Patents

Literature

107results about How to "Constant height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

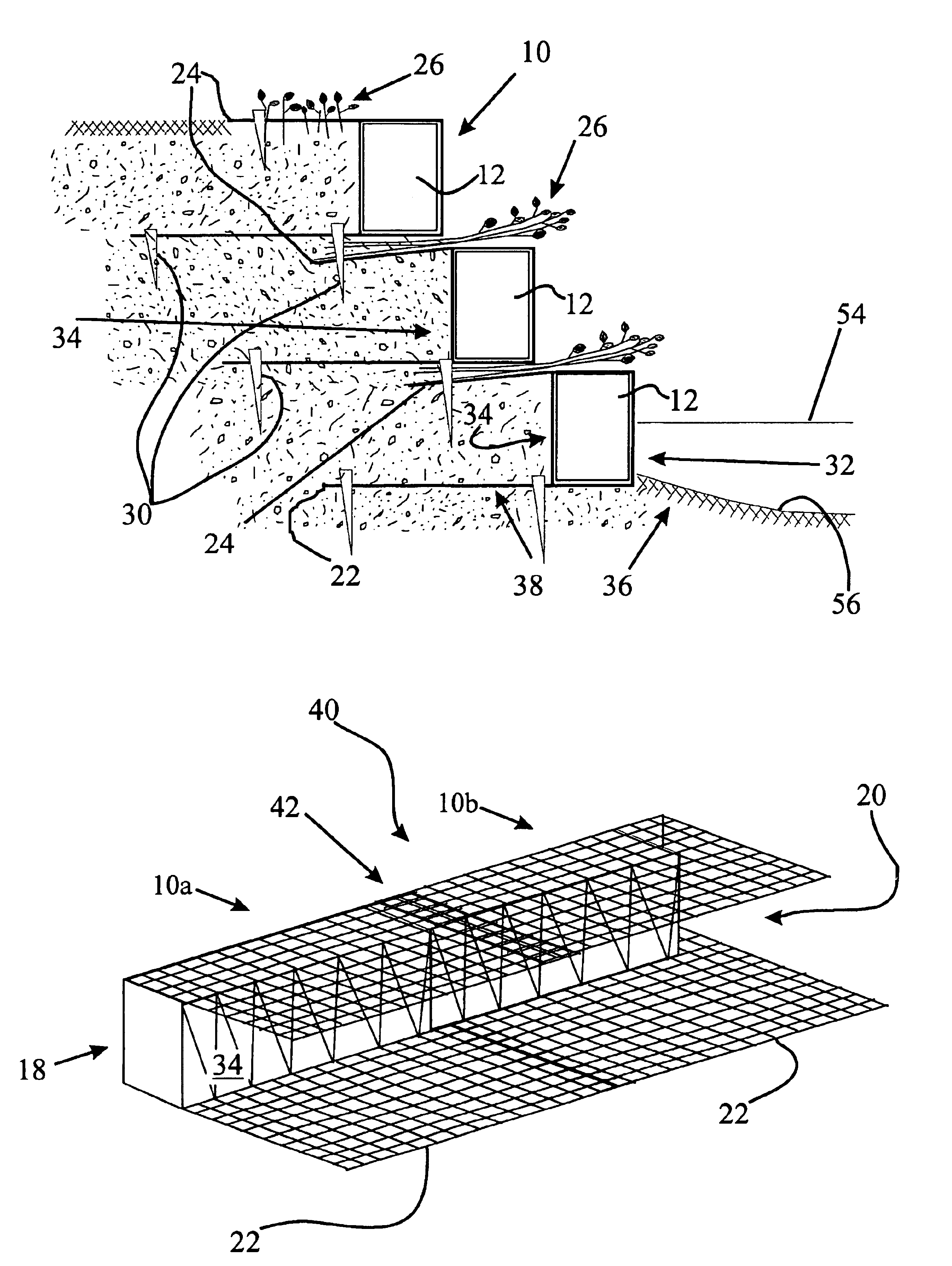

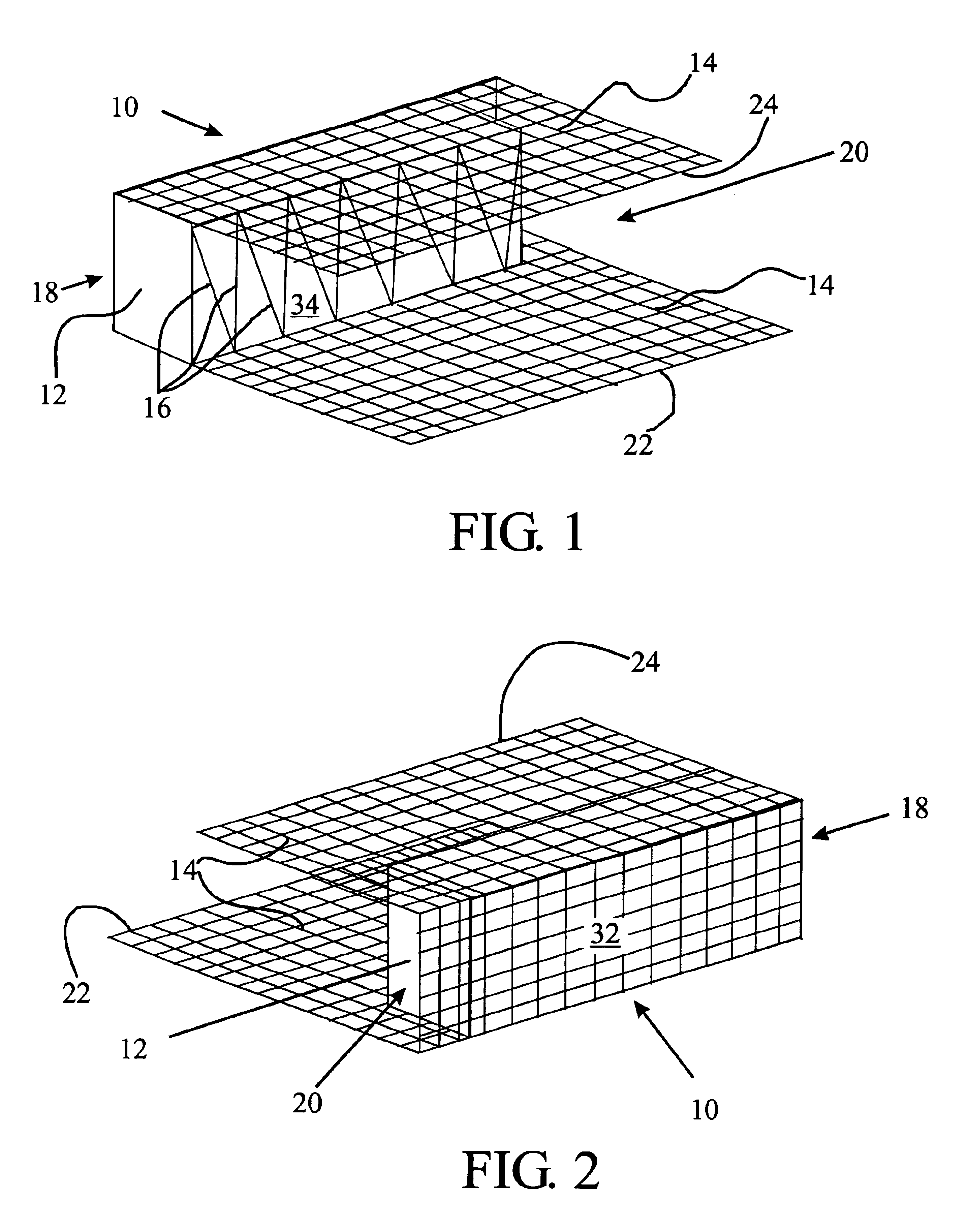

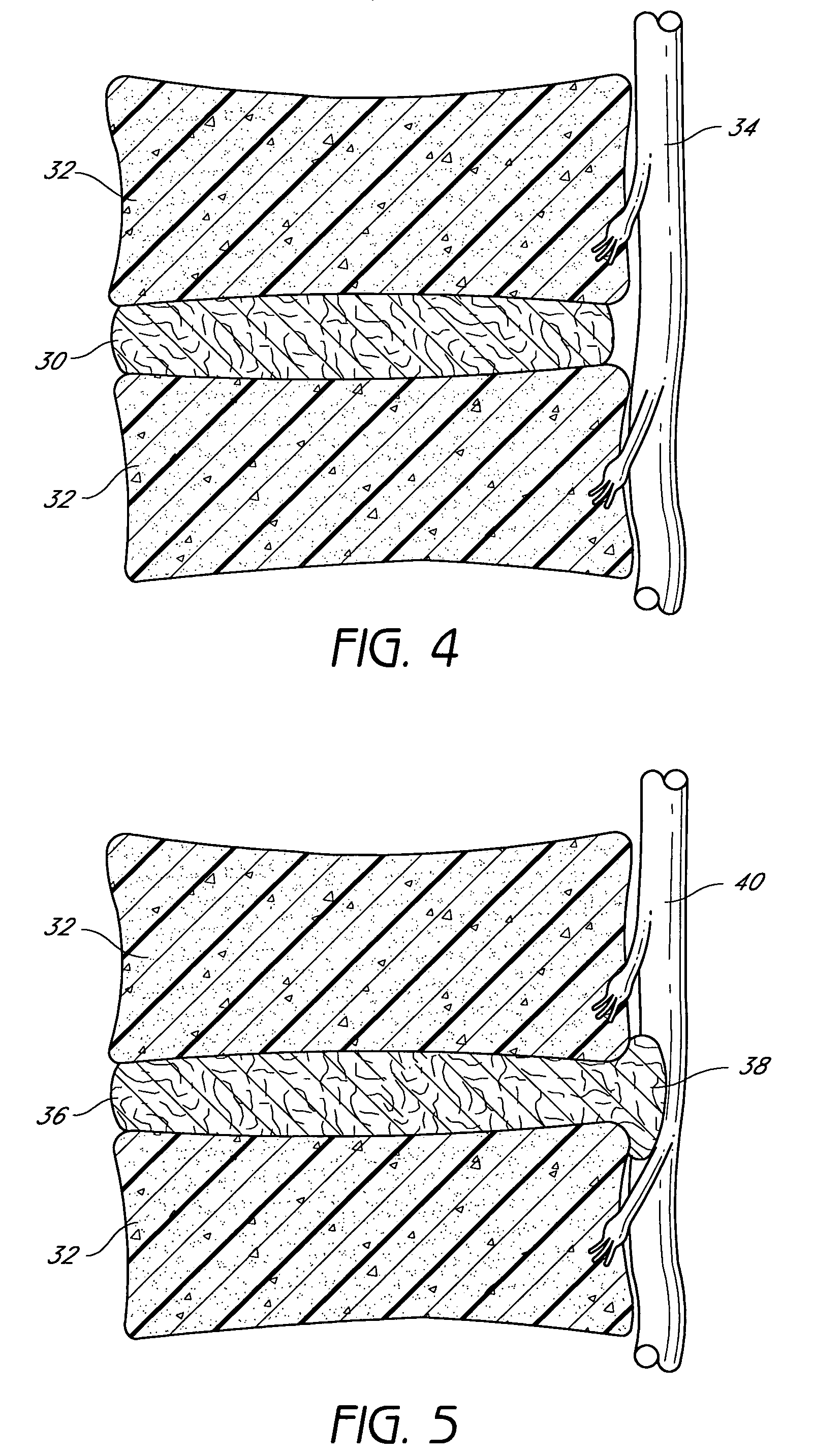

Self-anchoring fiber block system

InactiveUS6893193B2Promote vegetation growthEasy to installArtificial islandsClimate change adaptationFiberEngineering

A fiber block segment suitable for controlling erosion and stabilizing soil is described that comprises an elongated fiber block formed of a densely packed elongated thick fibrous material. The fiber block is wrapped with a fabric around three sides so that the fabric defines a top anchor portion and a bottom anchor portions extending from the block. The fiber block is securely attached to the wrapped fabric by another fabric or twine spanning the fourth side of the block. Additionally, the fabric is wrapped only up to the edges defining one end (a male end) and beyond the edges defining the opposite end (the female end) to define a pouch-like structure at the female end. The fiber block is made of coconut fibers (coir). The fabric is woven from coir twine, and coir twine secures the fabric to the fiber block.

Owner:SANTHA B LANKA

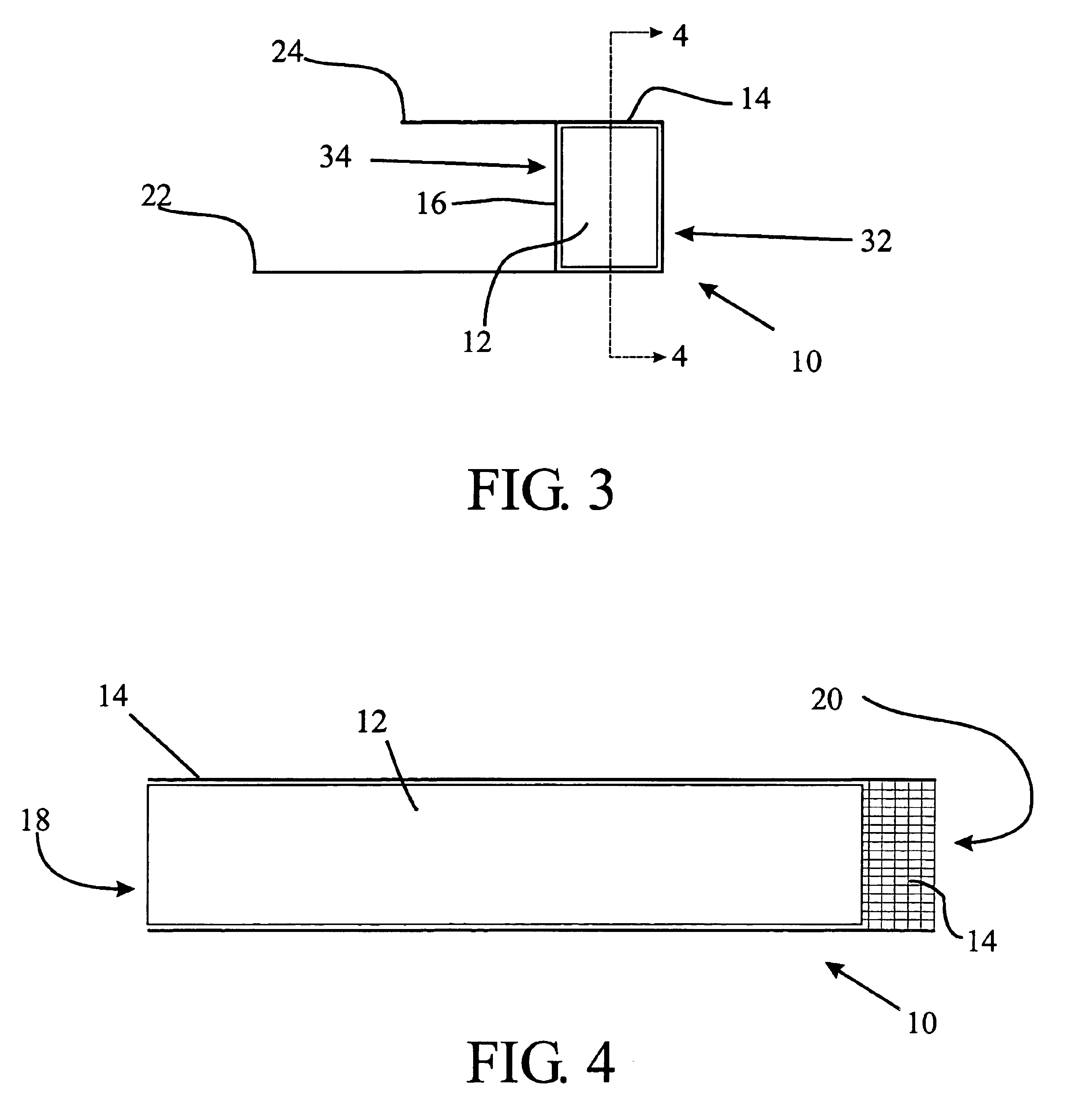

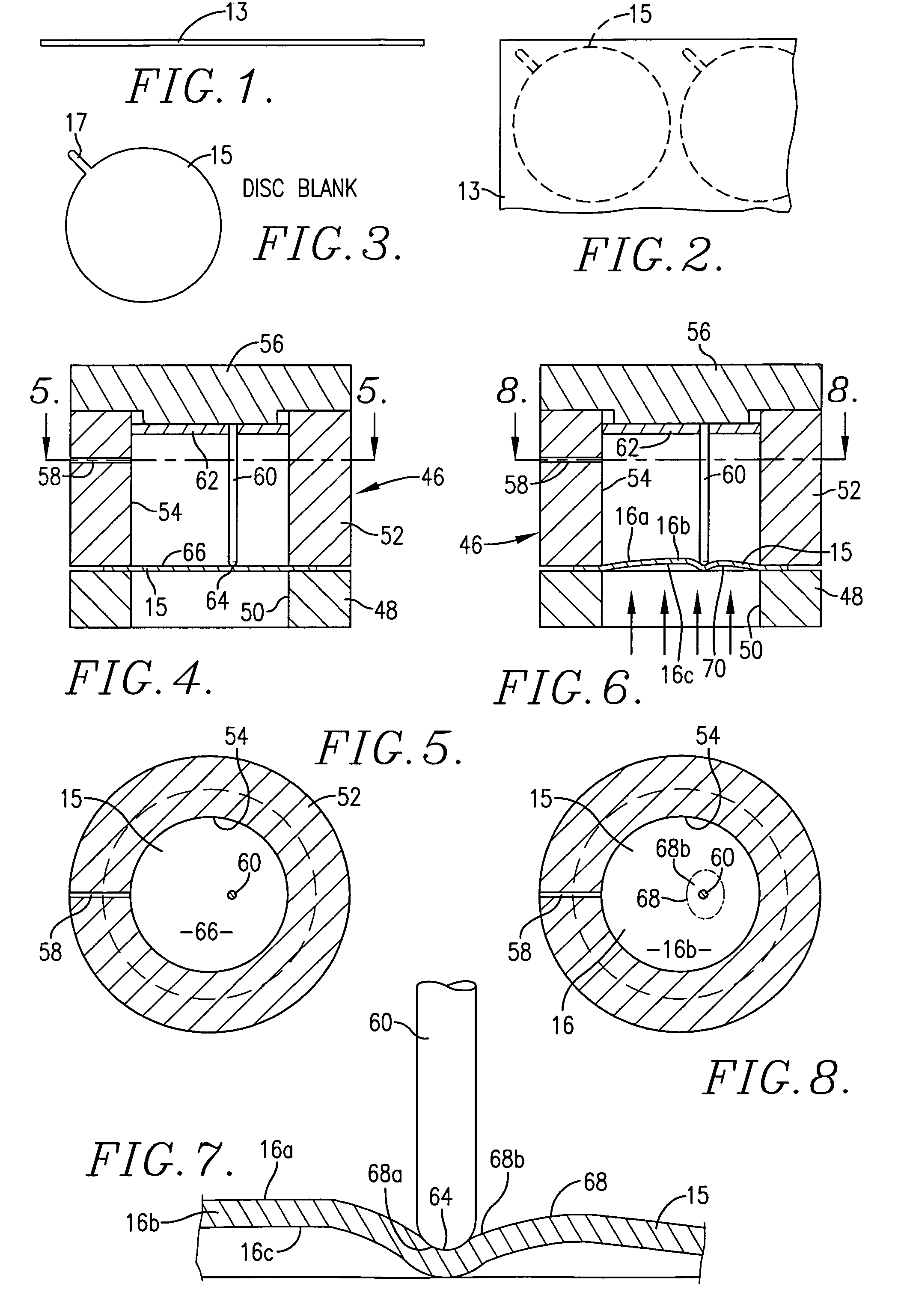

Reverse acting rupture disc with laser-defined electropolished line of weakness and method of forming the line of weakness

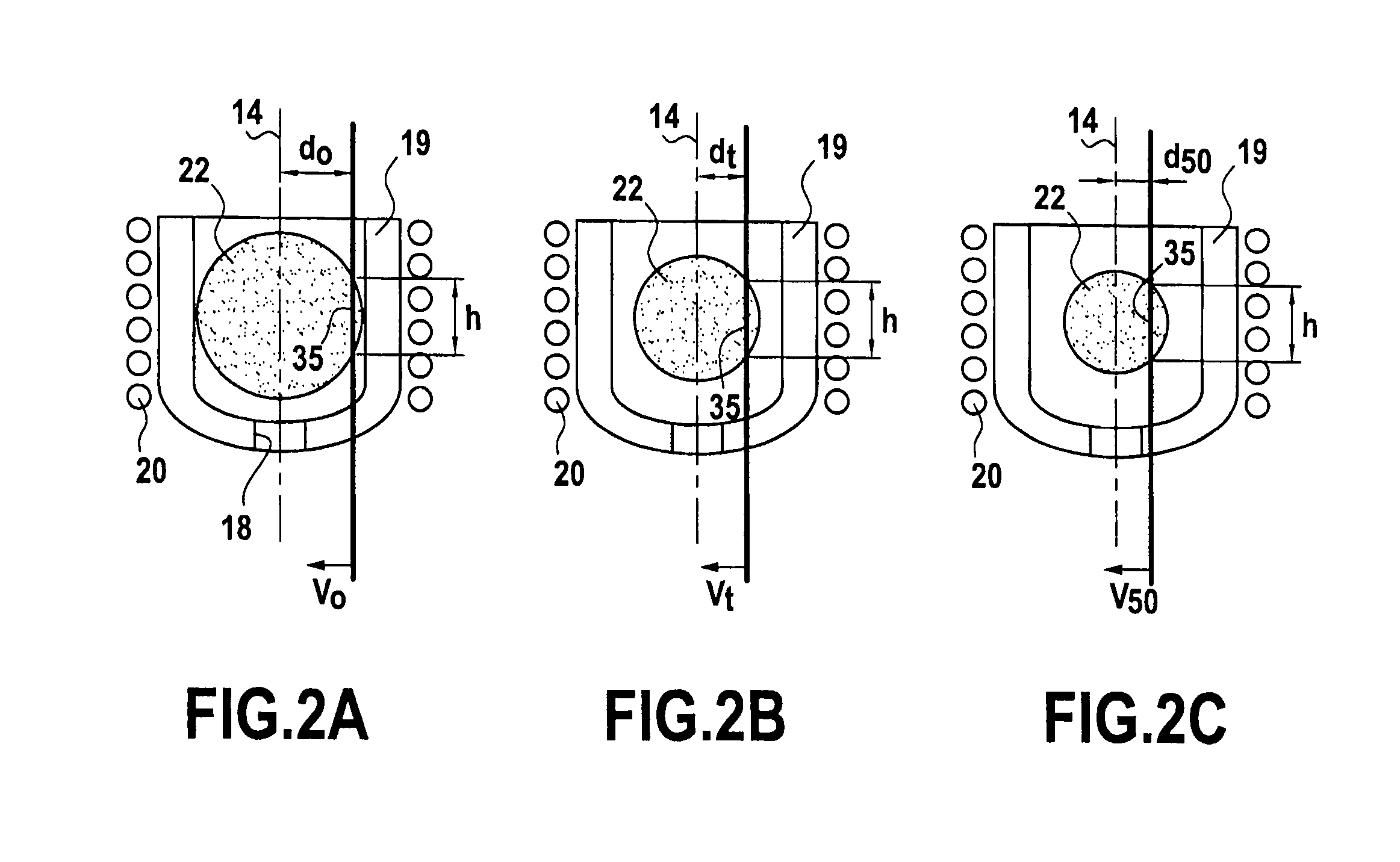

A reverse acting rupture disc is provided having a laser defined electropolished line-of-weakness recess, and an improved method of forming an electropolished line-of-weakness recess in a reverse acting rupture disc that assures full opening of the disc upon reversal. A rupture disc blank is pre-bulged, final bulged, and then provided with a layer of resist material. A laser is used to remove at least a portion of the layer of resist material corresponding to a desired line-of-weakness recess in the concave face of the bulged rupture disc. The disc is then subjected to an electropolishing operation to remove metal from the lased area of the rupture disc, thereby forming a lustrous polished line-of-weakness recess in the disc of desired configuration and of a predetermined depth that is related to material thickness. The electropolished line of weakness is defined by spaced opposed channel portions separated by a central raised crown portion wherein the channel portions are of greater depth than the crown portion. The burst / reversal pressure of the disc having an electropolished line-of-weakness recess may be selectively controlled by varying the pre-bulging pressure on the disc.

Owner:FIKE CORP

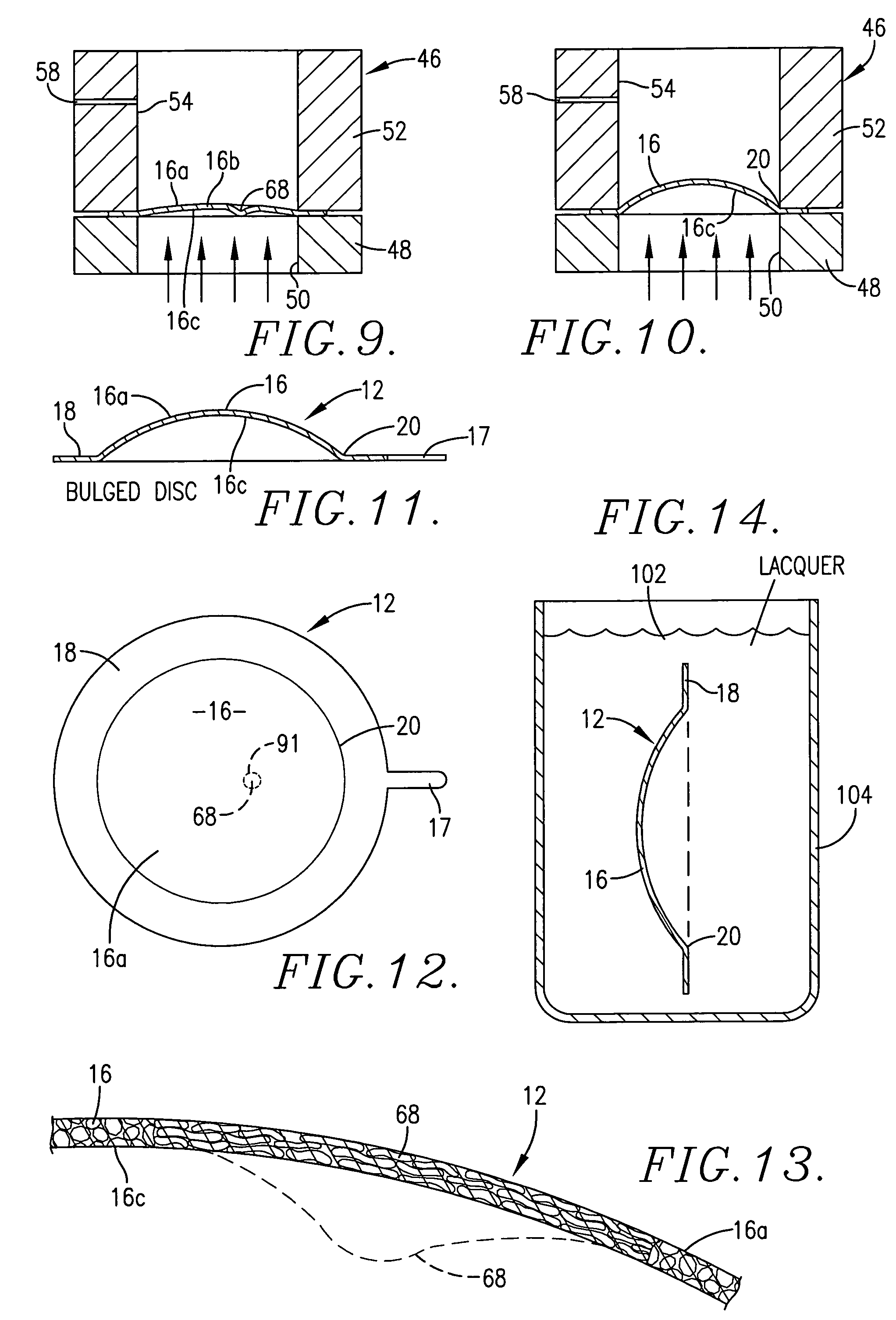

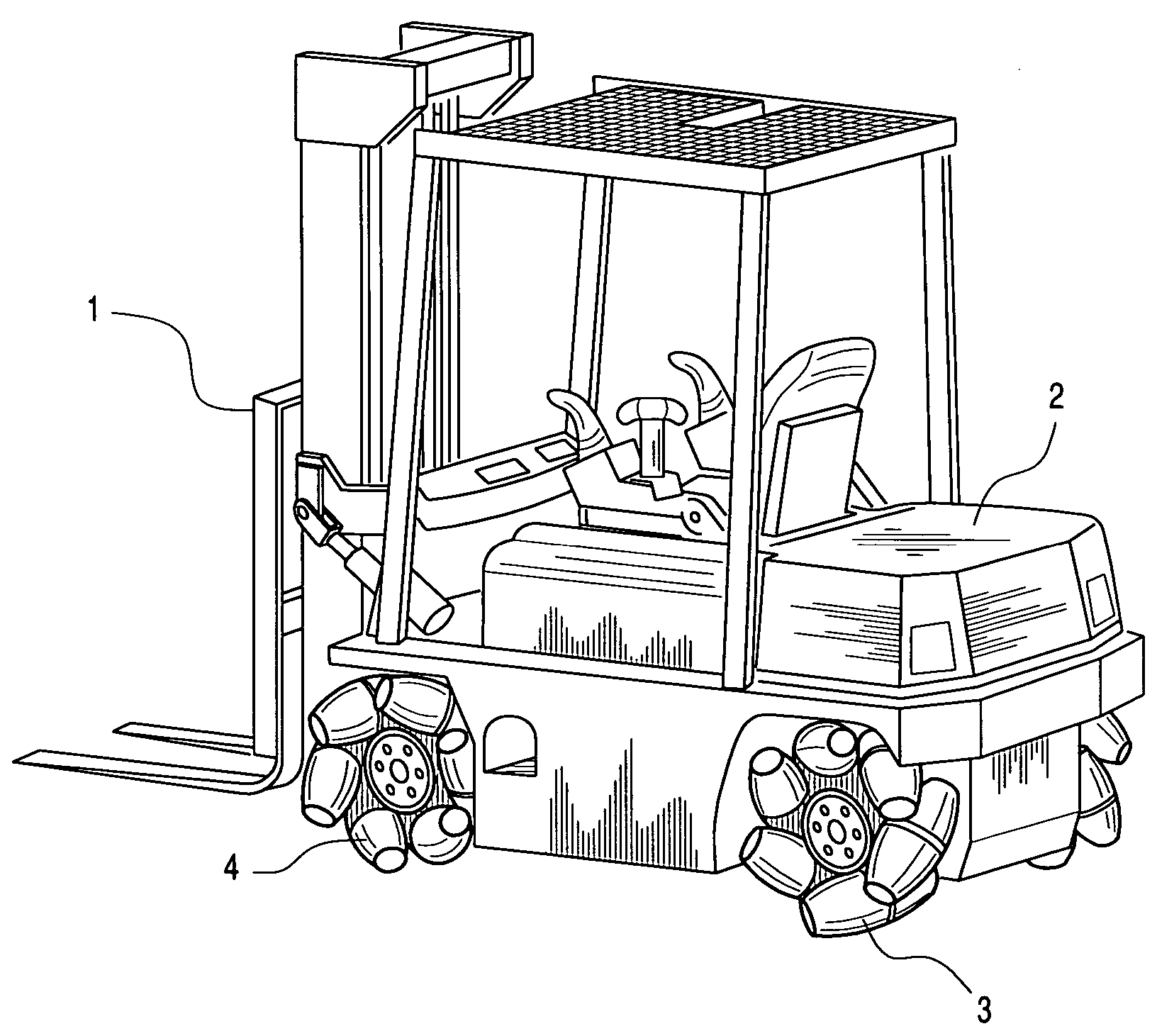

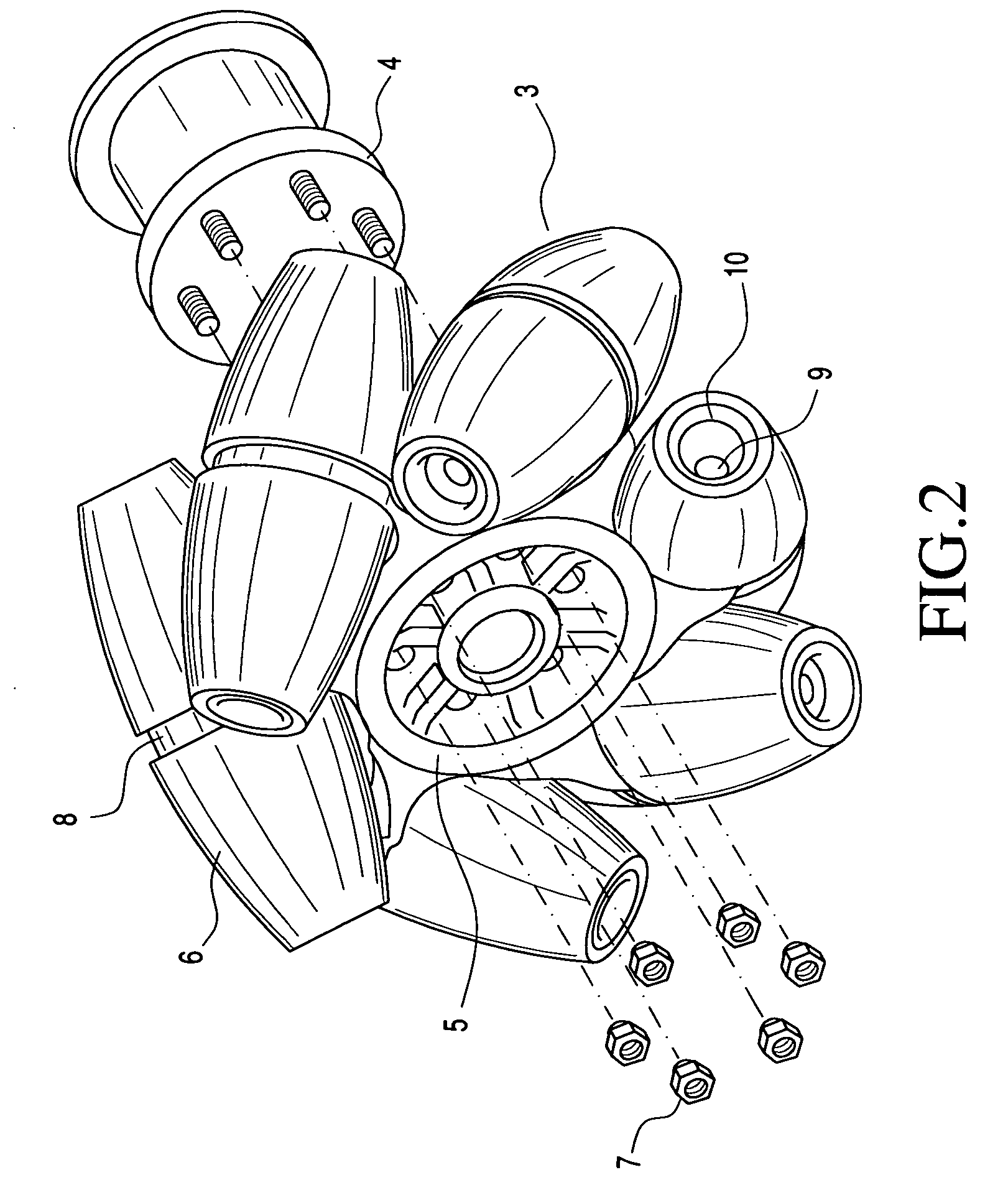

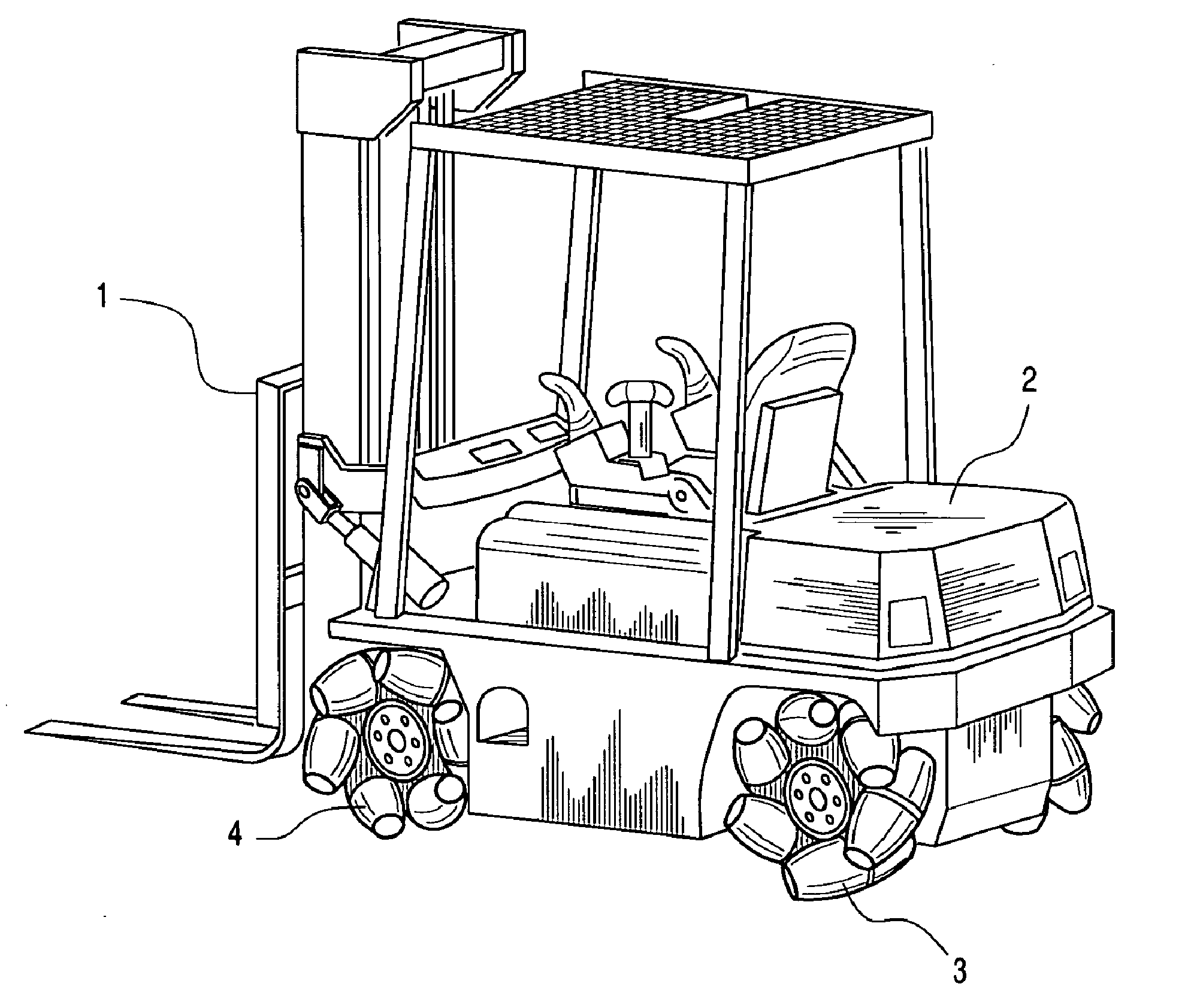

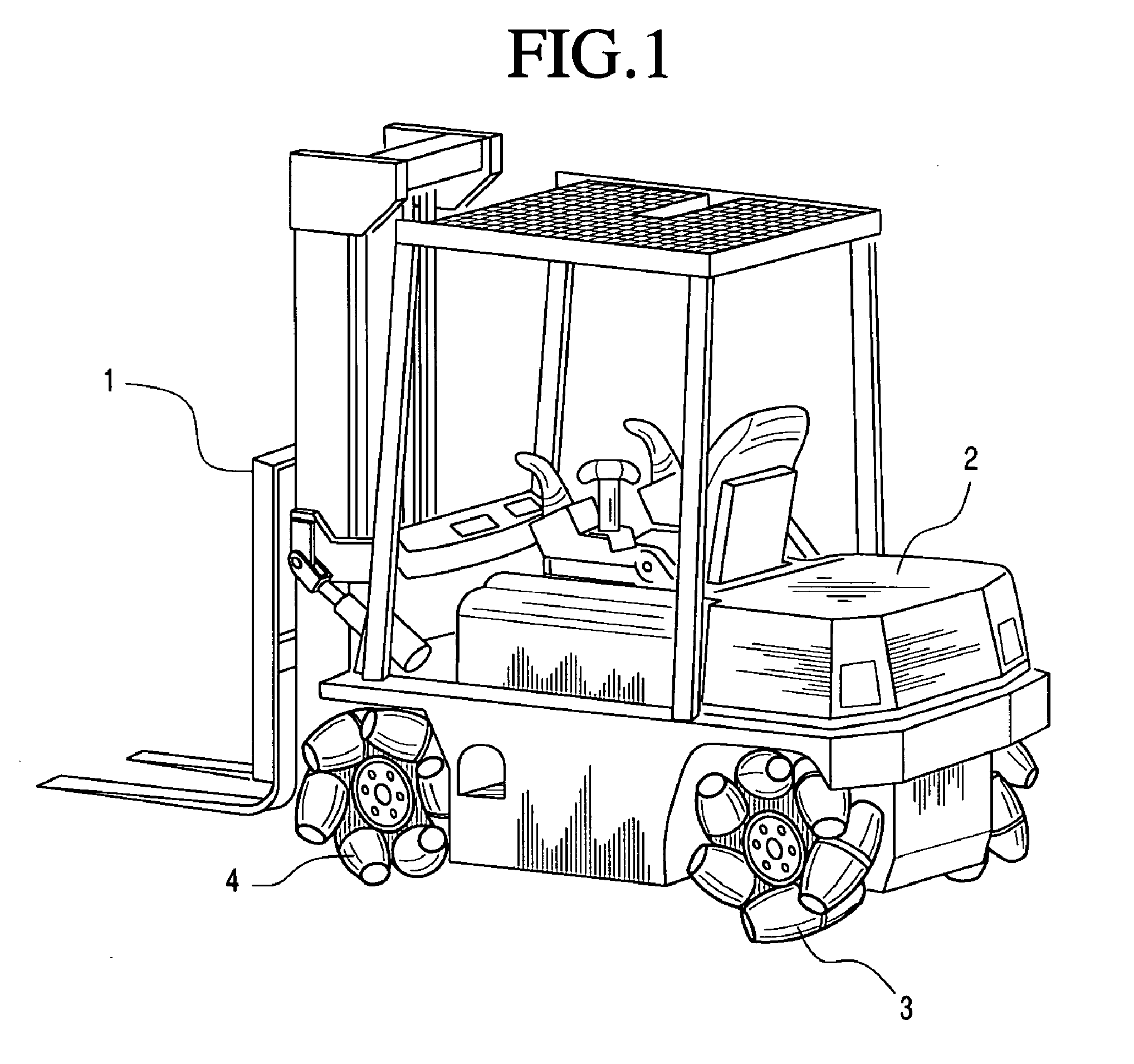

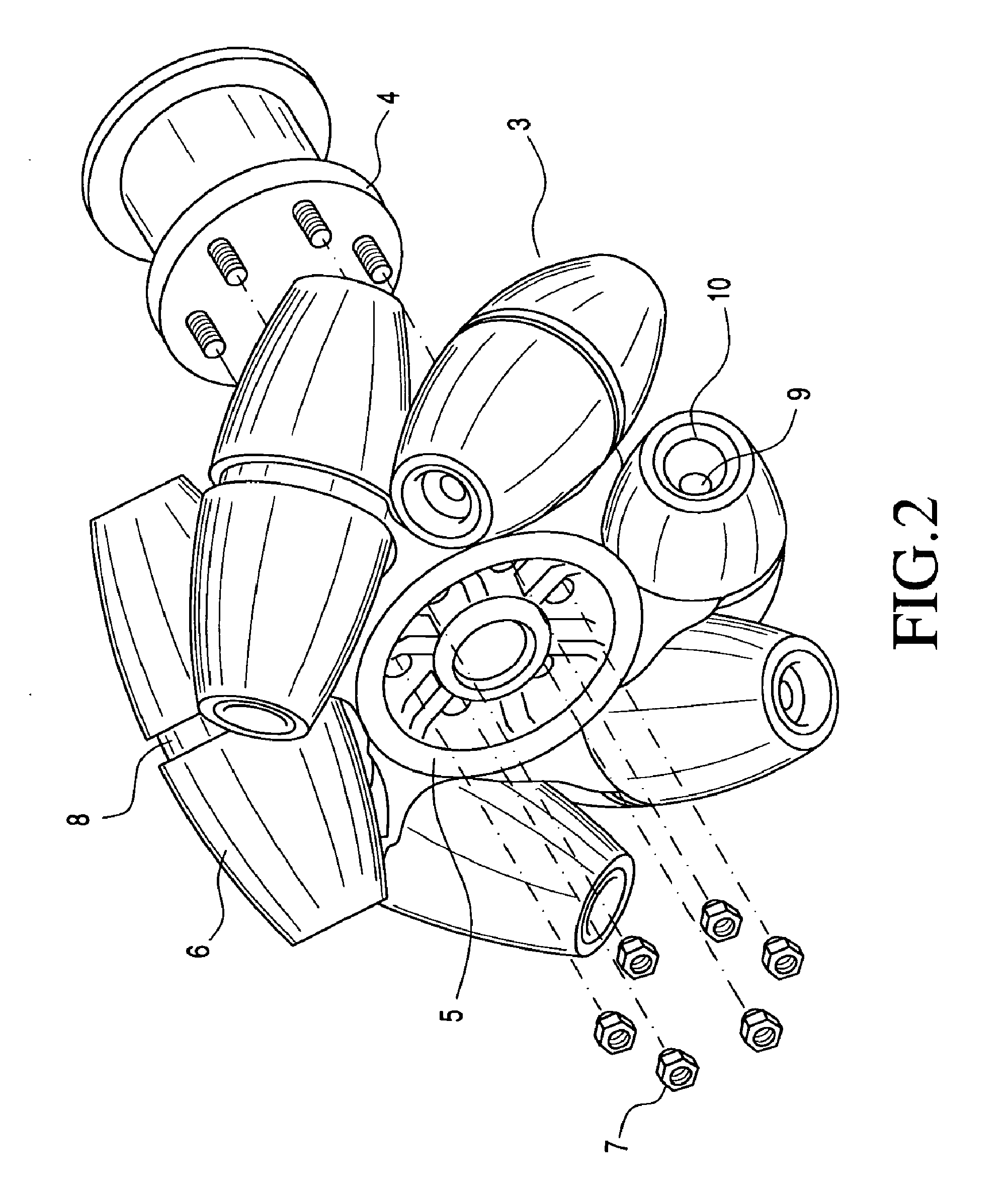

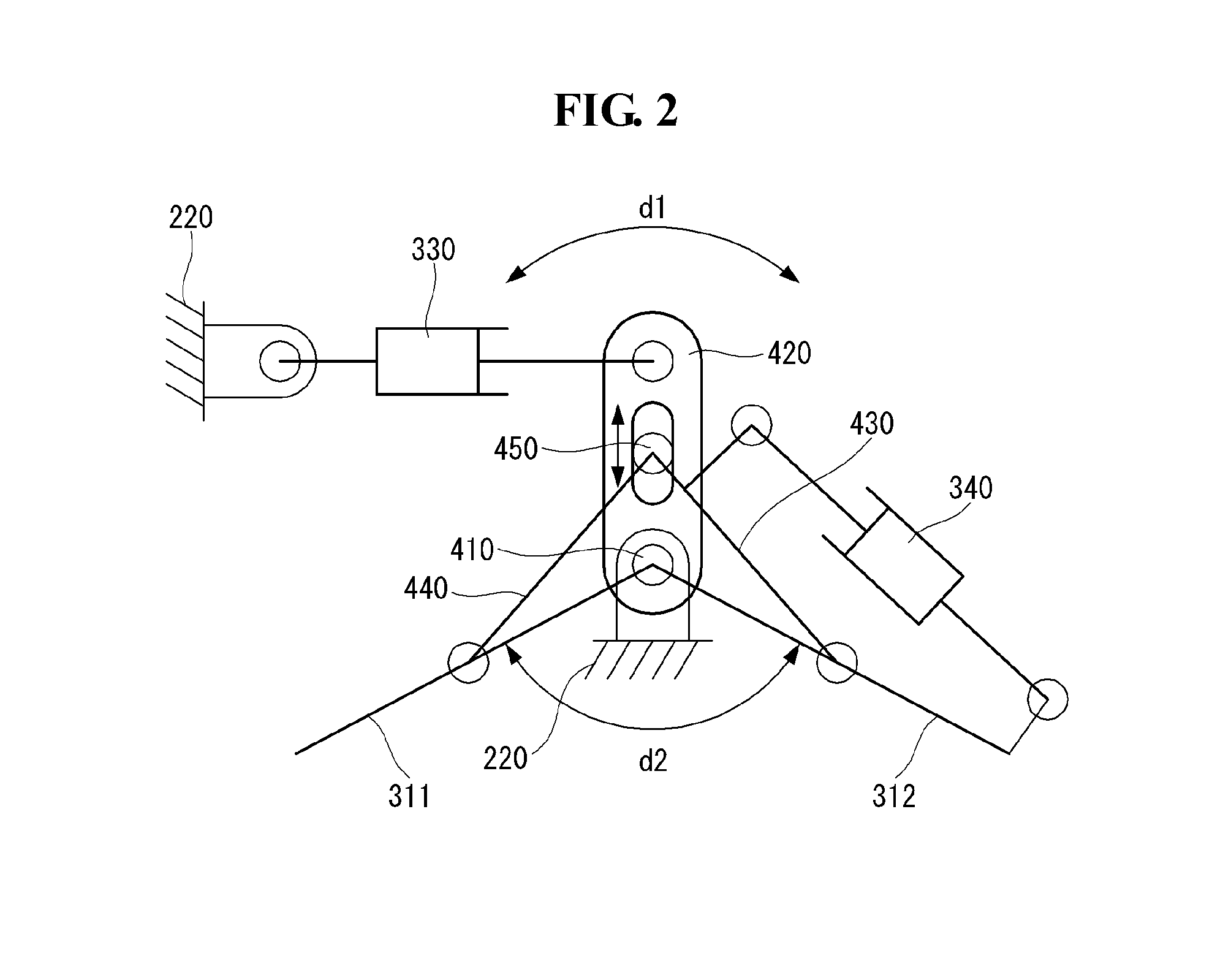

Omni-directional wheels and methods and vehicles employing same

InactiveUS20050183896A1Constant ride heightLow wheel vibrationHybrid vehiclesGas pressure propulsion mountingEngineeringOmni directional

Owner:AIRTRAX

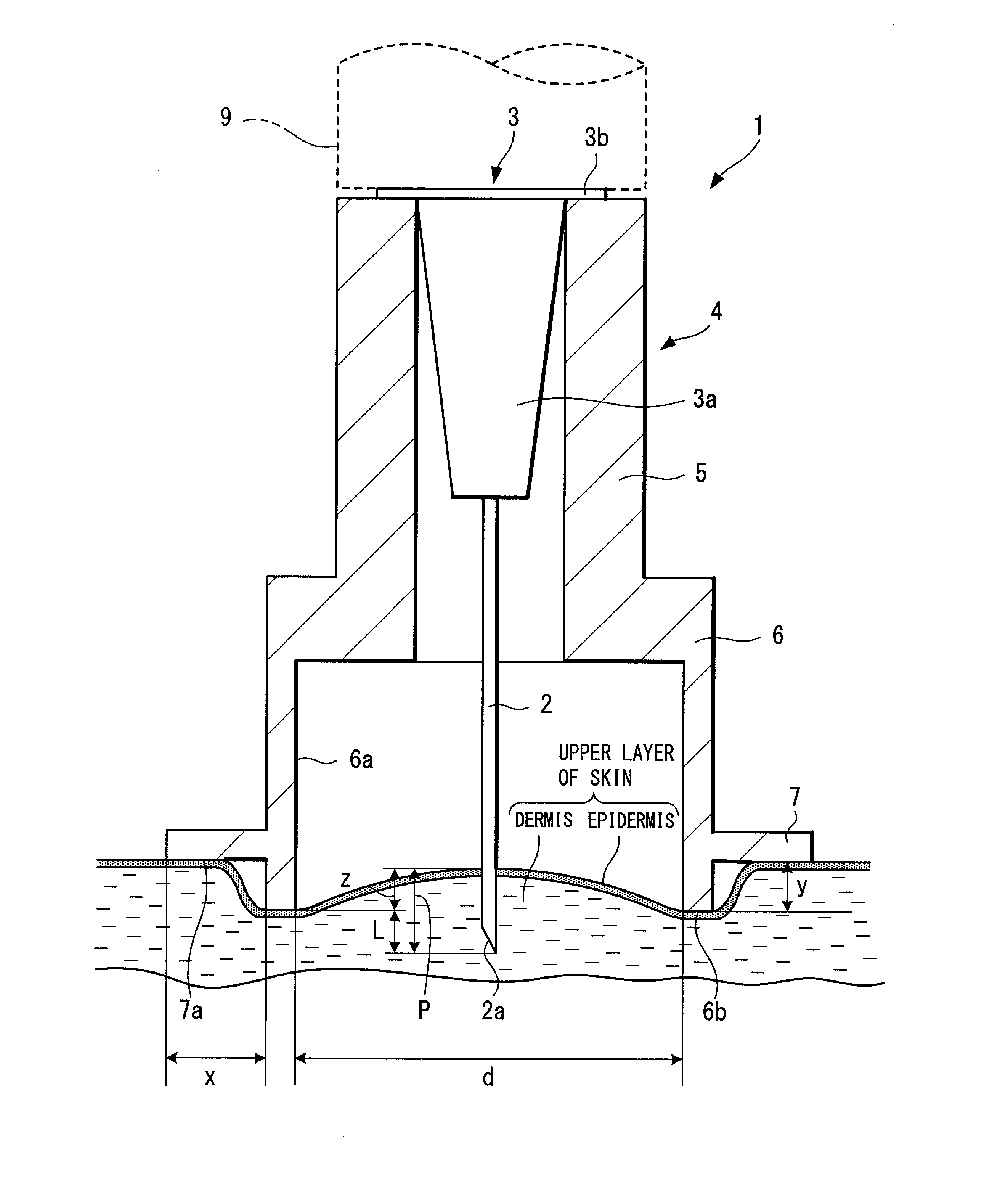

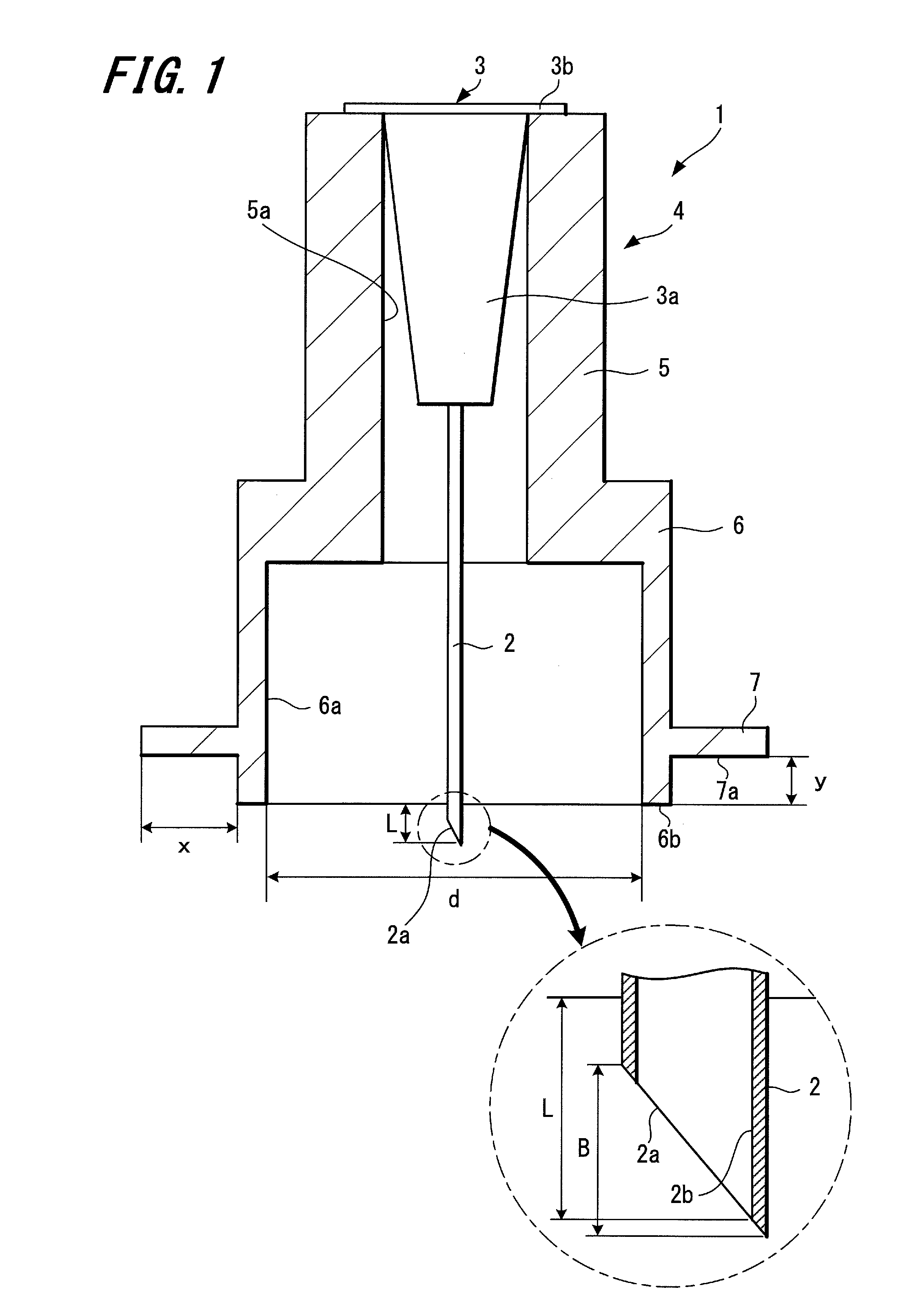

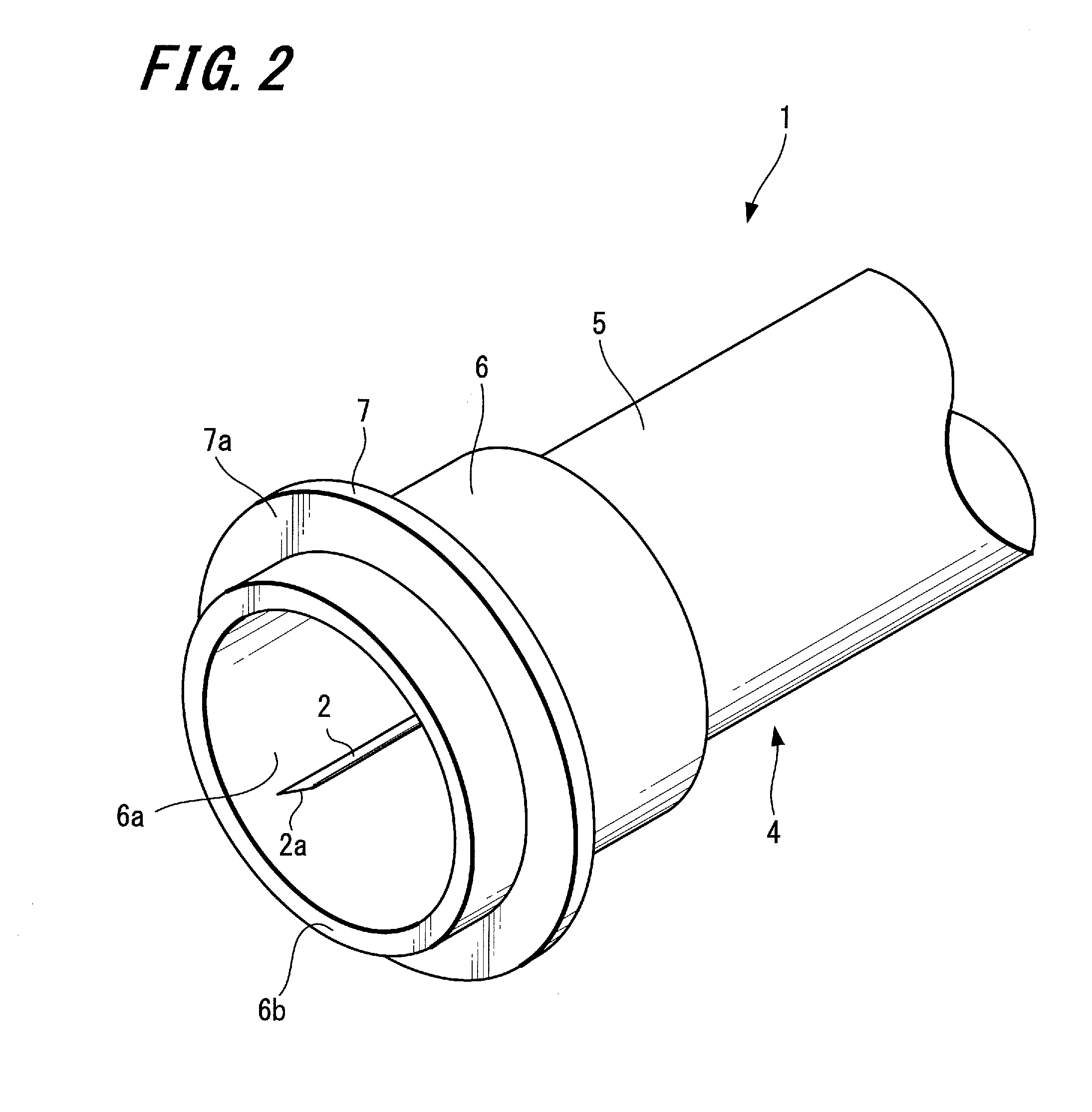

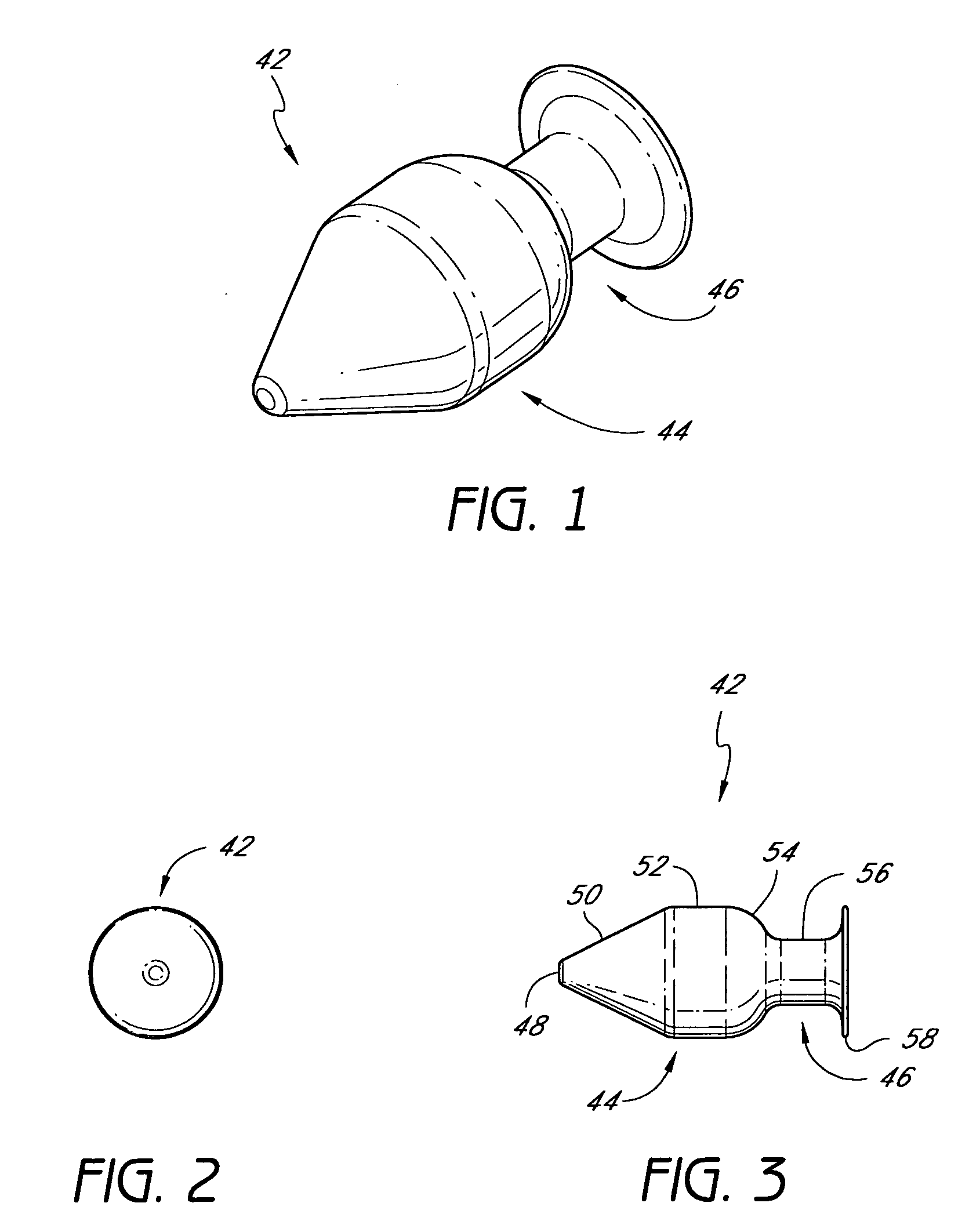

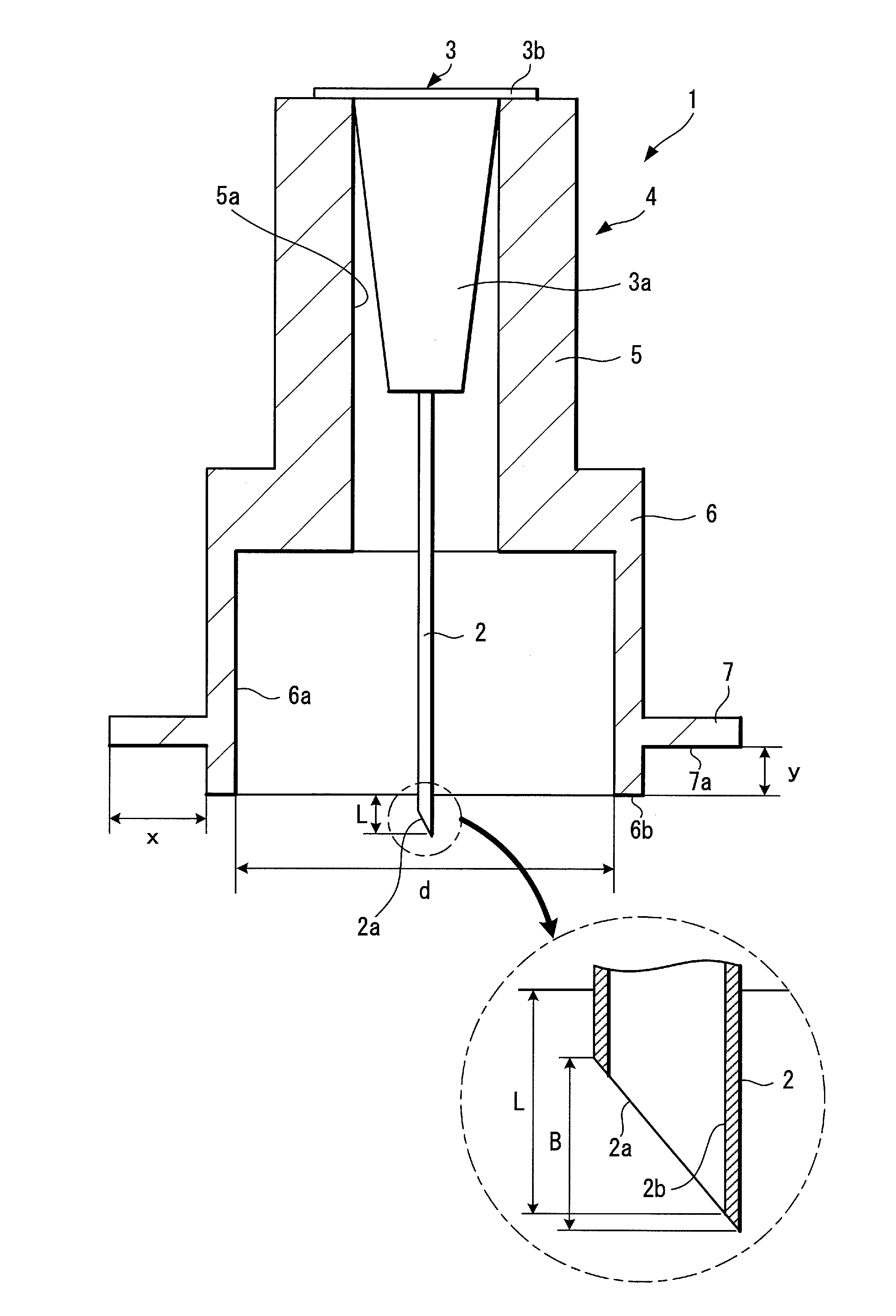

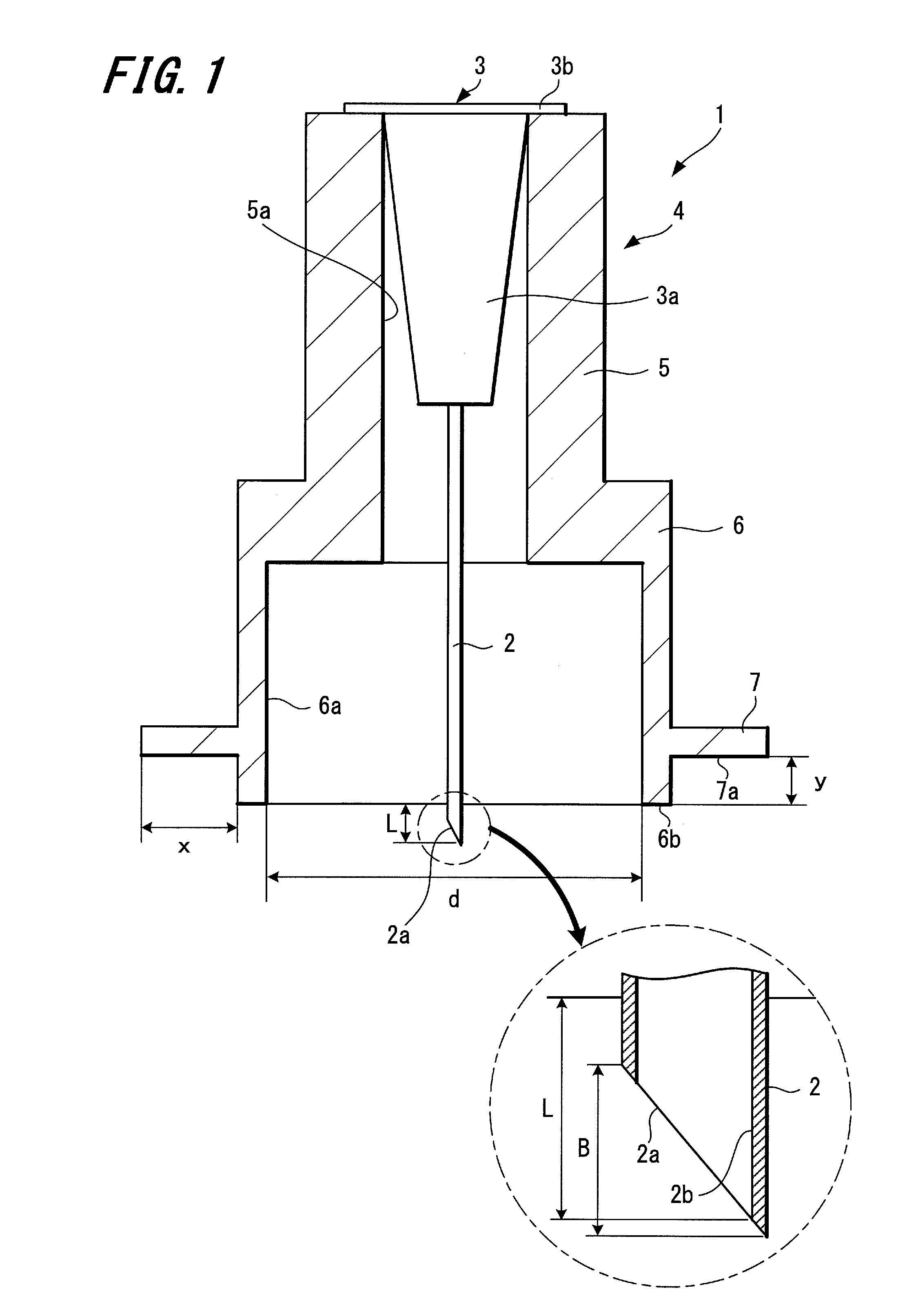

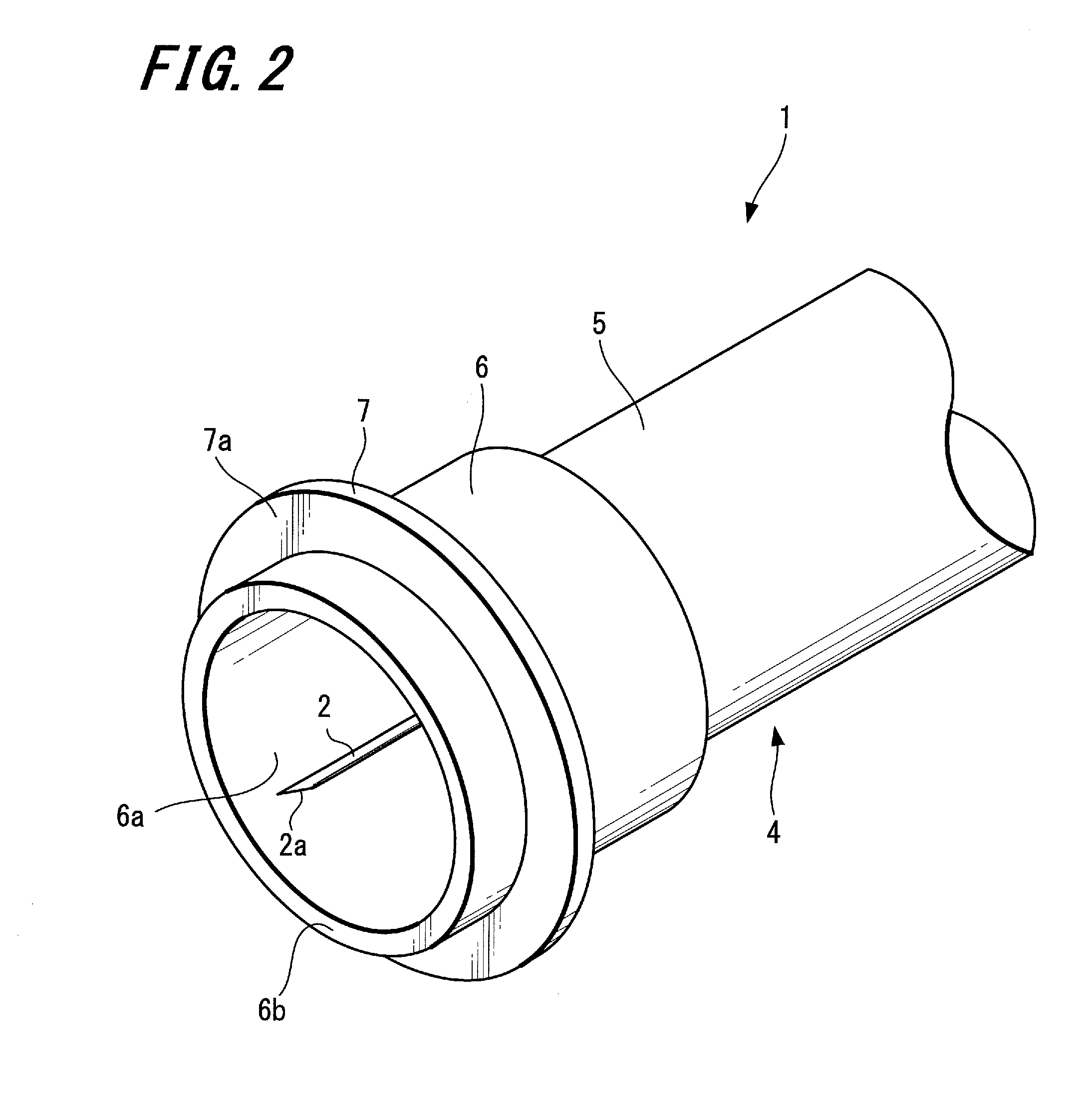

Injection needle assembly and drug injection device

To securely position a needle tip and a blade face of a needle tube inserted into the skin in a predetermined site of a living body, such as the upper layer of skin, an injection needle assembly includes a needle tube having a needle tip capable of puncturing a living body, a hub holding the needle tube, a stabilizer, and a guide portion. The stabilizer is formed in a tubular shape surrounding the circumference of the needle tube, and an end face is pressed against the skin, and thereby a raised portion of the skin is formed in a tube hole. The guide portion is arranged on the stabilizer, and is adapted to recognize a press-in distance y of the stabilizer to the skin.

Owner:TERUMO KK

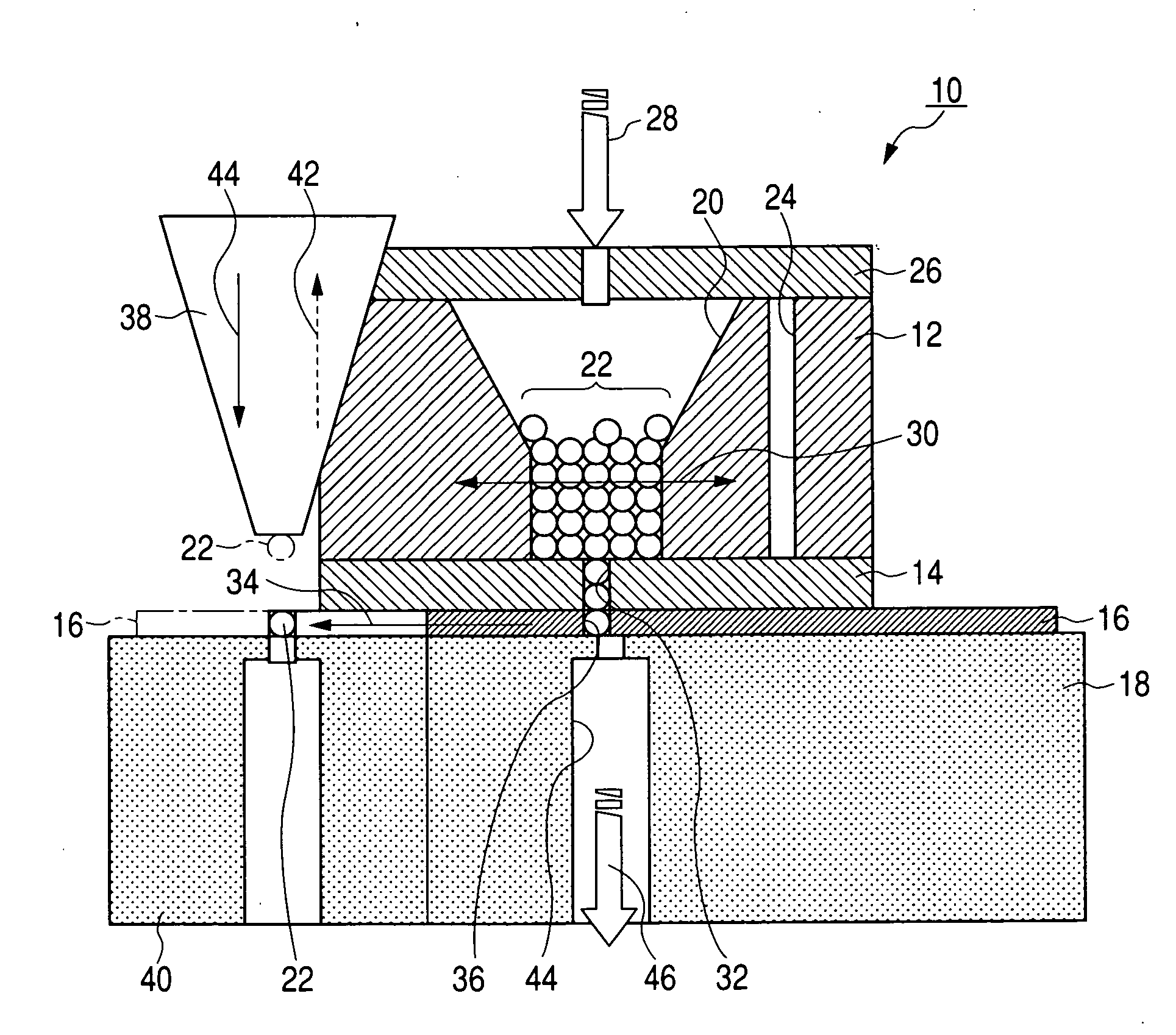

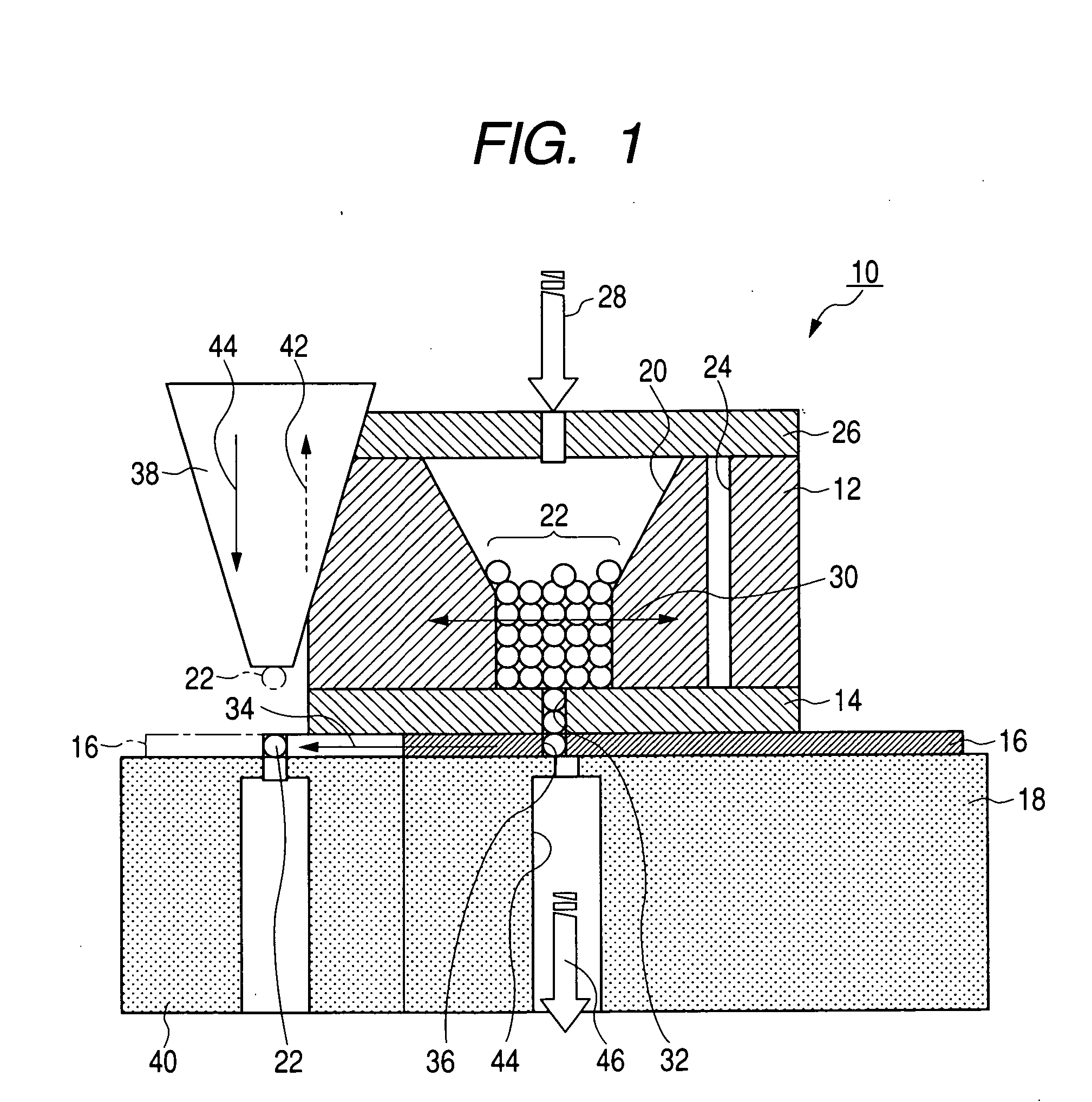

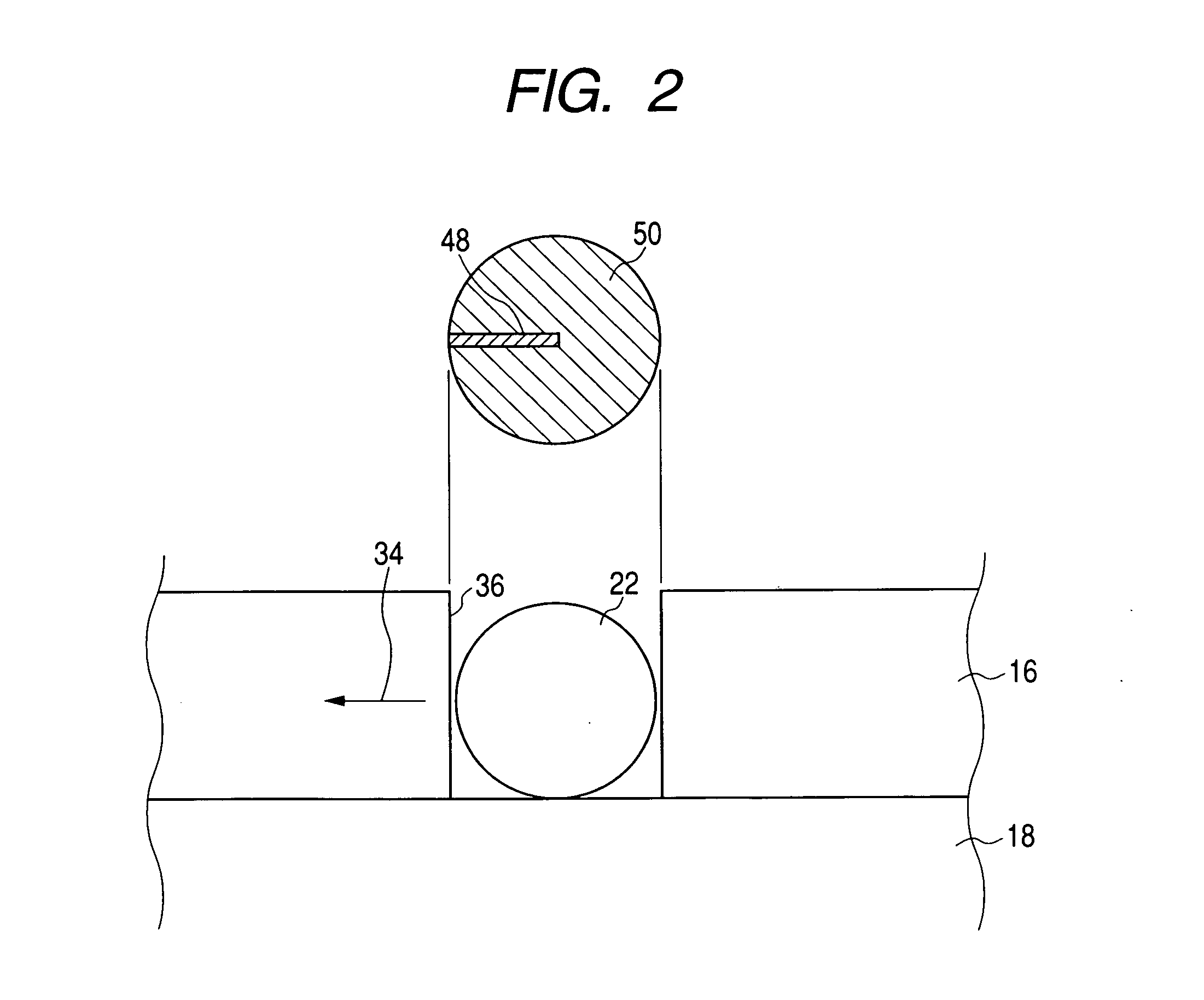

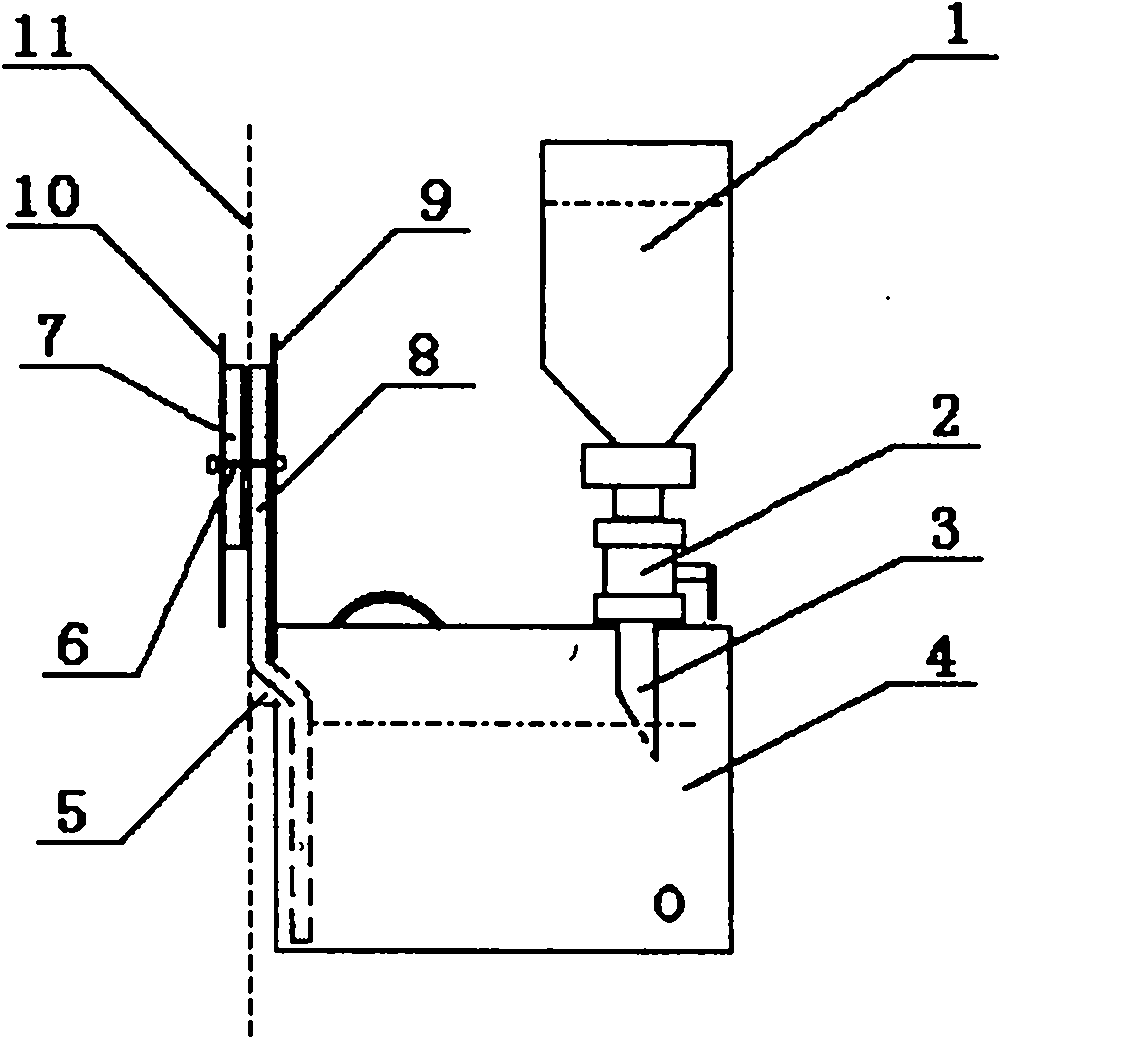

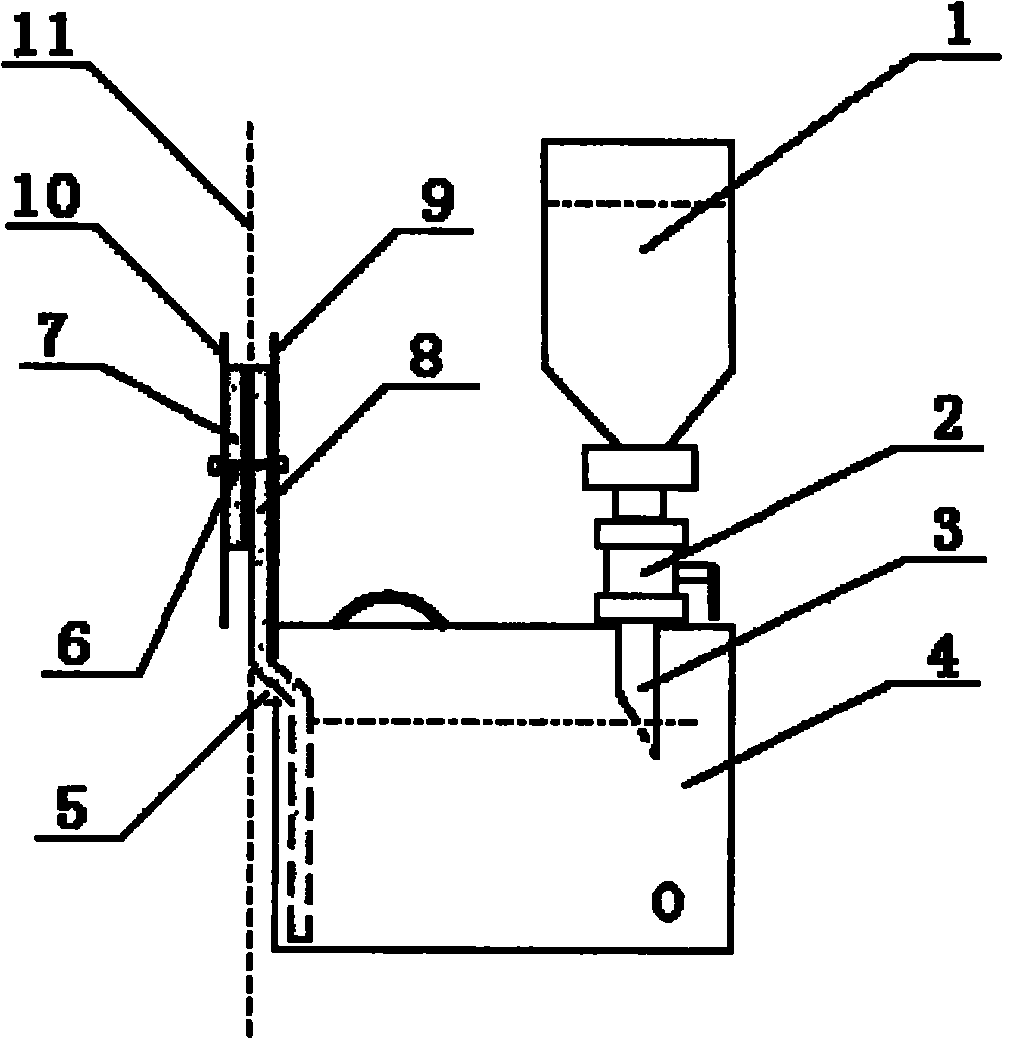

Solder ball supplying method and supplying device

InactiveUS20050045701A1Easy to disassembleSeparation is worsenedPrinted circuit assemblingWelding/cutting media/materialsSolder ballEngineering

After introducing a solder ball from a hopper into a receiving hole of a ball separator, the ball separator is slid between blocks, and the solder ball is sent out to a portion outside of the blocks. By suctioning the solder ball from within a projected region on a lower block which is situated inside of the receiving hole at a time when the solder ball is taken into the receiving hole and surrounds a rolling trajectory of the solder ball that has been taken into the receiving hole, the solder ball is forcibly introduced into the receiving hole.

Owner:SAE MAGNETICS H K LTD 50

Omni-directional wheels and methods and vehicles employing same

InactiveUS20080087484A1Constant ride heightLow wheel vibrationSteering linkagesLifting devicesEngineeringMechanical engineering

Owner:AIRTRAX

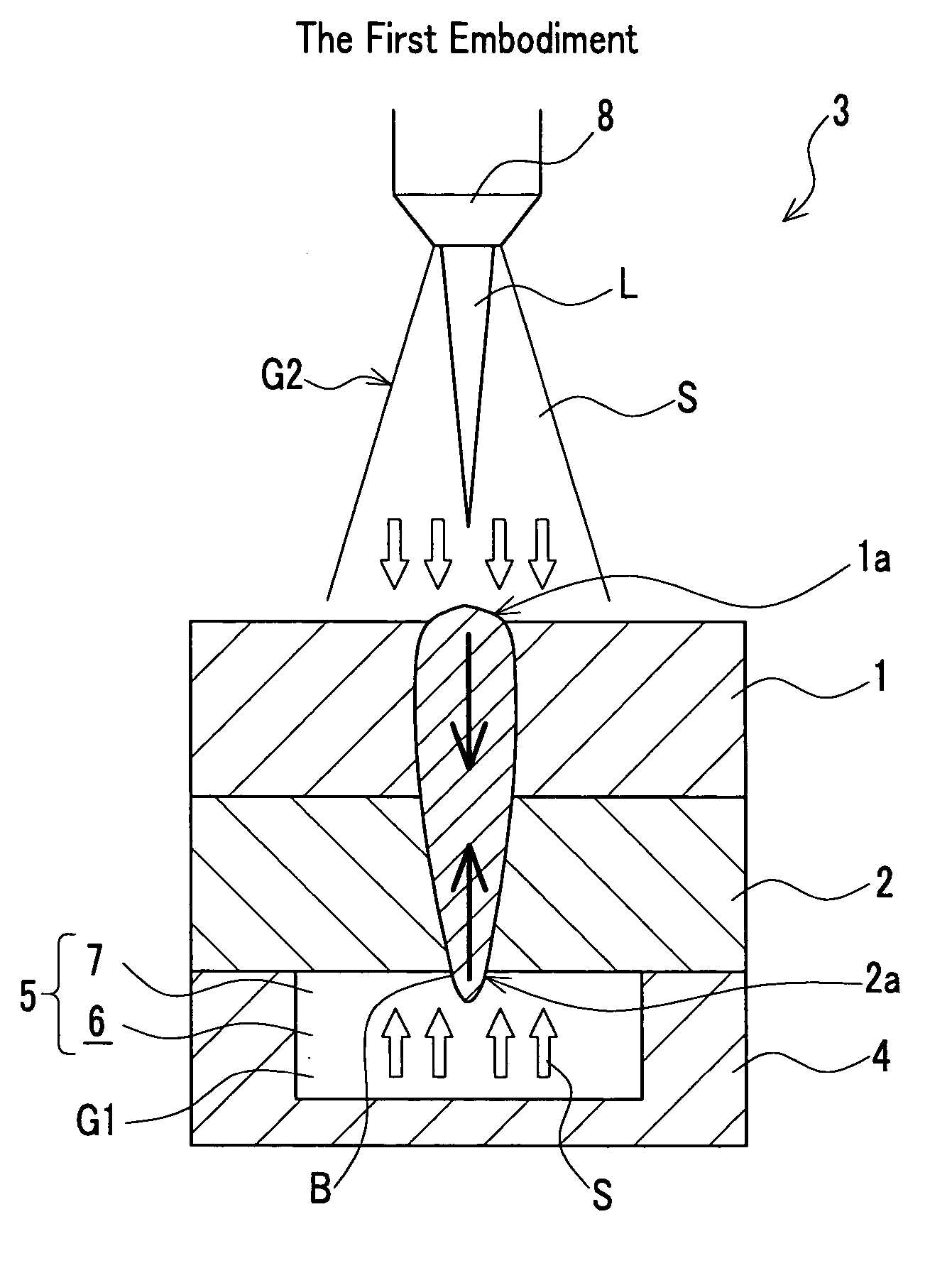

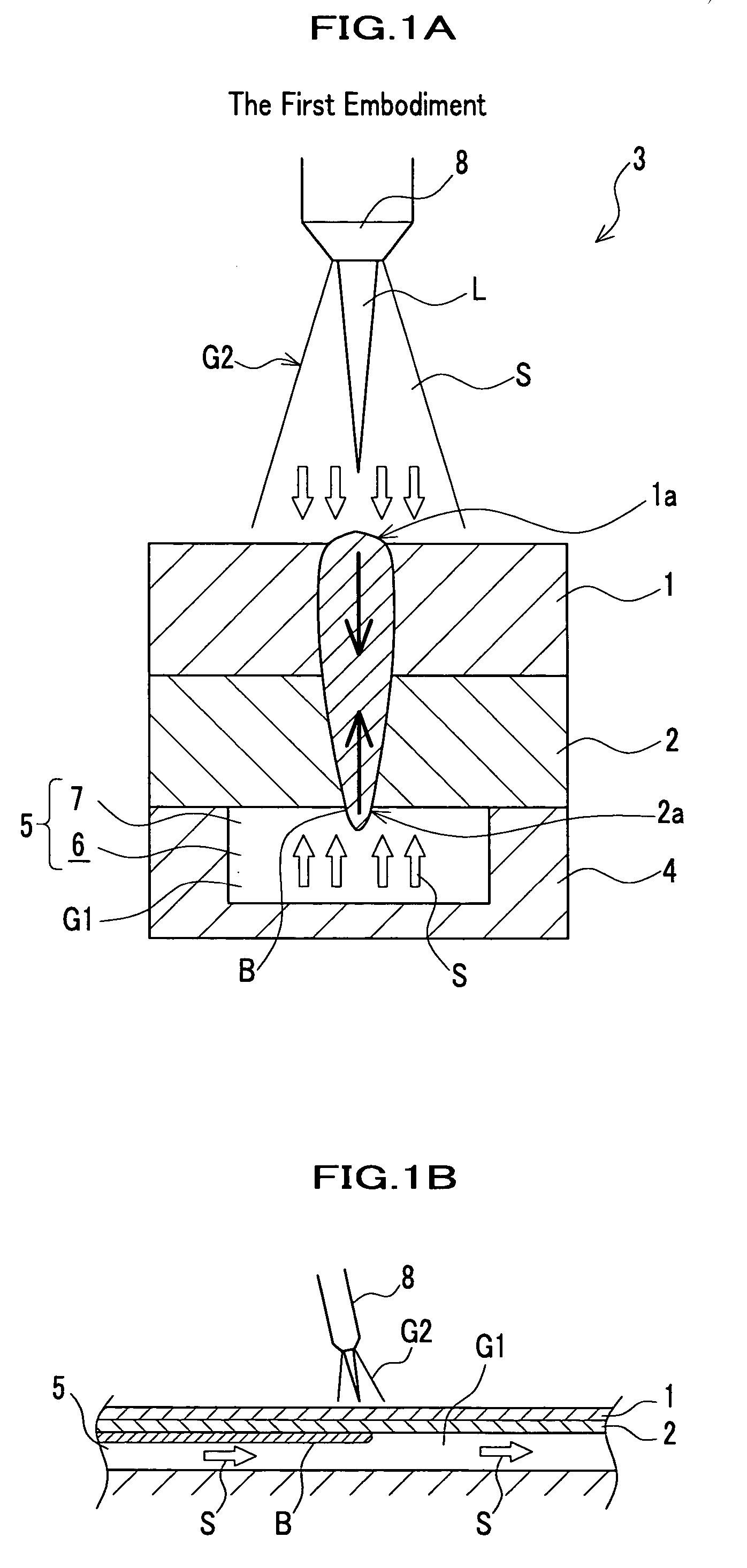

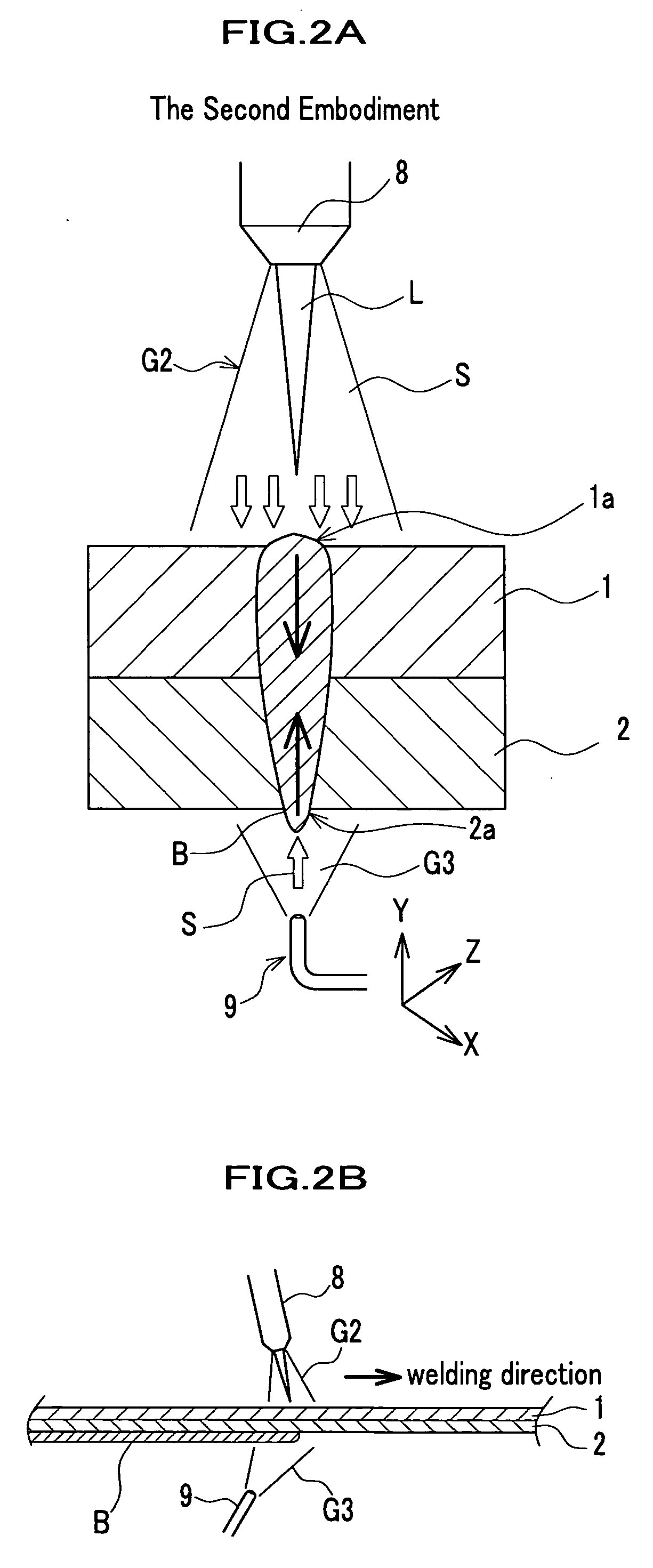

Through weld for aluminum or aluminum alloy base metals by using high-density energy beams

InactiveUS20040084425A1Avoid formingHigh bonding strengthElectron beam welding apparatusWelding/soldering/cutting articlesHigh energyShielding gas

This invention provides a new through weld method to carry out welding of a base metal made of aluminum or that of aluminum alloy using high energy beams wherein a shield gas ambience (an inert gas ambience) to cover a welding site in a submerged-scar is formed, even a shield gas ambience (an inert gas ambience) to cover a welding site irradiated by the high energy beams. Since the former shield gas ambience to cover the submerged-scar pushes the keyhole against the gravity and / or the gas pressure force of the latter shield gas supplied to the laser irradiation side, then the forming of hang down of beads and the resultant projection of the welding base metal are prevented.

Owner:HONDA MOTOR CO LTD

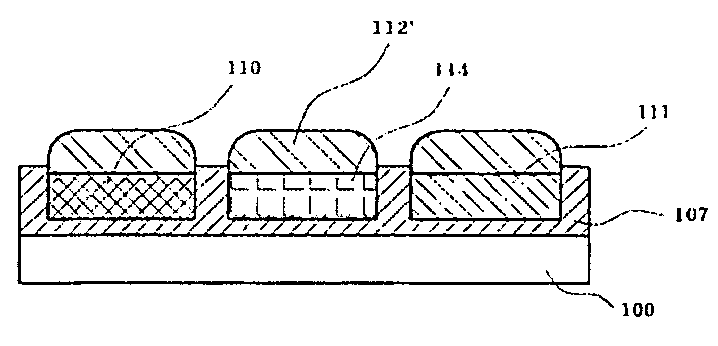

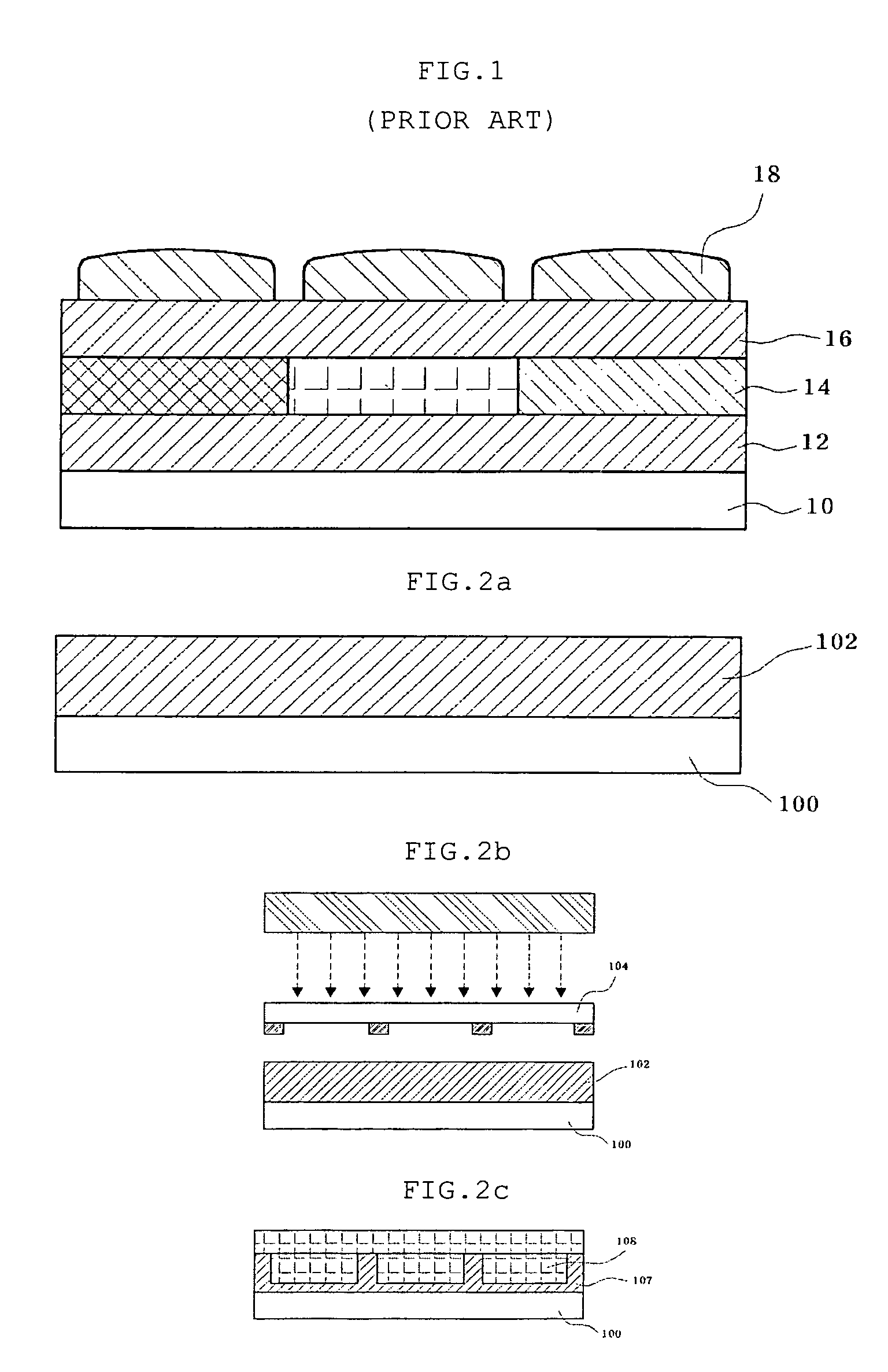

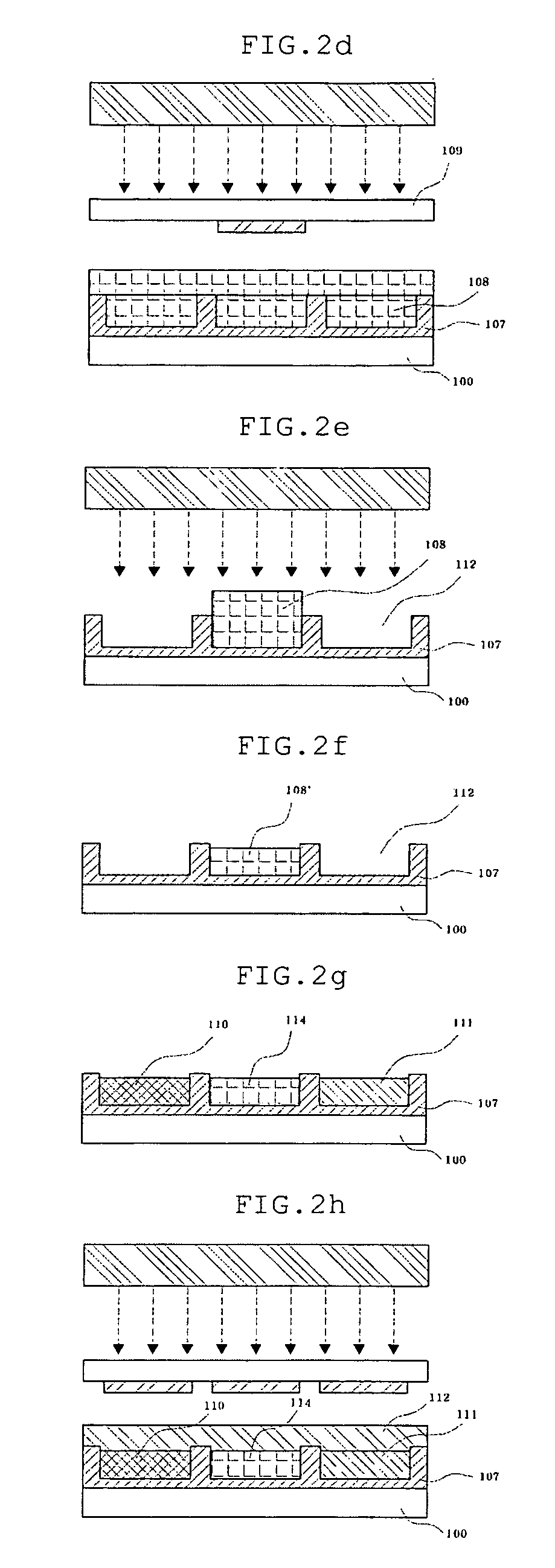

Method for manufacturing CMOS image sensor

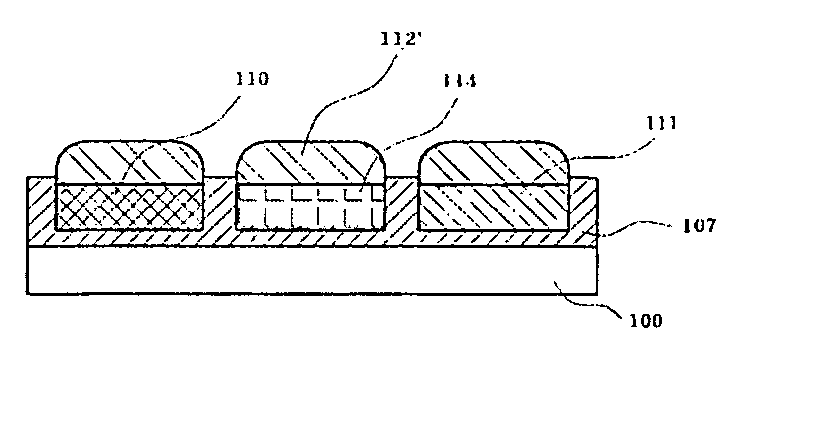

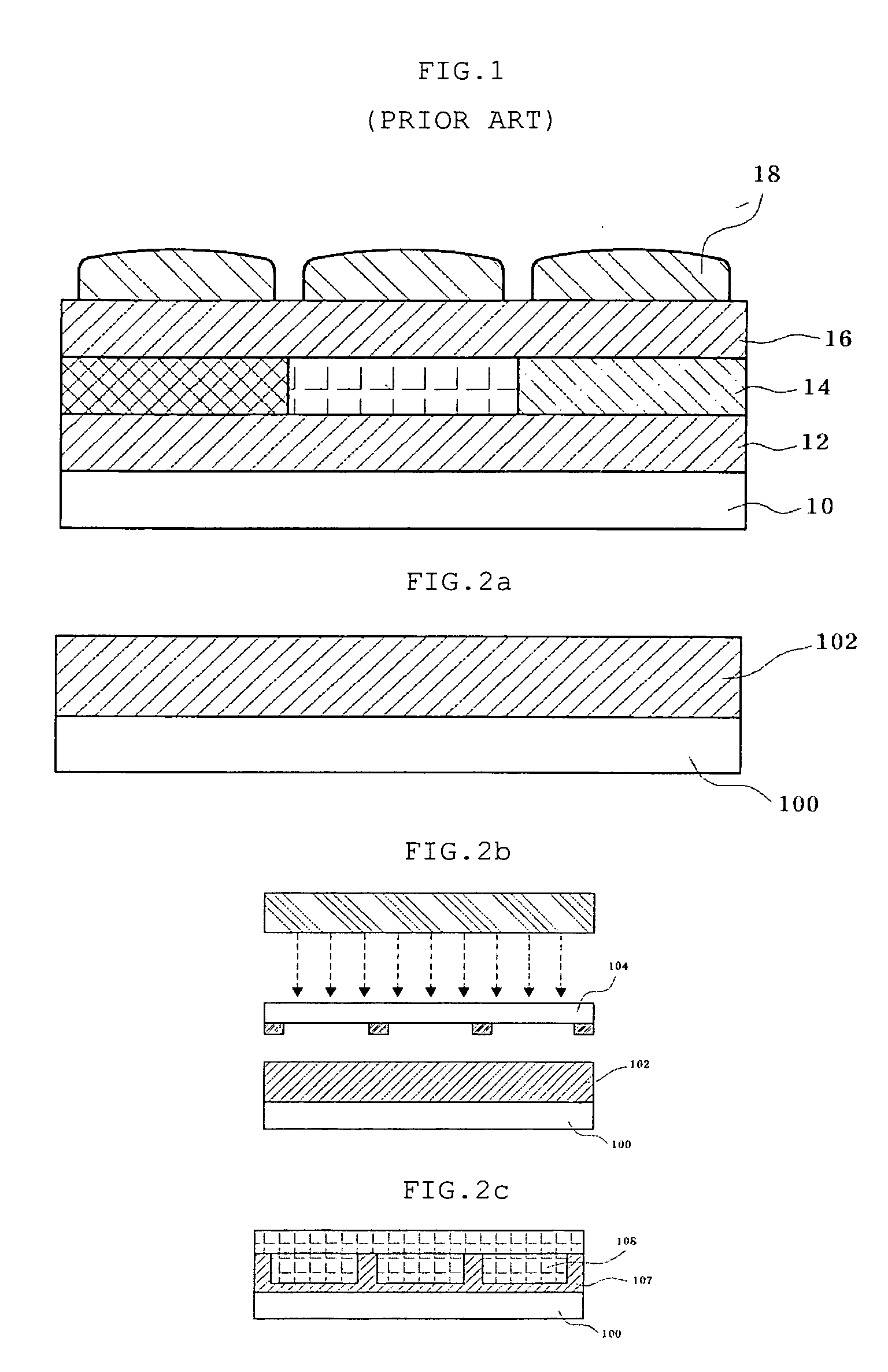

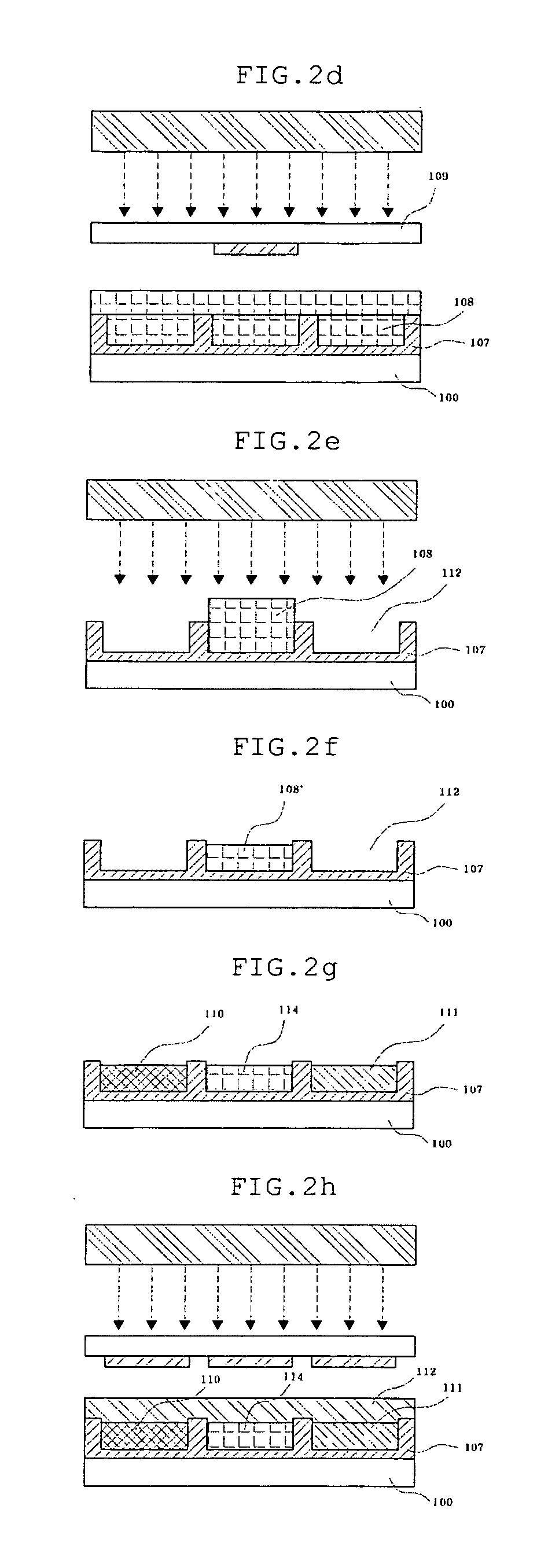

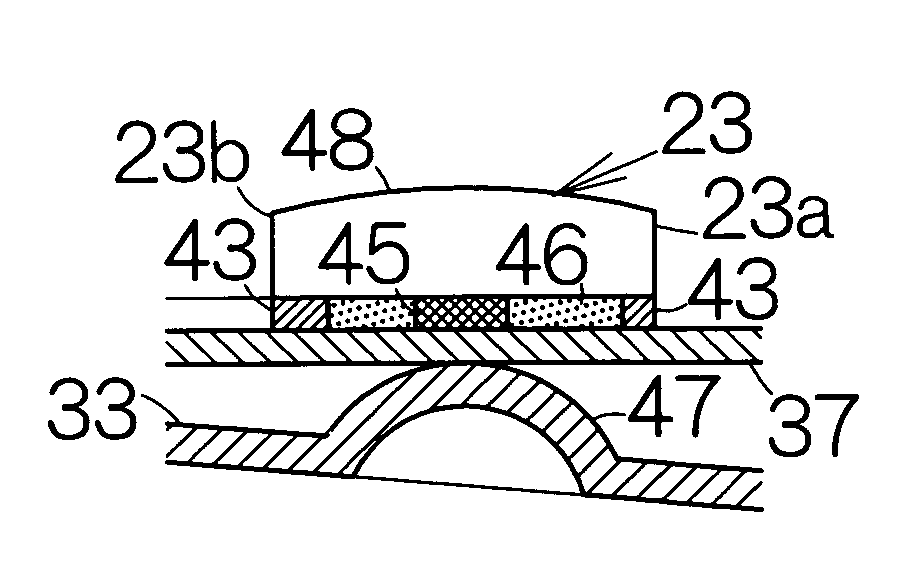

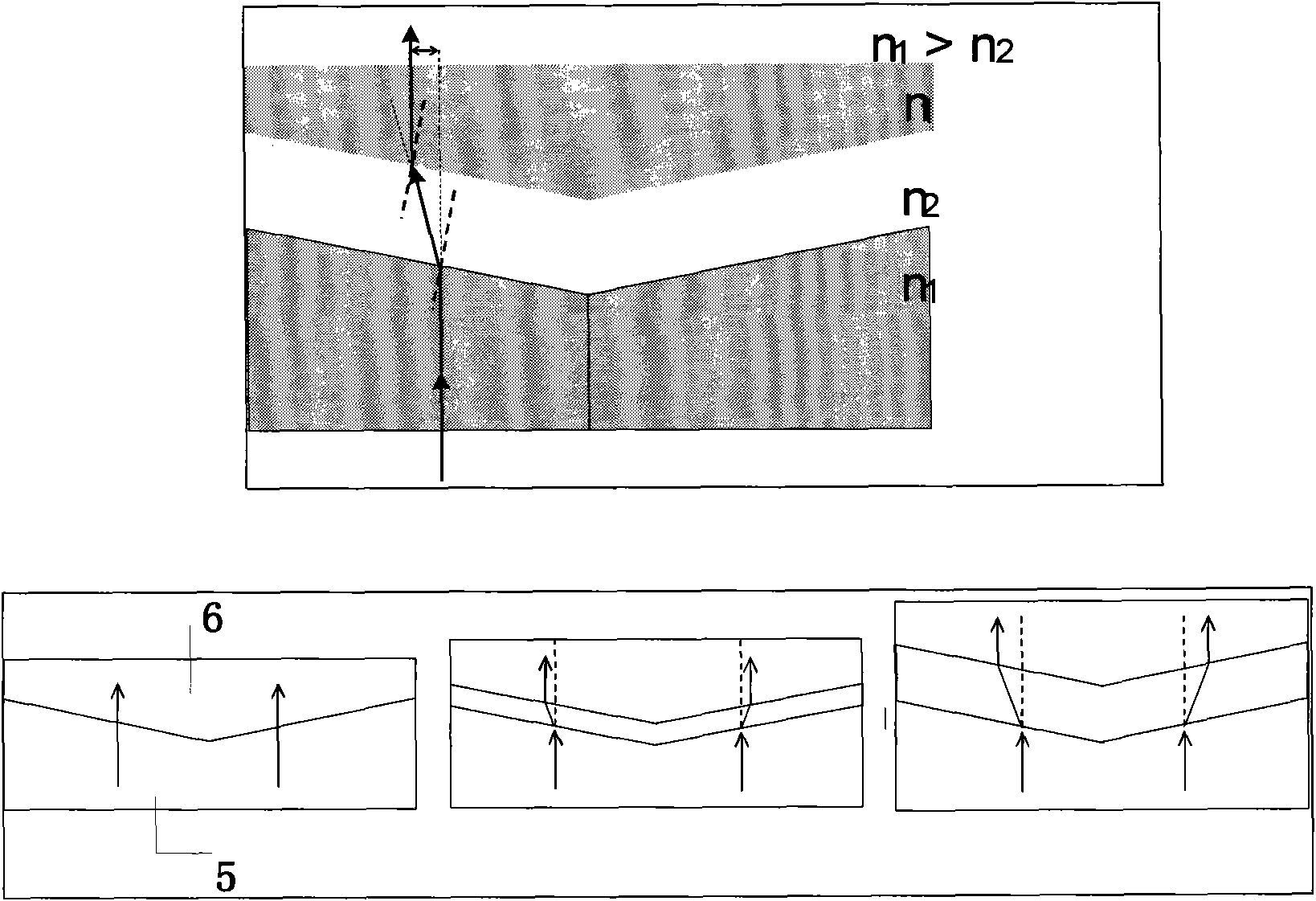

ActiveUS7163832B2Increase focal lengthConstant heightSolid-state devicesSemiconductor/solid-state device manufacturingCMOSMicrolens

The present invention discloses a method for manufacturing an image sensor which makes the boundaries between microlenses clear by forming a guide layer in advance and can increase the focal distance of light and the quantity of light by forming the spheres of the microlenses to have a constant height.

Owner:INTELLECTUAL VENTURES II

Method for manufacturing CMOS image sensor

ActiveUS20050101049A1Increase focal lengthConstant heightSolid-state devicesSemiconductor/solid-state device manufacturingCMOSMicrolens

The present invention discloses a method for manufacturing an image sensor which makes the boundaries between microlenses clear by forming a guide layer in advance and can increase the focal distance of light and the quantity of light by forming the spheres of the microlenses to have a constant height.

Owner:INTELLECTUAL VENTURES II

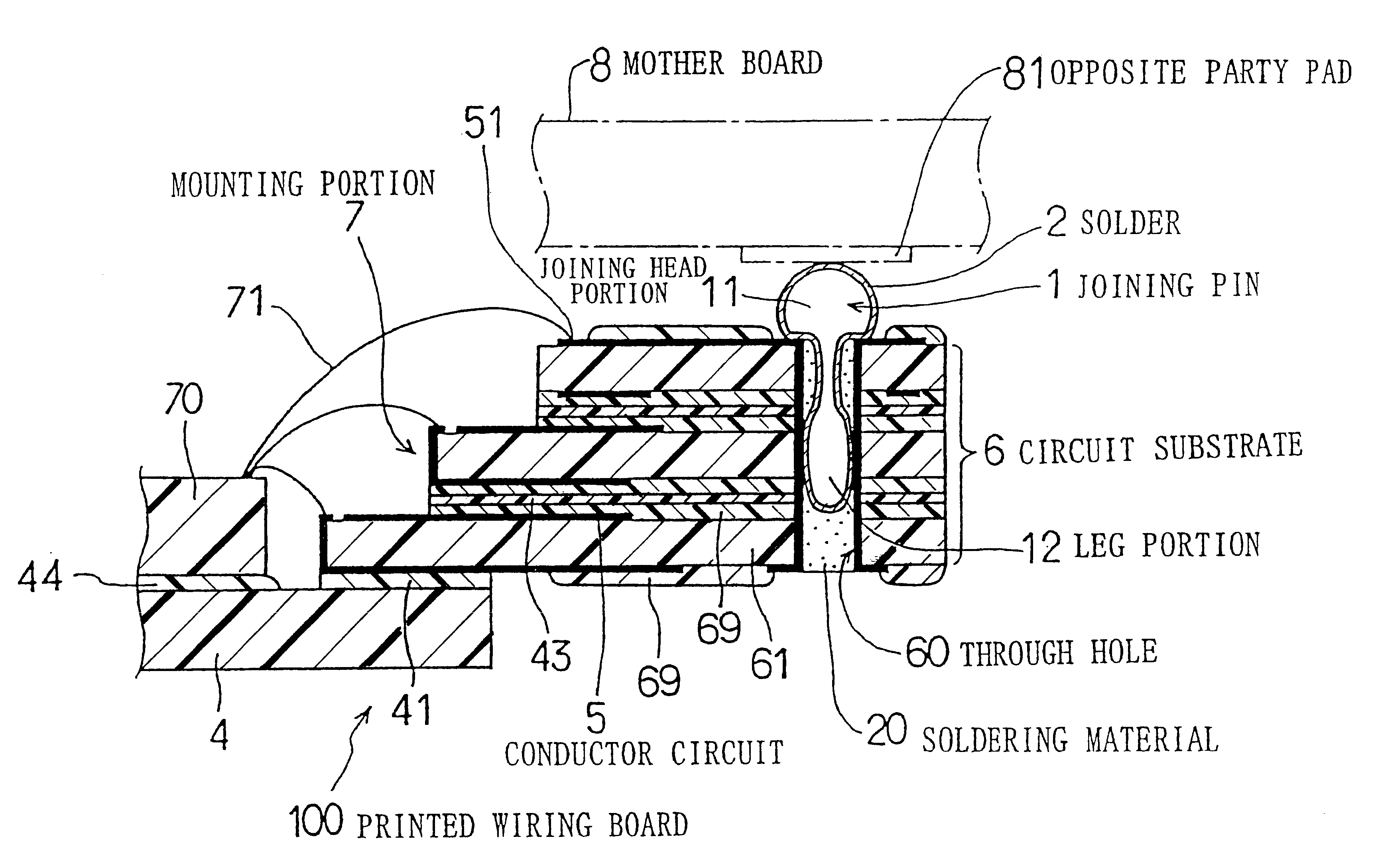

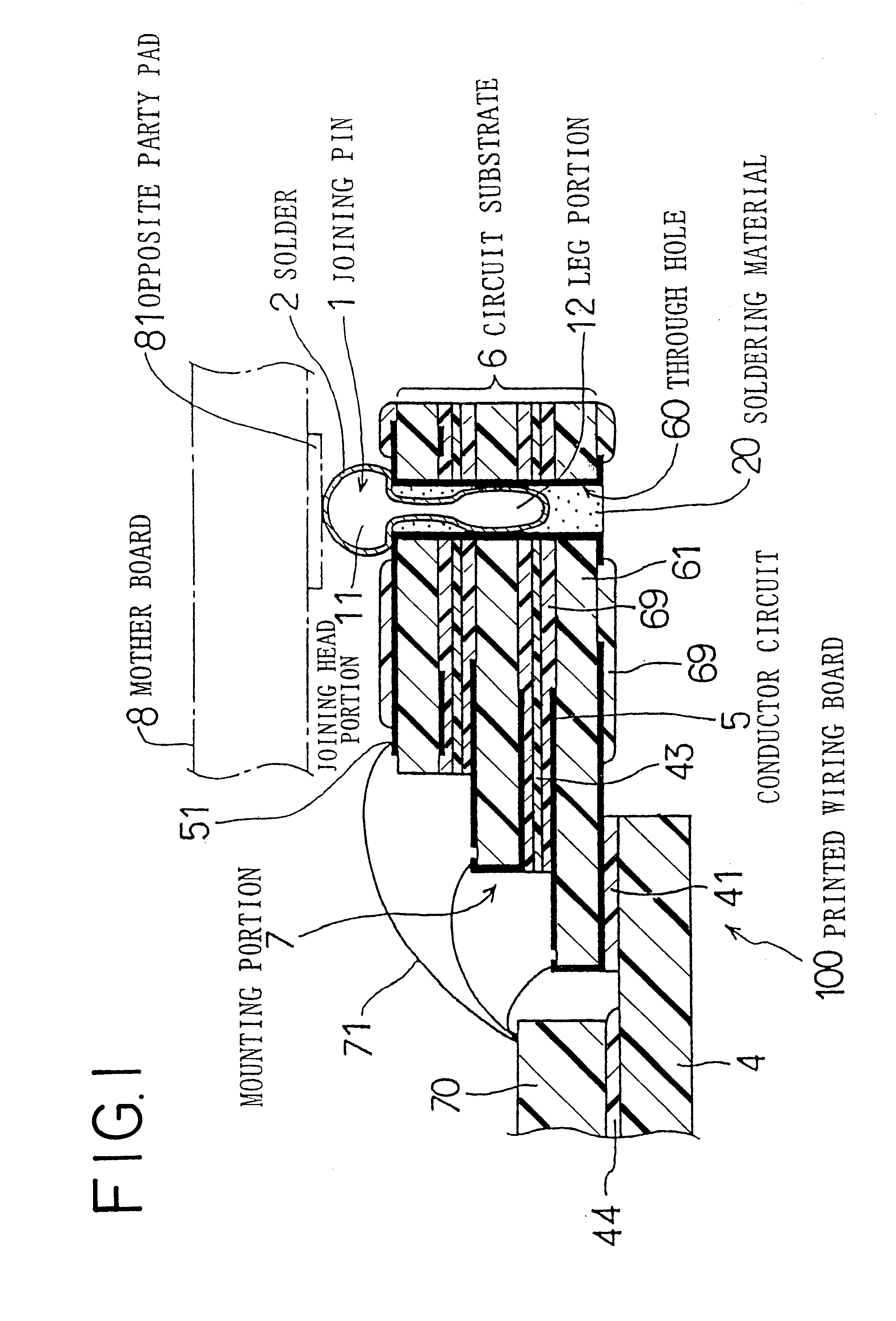

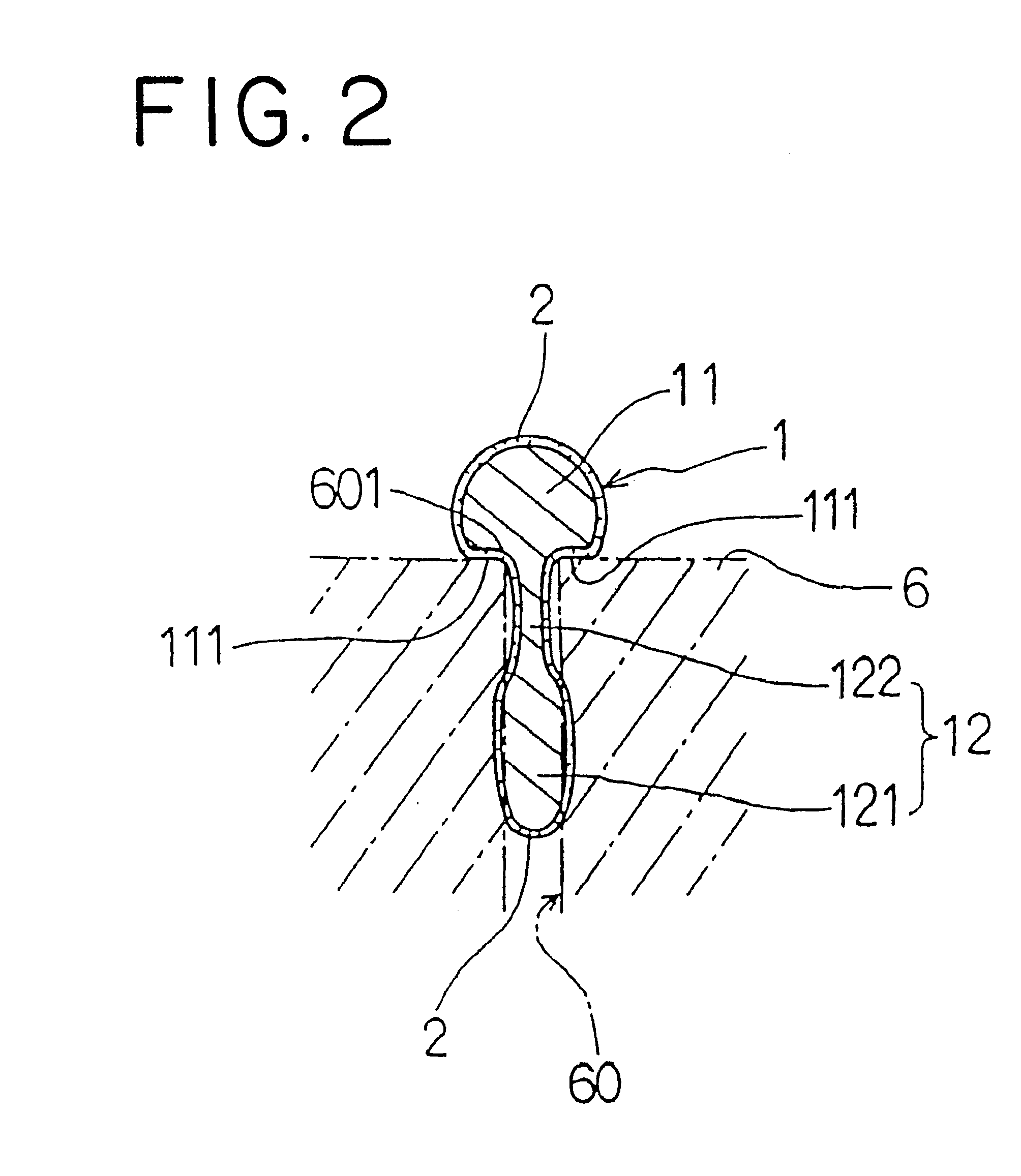

Printed wiring board with joining pin and manufacturing method therefor

InactiveUS6444924B1High densityConstant heightPrinted circuit assemblingFinal product manufactureConductive materialsEngineering

A printed wiring board has a circuit substrate 6 having a conductor circuit 5 and a through hole 60, and also has a joining pin 1 inserted into the through hole. The joining pin is manufactured by using a material unmelted at a heating temperature in joining the joining pin to an opposite party pad 81. The joining pin is constructed by a joining head portion 11 having a greater diameter than an opening diameter of the through hole. The joining pin forms a joining portion for joining and connection to the opposite party pad. The joining pin has a leg portion 12 having a diameter smaller than the through hole. The leg portion is inserted into the through hole and is joined to the through hole by a conductive material such as a soldering material 20, etc. In lieu of a joining pin, a joining ball approximately having a spherical shape can be joined to the through hole by the conductive material.

Owner:ISHIDA NAOTO +1

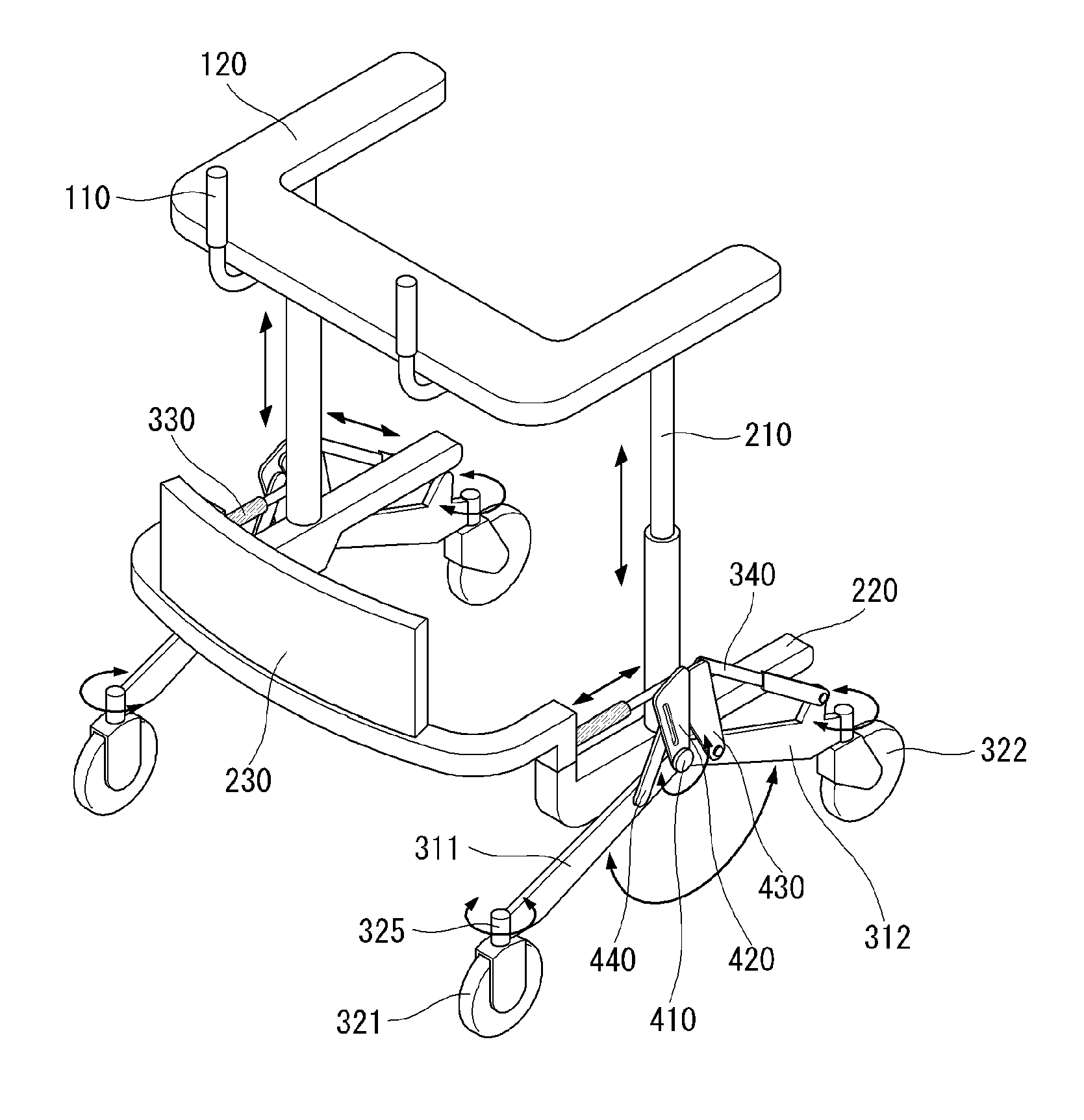

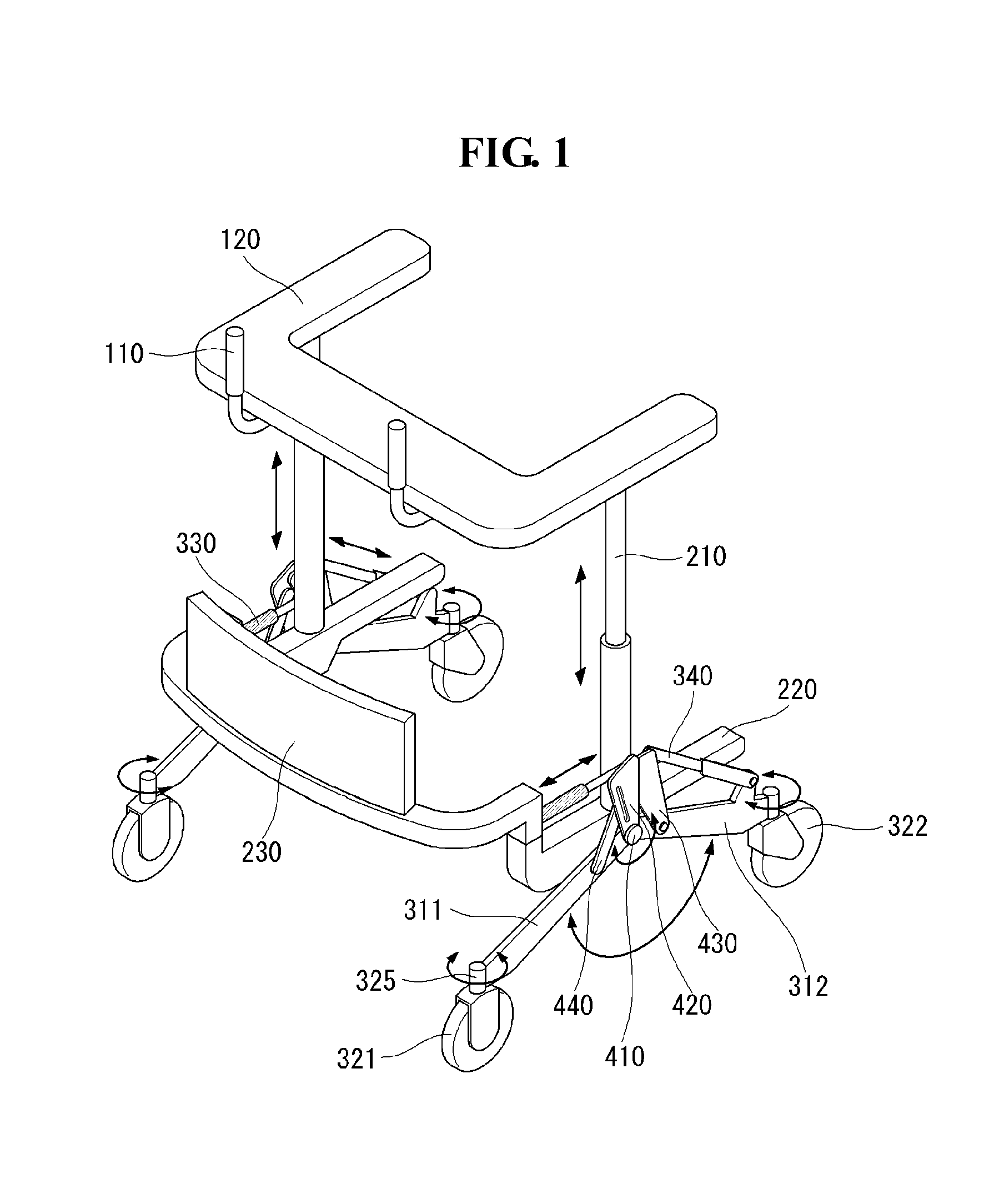

Walking-assistant device

InactiveUS8627909B2Assisting muscular strengthImprove efficiencySuspensionsWalking aidsEngineeringActuator

A walking-assistant device is provided comprising a driving unit that includes four wheels and four actuators for adjusting heights of the four wheels, a mechanism unit that includes two vertical frames whose length is adjusted and connection frames for fixing and connecting the vertical frames, and a manipulation unit that includes a plurality of sensors for grasping a user's moving intention and controls the driving unit and the mechanism unit based on a signal detected by the sensors.

Owner:LG ELECTRONICS INC

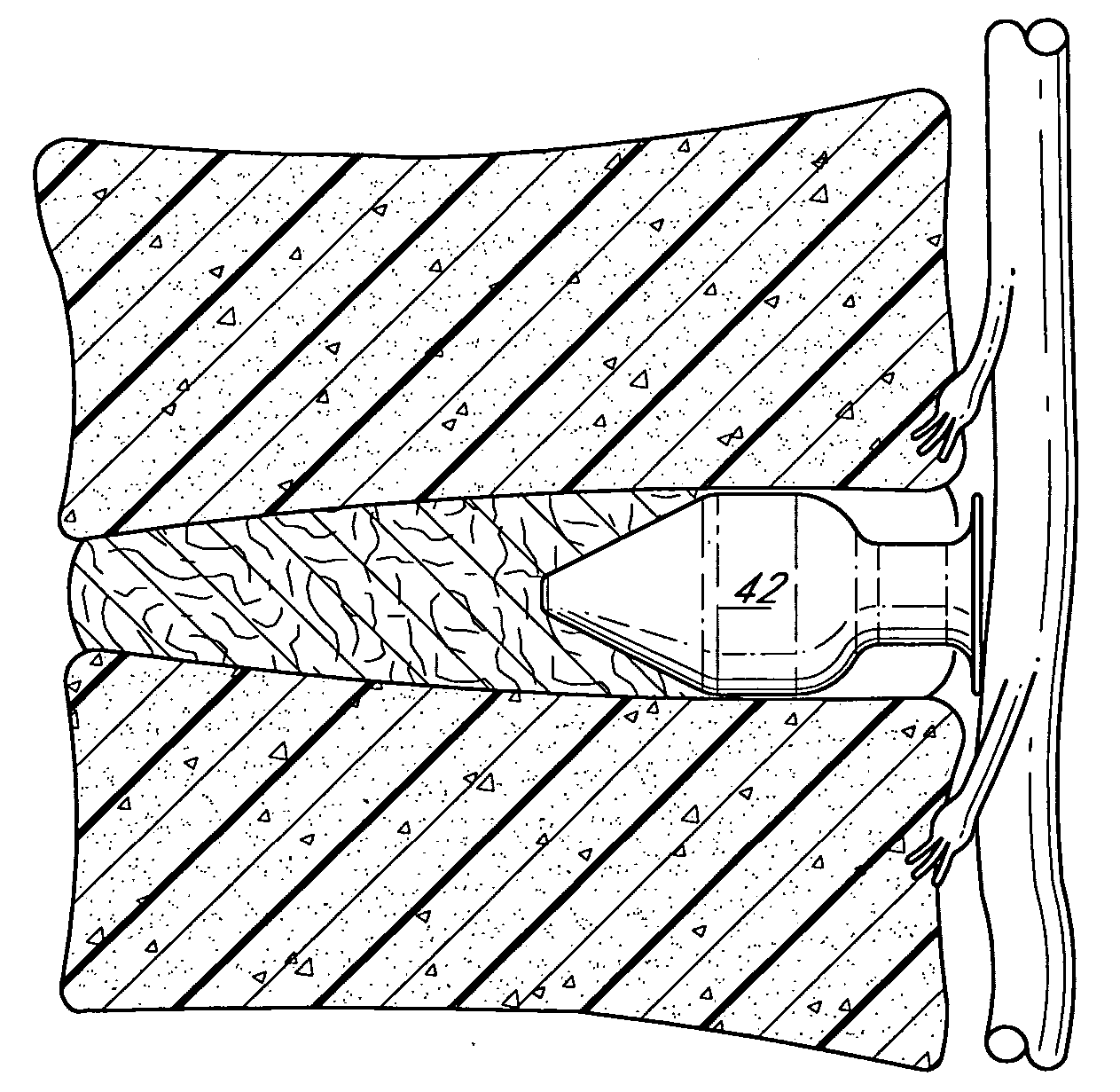

Spinal implants and methods of providing dynamic stability to the spine

InactiveUS20070050028A1Reduce relative motionSimple structureInternal osteosythesisDiagnosticsSpinal implantVertebra

The present application discloses a plurality of spinal implants and methods for repairing annular defects in intervertebral discs and for providing dynamic stability to the motion segment of the spine in the vicinity of the repaired disc. Each of the implants comprises a head portion and a tail portion. In the illustrated embodiments, the head portion of each implant is enlarged relative to the tail portion. Each of the head portions and tail portions is adapted to support adjacent vertebrae and resist collapse of the intervertebral disc. A tapered portion of each implant engages end plates of the adjacent vertebrae to resist forces tending to push the implant out of the intervertebral space. The tail portion of each implant includes a tail flange (which in some embodiments is of similar diameter to the head portion) that abuts extradiscal lips of the adjacent vertebrae and resists forces tending to push the implant deeper into the intervertebral space.

Owner:MAGELLAN SPINE TECH

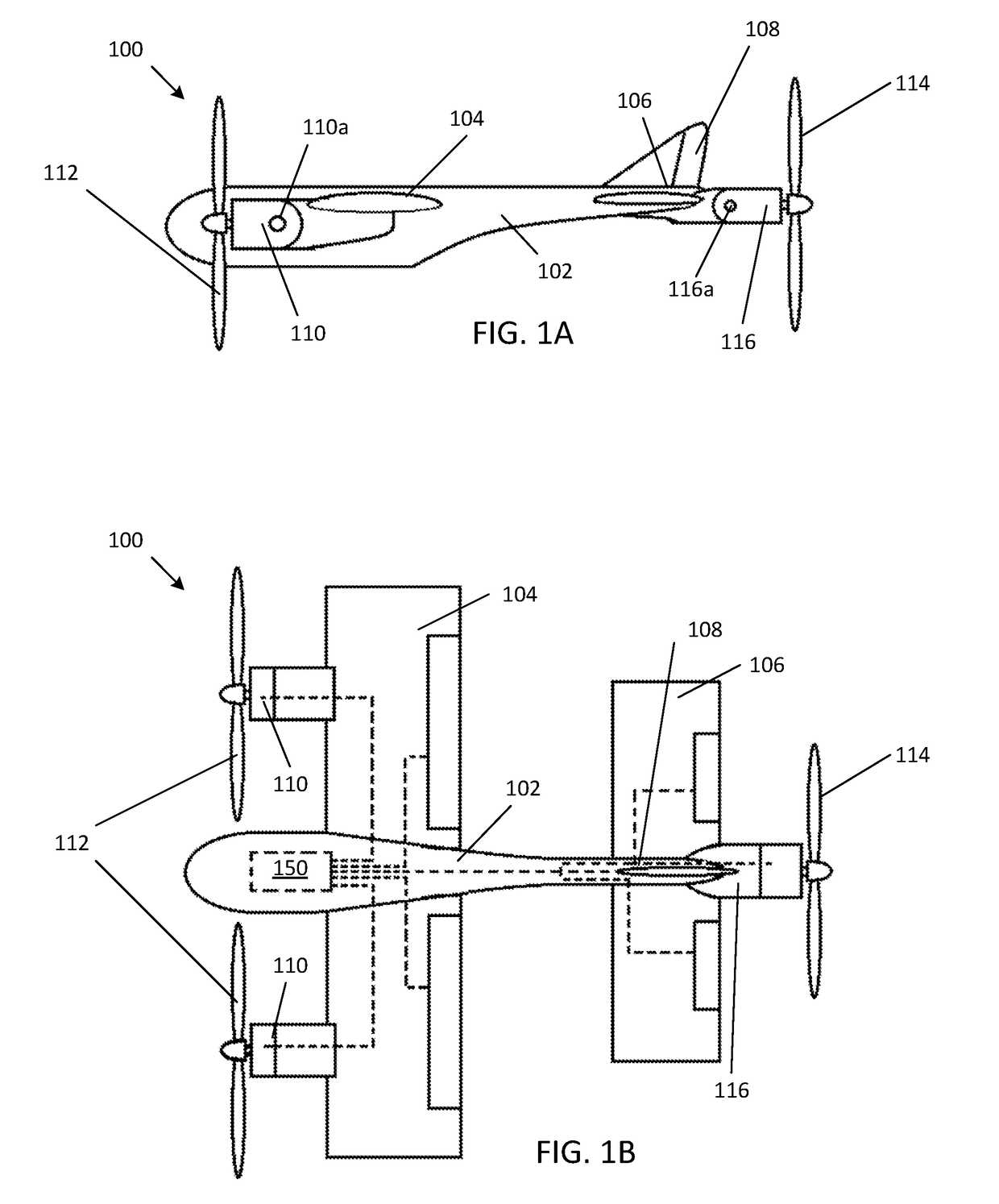

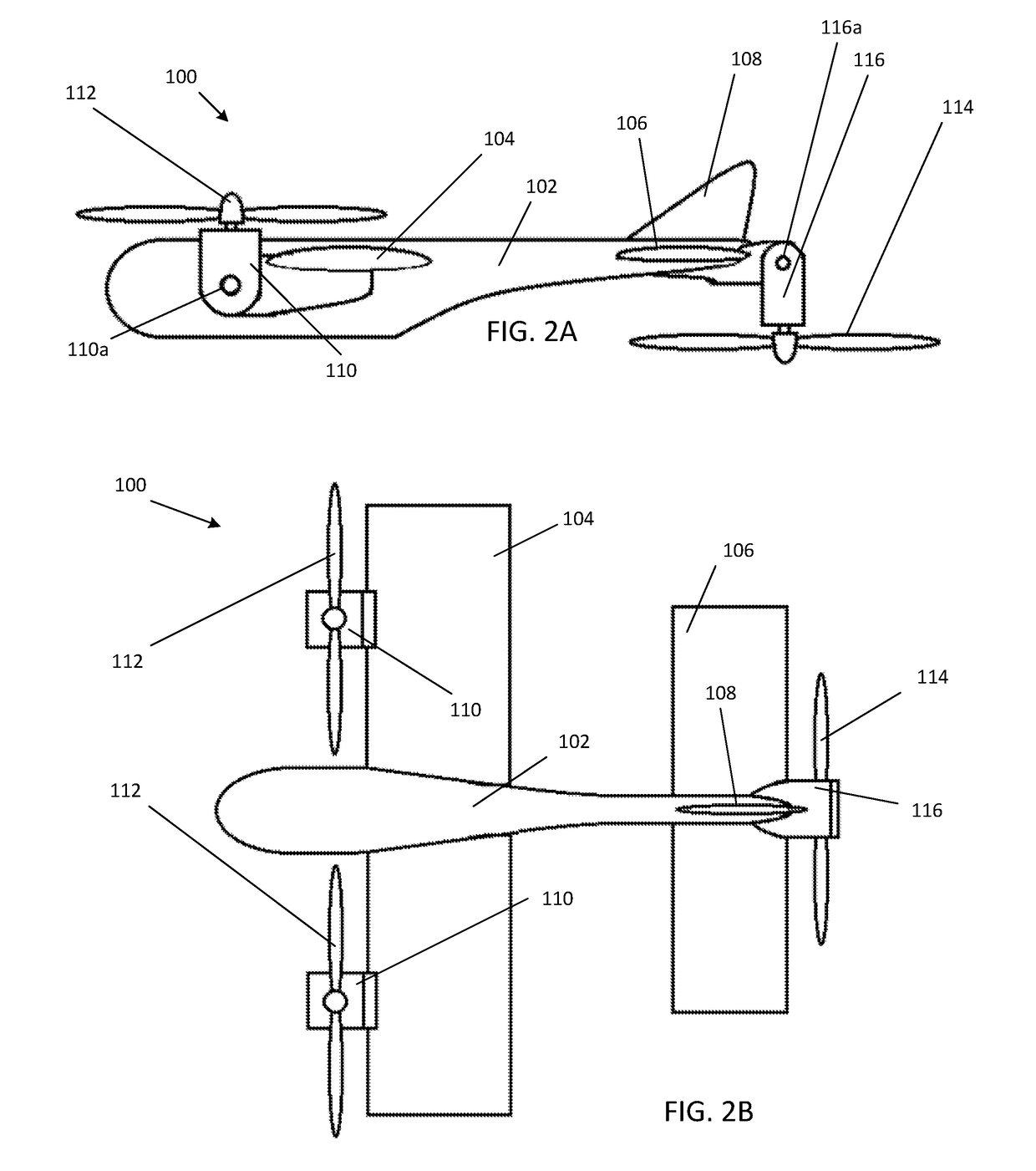

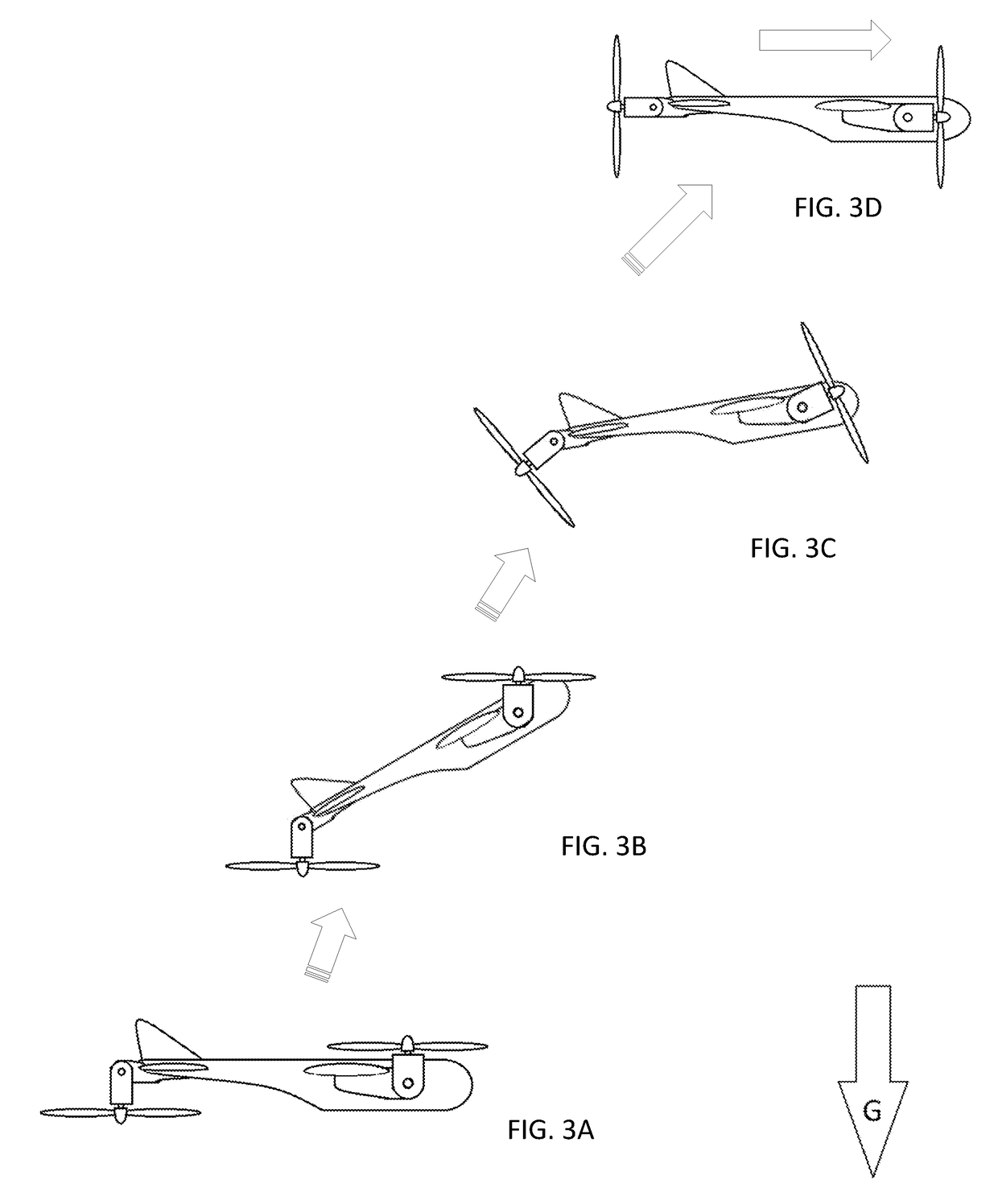

Vertical take off and landing (VTOL) aircraft with vectored thrust having continuously variable pitch attitude in hover

ActiveUS20190061936A1Constant altitudeContinuous regulationPropellersVertical landing/take-off aircraftsFlight vehicleSteady flight

The presently disclosed embodiments relate to vertical takeoff and landing (VTOL) aircraft that have the capability of hovering in both a “nose forward” and a “nose up” orientation, and any orientation between those two. The disclosed aircraft can also transition into wing born (non-hovering) flight from any of the hovering orientations. In addition, certain of the disclosed embodiments can, if desired, use only vectored thrust control to maintain stable flight in both hover and forward flight. No control surfaces (e.g. ailerons, elevators, rudders, flaps) are required to maintain a stable vehicle attitude. However, the disclosure contemplates aircraft both with and without such control surfaces.

Owner:NASA

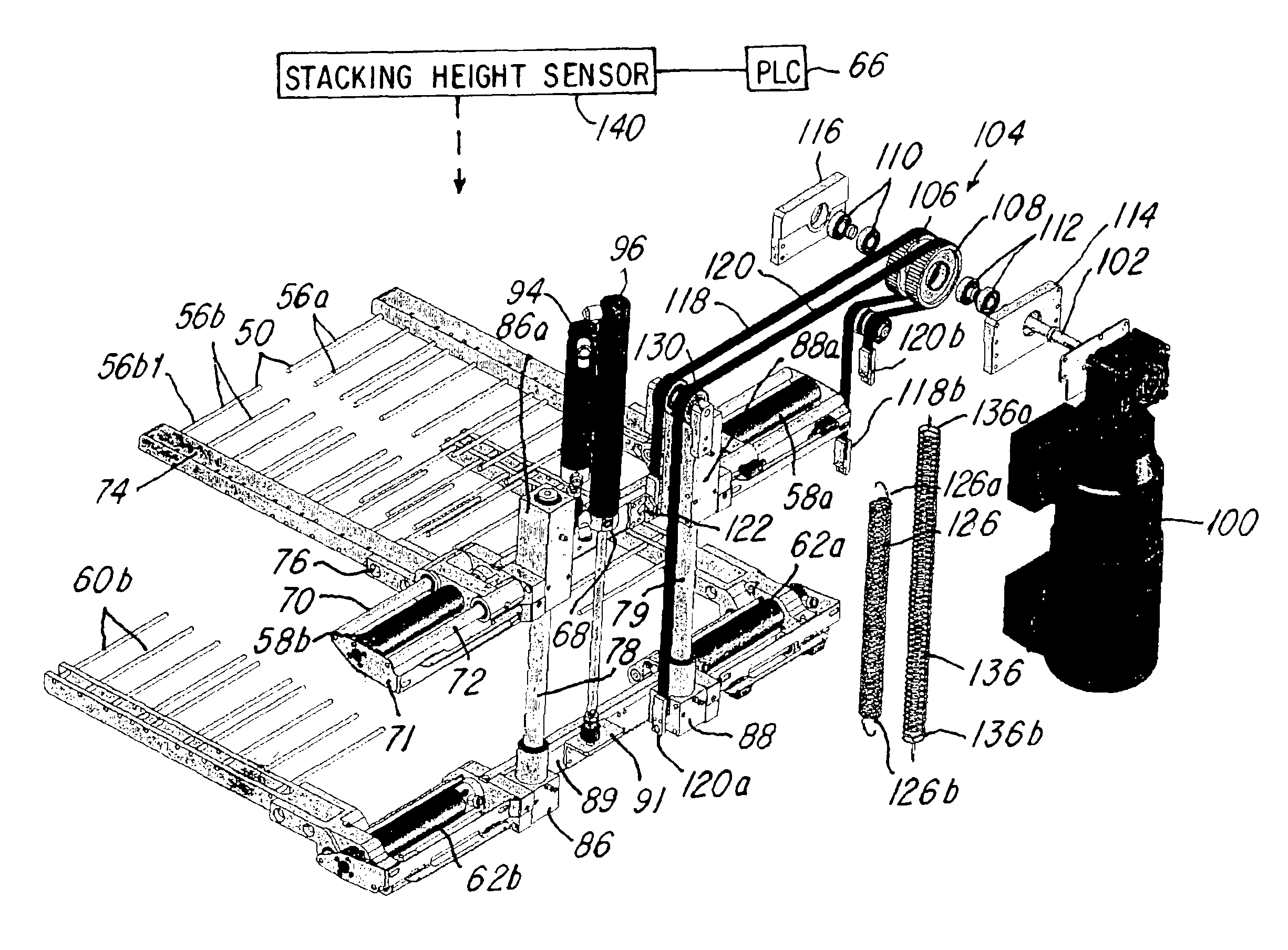

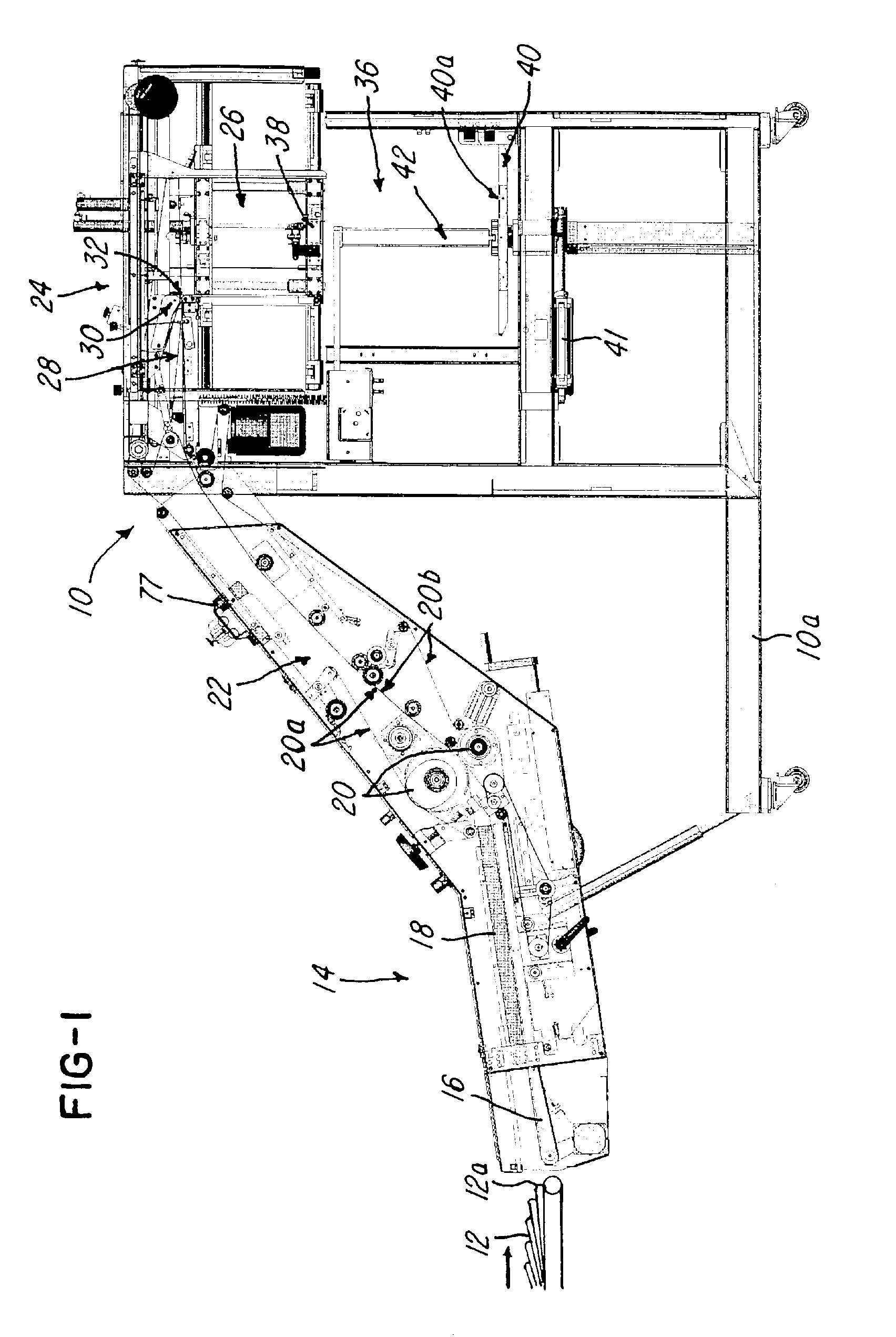

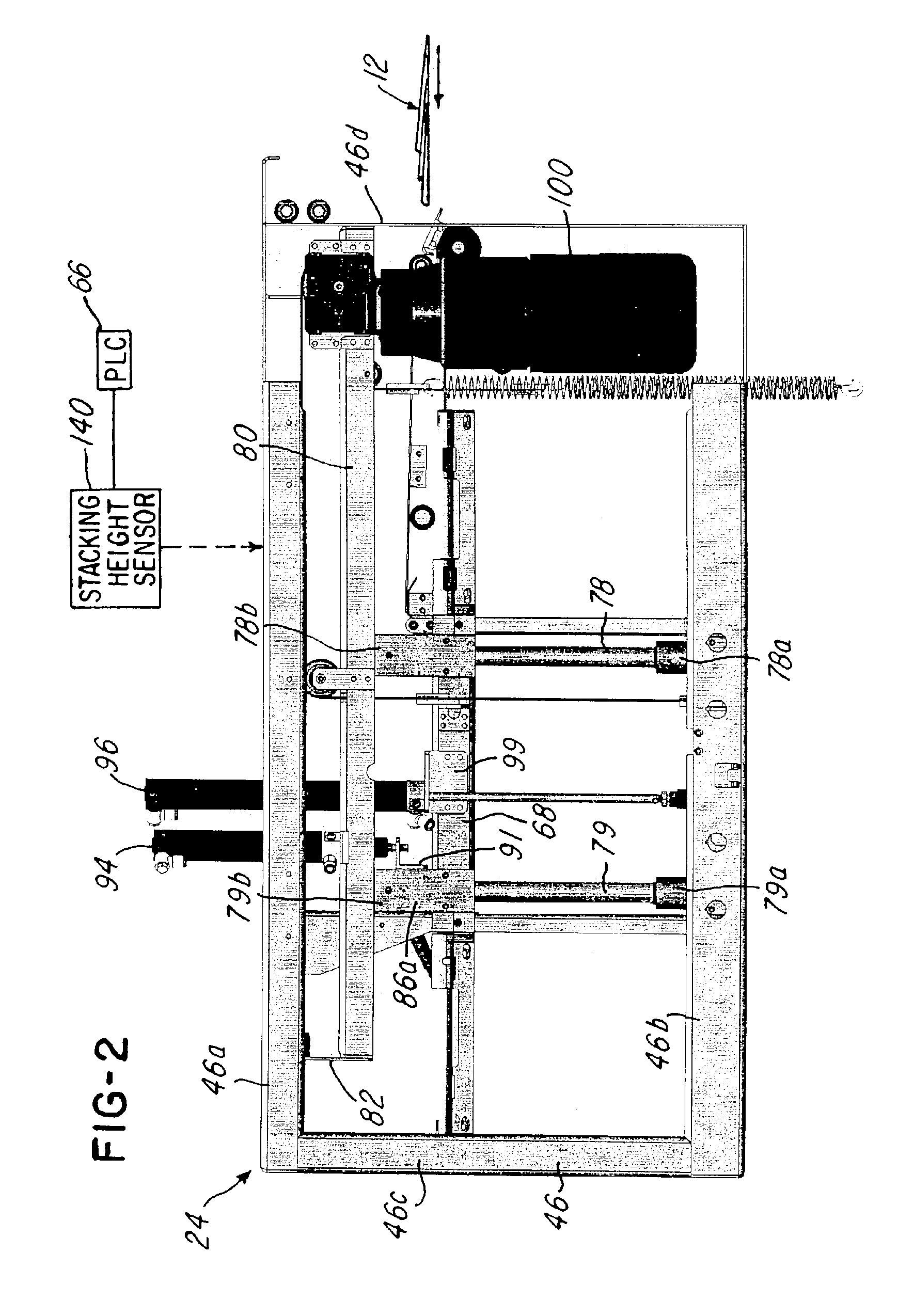

Stacker, stacking system or assembly and method for stacking

InactiveUS8356967B2Grow fastConstant heightDigital data processing detailsFunction indicatorsEngineeringStacker

A stacking system and method that utilizes a device control for precisely controlling the downward movement of at least one printed material support at a first speed, while substantially simultaneously permitting upward movement of the at least one support at a second speed which is greater than the first speed.

Owner:GAMMTECH CORP

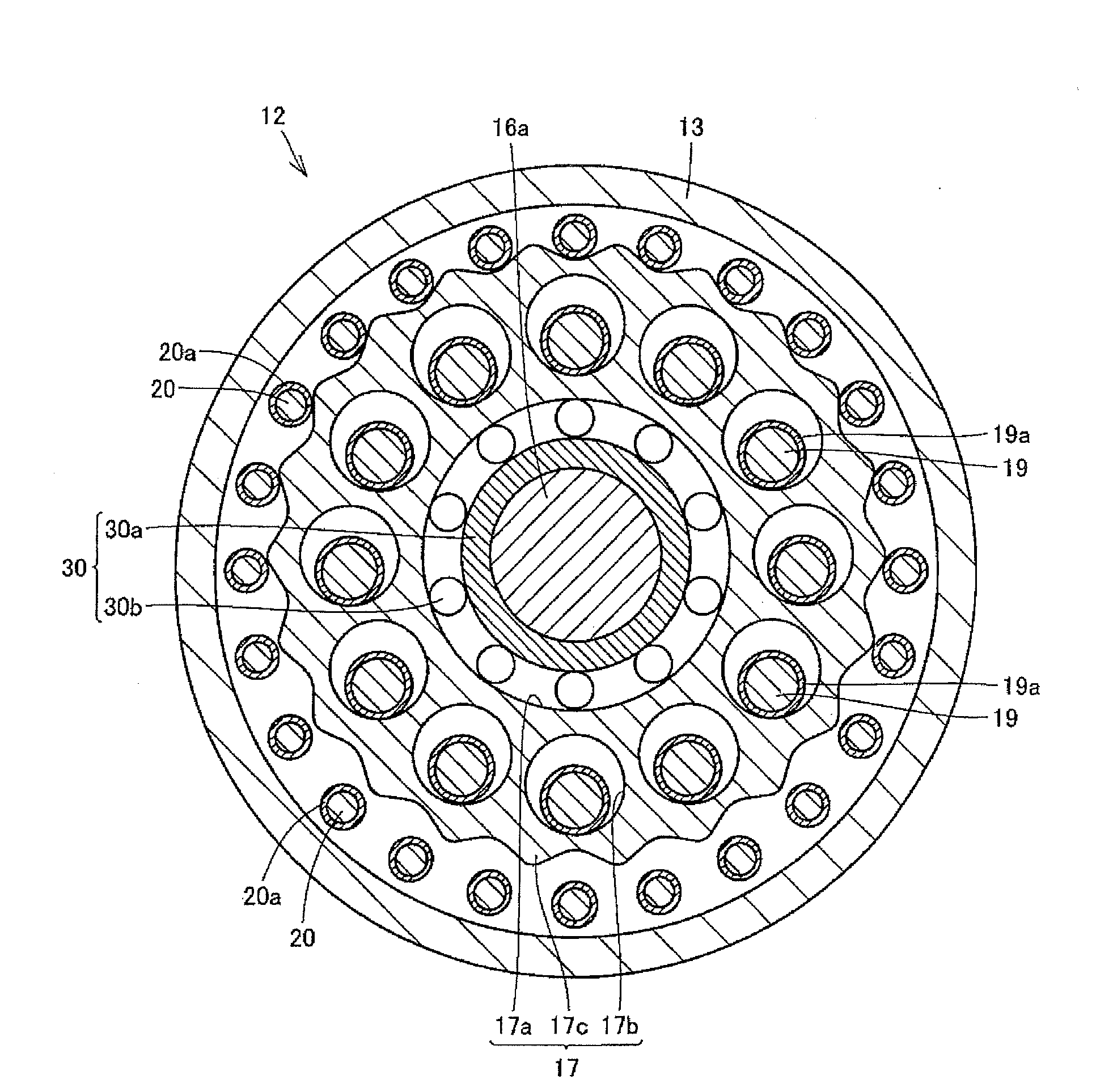

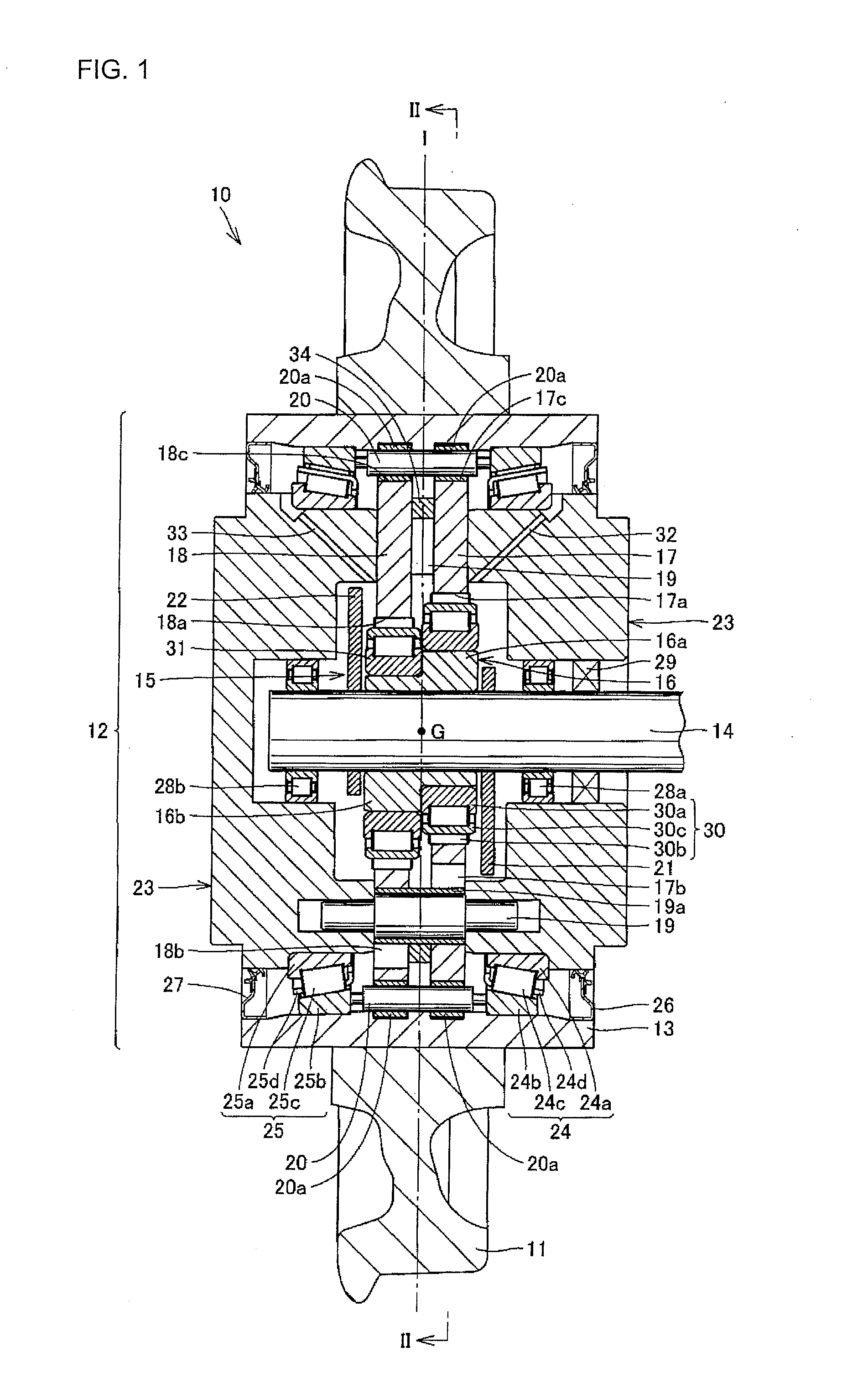

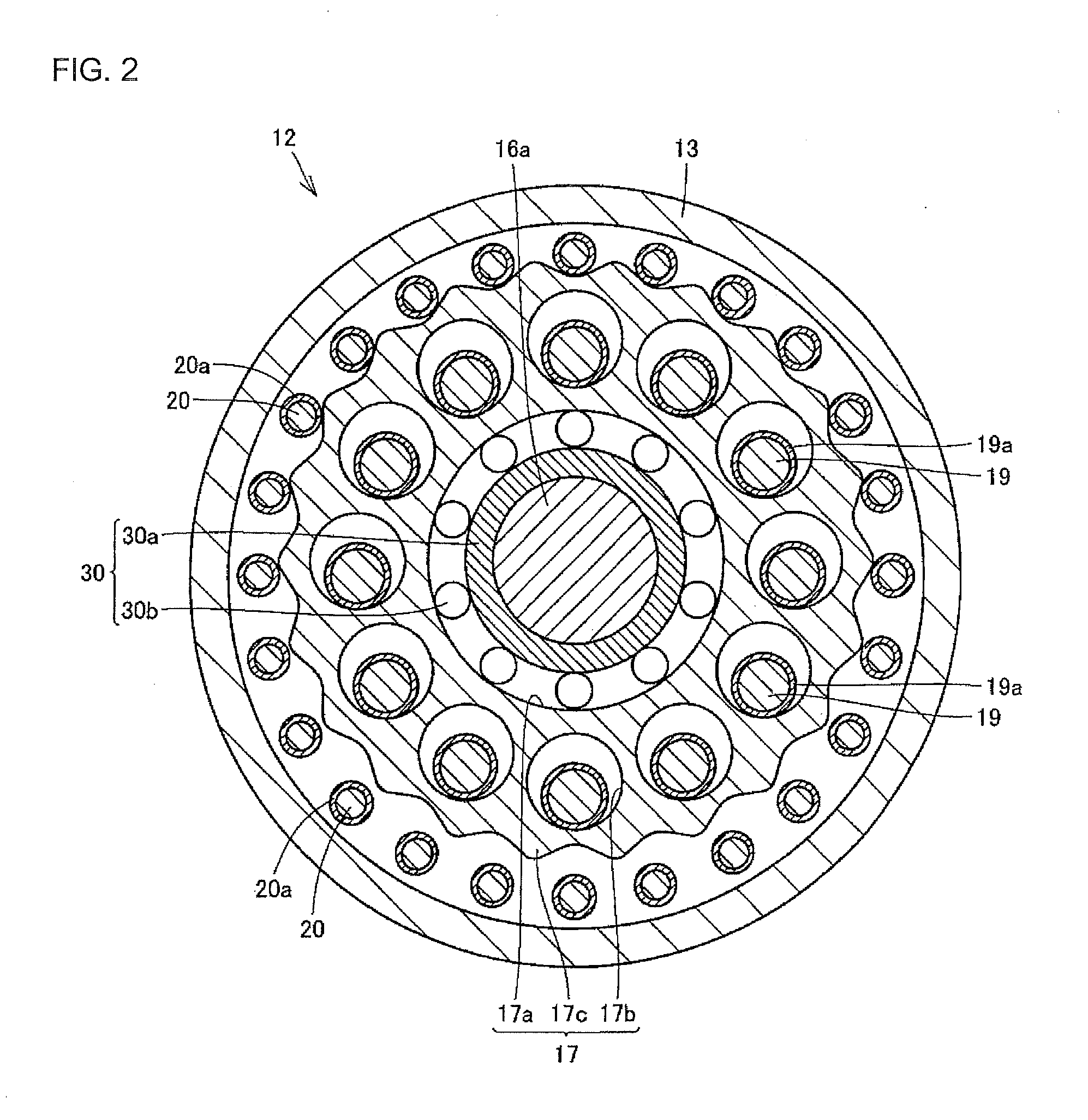

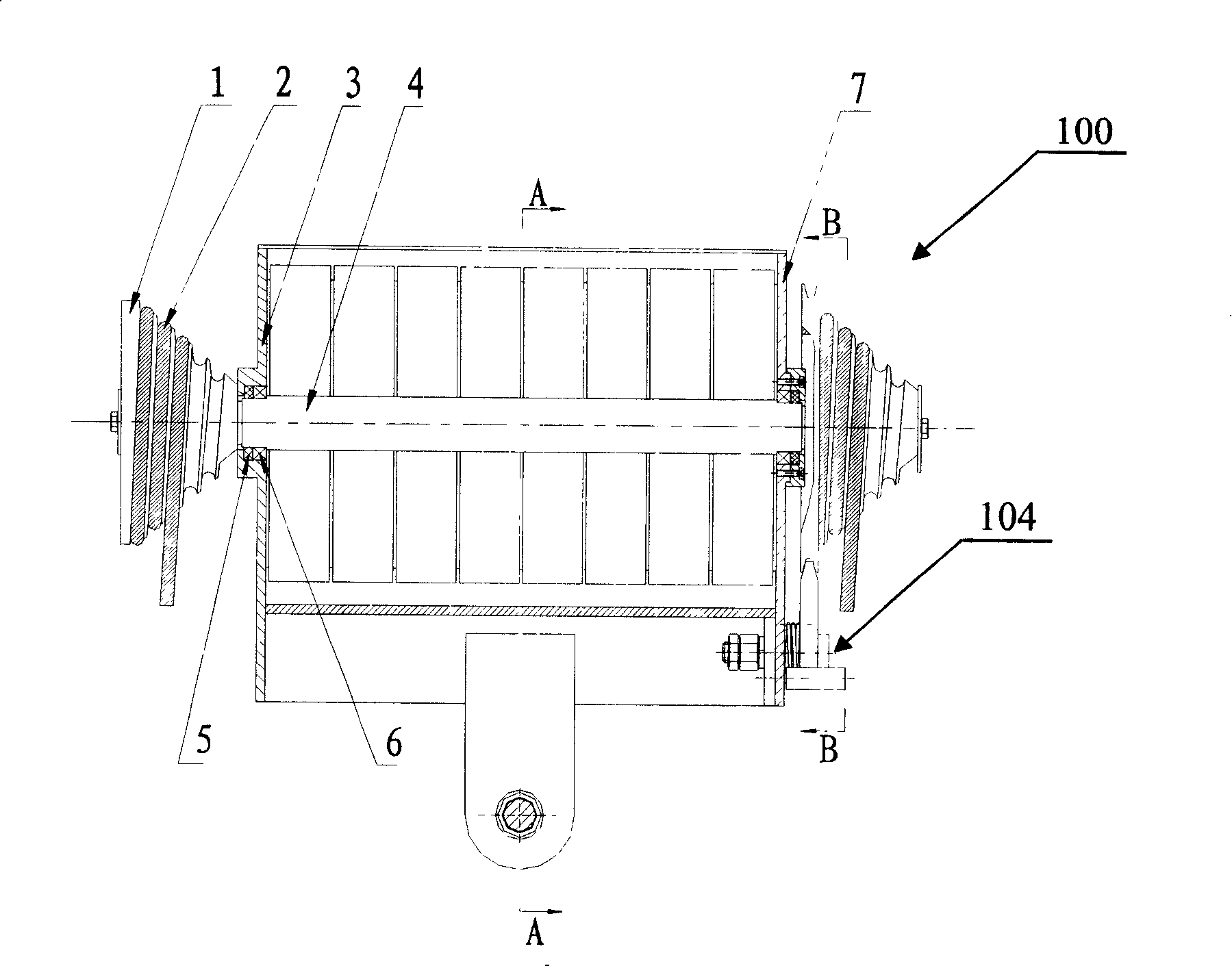

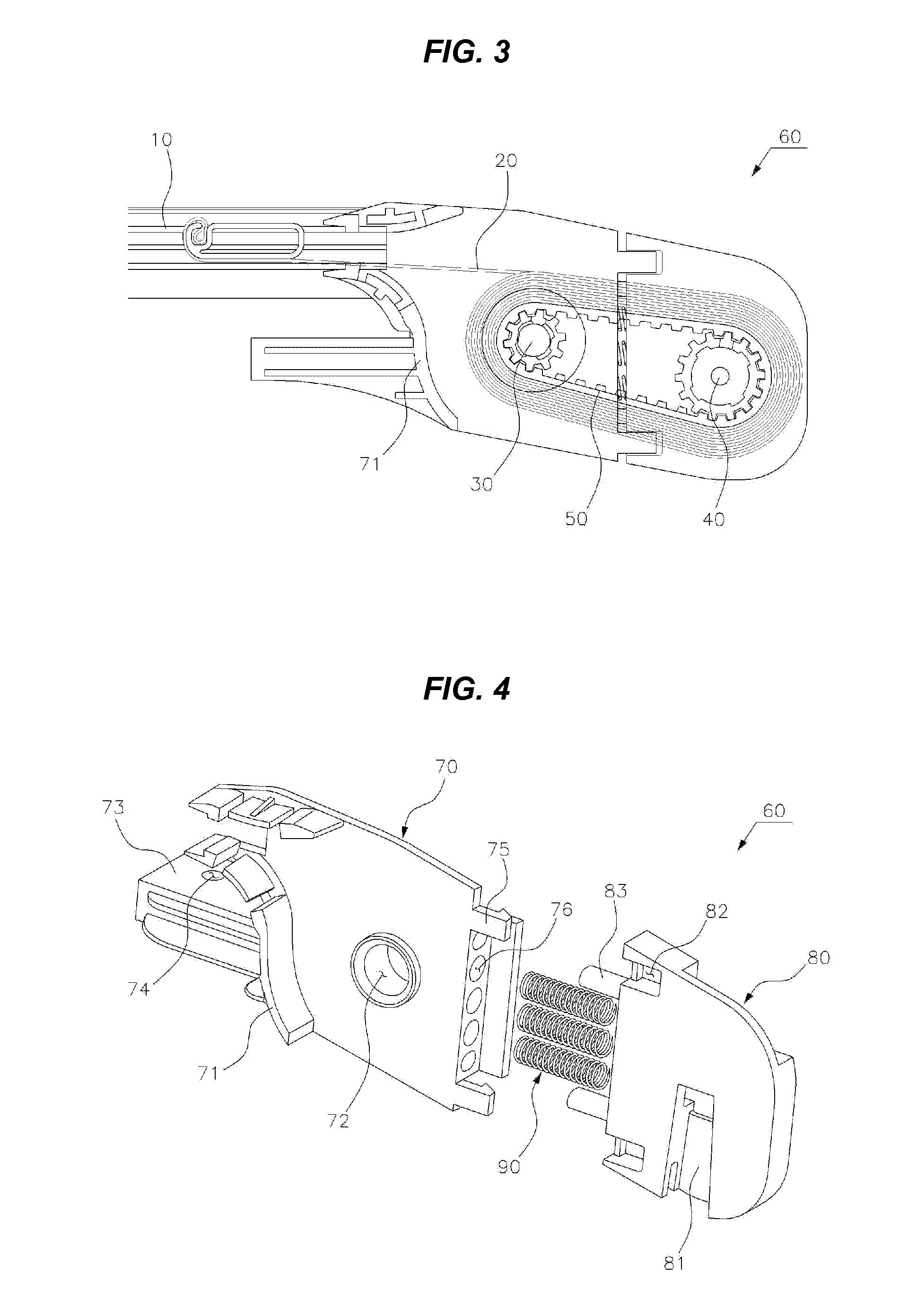

Railway vehicle drive unit

InactiveUS20110000394A1Improve the lubrication effectConstant heightToothed gearingsElectric motor propulsion transmissionReducerEngineering

A railway vehicle drive unit (12) is a drive unit to rotatably drive a wheel (11) of a railway vehicle. More specifically, it includes a reducer housing (13) held on an inner diameter surface of the wheel (11), and integrally rotating with the wheel (11), an input side rotation member (14) connected to a drive source, a reducing mechanism (15) to reduce rotation speed of the input side rotation member (14) and transmit it to the reducer housing (13), a fixed member (23) arranged in the reducer housing (13) and connected and fixed to a vehicle body, axle bearings (24) and (25) to rotatably support the reducer housing 13 with respect to the fixed member (23), and lubricant oil circulating mechanisms (32) and (33) to circulate a lubricant oil between the reducing mechanism and the axle bearings (24) and (25).

Owner:NTN CORP

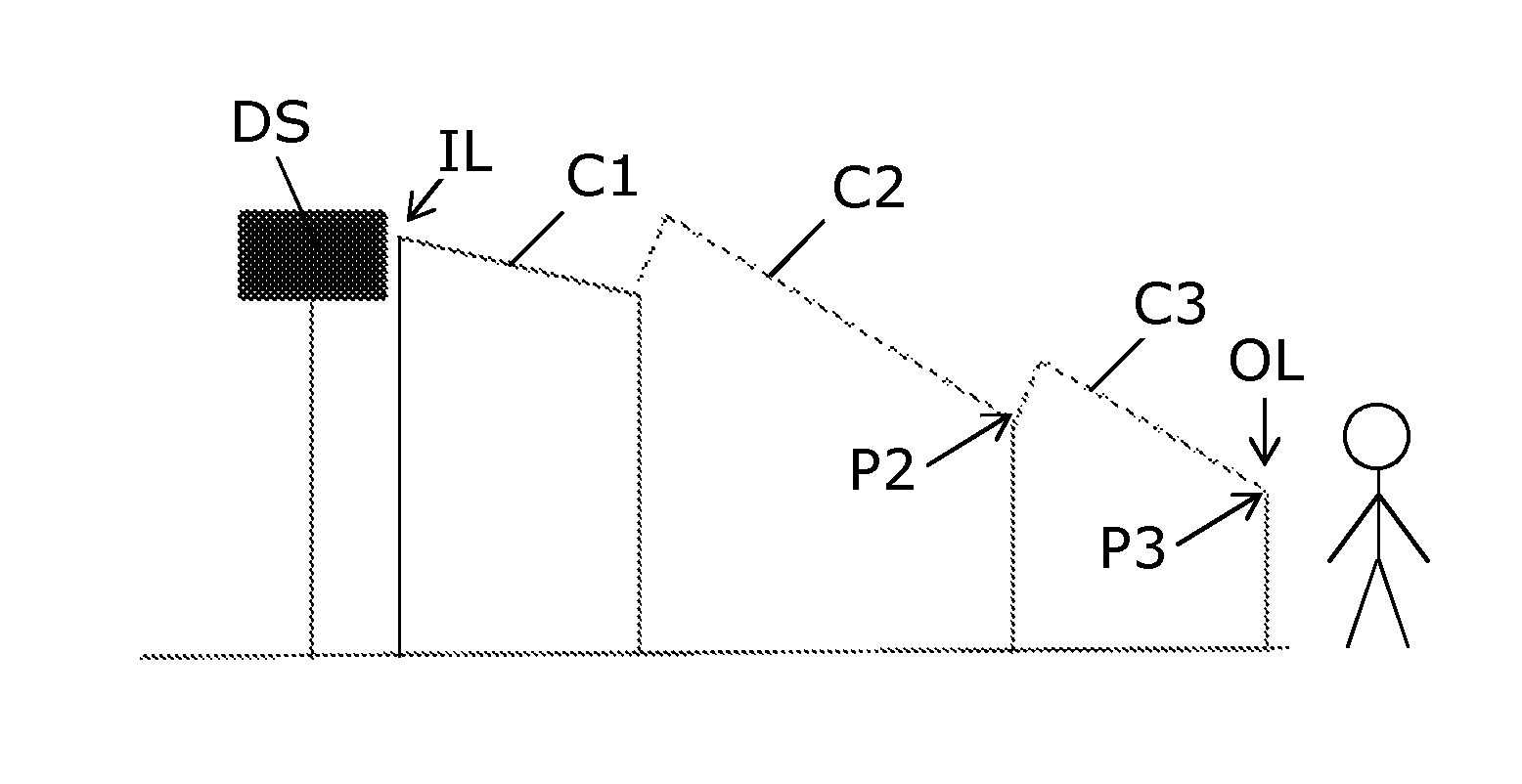

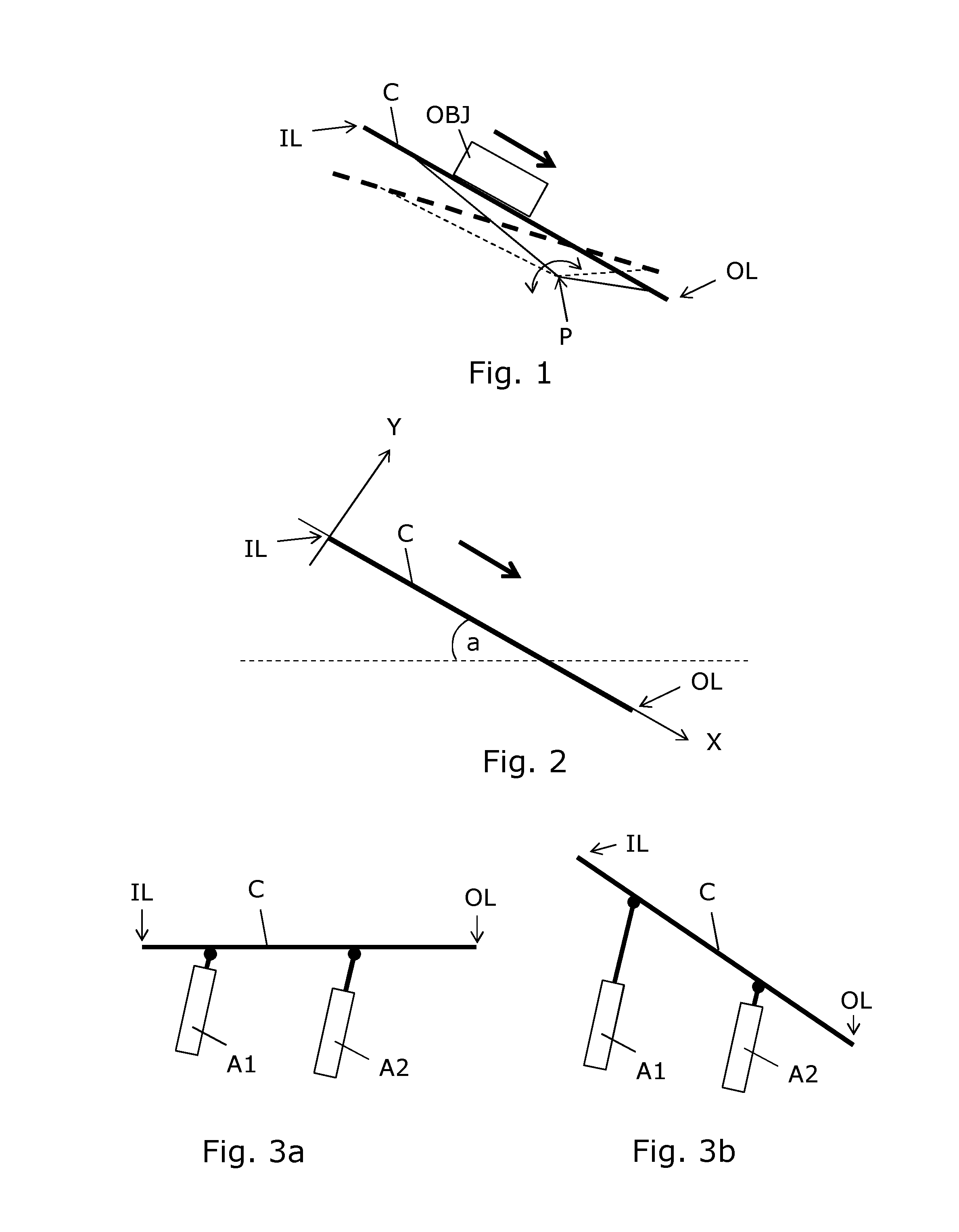

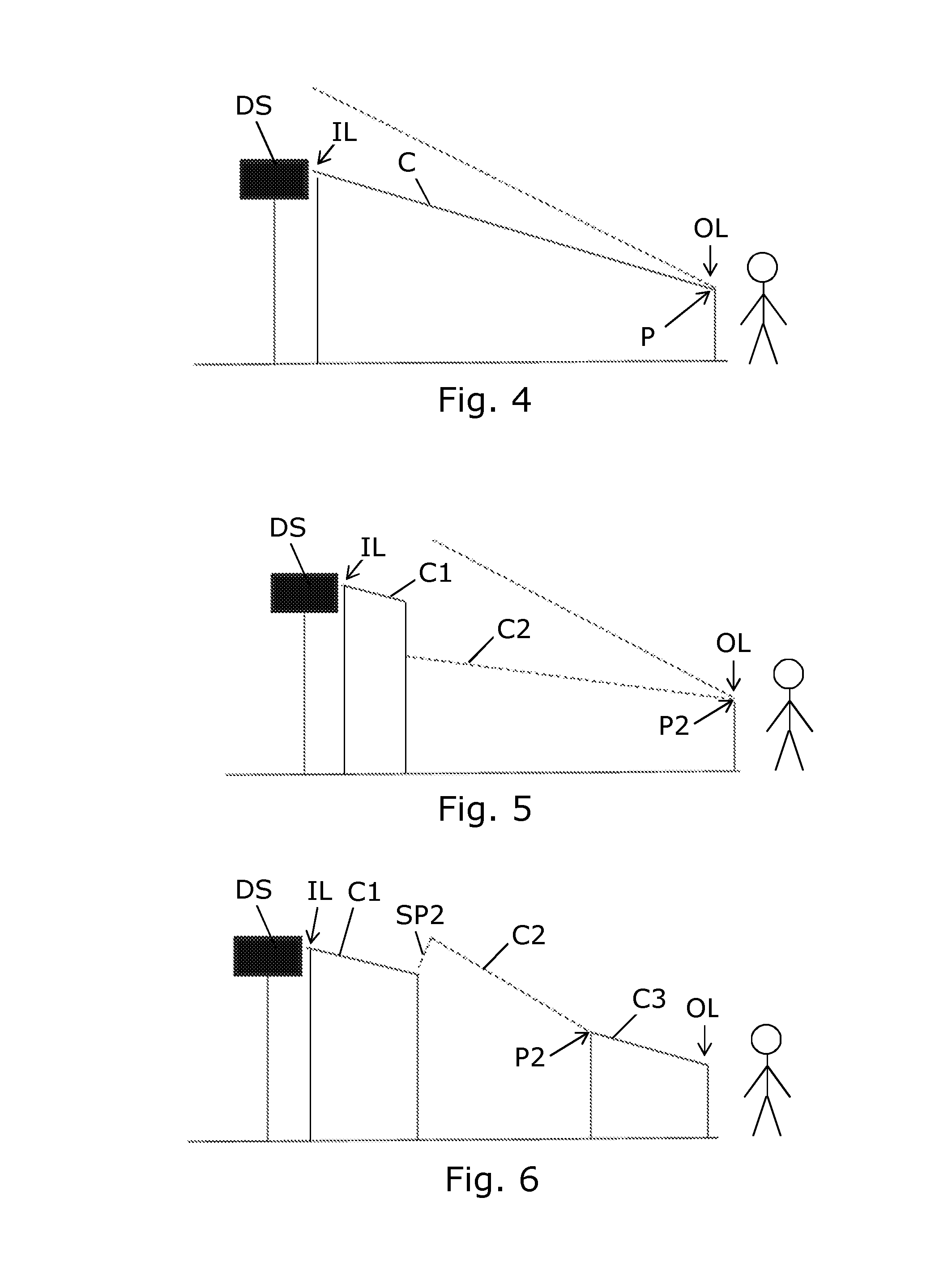

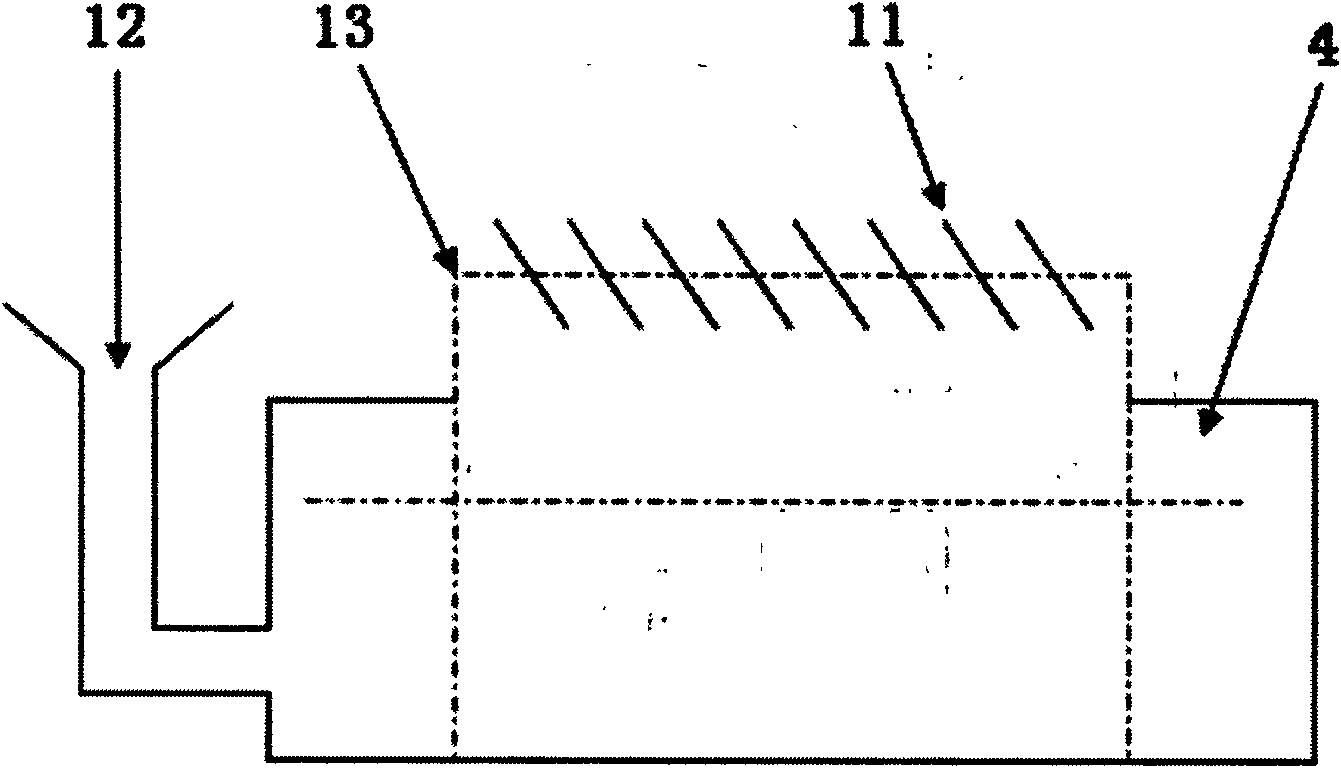

Chute system with adjustable angle of inclination

InactiveUS9278809B2Increase inclinationDecrease the inclinationSortingConveyor partsVision based systemsVision based

Owner:CRISPLANT

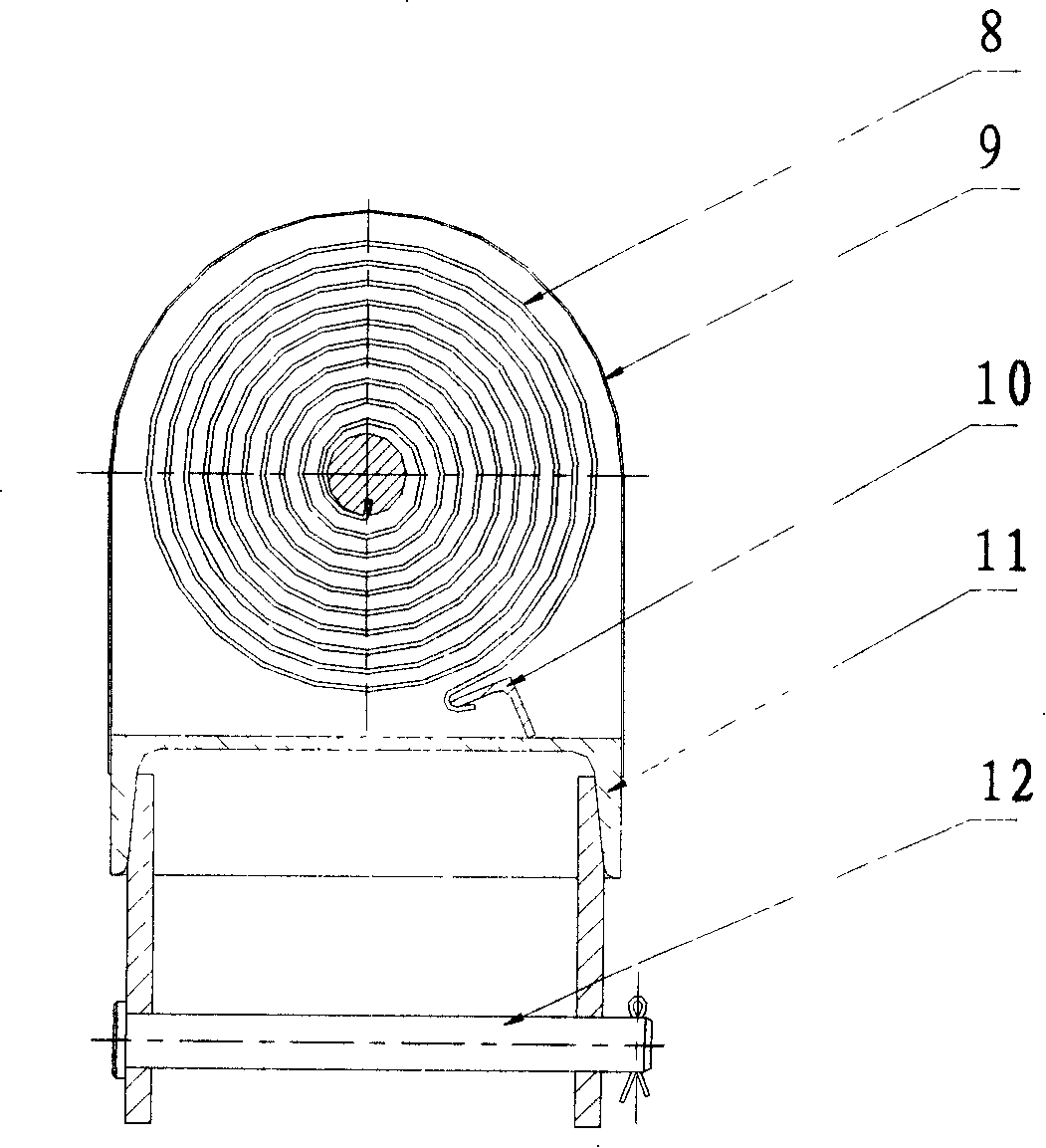

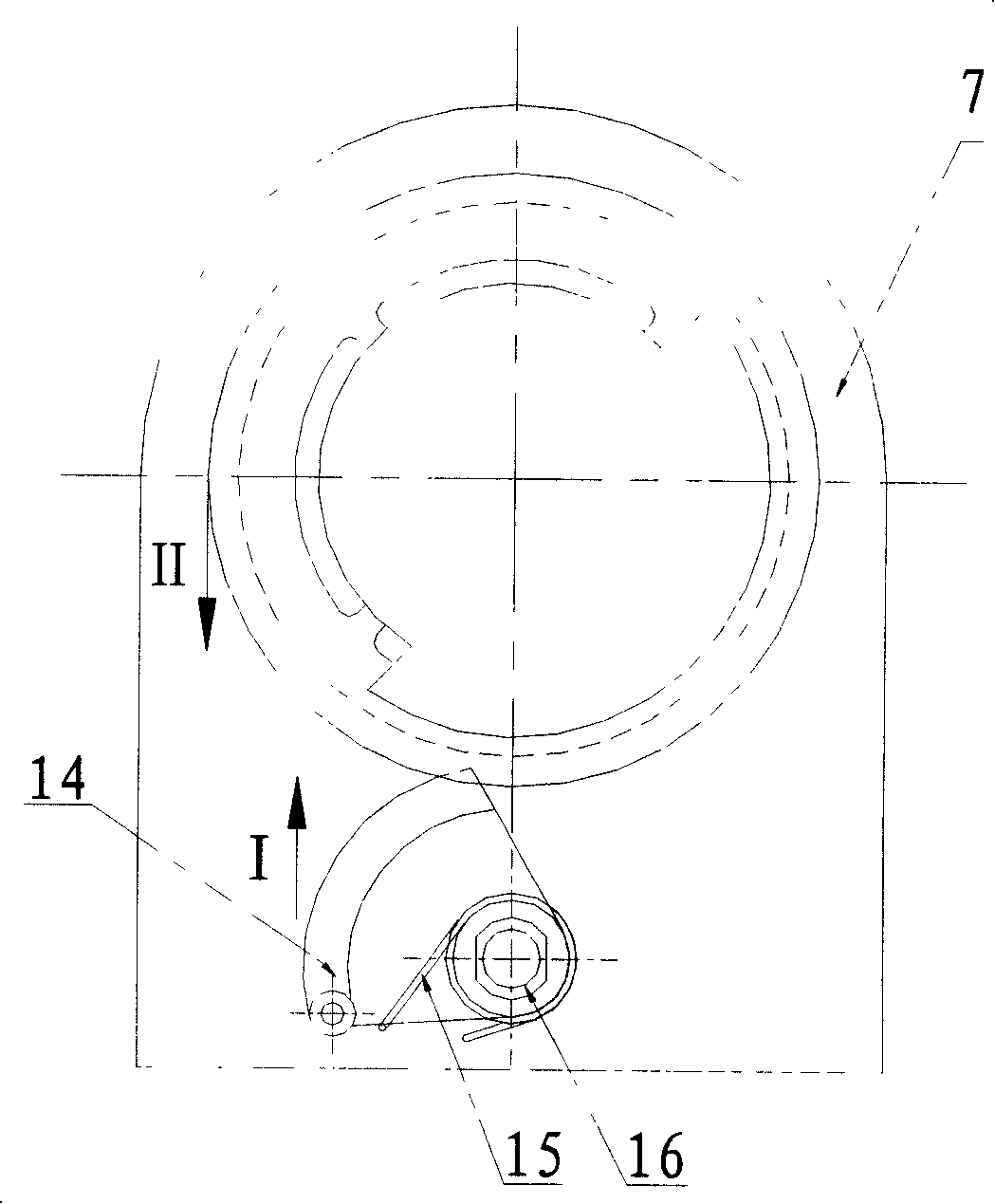

Constant tension spring compensating unit

The invention relates to a compensation device of a spring with constant tension, which essentially comprises a grooved pulley, a compensation rope, a left end plate, a main shaft, an oil seal, a bearing, a right end plate, a contact plane volute spring, an external cover, a fixed angle iron, an installation bottom plate, a hinge pin and a broken wire stopping device; wherein, the grooved pulley is fixed on the main shaft; the compensation rope is coiled and has an end fixed on the grooved pulley and the other end connected with an external contact net; the main shaft is supported on the left end plate and the right end plates by the oil seal and the bearing; the left end plate and the right end plate, the external cover, the fixed angle iron and the installation bottom plate form an enclosed box base; the hinge pin is connected to one side on the installation bottom plate far from the box base which is internally provided with the contact plane volute spring with an inner end bent hook connected with the main shaft and an outer end bent hook connected with the fixed angle iron on the box base. The compensation device of the spring with constant tension provided by the invention is compact in structure, small in size and light in weight. The invention can cause an electrified railway network to keep certain tension and reduce the loss catenary rate of the pantagraphs.

Owner:帖荣俊 +4

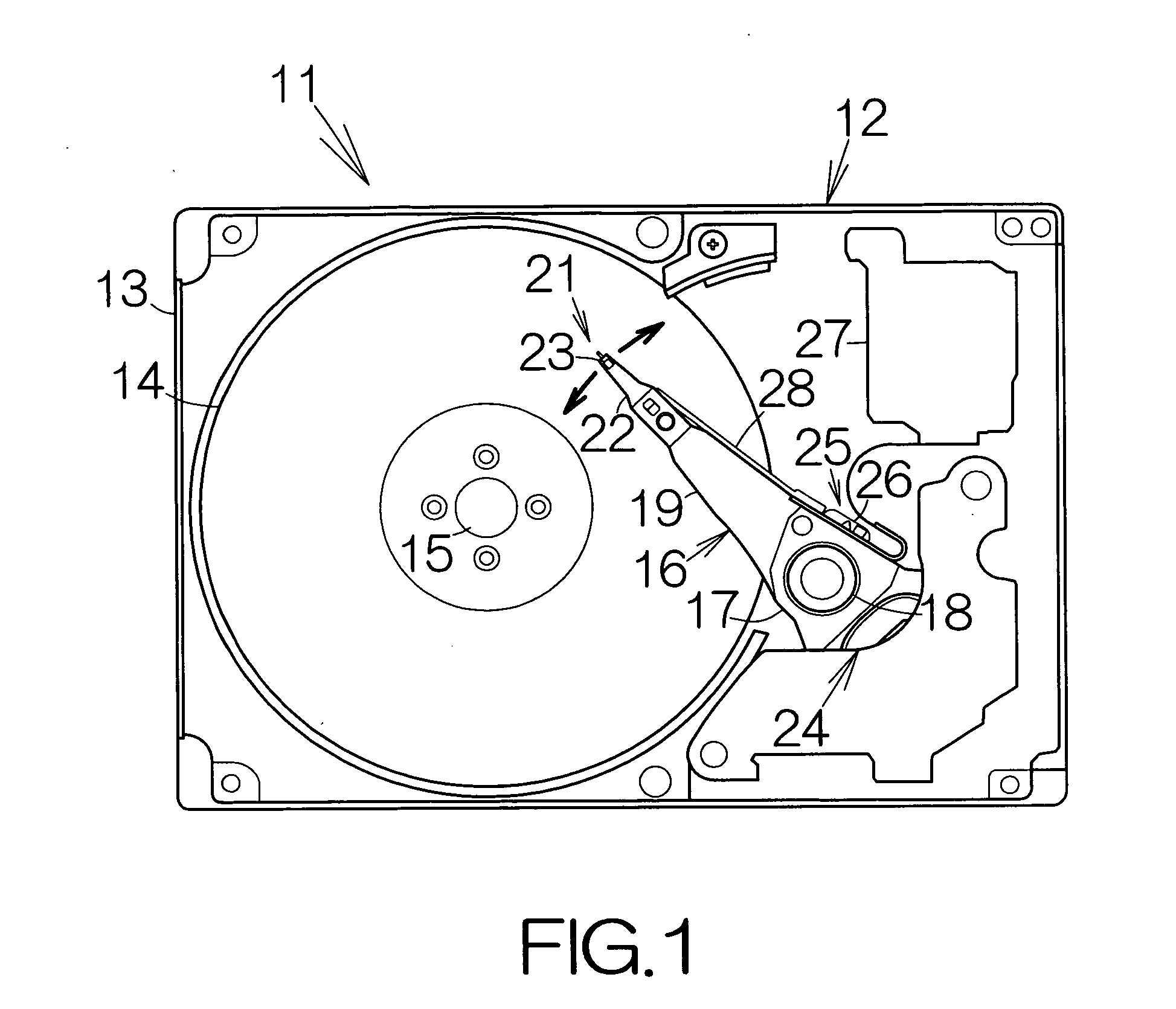

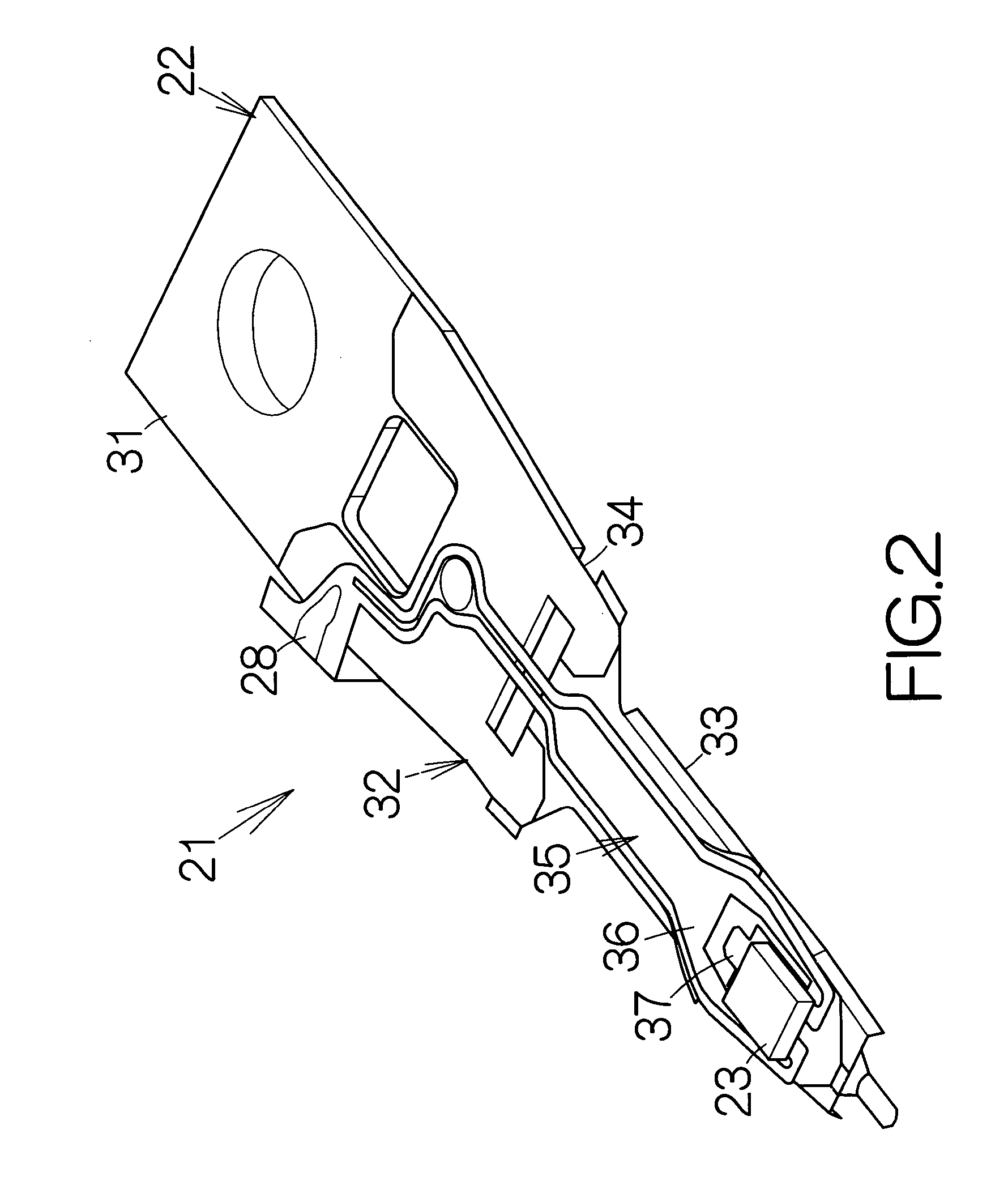

Head suspension assembly contributing to constant flying height of head slider

InactiveUS20060209462A1Avoid deformationEffectively contributing to establishmentRecord information storageFluid-dynamic spacing of headsEngineeringThermal expansion

An adhesive layer is interposed between a head slider and a support member for fixing the head slider to the support member. A deformation body is interposed between the head slider and the support member. The deformation body has a coefficient of thermal expansion larger than that of the adhesive layer. The deformation body expands in response to rise in temperature. An internal force is induced in the head slider so as to distance the head slider away from the support member. Since the adhesive layer serves to fix the head slider to the support member, the internal force is transformed into stress in the head slider. The thermal expansion induces stress in the head slider in response to the rise in temperature. The stresses are balanced with each other, so that the head slider is prevented from deformation.

Owner:FUJITSU LTD

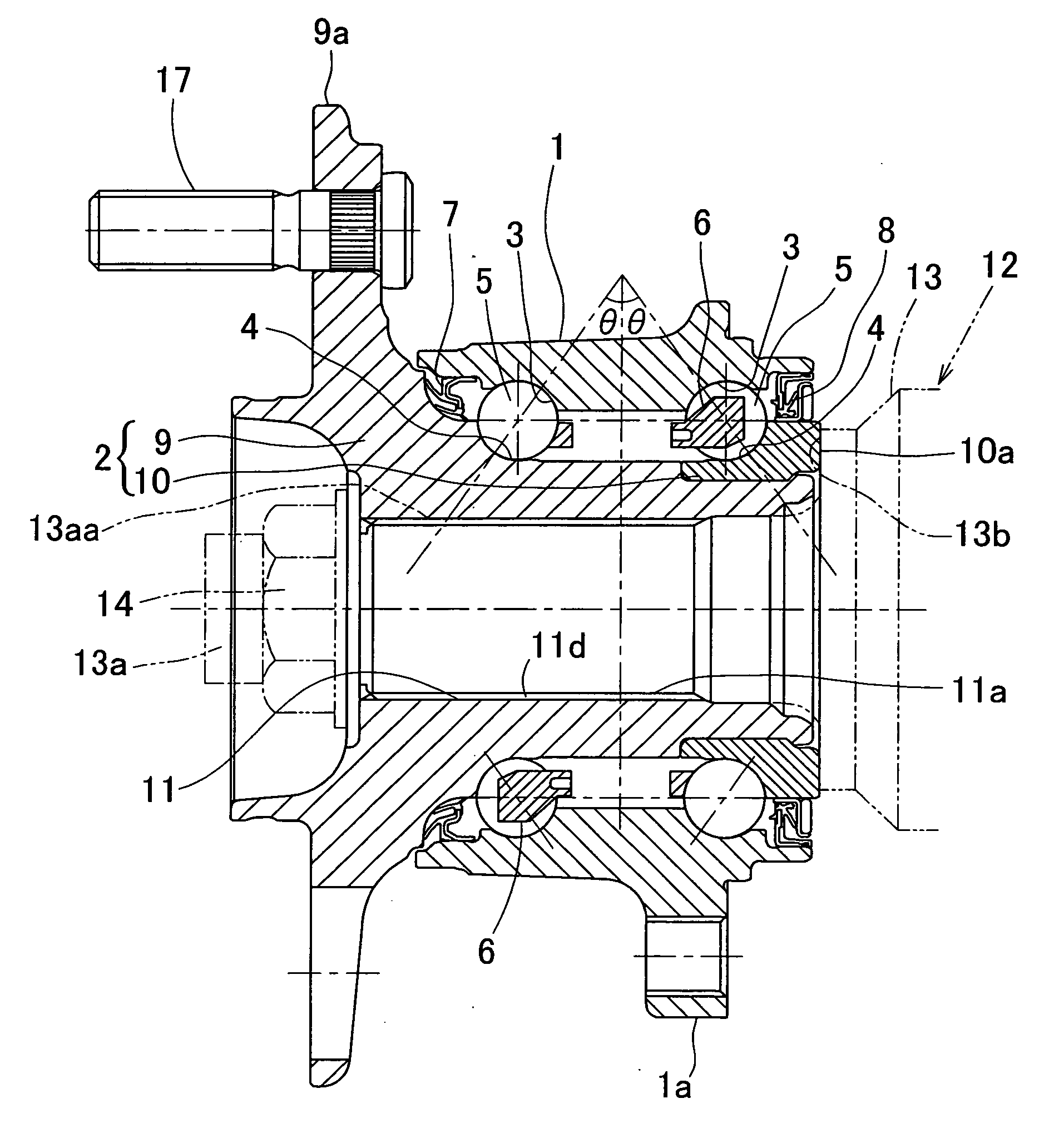

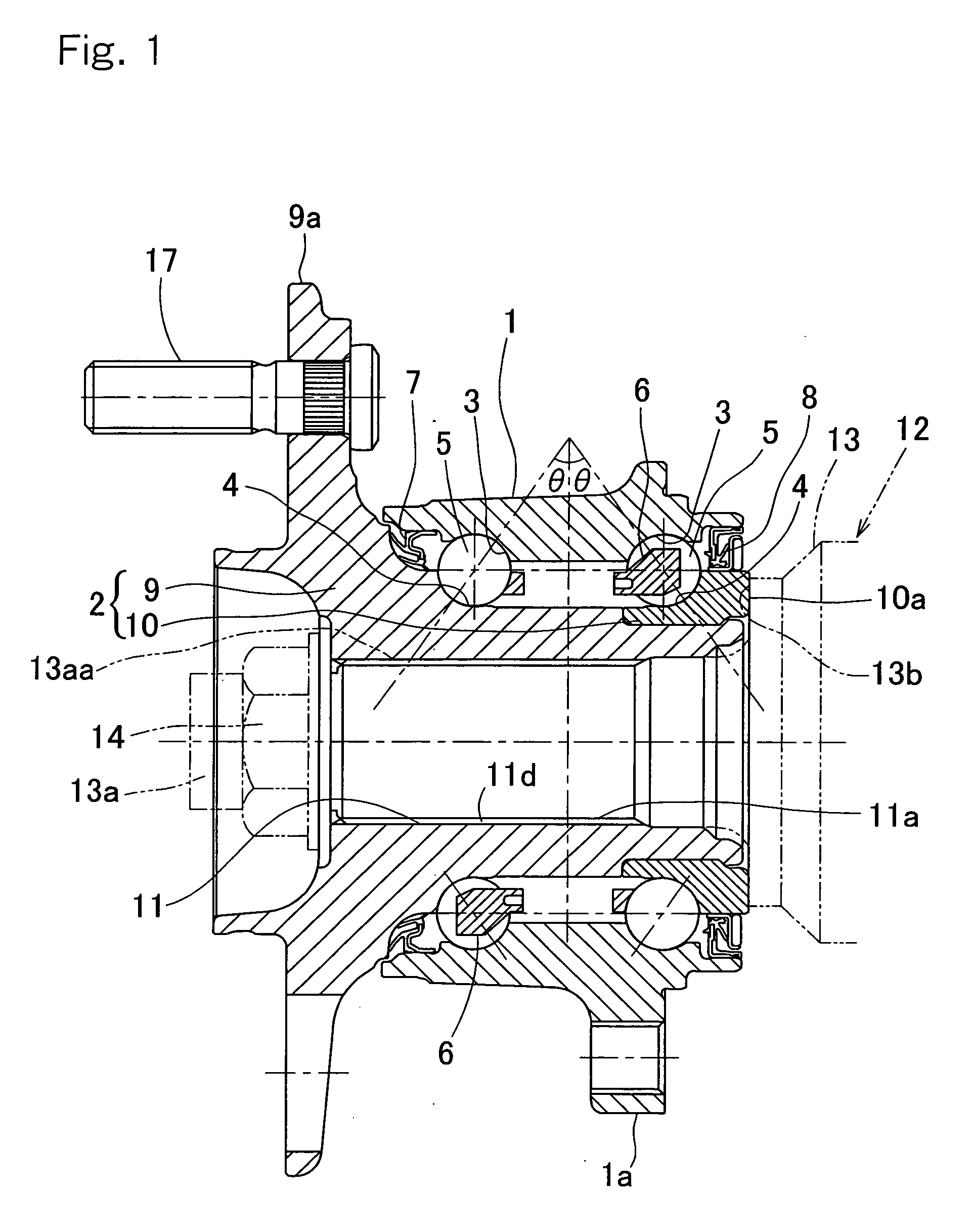

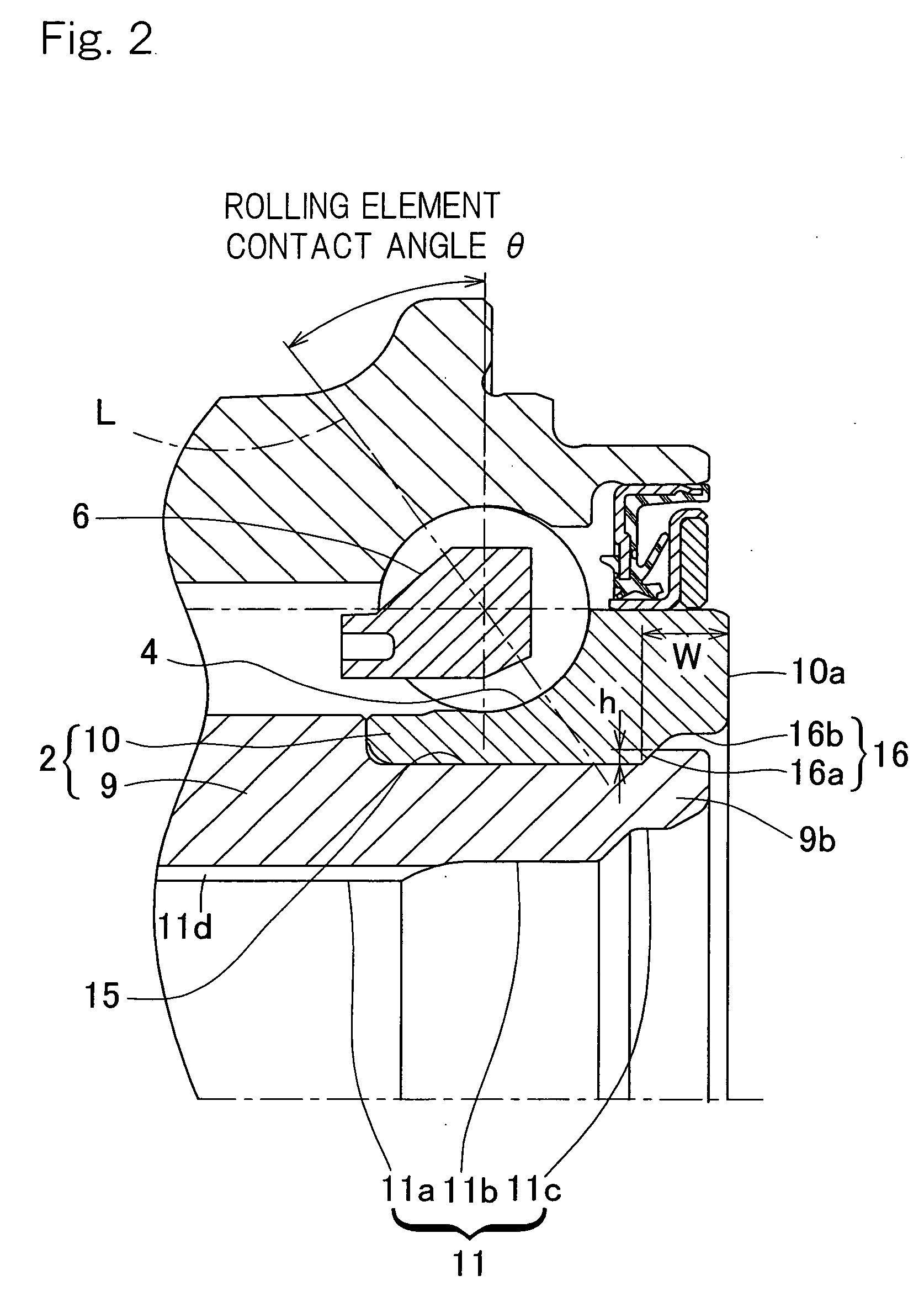

Wheel Support Bearing Assembly and Method of Manufacturing the Same

InactiveUS20090154856A1Easily and accurately be carriedAvoid interferenceRolling contact bearingsHubsEngineeringMechanical engineering

To provide a wheel support bearing assembly, which is effective to avoid an inner race detachment during assemblage onto an automotive vehicle. The assembly is provided with an inner member made up of a hub axle and an inner race mounted on an outer periphery of an inboard end portion of the hub axle. The inner race has an inner periphery provided with an stepped area that extends to an inboard annular face of the inner race and has a depth measured at an inner peripheral edge of an inboard annular face, and an inner surface of this stepped area is of a shape made up of a straight area and an inclined surface continued from an outboard end of the straight area to the inner peripheral surface, and a plastically deformed portion engageable with the inclined surface as a result of crimping is provided in the hub axle.

Owner:NTN CORP

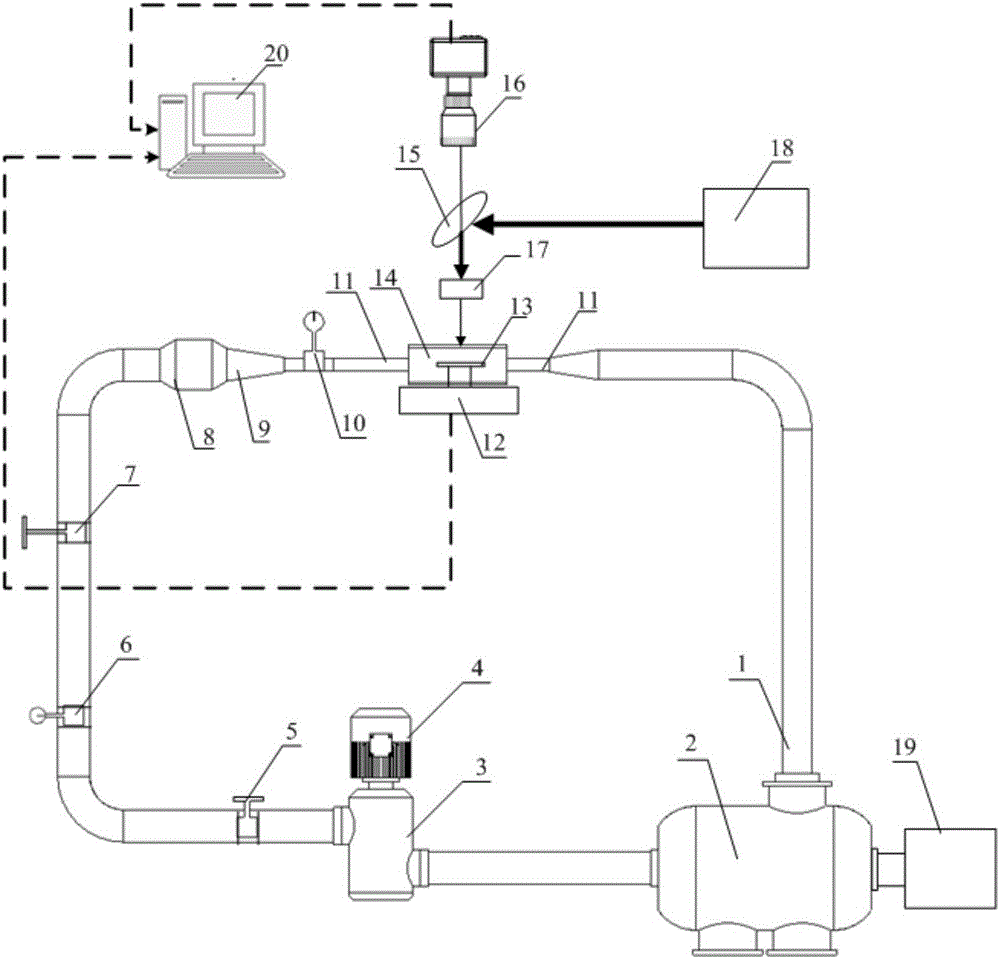

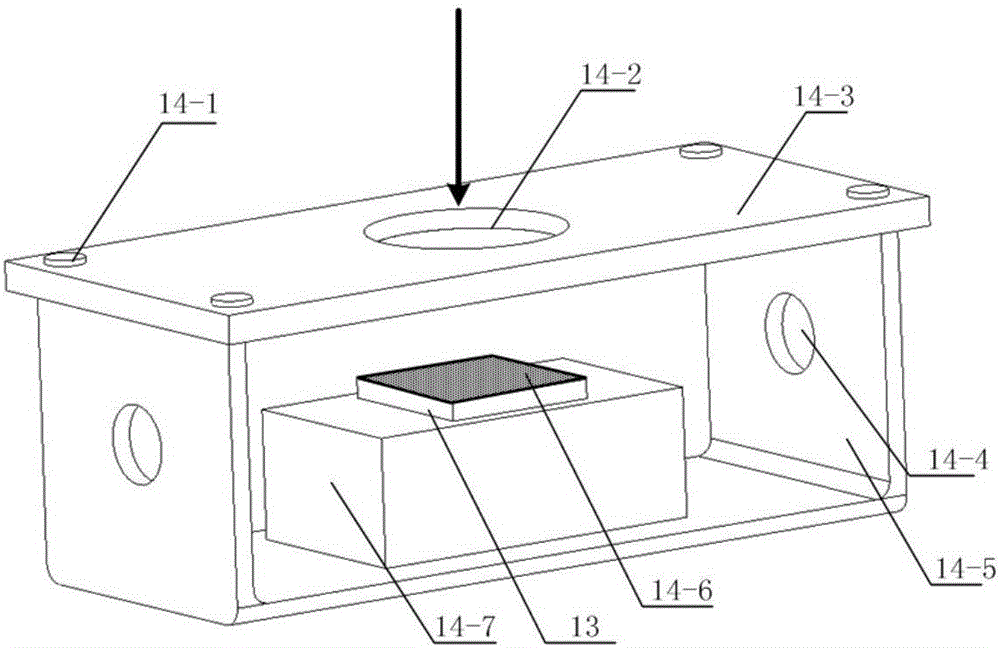

Controllable constrained laser micro shot peening intensification device and method thereof

The invention discloses a controllable constrained laser micro shot peening intensification device and a method thereof. The device comprises a circulating water system. A deionized water curtain is adopted as a constrained layer and is provided through the circulating water system; a high-speed camera is used for observing the growth and gathering situation of bubbles in a laser micro shot peening intensification process on line; a motor is used for driving a hydraulic pump to enable deionized water to circularly flow in the whole circulation water system; the pressure and the flow rate of the deionized water in the circulating water system are controlled to take away bubbles generated near a focal point in the laser micro shot peening intensification process so as to improve laser micro shot peening efficiency. The deionized water in the circulating water system is kept in certain pressure, so that the rigidity of the deionized water curtain on the surface of a laser micro shot peening metal sample is increased, the constraining function of the deionized water curtain for plasma explosion is improved, material surface laser-induced shock wave pressure is enhanced, and an active function is performed on improving a laser micro shot peening intensification effect.

Owner:CHINA UNIV OF MINING & TECH

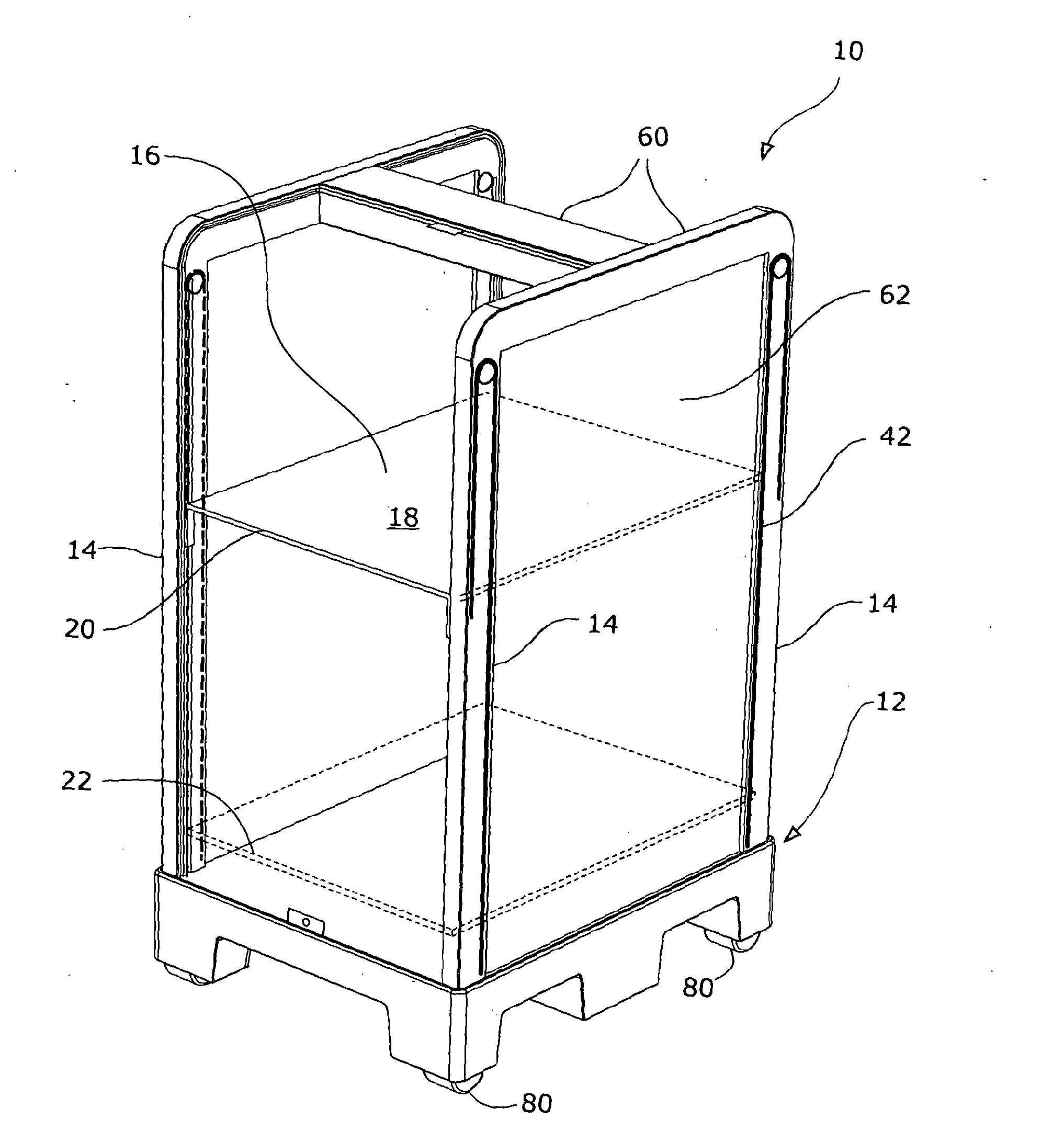

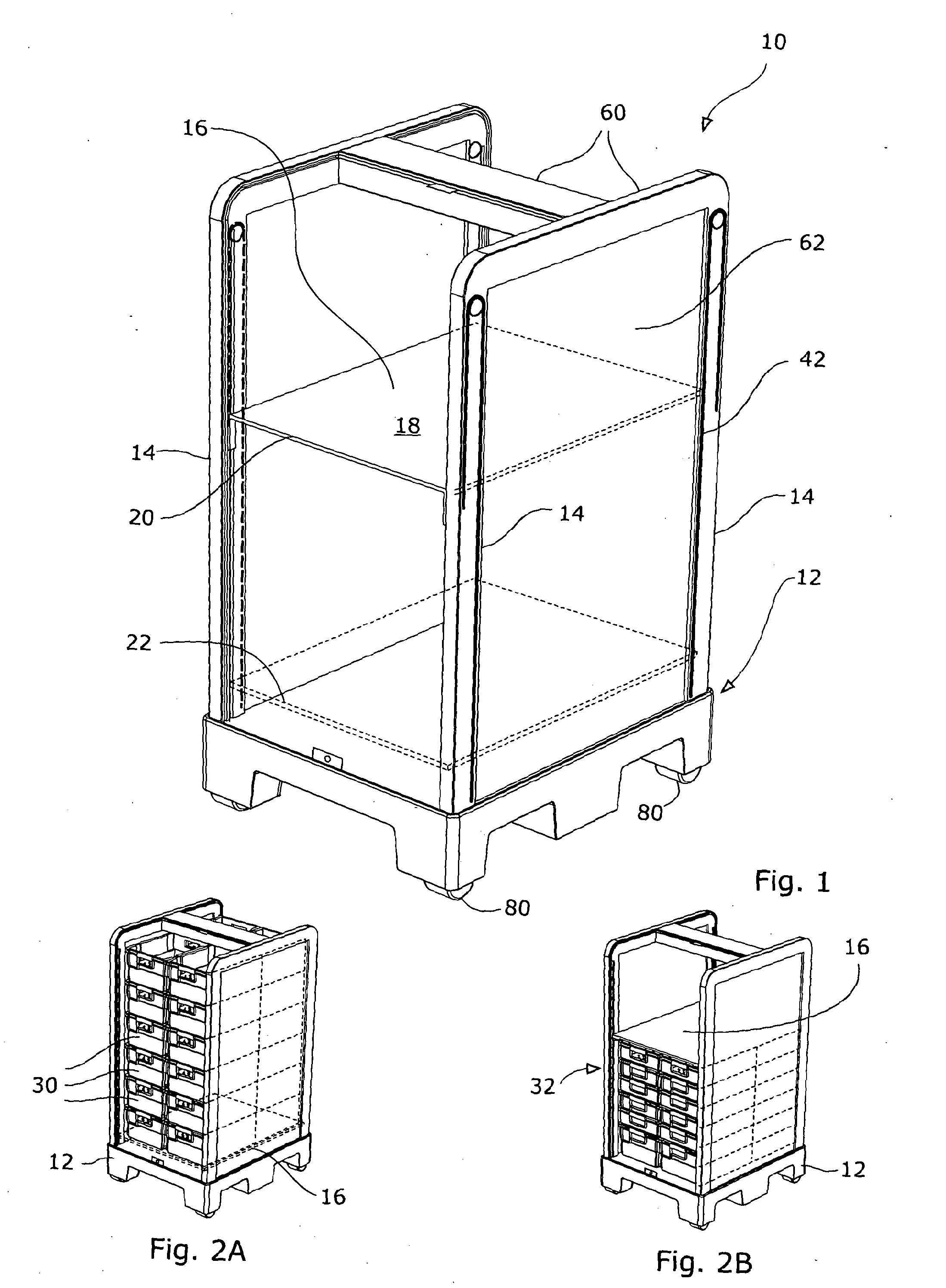

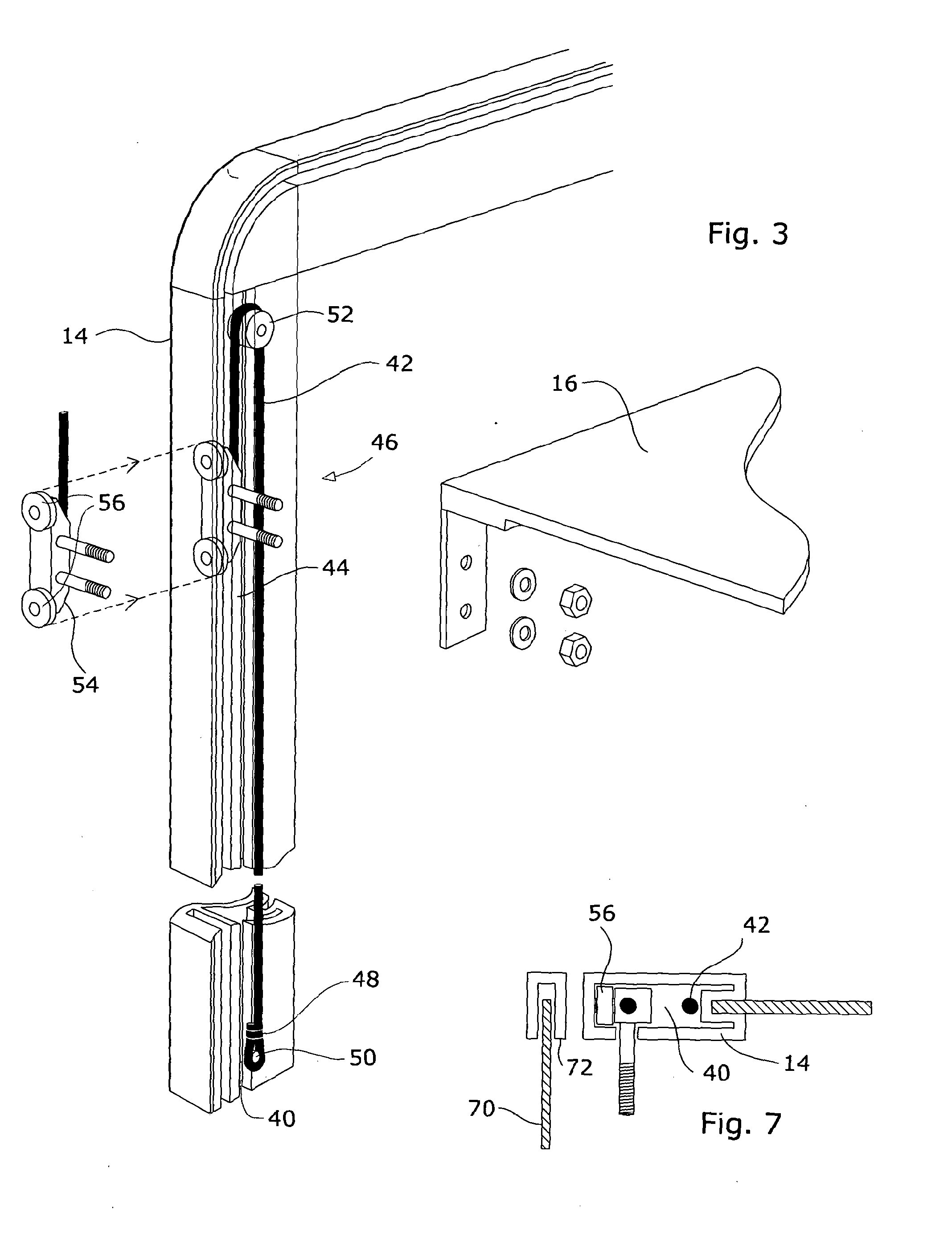

Apparatus for storing a plurality of objects such as trays

InactiveUS20150014264A1Easy to storeExpand accessFoldable tablesContainer/bottle contructionMarine engineering

Owner:LINNELL MICHAEL CHARLES SR +3

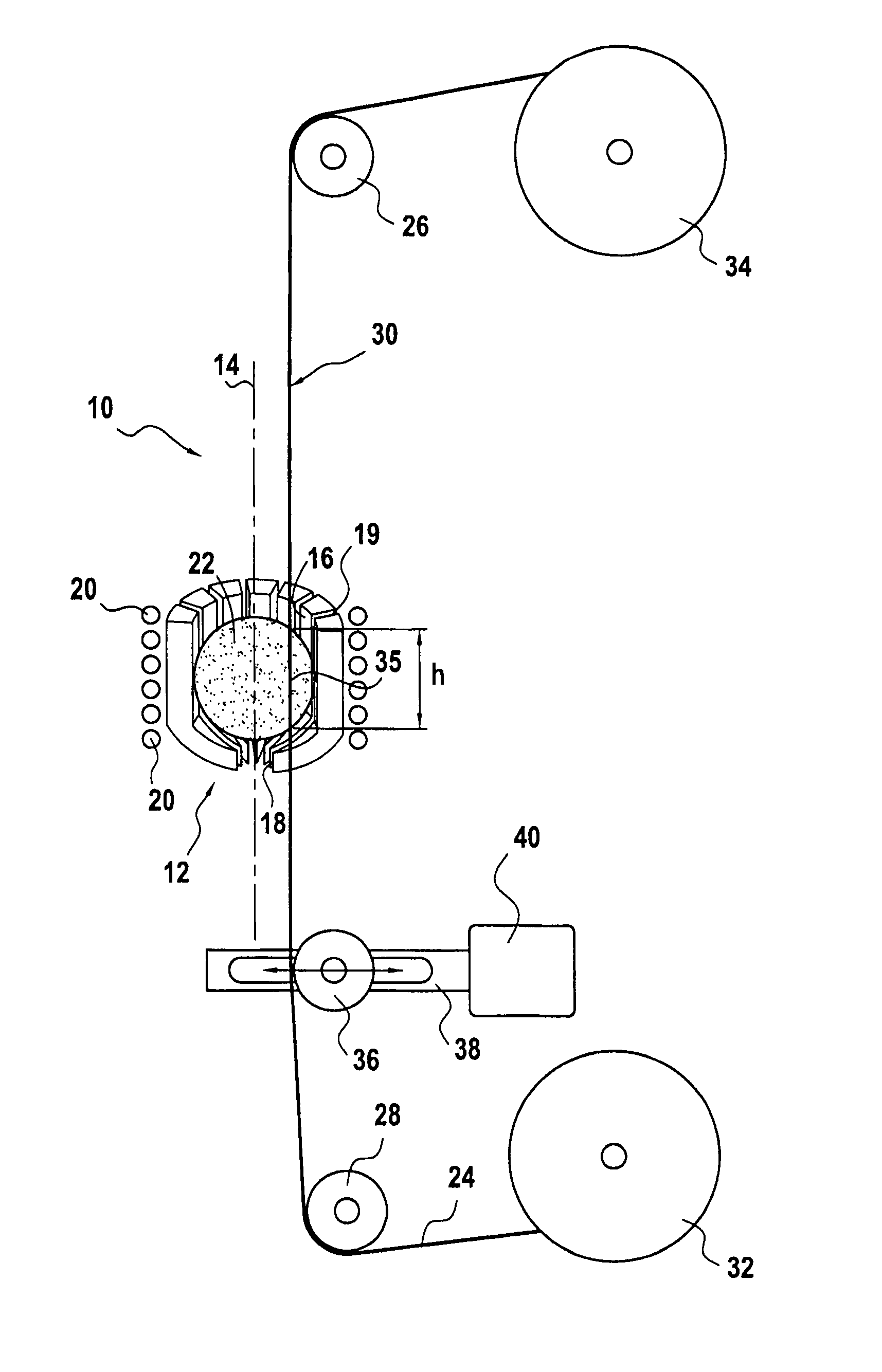

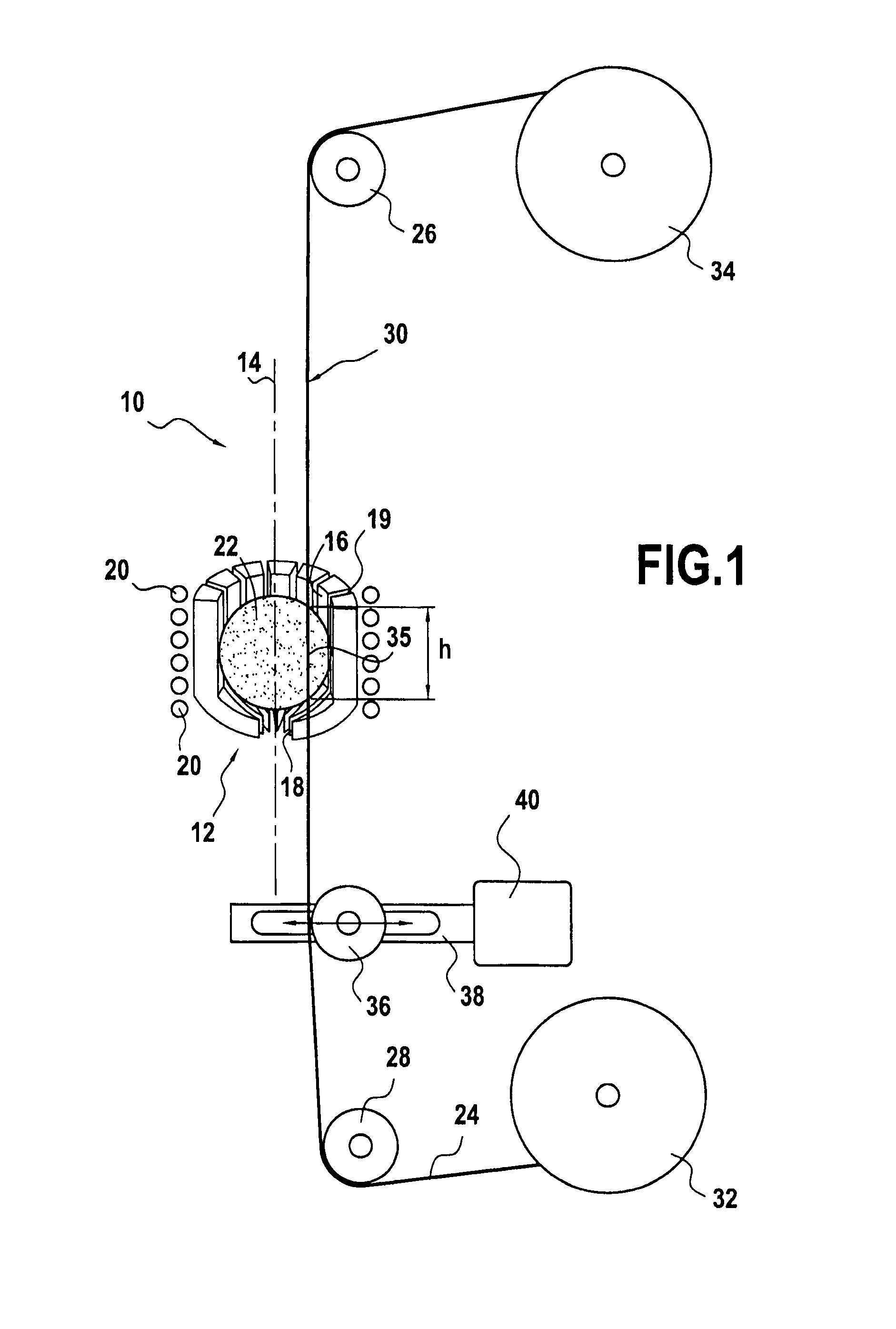

A method and a device for coating ceramic material fibers in metal by a liquid technique

ActiveUS20120064254A1Convenient lengthLow costHot-dipping/immersion processesLiquid surface applicatorsFiberMetal coating

A method of coating ceramic material fibers in metal using a liquid technique and a device implementing the method. The method maintains a charge of molten metal in levitation in a substantially spherical shape inside a crucible and causes a tensioned ceramic material fiber to travel at a predetermined speed between a bottom pulley and a top pulley disposed on either side of the crucible such that a portion of fiber is immersed in the charge to be covered in a metal coating. During coating, the portion of fiber that is immersed in the charge is shifted as a function of the remaining volume of the charge such that the instantaneous height of fiber that is immersed in the charge remains substantially constant throughout the coating operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

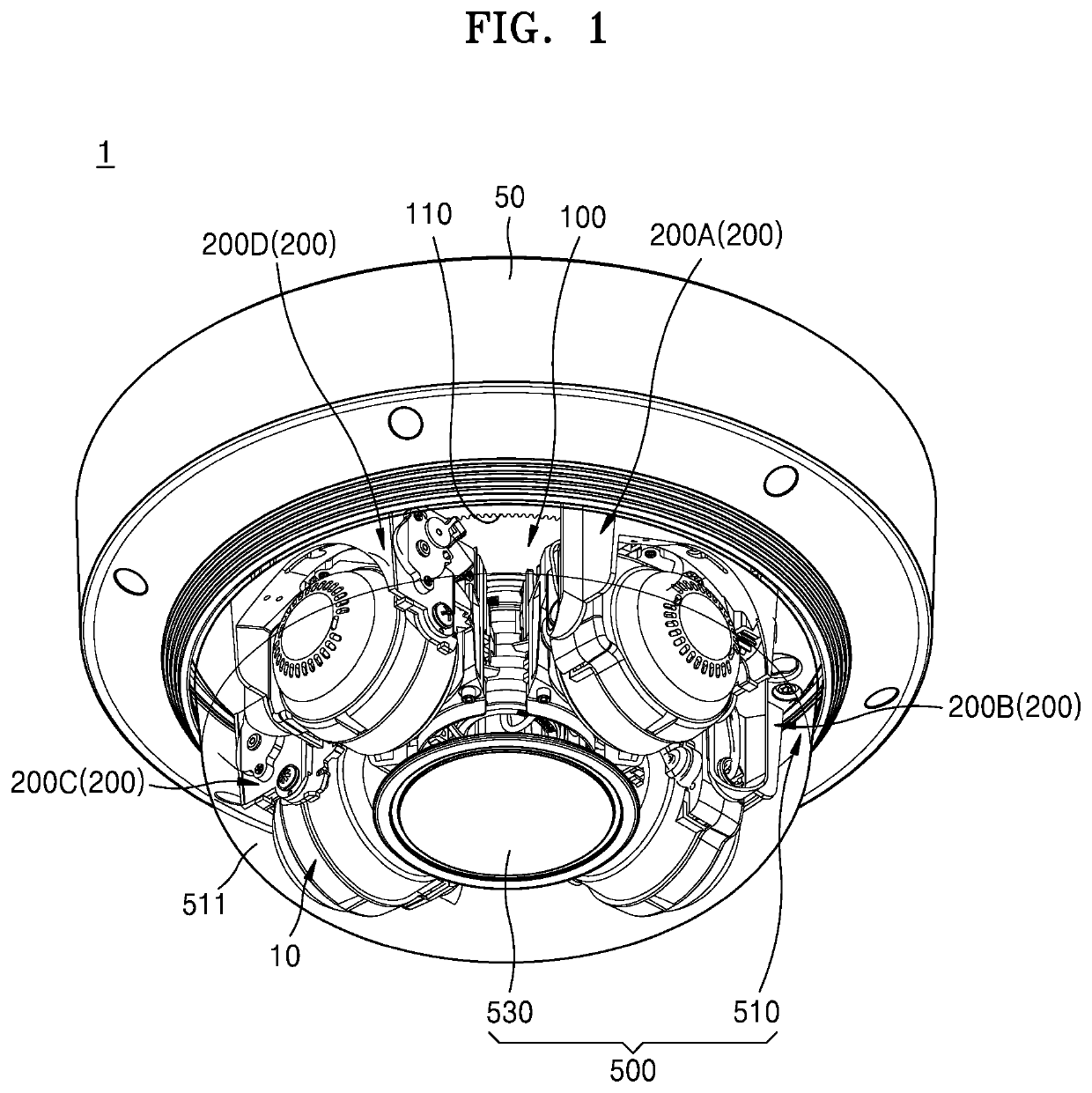

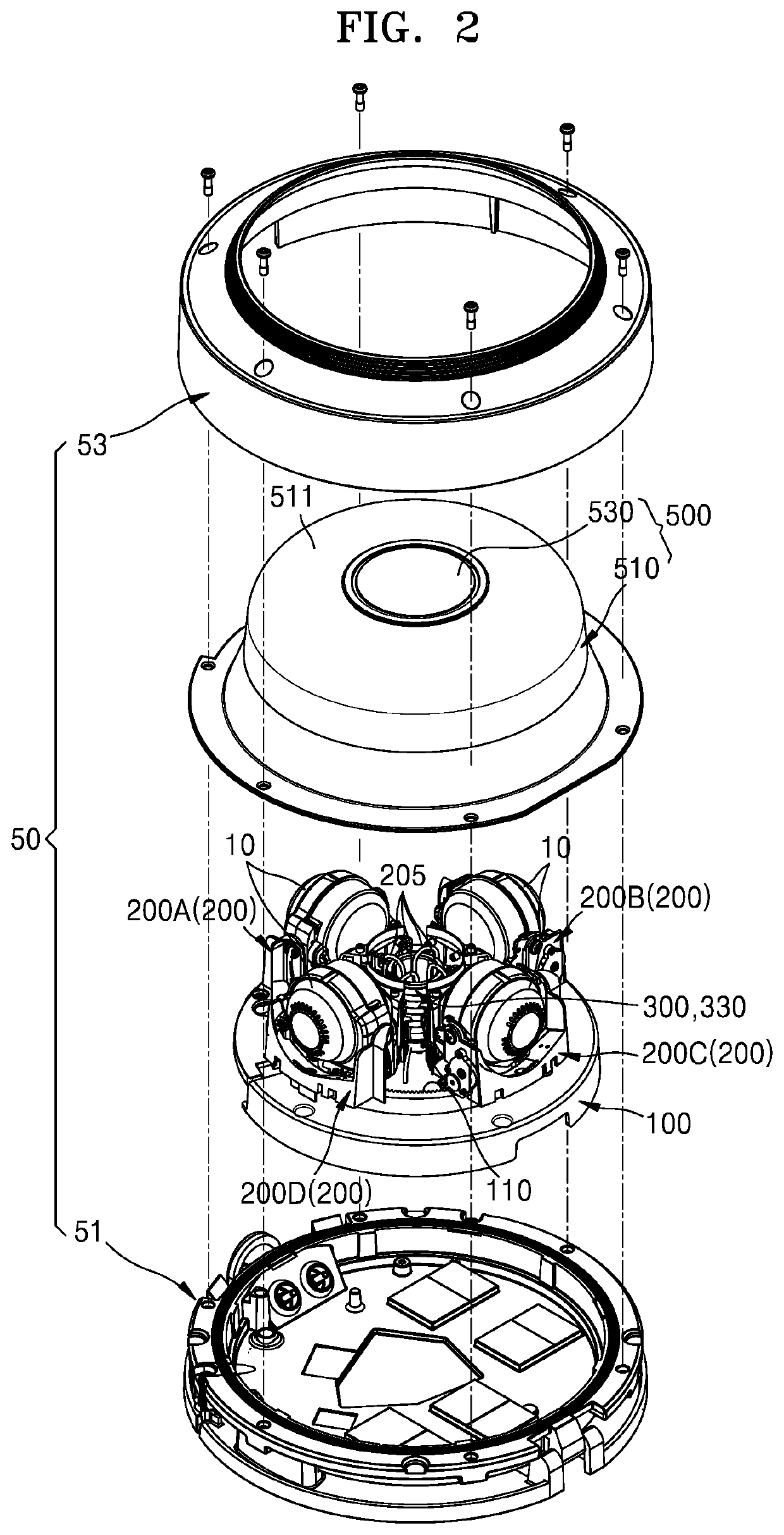

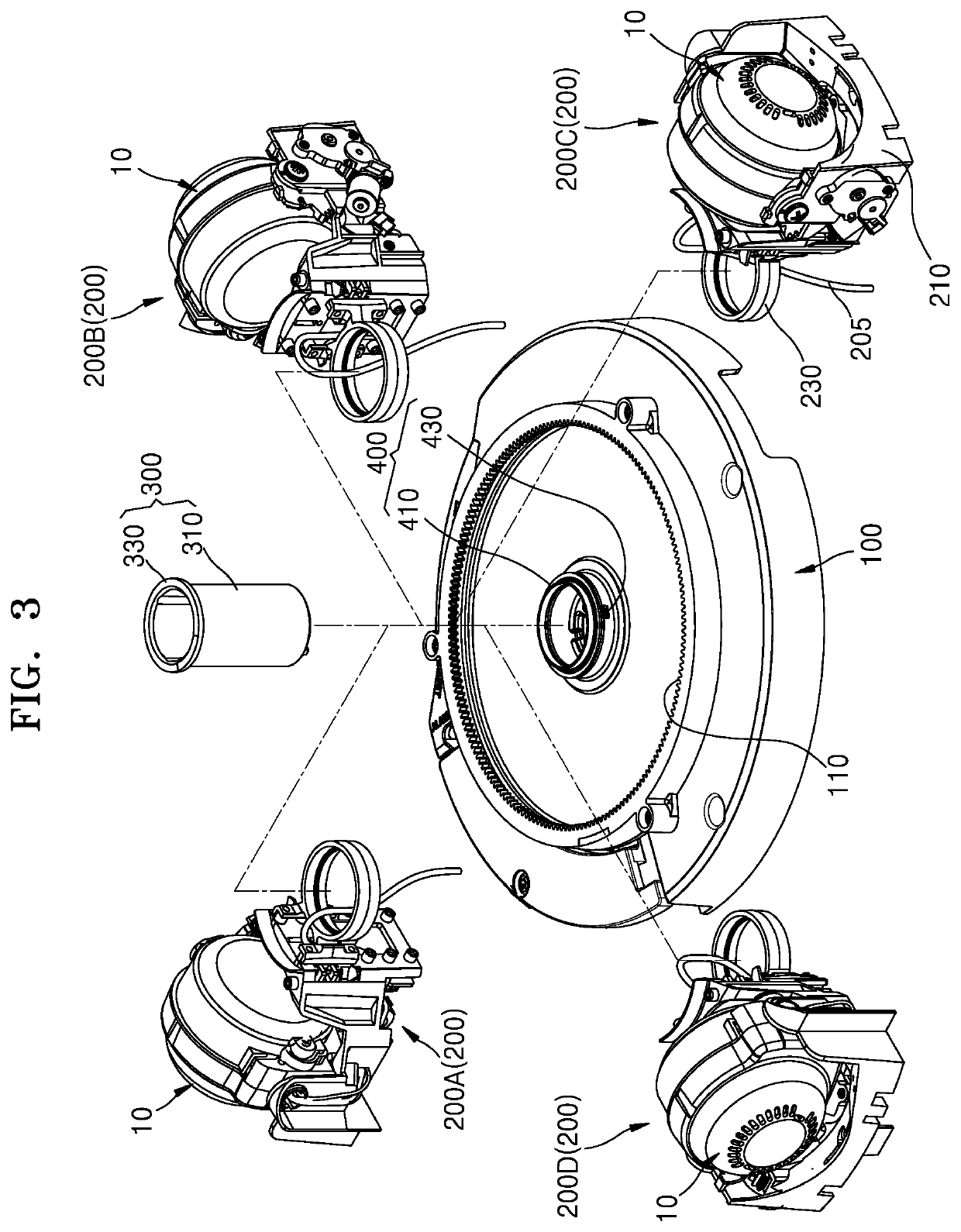

Multi-camera apparatus and image capturing system including the same

ActiveUS20210058556A1Reduce rotationConstant heightTelevision system detailsColor television detailsEngineeringCamera module

A multi-camera apparatus includes: a driving base in which a movement path is formed; at least one camera mount, each of which includes a respective camera module mounted therein, and is configured to contact the driving base and move along the movement path; and a shaft provided at a center of the driving base and coupled to the driving base, wherein each of the at least one camera mount is connected to the shaft and configured to move along a circumference of the driving base with the shaft as a rotational center.

Owner:HANWHA VISION CO LTD

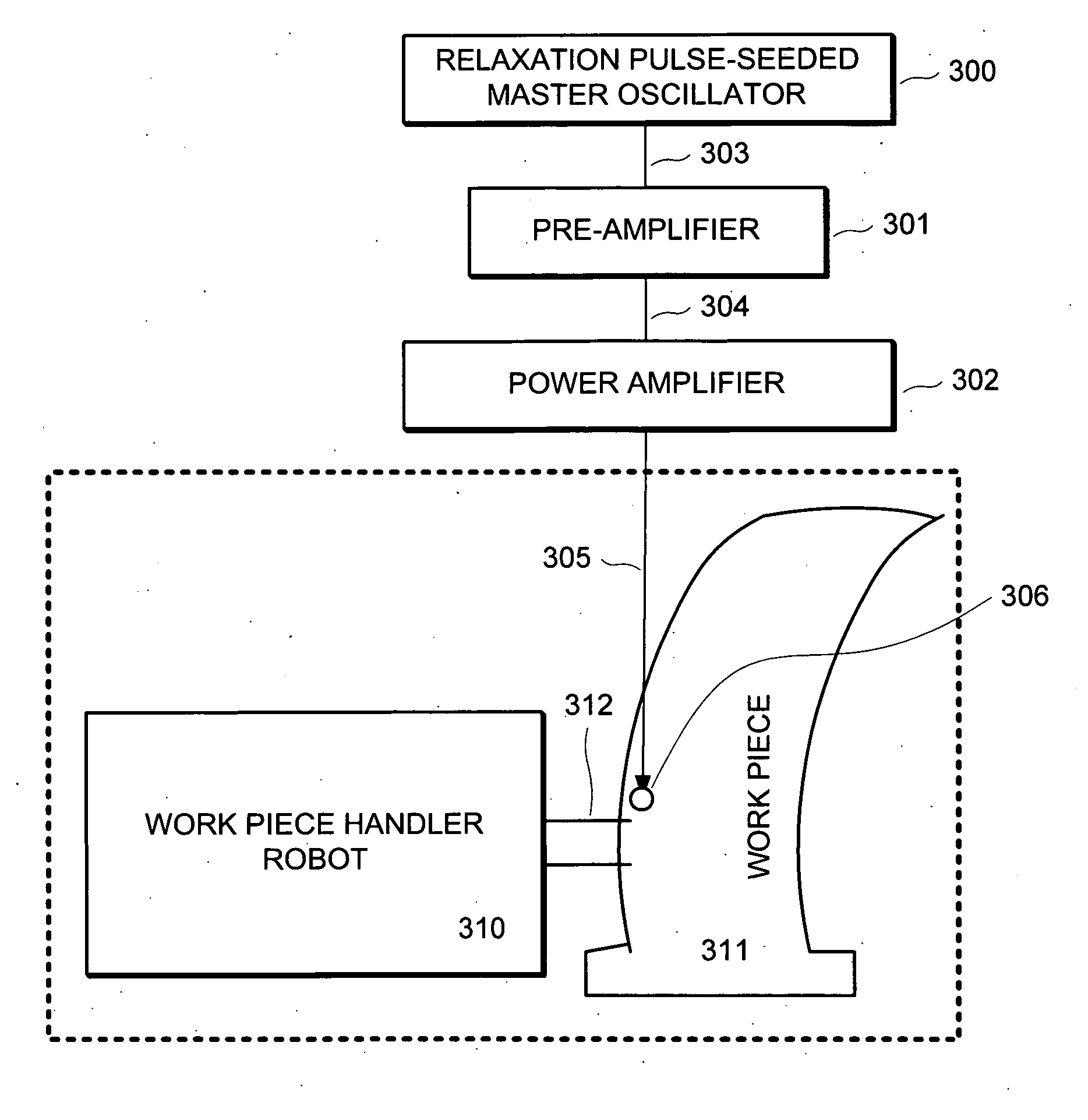

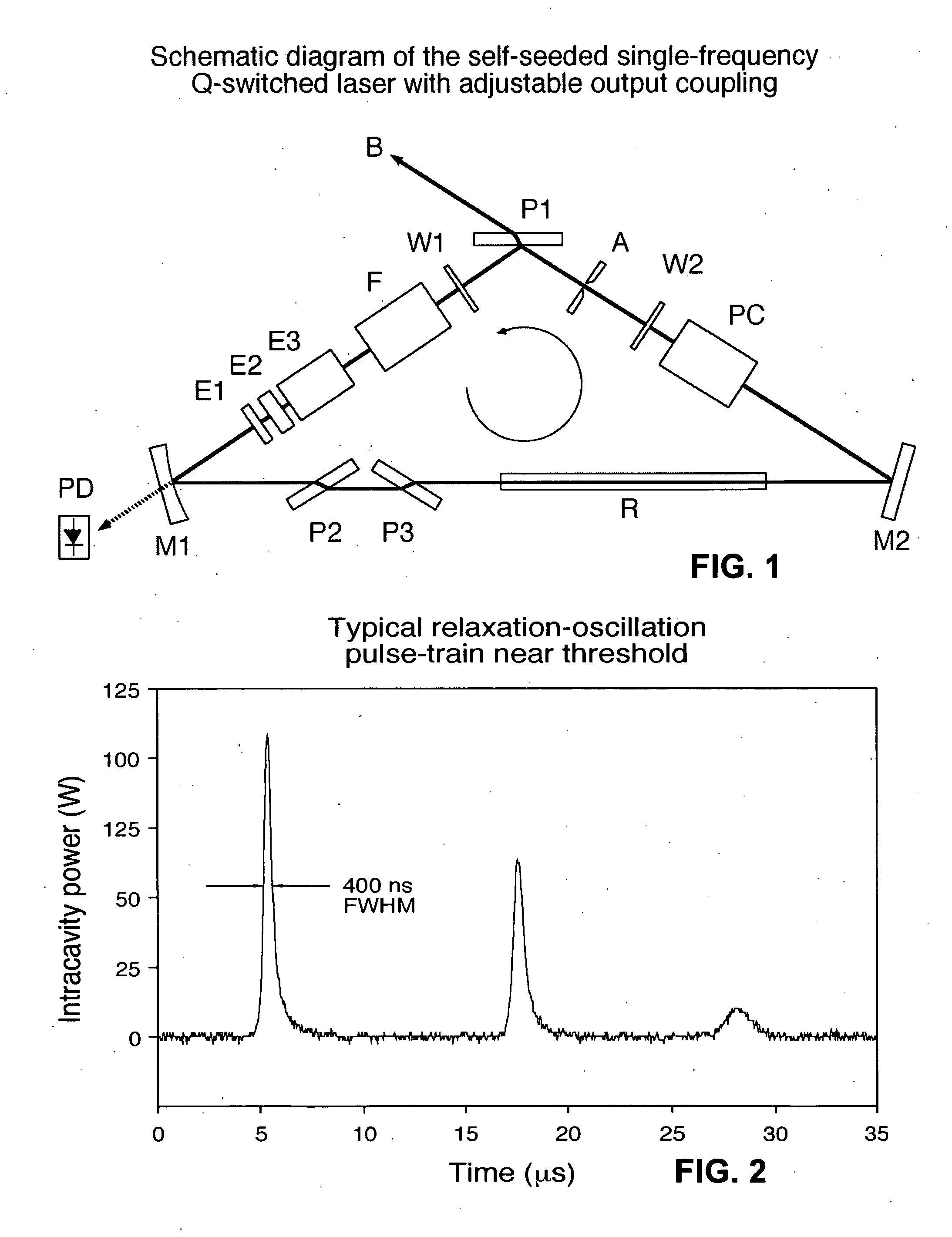

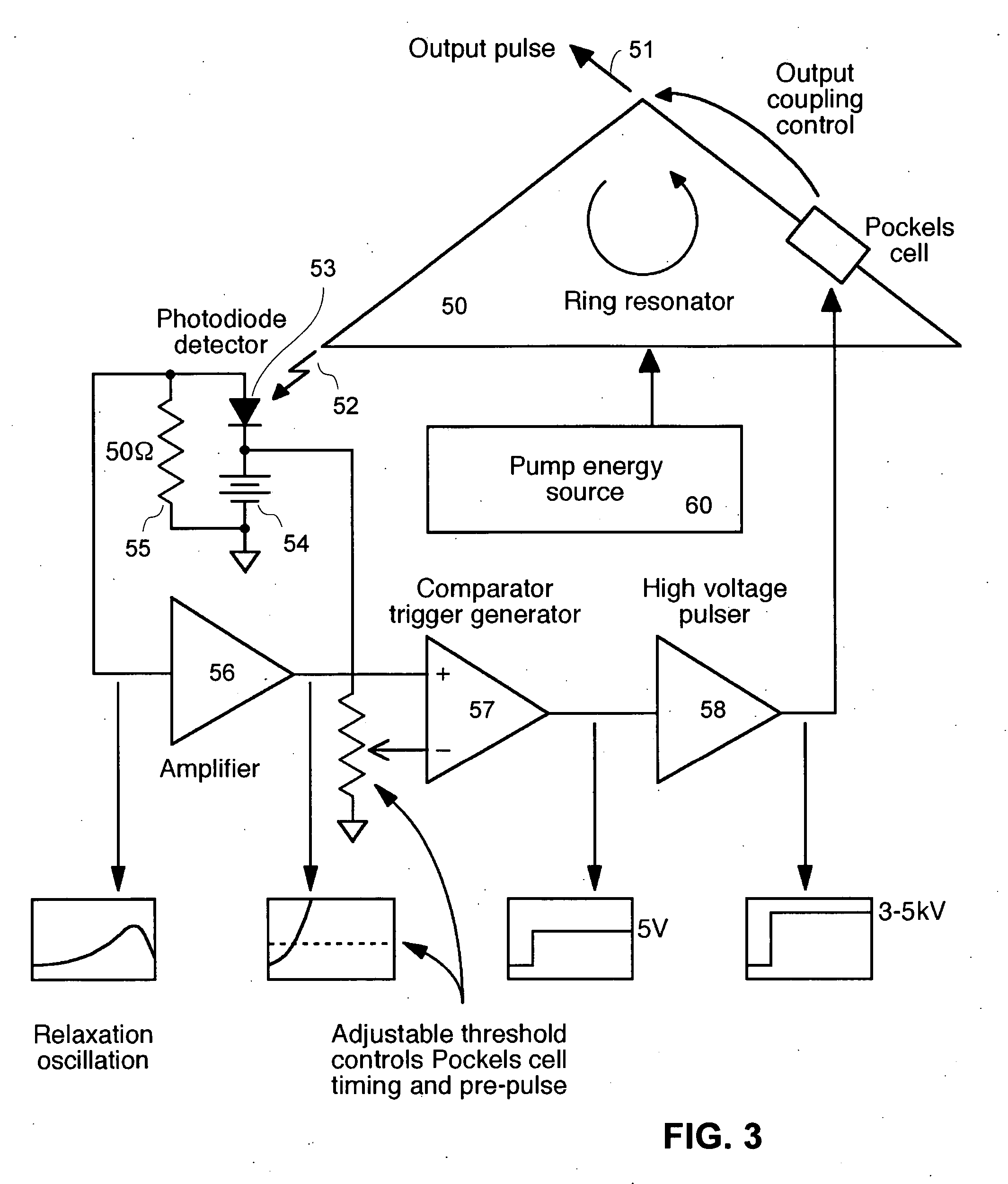

Self-seeded single-frequency laser peening method

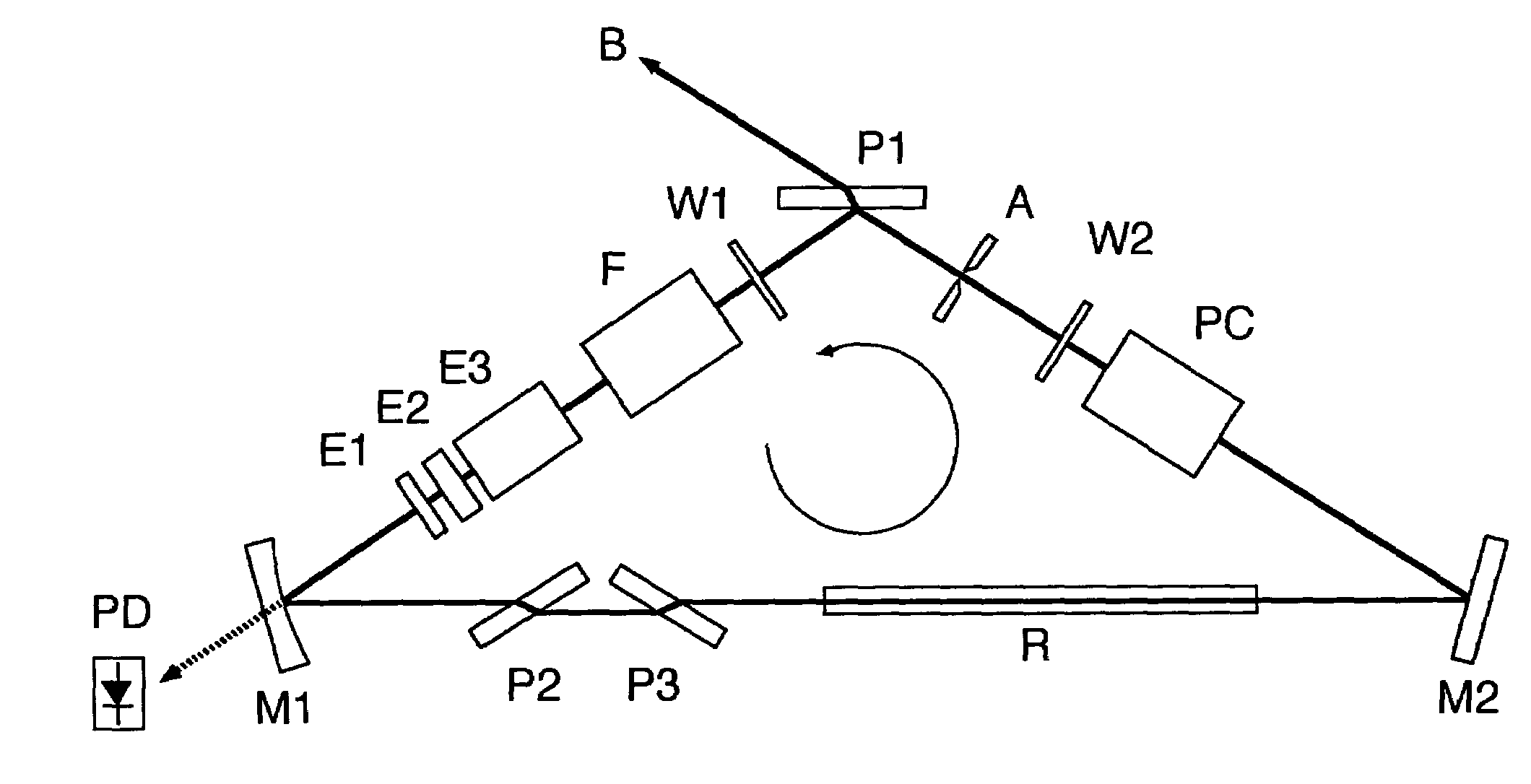

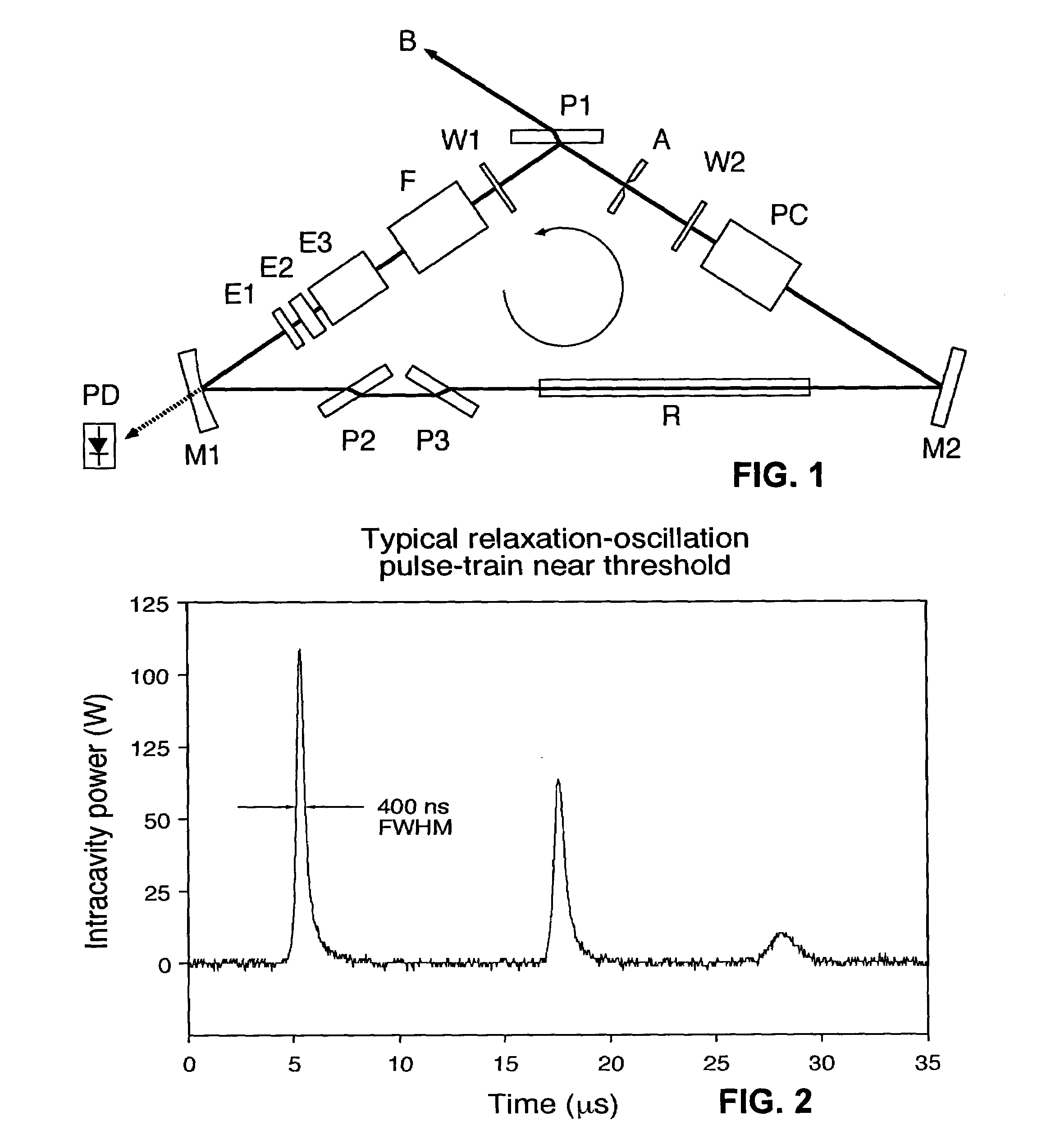

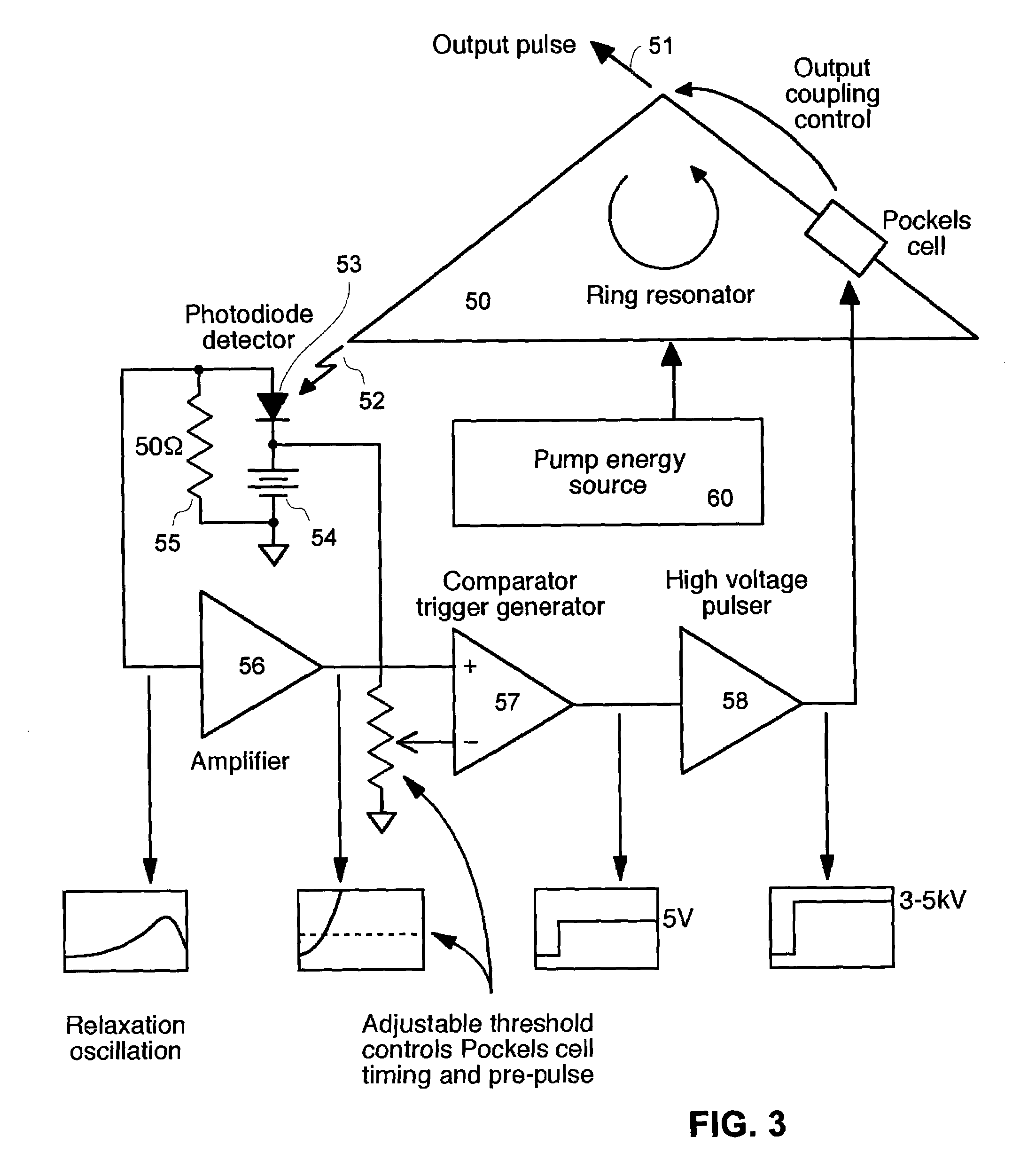

ActiveUS20060043079A1Simple designLess pulse durationLaser arrangementsSubstation equipmentPulse characteristicsLaser peening

A method of operating a laser to obtain an output pulse having a single wavelength, comprises inducing an intracavity loss into a laser resonator having an amount that prevents oscillation during a time that energy from the pump source is being stored in the gain medium. Gain is built up in the gain medium with energy from the pump source until formation of a single-frequency relaxation oscillation pulse in the resonator. Upon detection of the onset of the relaxation oscillation pulse, the intracavity loss is reduced, such as by Q-switching, so that the built-up gain stored in the gain medium is output from the resonator in the form of an output pulse at a single frequency. An electronically controllable output coupler is controlled to affect output pulse characteristics. The laser acts a master oscillator in a master oscillator power amplifier configuration. The laser is used for laser peening.

Owner:METAL IMPROVEMENT CO INC

Sealed lubricator of enameling machine

The invention relates to a sealed lubricator of an enameling machine and belongs to the technical field of the structures of lubricators. The sealed lubricator of the enameling machine is characterized in that: a control valve is installed on a cup mouth of an oil cup; an oil output pipe is connected to the other end of the control valve, and is inserted in an oil inlet on an oil box which is refueled through the oil cup at the top part; a felt fixing clamping plate is arranged at the upper end of one side of the oil box; a felt hole is arranged at the side face of the oil box at the lower end of the felt fixing clamping plate; parts of a first felt and a second felt are installed between the felt fixing clamping plate and a pressing plate in an adhering manner; a part of the second felt enters the oil box through the felt hole; lubricating oil permeates to the upper part of the second felt through the part of second felt stretched into the oil box; and an enameled wire penetrates through the two felts, so that the coating of the lubricating oil on the surface of the enameled wire is realized. The sealed lubricator has the advantages of reasonable design, fixed height of the liquid level in the oil box, uniform oil absorption of felts, no volatilization and waste of the lubrication oil and no pollution to the production environment. As the enameled wire penetrates through the two felts, the coating is more uniform.

Owner:山东蓬泰股份有限公司

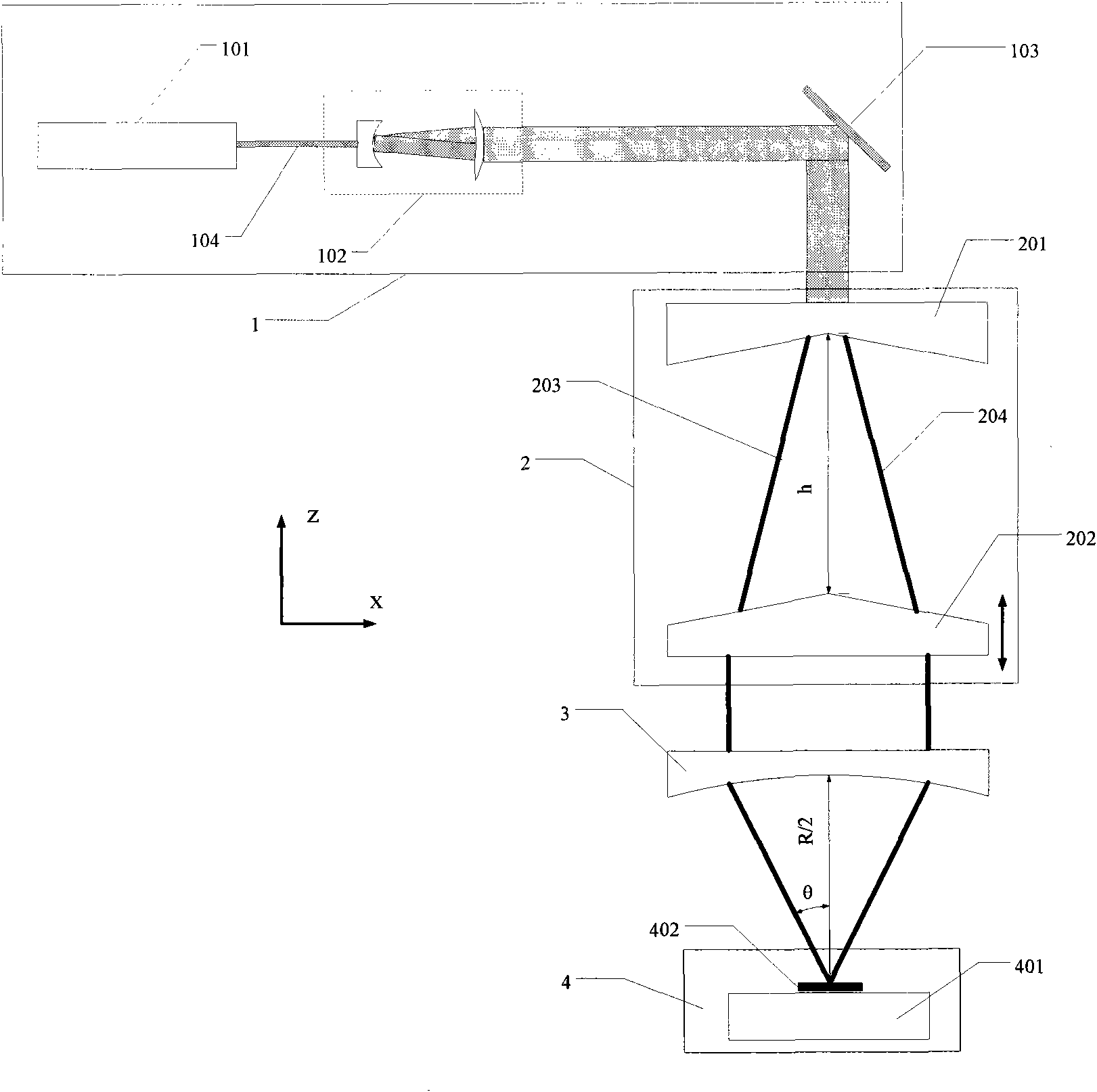

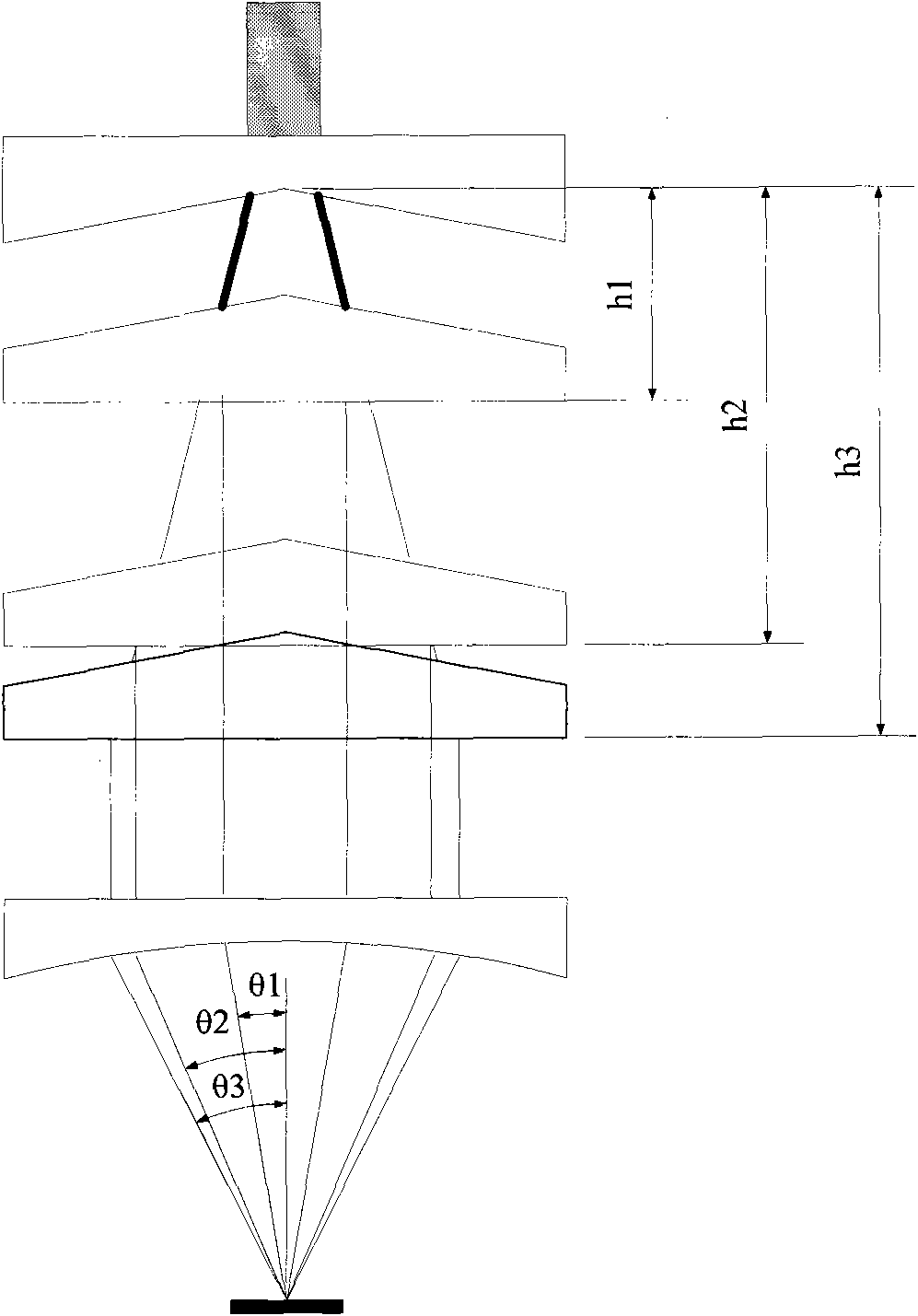

Exposure device and method of same

ActiveCN102736427AIncrease profitConstant heightPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical propagationLight beam

An exposure device and a method of the same are disclosed. The device comprises an illuminating unit sending out a coherent beam; a prism set through which the coherent beam is gathered into a plurality of parallel interference arms, and the plurality of parallel interference arms are sent out; an interference head which interferes in the parallel interference arms and makes them form interference fringes; and a base, the interference fringes are located on the surface of the base. The device is characterized in that the prism set comprises a first prism and a second prism, and spacing between the first prism and the second prism along on an optical propagation direction can be adjusted, and the height of the parallel interference arms gathered by the interference head is constant.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

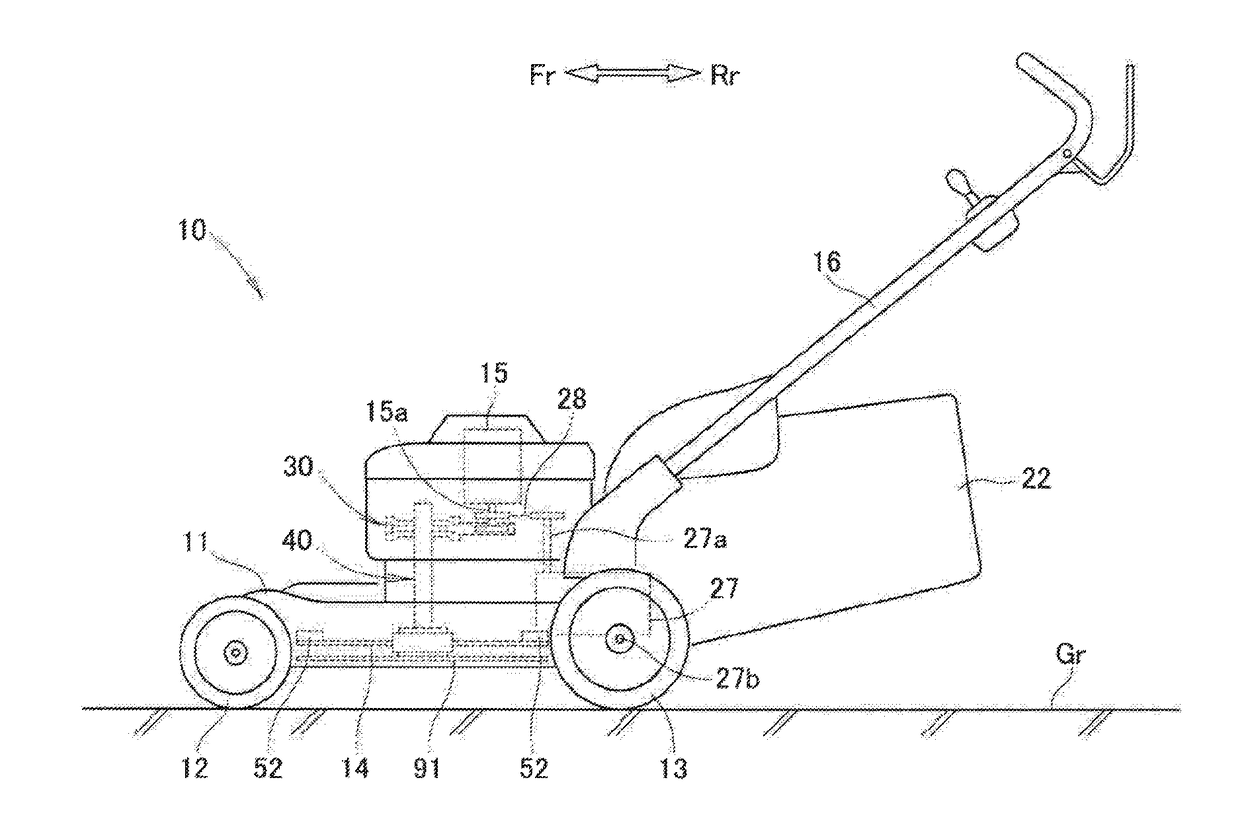

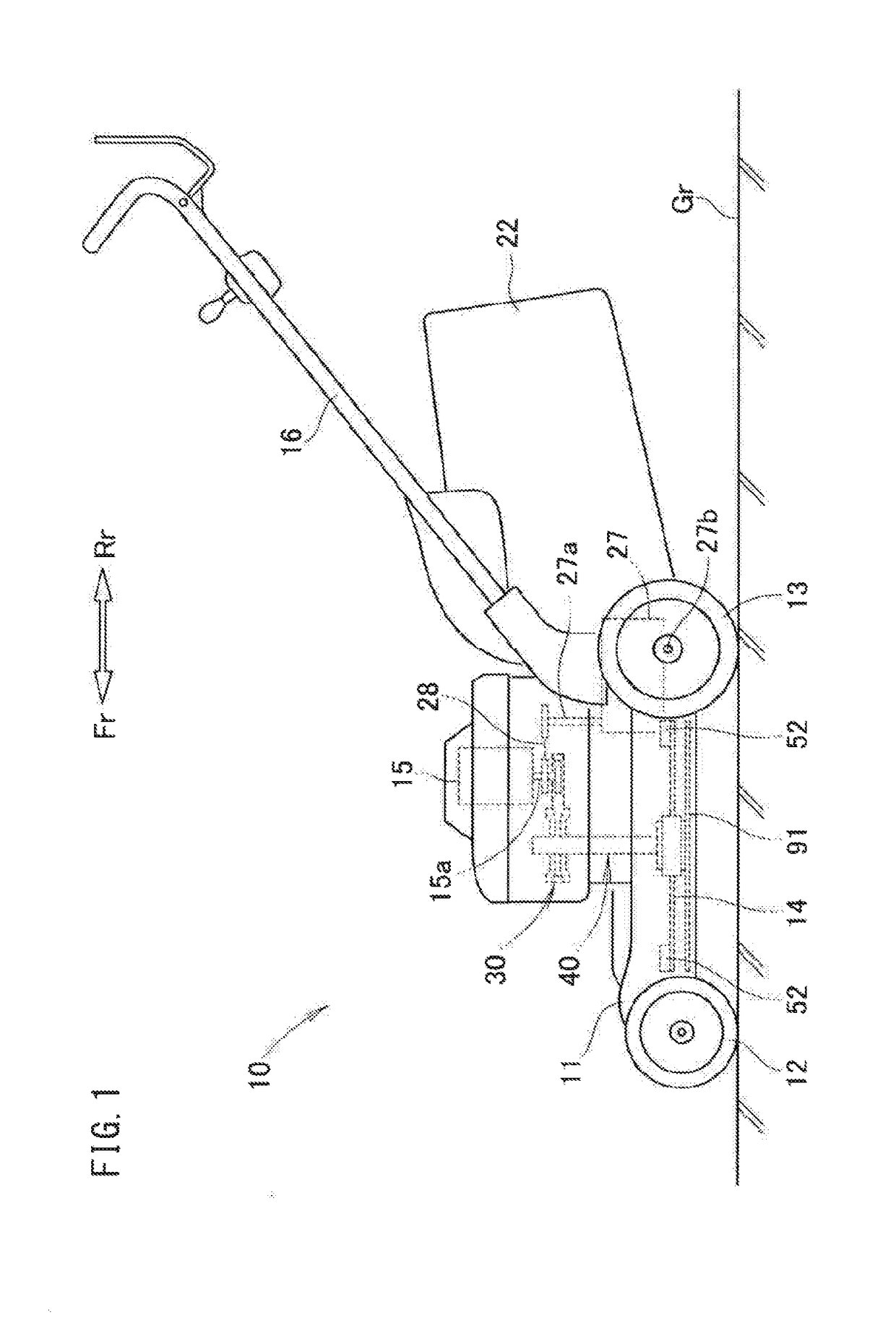

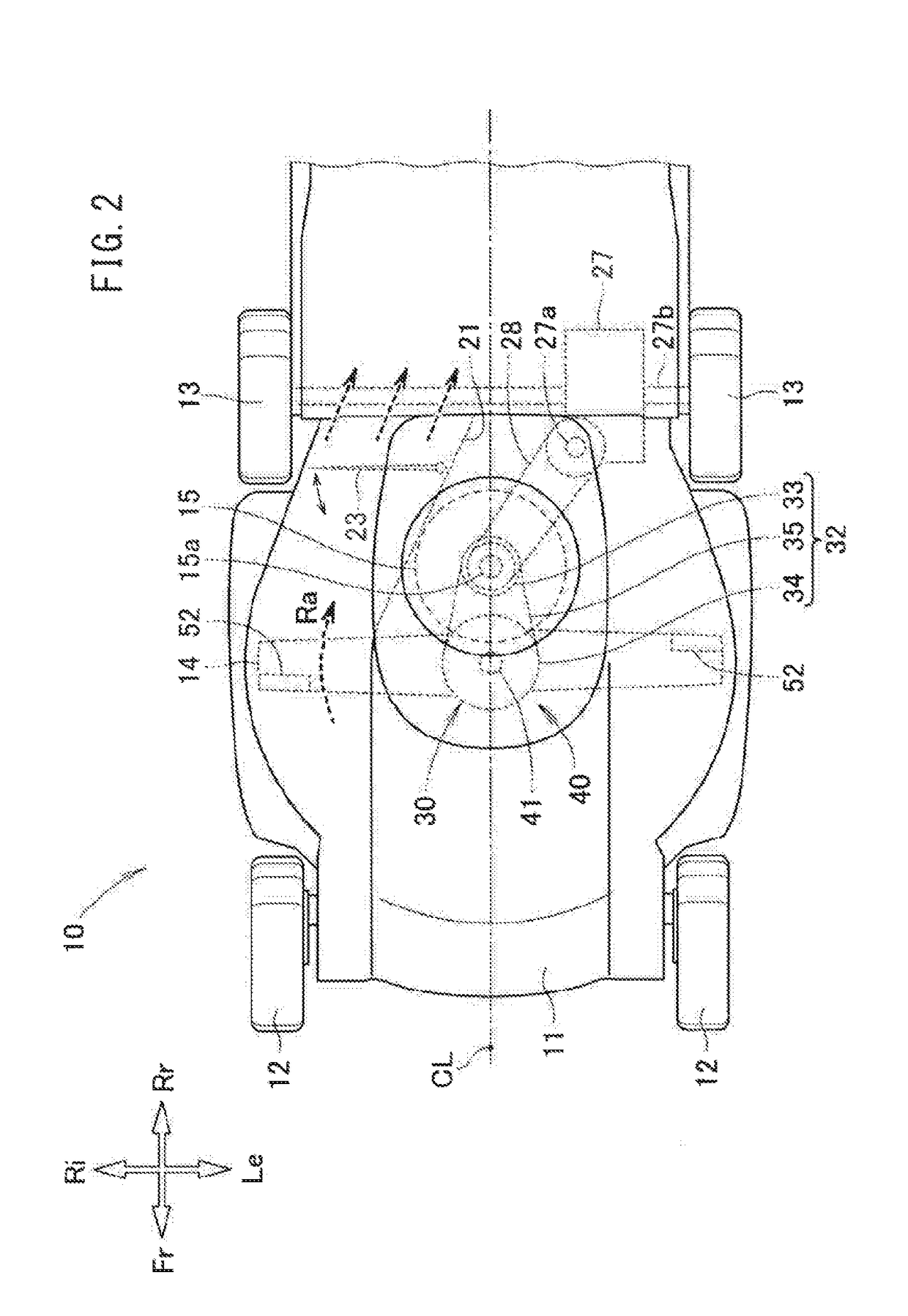

Lawn mower

A lawn mower includes a hollow shaft, a cutter blade, flaps, a belt type continuously variable transmission, and a transmission mechanism. The cutter blade extends along a horizontal line which is perpendicular to the hollow shaft. The flaps are provided for the cutter blade. Each of the flaps has a flap angle changeable along the horizontal line. A control force converter unit of the belt type continuously variable transmission converts a displacement force of the movable sheave relative to the fixed sheave in an axial direction into a control force that controls the flap angle of the flaps. The transmission mechanism is accommodated inside the hollow shaft, and transmits the control force to the flaps.

Owner:HONDA MOTOR CO LTD

Self-seeded single-frequency solid-state ring laser and system using same

ActiveUS7180918B2Simple designGood energyLaser arrangementsSubstation equipmentControl electronicsPulse characteristics

A method of operating a laser to obtain an output pulse having a single wavelength, comprises inducing an intracavity loss into a laser resonator having an amount that prevents oscillation during a time that energy from the pump source is being stored in the gain medium. Gain is built up in the gain medium with energy from the pump source until formation of a single-frequency relaxation oscillation pulse in the resonator. Upon detection of the onset of the relaxation oscillation pulse, the intracavity loss is reduced, such as by Q-switching, so that the built-up gain stored in the gain medium is output from the resonator in the form of an output pulse at a single frequency. An electronically controllable output coupler is controlled to affect output pulse characteristics. The laser acts a master oscillator in a master oscillator power amplifier configuration. The laser is used for laser peening.

Owner:METAL IMPROVEMENT CO INC +1

Injection needle assembly and drug injection device

To securely position a needle tip and a blade face of a needle tube inserted into the skin in a predetermined site of a living body, such as the upper layer of skin, an injection needle assembly includes a needle tube having a needle tip capable of puncturing a living body, a hub holding the needle tube, a stabilizer, and a guide portion. The stabilizer is formed in a tubular shape surrounding the circumference of the needle tube, and an end face is pressed against the skin, and thereby a raised portion of the skin is formed in a tube hole. The guide portion is arranged on the stabilizer, and is adapted to recognize a press-in distance y of the stabilizer to the skin.

Owner:TERUMO KK

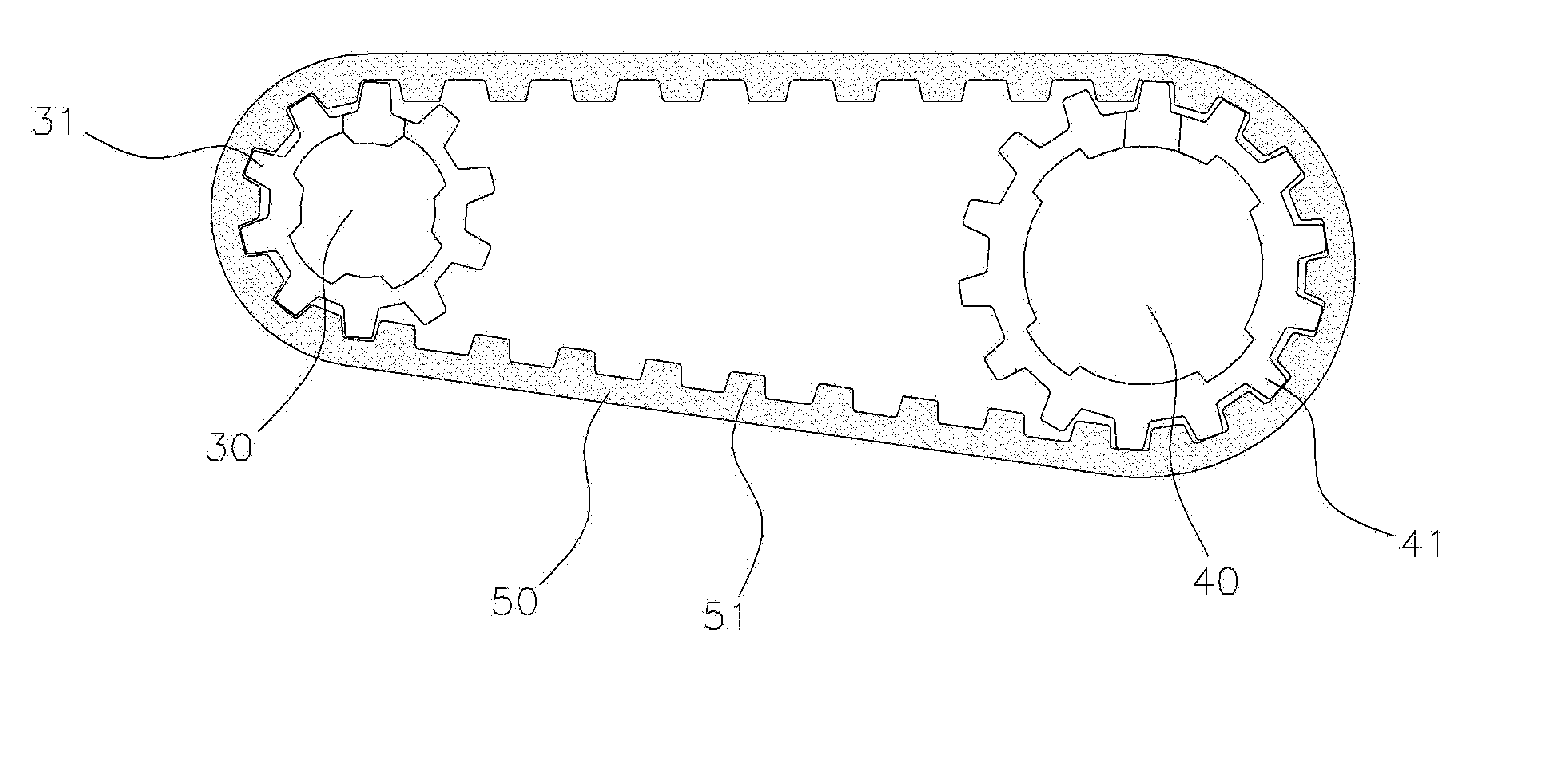

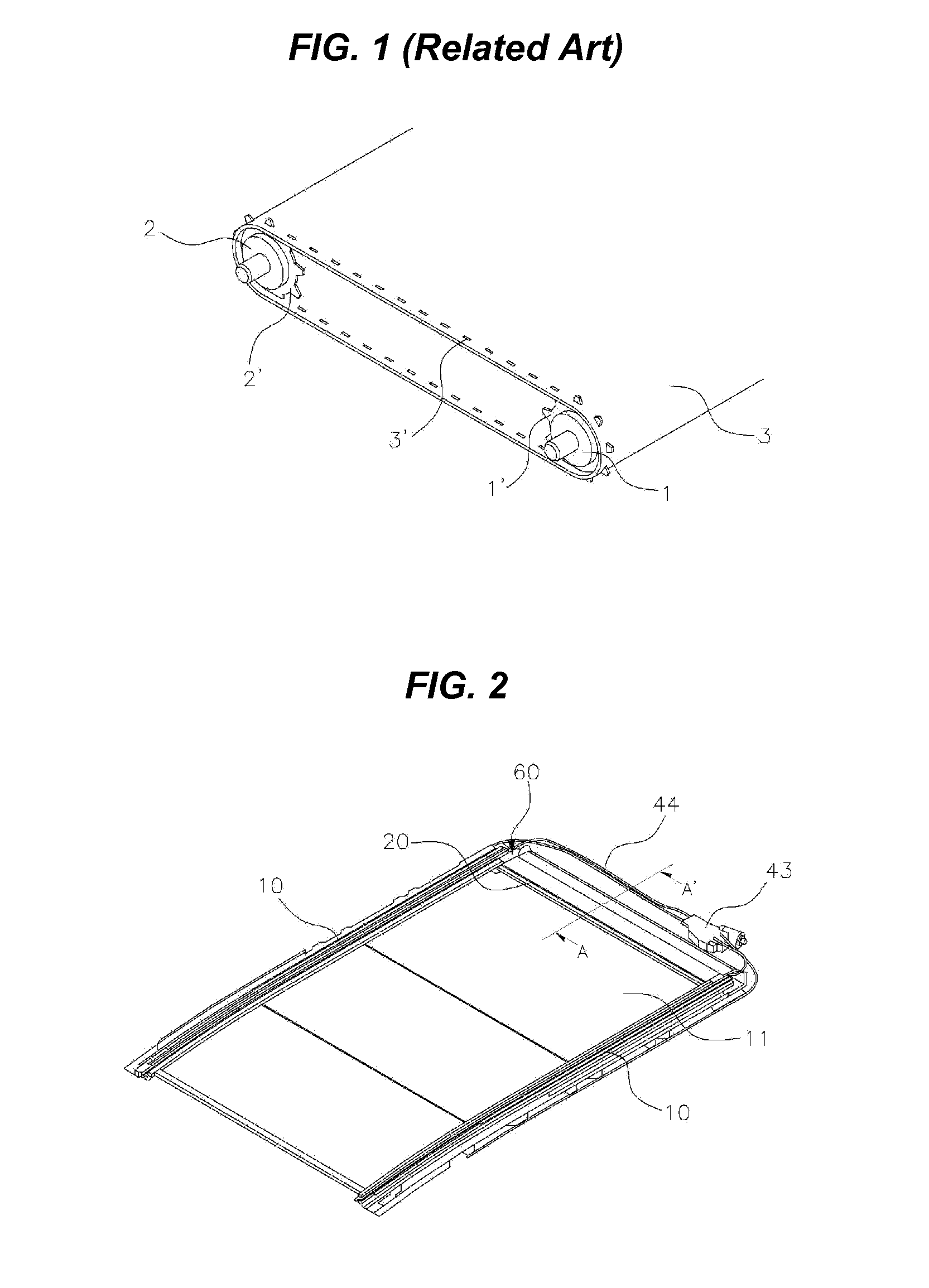

Structure of roll blind using dual roller

A structure of a roll blind that moves in a front-back direction of a vehicle to selectively shade a sunroof glass may include a pair of sunroof frames formed on both lower sides of the sunroof glass in a longitudinal direction of the vehicle, a main roller disposed at the one end of the sunroof frame in a vehicle width direction and can rotate through a motor, an idle roller disposed in the vehicle width direction adjacent to the main roller, a roller tube coupled to and wrapping the main roller and the idle roller to form a closed loop, and a roller guide coupled to both ends of the main roller and the idle roller and including a guide portion formed to protrude so that the blind maintains a constant height.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com