Polylactic acid-polyester composite material and preparation method thereof

A polyester composite material and composite material technology, applied in the field of polylactic acid-polyester composite materials, can solve the problems of limited toughening effect on impact resistance and tensile properties, reduced toxicity or biodegradation performance, etc., and achieve comprehensive mechanical properties Good, enhanced compatibility, good biodegradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

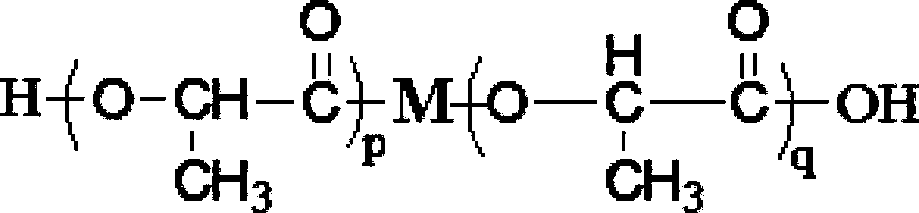

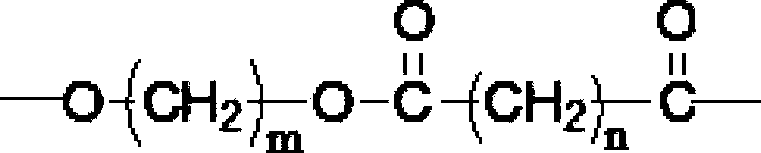

[0056] The tri-block copolyester can be prepared according to conventional methods. Preferably, the tri-block copolyester can be prepared according to the method disclosed in CN102443145A. Specifically, the preparation method of the three-block copolyester may include: in the presence of an organotin compound, under the esterification reaction conditions, under an inert atmosphere, make a linear aliphatic aromatic copolyester and acrylic acid Lactide contact, the linear aliphatic aromatic copolyester includes structural units as shown in the following formula 2 and formula 3,

[0057]

[0058] Formula 2

[0059]

[0060] Formula 3

[0061] Wherein, m is an integer of 1-20, preferably an integer of 2-10; n is an integer of 1-16, preferably an integer of 2-8; t is an integer of 1-20, preferably an integer of 2-10; The molar ratio of the structural units shown in formula 2 and formula 3 is 1:0.1-10, preferably 1:0.5-2; the weight average molecular weight of the linear al...

Embodiment 1

[0139] This example is used to illustrate the polylactic acid-polyester composite material of the present invention and its preparation method.

[0140] (1) Preparation of branched aliphatic aromatic copolyesters

[0141] Catalyst: The catalyst contains 57.8% by weight of lanthanum stearate (prepared according to the method of Example A5 in CN1807485A, the same below), 23.2% by weight of tetrabutyl titanate (purchased from Beijing Chemical Reagent Company, the same below), 10.0% by weight of dibutyltin oxide (purchased from Beijing No. 3 Chemical Plant, the same below) and 9.0% by weight of triphenylhydroxytin (purchased from Beijing Chemical Reagent Company, the same below).

[0142] Add 1.72mol of terephthalic acid, 2.77mol of 1,4-butanediol and 1.058g of the above catalyst into a 2.5L reactor, stir and heat to reflux under a nitrogen atmosphere, adjust the temperature to 230°C and Under the reaction, when the water generated by the reaction is completely distilled (the rea...

Embodiment 2

[0153] This example is used to illustrate the polylactic acid-polyester composite material of the present invention and its preparation method.

[0154] Mix 300g of L-polylactic acid, 60g of triblock copolyester TP1 prepared in step (2) of Example 1, and 140g of aliphatic aromatic copolyester P1 prepared in step (1) of Example 1, and then add 0.5 g of erucamide and 1 g of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane were mixed. The material obtained after mixing is extruded and granulated through a twin-screw extruder. The screw speed is controlled at 30 rpm. 170°C, 170°C and 165°C to prepare polylactic acid-polyester composite material A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com