Patents

Literature

31 results about "Amorphous magnetic material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous metals which contain certain alloy elements show superior soft magnetic properties through crystallization. It was commonly known that the characteristics of soft magnetic materials are "larger crystal grains yield better soft magnetic properties".

Apparatus and method for a communication device

InactiveUS6927738B2Improve permeabilityAvoid attenuationLoop antennas with ferromagnetic coreAntenna supports/mountingsEngineeringConductive materials

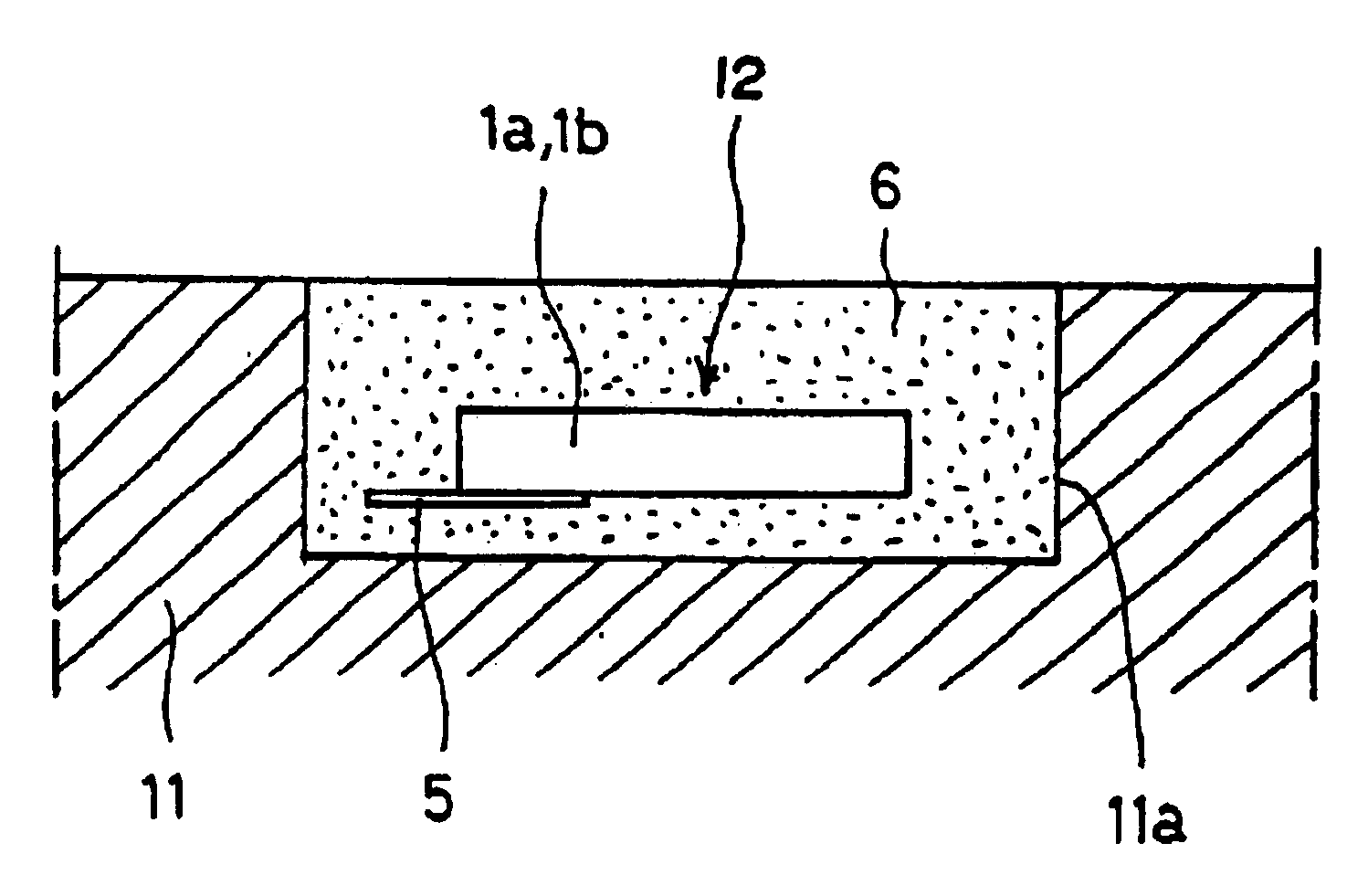

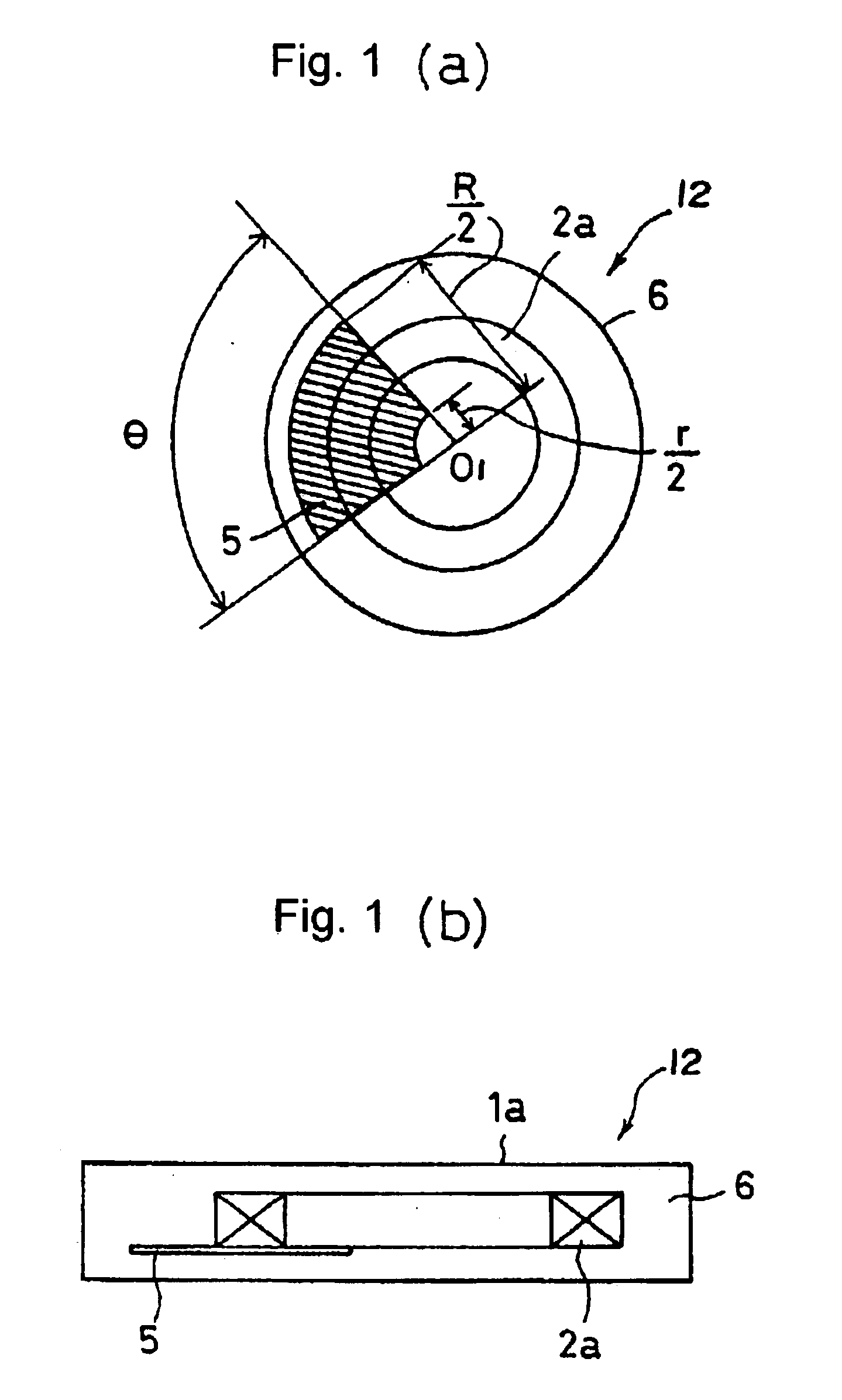

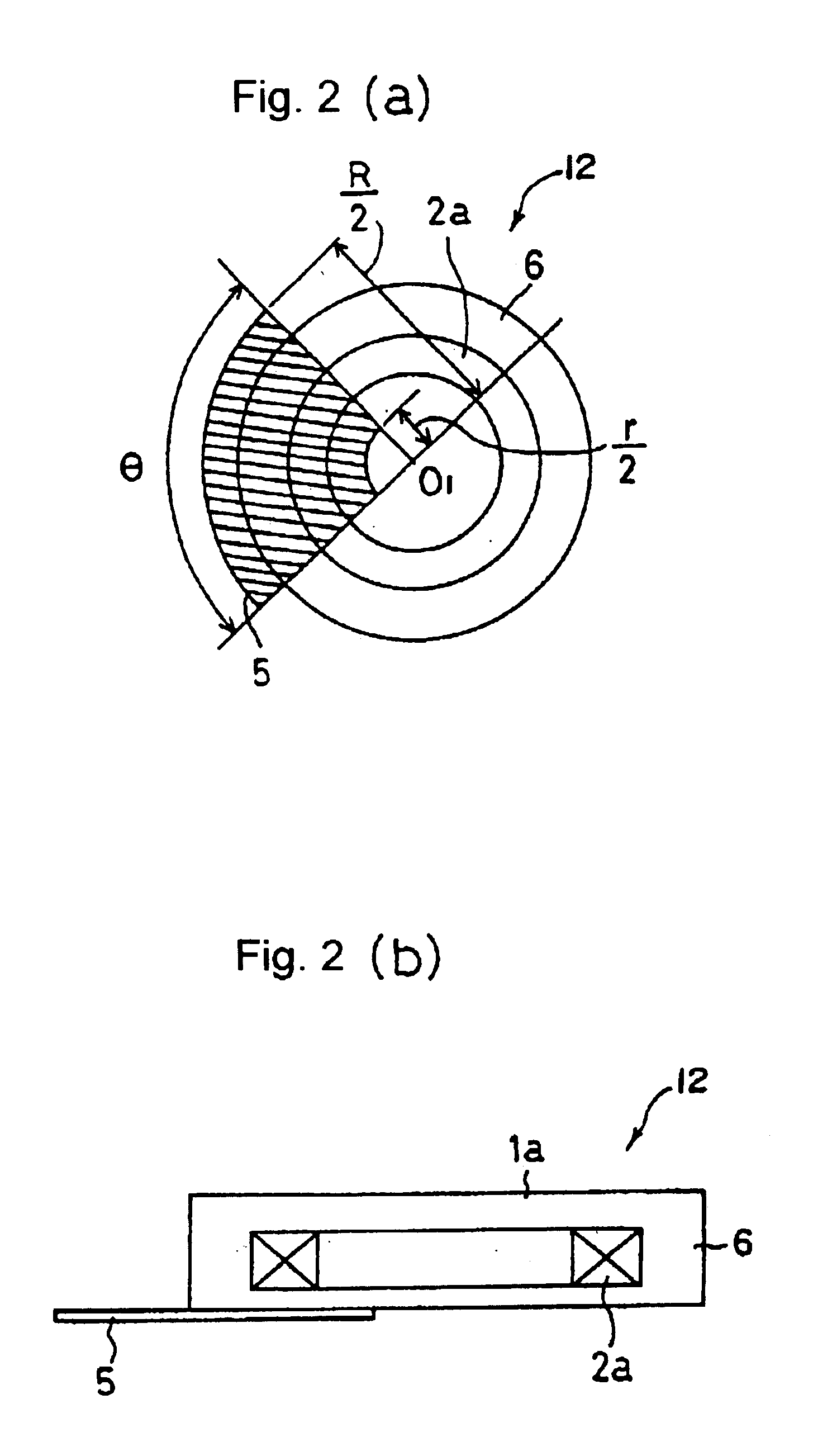

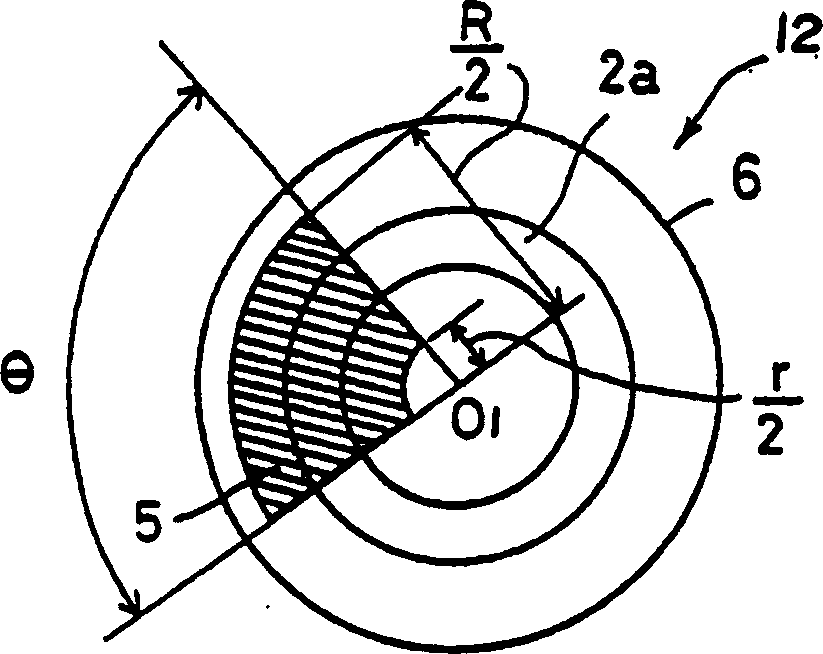

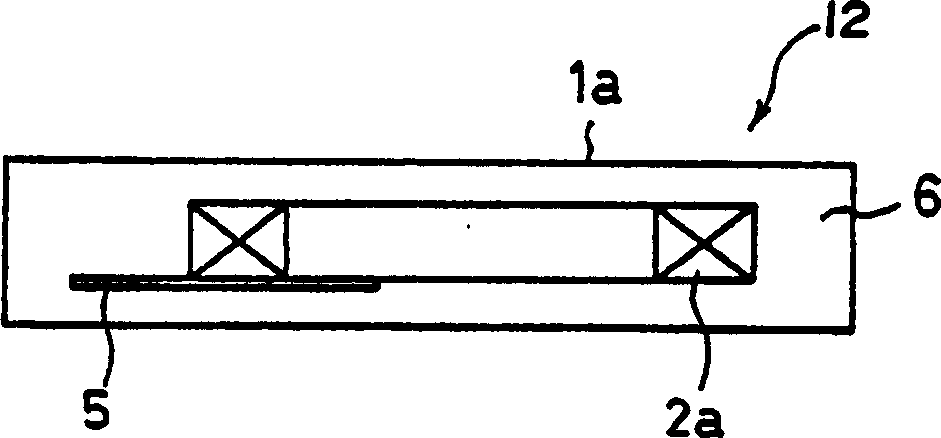

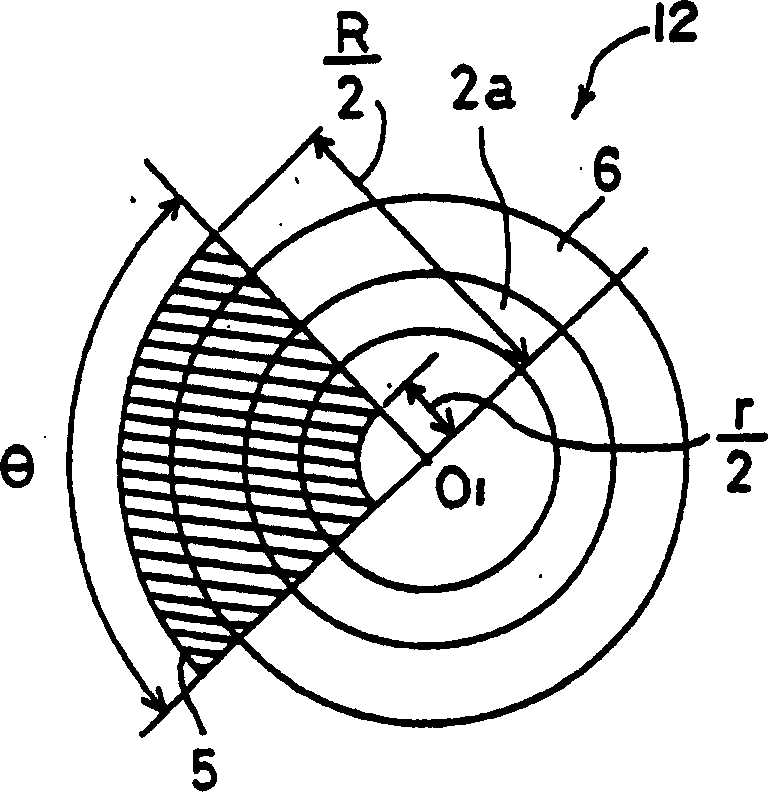

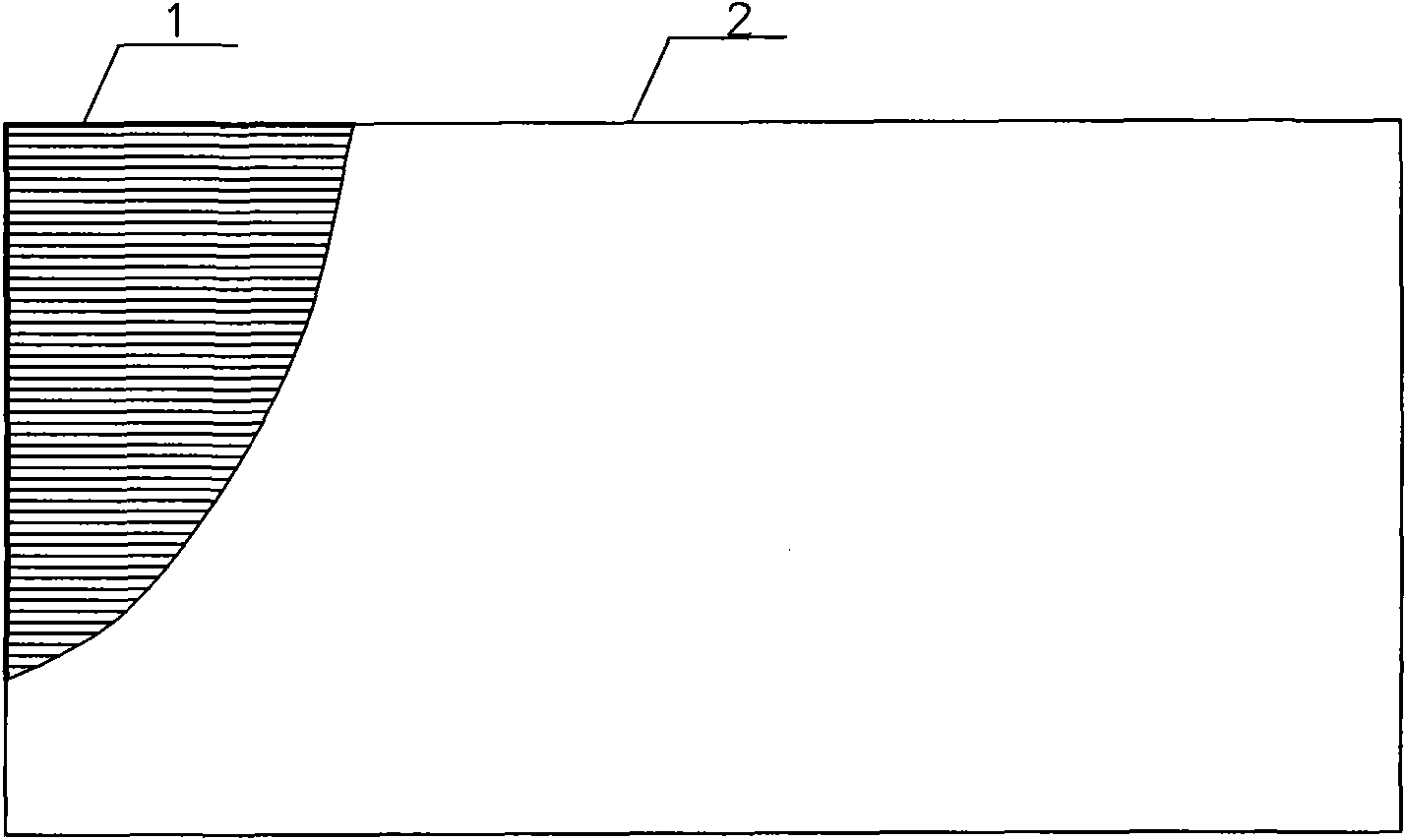

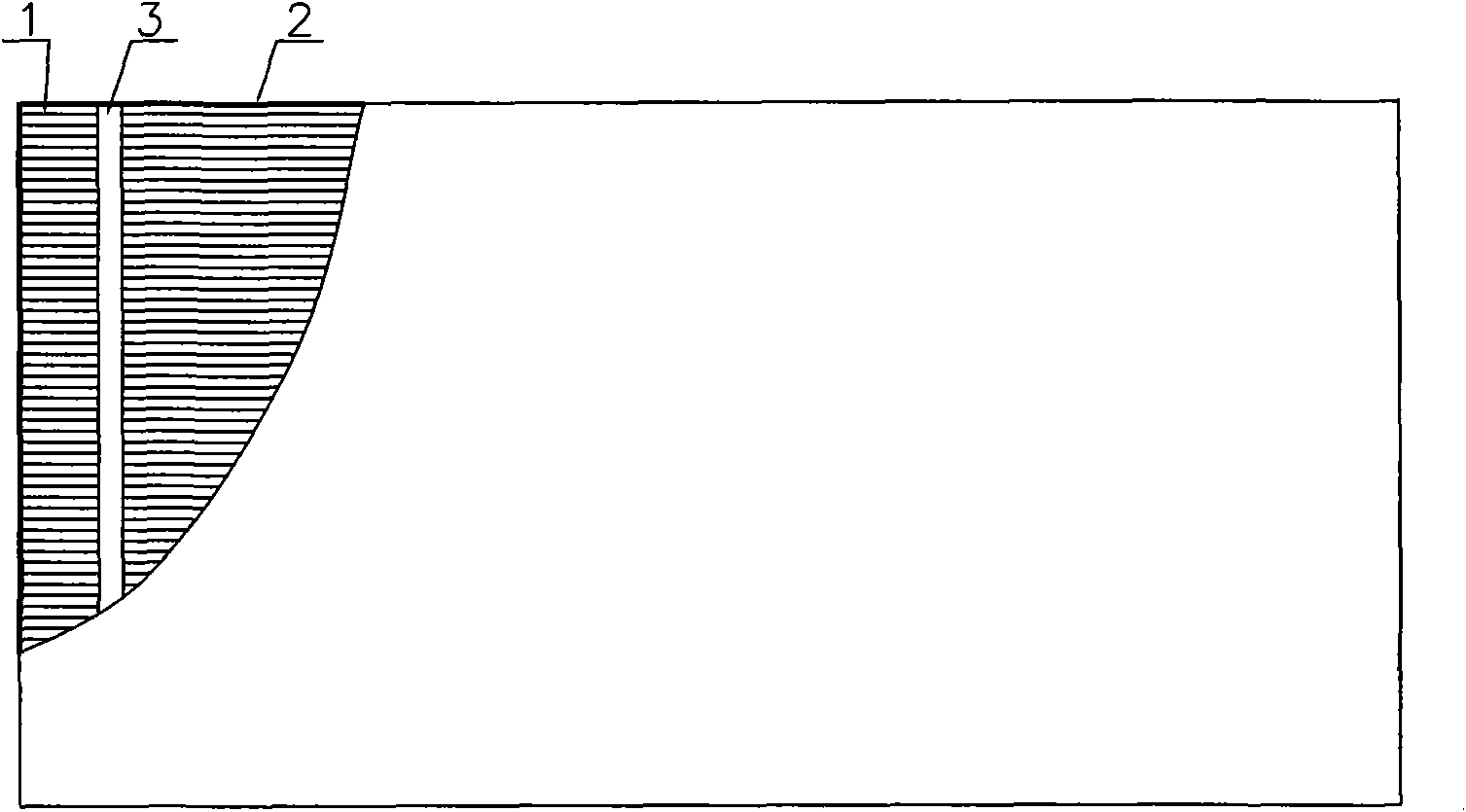

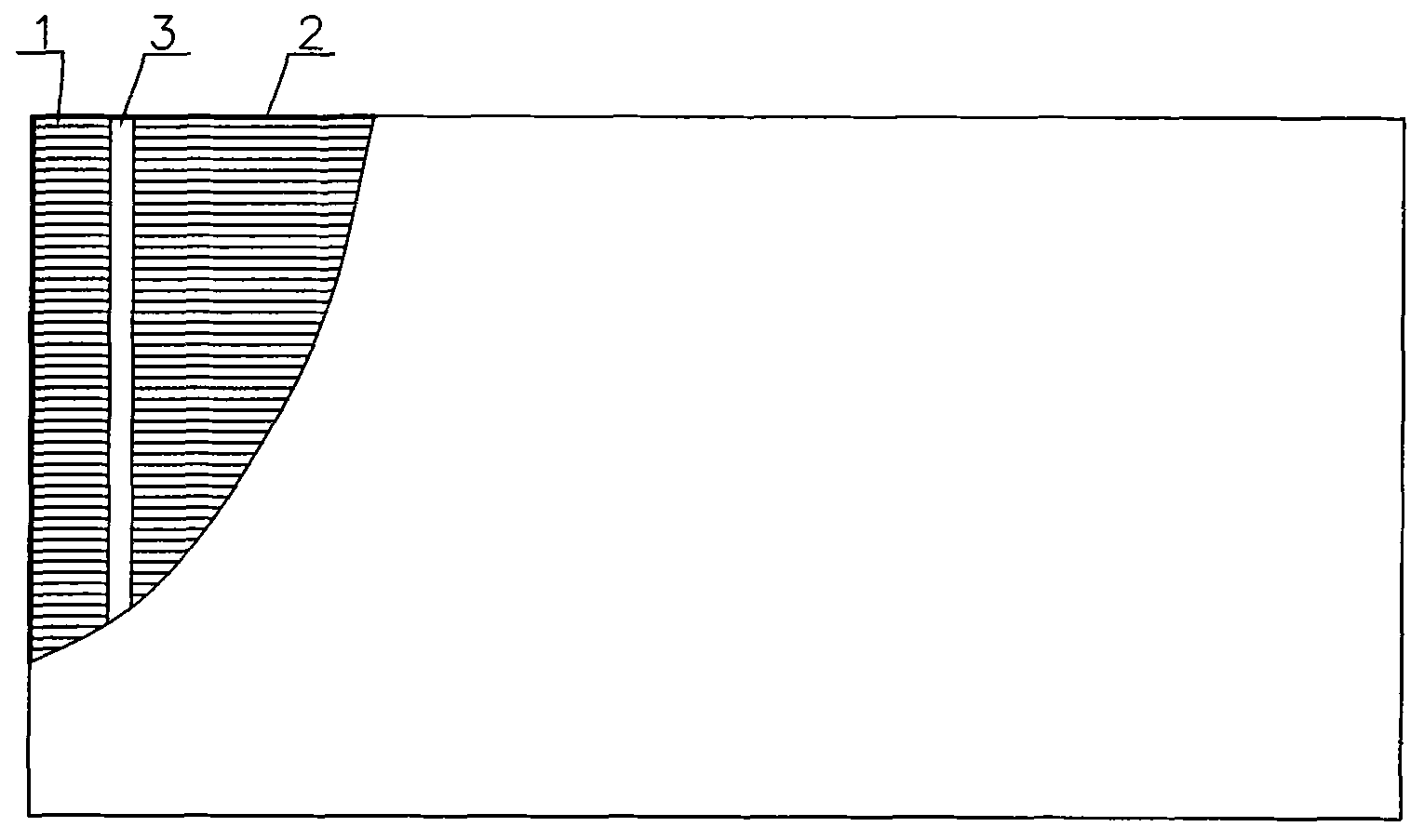

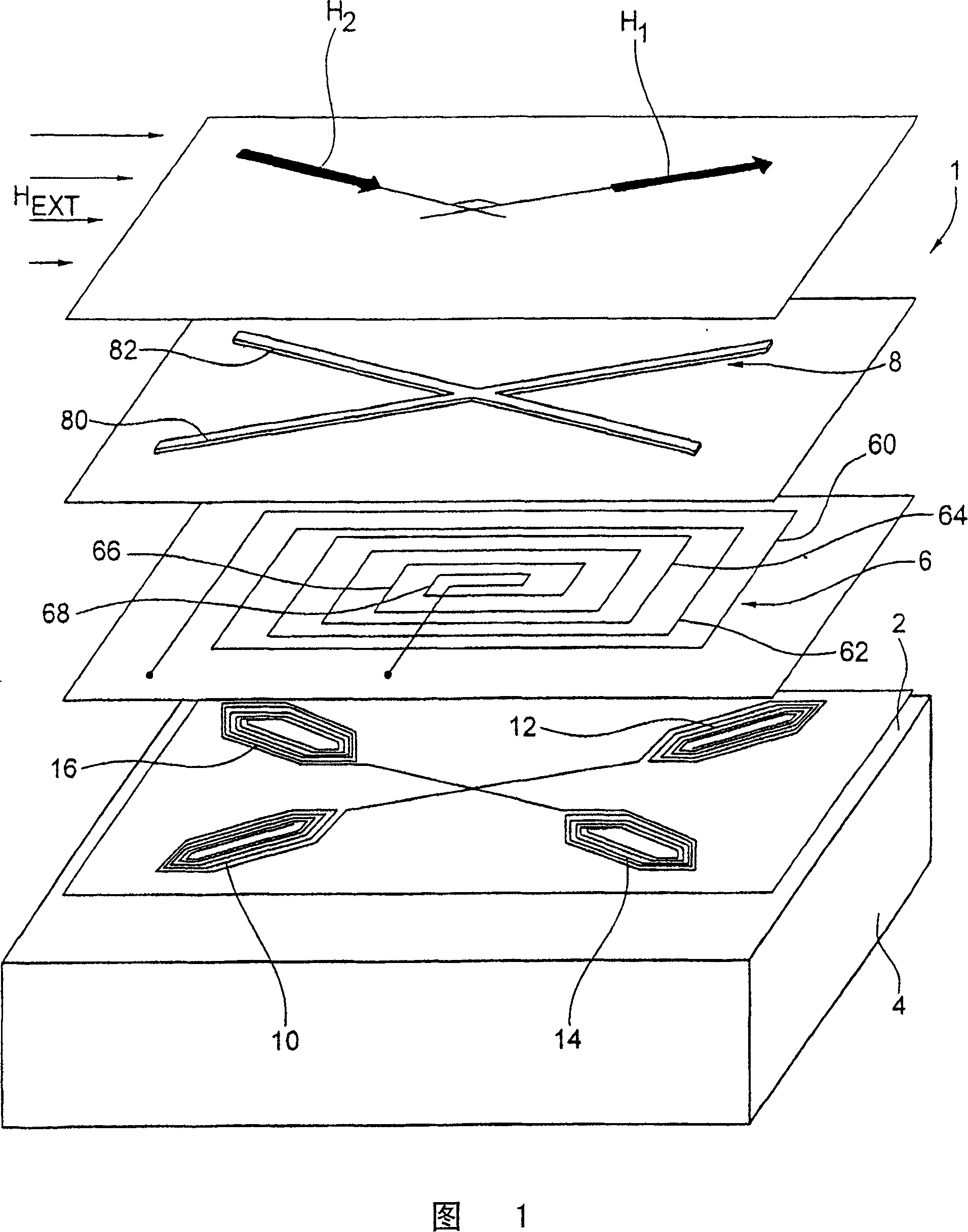

This invention aims to provide a communication device, installation structure for the communication device, a method of manufacturing the communication device, and a method of communication with the communication device in which the communication device is able to exceedingly restain a conductive material from attenuating magnetic flux and to expand communication distance even when the communication device is attached to a conductive member e.g., metal, in a closely contacting manner.This invention has a sheet-like amorphous magnetic material being arranged in a manner extending from a magnetic flux generating portion of a concentric disk-shaped antenna coil of an RFID tag serving as the communication device to an outer area of the antenna coil.

Owner:HANEX CO LTD

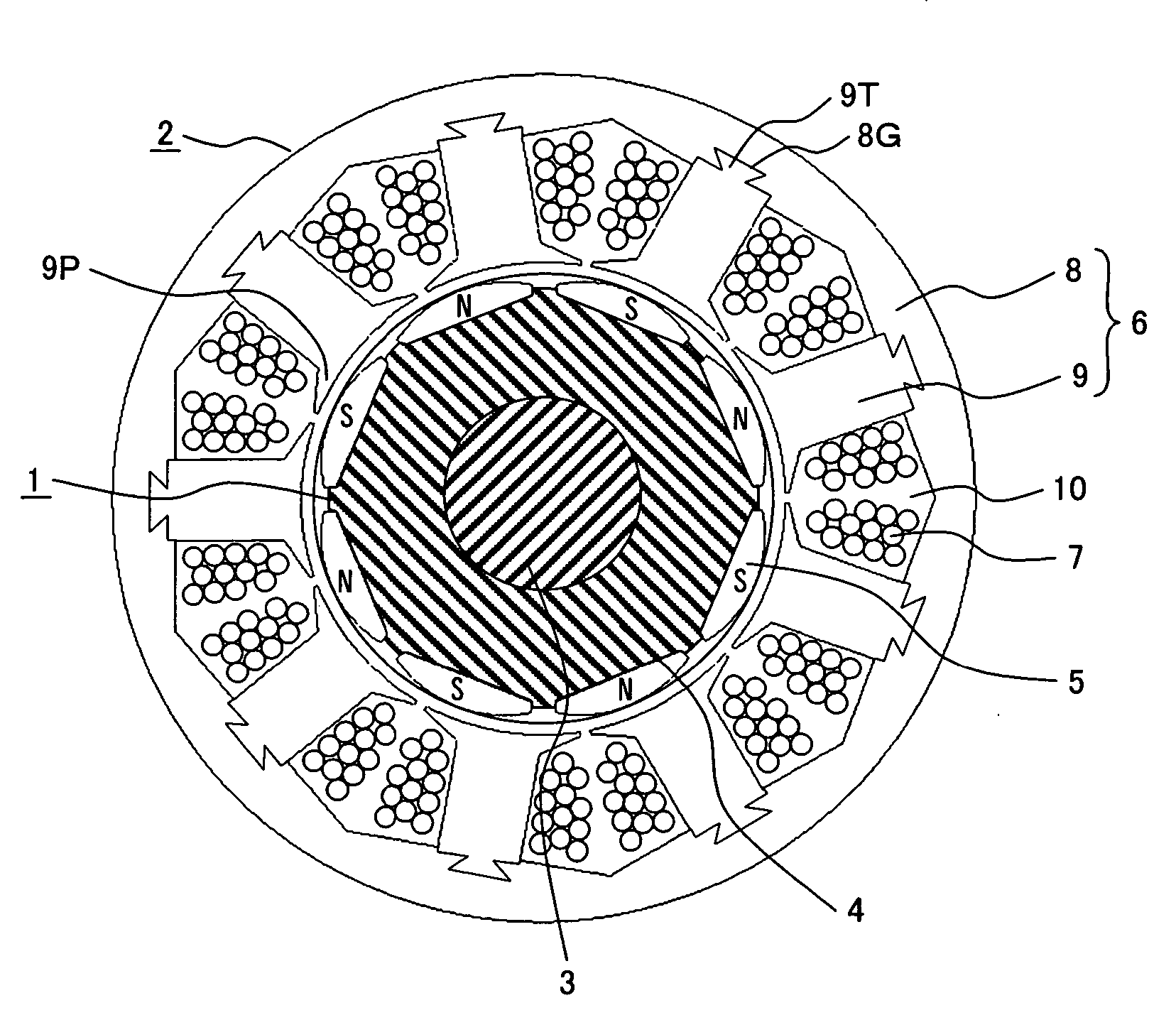

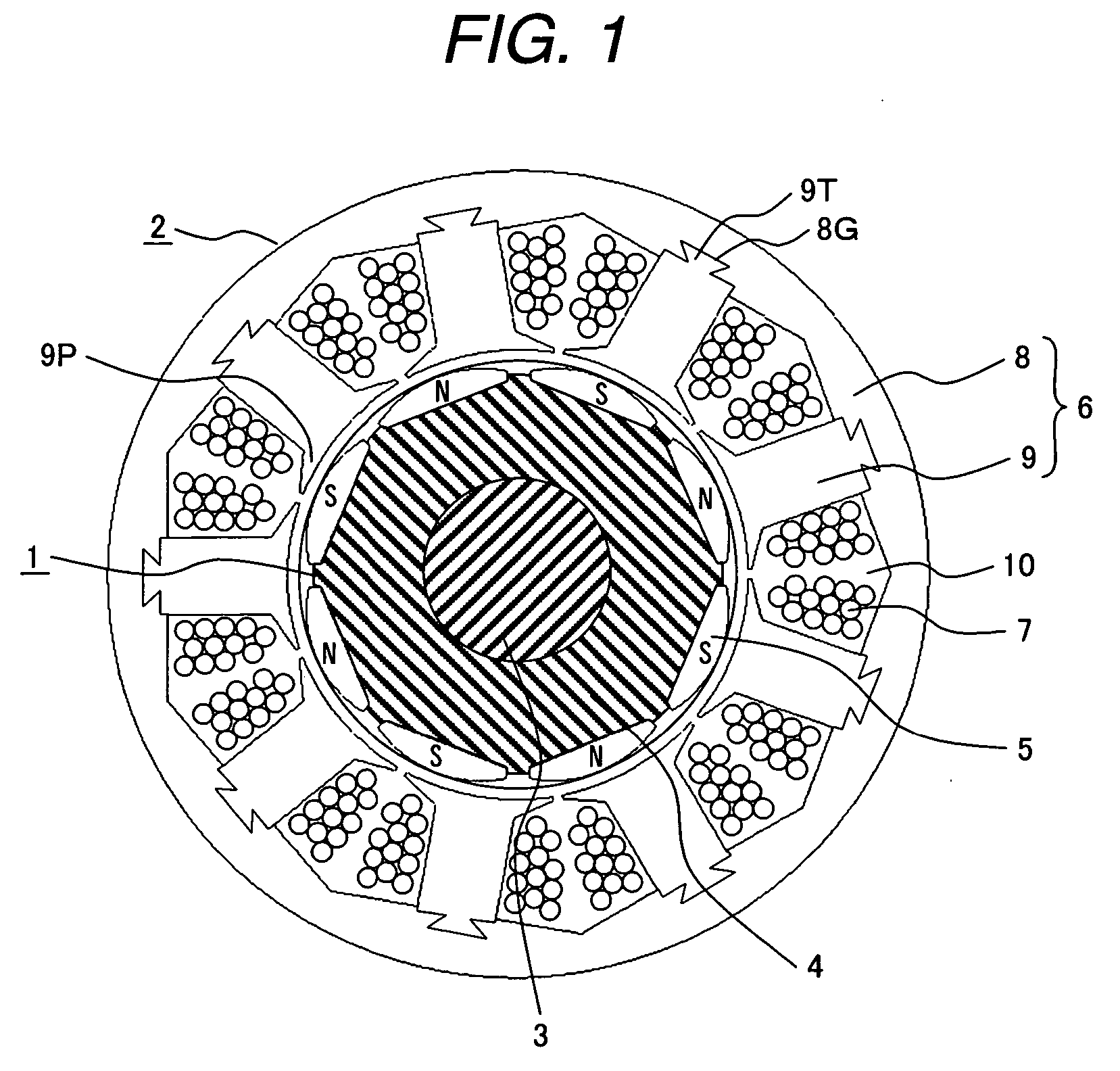

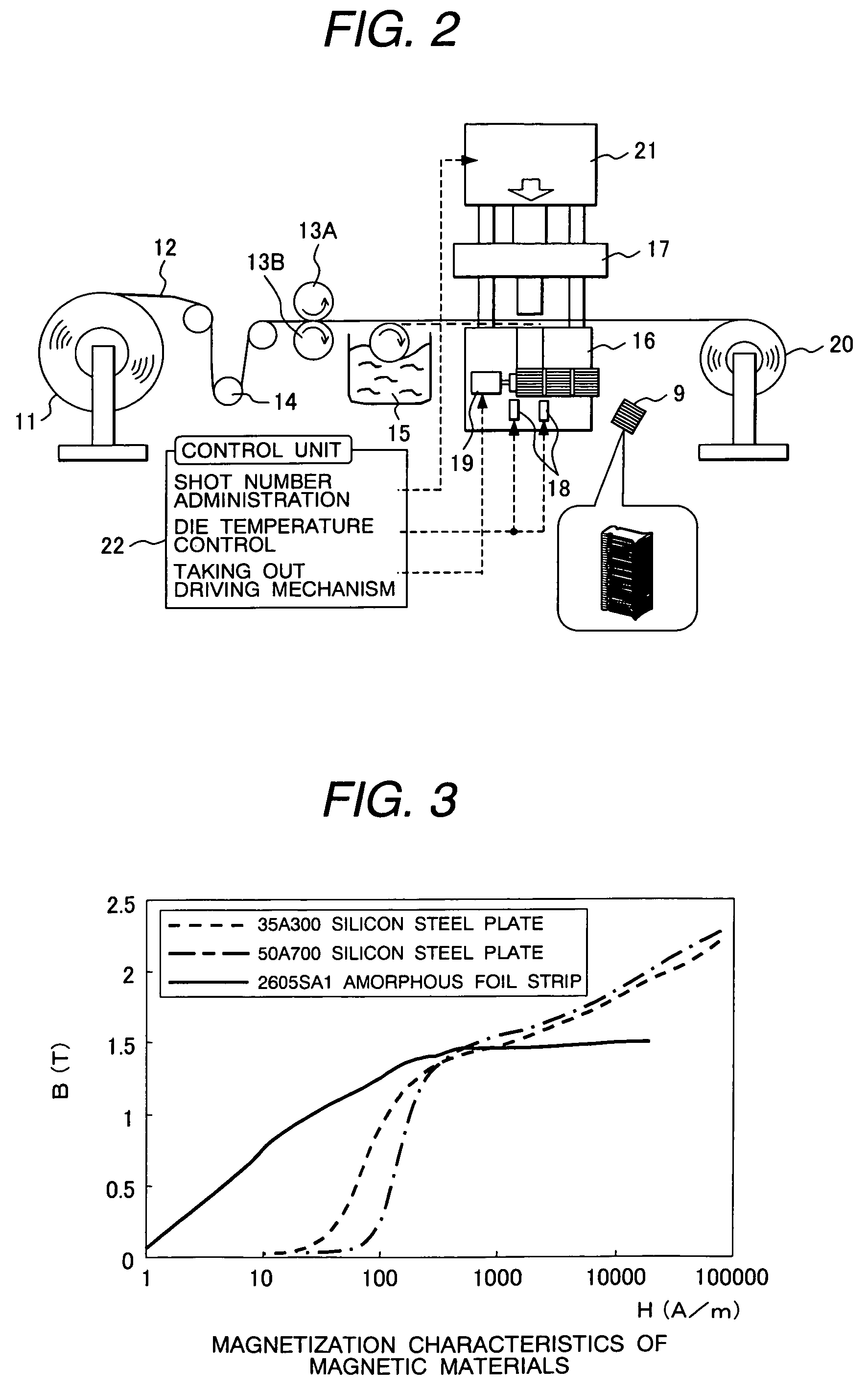

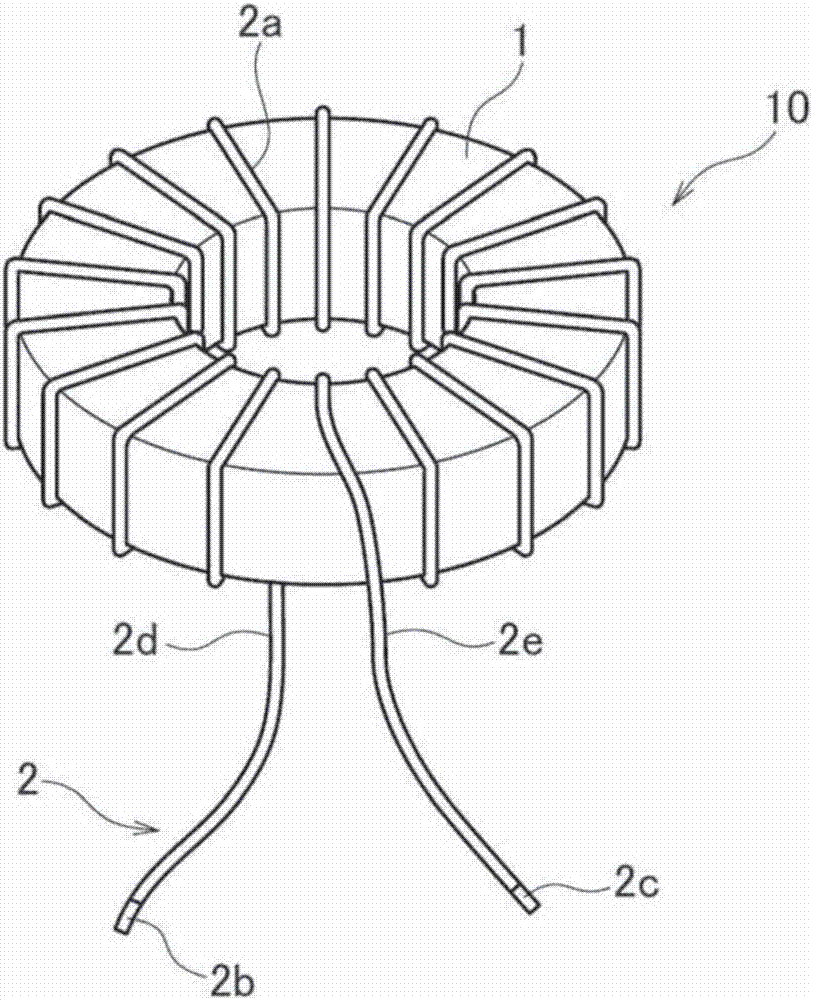

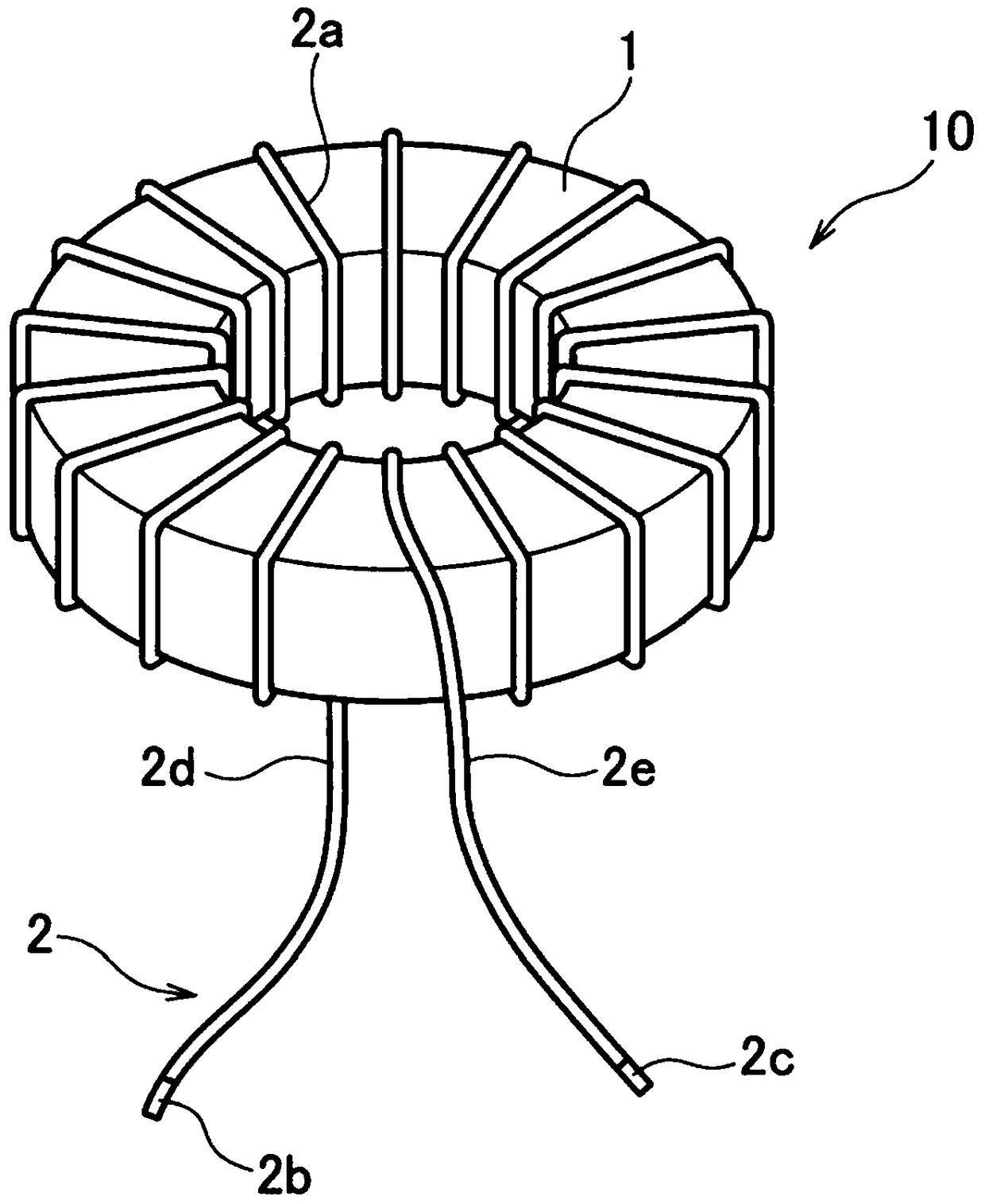

Electric rotating machine having permanent magnets and method of manufacturing teeth portions of the stator iron core

InactiveUS20060082241A1Reduced loss torqueReduce vibrationMagnetic circuit rotating partsManufacturing dynamo-electric machinesElectric machineEngineering

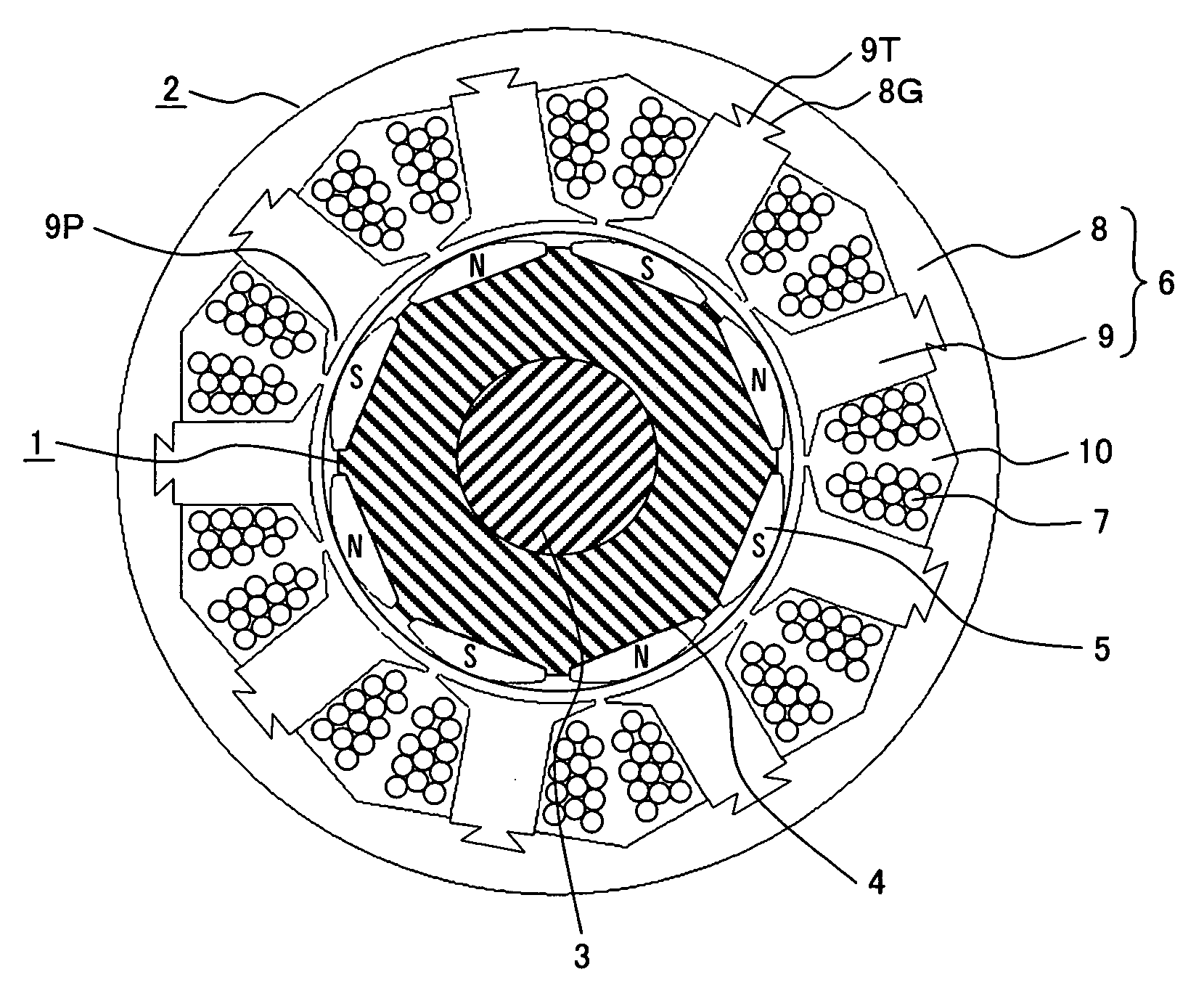

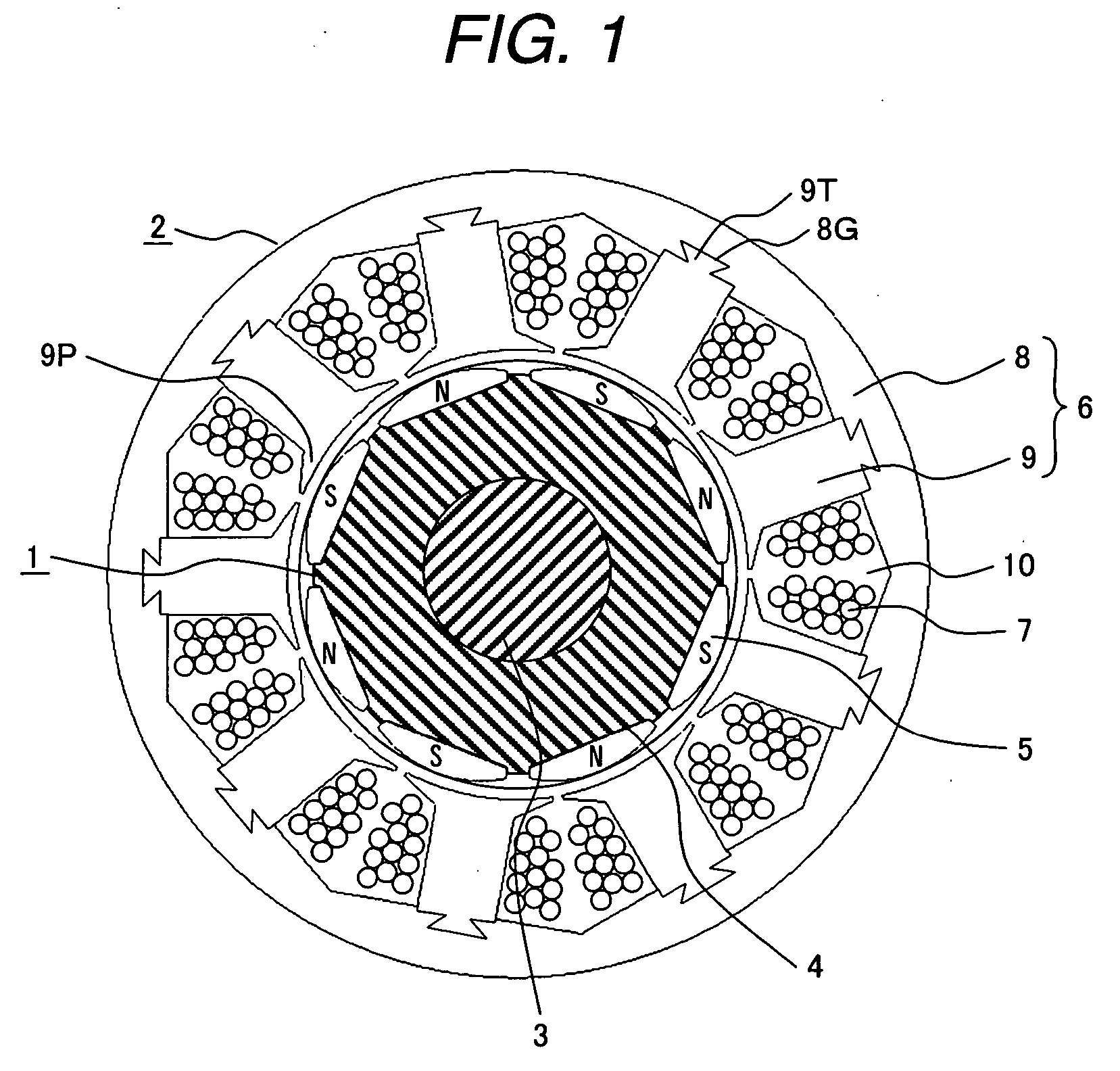

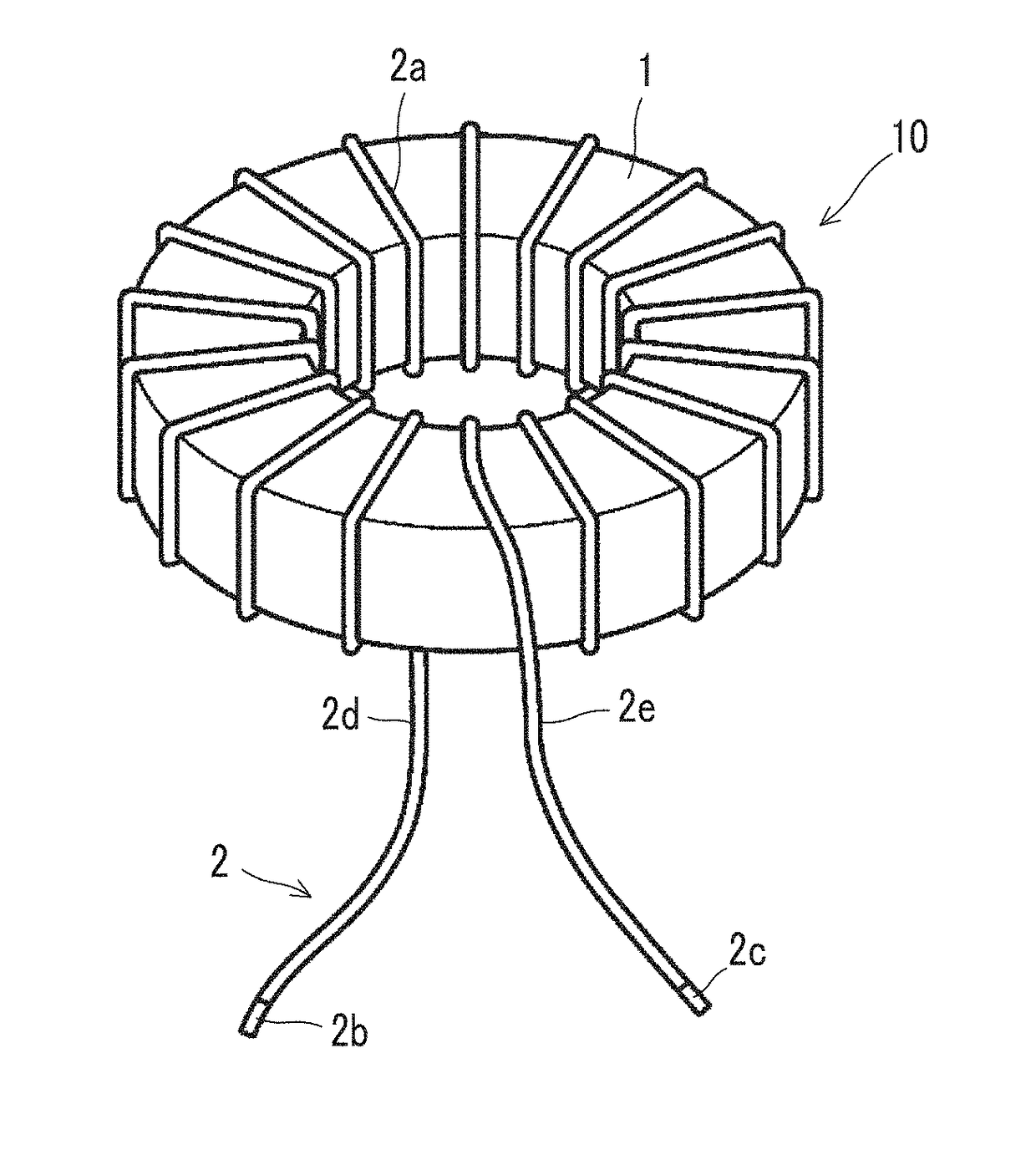

An electric rotating machine having permanent magnets comprising a rotor having a plurality of permanent magnets, a stator iron core disposed in opposite relation with the rotor, and a stator winding wound around the stator core, wherein the stator core is constituted by a yoke and a plurality of teeth portions disposed to the yoke. The teeth portions are projected towards the inner periphery of the rotor. The teeth portions is made of amorphous magnetic material.

Owner:JAPAN SERVO CO LTD +3

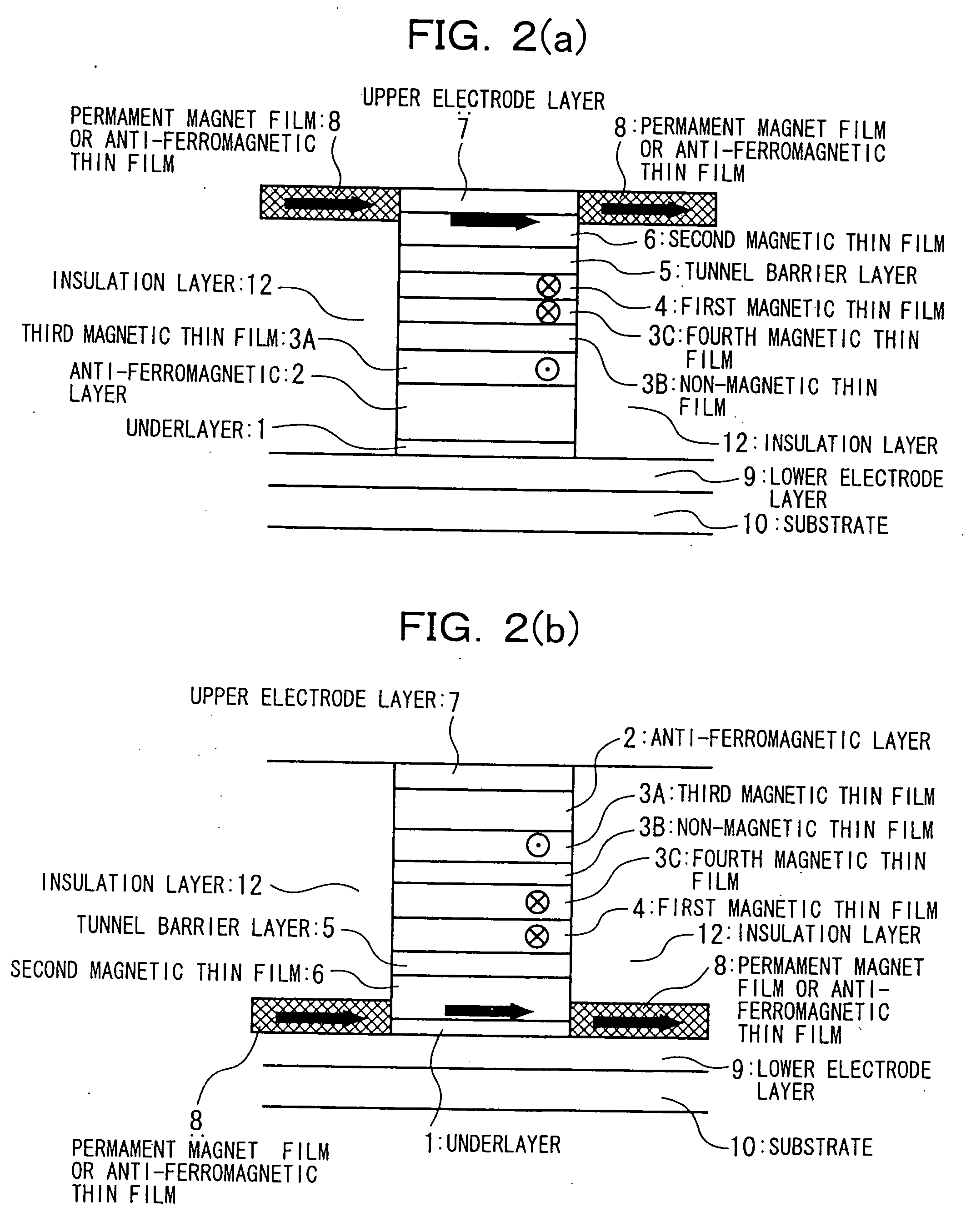

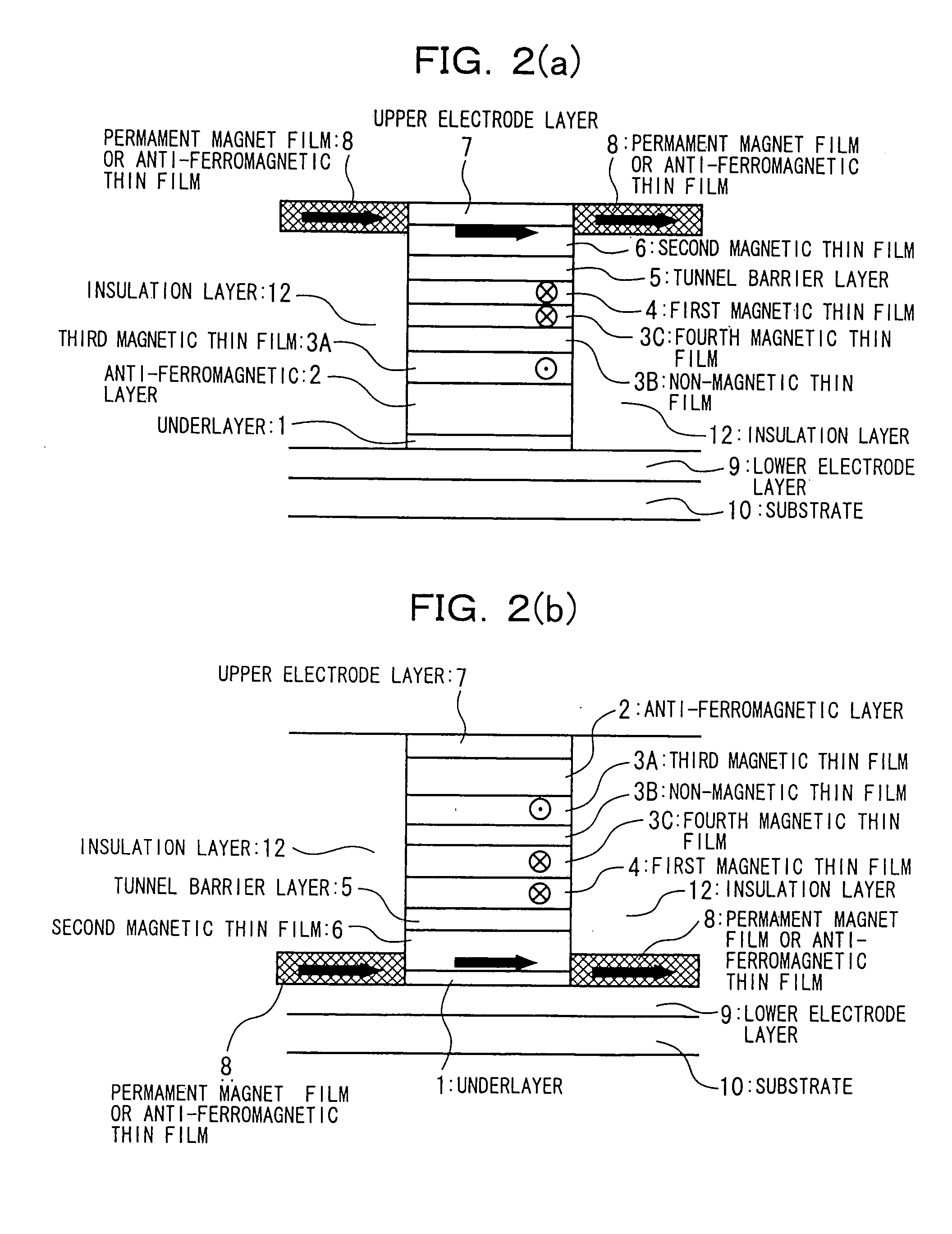

Spin tunnel magnetoresistive effect film and element, magnetoresistive sensor using same, magnetic apparatus, and method for manufacturing same

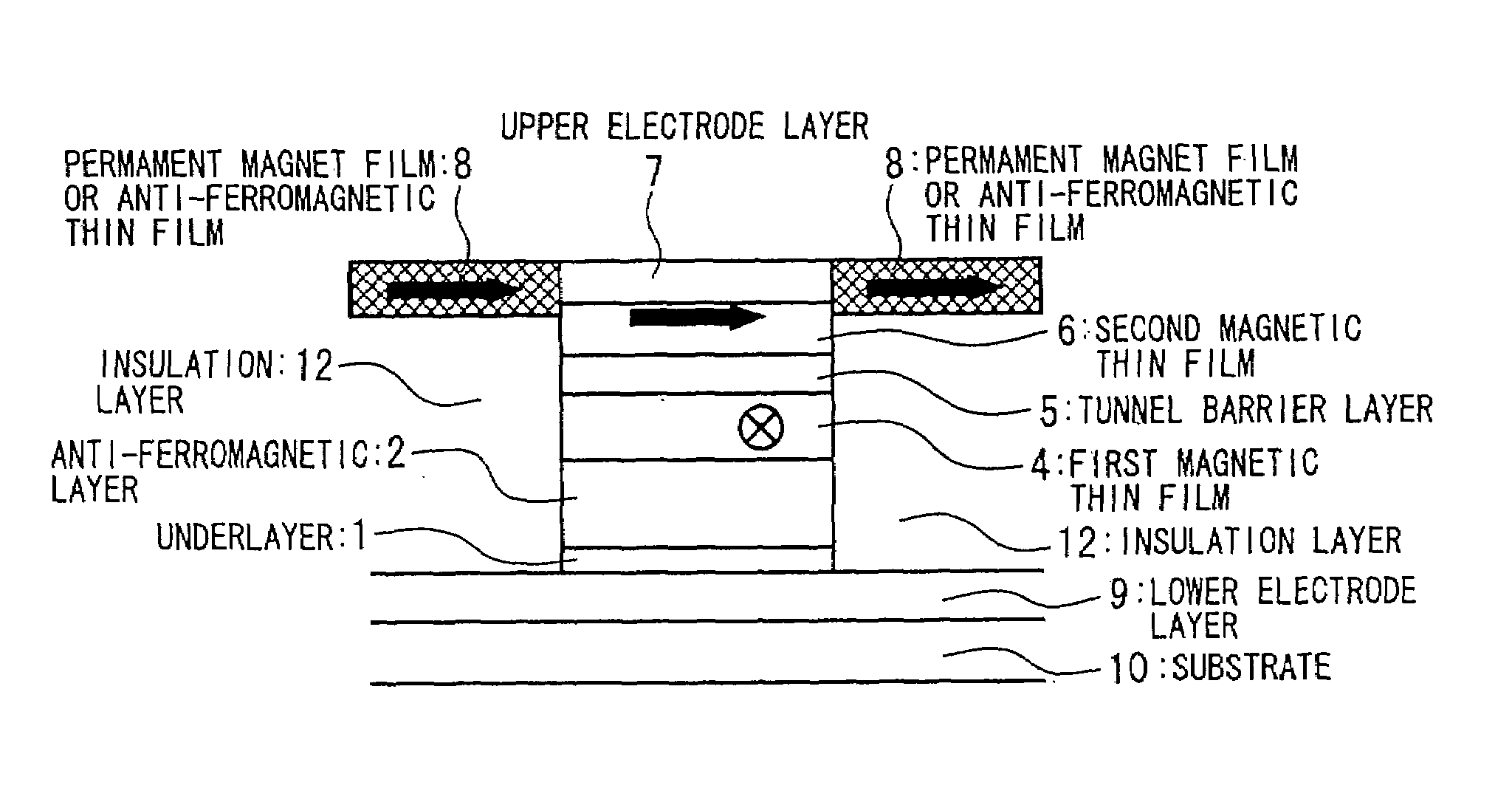

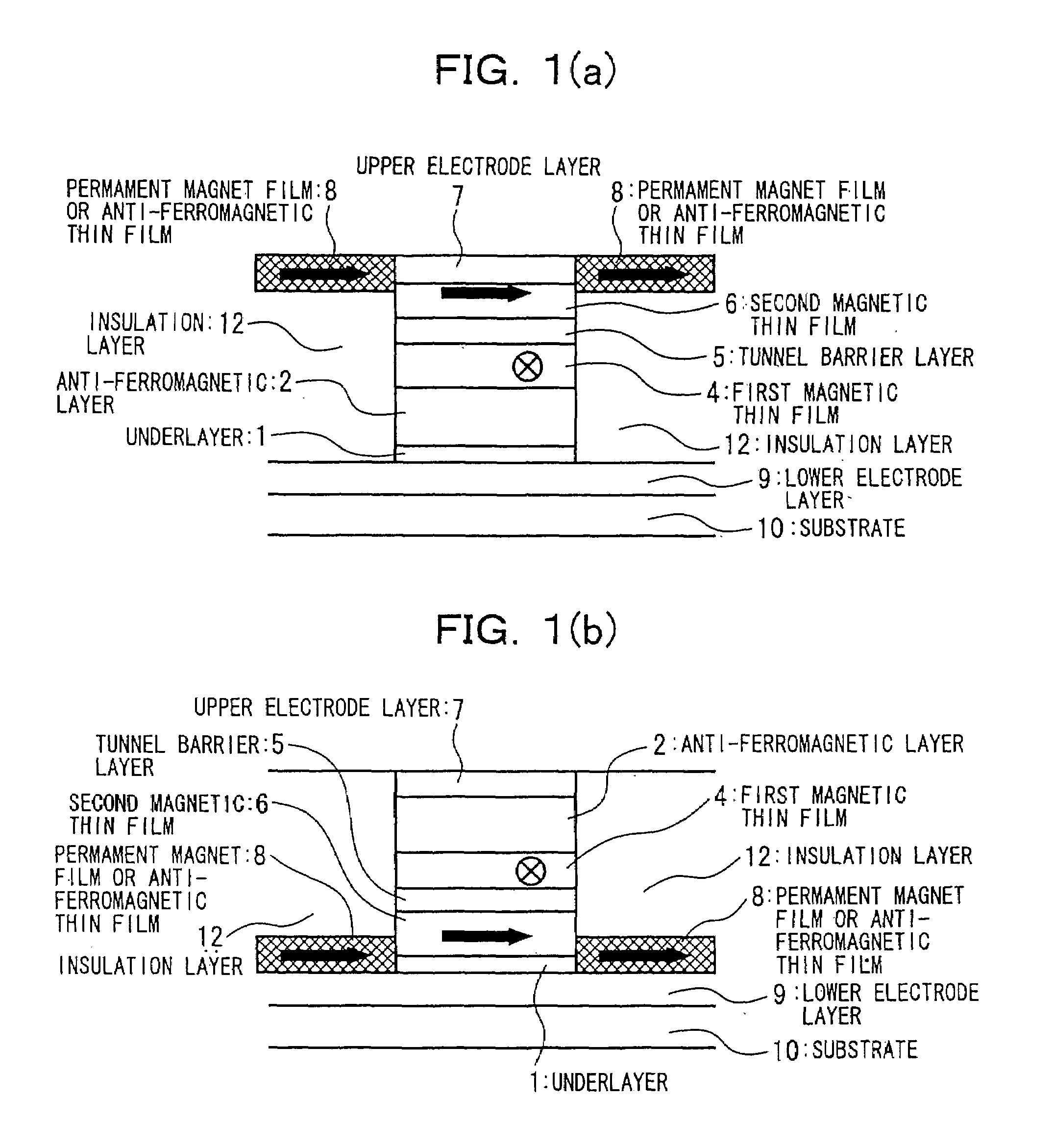

InactiveUS20050019610A1Reduced effectivenessPrevent oxidationNanomagnetismMagnetic measurementsNon magneticOxygen

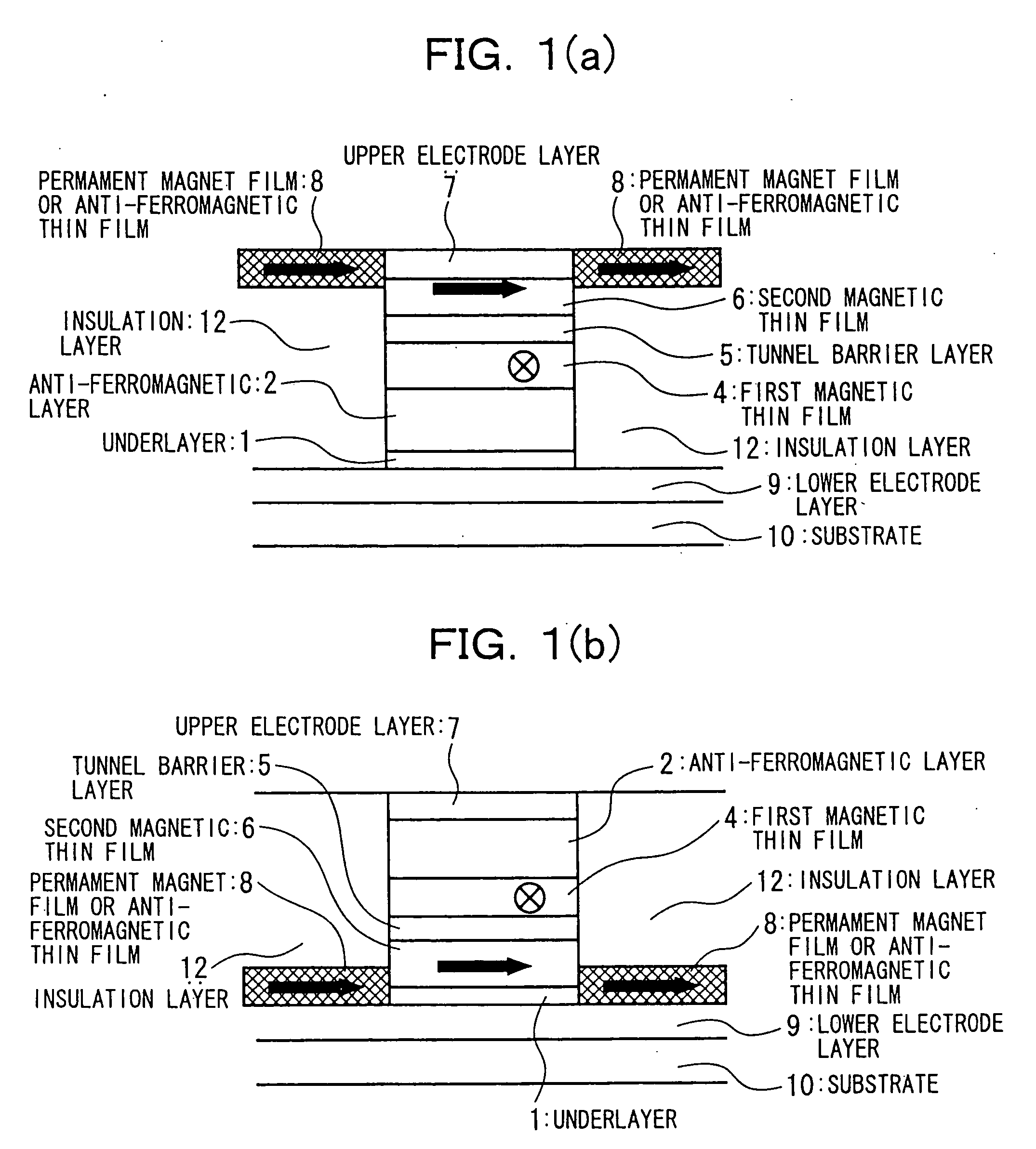

In a spin tunnel magnetoresistive effect film in which a magnetic thin film to which an exchange bias is applied by exchange coupling via an anti-ferromagnetic thin film and a magnetic thin film that detects a magnetic field are laminated, a magnetic thin film or an anti-ferromagnetic thin film (PtMn, PdMn, NiMn) is laminated onto an underlayer (Ta, Zr, Hf), the surface roughness thereof being in the range from 0.1 to 5 Angstroms. A means used to control the surface roughness introduces into the film growing chamber oxygen, nitrogen, hydrogen, or a gas mixture thereof into a vacuum of 10−6 Torr to 10−9 Torr, reduces the substrate temperature to 0° C. or lower during film growth, or oxidizes an underlayer. The lower electrode layer material used is a film laminate of a high-permeability amorphous magnetic material and a non-magnetic metallic layer.

Owner:NEC CORP

Method of diagnosing fatigue life of structural steelwork and a member of steelwork having life diagnostic function

InactiveUS6073493AEasily and accurately diagnosingEasy to diagnoseAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurementFatigue damageVoltage amplitude

In a method of diagnosing the fatigue life of structural steelwork according to the present invention, a Barkhausen noise measurement is performed under the condition of 5 mu m< / =d< / =1 mm where d is the detection depth of Barkhausen noise, by using a magnetic head constituted by an air-core coil detection head and a magnetic excitation head obtained by winding a copper wire such as an enameled wire on a U-shaped core made of a soft magnetic material such as a silicon steel sheet or an amorphous magnetic material. The degree of fatigue damage of a target measurement portion is diagnosed using the root-mean-square (RMS) voltage or voltage amplitude value of the Barkhausen noise. According to this method, the degree of fatigue and degradation by stress and strain in the structural steelwork can be accurately diagnosed prior to development of cracking without any limitation on diagnostic locations. A member of steelwork having a life diagnostic function is obtained by mounting the above magnetic head on a brace- or wall-like vibration-damping device made of very low-yield steel. According to this member of steelwork, the wall or covering material of a bridge or the like need not be removed even in practicing a fatigue life diagnosis. The degree of fatigue degradation in structural steelwork can be easily and accurately diagnosed prior to development of cracking even in a location where an operator cannot access due to the structural limitation.

Owner:NIPPON STEEL CORP

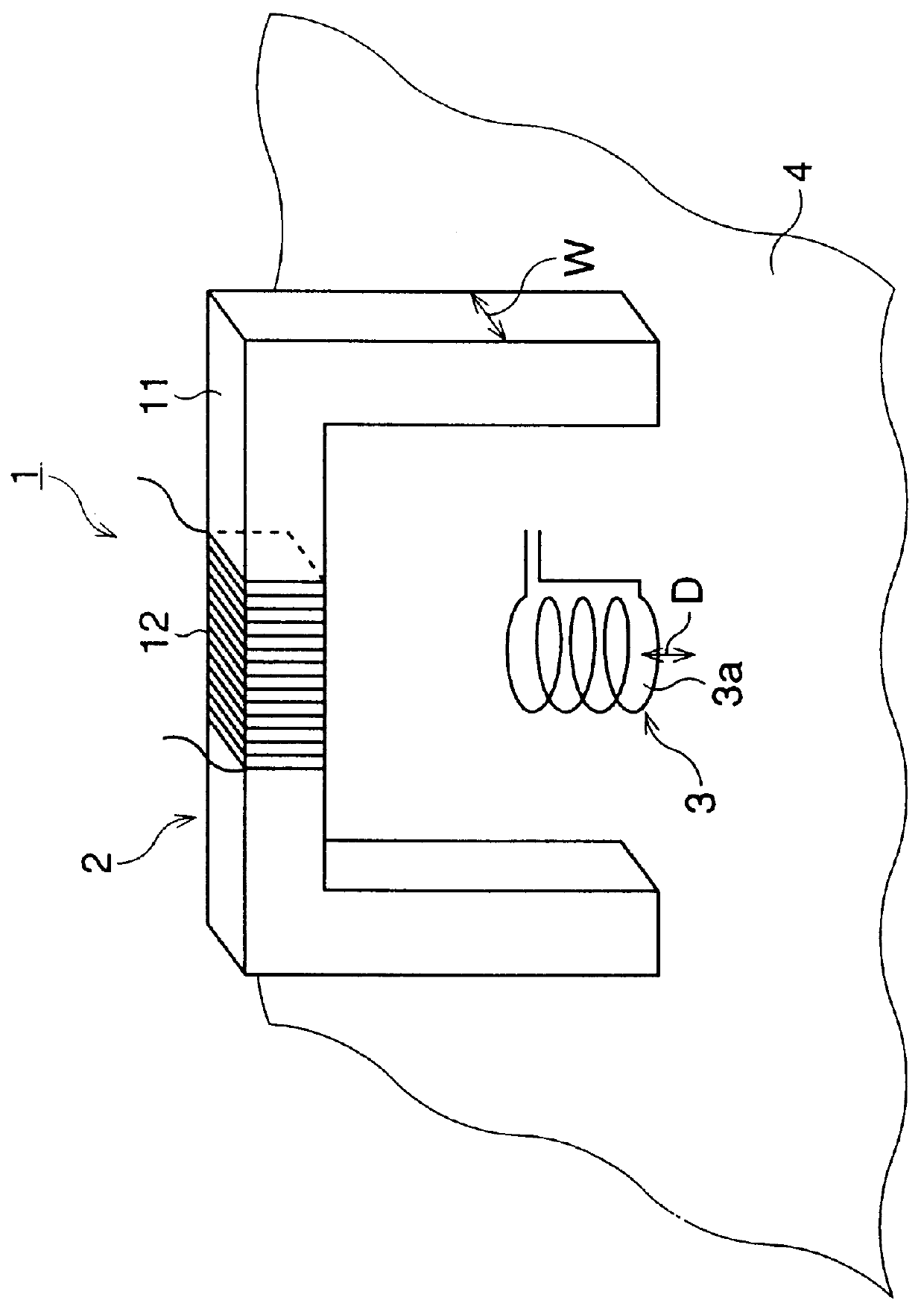

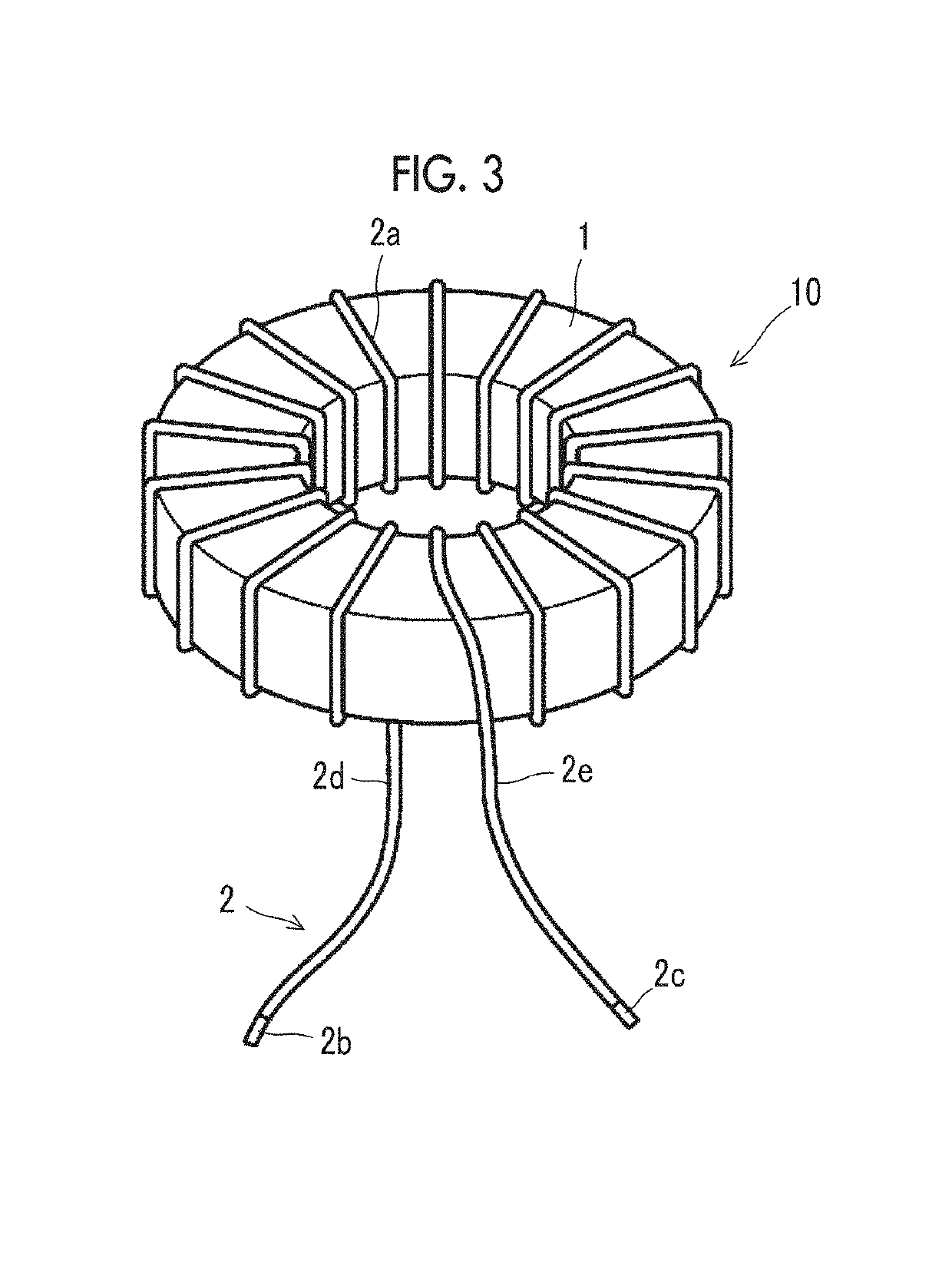

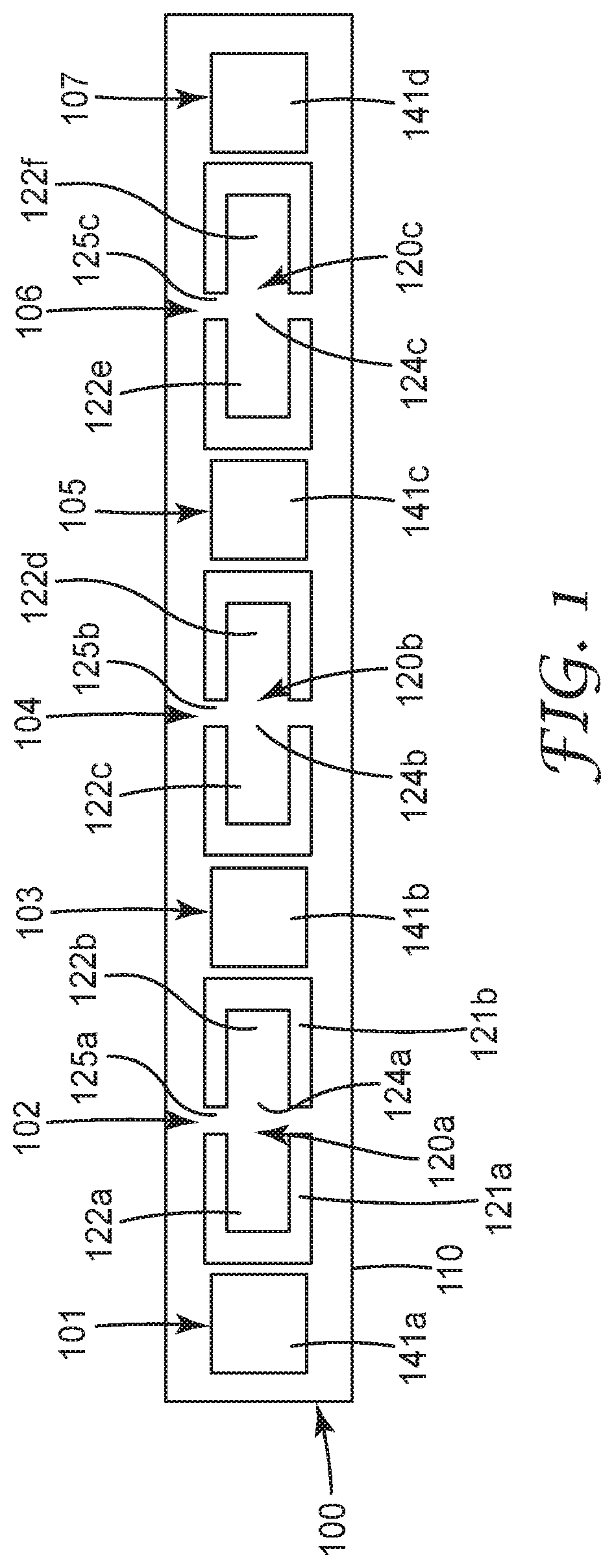

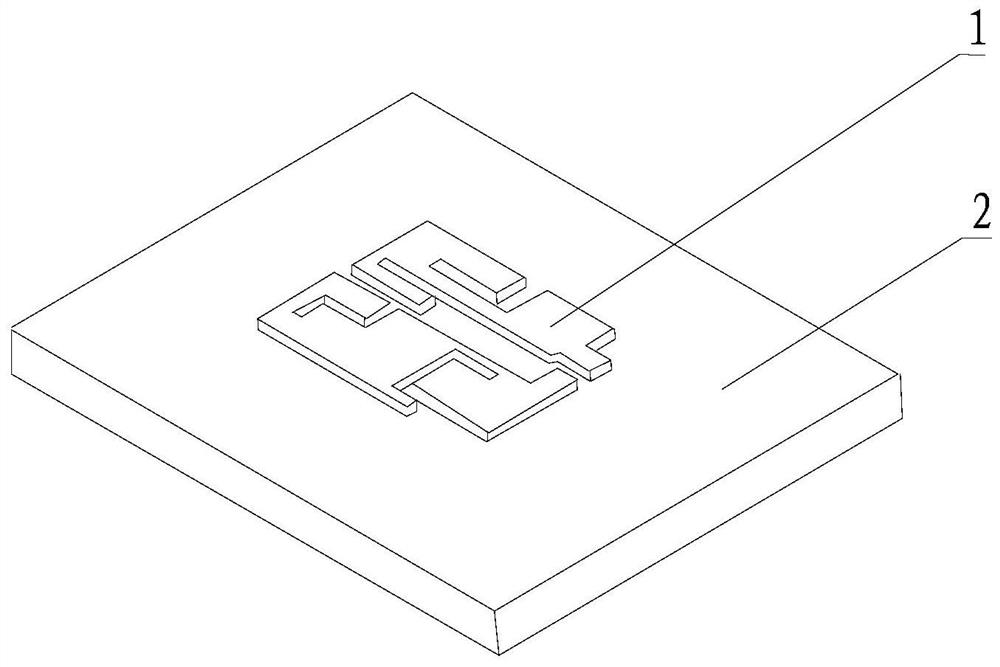

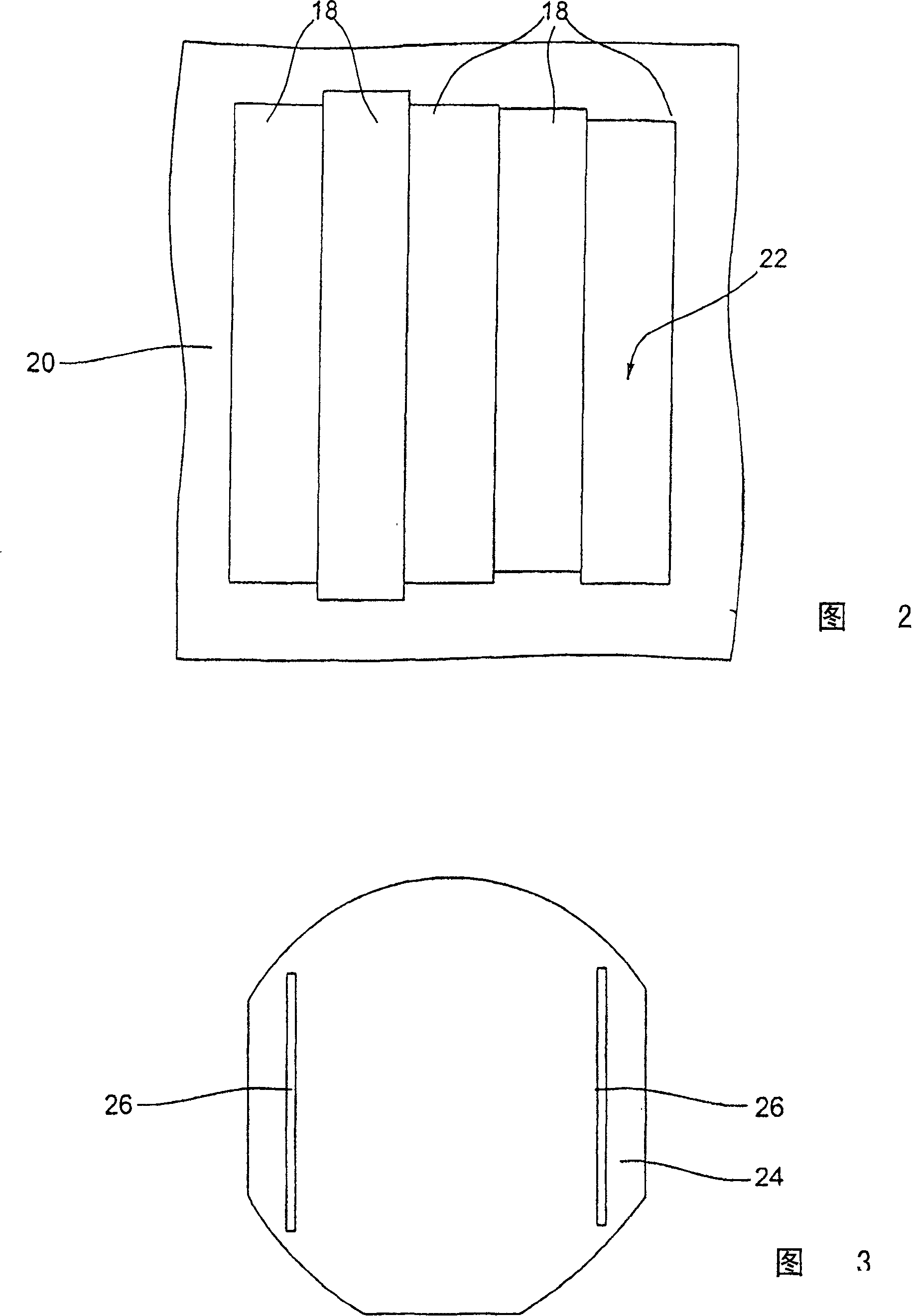

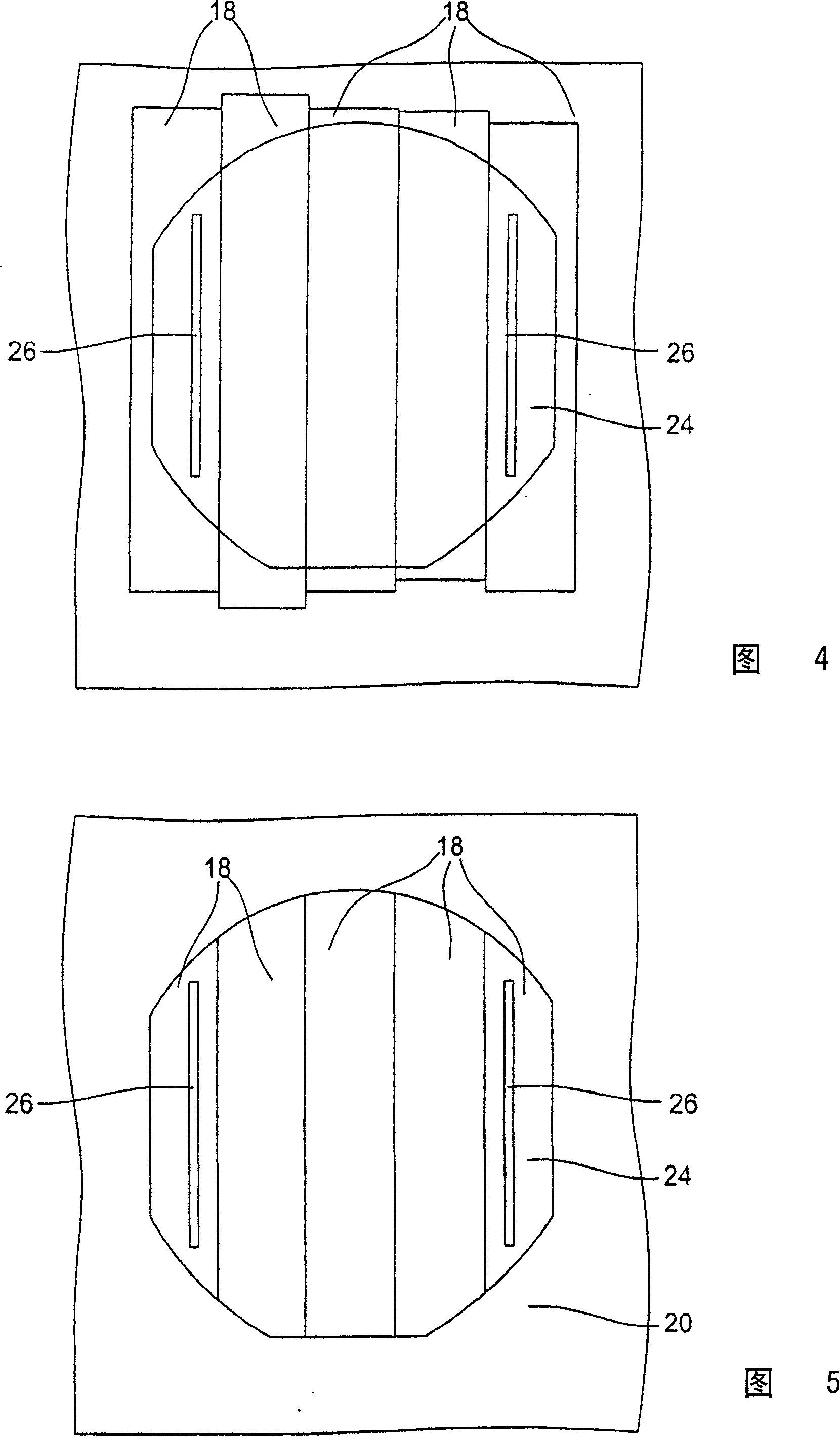

Method for mass production of a plurality of magnetic sensors

InactiveUS6949386B2Low costImprove uniformityMagnetic-field-controlled resistorsSolid-state devicesCondensed matter physicsSemiconductor

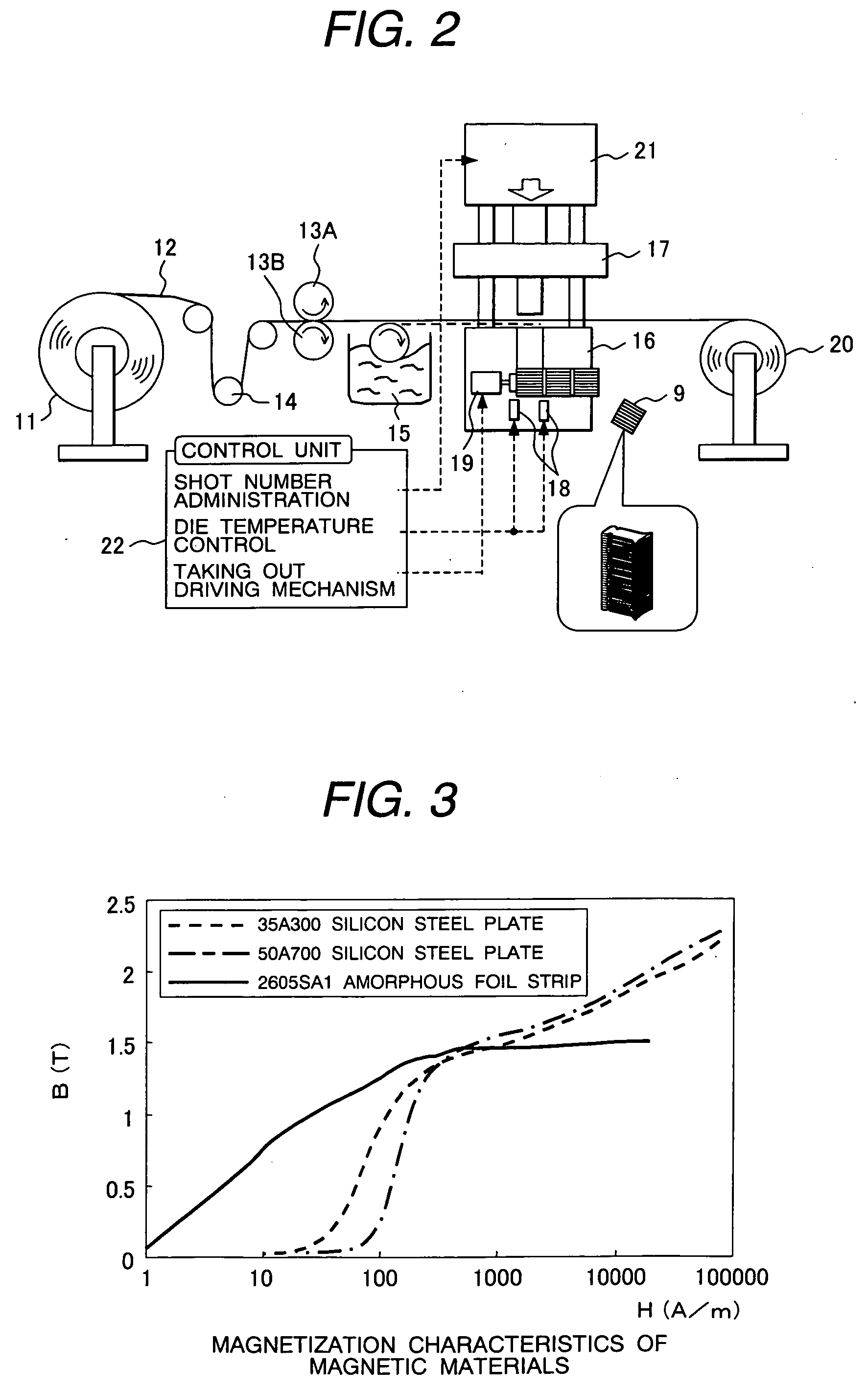

The present invention relates to a method for producing in large numbers a multiplicity of magnetic sensors produced on a semiconductor substrate, these sensors comprising at least one magnetic core produced in an amorphous magnetic material, characterised in that, after integration of the electronic circuits associated with the magnetic sensors, a film of amorphous magnetic material is glued onto the semiconductor substrate, this film being obtained from a band of amorphous magnetic material cut into a plurality of sections which are disposed one beside the other on a support, said film being then structured in order to form the magnetic cores of said magnetic sensors, the semiconductor substrate being finally cut up in order to provide a plurality of individual magnetic sensors.

Owner:ASULAB SA

Communication appts. and installing structure, mfg. method and communication method

InactiveCN1463229AHigh sensitivityImprove directionalityLoop antennas with ferromagnetic coreOther printing matterMetallic materialsConductive materials

Owner:HANEX CO LTD

Spin tunnel magnetoresistive effect film and element, magnetoresistive sensor using same, magnetic apparatus, and method for manufacturing same

InactiveUS7160572B2Reduced effectivenessPrevent oxidationNanomagnetismMagnetic measurementsNitrogen gasOxygen

In a spin tunnel magnetoresistive effect film in which a magnetic thin film to which an exchange bias is applied by exchange coupling via an anti-ferromagnetic thin film and a magnetic thin film that detects a magnetic field are laminated, a magnetic thin film or an anti-ferromagnetic thin film (PtMn, PdMn, NiMn) is laminated onto an underlayer (Ta, Zr, Hf), the surface roughness thereof being in the range from 0.1 to 5 Angstroms. A means used to control the surface roughness introduces into the film growing chamber oxygen, nitrogen, hydrogen, or a gas mixture thereof into a vacuum of 10−6 Torr to 10−9 Torr, reduces the substrate temperature to 0° C. or lower during film growth, or oxidizes an underlayer. The lower electrode layer material used is a film laminate of a high-permeability amorphous magnetic material and a non-magnetic metallic layer.

Owner:NEC CORP

Electric rotating machine having permanent magnets and method of manufacturing teeth portions of the stator iron core

InactiveUS7626301B2Reduced loss torqueReduce vibrationManufacturing dynamo-electric machinesMagnetic circuit characterised by magnetic materialsEngineeringConductor Coil

An electric rotating machine having permanent magnets having a rotor having a plurality of permanent magnets, a stator iron core disposed in opposite relation with the rotor, and a stator winding wound around the stator core, wherein the stator core is constituted by a yoke and a plurality of teeth portions disposed to the yoke. The teeth portions are projected towards the inner periphery of the rotor. The teeth portions are made of amorphous magnetic material.

Owner:JAPAN SERVO CO LTD +3

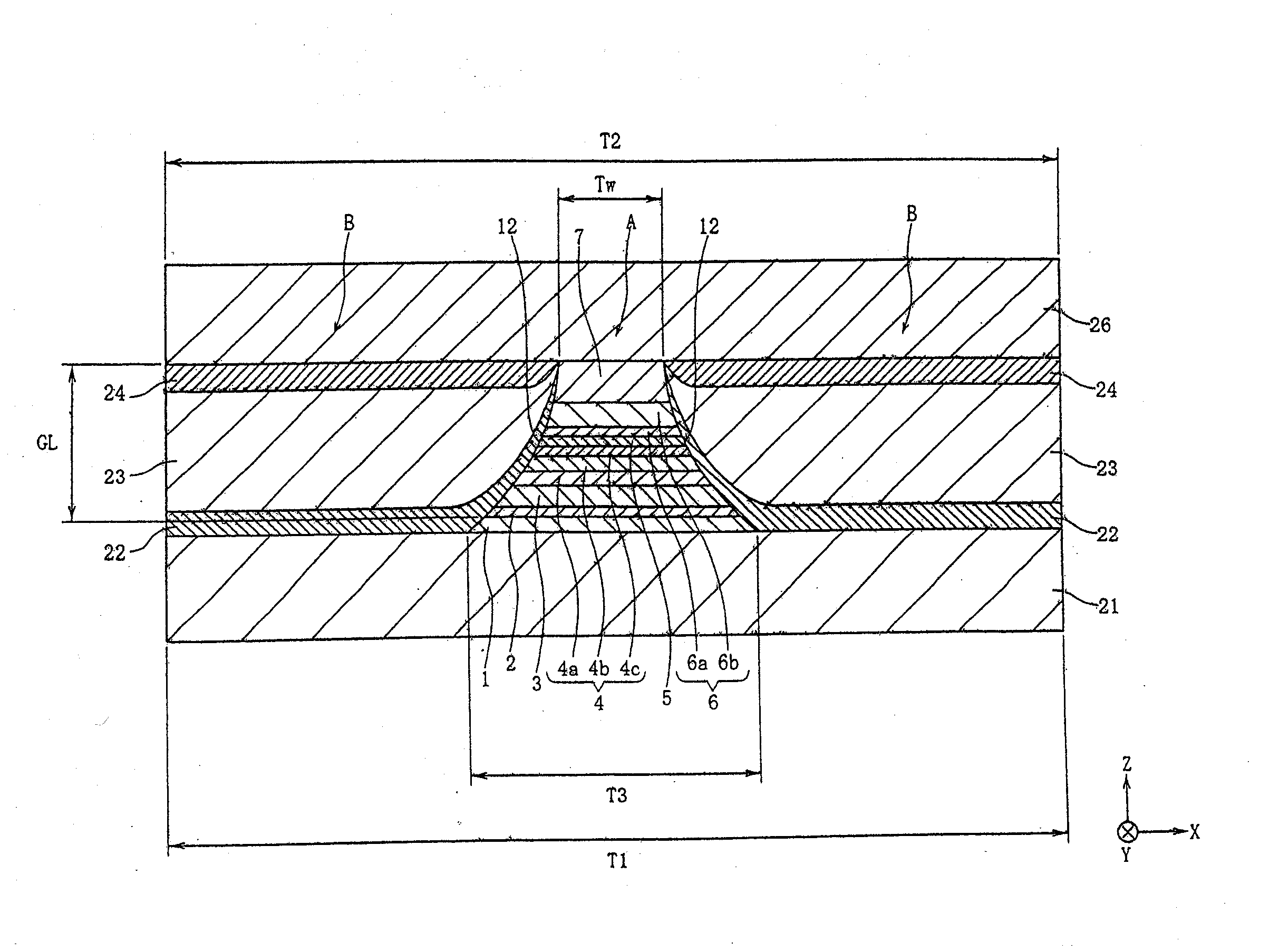

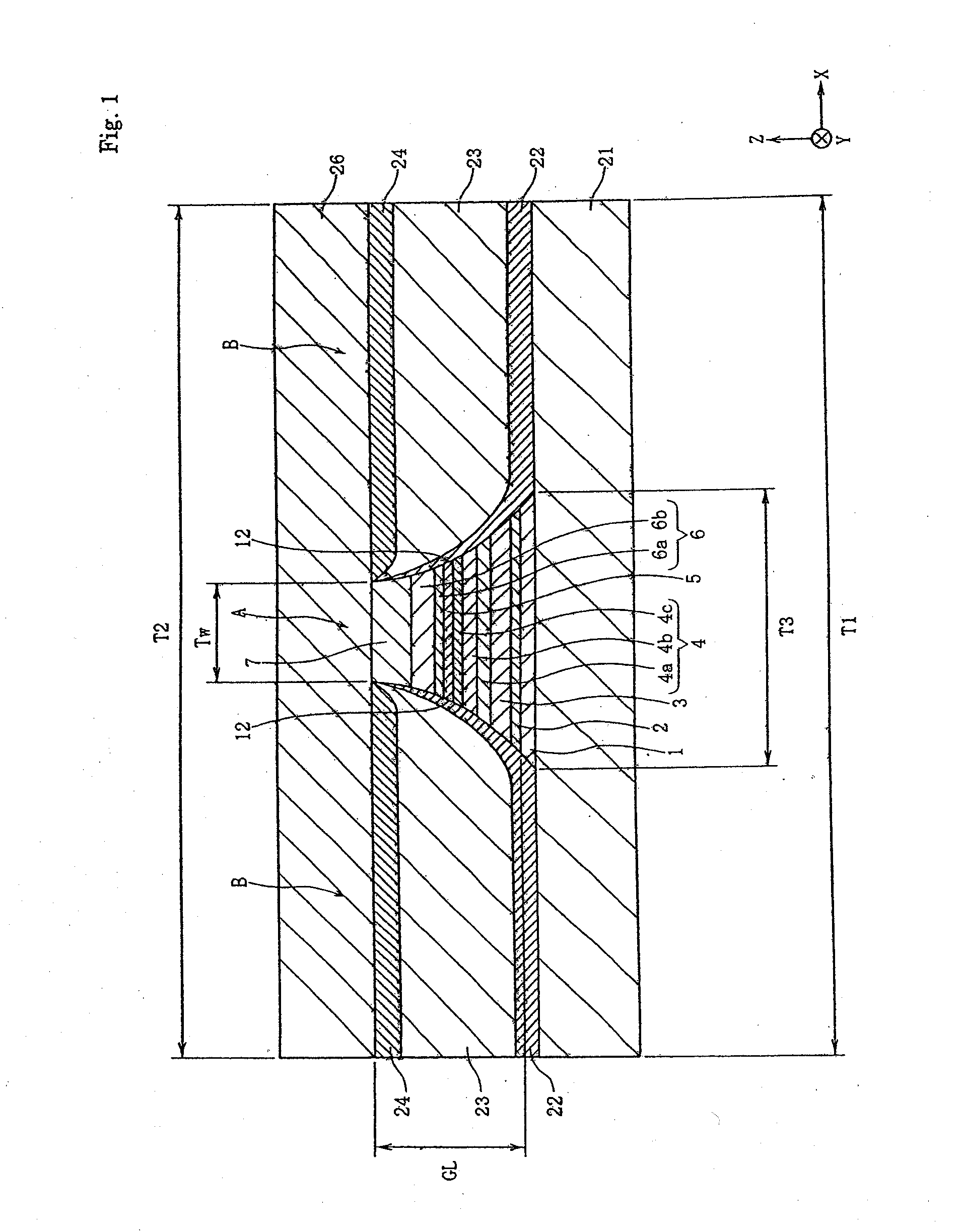

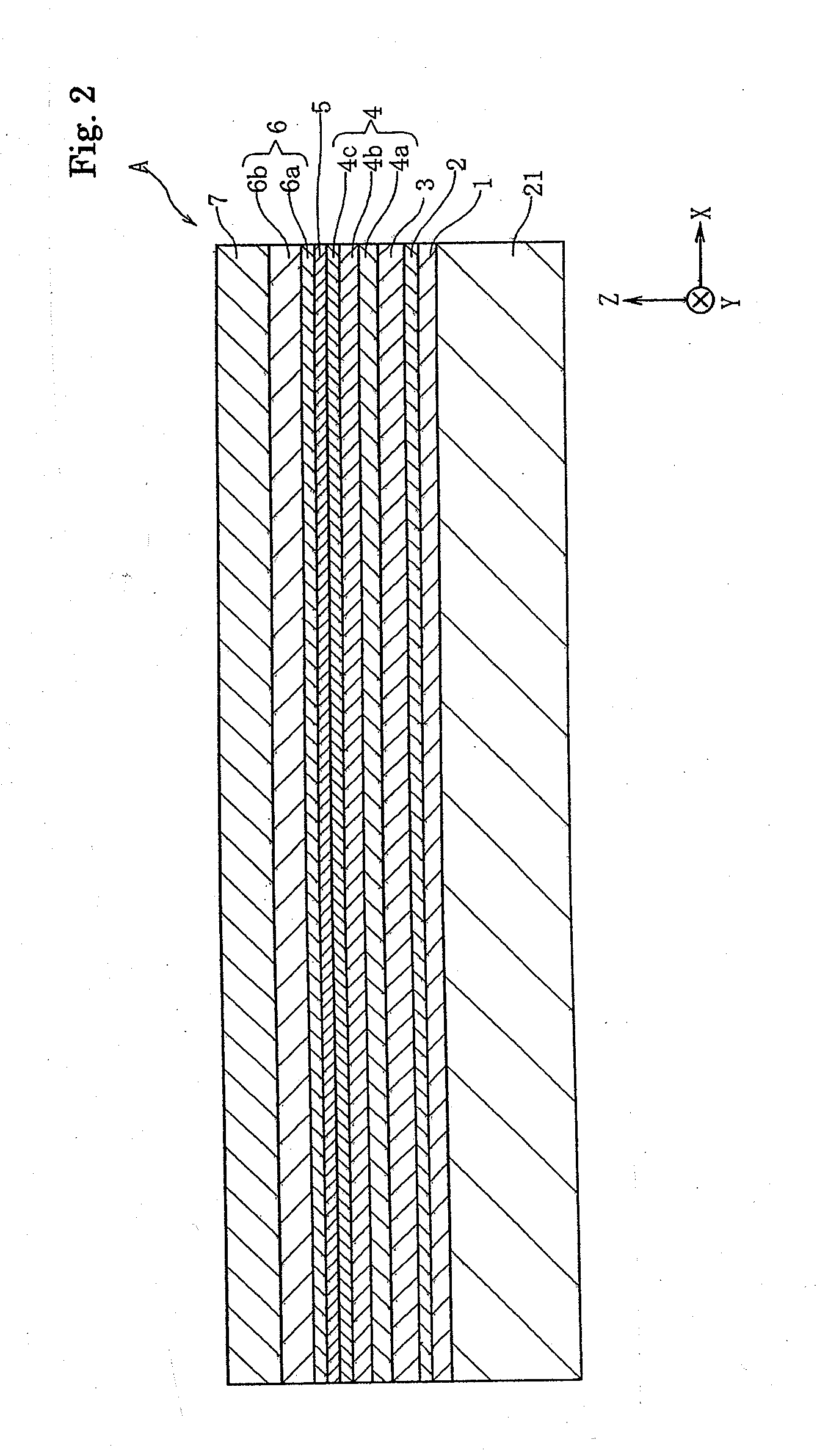

Magnetic sensing element and method for manufacturing the same

ActiveUS8009391B2Decrease in reproducing characteristicImprove recording densityNanomagnetismMagnetic measurementsRecording densityAmorphous magnetic material

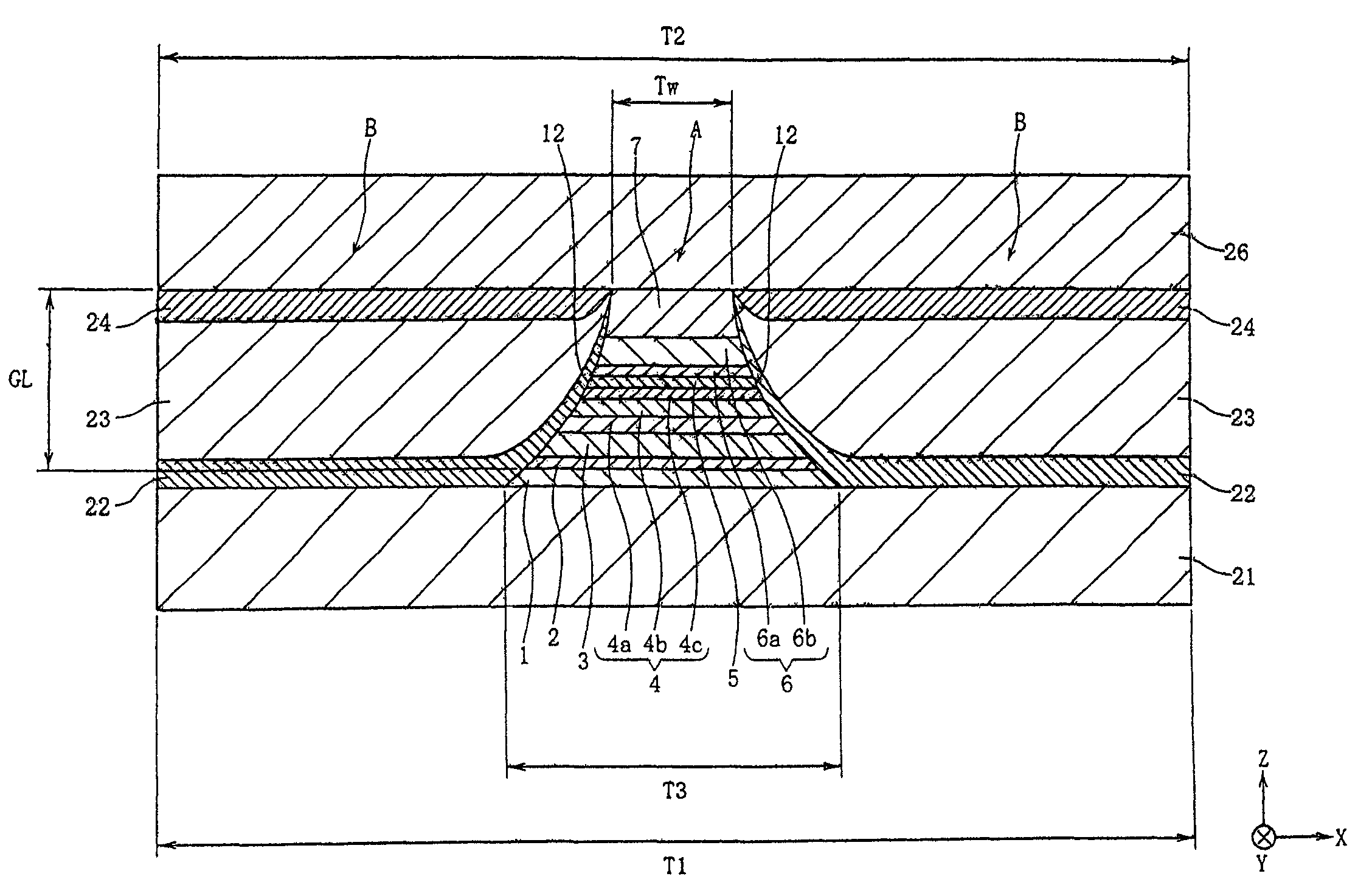

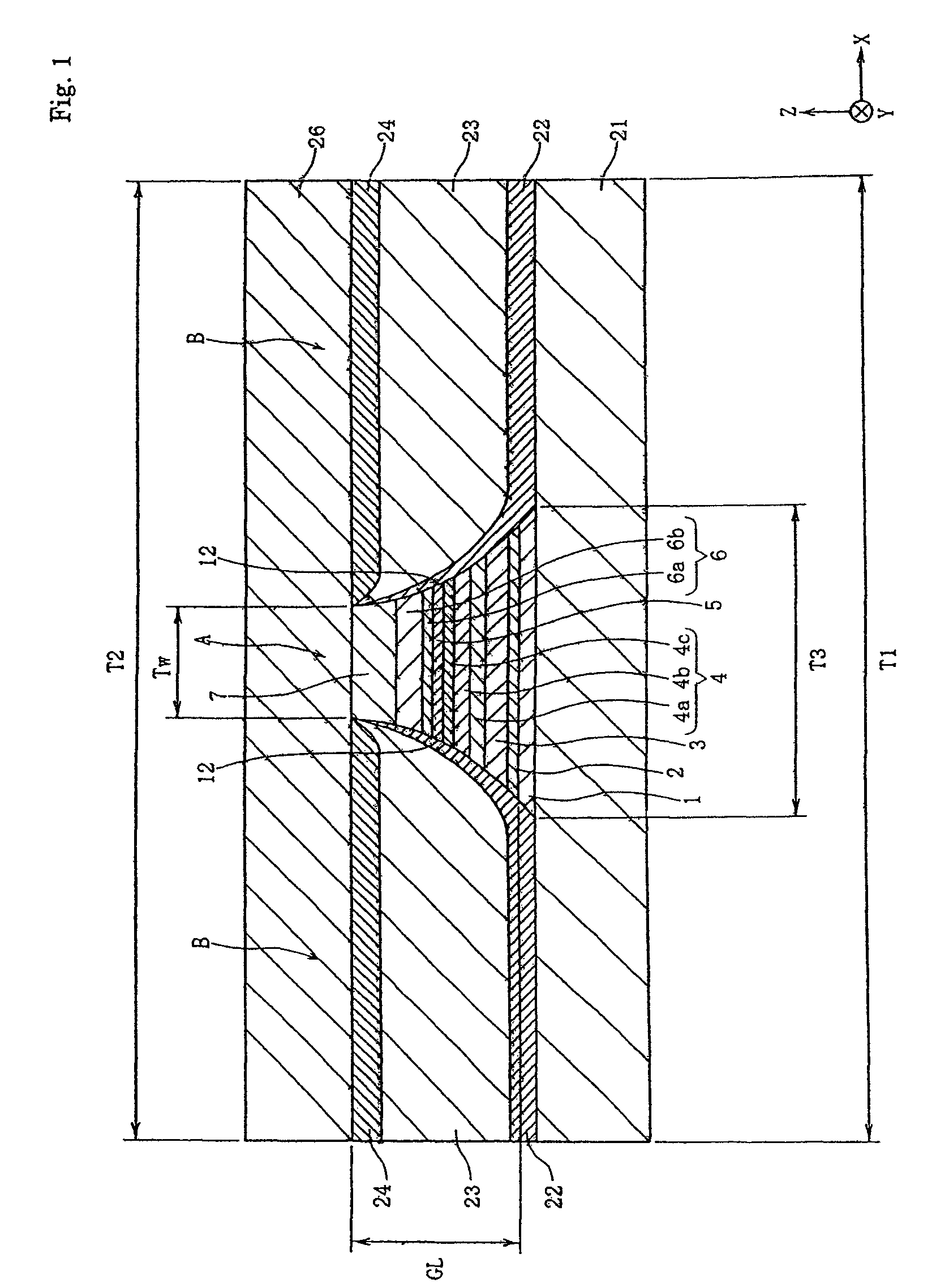

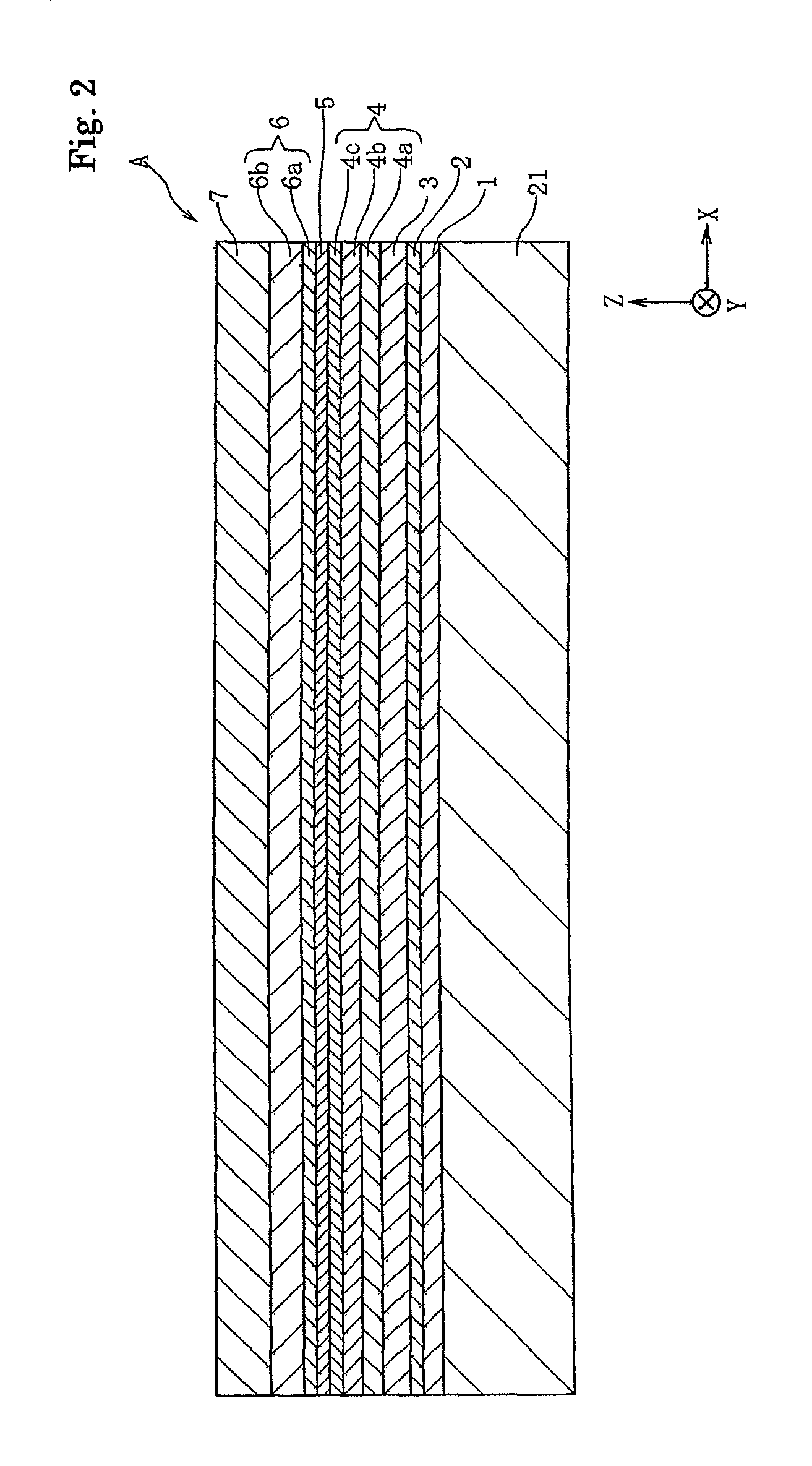

An underlying layer is composed of Co—Fe—B that is an amorphous magnetic material. Thus, the upper surface of the underlying layer can be taken as a lower shield layer-side reference position for obtaining a gap length (GL) between upper and lower shields, resulting in a narrower gap than before. In addition, since the underlying layer has an amorphous structure, the underlying layer does not adversely affect the crystalline orientation of individual layers to be formed thereon, and the surface of the underlying layer has good planarizability. Accordingly, PW50 (half-amplitude pulse width) and SN ratio can be improved more than before without causing a decrease in rate of change in resistance (Δ R / R) or the like, thereby achieving a structure suitable for increasing recording density.

Owner:TDK CORPARATION

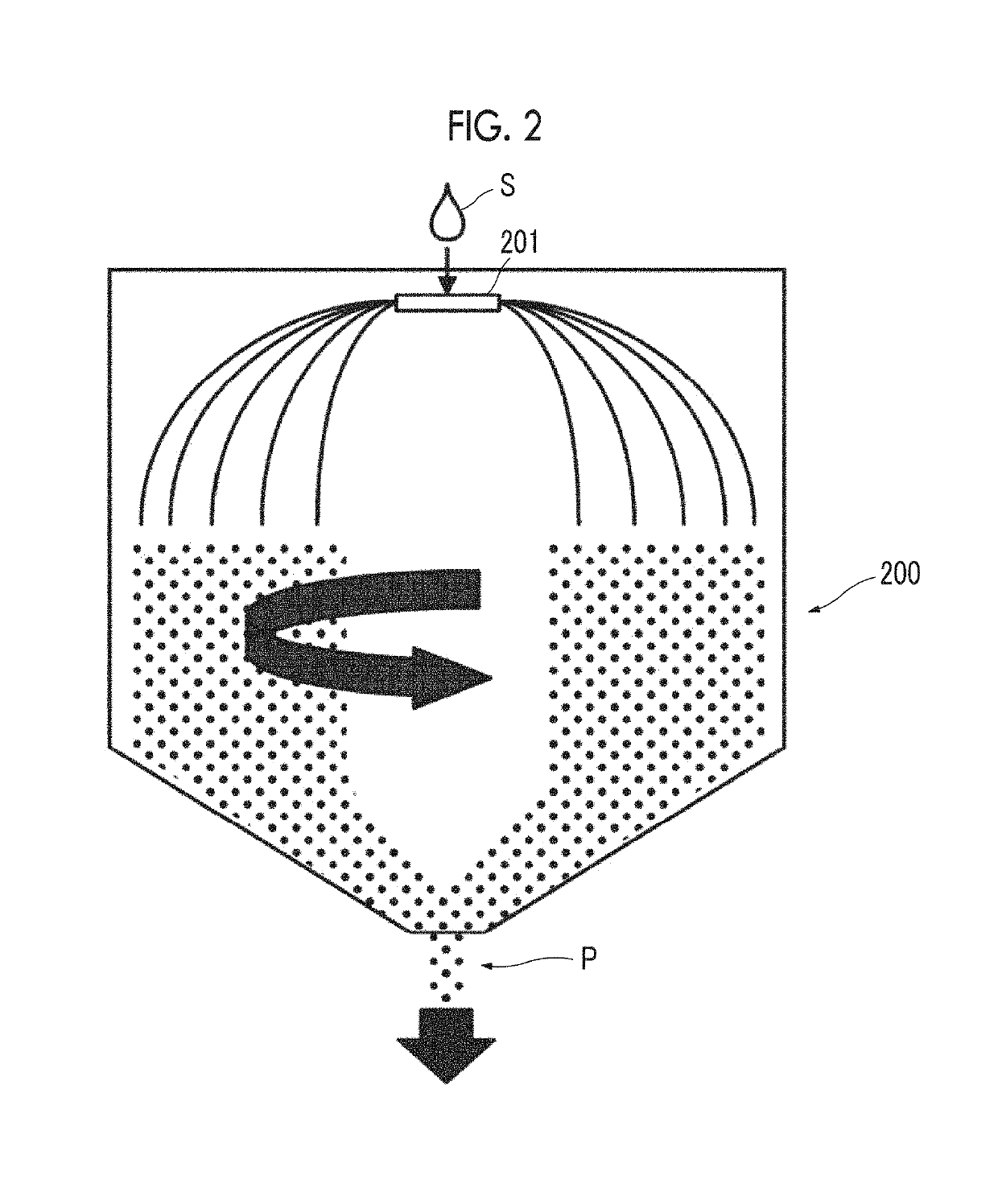

Powder core, manufacturing method of powder core, inductor including powder core, and electronic/electric device having inductor mounted therein

ActiveUS20170309387A1Excellent superposition characteristicReduce lossTransformers/inductances coils/windings/connectionsInorganic material magnetismMetallurgyInductor

A powder core includes: a powder of a crystalline magnetic material; and a powder of an amorphous magnetic material, in which a median diameter D50A of the powder of the amorphous magnetic material is 15 μm or less, and satisfies the expression: 1≦D50A / D50C≦3.5 with respect to a median diameter D50C of the powder of the crystalline magnetic material.

Owner:ALPS ALPINE CO LTD

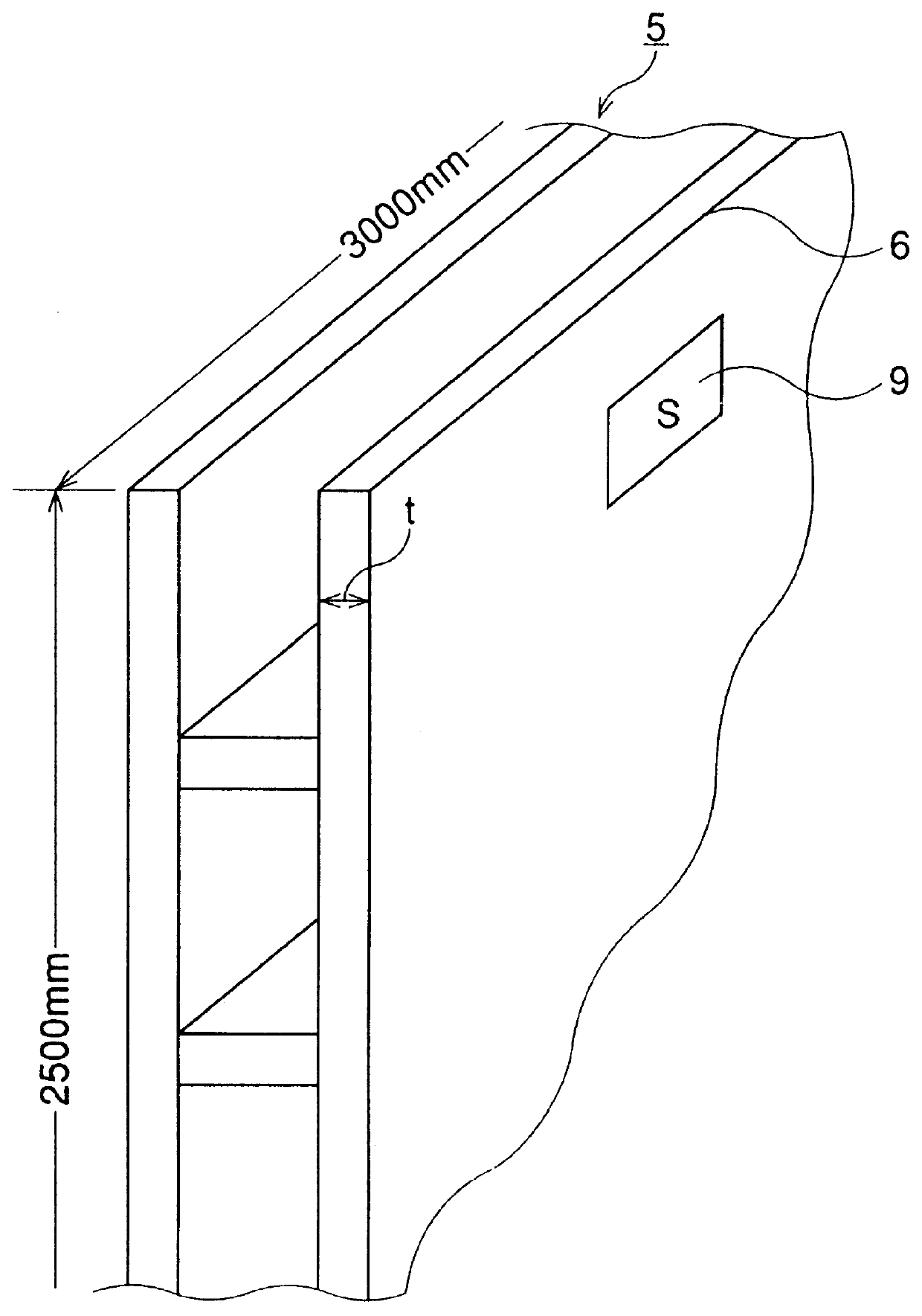

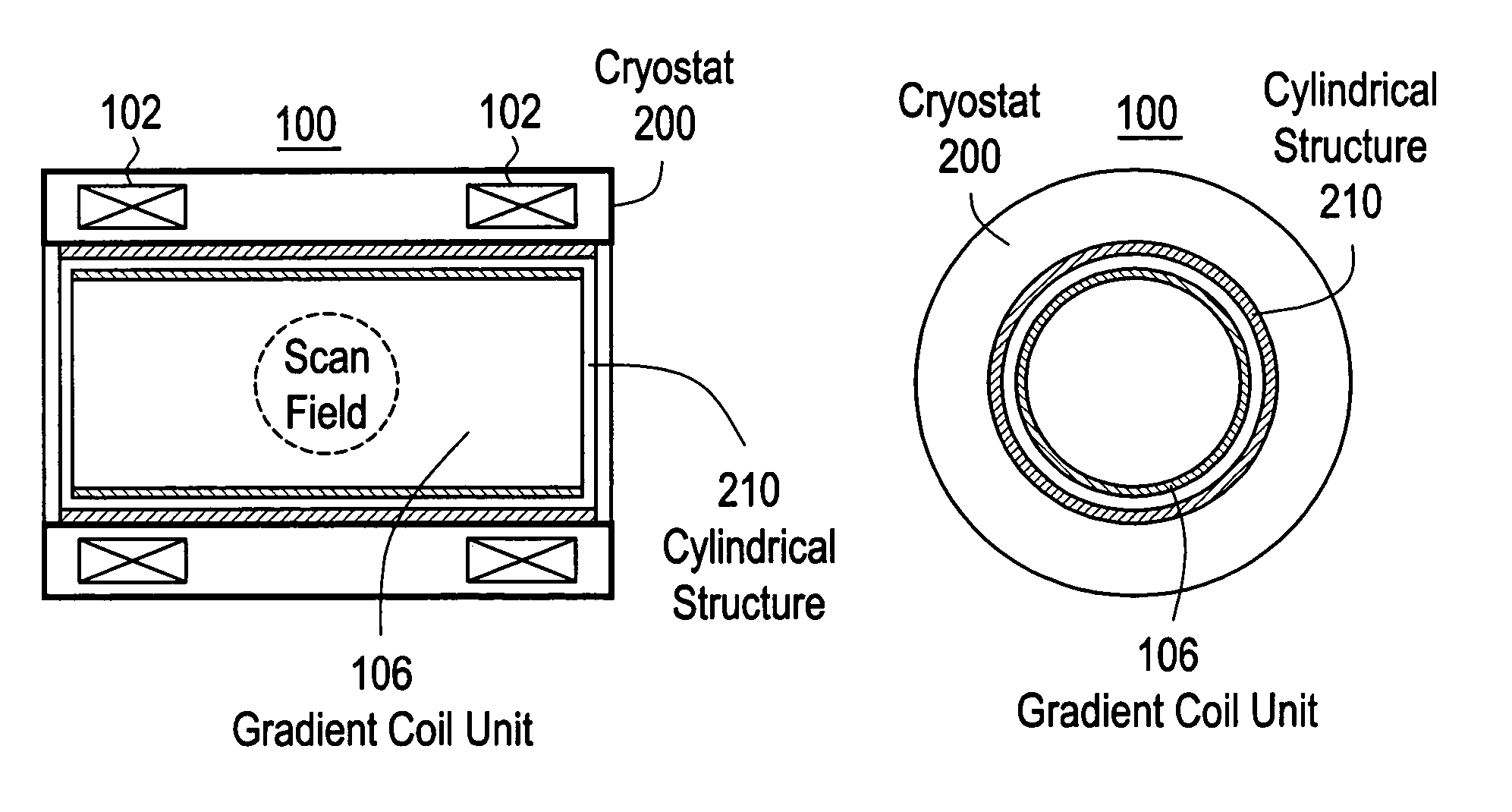

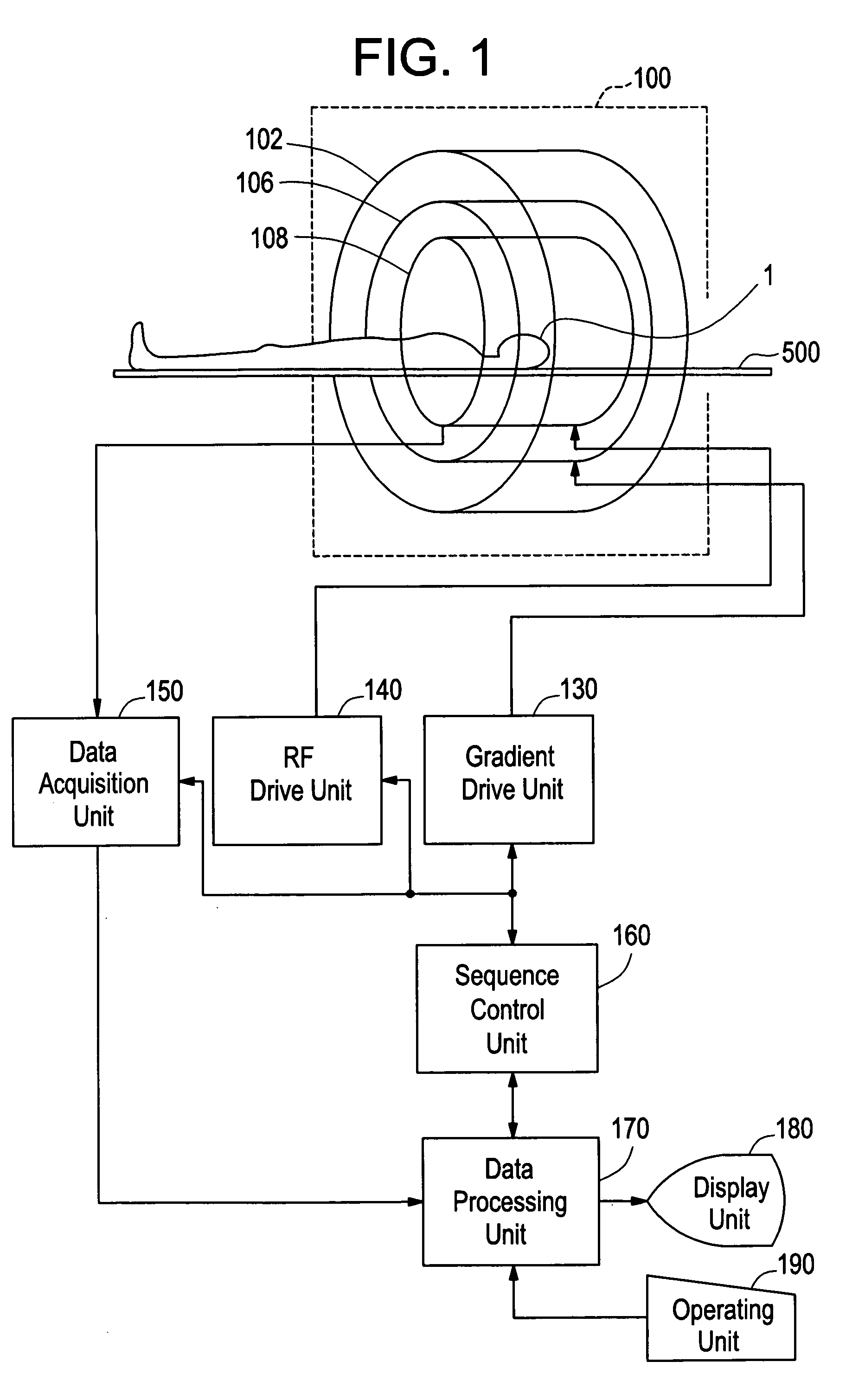

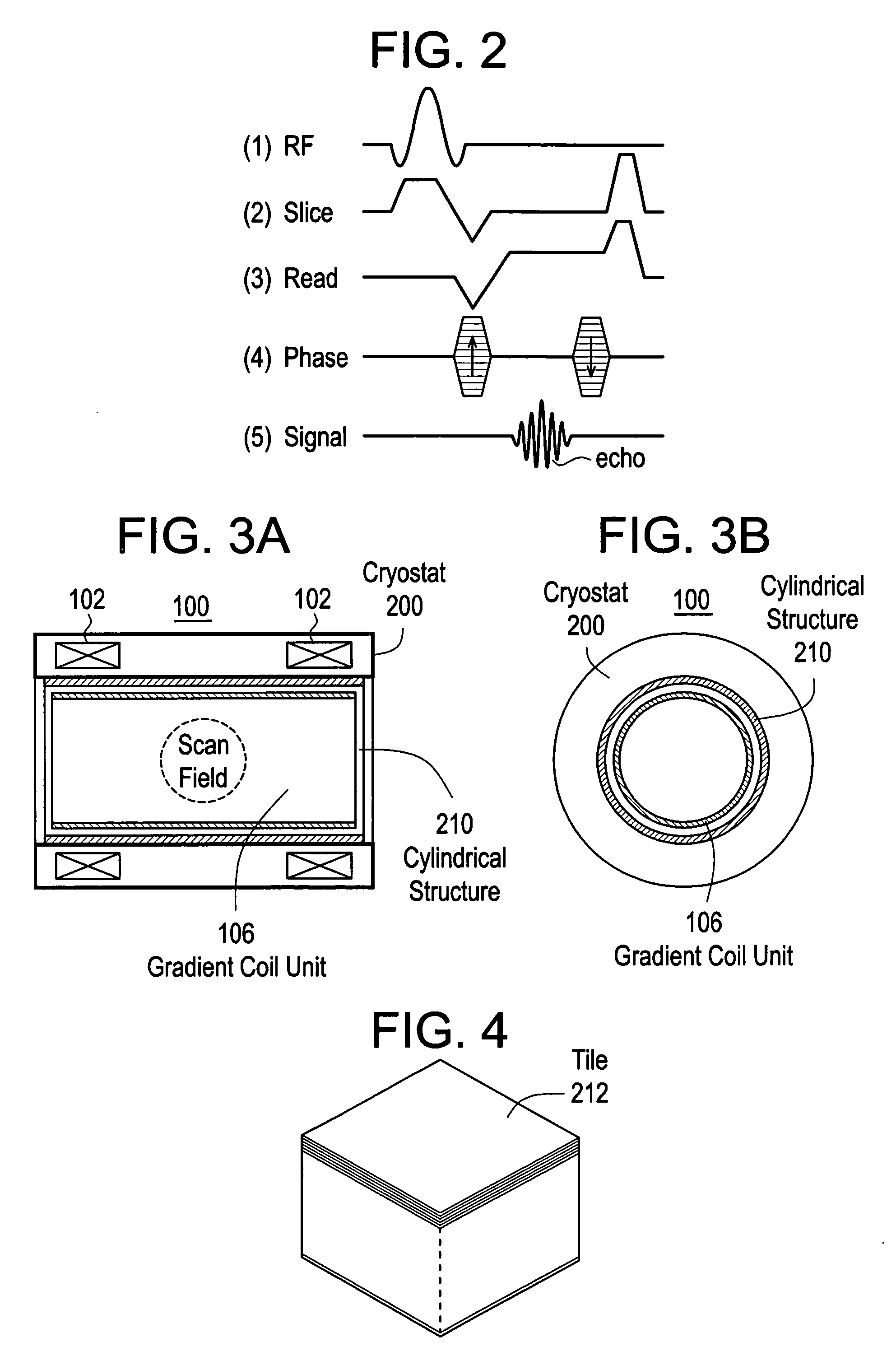

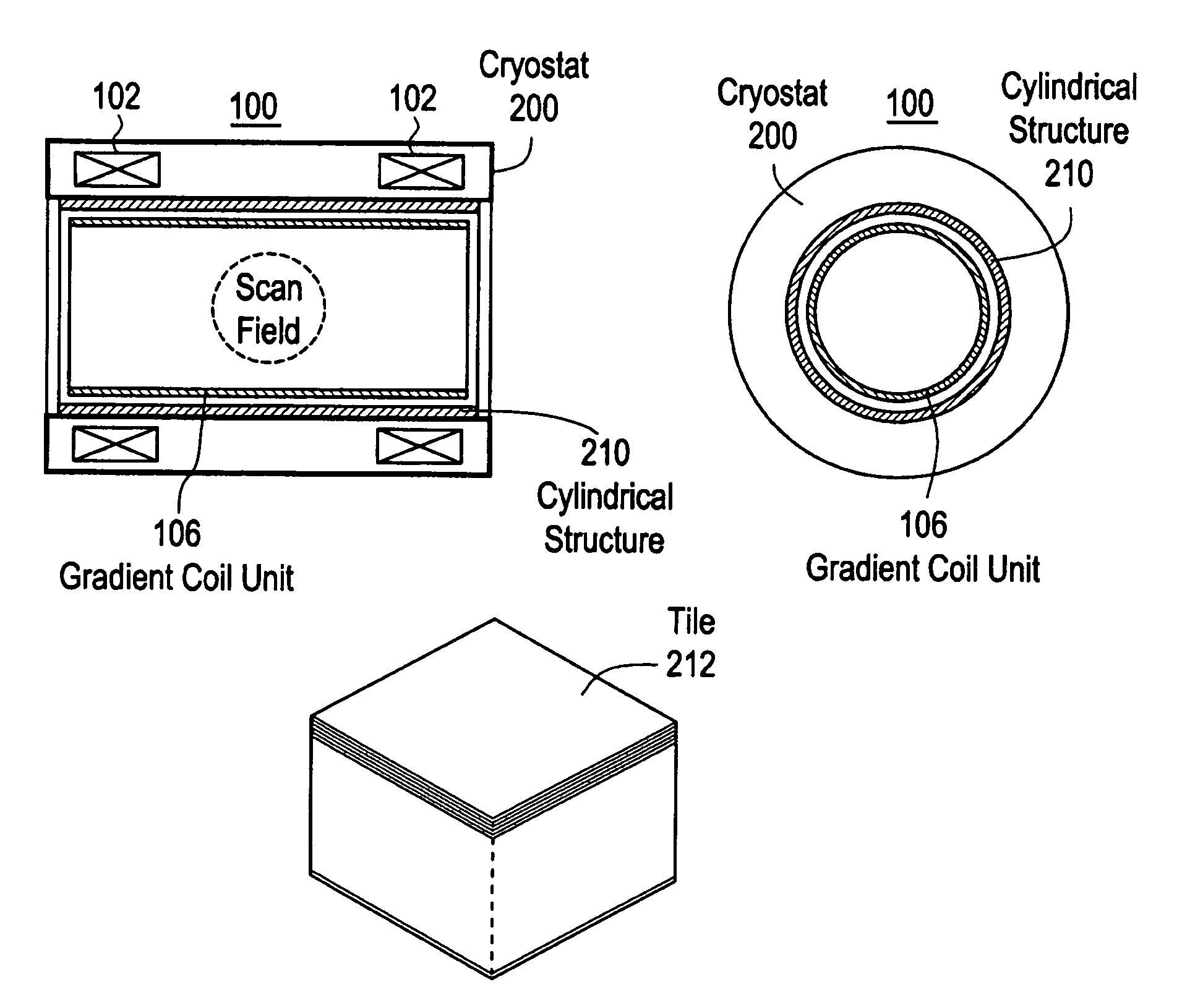

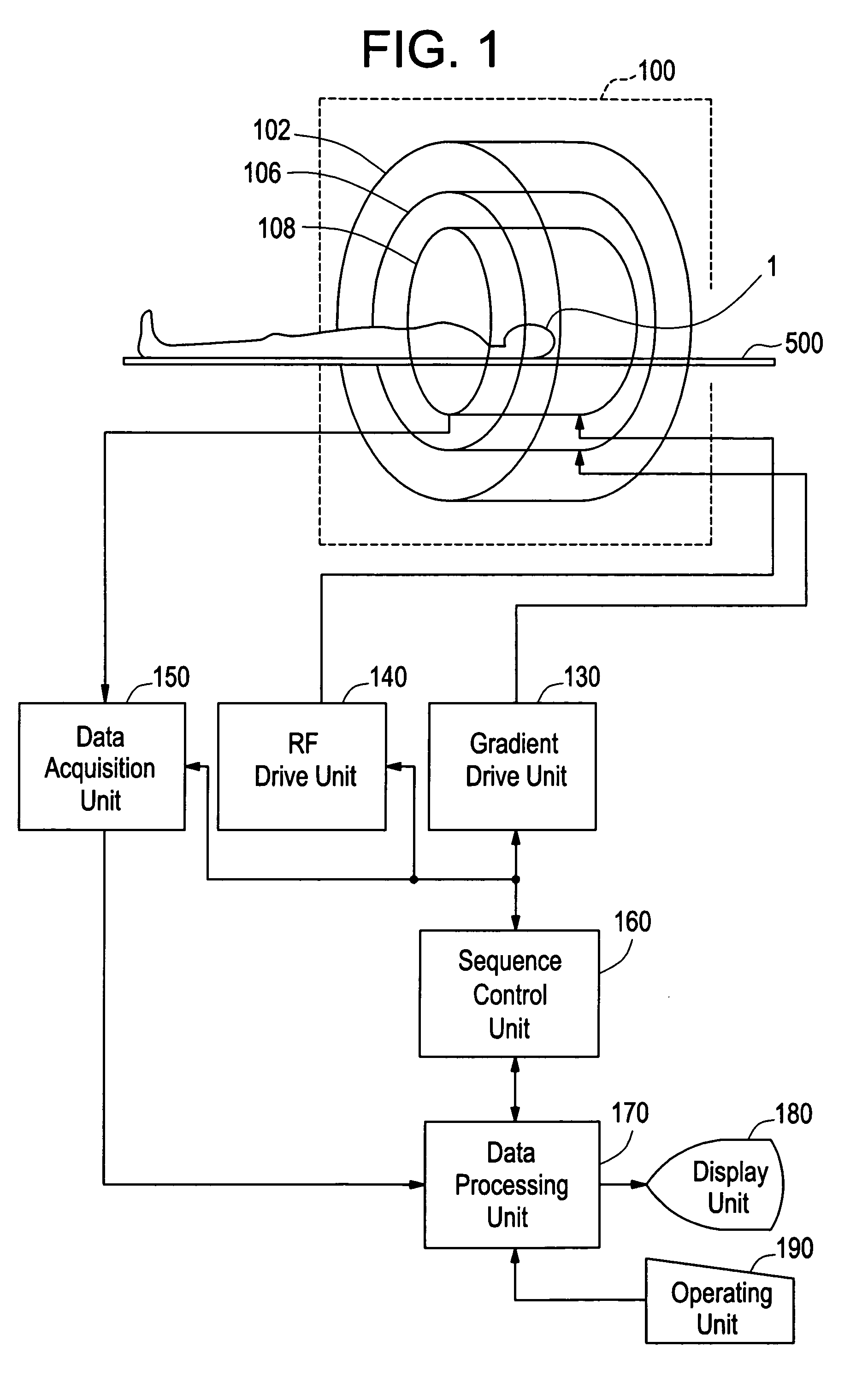

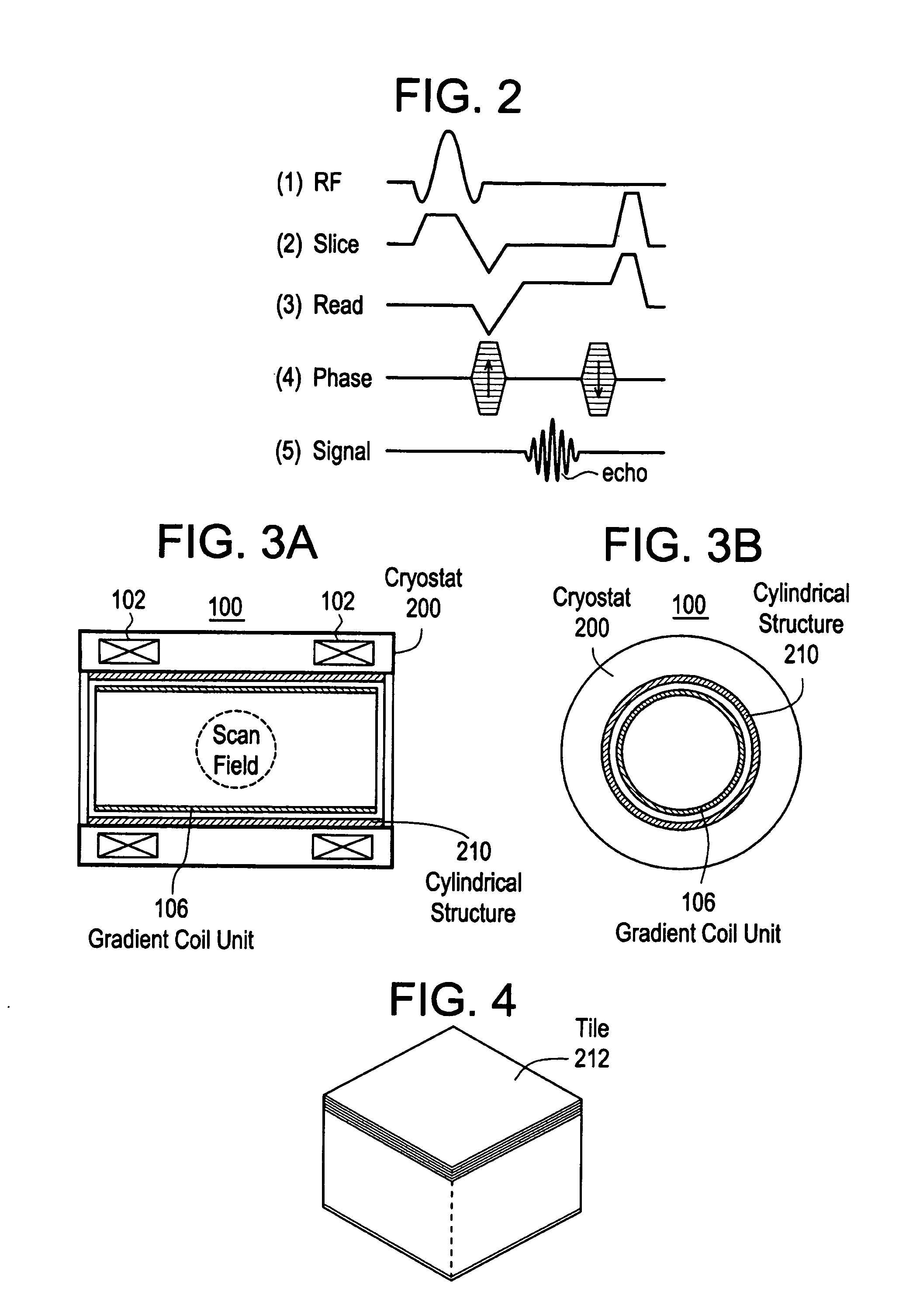

Magnet system and MRI system

InactiveUS20060113997A1Eddy currents can be effectively suppressedMagnetic measurementsElectric/magnetic detectionSuperconducting CoilsEngineering

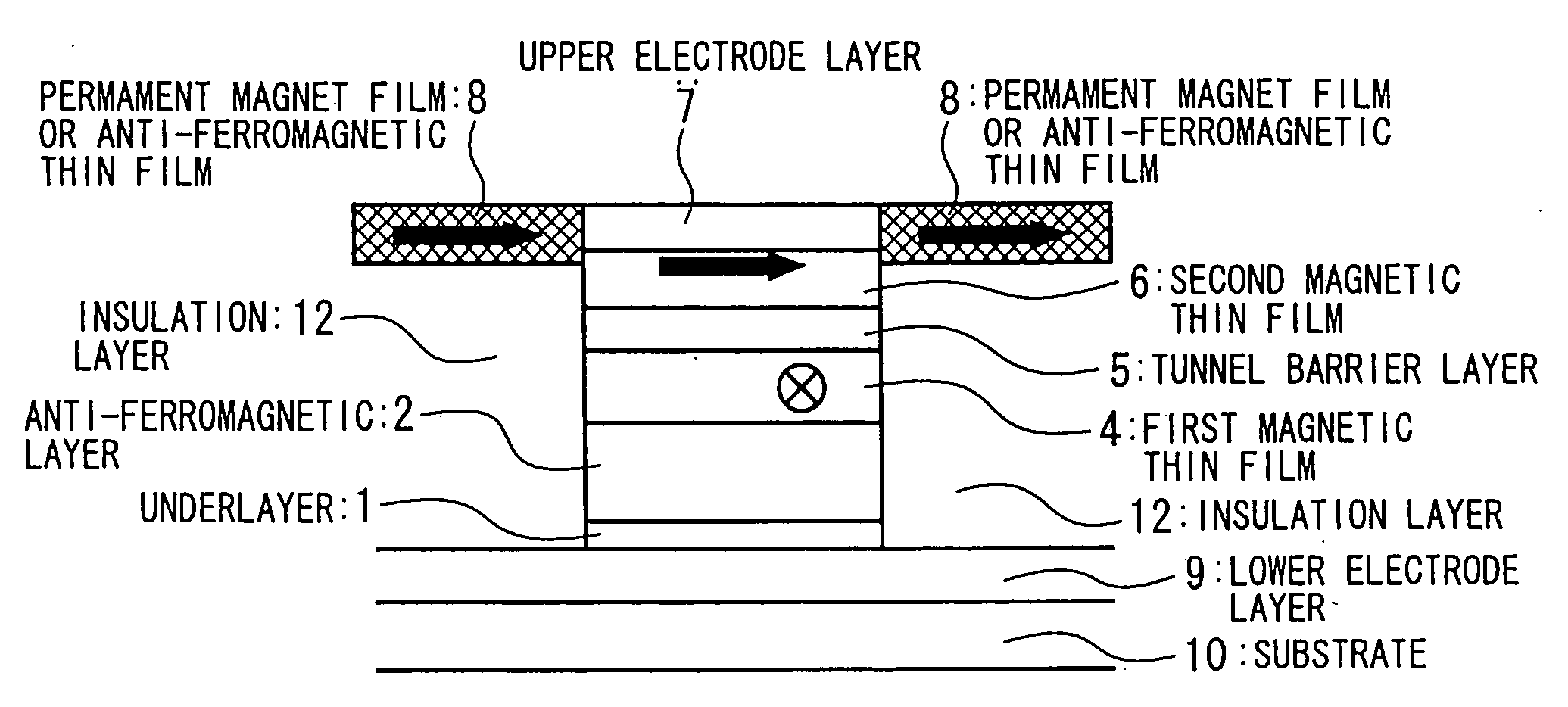

The present invention is intended to provide a magnet apparatus obviating the necessity of shield coils designed to suppress eddy currents. The magnet apparatus has gradient coils disposed in a bore of a cylindrical superconducting magnet, and includes a cylindrical structure that is realized with a combination of tiles made of a high-permeability material and that is interposed between the internal surface of the superconducting magnet and the external surface of the gradient coils. The tiles made of a high-permeability material are laminates made of a high-permeability material. The high-permeability material is a silicon steel plate or an amorphous magnetic material.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Magnetic sensing element and method for manufacturing the same

ActiveUS20080285180A1Reduce reproductionImprove recording densityNanomagnetismMagnetic measurementsAmorphous magnetic materialPhysics

An underlying layer is composed of Co—Fe—B that is an amorphous magnetic material. Thus, the upper surface of the underlying layer can be taken as a lower shield layer-side reference position for obtaining a gap length (GL) between upper and lower shields, resulting in a narrower gap than before. In addition, since the underlying layer has an amorphous structure, the underlying layer does not adversely affect the crystalline orientation of individual layers to be formed thereon, and the surface of the underlying layer has good planarizability. Accordingly, PW50 (half-amplitude pulse width) and SN ratio can be improved more than before without causing a decrease in rate of change in resistance (Δ R / R) or the like, thereby achieving a structure suitable for increasing recording density.

Owner:TDK CORPARATION

Dust core, method for manufacturing dust core, inductor including dust core, and electronic/electric device including inductor

ActiveUS20180021853A1Low core lossImprove dustproof effectTransportation and packagingMetal-working apparatusMetallurgyInductor

A dust core contains a powder of a crystalline magnetic material powder and a powder of an amorphous magnetic material. The sum of the content of the crystalline magnetic material powder and the content of the amorphous magnetic material powder is 83 mass percent or more. The mass ratio of the content of the crystalline magnetic material powder to the sum of the content of the crystalline magnetic material powder and the content of the amorphous magnetic material powder is 20 mass percent or less. The median diameter D50 of the amorphous magnetic material powder is greater than or equal to the median diameter D50 of the crystalline magnetic material powder.

Owner:ALPS ALPINE CO LTD

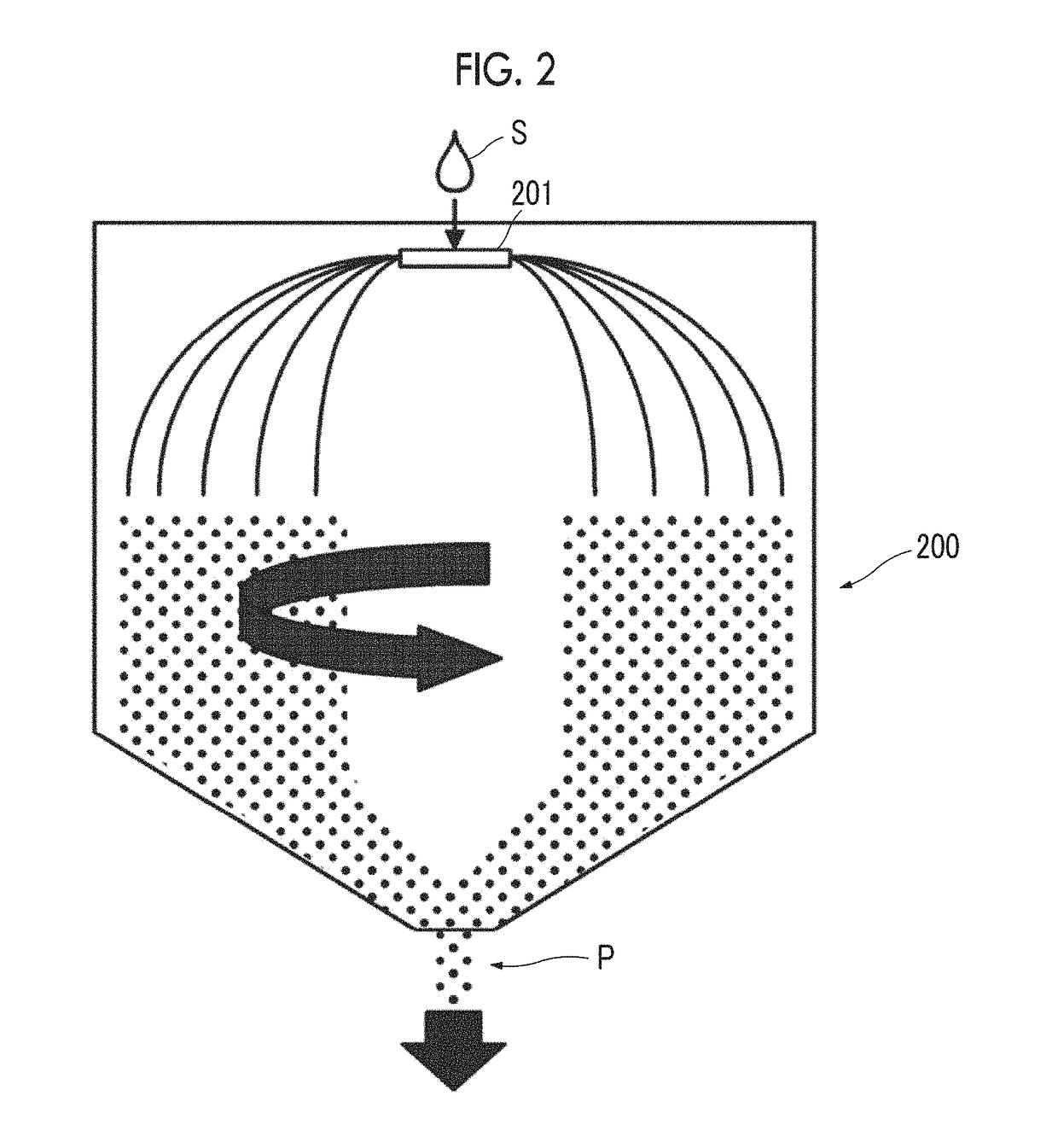

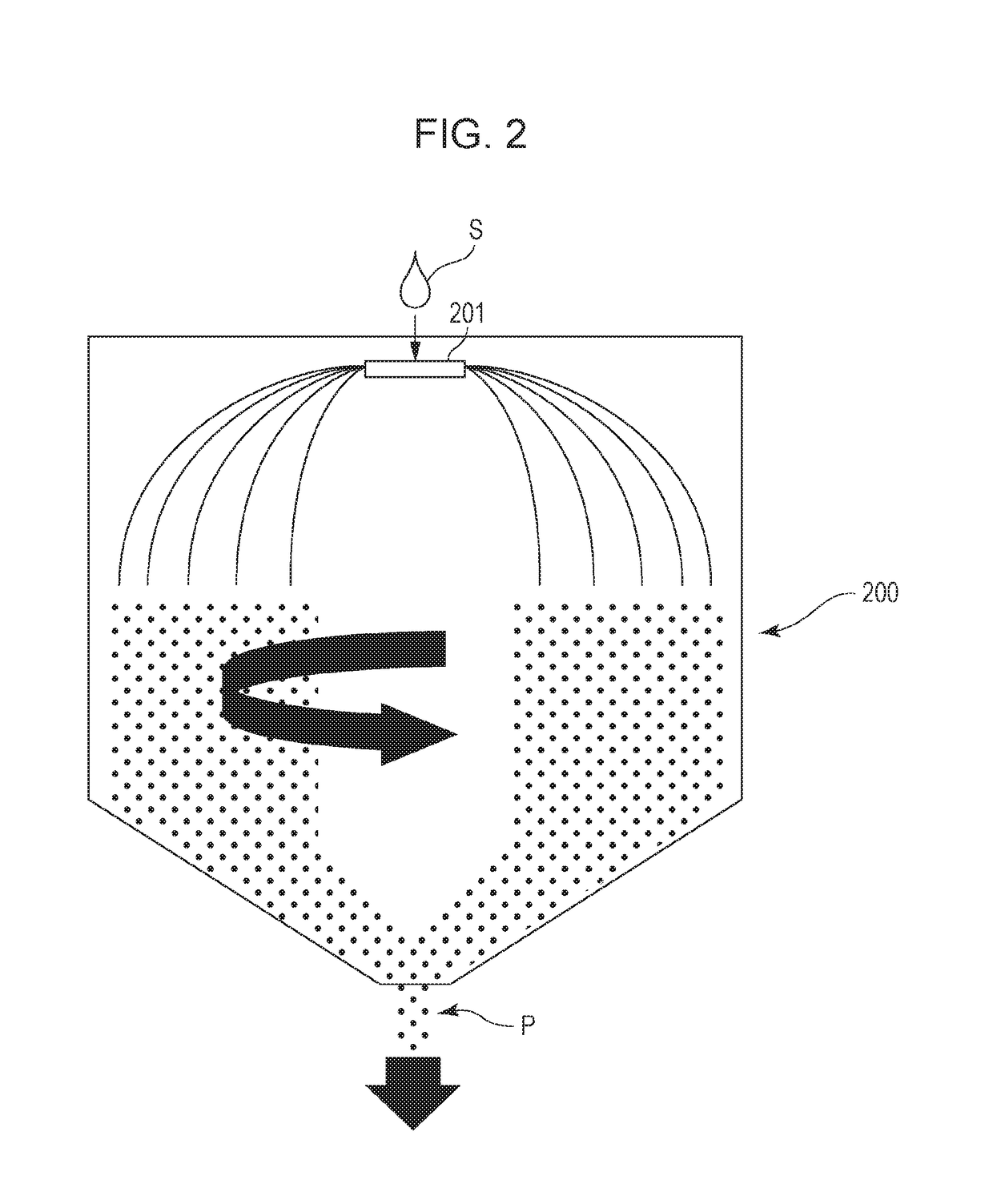

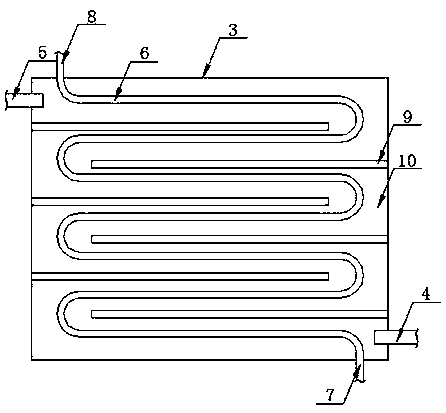

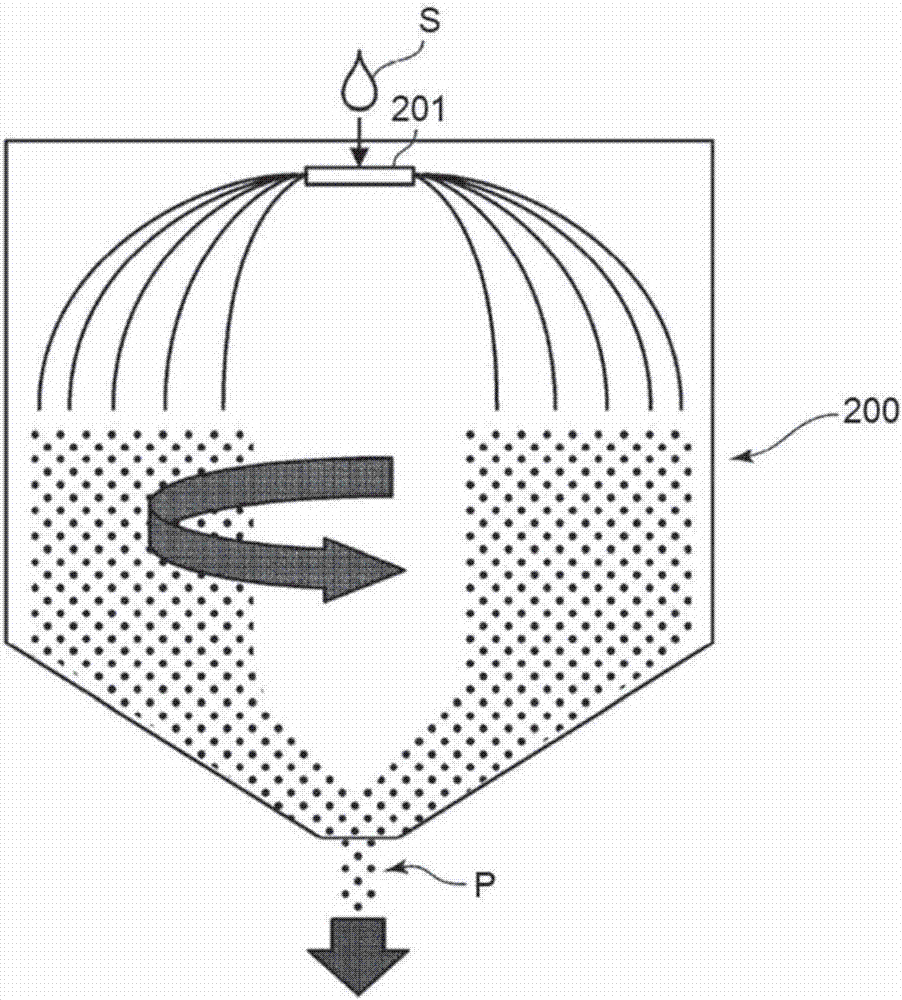

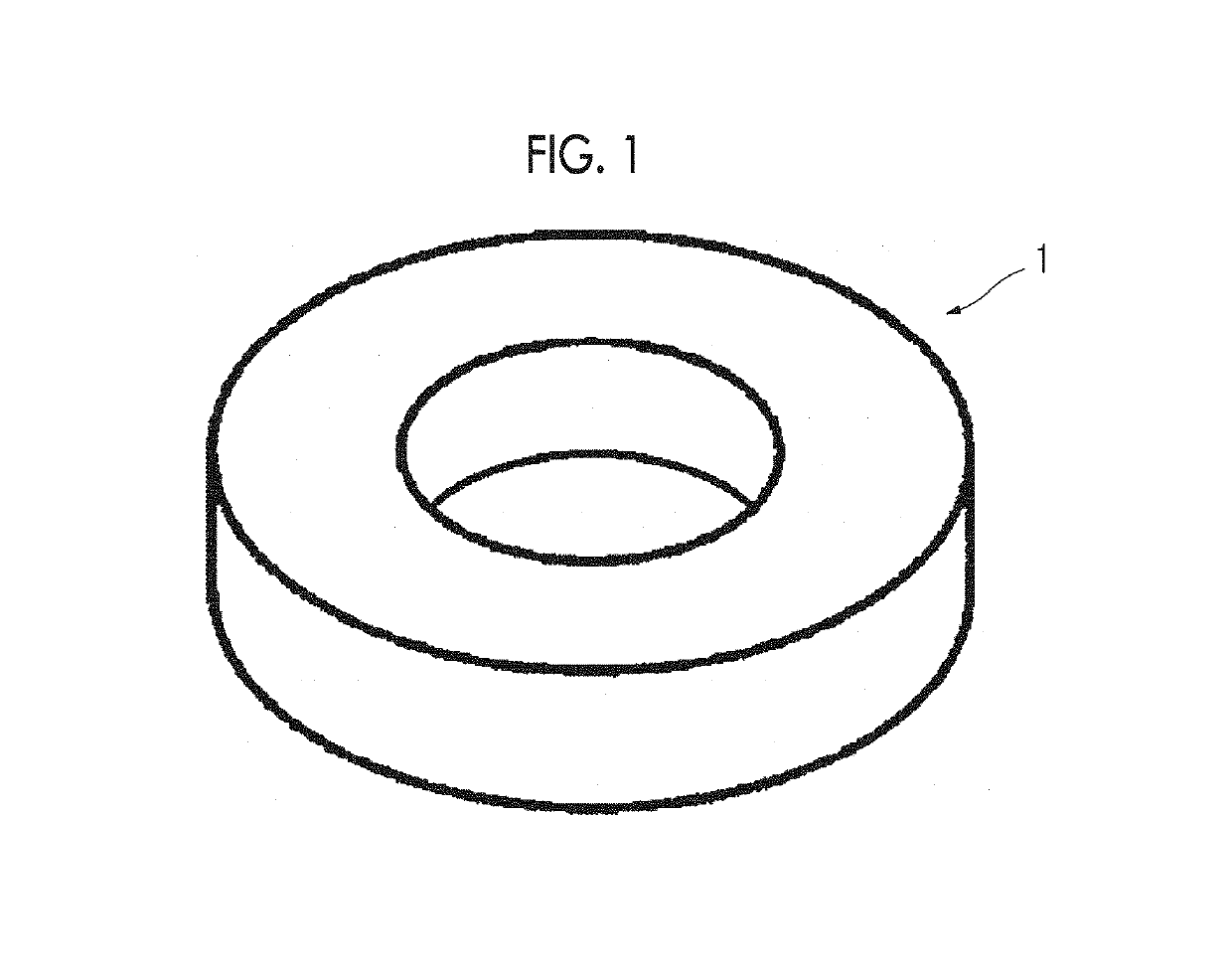

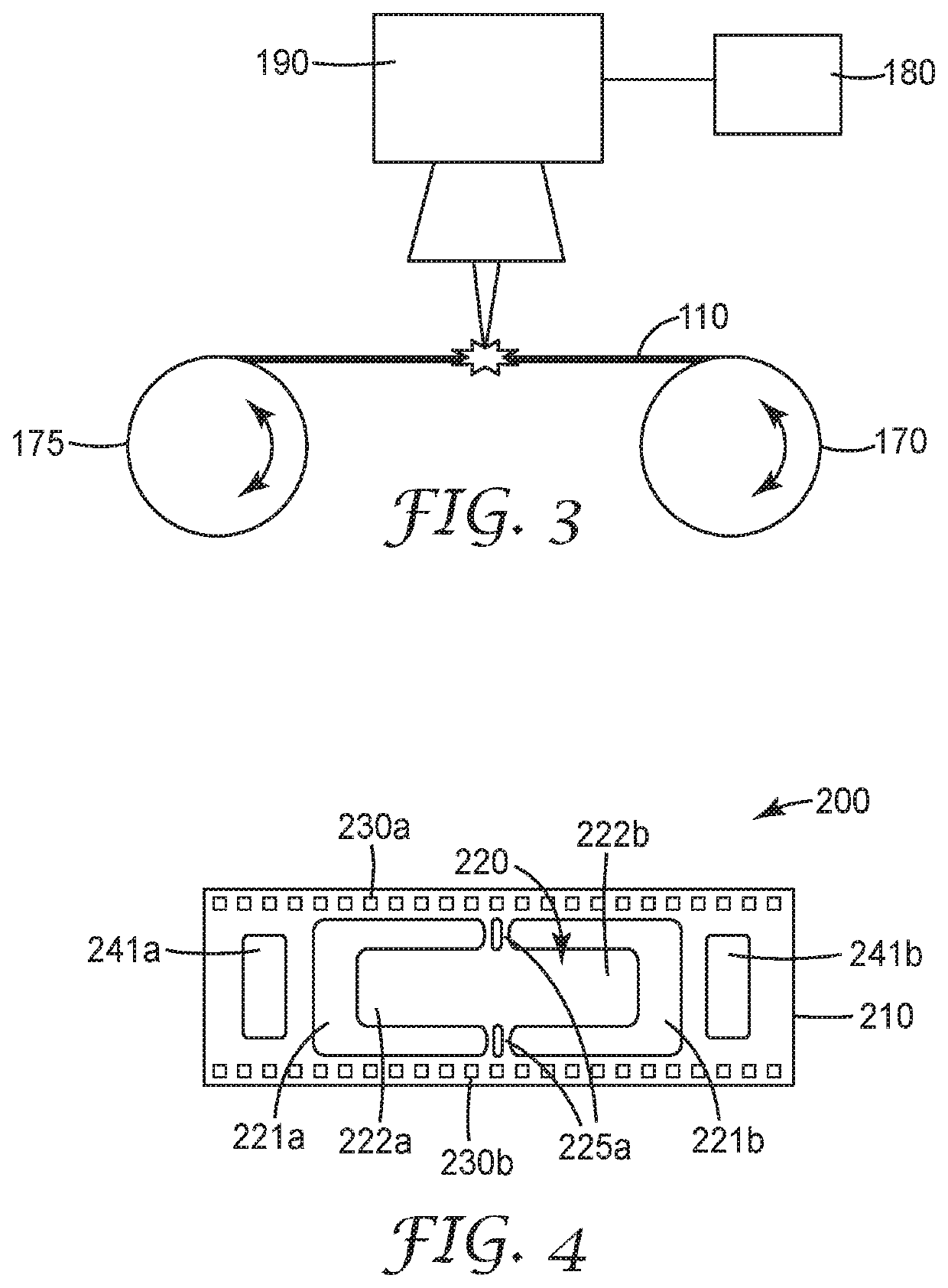

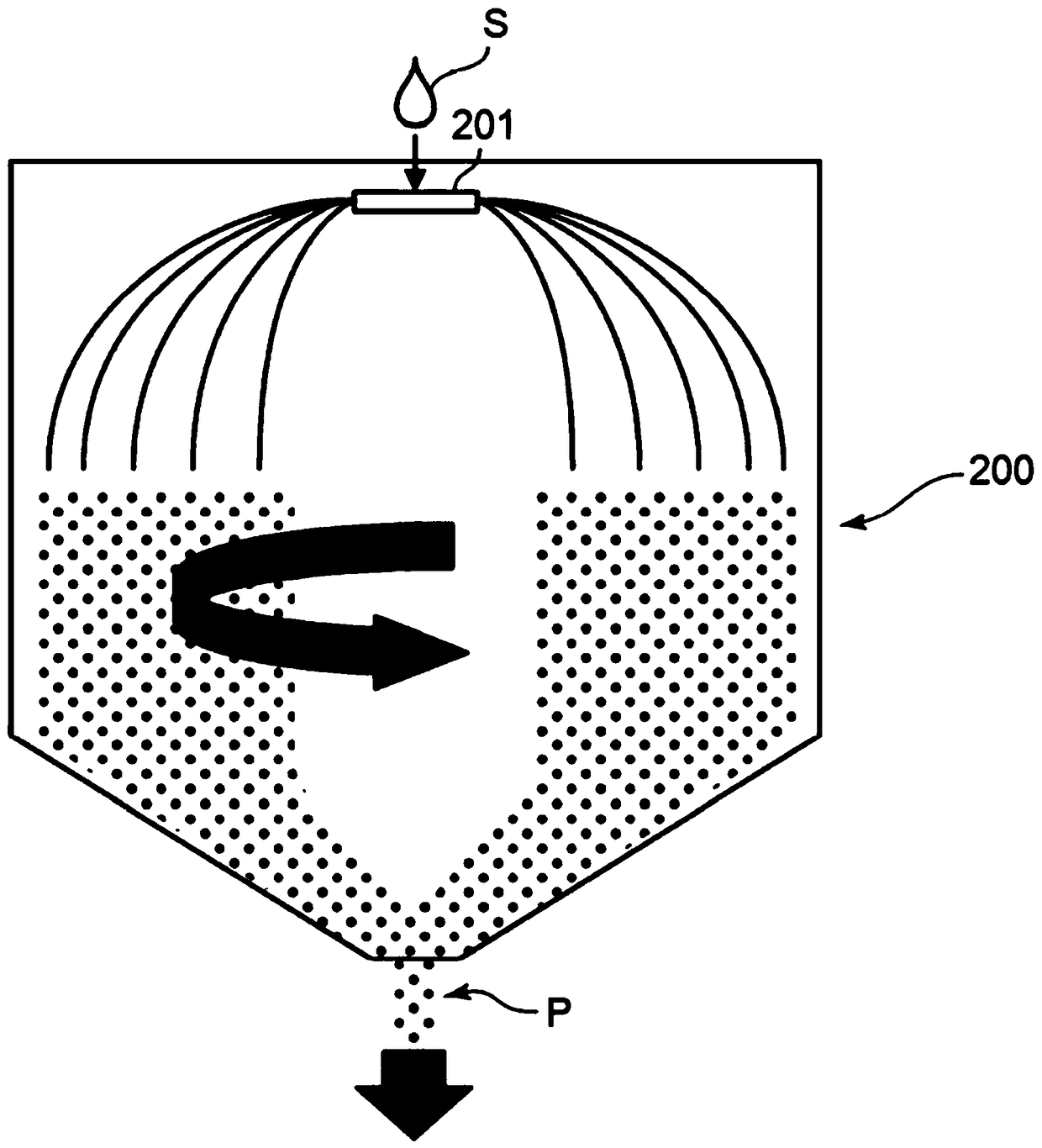

Heat conducting oil circular cooling system for amorphous magnetic materials

InactiveCN108788037ARapid coolingGuarantee the need for high-speed cycle useLiquid nitrogen coolingHeat conducting

The invention discloses a heat conducting oil circular cooling system made of for amorphous magnetic materials, comprising a heat conducting oil cooling roller, a cooling roller rotating shaft and a heat conducting oil cooling tank, wherein the two ends of the axis of the cooling roller rotating shaft are coaxially connected with a heat conducting oil input pipe and a heat conducting oil output pipe, the heat conducting oil cooling roller is provided with a heat conducting oil cooling passage for enabling the heat conducting oil input pipe and the heat conducting oil output pipe to communicatewith each other, the heat conducting oil input pipe and the heat conducting oil output pipe are connected with the heat conducting oil cooling tank, a liquid nitrogen cooling pipe is arranged in theheat conducting oil cooling tank, one end of the liquid nitrogen cooling pipe is connected with a liquid nitrogen input pipe located outside the heat conducting oil cooling tank, and the other end ofthe liquid nitrogen cooling pipe is connected with a liquid nitrogen output pipe located outside the heat conducting oil cooling tank. The heat conducting oil circular cooling system made of amorphousmagnetic material further improves the cooling efficiency of the cooling roller to improve the production efficiency of amorphous alloy magnetic strips.

Owner:芜湖君华材料有限公司

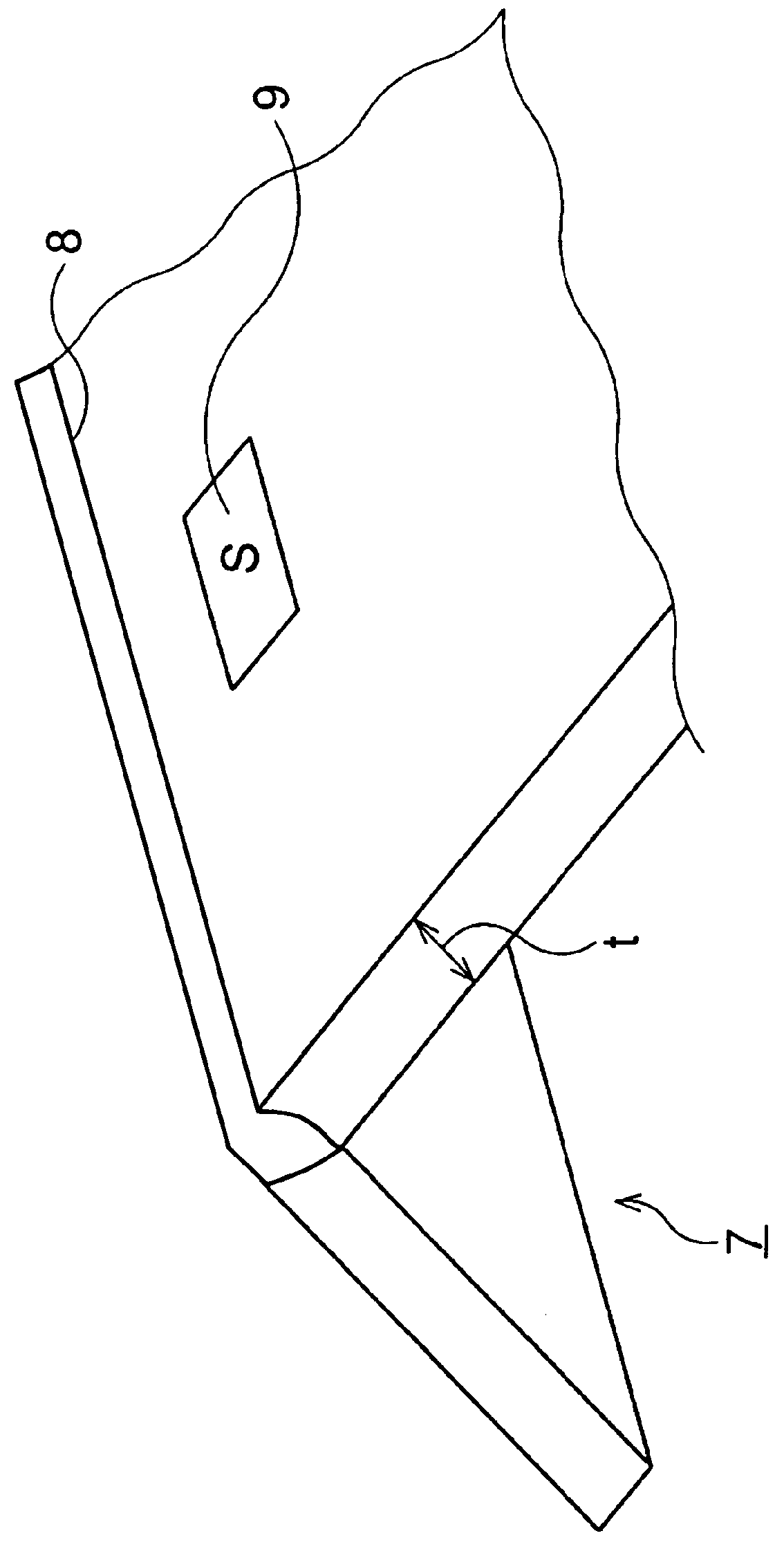

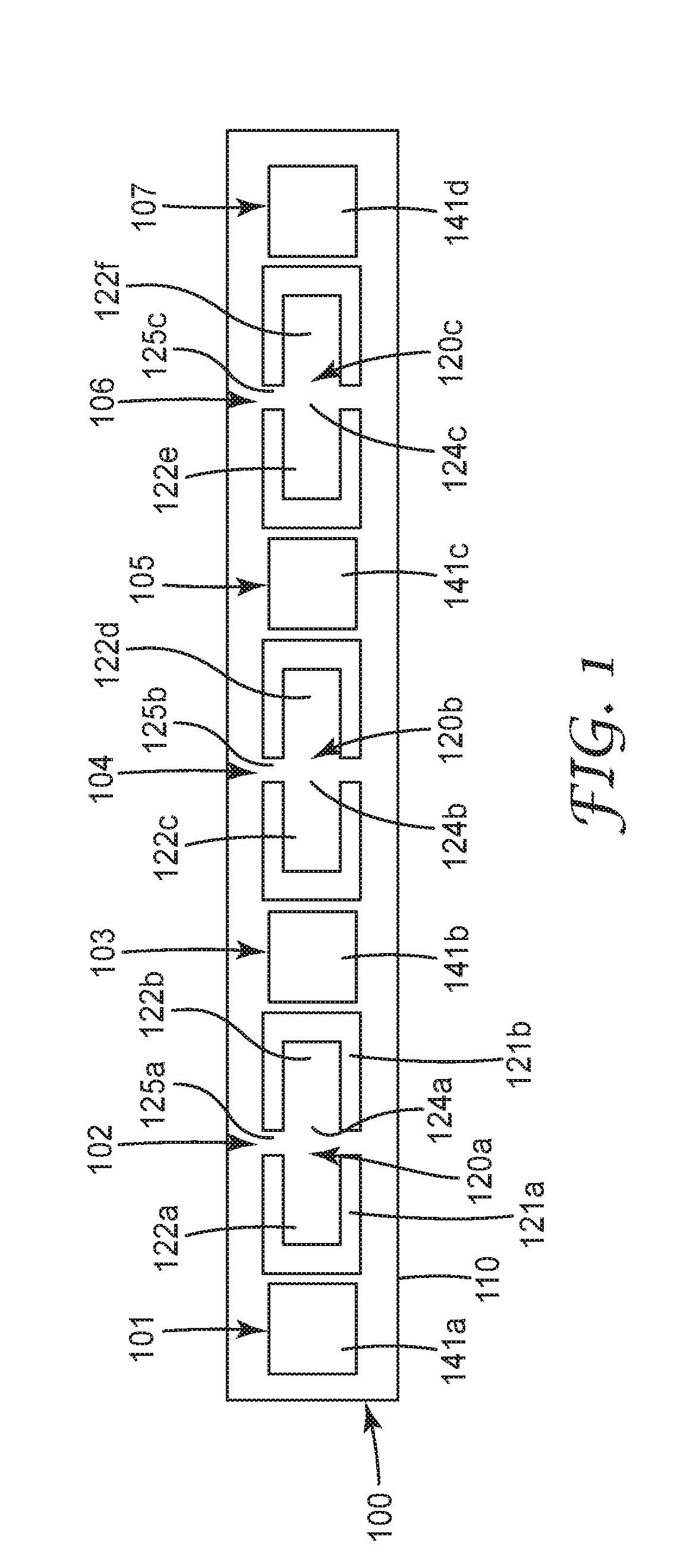

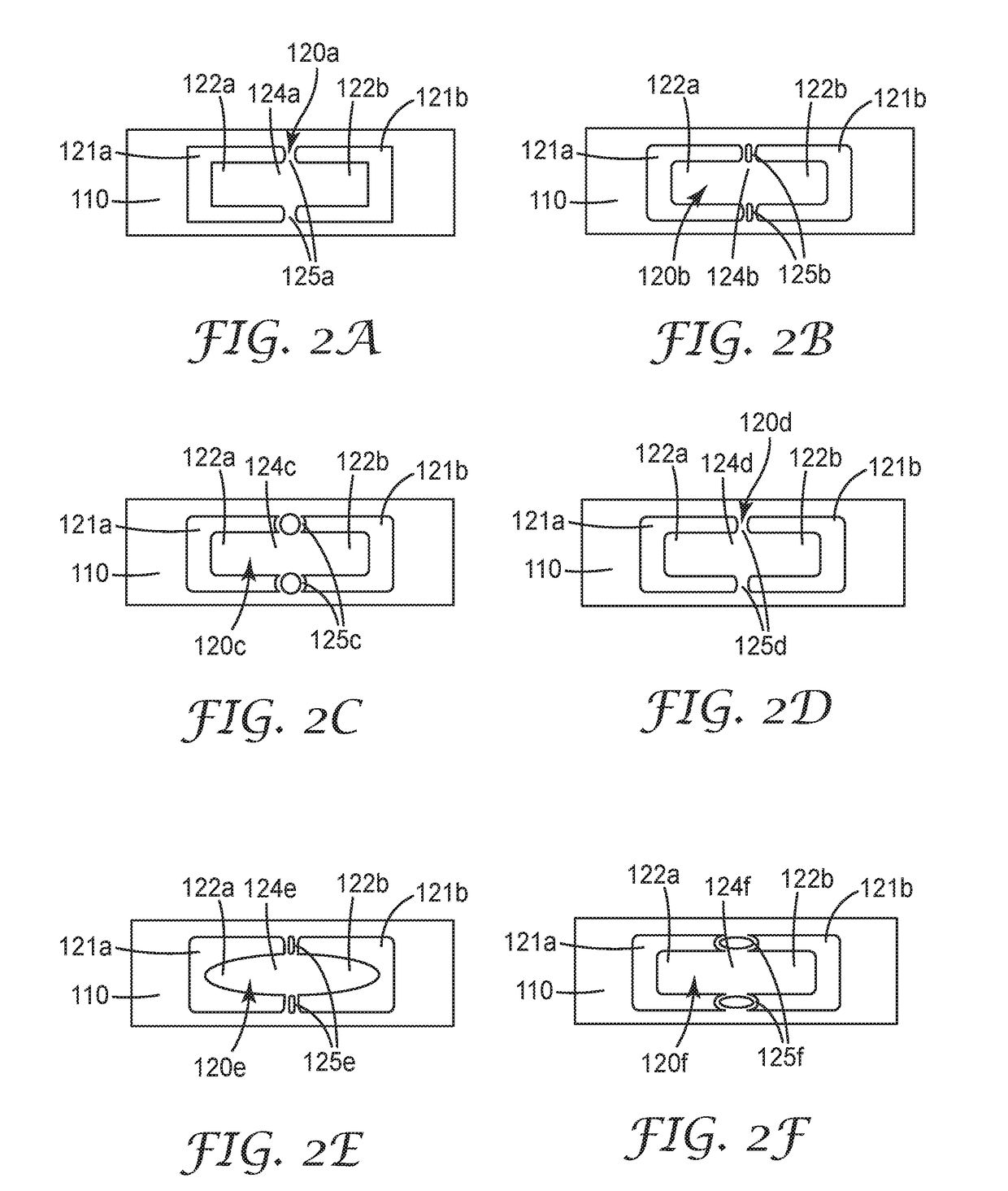

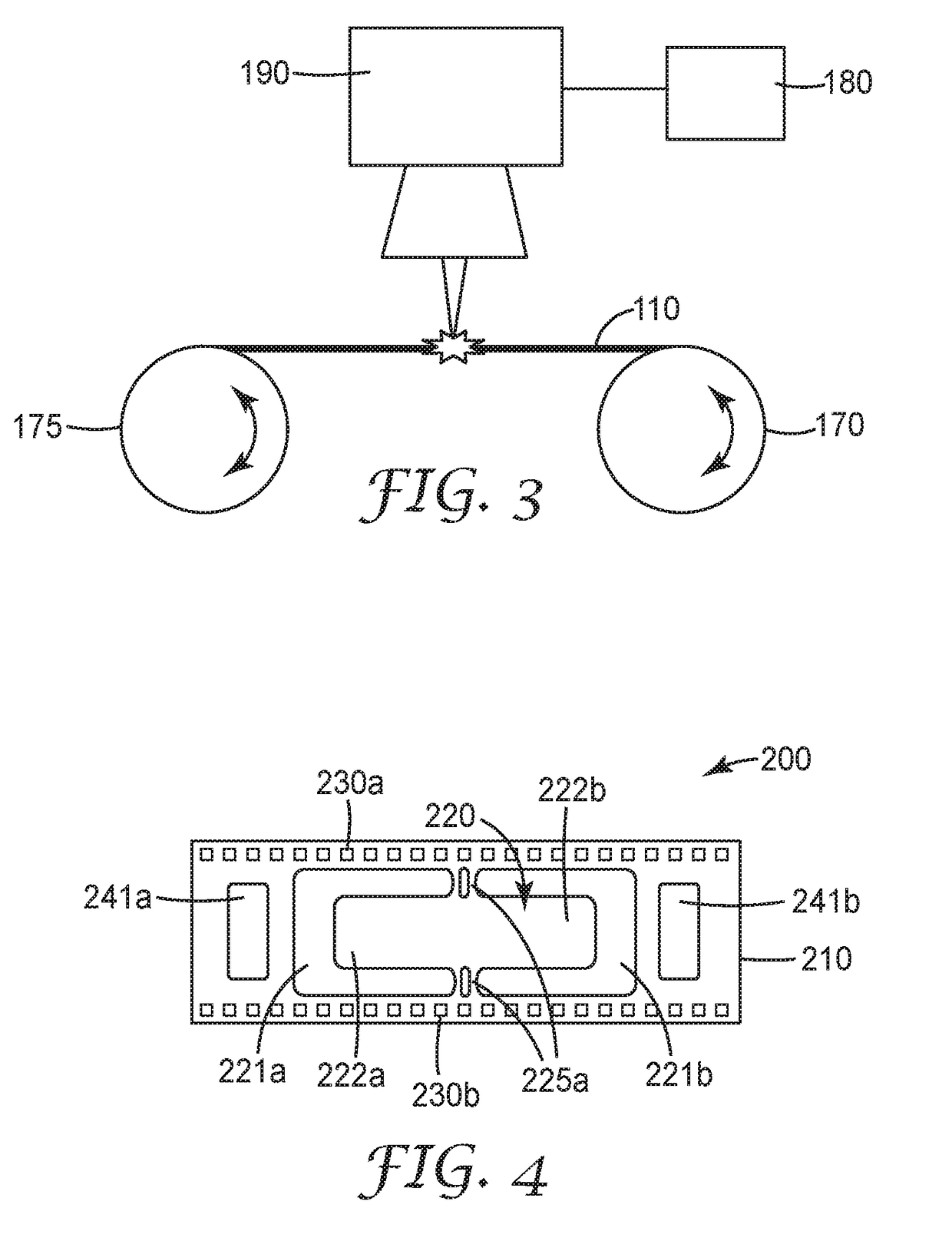

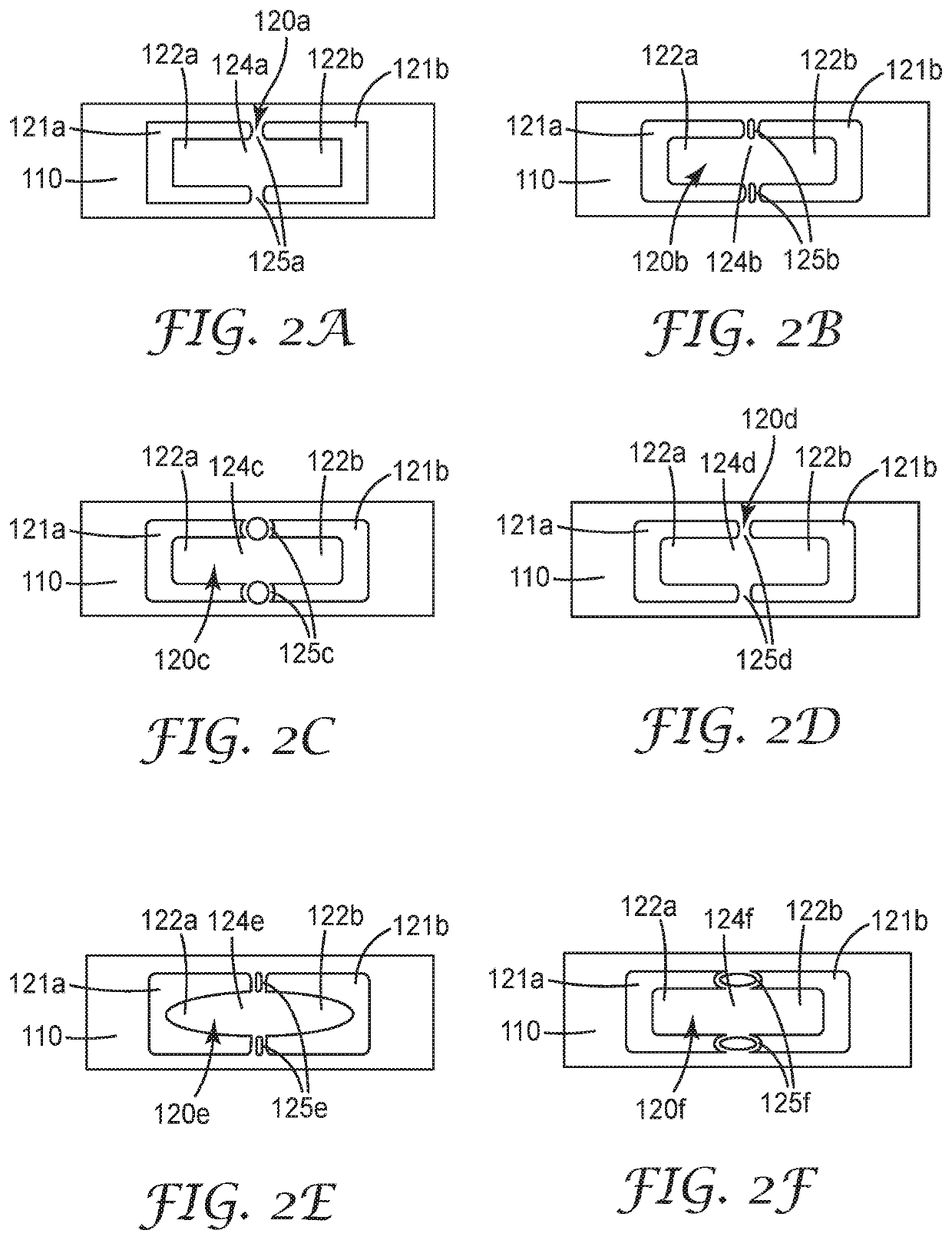

Tape format magnetoelastic resonator markers

ActiveUS20190011599A1Reduce the impactReduce impactImpedence networksPermanent magnetsMechanical energyEngineering

A tape format magnetoelastic resonator device comprises a continuous ribbon of amorphous magnetic material having a plurality of separate, hinged magnetoelastic resonator strips formed from the ribbon, linearly displaced along a longitudinal axis of the ribbon, wherein each magnetoelastic resonator strip is configured to couple to an external magnetic field at a particular frequency and convert the magnetic energy into mechanical energy, in the form of oscillations.

Owner:3M INNOVATIVE PROPERTIES CO

Amorphous magnetic shielding board for transformer and processing method thereof

InactiveCN101840773AReduce eddy current lossReduce lossMagnetic/electric field screeningUnwanted magnetic/electric effect reduction/preventionCardboardTransformer

The invention provides an amorphous magnetic shielding board for a transformer and a processing method thereof. The processing method comprises the following steps of: cutting an amorphous strip into amorphous magnetic boards in a needed size; then, sequentially overlapping several amorphous magnetic boards in a positive and negative opposition mode into an amorphous overlapping sheet and fixing the amorphous overlapping sheet with a clamp; and after annealing and curing the amorphous overlapping sheet in vacuum, coating the periphery of the amorphous overlapping sheet with an insulated paper board to form an amorphous magnetic shielding board. The amorphous magnetic shielding board made of amorphous magnetic material has the advantages of favorable magnetism-conducting performance, small size and light weight, can effectively reduce the vortex loss and the circuit loss of a transformer and can save energy approximate 25 percent.

Owner:江苏华晖磁性材料有限公司

Compressed powder core, method of manufacturing the compressed powder core, inductor comprising the compressed powder core and electronic-electric device mounted with the inductor

ActiveCN107093514AImprove DC Superposition CharacteristicsReduce iron lossTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureMetallurgyInductor

To provide a dust core containing a powder of crystalline magnetic material and a powder of amorphous magnetic material, and an inductor including such a dust core, where DC superposition characteristics are improved while reducing iron loss. In a dust core 1 containing a powder of crystalline magnetic material and a powder of amorphous magnetic material, the median size DA of the powder of amorphous magnetic material is 15 [mu]m or less, and the ratio to the median size D50C of the powder of crystalline magnetic material satisfies the following formula (1); 1<=D50A / D50C<=3.5 (1).

Owner:ALPS ALPINE CO LTD

Magnet system and MRI system

InactiveUS7205766B2Eddy currents can be effectively suppressedMeasurements using NMR spectroscopyElectric/magnetic detectionSuperconducting CoilsEddy current

The present invention is intended to provide a magnet apparatus obviating the necessity of shield coils designed to suppress eddy currents. The magnet apparatus has gradient coils disposed in a bore of a cylindrical superconducting magnet, and includes a cylindrical structure that is realized with a combination of tiles made of a high-permeability material and that is interposed between the internal surface of the superconducting magnet and the external surface of the gradient coils. The tiles made of a high-permeability material are laminates made of a high-permeability material. The high-permeability material is a silicon steel plate or an amorphous magnetic material.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Powder core, manufacturing method of powder core, inductor including powder core, and electronic/electric device having inductor mounted therein

ActiveUS10283266B2Improve superposition characteristicDecrease a core lossTransformers/inductances coils/windings/connectionsInorganic material magnetismMetallurgyInductor

A powder core includes: a powder of a crystalline magnetic material; and a powder of an amorphous magnetic material, in which a median diameter D50A of the powder of the amorphous magnetic material is 15 μm or less, and satisfies the expression: 1≤D50A / D50C≤3.5 with respect to a median diameter D50C of the powder of the crystalline magnetic material.

Owner:ALPS ALPINE CO LTD

Tape format magnetoelastic resonator markers

A tape format magnetoelastic resonator device comprises a continuous ribbon of amorphous magnetic material having a plurality of separate, hinged magnetoelastic resonator strips formed from the ribbon, linearly displaced along a longitudinal axis of the ribbon, wherein each magnetoelastic resonator strip is configured to couple to an external magnetic field at a particular frequency and convert the magnetic energy into mechanical energy, in the form of oscillations.

Owner:3M INNOVATIVE PROPERTIES CO

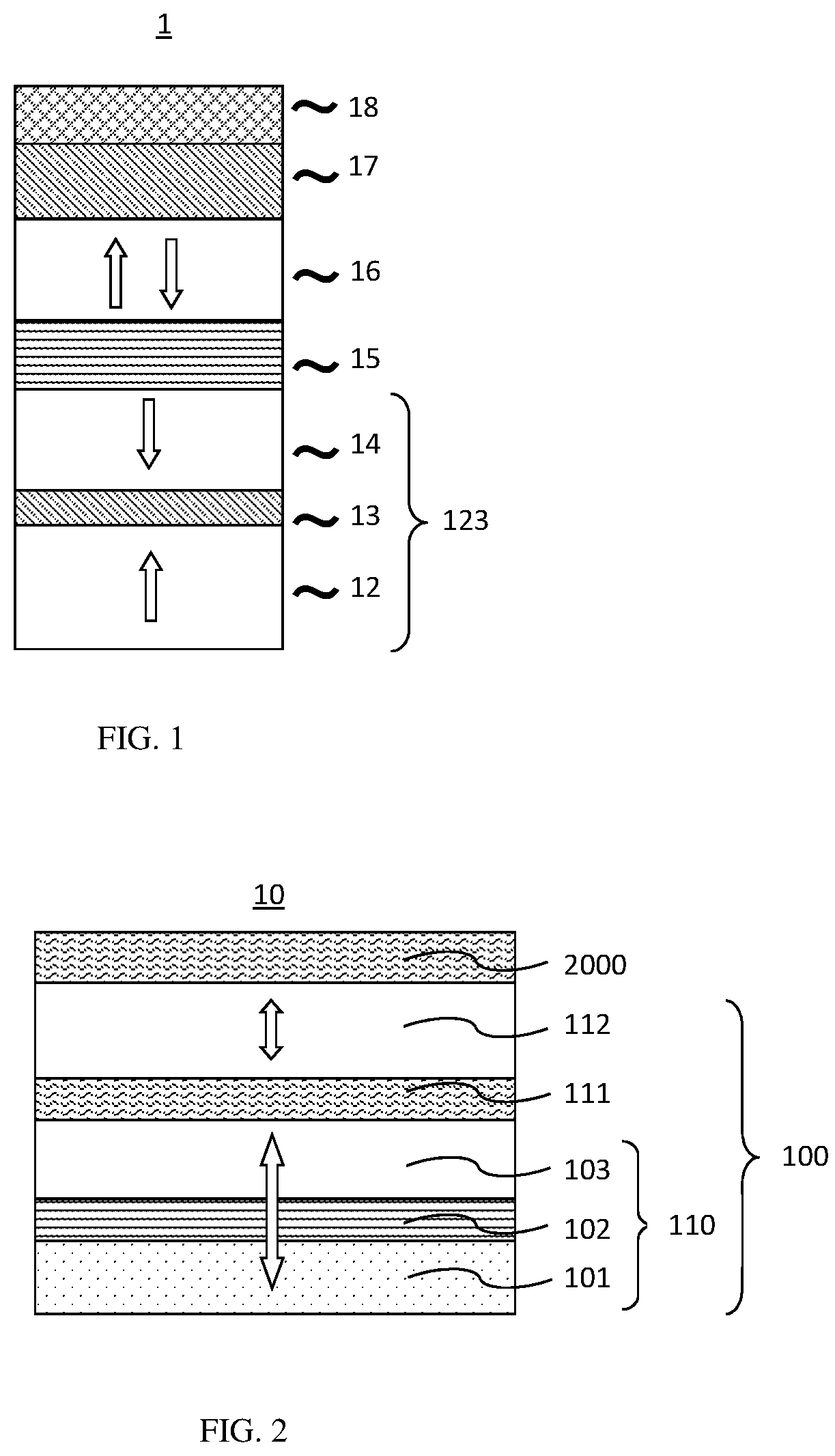

Composite recording structure for an improved write profermance

PendingUS20220246836A1High spin polarization degreeLarge spin transfer torqueSolid-state devicesGalvano-magnetic material selectionMagnetizationNon magnetic

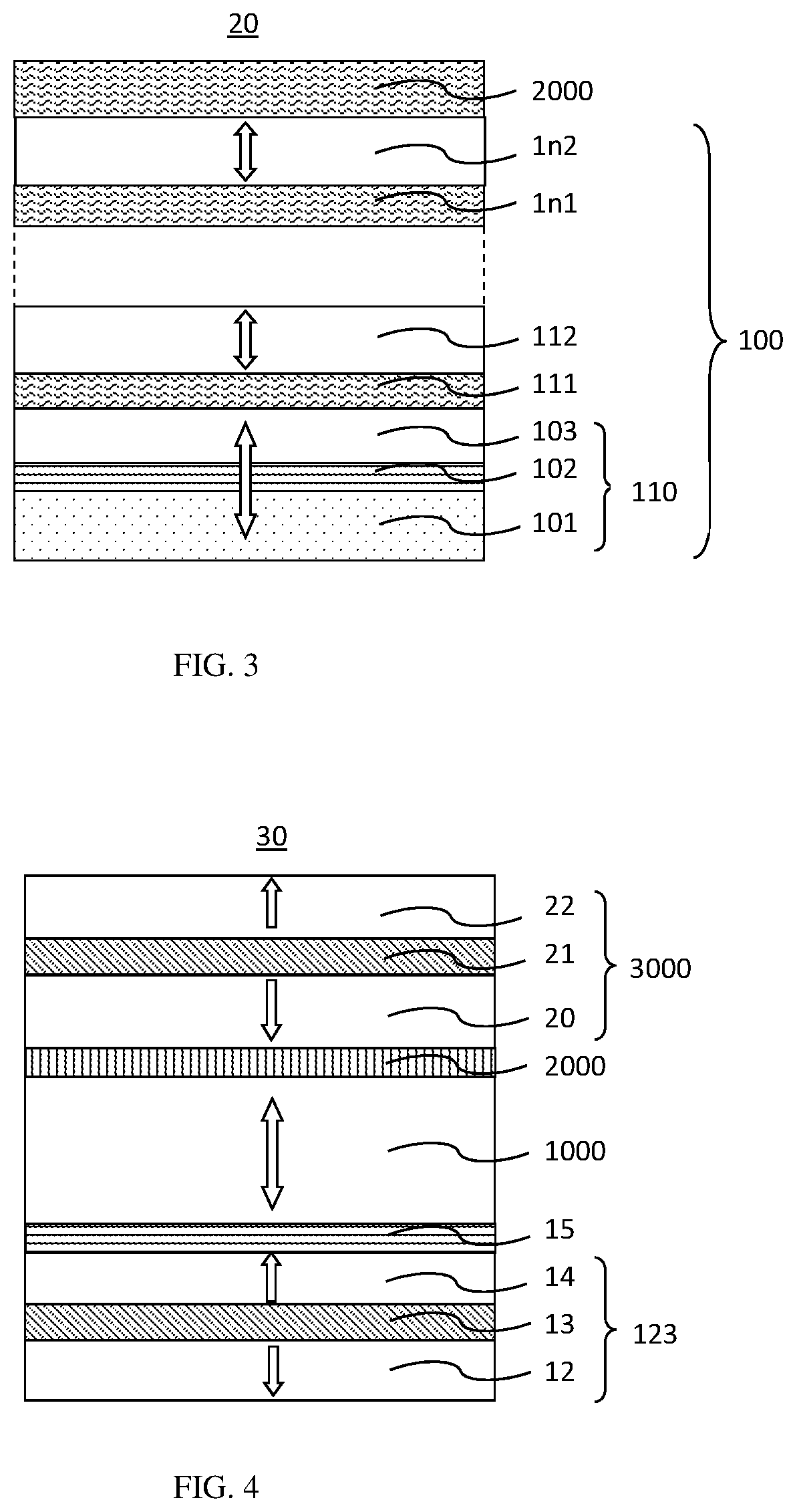

A composite recording structure comprising a first magnetic free layer comprising an amorphous magnetic material sub-layer, a Boron-absorbing material sub-layer atop the amorphous magnetic material sub-layer and a Co / Ni superlattice sub-layer atop the Boron-absorbing material sub-layer; one or many repeats of a substructure including a nonmagnetic spacing layer and a Co / Ni superlattice free layer, atop the first magnetic free layer, wherein said first magnetic free layer has a perpendicular magnetic anisotropy and a variable magnetization direction substantially perpendicular to a film surface, said each Co / Ni superlattice free layer has a perpendicular magnetic anisotropy and a variable magnetization direction substantially perpendicular to a film surface.

Owner:GUO YIMIN +2

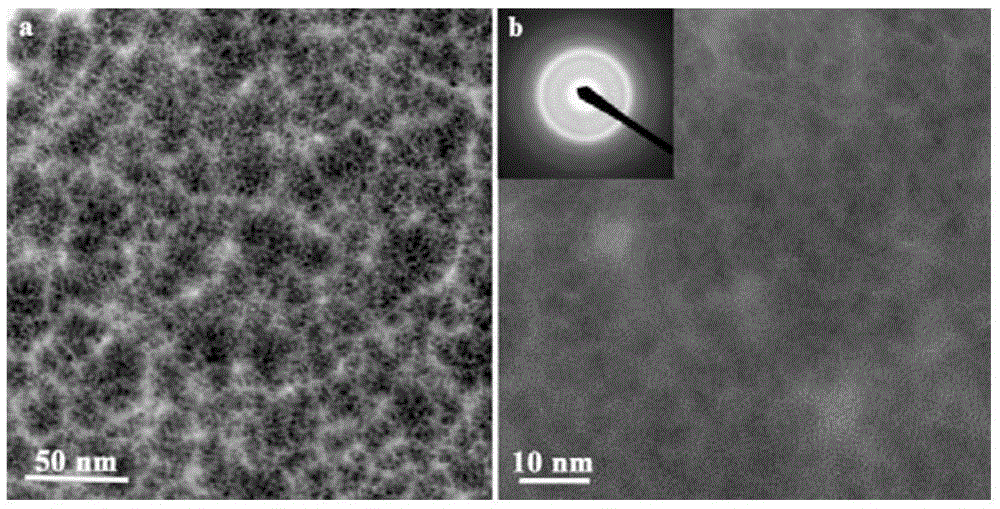

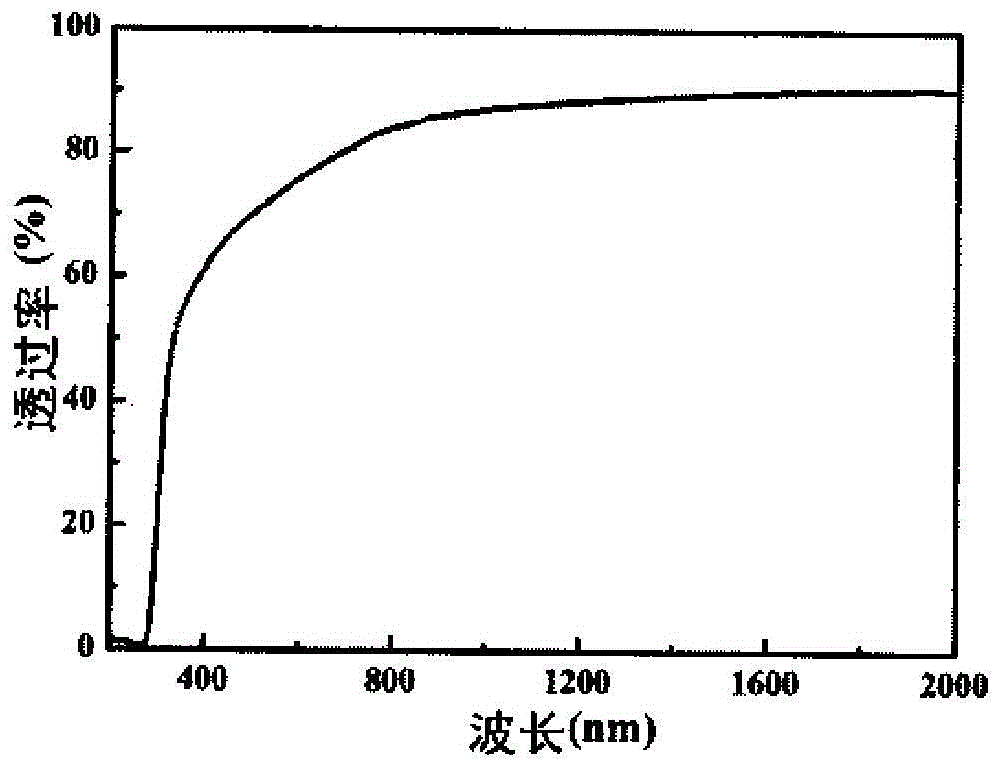

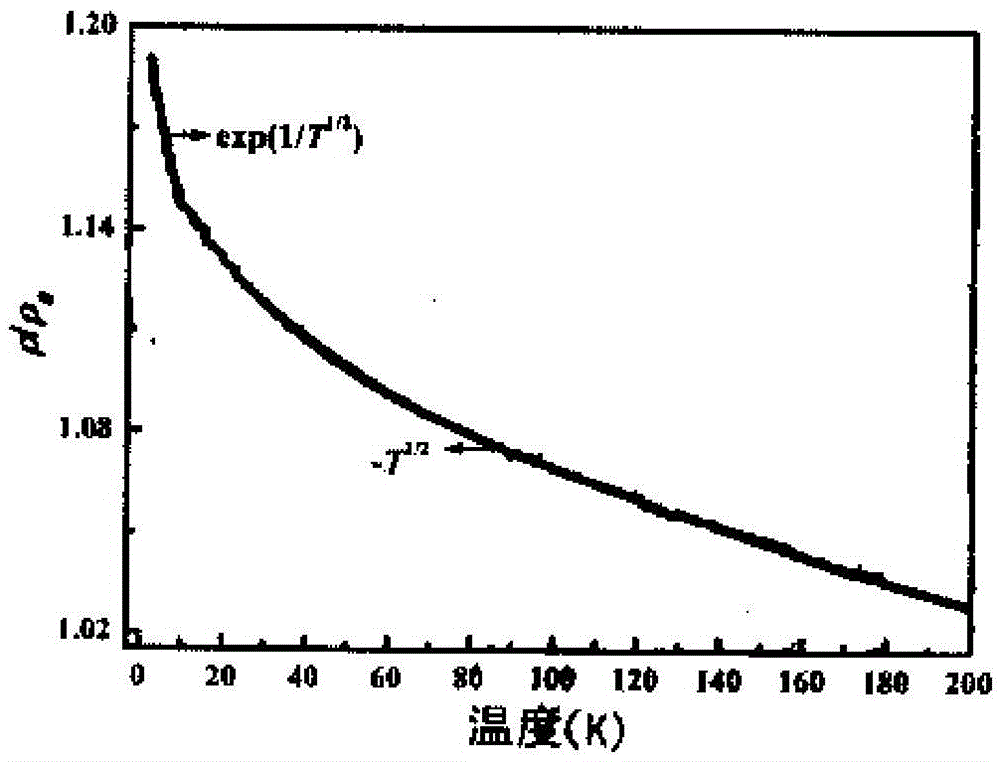

A kind of room temperature transparent ferromagnetic semiconductor material and its preparation method

ActiveCN103489557BSolve the technical problem that the Curie temperature is lower than room temperaturePhotoluminescenceGalvano-magnetic material selectionInorganic material magnetismSemiconductor materialsCurie temperature

Owner:TSINGHUA UNIV

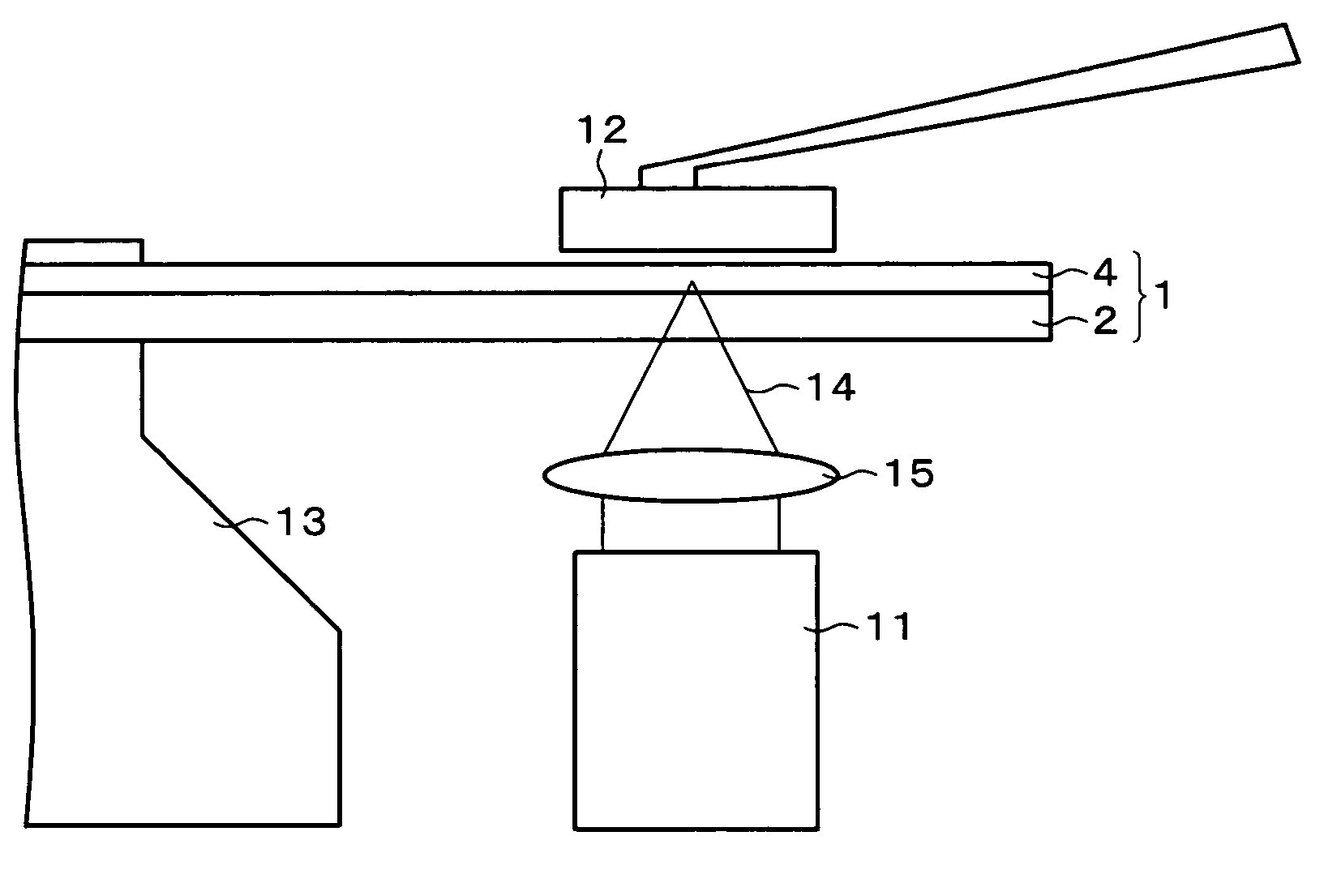

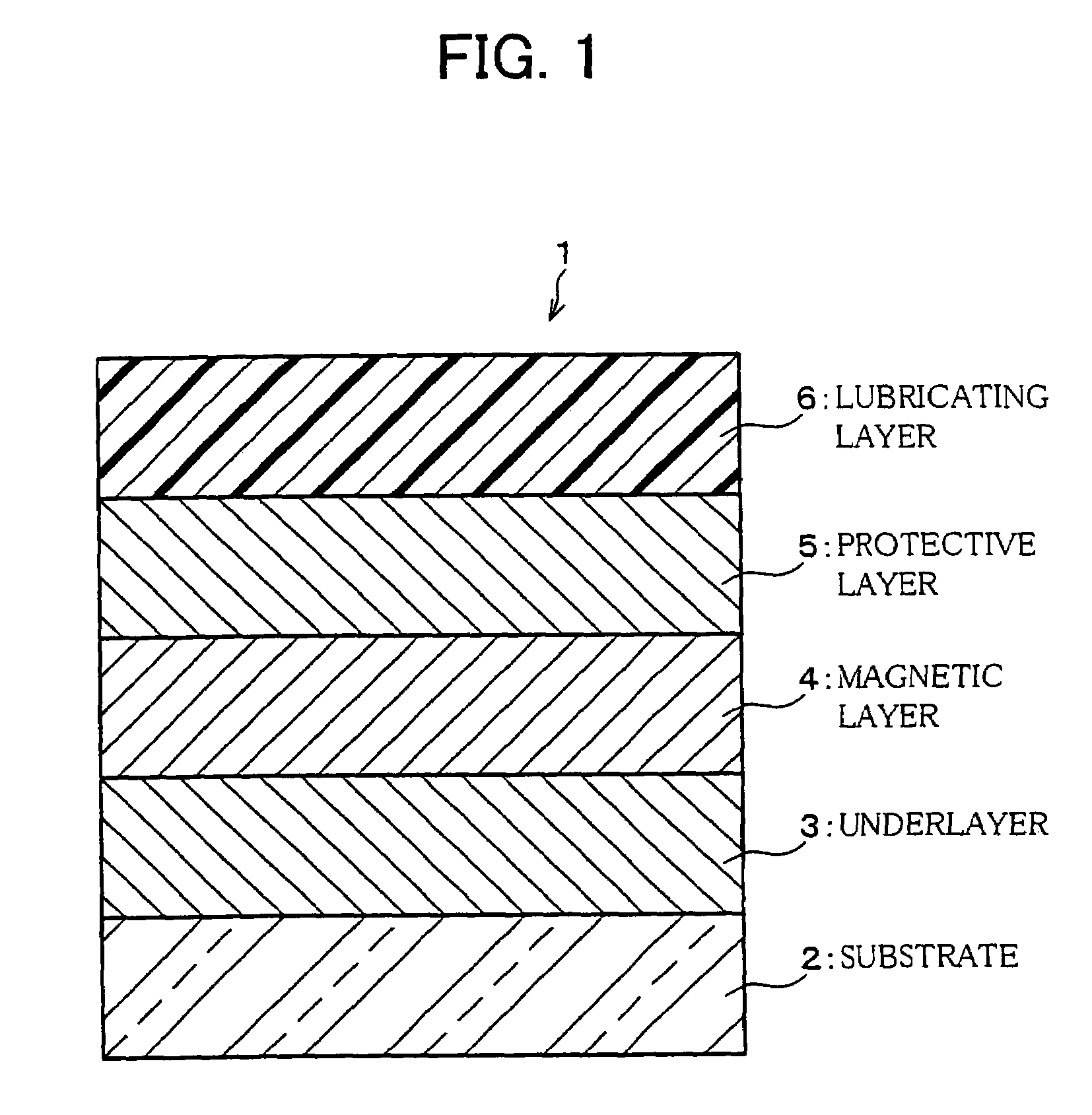

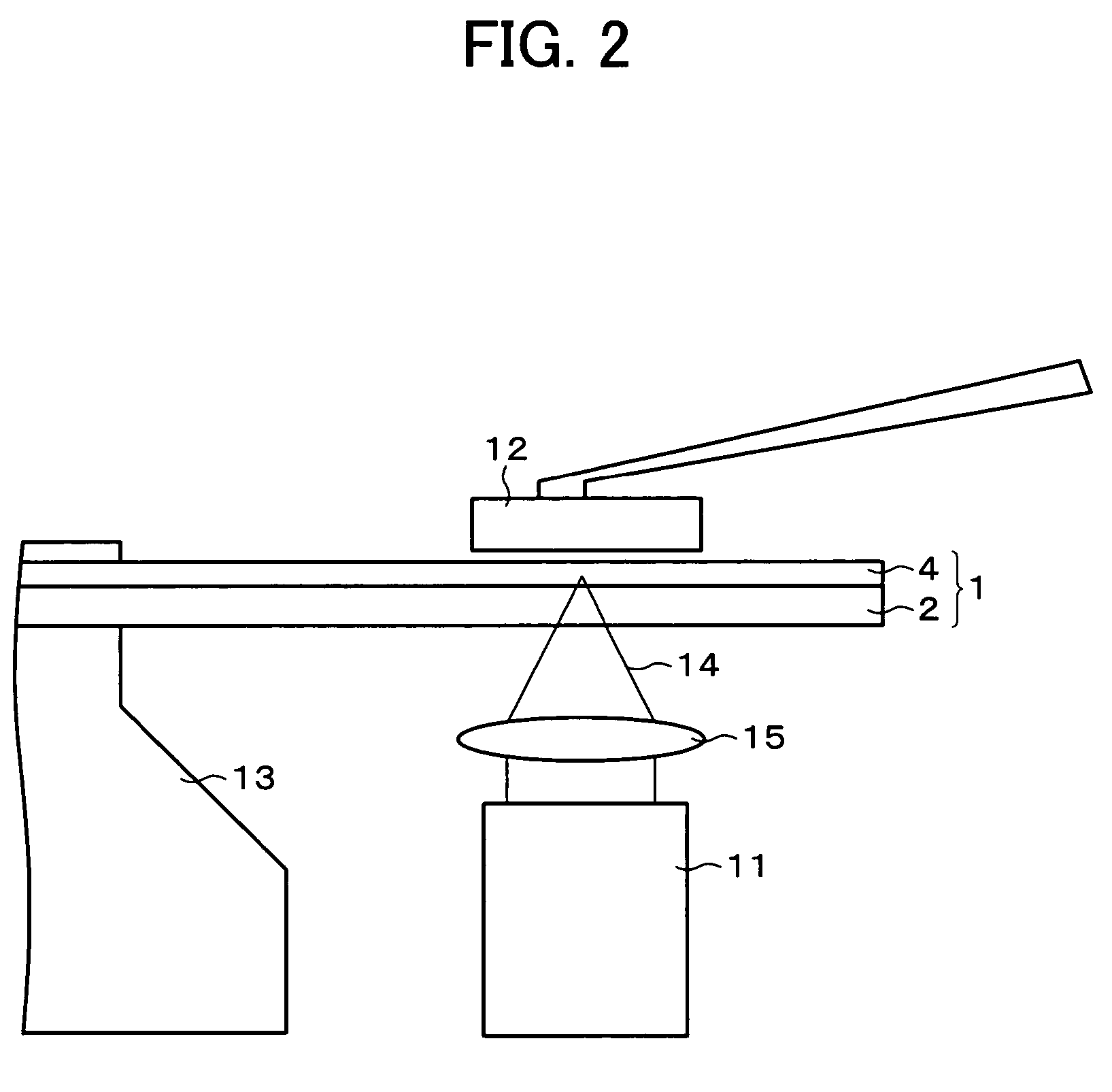

Magnetic recording medium and magnetic recording device using the same

InactiveUS7298569B2Short moving distanceImprove signal qualityBase layers for recording layersMechanical record carriersNon magneticLayer thickness

A magnetic recording medium includes: an underlayer constituted of at least a substrate and a nonmagnetic metal element; and an amorphous magnetic layer, made of amorphous magnetic material, which magnetically records information. In certain example embodiments, the amorphous magnetic layer has bumps on a surface thereof or the magnetic recording medium has bumps on a surface thereof (surface of a lubricating layer) so that density of the bumps is not less than 400 bumps / μm2 or so that height of the bumps is not less than 2% with respect to an average layer thickness of the amorphous magnetic layer. Thus, magnetic wall movement of the amorphous magnetic layer is effectively suppressed, so that it is possible to stably form a recording bit.

Owner:SHARP KK

Powder magnetic core, manufacturing method of powder magnetic core, inductor provided with powder magnetic core, and electronic/electrical equipment equipped with inductor

ActiveCN107093514BImprove DC Superposition CharacteristicsReduce iron lossTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureMetallurgyInductor

Provided is a powder magnetic core containing powder of a crystalline magnetic material and a powder of an amorphous magnetic material. In an inductor including the powder magnetic core, DC superposition characteristics can be improved and iron loss can be reduced. A powder magnetic core (1) comprising a powder of a crystalline magnetic material and a powder of an amorphous magnetic material, wherein the powder of the amorphous magnetic material has a median diameter D50A of 15 μm or less and is compatible with a crystalline magnetic material The median diameter D50C of the powder of the material satisfies the following formula (1), 1≤D50A / D50C≤3.5(1).

Owner:ALPS ALPINE CO LTD

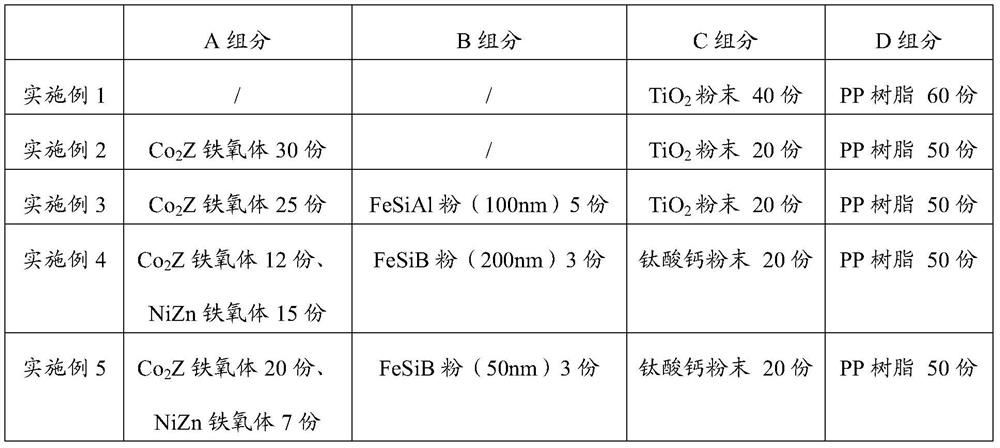

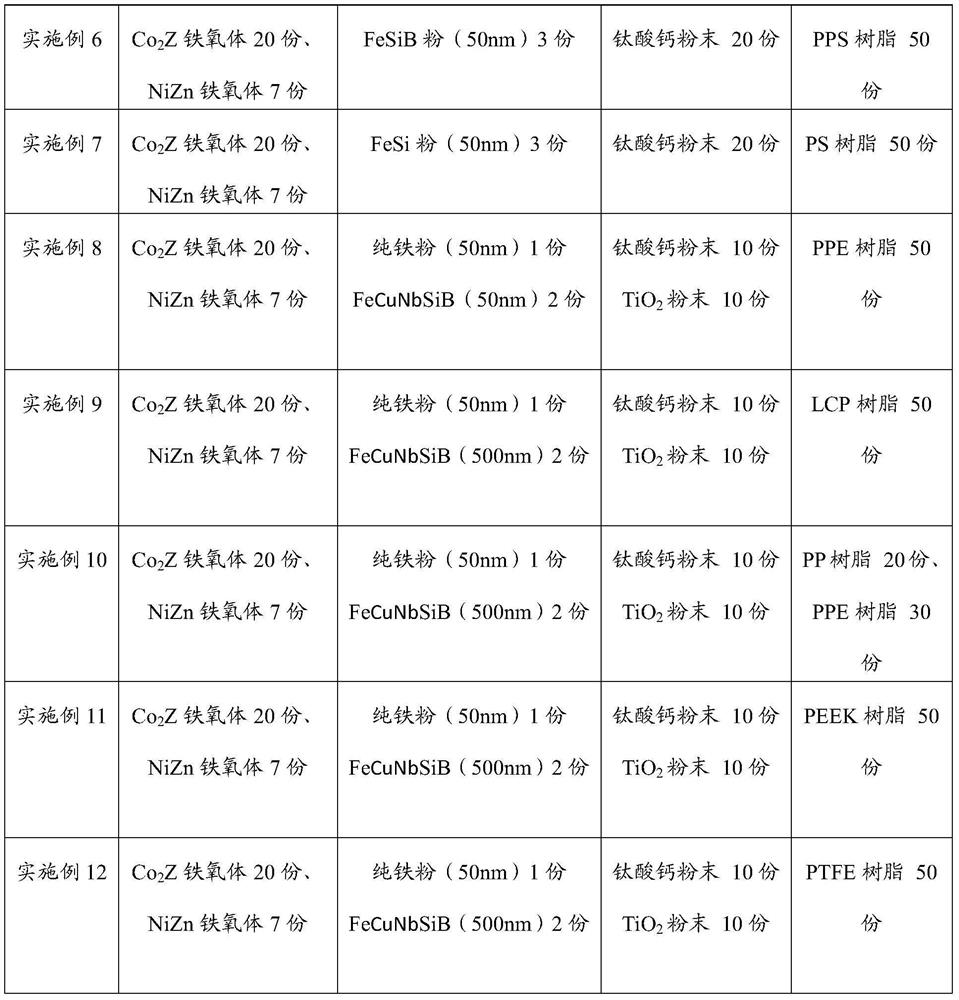

An antenna substrate material

The present invention relates to an antenna substrate material, comprising the following components by weight: 5-40 parts of component A, 1-10 parts of component B, 5-40 parts of component C and 30-90 parts of component D; The A component includes at least one of planar hexagonal ferrite and NiZn ferrite; the B component is a soft magnetic metal, and the B component includes pure iron, amorphous magnetic materials, nanocrystalline At least one of magnetic alloy materials, FeSi and FeSiAl; the C component is a dielectric ceramic; the D component has a low tanδ e (Df) resin material. The antenna substrate material of the present invention has the advantages of being able to work at 6GHz, reducing the size of the antenna, good impedance matching performance, wide bandwidth and high antenna efficiency.

Owner:SHENZHEN SUNWAY COMM

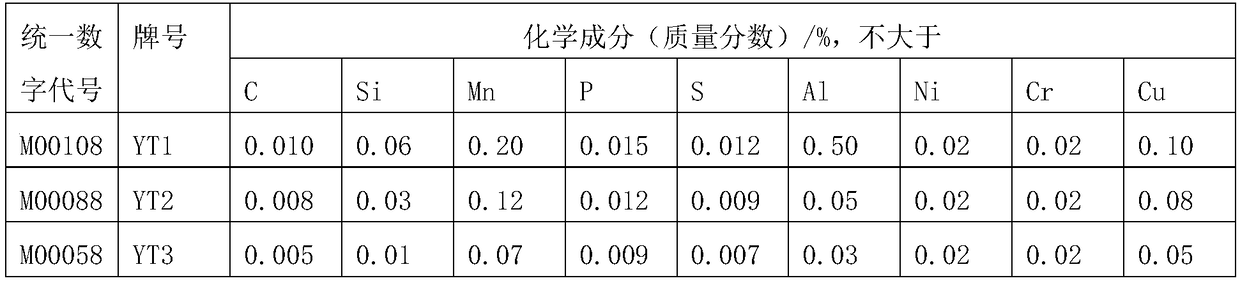

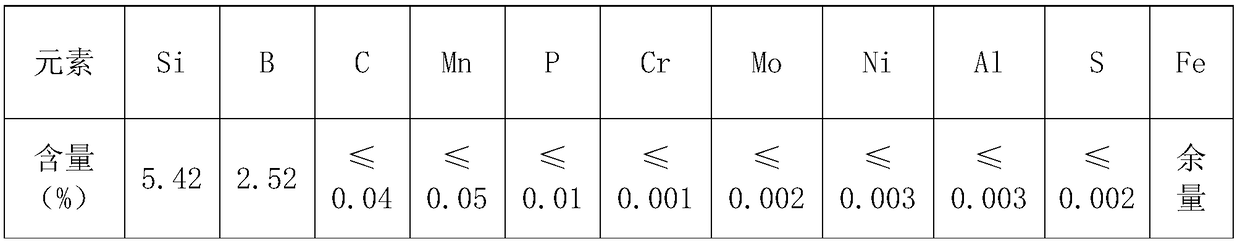

New process for producing amorphous state strip under non-vacuum

The invention relates to a new process for producing an amorphous state strip under non-vacuum. The new process is characterized by being performed according to the following steps that firstly, high-purity pure iron molten steel is produced, the high-purity pure iron molten steel is prepared by adopting ZL201410341008. 4, with the name of high-purity pure iron molten steel produced by a method for producing high-purity pure iron; secondly, Si, B and P alloys are matched into the high-purity pure iron molten steel to form amorphous magnetic material molten steel which flows onto a cooling copper roller rotating at a high speed through a nozzle wrapping seam of a spray nozzle of a crucible, and the molten steel is cooled into a thin strip suddenly and violently. According to the new process, an ultra-short flow path system composed of a coal-based vertical furnace and an intermediate frequency smelting system is utilized for producing low-impurity pure iron with iron larger than 99.9% to serve as a high-quality base material of an amorphous nanocrystalline soft magnetic material, and effective self control and improvement of the product quality are achieved. The new process is shorter than a traditional amorphous state strip technological process, little in tool equipment, saving in investment, low in energy consumption, low in cost and capable of performing self control on theproduct quality.

Owner:武汉桂坤科技有限公司

Packaging method of iron-based amorphous alloy strip

InactiveCN110656329AImprove wettabilitySimple methodLiquid surface applicatorsMetallic material coating processesEpoxyAlloy

The invention relates to the field of amorphous magnetic materials, in particular to a packaging method of an iron-based amorphous alloy strip. The iron-based amorphous alloy strip is subjected to oilremoval and cleaning and put into a CaSO4 water solution with the concentration being 0.02 to 0.03 mol / L, and the solution is heated to 25 to 85 DEG C and subjected to heat preservation for 30 min to5 hour; the strip is taken out and dried; and finally, the strip is immersed into epoxy resin and taken out, and the packaged iron-based amorphous alloy strip is obtained. The packaging method is simple, convenient, low in packaging preparing temperature, short in reaction time, and high in interface combination force, epoxy resin is evenly bonded on the strip surface, and the resin and alloy strip surface wettability is good.

Owner:NANCHANG UNIV

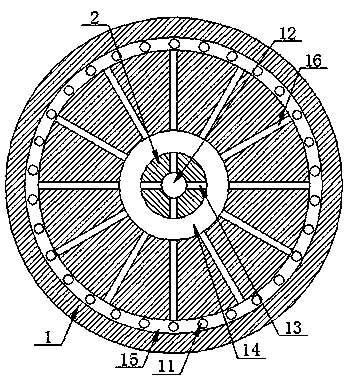

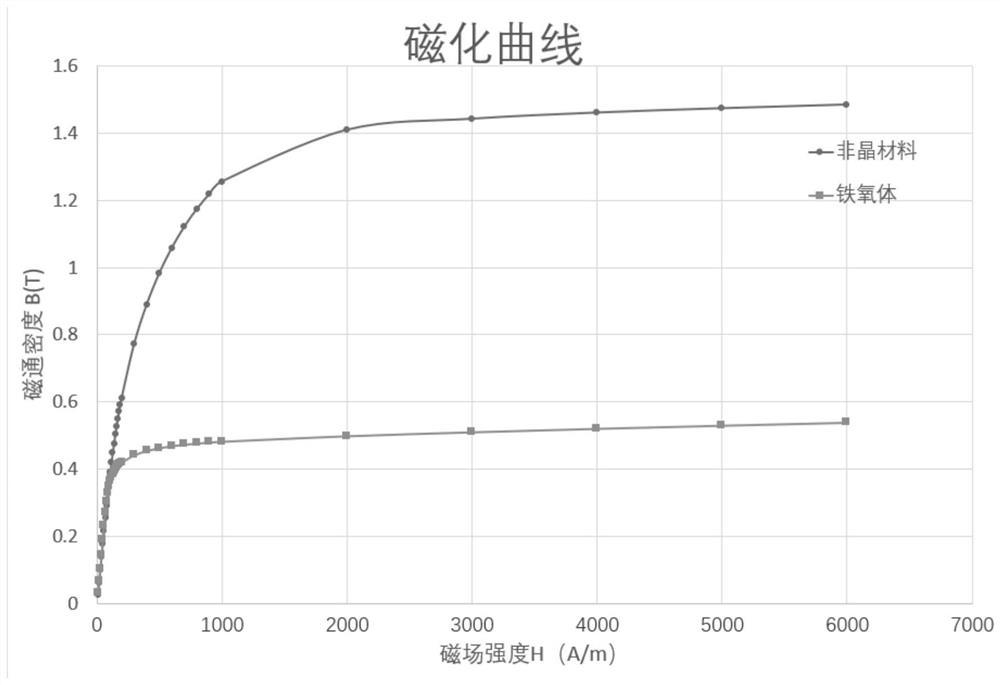

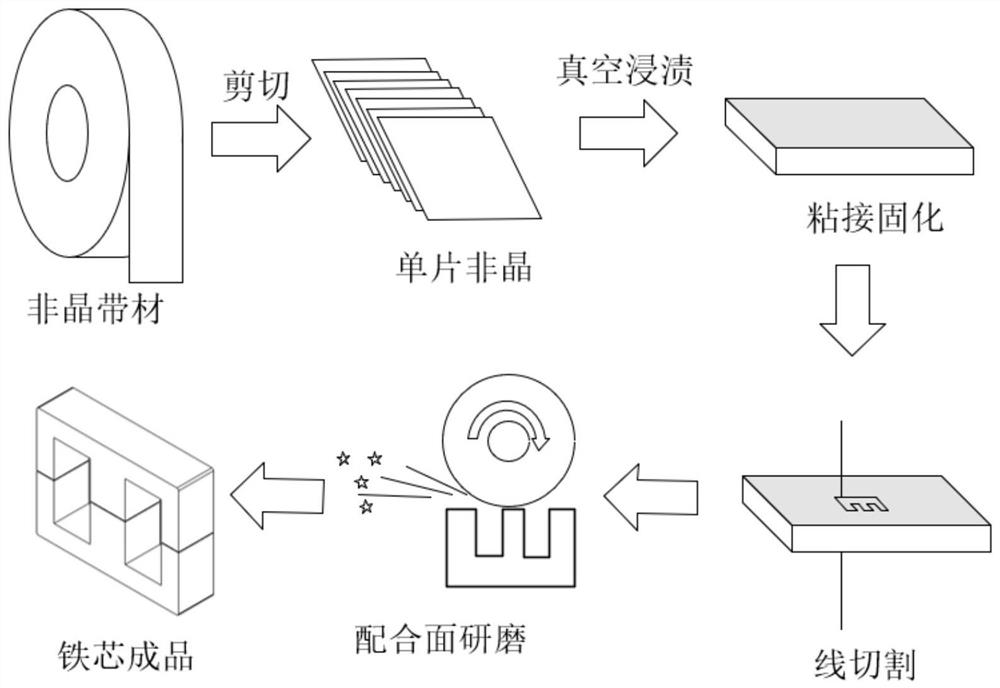

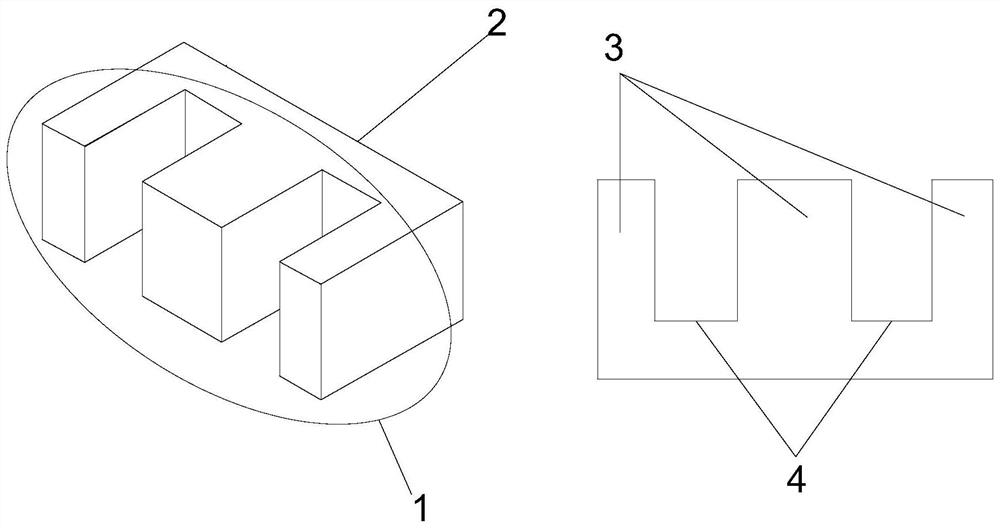

Amorphous magnetic material high-frequency transformer iron core and manufacturing method thereof

PendingCN113470944AImprove the working magnetic flux densityImprove power densityTransformers/inductances magnetic coresMagnetic materialsTransformerMiniaturization

The invention relates to the technical field of high-frequency transformers, and particularly relates to an amorphous magnetic material high-frequency transformer iron core and a manufacturing method thereof. The amorphous magnetic material high-frequency transformer iron core comprises a plurality of same amorphous magnetic material sheets, the amorphous magnetic material sheets are stacked into an amorphous magnetic material block, and the contact surfaces of every two adjacent amorphous magnetic material sheets are coated with a thermosetting resin composition. The manufacturing process comprises the working procedures of strip shearing, iron core forming, heating curing, cutting, grinding, forming and the like, on one hand, the amorphous magnetic material high-frequency transformer iron core can improve the working magnetic flux density applied to a high-frequency transformer of 10 kHz to 200 kHz, the power density of the high-frequency transformer is remarkably improved, and equipment miniaturization is facilitated; and on the other hand, the amorphous material has better toughness than ferrite and is not easy to damage in the transportation and use processes so that the reliability of equipment is improved.

Owner:SHENZHEN UNIV

Nanocrystalline and synthetic graphite non-adhesive composite material and preparation method thereof

InactiveCN109252128AImprove permeabilityHigh thermal conductivityMolten spray coatingHeat-exchange elementsMolten stateFree cooling

The invention relates to a nanocrystalline and synthetic graphite non-adhesive composite material and a preparation method thereof. The method comprises the steps of: a nanocrystalline raw material isheated to a molten state in a vacuum environment; the nanocrystalline material is sprayed in the molten state into the surface of the synthetic graphite conveyed through a roller shaft by the operation of the melt-spinning, and the composite graphite passes through a cooling zone to form a composite of an amorphous magnetic material and synthetic graphite; the composite of the amorphous magneticmaterial and the synthetic graphite is annealed at 500 to 600 DEG C to crystallize the amorphous portion of the composite; the composite is naturally cooled and fed into a press for stitching, and thecomposite material in which nanocrystals and synthetic graphite are combined can be obtained. The nanocrystalline and synthetic graphite non-adhesive composite material has high magnetic permeability, small magnetic loss at high frequency, and has high thermal conductivity.

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD

Method for mass production of plurality of magnetic sensors

InactiveCN100362674CGood repeatabilityMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentAmorphous magnetic materialSemiconductor

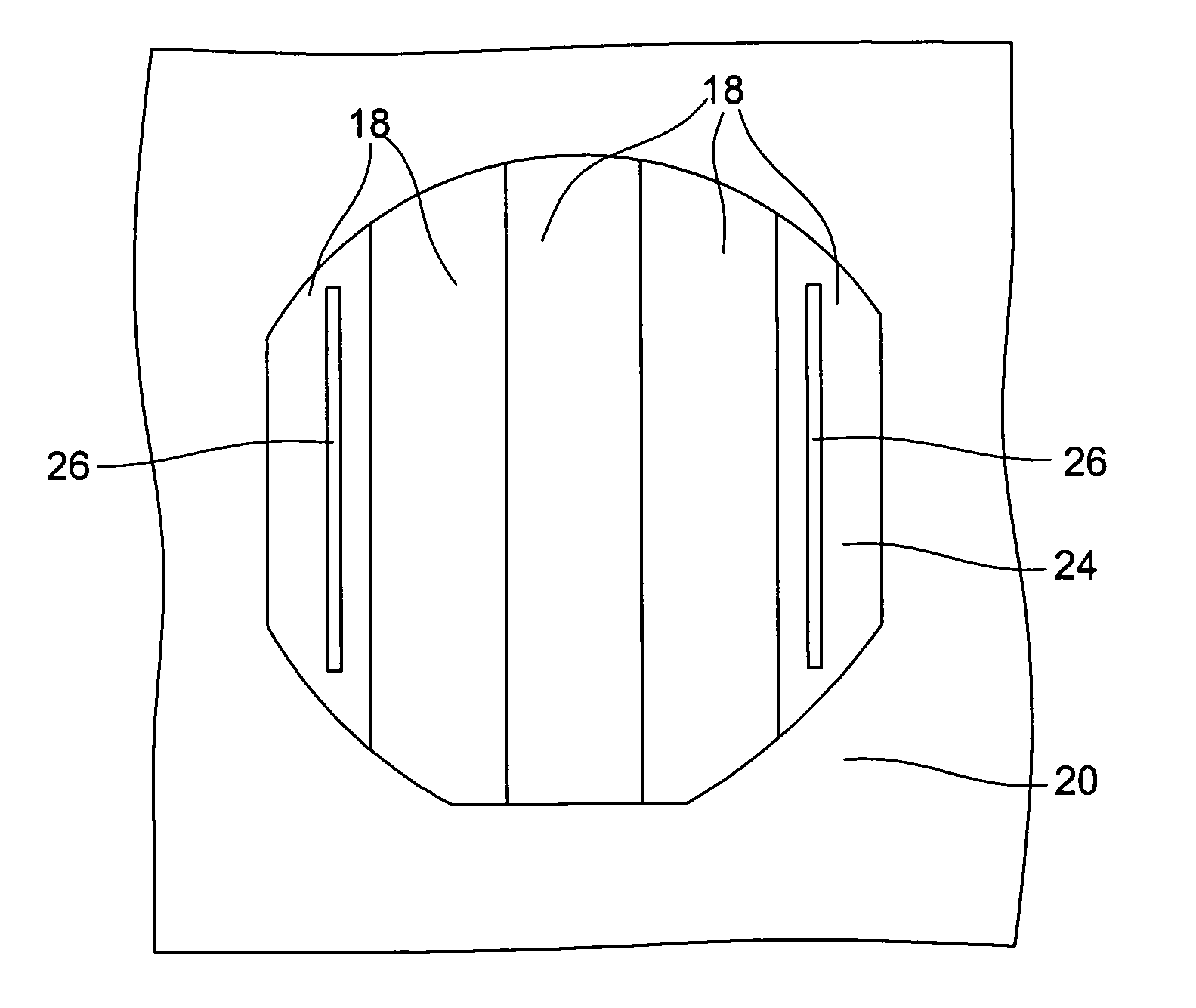

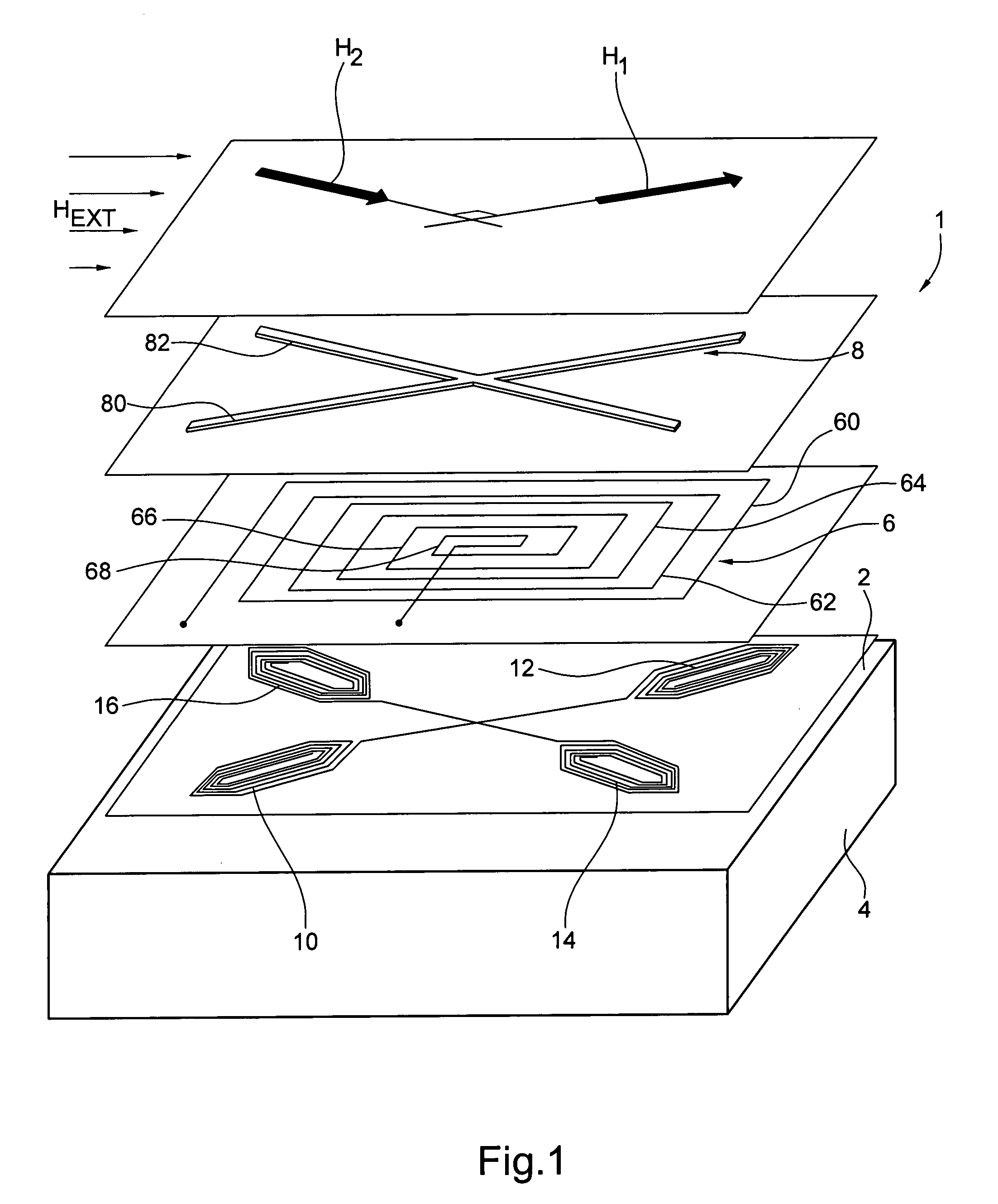

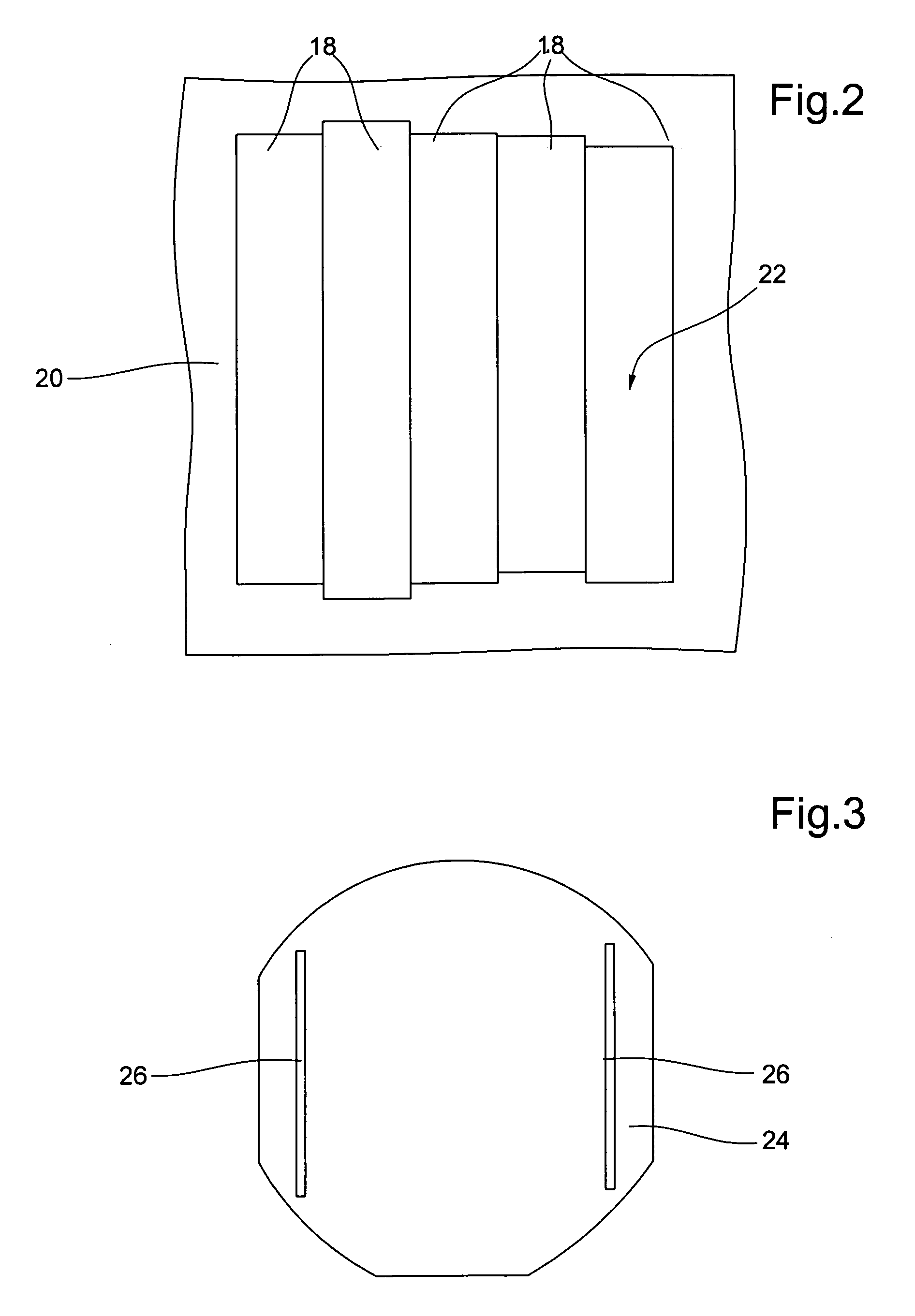

The invention concerns a method for mass production of a plurality of magnetic sensors (1) produced on a semiconductor substrate (4), said sensors (1) comprising at least a magnetic core (8) made of an amorphous magnetic material. The invention is characterised in that, after integrating electronic circuits associated with the magnetic sensors (1), an amorphous magnetic material film (22) is bonded on the semiconductor substrate (4), said film being obtained from an amorphous magnetic material strip cut out into several sections (18) which are arranged juxtaposed on a support (20), said film being then structured to form the magnetic cores (8) of said magnetic sensors (1), the semiconductor substrate (4) being finally cut out to provide a plurality of individual magnetic sensors (1).

Owner:ASULAB SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com