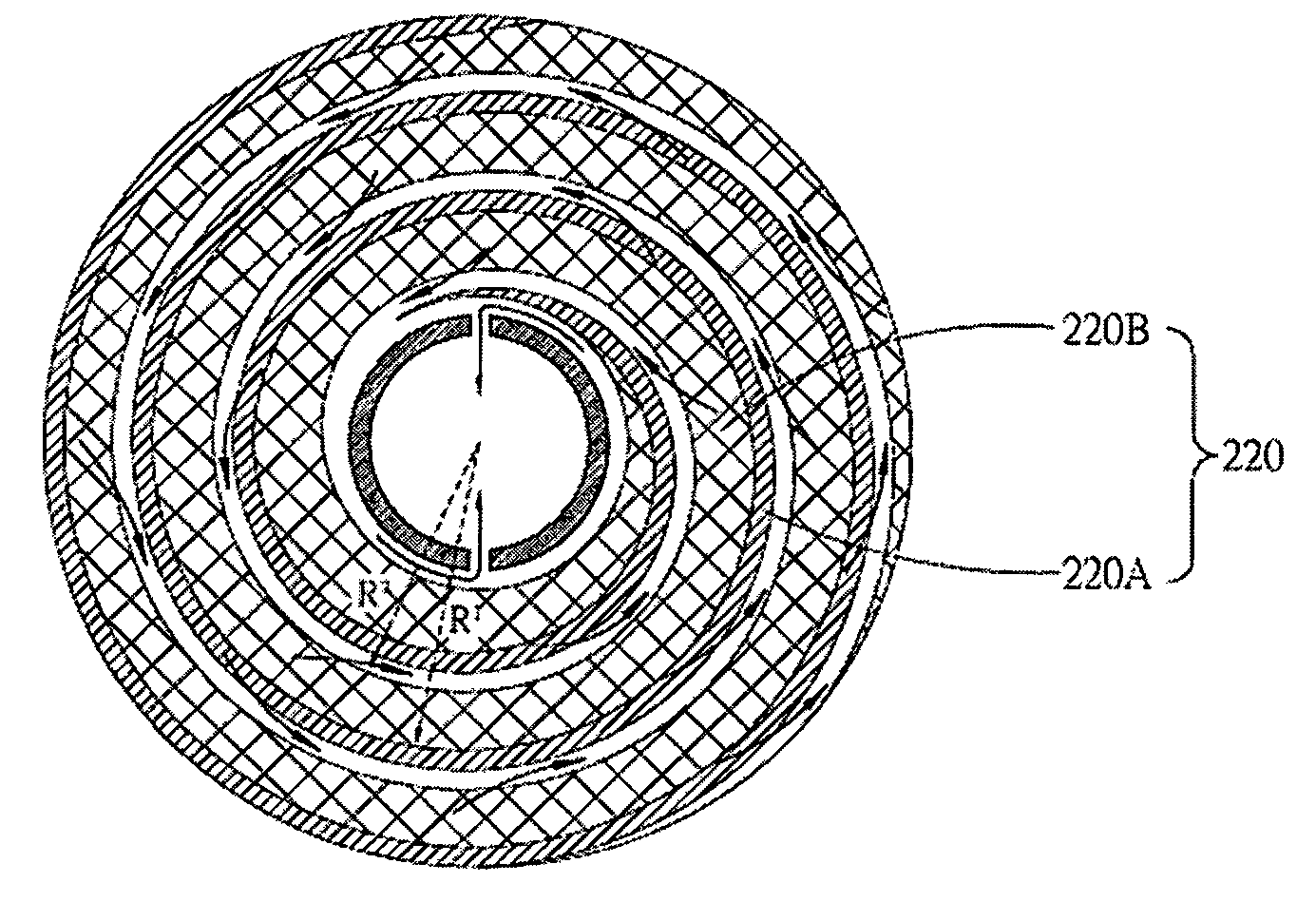

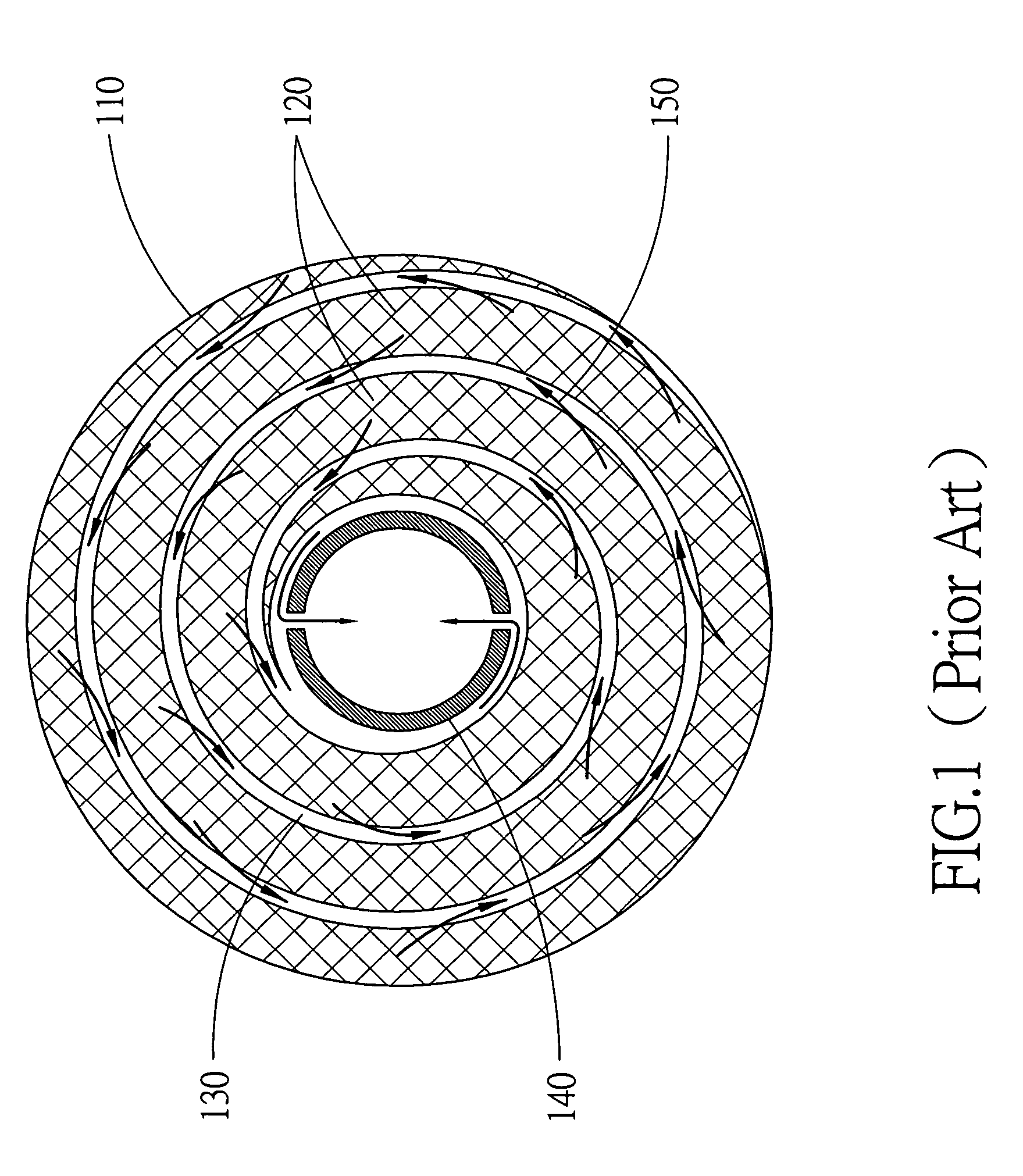

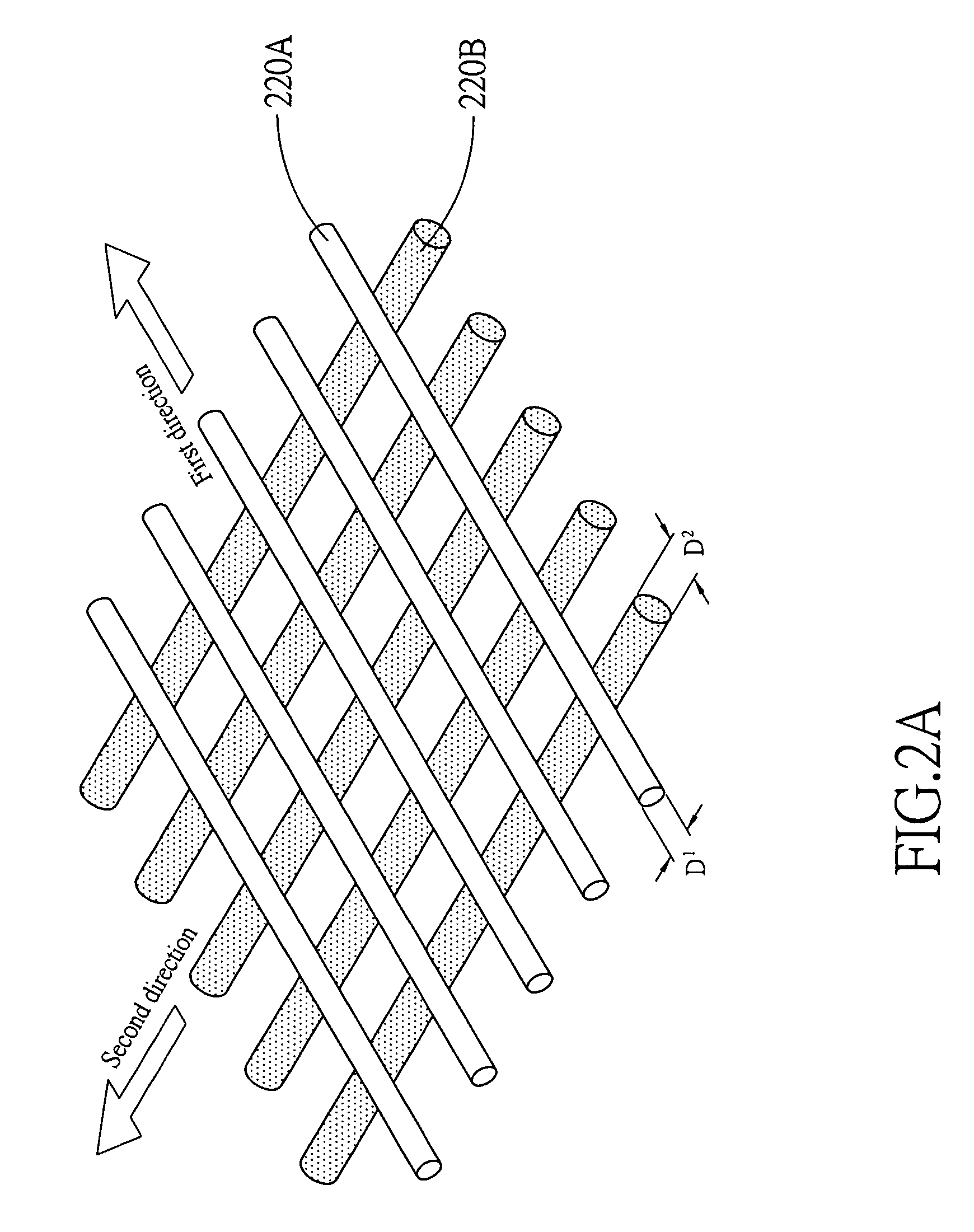

Feed spacer for spiral-wound membrane module

InactiveUS7459082B2Reduce shear rate differenceReduce overall outer diameterSemi-permeable membranesSettling tanks feed/dischargeSpiral woundEngineering

The present invention discloses a feed spacer, comprising a first layer and a second layer, for spiral-wound membrane module. The first layer consists of a plurality of first filaments, which are substantially in parallel to one another. Furthermore, the second layer also consists of a plurality of second filaments, which are substantially in parallel to one another. Moreover, the first layer is attached to the second layer, and the first filaments are disposed at an angle to the second filaments. Both the first layer and the second layer bend to the center of the spiral-wound. Additionally, the distance from the inside of the first layer to the center is bigger than that from the inside of the second layer to the center, and the diameter of the first filament is smaller than that of the second filament.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Xylose preparation method

ActiveCN103555865AExtend your lifeReduce acid and alkali consumptionSaccharides productionFiltrationEvaporation

The invention provides a xylose preparation method. The xylose preparation method mainly comprises the following steps: treating a raw material containing celluloses and hemicelluloses so as to obtain a xylose-containing solution; destaining the xylose-containing solution by using activated carbon, and then purifying the xylose-containing solution so as to obtain a destaining solution; carrying out protective filtration and / or spiral-wound membrane filtration on the destaining solution, then carrying out single vaporization and concentration on the destaining solution, desalting by using electrodialysis equipment so as to obtain electrodialysis liquid, carrying out membrane concentration on the electrodialysis liquid so as to obtain a membrane concentrated solution, finally carrying out single vaporization and concentration, destaining by using the activated carbon, carrying out ion exchange and secondary vaporization and concentration, crystallizing and centrifuging so as to obtain xylose crystals. The xylose preparation method has the advantages that the acid-base consumption and the water consumption are reduced by using electrodialysis desalination and membrane concentration for replacing calcium carbonate or lime neutralization, primary ion exchange and primary evaporation and concentration in a conventional technology, water can be saved by 55-75%, and the sewage discharge is substantially reduced; and the purposes of energy conservation, consumption reduction, pollution reduction and clean and efficient production are realized by adopting the technology.

Owner:SHANDONG FUTASTE

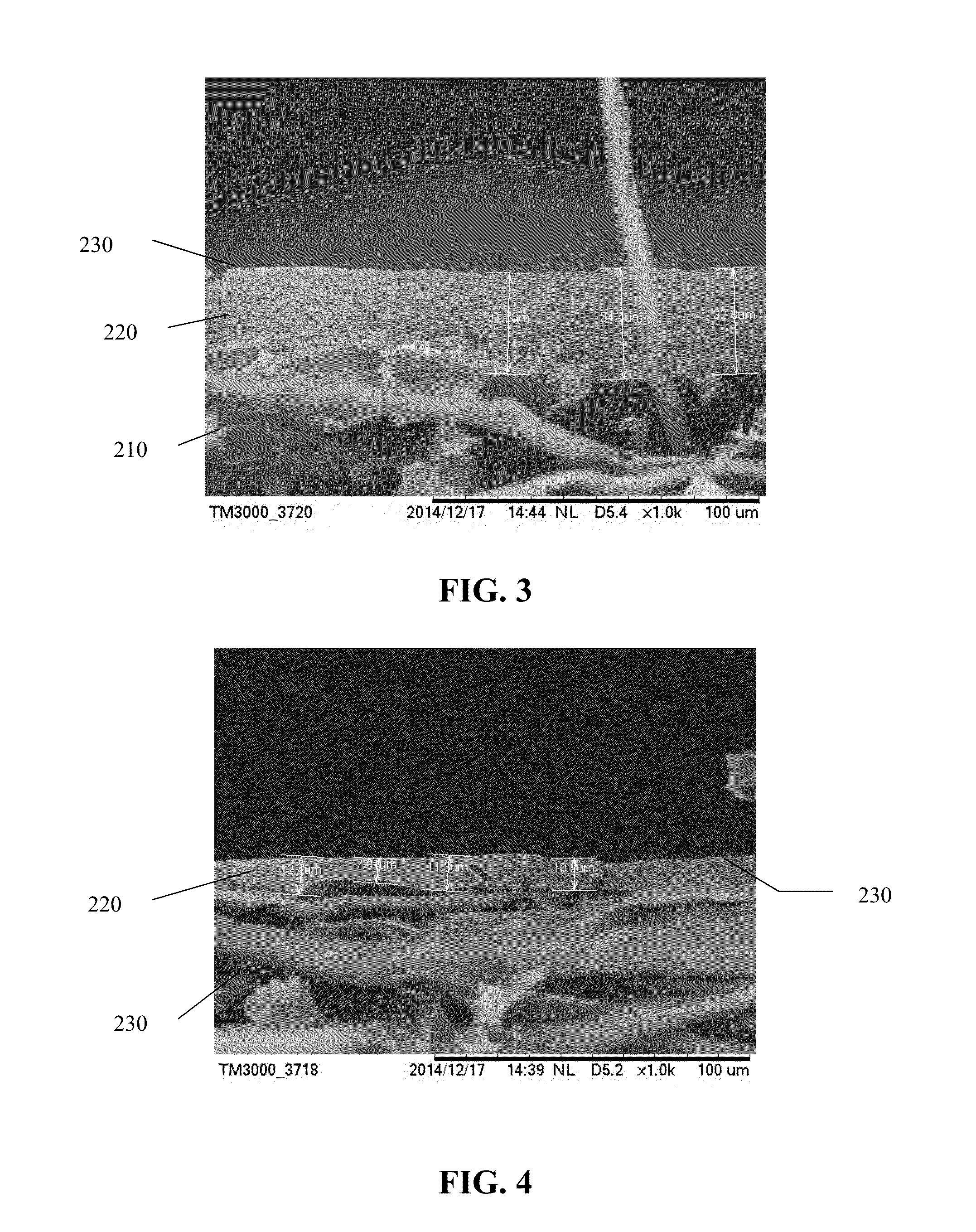

Thermo-sensitive type ultrafiltration membrane and preparation method thereof

InactiveCN103418255AImprove hydrophilicityImprove pollutionSemi-permeable membranesWater basedUltrafiltration

The invention relates to a thermo-sensitive type ultrafiltration membrane and a preparation method thereof. The thermo-sensitive type ultrafiltration membrane comprises main components of 85-90 wt% of a polyvinylidene fluoride membrane material and 10-15 wt% of a thermo-sensitive type amphiphilic water-based polymer. The preparation method is as below: first synthesizing the thermo-sensitive type amphiphilic water-based polymer; then mixing well the high-molecular film material and the polymer; mixing the mixture of the high-molecular film material and the polymer, a pore forming agent and a solvent for a film casting liquid to prepare a film casting liquid; and preparing the film casting liquid into a flat sheet membrane, a spiral-wound membrane and a hollow-fiber membrane. The ultrafiltration membrane provided by the invention has large flux, lasting hydrophilicity and anti-pollution performance, and can response to changes of environmental temperature.

Owner:NINGBO UNIV

Permeate tube

ActiveUS8101074B2Semi-permeable membranesGeneral water supply conservationViscosityMembrane configuration

A permeate tube for spiral wound membrane comprising at least one tubular unit, which unit has spaced along its length a plurality of permeate transfer means, and one or more external grooves forming flow channels connecting the permeate transfer means. The present invention relates further to a process for treating a material having a viscosity less than 50 cP by the use of a spiral wound membrane comprising a permeate tube having at least one tubular unit, which unit has spaced along its length a plurality of permeate transfer means, and one or more external grooves forming flow channels connecting the permeate transfer means, around the permeate tube are one or more permeate transfer leaves, one or more membrane leaves and one or more space leaves wound. The present invention relates also to a process of operating a spiral wound membrane. The present invention relates further to uses of the spiral wound membrane.

Owner:ALFA LAVAL CORP AB

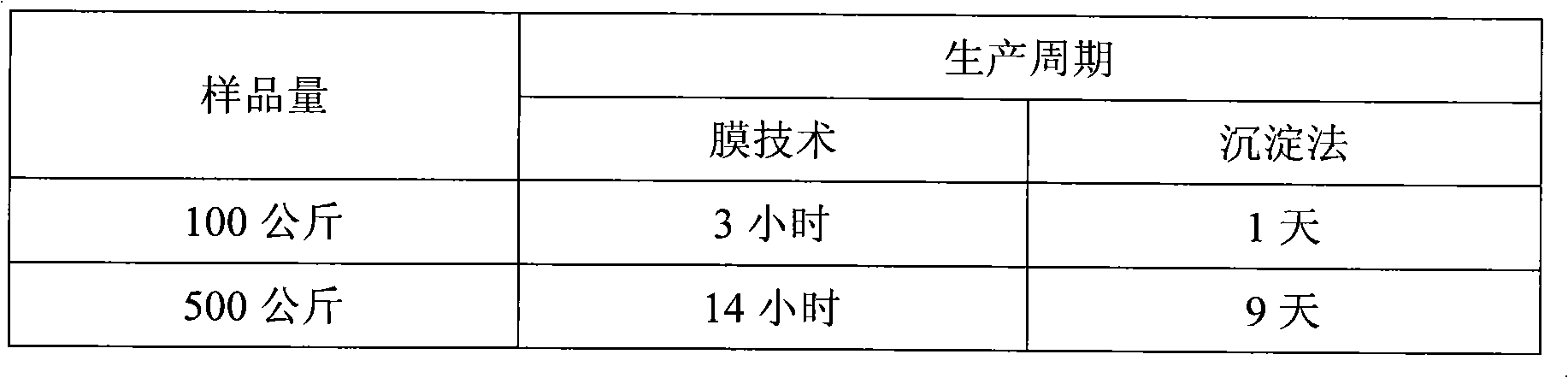

Method for preparing rehmanniae flavor for cigarette by using membrane separation technique

InactiveCN101586056ASolve residual problemsSimple methodSemi-permeable membranesTobacco treatmentReflux extractionSeparation technology

The invention discloses a method for preparing rehmanniae flavor for cigarette by using the membrane separation technique, belonging to the technical field of cigarette flavor preparation. The method is carried out according to the following steps: carrying out reflux extraction twice, obtaining the filtrate of rehmanniae extract A; filtering by a ceramic membrane with the aperture of 100nm, and obtaining the solution passing through the membrane called a filtrate B; and filtering the filtrate B through an organic spiral-wound membrane with the trapping molecular weight of 25 thousand, obtaining a filtrate C which is the rehmanniae flavor for cigarette. The method is simple, is easily implemented, and uses membrane separation technique to replace the original precipitation remelting method. The invention has the advantages of simple technology, short production period, low cost, remarkable economic benefits, improvement of automazation degree and enhancement of controllability of production technology, and solves the problems of aftertaste and remaining of cigarettes in mouths.

Owner:HUBEI CHINA TOBACCO IND

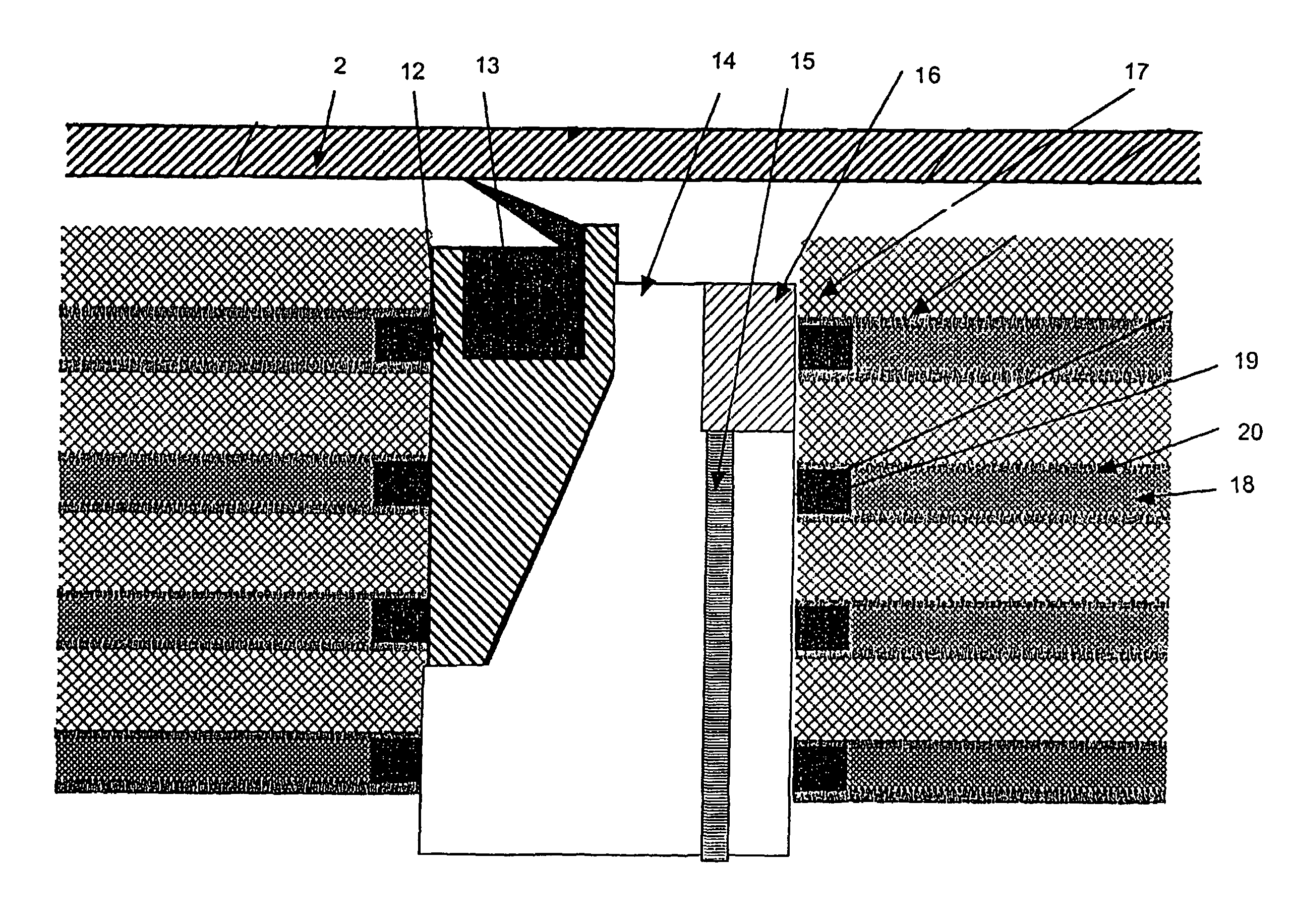

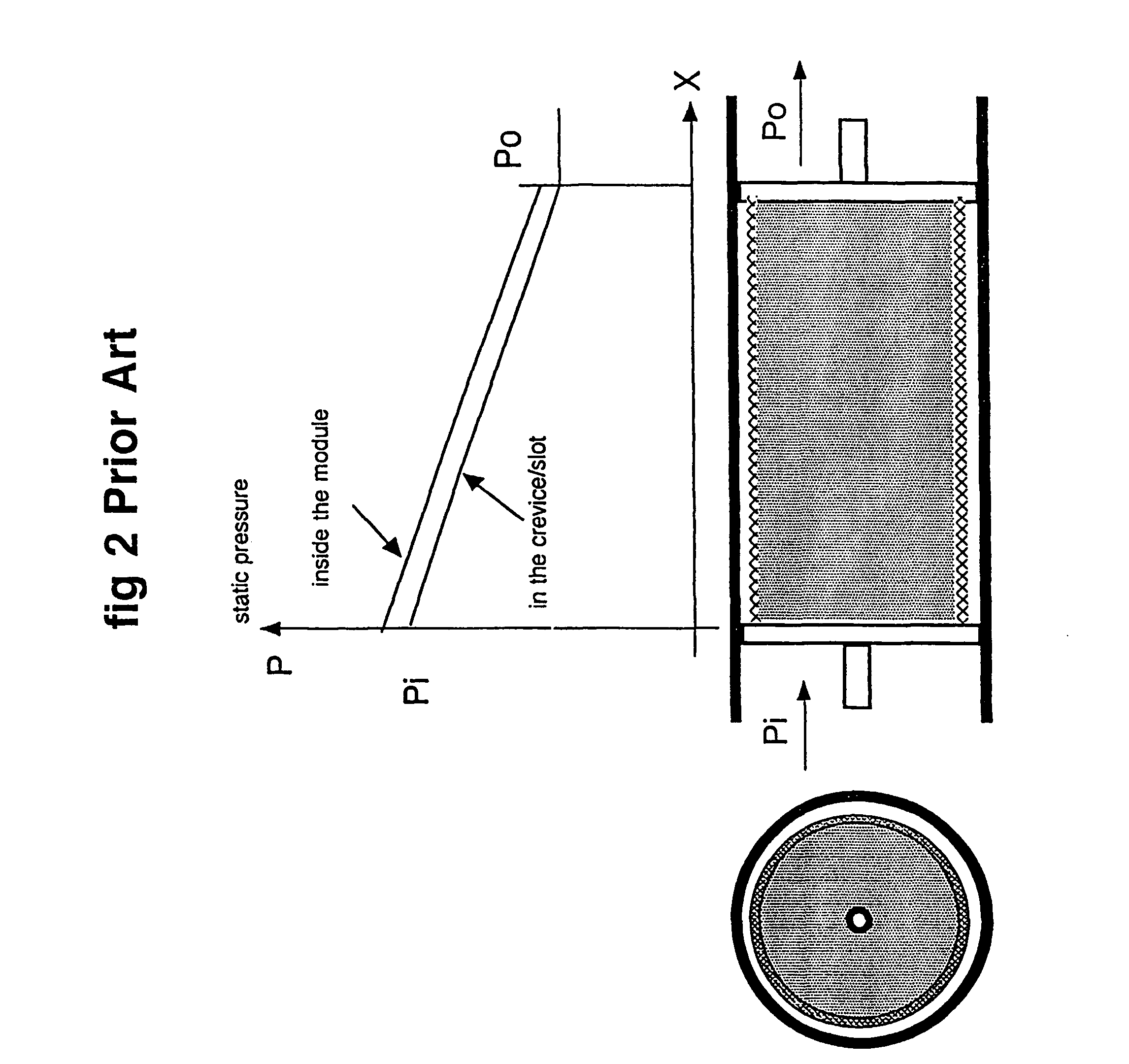

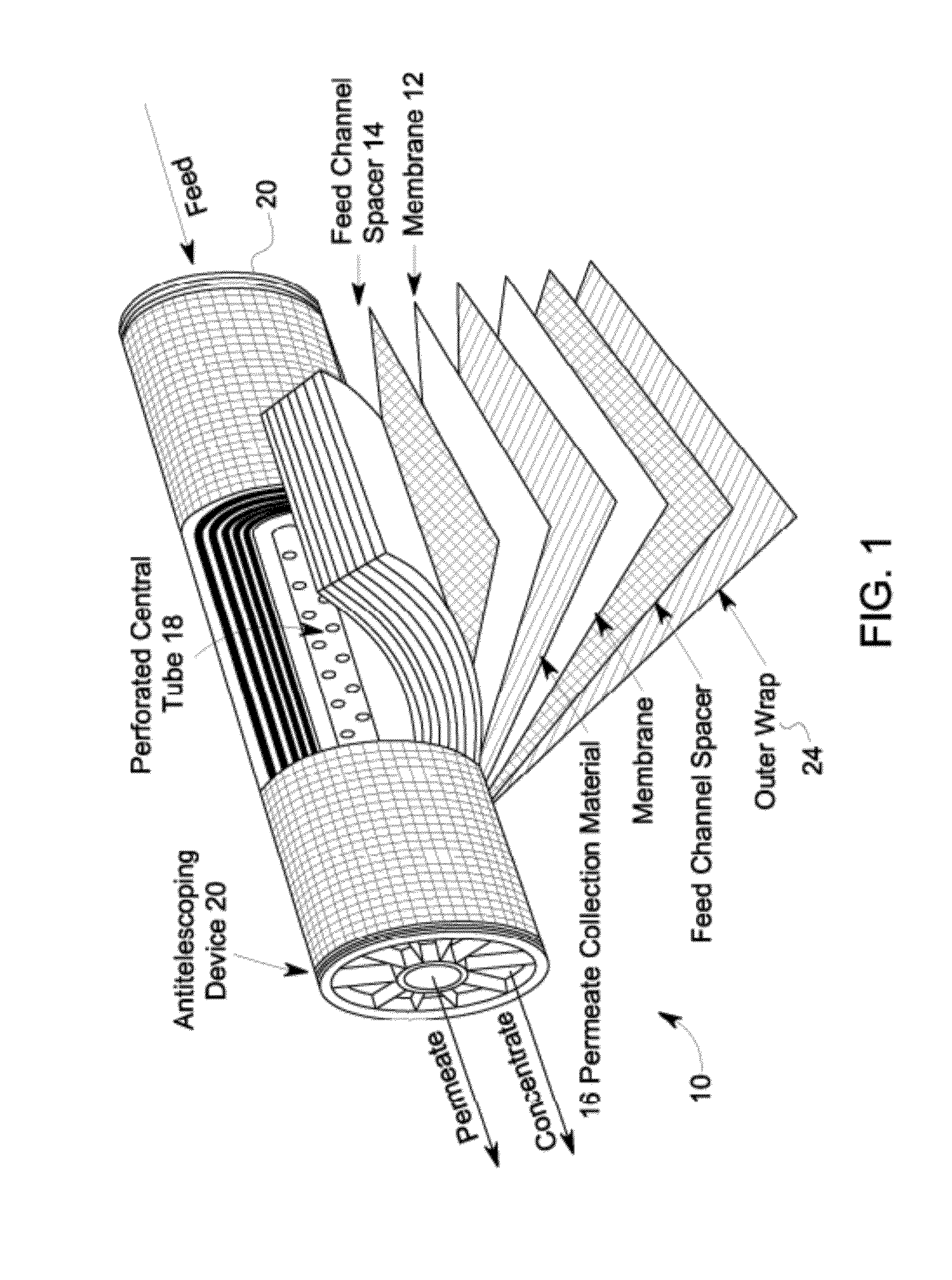

Spiral wound membrane element and a process for preventing telescoping of the filter element

InactiveUS7396463B2Enlarging woundImprove efficiencyMembranesApparatus sterilizationUltrafiltrationDifferential pressure

A process for ultrafiltration using a spiral wound membrane filter is disclosed where the pressure in the space between the filter element and the pressure vessel is higher than or equal to the pressure inside the filter element. Using these conditions the static force created by the pressure provides a high friction between different sheets in the spiral wound filter element, which efficient prevents unwinding or telescoping of the filter element. Using this configuration it is possible to perform the ultrafiltration using a higher differential pressure across the filter element than would otherwise have been possible which leads to a higher efficiency and a low energy consumption. Further an anti telescoping device (ATD) and a spiral wound filter element, which are particular suited for the disclosed process, are described.

Owner:ENVIRO HLDG

Preparation method of cheap ultra-filtration membrane for treating oil producing wastewater

ActiveCN104258742ANo post-processingSimple processSemi-permeable membranesWater bathsFiltration membrane

The invention provides a preparation method of a cheap ultra-filtration membrane for treating oil producing wastewater. The preparation method comprises the following steps: dissolving nano silicon dioxide into a polyvinyl chloride dissolving solvent under ultrasonic condition to prepare a suspension solution of nano particles; then sequentially and slowly adding a pore-forming agent, a de-foaming agent and polyvinyl chloride into the suspension solution; continuously and mechanically agitating in a water bath of 30-40 DEG C for more than 24 hours until a homogeneous membrane casting solution is formed; sufficiently de-foaming the membrane casting solution in a vacuum drying box and scraping a membrane by using a membrane scraping machine; after volatilizing the scraped new membrane in the air for 15-60 seconds, slowly putting the scraped new membrane into a coagulating bath for coagulation; and after separating the membrane from a glass plate, sufficiently immersing the membrane in pure water for 48 hours to obtain a nano silicon dioxide modified polyvinyl chloride flat plate membrane. The preparation method of the cheap ultra-filtration membrane can be used for nano silicon dioxide polyvinyl chloride hollow fiber type ultra-filtration membranes and micro-filtration membranes, reverse osmosis membranes, nano-filtration membranes, pipe type membranes, capillary tube membranes or spiral-wound membranes.

Owner:HARBIN ENG UNIV

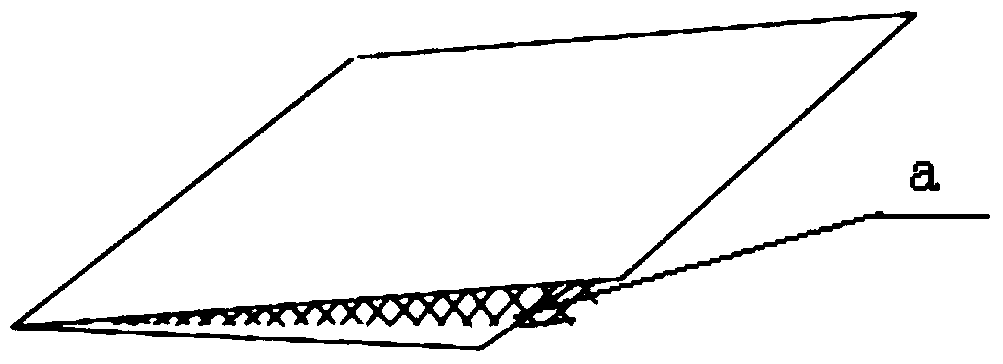

Spiral wound membrane module with reinforced fold line

ActiveUS20160236156A1Reduce the possibilityMembranesSemi-permeable membranesSpiral woundBiomedical engineering

A spiral wound module in which the membrane sheet is heat and pressure treated to collapse at least some of the pores of the support layer. The treated membrane can then be folded along the heat and pressure treated area to form a crease. Once folded, the membrane sheet can be wound around a perforated inner tube along with a feed channel spacer and a permeate collection sheet. The wound module can then be enclosed into a hard shell with anti-telescoping devices at each end. By collapsing at least some of the pores in the support layer, the membrane becomes less permeable to fluid in the treated area. As such, there will be less or no leakage of unfiltered fluid passing through the fold line of the membrane sheet during operation of the wound module.

Owner:LG NANOH2O

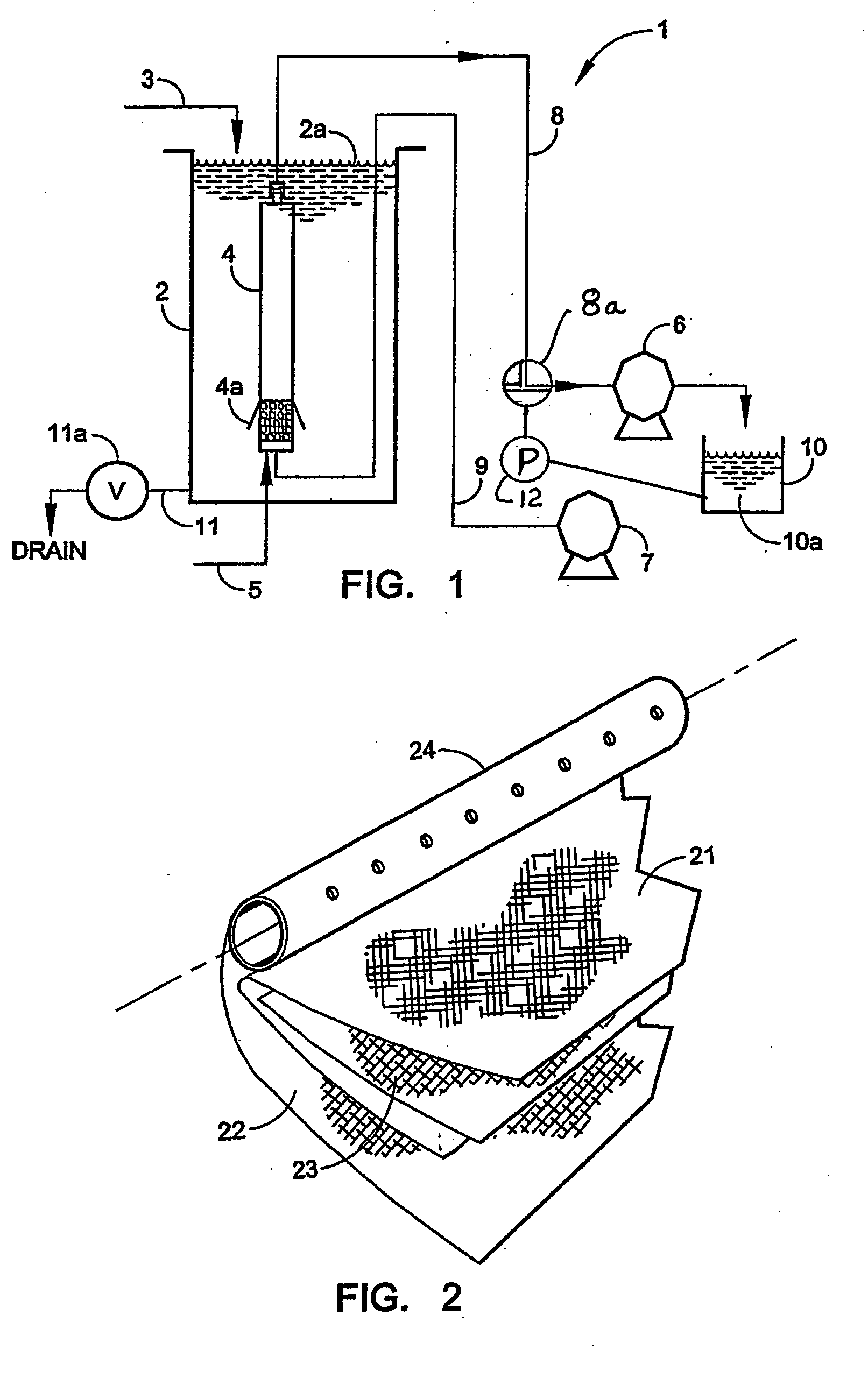

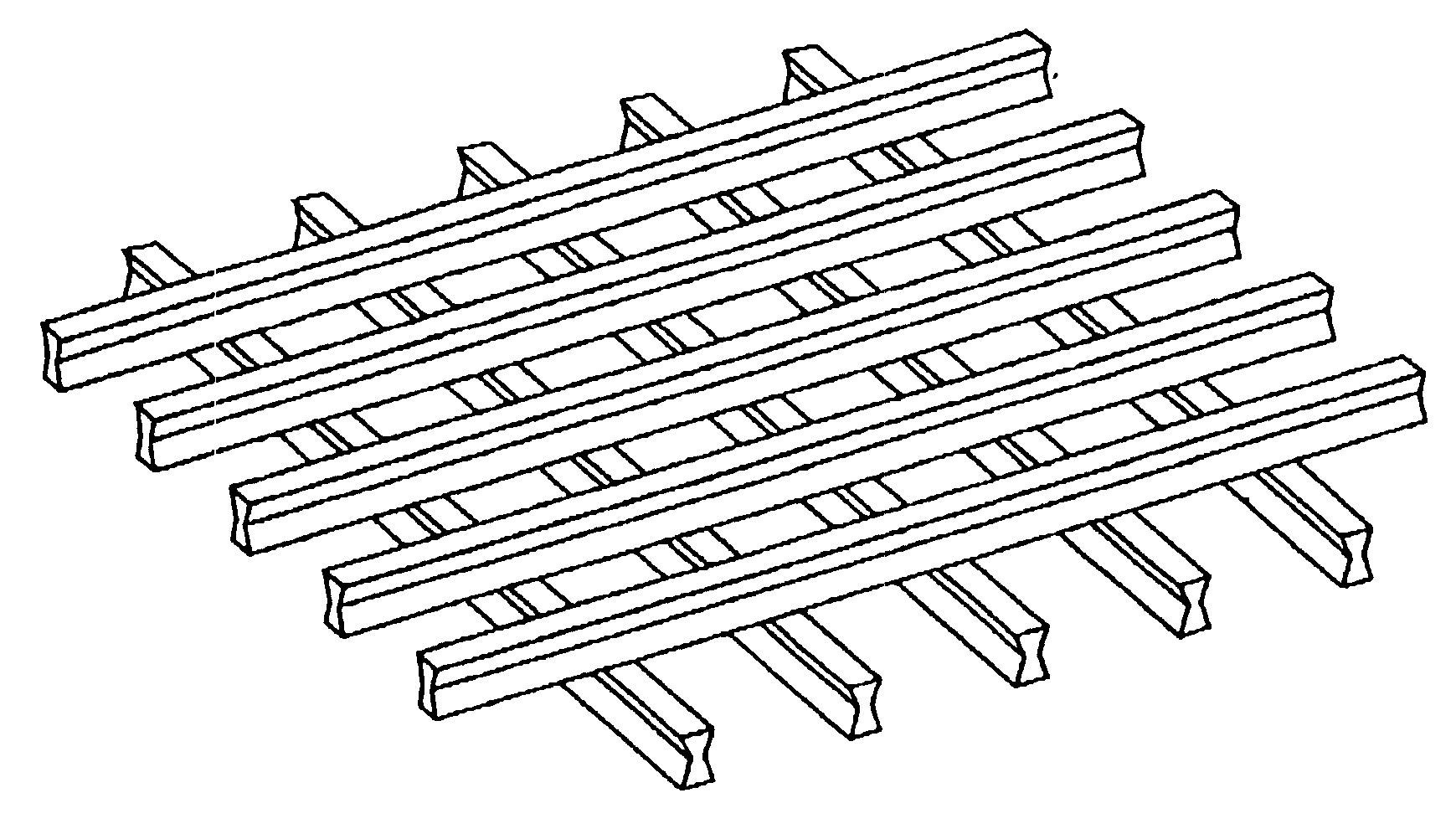

Feed spacers for filtration membrane modules

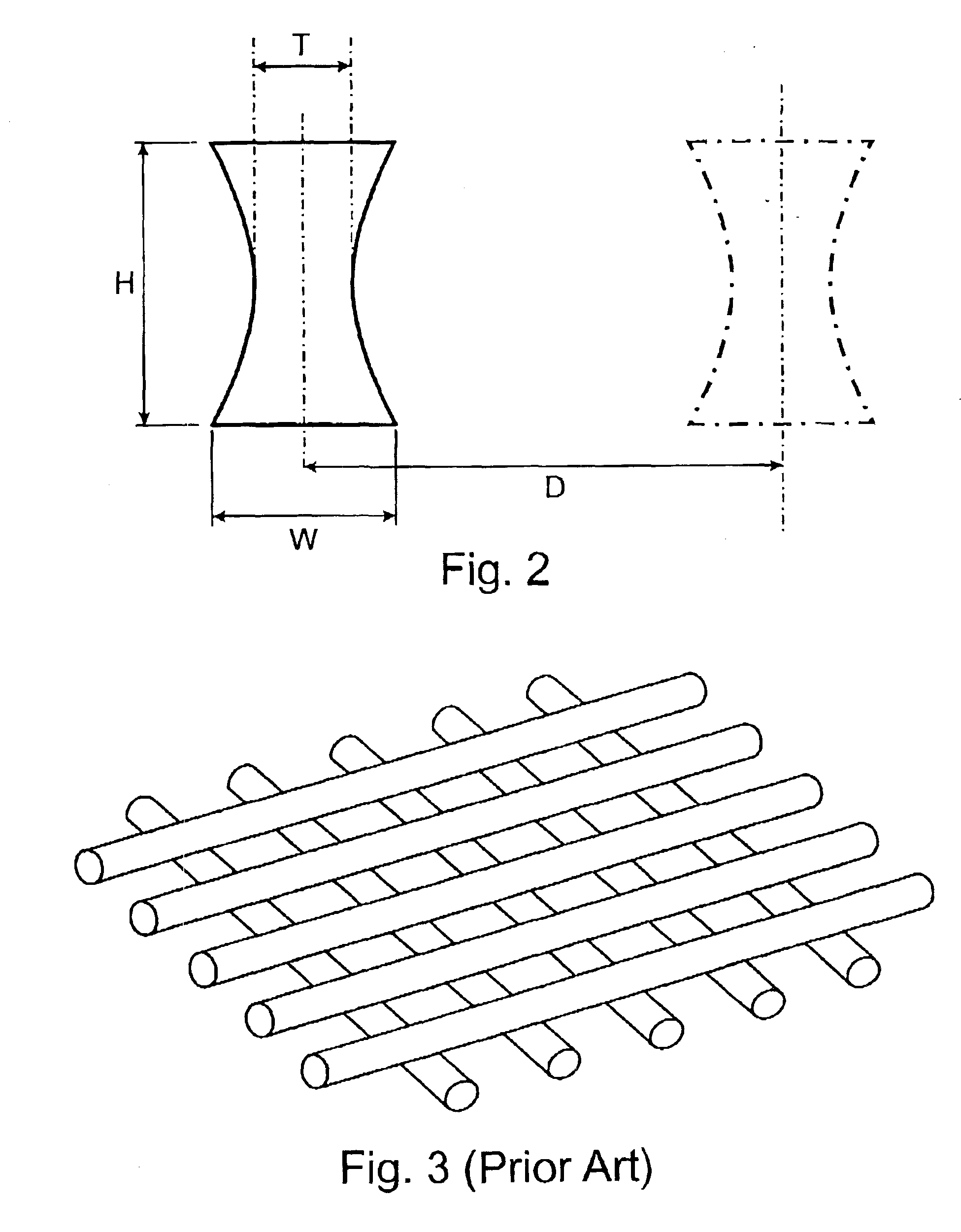

InactiveUS6989097B2Speed up the flowImprove efficiencyMembranesDispersed particle filtrationFiltration membraneCross-flow filtration

The invention disclosed relates to feed spacers used in various filtration membrane modules, such as in spiral wound membranes, used in cross-flow filtration. Such spacers have an influence in promoting the mixing between the bulk of the fluid and the fluid element adjacent to the membrane surface so as to keep the membrane surface relatively clean. To optimize these properties, novel spacer designs are disclosed having a plurality of rows of elongated strands, the strands in each row being arranged substantially in parallel to one another, with adjacent rows being attached and disposed at an angle to one another, the strands of at least one row when viewed in cross-section having a central portion of a width smaller than the width of its extremities. Novel membrane modules incorporating such feed spacers are also disclosed.

Owner:NAATIONAL RES COUNCIL OF CANADA

Seal ring holder for membrane element and membrane element

InactiveUS20070017860A1Increase the areaLarge caliberSemi-permeable membranesEngine sealsMechanical engineeringMembrane configuration

A seal ring holder for membrane elements which is capable of attaining an increase in the area of membranes packed per element; and a membrane element using the seal ring holder, are provided. The seal ring holder for membrane elements which is disposed at an end part of a spiral wound membrane element to hold a ring seal ring on the outer periphery thereof while allowing a raw liquid to flow into a membrane end part of the membrane element, includes: a first ring part which has a side wall facing an upstream-side membrane end part of the membrane element and is inserted into an end part of a sheathing member of the membrane element; a projecting ring part which has been formed upstream from the first ring part and has side walls respectively on both sides, an edge face of the sheathing member and the downstream-side edge face of the seal ring being fixable respectively to the side walls; a second ring part which is formed upstream from the projecting ring part and to the outer periphery of which the seal ring is to be fitted; and a third ring part which is formed upstream from the second ring part and to which the upstream-side end face of the seal ring is fixable.

Owner:NITTO DENKO CORP

Nanofiltration system for water softening with internally staged spiral wound modules

InactiveUS20050284806A1Easily and inexpensively modifiedHigh single recoveryMembranesUltrafiltrationFiltrationEngineering

A spiral wound membrane filtration module is operated with a single pass through the feed side and without cross-flow on the permeate side. Recovery is 70% or more and feed side velocities are between 0.05 and 0.4 feet per second. The module may have dams in the spacer material on the shell / feed side to provide a feed path with multiple passes across the membrane leaves. A small-scale system for using such a module, for example to soften and filter water with a nanofiltration membrane, is described. The system includes a chemical cleaning apparatus and process.

Owner:HUSAIN HIDAYAT +2

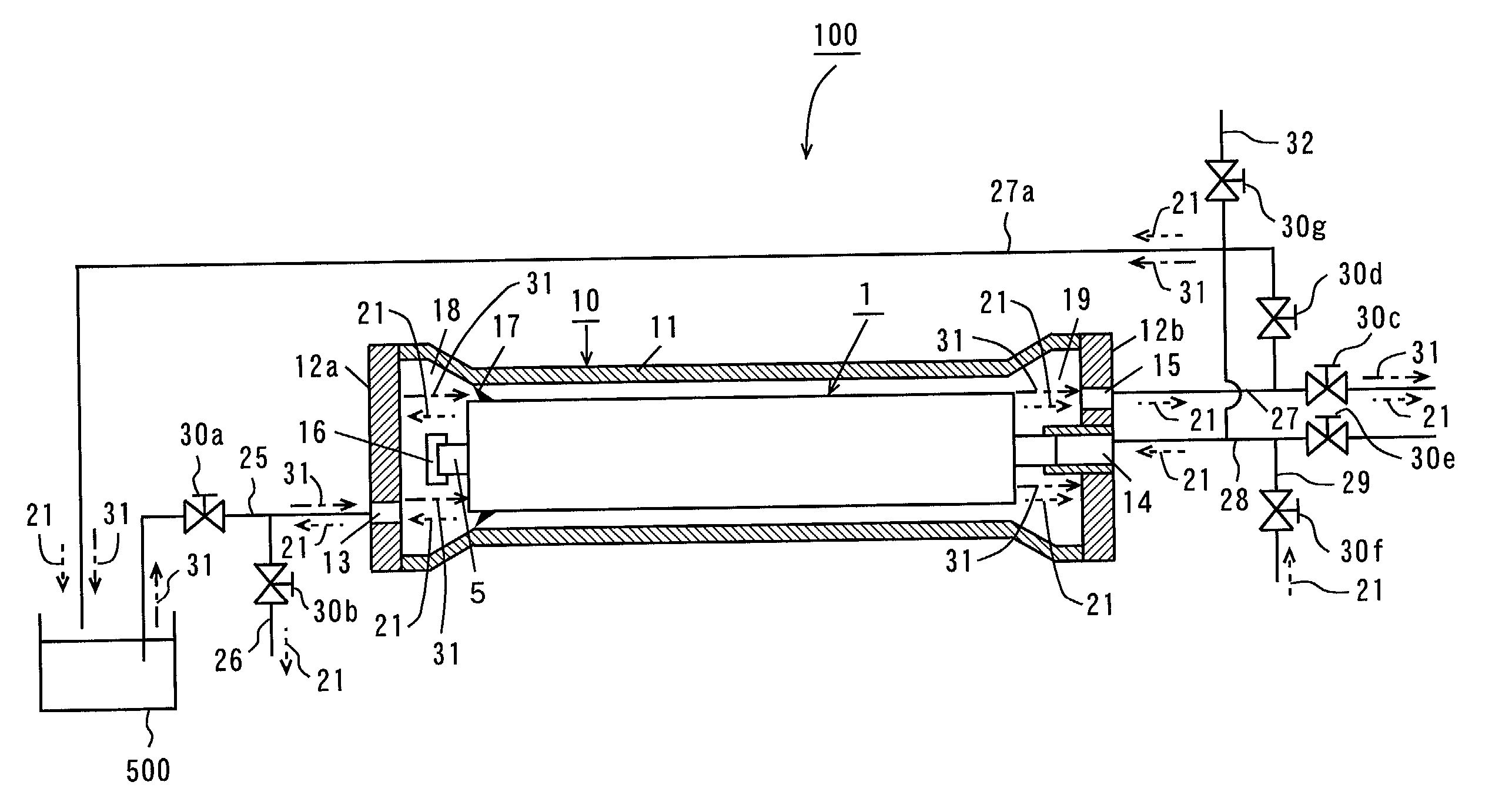

Running method and treatment system for spiral wound membrane element and spiral wound membrane module

InactiveUS20020060193A1Low costEasy to cleanLiquid separation auxillary apparatusMembranesFiltrationInjection air

Owner:NITTO DENKO CORP

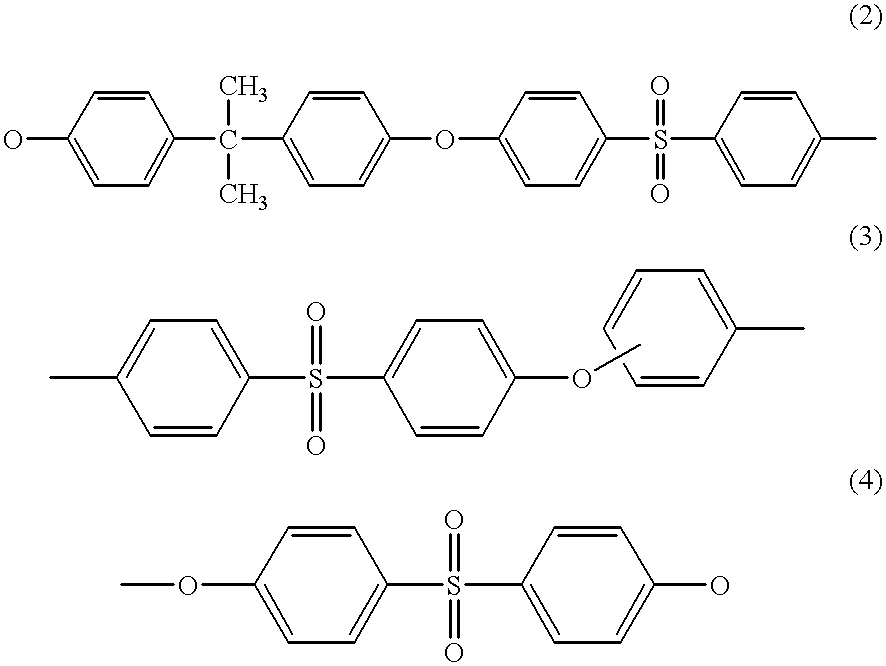

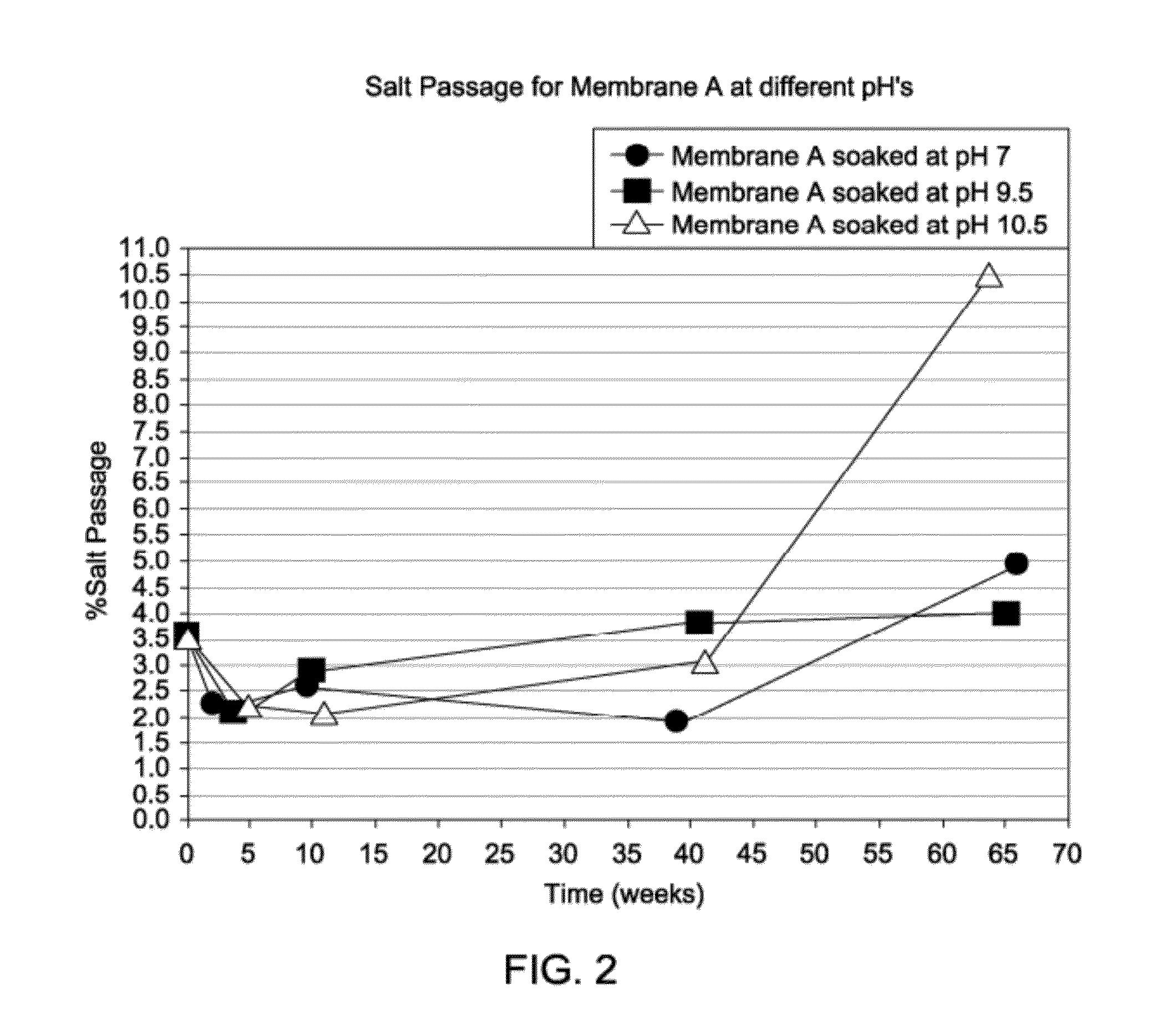

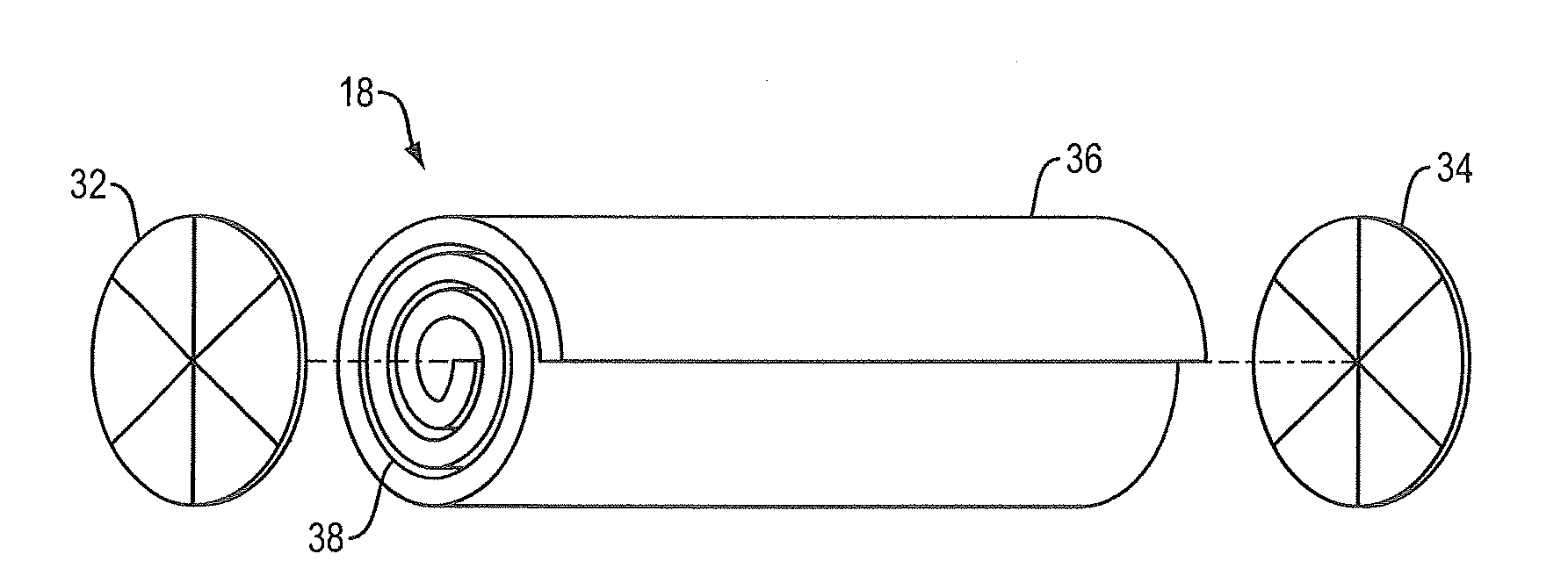

Spiral wound membrane element and treatment of SAGD produced water or other high temperature alkaline fluids

A spiral wound module is suitable for use with high temperature water that is also very alkaline or has a high pH, for example SAGD produced water. The module uses a polyamide-based membrane with a polysulfone or polyethersulfone backing material. For other components, the module uses primarily one or more of, EPDM; polyamide; polyphenylene oxide; polyphenylene sulfide; polysulfone; polyethersulfone; polysulfonamide; polyvinylidene fluoride; mylar; fiberglass; and, epoxy. Polyester is not used. Polypropylene is not used for the feed spacer. For example, a module may use a PVDF feed spacer, a nylon permeate spacer and a polysulfone center tube. The center tube may be provided with 4 rows of 0.063″ diameter holes and be rolled under high tension.

Owner:BL TECH INC

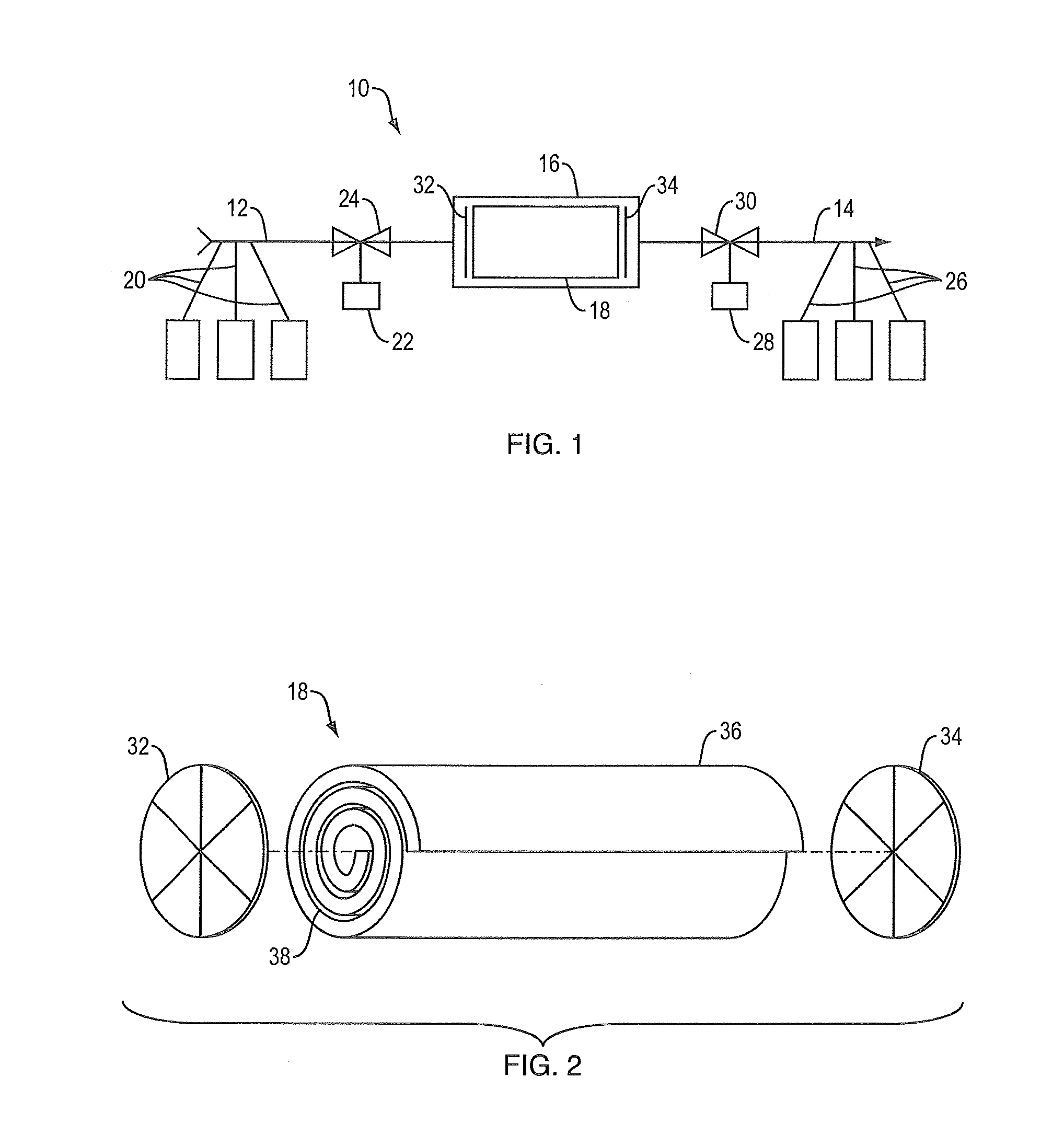

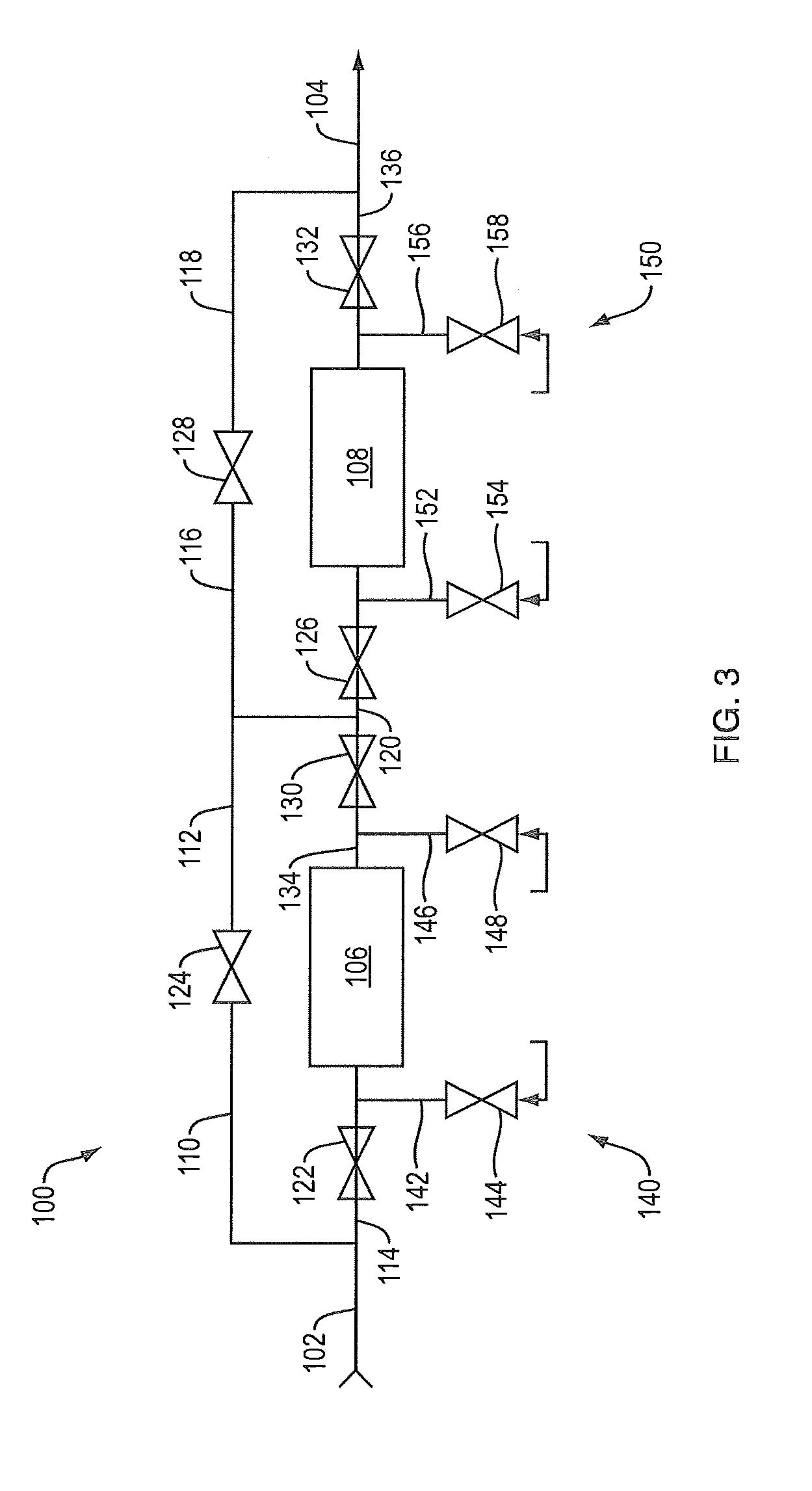

System and method for film-based chromatographic separation

InactiveUS20140151279A1Effective process scale-upIncrease the number of componentsIon-exchange process apparatusSemi-permeable membranesChromatographic separationFilm base

A film based chromatography system for capturing and releasing a material from a fluid. In one embodiment, the system includes a housing containing a spiral wound film element. The film element includes a material-capturing web and a fluid passageway web. In another embodiment, the system includes a series of such housings containing film element(s). In a further embodiment, the system includes a plurality of housings arranged in parallel and in series in various combinations. Controllers and valves are arranged to allow flexible fluid processing. The spiral wound film maximizes material contact area in the limited space and volume of the housing.

Owner:LEWA PROCESS TECH

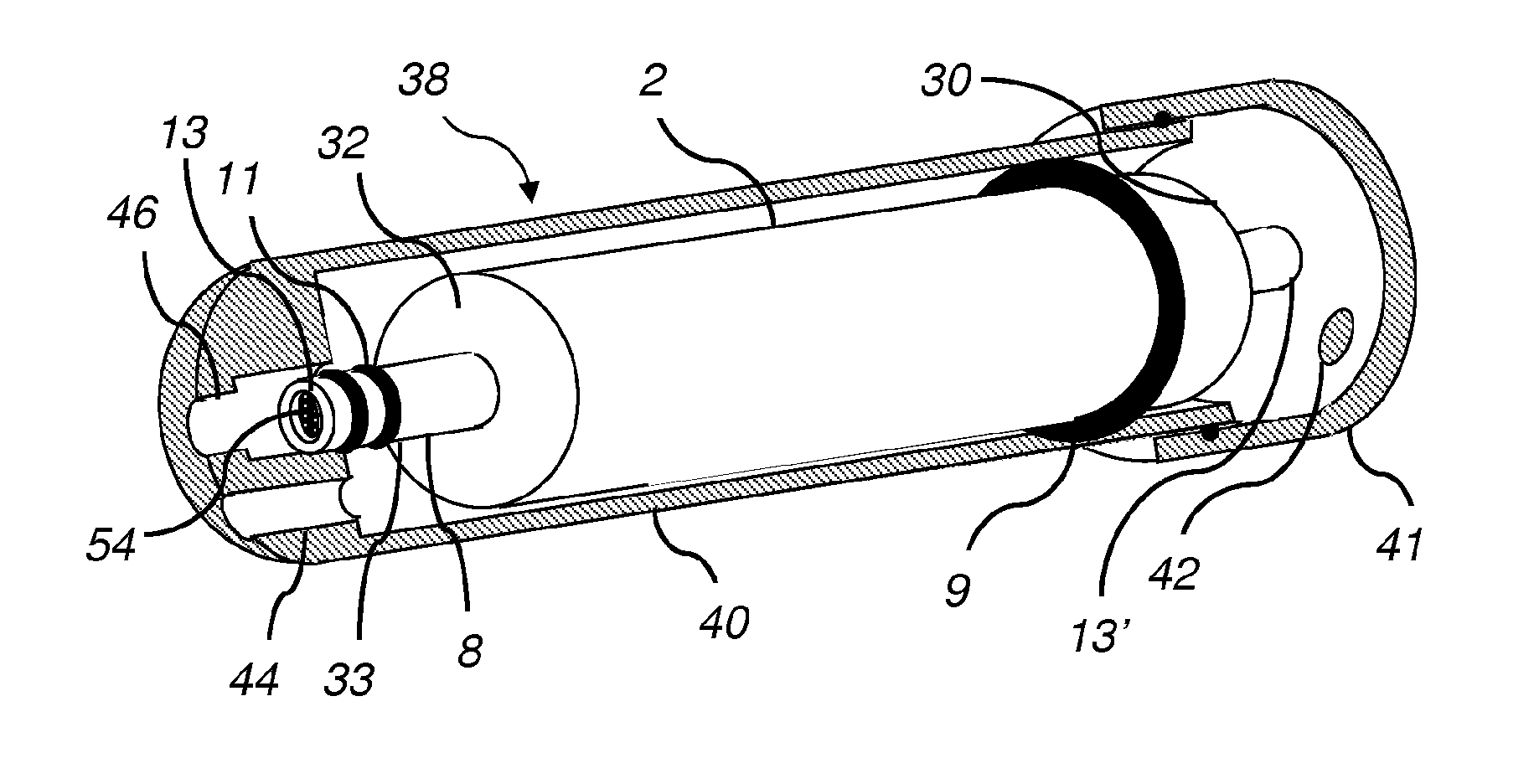

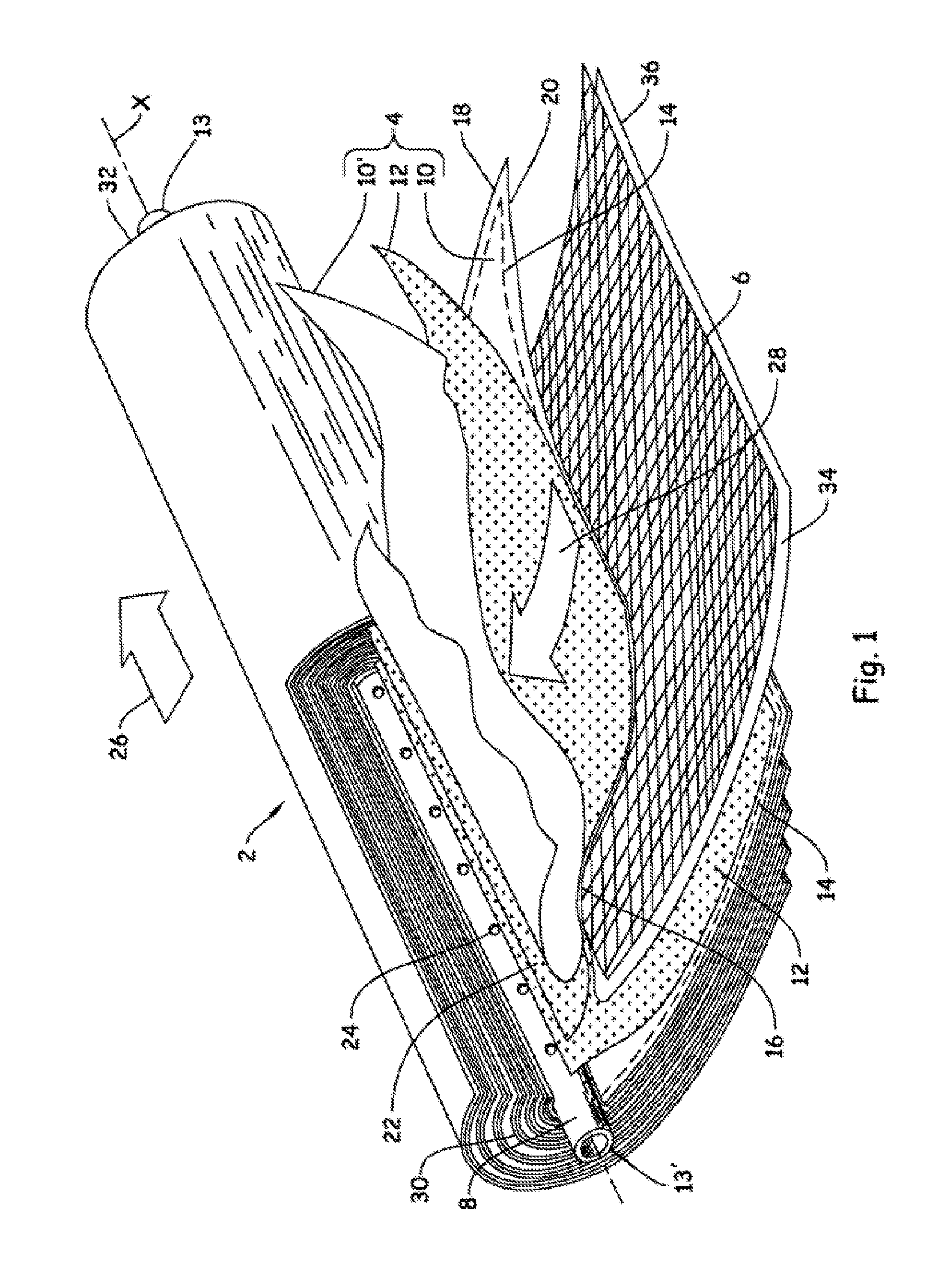

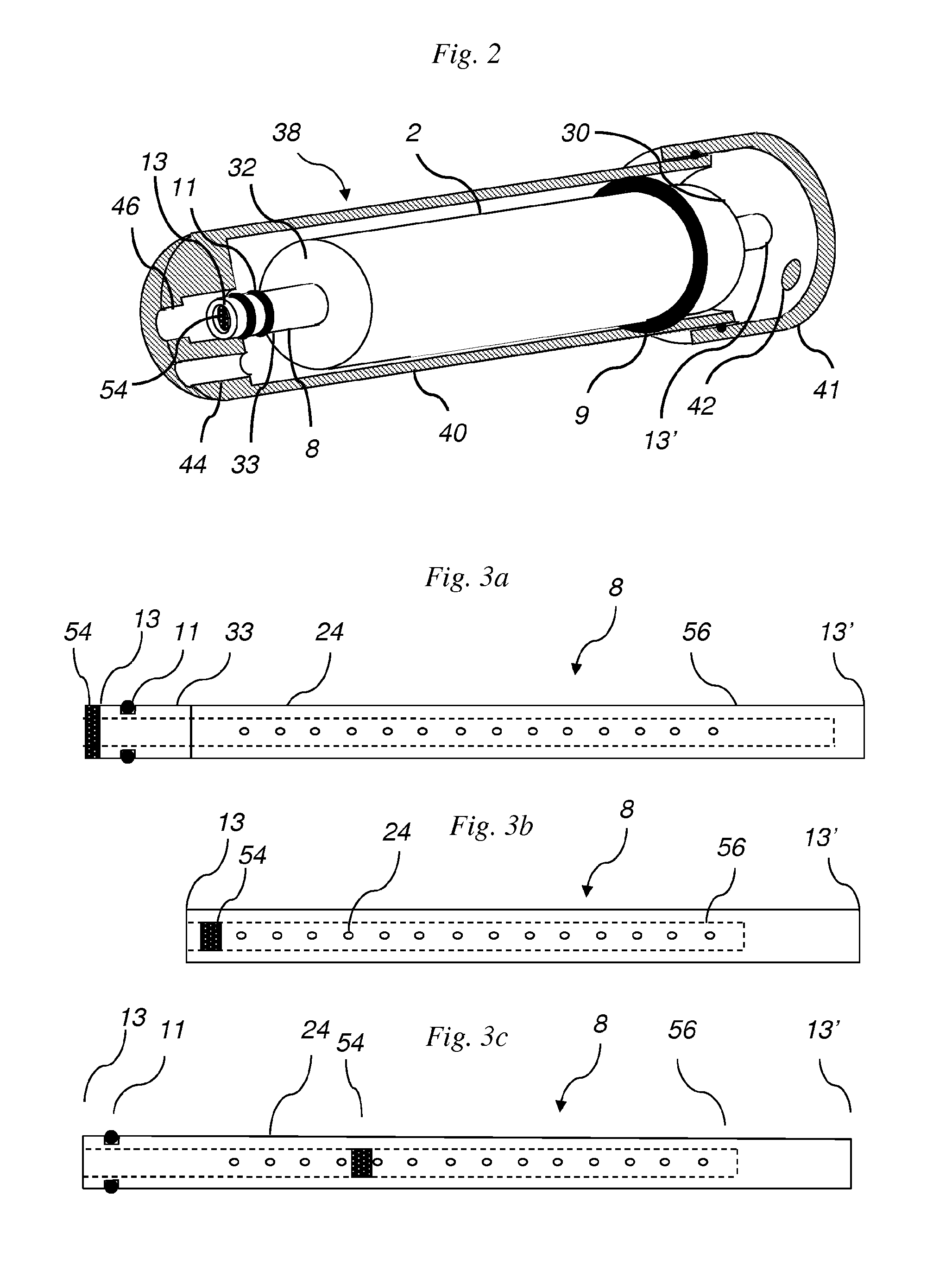

Spiral wound module with integrated permeate flow controller

A spiral wound membrane module (2) comprising at least one membrane envelope (4) wound about a permeate collection tube (8), wherein the module (2) is characterized by a flow controller (54) located within or fixed to the permeate collection tube (8) that provides a flow resistance that varies as a function of permeate flow.

Owner:DOW GLOBAL TECH LLC

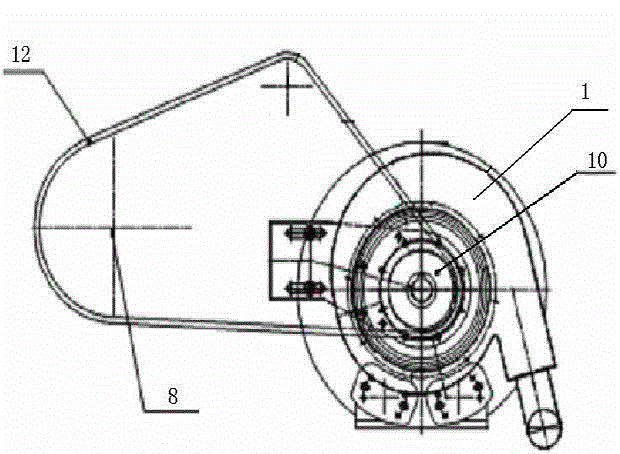

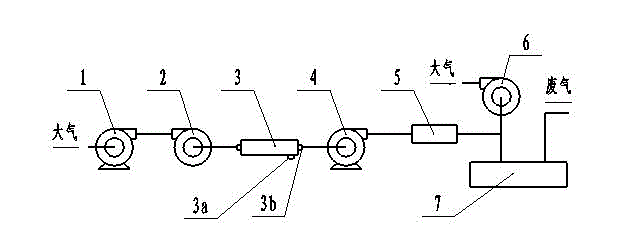

Device for plateau oxygen-enrichment axillary combustion of engine

InactiveCN102943725AImprove powerReduce fuel consumptionMachines/enginesAir intakes for fuelAir filterBuffer tank

The invention relates to a device for plateau oxygen-enrichment axillary combustion of an engine. The device comprises a pressure control module and a gas treating module, wherein the pressure control module comprises a fan and a gas ring vacuum pump, the gas treating module comprises an air filter, a spiral-wound membrane separator and a buffer tank, the output end of the fan is connected with the inlet of the air filter, the outlet of the air filter is connected with the inlet of the spiral-wound membrane separator, the spiral-wound membrane separator is provided with a nitrogen-enrichment outlet and an oxygen-enrichment outlet, the oxygen-enrichment outlet of the spiral-wound membrane separator is connected with the input end of the gas ring vacuum pump, the output end of the gas ring vacuum pump is connected with the inlet of the buffer tank, and the outlet of the buffer tank is connected with a gas inlet system of the engine. According to the device, the oxygen content in inlet gas of the engine is increased, and therefore the dynamic property and the economy of the engine are increased.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Purification method of antioxidant rosmarinic acid for tobacco

ActiveCN102952018ANo pollution in the processImprove pollutionCarboxylic acid esters separation/purificationChromatographic separationPurification methods

Belonging to the technical field of tobacco additives, the invention discloses a purification method of an antioxidant rosmarinic acid for tobacco. The purification method is carried out according to the steps of: (1) performing primary purification: first passing a rosmarinic acid-containing extraction solution A through a 30nm inorganic membrane, then passing it through an organic spiral-wound membrane with molecular weight cut-off of 3000, thus obtaining the filtrate B; (2) making sample loading preparation: subjecting the filtrate B to reverse osmosis membrane concentration to obtain a concentrated sample C; (3) conducting fine purification: carrying out chromatographic separation on the concentrated sample C by a gel column and collecting rosmarinic acid fraction; and (4) further concentrating and purifying the collected rosmarinic acid fraction by a pressure reduction distillation method and a recrystallization method in the prior art so as to make the rosmarinic acid content reach 80%-95%. The method provided in the invention is simple, safe, pollution-free, and is easy to implement.

Owner:HUBEI CHINA TOBACCO IND

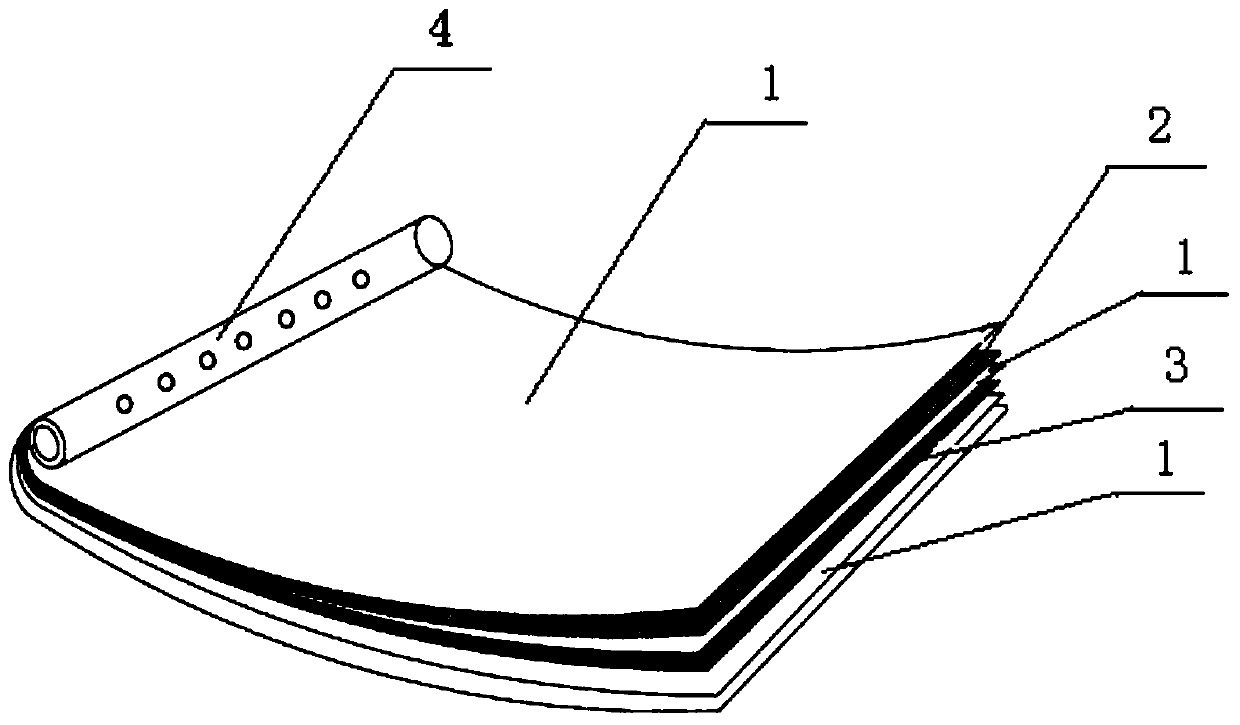

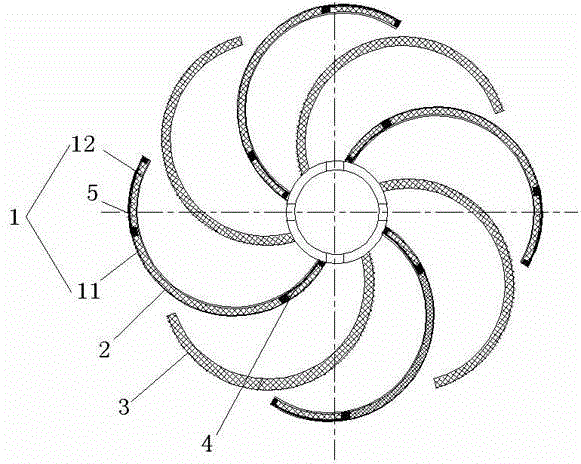

Spiral-wound membrane element winding method

ActiveCN103551039AIncrease effective areaIncrease profitSemi-permeable membranesEngineeringFresh water

The invention relates to a spiral-wound membrane element winding method, and belongs to the technical field of filters in water purifying devices. The spiral-wound membrane element winding method comprises the following steps: step one, gluing two sides of a membrane sheet along the length direction, and folding into an M shape, placing fresh water collecting nets in two successive V-shaped grooves in the M shape, and placing thick nets in V-shaped grooves corresponding to two successive V-shaped grooves; step two, superimposing a plurality of folded unit bodies in the step one together, and winding around a water collecting pipe to form coils by taking the lower edge of the M shape as an initial edge. The spiral-wound membrane element winding method provided by the invention has the advantages of reducing gluing edge amount, increasing the effective area of the membrane sheet, improving the utilization ratio of the membrane sheet and the like.

Owner:VONTRON TECH CO LTD

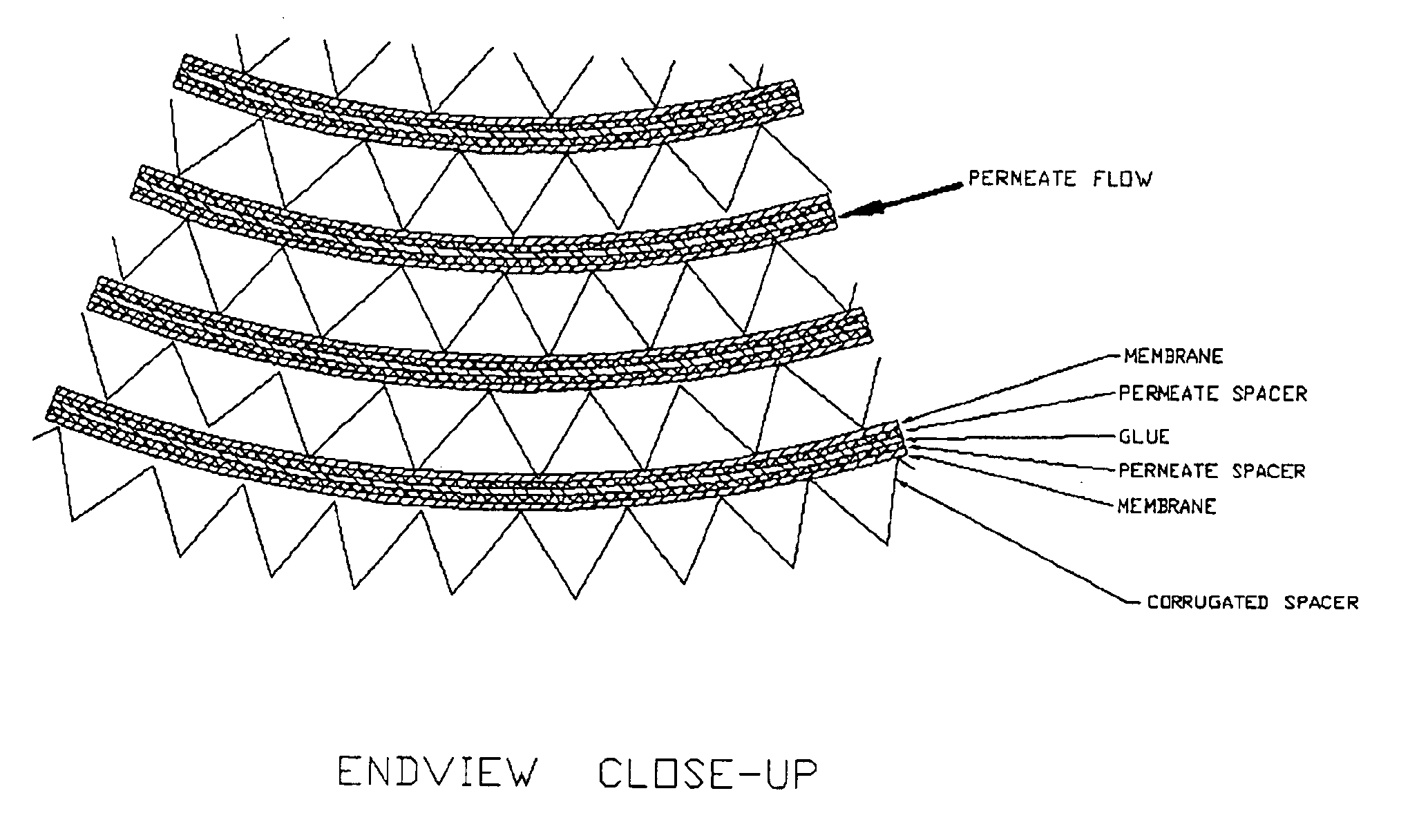

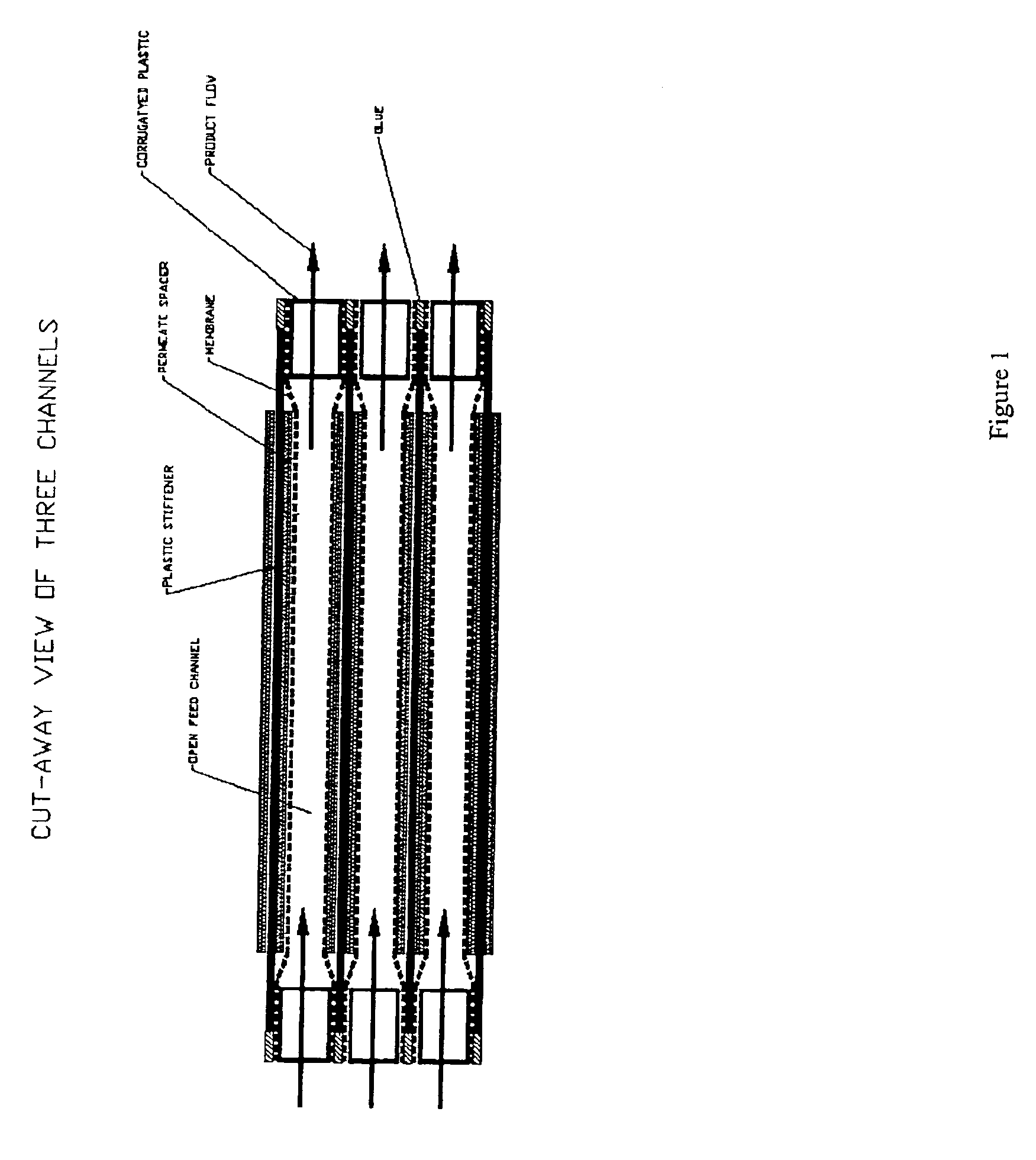

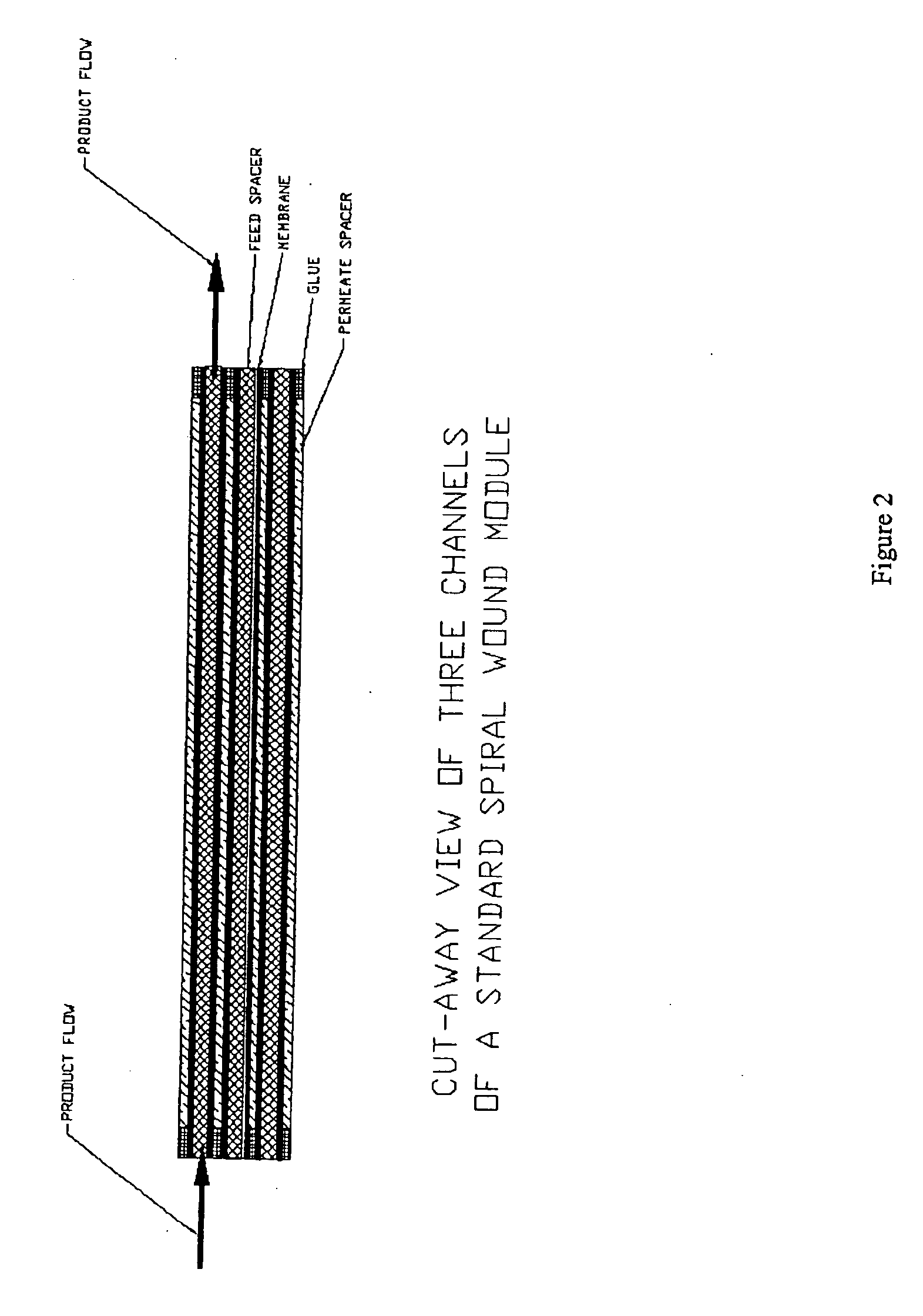

Open-channeled spiral-wound membrane module

InactiveUS6902672B2Reduce fluid flow resistanceIncrease radiusSemi-permeable membranesOther chemical processesSpiral woundEngineering

There is disclosed a spiral-wound membrane module design for various membrane filtration techniques having significantly reduced fluid flow resistance in the feed stream path. Specifically, the inventive spiral-wound membrane module is designed having a corrugated entrance and exit spacers together over less than 10% of the length of the spiral wound module and a stiffener sheet wound to provide for uniform feed channel gap width.

Owner:HYDRATION SYST

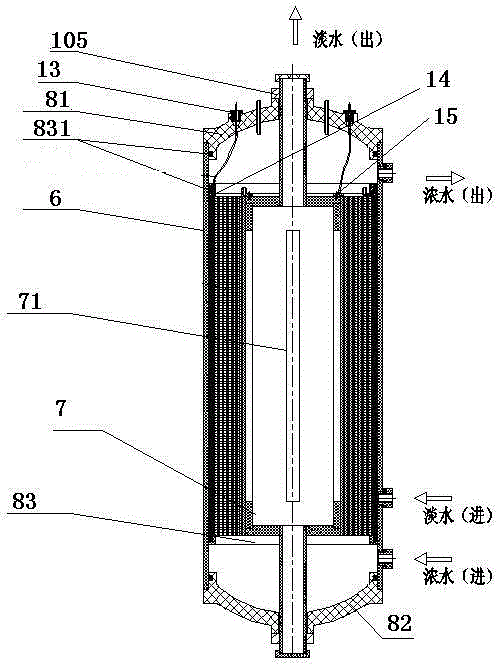

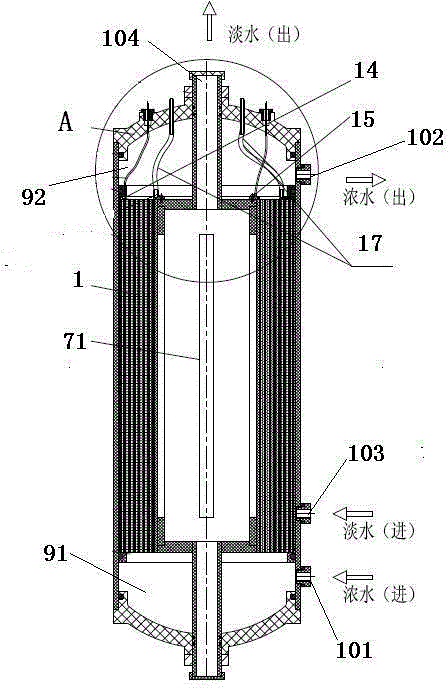

Membrane stack and electro-desalting assembly

ActiveCN104556315AReduce thicknessReduce energy consumptionDispersed particle separationWater/sewage treatment by ion-exchangeElectric fieldMembrane stack

The invention relates to a water treatment device and in particular relates to a membrane stack and an electro-desalting assembly. The membrane stack comprises membrane bags, a thickened water network and a fresh water network; each membrane bag comprises an anion exchange membrane and a cation exchange membrane; the thickened water network is arranged between the anion exchange membrane and the cation exchange membrane; the fresh water network is arranged in a gap between two adjacent membrane bags; a first electrode slice and a second electrode slice for forming an electric field are arranged at the two ends of the membrane bag; the first electrode slice or the second electrode slice is shorter than the anion exchange membrane or the cation exchange membrane. Water flow collecting grooves are formed evenly on the four sides of the central tube of the electro-desalting assembly; the membrane bags and the networks are spirally wound around the central tube to form a spiral-wound membrane core. The membrane core is arranged in a membrane shell to form the electro-desalting assembly. An uneven electric field is generated between the electrodes and the current density is uneven. The electro-desalting assembly has the advantages of high desalting efficiency, high hardness tolerance, low energy consumption and the like.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com