Controllable constrained laser micro shot peening intensification device and method thereof

A shot peening and laser technology, applied in the field of laser processing and surface modification, can solve the problems of difficult to accurately control depth, low cost, weak plasma, etc., and achieve the effect of reducing interval time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

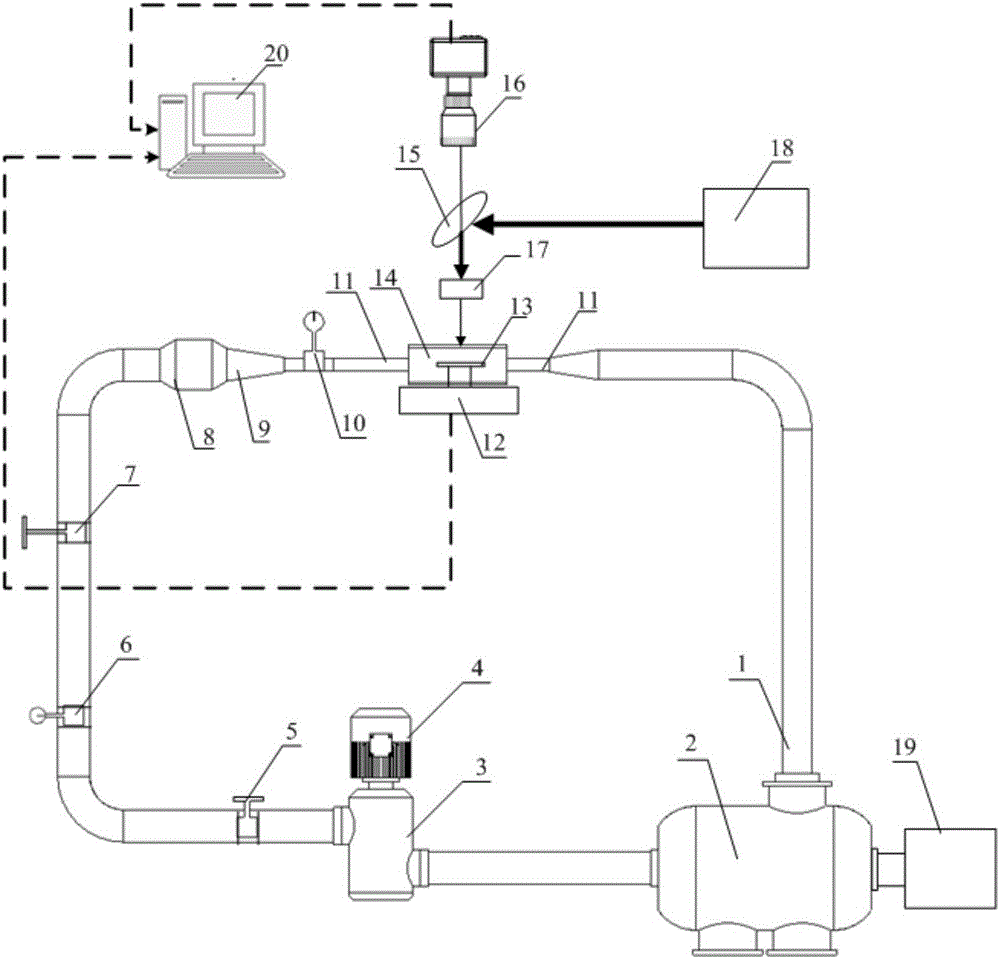

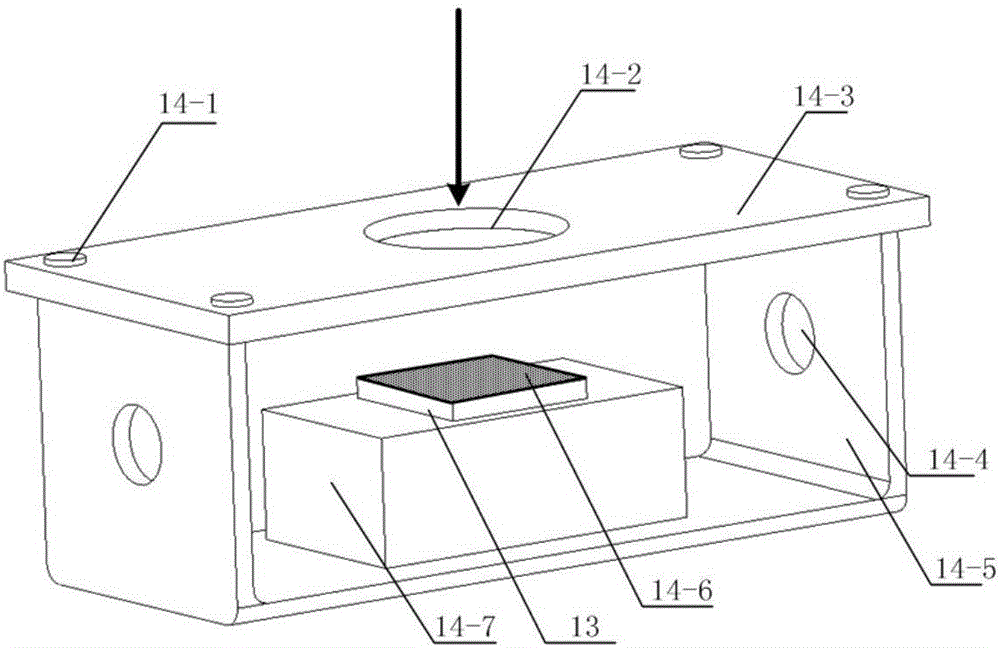

[0017] Such as figure 1 As shown, a controllable and constrained laser micro-peening strengthening device includes a water pipeline 1 for deionized water circulation; a water storage tank 2 for storing deionized water; and is used for inputting deionized water into the circulating water system Energy motor 4 and hydraulic pump 3; flow control valve 5 for controlling the flow of deionized water in the circulating water system; flowmeter 6 for measuring the flow of deionized water in the circulating water system; Pressure control valve 7 for pressure in deionized water; buffer section 8 for stabilizing deionized water; shrinking section 9 for accelerating deionized water velocity in circulating water system; pressure gauge for displaying deionized water pressure in circulating water system 10. The hose 11 used to connect the sample chamber 14 and the shrinkage section 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com