Amorphous magnetic material high-frequency transformer iron core and manufacturing method thereof

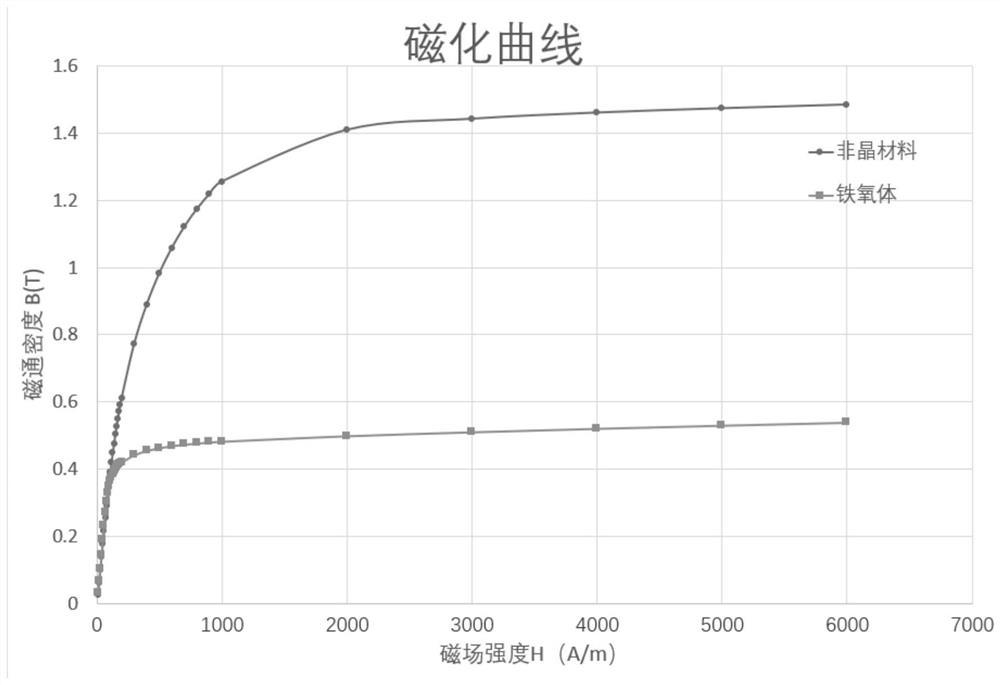

A technology of high-frequency transformers and magnetic materials, applied in the field of high-frequency transformers, can solve the problems of fragility, increase the cost of use, and brittle texture, and achieve the effects of improving the working magnetic flux density, being conducive to miniaturization, and improving power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

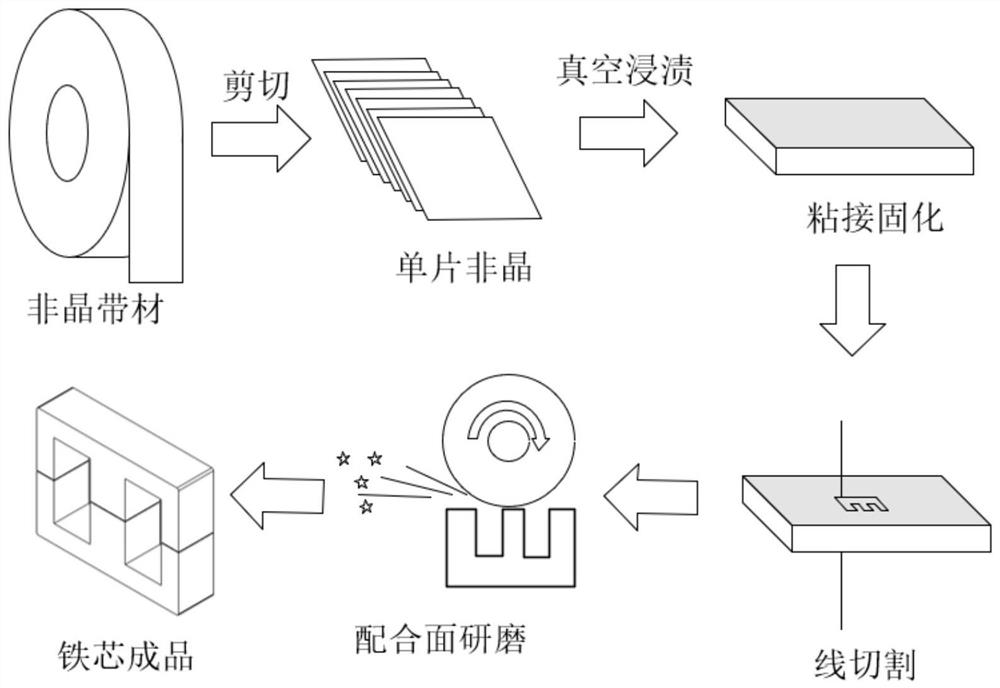

[0032] The original width of amorphous ribbon 142mm cross cut single length of 142mm square piece of amorphous material. The cut single sheets 600-2000 amorphous material are laminated together, by vacuum impregnation techniques thermosetting resin is pressed into the gap between the single sheets of amorphous material.

[0033] Thermosetting resin composed of the following components: 84 parts of a bisphenol A type epoxy resin, 12 parts of butyl glycidyl ether, 1 part of 3-aminopropyl triethoxysilane, 3 parts of diethyl tetramethyl imidazole ; bisphenol A type epoxy, butyl glycidyl ether, and 3-aminopropyl triethoxysilane mixing evenly, tetramethyl diethyl imidazole was heated to 50 ℃, and the mixture was stirred uniformly and in vacuo defoaming.

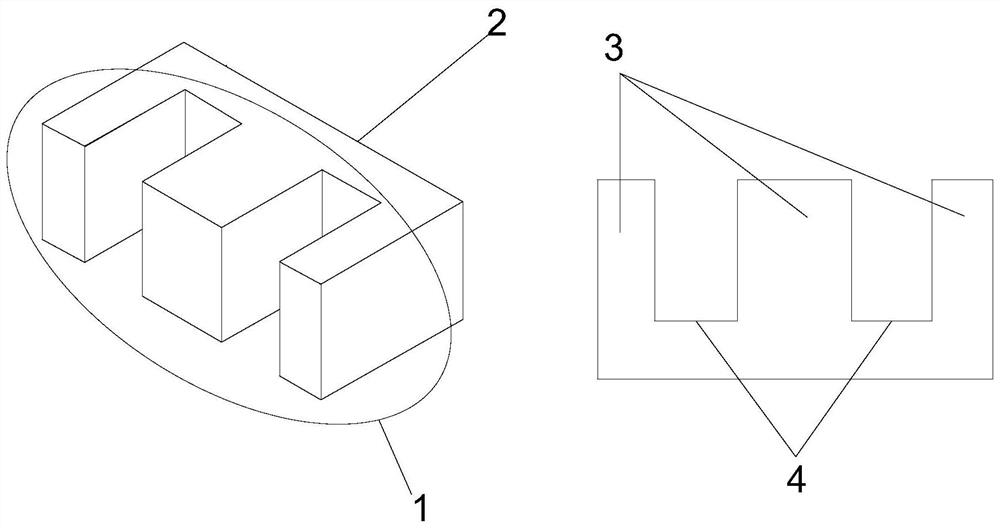

[0034] The amorphous material with a wire cutting block is cut E-shaped core, such image 3 , In which an uneven portion, a smooth portion 2, 3 is the convex portion, a concave portion 4, wire cutting molybdenum wire diameter of 180um, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com