Manufacture and products of hollow fiber membrane of outer pressured polyvinylidene fluoride by immersion gelation

A polyvinylidene fluoride and fiber membrane technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of affecting the mechanical properties and service life of hollow fibers, hollow fiber membranes are easy to be crushed, and manufacturing Difficult preparation of membrane solution, etc., to avoid melting difficulties, easy control of the process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: 18% (wt) polyvinylidene fluoride resin with brand name FR904 (weight average molecular weight: 800,000 Daltons) produced by Shanghai Sanaifu Materials Co., Ltd. was selected, and the intrinsic viscosity was 1.95. The (PVP) polyvinylpyrrolidone K-30 (weight-average molecular weight 45,000 Daltons) produced by Shanghai Shengpu New Material Co., Ltd. is 12.5% (wt), and the polyethylene glycol PEG-600 imported from Japan is 8% (wt). Tween-80 imported from Japan is 1.5% (wt), lithium nitrate 0.5% (wt), N-methylpyrrolidone 29.5% (wt) produced by Shanghai Chemical Reagent Company, 30% dimethylacetamide produced by BASF (wt), put the above substances (see Table 1) into the dissolution tank in order, stir at 85°C to obtain a uniform film-forming solution, circulate and degas the film-forming solution at 80°C, and keep the film-forming solution passing through at 80°C Double casing spinneret, which is sprayed together with the composite support liquid in the center t...

Embodiment 11

[0041] Embodiment 11: select polyvinylidene fluoride resin 18% (wt) of FR904 (weight average molecular weight 800,000 Daltons) produced by Shanghai Sanaifu Materials Co., Ltd. (PVP) produced by Shanghai Shengpu New Material Co., Ltd. Polyvinylpyrrolidone (weight-average molecular weight 45,000 Daltons) 12.0% (wt), Nanjing Jinlong Chemical Plant (weight-average molecular weight 1,000,000 Daltons) polyvinylpyrrolidone 0.5%, polyethylene glycol PEG-600 imported from Japan 8% (wt), Tween-80 1.5% (wt) imported from Japan, lithium nitrate 0.5% (wt), N-methylpyrrolidone 29.5% (wt) produced by Shanghai Chemical Reagent Company, dimethyl pyrrolidone produced by BASF Base acetamide 30% (wt), put the above substances into the dissolution tank in order, stir at 85°C to obtain a uniform film-forming liquid, circulate and degas the film-forming liquid at 80°C, and keep the film-forming liquid at 80°C The double-tube spinneret is ejected together with the composite support liquid in the cent...

Embodiment 12

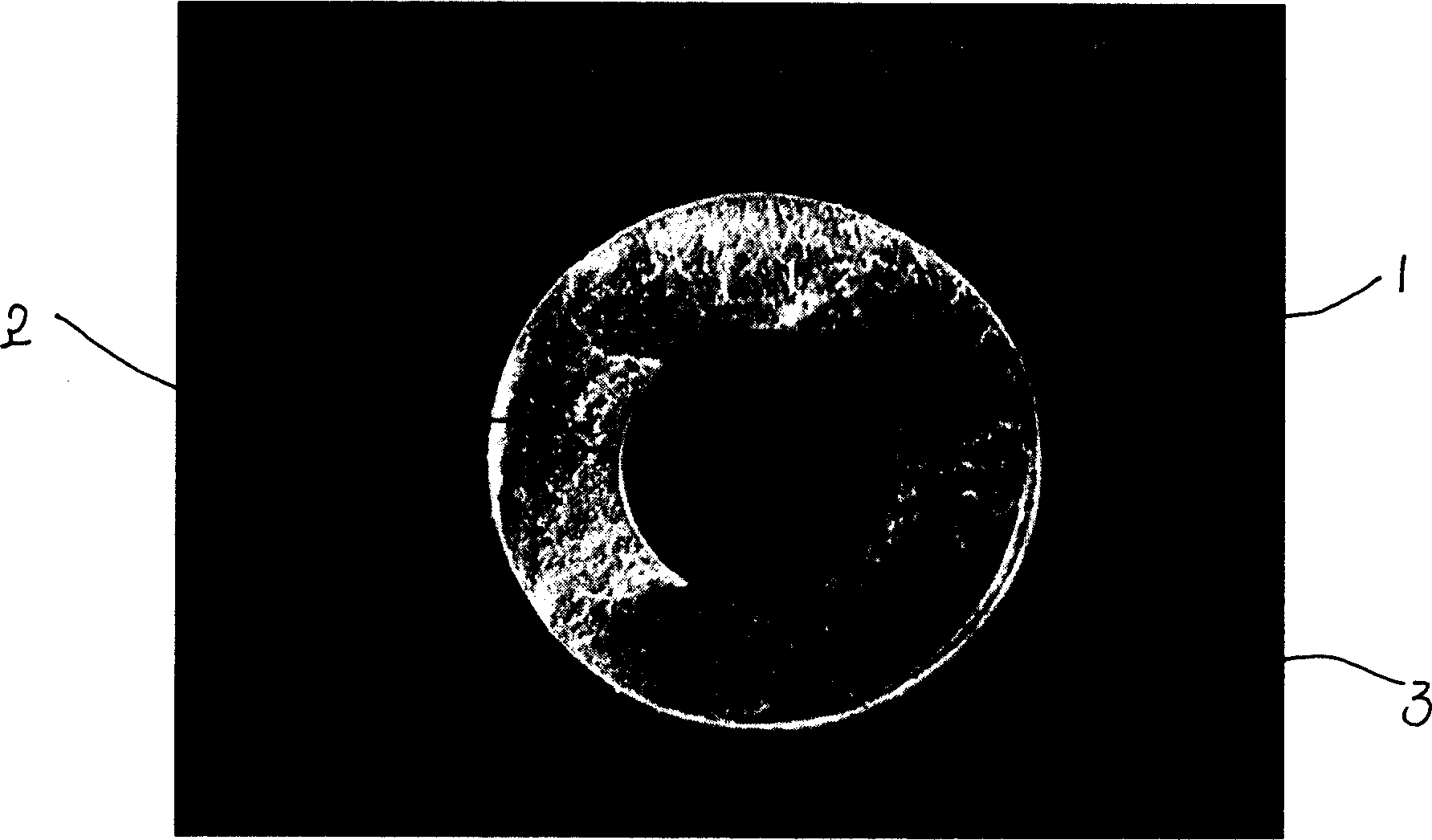

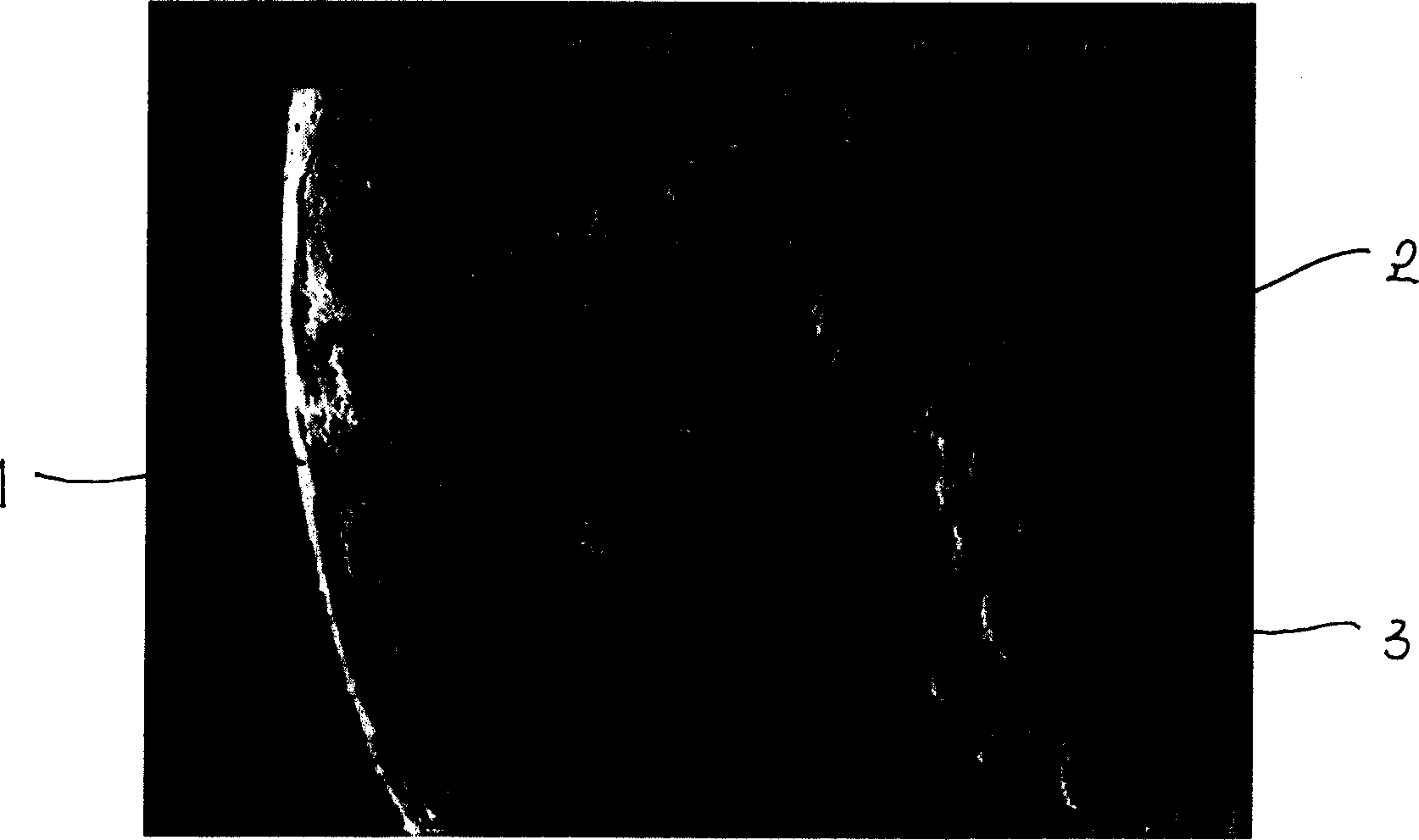

[0042] Embodiment 12: select the polyvinylidene fluoride resin 20.5% (wt) that Japan Kureha Chemical Industry Co., Ltd. produces the grade to be 1700 (weight average molecular weight 500,000 Daltons), produced by Shanghai Shengpu New Material Co., Ltd. (weight average molecular weight 45000 Dal) polyvinylpyrrolidone 9.5% (wt), polyethylene glycol PEG-400 (imported from Japan) 12% (wt), emulsifier 1.0% (wt), chemical reagent lithium chloride 0.5% (wt), BASF Dimethylacetamide 56.5% (wt) produced by the company, the above-mentioned material is made into a film according to the method of Example 1, and after about 0.02 seconds of evaporation, it enters the primary immersion solution of 60% (wt) polyvinylidene fluoride resin solvent In 1.5 seconds, by pulling into 30% (wt) polyvinylidene fluoride resin solvent secondary gel solution for precipitation for 30 seconds, the obtained hollow fiber external pressure ultrafiltration membrane double skin layer, the membrane cross section pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com