Preparation of seamless special-shaped steel pipe for low temperature resistance oil derrick electric transmission pole tower

A technology for special-shaped steel pipes and seamless steel pipes, which is applied in furnace types, manufacturing tools, heat treatment equipment, etc., can solve problems such as poor comprehensive mechanical properties, high manufacturing costs, and poor welding process performance, achieve good comprehensive mechanical properties, and improve the overall Quality level, good welding manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The invention relates to a method for manufacturing a seamless special-shaped steel pipe for a low-temperature-resistant oil derrick power transmission tower.

[0064] The percentage by weight of each chemical element in the material of the integral seamless steel tube round tube is: C0.15-0.18%, Mn 1.4-1.6%, Si 0.2-0.5%, and trace elements V 0.02-0.06%, Nb0.015-0.06 , Ti 0.02-0.06% and Al 0.02-0.05%, the balance is Fe and unavoidable impurities S≤0.020%, P≤0.020%, N≤0.020%, the specific process steps are as follows:

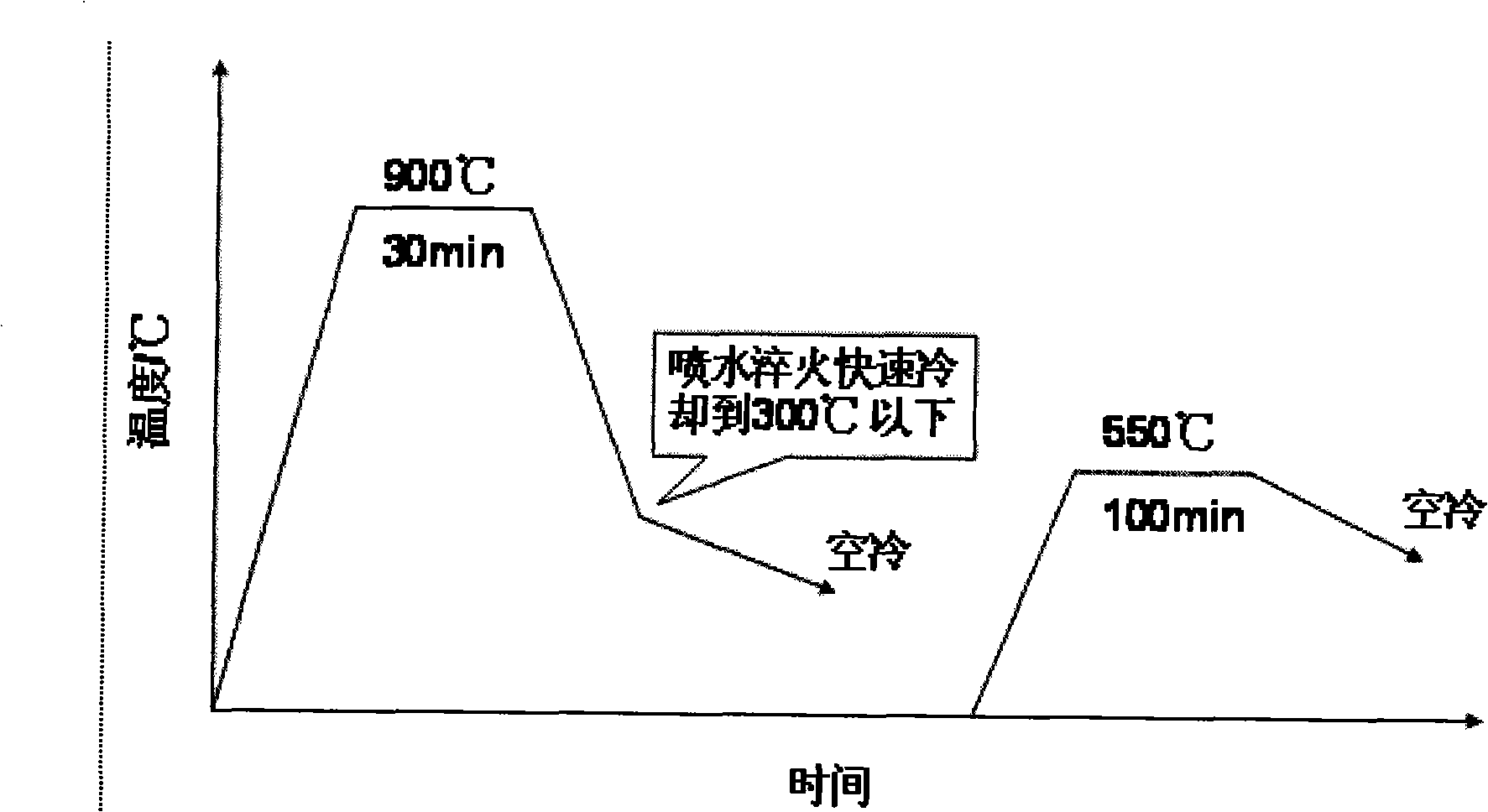

[0065] Step 1, annealing heat treatment

[0066] Annealing heat treatment hot-rolled steel tube billet, annealing temperature 850 ~ 880 ℃, holding time 30 minutes, air cooling,

[0067] Due to the inhomogeneity of hot rolling and cooling, the hot-rolled steel billet has a general hot-rolled bad structure and high hardness. After annealing heat treatment, the metallographic structure is refined, such as figure 1 . Improve the strength and plasticity to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com