Patents

Literature

1161results about How to "Good low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

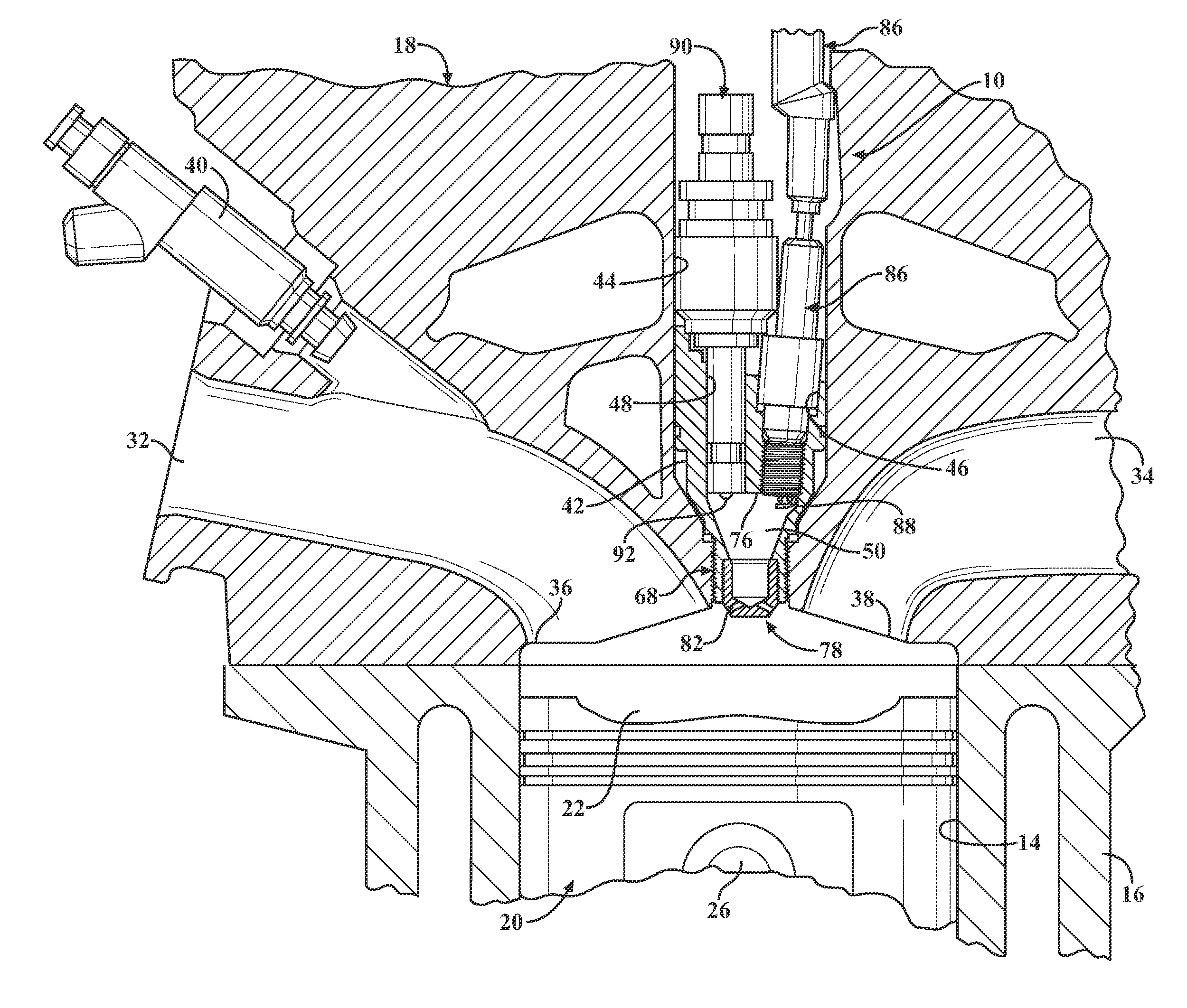

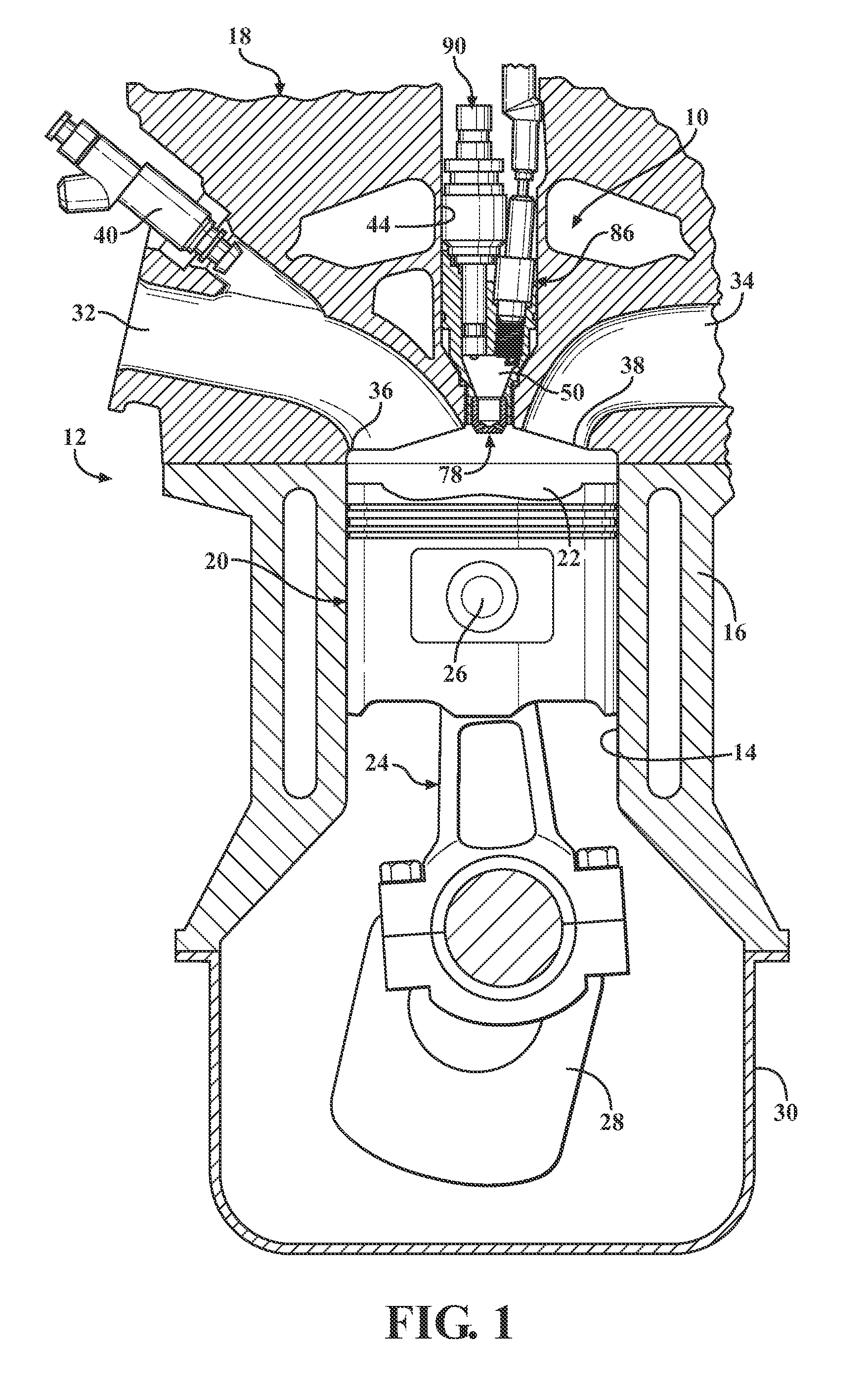

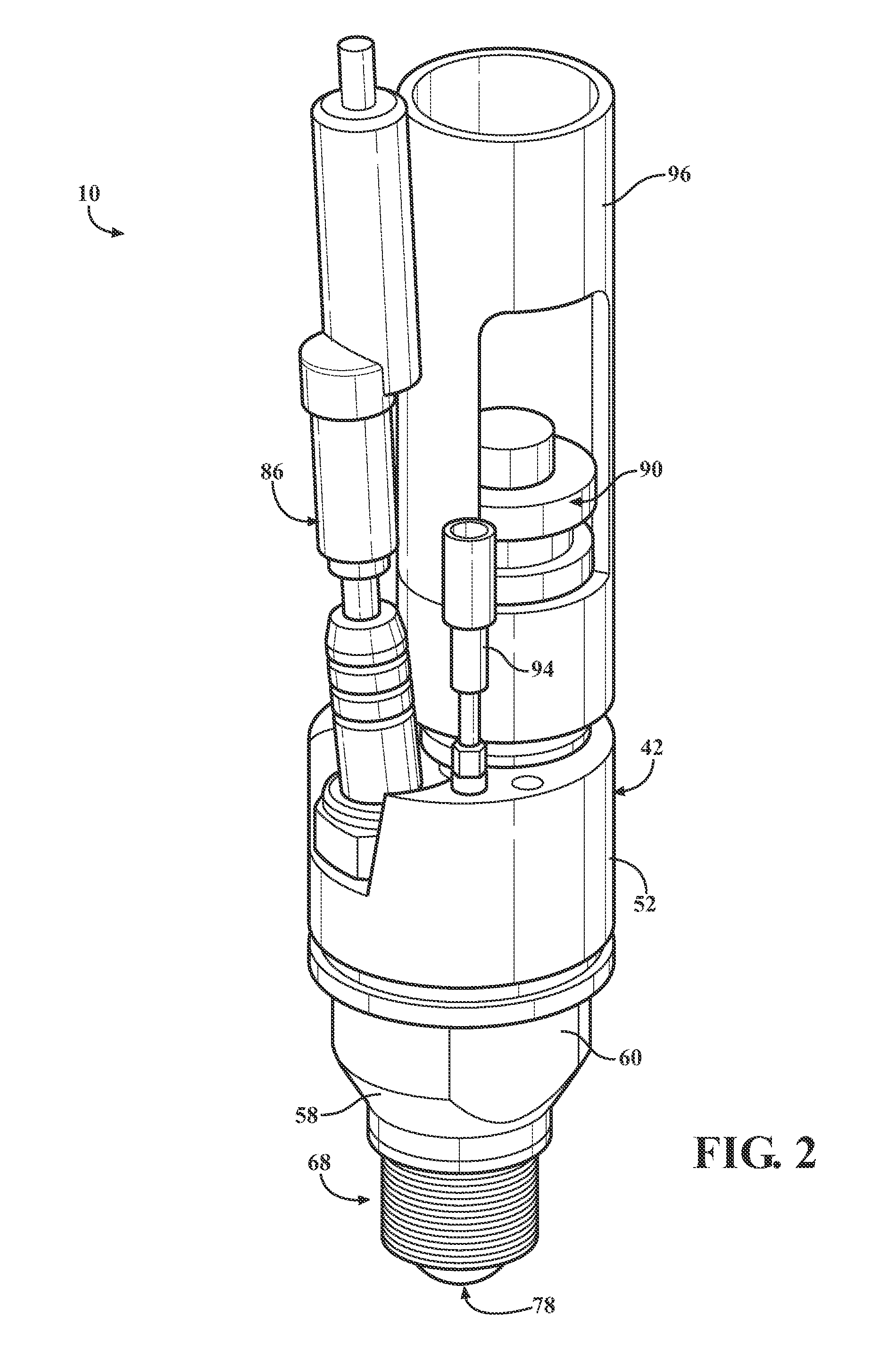

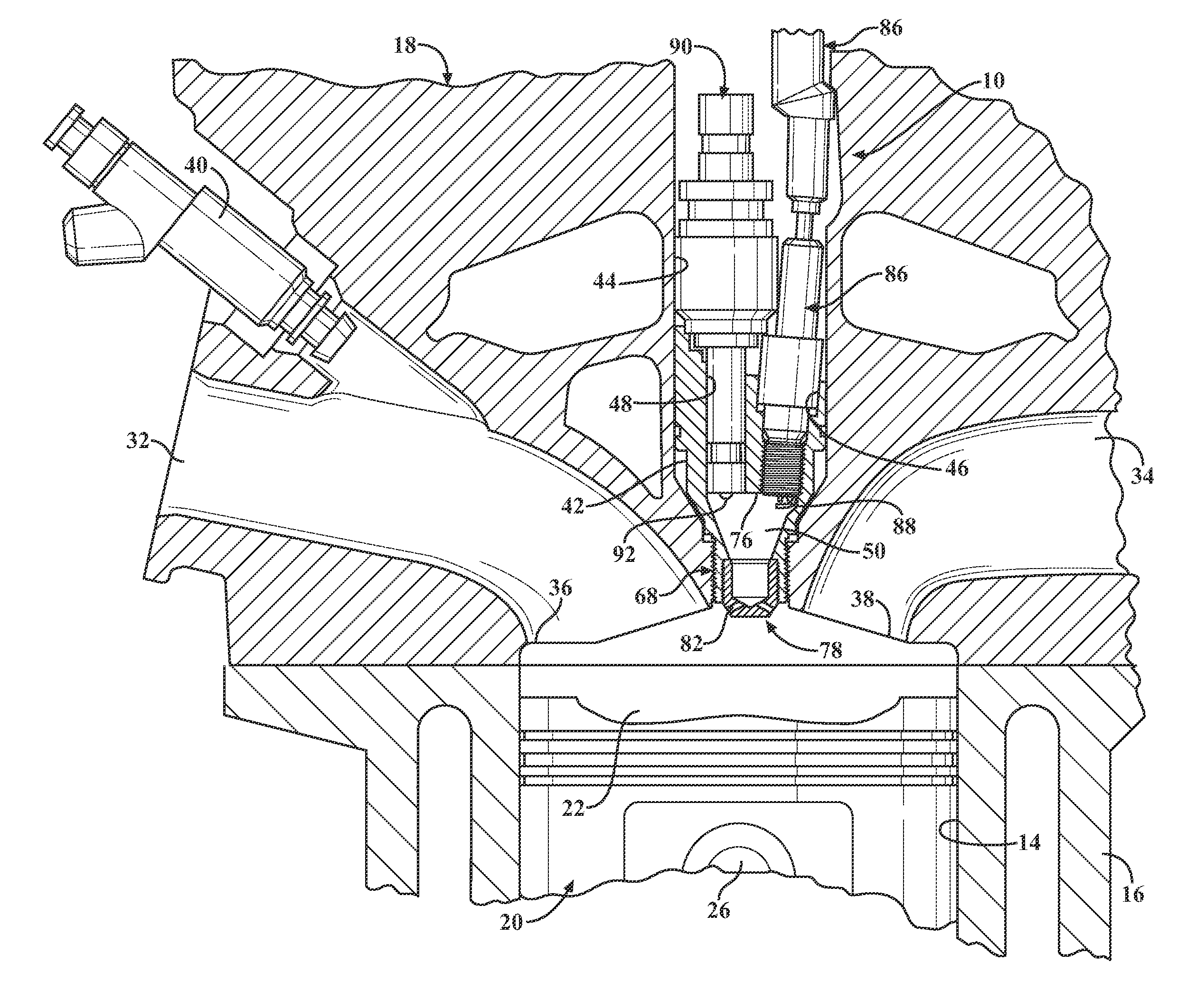

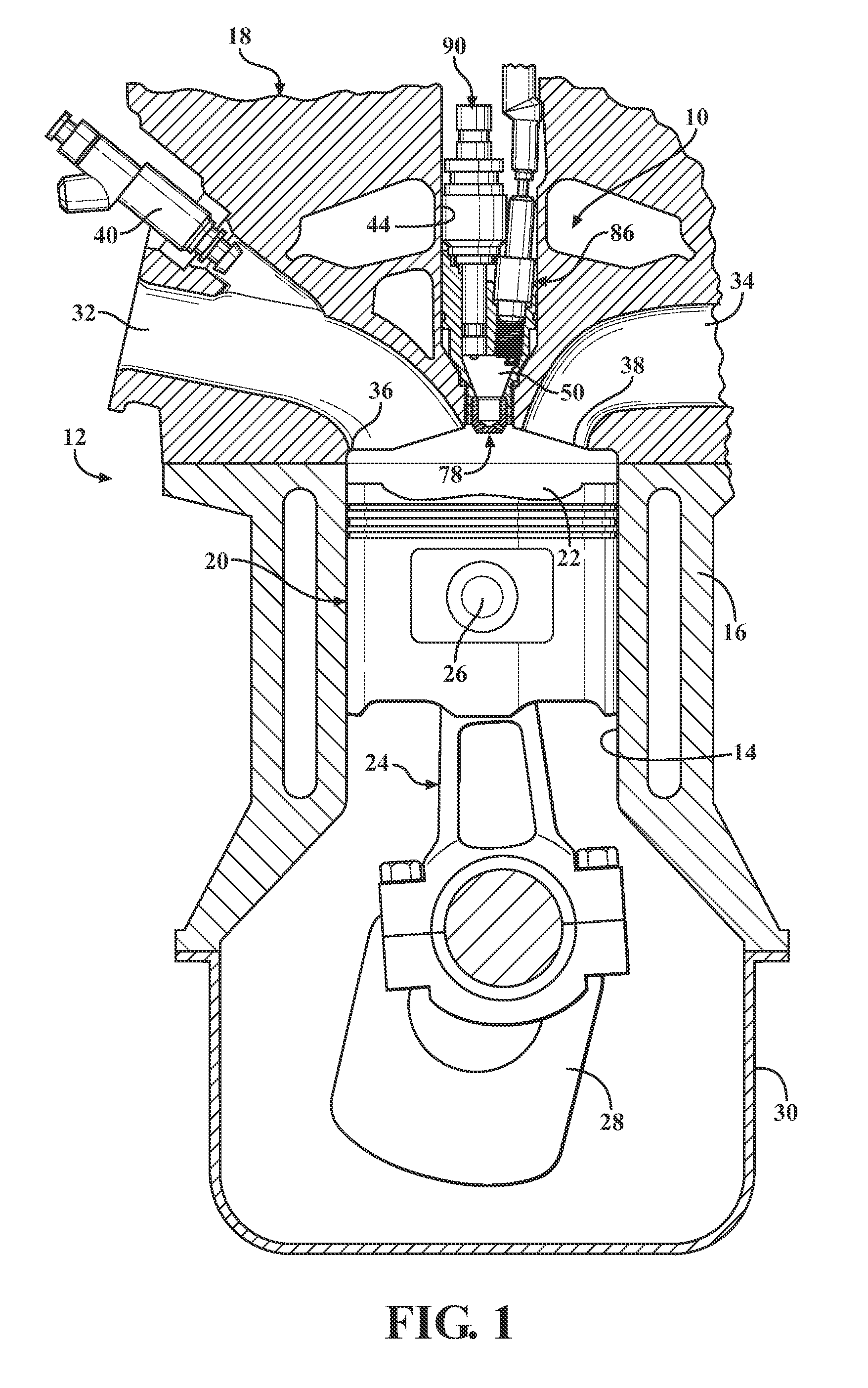

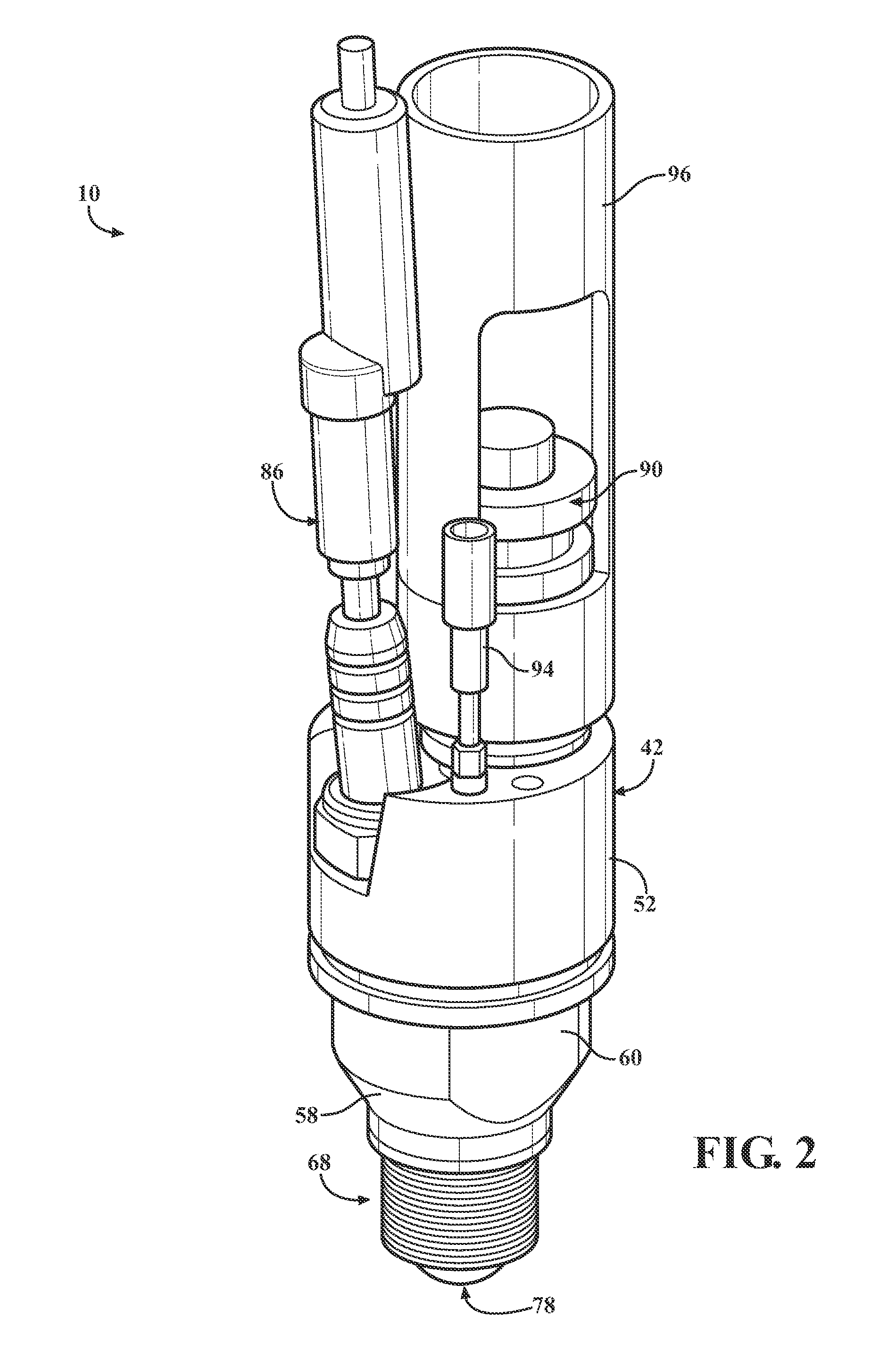

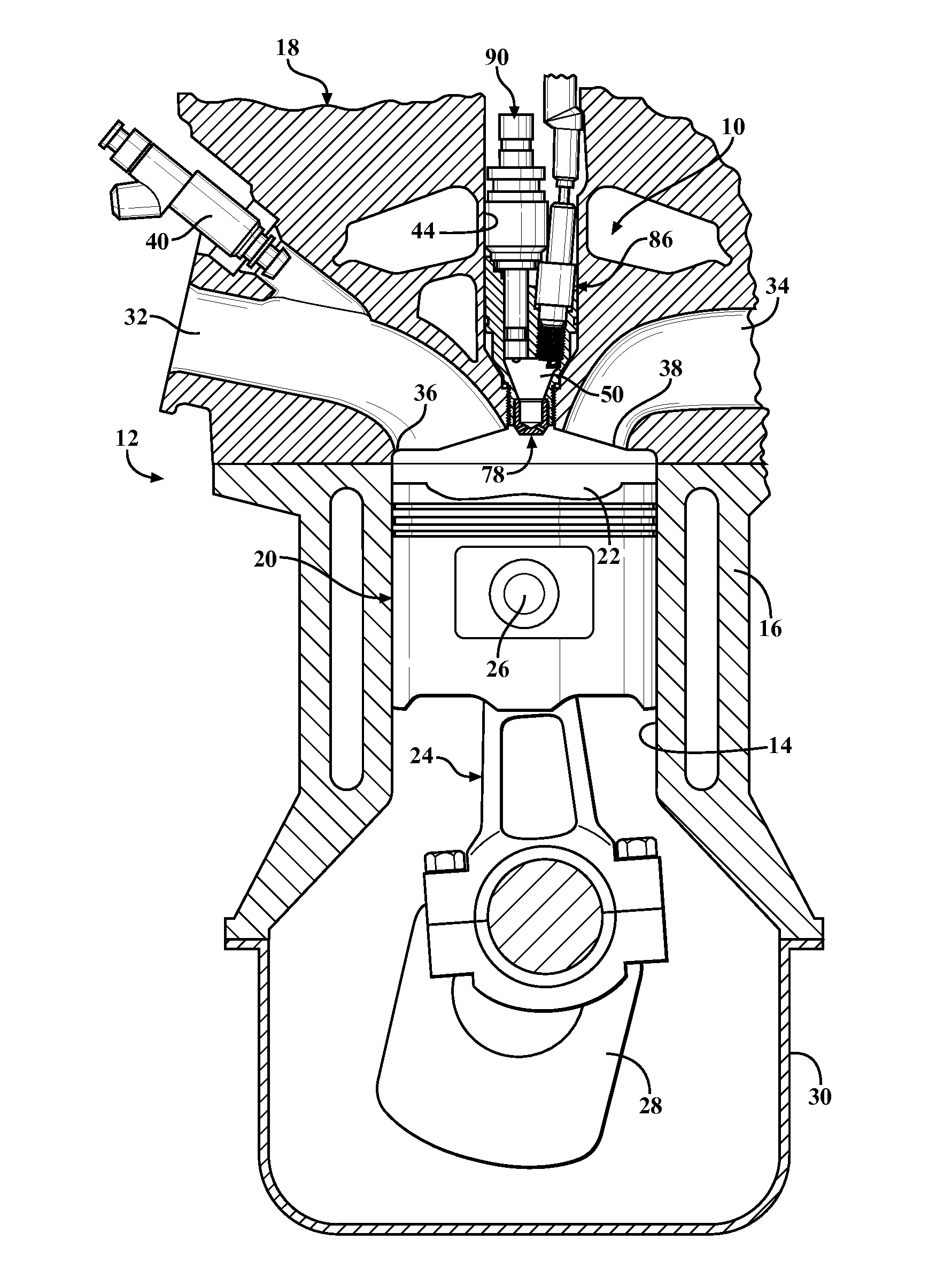

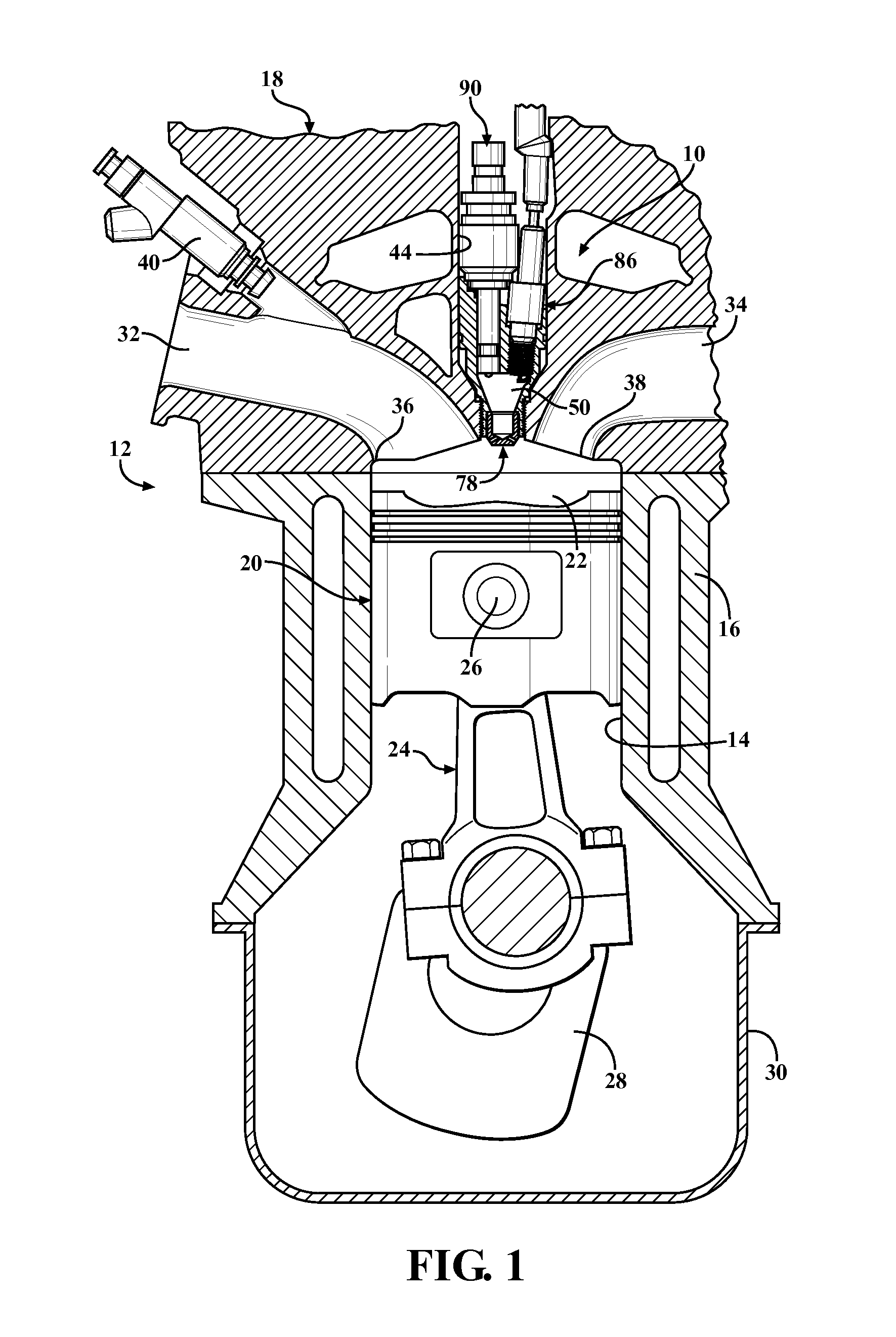

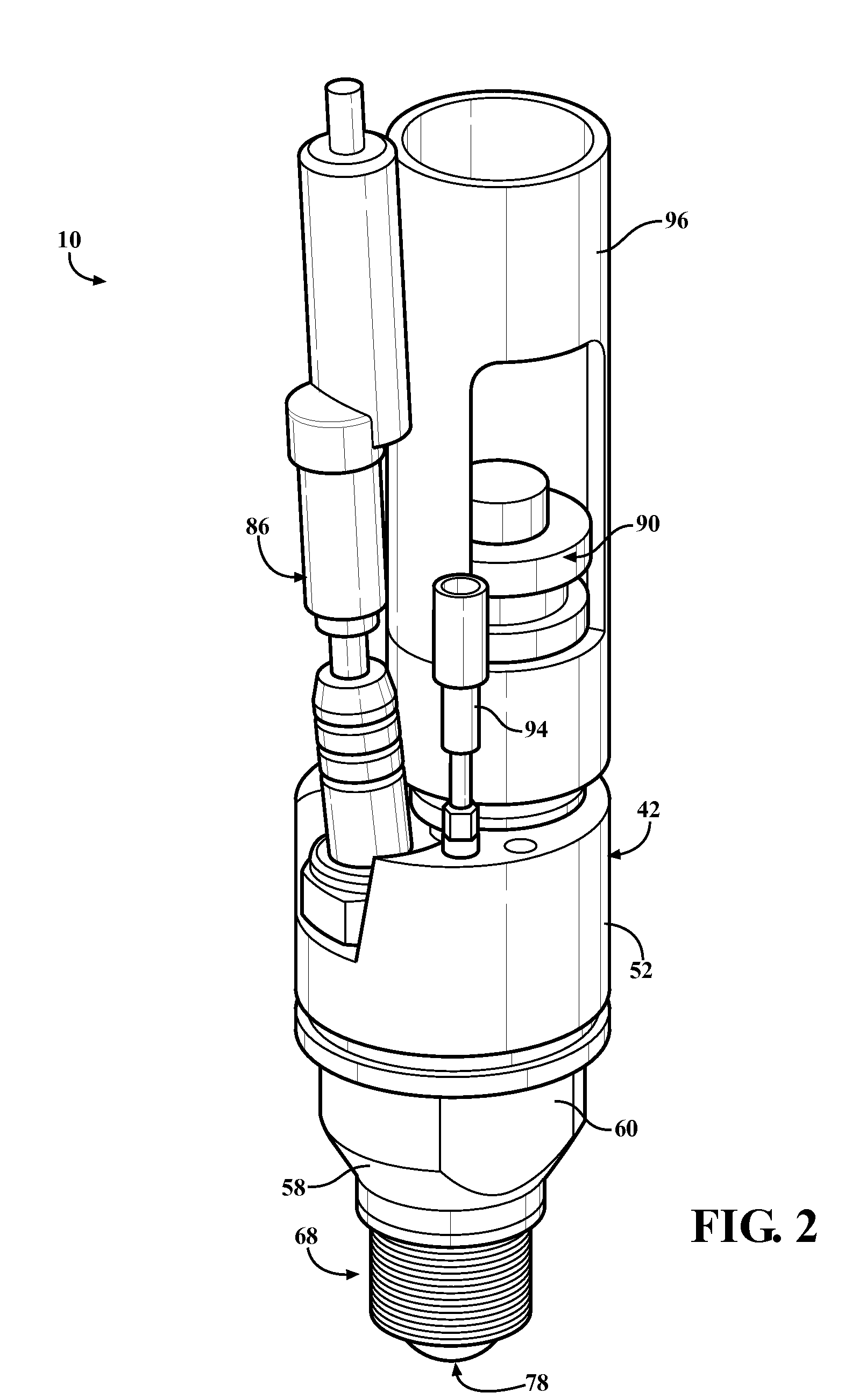

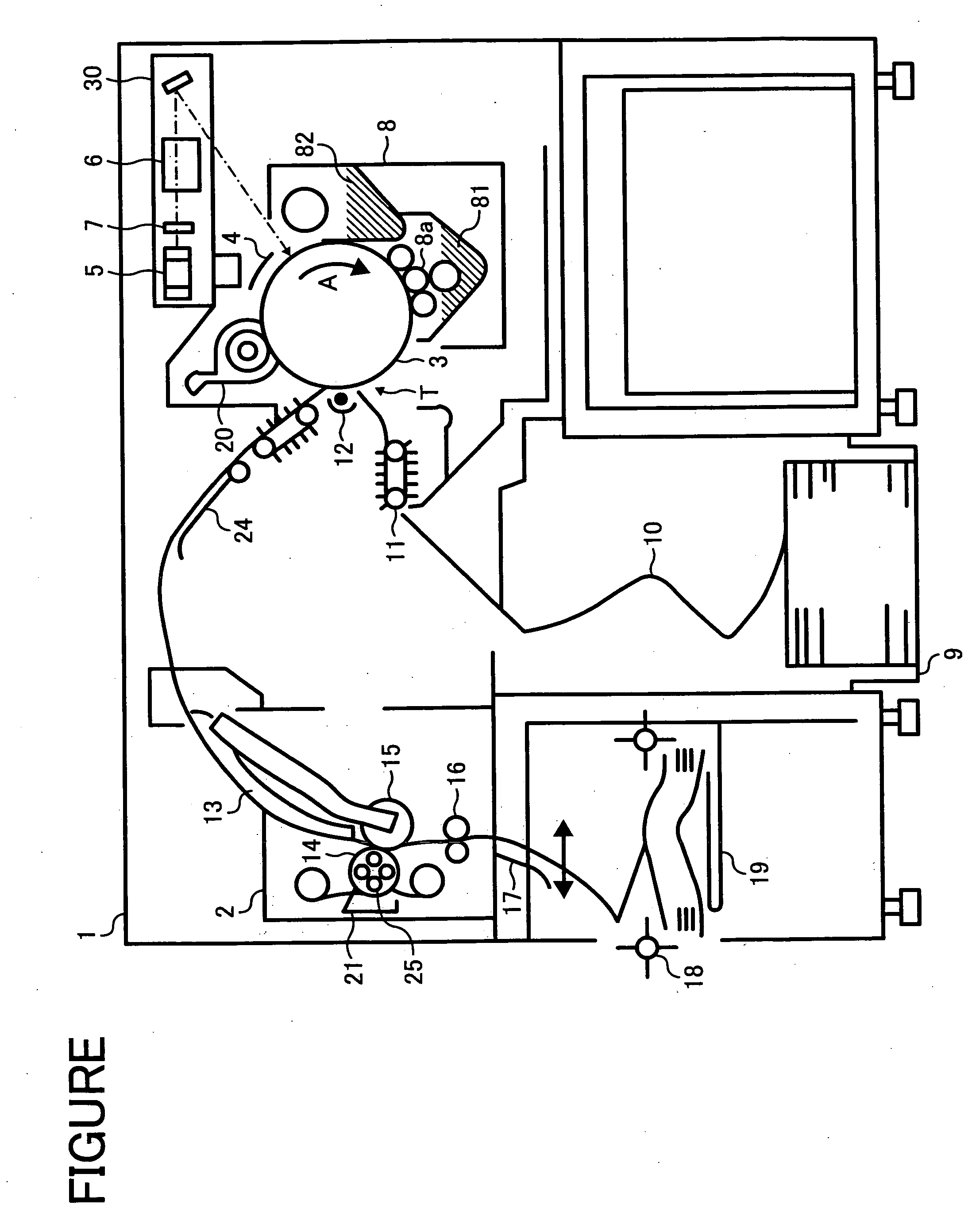

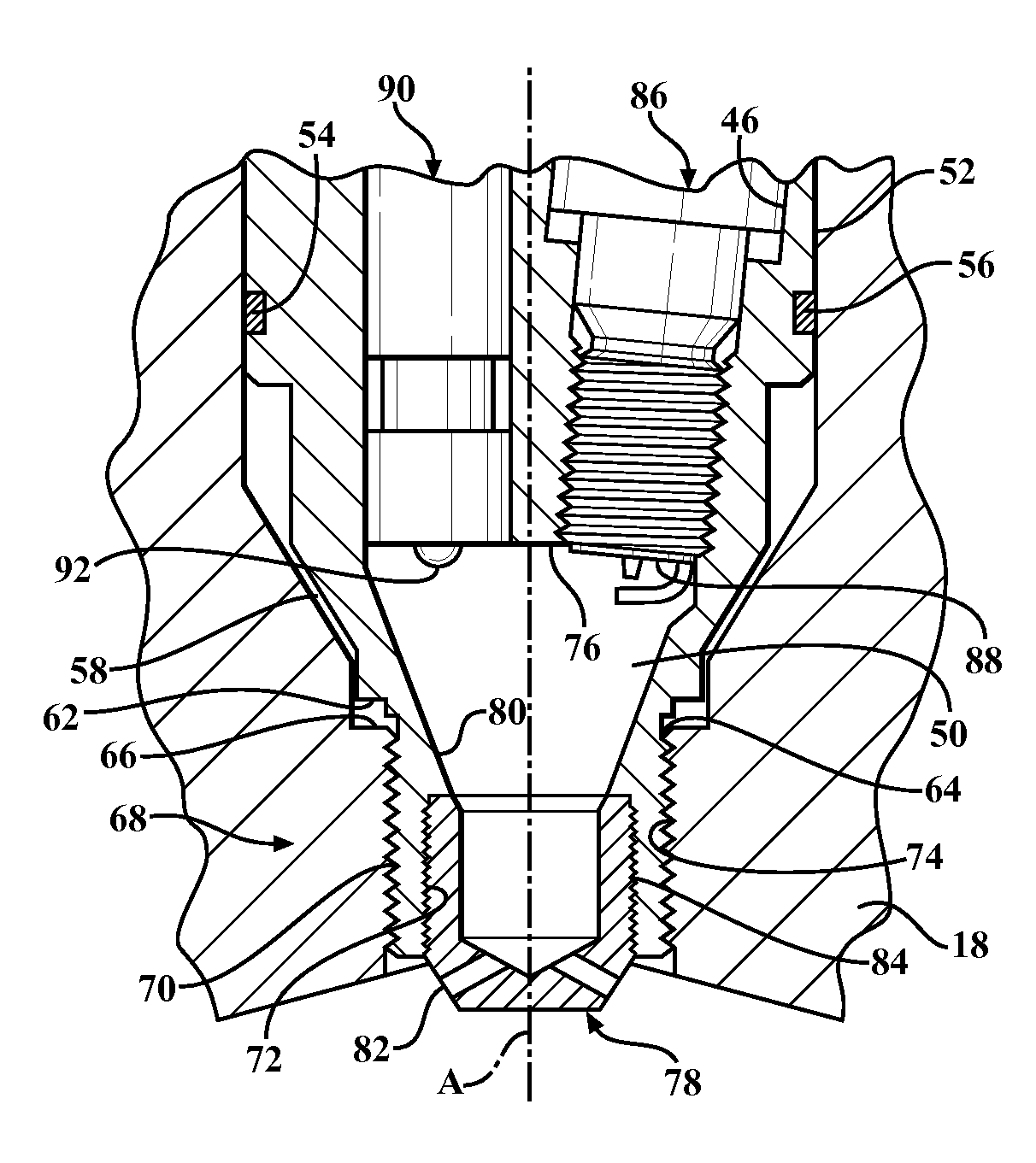

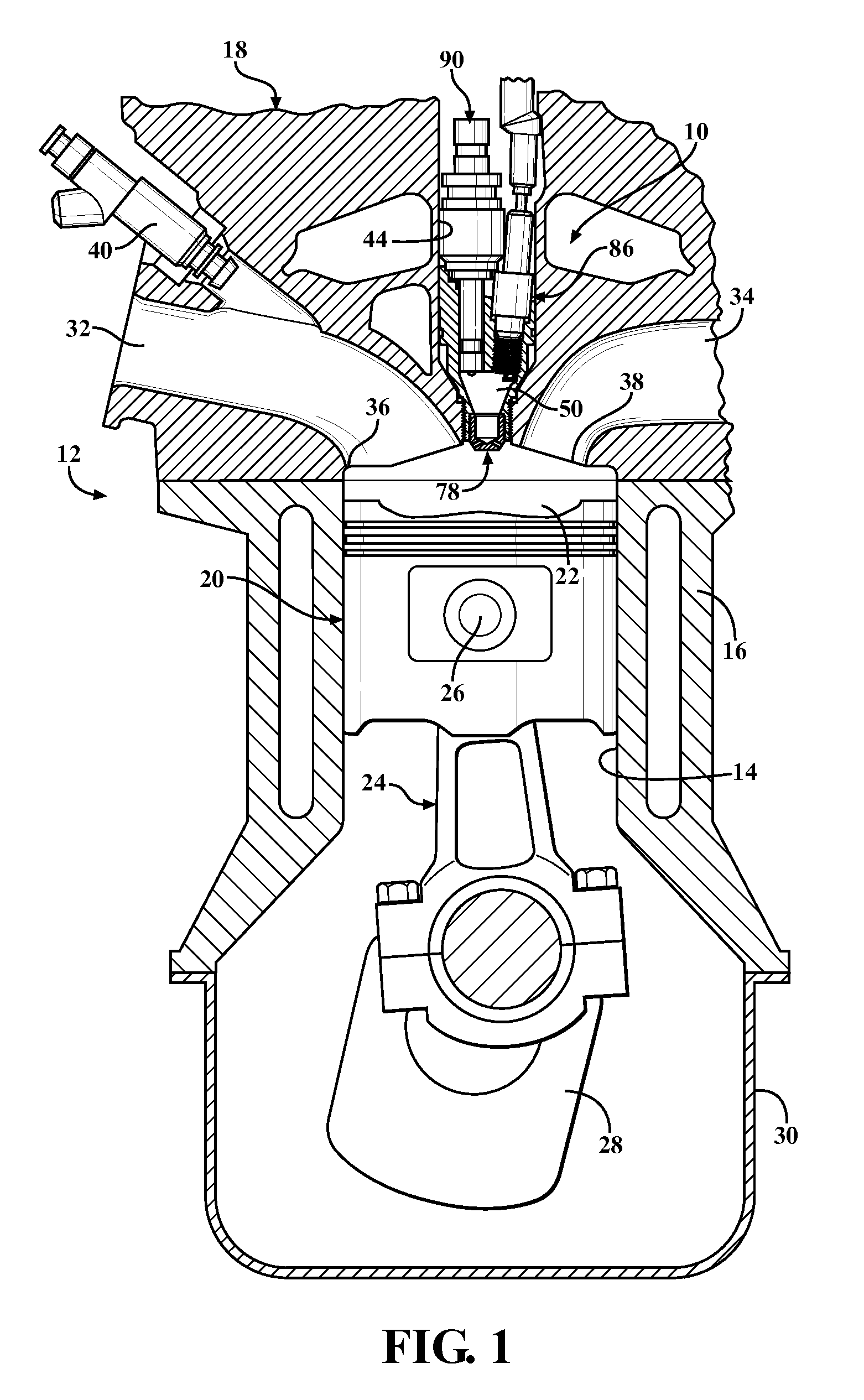

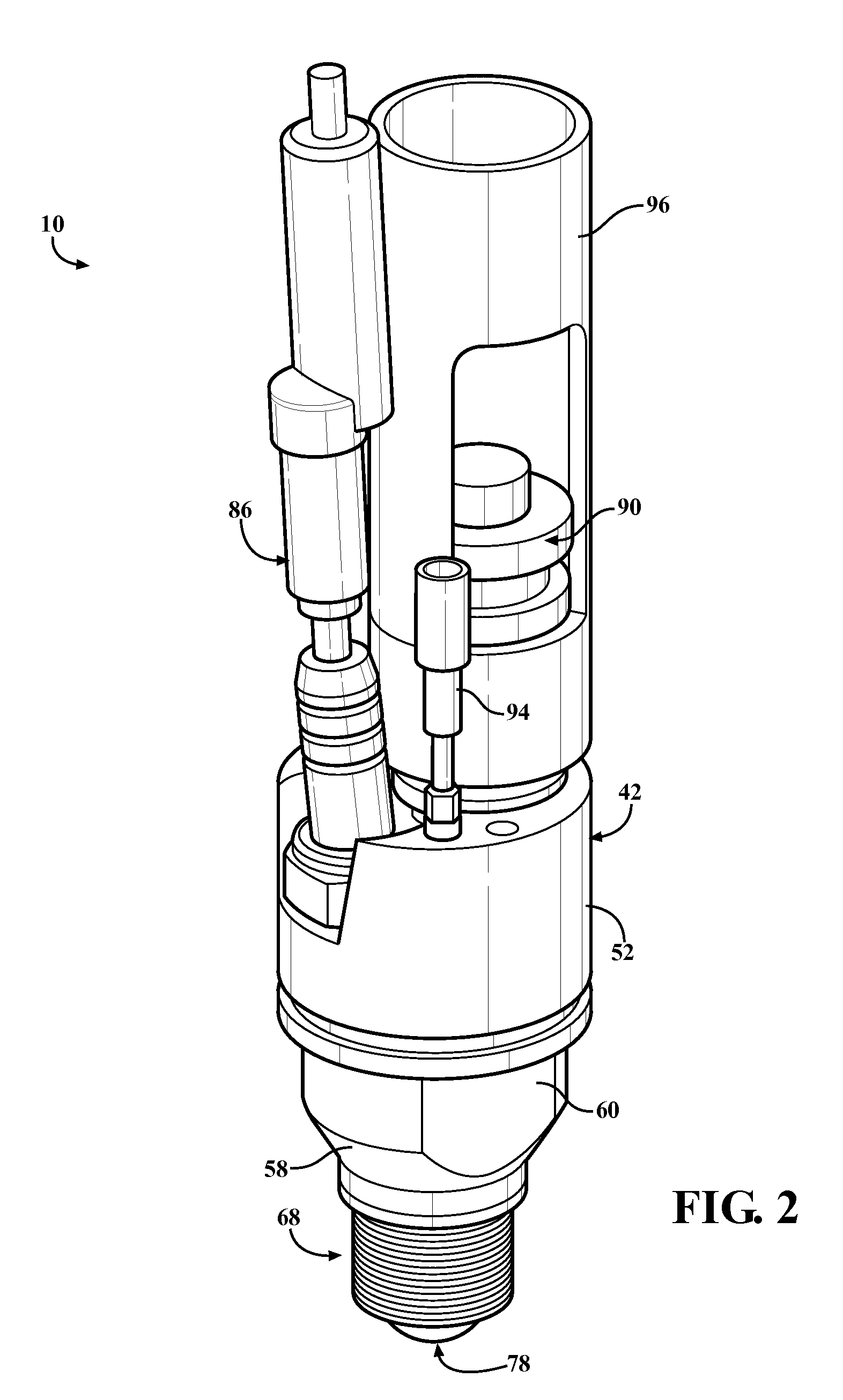

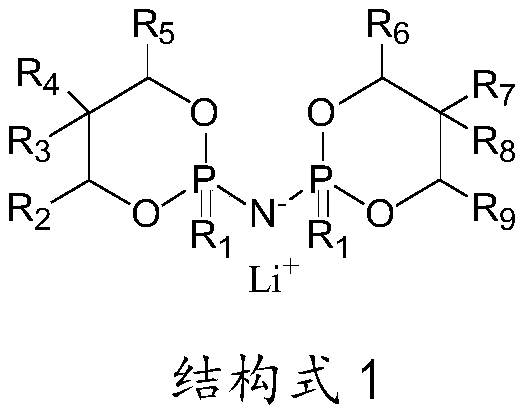

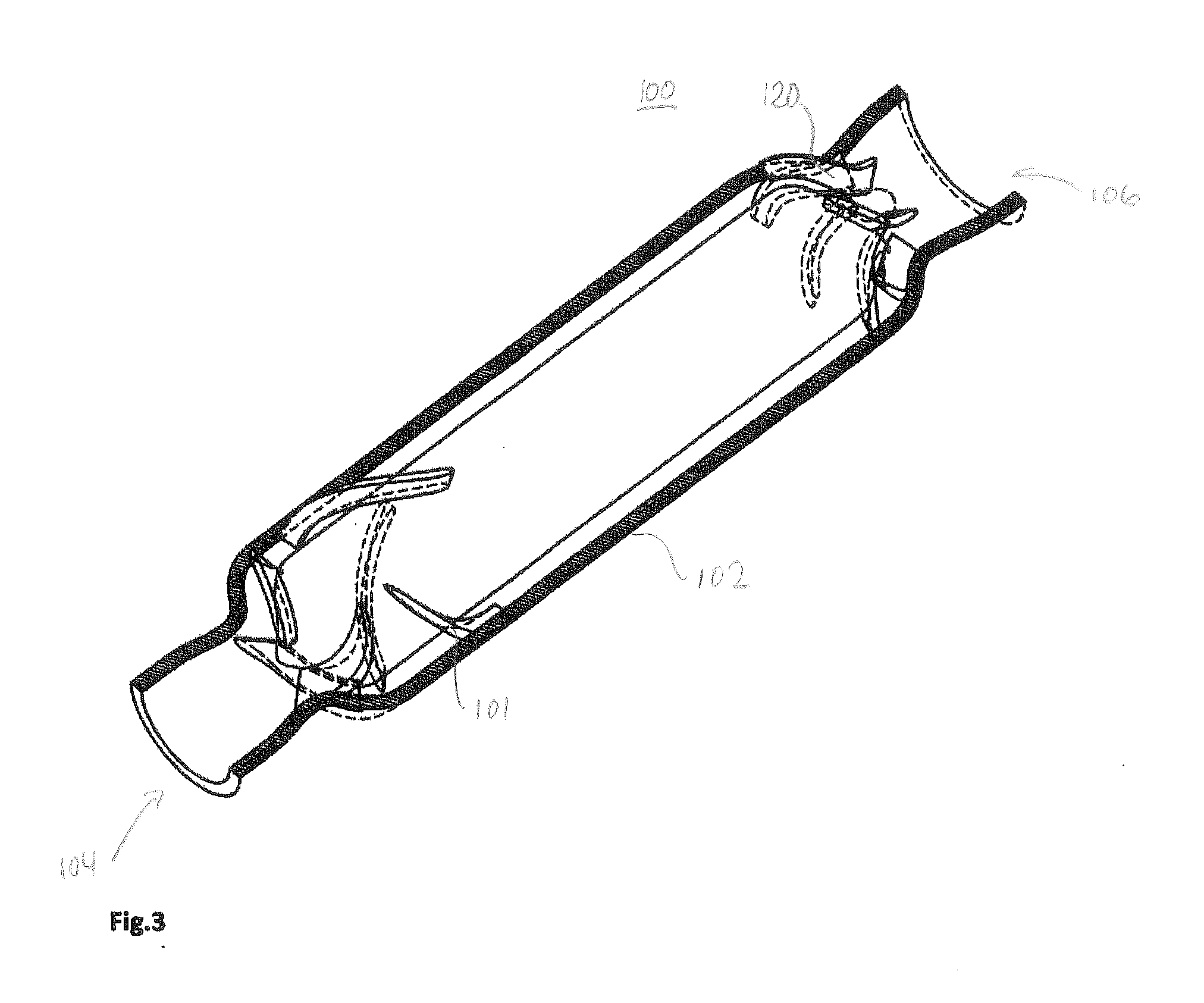

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS20120103302A1Promote flame quenchingHigh-drive cycle (part load) fuel economyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

Composite material containing modified basalt fiber and polymer and preparation method thereof

The invention provides composite material containing a modified basalt and a polymer and a preparation method thereof, wherein the main components of the composite material contains: 1200-1300 parts of polymer, 700-800 parts of modified basalt fiber, and 5-50 parts of surfactant coupling agent. The method, by means of the mechanical force, supersonic wave and electromagnetic force synthetic effect of the surfactant or coupling agent, comprises: uniformly dispersing the polymer and the modified basalt fiber into a solvent to prepare a uniform and stabile mixture, adding another solvent into the mixture, implementing the cladding or wrapping to the modified basalt fiber while precipitating the polymer from the mixture, and then forming the composite material of the modified basalt fiber containing polymer. The composite material can be used for preparing asphalt with excellent performances, the method has the advantages of low cost, simple operation and easy enlargement, and the method makes it easy for the modified basalt fiber to be uniformly dispersed in the polymer.

Owner:长沙北美孚新材料科技有限公司

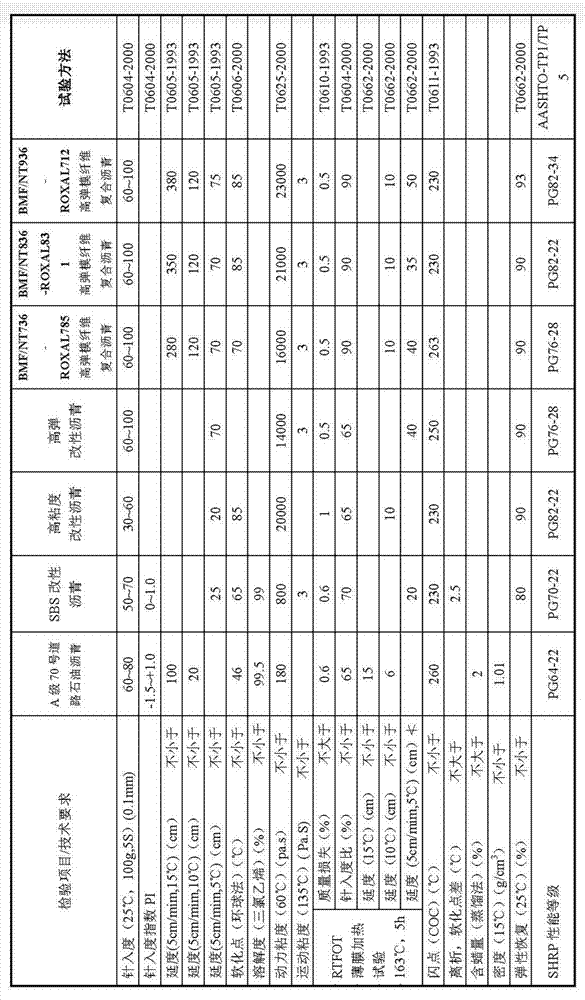

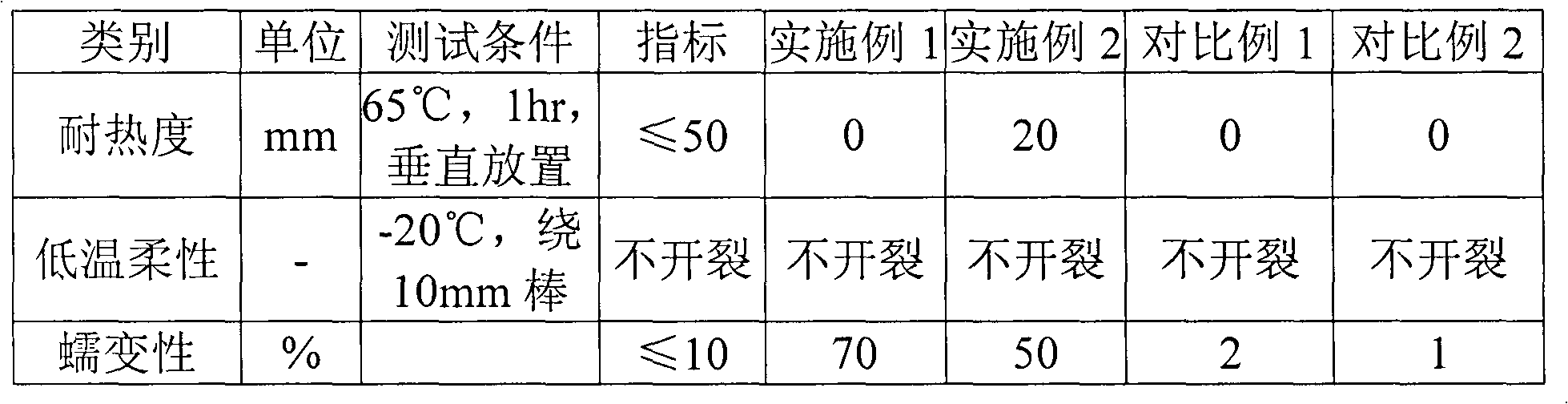

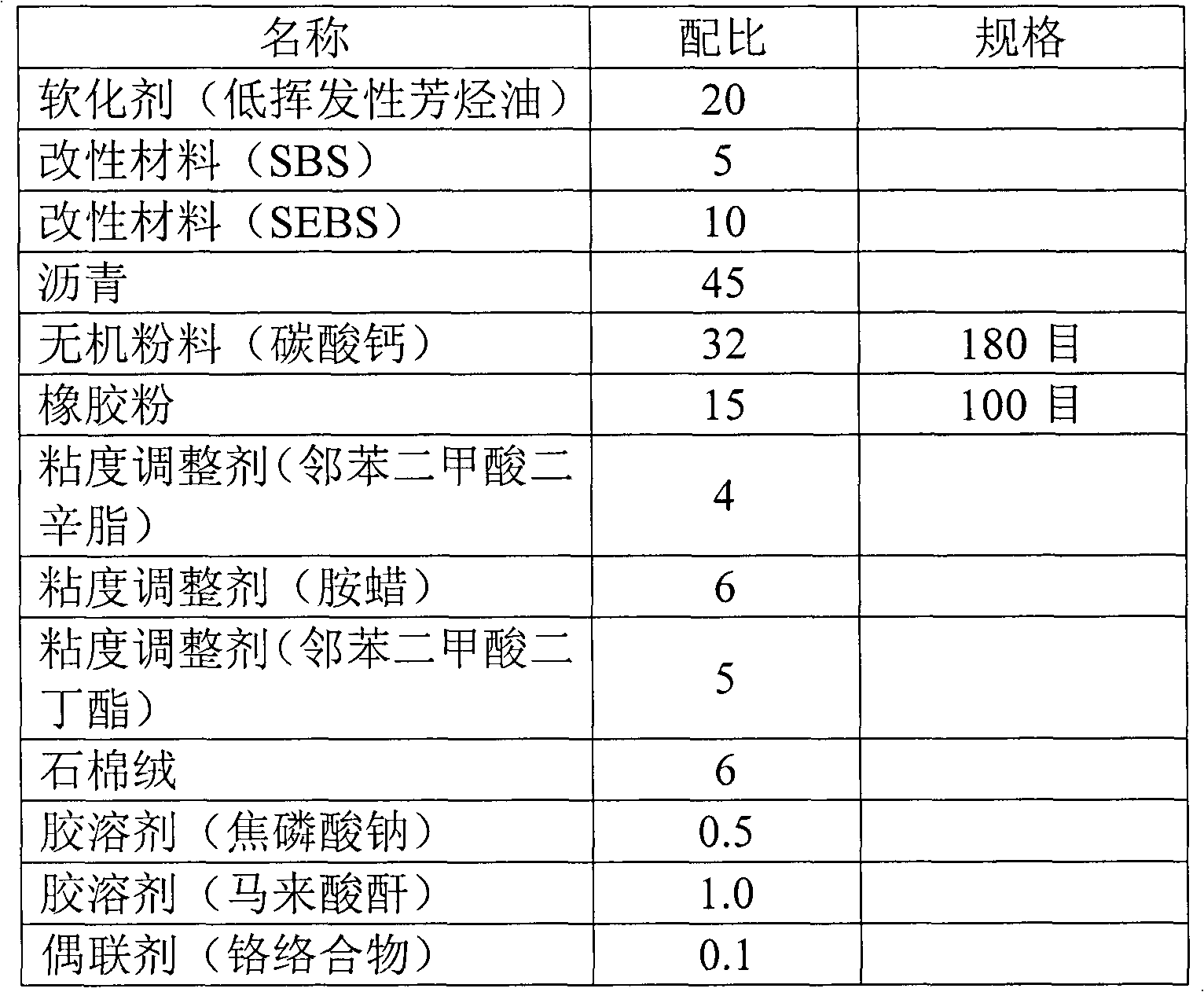

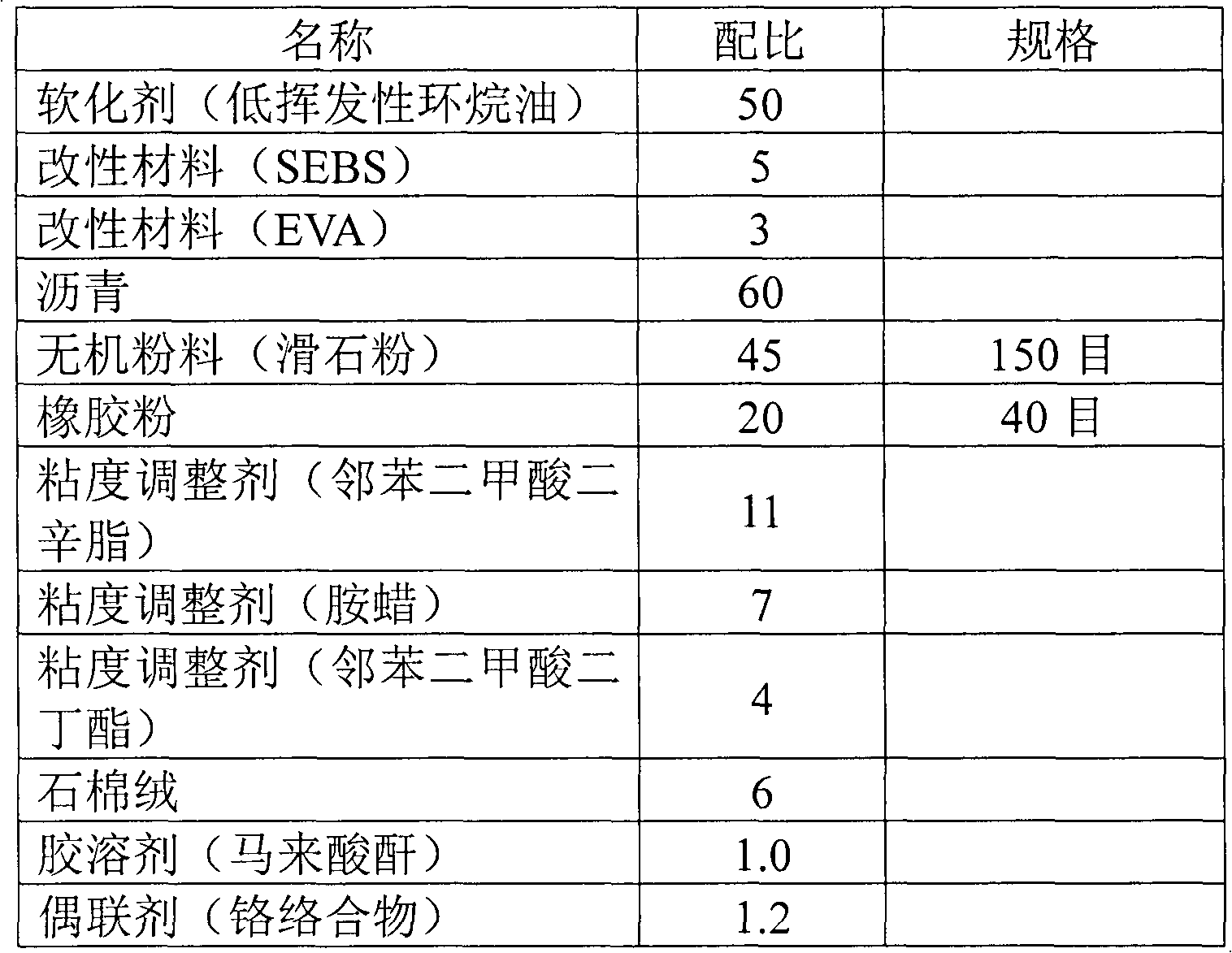

Modified asphalt composition with creeping characteristic and preparation method thereof

InactiveCN102020859AAvoid rapid agingExtended service lifeBuilding insulationsBituminous waterproofingMaterials science

The invention provides a modified asphalt composition with a creeping characteristic, which comprises the following components in parts by weight: 15-60 parts of asphalt, 3-15 parts of modifying material, 5-30 parts of rubber powder, 15-60 parts of softening agent, 15-60 parts of inorganic powder, 3-25 parts of viscosity regulating agent, 0.3-1.5 parts of peptizing agent and 0.1-2 parts of coupling agent. A preparation method of the modified asphalt composition comprises the following steps of: adding the softening agent into a reaction kettle, heating to 170 to 200 DEG C, adding the modifying material, agitating, adding the asphalt and the rubber powder, and agitating for 1-2 h to obtain an intermediate raw material; levigating the intermediate raw material to 150-250 meshes, and putting back to the reaction kettle; and finally, adding the inorganic powder, the viscosity regulating agent, the peptizing agent and the coupling agent into the reaction kettle, agitating and dispersing uniformly. The modified asphalt composition has the characteristics of excellent water-proof performance, strong binding capability and continuous binding capability, large elongation percentage and good low-temperature flexibility.

Owner:ZHEJIANG WOPUMAN HIGH NEW MATERIALS

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS8857405B2High-drive cycle (part load) fuel economyThermal efficiencyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS20150068489A1Promote flame quenchingHigh-drive cycle (part load) fuel economyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

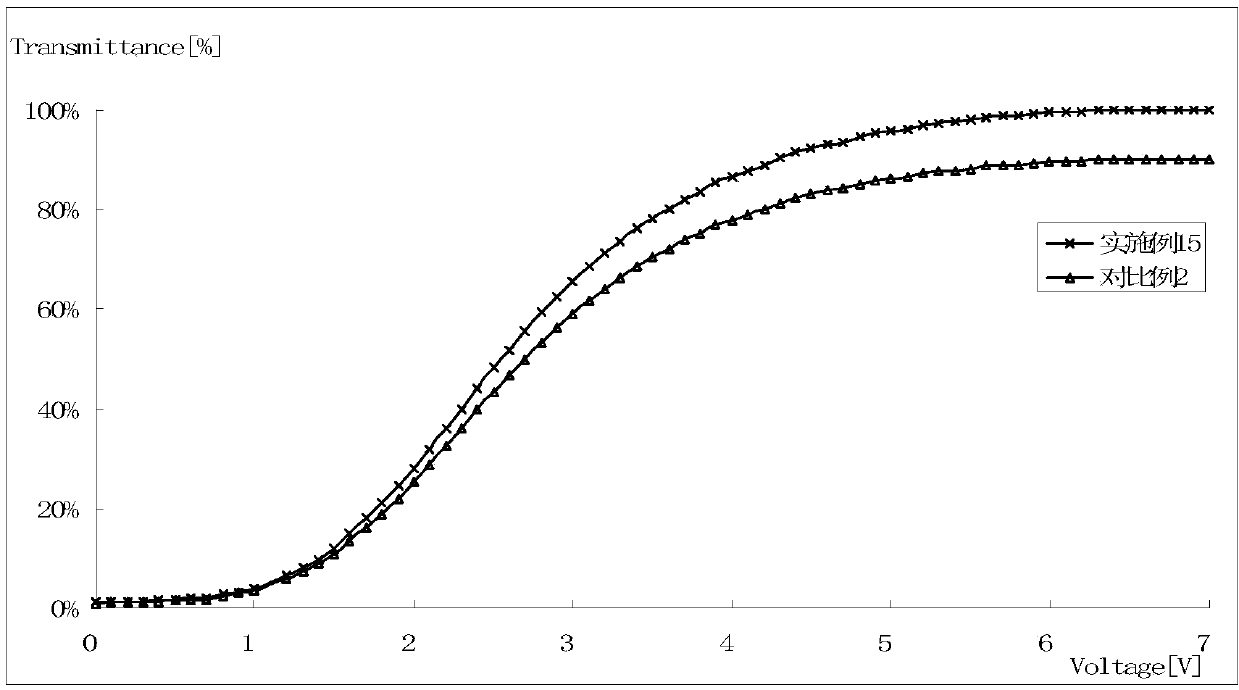

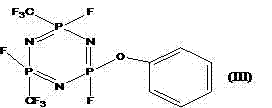

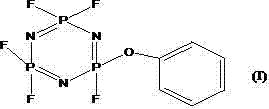

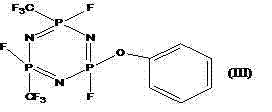

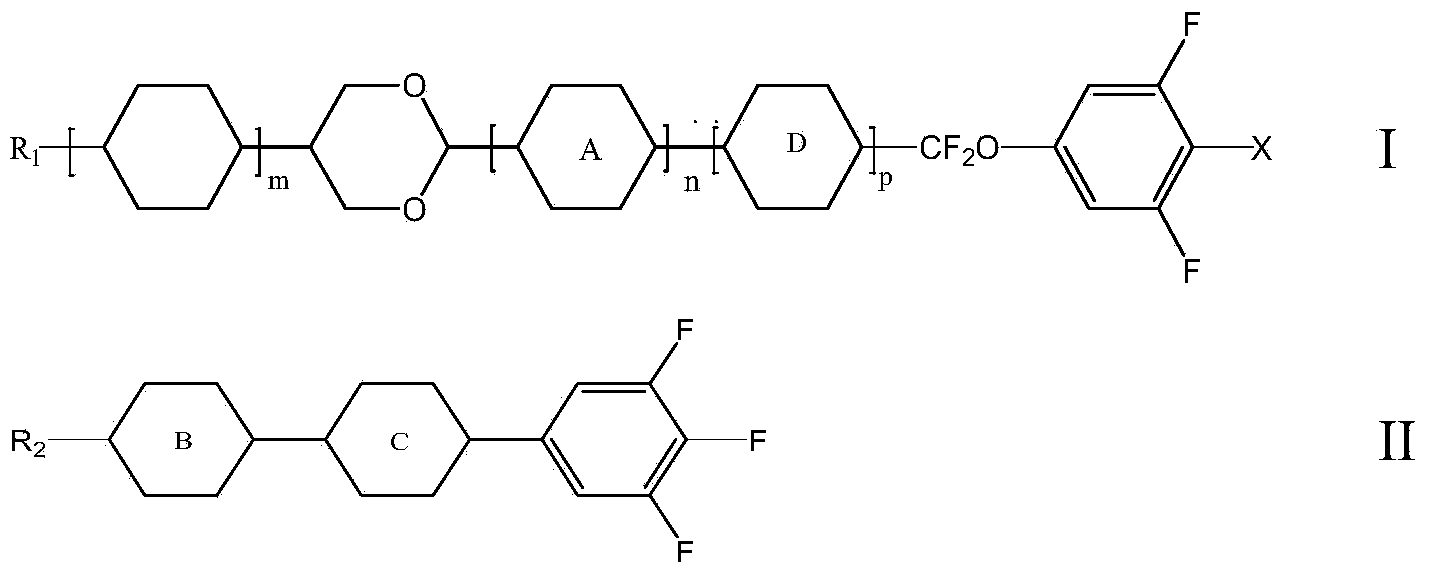

Liquid crystal composition and application thereof

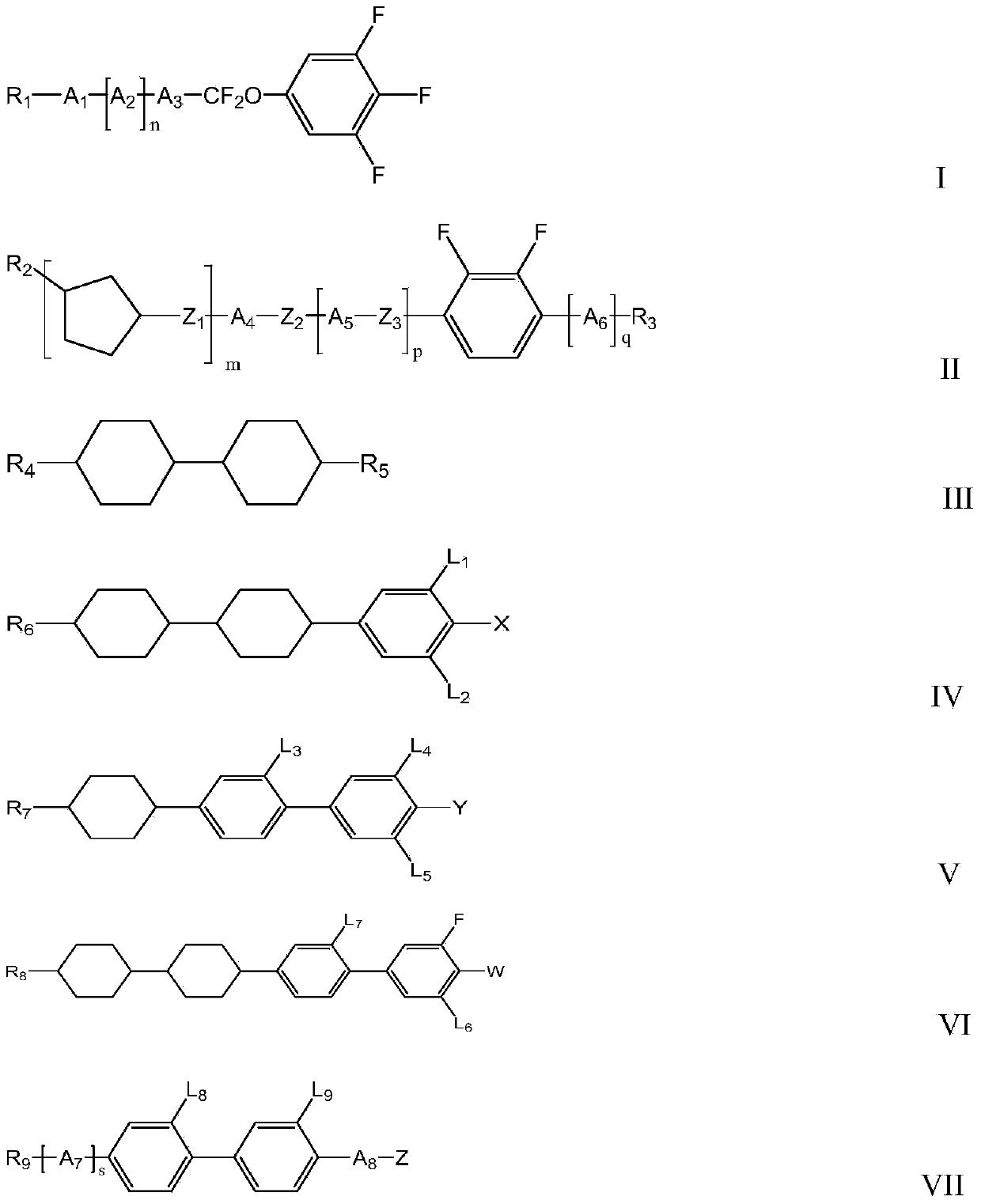

ActiveCN103740377ALow viscosityHigh resistivityLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides a liquid crystal composition which comprises the following components: 5-40% of one or more compounds shown by the general formula (I), 1-30% of one or more compounds shown by the general formula (II), 10-60% of one or more compounds shown by the general formula (III), 0-80% of one or more compounds shown by the general formula (IV) or (V) and 0-35% of one or more compounds shown by the general formula (VI) or (VII). The liquid crystal composition provided by the invention has the advantages of low viscosity, high resistivity, good low-temperature intersolubility, fast response and excellent transmittance feature, and can be applied to fast-response liquid crystal display of multiple display modes. By adopting the liquid crystal composition to a display of TN, IPS or FFS mode, the display effect of the liquid crystal display can be obviously improved; and the liquid crystal composition is particularly applicable to the FFS display mode and can effectively improve the transmittance feature of an FFS liquid crystal display.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

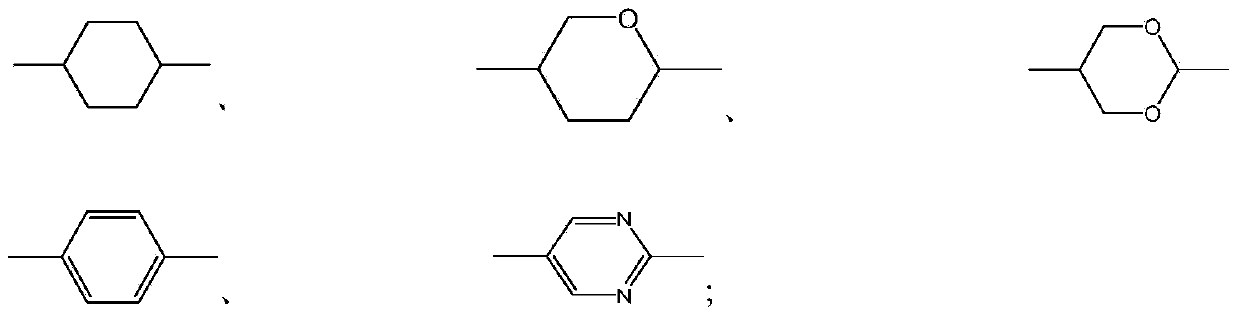

Toner, developer, and image forming apparatus

ActiveUS20070141498A1Good low temperatureHot offset resistanceDevelopersPolyesterCompound (substance)

A toner is provided including a binder resin; a release agent; a colorant; and a fatty acid amide compound, wherein the binder resin includes: an amorphous polyester (A) having a softening point of from 70 to 140° C.; an amorphous polyester (B) having a softening point of from 120 to 190° C.; and a crystalline polyester (C), and wherein the following relationship is satisfied: TmC<Tm(Asp), wherein TmC represents a softening point of the crystalline polyester (C) and Tm (Asp) represents a softening point of the fatty acid amide compound; and a developer and an image forming apparatus using the toner.

Owner:RICOH KK

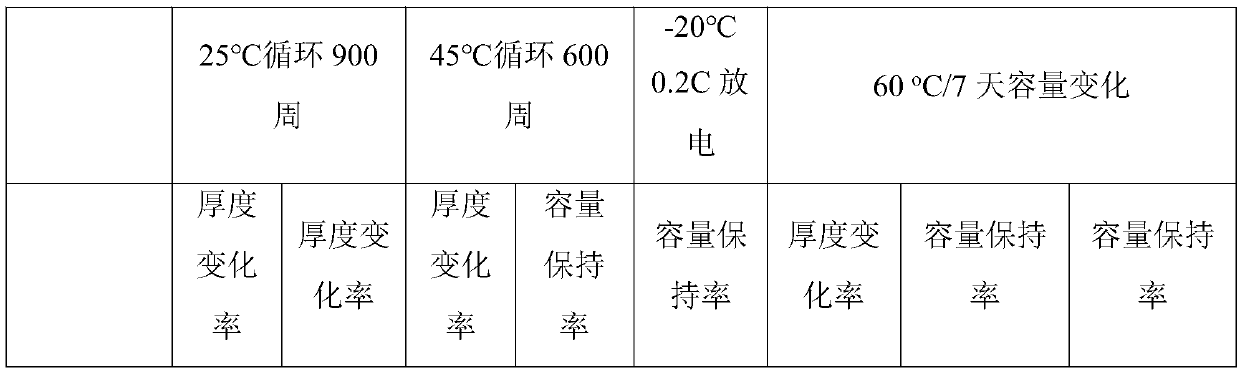

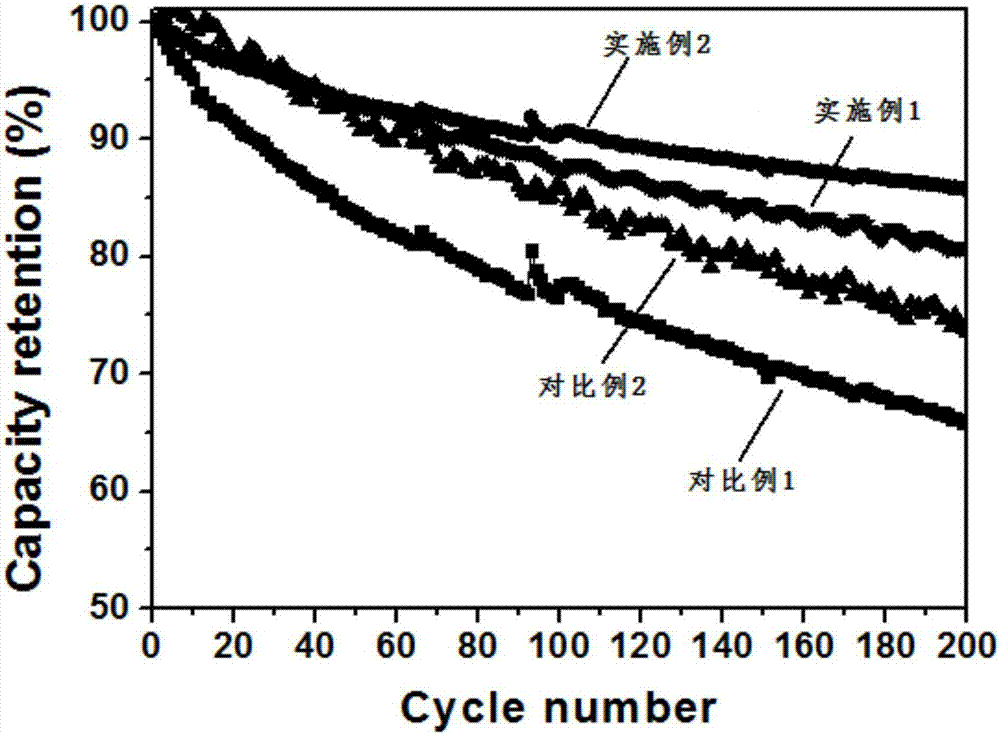

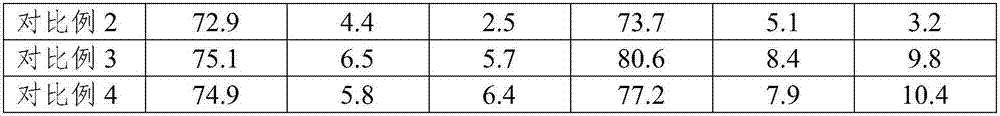

Lithium ion battery with nickel-based cathode, and electrolyte therefor

ActiveCN103208653AGood high temperature performanceGood low temperatureSecondary cellsElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries and particularly relates to electrolyte for a lithium ion battery with a nickel-based cathode. The electrolyte comprises non-aqueous organic solvent, lithium salt, boron-containing lithium salt additive, cyclic ether compound and cyclic phosphonitrile compound. The cyclic phosphonitrile compound is hexaphenoxycyclotriphosphazene or cyclic phosphonitrile derivative. Compared with the prior art, the electrolyte is provided with the boron-containing lithium salt additive capable of improving high temperature performance of the lithium ion secondary battery with nickel-based cathode material, the cyclic phosphonitrile compound, and the cyclic ether compound, and the addition of the cyclic phosphonitrile compound and the cyclic ether compound enables the battery to be fine in high temperature performance, low temperature performance and cycle performance. In addition, the invention discloses the lithium ion battery comprising the electrolyte.

Owner:DONGGUAN AMPEREX TECH

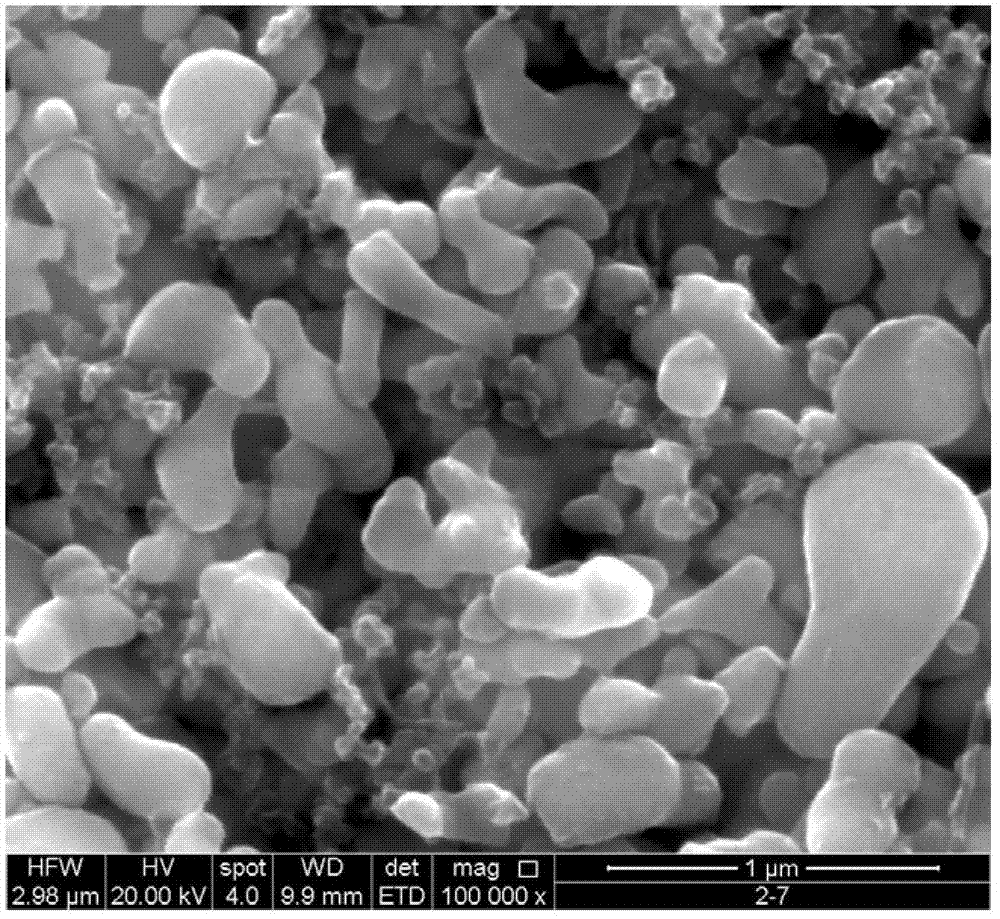

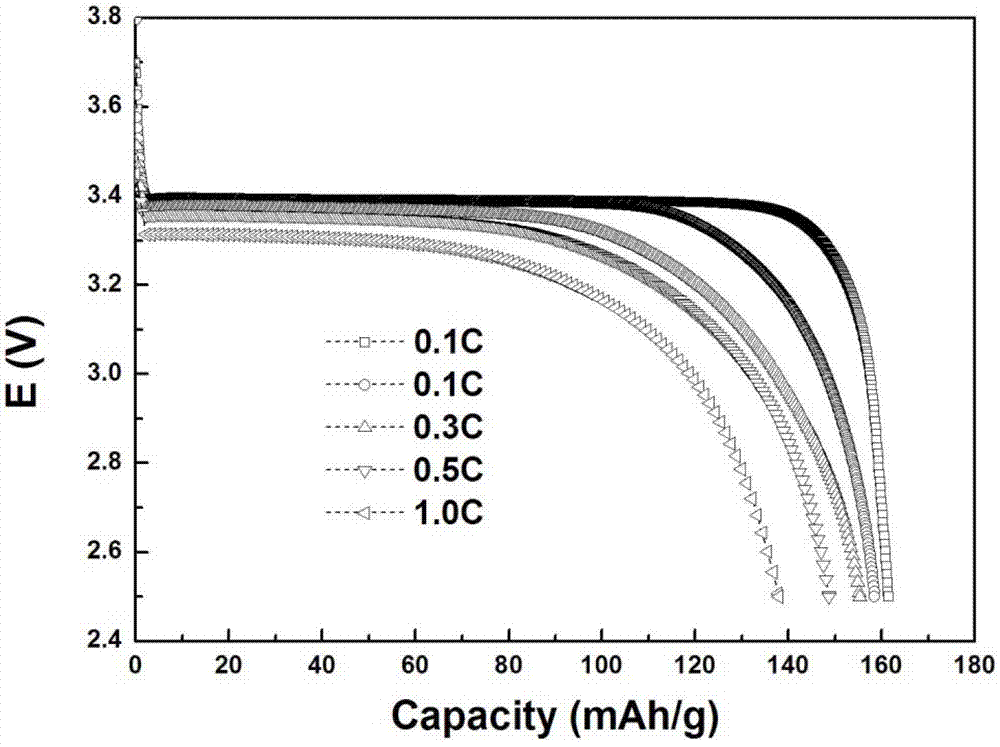

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

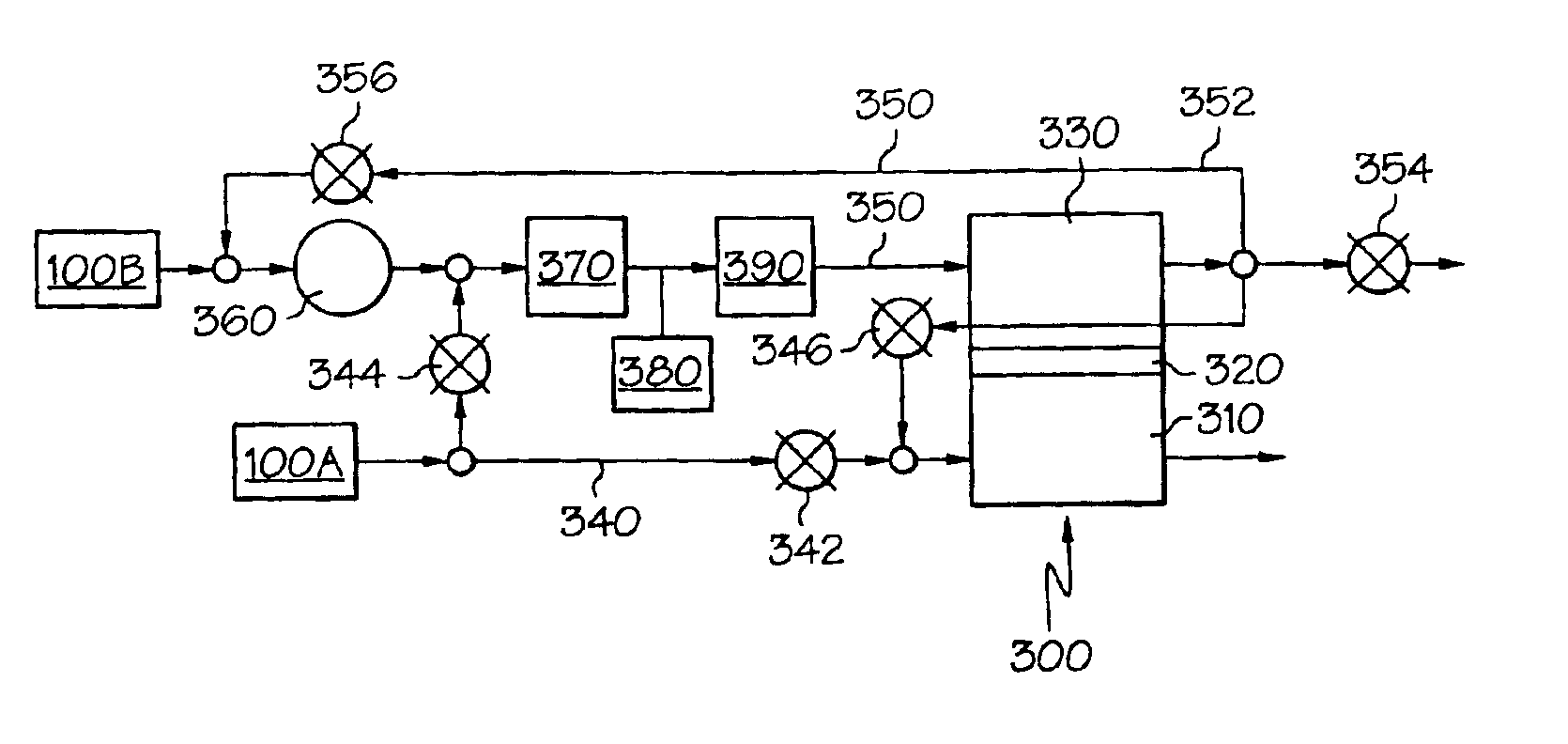

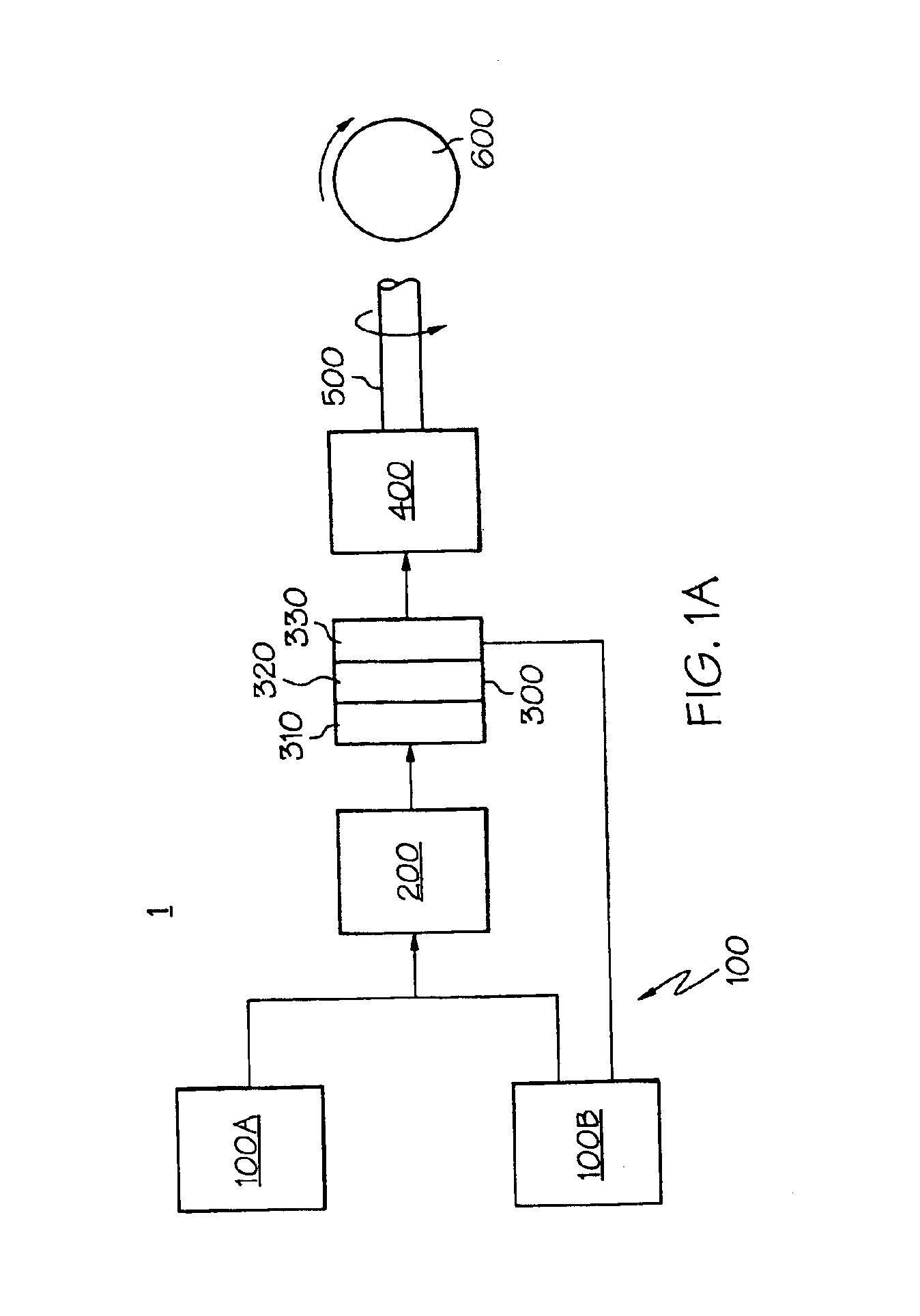

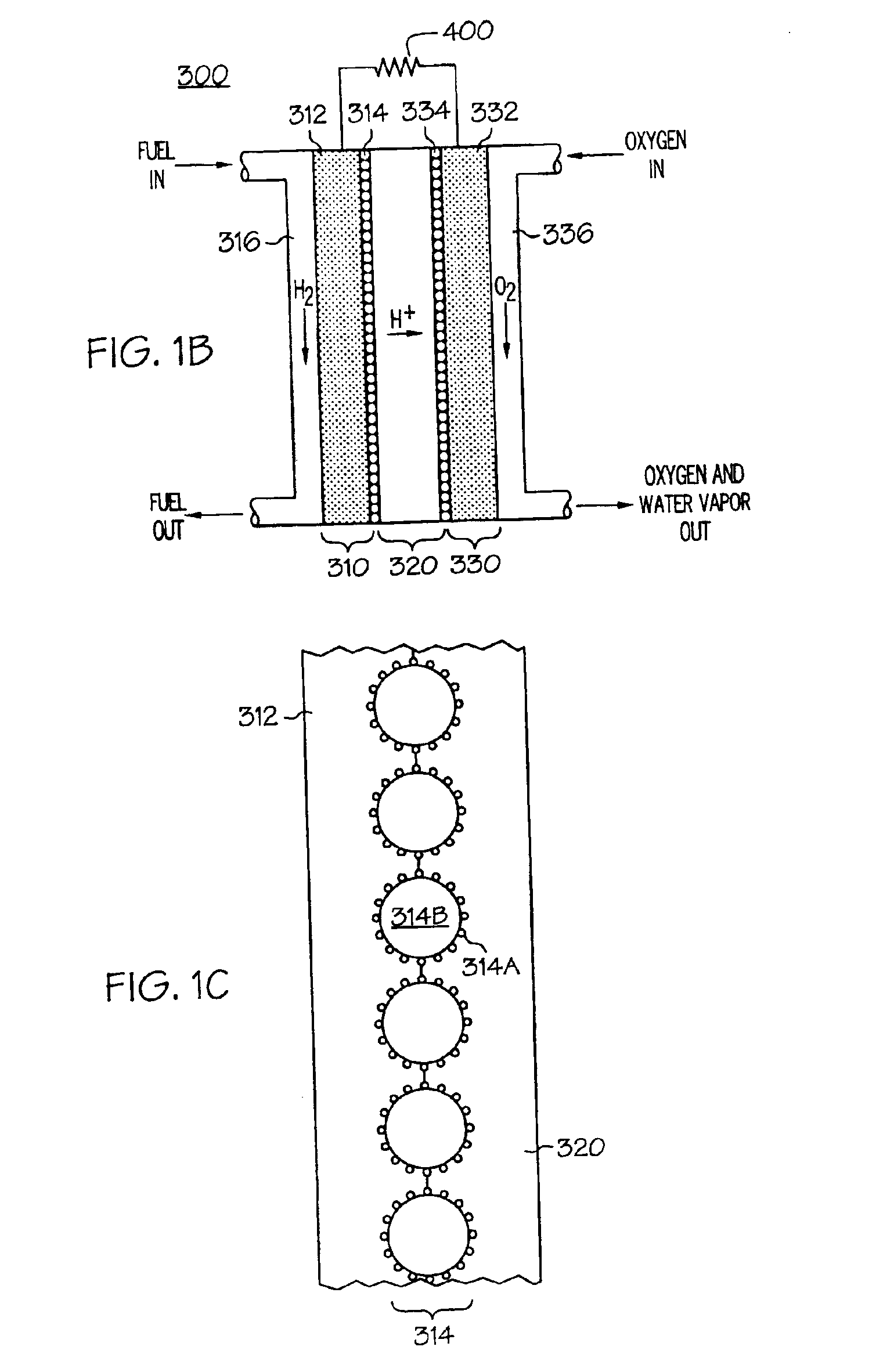

Fuel cell shutdown and startup using a cathode recycle loop

InactiveUS6939633B2Good low temperatureFuel cell heat exchangeSolid electrolyte fuel cellsHydrogenFuel cells

A method and device for operating a fuel cell system. A recirculation loop coupled to a fuel cell cathode ensures that fluids passing through the cathode are recycled, thereby enabling reaction between residual oxygen in the recycled fluid and fuel that has been introduced into the recirculation loop until substantially all of the oxygen is reacted, leaving a substantially oxygen-free, predominantly nitrogen compound in the cathode and related flowpath. Thereafter, this compound can be redirected to purge the remaining residual hydrogen resident in the fuel cell's anode and related flowpath. While the present invention is usable during any period of system operation, it is especially valuable for operational conditions associated with starting up and shutting down a fuel cell system to inhibit the formation of high voltage potentials that could otherwise damage fuel cell catalysts or catalysts supports.

Owner:GM GLOBAL TECH OPERATIONS LLC

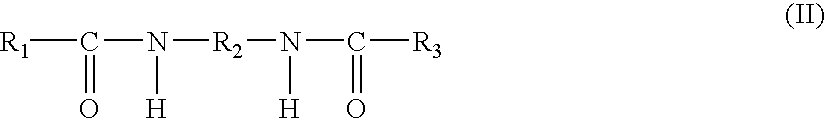

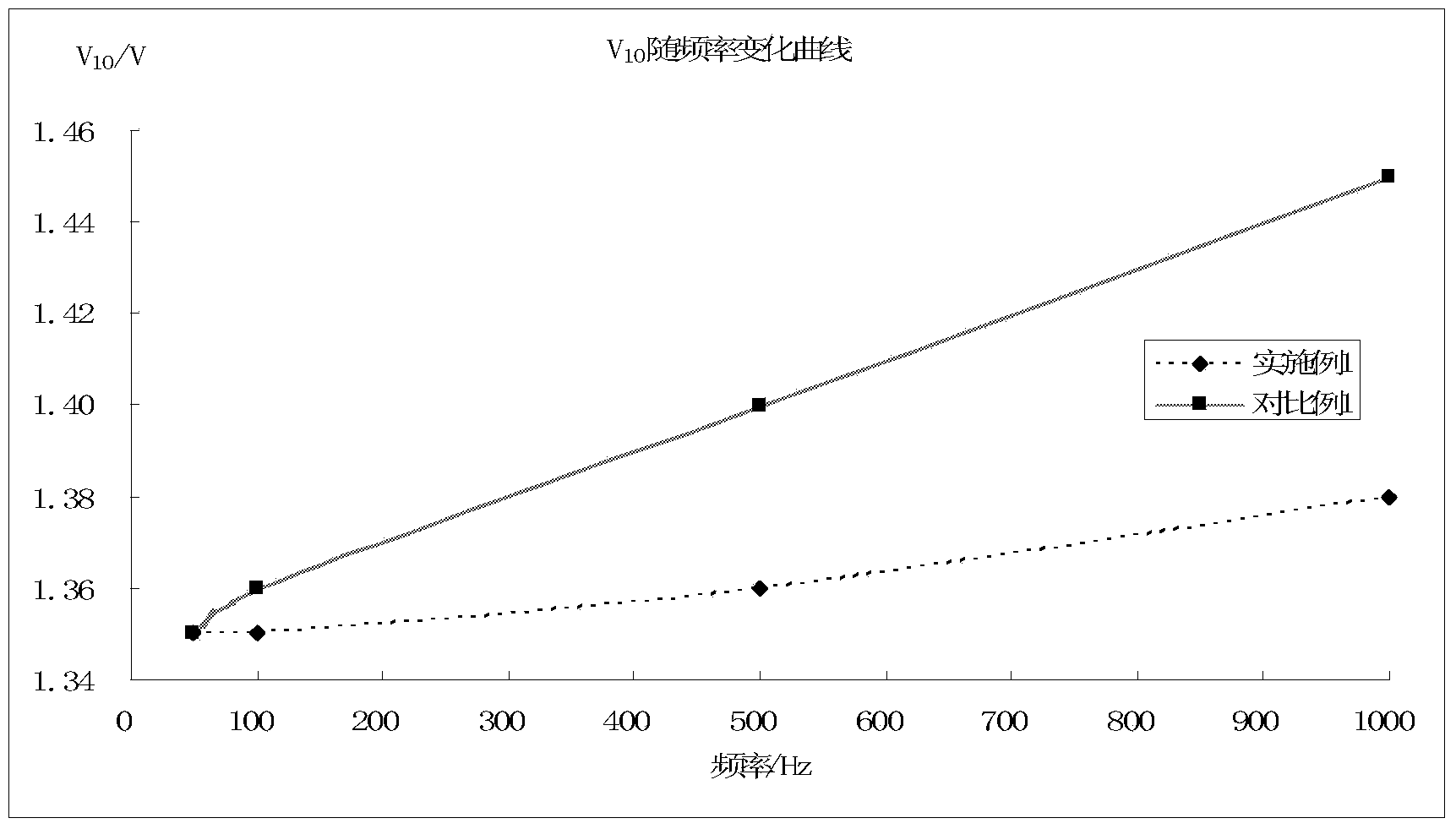

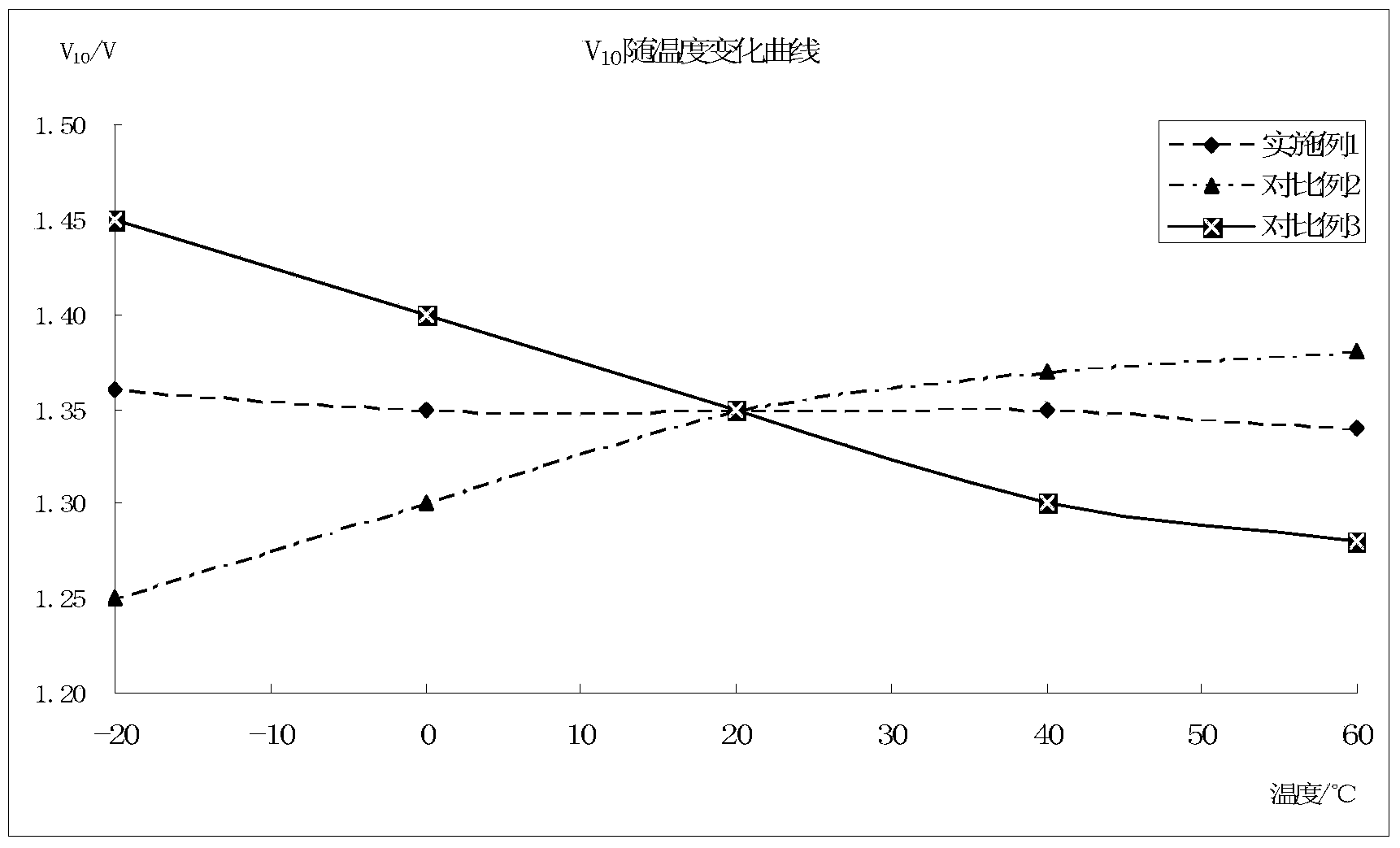

Liquid crystal composition with stable threshold voltage and application thereof

ActiveCN103937508AImprove thermal stabilityGood light stabilityLiquid crystal compositionsNon-linear opticsBenzeneCrystallography

The invention relates to a liquid crystal composition with a stable threshold voltage and an application thereof. The liquid crystal composition comprises the following components: (1) 5%-40% of a compounds shown in a general formula I; (2) 10%-40% of a compound shown in a general formula II; compounds with a dioxyheterocycle structure are taken as polar ingredients of the liquid crystal composition to overcome the defect that the photoelectric characteristic of the liquid crystal composition changes with frequency; the polar ingredients composed of compound type I having a difluoromethoxyl structure and the compound type II having a 3,4,5-trifluoro-benzene structure are used together for regulating the voltage temperature stability of the liquid crystal composition, so that the voltage characteristic of the liquid crystal composition does not change with the temperatures, and therefore the display effect of the liquid crystal composition is improved.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

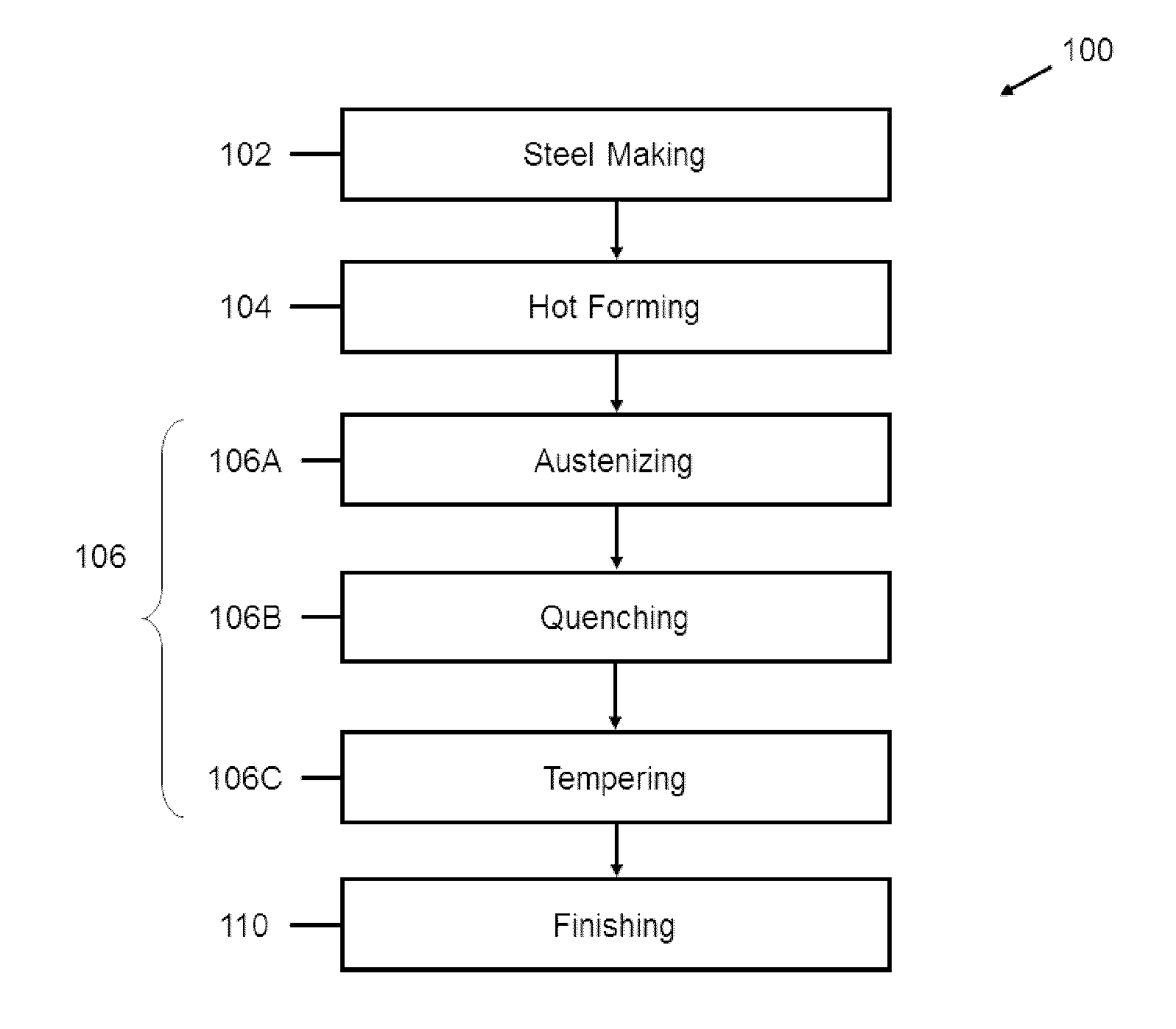

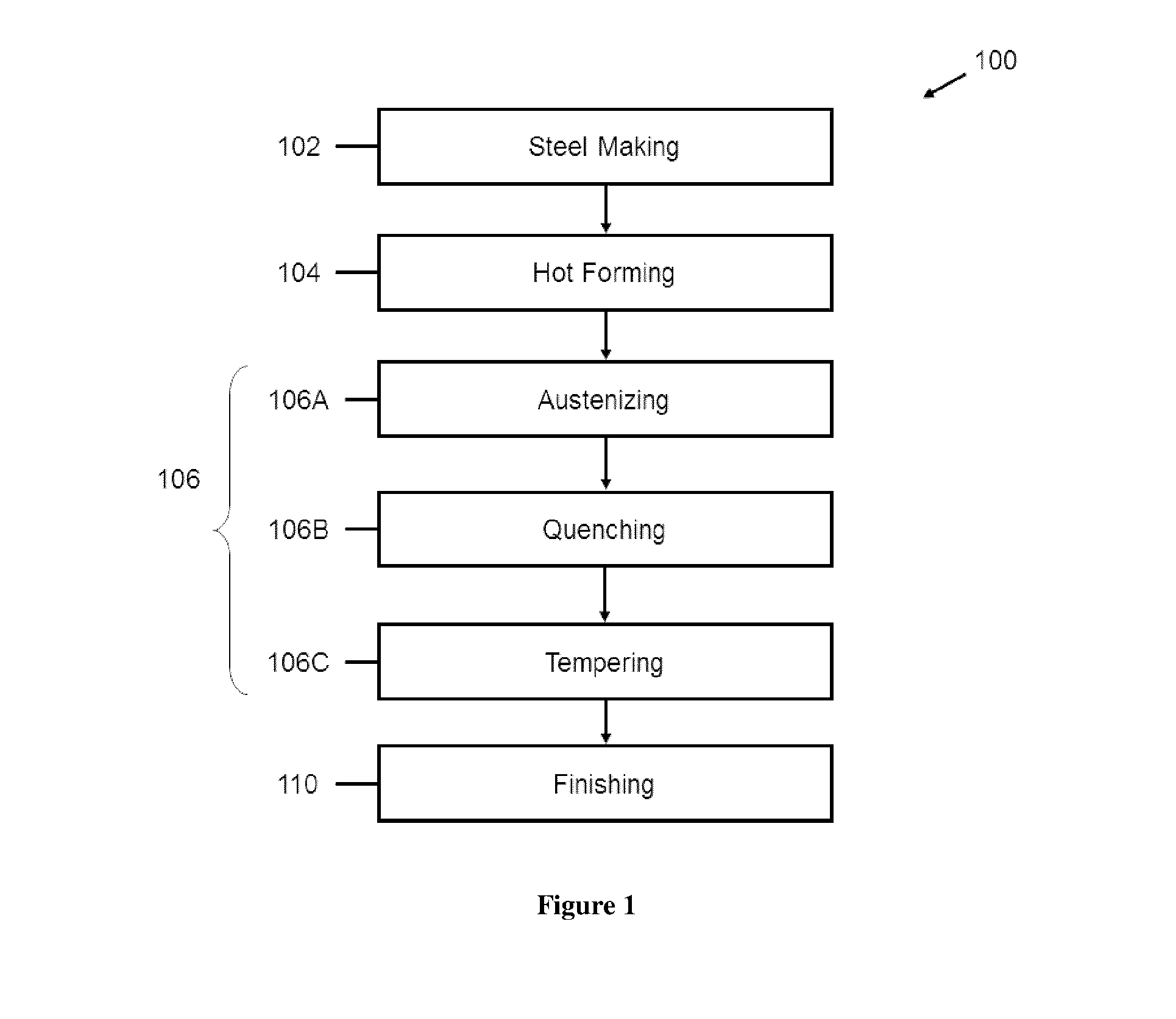

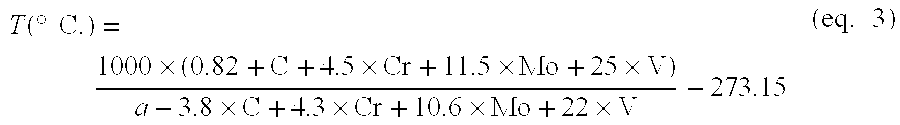

High strength medium wall quenched and tempered seamless steel pipes and related method for manufacturing said steel pipes

ActiveUS20140299236A1Good low temperatureImprove solderabilityFurnace typesHeat treatment process controlSteel tubeChemical composition

Disclosed herein are embodiments of a seamless quenched and tempered steel pipe which can have a wall thickness WT higher than or equal to 6 mm and lower than or equal to 35 mm. Some embodiments of the steel pipe can have a chemical composition comprising C, Mn, Si, Cr, Ni, Mo, Al, N, Ca, Nb, Ti, V, Zr, and Ta based on the composition weight, the remaining being iron and impurities. In some embodiments, wherein (V+Nb) content is lower than 0.07 wt %; defining a first parameter P1=(60×C)+Cr+[5×e(35×Mo / WT)]+50×(V+Nb), the chemical composition satisfies a first condition P1≦14.5.

Owner:DALMINE SPA

Lithium ion battery electrolyte and high-energy-density lithium ion battery using same

InactiveCN109659614AImproved High Temperature StoragePromote circulationSecondary cells servicing/maintenanceOrganic electrolytesHigh energyElectrical impedance

The invention provides a lithium ion battery electrolyte and a high-energy-density lithium ion battery using the same. The lithium ion battery electrolyte comprises a non-aqueous organic solvent, a lithium salt and additives. The additives comprise a negative electrode film-forming additive, a nitrile or ether nitrile compound, an acid anhydride compound and a lithium salt type additive. Accordingto the lithium ion battery electrolyte, 0.3-20wt% of the negative electrode film-forming additive such as vinylene carbonate and / or fluorocarbonate can form an excellent SEI film on a carbon-containing negative electrode, a silicon-containing negative electrode or a silicon carbon alloy negative electrode and the like, thereby stabilizing the negative electrode and ensuring excellent battery performance; 0.2-6.5wt% of the nitrile or ether nitrile compound, the acid anhydride compound and a combination of them can complex metal ions of a positive electrode or form a protective film on the surface of the positive electrode, thereby stabilizing the positive electrode and improving battery performance; and the 0.5-3 wt% of the lithium salt type additive in the lithium ion battery electrolytecan lower the impedance of the battery so as to improve the low temperature performance of the battery or improve the high temperature performance of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

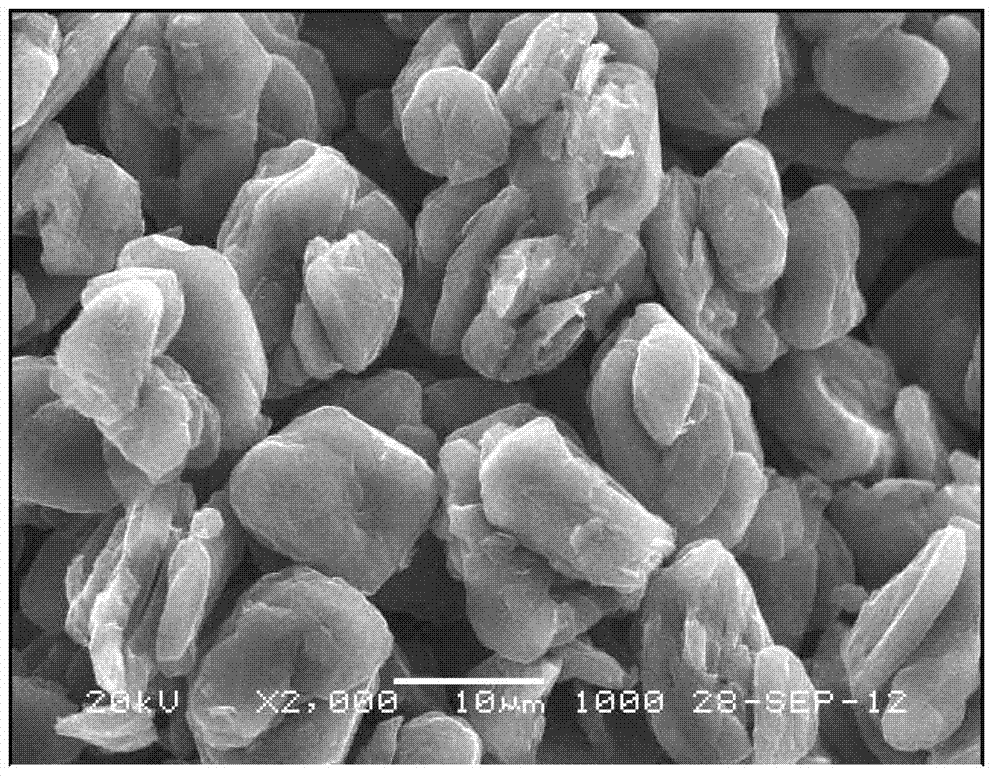

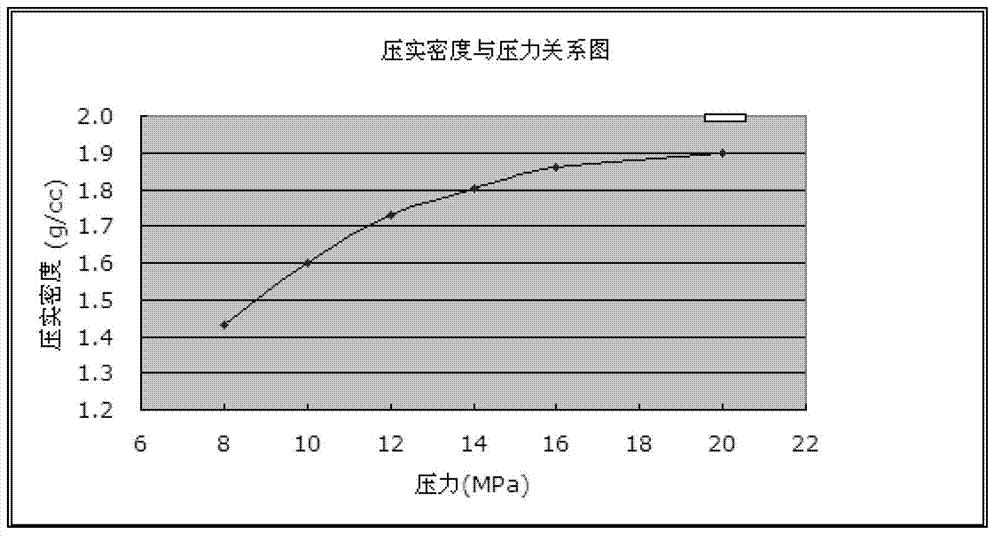

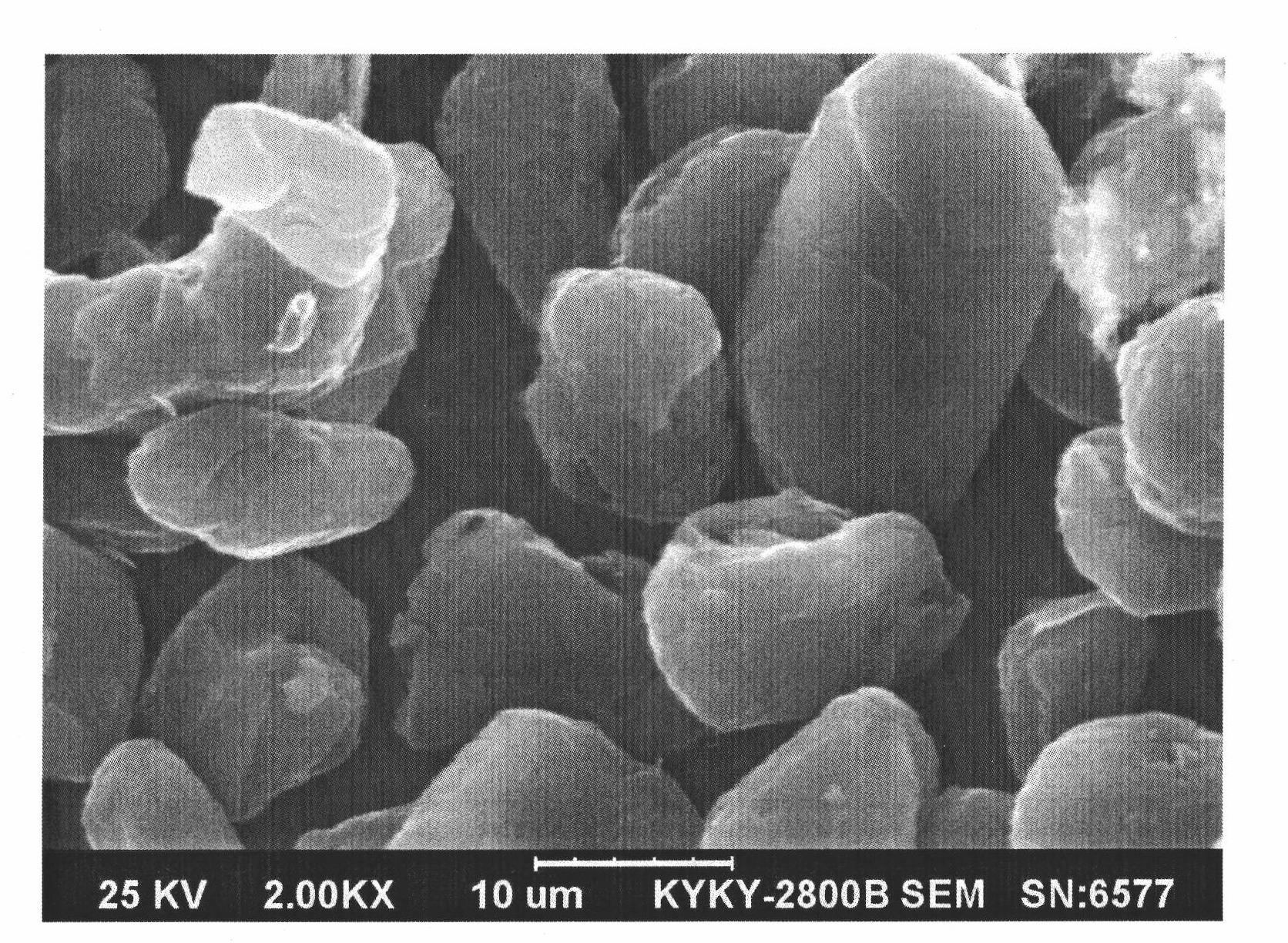

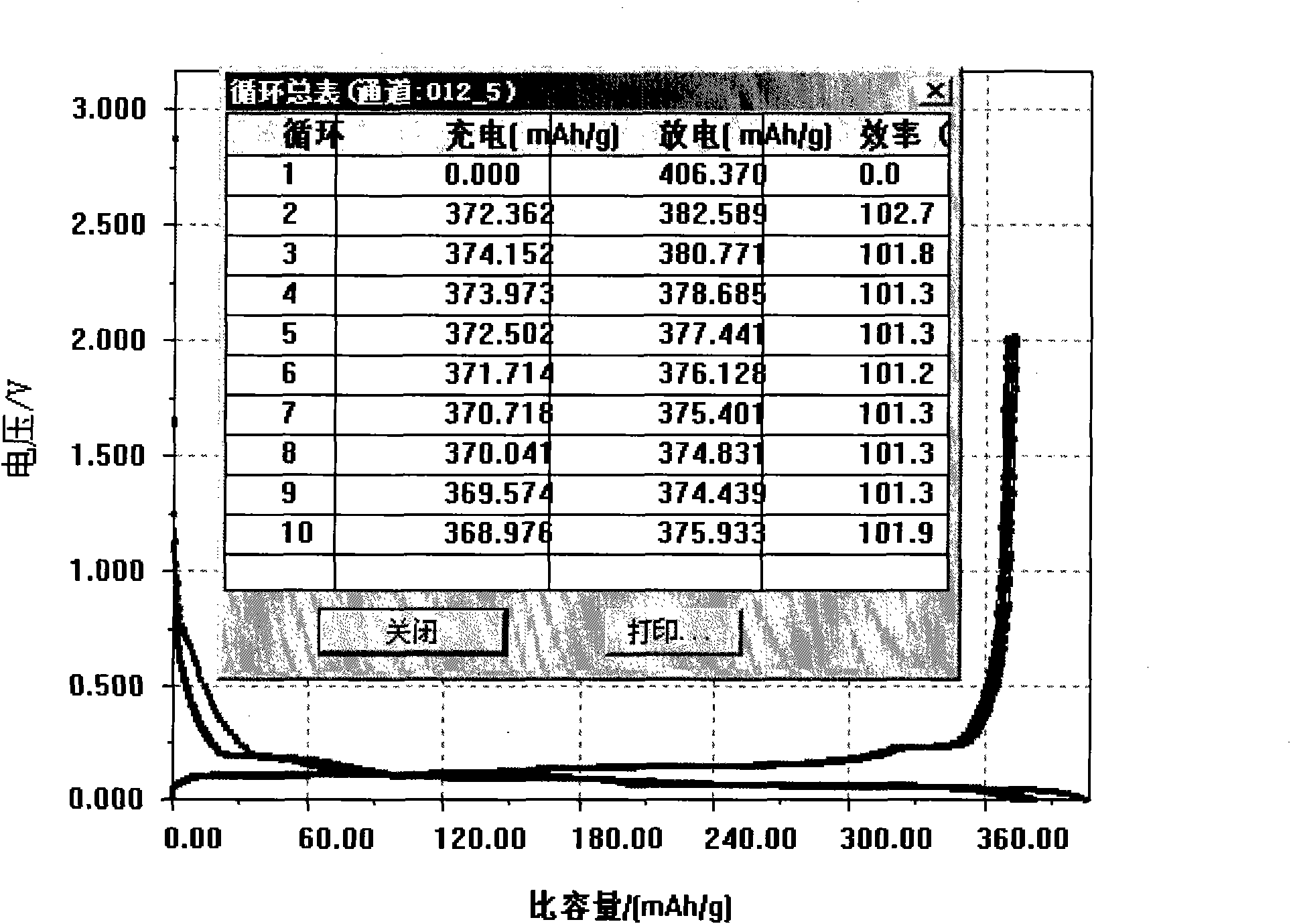

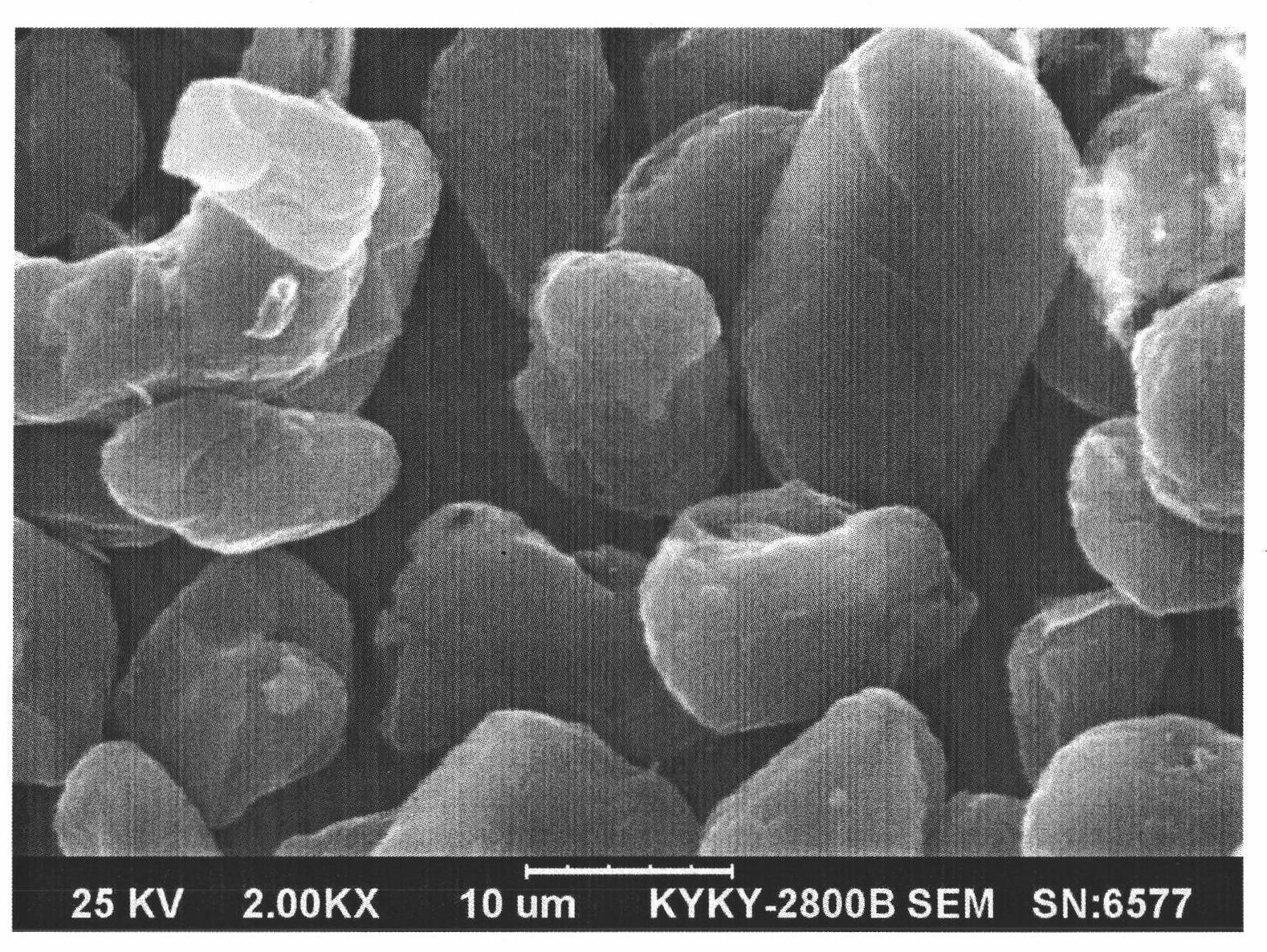

Preparation method of compound graphite material for lithium ion secondary battery

ActiveCN103241731AHigher than the surfaceHigh magnificationGraphiteCell electrodesLarge capacityLithium

The invention discloses a preparation method of a compound graphite material for a lithium ion secondary battery. The preparation method comprises the following steps of: firstly pouring natural graphite, a binding agent and a graphite catalyst which are taken as raw materials into a roller furnace, wherein the roller furnace rotates all the time in a raw material pouring process; then progressively heating the raw materials, namely heating the raw materials in the roller furnace by adopting a progressive heating mode while the roller furnace rotates in a heating process, and then carrying out natural cooling to normal temperature after the raw materials in the roller furnace are heated; and finally carrying out graphitizing treatment on the raw materials, thus the binding agent forms artificial graphite, and the artificial graphite forms a coating on natural graphite particles, so as to form a shell-core structure, and compound particles of the shell-core structure are further spliced to form compound graphite particles with the required grain diameter. The compound graphite material prepared by the invention is of the shell-core structure with the natural graphite as an inner core and an artificial graphite layer as a coating, and the compound graphite has good isotropy, high capacity, high compactness, excellent multiplying, low temperature and cyclic performances and low electrode expansion. The preparation method of the compound graphite material for the lithium ion secondary battery adopts a method that coating and splicing are carried out at the same time, the preparation method is simple and practicable, and the cost is low.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

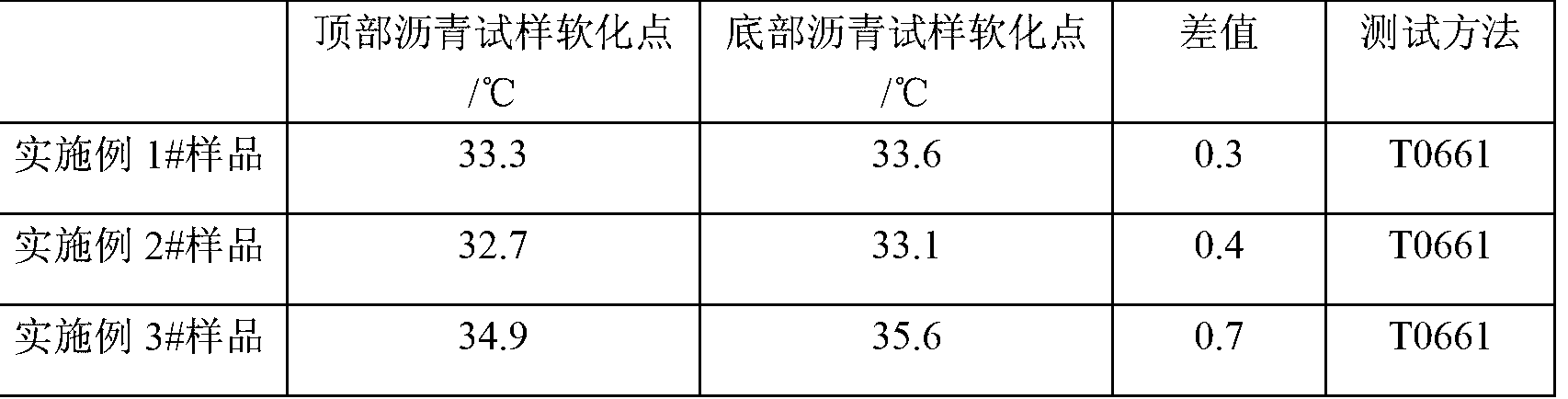

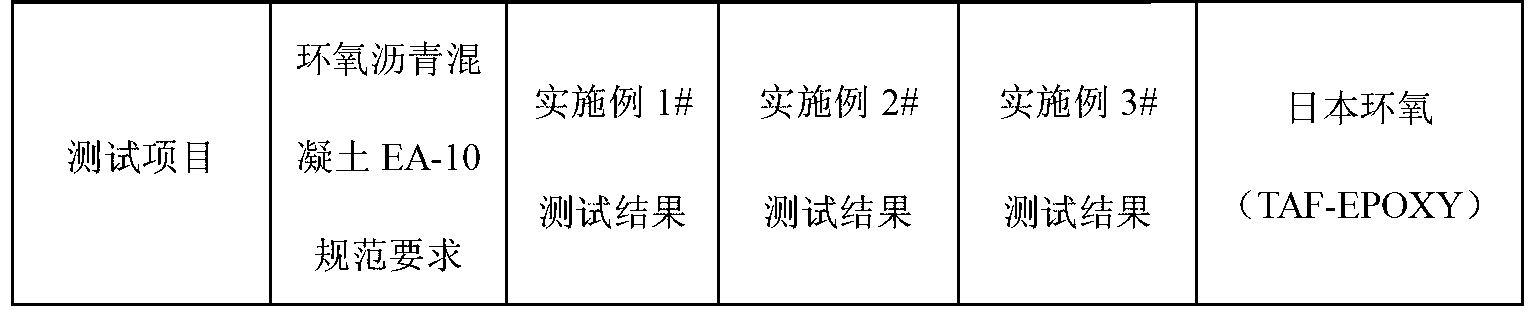

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

Poured epoxytar concrete material and its prepn process

InactiveCN101020601AImprove low temperature performanceReduce construction temperatureRoadwaysEpoxyEther

The present invention relates to poured road surface laying material, and is especially one kind of poured epoxy asphalt concrete material with low construction temperature, high flowability and construction convenience and its preparation process. The poured epoxy asphalt concrete material consists of component A and component B in the weight ratio of 8-50 as well as stone material in the amount of 3-9 times the component A. The component A consists of asphalt 45-90 weight portions, epoxy resin 4.5-36 weight portions, modified alkylphenol 9-27 weight portions and glycidol ether 0-3 weight portions, and the component B is curing agent. The poured epoxy asphalt concrete material is prepared through mixing the materials of the component A, stirring at 120-160 deg.c, adding stone material, and final adding the heated curing agent and maintaining the temperature for 0-120 min.

Owner:重庆市智翔铺道技术工程有限公司

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS9353674B2High-drive cycle (part load) fuel economyThermal efficiencyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

Owner:MAHLE POWERTRAIN

High strength high tenacity high weather resistant gas protecting welding wire

InactiveCN1593836AThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsChemical compositionLine tubing

The invention relates to a kind of high strength, high tenacity, high withering, and air protecting welding thread. It can avoid mismatching of present welding material, especially poor quality of prevent gas erode. The technique is flowing: first the chemical component is : C:0.04~0.12; Si:0.40~0.80; Mn:1.40~2.0;P<=0.020;S0.015;Ni:0.40~1.0;Cr:0.20~0.50;Ti:0.06~0.20;Cu:0.30~0.50;B:0.002~0.0079;Als<=0.02; a little Fe and other unavoidable impurities. The welding thread is protected by mix gas that is made of percent 80 Ar and percent 20 CO2. The thread head is better in gas eroding proof and mechanism. The tensile strength of the welding slot is as high as 735MPa. And AKv(-0.4 DEG C) of it is 182 J, AKv(-0.6 DEG C) of it is 173 DEG C. The thread is suited to gas protecting welding for important part of railroad, bridge, pipe and so on.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Ternary positive electrode material lithium ion battery electrolyte

The invention provides a ternary positive electrode material lithium ion battery electrolyte, and relates to the technical field of a lithium ion battery. The ternary positive electrode material lithium ion battery electrolyte comprises a carbonate ester organic solvent, a lithium salt and an additive, wherein the lithium salt is lithium hexafluorophate, the lithium hexafluorophate accounts for 12-18% of the total mass of the lithium salt and the carbonate ester organic solvent, and the additive accounts for 5-15% of the total mass of the lithium salt and the carbonate ester organic solvent. The carbonate ester organic solvent is used, so that the solvent is high in solubility of the lithium salt and low in viscosity; and meanwhile, fluoroethylene carbonate is used as a low-temperature additive, the electrolyte is compatible with the electrochemical performance such as capacity and internal resistance, the ternary positive electrode material battery also has excellent cycle property, and the cycle time of the battery under a low-temperature condition is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

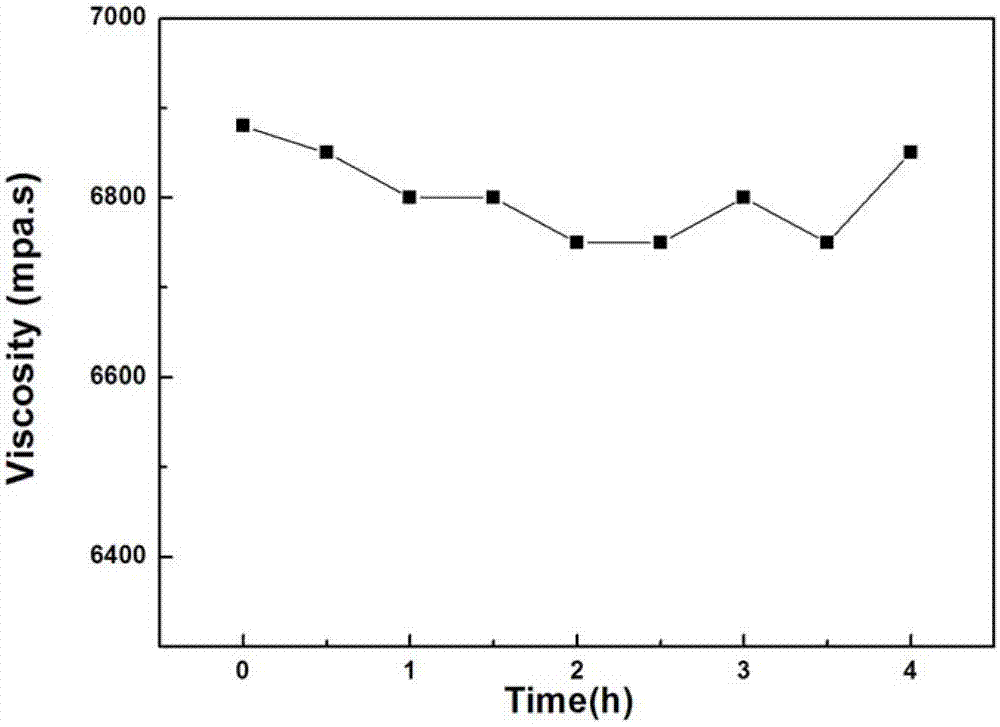

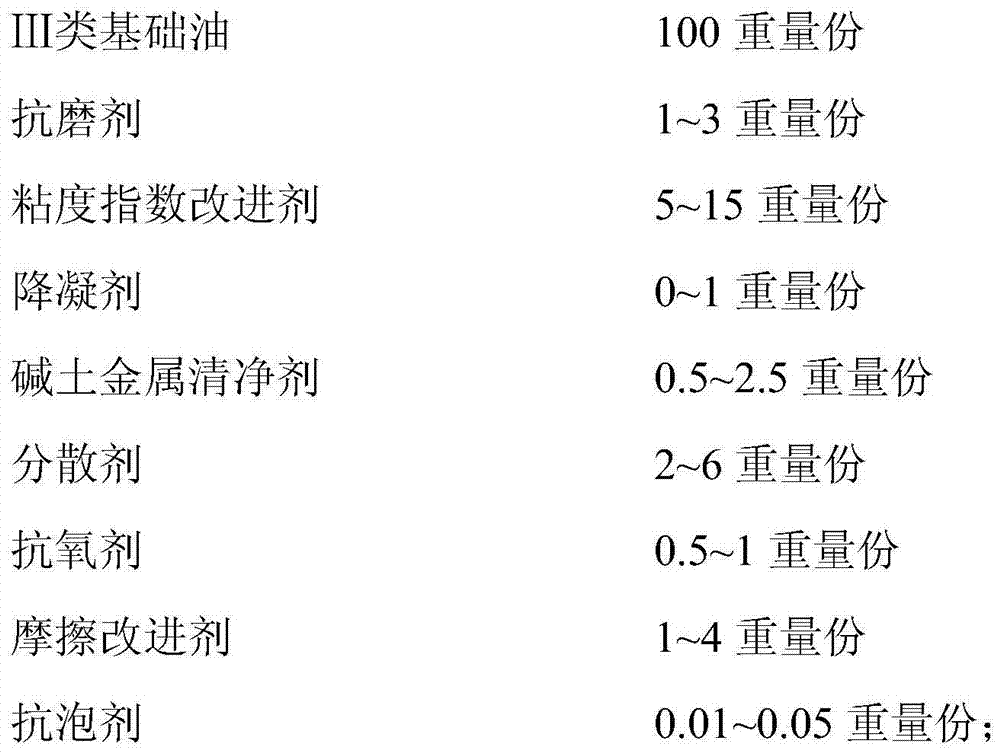

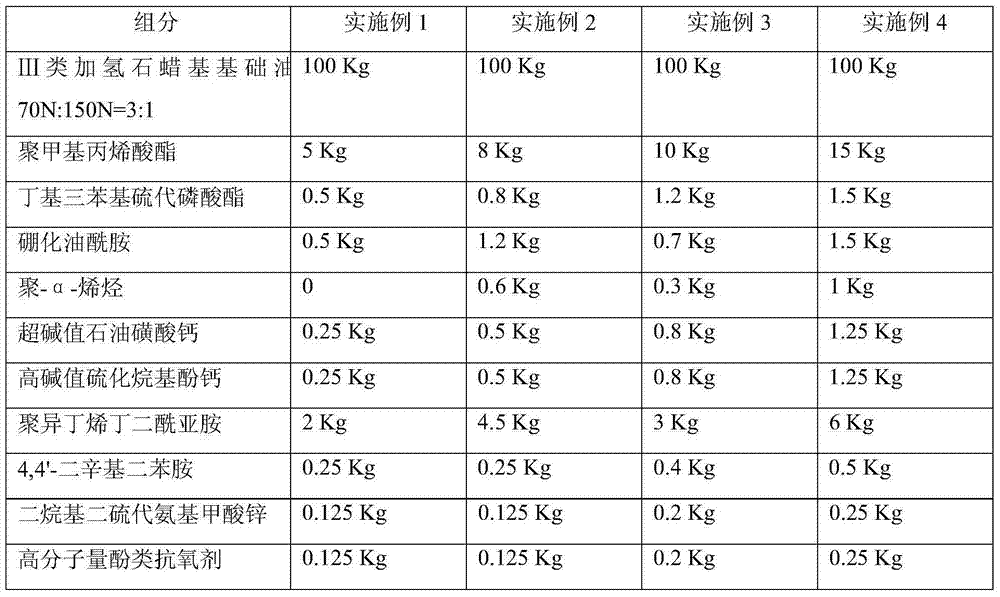

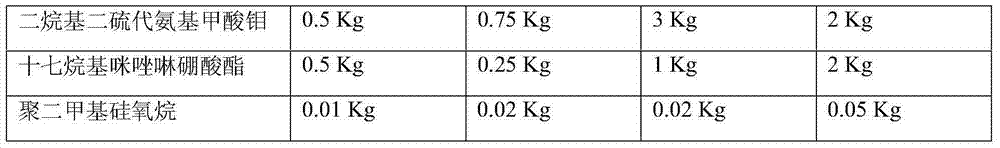

Automobile continuously variable transmission fluid and preparation method thereof

The invention discloses an automobile continuously variable transmission fluid and a preparation method thereof. The automobile continuously variable transmission fluid comprises the following components: 100 parts by weight of class III base oil, 1-3 parts by weight of antiwear agent, 5-15 parts by weight of viscosity index improver, 0-1 part by weight of pour point depressant, 0.5-2.5 parts by weight of alkaline earth clearing agent, 2-6 parts by weight of dispersant, 0.5-1 part by weight of antioxidant, 1-4 parts by weight of friction modifier and 0.01-0.05 part by weight of anti-foaming agent. According to the invention, the chosen additives are optimally combined together to obtain the CVTF, and the obtained CVTF has excellent comprehensive properties; the CVTF is excellent in viscosity index, oxidation stability, shear stability, wearing quality and cryogenic property, and more critically, large in torque, high in traction coefficient and high in transmission efficiency; and consequently, the use requirements of B-CVT and T-CVT can be met simultaneously.

Owner:GUANGZHOU MECHANICAL ENG RES INST

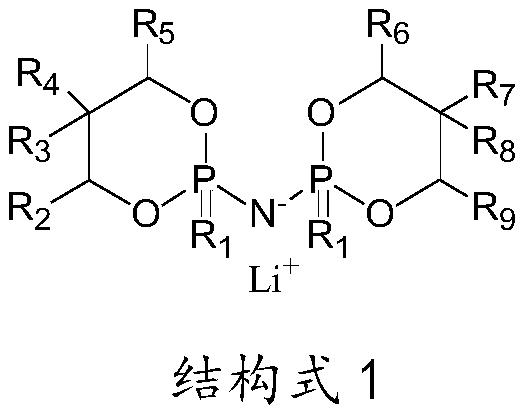

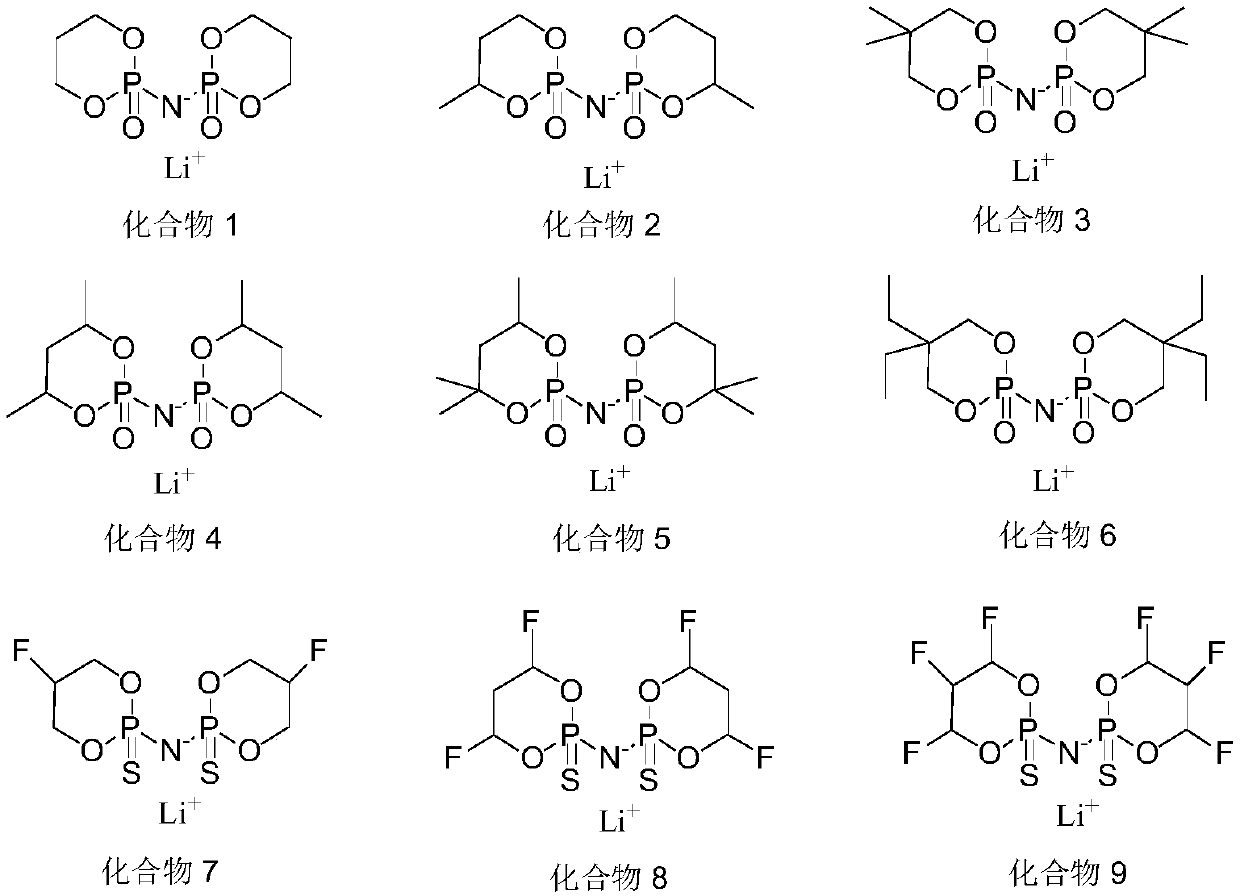

Novel lithium salt additive and non-aqueous electrolyte for lithium-ion batteries

ActiveCN110299562ALower oxidation potentialLower reduction potentialSecondary cellsOrganic electrolytesOrganic solventPhosphate

The invention provides a lithium-ion battery electrolyte, which is composed of an organic solvent, lithium salt, a novel additive and other conventional additives. The novel additive is a dicyclophosphimide lithium salt or lithium dicyclothiophosphimide lithium salt compound shown in a structural formula 1. The compound shown in structural formula 1 of the invention has a high reduction potentialwhen used as an electrolyte additive, so that the novel additive can participate in the formation of a solid electrolyte film on the surface of a negative electrode in preference to the conventional additives and improve the composition of the interfacial film. Because the additive has a cyclic phosphate structure, the phosphorus-oxygen bond is easy to break under high voltage, and the additive can participate in the formation of a positive electrolyte film and improve the interface stability of the positive electrode material. Therefore, the introduction of the additive can improve the high temperature performance, low temperature performance and cycle performance of lithium-ion batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Process for producing lithium-containing composite oxide for positive electrode for lithium secondary battery

ActiveUS20060154146A1Improve featuresSolve the small densityMagnesium halidesCell electrodesAlkaline earth metalNiobium

It is to provide a positive electrode active material for a lithium secondary battery, which has a large volume capacity density and high safety, is excellent in uniform coating properties and is excellent in the charge and discharge cyclic durability and low temperature characteristics even at a high charge voltage. A process for producing a lithium-containing composite oxide represented by the formula LipQqNxMyOzFa (wherein Q is at least one element selected from the group consisting of titanium, zirconium, niobium and tantalum, N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than the Q element and the N element, 0.9≦p≦1.1, 0<q≦0.03, 0.97≦x<1.00, 0≦y<0.03, 1.9≦z≦2.1, q+x+y=1 and 0≦a≦0.02) from a lithium source, an Q element source and an N element source, and if necessary, at least one source selected from the group consisting of an M element source and a fluorine source, characterized by using as the Q element source an Q element compound aqueous solution having a pH of from 0.5 to 11.

Owner:SUMITOMO CHEM CO LTD

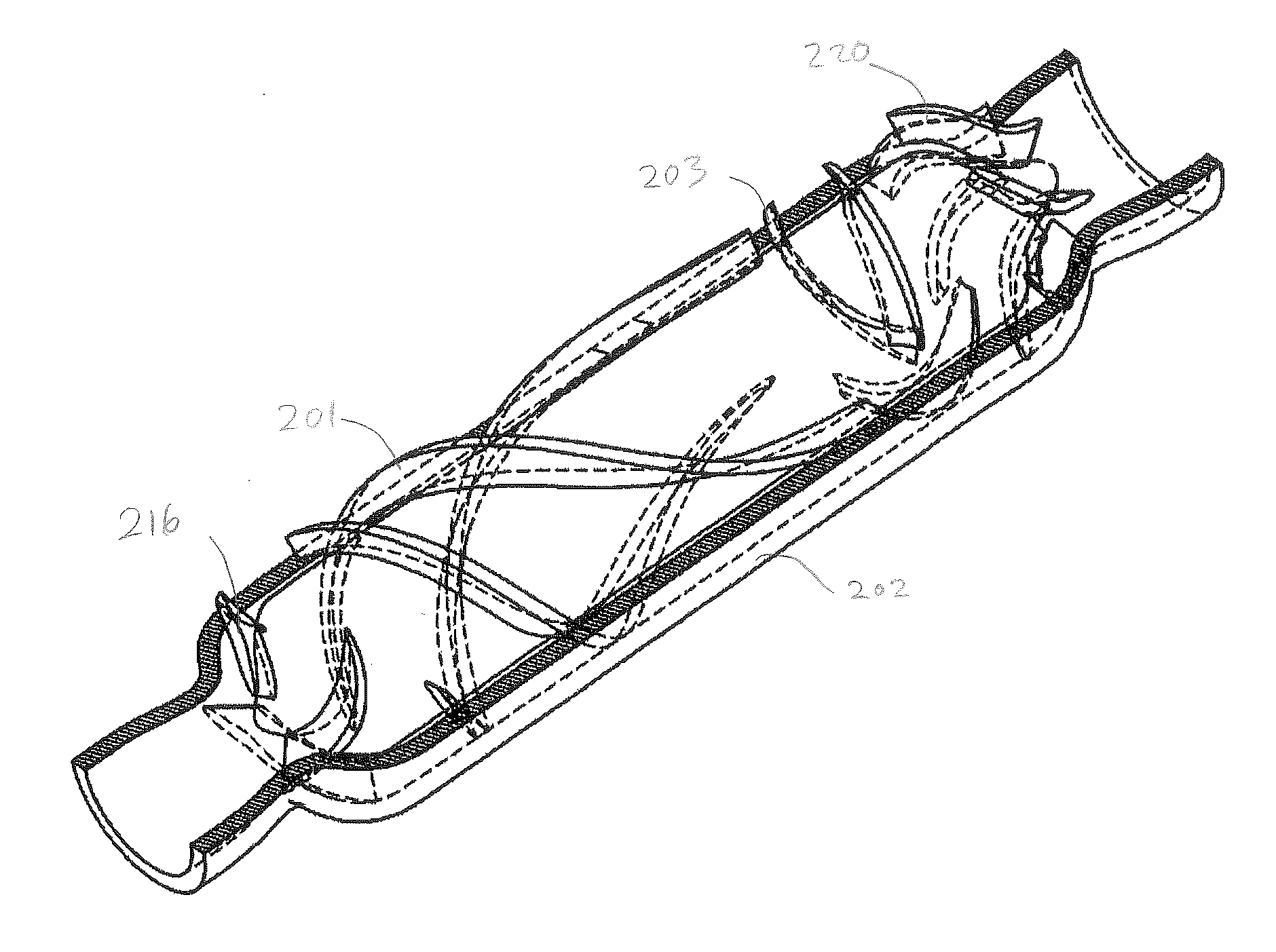

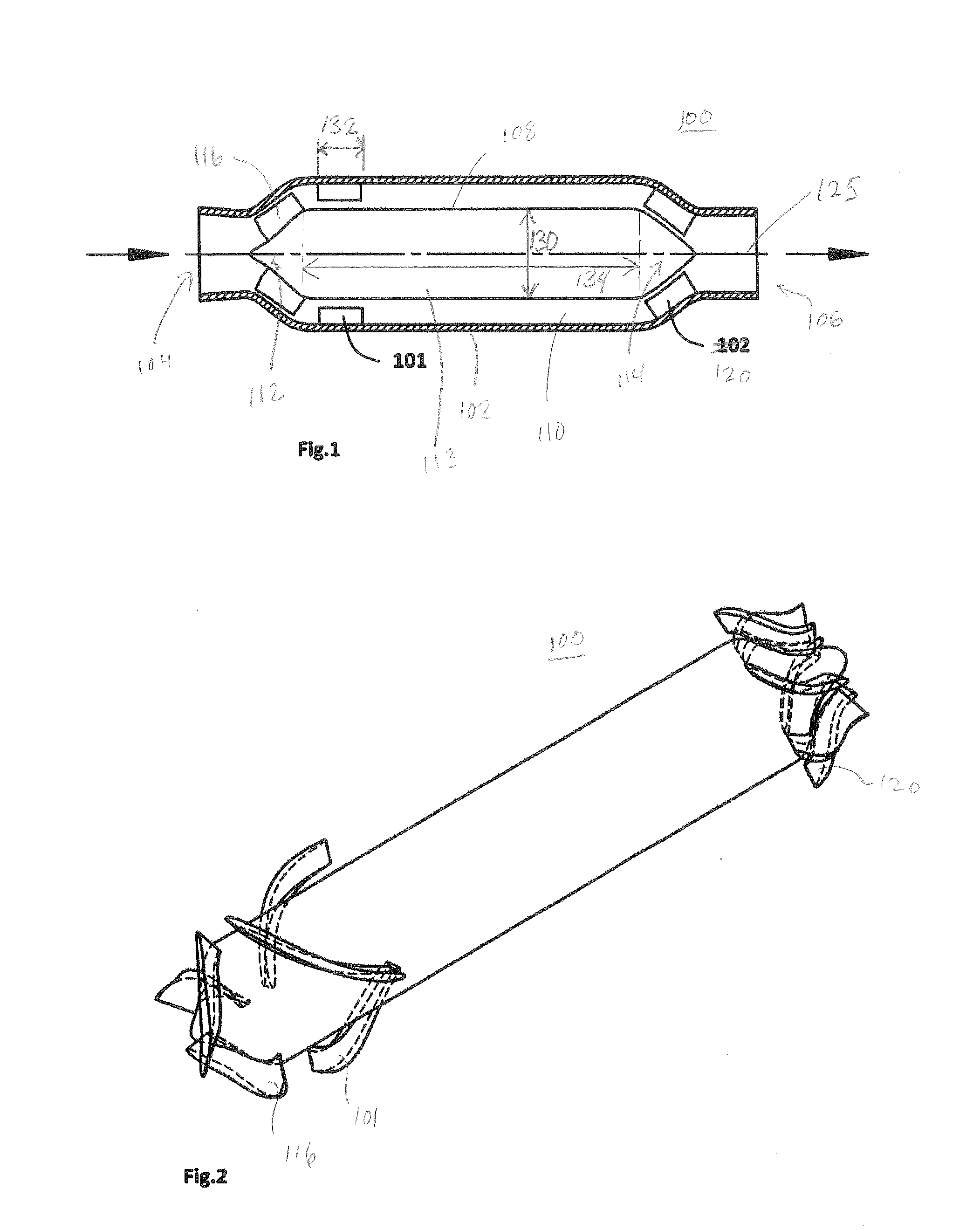

Blood pump with separate mixed-flow and axial-flow impeller stages and multi-stage stators

InactiveUS20140341726A1Reduce circumferential componentReduce risk of damagePump componentsBlood pumpImpellerMixed flow

A pump for a fluid which can be blood has a stator housing and a rotor hub with leading and trailing portions and an intermediate portion disposed therebetween. At least one impeller blade at the leading portion drives circumferential and axial components of a flow into a pump annulus or intermediate pathway portion. At least one stator blade extends radially inward from the stator housing within the intermediate pathway portion and is configured to reduce a circumferential component of the flow.

Owner:HEARTWARE INC

Electrostatic latent image developing toner and manufacturing method thereof

ActiveUS20060105258A1Good low temperatureLess in the warping (curling) properties of sheetDevelopersDynamic viscoelasticityLatent image

An electrostatic latent image developing toner including, as a binder resin, a crystalline resin and at least one kind of non-crystalline resin, wherein, in a dynamic viscoelasticity measurement by a sine wave vibration method, a minimum value of the relaxation elasticity H in a relaxation spectrum obtained from frequency dispersion characteristics measured at temperatures of 60 and 80 degrees centigrade with a measurement frequency set in the range of 0.1 to 100 rad / sec and measurement strain set in the range of 0.02 to 4.5% is in the range of 10 to 900 Pa / cm2, and a relaxation time λ corresponding to the minimum value is in the range of 1 to 10,000 sec.

Owner:FUJIFILM BUSINESS INNOVATION CORP

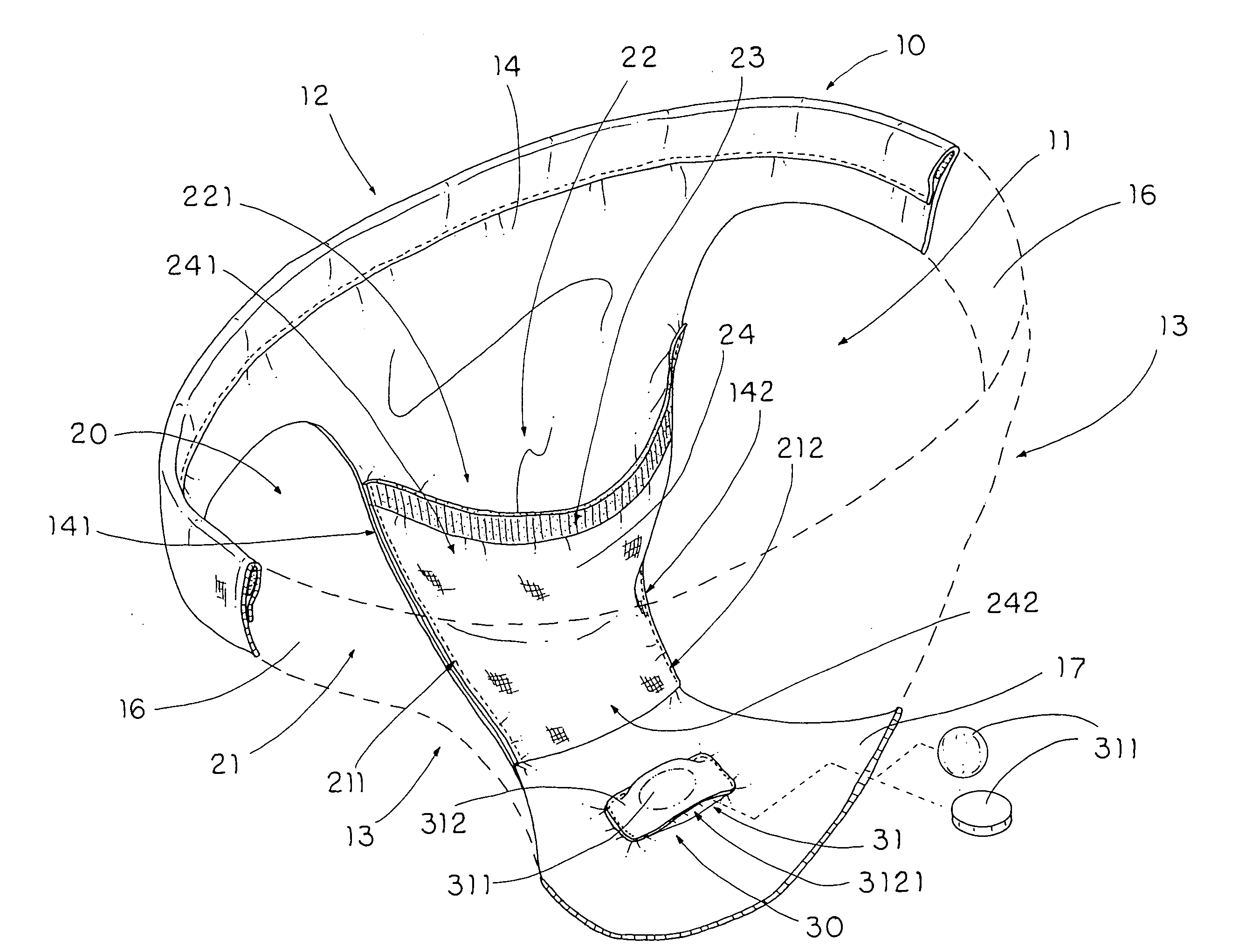

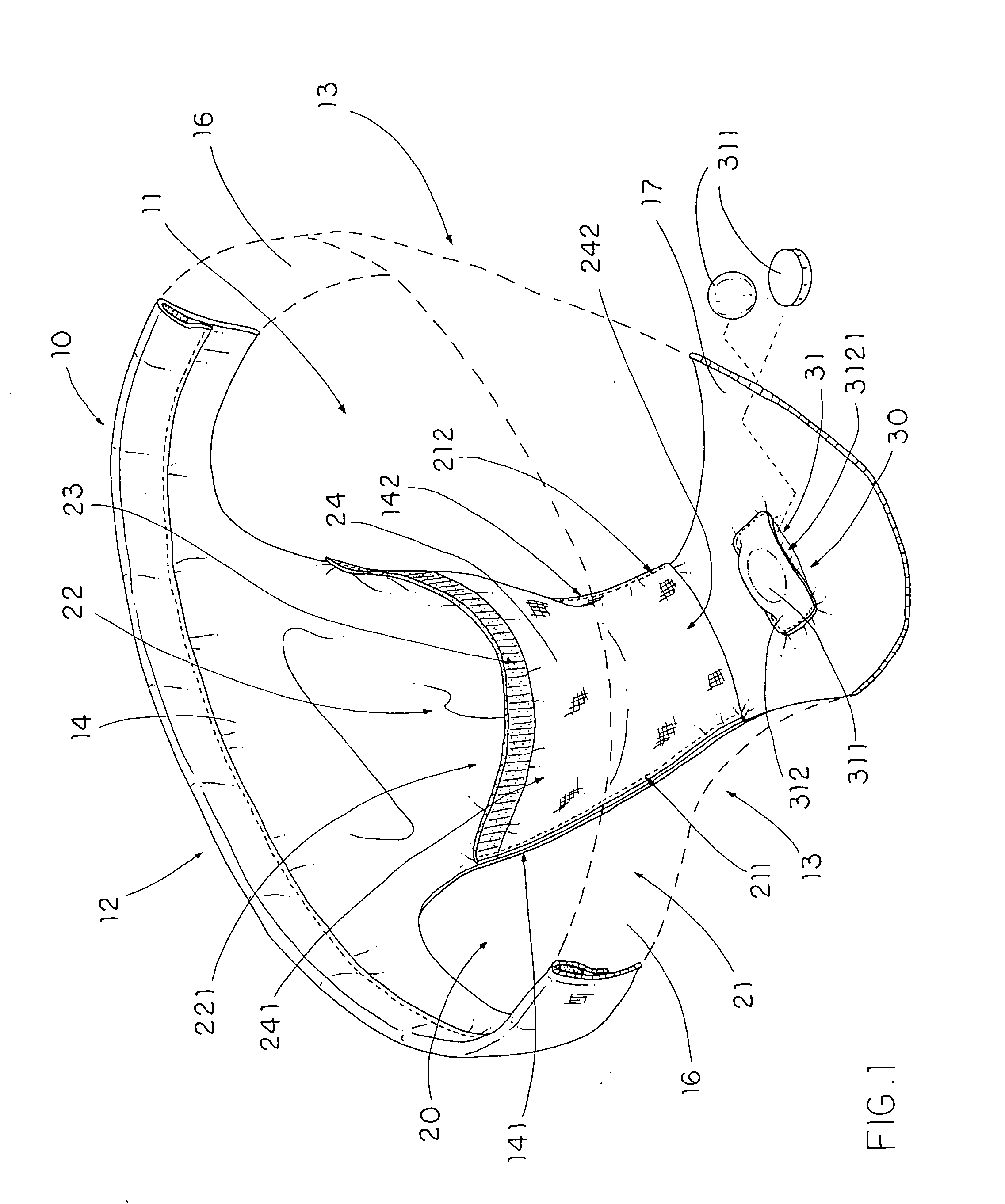

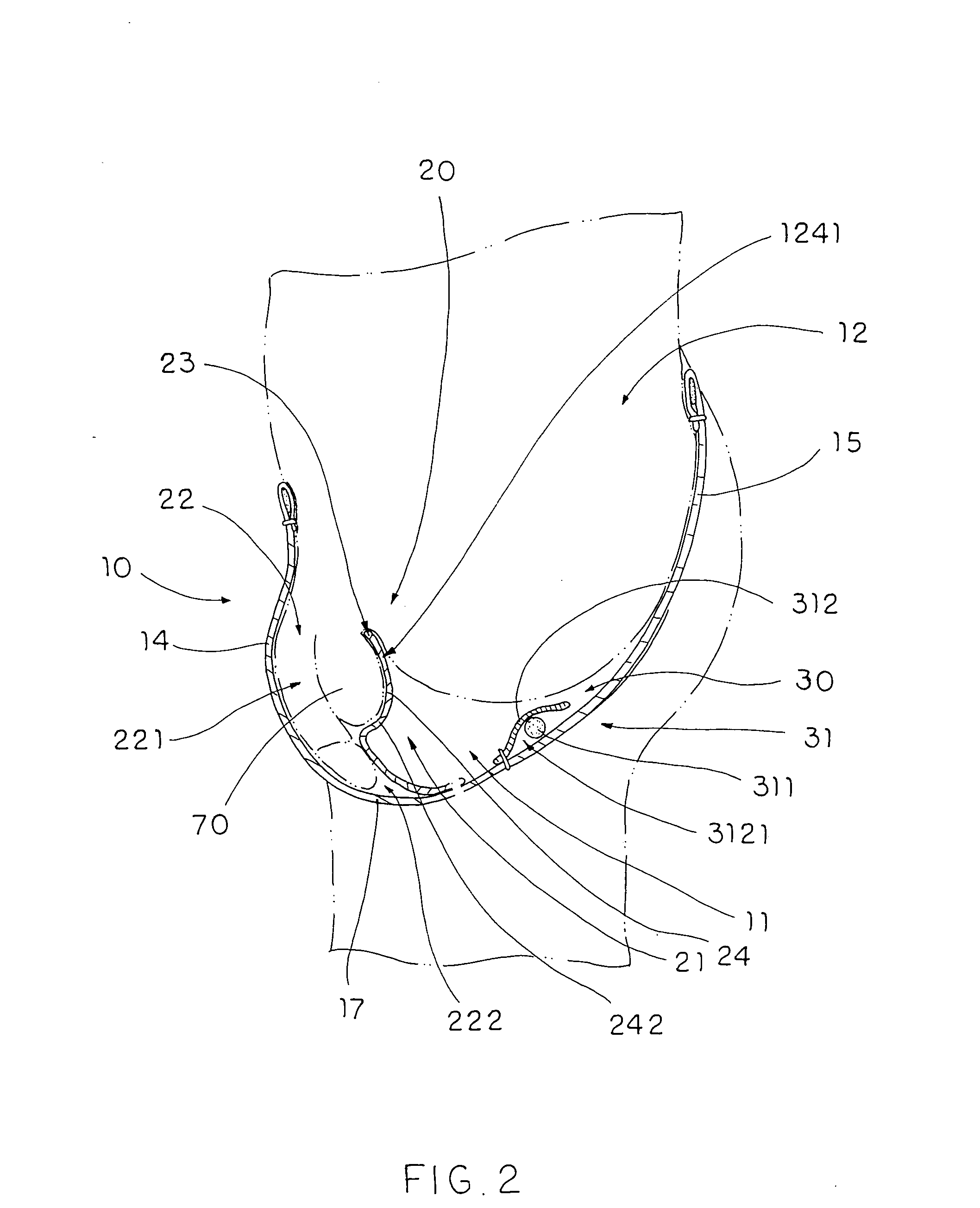

Treatment underwear

A pair of treatment underpants includes a body fitting and a testicles supporter. The body fitting, which is adapted for being worn at a groin portion of a wearer, has a wearing cavity, a waist opening, and two leg openings. The testicles supporter is provided within the wearing cavity of the body fitting at a position that when the body fitting is worn, the testicles supporter is adapted for supporting testicles to keep the testicles spacing apart from a body of the wearer so as to prevent a body temperature of the wearer directly transmitting toward the testicles.

Owner:XIA BOSHAN

Silicone modified acrylic-polyurethane heterocomplexing water dispersion and preparing method thereof

The invention provides an organosilicon modified acrylic polyurethane heterozygous aqueous dispersion as well as its preparing method, including the steps: make polyurethane prepolymer with hydrophilic group, make polyurethane prepolymer with side-chain activity double bonds, make propenoate monomer and anion polyurethane dispersion, and finally obtain it, which has interpenetrating network structure and nuclear shell structure. It has good heat resistance and solvent resistance, the performance advantages of polyurethane, crylic acid and organosilicon, and good dispersion stability; it has wide applications to monocomponent water carpentry paint and basal material in building paint, and its storage is stable.

Owner:SOUTH CHINA UNIV OF TECH

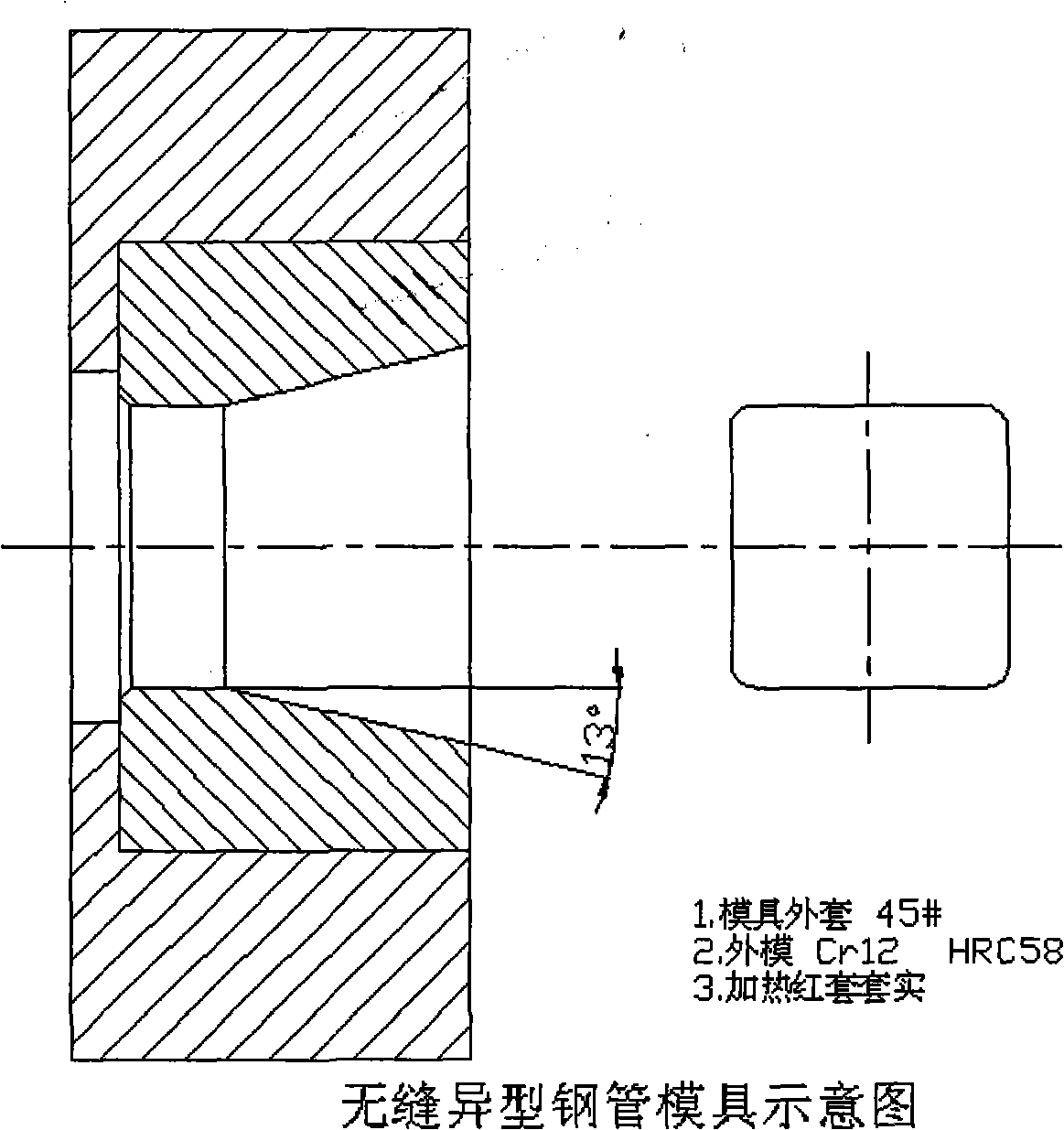

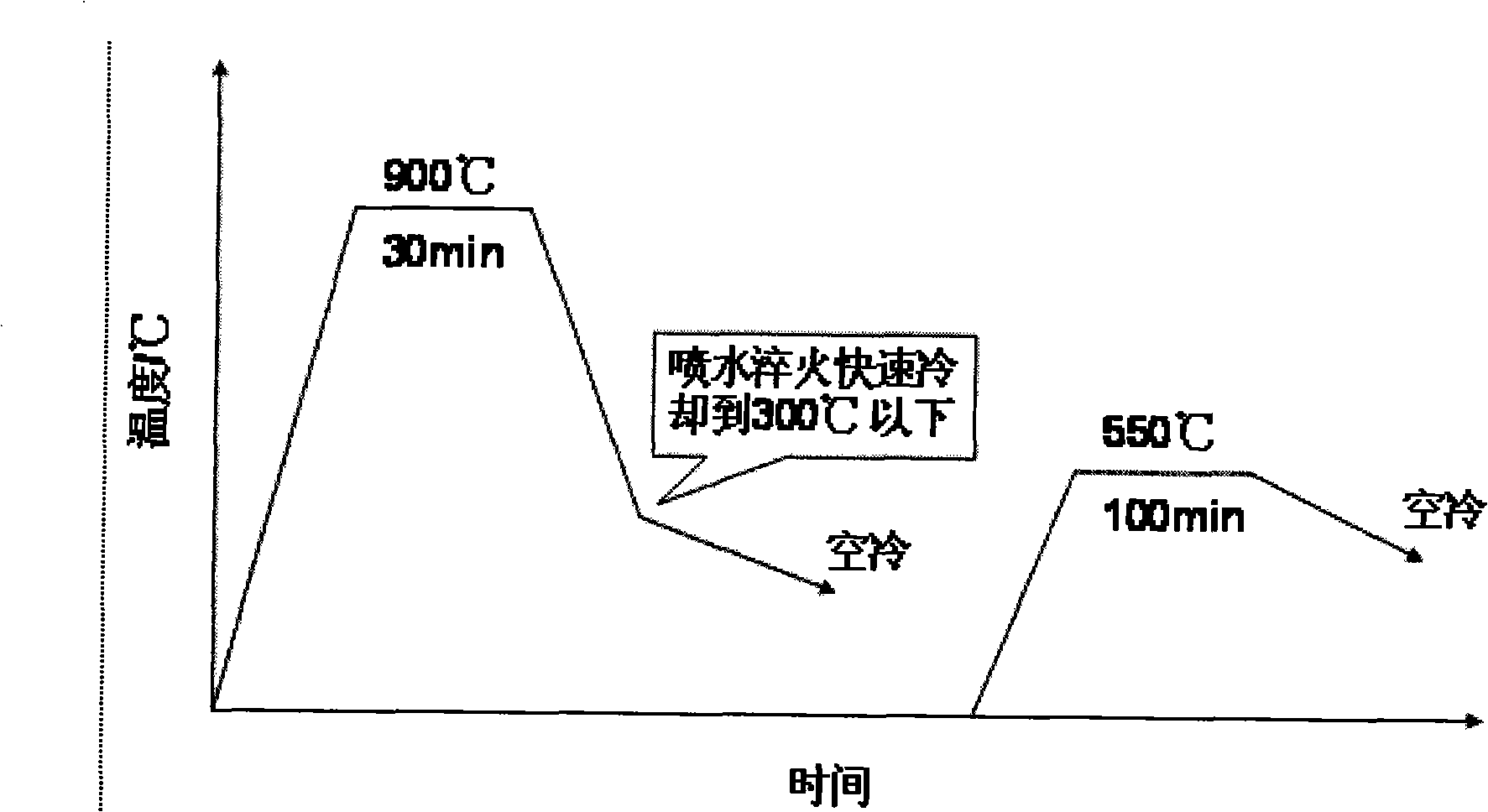

Preparation of seamless special-shaped steel pipe for low temperature resistance oil derrick electric transmission pole tower

InactiveCN101259582AGood comprehensive mechanical propertiesGood low temperature performanceFurnace typesHeat treatment furnacesSteel tubeQuenching

The invention relates to a manufacturing method of a seamless special steel pipe used in a low temperature tolerant petroleum derrick power transmission tower and is made of integral seamless steel pipe round pipe billet by adopting annealing heat treatment, process of setting and cold drawing and process of heat treatment of products; wherein, weight ratios of each chemical element of materials are as follows: C accounts for 0.15 to 0.18 percent, Mn accounts for 1.4 to 1.6 percent, Si accounts for 0.2 to 0.5 percent and trace elements of V accounts for 0.02 to 0.06 percent, Nb accounts for 0.015 to 0.06 percent, Ti accounts for 0.02 to 0.06 percent and Al accounts for 0.02 to 0.05 percent and the left is Fe and unavoidable impurities. The specific processing steps are as follows: annealing heat treatment and air cooling with the temperature of 850 to 880 DEG C for 30 minutes; setting and cold drawing; the heat treatment of the products adopts quenching, injection water cooling and tempering and hardening heat treatment process with the quenching temperature of 900 to 930 DEG C for 20 to 30 minutes, and air cooling is adopted after the fast injection water cooling is done under 300 DEG C with the tempering temperature of 550 DEG C for 100 minutes. The seamless special shaped steel pipe prepared by the method is characterized by good low temperature performance, high strength and comprehensive mechanical properties and lower cost, etc.

Owner:江苏界达特异新材料股份有限公司

Low-temperature zinc ion battery

InactiveCN108574085AImprove ionic conductivityHigh specific capacity and energy densityCell electrodesSecondary cellsSolventQuinone

The invention belongs to the technical field of batteries and particularly relates to a low-temperature zinc ion battery, comprising a cathode, an anode, and low-temperature electrolyte. The cathode is made from organics containing carbonyl functional groups, such as quinones, embedded compounds that may reversely dis-embed Zn2+, Li+ and Na+, or Prussian blue derivatives. The anode comprises a metal zinc sheet, zinc foil, zinc powder, a powdery porous zinc electrode, zinc alloy, or a zinc-based material applied to / deposited on another conductive substrate. The low-temperature electrolyte usesethyl acetate and its derivatives, or quinones or their derivatives as solvents, uses an organic zinc salt or inorganic zinc salt as a solute, and has a concentration of 0.01-10 mol / L. The low-temperature zinc ion battery may allow reversible charging and discharging through cathodic enolization and anode zinc dissolution / precipitation mechanism, and still has high specific capacity, high energy density, long cycle life and excellent power performance at the extreme low temperature (-70 DEG C).

Owner:FUDAN UNIV

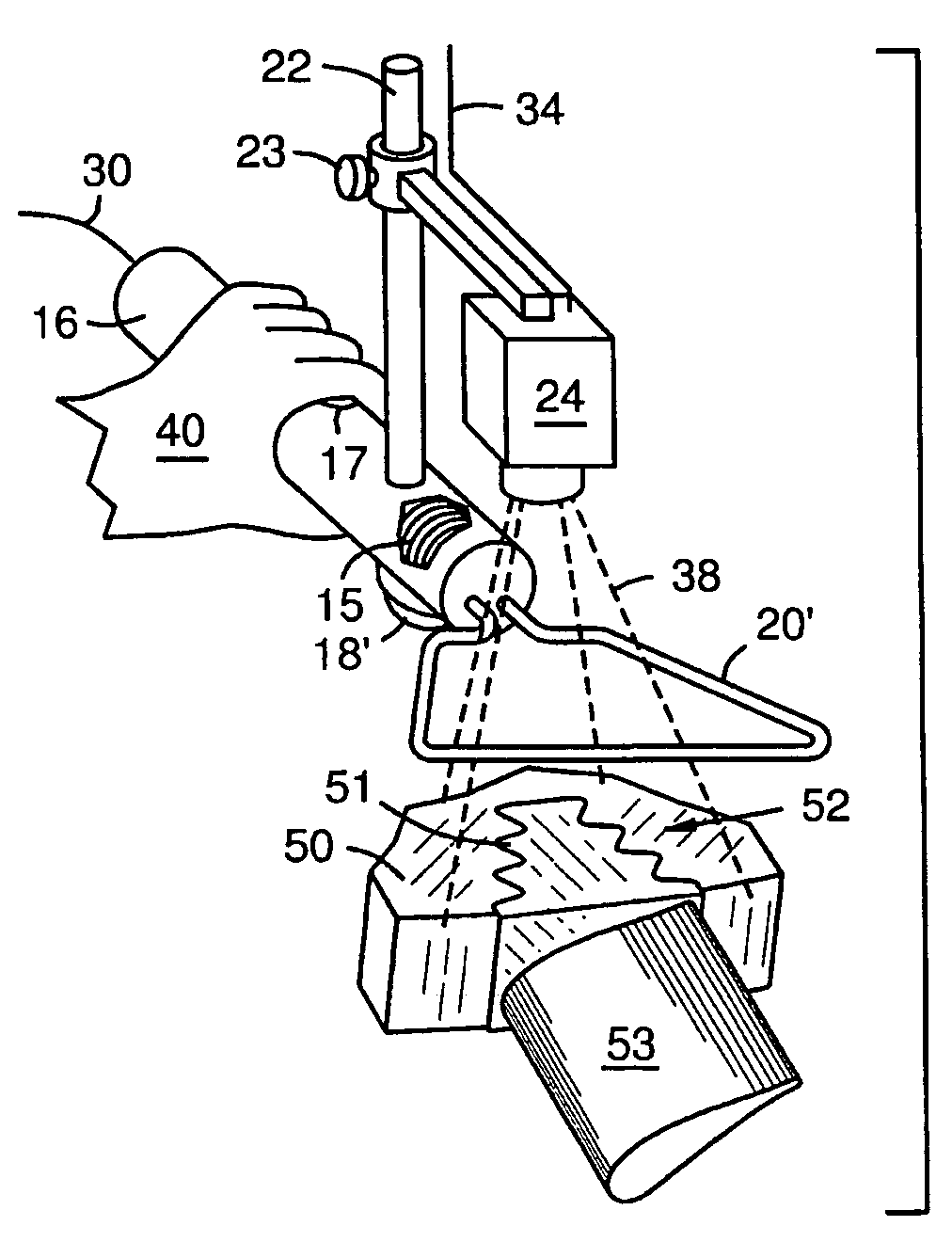

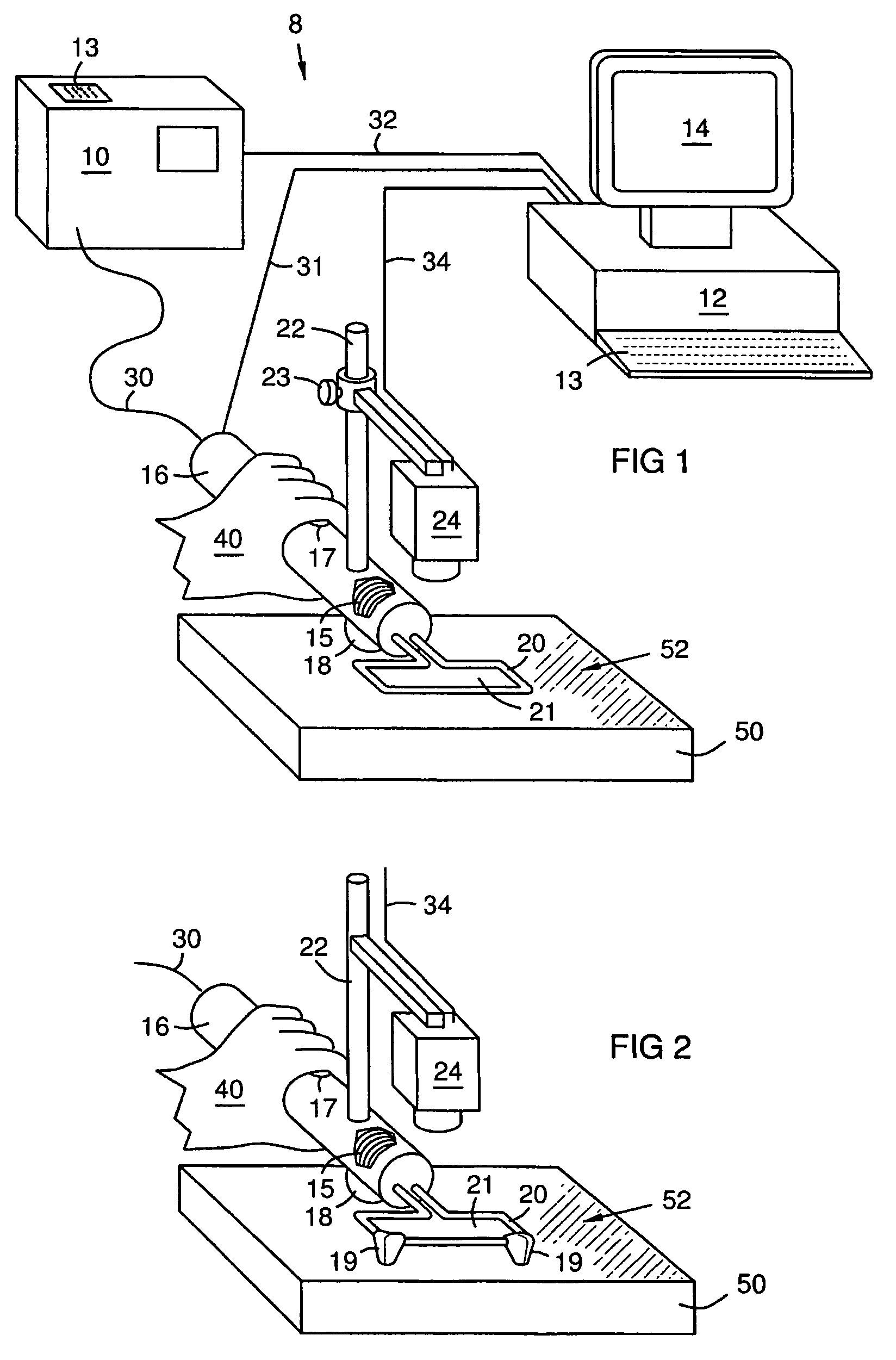

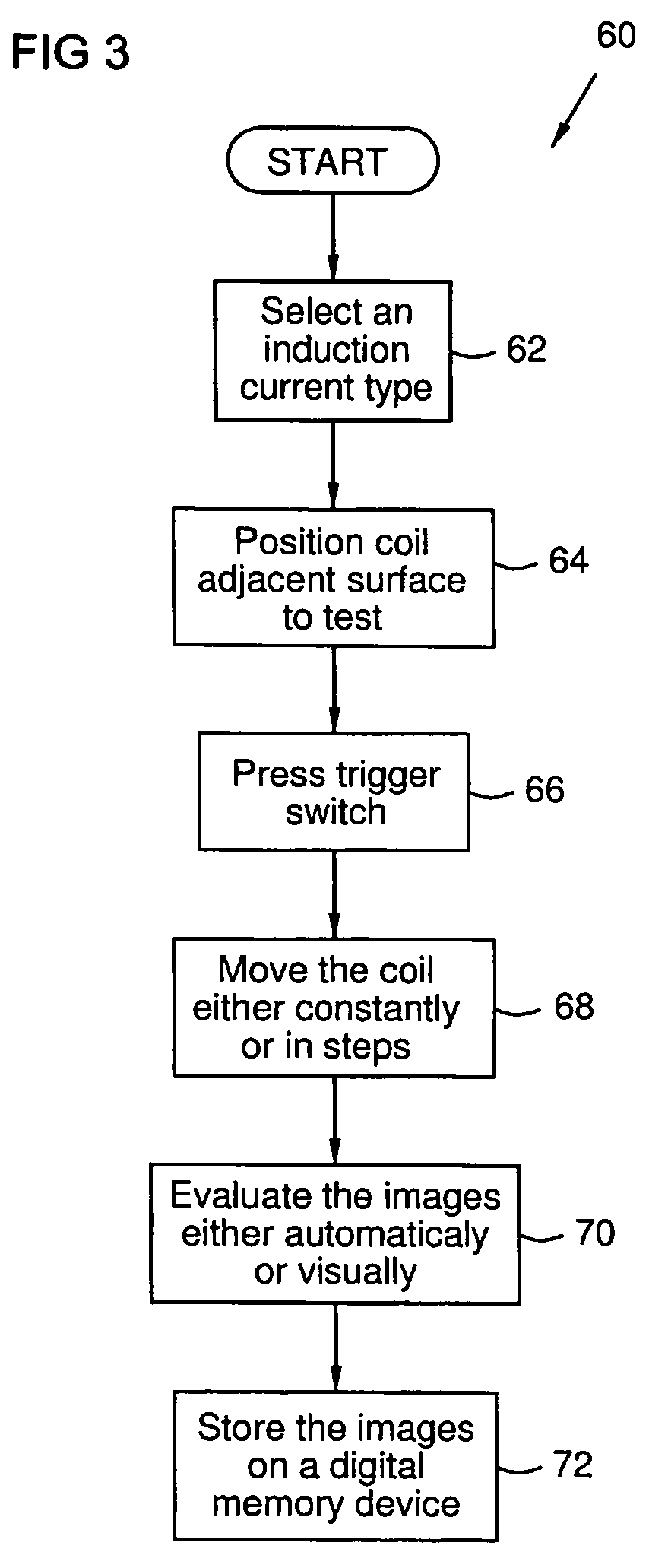

Hand held magnetic induction thermography system

InactiveUS7485882B2Total current dropReduce heatRadiation pyrometryThermometerTransformerDigital storage

A hand-held thermography system (8). A generator (10) supplies current to a transformer (15) in a handle (16). An induction coil (20) connected to the transformer (15) extends from the handle (16). The induction coil (20) induces eddy currents in a test object (50), producing a thermal topography on a surface (52) of the object (50) that reveals structural features including defects in the object. An infrared camera (24) mounted on the transformer (16) digitizes images of the thermal topography. A controller (12) processes the images, displays them on a monitor (14), and stores them in a digital memory (11) for evaluation. Digitized positional data relating the position of the image to the surface may also be stored. An operator (40) presses a trigger (17), signaling the controller (12) to start current to the induction coil (20) and simultaneously to acquire and process one or more images from the camera (24). The images may be evaluated visually and / or by computerized analysis techniques for analyzing defects in the object.

Owner:SIEMENS ENERGY INC

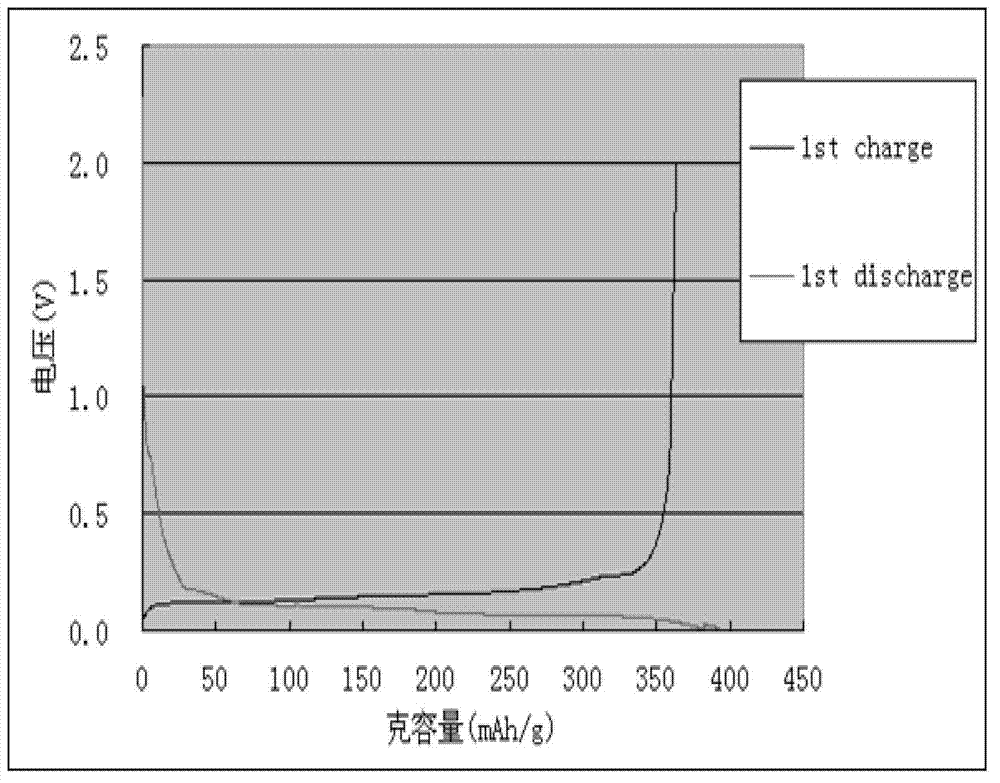

Anode material for lithium ion power battery and preparation method thereof

The invention discloses an anode material for a lithium ion power battery and a preparation method thereof, which aims to solve the technical problem of reducing the cost. The anode material for the lithium ion power battery of the invention takes spherical-like graphite, spheroid graphite with the major-minor axis ratio of 1.0-3.5, blocky graphite and / or flake graphite as a substrate, and non-graphite carbon material is coated outside the substrate to form composite particles. The preparation method comprises the following steps: mixing the precursors of the graphite and the non-graphite carbon material in liquid phase to obtain a suspensoid mixture; mixing and coating to obtain precursors of composite particles; and carbonizing to obtain the anode material for the lithium ion power battery. Compared with the prior art, the anode material for the lithium ion power battery of the invention has the characteristics of high capacity, high efficiency, excellent low-temperature performance, excellent magnification performance, superior absorption performance, simple preparation method and easy control, greatly reduces the cost of the lithium ion power battery, and is suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com