Method for mass production of plurality of magnetic sensors

A magnetic sensor, mass-produced technology, applied to field-controlled resistors, manufacturing/processing of electromagnetic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

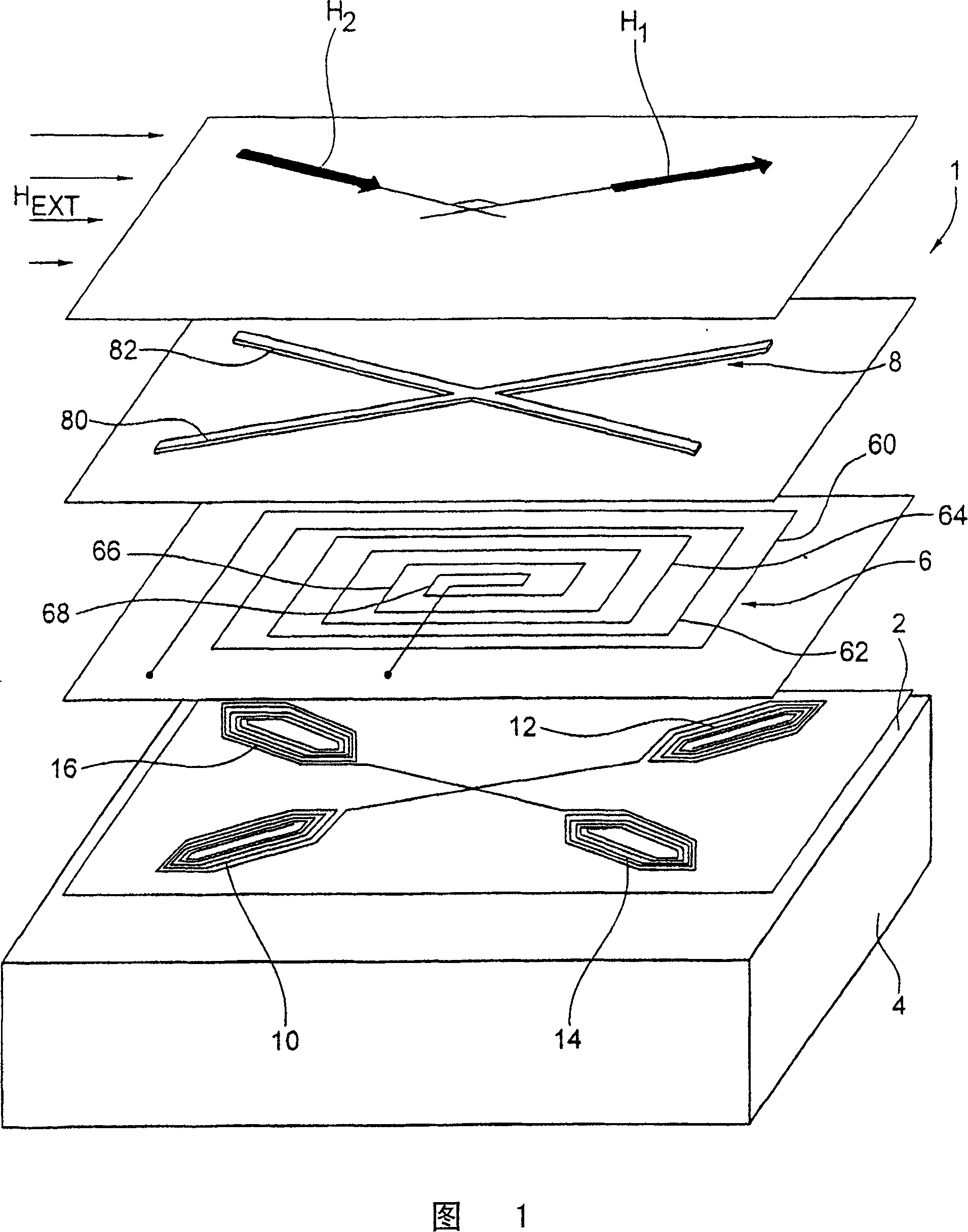

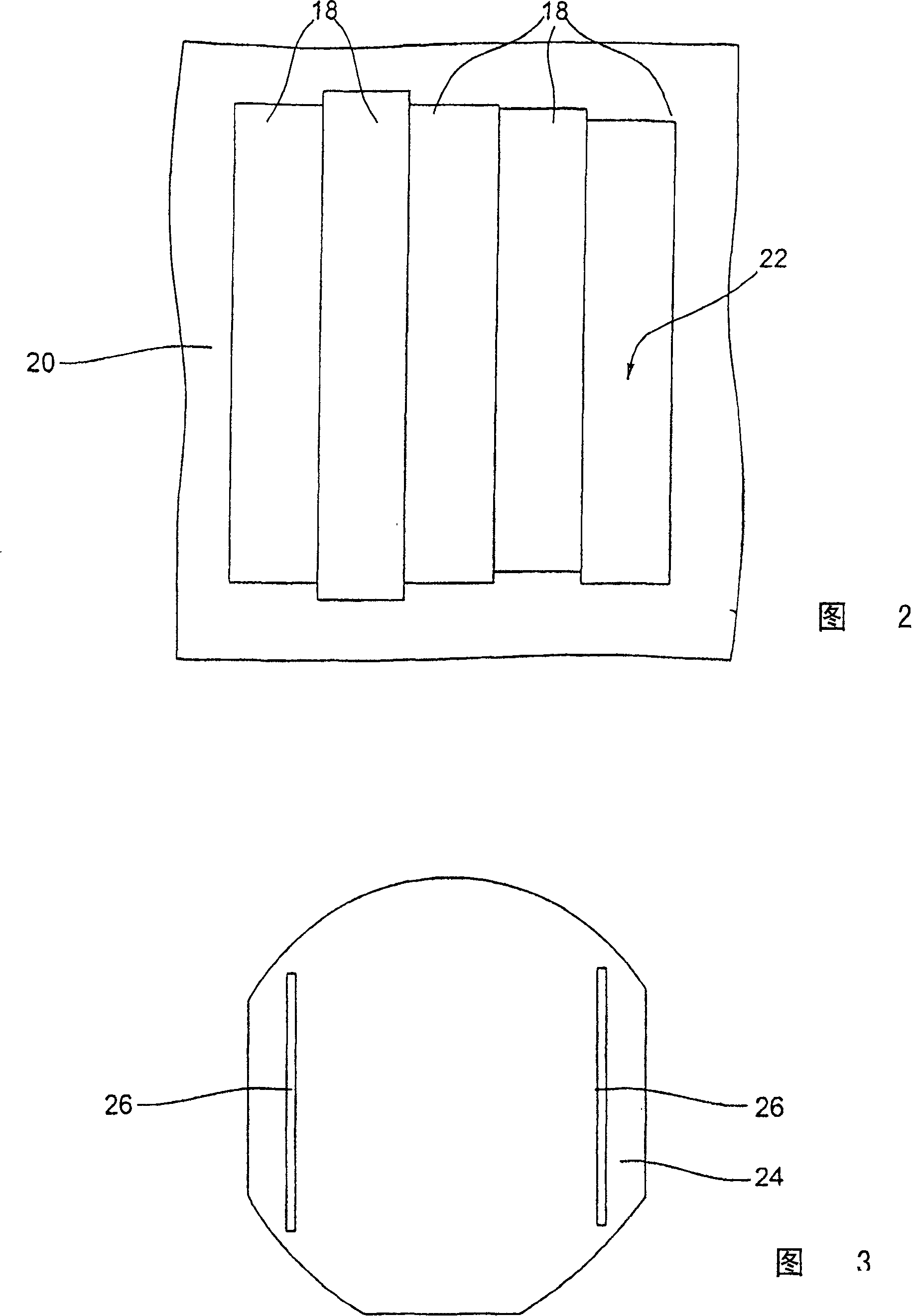

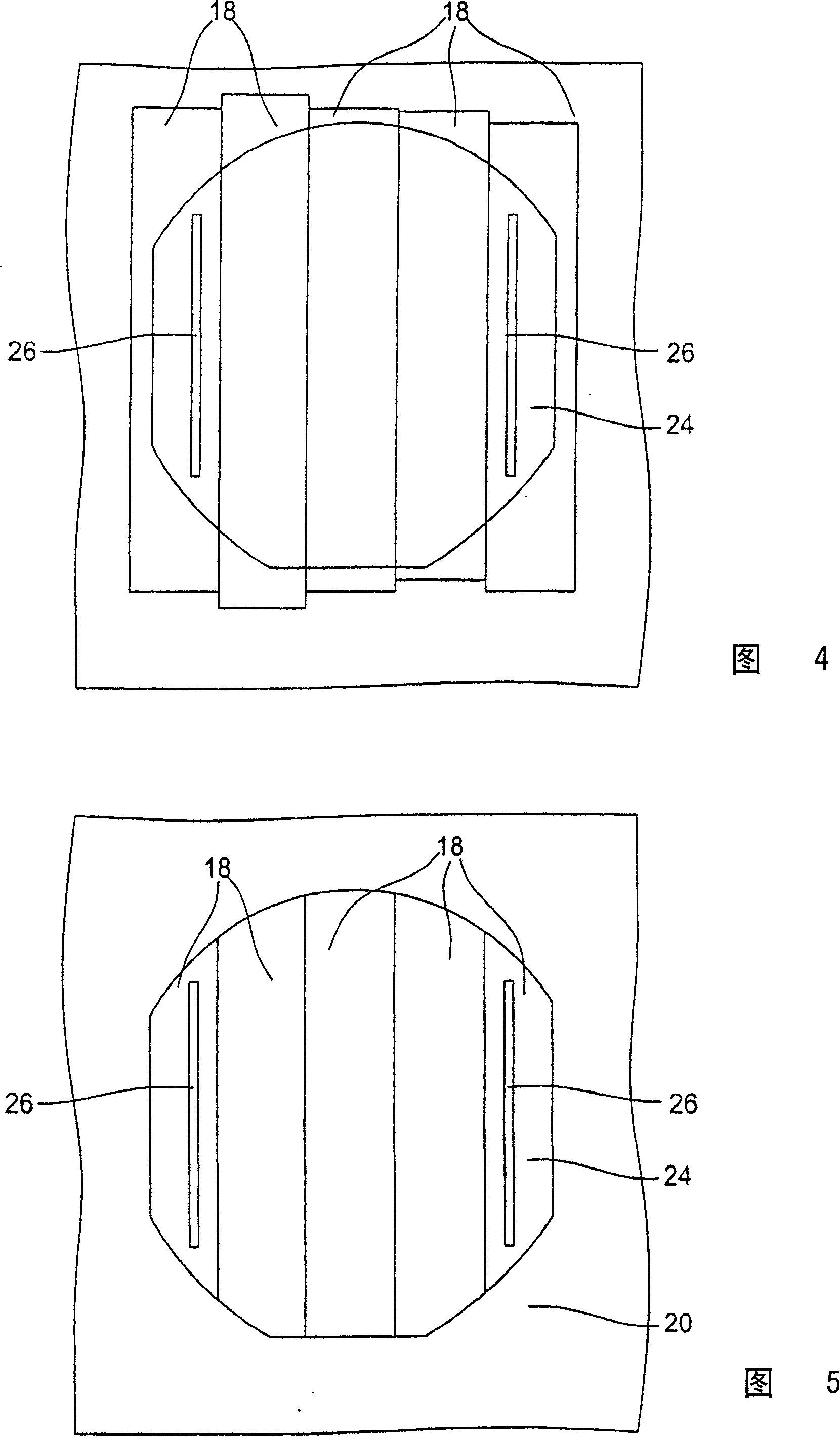

[0027] The present invention proceeds from an innovative general idea of forming a thin film of amorphous magnetic material from a plurality of strips of amorphous magnetic material arranged side by side on a support plate, and bonding the film thus obtained to a semiconductor On the wafer in which the electronic circuits associated with the magnetic sensor to be produced have previously been integrated. After this bonding step, the thin film of amorphous magnetic material is structured by etching in order to produce a magnetic core which constitutes the part of the magnetic sensor which is sensitive to an external magnetic field. Because of these characteristics, it solves the problems caused by the technology that is currently used to produce semiconductor devices but cannot make amorphous layers, and makes it possible to mass produce magnetic sensors with amorphous magnetic cores.

[0028] The invention will be described in connection with a magnetic sensor as described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com