Preparation method of aromatic polymer porous membrane

An aromatic polymer, porous membrane technology, applied in the field of membrane materials, can solve the problems of low decomposition temperature, difficult membrane production, and no patent literature reports on porous membrane materials, and achieves a short process, simple membrane production process, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

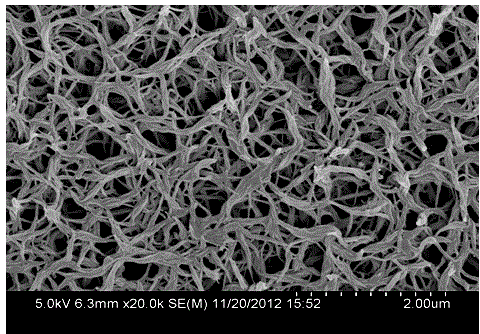

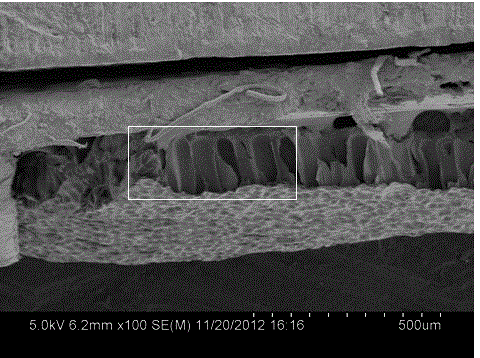

Image

Examples

Embodiment 1

[0042]Dissolve the PPTA resin with a mass fraction (the same below) of 3.5wt% in 86.5wt% concentrated sulfuric acid with a concentration of 98wt%, then add porogen PEG6000, heat up to 80°C to completely dissolve, and defoam in a vacuum oven to obtain casting solution required. Scrape-coat the casting liquid at room temperature to form a flat film, and immediately immerse it in ultrafiltered water at 16°C, and solidify and form it for 24 hours. The obtained membranes were placed in ice water at 5°C, room temperature at 25°C and hot water at 50°C for 24 hours of extraction and washing. Then perform a performance test: wash the residual liquid on the membrane with deionized water, and then filter the pure water at 0.1Mpa to measure its water flux. The water flux of the obtained membrane was 132.70 (L / m 2 h), 149.28 (L / m 2 h) and 165.87 (L / m 2 h).

Embodiment 2

[0044] As described in Example 1, with other conditions unchanged, the porogen was changed to PEG with molecular weights of 2,000, 10,000, or 20,000, and placed in ice water at 5°C for extraction and washing for 24 hours. Then perform a performance test: wash the residual liquid on the membrane with deionized water, then filter pure water at 0.1Mpa, and measure its water flux; the water flux of the obtained membrane is 79.62 (L / m 2 h), 82.94 (L / m 2 h) and 99.52 (L / m 2 h).

Embodiment 3

[0046] Dissolve 2.0wt% PPTA resin in concentrated sulfuric acid with a mass fraction of 88wt% and a concentration of 98wt%, then add 10wt% of composite porogens such as PVP60000 and PEG2000, heat up to 80°C to completely dissolve, and defoam in a vacuum oven. That is, the required casting solution is obtained. Scrape-coat the casting solution at room temperature to form a flat film, and put the prepared film in room temperature of 25°C and hot water at 50°C for extraction and washing for 24 hours. Then perform a performance test: wash the residual liquid on the membrane with deionized water, and then filter the pure water at 0.1Mpa to measure its water flux. The water flux of the obtained membrane was 265.39 (L / m 2 h) and 281.98 (L / m 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com