Patents

Literature

877results about How to "Process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular sieve based catalysts, preparation method and application thereof in crylic acid preparation by lactic acid dehydration

InactiveCN101602010AExtended service lifeReduce energy consumptionMolecular sieve catalystsOrganic compound preparationPhosphateAcid preparations

The invention discloses a molecular sieve based catalyst, a preparation method and an application thereof in crylic acid preparation by lactic acid dehydration. The method comprises the following steps: processing the ZSM-5 molecular sieve in aqueous alkali, or adopting an impregnation method to support phosphate, drying, roasting and finally obtaining the modified molecular sieve based catalyst. The catalyst realizes the reaction of crylic acid preparation by lactic acid dehydration in low temperature and has the advantages of high lactic acid conversion rate and crylic acid selectivity, and long-life of catalyst, the conversion rate of lactic acid dehydration reaction is 100%, and crylic acid selectivity can reach as high as 83.9%, thus having good industrial application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

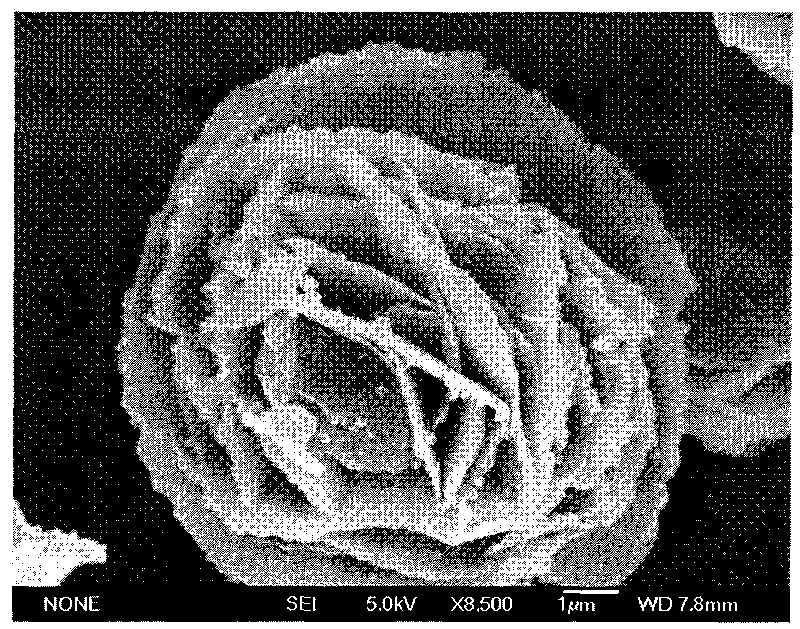

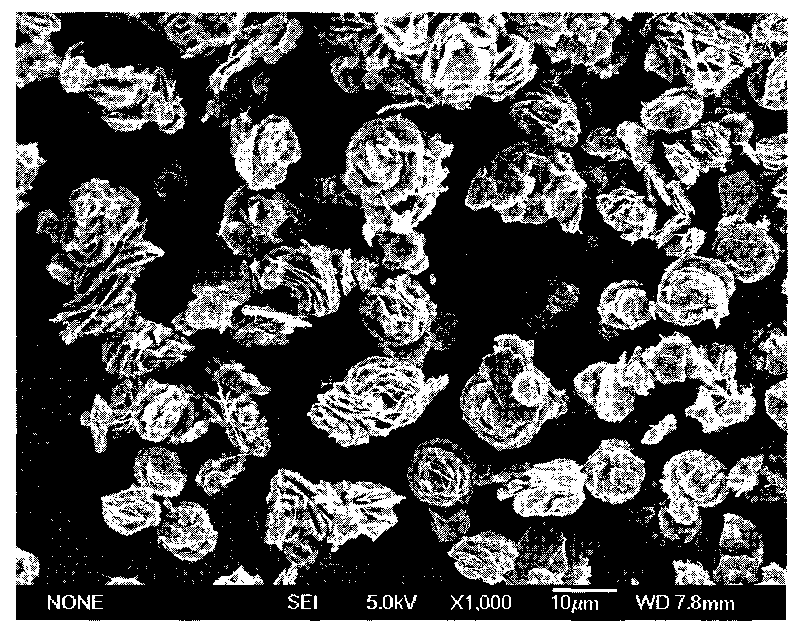

Lithium ion battery conductive additive and preparation method thereof

InactiveCN101997120AImprove performanceImprove conductivityCell electrodesAluminium-ion batteryLithium-ion battery

The invention discloses a lithium ion battery conductive additive and a preparation method thereof, and solves the technical problems of improving the conductive performance and cycle life of anode and cathode materials of a lithium ion battery. The lithium ion battery conductive additive is graphene, is black powder with grain size distribution of between 10 nanometers and 100 microns, and is a carbonaceous material consisting of single or 1,000 parallel or approximately parallel graphene lamellae. The preparation method comprises oxidization and stripping reduction. Compared with the prior art, the additive has higher electric conductivity; when the additive is applied to the electrode material, the performance of the conventional battery can be greatly improved only by a little amount; the material serving as the conductive additive has good conductive performance, is easy for dispersion, and can effectively enhance the conductive performance and the magnification charging and discharging performance of the electrode material of the lithium ion battery and prolong the cycle life; and the preparation method has low requirements for raw materials and equipment, is easy to control the process, and is suitable for industrialized production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH +1

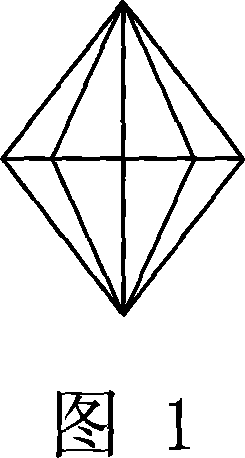

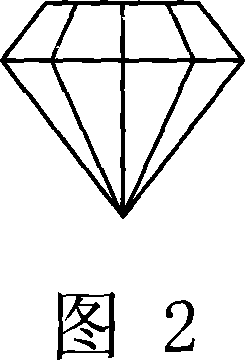

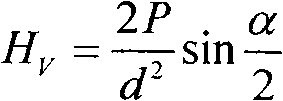

Method for polishing and grinding hydrant drill end and special polishing grinder

ActiveCN101073876AImprove processing efficiencyImprove qualityEdge grinding machinesConvex sideEngineering

The invention is concerned with simulation diamond end face polishing-grinding machining method and the expert polishing-grinding machining. Set stuff and put molding plastics-absorption tray on fixture tray and make the concave face of plastics-absorption tray upside, and the simulation diamond adsorbs on the convexity of the bottom to plastics-absorption tray. Set plastics-absorption tray on the polishing-grinding machining and mill the tine end of simulation diamond on calm millstone. The polishing-grinding machining relates rack with a level millstone at its middle, and there are two level trays. They are centrosymmetric to the axis of millstone on top of millstone and have plastics-absorption tray on them. There is up and down equipment for tray on top of level tray which connecting with two turning axes on two sides of millstone with level rack, and the other end of turning axis has running equipment of turning axis. It has large machining amount of each time, high produce efficiency, good ratio to excellent stuff, long work time, easy operation without waste of material.

Owner:虞雅仙

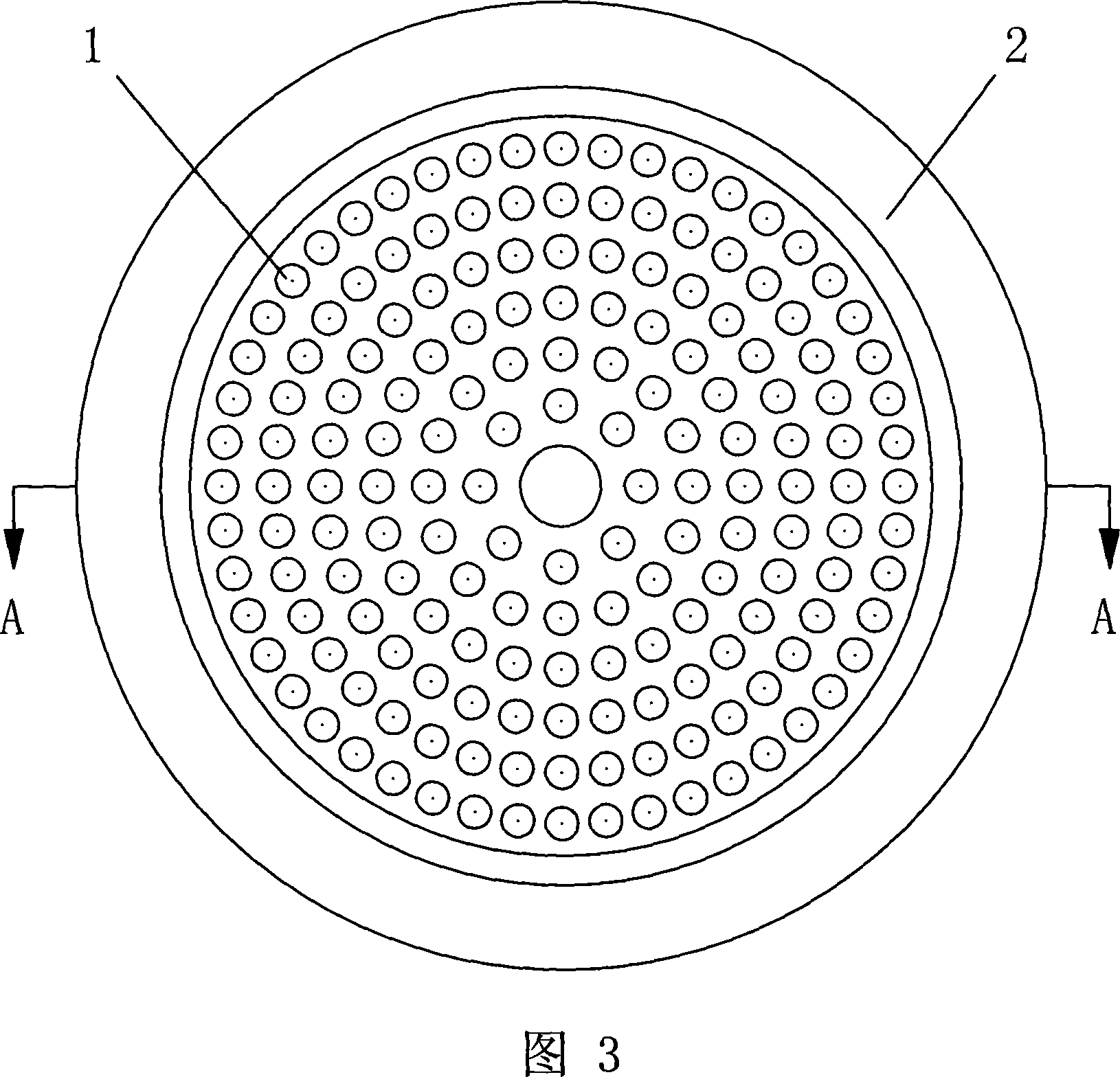

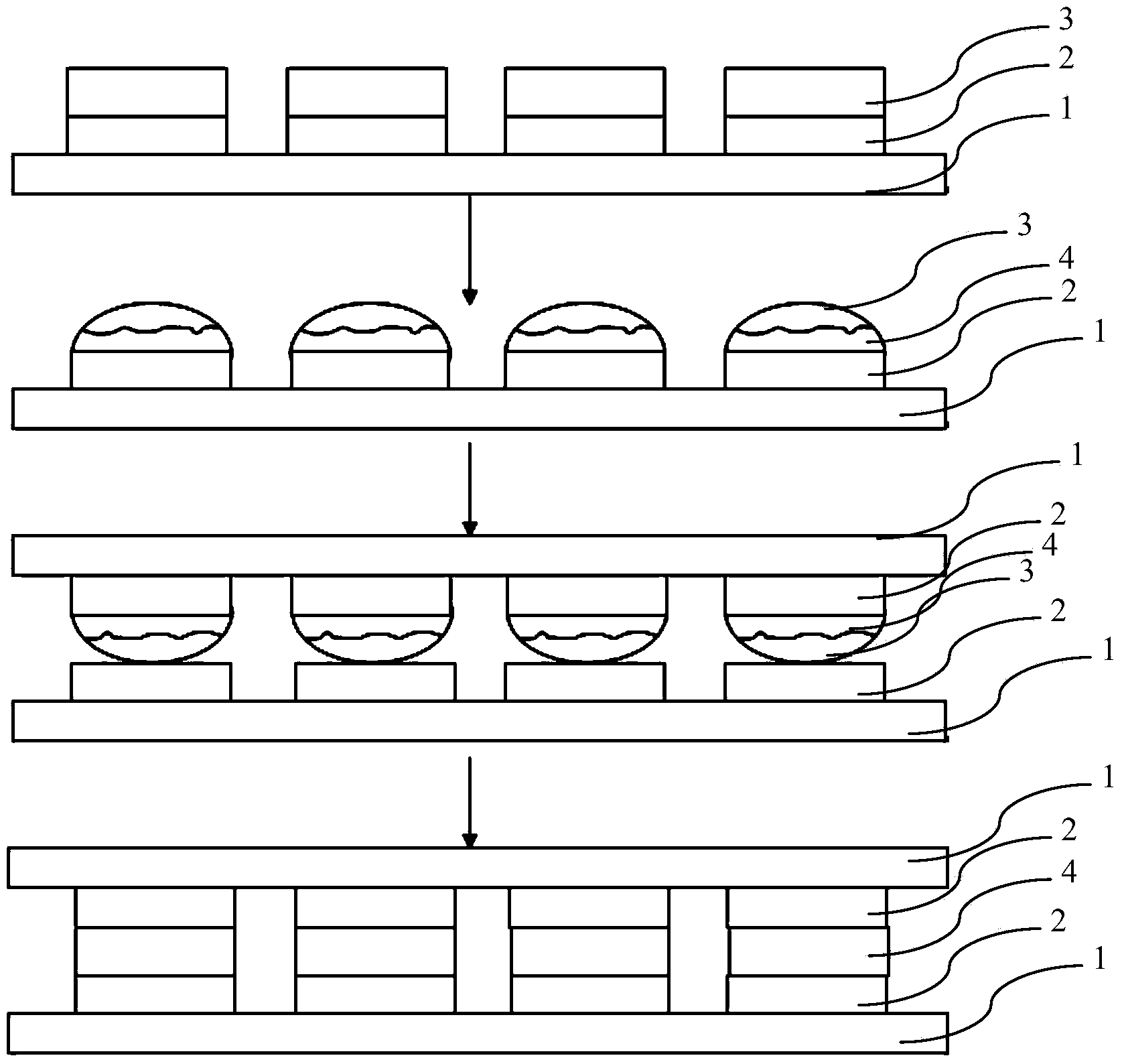

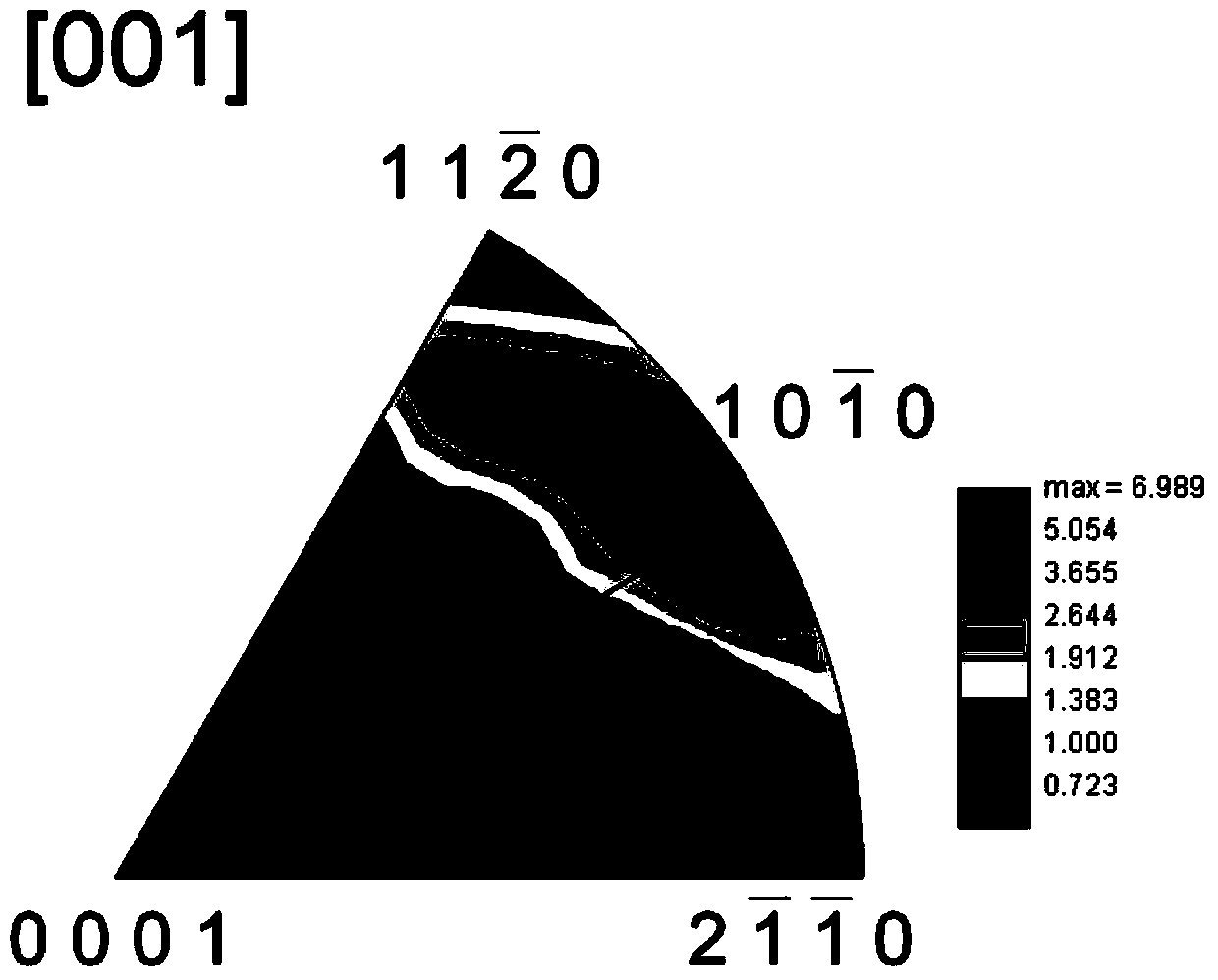

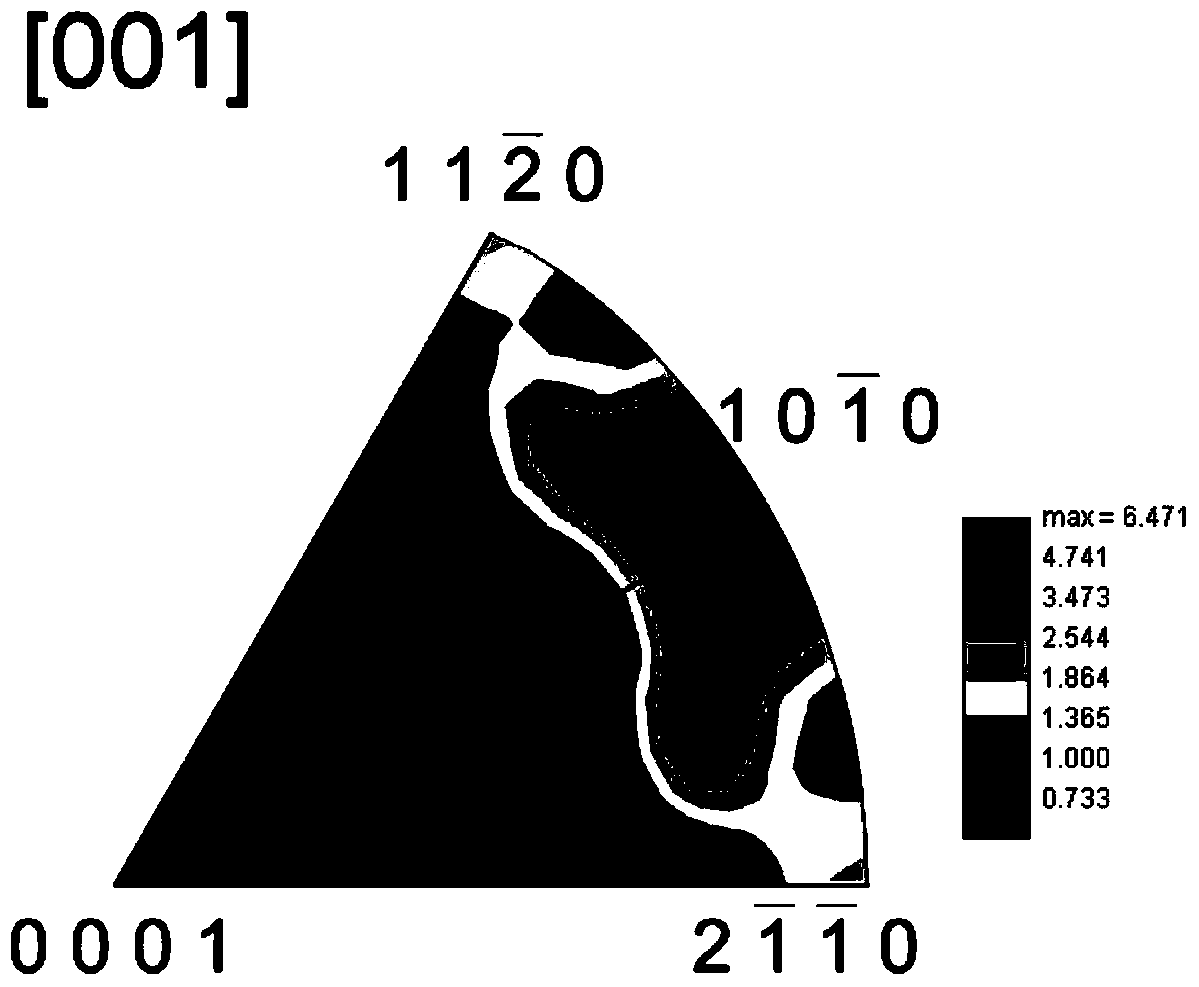

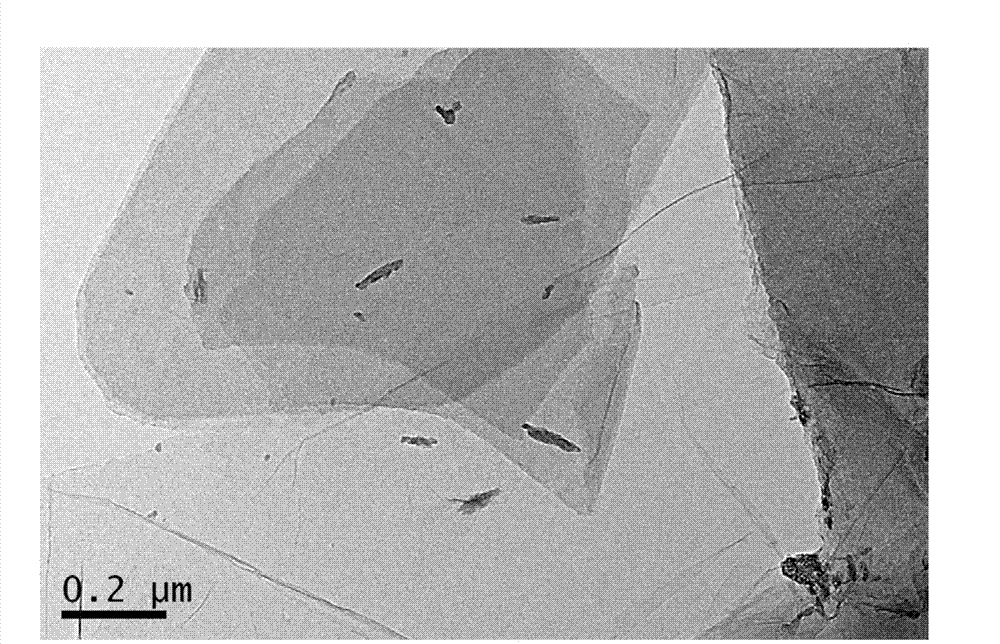

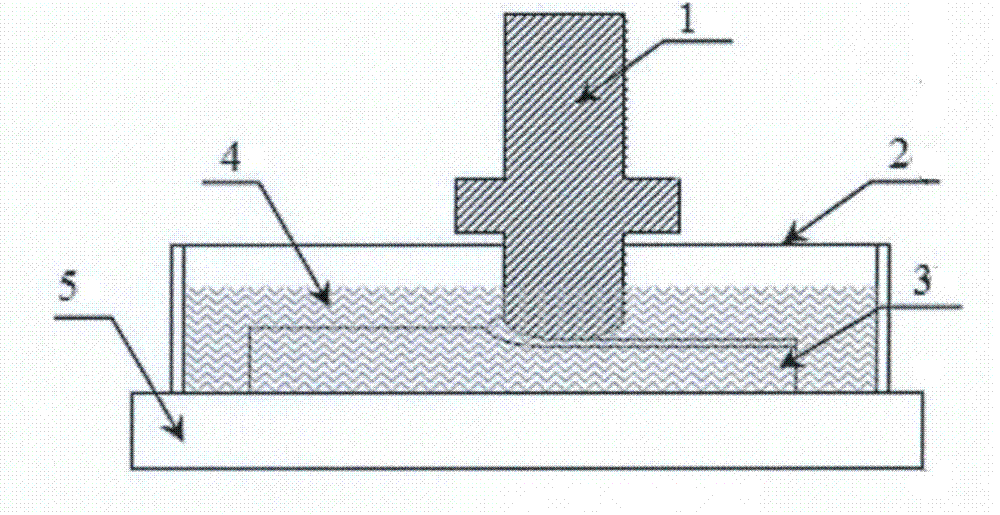

Method for preparing and applying single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure

ActiveCN103658899AAvoid premature failureUniform orientation distributionSolid-state devicesSemiconductor/solid-state device manufacturingProcess conditionsIntermetallic

The invention provides a method for preparing and applying a single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure. The method for preparing the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure comprises the first step of arraying a Cu welding disc on a wafer through the electroplating technology, the second step of manufacturing bosses by preparing brazing filler metal prepared on the Cu welding disc, the third step of carrying out hot-wind remelting on the manufactured bosses for 30s-120s, the fourth step of carrying out solid-phase aging processes on chips obtained in the third step, the fifth step of placing the welding point bosses prepared in the fourth step into hydrochloric acid, oscillating the welding point bosses through ultrasound, washing and drying the welding point bosses to obtain a preferred orientation Cu6Sn5 welding disc, the sixth step of reversely buckling the welding point bosses prepared in the fifth step into a corresponding circuit board Cu metal layer, and obtaining the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure through the reflow welding technology. Uniform and stable welding point structure can be obtained when the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure is applied to large two-level packaging at the appropriate conditions.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +3

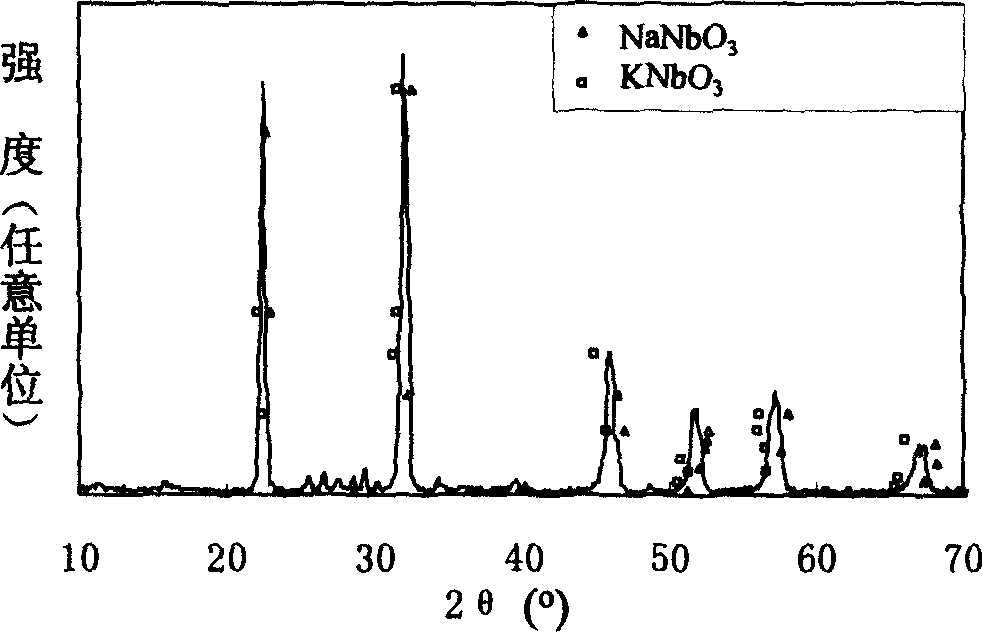

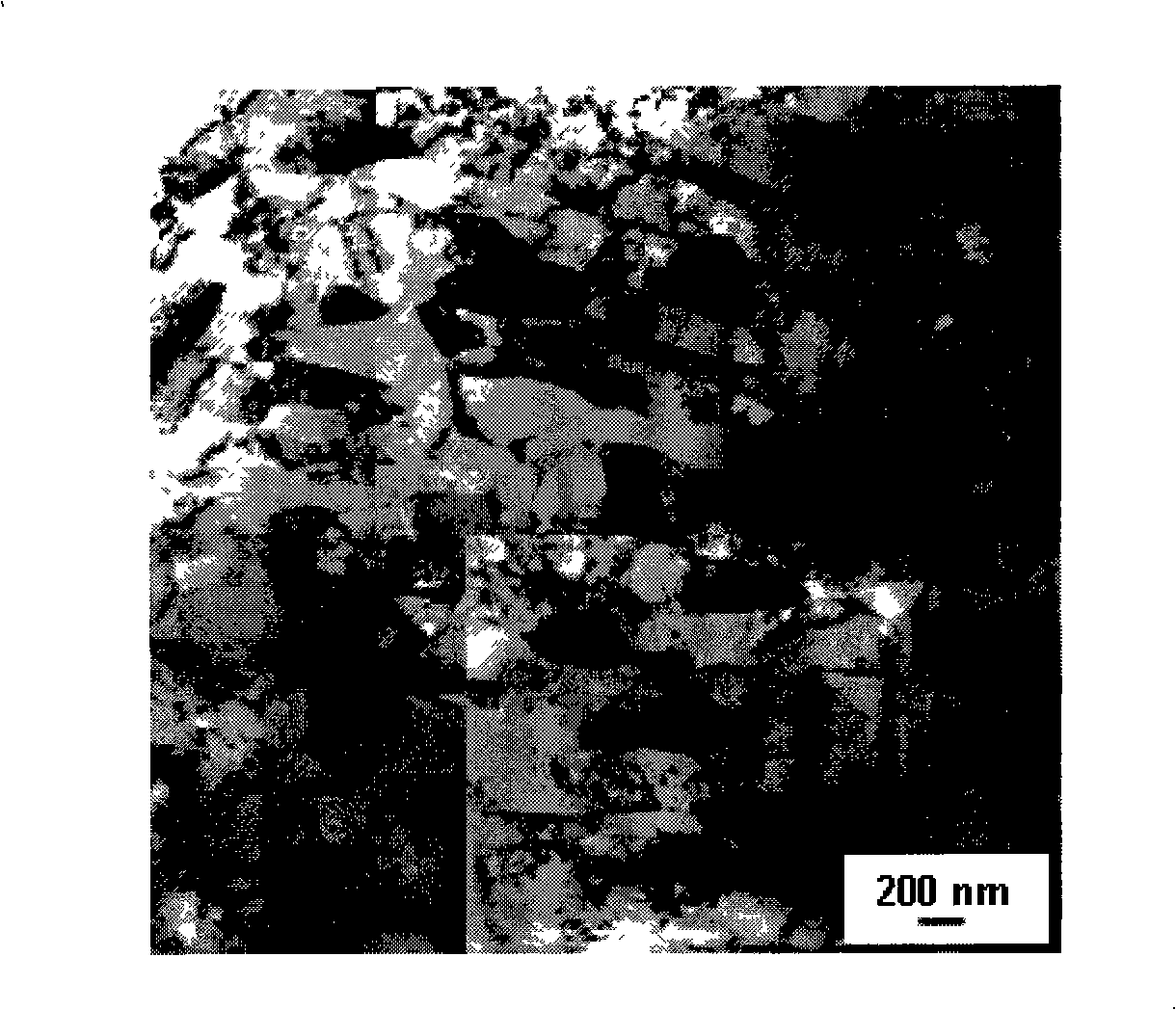

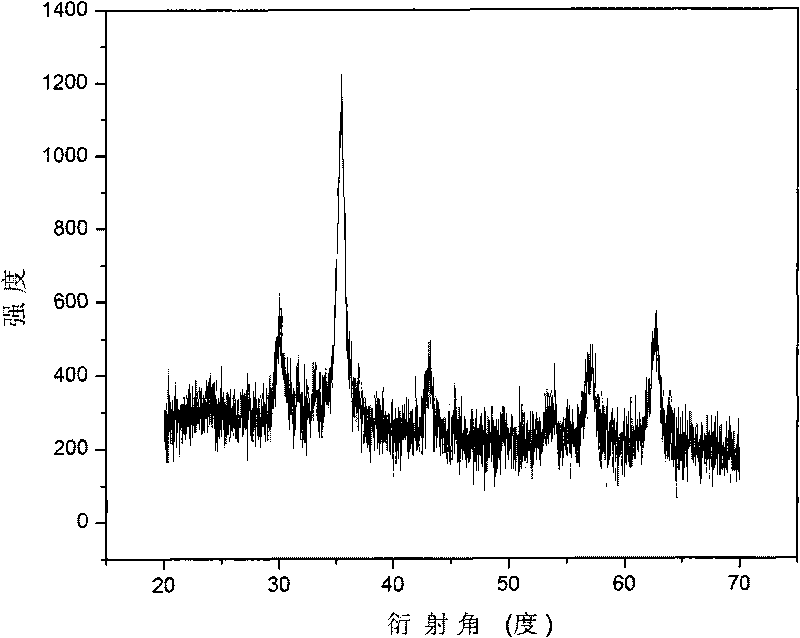

Lead free piezoelectric ceramics of potassium sodium niobate and preparation thereof

ActiveCN1644562ALower sintering temperatureShort sintering timePiezoelectric/electrostrictive/magnetostrictive devicesElectric fieldNatural state

A niobic acid potassium sodium system lead-free piezoelectric ceramic and its production are disclosed. The components of the niobic acid potassium sodium system lead-free piezoelectric ceramic are (1-n)KxNa1-xNbO3.nMH, it is prepared by SPS process. The production is carried out by grinding mixing raw materials, calcining synthesizing niobate, using SPS process for the obtained powdery material, annealing treating under oxygen atmosphere, and obtaining piezoelectric / ferroelectric ceramic materials. Its advantages include lead-free composition, good piezoelectric performance, low calcining temperature, short calcining time and fine tissue.

Owner:TSINGHUA UNIV +2

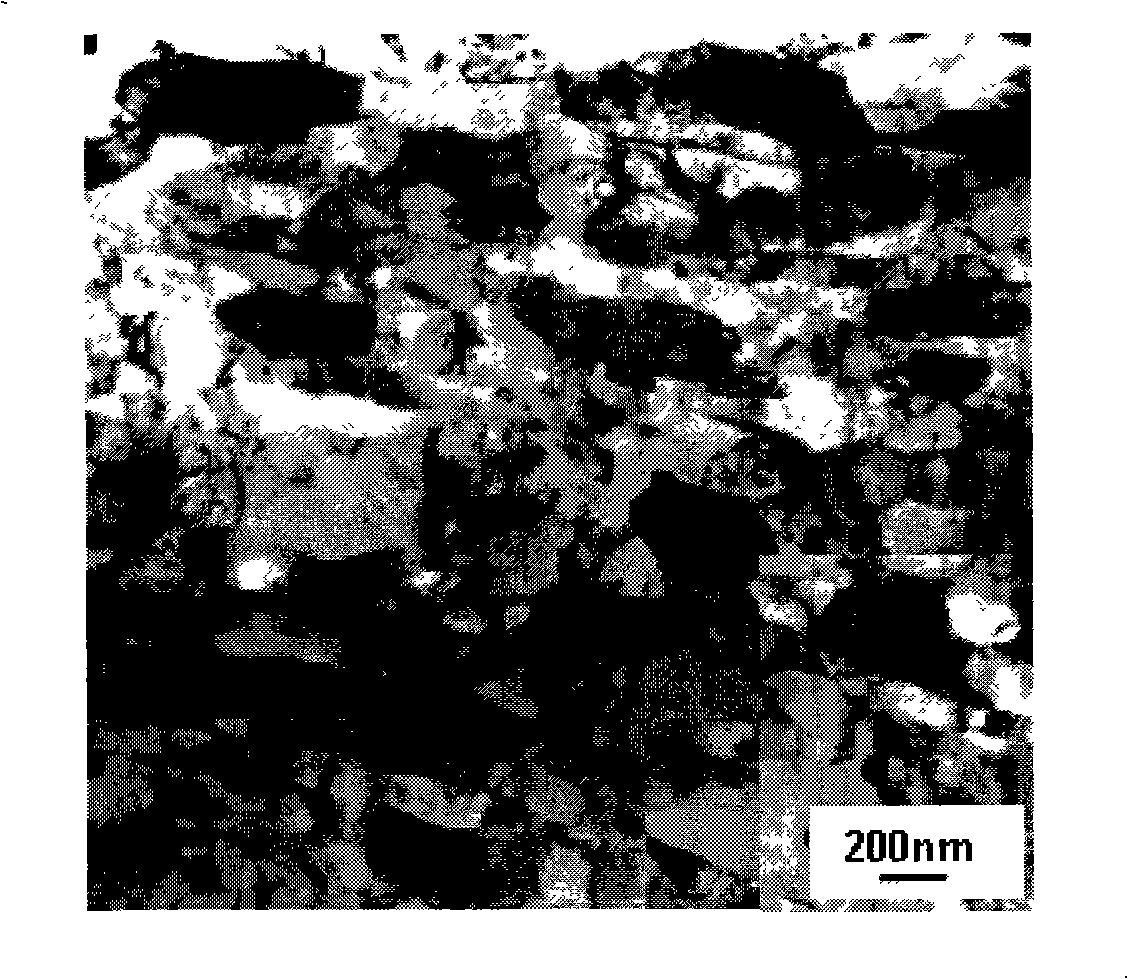

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

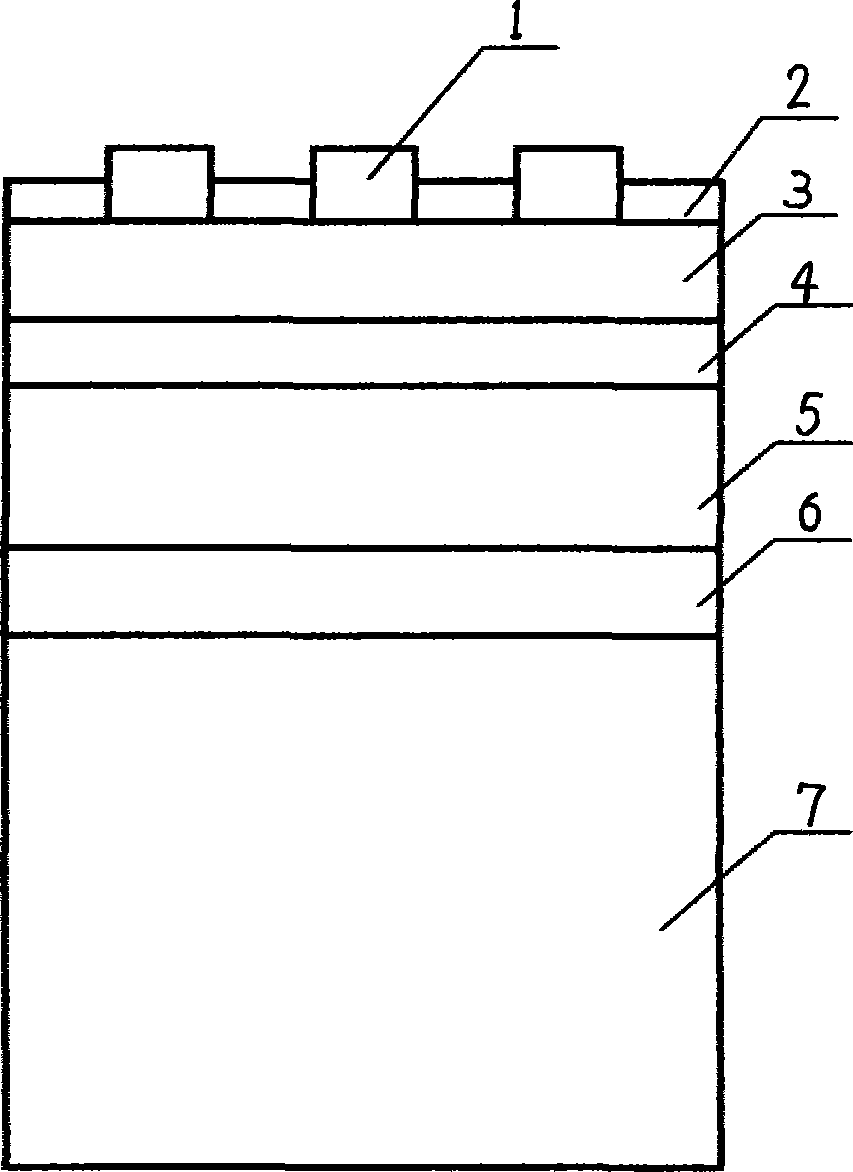

Flexible CIGS thin-film solar cell and absorption layer preparation thereof

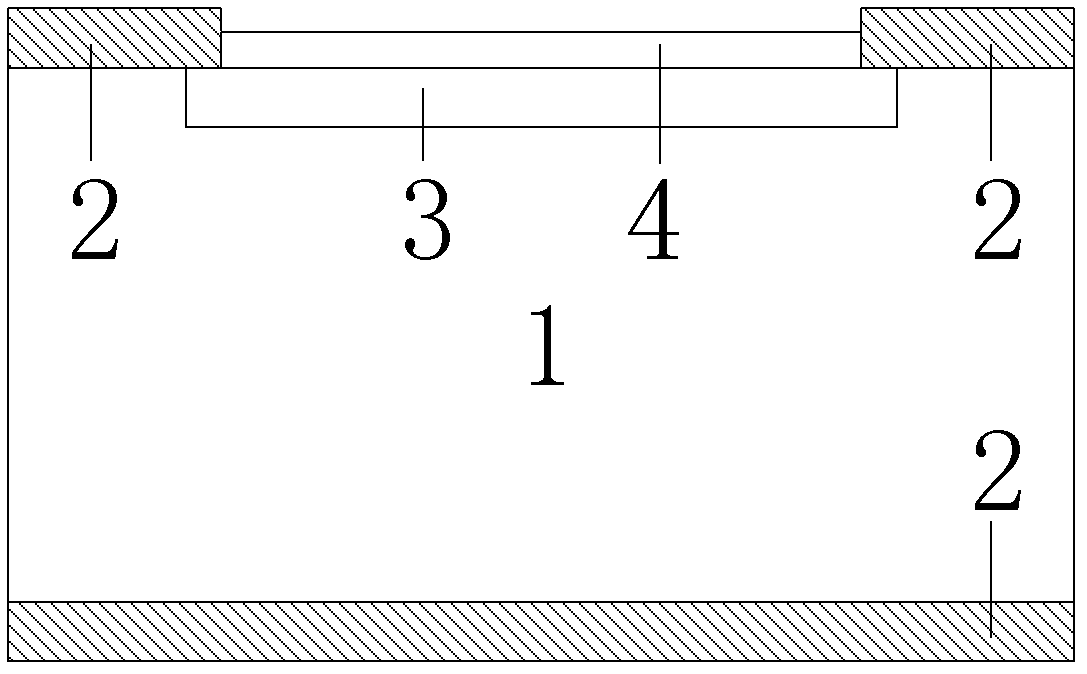

ActiveCN101459200AReduce dosageThe process is easy to controlFinal product manufacturePhotovoltaicsIndiumMetallic materials

The invention belongs to a flexible CIGS thin-film solar cell and a process for preparing an absorption layer thereof, the flexible CIGS thin-film solar cell is a multi-layer film structure, which comprises an substrate, a bottom electrode, an absorption layer, a buffer layer, a window layer, an anti-reflecting film and an upper electrode, and the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide. The process for preparing the adsorption layer of the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide, the bottom electrode Mo of the thickness of 0.5-1.5 mu m is deposited by magnetron sputtering, a metal prefabricating layer is prepared on a Mo thin-film, and is in vacuum seal to be placed in a furnace to heat, the temperature of the area of a solid selenium source is controlled between 180-300 DEG C to perform selenizing treatment, thereby enabling the metal prefabricating layer to be transformed into a semiconductor thin-film. Through performing selenizing or vulcanizing under saturation vapor pressure of selenium or sulfur in a vacuum seal silica tube, controllable repeatability of the technique process is fine, use quantity of selenium or sulfur is reduced, besides, the process is controllable and the equipment is simple.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

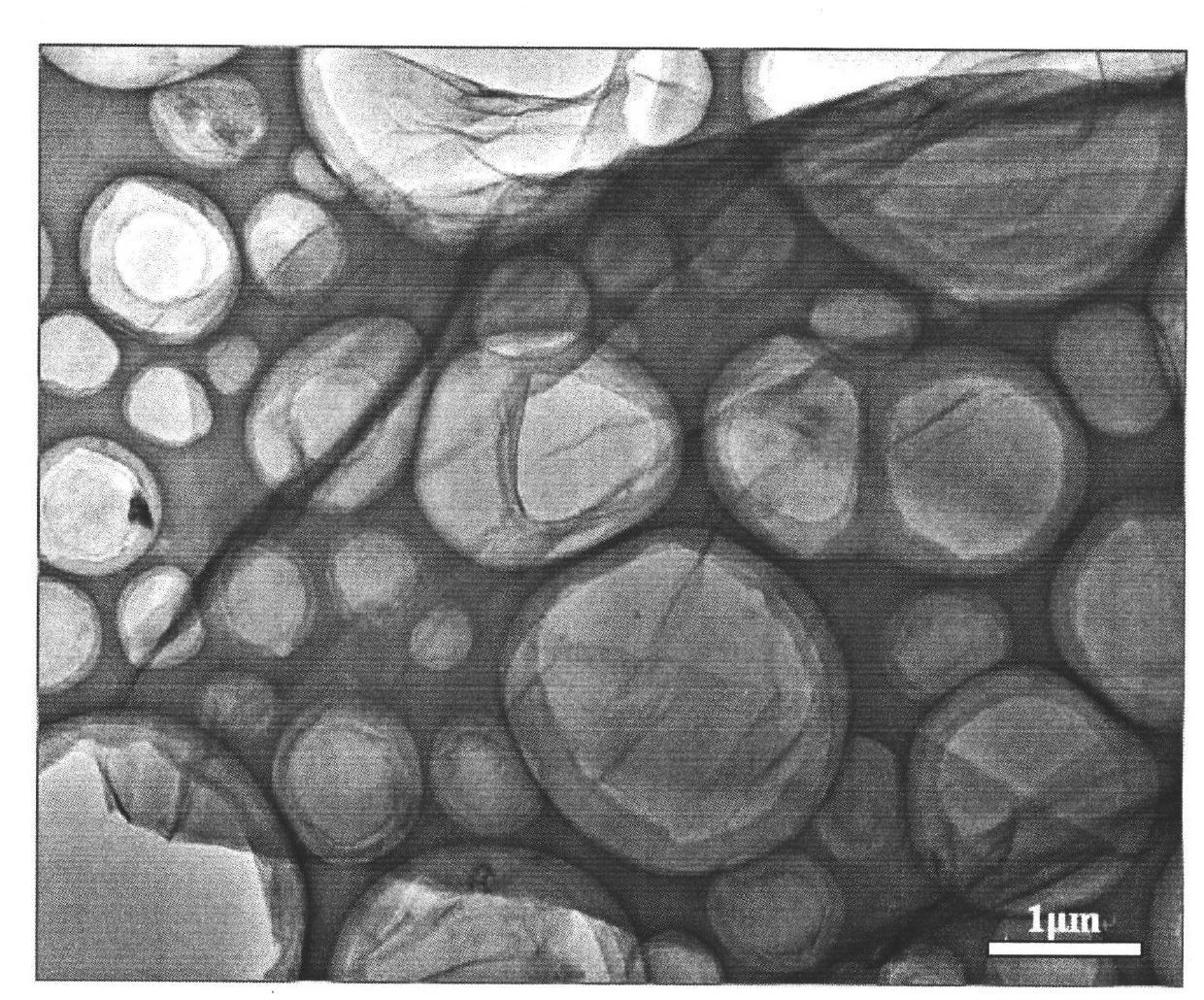

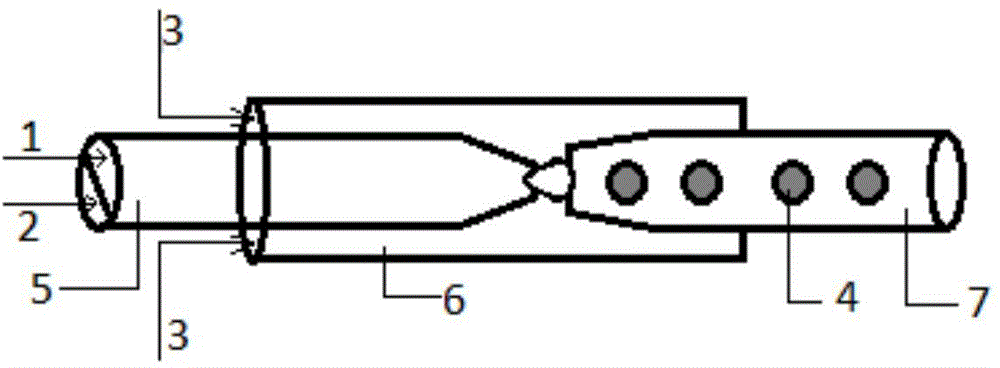

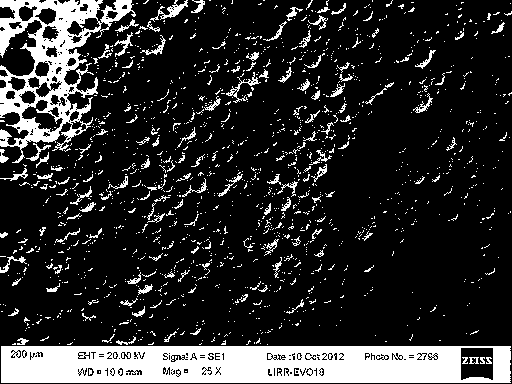

Preparation method of mono-dispersed gelatin embolic microsphere with precisely-controlled particle size

ActiveCN104829851AOvercoming Process ComplexityOvercome granularityPowder deliverySurgeryGelatin microspheresAqueous solution

The invention provides a preparation method of a mono-dispersed gelatin embolic microsphere with a precisely-controlled particle size. In the provided method, micro water-in-oil liquid drops are formed in a micro channel reactor at first through a micro-fluidic liquid drop control technology, then a crosslinking agent and a gelatin water solution are taken as the dispersing phase and introduced into the water-in-oil system, and then the mixture is directly cured to form microspheres. By adjusting the flowing speeds of the continuous phase and the dispersing phase, and the flowing speeds of two dispersing phases, the particle size and sphericility can be precisely controlled. The preparation technology is simple and rapid, and the process is controllable. The prepared gelatin microsphere can be used as an embolic agent or an antitumor drug carrier, and can also be applied to cell culture.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

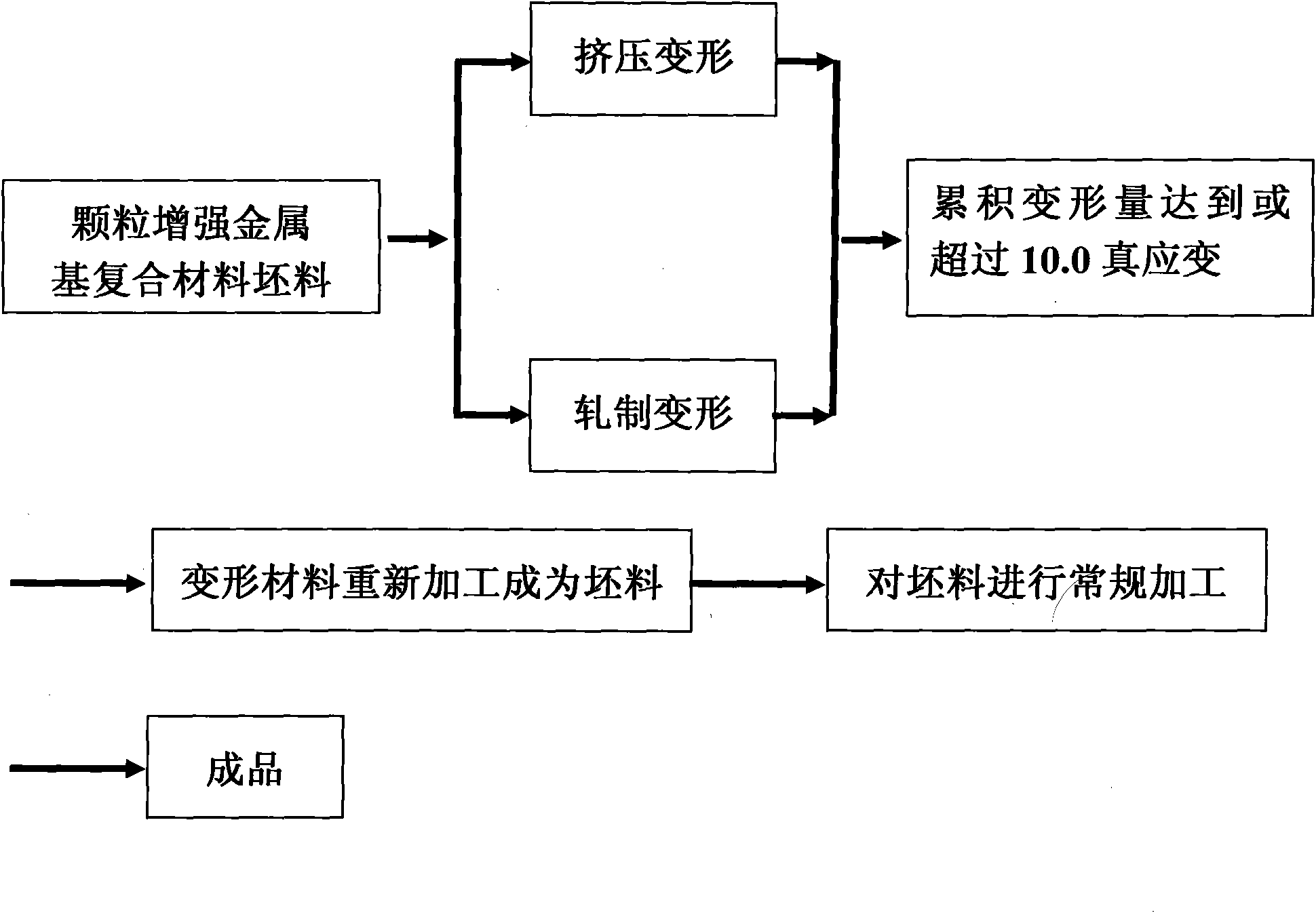

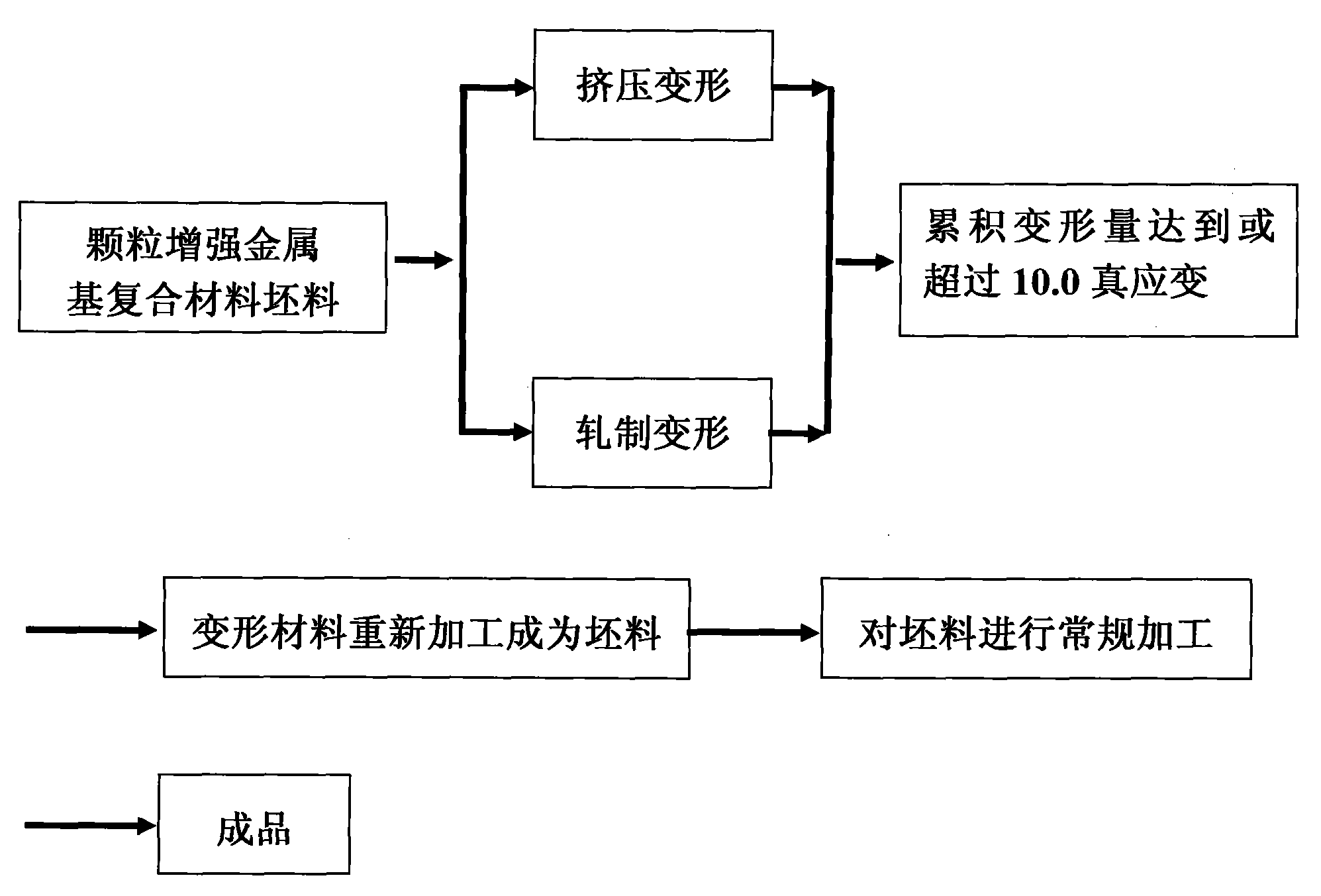

Uniformly-dispersed particle reinforced metal-based composite material and preparation method thereof

InactiveCN102134664AGood for comprehensive performanceEvenly distributedMetal rolling arrangementsMetal matrix compositeMaterials processing

The invention discloses a particle reinforced metal-based composite material product (rods, wires, sheets or belts, or parts) which is obtained, based on the severe plastic deformation theory of material, by the step of performing severe plastic / accumulated deformation processing on a particle reinforced metal-based composite material so that second phase particles agglomerated in a metallic matrix are uniformly distributed (dispersed) in the matrix, and then carrying out subsequent processing, thereby enhancing the quality and the yield of the particle reinforced composite material and lowering the processing cost of the material, and thus a particle reinforced metal-based composite material having the characteristic of the uniformly distributed second phase particles and excellent performance is obtained.

Owner:KUNMING UNIV OF SCI & TECH

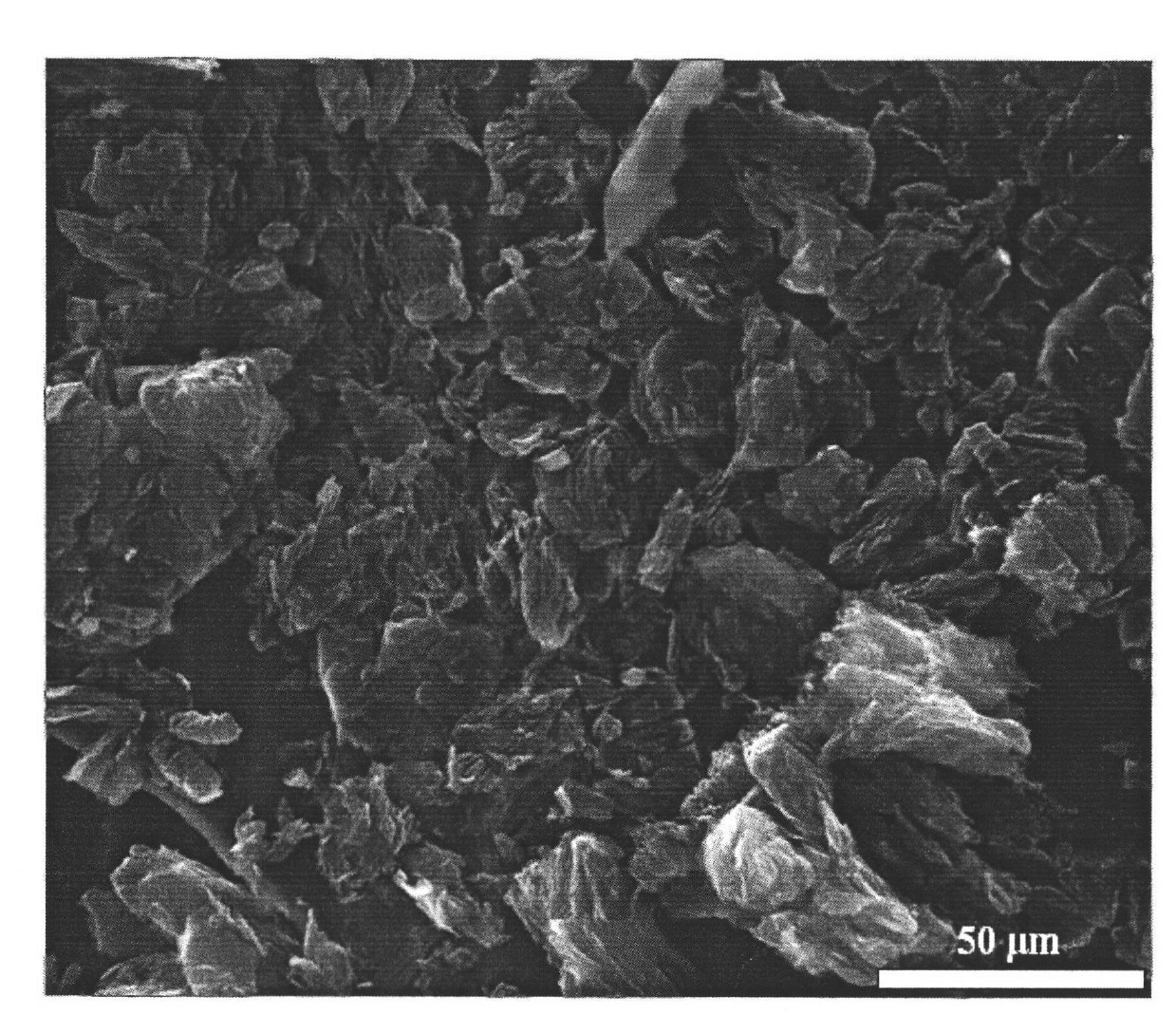

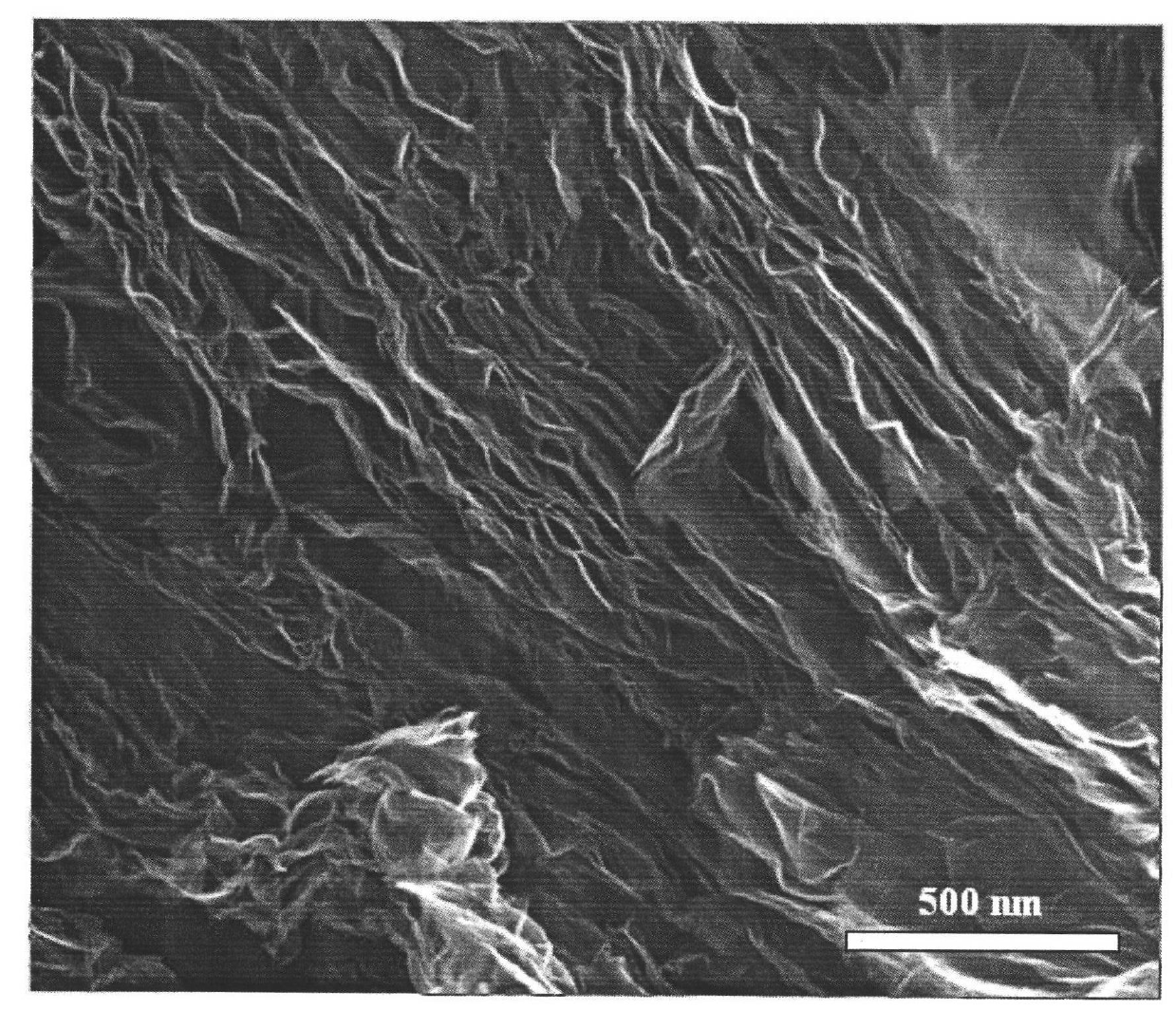

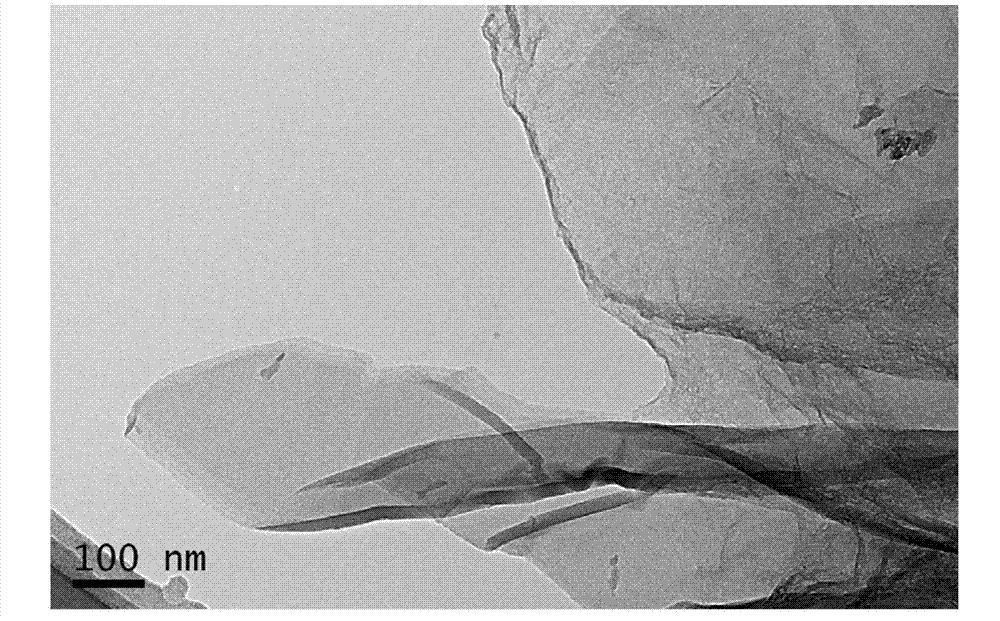

Method for preparing graphene energy storing material through electrochemical cathodic disbonding

ActiveCN102923697AProcess is easy to controlLow costGrapheneHybrid/EDL manufactureSolventCvd graphene

The invention relates to the field of new materials, and in particular to a preparation method of graphene, which is the method for preparing a graphene energy storing material through electrochemical cathodic disbanding. The method comprises steps as follows: getting noble electrode as anode, high-purity graphite as cathode, a quaternary ammonium salt organic solvent as electrolyte, and voltage adjustable direct current power as the power supply; carrying out high cathodic disbanding under a constant voltage of -5 to -100V; inserting the solvated quaternary ammonium salt into laminated graphite under an effect of a high cathode voltage so as to generate expansion on a surface of the graphite electrode in a single layer or a plurality of layers; and decomposing the solvent to obtain gas under an electric potential effect of the high cathode, so as to further strip the graphite to obtain the graphene. The method is carried out under a direct current stabilized power supply without other special equipment; the method for preparing the graphene is simple, convenient and easy to carry, a process is easy to control, cost is low, no pollution is generated, and convenience is provided for industrial popularization and application; and prepared graphene can be widely applied to fields such as an energy storage field, an energy conversion field, an electronic device field and a biosensing field.

Owner:CENT SOUTH UNIV +1

Method for producing Matrimony vine polysaccharide

Production of Barbary Wolfberry Fruit polysaccharide is carried out by taking Barbary Wolfberry Fruit as raw materials, soaking, crushing, extracting, enzyme hydrolysis reacting, column chromatography acting, depositing by alcohol, dealcoholizing and drying. It's cheap and simple, has short production period and better purity.

Owner:GUILIN NATURAL INGREDIENTS CORP

Preparation method of corundum/mullite light-weight heat insulating material

ActiveCN103011884ARapid in situ solidificationThe process is easy to controlCeramicwareMaterials preparationFoaming agent

The invention belongs to the technical field of heat insulating material preparation, and particularly relates to a preparation method of a corundum / mullite light-weight heat insulating material, which comprises the following steps: by using ceramic powder, silica sol, deionized water, ammonia water and dryness-control chemical additive as initial raw materials, carrying out ball milling to prepare a ceramic slurry; adding a foaming agent into the ceramic slurry, and foaming in a mechanical stirring mode to obtain a foam slurry; adding an NH4Cl solution into the foam slurry while stirring, injecting the uniformly stirred foam slurry into a mold, and quickly curing to form the foam slurry; and drying the demolded blank, and firing to obtain the corundum / mullite light-weight heat insulating material. The invention is characterized in that the gelation reaction of the silica sol is utilized to implement curing and formation of the foam slurry; meanwhile, the volume expansion generated by mullitization in the firing process is utilized to avoid sample cracking due to excessive sintering shrinkage; and in addition, the raw materials are nontoxic and cheap, and the preparation process is simple to control and suitable for industrial production.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

Silicon detector structure with broad spectral response and method of making same

InactiveCN102290481AWide spectral response rangeImprove absorption rateFinal product manufactureSemiconductor devicesSpectral responseSilicon detector

The invention relates to a silicon detector structure with a wide spectral response range, which comprises an n-type silicon substrate, a silicon dioxide medium masking layer, a p-type doping layer, a front surface contact electrode, an antireflection film layer, a broad-spectrum absorbing black silicon layer, a medium passivating layer and a back surface contact electrode, wherein a circular groove is arranged on the surface of the n-type silicon substrate; the silicon dioxide medium masking layer is formed around the circular groove on the surface of the n-type silicon substrate, and the middle of the silicon dioxide medium masking layer is an annular structure; the p-type doping layer is arranged in the circular groove of the n-type silicon substrate; the front surface contact electrode is produced on the inner wall of the annular structure of the silicon dioxide medium masking layer and covers the partial edge of the surface of the annular structure to form an annular structure; the antireflection film layer is produced in the annular structure of the front surface contact electrode and covers the surface of the p-type doping layer; the broad-spectrum absorbing black silicon layer is produced on the back surface of the n-type silicon substrate; the medium passivating layer is point-type and is formed on the surface of the broad-spectrum absorbing black silicon layer; and the back surface contact electrode is produced on the surface of the broad-spectrum absorbing black silicon layer and covers the point-type medium passivating layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

High-toughness casting aluminum alloy and preparation method thereof

Owner:宁波旭润铝业有限公司 +1

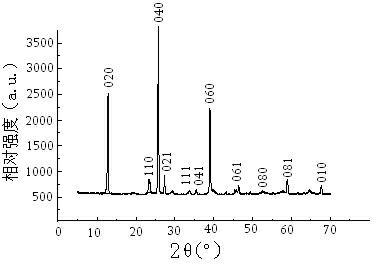

Method for preparing molybdenum trioxide material with orthorhombic phase single crystal nano belt structure

InactiveCN102139923AThe acidification process is simpleProcess is easy to controlNanotechnologyMolybdenum oxides/hydroxidesSingle crystalHydrothermal reaction

The invention discloses a method for preparing a molybdenum trioxide material with an orthorhombic phase single crystal nano belt structure. The method comprises the following steps: preparing molybdenum acid sol from ammonium heptamolybdate acidified by nitric acid; adding a template agent cetyltrimethylammonium bromide; and carrying out hydrothermal reaction, filtering, washing and drying so as to obtain the orthorhombic phase single crystal nano belt. In the method for preparing the molybdenum trioxide material with the orthorhombic phase single crystal nano belt structure, the ammonium heptamolybdate and the nitric acid are used as raw materials, the cetyltrimethylammonium bromide is used as the template agent, the acidification procedure is simple, process is easy to control, the reaction temperature is low, and the width and thickness of the product are small; the nano belt is of a single crystal structure and has good topography; and the preparation process is short in process flow period, the yield is high, the preparation equipment is simple and the cost is low. By using the method, the molybdenum trioxide material with the orthorhombic phase single crystal nano belt structure, which has width of 50-100nm, length of 1-10 mu m and thickness of 30-60nm, is obtained, and the powder grain size of the molybdenum trioxide nano belt is even.

Owner:XI'AN POLYTECHNIC UNIVERSITY

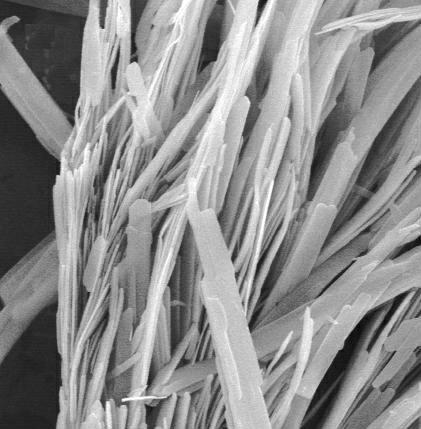

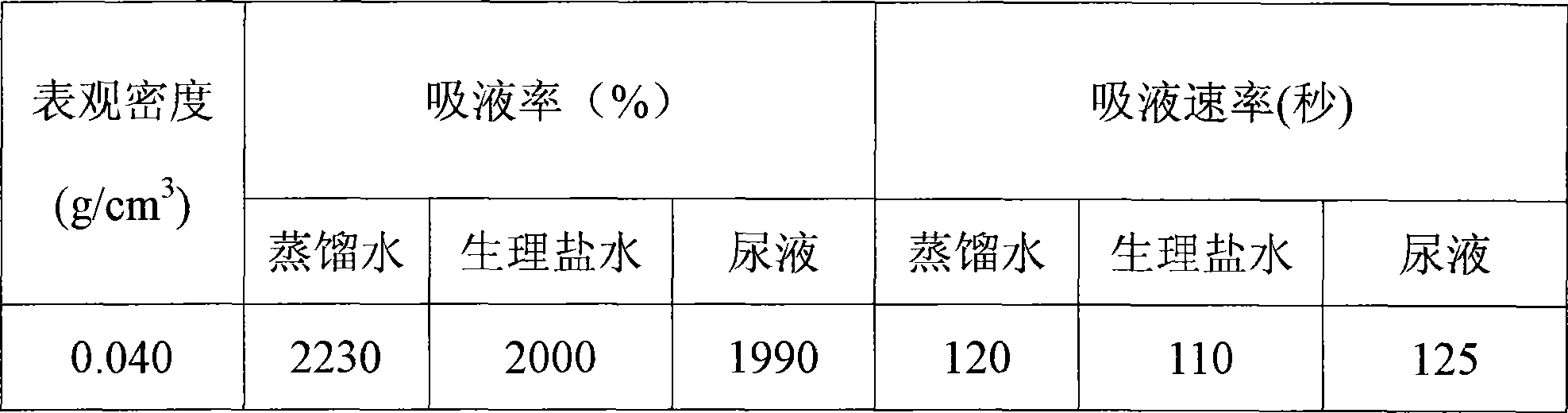

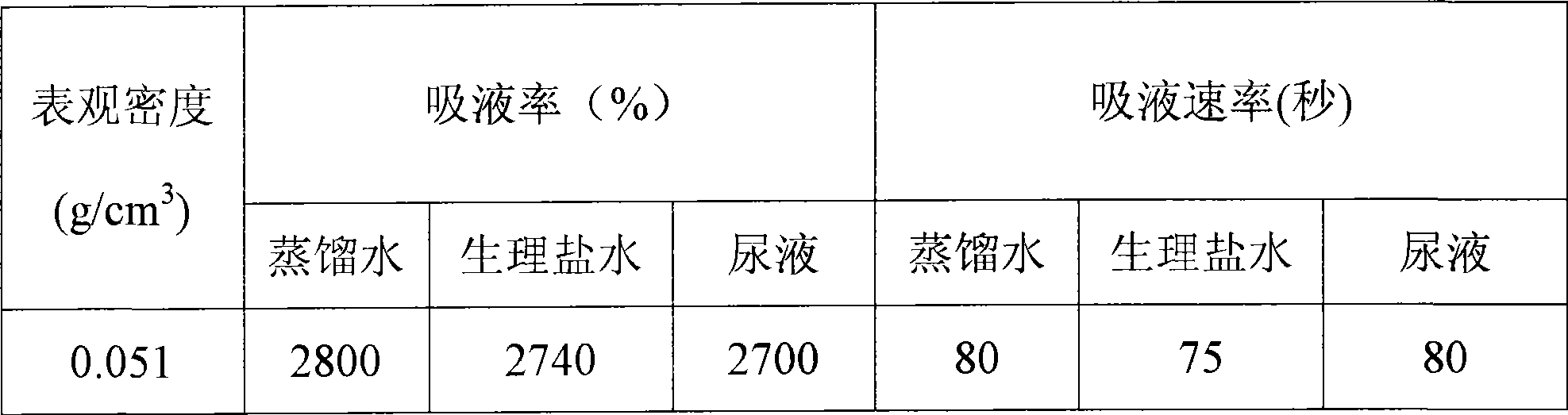

Preparation method of medical quick imbibition foam material

ActiveCN101507826ASimple preparation processProcess is easy to controlAbsorbent padsBandagesSaline waterChemistry

The invention relates to a method for preparing a medical quick liquid-absorbing foam material. The method comprises the steps of well mixing polyvinyl alcohol aqueous solution, aldehyde and a pore-forming agent, adding acid to the mixture, continuing to stir the mixture, pouring the mixed solution into a die, curing and molding the mixed solution, washing and drying the obtained product and obtaining a target object. The material has abundant mutually communicated opening structures through a method of using mechanical foaming together with the pore-forming agent. The prepared material is good in biological compatibility and excellent in hydrophilcity, has the liquid-absorbing capability much higher than common cotton yarn and paper, has the capability of quickly absorbing a large amount of distilled water, physiological saline and urine, turns into soft tenacious elastic sponge after absorbing liquid, is resistant to heat and ultraviolet radiation, and can be disinfected in a plurality of ways. The prepared material is a rigid foam material in a dry state, is a spongy material in a wet state, has the apparent density of between 0.04 and 0.09 g / cm and the liquid-absorbing ratio of between 1,800 and 2,800 percent, and can be applied to medical operations.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

600MPa grade low temperature high toughness weather corrosion resistant steel and its production method

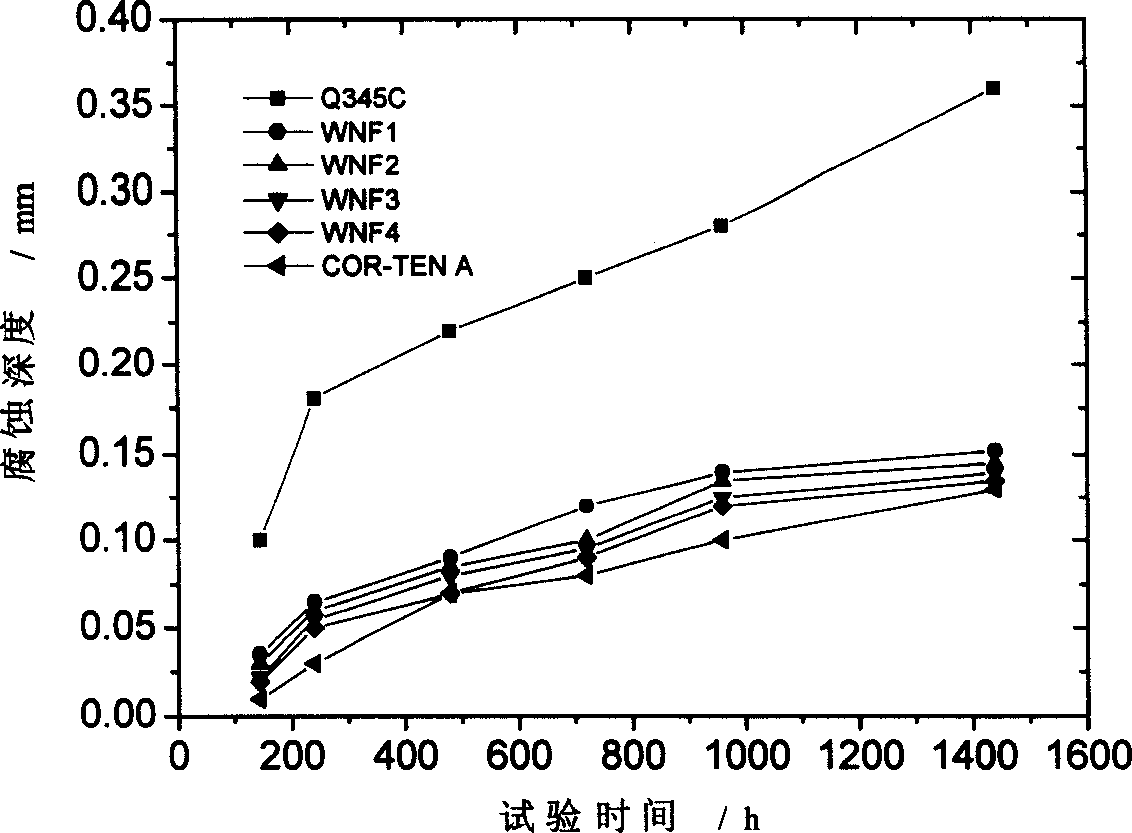

InactiveCN1718832ASimple chemical compositionThe process is easy to controlChemical compositionToughness

A steel with high low-temp toughness (600 MPa), weldability and the resistance to atmosphere corrosion contains C (0.05-0.09 wt.%), Si (0.45-0.7), Mn (2.10-3), P (0-0.02), S (0-0.01), Ti (0.005-0.009), Nb (0.095-0.19), Ni (0.1-0.19), Cu (0.45-0.65), Cr (0.75-1.5), Ca (0-0.02) and Fe (rest). It features that Cr+Ni+Cu is 0.70-2.50 and content of Nb is greater than that of 4Ti+3Ca.

Owner:WUHAN IRON & STEEL (GROUP) CORP

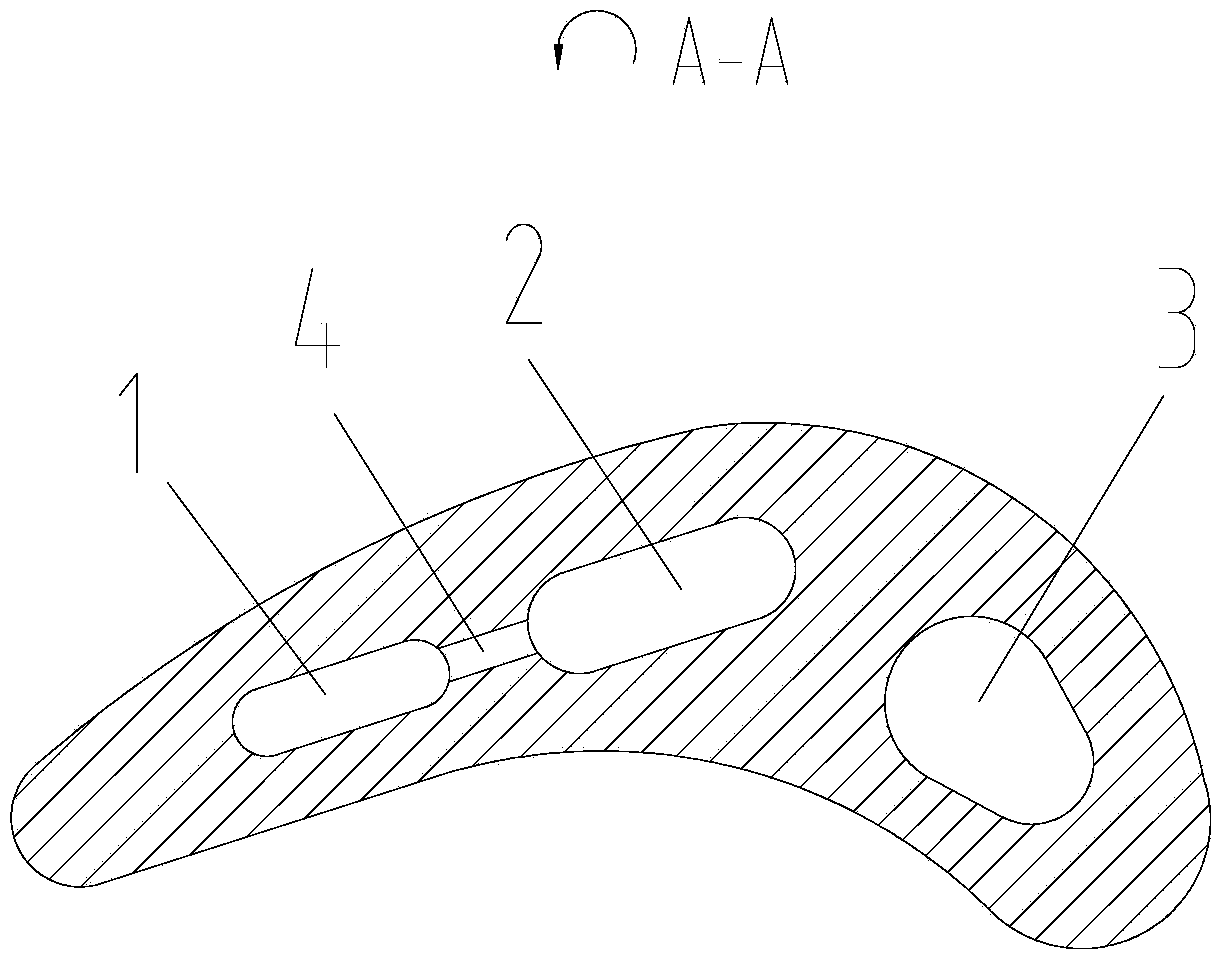

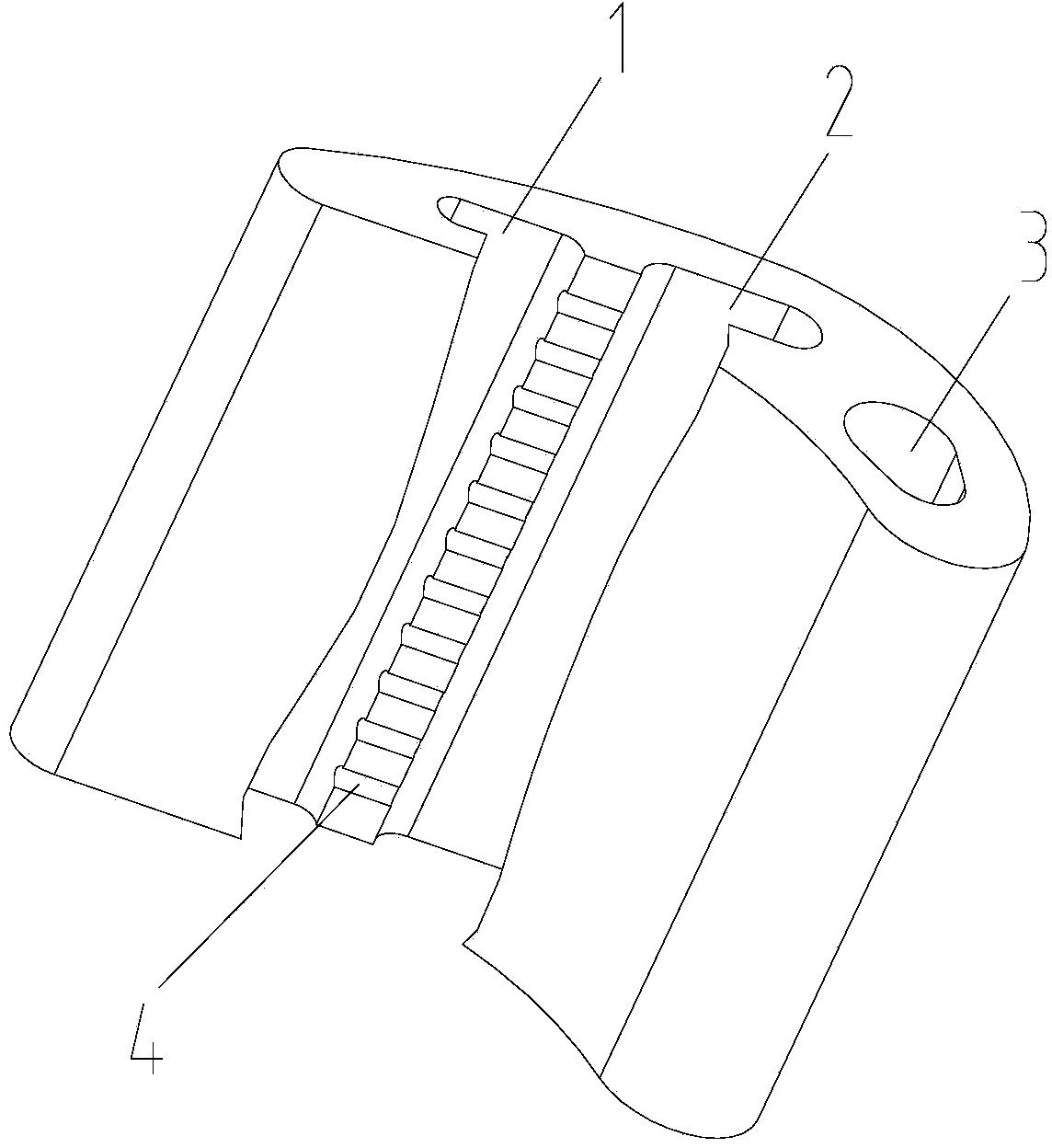

Manufacturing method of hollow turbine blade provided with impact hole structure

ActiveCN103990761ASolve the strength problemSolve the problem of easy breakageFoundry mouldsFoundry coresWaxTurbine blade

The invention relates to a manufacturing method of a hollow turbine blade provided with an impact hole structure. The method comprises the steps of firstly, preparing a plurality of aluminum oxide ceramic mold cores corresponding to a plurality of main cooling channels in the hollow turbine blade; after that, preparing an impact hole core between every two adjacent aluminum oxide ceramic mold cores, wherein a molybdenum wire is arranged in the center of each impact hole core, and a ceramic layer is arranged on the surface of each impact hole core; assembling the impact hole cores and the plurality of aluminum oxide ceramic mold cores in a combining way, putting the assembled product into a wax mould of the hollow turbine blade; injecting wax into a mold cavity of the wax mould, separating the wax mould after the wax is solidified, and spraying ceramic slurry onto the surface of a wax model to prepare a ceramic mold shell; melting the wax, and carrying out calcination to prepare a ceramic casting mould with a structure comprising the mold cores and the mold shell; and pouring high-temperature molten metal into the ceramic casting mould, and removing the ceramic casting mould after the molten metal is solidified to obtain the hollow turbine blade which comprises the plurality of main cooling channels and the impact hole structure. The manufacturing method mainly solves the problem that the impact hole cores are difficult to mold, are not enough in strength or low in core forming rate in an investment casting process.

Owner:XI AN JIAOTONG UNIV

Preparation method for polycarboxylic acid high-performance water reducer

The invention discloses a preparation method of a poly-carboxylic acid water reducing agent with high performance, the water reducing agent is made in simple process with low mixing amount and high dispersive property. The technical proposal is as the follow: A) methacrylic acid and methoxy polyethylene glycol with a mole ratio of 1 to 1.2: 1 are put into a reactor with catalyst, polymerization inhibitor and water carrying agent being added to be mixed and heated to 100 to 150 DEG C and kept reacting within 8 to 12 hours to obtain polyoxyethylene methacrylate; B) water and initiator are added into the reactor, then a mixing solution containing sodium allylsulfonate, the polyoxyethylene methacrylate and the methacrylic acid is added drop by drop slowly into the reactor, wherein the weight proportion of the water and the mixing solution is 2: 1 to 1.2, the solution is mixed and heated to the temperature of 80 to 120 DEG C. Chain transfer agent is added after reaction of 4 to 6 hours and the adding drop by drop being finished, and the solution is discharged after being kept mixing with heat preserved for 1 to 2 hours, the poly-carboxylic acid water reducing agent with high performance is obtained.

Owner:JIANGSU CHEM RES INST

Method for preparing ferroferric oxide nano-piece through microwave method

InactiveCN101717122AMicrowave reaction time is shortThe process is easy to controlNanostructure manufactureFerroso-ferric oxidesSodium acetateMicrowave method

The invention relates to a method for preparing ferroferric oxide nano-piece through a microwave method, which belongs to the field of preparation of nano-material through a wet chemical method. The method comprises the following steps of: preparing a ferric salt solution by using ethylene glycol by using a soluble trivalent ferric salt as a raw material , adding the sodium acetate and a surfactant in the ferric salt solution, evenly stirring, and irradiating by using microwave to generate ferroferric oxide, filtering and washing the product, drying the product at a constant temperature in air to obtain the ferroferric oxide nano-piece material. The ferroferric oxide nano-piece material synthesized by the method has a thickness of 100nm below as well as the length and width of 1-10microns. The invention has the advantages of high purity of the prepared ferroferric oxide nano-piece, simple synthetic line, short period of microwave reaction of only tens of minute and easy control of the whole process, meets the demands of practical production, and has god application prospect in the fields of catalysis, biological medicine, energy and environment and the like.

Owner:HUAZHONG NORMAL UNIV

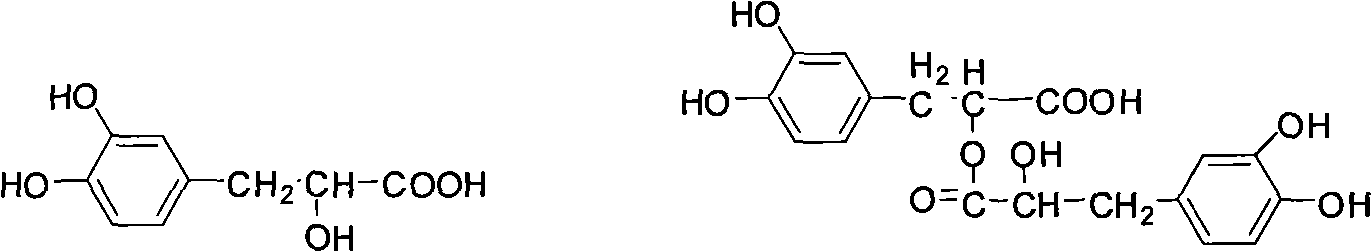

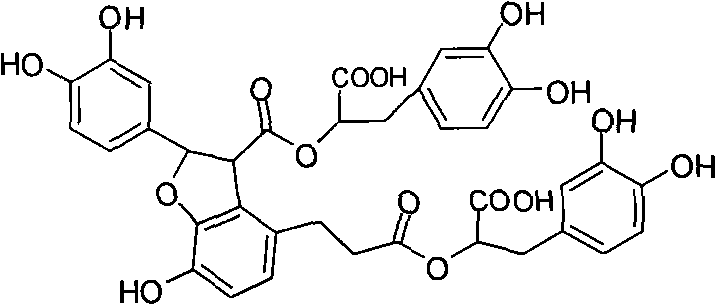

Process for abstracting high-purity tanshinol form salvia

ActiveCN101289385APrevent oxidative deteriorationSimple processCarboxylic compound separation/purificationPlant ingredientsSalvia miltiorrhizaPollution

The invention belongs to the technical field of plant drugs, and particularly relates to a method for extracting danshensu with high-purity from Salvia miltiorrhiza, which comprises the following steps: extracting solution is extracted from the Salvia miltiorrhiza medicine material containing danshensu by using a hot dripping method; the pH value of the extracting solution is adjusted by acid, the impurities are cleared and concentrated in a pressure reducing way; the eluting is carried out by using a macro porous adsorption resin and the danshensu is enriched; then concentration is carried out at low temperature, freezing and drying are carried out into solid; finally, ethanol is used for heating and dissolving, and the filter liquor is concentrated at low temperature after being filtered and precipitated, a crystallization is precipitated and the danshensu is obtained and the purity of the danshensu is more than 90 percent. The method for extracting danshensu with high-purity from Salvia miltiorrhiza has simple technology, high extracting efficiency, little pollution and low production cost, which can be controlled and is suitable for mass production.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Method for preparing BDO or succinic diester with by-product from maleic anhydride

InactiveCN101343211AEmission reductionThe process is easy to controlCarboxylic acid esters separation/purificationHydroxy compound separation/purificationDistillationWastewater

The invention discloses a method for using by-products of maleic anhydride to prepare BDO or succinic acid diester, wherein, the by-products comprise at least one of wastewater, waste residues and maleic anhydride residues, a preparation method thereof includes the major steps of esterification, distillation, reduction, etc., thereby obtaining a BDO or succinic acid diester product. The method can fully recycle maleic anhydride, fumaric acid, maleic acid, succinic acid, etc. in the by-products such as wastewater, waste residues and maleic anhydride residues in the production process of maleic anhydride, thereby obtaining products such as chemical intermediate BDO or succinic acid diester with great market demands, and maximally reducing the discharge of wastes; and the preparation method has advantages of simple and controllable technical process and rather low cost.

Owner:隆鑫

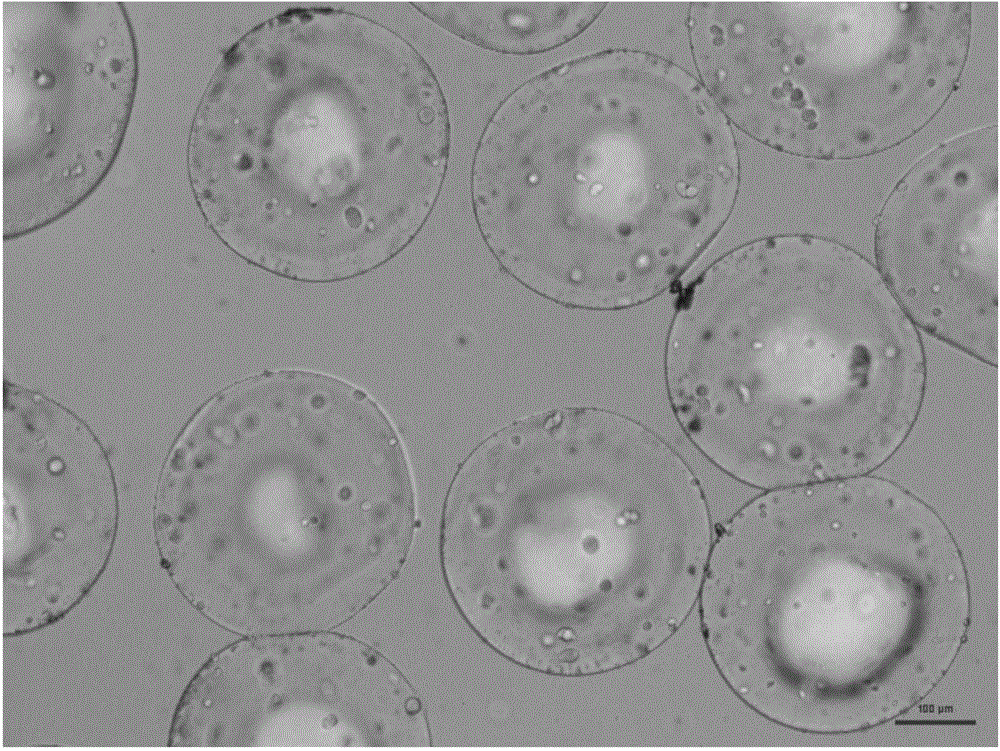

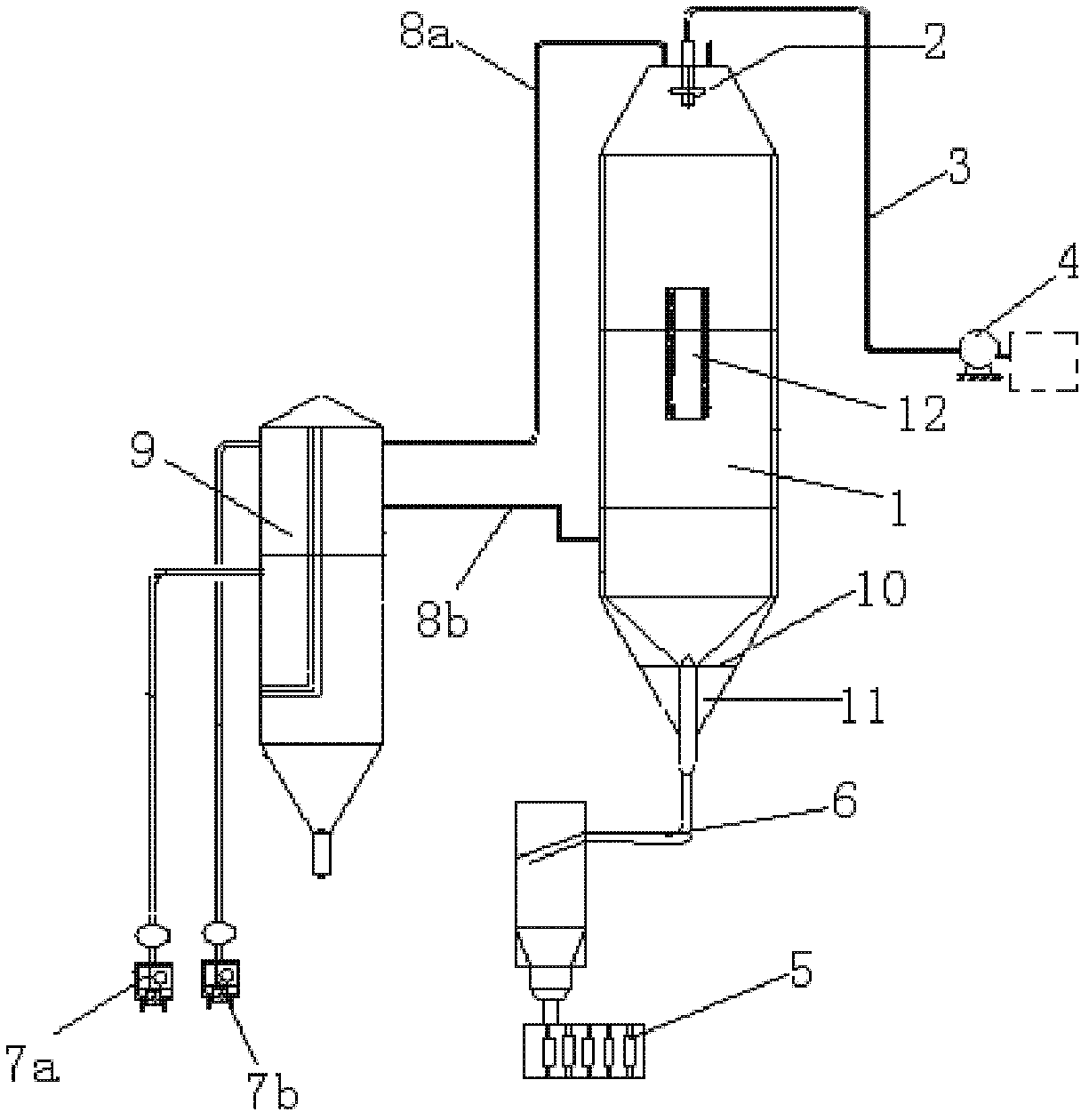

Production process of feeding lactobacillus microcapsule and microcapsule, application and premix thereof

ActiveCN103156063AImprove protectionHigh bacterial survival rateFeeding-stuffAnimal feeding stuffFreeze-dryingUltrasonic nozzle

The present invention relates to the technical field of lactobacillus coating, specifically relates to a production process of feeding lactobacillus microcapsules and microcapsules, application and a premix thereof. Trehalose and lactose which can rapidly form vitrification protection state at a low temperature are used, sodium glutamate, manganese sulfate, glycerin, and polyvinyl pyrrolidone are used as main components for a wall material, special ultrasonic wave spray drying equipment is used, an ultrasonic spray nozzle is used for atomization, vacuum and a protective gas such as nitrogen are used for drying at room temperature, thus the effects of low temperature of low temperature freeze-drying and high temperature of high temperature spray drying on lactobacillus activity are prevented, and survival rate of the bacteria can reach more than 90%. The process of the invention achieves that lactobacillus is dried at room temperature, the preparation process is easy to control, the obtained product has a long storage period, and the storage time of the product can be significantly extended.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Lithium ion battery preparation method and lithium ion battery

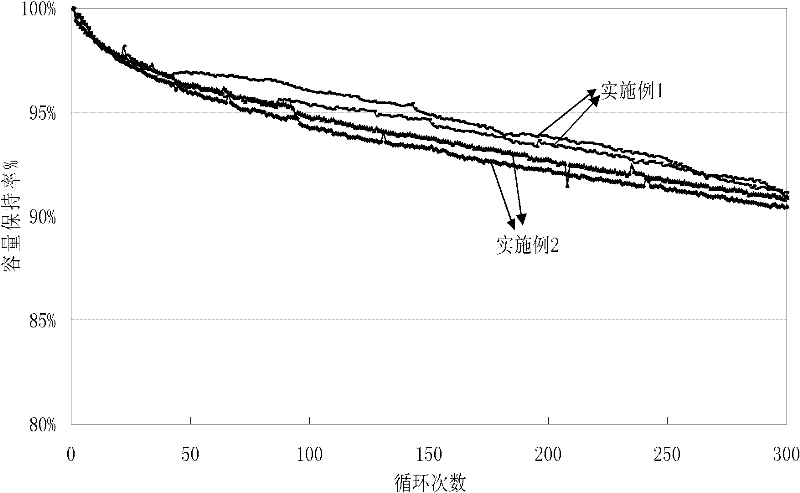

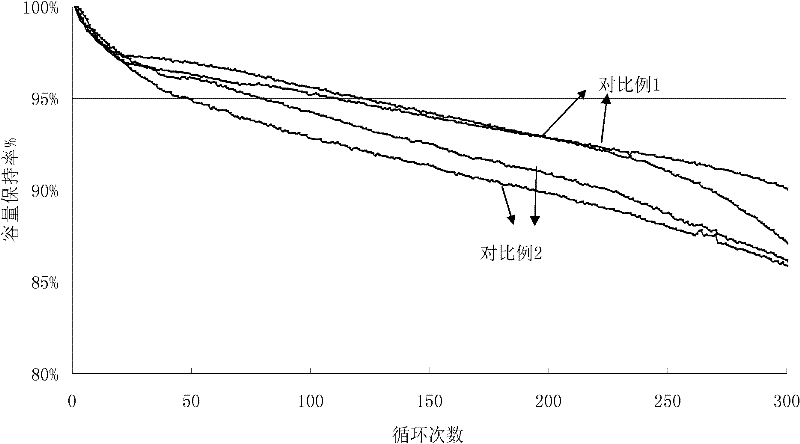

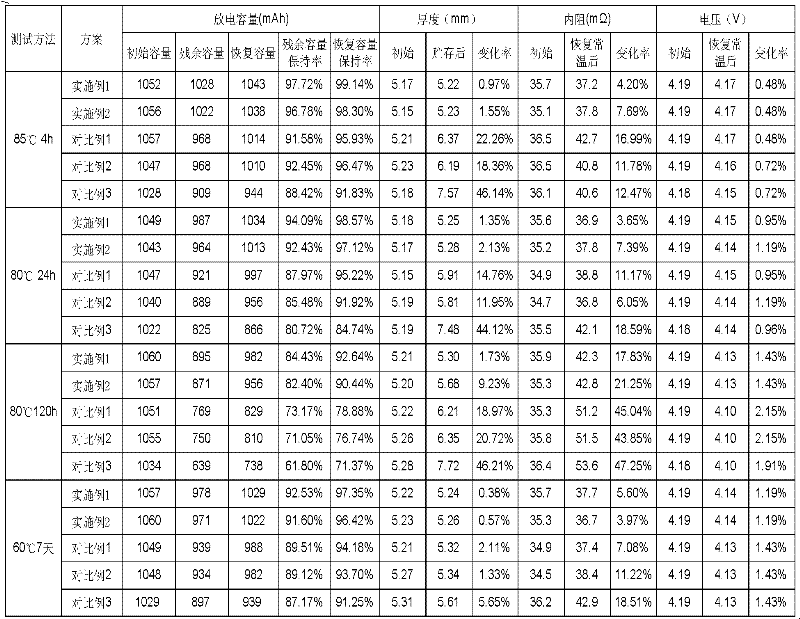

ActiveCN102544586AImprove high temperature storage performanceSuppress co-embeddingFinal product manufactureCell electrodesHigh temperature storageManganese

The invention discloses a lithium ion battery and a preparation method of the lithium ion battery. A positive electrode active material is made of lithium cobaltate or lithium cobaltate doped with a part of nickel manganese lithium manganate ternary materials, a negative electrode active material is made of natural modified graphite wrapped by carbon, electrolyte adopts mixed solvent of diethyl carbonate (DEC), ethyl cellulose (EC) and poly carbonate (PC), vinylene carbonate and propylene sulfite annexing agents are added, solid electrolyte interphase (SEI) film is formed preferentially, joint insertion of the organic solvent is restrained, and high temperature performance is excellent. A battery system obviously improves high temperature storage property of the battery on the premise of meeting safety performance, high and low temperature discharge performance and circulation performance of a conventional lithium ion battery. The preparation method is simple, manufacture procedures are easy to control, and the lithium ion battery is easy to popularize and apply.

Owner:ZHENGZHOU BAK BATTERY CO LTD

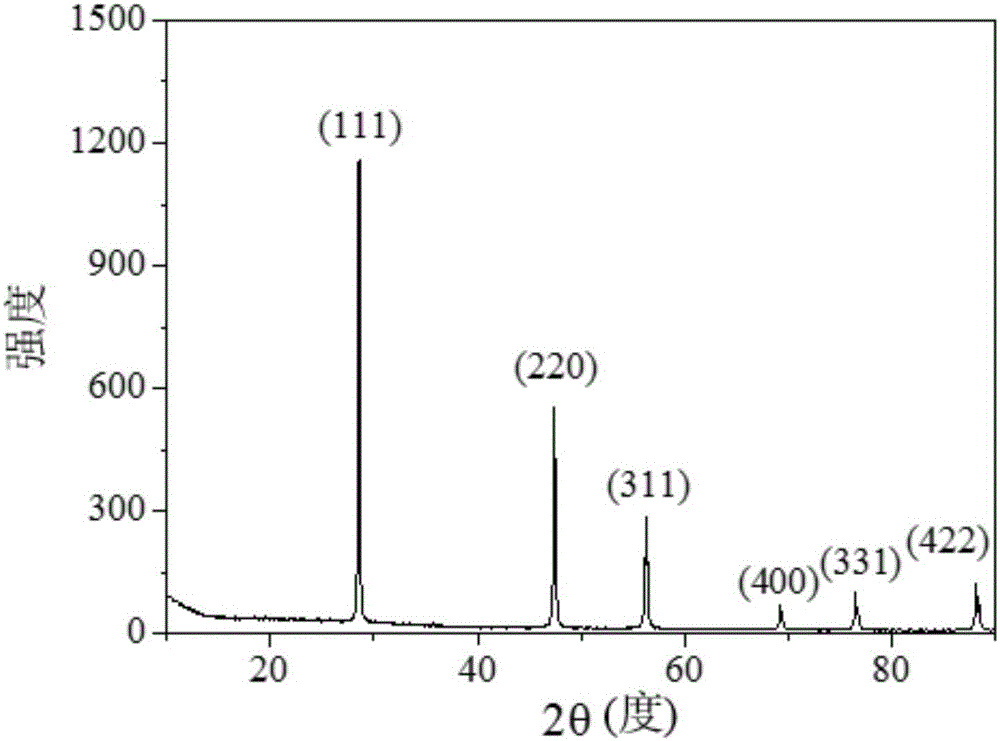

Porous silicon material, and preparation method and application thereof

ActiveCN105047892AImprove cycle stabilityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAcid etchingSpace group

The invention discloses a porous silicon material, and a preparation method and an application thereof. The porous silicon material is mainly prepared by mechanical milling and acid etching of metallurgical iron-silicon alloy as a raw material; the dimension of the porous silicon material is in micron / submicron level; the porous silicon material has a diamond structure, belongs to an Fd-3m (227) space group, and has a reaction phase which can react with lithium (Li); a large number of hierarchical porous structures with different dimensions are evenly distributed in the surface and the inside of the porous silicon material; the porous silicon material can be used as a lithium ion battery anode active material, and shows the characteristics of high (first) coulombic efficiency, high capacity, excellent cycling stability and the like when applied to a lithium ion battery; meanwhile, the preparation technology of the porous silicon material is simple, and can be carried out only by conventional equipment; the used raw materials are cheap and available; the technological process is easy to control; and the porous silicon material is good in repeatability, high in productivity, stable in product quality and suitable for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

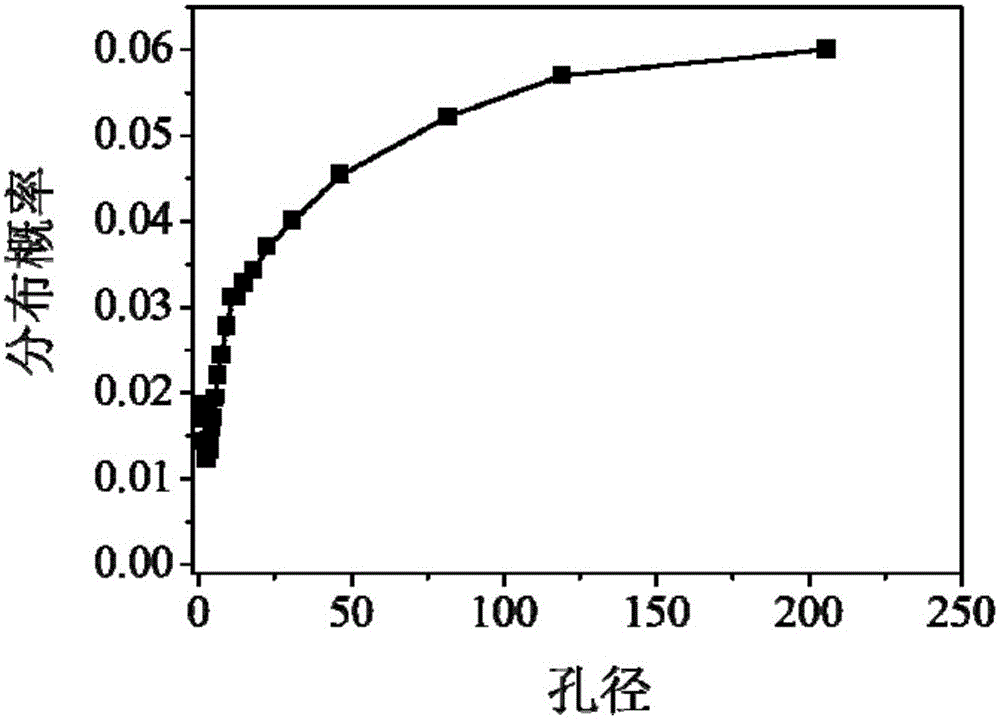

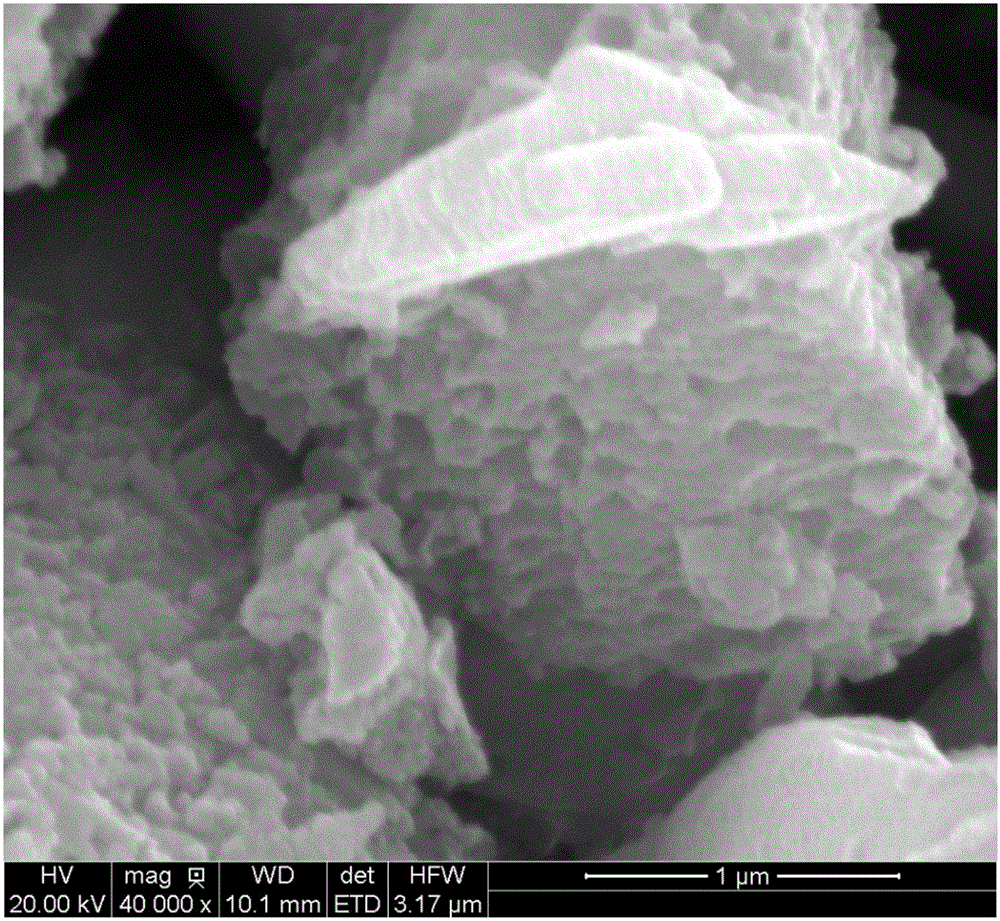

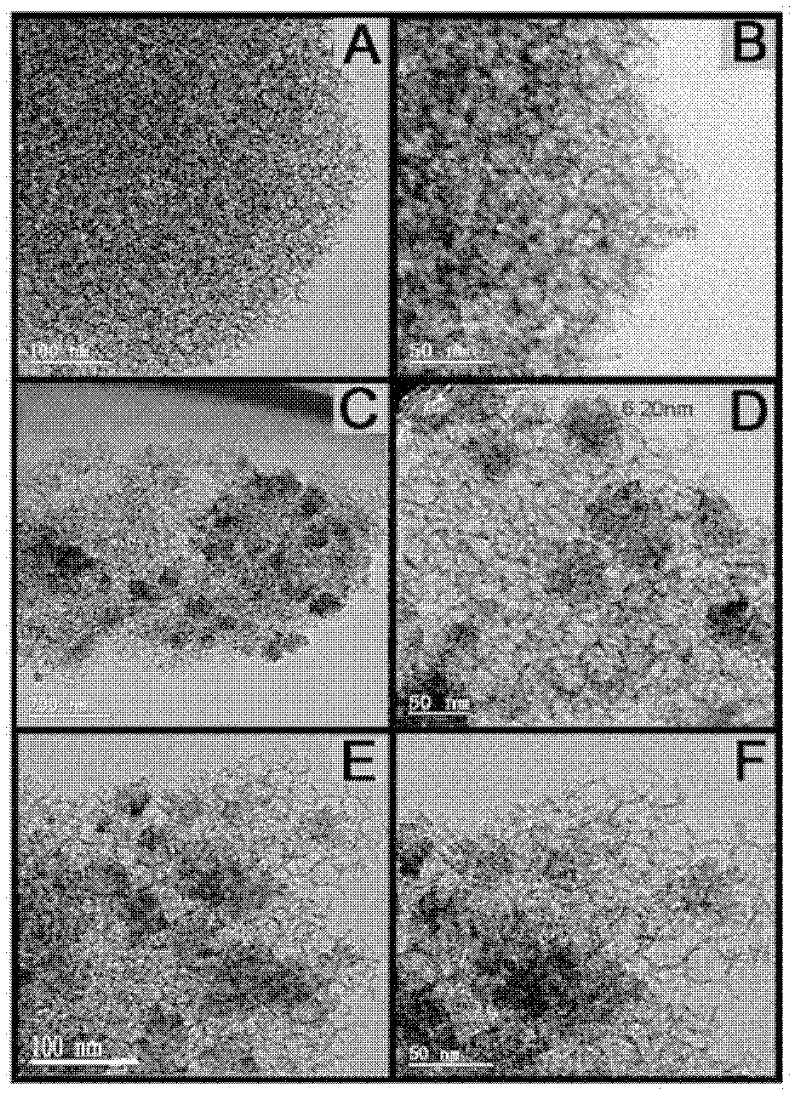

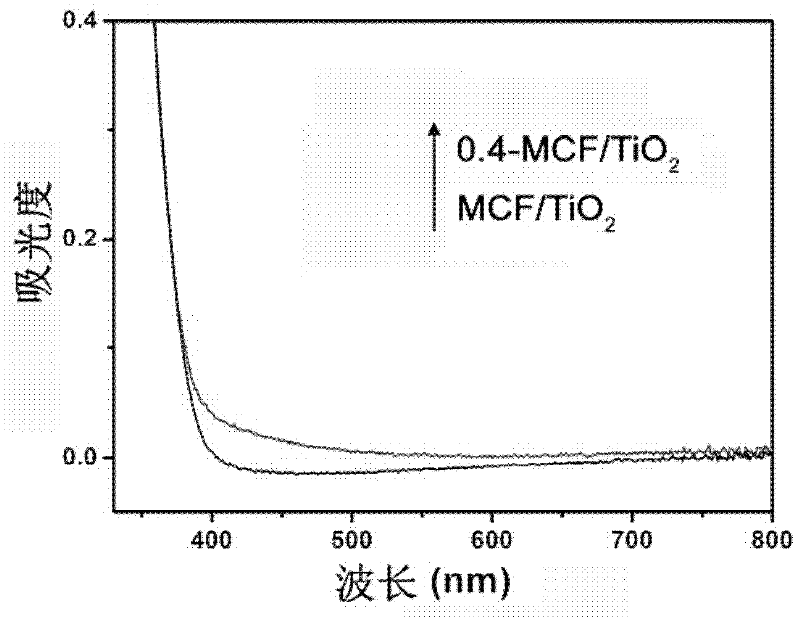

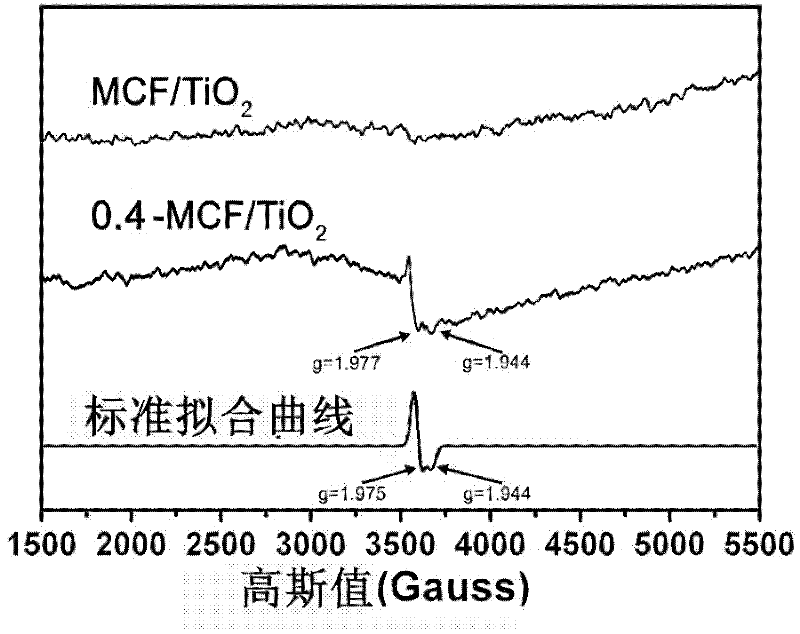

A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst

InactiveCN102266792ASynthetic operation is simpleLow toxicityMolecular sieve catalystsWater/sewage treatment by irradiationHigh concentrationActivation method

The invention relates to a synthesis method for a visible photocatalyst by modifying titanium dioxide (TiO2) by using ammonium fluoride (NH4F). The synthesis method comprises three steps of: preparing a mesocellular foam silica (MCF) molecular sieve, preparing an MCF carrying TiO2 catalyst and modifying MCF / TiO2 by using the NH4F. Compared with the prior art, the carrying catalyst MCF / TiO2 is subjected to NH4F hydrophobic modification through a hydrothermal process and a low-temperature vacuum activation method; as a mesoporous material has extremely high absorption capability, the visible photocatalyst has outstanding absorption performance and catalyzing and degrading performance on ultraviolet and visible light of high-concentration organic pollutants during degrading of organic compounds, such as rhodamine B and the like; furthermore, during hydrophobic modification, if isopropyl alcohol is found to be a solvent, the NH4F hydrophobic modification effect of the prepared catalyst isthe optimal and the hydrophobic stability is quite good; moreover, the synthesis method is simple in operation and low in cost, and the raw materials are easily obtainable.

Owner:EAST CHINA UNIV OF SCI & TECH

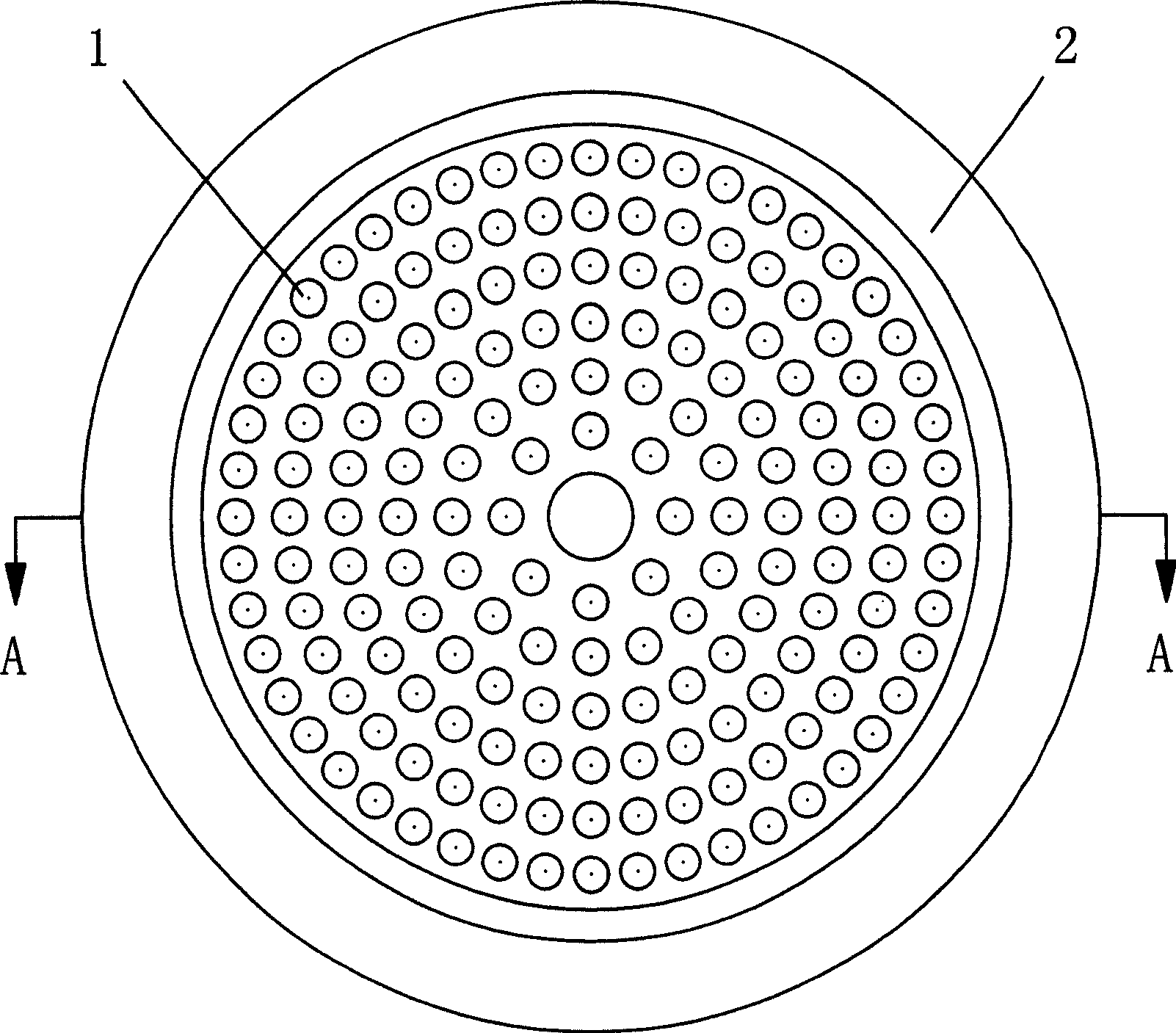

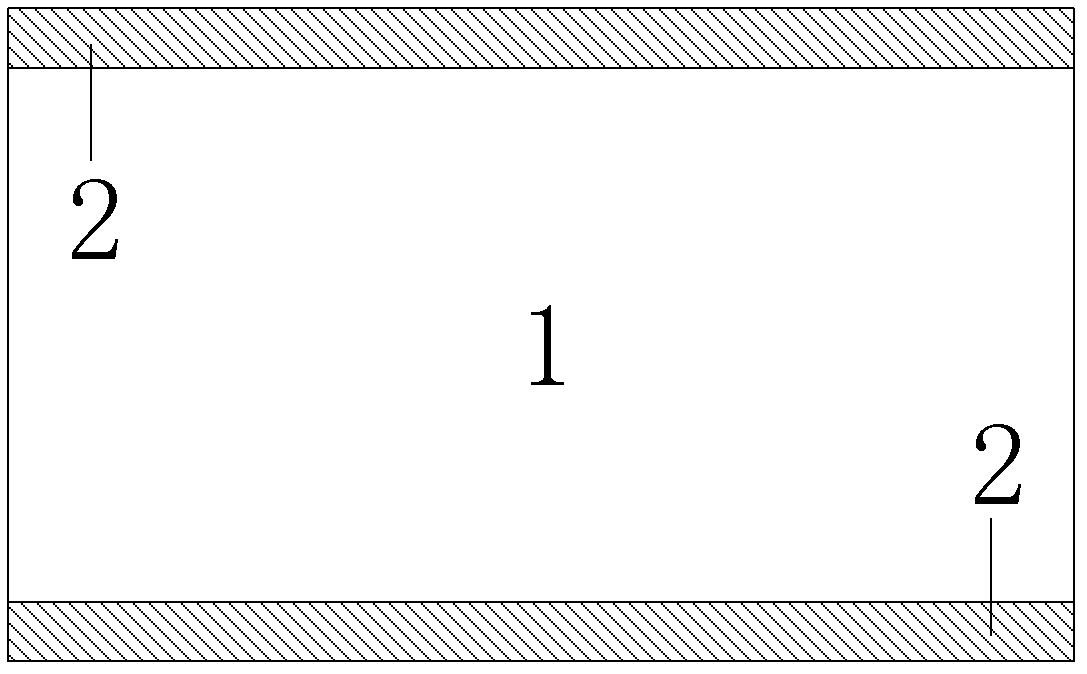

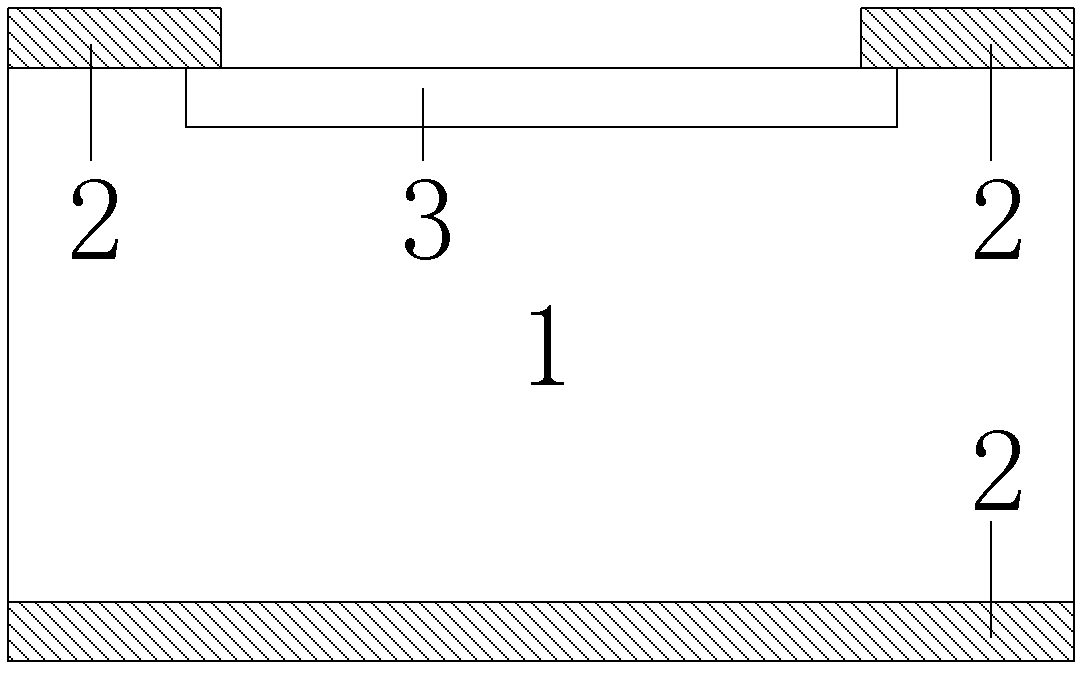

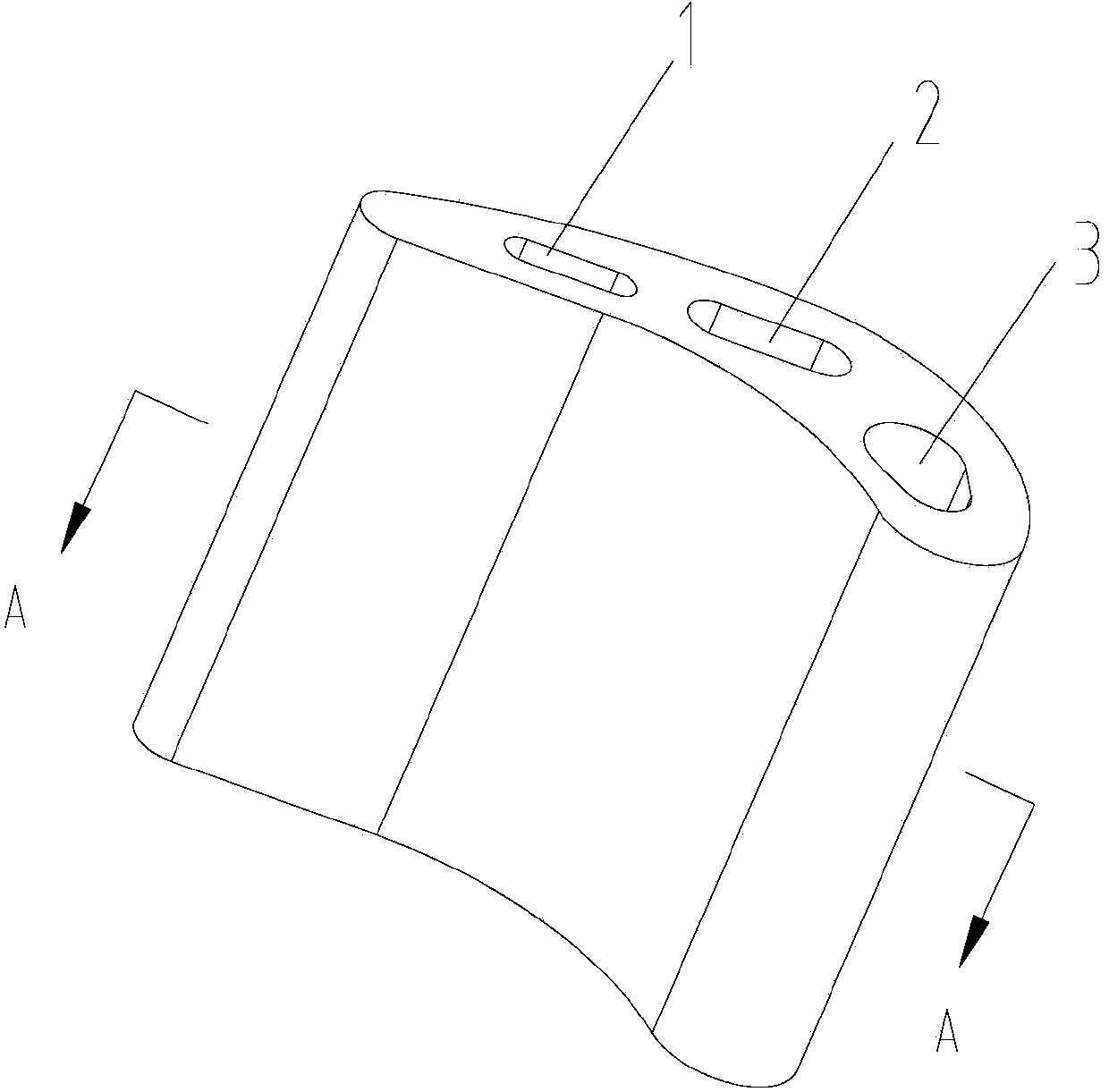

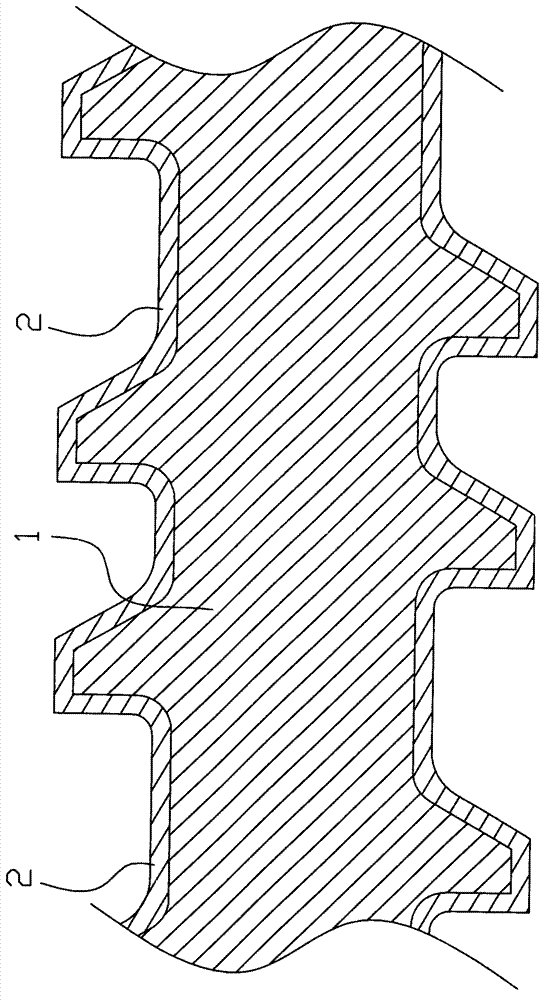

Metallic screw and manufacturing method for same

The invention discloses a metallic screw and a manufacturing method for the same. A chrome and molybdenum-containing alloy steel bar is taken as a screw mandrel (1) of the screw. A multi-element boride-based metal ceramic layer (2) is coated on the periphery of the screw mandrel (1) in a sintering way, and is a Mo2FeB2-Fe-based metal ceramic layer, a Mo2NiB2-Ni-based metal ceramic layer or a WCoB-Co-based metal ceramic layer. The manufacturing method comprises the following steps of: placing the screw mandrel into a sheath, and filling proportioned powdery raw materials into a gap between the screw mandrel and the sheath; placing the whole sheath into a closed container, and vacuumizing the closed container; and sintering the sheath in the closed container, and finely machining the multi-element boride-based metal ceramic layer to obtain the metallic screw. The multi-element boride-based superhard bimetallic or metallic screw has the advantages of low comprehensive cost, simple manufacturing process, long service life, suitability for industrialization, and the like, and can be used for replacing the conventional widely-used screws subjected to nitriding, spray welding, casting and the like.

Owner:浙江华业塑料机械股份有限公司

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com