Hydraulic cylinder block machining process

A processing technology and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of short service life, fast wear, low quality hydraulic cylinders, etc., and achieve long service life, improved wear resistance, and good comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

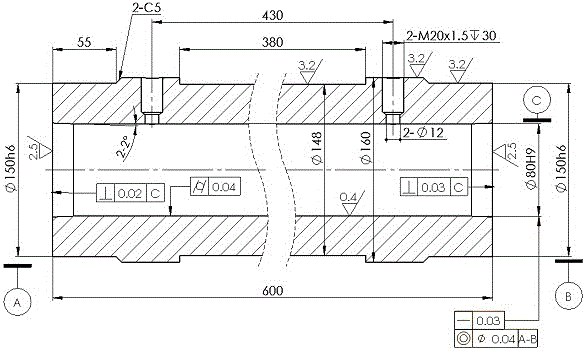

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be further described below in conjunction with the examples.

[0023] A process for processing a cylinder body of a hydraulic cylinder, the method comprising the steps of:

[0024] A: Select seamless steel pipe as the material of the hydraulic cylinder;

[0025] B: The sawing machine cuts and blanks the seamless steel pipe;

[0026] C: Perform quenching and tempering and carburizing treatment on the seamless steel pipe, and check the hardness of the seamless steel pipe after quenching and tempering and carburizing;

[0027] D: Outer circle, process thread, end face and chamfer of the seamless steel pipe described on the lathe;

[0028] E: Rough boring the seamless steel pipe first, then semi-finish boring, then fine boring the seamless steel pipe, and finally fine reaming the seamless steel pipe;

[0029] F: rolling the hole obtained after pushing and boring the deep hole with a rolling head;

[0030] G: Turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com