Patents

Literature

338results about How to "Shorten the interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

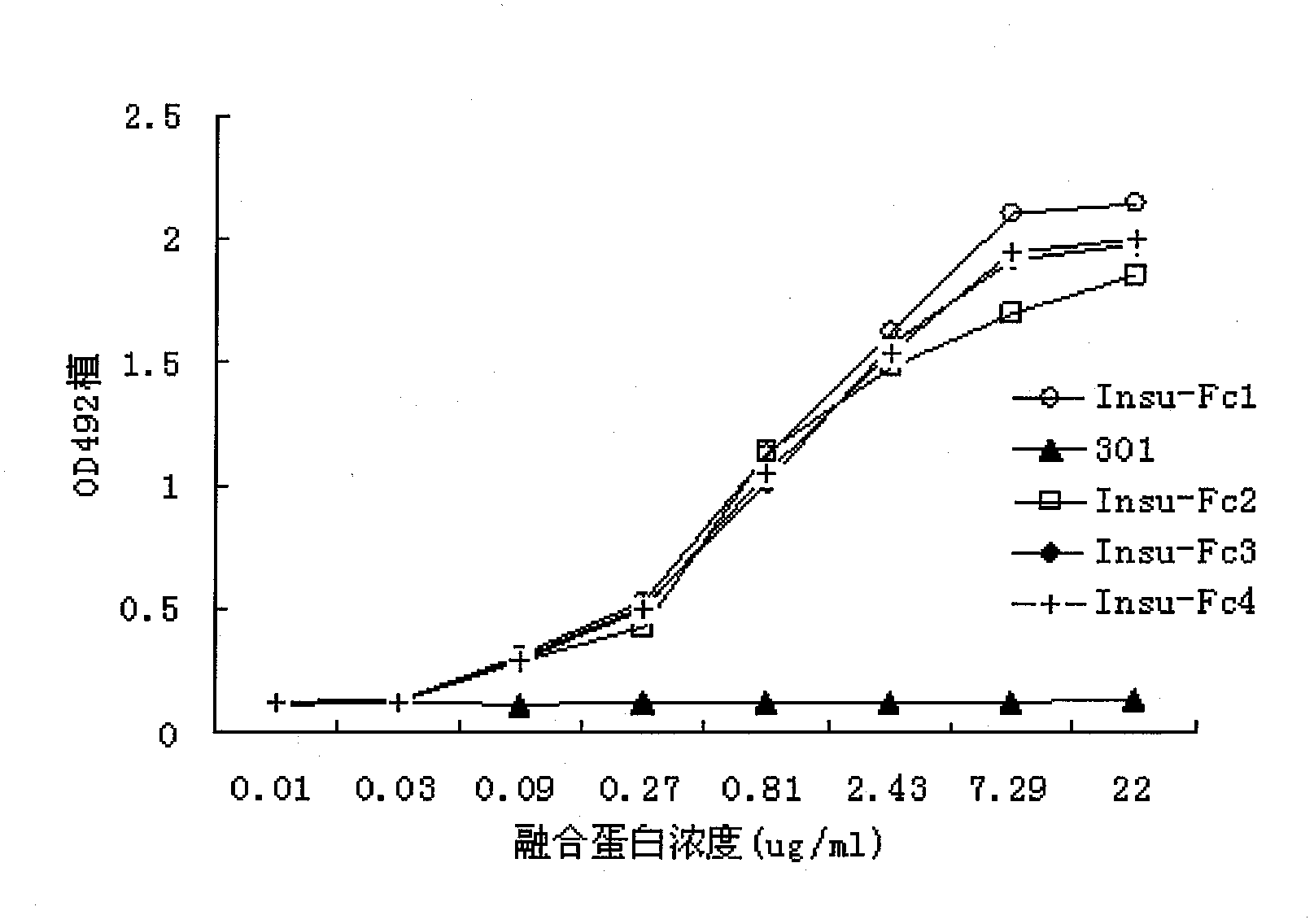

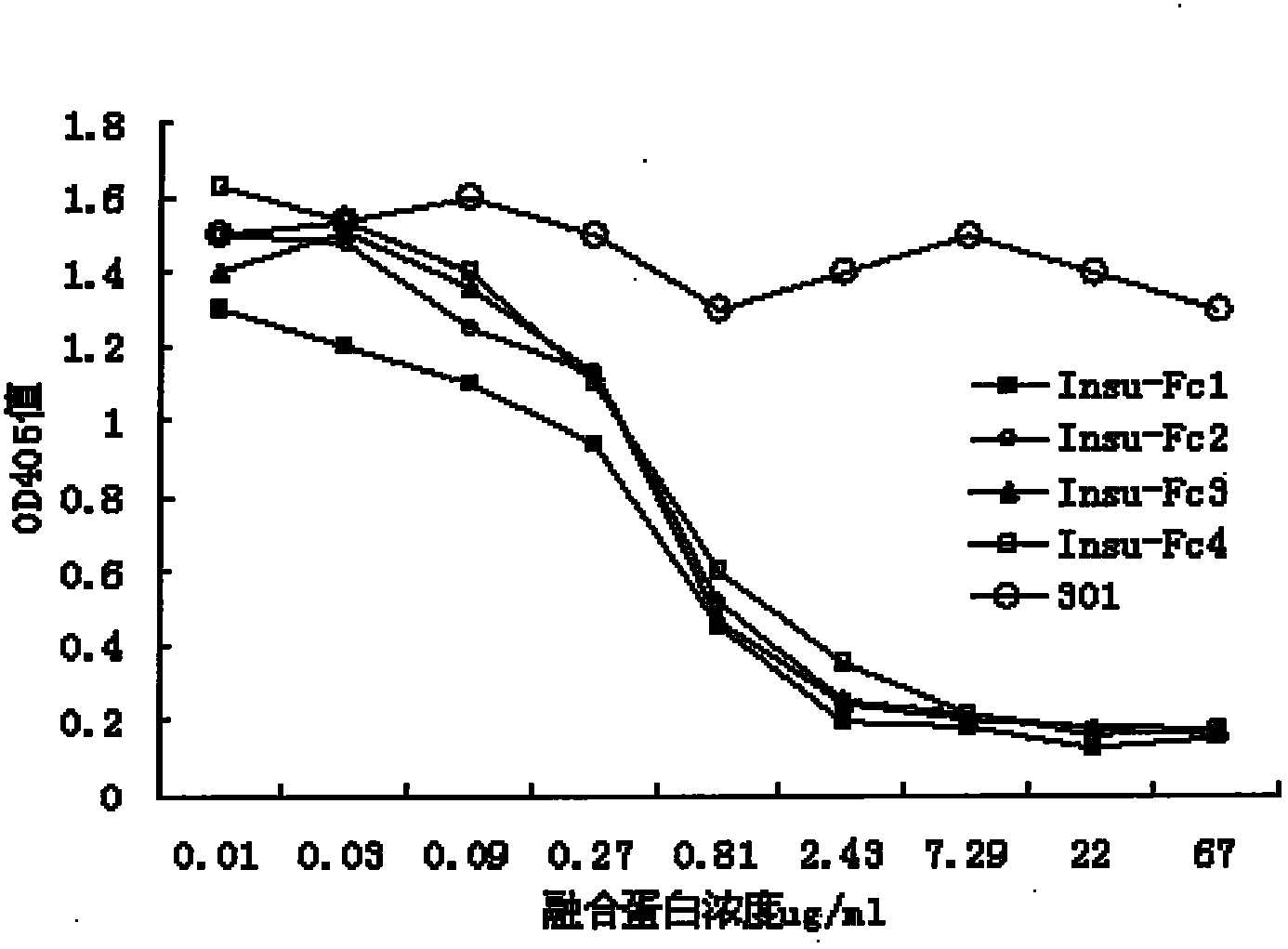

Insulin-Fc fusion protein

ActiveCN103509118AImprove pharmacokinetic performanceProlong half-life in vivoPeptide/protein ingredientsMetabolism disorderHalf-lifeMedicine

The invention belongs to a biological technology field, more concretely discloses an insulin-Fc fusion protein, a preparation method and applications thereof. The insulin-Fc fusion protein provided by the invention has a long half life, can reduce interval time of insulin usage, and can reduce medicine use pain.

Owner:SHANGHAI SINOMAB BIOTECHNOLOGY CO LTD

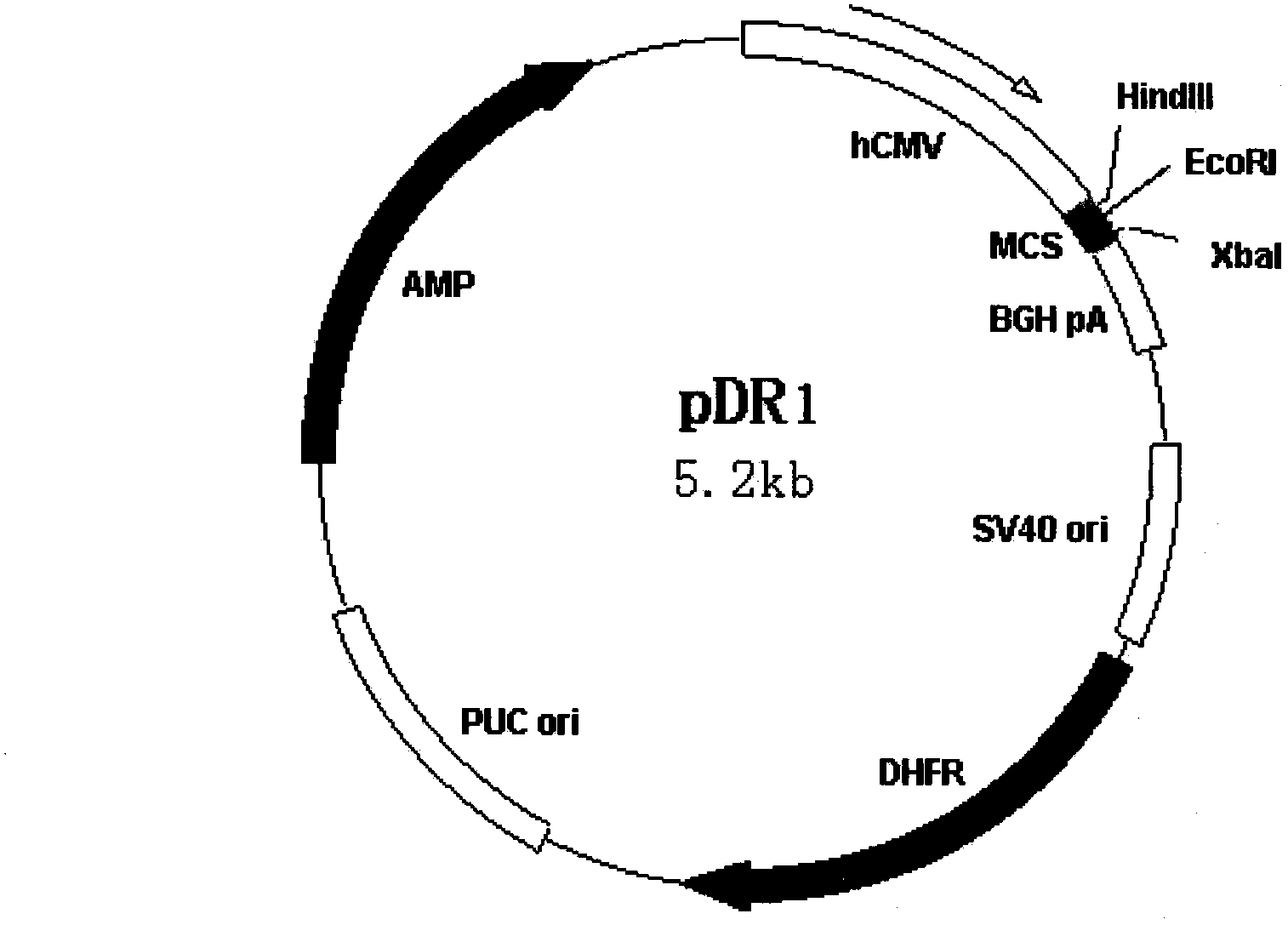

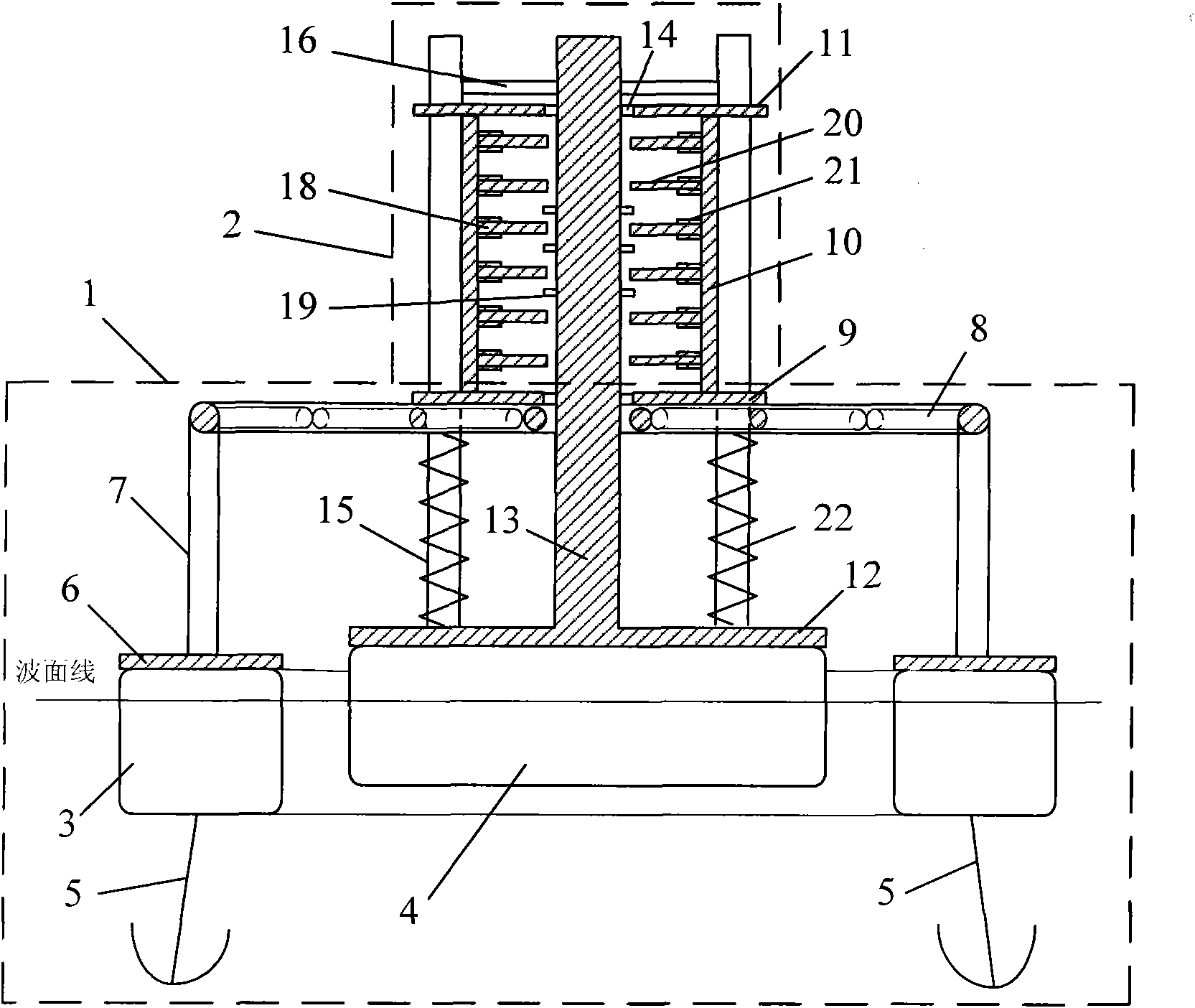

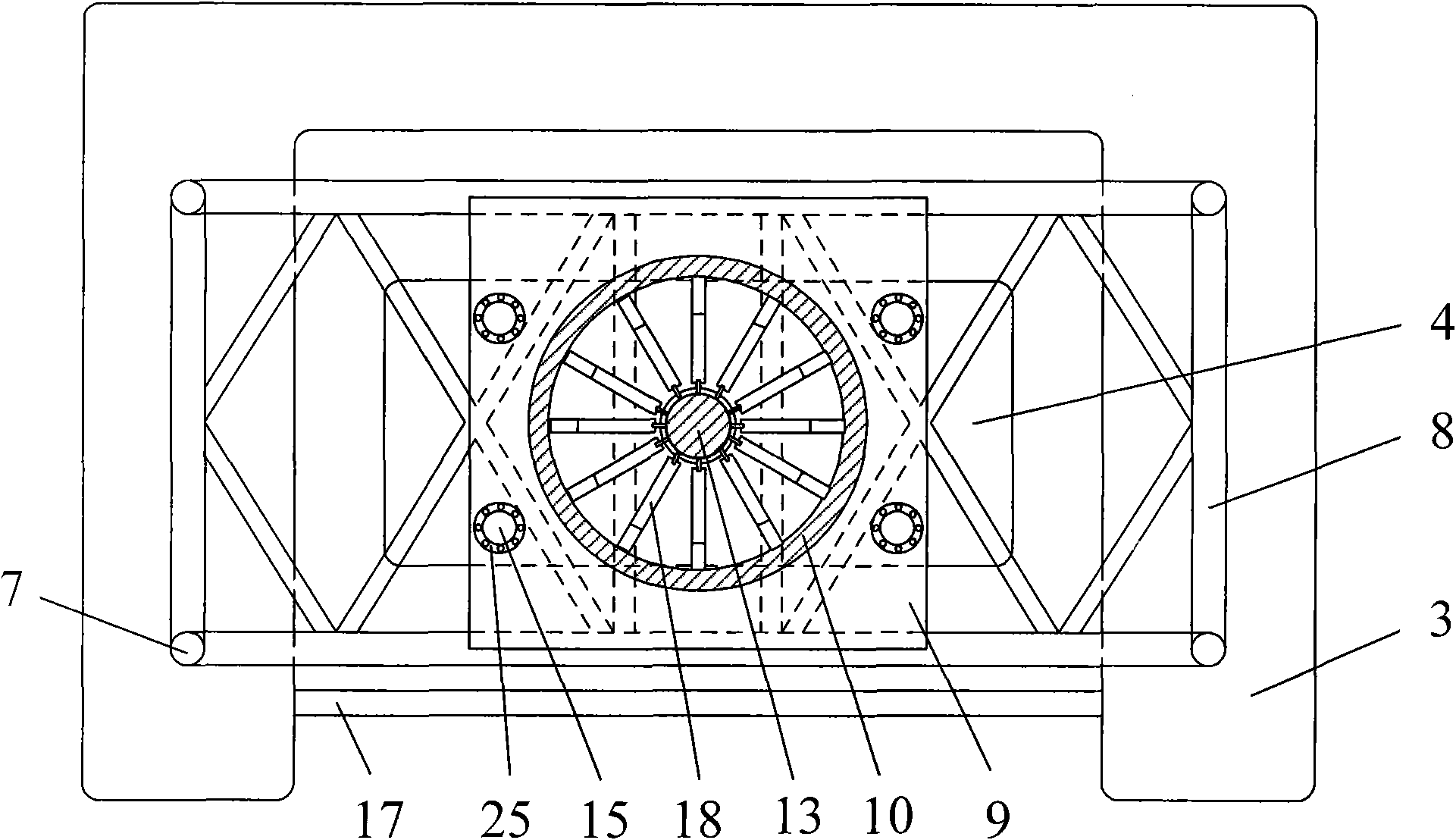

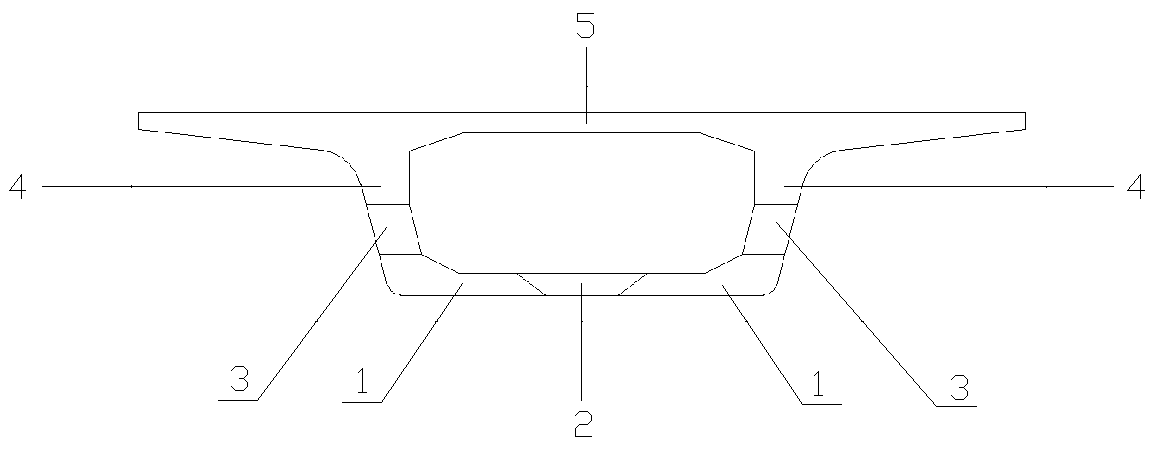

Wave power piezoelectric generating device

InactiveCN101814859AHigh outputReduce shockPiezoelectric/electrostriction/magnetostriction machinesElectricityDrive shaft

The invention relates to a wave power piezoelectric generating device which comprises a wave energy collector and more than one piezoelectric generating units, wherein the piezoelectric generating units are arranged on the wave energy collector; the wave energy collector comprises a U-shaped supporting floating body and a floating body, wherein the opening of the supporting floating body is connected through a rigid connecting rod; a supporting floating body framework is fixedly arranged on the supporting floating body, four support rods are fixedly arranged on the supporting floating body framework, and a generator soleplate, a generator round wall and a generator top plate are sequentially fixedly arranged at the tops of the four support rods through a generator frame; a floating body framework is arranged on the floating body, the floating body framework is rigidly connected with a driving shaft, and the driving shaft sequentially penetrates through the generator soleplate and the generator top plate; support posts sequentially penetrating through the generator soleplate and the generator top plate are fixedly arranged on the floating body framework, and the tops of the support posts are fixedly connected through connecting rods; and each piezoelectric generating unit comprises a plurality of piezoelectric vibrators and scribing sheets, wherein each piezoelectric vibrator comprises a middle layer and two piezoelectric sheets. The invention can realize sympathetic vibration under various incoming wave conditions and obtain higher wave energy conversion efficiency and output electrical energy.

Owner:TSINGHUA UNIV

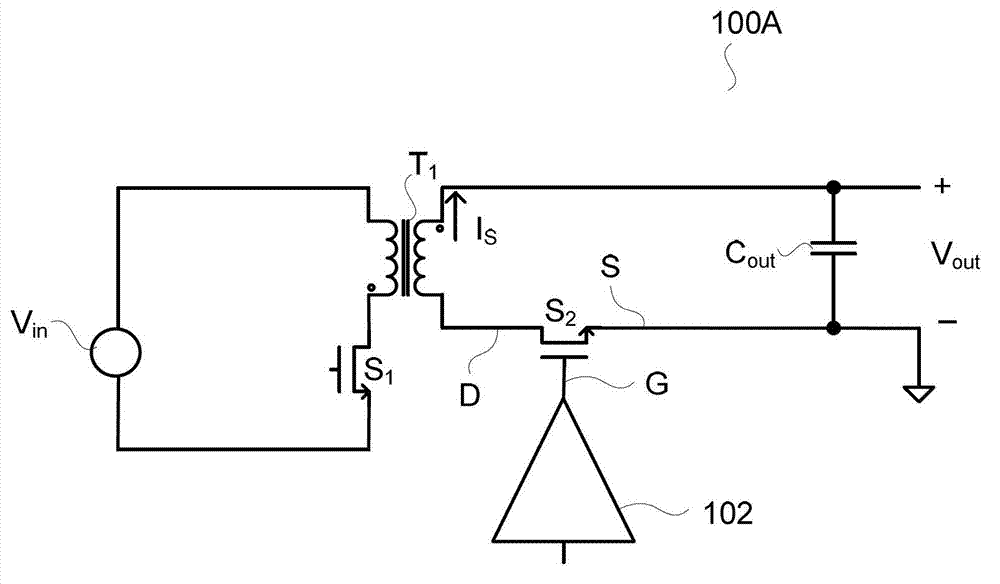

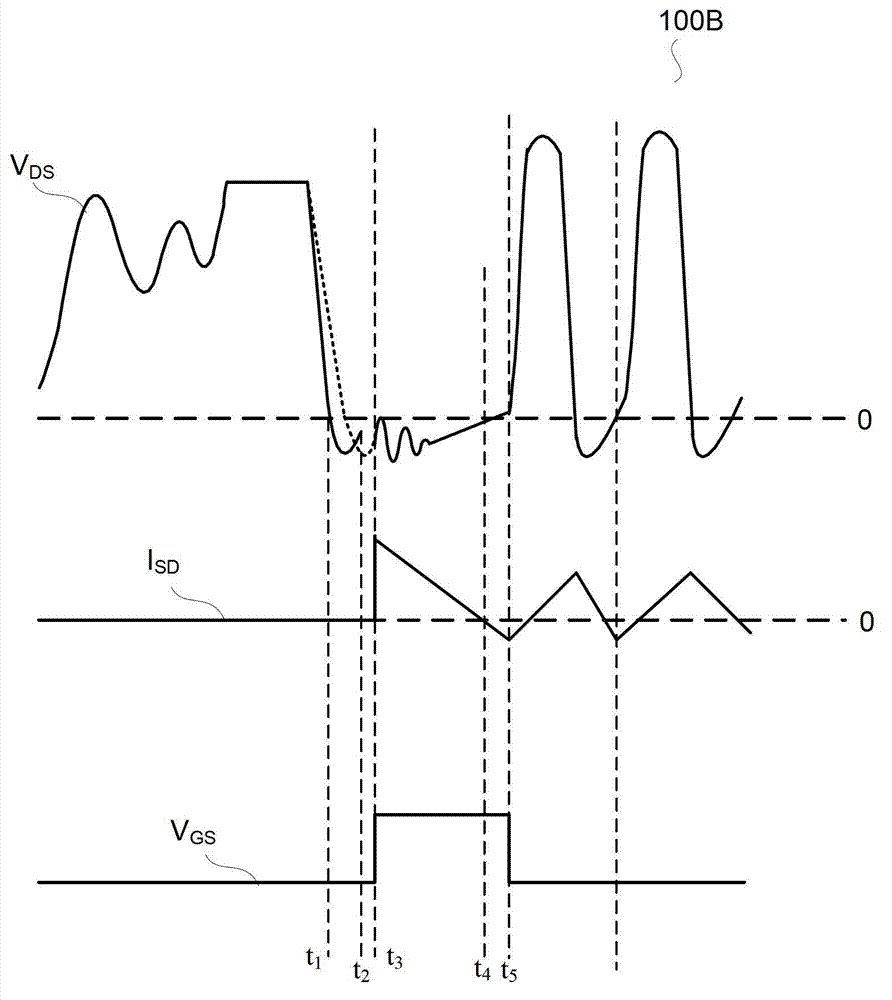

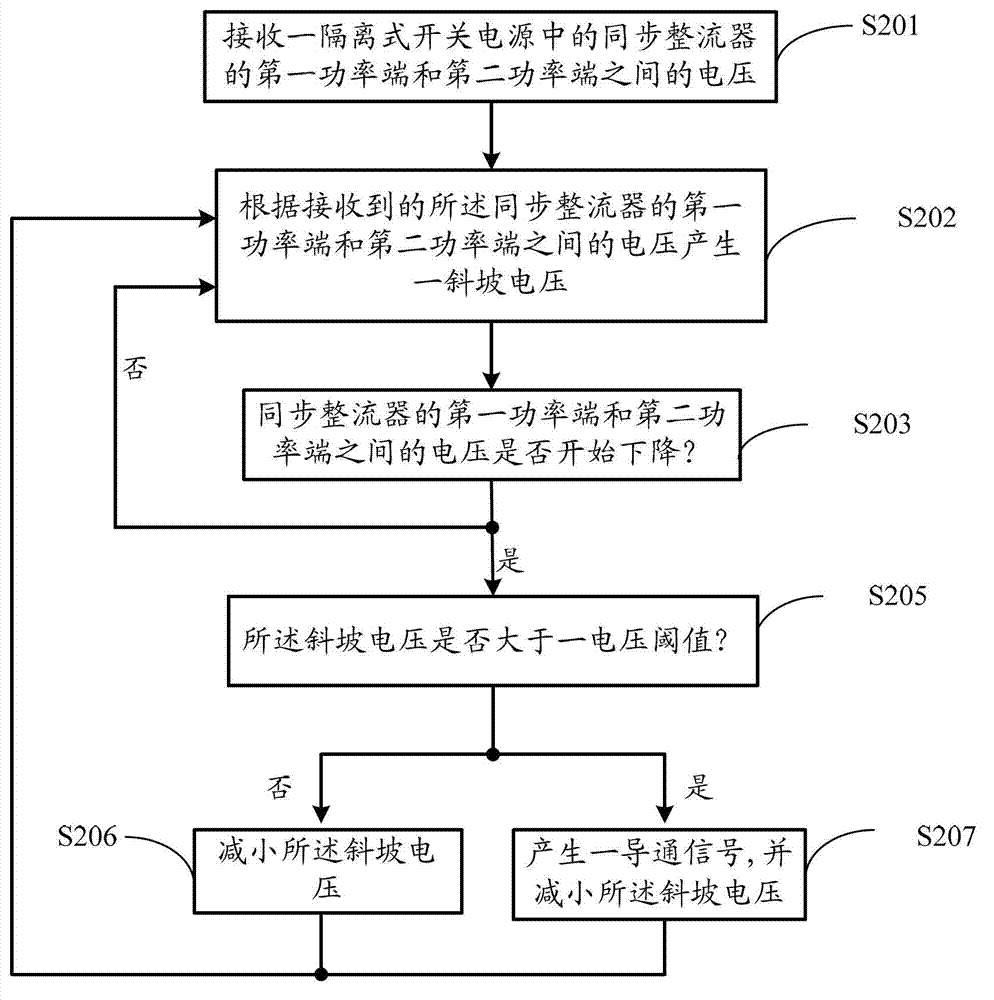

Synchronous rectifying control method and circuit

ActiveCN102882377AShorten the intervalReduce power lossEfficient power electronics conversionAc-dc conversionPeak valueEngineering

The invention discloses a synchronous rectifying control method and circuit for an isolated switching power supply. According to the synchronous rectifying control method in the embodiment of the invention, the switching-off moment of a main power device on the primary side is judged accurately according to the peak value of the ramp voltage between the first power end and the second power end of a synchronous rectifier, and the synchronous rectifier is started timely, thus the interval between the switch-off moment of the main power device and the switch-on moment of the synchronous rectifier is reduced as mush as possible, the power loss is reduced, and the highest work efficiency can be achieved.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

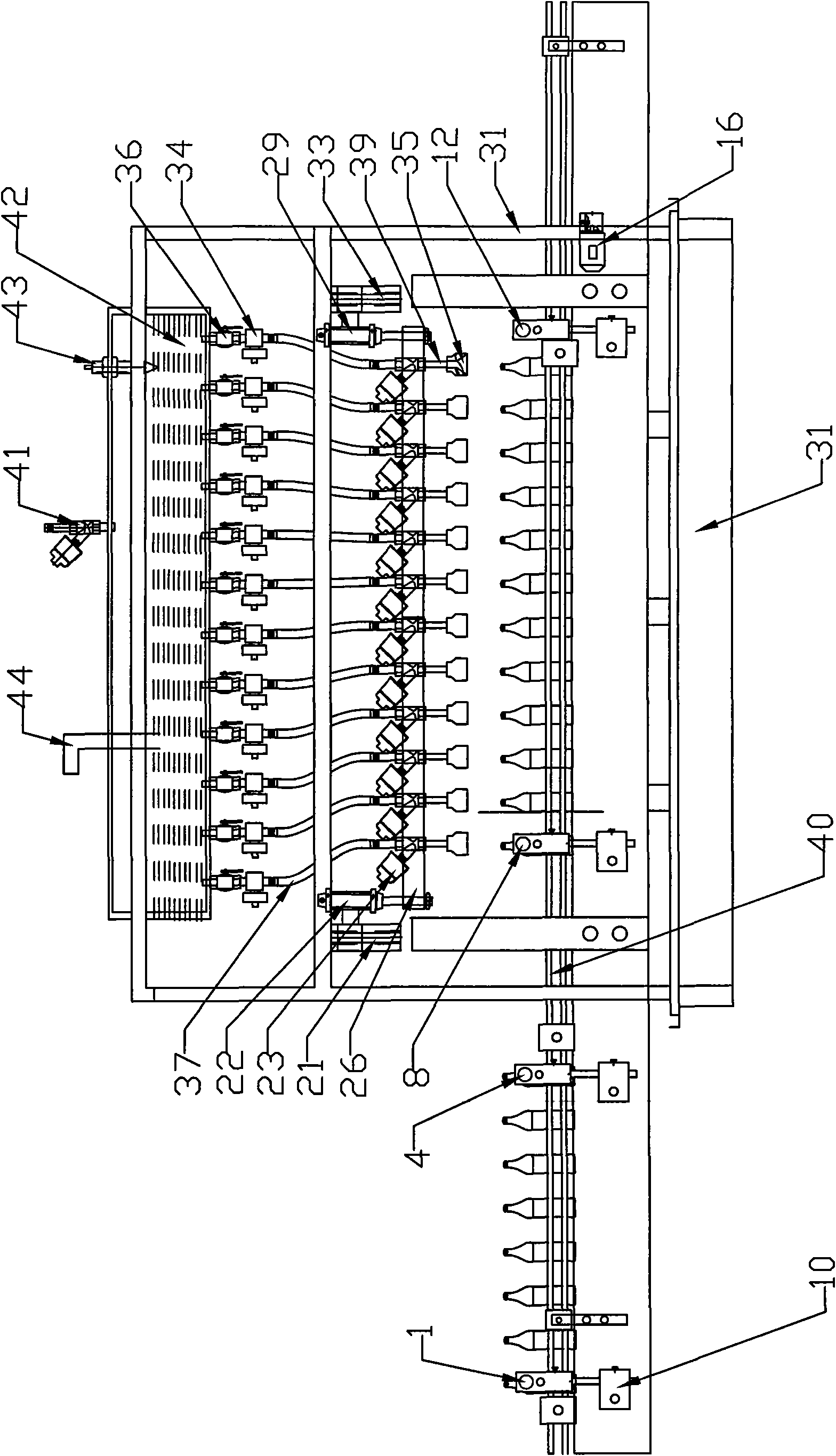

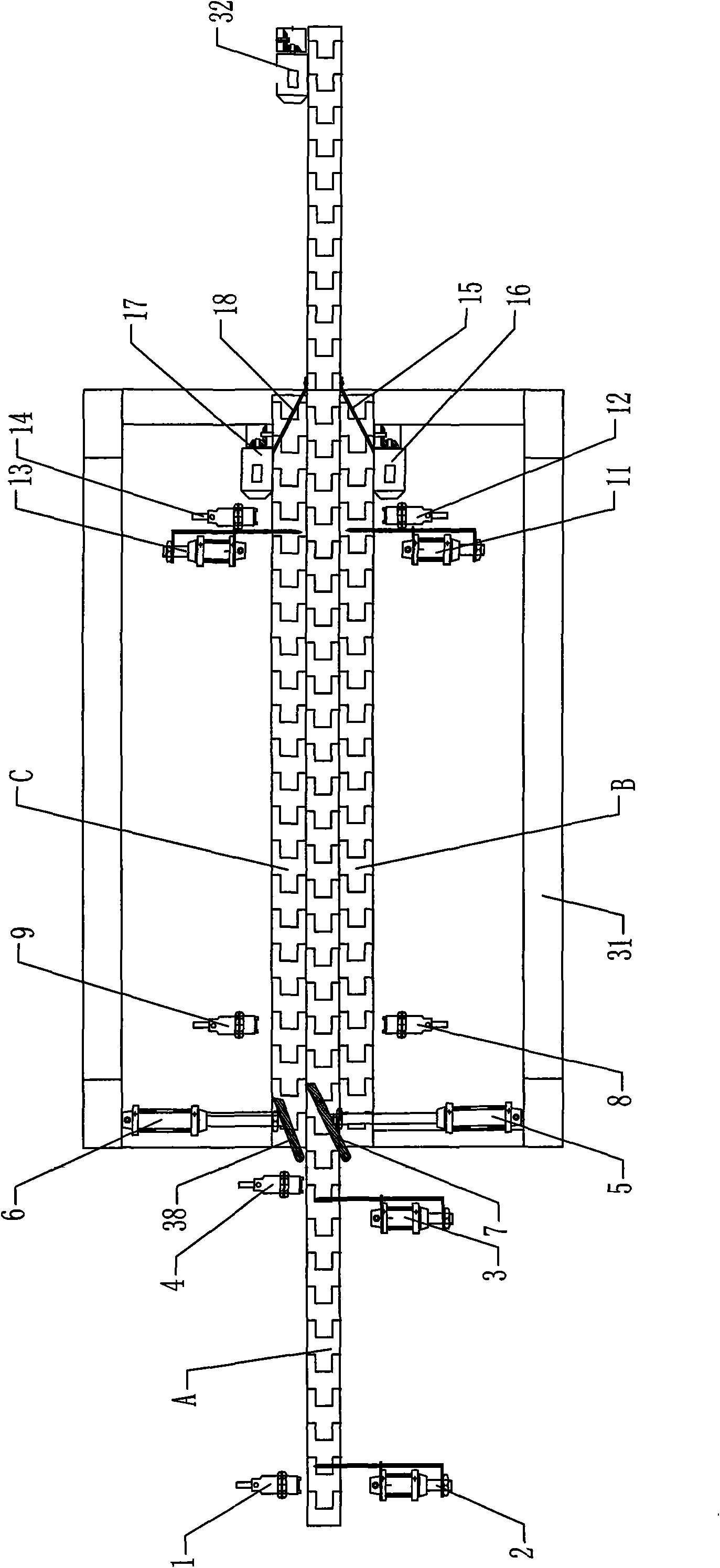

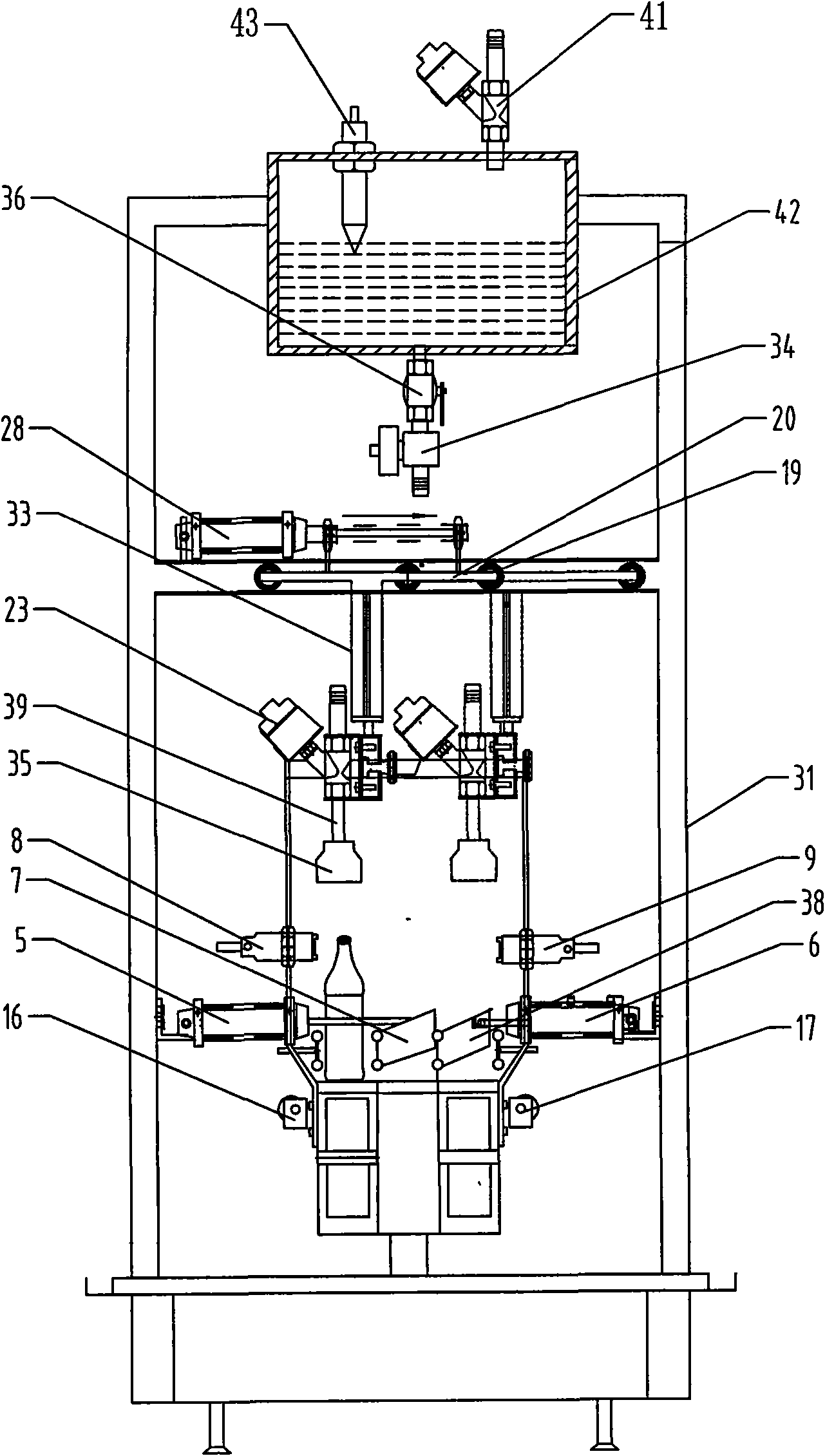

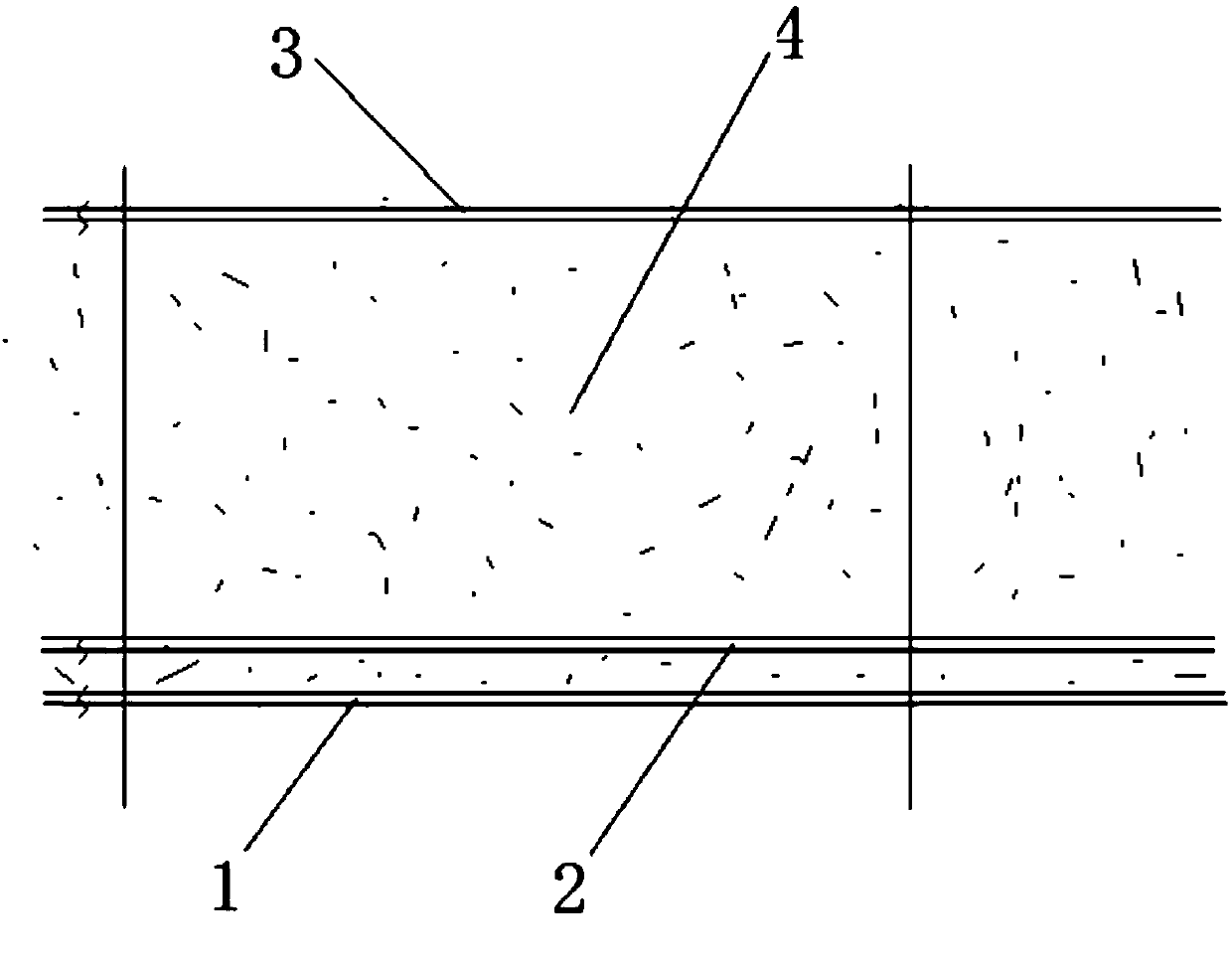

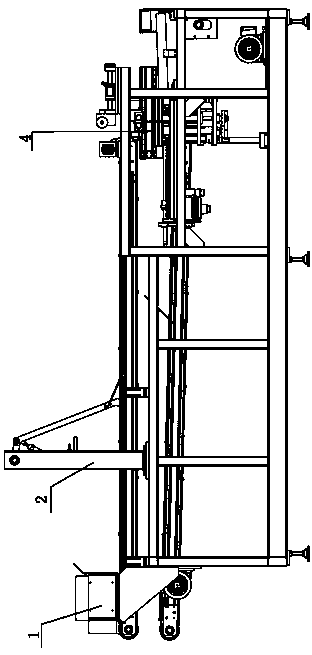

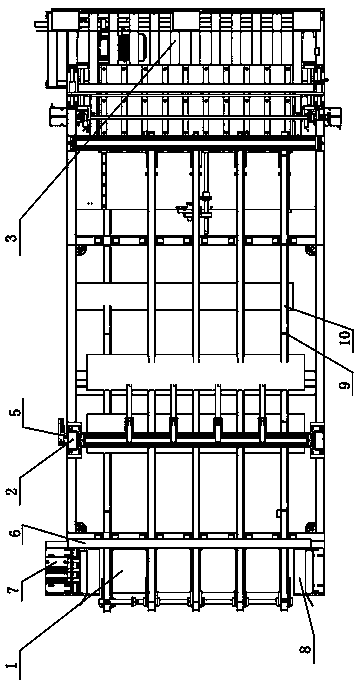

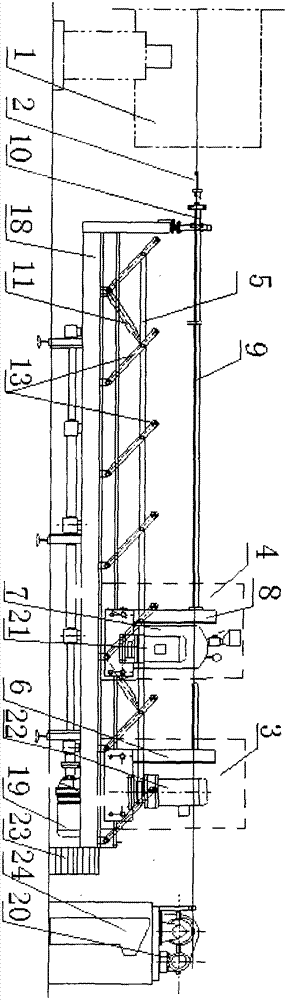

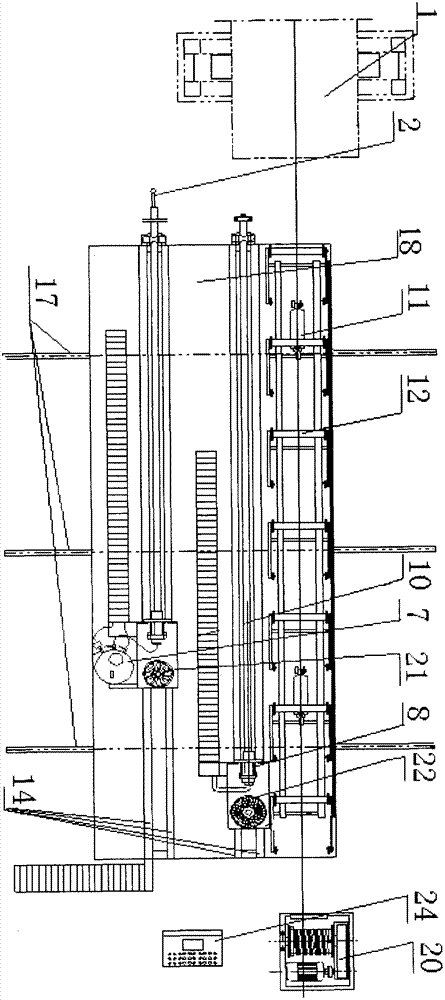

Three-row double-wire linear filling machine

InactiveCN101618845AShorten the intervalImprove filling efficiencyLiquid fillingAbnormal shapedEngineering

The invention discloses a three-row double-wire linear filling machine, comprising a frame. A bottle finishing and bottle conveying device and a liquid filling device are arranged on the frame, the bottle finishing and bottle conveying device comprises three rows of conveyer belts arranged in parallel, line exchanging devices are arranged between the three rows of conveyer belts, the bottle body can be continuously filled by carrying out line exchange on the bottle body, thereby overcoming the defect that the feeding of bottle needs to be waited when filling the bottle body by a traditional filling machine, shortening interval time between fed bottles and improving filling efficiency; the filling machine has the advantages of reasonable structure, high degree of automation, high precision, no drop leak, no discharge, simple capacity set, no bottle piling, strong applicability to abnormal shapes and high stability.

Owner:李真中

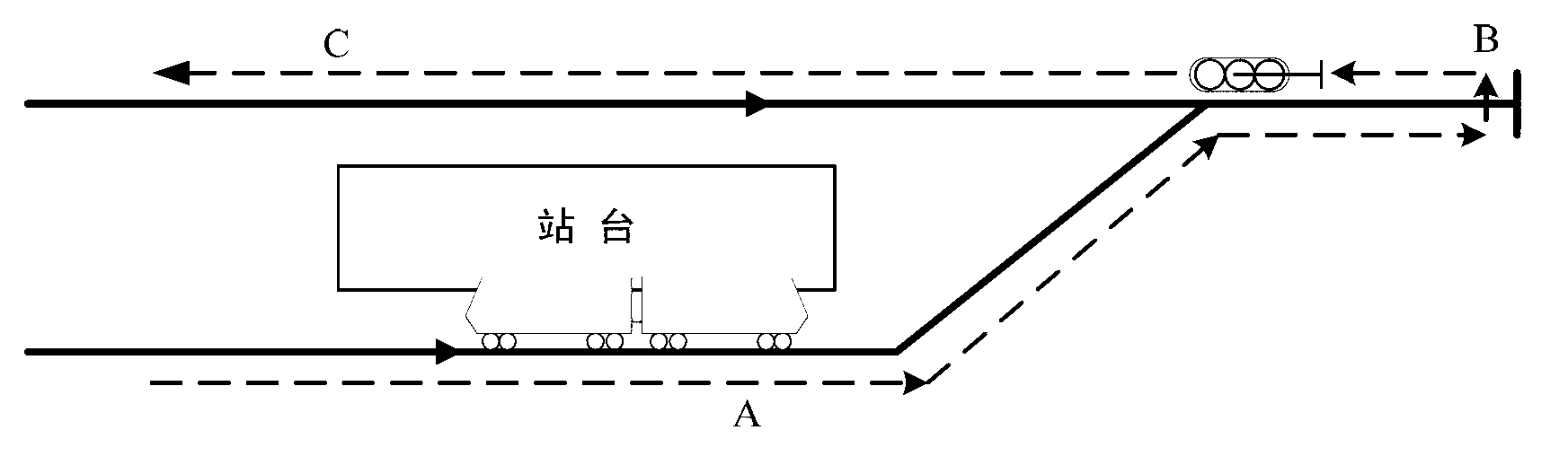

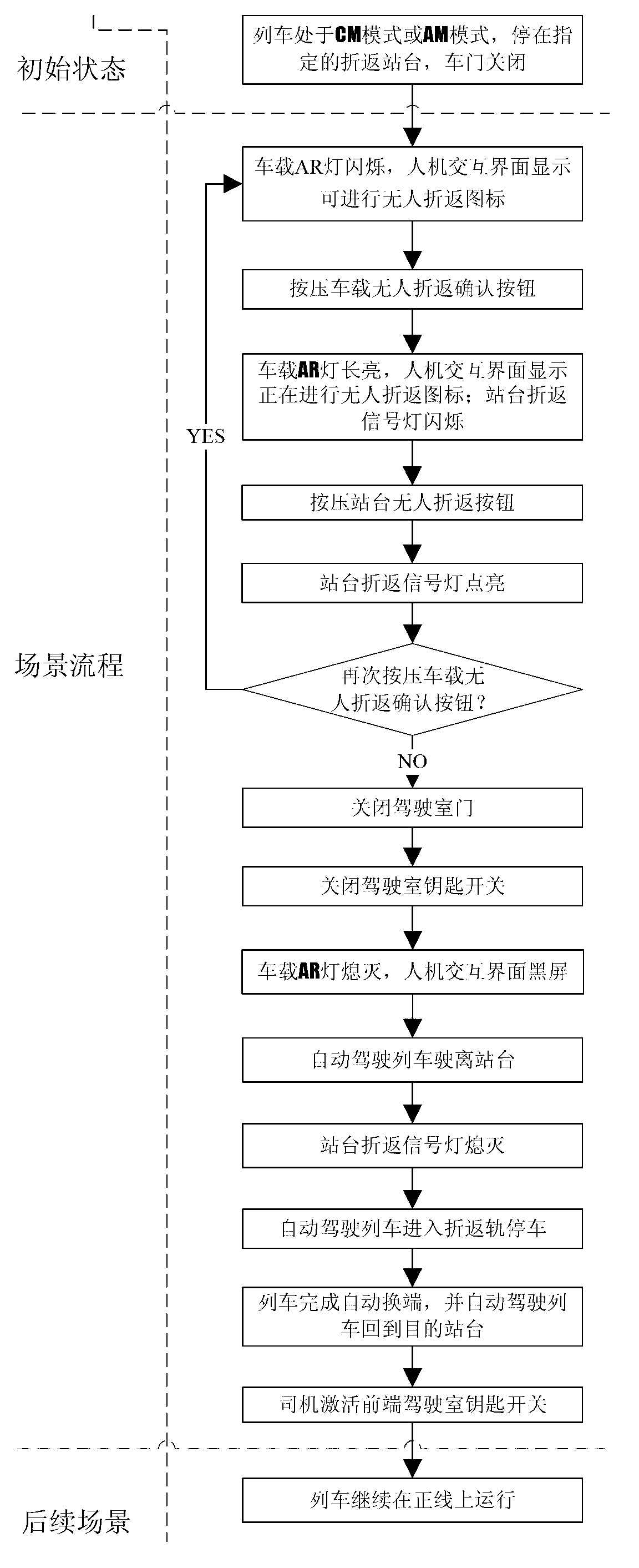

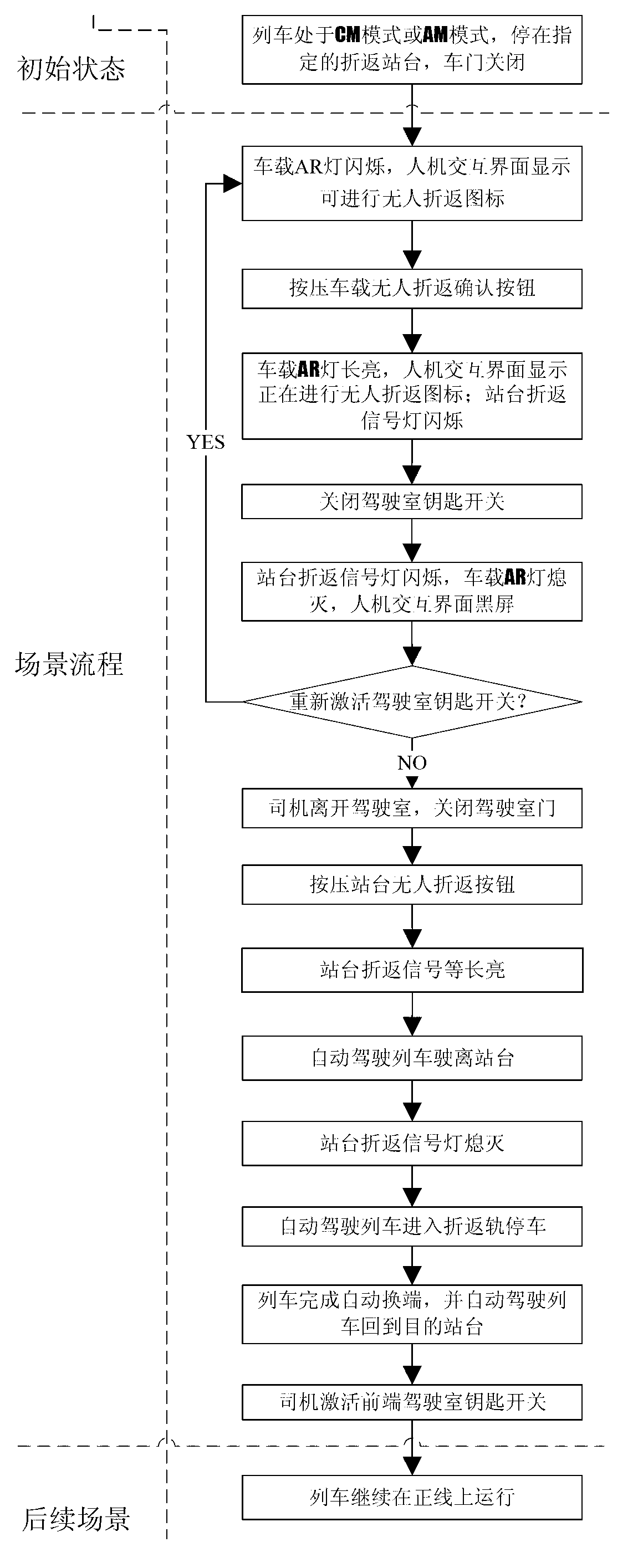

Train unmanned turning-back method based on CBTC (communication based train control) system

The invention relates to the technical field of the urban mass transit control, in particular to a train unmanned turning-back method based on a CBTC (communication based train control) system. According to the train unmanned turning-back method, an automatic driving subsystem of a train in the CBTC system is fully utilized in the train turning-back process, the turning-back process is completely controlled by equipment to be finished so as to realize the unmanned turning back of the train, the train dwell time in a turning-back area is greatly shortened, and the turning-back operation time is compressed so as to compress the train interval time and improve the line operation capability. Meanwhile, due to no artificial participation, the manpower cost is saved, and the workload of a driver is greatly reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

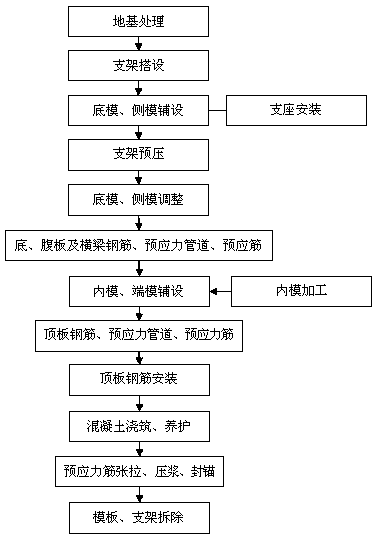

Cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction method

InactiveCN108951425AEliminates transverse cracking problemsShorten the construction periodBridge erection/assemblyPre stressProject management

The invention discloses a cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction method. The method includes the steps of foundation treatment, support erection, bottom mold and side mold laying, support pre-pressing, bottom mold and side mold adjustment, arrangement of bottom boards, webs and crossbeam reinforcing steel bars, prestressed pipelines and prestressed ribs, inner mold and end mold laying, arrangement of top board reinforcing steel bars, prestressed pipelines and prestressed ribs, top board reinforcing steel bar installation, concrete pouring and curing, prestressed rib tensioning, mud jacking and sealing anchorage, and formwork and support detachment. The problems of construction joints generated by a traditional construction processand transverse cracks of the jointing positions of flange plates and the webs can be solved, and the integral rigidity of a girder body is enhanced; the construction period of a continuous box girder is shortened, and the schedule of construction is quickened; and the use rate of a box girder formwork and steel pipe support transfer materials is increased, work efficiency is improved, treatmentof the construction joints is cancelled, erection and detachment work of supports in a box is reduced, working procedures are effectively switched, and expenditure of project management cost is reduced.

Owner:NINGBO CONSTR GRP

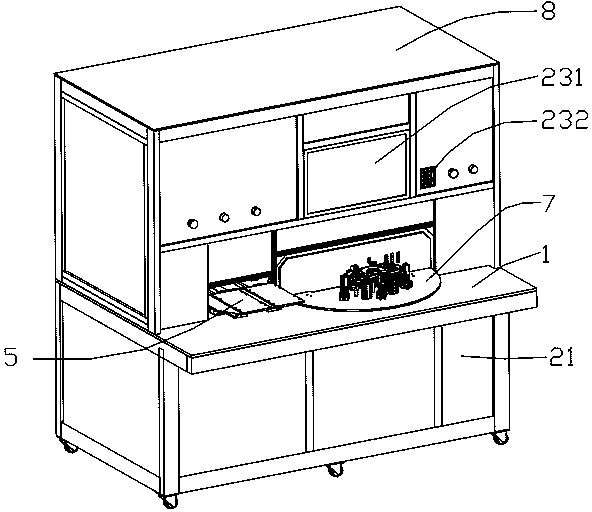

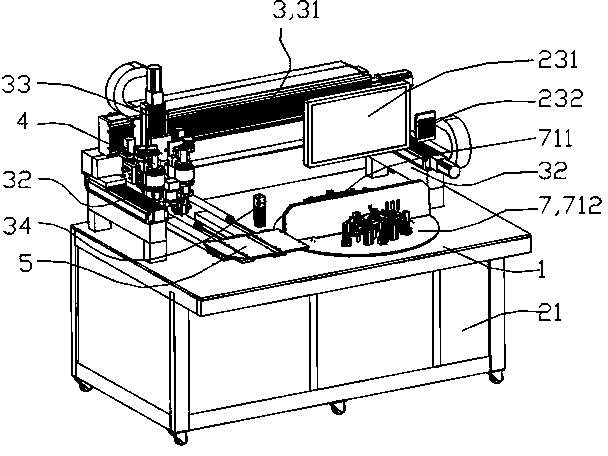

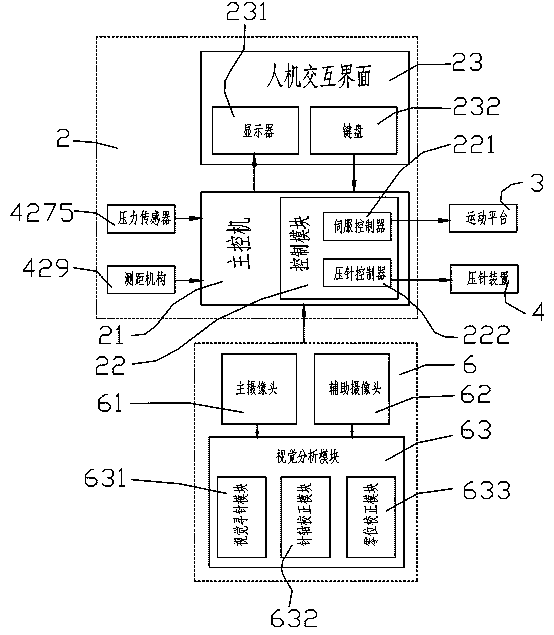

Automobile instrument automatic pointer pressing machine

ActiveCN104786034AHigh degree of automationImprove work efficiencyVehicle componentsMetal working apparatusMaterial supplyHead moving

The invention discloses an automobile instrument automatic pointer pressing machine which comprises a rack, a pointer pressing device arranged on the rack, a clamping device and a main controller, wherein the clamping device and the main controller are arranged on the rack. The machine further comprises a vision analyzing and positioning system and a material supply device arranged on the lower portion of the pointer pressing device; the pointer pressing device is arranged on the rack through a movement platform and comprises two pointer pressing machine heads moving in a staggered mode, and each pointer pressing machine head is provided with a picking and pressing mechanism; the clamping device comprises a rotary table on the rack, and the rotary table comprises an assembly station and a clamping station which can be rotationally switched; the vision analyzing and positioning system comprises a main camera on the pointer pressing device. By means of the two-station clamping device, pointer pressing time interval time can be effective shortened, the clamping device can be matched with the three-shaft moving pointer pressing device, automation of the pointer pressing is effectively improved, and pointer pressing production efficiency of an automobile instrument panel is improved.

Owner:NINGBO DAZHENG IND ROBOT TECH CORP

Mining area self-reserved roadway non-pillar mining method suitable for gently inclined coal seam

ActiveCN107725053AReduce excavation costsSave resourcesUnderground miningSurface miningCoal pillarStoping

The invention discloses a mining area self-reserved roadway non-pillar mining method suitable for a gently inclined coal seam. The method comprises the following steps of determining the exploitationrange for gob-side entry retaining without coal pillars in a coal mine, forming openings at main roadways, tunneling two mining area roadways and an air return roadway of a first-mining working face,and widening a crosscut to connect with a main air return roadway; connecting the three roadways and the crosscut, so as to form a preparation roadway and an air ventilation system of the mining area, which is the main feature of the method. The method is characterized in that the open-off cut is performed on a first working face, and various production systems are arranged; the stoping is performed on the first working face, and a gob-side entry retaining technique is used for remaining the roadway with a certain width as a transportation roadway of a second working face; the stoping is performed on the second working face, and the roadway with a certain width is remained as an air return roadway of a third working face; the steps are repeated for the subsequent working faces. The methodis used for realizing the stoping without roadway tunneling and coal pillars in the mining area.

Owner:SHANDONG UNIV OF SCI & TECH

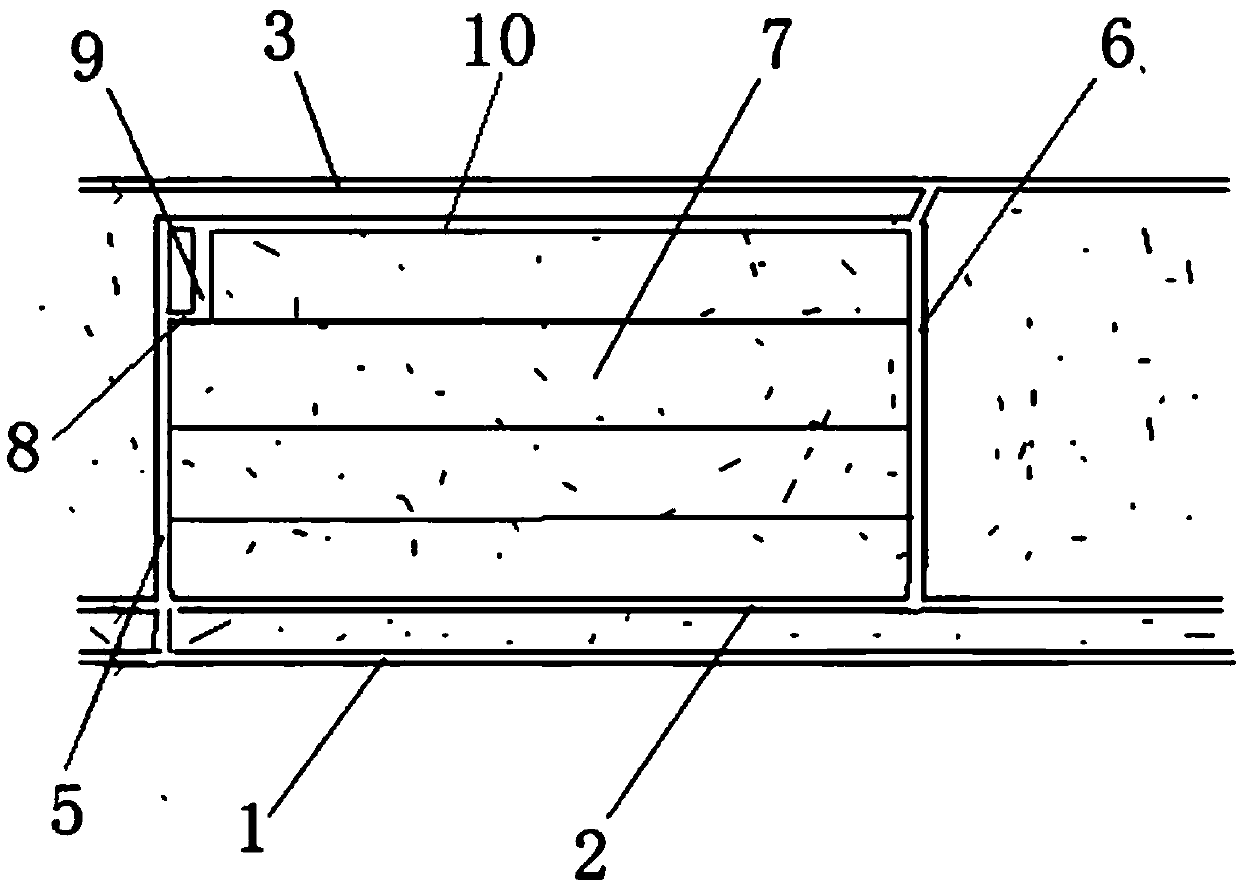

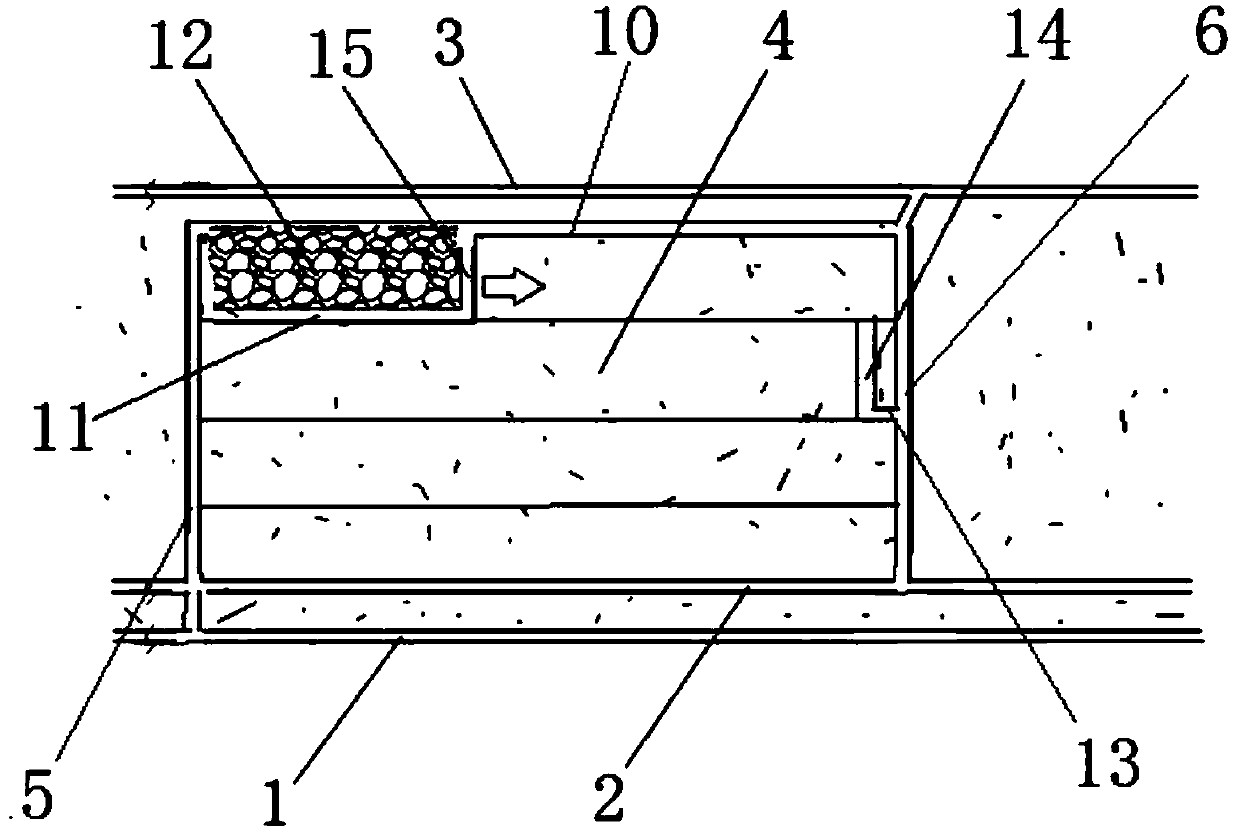

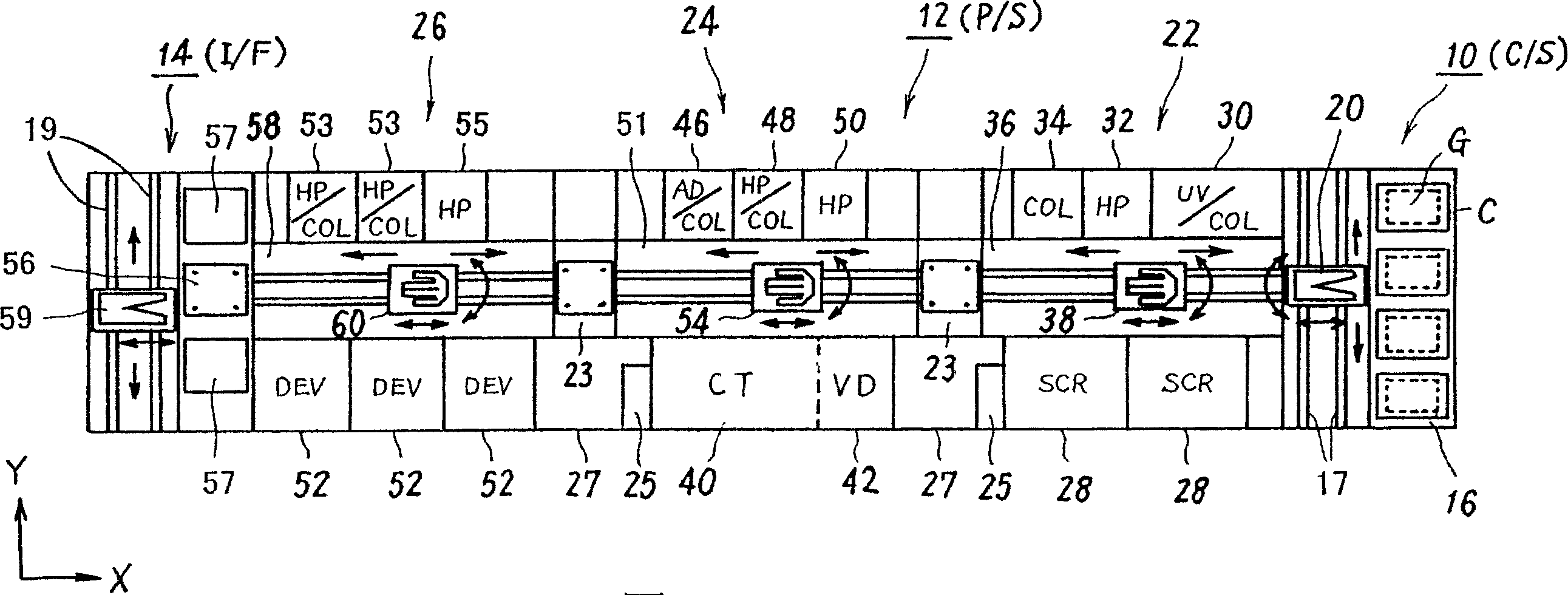

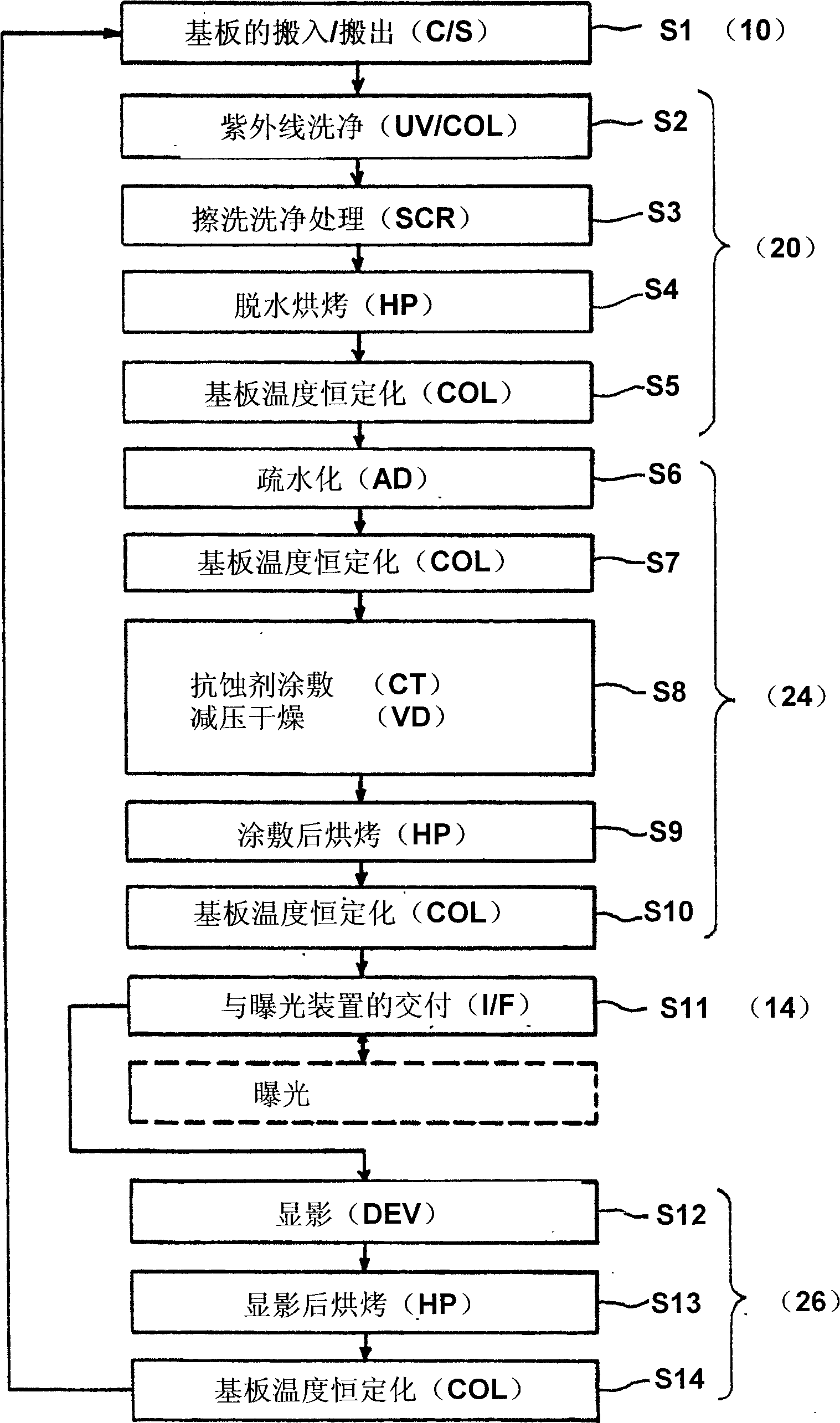

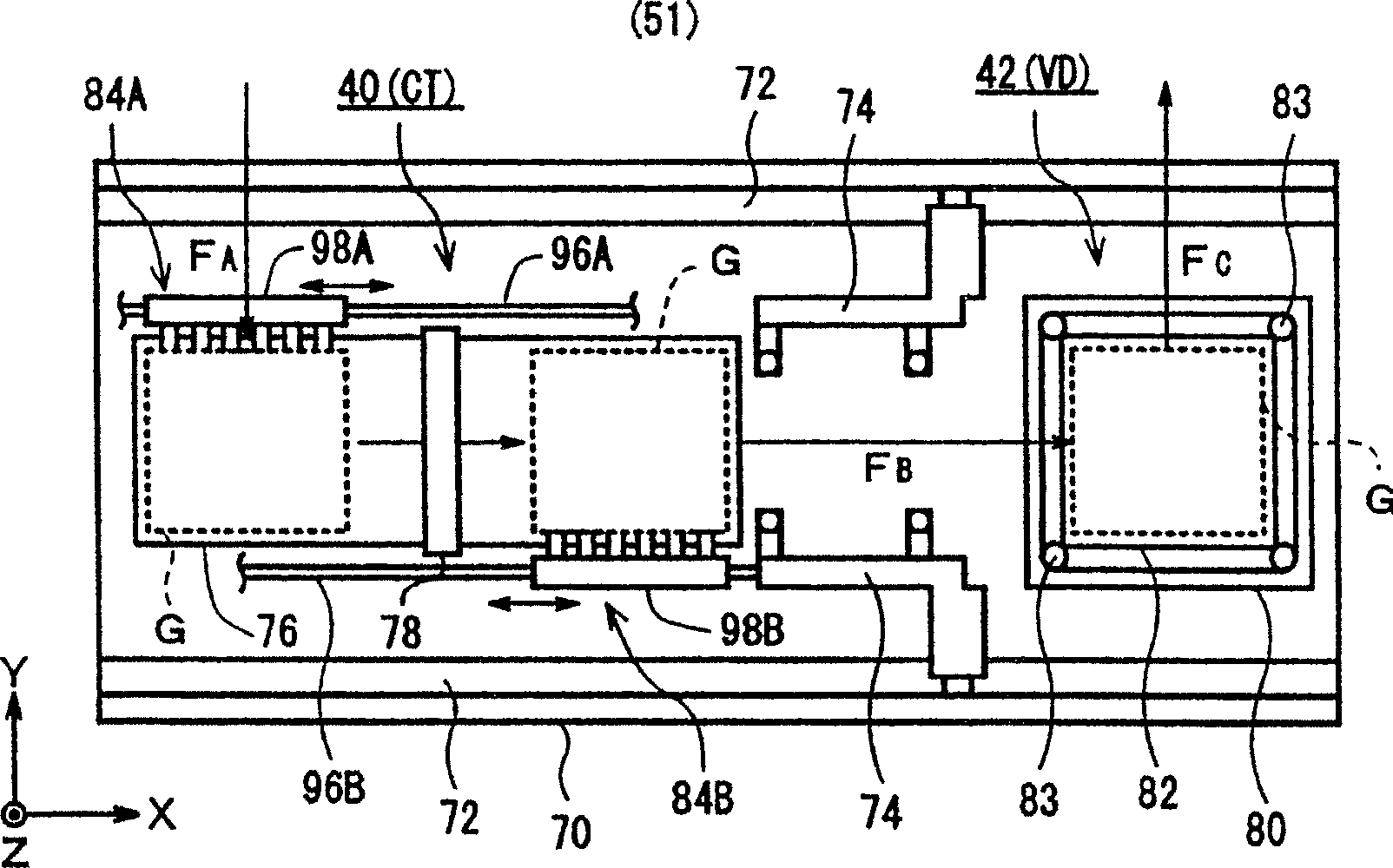

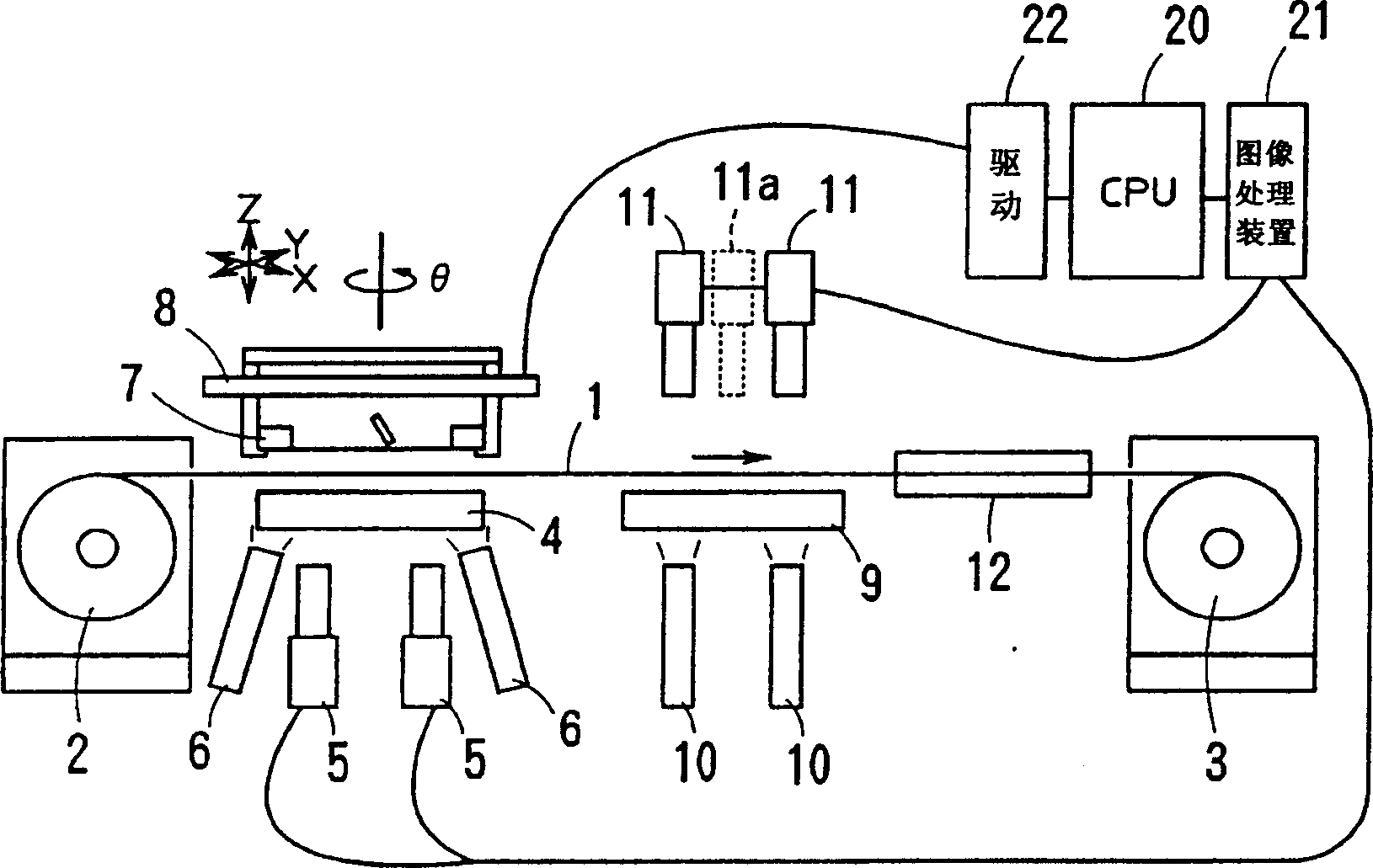

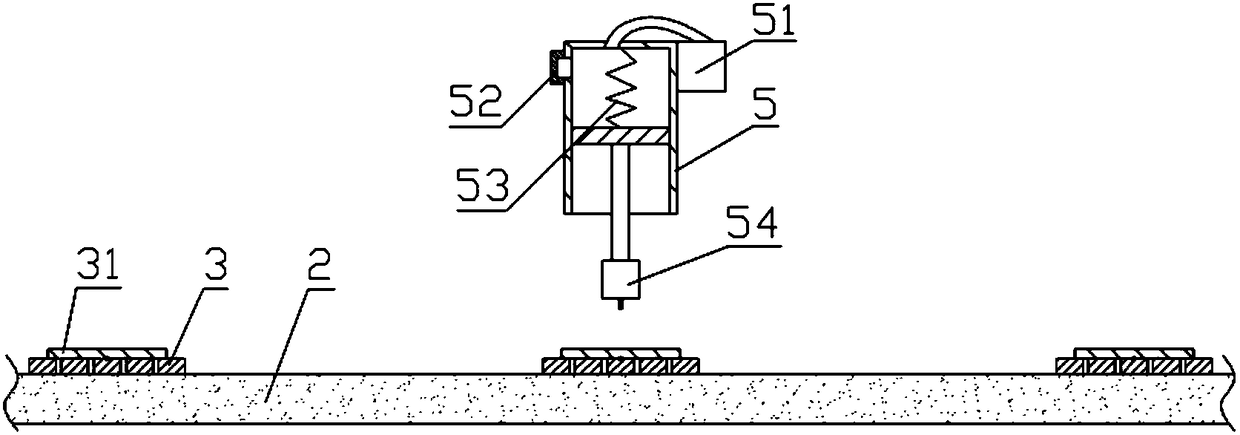

Substrate processing device, method and program

ActiveCN1828828AShorten the intervalLiquid surface applicatorsVibration massageMechanical engineeringCoating

This invention provides a base plate treating apparatus. The conveying parts (84A, 84B) of the first and the second base plate hold base plate (G) conveying interval, and the conveying interval refers to the interval from the coating starting position to the coating ending position instead of the total conveying interval from in-position to out-position. The first base plate conveying part (84A) conveys base plate (G [i]) to the coating ending position and returns to the in-position directly, then the base plate conveying part (84A) begins to convey the subsequent new base plate (G [i+1]). While the second base plate conveying parts (84B) conveys the base plate (G [i]) from the coating ending position to the out-position by itself, then the conveying parts (84B) returns to the coating starting position and waits for the arrival of next base plate (G [i+1]) conveyed by the first base plate conveying part (84A) itself. This invention can greatly shorten the intermittent time of supplying treatment fluid to the dealing base plate without rotation mode.

Owner:TOKYO ELECTRON LTD

Teak low-chipper sprout-promotion rapid-propagation seed-growing method

ActiveCN102696302AFast germinationImprove uniformitySeed and root treatmentClimate change adaptationField conditionsGreenhouse

The invention discloses a teak low-chipper sprout-promotion rapid-propagation seed-growing method. Seeds are soaked by lime water and gibberellin and then sowed, then seedlings are transplanted into a first nutrition substance container to cultivate mother seedlings to a stage when leaves are mutually overlapped, then the seedlings are graded and arranged according to certain planting space, when ground diameter of the mother seedlings is 0.4-0.8cm, the mother seedlings are planted into a plastic pot with a bottom support to be bred, wherein the mother seedlings are not separated from container cups, and second nutrition substance is arranged in the plastic pot. After 10-15 days, the mother seedlings are cut at a position where base parts of the mother seedling are close to the ground to promote sprouting, collecting cuttings and arranging the cuttings in a container cup provided with third nutrition substances in cottage mode, growing seedlings on an elevated seedling bed in a plastic greenhouse, controlling air temperature and relative humidity of a cottage bed by utilizing a greenhouse temperature and moisture adjuster, and thus obtaining teak container cottage seedlings. By means of the teak low-chipper sprout-promotion rapid-propagation seed-growing method, cottage branches are short, interval time of cutting collection is shortened, breeding efficiency is improved, field condition requirements of nursery gardens are not strict, management is convenient, cutting quality is easy to control, cottage survive rate is high, and economic benefit is good.

Owner:GUANGXI FORESTRY RES INST

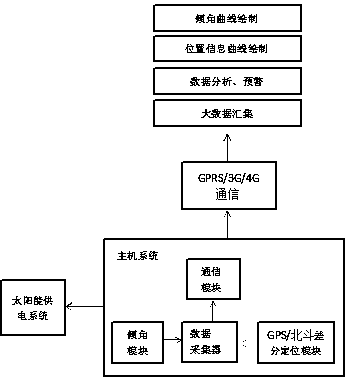

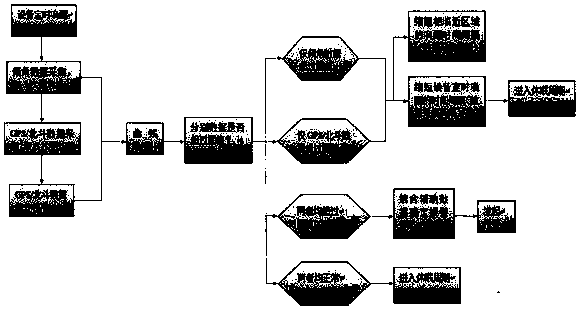

Landslide monitoring method and monitoring system applying same

InactiveCN107808498AEliminate fixed errorsHigh precisionTransmission systemsAlarmsTroposphereTime delays

The invention discloses a landslide monitoring method and a monitoring system applying the same. A mountain body movement state is monitored in a mode of creatively combining a tilt sensor and GPS / Beidou differential positioning, and accurate original data is provided for landslide judgment and early warning. The GPS / Beidou-based differential positioning method is applied to monitoring landslide mass, position data of a plurality of monitoring points of a mountain body is monitored, fixed errors of satellite clock, satellite ephemeris, ionized layer time delay and troposphere time delay and the like are eliminated, and the GPS / Beidou positional accuracy is greatly improved.

Owner:SICHUAN HUIYUAN OPTICAL COMM CO LTD

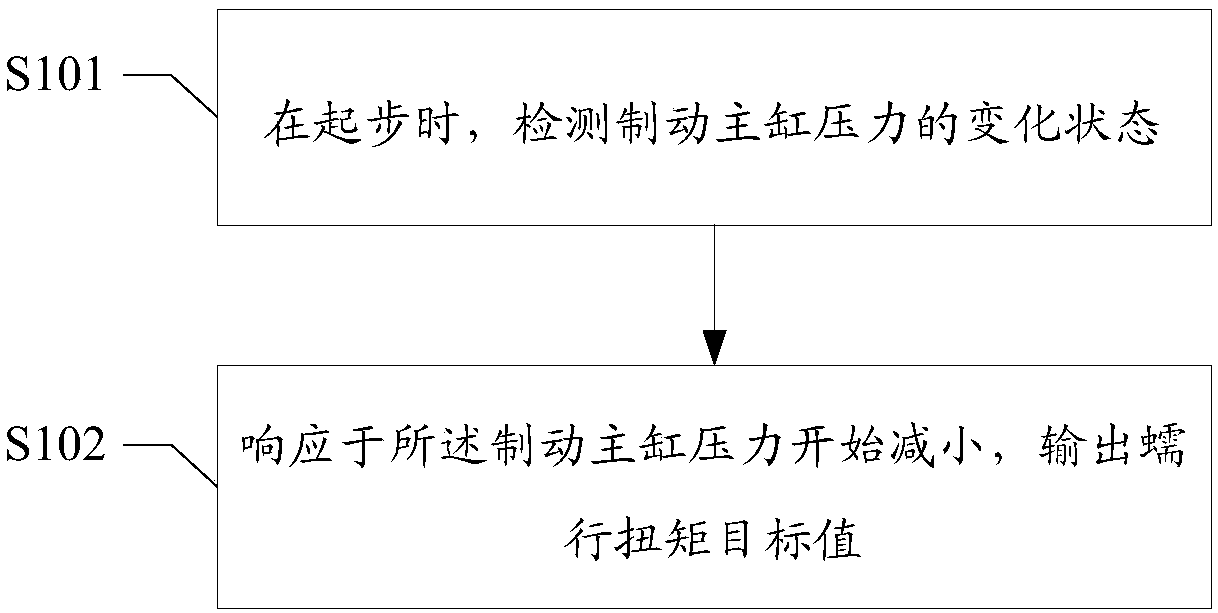

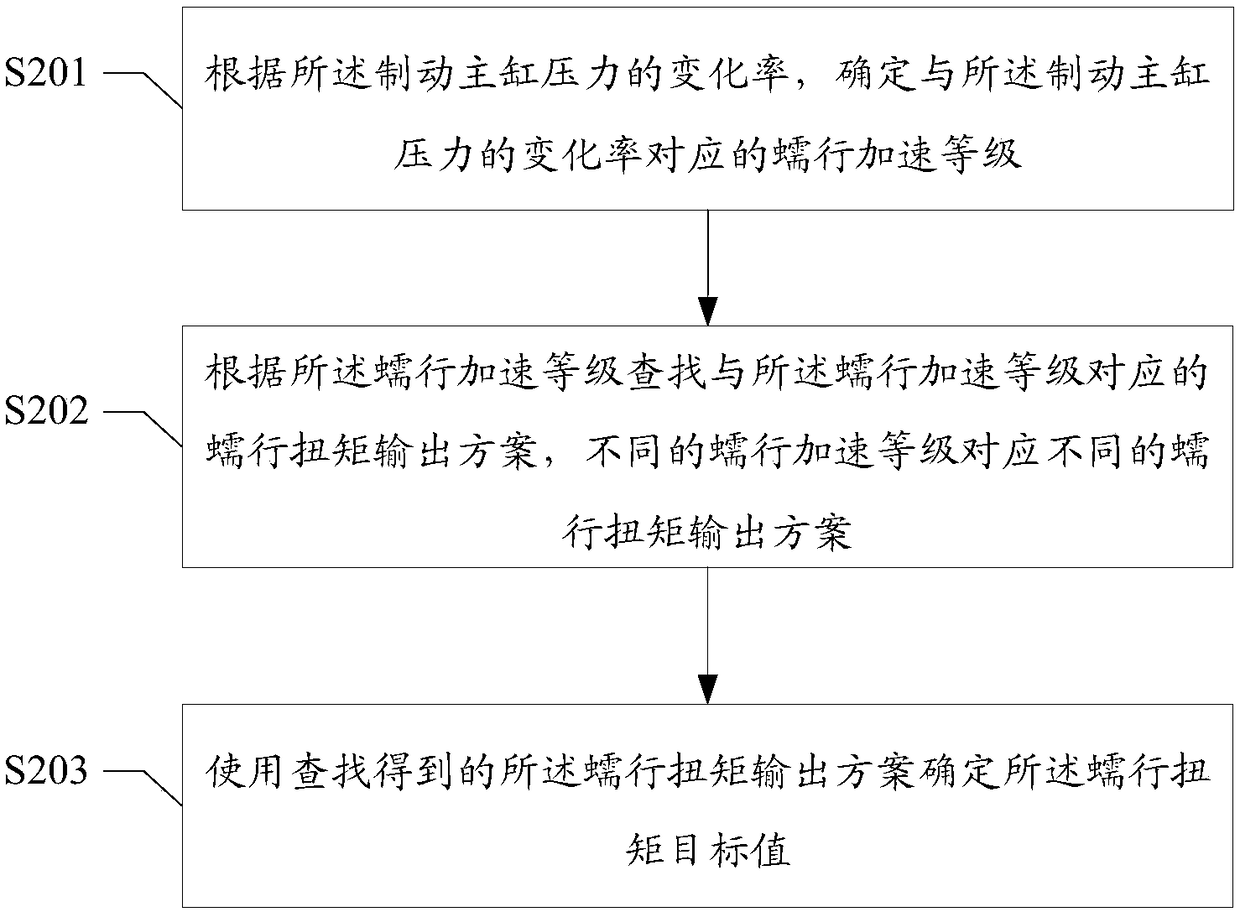

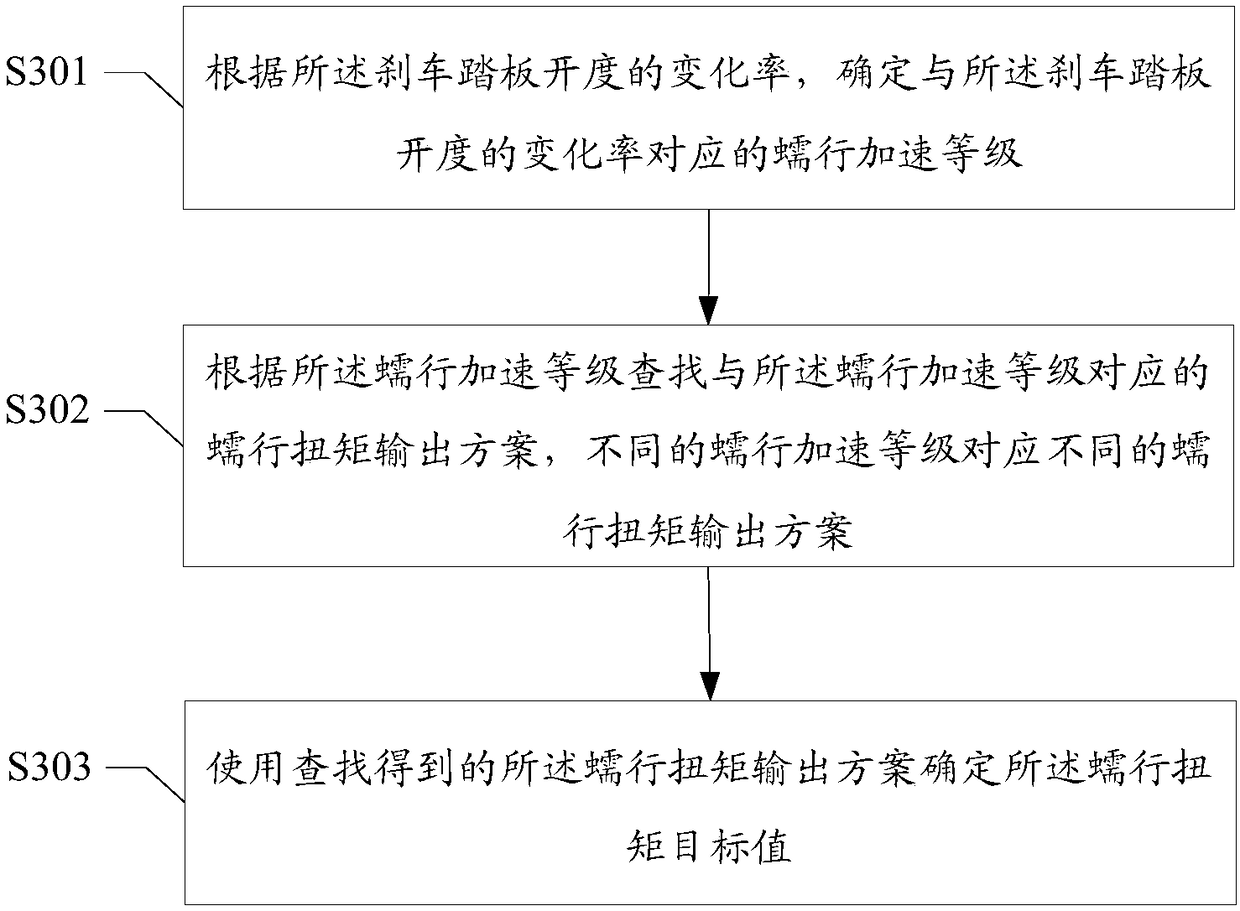

Crawling torque output control method and device, and automobile

ActiveCN108128210AReduce adverse effectsShorten the intervalSpeed controllerDriver interactionsMaster cylinderControl theory

The invention provides a crawling torque output control method and device, and an automobile. The method comprises the following steps of during starting, detecting the change state of braking main cylinder pressure; responding to the condition that the braking main cylinder pressure starts to decrease, outputting a crawling torque target value. By using the scheme, when the automobile starts, theinterval time from the crawling operation started by a driver to the crawling torque outputted by a motor can be shortened, so that the crawling torque response speed can be accelerated.

Owner:SAIC MOTOR

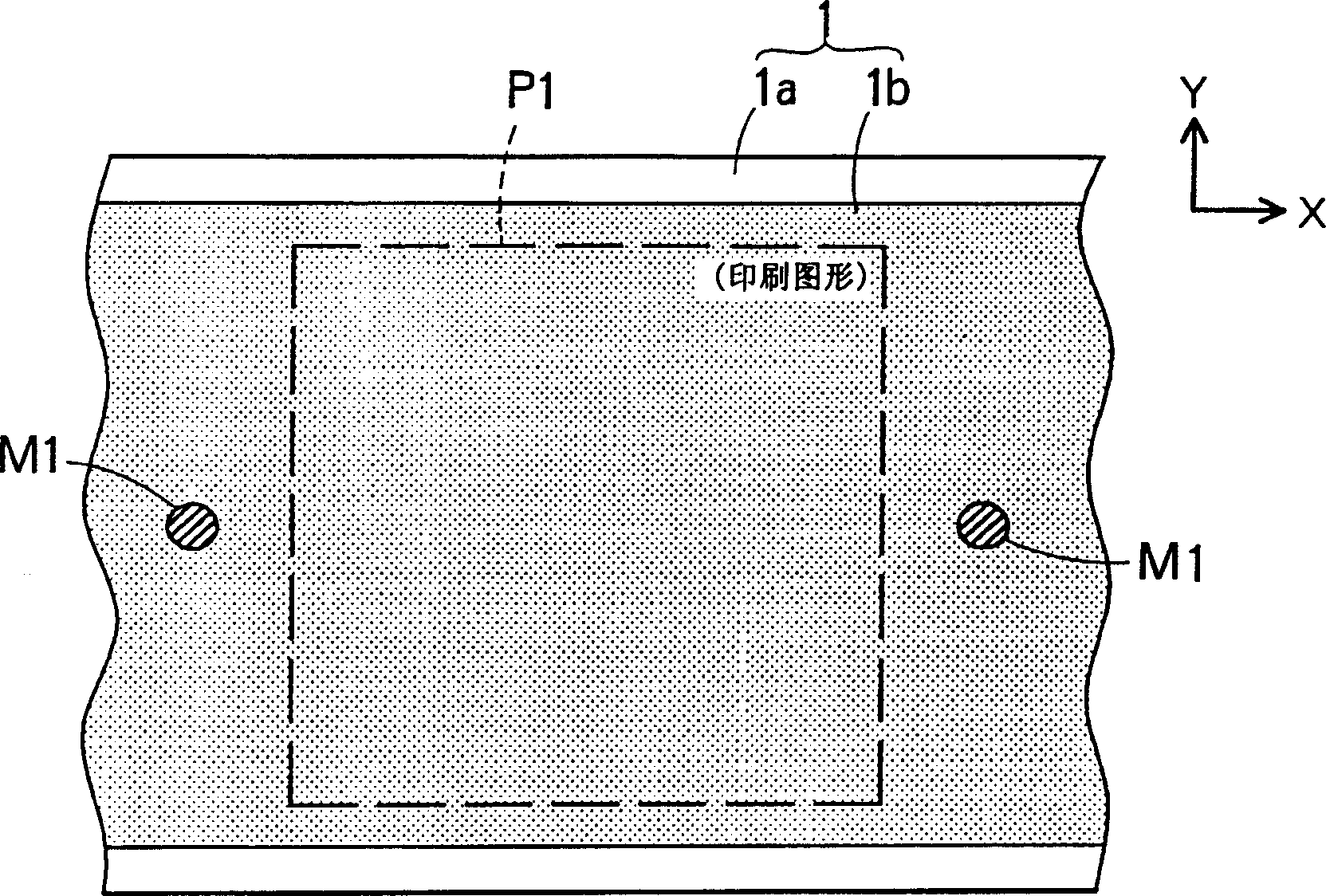

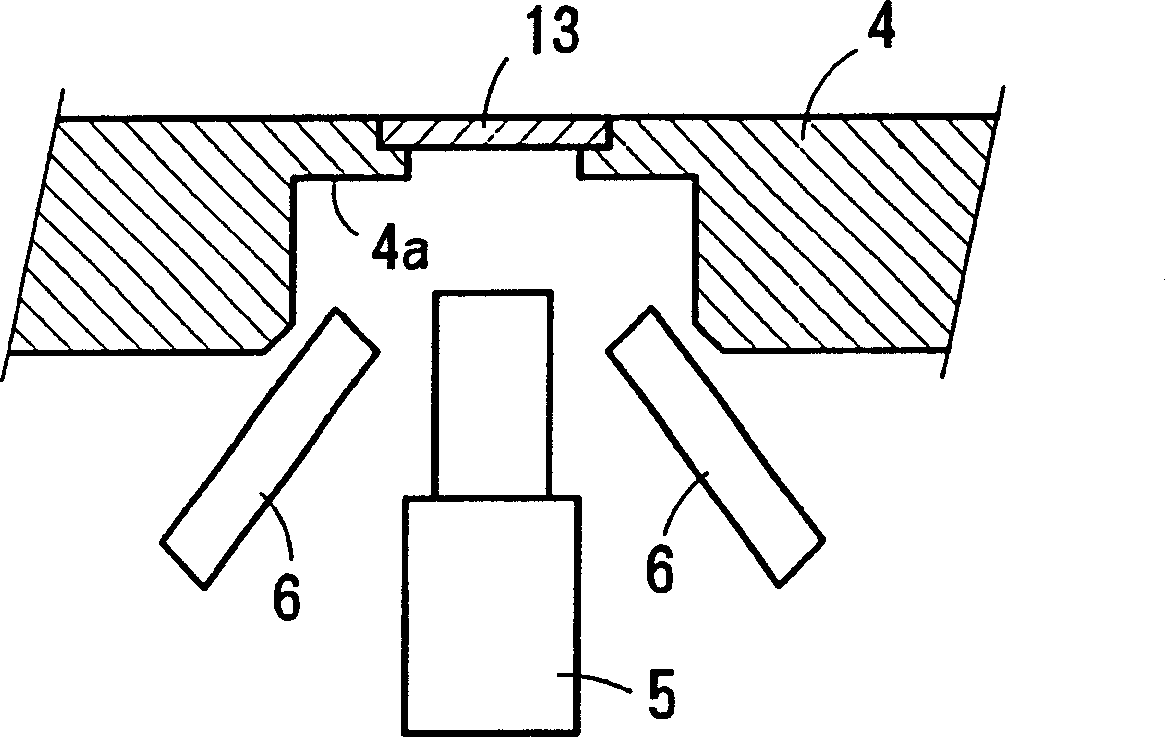

Printing method and printing device for non-individual body sheet

InactiveCN1429707AEliminate printing offsetShorten the intervalScreen printersConductive pattern formationImaging processingFeedback control

The invention provides a method for printing a continuous body sheet by which the position of the sheet can be registered highly precisely without applying an excess tensile stress to the sheet, and a printer. This method comprises a step to prepare a printing plate arranged above a printing stage, a step to retain the continuous body sheet on the printing stage by suction, a step to screen-print a specified pattern on the suction-retained continuous body sheet by the printing plate and at the same time, screen-print a position discerning mark of the printing plate on the sheet, a step to convey the sheet to a feedback stage from the printing stage and retain the sheet by suction, a step to seek a deviation level between each of the position registering marks of the sheet retained on the feedback stage by suction and each of the printed position discerning marks of the printing plate by image processing and a step to control the positions of the printing plate in a feedback mode according to the sought deviation level.

Owner:MURATA MFG CO LTD

Aphrodisiac supplementary-feeding compound feed for sow after weaning

InactiveCN102640860AShorten the intervalHeat as soon as possibleFood processingAnimal feeding stuffVitaminFodder

The invention relates to an aphrodisiac supplementary-feeding compound feed for sows after weaning, which is mainly prepared by mixing and crushing the following components: 20-40% of wheat bran, 25-35% of corn, 5-15% of corn bran, 5-15% of corn DDGS, 0-15% of glucose, 3-9% of soybean meal, 1-2% of stone flour, 1-2% of calcium hydrophosphate, 0-0.5% of corn oil, 0.1-0.5% of table salt, 0.1-0.3% of amino acids, 0.2-0.65 of composite trace elements, 0.3-0.4% of composite vitamins, and the particle size is less than 1 mm. The invention is used for feeding of sows after weaning, can effectively shorten the number of days from weaning to oestrum for sows, increase the feed intake of weaning sows, and promote sow oestrus. The invention has important significance on the improvement of sow production efficiency.

Owner:LIAONING WELLHOPE AGRI TECH

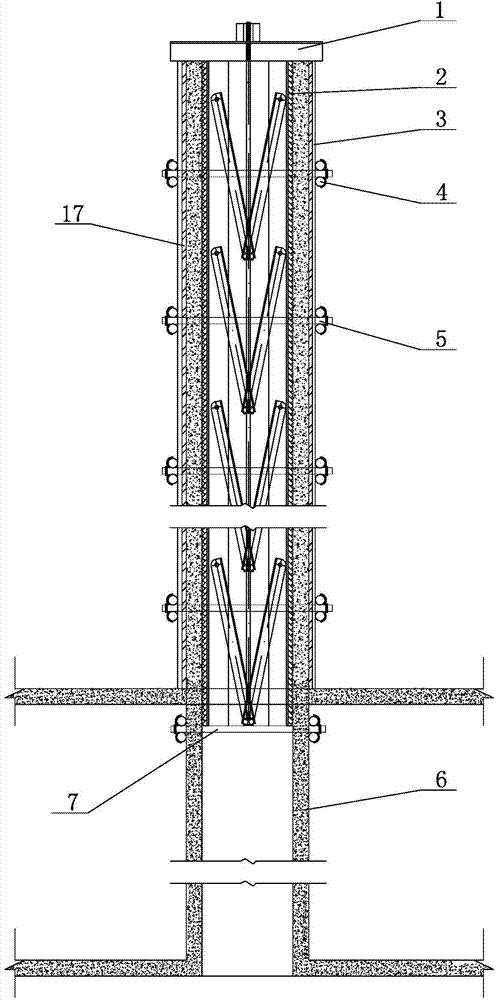

Construction technology for pouring concrete of walls on two sides of deformation joint

The invention belongs to the field of constructional engineering and particularly relates to a construction technology for pouring concrete of walls on two sides of a deformation joint. The construction technology comprises the following steps of 1 performing steel bar framework construction; 2 installing a wall board thickness control support; 3 performing positioning and paying-off; 4 installing a bottom-layer interior wall template and a scissors type connecting rod keel supporting system; 5 installing a wall outer-side template and a keel supporting system; 6 pouring the concrete; 7 template removal; 8 pouring the concrete of the walls on two sides of the upper-layer deformation joint; 9 repeating the step 8 till all of required floor pouring is finished. The construction technology is simple, convenient and efficient. Materials are saved. The quality accuracy is high. The root portion position control is good.

Owner:DONGHAI CONSTR GRP

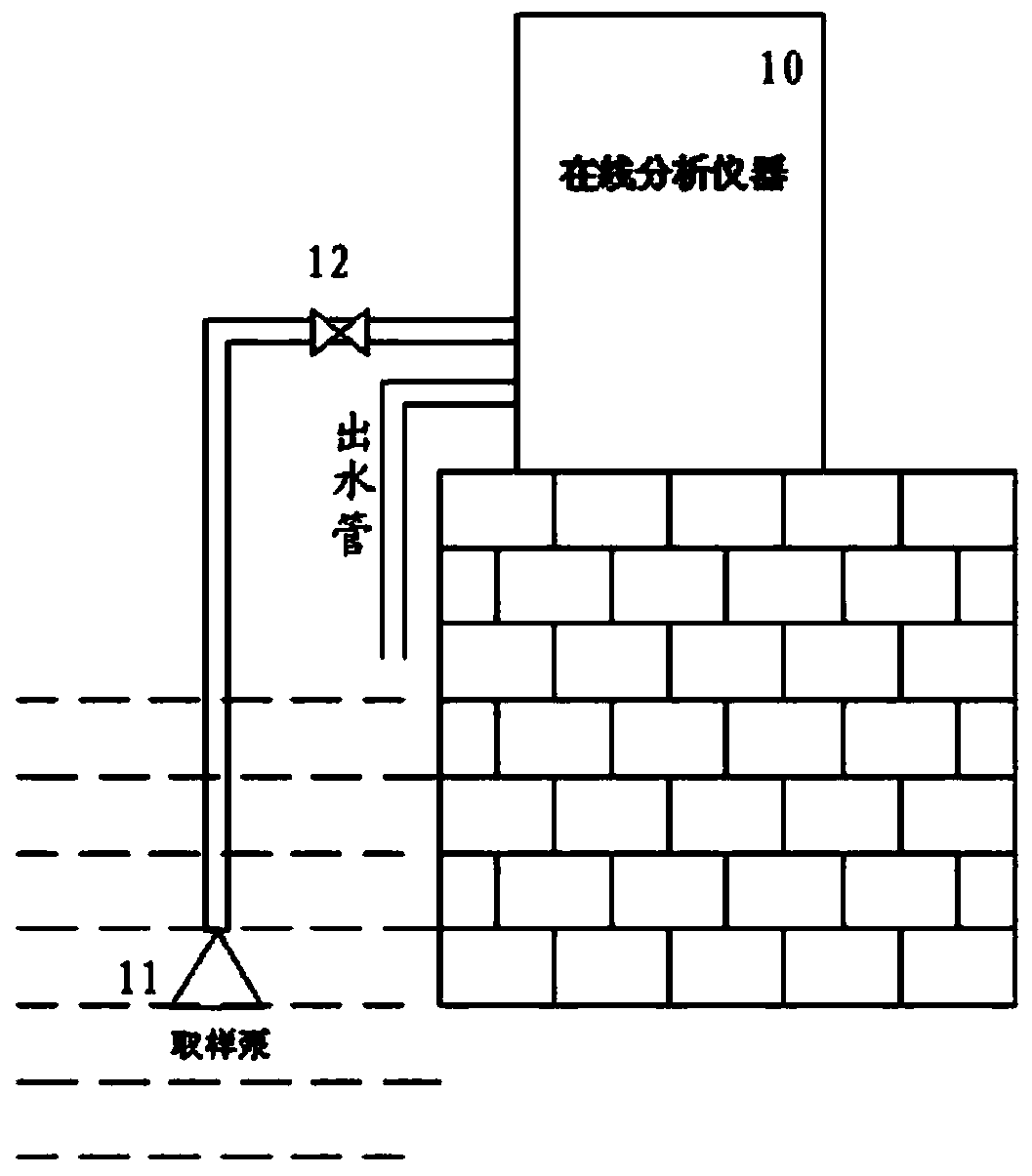

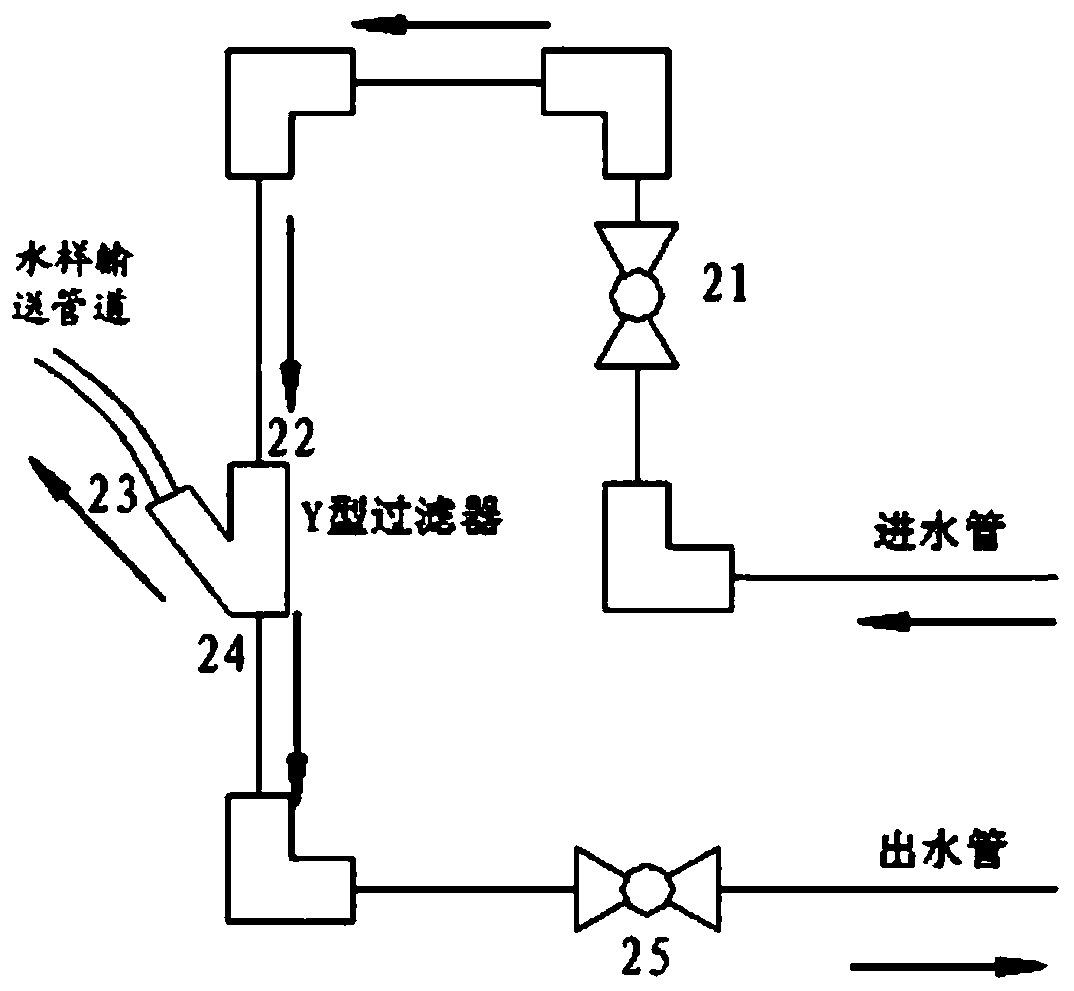

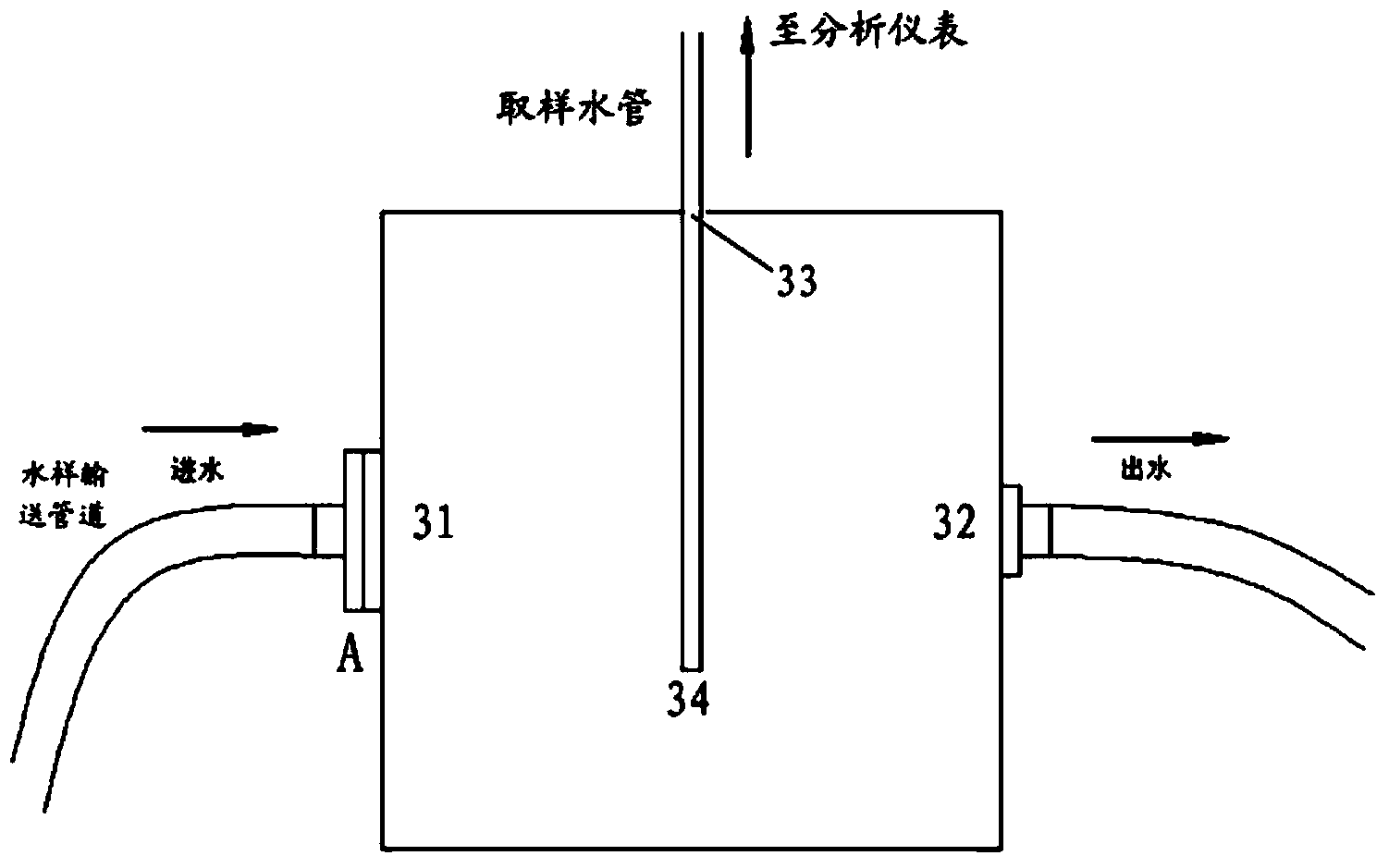

Water-quality monitoring pre-treatment device and water quality monitoring system

ActiveCN103645292AImprove representationEffective filteringPreparing sample for investigationTesting waterFiltrationMonitoring system

The invention provides a water-quality monitoring pre-treatment device. The water-quality monitoring pre-treatment device comprises a Y-type filter, a water inlet ball valve, a water outlet ball valve and a filter screen, wherein a water inlet of the Y type filter is connected with a sampling pump by a water inlet tube, so that primary filtration treatment is carried out on an original water sample collected by the sampling pump; a first outlet of the Y type filter is connected with the water inlet of a sampling cup by a water sample conveying pipeline; the filter screen is arranged at the water inlet of the sampling cup; the filter screen is used for carrying out secondary filtration treatment on the primarily filtered water sample conveyed by the water sample conveying pipeline; a second outlet of the Y type filter is used for discharging the primarily-filtered substances through the water outlet tube; the water inlet ball valve is arranged in the water inlet tube; the water outlet ball valve is arranged in the water outlet tube; water sample flow rate in the water sample conveying pipeline is controlled by regulating opening degree of the water inlet ball valve and / or the water outlet ball valve. Besides, the invention further provides a water quality monitoring system which is used for improving representativeness of a water sample and accuracy of the monitored result.

Owner:BEIJING SDL TECH

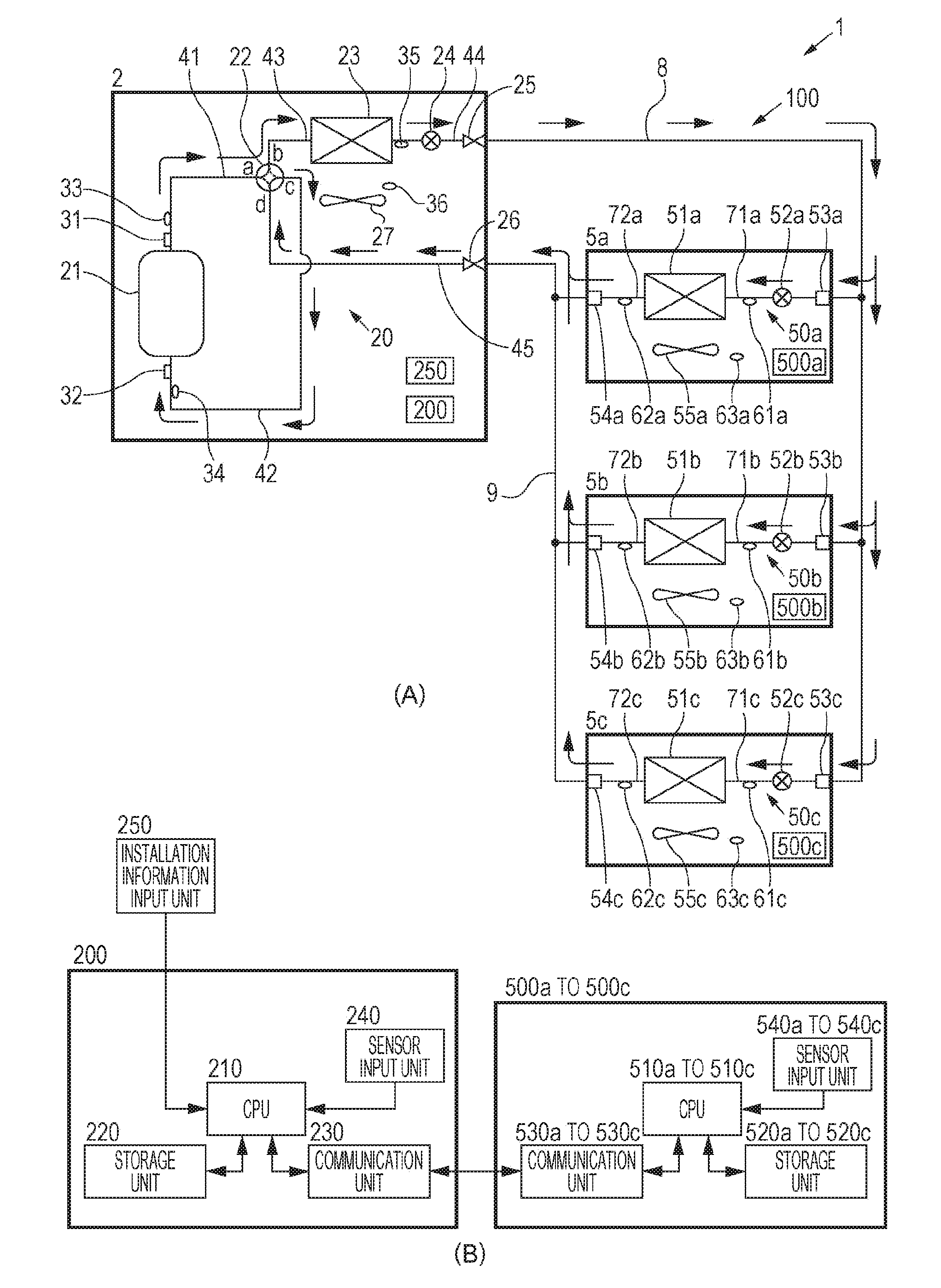

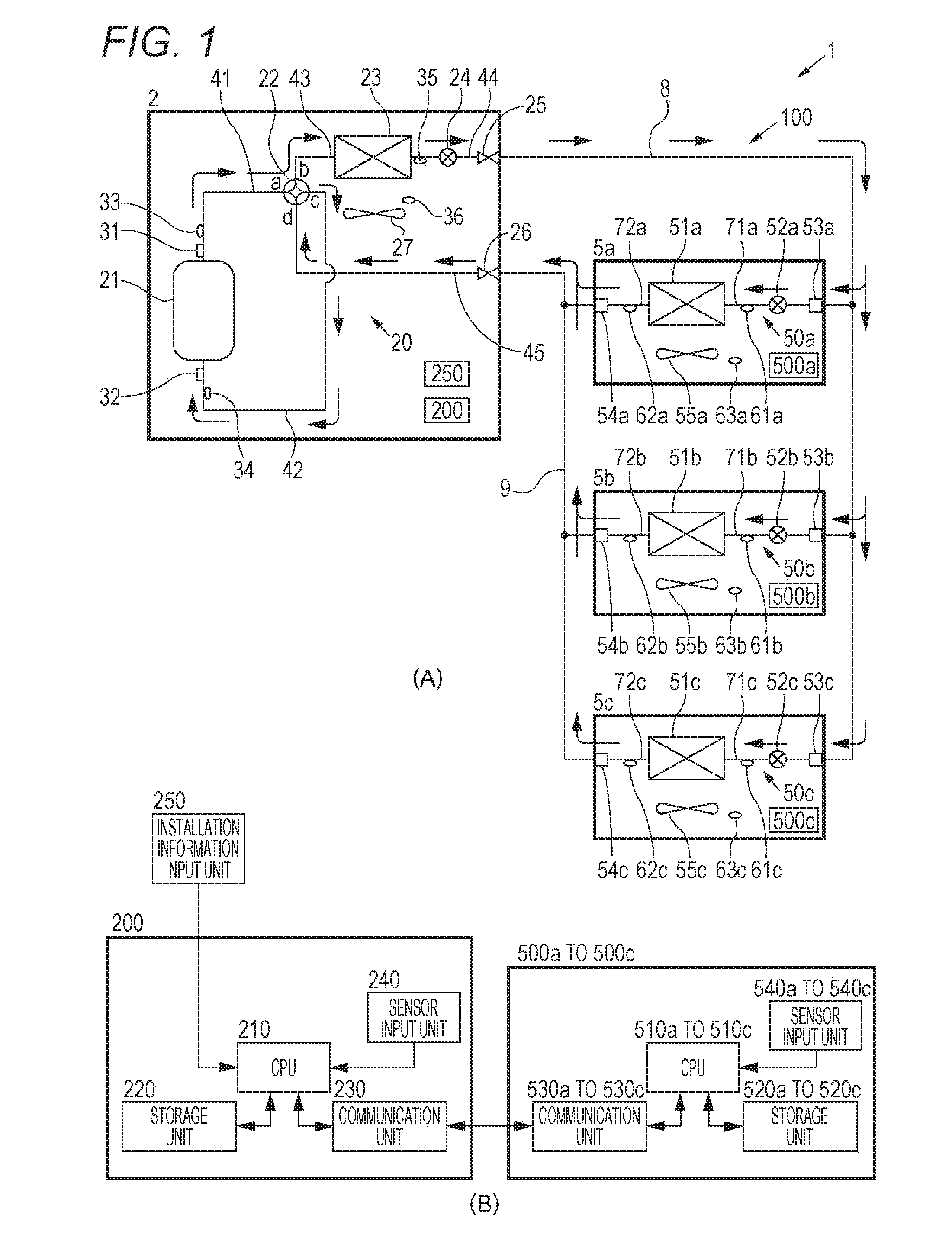

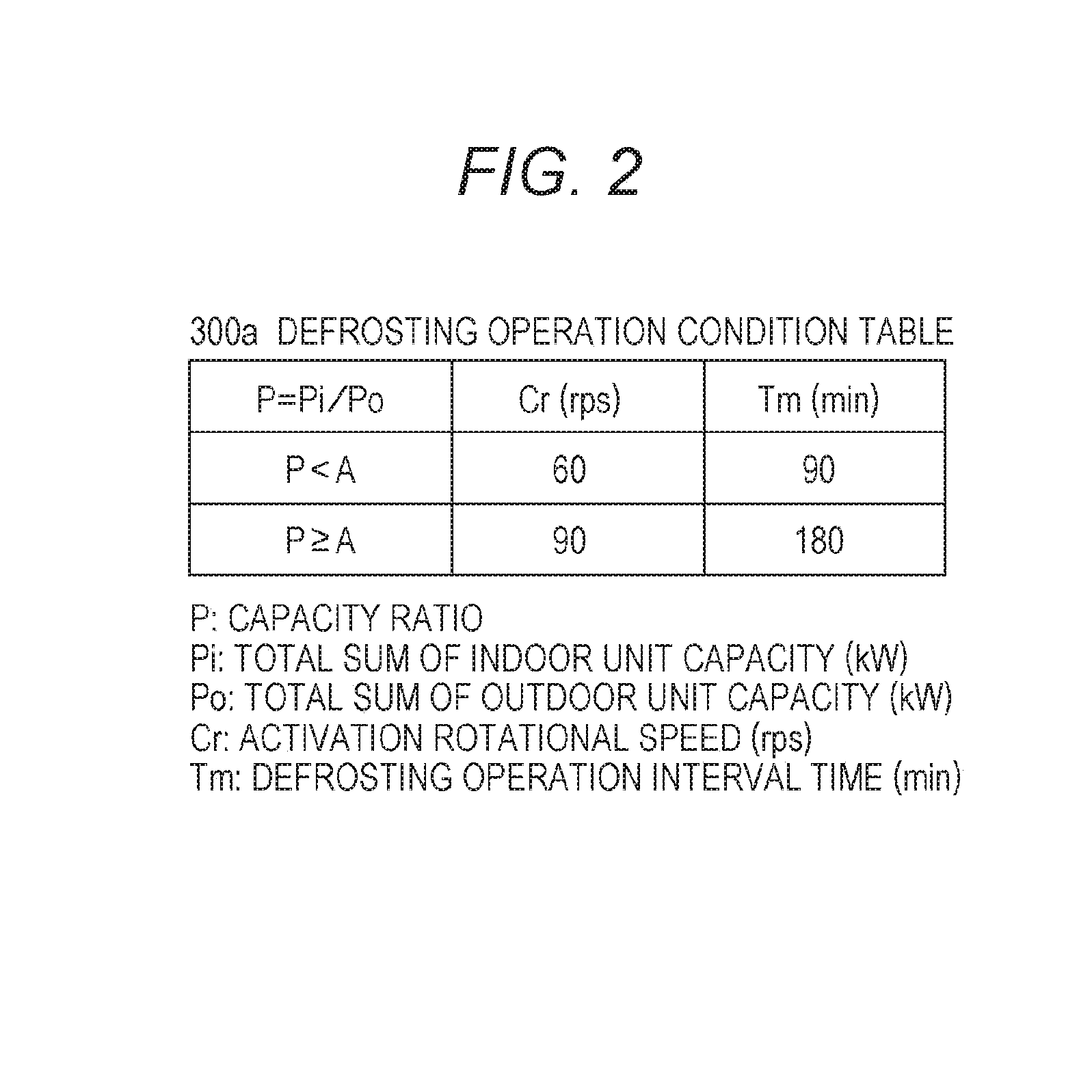

Air conditioner

ActiveUS20160178259A1Restoration is delayedDefrost operationMechanical apparatusCorrosion preventionProcess engineeringRefrigerant

An outdoor unit control unit 200 has a defrosting operation condition table 300a that defines a defrosting operation interval time Tm in accordance with a total sum of rated capacity of indoor units 5a to 5c and a refrigerant pipe length as lengths of a liquid pipe 8 and a gas pipe 9. The outdoor unit control unit 200 uses the total sum of the rated capacity of indoor units 5a to 5c input by using an installation information input unit 250 and refers to the defrosting operation condition table 300a, so as to determine the defrosting operation interval time Tm. Then, the outdoor unit control unit 200 forcibly performs a defrosting operation when the defrosting operation interval time Tm elapses without establishment of a defrosting operation start condition since the last defrosting operation is terminated.

Owner:FUJITSU GENERAL LTD

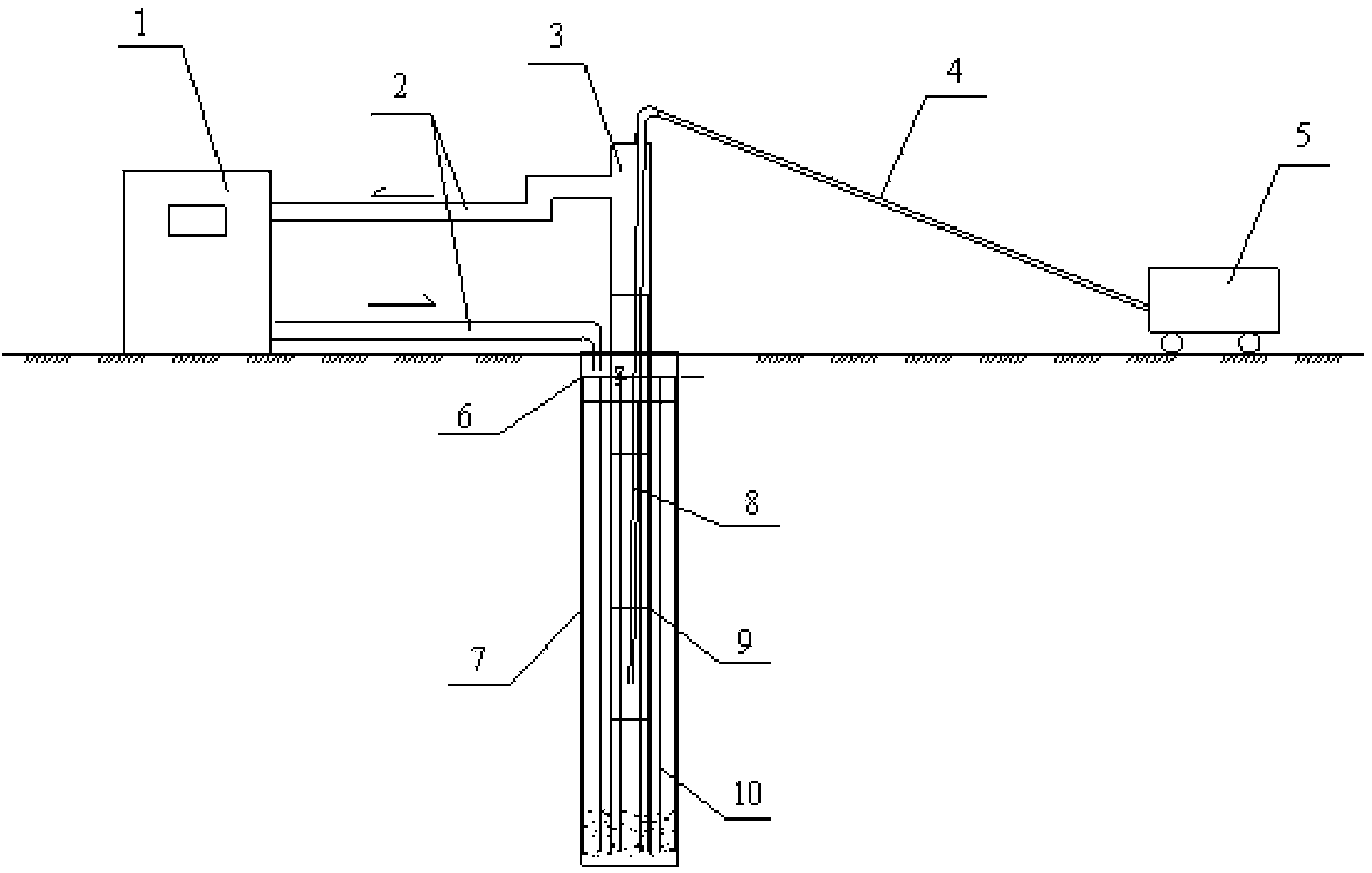

Cast-in-situ bored pile constructing method for cleaning sediment by gas lift reverse circulation method

InactiveCN104343114AShorten the intervalReduce the use effectFlushingBulkheads/pilesSlurryEngineering

The invention relates to a cast-in-situ bored pile constructing method for cleaning sediment by a gas lift reverse circulation method. The cast-in-situ bored pile constructing method comprises the following steps: measuring and arranging a pile position, arranging a steel casing at an upper opening of a pile hole, and placing a drilling machine; drilling the pile hole by using the drilling machine, cleaning the pile hole, and installing a reinforcing cage; installing a concrete pipe at the inner lower part of the reinforcing cage; installing a sediment discharging pipe at the top end of the concrete pipe, installing a rubber pipe at a preserved port in the sediment discharging pipe, and enabling the rubber pipe to stretch into the pile hole from the interior of the sediment discharging pipe; connecting the other end of the rubber pipe to an air compressor; connecting the sediment discharging pipe to a slurry purifying device by using a soft pipe; starting up the air compressor, and starting to clean the hole through gas lift reverse circulation; after hole cleaning, pulling the rubber pipe out of the sediment discharging pipe, detaching the sediment discharging pipe, and casting concrete into the pile hole. Before sediment cleaning, construction can be performed only by installing the sediment discharging pipe at the top end and putting down the rubber pipe and by taking out the sediment discharging pipe and the rubber pipe before concrete casting, so that the sediment treatment time is reduced and the sediment treatment effect is very good.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

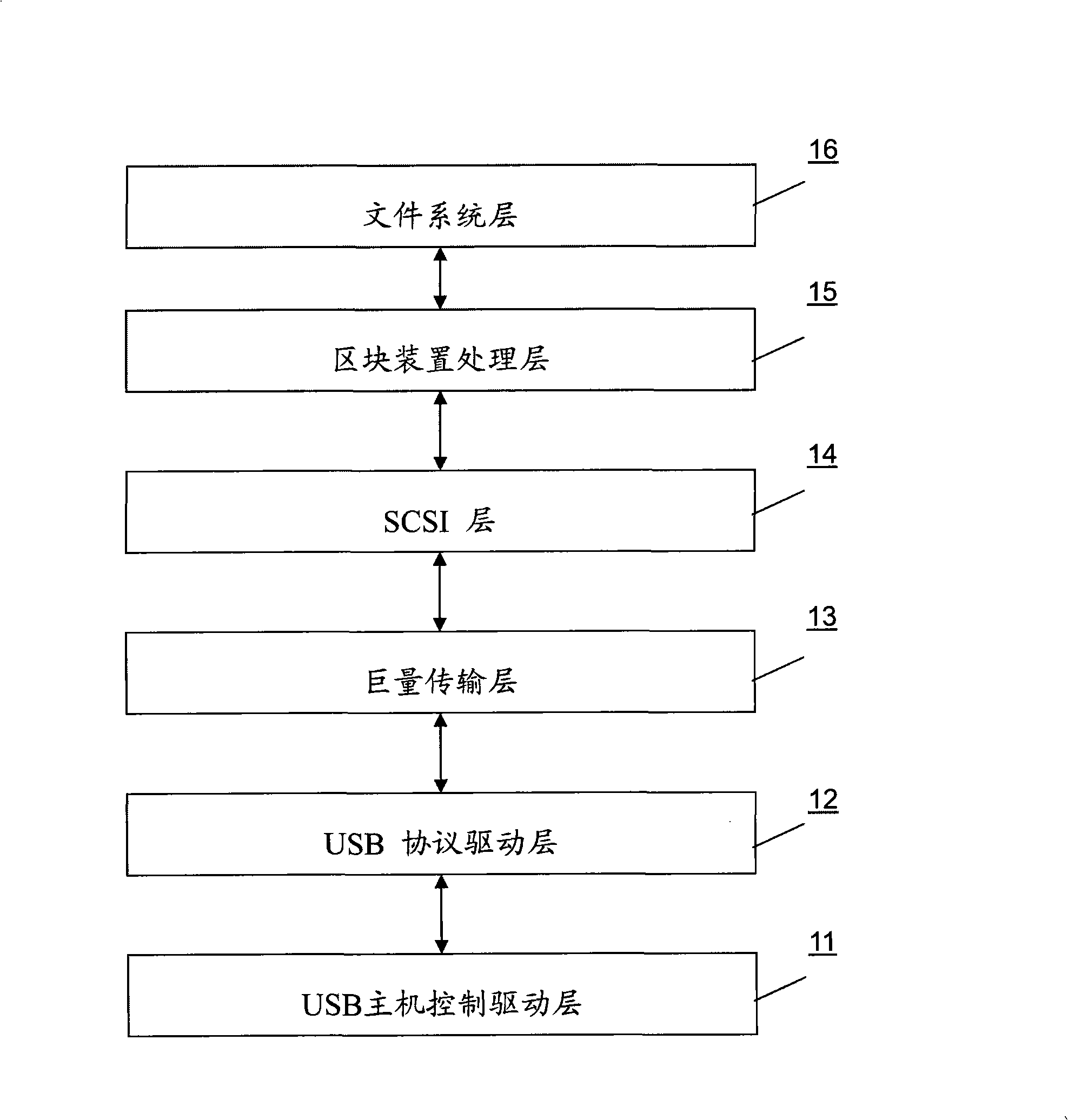

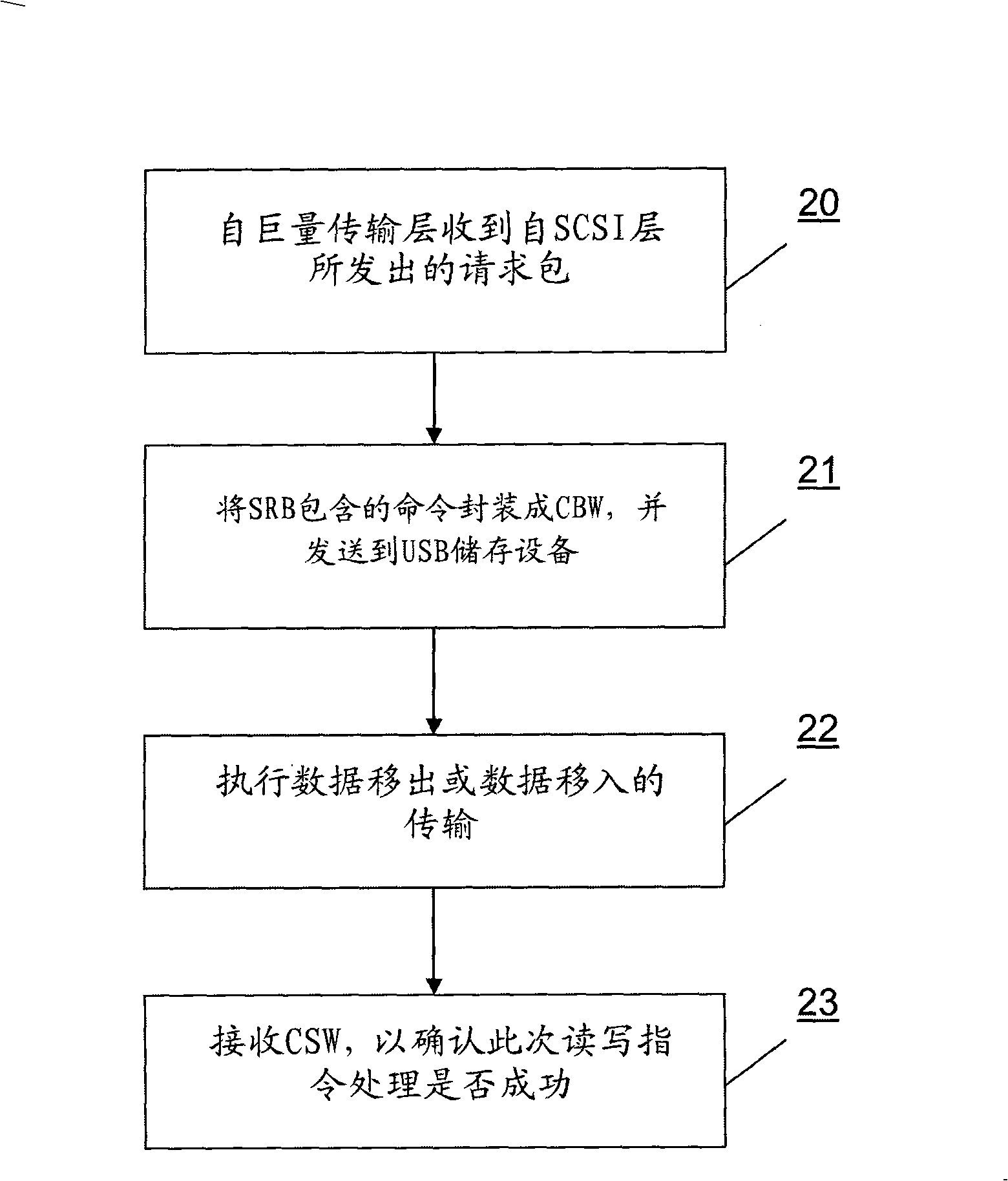

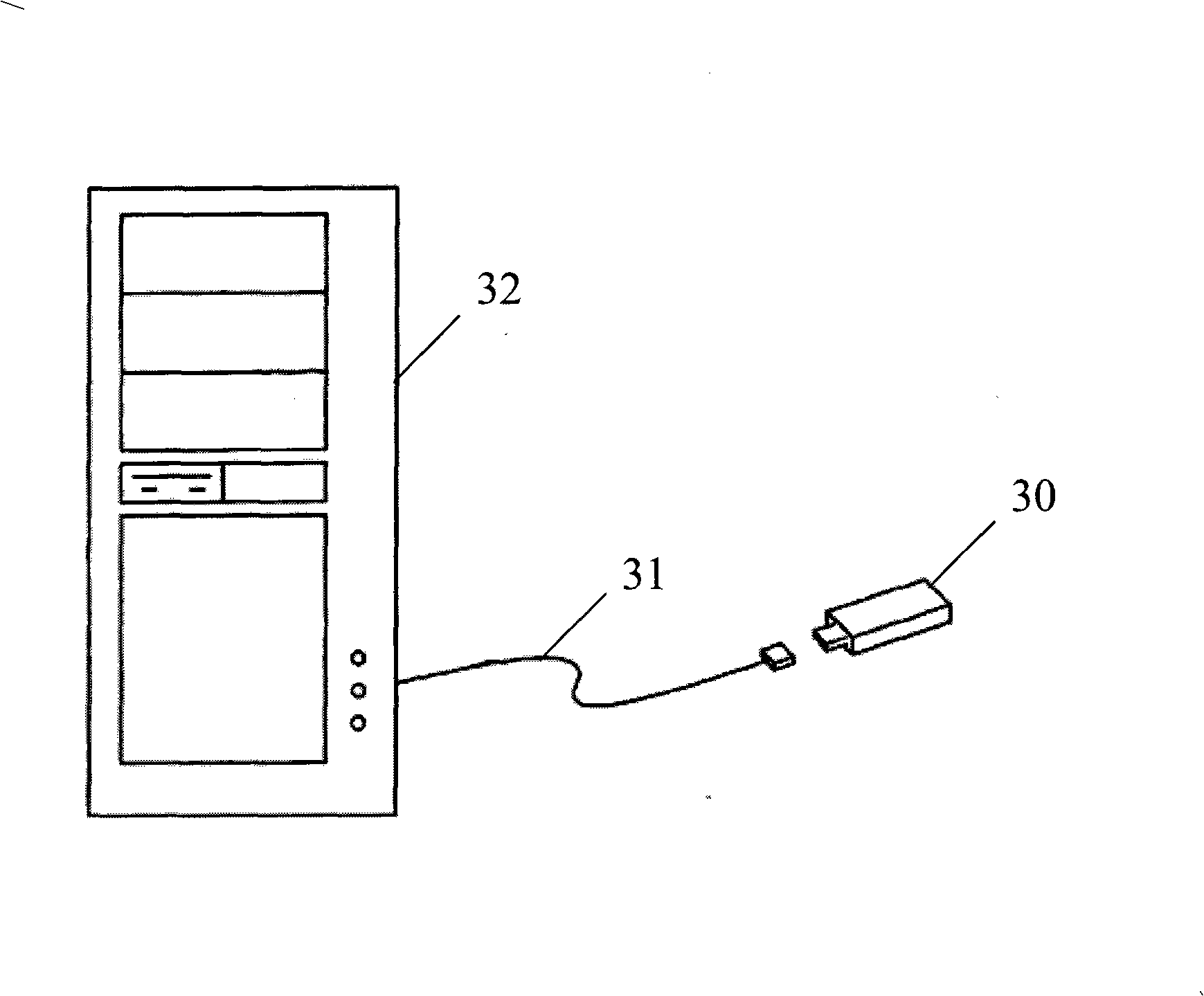

Method for improving read-write data speed of all-purpose sequence bus storage equipment

ActiveCN101303685AImprove data read and write speedReduce the number of timesElectric digital data processingCapacity valueData rate

The invention discloses a method which can upgrade the reading and writing speed of a universal serial bus (USB) storage device. In a first embodiment, when a reading command with a larger storage capacity value to be read / written is received and the address of the reading command is continuous, then a data transmission procedure in which the CBW is not needed to be transmitted is implemented. In a second embodiment, a plurality of writing commands with continuous addresses are arranged in a storage buffer and are combined into a larger requiring command and transmitted to the USB storage device again, thereby the times for the CBW and CSW needed to be transmitted can be reduced during data transmission. In a third embodiment, when the reading command is received, more data is read in ahead and is stored in the buffer to lead a next reading command to be capable of reading data from the buffer, thus accelerating the speed to read the data.

Owner:REALTEK SEMICON CORP

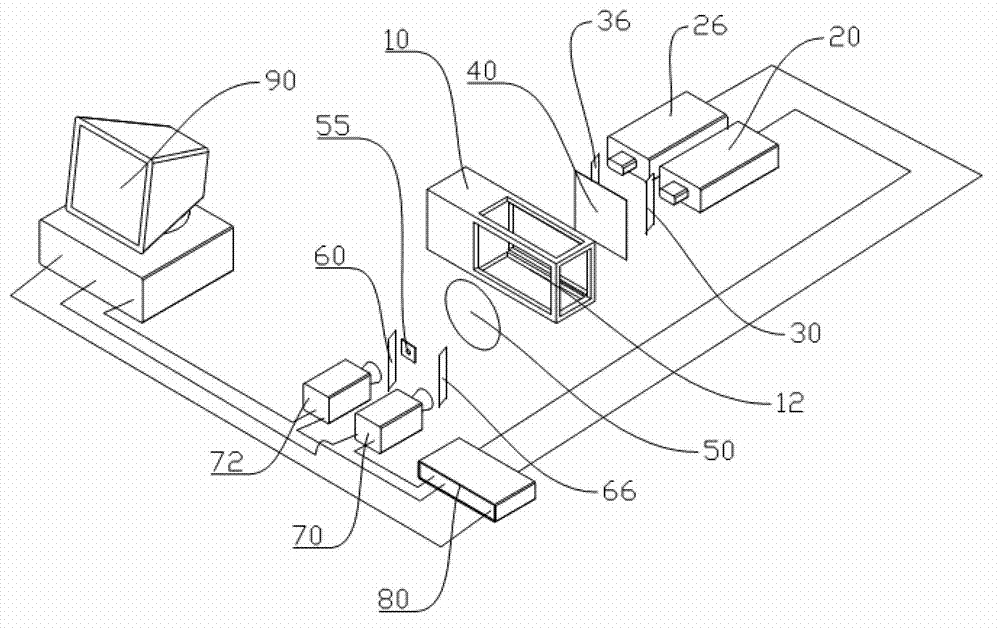

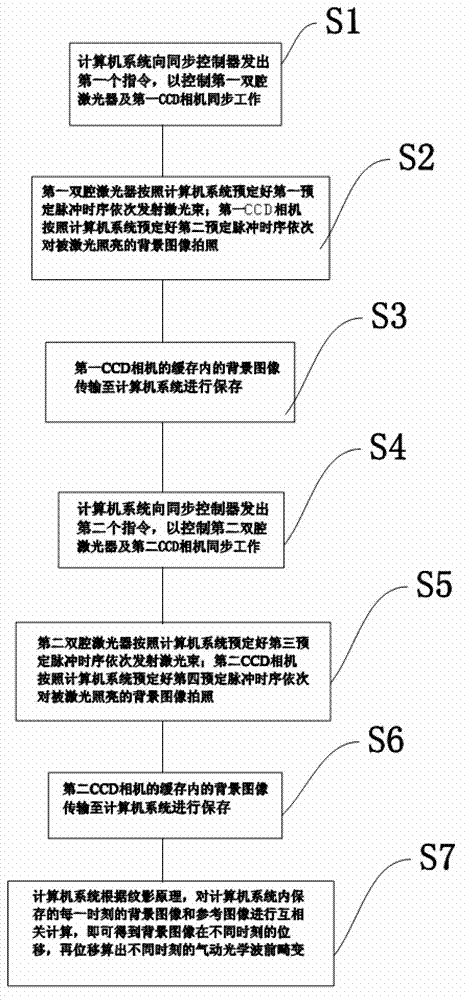

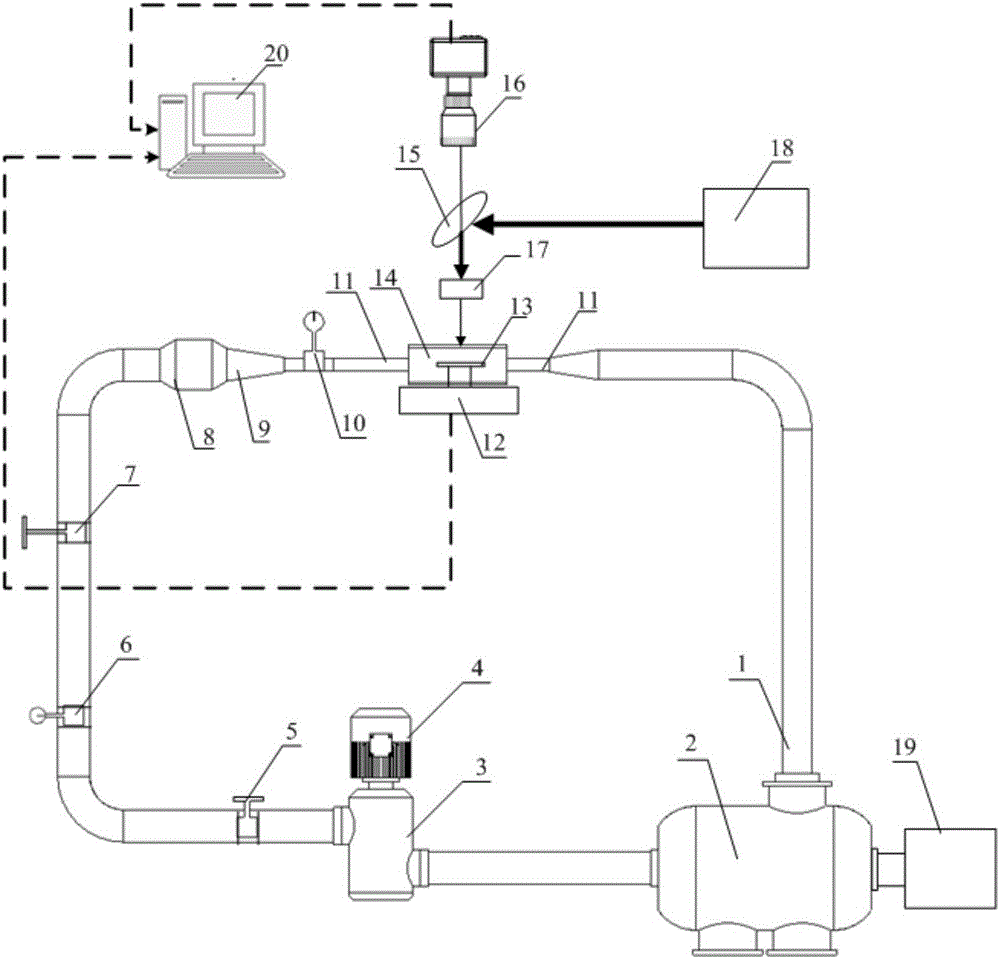

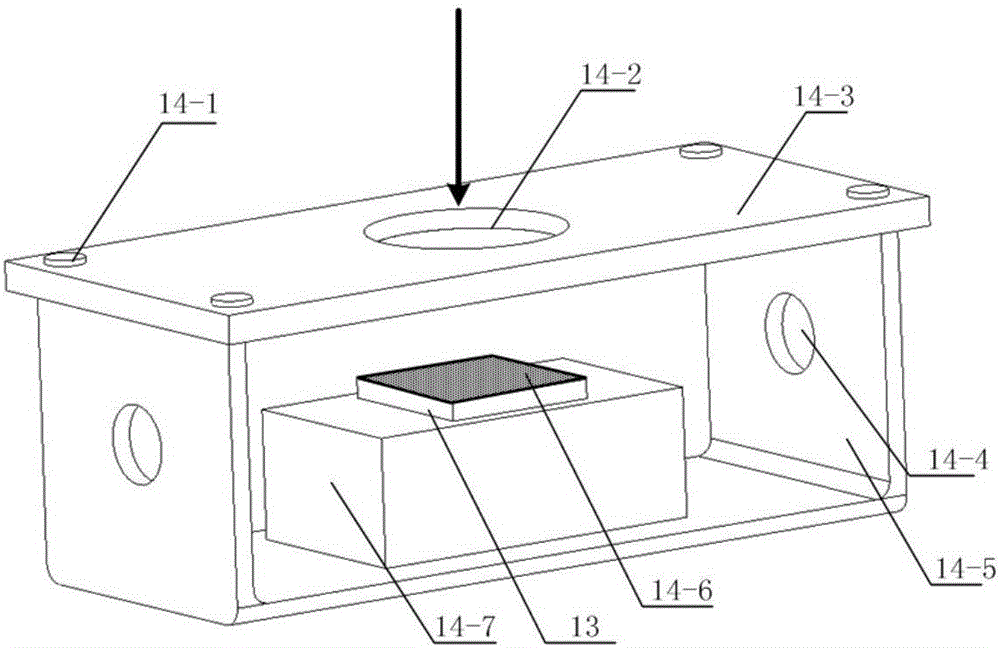

Pneumatic optical wavefront ultra-high frequency measurement system and method

ActiveCN102853918AShorten the intervalEnables UHF MeasurementsOptical measurementsAerodynamic testingCamera lensCcd camera

The invention provides a pneumatic optical wavefront ultra-high frequency measurement system. The pneumatic optical wavefront ultra-high frequency measurement system comprises a first dual-cavity laser device and a second dual-cavity laser device, a first semi-transparent mirror opposite to a light outlet of the first dual-cavity laser device, a first reflector opposite to the light outlet of the second dual-cavity laser device, a first CCD (charge coupled device) camera and a second CCD camera, a synchronous controller, a computer system, a second semi-transparent mirror, a second reflector, a background image, a convex lens and a pore, wherein the first CCD camera and the second CCD camera are arranged in parallel; the computer system is connected to the first CCD camera, the second CCD camera and the synchronous controller; the second semi-transparent mirror is opposite to the lens of the second CCD camera; the second reflector is opposite to the lens of the first CCD camera; the backlight image, the convex lens and the pore are respectively arranged at two opposite sides of a wind tunnel experiment module; the backlight image and the second dual-cavity laser device are arranged at the same side; and the first CCD camera, the second CCD camera, the first dual-cavity laser device and the second dual-cavity laser device are connected to the synchronous controller respectively. The invention also relates to a measurement method. According to the method, the shot background image is subjected to analysis calculation by the computer, so that ultra-high frequency measurement of whole-field pneumatic optical wavefront distortion is achieved.

Owner:NAT UNIV OF DEFENSE TECH

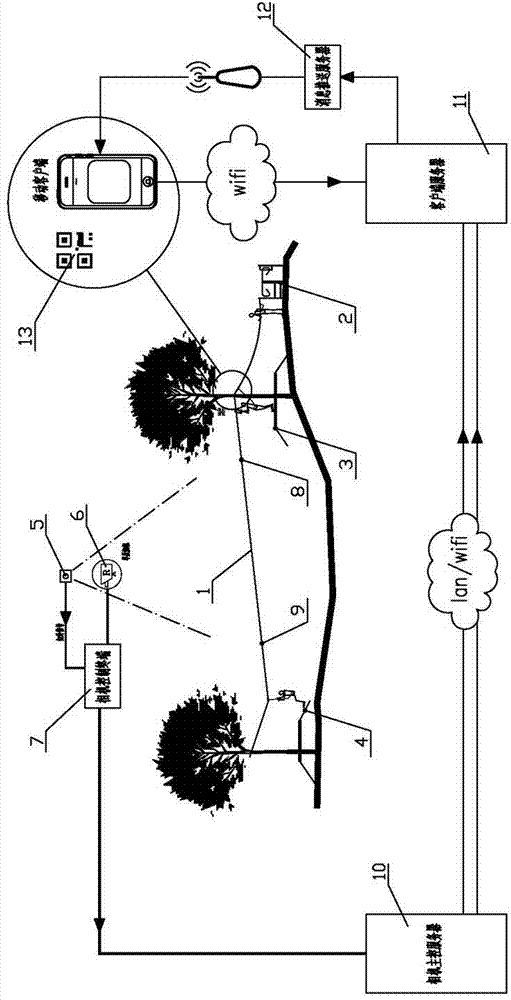

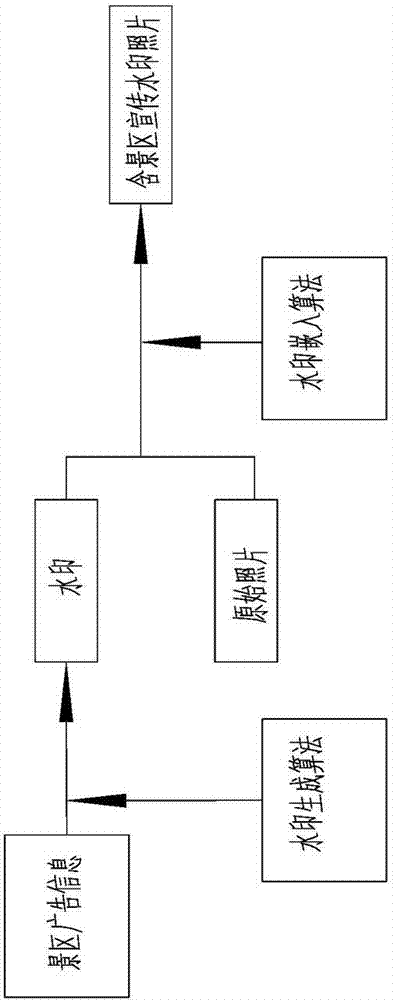

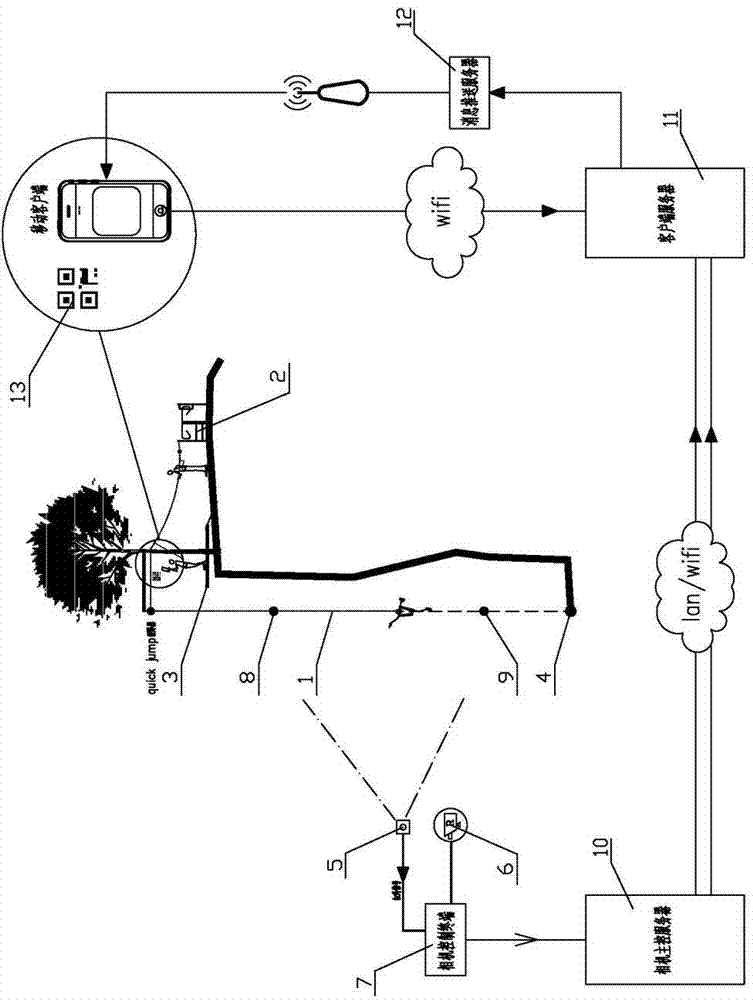

Outdoor sports picture shooting system based on rope and picture obtaining method

ActiveCN103888533AFast and timely accessReduce transfer timeTelevision system detailsData processing applicationsComputer graphics (images)Computer terminal

The invention relates to an outdoor sports picture shooting system based on a rope and a picture obtaining method. According to the outdoor sports picture shooting system based on the rope and the picture obtaining method, pictures of motions and expressions of a tourist in the tour process are shot, are stored and are pushed to a mobile phone of the tourist, and it is ensured that the pictures of the tourist are only pushed to the mobile phone of the tourist. According to the technical scheme, the outdoor sports picture shooting system based on the rope comprises a transmission cable, a picture shooting device and a service terminal, wherein the transmission cable is divided into a preparation area and a sports area in sequence in the advance direction, the preparation area and the sports area use the playing start point for the beginning of the sports as the boundary, the initial end of the preparation area is provided with a one-way door, the tail end of the sports area serves as the playing end point for finishing the sports, the picture shooting device is used for shooting the pictures of the tourist in the sports process in the sports area, the service terminal is connected with the picture shooting device through a data line, and is used for receiving the pictures transmitted by the picture shooting device, and pushing the pictures to the mobile phone of the corresponding tourist. The outdoor sports picture shooting system based on the rope and the picture obtaining method are used for items such as the strop ropeway sports and the downhill sports in scenic regions.

Owner:HANGZHOU SELFIE SHOW TECH CO LTD

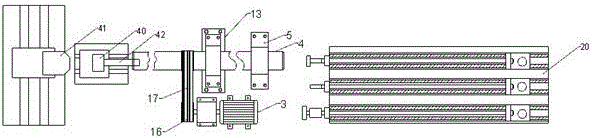

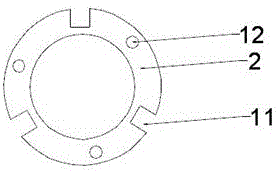

Centrifugal casting system for internal combustion engine air cylinder sleeve

The invention discloses a centrifugal casting system for an internal combustion engine air cylinder sleeve. The centrifugal casting system comprises a centrifugal machine, a pouring device, a spraying device, a pipe drawing device and a cleaning device. The centrifugal machine comprises a mould barrel for molding the air cylinder sleeve, end covers arranged at the two ends of the mould barrel, a power device and a transmission device connected with the power device. The transmission device comprises a hollow rotary shaft, the mould barrel is coaxially sleeved with the hollow rotary shaft, the hollow rotary shaft is supported on a bearing pedestal through a bearing, the power device drives the hollow rotary shaft to rotate, and therefore the mould barrel is driven to rotate. Compared with the prior art, the centrifugal casting system has the beneficial effects that the mould barrel is circumferentially restrained on the hollow rotary shaft, throbbing of centrifugal movement of the mould barrel is reduced, the rotating precision of the mould barrel is improved, and the quality and casting efficiency of a casting are improved; and when the mould barrel rotates at a high speed, weight blocks are subjected to the action of centrifugal force to move outwards, and therefore the end covers are locked through moving rods, and molten metal is prevented from being splashed.

Owner:ZYNP GRP ANHUI CO LTD

Flexible circuit board welding device

InactiveCN108115242ANo manual operation requiredReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesFlexible circuitsEngineering

The invention relates to the field of circuit board production, and particularly discloses a flexible circuit board welding device comprising a machine frame, a cooling fan, a conveyor belt, a weldingmechanism and a control mechanism, wherein a supporting plate is fixed on the conveyor belt; the welding mechanism comprises an electric soldering iron, a cylinder and a welding fan; the cylinder isprovided with an exhaust port, and a returning spring is arranged in the cylinder; the control mechanism includes a stopping mechanism and a cooling mechanism, and the stopping mechanism and the cooling mechanism each include a cooling fan and an air bag, the air bag and the cooling fan are located on both sides of the conveyor belt respectively, the cooling fan is fixed on the machine frame, andthe air bag can slide relative to the machine frame. A first heated expansive substance is stored in the air bag of the stopping mechanism, a second heated expansive substance is stored in the air bagof the cooling mechanism, a closing switch is fixed on the machine frame, and the closing switch can shut down the conveyor belt and the welding fan, and the machine frame is provided with a compression spring. According to the scheme, the supporting plate can be cooled while a circuit board is welded.

Owner:宁波隆锐机械制造有限公司

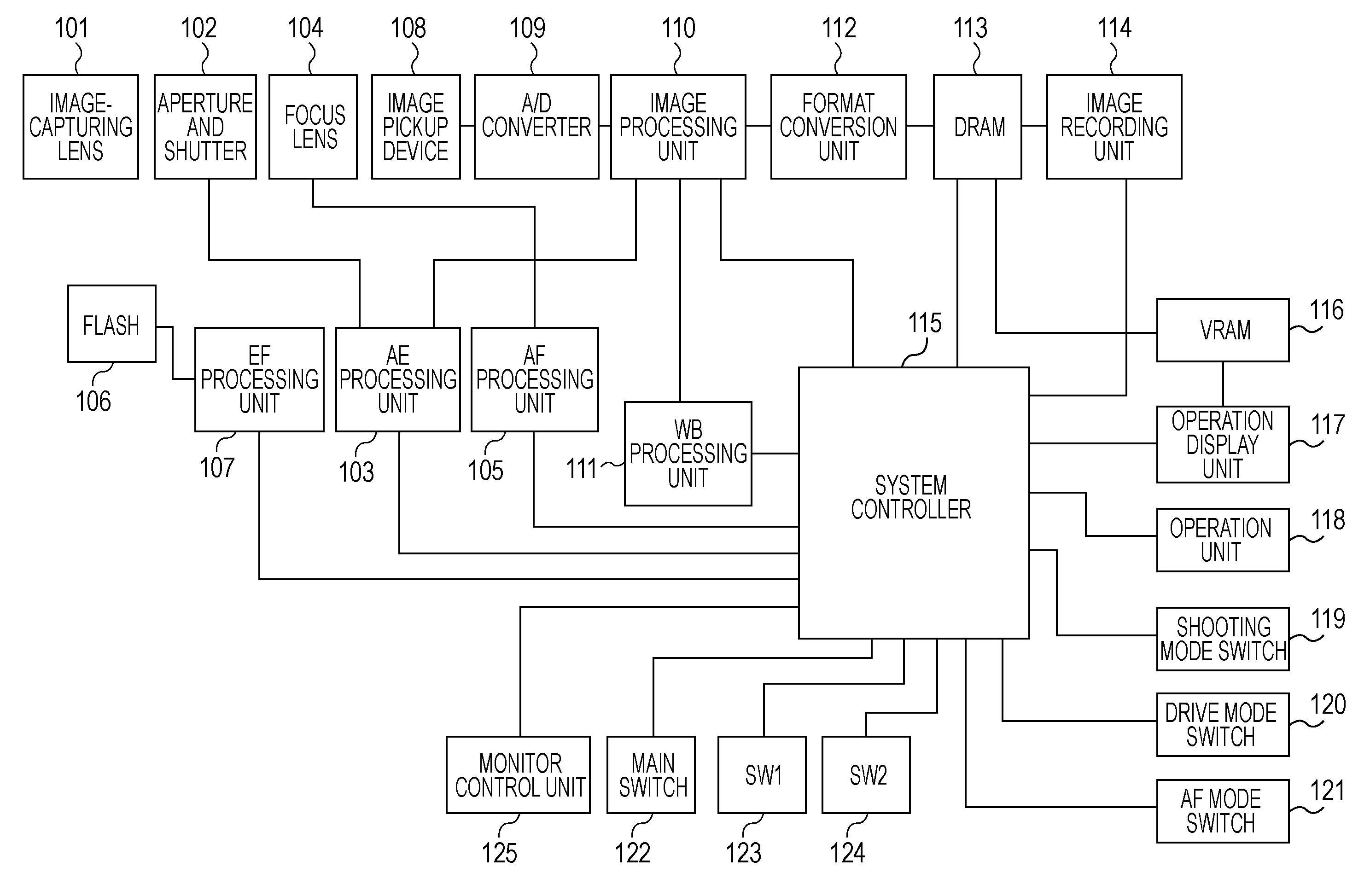

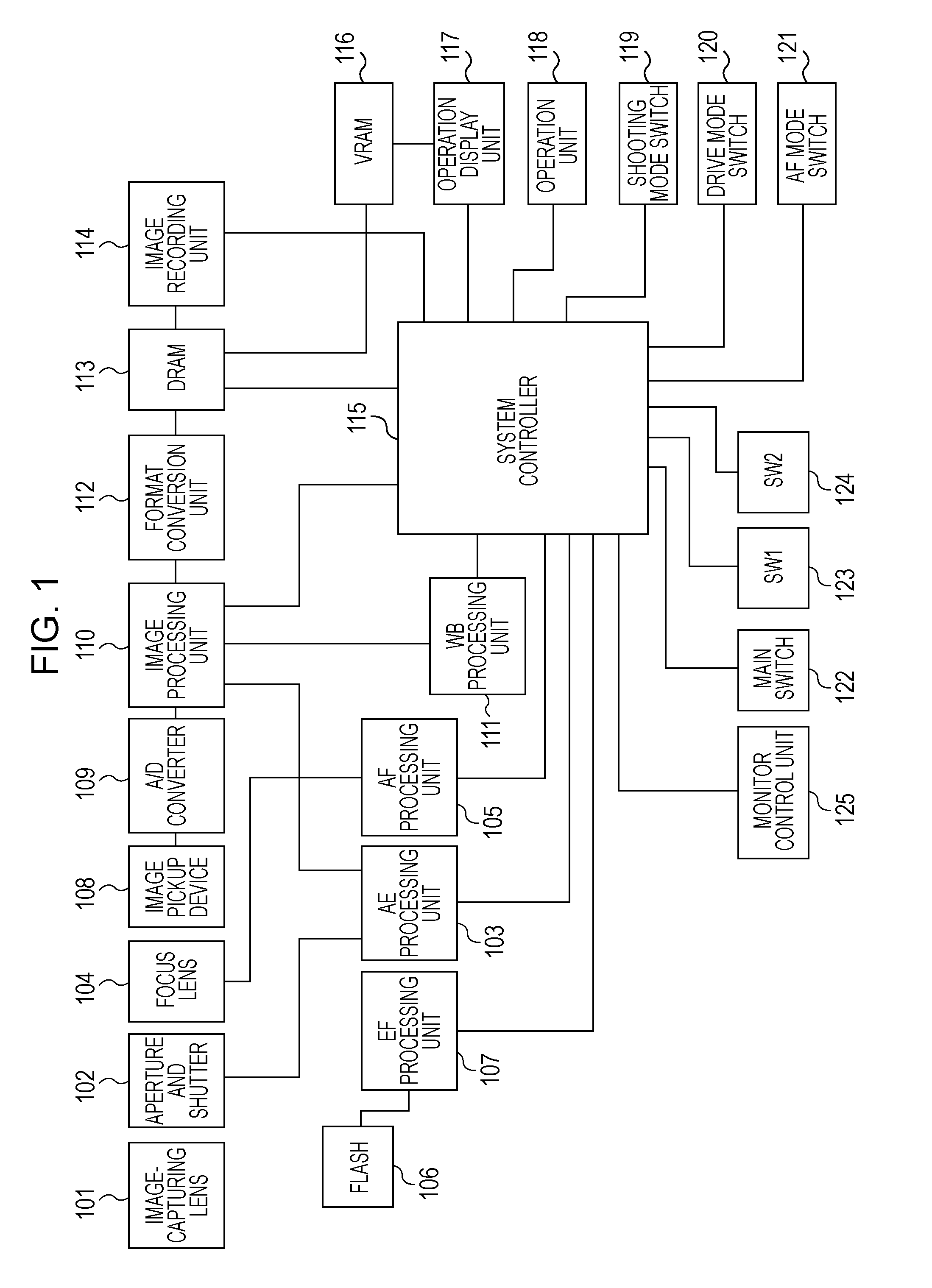

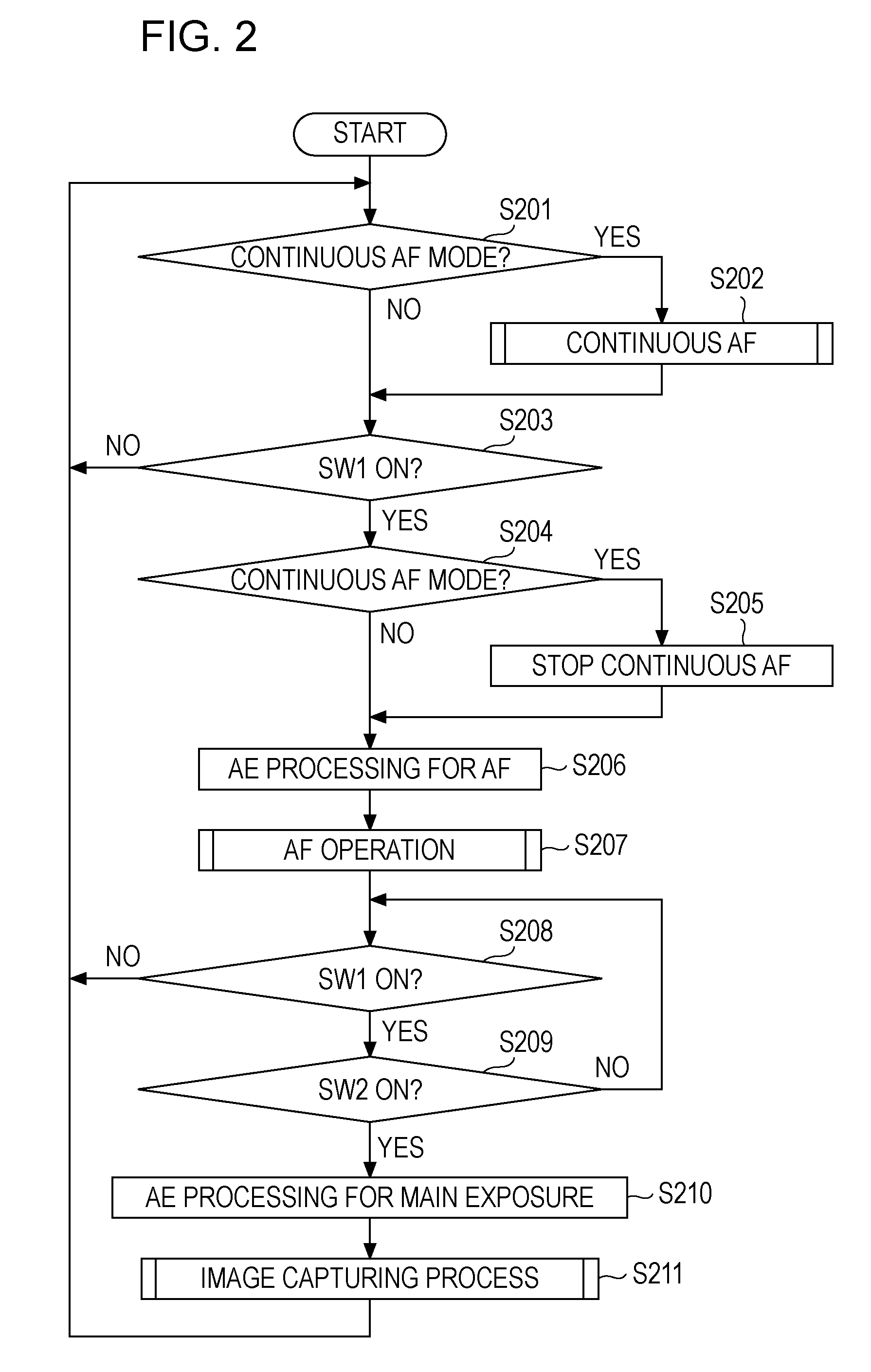

Image pickup apparatus

InactiveUS20070195189A1Shorten the intervalTelevision system detailsColor television detailsComputer visionContrast ratio

An image pickup apparatus performs focus control by a contrast detection method during a continuous shooting interval. After the image pickup apparatus controls the movement of the focus lens and captures an image for recording in the continuous shooting mode, the image pickup apparatus controls the movement of the focus lens before capturing the subsequent image for recording concurrently with performance of a development process of the captured image.

Owner:CANON KK

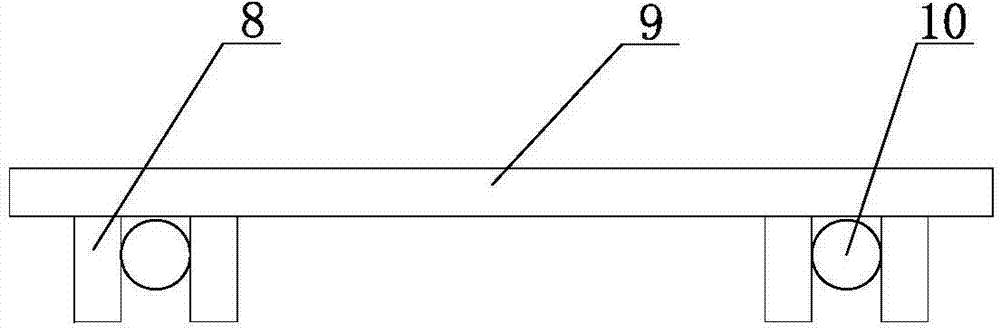

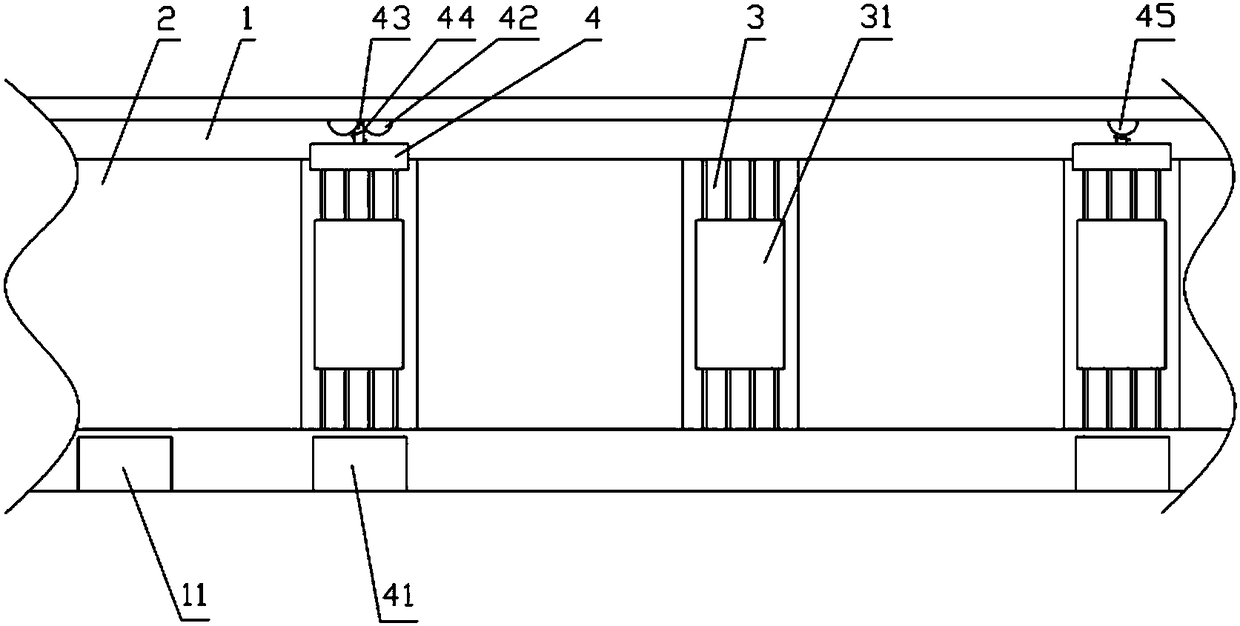

Floor turnover machine

InactiveCN104340662AFully automatedReliable technologyConveyor partsProgrammable logic controllerEngineering

The invention discloses a floor turnover machine which comprises a frame body, wherein at least two belt wheels are mounted on the frame body in parallel; a belt is arranged on each belt wheel and is used for conveying floors; driving blocks are arranged on each belt at a certain distance; a floor turning device is arranged on the frame body and is positioned above the belts; the floor turning device at least comprises two floor turning grabbing hooks; the floor turning grabbing hooks control to turn over the floor by an air cylinder; the floor on the belt passes through a sensor before reaching the turning device; after the sensor receives signals transmitted by the floor, the signals are transmitted to a PLC (Programmable Logic Controller); the PLC filters the signals and feeds the spaced signals to the air cylinder, so that the air cylinder controls the floor turning grabbing hooks to turn the floor. According to the floor turnover machine disclosed by the invention, the automation of floor turning is realized, so that a large amount of human resources are saved; besides, the working efficiency is greatly improved.

Owner:无锡沃格自动化科技股份有限公司

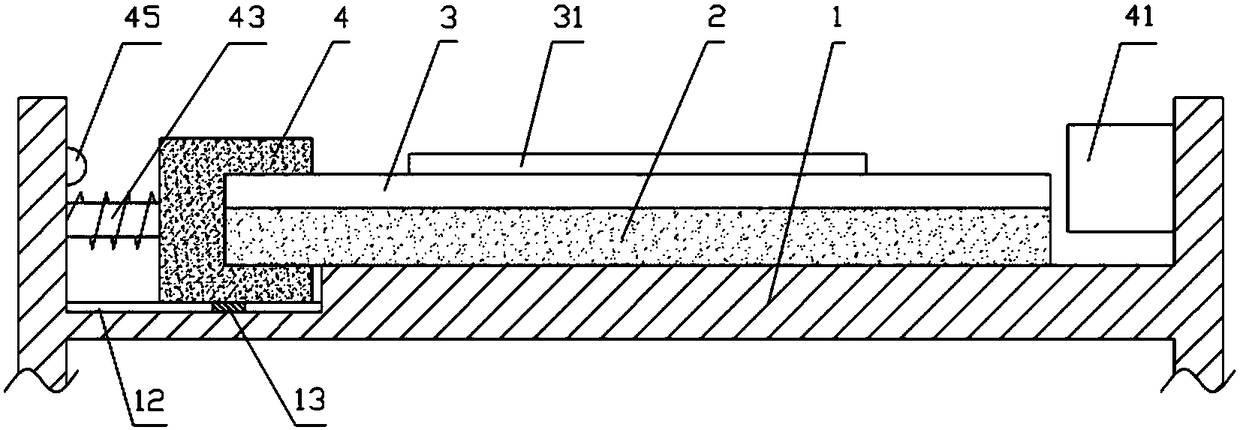

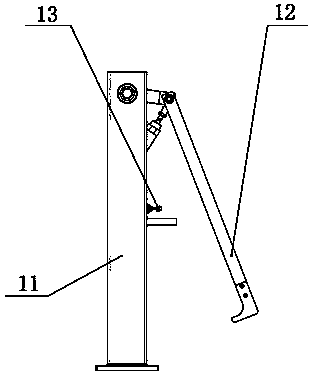

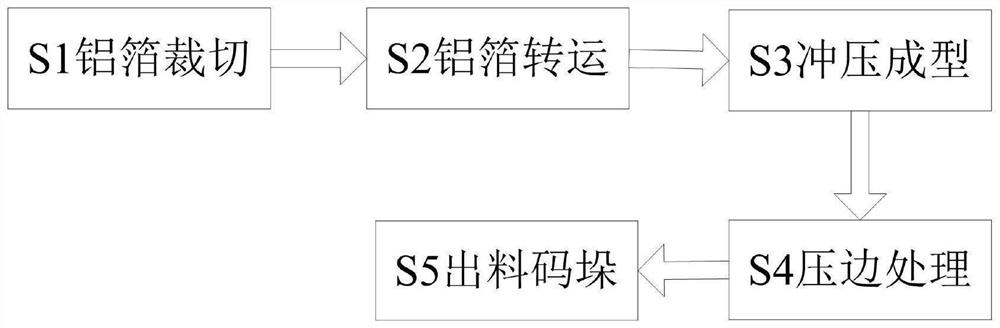

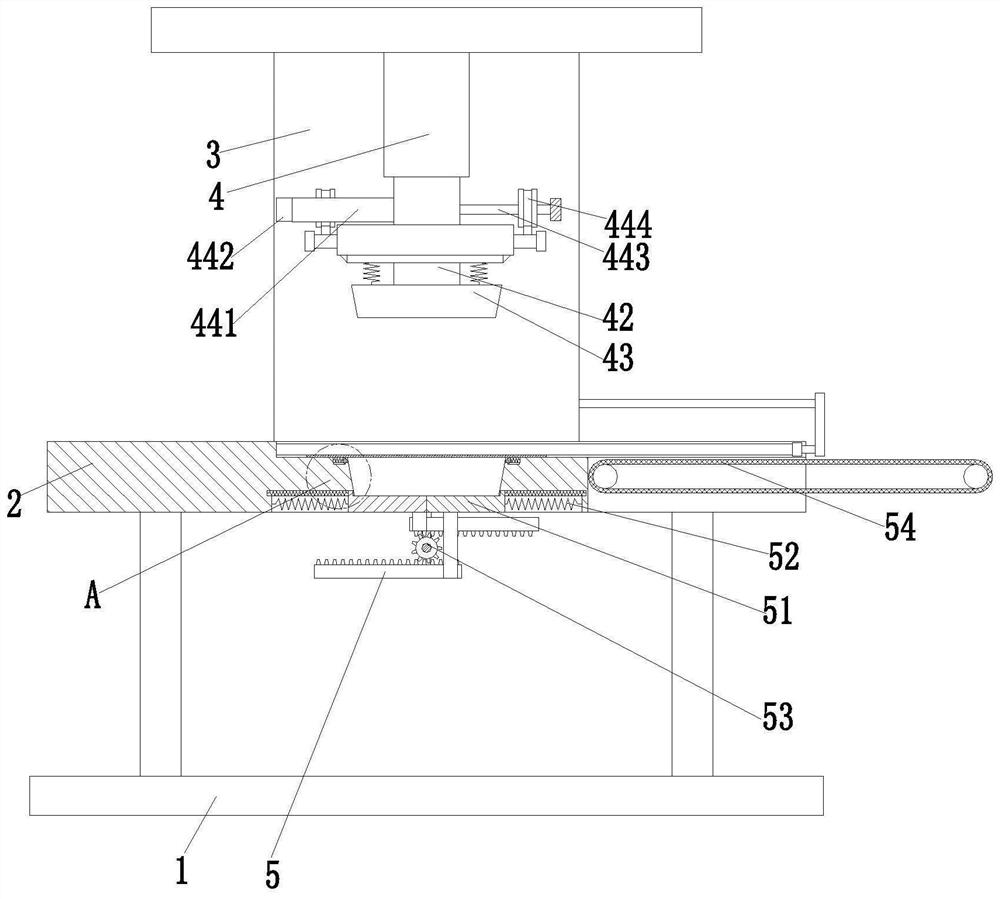

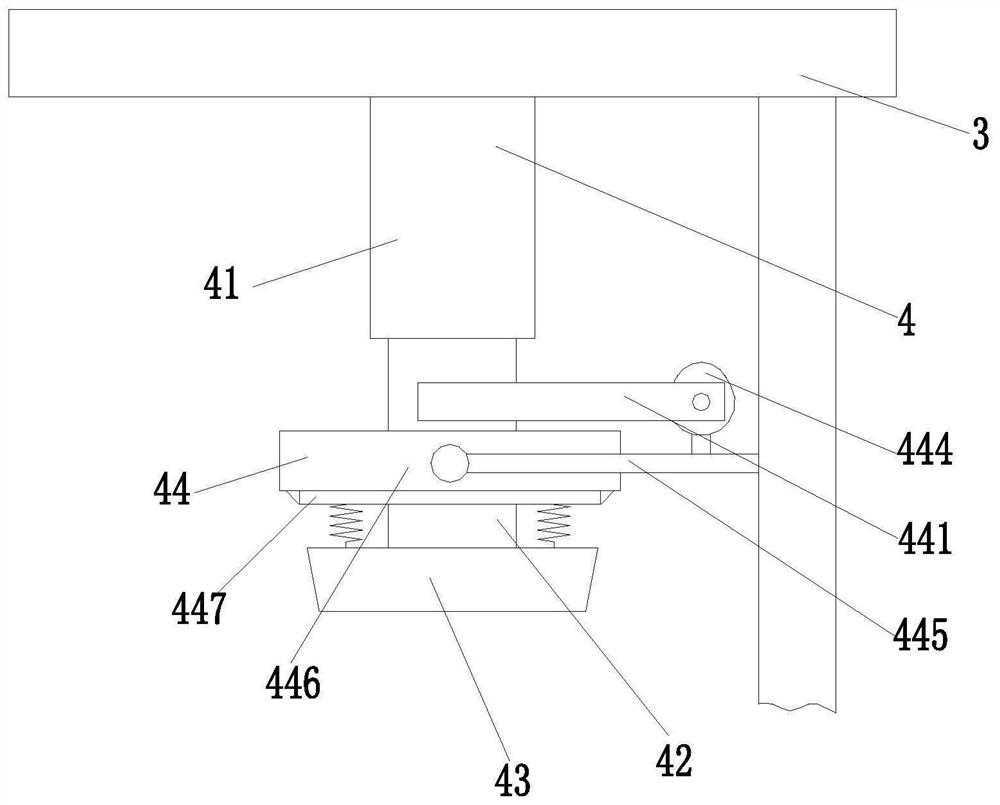

Preparation process of heatable aluminum foil packaging lunch box

ActiveCN112045085AAvoid position shiftWill not deformMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to a preparation process of a heatable aluminum foil packaging lunch box, which uses punch forming equipment. The punch forming equipment comprises a bottom plate, a workbench, amounting frame, a punching device and a material placing device, and the specific process flow for preparing the aluminum foil packaging lunch box by adopting the punch forming equipment is as follows: aluminum foil cutting, aluminum foil transferring, punch forming, edge pressing processing and discharging stacking; a punching device comprises a lifting air cylinder, a mounting block, a punchinghead and an edge pressing mechanism. According to the preparation process of the heatable aluminum foil packaging lunch box provided by the invention, an aluminum foil is punched and formed through the cooperation of the material placing device and the punching device, so that the flaky aluminum foil is made into a lunch box finished product, edge pressing treatment can be conducted on the lunchbox in the punching process at the same time, production equipment for edge pressing of the lunch box does not need to be additionally arranged, and in the aluminum foil moving process, the aluminum foil is guided and positioned in an air blowing mode, position deviation of the aluminum foil is avoided, and meanwhile aluminum foil deformation caused by extrusion is avoided.

Owner:宁波友邦铝箔制品有限公司

Controllable constrained laser micro shot peening intensification device and method thereof

The invention discloses a controllable constrained laser micro shot peening intensification device and a method thereof. The device comprises a circulating water system. A deionized water curtain is adopted as a constrained layer and is provided through the circulating water system; a high-speed camera is used for observing the growth and gathering situation of bubbles in a laser micro shot peening intensification process on line; a motor is used for driving a hydraulic pump to enable deionized water to circularly flow in the whole circulation water system; the pressure and the flow rate of the deionized water in the circulating water system are controlled to take away bubbles generated near a focal point in the laser micro shot peening intensification process so as to improve laser micro shot peening efficiency. The deionized water in the circulating water system is kept in certain pressure, so that the rigidity of the deionized water curtain on the surface of a laser micro shot peening metal sample is increased, the constraining function of the deionized water curtain for plasma explosion is improved, material surface laser-induced shock wave pressure is enhanced, and an active function is performed on improving a laser micro shot peening intensification effect.

Owner:CHINA UNIV OF MINING & TECH

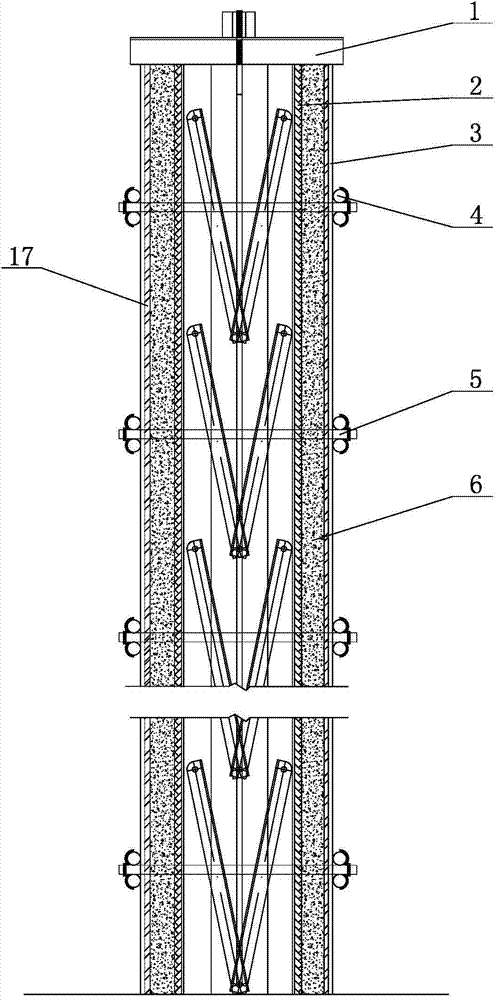

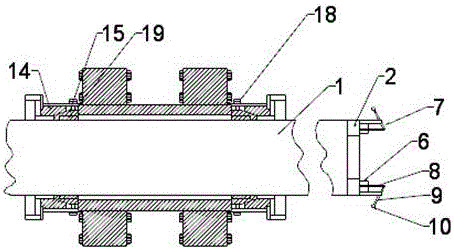

Pipe pulling and supporting, cleaning and spraying integrated unit for horizontal centrifugal casting machine

The invention discloses a pipe pulling and supporting, cleaning and spraying integrated unit for a horizontal centrifugal casting machine, which comprises a cleaning device and a spraying device and further comprises a locating cart, a control board and a pipe pulling and supporting roller device, wherein the pipe pulling and supporting roller device comprises a pipe supporting roller set and a winding machine, a guide rail is fixed on the ground surface of the tail end of the casting machine, the locating cart is arranged on the guide rail, the pipe supporting roller set, the cleaning device and the spraying device are arranged on the locating cart in parallel, the winding machine is arranged at the right end of the locating cart and at the axle of the centrifugal casting machine, and the control board is arranged near the winding machine. According to the pipe pulling and supporting, cleaning and spraying integrated unit for the horizontal centrifugal casting machine, the pipe supporting roller set, the cleaning device and the spraying device are arranged on the same locating cart in parallel, the equipment is reasonable in structure and small in floor area, automatic locating control is realized, the spacing interval between two working procedures is shortened, and the work efficiency is greatly improved.

Owner:QINGDAO NPA IND

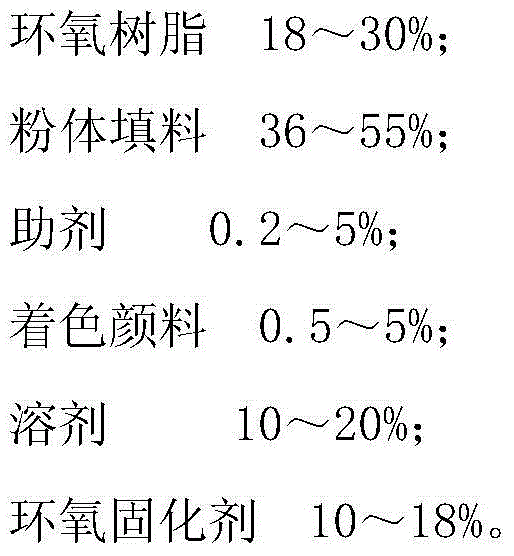

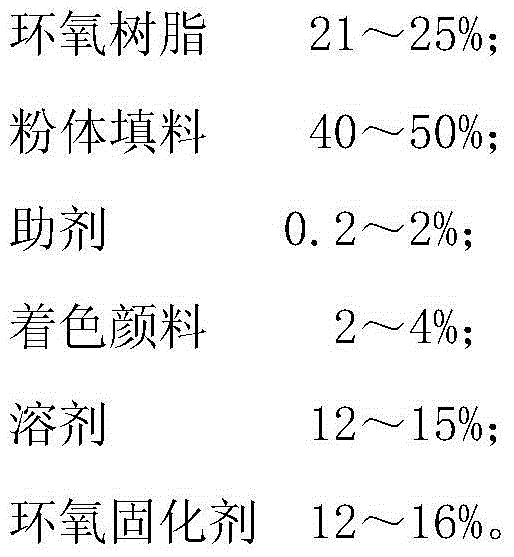

Wear-resisting type paint for dry bulk carrier cargo hold

InactiveCN104559662AShorten the intervalImprove mechanical propertiesEpoxy resin coatingsPolyamideFirming agent

The invention discloses wear-resisting type paint for a dry bulk carrier cargo hold. The wear-resisting paint comprises raw materials of components in percentage by weight as follows: 18%-30% of epoxy resin adopting one of E-54 epoxy resin, E-51 epoxy resin, E-42 epoxy resin and E-20 epoxy resin, 36%-55% of powder filler, 0.2%-5% of an auxiliary adopting one of organobentonite, fumed silica, hydrogenated castor oil or polyamide wax, 0.5%-5% of a tinting pigments adopting one or two of iron oxide red, iron oxide black and titanium dioxide, 10%-20% of solvents adopting one or two of n-butanol, dimethylbenzene and trimethylbenzene as well as 10%-18% of an epoxy curing agent adopting a polyamide curing agent or a phenol-aldehyde amine curing agent. The paint has good mechanical performance, a test result meets and far exceeds GB / T9262 marine cargo hold paint specifications, as a special paint, the wear-resisting type paint can effectively protect steel plates on the bottom layer and side walls of the dry bulk carrier cargo hold for more than five years, the maintenance time of a dry bulk carrier is shortened, and the operation cost is reduced.

Owner:SHANGHAI HILONG PETROCHEM RES INST +2

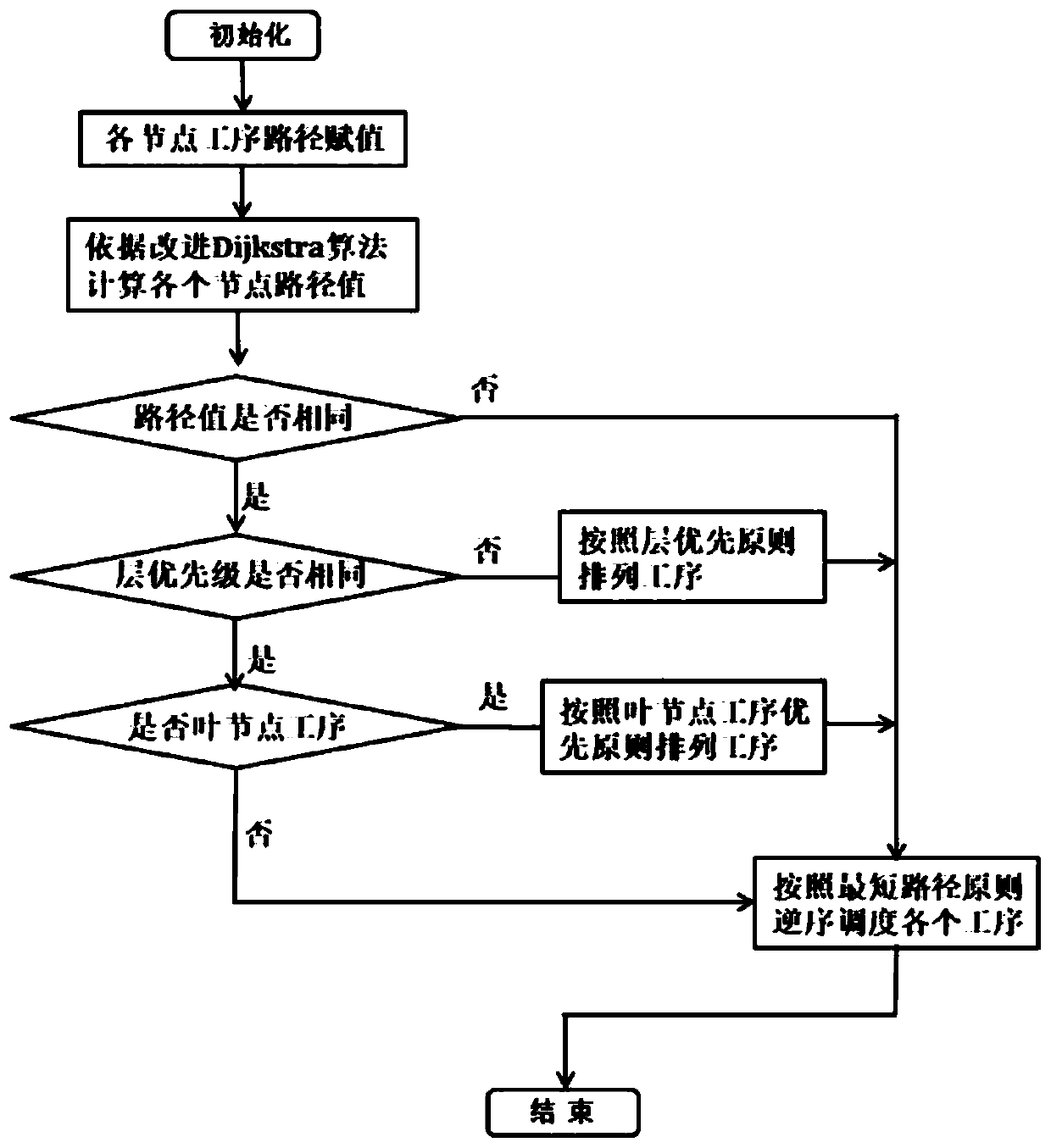

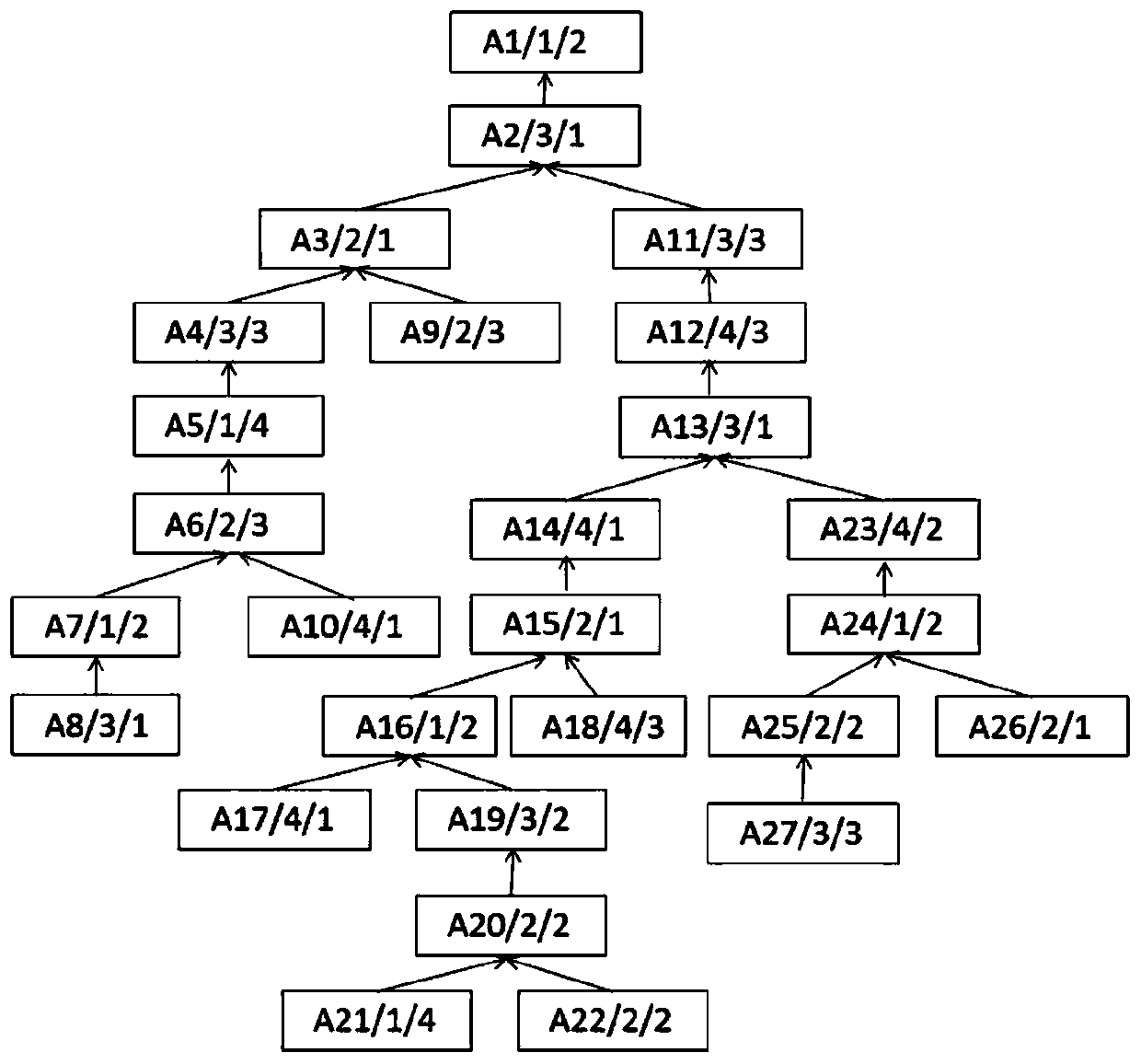

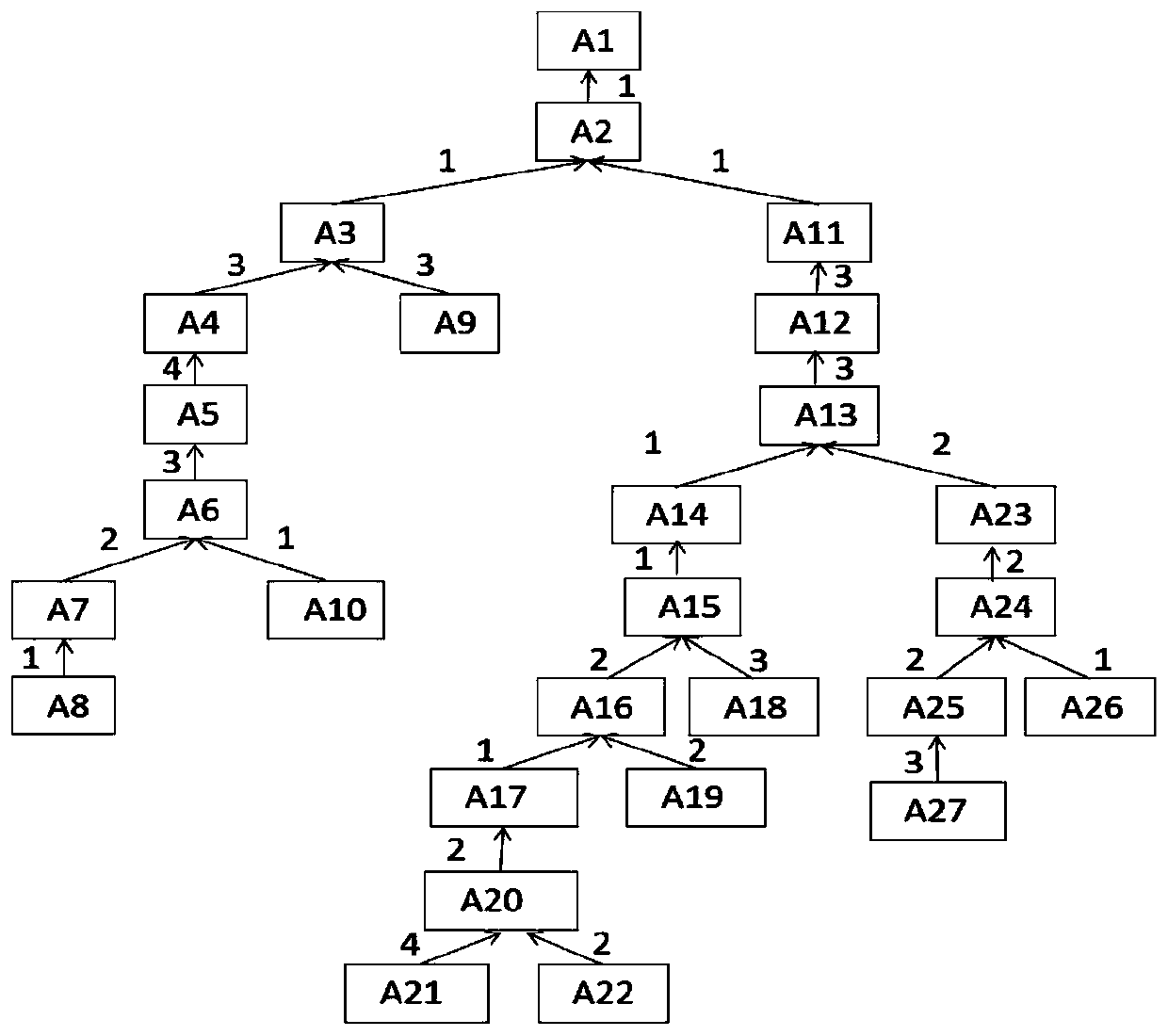

Comprehensive scheduling method based on Dijkstra algorithm

The invention provides a comprehensive scheduling method based on a Dijkstra algorithm, and the method comprises the steps: extracting the processing time of each process according to the natural attribute of a complex product process, and carrying out the path assignment of all processes; calculating a layer priority, an equipment priority and a process constraint degree of each process; according to a Dijkstra algorithm, respectively calculating path values from the root node process to all other processes; and according to the path value judgment strategy, the layer priority judgment strategy and the leaf node process judgment strategy, reversely scheduling each process according to the shortest path principle. The method provided by the invention provides a new method for solving comprehensive scheduling of general complex products, expands thinking for further deep research on comprehensive scheduling, and has certain theoretical and practical significance.

Owner:JILIN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com