Lithium ion battery conductive additive and preparation method thereof

A conductive additive, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of decreased electrode capacity, small addition, large addition, etc., to improve performance, easy to disperse, and improve cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the lithium ion battery conductive additive of the present invention adopts oxidation, stripping, reduction preparation process, comprises the following steps:

[0025]1. Oxidation of graphite: at room temperature, put a strong acidic solution in a container, use a DC-2006 low-temperature constant temperature bath from Ningbo Xinzhi Biotechnology Co., Ltd., and cool it to 0-4°C in a water bath, preferably 0°C, and place the graphite Add the mixture of powder and nitrate into the above strong acid solution, and use the JJ-1 timing electric mixer of Jincheng Guosheng Experimental Instrument Factory in Jintan City, Jiangsu Province to slowly add a strong oxidant at a stirring speed of 60-3000rpm, and wait until strong After the oxidant is added, continue to stir for 0.5-12h, then control the temperature of the mixture within the range of 32-38°C, continue to stir for 0.5-12h, then slowly add 0.5-4 times the volume, preferably 2 times the strength o...

Embodiment 1

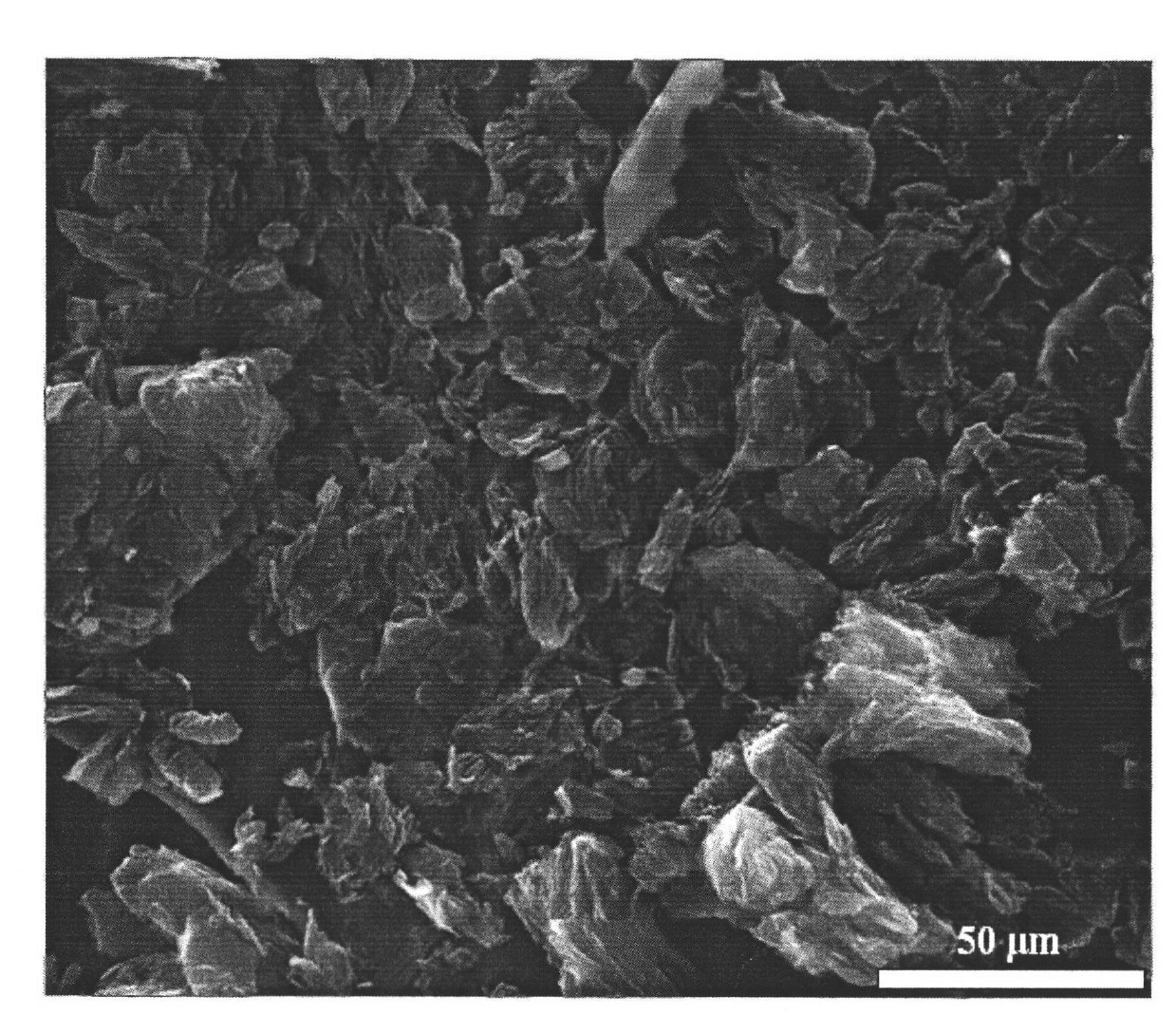

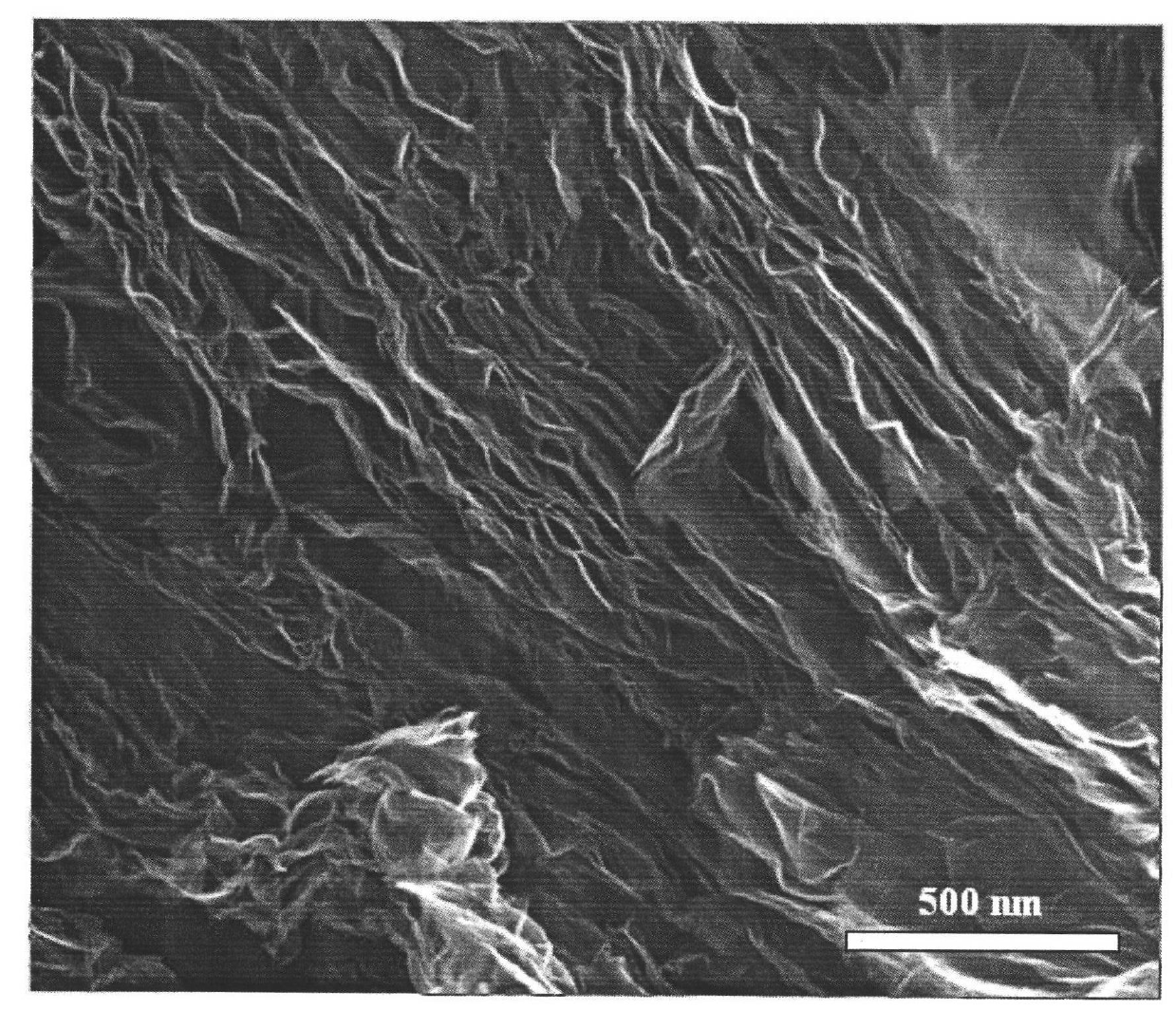

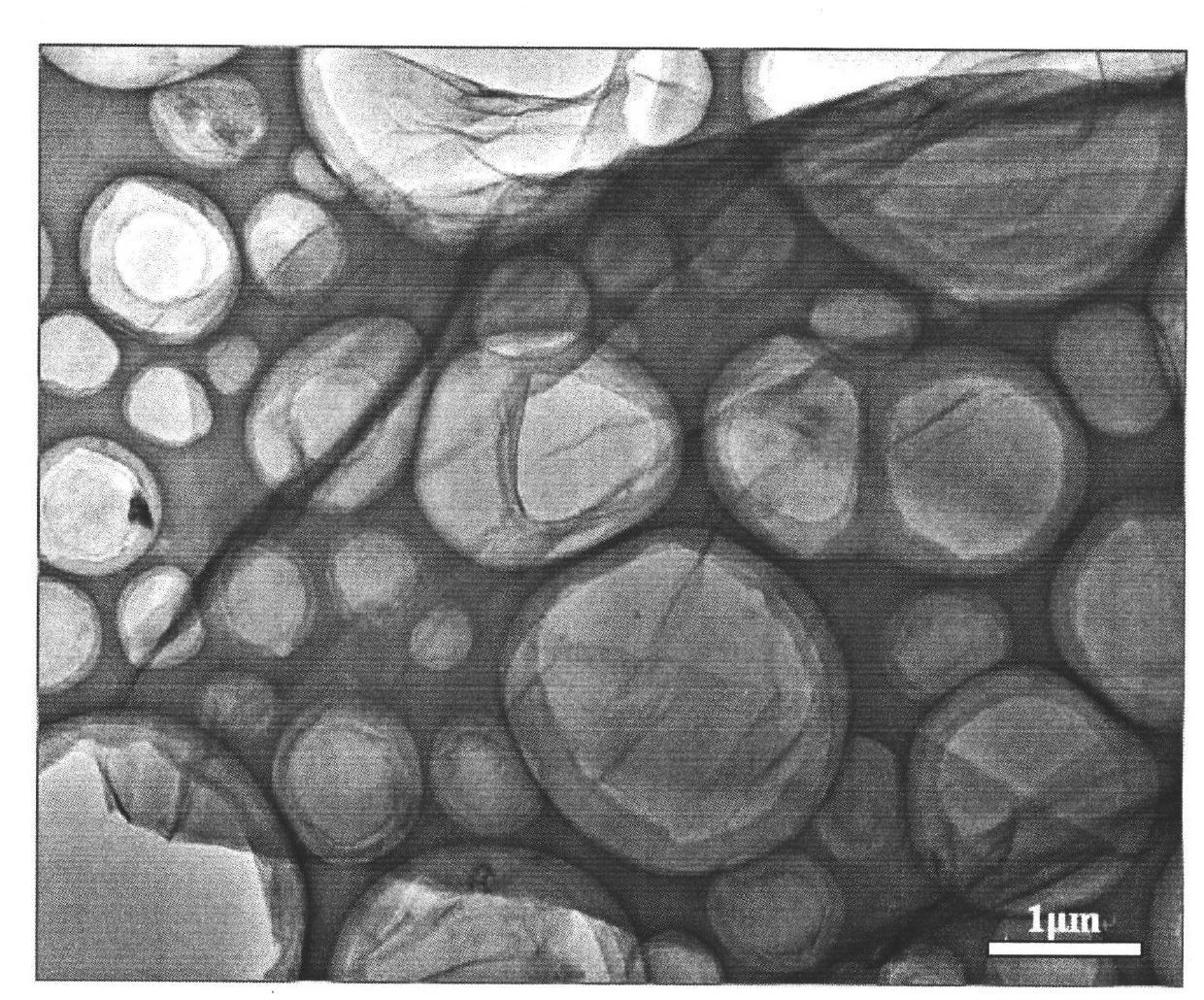

[0050] The graphene powder that embodiment 1 prepares, after testing, specific surface area is 200-400m 2 / g, the conductivity is 5×10 4 -9×10 4 S / m. Such as figure 1 with figure 2 As shown, the particle size distribution is black powder between 5-50μm. Such as image 3 with Figure 4 As shown, it is a carbonaceous material composed of 5-500 layers of parallel or nearly parallel graphene sheets.

[0051] The graphene powder prepared in Example 1 is combined with the lithium iron phosphate positive electrode material, and the preparation method of the positive electrode sheet is as follows: lithium iron phosphate positive electrode material, conductive additive, and binder PVDF are in a mass ratio of 94:3: 3. Using NMP as a solvent, stir in a mixer at a speed of 2000rpm for 4 hours, apply the evenly mixed slurry on an aluminum foil, dry it at 120°C, and then roll it to obtain a positive pole piece; The diaphragm and the negative pole piece were wound, liquid injected, ...

Embodiment 2

[0059] The negative electrode sheets used in Example 2 and Comparative Example 2 are the same, and the manufacturing method is the same as that of the negative electrode sheets in Example 1 and Comparative Example 1. The electrical performance tests of Example 2 and Comparative Example 2 are shown in Table 3.

[0060] Table 3 embodiment 2 and comparative example 2 electrical performance test results

[0061]

[0062] Composite the graphene powder prepared in Example 3 with natural graphite, a negative electrode material for lithium-ion batteries, to make a negative electrode for the battery. The production method of the negative electrode sheet is as follows: graphite negative electrode material, conductive additive graphene powder, binder SBR, thickener CMC according to the mass ratio of 94:2:2.5:1.5, with water as the solvent, in the mixer with a speed of 1500rpm Stir for 3 hours, coat the uniformly mixed slurry on the copper foil, dry at 100°C, and then roll to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com