Method for finishing antistatic antibacterial and hydrophilic polyester fabric

A polyester fabric, hydrophilic technology, applied in fiber treatment, plant fibers, textiles and papermaking, etc., can solve the problems of easy to change the excellent properties of fibers, poor hygroscopicity of polyester fabrics, and reduced clothing comfort, etc., to achieve good affinity Effect of water-based properties, enhanced hygroscopicity and hydrophilicity, good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

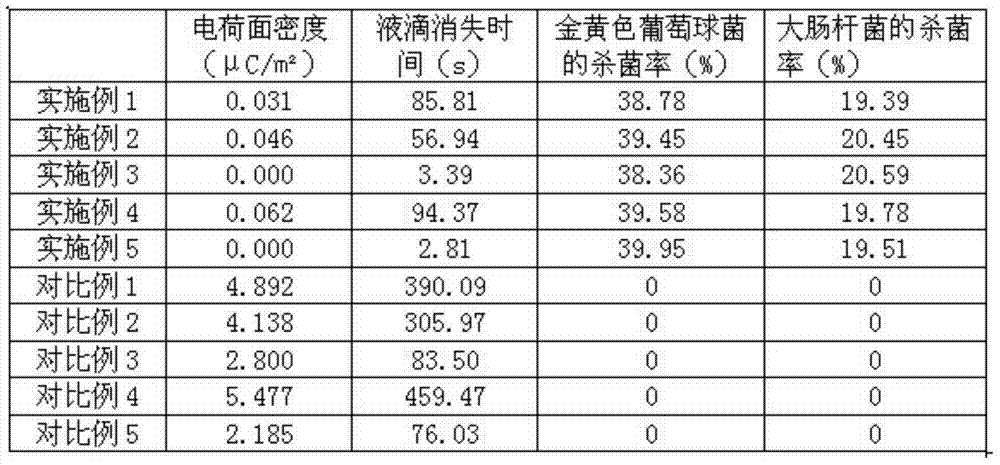

Examples

preparation example Construction

[0022] The preparation process of step 10) is: adding chitosan to the container, and then adding a 99.7% isopropanol solution, wherein the mass ratio of the chitosan to the isopropanol solution is 1:8-16, While stirring the chitosan and isopropanol solutions, add a 40% mass fraction of NaOH solution. The mass ratio of chitosan to NaOH solution is 1:1 to 6 to form a mixed solution. Stir the mixed solution at 44°C. After the chitosan is melted for 2 to 4 hours, a 50% mass fraction of chloroacetic acid aqueous solution is dropped in 20min to 1.5h, and the mass ratio of chitosan to chloroacetic acid aqueous solution is 1:1 to 5; after dropping the chloroacetic acid aqueous solution , Reacting at 50-65°C for 4-10h to prepare N,O-carboxymethyl chitosan solution with a degree of substitution of 40-150%. If the amino group at position 2 and the hydroxyl group at position 6 in the chitosan molecular structure are all substituted, the degree of substitution should be 200%. Although theo...

Embodiment 1

[0031] A finishing method of polyester fabric, the polyester fabric is made of polyester, including the following steps:

[0032] Step 10): Prepare N,O-carboxymethyl chitosan solution: add chitosan with a molecular weight of 100000 Da into the container, and then add a 99.7% isopropanol solution, where chitosan and isopropyl The mass ratio of the alcohol solution is 1:8. While stirring the chitosan and isopropanol solutions, add a 40% mass fraction of NaOH solution. The mass ratio of chitosan and NaOH solution is 1:1 to form a mixed solution. Stir the mixed solution at 44℃. After alkalizing the chitosan for 2 hours, drop a 50% mass fraction of chloroacetic acid aqueous solution within 20 minutes. The mass ratio of chitosan to the chloroacetic acid aqueous solution is 1:1; finish dropping the chloroacetic acid aqueous solution Then, the reaction was carried out at 50° C. for 4 hours to obtain a N,O-carboxymethyl chitosan solution with a degree of substitution of 90%.

[0033] Step ...

Embodiment 2

[0036] A finishing method of polyester fabric, the polyester fabric is made by mixing polyester and nylon with a mass ratio of 50:50, and includes the following steps:

[0037] Step 10): Prepare N, O-carboxymethyl chitosan solution: add chitosan with a molecular weight of 20000 Da into the container, and then add a 99.7% isopropanol solution, where chitosan and isopropyl alcohol The mass ratio of the propanol solution is 1:16. While stirring the chitosan and isopropanol solutions, add a 40% mass fraction of NaOH solution, the mass ratio of chitosan and NaOH solution is 1:6 to form a mixed solution. Stir the mixed solution at 44°C and alkalize the chitosan for 3.5 hours, drop a 50% mass fraction of chloroacetic acid aqueous solution within 50 minutes, the mass ratio of chitosan to chloroacetic acid aqueous solution is 1:3; After the acetic acid aqueous solution, the reaction was carried out at 60° C. for 7 hours to obtain a 126% N,O-carboxymethyl chitosan solution.

[0038] Step 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com