Thermo-sensitive type ultrafiltration membrane and preparation method thereof

A temperature-sensitive, ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to improve anti-pollution performance, solve hydrophilicity, and improve anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

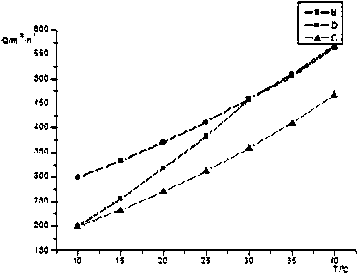

Image

Examples

Embodiment 1

[0026] Step 1: Dissolve N-isopropylacrylamide (NIPAAM) and polyethylene glycol methacrylate (PEGMA) in tert-butanol at a mass ratio of 0.62:1 and add it to a 250mL three-necked flask. Add NIPAAM and The initiator azobisisobutyronitrile of 3% of the total mass of PEGMA was reacted at 78°C for 12 hours under the protection of nitrogen, and after the reaction was completed, separation and purification were carried out to obtain a temperature-sensitive double-hydrophilic polymer.

[0027] Step 2: Mix polyvinylidene fluoride and temperature-sensitive double-hydrophilic polymer evenly at a mass ratio of 85% and 15%, and then mix the mixture of the two, isopropanol and dimethylacetamide at a ratio of 14%:5% : 81% mass percentage preparation, the mixture and dimethylacetamide are heated and stirred at 75°C to dissolve, and after the dissolution is uniform, isopropanol is added to stir and mix to obtain a casting solution, and then stand for defoaming;

[0028] Step 3: The prepared cas...

Embodiment 2

[0031] Step 1: Dissolve N-isopropylacrylamide (NIPAAM) and polyethylene glycol methacrylate (PEGMA) in tert-butanol at a mass ratio of 1:1 and add it to a 250mL three-necked flask. Add NIPAAM and The initiator azobisisobutyronitrile of 2% of the total mass of PEGMA was reacted at 78°C for 12 hours under the protection of nitrogen, and the temperature-sensitive double-hydrophilic polymer was obtained by separation and purification after the reaction was completed.

[0032] Step 2: Mix polyvinylidene fluoride and temperature-sensitive double-hydrophilic polymer evenly at a mass ratio of 85% and 15%, and then mix the mixture of the two, isopropanol and dimethylacetamide at a ratio of 16%: 4% : 80% mass percentage preparation, the mixture and dimethylacetamide are heated and stirred at 75°C to dissolve, and after the dissolution is uniform, isopropanol is added to stir and mix to obtain a casting solution, and then stand for defoaming;

[0033] Step 3: Scrape the prepared casting ...

Embodiment 3

[0036] Step 1: Dissolve N-isopropylacrylamide (NIPAAM) and polyethylene glycol methacrylate (PEGMA) in tert-butanol at a mass ratio of 1.5:1 and add it to a 250mL three-necked flask. Add NIPAAM and The initiator azobisisobutyronitrile of 2% of the total mass of PEGMA was reacted at 78°C for 12 hours under the protection of nitrogen, and the temperature-sensitive double-hydrophilic polymer was obtained by separation and purification after the reaction was completed.

[0037] Step 2: Mix polyvinylidene fluoride and temperature-sensitive double-hydrophilic polymer at a mass ratio of 85% and 15%, and then mix the mixture of the two, isopropanol, methylenebisacrylamide and dimethylethylene The amide is prepared according to the mass percentage of 15.1%: 4%: 0.9%: 80%. First, heat and stir the mixture and dimethylacetamide at 75°C to dissolve. After the dissolution is uniform, add isopropanol and methylenebisacrylamide and stir. Mix to obtain the casting solution, then let it stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com