Patents

Literature

156 results about "Amorphous ribbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

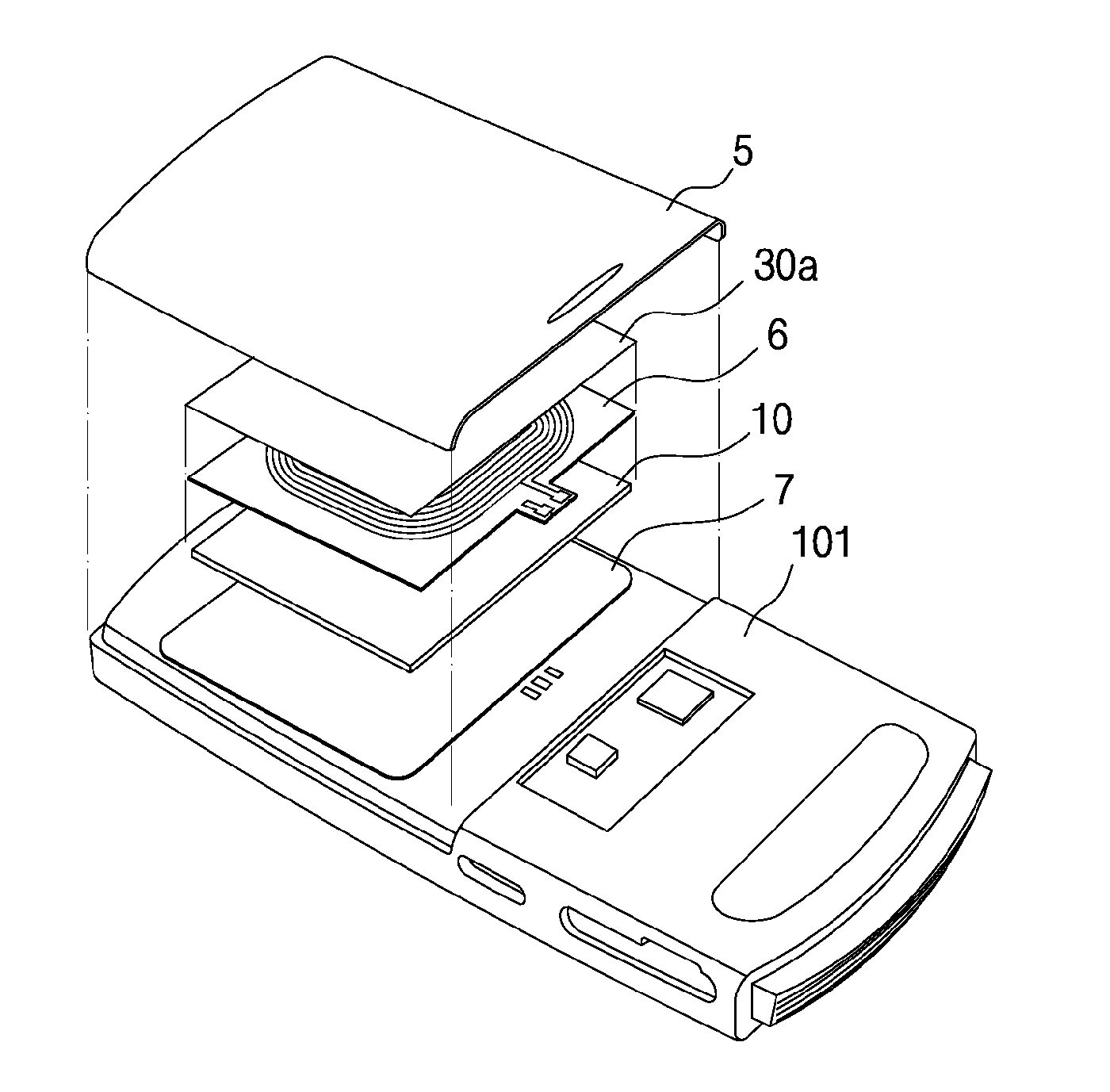

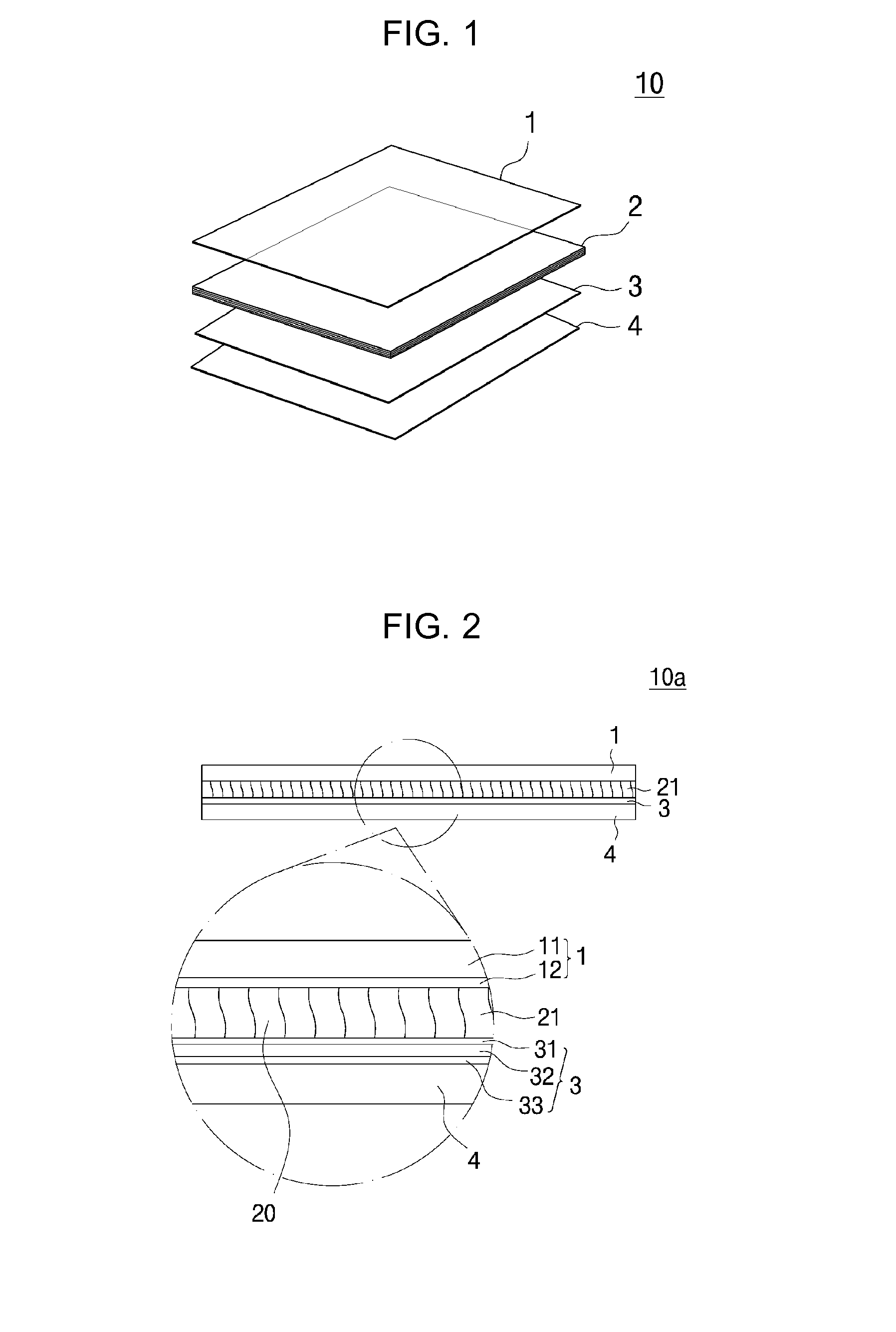

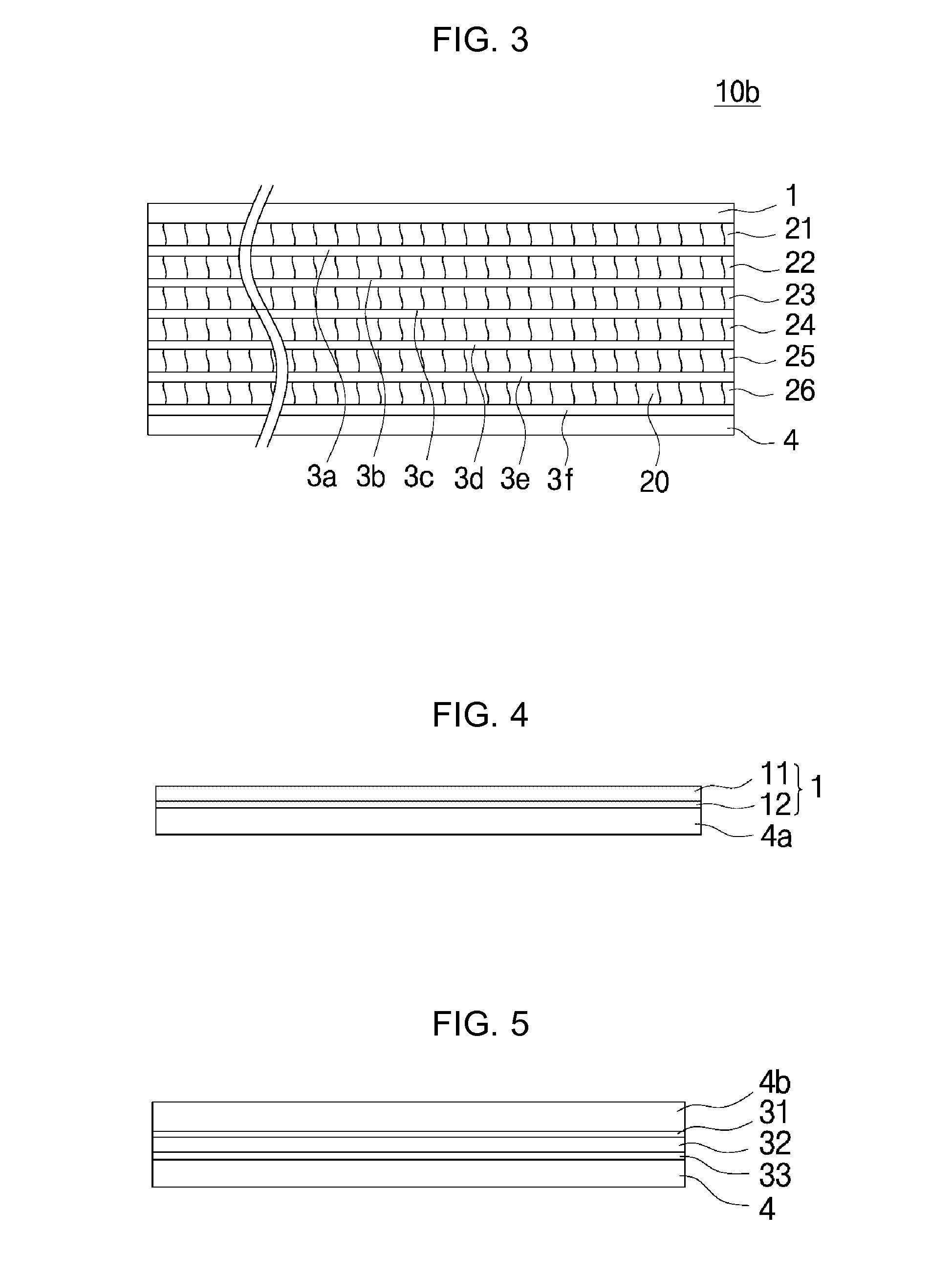

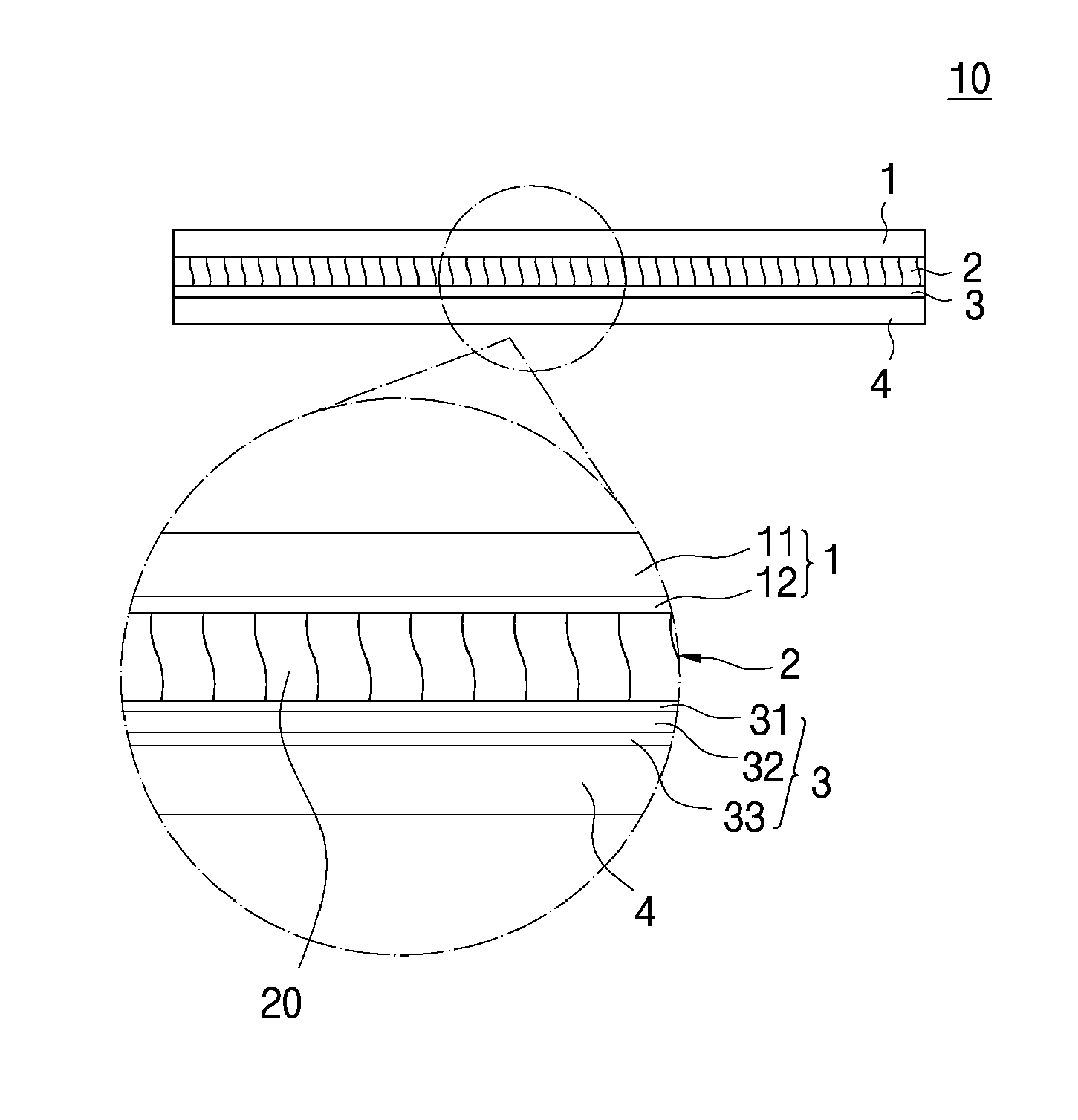

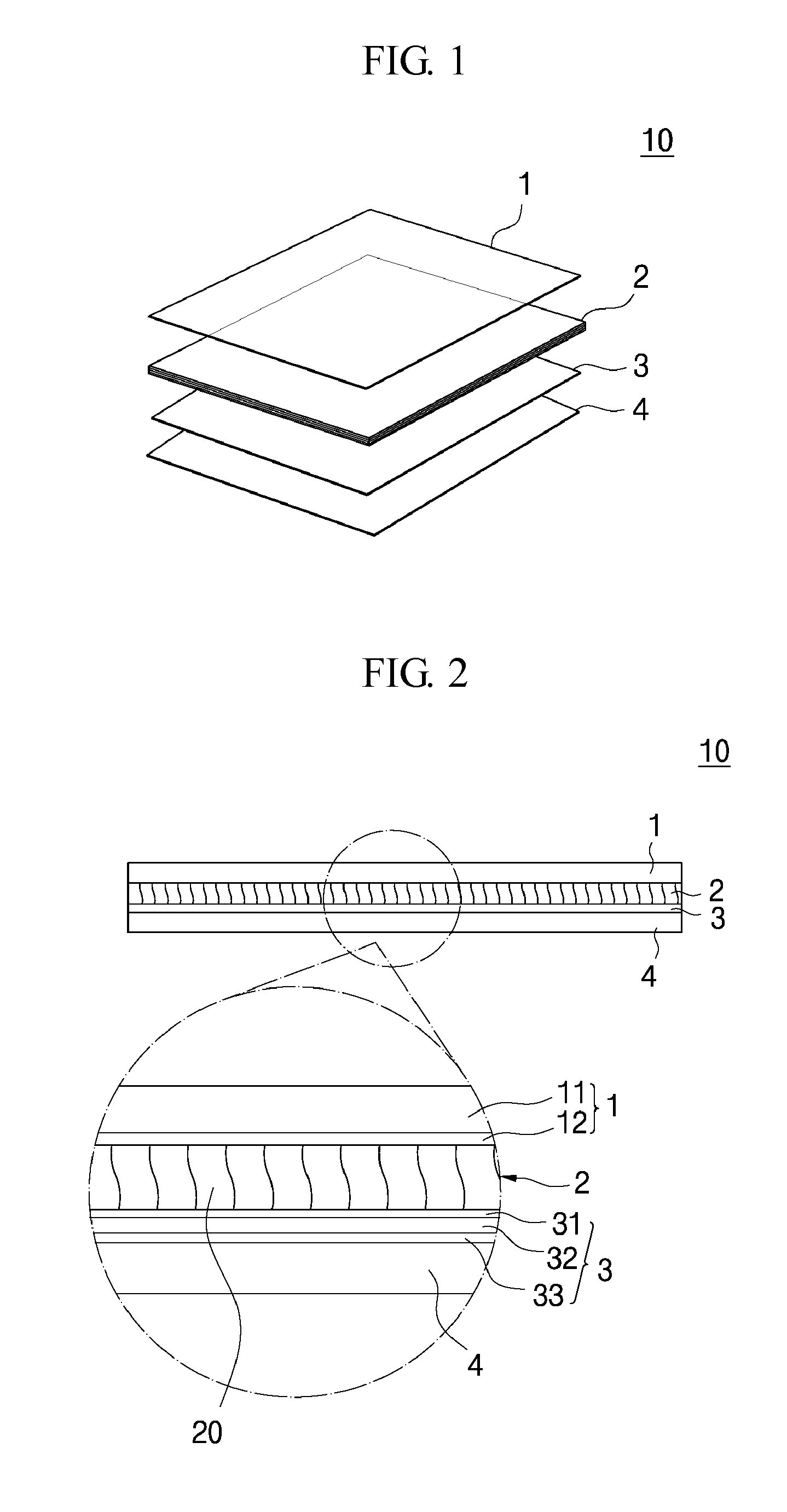

Magnetic field shielding sheet for a wireless charger, method for manufacturing same, and receiving apparatus for a wireless charger using the sheet

ActiveUS20150123604A1Reduce lossesHigh quality factorNear-field transmissionShielding materialsElectric power transmissionTerminal equipment

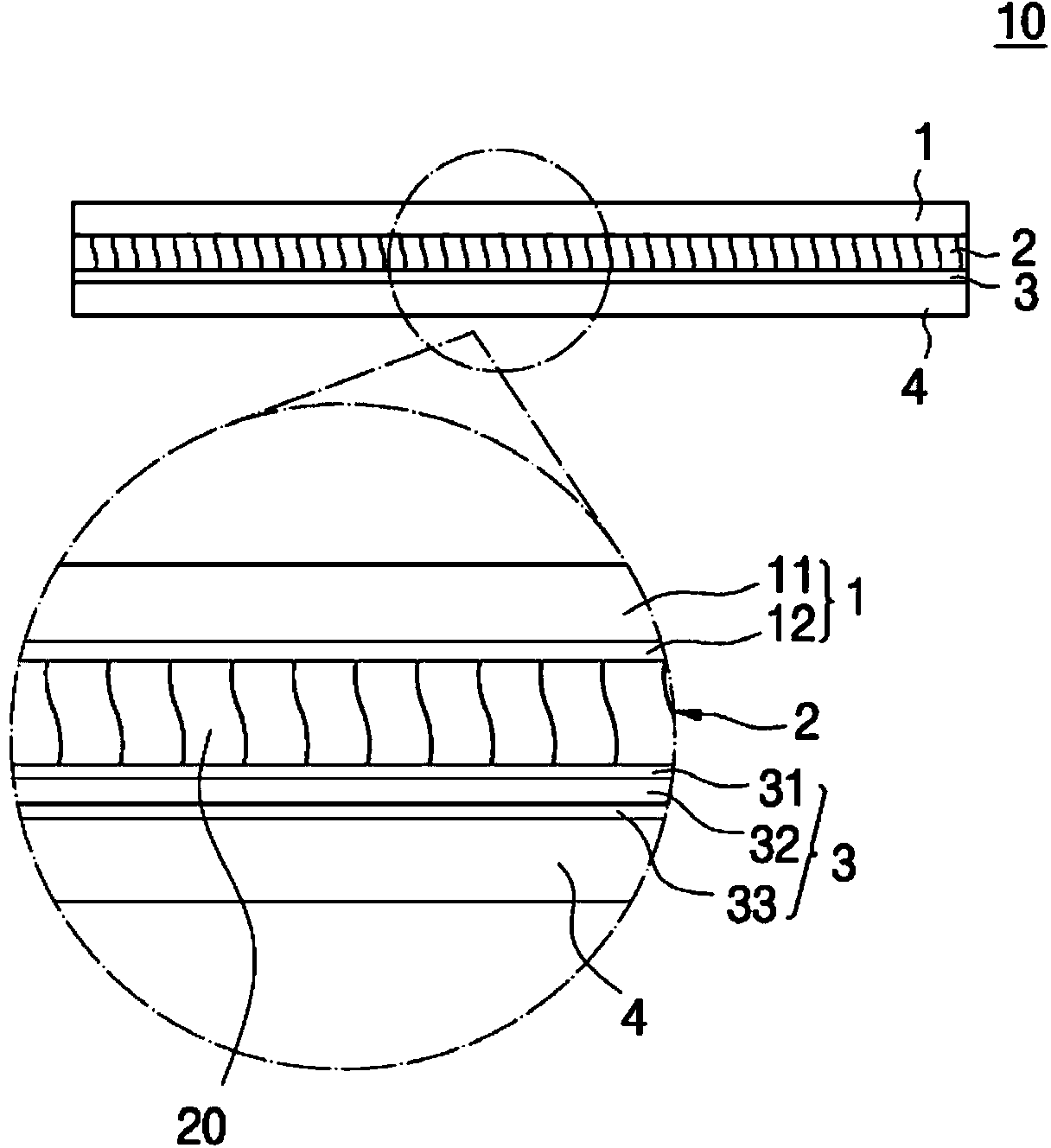

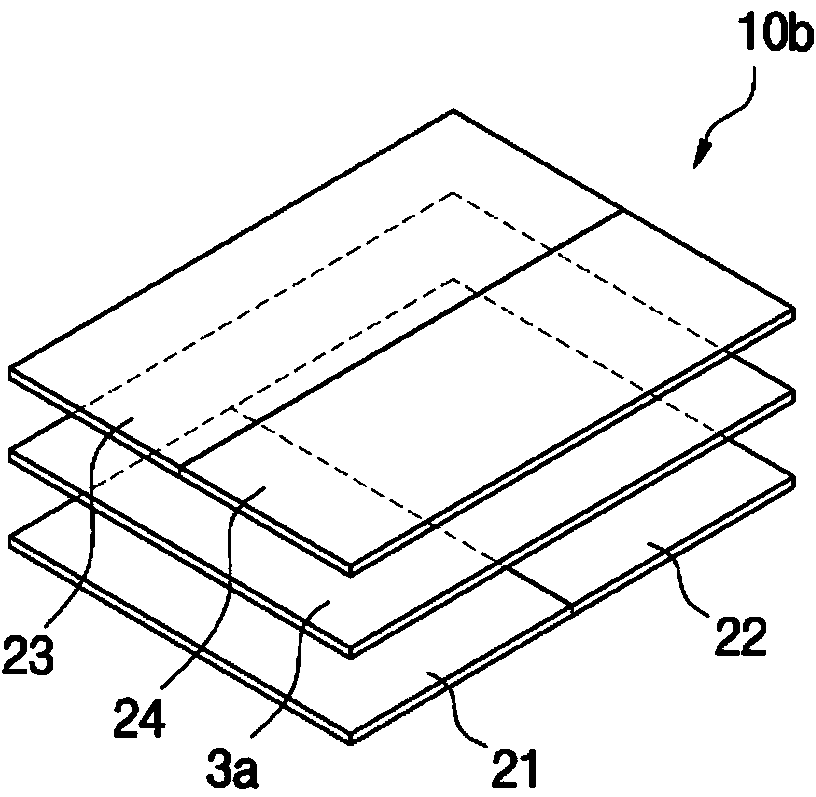

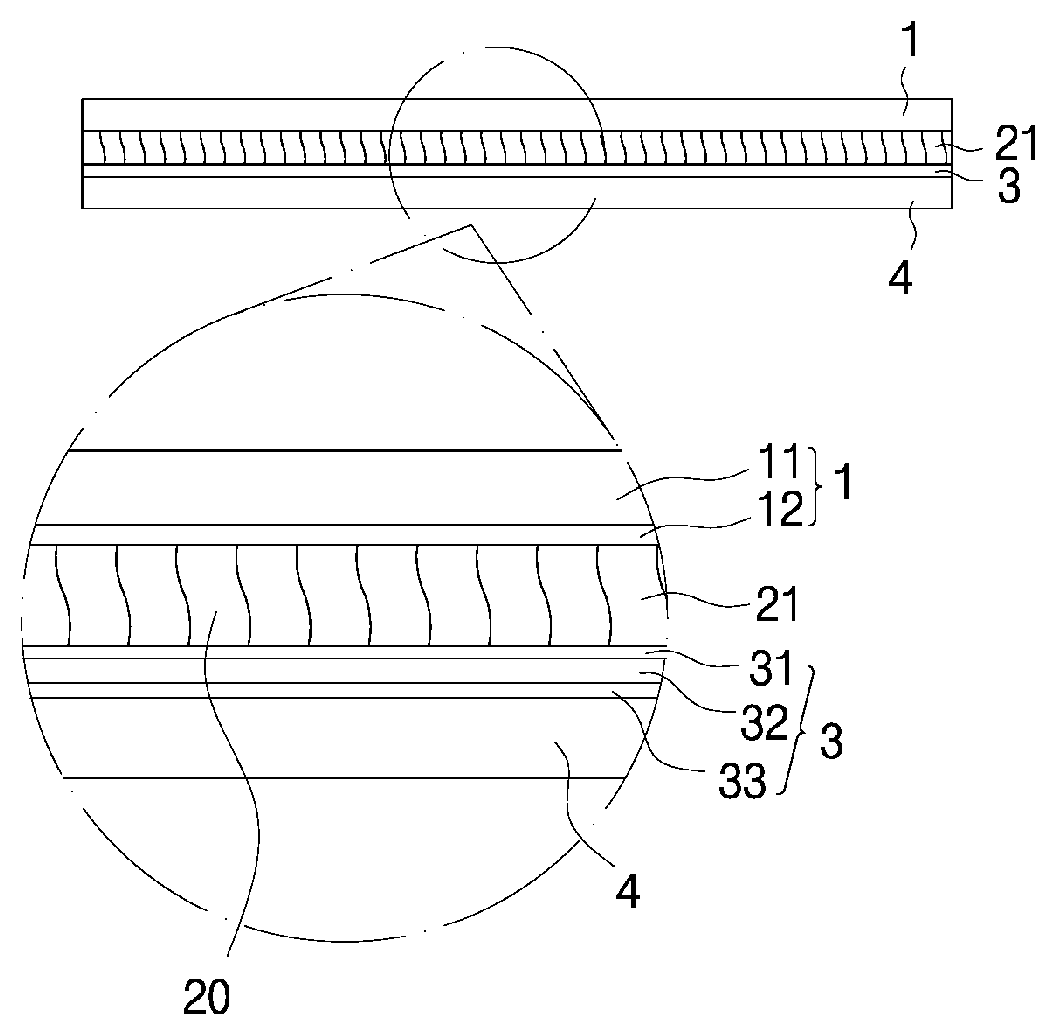

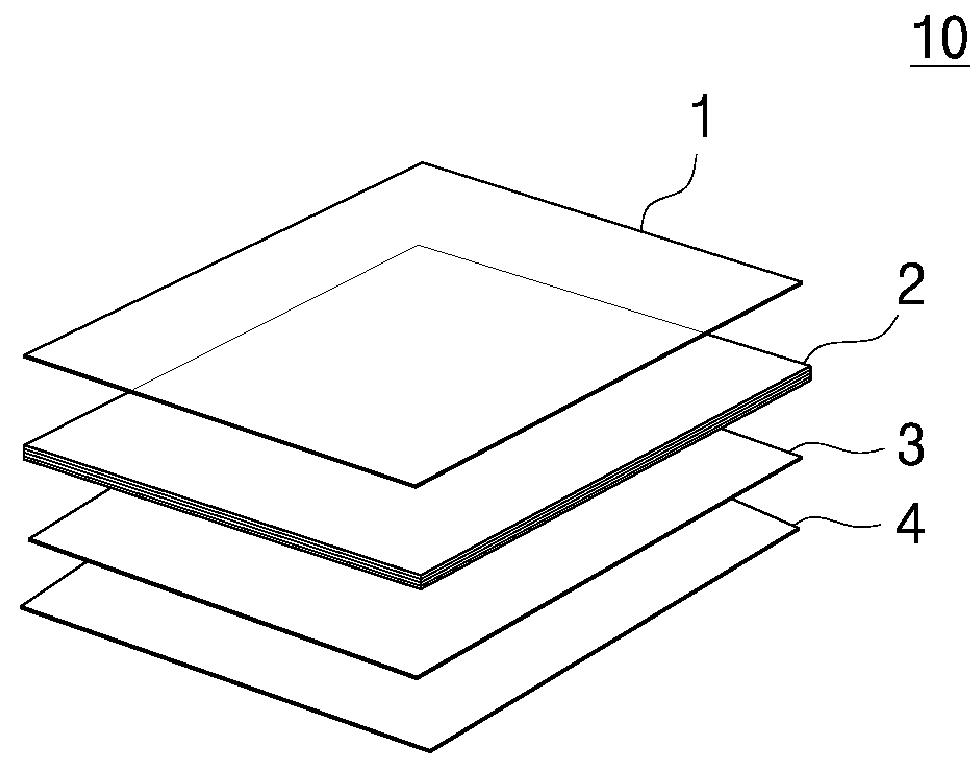

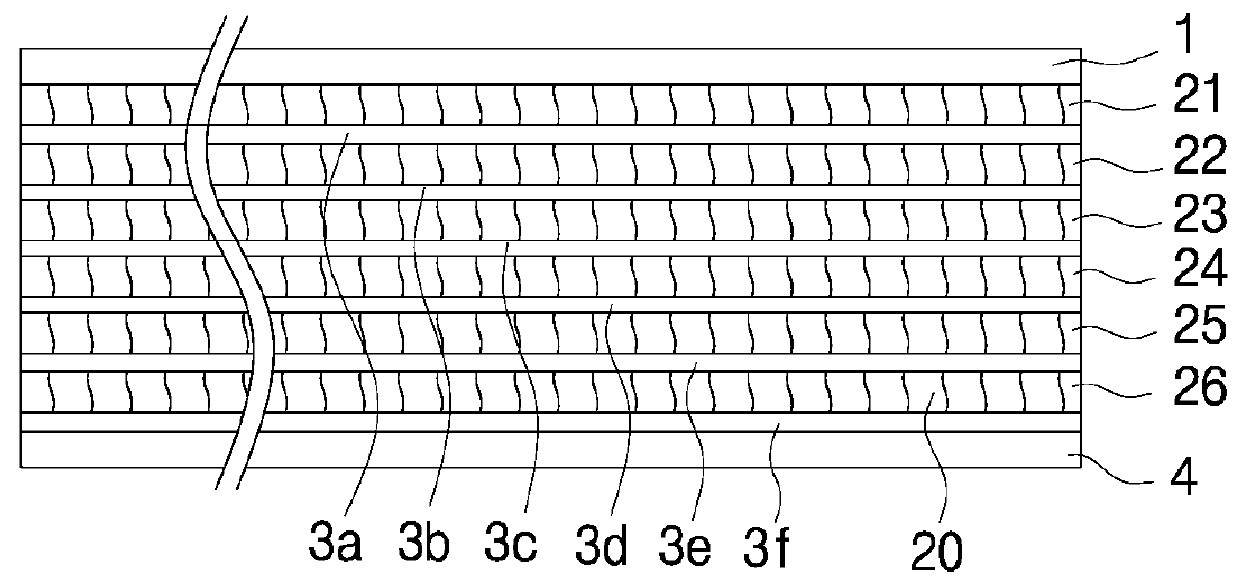

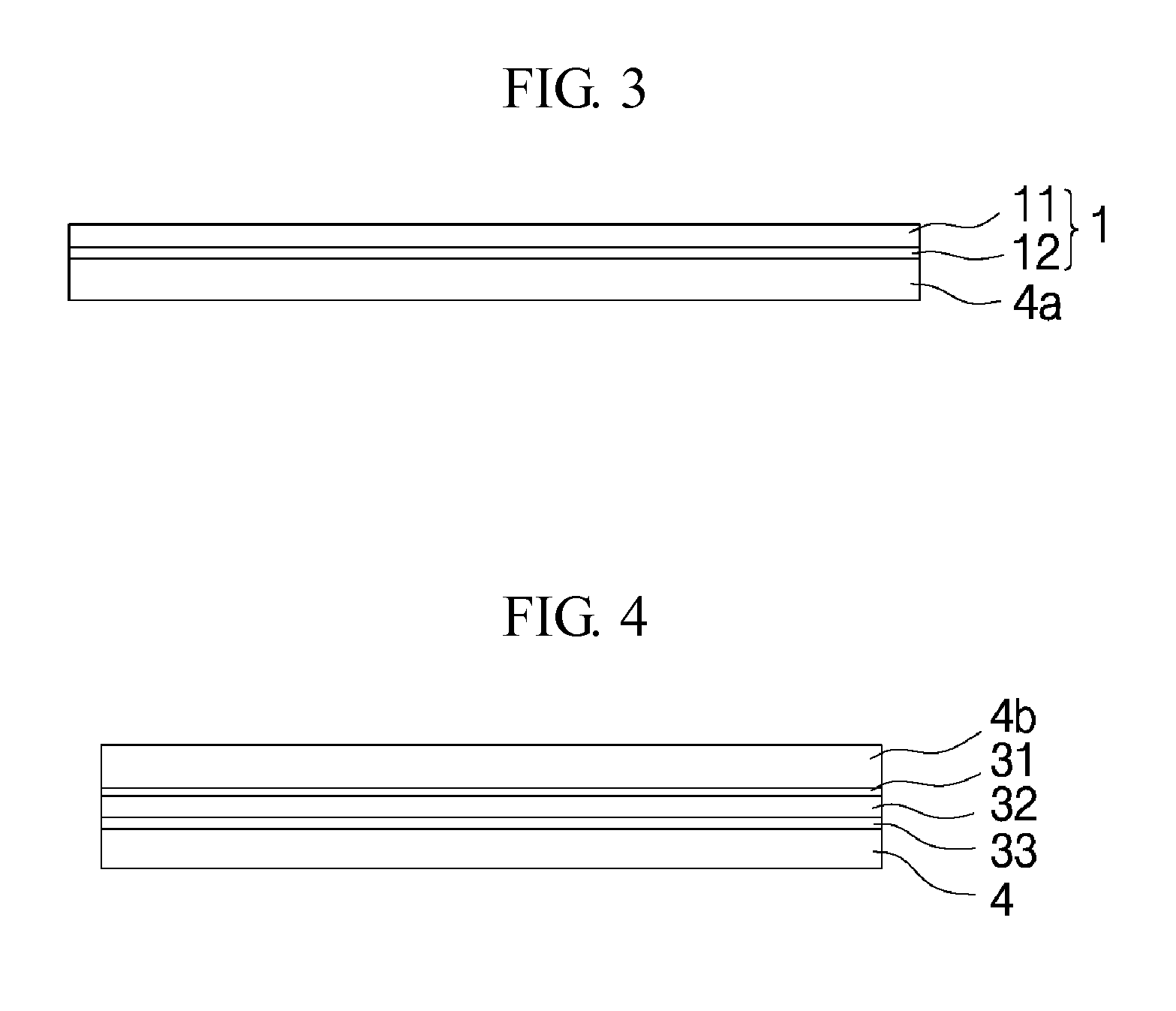

Provided are a magnetic field shield sheet for a wireless charger, which blocks an effect of an alternating-current magnetic field generated when a charger function for a portable mobile terminal device is implemented in a non-contact wireless manner on a main body of the portable mobile terminal device and exhibits excellent electric power transmission efficiency, a method of manufacturing the sheet, and a receiver for the wireless charger by using the sheet. The sheet includes: at least one layer thin magnetic sheet made of an amorphous ribbon separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape, wherein gaps among the plurality of fine pieces are filled by some parts of the first and second adhesive layers, to thereby isolate the plurality of fine pieces.

Owner:AMOSENSE

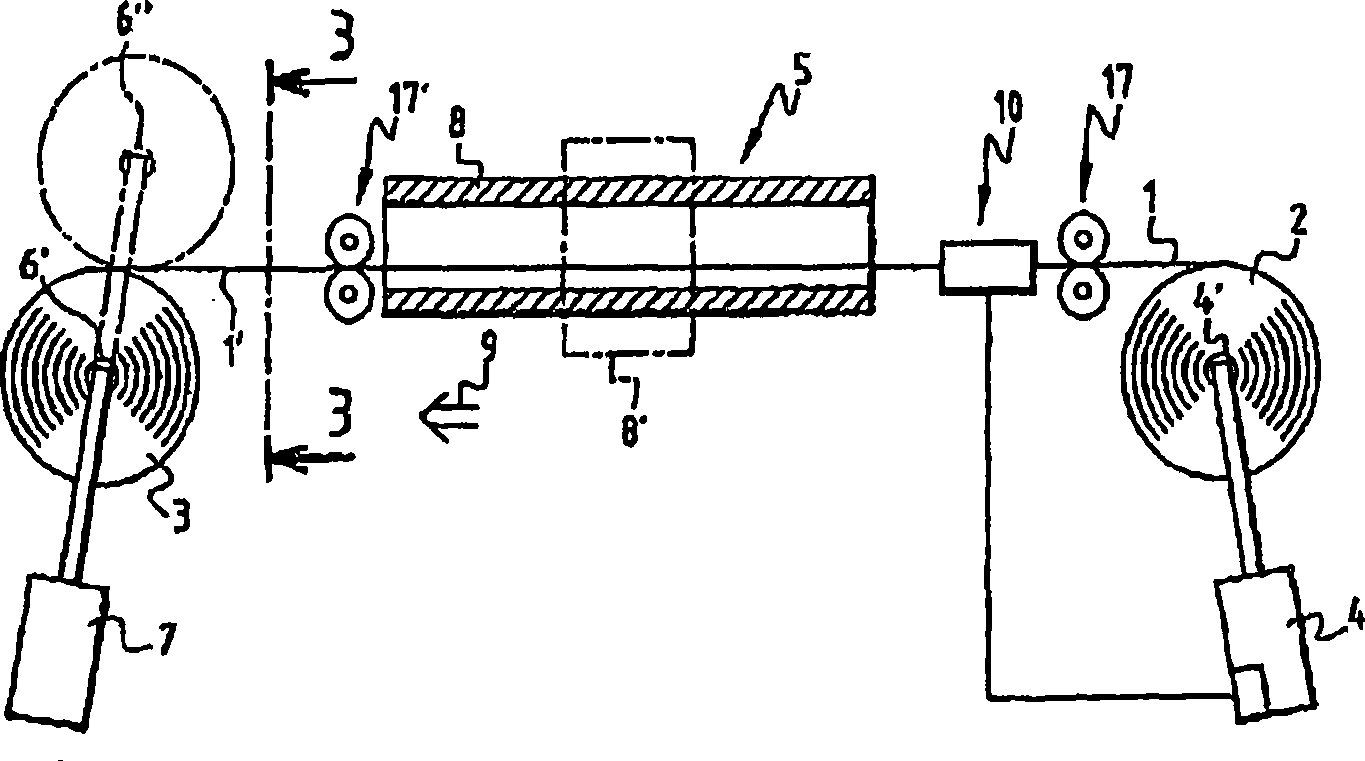

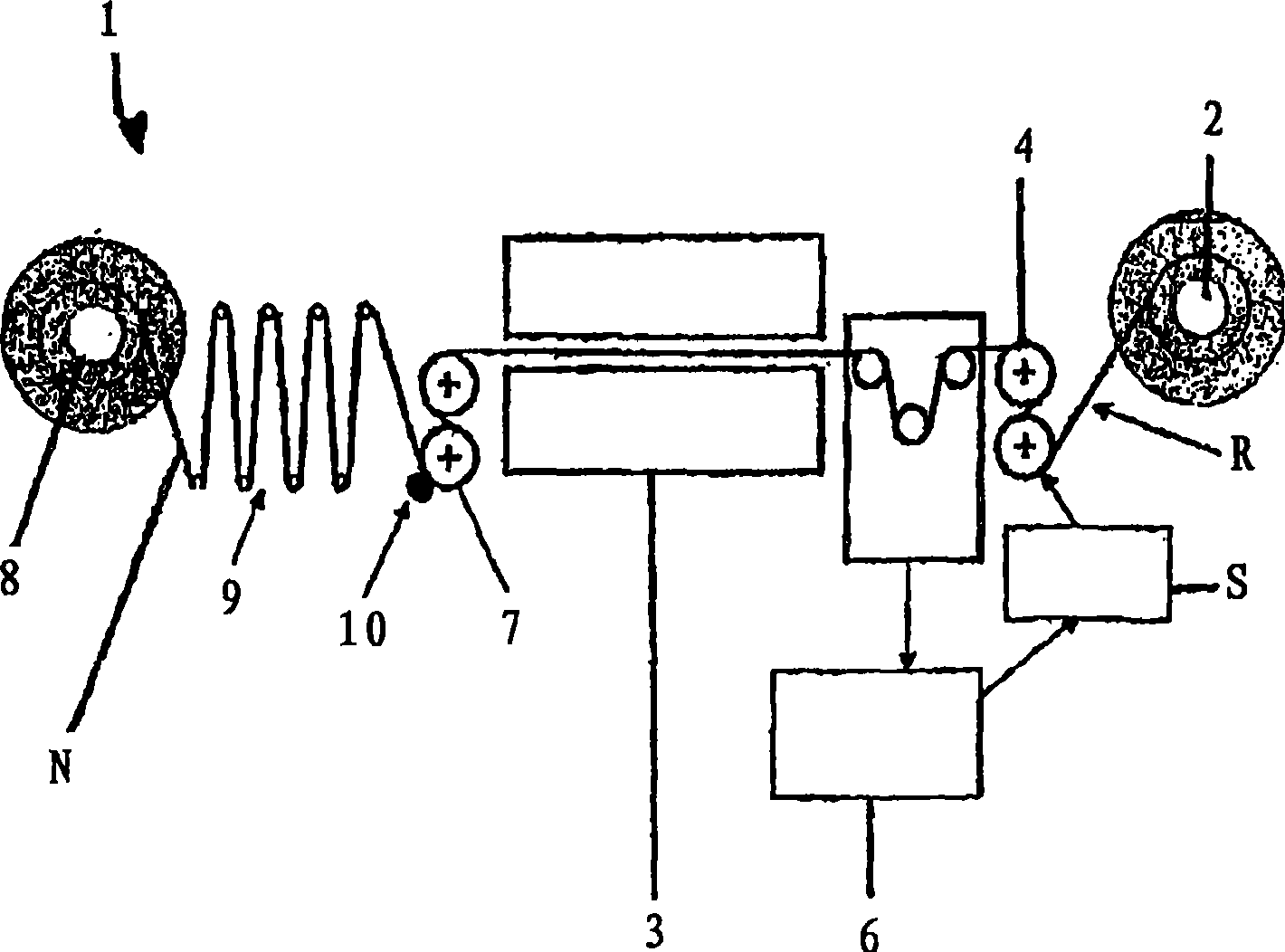

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

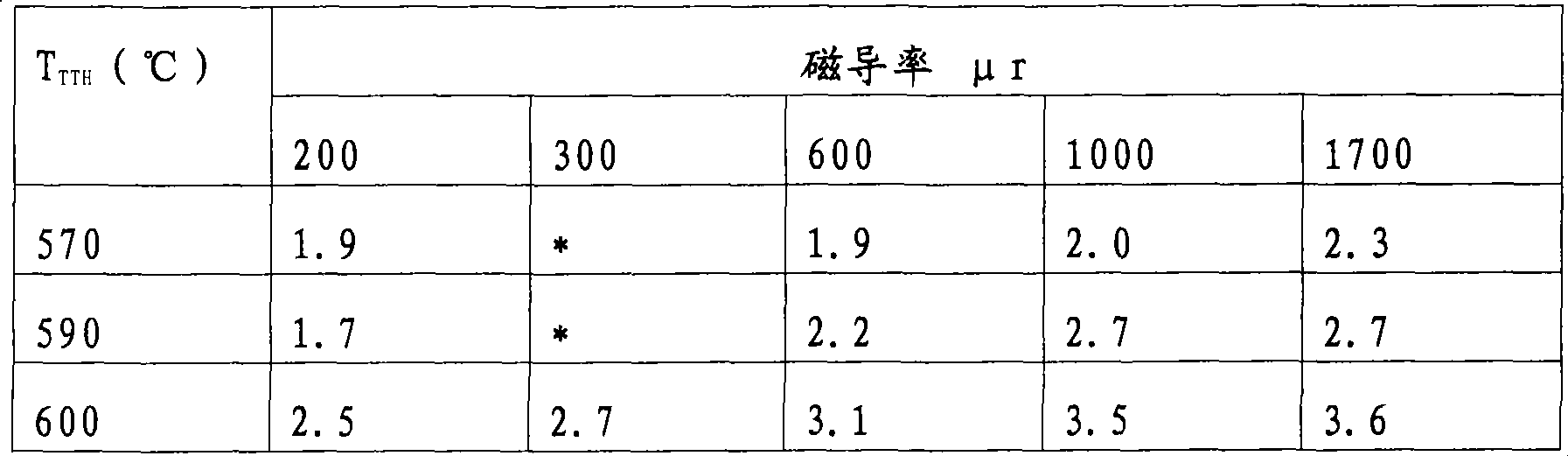

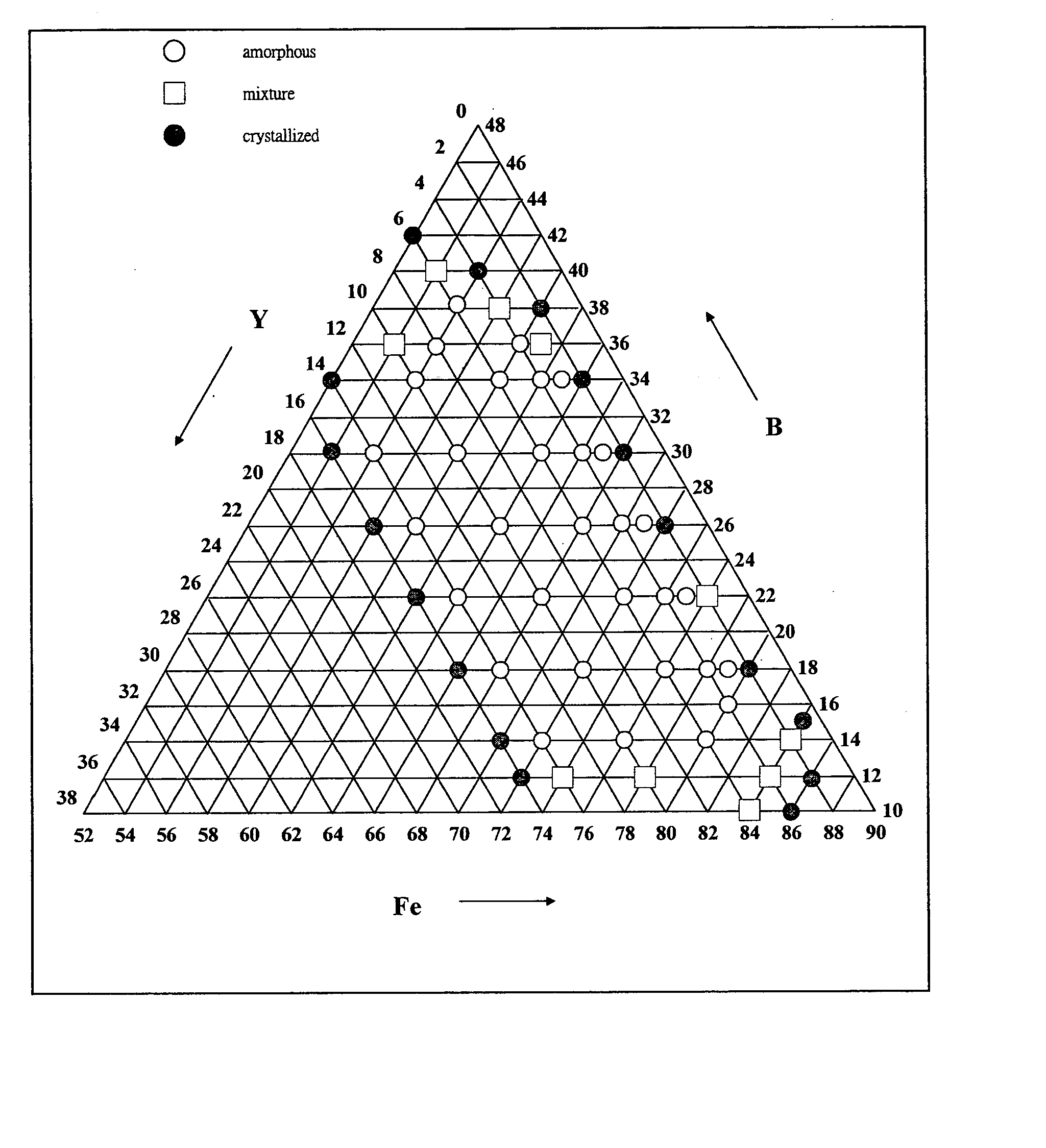

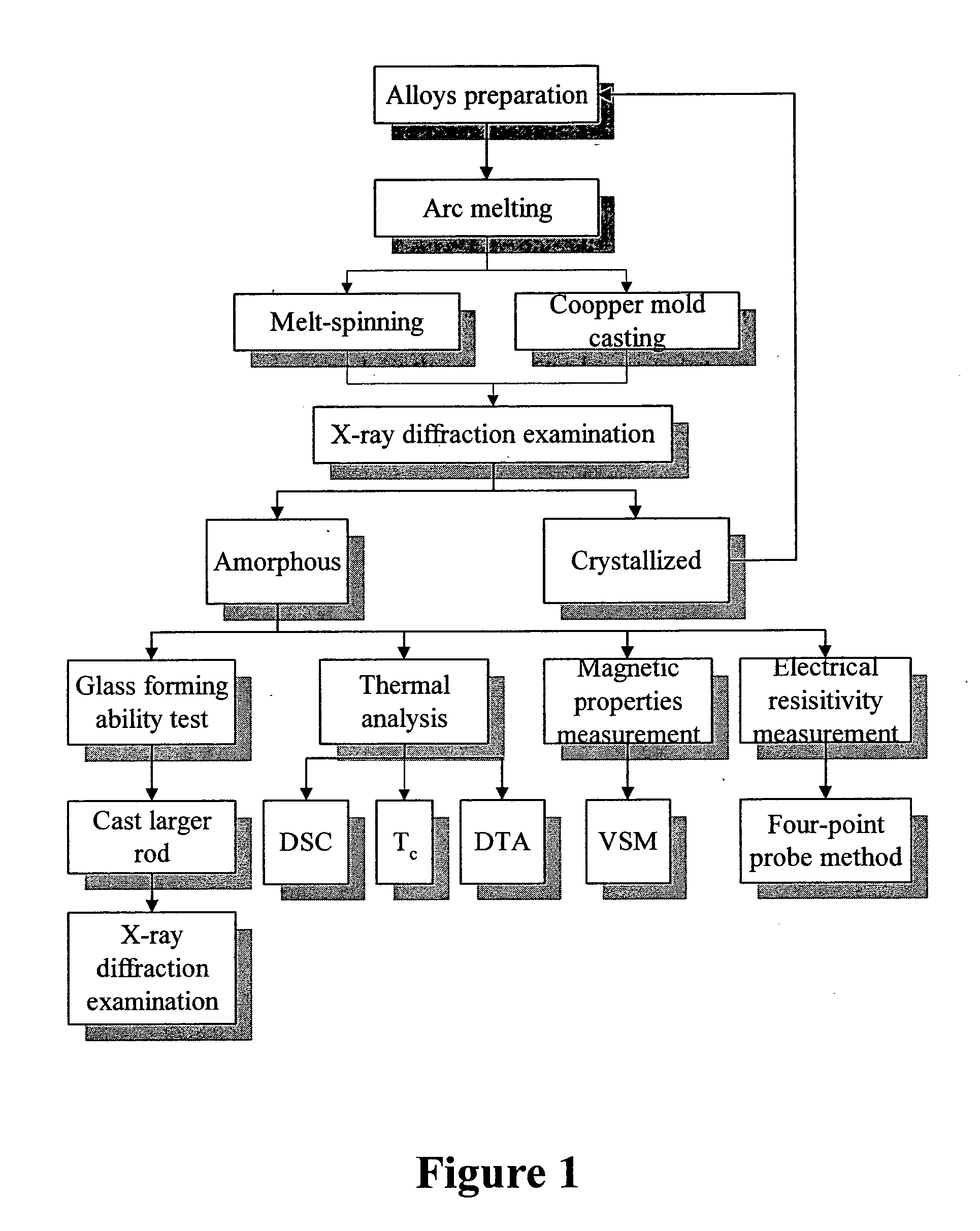

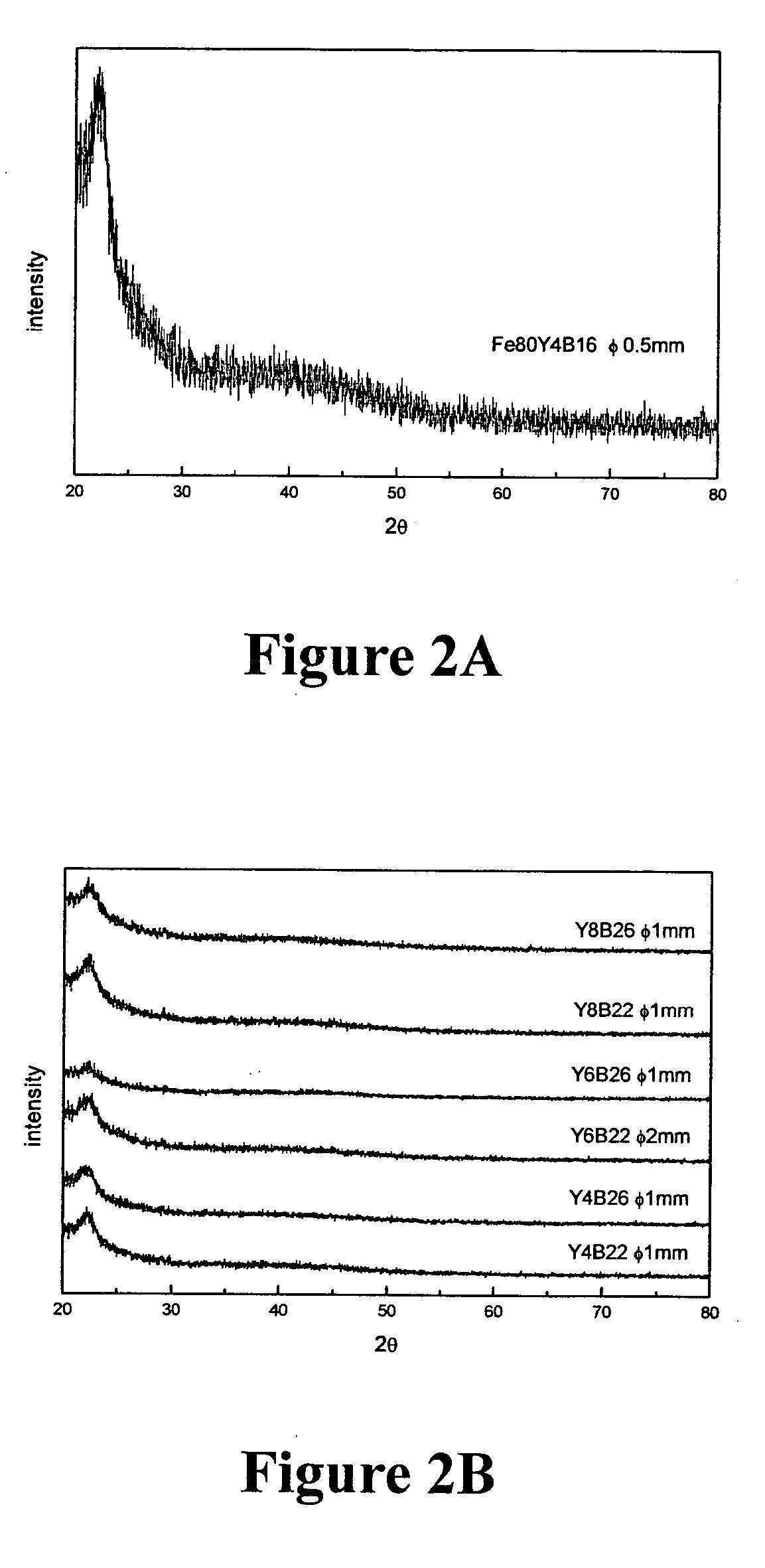

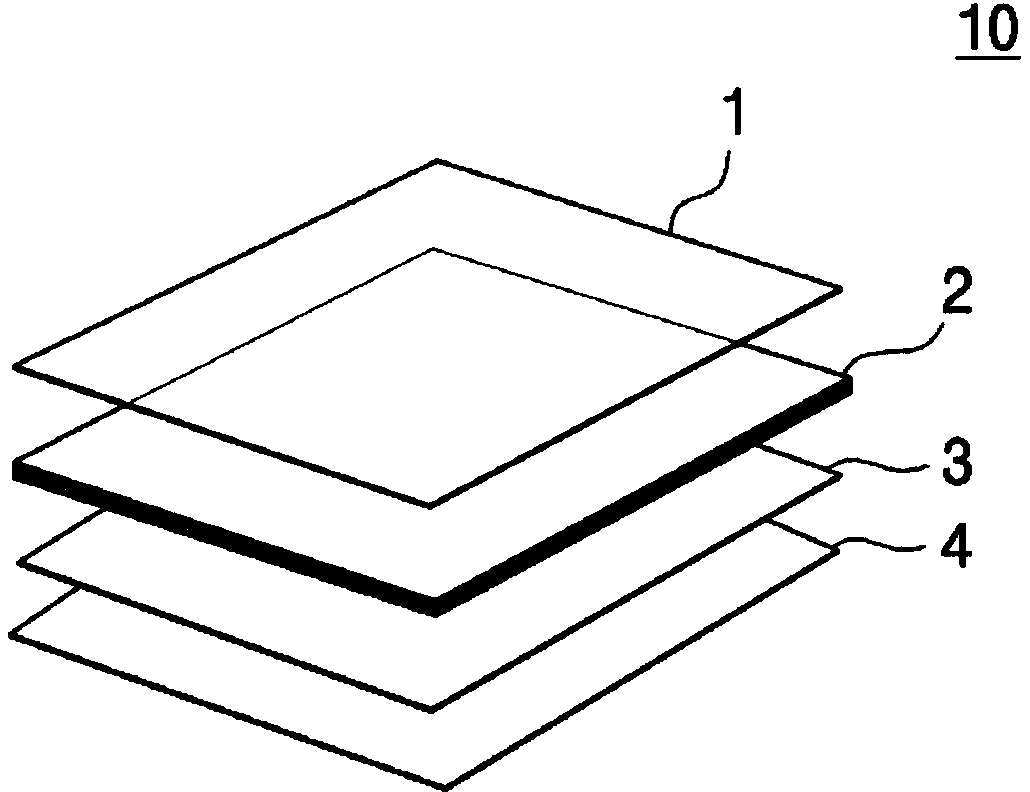

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

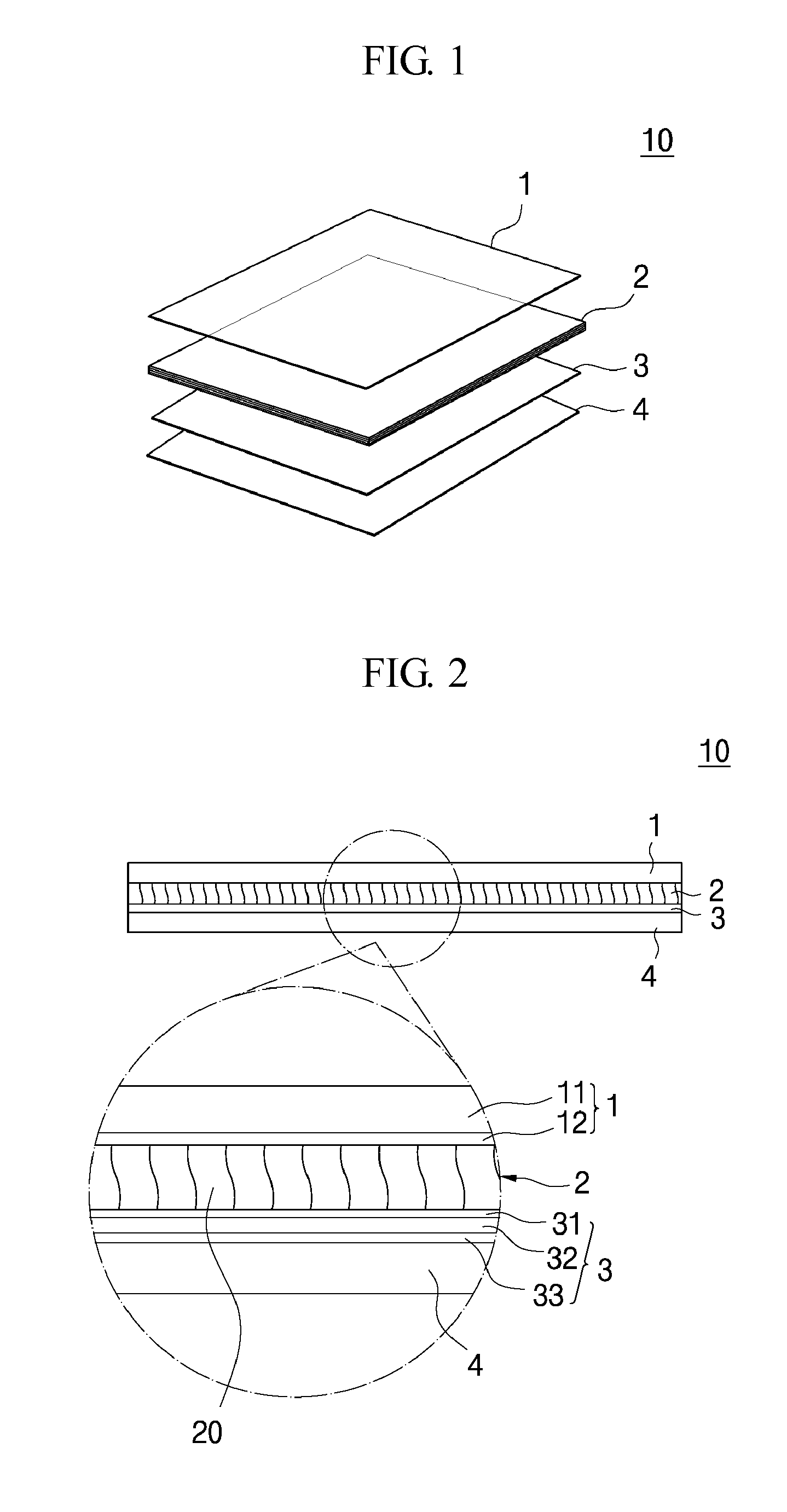

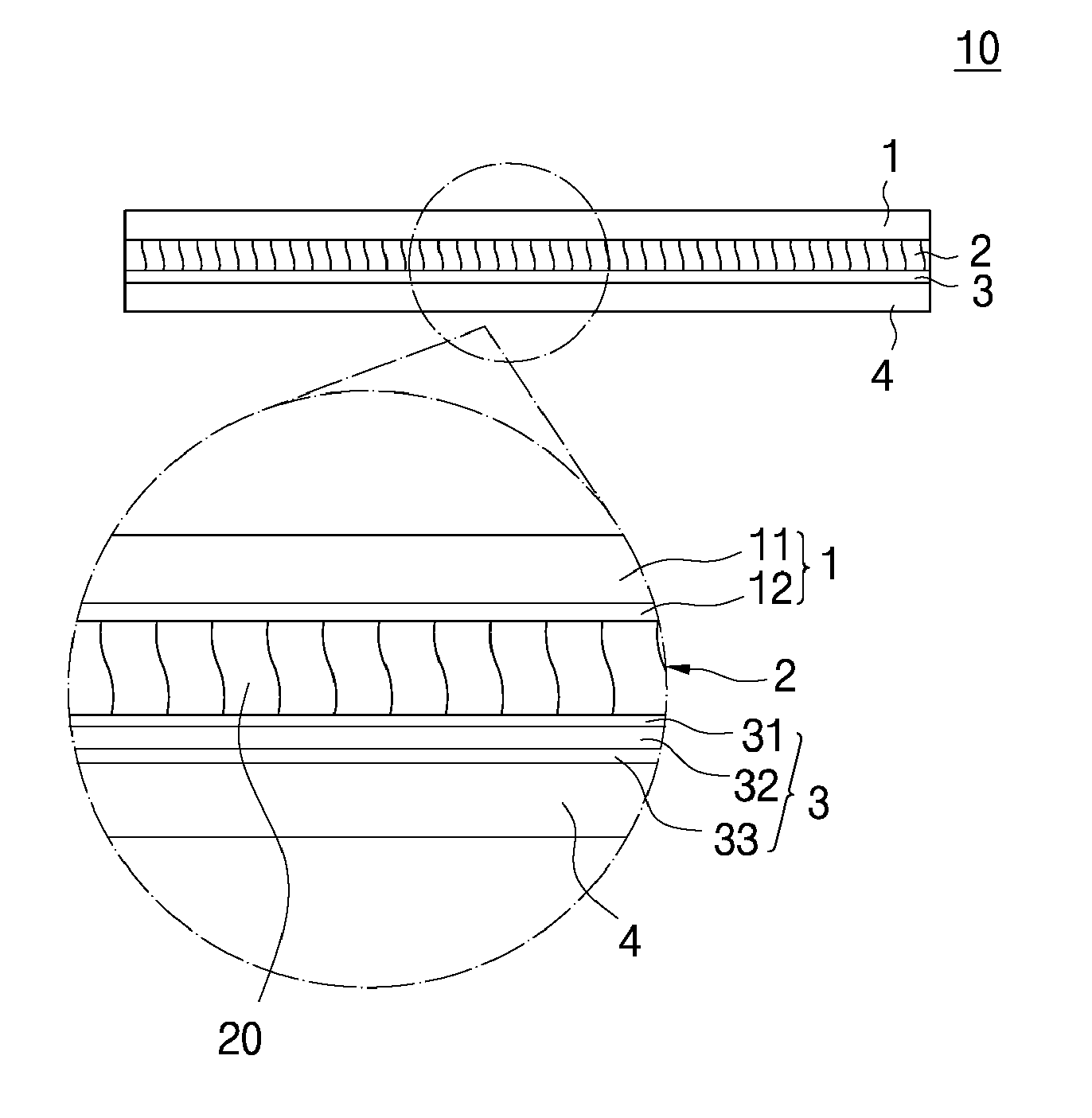

Magnetic field shielding sheet for digitizer, manufacturing method thereof, and portable terminal device using same

ActiveCN104054409AImprove permeabilityBroaden your optionsShielding materialsNanomagnetismTerminal equipmentAlloy

The present invention relates to: a magnetic field shielding sheet for a digitizer which minimizes an influence on a geomagnetic sensor, shields the electromagnetic field generated from various constituent elements of a main body of a portable terminal device when preparing a digitizer function for the portable terminal device, and can simultaneously improve the sensitivity of an electronic pen; a manufacturing method thereof; and the portable terminal device using the same. The magnetic field shielding sheet of the present invention comprises: a thin magnetic sheet having at least one layer which is formed with a nano-crystalline alloy and is divided into a plurality of fine pieces by flake treatment; a protective film attached to one side of the thin magnetic sheet through a first adhesive layer; and double-sided tape attached to the other side of the thin magnetic sheet through a second adhesive layer formed on one side, wherein the thin magnetic sheet is characterized by heat-treating an amorphous ribbon formed with the nano-crystalline alloy at a temperature of 300 DEG C to 700 DEG C.

Owner:AMOSENSE

Magnetic field shielding sheet for a wireless charger, method for manufacturing same, and receiving apparatus for a wireless charger using the sheet

ActiveUS9252611B2High quality factorReduce lossesNear-field transmissionShielding materialsElectric power transmissionTerminal equipment

Owner:AMOSENSE

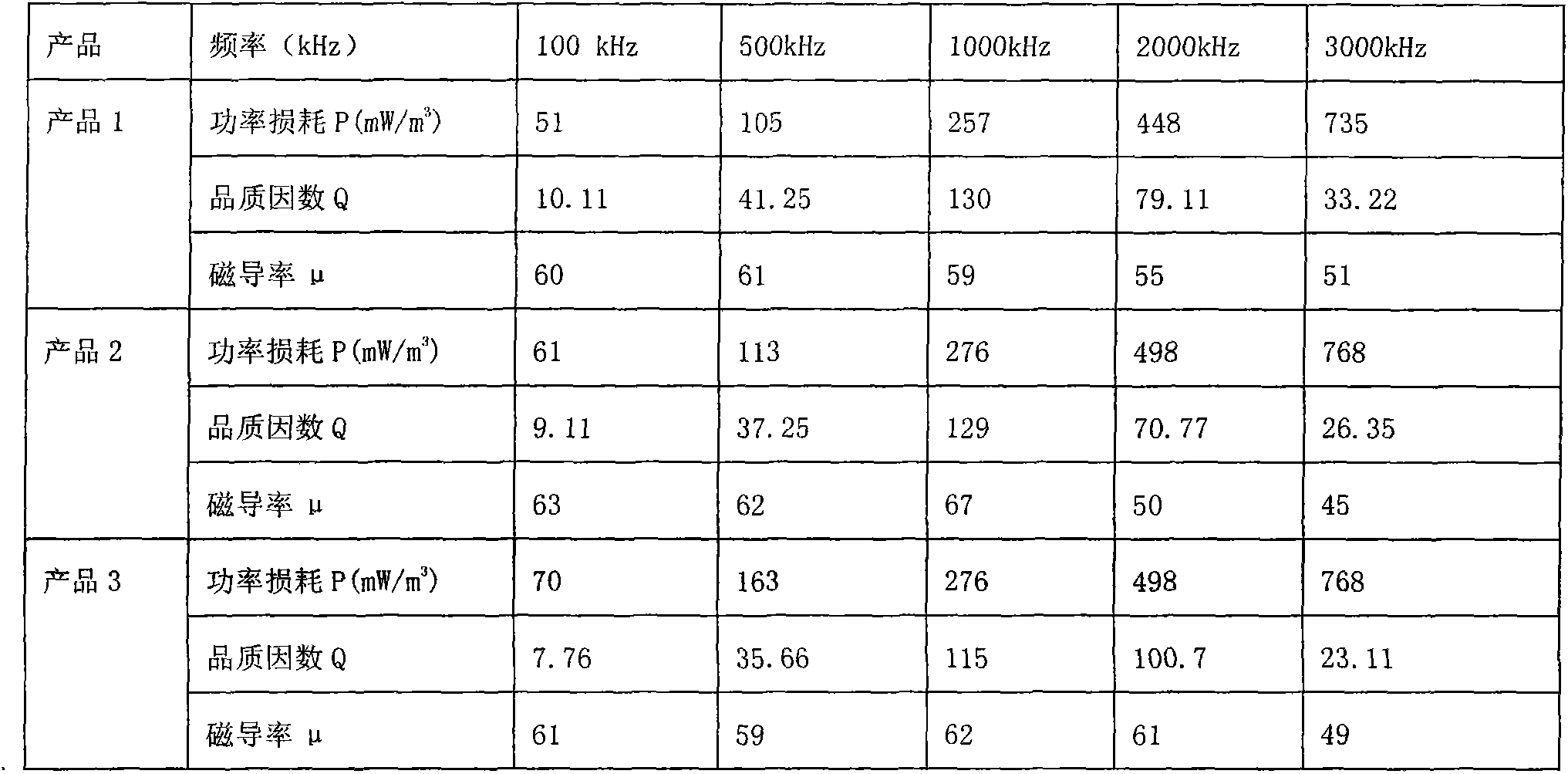

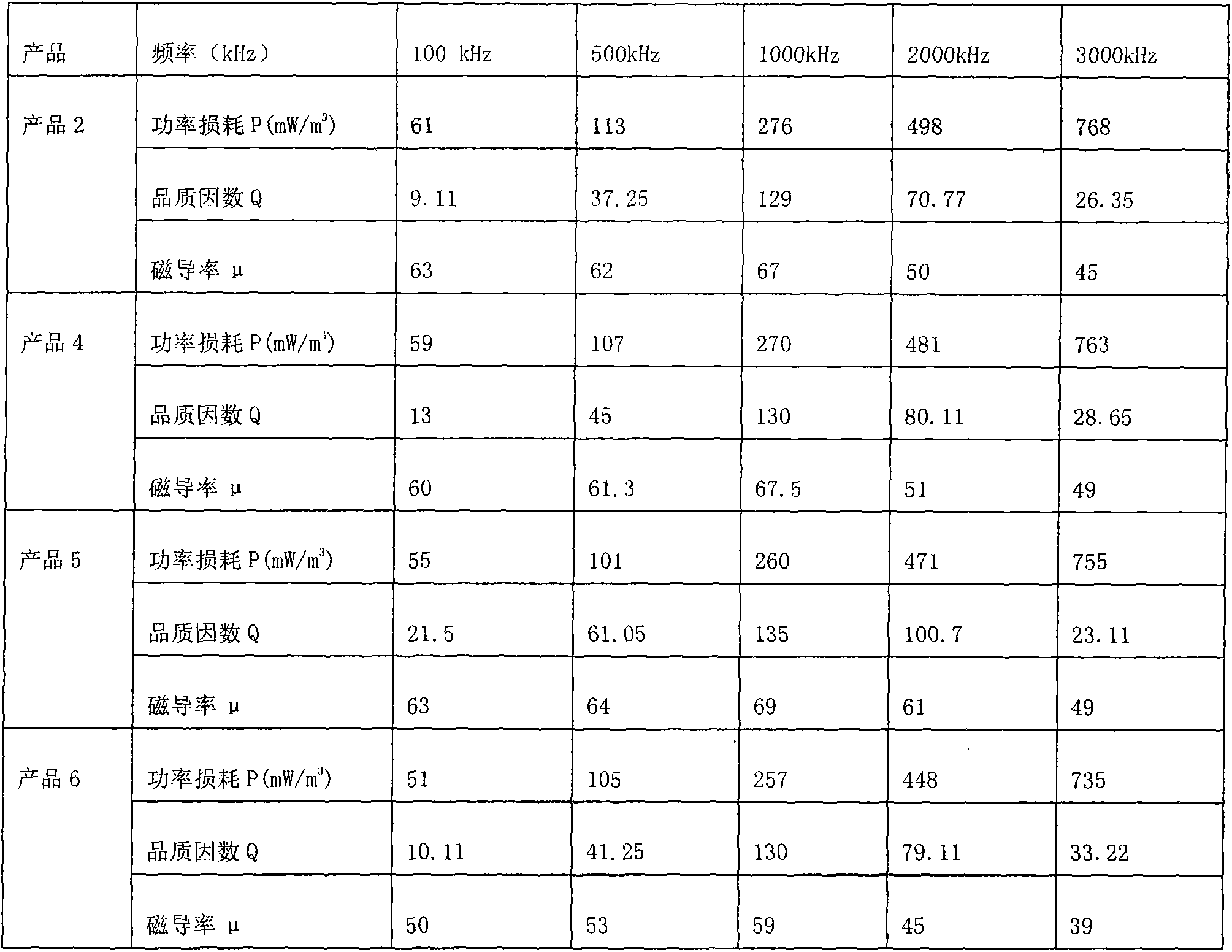

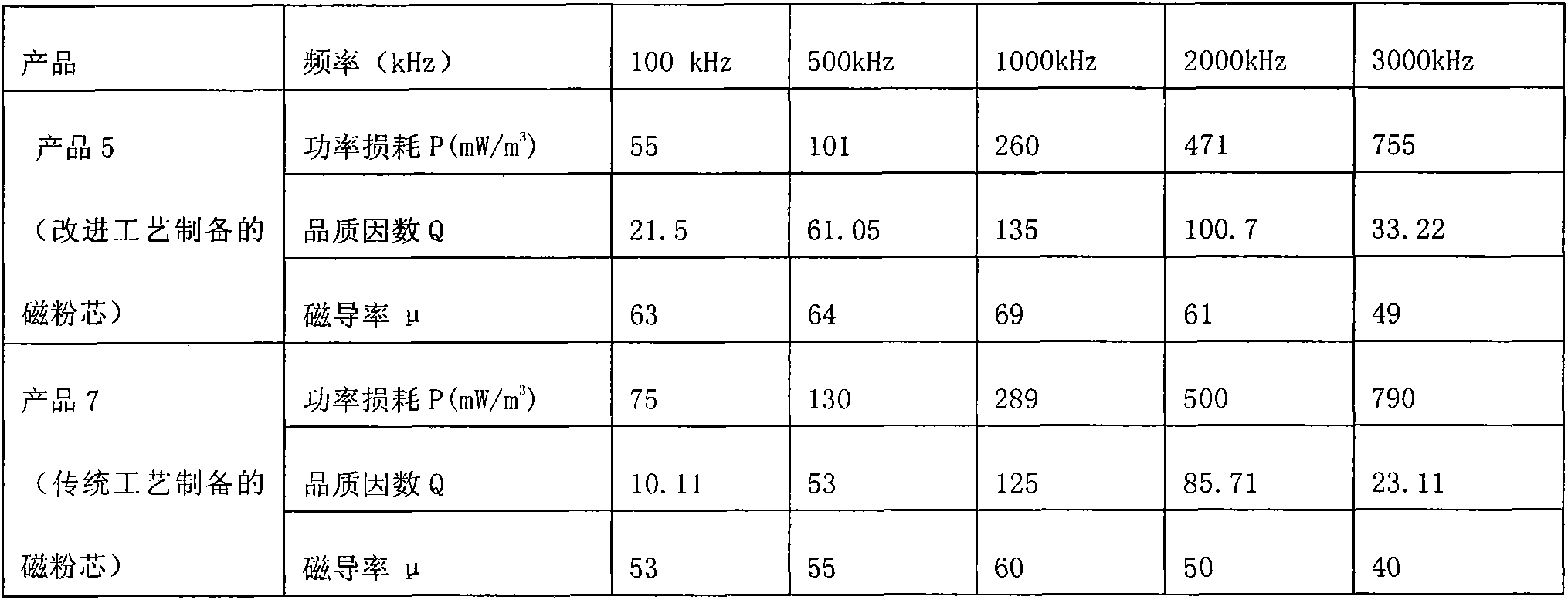

One-step heat treatment preparation process method for soft nanocrystalline magnetic powder core

InactiveCN103456480AImprove magnetismImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureHigh energyPhosphoric acid

The invention relates to an one-step heat treatment preparation process method for a soft nanocrystalline magnetic powder core and belongs to a nanocrystalline magnetic powder core preparation technology. Amorphous ribbon fragments of which the component is Fe73.5Cu1Nb3Si13.5B9 are directly placed into a high-energy omnibearing planetary ball mill to carry out ball milling crushing without being subjected to heat treatment; the crushed amorphous ribbon fragments are sieved into amorphous powder with different particle sizes and the amorphous powder is mixed; the mixed amorphous powder is passivated and dried in phosphoric acid solution; the passivated amorphous powder is uniformly mixed with an insulating binding agent in a wet mode; the mixture is subjected to heating volatilization and insulating coating; the amorphous powder subjected to insulating coating is placed into a die to be subjected to pressing forming; and after a formed magnetic powder core is subjected to heat treatment under the protection of inert gas, the magnetic powder core is impregnated in insulating glue. The one-step heat treatment preparation process method has high magnetic conductivity, low loss and high stability; meanwhile, preparation process steps are reduced; and production energy consumption of the nanocrystalline magnetic powder core is reduced.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

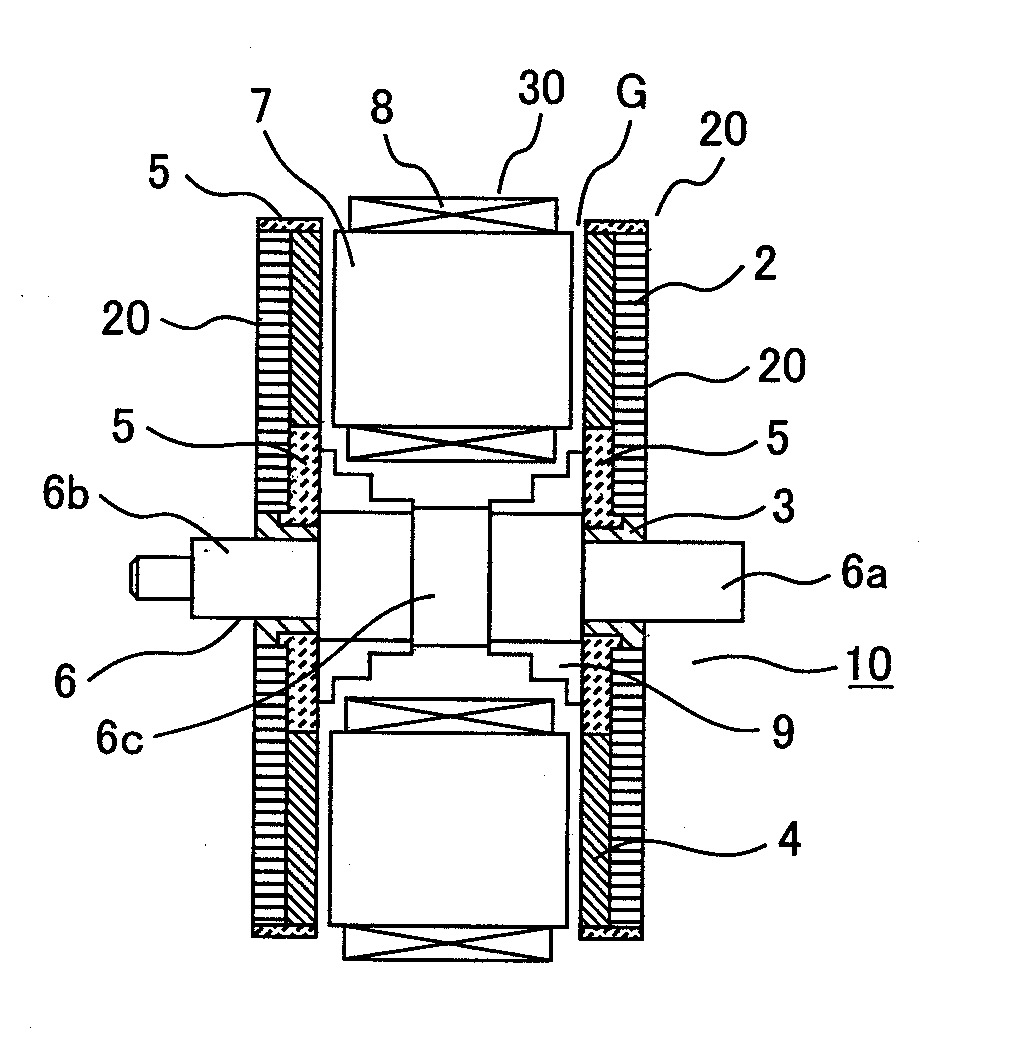

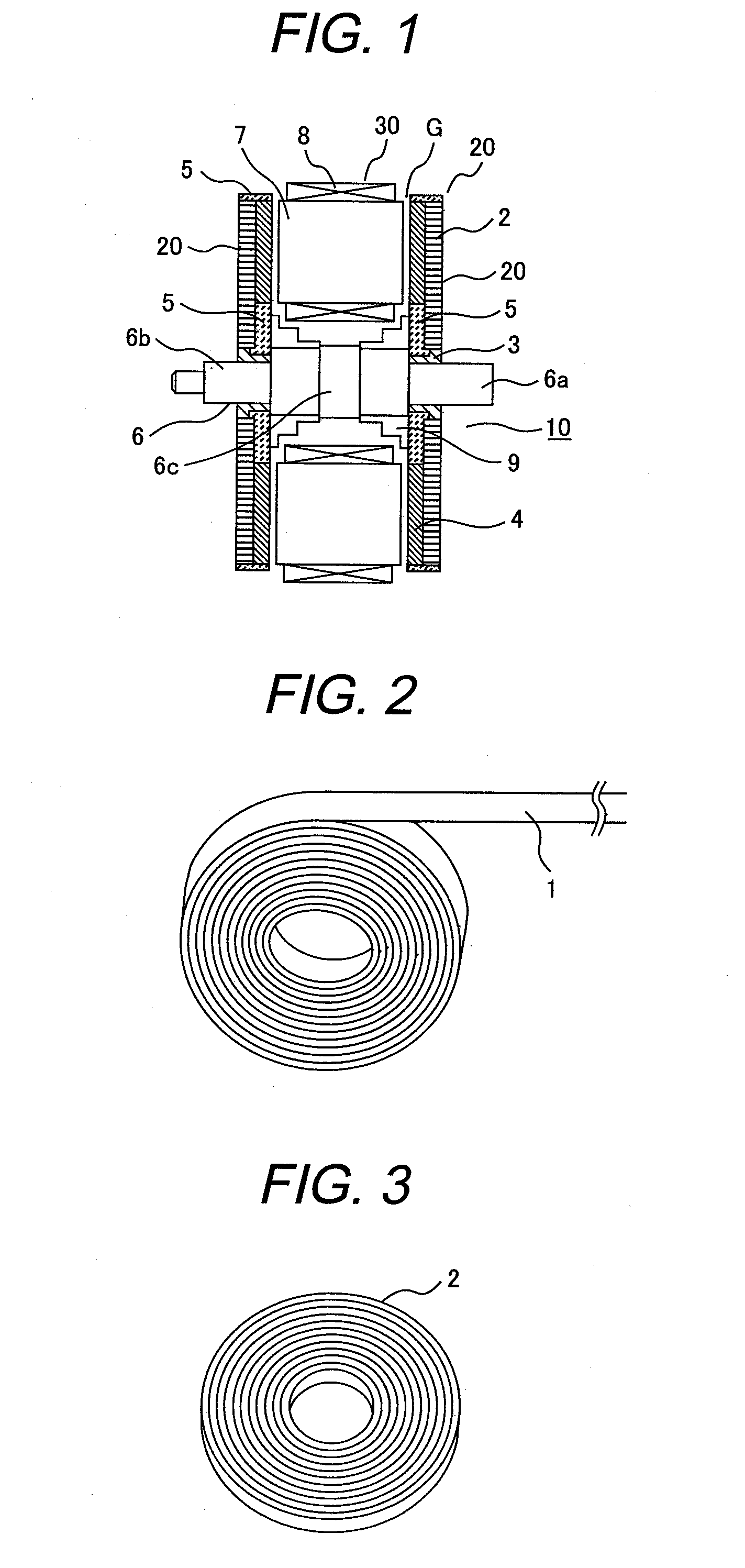

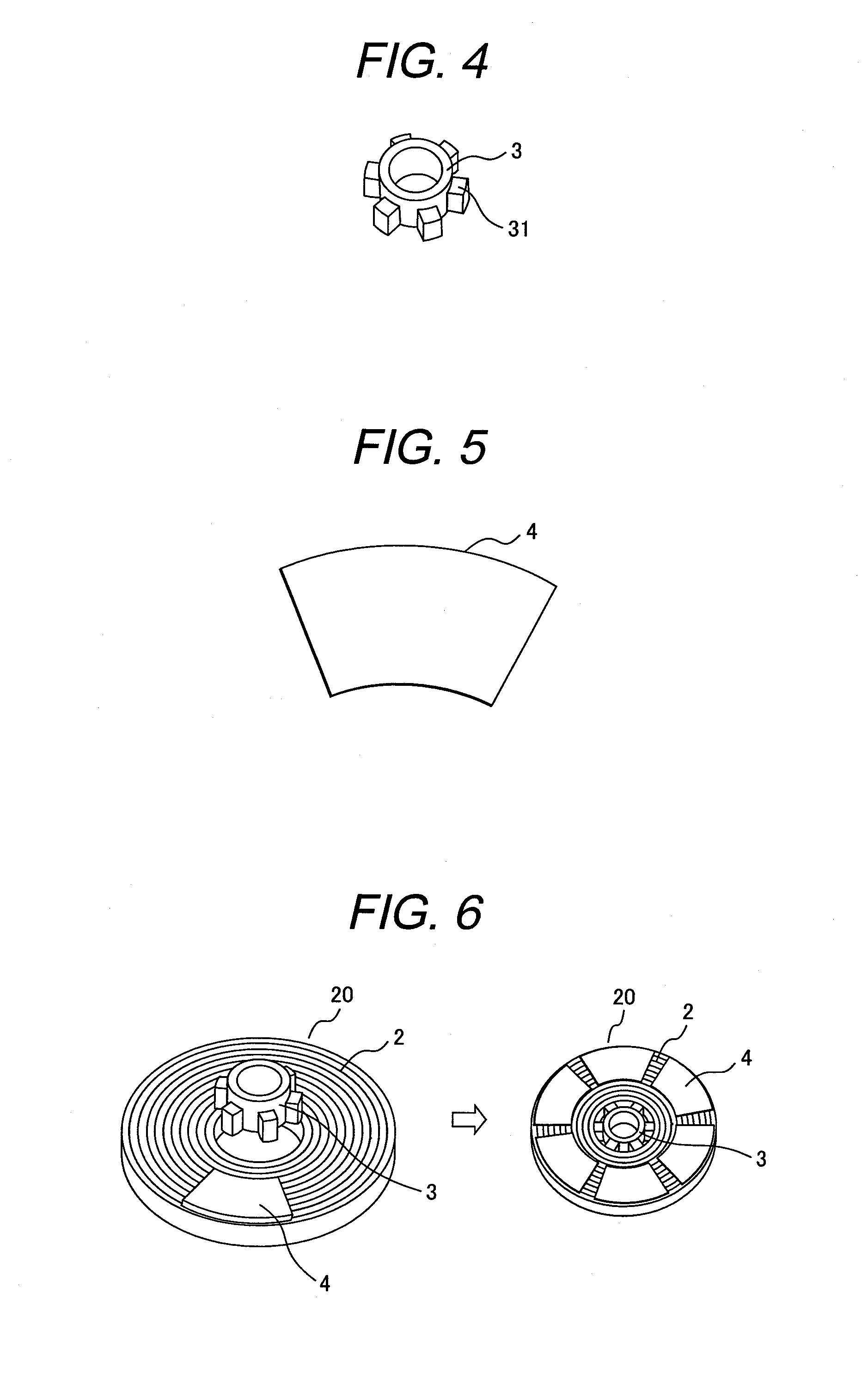

Axial gap rotating electrical machine and rotor used therefor

ActiveUS20110156519A1Reduce eddy current lossSimple manufacturing processMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEngineering

In the axial gap rotating electrical machine, the rotor includes a rotor yoke that is formed by wrapping amorphous ribbon wound toroidal core, which is obtained by winding an amorphous magnetic metal ribbon into a toroidal core. Magnets having plural poles are circumferentially disposed on a stator-facing surface of the amorphous ribbon wound toroidal core.

Owner:HITACHI METALS LTD

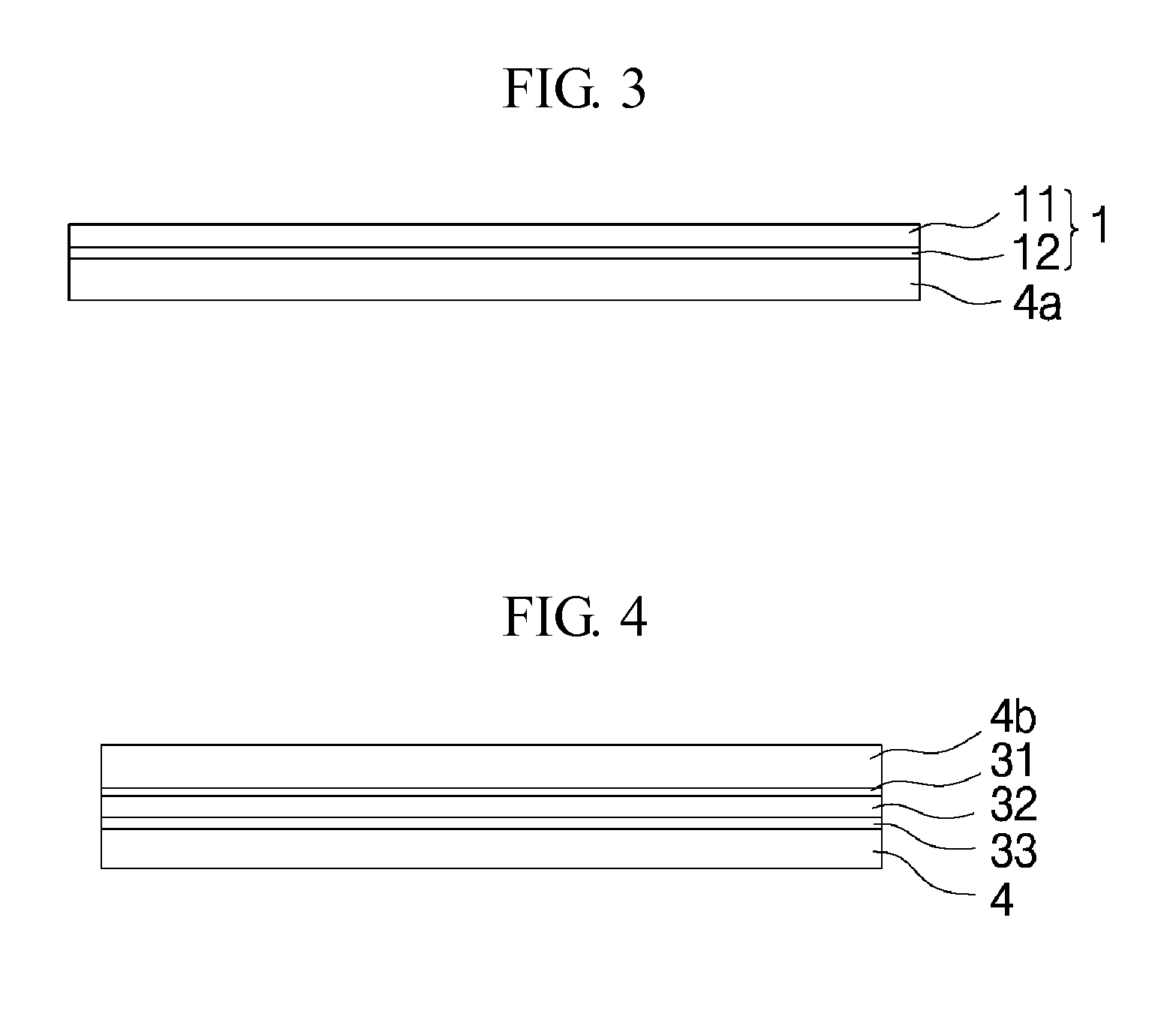

Magnetic field shielding sheet for digitizer and method of manufacturing the same and portable terminal device using the same

ActiveUS20150124402A1Prevent magnetic saturationAvoid distortionShielding materialsMagnetic materialsTerminal equipmentComputer terminal

A magnetic field shielding sheet includes: at least one layer thin magnetic sheet made of a Fe-based amorphous alloy and flake-treated so as to be separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape, wherein the thin magnetic sheet is obtained by heat treating an amorphous ribbon sheet made of the Fe-based amorphous alloy at a temperature of 300° C. to 480° C. A method of manufacturing the magnetic field shielding sheet, and a portable terminal device using the magnetic field shielding sheet are disclosed.

Owner:AMOSENSE

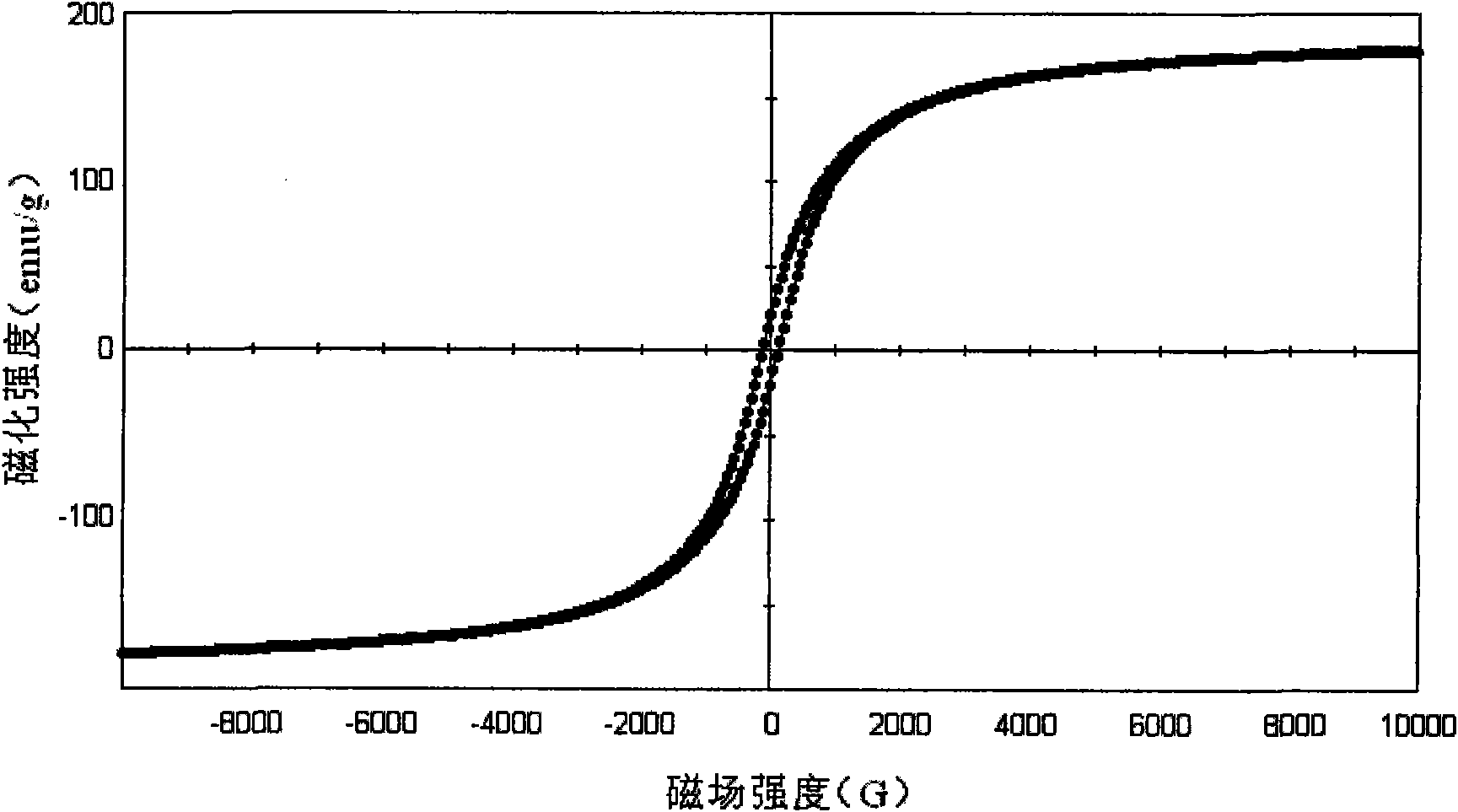

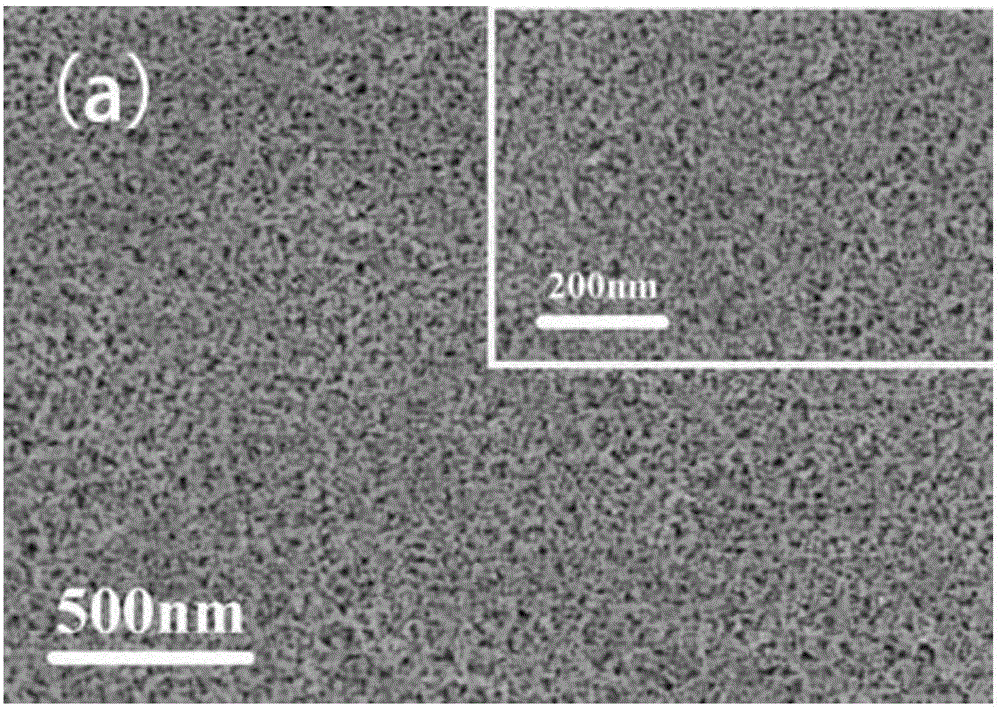

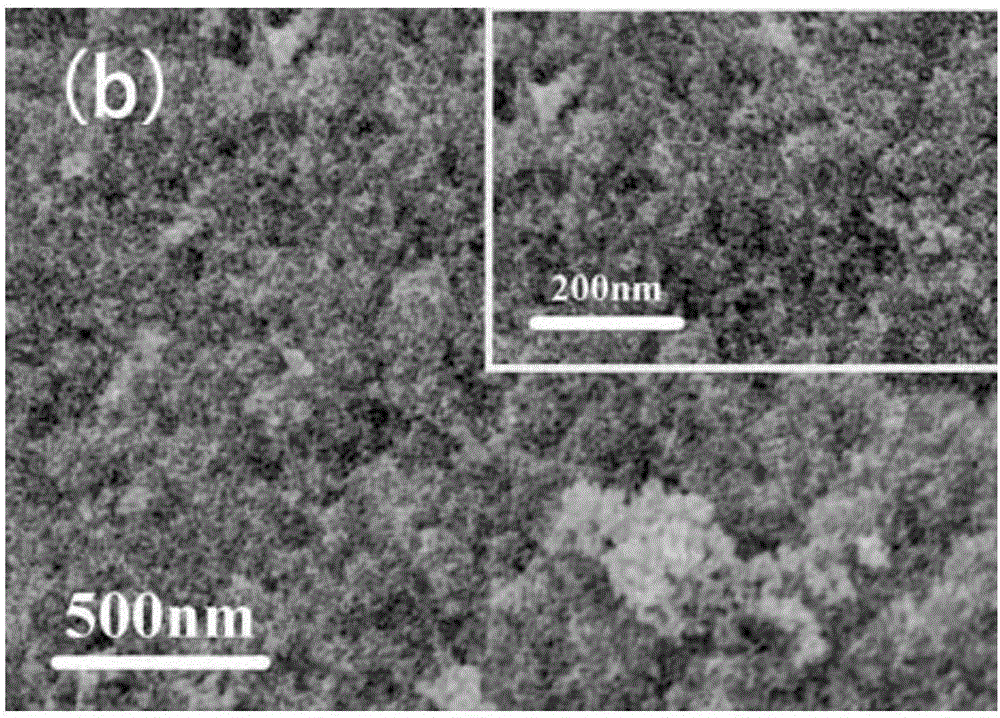

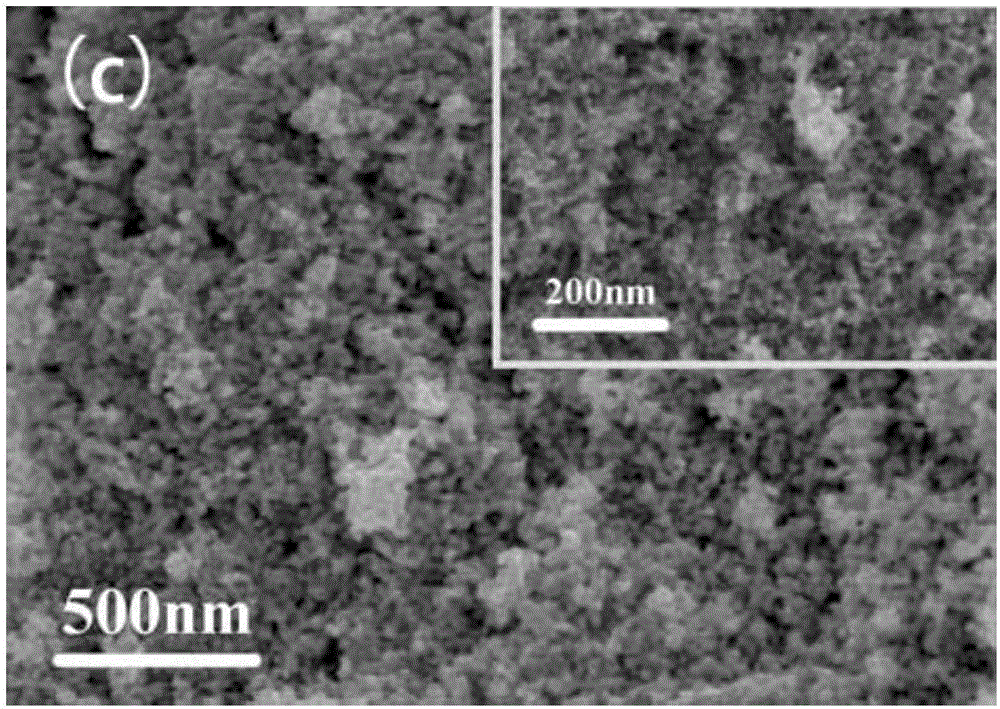

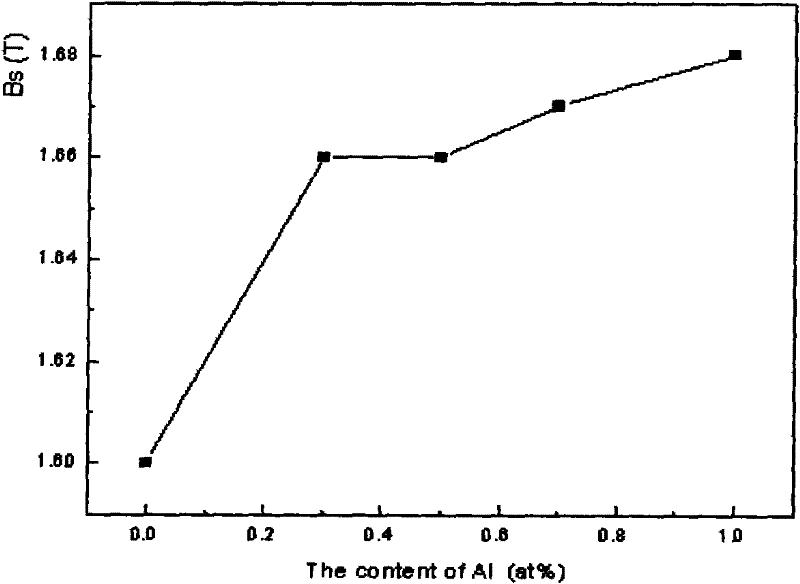

Block-shaped nanocrystalline magnetically soft alloy material and preparation method thereof

The invention relates to a block-shaped nanocrystalline magnetically soft alloy material and a preparation method thereof. The block-shaped nanocrystalline magnetically soft alloy material is an Fe-Co-Cu-B-X alloy material and contains the following atomic content of each component in percentage by weight in the total atomic weight of the alloy material: 42-45% of Fe, 42-45% of Co, 0.5-1.5% of Cu, 6-10% of B and 3-8% of X, wherein X is selected from one or two of Nb and Sm. The preparation method of the block-shaped nanocrystalline magnetically soft alloy material comprises the following steps: smelting, thin amorphous ribbon spurting, heat treatment, pulverization and spark plasma sintering. The block-shaped nanocrystalline magnetically soft alloy material has higher Curie temperature and saturated magnetization intensity and extensive application.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

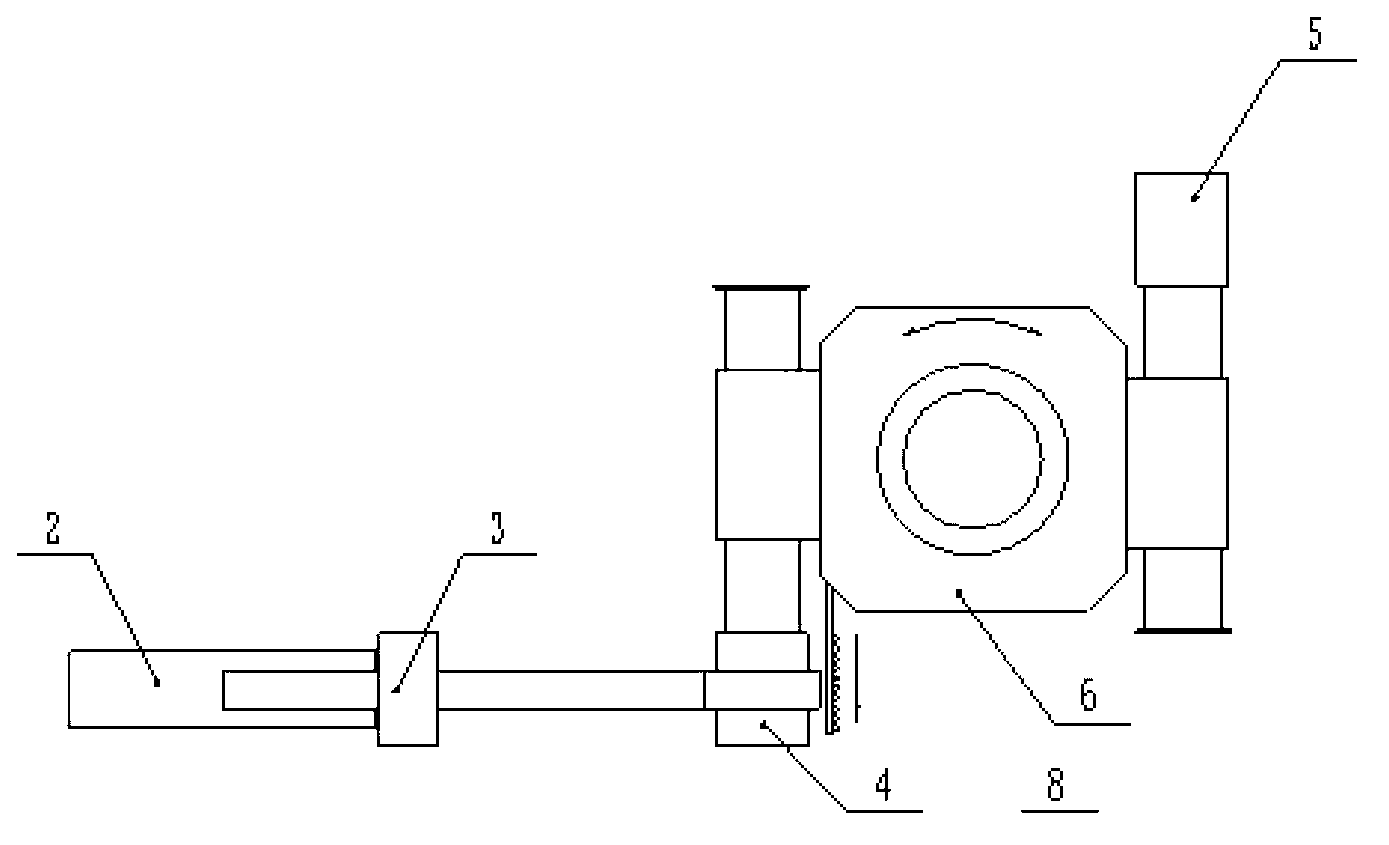

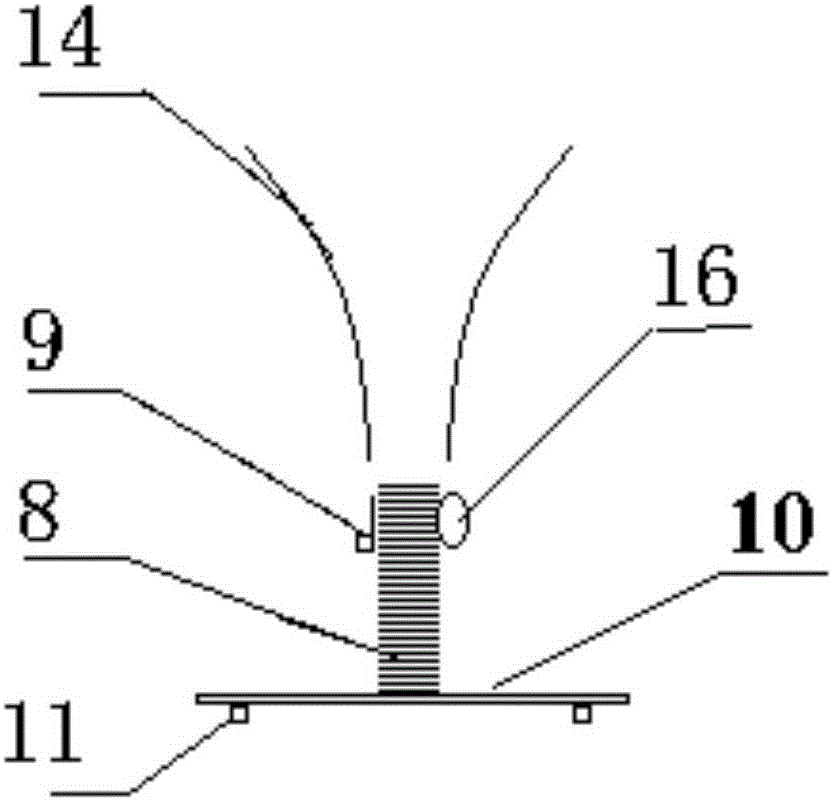

Online reeling device for amorphous ribbon

The invention provides an online reeling device for an amorphous ribbon. The device comprises a first reeling shaft, a second reeling shaft, a rotary platform and a working platform. The first reeling shaft and the second reeling shaft are respectively arranged at two sides of the rotary platform of the working platform. The first reeling shaft and the second reeling shaft are respectively provided with a first reeling cylinder and a second reeling cylinder. The first reeling cylinder is located on a reeling station and reels the amorphous ribbon through negative pressure. After the amorphous ribbon is fully reeled, the amorphous ribbon is broken through a breaking shear. A reeling platform rotates 180 degrees. After the second reeling cylinder arrives at the reeling station, working steps of the first reeling cylinder are repeated. When the second reeling cylinder reels the amorphous ribbon, the first reeling cylinder unloads the ribbon, a hollow reeling cylinder is assembled and prepares for reeling the amorphous ribbon and continuous grabbing of the amorphous ribbon is achieved. The online reeling device for the amorphous ribbon is particularly suitable for online automatic reeling of the mass produced amorphous ribbon in industry.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Magnetic field shielding sheet for digitizer and method of manufacturing the same and portable terminal device using the same

ActiveUS9392735B2Avoid distortionImprove breathabilityShielding materialsLamination ancillary operationsTerminal equipmentAlloy

A magnetic field shielding sheet includes: at least one layer thin magnetic sheet made of a Fe-based amorphous alloy and flake-treated so as to be separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape, wherein the thin magnetic sheet is obtained by heat treating an amorphous ribbon sheet made of the Fe-based amorphous alloy at a temperature of 300° C. to 480° C. A method of manufacturing the magnetic field shielding sheet, and a portable terminal device using the magnetic field shielding sheet are disclosed.

Owner:AMOSENSE

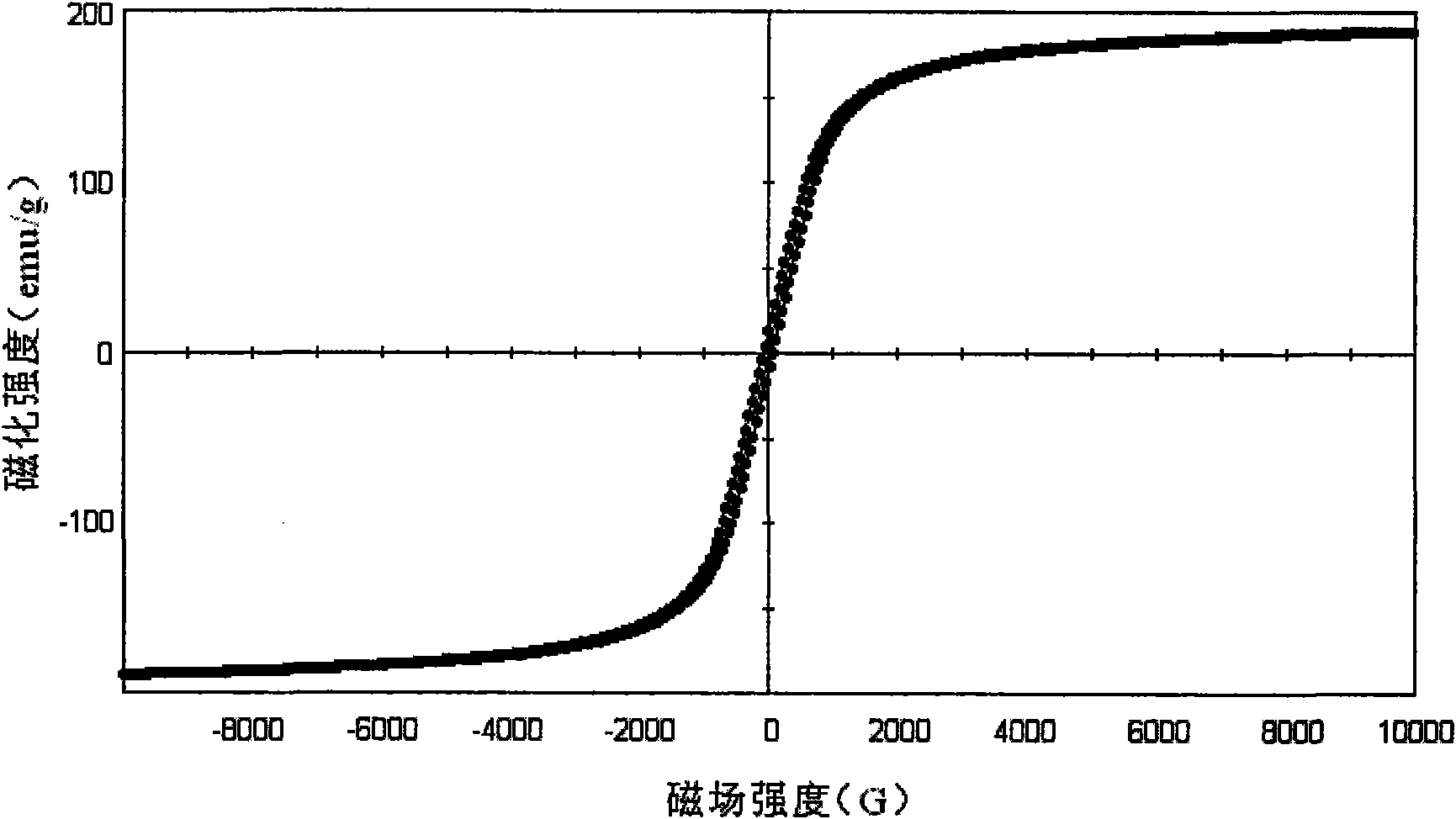

Preparation method of iron-based amorphous nanocrystalline soft magnetic alloy for industrial production

The invention discloses a preparation method of an iron-based amorphous nanocrystalline soft magnetic alloy for industrial production. The preparation method comprises the following steps: firstly, preparing master-alloy raw materials; smelting the master-alloy raw materials repeatedly, and casting into an alloy ingot; smashing the alloy ingot, re-smelting, and covering the molten alloy with a steel-making slag forming agent; preparing an amorphous ribbon through quenching by using a single roller; putting the obtained amorphous ribbon into a vacuum annealing furnace, annealing isothermally, and crystallizing; and cooling the amorphous ribbon to room temperature in the vacuum annealing furnace to obtain the iron-based amorphous nanocrystalline soft magnetic alloy. The amorphous ribbon can be wound into a magnetic core with the sizes of 13.2mm*21.5mm*10mm before being nano-crystallized. Because the preparation method adopts low-cost industrial raw materials, the cost of the iron-based amorphous nanocrystalline soft magnetic alloy can be reduced greatly. The prepared iron-based amorphous nanocrystalline soft magnetic alloy has high magnetic conductivity and low loss.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

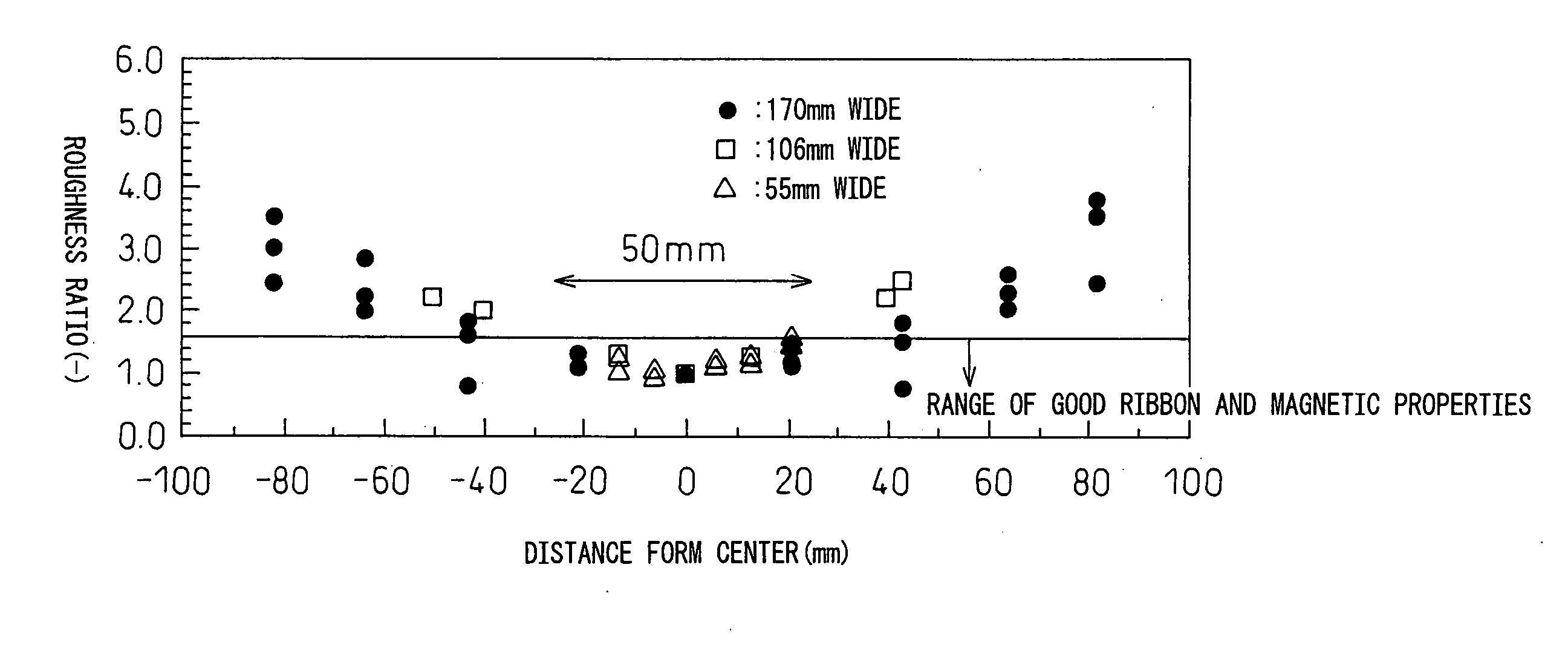

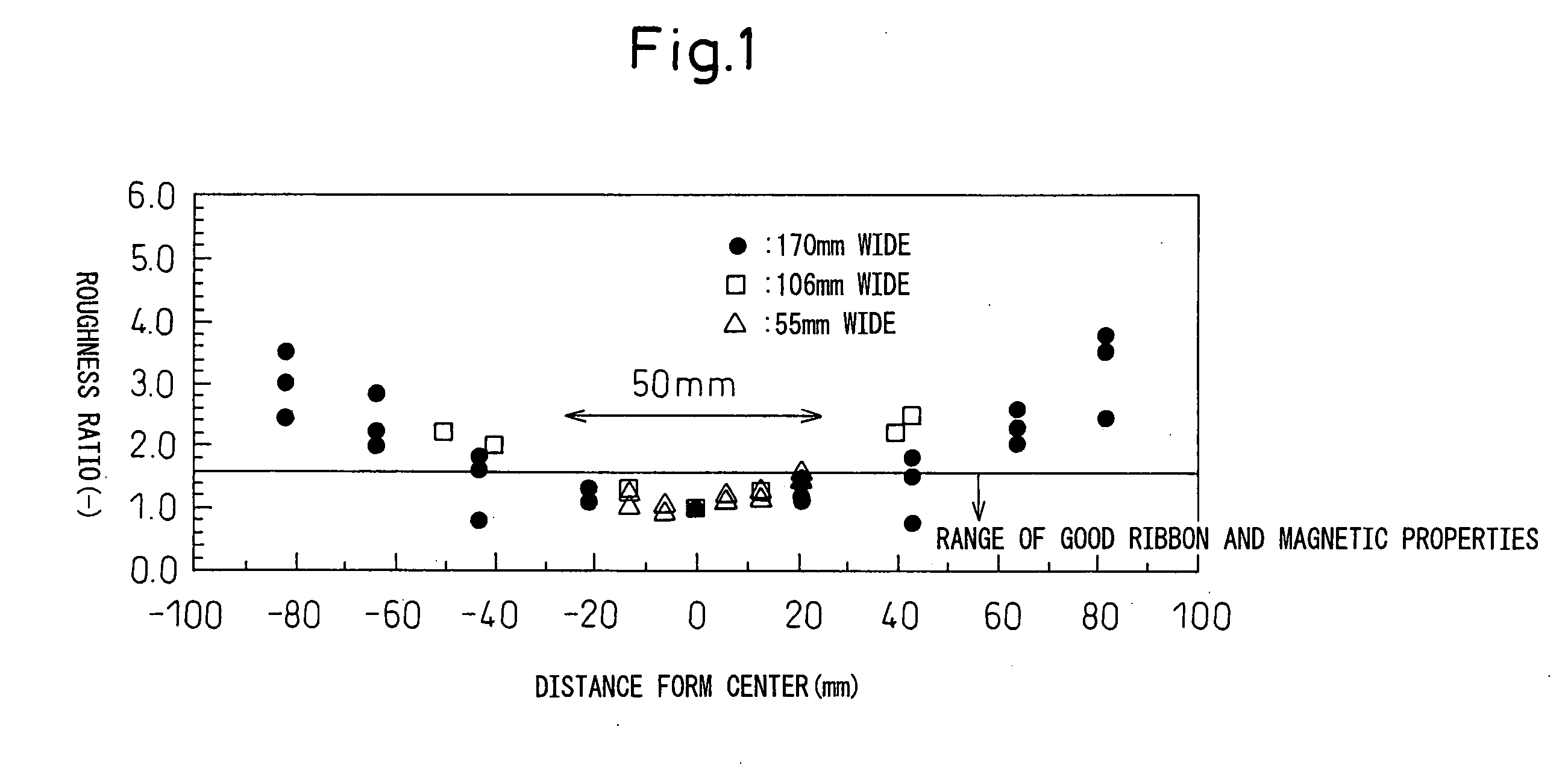

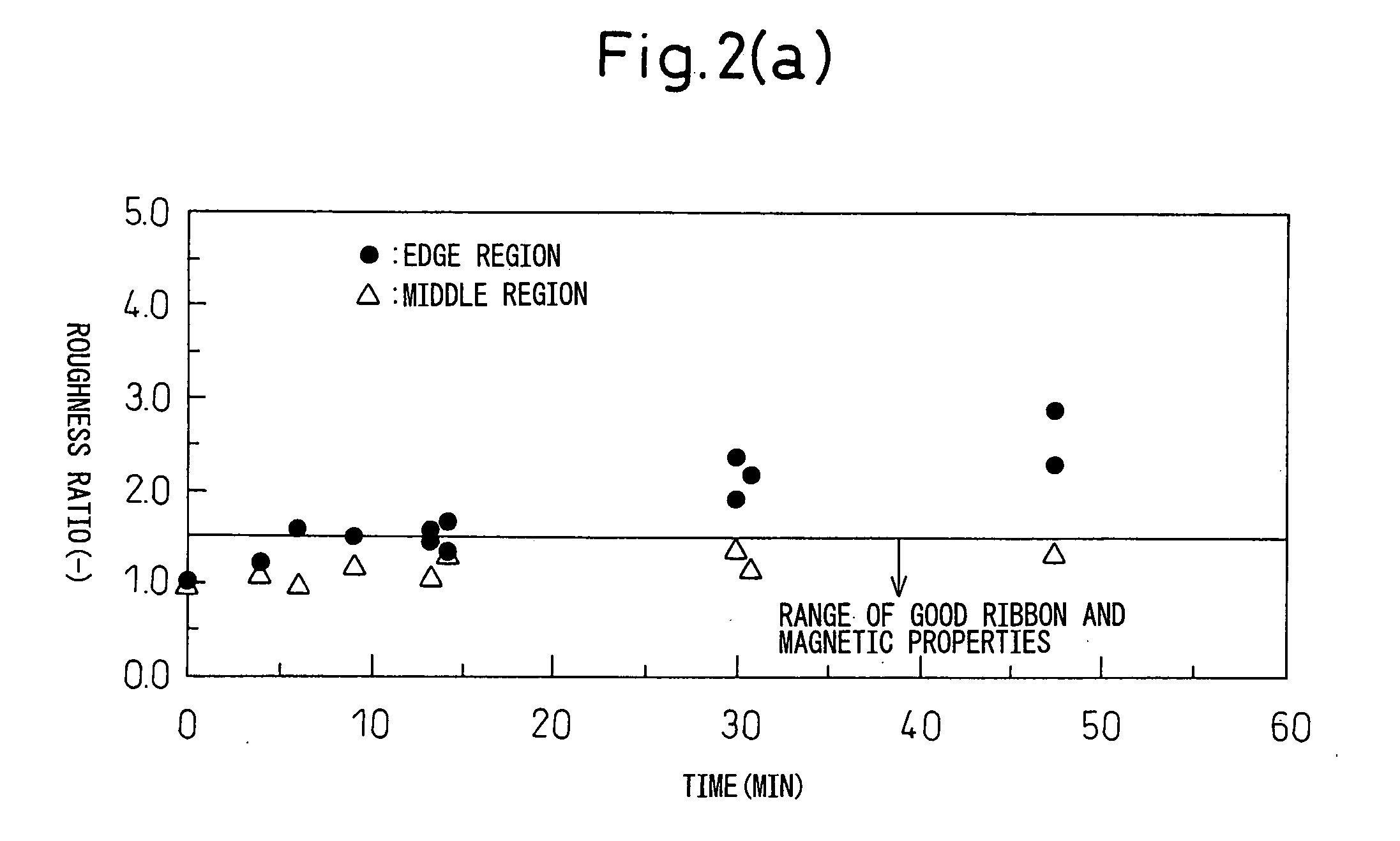

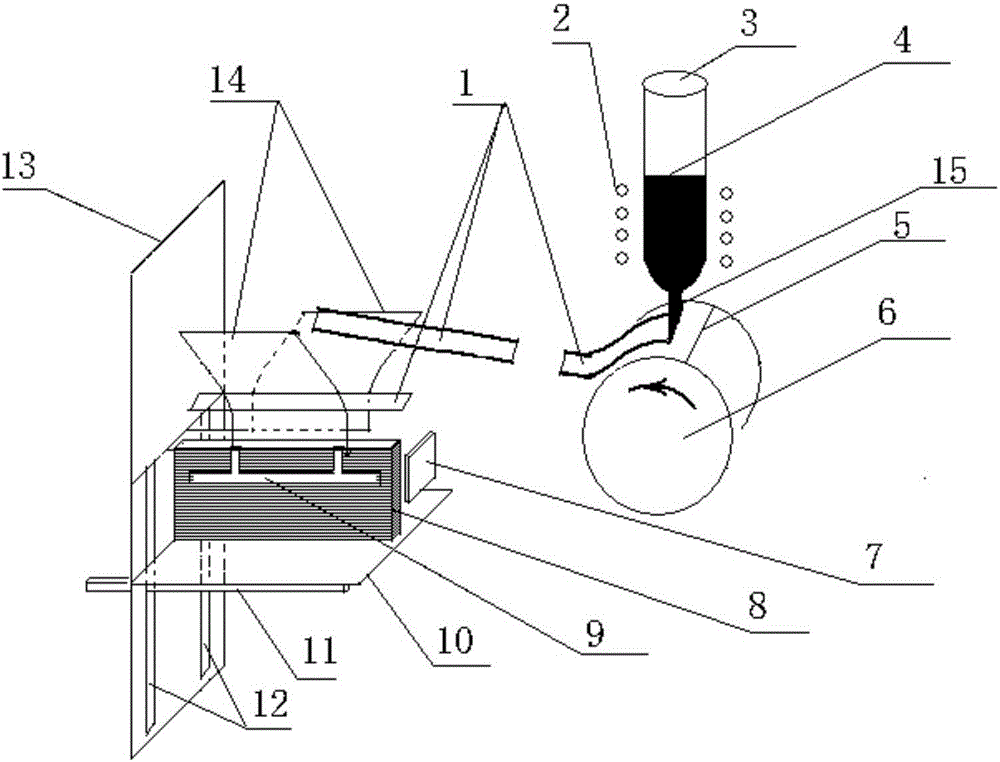

Method and apparatus for producing amorphous ribbon

ActiveUS20100132907A1Improve magnetic propertiesMelt-holding vesselsMoulding machinesAmorphous ribbonMolten alloy

A method and apparatus are provided for producing an amorphous ribbon by ejecting and rapidly solidifying molten alloy on a circumferential surface of a rapidly rotating cooling roll, wherein the cooling roll is polished online during amorphous ribbon production. When the circumferential surface of the cooling roll after peeling off the ribbon is polished using a polishing member, the circumferential surface of the cooling roll is polished continuously or intermittently across its lateral direction while differentiating the polishing mode in accordance with the surface properties.

Owner:NIPPON STEEL CORP

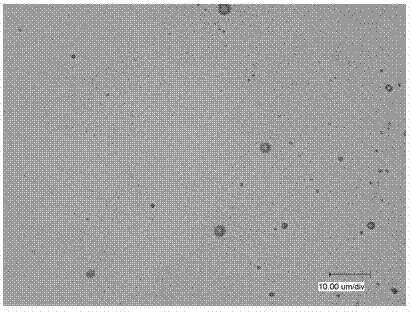

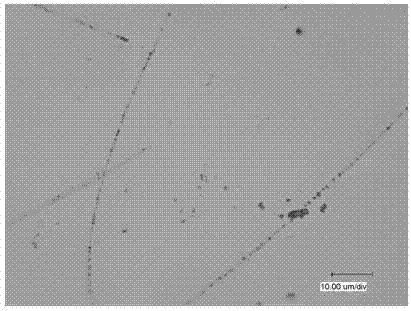

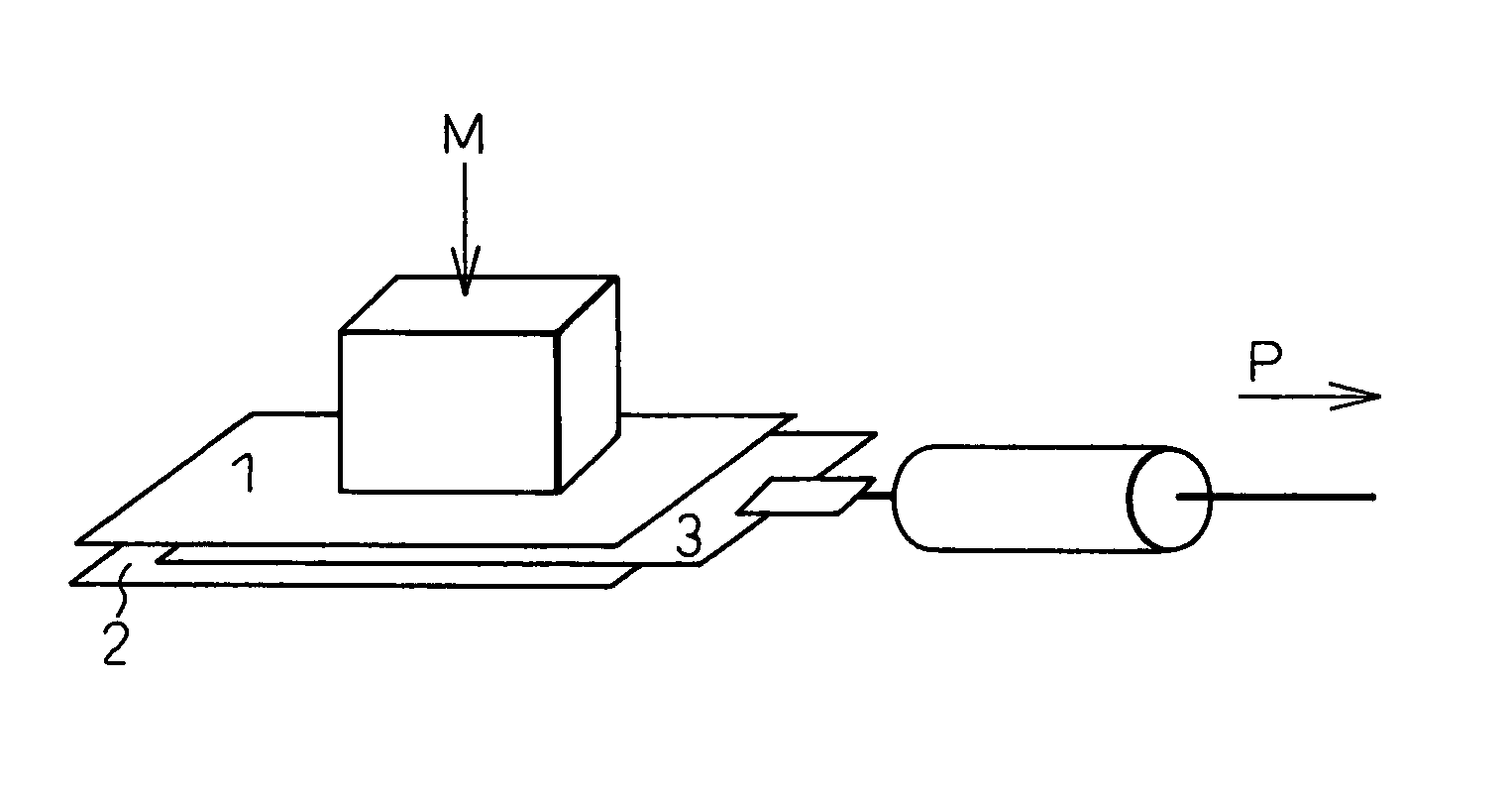

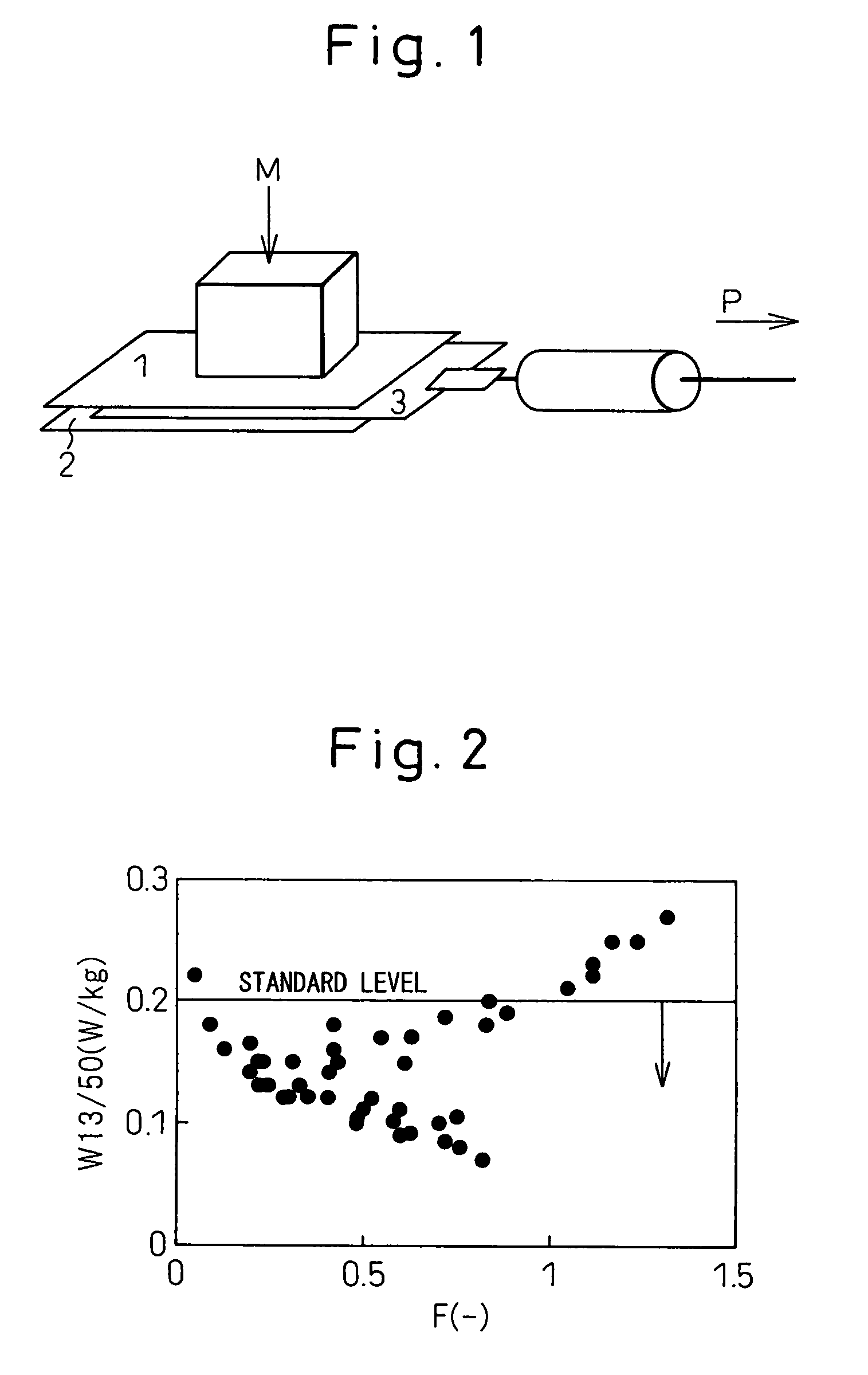

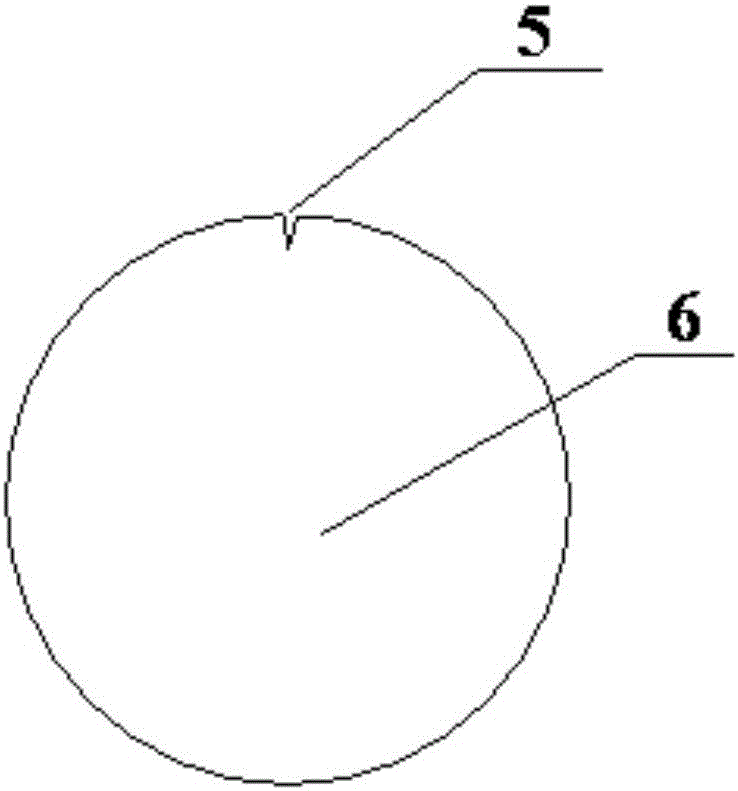

Amorphous Alloy Ribbon Superior in Magnetic Characteristics and Lamination Factor

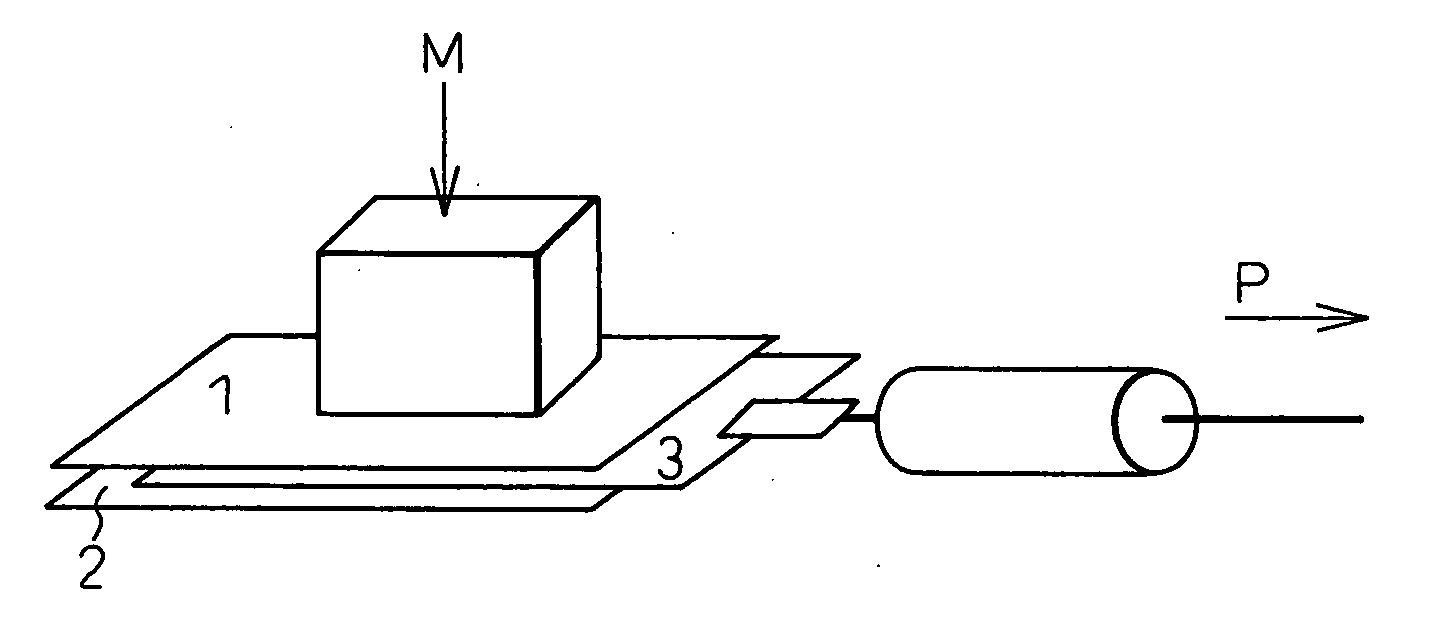

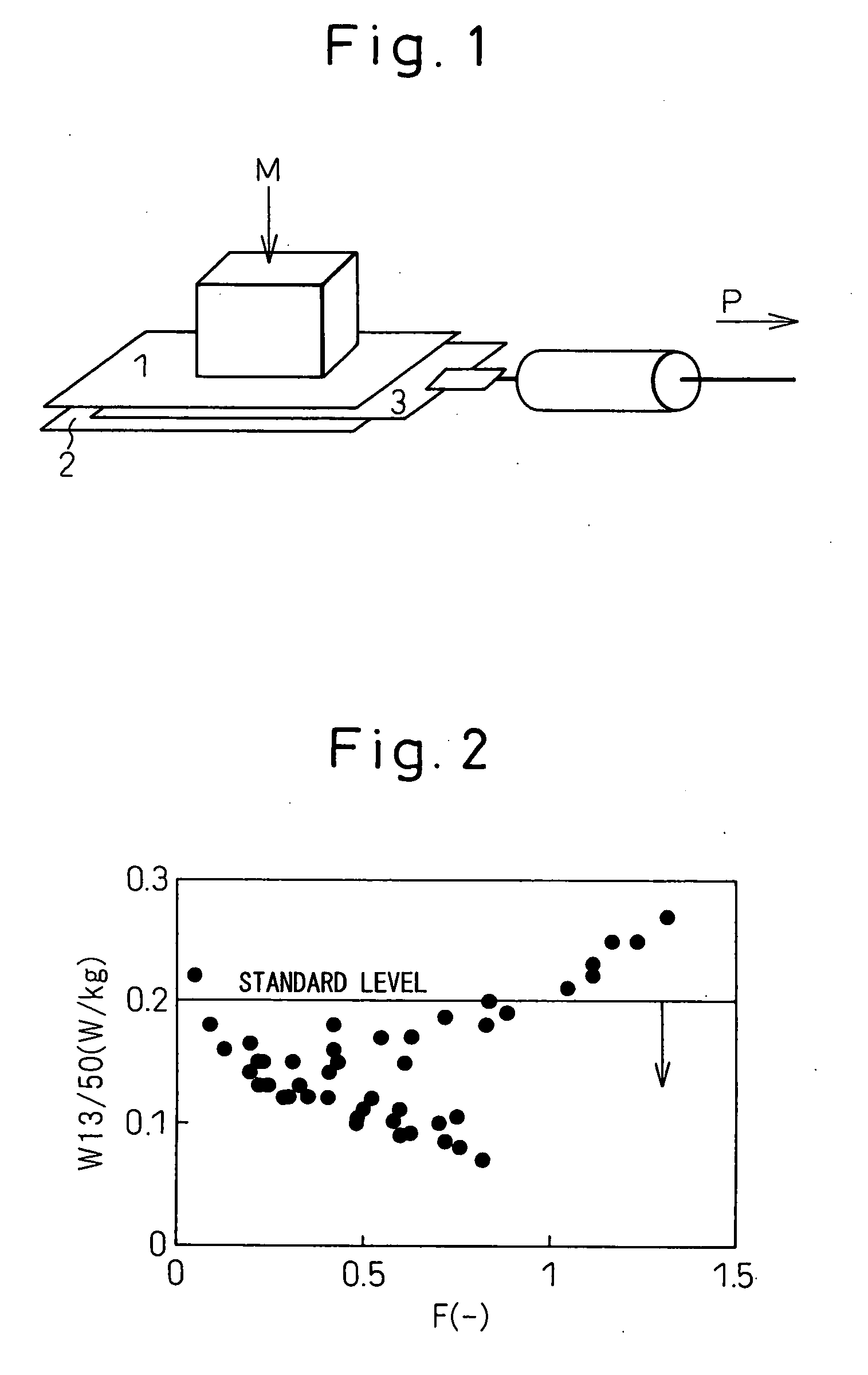

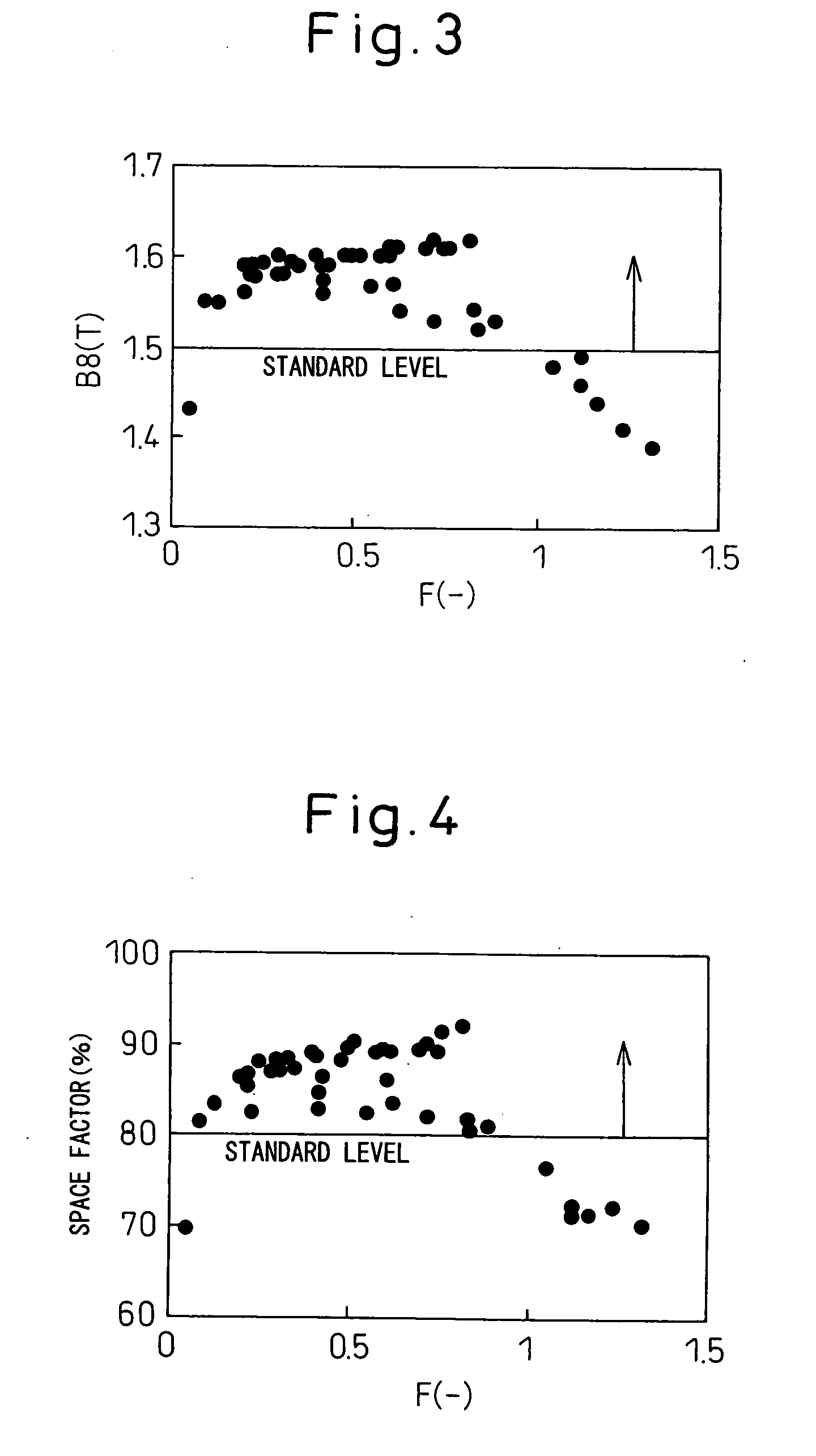

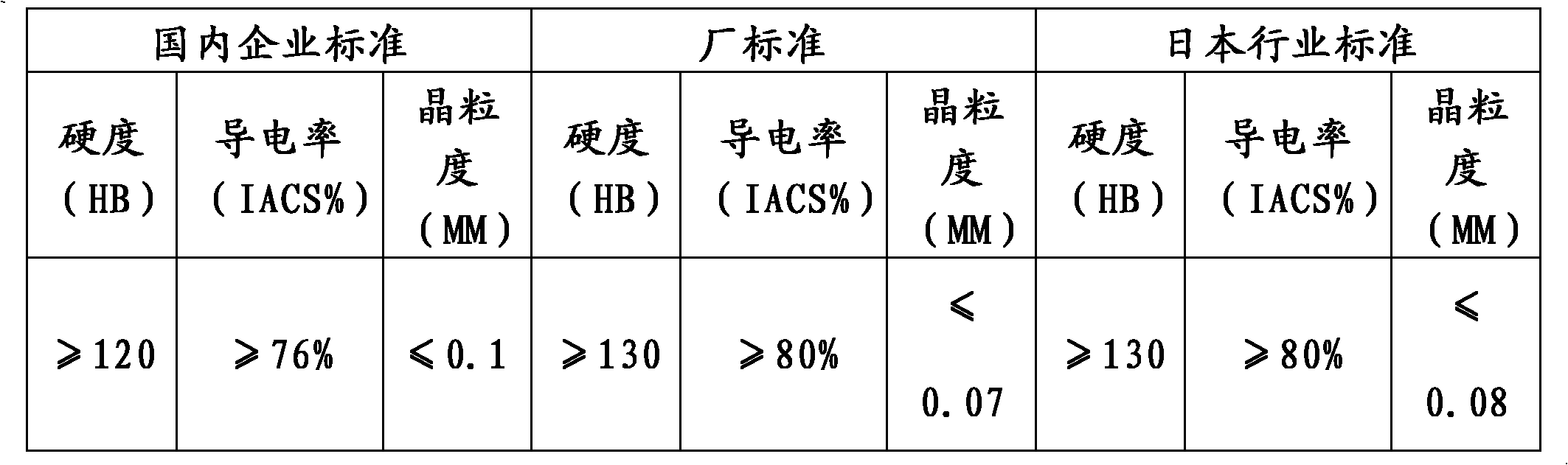

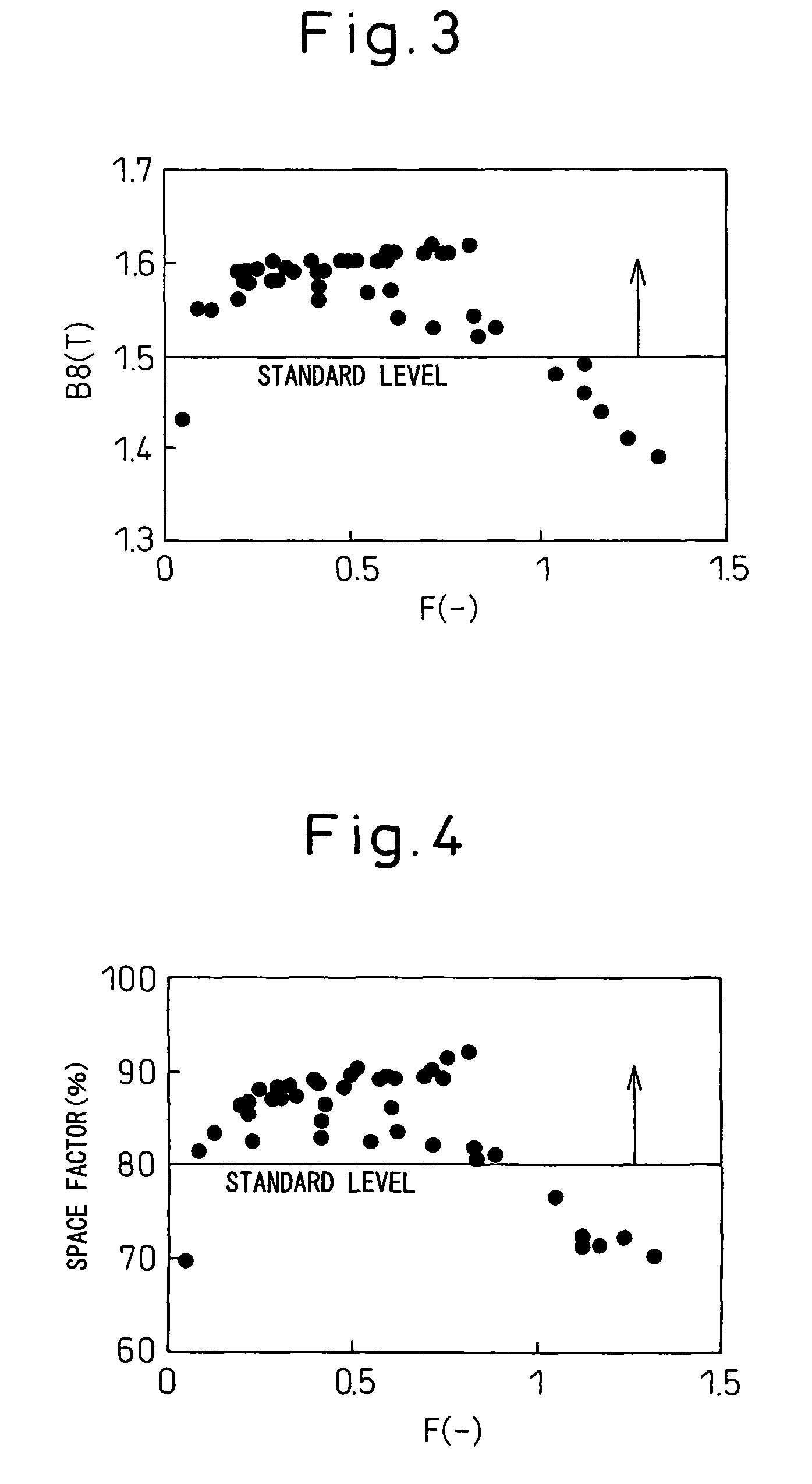

The present invention provides an amorphous alloy ribbon superior in magnetic characteristics and lamination factor by defining the slip property of the amorphous alloy ribbon surface in a specific range, that is, an amorphous alloy ribbon superior in magnetic characteristics and lamination factor produced by the single roll method, characterized in that the slip property of the ribbon surface satisfies the following equation:0.1≦F=P / M≦1.0where, F is the slip friction coefficient, P is the force pulling the intermediate part of the amorphous ribbon when applying weight from above to three amorphous ribbons stacked together, and M is the load applied from the top of the amorphous ribbon (5 kg).

Owner:NIPPON STEEL CORP

Preparation method of chromium-zirconium-copper cooling roll for amorphous ribbon

The invention discloses a preparation method of a chromium-zirconium-copper cooling roll for an amorphous ribbon, which relates to a novel process of a chromium-zirconium-copper alloy material, more specifically relates to the preparation method of the chromium-zirconium-copper cooling roll for the amorphous ribbon. The invention provides the preparation method of the chromium-zirconium-copper cooling roll for the amorphous ribbon which can thoroughly overcome the loosening, air holes, slag, cracks and other defects of a chromium-zirconium-copper ingot, and solve the quality problem of the ingot. The preparation method comprises the steps of fusion casting, forging, high-temperature solution heat treatment, cold processing, aging heat treatment and machining.

Owner:SHENYANG XINGGONG COPPER IND

Method and system for preparing winding-free high-efficiency amorphous ribbon

The invention discloses a method and system for preparing a winding-free high-efficiency amorphous ribbon. The method comprises the steps that a plurality of small-bore small melt spraying holes are formed in a melt nozzle at certain intervals, and after a mother alloy molten mass injected out of the small-bore small spraying holes is sprayed to a rapid quenching cooling roll face, the amorphous ribbon is formed independently; the system for preparing the winding-free high-efficiency amorphous ribbon comprises a blending device, a throw-preparing device and an amorphous ribbon automatic collector. The mother alloy is heated to be molten through the high-frequency induction technology, and the alloy melt is sprayed to the cooling roll face which is provided with a transverse groove and rotates fast through the spraying holes with the diameter smaller than 1 mm, wherein the surface of the cooling roll face is polished. The alloy melt sprayed to the cooled roll face is fast cooled on the smooth roll face to form the amorphous ribbon with even thickness and width.

Owner:ZHEJIANG NORMAL UNIVERSITY

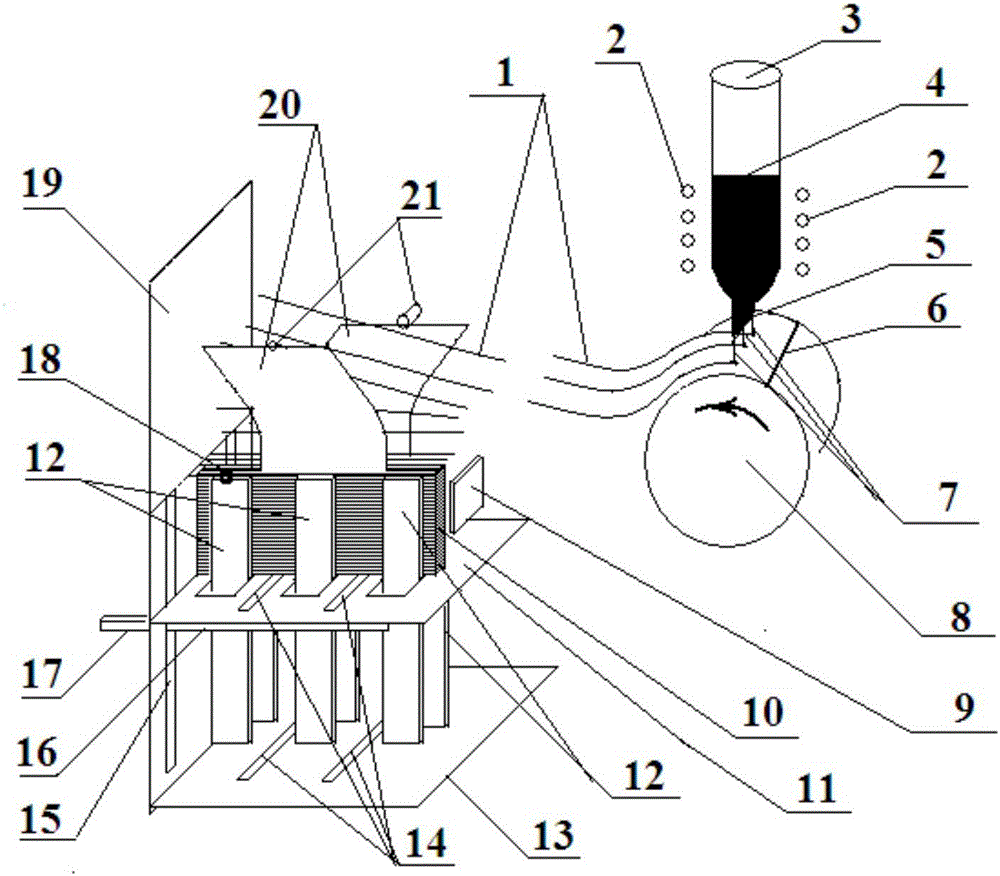

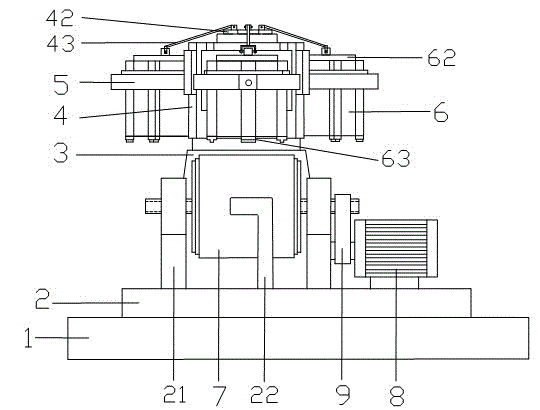

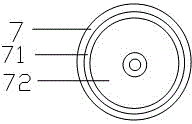

Automatic multi-crucible combined amorphous ribbon making machine

ActiveCN103909238AEase of mass productionQuality improvementMelt-holding vesselsAutomatic controlCrucible

The invention discloses an automatic multi-crucible combined amorphous ribbon making machine. The amorphous ribbon making machine comprises a frame, and is characterized in that a base is arranged on the frame; a processing mechanism, a revolving shaft driving device and a stripper are arranged on the base; the processing mechanism comprises a support frame, a revolving shaft, a guide seat, a movable seat and a cooling roller; an upright post stage is arranged on the frame; a control mechanism is arranged in the upright post stage; a rotatable upright post is arranged on the upright post stage; servo motors, coil units and crucible bases are arranged on the outer side of the upright post; rotatable crucibles are arranged in the crucible bases; the servo motors can be used for adjusting the lifting of the crucible bases; the inner diameters of the coil units are greater than the outer diameters of the crucible bases, and the coil units can be lifted; an uncovering device is arranged on the top of the upright post; the control mechanism is connected with the components of the servo motor, the coil units and the crucible bases to realize automatic control of the entire machine. The amorphous ribbon making machine is safe and reliable, high in processing accuracy and wide in application range, and can fully meet the market demand of high-quality amorphous ribbons.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

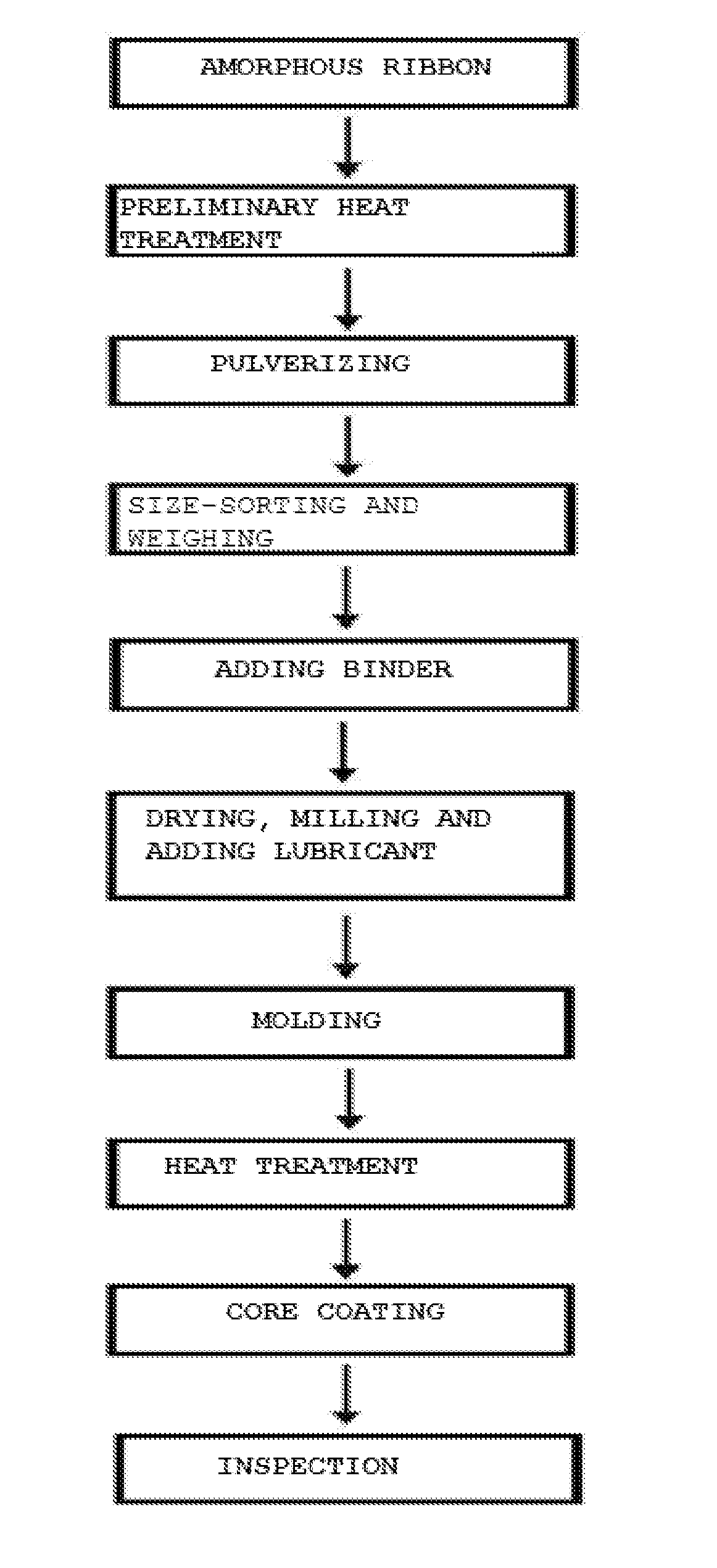

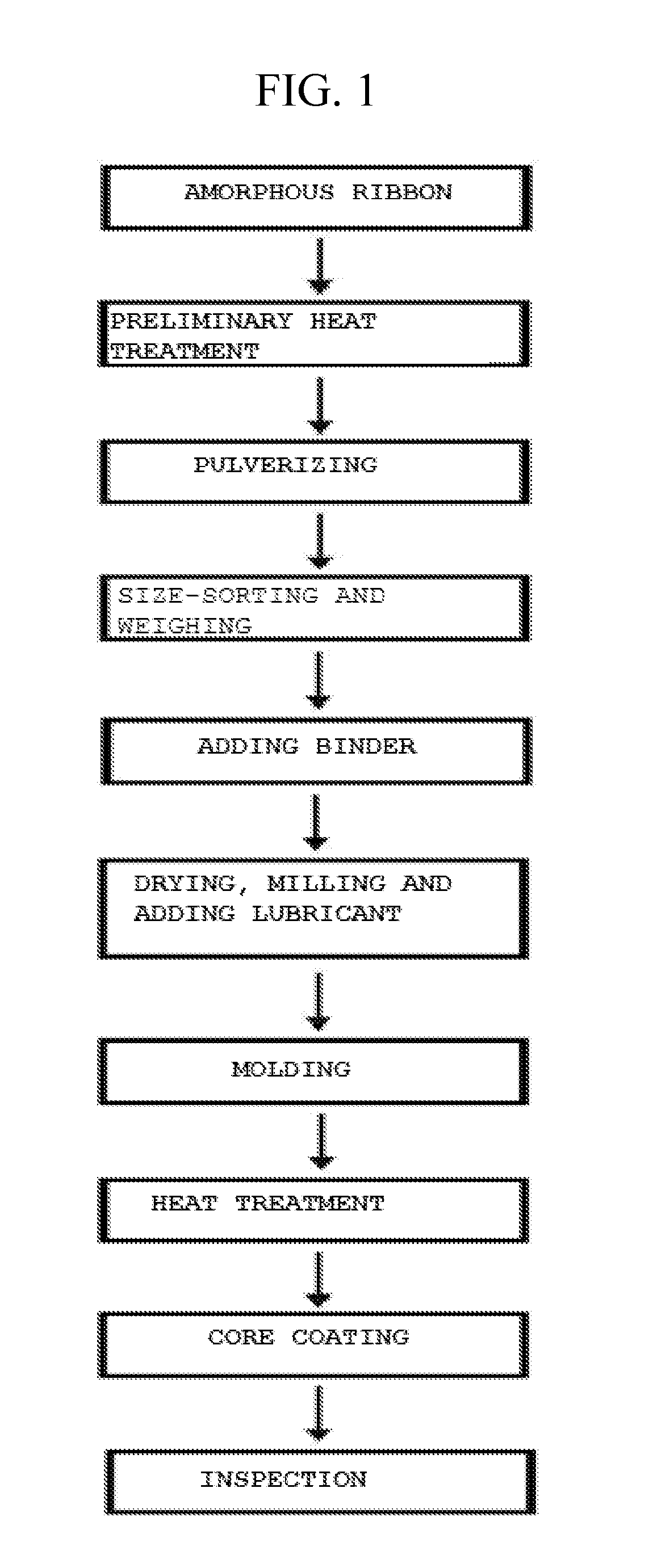

METHOD FOR MANUFACTURING Fe-BASED AMORPHOUS METAL POWDER AND METHOD FOR MANUFACTURING AMORPHOUS SOFT MAGNETIC CORES USING SAME

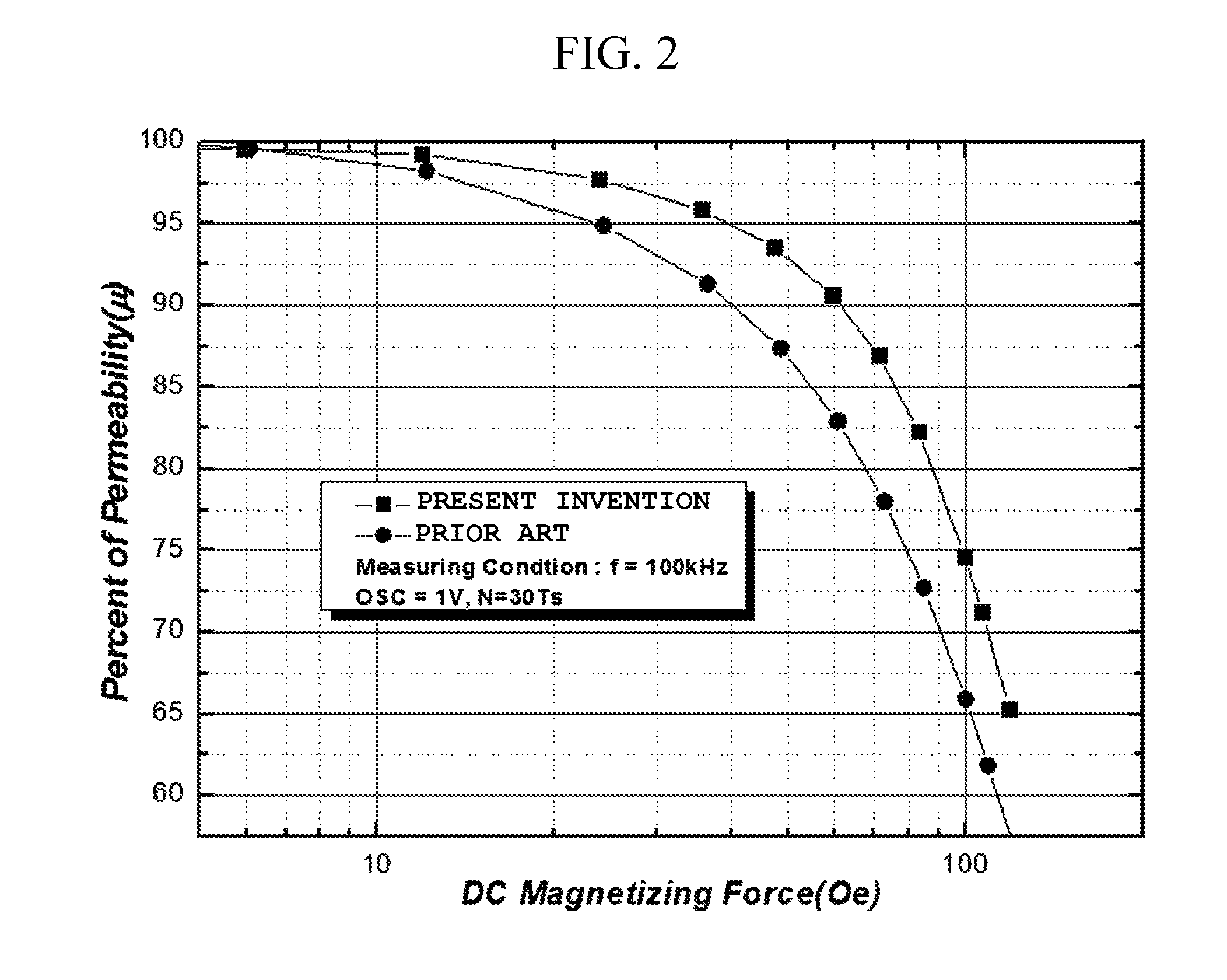

ActiveUS20150357118A1Excellent DC bias characteristicLow core lossTransportation and packagingMetal-working apparatusMetallurgyAmorphous ribbon

A manufacturing method of an amorphous soft magnetic core using a Fe-based amorphous metallic powder includes size-sorting an amorphous metallic powder obtained by pulverizing an amorphous ribbon prepared by a rapid solidification process (RSP) and then using the amorphous metallic powder having a particle size distribution so as to comprise 10 to 85 wt. % of powder having a particle size of 75 to 100 μm, 10 to 70 wt. % of powder having a particle size of 50 to 75 μm, and 5 to 20 wt. % of powder having a particle size of 5 to 50 μm to manufacture an amorphous soft magnetic core with excellent high-current DC bias characteristic and good core loss characteristic.

Owner:AMOGREENTECH CO LTD

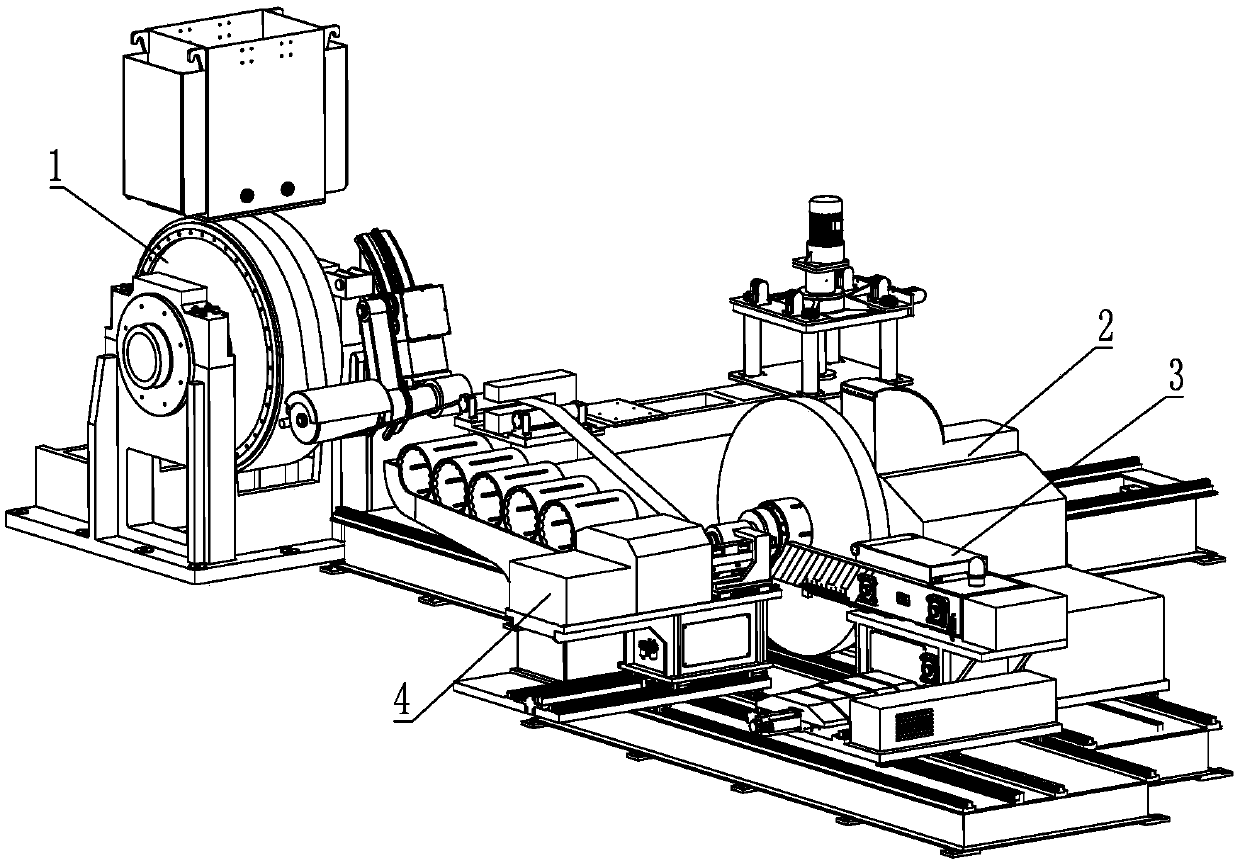

Single take-up type full-automatic coil changing machine for amorphous thin strip

PendingCN107738942AReduce replacement timeRealize automatic loading, unloading and replacementWebs handlingWinding machineEngineering

The invention discloses a single take-up type full-automatic coil changing machine for an amorphous thin strip. The single take-up type full-automatic coil changing machine comprises a winding machine, wherein the winding machine comprises a winding guide rail seat; a winding base is mounted on the winding guide rail seat in a sliding manner; a winding engine base is mounted on the winding base; awinding main shaft seat is mounted on the winding engine base; a winding main shaft is rotatably mounted on the winding main shaft seat; a winding core locking device is mounted at one end of the winding main shaft seat; a winding core is mounted on the winding core locking device; a coil loading device is mounted at the outer side of the winding core locking device; a coil supply device is mounted at an inlet side of the winding core of the core loading device in a matched manner; a coil unloading device is mounted at the rear side of the winding core. According to the single take-up type full-automatic coil changing machine for the amorphous thin strip, full-automatic loading, unloading and replacement of a strip coil can be realized, so that the replacement time of the strip coil is greatly shortened, the quantity of operators is reduced, the production efficiency is improved and the production cost is reduced.

Owner:李艳开

Manufacturing method for magnetic core of iron-based nanocrystalline high-power switching power supply transformer

ActiveCN103700480AImprove frequency characteristicsReduce high frequency eddy current lossInductances/transformers/magnets manufactureO-Phosphoric AcidTransformer

The invention discloses a manufacturing method for a magnetic core of an iron-based nanocrystalline high-power switching power supply transformer. The method comprises the following specific steps: performing vacuum isothermal annealing on an iron-based amorphous ribbon to obtain a nanocrystalline ribbon; crushing the obtained nanocrystalline ribbon to obtain nanocrystalline metal powder; performing phosphorization and insulated coating treatment on the nanocrystalline metal powder in sequence, adding zinc stearate and silicon carbide micro powder, and performing compression molding. After phosphorization is performed on the components of ammonium molybdate, phosphoric acid, diammonium hydrogen phosphate and sodium fluoride in the nanocrystalline metal powder, a layer of phosphate film is formed on the surface of the powder, so that the frequency characteristic of the magnetic core can be improved remarkably, and the high-frequency magnetic loss is reduced; after the phosphorization, alloy powder is coated in an insulated way by the substances of polyamide-imide resin and nano-attapulgite, so that the resistivity among powder particles is increased, and the high-frequency eddy current loss of the magnetic core is reduced.

Owner:TONGLING SANJIA TRANSFORMER

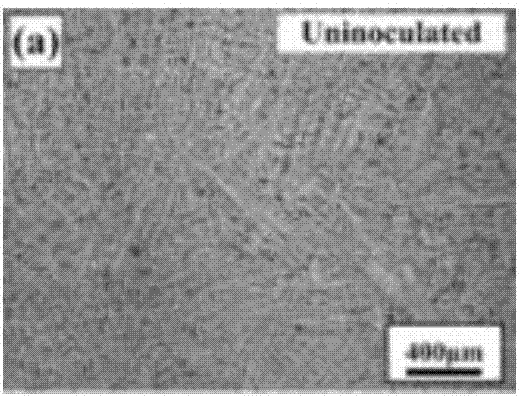

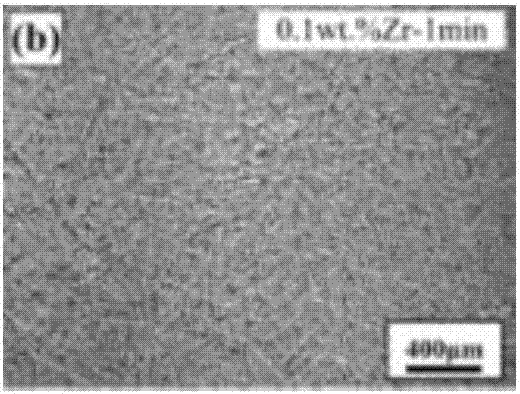

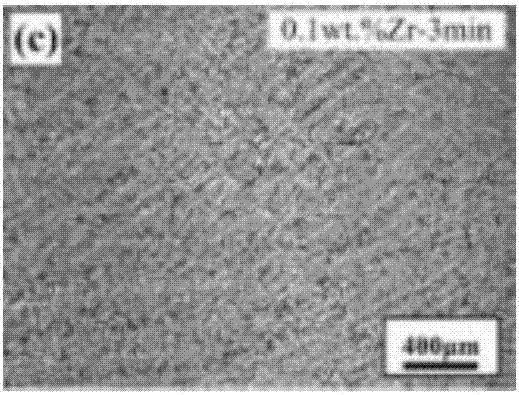

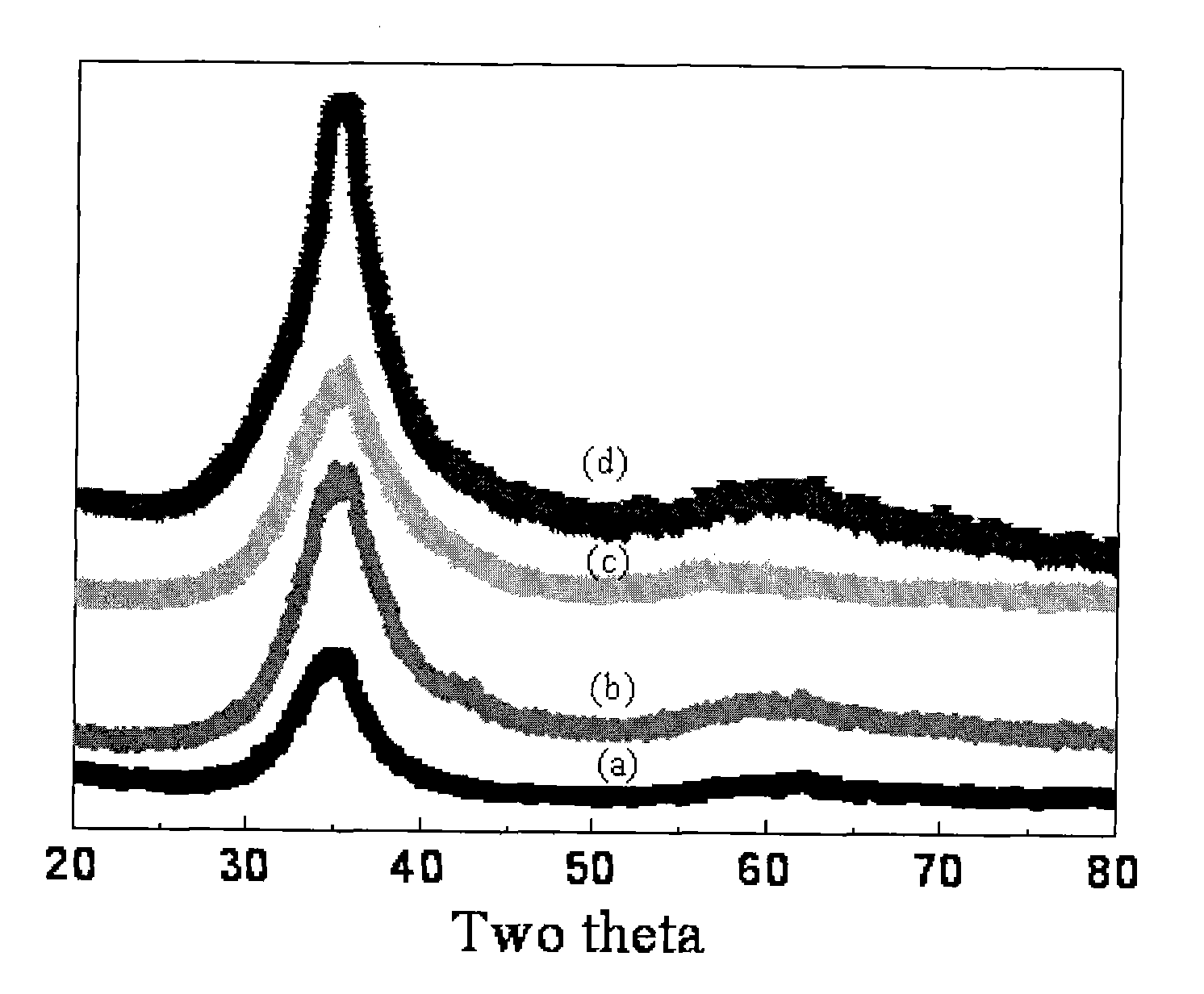

Method for refining aluminum alloy by using metallic glass

The invention discloses a method for refining aluminum alloy by using metallic glass and relates to the field of aluminum alloy processing. The method comprises the four steps of preparation of the metallic glass, preparation of amorphous ribbons, preparation of non-refined aluminum alloy and refinement of the aluminum alloy. By means of the technical scheme, the steps are reasonable; the refinement efficiency is high; the strength and toughness of the aluminum alloy are improved substantially; inoculation is efficient; and the method is low in cost and has huge industrial application potential and value.

Owner:JILIN UNIV

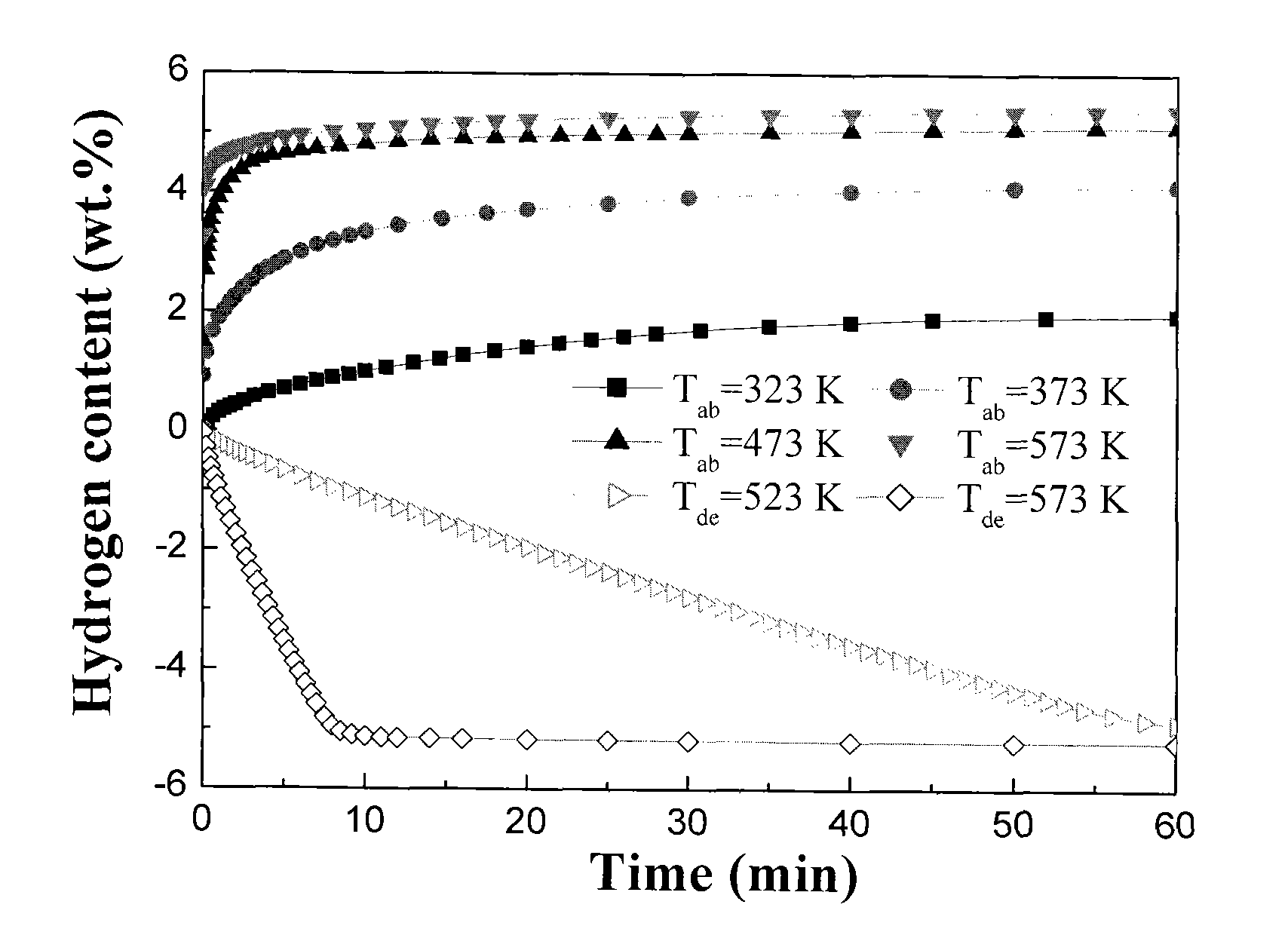

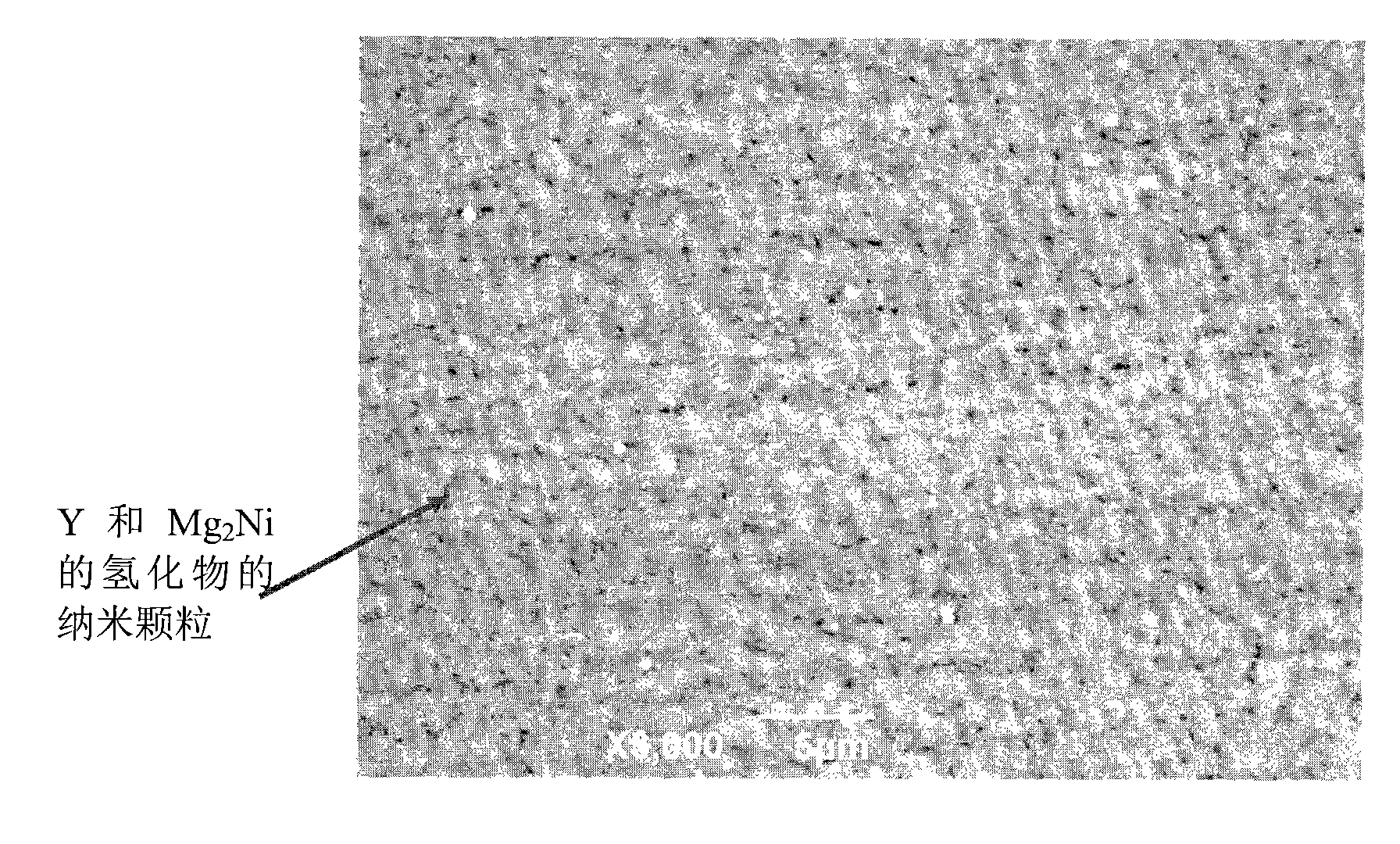

Amorphous magnesium-yttrium-transition metal hydrogen storage material and preparation method thereof

The invention provides an amorphous magnesium-yttrium-transition metal hydrogen storage material and a preparation method thereof, belonging to the technical field of hydrogen storage materials. The content of Mg in the hydrogen storage material is 70-90at.%, the transition metal is Co, Ni and Cu, and the yttrium and the transition metal are added in a combined addition manner based on the mol ratio of 1 to 1. The preparation method comprises the steps of: firstly, melting and preparing intermediate alloy of the yttrium and the transition metal by using an induction melting furnace; secondly, remelting and rapidly quenching the metal Mg and the intermediate alloy of the yttrium and the transition metal in a vacuum single-roller liquor rapid quenching furnace, wherein the prepared material is an amorphous ribbon with the width of 3mm and the thickness of 30-50 microns; and grinding the prepared amorphous ribbon into powder with different granularities in a glove box, wherein the amorphous ribbon or powder is the finished products of hydrogen storage materials. In the invention, the provided hydrogen storage material overcomes the disadvantage of low hydrogen storage amount; the combined addition of the Y and the transition metal facilitates the formation of the amorphous body and improves the hydrogen storage performance of the material. In addition, the invention has the characteristics of simple preparation method and low cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

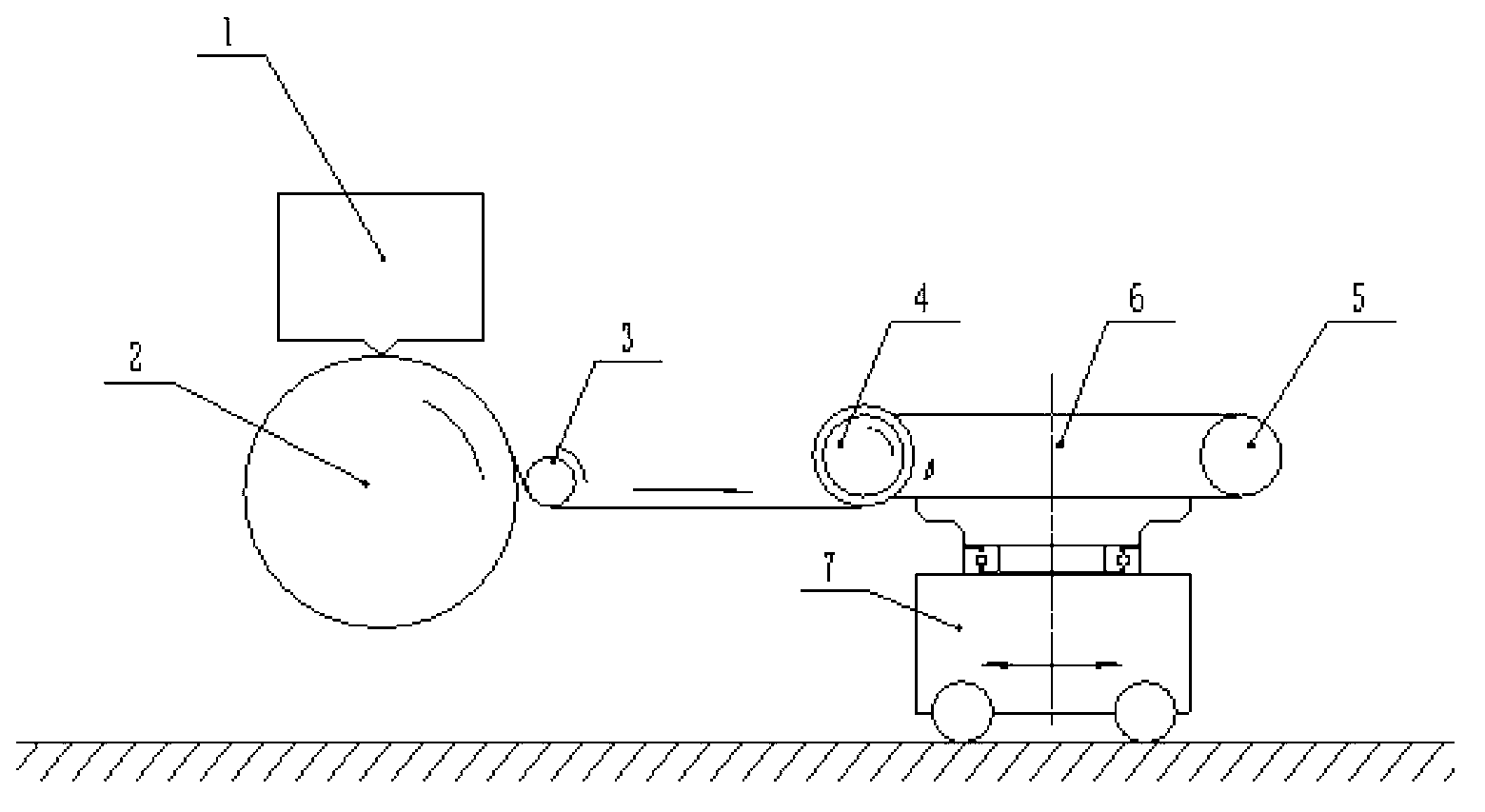

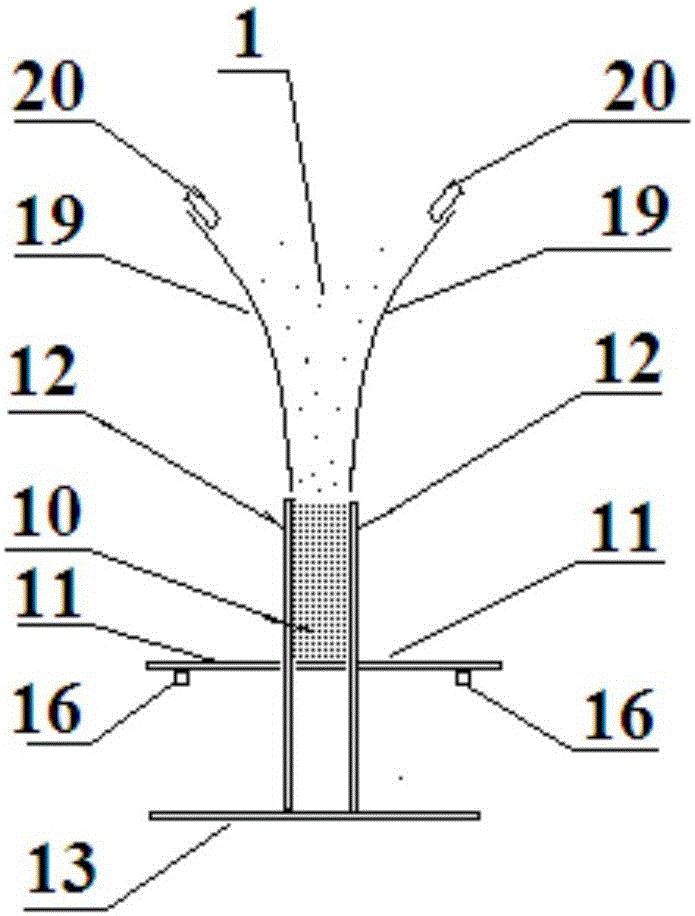

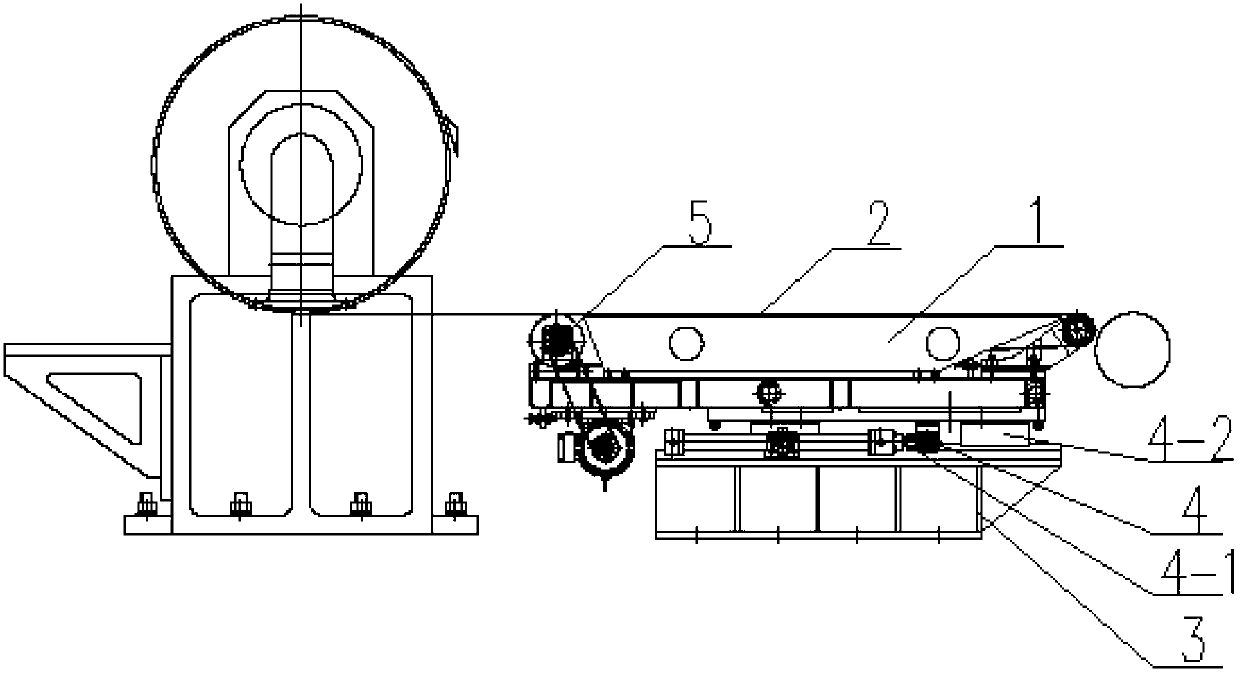

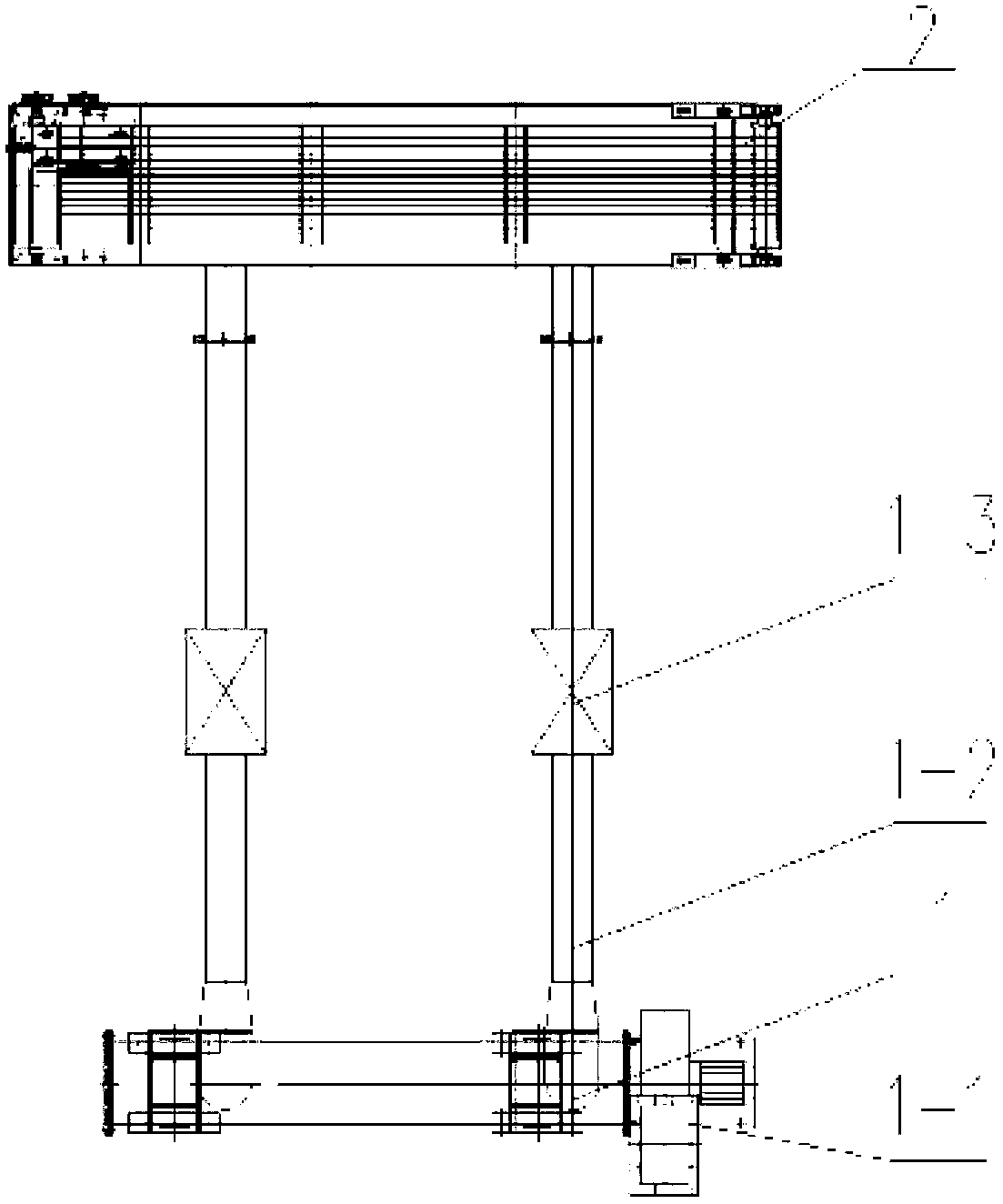

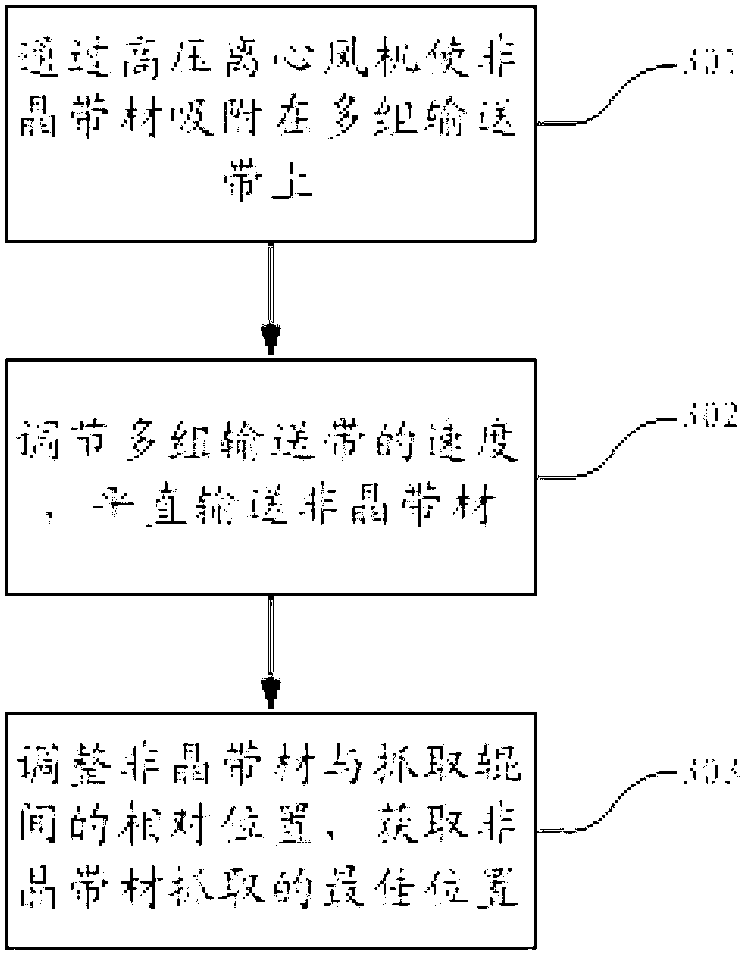

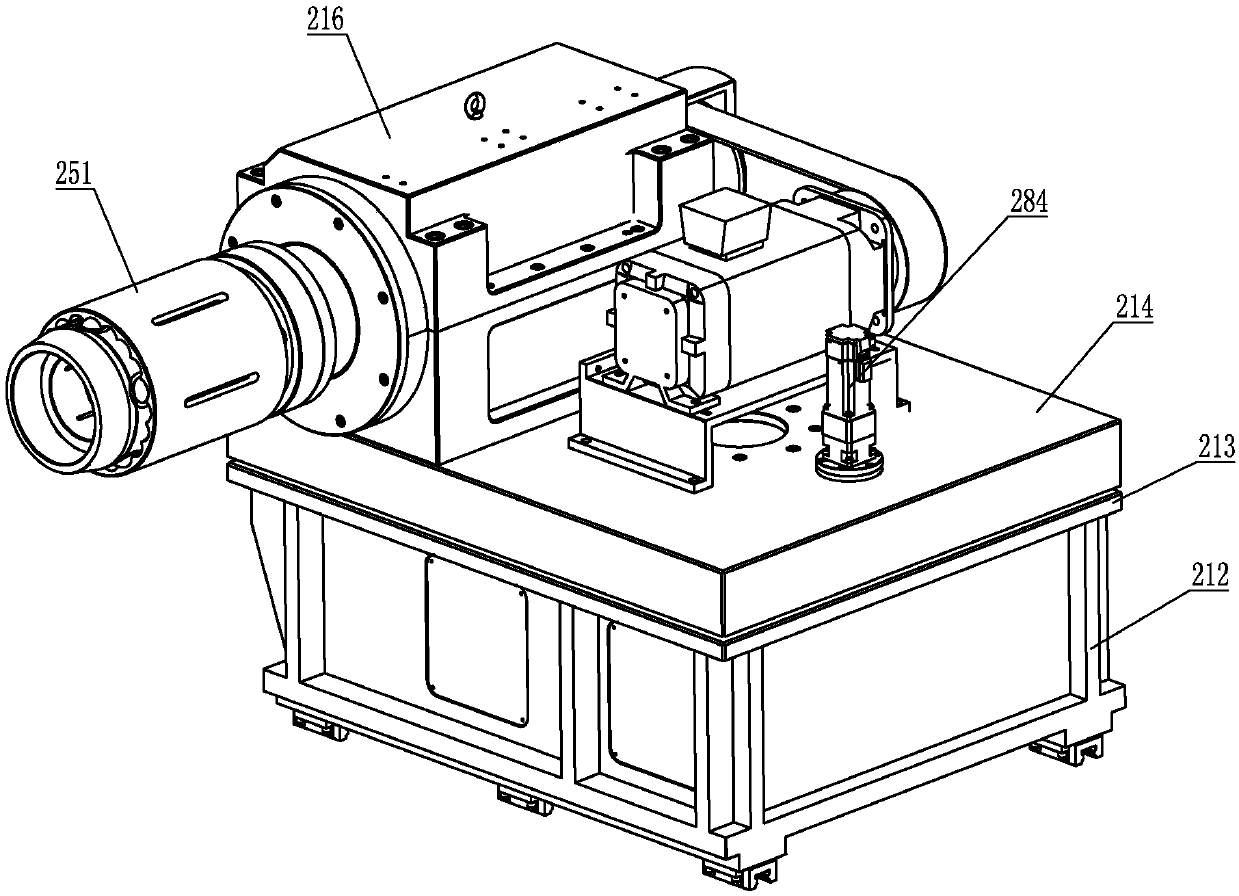

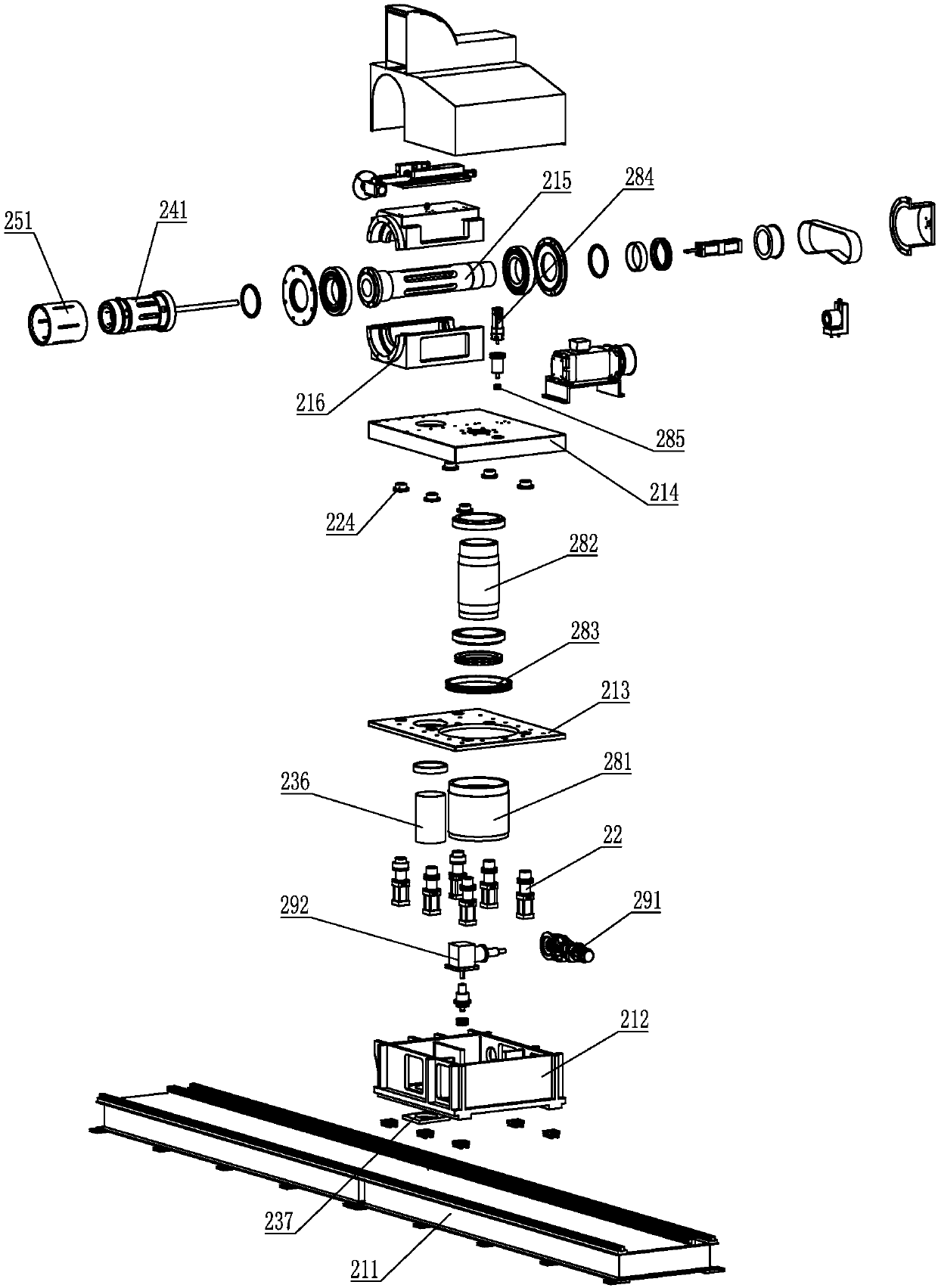

Online amorphous ribbon conveying equipment and realization method thereof

ActiveCN102992070ARealize long-distance grabbingImprove material yieldWebs handlingSuction forceStructural engineering

The invention relates to online amorphous ribbon conveying equipment and a realization method thereof. The realization method comprises the following steps of: causing amorphous ribbons breaking away from ribbon manufacturing rollers to be adsorbed on multiple groups of conveying belts through suction generated by a high-pressure centrifugal blower; adjusting the speed of the multiple groups of conveying belts so that the amorphous ribbons have tensile force in the conveying process and are straightly conveyed to grabbing rollers; and grabbing the amorphous ribbons after adjusting the relative positions between the amorphous ribbons and the grabbing rollers to the best grabbing positions according to the relative positions between the amorphous ribbons conveyed by the multiple groups of conveying belts and the grabbing rollers. According to the realization method, the amorphous ribbons are prevented from having head upwarping or breaking away from the conveying belts through the multiple-group combination manner of the multiple groups of conveying belts. The yield of the amorphous ribbons is increased by using a distance fine adjusting system for adjusting the best positions for grapping; and a reeling technology is optimized so that the safety is greatly increased, and the problems of low yield, poor reliability and difficulty in treatment of waste ribbons in the ribbon coiling process are avoided.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

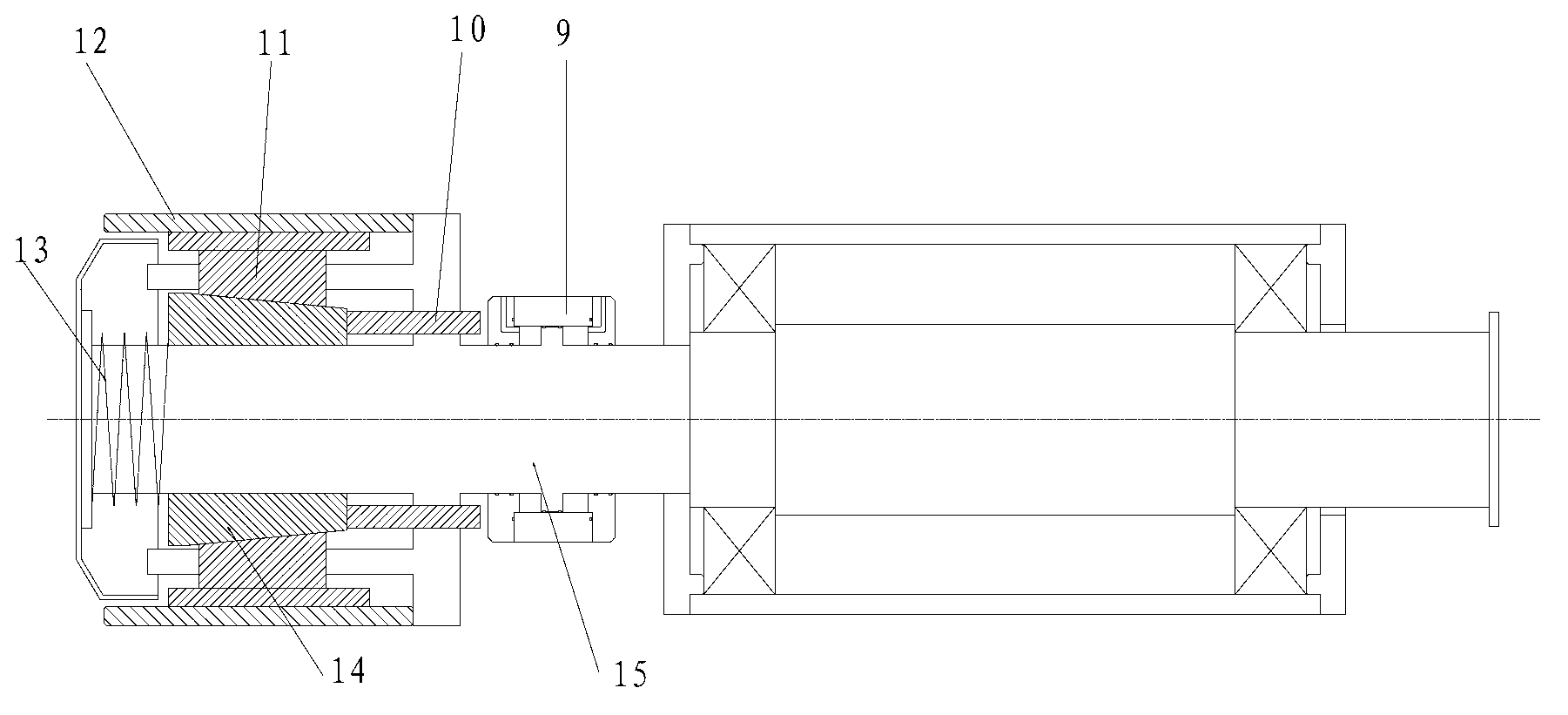

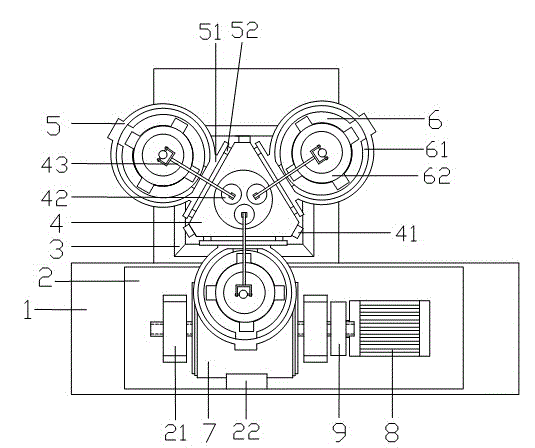

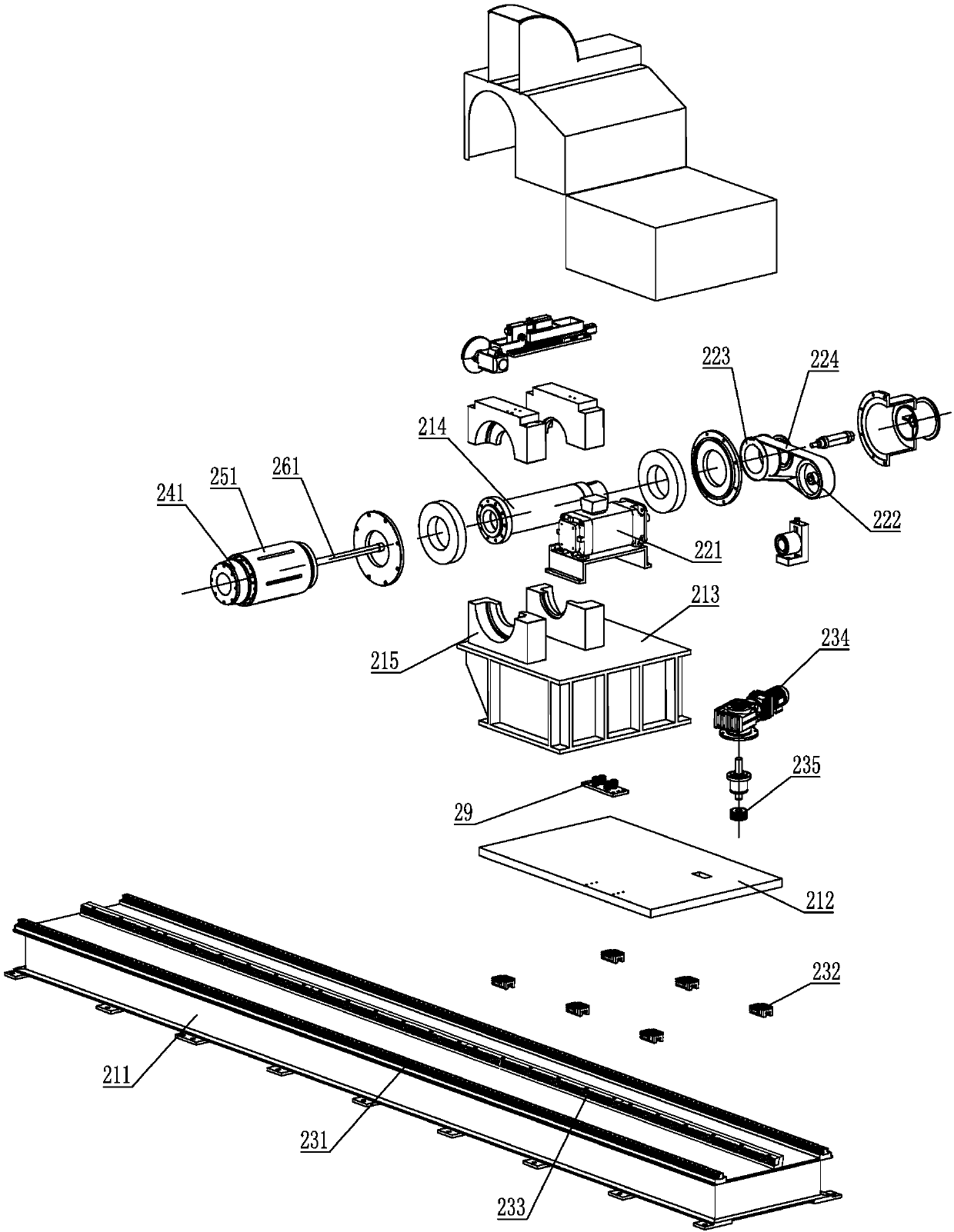

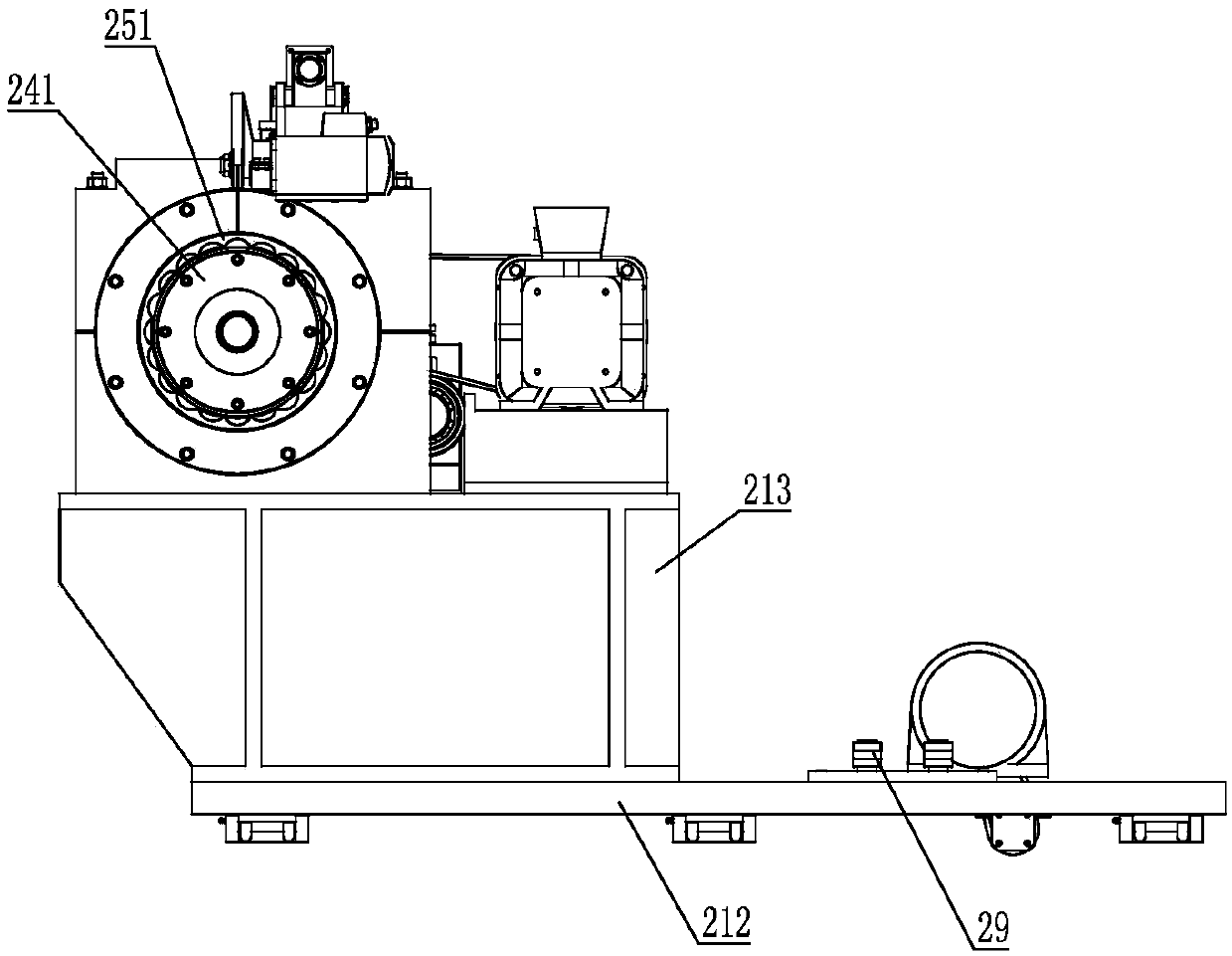

Winding machine for dual-winding full-automatic amorphous thin strip roll changing machine

The invention discloses a winding machine for a dual-winding full-automatic amorphous thin strip roll changing machine. The winding machine comprises a winding guide rail seat, wherein a winding machine seat is mounted on the winding guide rail seat in a sliding manner; a rotary platform is mounted on the winding machine seat in a rotatable manner; a main shaft box is mounted on the rotary platform; a winding main shaft is mounted in the main shaft box in a rotatable manner; a roll core locking device is mounted at one end of the winding main shaft; a rotary locating device is mounted betweenthe winding machine seat and the rotary platform; the winding guide rail seat is provided with two negative pressure connectors; negative pressure pipelines for communicating the negative pressure connectors with a roll core are mounted on the winding machine; during working, the roll core is mounted on the roll core locking device, and the winding main shaft rotates to drive the roll core to rotate to realize winding; and when two winding machines work side by side, the radial centers of the roll cores of the two winding machines are in tangent overlapping, and the rotary platform structure can realize that the two winding machines avoid each other and realize continuously alternate winding of the two winding machines, so that waste of strip rolls is prevented, the production efficiency is improved, and the production cost is reduced.

Owner:李艳开

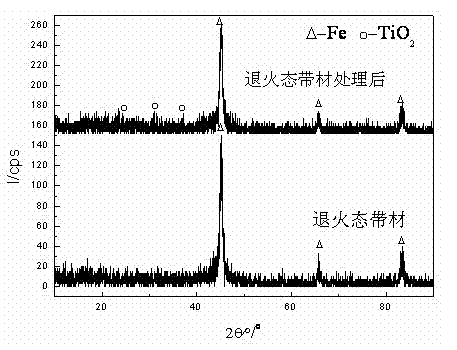

Method for preparing TiO2 coating on surface of iron-based amorphous ribbon through sol-gel method

InactiveCN102268660AGood weather resistanceGood chemical resistanceSolid/suspension decomposition chemical coatingSolventSide reaction

The invention provides a method for preparing a TiO2 coating on the surface of an iron-based amorphous ribbon through a sol-gel method. The preparation process steps of the TiO2 coating are as follows: (1) selecting raw materials; and (2) preparing the coating: 1) using NaOH, Na2CO3, Na3PO4.12 H2O and Na2SiO3 as the solute and deionized water as the solvent to prepare solution; 2) placing the iron-based amorphous ribbon in the oil-removing solution prepared in the step 1); 3) soaking the iron-based amorphous ribbon obtained in the step 2) in a 80-95 DEG C of water bath to perform ultrasonic treatment for 10-15 minutes; and 4) cleaning the iron-based amorphous ribbon with distilled water. The invention has the following advantages: (1) the reaction process is easy to control, side reactions are fewer, the process operations are simple; and (2) titanium dioxide is characterized by good weather resistance, chemical resistance and ultraviolet resistance, excellent transparency, uniform size distribution and the like, thus the comprehensive performance of the surface of the iron-based amorphous ribbon can be increased.

Owner:NANCHANG UNIV

Amorphous alloy ribbon superior in magnetic characteristics and lamination factor

The present invention provides an amorphous alloy ribbon superior in magnetic characteristics and lamination factor by defining the slip property of the amorphous alloy ribbon surface in a specific range, that is, an amorphous alloy ribbon superior in magnetic characteristics and lamination factor produced by the single roll method, characterized in that the slip property of the ribbon surface satisfies the following equation:0.1≦F=P / M≦1.0where, F is the slip friction coefficient, P is the force pulling the intermediate part of the amorphous ribbon when applying weight from above to three amorphous ribbons stacked together, and M is the load applied from the top of the amorphous ribbon (5 kg).

Owner:NIPPON STEEL CORP

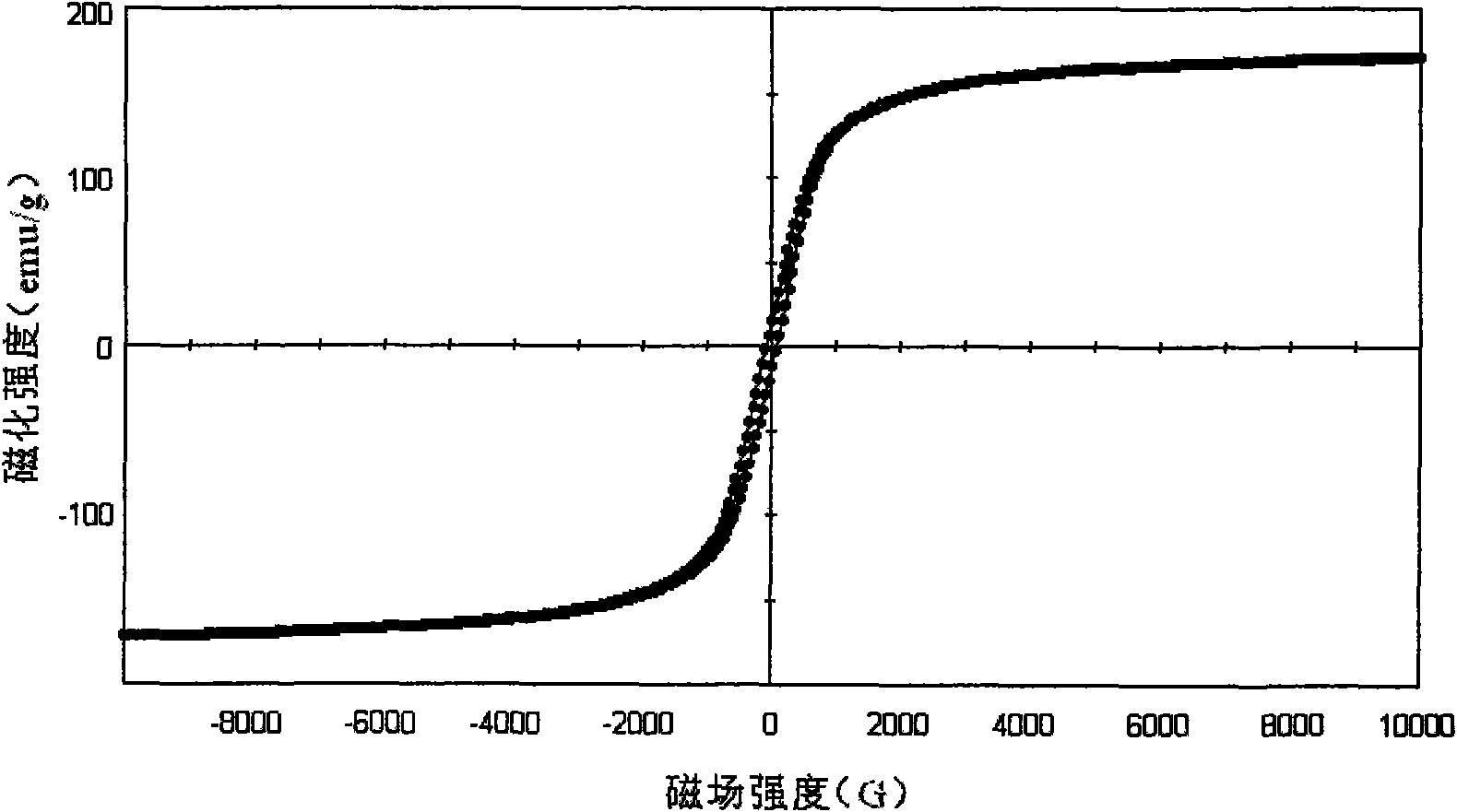

Mg-Mo series Fe-based amorphous alloy ribbon and preparation method thereof

InactiveCN103352187AImprove stress distributionImprove toughnessFurnace typesMagnetic materialsAlloyAmorphous ribbon

The invention discloses an Mg-Mo series Fe-based amorphous alloy ribbon. The Mg-Mo series Fe-based amorphous alloy ribbon is characterized in that the Mg-Mo series Fe-based amorphous alloy ribbon comprises 7-9% of Mg, 2-3% of Mo, 0.9-1.2% of V, 0.04-0.06% of Ta, 5.8-6.4% of Zn, 2.1-2.3% of Ni, 0.04-0.06% of W, 0.12-0.16% of Tm, and the balance Fe. A preparation method of the amorphous ribbon is similar to preparation methods of routine amorphous ribbons, treats Mg-Mo as a basic doping material, allows other components of V, Ta and the like to be added, optimizes the heat treatment technology, and obviously improves the stress distribution of the amorphous alloy ribbon, so the amorphous alloy material has an excellent toughness, a good plasticity, an excellent soft-magnetic performance and a good amorphous formation capability, and can be widely used for various amorphous ribbon ring materials.

Owner:全椒君鸿软磁材料有限公司

Preparation and application of palladium/copper oxide nano porous structure composite material loaded with titanium dioxide nanoparticles

InactiveCN106654291AHigh catalytic activityEasy to operateCell electrodesSynthesis methodsOxide composite

The invention discloses a preparation method of a palladium / copper oxide nano porous structure composite material loaded with titanium dioxide nanoparticles. The preparation method comprises the following steps: preparing a Ti-Cu-Pd amorphous ribbon into a Pd / CuO nano porous structure to be compounded by utilizing a chemical dealloying manner; adding a certain amount of oleic acid, tetrabutyl titanate and oleylamine into cyclohexane in sequence, and stirring continuously; then transferring a mixture into a reaction kettle and carrying out a hydrothermal reaction to obtain the titanium dioxide nanoparticles; adding the Pd / CuO nano porous structure into a normal hexane solution and carrying out ultrasonic treatment to obtain a black suspension solution; adding different amounts of the titanium dioxide nanoparticles into the black suspension solution; and magnetically stirring, washing and drying to obtain the palladium / copper oxide nano porous structure composite material loaded with the titanium dioxide nanoparticles. The preparation method is simple in preparation process, low in implementation cost and low in cost and is an efficient and economical synthesis method. The oxide composite material obtained by the method has the advantages of improvement of an anti-poisoning capability of the material and high catalytic activity.

Owner:TIANJIN UNIV

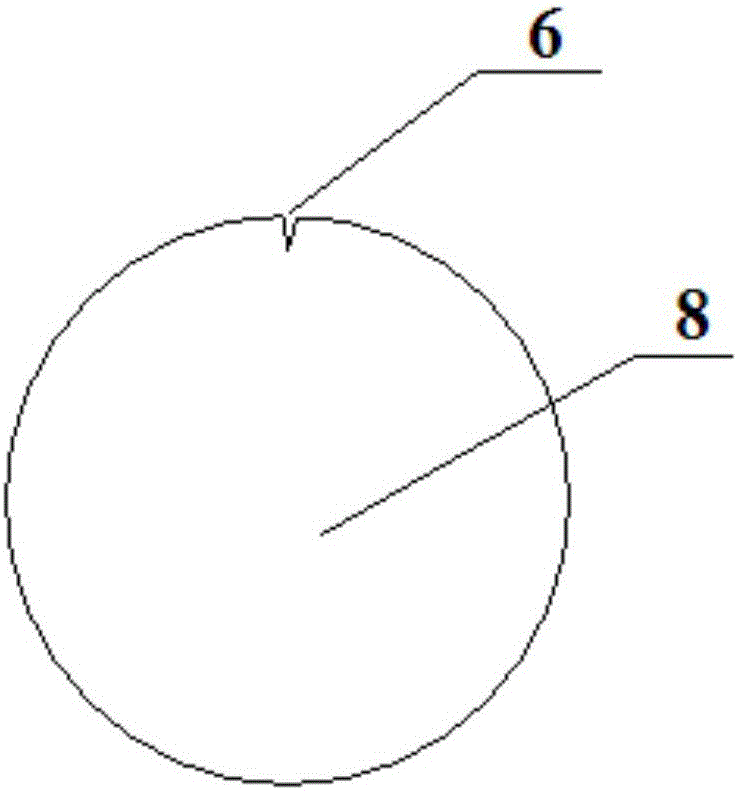

Slitting-free non-winding amorphous ribbon preparation method and preparation system

The invention discloses a slitting-free non-winding amorphous ribbon preparation method and a preparation system. According to the preparation method, a plurality of grooves are formed in a cooling roller face perpendicular to the rotating direction of a rapid-quenching cooling roller so that an amorphous ribbon can be automatically broken at groove positions in the throwing process, and a segment-shaped amorphous ribbon is formed. The preparation system comprises a melting device, a throwing device and an automatic segment-shaped amorphous ribbon collector. By means of the preparation method and the preparation system, the segment-shaped amorphous ribbon with a needed length can be directly obtained in the throwing process of the amorphous process, the redundant procedures that in the prior art, the amorphous ribbon is wound firstly and then is disengaged from a disk and slit are omitted, the production efficiency is improved, the production cost and the equipment investment are reduced, and meanwhile, the situation that as stress action is introduced by winding, the performance of the amorphous ribbon is reduced is avoided.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of iron-based amorphous thin strip and its manufacturing method

InactiveCN101787500BReduce manufacturing costSize shape heightChemical compositionIntermediate frequency

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com