Preparation process of heatable aluminum foil packaging lunch box

A preparation process and lunch box technology, which is applied in the field of the preparation process of heatable aluminum foil packaging lunch boxes, can solve the problems of prolonging the operation time, increasing the manufacturer's input cost, affecting the processing accuracy, etc., so as to eliminate the possibility of deformation of the aluminum foil and improve the overall operation. Efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

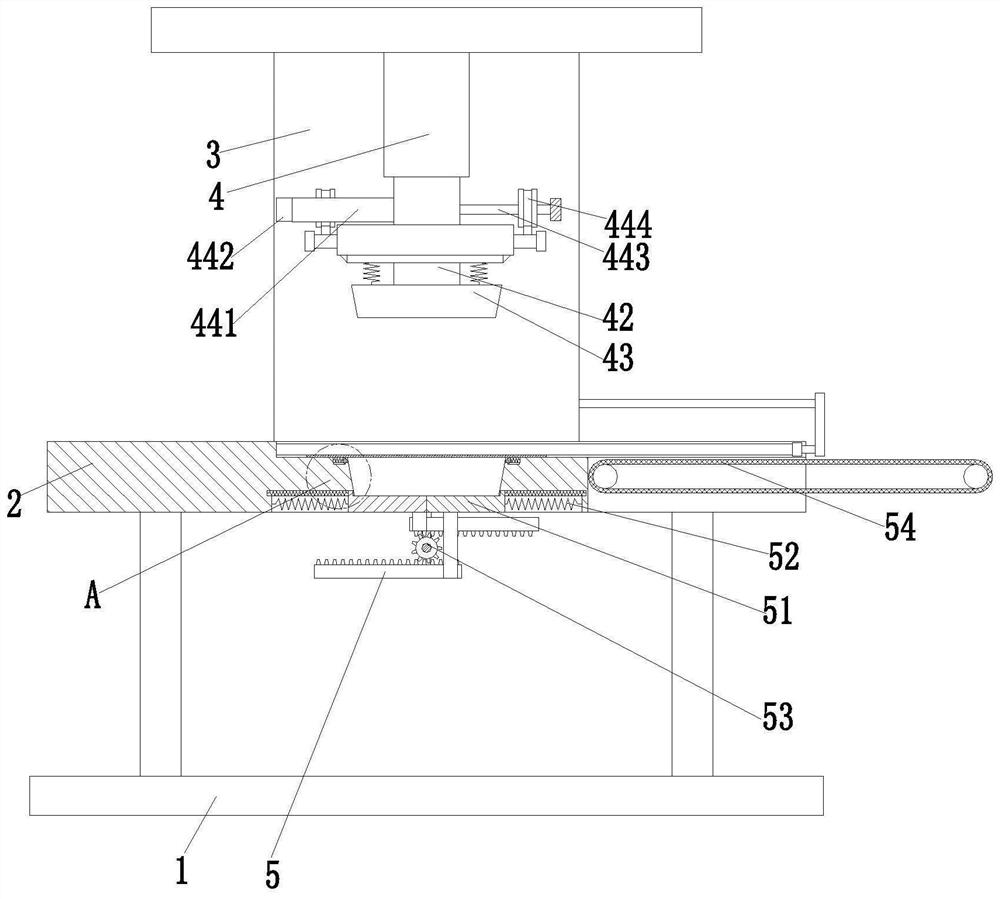

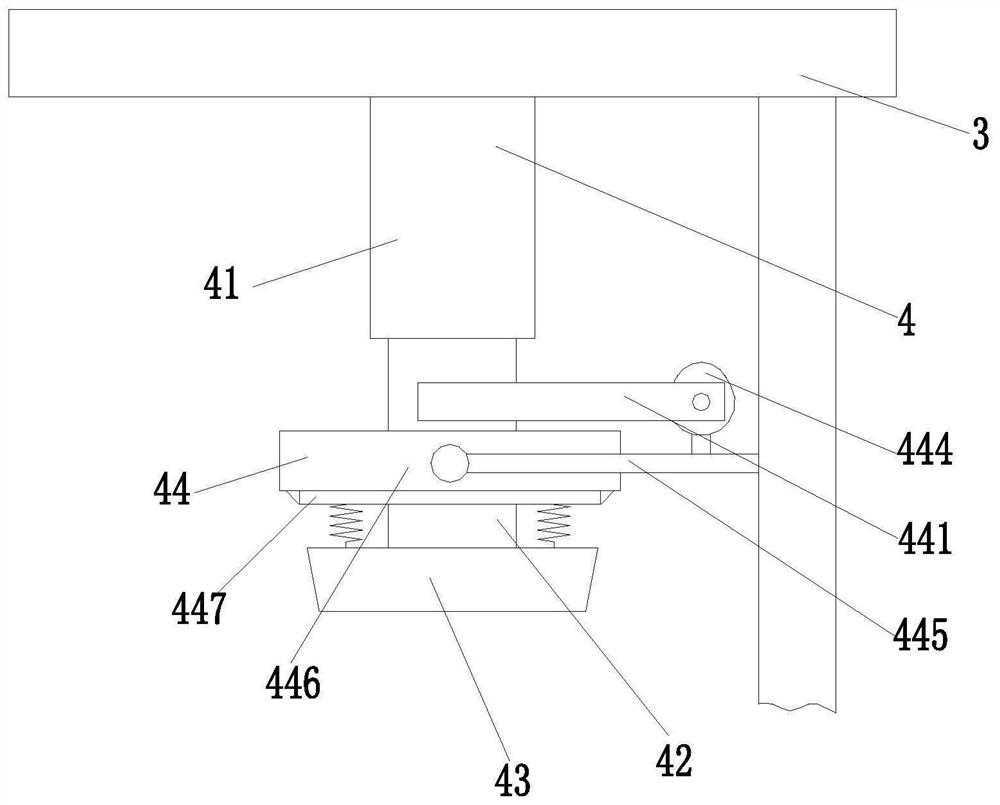

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

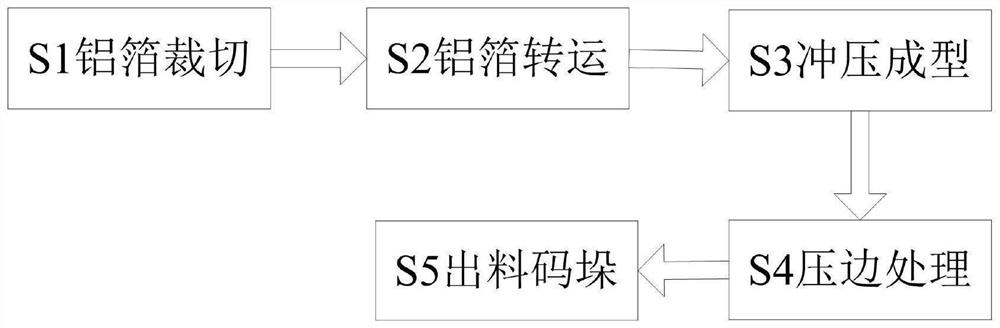

[0039] Such as Figure 1 to Figure 10 As shown, a heatable aluminum foil packaging lunch box preparation process, which uses a stamping forming equipment, the stamping forming equipment includes a bottom plate 1, a workbench 2, a mounting frame 3, a stamping device 4 and a feeding device 5, using the above The specific process for the preparation of aluminum foil packaging lunch boxes by stamping equipment is as follows:

[0040] S1. Aluminum foil cutting: according to the actual size of the lunch box, the aluminum foil sheet is cut into an appropriate size;

[0041] S2. Aluminum foil transfer: the aluminum foil to be processed in S1 is transferred to the stamping and forming equipment for later use;

[0042] S3. Stamping forming: the aluminum foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com