Patents

Literature

182 results about "Antiferromagnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

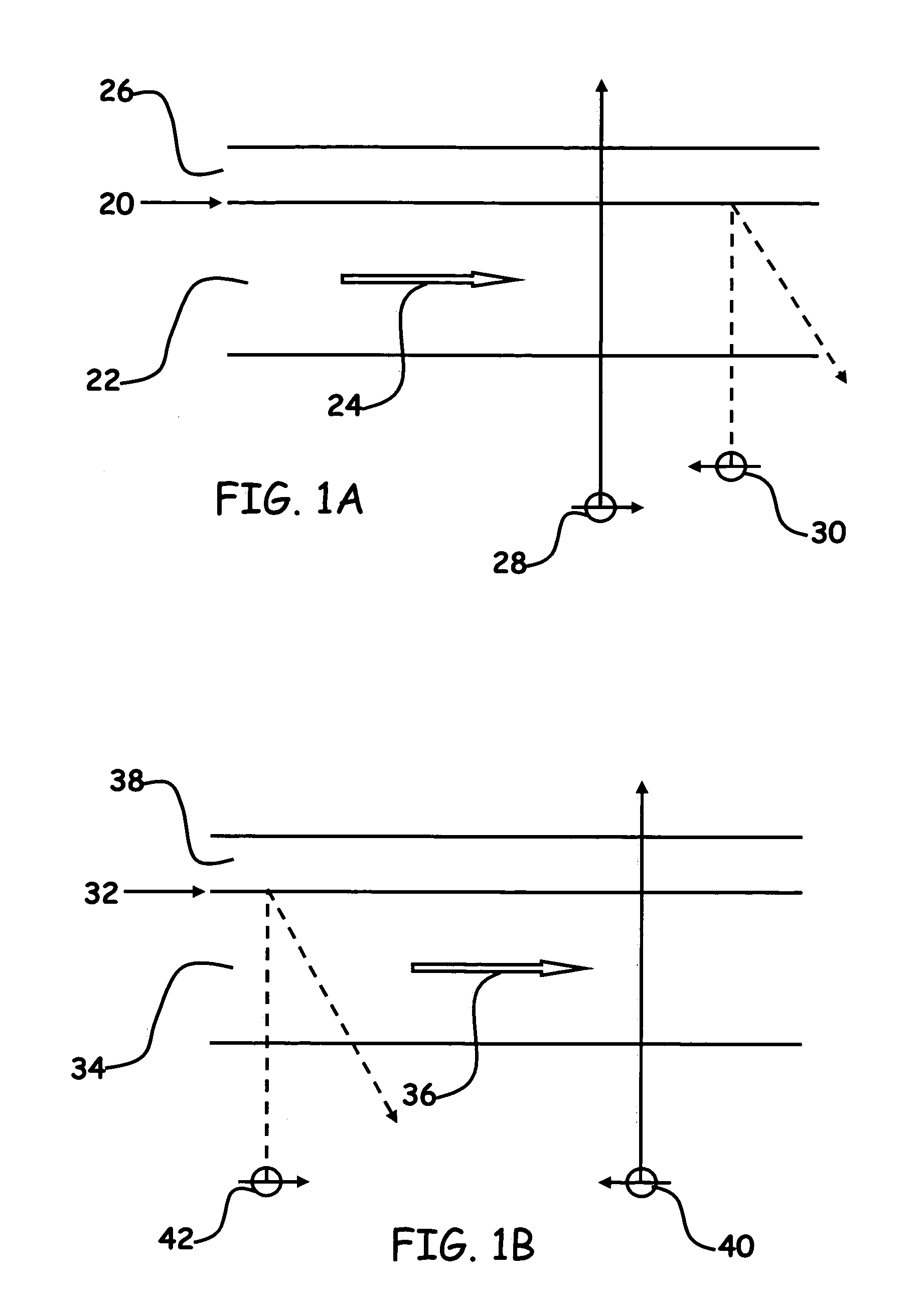

In materials that exhibit antiferromagnetism, the magnetic moments of atoms or molecules, usually related to the spins of electrons, align in a regular pattern with neighboring spins (on different sublattices) pointing in opposite directions. This is, like ferromagnetism and ferrimagnetism, a manifestation of ordered magnetism.

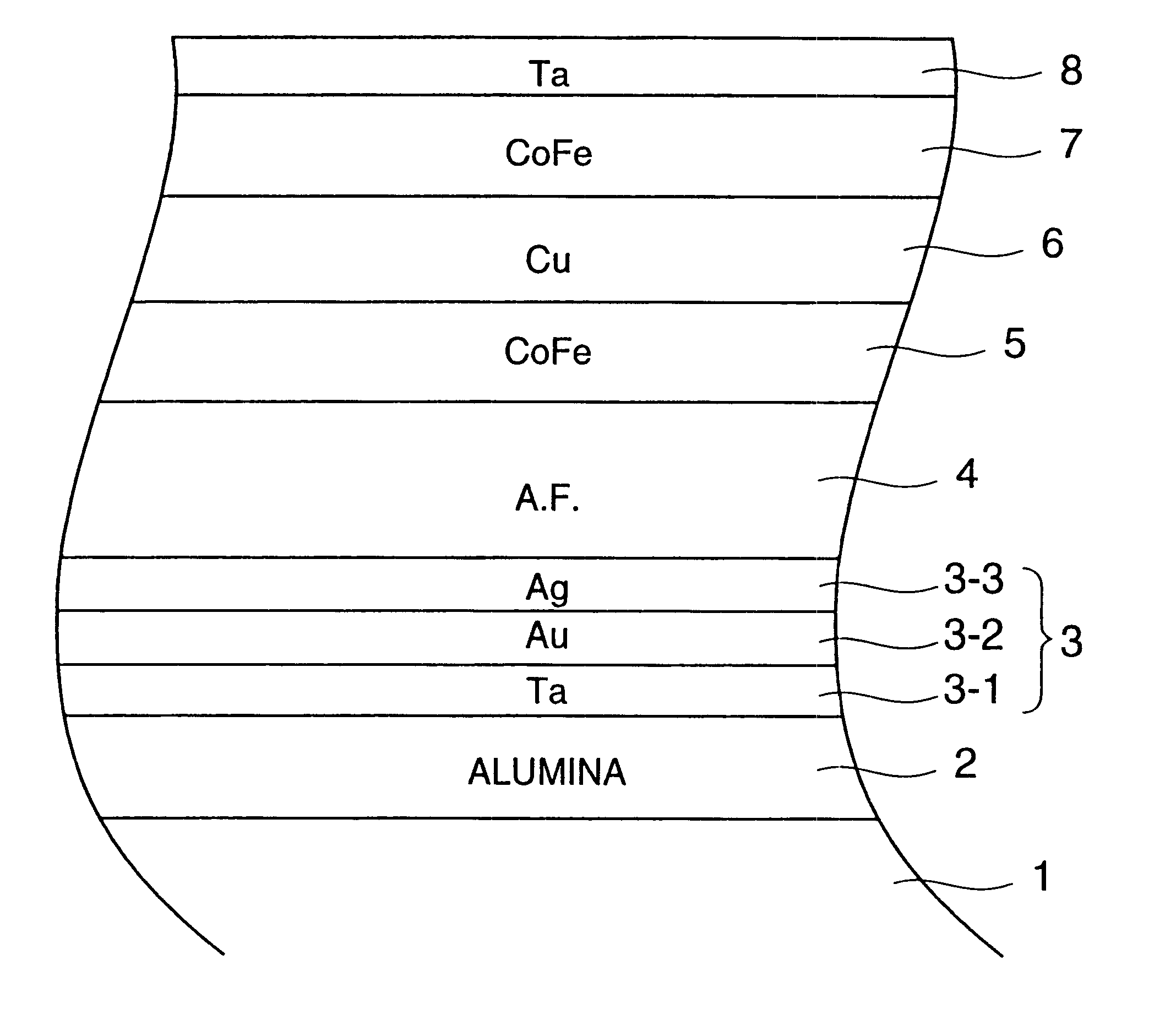

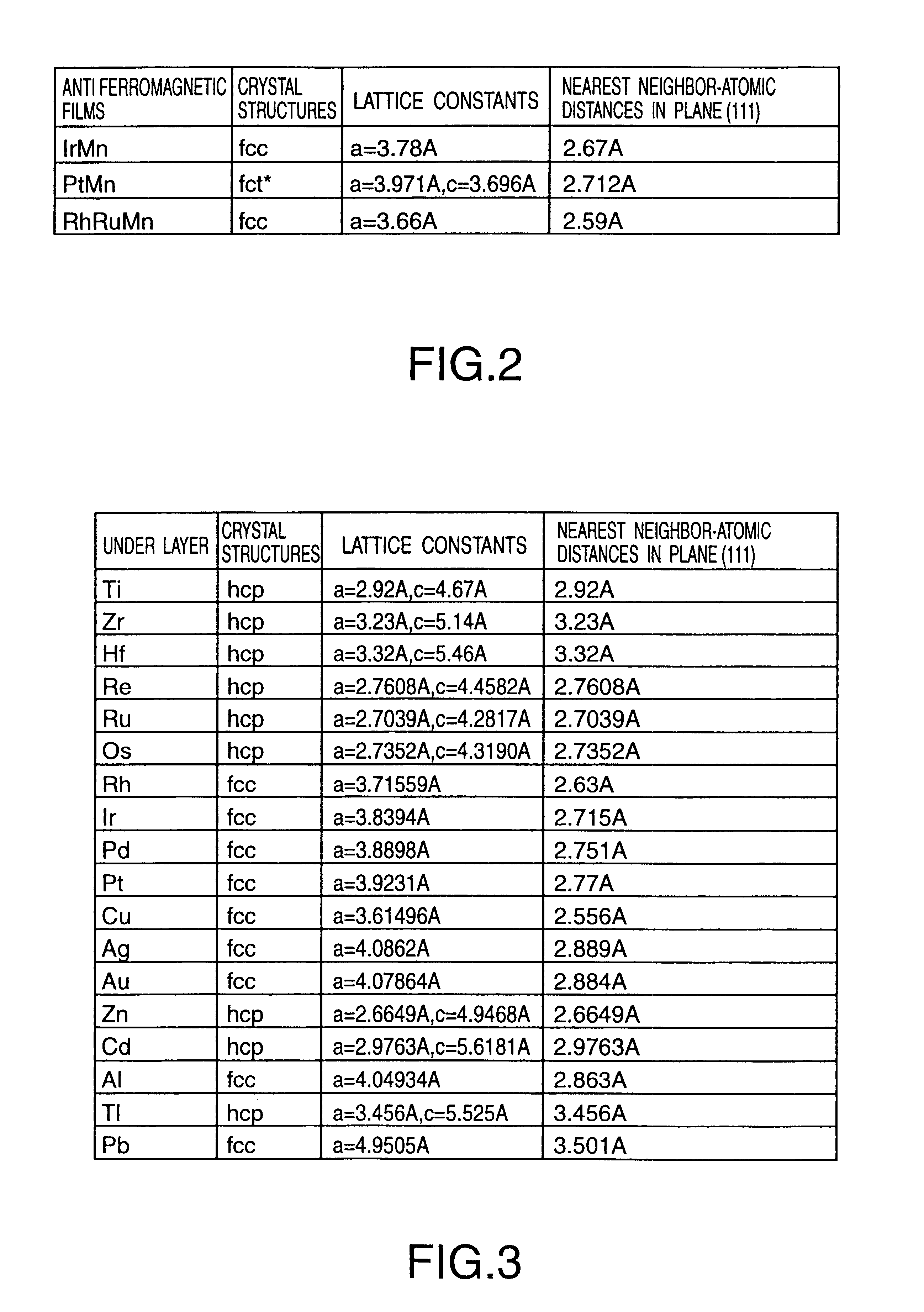

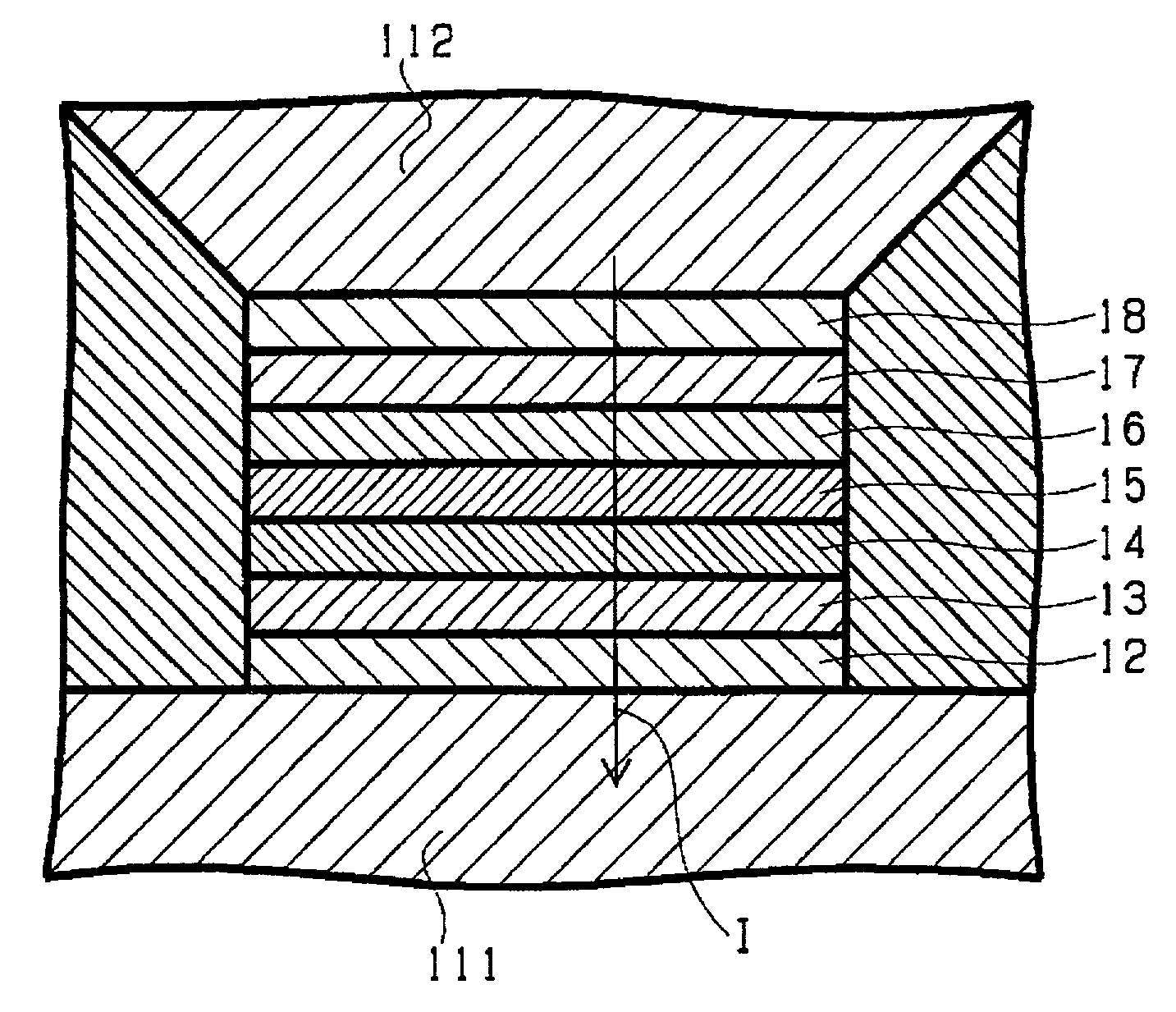

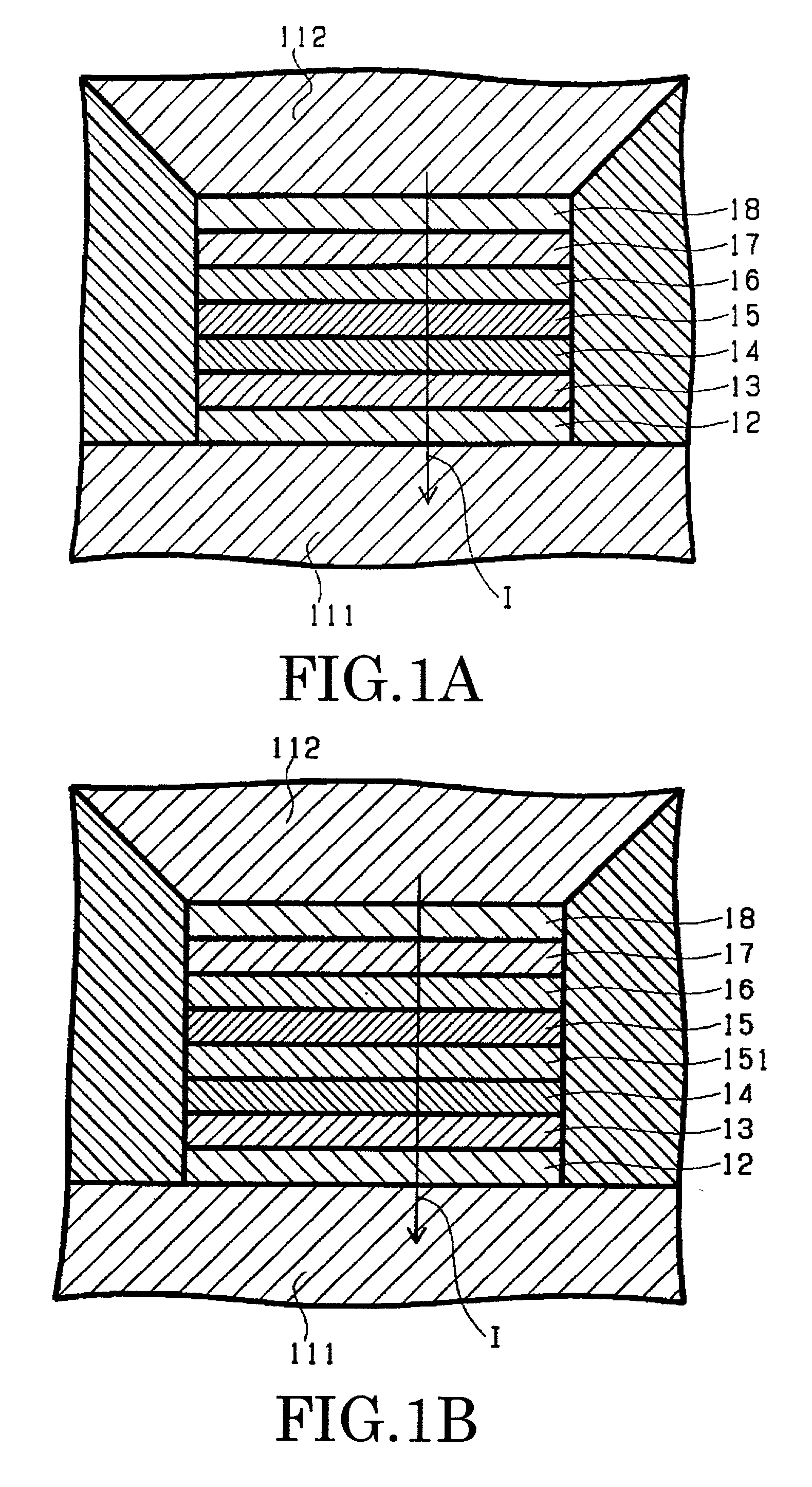

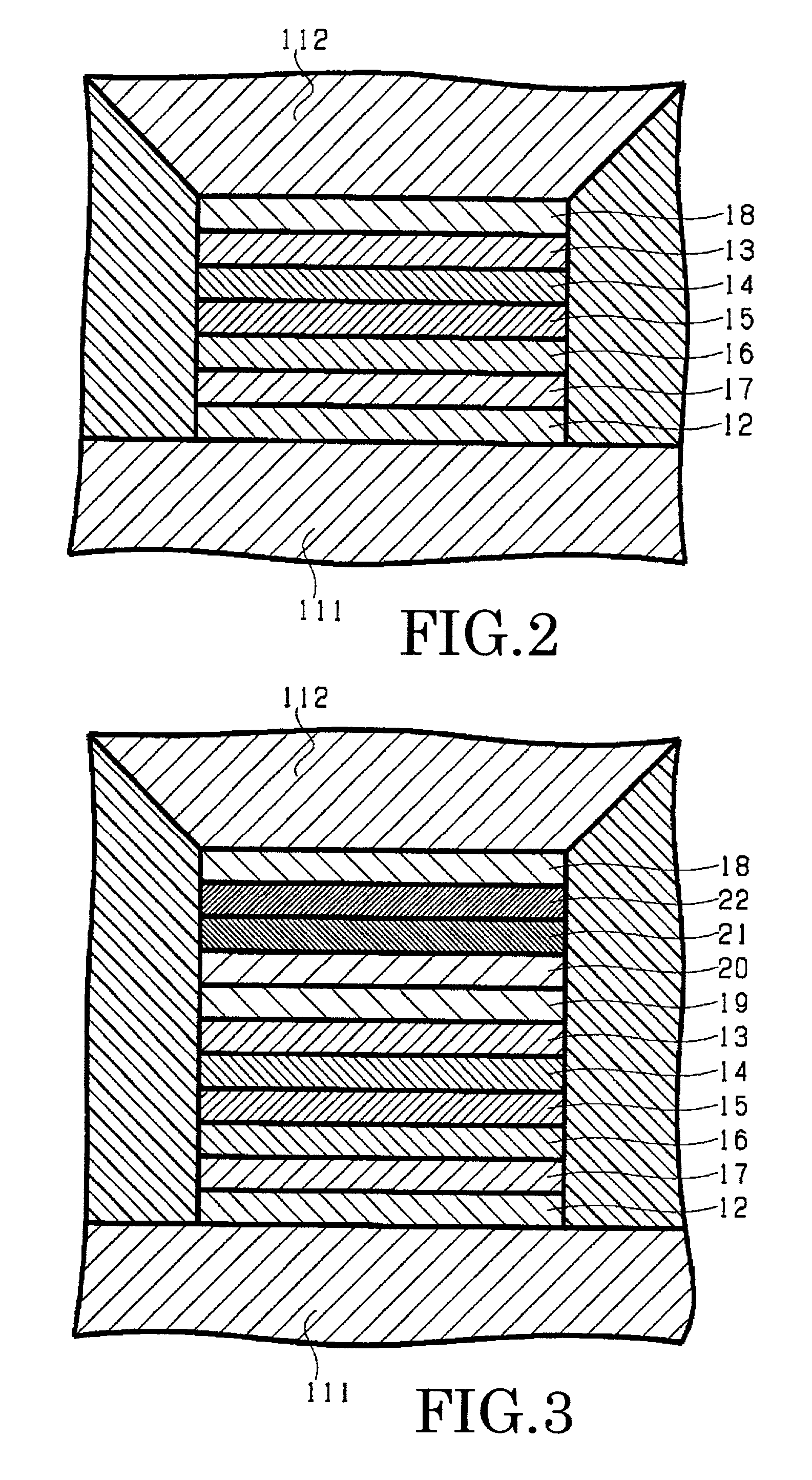

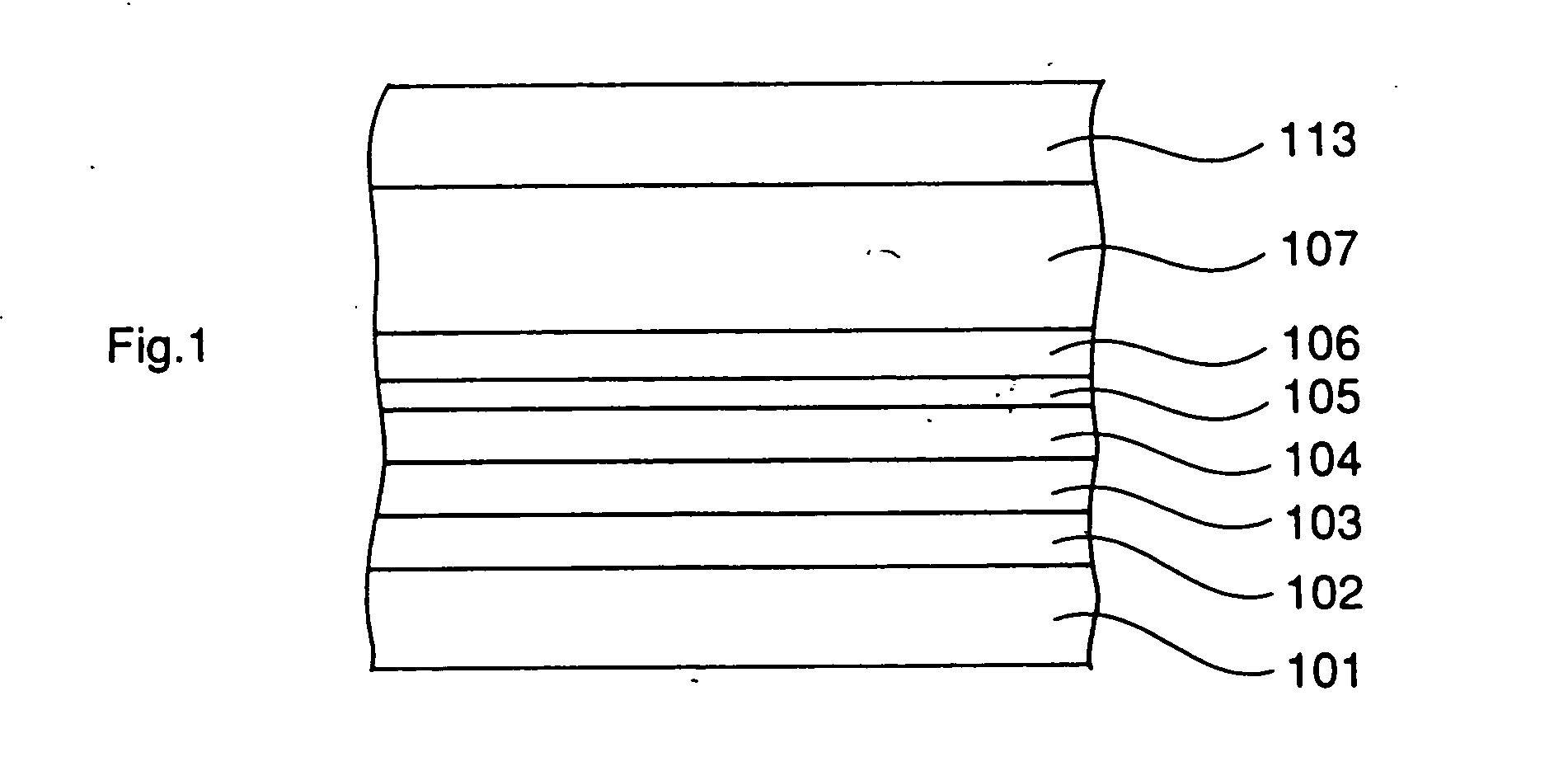

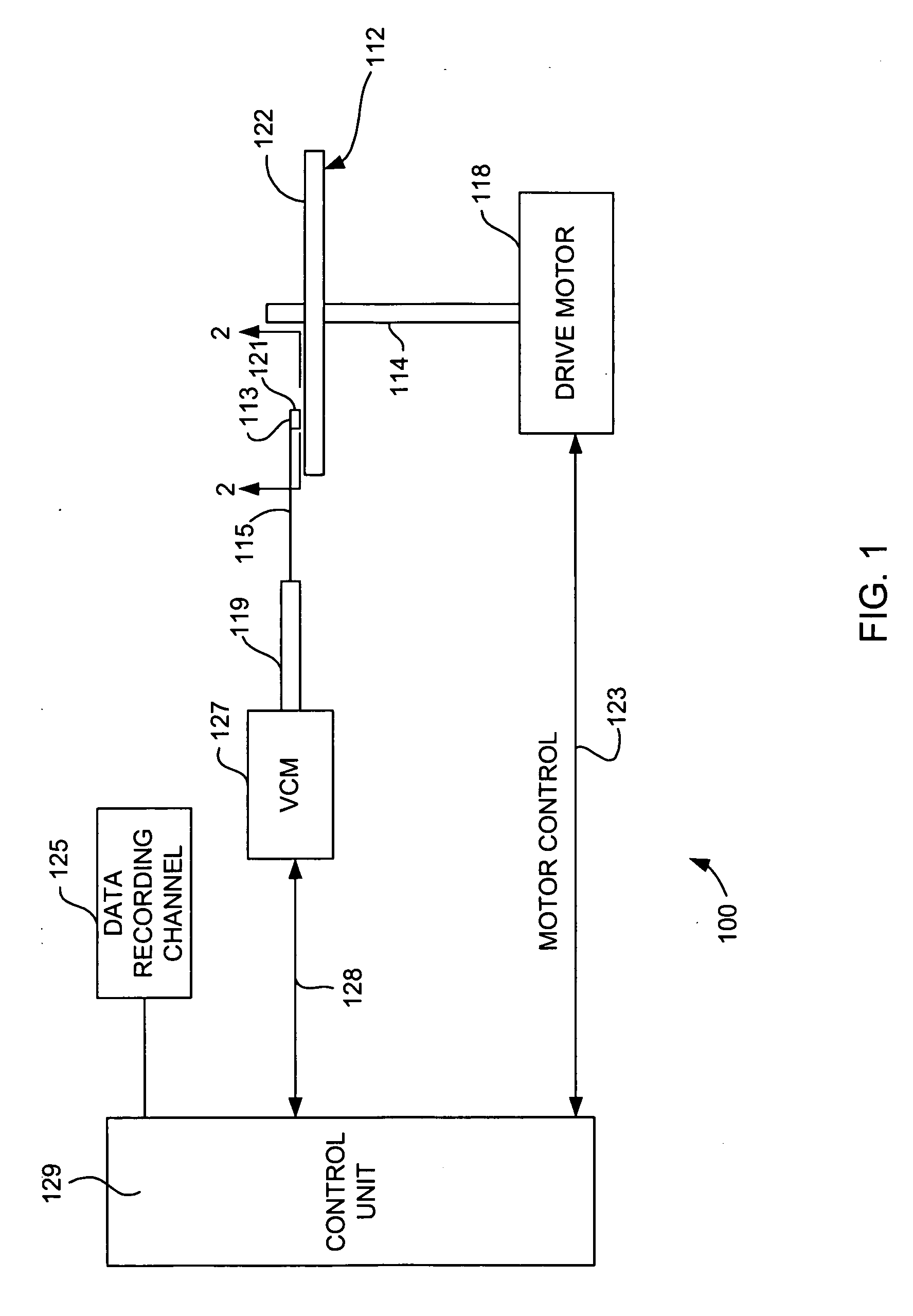

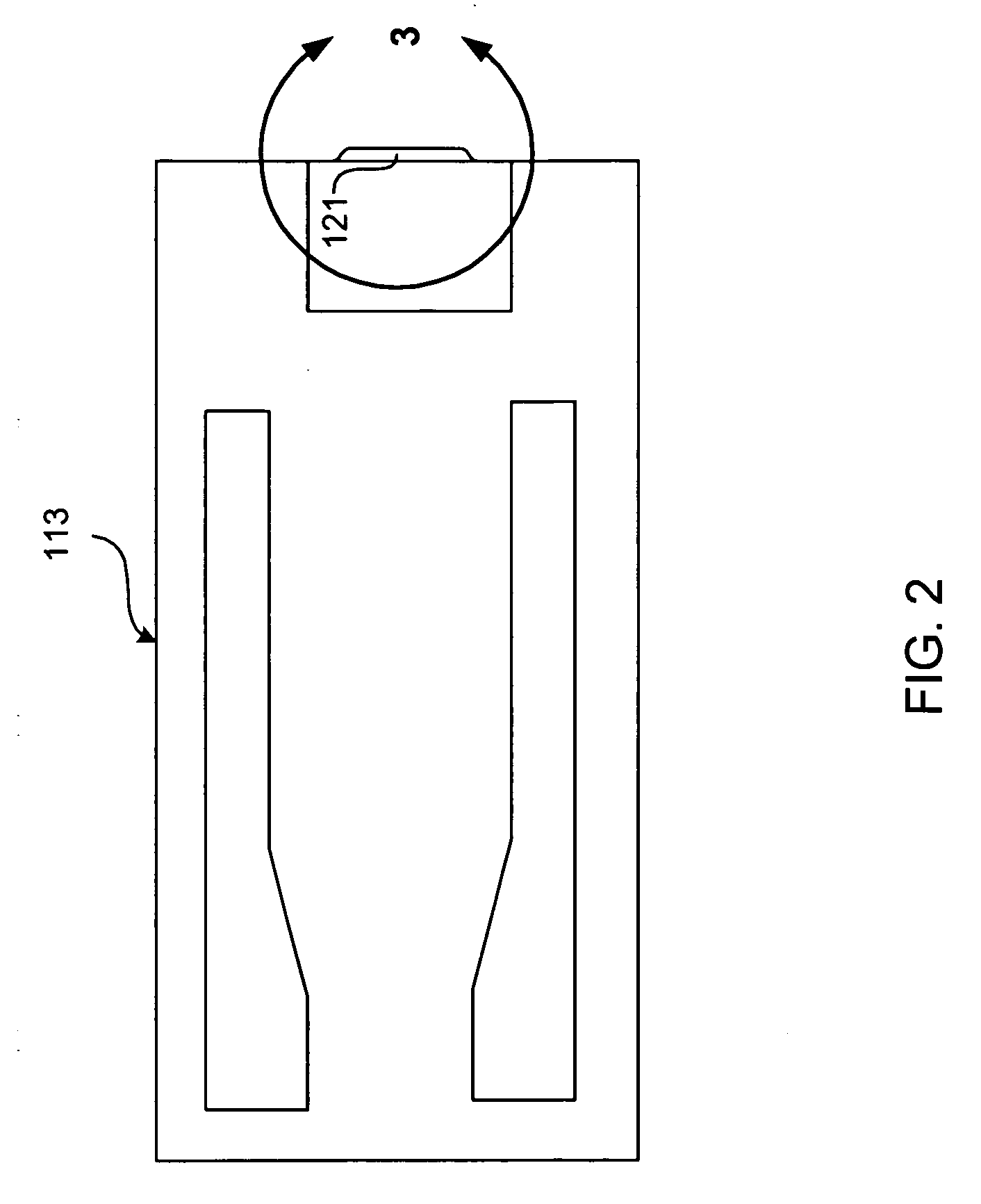

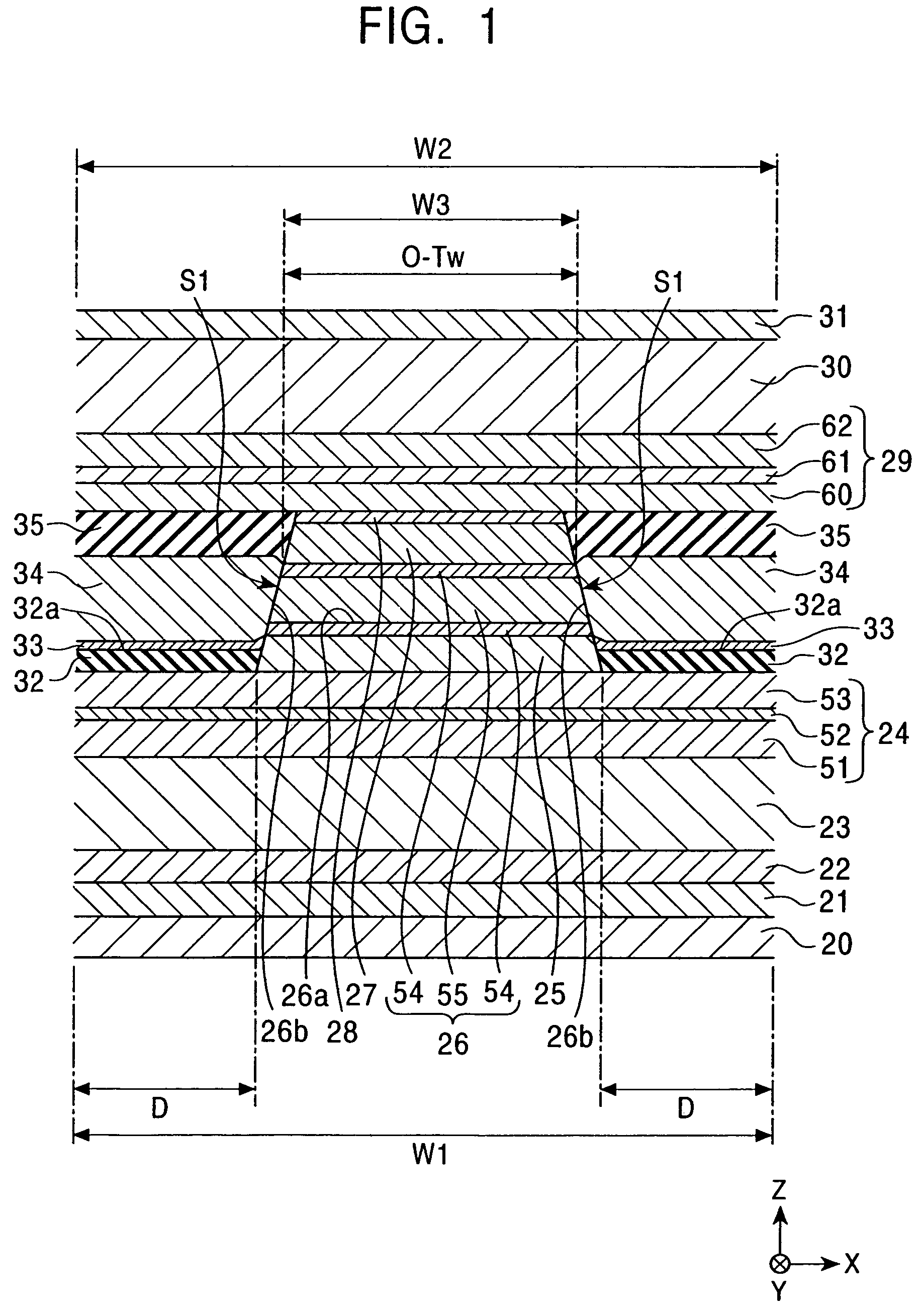

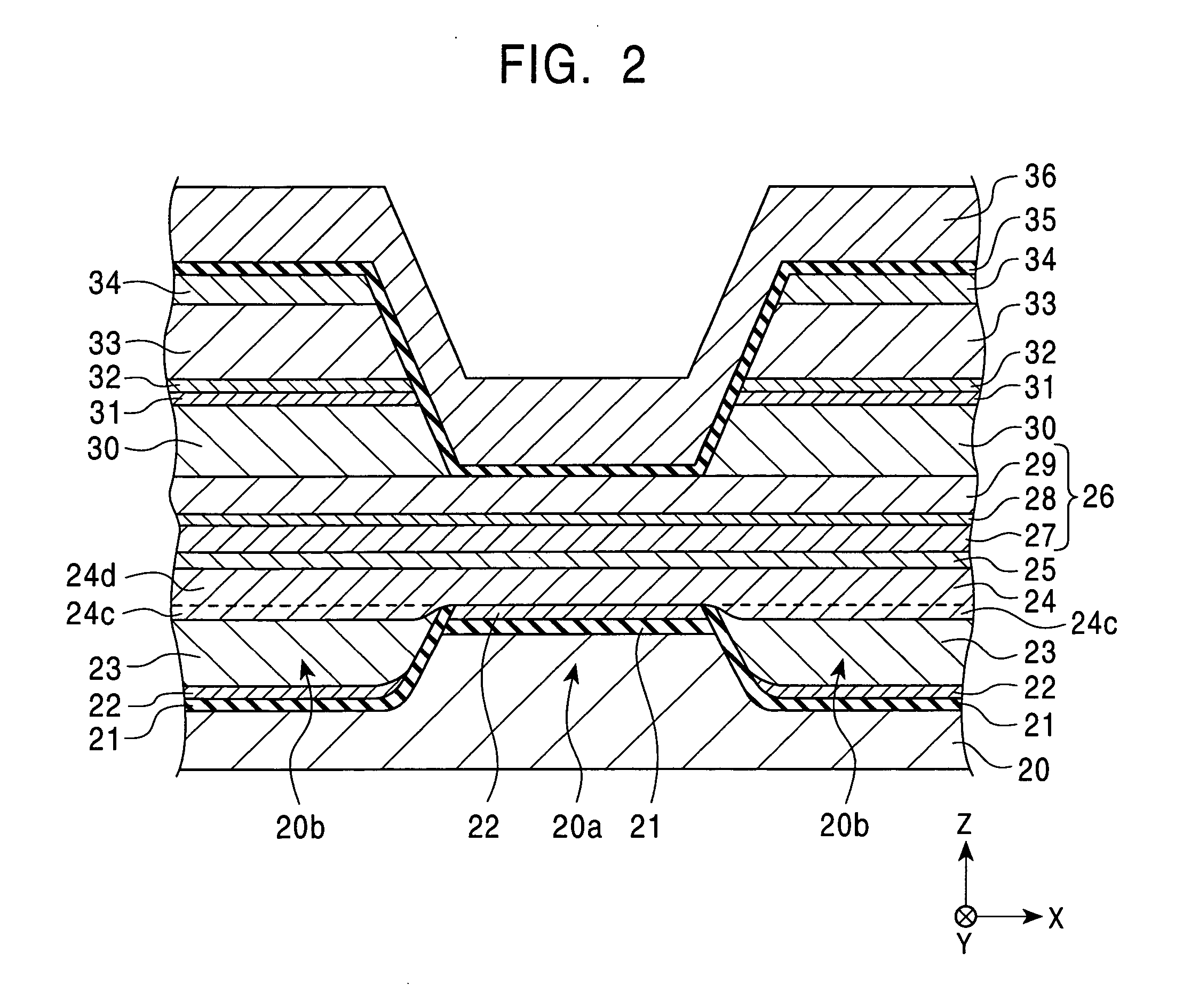

Laminated magnetorestrictive element of an exchange coupling film, an antiferromagnetic film and a ferromagnetic film and a magnetic disk drive using same

InactiveUS6313973B1Stable output voltageRaise the ratioNanomagnetismNanoinformaticsGiant magnetoresistanceCoupling

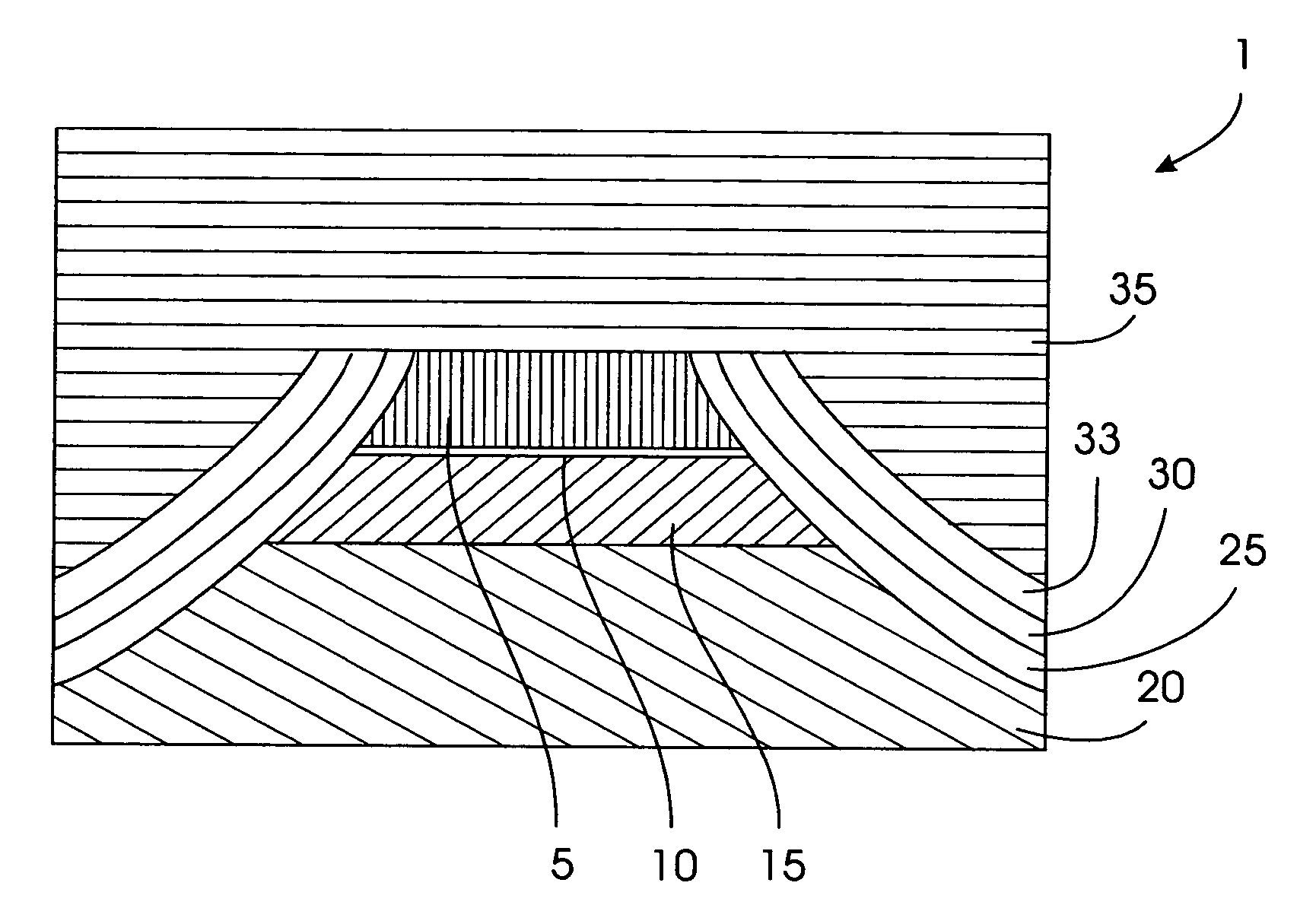

A magnetoresistive element comprises an exchange coupling film having a under layer, an antiferromagnetic film and a ferromagnetic film, which are laminated in that order, the under layer including a metal having a face centered cubic crystal structure or hexagonal closest packing crystal structure which have a longer nearest neighbor atomic distance than that of the antiferromagnetic film. With this construction, it is possible to improve the exchange coupling field and to satisfy a stable output over a long period of time. A magnetoresistive element having a dual spin valve structure has a magnetization adjusting layer, which is antiferromagnetically connected to a pinned layer via an anti-parallel connection layer, to adjust the value of the product of the saturation magnetization of each of the magnetization adjusting layer and the pinned layer by the thickness thereof. Moreover, a magnetoresistance head use a giant magnetoresistance effect, and has at least one pair of pinned layer and free layer arranged via a non-magnetic spacer layer. The pinned layer has a pair of ferromagnetic layers which have different compositions and different coercive forces and which are antiferromagnetically connected to each other via a connection layer, so that the effective exchange coupling field of the pinned layer is 200 Oe or more.

Owner:KK TOSHIBA

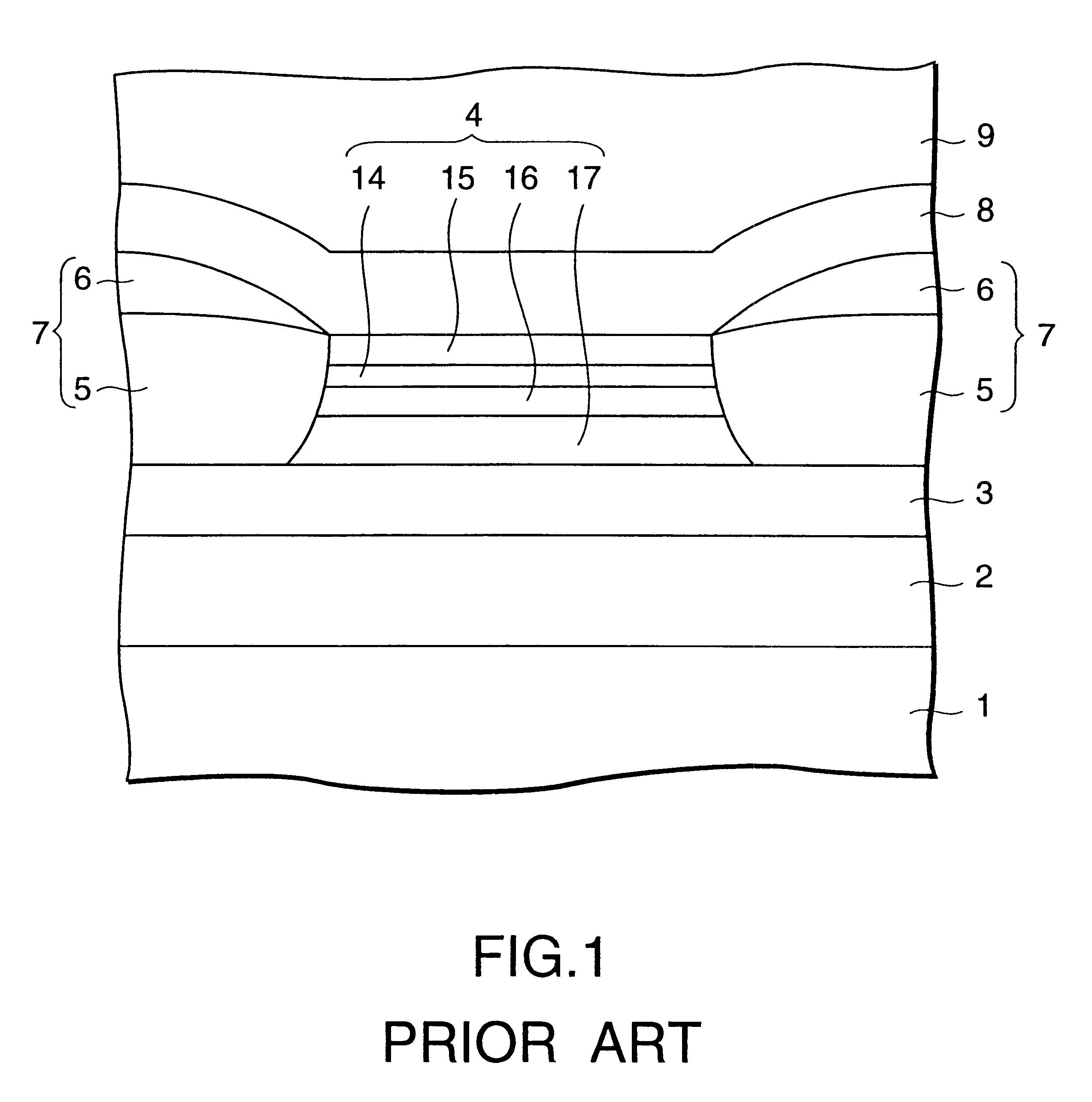

GMR magnetic sensing element having an antiferromagnetic layer extending beyond the track width and method for making the same

InactiveUS7050276B2Easy to disassembleHigh outputNanomagnetismMagnetic measurementsMagnetic layerAntiferromagnetism

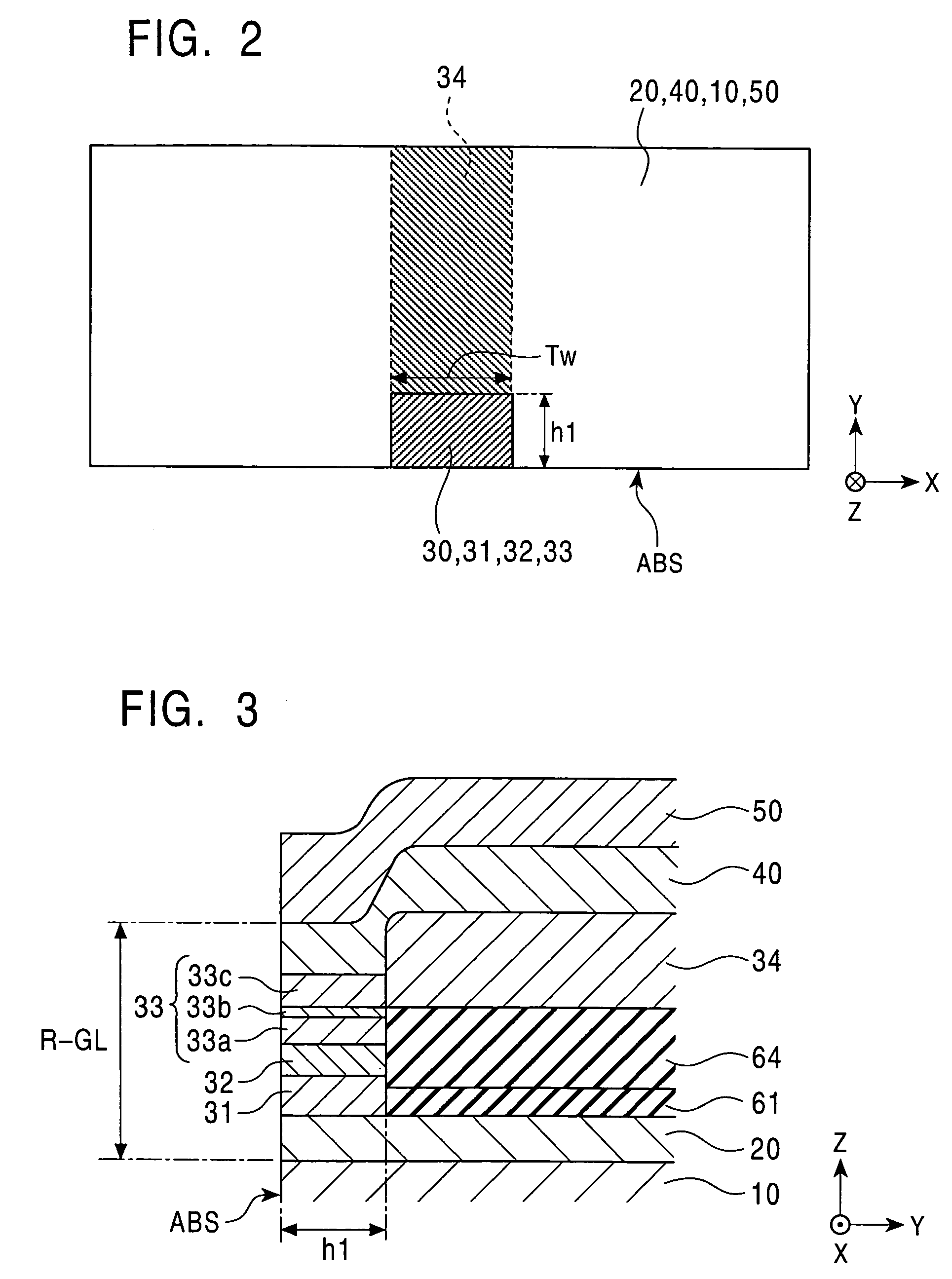

A magnetic sensing element with improved magnetic detection output and a method for making the same are provided. In the magnetic sensing element, the length of an upper pinned magnetic layer an upper antiferromagnetic layer in a track width direction is larger than the length of a free magnetic layer in the track width direction. In making the magnetic sensing element, there is no need to remove side portions of the upper pinned magnetic layer and the upper antiferromagnetic layer. The materials of the upper pinned magnetic layer and the upper antiferromagnetic layer are thus prevented from redepositing on two side faces of the free magnetic layer during milling.

Owner:TDK CORPARATION

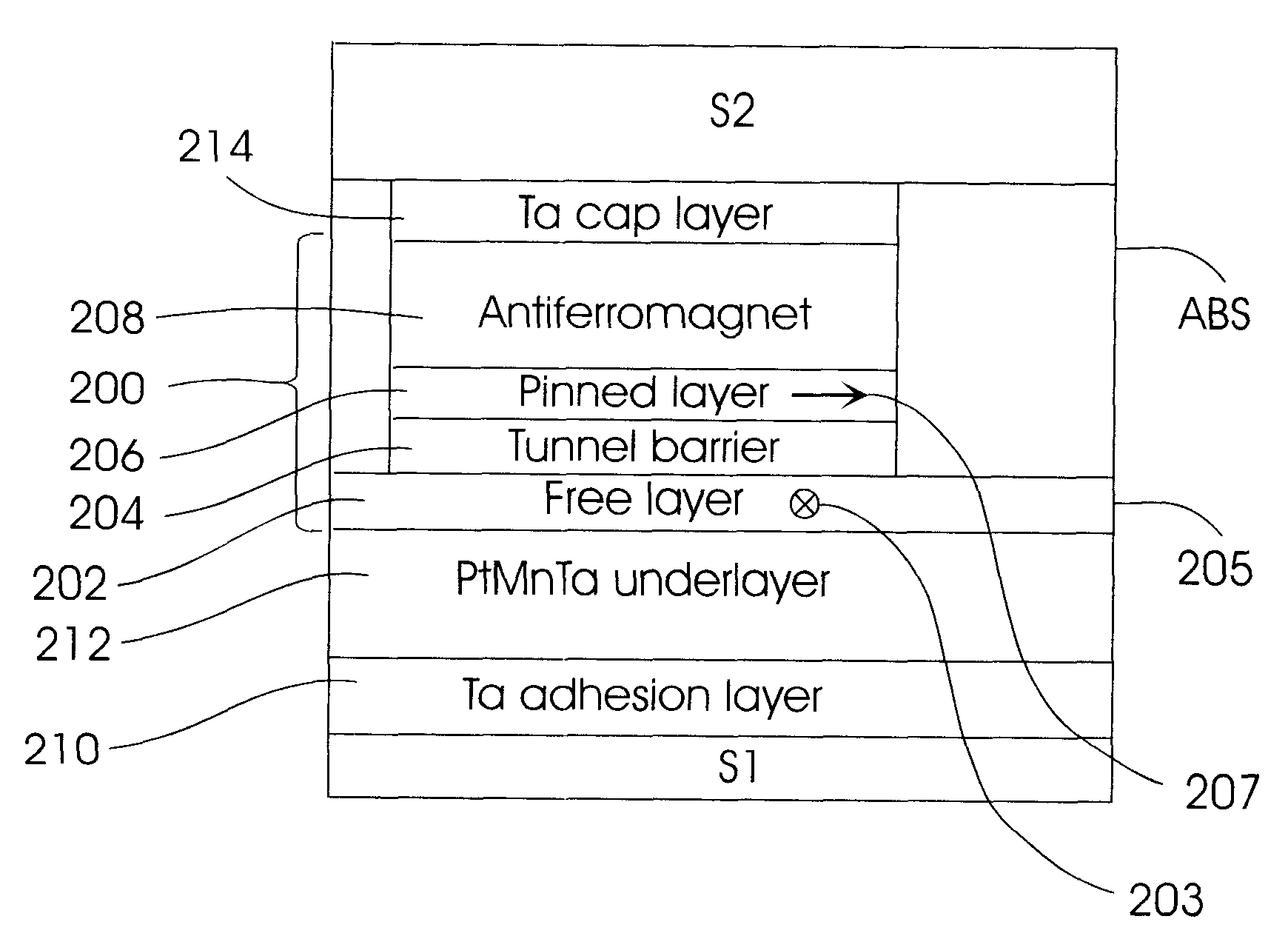

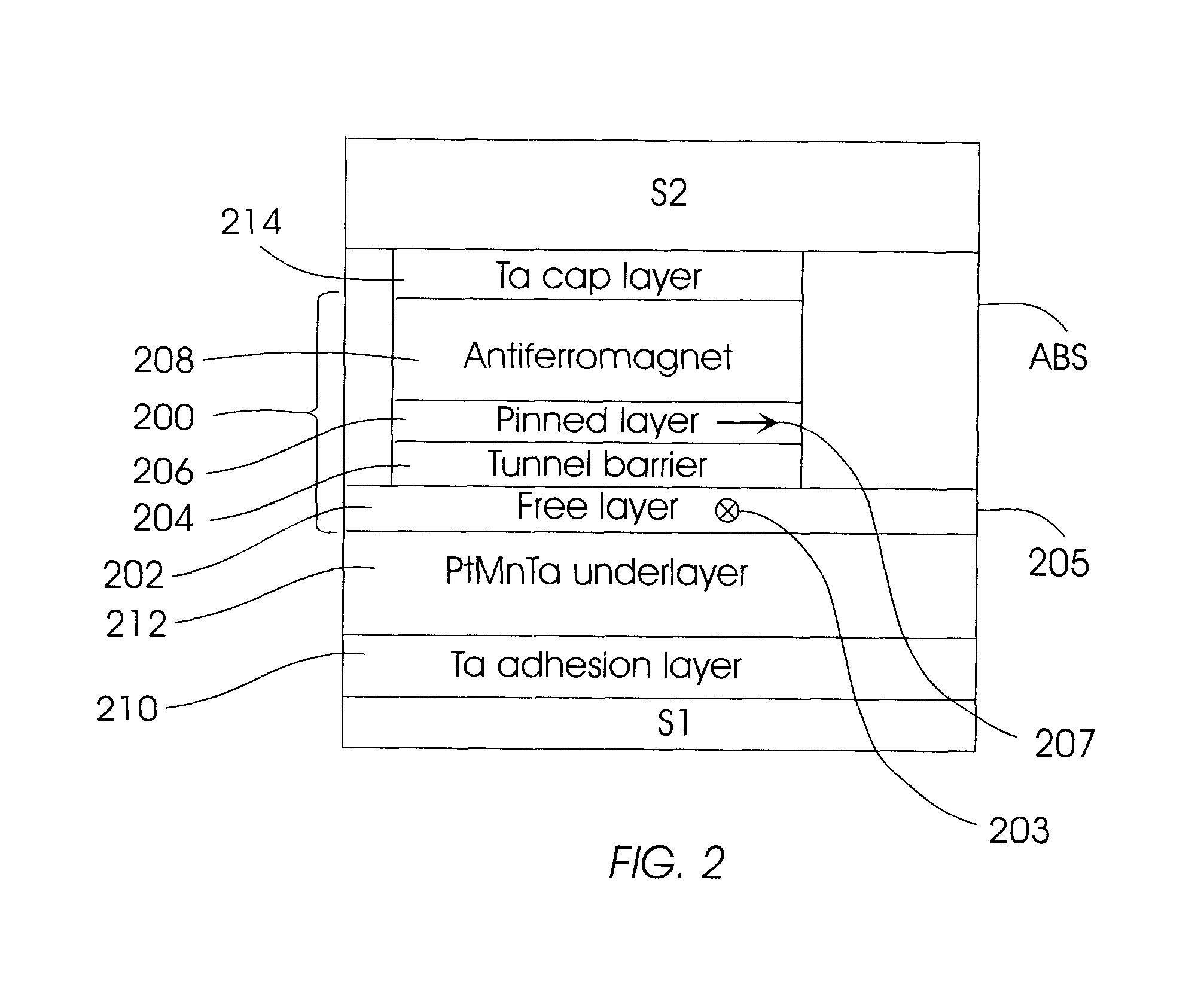

Magnetic tunnel junction device with bottom free layer and improved underlayer

A magnetic tunnel junction (MTJ) device usable as a magnetic memory cell or magnetoresistive sensor, such as a MTJ read head for magnetic recording, has the free ferromagnetic layer located on the bottom of the device, the bottom free layer being formed on a special underlayer. The MTJ read head may be a flux-guided head that uses the free layer as a flux guide for directing magnetic flux from the magnetic media to the sensing region of the MTJ. The special underlayer for the growth of the free layer is an alloy comprising Mn, one of Pt, Ni, Ir and Os, and an additive X selected from Ta, Al, Ti, Cu, Cr and V. Without the additive, the underlayer alloy is antiferromagnetic. The additive is present in an amount sufficient to render the alloy to have no magnetic ordering, i.e., it is neither antiferromagnetic nor ferromagnetic, but without substantially affecting the preferred crystalline texture and unit cell size so that the underlayer is well-suited as a growth-enhancing underlayer for the free layer.

Owner:WESTERN DIGITAL TECH INC

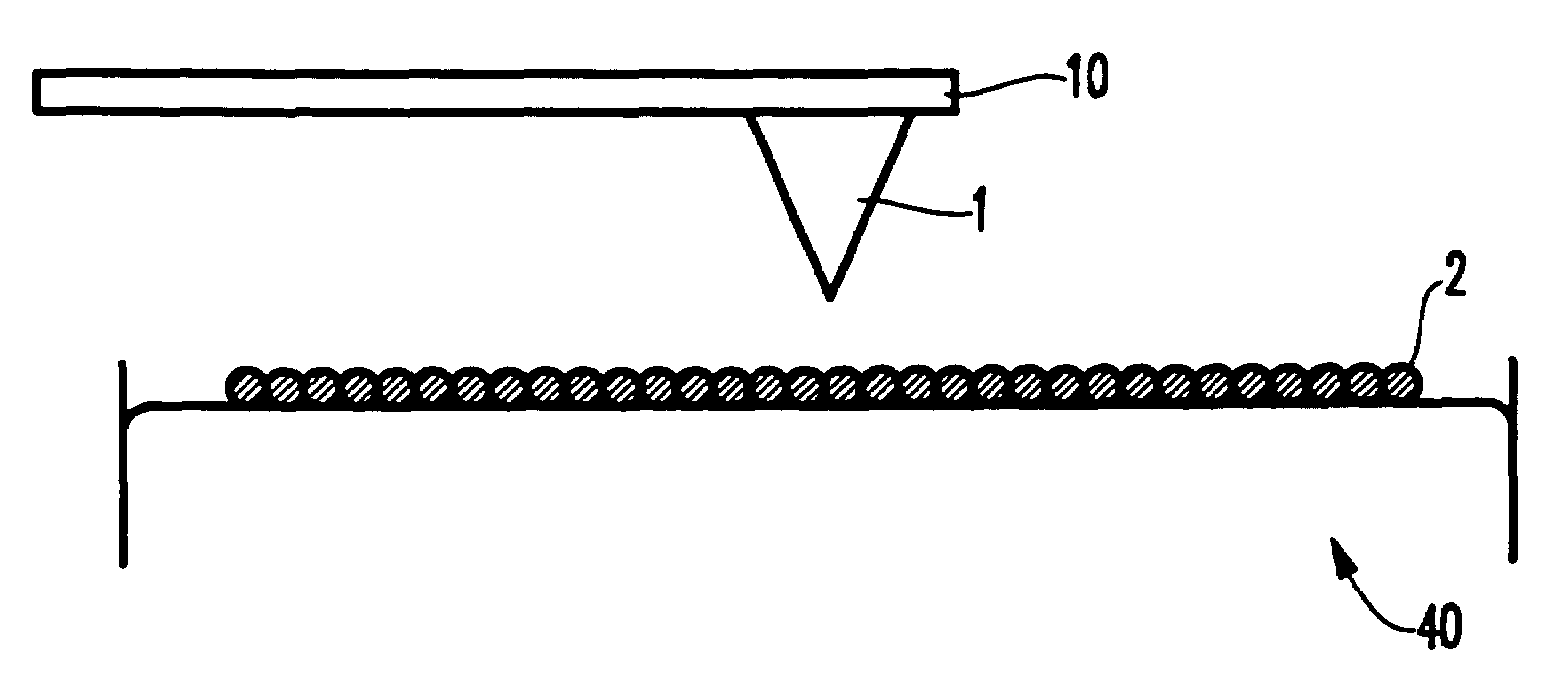

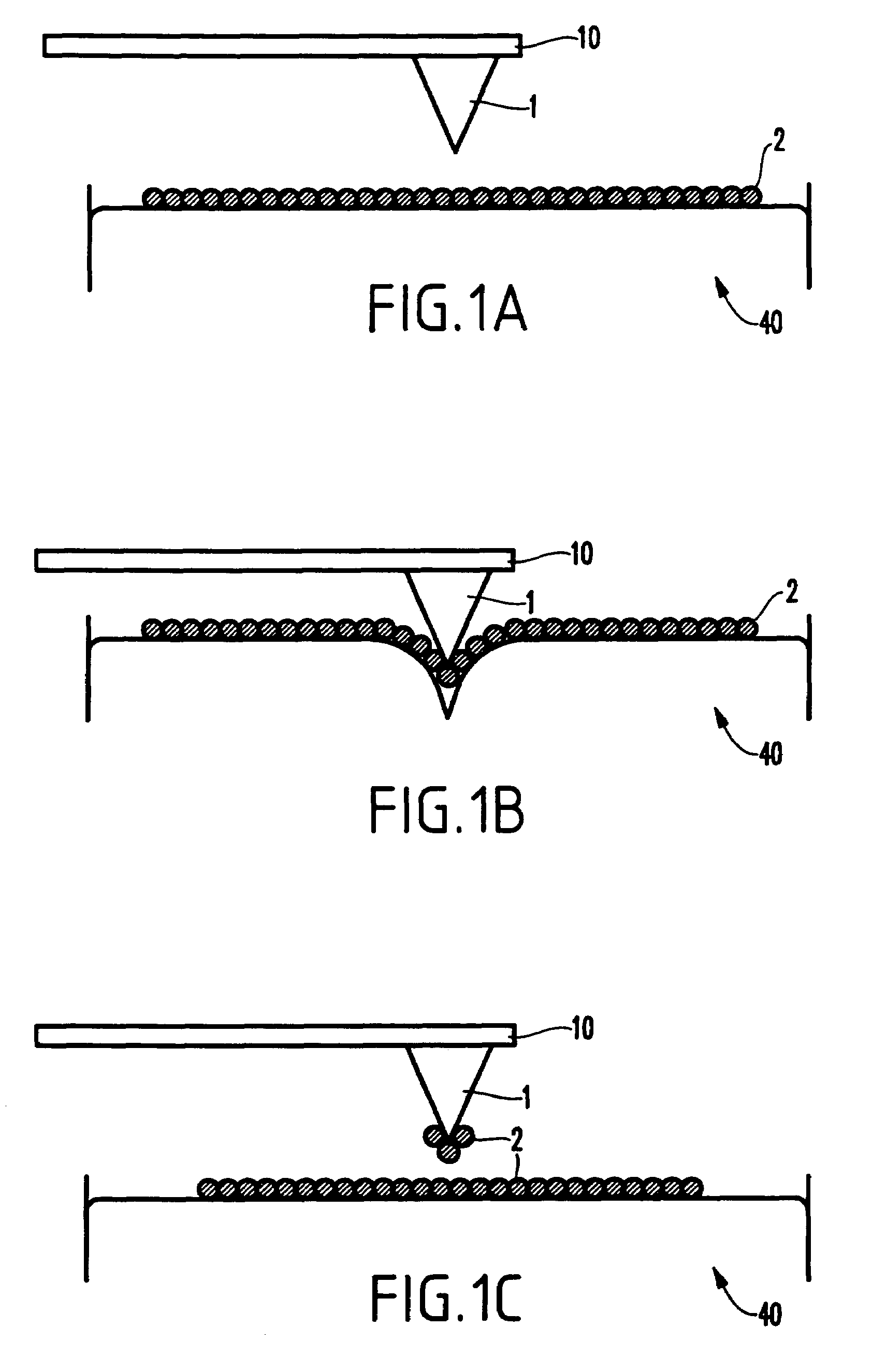

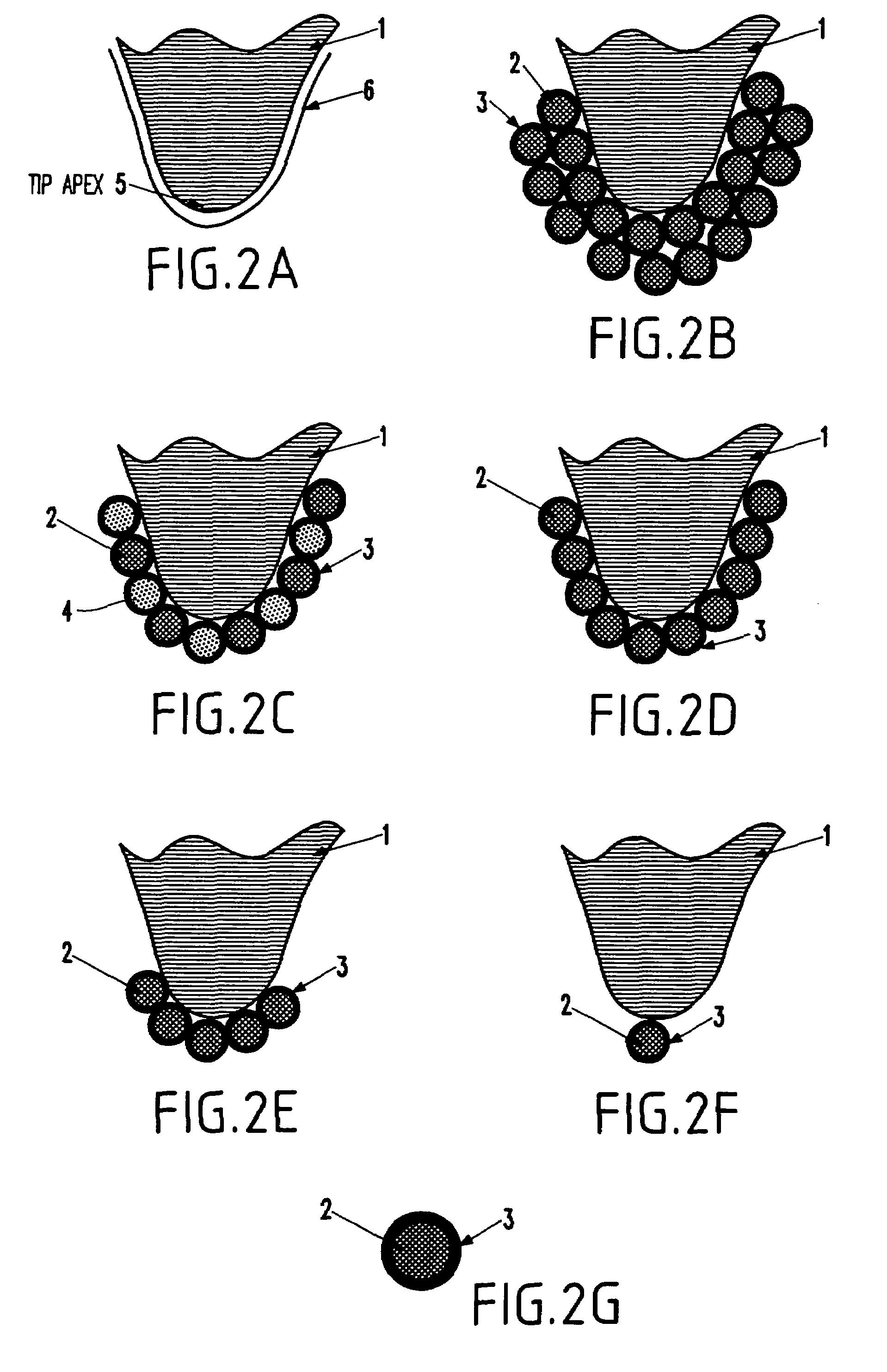

Scanning probe microscopy tips composed of nanoparticles and methods to form same

InactiveUS7282710B1Improve spatial resolutionImprove adhesionMaterial analysis using wave/particle radiationLayered productsChemical synthesisFluorescence

A structure and method for improving the spatial resolution of a scanning probe microscope (SPM) tip, which has been coated with a layer of chemically-synthesized nanoparticles. The nanoparticles are either single-species or heterogeneous, such that the single-species nanoparticles can be either ferromagnetic, paramagnetic, superparamagnetic, antiferromagnetic, ferrimagnetic, magneto-optic, ferroelectric, piezoelectric, superconducting, semiconducting, magnetically-doped semiconducting, insulating, fluorescent, or chemically catalytic. The layer of nanoparticles is at least two nanoparticles thick, or alternatively, is a single layer of nanoparticles thick, or alternatively, is a single layer of nanoparticles thick and covers only the tip apex portion of the tip, or alternatively, only a single nanoparticle is affixed to the tip apex. Alternatively, the layer of nanoparticles is transformed into an electrically-continuous magnetic film by annealing at a high temperature.

Owner:IBM CORP

Magnetic tunnel transistor with high magnetocurrent

InactiveUS20080180863A1Improve performanceNanomagnetismNanoinformaticsMagnetic currentMagnetic anisotropy

Owner:WESTERN DIGITAL TECH INC

Magnetoresistive effect element, magnetic head and magnetic reproducing apparatus

In a CPP element using a metal intermediate layer excellent in shot noise and response to high frequencies unlike a TMR element, its magnetoresistive effect film includes a magnetic layer mainly made of a half-metal exhibiting ferromagnetism, ferrimagnetism or antiferromagnetism, and largely variable in way of conduction in response to spin direction of electrons.

Owner:KK TOSHIBA

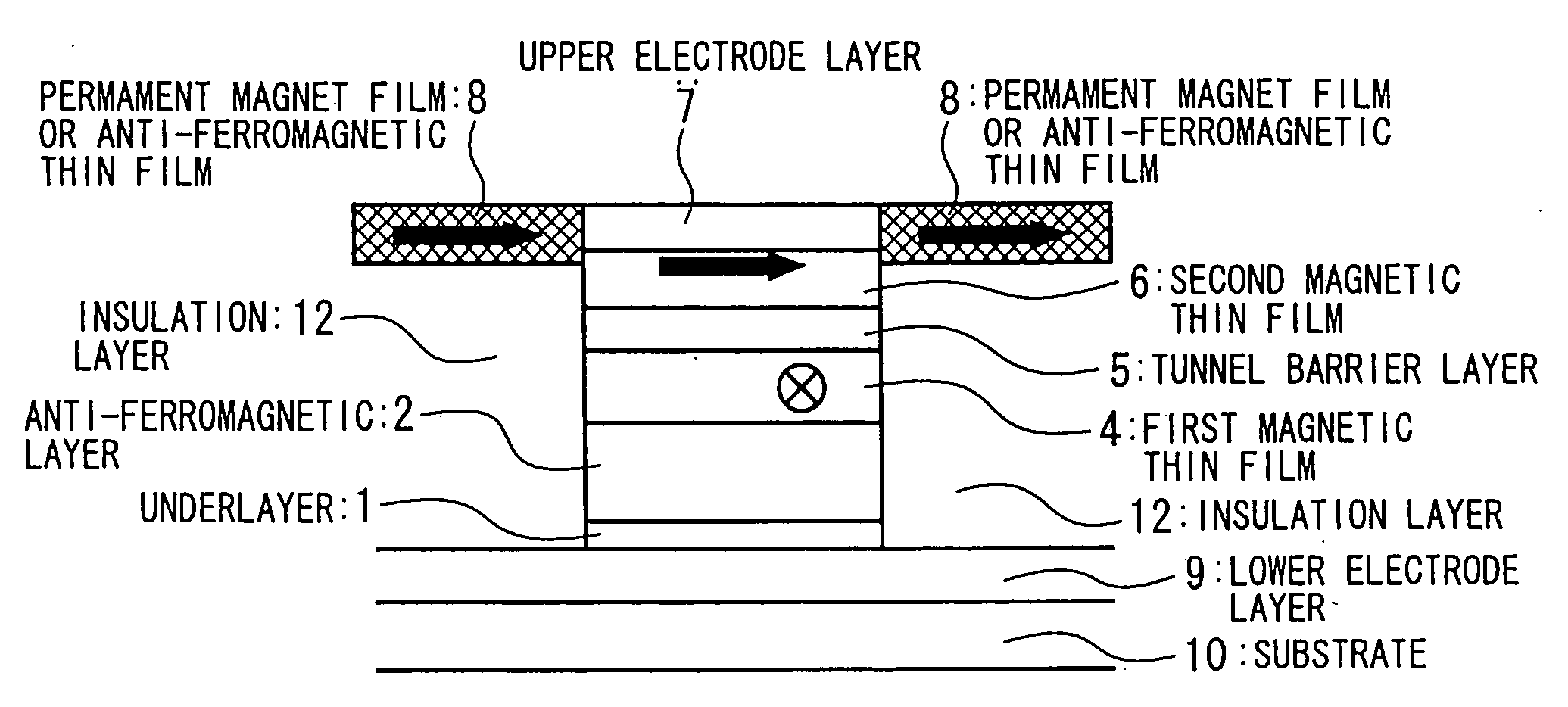

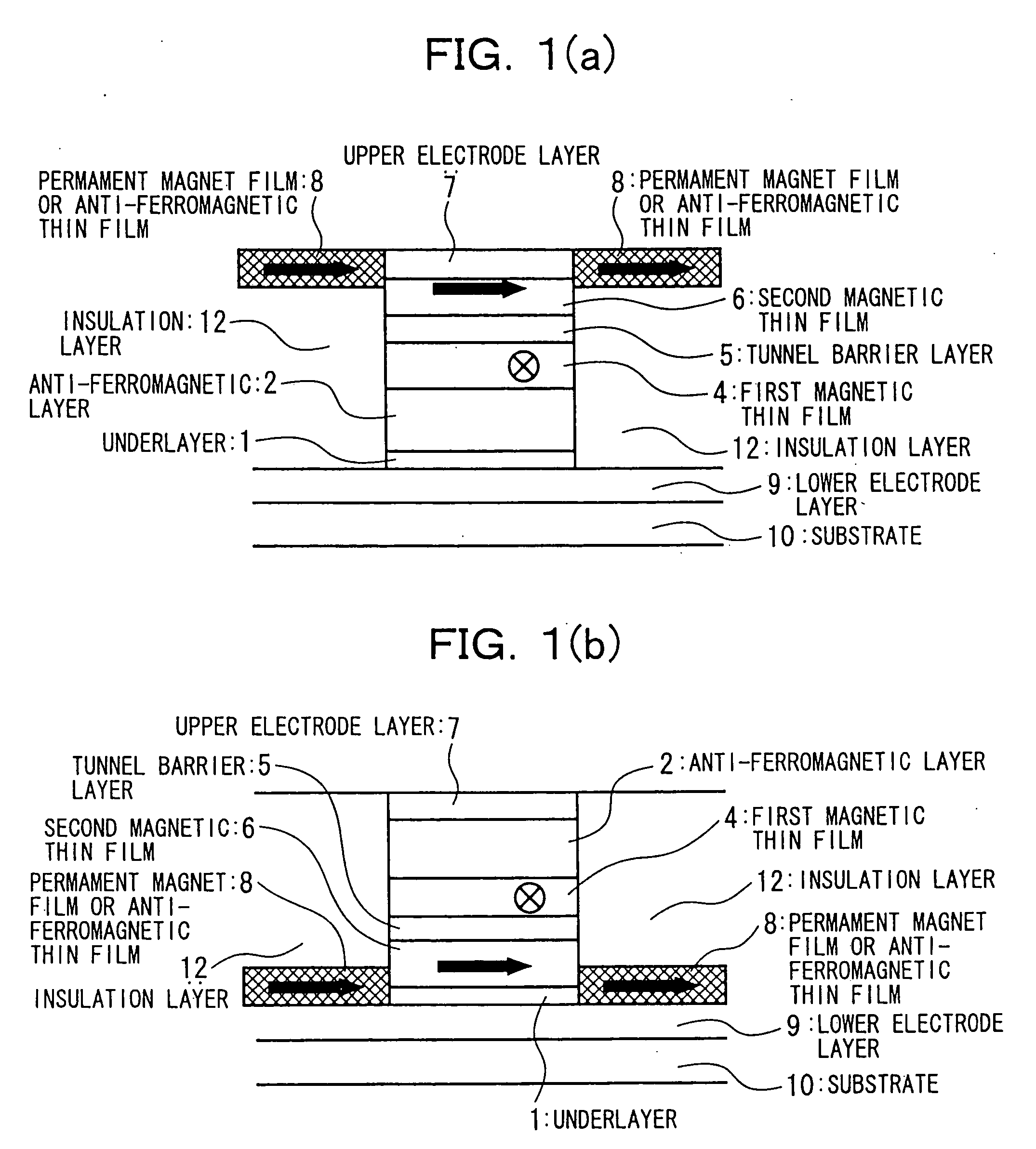

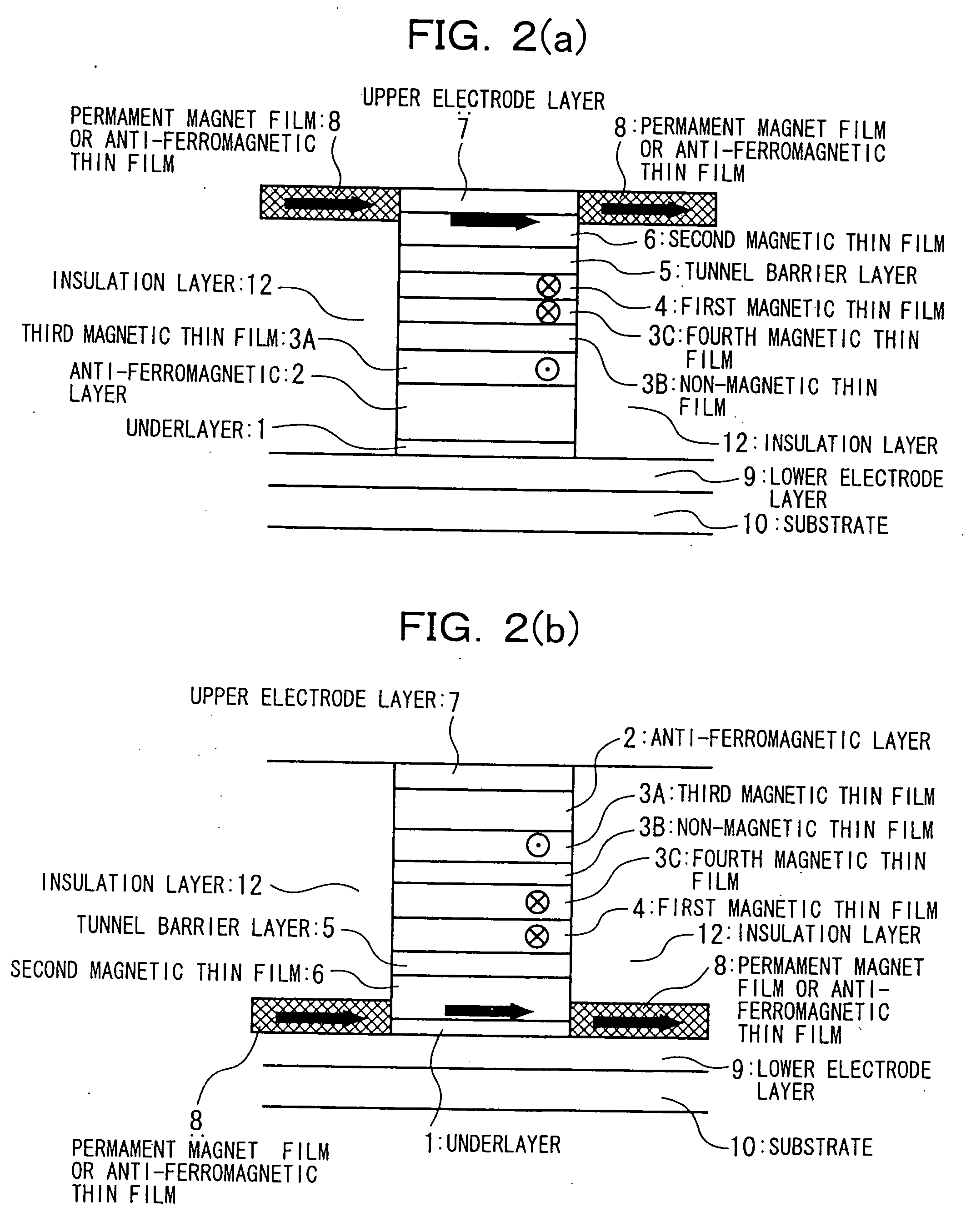

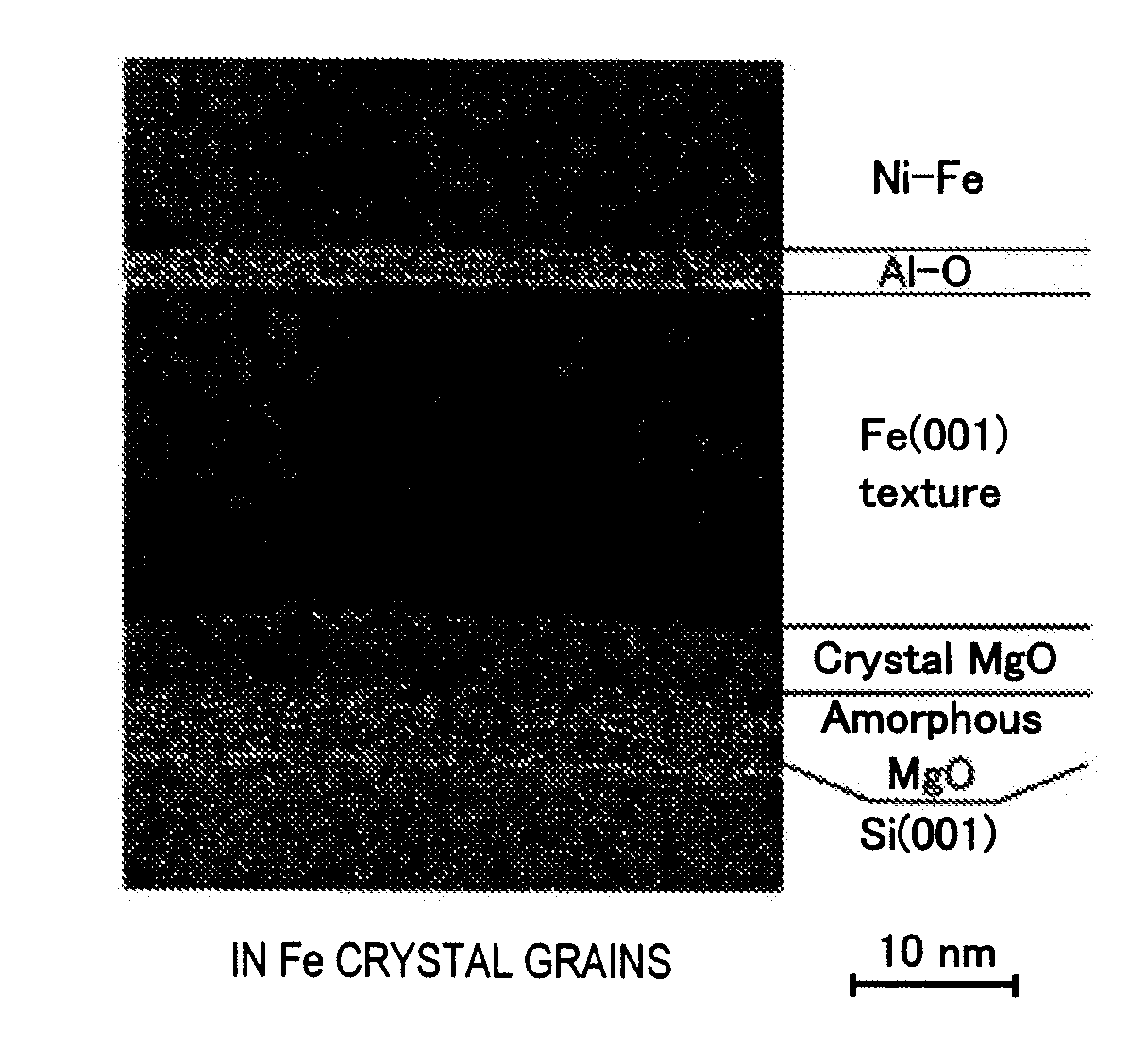

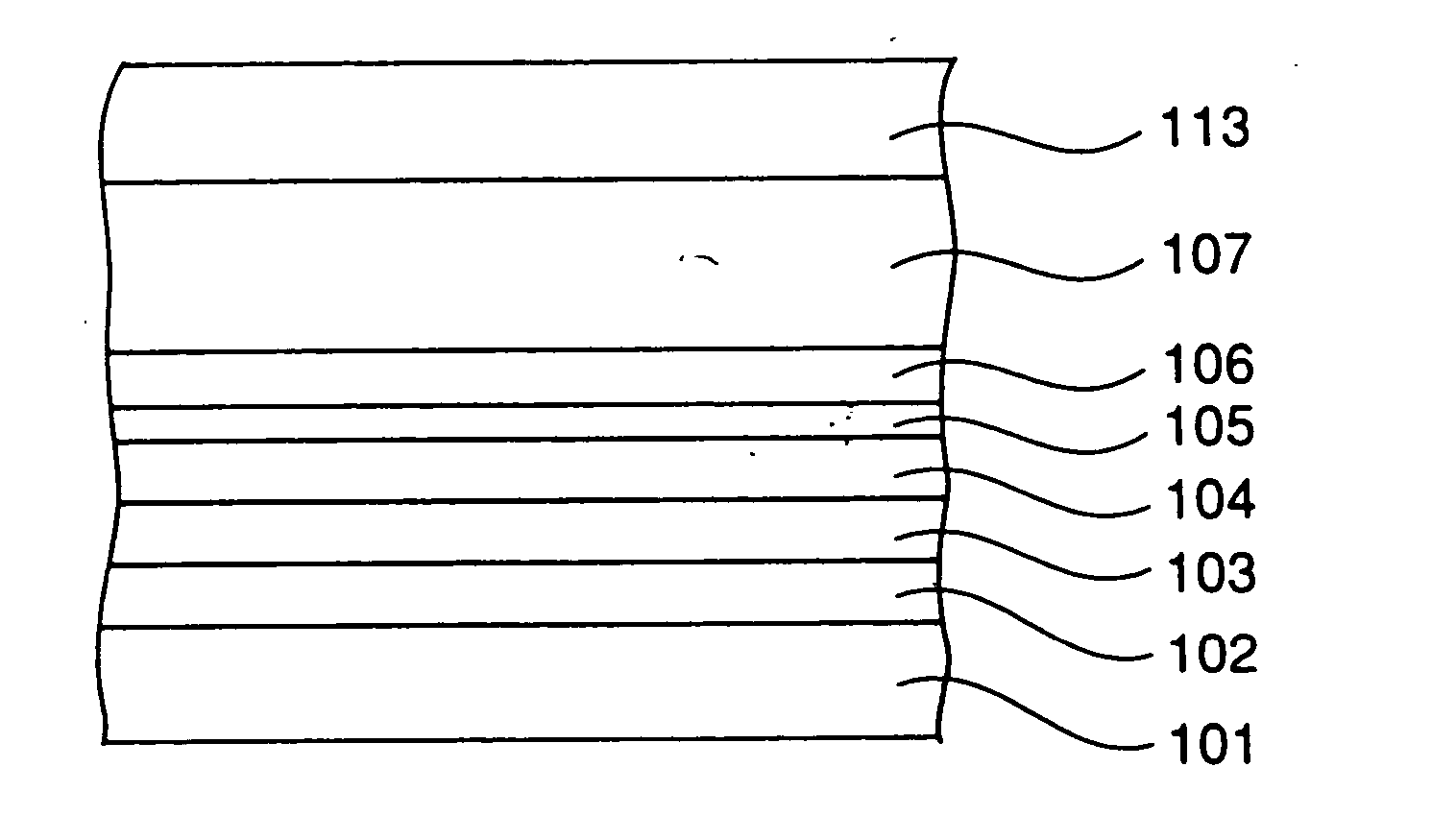

Spin tunnel magnetoresistive effect film and element, magnetoresistive sensor using same, magnetic apparatus, and method for manufacturing same

InactiveUS20050019610A1Reduced effectivenessPrevent oxidationNanomagnetismMagnetic measurementsNon magneticOxygen

In a spin tunnel magnetoresistive effect film in which a magnetic thin film to which an exchange bias is applied by exchange coupling via an anti-ferromagnetic thin film and a magnetic thin film that detects a magnetic field are laminated, a magnetic thin film or an anti-ferromagnetic thin film (PtMn, PdMn, NiMn) is laminated onto an underlayer (Ta, Zr, Hf), the surface roughness thereof being in the range from 0.1 to 5 Angstroms. A means used to control the surface roughness introduces into the film growing chamber oxygen, nitrogen, hydrogen, or a gas mixture thereof into a vacuum of 10−6 Torr to 10−9 Torr, reduces the substrate temperature to 0° C. or lower during film growth, or oxidizes an underlayer. The lower electrode layer material used is a film laminate of a high-permeability amorphous magnetic material and a non-magnetic metallic layer.

Owner:NEC CORP

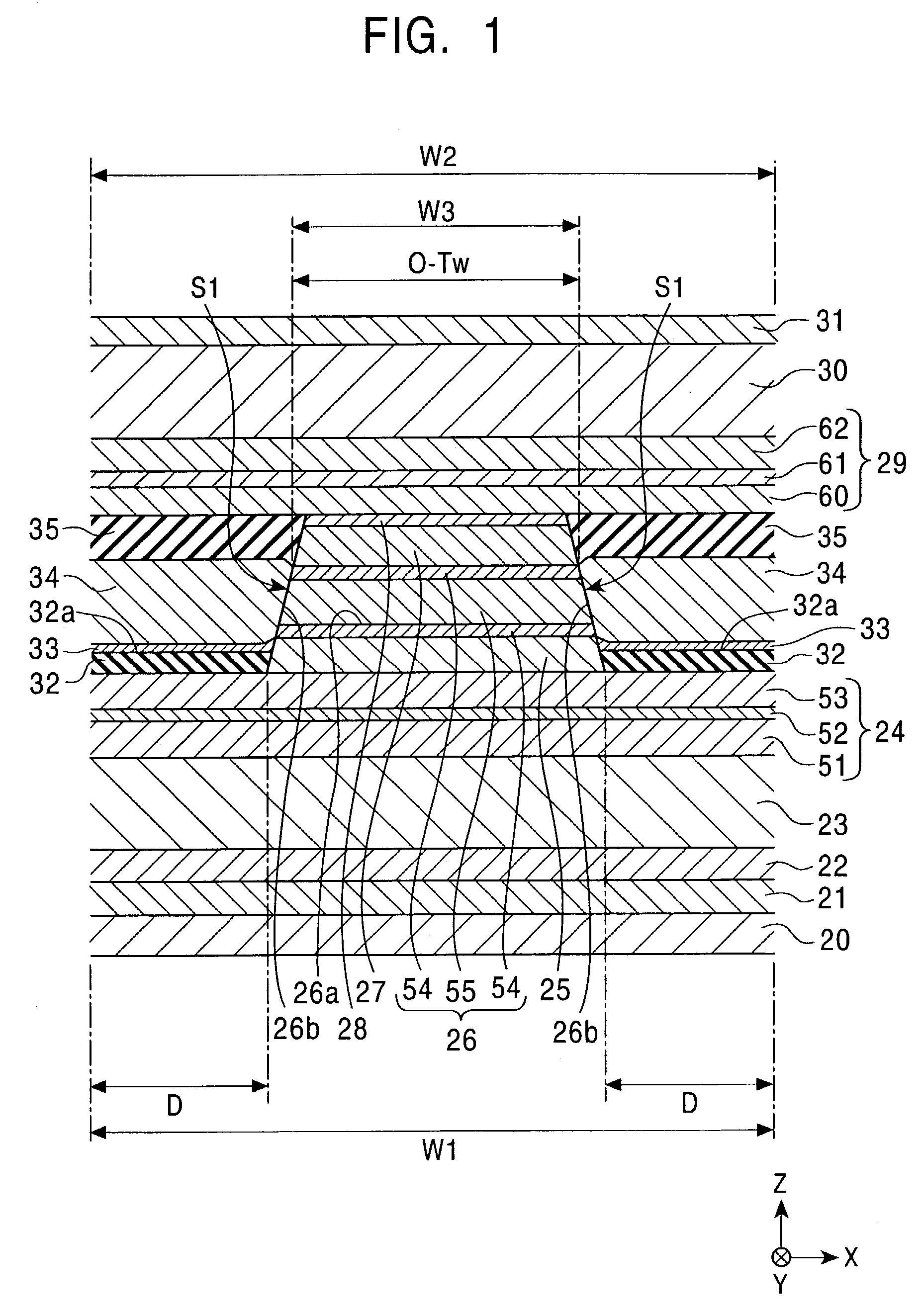

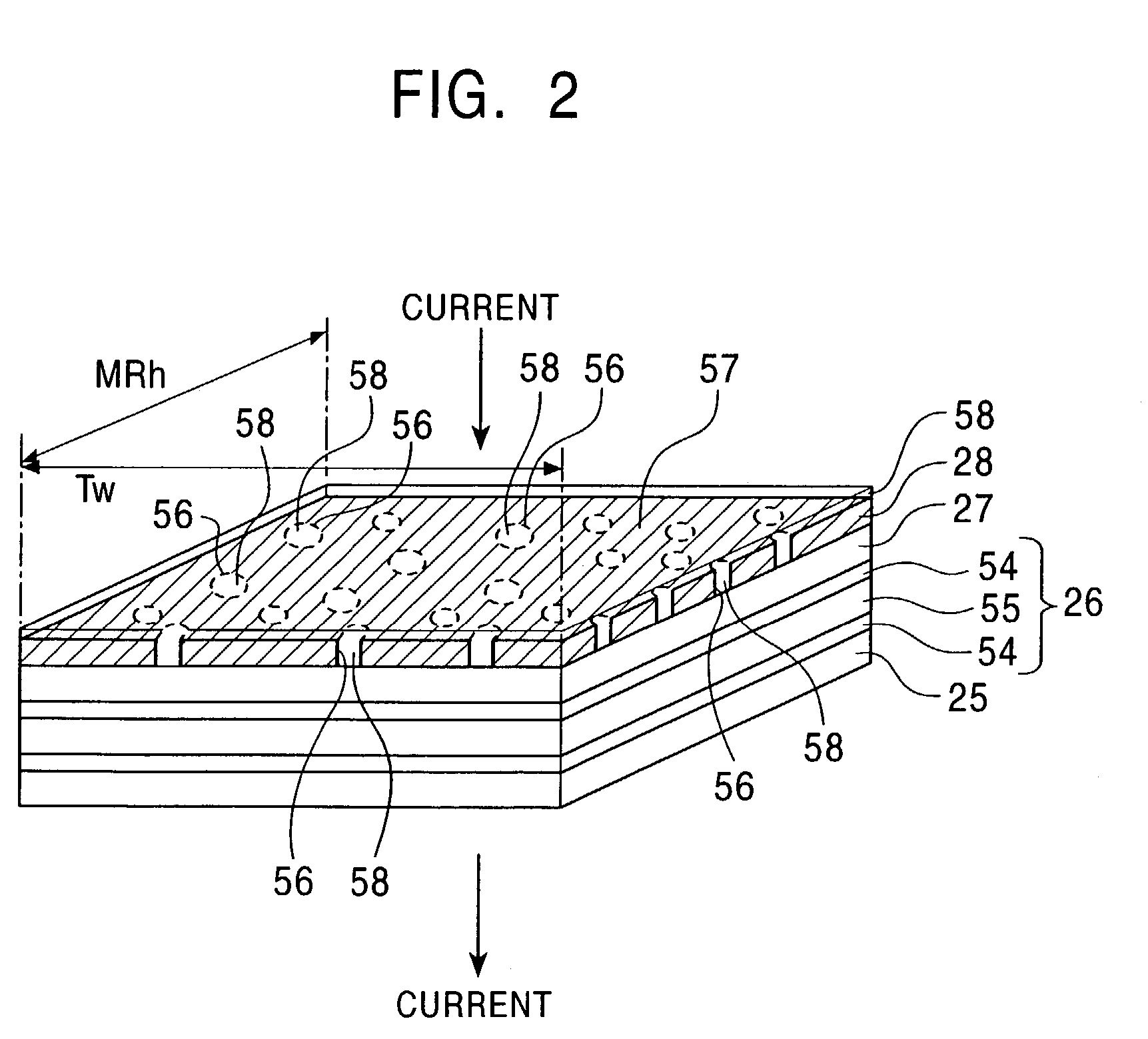

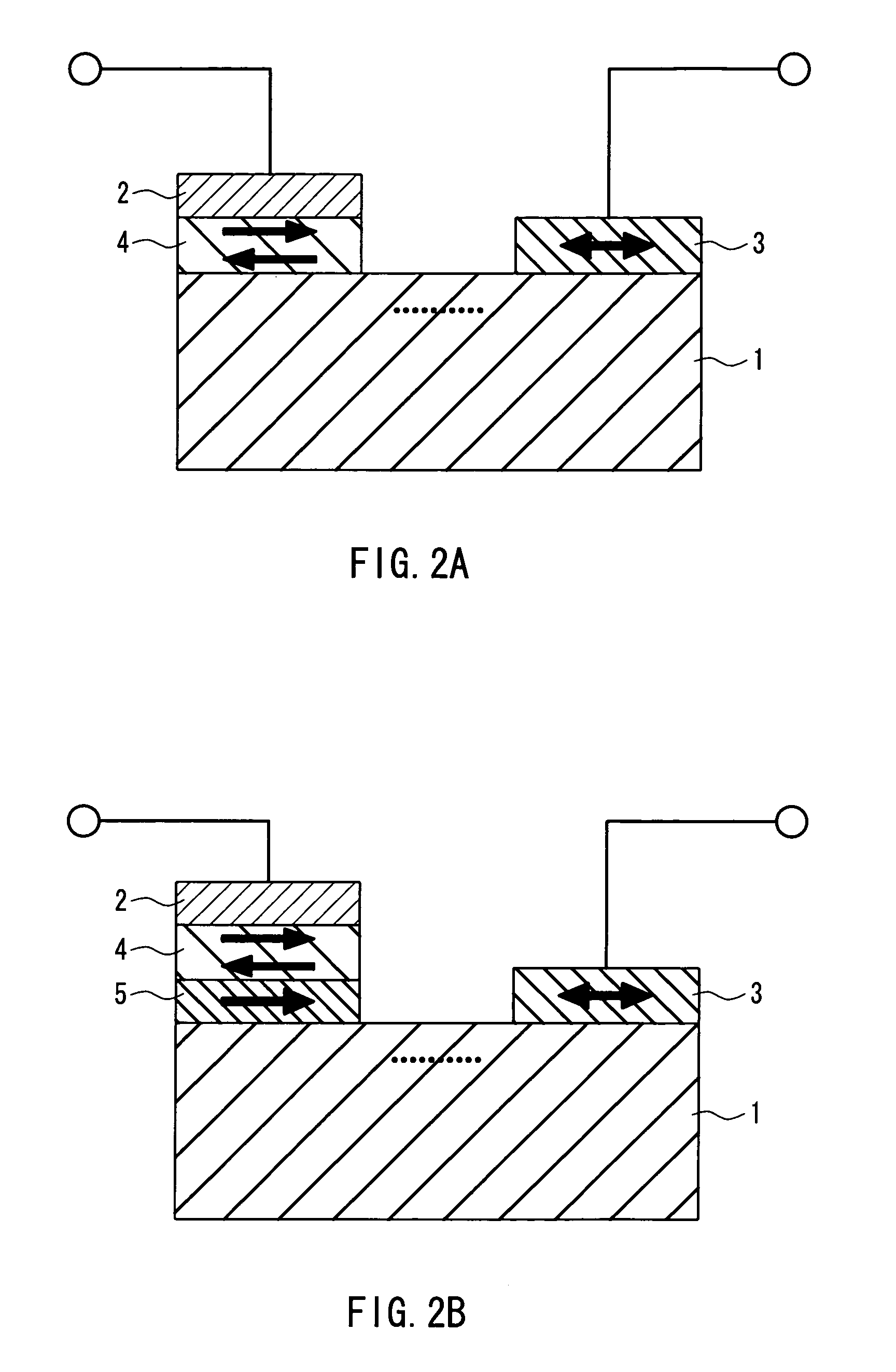

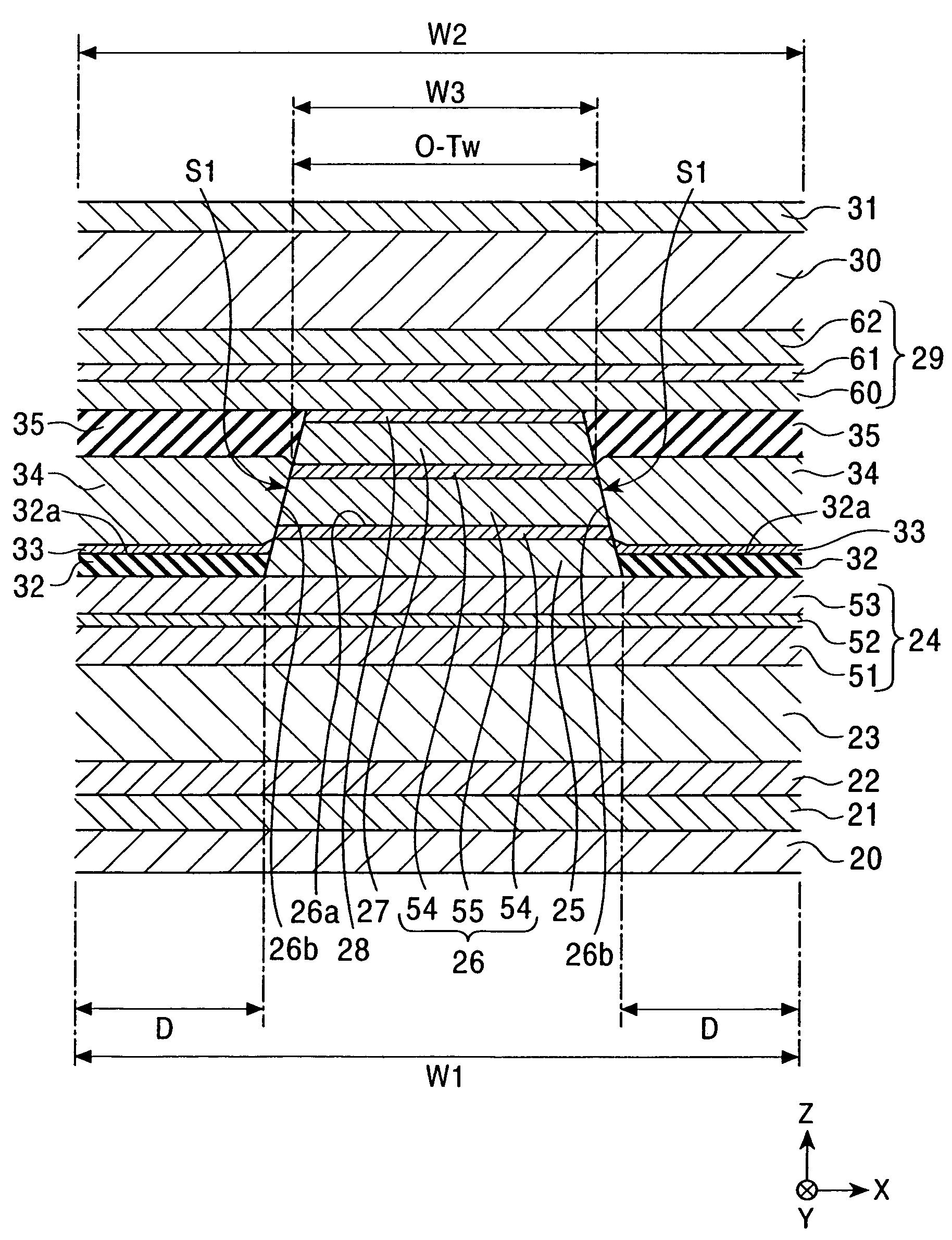

Thin film magnetic head having a pair of magnetic layers whose magnetization is controlled by shield layers

InactiveUS20100067148A1Increase rate of changeRead gap is easyNanomagnetismDisposition/mounting of recording headsMagnetizationNon magnetic

A thin film magnetic head comprises an MR laminated body that has first and second magnetic layers, a nonmagnetic middle layer, and the first and second magnetic layers and the nonmagnetic middle layer are laminated to make contact with each other in respective order. First and second antiferromagnetic layers are provided with the first and second magnetic layers respectively. The first antiferromagnetic layer and / or the second antiferromagnetic layer contains a void part or a thin portion at least in a portion of the projection area toward the orthogonal direction to the film surface of the MR laminated body.

Owner:TDK CORPARATION

Production of a device comprising magnetic structures formed on one and the same substrate and having respective different magnetization orientations

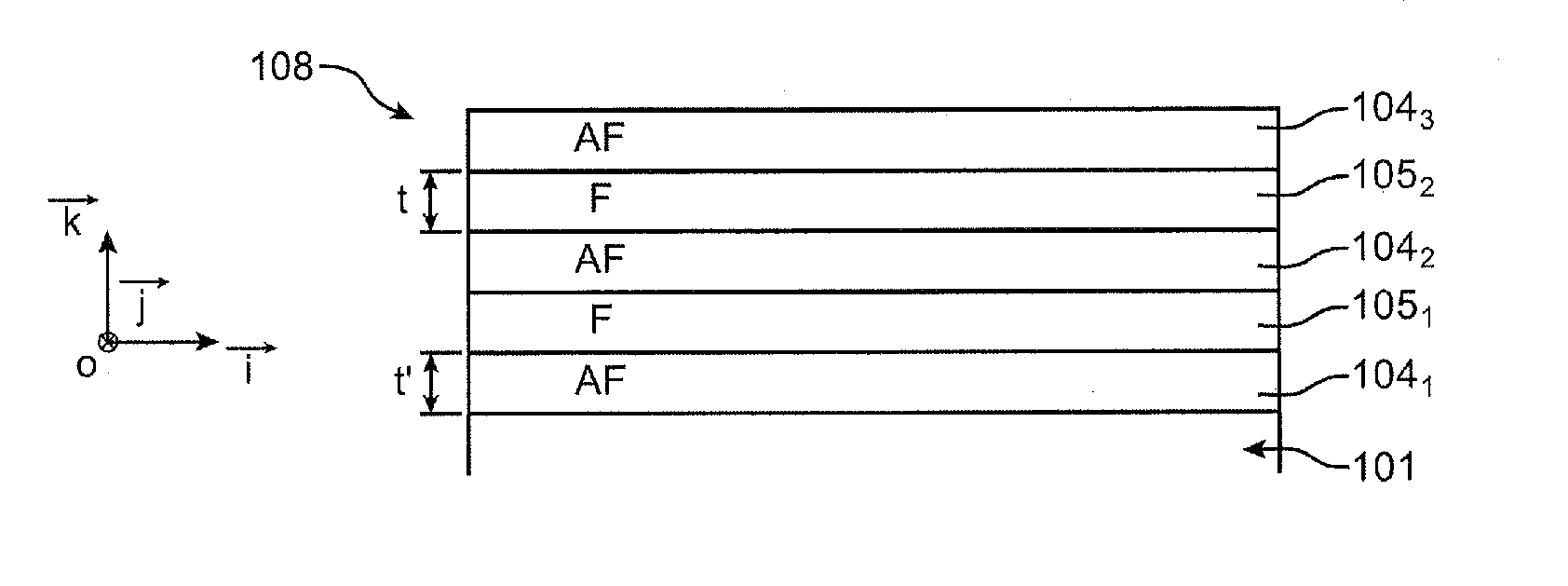

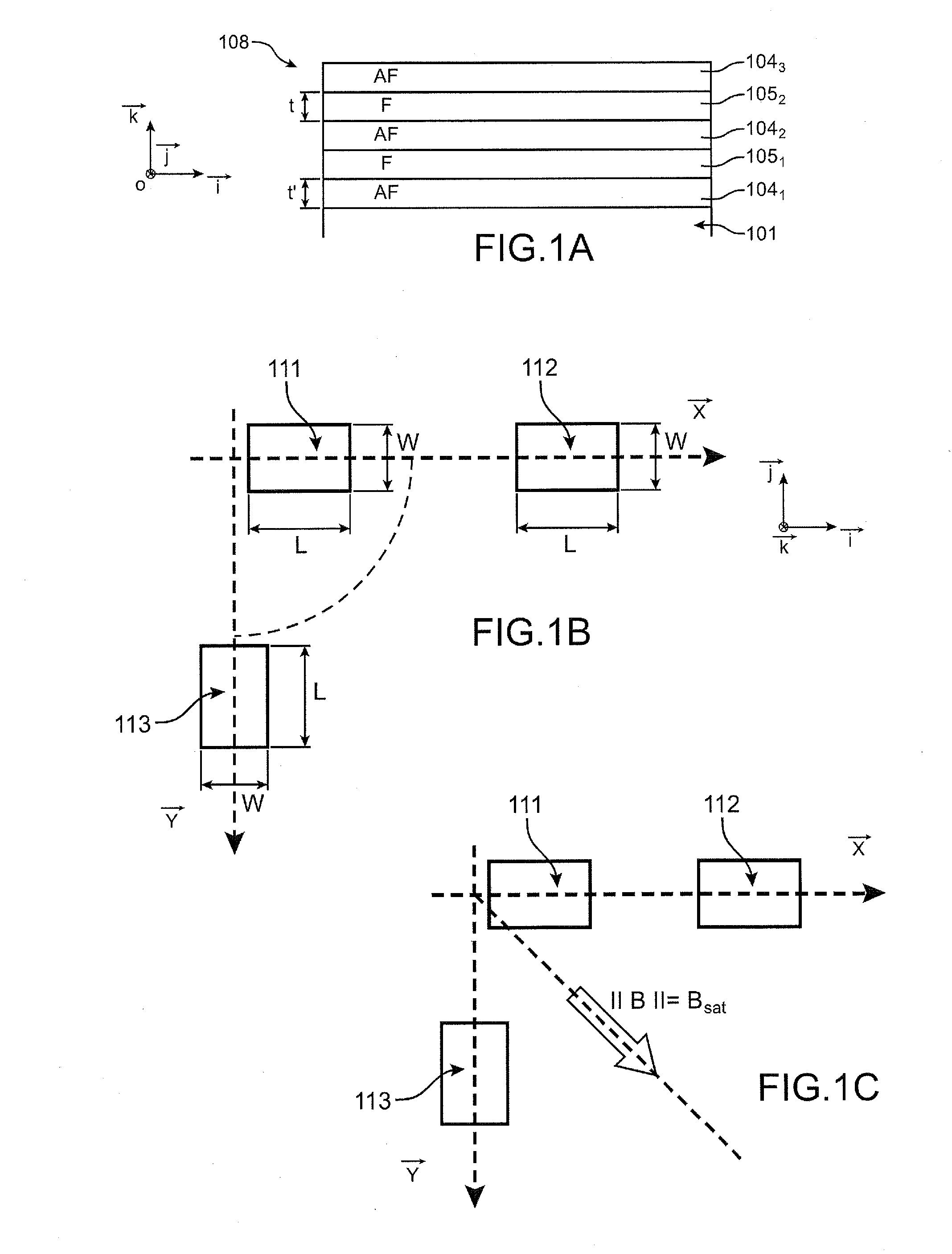

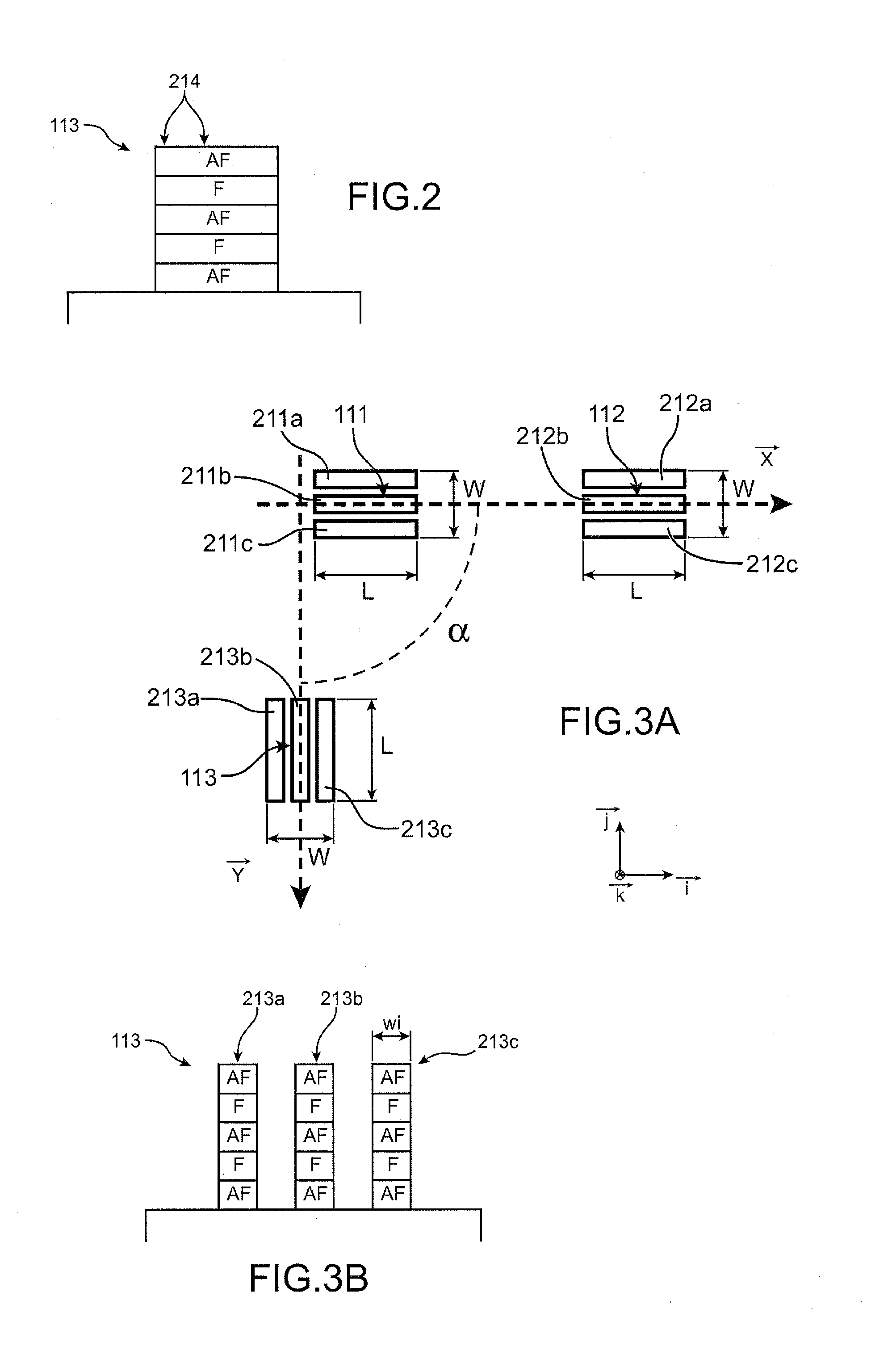

ActiveUS20110151589A1Avoid problemsSaturation magnetizationNanomagnetismSemiconductor/solid-state device manufacturingNéel temperatureMultiple layer

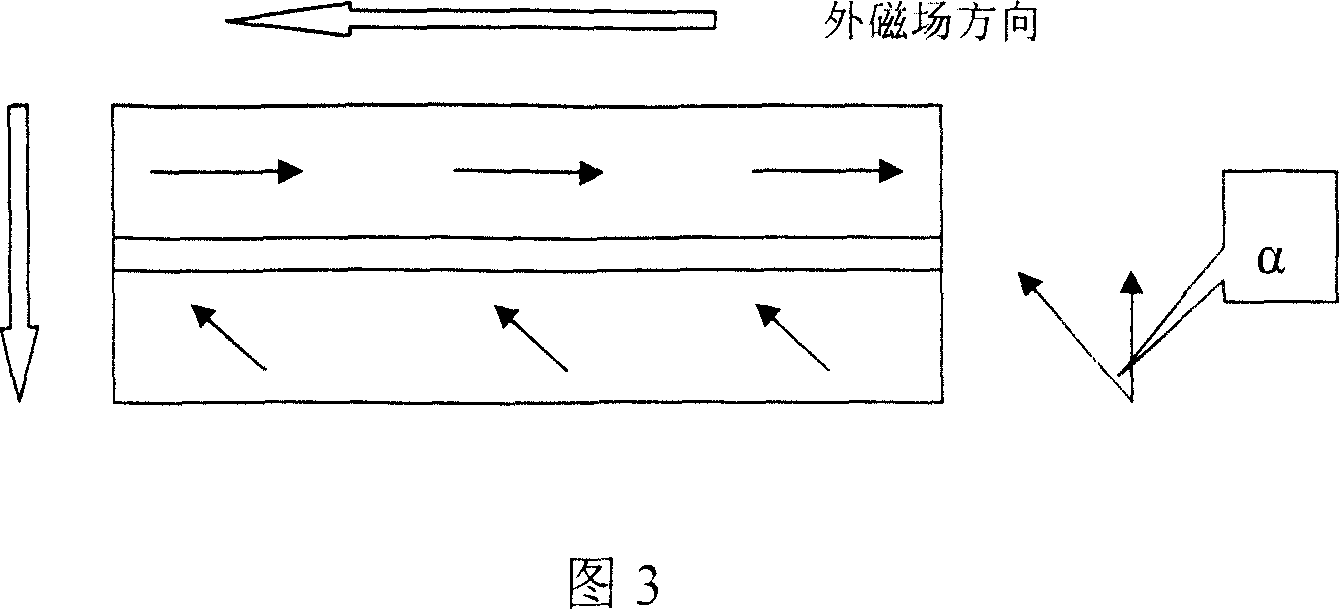

The invention relates to a method for producing a device comprising magnetic blocks magnetized in different directions, comprising steps of:a) forming, in a stack of one or more layers of at least one antiferromagnetic material and one or more layers of at least one ferromagnetic material resting on a substrate, at least one first block and at least one second block, said blocks being longilineal and separate and extending respectively in a first main direction and in a second main direction, the first and the second main direction forming between them a first non-zero angle α,b) annealing said blocks at a temperature greater than the ordering temperature of said antiferromagnetic material or than the blocking temperature or than the Néel temperature of said antiferromagnetic material.

Owner:COMMISSARIAT A LENERGLE ATOMIQUE & AUX ENERGIES AKTERNATIV

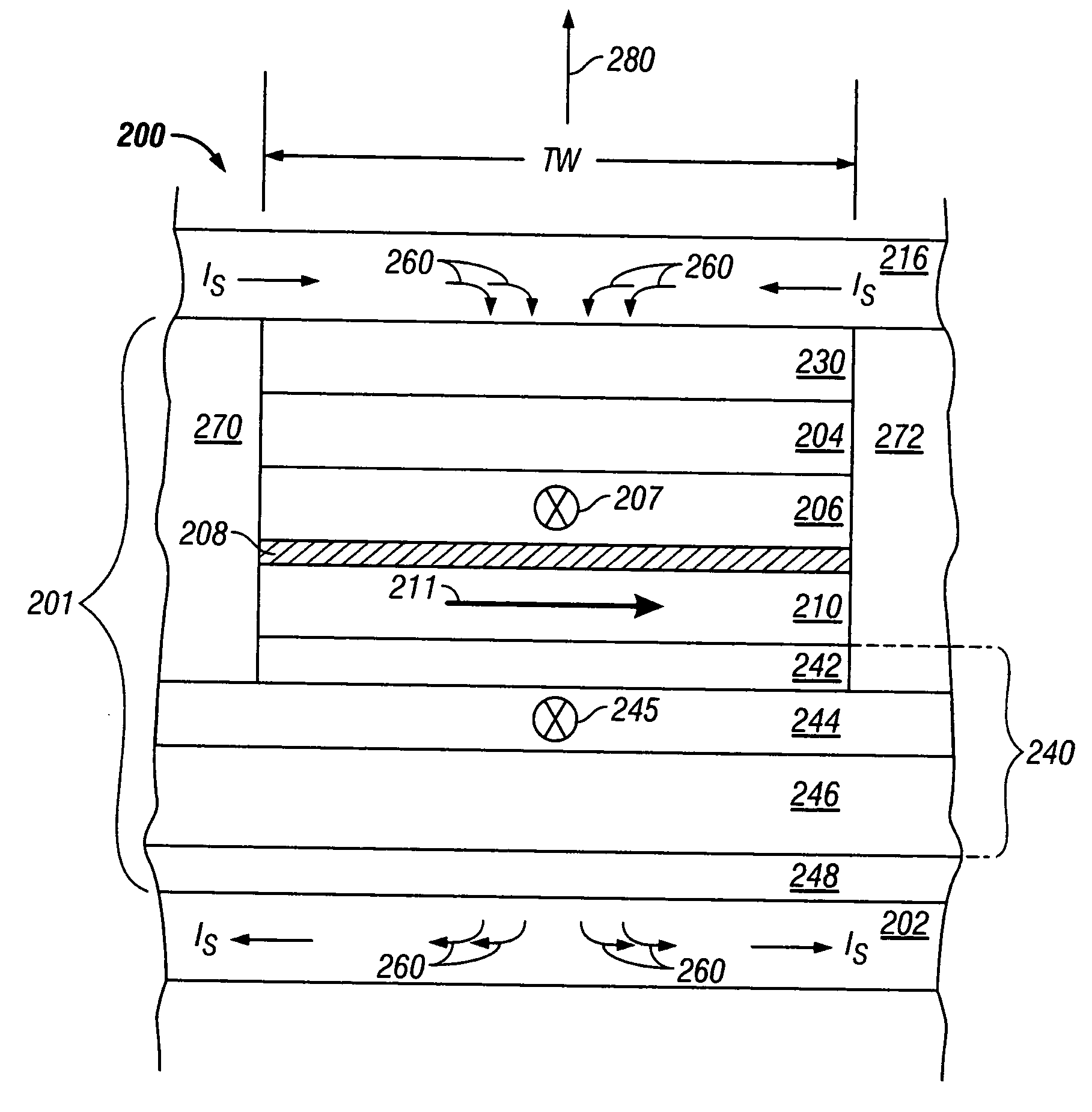

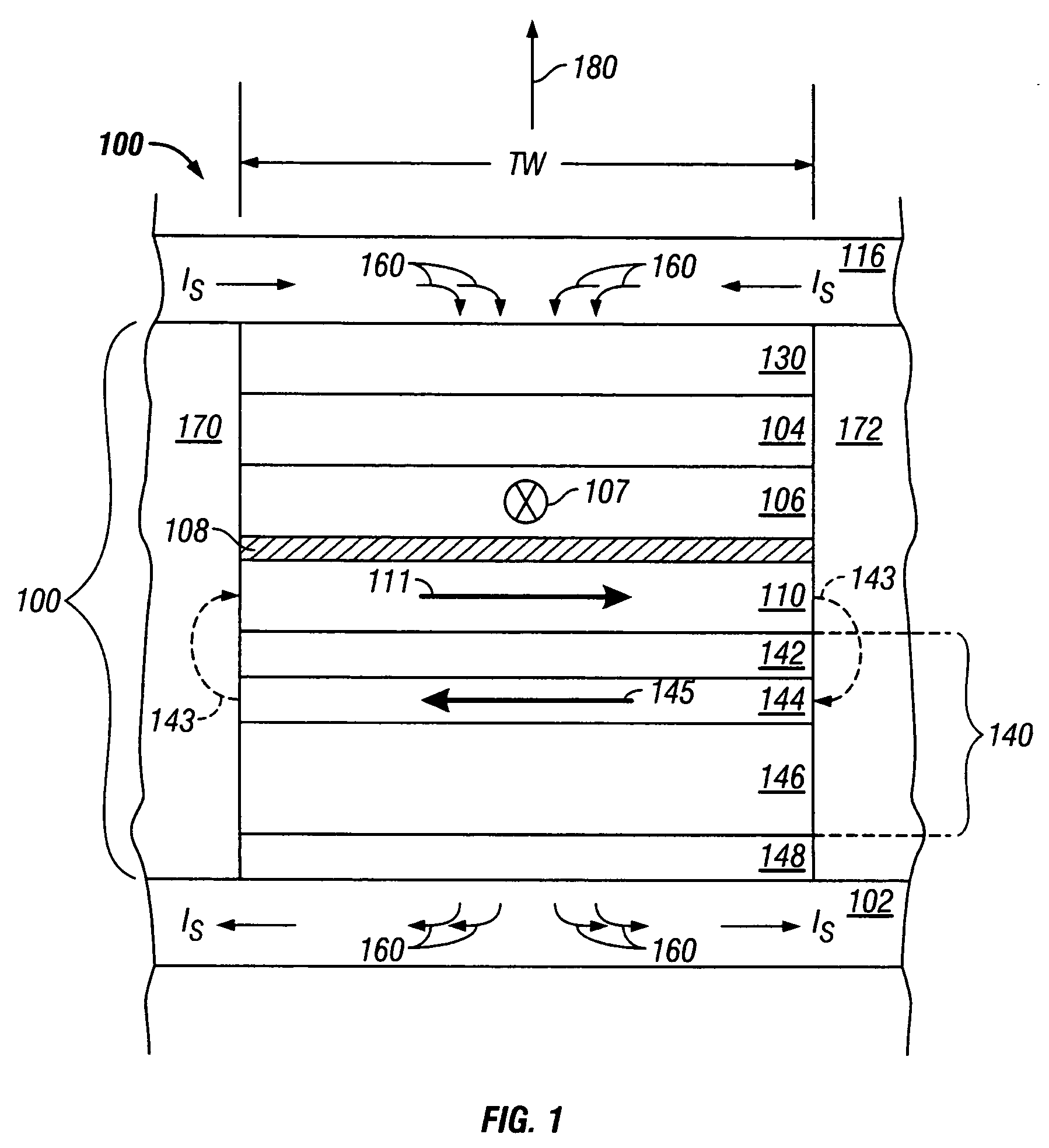

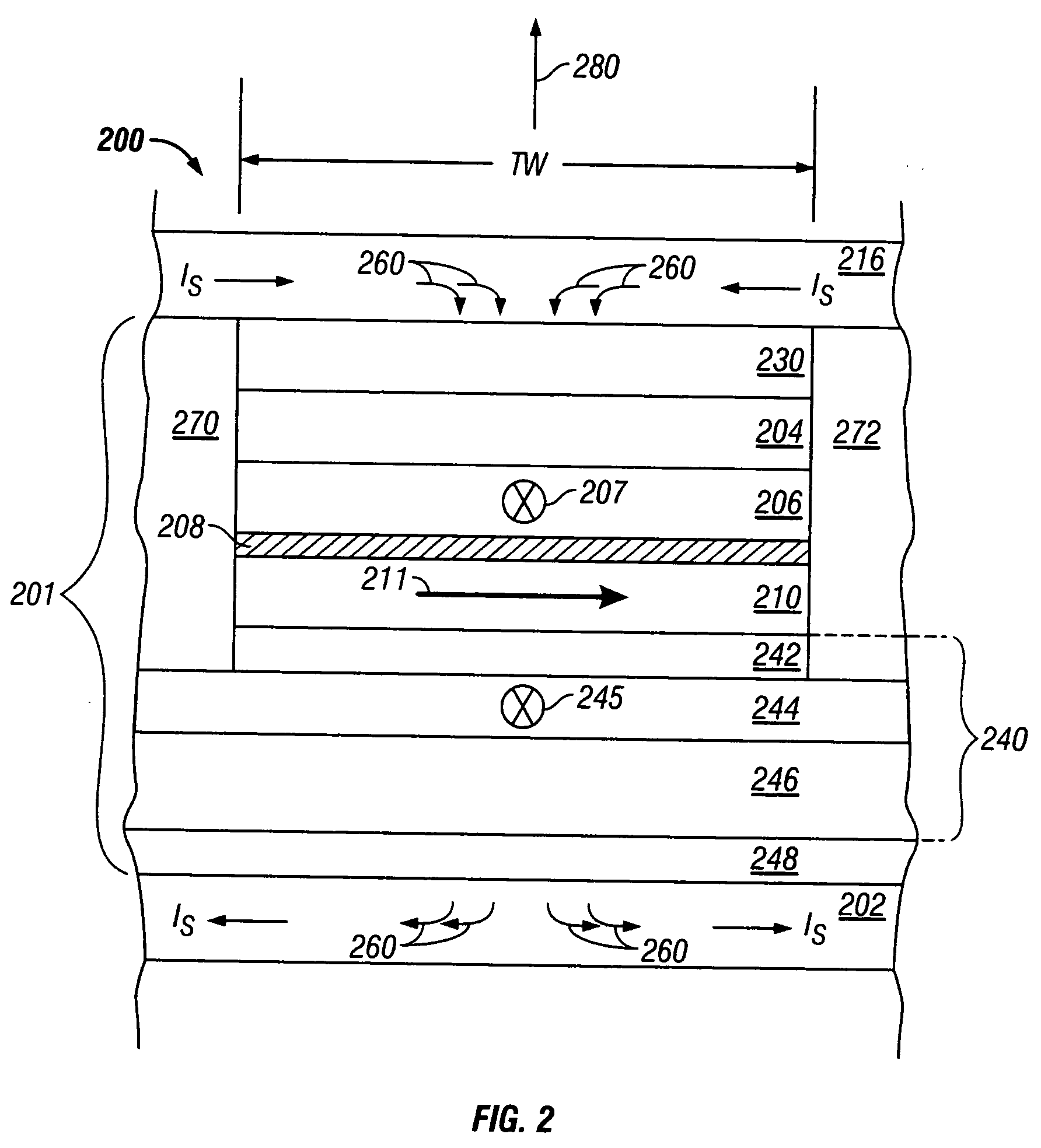

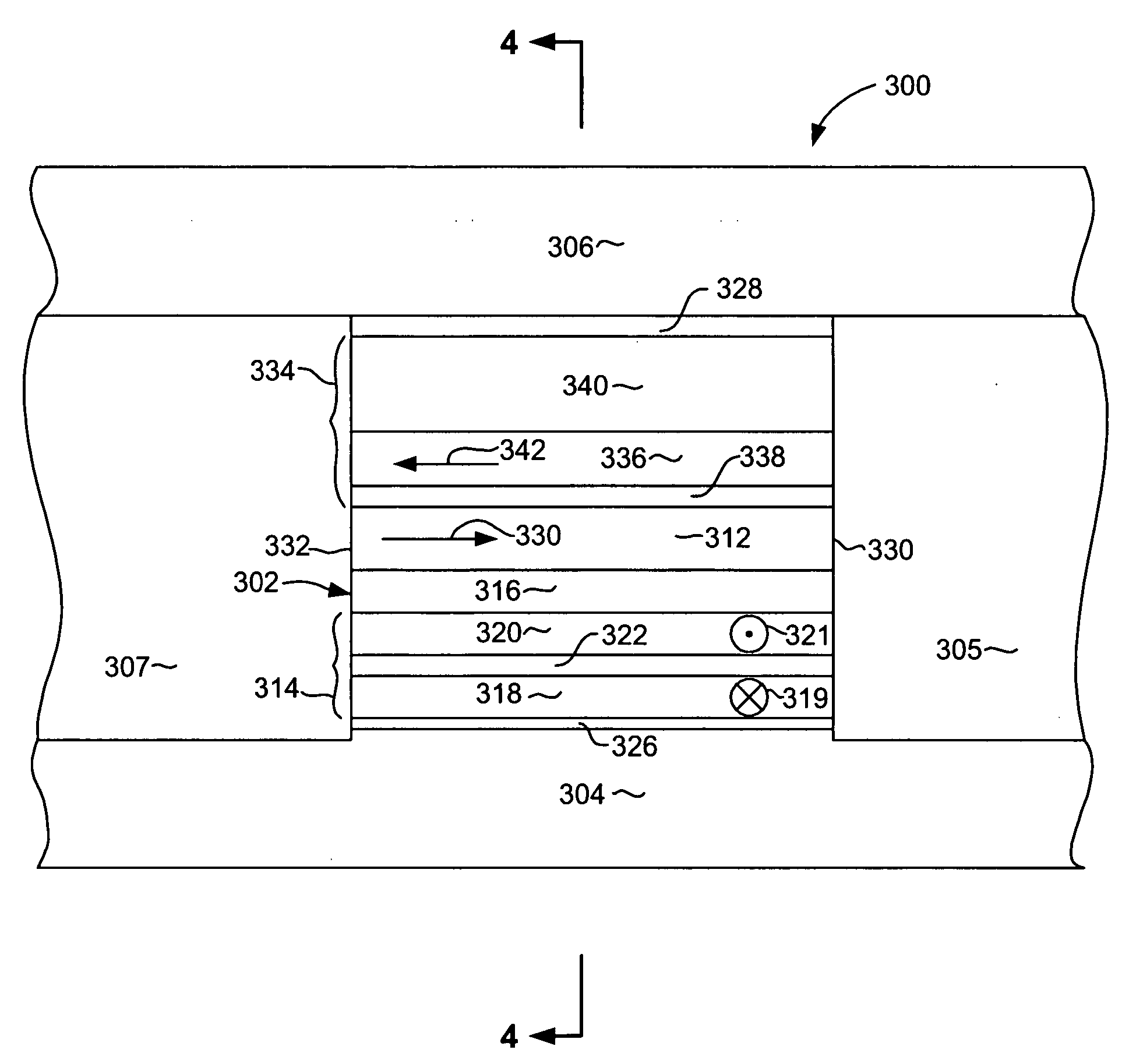

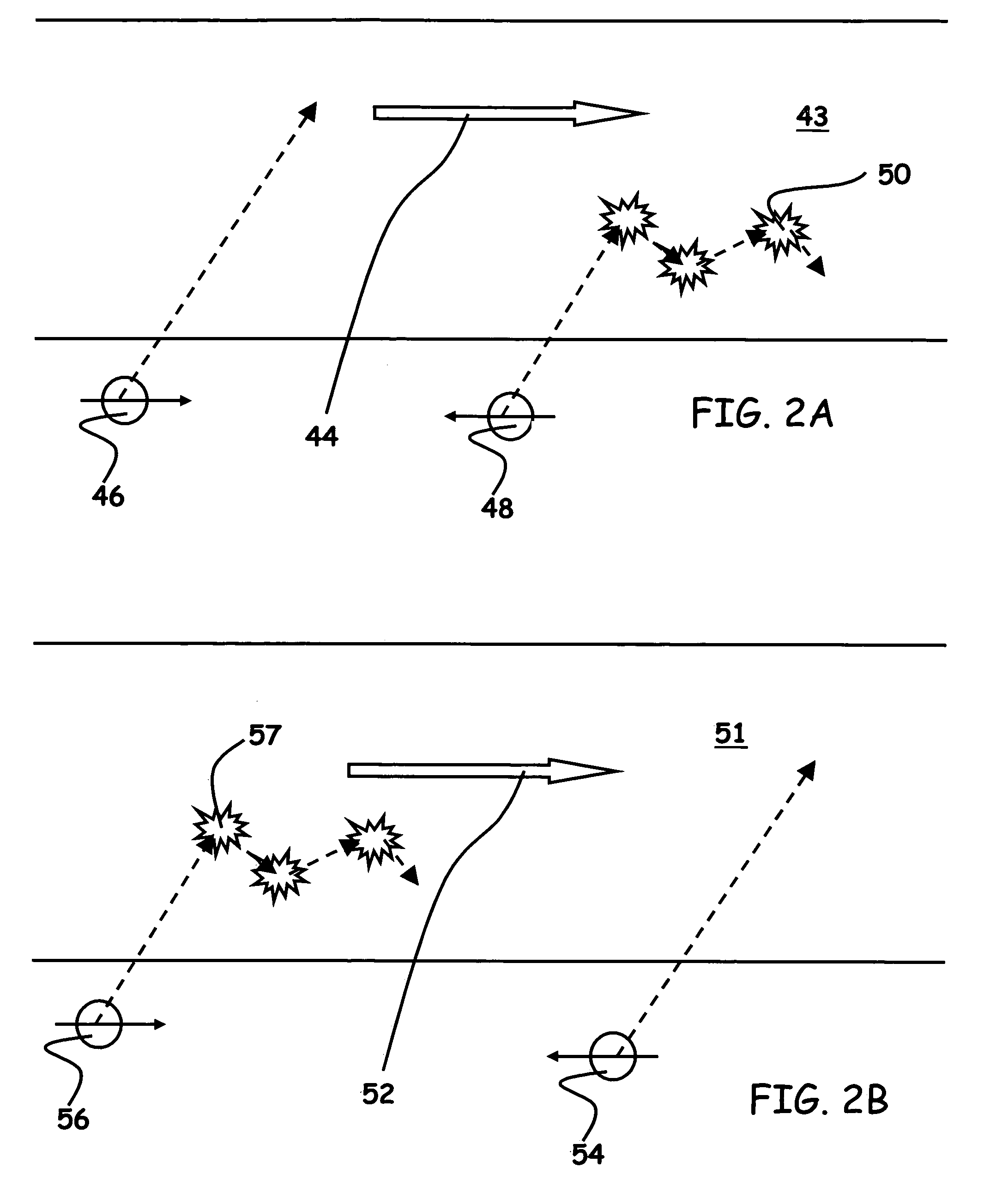

Current-perpendicular-to-plane magnetoresistive sensor with free layer stabilized by in-stact orthogonal magnetic coupling to an antiparallel pinned biasing layer

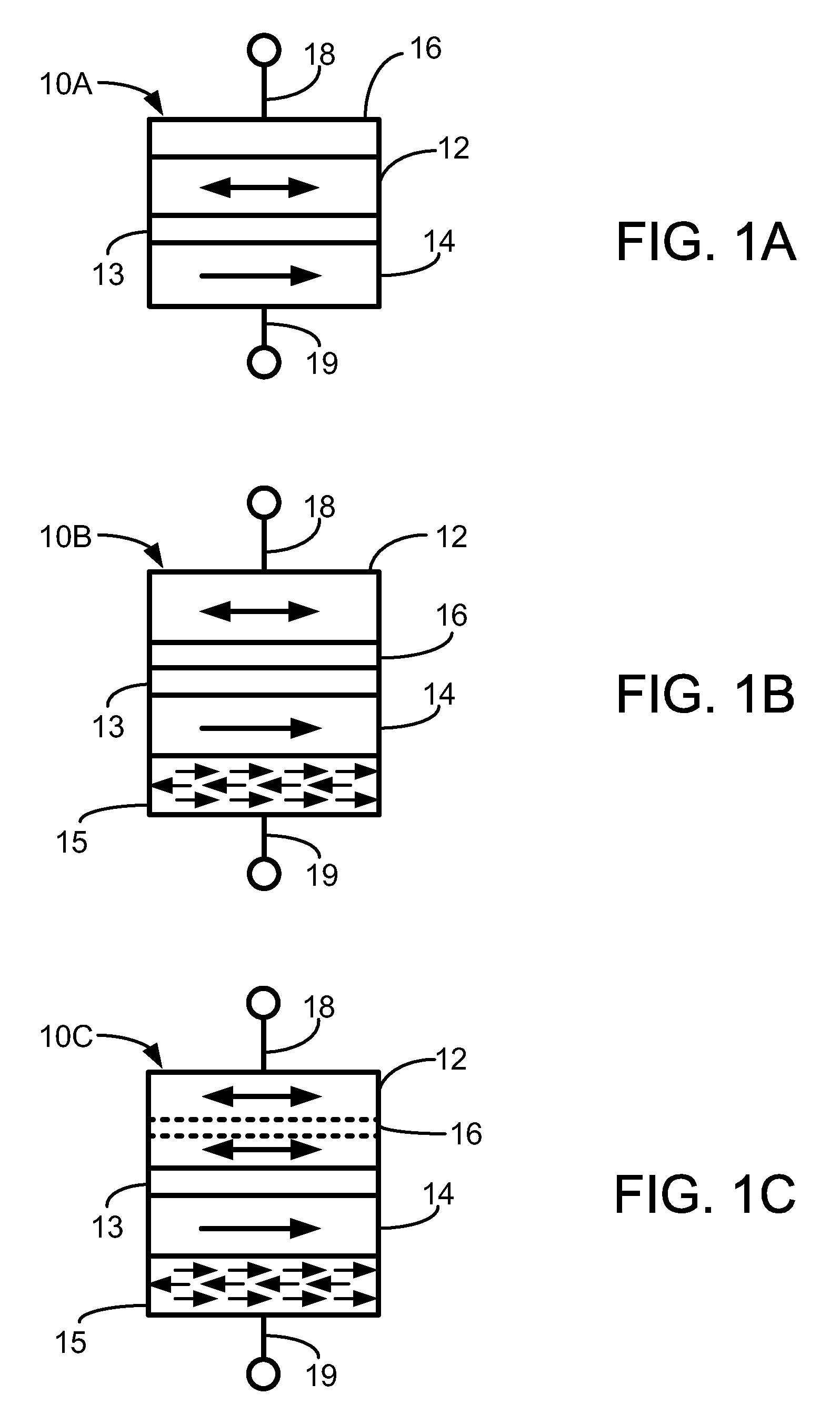

A magnetically-coupled structure has two ferromagnetic layers with their in-plane magnetization directions coupled orthogonally across an electrically-conducting spacer layer that induces the direct orthogonal magnetic coupling. The structure has application for in-stack biasing in a current-perpendicular-to-the-plane (CPP) magnetoresistive sensor. One of the ferromagnetic layers of the structure is an antiparallel-pinned biasing layer and the other ferromagnetic layer is the sensor free layer. The antiparallel-pinned biasing layer has first and second ferromagnetic films separated by an antiferromagnetically-coupling film. An antiferromagnetic layer exchange-couples the first ferromagnetic film of the biasing layer to fix the net moment of the biasing layer parallel to the moment of the sensor pinned layer. This allows a single annealing step to be used to set the magnetization direction of the biasing and pinned layers.

Owner:WESTERN DIGITAL TECH INC

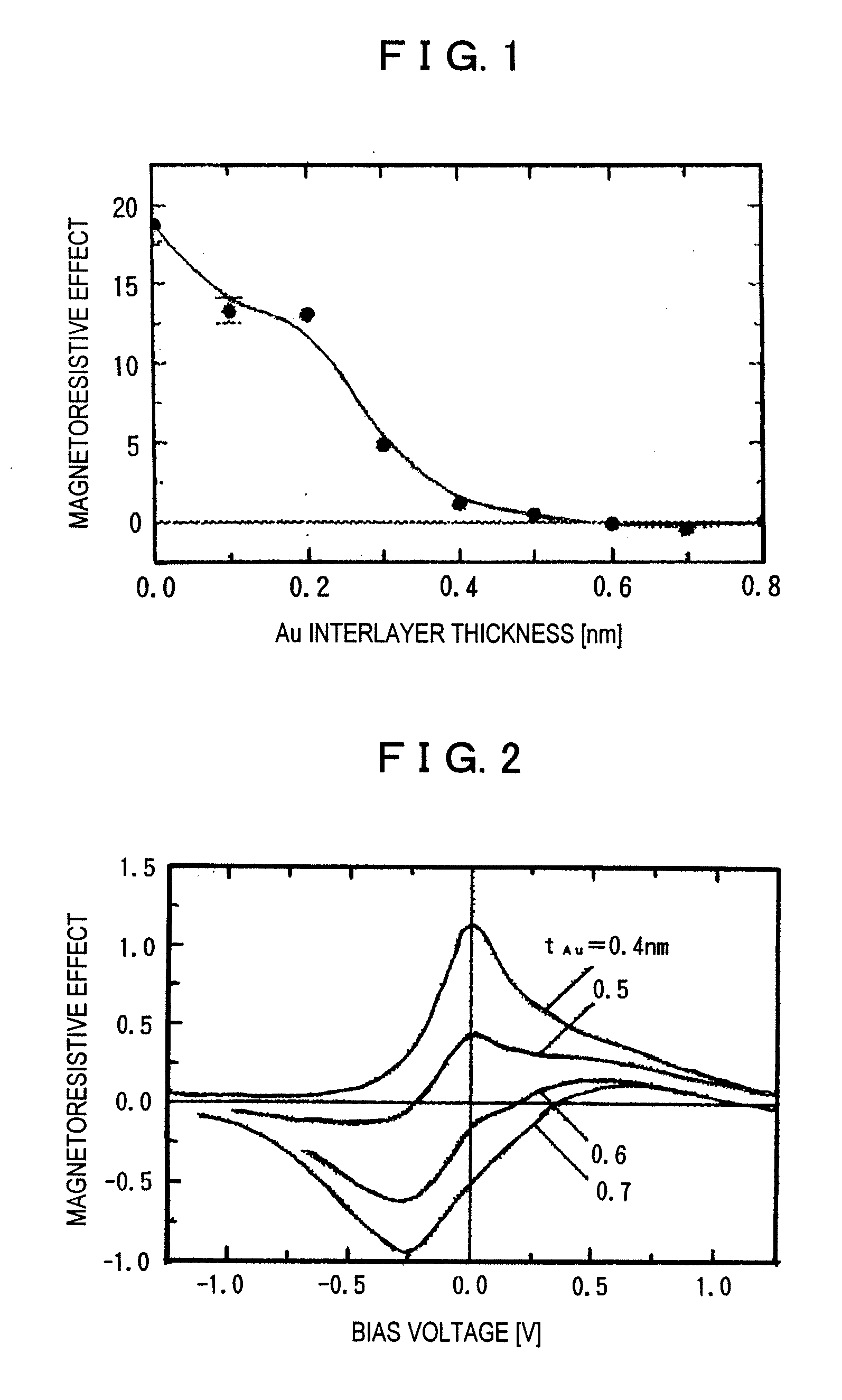

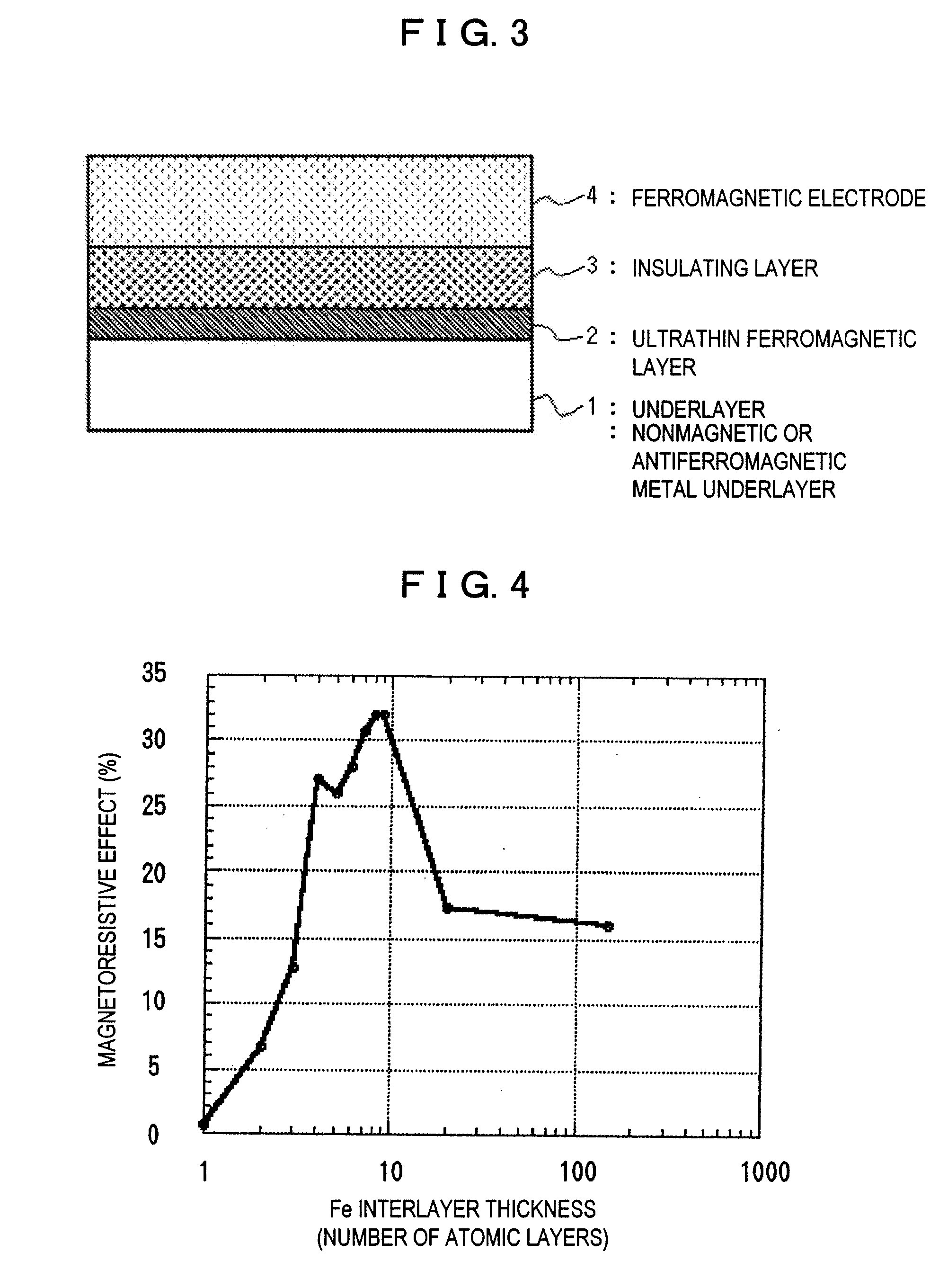

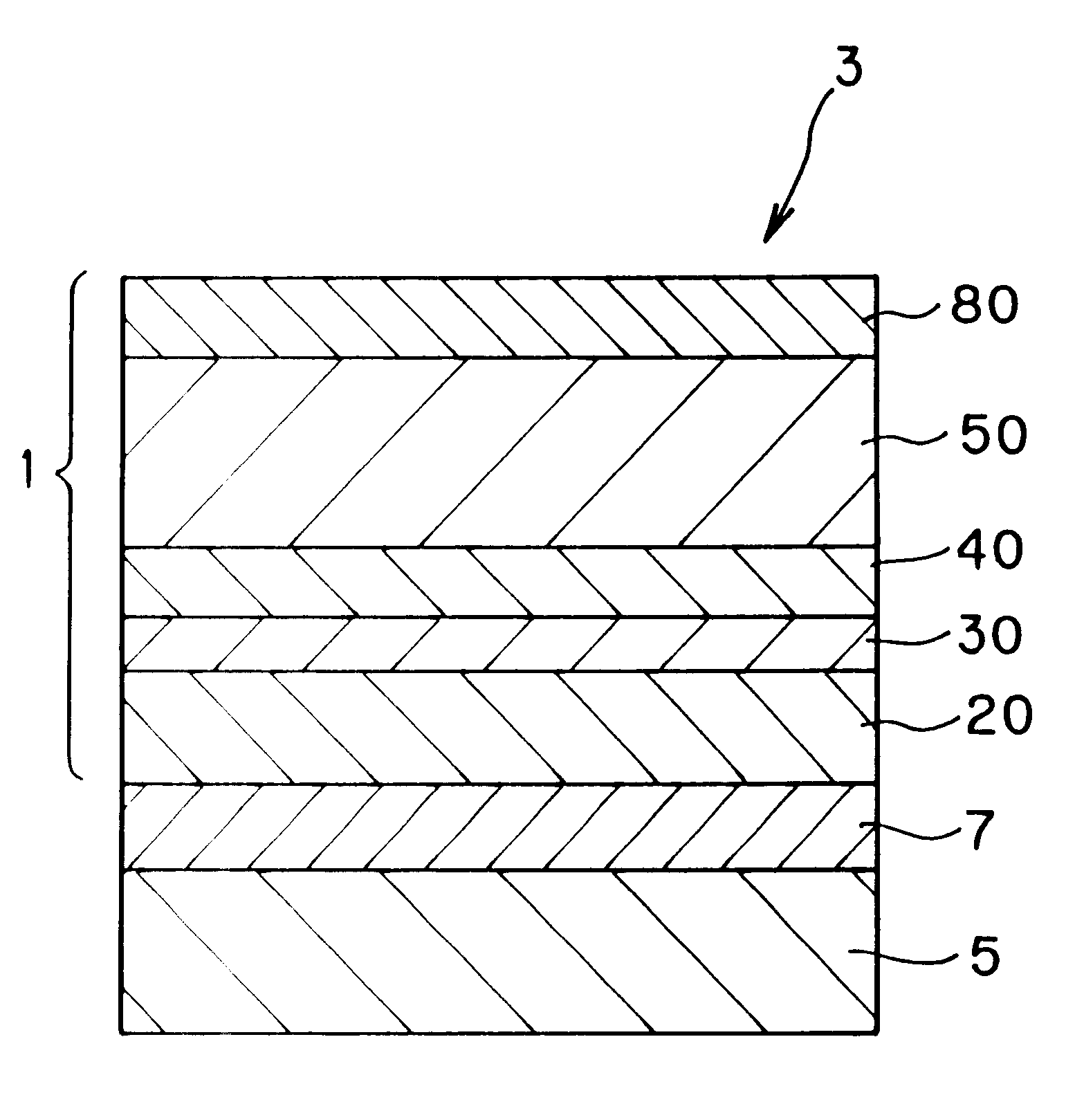

Tunnel magnetoresistance element

InactiveUS20070128470A1Electron scattering of a nonmagnetic interlayer is preventedGood effectNanomagnetismNanoinformaticsChemical compositionMagnetic reluctance

By varying only the thickness of a known material having superior magnetic characteristics to increase spin polarization without changing the chemical composition, a tunnel magnetoresistive element capable of producing a larger magnetoresistive effect is provided. The tunnel magnetoresistive element includes an underlayer (nonmagnetic or antiferromagnetic metal film); an ultrathin ferromagnetic layer disposed on the underlayer; an insulating layer disposed on the ultrathin ferromagnetic layer; and a ferromagnetic electrode disposed on the insulating layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Magnetoresistance effect film and magnetoresistance effect type head

InactiveUS6195239B1Record information storageManufacture of flux-sensitive headsMagnetic reluctanceThermal stability

In a spin valve type magnetoresistance effect film, an antiferromagnetic layer is made of MxMn100-x wherein M represents at least one selected from Ru, Rh, Re, Pt, Pd, Au, Ag, Fe, Ni, Ir and Cr, and 15<=x<=58 (unit of x: atomic %), and a protective layer formed thereon is made of at least one selected from Rh, Ru, Zr and Ti. With this arrangement, a magnetoresistance effect film highly excellent in thermal stability and small in deterioration of the MR ratio, as well as a magnetoresistance effect type head having such a magnetoresistance effect film can be obtained.

Owner:TDK CORPARATION

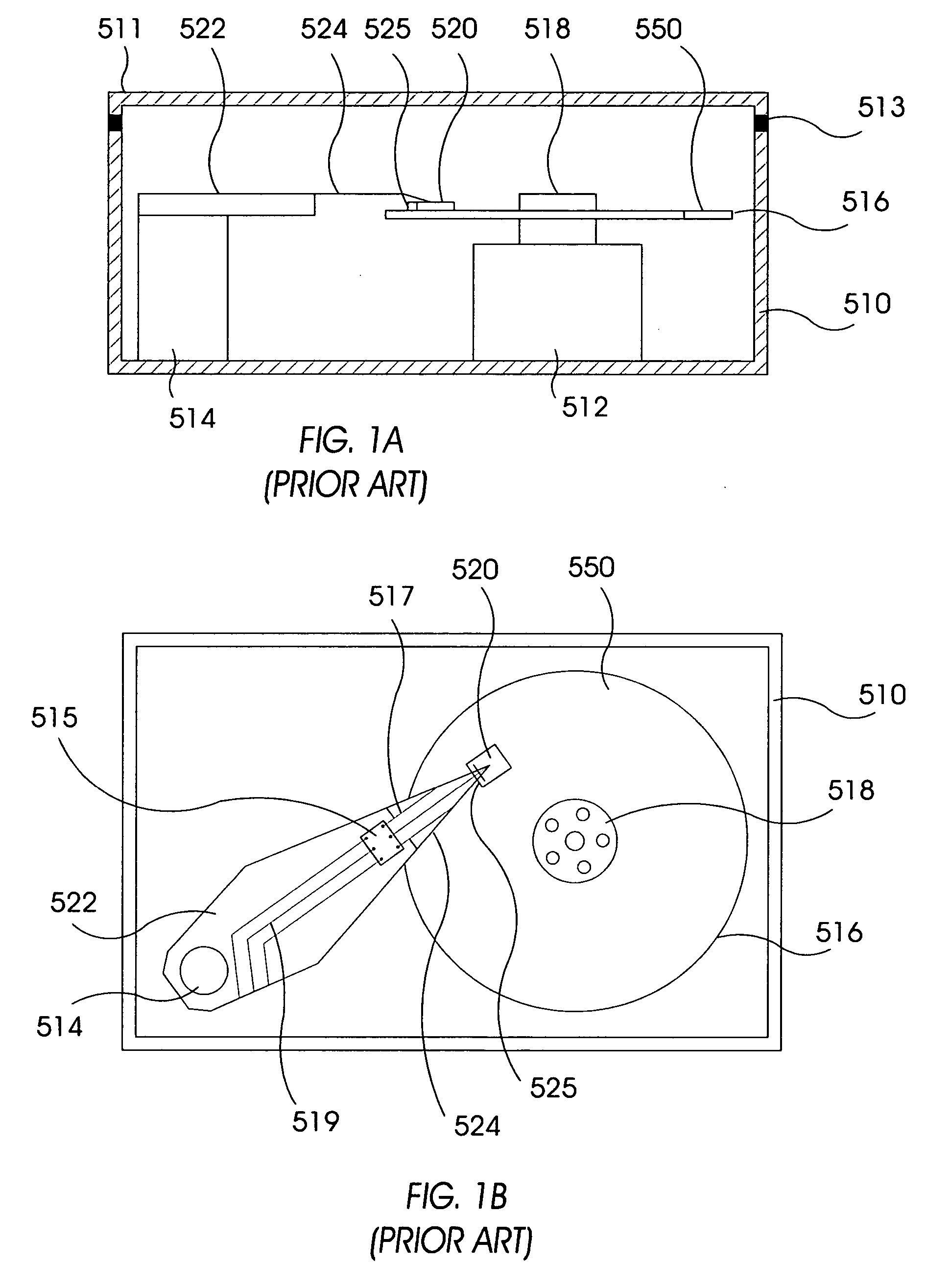

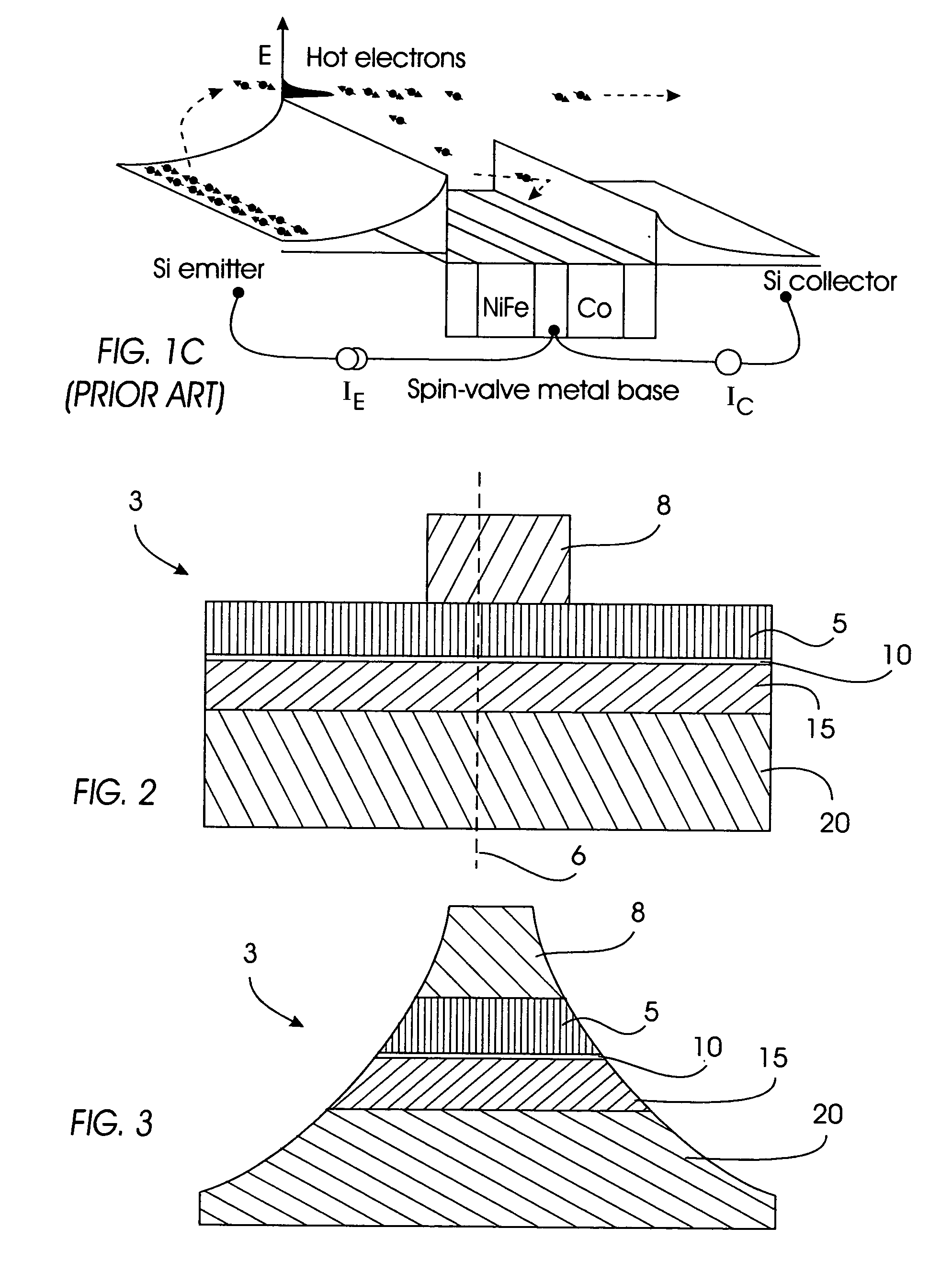

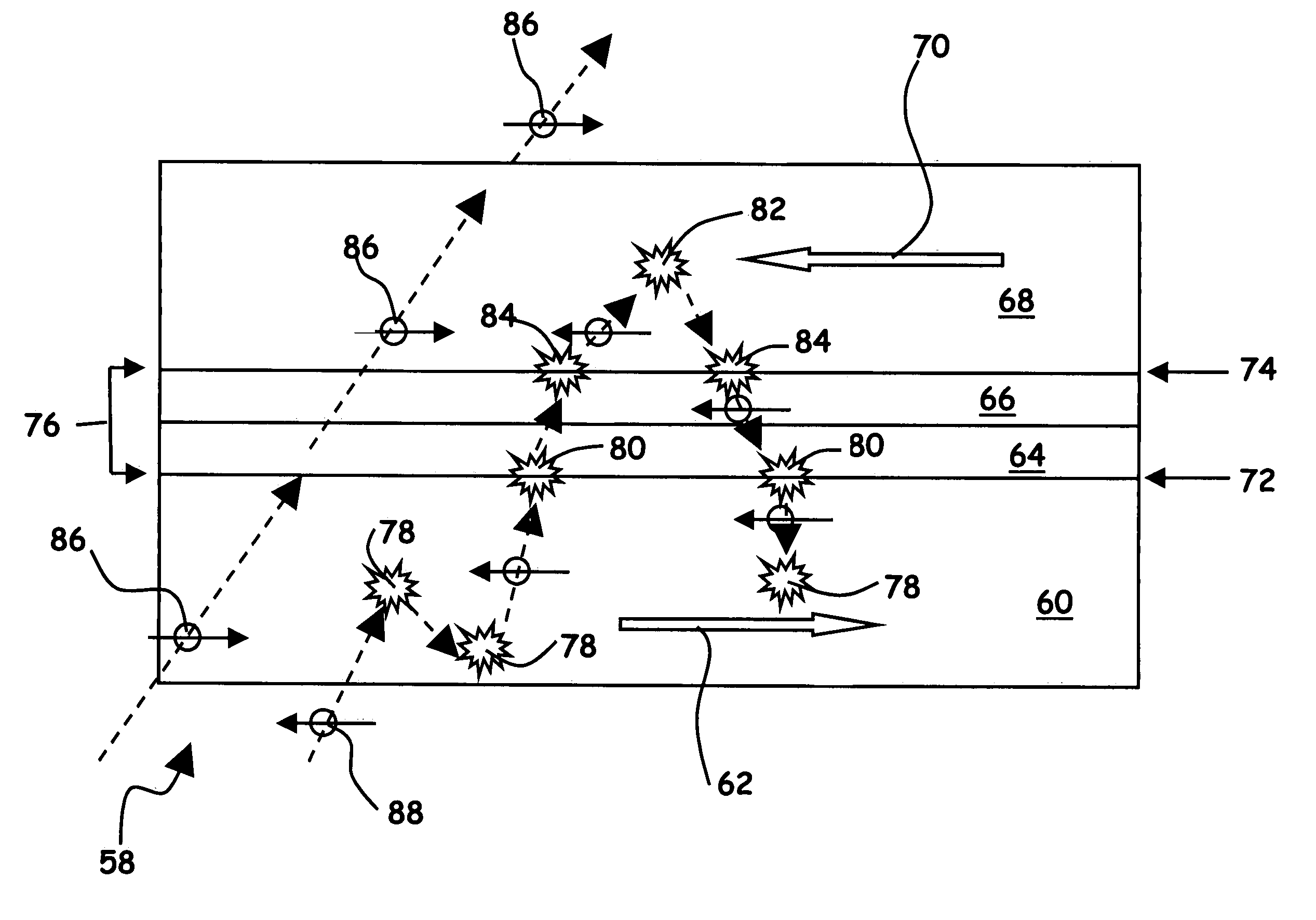

Spin valve transistor with stabilization and method for producing the same

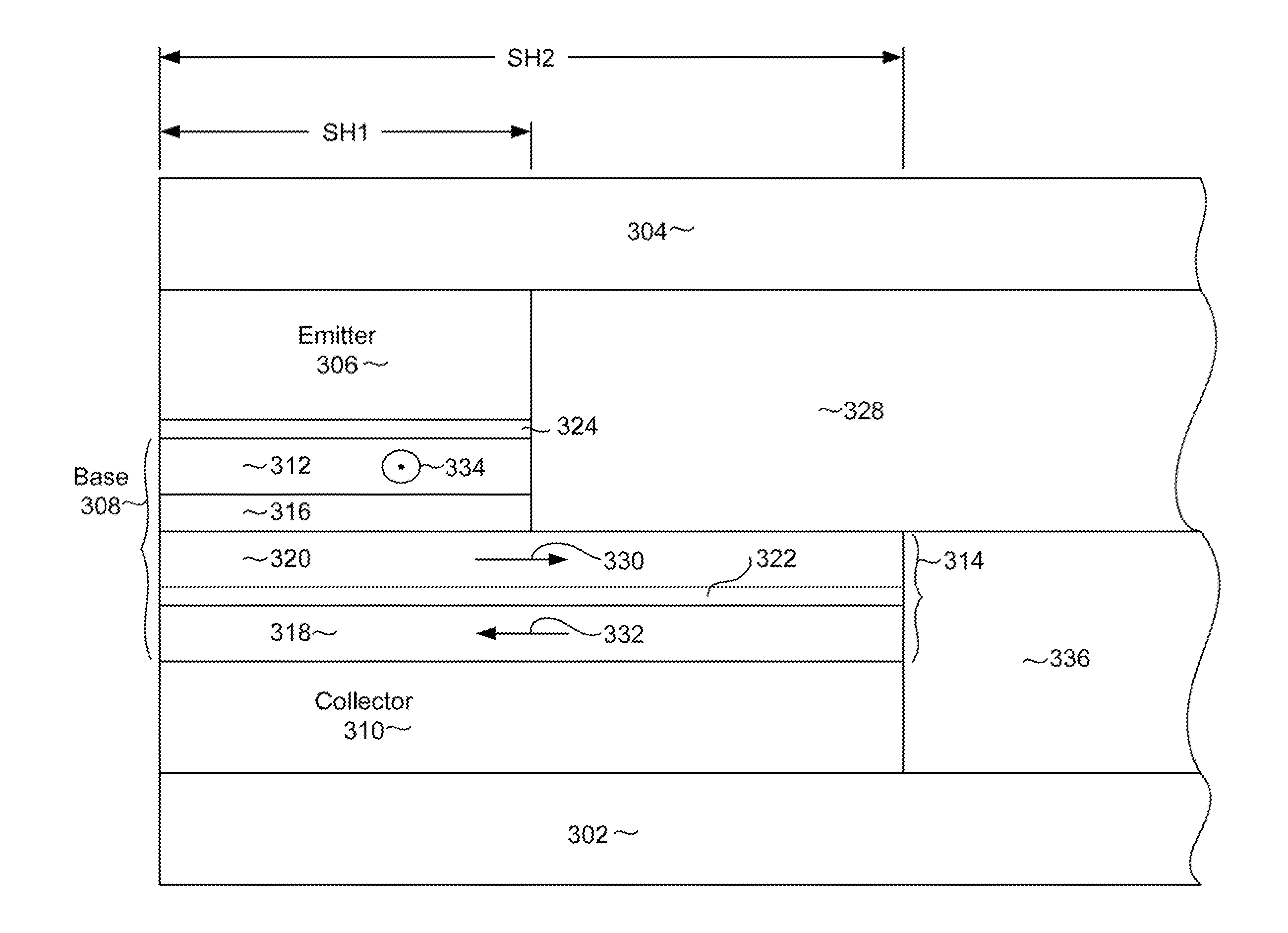

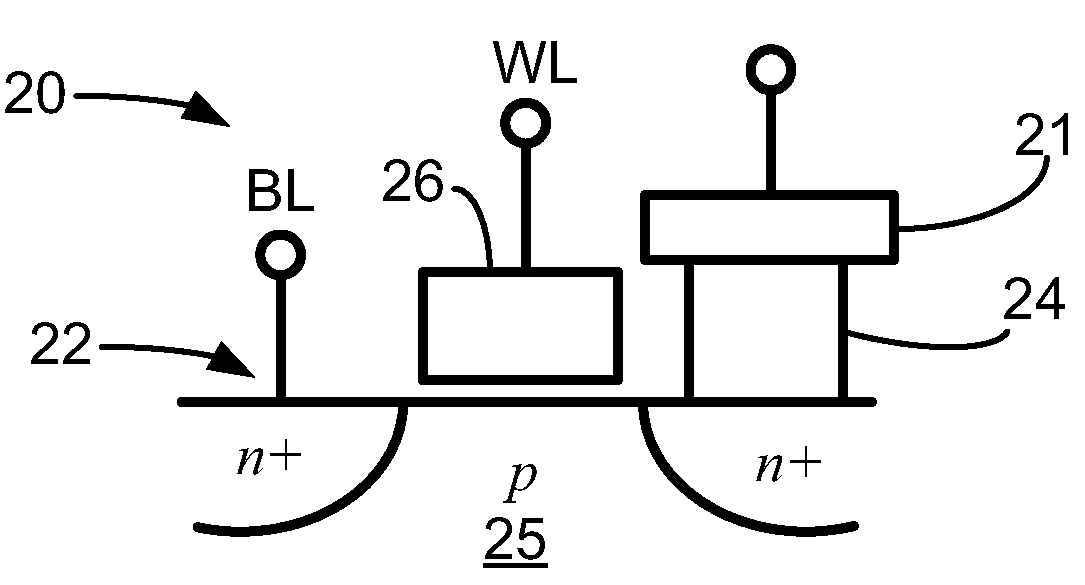

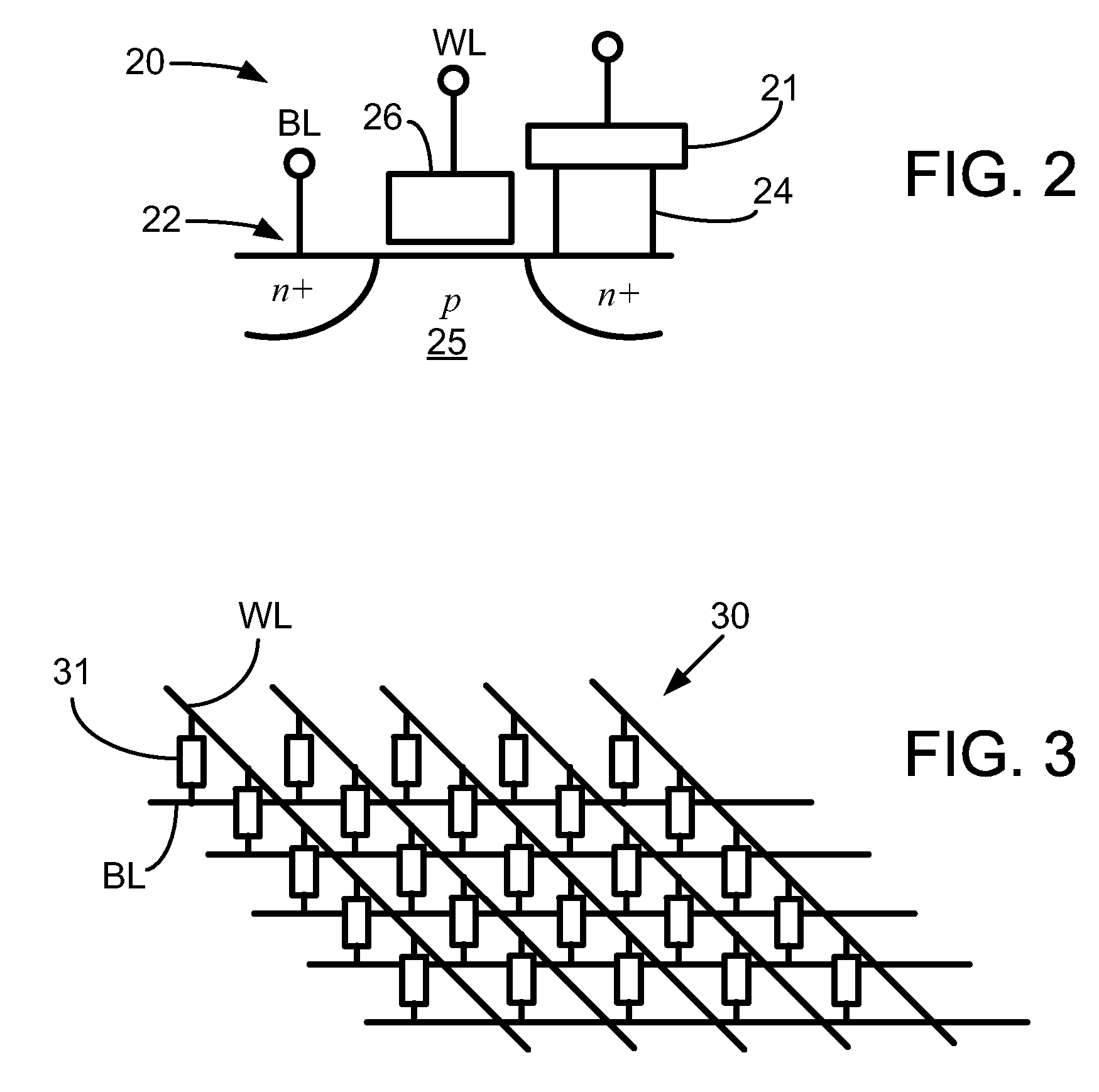

A method and structure for a spin valve transistor (SVT) comprises a magnetic field sensor, an insulating layer adjacent the magnetic field sensor, a bias layer adjacent the insulating layer, a non-magnetic layer adjacent the bias layer, and a ferromagnetic layer over the non-magnetic layer, wherein the insulating layer and the non-magnetic layer comprise antiferromagnetic materials. The magnetic field sensor comprises a base region, a collector region adjacent the base region, an emitter region adjacent the base region, and a barrier region located between the base region and the emitter region. The bias layer is between the insulating layer and the non-magnetic layer. The bias layer is magnetic and is at least three times the thickness of the magnetic materials in the base region.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

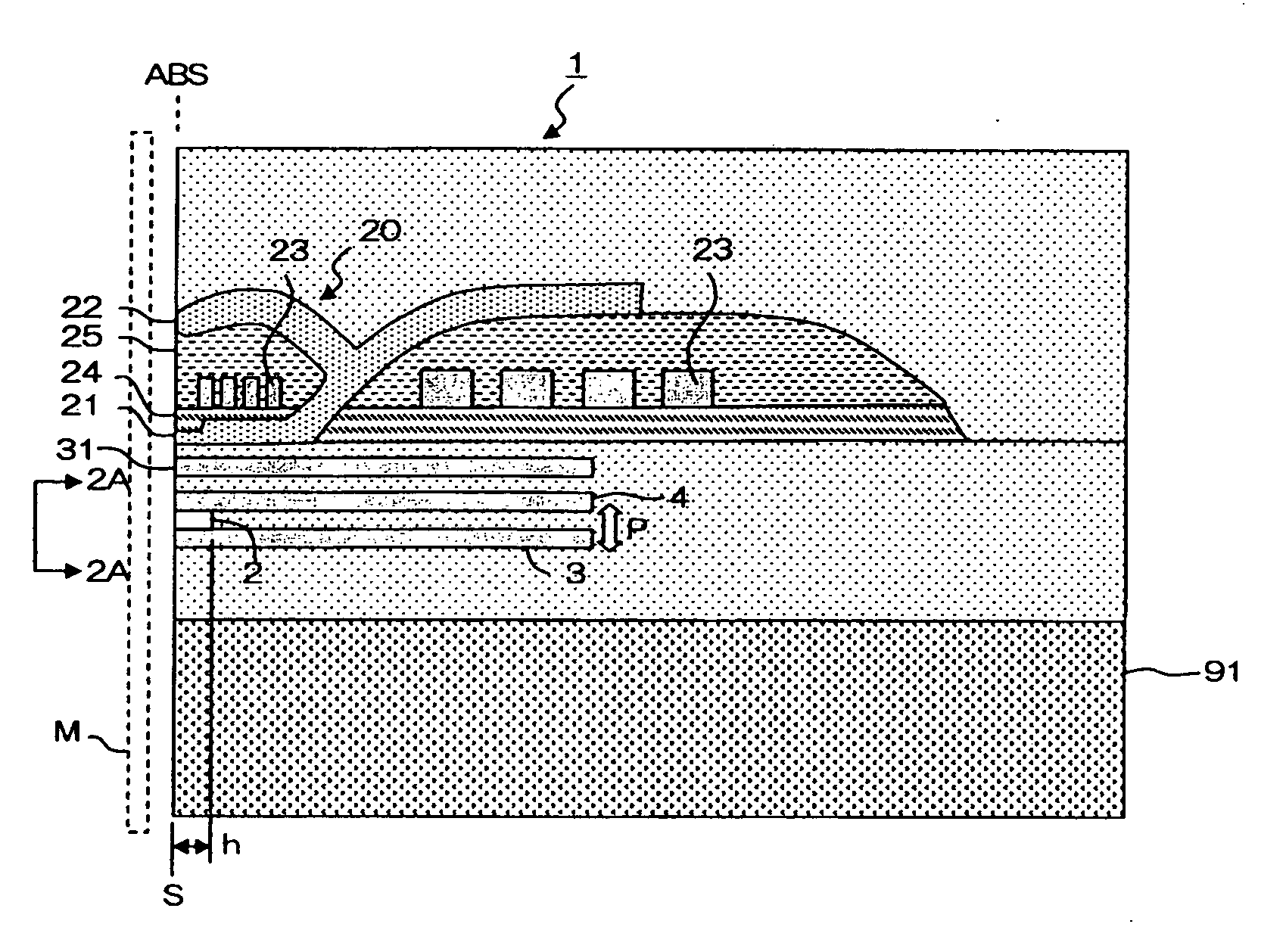

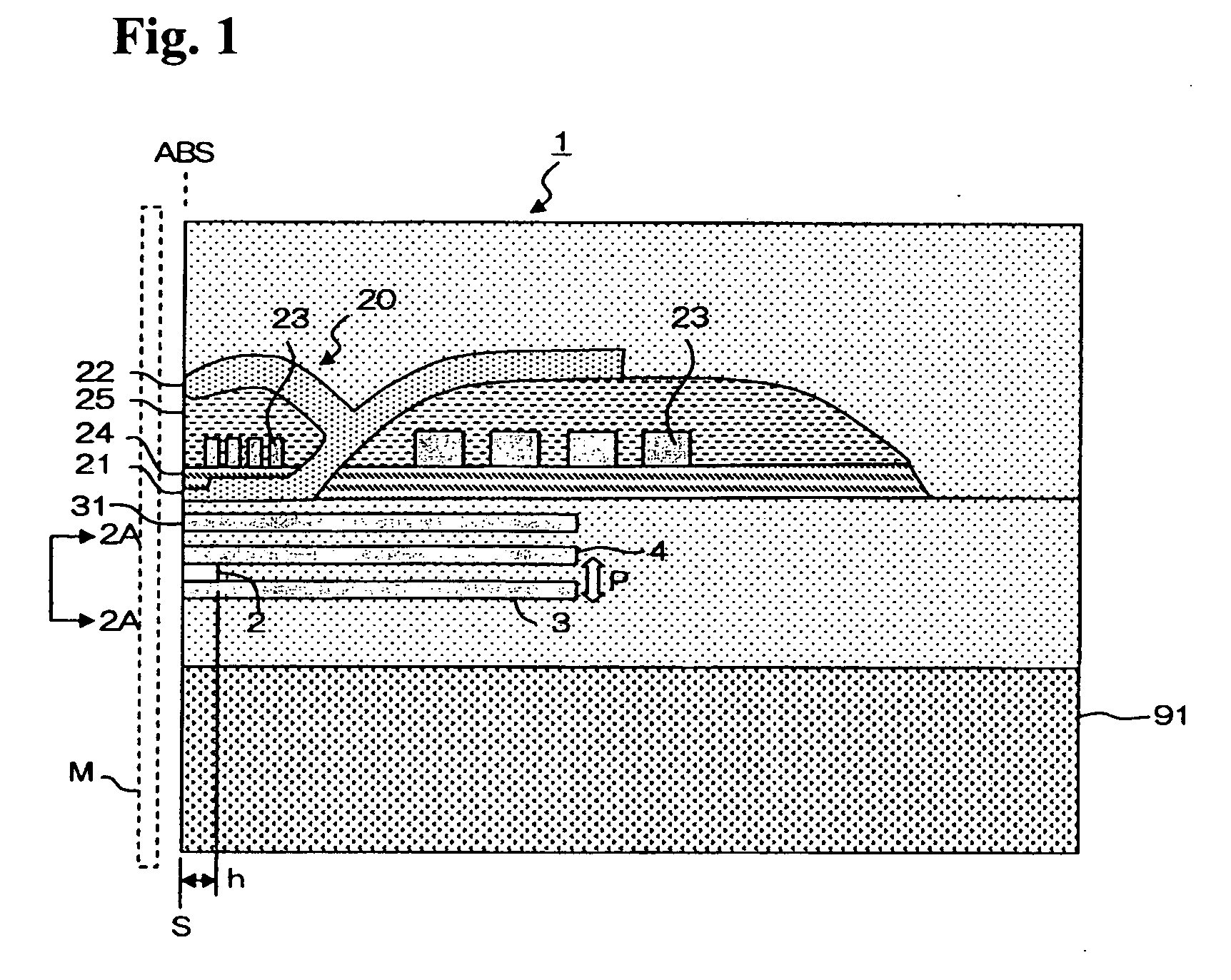

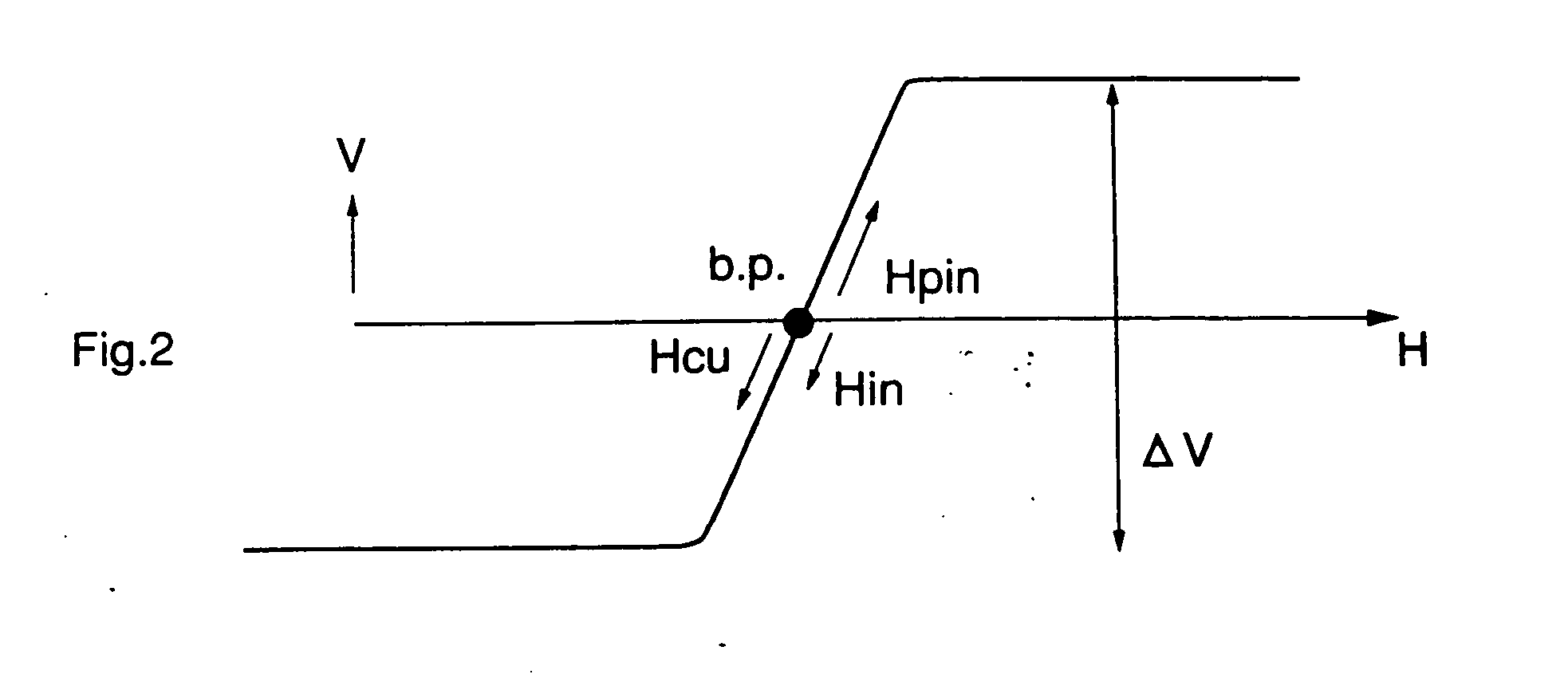

Magnetoresistance effect element, magnetic head, magnetic head assembly, magnetic storage system

InactiveUS20050030676A1Increase contactEffectively applying the bias magnetic fieldNanomagnetismMagnetic measurementsMagnetic storageCoupling

Disclosed are a high-sensitivity and high-reliability magnetoresistance effect device (MR device) in which bias point designing is easy, and also a magnetic head, a magnetic head assembly and a magnetic recording / reproducing system incorporating the MR device. In the MR device incorporating a spin valve film, the magnetization direction of the free layer is at a certain angle to the magnetization direction of a second ferromagnetic layer therein when the applied magnetic field is zero. In this, the pinned magnetic layer comprises a pair of ferromagnetic films as antiferromagnetically coupled to each other via a coupling film existing therebetween. The device is provided with a means of keeping the magnetization direction of either one of the pair of ferromagnetic films constituting the pinned magnetic layer, and with a nonmagnetic high-conductivity layer as disposed adjacent to a first ferromagnetic layer on the side opposite to the side on which the first ferromagnetic layer is contacted with a nonmagnetic spacer layer. With that constitution, the device has extremely high sensitivity, and the bias point in the device is well controlled.

Owner:KK TOSHIBA

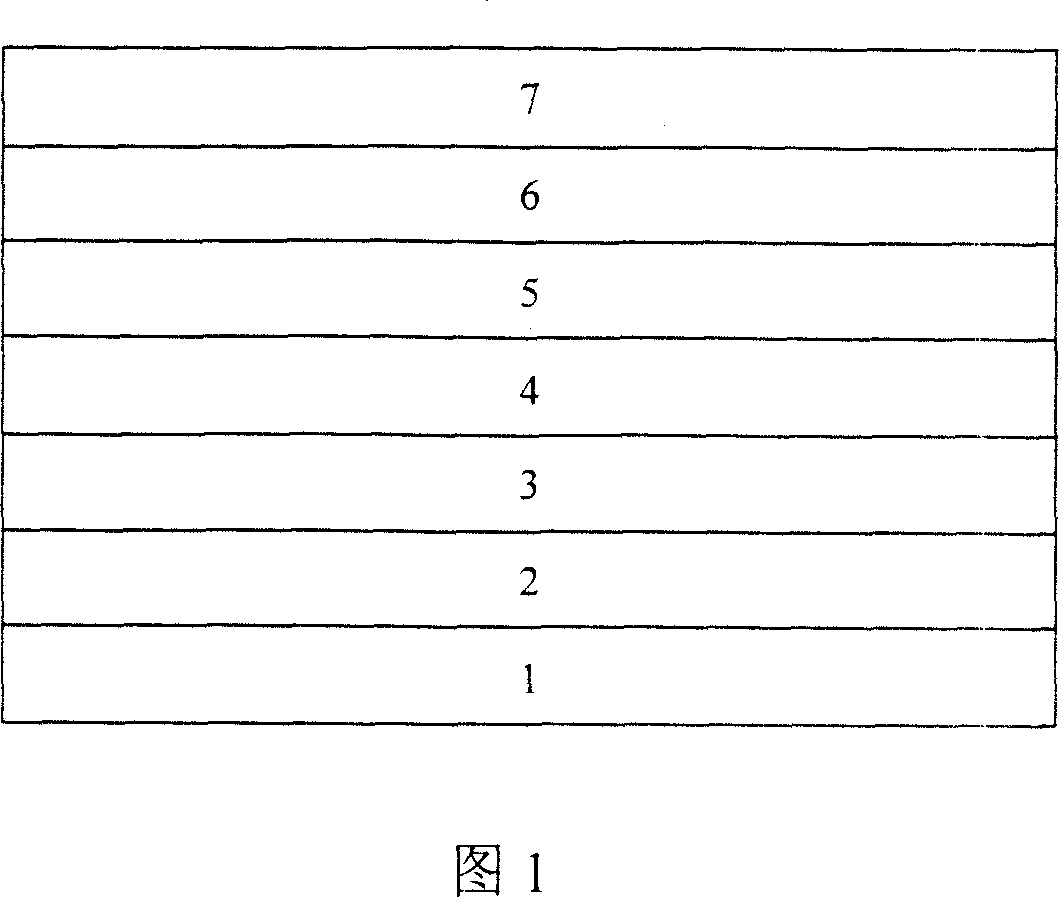

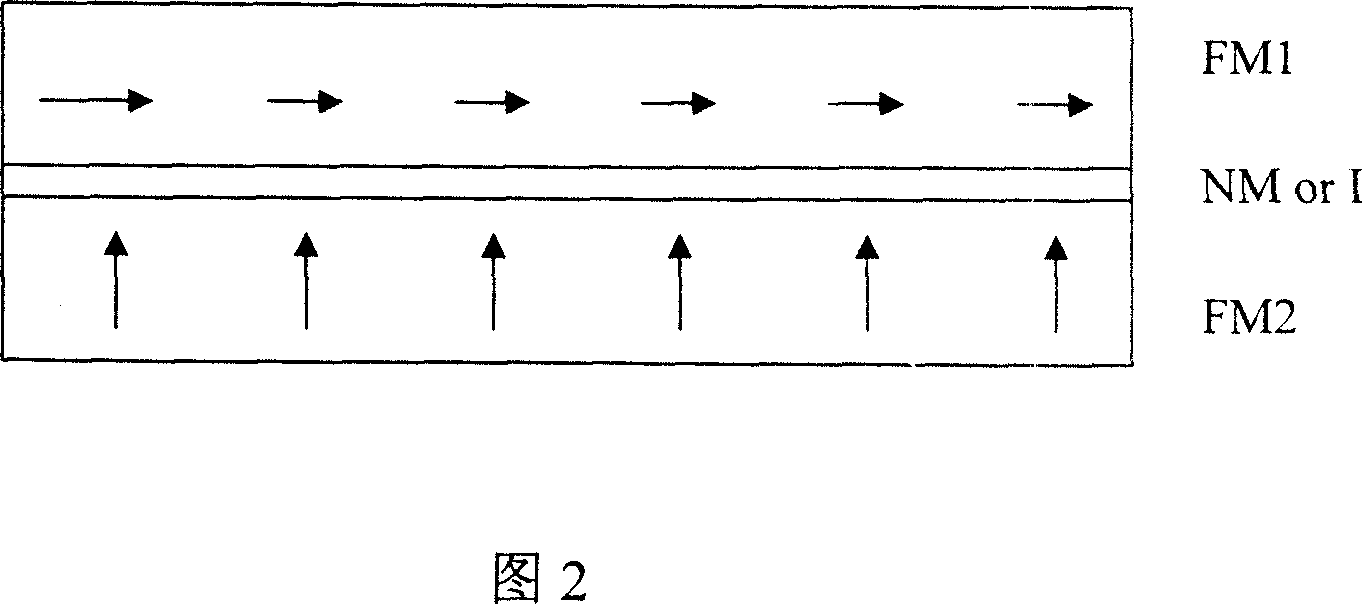

Magnetic multilayer film with linear magnetoresistance effect and its application

ActiveCN1967891ALow costReduce manufacturing costMagnetic measurementsMagnetic-field-controlled resistorsNon magneticMagnetic layer

The invention relates to a magnetic multilayer film with linear magnetic resistance effect, wherein it is self-rotation valve magnetic resistance made from the magnetic material whose magnetic torque is vertical to horizontal plane; it comprises one substrate deposited with buffer layer, the first magnetic layer, non-magnetic metal conductive layer or insulated layer, the second magnetic layer, antiferromagnetism nail layer and cover layer; the magnetic torque of first magnetic layer is upright; the magnetic torque of second magnetic layer is horizontal; the magnetic torque of first magnetic layer is vertical to the second magnetic layer. The inventive magnetic multilayer film can be used in magnetic sensor and magnetic head. And the magnetic sensor can realize measurement on vertical magnetic field, without changing sensor position and direction.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

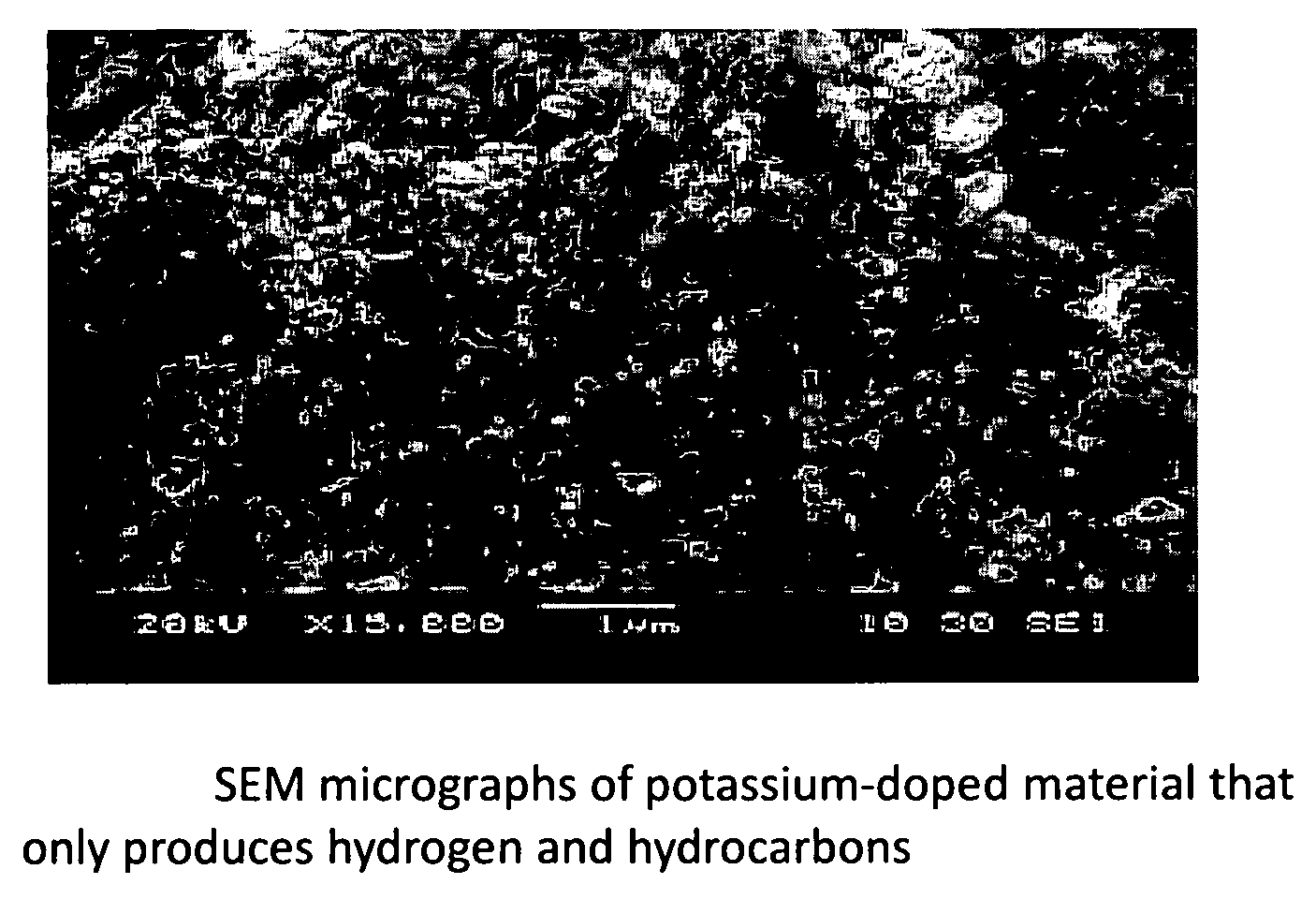

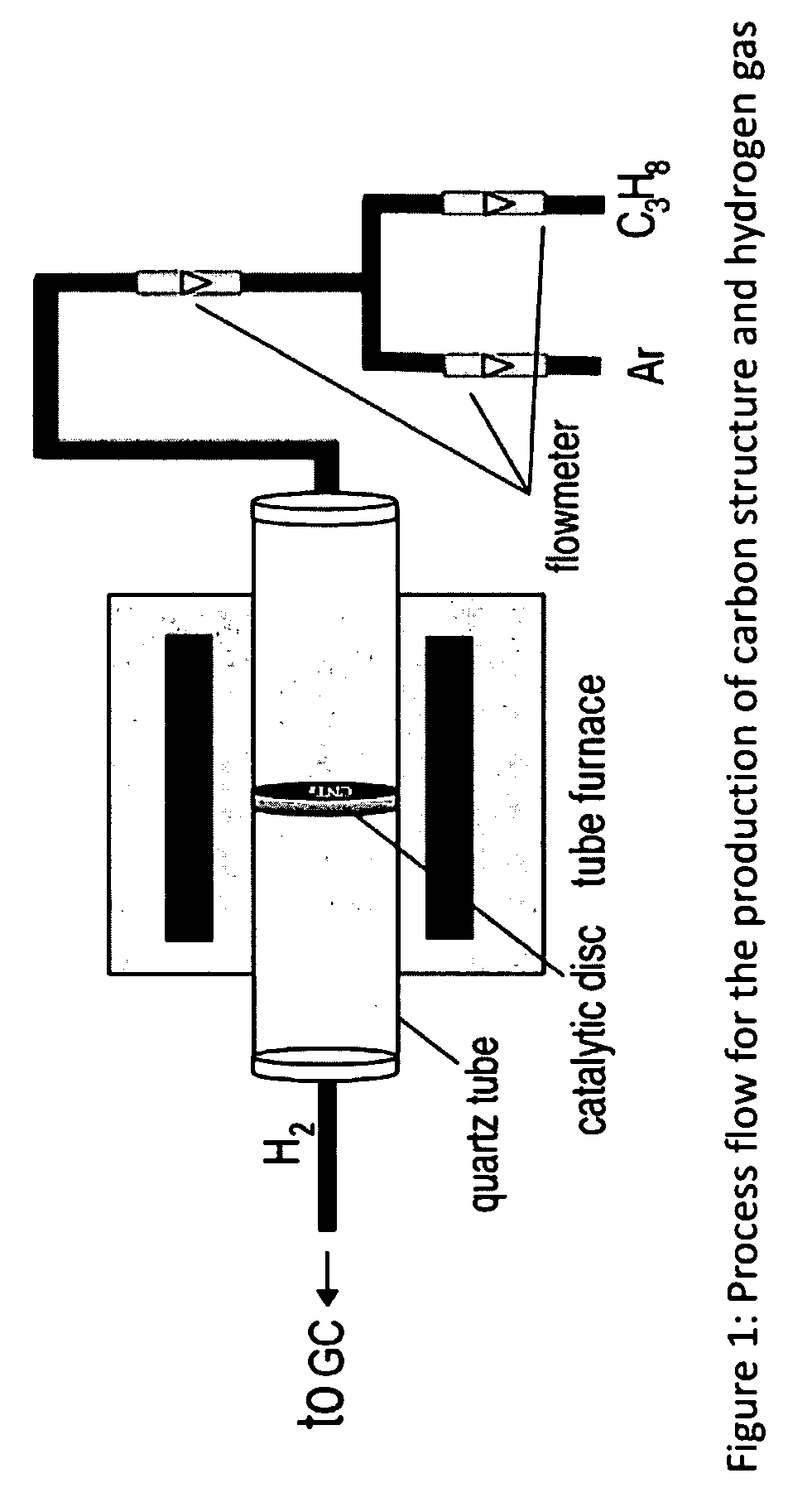

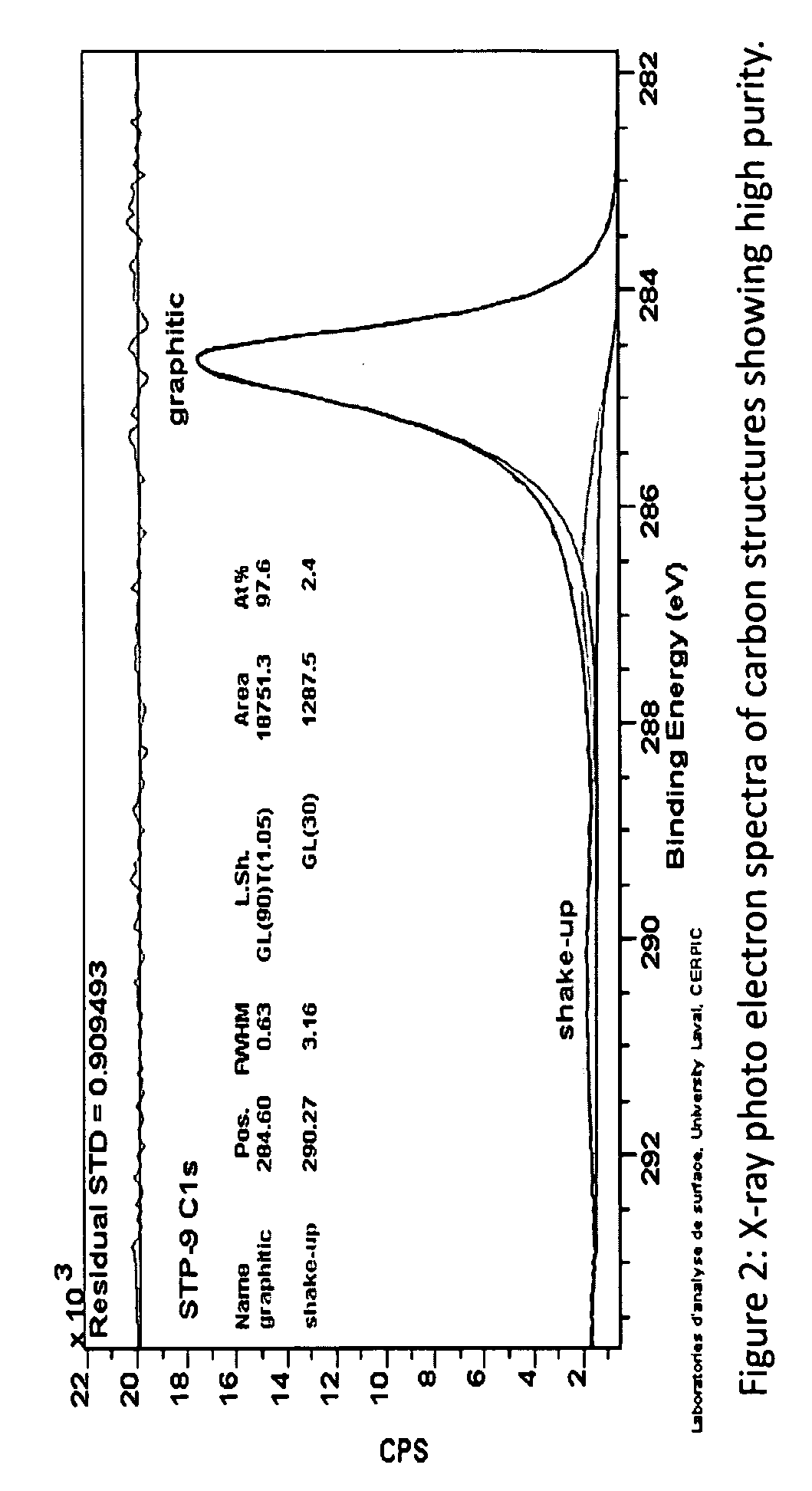

Novel catalyst to manufacture carbon nanotubes and hydrogen gas

This invention relates primarily to a novel method to manufacture single / multi / fibers carbon filaments (nano tubes) in pure form optionally with antiferromagnetic and electrical property wherein the byproduct is hydrogen gas resulting in reduction of environmental carbon emissions by at least 20%; both carbon filaments and resultant exhaust are useful products.

Owner:QUAID E AZAM UNIV

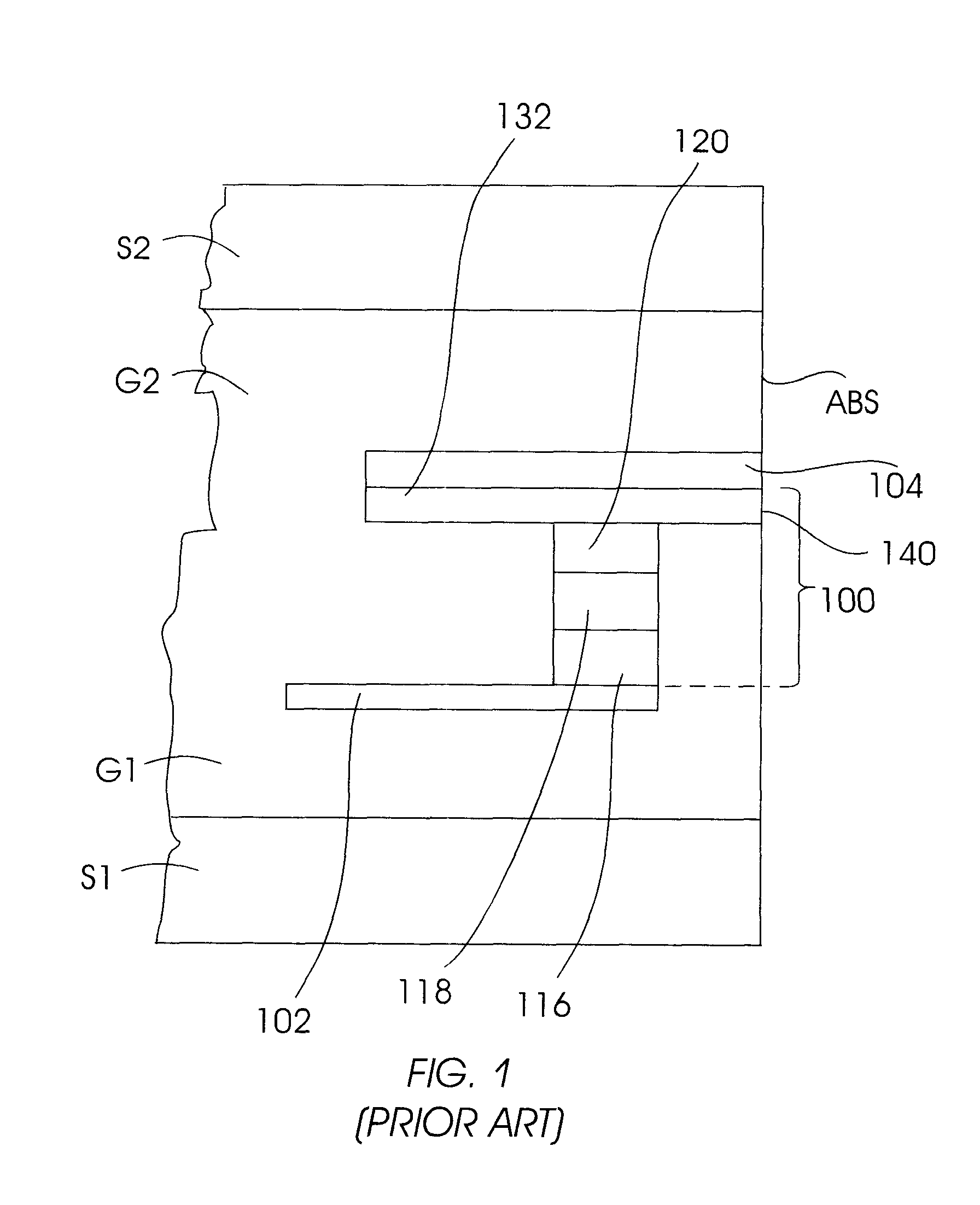

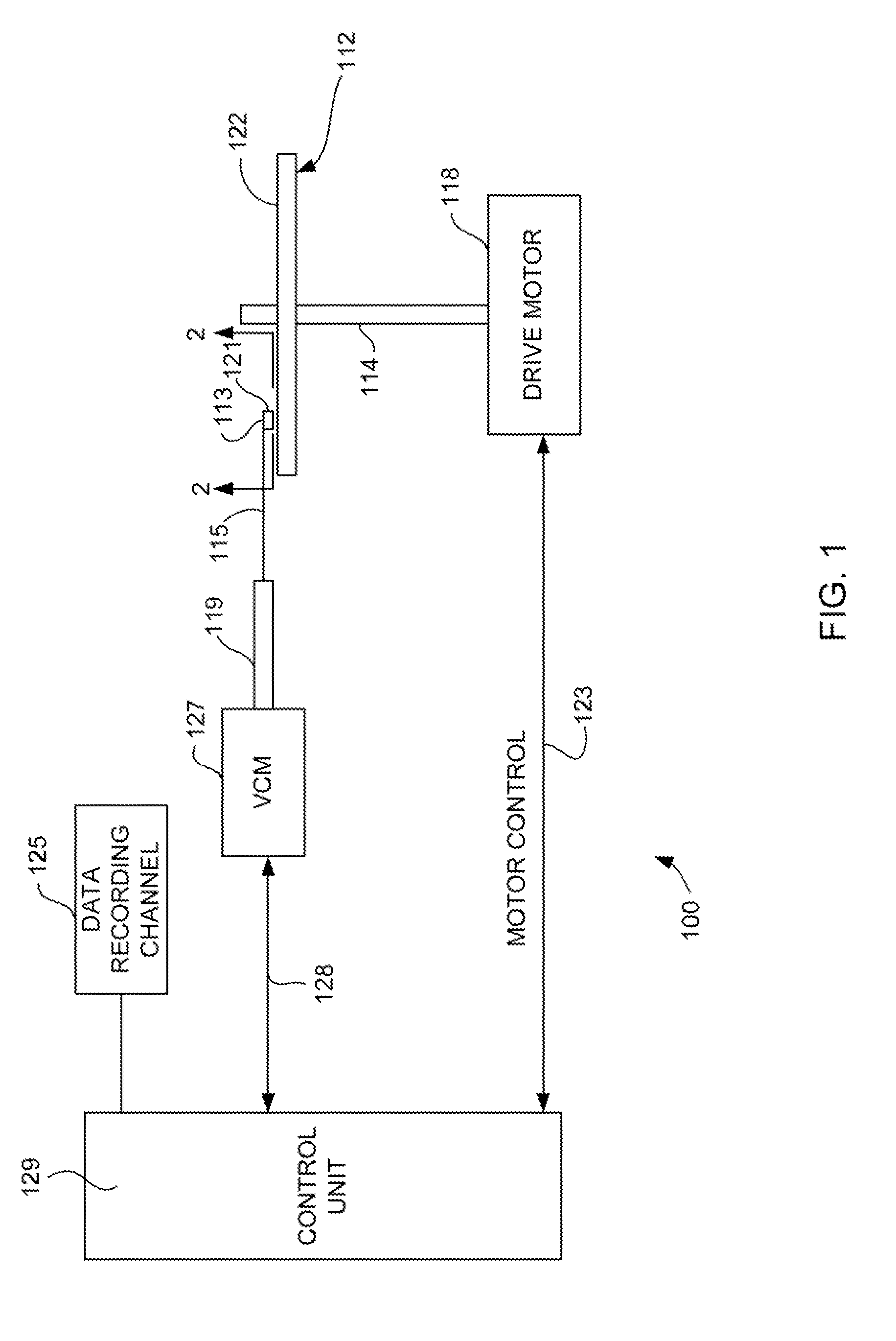

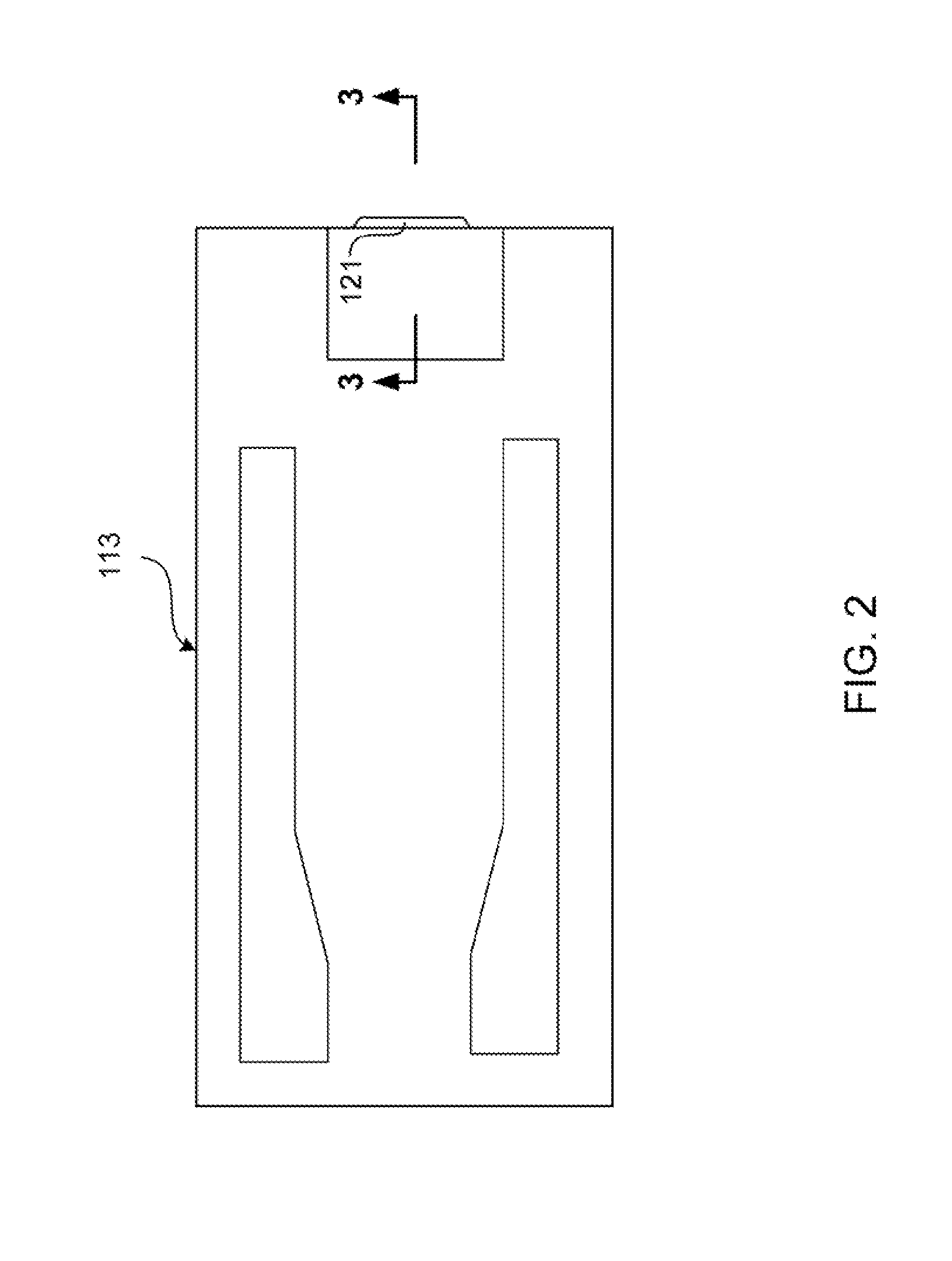

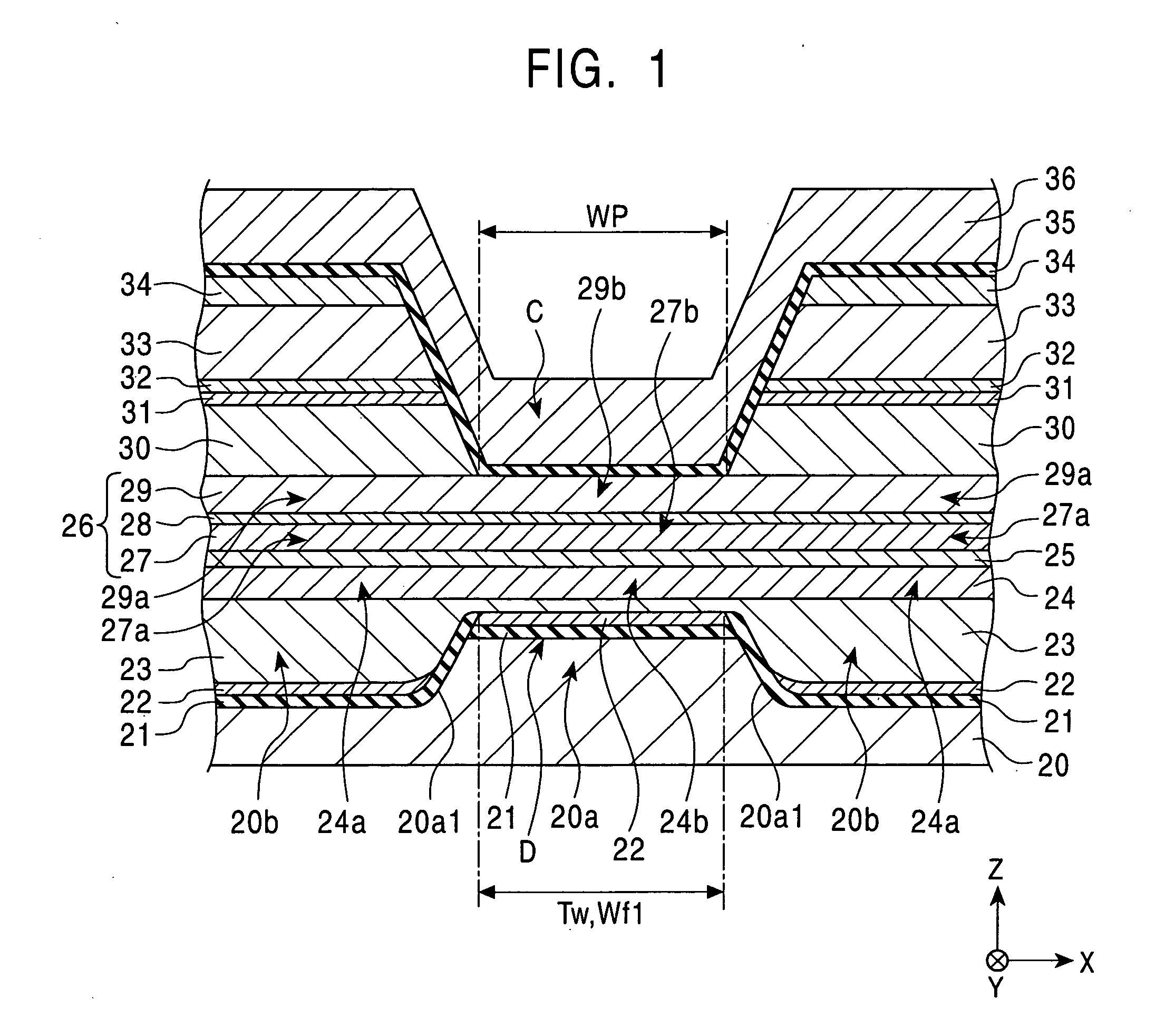

Current perpendicular to plane magnetoresistive sensor having a shape enhanced pinned layer and an in stack bias structure

InactiveUS20070133133A1Strong magnetic anisotropyEasy to fixNanomagnetismMagnetic measurementsCouplingEngineering

A magnetoresistive sensor having an in stack bias structure and a pinned layer having shape enhanced anisotropy. The sensor may be a partial mill design wherein the track width of the sensor is defined by the width of the free layer and the pinned layers extend beyond the trackwidth of the sensor. The sensor has an active area defined by the stripe height of the free layer. The pinned layer extends beyond the stripe height defined by the free layer, thus providing the pinned layer with the shape enhanced anisotropy. The pinned layer structure can be pinned by exchange coupling with a layer of antiferromagnetic material (AFM) layer, with pinning robustness being improved by the shape enhanced anisotropy, or can be a self pinned structure which is pinned by a combination of magnetostriction, AP coupling and shape enhanced anisostropy.

Owner:WESTERN DIGITAL TECH INC

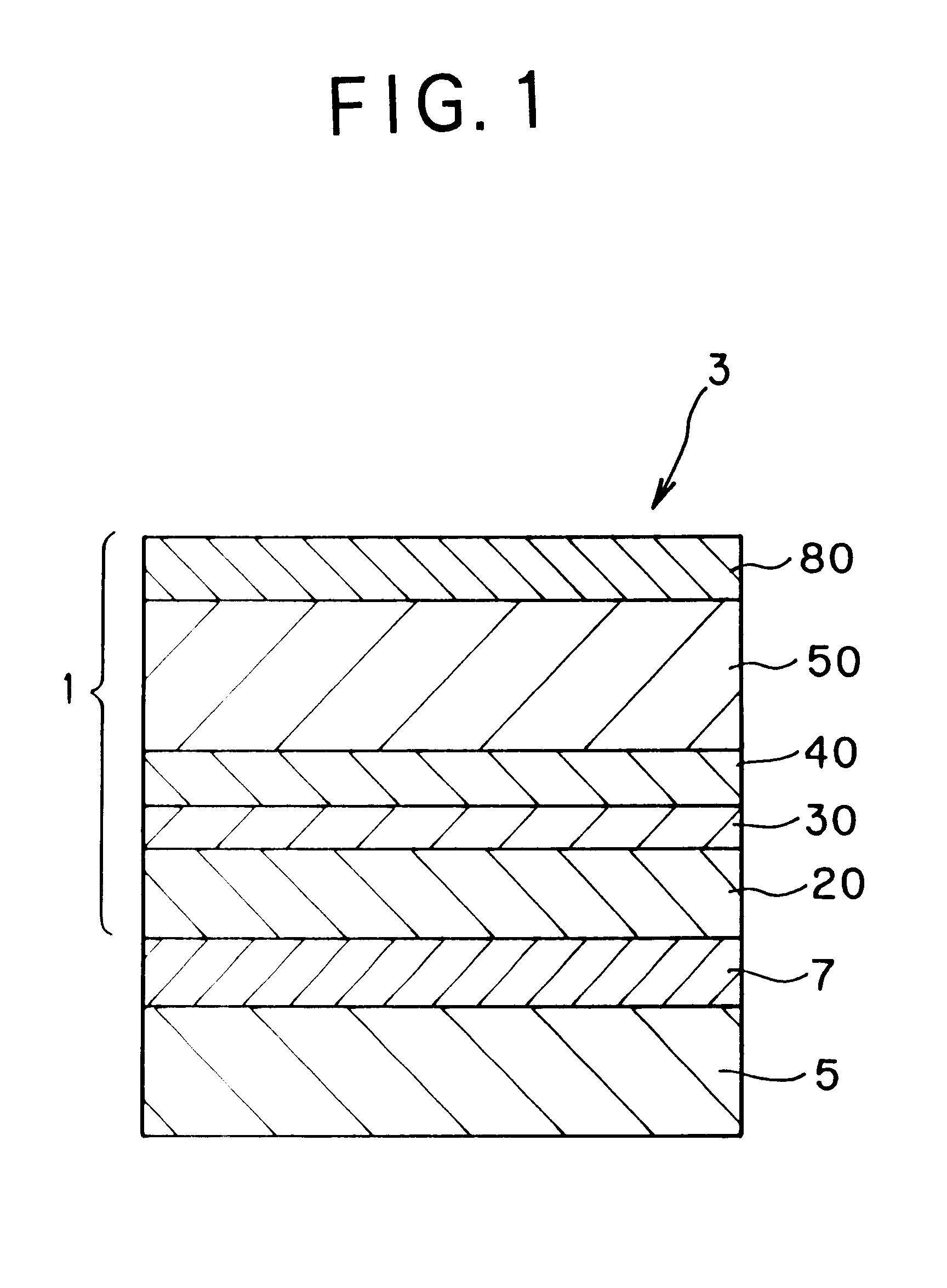

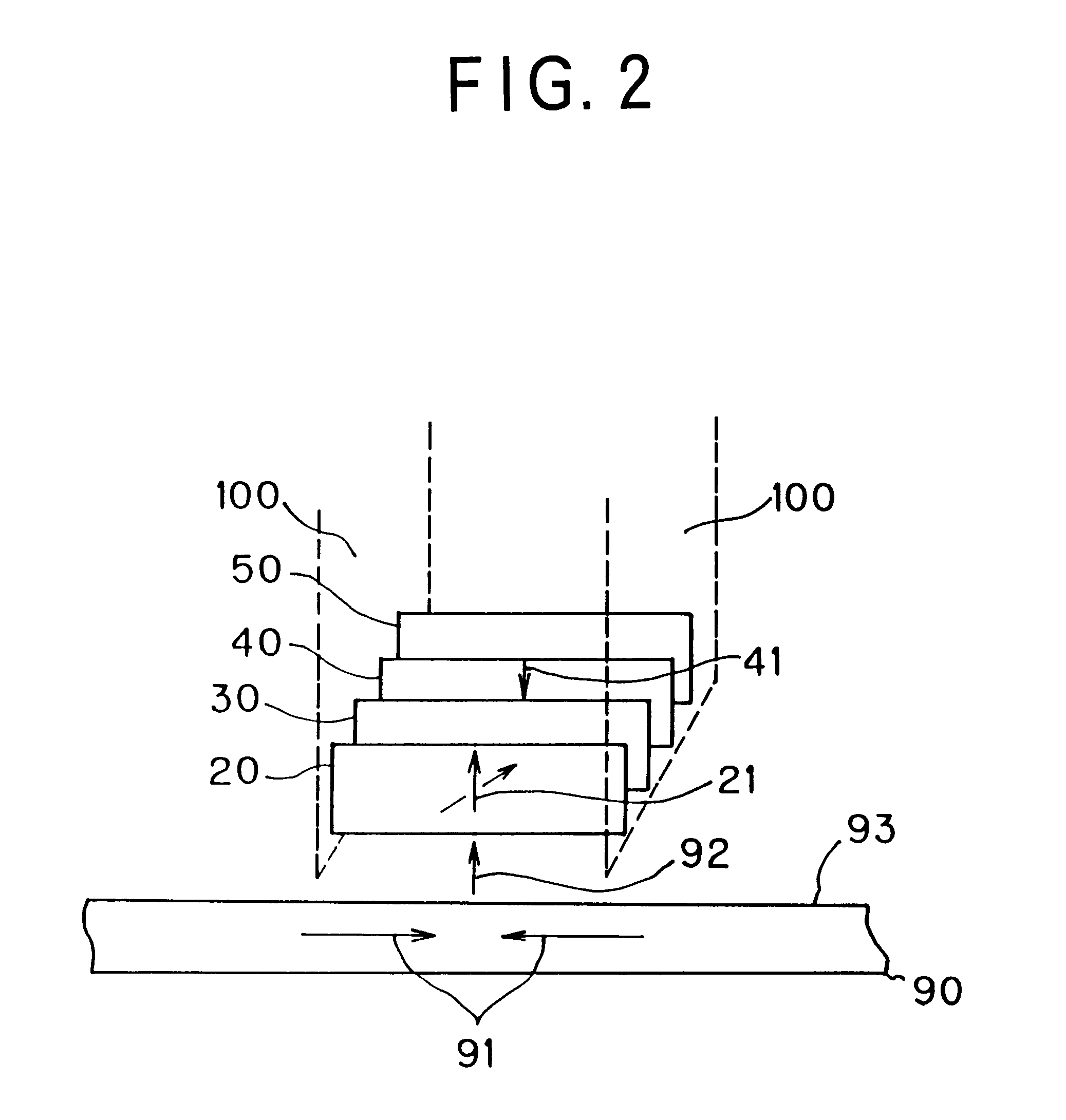

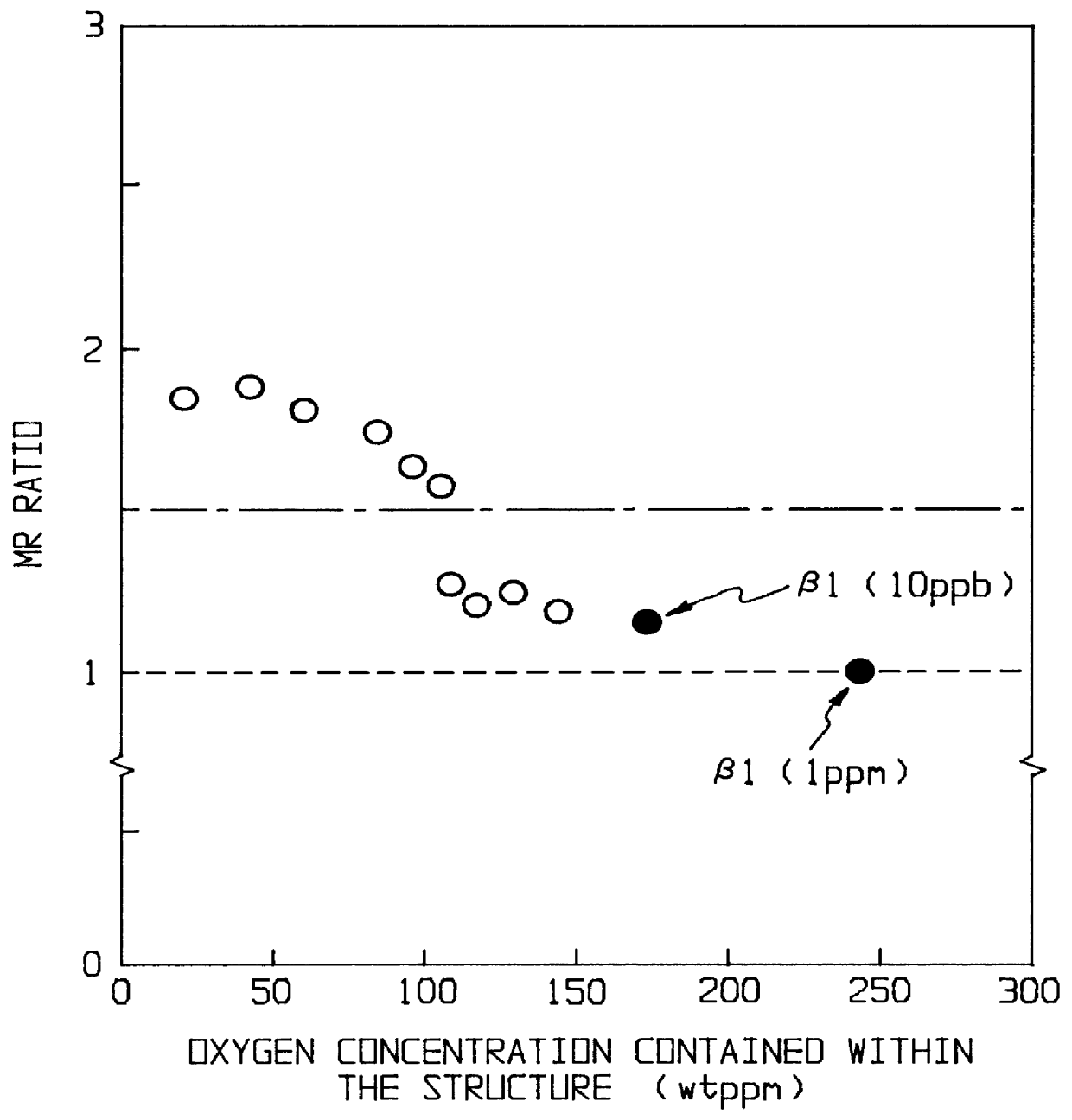

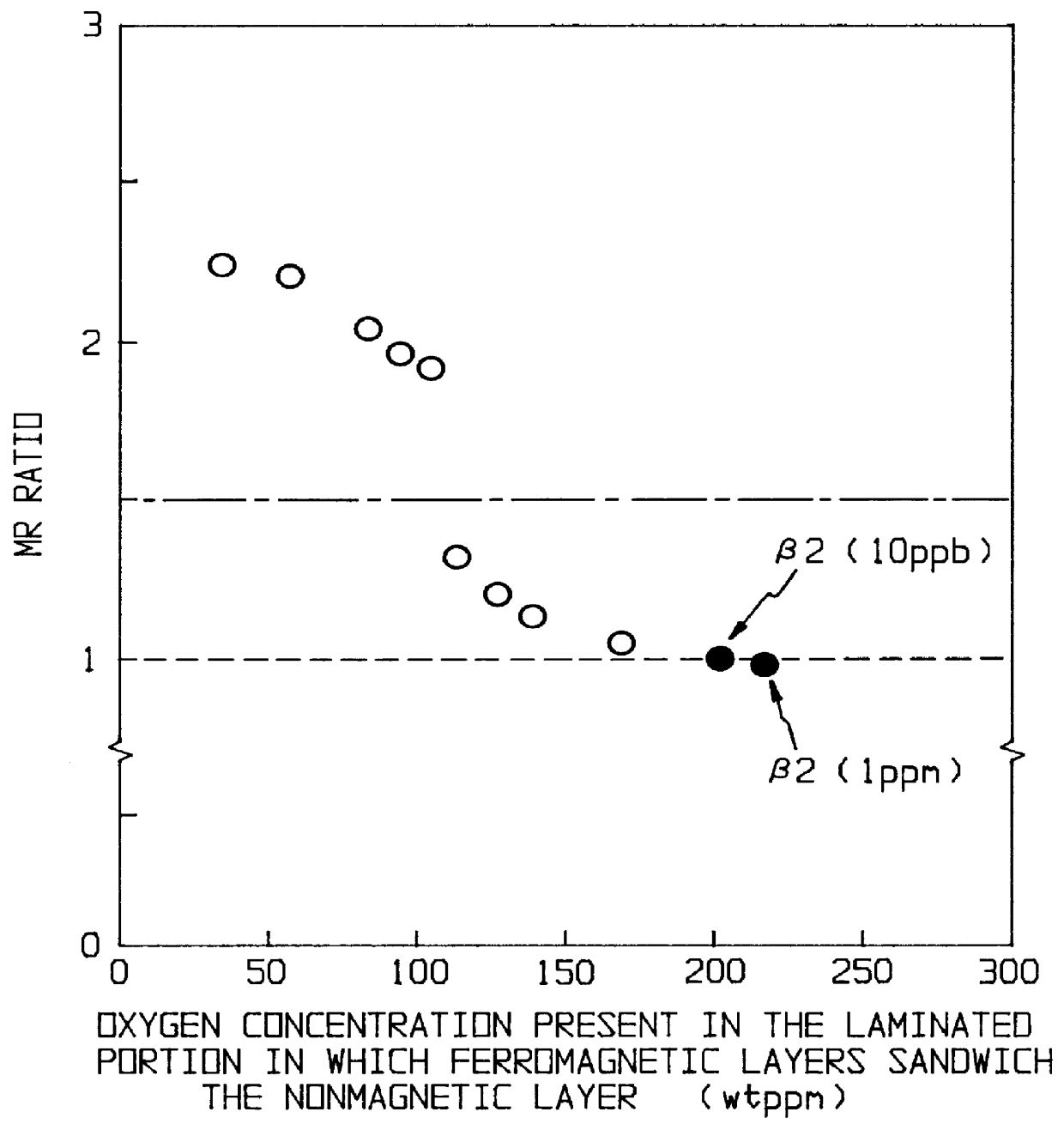

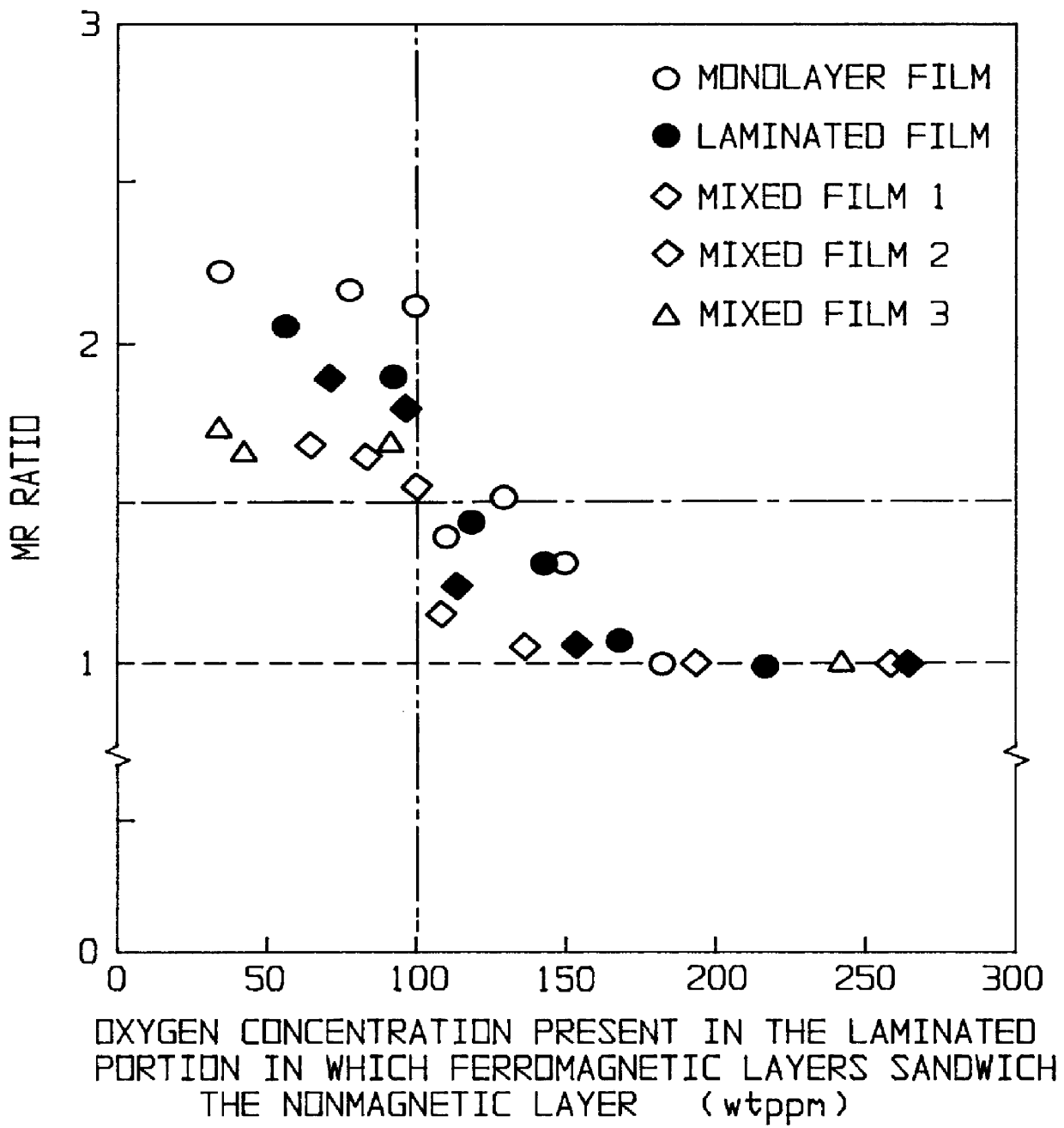

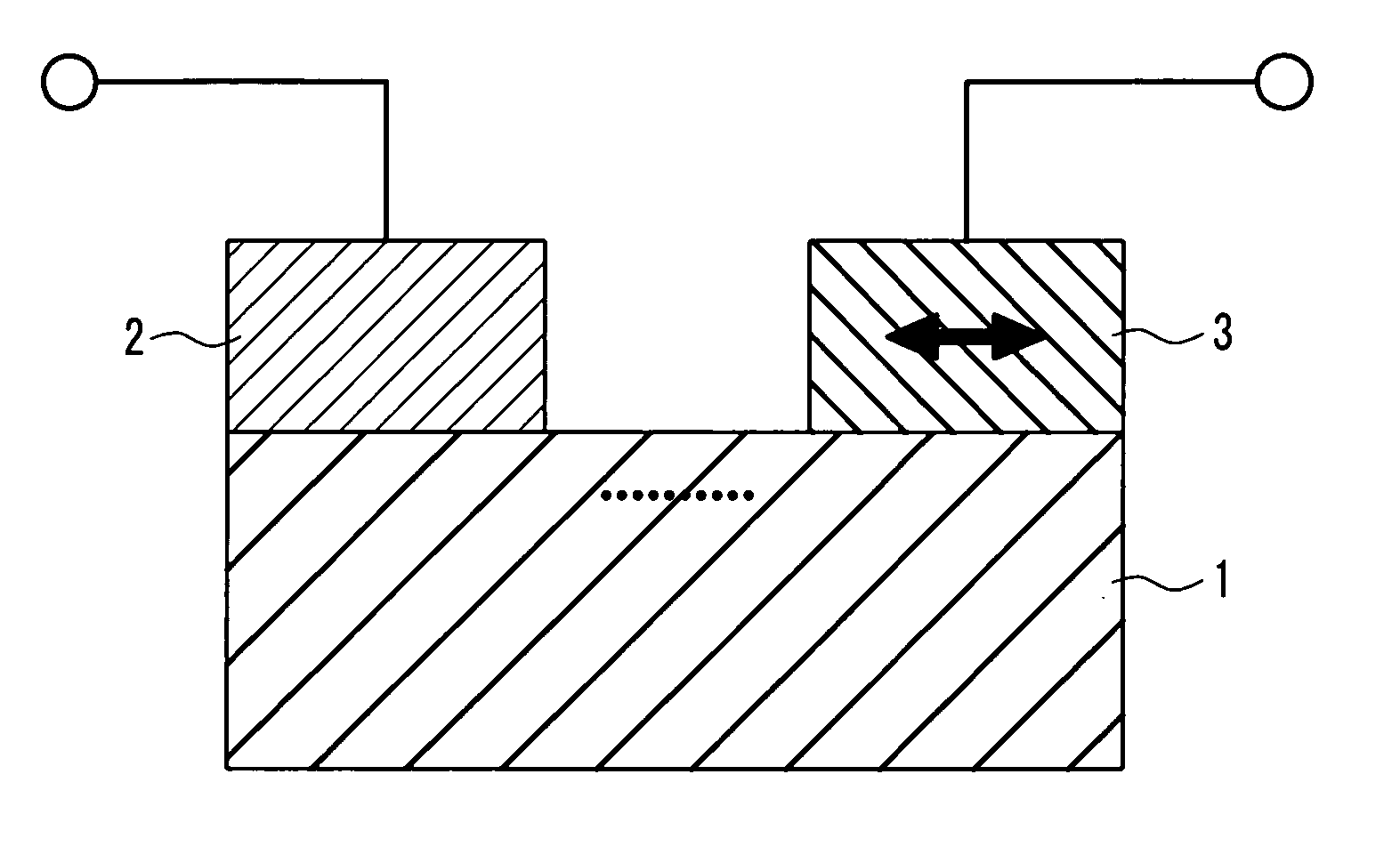

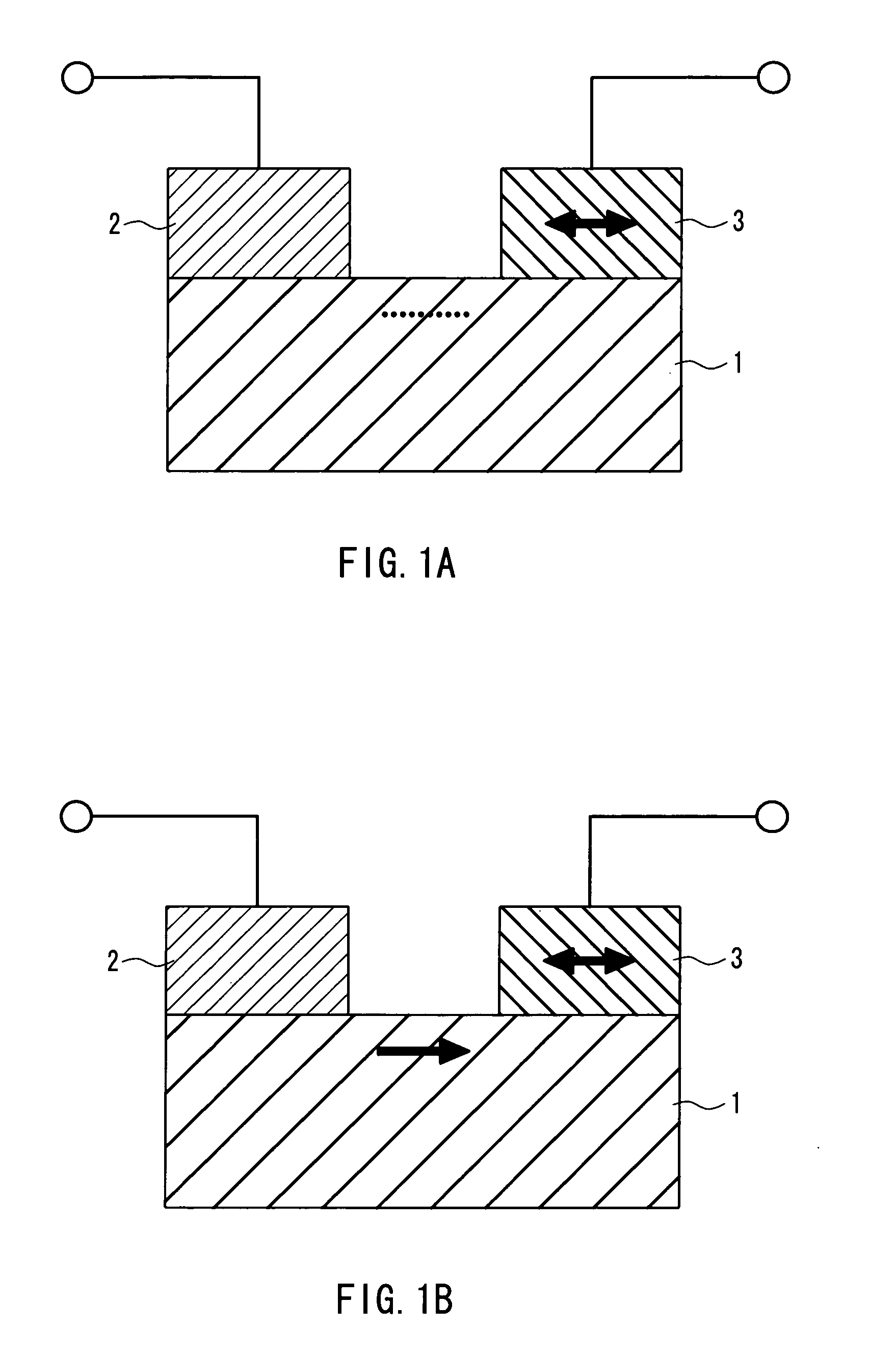

Magnetoresistance element and its manufacture

InactiveUS6051304AEasy to getRaise the ratioNanostructure applicationNanomagnetismMagnetic reluctanceMaterials science

PCT No. PCT / JP96 / 02120 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Jul. 26, 1996 PCT Pub. No. WO97 / 05664 PCT Pub. Date Feb. 13, 1997A magnetoresistance element for reproducing magnetic signals with higher sensitivity and its manufacturing method. The magnetoresistance element has a structure including alternate layers of ferromagnetic material and nonmagnetic material on a substrate, and the oxygen concentration in the structure is less than 100 wt. ppm. Alternatively, the magnetoresistance element comprises a substrate, a nonmagnetic layer on the substrate, a ferromagnetic layer on the nonmagnetic layer on the substrate, a ferromagnetic layer on the nonmagnetic layer, and an antiferromagnetic layer on the ferromagnetic layer, and the oxygen concentration in the part where the ferromagnetic material layers are laminated with the nonmagnetic material layers in between is less than 100 wt. ppm.

Owner:TAKAHASHI MIGAKU

Magnetic switching device and memory using the same

InactiveUS20050122828A1Reduce energy consumptionImprove energy conversion efficiencyMagnetic-field-controlled resistorsSolid-state devicesRare-earth elementAlkaline earth metal

A magnetic switching device of the present invention includes: at least one transition member; at least one electrode; and at least one free magnetic member. The transition member contains a perovskite compound that contains at least a rare earth element and an alkaline-earth metal, the electrode and the free magnetic member are arranged in parallel and in a noncontact manner on the transition member, at least one of the free magnetic members is coupled magnetically with the transition member, and the transition member undergoes at least ferromagnetism-antiferromagnetism transition by injecting or inducing electrons or holes, whereby a magnetization direction of at least one of the free magnetic members changes. This configuration is applicable to a magnetic memory that records / reads out magnetization information of the free magnetic layer and various magnetic devices that utilize a resistance change of the magnetoresistive effect portion.

Owner:PANASONIC CORP +1

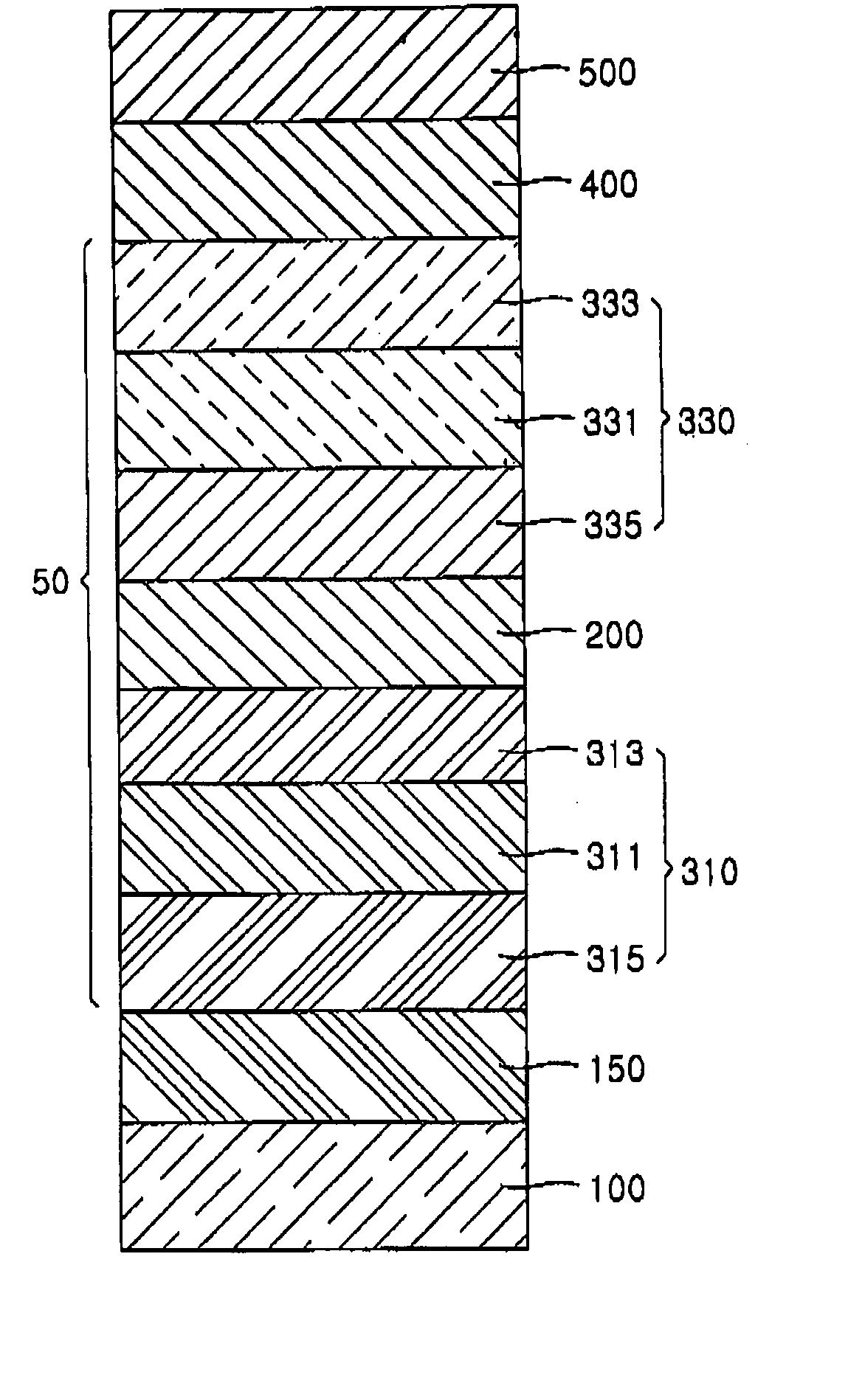

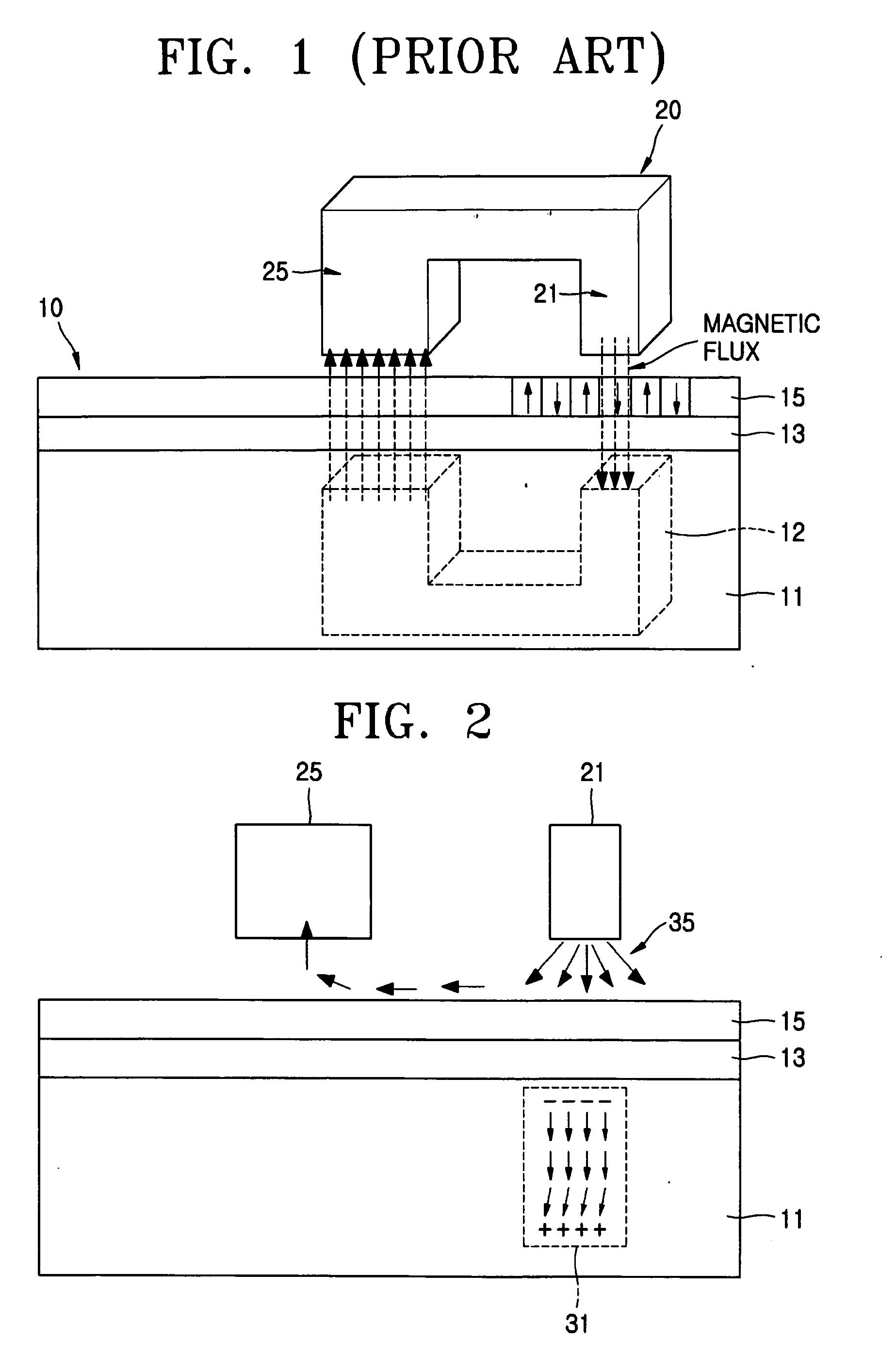

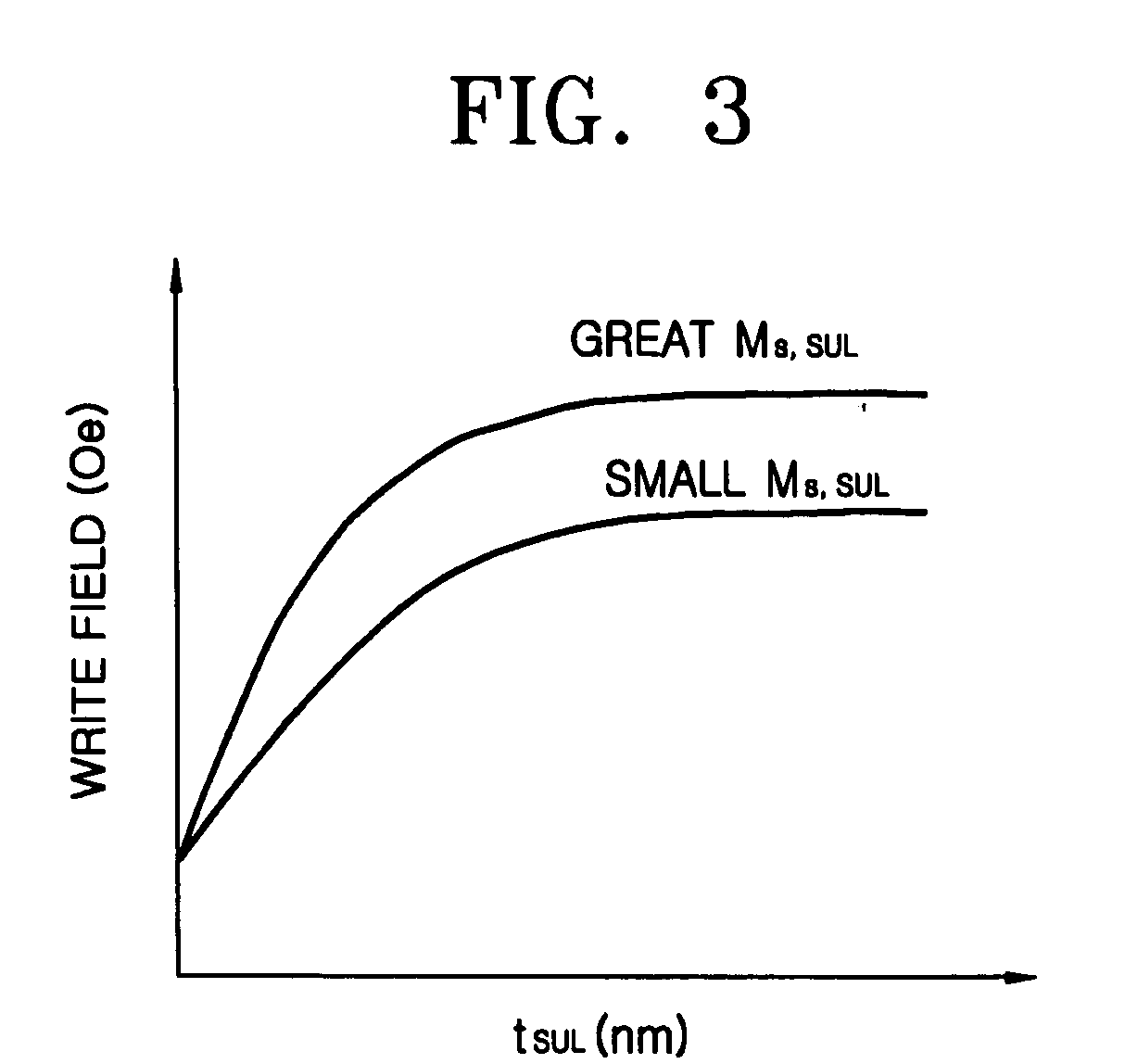

Perpendicular magnetic recording media with laminated soft magnetic underlayer

InactiveUS20060093865A1Suppress magnetic domain noiseImprove write performanceRecord information storageMagnetic recordingNon magneticRecording layer

A recording medium including a perpendicular magnetic recording layer and a laminated SUL formed on a substrate is provided. The SUL includes an antiferromagnetic layer interposed between laminated structures including a magnetic layer, a non-magnetic layer and a magnetic layer. The layers may each have a thickness of 20 nm or less and the layers below the antiferromagnetic layer may be thinner than the layers on the antiferromagnetic layer. The laminated structures formed on and below the antiferromagnetic layer have unidirectional magnetic anisotropies set in the opposite radial direction to each other by an exchange bias. As a result, media magnetic domain noise can be diminished.

Owner:SAMSUNG ELECTRONICS CO LTD

Magnetic-particle photocatalyst with core-shell structure, preparation and application thereof

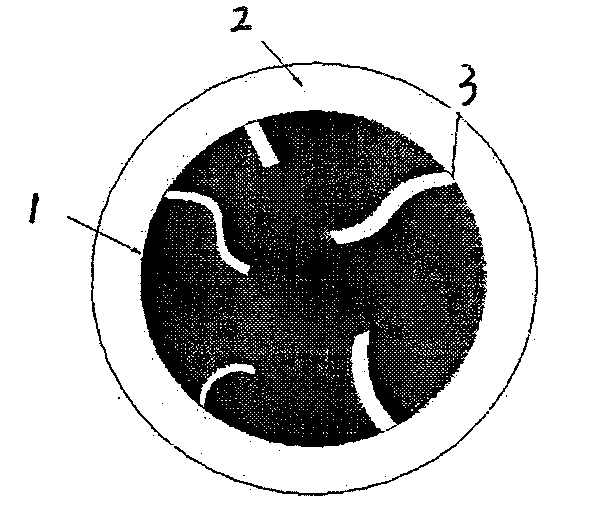

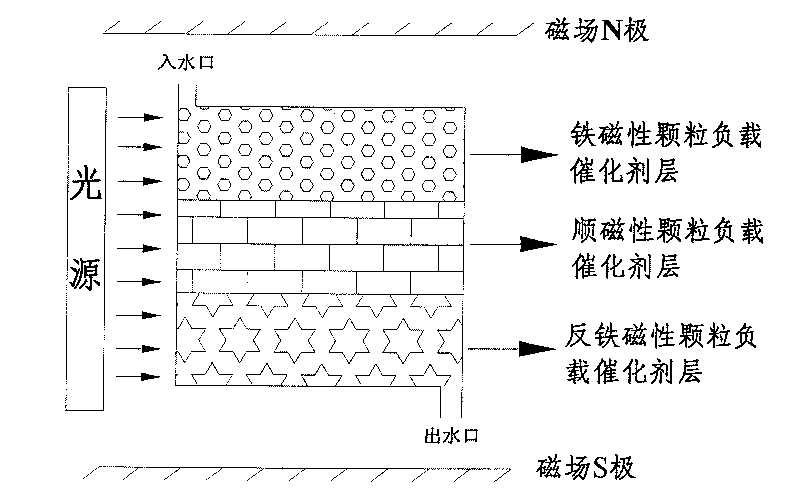

ActiveCN101757926AFacilitate Gradient DistributionImprove degradation efficiencyWater/sewage treatment by irradiationWater contaminantsParamagnetismFerromagnetism

Magnetic-particle photocatalyst with a core-shell structure takes a ferromagnetism particle, a paramagnetism particle or a diamagnetism particle as a core, and photocatalyst as a shell. The ferromagnetism, paramagnetism or diamagnetism particles are gamma-Fe2O3, SiO2 or MnO particle respectively, and the photocatalyst is Gd3-xBixSbO7, Gd3-xYxSbO7 and In3-xBixTaO7 respectively, wherein the grain diameter of the gamma-Fe2O3, SiO2 and MnO is 80-2,000nm. Water-treatment is carried out on the photocatalyst in a magnetic field-photocatalytic system, and the periphery of a reaction system for water-treatment is provided with an alternating magnetic field generator with adjustable magnetic field intensity, wherein the range of the magnetic field intensity is 0-15T, and radiation light sources of the reaction system adopt a 300W xenon lamp and a 400W high-voltage mercury lamp; the ferromagnetism particle, paramagnetism particle and diamagnetism particle respectively account for 33+ / -10% in themagnetic-particle core for coating the photocatalyst, and are completely and uniformly dispersed in aqueous solution, thus the composite photocatalyst is uniformly distributed in the upper, middle and lower layers of the aqueous solution.

Owner:NANJING UNIV

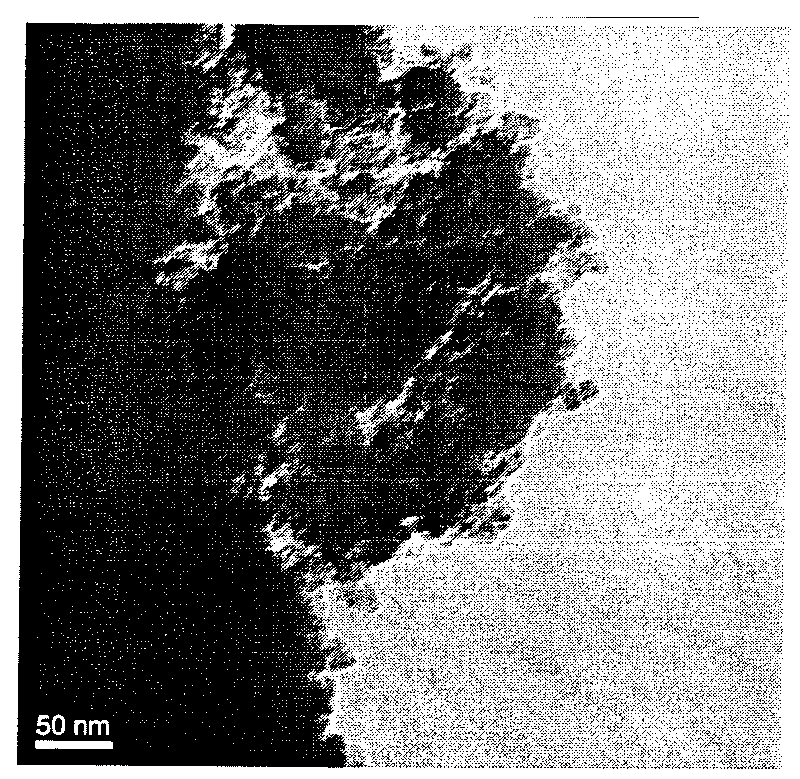

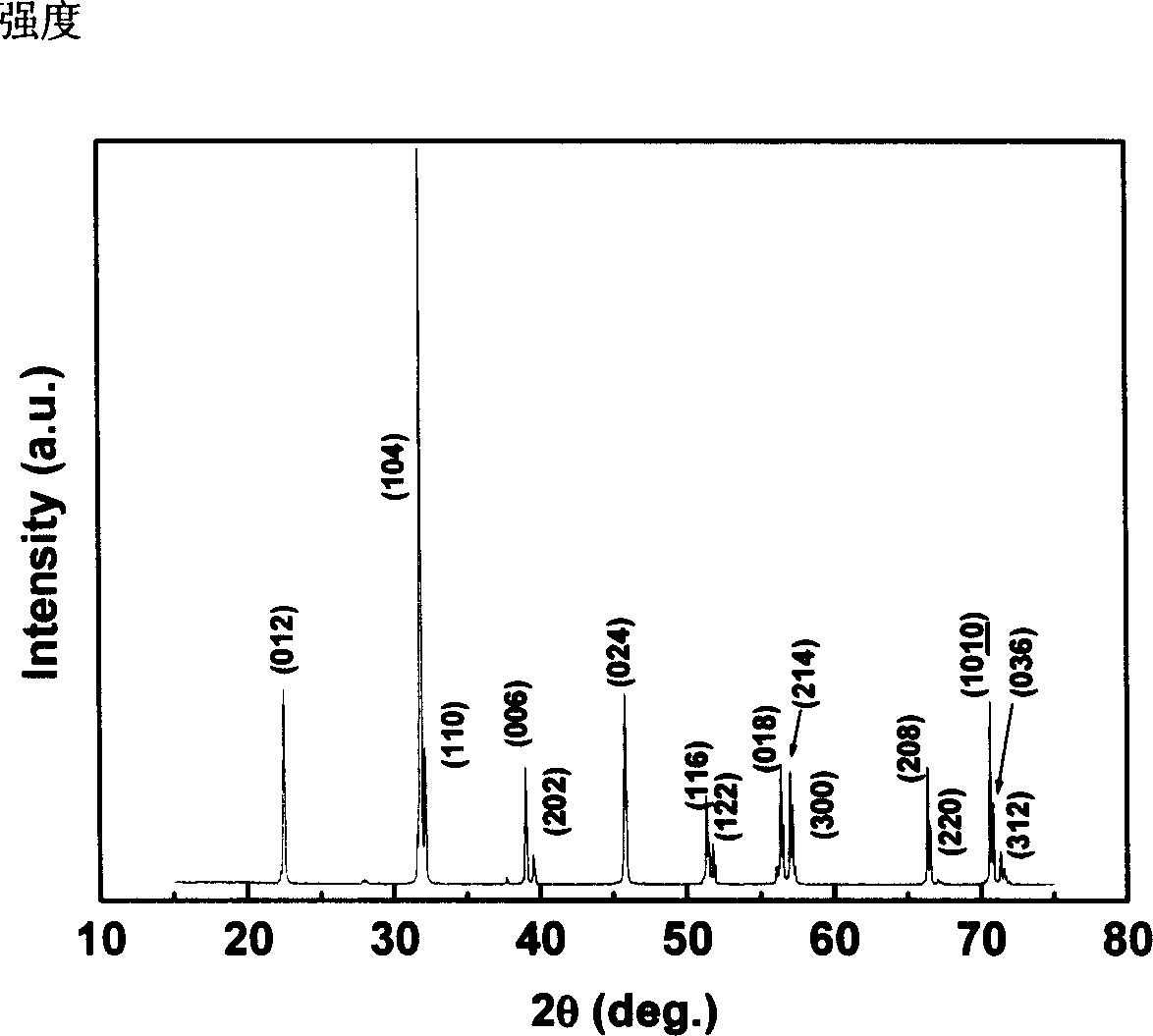

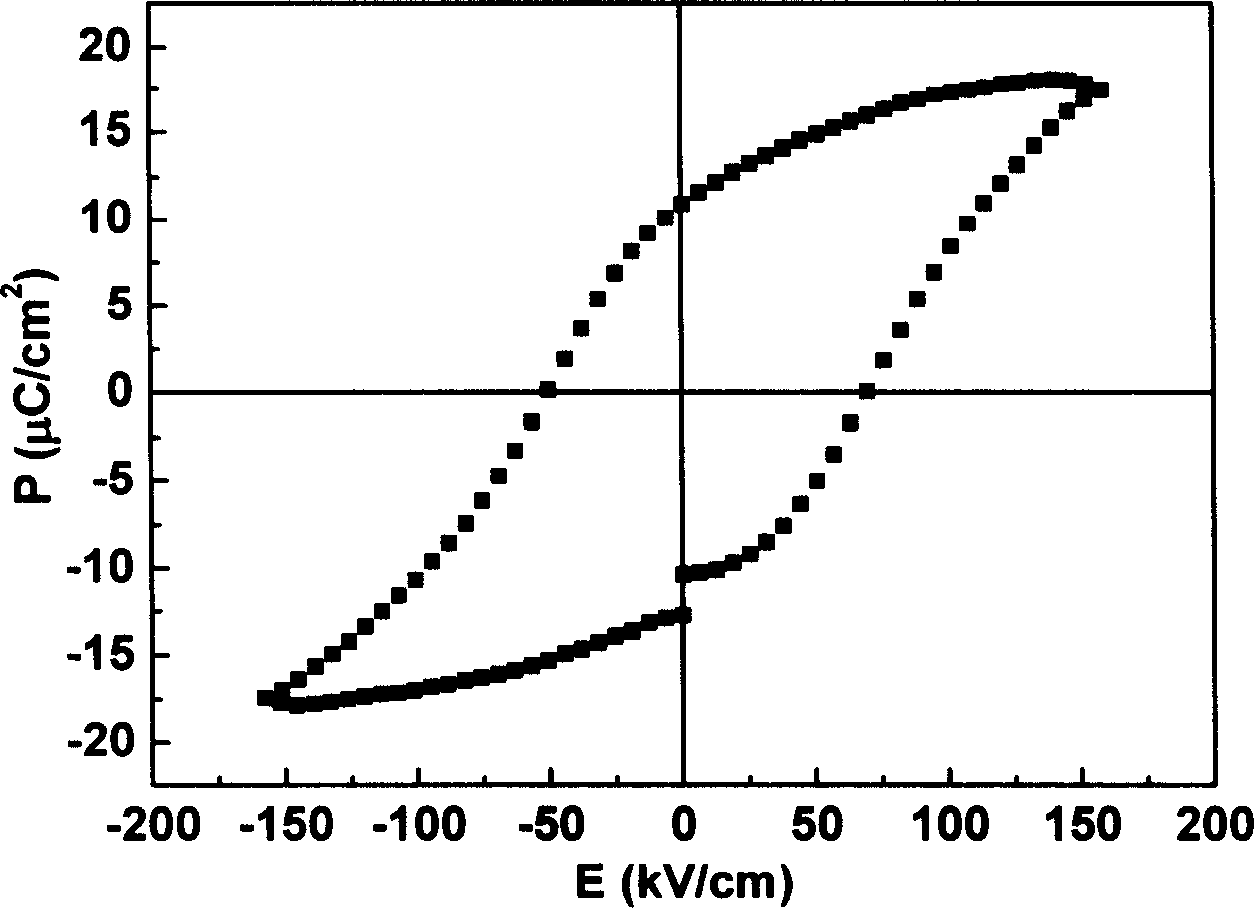

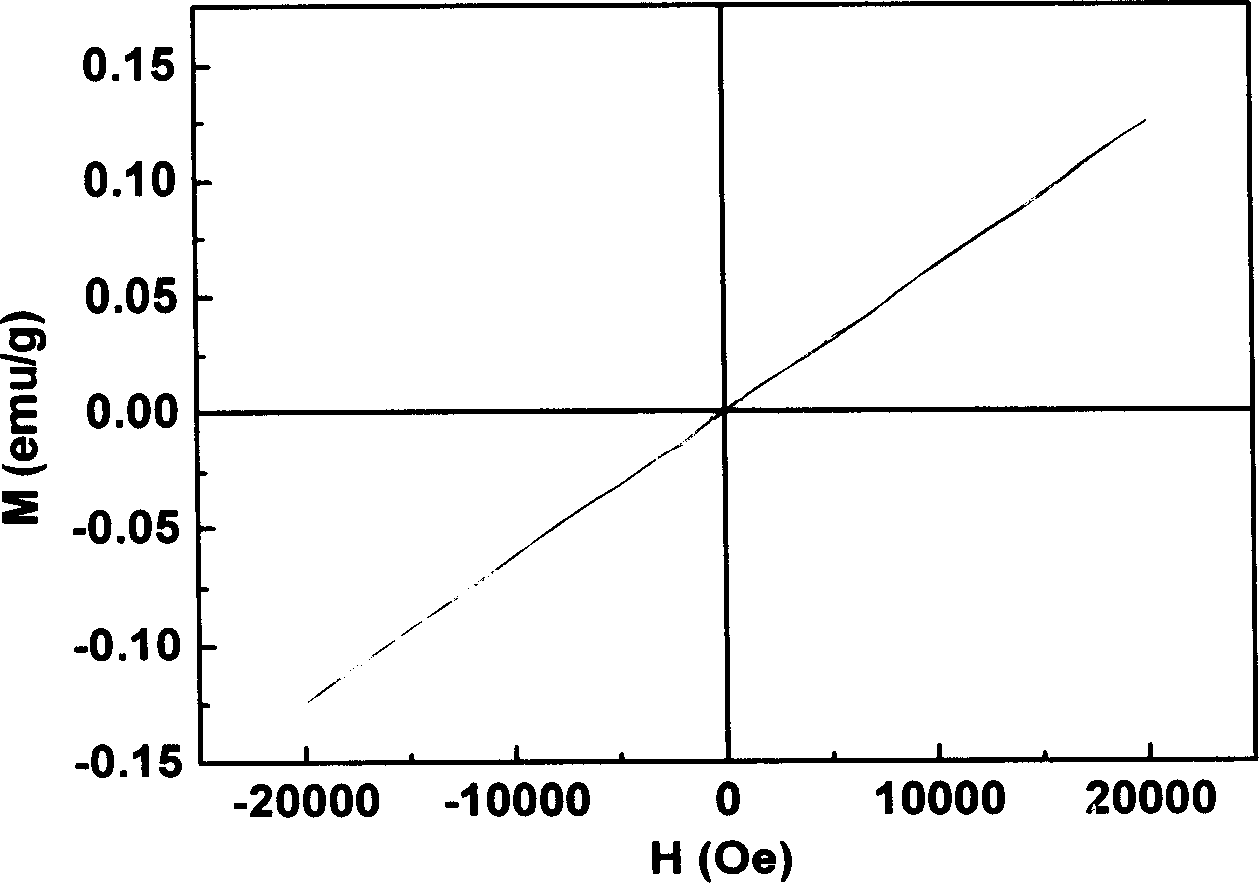

Method for preparing single-phase BiFeO3 ceramics through hardening process

InactiveCN1686932AImprove insulation performanceImprove ferroelectric propertiesCrucibleHeating furnace

The present invention relates to a method for preparing single-phase BiFeO3 ceramic by utilizing quenching process. It is characterized by quickly cooling sintered BiFeO3 ceramic. Said method includes the following steps: weighing Bi2O3 powder and Fe2O3 powder according to the mole ratio of 1:1, ball-grinding for 4-12 hr according to 100-500 rpm, uniformly mixing two powdes, drying the above-mentioned mixed powder, pressing the mixed powder into thin sheet, then placing proper quantity of the above-mentioned mixed powder into Al2O3 crucible, placing the thin sheet into the crucible, and using correspondent powder to cover the thin shet to make the thin sheet and powder be in sealed state, then placing the above-mentioned crucible into heating furnace, heating to sintering temperature, heating speed is 2-8 deg.C / min, sintering temperature is 830-920 deg.C and sintering time is 30-60 min., after sintering process is completed, promptly quenching so as to obtain the invented product.

Owner:NANJING UNIV

CPP giant magnetoresistive head with large-area metal film provided between shield and element

InactiveUS7327539B2Reduce noiseConstant thicknessMagnetic-field-controlled resistorsHeads using thin filmsMagnetizationNon magnetic

A CPP giant magnetoresistive (GMR) head includes lower and upper shield layers; and a GMR element disposed between the upper and lower shield layers and comprising a pinned magnetic layer, a free magnetic layer, and a nonmagnetic layer disposed between the pinned magnetic layer and the free magnetic layer. Nonmagnetic metal films are provided directly above the lower shield layer and below the upper shield layer making direct contact with and having larger areas than the pinned magnetic layer and the free magnetic layer, respectively. An antiferromagnetic layer is provided in the rear of the GMR element in the height direction, for pinning the magnetization direction of the pinned magnetic layer. Alternatively, the dimension of the pinned magnetic layer in the height direction is larger than the dimension in the track width direction so that the magnetization direction of the pinned magnetic layer is stabilized without using an antiferromagnetic layer.

Owner:TDK CORPARATION

Magnetic stack having reduced switching current

InactiveUS20100091564A1NanomagnetismMagnetic-field-controlled resistorsSwitched currentMagnetic memory

A magnetic stack having a ferromagnetic free layer, a ferromagnetic pinned reference layer, a non-magnetic spacer layer between the free layer and the reference layer, and a variable layer proximate the free layer. The variable layer is antiferromagnetic at a first temperature and paramagnetic at a second temperature higher than the first temperature. During a writing process, the variable layer is paramagnetic. For magnetic memory cells, such as magnetic tunnel junction cells, the variable layer provides reduced switching currents.

Owner:SEAGATE TECH LLC

Spin polarization enhancement artificial magnet

InactiveUS7099122B2Increased polarizationImprove stabilityNanoinformaticsRecord information storageSpinsElectron scattering

A spin polarization enhancement artificial (SPEA) magnet comprises combinations of positive spin asymmetry interfaces and inverse spin asymmetry interfaces arranged antiferromagnetically such that current passed through the SPEA magnet has enhanced spin polarization. The SPEA magnet additionally may combine bulk material properties of electron scattering to either supplement or replace the interfacial spin differentiation. A basic functional unit of the SPEA magnet includes two ferromagnetic layers separated by two spacer layers. Each spacer forms an interface such that adjacent ferromagnetic layers produce different spin symmetry. Antiferromagnetic arrangement of adjacent ferromagnetic layers coordinates the different spin symmetries such that a single spin state is selected and also provides additional stabilization to the SPEA magnet.

Owner:SEAGATE TECH LLC

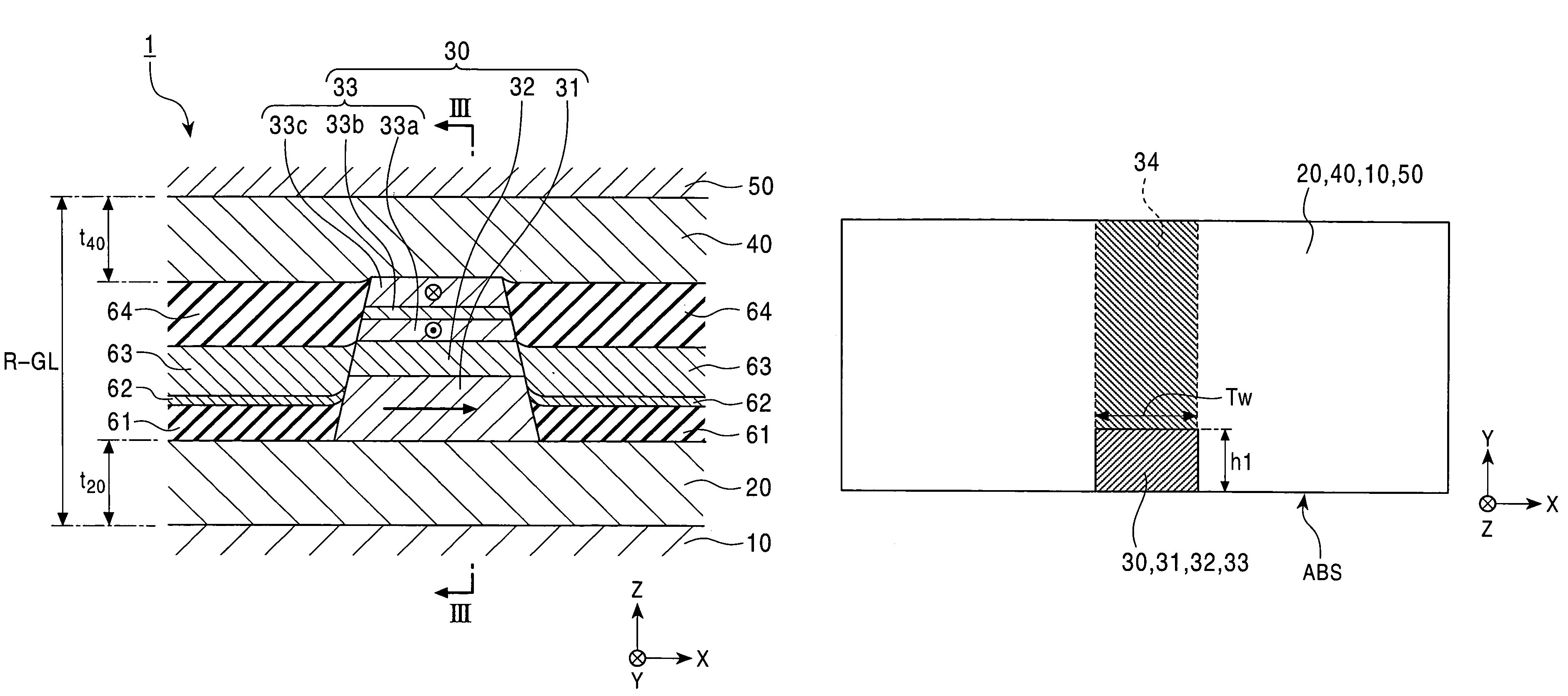

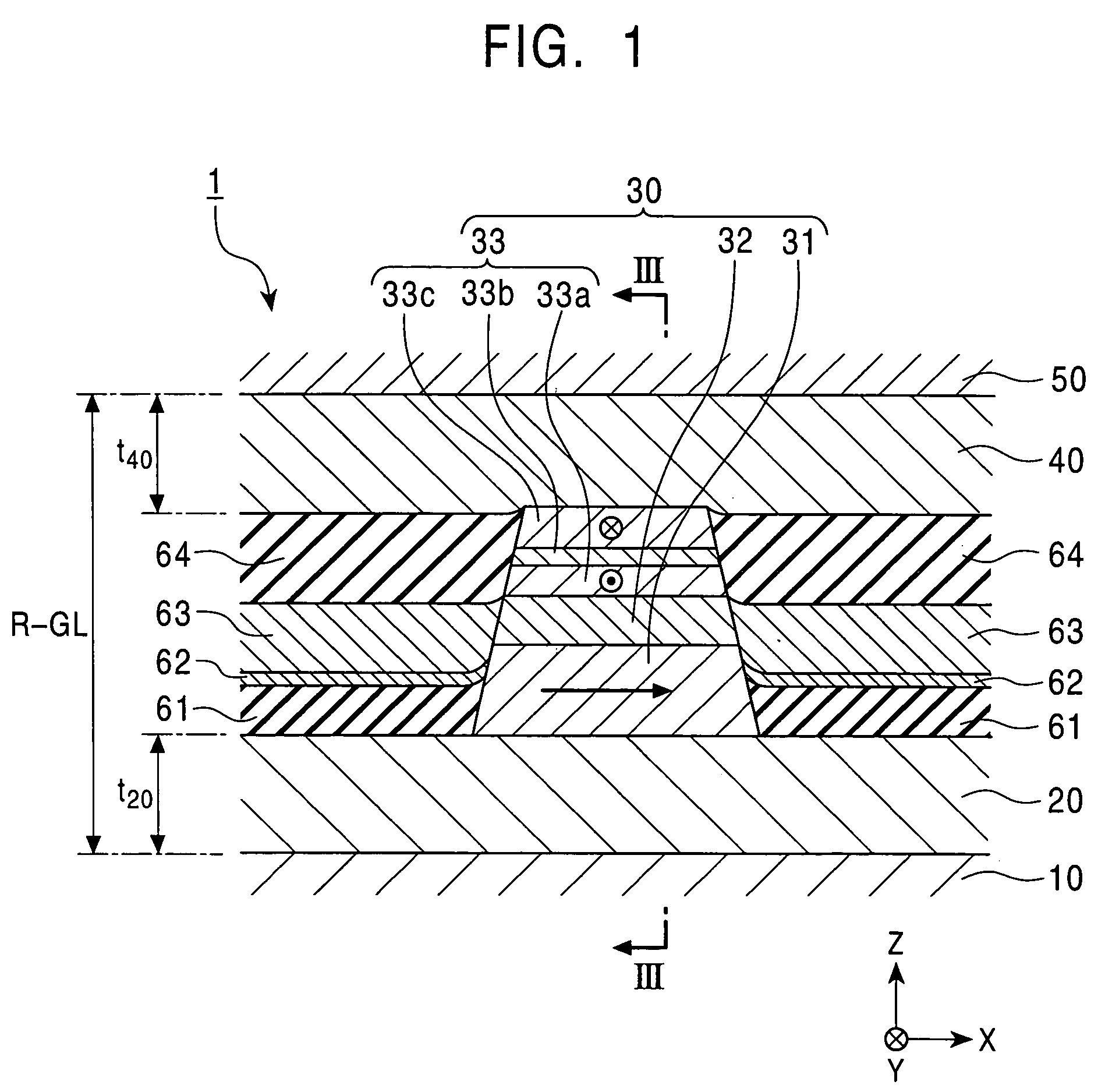

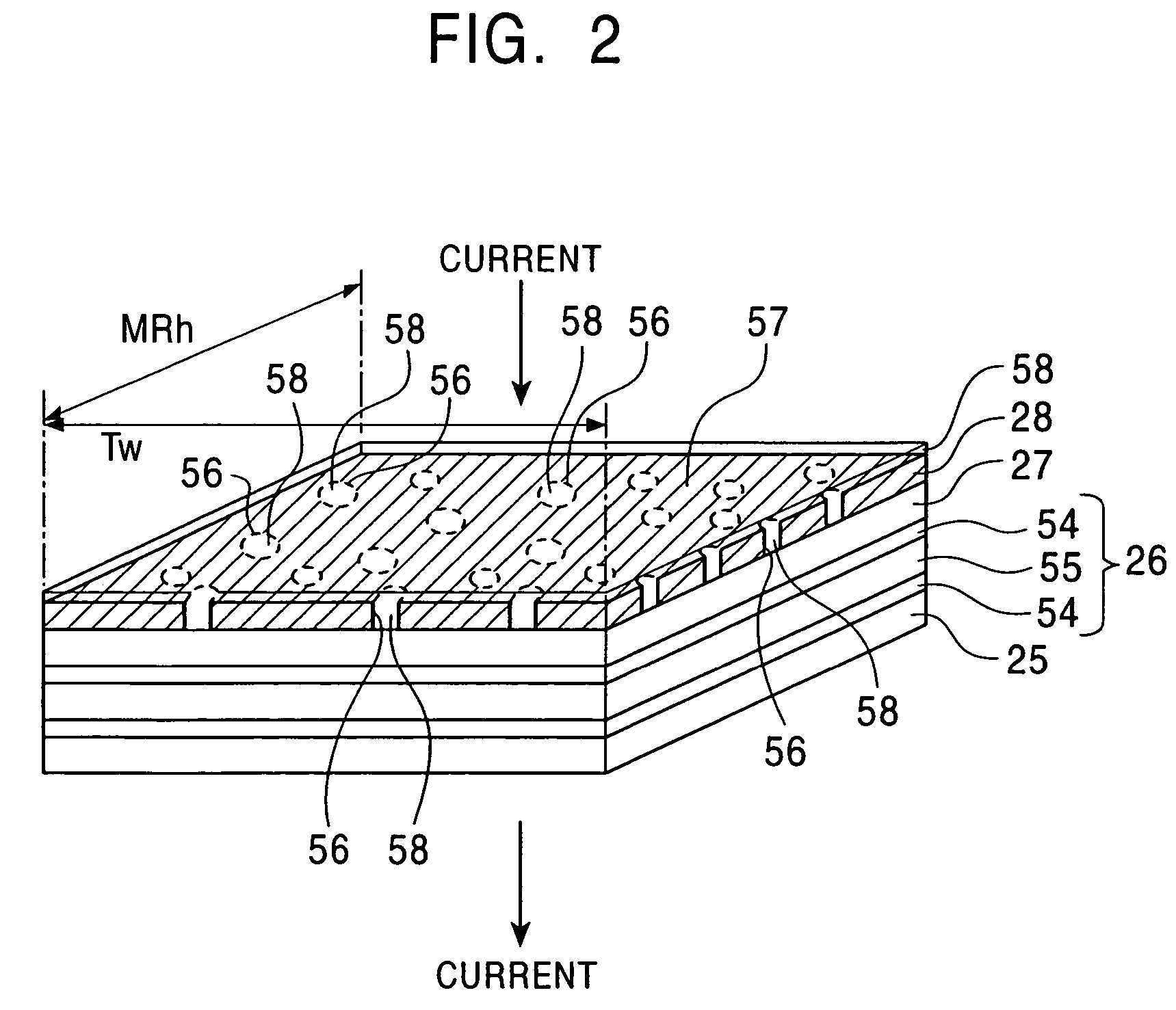

GMR magnetic sensing element having an antiferromagnetic layer extending beyond the track width and method for making the same

InactiveUS7372672B2High outputQuality improvementNanomagnetismNanoinformaticsMagnetic layerAntiferromagnetism

A magnetic sensing element with improved magnetic detection output and a method for making the same are provided. In the magnetic sensing element, the length of an upper pinned magnetic layer an upper antiferromagnetic layer in a track width direction is larger than the length of a free magnetic layer in the track width direction. In making the magnetic sensing element, there is no need to remove side portions of the upper pinned magnetic layer and the upper antiferromagnetic layer. The materials of the upper pinned magnetic layer and the upper antiferromagnetic layer are thus prevented from redepositing on two side faces of the free magnetic layer during milling.

Owner:TDK CORPARATION

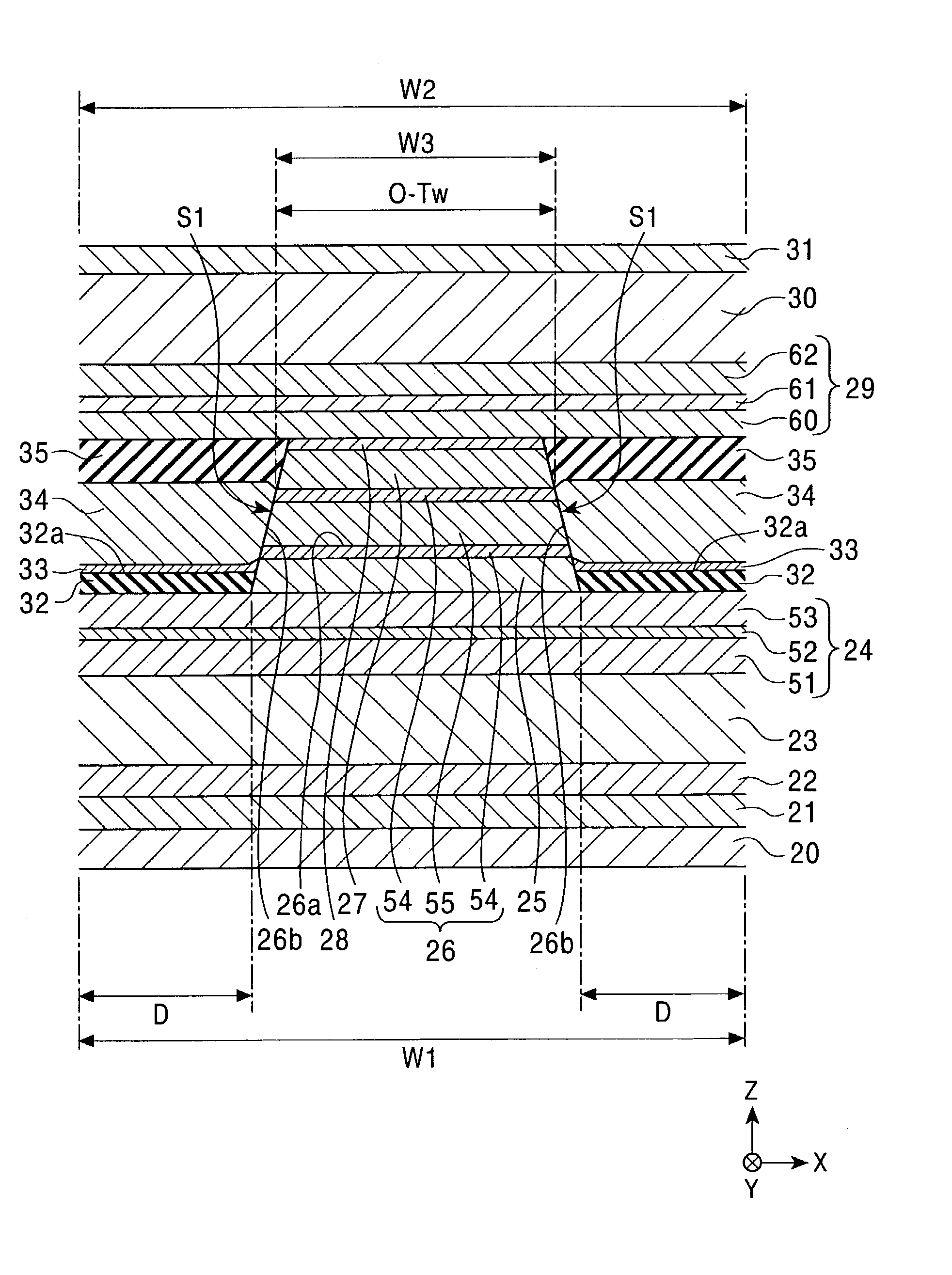

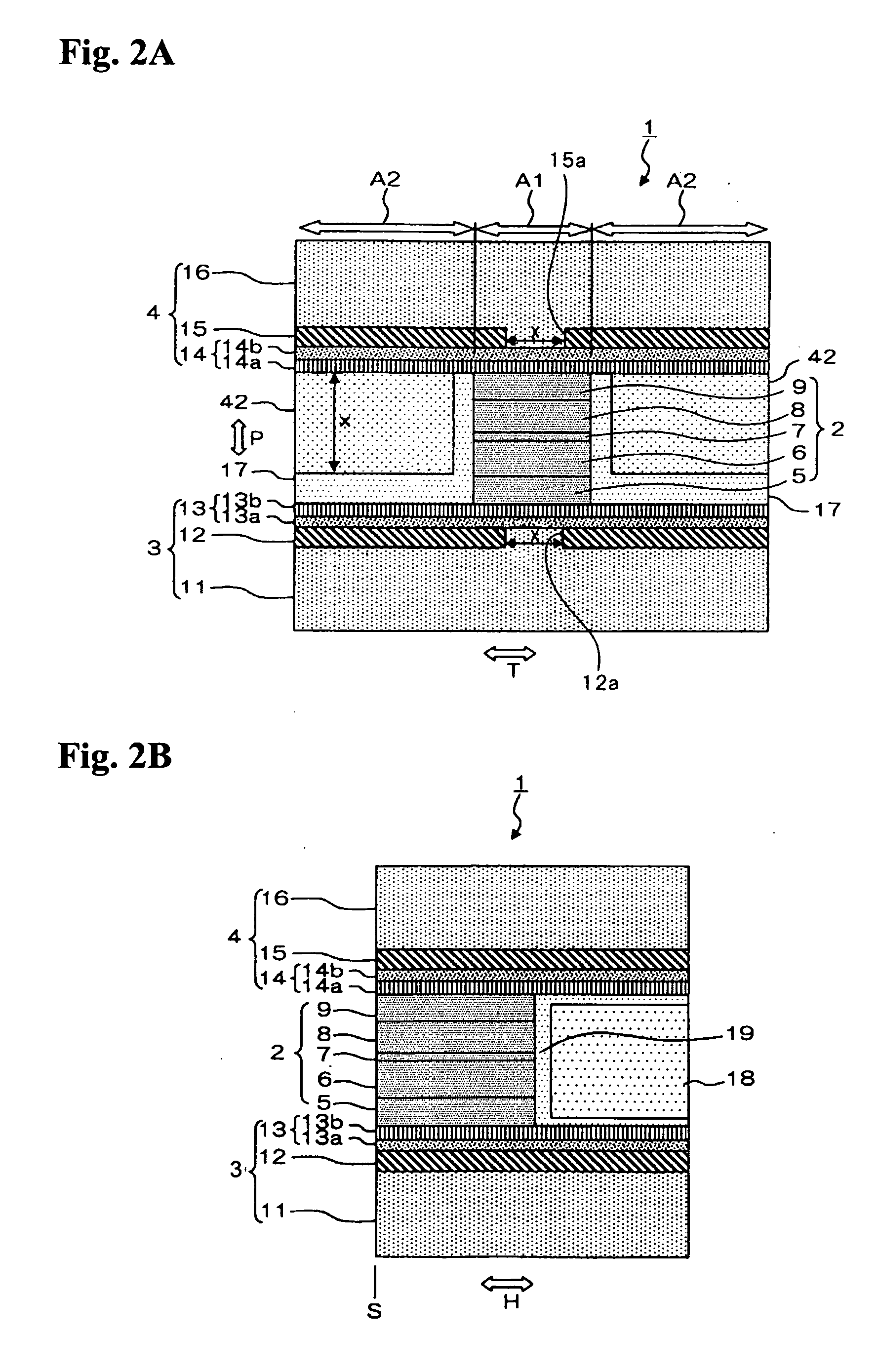

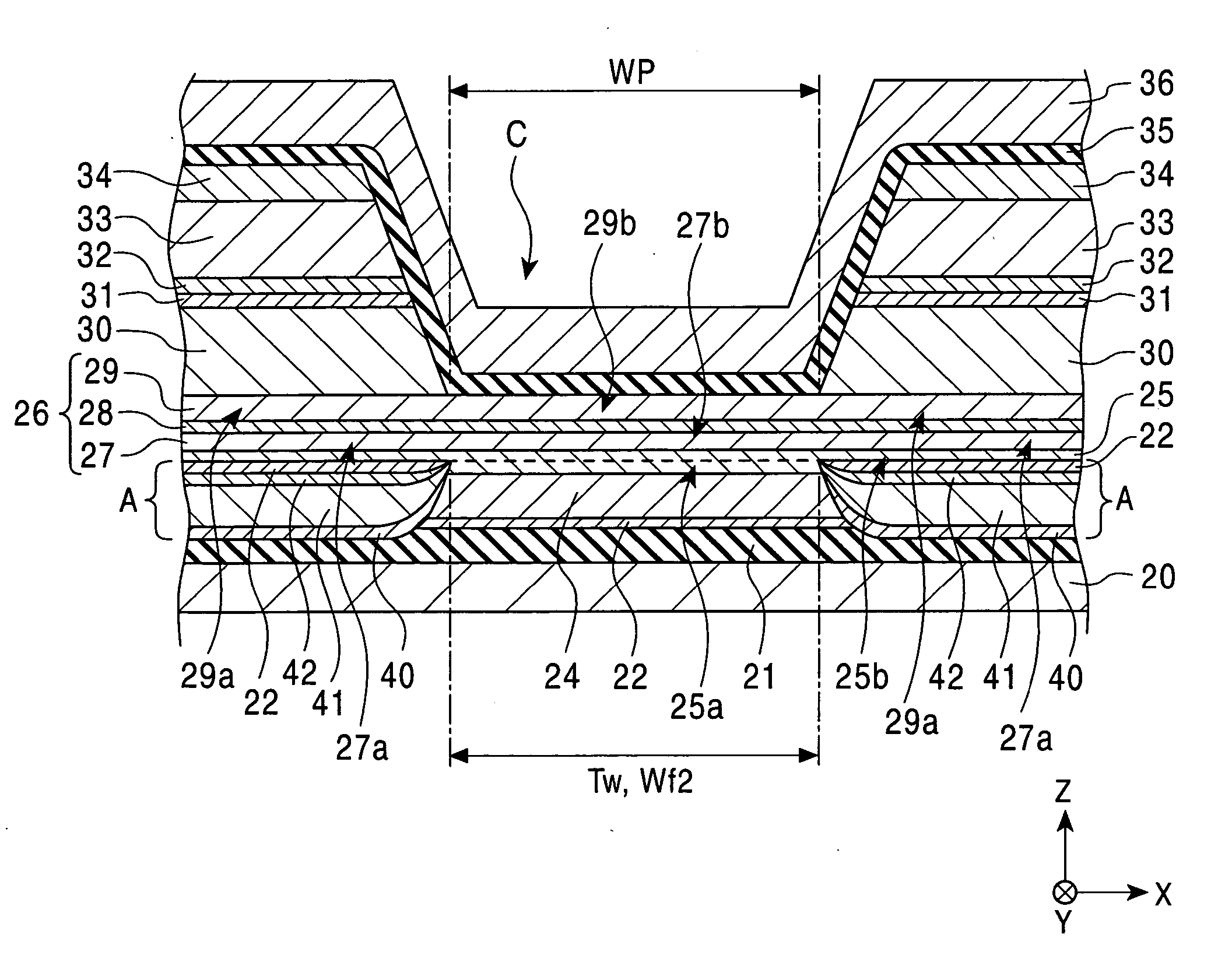

Magnetic detecting element having antiferromagnetic film having predetermined space in track width direction and method for manufacturing the same

InactiveUS20050276997A1Reproduction output is increasedHigh outputNanomagnetismMagnetic measurementsHigh resistanceMagnetization

The present invention provides a magnetic detecting element including a pinned magnetic layer and a first antiferromagnetic layer which constitutes an exchange coupling film and the structures of which are optimized for properly pinning magnetization of the pinned magnetic layer, improving reproduction output and properly complying with a narrower gap, and a method of manufacturing the magnetic detecting element. The pinned magnetic layer has a synthetic ferrimagnetic structure, and the first antiferromagnetic layer has a predetermined space C formed at the center in the track width direction to produce exchange coupling magnetic fields only between the first antiferromagnetic layer and both side portions of a first magnetic layer of the pinned magnetic layer. Therefore, the magnetization of the pinned magnetic layer can be pinned, and an improvement in reproduction output and gap narrowing can be realized. Furthermore, a magnetic detecting element with high resistance to electrostatic damage (ESD) can be manufactured. Thus, a magnetic detecting element adaptable for a future higher recording density can be provided.

Owner:TDK CORPARATION

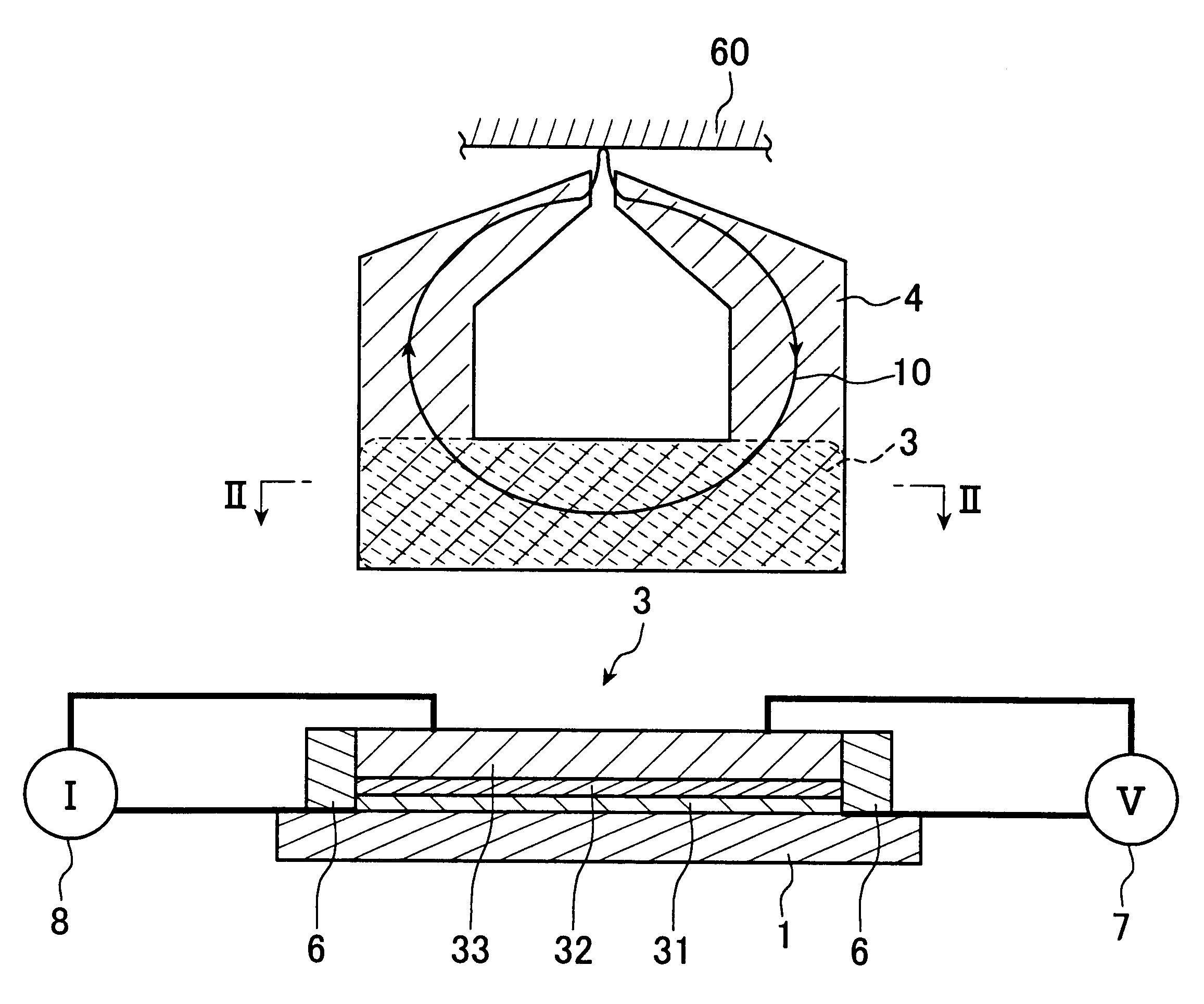

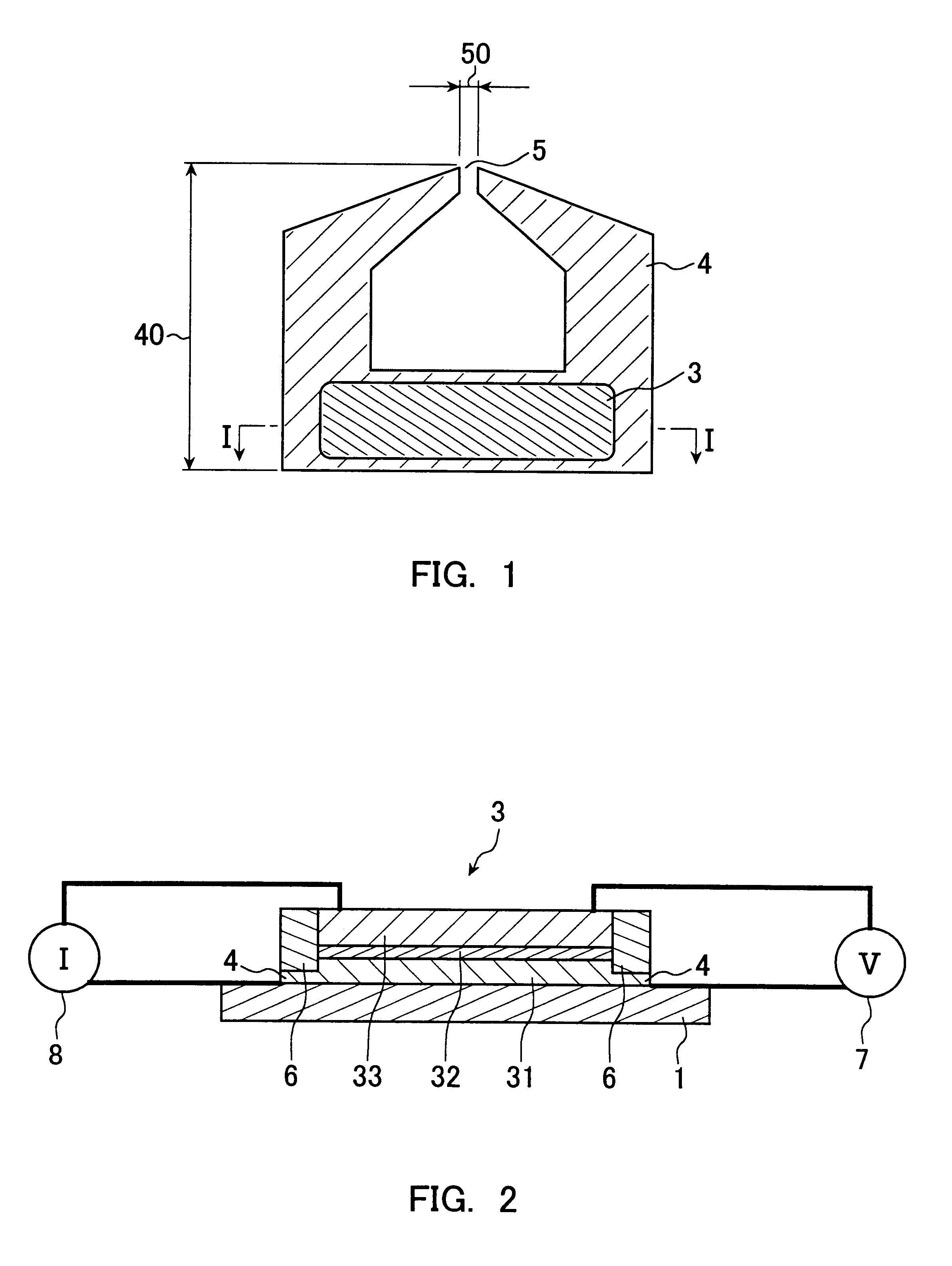

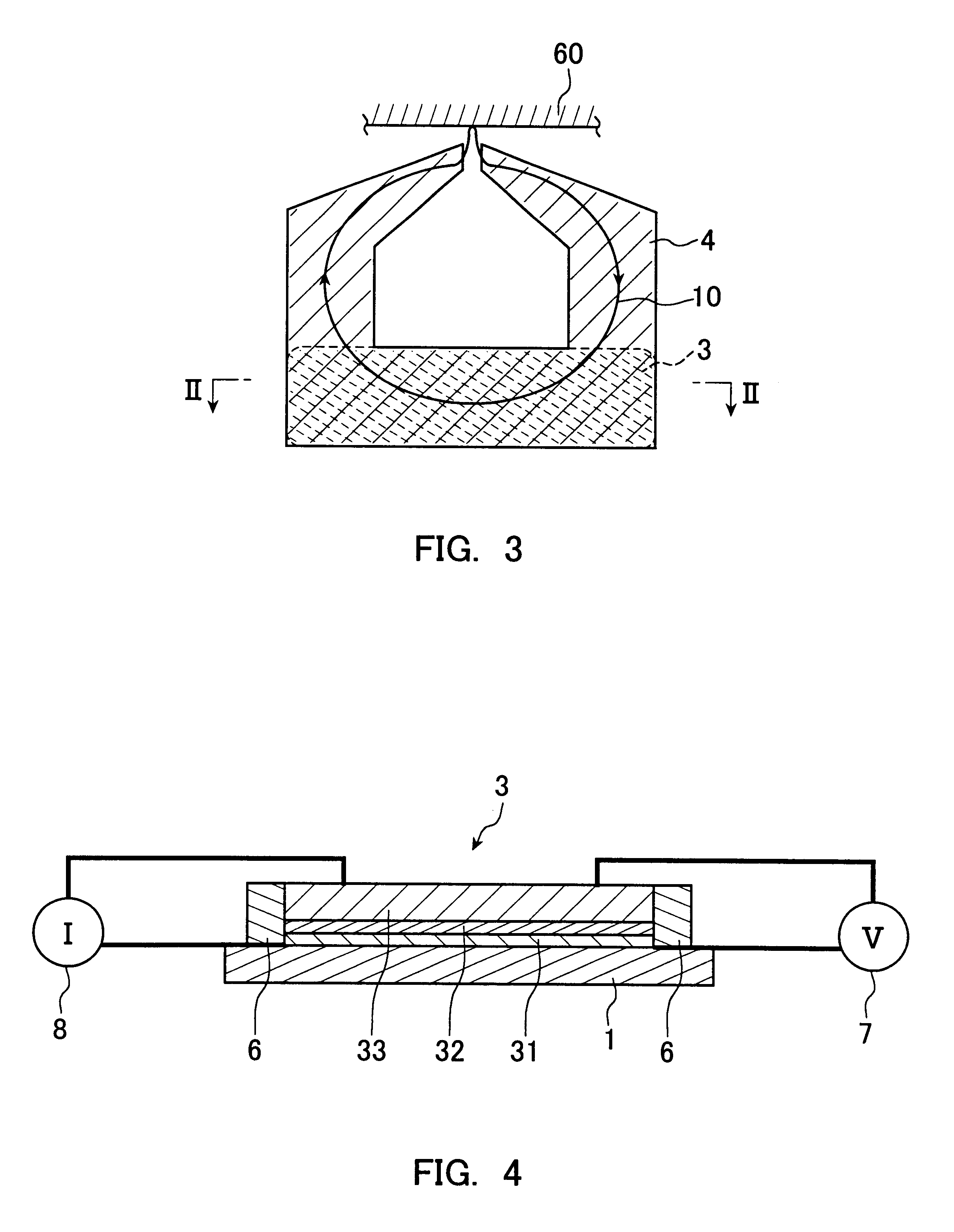

Magnetic head comprising a multilayer magnetoresistive device and a yoke for introducing magnetic flux from a medium to the magnetoresistive device

The present invention provides a magnetic head having improved characteristics, using a magnetoresistive device in which current flows across the film plane such as a TMR device. In a first magnetic head of the present invention, when the area of a non-magnetic layer is defined as a device cross-section area, and the area of a yoke is defined as a yoke area, viewed along the direction perpendicular to the surface of the substrate over which the yoke and the magnetoresistive device are formed, then the device cross-section area is not less than 30% of the yoke area, so that a resistance increase of the device cross-section area is suppressed. In a second magnetic head of the present invention, a magnetoresistive device is formed on a substrate, and a yoke is provided above a non-magnetic layer constituting the device. In a third magnetic head of the present invention, the free layer of the magnetoresistive device includes at least two magnetic films and at least one non-magnetic film that are laminated alternately, and the thickness of the non-magnetic layer is not less than 2 nm and not more than 10 nm, and magnetostatic coupling is dominant. In a fourth magnetic head of the present invention, a magnetic gap is provided adjacent to the magnetoresistive device and the magnetic films are coupled antiferromagnetically.

Owner:PANASONIC CORP

Ferromagnetic resonance excitation and its use for heating substrates that are filled with particles

InactiveUS7273580B2Improve efficiencyDielectric heatingLamination ancillary operationsSuperparamagnetismElectromagnetic radiation

Process for heating a substrate, which contains, relative to the total weight of the substrate, 0.1 to 70 wt. % of metallic, magnetic, ferrimagnetic, ferromagnetic, antiferromagnetic or superparamagnetic particles having an average particle size of between 1 and 5000 nm, wherein the substrate is exposed to electromagnetic radiation, characterized in that the electromagnetic radiation comprises microwave radiation with a frequency in the range from 1 to 300 GHz and the substrate is simultaneously exposed to a direct-current magnetic field, the field strength of which is at least twice the strength of the earth's magnetic field; use of the process for producing or detaching adhesive bonds; device for the simultaneous production of microwave radiation with a frequency within the range from 1 to 300 GHz and a direct-current magnetic field, the field strength of which is at least twice the strength of the earth's magnetic field.

Owner:HENKEL KGAA

Magnetic sensor

ActiveCN105891739AStable Bias Magnetic FieldElectric/magnetic position measurementsUsing electrical meansMagnetizationNon magnetic

A magnetic sensor includes an MR element and a bias magnetic field generation unit. The MR element includes a magnetization pinned layer, a nonmagnetic layer and a free layer stacked along Z direction. The bias magnetic field generation unit includes a first antiferromagnetic layer, a ferromagnetic layer and a second antiferromagnetic layer stacked along the Z direction. The bias magnetic field generation unit has a first end face and a second end face located at opposite ends in the Z direction. The MR element is placed such that the entirety of the MR element is contained in a space formed by shifting an imaginary plane equivalent to the first end face of the bias magnetic field generation unit away from the second end face along the Z direction.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com