Online reeling device for amorphous ribbon

A technology of amorphous strip and coiling device, which is applied in the field of amorphous strip manufacturing, can solve the problems of cumbersome operation, time-consuming loading and unloading of coiling drum, restriction of continuous operation and mass production, etc., so as to improve material yield and reduce waste Band rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

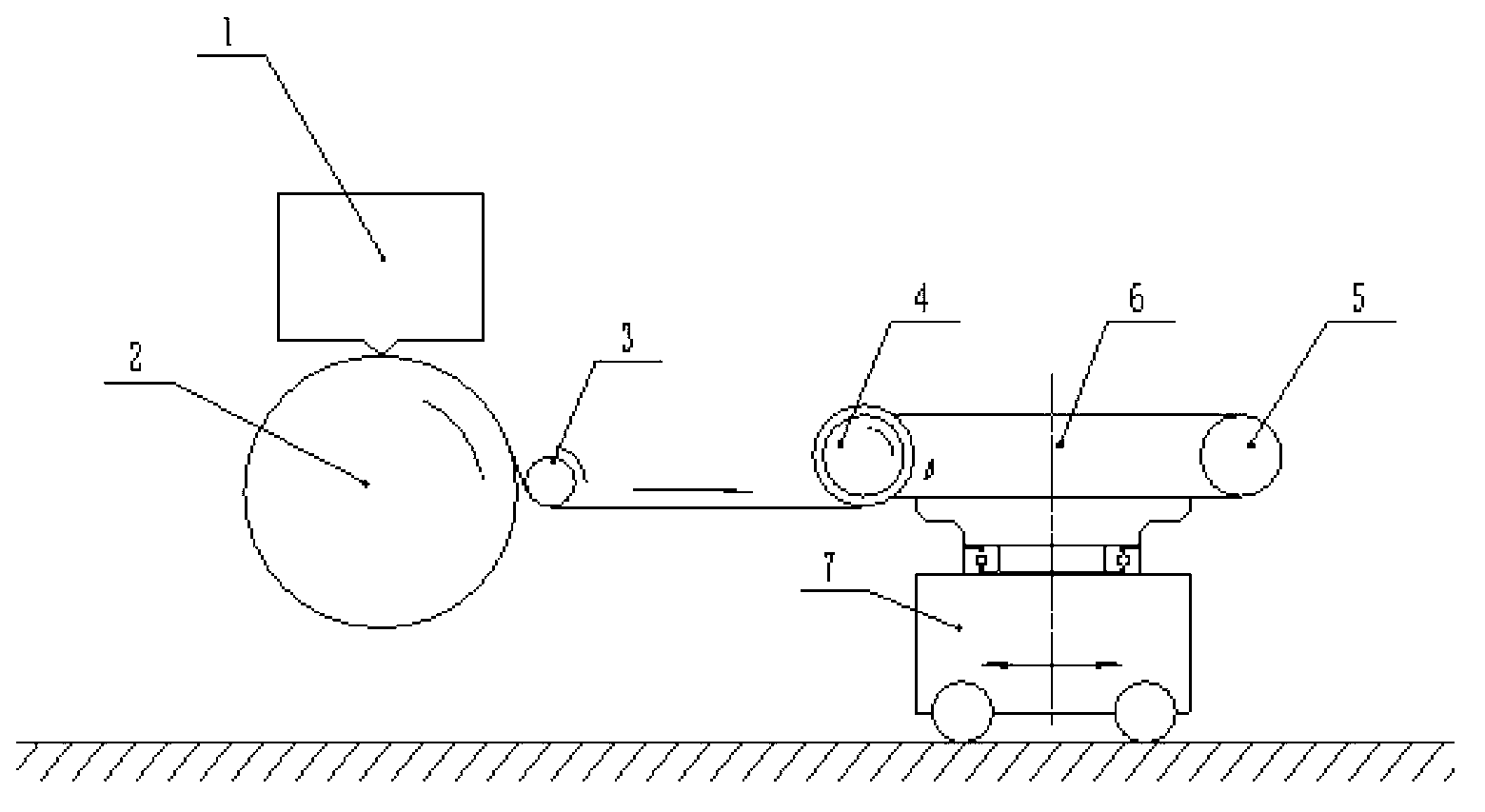

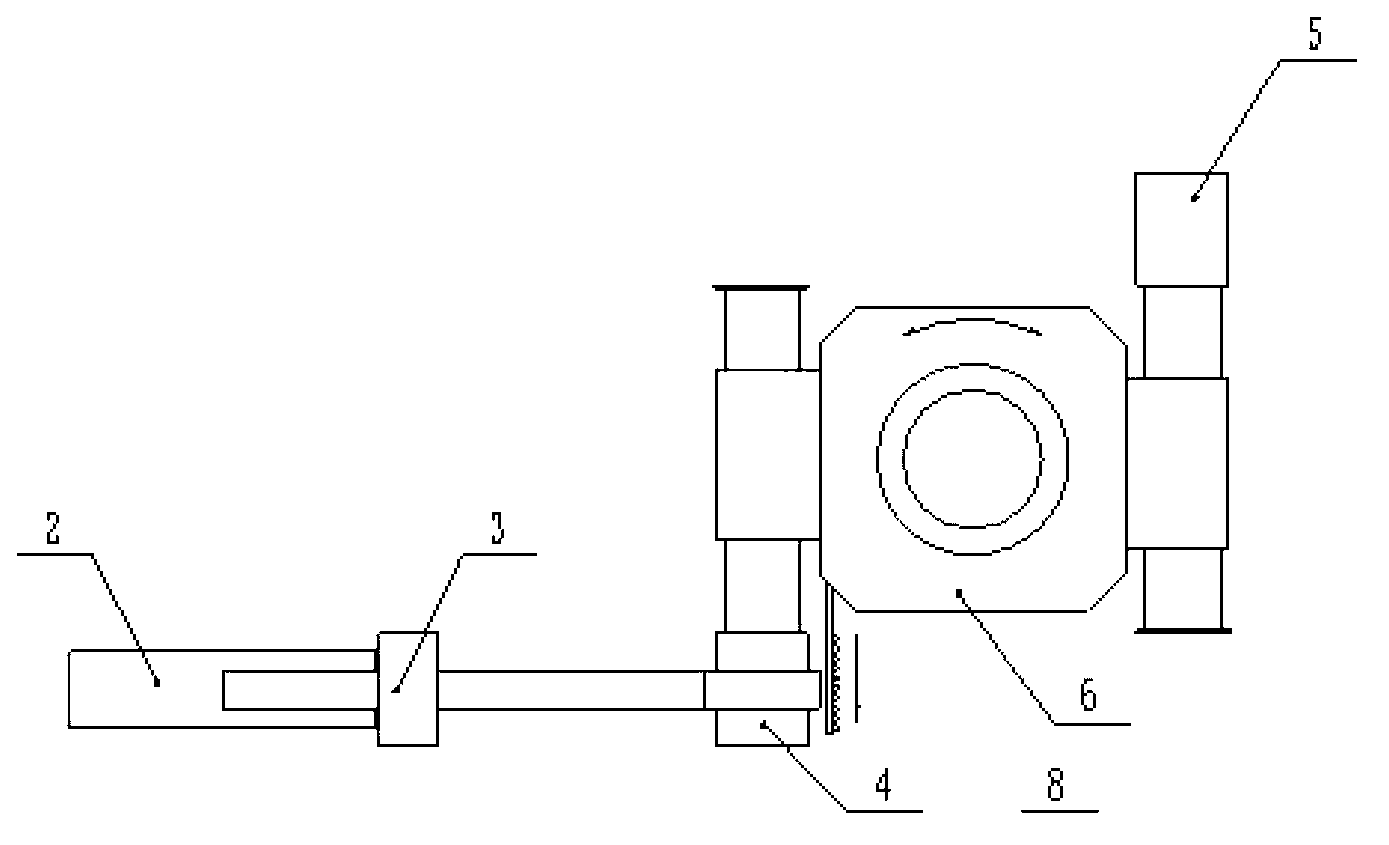

[0012] figure 1 is a schematic structural view of an online coiling device for an amorphous strip according to an embodiment of the present invention.

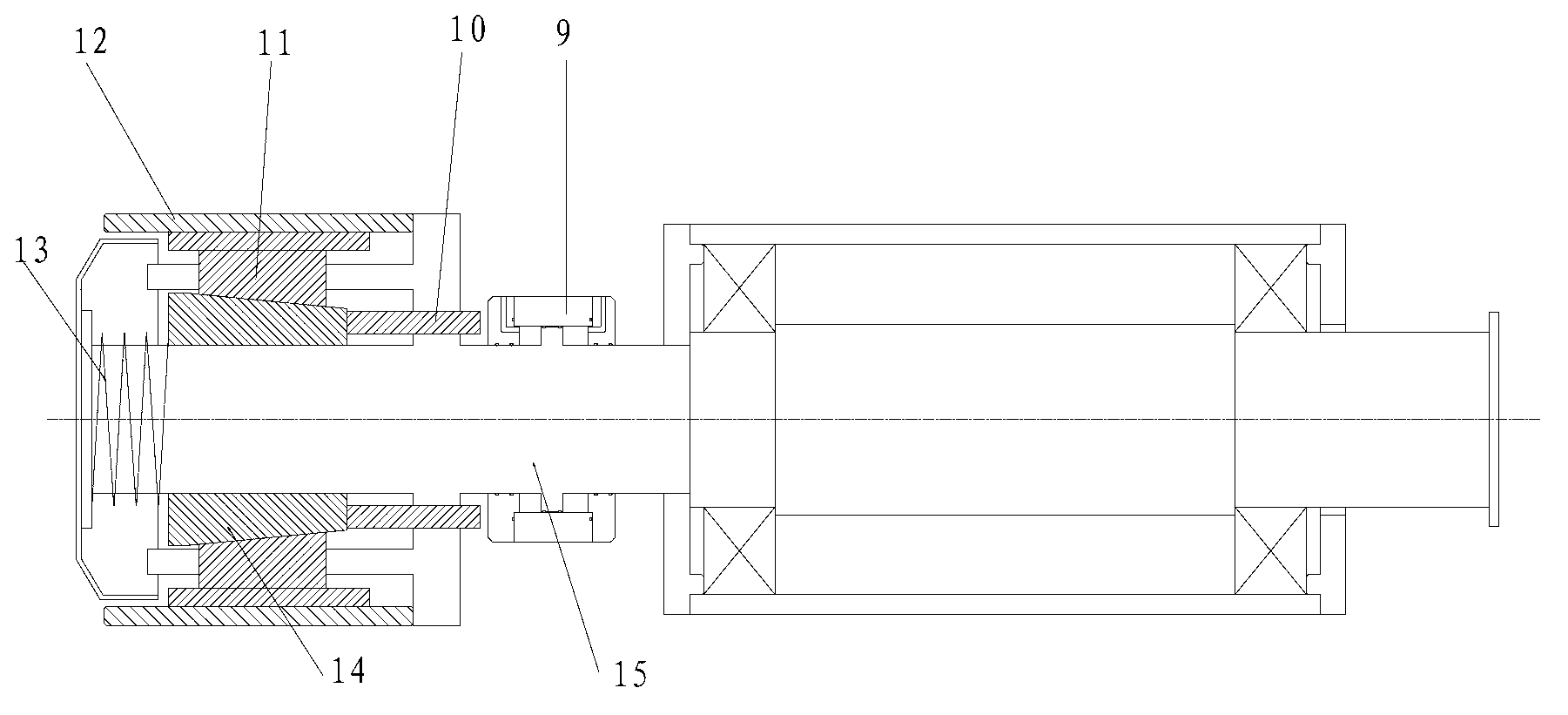

[0013] Such as figure 1 As shown, the online coiling device of this embodiment includes a cantilevered first coiling shaft 4, a cantilevered second coiling shaft 5, a rotating platform 6, and a working platform 7; wherein, on the movable working platform 7, a The rotating platform 6 that can rotate horizontally and reciprocatingly by 180°, the first winding shaft 4 and the second winding shaft 5 are installed on both sides of the rotating platform 6, and the winding drum can be installed on it through the internal hydraulic contraction and mechanical spring tensioning mechanism .

[0014] The spray ladle 1 sprays molten steel above the crystallizer 2, and forms an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com