Anode active substance, production method thereof, and lithium ion battery employing anode active substance

A positive active material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problem of large apparent specific surface area (mainly affected by light carbon elements, lithium iron phosphate powder vibration The problems of low compaction and compaction density, and difficult implementation of the carbon coating method have achieved the effect of superior high-temperature storage performance, significant production practical significance, and improved market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] 1. Preparation of negative electrode sheet: mix the negative electrode active material (such as graphite), conductive agent (such as carbon black SP), polyvinylidene fluoride (PVDF, as a binder) uniformly, and add it to the solvent N, N dimethyl ratio And then mix and stir evenly to obtain a fluid negative electrode slurry. The negative electrode slurry is evenly coated on the negative electrode current collector (such as copper foil) and then dried to make the negative electrode slurry completely in A negative electrode active material layer (ie, negative electrode slurry coating) is formed on the surface of the negative electrode current collector, thereby preparing a negative electrode sheet. In addition, in the present invention, the metal lithium sheet can be used as the negative electrode active material directly as the negative electrode.

[0063] 2. Preparation of positive electrode sheet: the positive electrode active material of the present invention (such as lit...

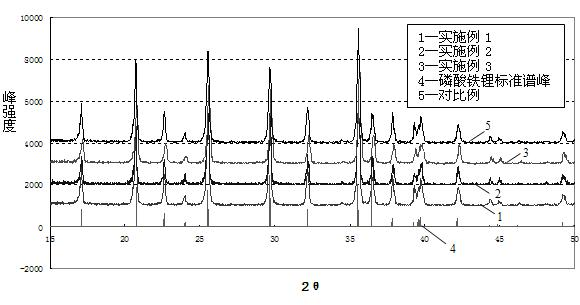

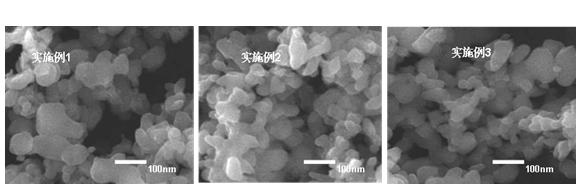

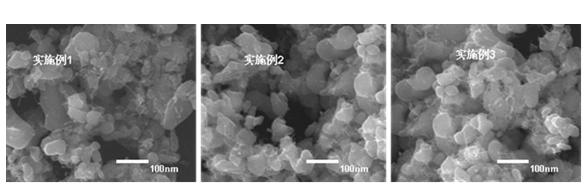

Embodiment 1

[0087] First, mix the aqueous solution of lithium hydroxide and phosphoric acid in a molar ratio of 3:1, and stir to form a white lithium phosphate suspension, and then mix ferrous sulfate with a molar ratio of 1:0.002 and the organic acid additive citric acid. The resulting mixed solution was added dropwise to the suspension, stirred and adjusted the pH value to about 4.8, then the suspension was transferred to the reactor, and reacted at 230°C for 8-12 hours. After the reaction, Obtain a light green precipitate, and then wash it with water or ethanol several times, then go through ball milling for 4-8 hours, then dry it under a vacuum of 80°C, and then calcinate at a temperature of 650°C under a protective atmosphere to sinter Obtain nano-lithium iron phosphate, and finally mix the obtained nano-lithium iron phosphate and high-conductivity carbon nanotubes (CNT) together to obtain a lithium metal phosphate compound Li x M y PO 4 A composite material formed by mixing with carbo...

Embodiment 2

[0089] The positive electrode active material was prepared in the same manner as in Example 1, except that the calcination temperature was changed to 600°C, and the same method as in Example 1 was used to prepare a lithium metal phosphate compound Li x M y PO 4 A composite material formed by mixing with carbon nanotube CNT (that is, the positive electrode active material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com