Magnetic multilayer film with linear magnetoresistance effect and its application

A magnetoresistance, multi-layer film technology, applied in spin-exchange-coupled multi-layer films, magnetic films, magnetic field-controlled resistors, etc., can solve the problems of narrow magnetic field range, high signal amplification, and low sensitivity of magnetic field sensors. To achieve the effect of reducing costs and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

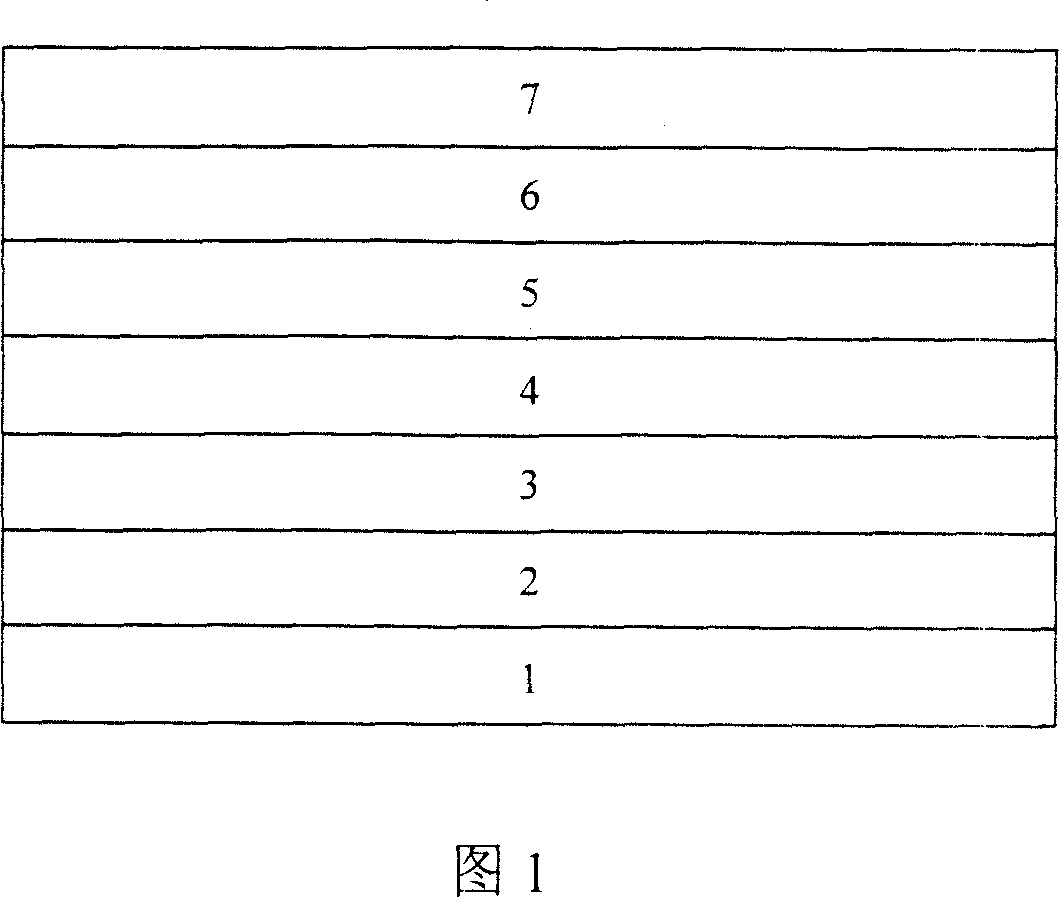

[0041] Magnetic multilayer films were prepared by magnetron sputtering. The substrate is Si / SiO 2 , the magnetic multilayer film structure is: Ru(5nm) / Pt(10nm) / [Co(0.4nm) / Pt(0.6nm)] 5 / Co(0.4nm) / Cu(2nm) / Co(3nm) / IrMn(12nm) / Ru(5nm). Magnetic multilayer film growth conditions: backup vacuum: 5×10 -7 Pa; high-purity argon gas pressure for sputtering: 0.07 Pa; sputtering power: 120 watts; sample holder rotation rate: 20rmp; growth temperature: room temperature; Growth time: film thickness / growth rate.

[0042] Microfabrication is carried out by means of ultraviolet lithography and argon ion etching. UV lithography conditions: photoresist: S9918; exposure dose: 55mJ / cm 2 ; Exposure time: 17 seconds; Developer: MF319; Development time: 45 seconds; Baking time: 60 seconds; Baking temperature: 95 degrees. Argon ion etching conditions: power: 300 watts; argon pressure: 30 mTorr.

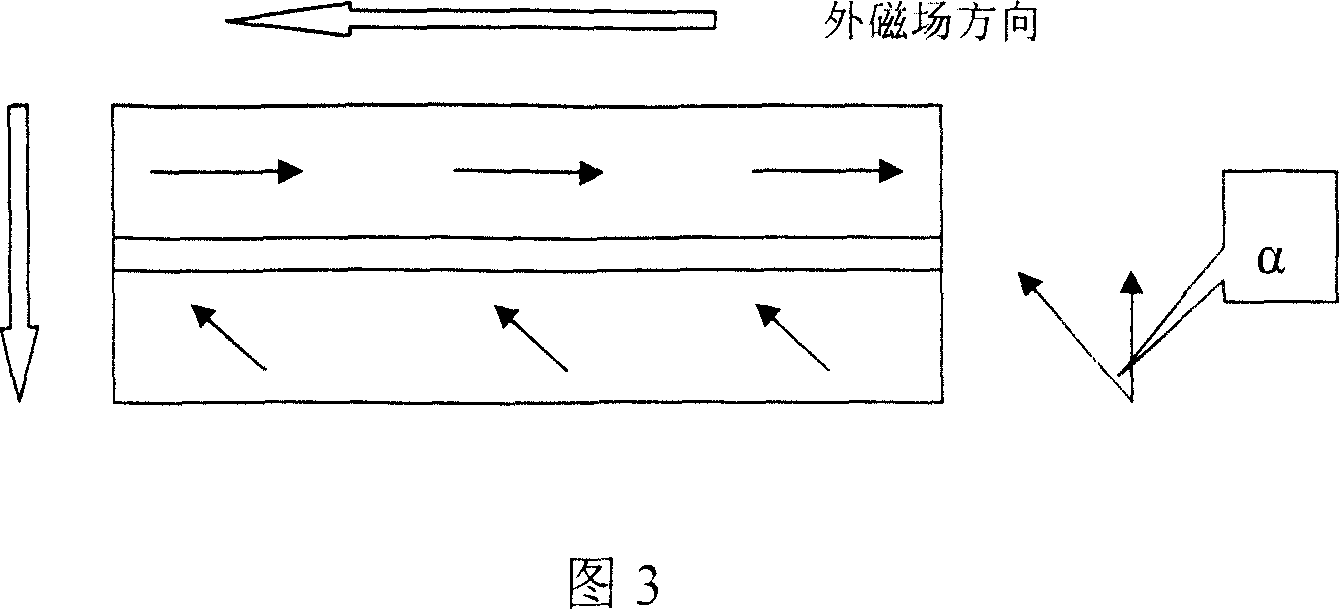

[0043] The graphic shape is an ellipse cylinder, the length of the major axis of the ellipse is 8 mi...

Embodiment 2

[0046] Magnetic multilayer films were prepared by magnetron sputtering. The substrate is Si / SiO 2 , the magnetic multilayer film structure is: Ru(5nm) / Pt(10nm) / [Co(0.4nm) / Pt(0.6nm)] 5 / Co(0.4nm) / Cu(2nm) / Co(3nm) / IrMn(12nm) / Ru(5nm). Magnetic multilayer film growth conditions: backup vacuum: 5×10 -7 Pa; high-purity argon gas pressure for sputtering: 0.07 Pa; sputtering power: 120 watts; sample holder rotation rate: 20rmp; growth temperature: room temperature; Growth time: film thickness / growth rate.

[0047] The microfabrication is carried out by ultraviolet lithography and electron beam exposure combined with argon ion etching. UV lithography conditions: photoresist: S9918; exposure dose: 55mJ / cm 2 ; Exposure time: 17 seconds; Developer: MF319; Development time: 45 seconds; Baking time: 60 seconds; Baking temperature: 95 degrees. Electron beam exposure conditions: photoresist: PMMA950; exposure dose: 120mJ / cm 2 ; Developer: MIBK / IPA; Fixer: IPA Developing time: 40 seconds...

Embodiment 3~6

[0051] A magnetic multilayer film was prepared by the same method as in Example 1. The composition of the magnetic multilayer film is listed in Table 1.

[0052] Reality

[0053] The same microfabrication method as in Example 1 can be used to obtain a magnetic multilayer film with a magnetic field selectivity and a certain shape that responds linearly to the magnetic field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com