Patents

Literature

466 results about "Flat sheet membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

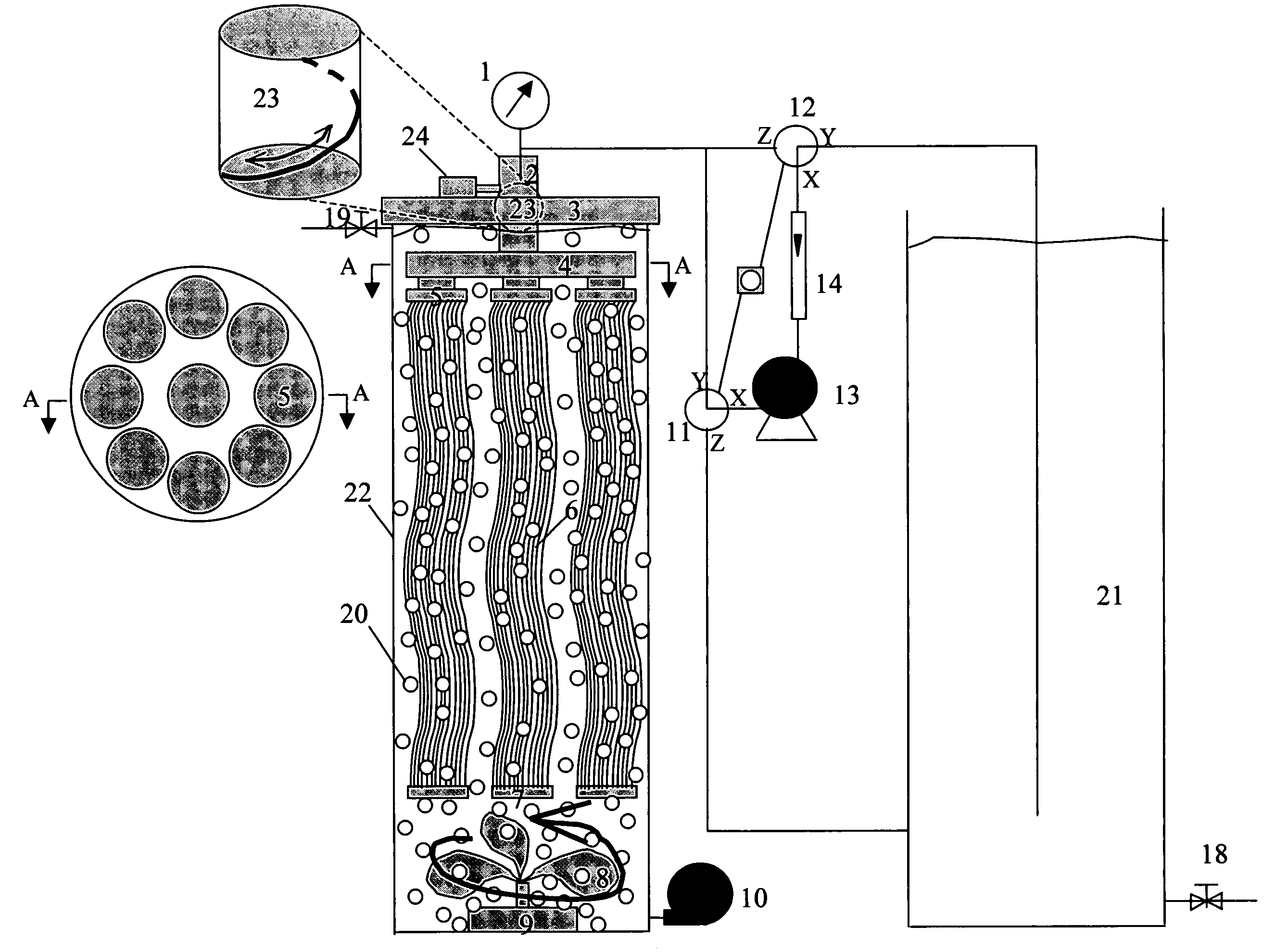

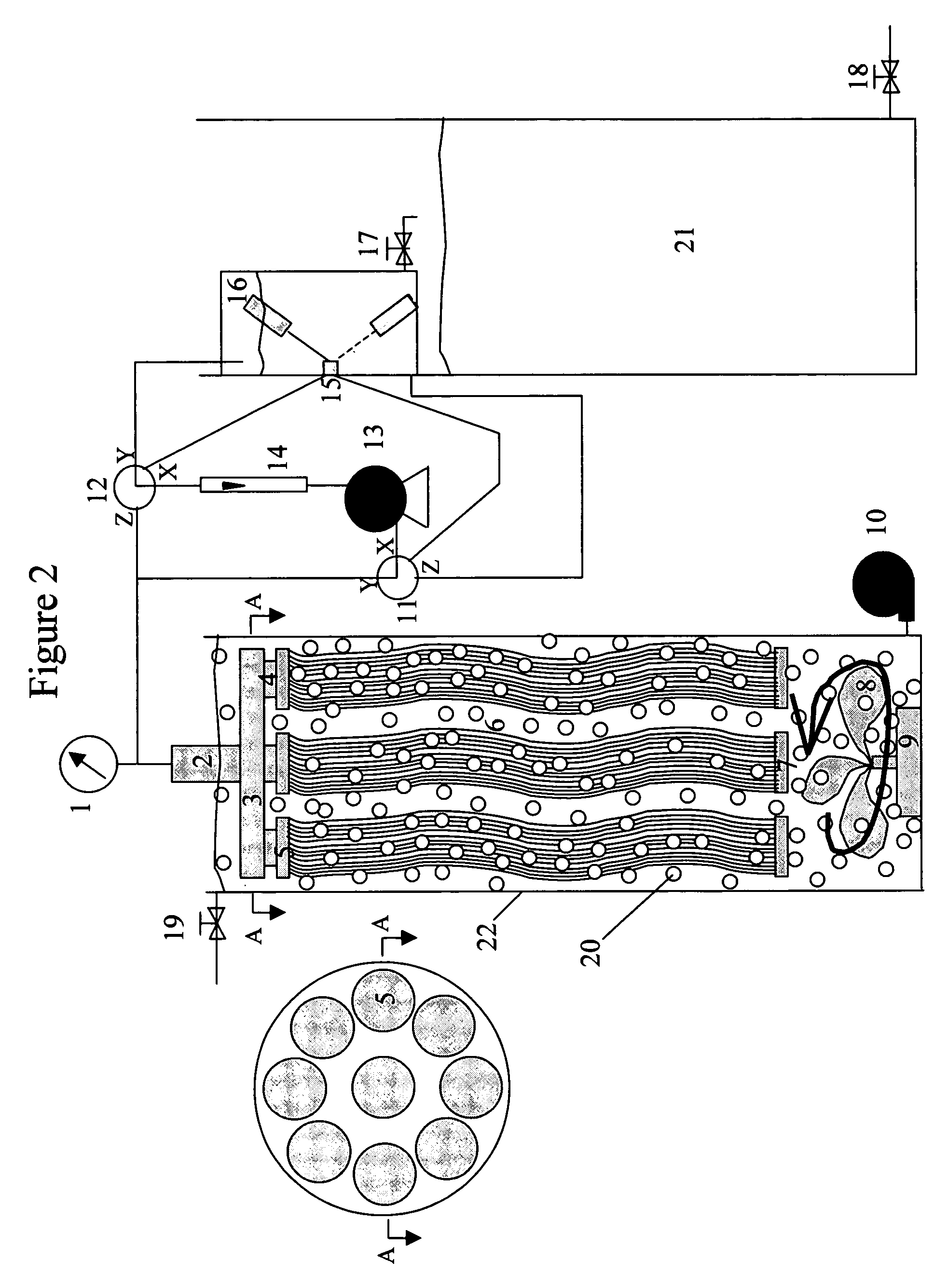

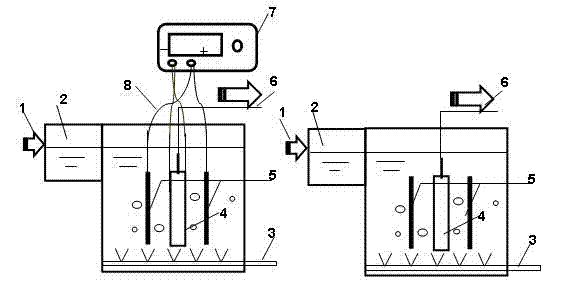

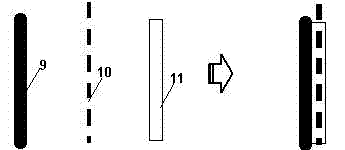

Advanced submerged membrane modules, systems and processes

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

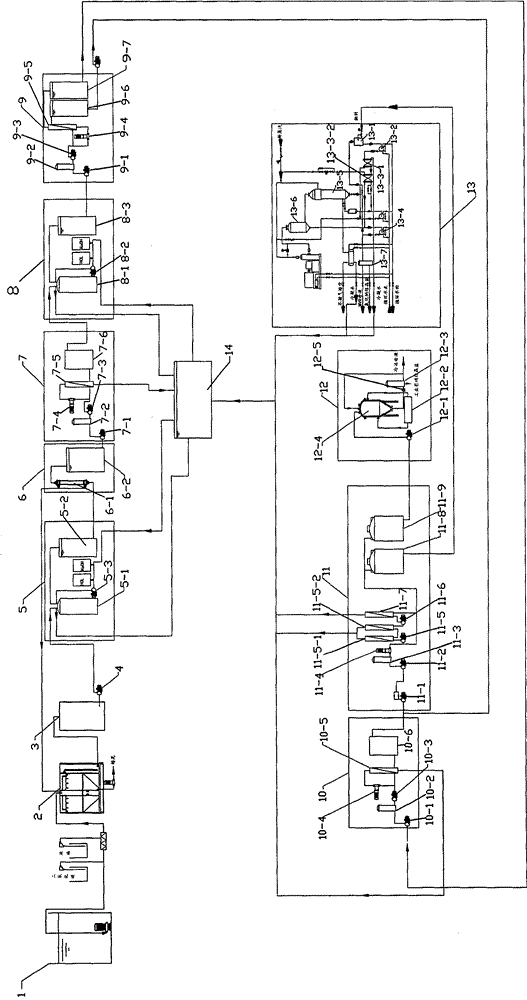

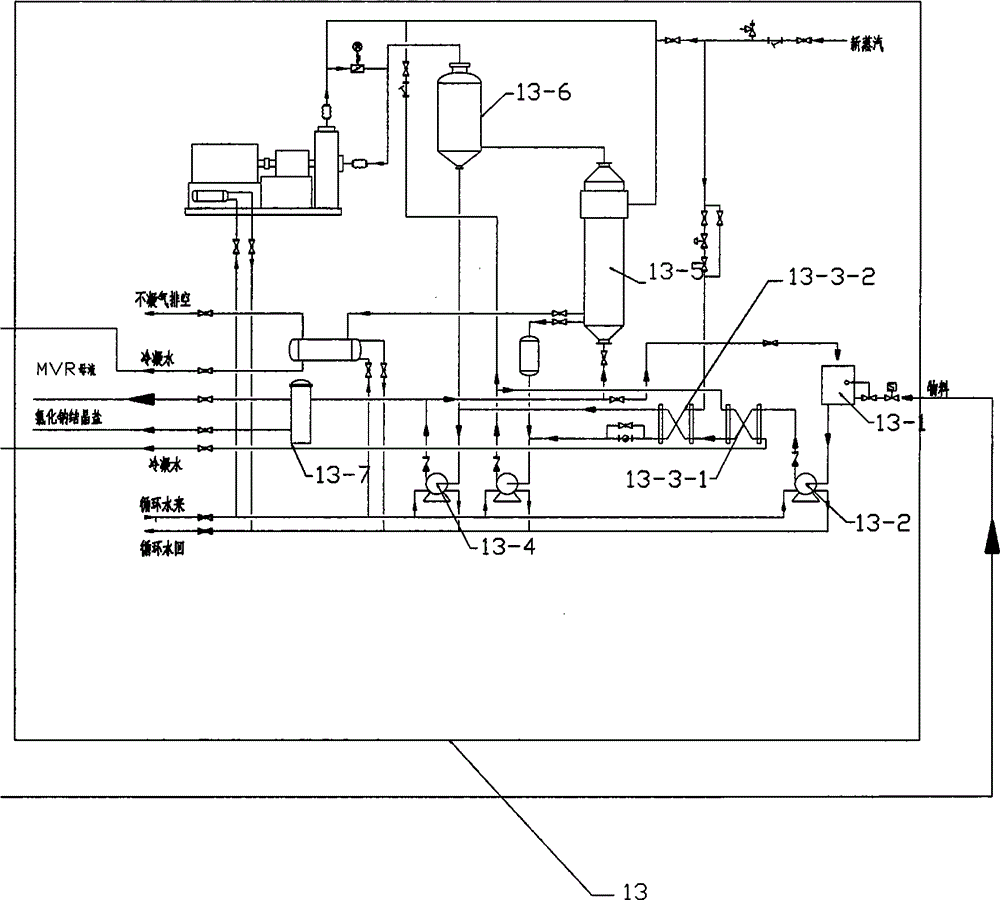

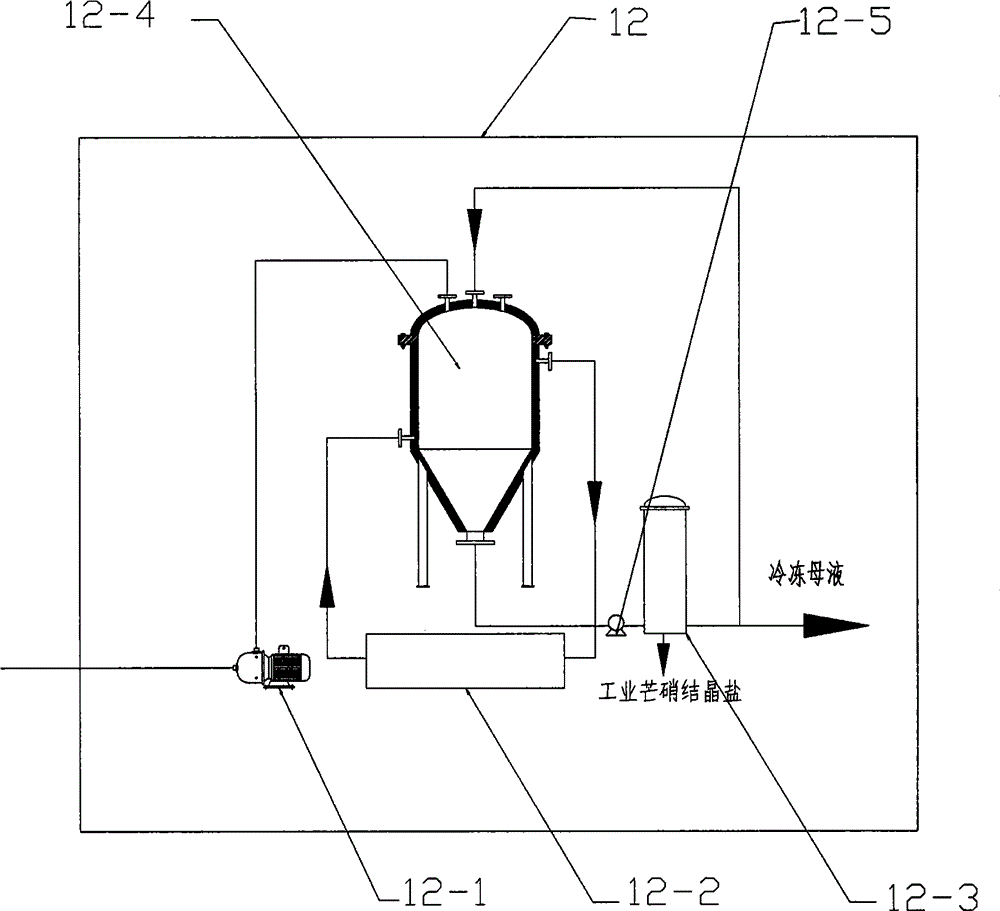

Treatment method of high saline wastewater

ActiveCN104692574ATake advantage of the combinationAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentSocial benefitsFiltration

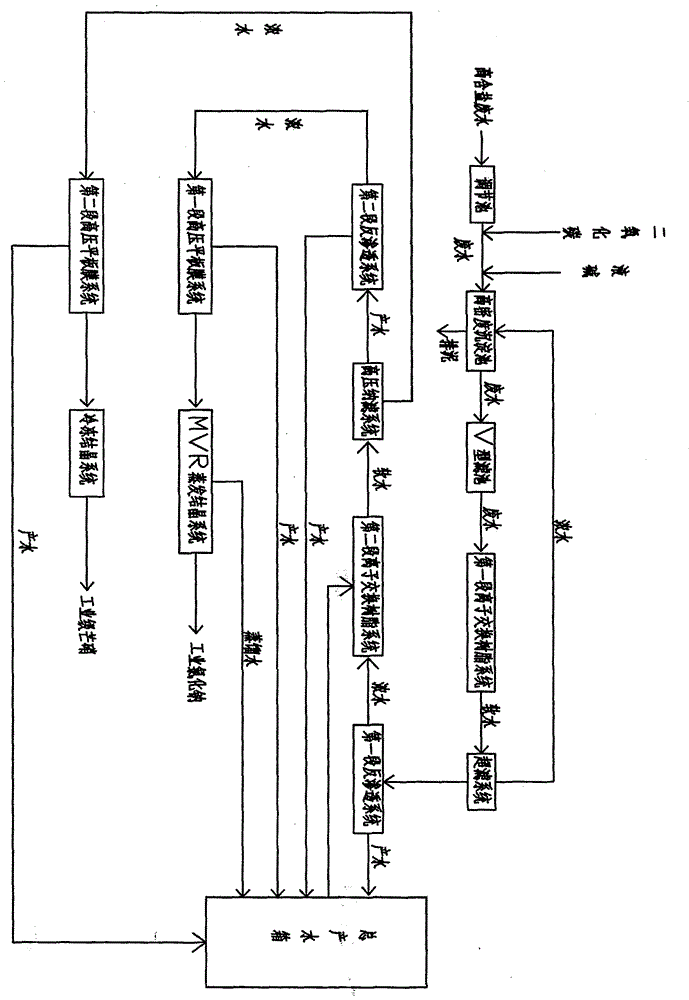

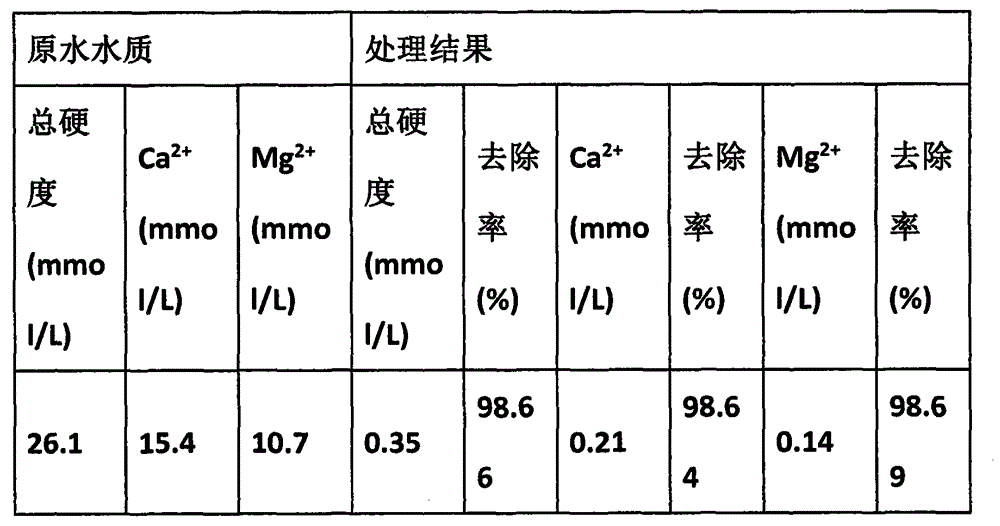

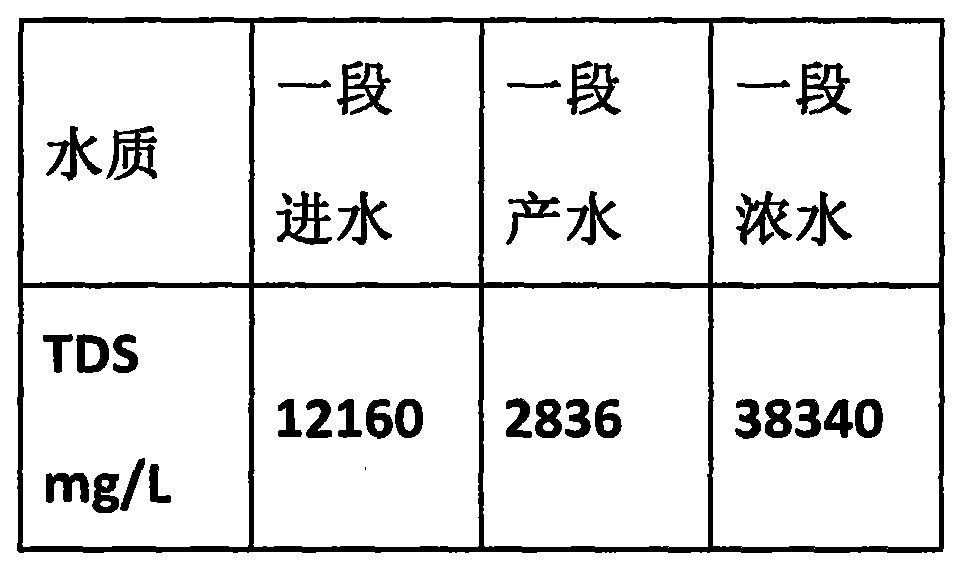

The invention discloses a treatment method of high saline wastewater, and relates to the treatment technology. The method comprises the following steps: preparing high saline wastewater, regulating in a regulating pond, chemically pre-treating in a settling pond, filtering in a V-shaped filter pond, the first section ion exchange softening, ultrafiltering in an ultrafiltration system, reverse osmosis treating through a first section reverse osmosis system, the second ion exchange softening, nano-filtering through a high-pressure nano-filtration system, nano-filtering to produce water, reverse osmosis treating through a second section reverse osmosis system, concentrating through a first section high-pressure flat film system, MVR evaporating and crystallizing to obtain the industrial level sodium chloride; nano-filtering to concentrate water, concentrating through a second section high pressure flat film system, freezing and crystallizing to obtain the industrial level mirabilite. The ultra-filtration, the nano-filtration, the reverse osmosis and high-pressure flat film methods are reasonably coupled to combine with the MVR crystallization and freezing crystallization to treat the high saline wastewater, the defect of single technology is overcome, the combination advantage is developed, the problems of efficiently and economically treating and recycling the high saline wastewater can be solved, and the treatment method has obvious economic benefit and social benefit.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

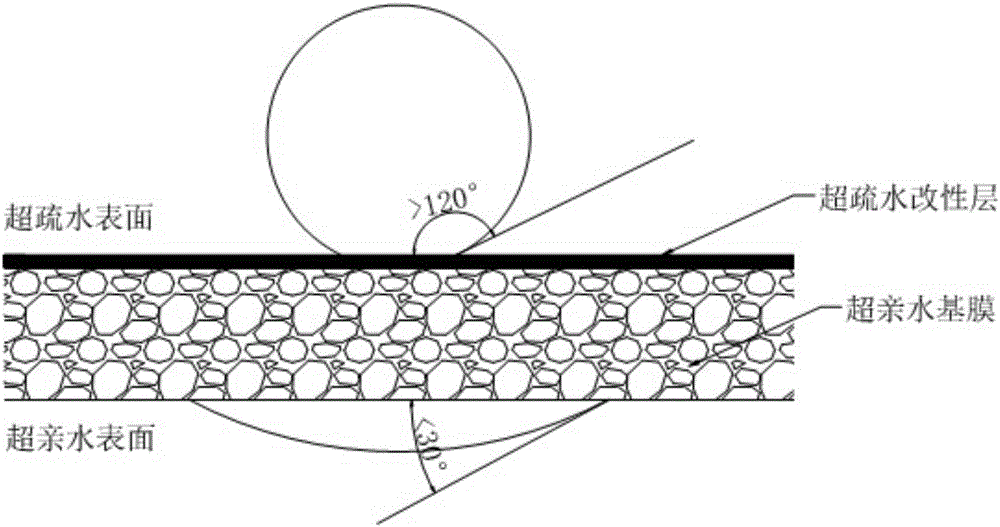

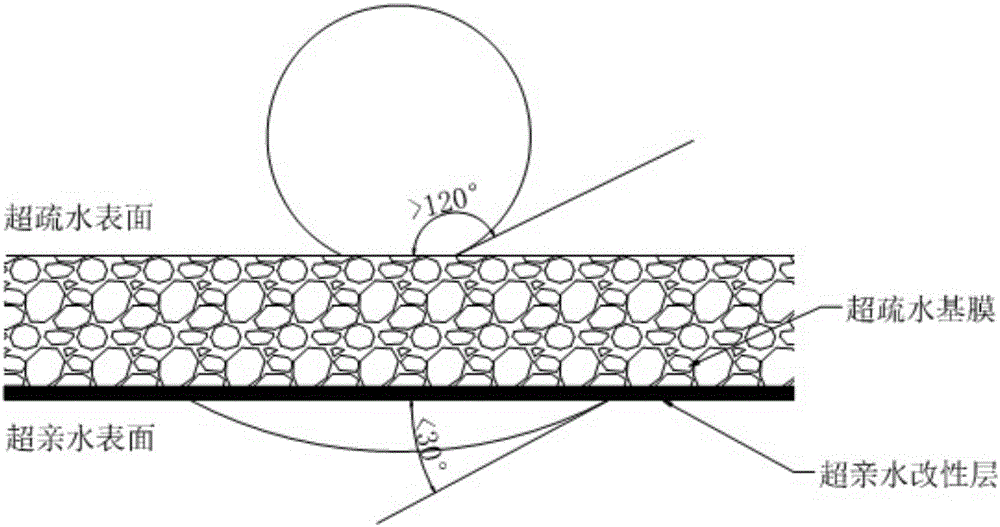

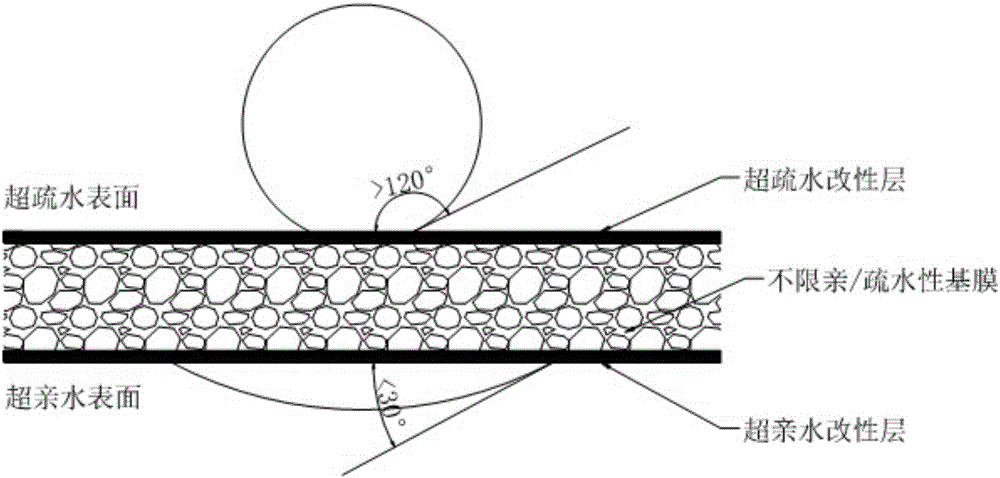

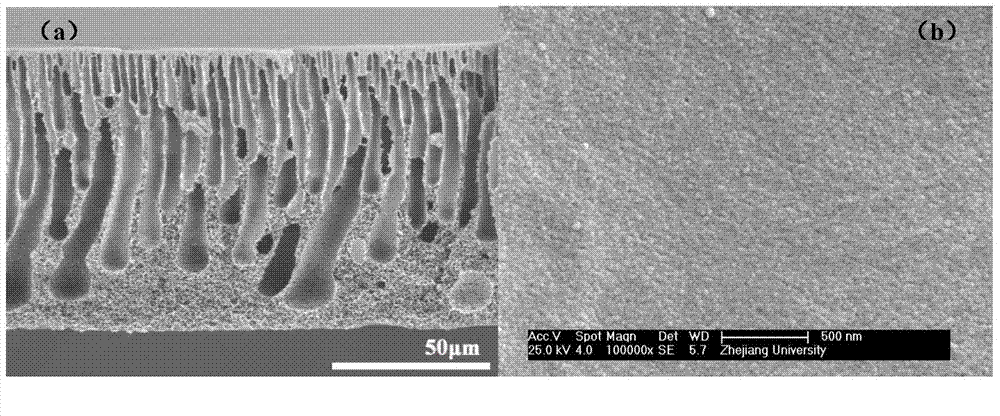

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

ActiveCN106268355AImprove anti-pollution performanceReduce adhesionMembranesSemi-permeable membranesPore diameterHollow fiber membrane

The invention relates to a membrane separation technique and aims at providing an asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane and a preparation method thereof. According to the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane, a base membrane is a flat sheet membrane or a hollow fiber membrane, one side of the base membrane is a hydrophilic side, the water contact angle of the hydrophilic side is not greater than 30 degrees, the other side of the base membrane is a hydrophobic side, and the water contact angle of the hydrophobic side is not smaller than 120 degrees. The prepared asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane is of the type of the flat sheet membrane or the hollow fiber membrane and belongs to an ultra-micro filter membrane category, and the pore diameter range of the membrane is 0.01-2.0 microns. Therefore, the hydrophilic and hydrophobic properties on double sides are different, one side is hydrophilic, the other side is hydrophobic, and the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane shows asymmetric hydrophilic / hydrophobic properties and is a novel water treatment membrane.

Owner:ZHEJIANG UNIV

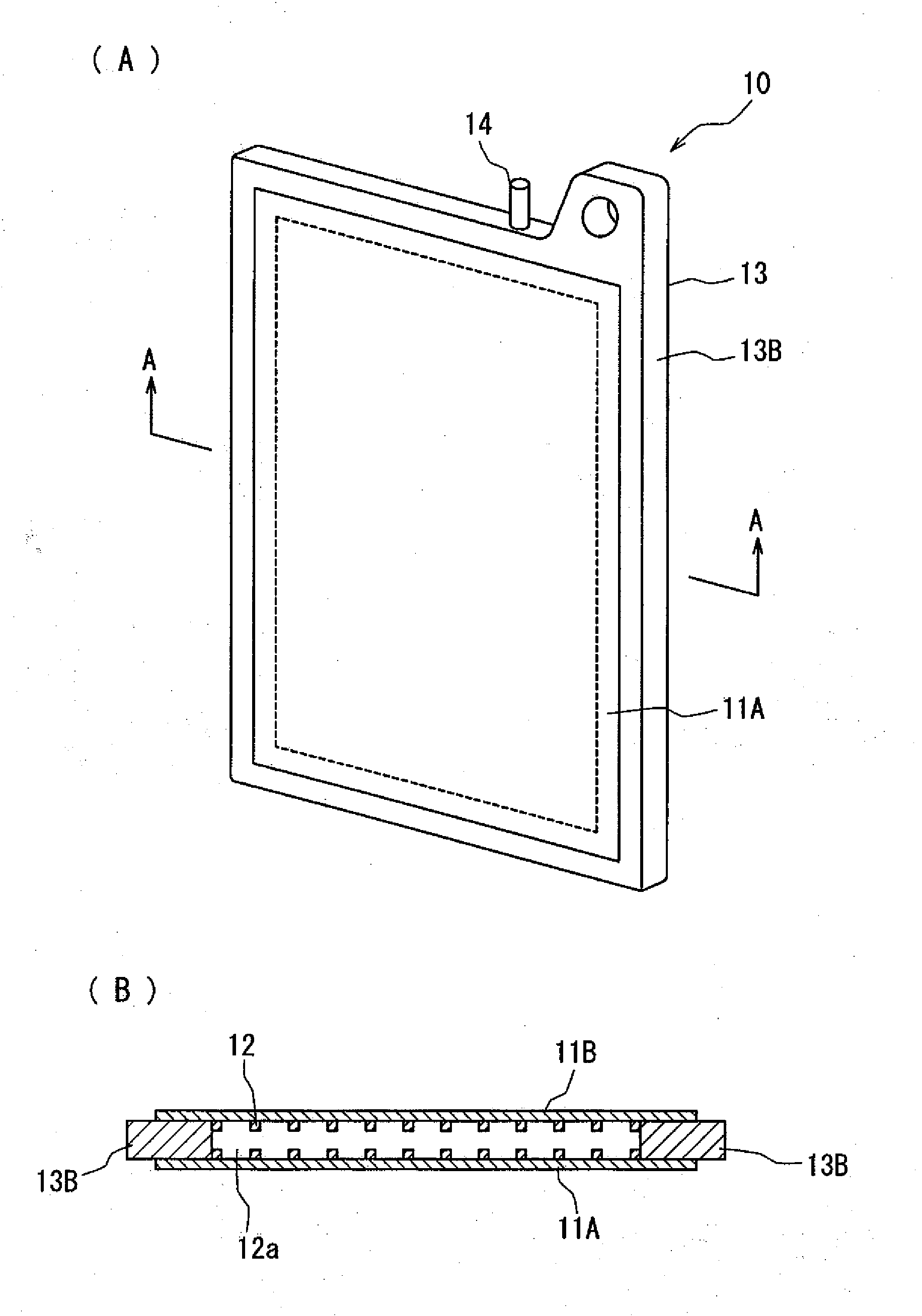

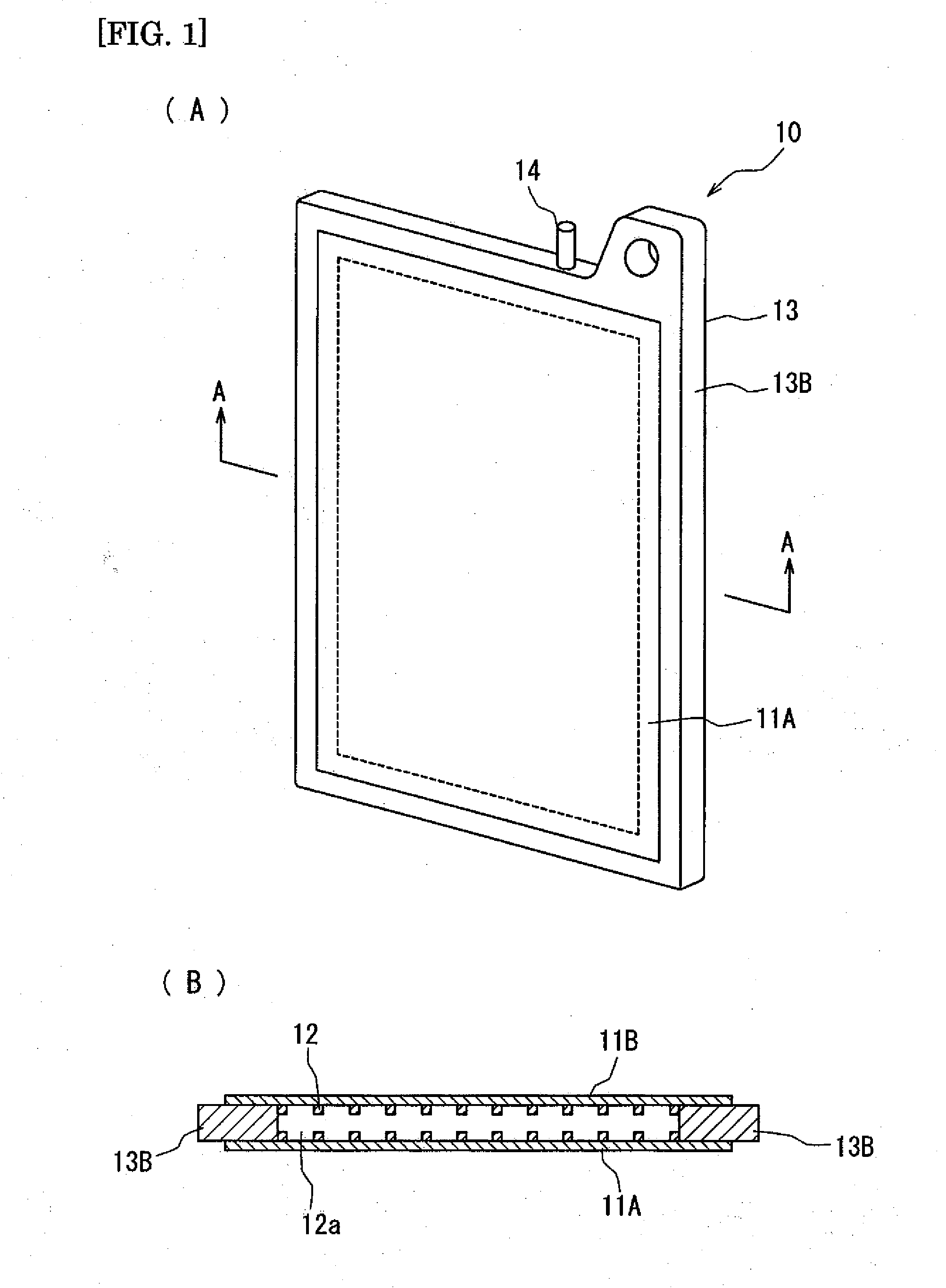

Flat sheet membrane element for filtration and flat sheet membrane filtration module

InactiveUS20100096317A1Improve performanceStable permeation flow rateMembranesUltrafiltrationFiltration membranePorous membrane

A flat sheet membrane element for performing solid-liquid separation by immersion in a liquid to be treated which contains a suspended component includes sheet-shaped filtration membranes disposed opposite to each other with a space for a treated liquid flow path, a support portion for securing the space for the treated liquid flow path, and a peripheral sealing portion for sealing the peripheral edges of the filtration membranes arranged opposite to each other so as to form at least one treated liquid outlet, the filtration membranes including at least expanded PTFE (polytetrafluoroethylene) porous membranes.

Owner:SUMITOMO ELECTRIC IND LTD

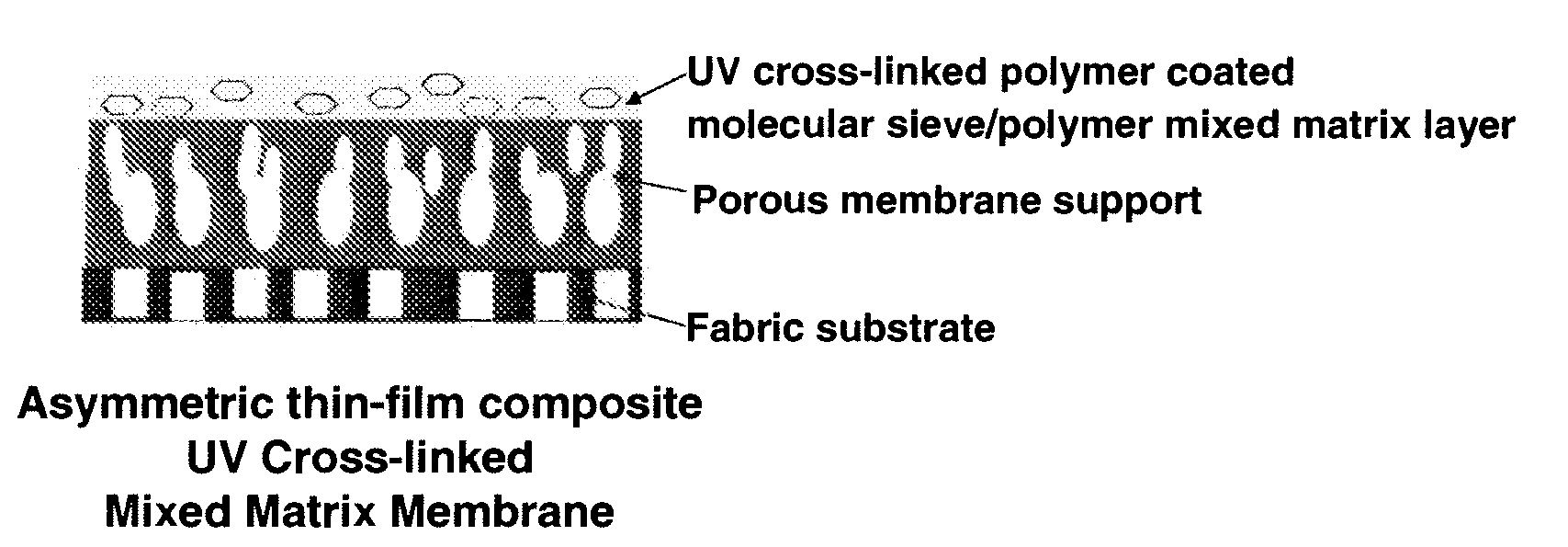

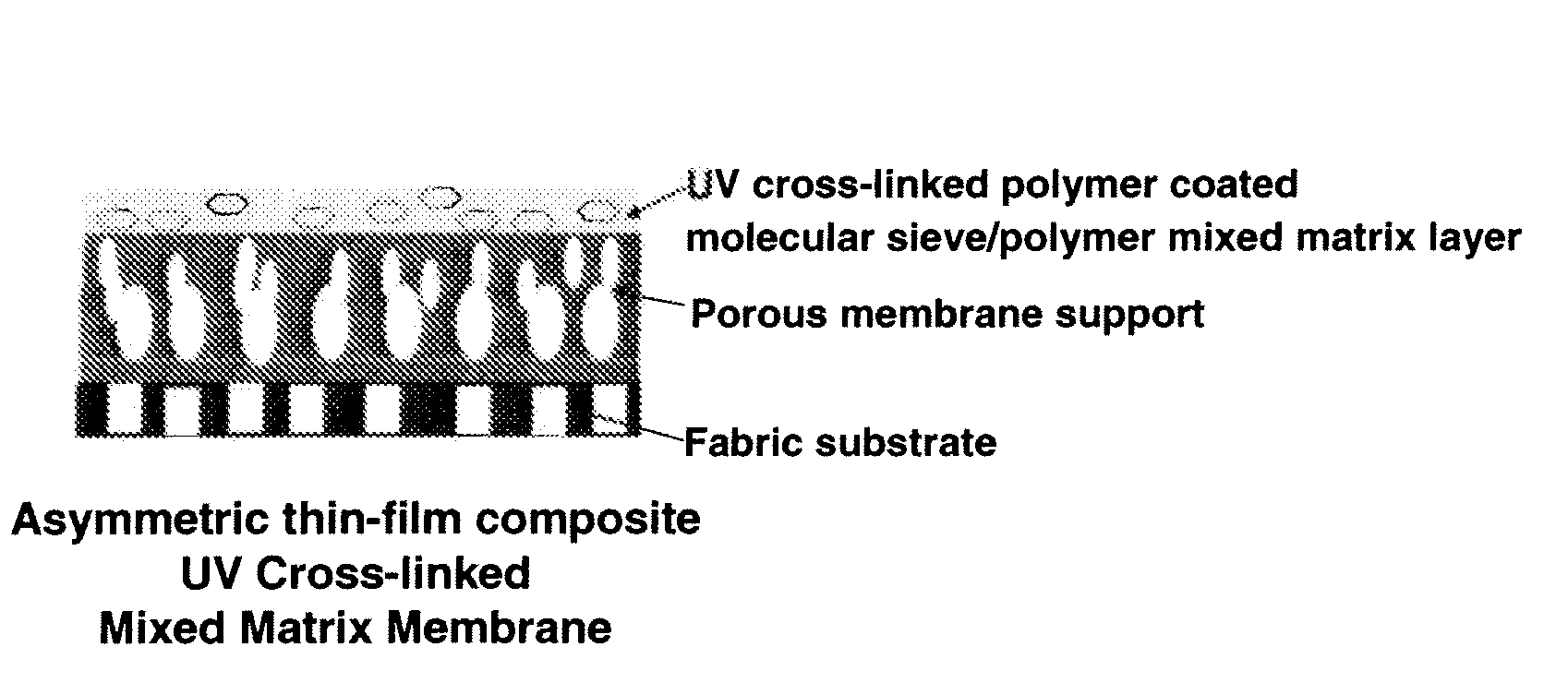

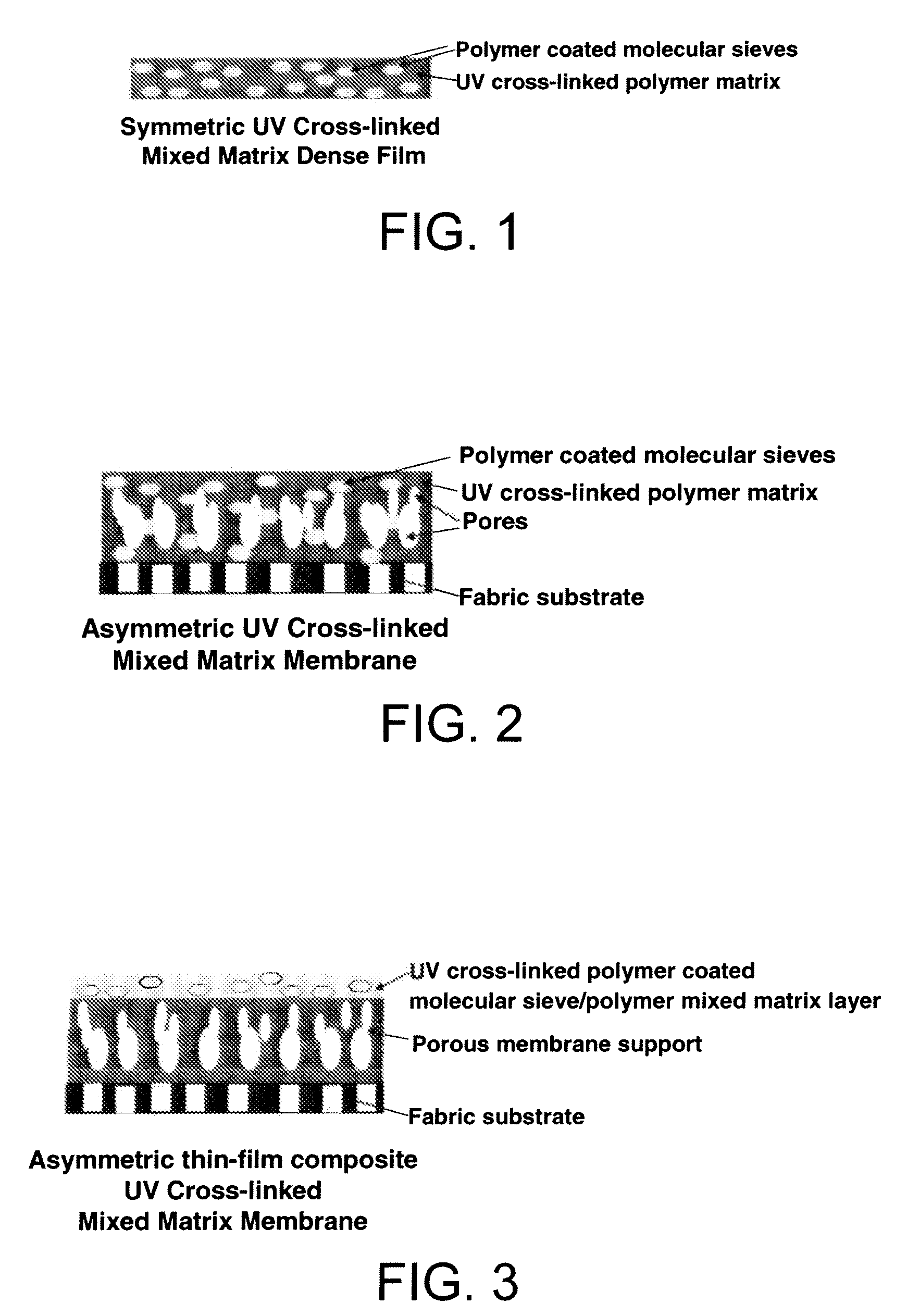

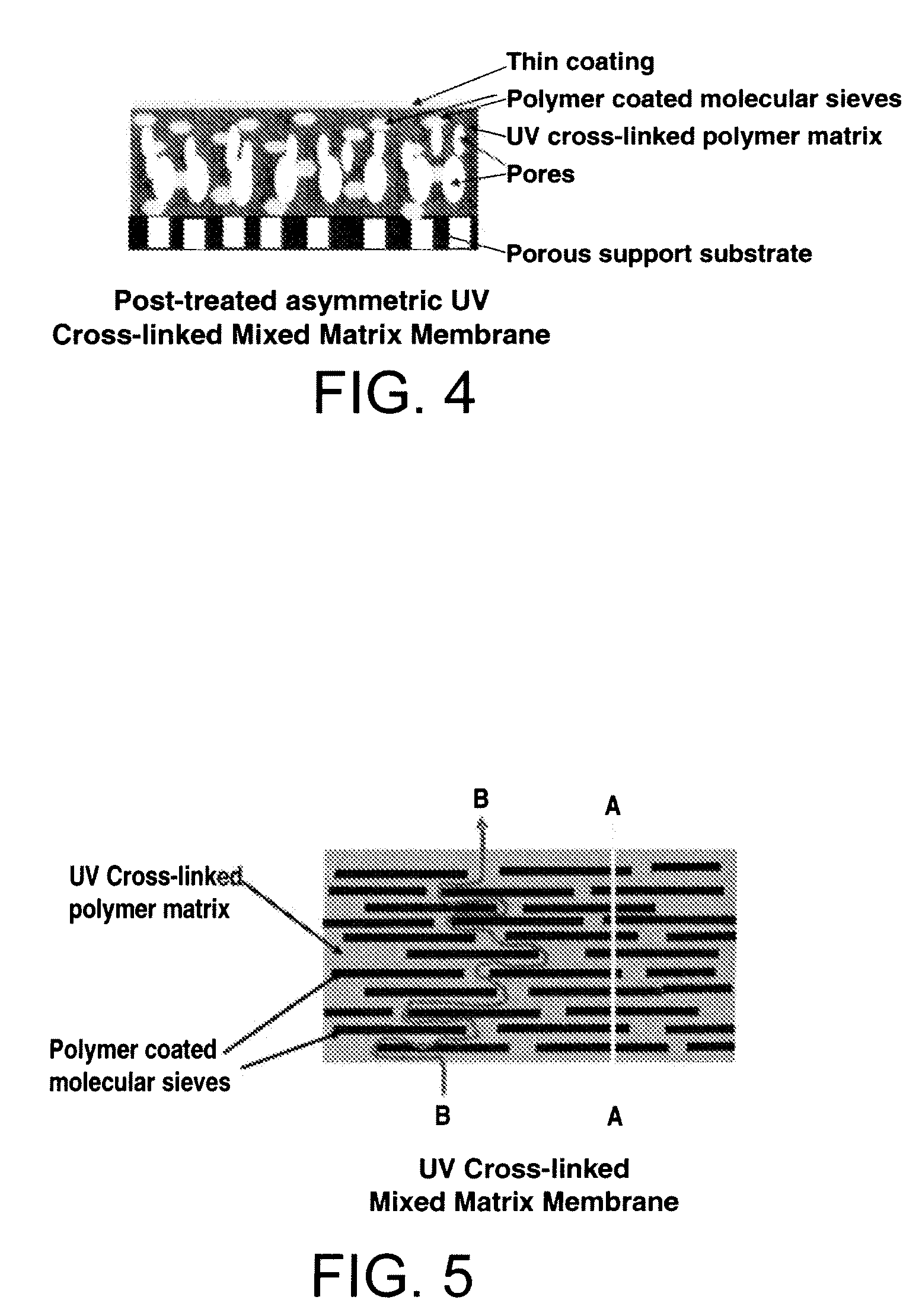

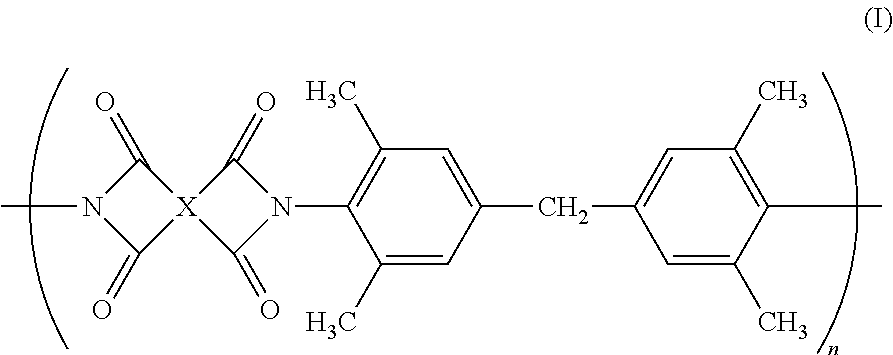

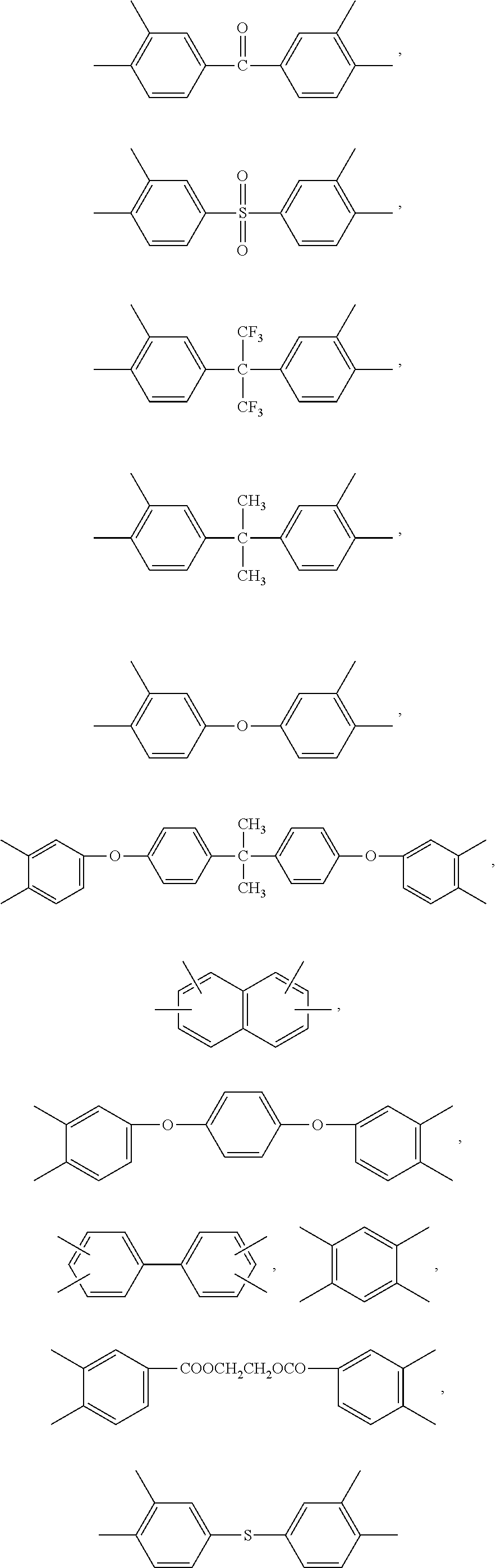

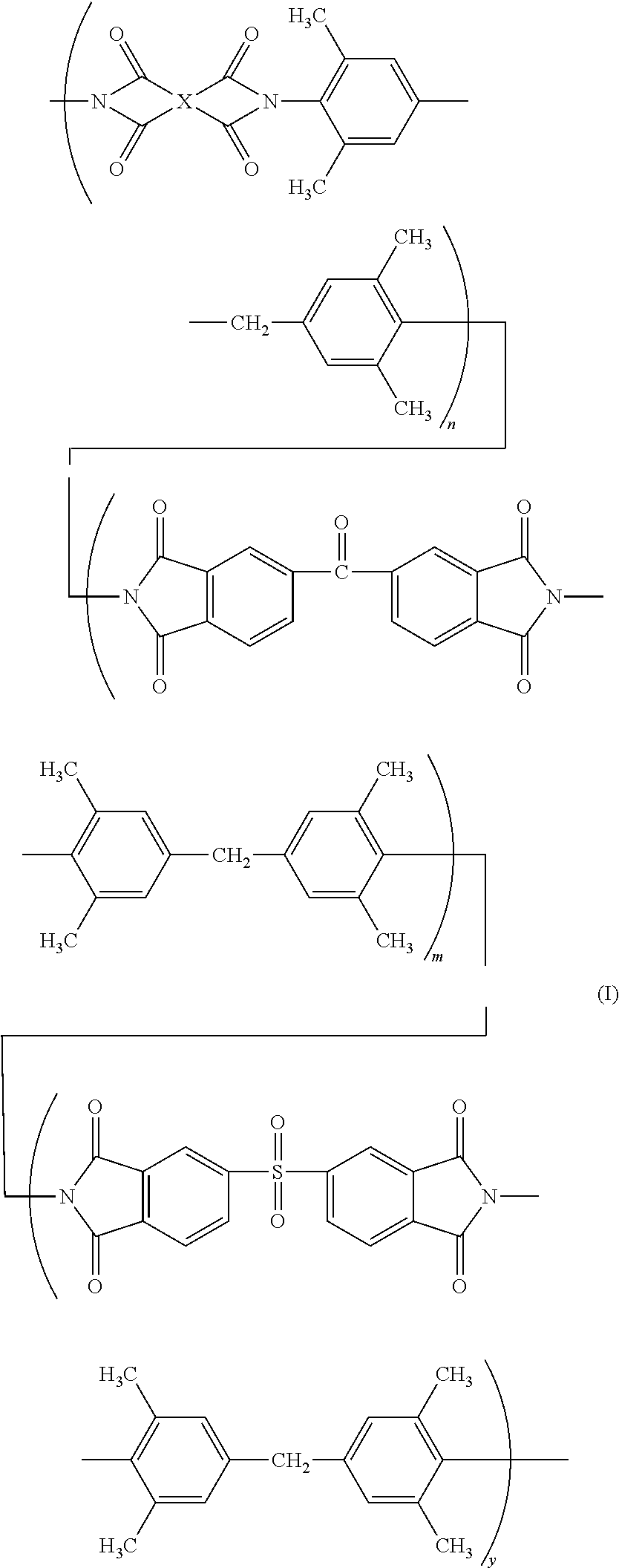

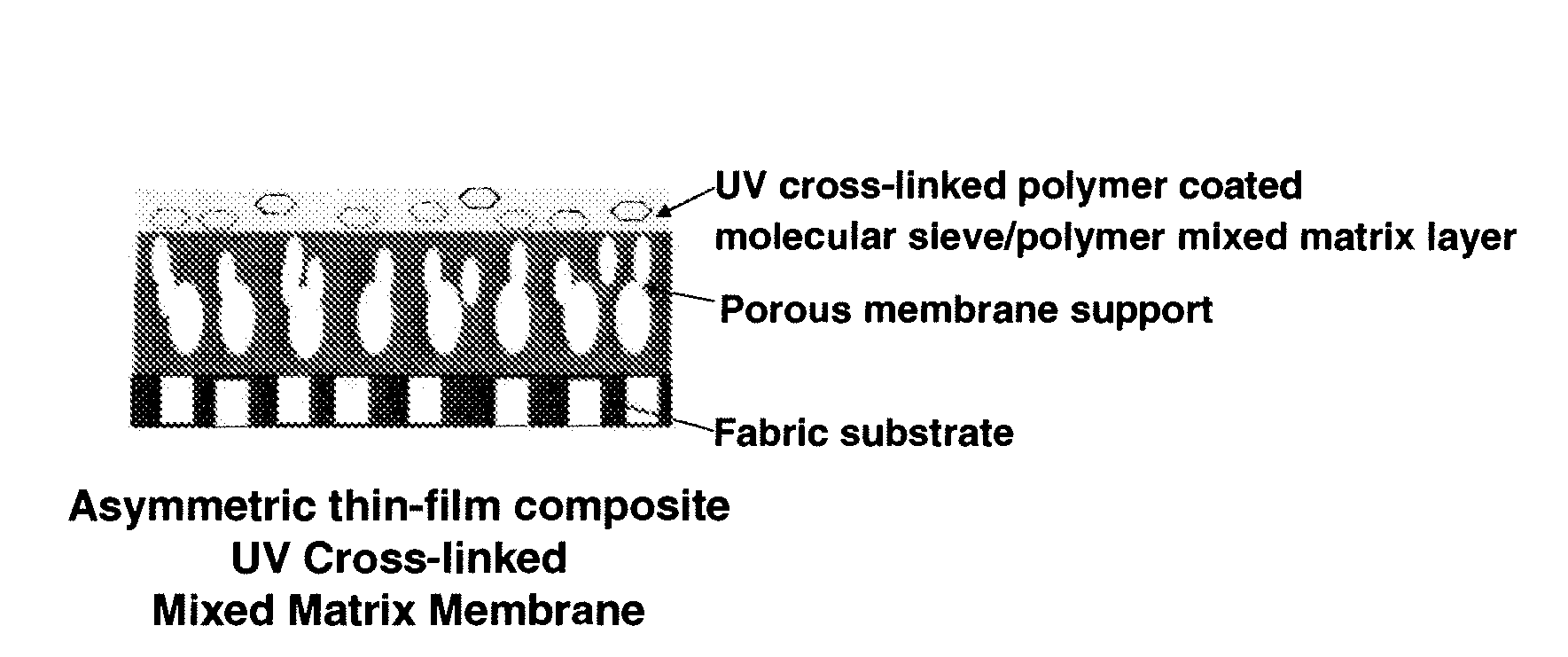

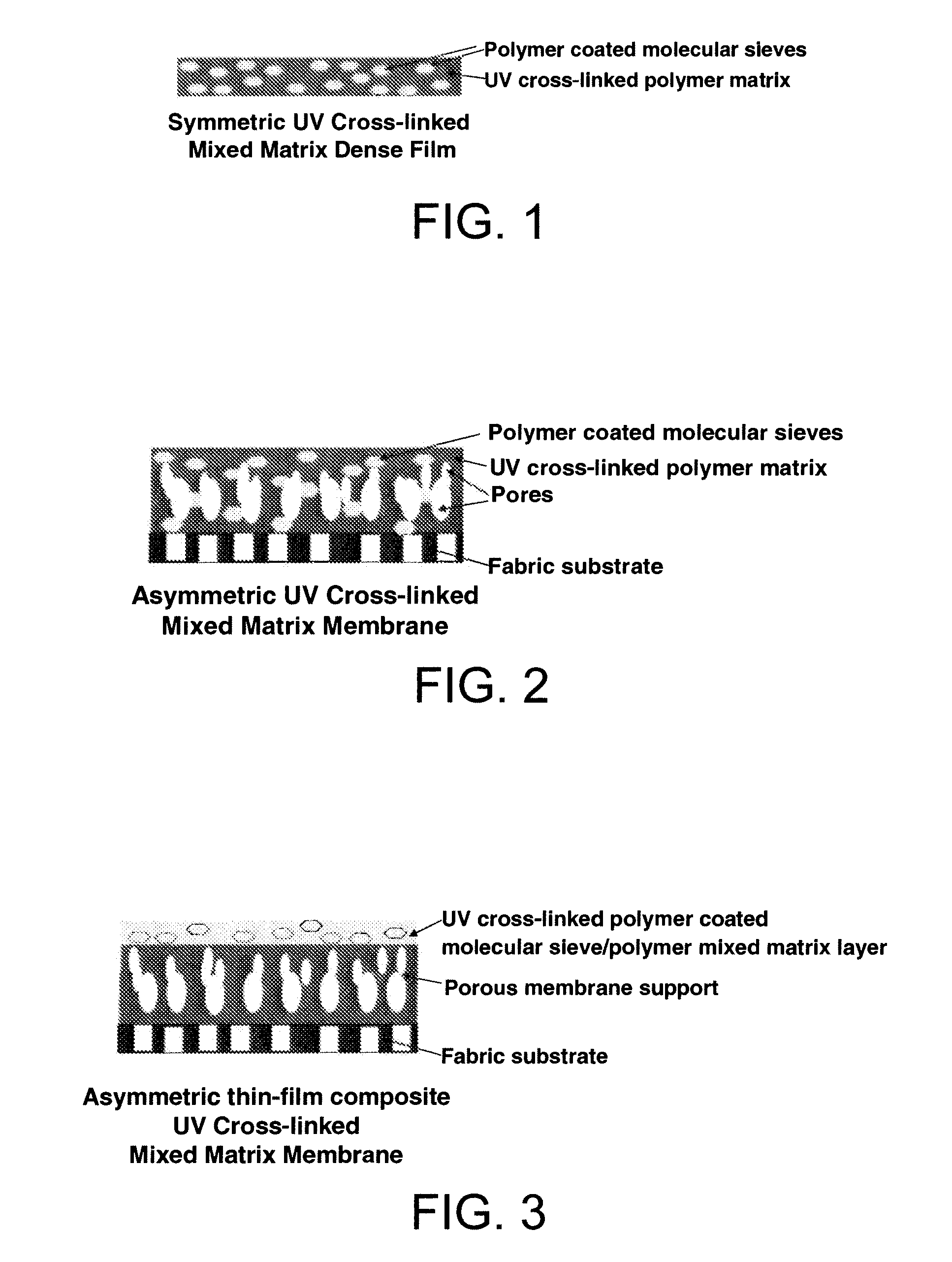

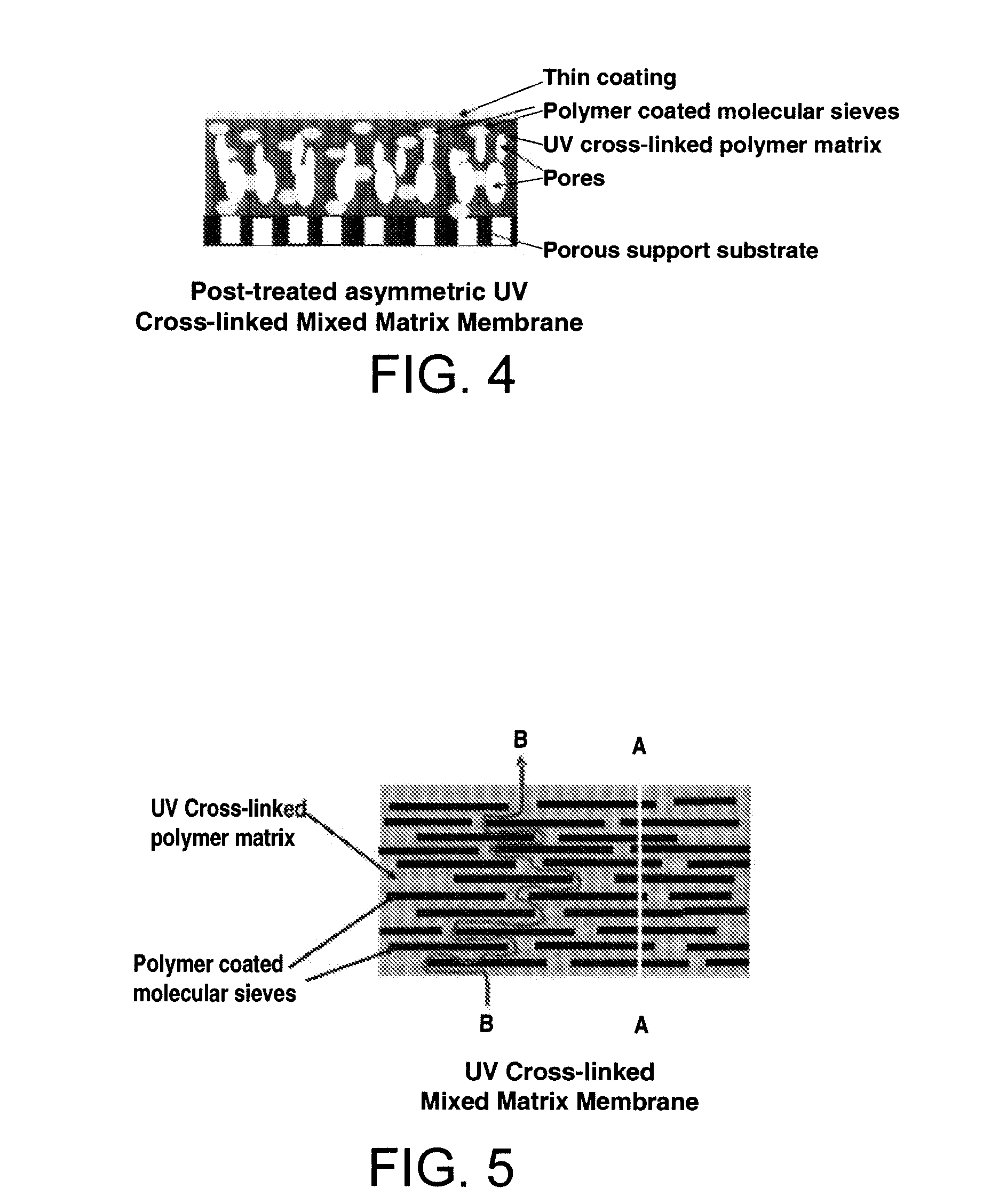

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

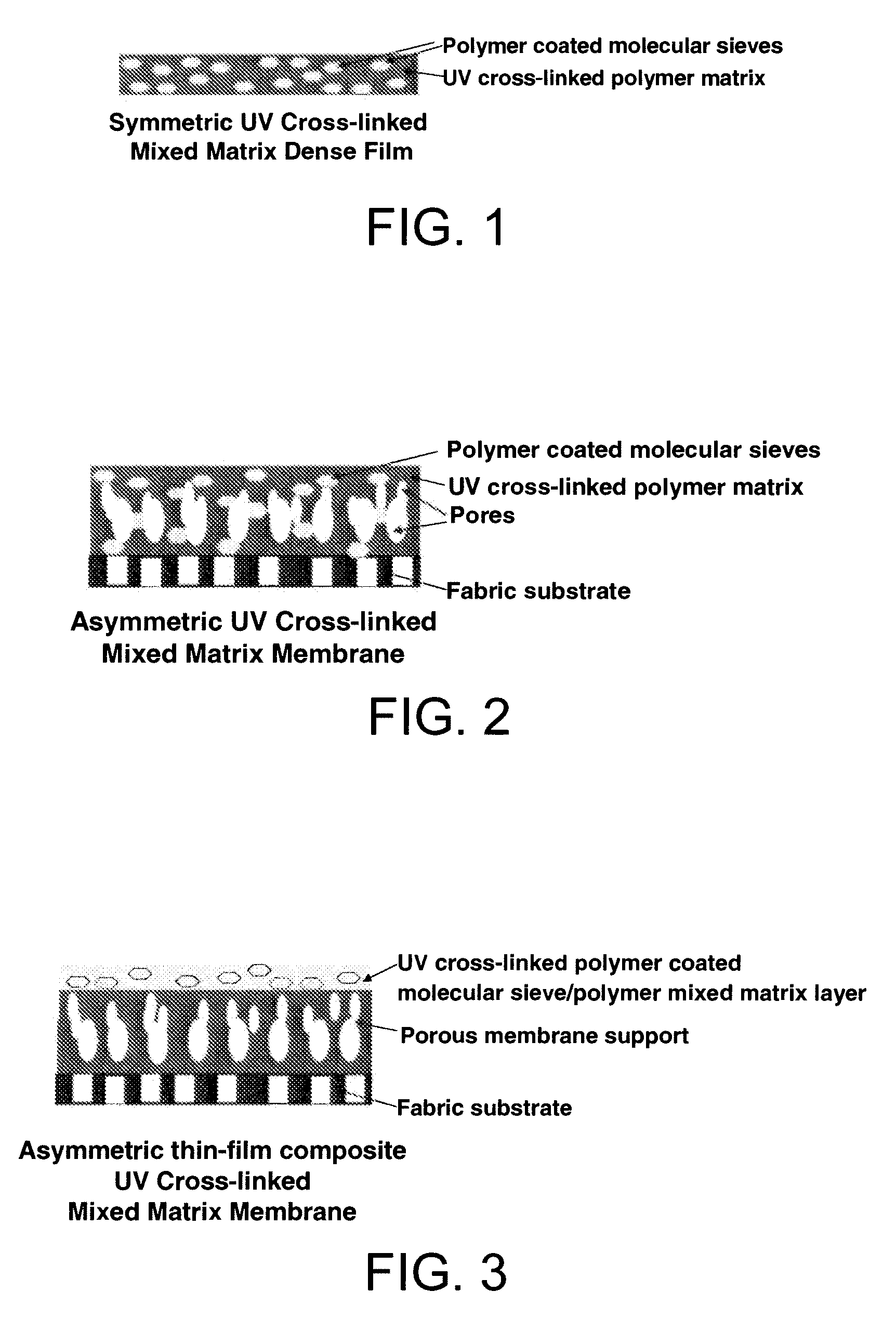

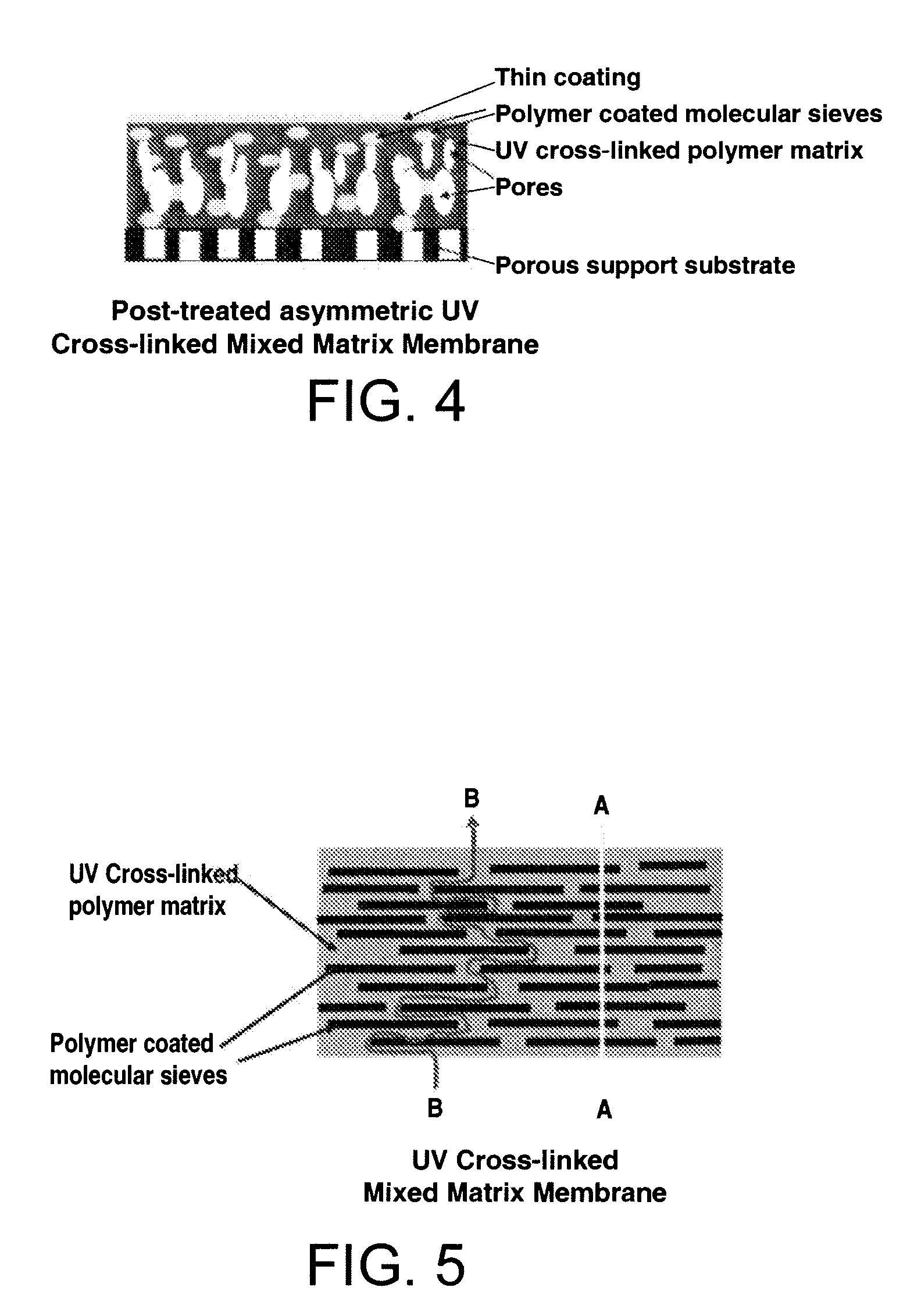

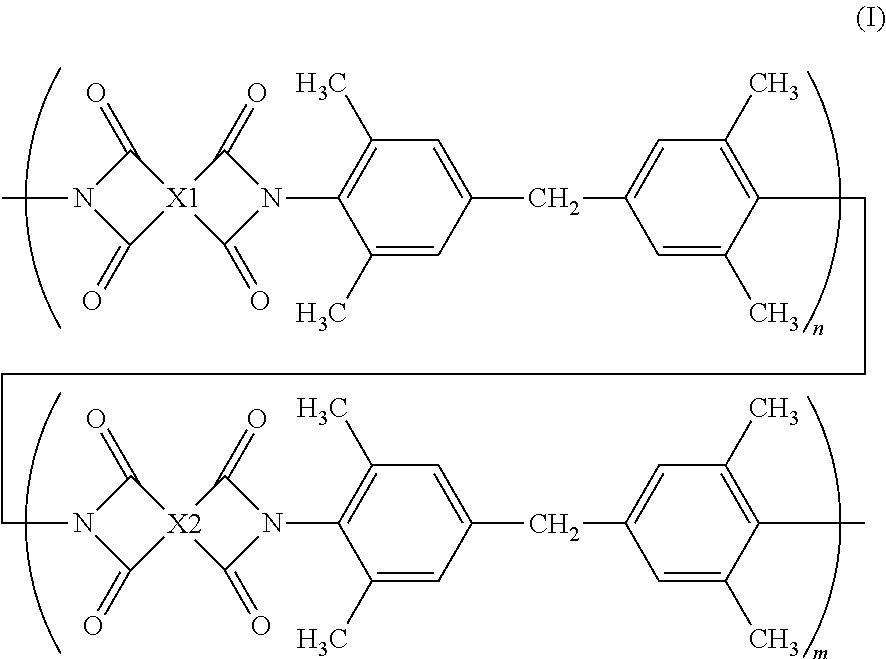

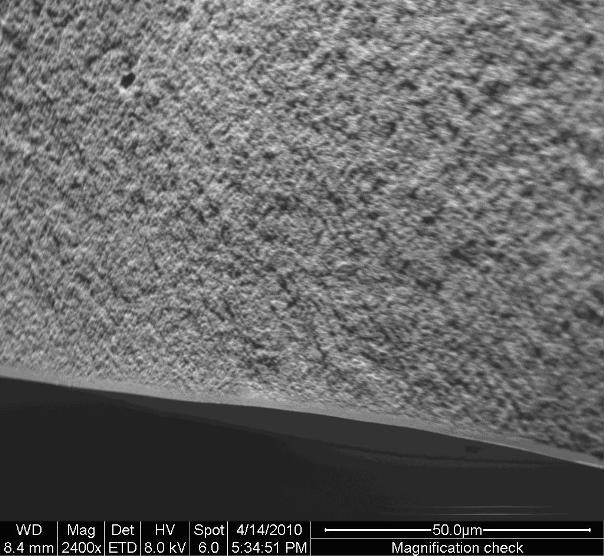

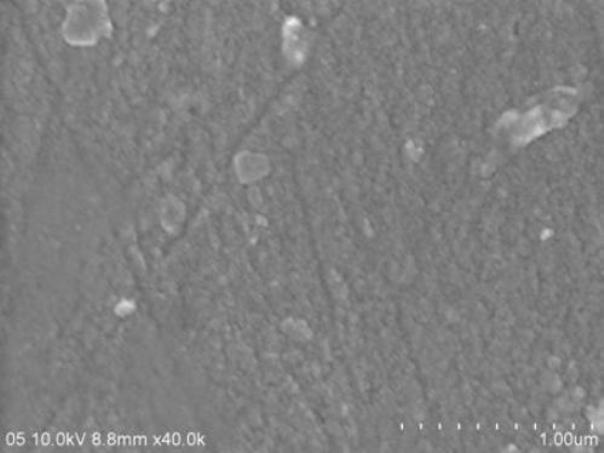

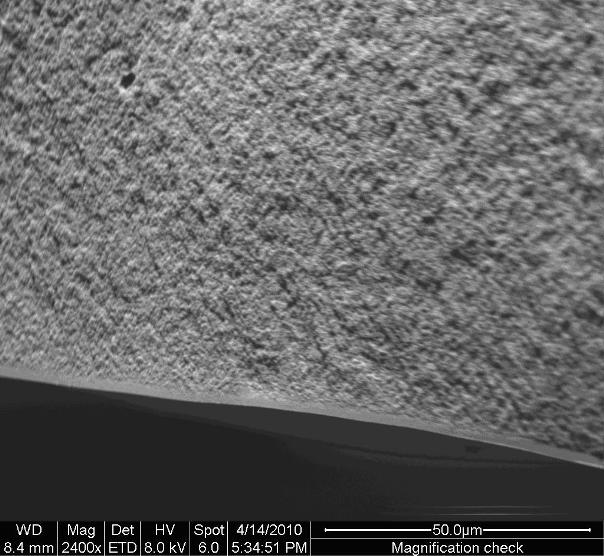

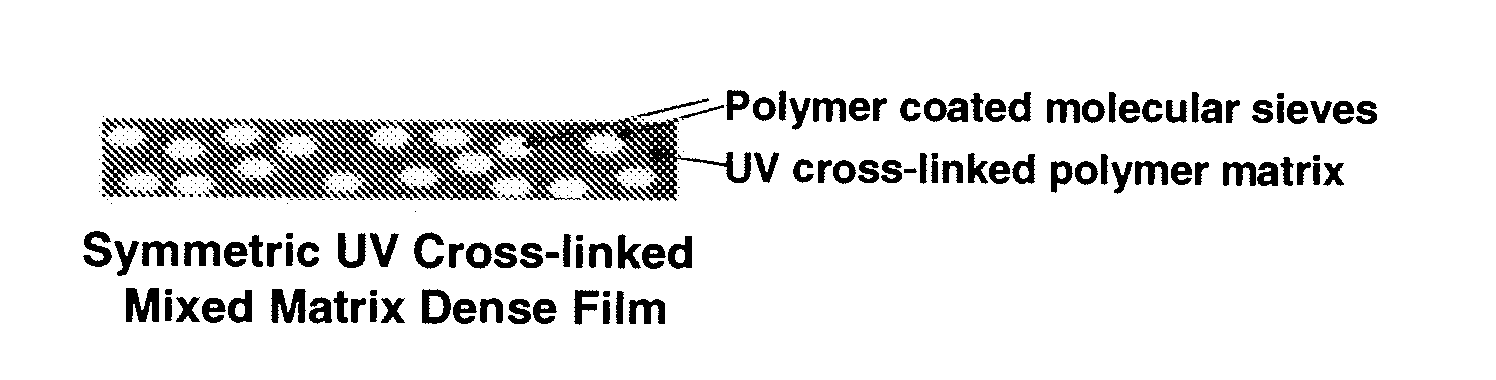

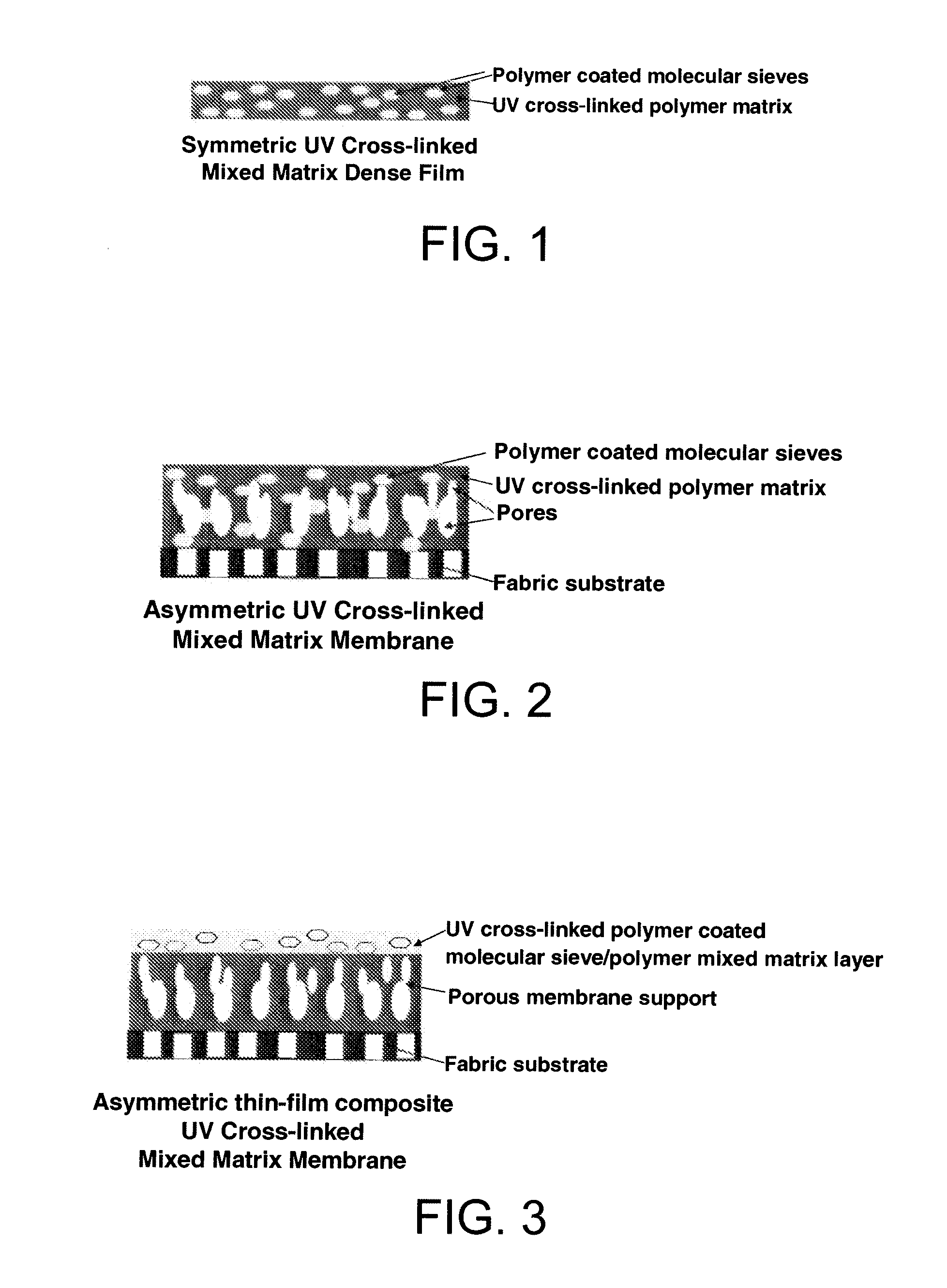

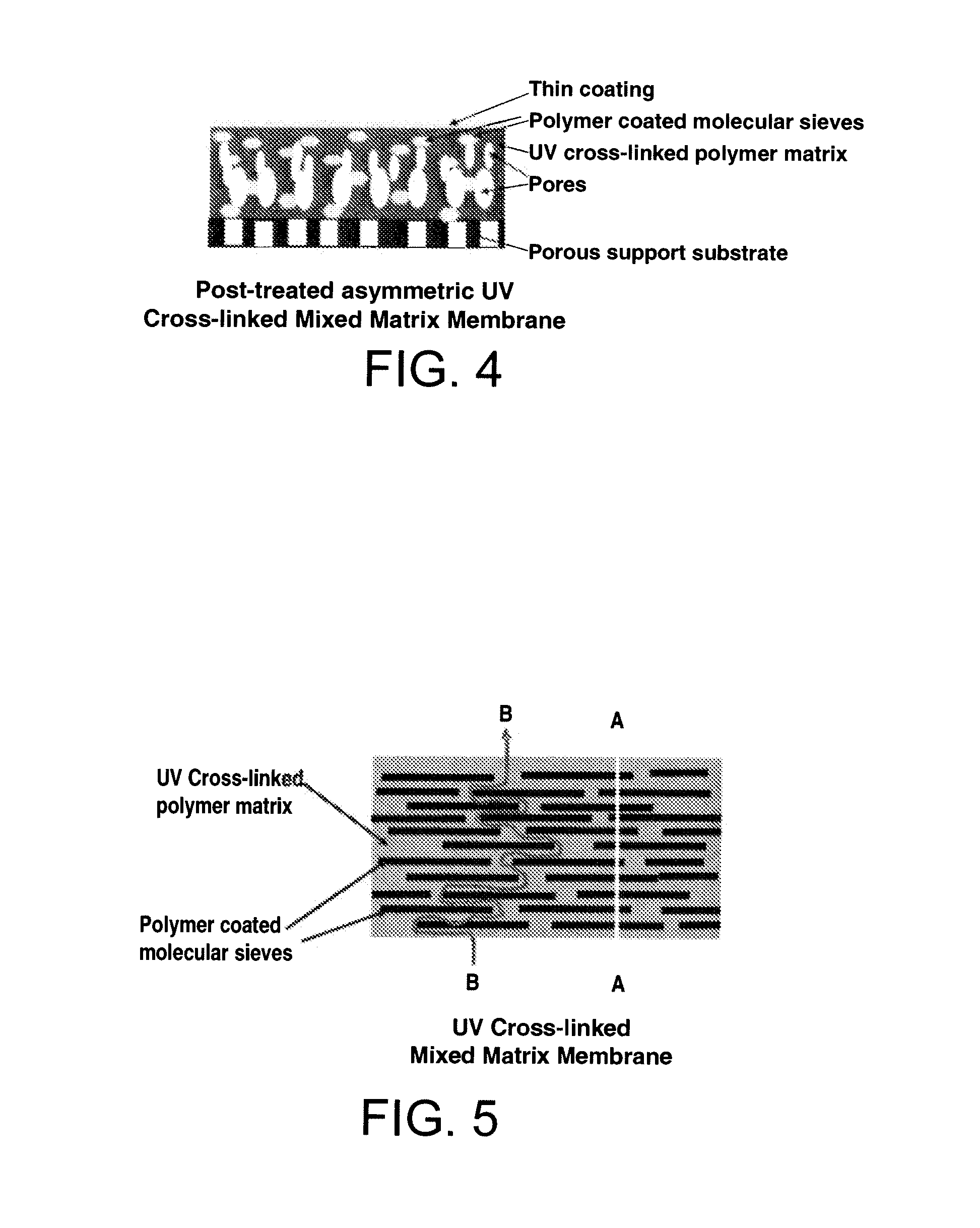

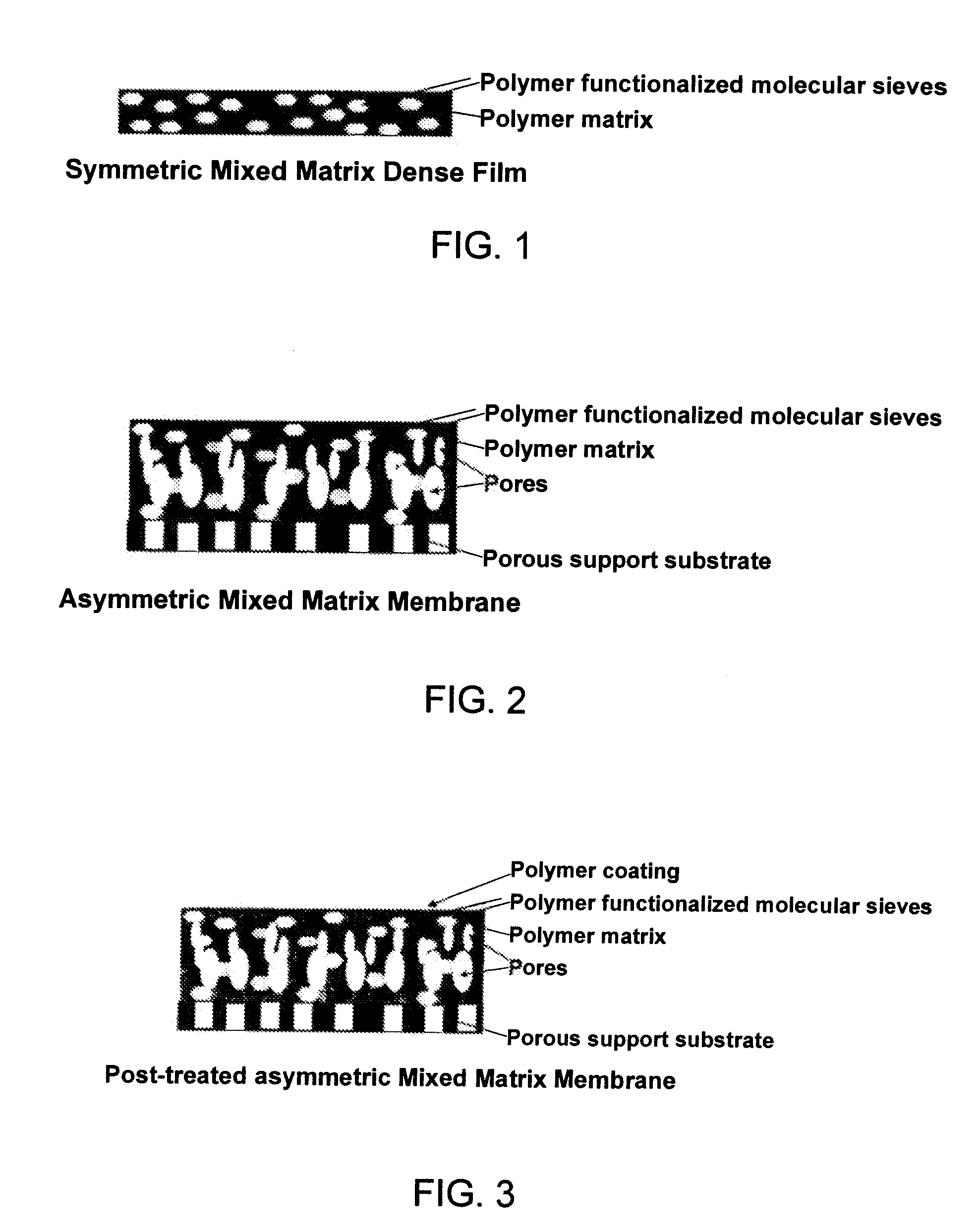

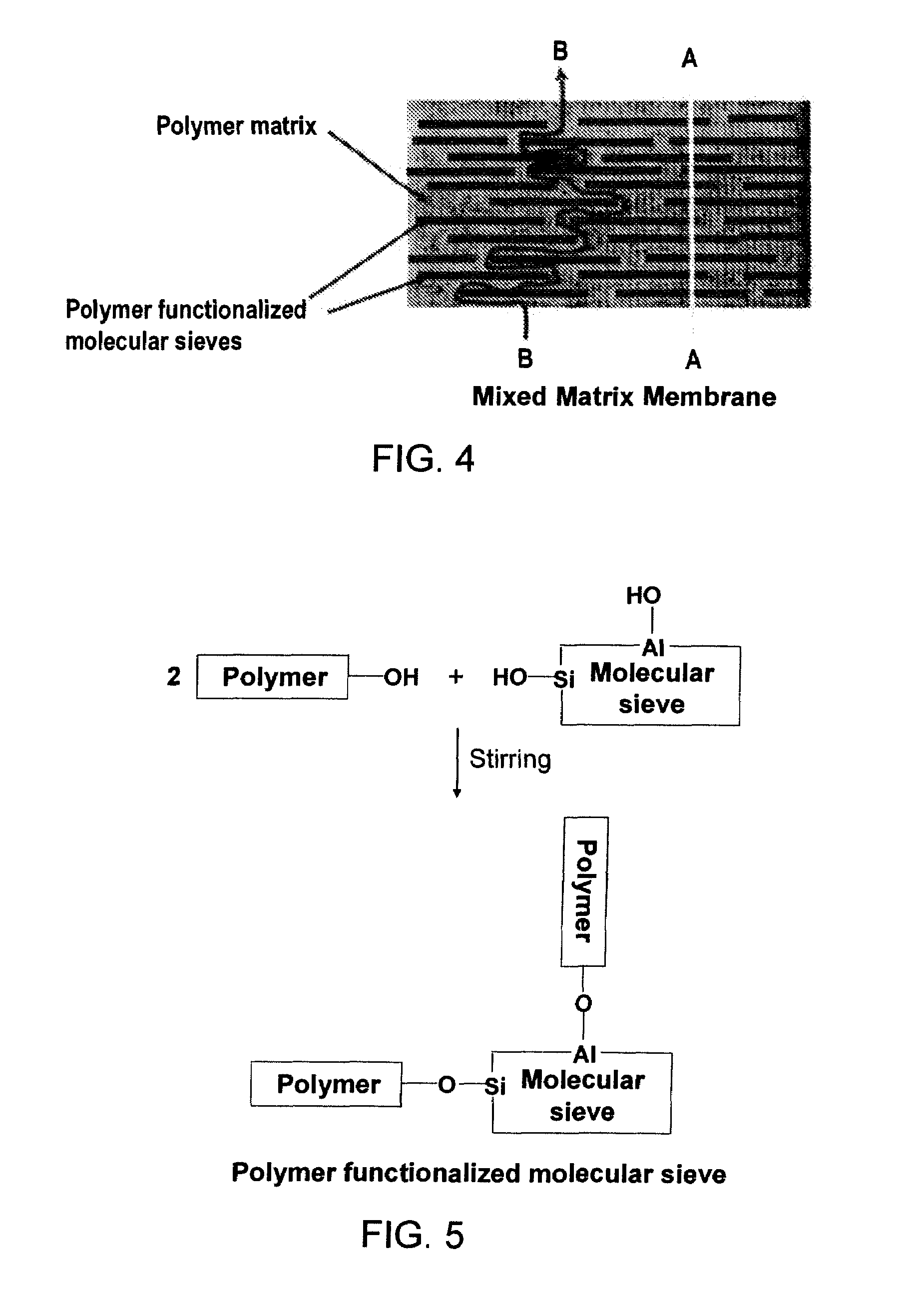

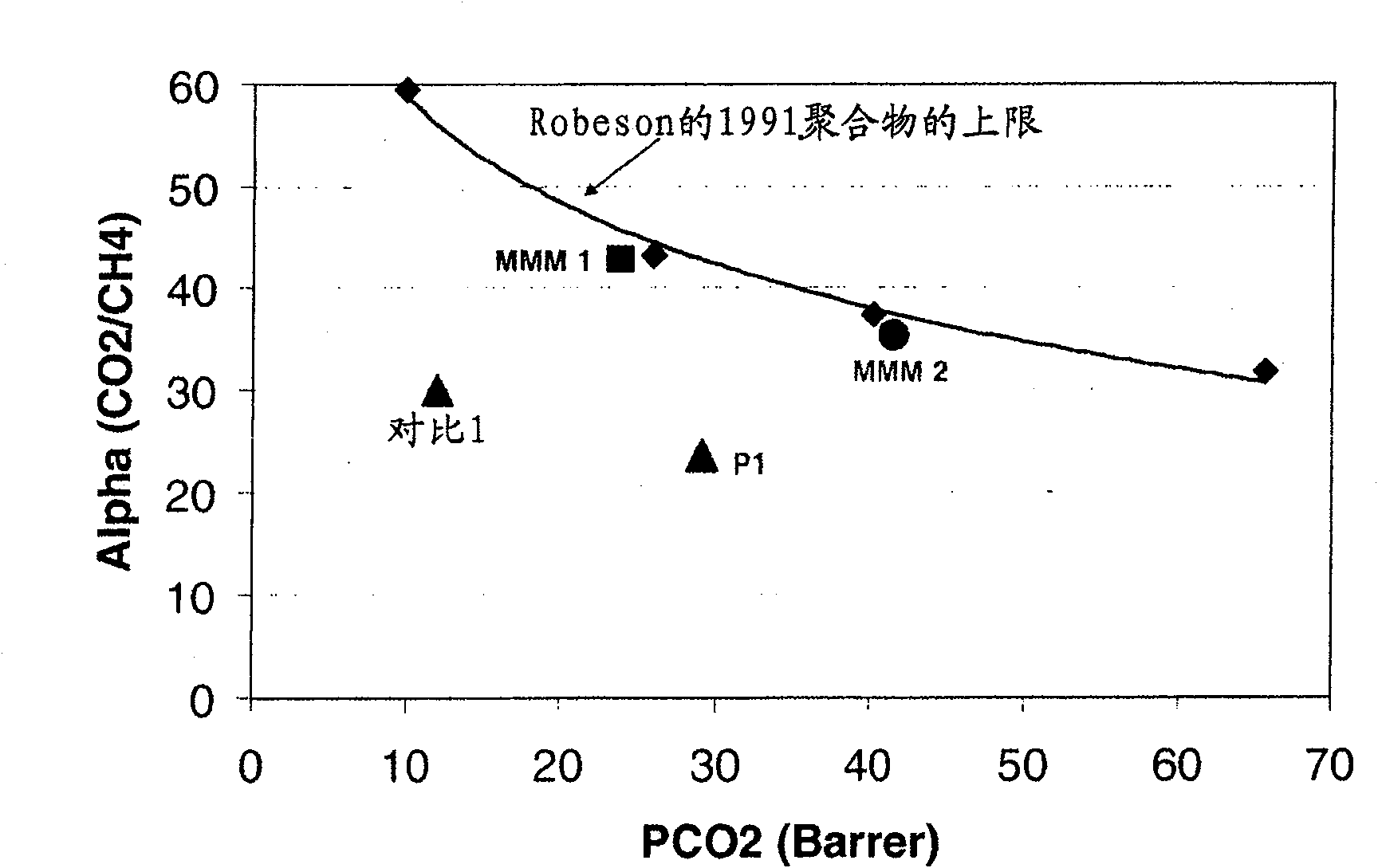

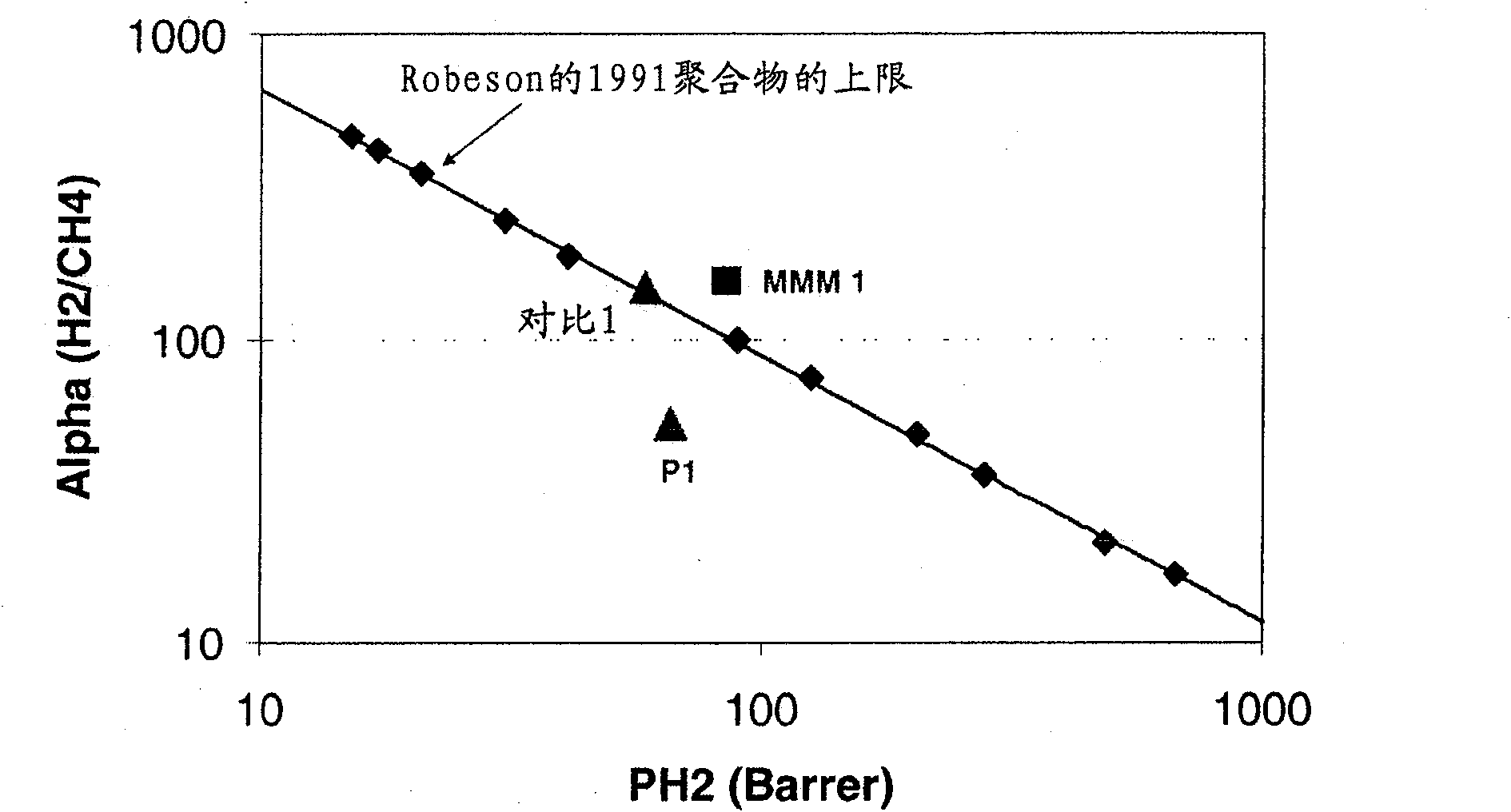

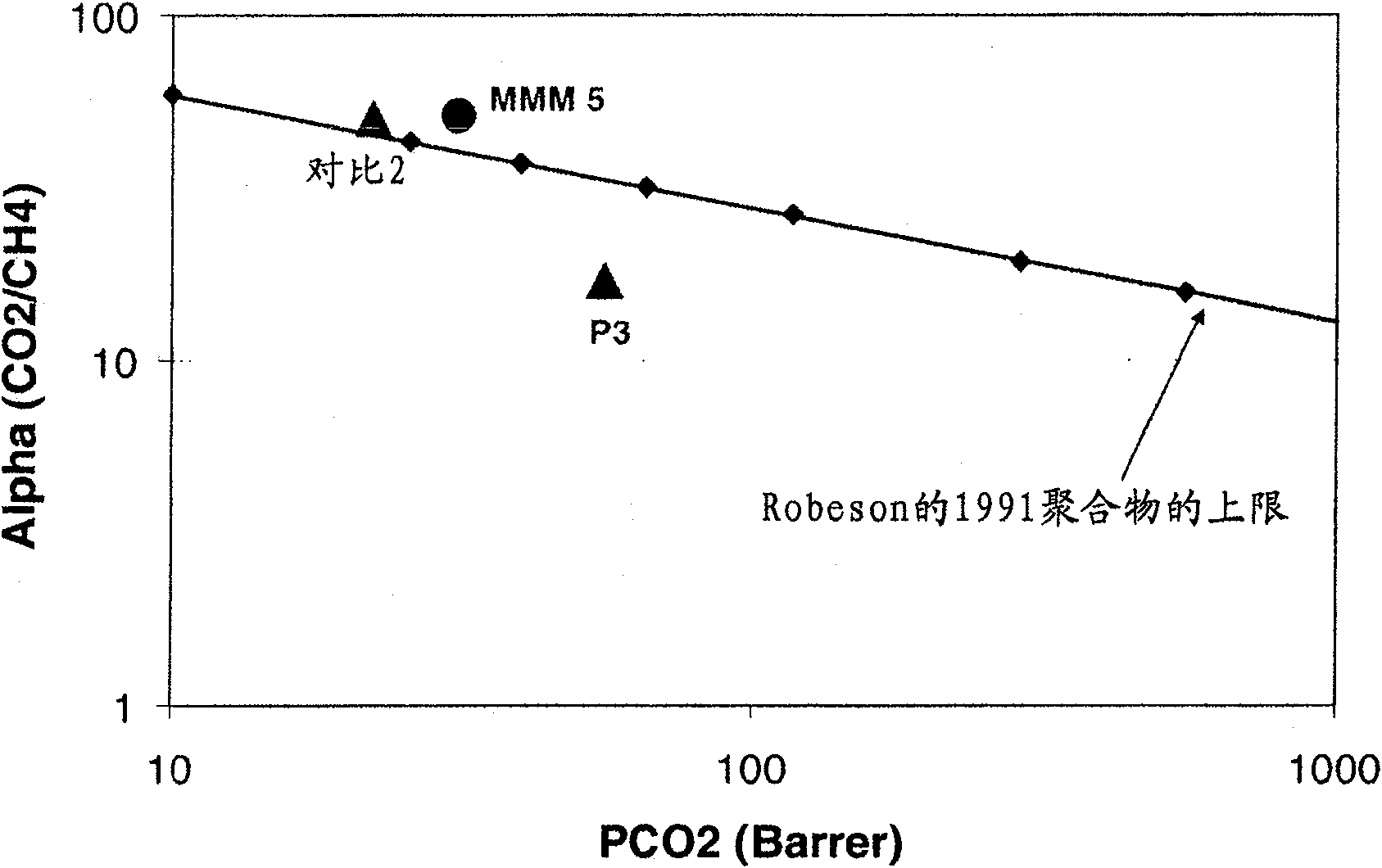

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

High performance cross-linked polyimide asymmetric flat sheet membranes

The present invention discloses high performance cross-linked polyimide asymmetric flat sheet membranes and a process of using such membranes. The cross-linked polyimide asymmetric flat sheet membranes have shown CO2 permeance higher than 80 GPU and CO2 / CH4 selectivity higher than 20 at 50° C. under 6996 kPa of a feed gas with 10% CO2 and 90% CH4 for CO2 / CH4 separation.

Owner:UOP LLC

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Method for preparing asymmetric nanofiltration membrane by blending polyether sulfone and sulfonated polysulfone high polymers

InactiveCN101979132AChlorine resistantHigh temperature resistantSemi-permeable membranesPolymer scienceFluid phase

The invention discloses a method for preparing an asymmetric nanofiltration membrane by blending polyether sulfone and sulfonated polysulfone high polymers. A blending nanofiltration membrane with an asymmetric structure is prepared in one step by the nanofiltration membrane through a phase transformation method. The method comprises the following steps of: preparing casting membrane liquid, namely mixing the polyether sulfone, the sulfonated polysulfone high polymers, an additive and a solvent to prepare the casting membrane liquid; and forming a membrane by the phase transformation method, wherein the membrane comprises a flat membrane and a hollow fibrous membrane. The interception rate of the nanofiltration membrane to 0.5 to 1.5 g / L sodium chloride and 0.5 to 1.5 g / L sodium sulfate under the operating pressure of between 0.1 and 0.8 MPa is between 20 and 95 percent, the interception rate of the nanofiltration membrane to polyethylene glycol with the relative molecular mass of between 600 and 2,000 is between 40 and 99.9 percent, and the pure water flux of the membrane is between 10 and 250 L / (m2hbar). The asymmetric nanofiltration membrane of the invention has the advantages of high strength and toughness, high compactness resistance, chlorine resistance and high-temperature resistance, and can be applied to aspects of water treatment, wastewater treatment, material separation and the like.

Owner:天津森诺过滤技术有限公司

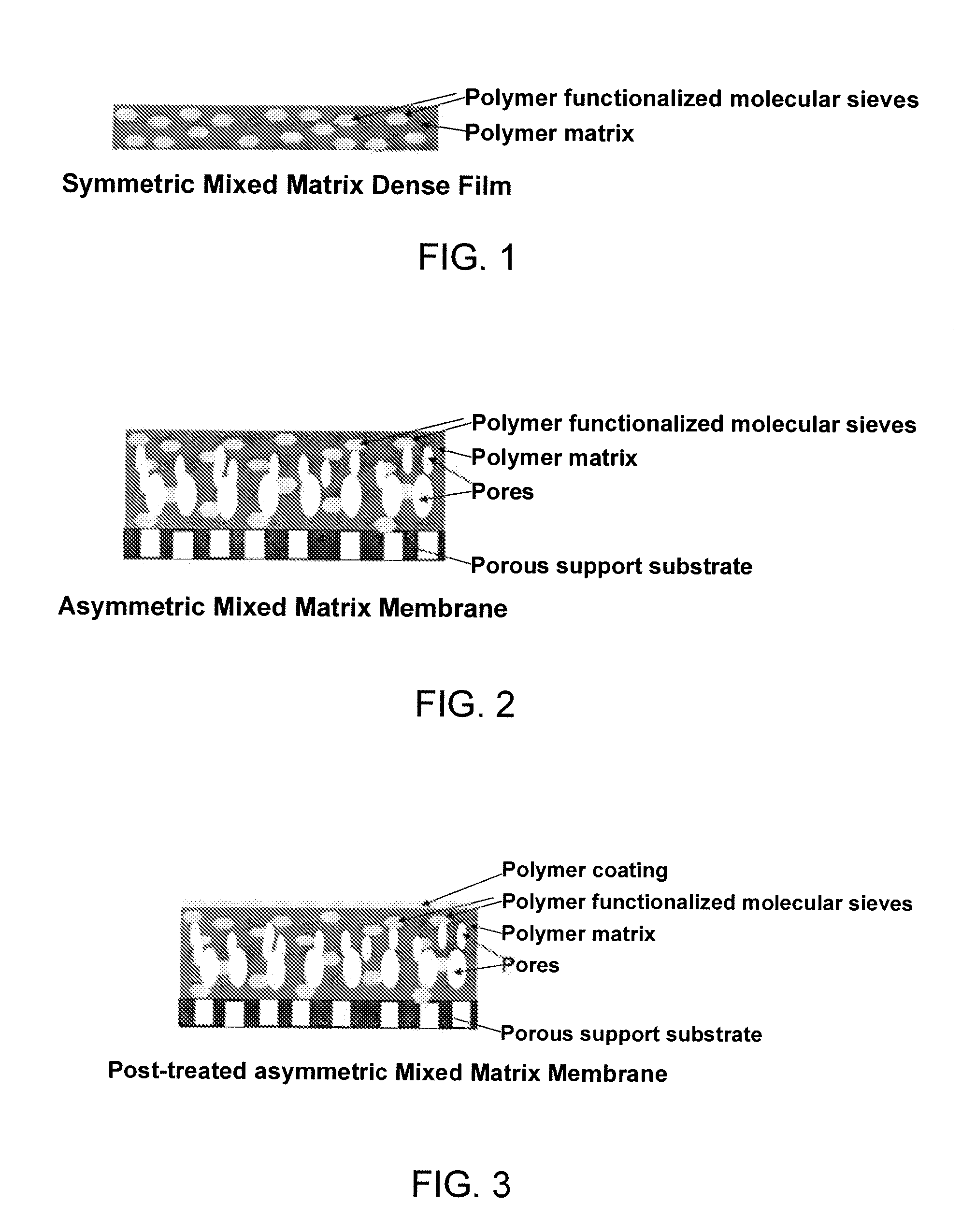

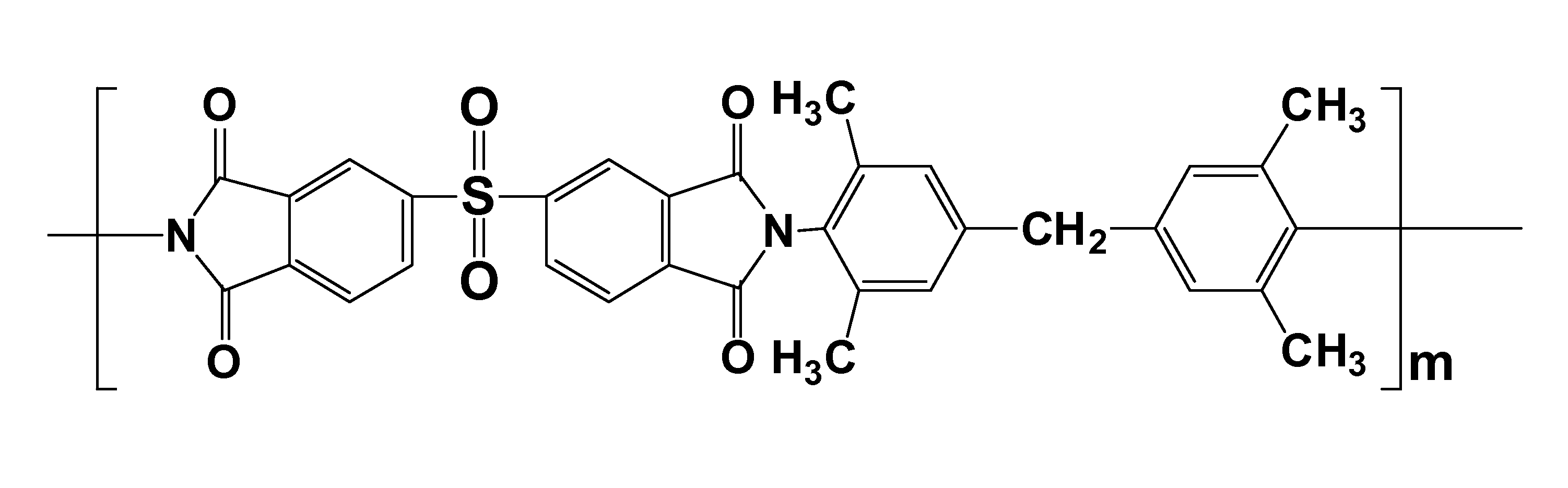

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

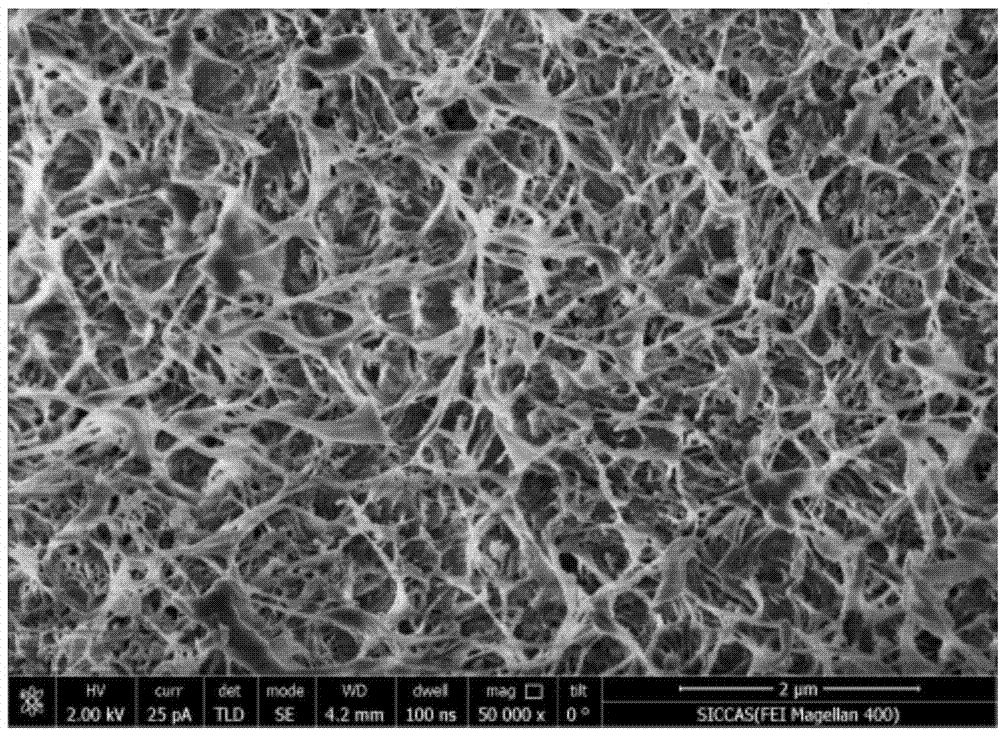

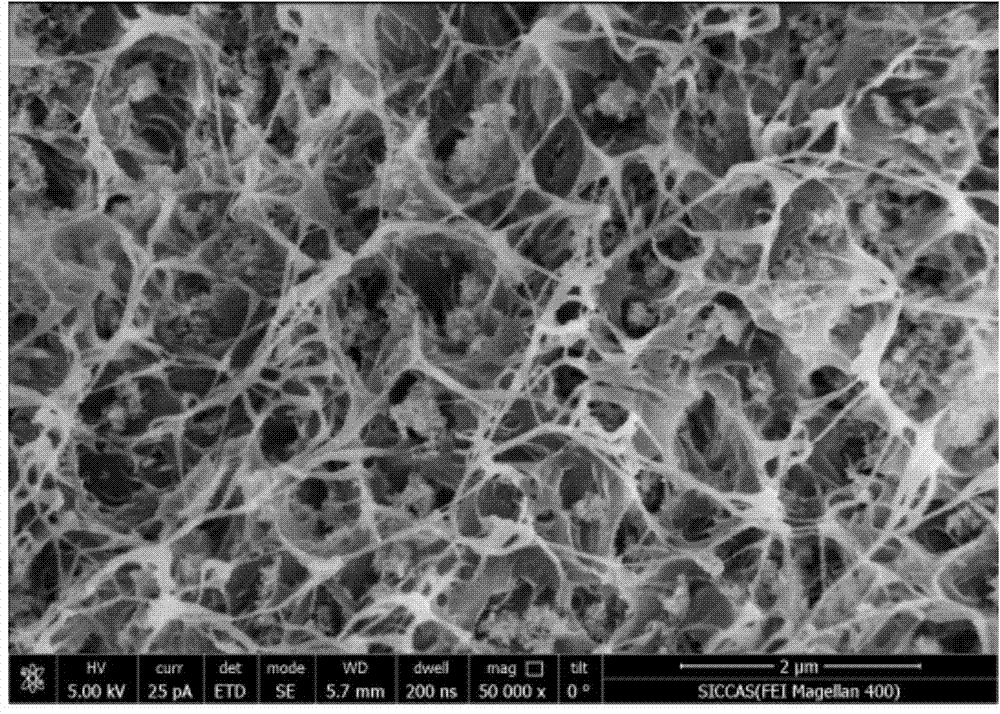

InactiveUS20080296527A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPliability

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

High Performance Mixed Matrix Membranes Incorporating at Least Two Kinds of Molecular Sieves

InactiveUS20090120875A1High selectivityNot to damageMembranesSemi-permeable membranesMolecular sievePolymer science

The present invention discloses a new type of high performance mixed matrix membranes (MMMs) and methods for making and using the same. The MMMs comprise a continuous polymer matrix and at least two types of molecular sieves dispersed therein. The continuous polymer matrix in the MMM contains at least one type of polymer. The MMM in the form of a dense film, asymmetric flat sheet membrane or otherwise prepared exhibits simultaneously improved selectivity and permeability for gas separations compared to polymer membranes made from a continuous polymer matrix without any molecular sieves or with only one type of molecular sieve. MMMs of the present invention are suitable for a wide range of gas, vapor, and liquid separations such as alcohol / water, CO2 / CH4, H2 / CH4, O2 / N2, CO2 / N2, olefin / paraffin, iso / normal paraffins, and other light gases separations.

Owner:UOP LLC

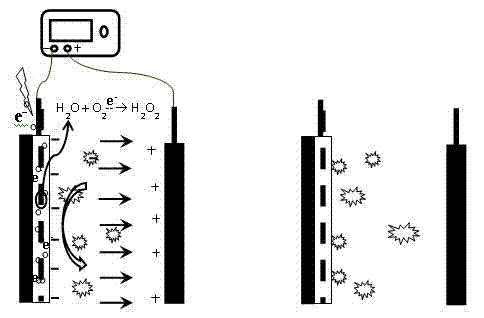

Conductive filter membrane and application thereof

ActiveCN104289114AReduce pollutionReduce cleaning frequencySemi-permeable membranesSustainable biological treatmentGraphitePotentiostat

The invention relates to a conductive filter membrane and its application. Based on manufacturing of a flat sheet membrane, a stainless steel screen is embedded to prepare a conductive membrane, and a conductive filter membrane is formed. The conductive filter membrane is directly used as a negative electrode, conductive corrosion-resistant materials such as graphite, stainless steel and the like are used as a positive electrode, and facilities such as a constant potential rectifier and the like are used along with a power supply so as to make the conductive filter membrane negatively charged. Electronegative pollutants in mixed liquor are obstructed by electrostatic repulsion so as to be deposited on the surface of the membrane. Meanwhile, the conductive filter membrane is directly used as a negative electrode, and a certain amount of H2O2 will be generated near the negative electrode (near the membrane) under the electrochemical action. By strong oxidizing ability, a certain amount of pollutants on the surface of the membrane can be removed by oxidation so as to enhance anti-pollution capacity. A routine filter membrane material determines practical applicability of the conductive filter membrane. The conductive filter membrane is directly used as the electrode to enhance fusion of an electrochemical system and an MBR system and strengthen effect of an electrical field.

Owner:TONGJI UNIV

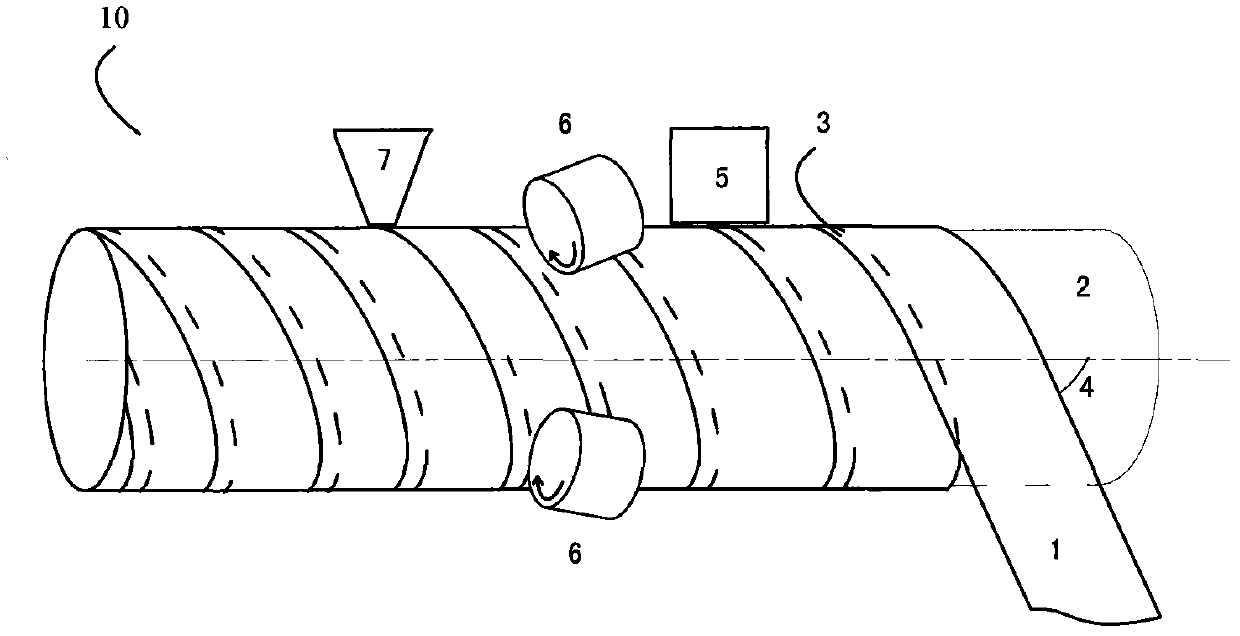

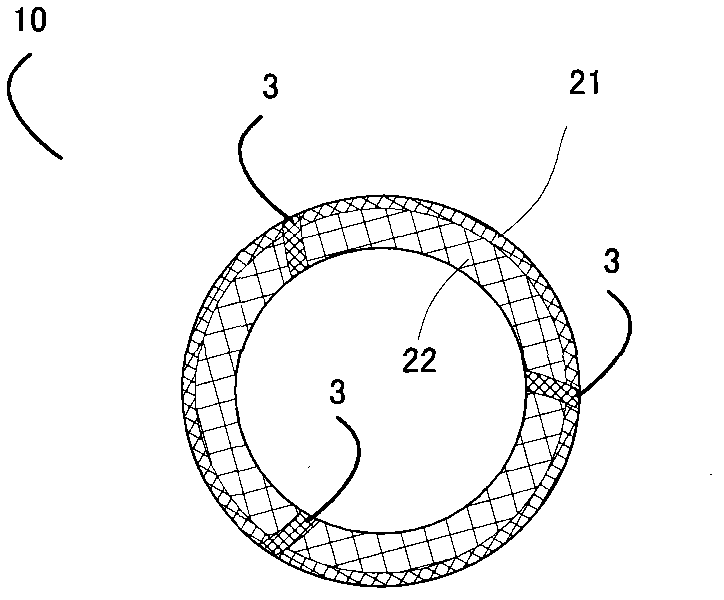

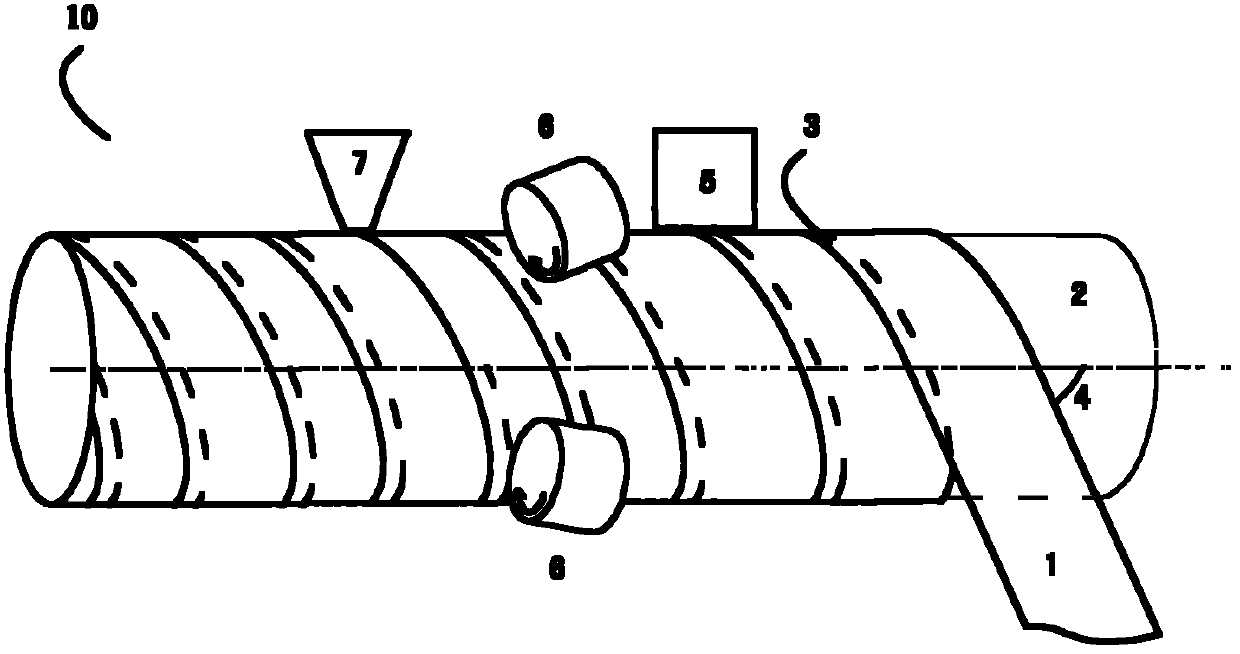

Method for preparing hollow fiber membranes and tubular membranes with microporous PTFE hybrid flat membrane wrapping method

ActiveCN103386256AHigh hardnessEasy to cutSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention discloses a method for preparing hollow fiber membranes and tubular membranes with a microporous PTFE hybrid flat membrane wrapping method. Dispersed PTFE resin and polyvinylidene fluoride resin are mixed with a liquid lubricant, and microporous PTFE hybrid flat membranes are prepared from the mixture through extrusion, calendaring, stretching and sintering. Then the microporous PTFE hybrid flat membranes are cut into membrane strips which wrap around supporting tubes, and finally the wrapped supporting tubes are sintered to obtain the hollow fiber membranes and the tubular membranes. The polyvinylidene fluoride resin added into the products of the invention has a melting point around 160 DEG C, fuses while sintered at a temperature between 250 and 340 DEG C, and can largely increase the hardness of the flat membranes after solidification, which facilitates slitting of the flat membranes. During the process of sintering after wrapping, the polyvinylidene fluoride resin contained in the flat membranes fuses again when sintered at a temperature between 260 and 340 DEG C, and thus can be used as overlapping parts between the wrapped flat membranes and as binders between the flat membranes and the microporous supporting tubes, so that the bonding strength is substantially improved.

Owner:ZHEJIANG SCI-TECH UNIV

Mixed Matrix Membranes Containing Low Acidity Nano-Sized SAPO-34 Molecular Sieves

InactiveUS20090149313A1High selectivityLost timeMembranesSemi-permeable membranesFiberPolymer science

The present invention discloses mixed matrix membranes (MMMs) containing polymer-functionalized low acidity, ultra low silica-to-alumina ratio, nano-sized SAPO-34 small pore molecular sieves and a continuous polymer matrix and methods for making and using these membranes. The surface functionalization of these molecular sieves provides a desired interfacial adhesion between SAPO-34 nano-particles and the continuous polymer matrix, which results in either no macrovoids or voids of less than 5 angstroms at the interface of the continuous polymer matrix and SAPO-34 in the MMMs. These MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes, have good flexibility and high mechanical strength, and exhibit remarkably enhanced CO2 permeability (or CO2 permeance) and maintained CO2 / CH4 selectivity over the continuous polymer matrices for CO2 / CH4 separation. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor.

Owner:UOP LLC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080300336A1Separation efficiency can be improvedEasy to separateMembranesSemi-permeable membranesCross-linkPolymer chemistry

The present invention discloses a method of making high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AlPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

High permeance polyimide membranes for air separation

ActiveUS8366804B2High permeance polyimideMembranesSemi-permeable membranesHollow fibreAir separation

The present invention discloses a new type of polyimide membranes including hollow fiber and flat sheet membranes with high permeances for air separations and a method of making these membranes. The new polyimide hollow fiber membranes have O2 permeance higher than 300 GPU and O2 / N2 selectivity higher than 3 at 60° C. under 308 kPa for O2 / N2 separation. The new polyimide hollow fiber membranes also have CO2 permeance higher than 1000 GPU and single-gas selectivity for CO2 / CH4 higher than 20 at 50° C. under 791 kPa for CO2 / CH4 separation.

Owner:UOP LLC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

InactiveUS20080295691A1Separation efficiency can be improvedEasy to separateSemi-permeable membranesMembranesCross-linkPliability

The present invention discloses methods of separating gases using high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs were prepared by incorporating polyethersulfone (PES) functionalized molecular sieves such as AIPO-14 and UZM-25 small pore microporous molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

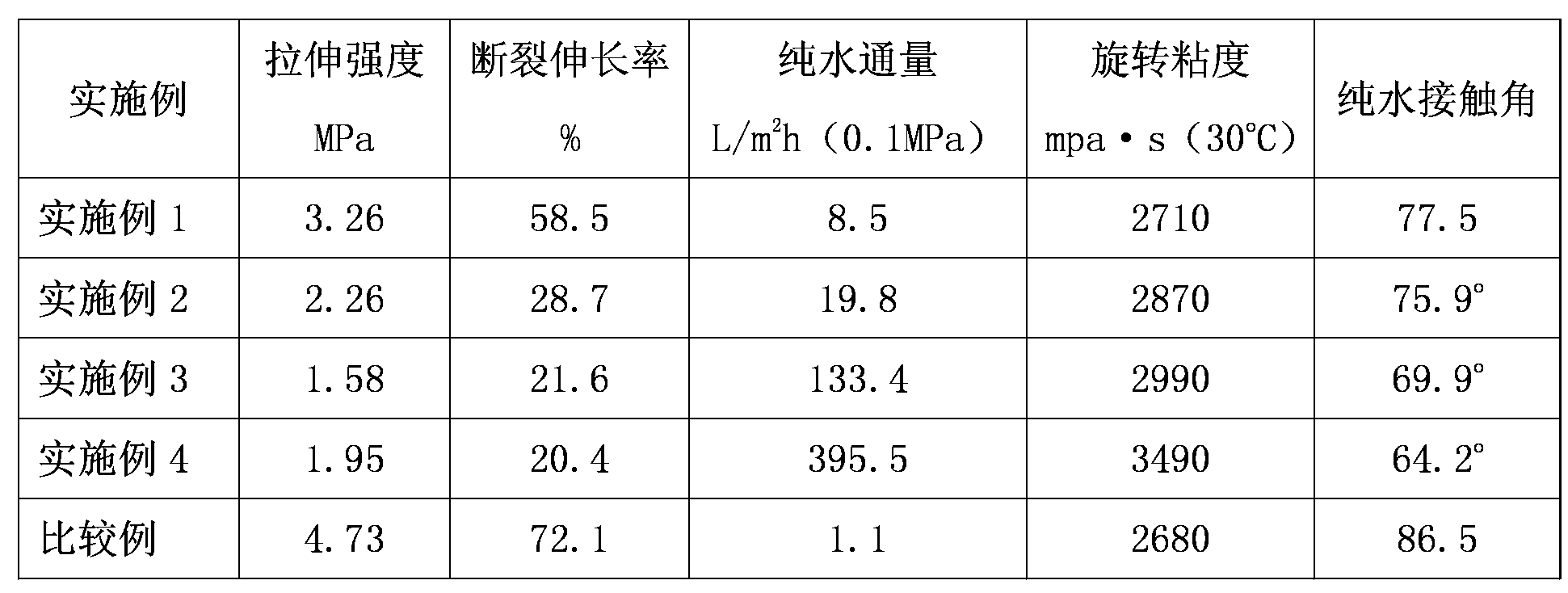

Polyvinylidene fluoride hydrophilic modified membrane and preparation method thereof

InactiveCN103127841ASimple and fast operationSemi-permeable membranesPhysical chemistryMembrane bioreactor

The invention discloses a polyvinylidene fluoride hydrophilic modified membrane and a preparation method of the polyvinylidene fluoride hydrophilic modified membrane. The polyvinylidene fluoride hydrophilic modified membrane is composed of 12-22% polyvinylidene fluoride hydrophilic, 0.5-15% hydrophilic polymer and 63-87.5% polarity good solvent. By means of the prepared polyvinylidene fluoride hydrophilic modified membrane, a pore-forming agent does not need to be added. Compared with the prior art, the polyvinylidene fluoride hydrophilic modified membrane and the preparation method of the polyvinylidene fluoride hydrophilic modified membrane have the advantages of being simple in operation method, big in water flux, relatively small in water contact angle, good in hydrophilicity, good in uniformity and the like. The prepared polyvinylidene fluoride hydrophilic modified membrane is suitable for being made into a composite type flat sheet membrane and used for a membrane bioreactor.

Owner:SINOCHEM LANTIAN +1

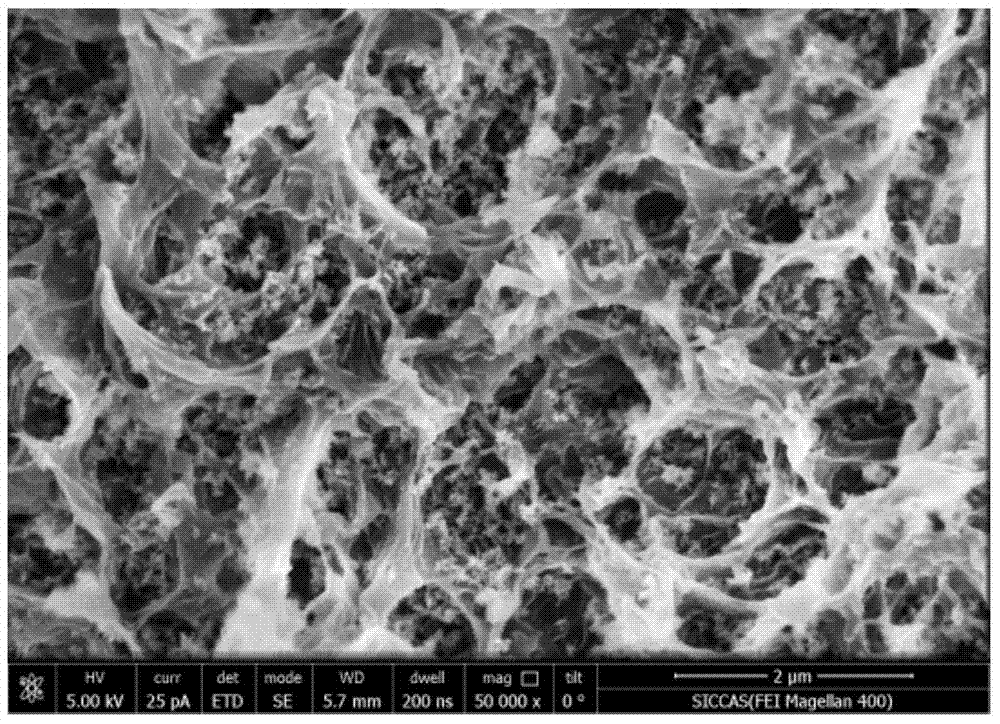

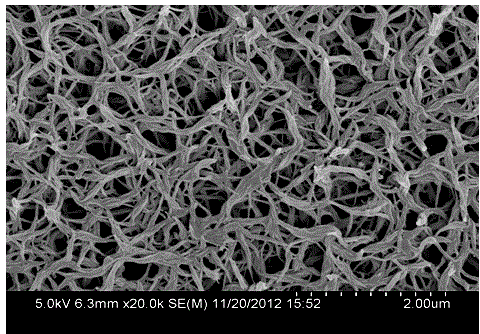

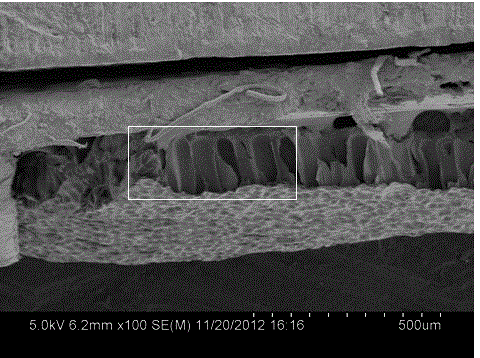

Preparation method for novel carbon-nanotube-doped composite membrane with double selective layers

InactiveCN105013340AImprove anti-pollution performanceExtended service lifeSemi-permeable membranesHollow fibre membraneCarbon nanotube

The invention relates to a preparation method for a novel carbon-nanotube-doped composite membrane with double selective layers. The preparation method specifically comprises the following steps of: (1) preparing a base membrane; (2) putting the prepared base membrane into a dopamine solution containing a carbon nanotube to carry out oscillating reaction to obtain a base membrane which is adhered with carbon-nanotube-containingpolydopamine composite layers in membrane surface and membrane bottom surface; (3) draining off the base membrane, which is adhered with carbon-nanotube-containingpolydopamine composite layers in membrane surface and membrane bottom surface, obtained in the step (2), then, soaking the base membrane into a trimesoyl chloride solution, and adopting an interface polymerization method to obtain a composite membrane with double selective layers; and (4) carrying out thermal treatment on the composite membrane in the step (3), thereby obtaining the carbon-nanotube-containing composite membrane with double layers. According to the preparation method, the structure of the base membrane is not damaged, so that the base membrane not only can be suitable for a flat sheet membrane, but also can be prepared into a hollow fiber membrane; water molecule channels are greatly increased; the antifouling property of the membrane is improved; and the service life of the membrane is prolonged. The preparation method is simple.

Owner:OCEAN UNIV OF CHINA

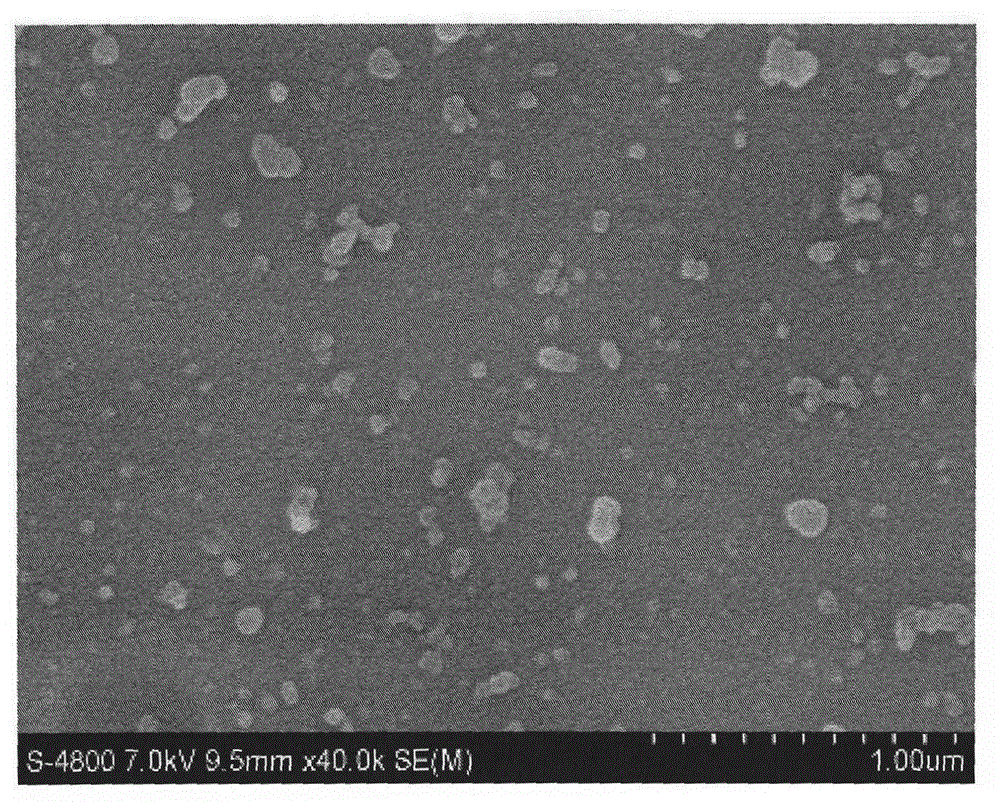

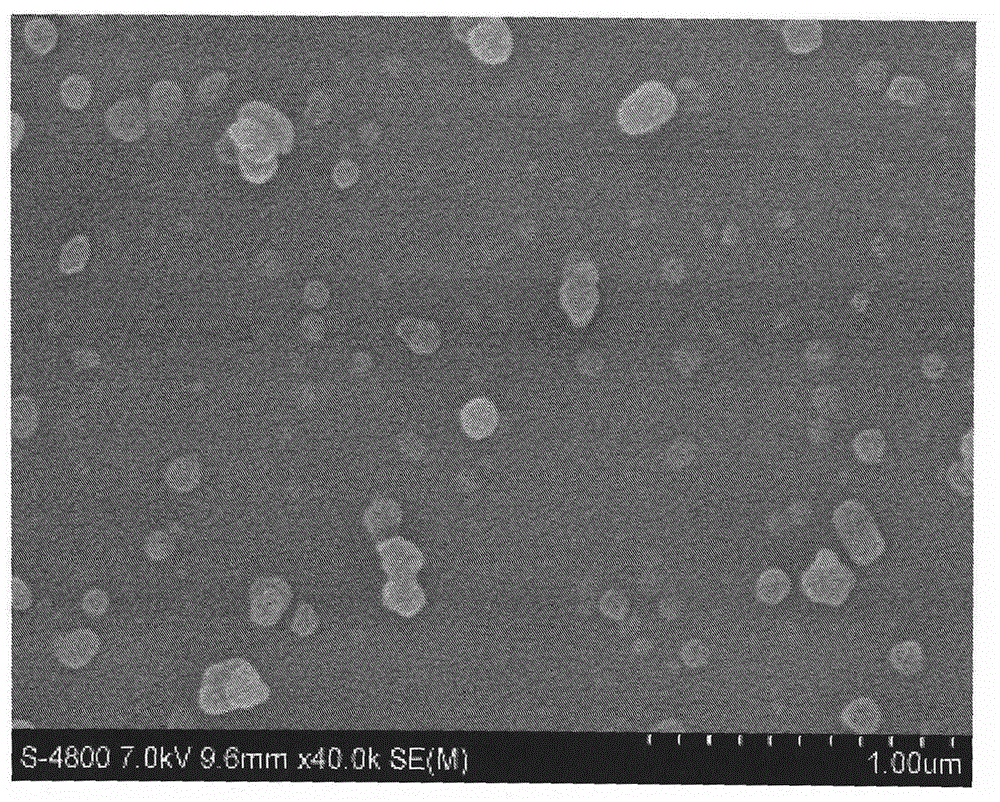

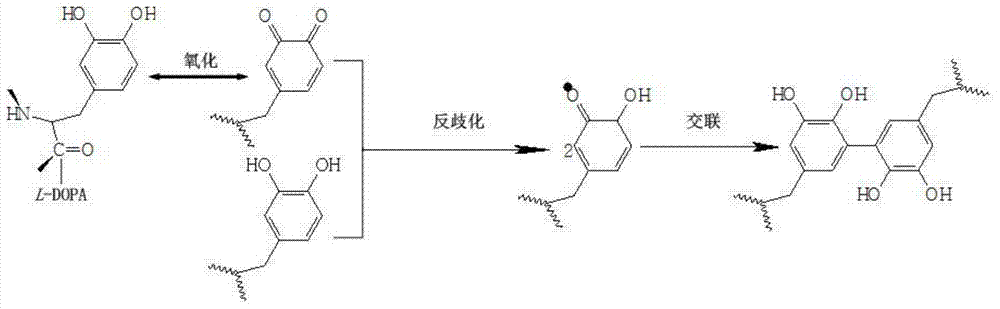

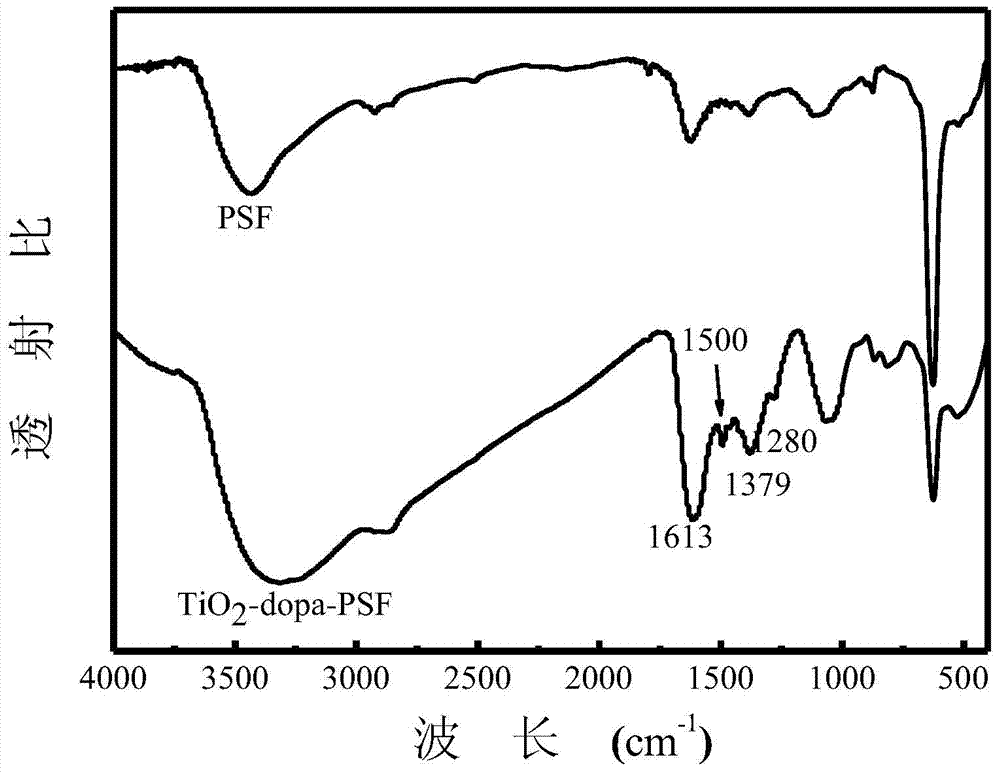

Inorganic filler and dopamine compound inorganic and organic hybrid membrane as well as preparation method and application of membrane

ActiveCN104772048AImprove hydrophilicitySimple structureUltrafiltrationPhase conversionInorganic particle

The invention discloses an inorganic filler and dopamine compound inorganic and organic hybrid membrane as well as a preparation method and application of the membrane. With linear or tubular nano particle as a carrier, L-dopamine is grafted on the surface of the carrier to obtain compound inorganic particle and membrane material polymer mixture and a flat sheet membrane is prepared through submersion phase conversion. By virtue of the L-dopamine, the hydrophilicity of the blend and hybrid flat sheet membrane is improved; the osmosis performance of the prepared inorganic filler and dopamine compound inorganic and organic hybrid membrane is remarkably improved; the pure water flux is increased; the filtering efficiency is high and the retention rate is increased.

Owner:ZHEJIANG UNIV OF TECH

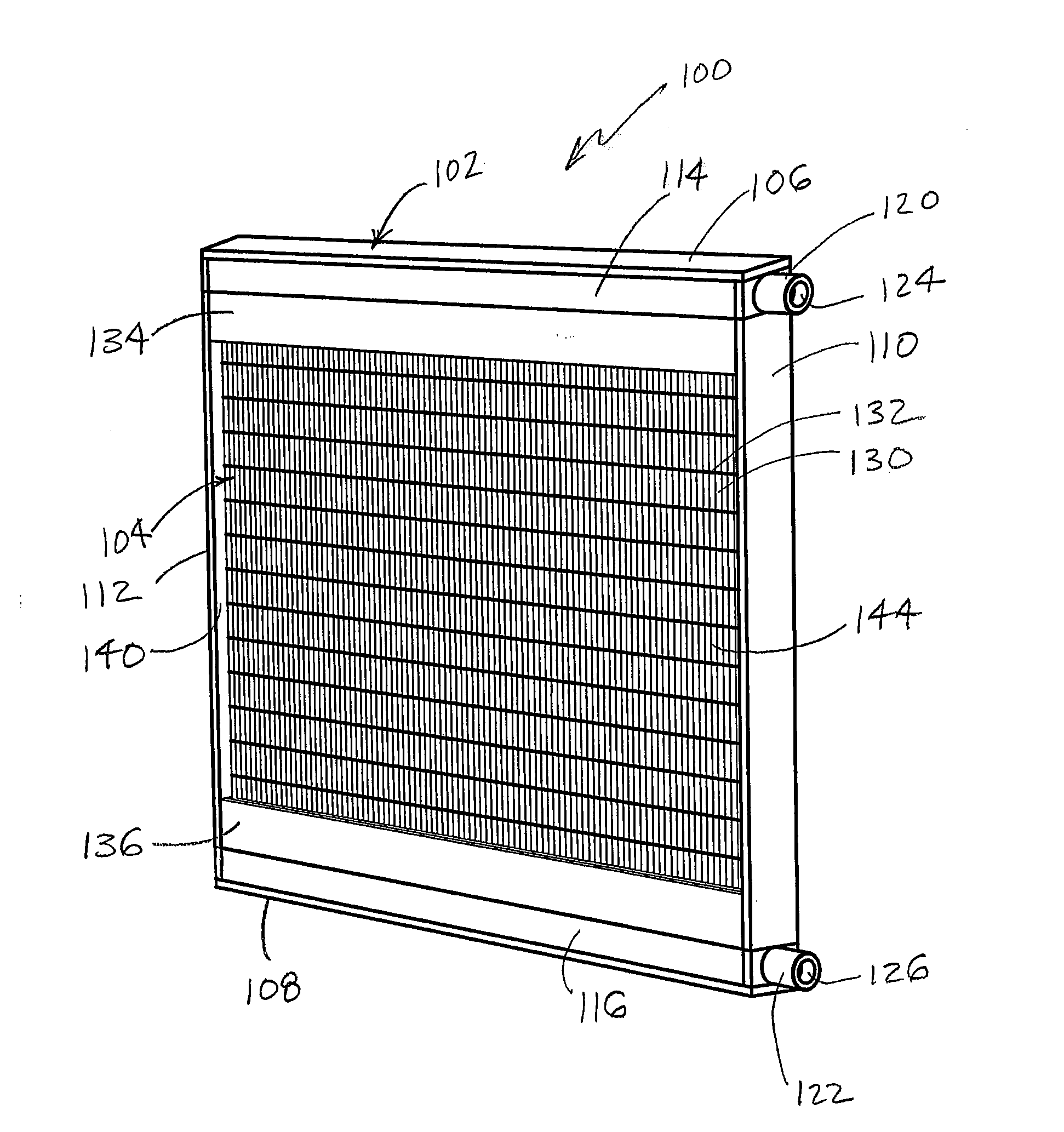

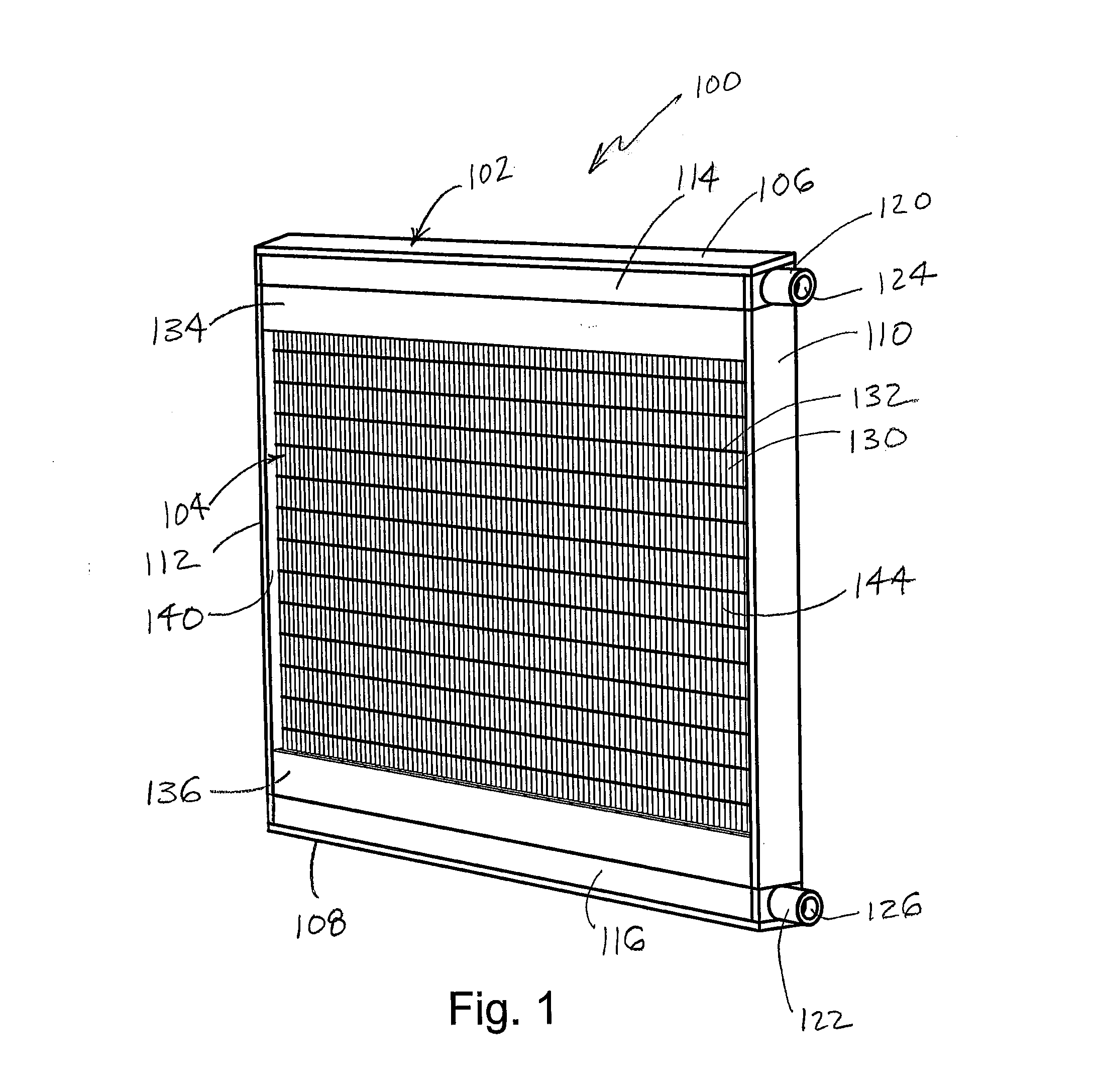

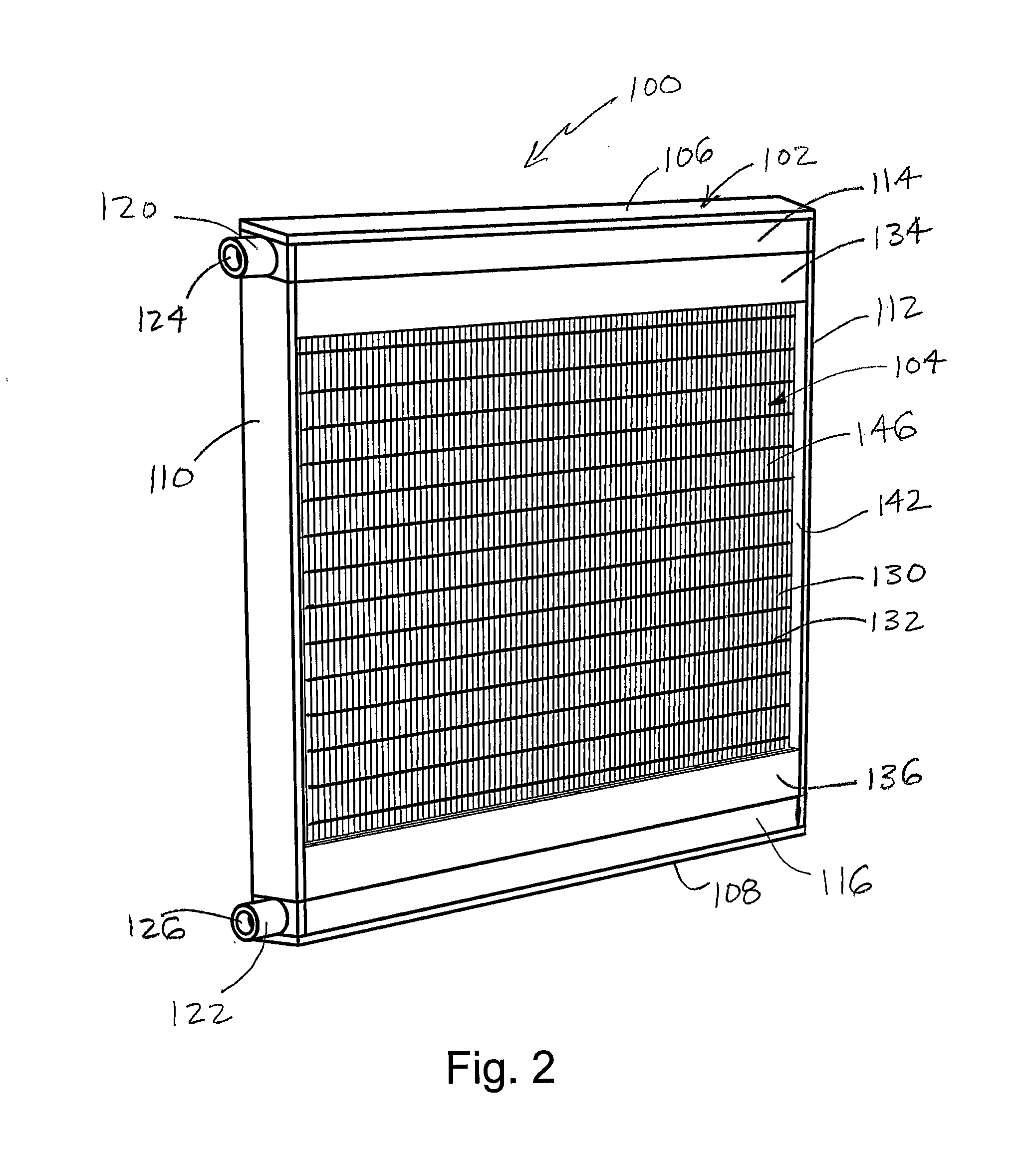

Flat panel contactors and methods

ActiveUS20120304862A1Economically beneficialIncrease air volumeSemi-permeable membranesGas treatmentFiberPorous membrane

Porous membrane contactors and / or their methods of manufacture and / or use are provided. In at least selected embodiments, the present invention is directed to flat panel hollow fiber or flat sheet membrane contactors and / or their methods of manufacture and / or use. In at least certain particular embodiments, the present invention is directed to hollow fiber array flat panel contactors, contactor systems, and / or their methods of manufacture and / or use. In at least particular possibly preferred embodiments, the contactor is adapted for placement in an air duct (such as an HVAC ductwork) and has a rectangular frame or housing enclosing at least one wound hollow fiber array or membrane bundle.

Owner:3M INNOVATIVE PROPERTIES CO

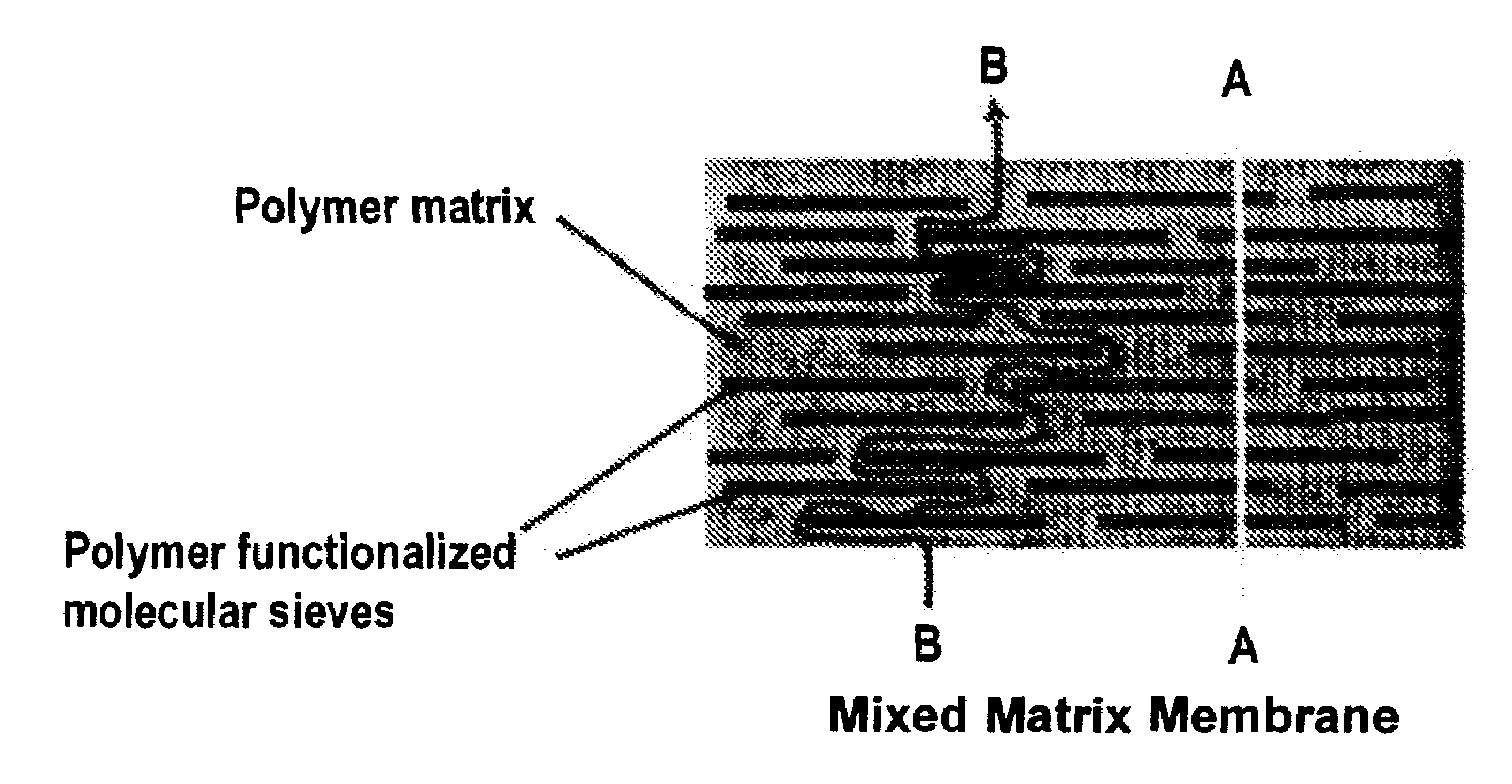

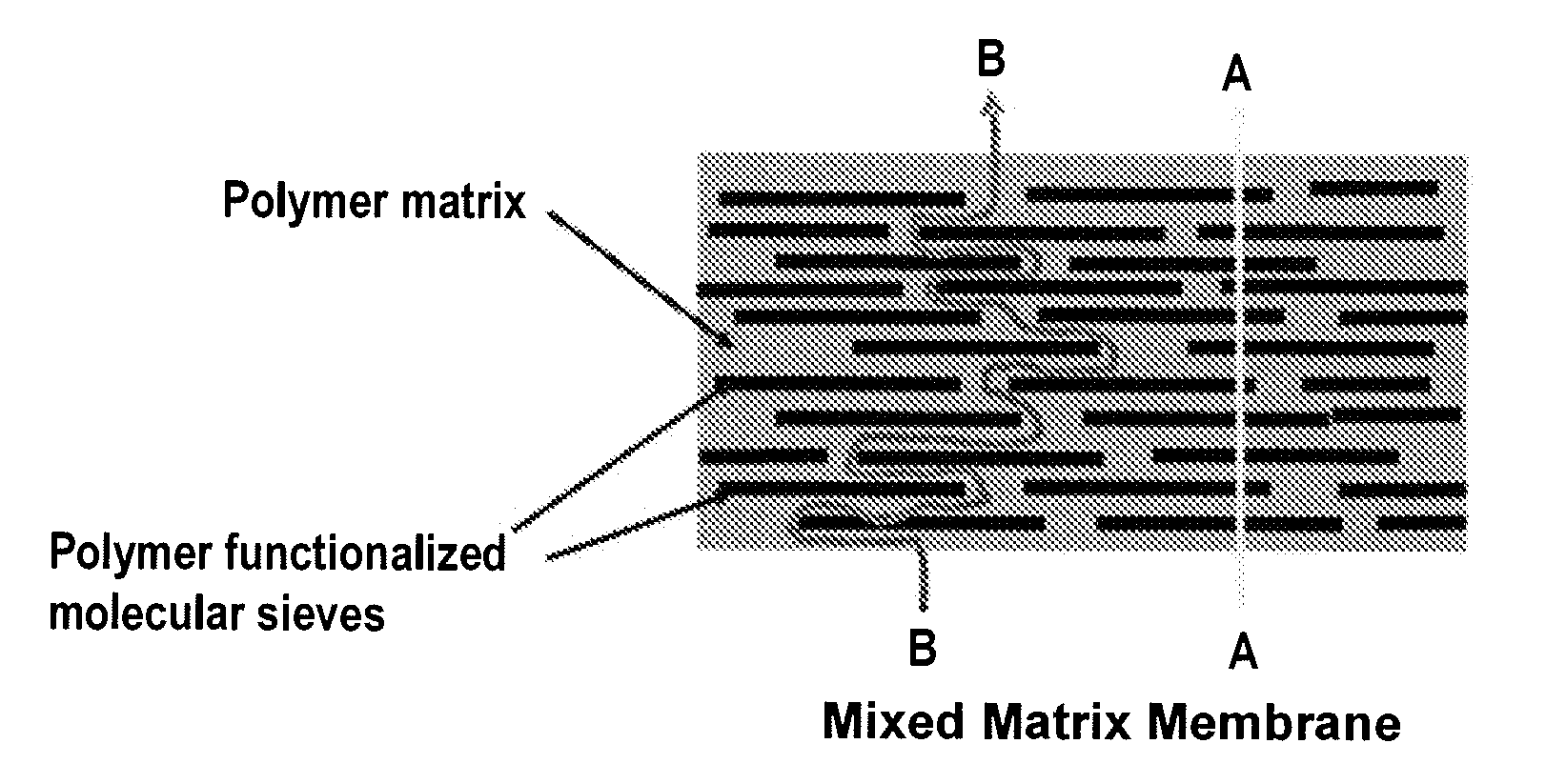

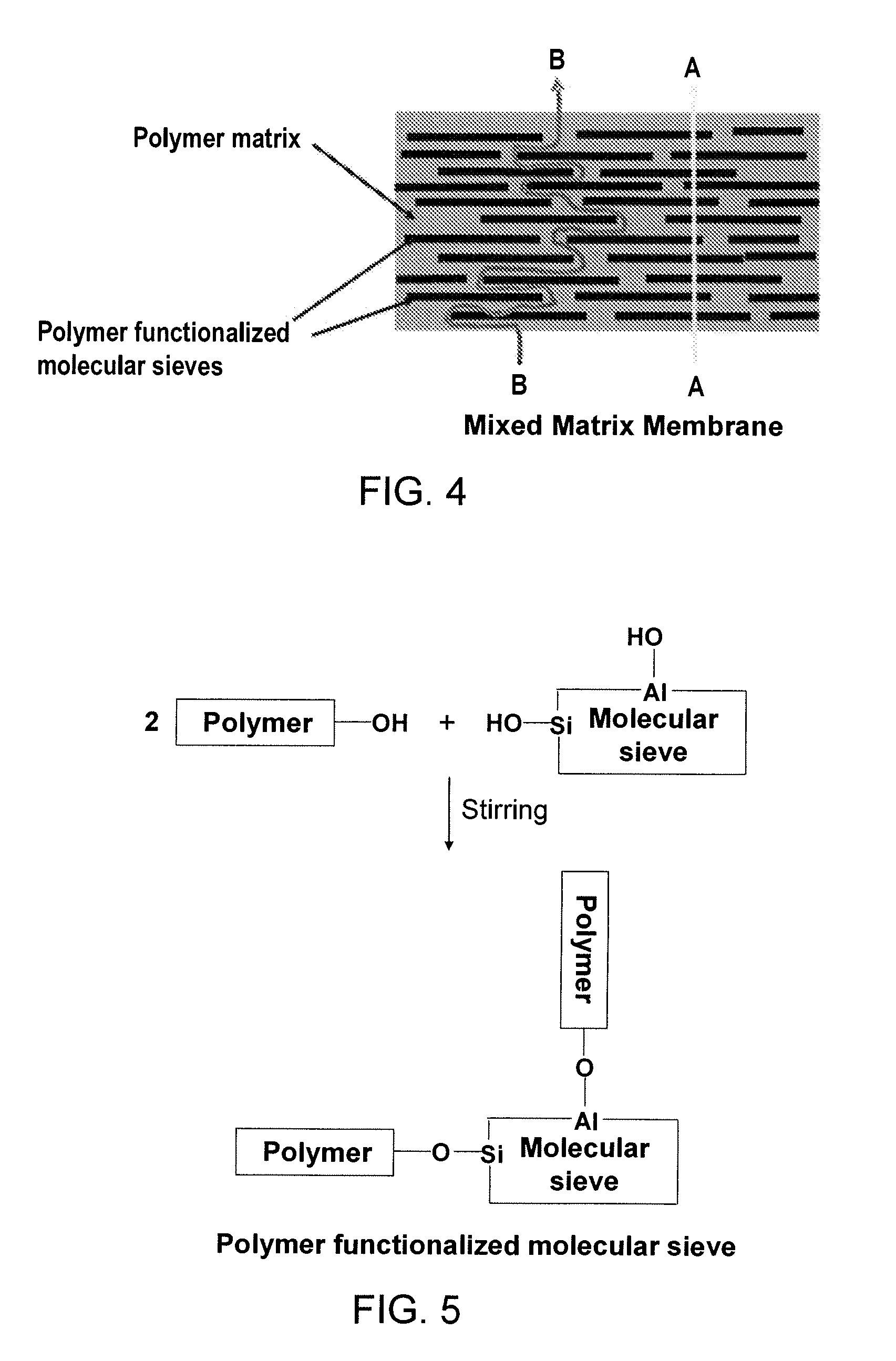

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126570A1Easy to separateAverage permeabilitySemi-permeable membranesIsotope separationFiberHollow fibre

The present invention discloses polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes

The present invention discloses a method of making, compositions and method of using high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several angstroms at the interface of the polymer matrix and the molecular sieves. These UV cross-linked MMMs are prepared by incorporating polymer functionalized molecular sieves into a continuous UV cross-linkable polyimide polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes have good flexibility, high mechanical strength, and exhibit significantly enhanced selectivity and permeability over polymer membranes made from corresponding continuous polyimide polymer matrices for carbon dioxide / methane and hydrogen / methane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

Organic-inorganic composite lithium ion battery diaphragm and preparation method thereof

InactiveCN103682218AStrong penetrating powerImprove high temperature stabilitySynthetic resin layered productsCell component detailsPorosityWater baths

The invention discloses an organic-inorganic composite lithium ion battery diaphragm and a preparation method thereof. The diaphragm is a composite membrane formed by reinforcing organic resin by inorganic particles, wherein the inorganic particles account for 0.1 percent by mass to 20 percent by mass and the organic resin accounts for 10 percent by mass to 70 percent by mass. Preparation of the diaphragm comprises the following steps of: firstly, stirring the organic resin, the inorganic particles and a diluent according to a certain proportion at a temperature of 150 to 280 DEG C to form homogeneous solution; then carrying out hot-pressing on the obtained homogeneous solution at a temperature of 150 to 220 DEG C to form a flat sheet membrane with a thickness of 20 to 1,000 micron; cooling the flat sheet membrane to the room temperature by adopting water bath with a temperature of 0-100 DEG C or at a cooling speed of 0-200 DEG C / min; finally, carrying out operation of firstly stretching and then extracting or firstly extracting and then stretching and drying processing on the cooled flat sheet membrane. The diaphragm provided by the invention has the advantages of easiness for controlling the porosity, adjustability for the aperture, micropore penetration, good high-temperature stability and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

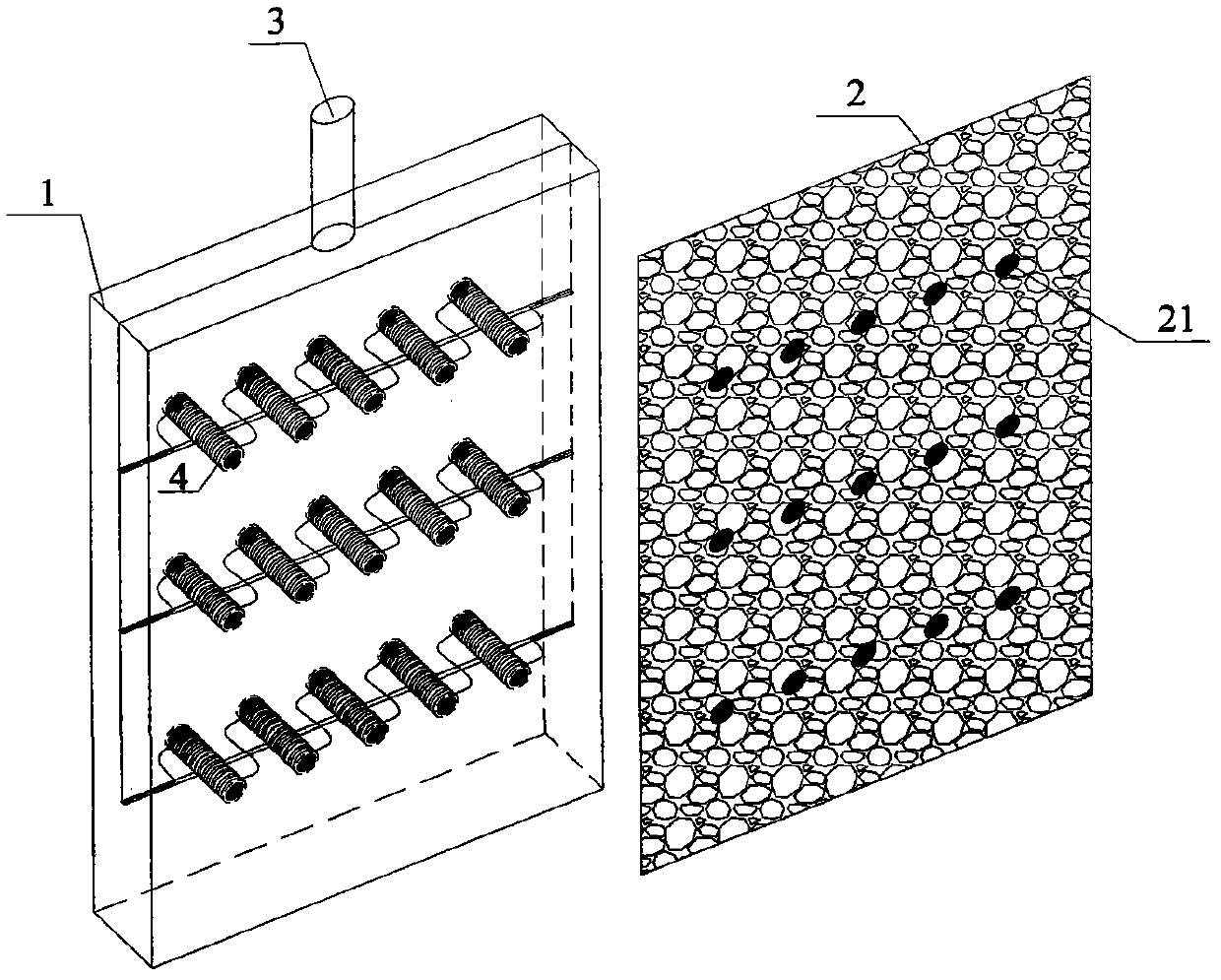

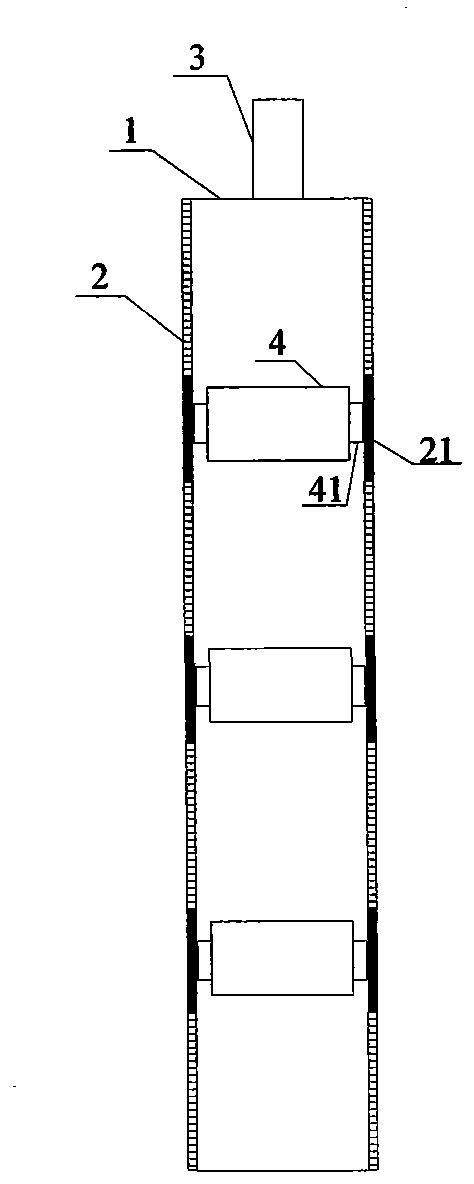

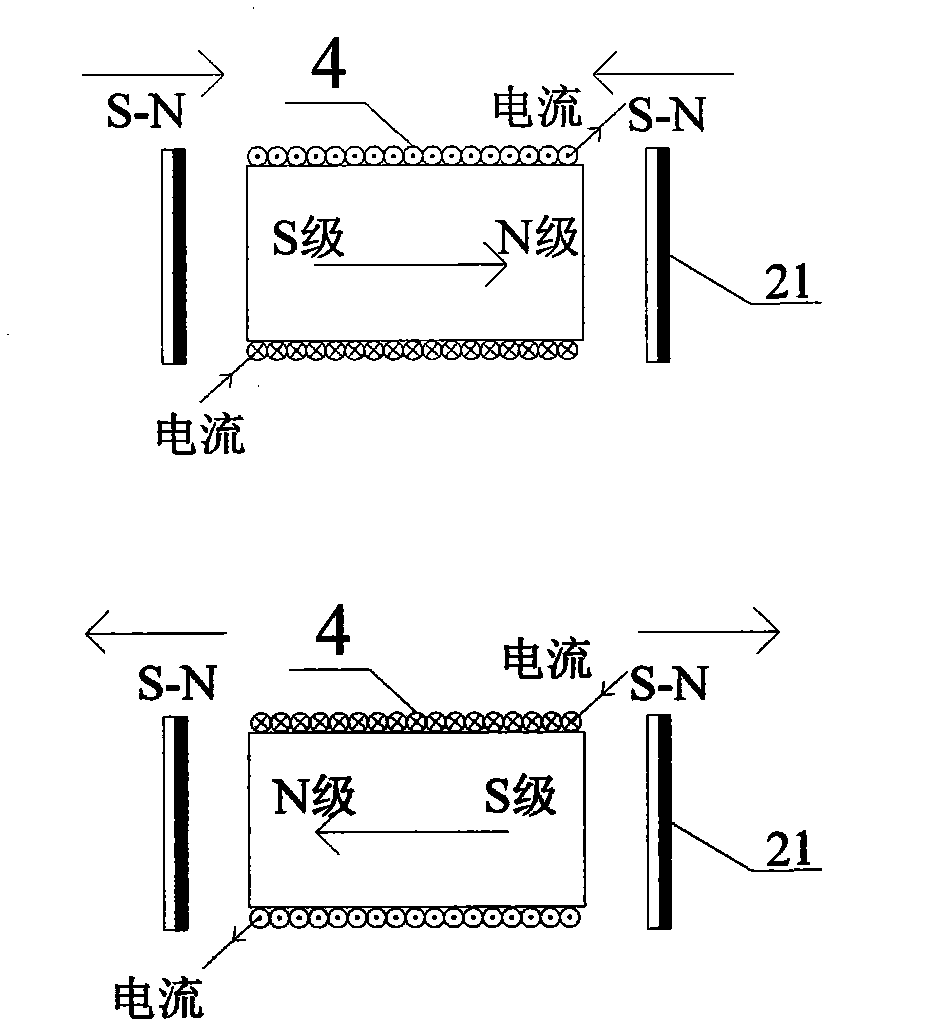

Pollution resistant membrane module and use method thereof

InactiveCN102228796AReduce pollutionExtended service lifeSemi-permeable membranesPollutantElectricity

The invention provides a pollution resistant membrane module which is a flat membrane module. The membrane module comprises a frame and two filter membranes, wherein the two filter membranes respectively cover the two sides of the frame; a liquid flow channel is formed between the two filter membranes; a water outlet is arranged at one end of the frame; at least a conducting coil pipe vertical to the filter membranes is arranged between the two filter membranes; magnetic chips are arranged in the positions corresponding to the coil bodies on the filter membranes; and the orientations of the south and north poles of the two magnetic chips in the same positions on the two filter membranes are identical. The pollution resistant membrane module has the following beneficial effects: when being electrified, the conducting coils in the pollution resistant membrane module generate south and north poles and generate attractive forces or repulsive forces towards the filter membranes or supporting filter plates which are provided with the magnetic chips with south and north poles; the directions of the south and north poles of the conducting coils are changed by changing the current directions, so that the filter membranes can be continuously shaken to shake off the pollutants, thus alleviating membrane pollution and prolonging the service lives of the membranes; and less electricity is used, so the aeration energy consumption can be reduced and the operation cost can be lowered.

Owner:叶茂盛

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126566A1Easy to separateAverage permeabilitySemi-permeable membranesMembranesFiberHollow fibre

The invention discloses the use of polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), propylene / propane separations and a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

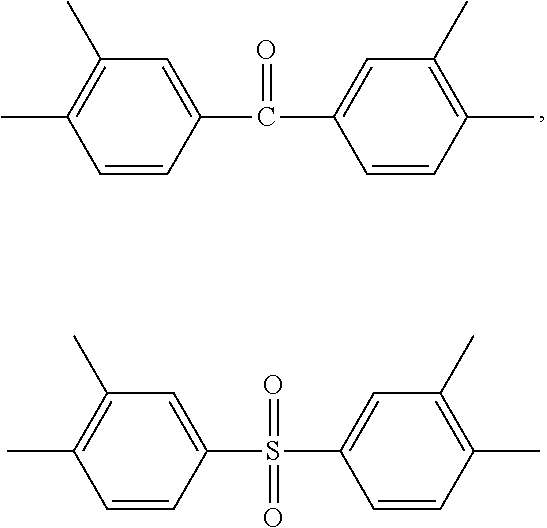

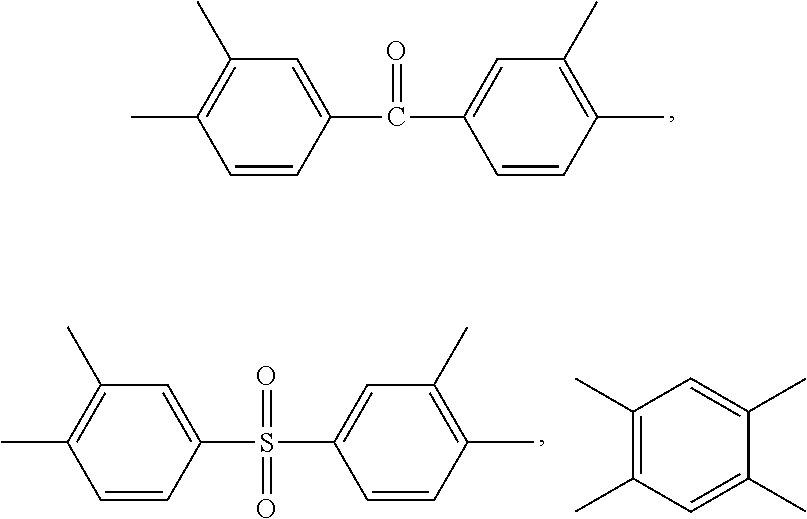

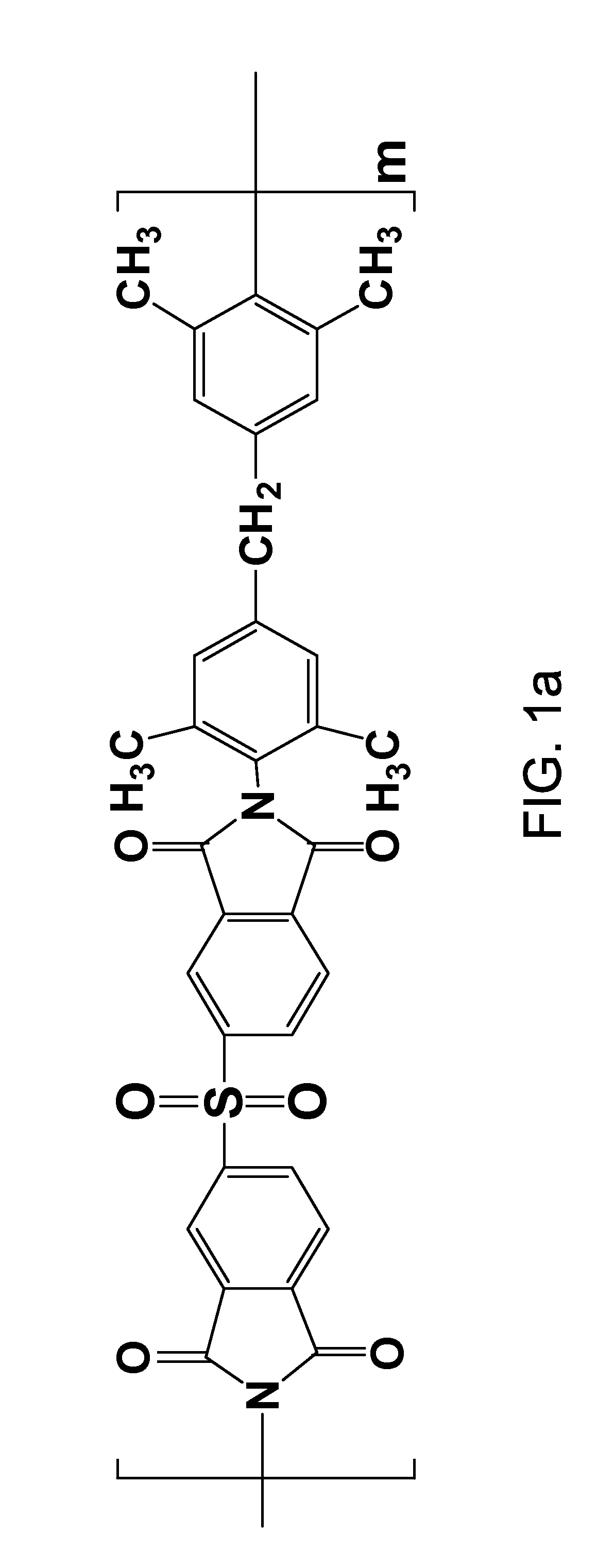

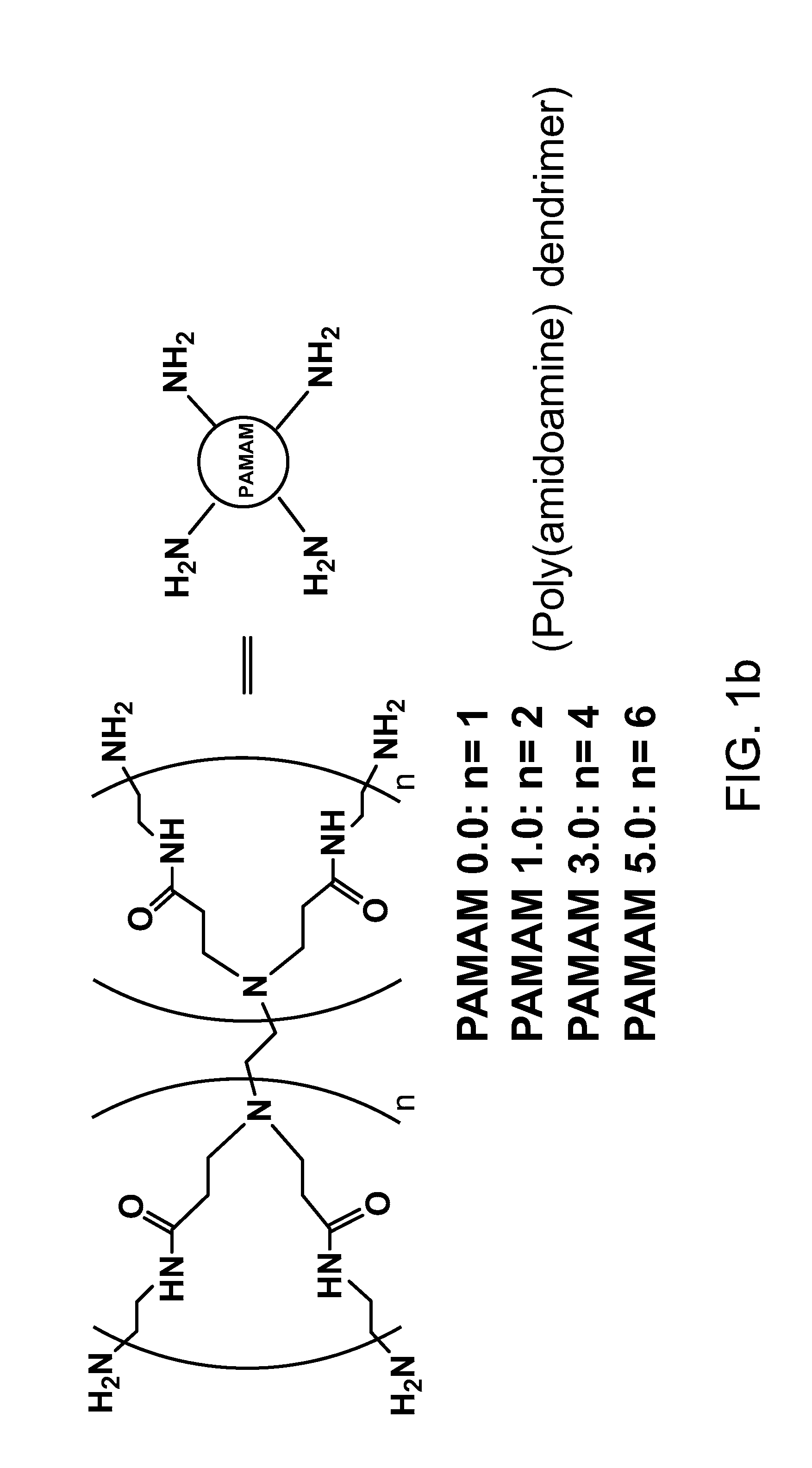

Cross-linked polyimide membranes for separations

InactiveUS20140137734A1Reduces polyimide polymer chain flexibilityEasy to distinguishSemi-permeable membranesGas treatmentCross-linkPAMAM dendrimer

The present invention discloses new types of poly(amidoamine) (PAMAM) dendrimer-cross-linked polyimide membranes and methods for making and using these membranes. The membranes are prepared by cross-linking of asymmetric aromatic polyimide membranes using a PAMAM dendrimer as the cross-linking agent. The PAMAM-cross-linked polyimide membranes showed significantly improved selectivities for CO2 / CH4 compared to a comparable uncrosslinked polyimide membrane. For example, PAMAM 0.0 dendrimer-cross-linked asymmetric flat sheet poly(3,3′,4,4′-diphenylsulfone tetracarboxylic dianhydride-3,3′,5,5′-tetramethyl-4,4′-methylene dianiline) (DSDA-TMMDA) polyimide membrane showed CO2 permeance of 135.2 A.U. and CO2 / CH4 selectivity of 20.3. However, the un-cross-linked DSDA-TMMDA asymmetric flat sheet membrane showed much lower CO2 / CH4 selectivity (16.5) and higher CO2 permeance (230.8 GPU).

Owner:UOP LLC

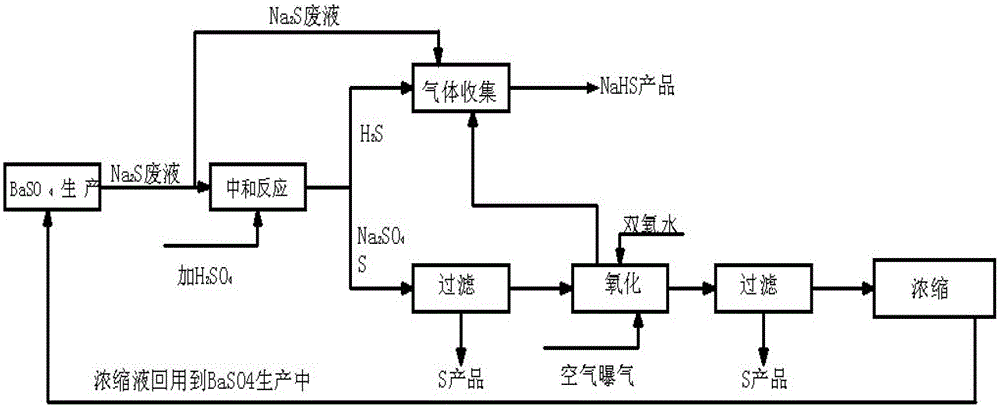

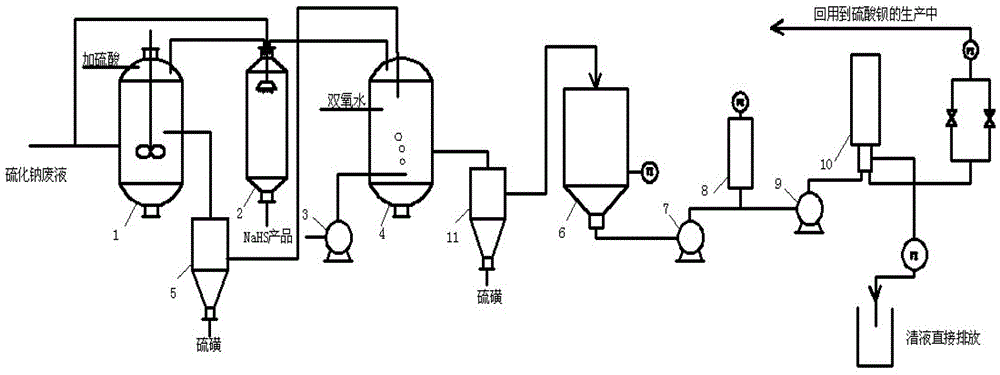

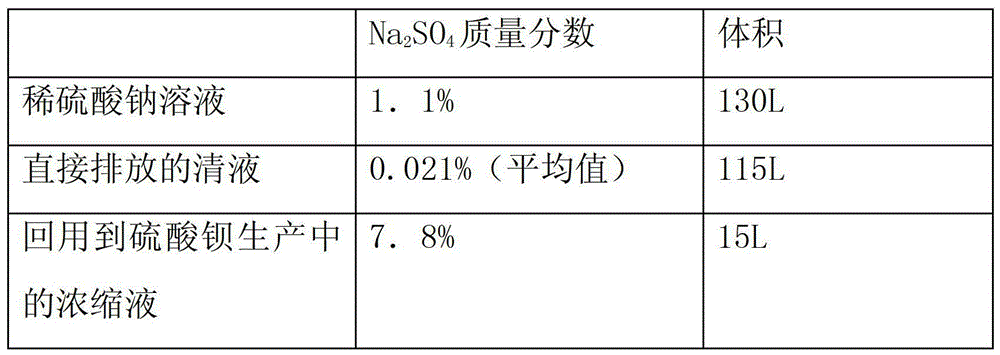

Process and device for recovering sodium sulphide wastewater in barium sulphate production

InactiveCN103058227AIncrease concentrationSulfate/bisulfate preparationSulfur preparation/purificationReverse osmosisHigh pressure

The invention discloses a process and a device for recovering sodium sulphide wastewater in barium sulphate production, belonging to the technical field of wastewater recovery. The process comprises the following steps performed by the corresponding devices: adding sulphuric acid to neutralize dilute sodium sulphide waste solution; absorbing hydrogen sulphide by a sodium sulphide spray tower; adding hydrogen peroxide in the sodium sulphate solution, so as to oxidize hydrogen sulphide which is dissolved in sodium sulphate solution into sulphur; filtering the sodium sulphate solution; and finally charging the sodium sulphate dilute solution in a disc-tube type reverse osmosis membrane system or a high-pressure flat-sheet membrane system, then concentrating, reusing the concentrate in barium sulphate production, and directly draining clear solution, so as to achieve the effect of turning waste into wealth.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for external pressure tubular membrane

InactiveCN102600730AHigh mechanical strengthLow costSemi-permeable membranesTextile fiberUltrafiltration

The invention belongs to the field of manufacture of separating membranes, and relates to a preparation method for an external pressure tubular membrane. A prepared porous membrane can be used for fields of environmental protection, water treatment, membrane separation and the like. The preparation method includes steps that a strip-shaped flat membrane is continuously wound on a center shaft in a certain winding angle, during winding, a membrane separating layer is outward, two sides of a membrane strap are mutually overlapped, the overlapped portions are integrally adhered or ultrasonically welded, then a prepared membrane tube is separated from the center shaft, and accordingly the external pressure tubular membrane is obtained. A combination of the separating layer of the external pressure tubular membrane and non-woven fabrics is firmer than a combination of the separating layer of the external pressure tubular membrane and braided tube textile fibers, so that the external pressure tubular membrane is not easy to shed; the mechanical strength of the external pressure tubular membrane is better than that a braided tube reinforcing membrane, and accordingly the external pressure tubular membranes are not easy to fall laterally or twined mutually; and membrane manufacturing efficiency is high, the external pressure tubular membrane is suitable for batch production and can be recoiled. The external pressure tubular membrane comprises a microfiltration membrane or an ultrafiltration membrane or a nanofiltration membrane, and is particularly suitable for membrane bioreactors and a recycled water process.

Owner:北京坎普尔环保技术有限公司

Preparation method of aromatic polymer porous membrane

ActiveCN103143273AIncreased pure water fluxHigh separation precisionSemi-permeable membranesFiberHollow fibre

The invention discloses a preparation method of an aromatic polymer porous membrane. The porous membrane comprises a flat membrane and a hollow fibrous membrane. The preparation method adopts the following porous membrane casting solution and solution-phase conversion membrane preparation technique. The membrane casting solution comprises the following components in percentage by mass: 1.5-15 wt% of PPTA (poly(p-phenylene terephthalamide)), 4.5-10 wt% of pore-forming agent and 86.5-94 wt% of solvent. The pore-forming agent is a soluble high polymer selected from at least one of PEGs (polyethylene glycols) with the average molecular weight of 600-20000 and PVPs (polyvinyl pyrrolidones) with the average molecular weight of 10000-100000; and the solvent is 98-100 wt% concentrated sulfuric acid. The porous membrane preparation technique comprises the following steps: 1) preparing the membrane casting solution; and 2) preparing the flat porous membrane by a wet process, or preparing the hollow fiber porous membrane by dry-wet spinning formation.

Owner:TIANJIN POLYTECHNIC UNIV

High-flux ceramic flat sheet membrane and preparation method thereof

The invention relates to a high-flux ceramic flat sheet membrane and a preparation method thereof. The high-flux ceramic flat sheet membrane comprises a ceramic flat sheet membrane supporting body and a separation membrane layer wrapping the outer surface of the ceramic flat sheet membrane supporting body. The ceramic flat sheet membrane support body is prepared from the following raw materials in parts by mass: 40-57 parts of diatomite, 30-40 parts of alpha-alumina powder, 4-12 parts of a pore forming agent, 20-40 parts of a support body binding agent, 8-12 parts of a lubricant, 9-13 parts of a plasticizer and 12-18 parts of chopped fibers. The separation membrane layer is prepared from the following raw materials in parts by mass: 40-43 parts of ceramic powder particles, 4-6 parts of ethanol, 19-40 parts of a separation membrane layer binding agent and 9-12 parts of polyethylene glycol. The high-flux ceramic flat sheet membrane product is low in sintering temperature, low in production cost, high in product porosity, small in filtering resistance and high in water flux.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com