Lithium ion battery preparation method and lithium ion battery

A lithium-ion battery and lithium salt technology, applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of restricting the use environment of lithium-ion batteries, potential safety hazards, and rapid capacity decay, and improve high-temperature storage performance. , The effect of high residual capacity retention rate and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

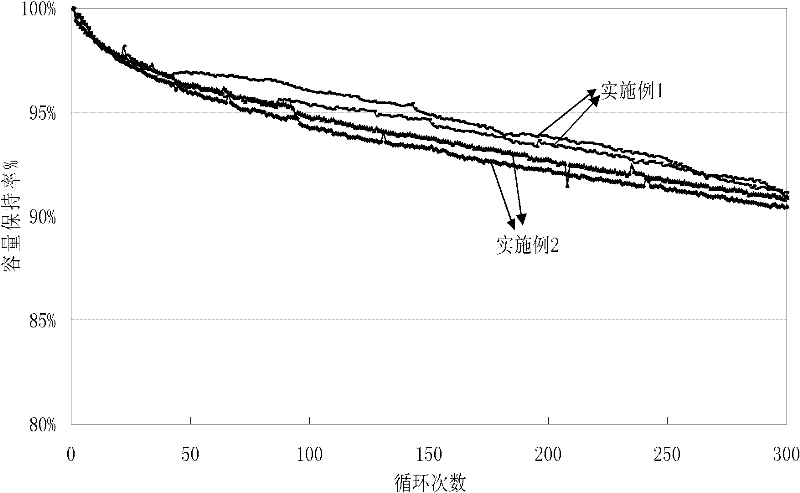

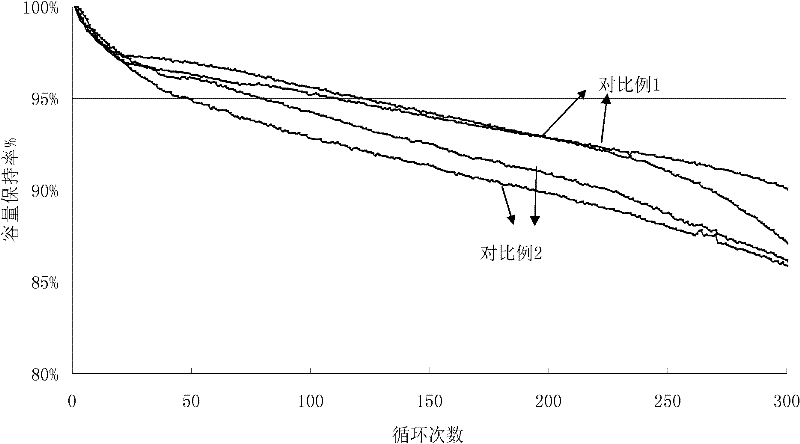

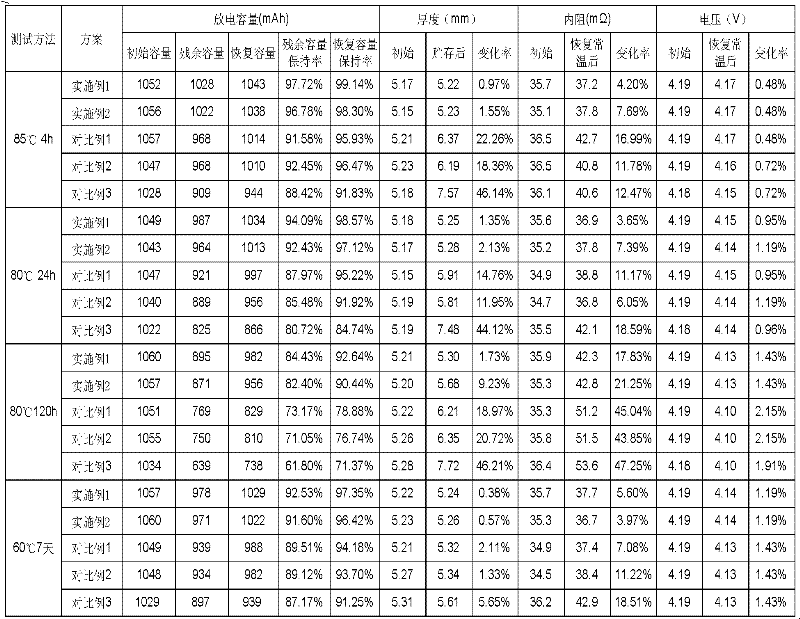

Embodiment 1

[0017] A lithium-ion battery with a model number of 083448S and a nominal capacity of 1050mAh was prepared, and the specific preparation steps were as follows.

[0018] 1) Ingredients. The positive electrode active material lithium cobaltate (LiCoO 2 ), positive electrode conductive agent acetylene black (cabot CABOT superconducting carbon black BP2000), positive electrode binder PVDF (model RC10214) and solvent NMP were mixed and stirred evenly to make positive electrode slurry. Among them, the median particle size D50 of lithium cobaltate is 5-15um, and the specific surface area is 0.22-0.90m 2 / g, the tap density is 2.0~3.0g / cm 3 .

[0019] Mix the natural modified graphite coated with negative electrode active material carbon and the negative electrode conductive agent acetylene black, and then uniformly disperse it in the configured aqueous solution of sodium carboxymethylcellulose (CMC), and add styrene-butadiene rubber (SBR) therein as The binder is uniformly stirre...

Embodiment 2

[0037] A lithium-ion battery with a model number of 083448S and a nominal capacity of 1050mAh was prepared, and the specific preparation steps were as follows.

[0038] 1) Ingredients. The positive electrode active material lithium cobaltate (LiCoO 2 ) and doped part of nickel-cobalt lithium cobalt oxide, positive electrode conductive agent acetylene black (using Cabot CABOT superconducting carbon black BP2000), positive electrode binder PVDF (model RC10214) and solvent NMP mixed and stirred evenly to make positive electrode slurry . Among them, the median particle size D50 of lithium cobaltate is 5-15um, and the specific surface area is 0.22-0.90m 2 / g, the tap density is 2.0~3.0g / cm 3 . The doping amount of lithium nickel cobalt cobalt oxide is 0-30wt%.

[0039] Mix the natural modified graphite coated with negative electrode active material carbon and the negative electrode conductive agent acetylene black, and then uniformly disperse it in the configured aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com