Patents

Literature

138results about How to "Simple film making process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

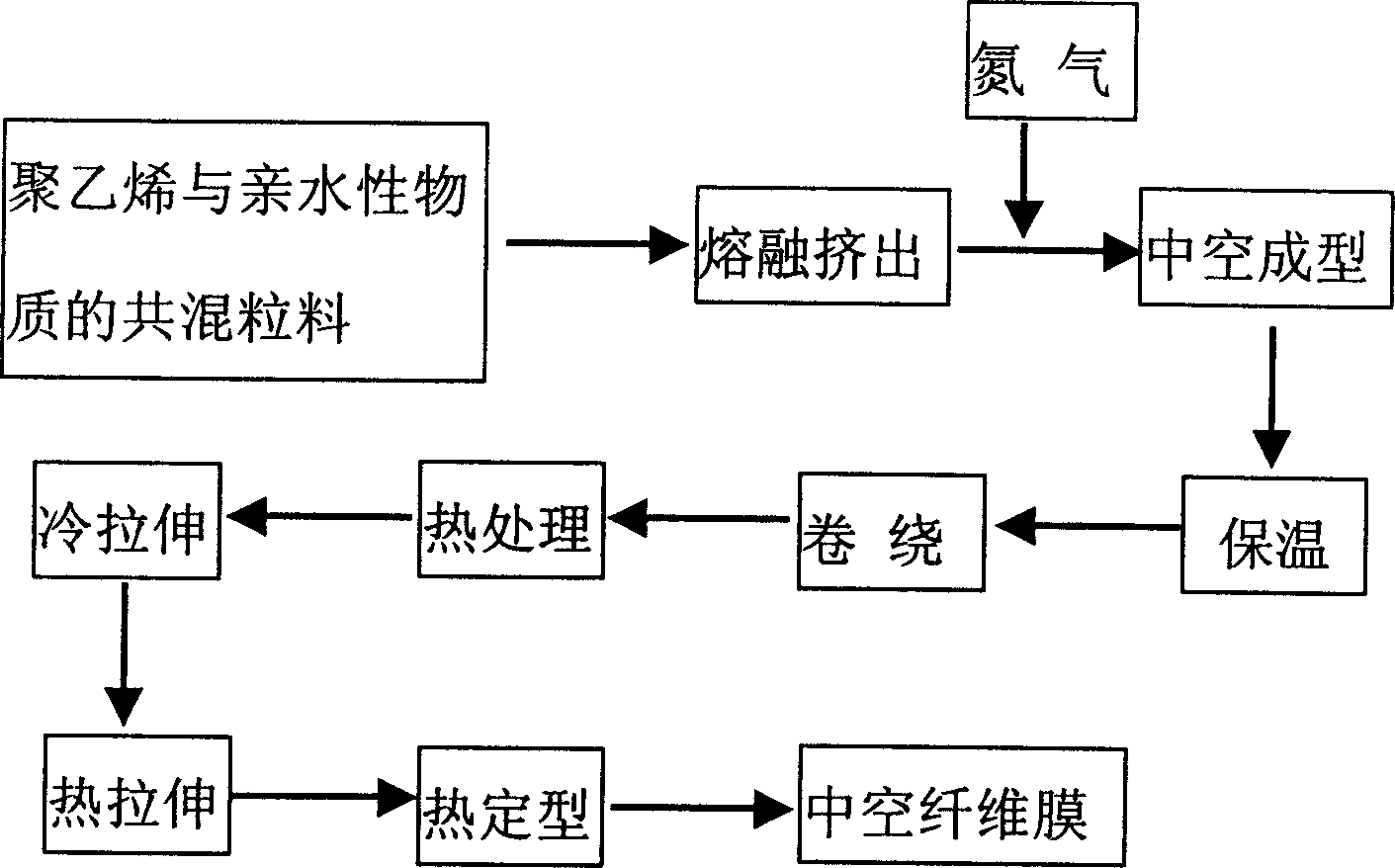

Hydrophilic modified preparation method for polyethylene hollow fiber microporous membrane

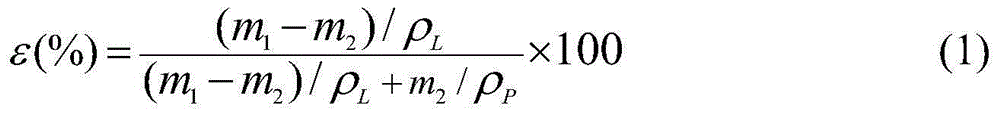

InactiveCN1654113ASmall amount neededExcellent porositySemi-permeable membranesStretch-spinning methodsPorosityFiber

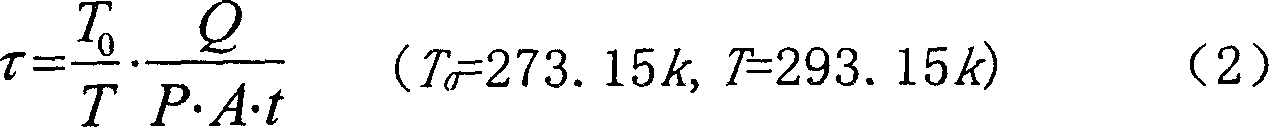

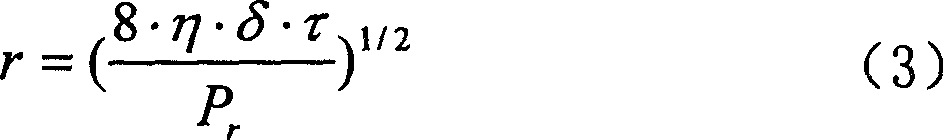

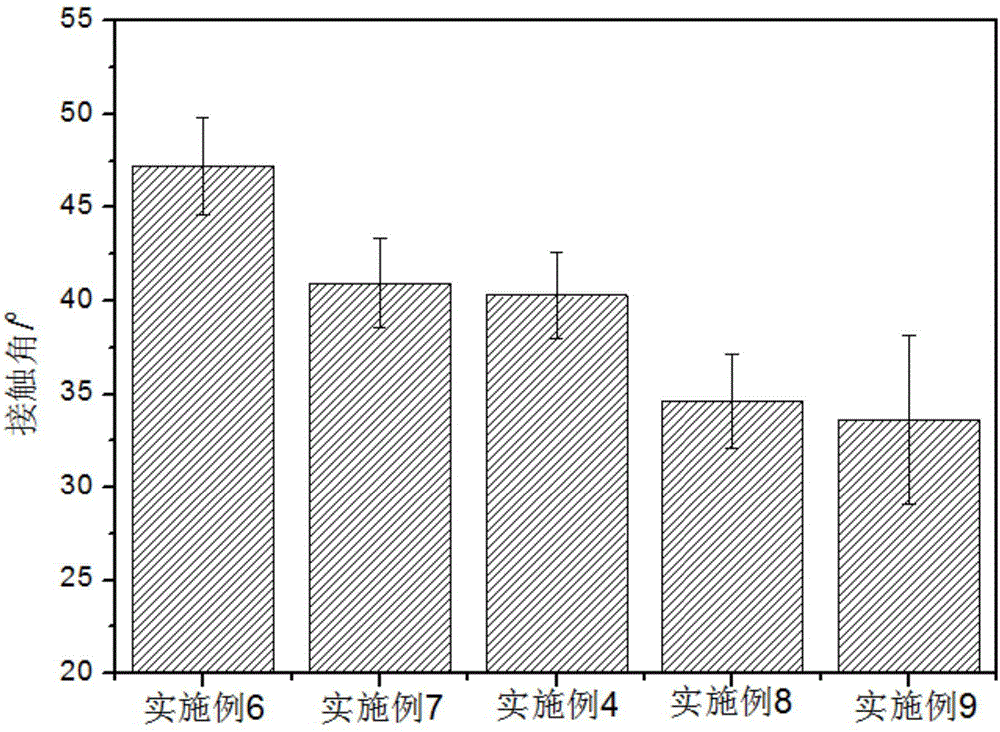

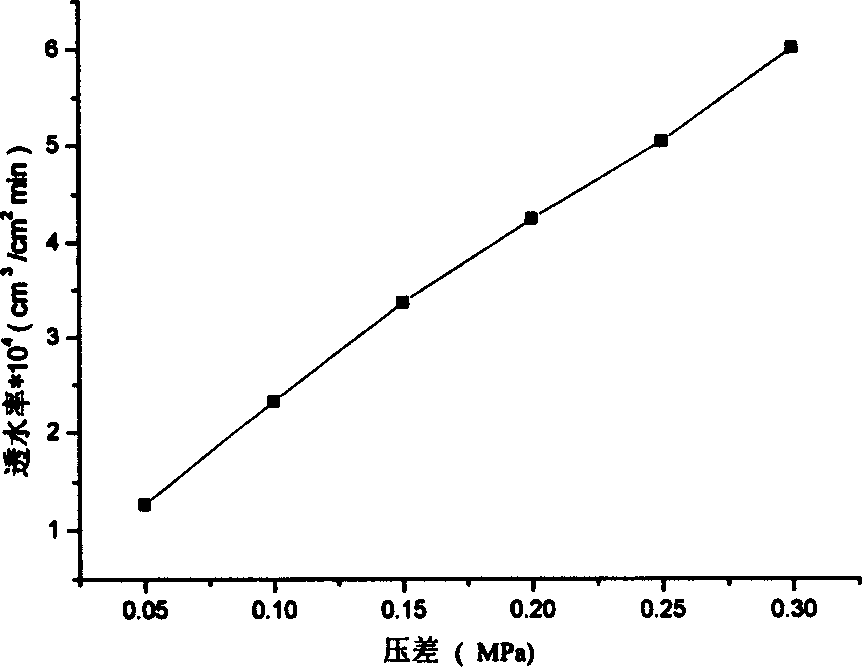

The present invention discloses preparation process of hydrophilic modified hollow microporous polyethylene film. Some hydrophilic matters with relatively high surface energy are used to mix with fused polyethylene. The present invention features that the prepared hollow microporous polyethylene film has improved hydrophilicity, including contact angle reduced by over 20 deg, film porosity of 40-80 %, average pore size of 0.1-0.5 micron and air permeability of 0.01-1 cu cm / sq cm.s.cmHg. The film has inner diameter of 250-500 microns and thickness of 30-60 microns. The prepared hollow microporous polyethylene film of the present invention has average pore size, porosity and hydrophilicity much higher than those of hollow polyethylene fiber film prepared through fusion spinning-stretching process, and has no obvious change in tension strength, rebound degree, etc.

Owner:ZHEJIANG UNIV

Permeating gasification film used for separation of methanol/dimethyl carbonate azeotropic liquid, and its preparing method

InactiveCN101003002ALow priceReduce energy consumptionDistillationCarbonic/haloformic acid esters purification/separationMethyl carbonateALLYL SUCROSE

A gasifying osmotic film for separating the azeotropic methanol / dimethyl carbonate solution is prepared from polyvinyl alcohol and polyacrylic acid. Its preparing process is also disclosed.

Owner:山东蓝景膜技术工程有限公司

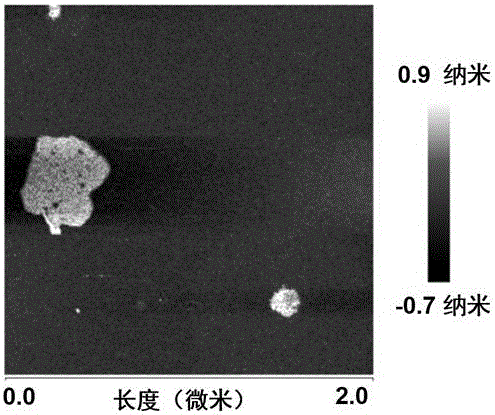

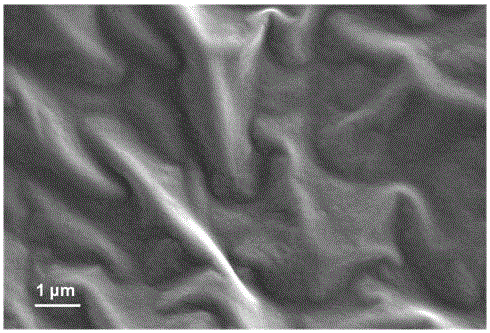

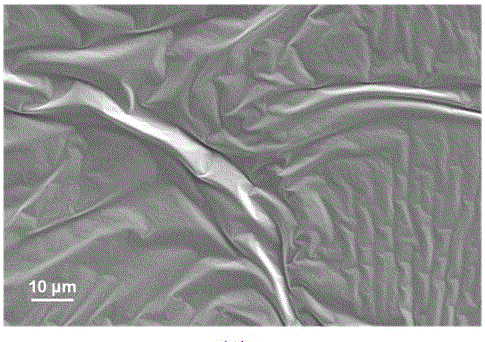

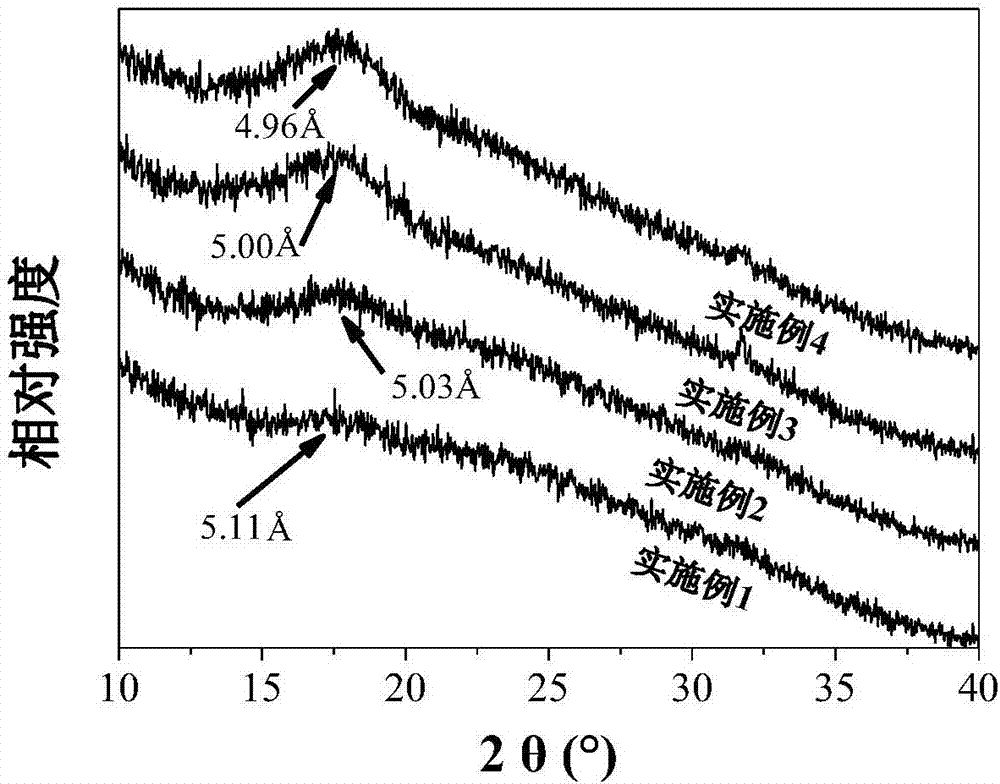

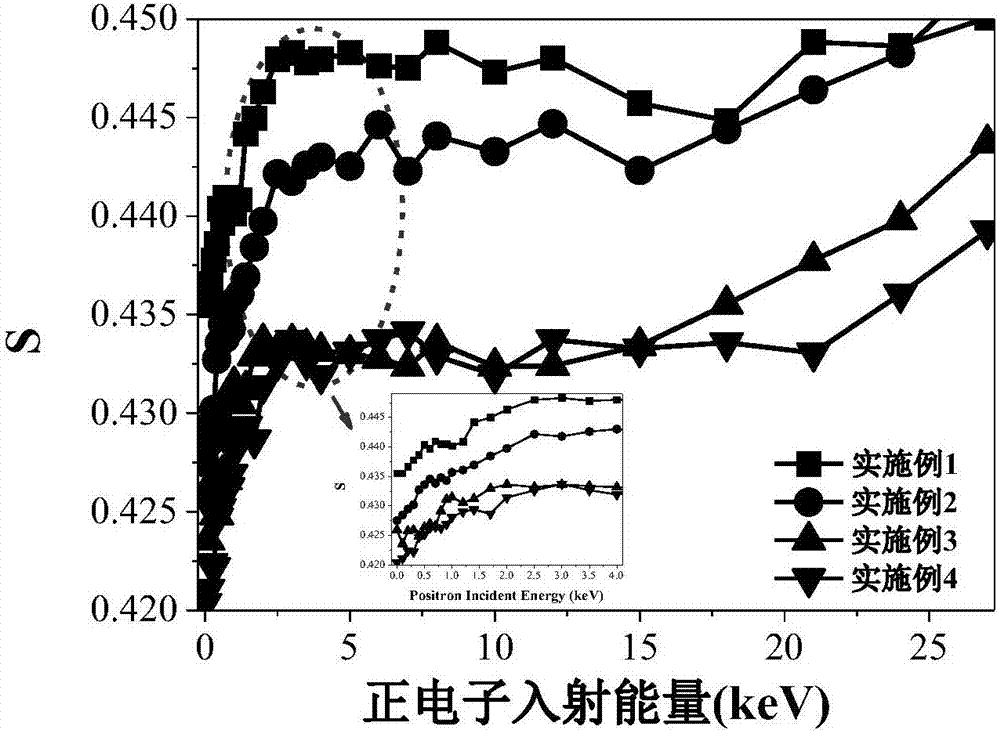

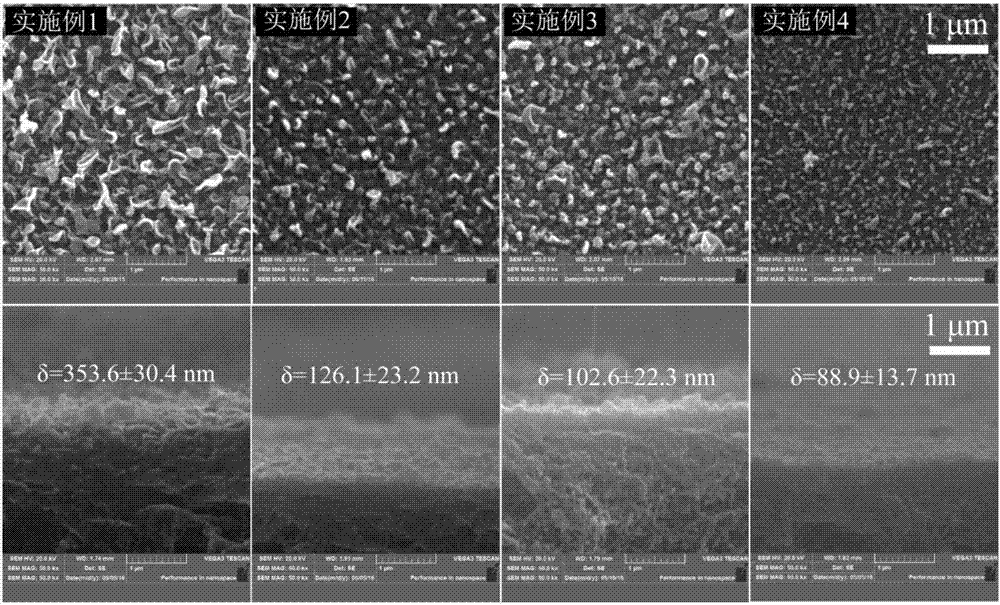

Preparation method of two-dimensional laminar covalent organic framework membrane

ActiveCN106512754APrecise thickness controlSimple film making processSemi-permeable membranesWater bathsOrganic solvent

The invention discloses a preparation method of a two-dimensional laminar covalent organic framework membrane. The method comprises the specific steps: (1) mixing a two-dimensional laminar covalent organic framework powder material with an organic solvent, uniformly mixing the mixture after discharging air in a bottle with nitrogen and sealing the bottle, then putting the bottle in an ultrasonic water bath for treatment, and peeling off the covalent organic framework material layer by layer to obtain a dispersion liquid of single atom layer sheets; and (2) depositing the dispersion liquid of the peeled covalent organic framework sheets to the surface of a vector, and after a solvent is fully evaporated, repeating the depositing process many times to obtain a continuous covalent organic framework membrane layer. Compared with an existing membrane forming technology of the covalent organic framework material, the preparation method is simple in process and easy to control, continuous to form membrane and relatively good in repeatability.

Owner:SOUTH CHINA UNIV OF TECH

Polyamide film composite membrane and preparation method and application thereof

InactiveCN106914152AIncrease water fluxLow reverse salt fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolyamideActive layer

The invention discloses a polyamide film composite membrane and a preparation method and application thereof. The composite membrane comprises a polymer support layer and a polyamide active layer. The polyamide active layer is obtained by a reaction of a multielement acyl chloride solution and a polyamine aqueous solution containing a tertiary amine additive. In the preparation process, the polyamine aqueous solution containing the tertiary amine additive and the multielement acyl chloride solution undergo an interfacial polymerization reaction to produce the modified polyamide active layer so that the film-forming process is greatly simplified. The composite membrane has a high crosslinking degree and high compactness, and has a high water flux in membrane separation, a low reverse salt flux and good anti-fouling properties.

Owner:HUAZHONG UNIV OF SCI & TECH

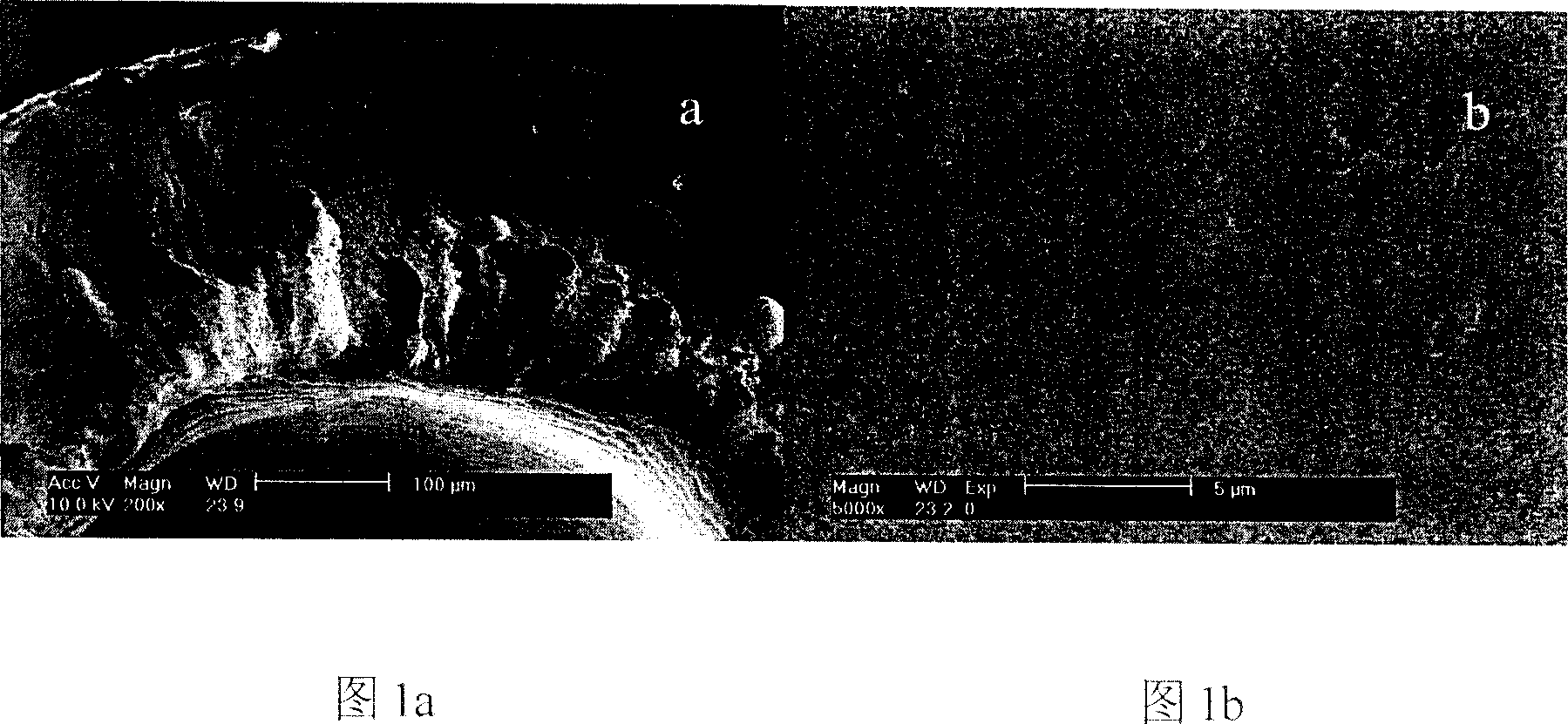

Manufacture and products of hollow fiber membrane of outer pressured polyvinylidene fluoride by immersion gelation

The invention relates to a preparation method of exo-pressure type poly (vinylidene fluoride) hollow fiber membrane spinned utilizing an immersion-coagulation method and the product thereof. The invention is performed mainly through the following steps: dissolving and stirring at a certain temperature to obtain a membrane forming solution; by means of a double-tube orifice, spinning the membrane forming solution together with a composite supporting solution which is in the inner tube of the orifice; after a rapid evaporation, performing the two-stage phase-separating coagulations; after a potch, hydrophilizating the resulted phase inversion membrane; thus, obtaining integrally and continuously the exo-pressure type hollow fiber membrane having double barrier layers and a completely spongy supporting layer. Therefore, the invention is provided with a lot of characteristics, such as the formulation of the membrane forming solution being reasonable, the evaporation and immersion spinning method, the two-stage phase-separation coagulations, and the hydrophilization treatment, as well as the technique for forming membrane integrally and continuously being simple and easy without high restricts to device, the technique process being controlled easily, etc. And the membrane is provided with high compression strength and large water permeation flux, and its property is deteriorated very slowly, and cut-off deposits are difficult to form on the membrane surface.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

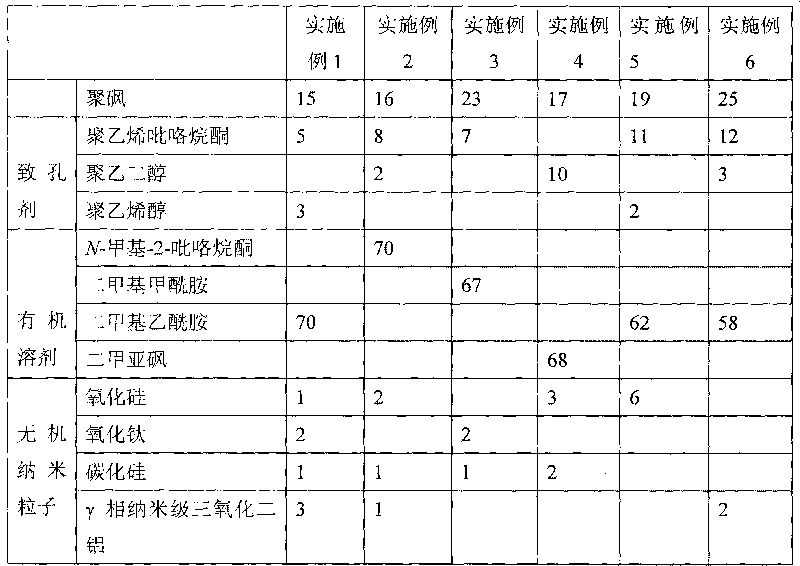

Blending modified hollow polysulfone fiber film, preparation method and application thereof

InactiveCN101711954AImprove featuresGood biocompatibilitySemi-permeable membranesSuction devicesFiberPolyethylene glycol

The invention relates to a blending modified hollow polysulfone fiber film which comprises the following components in percentage by weight: 3-40 percent of polysulfone, 0.5-20 percent of porogen, 50-90 percent of organic solvent and 0.5-20 percent of inorganic nano particles, wherein the inorganic nano particles are one or the mixture of more than two of silicon oxide nano particles, titanium oxide nano particles, silicon carbide nano particles and gamma-phase aluminium oxide nano particles; the viscosity-average molecular weight of the polysulfone is 40,000-200,000; the organic solvent is one of N-methyl-2-pyrrolidone, dimethyl acetamide or dimethyl sulfoxide; and the porogen is one or a mixture of any two of polyvinylpyrrolidone, polyethylene glycol and polyvinyl alcohol. The invention improves the surface property, the hydrophilic property and the mechanical strength of the film through modifying the hollow polysulfone fiber film, has simple film preparation process, and can realize industrial mass production.

Owner:江苏朗生生命科技有限公司

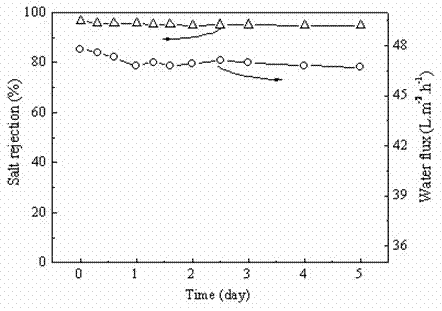

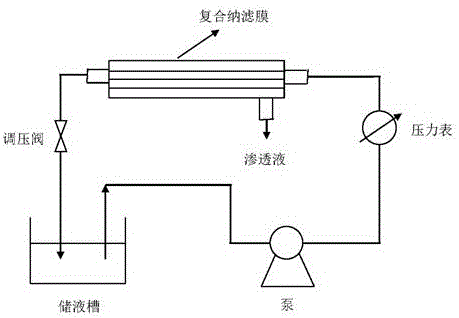

A kind of high permeability nanofiltration membrane containing zwitterion and preparation method thereof

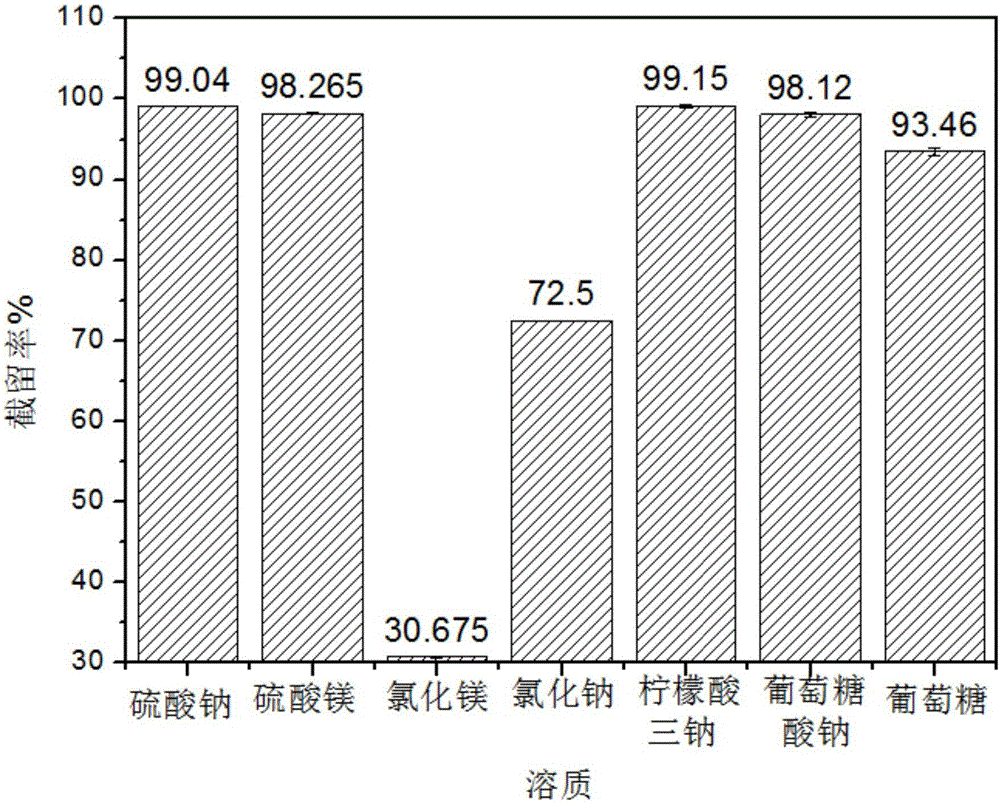

ActiveCN102294176AEasy to separateGood pollution resistanceSemi-permeable membranesCross-linkWater soluble

The invention discloses a high permeability nanofiltration membrane containing zwitterion and a preparation method. The nanofiltration membrane is composed of a polysulfones supporting layer and a functional layer containing a terpolymer of zwitterion group; the preparation process comprises the following steps: acquiring the water-soluble terpolymer through free radical copolymerization reactioncontaining zwitterion, preparing the copolymer and a cross-linking agent to an aqueous solution with a certain concentration, dipping one layer of the aqueous solution on the surface of the polysulfones supporting layer, then solidifying to obtain the membrane. The water flux of the nanofiltration membrane containing zwitterion is 30-45L.m-2.h-1 under the operation pressure of 0.6 MPa, and the nanofiltration membrane has high retention rate to bivalent ions with the highest of 97.5%, the retention rate to the monovalent cation is lower than 60%. The prepared nanofiltration membrane containingzwitterion has high permeability and stain resistane, the method for preparing the membrane is simple and easy which has low cost, and has good industrialization application prospect.

Owner:ZHEJIANG UNIV

Polyamide composite membrane and preparation method thereof

InactiveCN106582315ASimple film making processLow reverse salt fluxSemi-permeable membranesPolyamideChloride

The invention relates to a polyamide composite membrane and a preparation method thereof, and belongs to the field of membrane separation. The composite membrane comprises a polymer support layer and a polyamide active layer composited on the polymer support layer; the polyamide active layer is obtained by carrying out a reaction of a polyamine aqueous solution containing a tertiary amine additive with a polyacyl chloride solution; in the preparation process, the polyamine aqueous solution containing the tertiary amine additive and the polyacyl chloride solution undergo interfacial polymerization, and the body modified polyamide active layer is obtained, so that the membrane preparation process is greatly simplified. The composite membrane has high water flux, low reverse salt flux, good anti-pollution performance and good membrane separation performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Zinc-silver battery composite diaphragm with inorganic coating and preparation method of composite diaphragm

InactiveCN103400953AImprove electrical performanceExtended service lifeCell component detailsAdhesiveAbsorption rate

The invention relates to the field of preparation of diaphragms of alkaline batteries such as zinc-silver batteries, and in particular relates to a zinc-silver battery composite diaphragm with an inorganic coating and a preparation method of the zinc-silver battery composite diaphragm. The composite diaphragm comprises an organic polymer material bottom film and the inorganic coating which is coated on the surface of the organic polymer material bottom film. The organic polymer material bottom film is used for ensuring the flexibility of the diaphragm, and a hydrophilic inorganic material endows the diaphragm with high liquid absorption rate, high oxidation resistance and high alkaline corrosion resistance. Meanwhile, inorganic particles have a function of regulating the aperture size of the composite diaphragm. Film-coating paste is obtained by mixing the inorganic particles, an adhesive, additives and the like, the inorganic coating is coated on the surface of the organic polymer material bottom film, and the composite diaphragm is obtained through a drying process and the like. An inorganic material and a conventional organic polymer material are composited, the advantages of the two materials are integrated, and the defects of a conventional zinc-silver battery diaphragm are overcome. The zinc-silver battery composite diaphragm has the characteristics of simple filming process, low cost, high comprehensive performance and the like, and the large-scale and large-size production of diaphragms is facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite membrane for water treatment, and preparation method thereof

InactiveCN106345318ASimple film making processImprove hydrophilicitySemi-permeable membranesMembranesHydrogen atomCyclodextrin

The invention discloses a composite membrane for water treatment, and a preparation method thereof. The composite membrane comprises a polymer supporting layer and a polyamide active layer, wherein the polyamide active layer comprises polymerized cyclodextrin amine derivatives and polyacyl chloride; and the cyclodextrin amine derivatives comprise at least two substituent groups shown in the formula I, wherein R is a hydrogen atom or organic amine of C1 to C 6. The composite membrane is prepared by performing interfacial polymerization to cyclodextrin amine derivatives and polyacyl chloride, so that the membrane production technology is greatly simplified; the annular cavities of the cyclodextrin amine derivatives are embedded in the polyamide active layer of the composite membrane, so that the permeation resistance of water molecules can be reduced, and the permeation of the polyamide active layer is improved; and the composite membrane with high water throughout and good hydrophilicity can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

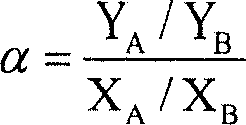

Preparation method of pervaporation film with preferential penetration of dimethyl carbonate

The invention relates to a preparation method of a pervaporation film with the preferential penetration of dimethyl carbonate. Film casting liquid containing vinyl polydimethylsiloxane (Vi-PDMS), hydrogen-containing polydimethylsiloxane (H-PDMS), hydrophobic nano SiO2, a catalyst and a solvent is adopted, a film is coated on an upper layer of a porous ultrafiltration film supported by a polyester non-woven fabric, is aired at room temperature and is also heated, and the cross linkage of the film is finished. An additive type polydimethylsiloxane compound film filled with the hydrophobic nano SiO2, which is obtained by the preparation method of the pervaporation film with the preferential penetration of the dimethyl carbonate, has a simple film preparation process, adopts the materials with low price, strong swelling resistance in dimethyl carbonate / methanol azeotropic liquid, and excellent performance of preferential penetration of the dimethyl carbonate. When the filling mass proportion of the hydrophobic nano SiO2 is 15 percent, the separation factor alpha of the pervaporation film is equal to 3.97, and the penetration flux J is equal to 0.707kg / m2h ([DMC]=30wt%, 40 DEG C).

Owner:TSINGHUA UNIV

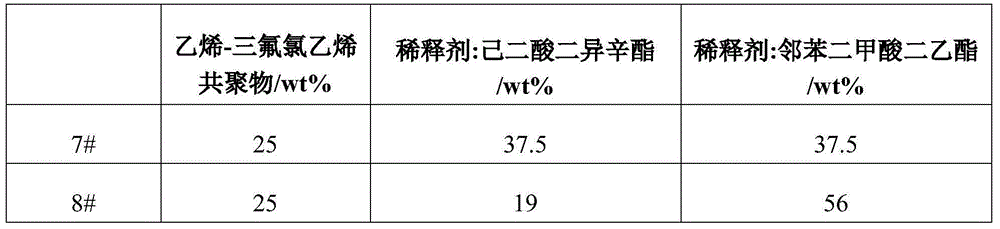

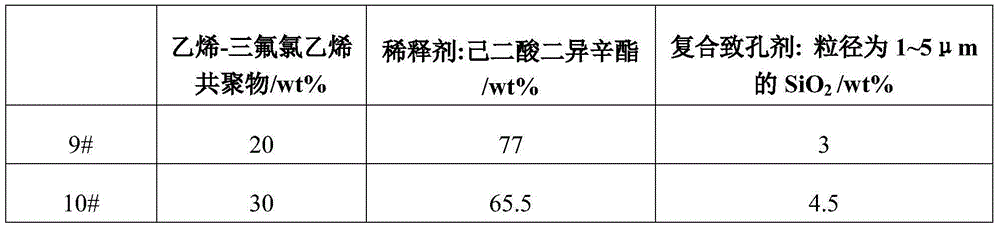

Method for producing polyvinylidene fluoride porous membrane by using composite thinning agent

InactiveCN101138708ASimple film making processMembrane conditions are easy to controlSemi-permeable membranesWater bathsHollow fibre membrane

The present invention relates to a manufacture method of a polyvinylidene fluoride multi-pore membrane and comprises a flat membrane and a hollow fiber membrane. The manufacture method is that the polyvinylidene fluoride and a mixed solvent of a plurality of diluents are added into a dissolving tank; the content of the polyvinylidene fluoride is 20wt-40wt percent, and the content of the mixed solvent is 80wt-60wt percent; the polyvinylidene fluoride and the mixed solvent are mixed and dissolved under a high temperature to form a transparent solution, which is extruded out after deaerated; an air section is cooled down in a water bath to form an initial product; then the diluents are extracted to get the multi-pore product.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

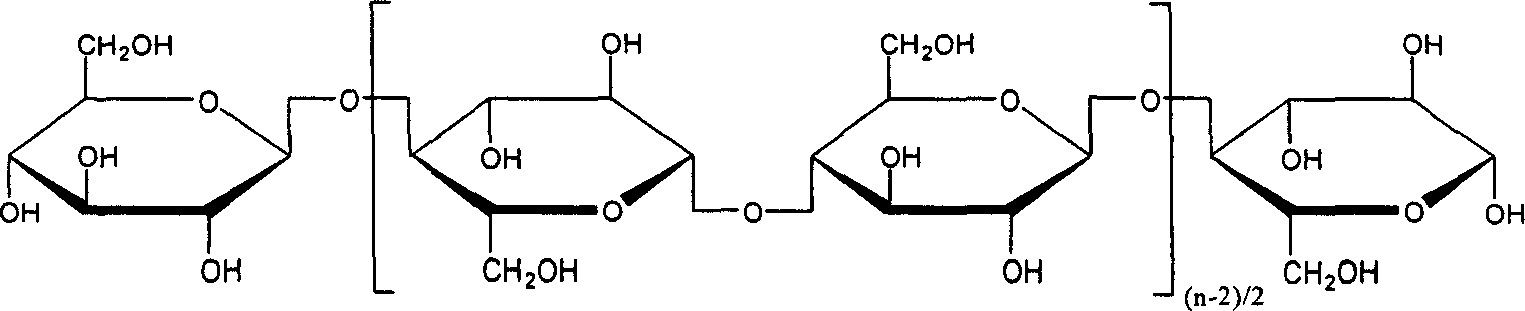

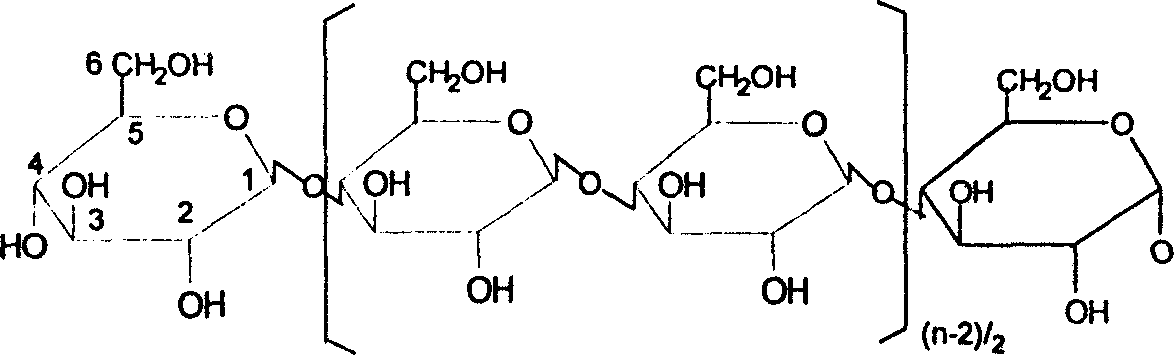

Cellulose asymmetric hollow fiber ultrafiltration membranes and preparation method thereof

InactiveCN101007240AGood chemical stabilityImprove anti-pollution performanceSemi-permeable membranesHollow fibreFiber

A cellulose hollow fiber ultrafiltration membrane with figure-type hole support layer dissymmetrical structure; the process is: 1) mixing, solving and debubbling the NMMO .H2O 88-93wt% with and fiber in 95DEG C to prepare uniform casting film solution which cellulose concentration is 7-12wt%; 2) weaving the residual solvent in films; 4) plasticizing it with 30% -50% glycerol and preparing the wet hollow film. Compared with traditional renewable and modified cellulose film, the crystallinity, mechanical strength, the capabilities of resistance organic solvents, alkali and acid of the hollow film is good, the anti-pollution capability is stronger, and the water treatment prospect is good.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

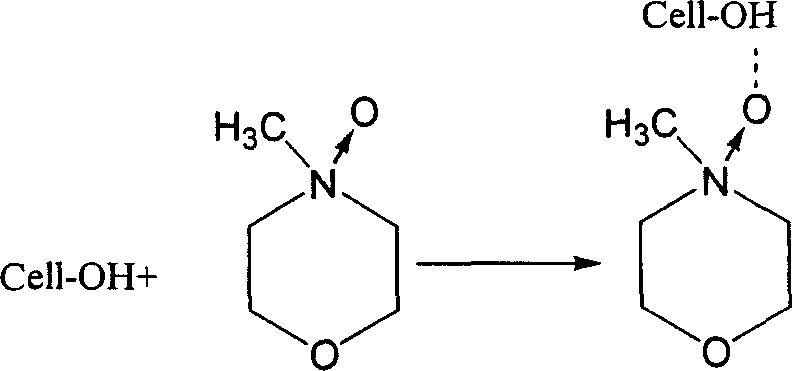

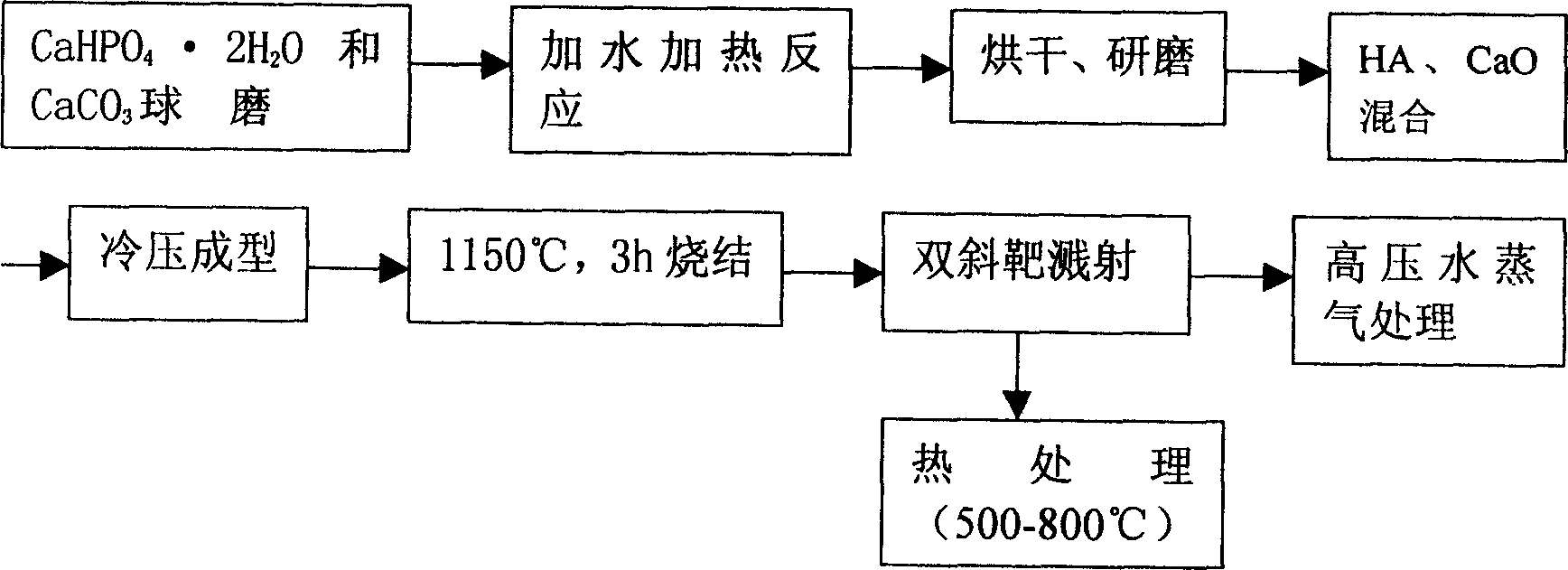

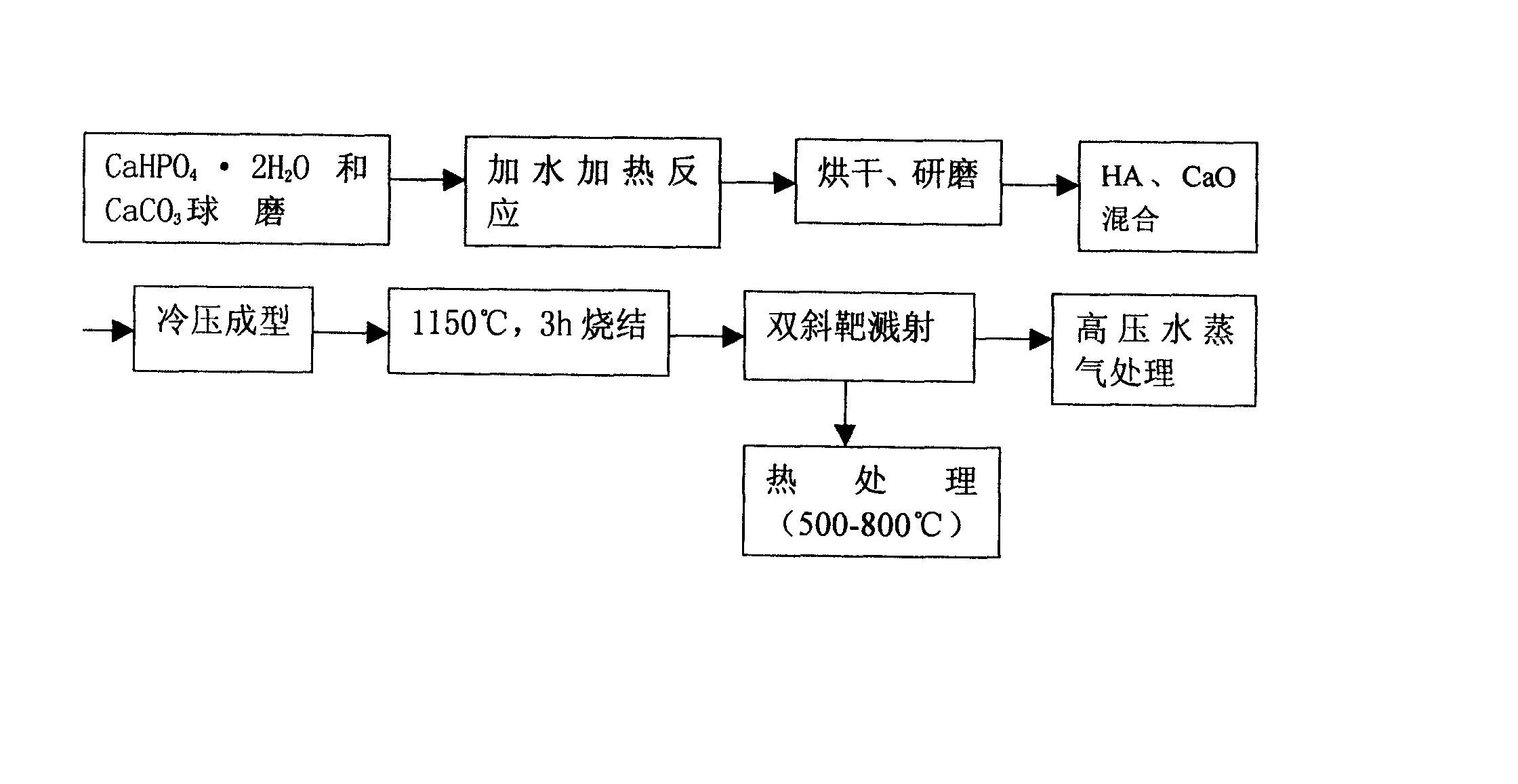

Method and product of sputtering and depositing bioactive gradient hydroxyapatite/Ti layer on Ti alloy surface

InactiveCN1487117AImprove stabilityWeakening interface mutationVacuum evaporation coatingSputtering coatingTitaniumBiological activation

The method of sputtering and depositing bioactive gradient hydroxyapatite / Ti layer on Ti alloy surface includes the following steps: mixing and ball milling material powder; hydrothermal reaction; stoving and grinding; mixing target material; cold pressing at 200-300 MPa to form; sintering; double-inclined target sputtering; and heat treatment of the sputtered film. The product has multilayer structure of Ti alloy matrix, compact transition TiO2 layer I with dispersed hydroxyapatite, TiO2 reinforced transition hydroxyapatite layer II, and porous hydroxyapatite layer. The present invention realizes the double gradient of both component and structure, and raises the interface binding strength effectively. The present invention has simple film preparing process and homogeneous film thickness, is suitable for surface activation of implant with complicated shape, and can prepare hard tissue for clinical need, especially as bearing bone repairing and substituting material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

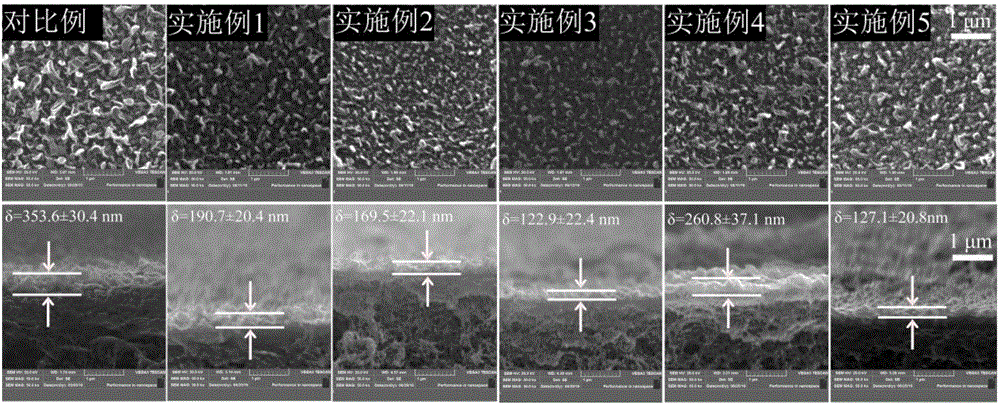

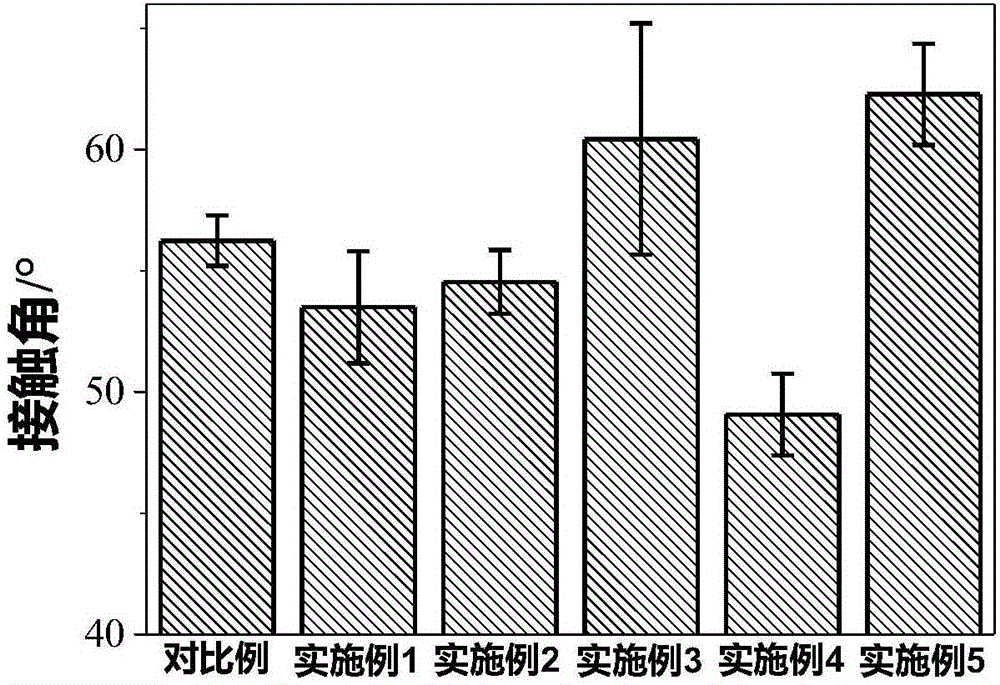

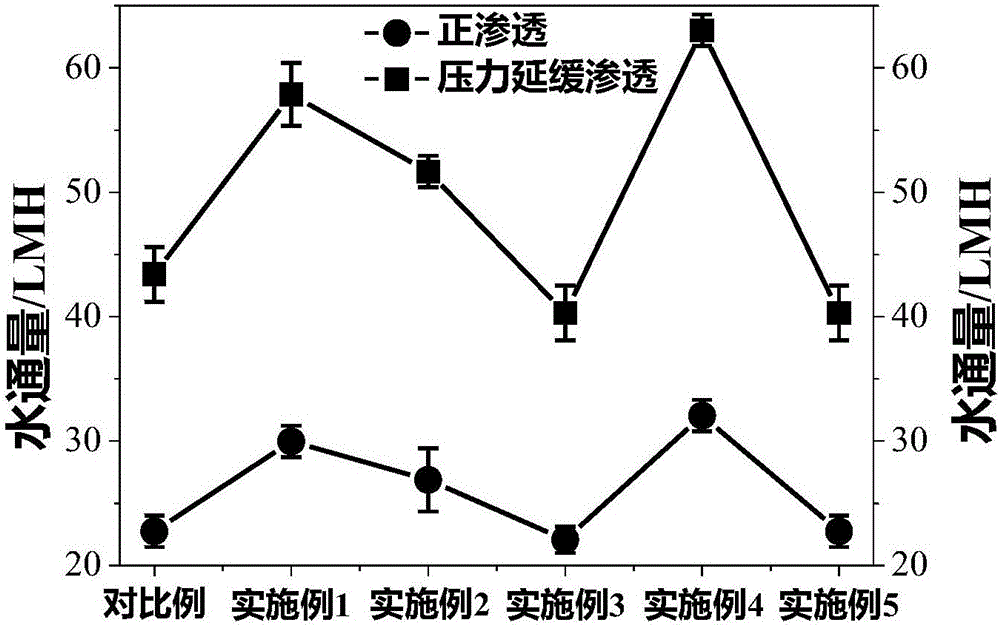

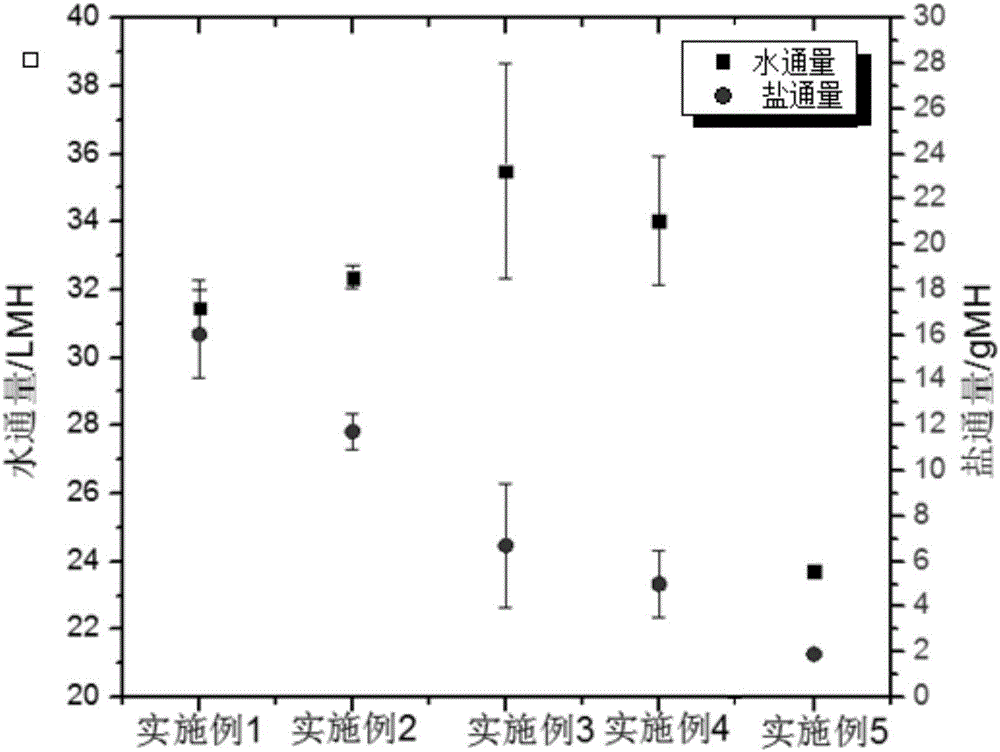

Preparation method of polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane

ActiveCN106731901ATightly boundSolve the problems of easy falling off and complicated multi-program film making processMembranesSemi-permeable membranesWater bathsFiber

The invention discloses a preparation method of a polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane. The preparation method comprises the following steps of confecting a polymer, an organic additive, an inorganic additive and an organic solvent to be homogeneous membrane casting liquid according to a proportion; uniformly coating the membrane casting liquid on the outer wall and an internal pore canal of a polyester fiber braided tube, so as to obtain a braided tube of which the inner wall and the outer wall are coated with membranes; making the membrane coated braided tube pass a certain air residence time and then enter a coagulation bath to carry out phase-inversion membrane formation; soaking a primarily formed membrane in deionized water to remove the residual organic solvent, soaking the primarily formed membrane in a hot water bath, finally, soaking the primarily formed membrane in a glycerol aqueous solution, and then taking out and airing the primarily formed membrane, so that the polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane is made. According to the preparation method, polymer membrane casting liquid is coated on the inner wall and the outer wall of the braided tube in a one-step manner by adopting an immersion precipitation phase inversion method to obtain a high-strength composite hollow fiber forward osmotic membrane; the film making process is simple; the water flux, the selectivity, the hydrophilism, the performance stability and the service life of a membrane are improved by an organic and inorganic blending membrane making method.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Positively charged composite nanofiltration membrane and preparation method thereof

InactiveCN101733024ASeparation performance is differentHigh retention rateSemi-permeable membranesAqueous solutionNanofiltration

The invention discloses a positively charged composite nanofiltration membrane and a preparation method thereof. The positively charged composite nanofiltration membrane consists of a porous support layer and polymer containing two functional groups, namely cations and hydroxyl; and the preparation process comprises the following steps: firstly, obtaining the polymer through free radical copolymerization reaction; secondly, preparing the polymer and a crosslinking agent into aqueous solution with certain concentration; and thirdly, coating the aqueous solution on the support layer, and crosslinking to obtain the composite membrane. The nanofiltration membrane prepared by the method has water flux of between 15 and 30L.m-2.h-1 under the operating pressure of 0.6MPa, has high retention ratio of bivalent cations which can reach 94.3 percent maximally, and has the retention ratio of monovalent cations lower than 60 percent. The prepared positively charged composite nanofiltration membrane has good separation performance; and the method for preparing the membrane is simple and feasible, low in cost and suitable for industrial production.

Owner:ZHEJIANG UNIV

Preparation method of glycine betaine colloid nano particle modified chitosan nanofiltration membrane

ActiveCN103316599AStrong pollution resistanceIncreased permeability selectivitySemi-permeable membranesCross-linkBetaine

The invention discloses a preparation method of a glycine betaine colloid nano particle modified chitosan nanofiltration membrane which comprises a porous polysulfone support layer and a functional layer formed by glycine betaine colloid nano particle modified chitosan. The preparation method comprises the steps of: firstly, carrying out solution polymerization reaction to obtain a glycine betaine colloid nano particle; and then preparing the nano particle, chitosan and a cross-linking agent into a water solution with a certain concentration, dipping one layer of water solution on the surface of the porous polysulfone support layer, and then curing and crosslinking to obtain the nanofiltration membrane. According to the nanofiltration membrane, under the operation pressure of 0.6MPa, the water flux is 25-35L.m<-2>.h<-1>, the retention rate of divalent cations is generally higher than 97 percent, and the retention rate of monovalent salts is lower than 60 percent; meanwhile, the nanofiltration membrane shows good pollution resistance. Therefore, the prepared glycine betaine colloid nano particle modified chitosan nanofiltration membrane has high permeation selectivity and pollution resistance; the preparation method is simple and easy to operate and low in cost, and has a good industrialized application prospect.

Owner:ZHEJIANG UNIV

Gas separation film made of cellulosic hollow fiber and the preparation process thereof

InactiveCN1234448CHigh crystallinityHigh mechanical strengthSemi-permeable membranesDispersed particle separationFiberHollow fibre

A gas separating film of hollow fibers from cellulose and its preparation. The film has an even and compact texture. Solving cellulose directly by the aqueous solution of methyl morpholine oxide, spinning hollow fibers of cellulose by an immersing phase conversion method. The preparation method is:1) mixing 80-93% of MMNO.H2O by weight with cellulose, and debubbling, obtaining a transparent casting-film solution containing 7-20% of cellulose by weight;2) spinning hollow fibers by an immersing phase conversion method;3) wash off residual solvent in the film; 4) drying naturally with the relative humidity of 40%-90%, getting dried hollow film. Compared with traditional regenerative and modified cellulose films, the hollow film is better in crystallization, mechanical strength, capacities of resisting organic solvents, acids and bases, and has great performance in penetrating and separating gases, especially adapts to separate and recycle acidic gases such as CO2 and SO2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation and usage of hollow cellulose gas humidification membrane

InactiveCN1621136AProtective propertiesProtect biocompatibilitySemi-permeable membranesCell electrodesHollow fibrePolymer science

The hollow cellulose fiber gas humidifying membrane is homogeneous compact structure prepared through direct dissolving cellulose with N-methyl morpholine monohydrate as solvent and spinning vian immersing phase converting process. The preparation process includes: dissolving cellulose with 80-93 % concentration MMNO.H2O at 80-110 deg.c and debubbling to obtain membrane forming liquid of 7-20 wt% cellulose concentration; spinning hollow membrane through immersing phase converting process; washing to eliminate residual solvent in the membrane; and drying naturally to obtain dry hollow membrane. The cellulose fiber gas humidifying membrane thus prepared has high crystallization degree, high mechanical strength, high organic solvent, acid and alkali resistance, high water penetrating capacity, and small oxygen and hydrogen osmosing coefficient, and is very suitable for use in gas humidifying system in fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Gas separation film made of cellulosic hollow fiber and the preparation process thereof

InactiveCN1485125AGood osmotic separation performanceProtective propertiesSemi-permeable membranesDispersed particle separationFiberPolymer science

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

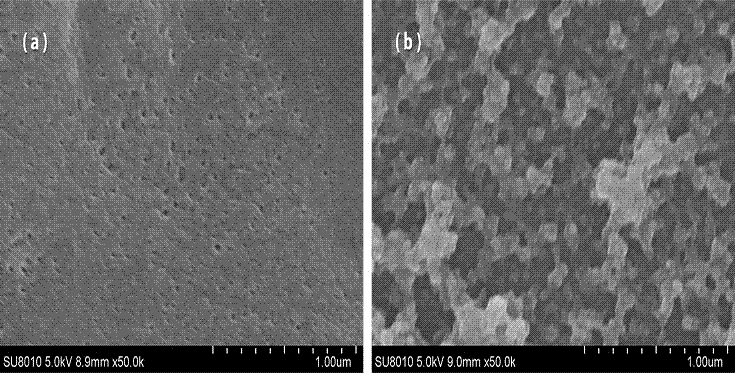

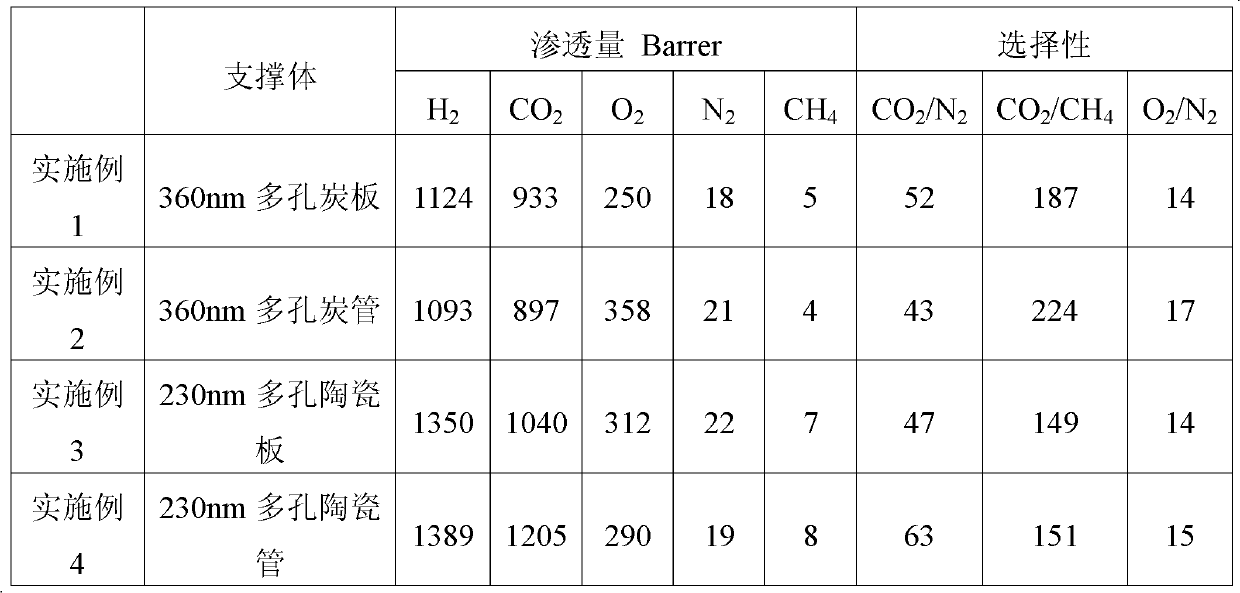

Zeolite imidazate-doped polyether block amide gas separation membrane, and preparation method and application thereof

ActiveCN108097070AThe preparation process is simple and controllableMild conditionsNitrogen purification/separationSemi-permeable membranesPolyamideInorganic materials

The invention discloses a zeolite imidazate-doped polyether block amide (PEBA) gas separation membrane, and a preparation method and application thereof. According to the preparation method provided by the invention, two inorganic nano-materials, i.e. ZIF-8 and Zn / Ni-ZIF-8 are successfully prepared and are mixed and stirred with polyether block amide at 40 to 80 DEG C, and a ZIF-8-PEBA and Zn / Ni-ZIF-8-PEBA mixed matrix membrane is prepared through a dry phase transformation method. The zeolite imidazate-doped polyether block amide gas separation membrane, and the preparation method and the application thereof provided by the invention have the advantages that the preparation method of the inorganic materials is simple, the conditions are mild, the operation is easy, and the inorganic material is environmentally friendly; the prepared membrane is acid and alkali resistant and good in flexibility; the membrane has excellent comprehensive performance when being used for gas separation; particularly, the Zn / Ni-ZIF-8-PEBA mixed matrix membrane with the adding content being 10 percent by weight has high CO2 permeation flux and CO2 / N2 selectivity.

Owner:TAIYUAN UNIV OF TECH

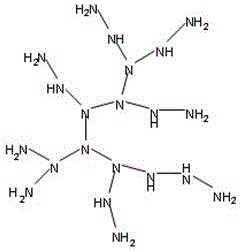

Preparation method of positively-charged hollow polytetrafluoroethylene composite nanofiltration membrane

ActiveCN105854640ACompact structureSmall footprintMembranesSemi-permeable membranesPolymer scienceOrganosolv

The invention discloses a preparation method of a positively-charged hollow polytetrafluoroethylene composite nanofiltration membrane. The method includes the following steps of injecting a carboxylation chitosan aqueous solution into a hydrophobic polytetrafluoroethylene hollow fiber membrane through an injector to obtain an active base membrane, injecting a hyperbranched polyethylenimine aqueous solution into the active base membrane to obtain a middle membrane 1, injecting acyl chloride monomer organic solvent into the middle membrane 1 to obtain a middle membrane 2, injecting deionized water into the middle membrane 2, and putting the middle membrane into a drying box to be dried to obtain the positively-charged hollow polytetrafluoroethylene composite nanofiltration membrane. Reactivity of carboxylation chitosan, hyperbranched polyethylenimine and acyl chloride monomer is adopted, and the membrane preparation process is simple. In addition, due to the unique molecular structure of hyperbranched polyethylenimine, the prepared composite nanofiltration membrane is positively charged, has the advantage of being high in reject rate and can be used for the fields of water treatment and the like.

Owner:广州市东泓氟塑料股份有限公司

Formula for preparing fluorocopolymer porous membranes and method for preparing porous membranes according to formula

ActiveCN104607062ALow film forming temperatureSuitable for industrial implementationMembranesSemi-permeable membranesHollow fibreFiber

Owner:苏州孝义家光电科技有限公司

Method for preparing mesoporous ceramic membrane based on novel two-dimensional material

ActiveCN108097064APrevent infiltrationModify macroporous defectsSemi-permeable membranesBrickRepeatability

The invention relates to a method for preparing a mesoporous ceramic membrane based on a novel two-dimensional material. The method comprises the following steps: introducing the novel two-dimensionalmaterial into sol and carrying out uniform dispersion to prepare coating liquid; and coating a support body with the prepared coating liquid in a one-shot coating manner so as to prepare the mesoporous ceramic membrane with bore diameters of 2 to 10 nm. According to the invention, the novel two-dimensional flaky material and sol particles or a sol polymer are assembled to form a brick structure so as to reduce capillary pulp suction effect and modify macroporous defects on the surface of the support body, so inward infiltration of sol is effectively prevented, and water permeation flux is increased; and gel toughening effect is obtained, and the cracking defect of the membrane is effectively avoided. The preparation method provided by the invention is simple in process, short in preparation period, good in repeatability and high in permeation flux; and the method can realize high-efficiency preparation of the mesoporous ceramic membrane and is suitable for mass production.

Owner:NANJING UNIV OF TECH

Preparation method of polyethylene imine/sodium lignin sulfonate composite membrane

InactiveCN107261871AGood separation performanceSimple film making processReverse osmosisUltrafiltrationIon

The invention discloses a preparation method of a polyethylene imine / sodium lignin sulfonate composite membrane. The preparation method includes: using a polysulfone ultrafiltration membrane with an electronegative surface as the base membrane, polyethylene imine and sodium lignin sulfonate are sequentially self-assembled to the base membrane to form a self-assembled composite layer, and the self-assembled composite layer is allowed to form a structurally-stable composite layer through glutaraldehyde crosslinking. The preparation method has the advantages that the electrostatic interaction among electrolyte with different charges is utilized to allow cation and anion polyelectrolyte to attach to the surface of the polysulfone ultrafiltration membrane, and layer-by-layer self-assembling of the polyelectrolyte is achieved; when the number of polyelectrolyte double-layers is 7, and composite nanofiltration membrane has good separation performance.

Owner:BEIJING FORESTRY UNIVERSITY

Dimethylpolysiloxane composite membrane and preparation method and application thereof

InactiveCN109621754AEasy to separateSimple film making processDistillationModified carbonMetal-organic framework

The invention discloses a dimethylpolysiloxane composite membrane and a preparation method and application thereof, and belongs to the field of membrane separation. The dimethylpolysiloxane compositemembrane comprises a mixed substrate layer, the mixed substrate layer is a membrane which is formed by porous hybrid material doped dimethylpolysiloxane after the dimethylpolysiloxane is cured, a porous hybrid material is the hybrid material of a metal organic framework material and a carboxyl group modified carbon material, and the metal organic framework material is connected with the carboxyl group modified carbon material through hydrogen bonds. The dimethylpolysiloxane composite membrane comprises a supporting layer, any of the surfaces of the supporting layer is coated with the mixed substrate layer, the supporting layer is a polymeric membrane, the supporting layer is non-woven fabric or the supporting layer is non-woven fabric which is coated with the polymeric membrane. Accordingto the dimethylpolysiloxane composite membrane, the composite membrane is prepared through a solution blending method, a membrane preparation technology is greatly simplified, inorganic particle aggregation is not caused, and the content of organic solvent separation factors of the obtained composite membrane is high.

Owner:HUAZHONG UNIV OF SCI & TECH

ZSM-5 molecular sieve filled silicon rubber/cellulose acetate composite membrane and preparation method thereof

InactiveCN101816897ALow priceTo achieve the separation effectSemi-permeable membranesCellulose acetateEvaporation

The invention relates to a ZSM-5 molecular sieve filled silicon rubber / cellulose acetate composite membrane and a preparation method thereof. In the composite membrane, a cellulose acetate support membrane is used as a support layer, and the composite membrane also comprises the following components in parts by weight: 2-20 parts of ZSM-5 molecular sieve, 3-15 parts of cross-linking agent and 100 parts of silicon rubber. The preparation method comprises the following steps of: preparing materials, pretreating the molecular sieves, preparing a membrane casting solution, pretreating the support membrane and forming a membrane. Compared with the prior art, a penetration and evaporation membrane is prepared by adopting the ZSM-5 molecular sieves, the silicon rubber and the cellulose acetate, and the composite membrane preferentially permeates aldehyde and can be used for removing the aldehyde in waste water by a pervaporation method so as to achieve a separation effect. The composite membrane has the advantages of small pollution, low energy consumption, high efficiency, and the like, and meanwhile, the composite membrane has higher selectivity and flux. Moreover, the membrane preparation process is reasonable and simple, and the selected materials have low price and low production cost, thus the composite membrane has wide application range.

Owner:TONGJI UNIV

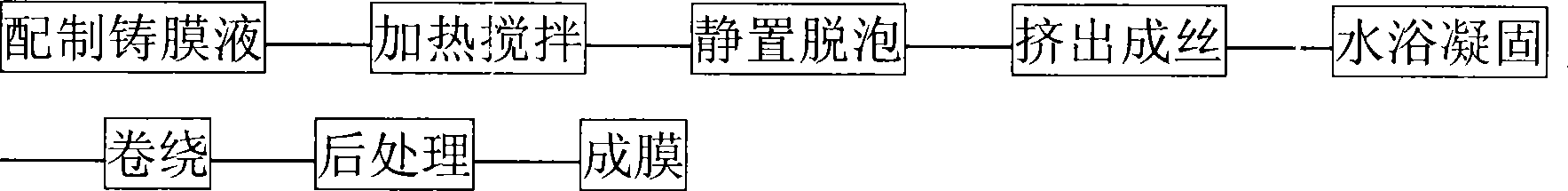

Method for preparing hollow fiber hyperfiltration membrane with low molecular weight cut-off

InactiveCN101497005ASimple film making processLow costSemi-permeable membranesHollow fibreDimethyl formamide

The invention relates to a method for preparing a macromolecular ultrafiltration membrane. The method for preparing a low trapped molecular weight hollow fibre ultrafiltration membrane comprises the following steps: (1) preparation of a casting membrane liquid: the method uses polysulfone as a raw material, dimethylfomamide or dimethylacetamide as a solvent and polyvinylpyrrolidone as an additive to prepare the casting membrane liquid, wherein each composition has the following mass percentage: 15 to 40 percent of the polysulfone, 50 to 80 percent of the dimethylfomamide or dimethylacetamide and 5 to 20 percent of the polyvinylpyrrolidone; and the casting membrane liquid is heated and stirred at a temperature of between 30 and 80 DEG C so that each composition is fully dissolved, sealed, kept stand and defoamed; (2) membrane forming: the casting membrane liquid prepared in the step (1) passes through a spinning plate, injected to a heating water bath through the distance of an air section and condensed to form the hollow fibre ultrafiltration membrane; and (3) posttreatment: the hollow fibre ultrafiltration membrane prepared in the step (2) is soaked in a mixed solution of glycerin, Tween-80 and water.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

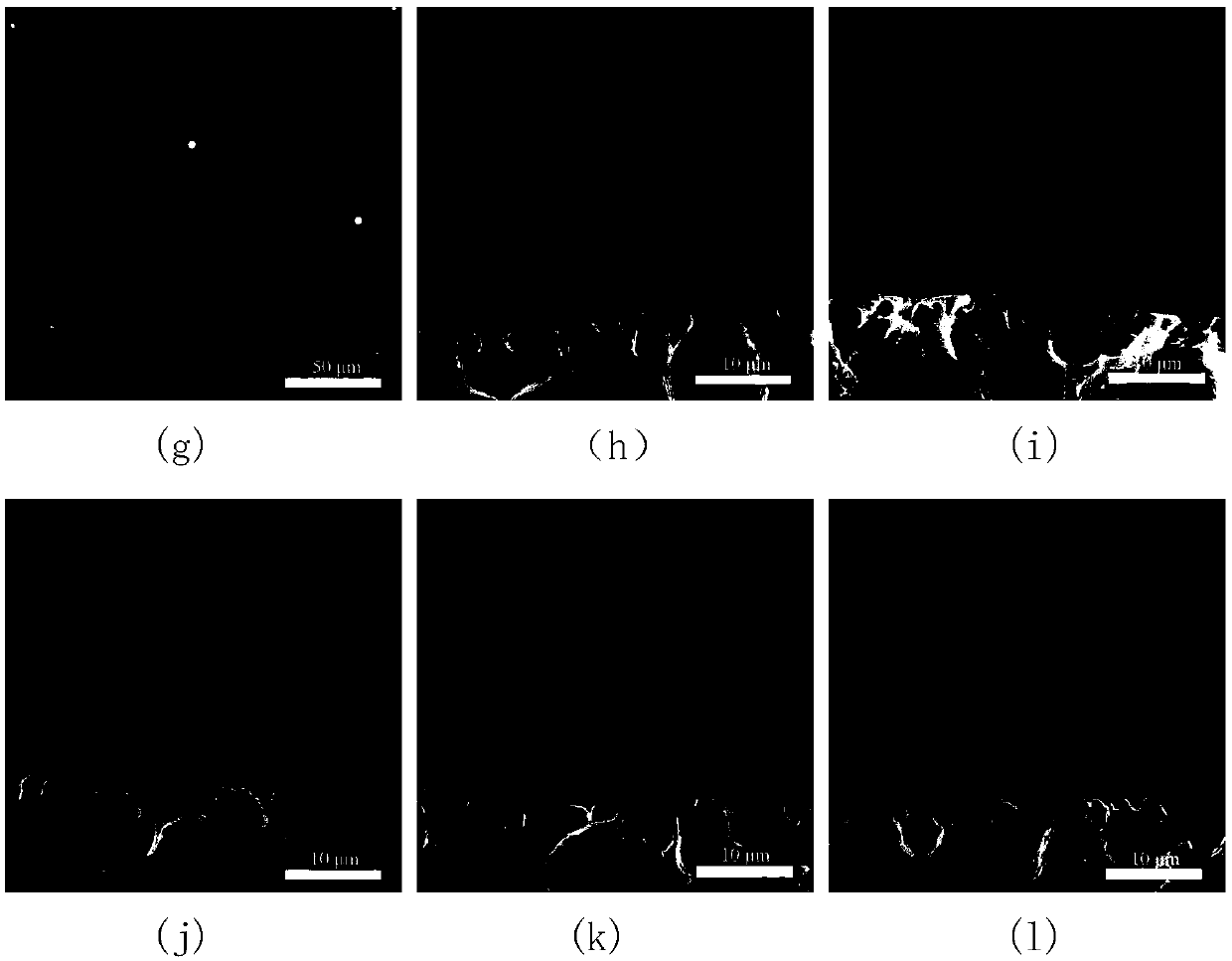

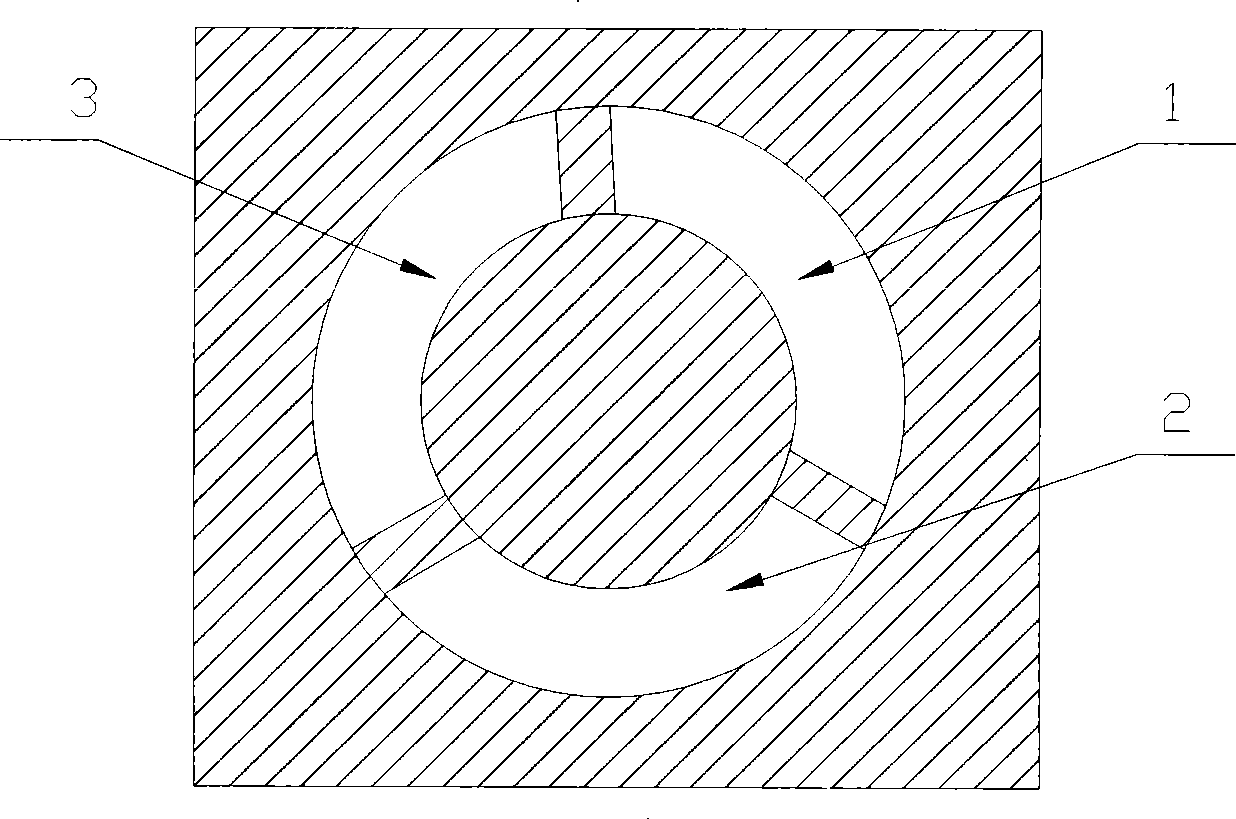

Composite carbon diaphragm with mesoporous and microporous gradient structure and preparation method for diaphragm

ActiveCN102580567AAvoid big dropsSimple film making processSemi-permeable membranesMicrometerGas separation

The invention relates to a composite carbon diaphragm with a mesoporous and microporous gradient structure and a preparation method for the diaphragm. The composite carbon diaphragm with the mesoporous and microporous gradient structure consists of a porous support body, a mesoporous intermediate layer and a surface separation layer, and is characterized in that the pore diameter of the porous support body is 100 to 500 nanometers, the breaking strength is 2 to 15MPa, and the anti-explosion strength is 3 to 10MPa; the pore diameter of the mesoporous intermediate layer is 2 to 10 nanometers, the specific surface area is 400 to 1,000 m<2> / g, the porosity is 30 to 50 percent, and the thickness is 1 to 10 micrometers; and the pore diameter of the surface separation layer is 0.3 to 0.5 nanometer, the specific surface area is 300 to 600 m<2> / g, the porosity is 20 to 40 percent, and the thickness is 0.1 to 5 micrometers. By the composite carbon diaphragm with the mesoporous and microporous gradient structure, the phenomenon that the gas separation performance of the composite carbon diaphragm is greatly reduced due to the defect of the surface of the support body is avoided, and the permeability of the prepared composite carbon diaphragm is improved obviously on the basis of keeping high gas separation selectivity.

Owner:DALIAN UNIV OF TECH

Preparation method of positively charged nanofiltration membrane

ActiveCN106621841AHigh desalination rateImprove throughputSemi-permeable membranesMembranesHydrophilic hydrophobicNanofiltration

The invention relates to a preparation method of a positively charged nanofiltration membrane. The preparation method comprises the steps of preparation of a pretreatment base membrane, preparation of a coating solution, coating and solidifying. The positively charged nanofiltration membrane has good stability and leaching resistance. According to the preparation method, the charge performance and the hydrophilic-hydrophobic property of the positively charged nanofiltration membrane can be improved through adjusting components and proportions of a copolymer monomer and the water flux of the positively charged nanofiltration membrane can be effectively improved. The preparation method of the positively charged nanofiltration membrane is simple, the production cost is low, the used functional polymer material is simple and available and has a good industrial application prospect.

Owner:BEIJING ORIGIN WATER FILM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com