New process for producing amorphous state strip under non-vacuum

An amorphous, non-vacuum technology, used in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problem of high investment, achieve the effect of saving investment, broad market area, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described in conjunction with embodiment.

[0038] A new process for producing amorphous strips under non-vacuum is characterized in that it is carried out according to the following steps:

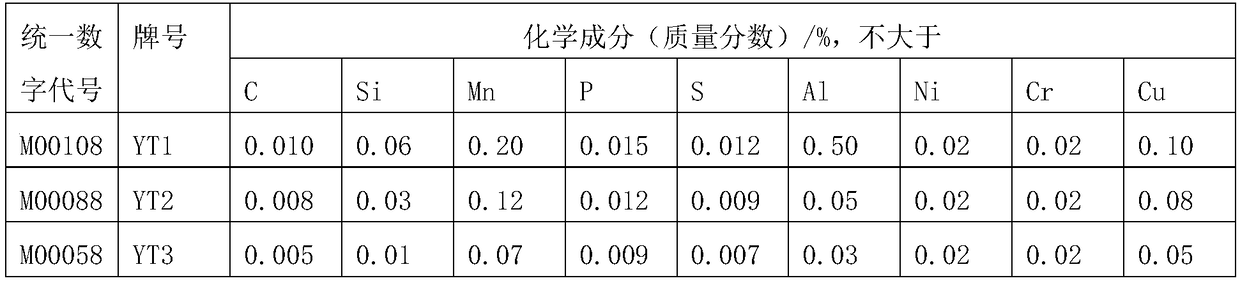

[0039] Step 1, producing high-purity pure iron molten steel, the preparation of high-purity pure iron molten steel adopts ZL201410341008.4, and the name is: a high-purity pure iron molten steel produced by a method for producing high-purity pure iron;

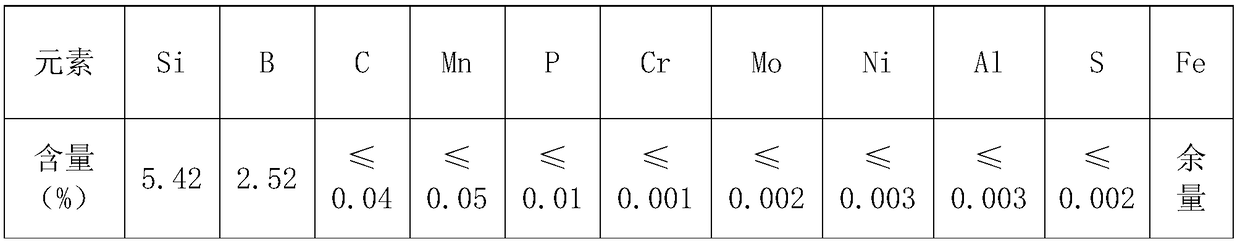

[0040] Step 2: Add Si, B and P alloys into the high-purity pure iron molten steel to form amorphous magnetic material molten steel, flow through the crucible nozzle to the high-speed rotating cooling copper roller, and the molten steel is super-rapidly quenched into thin ribbon.

[0041] Apparently, the present invention has shorter technical process than the traditional amorphous strip, less tooling equipment, less investment, low energy consumption, low cost, and self-controllable product quality....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com